Patents

Literature

424results about How to "Washable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

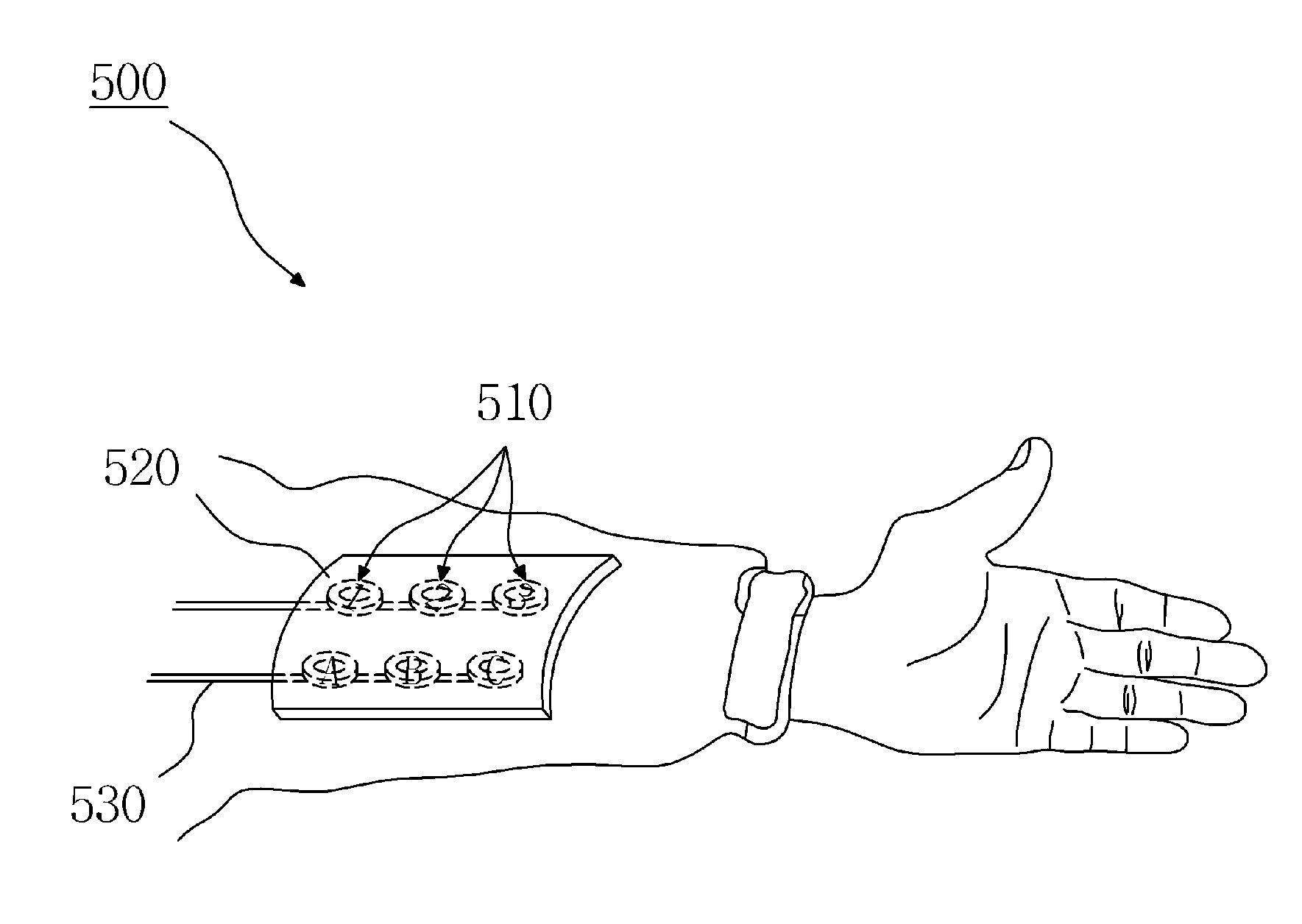

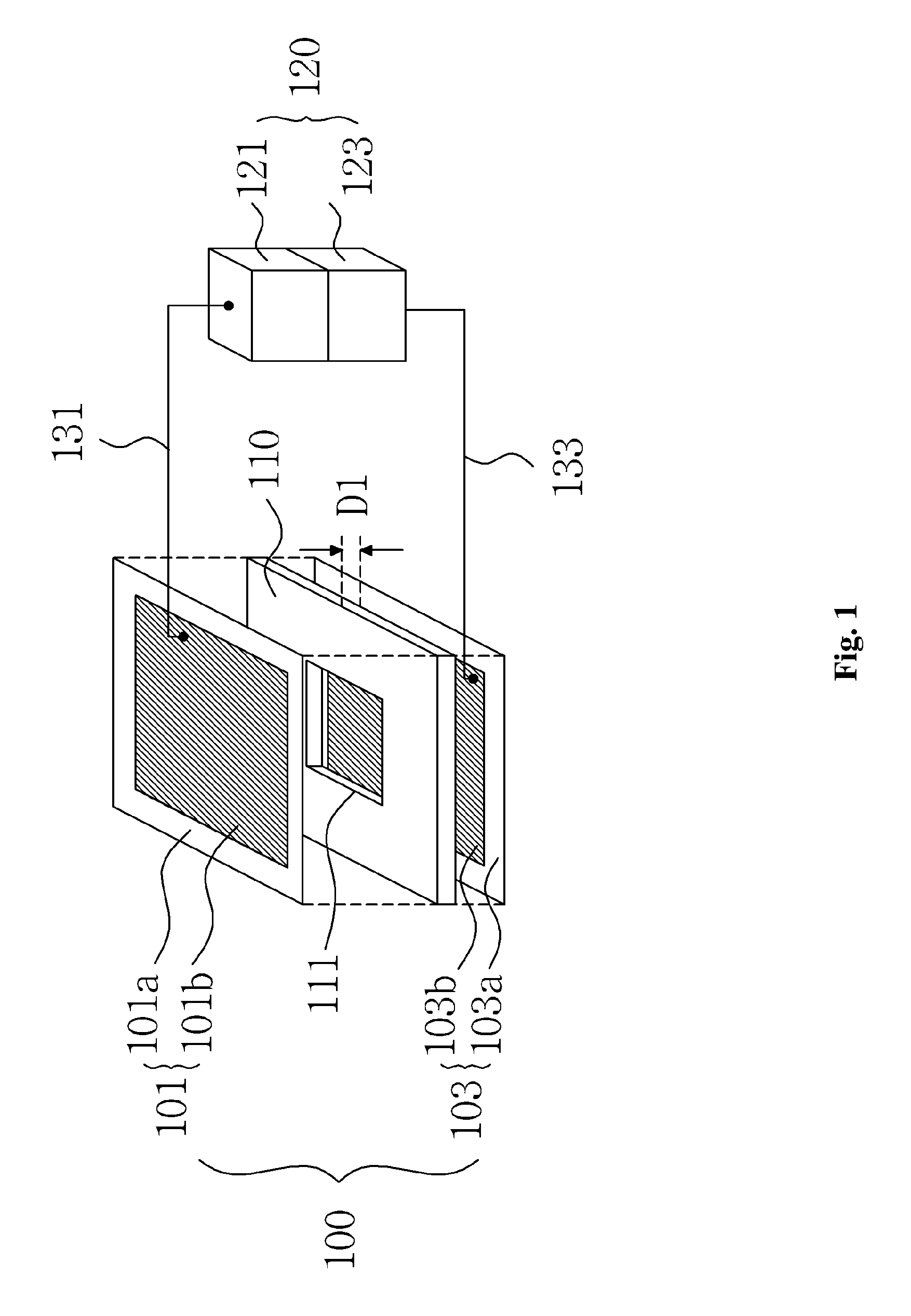

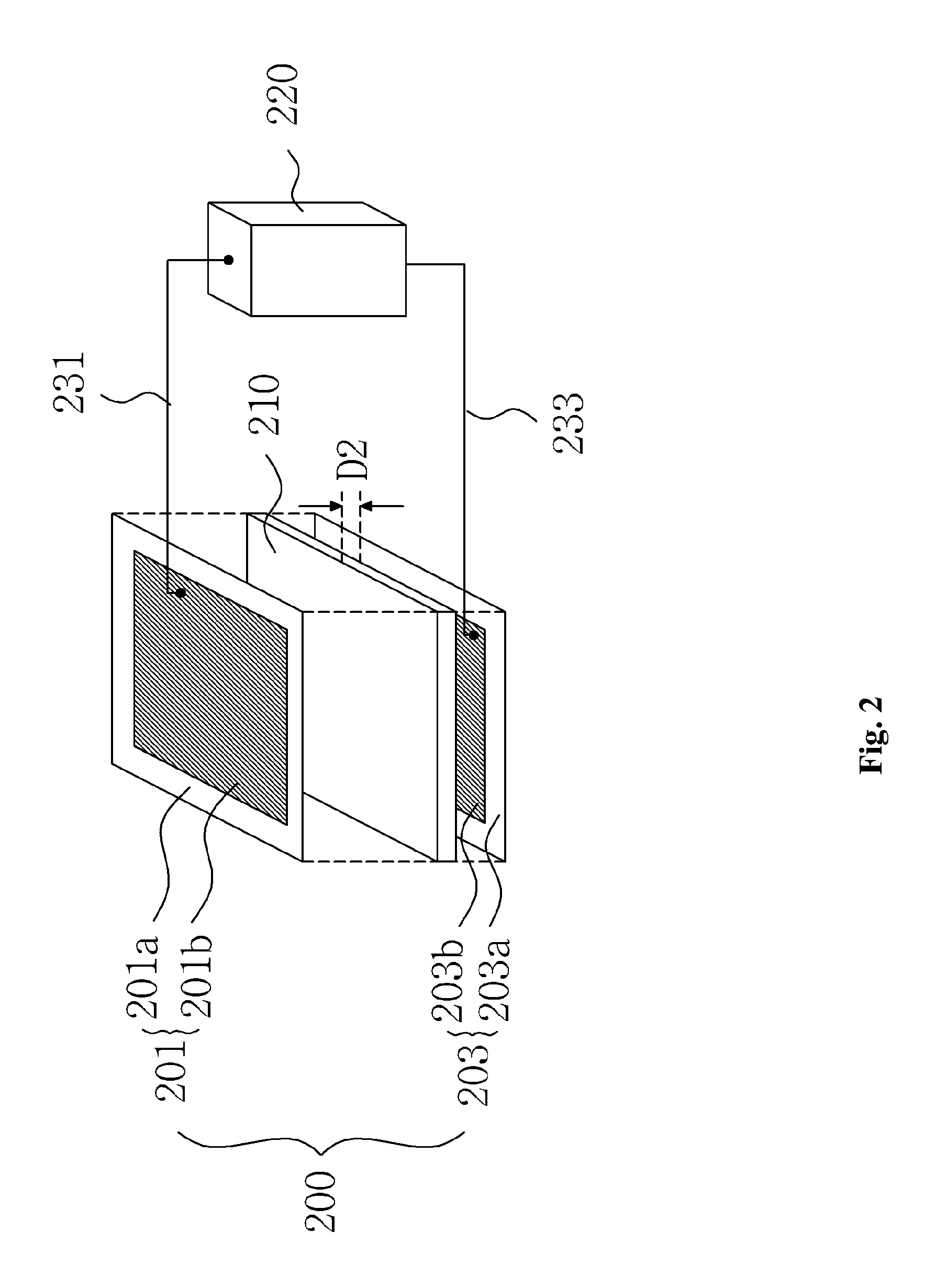

Fabric type input device

InactiveUS20100103112A1Minimizing feelingWashableInput/output for user-computer interactionCathode-ray tube indicatorsConductive materialsForeign body

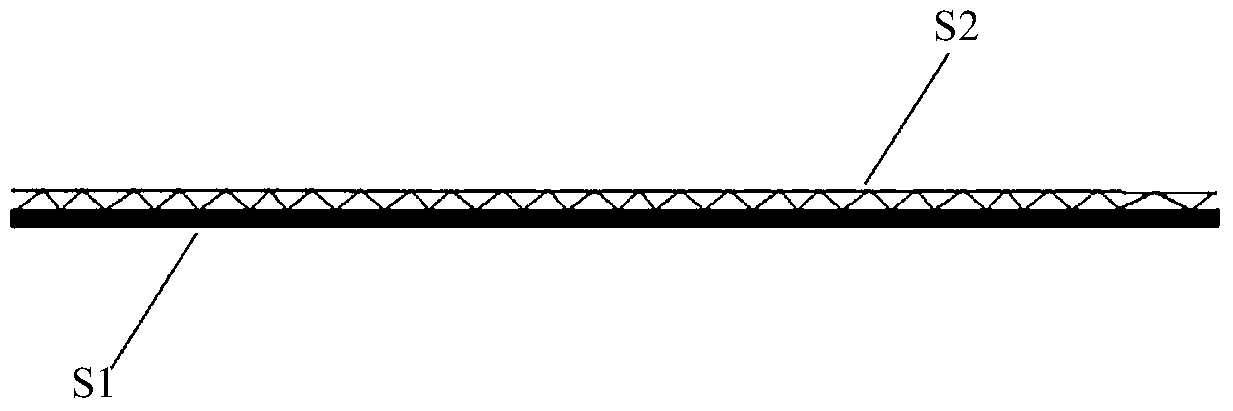

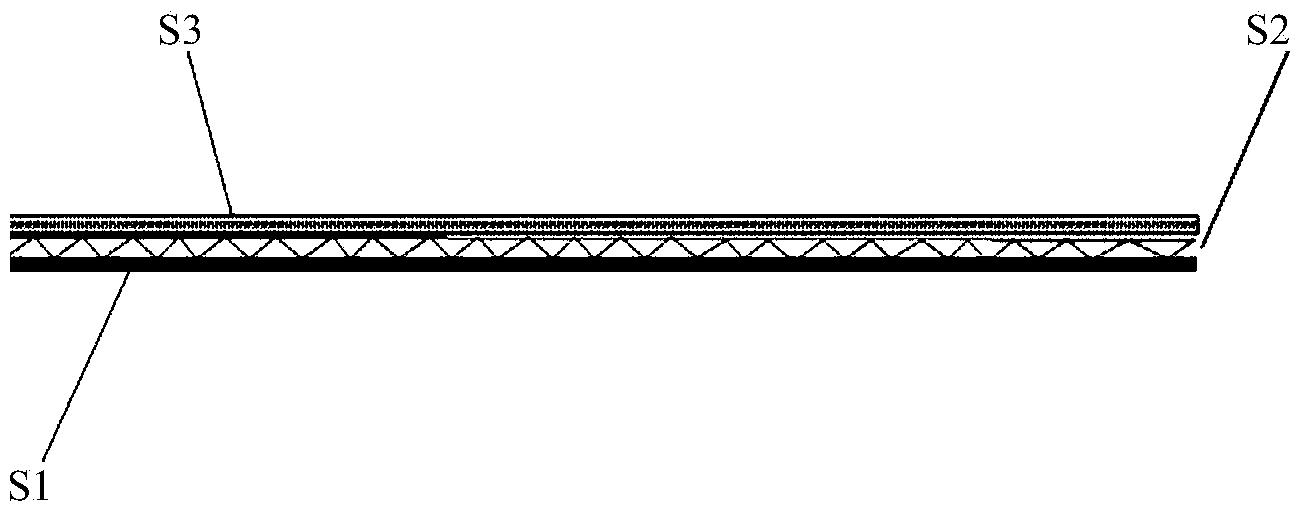

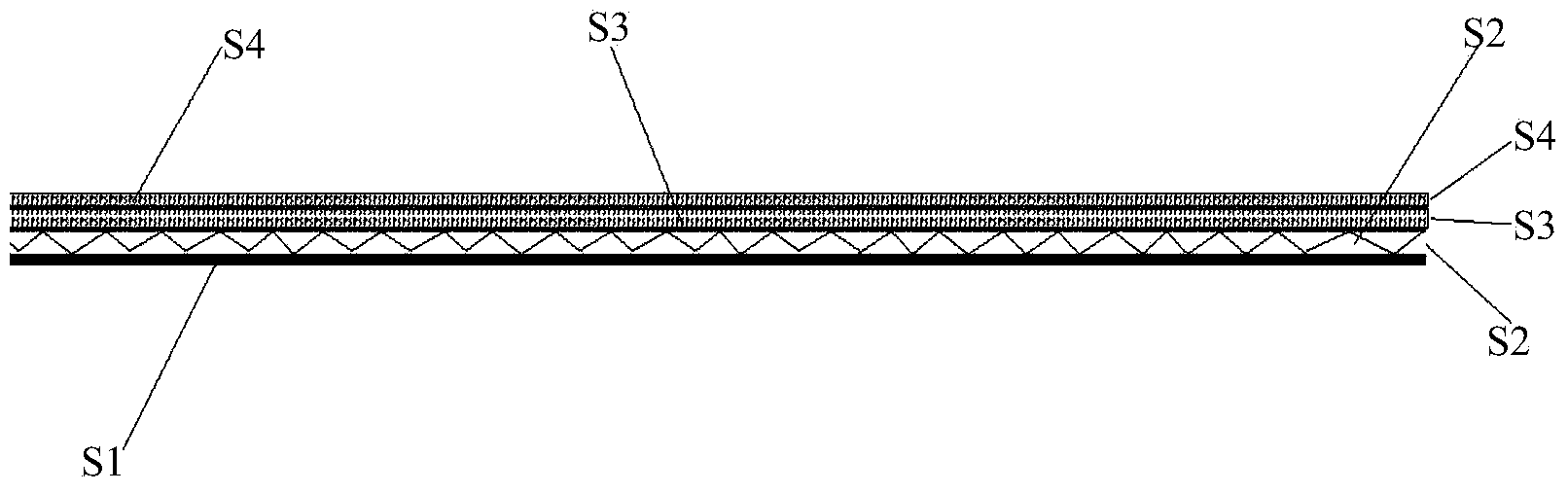

There is a fabric type input device. The fabric type input device comprise a fabric type electrode unit comprising first and second fabric type electrodes formed opposite to each other, the first and second fabric type electrodes each comprising a fabric and a lead pattern formed by patterning a conductive material on the fabric, a fabric type substrate unit interposed between the first and second fabric type electrodes so that the first and second fabric type electrodes are spaced apart from each other, the fabric type substrate unit having a connection hole formed so that the first and second fabric type electrodes are in contact with each other and a control unit supplying an input signal to the fabric type electrode unit, the control unit sensing the supplied input signal. The fabric type input device is formed using a fabric patterned with a conductive material, thereby minimizing foreign-body feeling.

Owner:KOREA ADVANCED INST OF SCI & TECH

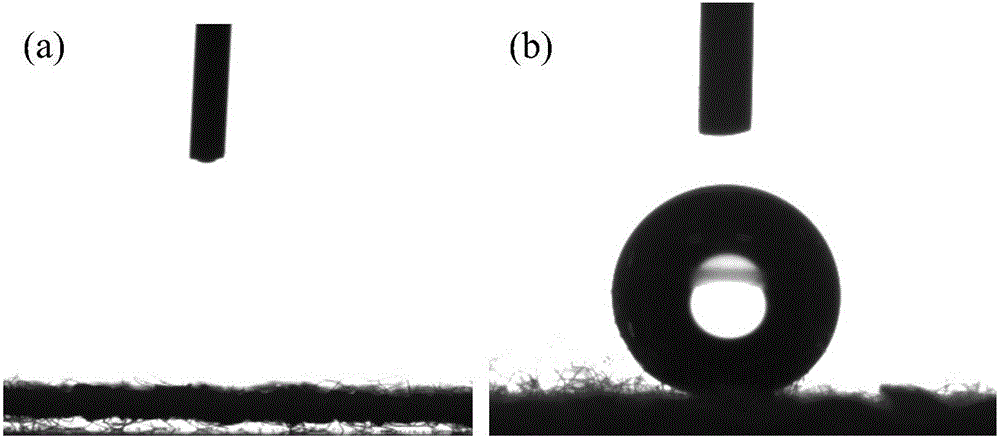

Method for preparing super-hydrophobic textile from thiol-ene click chemistry-modified fiber

InactiveCN105696306AWashableWear-resistantLiquid repellent fibresAbrasion resistant fibresFiberPolyester

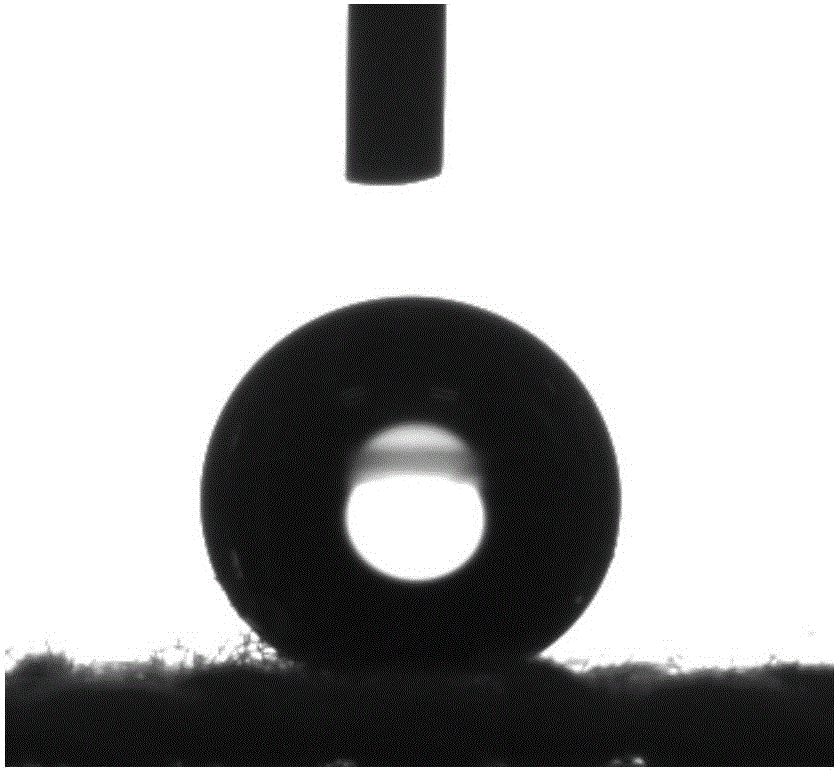

The invention relates to a preparation method of a functional textile, and belongs to the field of textile surface grafting modification. The method for preparing a super-hydrophobic textile from a thiol-ene click chemistry-modified fiber is characterized by comprising the steps that alkali liquor steaming treatment is performed on a polyester fiber, then mercaptosilane is fixed to the surface of the polyester fiber, finally a methacrylate monomer is grafted to the surface of the polyester through a thiol-ene click chemistry reaction to reduce the surface tension of the fiber, and then the super-hydrophobic polyester textile is obtained. The contact angle between the polyester textile prepared through the method and water drops is larger than 150 degrees, and the polyester textile is stable to acid, alkali, salt and solvent and capable of resisting friction and washing and has the very good hydrophobic stability.

Owner:SHAANXI UNIV OF SCI & TECH

Nano photocatalyst-active carbon fiber composite filter medium

ActiveCN101804275AImprove adsorption capacityPlays the role of immobilizing and binding nanoparticlesFiltration separationFiberCarbon fibers

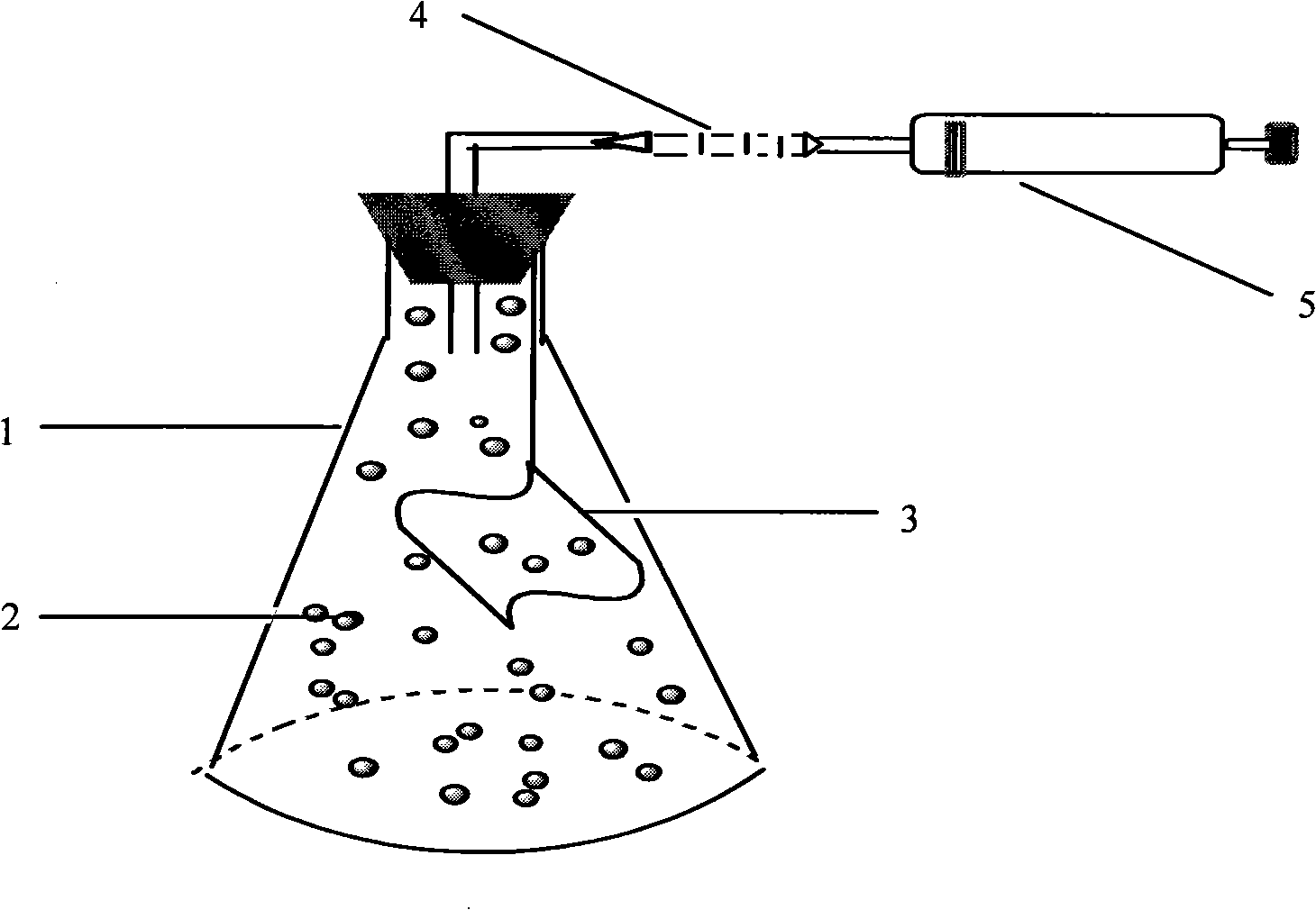

The invention belongs to the technical field of air filter materials, and particularly relates to a nano photocatalyst-active carbon fiber composite filter medium. The nano photocatalyst-active carbon fiber composite filter medium is characterized in that the filter medium consists of a nano photocatalyst-active carbon fiber non-woven fabric and a filter base material, wherein the nano photocatalyst-active carbon fiber non-woven fabric comprises the following components in percentage by weight: 0.5 to 1.0 percent of nano photocatalyst, 1.0 to 4.0 percent of nano active carbon and 95 to 98.5 percent of carrier resin. The filter medium enables organic molecular aerosol which cannot be trapped by a conventional efficient filter layer to be quickly adsorbed by active carbon grains of nano carbon fiber, has the properties of tolerating water washing and holding carbon grains, and can be combined and used with various efficient filter media calendared by other materials. In addition, the filter can be placed in the sun or under an ultraviolet lamp to perform illumination and regeneration after adsorbed saturation, and the service life of the whole filter can be greatly prolonged.

Owner:HANGZHOU FILTECH INTELLIGENT CO LTD

Sewing-free hot melt adhesive TPU-PU leather and preparation method thereof

ActiveCN103437195AExcellent physical and chemical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolymer science

The invention provides a piece of novel sewing-free hot melt adhesive TPU-PU leather, and a preparation method thereof. The TPU-PU leather comprises release paper, a hot melt adhesive film, a TPU film and a dry-type PU film, wherein the release paper comprises a paper bottom layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material is composed of polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; a TPU raw material is composed of polymer polybasic alcohol, 1,4-cyclohexane-diisocyanate, a chain extender and a plurality of functional additives; a PU raw material is composed of polyester dibasic alcohol, straight chain diol, isocyanate, TDI trimer, dimethyl formamide, butanone, black sand, and a plurality of functional addictives. Through the adoption of the preparation method, innovations are conducted on the raw material components of the release paper, the hot melt adhesive, the TPU film and the PU film; the manufactured sewing-free TPU-PU leather has the technical advantages of firmness in adhesion, durability, environment-friendly materials, no invisible harm to a human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Method for preparing silver metallized organic fiber and textile

This is a argent metallization producing method of organic fibre and fabric, which belongs to vacuum membrane plating and electroplating technologic field and mainly solves the problems of quality and producing batches of silver-gilt organic and fabric. Through physical vapour phase deposition technology, it firstly arranges smoothly and rolls up tidily the organic fibre bundle and fabric; lay them in the vacuum room, plate silver by magnetic controlling and sputtering, and monolayer or multilayer continuously plate membrane; then plate mulriple argent membrane according to different using demands. The binding force of the metallic argentic ion and organ fibre of the present invention is strong, it has no pollution, low costs and can be continuously produced. The products are applied in such industry as electronics, war industry communication, medical treatment, special type of spinning and so on. For instance, electric shielded products, military used shielded tent, special type of spinning antibacterial materials and civil health care spinning products.

Owner:夏芝林

Preparation of environment-friendly type antibiotic and odor removing textile

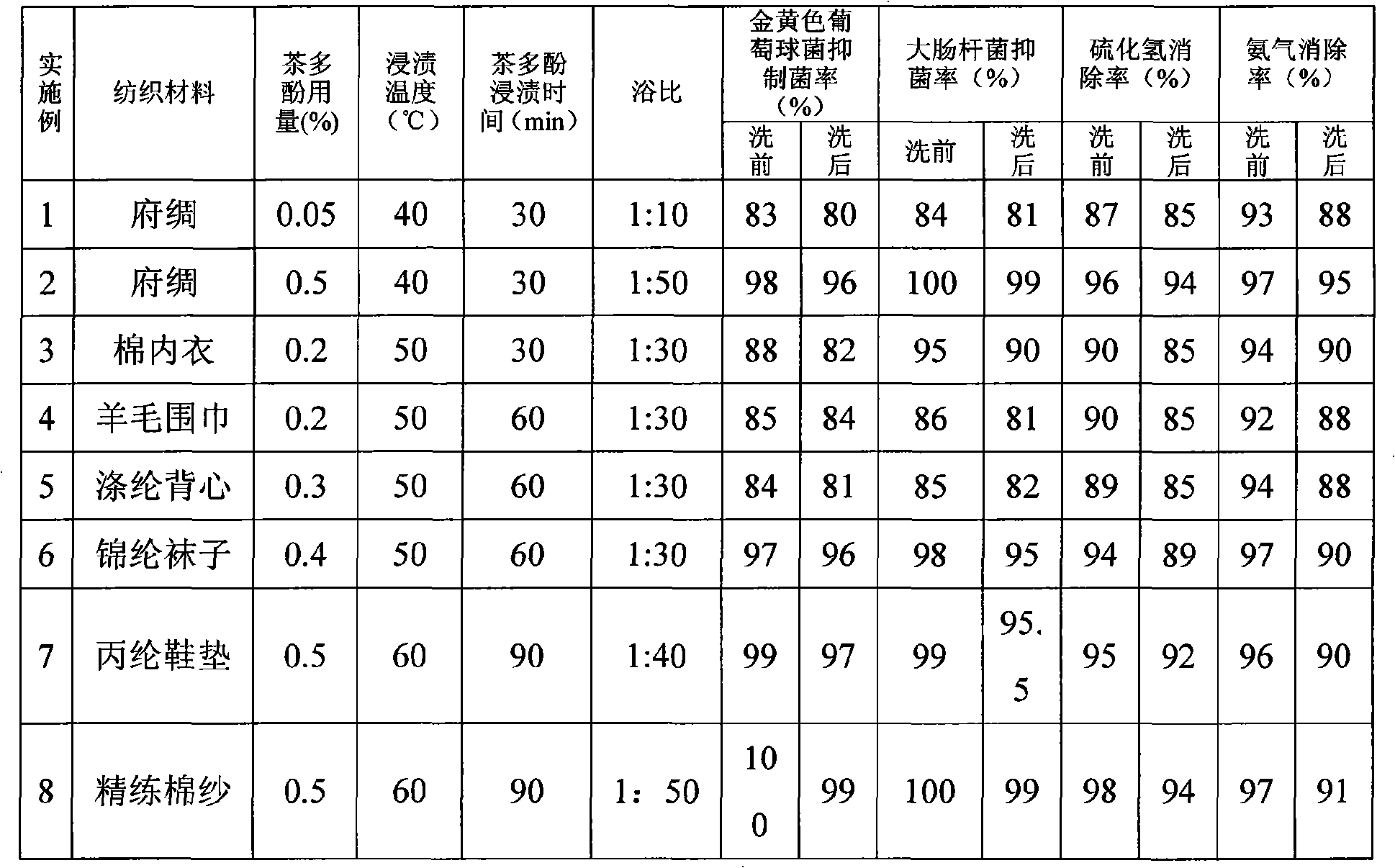

The invention discloses a preparation method of an environment-friendly, antisepsis and deodorant fabric product and comprises following steps: (1) a fabric material or a fabric product is soaked and processed in a tea polyphenol solution with the concentration of 0.05 to 0.5 percent by weight for 30 to 90 minutes, the weight ratio of the fabric material or the fabric product to the tea polyphenol solution is between 1 : 10 to 50, and the soaking temperature is 40 to 60 DEG C; (2) a metallic ion solution that is equimolar with the tea polyphenol is added, and the fabric material or the fabric product is soaked and processed for 60 minutes, water rinsed, and then parched or dried. The preparation method of the environment-friendly, antisepsis and deodorant fabric product is applicable to various fibers such as multiple kinds of natural fibers like cotton hemp, wool and dacron, and synthesized chemical fibers. The preparation method can be adopted to produce various antisepsis and deodorant garment materials, home-textile materials (such as bedding fabrics, decorative sofa materials and carpets), socks and foot pads. The antisepsis and deodorant fabric of the invention is characterized by environmental protection, high efficiency and wash resistance, etc., and the preparation method thereof is characterized by simple technique and low processing cost, etc.

Owner:ZHEJIANG SCI-TECH UNIV

Treatment method for antibacterial and anti-ultraviolet cotton fabrics

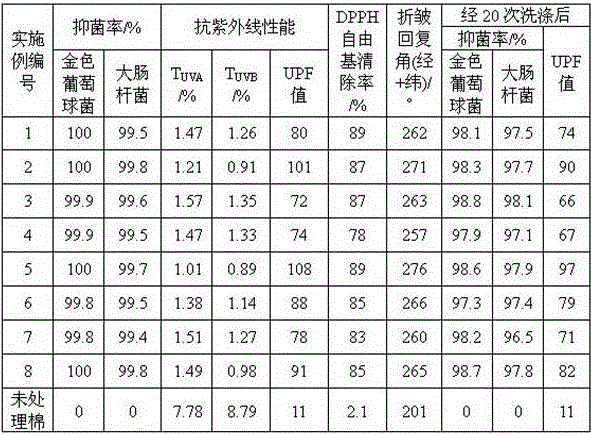

ActiveCN106758216AImprove antibacterial propertiesImproves UV resistanceBiochemical fibre treatmentLight resistant fibresGrape seedUltraviolet

The invention discloses a treatment method for antibacterial and anti-ultraviolet cotton fabrics. The treatment method comprises the following steps: step 1, soaking the cotton fabrics with a nonionic surfactant; step 2, modifying the cotton fabrics with chitosan quaternary ammonium salt; step 3, dipping the cotton fabrics with antibacterial finishing liquid prepared by mixing 5-15 parts of a natural antibacterial agent composed of extracts of grape seeds, persimmon leaves, ginkgo leaves and licorice roots, 0.3-1 part of polyoxyethylene-40 hydrogenated castor oil and 1000 parts of water; step 4, soaking the cotton fabrics in a mixed aqueous solution containing 0.001-0.005mol / L of silver nitrate or silver sulfate or silver acetate and 1-3 g / L of soluble starch or hydroxyethyl cellulose to prepare the nano-silver attached antibacterial cotton fabrics. The prepared cotton fabrics not only have good antibacterial performance and anti-ultraviolet performance, but also have performance of resisting oxidation and scavenging free radicals, and have improved anti-wrinkle performance and good washing durability.

Owner:EASTERN LIAONING UNIV

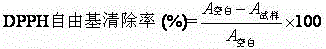

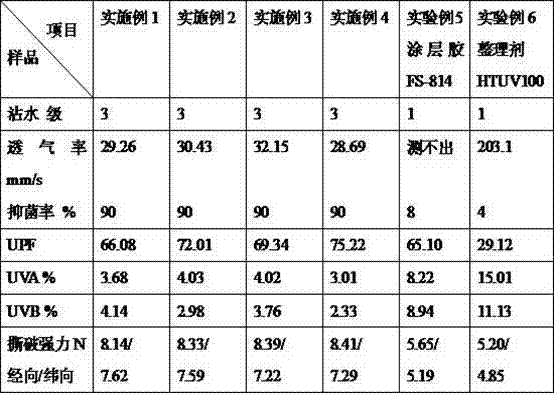

Waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive for textile and preparation method of waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive

ActiveCN104727151AGuaranteed waterproof performanceAntimicrobial GuaranteeFibre treatmentPolyesterWater based

The invention provides waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive for textile and a preparation method of the waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive. The adhesive is prepared by mixing the following raw materials in parts by weight: 65-68 parts of a water-based polyurethane waterproof permeable adhesive, 10-15 parts of polyethylene glycol having the average molecular weight of 600, 2-3.5 parts of a TDI tripolymer curing agent, 3-4 parts of anionic amino silicon oil emulsion, 5-7 parts of an anionic or non-ionic fluorine-containing waterproof agent, 5-7 parts of a phenylamide anionic antibacterial deodorant agent, 1.5-2.5 parts nano-zinc oxide powder and 1-2 parts of nano-titanium dioxide powder. The coating adhesive is simple and convenient to produce and convenient to use, has good waterproof color fastness, and is suitable for 10D-20D polyester, chinlon cloth fabric functional coatings.

Owner:DANDONG UNIK TEXTILE

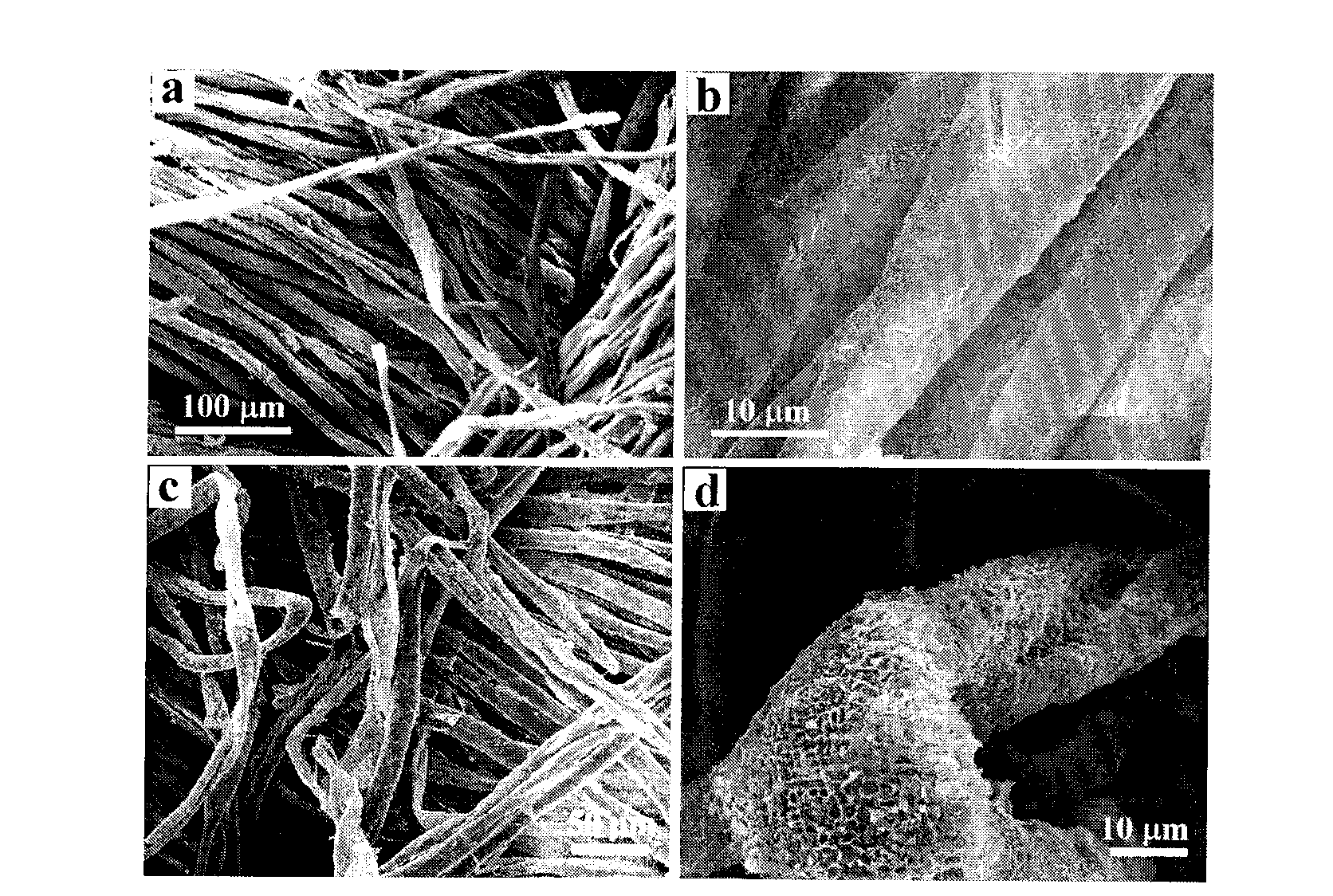

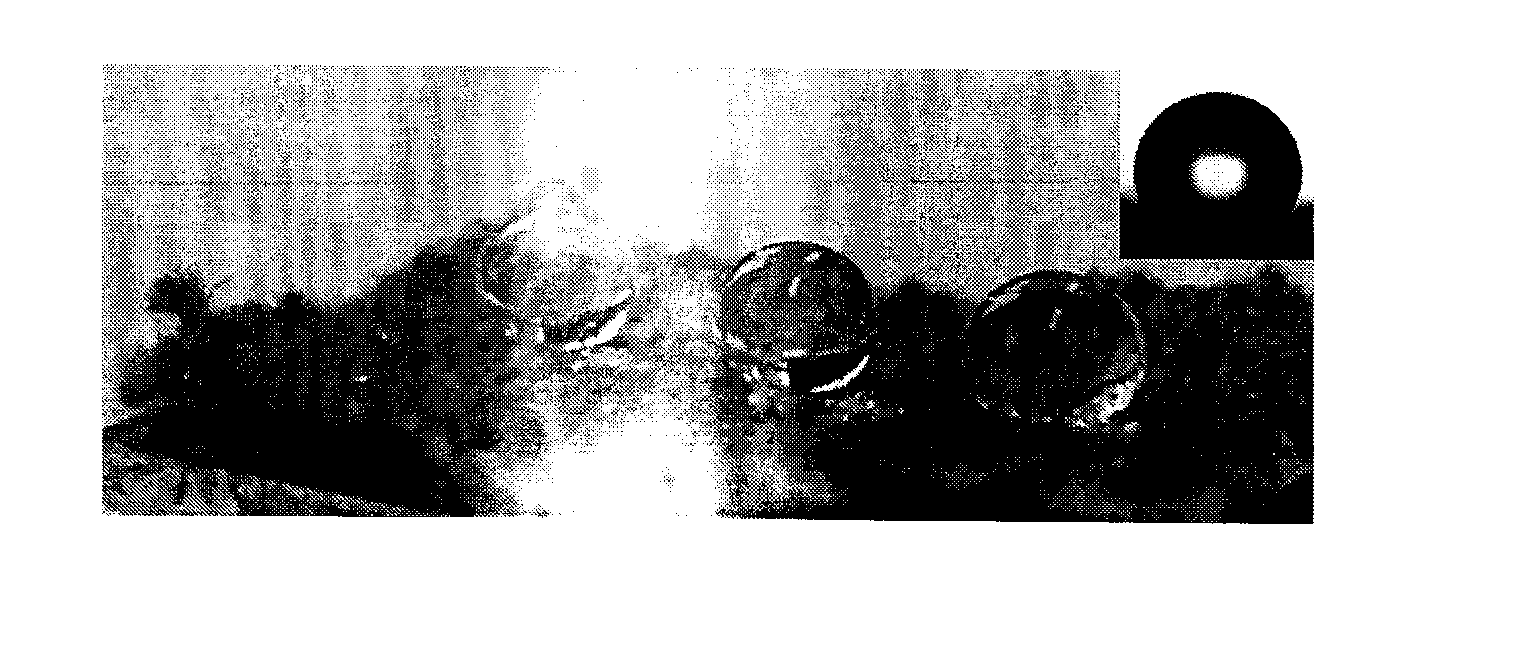

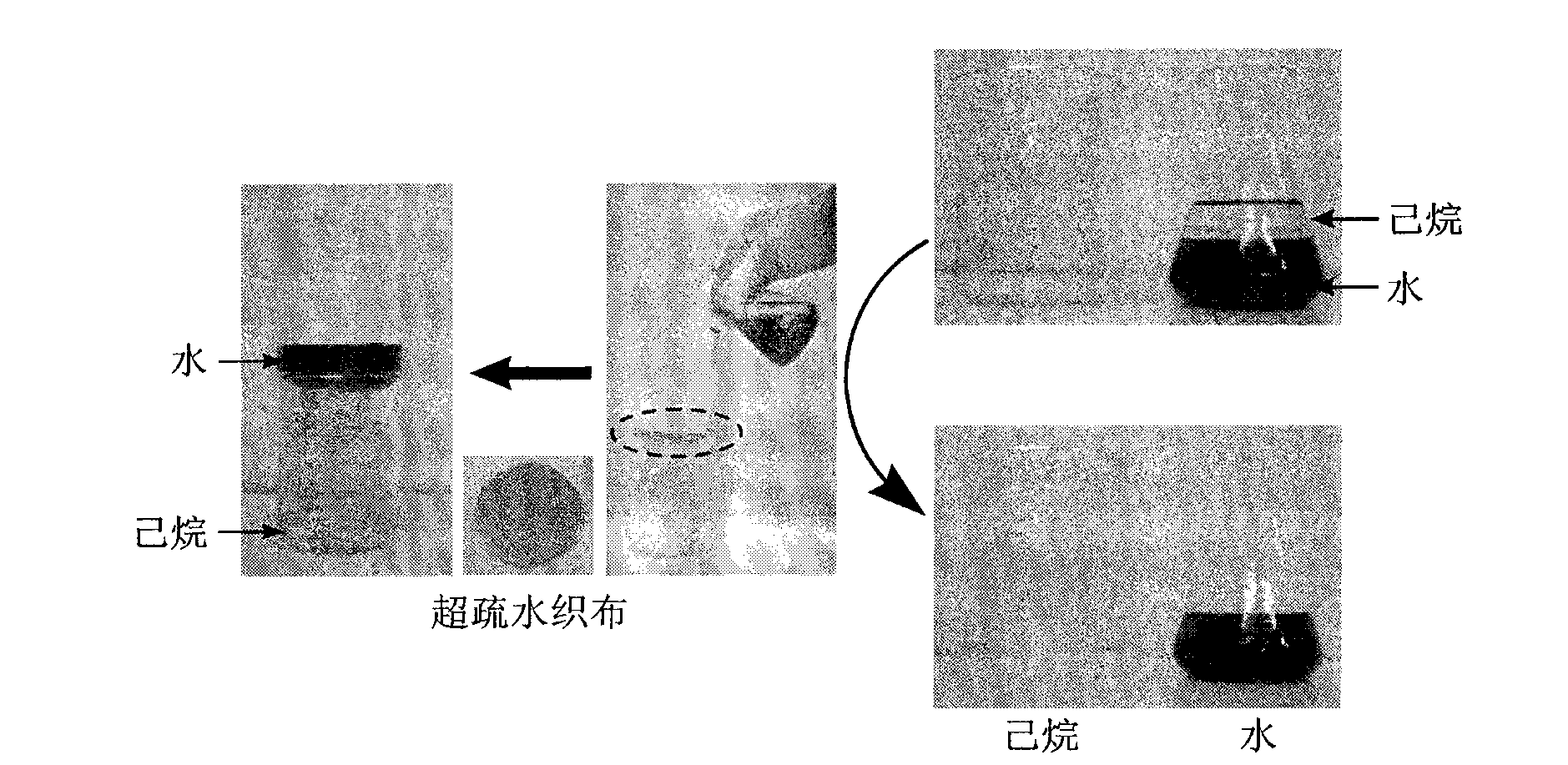

Preparation method of superhydrophobic woven fabric for oil-water separation

ActiveCN103173998ASimple processEasy to operateFibre treatmentFiltration separationOil waterTemperature resistance

The invention discloses a preparation method of superhydrophobic woven fabric for oil-water separation. According to the preparation method disclosed by the invention, transition metal nanoparticles are modified on the surface of woven fabric, the obtained woven fabric has special properties endowed by a transition metal, for example, the superhydrophobic woven fabric modified by Fe3O4 has magnetism, the superhydrophobic woven fabric modified by Ag has good antibacterial performance and excellent superhydrophobic property, the contact angle with water is larger than 150 degrees, the rolling angle is smaller than 10 degrees, and the superhydrophobic woven fabric has high temperature resistance, washing resistance and permanent superhydrophobic property, and can be successfully applied to oil-water separation.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

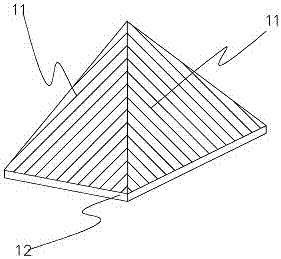

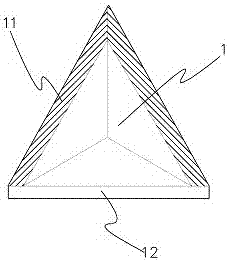

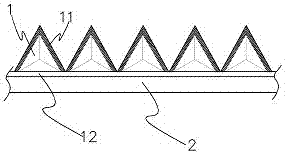

Micron order prism pyramid monomer and manufacturing method thereof

PendingCN107144903AAvoids the phenomenon of sedimentation at the bottom of the fluidImprove reflective effectOptical elementsMicron scalePolymer science

The invention relates to the light reflection material technology field and provides a micron order prism pyramid monomer and a manufacturing method thereof. The prism pyramid is capable of accommodating both the light flashing and light reflecting effects, and can exist independently without being attached to a carrier film. Only with adhesive glue, oil painting, hair glue and nail polishing oil and other colorless or colored transparent fluid or liquid media, it is possible to let the prism pyramid monomer to be attached on objects such as films, cloth, wires and plates requiring to be added with light or to realize light flash so that these materials can present the lighting effect. The monomer can be applied widely in great practical use, and the manufacturing method for the monomer is also simple and easy to implement. Therefore, with the method, batched monomer can be produced and used.

Owner:YEAGOOD INC

Down feather composite fiber modified by polypropylene fiber and preparation method of down feather composite fiber

InactiveCN104195664AThe ratio is scientific and reasonableDelicate feelMonocomponent protein artificial filamentArtifical filament manufactureSucrosePhosphoric acid

The invention discloses a down feather composite fiber modified by polypropylene fiber. The down feather composite fiber modified by polypropylene fiber is prepared from the following raw materials in parts by weight: 18-20 parts of superfine duck down powder, 25-30 parts of puffed goose feather powder, 12-15 parts of polypropylene fiber, 3-5 parts of kaolin, 0.3-0.6 part of calcium saccharate, 1-2 parts of wolfberry fruit, 2-4 parts of fruit of Chinese magnoliavine, 1-3 parts of radix rehmanniae, 3-5 parts of cucumber juice, 0.1-0.3 part of ammonium dihydrogen phosphate, 120-130 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 110-140 parts of 1-ethyl-3-diethyl methyl imidazole phosphoric acid, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber modified by polypropylene fiber, the components such as the polypropylene fiber, the wolfberry fruit, the fruit of Chinese magnoliavine and the radix rehmanniae are added; the prepared product is soft and smooth in hand feeling, has the characteristics of the down feather, also has the characteristics of being light, soft, warm, breathable, moisture permeable, mildew-proof, mothproof and washable, and is wide in application prospect and further and more competitive in the market.

Owner:ANHUI LION GOOSE PROD

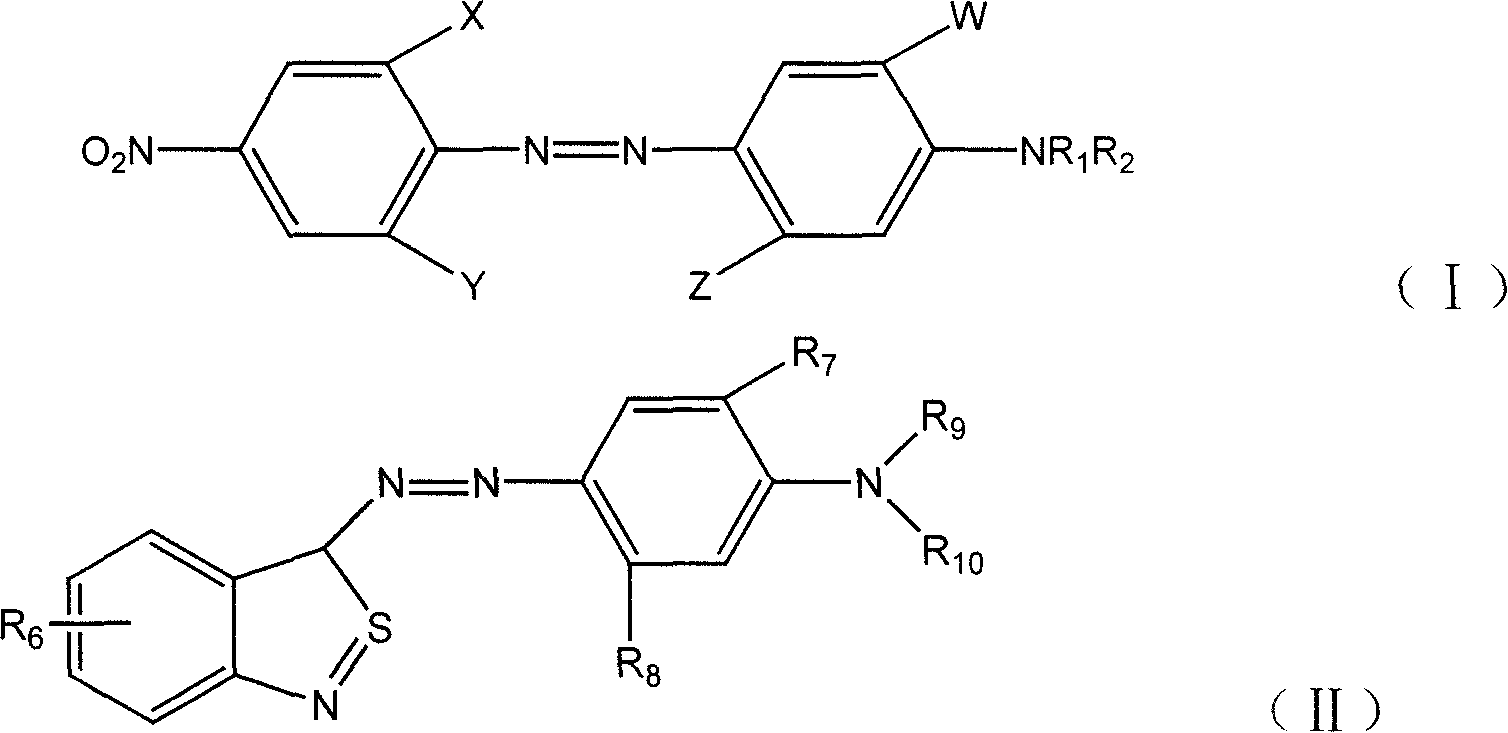

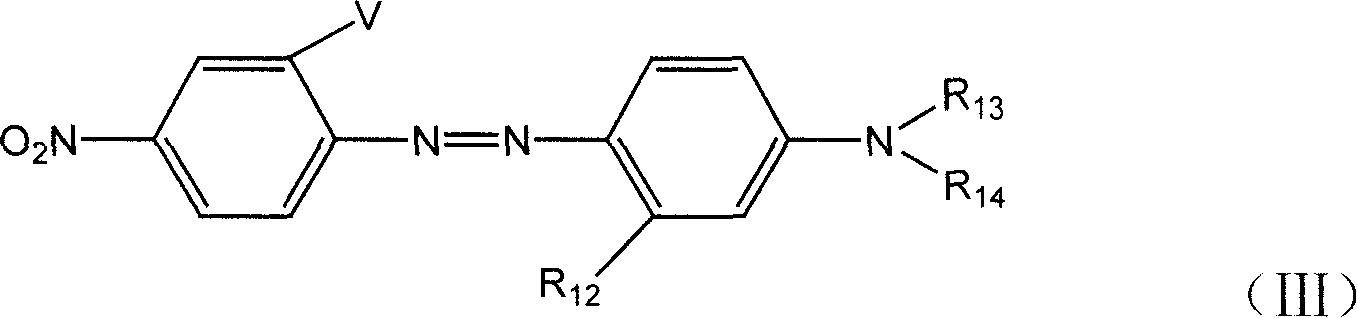

Disperse dye composition

The disperse blue dye composition consists of component A in 1-99 wt% and component B in 1-99 wt% basically, with the structures of component A and component B being shown. The disperse blue dye based on the disperse blue dye composition may be liquid state with particle, emulsion, powder or granule. The disperse blue dye based on the disperse blue dye composition is used in dyeing polyester fiber material, and through regulating the ratio of different components, excellent deep blue dyed fabric with bright color, excellent dispersivity, sunfast property, water resistance, sweat resistance and other advantages may be obtained.

Owner:ZHEJIANG LONGSHENG GROUP

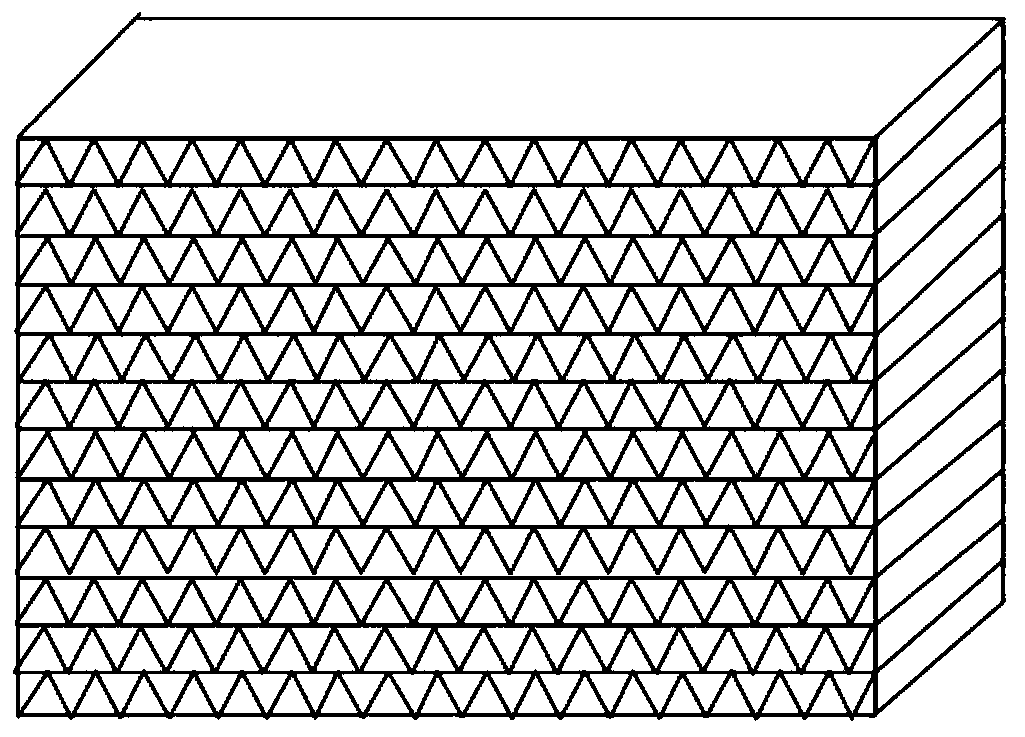

Method for manufacturing fluffy temperature-regulating warm-keeping material and fluffy temperature-regulating warm-keeping material

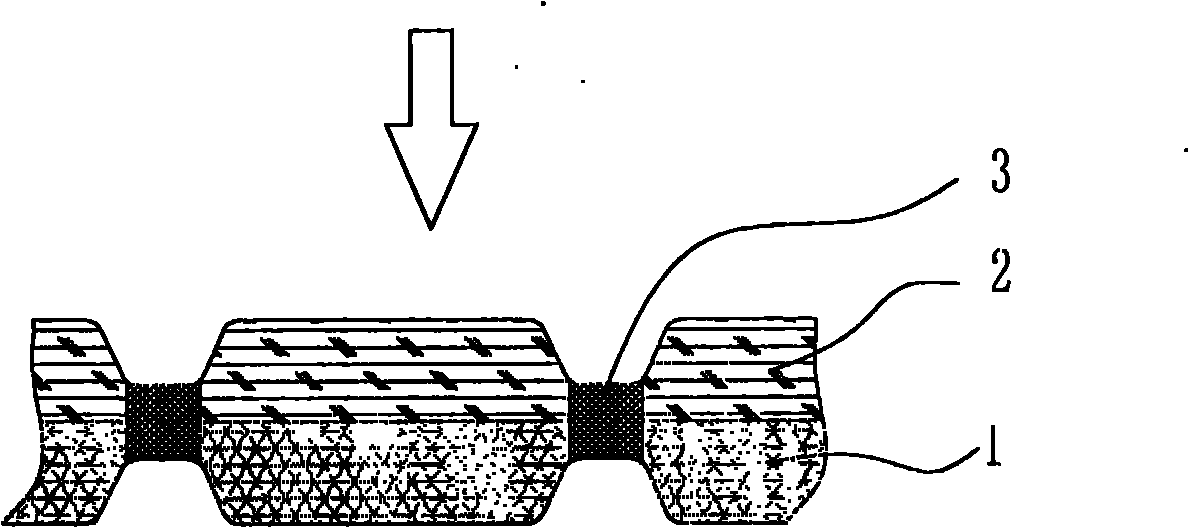

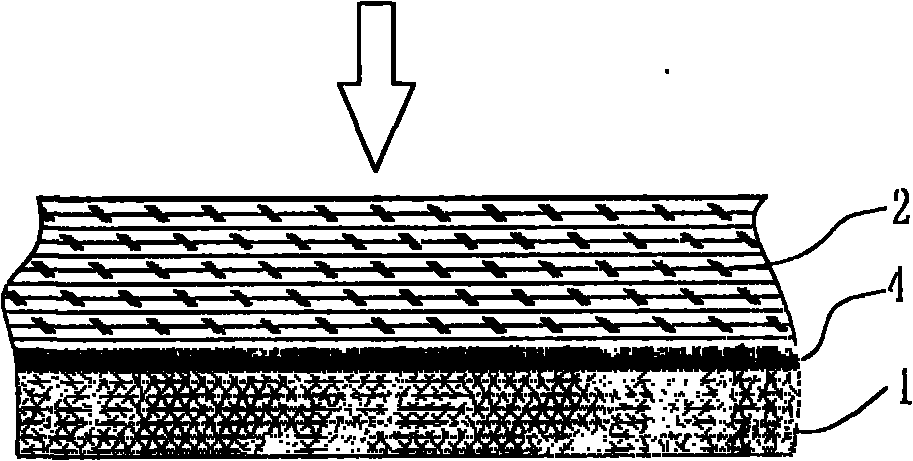

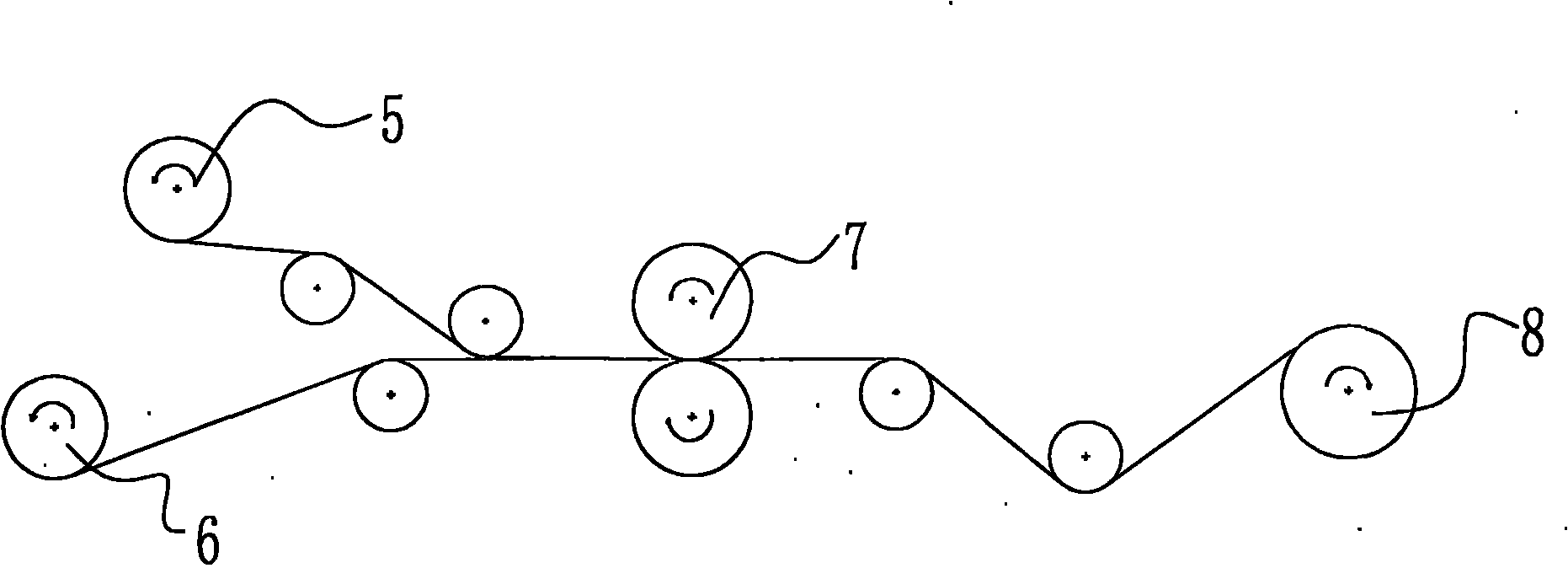

ActiveCN104593948AGood temperature regulationSatisfied with the temperature adjustment effectNon-woven fabricsSpray coatingPhase-change material

A method for producing a fluffy temperature regulating warmth retention material and the fluffy temperature regulating warmth retention material produced therefrom are disclosed. The method comprises: selecting a low melting point fiber and an additional fiber; carding to form a single web; spray coating a phase change material along at least part of the length of a surface of the single web; lapping layer by layer of the single web; and performing a heat setting reinforcement to form the warmth retention material. According to the present invention, a fluffy temperature regulating warmth retention material comprising an appropriate ratio of a phase change material may be obtained and the material exhibits a satisfactory temperature regulating effect, and meanwhile, it can maintain, to the full extent, or is close to, the original filling power and soft hand feeling where no phase change material is incorporated. In addition, the phase change material can be retained very well within the fluffy temperature regulating warmth retention material and thus has a wash resistance property.

Owner:3M INNOVATIVE PROPERTIES CO

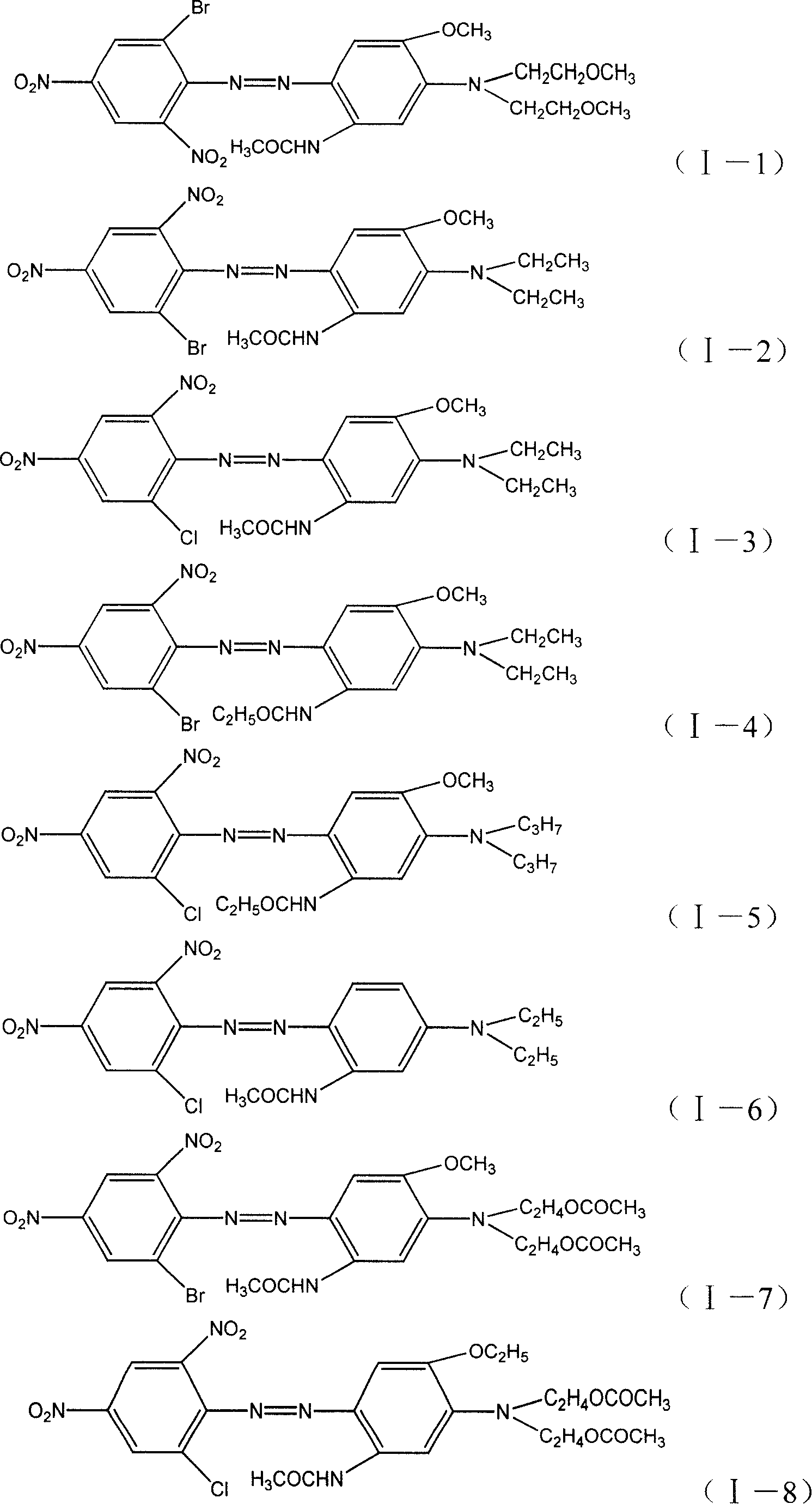

Functional intertwined medical textile fabric with natural antibacterial and moisture absorption quick-drying functions

InactiveCN102965792AGood deodorant performanceDimensionally stableWoven fabricsHemp fiberPlain weave

The invention discloses a functional intertwined medical textile fabric with natural antibacterial and moisture absorption quick-drying functions, which is formed by interweaving warp and weft, wherein the warp is selected from COOLMAX fiber / chitin viscose fiber blended yarns, and the weft is selected from cotton fiber / hemp fiber / silver fiber blended yarns; and the warp and the weft adopt an up-and-down plain weave structure. The selected fiber has the special durable functions of moisture absorption quick-drying, green health care and the like, so that the textile fabric not only has good antibacterial and anti-odor properties, but also has the characteristics of ultra-strong moisture absorption quick-drying, static resistance, radiation resistance, stable size, washing resistance, comfortable wearing and cooling, can be used for medical professional clothing in summer such as nurse clothes, nurse caps and patient clothes, and is an excellent textile fabric with ultra-strong antibacterial and green health care functions in a medical system.

Owner:SHAOXING SHULILE TEXTILE PROD

Raw material prescription of the heat preserving waterproof paint and method of preparing the same

InactiveCN101585987AHigh solar reflectanceIncrease elasticityReflecting/signal paintsEmulsionSun protection

The invention belongs to a heat preserving waterproof paint for structures such as exterior wall of building, thin roofing, and metal tank housing and so on and fabricating method thereof. Raw material prescription of the heat preserving waterproof paint of the invention based on weight is: 10 parts to 90 parts of water, 10 parts to 90 parts of elastic polyacrylic emulsion, 10 parts to 50 parts of filler, 1 part to 10 parts of propylene glycol, 1 part to 10 parts of thickener, 1 part to 10 parts of rutile type titanium dioxide, 1 part to 3 parts of water- and stain-proofing agent of exterior wall. The paint of the invention is great in heat preservation, waterproofing property, self-cleaning property, filling property, radioresistance and sun protection and has long service life.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

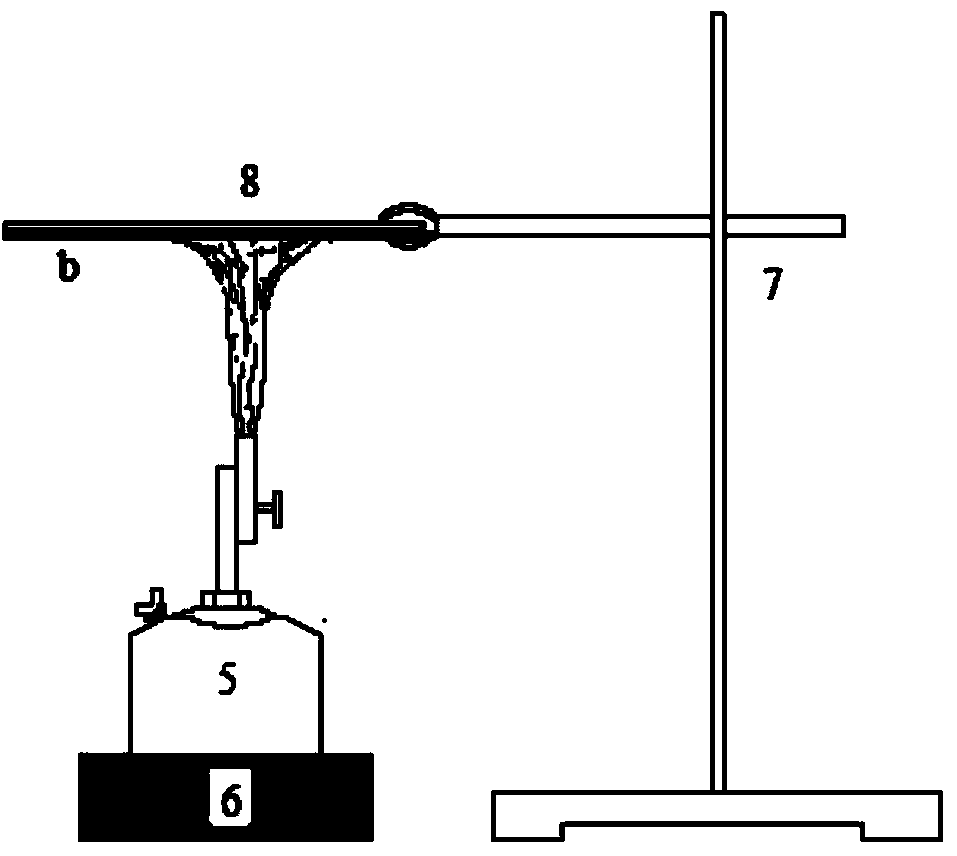

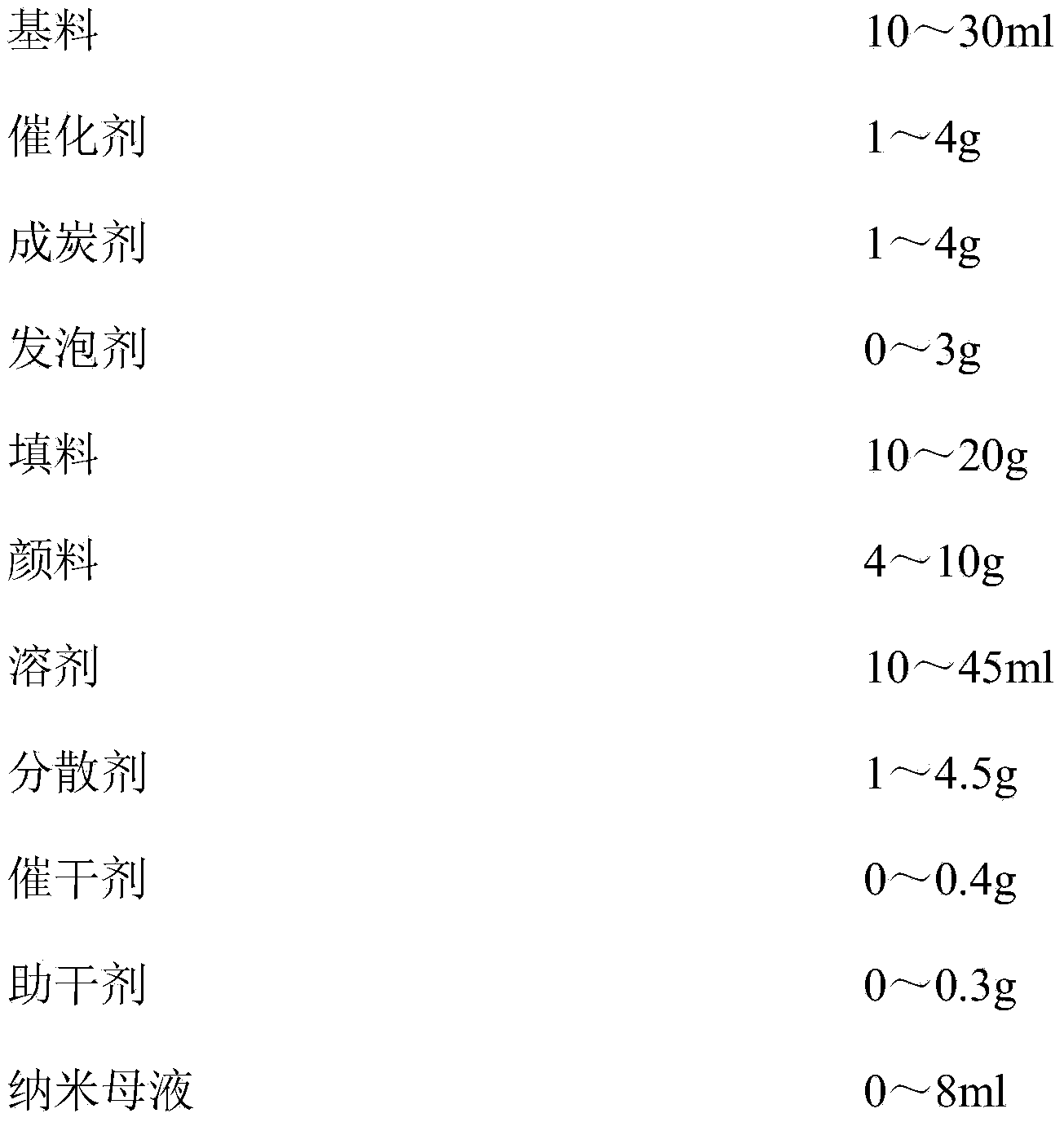

Fire-retardant coating with photo-catalytic performance and preparation method thereof

The invention discloses a fire-retardant coating with photo-catalytic performance and a preparation method thereof, belonging to the field of fire-retardant coatings. The coating comprises a base material, a catalyst, a charring agent, a foaming agent, a filler, a pigment, a solvent, a dispersant, a drier, a drying aid, a nano mother solution and the like, wherein the base material is aluminum dihydrogen phosphate, the catalyst is ammonium polyphosphate, the charring agent is pentaerythritol, the foaming agent is melamine, the filler is ultra-fine slag powder, the pigment is Cu-La / TiO2, the solvent is water, the dispersant is a BYK180 polymeric dispersant, the drier is lead oxide, the drying aid is zinc powder, and the nano mother solution is a nano SiO2 mother solution. The fire-retardant coating disclosed by the invention reduces the environment pollution to the maximum extent by using industrial waste residues as the filler; meanwhile, the coating has a function of realizing photocatalytic degradation of formaldehyde gas under a visible light source to endow conventional fire-retardant coatings with a brand-new function, and the fire-retardant coating accords with the development trend of national green ecological building materials.

Owner:镇江新智生物科技有限公司

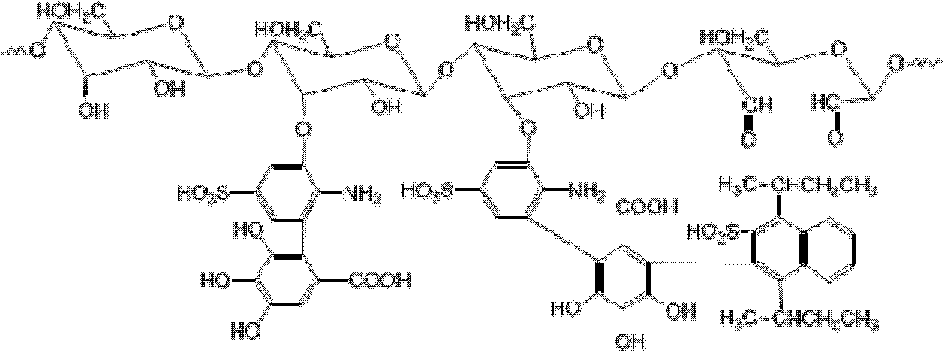

Method for preparing modified starch tanning agent

InactiveCN102020719AImprove absorption rateIncrease shrinkage temperatureTanning treatmentHigh absorptionGallic acid ester

The invention discloses a method for preparing a modified starch tanning agent, comprising the following steps of: firstly, degrading corn starch; in the presence of HRP (Horse Radish Peroxidase) / hydrogen peroxide (H2O2), grafting and modifying the degraded starch with sulfanilic acid, gallic acid and nekal; and then oxidizing the grafted starch with periodic acid. The invention has the innovation points that a nekal structure unit is introduced in the starch structure so as to improve the permeation wetting function of the modified starch tanning agent; the gallic acid structure unit is introduced to improve the tanning properties of the modified starch tanning agent, the sulfanilic acid is introduced to increase the dispersivity of the modified starch tanning agent, and dialdehyde action is used for improving the tanning properties of the modified starch tanning agent. The preparation method of the invention is peculiar and practical, and the obtained tanning agent is an environmentally-friendly leather tanning agent and is suitable for primary tanning and retanning. The shrinkage temperature (Ts) of pickled leather after primary tanning can be improved to 75-80 DEG C; and the retanned product has the advantages of wash resistance, high absorption rate on dyes and fatting agents and the like, is soft and plump.

Owner:SHAANXI UNIV OF SCI & TECH

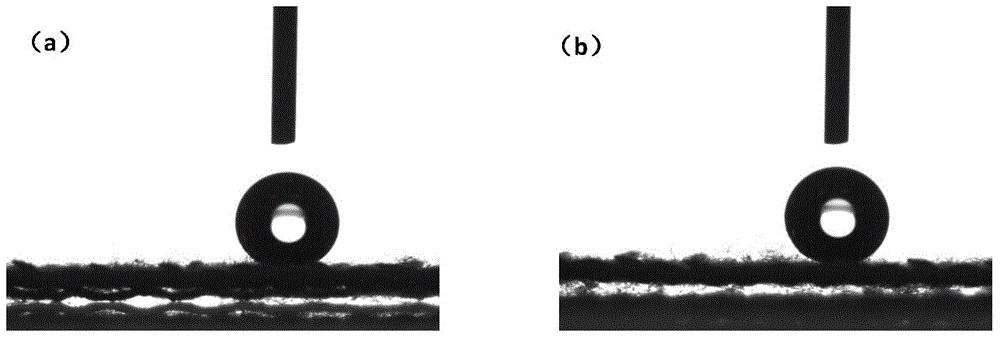

Method for preparing super-hydrophobic textiles through fiber surface polymerization modification

The invention relates to a method for preparing functional textiles, belongs to the field of material surface graft modification, and provides a method for preparing super-hydrophobic textiles through fiber surface polymerization modification. The method comprises steps as follows: polyester fibers are washed with alkali, bromo-initiators are fixed on surfaces of the polyester fibers, then metacrylic acid ester monomers are grafted onto polyester surfaces with an SI-ATRP (surface-initiated atom transfer radical polymerization) method, and macromolecular polymer hydrophobic layers are formed on the surfaces of the fibers, so that the super-hydrophobic polyester textiles are obtained. Contact angles of the polyester textiles prepared with the method and water drops are larger than 150 degrees, and the polyester textiles are stable to acid, alkali, salts and solvents, wear-resistant and washable and have good hydrophobic stability.

Owner:SHAANXI UNIV OF SCI & TECH

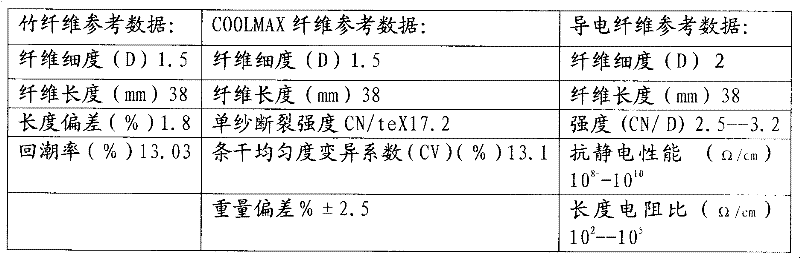

Bamboo fiber, Coolmax fiber and conductive fiber blended yarn and method for producing same

The invention discloses a bamboo fiber, Coolmax fiber and conductive fiber blended yarn and a method for producing the same. The bamboo fiber, Coolmax fiber and conductive fiber blended yarn has functions and characters of the three types of fibers, has complementary advantages, and has unique nobility by being spun by siro-spinning technology. The functional yarn can be used for knitting and tatting. A fabric made of the bamboo fiber, Coolmax fiber and conductive fiber blended yarns has the functions and characters of high strength, fine shape retention, high breathability, high moisture absorption, high sweat releasing, antibiosis, dust proofing, electrostatic resistance, ultraviolet resistance, environment-friendliness, easiness in caring, resistance to washing, stable size, softness and smoothness in touch and the like, is especially suitable for being made into knitted sports underwear, underpants, T-shirts, sportswear, shirts, hats and the like, and contributes to clothing grade increase and improvement on people's life quality, and commercial opportunities are supplied to textile enterprises. Therefore, great social benefit and economic benefit are achieved.

Owner:SHAOXING HENGMEI FANCY SILK +1

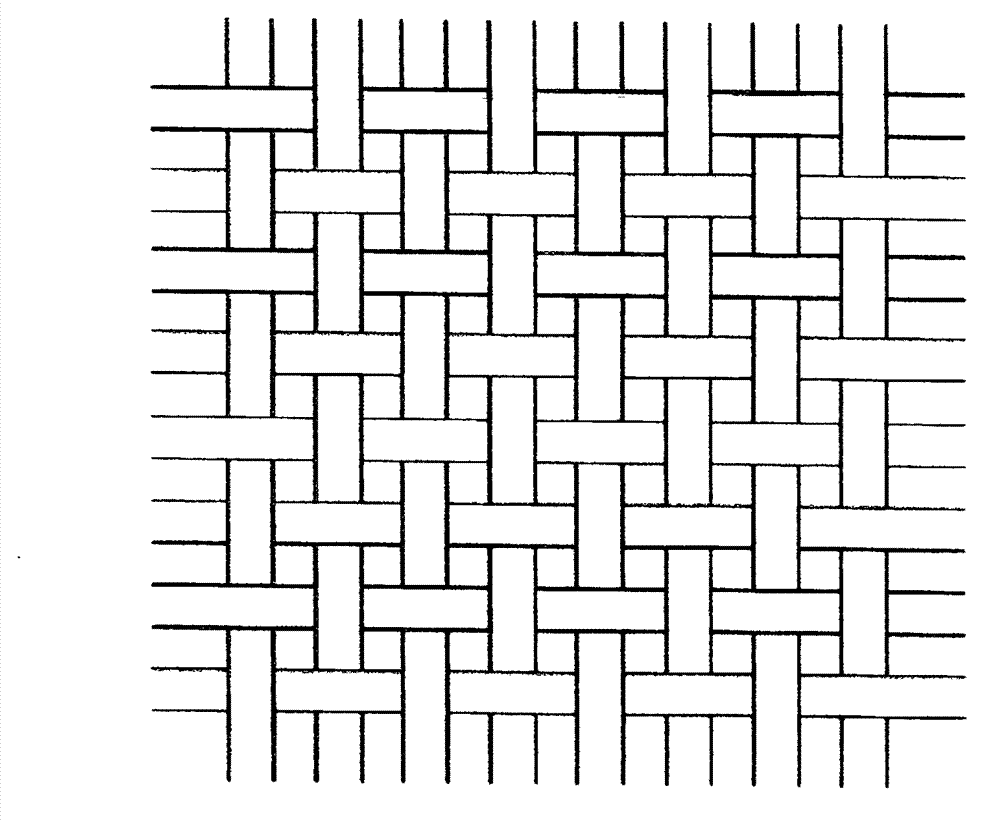

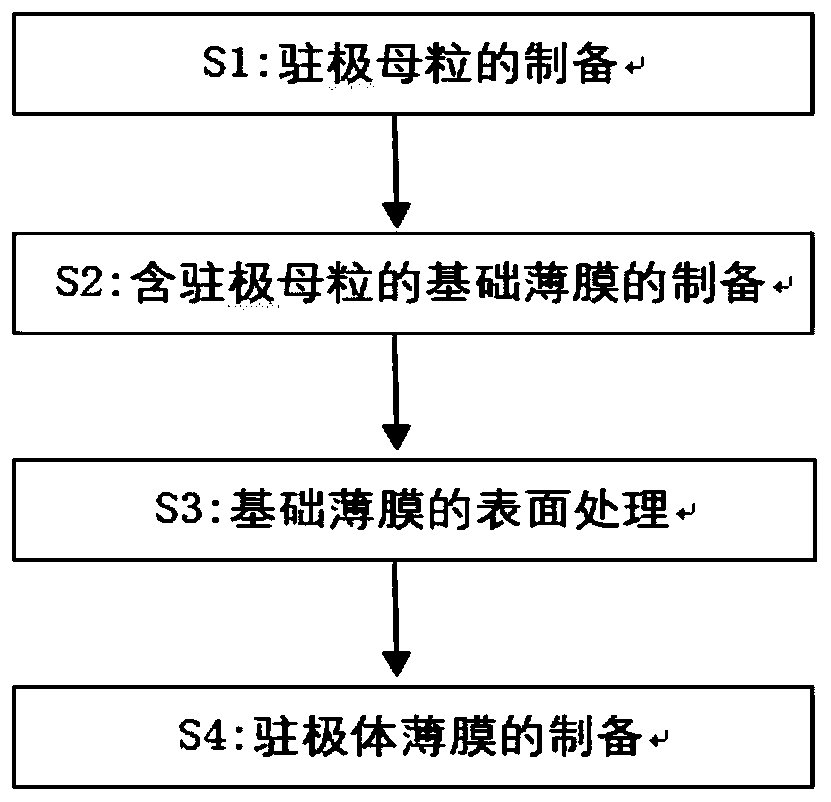

Electret film, preparation method, application, and air purification device

PendingCN111019233AImprove performanceImprove filtration efficiencyMechanical apparatusLighting and heating apparatusAir cleaningThin membrane

The invention provides an electret film, a preparation method, application, and an air purification device, and relates to the technical field of electret materials and preparation methods. The electret film is mainly prepared from the following raw materials in percentage by weight: a first polymer and 2-10% of an electret master batch, wherein the electret master batch comprises the following components in parts by weight: 1-20 parts of an inorganic electret additive, 5-50 parts of an organic electret additive and 40-90 parts of a second polymer. The thin film air filtration material comprises a polymer substrate and the electret master batch capable of increasing charge density. The electret film air filtering material prepared by the invention has very high charge density and electrostatic voltage, can generate a durable and stable electrostatic field which is not easy to attenuate. The film material can capture and bear fine dust particles by utilizing electrostatic adsorption force, has the advantages of repeated washing and repeated utilization, and can be applied to the field of air filtration.

Owner:ZHEJIANG GOLDENSEA ENVIRONMENT TECH

Powdered medicine active carbon mixture and preparation method thereof

InactiveCN101125190ALasting effectGood securityAntibacterial agentsHeavy metal active ingredientsHerbActivated carbon

The present invention relates to a mixture of medicinal powder and activated carbon and the preparation method thereof, which pertains to the traditional Chinese medicine products; the formula of the mixture is composed of 80 traditional Chinese medicine ingredients of abrus herb, shinyleaf pricklyash root, Chinese arborvitae twig, winged euonymus twig, ovientvine, buerger pipewort flower, radix ranunculi ternati etc. and maifanite, germanite and crystal minerals, and the mixture is prepared by smashing, mixing, water soaking, boiling, filtering, drying, carbonization, activation, rubber refining, redrying and smashing processes; the mixture has good effects of health care for the human body, treatment and prevention of the diseases, furthermore, the functions are extensive, the cost of the product is low, the usage is convenient, the application scope is wide, the preparation method is simple and the operations are easy to control.

Owner:关艳龙 +1

Halogen free flame retardant liquid and method for preparing flame retardant sponge using same

The invention relates to a halogen free flame retardant liquid and a method for preparing a flame retardant sponge using the same. The halogen free flame retardant liquid has the flame retardant effect up to a UL V-0 grade, durable flame retardant effect and no smoke toxicity and comprises 100 parts of water based adhesive, 0.5-5 parts of curing agent, 0.1-5 parts of anti-settling agent, 0-2 parts of color fixing agent, 0-100 parts of colorant, 100-300 parts of environment-friendly flame retardant, 100-400 parts of inorganic flame retardant and 1200-1800 parts of water, wherein the anti-settling gent is at least one of organic modified bentonite, fumed silica, polyethylenewax, polyamide wax or titanate coupling agent, and the environment-friendly flame retardant is at least one of phosphorus flame retardant or phosphorus and nitrogen flame retardant. The method for preparing the flame retardant sponge comprises the step of immersing an open-cell sponge in the above halogen free flame retardant liquid and drying to obtain the product. The halogen free flame retardant liquid can be obtained through a conventional mixing process, and the method for preparing the flame retardant sponge is simple, can be in continuous production, improve production efficiency and lower cost.

Owner:CHANGZHOU XINQISHENG MACROMOLECULE TECH

Water-washable silk composite fiber and preparation method thereof

InactiveCN104213247AUV resistantAntistaticConjugated cellulose/protein artificial filamentsArtifical filament manufacturePolyesterFiber

Disclosed water-washable silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 18-22 parts of silk, 11-13 parts of wool, 4-7 parts of cuprammonium rayon, 6-8 parts of polyester fiber, 8-10 parts of newdal fiber, 10-12 parts of bast fiber, 0.6-1.1 parts of nanometer TiO2, 6-9 parts of aloe viscose fiber, 0.7-0.9 parts of hydroxypropyl methyl cellulose, 0.8-1.4 parts of polypropylenglycol diglycidyl ether, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 110-120 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 1-3 parts of radix aucklandiae, 2-4 parts of cortex moutan, 3-5 parts of an auxiliary agent, and proper amount of water. By adding cuprammonium rayon and nanometer TiO2, the silk composite fiber has performances of resisting ultraviolet, resisting static electricity, resisting water washing and the like; and additionally by adding aloe viscose fiber, the Chinese herbal medicines and other compositions, the prepared silk composite fiber has the characteristics of resisting bacteria, diminishing inflammation, light and soft texture, excellent air permeability, high strength and high elasticity, and thus the silk composite fiber is repeatedly cleanable and keeps comfortableness, and is not flat or sunk after being used for a long time.

Owner:TONGCHENG SHUANGLONG SILK

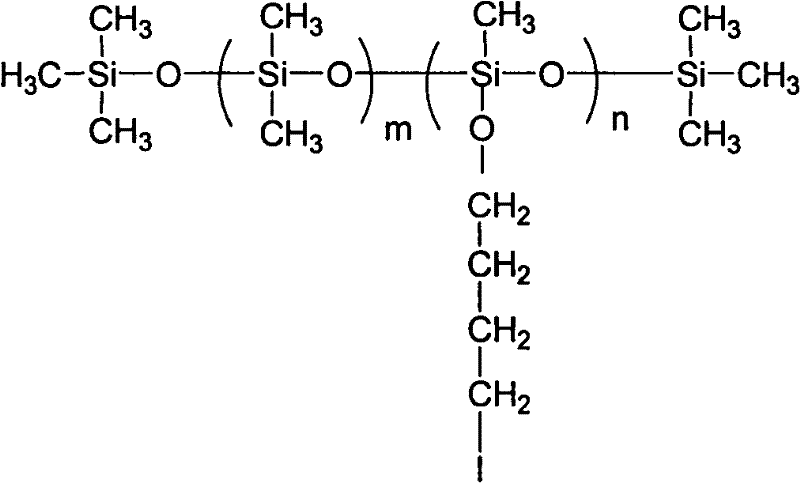

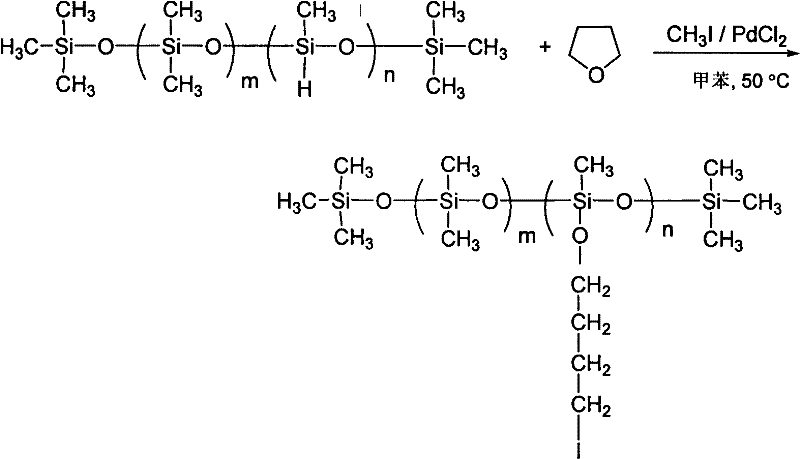

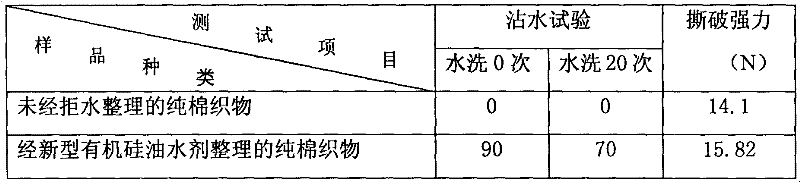

Preparation method of novel organic silicone oil water repellent agent used for cotton fabric

The invention relates to a preparation method of a novel organic silicone oil water repellent agent used for cotton fabric. The preparation method comprises the steps of: under the protection of nitrogen, adding 2 times of molar weight of toluene used as a solvent to a three-neck flask, then respectively adding hydrogen-containing silicone oil with 1 time of molar weight of active hydrogen, 3 times of molar weight of tetrahydrofuran and 4 times of molar weight of iodomethane to the three-neck flask, then adding 0.01 time of molar weight of palladium chloride catalyst, and reacting under the action of the palladium chloride catalyst to prepare the organic silicone oil water repellent agent with active group. The obtained organic silicone oil water repellent agent is mainly used for water repelling finishing of the cotton fabric, can improve water repellent property of the fabric as well as the water repellent durability and tearing resistance of the finished fabric, and is a novel printing and dyeing auxiliary agent.

Owner:金伦(苏州)织造有限公司

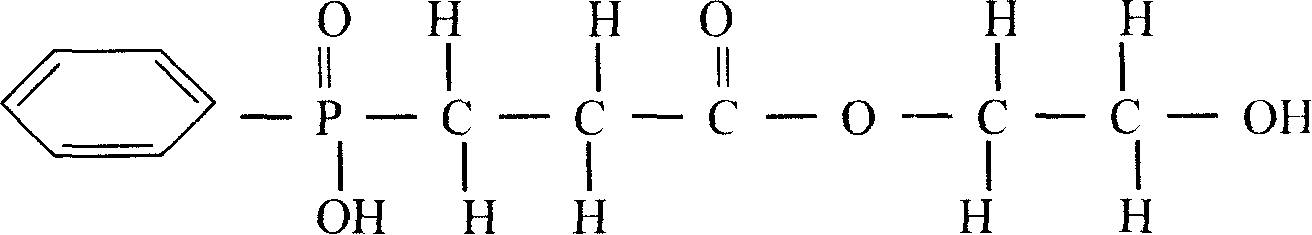

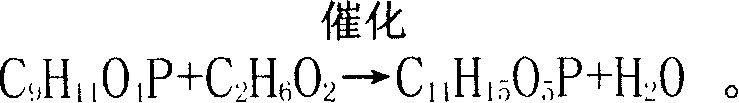

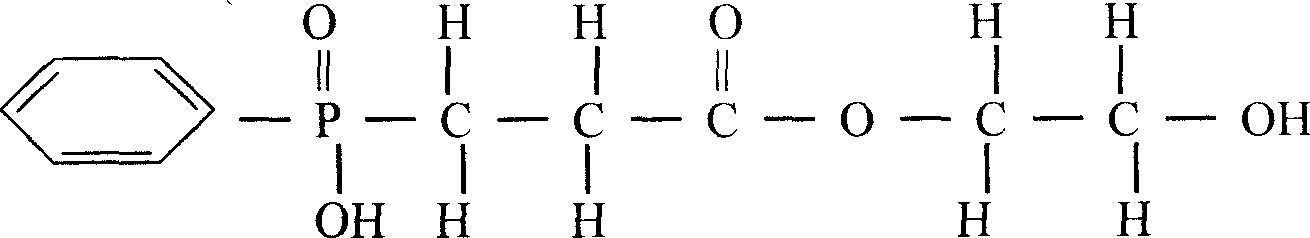

Non-halogen fire retardant for terylene polyester chips and its production technology

A non-halogen fire retardant for terylene polymer chips used to prepare polyester fibres is prepared from ethanediol (C2H6O2) and 2-carboxyethyl phenylphosphoric acid (C9H11O4P) through adding catalyst, stirring, heating, negative-pressure reaction, and cooling.

Owner:南通联华阻燃科技有限公司

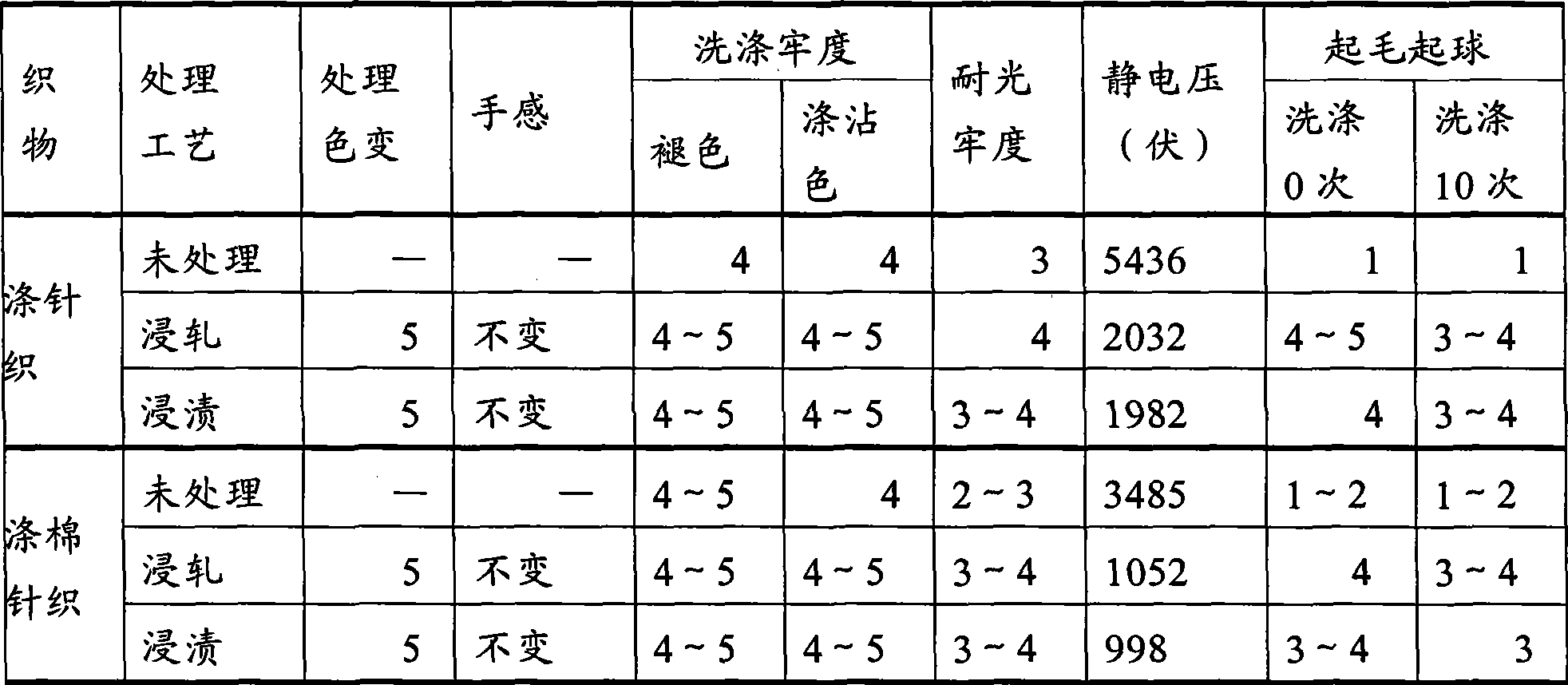

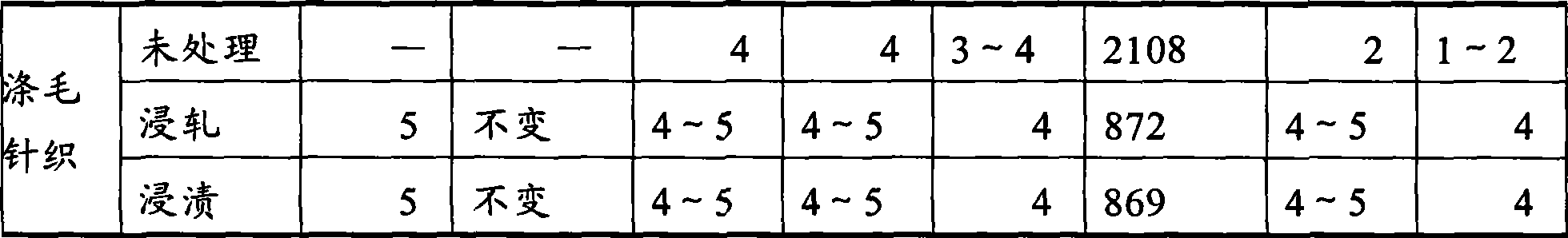

Anti-fuzzing and anti-pilling finishing agent for fabric

The invention relates to an auxiliary agent in the printing and dyeing industry, in particular to a surface finishing auxiliary agent for fabric. An anti-pilling finishing agent for the fabric is nonionic macromolecular polymer, and is characterized in that the anti-pilling finishing agent for the fabric is formed by copolymerizing 10 to 20 portions of high-hydro silicone oil, 30 to 50 portions of polyurethane prepolymer and 30 to 50 portions of polypropylene ester copolymer under the conditions of catalyst and heating; and the portion is weight portion. The fabric anti-pilling finishing agent is suitable for various fibers and fabrics; and in particular, polyester fabric treated by the anti-pilling finishing agent has basically unchanged tone and handfeel, improves the fastness to washing and light fastness, greatly improves the antistatic performance, has certain dust resistance and obviously improves the anti-pilling performance.

Owner:上海德桑精细化工有限公司

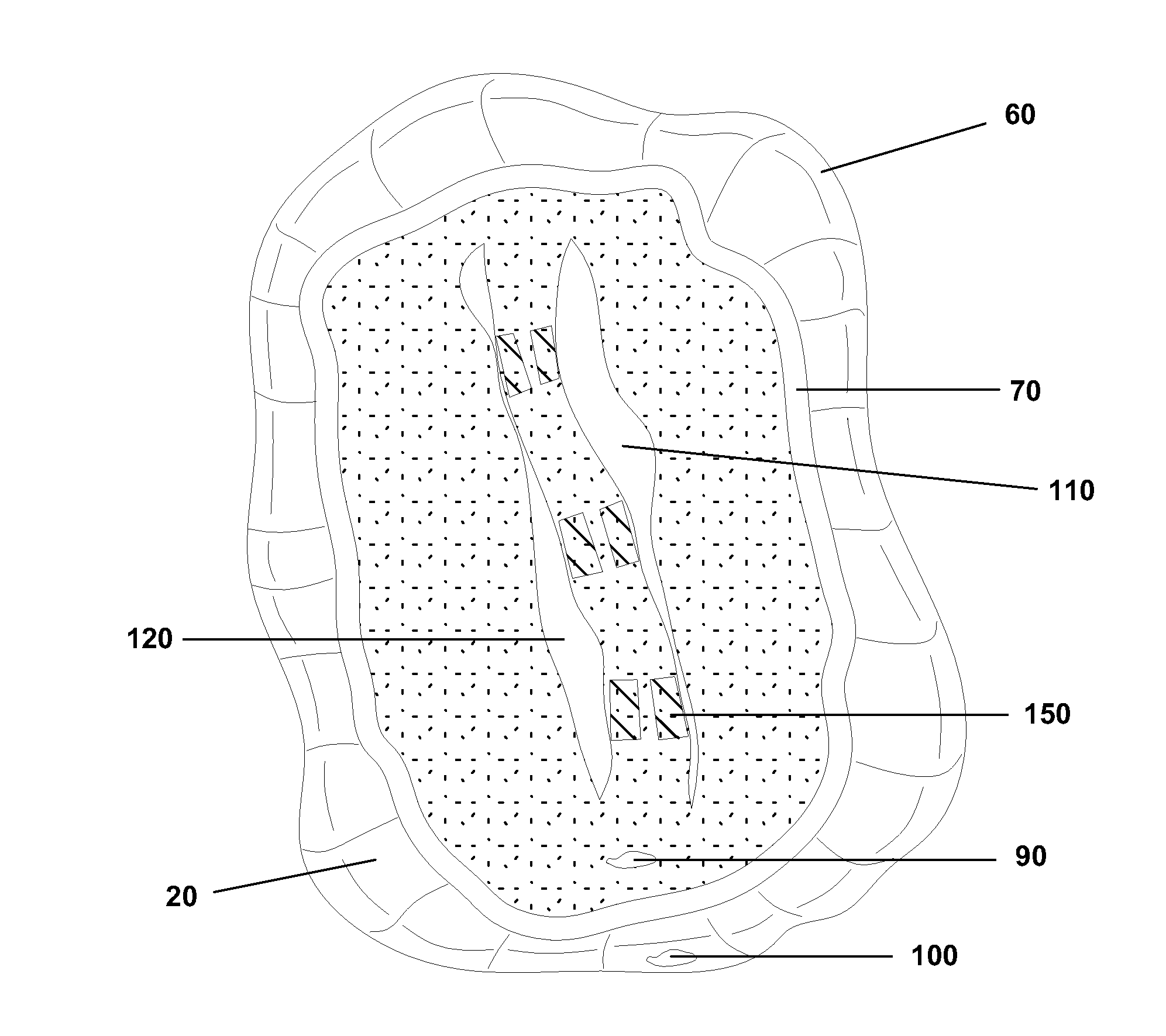

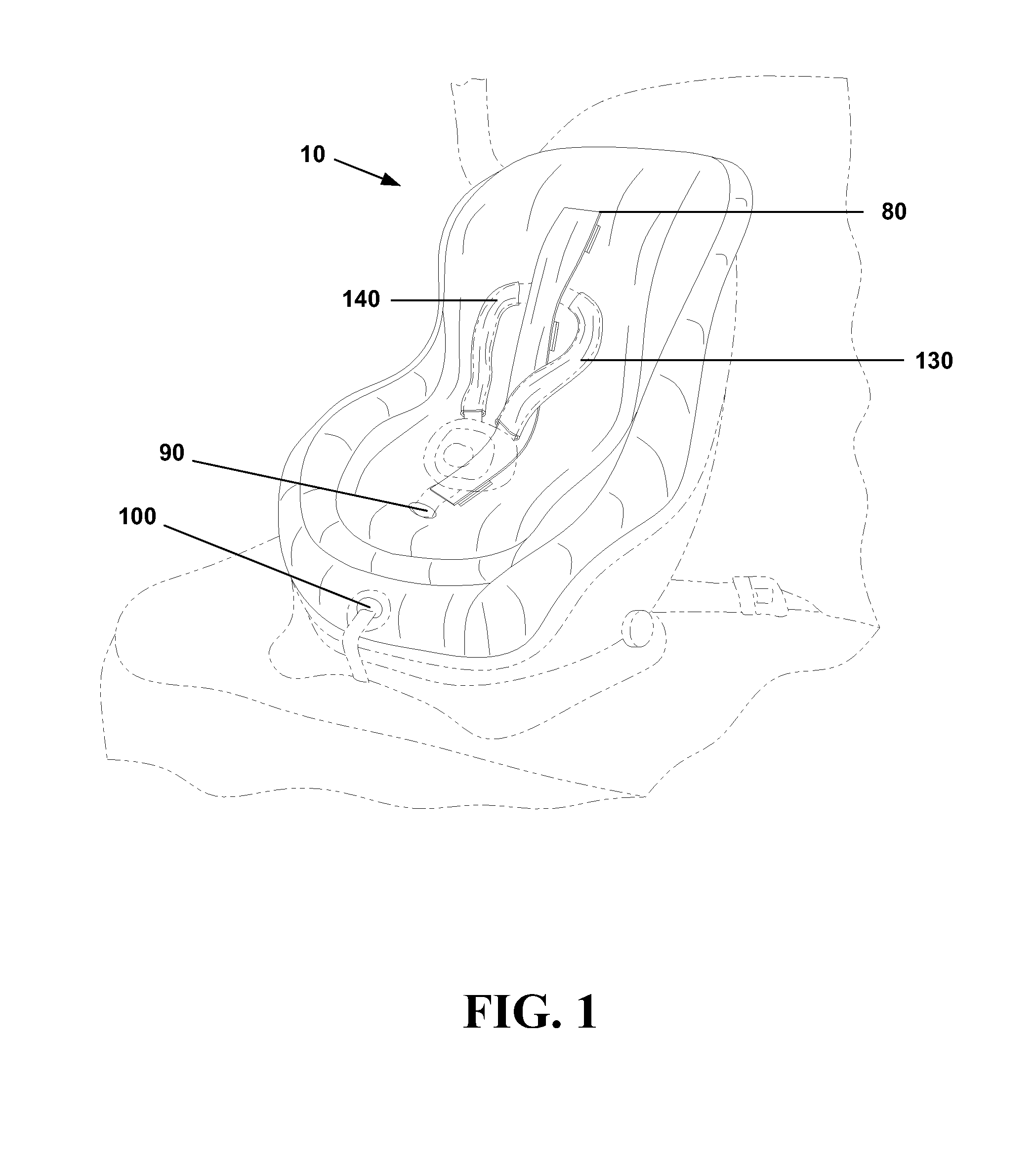

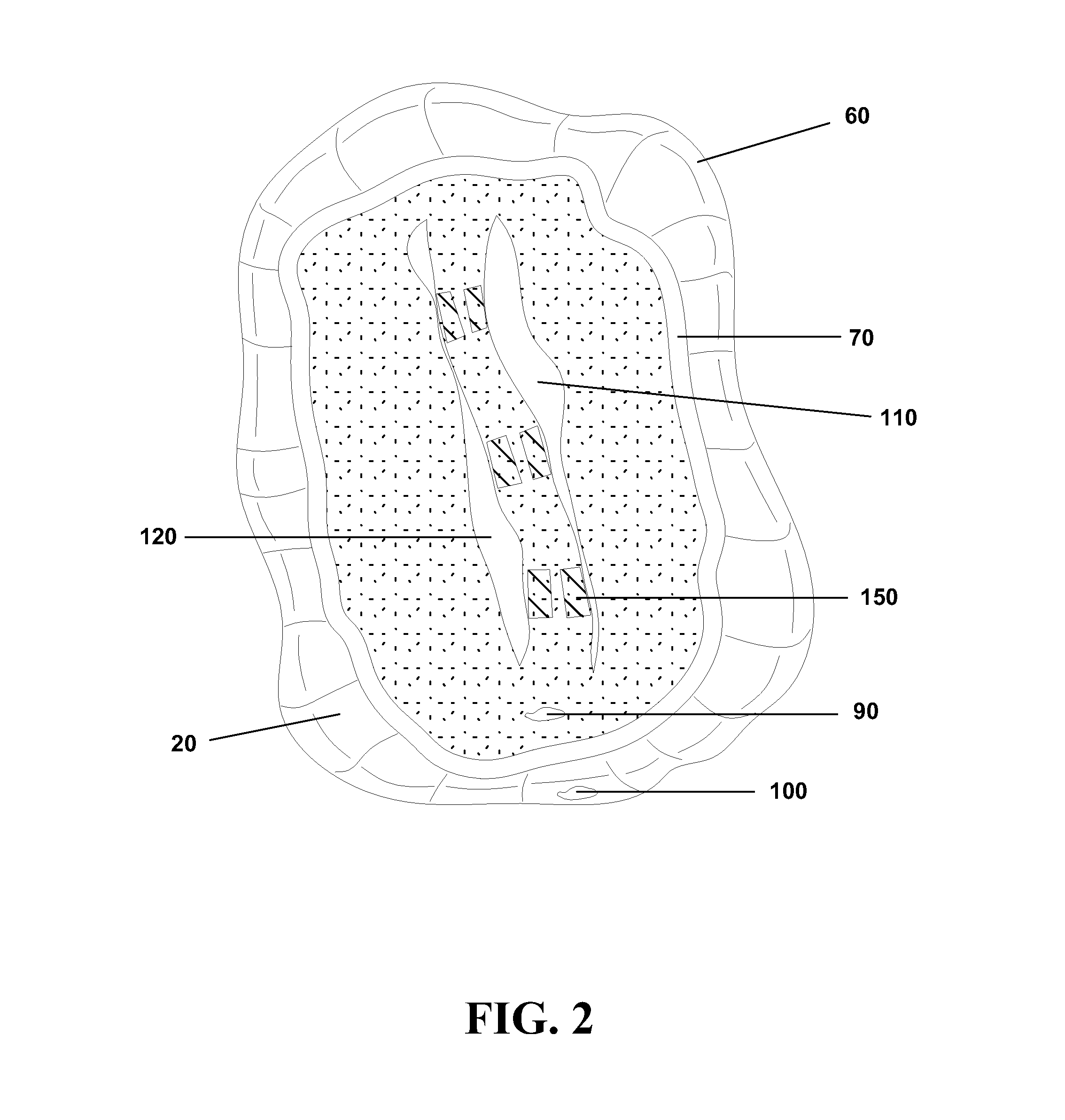

Child Car Seat Cover

InactiveUS20080150335A1Easy to disassembleEasily removable from the car seatVehicle seatsSeating furnitureCar seatEngineering

A child car seat cover is disclosed. This device provides an easily removable, cleanable and adjustable cover for a child car seat that restricts the passage of food, dirt and liquids to the car seat material. The device is comprised of multiple layers of fabric, strap covers, strap openings and strap closures, and has waterproof backing.

Owner:GLORY KOGYO KK

Modified wood dyeing method

The invention provides a modified wood dyeing method. A modified wood board or modified wood powder is put in a dyeing container of supercritical CO2 fluid dyeing equipment for dyeing with CO2-H2O serving as a dyeing medium, disperse dye serving as a dyeing agent, the temperature of 100-140 DEG C, the pressure of 10-40 MPa and the time of 10-600 minutes. After the dyeing is finished, the CO2 and the disperse dye are recovered by reducing the pressure and the temperature so as to obtain the dyed modified wood board or the dyed modified wood powder; and the hot press molding can be further performed for the dyed modified wood powder to obtain the dyed modified wood board. The dyed wood board has such effects as rich colors, bright colors and uniform colors; and the dyeing process has such advantages as cleanness and environmental protection. The color board can be applied to the indoor or outdoor decoration engineering, can particularly serve as a beautiful decoration material in a humid environment, and has wide application prospect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Natural down flocculus made of composite thermal insulation materials and manufacturing process of the natural down flocculus

The invention relates to a natural down flocculus made of composite thermal insulation materials, which is made through taking down mainly comprising duck down and goose down as a main material, as well as a manufacturing process of the natural down flocculus. The natural down flocculus made of the composite thermal insulation materials is made of blend fiber and down mainly comprising duck down and goose down, wherein the blend fiber is formed by blending meldable fibers and polyester staple fibers according to weight ratio of (13-18):(6-15); and the blended ratio of the down and the blend fiber is determined according to the requirement of a down product. In manufacturing, animal down serves as a main material while the meldable fibers and the polyester staple fibers serve as auxiliary materials; and the composite thermal insulation material with the down content of above 65% is produced according to different ratios of all materials. The down flocculus has a good thermal insulation property like a down product or a cashmere product, is green and environment-friendly, and also has spinnability and tailorability. The process is relatively low in cost, concise and mature in process and easy to operate, and has a great market potential.

Owner:河北兴瑞羽绒制品有限公司

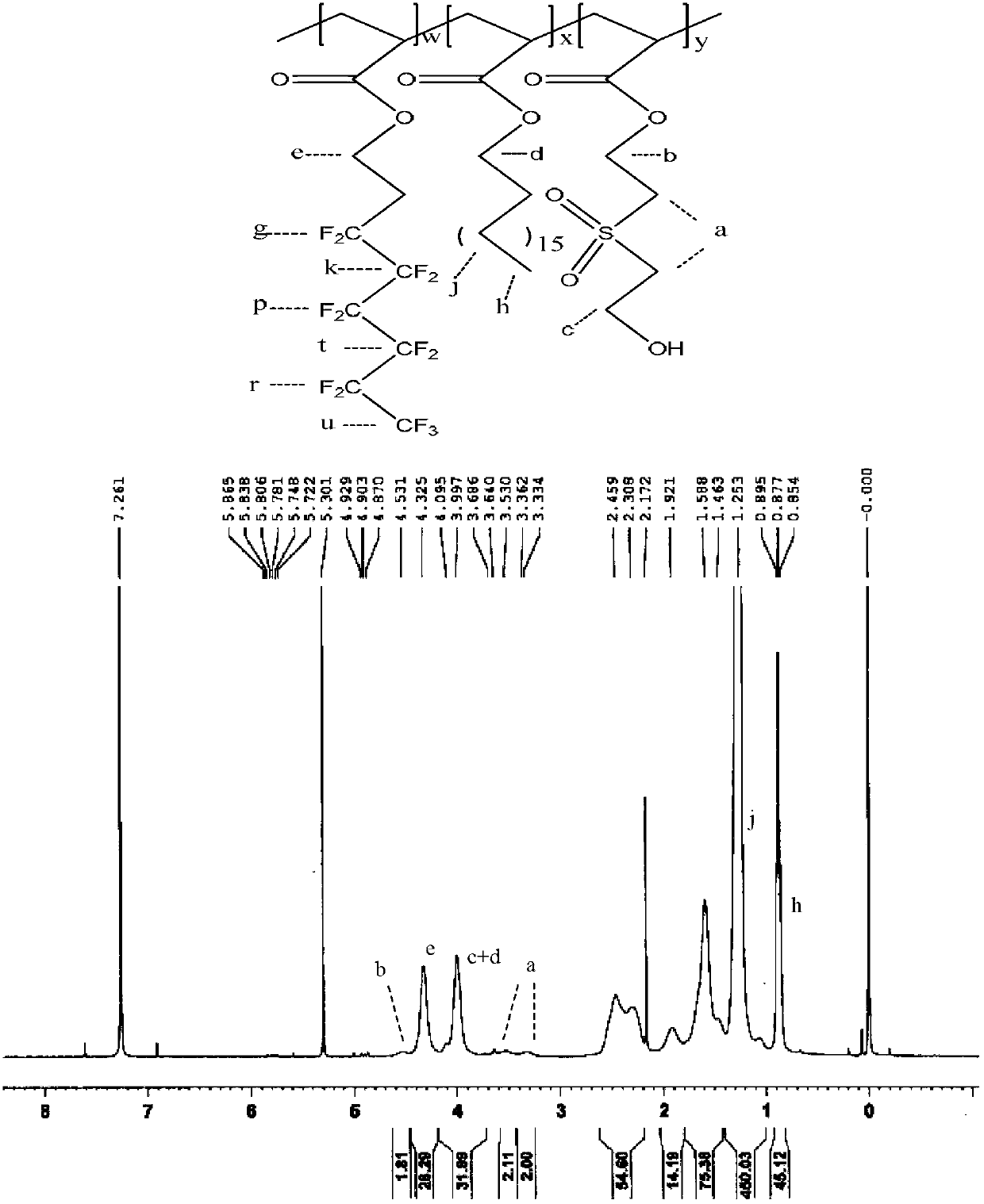

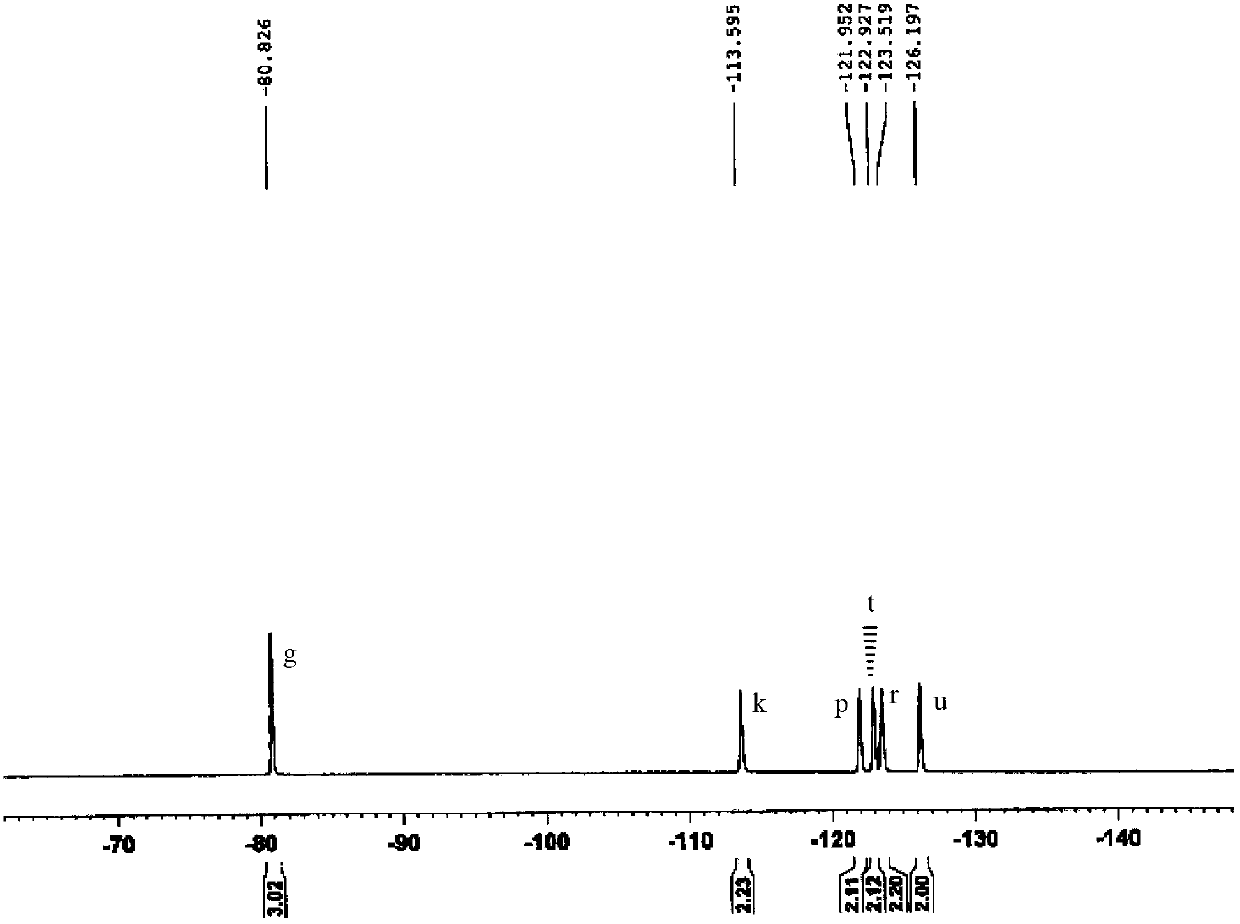

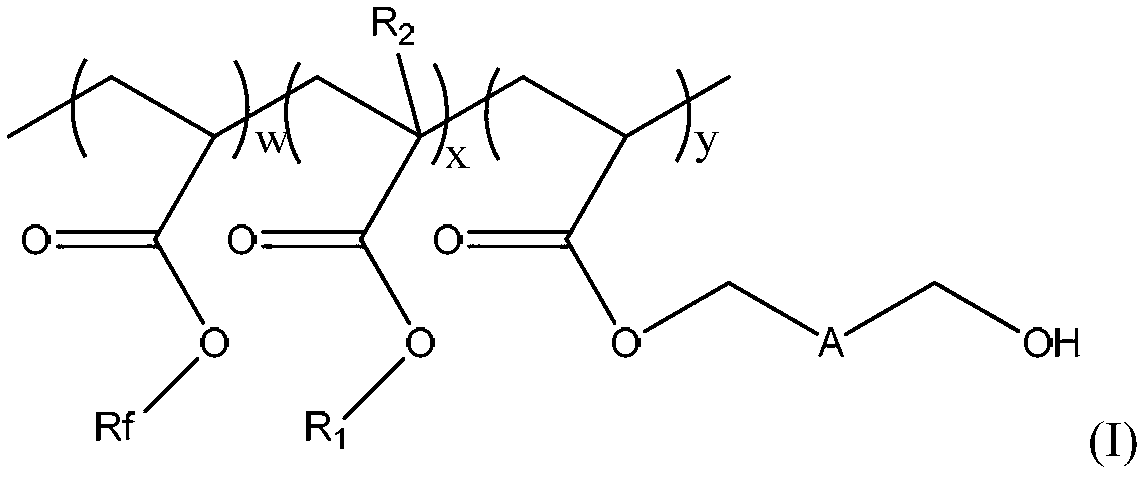

Preparation method of fluorine-containing acrylate terpolymer emulsion

ActiveCN103130950AWater repellent and oil repellentWashableFibre treatmentACRYLATE TERPOLYMERPolymer chemistry

The invention relates to a preparation method of a fluorine-containing acrylate terpolymer emulsion, which comprises the following steps: by taking perfluorohexyl ethyl (methyl) acrylate, high fatty alcohol (methyl) acrylate and a crosslinking monomer as main raw materials, taking persulfate as initiator and using composite emulsifier and a proper amount of co-emulsifier, chain transfer agent and deionized water, performing high-speed shearing at 40 DEG C for 0.5-2 hours, and then performing ultrasonic emulsification for 20-60 minutes to obtain a stable pre-emulsion; and taking part of the pre-emulsion, adding part of the initiator, heating to 50-90 DEG C, reacting for 0.5-1 hours, dropwisely adding the residual pre-emulsion and residual initiator, reacting for 3-6 hours while keeping the temperature, cooling, and regulating the pH value. The prepared emulsion is uniform and stable in particle size and does not contain harmful ingredients such as PFOS / PFOA and the like; and a coated film formed by the emulsion has favorable water repellency and oil repellency.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com