Full-automatic drink making robot

A robotic and fully automatic technology, which is applied in the fields of equipment automation, mechanical design and manufacturing, and automatic beverage production. It can solve the problems of inability to realize automation, unmanned, limited types, and inability to realize quantitative combination of various ingredients and personalized modulation of beverage formulas, etc. problems, to achieve the effect of ensuring the taste and processing effect, improving production efficiency, improving viewing and interest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

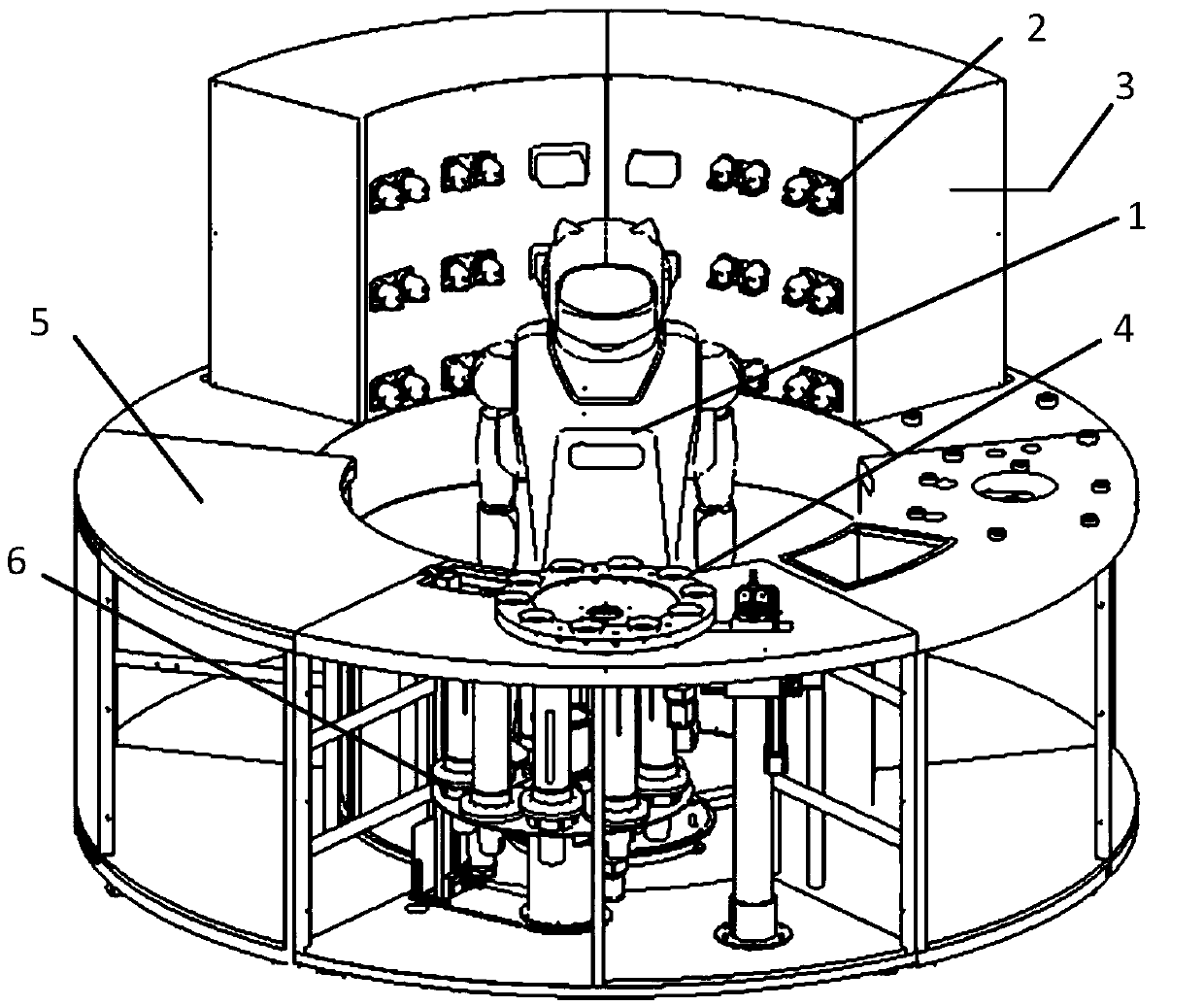

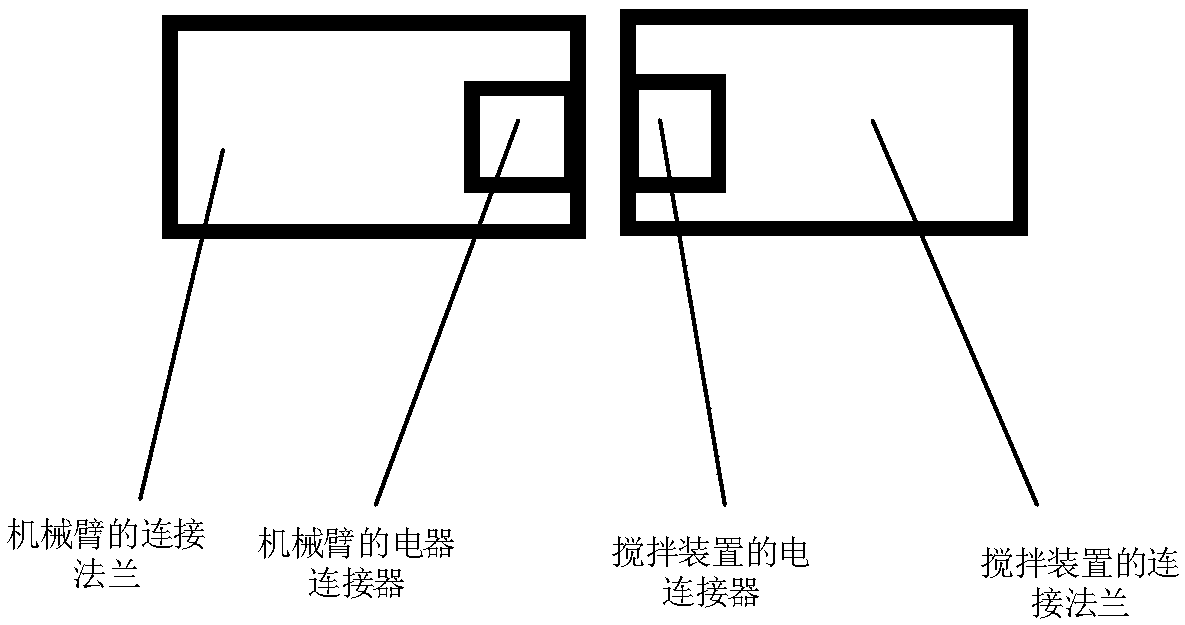

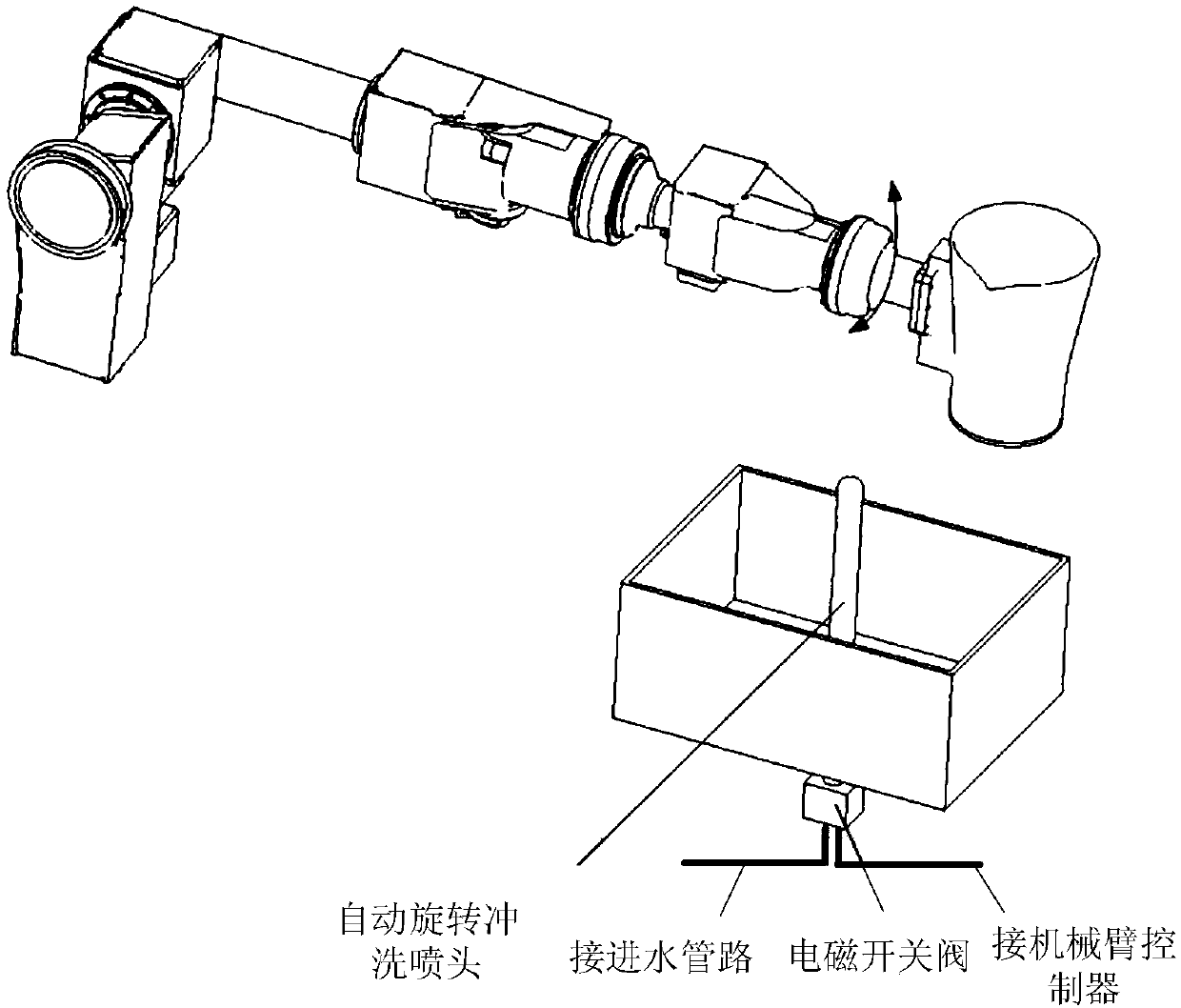

[0058] Such as figure 1 As shown, the present invention includes a double-arm robot 1, a quantitative discharge cabinet 3 (2 is a discharge port), an automatic delivery device 4, an automatic cup discharge device 6, a self-service order system and a centralized control system; A stirring device is installed at the end of one arm of the robot, and the other arm is a manipulator;

[0059] The automatic cup output device separates a stack of paper / plastic cups and transfers them to the preset grabbing position, from which the robot grabs the paper cups / plastic cups; the self-service ordering system provides an ordering interface, where customers order The beverage formula is selected on the interface, and the centralized control system obtains the beverage formula and analyzes it, and analyzes the ingredient position, ingredient amount, and distribution of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com