Patents

Literature

2667results about "Liquid repellent fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

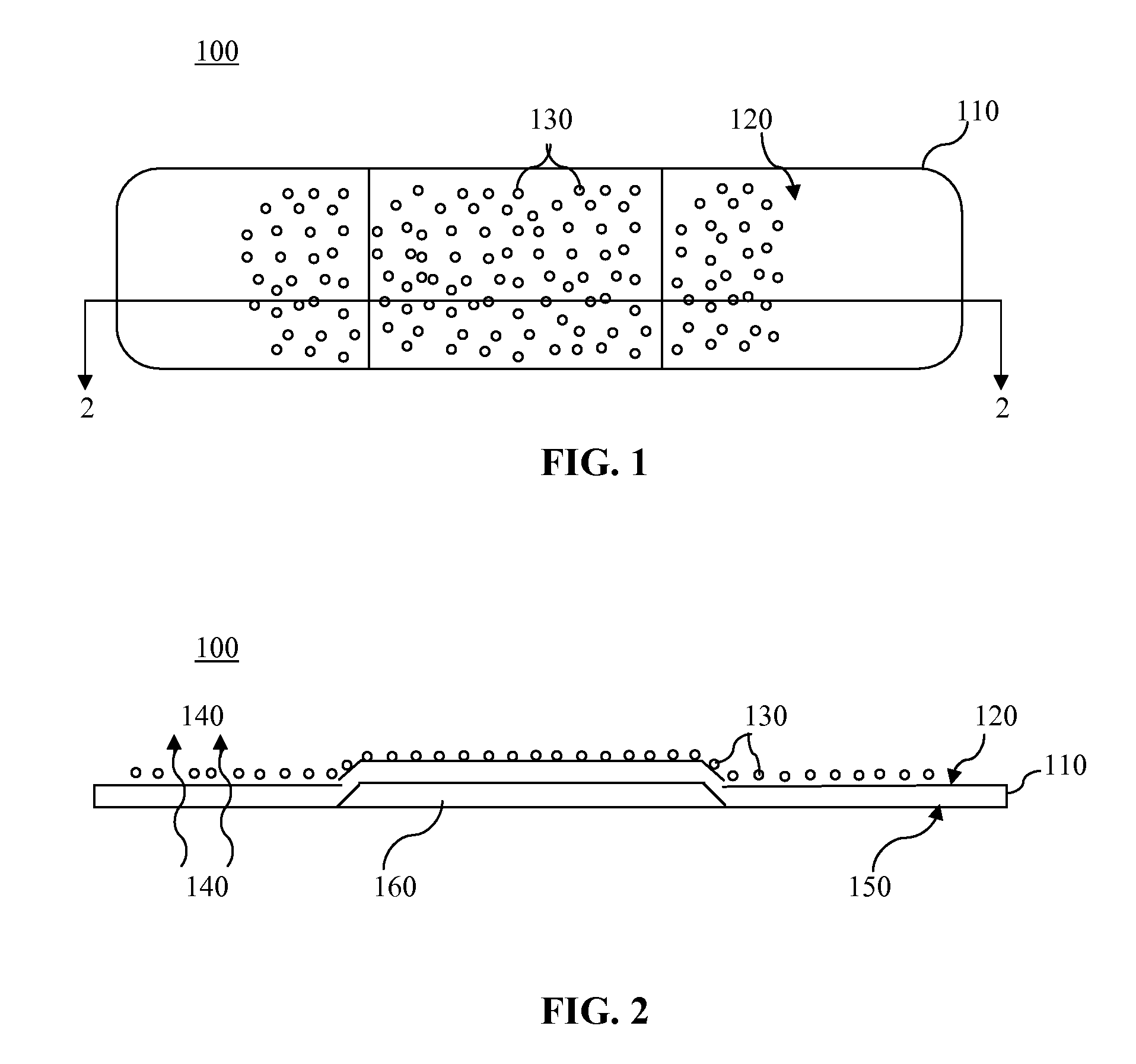

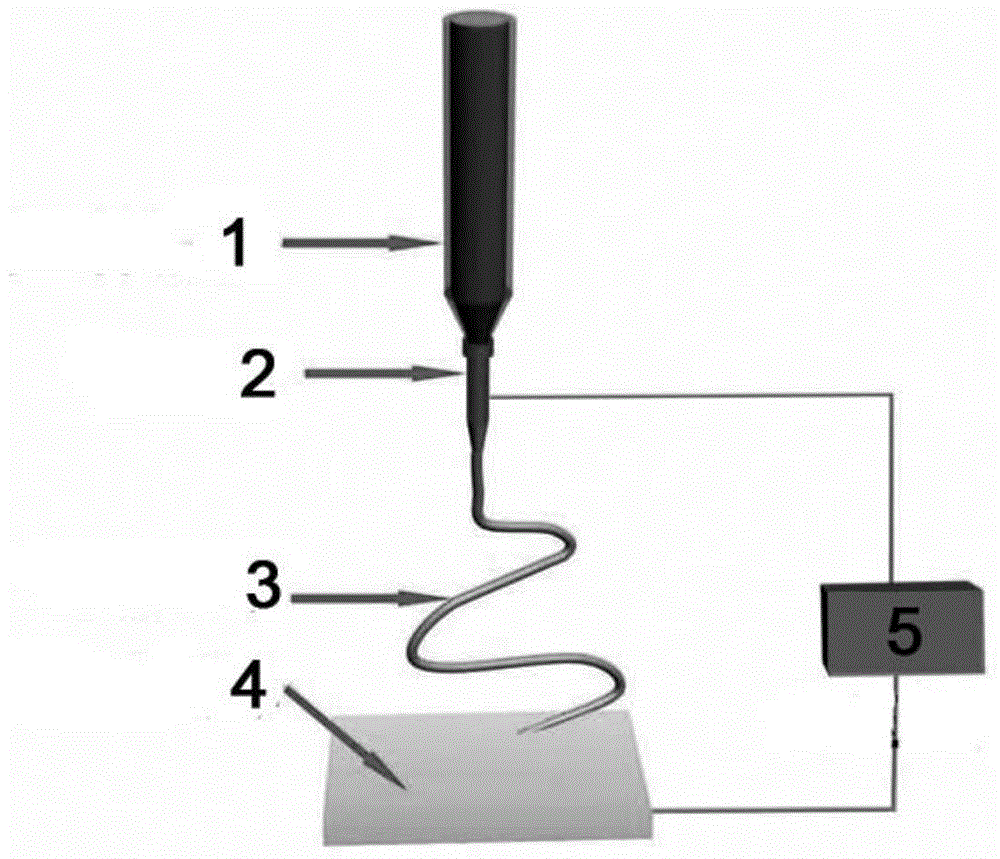

Apparatus and methods for plasma enhanced chemical vapor deposition of polymer coatings

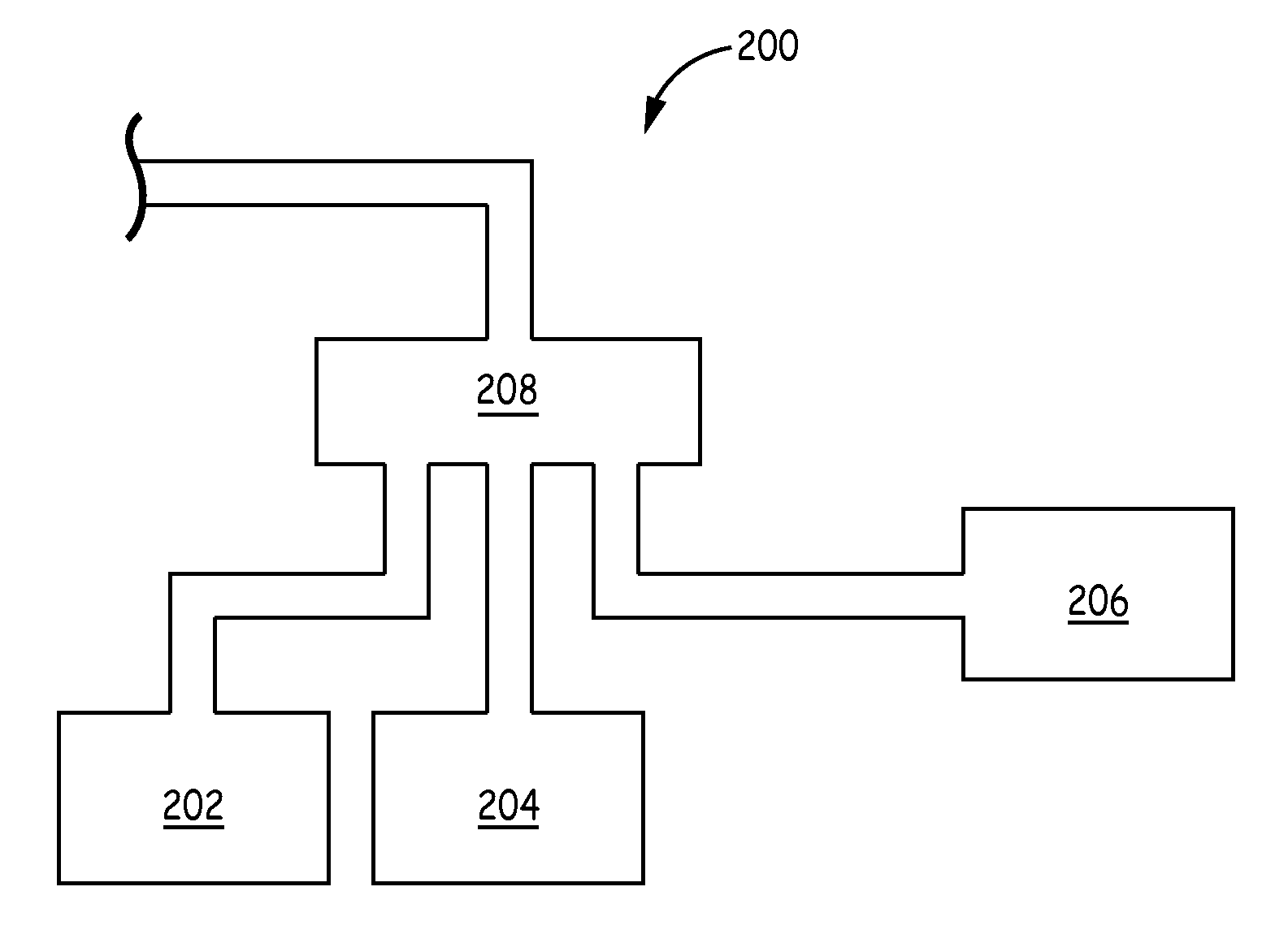

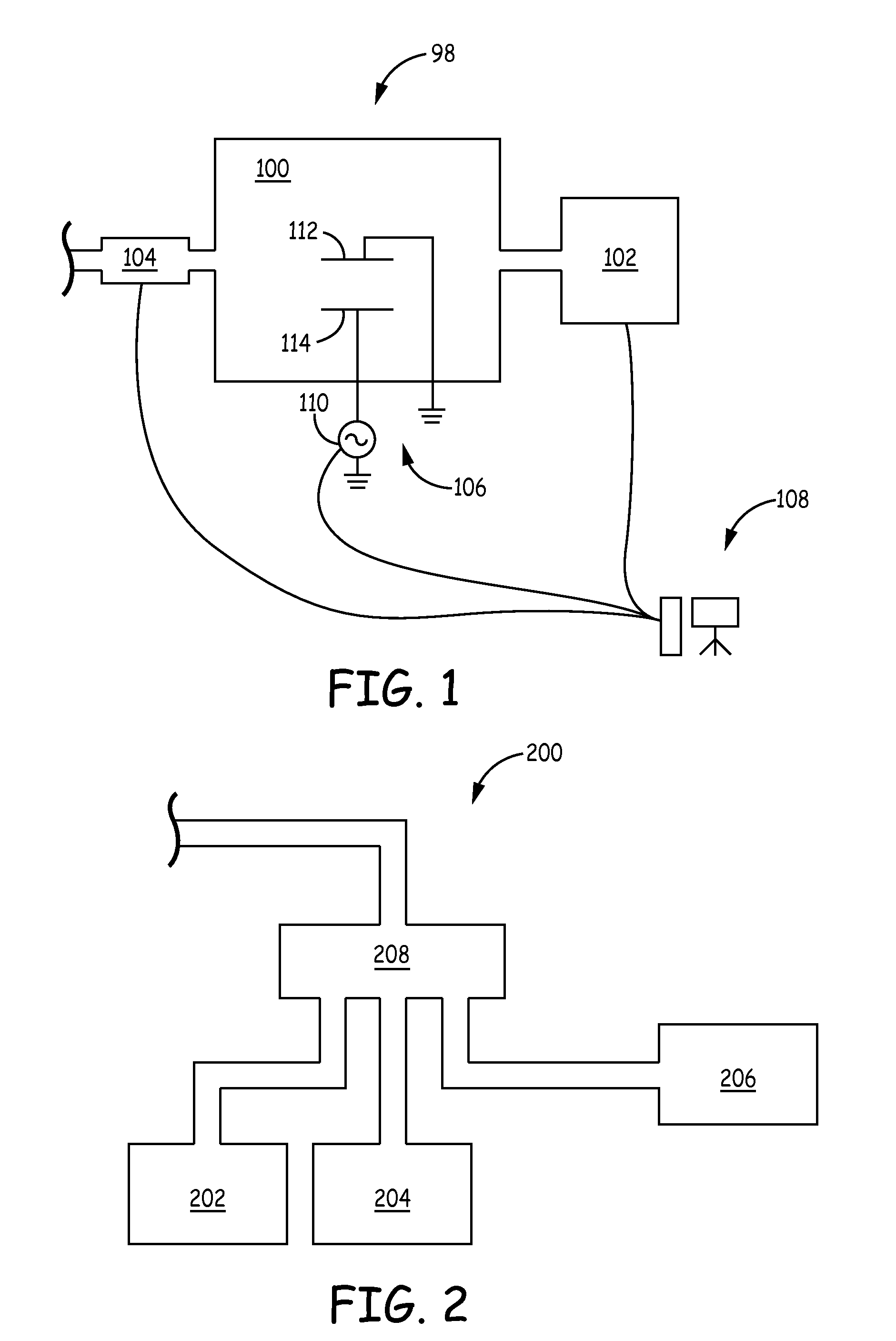

Apparatuses and methods are described that involve the deposition of polymer coatings on substrates. The polymer coatings generally comprise an electrically insulating layer and / or a hydrophobic layer. The hydrophobic layer can comprise fused polymer particles have an average primary particle diameter on the nanometer to micrometer scale. The polymer coatings are deposited on substrates using specifically adapted plasma enhanced chemical vapor deposition approaches. The substrates can include computing devices and fabrics.

Owner:LIQUIPEL IP

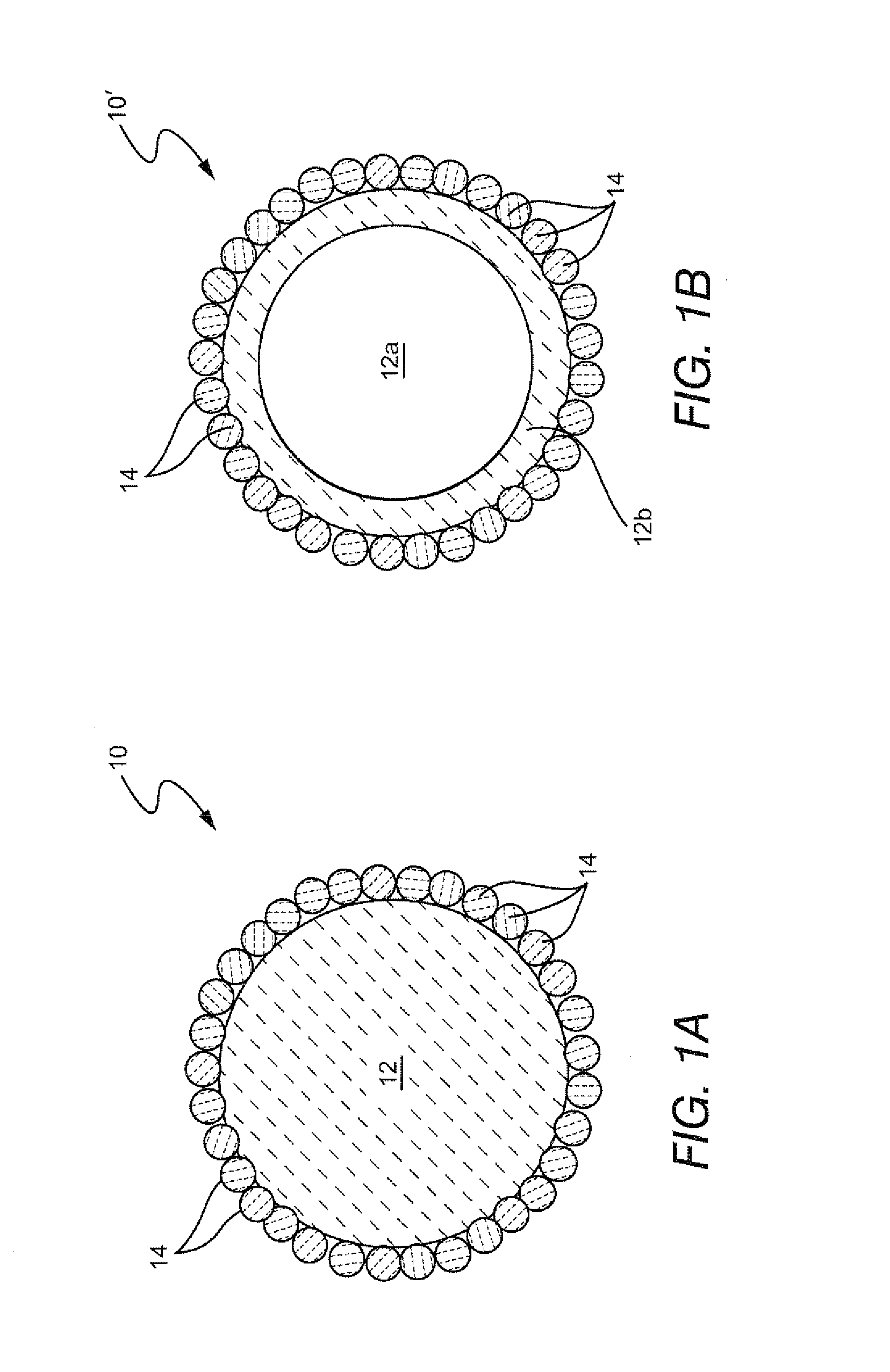

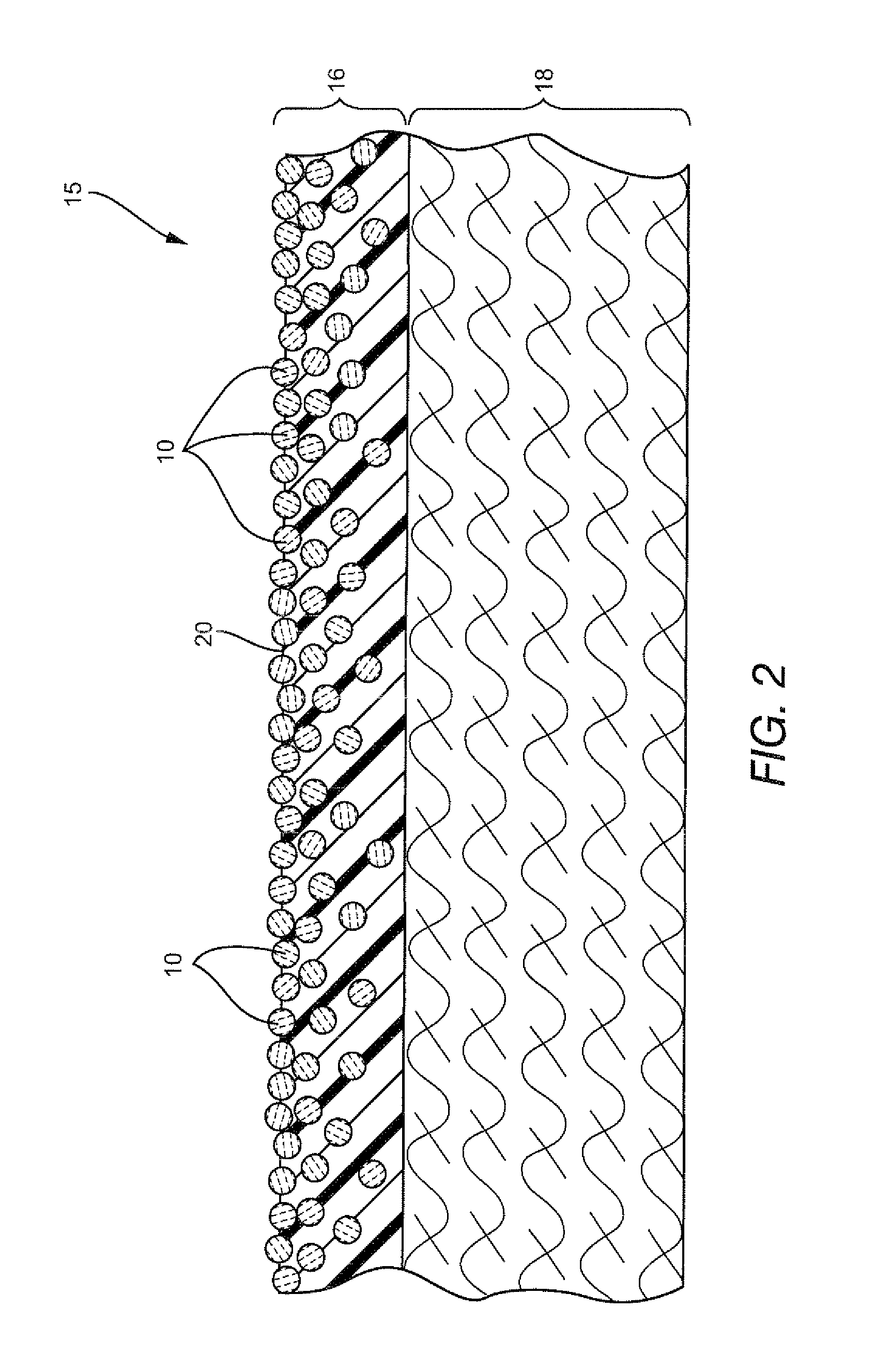

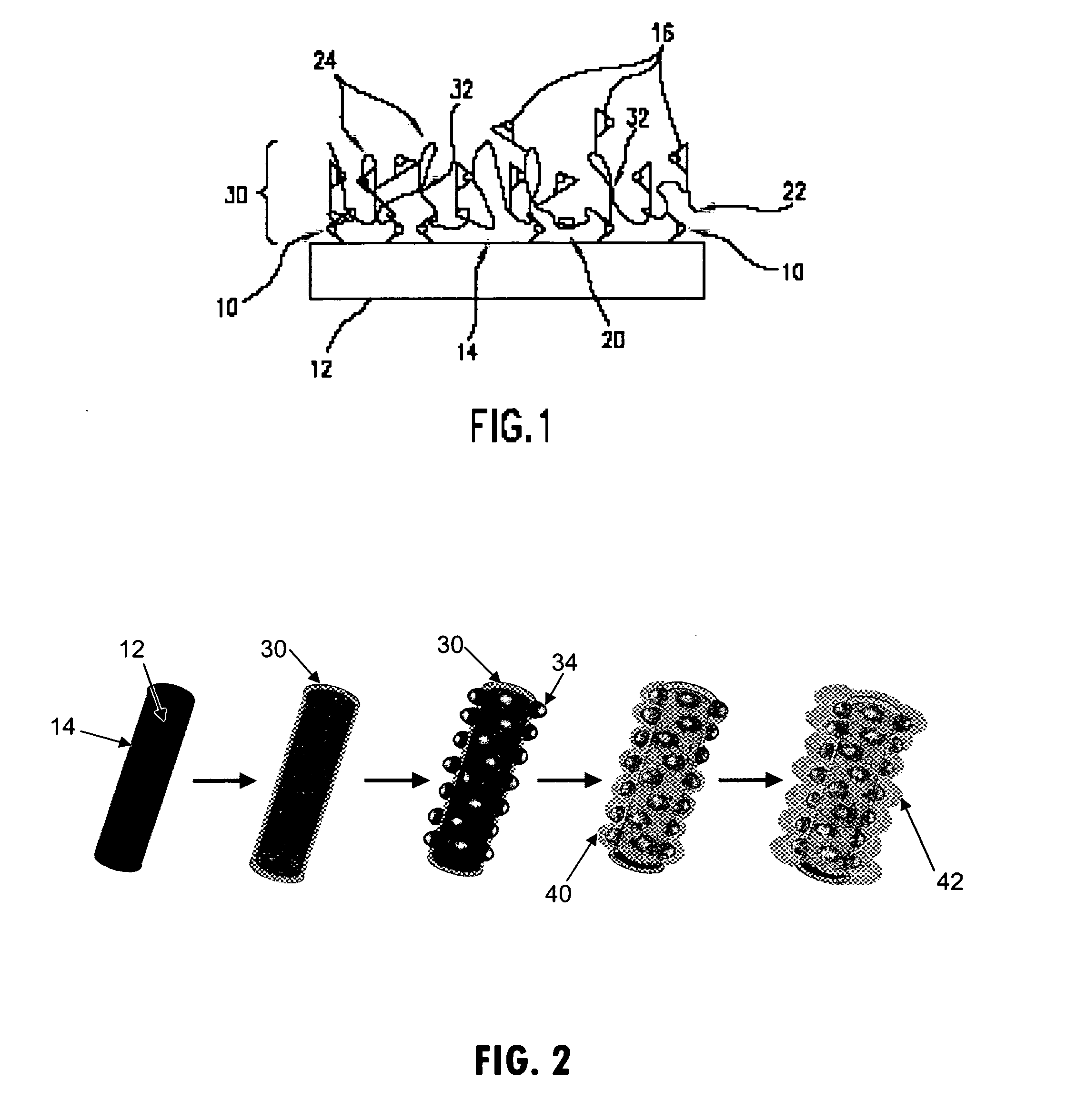

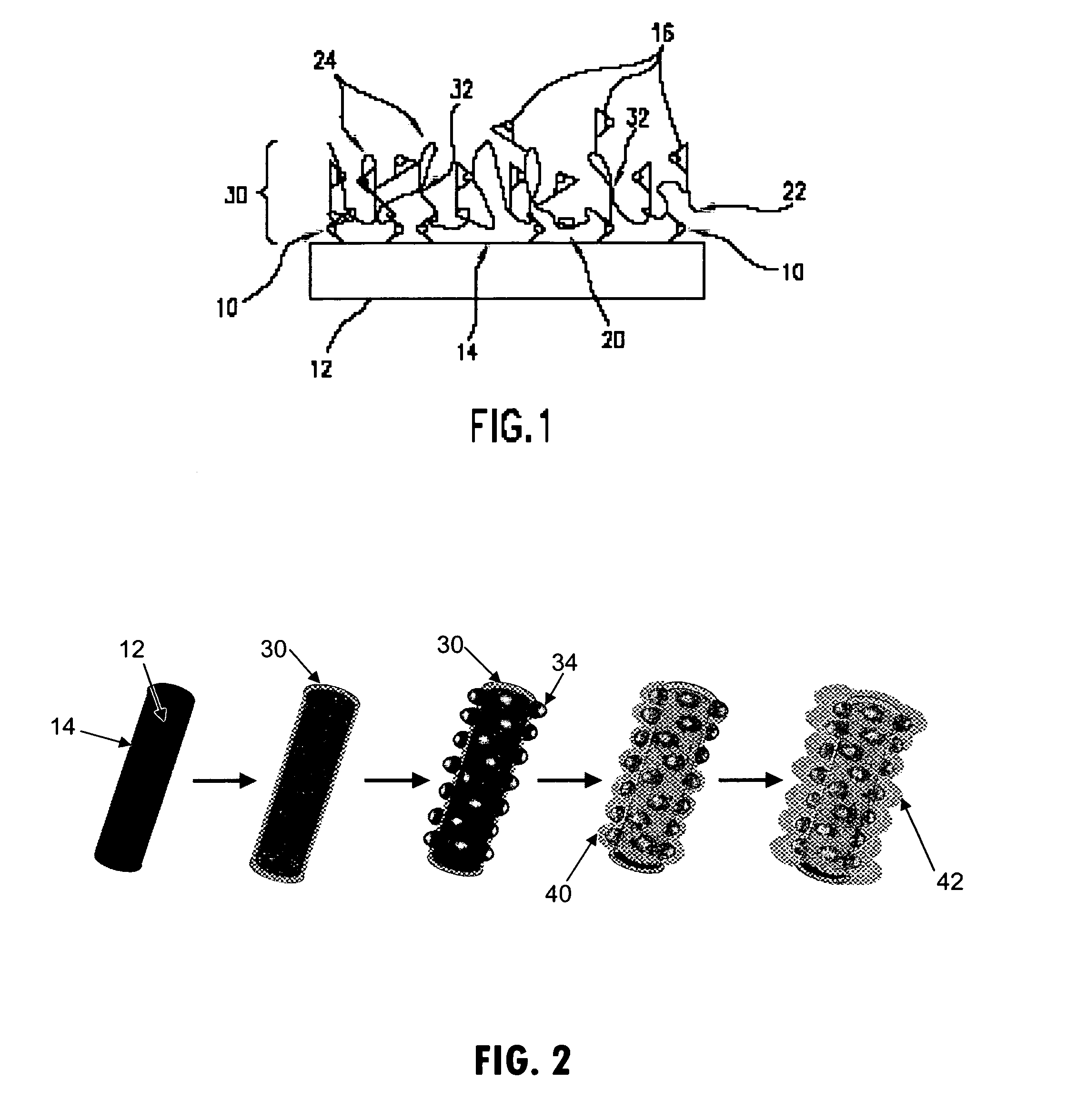

Additive particles having superhydrophobic characteristics and coatings and methods of making and using the same

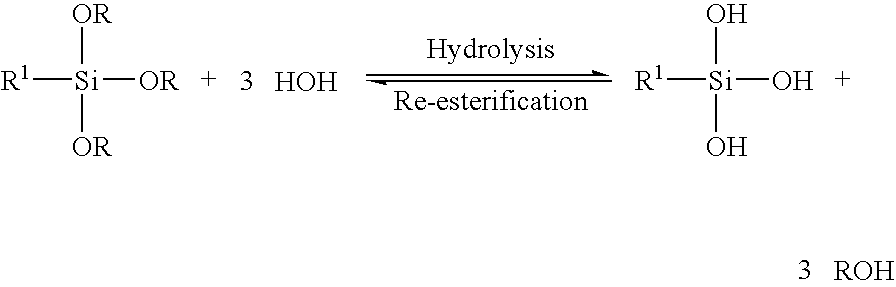

InactiveUS20090298369A1Non-macromolecular adhesive additivesLiquid repellent fibresCoating systemSilanes

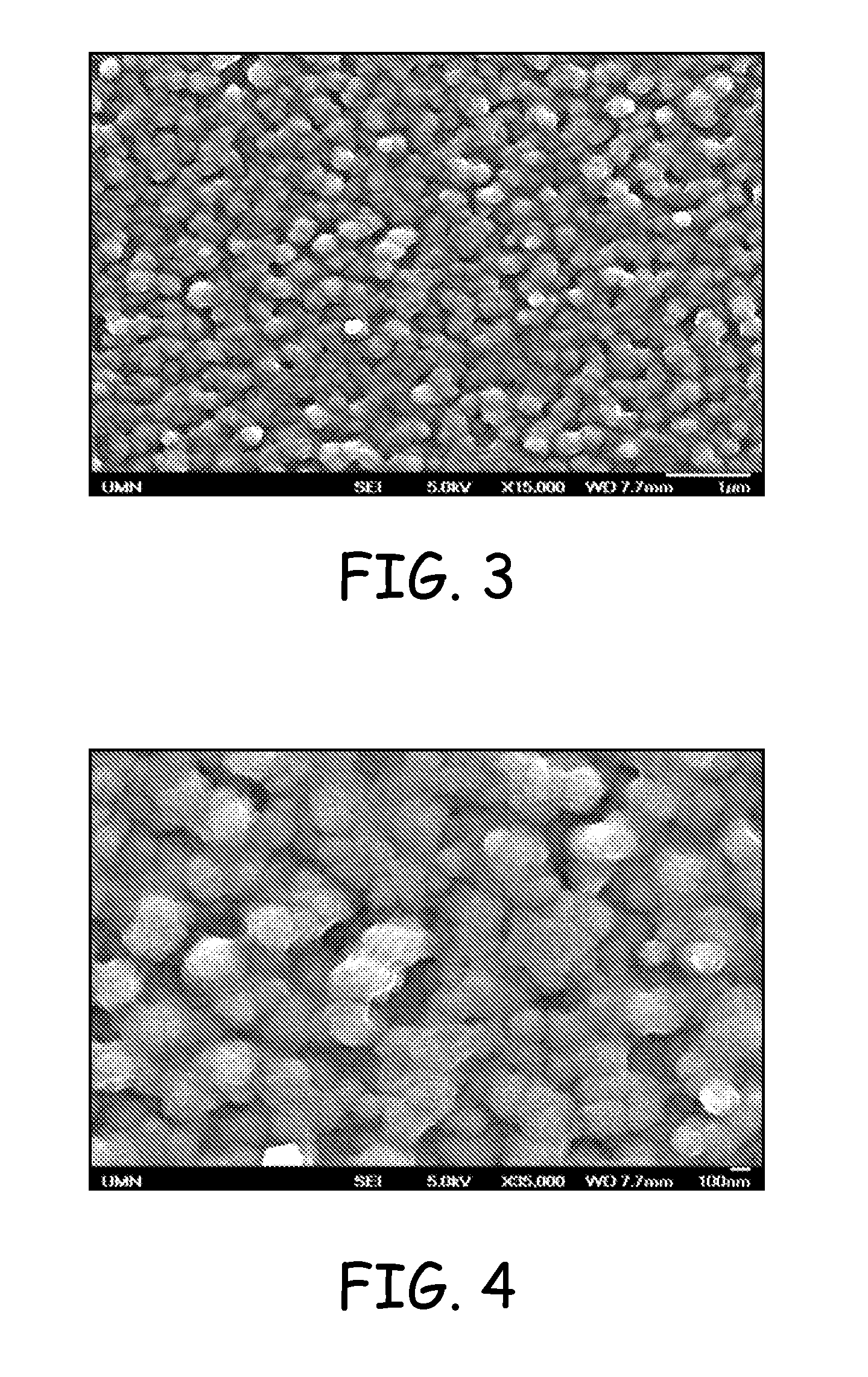

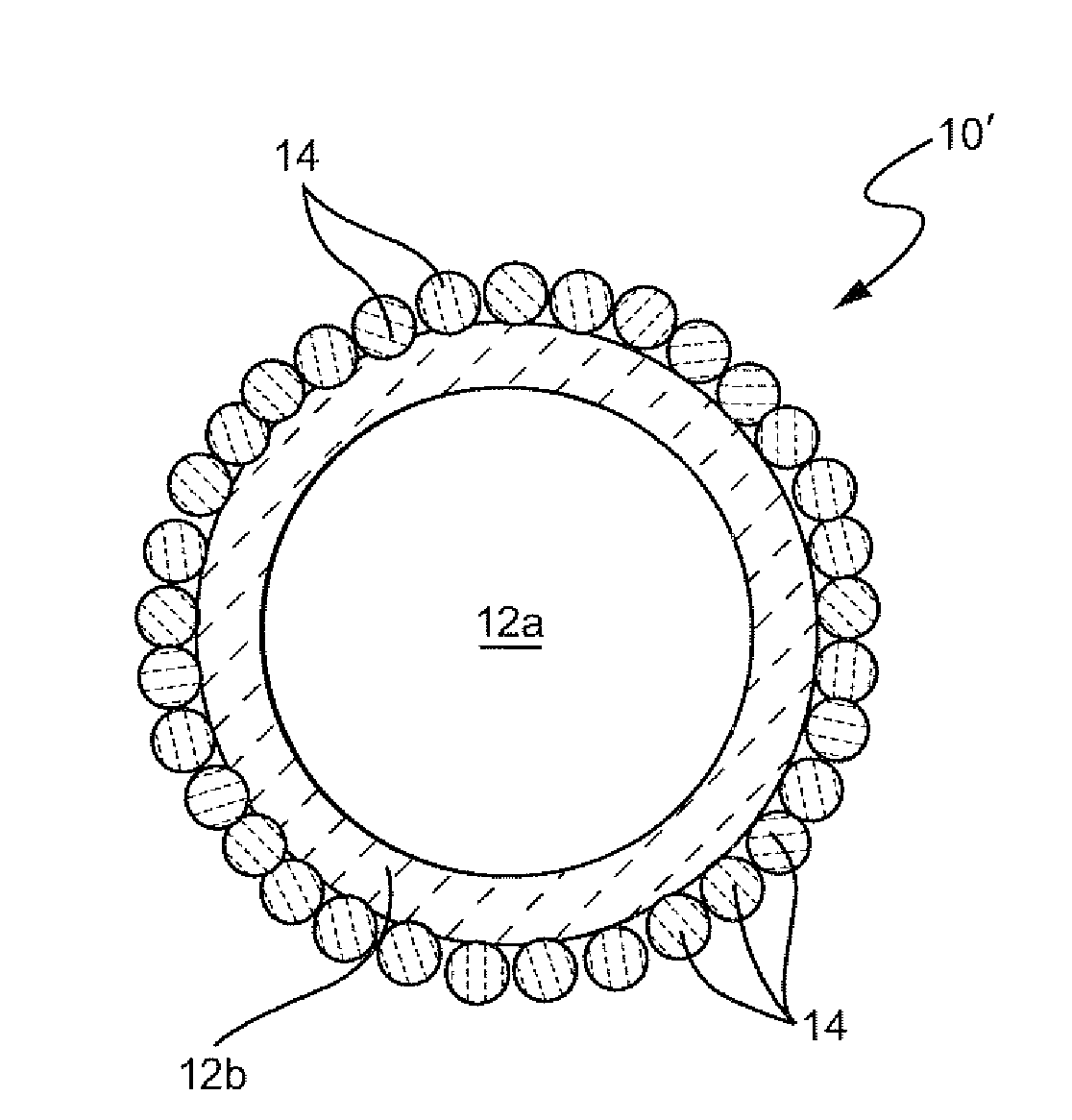

Additive particles may be employed in sufficient amounts to impart superhydrophobicity to a coating system in which the additive particles are incorporated. The additive particles include carrier microparticles and a dense plurality of nanoparticles adhered to the surfaces of the carrier microparticles (e.g., preferably by electrostatic deposition or covalent bonding). The additive particles are advantageously incorporated into a coating material (e.g., a polymeric material) in amounts sufficient to render a substrate surface superhydrophobic when coated with the coating material. The substrate may be rigid (e.g., glass, ceramic or metal) or flexible (e.g., a polymeric film or sheet or a fabric). In some preferred embodiments, both the microparticle and nanoparticles are formed of silica and are surface treated with a hydrophobic treatment so as to impart superhydrophobic properties thereto. Especially preferred are particles treated with silicone fluid comprised of a polysiloxane and / or a perfluoro silane having between 1 and 40 carbon atoms.

Owner:LUNA INNOVATIONS

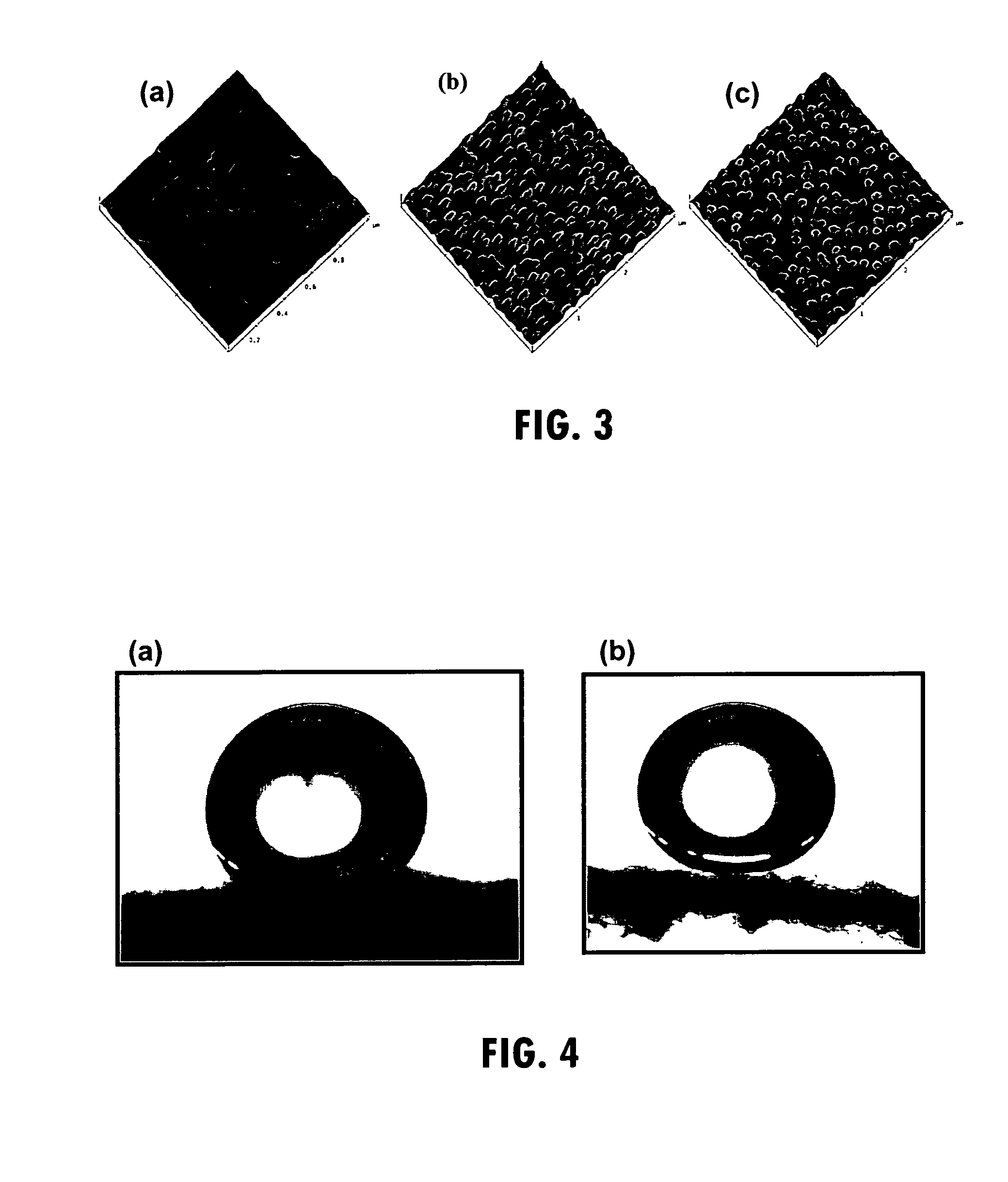

Ultrahydrophobic substrates

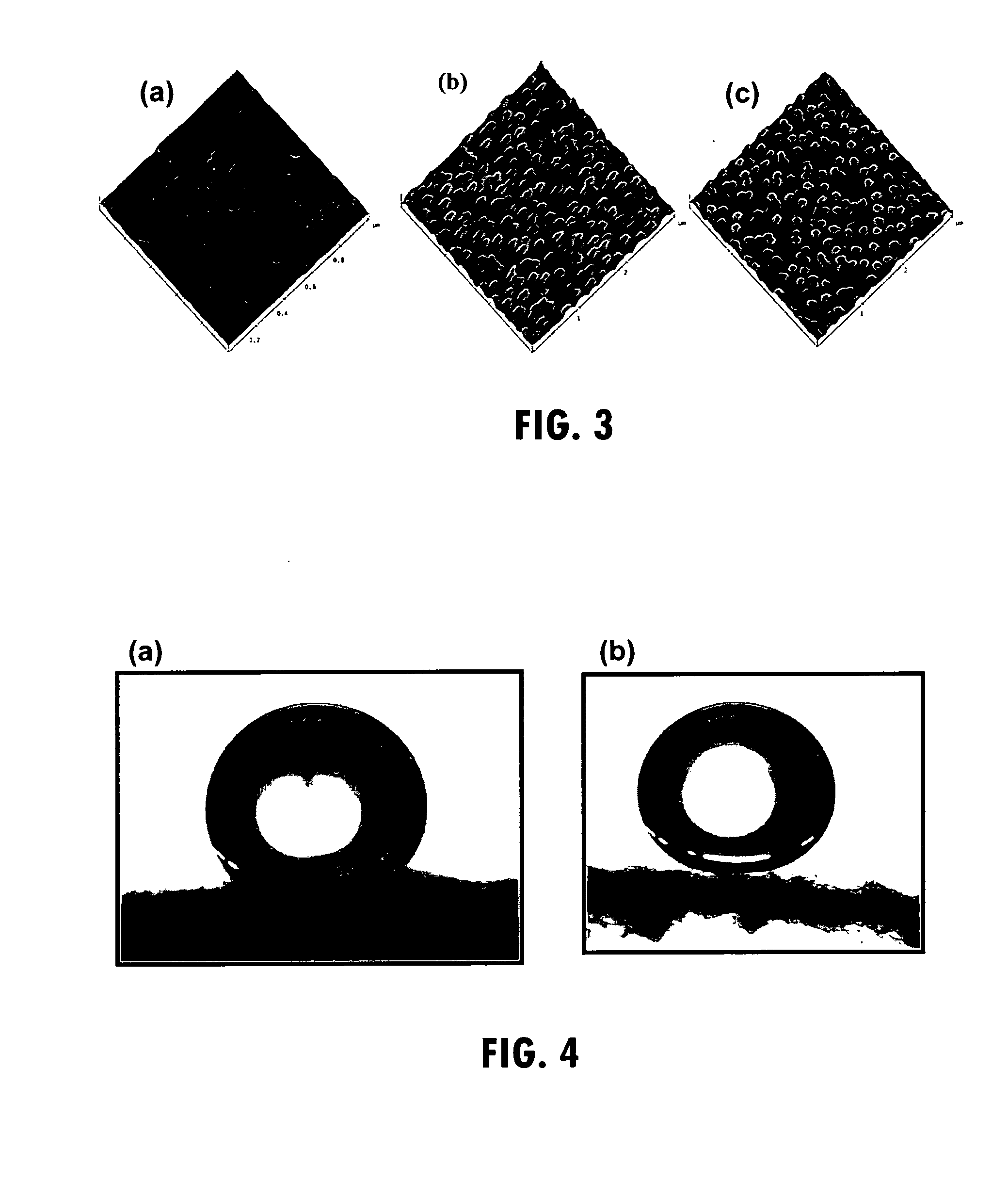

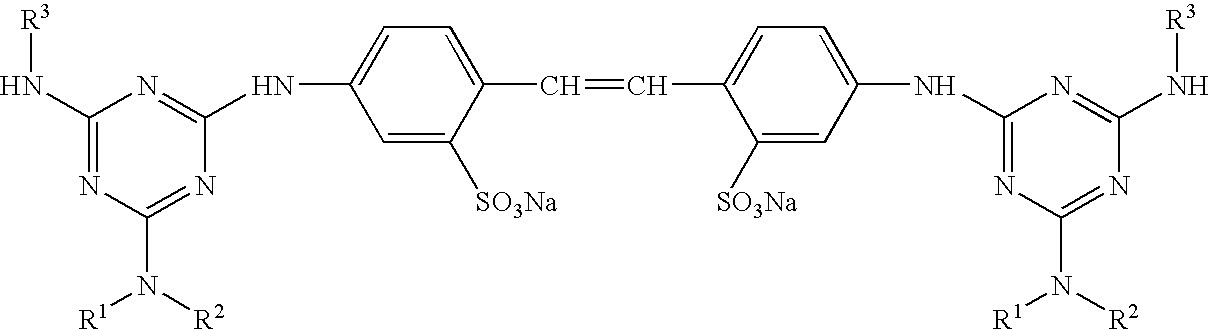

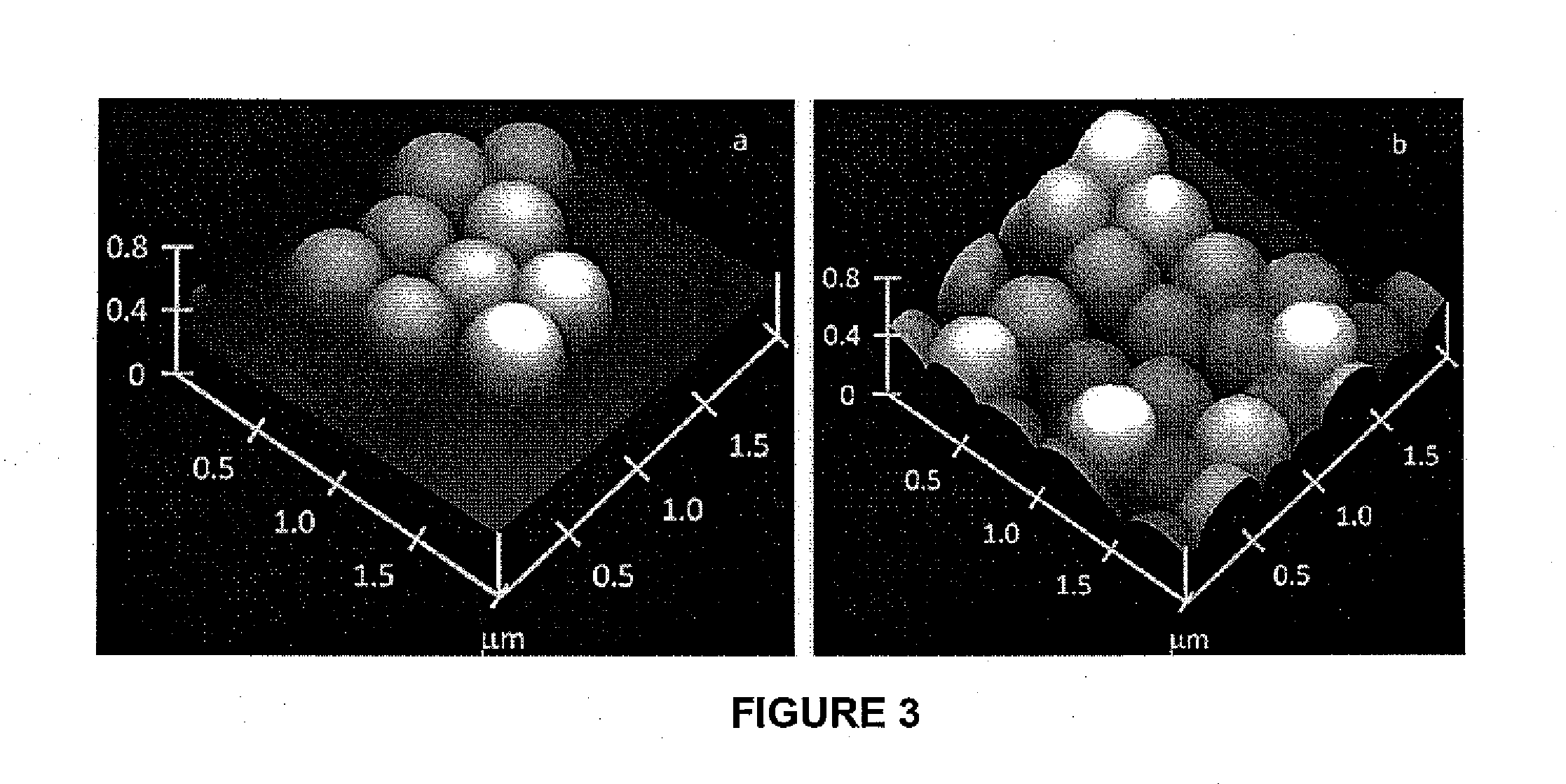

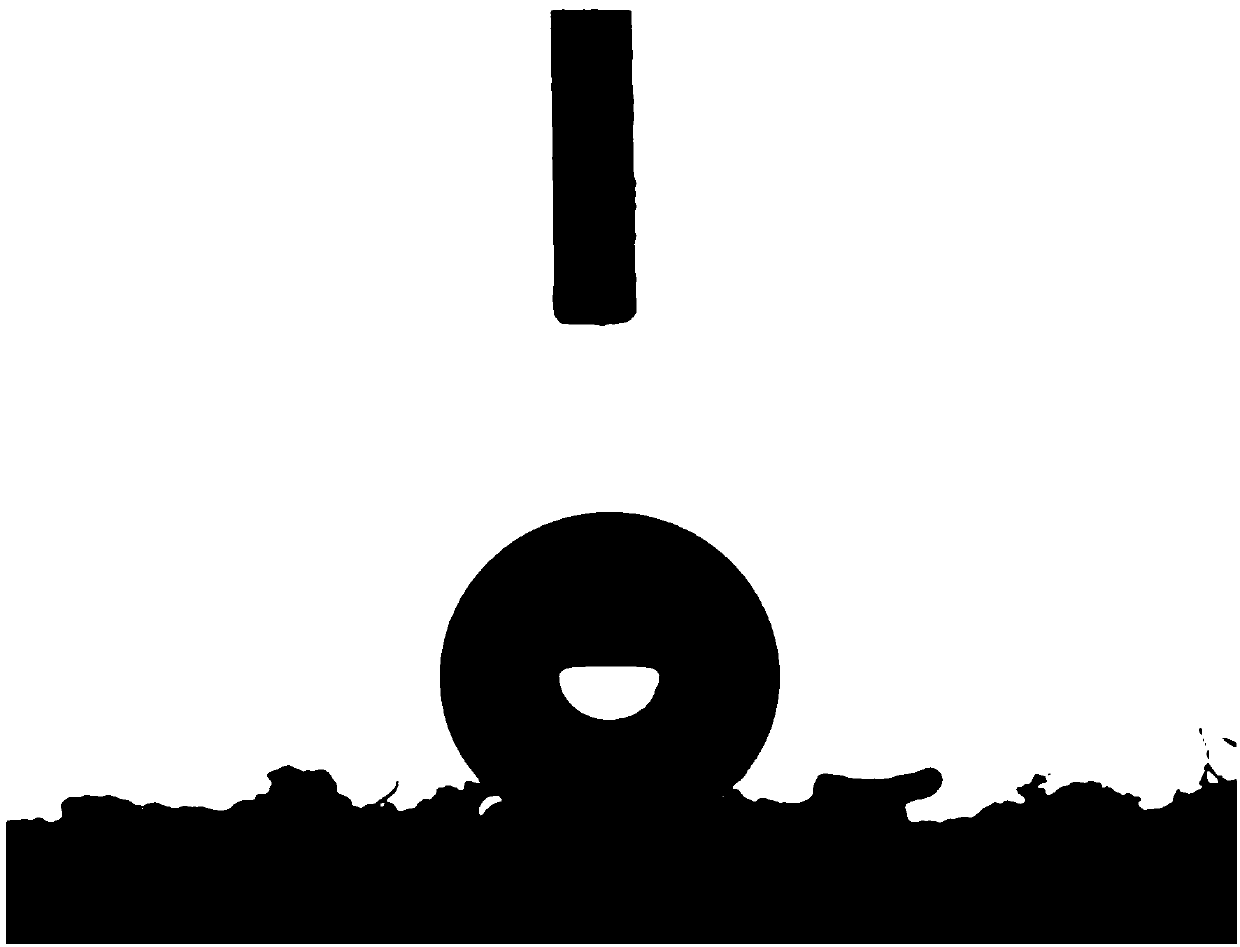

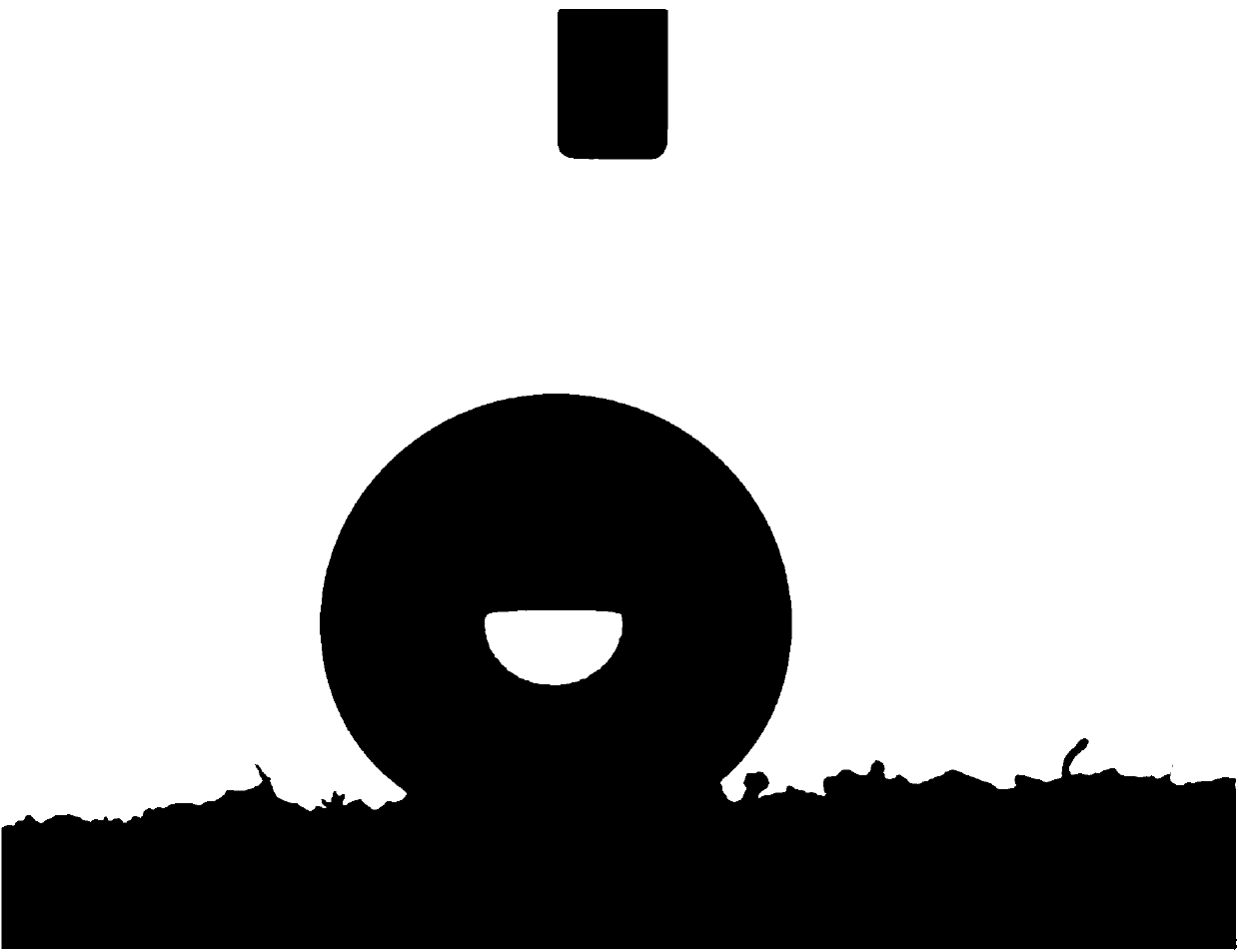

ActiveUS20070026193A1Improve surface roughnessImprove surface hydrophobicityFouling preventionLotus effect fibresSurface roughnessEngineering

Disclosed is a process for modification of a substrate so as to form an ultrahydrophobic surface on the substrate. Also disclosed are surface-modified substrates that can be formed according to the disclosed processes. The process includes attachment of a multitude of nano- and / or submicron-sized structures to a surface to provide increased surface roughness. In addition, the process includes grafting a hydrophobic material to the surface in order to decrease the surface energy and decrease wettability of the surface. The combination of increase surface roughness and decreased surface energy can provide an ultrahydrophobic surface on the treated substrate.

Owner:CLEMSON UNIVERSITY

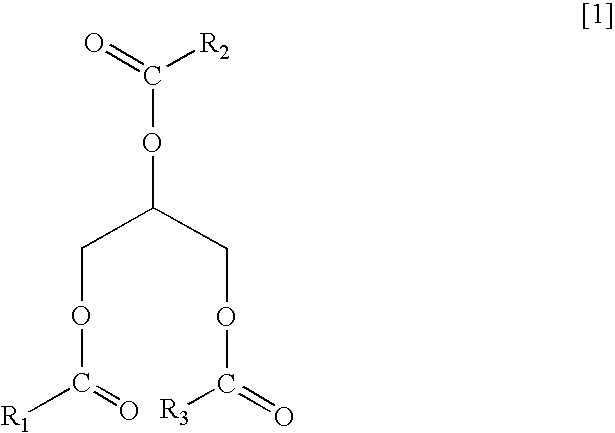

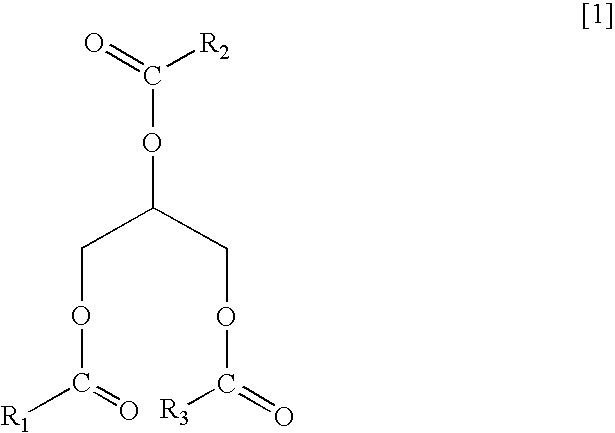

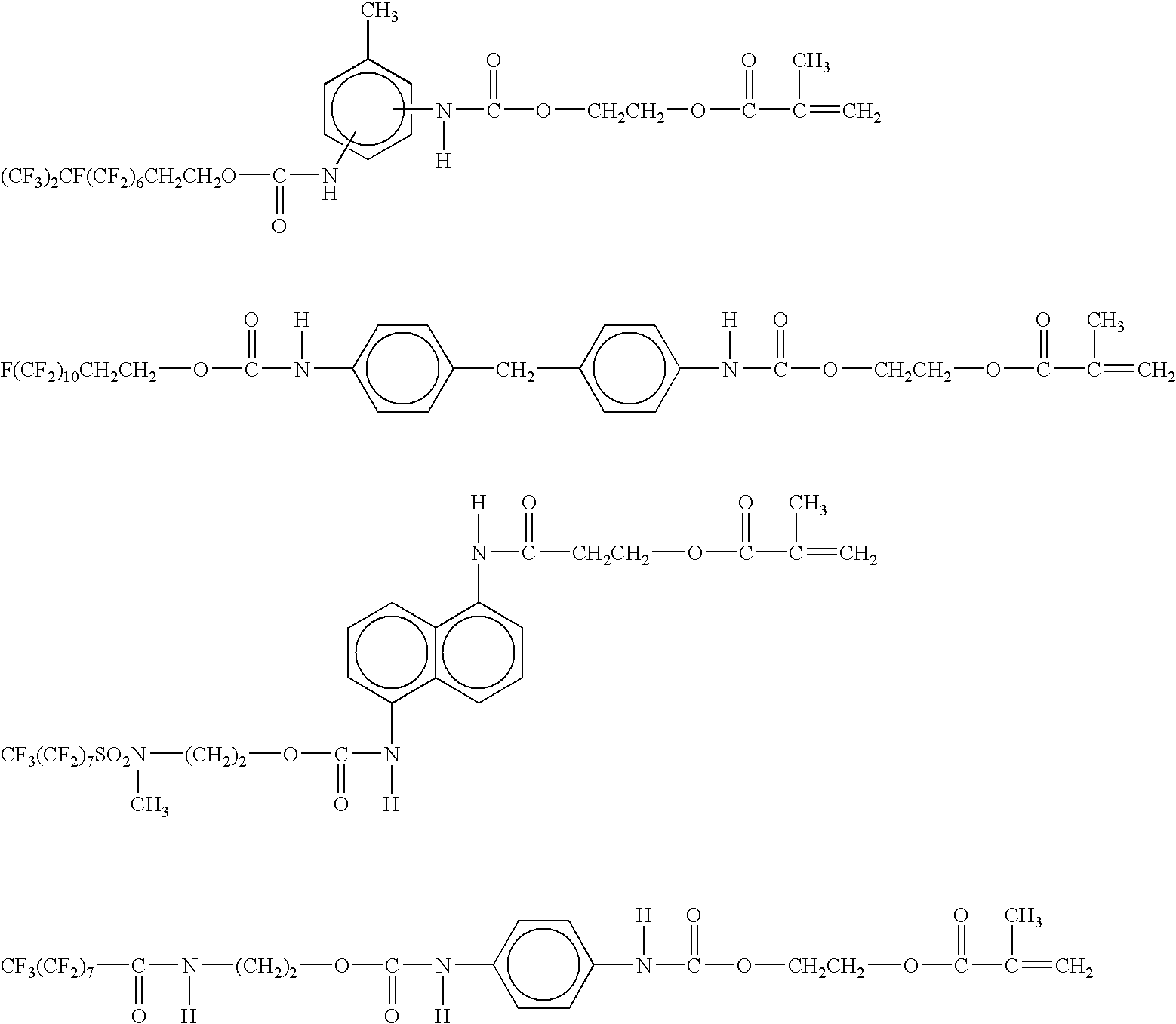

Fluorochemical composition comprising a fluorinated polymer and treatment of a fibrous substrate therewith

InactiveUS7094829B2Easy to oilGood water repellency propertyStain/soil resistant fibresLiquid repellent fibresFiberOrganic solvent

A fluorochemical composition for rendering fibrous substrates oil repellent, water repellent, and / or stain repellent and comprising a fluorinated polymer dispersed in water or dissolved or dispersed in an organic solvent, the fluorinated polymer comprising units derived from (i) a mixture of two or more fluorinated polyether monomers that differ in at least their molecular weight, the fluorinated polyether monomers having an ethylenically unsaturated group and a perfluorinated polyether group and wherein at least 90% by weight of the mixture consists of fluorinated polyether monomers that have a perfluorinated polyether group having a molecular weight of at least 750 g / mol and (ii) one or more units derived from one or more co-monomers other than a fluorinated polyether monomer and wherein the co-monomers comprise at least one non-fluorinated monomer. Also, method for treating fibrous substrate with such composition, fluorinated polyether monomers, and fluorinated polymers derived from such monomers.

Owner:3M INNOVATIVE PROPERTIES CO

Fabric treatment for stain release

InactiveUS20050229327A1Minimizing fiber wearMaintain fabric appearancePhysical treatmentDry-cleaning apparatus for textilesZeta potentialWrinkle skin

A fabric treatment composition that includes a hydrophobic agent with a melting point or glass transition temperature below 100° C. and optionally, a fluoropolymer, that imparts fabric protection benefits, including improved stain and soil resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Compositions may further include a zeta potential modifier in an amount sufficient to adjust the zeta potential of the composition to be positive and greater, than zero millivolts. The composition can be used as a pretreatment prior to drying or ironing, through soaking or direct spray application, or used prior to or during the drying cycle of an automatic drying machine or clothing refresher machine, or used prior to or in conjunction with an ironing device. The fabric treatment is complete when the fabric treated by contact with the protective composition is then cured by drying and / or heating. The invention further includes a kit providing a means for convenient dispensing of the protective composition to effect treatment and curing of fabric articles.

Owner:THE CLOROX CO

Fabric care formulations and methods

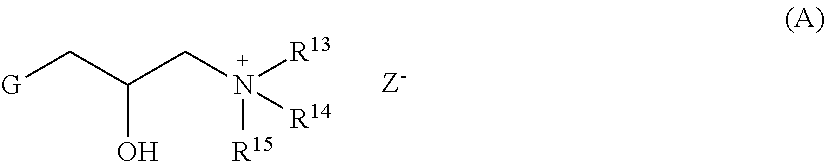

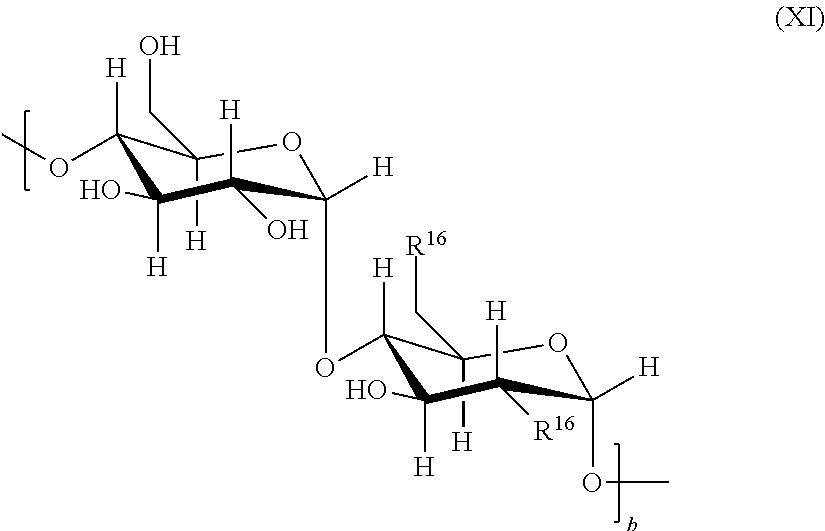

InactiveUS20120077725A1Improve antifouling performanceStain/soil resistant fibresOrganic detergent compounding agentsMedicineParticulate material

Fabric care compositions for providing improved stain repellency are described. The fabric care composition includes a mixture including a hydrophobic fluid, a particulate material and an amphoteric or cationic oligomeric / polymeric deposition aid. Methods for providing improved stain repellency for a textile by treating the textile with the fabric care composition are also described.

Owner:THE PROCTER & GAMBLE COMPANY

Finishing of textile fibers, tissues and fabrics

InactiveUS7056845B2Improve the level ofImprove functional propertiesOther chemical processesPhysical treatmentTextile fiberEngineering

A method is provided for the application of a finishing layer to a textile support material. A water repellent or oil repellent layer, a so-called finishing layer, is applied to a textile support material selected from the group of fibers, tissues, and fabrics. The water repellent or oil repellent finishing layer comprises at least two water repellent or oil repellent components wherein a first component comprises one or more dispersants and a second component comprises one or more dispersed phases or colloids, and wherein the dispersant and the dispersed phase are present in the gel state.

Owner:SCHOELLER TEXTIL

Hydrophobic additive for use with fabric, fiber, and film

The present invention relates to a hydrophobic additive for use with fabric, fiber, and film. One aspect of the present invention comprises a master batch composition for use in preparing a non-woven fabric in order to increase the hydrophobicity of the non-woven fabric. In one embodiment, the master batch composition includes a polymer and a lipid ester. The lipid ester comprises from 10 wt. % to 40 wt. % of the master batch. The fabric, when including the master batch composition, has a contact angle ranging from 100° to 125° when measured according to test method ASTM D2578.

Owner:TECHMER PM

Hydrophobic and Lyophobic Coating

InactiveUS20080090004A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingCoated surfaceSolid substrate

The invention provides a method for forming a hydrophobic coating on the surface of a solid substrate, the method comprising: a) applying to the surface a composition comprising hydrophobic nano-sized particles, wherein at least some of the hydrophobic nano-sized particles are particles having at least one fluoro-substituted non-polar group on the surface of the particle; and b) curing the applied composition to form a coating bound to the surface, wherein the nano-sized particles provide the surface of the coating with nano-scale roughness. The method can be used to form a hydrophobic and lyophobic coating on the surface of a textile.

Owner:NEWSOUTH INNOVATIONS PTY LTD

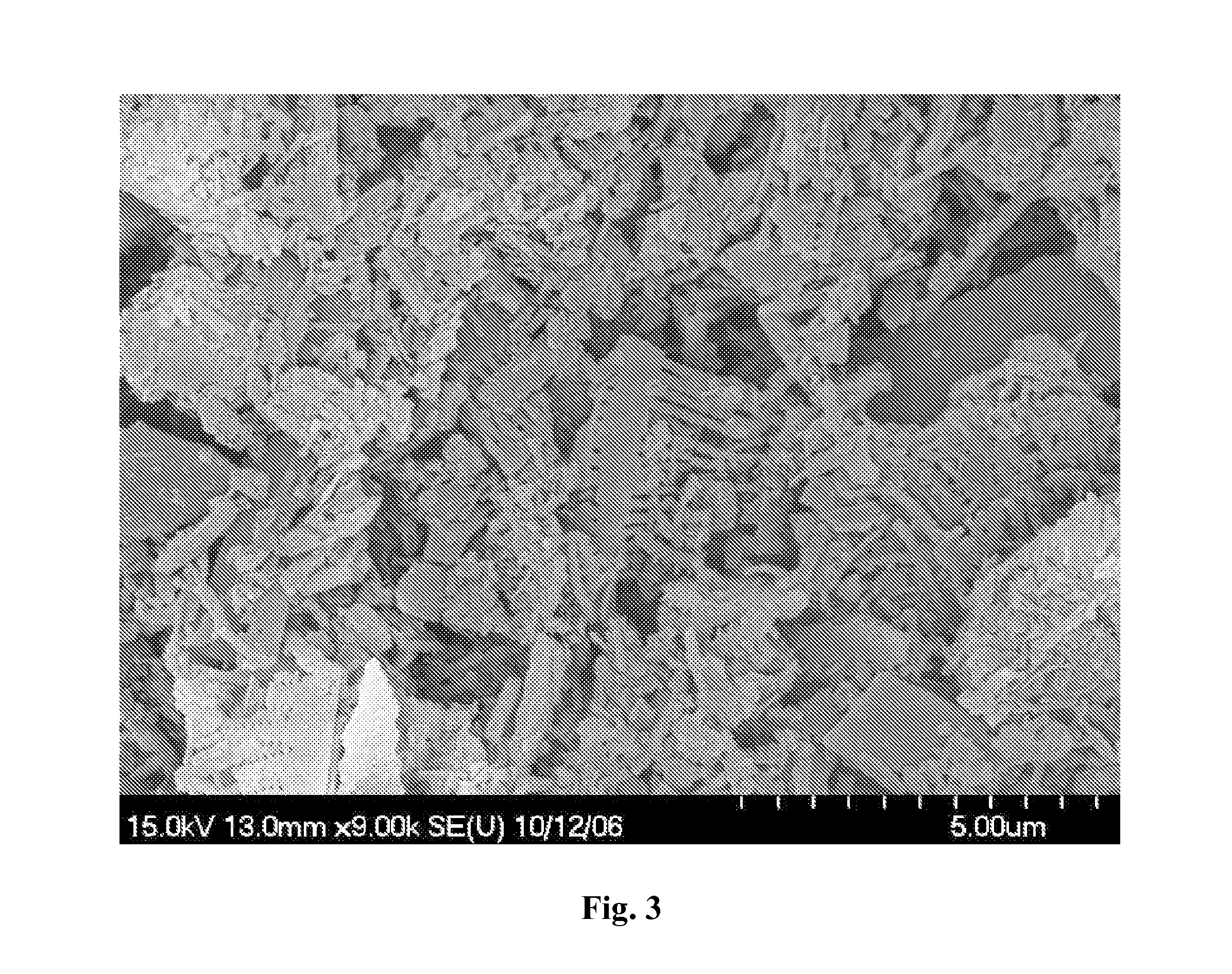

Super-hydrophobic water repellant powder

A composition of matter is a plurality of solid particles of at least 100 nm to about 10 μm in size having a plurality of nanopores where at least some of the nanopores provide flow through porosity, and the surface of the particles displays a plurality of spaced apart nanostructured features with a contiguous material protruding at the surface and optionally at least one interpenetrating recessing contiguous material. The particles are superhydrophobic when the protruding material is hydrophobic or a hydrophobic coating conforms to the surface of the particle. Articles with superhydrophobic surfaces can be formed by the coating of the particles on a solid substrate.

Owner:UT BATTELLE LLC

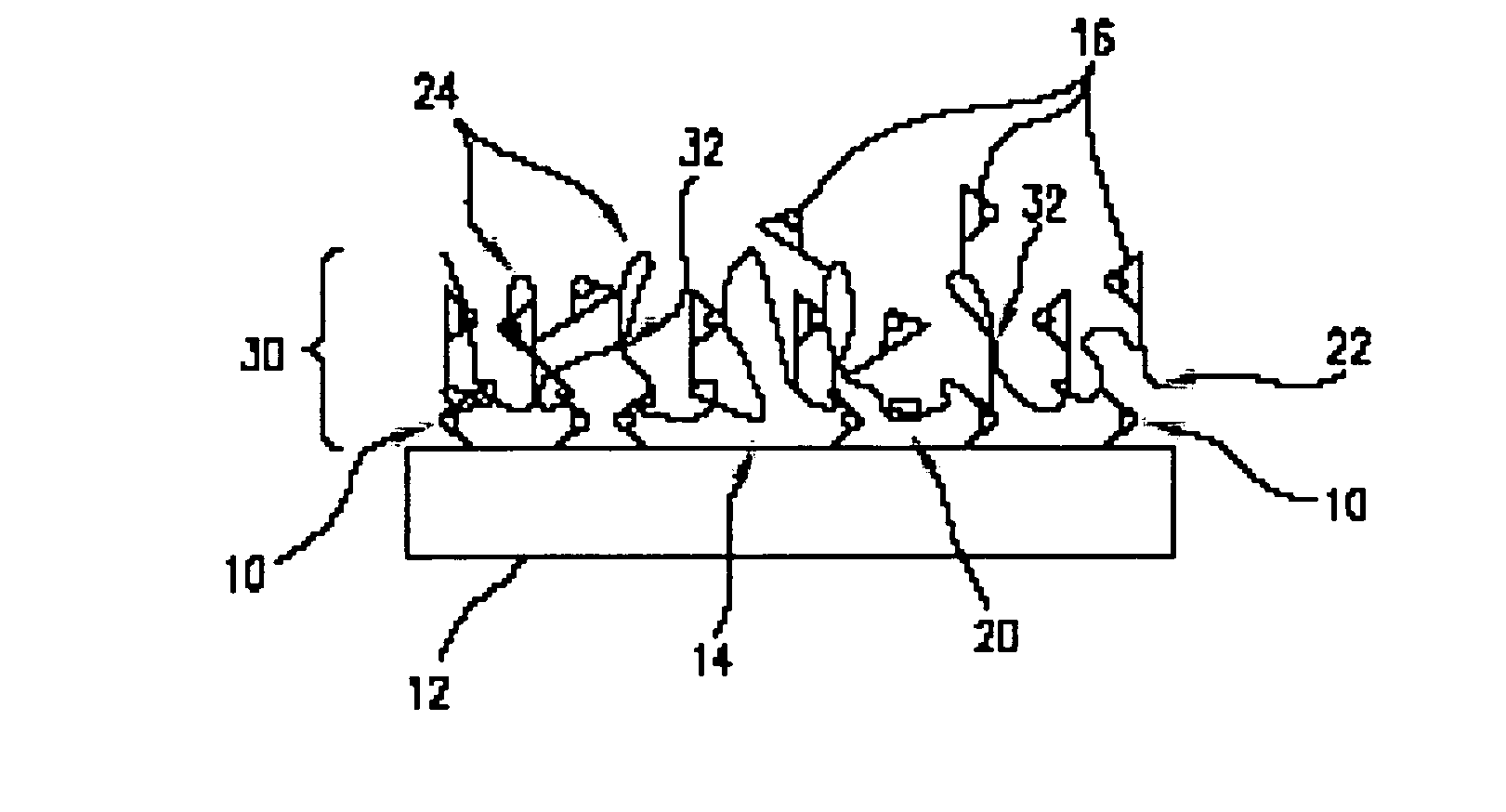

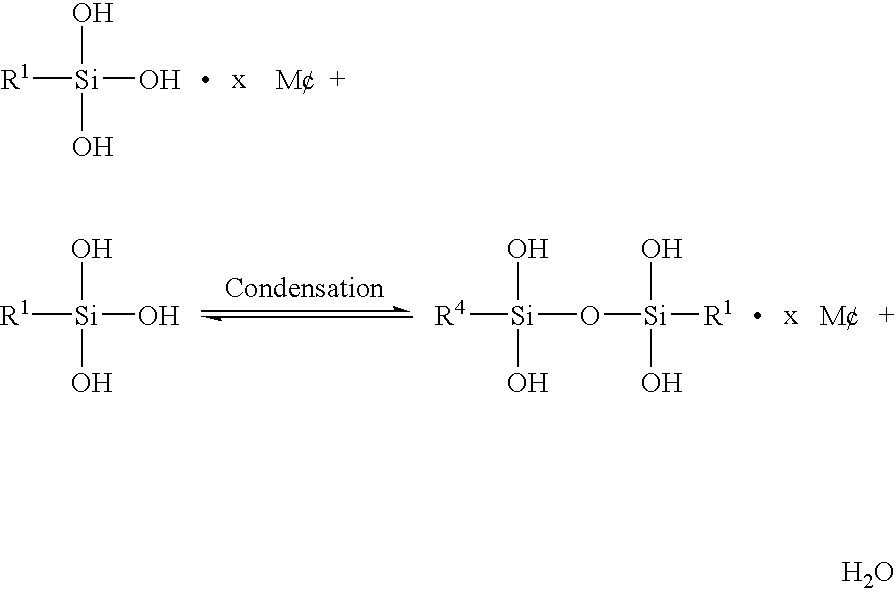

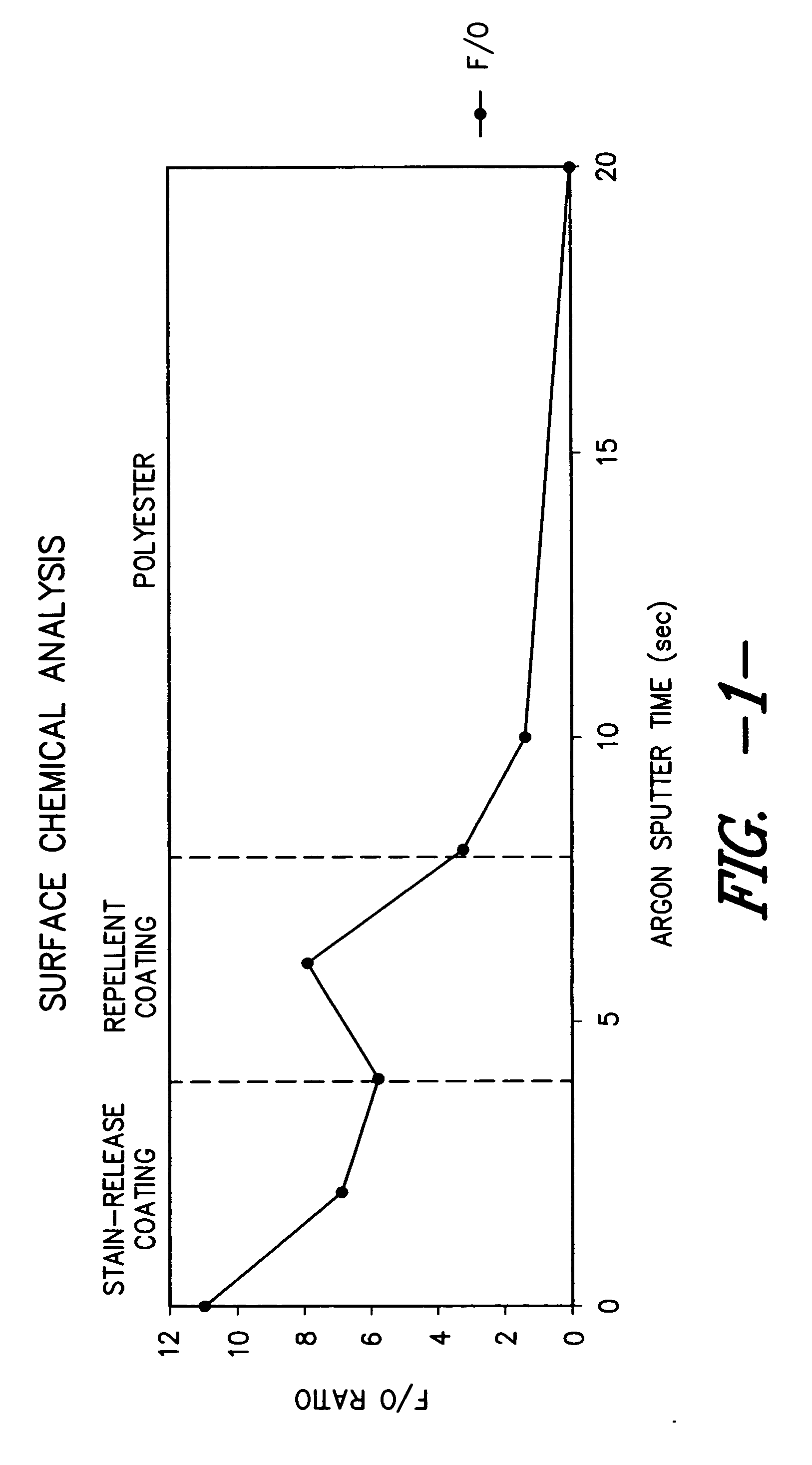

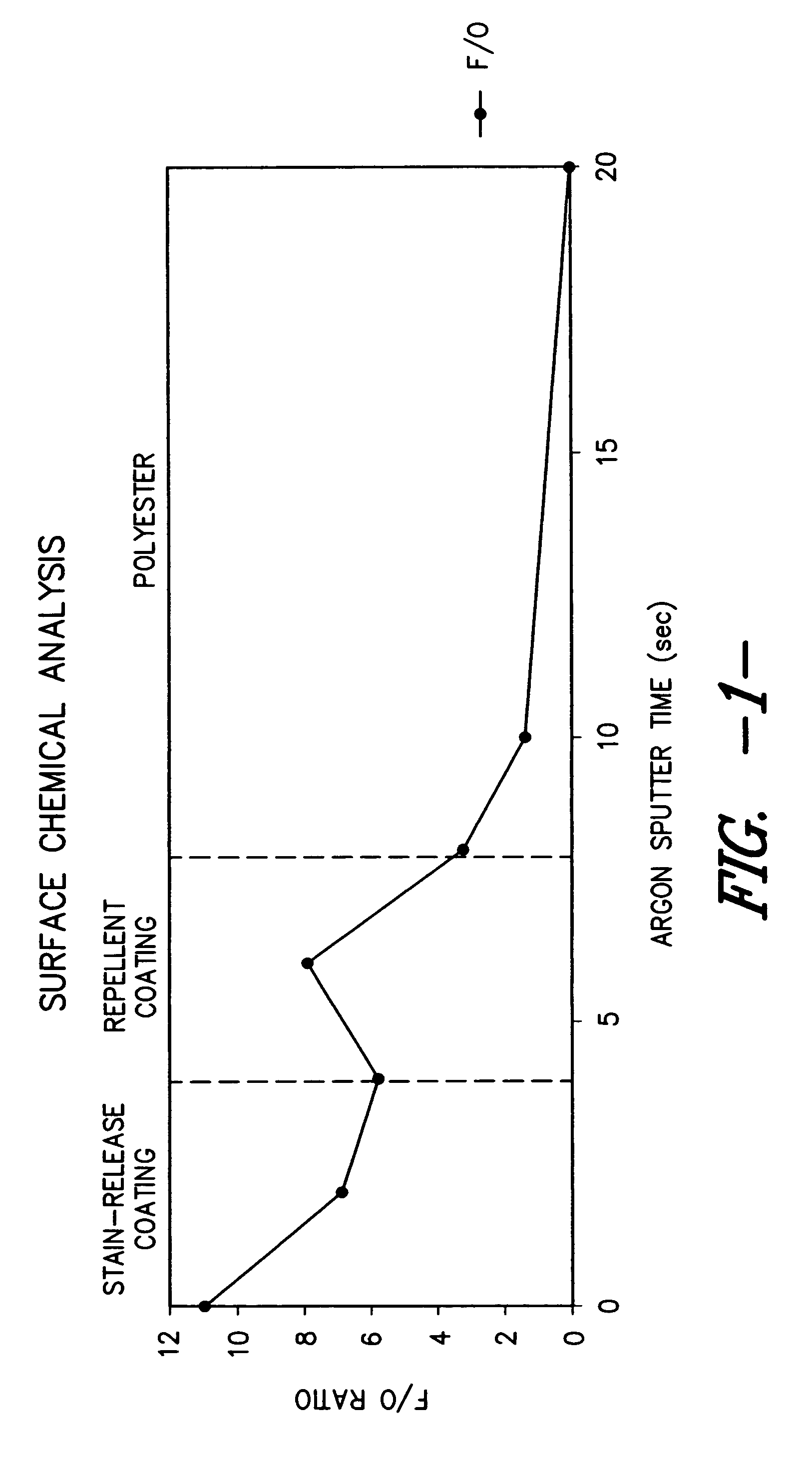

Textile substrates having layered finish structure for improving liquid repellency and stain release

This invention relates to textile substrates to which a finishing treatment has been applied during the manufacturing process. Such a finishing treatment provides improved water and / or oil repellency and stain and soil resistance. The finishing treatment generally includes a repellent agent, a stain release agent, and a particulate component. Other compounds may be added to the treatment, such as stain-blocking agents, crosslinking agents, coupling agents, antimicrobial agents, and pH adjusting agents. The components of the finishing treatment are generally applied to the textile substrate using an application process that results in layered structures on the surface of the treated substrate, which has been found to greatly improve the durability of the treatment. Such treated textile substrates thus exhibit excellent stain and soil resistance and water and / or oil repellency properties.

Owner:MILLIKEN & CO

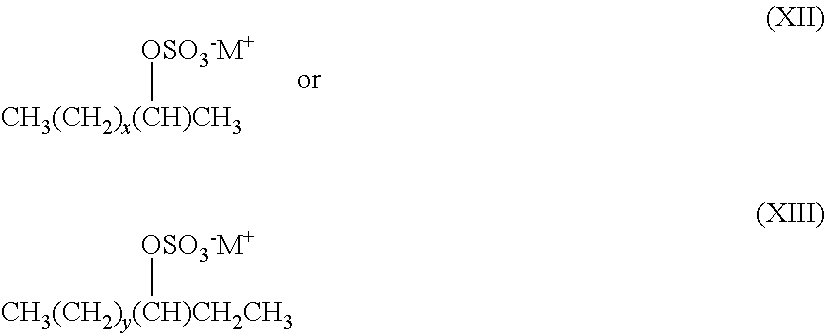

Method of treatment of a textile or non-woven substrate to render same water and oil repellent

The present invention relates to a method of treating a non-woven substrate or textile, comprising the step of applying to said non-woven substrate or textile a fluorochemical composition comprising a fluoropolymer that comprises:(a) between 10 and 97 mole % of units that can be derived from fluorinated monomer selected from the group consisting of monomers according to the general formula: Rf-X—OC(O)—C(R)═CH2 wherein Rf represents a perfluorinated aliphatic group having 3 or 4 carbon atoms, X is an organic divalent linking group and R represent hydrogen or a lower alkyl group having 1 to 4 carbon atoms; (b) between 3 and 75 mole % of units derived from a chlorine containing comonomer selected from the group consisting of vinylidene chloride, vinyl chloride and mixtures thereof; and (c) optionally further units derived from monomers other than a fluorinated monomer and said chlorine containing comonomers; wherein the amount of units (a), (b) and (c) adding up to 100%, whereby said fluorochemical composition is applied in such amount that the weight of fluoropolymer on said non-woven substrate or textile is not more than 3% by weight based on the weight of said non-woven substrate or textile.

Owner:3M INNOVATIVE PROPERTIES CO

Emulsion polymerization of fluorinated monomers

InactiveUS7045571B2Good chemical stabilityEasy to cleanCosmetic preparationsToilet preparationsIonomerPolymer science

The use of perfluorinated polymers and / or fluorinated ionomers as surfactant emulsifiers in emulsion polymerization of fluorinated monomers.

Owner:3M INNOVATIVE PROPERTIES CO

Fabric Treatment For Stain Release

ActiveUS20080148491A1Feel goodMinimizing fiber wearNon-ionic surface-active compoundsOrganic detergent compounding agentsWrinkle skinZeta potential

A fabric treatment composition that includes at least one zeta potential modifier and a hydrophobic agent with a melting point or glass transition temperature below 100° C. that imparts fabric protection benefits, including improved stain and soil resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Treatment compositions can be used as a pretreatment prior to washing, through soaking, or added to the treatment liquor, that is either the wash or rinse cycle of an automatic washing machine, to first provide and then maintain and restore the beneficial fabric protection benefits imparted to the fabrics during a first treatment operation. The fabric treatment is complete when the fabric is cured by drying and / or heating. Following use of a first treatment composition, protective benefits are maintained and restored by means of a second treatment operation employing a second treatment composition with lower active levels of the protective agents to provide for economical and continual maintenance of the imparted fabric protection benefits through a delivered second fabric treatment benefit with each subsequent treatment operation employing the fabric treatment compositions.

Owner:VAN BUSKIRK GREGORY

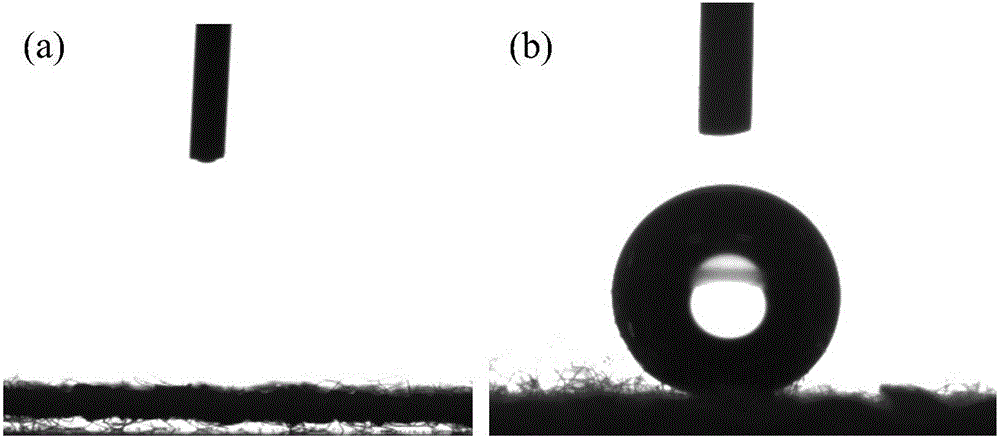

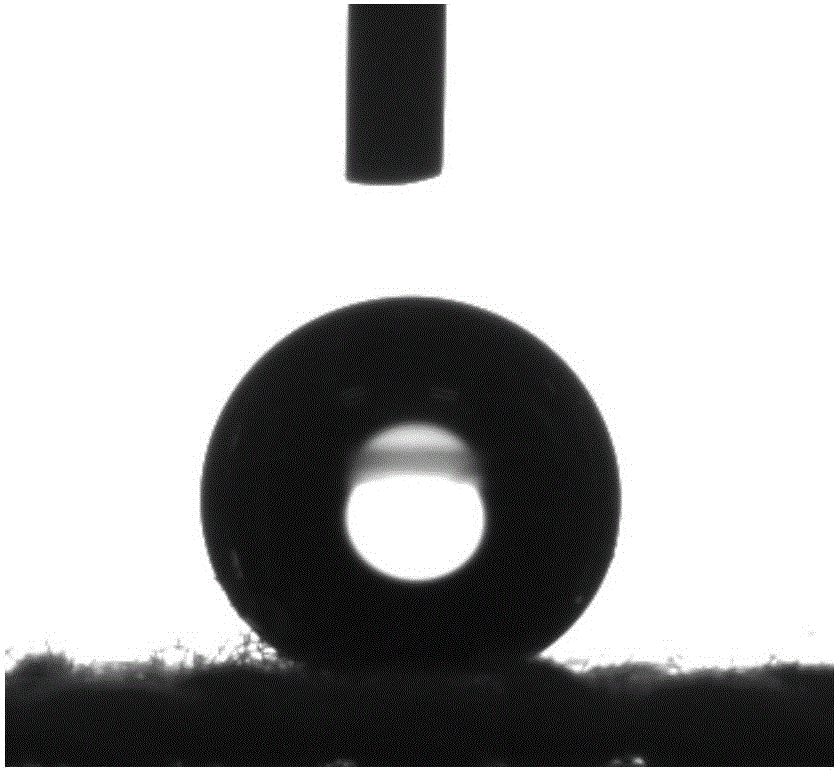

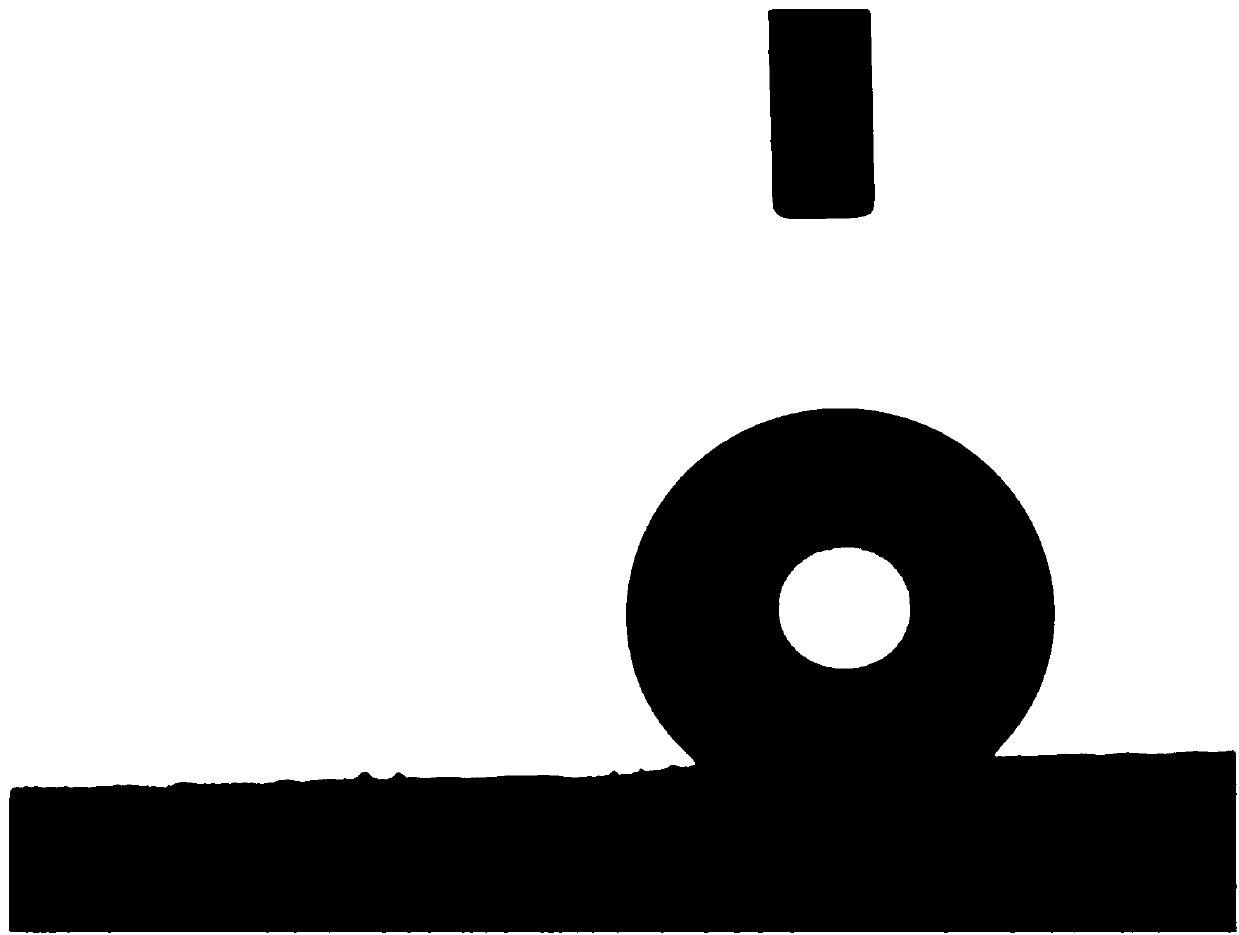

Method for preparing super-hydrophobic textile from thiol-ene click chemistry-modified fiber

InactiveCN105696306AWashableWear-resistantLiquid repellent fibresAbrasion resistant fibresFiberPolyester

The invention relates to a preparation method of a functional textile, and belongs to the field of textile surface grafting modification. The method for preparing a super-hydrophobic textile from a thiol-ene click chemistry-modified fiber is characterized by comprising the steps that alkali liquor steaming treatment is performed on a polyester fiber, then mercaptosilane is fixed to the surface of the polyester fiber, finally a methacrylate monomer is grafted to the surface of the polyester through a thiol-ene click chemistry reaction to reduce the surface tension of the fiber, and then the super-hydrophobic polyester textile is obtained. The contact angle between the polyester textile prepared through the method and water drops is larger than 150 degrees, and the polyester textile is stable to acid, alkali, salt and solvent and capable of resisting friction and washing and has the very good hydrophobic stability.

Owner:SHAANXI UNIV OF SCI & TECH

Hydrophobic additive for use with fabric, fiber, and film

The present invention relates to a hydrophobic additive for use with fabric, fiber, and film. One aspect of the present invention comprises a master batch composition for use in preparing a non-woven fabric in order to increase the hydrophobicity of the non-woven fabric. In one embodiment, the master batch composition includes a polymer and a lipid ester. The lipid ester comprises from 10 wt. % to 40 wt. % of the master batch. The fabric, when including the master batch composition, has a contact angle ranging from 100° to 125° when measured according to test method ASTM D2578.

Owner:TECHMER PM

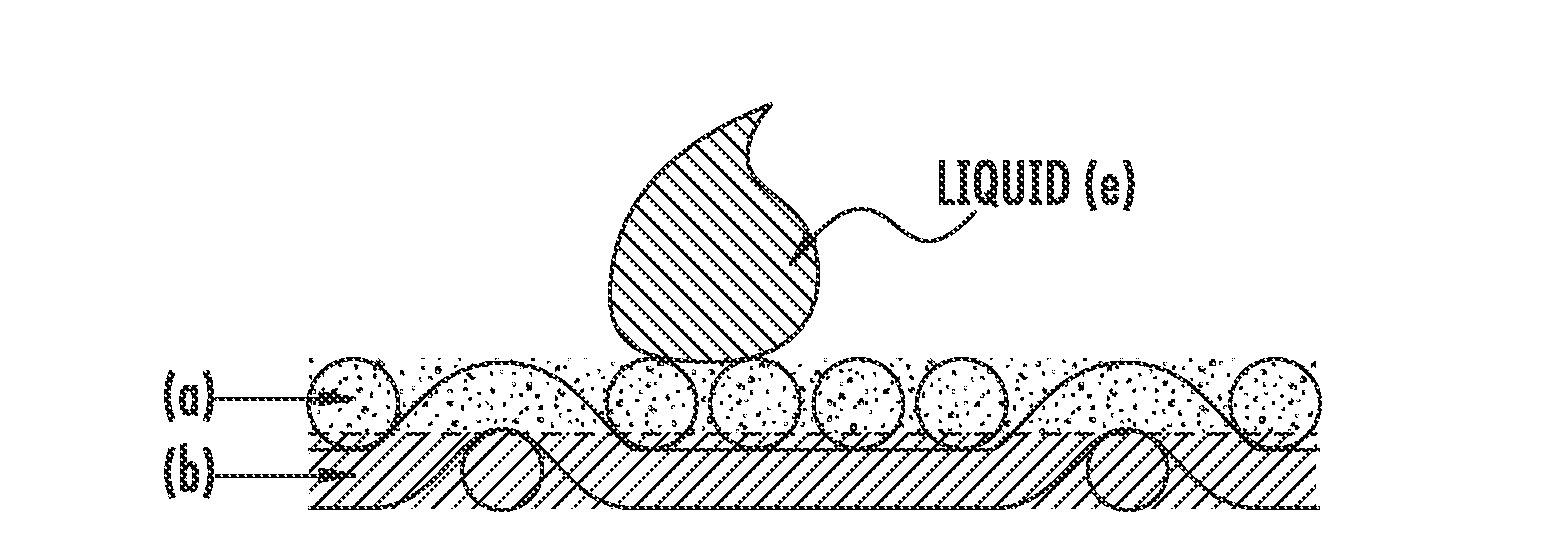

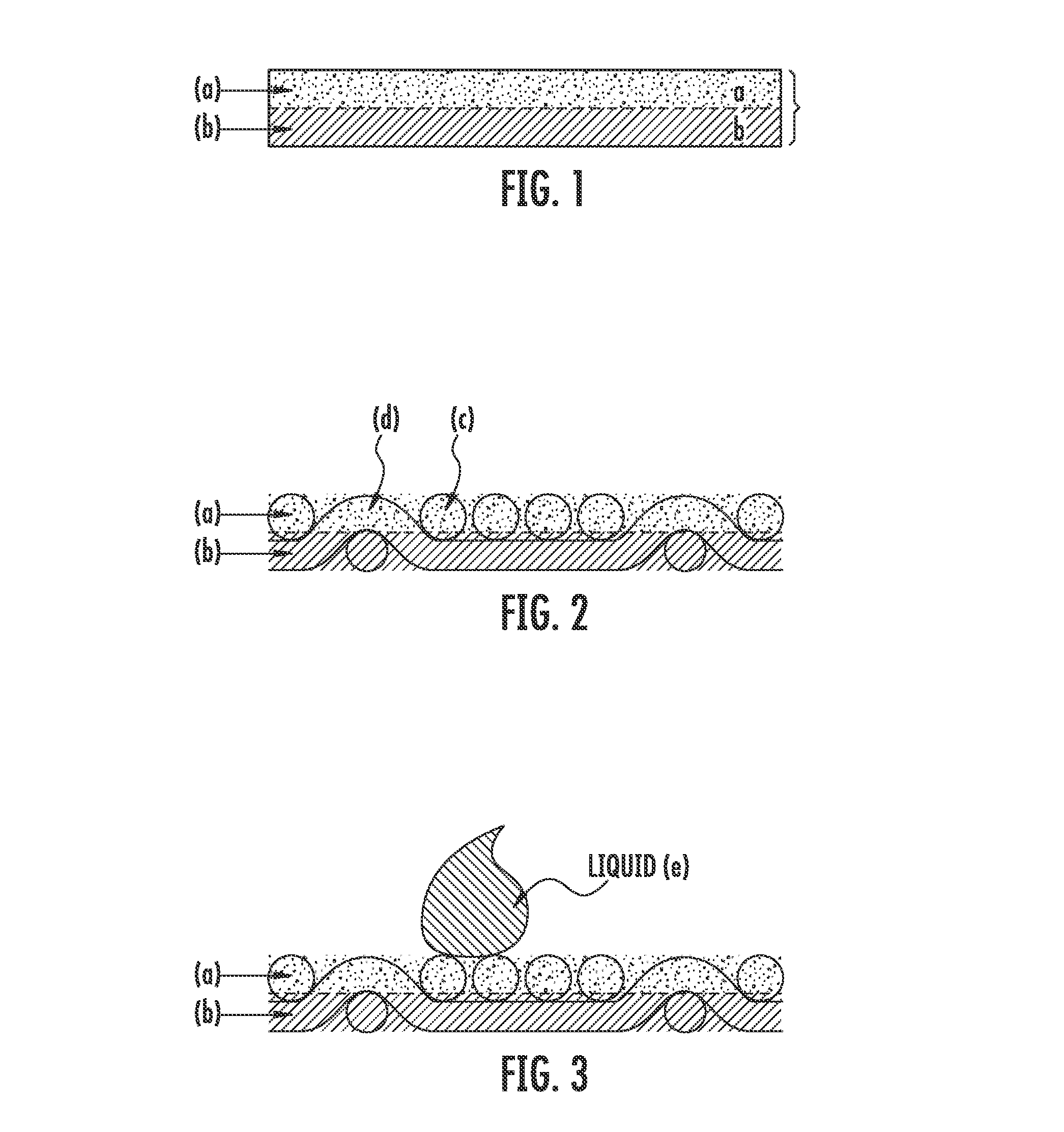

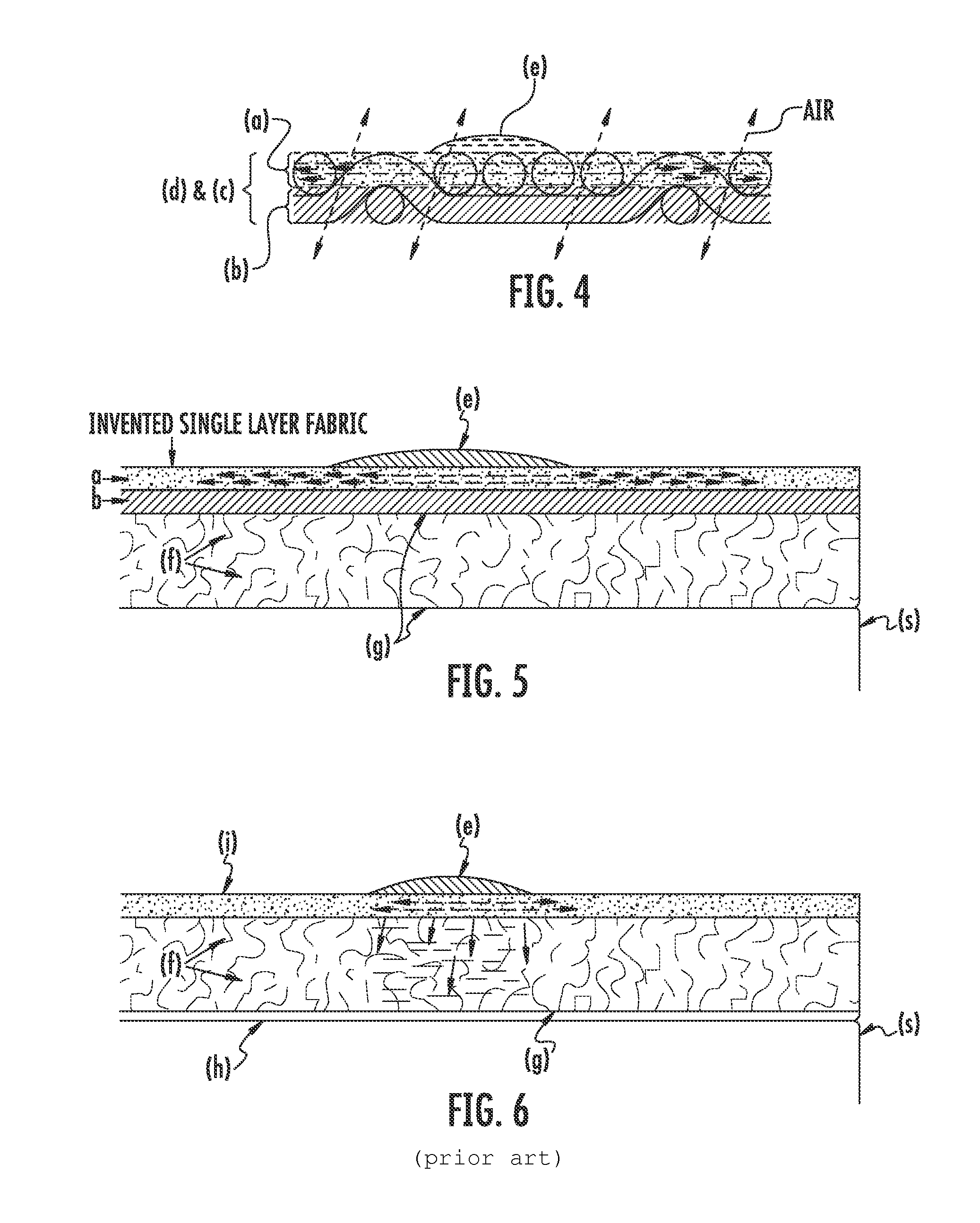

Semi-absorbent, semi-resistant, breathable fabric

A semi-absorbent, semi-resistant, breathable fabric includes a single-layer having a first, hydrophilic side that absorbs water, and a second, hydrophobic side; wherein the first, hydrophilic side of the single-layer fabric quickly spreads out a liquid that is absorbed laterally to a wider area such that the absorbed liquid does not seep or pass through to the second, hydrophobic side of the single-layer fabric under gravitational force. A method of making a semi-absorbent, semi-resistant, breathable fabric includes: subjecting a first side of a single-layer fabric to a hydrophilic amino functional polysiloxane softener; treating a second opposite side of the fabric with a fluorocarbon compound under low pressure such that the fluorocarbon compound penetrates no more than half of the fabric thickness; and drying and curing the fabric, preferably at a temperature of about 145° C. to 155° C. for about three minutes to about five minutes.

Owner:WELSPUN INDIA LTD

Superhydrophobic, diatomaceous earth comprising bandages and method of making the same

A bandage comprising a substrate having a first surface with a plurality of superhydrophobic particles attached to the first surface. The plurality of superhydrophobic particles can be porous diatomaceous earth particles having a hydrophobic layer conforming to the surfaces of the DE particles, where the hydrophobic layer is bound to the DE particles. The plurality of attached superhydrophobic particles can render the first surface superhydrophobic, while a second surface opposite the first surface can be hydrophilic or hydrophobic. The substrate can be breathable in order to maintain skin health for the tissue underlying the bandage. The substrate can be selected from porous films, apertured films, textiles, nonwoven materials, impregnated composites thereof, and combinations thereof.

Owner:UT BATTELLE LLC

Method of manufacturing ultrahydrophobic substrates

ActiveUS7985451B2Improve surface roughnessImprove surface hydrophobicityFouling preventionLotus effect fibresSurface roughnessMaterials science

A process for modification of a substrate so as to form an ultrahydrophobic surface on the substrate is provided. Surface-modified substrates that can be formed according to the disclosed processes are also provided. The process includes attachment of a multitude of nano- and / or submicron-sized structures to a surface to provide increased surface roughness. In addition, the process includes grafting a hydrophobic material to the surface in order to decrease the surface energy and decrease wettability of the surface. The combination of increased surface roughness and decreased surface energy can provide an ultrahydrophobic surface on the treated substrate.

Owner:CLEMSON UNIVERSITY

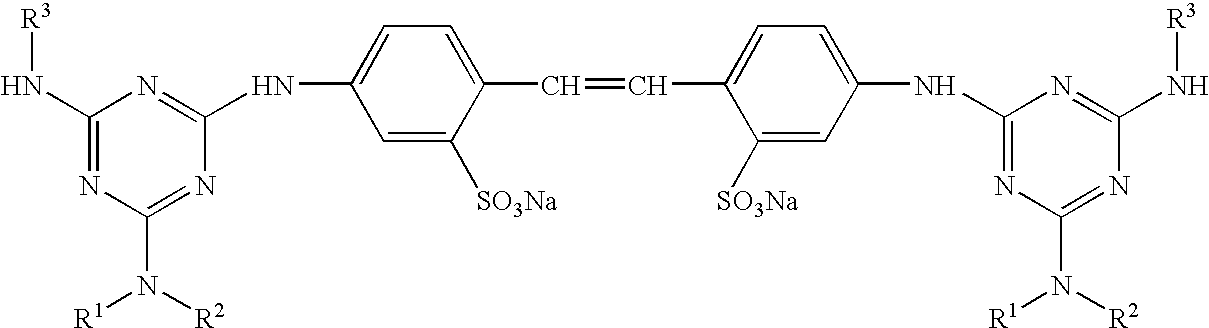

Treated textiles and compositions for treating textiles

InactiveUS20050062010A1Good liquid repellencyPhysical treatmentDecorative surface effectsChemical compositionCompound (substance)

Certain chemical compositions provide superior repellency, durability, and soil (stain) release properties when applied to a textile or fabric. Compositions may contain a fluorochemical-containing soil release component or a crosslinking component, or both, and also may contain an antimicrobial agent. In some applications, the crosslinking component may be hydrophobic, so as to be generally not compatible with aqueous environments. Compositions having less than about 6 weight percent of a fluorochemical-containing soil release component, based upon the weight of the treating composition, may be employed in some applications.

Owner:SAGE AUTOMOTIVE INTERIORS INC

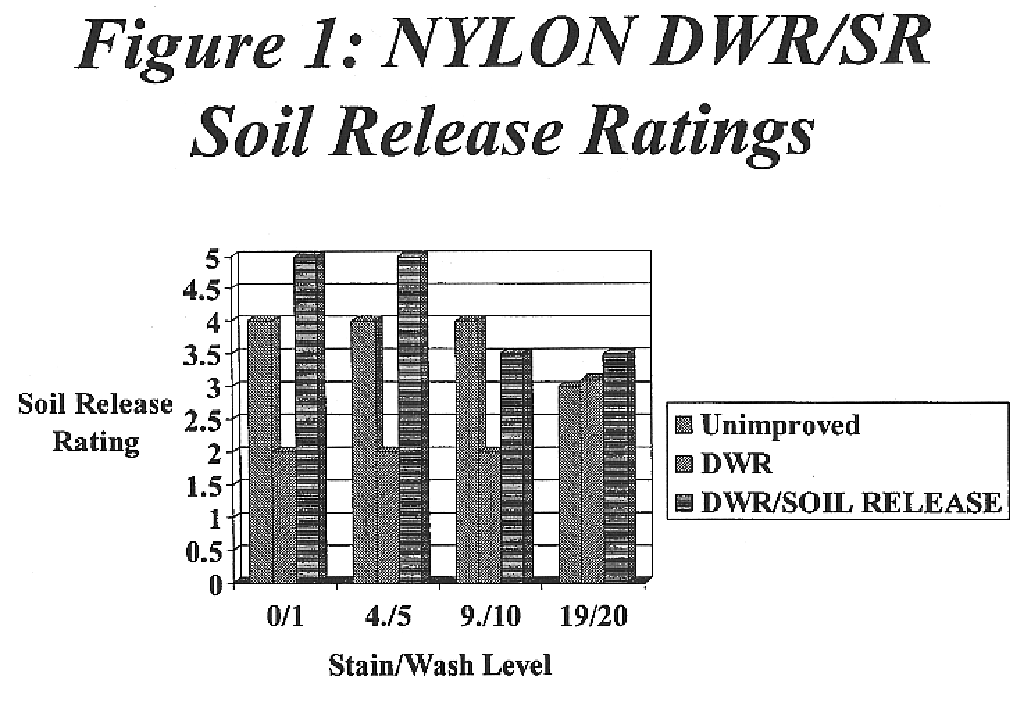

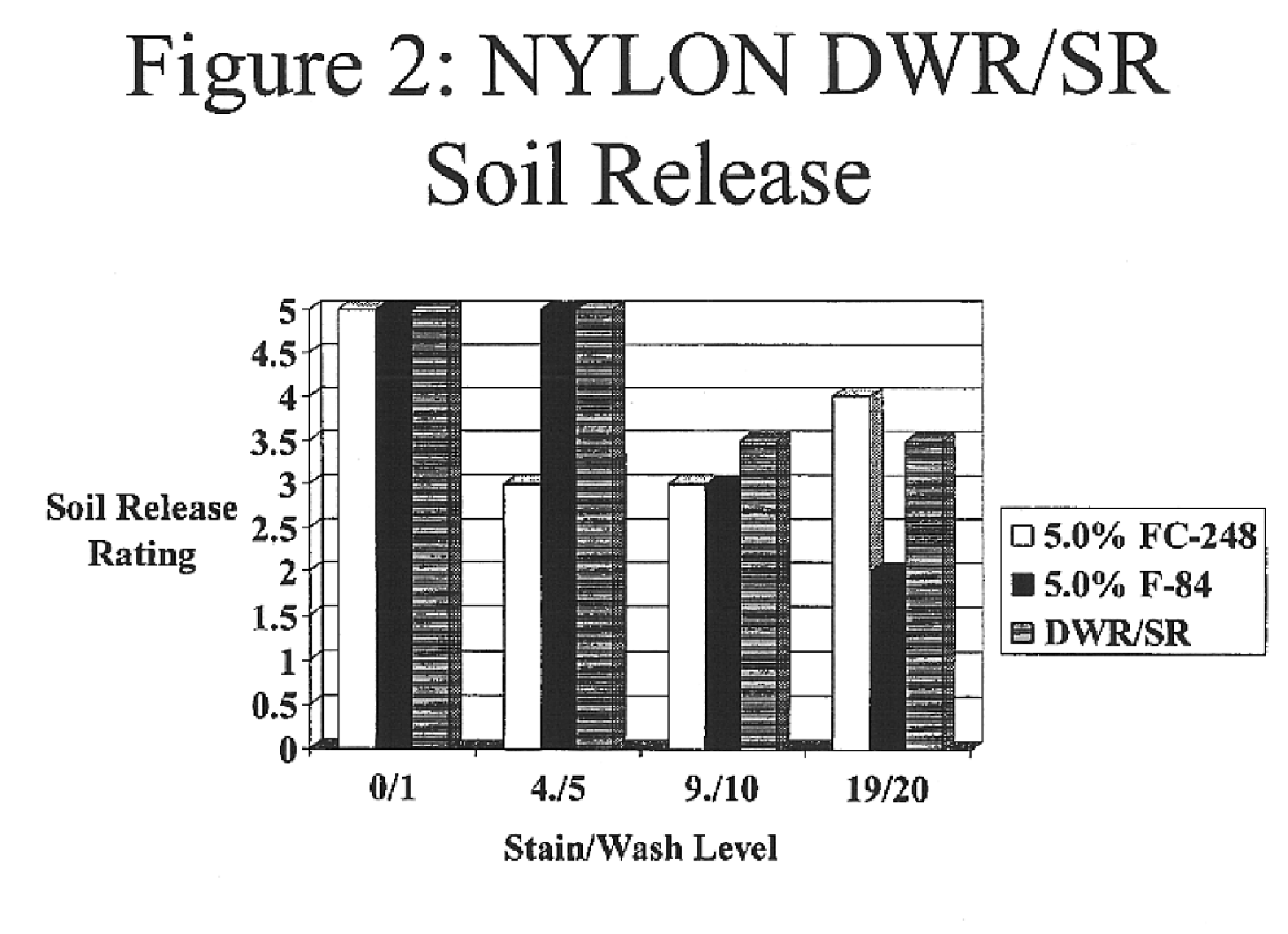

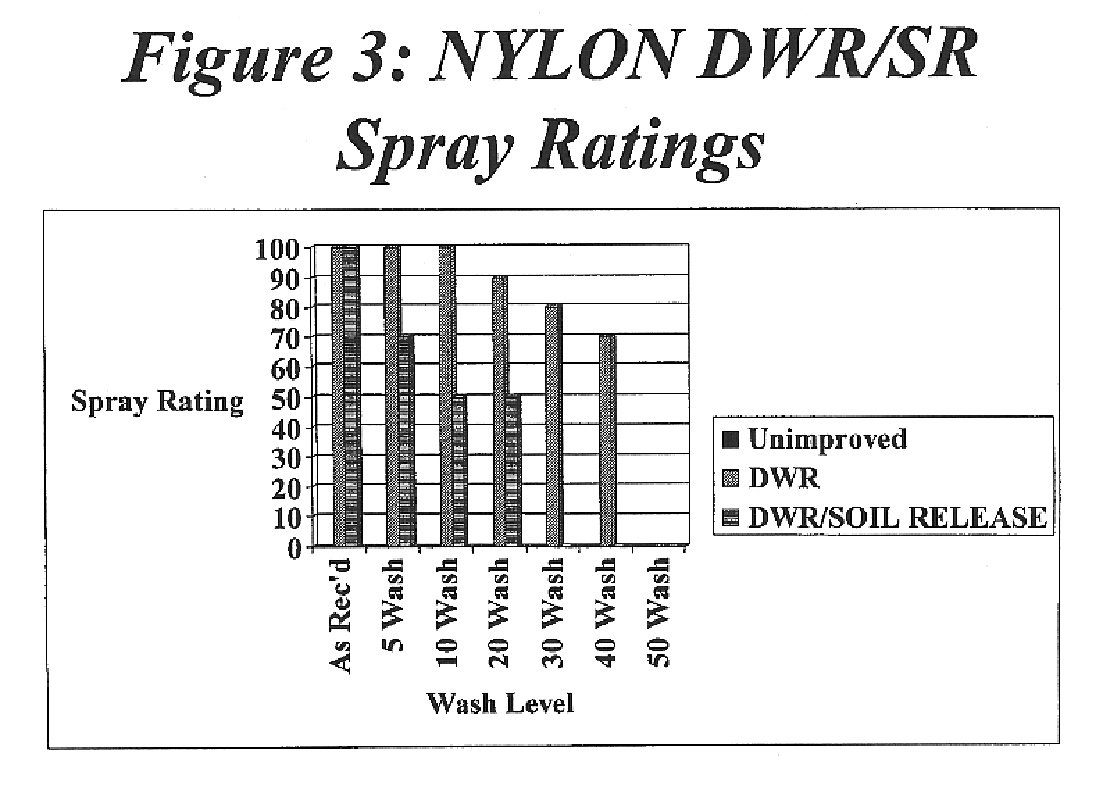

Method of producing textile substrates having improved durable water repellency and soil release

InactiveUS6818253B2Improved durable water and oil repellencyFacilitated releaseOther chemical processesSynthetic resin layered productsPolyesterAramides

Owner:MILLIKEN & CO

Water- and oil-repellent compositions

InactiveUS6960642B2Improve thermal stabilityOther chemical processesLiquid repellent fibresFiberOligomer

Fiber, fabric, film, molded or blown article comprising a water- and oil-repellent composition comprising a melt blend of components (a) and (b) in which:(a) comprises a repellency-imparting, fluorochemical composition comprising at least one fluorine-containing aromatic ester oligomer comprising(1) at least two repeat units derived or derivable from the reaction of at least one dicarboxylic acid (or a derivative thereof) and at least one polyol, with the proviso that either the dicarboxylic acid (or derivative) or the polyol (or both) is aromatic or heteroaromatic, and(2) fluorochemical endgroups derived or derivable from the reaction of(i) the dicarboxylic acid (or derivative) and at least one fluorine-containing monoalcohol, or(ii) the polyol and at least one fluorine-containing monocarboxylic acid; and(b) comprises a treatable substrate material; with the proviso that, when the treatable substrate material comprises a mixture of at least two polymers, the mixture is non-stratifying.

Owner:3M INNOVATIVE PROPERTIES CO

Emulsion Polymerization of Fluorinated Monomers

InactiveUS20060160947A1Good chemical stabilityEasy to cleanTransportation and packagingOrganic dyesIonomerPolymer science

The use of perfluorinated polymers and / or fluorinated ionomers as surfactant emulsifiers in emulsion polymerization of fluorinated monomers.

Owner:3M INNOVATIVE PROPERTIES CO

Method for treating surfaces of textile

InactiveUS20050271821A1Drying processUniform coatingWater-repelling agents additionPretreated surfacesAnti bacterialViscosity

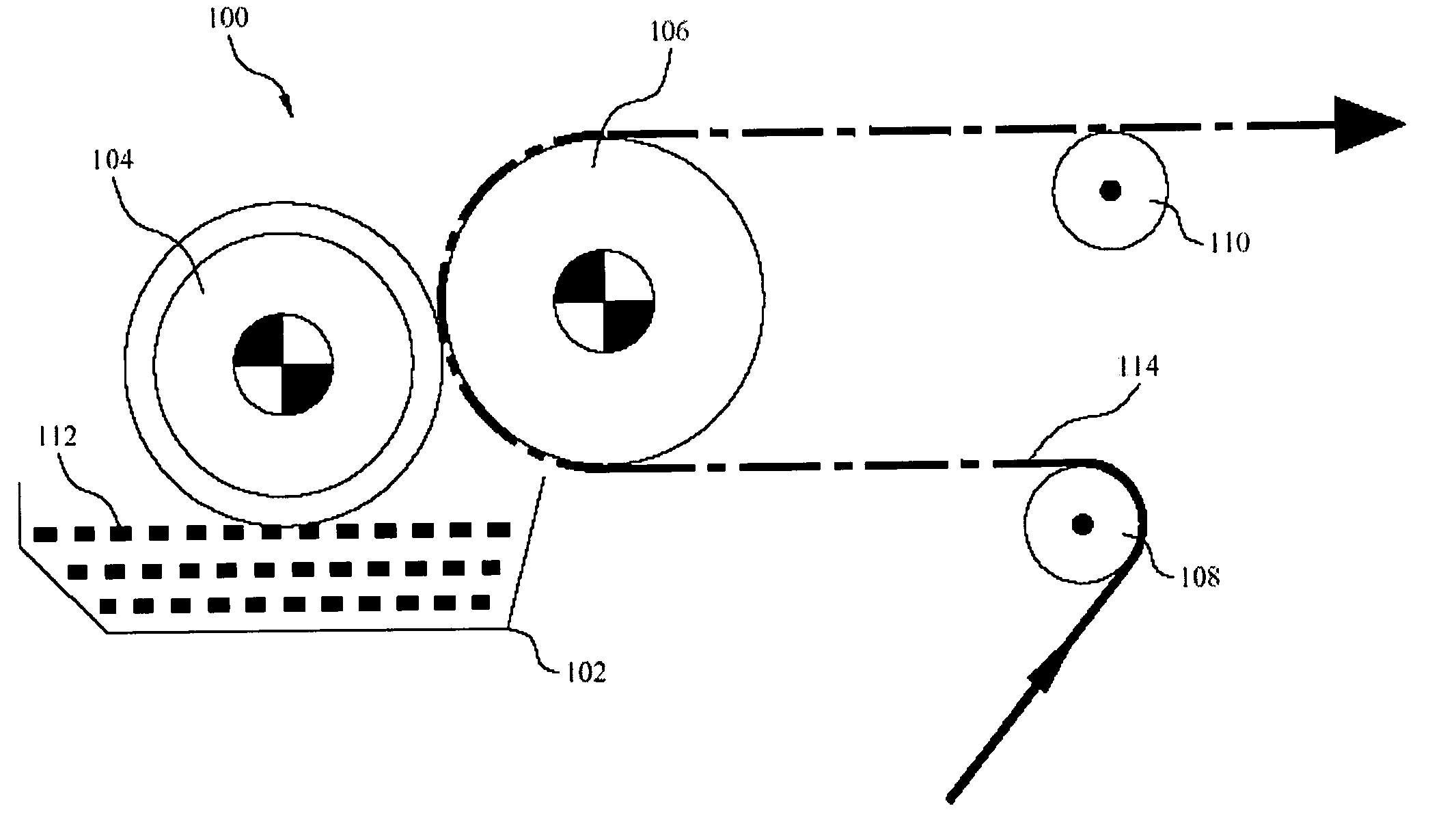

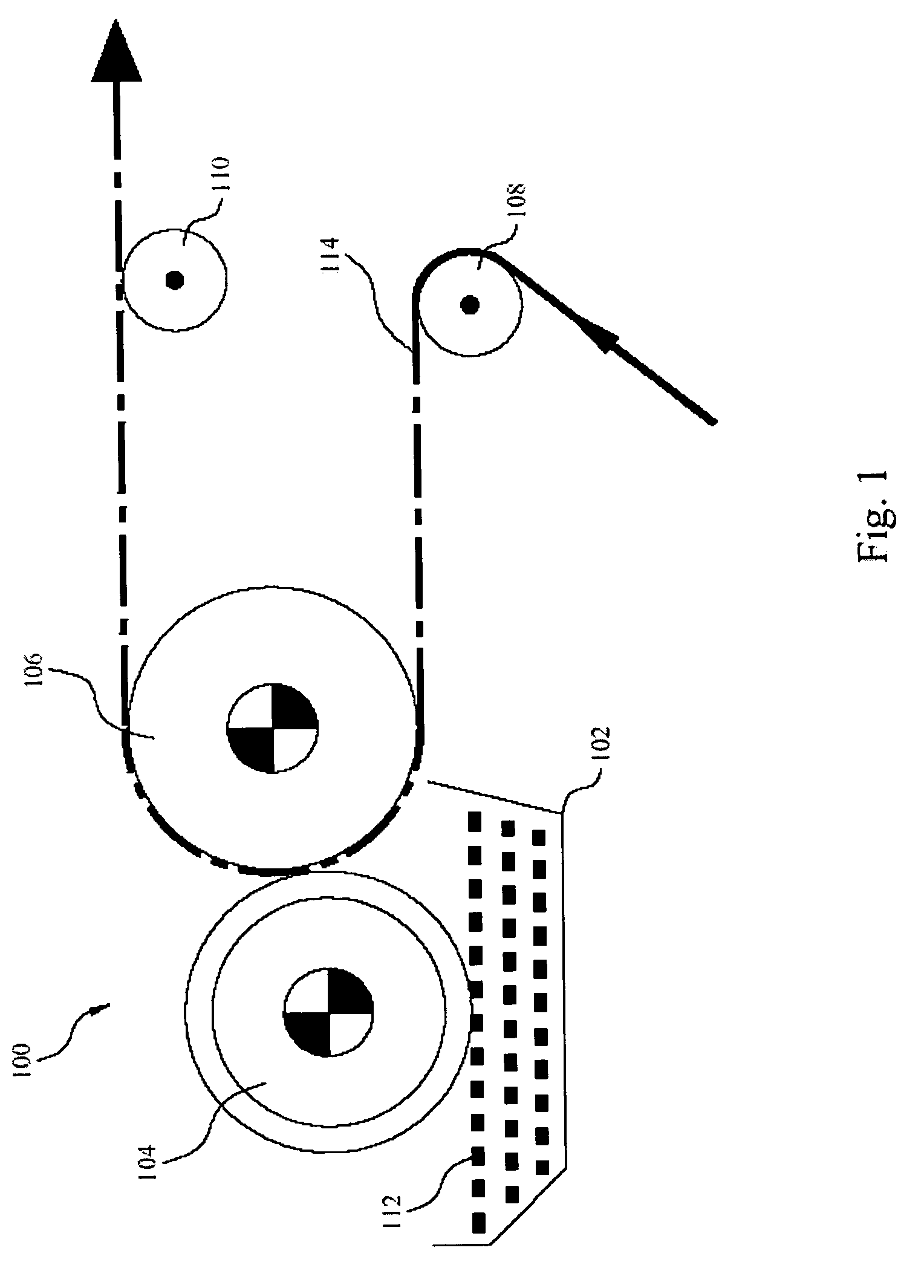

A method for treating surfaces of textile is disclosed. A coating solution, in which a polymer with reactive groups is utilized to give various functions, such as hydrophobicity, anti-bacteria or hydrophilicity (hygroscopicity) is formed. The coating solution with different viscosities, specially low viscosity, 100 cps or less, can be continuously coated onto a surface of the textile by employing a surface treating technique of gravure coating and appropriately adjusting the gravure meshes. After drying, a highly durable, washable and firm textile with single or multi-functions, such as outer hydrophobic surface and inner anti-bacterial and (or) hydrophilic (hygroscopic) surface.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

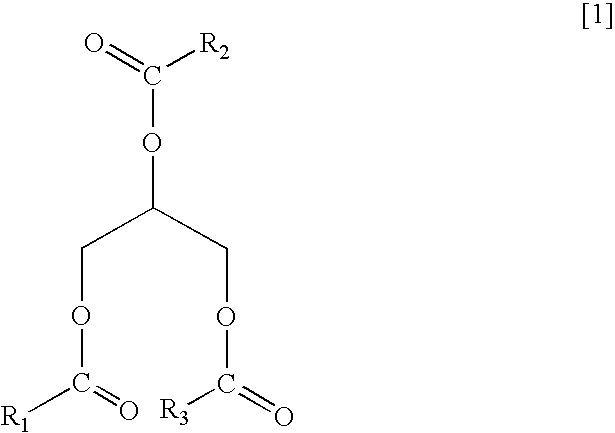

Composition and treatment agent

A composition comprising (A) a copolymer which comprises (I) repeating units which are derived from a monomer having a fluoroalkyl group, a carbon-carbon double bond, (II) optional repeating units which are derived from a monomer having at least two urethane or urea bonds and a carbon-carbon double bond, but no fluorine atom, (III) optional repeating units which are derived from a monomer, the homopolymer of which having a glass transition temperature (Tg) of 50° C. or less, (IV) optional repeating units which are derived from a monomer having a hydrophilic group and a carbon-carbon double bond, and (V) optional repeating units which are derived from a monomer having a chlorine atom and a carbon-carbon double bond; and (B) a film-forming auxiliary can impart high water and oil repellency by drying at room temperature (0 to 30° C.) without requiring a heat treatment step.

Owner:DAIKIN IND LTD

Textile substrates having layered finish structure for improving liquid repellency and stain release

This invention relates to textile substrates to which a finishing treatment has been applied during the manufacturing process. Such a finishing treatment provides improved water and / or oil repellency and stain and soil resistance. The finishing treatment generally includes a repellent agent, a stain release agent, and a particulate component. Other compounds may be added to the treatment, such as stain-blocking agents, crosslinking agents, coupling agents, antimicrobial agents, and pH adjusting agents. The components of the finishing treatment are generally applied to the textile substrate using an application process that results in layered structures on the surface of the treated substrate, which has been found to greatly improve the durability of the treatment. Such treated textile substrates thus exhibit excellent stain and soil resistance and water and / or oil repellency properties.

Owner:MILLIKEN & CO

Magnetic response type high-efficiency oil-water separation fiber membrane and preparation method thereof

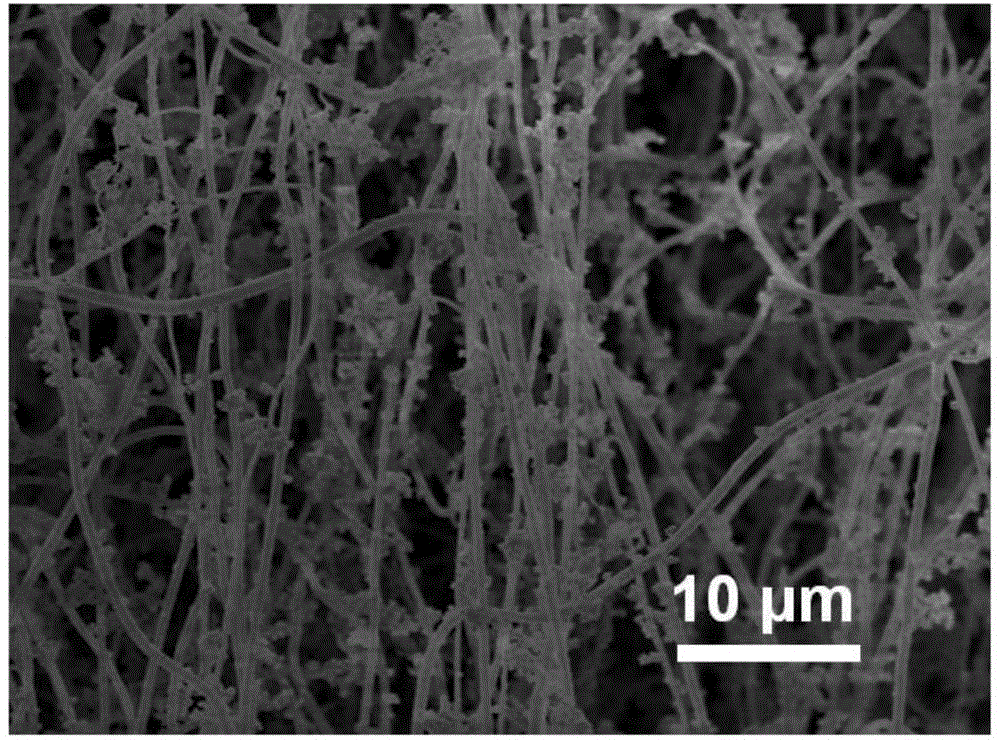

InactiveCN104436760AResponsiveMagnetic field responsiveLiquid repellent fibresNon-woven fabricsFiberMicro nano

The invention discloses a magnetic response type high-efficiency oil-water separation fiber membrane and a preparation method thereof, and belongs to the field of functional micro-nano fiber materials. The magnetic response type high-efficiency oil-water separation fiber membrane disclosed by the invention is prepared by the following steps: dissolving hydrophobic polymers, such as polyvinylidene fluoride, polyurethane or polycaprolactone, as main raw materials into an organic solvent to form a polymer solution; preparing a non-woven fiber membrane material prepared from micro-nano structure fibers by adopting an electrospinning method; forming a sticky polydopamine membrane through polymerization of polydopamine in an alkaline solution, and firmly attaching magnetic nanoparticles onto the surface of an electrospinning fiber membrane by adopting the sticky polydopamine membrane, so as to prepare the magnetic response type high-efficiency oil-water separation fiber membrane. The fiber membrane disclosed by the invention has a super-hydrophobic / super-oleophilic property in air, and has an excellent adsorptive property on a plurality of common oils; the preparation method of the high-efficiency oil-water separation fiber membrane, disclosed by the invention, is simple, low in energy consumption, and high in efficiency,and can be widely applied to the fields such as remote controllable efficient separation of oily wastewater, and the magnetic responsiveness is realized.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Methods for treating fabric to facilitate moisture transfer from one side to the other

ActiveUS7842625B1Synthetic resin layered productsLiquid repellent fibresMoisture transferCivil engineering

The present invention relates to methods and compositions for treating fabrics to facilitate moisture transfer from one side of the fabric to the other, and fabrics made according to such methods. The fabrics generally have one side or surface of the fabric treated with a net hydrophobic composition, whereas the opposing surface of the fabric is not treated with the net hydrophobic composition.

Owner:NANO TEX

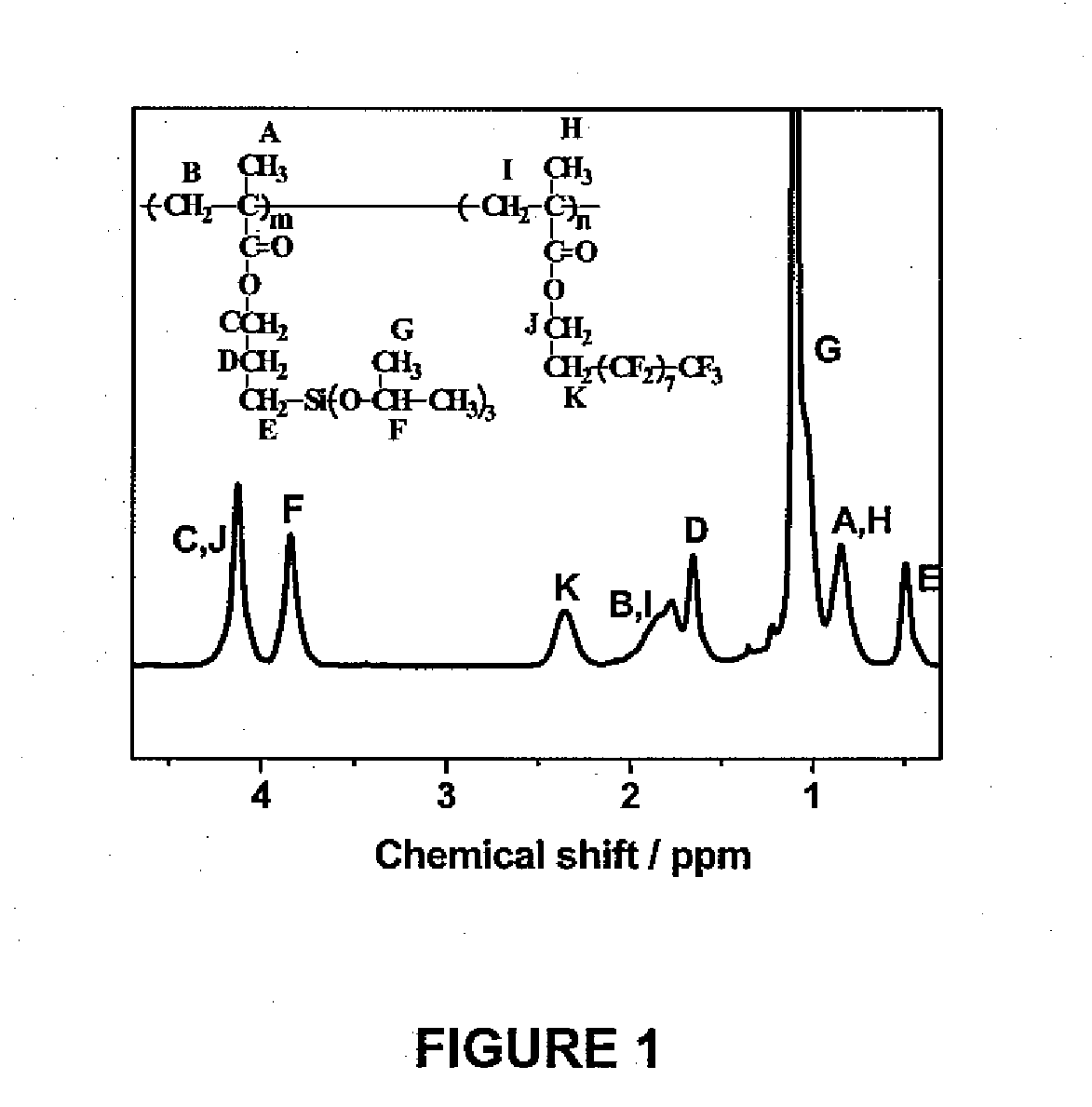

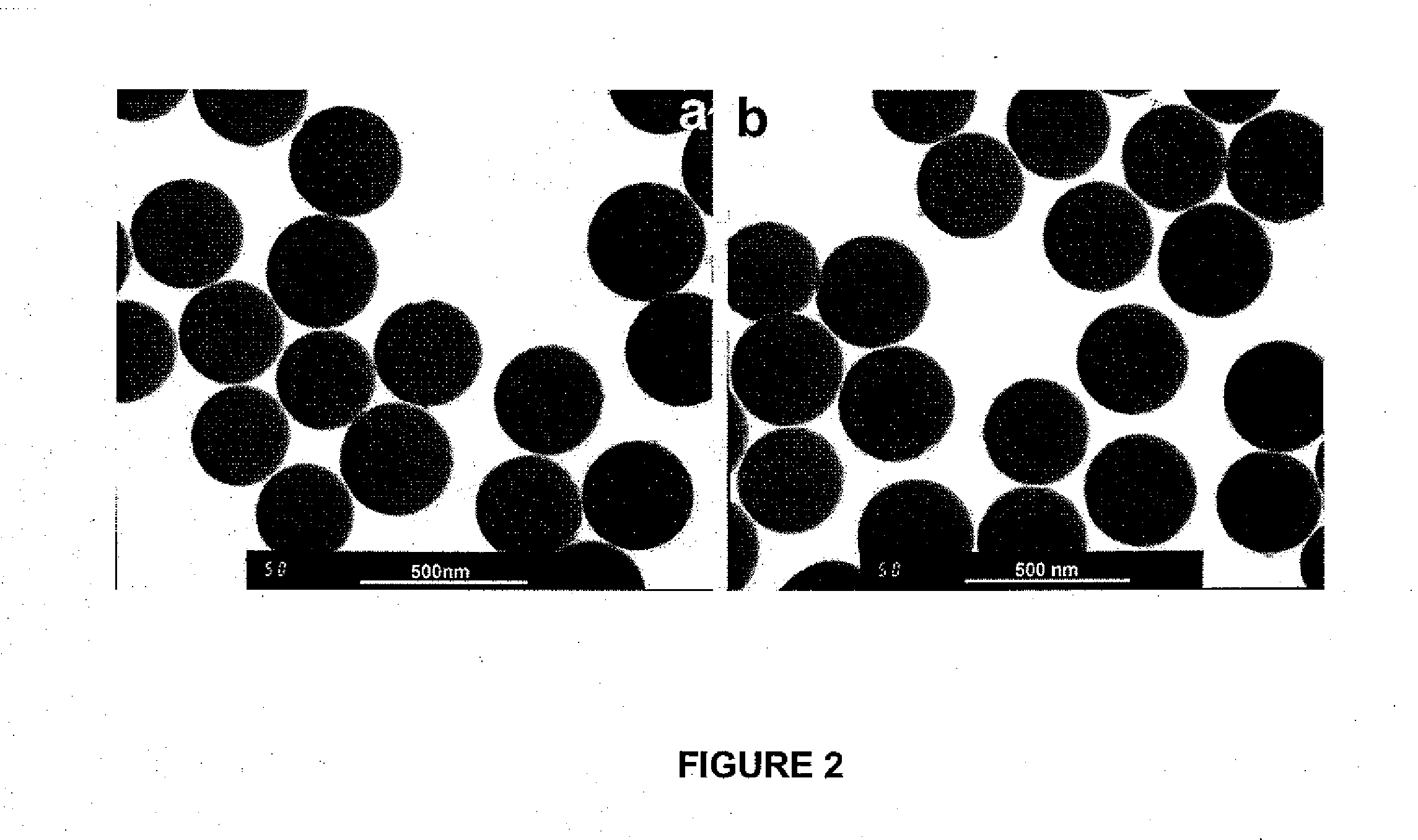

Amphiphobic Surfaces from Block Copolymers

InactiveUS20120264884A1Surface energy is lowEnhanced interactionLiquid repellent fibresCoatingsSilica nanoparticlesPolymer science

Provided are amphiphobic block copolymers, methods for preparing amphiphobic block copolymers, and applications thereof. Amphiphobic block copolymers can be used to prepare amphiphobic coatings on material surfaces, such as glass, printing paper or fabric. Amphiphobic block copolymers can also be used to coat particles, e.g., silica nanoparticles, which are then used to coat material surfaces. Such coated particles and uses thereof are also provided herein.

Owner:QUEENS UNIV OF KINGSTON

Preparation method for super-hydrophobic material

The invention provides a preparation method for a super-hydrophobic material. The method comprises the following steps: (1) modifying the integral three-dimensional structure of a substrate material by using a nanomaterial with a nanotechnology, so that the roughness of the integral three-dimensional structure of the material is increased; (2) coating the material with a low-surface-energy substance through a surface modifying technology to obtain the super-hydrophobic material. The static contact angle between the super-hydrophobic material and water is 152-158 degrees. The prepared super-hydrophobic material has superior hydrophobicity, the preparation process is simple, the reaction conditions are mild, and special machining equipment is not needed.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com