Patents

Literature

2526results about How to "Guaranteed coaxiality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

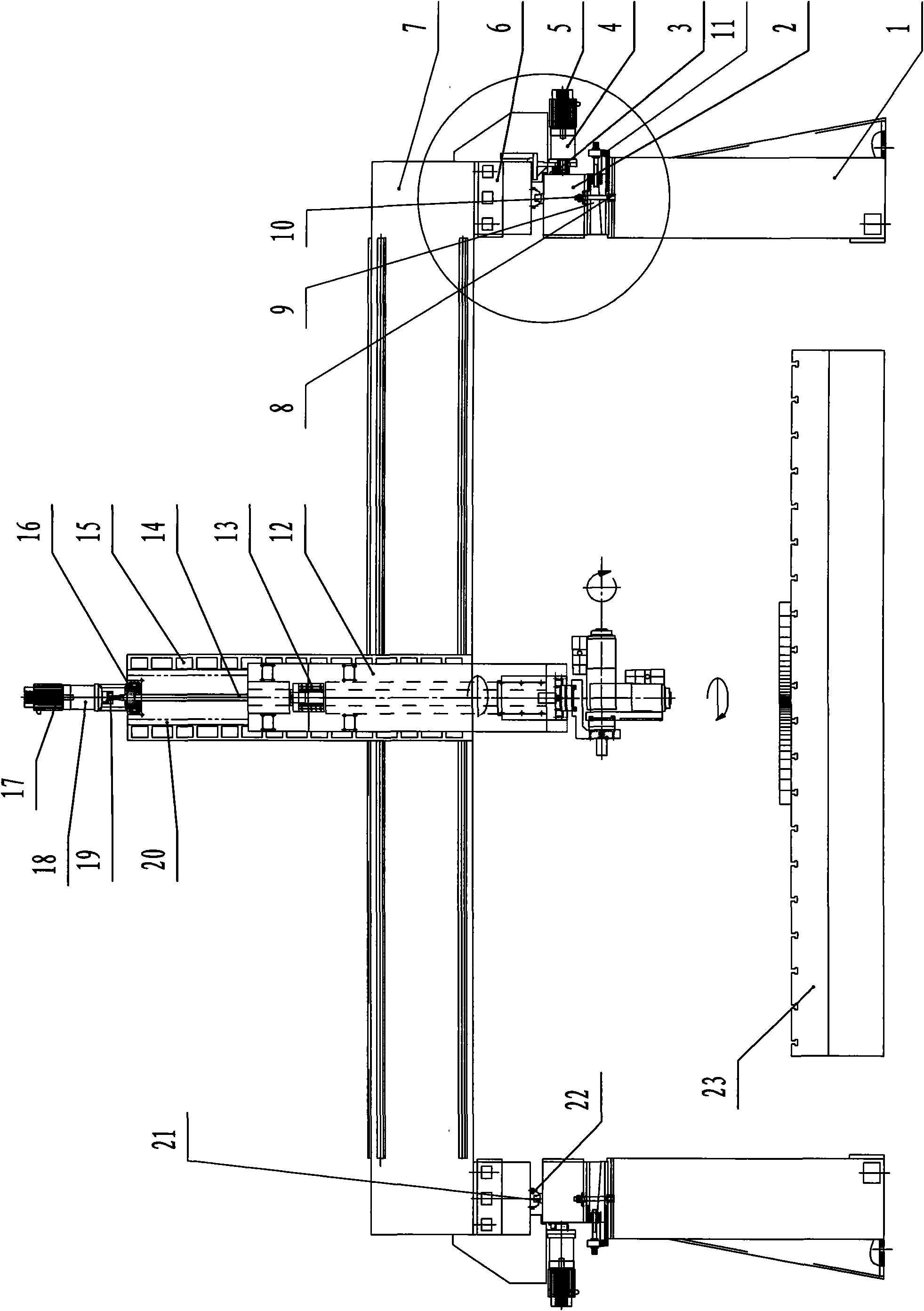

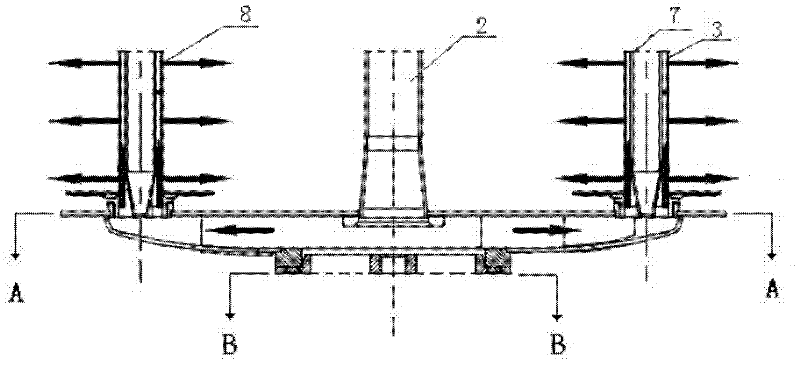

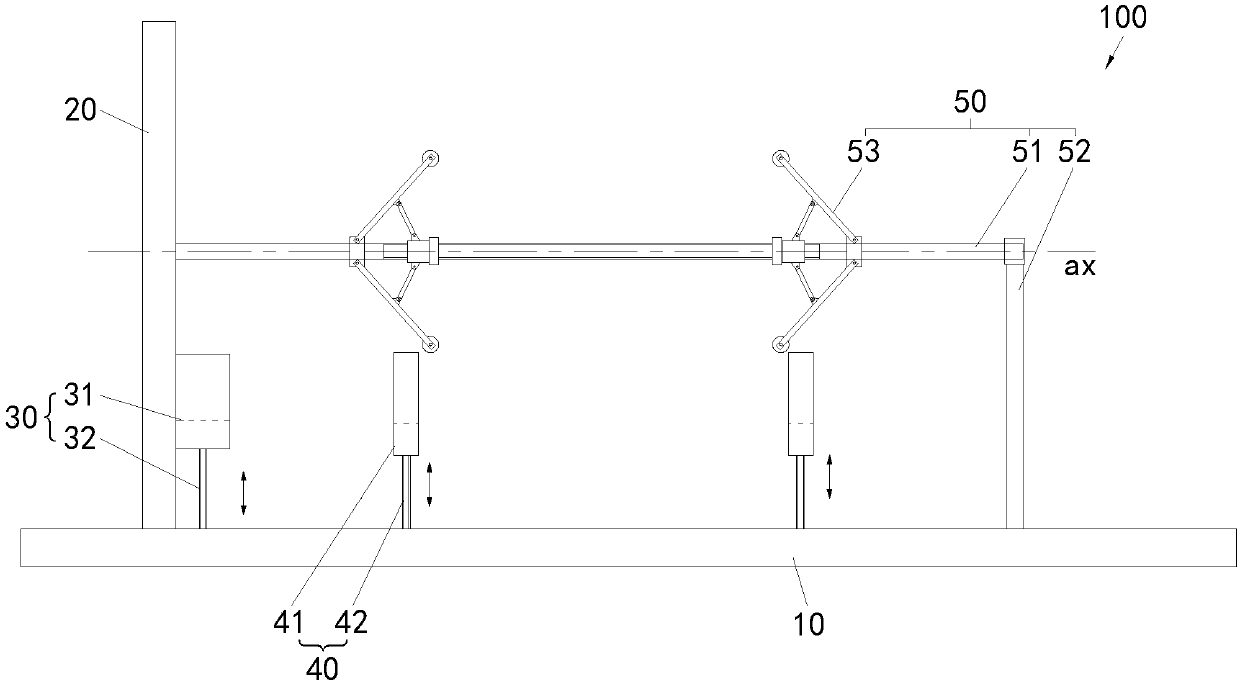

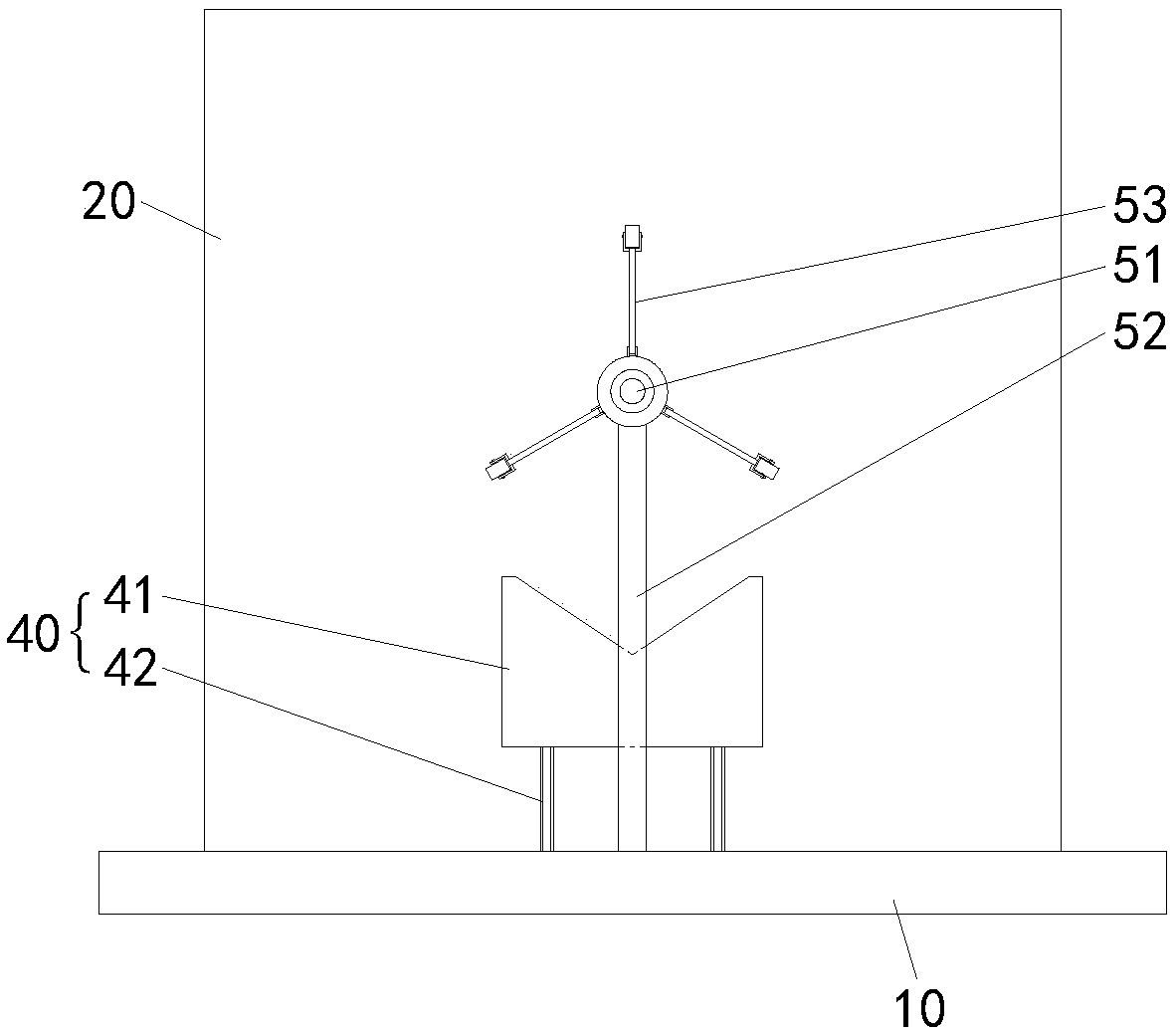

Vehicle supporting bridge pipe and end face flange welding machine and welding method thereof

ActiveCN108032027AReduce welding distortionImprove coaxialityWelding/cutting auxillary devicesAuxillary welding devicesWelding deformationFlange

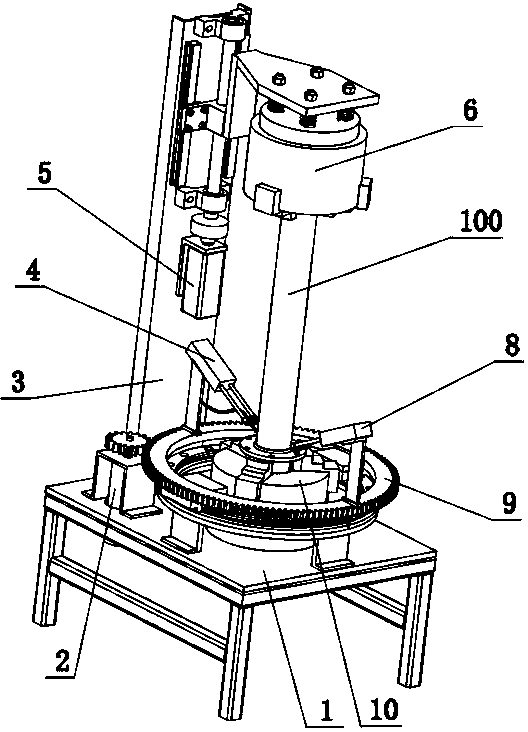

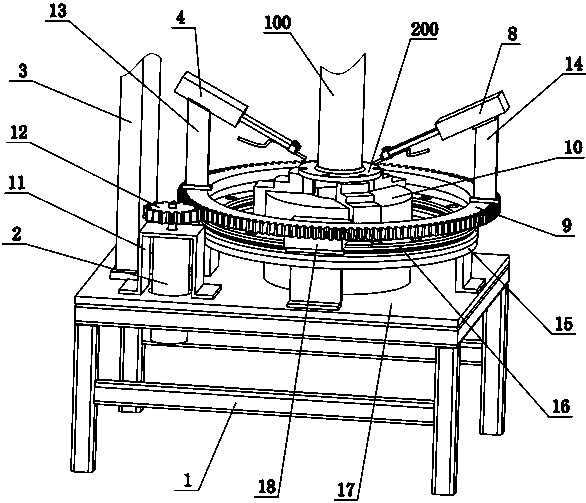

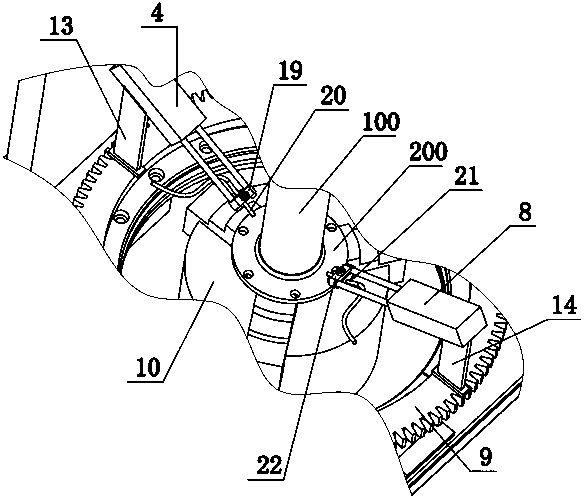

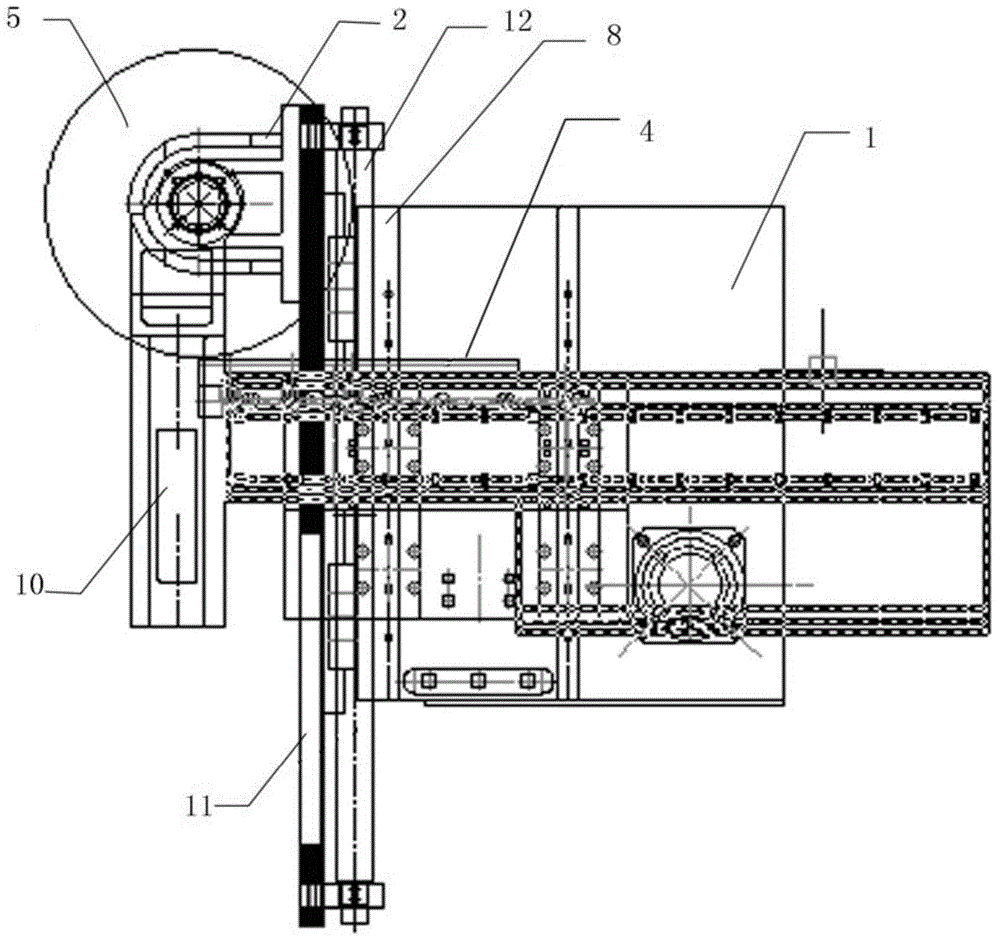

The invention provides a vehicle supporting bridge pipe and end face flange welding machine and a welding method thereof. The welding machine comprises a welding seat, a supporting flange plate is fixed at the upper end of the welding seat, a second three-claw chuck is fixed on the supporting flat plate, a circumferential rotating device coaxial with the second three-claw chuck is arranged on thesupporting flat plate, two welding guns are fixed on two sides of the center of the circumferential rotating device, a vertical beam is fixed on the supporting flat plate, a lifting mechanism is fixedon the vertical beam and fixed to a first three-claw chuck through elastic connection, a second three-claw chuck and the first three-claw chuck are fixed to a flange and a supporting bridge pipe respectively, and the welding guns weld the flange and the bridge pipe when rotating. The welding guns with two circumferential sides in symmetry are adopted to weld a welding position at the same time, welding deformation of the supporting pipe and the flange caused by welding stress is reduced, and coaxiality between the supporting pipe and the flange is improved.

Owner:ANYANG INST OF TECH

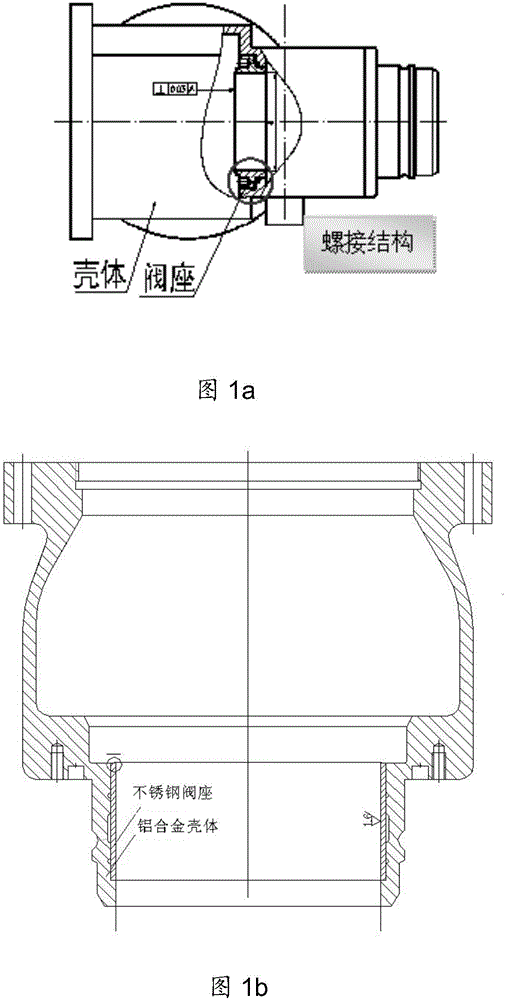

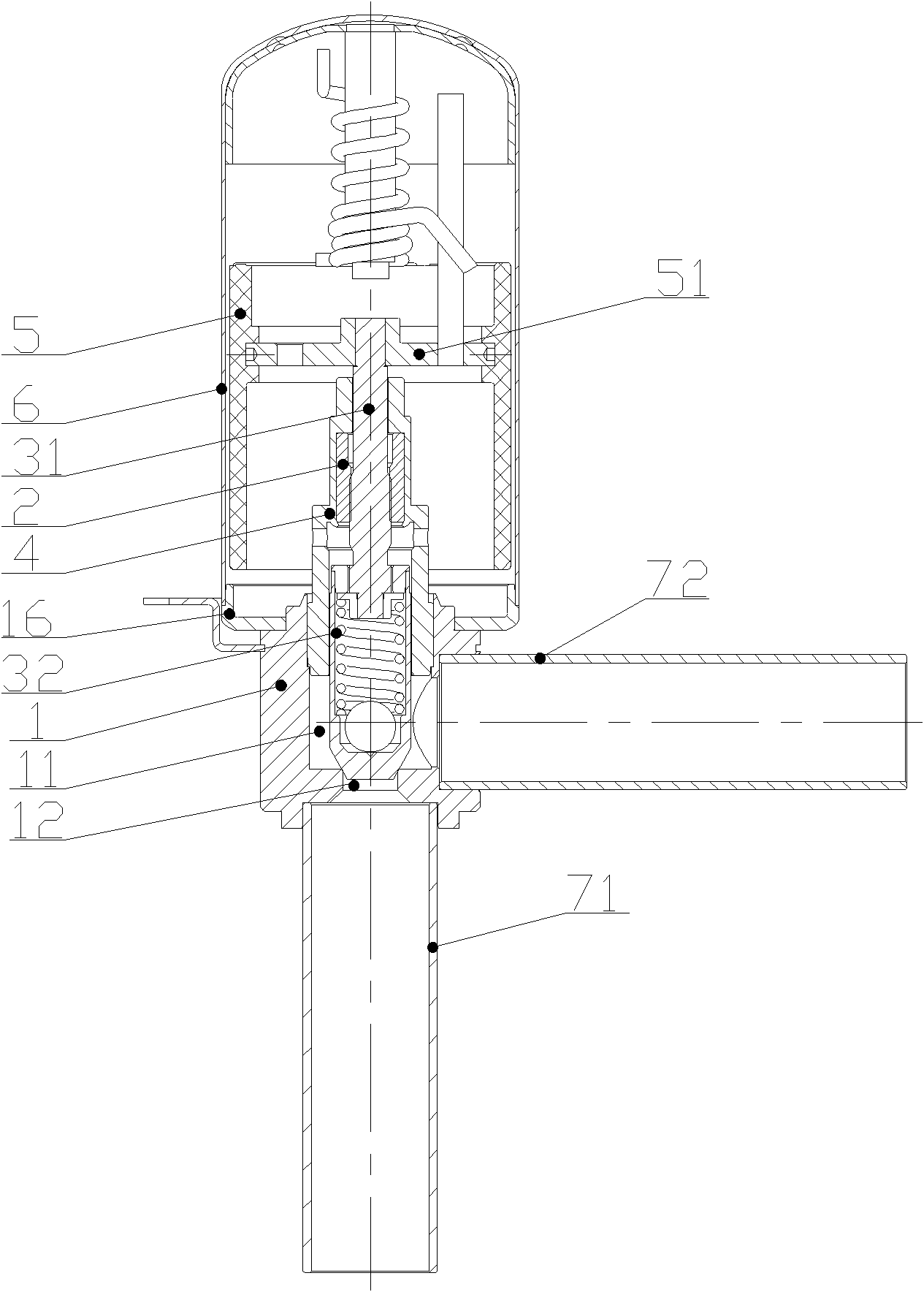

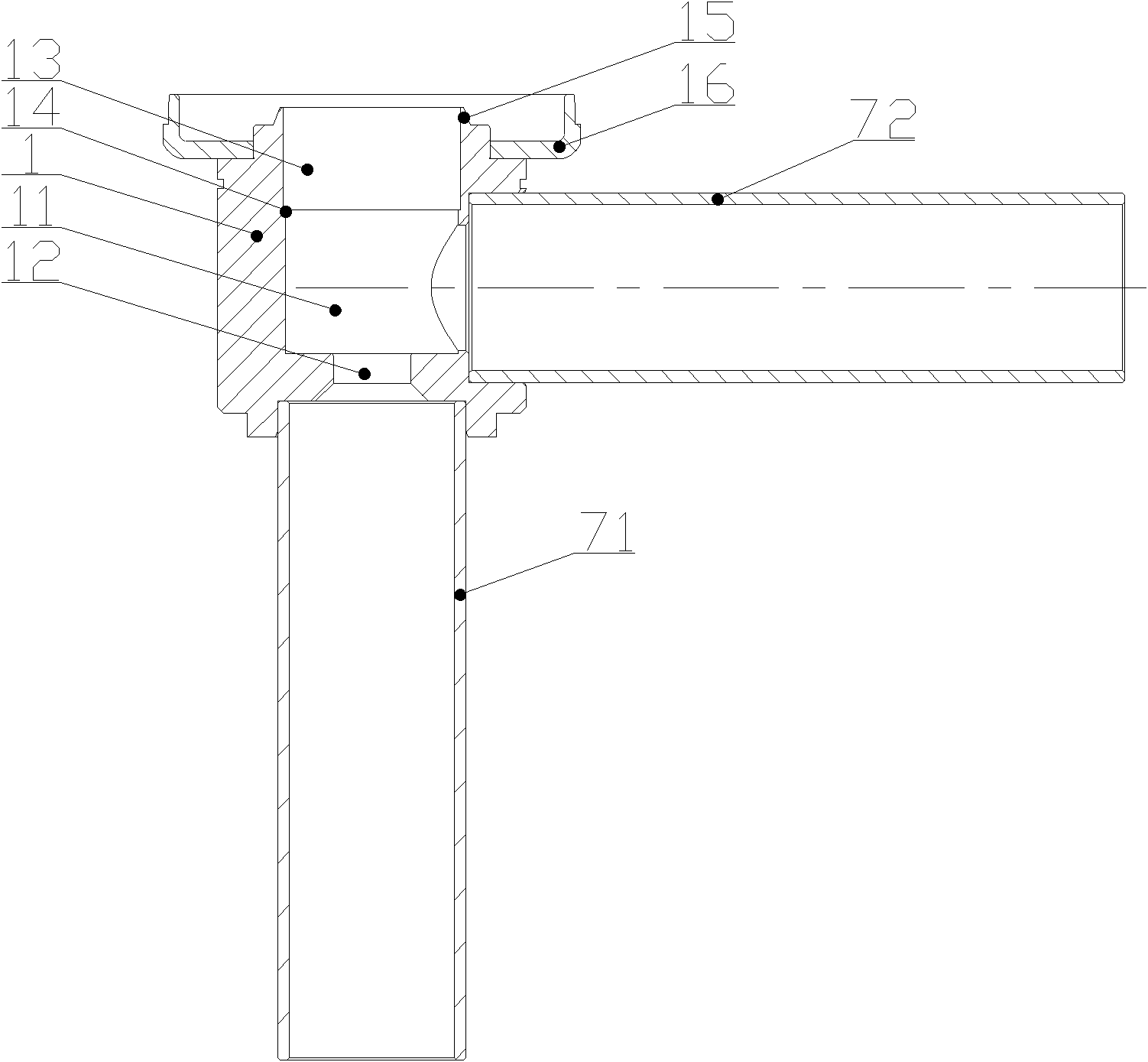

Electric valve

InactiveCN102454818AHigh operational reliabilityAvoid eccentric wearOperating means/releasing devices for valvesLift valveControl valvesFriction force

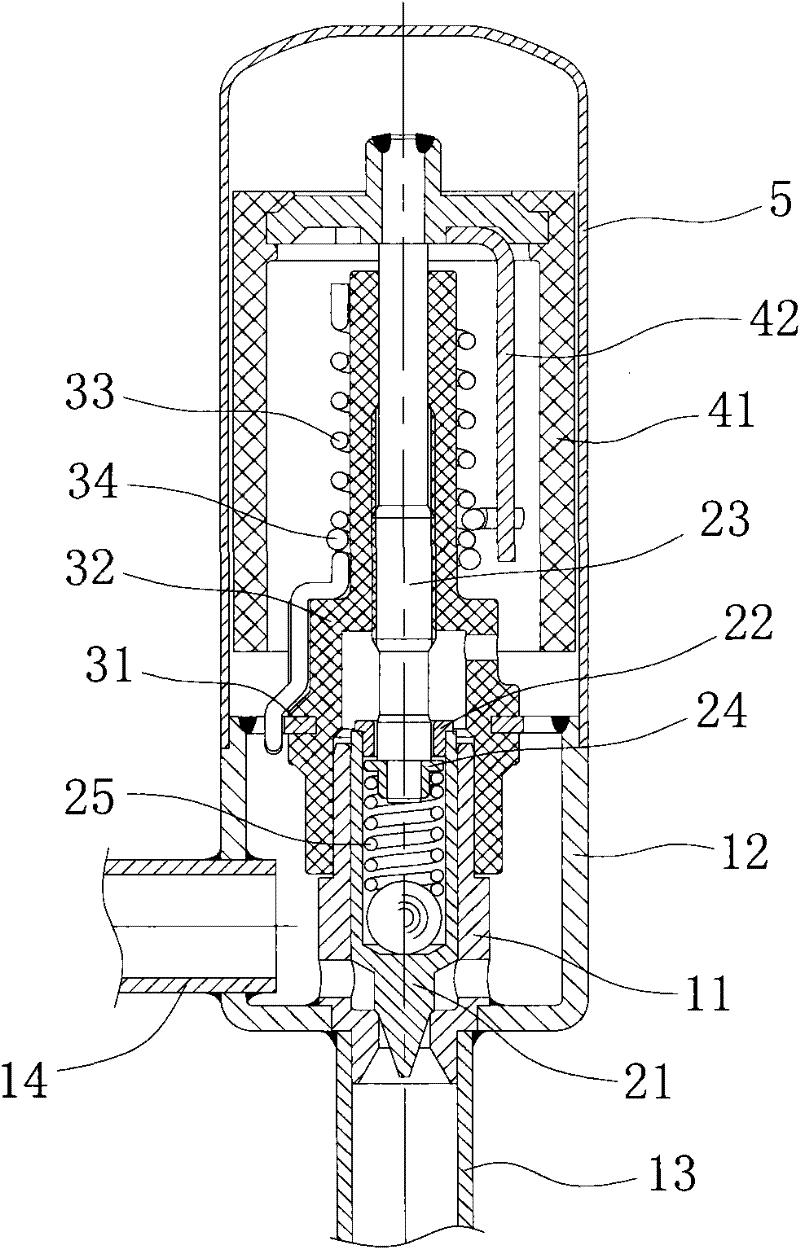

The invention relates to the technical field of control valves, in particular to an electric valve for regulating fluid flow. The electric valve comprises a valve seat component, a nut component and a valve needle lead screw component, wherein the valve seat component comprises a valve seat and a valve core seat; the nut component comprises a nut for mounting the valve needle lead screw component; and the lower end of the nut is sleeved with the upper end of the valve core seat. By the electric valve, the lower end of the nut which is used for mounting the valve needle lead screw component is connected with the upper end of the valve core seat in a sleeved mode, so that the coaxiality of the nut and a valve port of the valve core seat is extremely easy to guarantee, the coaxiality of a valve needle and the valve core seat is higher, and the problem that the valve port is loosely sealed or is subjected to eccentric wear can be solved. Meanwhile, because the coaxiality of the valve needle and the valve port is improved, the friction force can be obviously reduced when a rotor of a rotor component rotates, and the action reliability of the electric valve can be improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

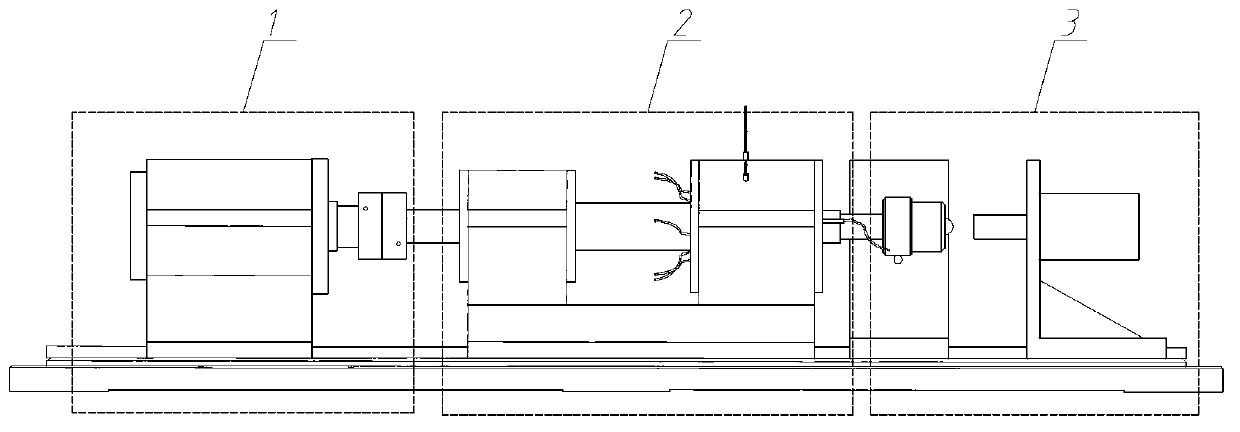

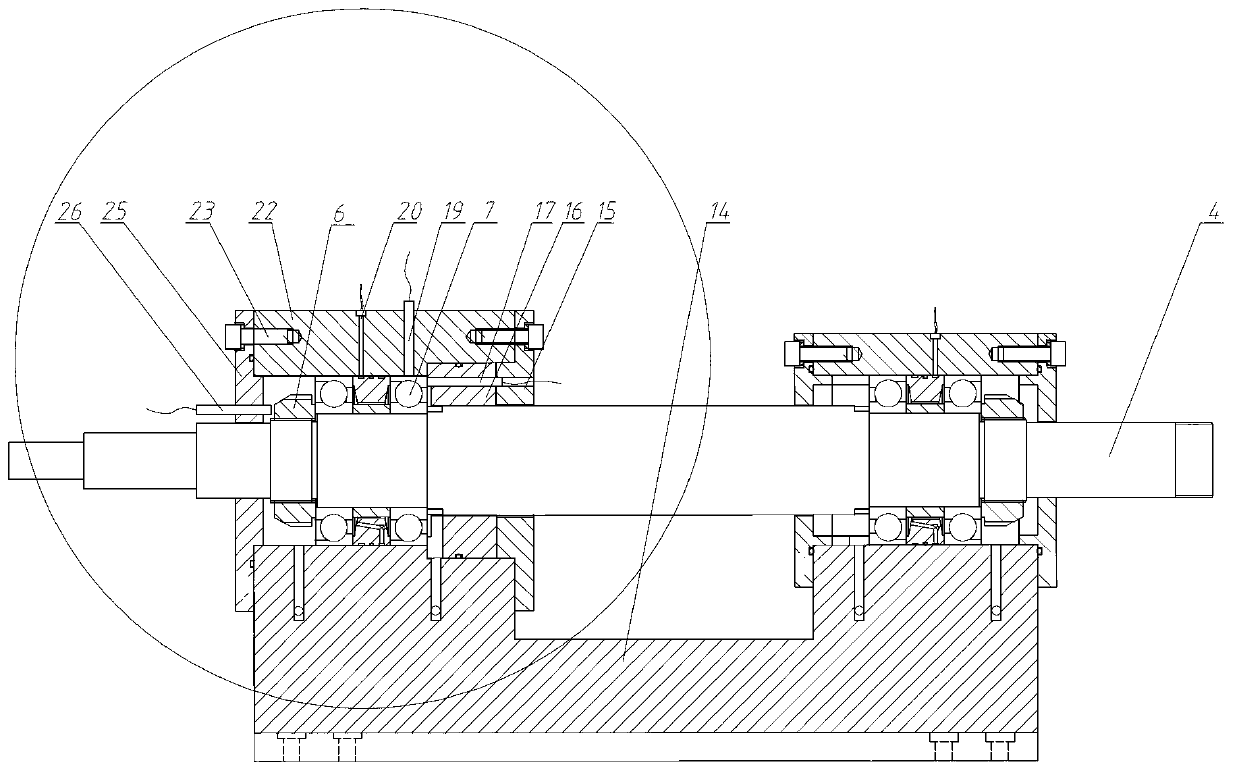

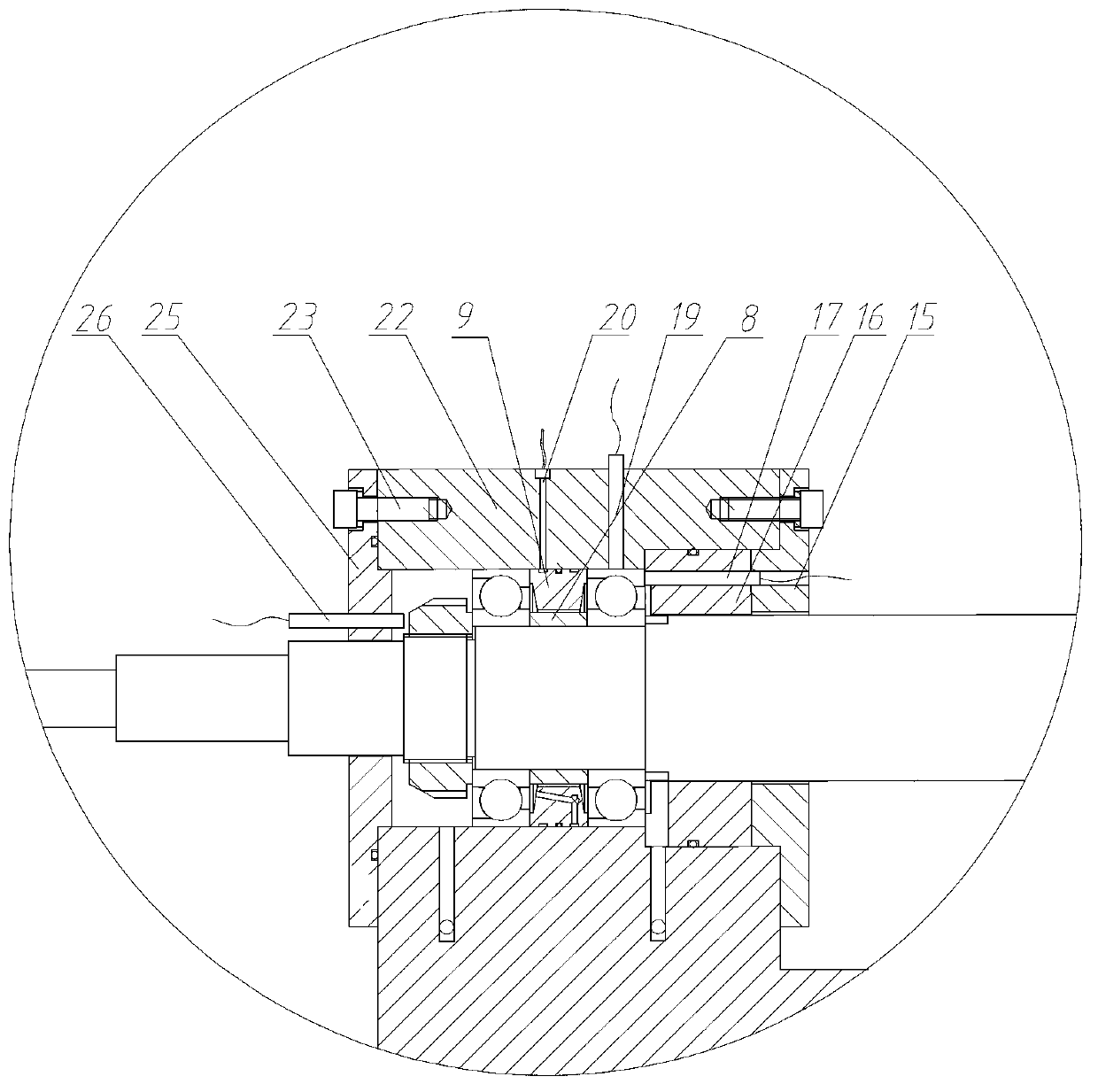

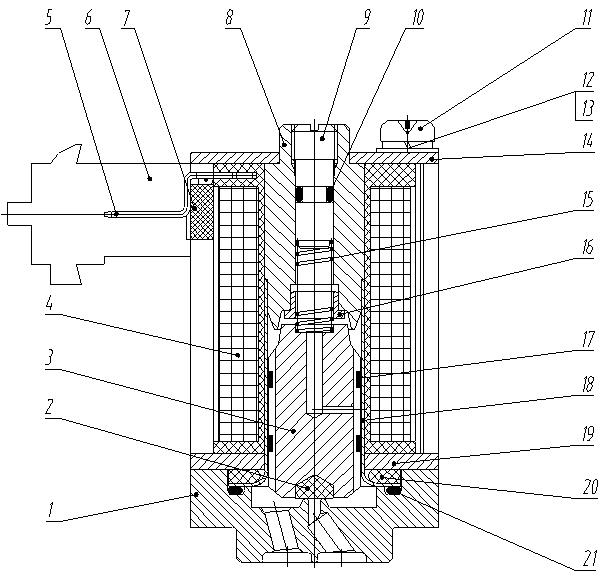

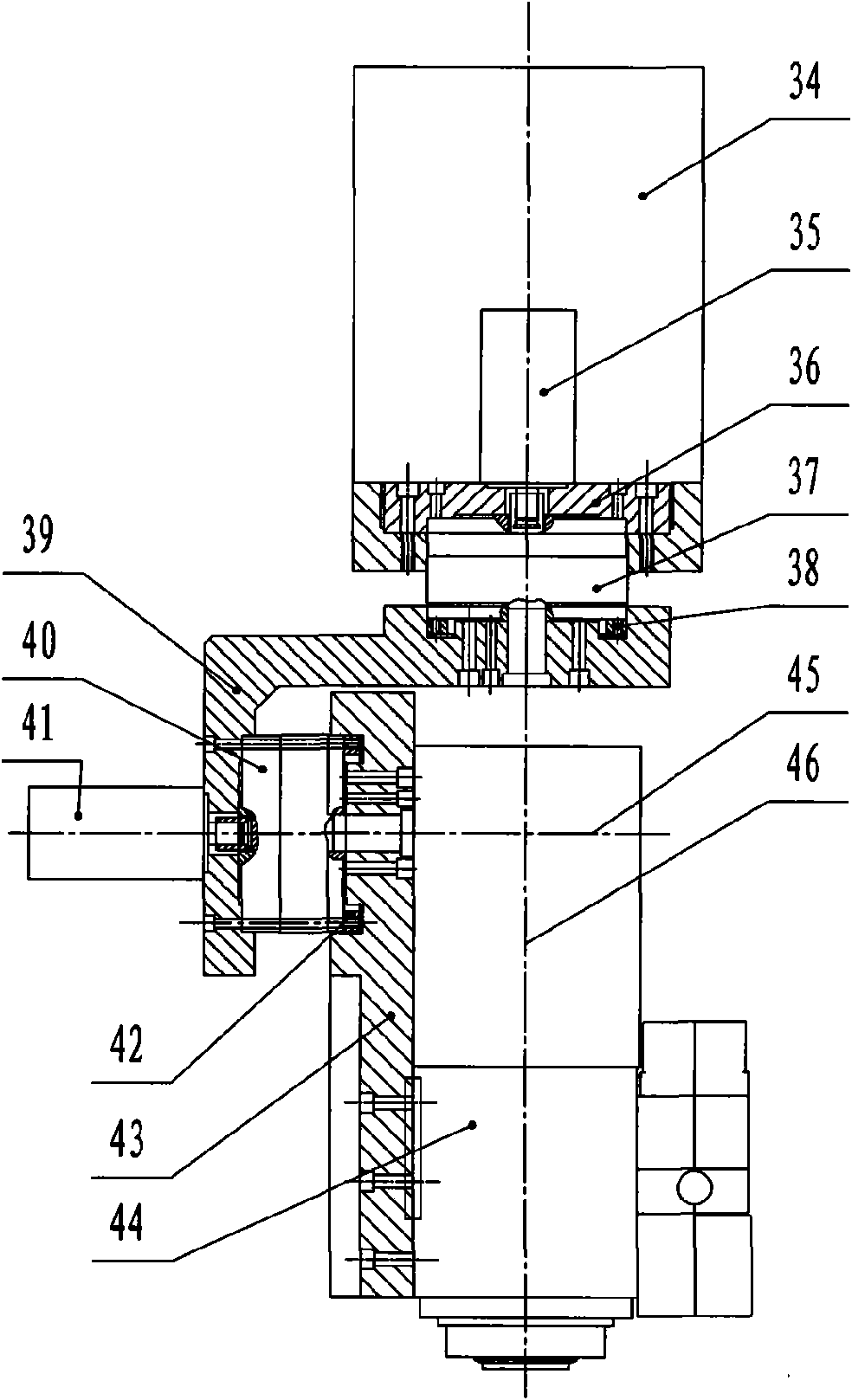

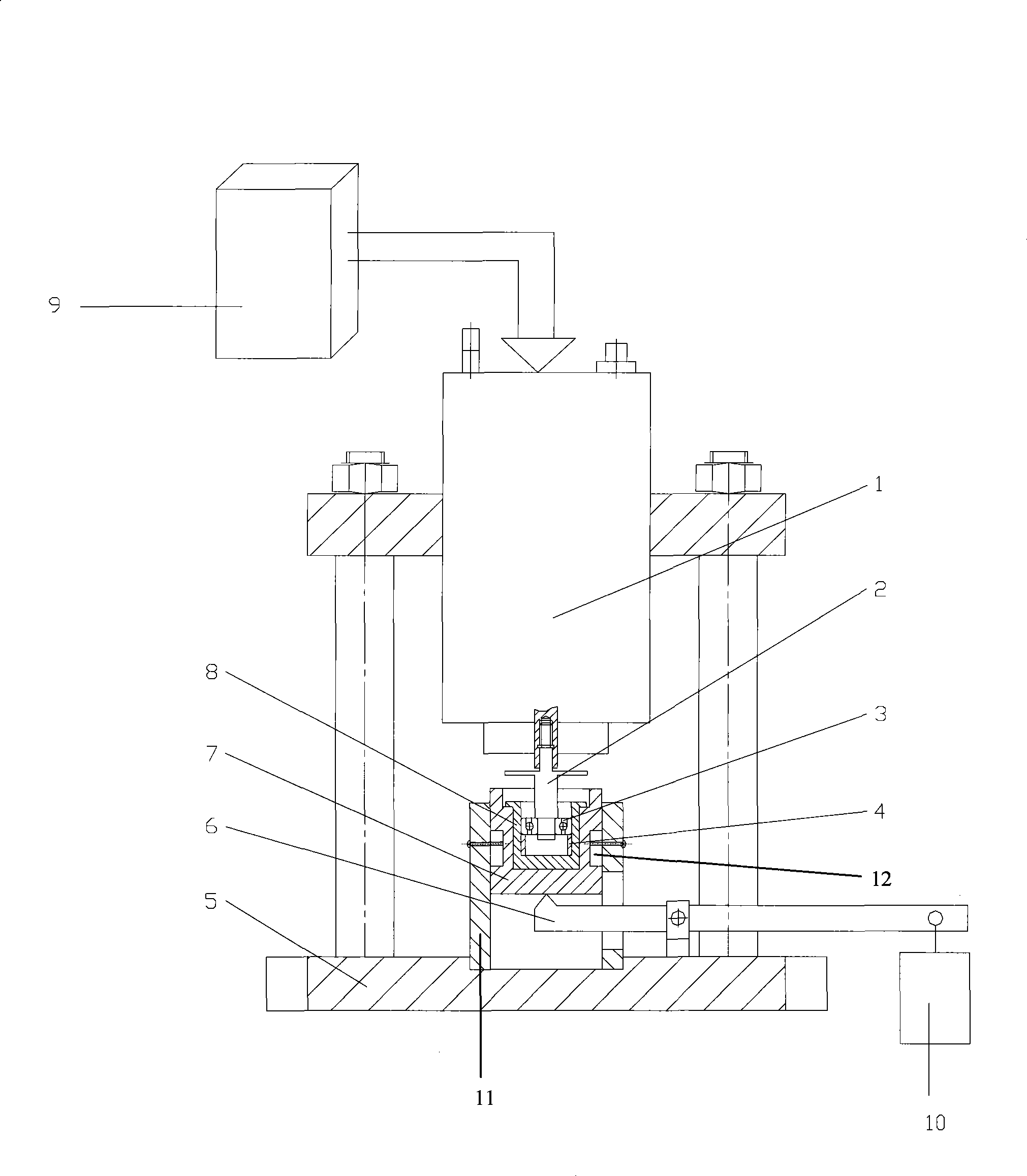

Strong-generality comprehensive experiment table for testing dynamic and static properties of spindle system

InactiveCN102866006ARealize the experimentVerify service performanceMachine bearings testingBall bearingPiezoelectric actuators

The invention discloses a strong-generality comprehensive experiment table for testing dynamic and static properties of a spindle system. The experiment table mainly comprises a driving electric spindle module, a mechanical spindle module and a hydraulic loading module, wherein the mechanical spindle module comprises a spindle, a bearing, a bearing pedestal, a pre-tightening force self-adaptive adjustment device, a temperature sensor, a displacement sensor, a pressure sensor and an air-oil lubrication device. The pre-tightening force self-adaptive adjustment is completed by six evenly distributed piezoelectric actuators, so as to realize the accurate control of the pre-tightening force of an angular contact ball bearing in the spindle system. According to the experiment table, different bearing configuration manners and different lubrication manners can be used, so that the properties of the experiment table are greatly expanded. Through controlling the rotation speed of an electric spindle, property test data such as temperature rise, rigidity and the like of the spindle under different configuration and pre-tightening conditions can be obtained by using the temperature sensor, the displacement sensor and the pressure sensor.

Owner:XI AN JIAOTONG UNIV

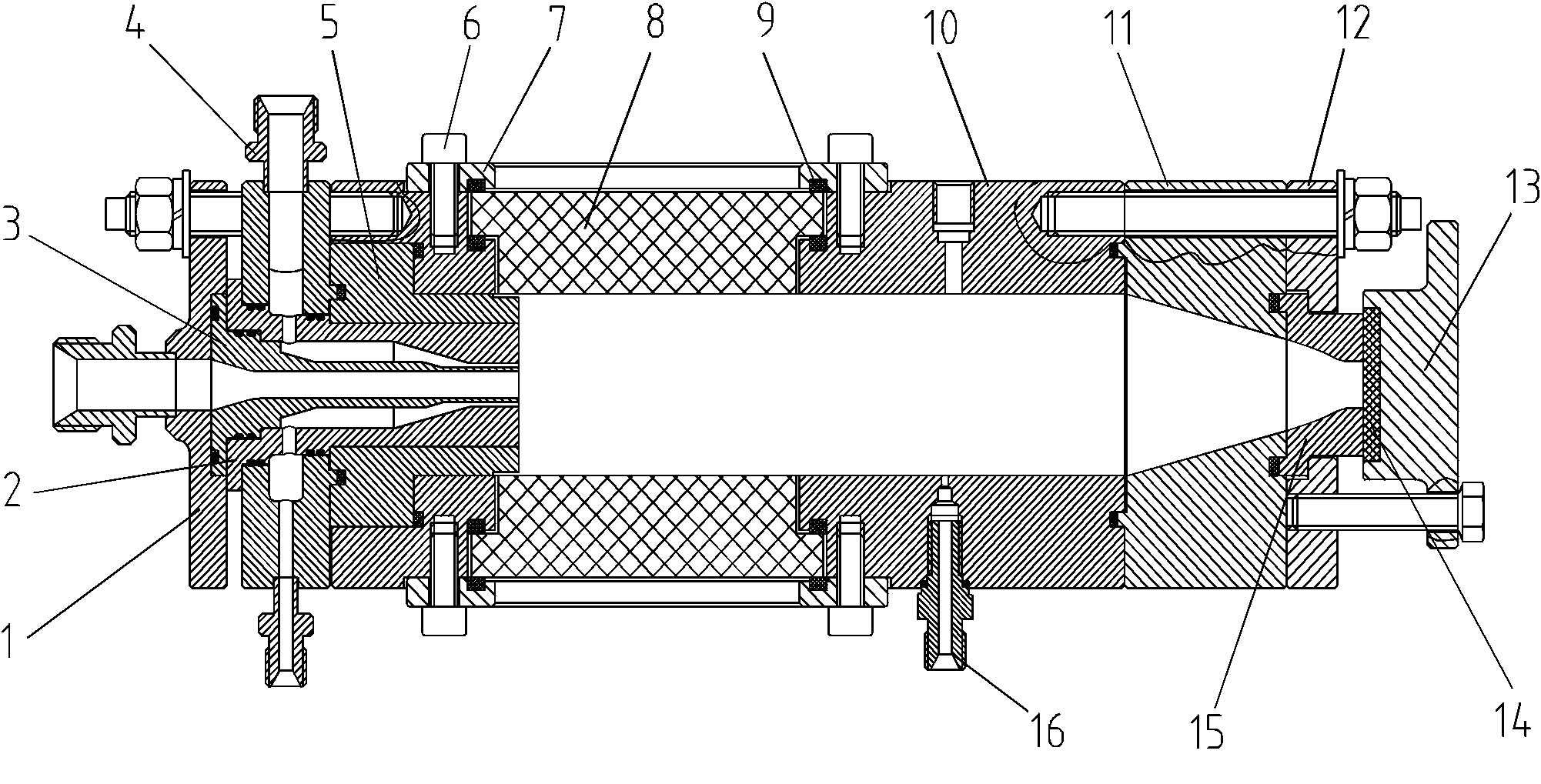

Transparent combustion chamber with square interior passage

InactiveCN102062020APromise not to touchReduce distractionsRocket engine plantsStress concentrationCombustion chamber

The invention discloses a transparent combustion chamber with a square interior passage, belonging to the field of the design of transparent combustion chambers for liquid-propellant rocket engines. The transparent combustion chamber comprises a head mechanism, a combustion chamber body mechanism, an observation window mechanism and a guiding mechanism; wherein the head mechanism comprises an oxidant cavity, a fuel nozzle, an oxygen nozzle and a fuel cavity; the combustion chamber body mechanism comprises a combustion chamber body substrate and a pressure-measuring filler neck; the observation window mechanism comprises an observation window cover plate and quartz glass; and the guiding mechanism comprises an head guiding slot and a tail guiding flange. In the invention, the observation window cover plate, the quartz glass and the combustion chamber substrate are mutually sealed with square graphite which expands to fill gaps among the observation window cover plate, the quartz glass and the combustion chamber substrate, so that glass can be ensured to be contactless with metal so as to play the role of protecting the quartz glass. The design of the square interior channel of the combustion chamber is favorable for leveling a quartz glass sheet to the inner wall surface of the combustion chamber and reducing the disturbance to an inner flow field of the combustion chamber; and four corners of the square interior channel are transitioned by adopting large circular arcs so as to prevent stress concentration.

Owner:BEIHANG UNIV

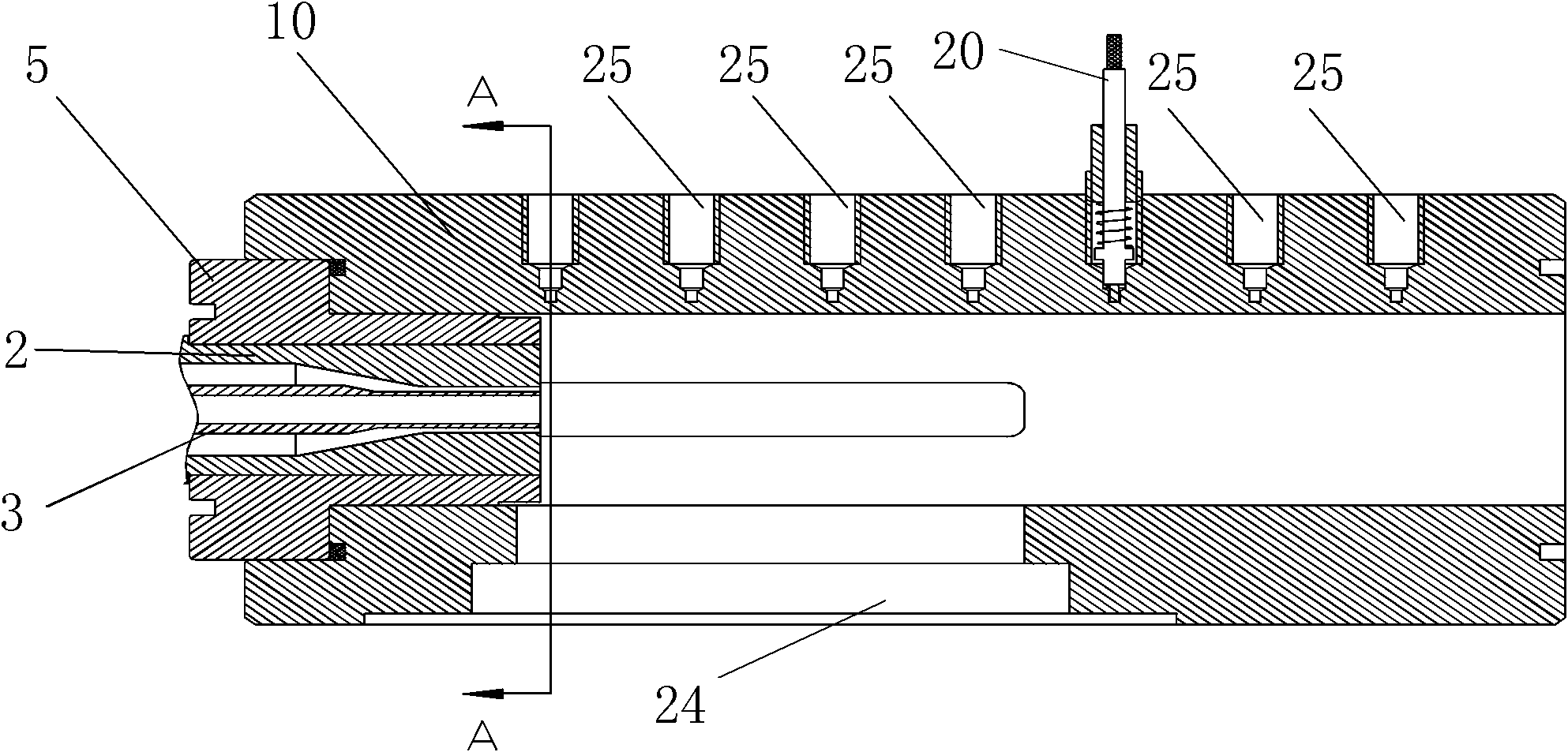

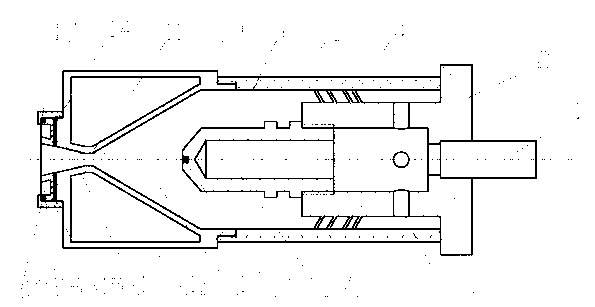

Proportional electromagnetic valve for electrically controlled high-pressure common-rail fuel injection system of diesel engine

InactiveCN102506217AMeet the use requirementsControl on and offOperating means/releasing devices for valvesFuel injection apparatusDriving currentCommon rail

The invention discloses a proportional electromagnetic valve for an electrically controlled high-pressure common-rail fuel injection system of a diesel engine and relates to an electromagnetic valve. A position at which a fixed iron core (8) and a movable iron core (3) of the electromagnetic valve attract each other is a conical polar plane. The fixed iron core (8), the movable iron core (3), a guide pipe (18), a spiral spring (15), an electromagnetic coil (4), a square iron core (19), a shell (14) and a valve body (1) jointly form the electromagnetic valve in an assembling way. When driving current is input into the electromagnetic coil, a magnetic field is generated through a magnetic path in the valve, electromagnetic force with magnitude which is in proportion with the magnitude of the driving current and is not related to a stroke is generated relative to the movable iron core, the movable iron core is enabled to overcome spring force to move, the movable iron core stops moving at a balance point of the two kinds of force and therefore is kept at a stable position, and the movable iron core can proportionally and continuously move according to the magnitude of the driving current to control the opening of the valve. Under complex working conditions under which the diesel engine works, the electromagnetic valve not only can stably control the on / off of a fuel path, but also can accurately and proportionally control the flow of the fuel path according to the driving current.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

Gantry type five axes numerical control machine tool

ActiveCN101623824AStable supportGuaranteed coaxialityLarge fixed membersNumerical controlEngineering

The invention discloses a gantry type five axes numerical control machine tool, belonging to the machining field of a numerical control mechanism. The technical scheme is as follows: the traditional vertical rod is replaced by an X-direction guide way, so that support force to a beam is great, and the beam can be ensured to be stably move along the X-direction guide way; an automatic bidirectional revolute joint which is fixedly connected with a Z axes servo drive assembly can drive an electrical main shaft to rotate around a horizontal A axes and along the C axes of an electrical main shaft; and the Z axes servo drive assembly also can move along the beam to realize the move of a Y axes. Therefore, under the condition that a work table prevents from rotating and moving, namely, under the condition that the work table is static relative to the ground, the numerical control machine tool skillfully realizes the five axes numerical control machining, conquers the defect of large floor space caused by the move and the rotation of the work table, and can realize the numerical control machining of a large component with high precision.

Owner:JINAN SINGHUI CNC TECH

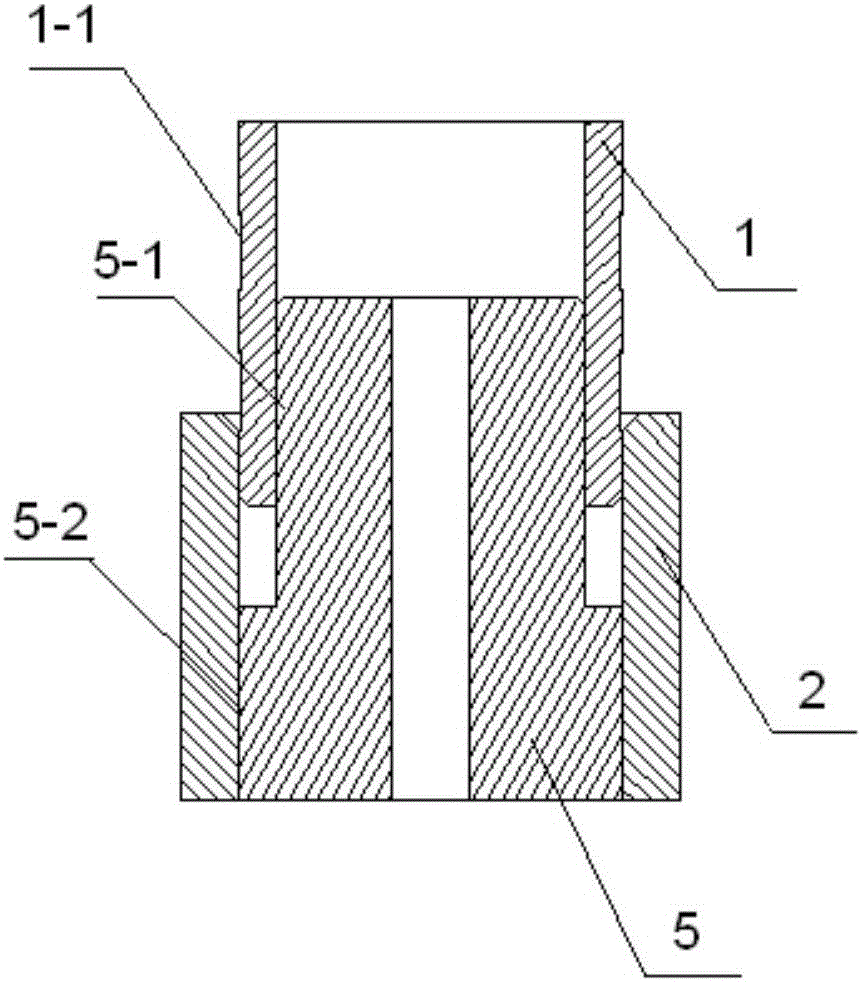

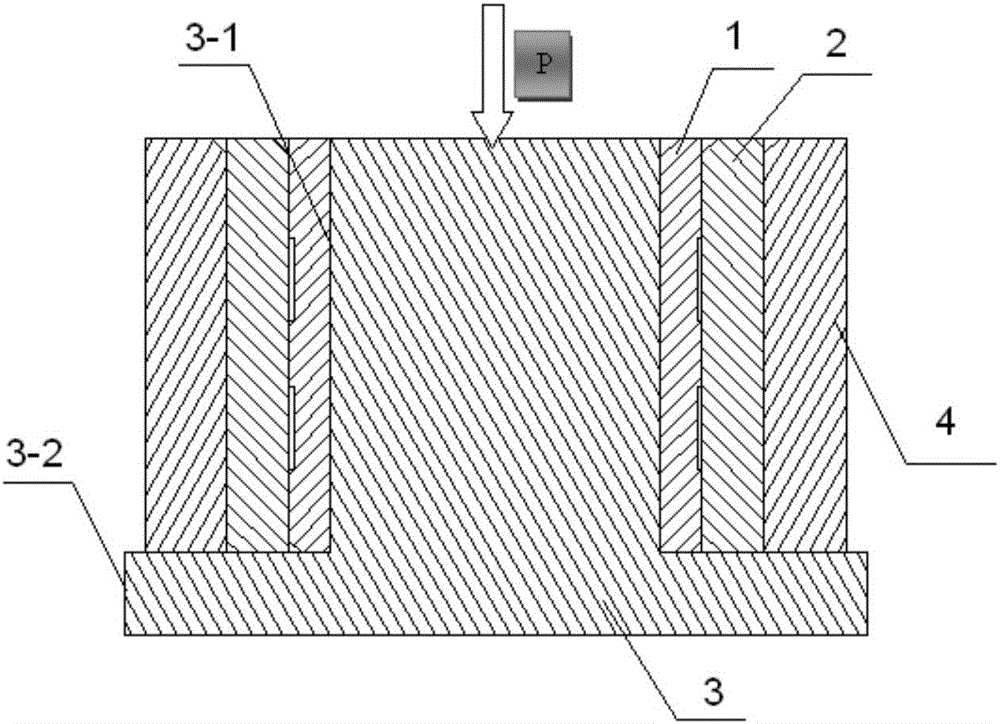

Diffusion welding method of dissimilar metal

ActiveCN106808078AGuarantee welding qualityGuaranteed coaxialityWelding/soldering/cutting articlesNon-electric welding apparatusAxial pressureConcentration gradient

The invention relates to a diffusion welding method of dissimilar metal. A specially designed outer side limiting tool and an inner support tool are adopted for thermal expansion constraint in the welding process of an assembled to-be-welded dissimilar metal part, thus, sufficient and even welding pressure on the radial welding face is obtained, and reliable welding guarantee is provided for diffusion welding of the dissimilar metal. The expansion constraint pressurizing idea is provided by the invention for dissimilar metal interface radial pressurizing, radial expansion of the to-be-welded part is constrained through an inner side limiting tool and the outer side limiting tool, and axial expansion of the to-be-welded part is constrained through axial pressure applied by a diffusion welding device or tool, so that expansion pressure is effectively applied to the welding interface of the dissimilar metal, and the dissimilar metal weld part with good joint performance and airtightness is obtained; and the seaming condition of the whole welding interface is good, obvious concentration gradient of the welding interface exists, and the diffusion characteristic is met.

Owner:CAPITAL AEROSPACE MACHINERY +1

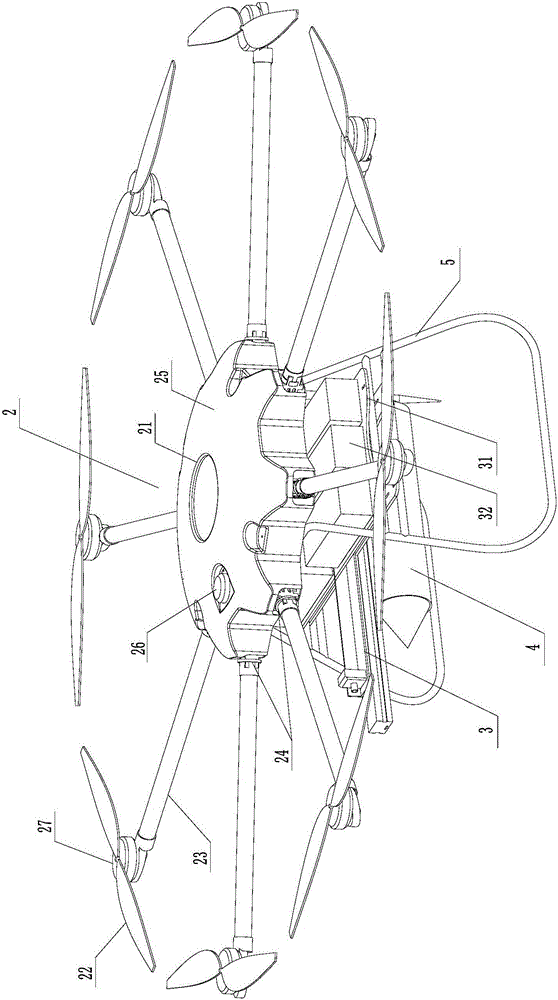

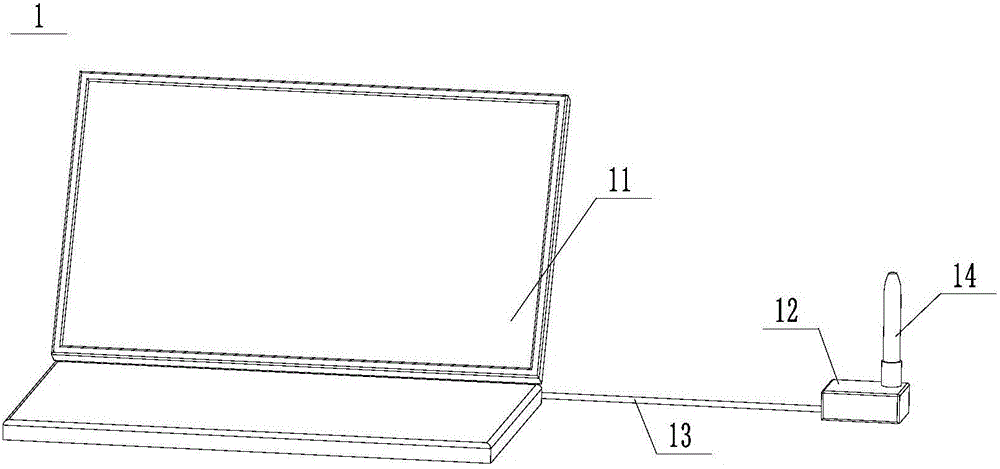

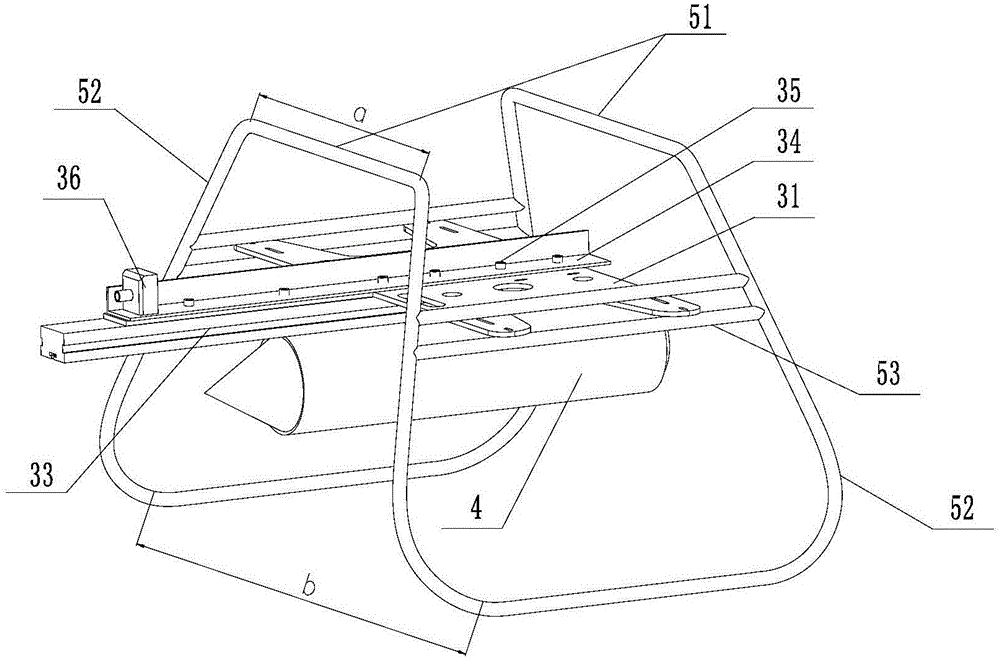

Fire extinguishing bomb launching system for unmanned aerial vehicle

InactiveCN105667795AAvoid obstaclesFlexible shuttleAircraft componentsLaunching weaponsUncrewed vehicleEngineering

The invention provides a fire extinguishing bomb launching system for an unmanned aerial vehicle. The fire extinguishing bomb launching system comprises a ground station as well as the unmanned aerial vehicle, a hanging rack and fire extinguishing bombs which are sequentially connected from top to bottom, wherein the hanging rack comprises a launch platform, batteries which are in line connection with the unmanned aerial vehicle are arranged above the launch platform, a guide rail assembly is arranged below the launch platform, the fire extinguishing bombs are hung below the guide rail assembly, the ground station comprises a ground portable computer and a ground radio station, and the ground portable computer is connected with the ground radio station through a data connecting line. According to the fire extinguishing bomb launching system for the unmanned aerial vehicle, provided by the invention, fire-fighting fire extinguishing and relief operations for high-rise buildings are implemented by adopting the unmanned aerial vehicle to carry the fire extinguishing bombs, so that ground obstacles can be effectively evaded; the unmanned aerial vehicle flexibly shuttles among the buildings, maintains unimpeded communication contact with the ground, transmits information on a fire scene to a ground command center by means of images and data, receives ground commands and implements window breaking, aiming and fire extinguishing bomb launching so as to implement fire extinguishing.

Owner:常州市丁鼎硬质合金有限公司

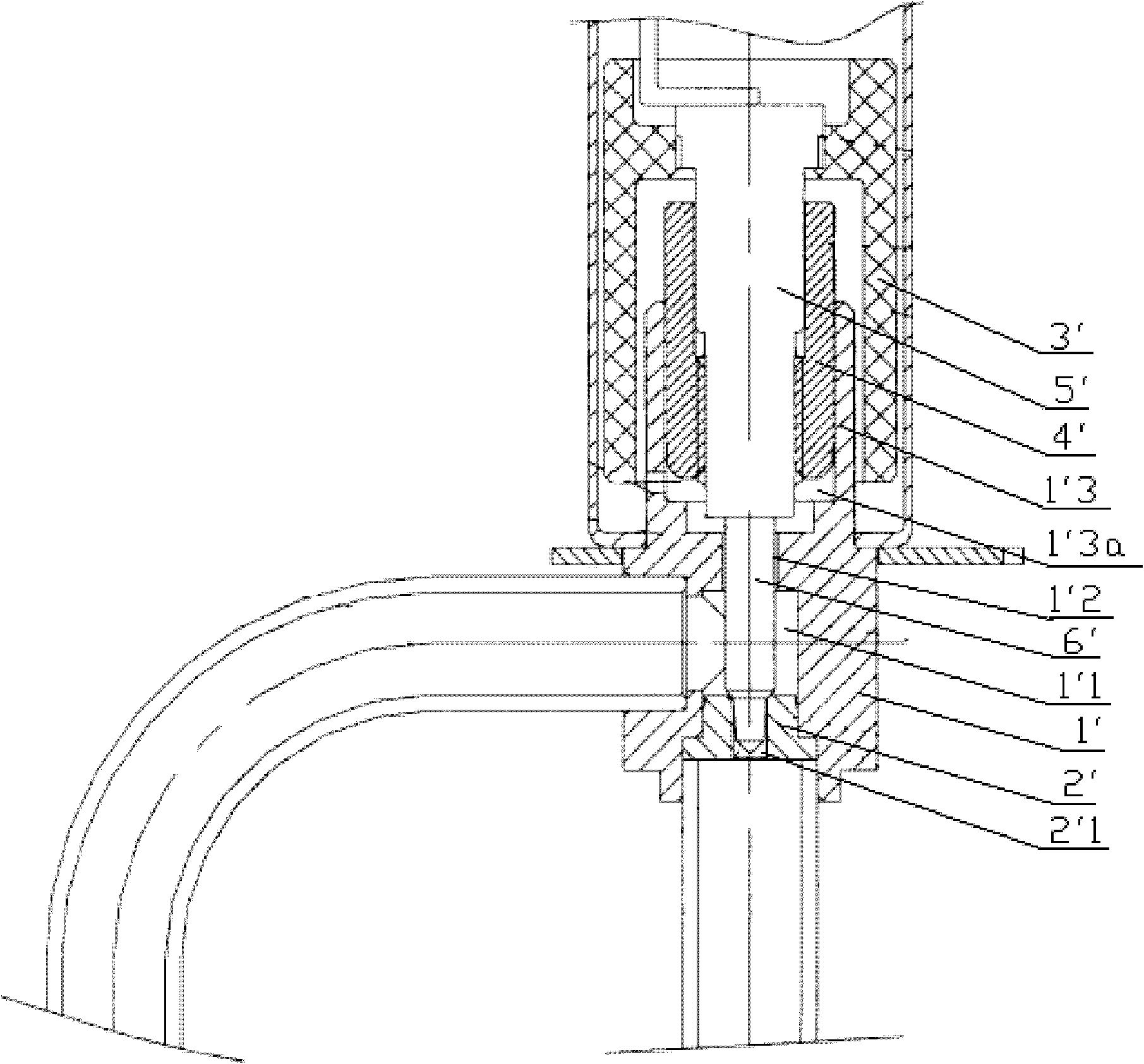

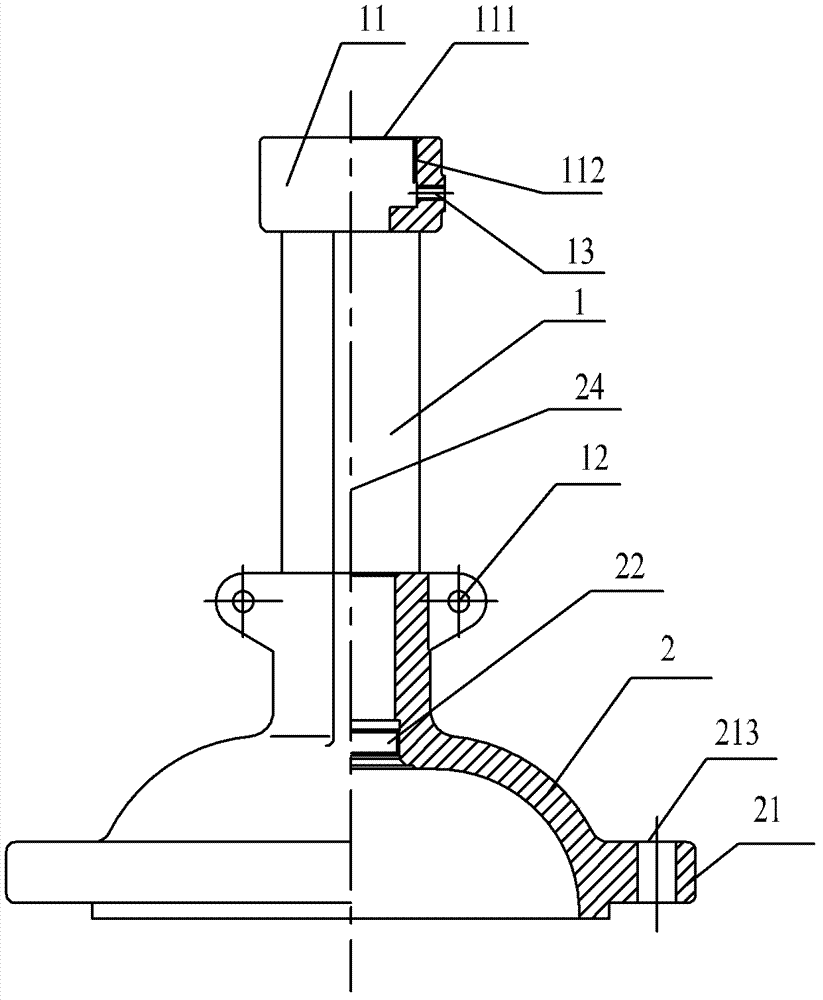

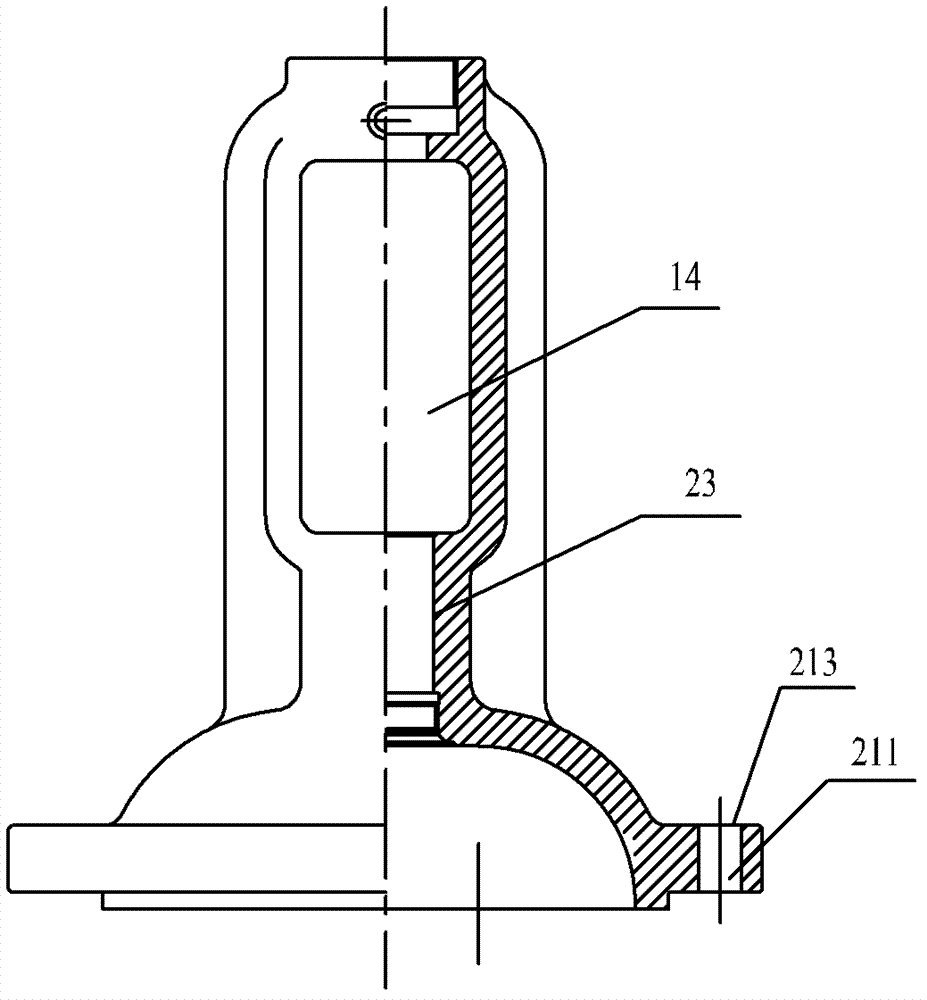

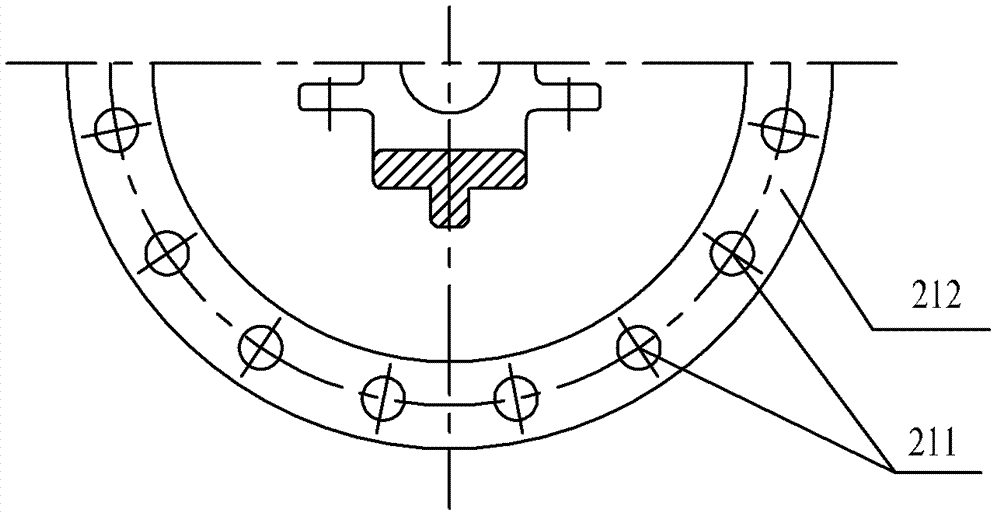

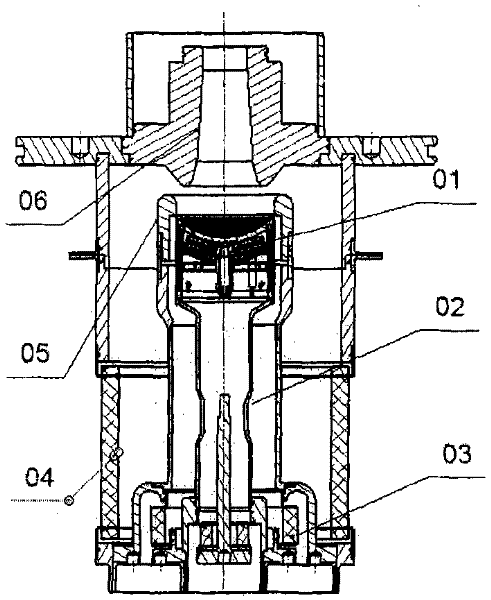

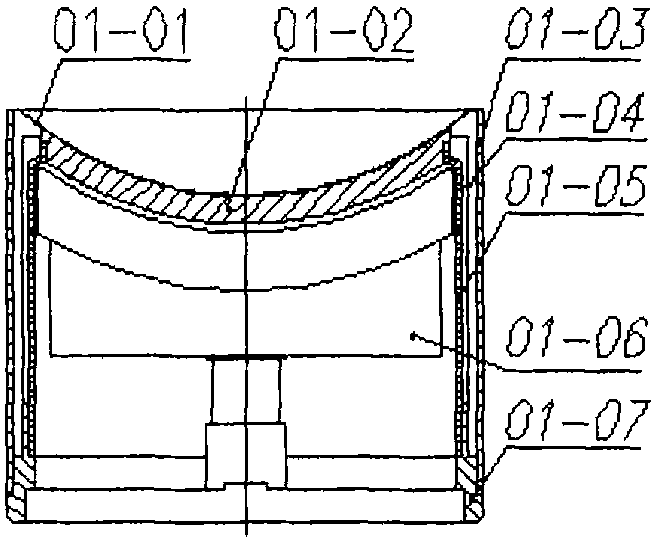

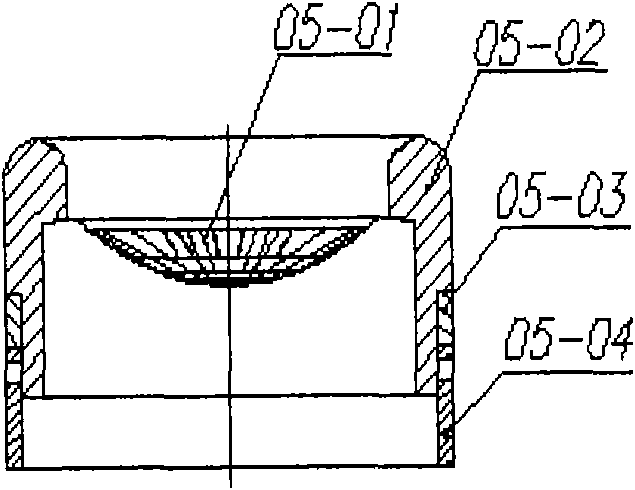

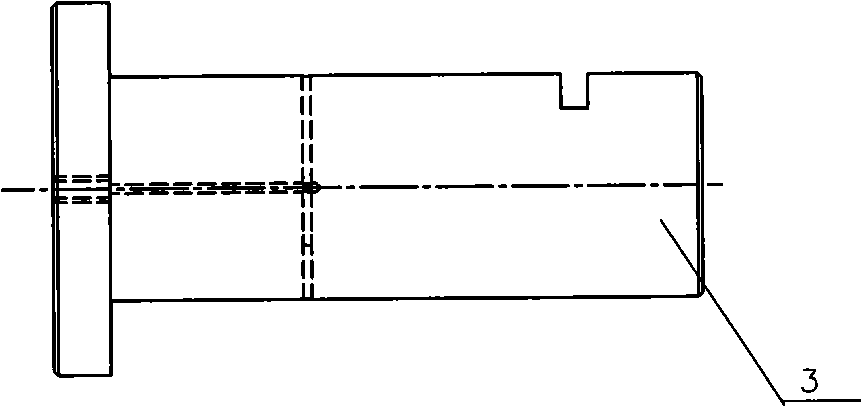

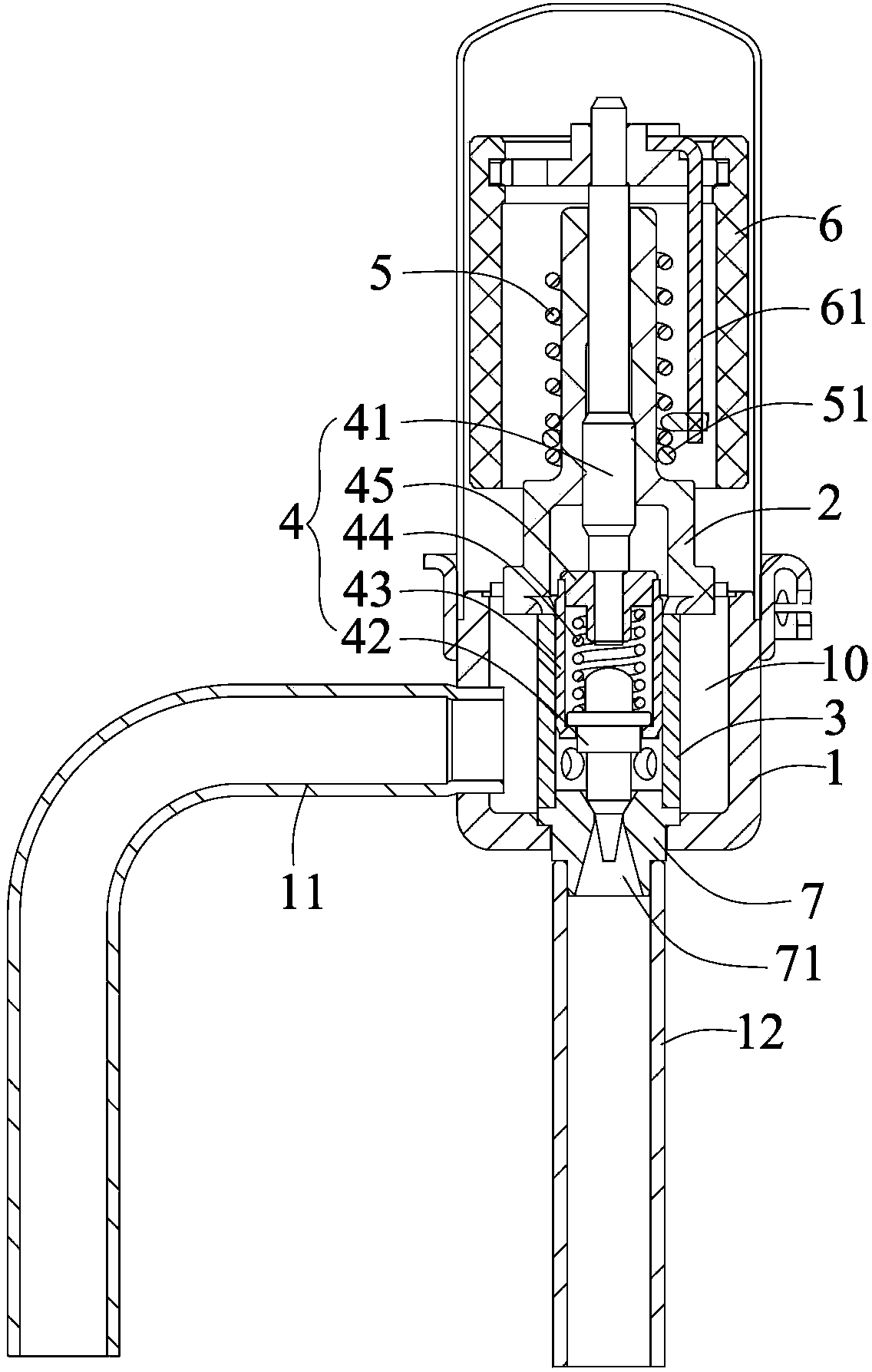

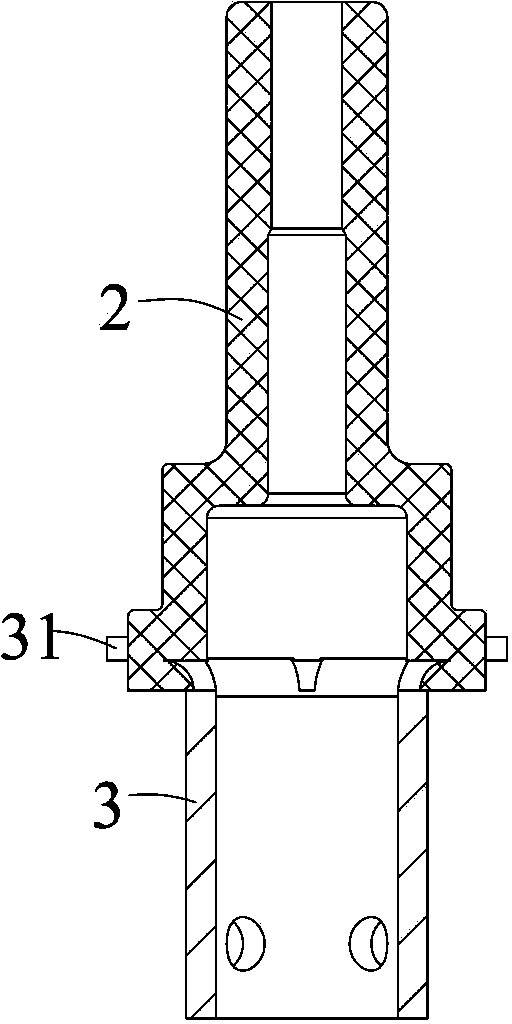

Electronic expansion valve

ActiveCN102734476AReduce material costsGuaranteed coaxialityEfficient regulation technologiesFluid circulation arrangementNeedle guideElectronic expansion valve

The invention discloses an electronic expansion valve which comprises a valve seat (1), a nut (2) and a valve needle assembly and also comprises a bearing block (4), wherein the valve seat (1) is provided with a valve cavity (11) and a valve port (12); the nut (2) is connected with the valve seat (1); the valve needle assembly is matched with the nut (2) through a screw (31) via a thread; a bearing block mounting hole (13) for installing the bearing block (4) is formed on the valve seat (1); the nut (2) is connected with the valve seat (1) through the bearing block (4); and a valve needle guide hole (41) is formed on the bearing block (4), and a valve needle (32) of the valve needle assembly passes through the valve needle guide hole (41) and is matched with the valve port (12). According to the structure design of the electronic expansion valve, on one hand, the coaxiality between corresponding holes of the valve seat (1) can be improved, on the other hand, the processing efficiency of the valve seat (1) can be improved, and the expenditure of material cost is reduced.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Whole forging near net forming process for inner ball cage sliding sleeve

InactiveCN102248101AGuaranteed coaxialityGuaranteed Wall Thickness DifferenceMetal-working apparatusManufacturing engineeringHigh density

The invention provides a whole forging near net forming process for an inner ball cage sliding sleeve, comprising the following steps of: blanking, machining to prepare a blank, shot blasting, surface coating, rod part forward extruding, barrel part upsetting, barrel part reverse extruding, spheroidizing and annealing, phosphorus saponifying and barrel part finishing and forming. The inner ball cage sliding sleeve manufactured by adopting the process provided by the invention has the advantages of uniform structure, high density, strength and hardness, small size error, no follow-up machining, high processing efficiency, short production period, material conservation and high practical value.

Owner:JIANGSU CHUANGYI PRECISION FORGING

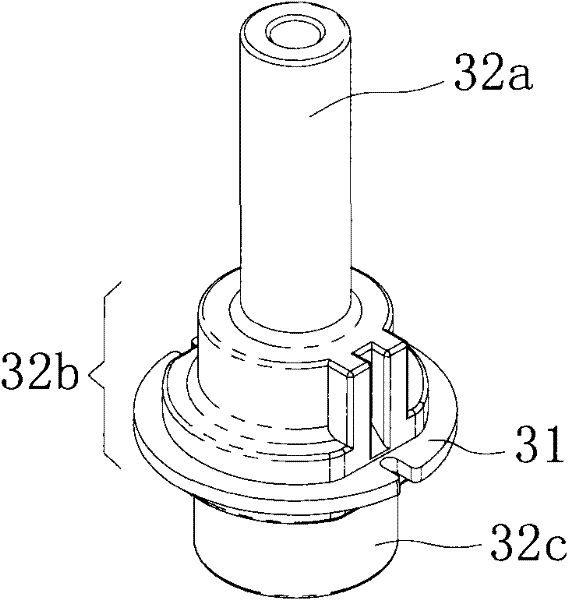

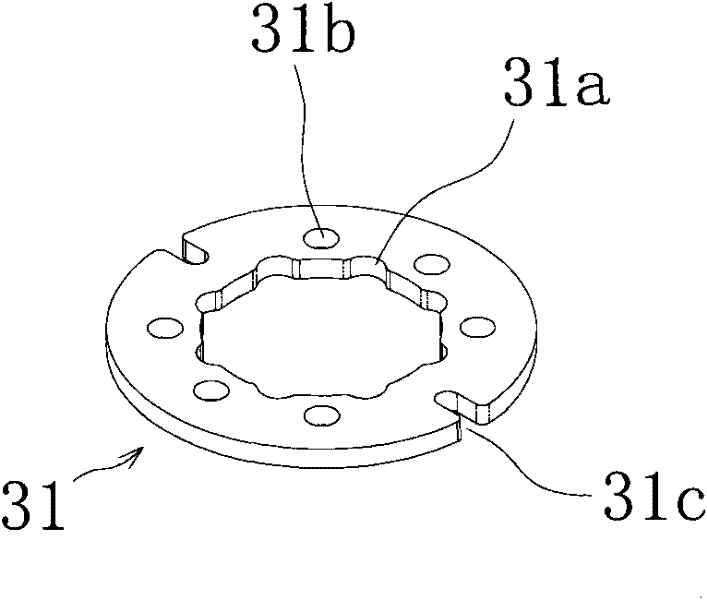

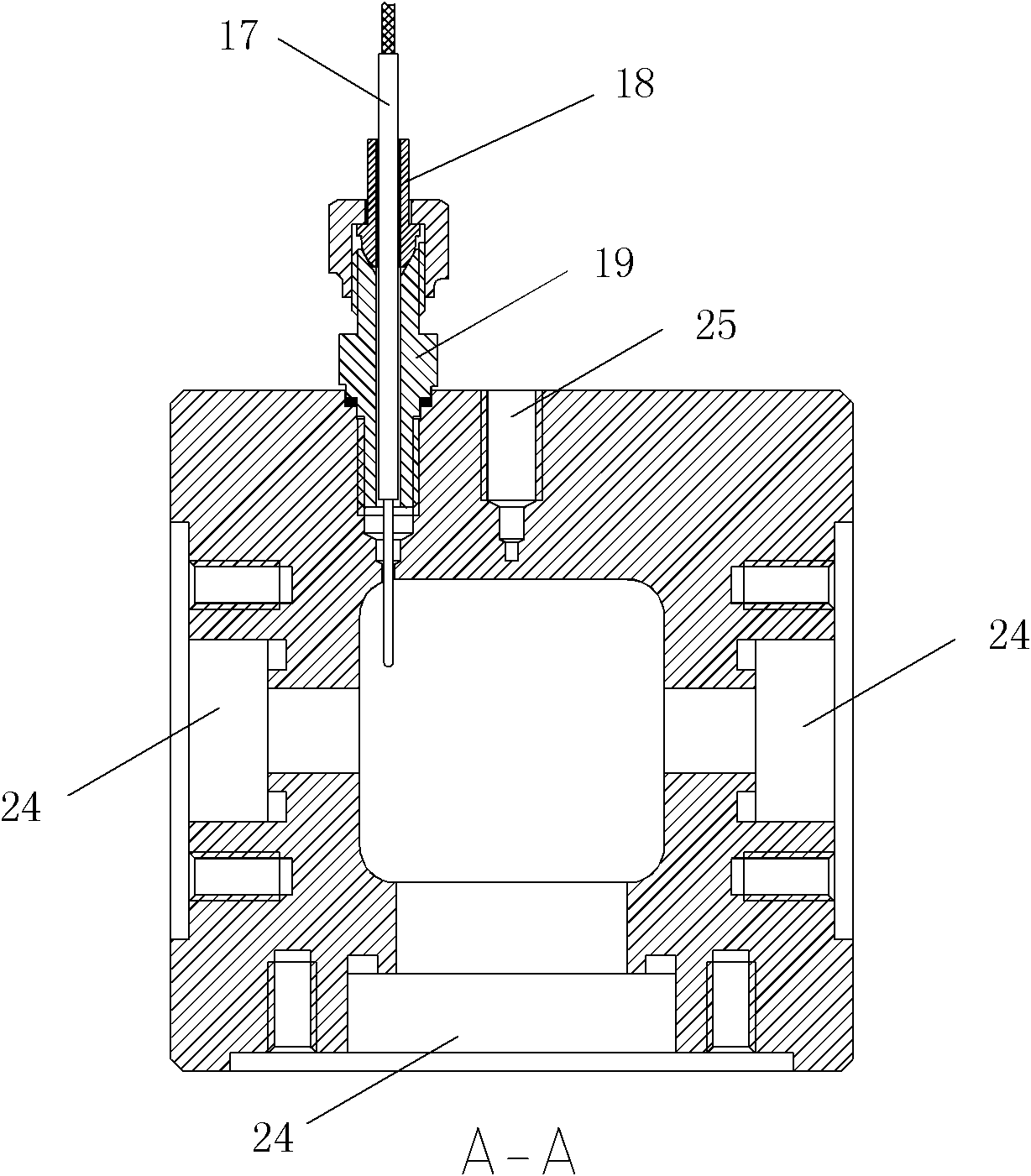

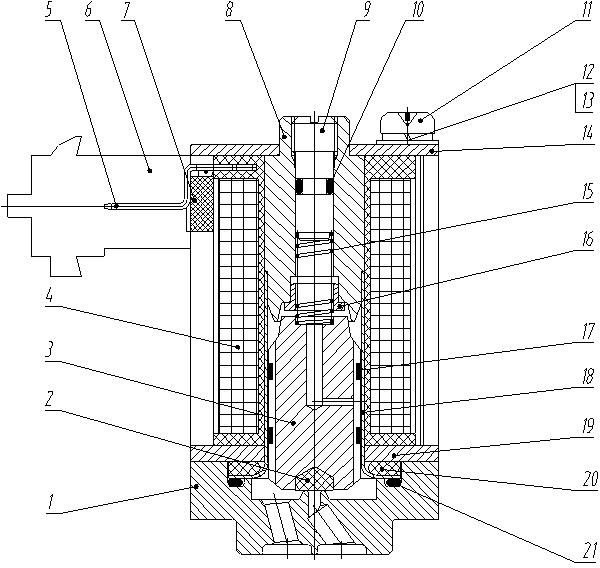

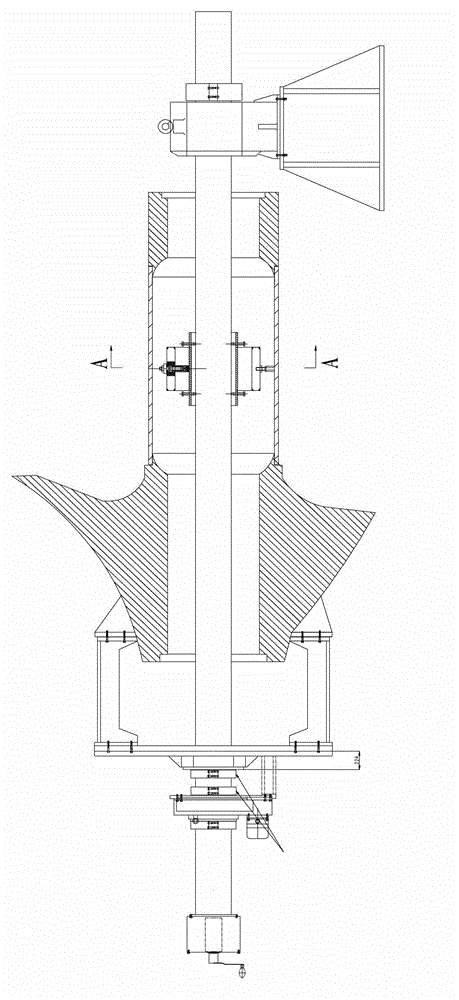

Fatigue life test stand for angular contact ball bearing

InactiveCN101419126AGuaranteed coaxialityReduce the impactMachine bearings testingFrequency changerBall bearing

The invention provides an apparatus for testing the fatigue life of a high-speed angular contact ball bearing. The apparatus tests the fatigue life of the angular contact ball bearing under the working condition of various rotary speeds and loads by adoption of a frequency converter to realize infinite variable speed of a high-frequency motor, adoption of a transmission shaft to drive the angular contact ball bearing to rotate at a high speed under certain pretightening force, and adoption of a weight to adjust and load the axial pretightening force. The apparatus overcomes the defects of complex structure, expensive price, trivial operation, large noise and so on of the prior apparatus for testing the fatigue life of the angular contact ball bearing, realizes zero transmission and lever loading, and has the advantages of superior high-speed performance, reliable test results, simple structure and low cost.

Owner:SOUTHEAST UNIV

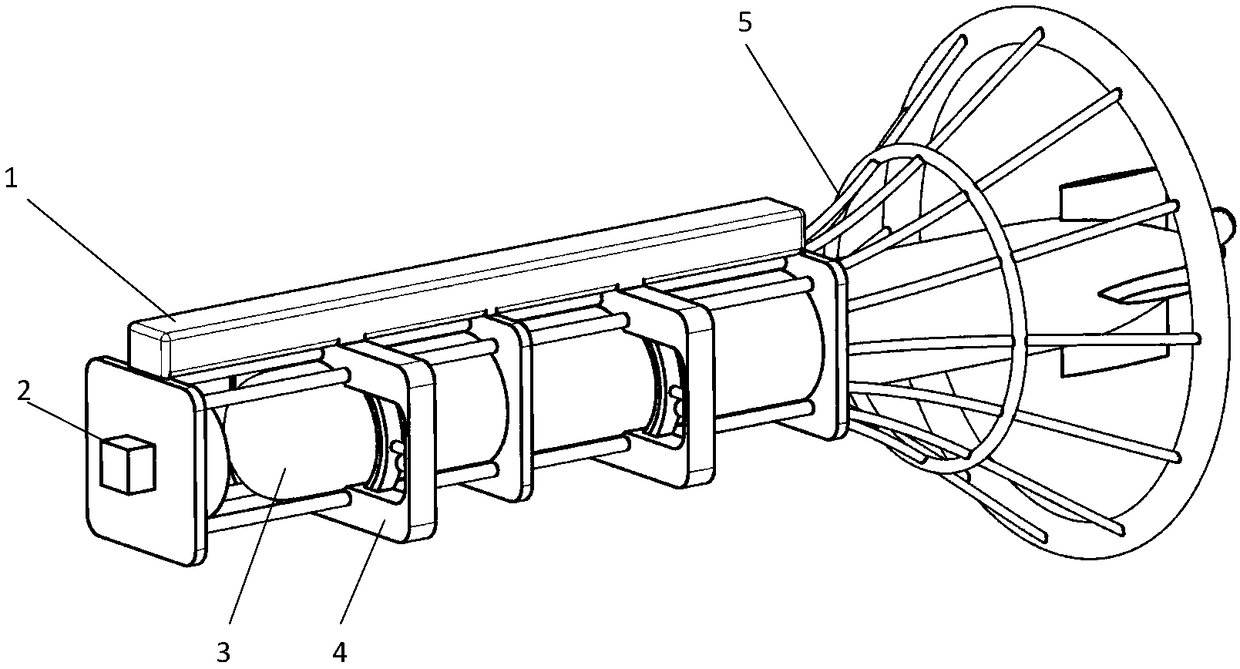

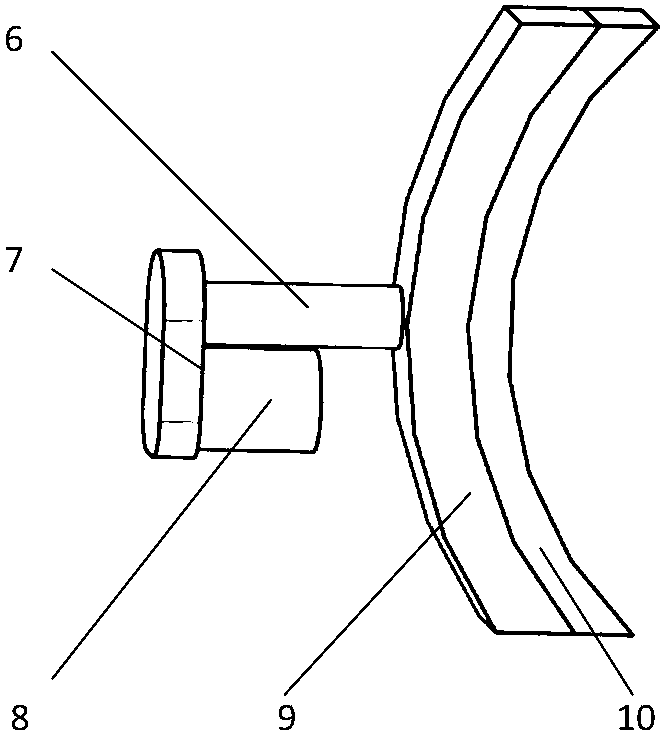

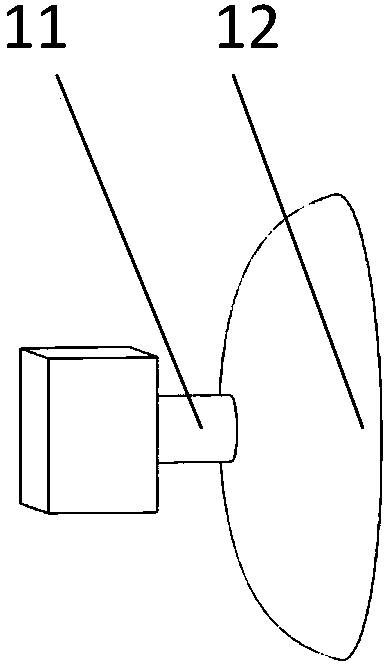

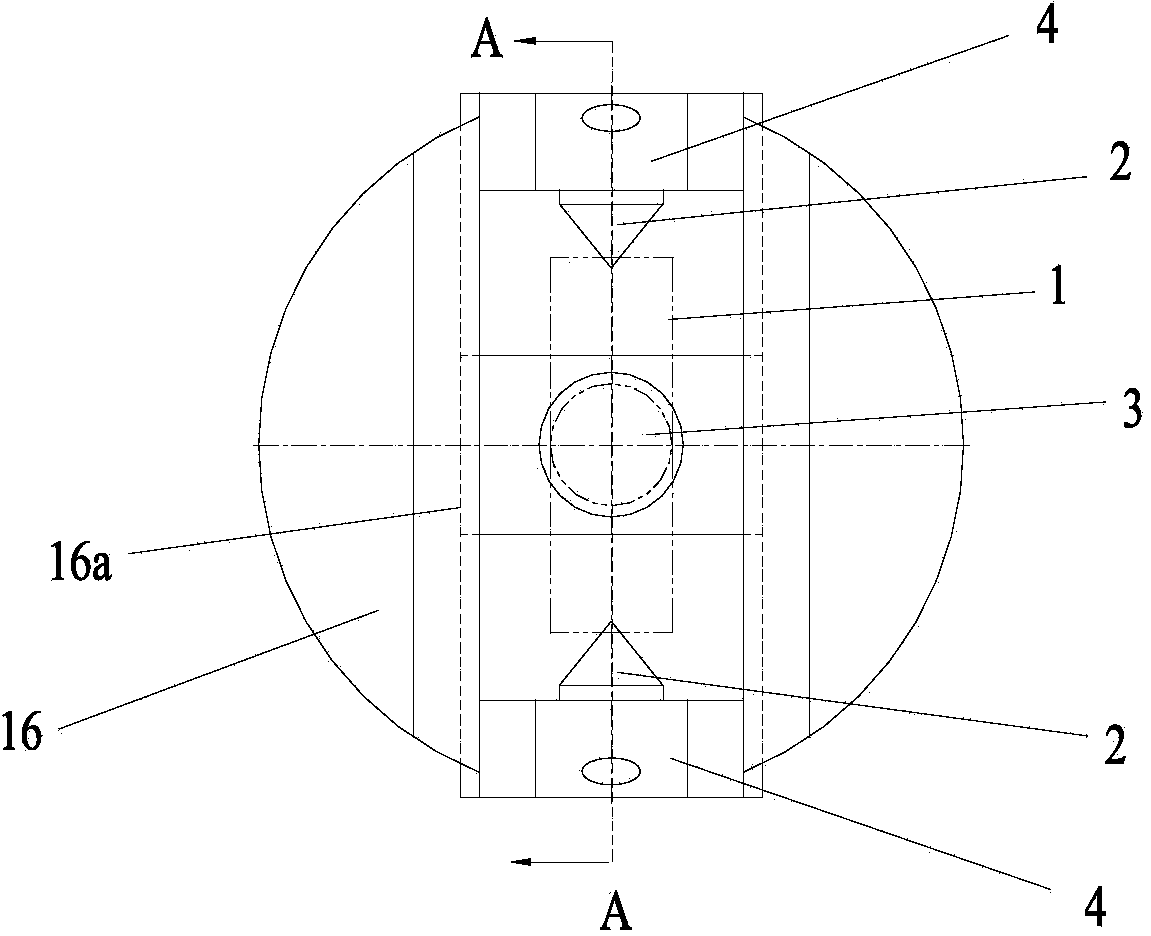

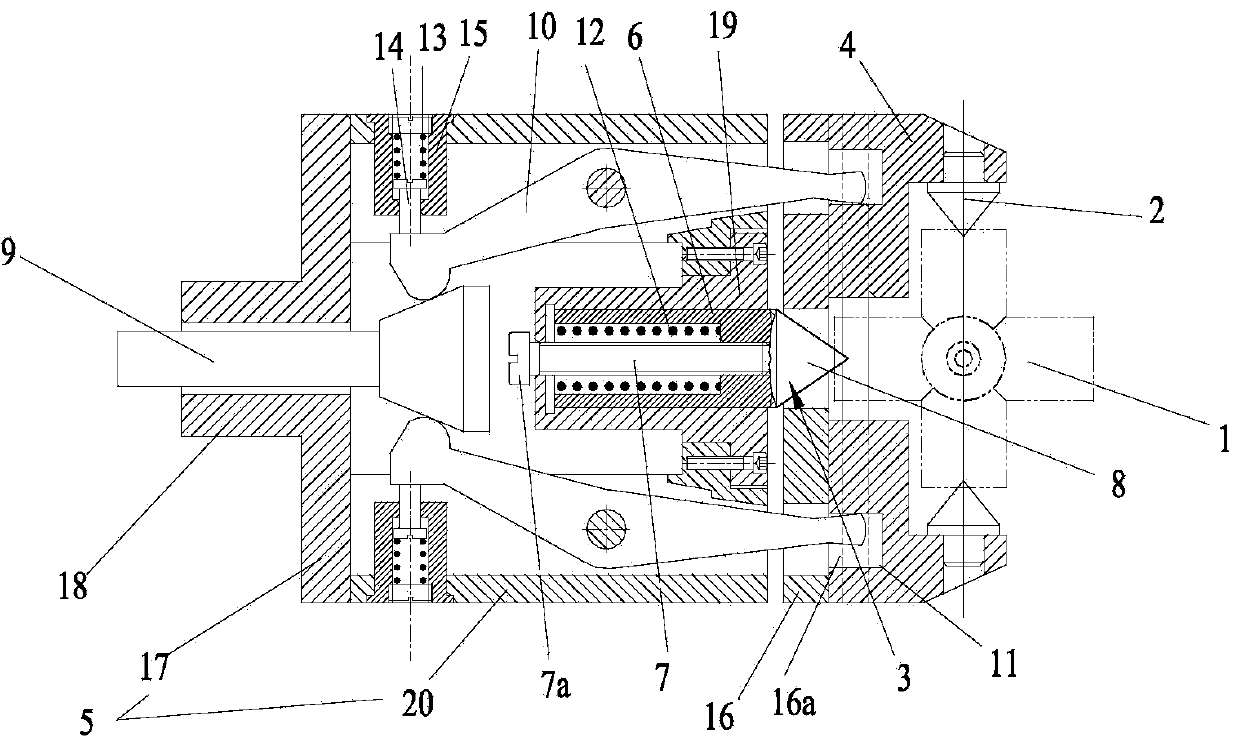

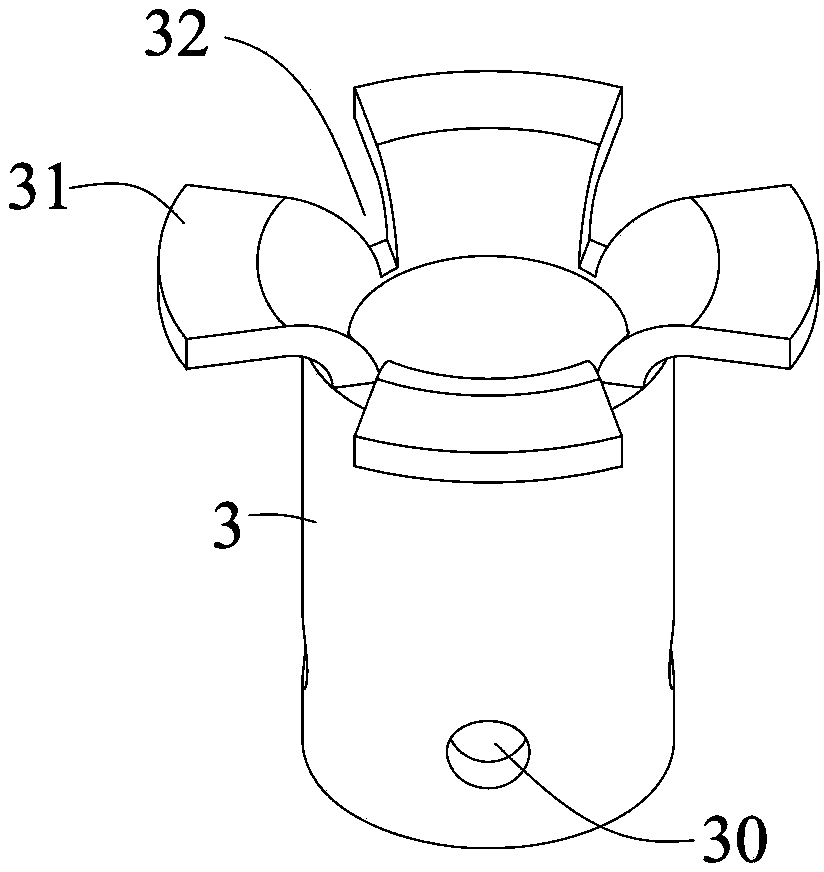

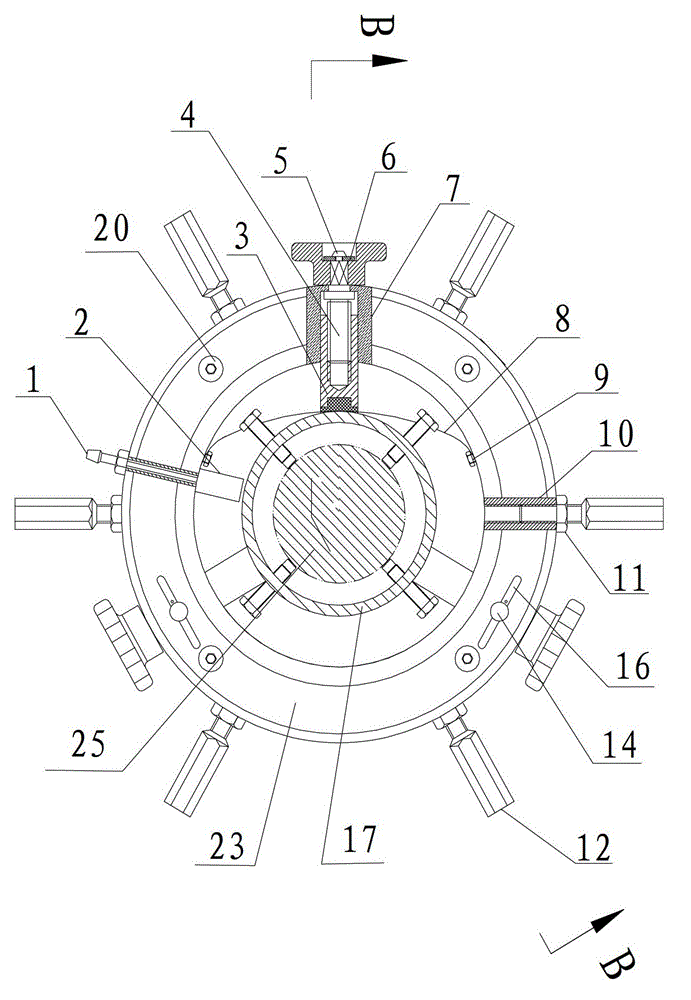

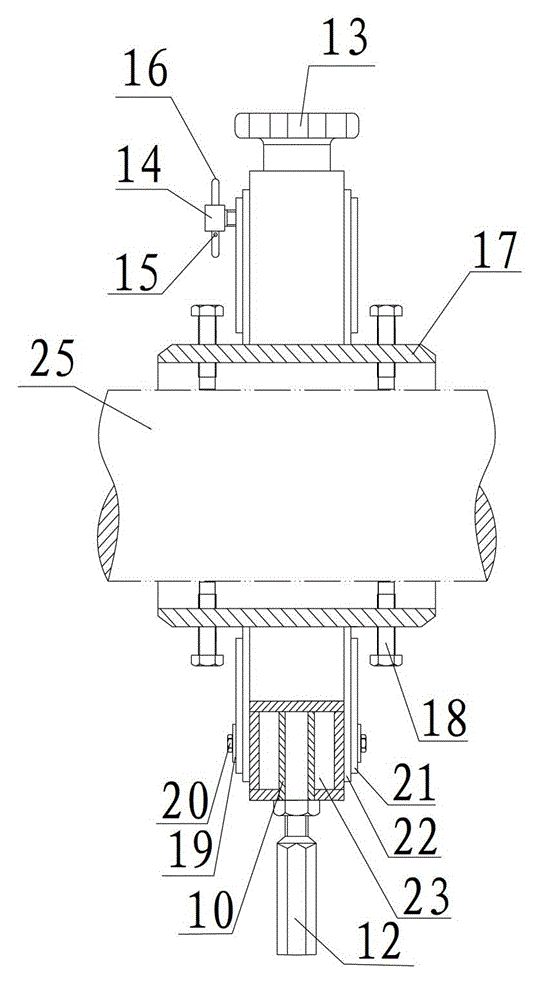

AUV (Underwater Autonomous Vehicle) underwater recovery locking mechanism

ActiveCN108569385AGuaranteed coaxialityGuaranteed contact areaUnderwater equipmentUnderwaterMarine engineering

The invention discloses an AUV (Underwater Autonomous Vehicle) underwater recovery locking mechanism which comprises an AUV abutting recovery device, a locking mechanism mounting rack, a locking mechanism, a limiting mechanism and a battery bin. The AUV underwater recovery locking mechanism disclosed by the invention on the basis of the AUV underwater abutting recovery device is simple and convenient to mount and disassemble, stable and reliable in structure and convenient to use. A structure with four groups of circular arc-shaped structural claws and an elastic circular arc-shaped device isadopted and is combined with an underwater hydraulic push rod structure to be mounted on the locking mechanism mounting rack together, so that two groups of locking devices can be obtained, coaxialityand a contact area in the AUV locking process can be ensured and reliability of the AUV locking process is improved; a head circular top disk, a spring push rod and a limiting switch are adopted to form a corresponding locking control structure, so that a motion posture of an AUV in the recovering process can be ensured to a certain degree; meanwhile, by adopting the limiting switch, safety of the AUV in the recovering process can be ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

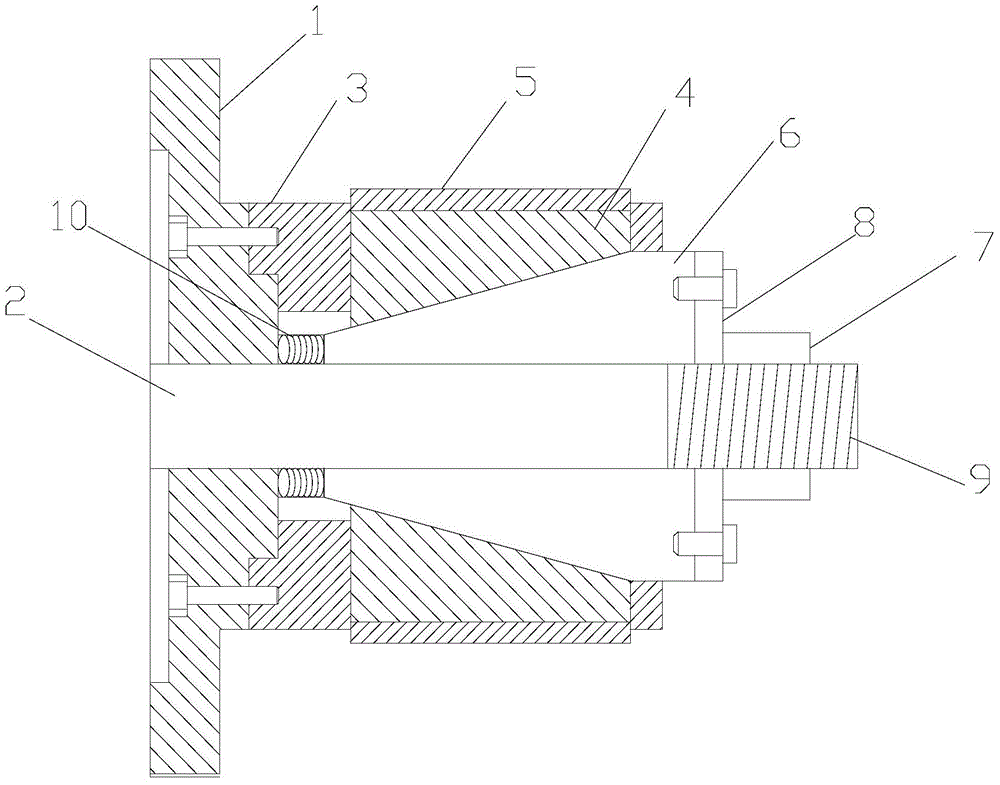

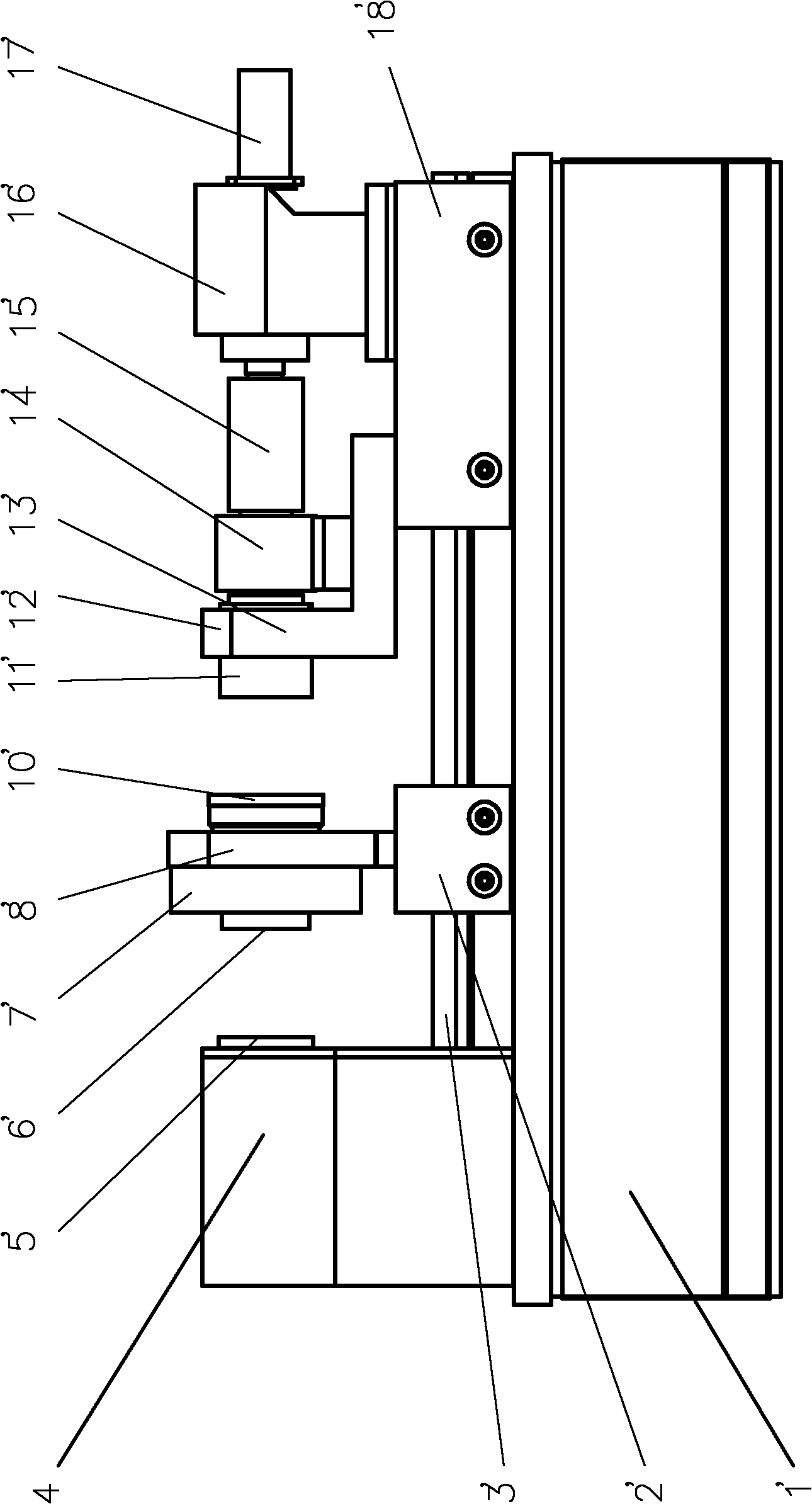

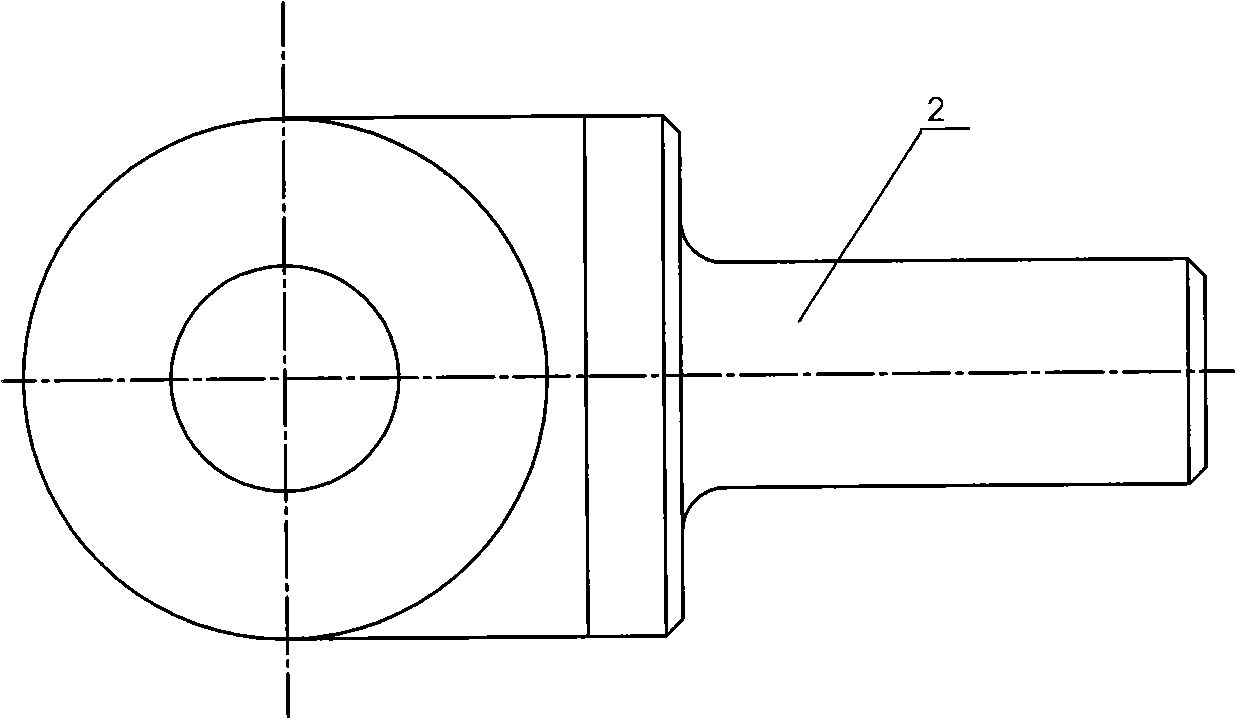

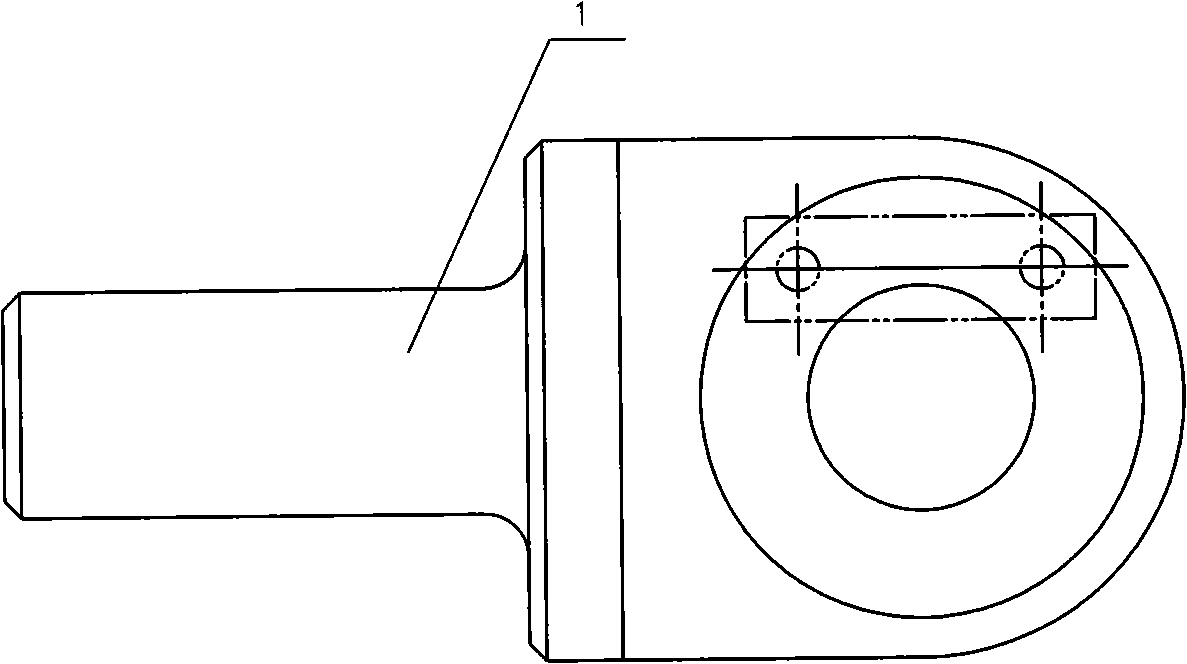

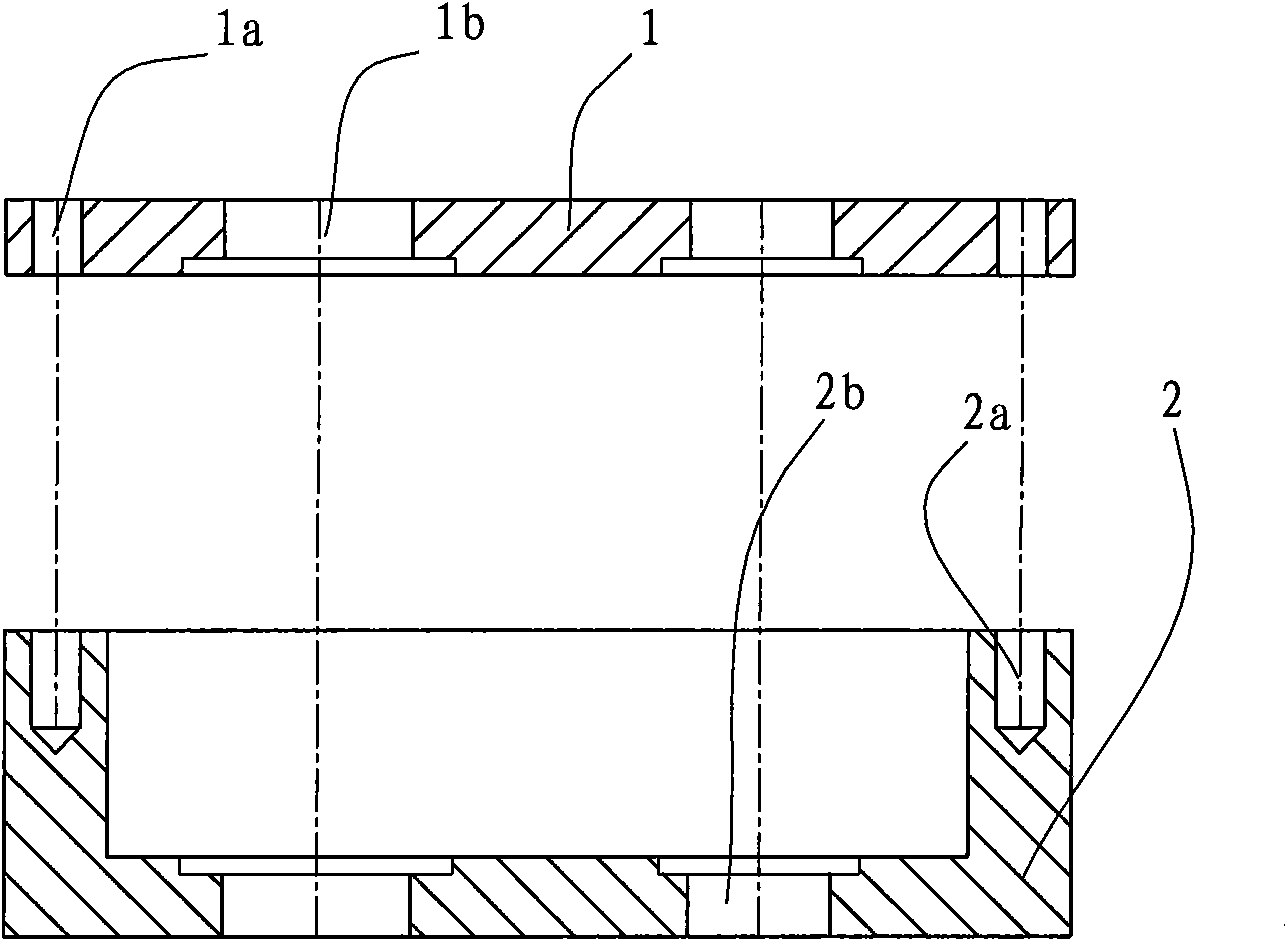

Clamp for turning universal joint

ActiveCN103737350AGuaranteed coaxialityEnsure stable positioningPositioning apparatusMetal-working holdersUniversal jointEngineering

The invention discloses a clamp for turning a universal joint. The clamp comprises a first locating mechanism used for locating a universal joint work-piece (1) in the vertical shaft direction of the universal joint work-piece (1), and a second locating mechanism used for locating the universal joint work-piece (1) in the horizontal shaft direction of the universal joint work-piece (1). The first locating mechanism and the second locating mechanism can locate the universal joint work-piece in the vertical shaft direction and the horizontal shaft direction at the same time, and therefore the universal joint work-piece can be clamped in a centring mode, firm locating in the turning process is guaranteed, and the coaxiality of two cylindrical shafts on the two sides of a machined cylindrical shaft is guaranteed. The clamp can clamp and locate the universal joint work-piece accurately.

Owner:ZOOMLION HEAVY IND CO LTD

Expansion fixture suitable for blank surfaces

The invention relates to an expansion fixture suitable for blank surfaces. The fixture comprises a flange, a mandrel fixed in the center of the flange, and a retainer connected with the flange through a bolt. A plurality of sliders are evenly distributed in the circumference direction of the retainer, a cushion block is fixed to each slider, a conical expansion sleeve is further arranged between the retainer and the mandrel, the conical expansion sleeve is tightly connected with the sliders, a spring is connected between the front end of the conical expansion sleeve and the flange, and the tail end of the conical expansion sleeve is provided with a fastening nut arranged on the mandrel in a sleeving mode. The expansion fixture has the advantages of being simple in structure, capable of improving production efficiency, capable of being used for machining the blank surfaces with different diameters and the like.

Owner:CHANGZHOU YINBAO NICKEL NETWORK

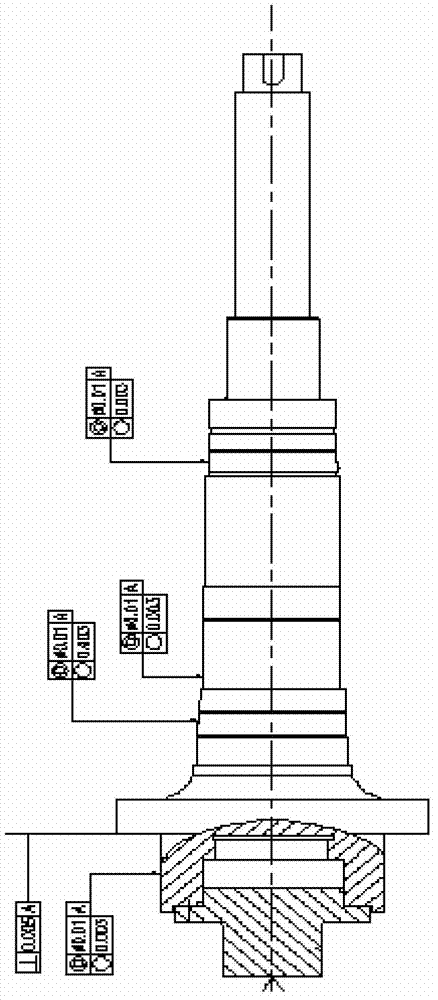

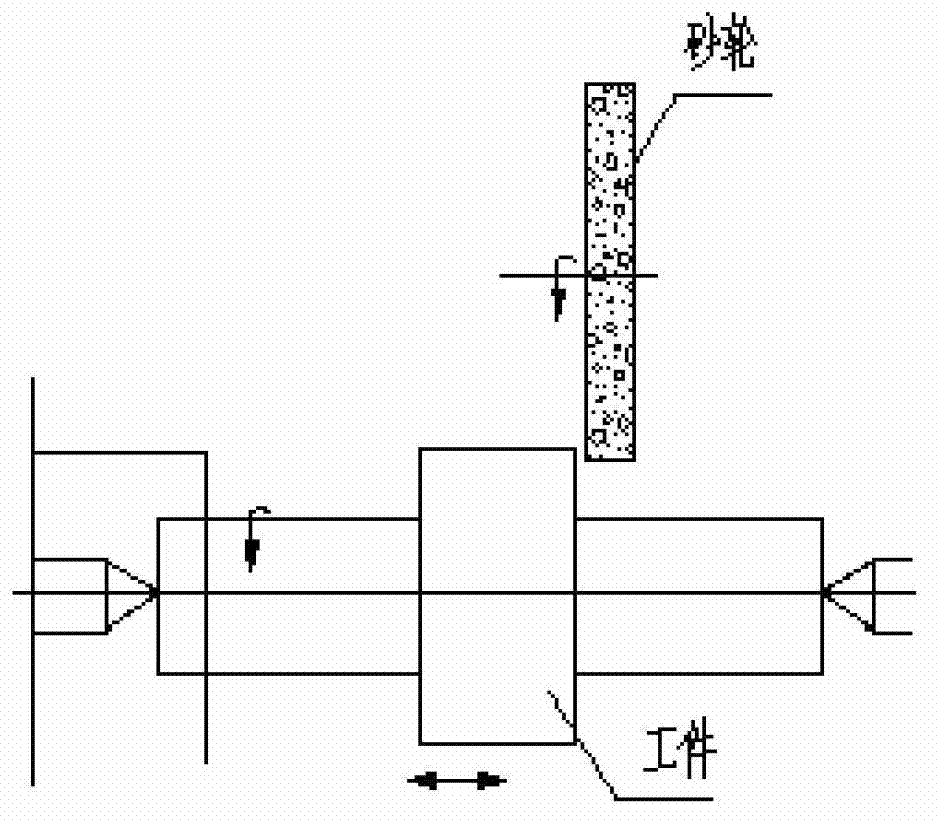

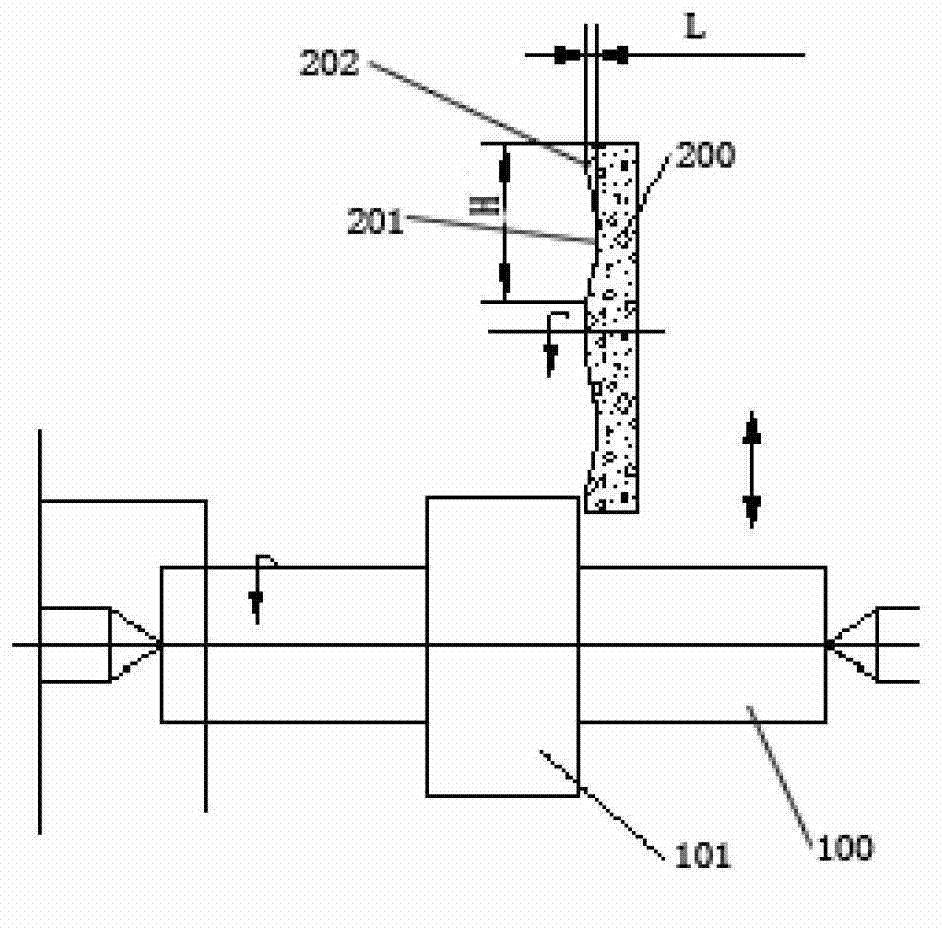

Machining method of high-accuracy cutter shaft of rotary shear

ActiveCN102825515AGuaranteed beatGuaranteed meshing accuracyPlane surface grinding machinesCircular discResonance

The invention discloses a machining method of a high-accuracy cutter shaft of a rotary shear. The machining method is sequentially performed according to the following steps of: 1, forging a blank and normalizing; 2, performing rough turning; 3, performing hardening and tempering, i.e., performing quenching and high-temperature tempering treatment on the cutter shift; 4, performing semi-fine turning; 5, performing semi-fine milling; 6, performing fine turning; and 7, performing fine milling, i.e., milling a main outer circle and a taper of the cutter shaft, and meanwhile, arranging a groove in a middle part of an axial end face of a milling grinding wheel, wherein a part which is clamped between the groove and the circumferential surface of the grinding wheel is a milling part of the grinding wheel, so that the milling part of the grinding wheel in a rotation process is used for milling an end face of a cutter shaft shoulder which is kept in the rotation process after being clamped on a machine tool, and the grinding wheel does reciprocating motion in the radial direction of the cutter shaft in a milling process. According to the machining method, a contact area of the grinding wheel and the shaft shoulder can be reduced, jumping of a grinding wheel and aggravation of jumping of the shaft by resonance of an end face of the shaft shoulder and the grinding wheel in a milling process are prevented, and the milling accuracy of the axial end face is guaranteed to be within 0.005 mum.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

Shaft force and torque combined testing machine for fastening piece

ActiveCN102095546AReliable dataWell positionedMeasurement of torque/twisting force while tighteningStrength propertiesTorque sensorMicro computer

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST +1

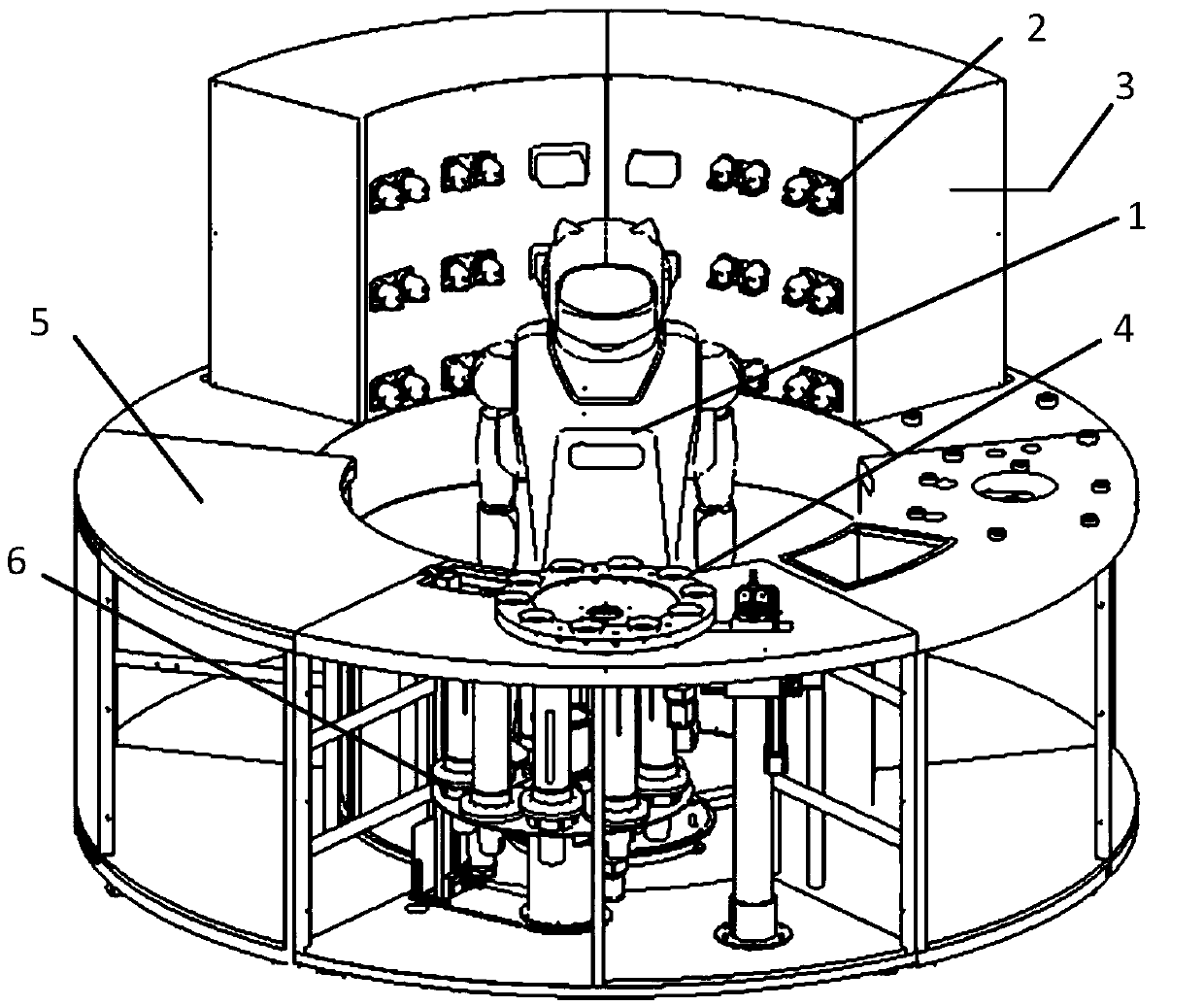

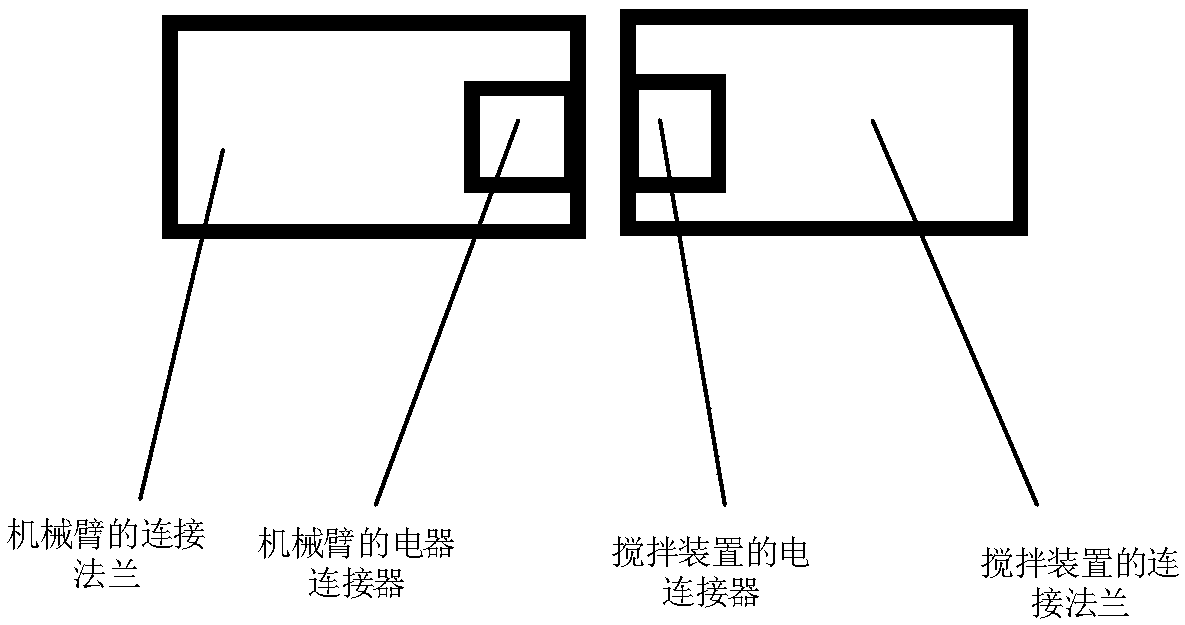

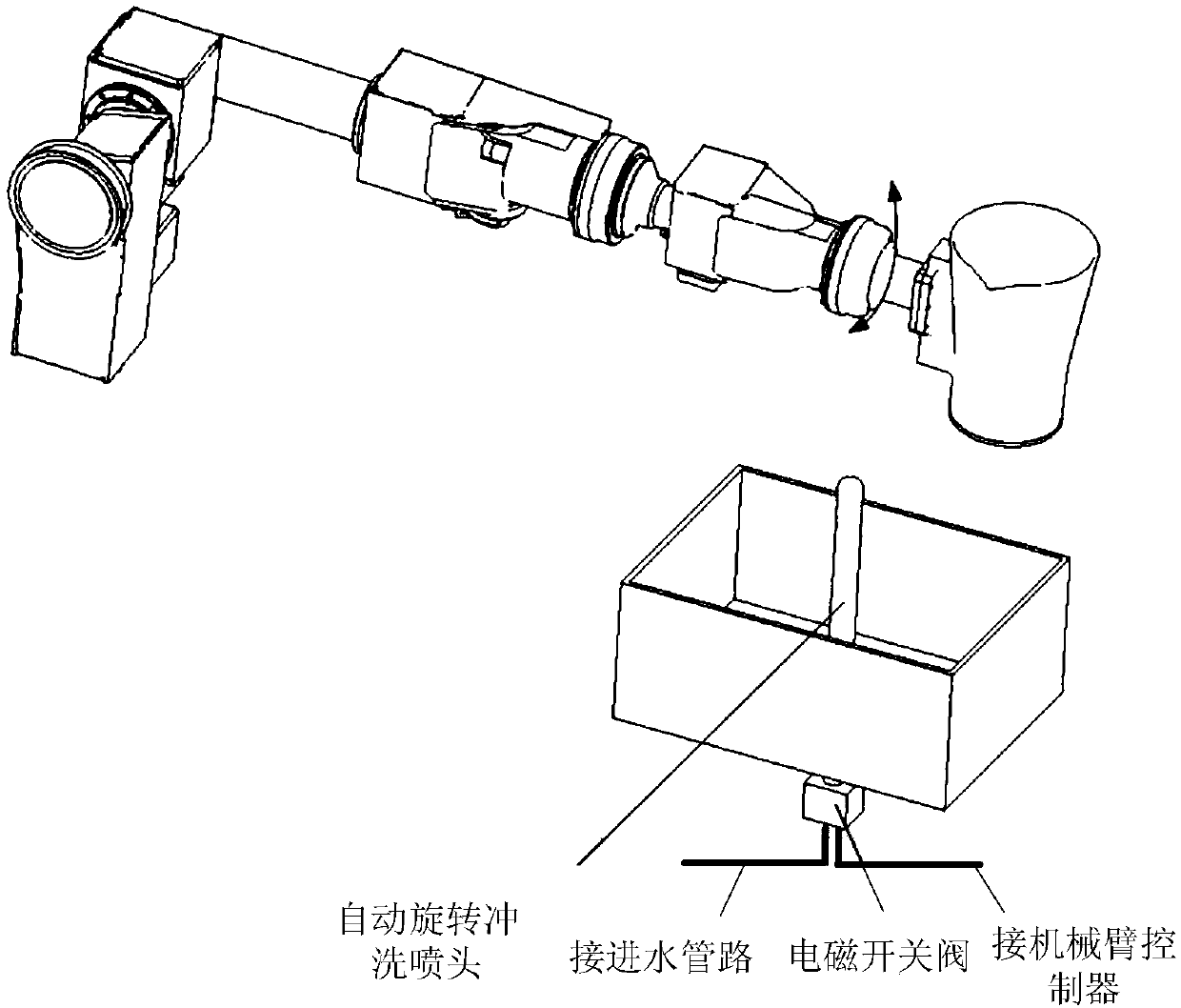

Full-automatic drink making robot

ActiveCN109605395ARealize personalized customizationImprove the production efficiency of production targetsProgramme-controlled manipulatorGripping headsControl systemBiochemical engineering

The invention discloses a full-automatic drink making robot. A stirring device is mounted at the tail end of one arm of a dual-arm robot, and a mechanical hand is arranged on the other arm of the dual-arm robot. An automatic cup discharging device separates a pile of paper cups, the paper cups are conveyed to preset grabbing positions, and the mechanical hand grabs the paper cups from the grabbingpositions. A self-service ordering system provides an ordering interface, customers select drink formulas from the ordering interface, a centralized control system acquires the drink formulas and carries out analysis, the tail ends of the corresponding mechanical arms of the dual-arm robot are controlled to be arranged on corresponding discharging points of a quantitative discharging cabinet sequentially according to the receiving sequence and the ingredient positions, and the quantitative discharging cabinet is controlled to carry out discharging according to the ingredient quantity. The stirring device stirs ingredients. The mechanical hand of the dual-arm robot is controlled to grab the paper cups from the preset positions, and the ingredients which do not need to be stirred are received. After the stirring device carries out stirring for preset stop time, drink is poured into the paper cups, the mechanical hand puts the paper cups at the preset positions on an automatic delivery device, and the automatic delivery device rotates to-be-delivered cup positions to the positions where the customers take the cups.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

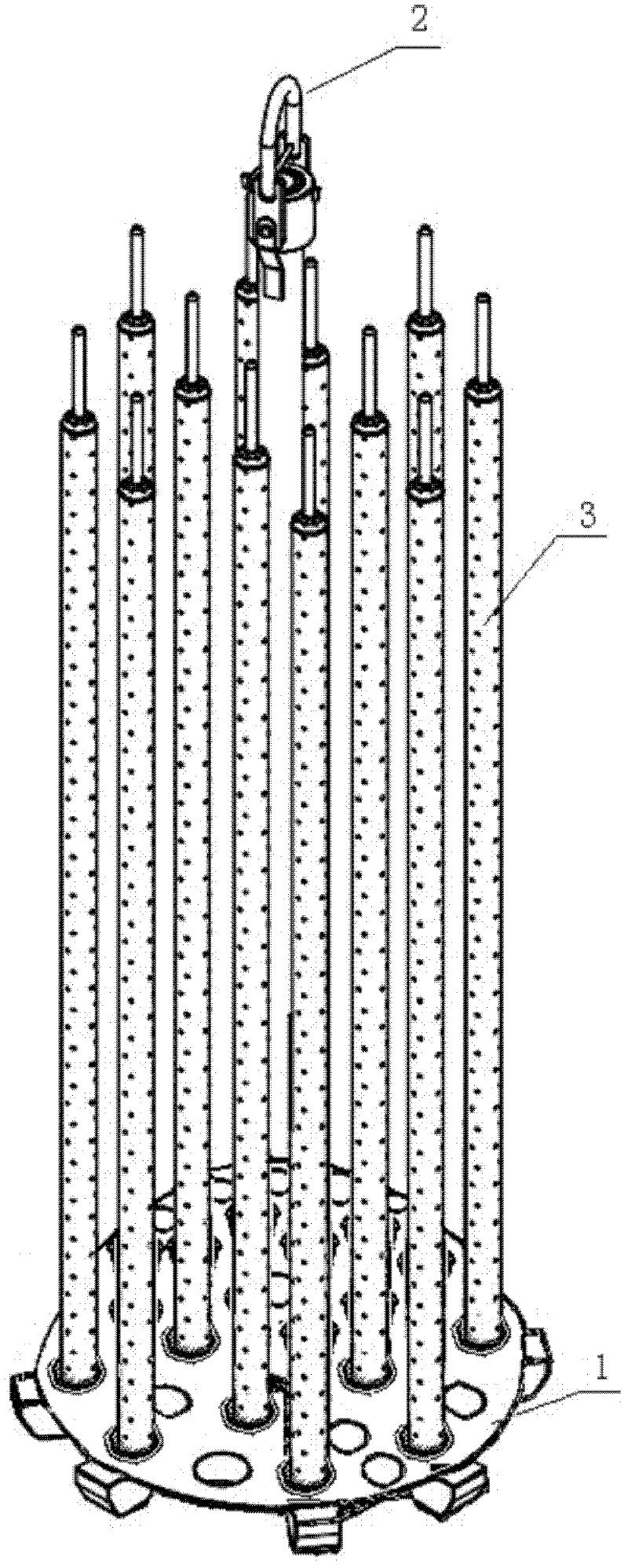

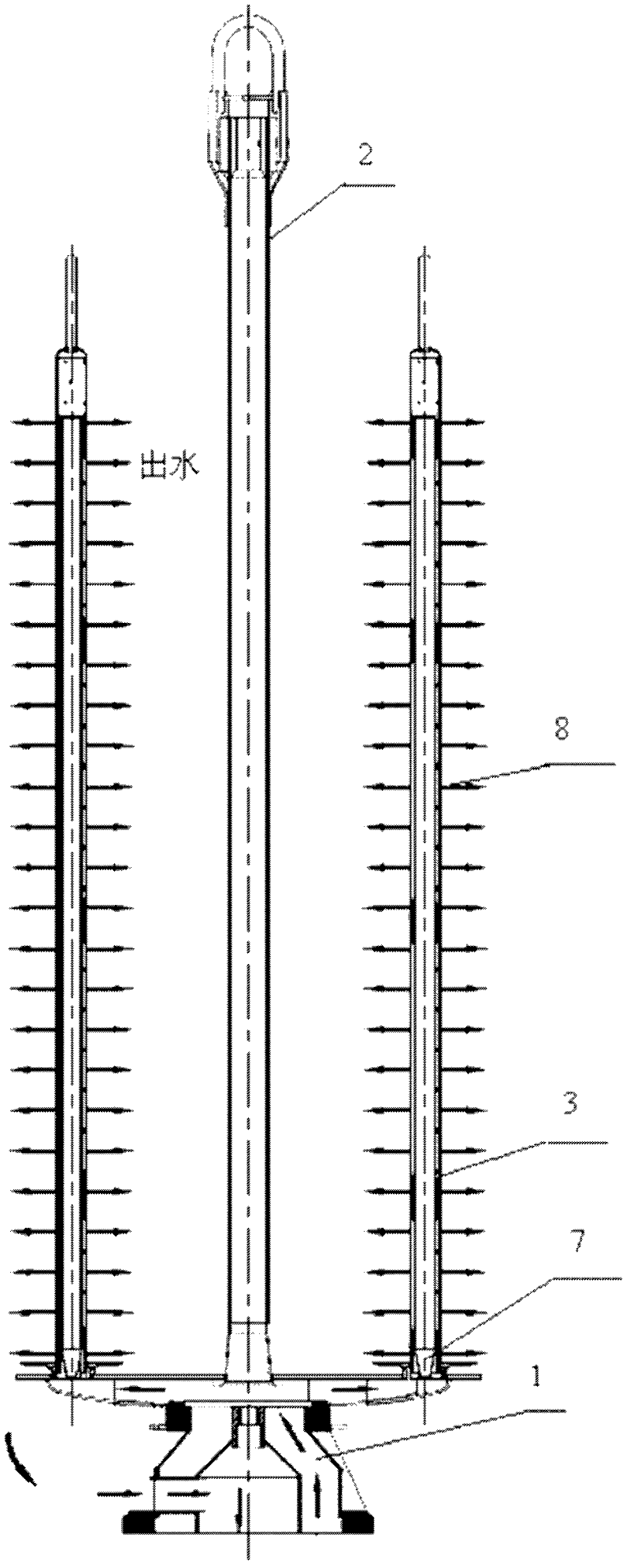

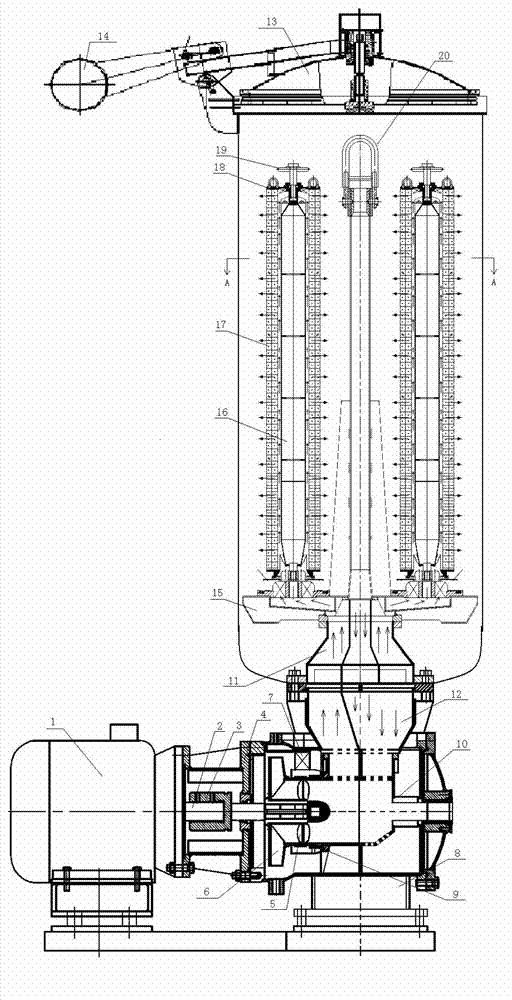

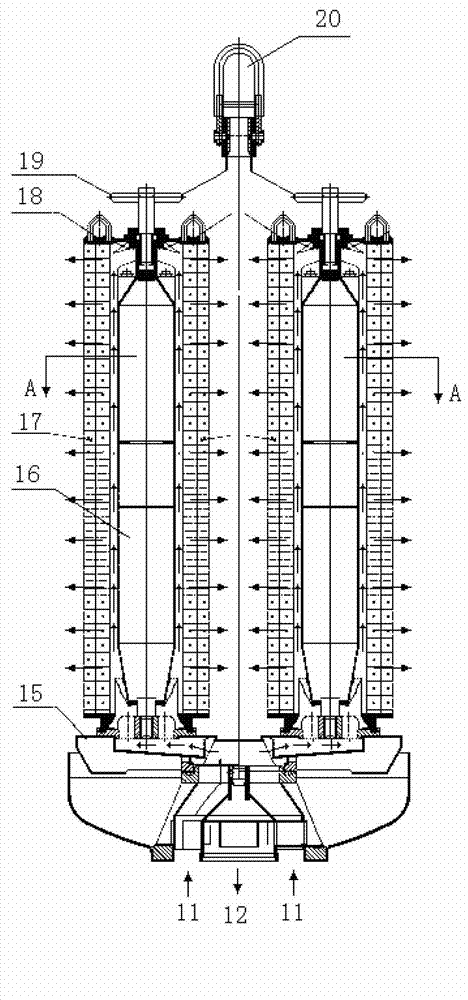

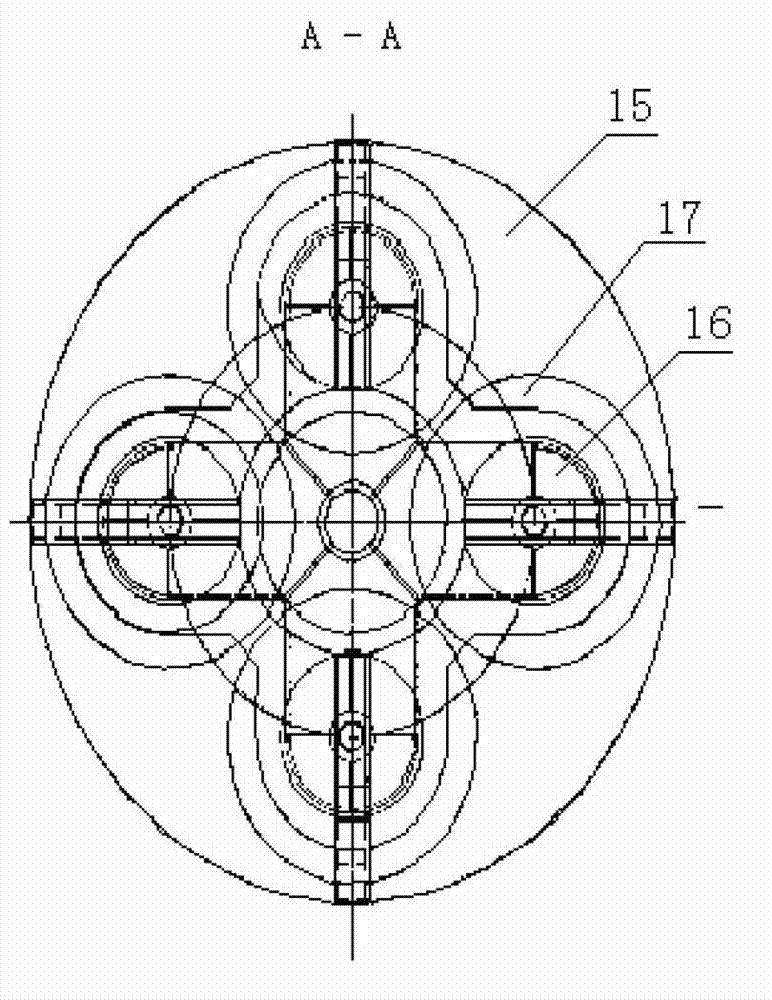

A creel device for an ultra-low liquor ratio yarn dyeing machine

InactiveCN102296436AReduce the cross-sectional areaGuaranteed coaxialityTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentWater bathsYarn

The invention discloses a creel device of a yarn dyeing machine with an ultra-low bath ratio, which comprises a sand table, a suspender and a yarn rod, wherein the upper surface of the sand table is in a disk shape; the lower end of the sand table is in a cavity structure; the yarn rod is in a hollow barrel structure; a water drum is arranged in the barrel of the yarn rod and is in a hollow or solid columnar structure; the center line of the yarn rod and the center line of the water drum are same; the ratio of the hollow internal diameter of the yarn rod and the external diameter of the waterdrum is 10:7-9; and the barrel of the yarn rod is evenly provided with a plurality of water outlets along the circumference of horizontal cross sections of different heights. The hollow barrel of theyarn rod disclosed by the invention is provided with the water drum, which is favorable for reducing the volume of dye liquor in the yarn rod and for reducing a water bath ratio; under the same main pump power, the water drum is favorable for improving the practical lift of a pipeline relatively, the flow rate of the dye liquor in the yarn rod is improved, the levelling property of cheeses of upper layers and lower layers can be better guaranteed, and the one-time success rate for dyeing is improved; and from the bottom to the top, the water outlets on the barrel of the yarn rod at the outer side of the water drum are thicker at the higher place of the yarn rod, which is favorable for realizing the purpose of even dye transfer.

Owner:高勋绿色智能装备(广州)有限公司

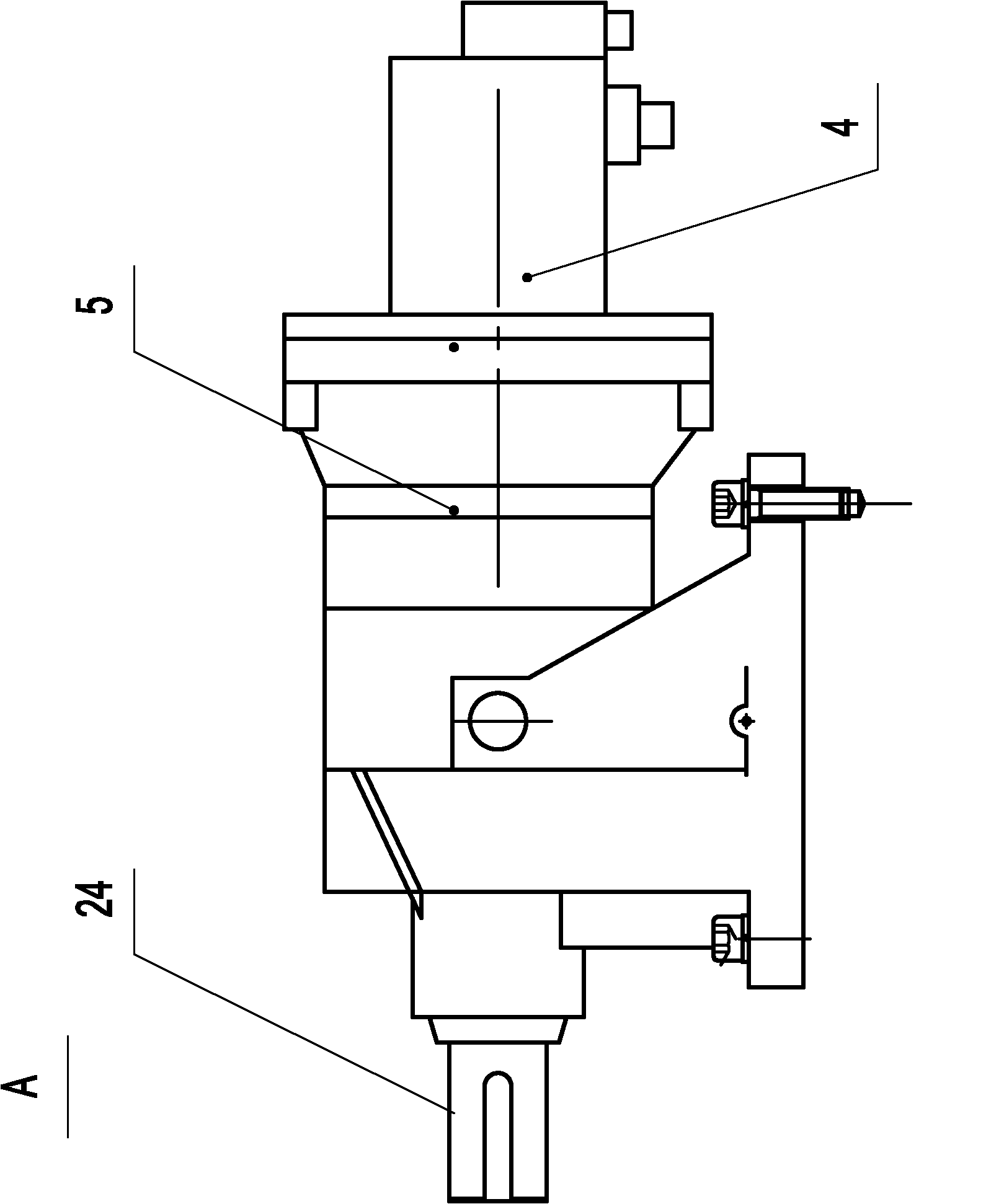

Bonnet support processing method and clamp and processing equipment for bonnet support

ActiveCN103240567AAvoid Machining PrecisionAvoid Processing RequirementsOther manufacturing equipments/toolsLarge fixed membersProduct processingLubrication

The invention discloses a bonnet support processing method and clamp and processing equipment for a bonnet support. The bonnet support processing method includes fixing a bonnet support through the special clamp to enable the central line of the bonnet support to be coaxial with the processing equipment; cutting a flange plane and an end face of a valve rod nut through the processing equipment; changing a cutter, rough-boring or fine-boring a valve rod nut hole, assembling a seal seat and a gland box; changing a cutter to enable the cutter to be coaxial with the processing equipment, rotating a rotation disc at 180 degrees, and finish-milling a thread of the valve rod nut; changing a cutter to enable the cutter to be coaxial with the processing equipment, rotating the rotation disc at 180 degrees, and drilling a flange hole; rotating the rotation disc at 90 degrees, and drilling an eyelet bolt hole and a lubrication hole of the valve rod nut on the support; changing a cutter, rotating the rotation disc at 90 degrees, scraping reversely and facing the back end face of the flange hole; and after finishing processing the back end face of the flange hole, disassembling the bonnet support. By the bonnet support processing method, processing on components can be finished through being clamped only once, and product processing accuracy and quality are improved.

Owner:SHANGHAI HONGGONG MASCH TECH CO LTD

Method for frame mounting of non-intercepting gridded electron gun of klystron

InactiveCN102208308AEasy to makeReduce size and weightTransit-tube electron/ion gunsKlystronsEngineeringPower flow

The invention, which relates to the technology of an electron gun of a klystron, discloses a method for frame mounting of a non-intercepting gridded electron gun of a klystron. The method comprises the following steps: (a), respectively welding a heater-cathode assembly, a heater-cathode support assembly, a gridded lead assembly, an insulating segment assembly, a buncher assembly, and an anode assembly of an electron gun into a independent part; and (b), positioning, welding, and assembling the six parts in sequence by correlative dies. According to the method provided in the invention, the coaxiality of the frame mounting of the whole electron gun parts is ensured. Compared with a cathode control klystron that is used currently, the non-intercepting gridded klystron, which is constructedby the non-intercepting gridded electron gun assembly by the method provided in the invention, has advantages that an agility of a pulse width and a repetition period is allowed and a flexibility of a wave beam is obtained. Moreover, according to the invention, the radar becomes light and small; current provided by a modulator is reduced and the load of a switching tube is also reduced.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Method for mounting large-scale gangplank of ro-ro vessel

InactiveCN101269696AGuaranteed coaxialityExtended service lifeVessel partsEngineeringMechanical engineering

The invention relates to a method used for mounting a large-scale springboard of a Ro-Ro ship. The major technics of the invention is that gemel supporting seat holes are bored first, then the assembly is carried out, and positioning dummy spindles are adopted to carry out the positioning and the installation of a plurality of gemel supporting seats. Reasonable technics of controlling the welding deformation is made and carried out to guarantee the assembly accuracy as well as to regulate the welding deformation, so that the installation accuracies of the coaxiality among gemels, the openings of gemels, the axes verticality, etc. and the construction quality are met the design requirements.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

Prefabrication platform and prefabrication method for jacketed pipe

PendingCN107855721AEasy to penetrate and installGuaranteed verticalityWelding/cutting auxillary devicesAuxillary welding devicesFiberCompound (substance)

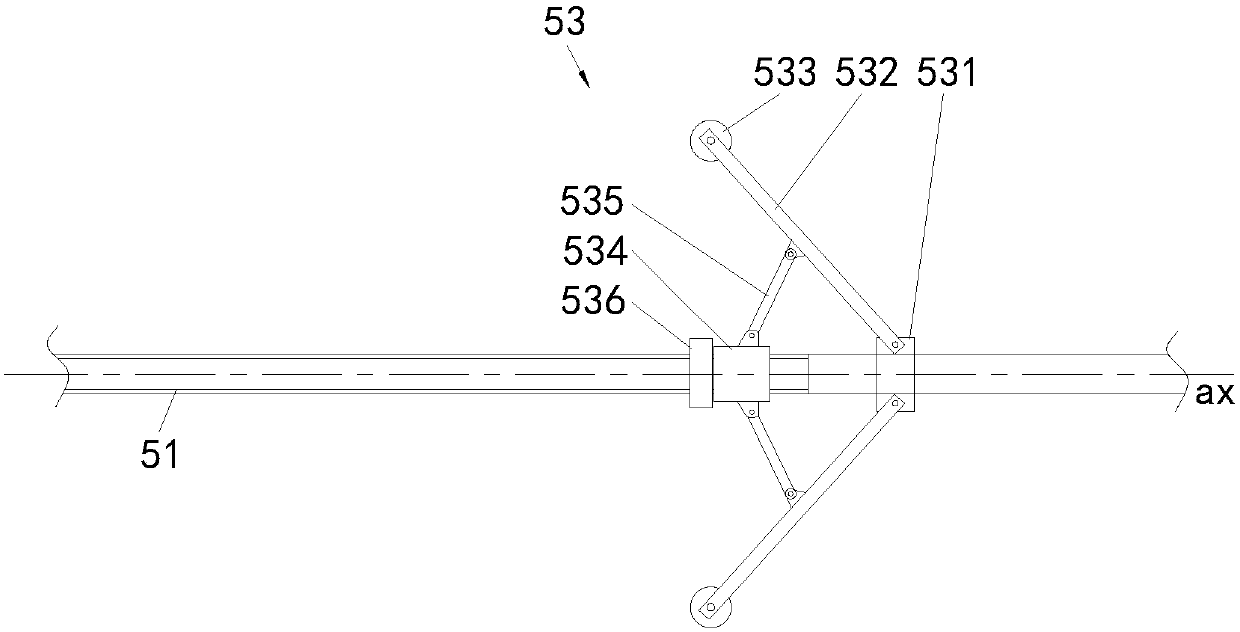

The invention discloses a prefabrication platform and a prefabrication method for a jacket pipe and relates to the technical field of petrochemical engineering and chemical fiber equipment installation. The prefabrication platform and the prefabrication method for the jacketed pipe are provided to solve the problems that according to existing prefabrication construction for a straight pipe sectionof a major-diameter jacketed pipe, operation is relatively complex, and the working efficiency is low. The prefabrication platform is composed of a flange plate positioning frame, an inner pipe positioning assembly and a plurality of outer pipe positioning assemblies. A first adjusting rod arranged on the bottom of a positioning base can adjust the height of a flange plate. The inner pipe positioning assembly is composed of a center rod perpendicularly fixed to a back plate, an extensible and retractable guide wheel supporting frame arranged on the center rod in a sleeving manner and a supporting frame connected to the other end of the center rod, wherein the extensible and retractable guide wheel supporting frame is composed of a fixing casing pipe arranged on the center rod in a sleeving manner, supporting rods which are evenly distributed in the radial direction of the axis of the center rod and hinged to the fixing casing pipe and extensible and retractable supports, one end of each extensible and retractable support is hinged to the corresponding supporting rod, the other end of each extensible and retractable support is hinged to the center rod, and the other end of each supporting rod is provided with a guide wheel. The outer pipe positioning assembly comprises an outer pipe support and a second adjusting rod which are detachably connected.

Owner:SHANGHAI INSTALLATION ENG GRP

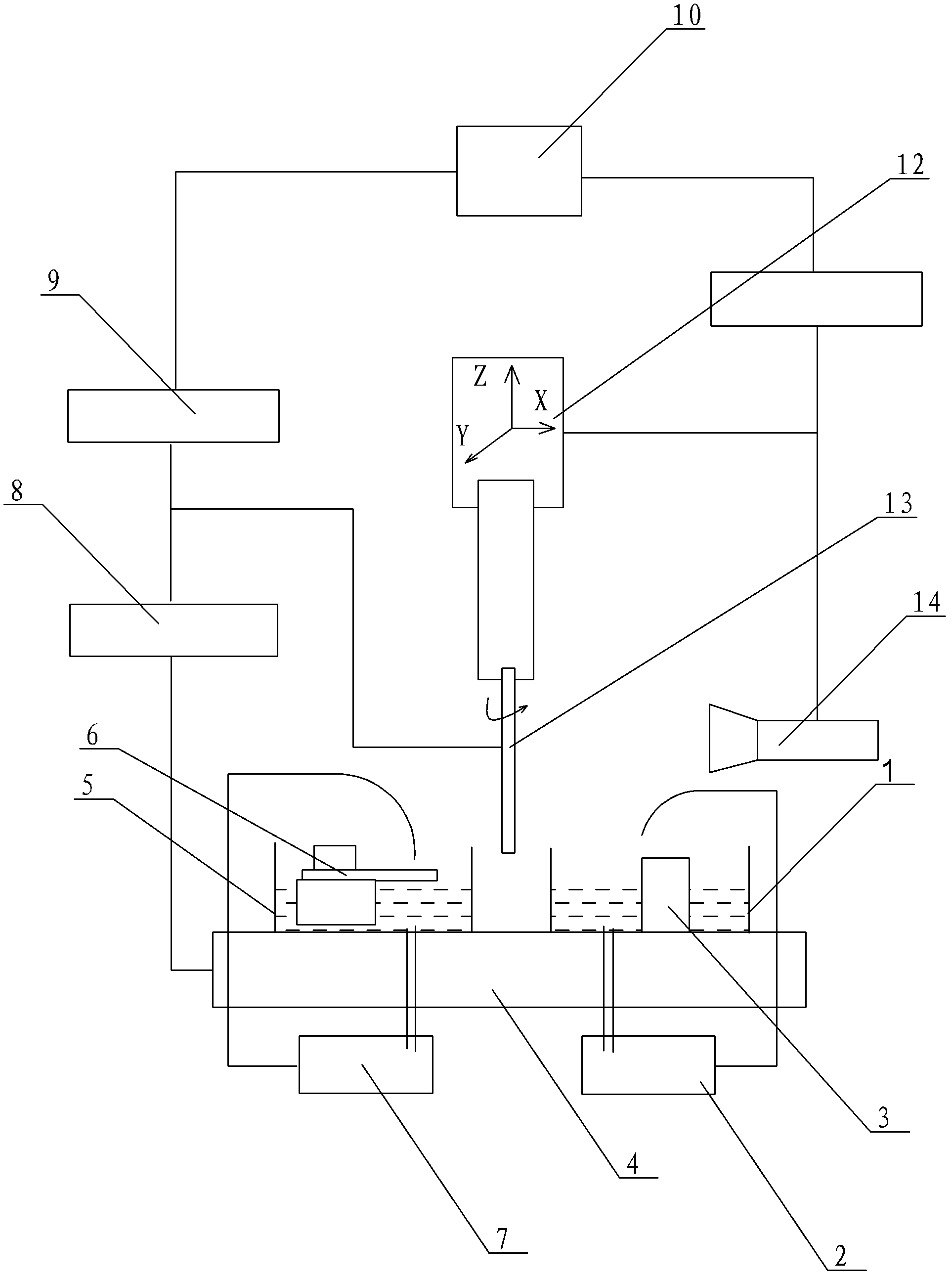

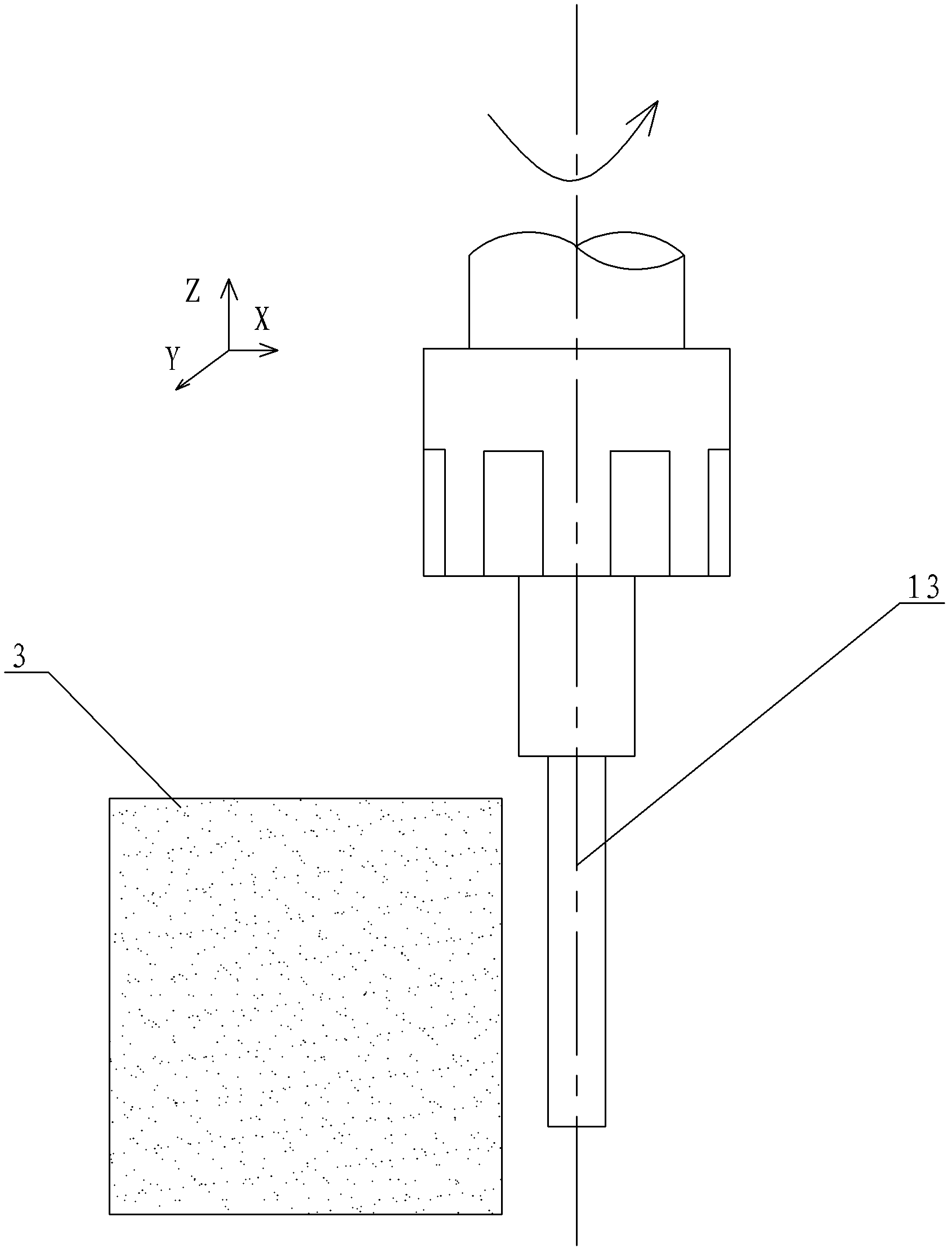

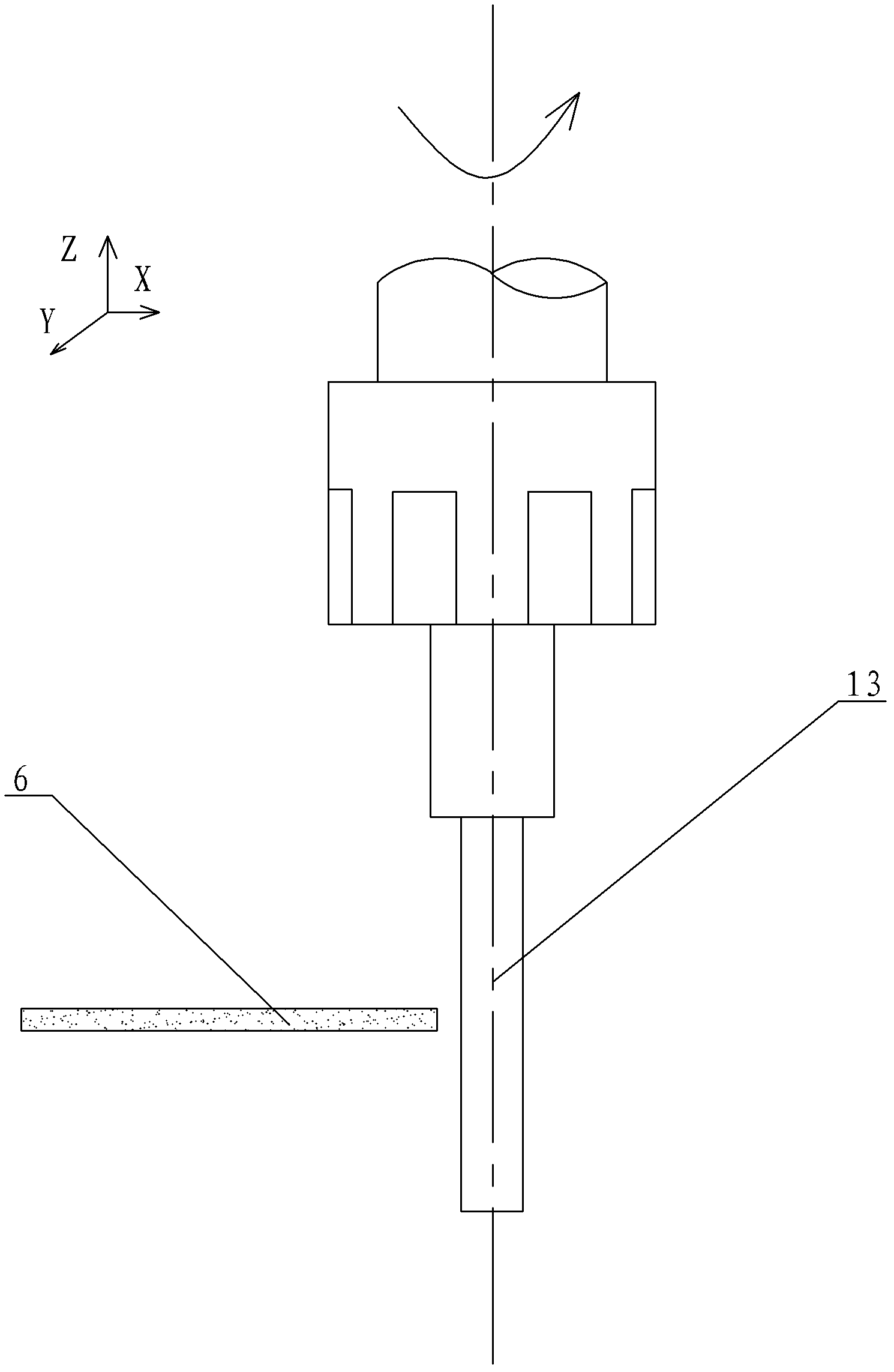

Electric spark and electrochemical composite machining method of micro-electrode

The invention provides an electric spark and electrochemical composite machining method of a micro-electrode, relates to an electric spark and electrochemical composite machining method, and belongs to the field of special machining. The electric spark and electrochemical composite machining method of the micro-electrode is provided in order to solve the problems that: the traditional electric spark grinding method of a block electrode has machining taper error, poor quality of an electrode surface, and a micro-electrolytic grinding method of an edge electrode has low machining efficiency. The method comprises the following: step 1. a machine tool is initialized, and tools and electrodes are clamped; step 2. a block electrode of an electrode (13) is subjected to electric spark grinding machining; step 3. the electrode (13) is subjected to electrolytic grinding finish machining; and step 4. the electrode (13) after being subjected to the electrolytic grinding finish machining is tested. The electric spark and electrochemical composite machining method is particularly applicable to the machining of micro cylindrical electrodes.

Owner:HARBIN INST OF TECH

Processing method of case body and case cover of gear case

The invention discloses a processing method of a gear case, which comprises the following steps: a. processing a case cover; b. processing a case body; c. assembling, and fixing by pin bolts. The processing method of the gear case has the beneficial effects of: 1. respectively processing the case body and the case cover into finished products according to drawing requirements, and then assemblingthe case body and the case cover, thus being capable of guaranteeing the coaxiality and good interchangeability of two bearing holes, guaranteeing the quality, and simultaneously being applicable to be produced in batch without pairing or marking, and having low scrap rate; 2. adopting a novel technique for positioning, drilling and boring of a center drill, thus guaranteeing the center distance;and 3. leading the coaxiality of the assembled S1 and S2 to be 0.1 to 0.30, thus completely meeting the requirements of users.

Owner:CHONGQING QINGPING MACHINERY

Ultralow liquor ratio zipper dyeing machine and dyeing process thereof

InactiveCN103088574AHollow volume reductionReduced cavity cross-sectional areaPump componentsTextile treatment machine arrangementsPolymer scienceEngineering

The invention discloses an ultralow liquor ratio zipper dyeing machine and dyeing process thereof. The dyeing machine comprises a tube cylinder, a cylinder cover and a zipper warp beam plate frame embedded into the tube cylinder. The zipper warp beam plate frame comprises a zipper plate seat, a hollow water drum, a zipper woven belt, a zipper tube sleeve, a locking bolt, and a zipper frame lifting ring. The lower end of the hollow water drum is fastened on the zipper plate seat, the zipper tube sleeve is sleeved on the outer side of the hollow water drum, and a diversion inlet and a diversion outlet are arranged below the zipper plate seat and connected with an infusion pump through a horn-shaped pipe sleeve. The dyeing process comprises the stages of scouring and bleaching, dyeing and water scrubbing. According to the ultralow liquor ratio zipper dyeing machine and the dyeing process thereof, a lift range required by zipper woven belt dyeing water level can be achieved when the height of dye liquor in the dyeing machine is lower than the zipper plate seat, the effect of ultralow liquor ratio zipper dyeing is achieved, the dyeing machine has a lower dying liquor ratio than a traditional zipper dying machine, and the purposes of saving electric energy, steam and the dye liquor, shortening dyeing and finishing periods, and saving energy and reducing emission are achieved.

Owner:高勋绿色智能装备(广州)有限公司

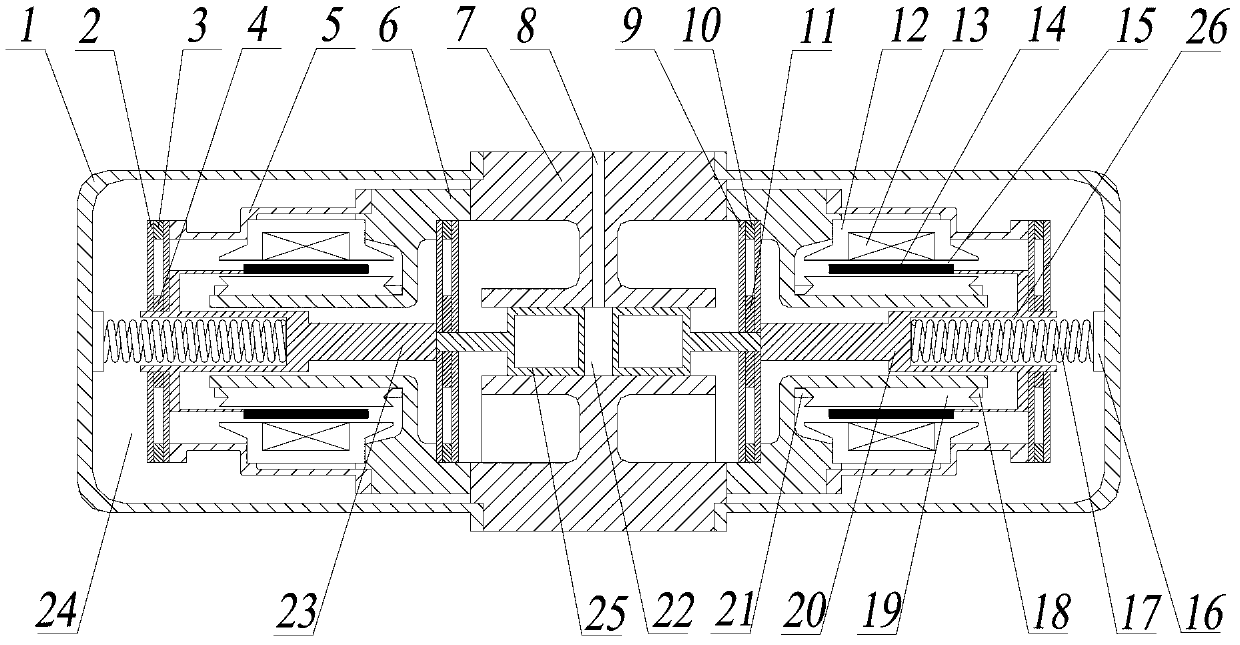

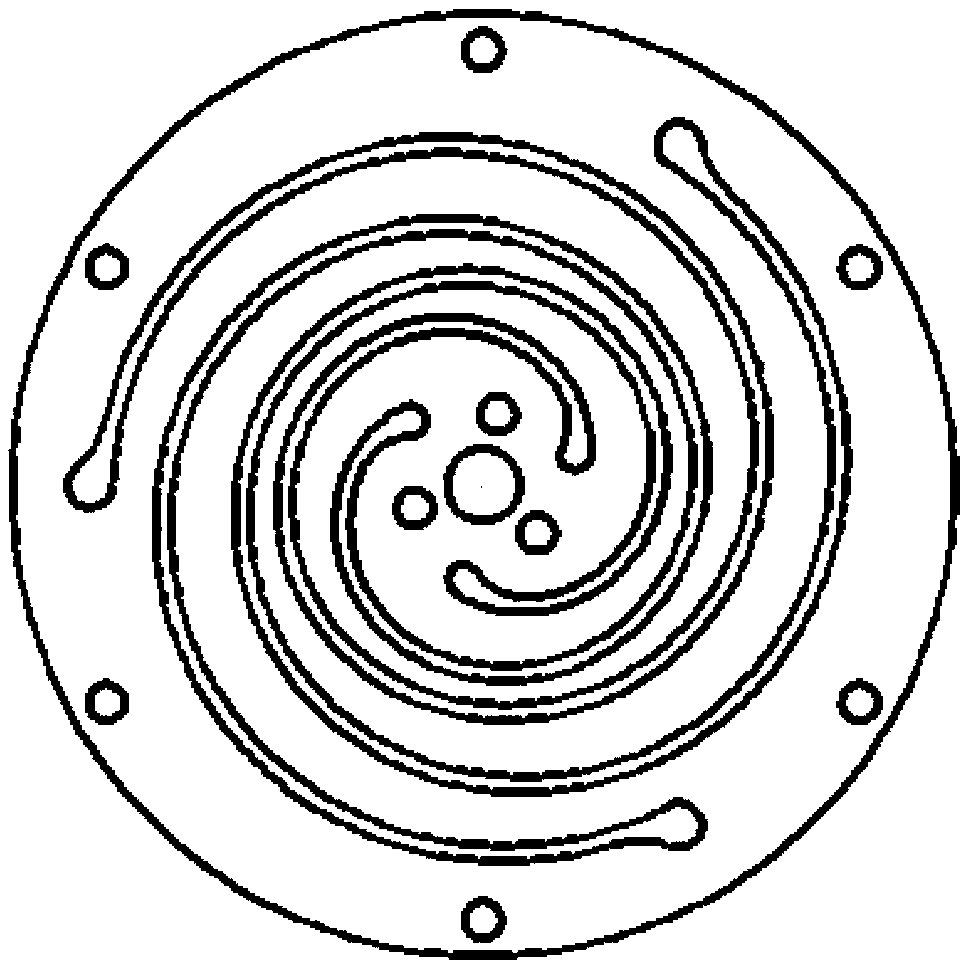

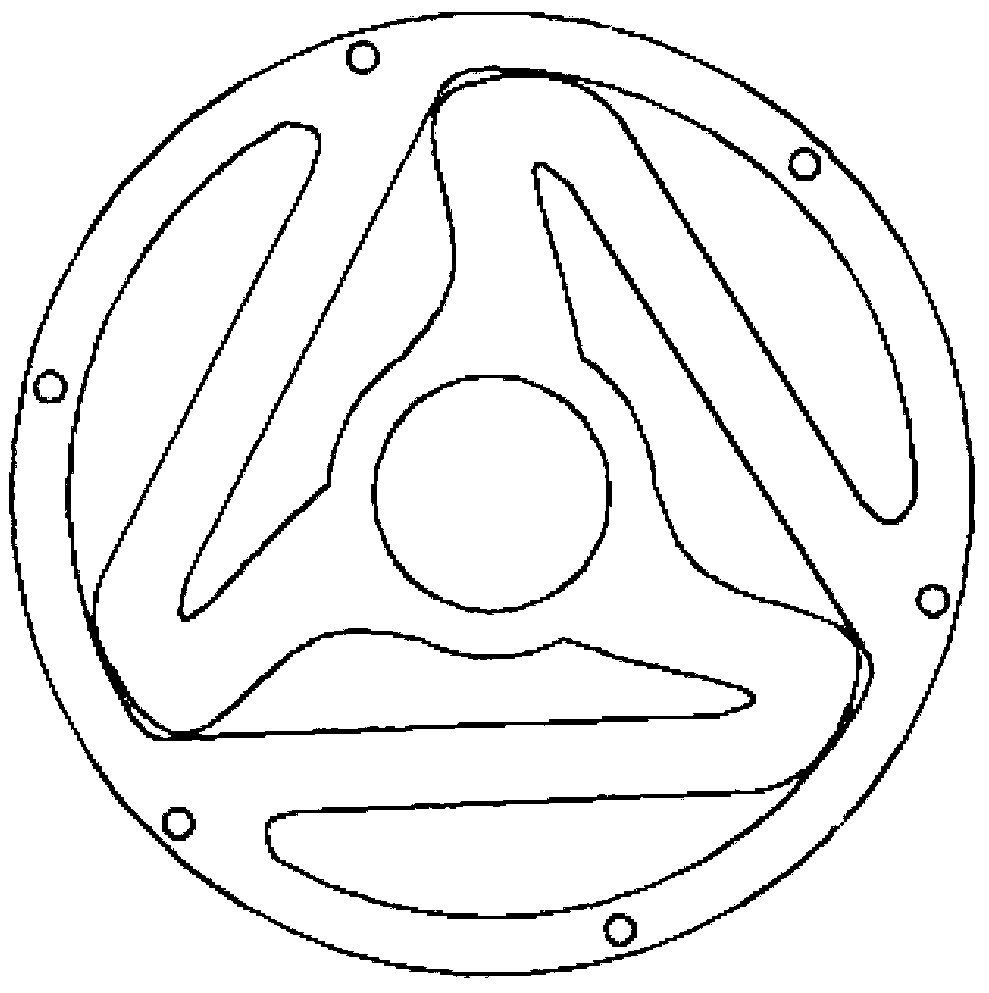

Linear compressor supported by three kinds of springs

InactiveCN103122837AEasy to fixImprove axial stiffnessPiston pumpsPositive-displacement liquid enginesReciprocating motionLinear compressor

The invention discloses a linear compressor supported by three kinds of springs. The linear compressor supported by the three kinds of springs comprises a support, a cylinder fixed with the support, two pistons in clearance fit with the inner wall of the cylinder, and two linear motors driving the two pistons to make coaxial and reciprocating motions, wherein the two linear motors are in transmission with the pistons correspondingly and respectively through piston shafts, two end portions of each piston shaft are fixed with the support respectively through a vortex arm plate spring assembly and a linear arm plate spring assembly, the vortex arm plate spring assemblies are close to the pistons, and a cylinder spiral spring used for providing axial elastic force is arranged between an end portion, far away from a corresponding piston, of each piston shaft and the support. Due to the fact that the linear compressor is supported by the three kinds of springs, clearance gap seal and oil-free lubrication technology are guaranteed, and axial rigidity of the springs is effectively improved. For a linear compressor with big rotor quality, high frequency resonance operation is achievable, operating efficiency is improved, and character match between the linear compressor and a cooling head of a low temperature refrigerator is achieved.

Owner:ZHEJIANG UNIV

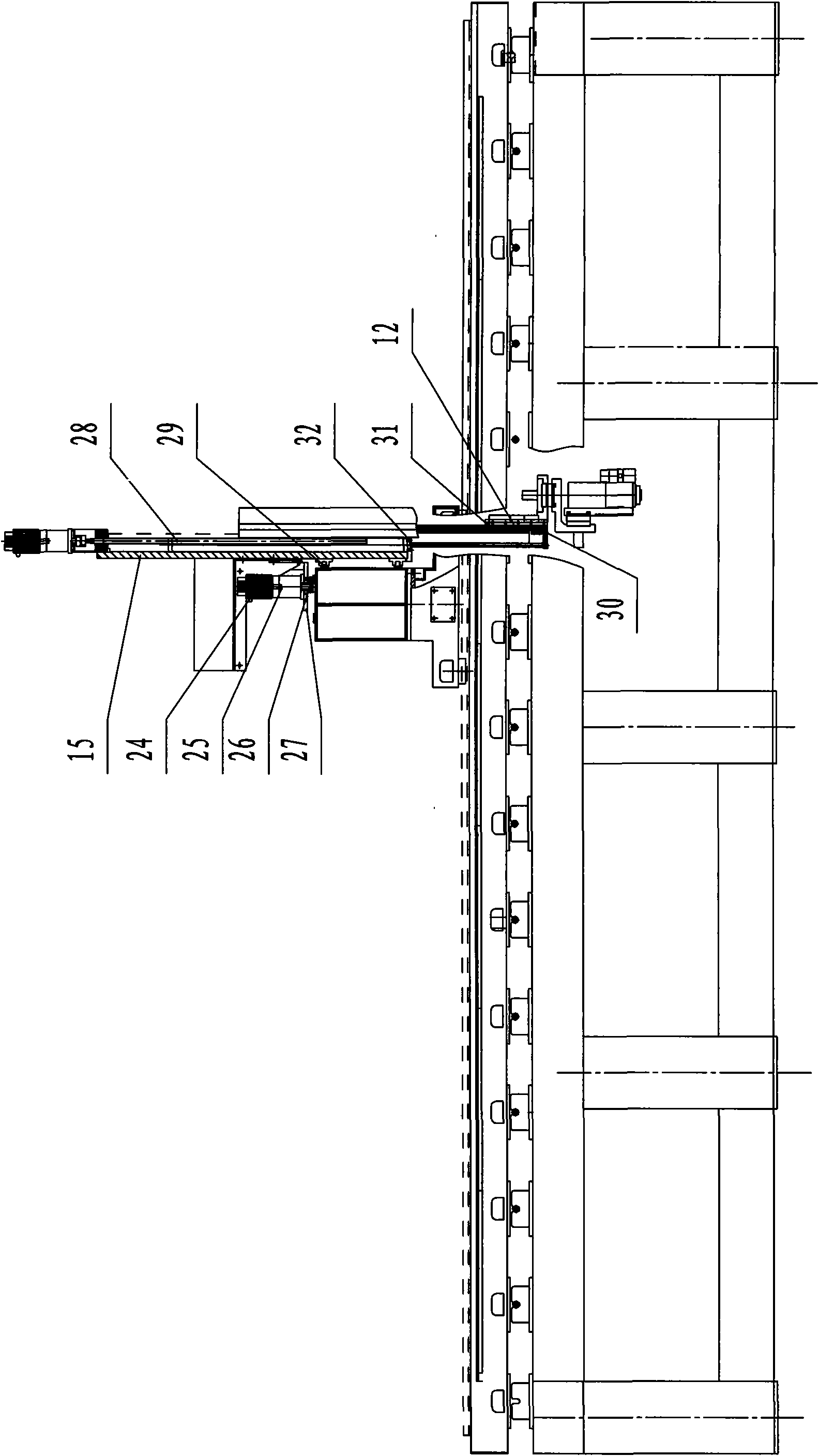

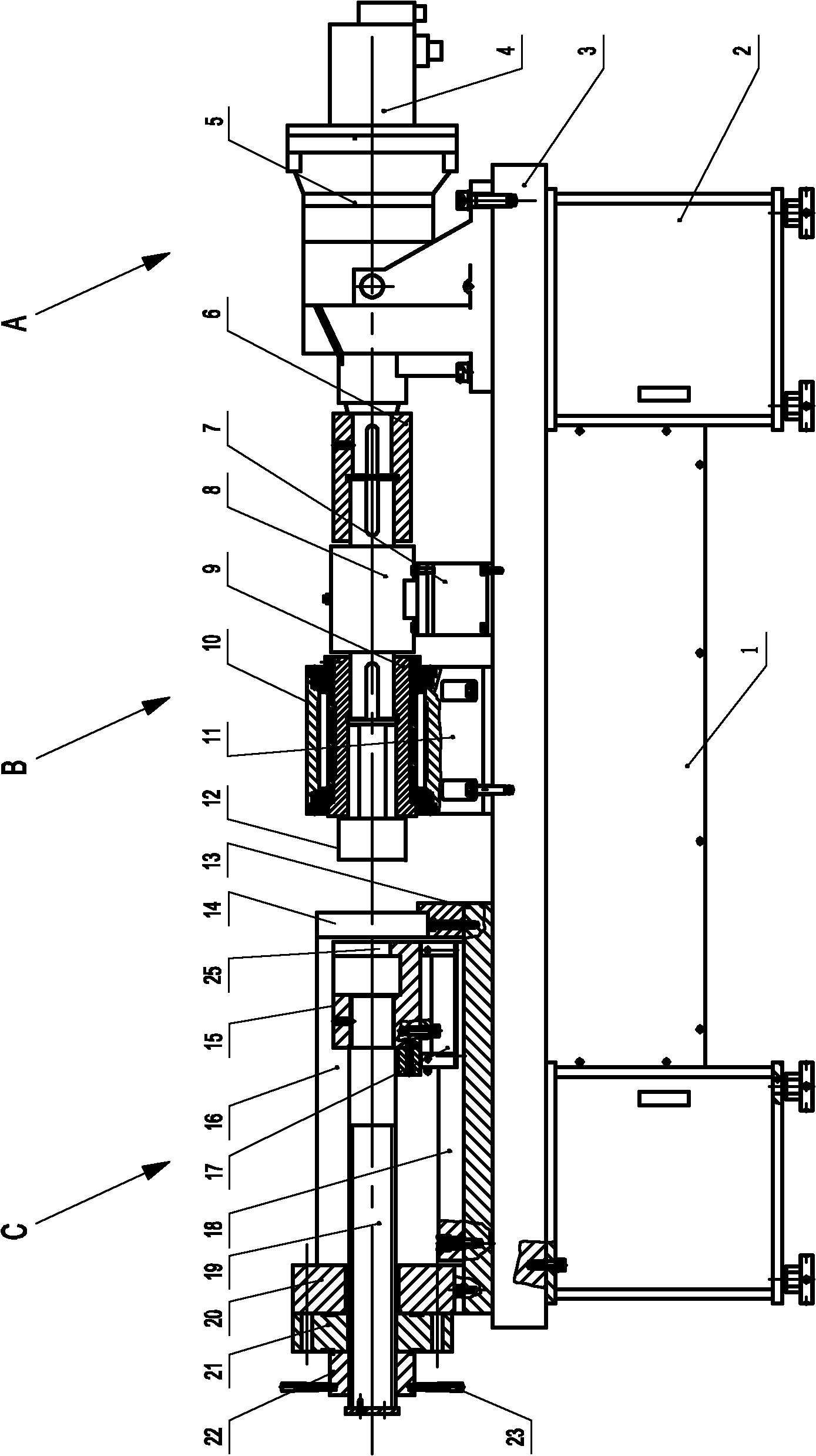

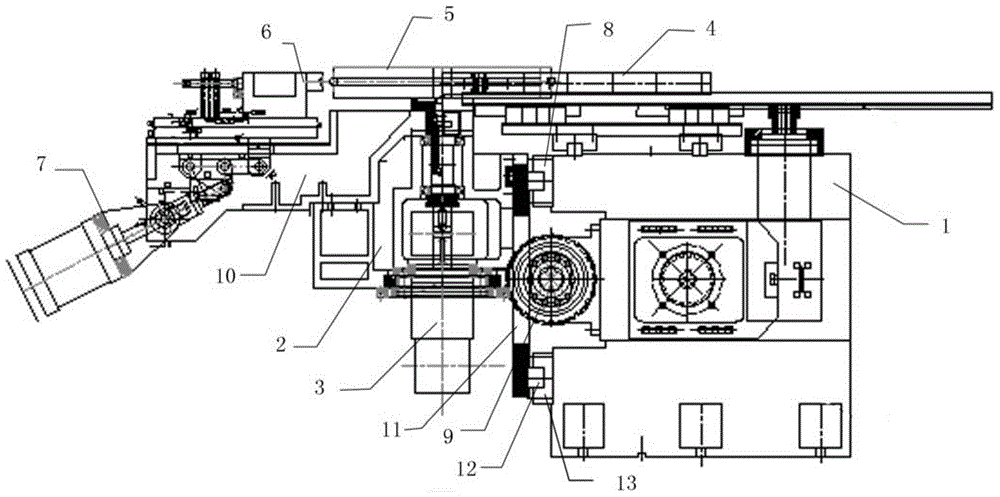

Pipe bending device of pipe bending machine applied for molding heat transferring tube of nuclear power evaporator

ActiveCN104475515AGuaranteed coaxialityGuaranteed parallelismMetal-working feeding devicesPositioning devicesNuclear powerEngineering

The invention discloses a pipe bending device of pipe bending machine applied for molding heat transferring tube of nuclear power evaporator; the pipe bending device of pipe bending machine applied for molding heat transferring tube of nuclear power evaporator comprises a machine head, and an auxiliary pushing device; the auxiliary pushing device is slidably mounted on the machine head along the axial direction of the bending steel pipe; the pipe bending device further comprises a machine seat which is slidably mounted on the machine head; the sliding direction of the machine seat is perpendicular to the axial direction of the steel pipe; the machine seat is connected with a machine seat drive device; a main shaft is mounted on the machine seat; a bending die is mounted on the upper end of the main shaft; a pipe bending arm is rotatably mounted on the machine seat; an arm driving device drives the pipe bending arm to rotate around the main shaft; a clamping device is movably mounted on the pipe bending arm; and the clamping device clamps the steel pipe when bending the pipe. The pipe bending device uses the auxiliary pushing device to position the steel pipe, thus ensuring the levelness on two ends of the steel pipe; then uses the movable bending die to approach the auxiliary pushing device for achieving bending the pipe, thereby the parallelism and the perpendicularity of the bent steel pipe can meet the requirements.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST

Electronic expansion valve

InactiveCN104279342AReduce wearImprove coaxialityEfficient regulation technologiesFluid circulation arrangementInjection mouldingRefrigeration

The invention discloses an electronic expansion valve, belongs to the technical field of refrigeration system control, and solves the technical problem of wear caused by the coaxiality difference between the existing electronic expansion valve nut and a valve needle assembly. The electronic expansion valve comprises a valve body, a nut, a valve needle assembly and a guide sleeve, wherein the nut and the guide sleeve are assembled on the valve body, and the valve needle is arranged on the nut; the nut and the guide sleeve are integrally molded by injection.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

Anode of supersonic plasma torch, and supersonic plasma torch

The invention discloses an anode of a supersonic plasma torch, and the supersonic plasma torch. Mainly, the conventional laval-type anode is divided into two parts, wherein one part near a cathode body is called as a basic anode; the other part far away from the cathode body is called an auxiliary anode; and the two parts are isolated by a high-temperature-resistant insulation ceramic chip. The cathode body is fixed on a conductive torch core and is sequentially connected with the basic anode and the auxiliary anode in an axial direction. When the anode works, an arc root is transferred from the basic anode to the auxiliary anode, so that a nozzle of the laval-type basic anode with a complicated structure is protected while an electric arc is lengthened. Therefore, the voltage is increased under the condition that the working current is unchanged. As a result, the energy utilization rate is improved.

Owner:NANJING UNIV OF SCI & TECH

Adjustable middle support device for machining overlength shaft

ActiveCN102974859AEliminate shock effectsFlexible structureBoring barsTool holdersLong axisEngineering

The invention provides an adjustable middle support device for machining an overlength shaft. The adjustable middle support device comprises a transition sleeve and a support frame, wherein the transition sleeve is radially provided with a transition sleeve adjusting device capable of adjusting a distance between the transition sleeve and a boring rod, the support frame is a hollow circular sleeve and is sleeved on the transition sleeve, two end parts of the support frame are in airtight connection with the transition sleeve, the support frame is radially and symmetrically provided with a support frame adjusting device I capable of adjusting the distance between the support frame and the transition sleeve and a support frame adjusting device II capable of adjusting the supporting frame and a hole wall inside a stern shaft tube, a cavity of the support frame is internally provided with a rubber hose, one end of the rubber hose is in contact with the excircle of the transition sleeve, the other end of the rubber hose is connected with an outlet end of an oil filling nozzle which is fixedly arranged inside the cavity of the support frame, and the top end of the oil filling nozzle extends out of the support frame. The adjustable middle support device disclosed by the invention can be used for not only supporting the long boring rod but also guaranteeing the coaxiality in boring a long shaft hole, and has a higher practical value.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com