Patents

Literature

3667results about How to "Meet the process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

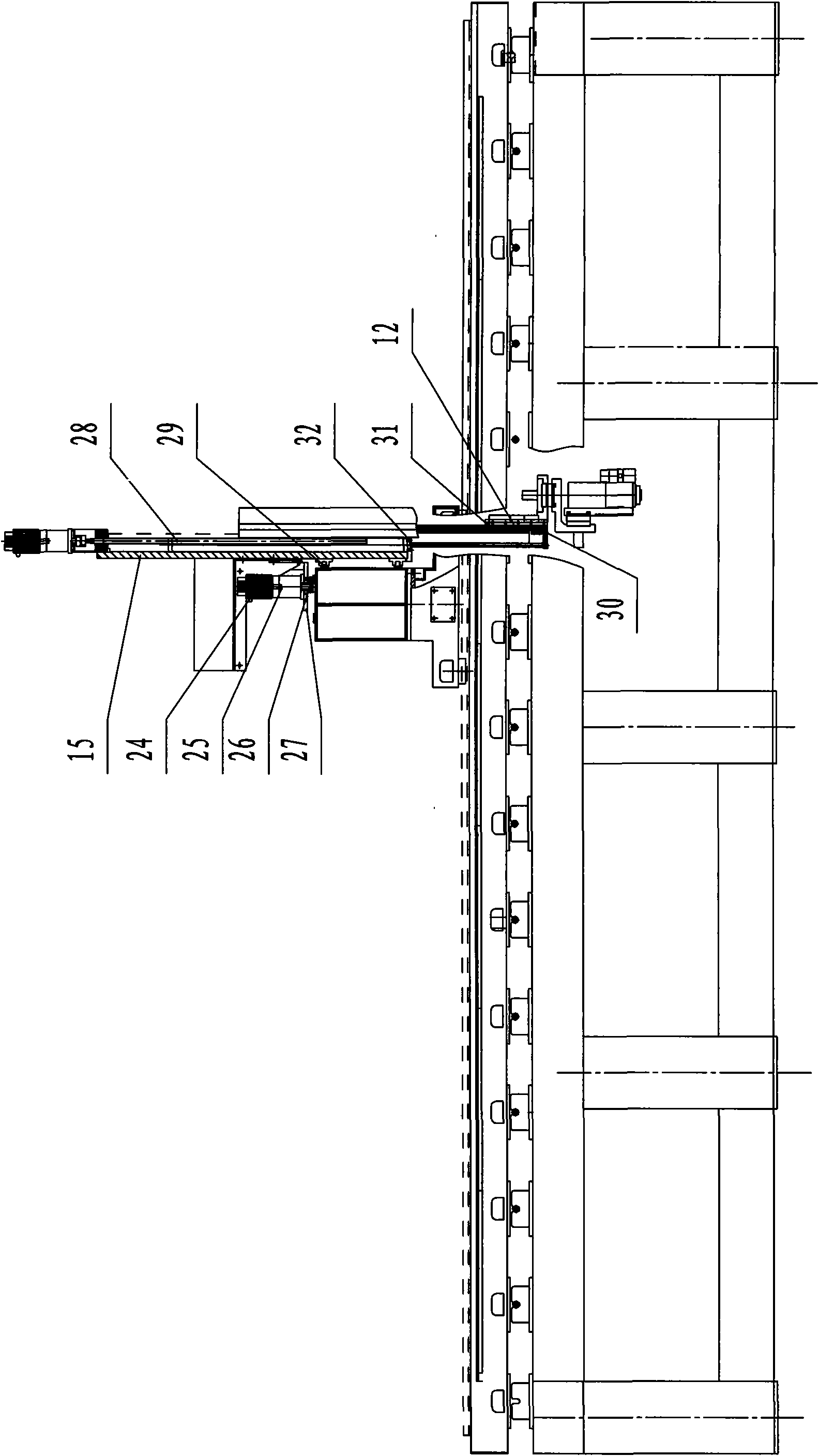

Selective laser melting rapid prototyping equipment for direct manufacturing of large parts

ActiveCN102266942AMeet the process requirementsReduce construction costsIncreasing energy efficiencySelective laser meltingLaser array

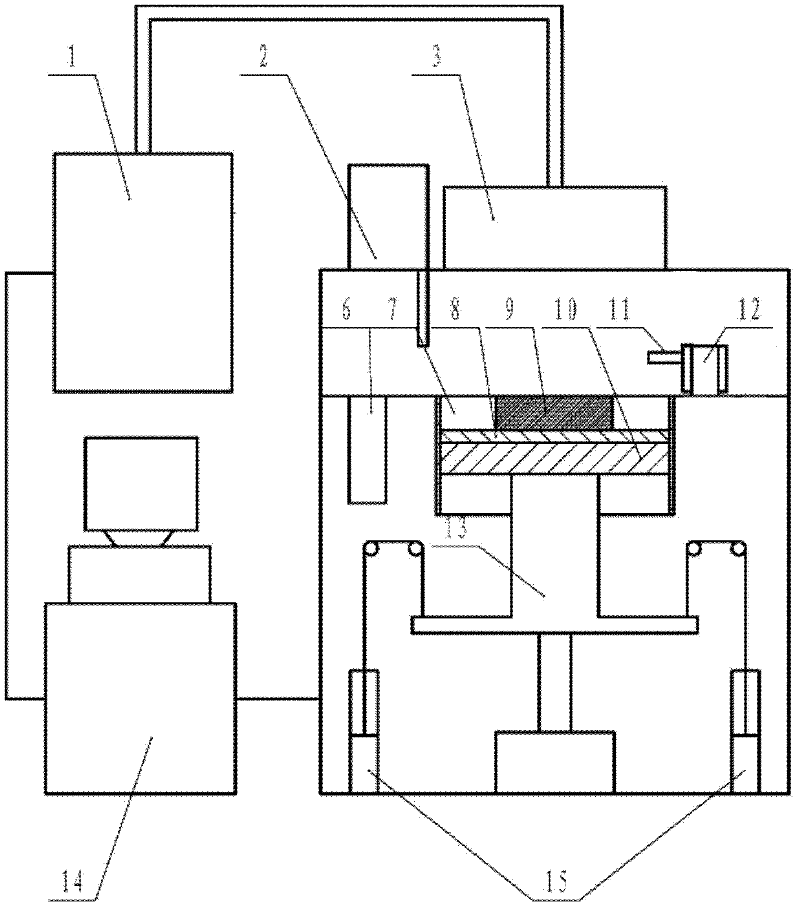

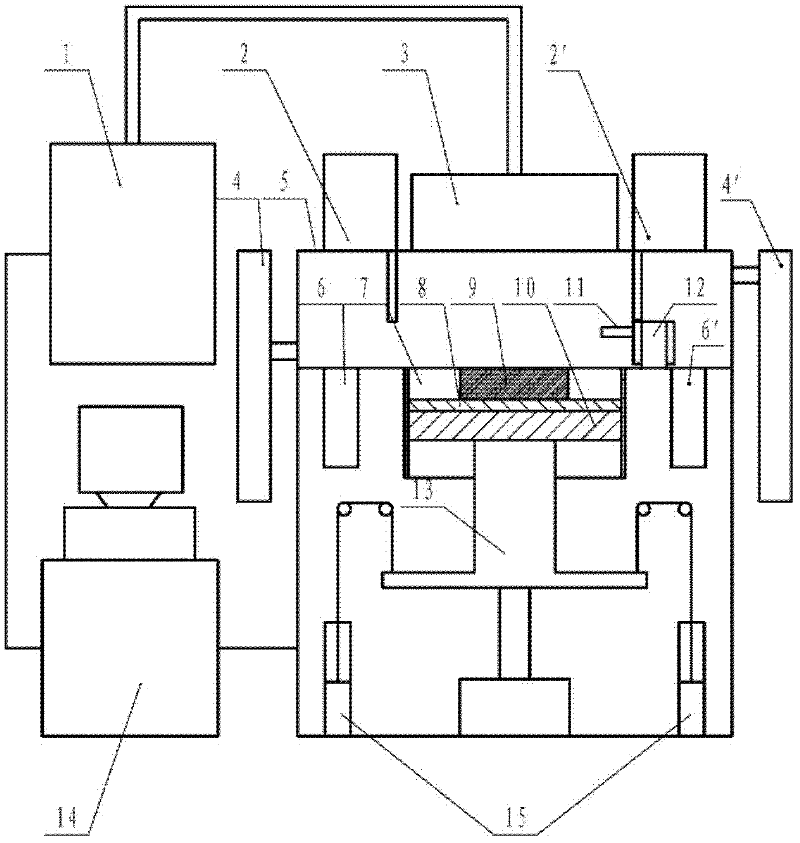

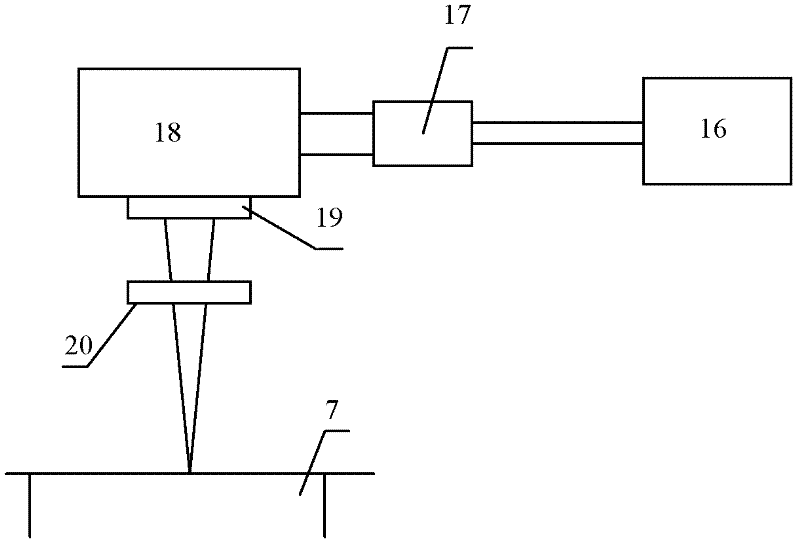

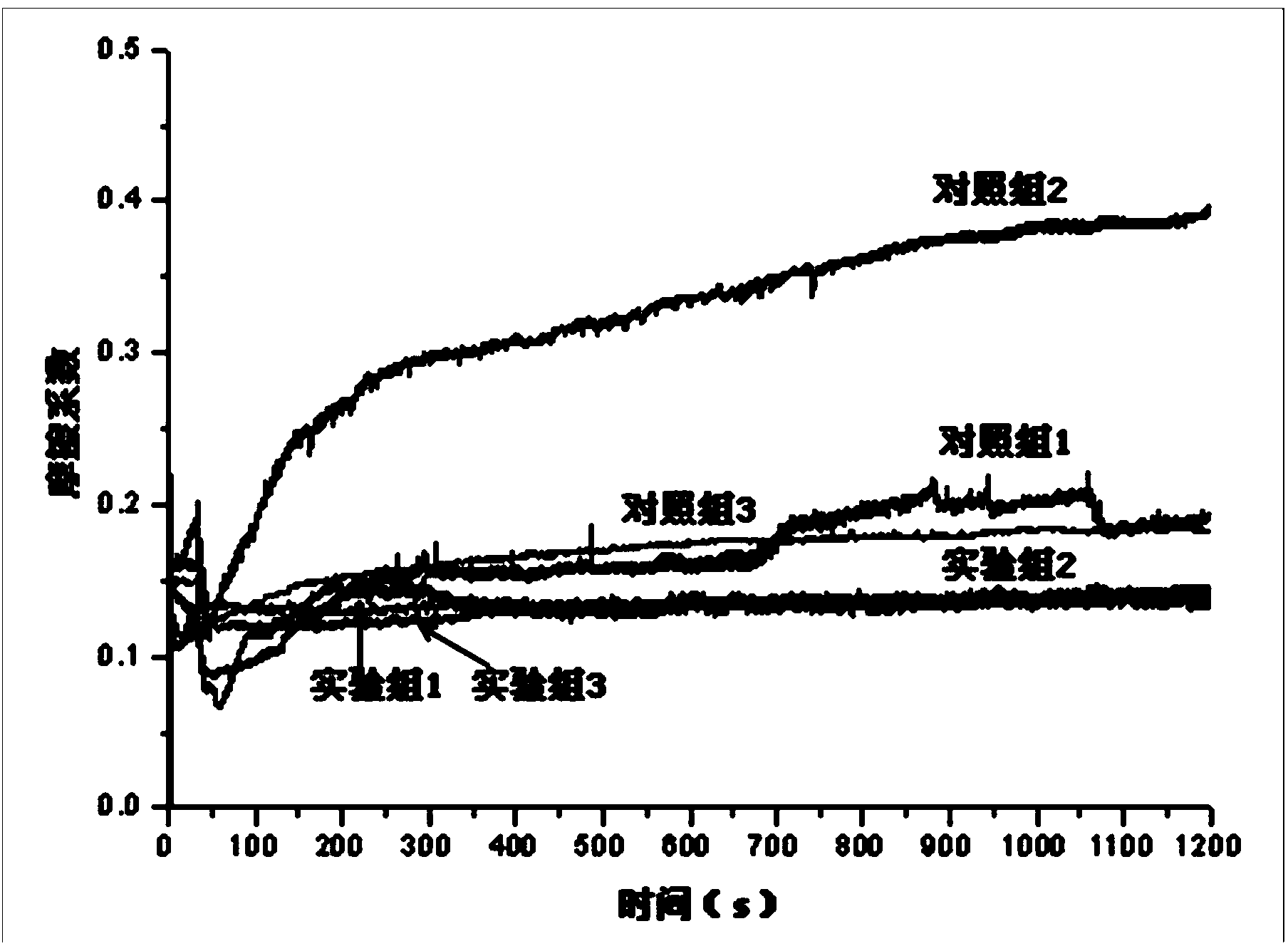

The invention discloses a selective laser melting rapid forming device for directly manufacturing large-size compact parts, which mainly comprises a laser array, an optical system array, a forming cylinder, a forming cylinder vertical sectional heating thermal-insulation structure, a forming cylinder weight balancing system, a substrate leveling device, a double-recovering cylinder, a double powder storing box, a double quantitative powder sending and discharging device, a powder paving device, a protective atmosphere cover, a gas purifying system and a control system, wherein an adopted optical system is composed of a plurality of optical system units and a mechanical moving platform, and the coverage area of the optical system can be randomly expanded or reduced. The size of the parts manufactured by using the selective laser melting rapid forming device provided by the invention is more than the size of the parts manufactured by using the existing national and foreign selective laser melting processes. The forming efficiency is multiplied while the forming precision, the parts complexity and the mechanical property are not changed.

Owner:TECH LASER TECH SHANGHAI CO LTD

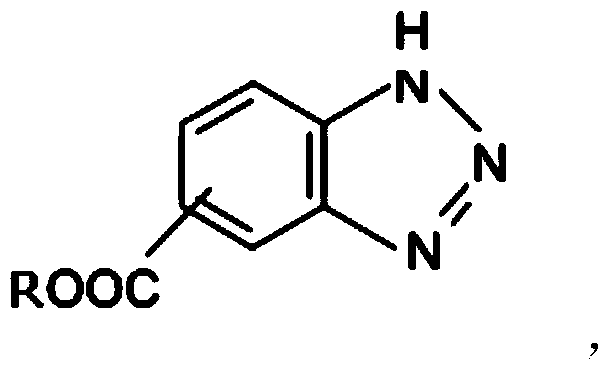

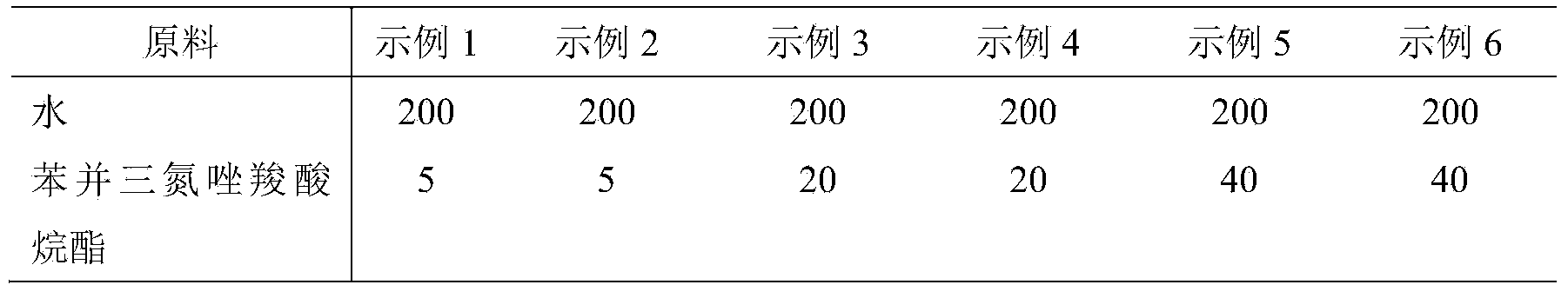

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

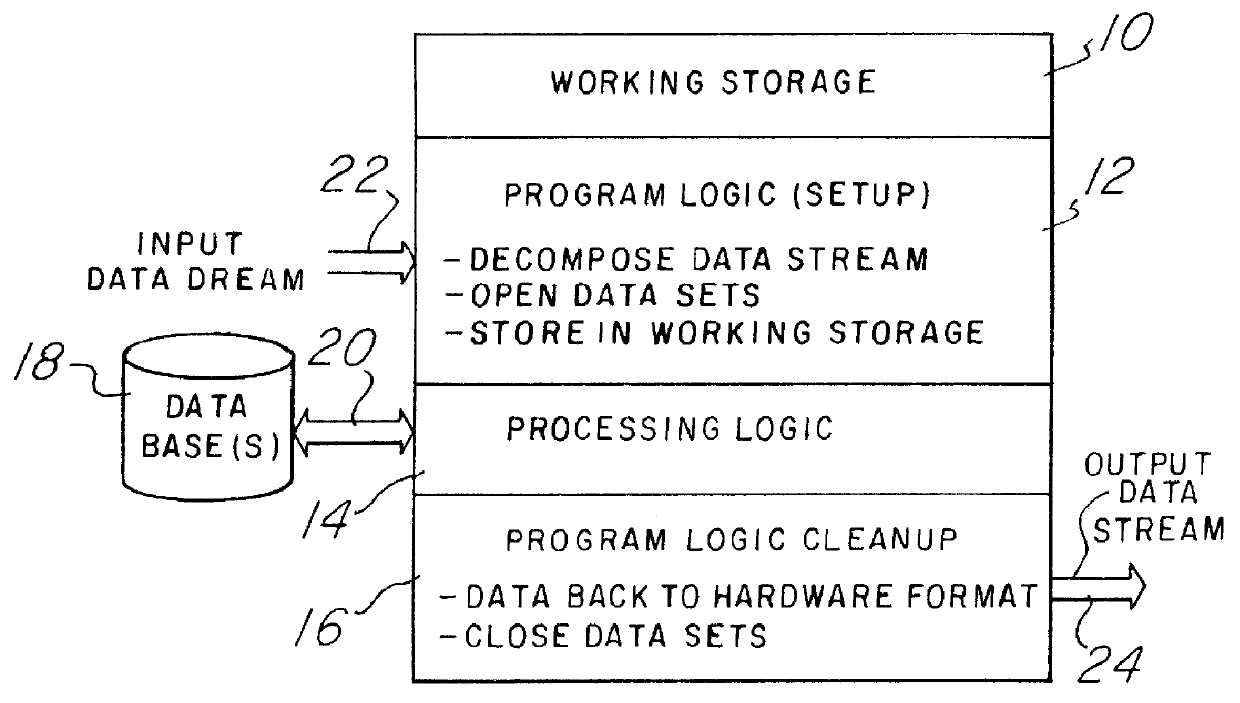

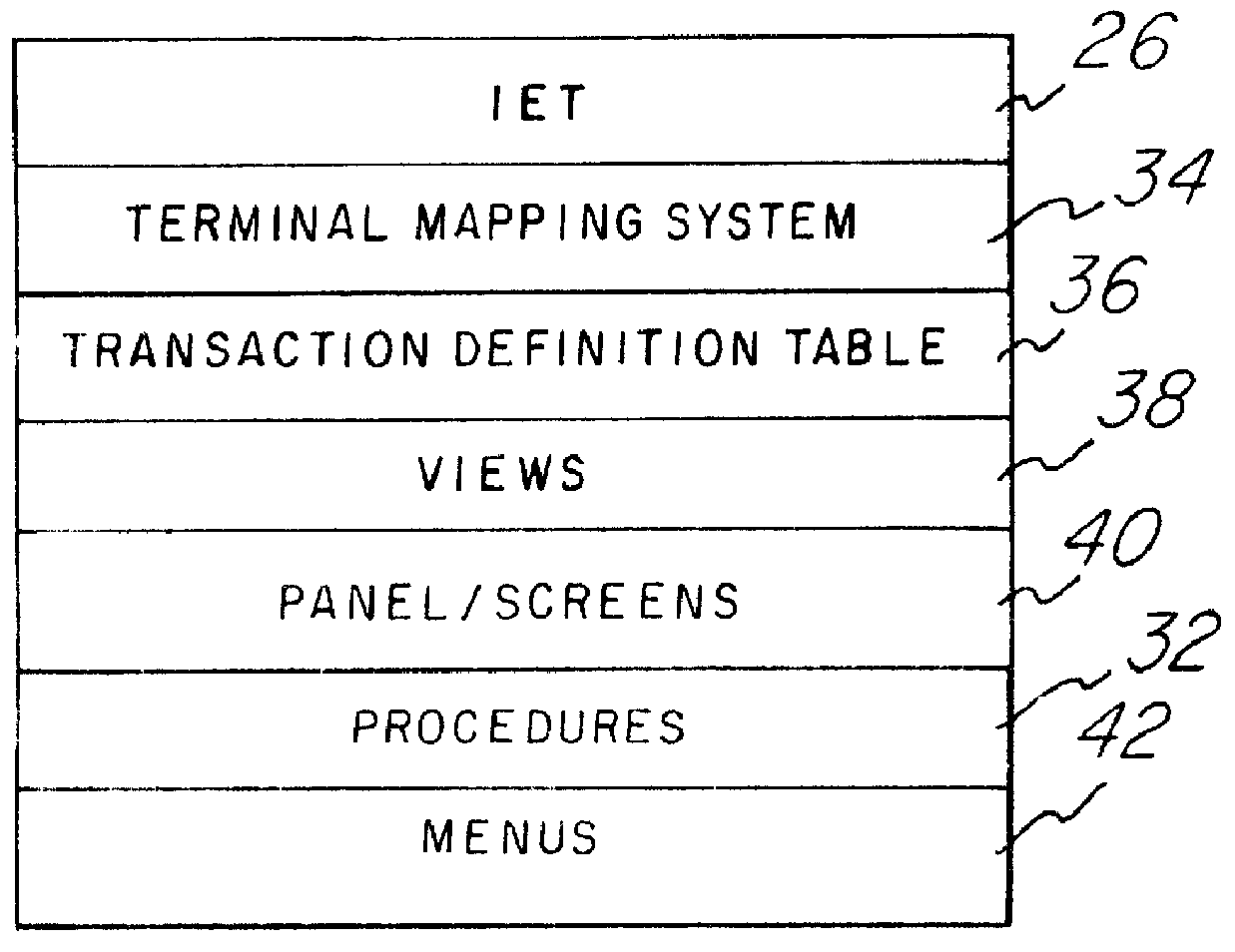

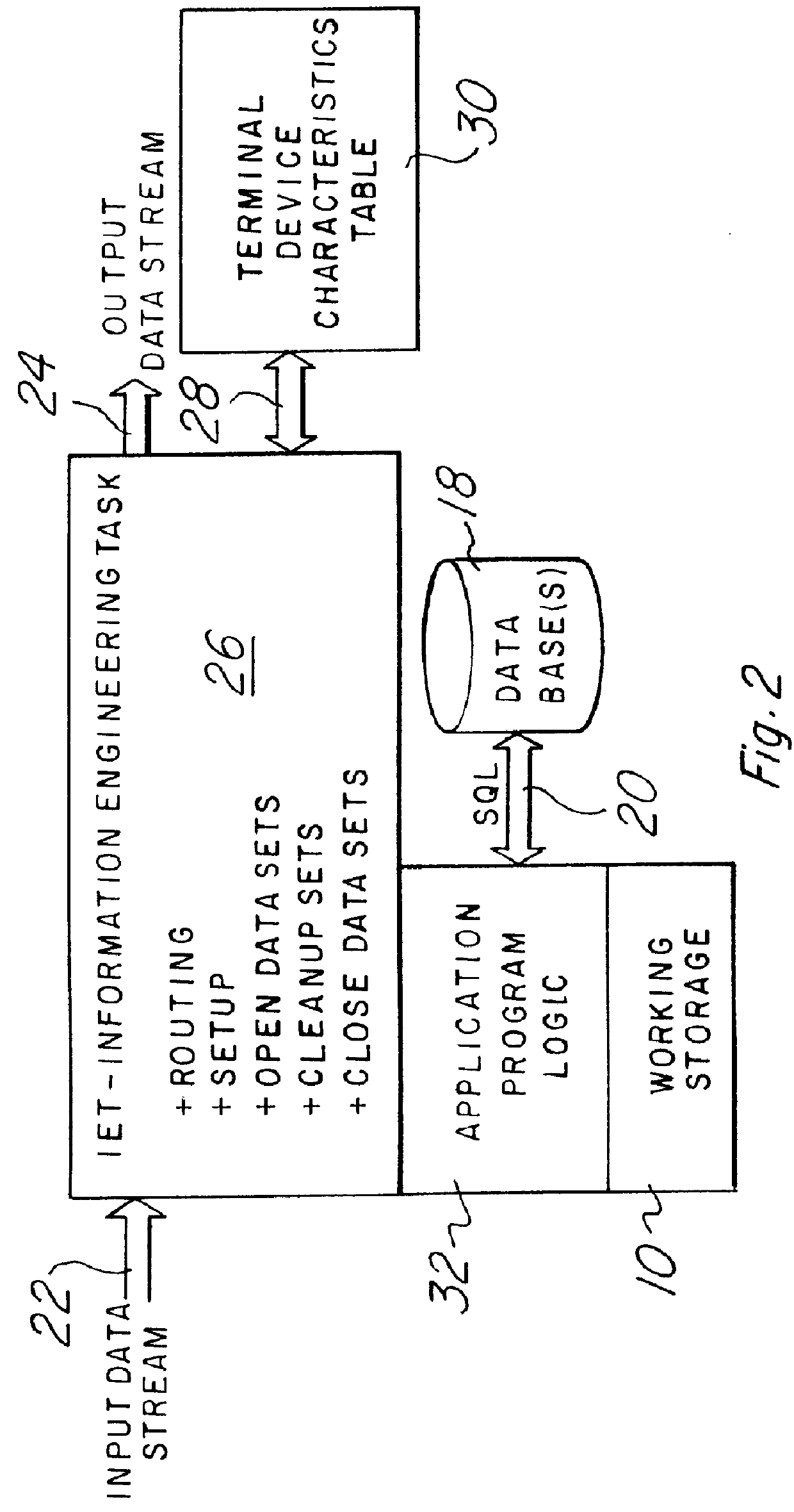

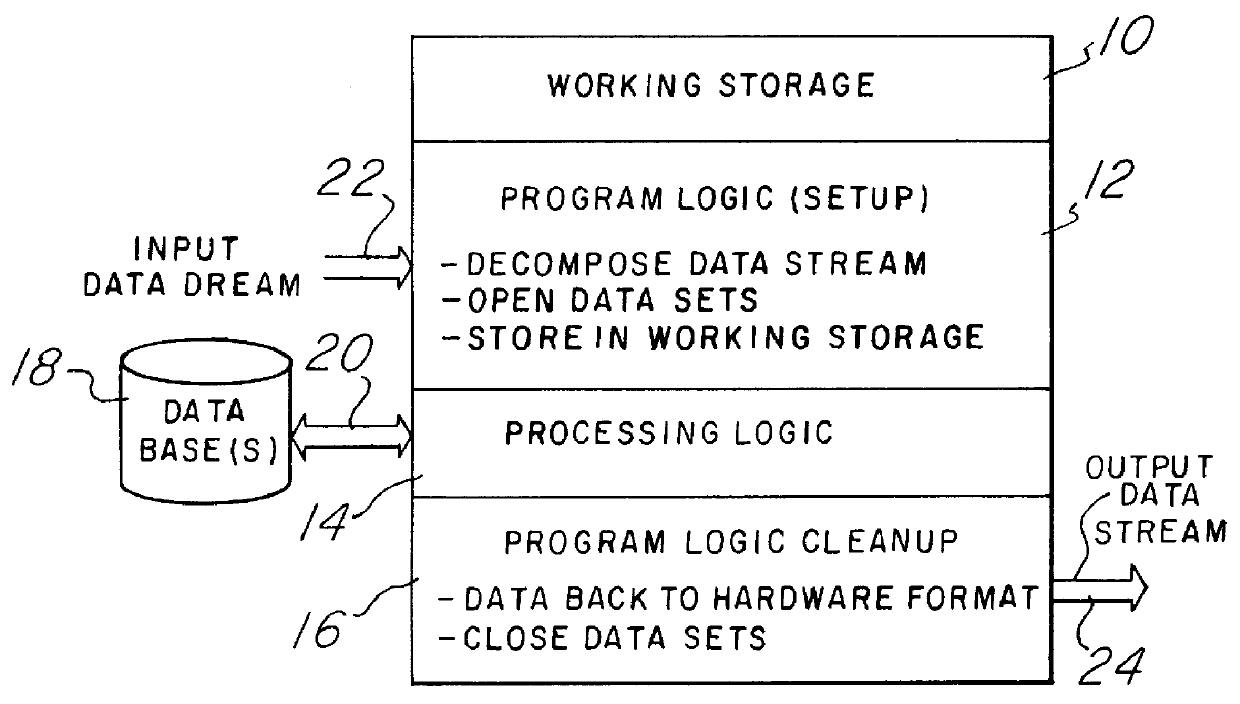

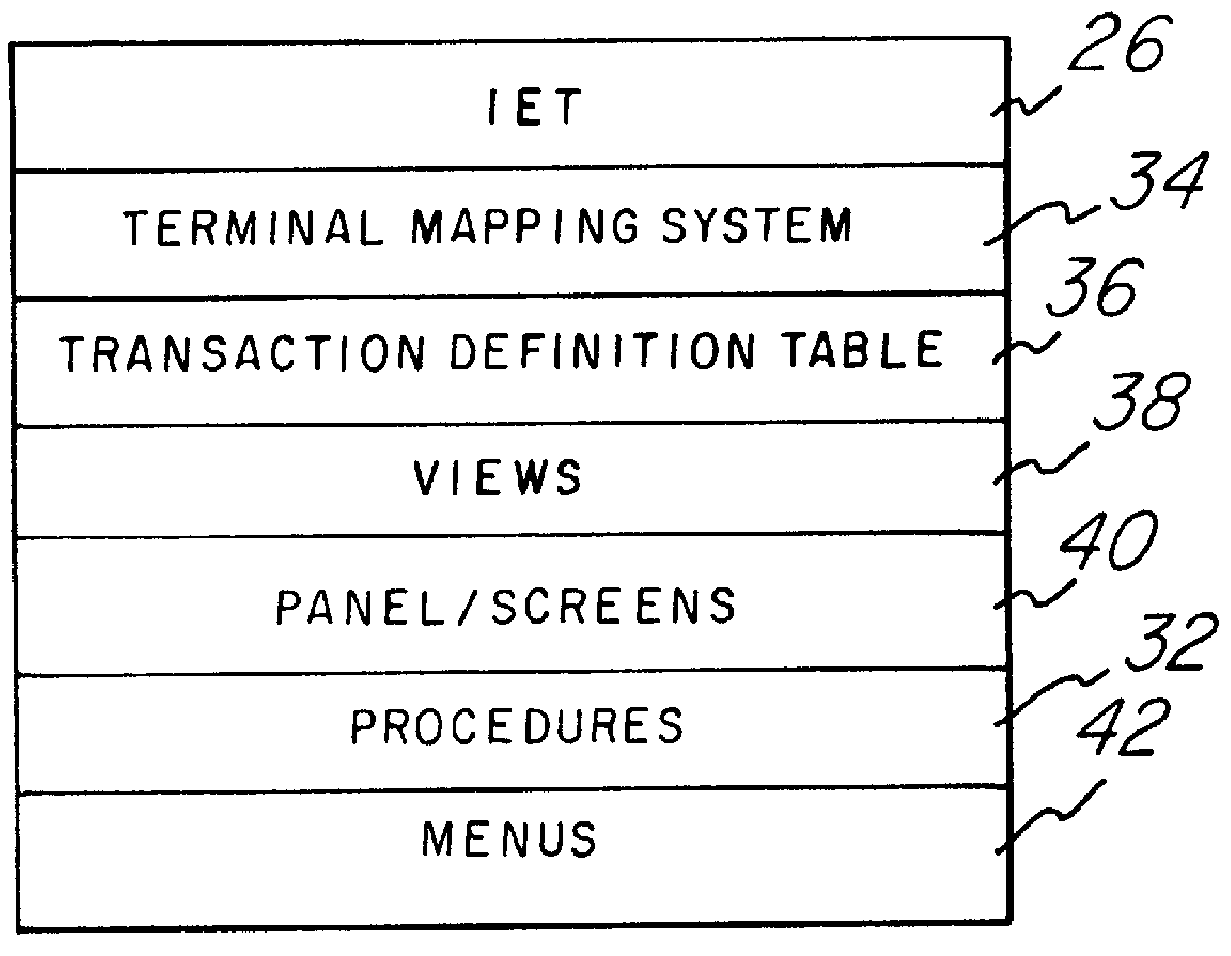

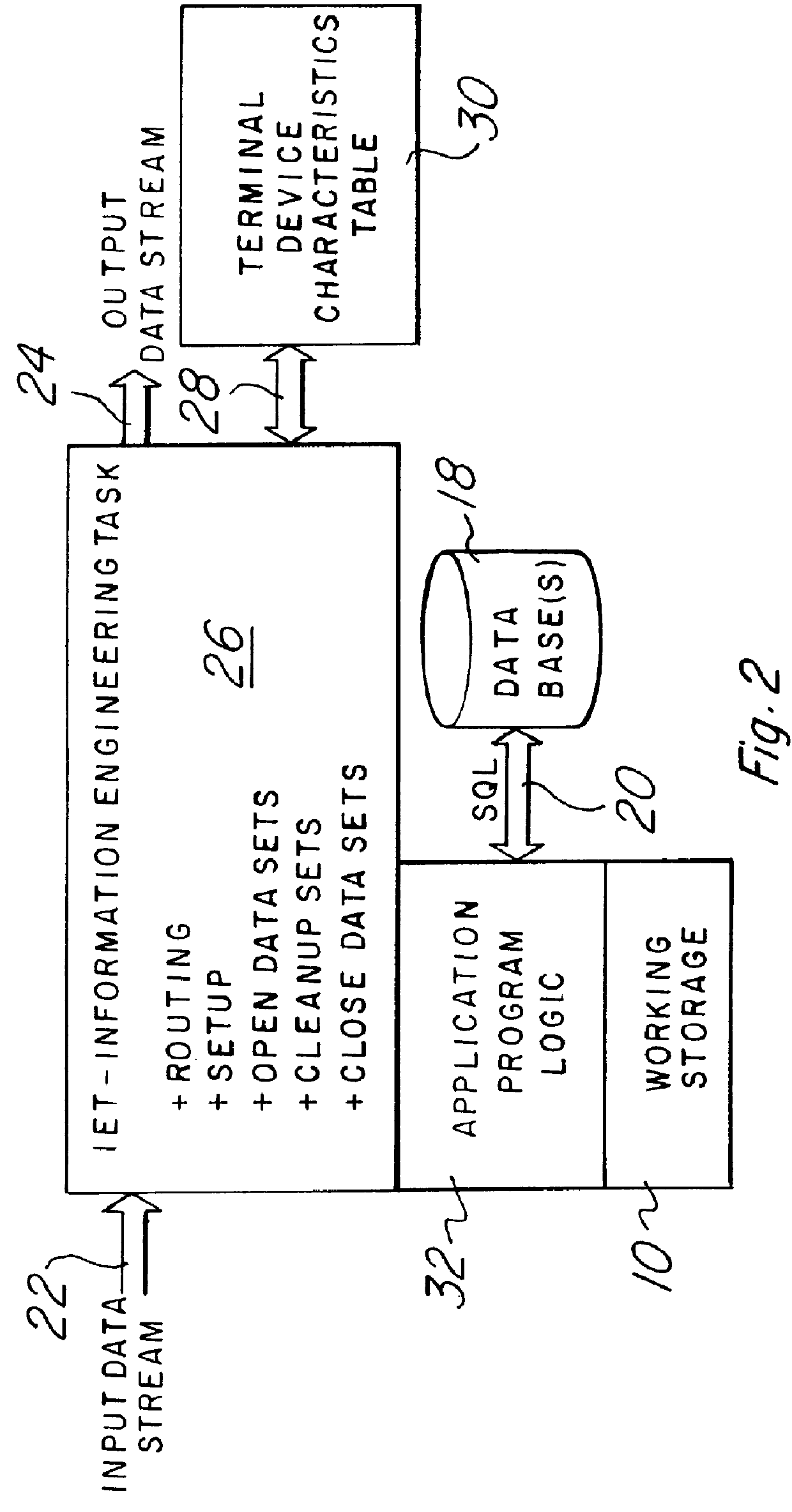

Method and apparatus for generating transactions and a dialog flow manager

InactiveUS6115711AImprove productivityReduce needData processing applicationsProgram control using stored programsApplication procedureTheoretical computer science

A method for generating distributed application architecture transactions includes providing menus to obtain names and relationships of variables for desired transaction and input data form from an application developer. The input data is stored At least one transaction definition table, information interchange panel and application procedure in binary form is constructed based on the input data. The binary form is link-edited into an executable transaction.

Owner:COMP ASSOC THINK INC

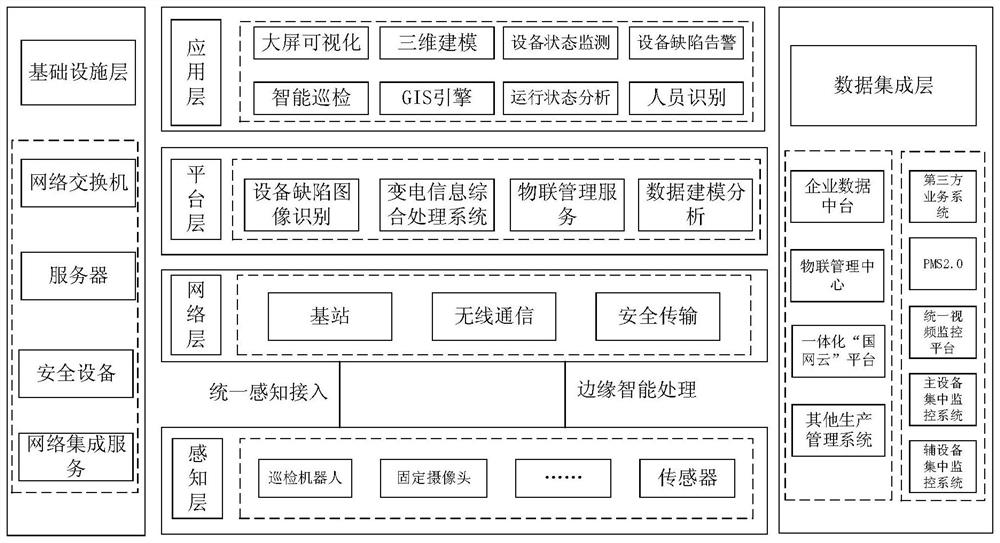

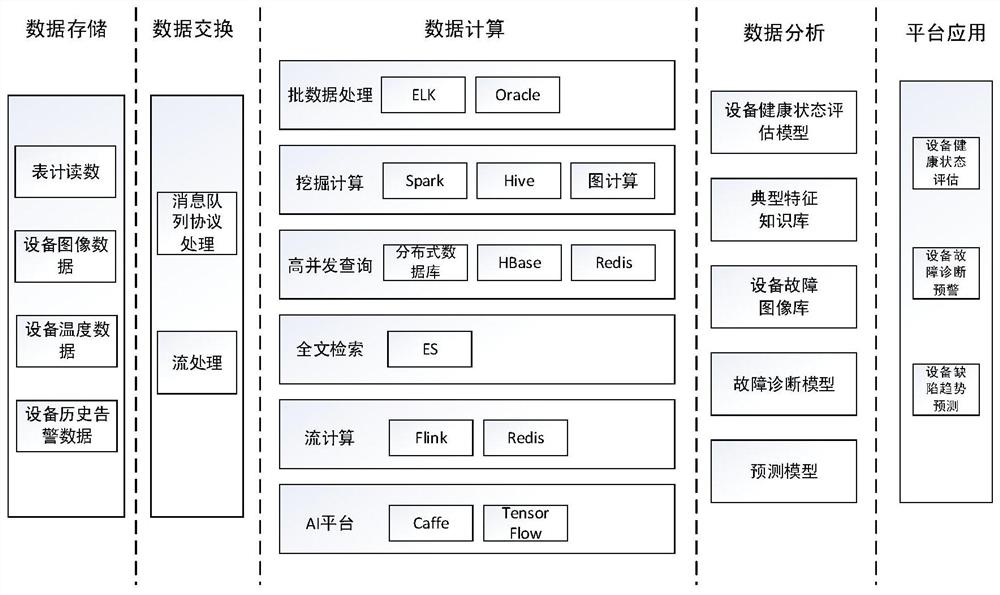

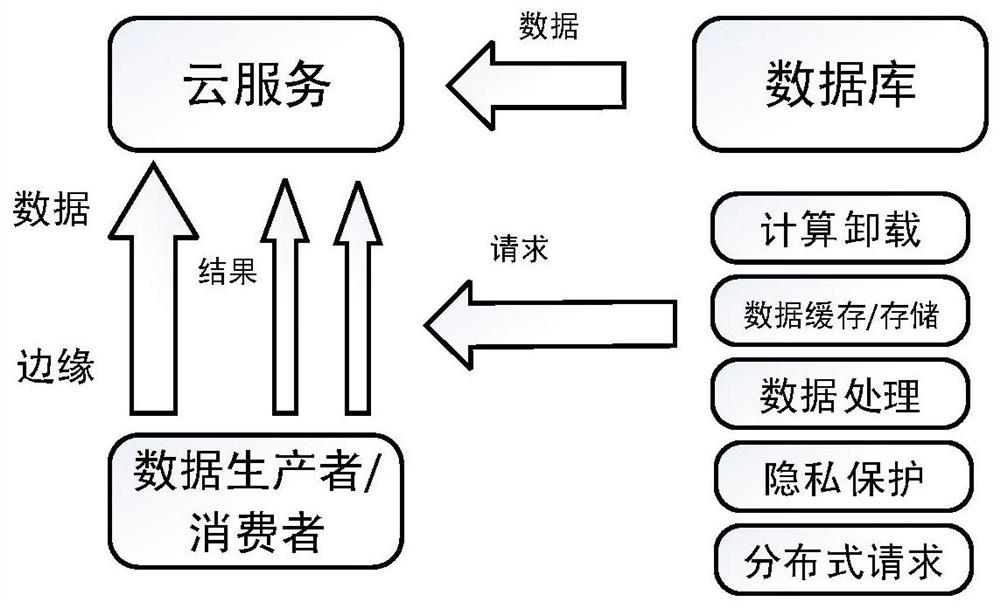

Transformer substation electrical equipment comprehensive physical examination system based on cloud side end collaborative perception

ActiveCN111784026ARealize local intelligent processingRealize real-time trackingCircuit arrangementsInterprogram communicationTransformerElectric power equipment

The invention relates to a transformer substation electrical equipment monitoring, analyzing and processing system and particularly relates to a transformer substation electrical equipment comprehensive physical examination system based on cloud side end collaborative perception. The system is characterized in that multi-node detection and unified perception access are realized through an integrated communication network architecture on the edge side of a station end, an intelligent sensing terminal is comprehensively covered in real time. Meanwhile, local intelligent data processing is realized by utilizing an edge computing technology; an omnibearing intelligent diagnosis and analysis system of the transformer substation is constructed at a cloud end, and multiple functions such as abnormal real-time early warning and intelligent sensing prediction are realized, so that the real-time tracking of the operation state of the power equipment of the transformer substation is realized. Themethod has the advantages that the transformer substation can be covered, monitoring data can be comprehensively utilized, an intelligent processing scheme can be provided, construction of the intelligent transformer substation is promoted, and the intelligent evaluation and safety early warning level of the electrical equipment state of the transformer substation is improved.

Owner:STATE GRID INFO TELECOM GREAT POWER SCI & TECH +2

Portable and dynamic distributed transaction management method

InactiveUS6115710AImprove productivityReduce needData processing applicationsProgram control using stored programsComputer resourcesGoal system

A system and method is shown for enabling a plurality of computers and associated computer resources, some or all of which may be of heterogeneous configuration, to cooperatively process various applications such that the execution is transparent to the user regardless of where the application is actually executing. This distributed applications architecture performs an information distribution service between multiple transaction processing systems by working with a transaction processor via communication channels to other hosts within the network and a dialog manager which uses a transaction processor interface to communicate with the transaction processor. The architecture employs a map service which provides an editor to create the maps for the application panels, a compiler to generate the maps into a linkable form, and a linkable interpreter which translates the linkable form into the screen presentation format for that platform. To distribute an application, the source code for the procedures, view and panels are moved as a block to the new system. This is possible because once the application source code is complete, all application logic, user interface control tables, view definitions, and other application-specific tables for one transaction definition are packaged by the present invention in a single load module on the system where the application will reside. The load module is then compiled using the target system's compiler, link editor, and bind process. Thus, all environment-dependent variations of import / export are automatically integrated with the application at load module bind time, requiring no source code changes.

Owner:COMP ASSOC THINK INC

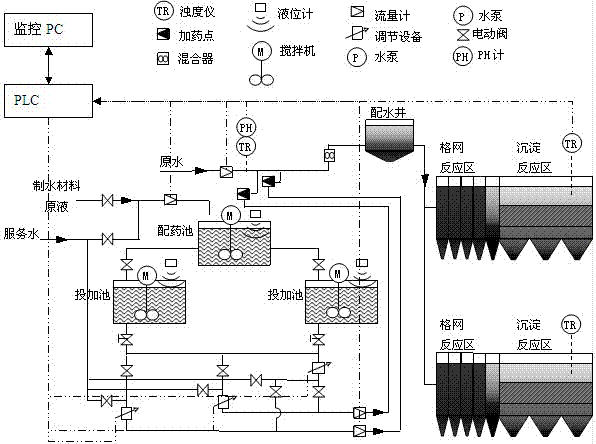

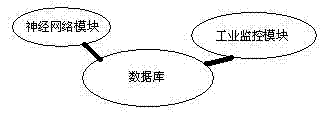

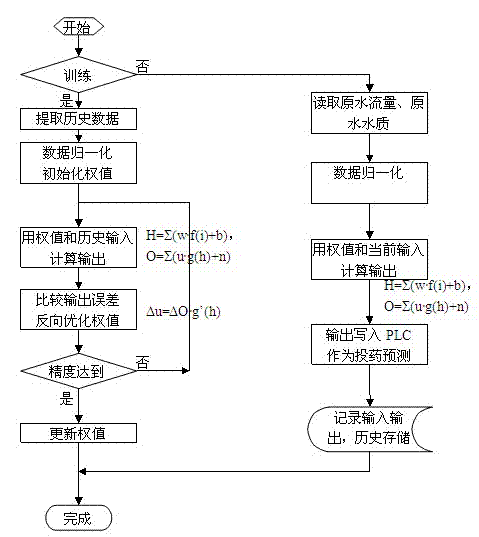

Method for controlling automatic chemical dosing of high-turbidity water system

InactiveCN103011356AGuaranteed effluent turbidity indexThe turbidity index of the effluent reachesWater/sewage treatment by flocculation/precipitationNetwork modelValve opening

Owner:CHONGQING WATER GROUP

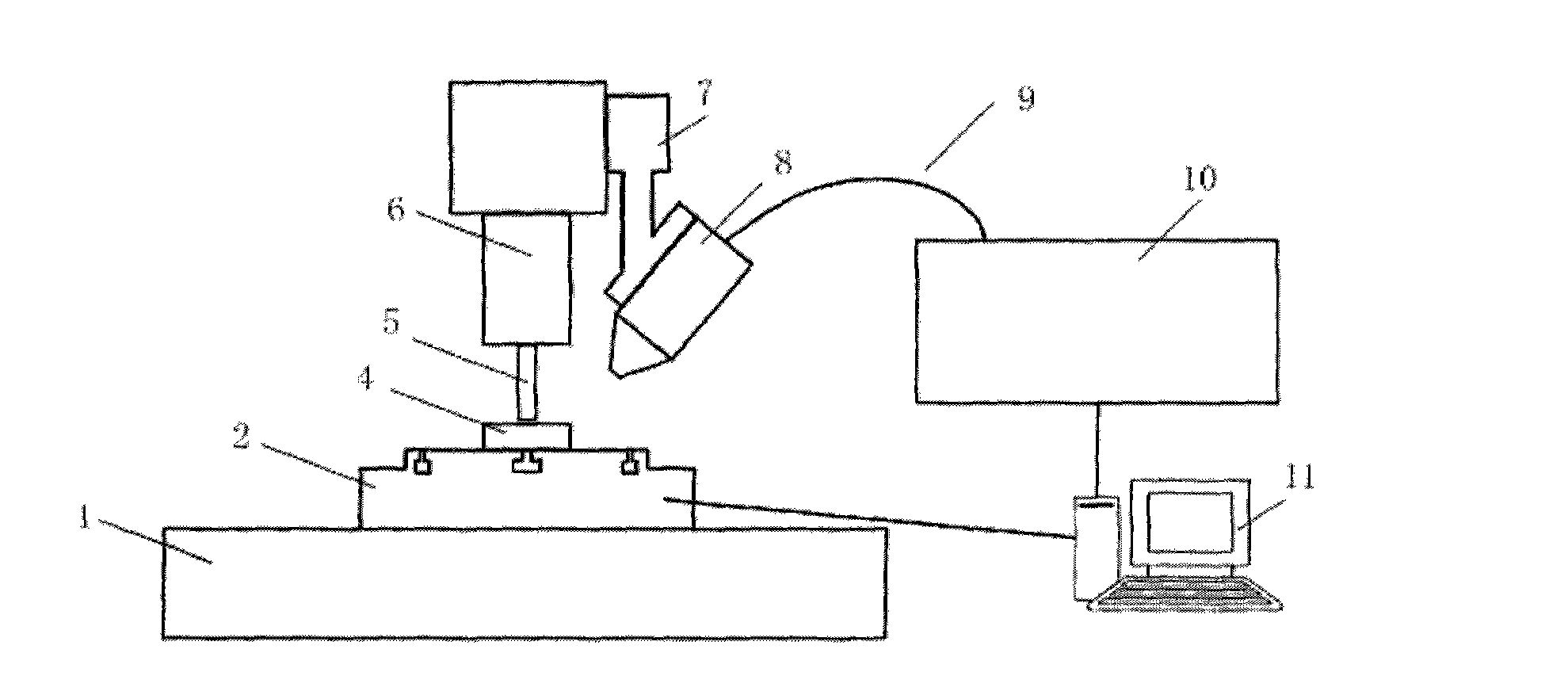

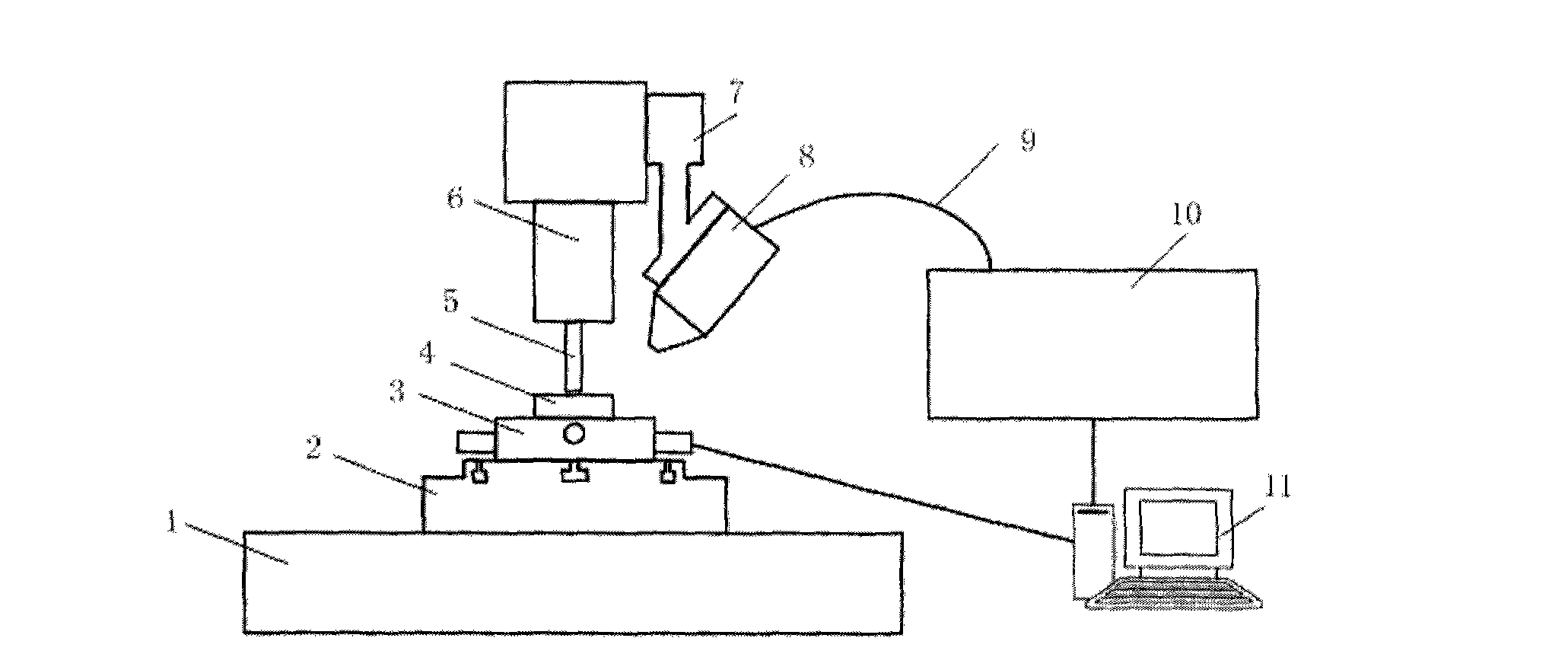

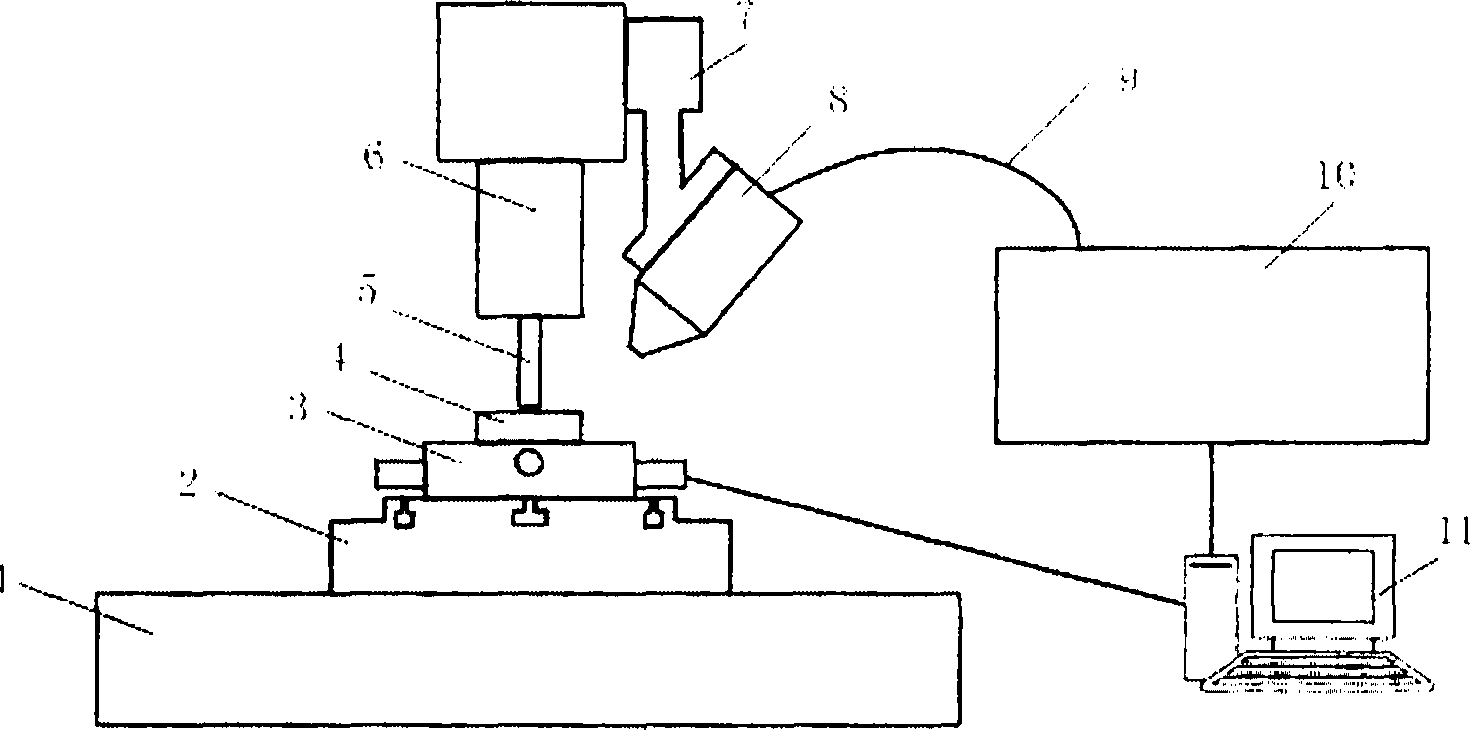

Auxiliary laser heating milling device and method

InactiveCN102430904AEasy to set upEasy to operateMilling equipment detailsNumerical controlMilling cutter

The invention discloses an auxiliary laser heating milling device and method. A laser focusing head is arranged on the traditional numerical control milling machine, and laser is introduced in through optical fiber to increase the local workpiece temperature so as to achieve the purpose of improving the material processability. A rotating workbench is additionally arranged on the condition that the laser focusing head and a milling cutter are fixed relatively, and the method of rotating a workpiece is adopted so that the workpiece direction relative to the laser incidence direction is changed and the auxiliary laser heating milling of the complex workpiece is hereby realized. The invention overcomes the defect that the auxiliary heating milling direction can not be changed and provides a new method for processing the complex workpiece made of the material which is difficult to process.

Owner:HARBIN INST OF TECH

Expanding fire retardant composition without halide for polyolefine

The fire retardant composition consists of pentaerythritol phosphate 18-54 wt%, melamine polyphosphate 40-80 wt%, stearic acid or zinc stearate 0.1-5 wt%, coupling agent 0.1-5 wt% and stuffing 0.1-5 wt%. It is used as fire retardant for polypropylene powder or grains, and when the addition amount is 28 wt% fireproof level of UL94V-0 is reached; and is also used as fire retardant for polyethylene,and when the addition amount is 30 wt% fireproof level of UL94V-0 is reached.

Owner:BALING PETRO CHEM CO LTD SINOPEC

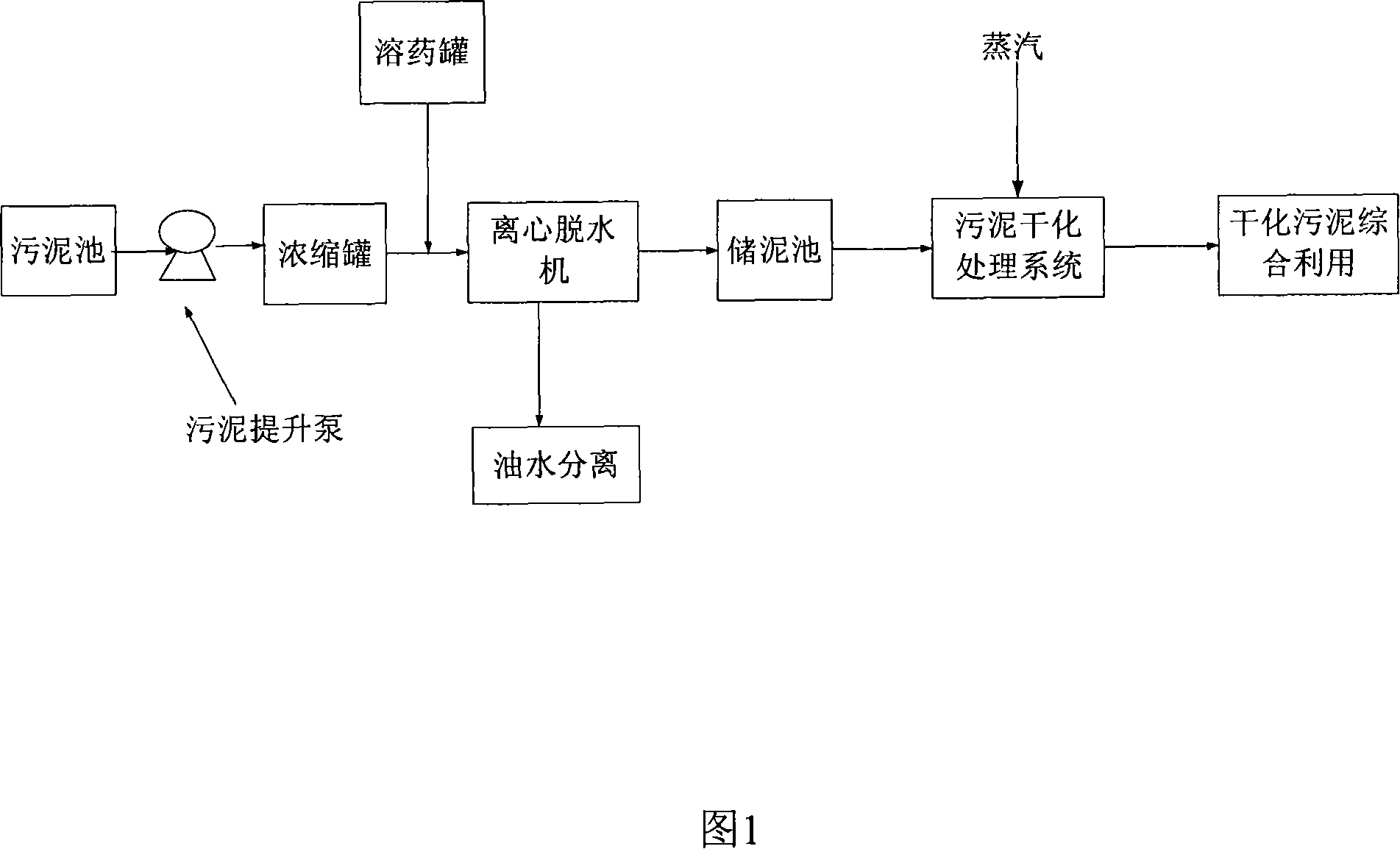

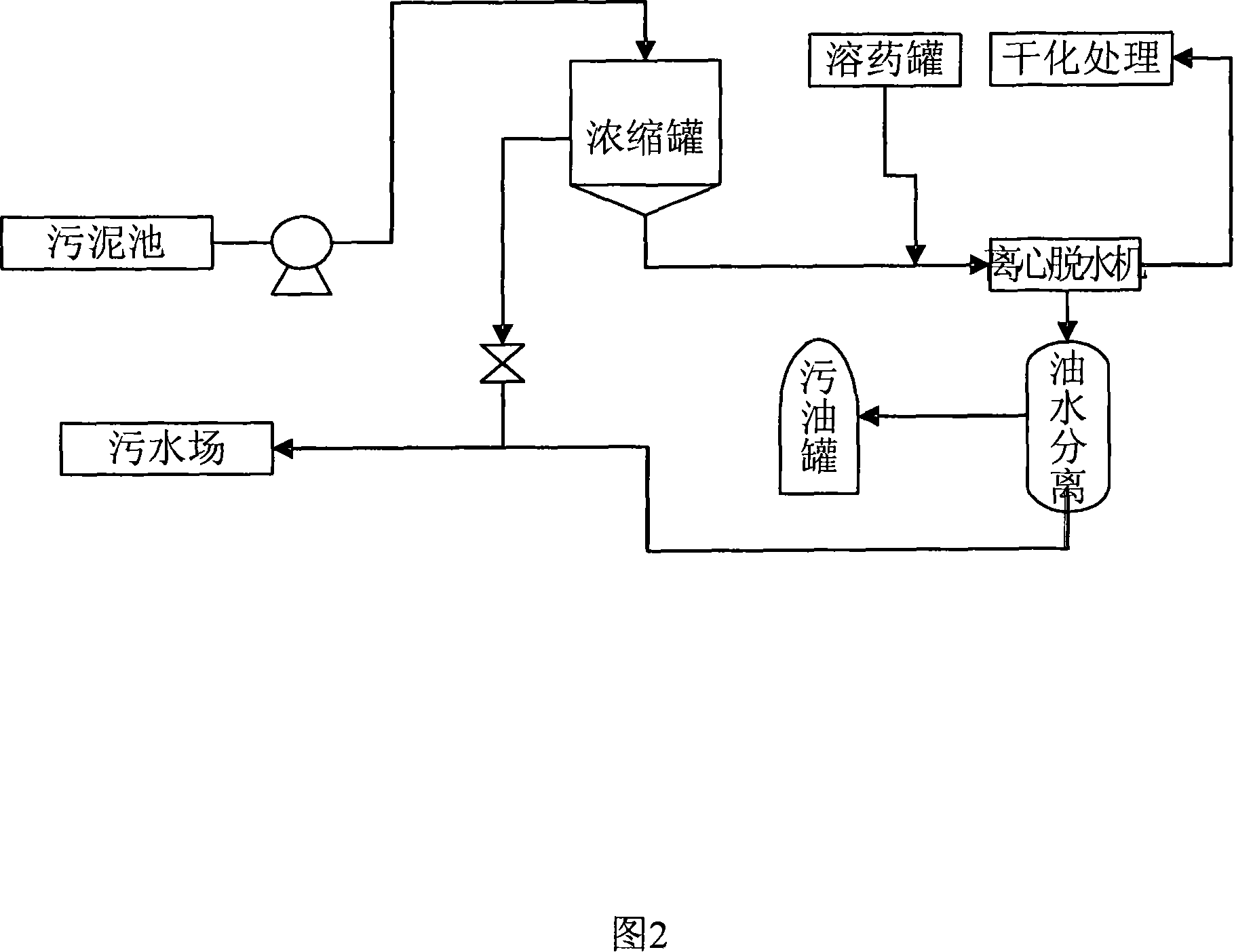

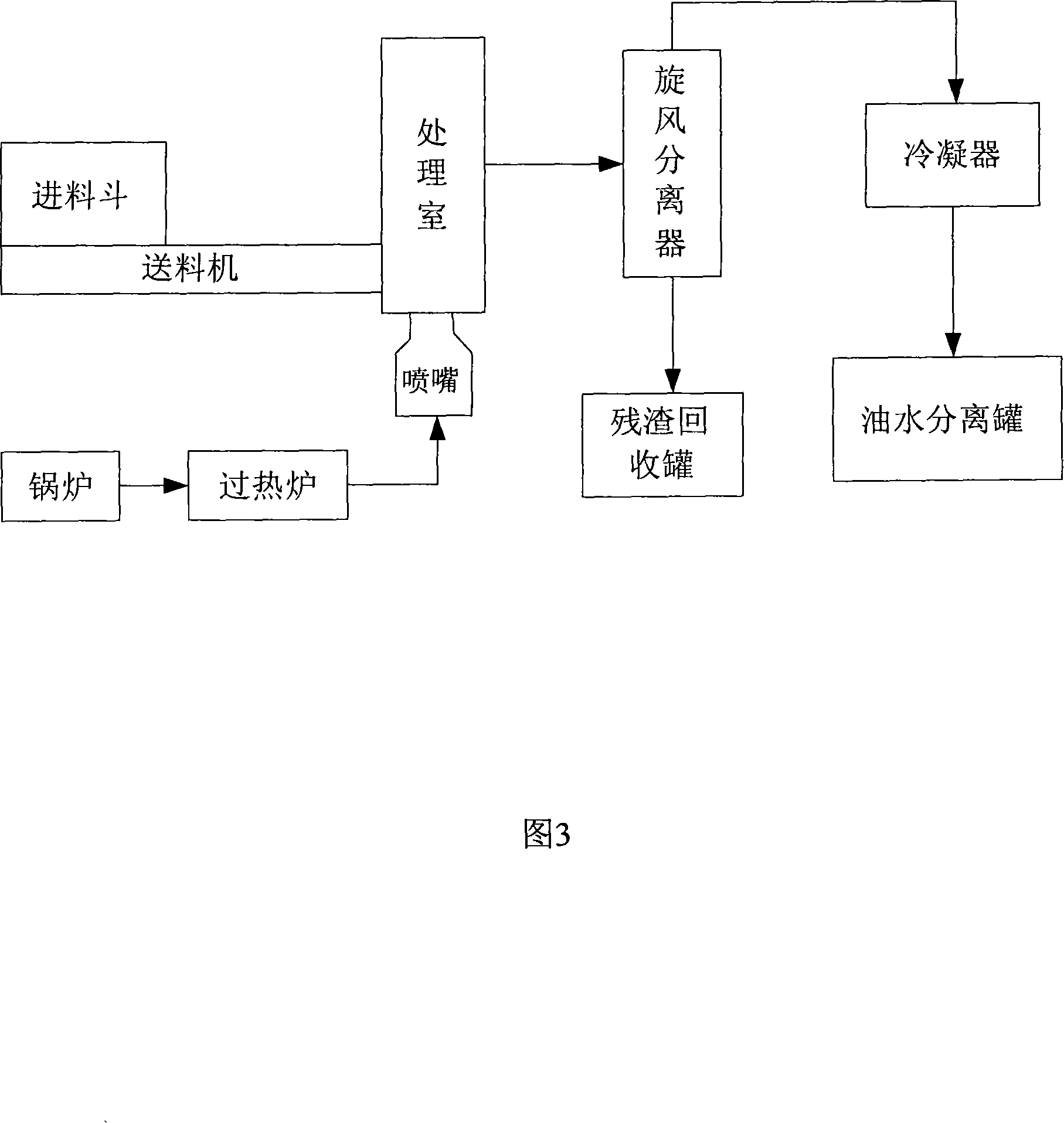

Process for treating oil-containing sludge

InactiveCN101148310AAdapt to wideSystem processing effectSludge treatment by de-watering/drying/thickeningSludgeEngineering

The present invention is oil-containing sludge treating process, which includes one concentrating treatment step, one flocculating and centrifugally dewatering step and one drying step. The settled and concentrated sludge is discharged to the concentrated sludge conveying pipeline while flocculant is added for mixing with the concentrated sludge to react, and the flocculated sludge is dewatered in a centrifugally dewatering machine and dried in a steam jetting sludge treating system, with the dried sludge being further utilized externally. The process includes also one odorous material fixing and eliminating step. The process has high treating effect, universality, no secondary pollution, capacity of recovering petroleum resource, low power consumption, low running cost and other advantages.

Owner:BEIJING ZHONGYOU AISUO ENVIRONMENT ENG TECH

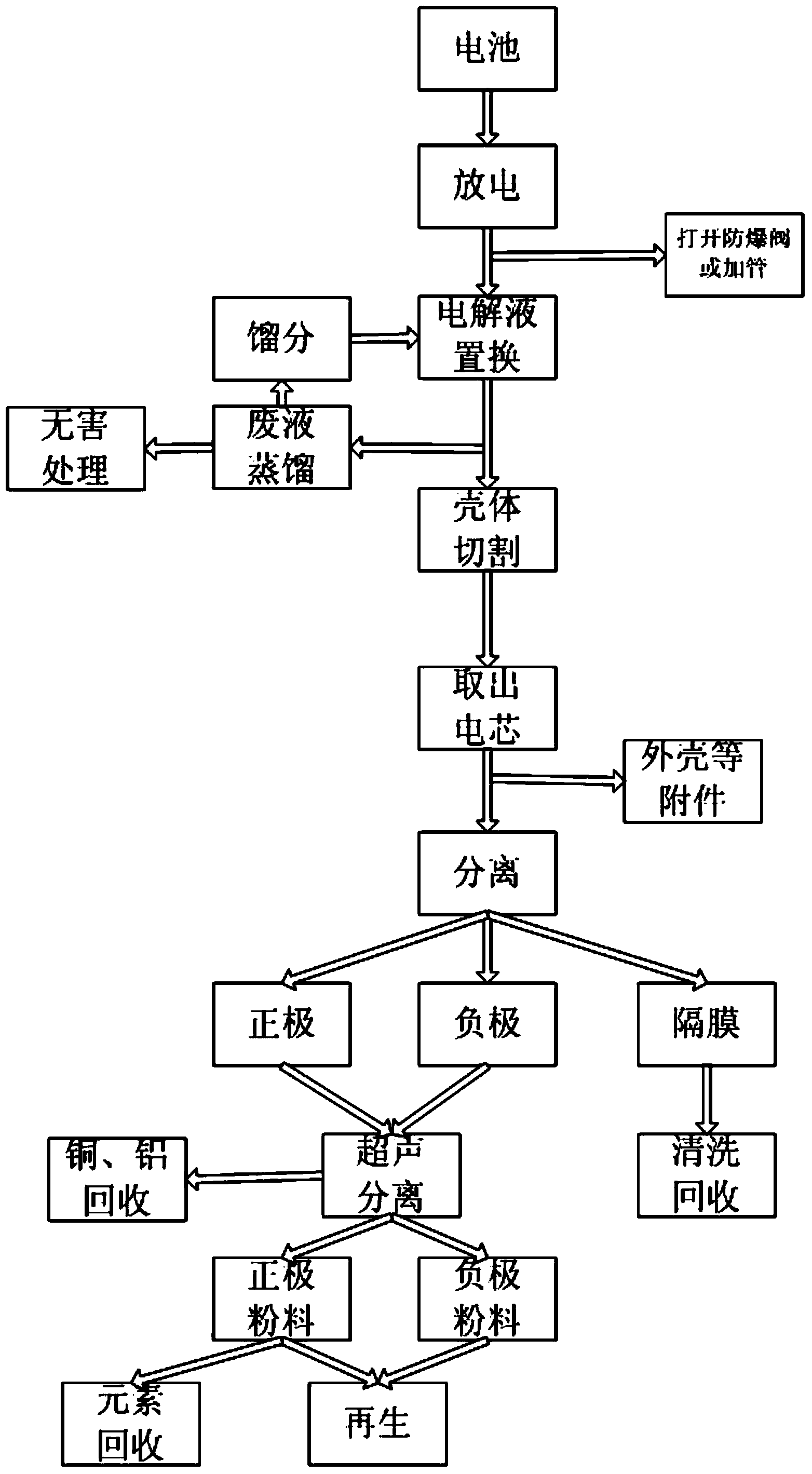

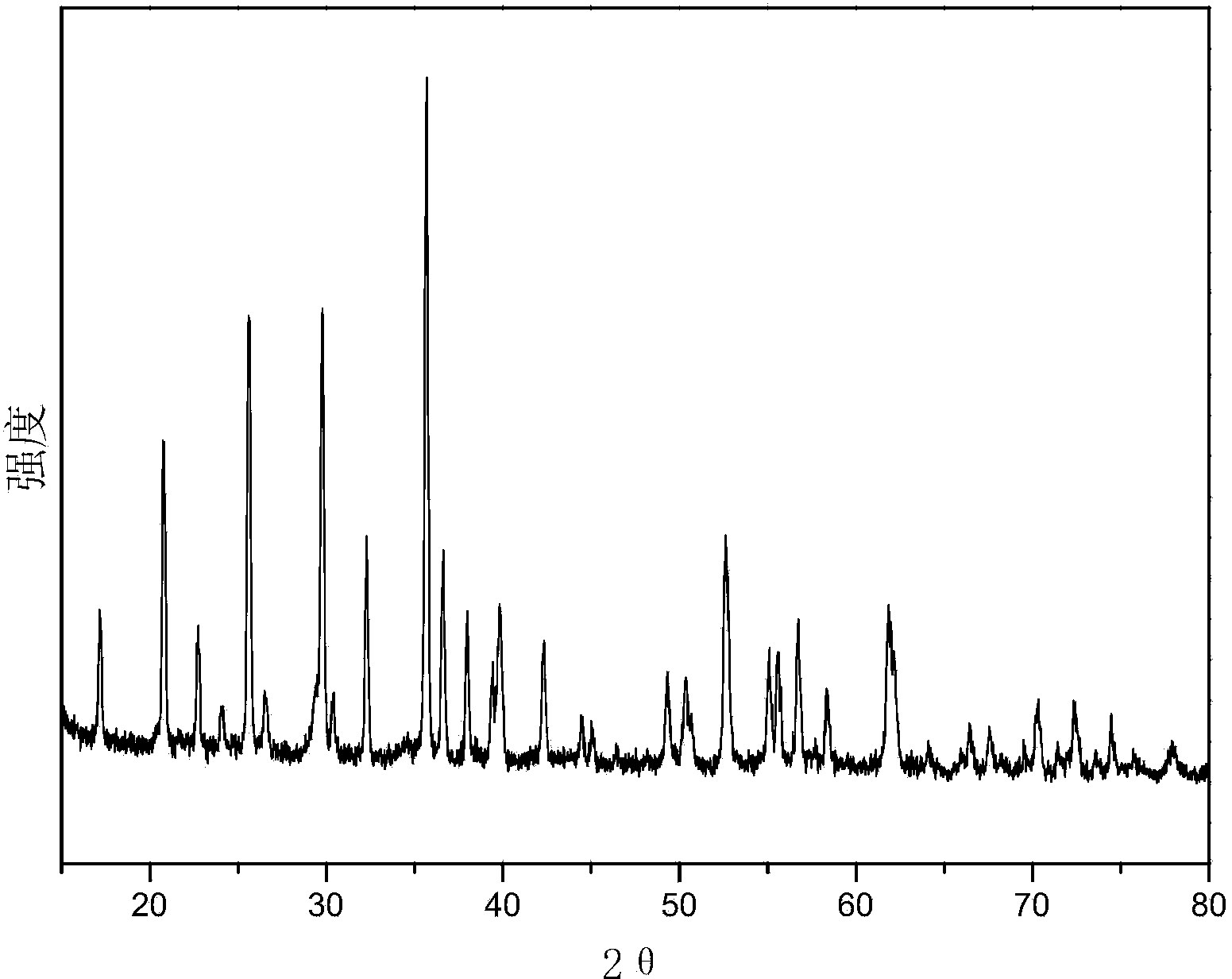

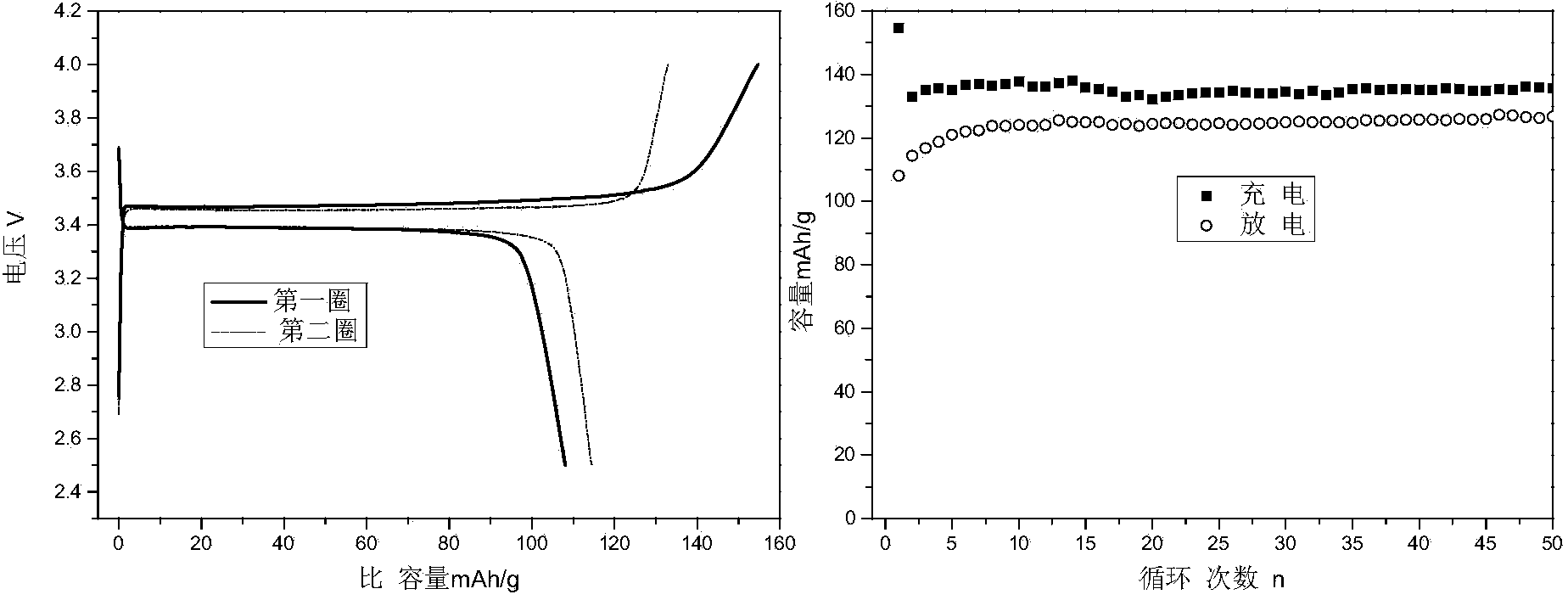

Demonstration process for recovering waste and old dynamic lithium iron phosphate cell in environmental protection mode

InactiveCN103825064AHarm reductionAvoid it happening againWaste accumulators reclaimingCell component detailsLithium iron phosphateSolvent

The invention relates to a demonstration process for recovering a waste and old dynamic lithium iron phosphate cell in an environmental protection mode, which belongs to the technical field of recovery of the power lithium iron phosphate cell. The method comprises the following steps: completely discharging the cell, extracting an electrolyte in the cell, adding a certain amount of solvent or displacement liquid, standing for 30 minutes and extracting the inner liquid of the cell, and distilling the extracted electrolyte to obtain the liquid for cycle usage when the electrolyte is displaced. According to the invention, the cell is cut by 1cm at the position along the cell top through a water jet, an electrical core is taken, wherein the steel casing, or aluminium casing or a PP plate can be directly recovered for usage. The anode, the cathode and a diaphragm are separated, and the diaphragm can be directly recovered through cleaning by ethanol. After the anode and the cathode are separated through physical methods such as ultrasound, a copper foil and an aluminium foil can be directly recovered, anode and cathode powder can be reused to be a cell material through high temperature treatment, and the purposes of no waste and no pollution can be reached by recovering the elements through a chemical method.

Owner:BEIJING UNIV OF TECH +1

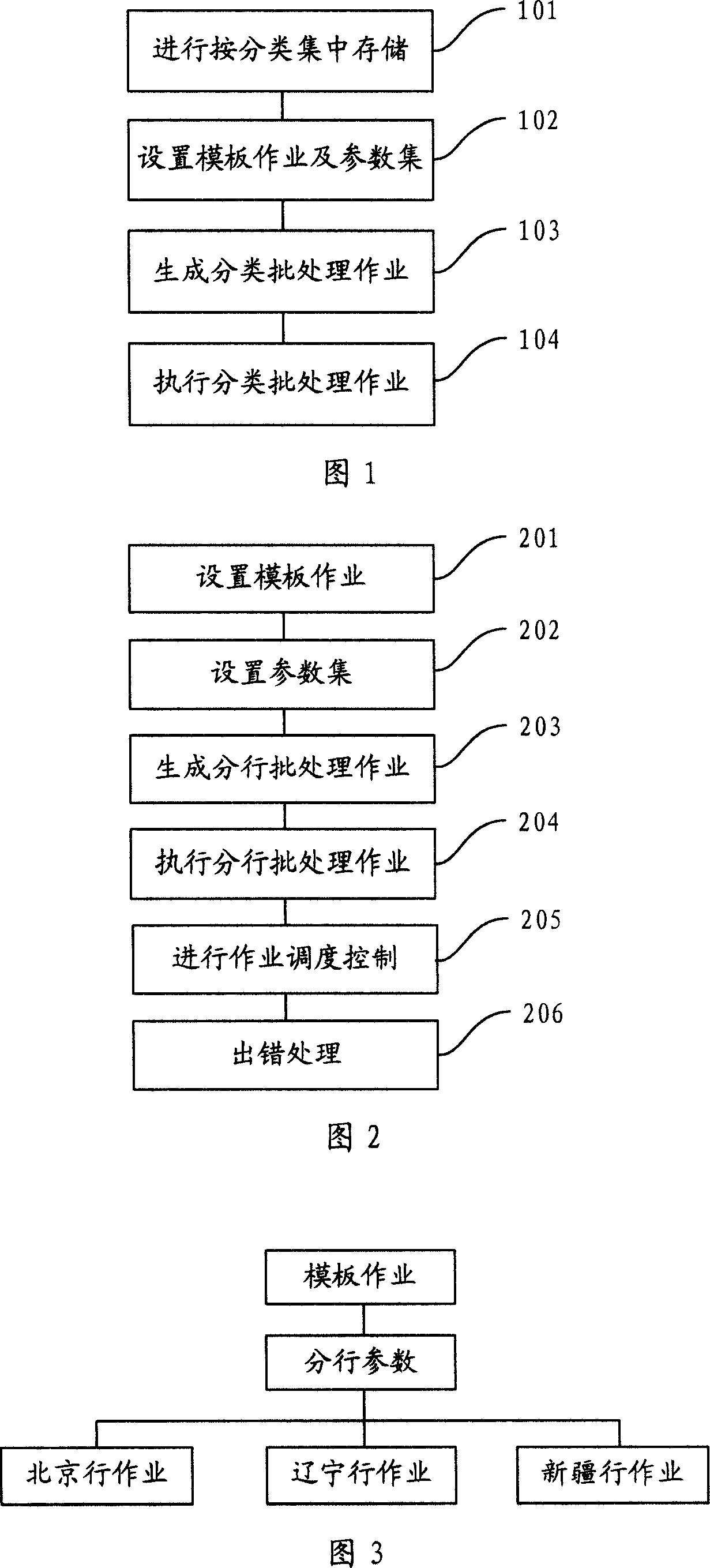

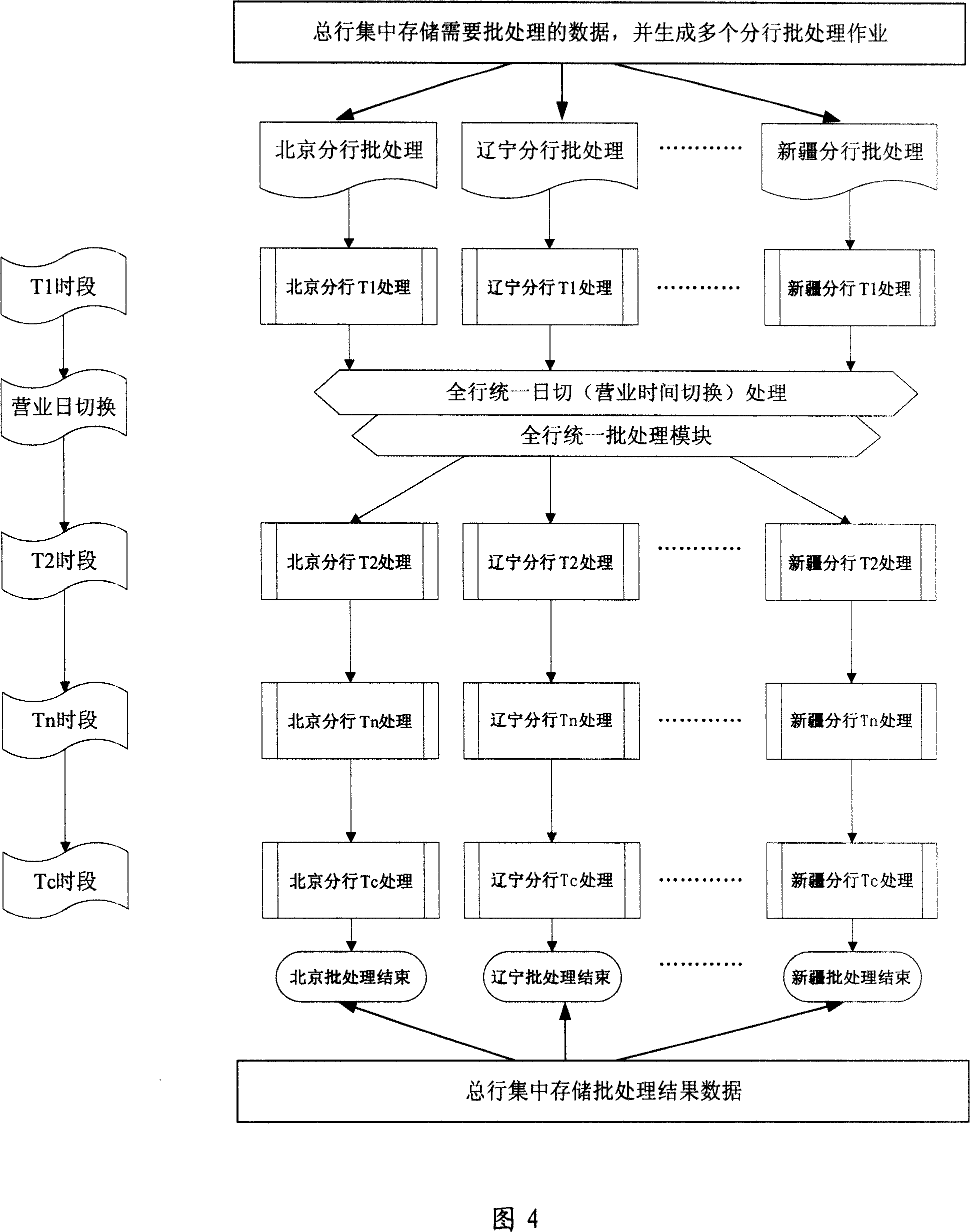

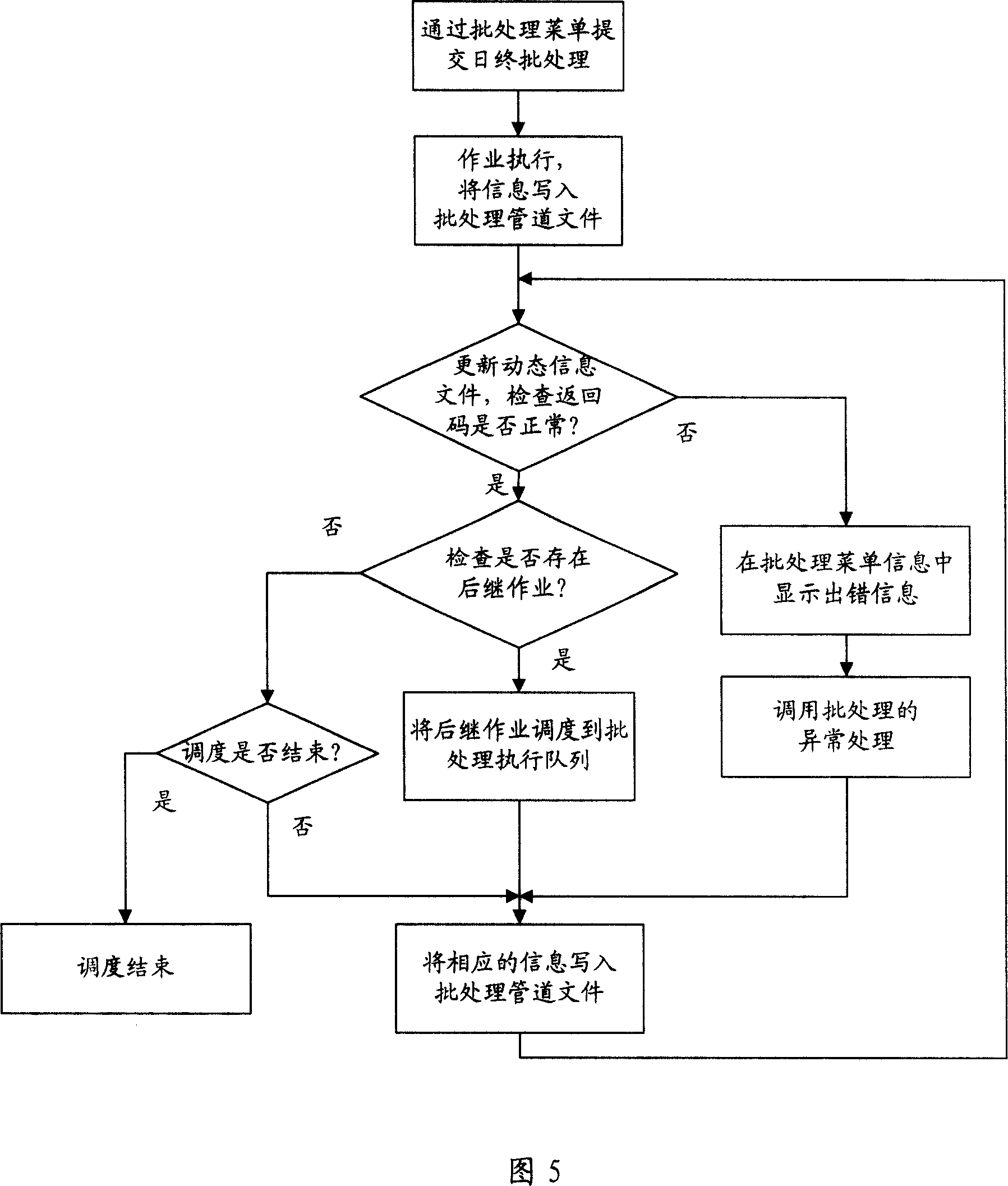

Method and device for categorical data batch processing

InactiveCN101017546AImprove processing efficiencyGood processing effectivenessFinanceMultiprogramming arrangementsBatch processingData mining

This invention discloses one method and device to sort data batch process, which comprises the following steps: integrating and storing disperse stored data; setting mode operation and parameters set to store different sorts of data process parameters; the said mode board is to generate different sort data batch process; according to the mode operation and the said parameters generation different sort of data batch; executing the said operations. This invention legally uses systematic materials to quicken process operation speed.

Owner:CHINA CONSTRUCTION BANK

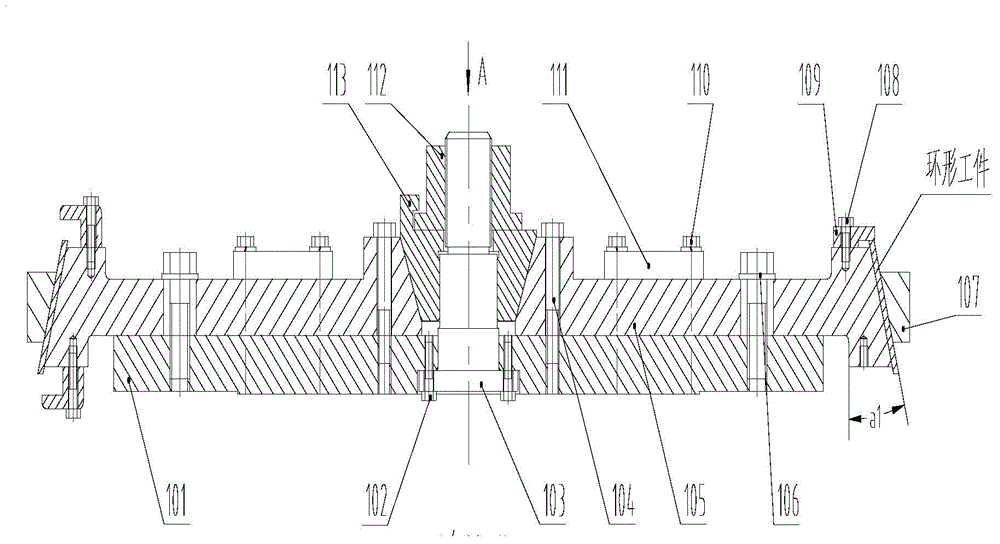

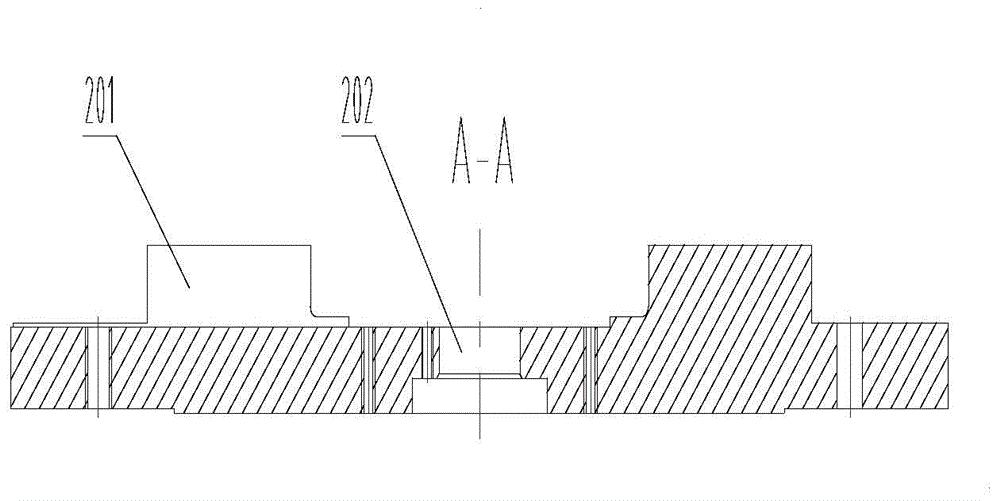

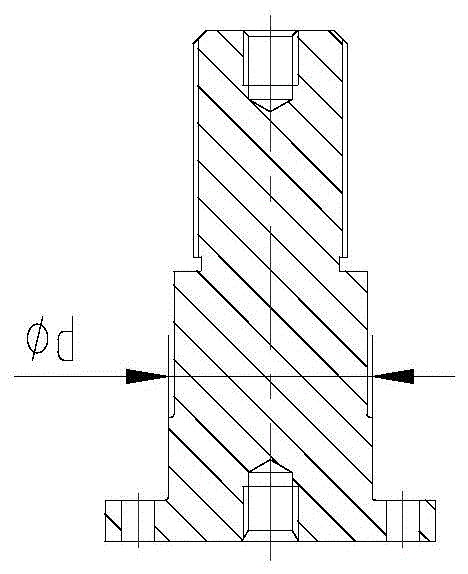

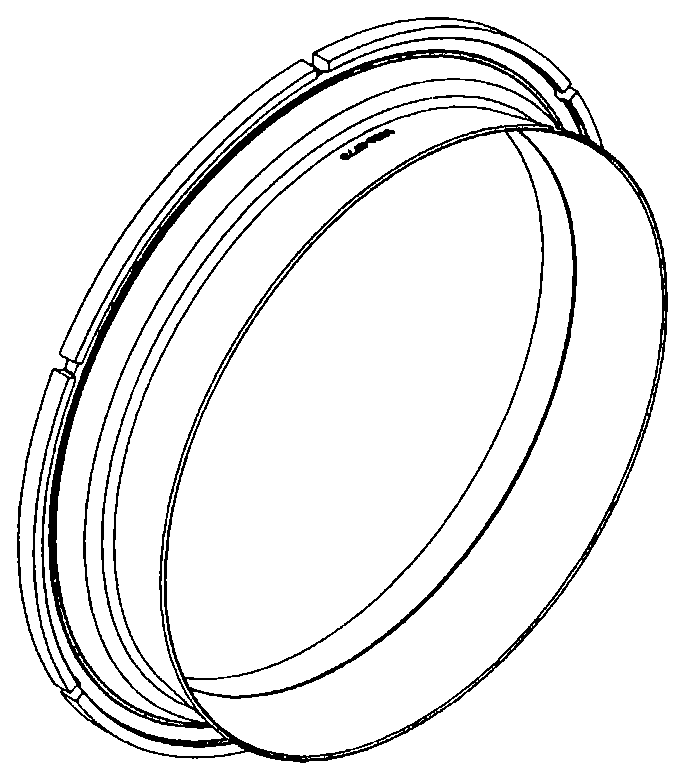

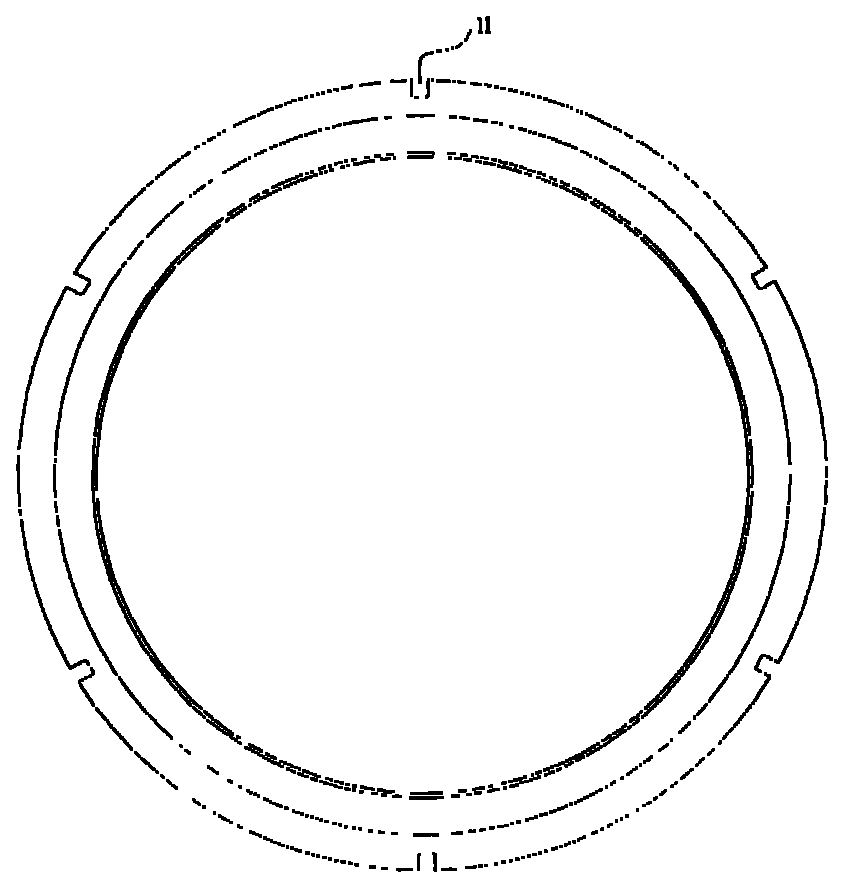

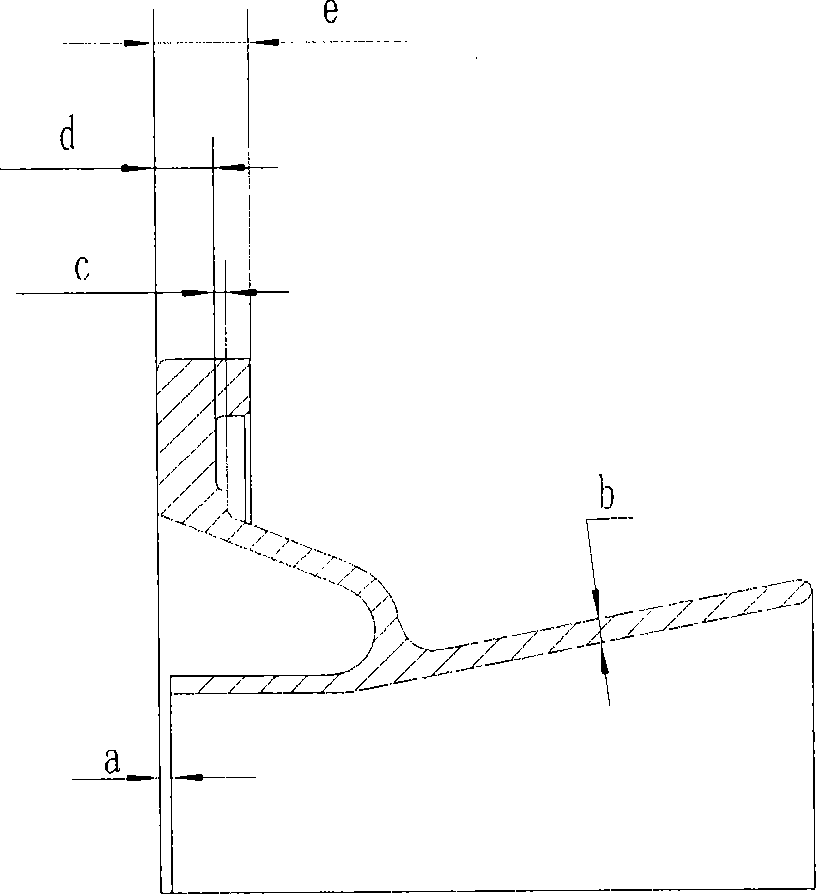

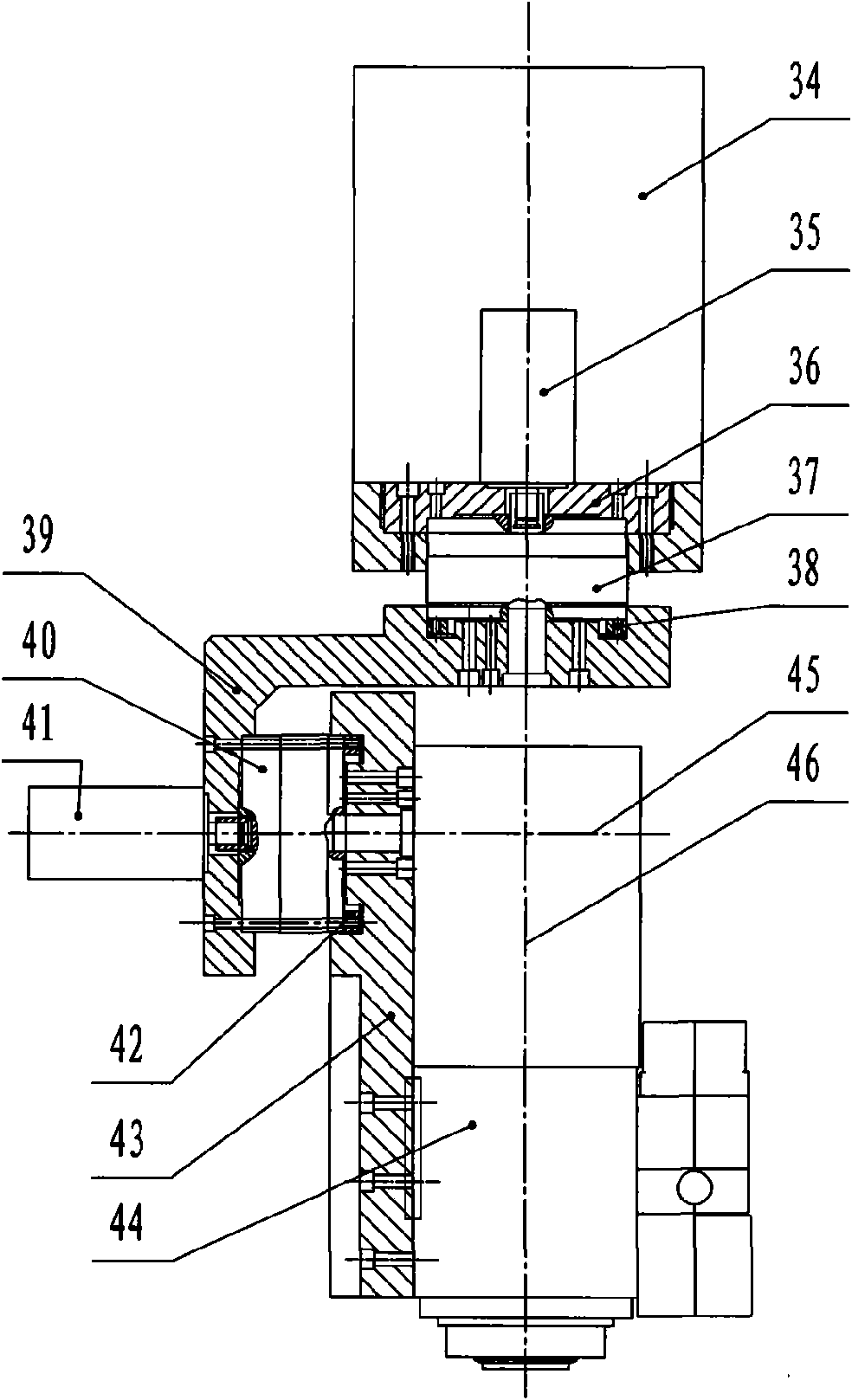

Tool for vertical lathe machining of ring-cone-shaped thin-walled part and application thereof

ActiveCN104589099AImprove rigidityReduce vibrationPositioning apparatusMetal-working holdersEngineeringSpatial interaction

The invention discloses a tool for vertical lathe machining of a ring-cone-shaped thin-walled part. The tool for vertical lathe machining of the ring-cone-shaped thin-walled part comprises a tool base plate, a plurality of expanded sliding blocks and a conical block. The tool base plate is in a disk shape, and a through hole is formed in the center of the tool base plate. One end of a mandrel penetrates through the through hole in the center and then is fixed to the tool base plate. One end of each expanded sliding block is used as a clamping face, the outline of the end face of each expanded sliding block is matched with the curved surface of the inner wall surface of a workpiece to be machined, the other end of each expanded sliding block is used as a driving end, and the end face of the driving end of each expanded sliding block is an inclined face. The conical block is connected to the mandrel in a sleeving mode, and the conical surface of the conical block is matched with a conical space. The conical block can be driven to conduct interaction with the conical space, so that the expanded sliding blocks are driven to slide on guide rails in the radial direction to enable the clamping faces of the expanded sliding blocks to abut against the inner wall of the workpiece, and therefore the workpiece is clamped and fixed to be machined. The invention further discloses the application of the tool to vertical lathe machining. The tool for vertical lathe machining of the ring-cone-shaped thin-walled part can clamp and fix the ring-cone-shaped thin-walled part, it is guaranteed that when the workpiece is machined, the gaps between the workpiece and clamps are even, the workpiece will not slide axially, and therefore the machining precision is high. In addition, the tool is convenient to assemble and disassemble.

Owner:WUHAN MARINE MACHINERY PLANT

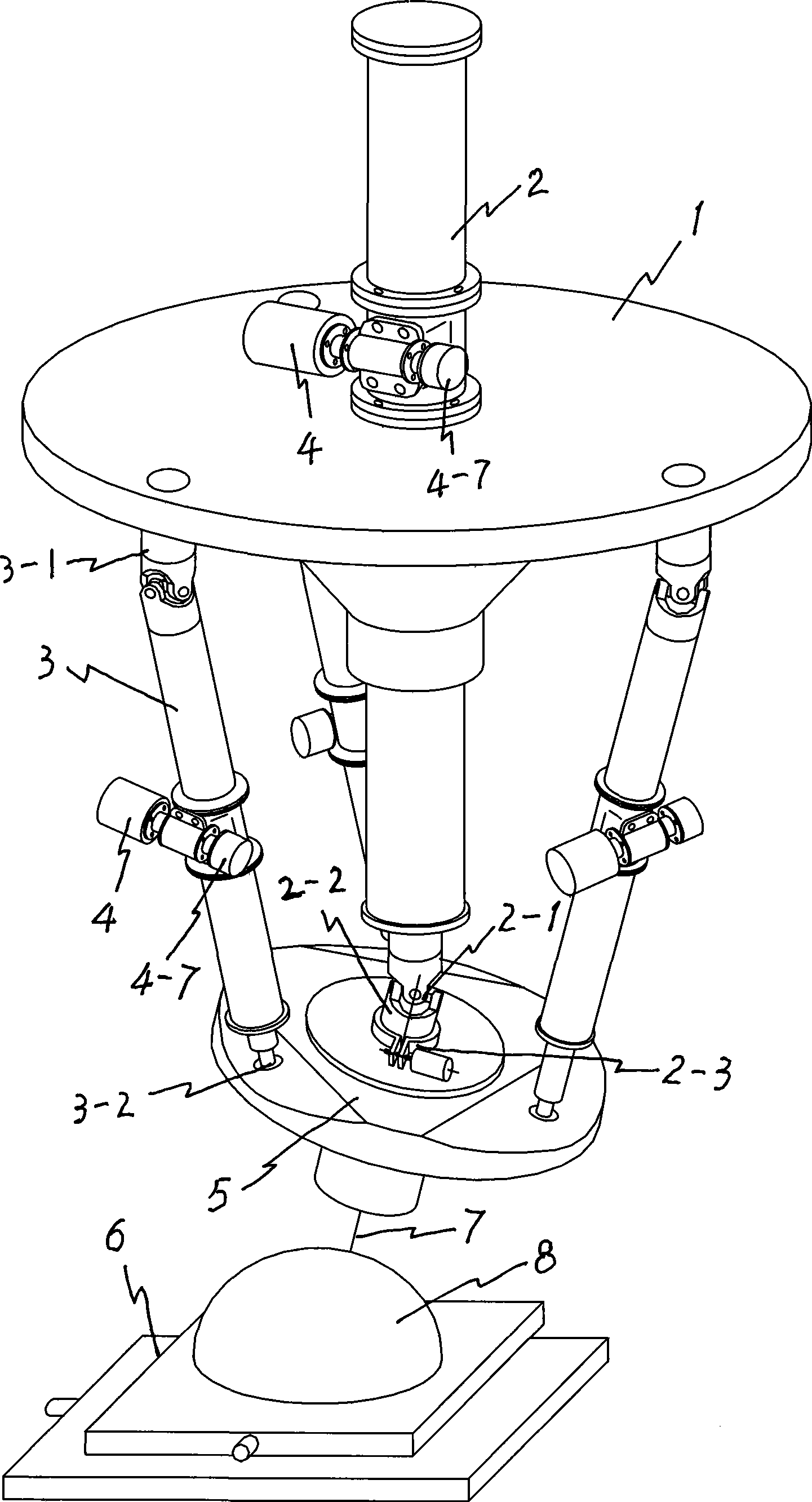

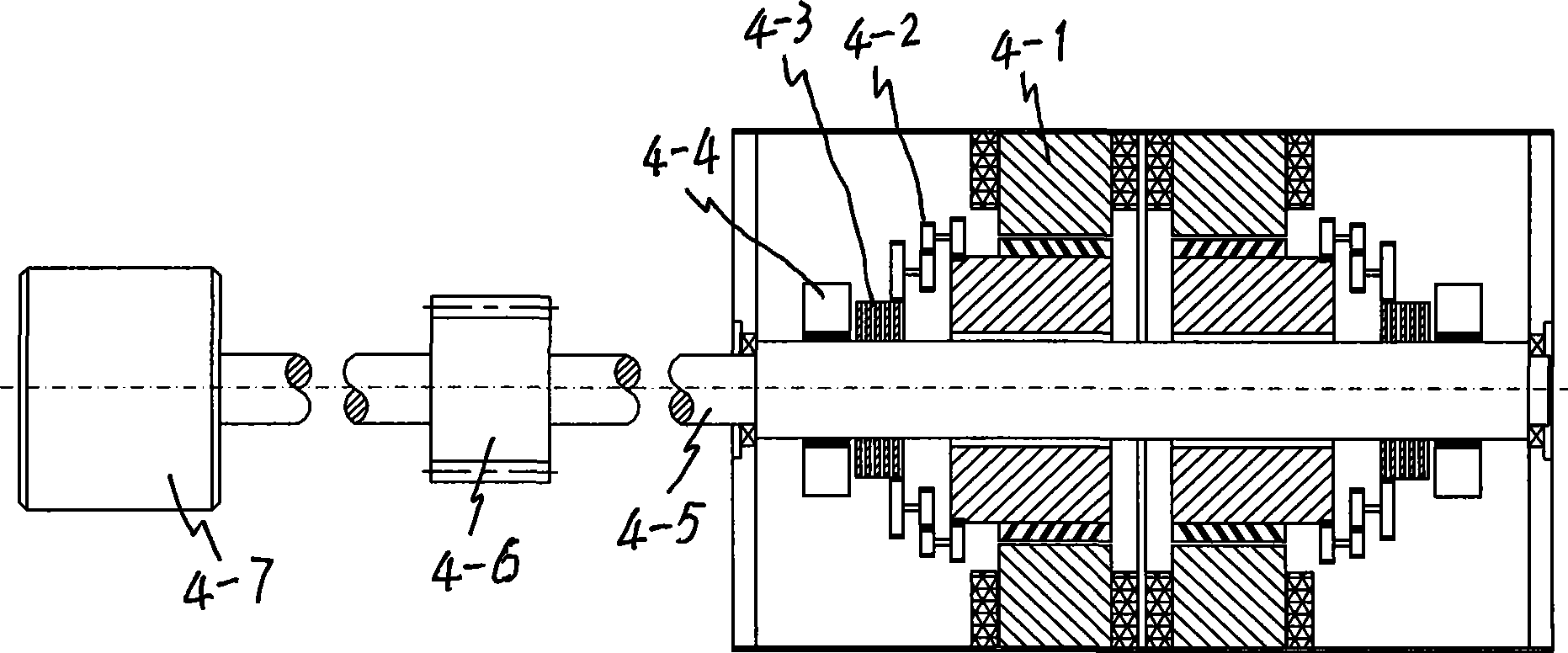

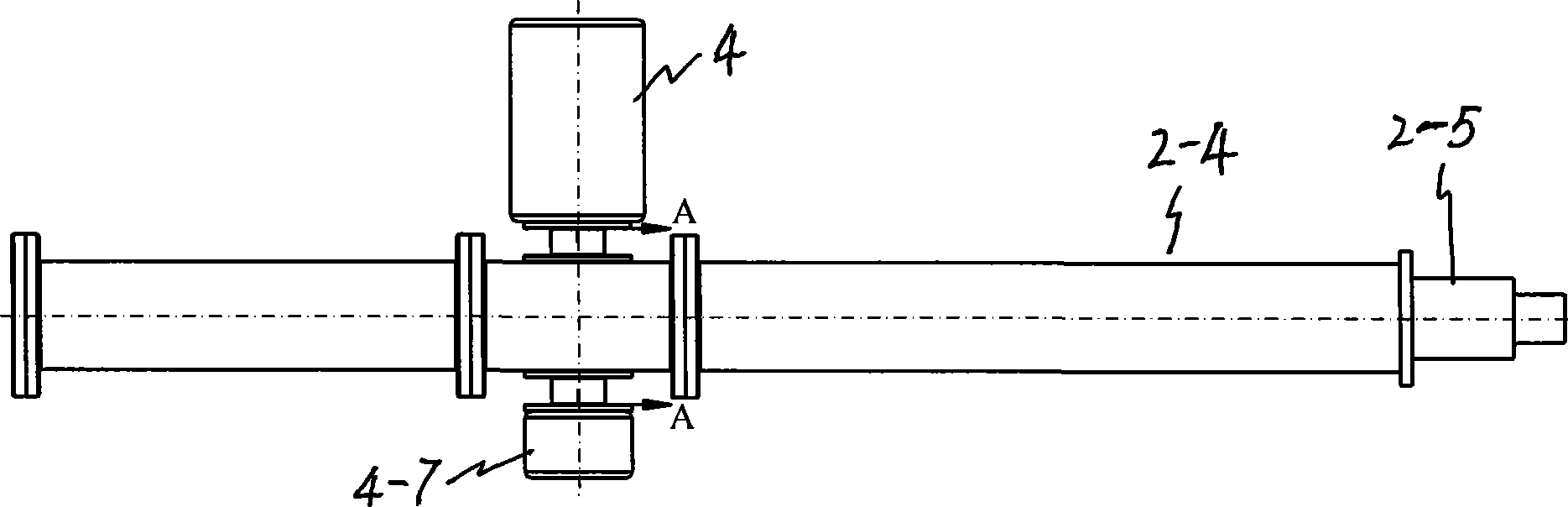

Reconstructable hybrid machine tool of mechanical system and fault tolerance correcting method

InactiveCN101444892AImplement refactoringImprove efficiencyLarge fixed membersMetal working apparatusFault toleranceNumerical control

The invention belongs to a numerical control processing machine tool, comprising a fixed platform, a movable platform, a space parallel connection closed chain mechanism formed by the central leg and the surrounding leg of a redundancy drive device which are arranged between the two platforms and are all provided with a transmission system, a locking device arranged between the hinged saddle of the central leg and the movable platform, a gear rack transmission mechanism arranged between the redundancy drive device and the central leg and between the redundancy drive device and the surrounding leg, a working platform which can move along X direction and Y direction, and a control system. The reconstruction and fault tolerance correcting method in the operation of the machine tool is as follows: when one transmission system in any drive device goes wrong, a redundancy transmission system automatically converts; when two transmission systems in any drive device go wrong, a corresponding leg thereof is converted into a driven leg, thus leading the parallel connection closed chain mechanism to be changed from four freedom degrees into three freedom degrees so as to maintain the normal operation of the machine tool, thereby being capable of effectively improving the efficiency, safety and reliability of the hybrid machine tool, and avoiding the quality or safety accidents caused by sudden failures in the operation of the machine tool.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

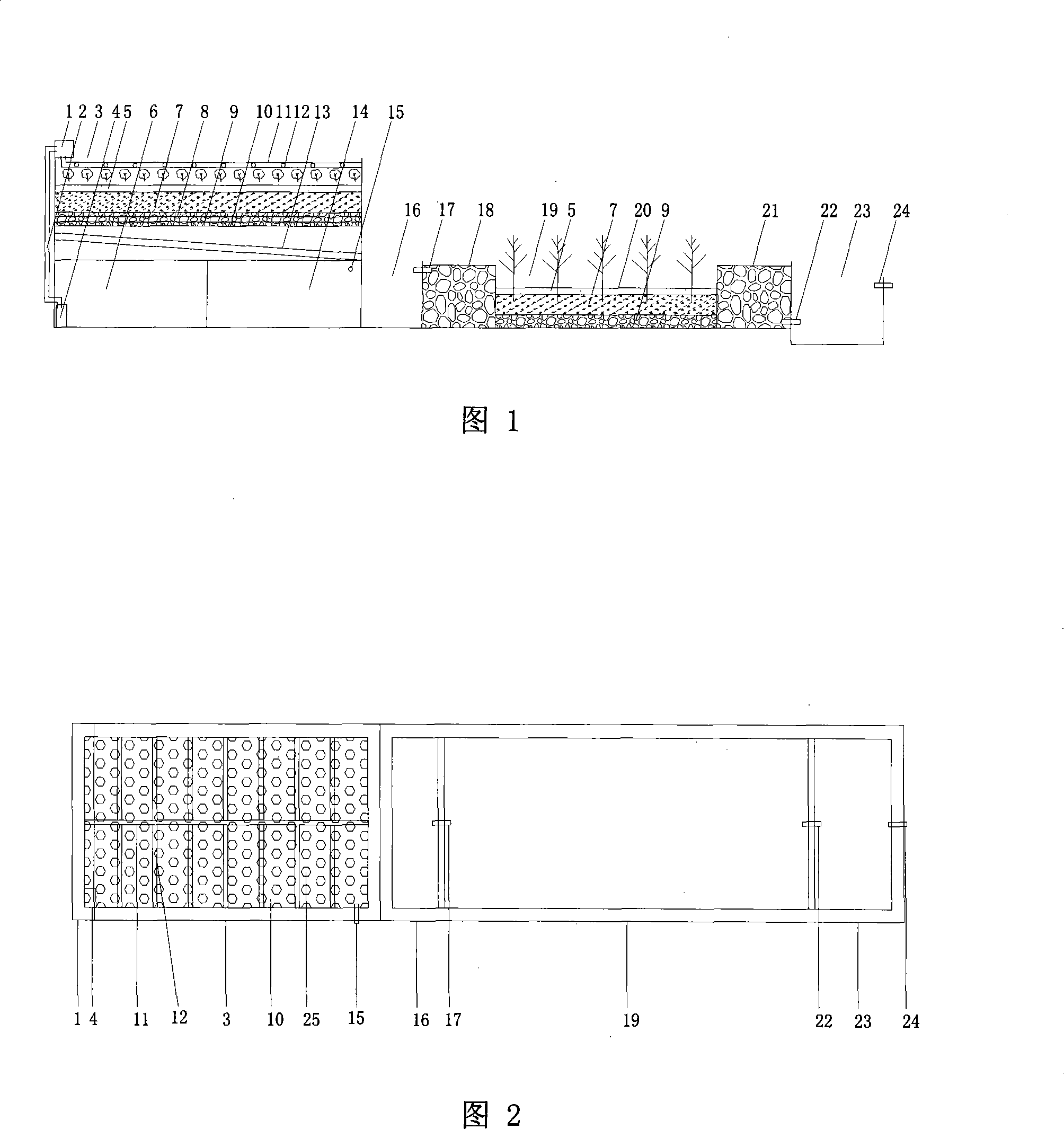

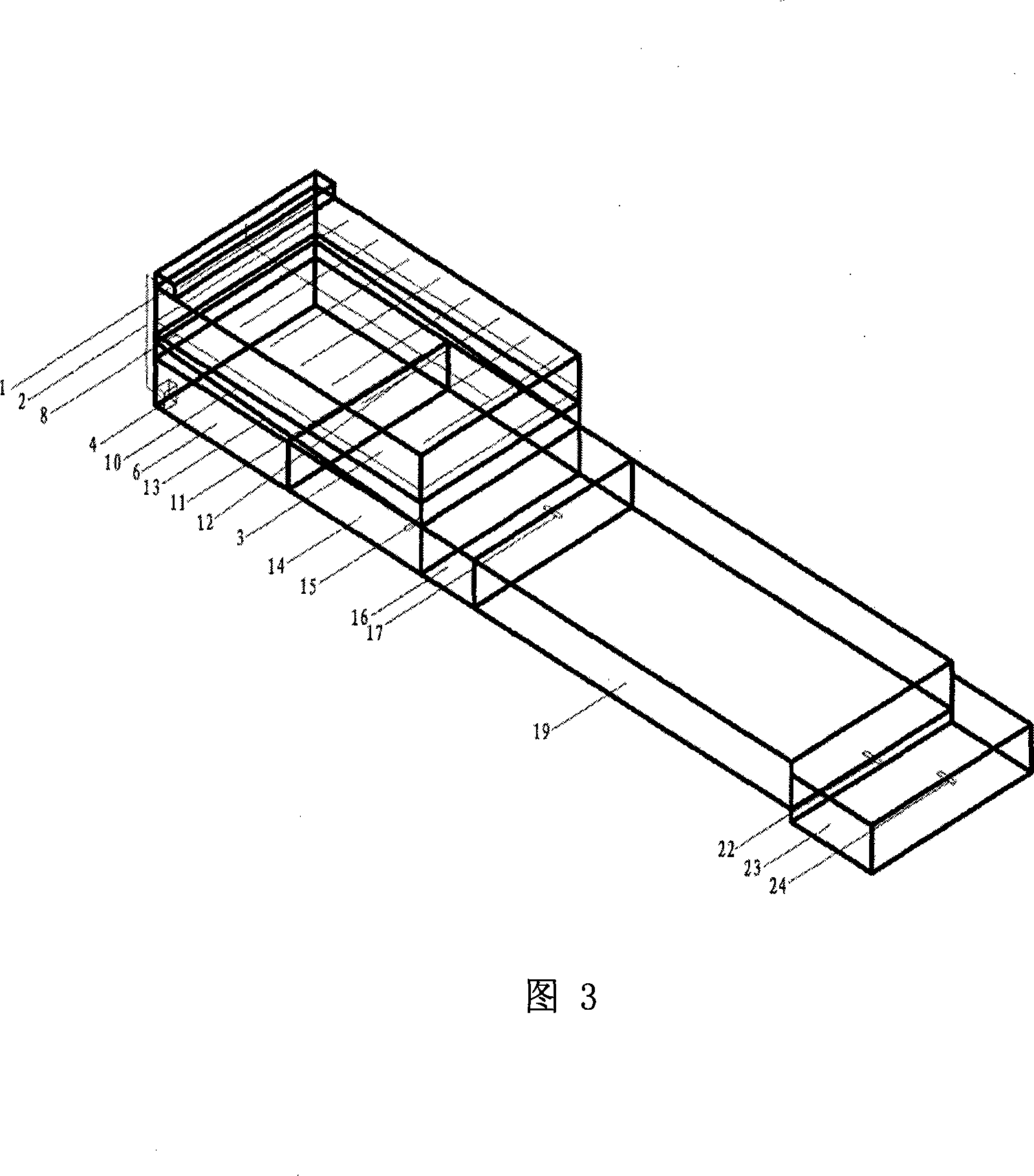

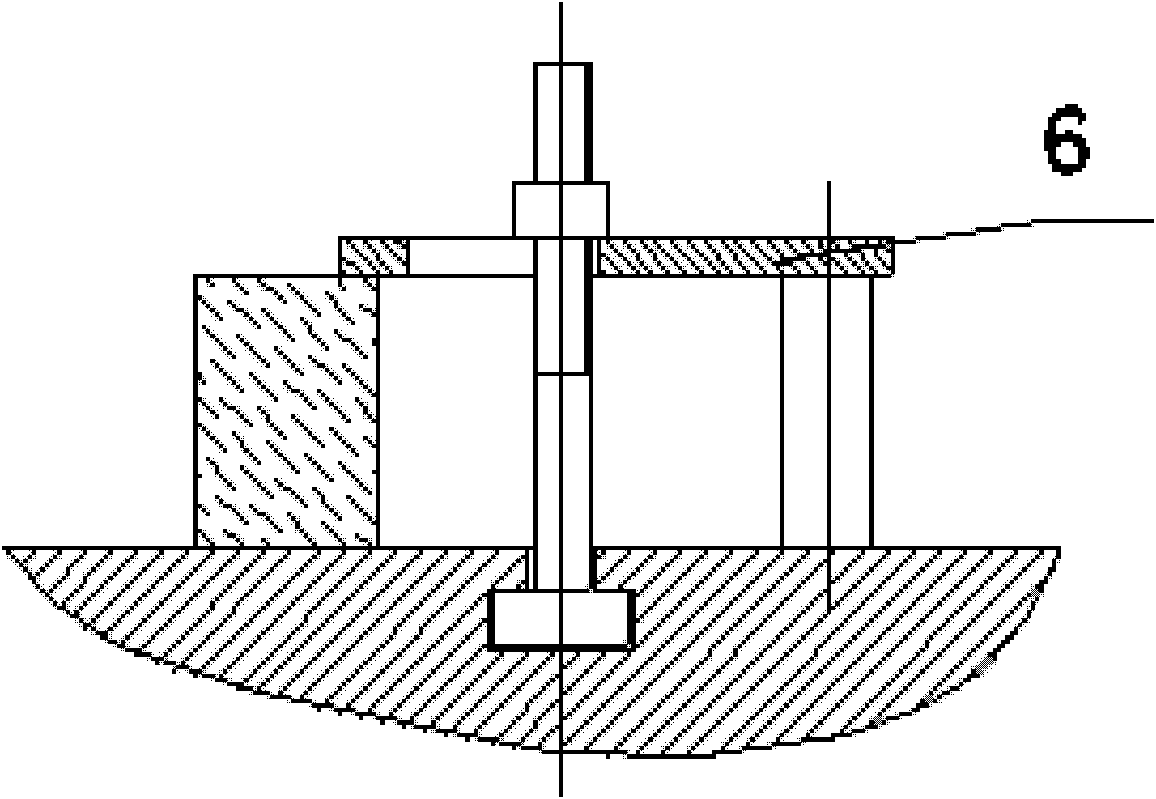

Stereo artificial wetland system for treating sewage

InactiveCN101186382AReduce closureHigh porositySustainable biological treatmentBiological water/sewage treatmentConstructed wetlandIndustrial waste water

The invention relates to the technical field of sewage treatment, in particular to a sewage treatment tridimensional artificial wetland system that is used for the industrial waste water treatment of small-scale isolated pollution sources. The invention aims at providing a tridimensional artificial wetland system that is used for sewage treatment and that has small floor occupancy, high hydraulic load, high pollution load and long service life so as to overcome the defects of the current sewage treatment of big artificial wetland floor occupancy, low hydraulic load, low pollution load and short system service life. The key points of the invention are that: the artificial wetland for sewage treatment adopts a tridimensional assembled structure of vertical current artificial wetland and horizontal subsurface flow artificial wetland, and base materials are filled in various directions to form the tridimensional artificial wetland system for sewage treatment; the tridimensional artificial wetland system for sewage treatment comprises a water collecting header, a porous water-filtering vertical current artificial wetland bed, a first-stage regulating tank, a water drop chute, a grid tank, a second-stage regulating tank, a horizontal subsurface flow artificial wetland bed and a water collecting tank.

Owner:ZHEJIANG NORMAL UNIVERSITY

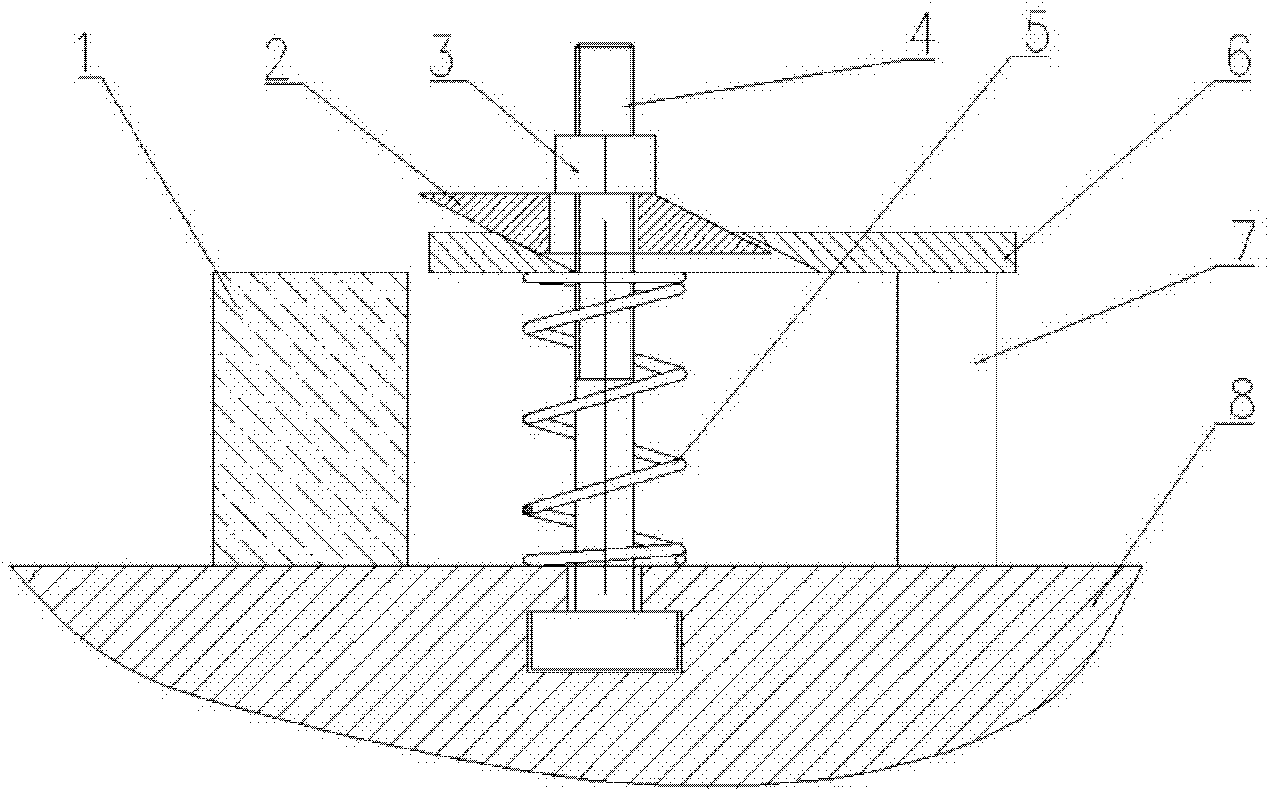

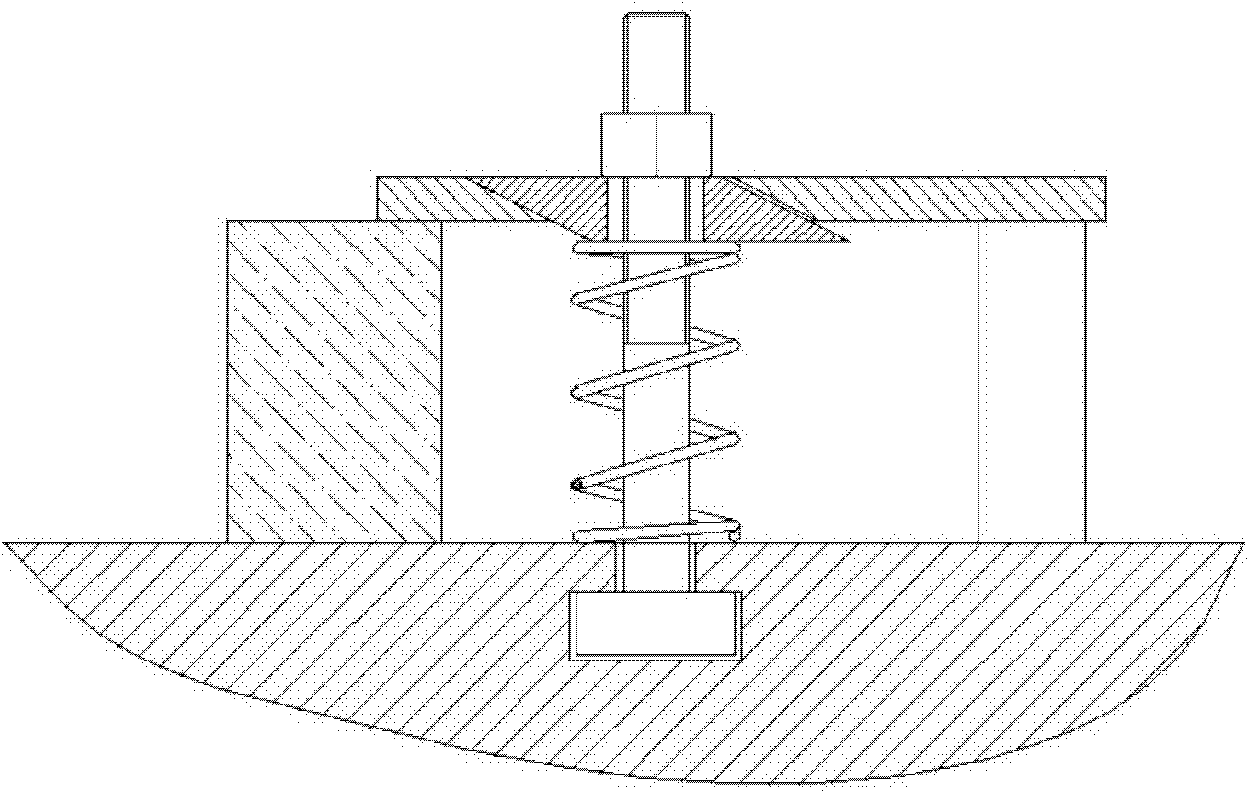

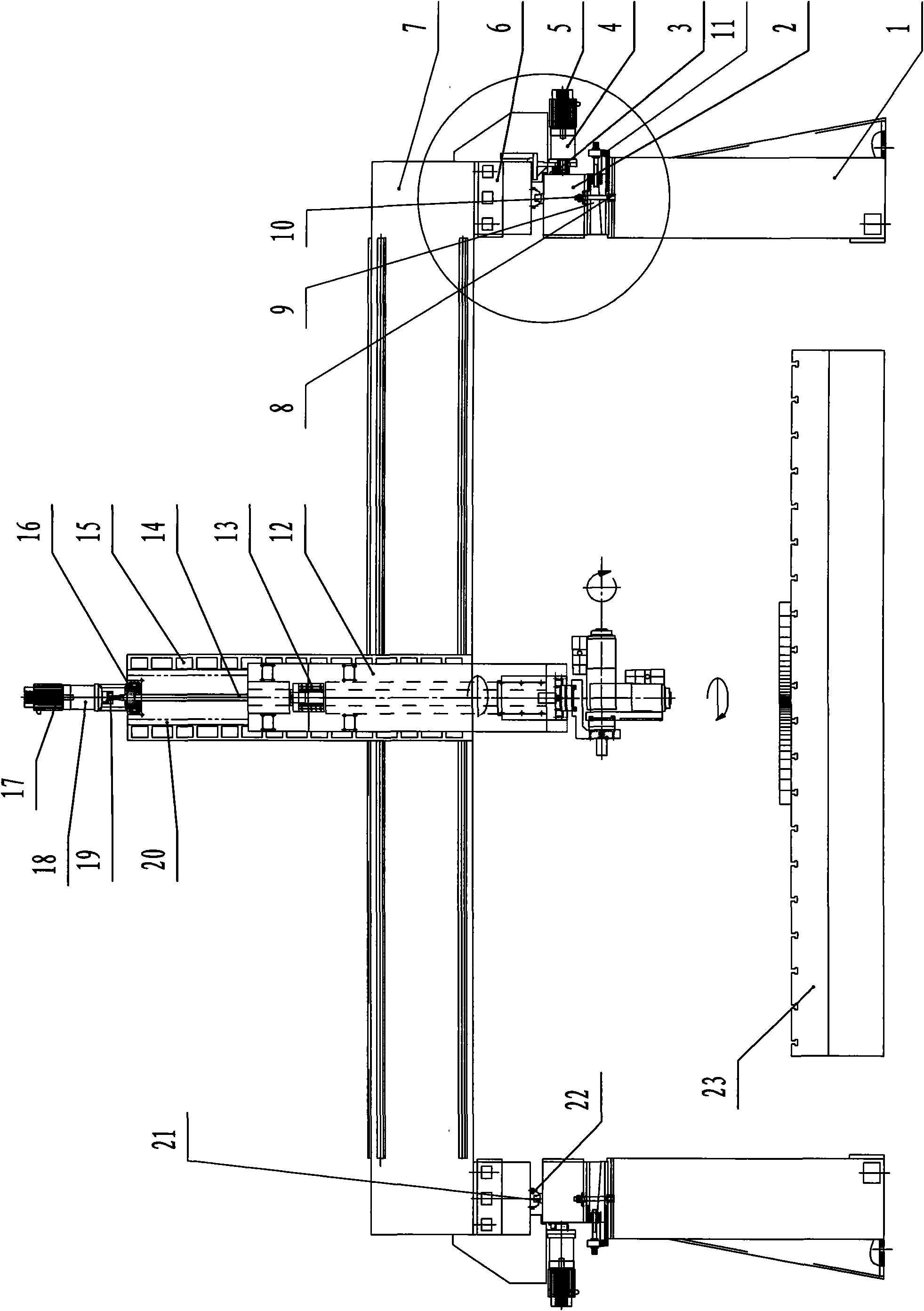

Pressure plate automatic translation clamping machine

InactiveCN101829971ASimple structureEasy to makeWork holdersPositioning apparatusEngineeringAutomatic translation

The invention discloses a pressure plate automatic translation clamping machine. A pressure plate remains horizontal under the action of the elasticity of a spring, and an inclined pressure block is contacted with an inclined plane on the left side of the pressure plate under the action of a nut. When the nut is rotated, the inclined pressure block moves downwards under the action of the nut; the pressure plate is pushed to move left through the inclined plane on the left side of the inclined pressure block (because of the action of the spring, the pressure plate still remains horizontal) until the pressure plate moves above a workpiece; and at the moment, the inclined pressure block is pressed above the pressure plate, the nut is continuously screwed, and then the workpiece is pressed tightly. The loosening process is just opposite to the clamping process. When the nut is loosened, the pressure plate pushes the inclined pressure block to move upwards under the action of the spring; and meanwhile, the inclined pressure block drives the pressure plate to move right so as to separate from the workpiece.

Owner:CITIC DICASTAL

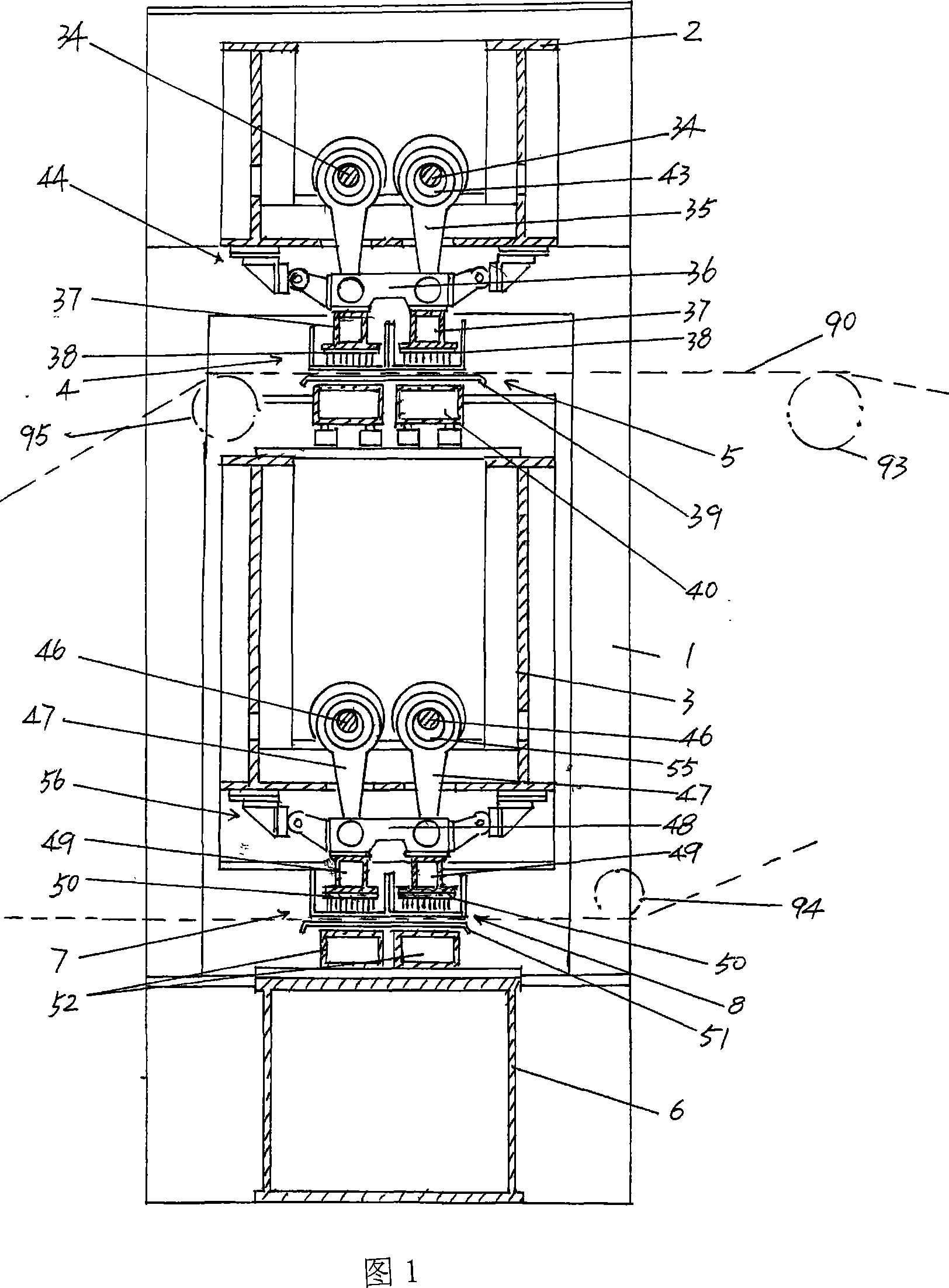

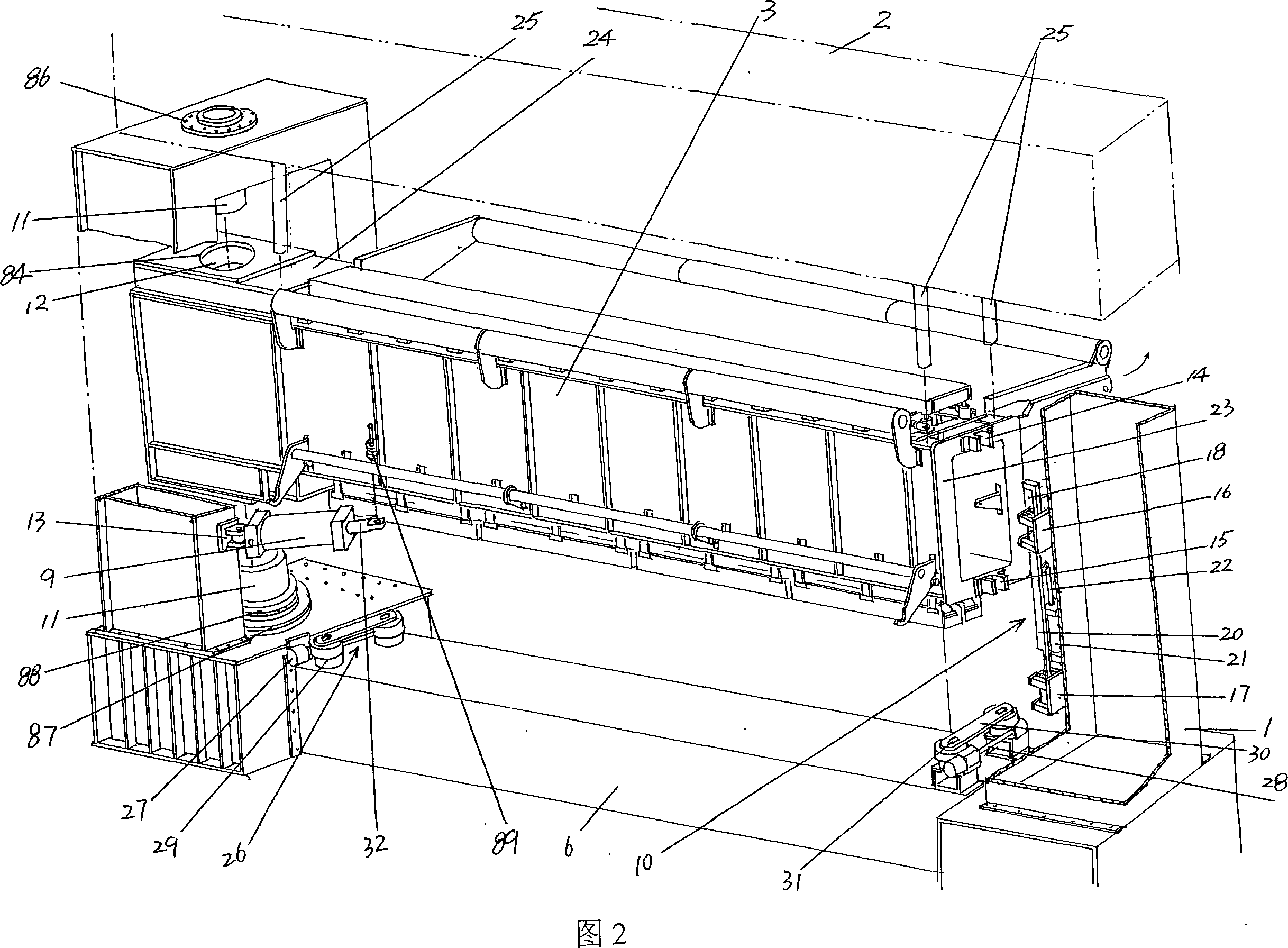

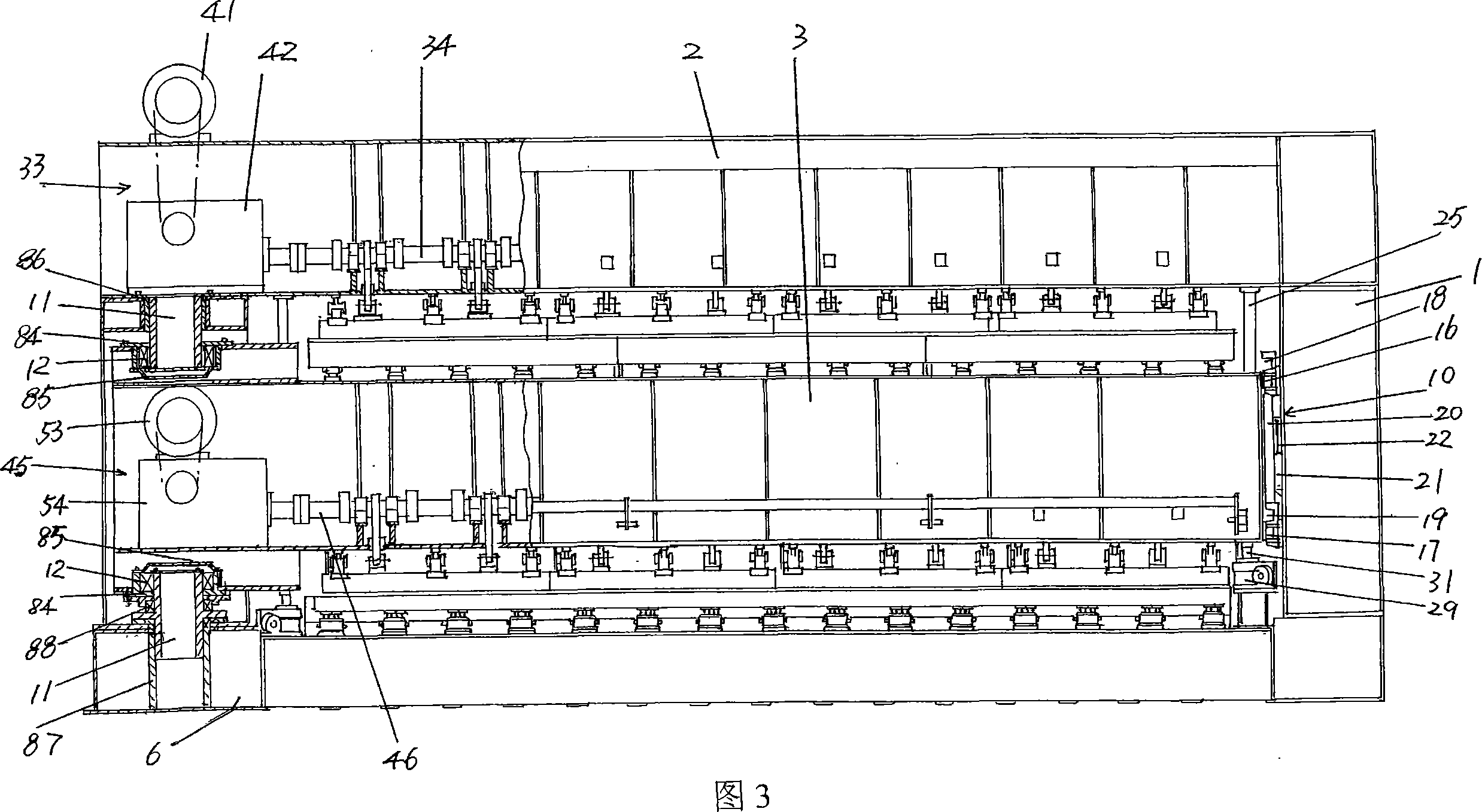

Joint-free industrial felt needle machine with four needle regions needle prick

InactiveCN101122068AReduce labor intensityMeet processing requirementsNeedling machinesIndustrial machineNonwoven fabric

The utility model relates to a non-joint industrial wool needle loom with four needle zones, which belongs to the technical field of non-woven machinery. It includes a frame with a bottom beam, an outer needle punching mechanism for needle punching the outside of the non-woven fiber base cloth on the first beam of the frame, and an openable second needle punching mechanism on the frame. On the beam and corresponding to the inner needling mechanism for needling the inner side of the non-woven fiber base cloth under the outer needling mechanism, the outer needling mechanism constitutes a first and a second outer needling area, The inner needling mechanism is composed of first and second inner needling areas. Advantages: Since the outer and inner needling mechanisms respectively used to simultaneously needling the outer side and inner side of the non-woven fiber base fabric each constitute a pair of needling areas, it is possible to perform needling in four needling areas simultaneously, which has the advantages of Excellent processing efficiency, during the acupuncture process, there is no need to turn over the base fabric, which can reduce the labor intensity of workers; the second beam can be opened and closed, which can meet the processing requirements for wide-width blankets and belts.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

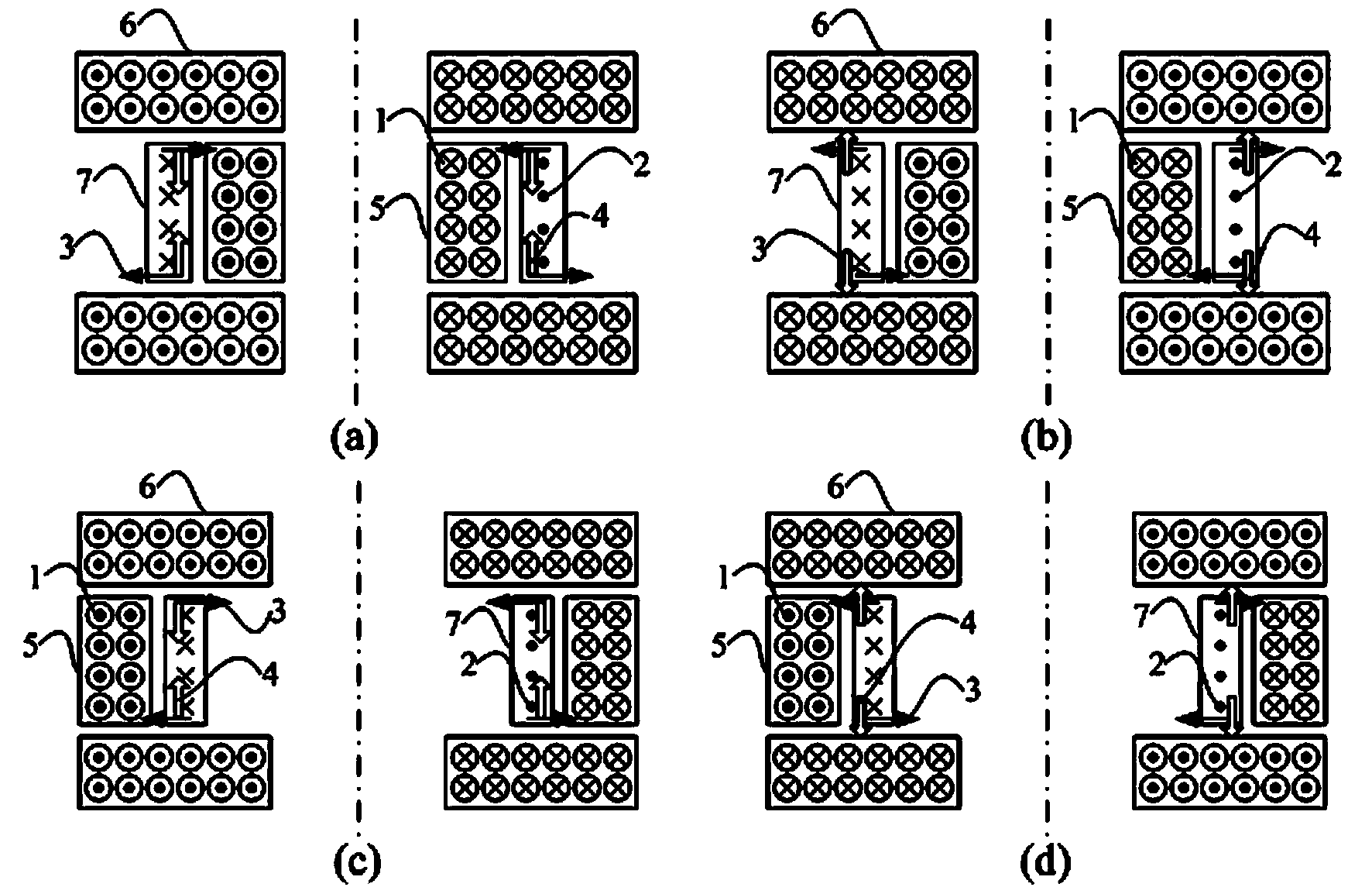

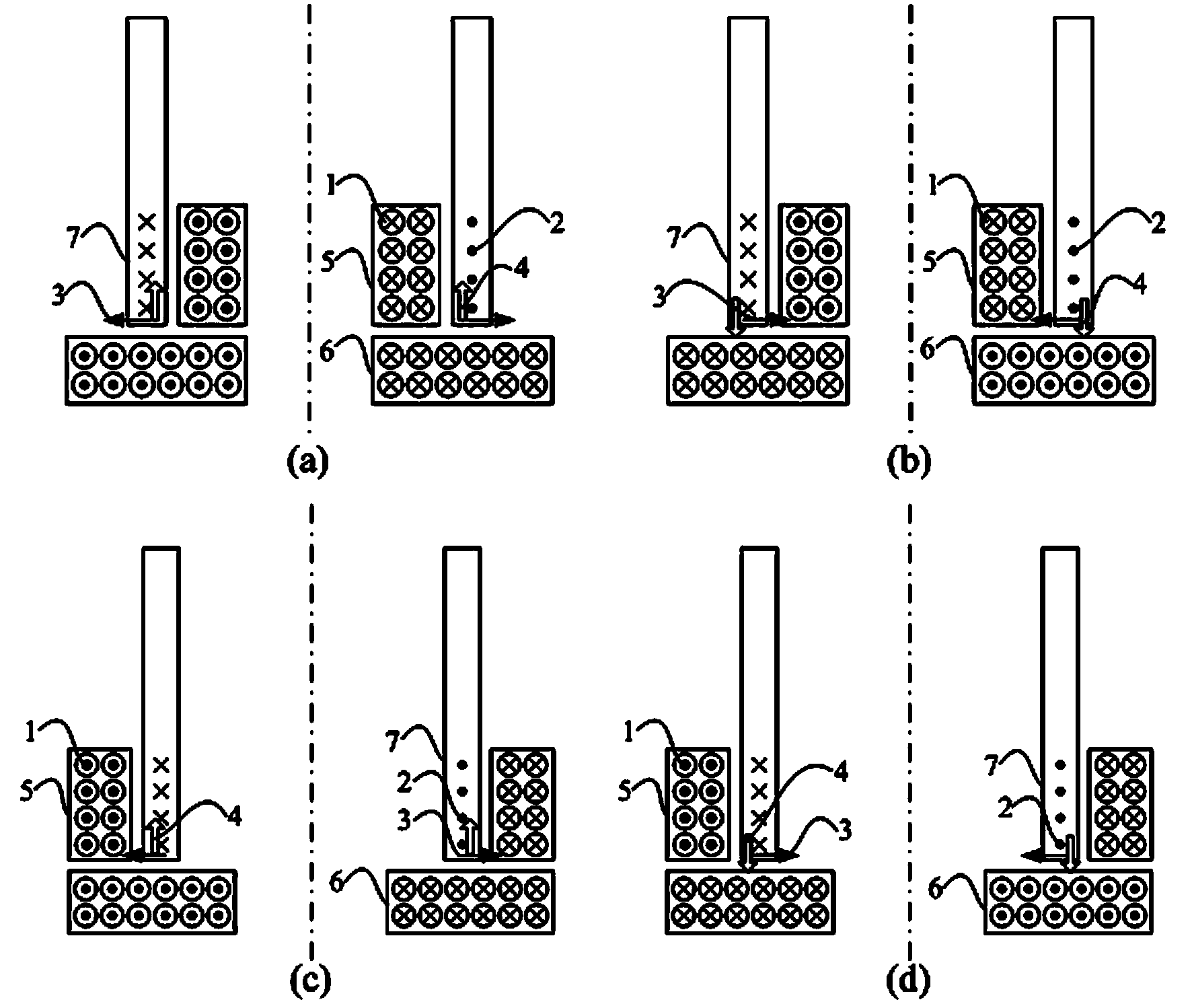

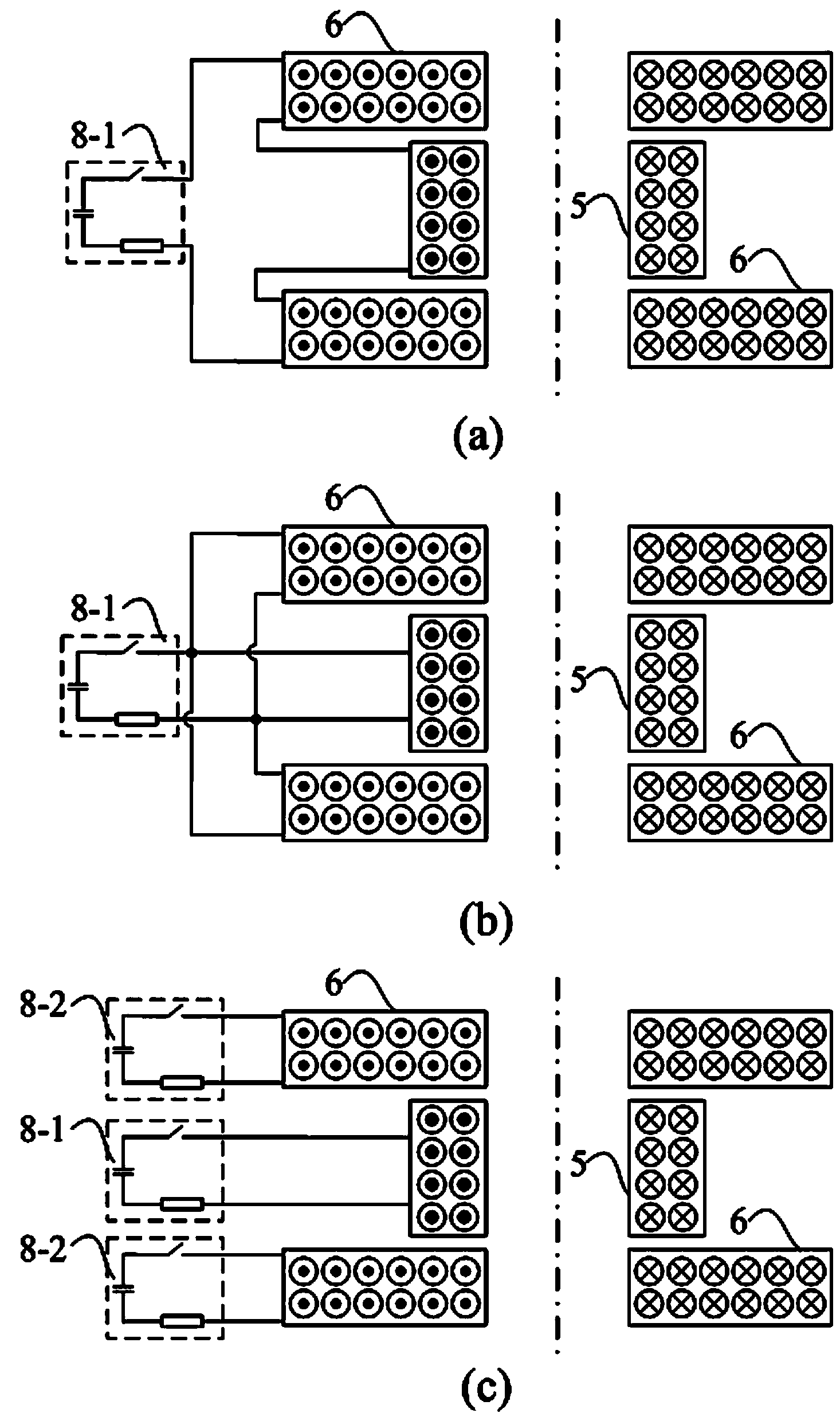

Method and device for electromagnetically forming metal pipe fitting in radial and axial loading mode

ActiveCN103406418ASolve the single load of electromagnetic forming factorSolve the problem caused byAxial compressionPipe fitting

The invention discloses a method and a device for electromagnetically forming a metal pipe fitting in a radial and axial loading mode. The device mainly comprises an eddy current coil, magnetic field coils and power systems. The eddy current coil generates induced eddy currents, the magnetic field coils generate radial magnetic fields, and the eddy current coil and the magnetic field coils are powered by the power systems. The method and the device have the advantages that electromagnetic force can be radially and axially loaded simultaneously in a procedure for electromagnetically forming the metal pipe fitting, an electromagnetic force loading mode can be adjusted, and accordingly machining requirements of different workpieces can be met; the axial compression type pipe fitting is electromagnetically expanded, so that the thickness reduction of a pipe wall in an expansion procedure can be effectively reduced, the forming limit of a formed workpiece is increased, and the forming performance of the formed workpiece is improved; high-speed deformation experiment conditions in different load forms can be provided for metal pipe fittings by the method for electromagnetically forming the metal pipe fitting in the radial and axial loading mode, and novel experiment measures are provided for research on high-speed deformation mechanisms of materials.

Owner:湖北继扬电力科技有限公司

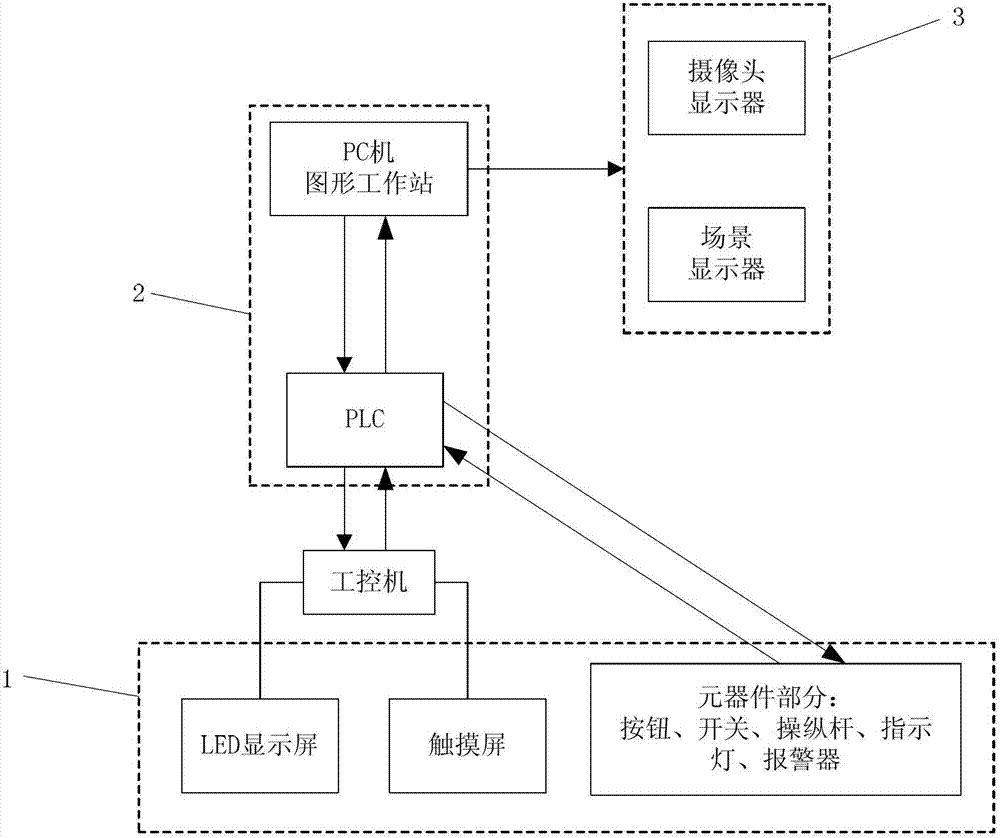

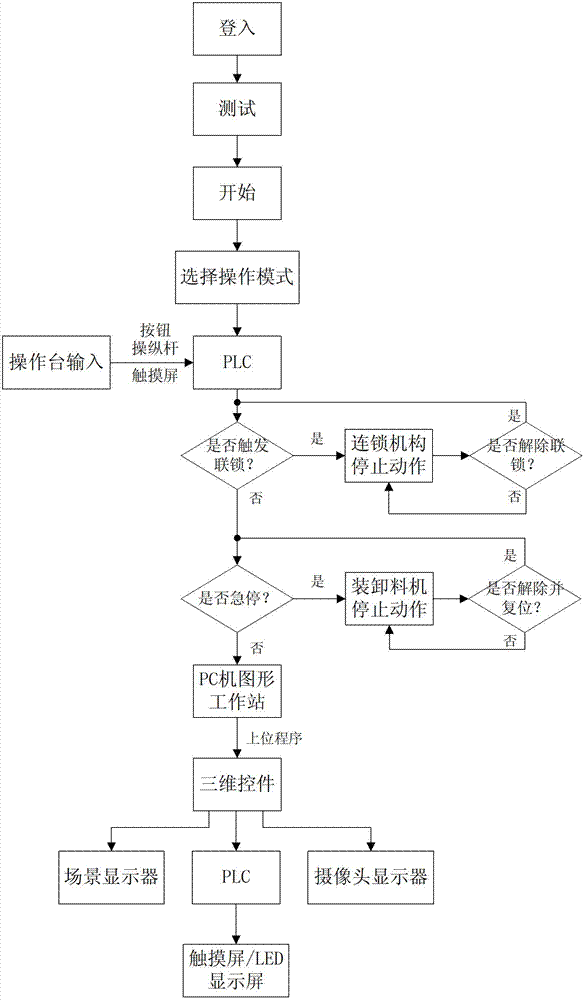

Simulation system of loading and unloading operation processes in pressurized water reactor nuclear power plants

ActiveCN102903271AMeet the process requirementsReflect vividlyCosmonautic condition simulationsSimulatorsPressurized water reactorNuclear power

The invention relates to a simulation system of loading and unloading operation processes in pressurized water reactor (PWR) nuclear power plants. The system comprises an LED (light emitting diode) display screen, a touch screen, an operation control table consisting of a component part consisting of a button, a switch, an operating rod, an indicator lamp and an alarm, an information communication and processing device consisting of a programmable logic controller PLC (programmable logic controller) and a PC graphic workstation, a display device consisting of a scene display and a camera, and an industrial personal computer. The simulation system of the loading and unloading operation processes is designed in strict accordance with functions of real loading and unloading machines, is featured with rich simulated objects, reliable simulation data and strong reality, simulates various common abnormal states or failure states, allows interactive operation, clears faults and has a component showing function; the touch screen has an interface control function; the system simplifies layout of an operation table, expands subsequent functions, effectively trains loading and unloading operators and is widely applied to nuclear power stations and related analogue simulation systems.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Technique for reclaiming ethylene alkali-washing waste liquid

InactiveCN1789162AOvercome the disadvantage of dilutionReduce viscosityWater/sewage treatment by centrifugal separationWater/sewage treatment by ion-exchangeLiquid wasteEconomic benefits

The invention relates to a process of reactivating the ethane alkali washing liquid, comprising the following operating steps: deoiling, causticizing and desulfurizing the alkali waste liquid, adding loading flocculating agent and metallic oxide during the above steps. The invention is characterized by the simple process, sound deoiling effect and complete meeting the ethane alkali washing process demand of the regenerated alkali liquid. The side product got in the course of causticizing and desulfurizing, by transforming the S2- into sulfide of high added value by applying sulfide conversion method, can be sale as commercial articles, which simplifies the waste alkali liquid treating course and brings higher economic benefit for the waste alkali liquid treating.

Owner:HEBEI UNIV OF TECH

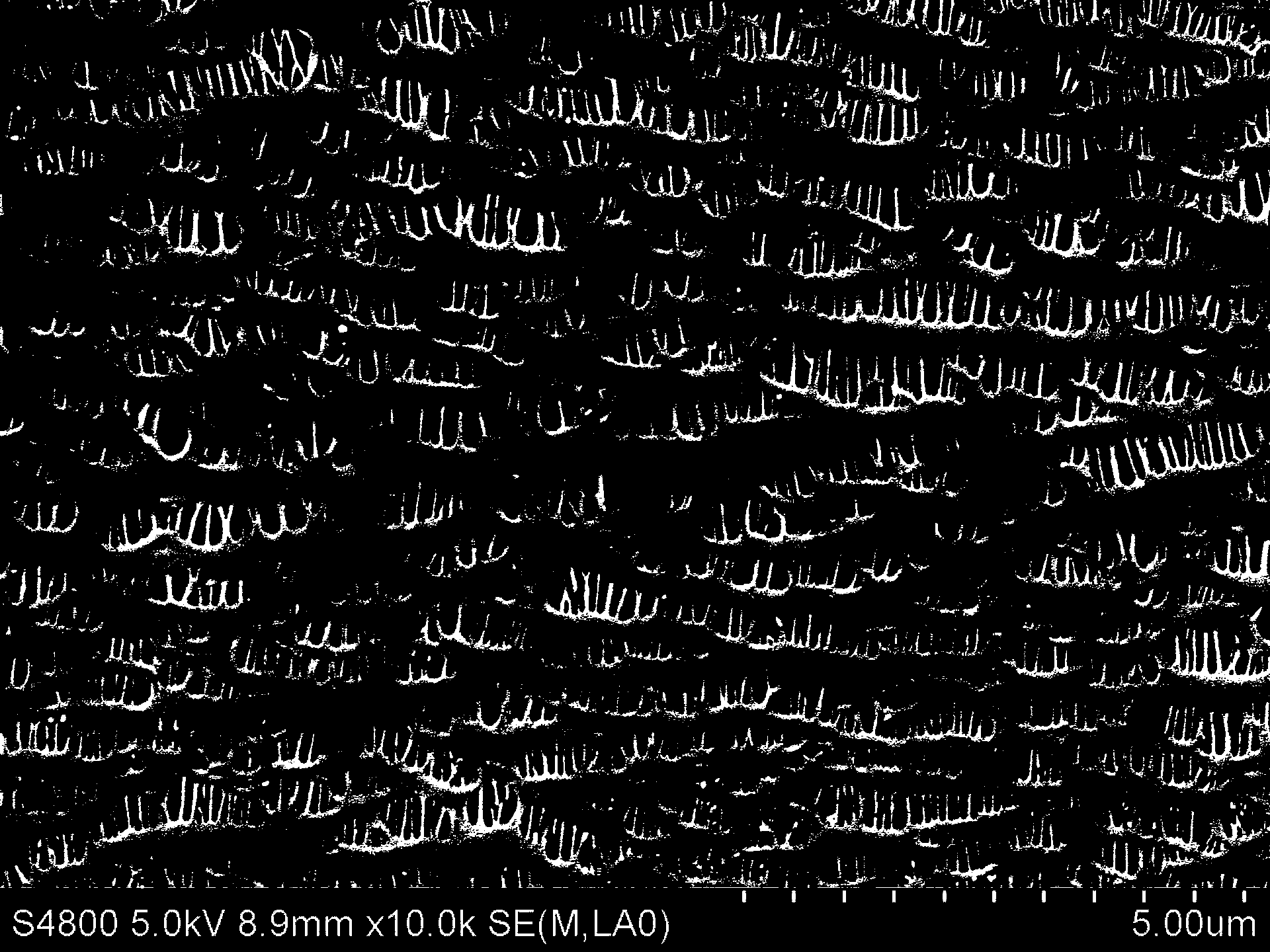

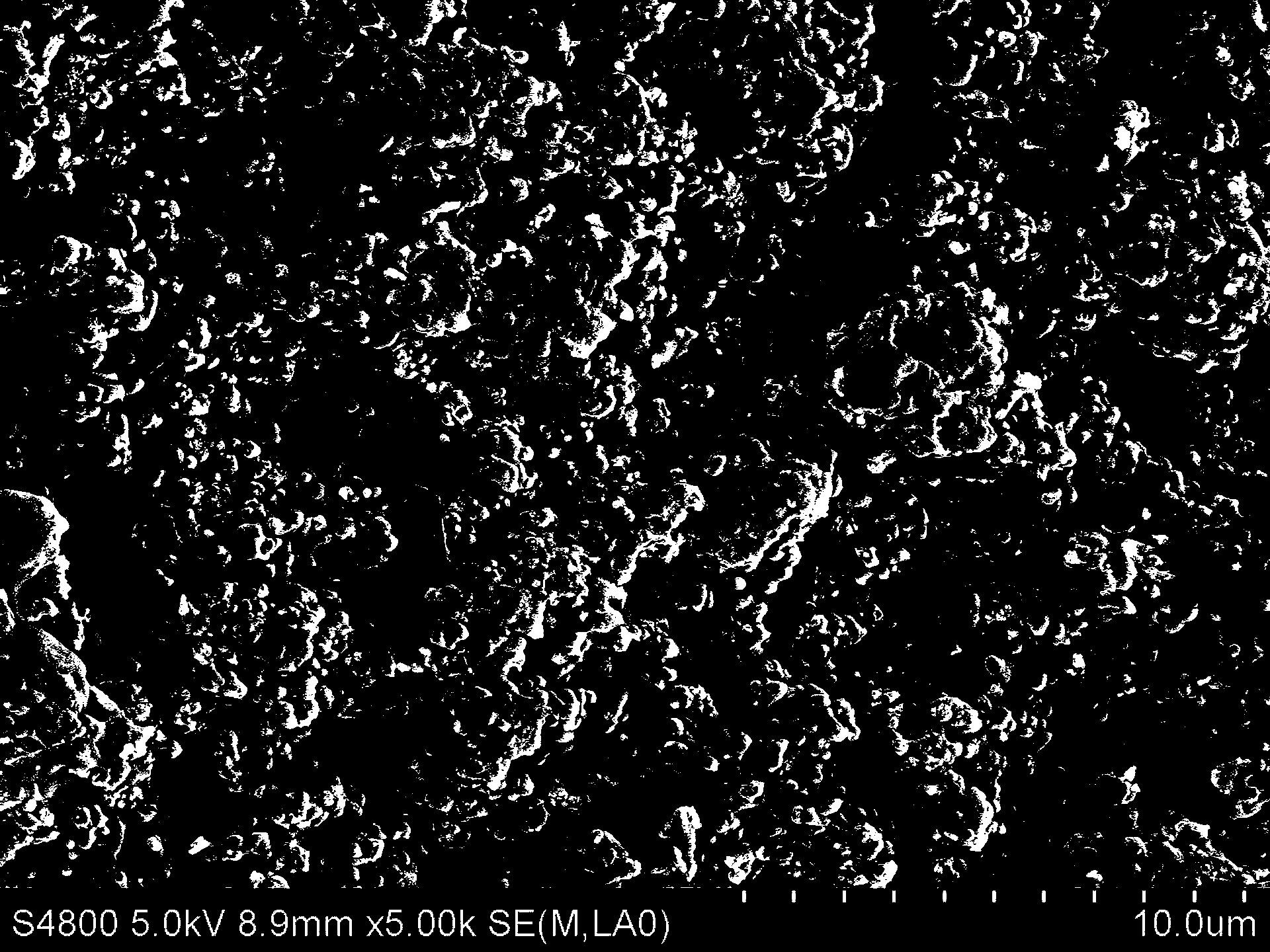

Composite membrane for lithium ion batteries and preparation method thereof

ActiveCN103956450AAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite membrane for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery membrane. The ceramic protective layer is mainly prepared from a ceramic-adhesive mixture subjected to graft modification by a sodium-sulfonate / sodium-carboxylate-group-containing anionic surfactant. The grafting is completed by using a grafting-to process under the action of a dehydrating agent; the grafting ratio of the ceramic is higher; the high-temperature-resistant large-surface-area nano ceramic is introduced to the conventional PP (polypropylene) membrane surface, the insulativity and electrolyte wettability of the modified ceramic membrane are greatly enhanced; and the membrane has excellent high-temperature heat stability especially at the high temperature of 130 DEG C, 150 DEG C and 180 DEG C. The lithium battery composite membrane avoids the thermal shrinkage of the convention membrane, thereby avoids the thermorunaway in the battery due to thermal shrinkage, and further enhancing the safe reliability of the lithium ion battery.

Owner:DONGFANG ELECTRIC CORP LTD

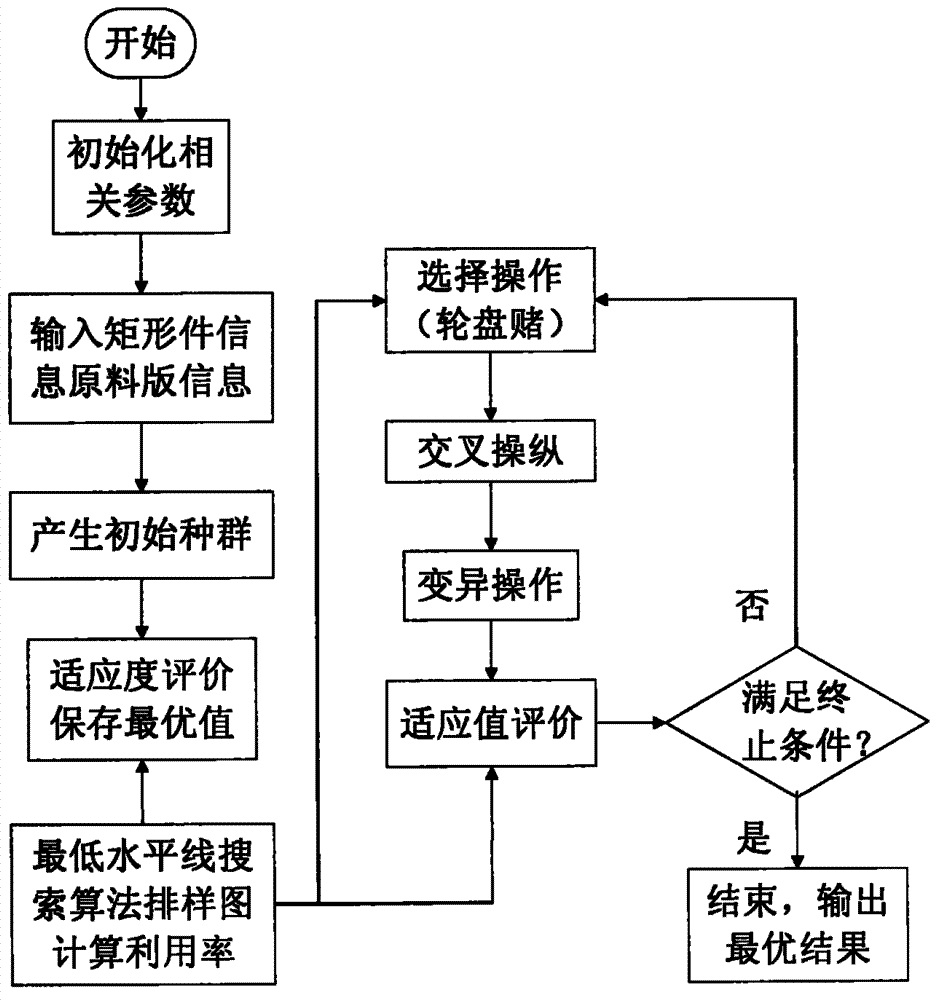

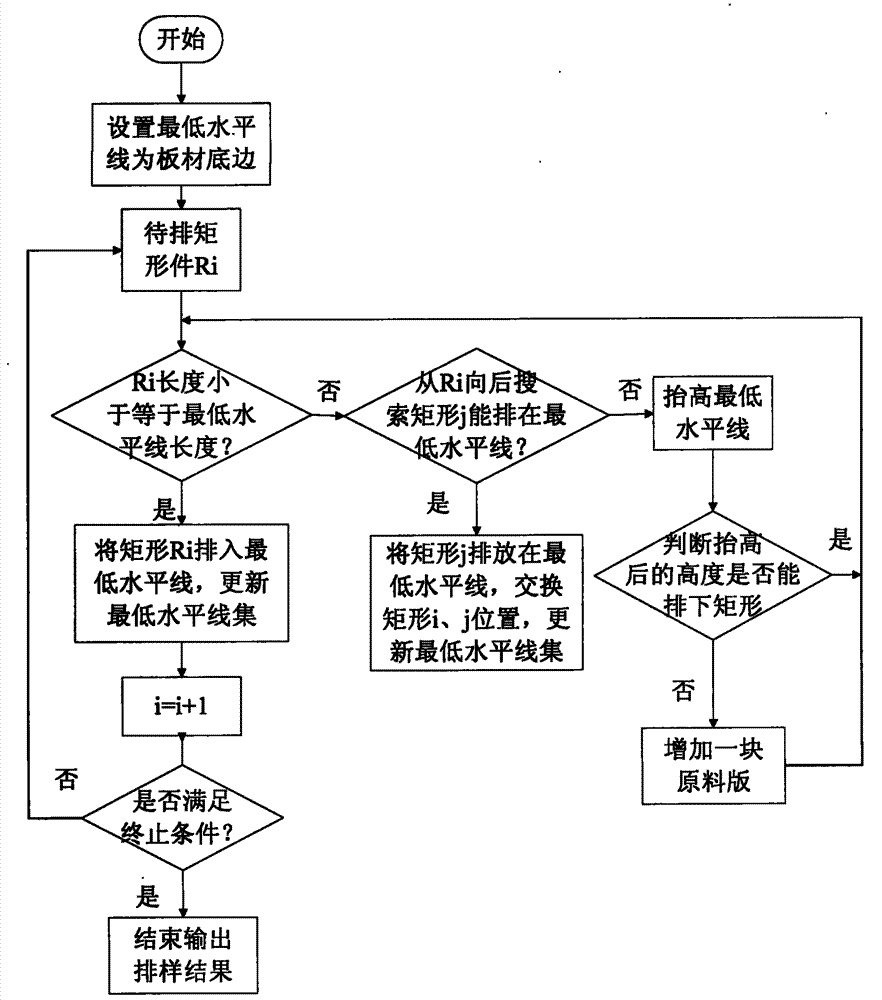

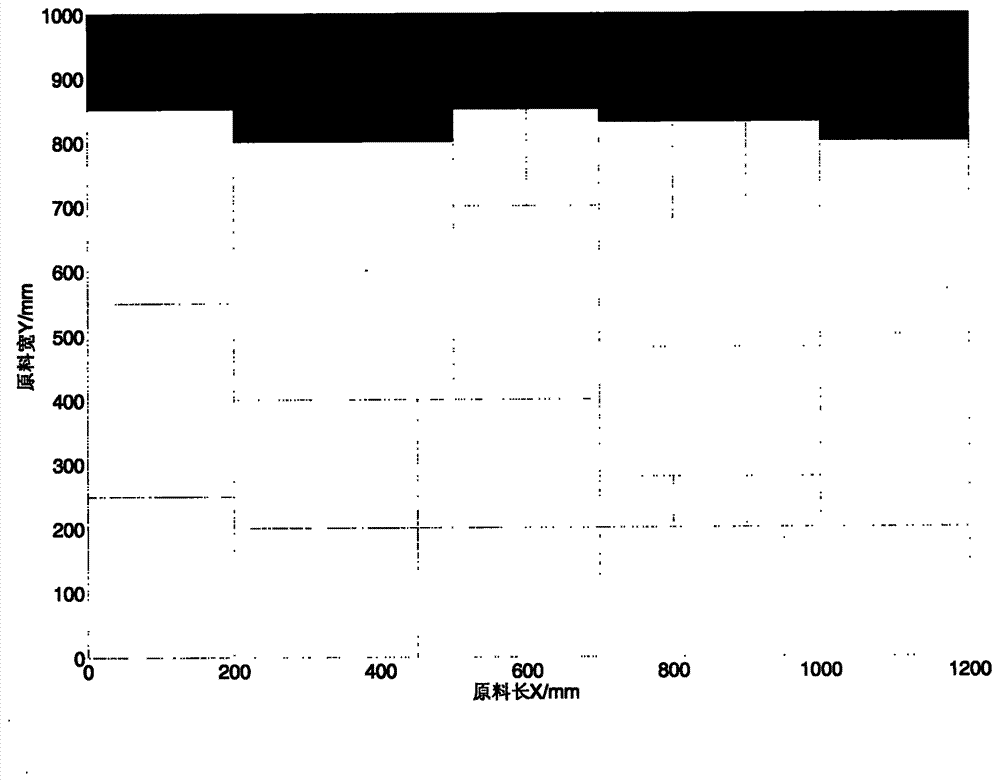

Intelligent layout method used for rectangular part

InactiveCN103500255AMeet the process requirementsEfficient searchSpecial data processing applicationsRelevant informationAlgorithm

The invention discloses an intelligent layout method used for a rectangular part. The method comprises the steps that S1 relative parameters of the genetic algorithm are initialized; S2 relative information of the rectangular part is extracted from a rectangular part bank to be laid out; S3 relative information of raw material boards is extracted from a board tank; S4 the obtained information is coded, and primary species are generated randomly; S5 one-by-one decoding is conducted on the primary species by means of the lowest horizontal line search algorithm to obtain solution using efficiency; S6 selection, crossover and mutation operation is conducted according to the genetic algorithm until iteration is finished, and the optimal layout scheme is output. According to the intelligent layout method, the process requirement of the rectangular part can be met well, the intelligent algorithm and the heuristic algorithm are combined, one optimizing scheme can be found rapidly and efficiently, and therefore the material using rate of an enterprise is greatly improved, layout time can be obviously shortened, and layout efficiency is improved.

Owner:NANTONG UNIVERSITY

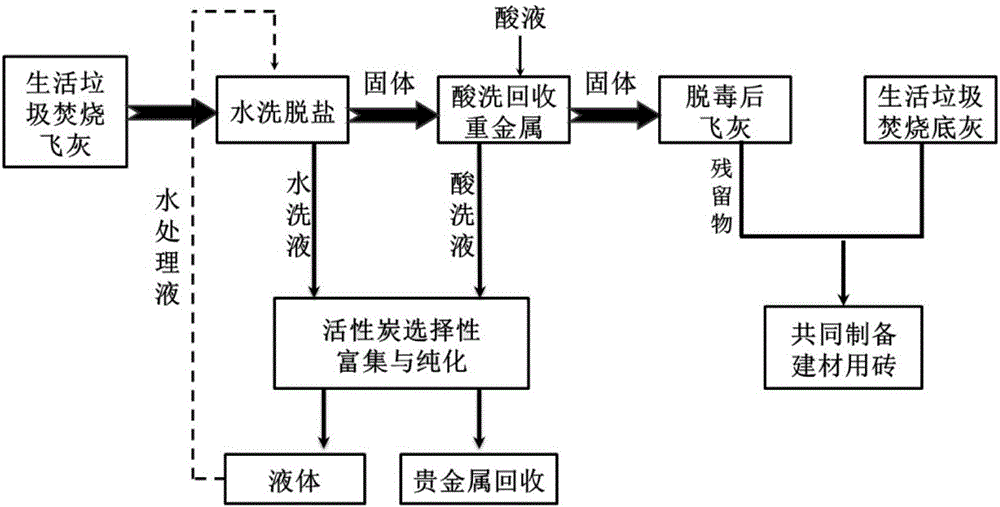

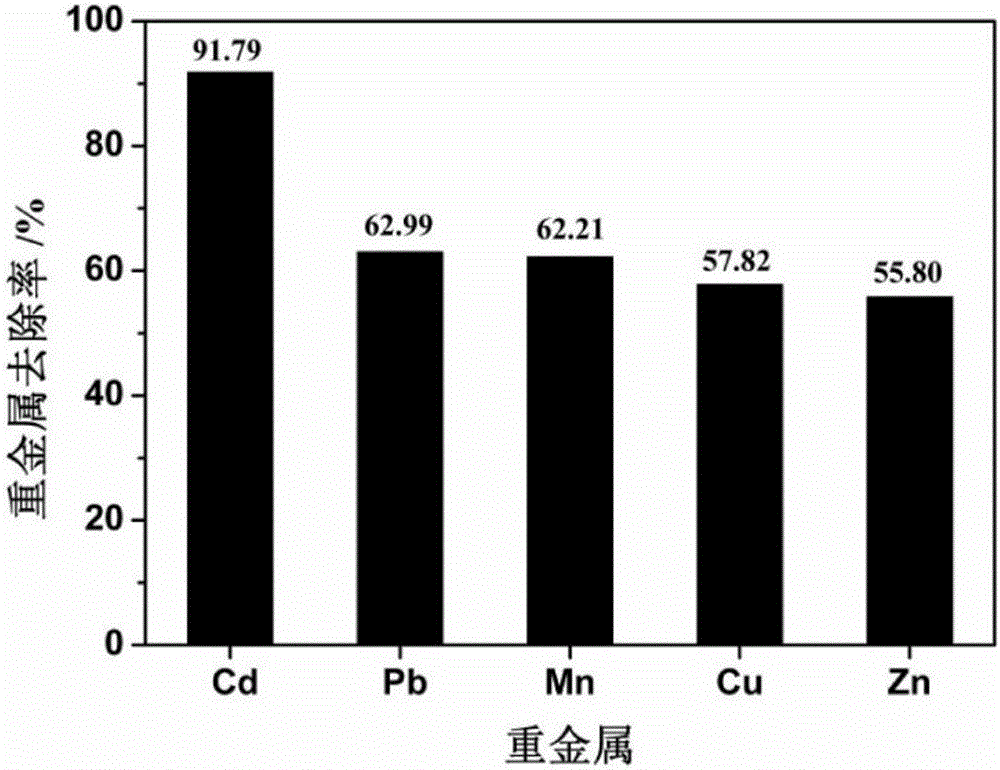

Detoxification graded resource utilization method for household garbage incineration fly ash

ActiveCN106282585AAddress high soluble salt contentSolving Chlorine ProblemsSolid waste disposalProcess efficiency improvementLiquid wasteBrick

The invention relates to a detoxification graded resource utilization method for household garbage incineration fly ash. The method includes the steps that the household garbage incineration fly ash is subjected to desalination and dechlorination through washing, and then subjected to heavy metal removal through acid pickling, and obtained detoxified fly ash and household garbage incineration bottom ash are compounded to prepare water permeable bricks; and a washing solution and an acid pickling solution are mixed, precious metal is enriched and purified selectively through activated carbon, and after soluble salt recovery is conducted on the residual liquid phase, obtained water treating fluid is reused in the washing step. By means of the detoxification graded resource utilization method, soluble salt, the chlorine element and the precious metal in the fly ash can be effectively removed, and the leaching toxicity of residual heavy metal in the fly ash completely meets the national standard; and meanwhile, the precious metal and the soluble salt in the fly ash are effectively recovered, and cyclic utilization of waste liquid and activated carbon is guaranteed. The method has the advantages that energy is saved, the method is ecological and environmentally friendly, resources are recycled, and waste is turned into wealth; and meanwhile, the detoxified fly ash can be safely applied to the industries including construction, environmental protection and the like, and the application and popularization value is quite high.

Owner:中陕核生态环境有限公司

Technical for manufacturing jewelry by using hard gold

InactiveCN101810387AHigh hardnessIncrease elasticityJewelleryElectroforming processesManufacturing technologyEngineering

The invention provides a process for manufacturing jewelry by using hard gold. The technique mainly comprises the following steps of: 1, molding; 2, opening a jelly mould; 3, injecting wax; 4, trimming the wax; 5, applying silver oil; 6, manufacturing a raw blank; 7, removing the wax; 8, removing silver; 9, welding; 10, modifying the mould; 11, picking stones and embedding stones; 12, treating the surface; and 13, carving by laser. The method ensures that the molecular structure of gold changes by utilizing hard gold jewelry manufacturing technology and applying the metal reinforcing technology in aerospace science and technology to jewelry manufacture and adjusting temperature, pH value, current, pulse power supply, additive and other technical parameters of electrotyping solution in an electrotyping process, thereby effectively improving the hardness and the elasticity of the gold. On the premise of ensuring the purity of the gold, the hardness of the gold is 4 times that of the traditional gold, so that the technique requirements of the fashion jewelry design are met. The gold jewelry and art decorations manufactured by the method cannot be easily scratched or deform, so that the artistic quality of the jewelry and decorations can be greatly improved.

Owner:惠州市博艺黄金珠宝有限公司

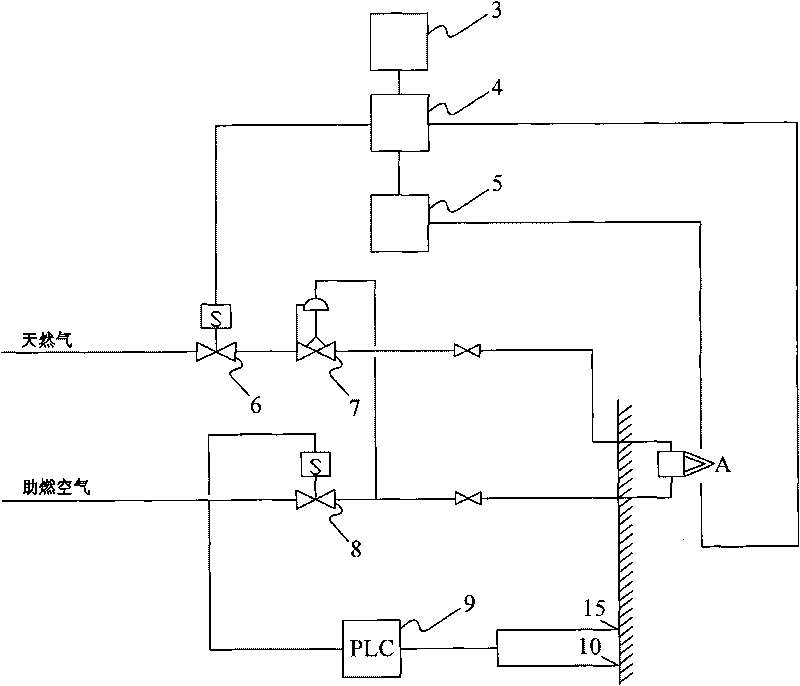

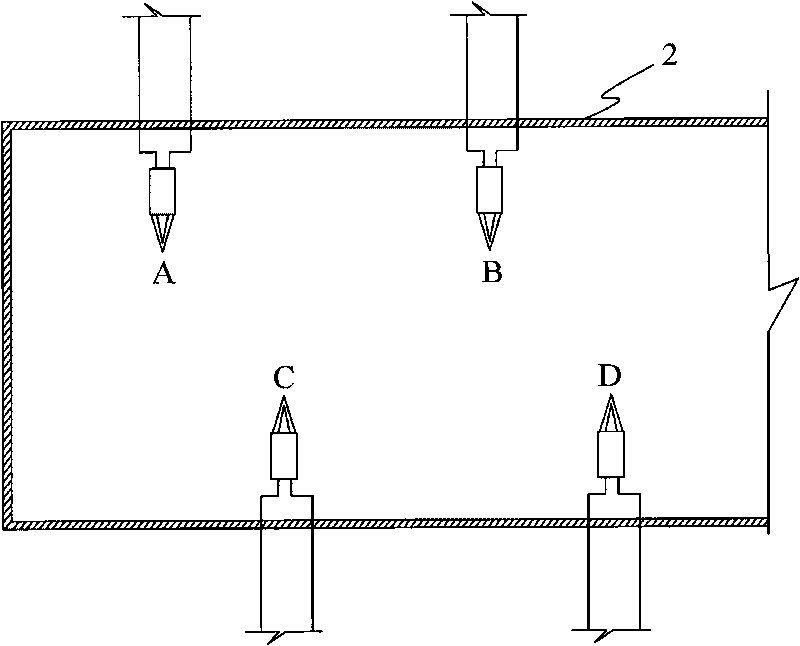

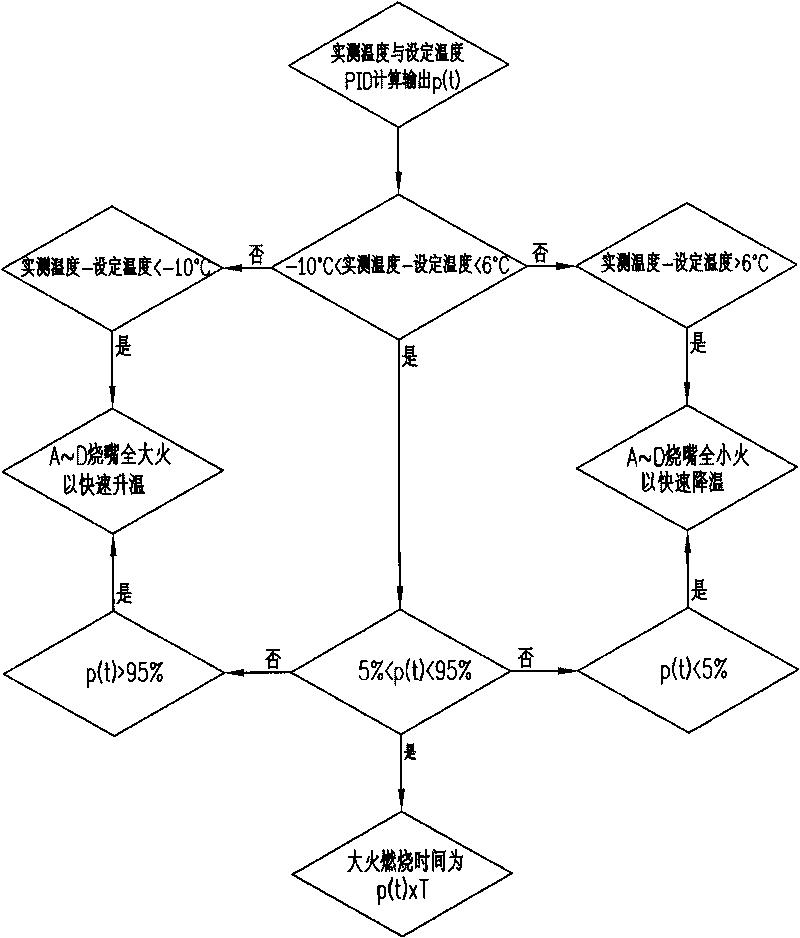

Pulse combustion control system and control method

ActiveCN101737797ALow costFlexible control abilityCombustion regulationTemperature controlControl system

The invention provides a method for controlling pulse combustion which uses a Programmable Logic Controller (PLC) programme to replace a pulse combustion controller to achieve the pulse combustion control, and mainly comprises an adjustment step, a nonlinear treatment step and an output step. The pulse combustion control is innovatively achieved through three steps of PLC programme, the nonlinear treatment step and the output. The method not only saves a large number of costs required for buying pulse controllers, but also has the control effect which is more flexible than the control effect of the pulse controllers, and the temperature control accuracy and the uniformity can well meet process requirements.

Owner:BERIS ENG & RES CORP

Copper base material cleaning agent and preparation method thereof

The invention provides a copper base material cleaning agent. The copper base material cleaning agent is composed of, by weight, 0.05%-2% of organic acid activators, 0.05%-1% of a nonionic surface activator, 0.01%-0.6% of an anion surface activator, 0.005%-0.2% of an antioxidant, 0.005%-0.2% of a chelating agent, and the balance deionized water. In addition, the invention discloses a preparation method of the copper base material cleaning agent. The copper base material cleaning agent is free of attenuation and controlling over the attenuation, can be directly used, does not contain heavy metal, is free of residues and can meet the processing requirements for copper before hot dipping; the surface of a copper base material processed by the cleaning agent is pure and is free of dark spots, oil contaminations, fingerprints and the like; accessories obtained after tinplating are free of exposed copper, dark spots and other defects, and the surfaces of the accessories are smooth.

Owner:THE NORTHWEST MACHINE

Production process of 6-inch lithium niobate or lithium tantalite chips

InactiveCN103921205AIncrease profitEasy dischargePolishing machinesSemiconductor/solid-state device manufacturingHigh volume manufacturingMegasonic cleaning

The invention belongs to the technical field of tools for lithium chips and particularly relates to a production process of 6-inch lithium niobate or lithium tantalite chips. The production process includes the steps of A, cutting to obtain chips 0.6-1mm in thickness; B, charging the chips into a reduction furnace for reduction; C, after grinding, cleaning by ultrasonic; D, pasting the chips; E, grinding; F, polishing; G, cleaning, and boxing. Internal stress of the chips is removed by double corroding, electrostatic charge is removed from the chips by blackening, ultra-smooth planes are obtained by mechanical chemical polishing, TTV is smaller than 5 um, BOW is smaller than 40 um, warp is smaller than 40 um, PLTV is larger than 95%, and the production process is suitable for mass production.

Owner:DEQING JINGHUI OPTOELECTRONICS TECH

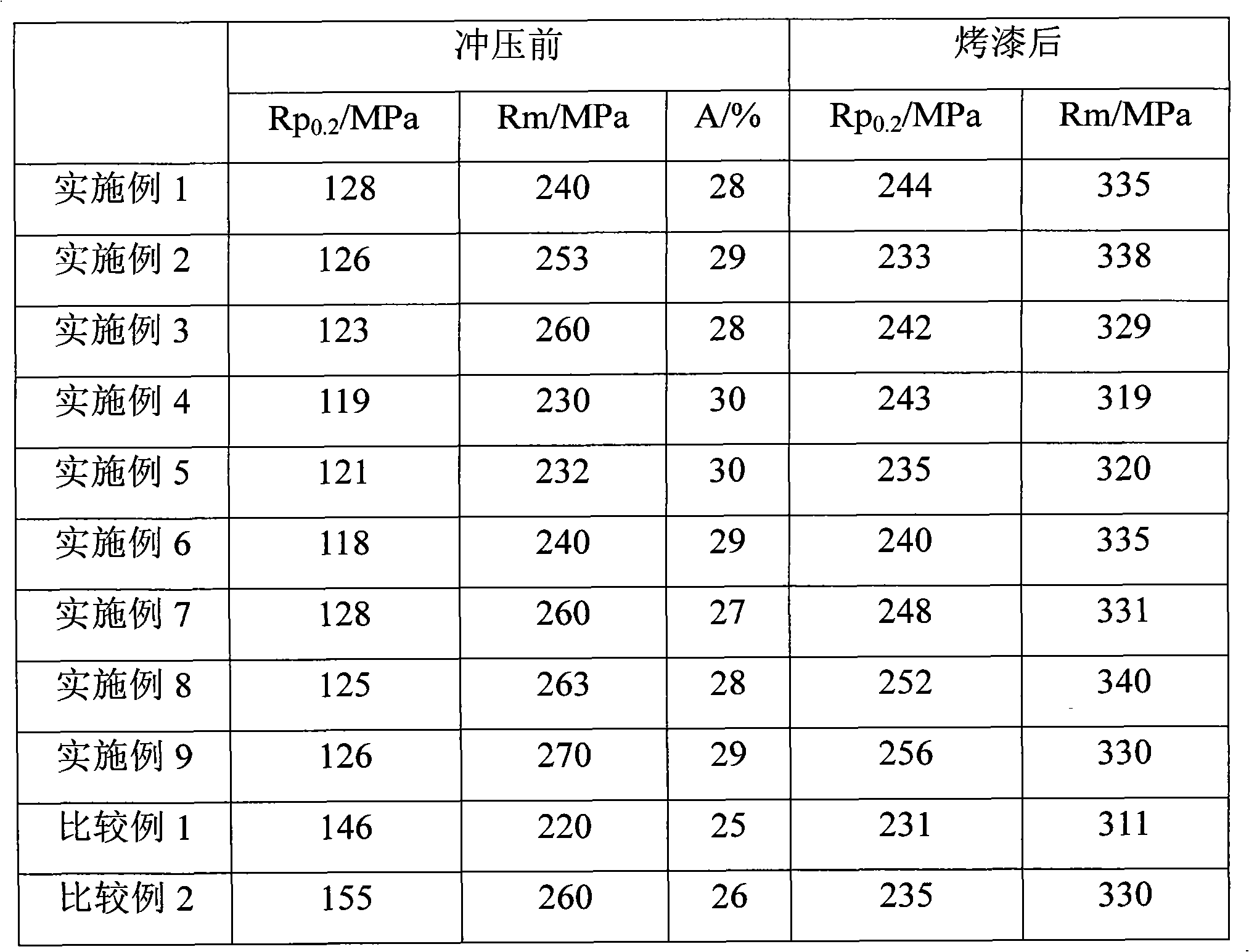

Aluminum alloy material with high bake hardening capability for 6-series automobile bodies

InactiveCN101985707AHigh bake hardening propertiesLower yield strengthSolution treatmentNatural aging

The invention provides an aluminum alloy material with high bake hardening capability for 6-series automobile bodies, which comprises the following components: 0.50-1.00wt% of Si, 0.60-1.30wt% of Mg, 0.01-0.30wt% of Cu, 0.05-0.20wt% of Mn, less than or equal to 0.10wt% of Cr, less than or equal to 0.15wt% of Ti, 0.05-0.25wt% of Fe and the balance of Al. After the material is formed by casting, the material is treated by homogenizing annealing, hot rolling, cold rolling, solution treatment and then natural aging. Before stamping, the yield strength of the material is lower than 130MPa; and after baking, the yield strength of the material is greater than 230MPa, and the tensile strength of the material is greater than 310MPa. The material has higher bake hardening ability, and simultaneously, the forming property of the material meets the using requirements, thus the material is an ideal material for manufacturing automobile bodies.

Owner:苏州有色金属研究院有限公司

Machining process of thin-wall groove milling stainless steel part

The invention discloses a machining process of a thin-wall groove milling stainless steel part. The machining process of the thin-wall groove milling stainless steel part mainly comprises the following steps of heat treatment of a rough casting, rough machining, natural aging processing, subsequent rough groove milling, finish machining and finish groove milling. Through the design of a machining route, the machining process of the thin-wall groove milling stainless steel part reduces production of stress as much as possible, and effectively avoids deformation caused by stress concentration, thereby improving machining precision and the accuracy degree.

Owner:ANHUI YINGLIU ELECTROMECHANICAL

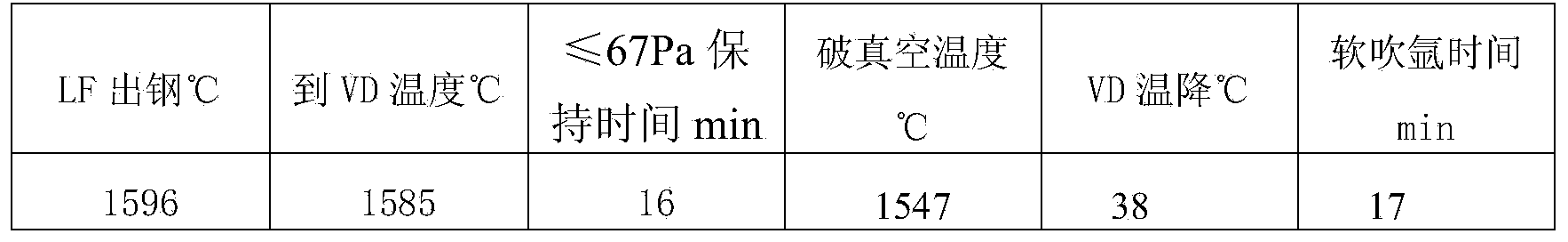

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Gantry type five axes numerical control machine tool

ActiveCN101623824AStable supportGuaranteed coaxialityLarge fixed membersNumerical controlEngineering

The invention discloses a gantry type five axes numerical control machine tool, belonging to the machining field of a numerical control mechanism. The technical scheme is as follows: the traditional vertical rod is replaced by an X-direction guide way, so that support force to a beam is great, and the beam can be ensured to be stably move along the X-direction guide way; an automatic bidirectional revolute joint which is fixedly connected with a Z axes servo drive assembly can drive an electrical main shaft to rotate around a horizontal A axes and along the C axes of an electrical main shaft; and the Z axes servo drive assembly also can move along the beam to realize the move of a Y axes. Therefore, under the condition that a work table prevents from rotating and moving, namely, under the condition that the work table is static relative to the ground, the numerical control machine tool skillfully realizes the five axes numerical control machining, conquers the defect of large floor space caused by the move and the rotation of the work table, and can realize the numerical control machining of a large component with high precision.

Owner:JINAN SINGHUI CNC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com