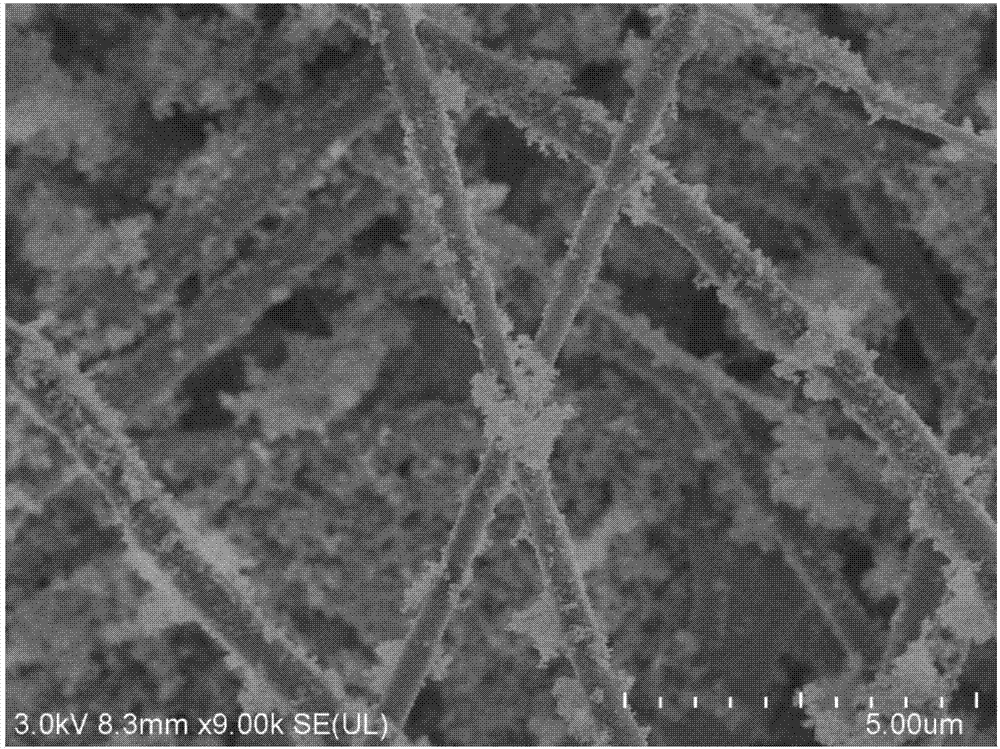

Ultra-high-flux nano-fiber waterproof gas-permeable membrane and preparation method thereof

A technology of waterproof and breathable membrane and nanofiber membrane, applied in the direction of liquid repellent fiber, fiber type, fiber treatment, etc., can solve the problems of poor waterproof and moisture permeability, complicated preparation process, and resistance to rubbing, etc., and achieve a wide range of applications. Practical application prospects, high moisture permeability, and the effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An ultra-high-throughput nanofiber waterproof and breathable membrane and a preparation method thereof, comprising:

[0044] Step 1: Prepare 100 g of nano silica toluene dispersion liquid of 0.5% mass concentration, and then prepare 10% of dihydro-3-[3-(trimethoxysilyl) propyl] furan-2,5-dione 5g of toluene solution, 5g of toluene solution of 10% hexadecyltrimethoxysilane were added alternately to the nano-silica toluene dispersion several times. -3-[3-(trimethoxysilyl)propyl]furan-2,5-dione is hydrolyzed to form two carboxyl groups to form a bifunctional group-modified nano-silica toluene dispersion;

[0045] Step 2: Prepare the spinning solution of polyvinyl alcohol, the solvent is water, the mass concentration is 12%, and electrospinning is carried out, the spinning distance is 15cm, the spinning voltage is 35kv, after the polyvinyl alcohol nanofiber membrane is obtained, pass 1% After the γ-aminopropyltriethoxysilane ethanol solution is processed, the polyvinyl alc...

Embodiment 2

[0049] An ultra-high-throughput nanofiber waterproof and breathable membrane and a preparation method thereof, comprising:

[0050] Step 1: prepare 100 g of nano-silica ethanol dispersion liquid of 0.5% mass concentration, then prepare 5 g of ethanol solution of 10% gamma-aminopropyltriethoxysilane, 10% tridecafluorooctyltrimethoxysilane 5g of the ethanol solution was added alternately to the ethanol dispersion of nano-silica in multiple times to form the ethanol dispersion of nano-silica modified by bifunctional groups;

[0051] Step 2: Prepare the spinning solution of chitosan with 90% deacetylation, the solvent is glacial acetic acid, the mass concentration is 9%, and electrospinning is carried out, the spinning distance is 18cm, and the spinning voltage is 70kv to obtain porous chitosan nano Fiber membrane;

[0052] Step 3: spray the nano-silica ethanol dispersion liquid modified by the bifunctional group prepared in step 1 on the surface of the chitosan nanofiber membran...

Embodiment 3

[0055] An ultra-high-throughput nanofiber waterproof and breathable membrane and a preparation method thereof, comprising:

[0056] Step 1: Prepare 100 g of nano silicon dioxide ethanol dispersion liquid of 0.5% mass concentration, then prepare 5 g of ethanol solution of 10% gamma-aminopropyltriethoxysilane, 10% ethanol of vinyltriethoxysilane 5g of the solution was alternately added to the ethanol dispersion of nano-silica in multiple times to form a bifunctional group-modified ethanol dispersion of nano-silica;

[0057] Step 2: Prepare a spinning solution of polyacrylonitrile, the solvent is N,N-dimethylformamide, the mass concentration is 12%, and electrospinning is carried out, the spinning distance is 16cm, and the spinning voltage is 60kv to obtain polyacrylonitrile The nanofibrous membrane is treated with 10% sodium hydroxide solution, cleaned and then treated with 15% hydrochloric acid, and dried to obtain a carboxyl-modified polyacrylonitrile nanofiber membrane with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com