Patents

Literature

15969results about How to "Stir well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

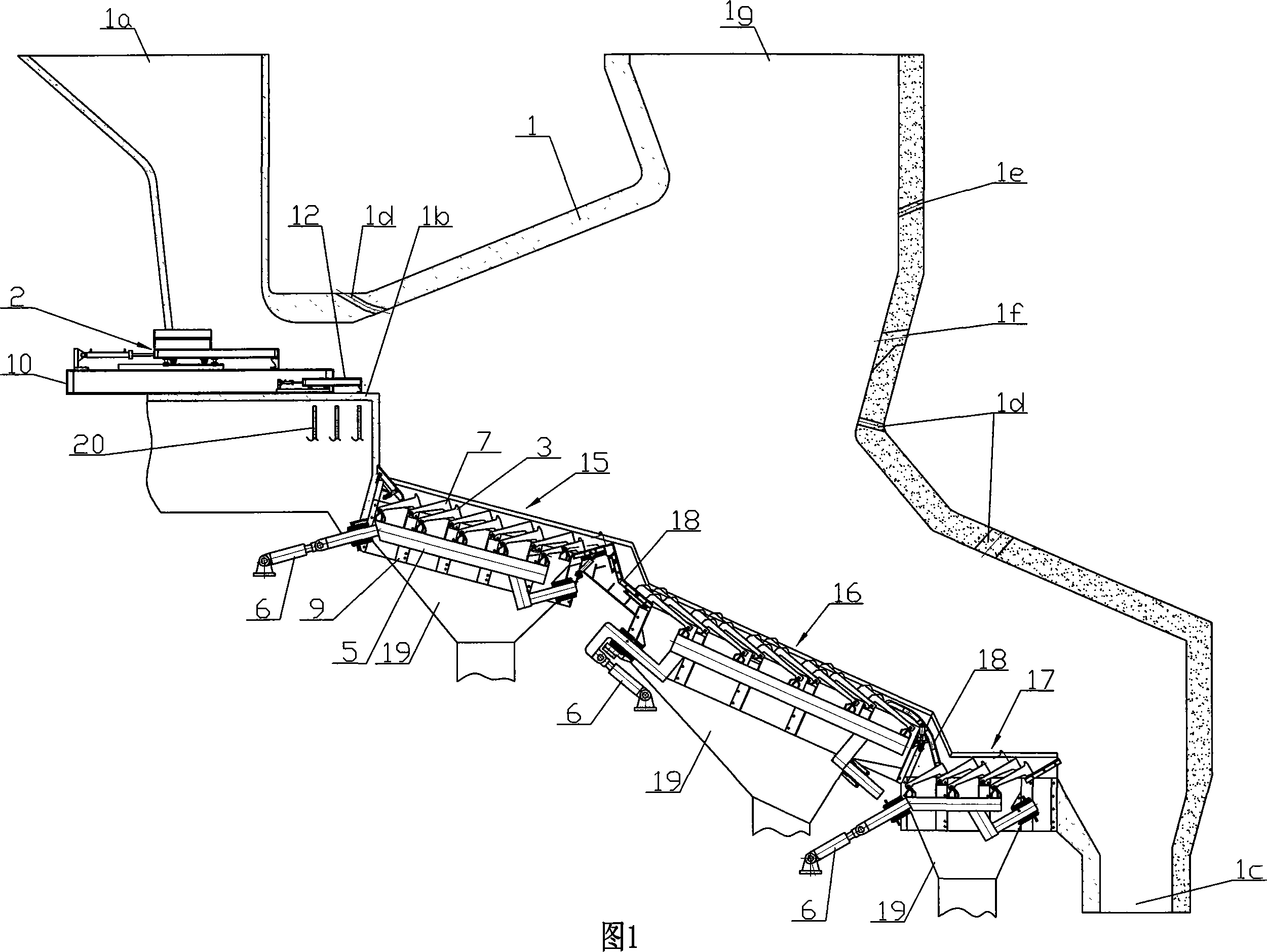

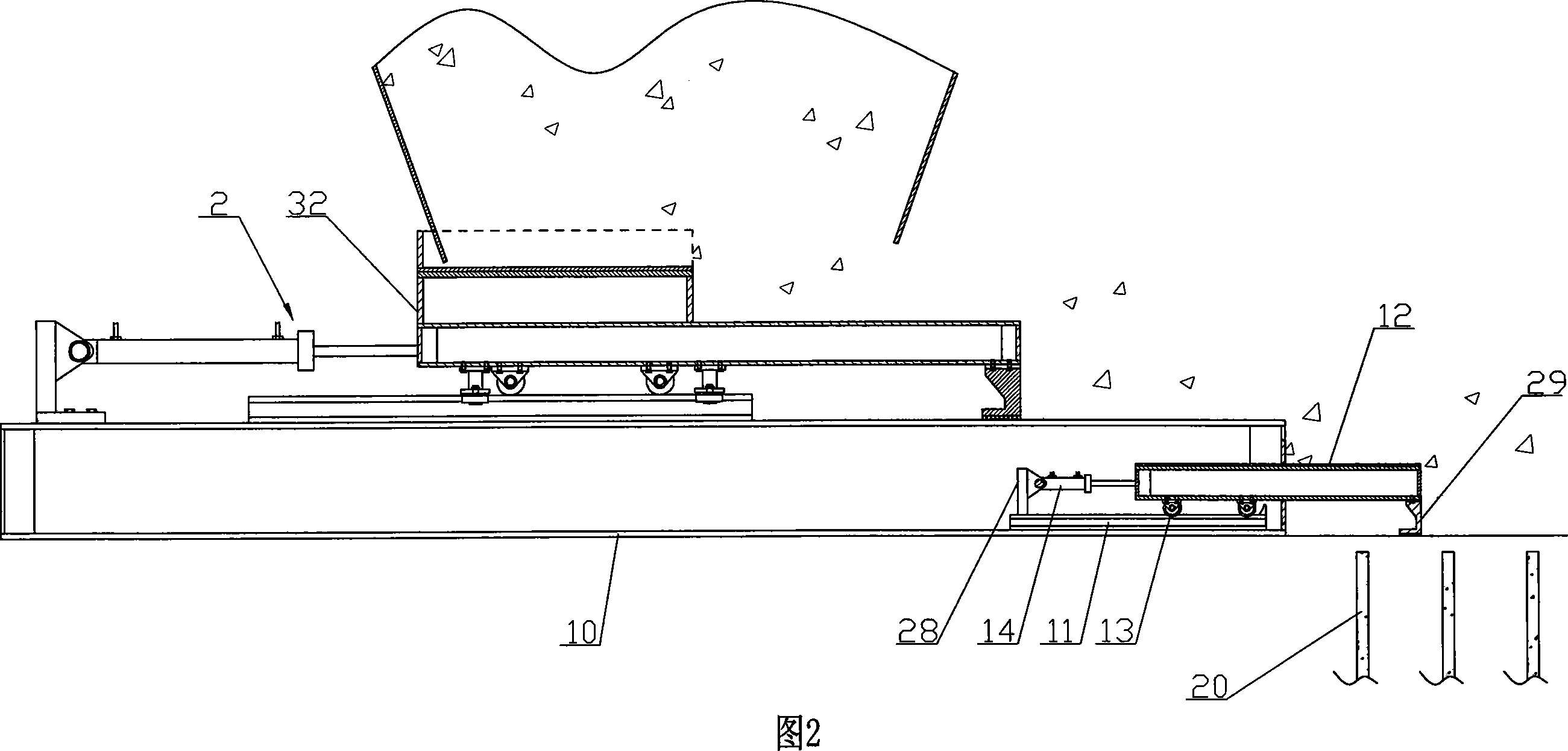

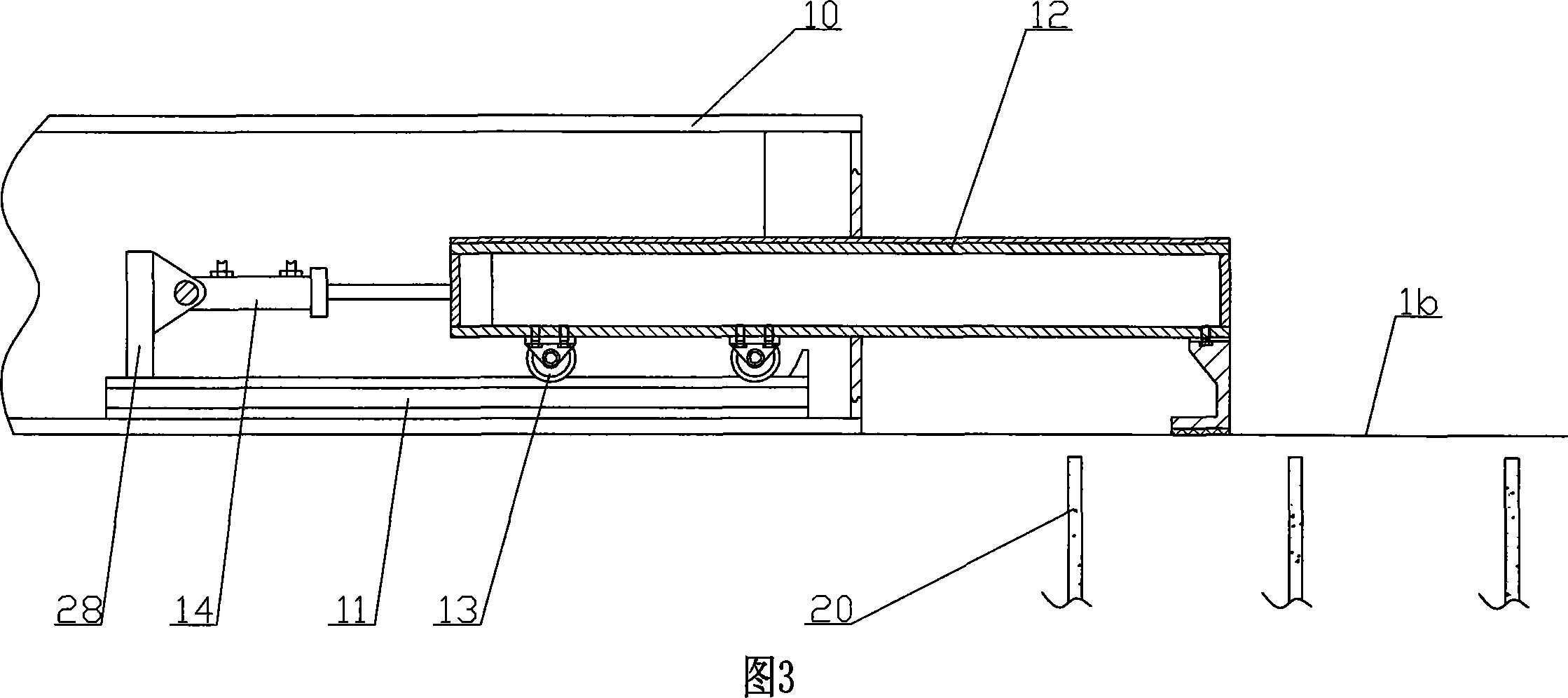

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Waterproof sealing paste producing chemical crosslinking and physical mortising with cement

ActiveCN103304862AImprove adhesionStrong tear resistanceOther chemical processesBuilding insulationsPlasticizerAdsorption effect

The invention provides waterproof sealing paste producing chemical crosslinking and physical mortising with cement. The sealing paste is characterized by comprising the following raw materials in parts by weight: 40-60 parts of synthesized rubber latex, 20-30 parts of rubber modified emulsified asphalt, 1-2 parts of a functional additive, 10-30 parts of filler, 0.5-5 parts of plasticizer, 1-3 parts of a thickener and 2-5 parts of water. A principle is that part of molecules in the synthesized rubber and the asphalt are coupled into macromolecules with reactivity under the coupling effect of the functional additive; when the macromolecules are contacted with a basic surface, the non-reactivity molecule sections of the rubber and the asphalt form a physical adsorption effect with the basic surface, and the reactivity molecule sections react with the basic surface to form a chemical bonding effect so as to generate a powerful bonding force; and the bonding effect is difficultly influenced by outside environment factors after the bonding operation is finished. Therefore, the sealing paste is very excellent in waterproof performance.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Anti-bacterial water-based paint and preparation method thereof

InactiveCN102702889AImprove aging resistanceImprove the pulverization performanceBiocideAntifouling/underwater paintsWater basedEscherichia coli

The invention relates to anti-bacterial water-based paint and a preparation method thereof. The paint comprises the following components in parts by weight: 0.2-11 parts of anti-bacterial agent, 8-33 parts of nano material, 23-64 parts of water-based resin dispersoid and 0.75-18 parts of adhesive resin or plasticizer. The preparation method comprises the following steps: firstly preparing a nano silver anti-bacterial agent; mixing deionized water, the anti-bacterial agent, a wetting agent, a dispersing agent and a defoaming agent and uniformly mixing, adding the nano material, uniformly dispersing to obtain the water-based dispersoid; adding the obtained water-based dispersoid to the mixed emulsion or water-based resin dispersoid, then adding the adhesive resin or plasticizer and various conventional assistants, stirring and dispersing evenly; adding pigments or colorant; and supplementing water to obtain the anti-bacterial water-based paint. The long-acting broad-spectrum antibacterial water-based paint has high fungicidal efficiency (more than 99%) on escherichia coli, staphylococcus aureus, black varietas of bacillus subtilis and the like and can reduce the high concentrate of organic matters of formaldehyde to the range of specified concentration index.

Owner:ANHUI JINDUN PAINT

Green bioactive organic fertilizer

InactiveCN101786931APrevent compactionAvoid pollutionBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention relates to a green bioactive organic fertilizer, which effectively solves the problems of soil hardening, environmental pollution, and harm from residual chemical substances of grains, vegetables and fruits to human bodies. The solved technical scheme is that the green bioactive organic fertilizer is prepared by taking sludge, waste powder, poultry and animal feces, straw powder, residues, feather powder, amino acid original powder, phosphoesterases complex, a first group of complex bacteria, and a second group of complex bacteria as raw materials; uniformly mixing the sludge, the waste powder, the poultry and animal feces, the straw powder, the phosphoesterases complex and the first group of complex bacteria; stacking and covering the mixture with a sack for performing a biogenic reaction, and keeping a reaction product at the temperature of 50 to 55 DEG C for 2 days; adding the residues, the feather powder, the amino acid original powder into the reaction product, uniformly mixing the mixture for performing a secondary reaction, and keeping a reaction product at the temperature of 50 to 55 DEG C for 7 to 10 days; and adding the second complex bacteria into the latest reaction product, uniformly mixing, palletizing, checking and packaging the mixture. The green bioactive organic fertilizer has the advantages of scientific formulation, simple preparation method, good effect, no pollution and no harm to human bodies.

Owner:徐贵阁

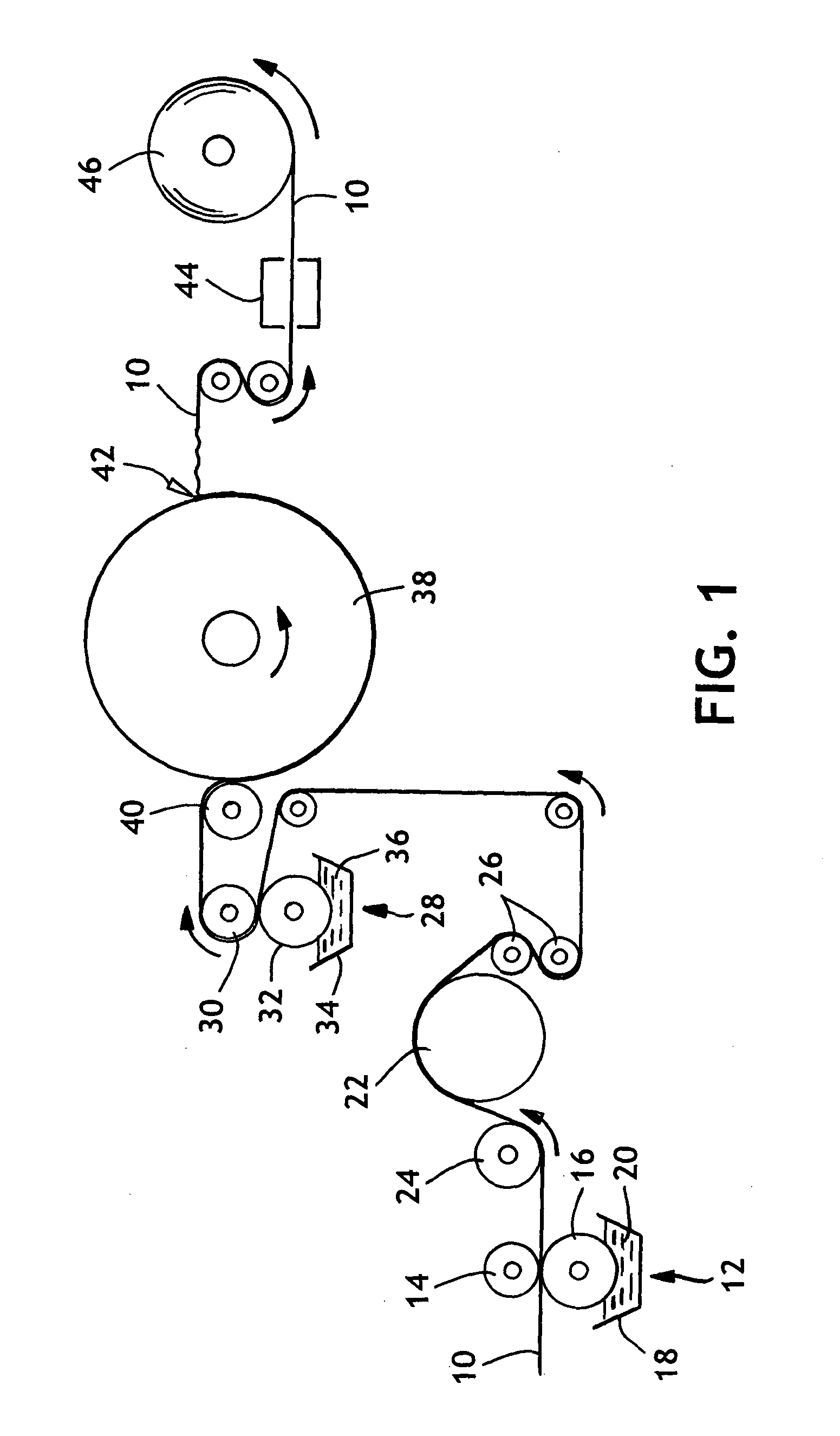

Low odor binders curable at room temperature

InactiveUS20050045294A1Easy to storePromote hydrolysisNon-fibrous pulp additionNatural cellulose pulp/paperPolymer sciencePaper towel

Topically-applied binder materials for imparting wet strength to soft, absorbent paper sheets, such as are useful as household paper towels and the like, include an epoxy-reactive polymer, such as a carboxyl-functional polymer, and an epoxy-functional polymer. These binder materials can be cured at ambient temperature over a period of days and do not impart objectionable odor to final product when wetted.

Owner:KIMBERLY-CLARK WORLDWIDE INC

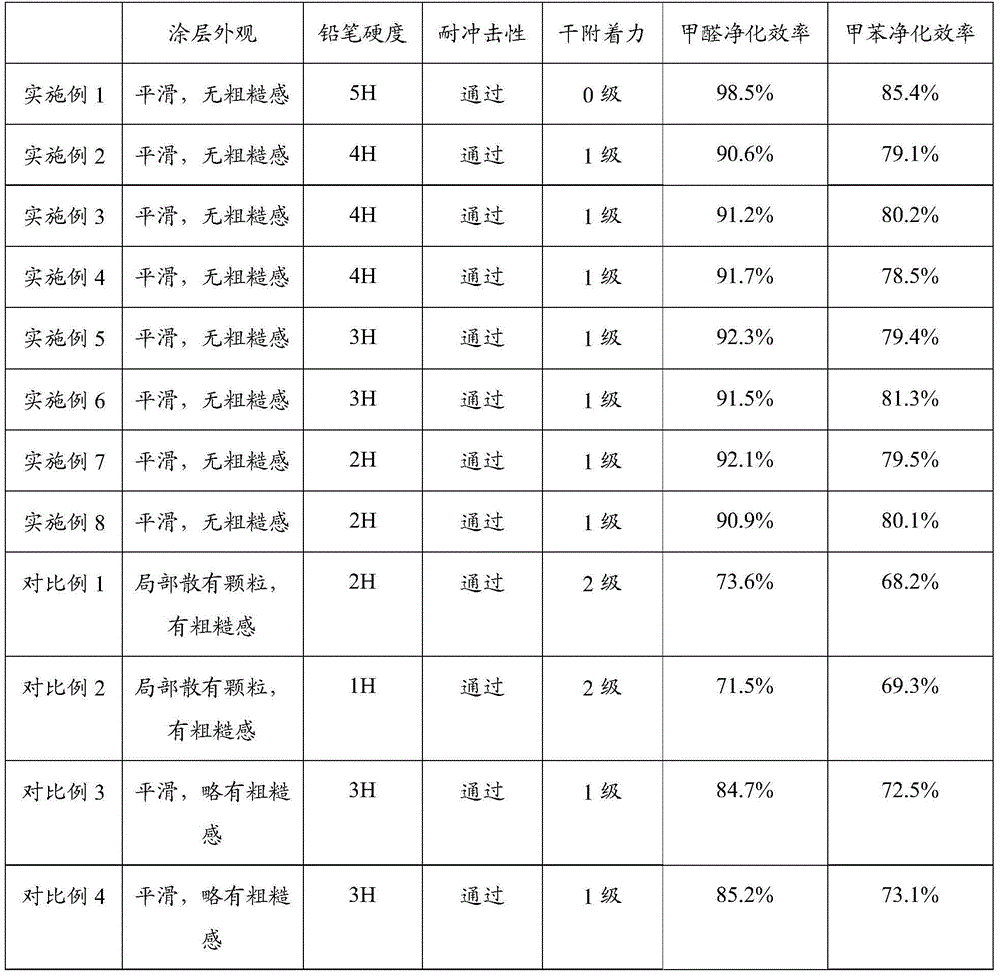

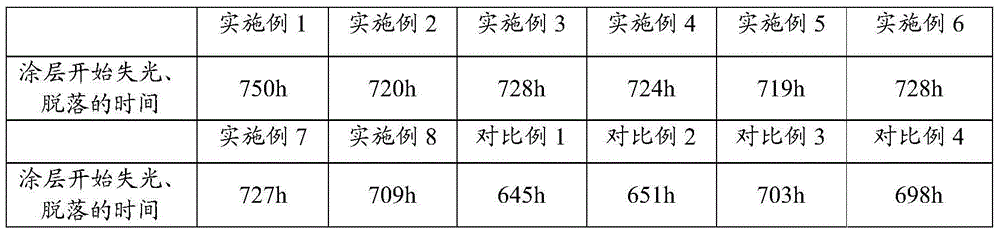

Multifunctional inorganic diatom ooze coating and preparation method thereof

InactiveCN104387816AStir wellNot easy to reuniteAntifouling/underwater paintsAlkali metal silicate coatingsCelluloseEmulsion

The invention relates to a multifunctional inorganic diatom ooze coating, which is prepared from the following components in percentage by mass: 10%-25% of water, 0.4%-0.8% of cellulose, 10-30% of a mixture of potassium metasilicate and silica sol, 0.2%-0.4% of a stabilizer, 0.1%-0.3% of a dispersing agent, 0.1%-0.3% of a silicon additive, 0.3%-0.5% of a defoaming agent, 0.1%-0.3% of an antibacterial agent, 0-20% of titanium dioxide, 5%-15% of nanometer kieselguhr, 10%-30% of coarse whiting, 2%-4% of talcum powder, 1%-3% of medical stone, 0-1.5% of anion, 0-2% of a nano-photocatalyst, 1%-2% of inorganic gel powder, 0-9% of an order-removing emulsion and 0-1.5% of pigment, wherein the sum of the components is 100%. The invention also provides a preparation method of the coating. The coating disclosed by the invention has the functions of sterilizing, preventing mold, purifying air and the like; and the preparation method disclosed by the invention is simple and easy to operate.

Owner:佛山市南海万磊建筑涂料有限公司

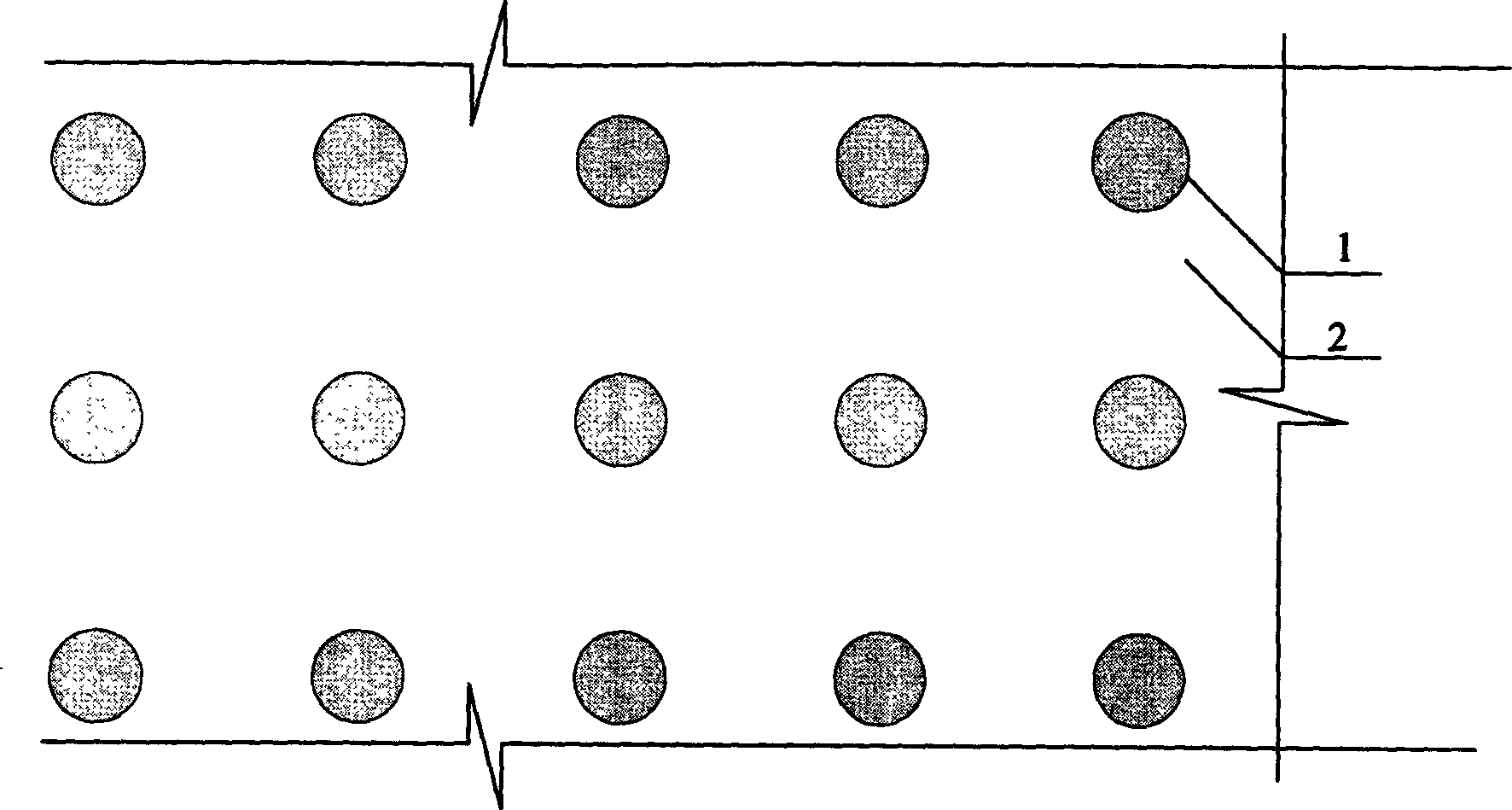

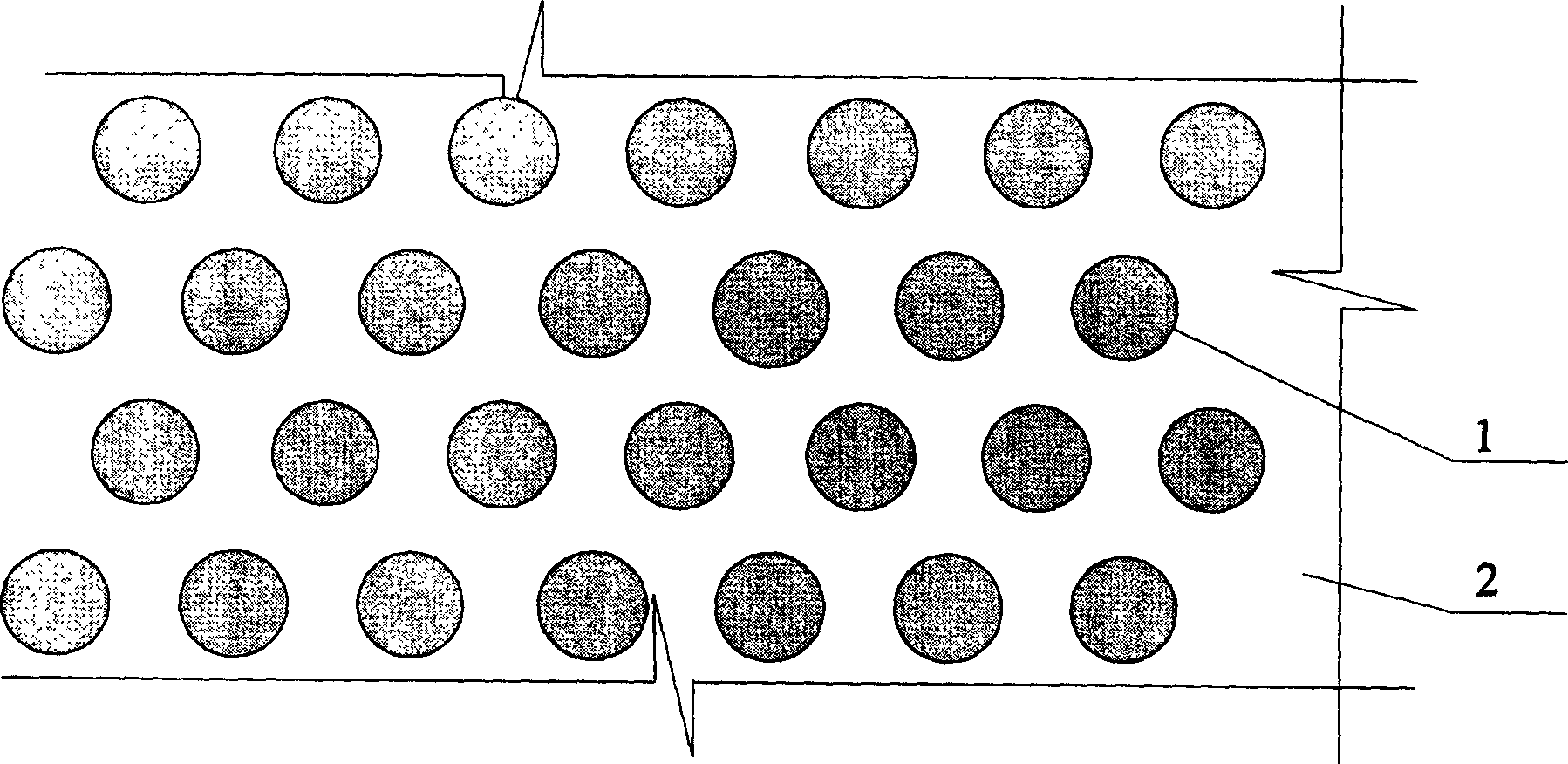

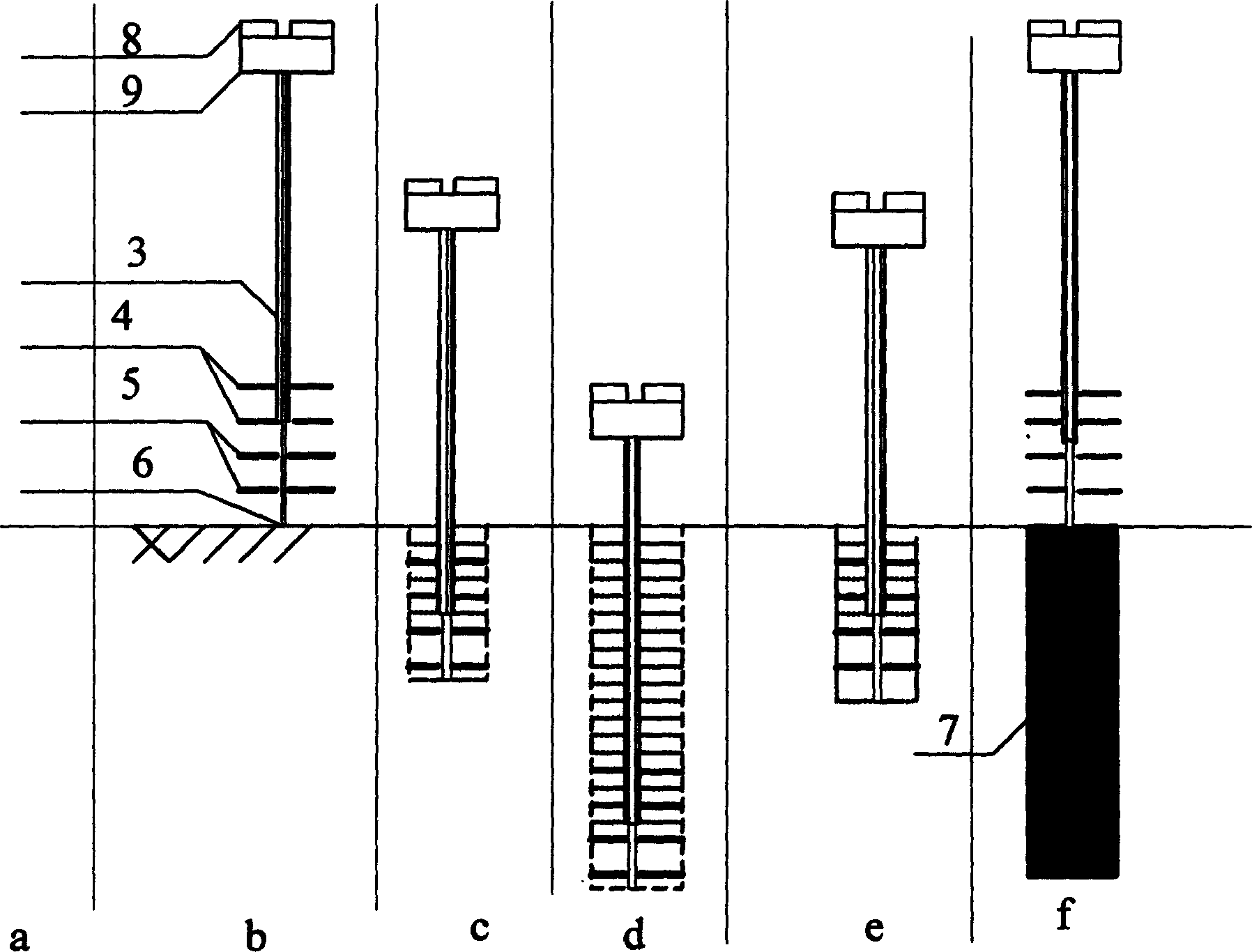

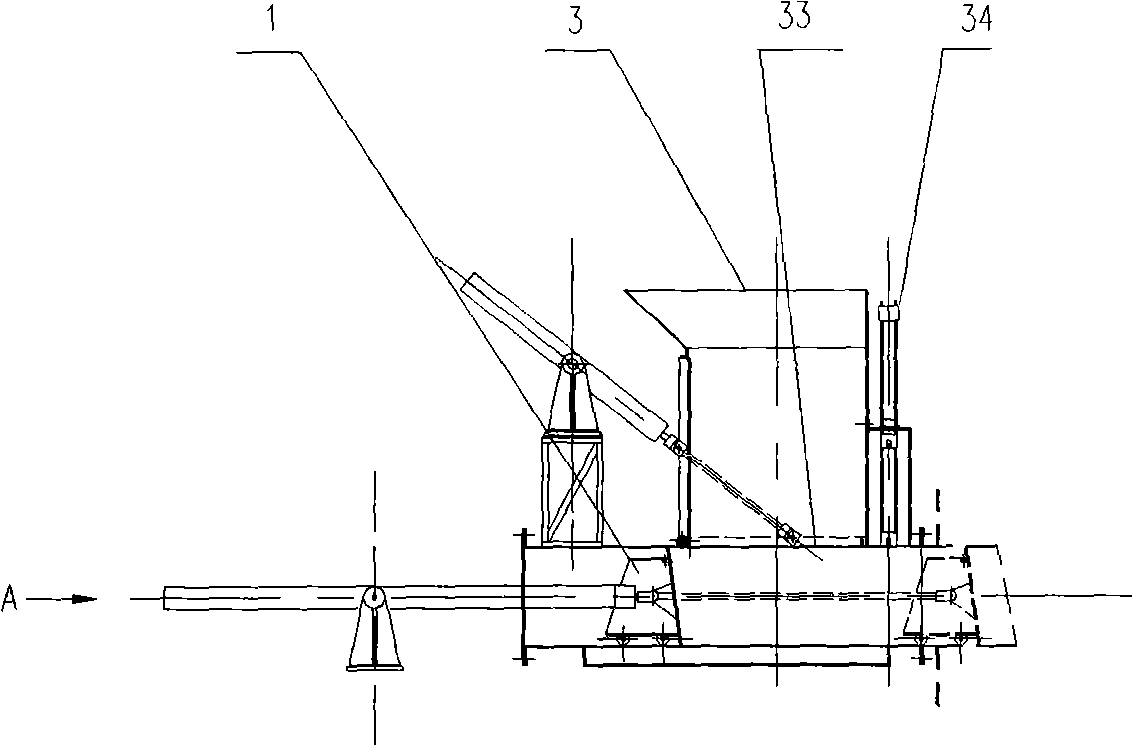

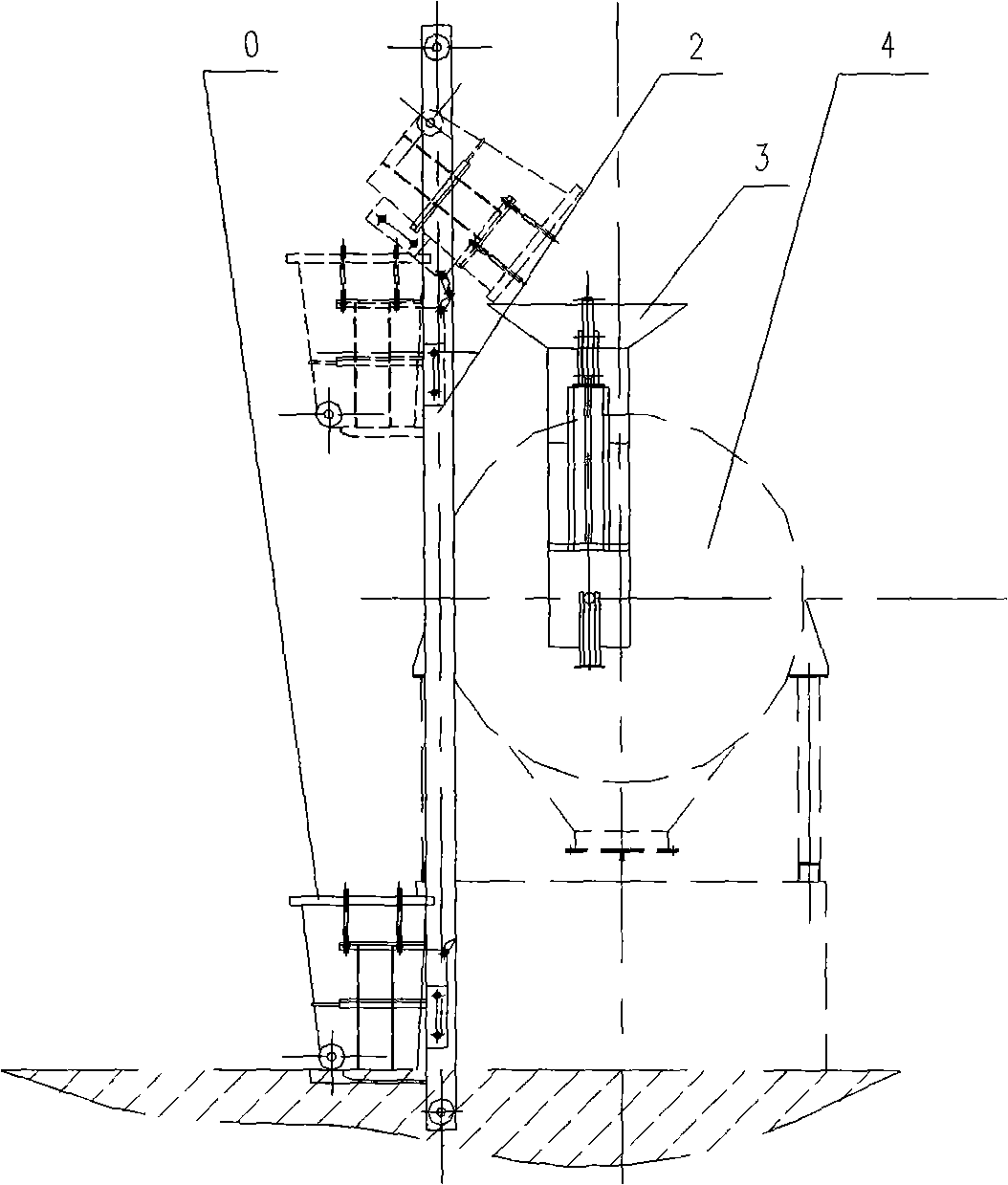

Pile forming operation method for bi-directional stirring piles

The piling operation method of two-way mixing pile is a foundation treatment method, which is suitable for soft soil foundation treatment. The operation method is: a: leveling the site; Centering; c: Stirring and sinking: start the two-way stirring pile driver, make the drill pipe of the two-way stirring pile driver cut the soil downward along the guide frame, turn on the slurry pump, spray cement slurry to the soil, and the drill pipe of the two-way stirring pile driver is respectively positive , The counter-rotating blades rotate at the same time to stir the cement and soil; d: The drill pipe of the two-way stirring pile machine continues to sink and stir the cement and soil until the design depth; e: While stirring and lifting, the drill pipe of the two-way stirring pile machine rotates forward and reverse f: lift and stir to the ground surface or 50cm above the design elevation, and complete the construction of the two-way mixing cement-soil mixing pile (1). The cement-soil mixing pile (1) is arranged in a plum blossom shape or square to ensure quality and pile quality.

Owner:南京路鼎搅拌桩特种技术有限公司

Bio-organic fertilizer

InactiveCN104774054ALow costQuick costBio-organic fraction processingOrganic fertiliser preparationSnow moldMicrobial agent

The invention discloses bio-organic fertilizer, and belongs to the technical field of organic fertilizer. The proportion by weight of all raw materials of the bio-organic fertilizer is dried chicken manure : edible mushroom : compound microbial agent : corn flour or rice bran : functional strain = 110-140 : 390-360 : 0.1-0.5 ; 0.1. The compound microbial agent comprises mould, bacillus, lactic acid bacteria, actinomycetes and saccharomycetes. The strains are efficient viable bacteria. Each gram of the compound microbial agent comprises the number of the mould ranges from 5 hundred million to 8 hundred million, the number of the efficient viable bacteria of bacillus ranges from 12 hundred million to 15 hundred million, and the number of the actinomycetes ranges from 10 hundred million to 12 hundred million and the saccharomycetes of 15 hundred million to 18 million. According to the bio-organic fertilizer, the chicken manure and mushroom dregs serve as main materials, and the high-quality organic fertilizer can be fermented quickly by adding the compound microbial agent and the functional strain.

Owner:YONGZHOU WANXIDENG AGRI DEV

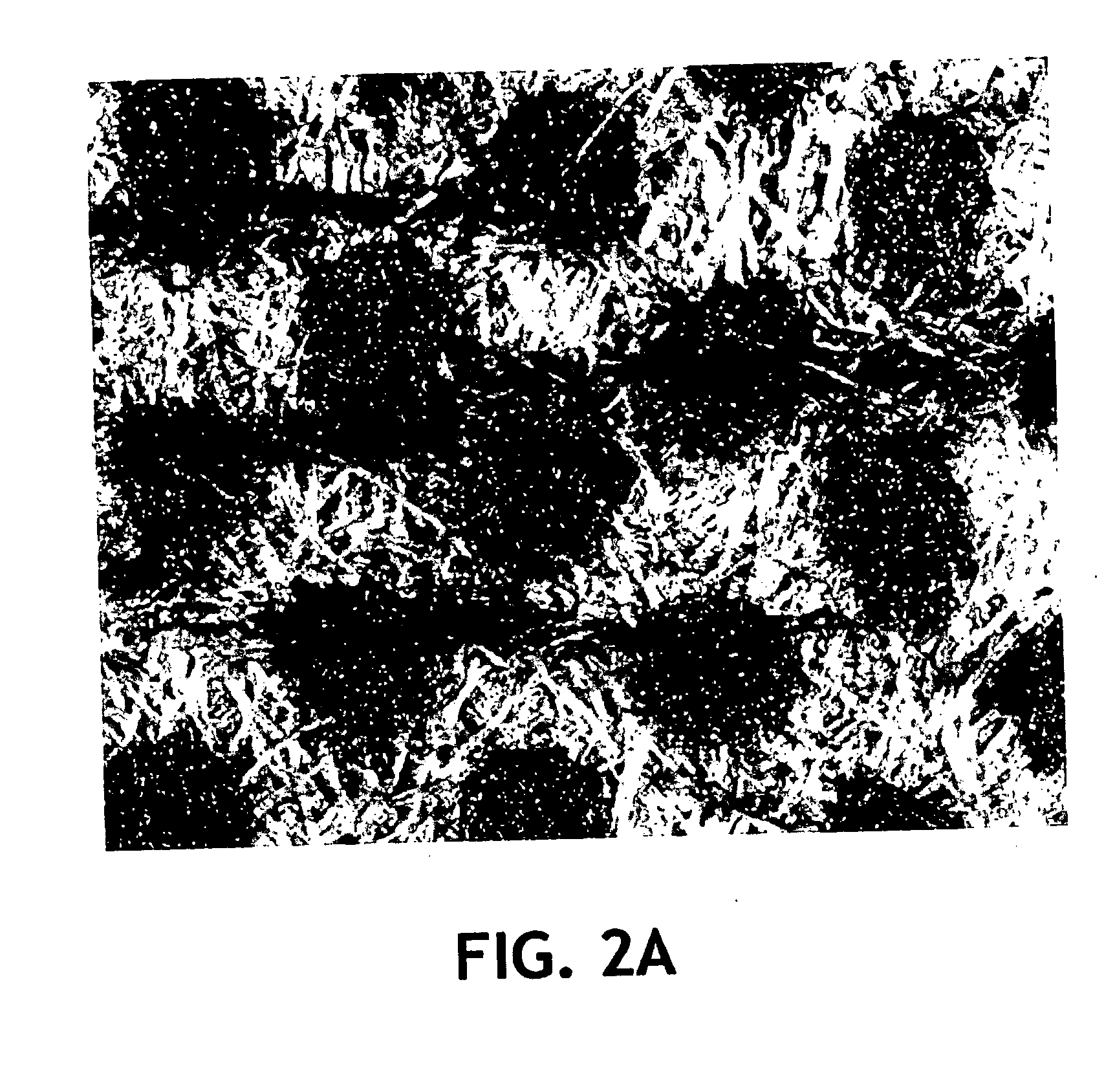

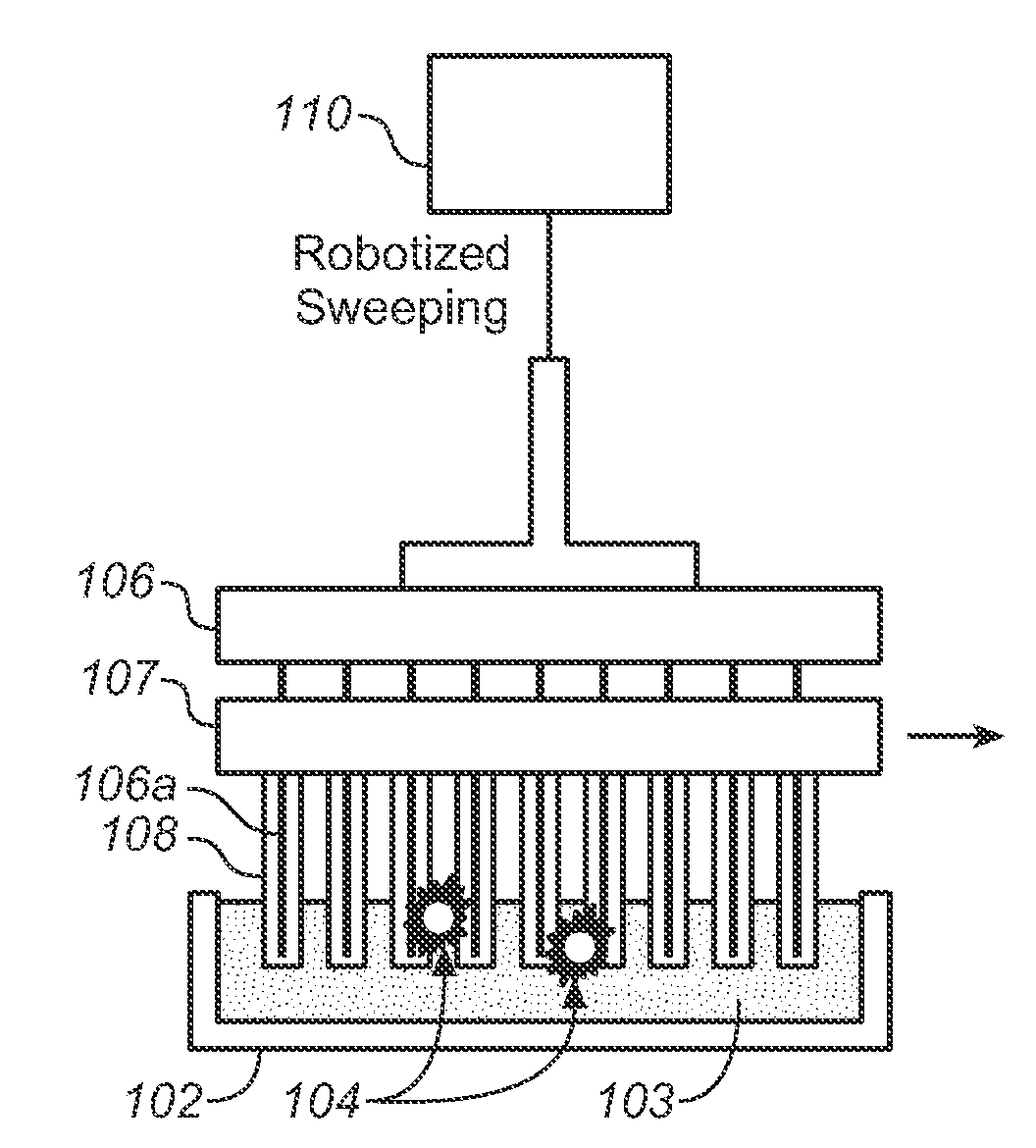

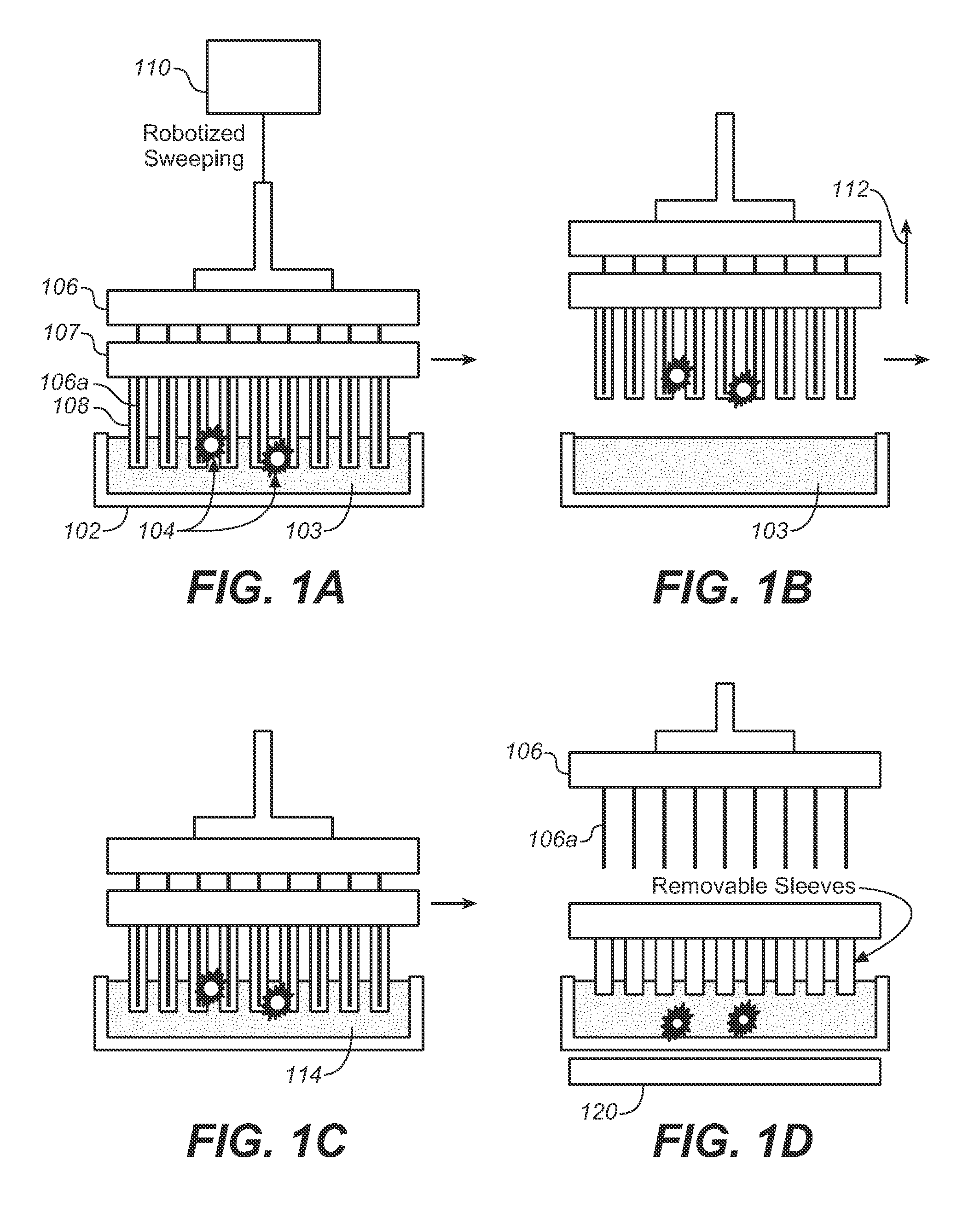

Methods and Apparatus for Magnetic Separation of Cells

ActiveUS20090220979A1Increase the magnetic field strengthStir wellBioreactor/fermenter combinationsBiological substance pretreatmentsSuperparamagnetic beadsTumor cells

Described here is an automated robotic device that isolates circulating tumor cells (CTCs) or other biological structures with extremely high purity. The device uses powerful magnetic rods covered in removable plastic sleeves. These rods sweep through blood samples, capturing, e.g., cancer cells labeled with antibodies linked to magnetically responsive particles such as superparamagnetic beads. Upon completion of the capturing protocol, the magnetic rods undergo several rounds of washing, thereby removing all contaminating blood cells. The captured target cells are released into a final capture solution by removing the magnetic rods from the sleeves. Additionally, cells captured by this device show no reduced viability when cultured after capture. Cells are captured in a state suitable for genetic analysis. Also disclosed are methods for single cell analysis. Being robotic allows the device to be operated with high throughput.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

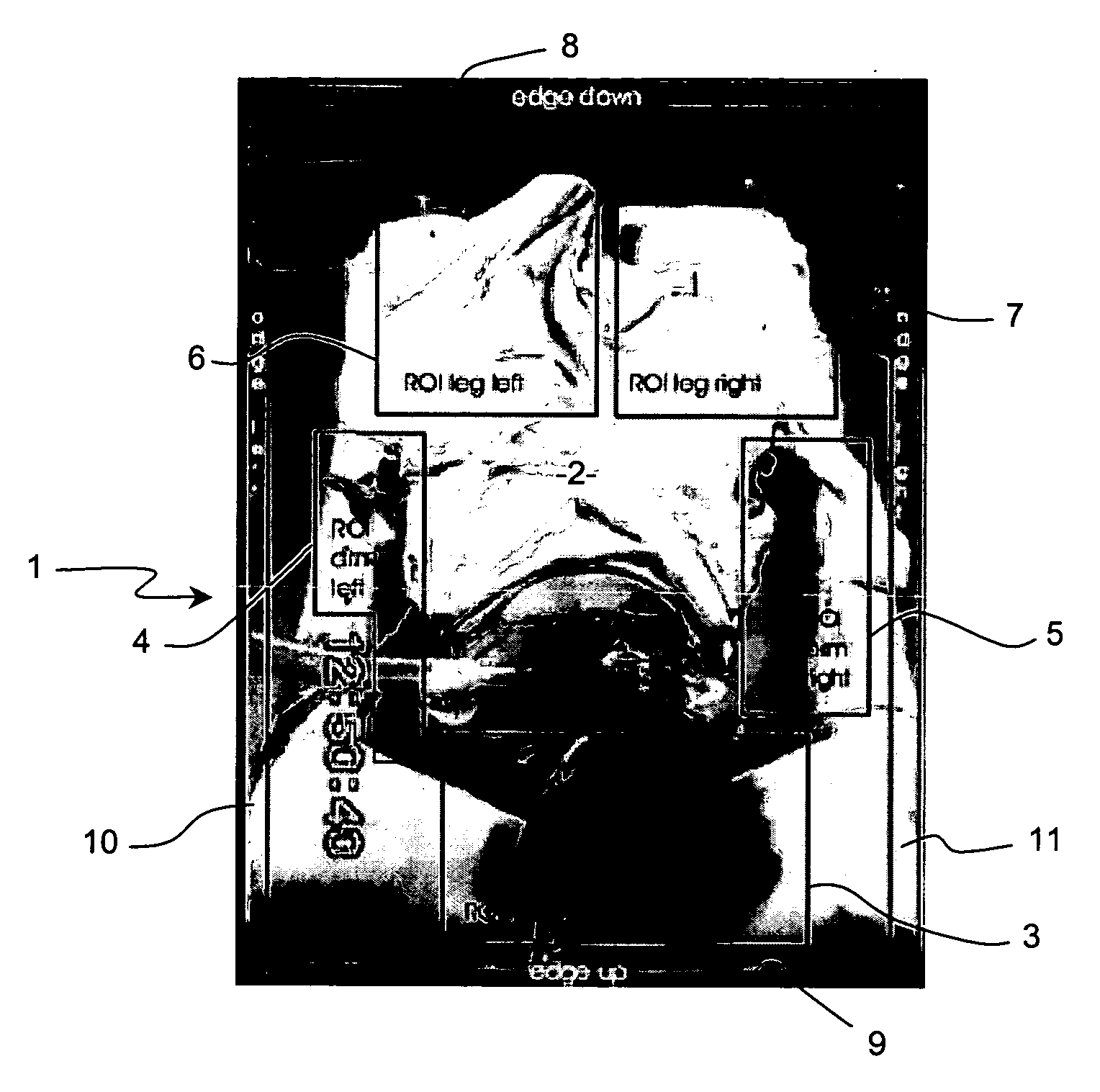

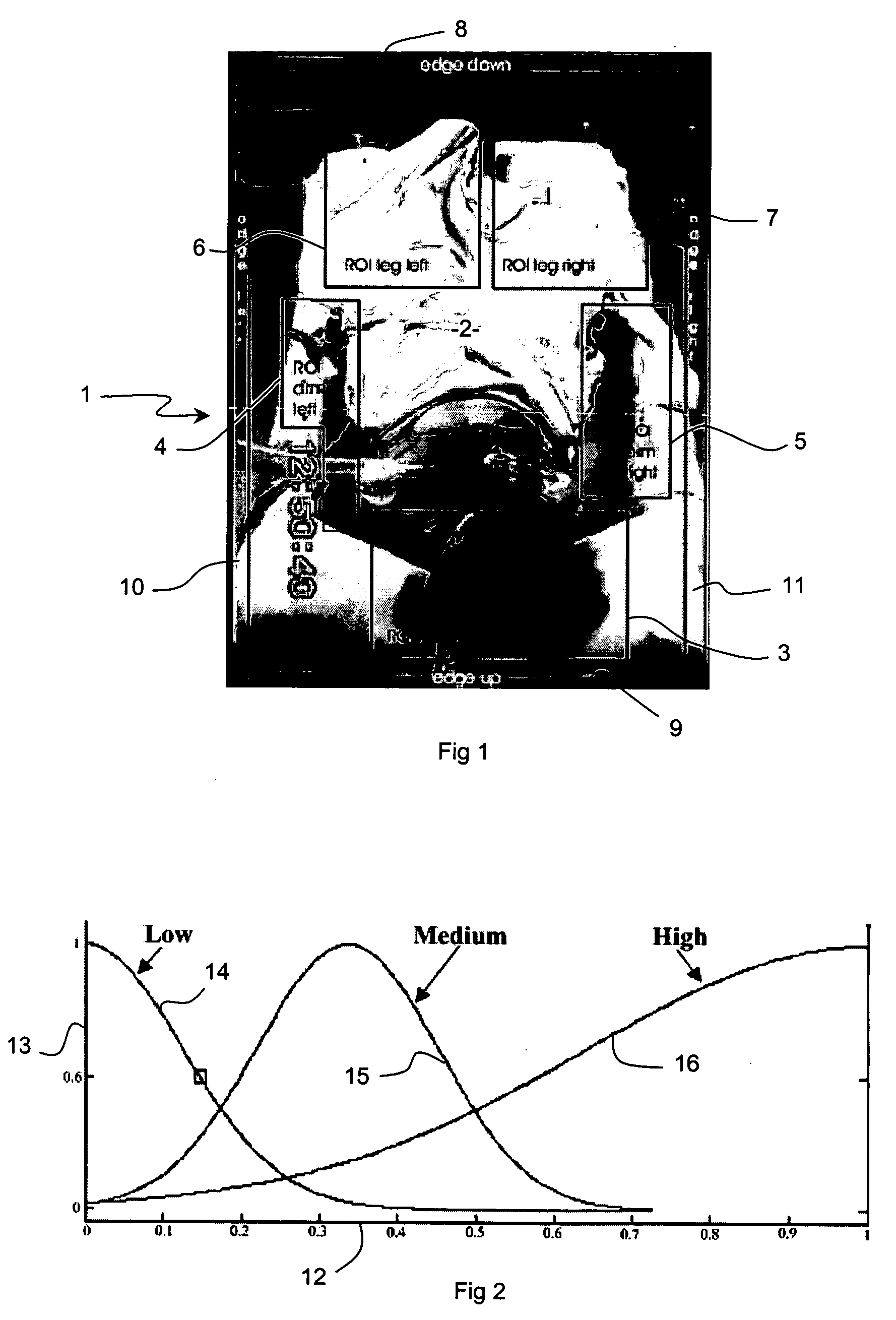

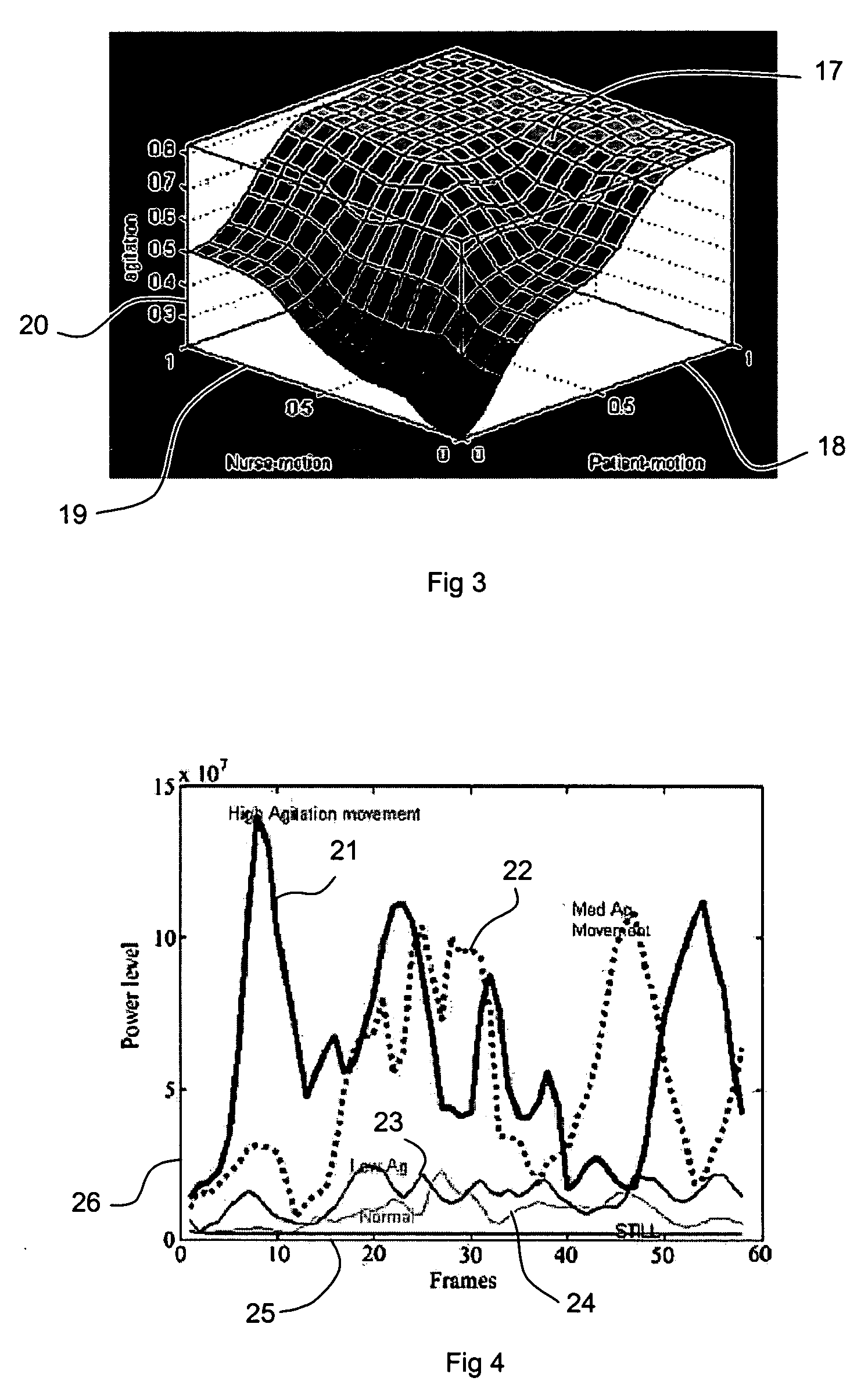

Method and system for assaying agitation

InactiveUS20060058590A1Increase volumeReduce effectElectroencephalographyMedical automated diagnosisNervous systemMedical staff

A method of physiologically quantifying patient agitation presented is based on reliable, objective physiological signals. The present invention is capable of quantifying autonomic nervous system interactions to provide an objective measurement of agitation. Adaptive autoregressive (AR) signal processing techniques are used to analyze heart rate (HRV) and blood pressure (BPV) variability and are combined with a fuzzy quantifier to measure agitation levels. Results show that agitation in normal subjects can be assessed and quantified using this approach, including differentiating periods of calm. Additionally, it has been shown that detected periods of agitation in ICU patients correlate well with subjective assessment by trained medical staff using the modified Riker SAS and with the objective assaying of patient motion. These results show that agitation can be quantitatively measured and assessed using common biomedical signals. Finally, agitation induced in normal subjects correlates well to agitation in ICU patients, as both show similar changes in the measured biomedical signals during agitated periods.

Owner:CANTERPRISE LTD

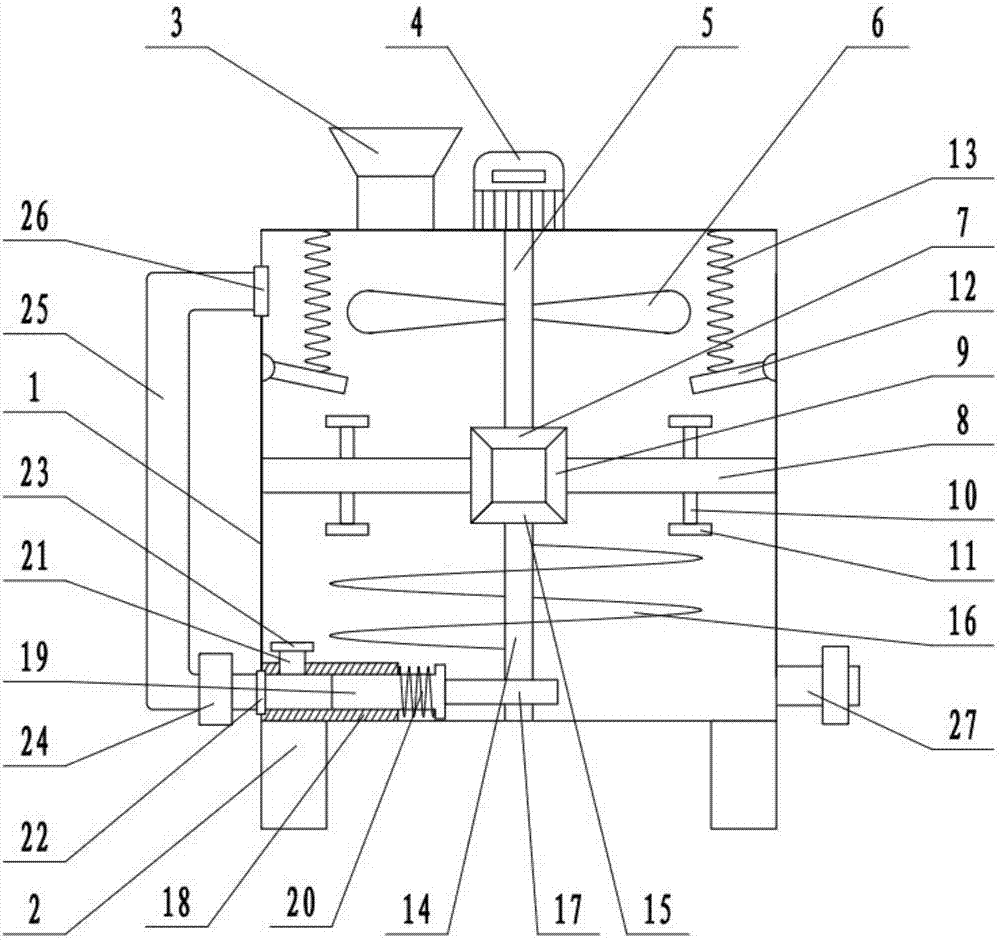

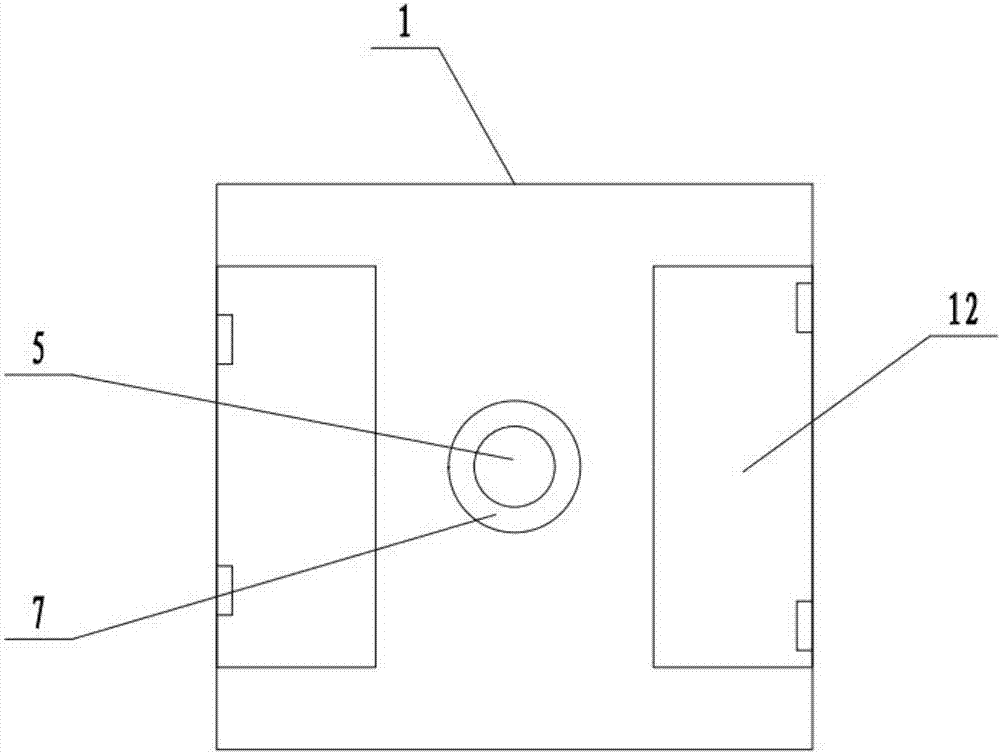

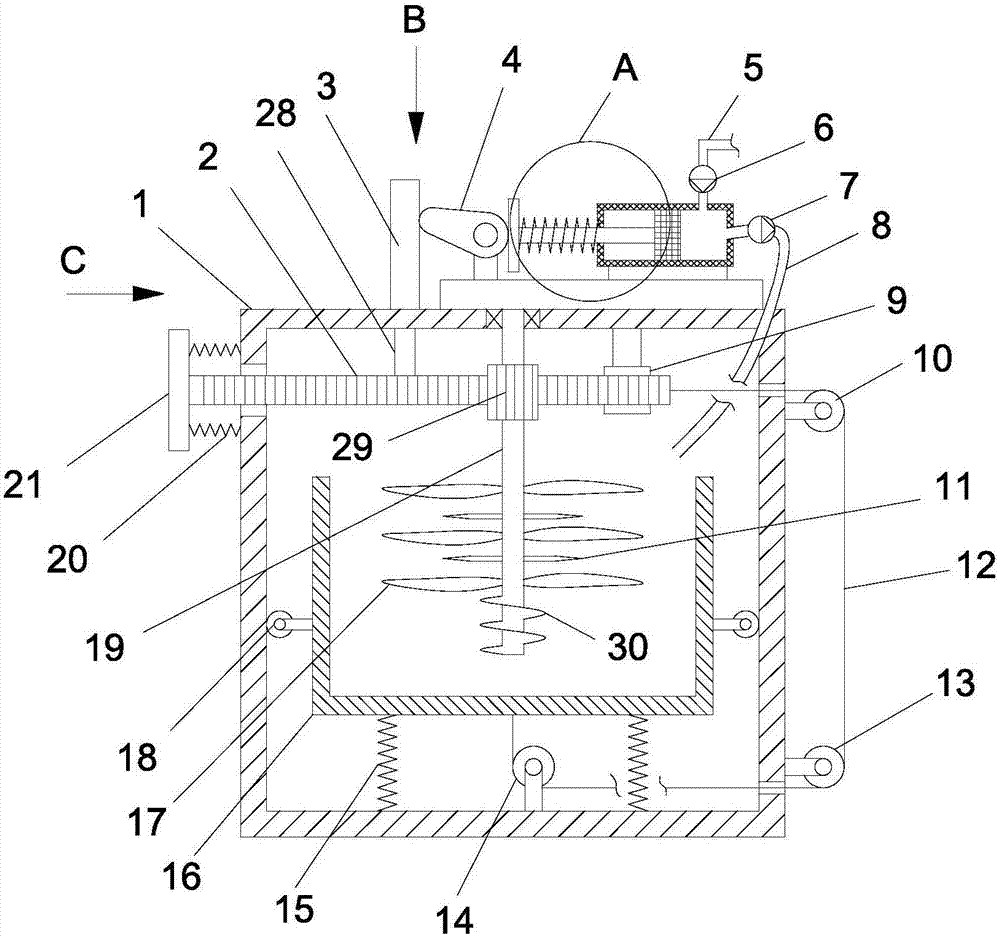

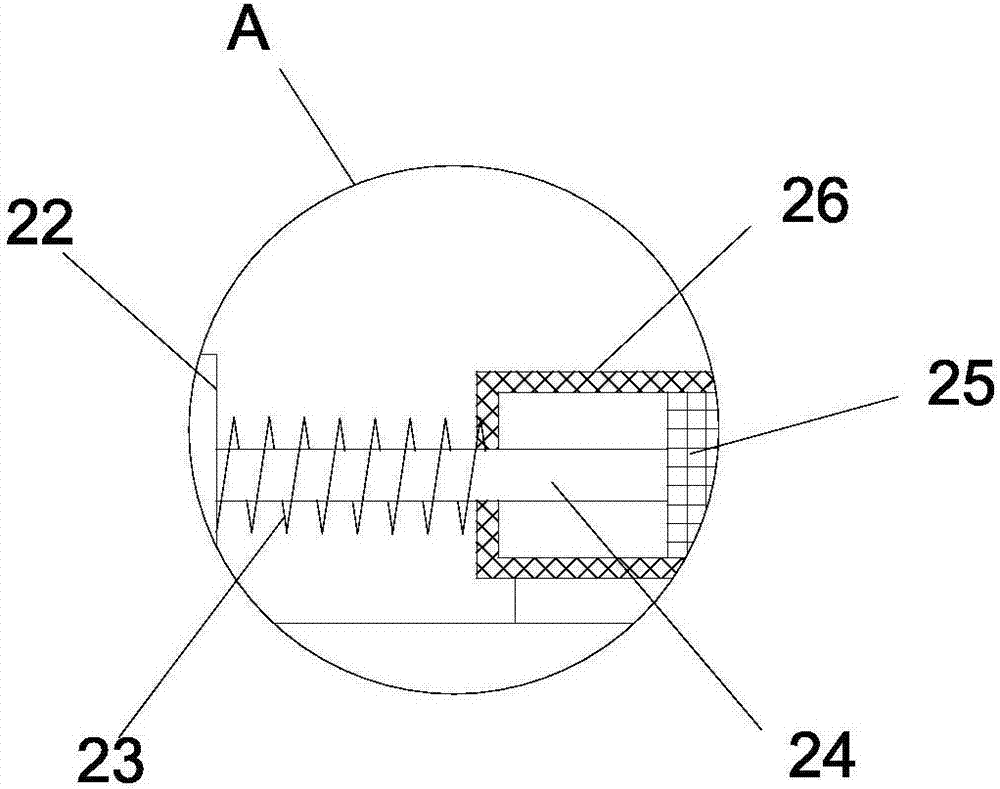

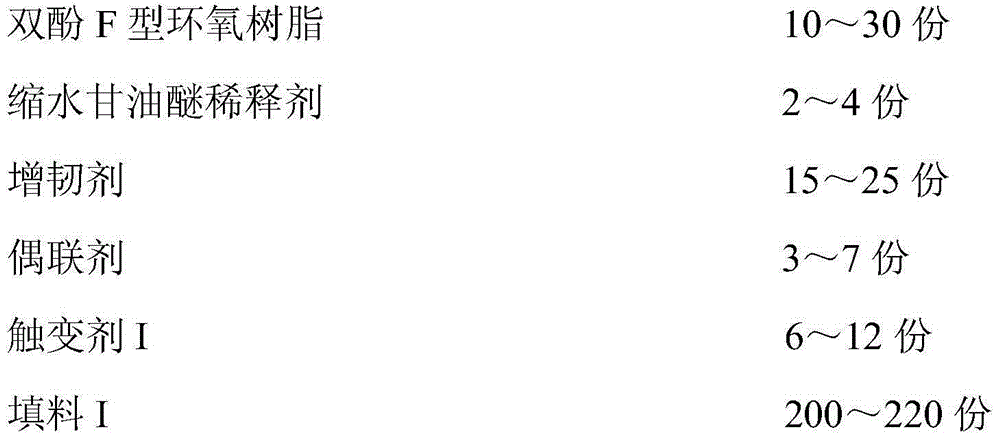

Self-circulating type coating stirring device for architectures

InactiveCN107308834AStir wellImprove stirring efficiencyShaking/oscillating/vibrating mixersFlow mixersHelical bladeInner loop

The invention discloses a self-circulating type coating stirring device for architectures. The self-circulating type coating stirring device comprises a tank body, support legs, a feeding opening, stirring blades, a helical blade and a discharging opening, wherein a motor is fixedly connected to an upper surface of the tank body; an upper rotating shaft penetrates through a top part of the tank body and deepens into the tank body; side rotating shafts are respectively arranged at a left side and a right side of the upper rotating shaft; a lower rotating shaft is arranged on a lower part of the upper rotating shaft; the helical blade is fixedly connected to the lower rotating shaft; a cam is arranged at a tail end of the lower rotating shaft in a sleeving manner; a sleeve is fixedly connected to a bottom part of the tank body; a piston cylinder is arranged inside the sleeve; a right end of the piston cylinder is pressed against the cam; a circulating pipeline is mounted on a side wall of the tank body; the coatings are poured into the tank body, an upper layer of coatings are stirred by utilizing the stirring blades, and a permanent magnet rotates continuously; when the permanent magnet is relatively close to a movable plate, the movable plate is attracted to rotate downwards, and when the permanent magnet is away from the movable plate, the movable plate rotates upwards under an effect of a first spring so as to stir the coatings; the coatings are circulated in the tank body, so that a stirring effect is further improved.

Owner:HUIAN WEIKE ELECTRONICS TECH CO LTD

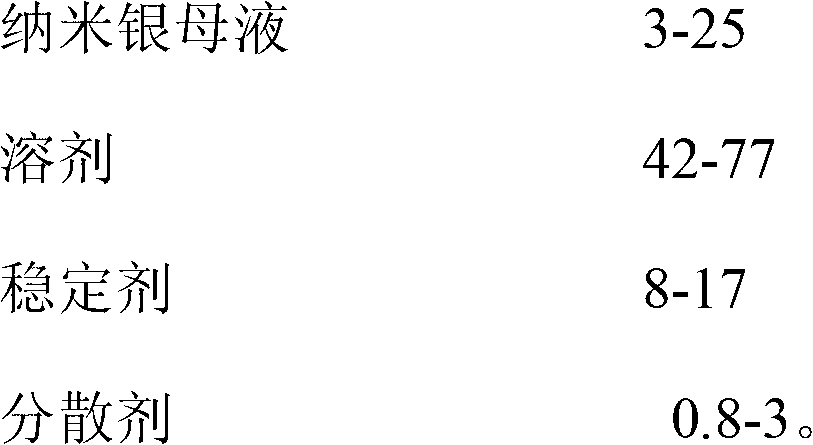

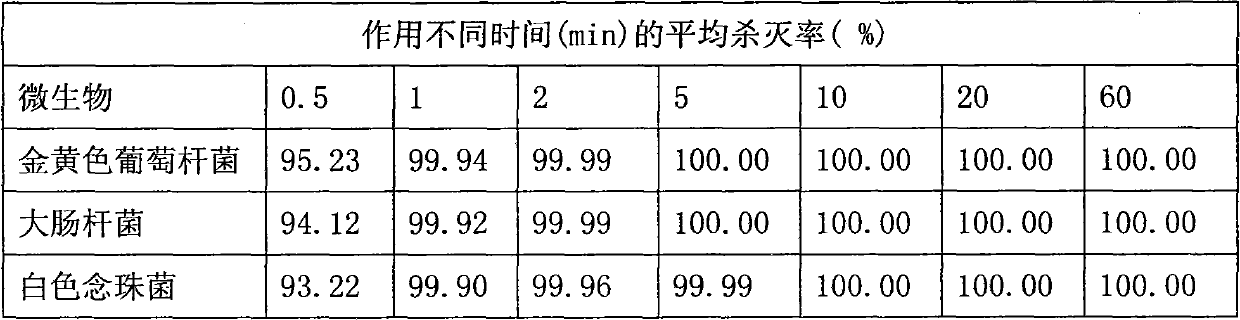

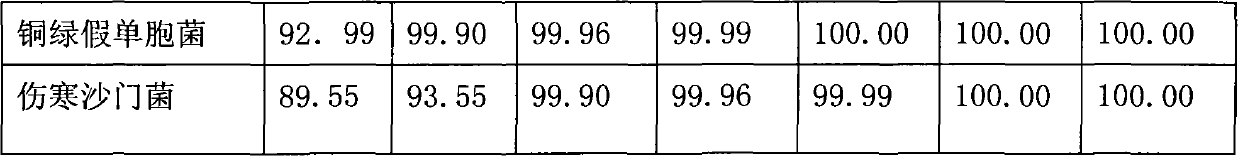

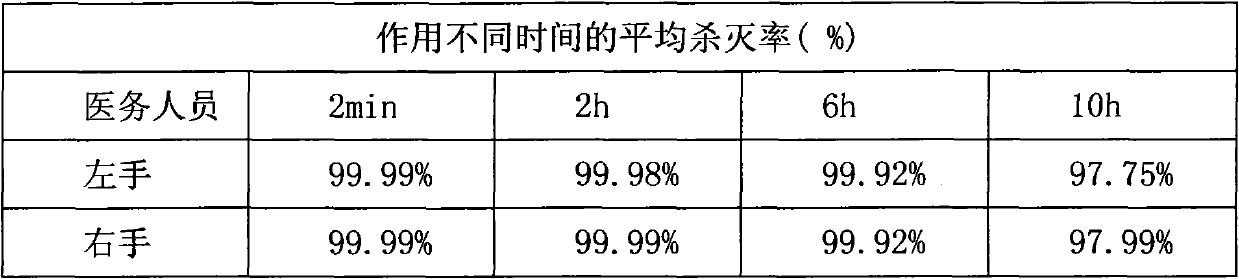

Washing-free antibacterial hand sanitizer and preparation method thereof

InactiveCN101766552AAvoid damageSimple processAntibacterial agentsCosmetic preparationsHand sanitizerChlorhexidine

The invention discloses a washing-free antibacterial hand sanitizer and a preparation method thereof. Raw materials of the washing-free antibacterial hand sanitizer calculated at 100ml include 1-10g of chlorhexidine salt, 5-1,000ug of silver nitrate, 30-90ml of alcohol, 2-50g of skin care agent, 0.5-3g of tackifier, 0.5-3g of surfactant, 0.5-5g of p+H regulator and 15-50ml of deionized water. In the preparation method, the skin care agent and the chlorhexidine salt are added to the alcohol and dissolved under the temperature of 30-70 DEG C to form alcoholic solution; the tackifier, the surfactant and the silver nitrate are added to the deionized water to form aqueous solution; finally, the aqueous solution and the pH regulator are added to the alcoholic solution to prepare the washing-free antibacterial hand sanitizer. The washing-free antibacterial hand sanitizer contains various antibacterial components, has very strong broad-spectrum antibacterial and bactericidal effects on various bacteria and fungi, and has long-acting antibacterial effect.

Owner:ZHEJIANG KUNZHILIN BIOMEDICINE TECH

Ultraviolet curing coating for preventing static on plastic surface and method for preparing the same

InactiveCN101423675ALight weightGood electrical conductivityElectrically-conductive paintsSolventPhotoinitiator

The invention relates to an ultraviolet photo-cured coating for the electrostatic prevention of the surface of plastic and a preparation method thereof, in particular to a photo-cured coating containing conductive powder of a metal oxide system or composite conductive powder. The coating comprises the following compositions in weight percent: 30 to 70 percent of oligomer, 25 to 65 percent of active thinner, 0.5 to 10 percent of light evocating agent, 5 to 40 percent of conductive powder, 0.2 to 8 percent of additive and 0 to 50 percent of solvent. As the added conductive powder of the metal oxide system and the composite conductive powder is white or light color, the prepared photo-cured has the characteristic of easy color modulation, has lasting antistatic property, high rigidity and wearing resistance, can be used for electrostatic prevention of the surface of electronic equipment, plastic vessel, shell of an electric appliance, office supplies, sports equipment and other plastic products.

Owner:SICHUAN UNIV

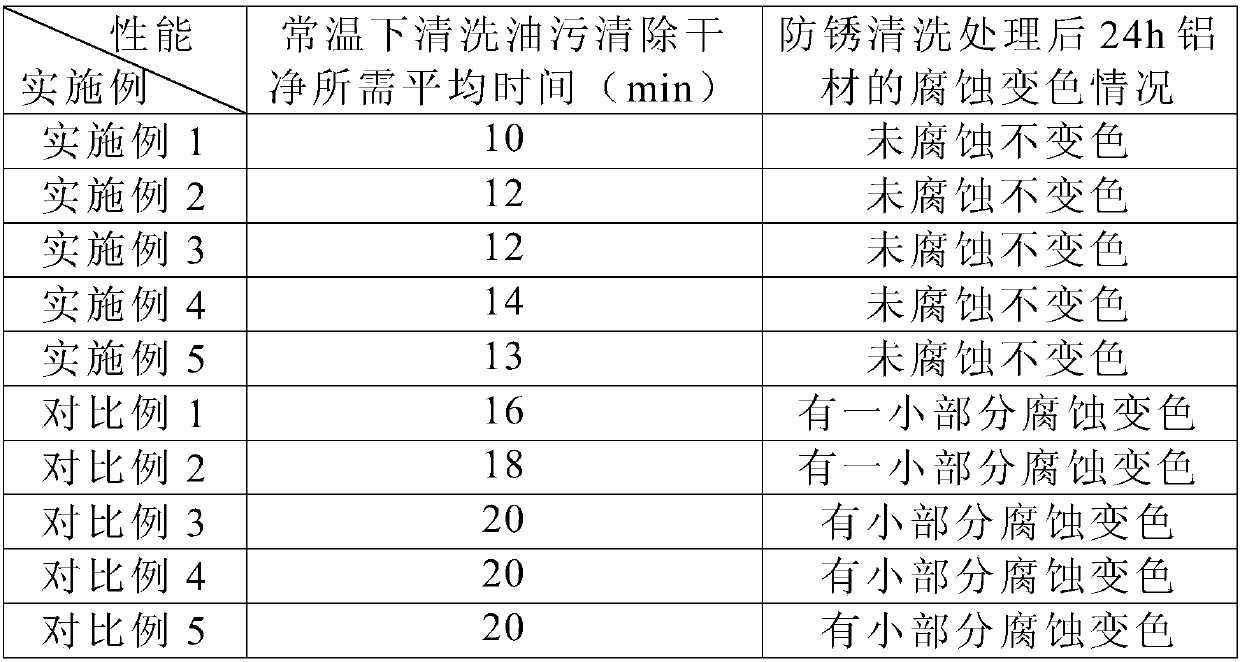

Aluminum and aluminum alloy anti-rust cleaning agent and preparation method thereof

The invention belongs to the technical field of chemicals, provides an aluminum and aluminum alloy weakly-alkaline anti-rust cleaning agent and a preparation method thereof, and particularly relates to a weakly-alkaline cleaning agent capable of being used for cleaning pure aluminum and aluminum alloys and having corrosion inhibition and bright effects. According to the weakly-alkaline cleaning agent, grease and oil dirt on the surface of an aluminum product can be effectively removed, and corrosion and color change are avoided. The weakly-alkaline cleaning agent comprises the following components of, by weight, 3-7 parts of an alkaline detergent assistant, 0.1-2 parts of organic carboxylic acid, 0.1-1 part of ternary polycarboxylate, 0.1-2 parts of compound-type low-foam surfactants, 0.5-2 parts of complexing agents, 0.10-3 parts of corrosion inhibitors, and 85-90 parts of water. According to the aluminum and aluminum alloy anti-rust cleaning agent, through the synergistic effect of various alkaline inorganic detergent assistants, the good cleaning effect is achieved, and the problem that as for an existing cleaning agent, due to the high pH valve, corrosion and color change of aluminum materials are caused can further be solved.

Owner:广东锴力环保新材料有限公司

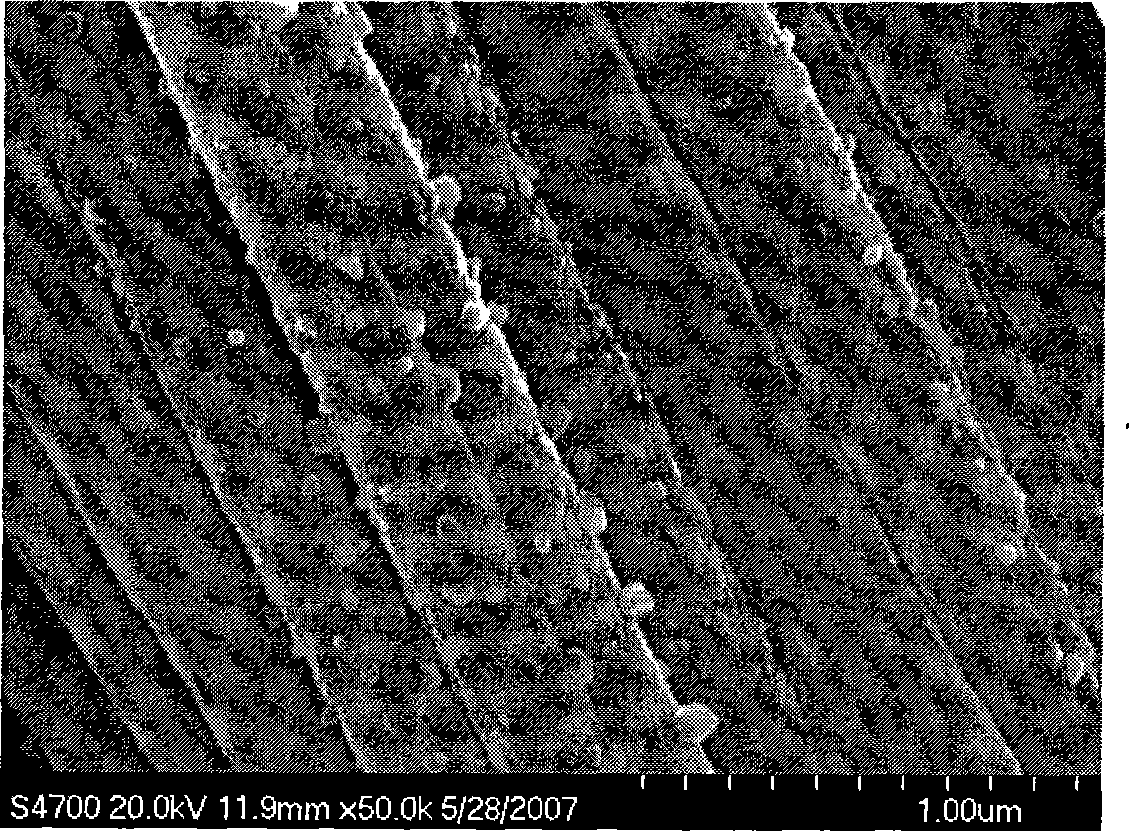

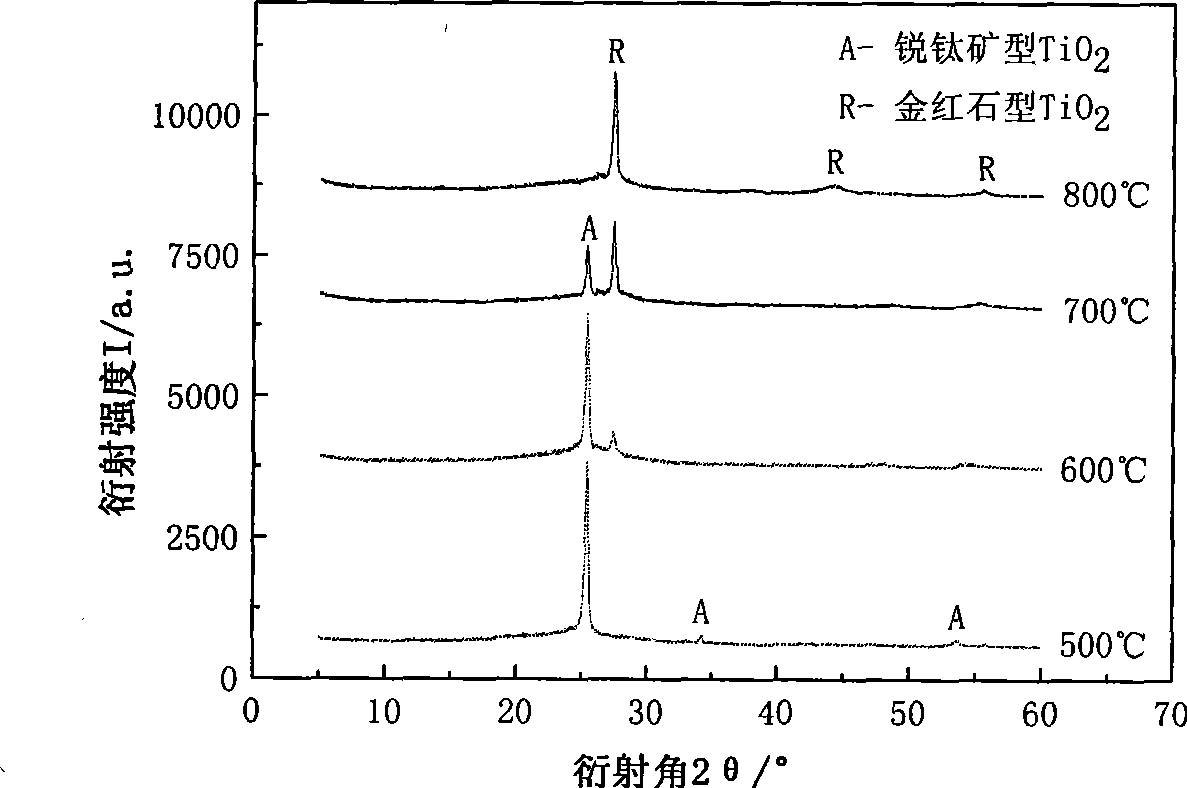

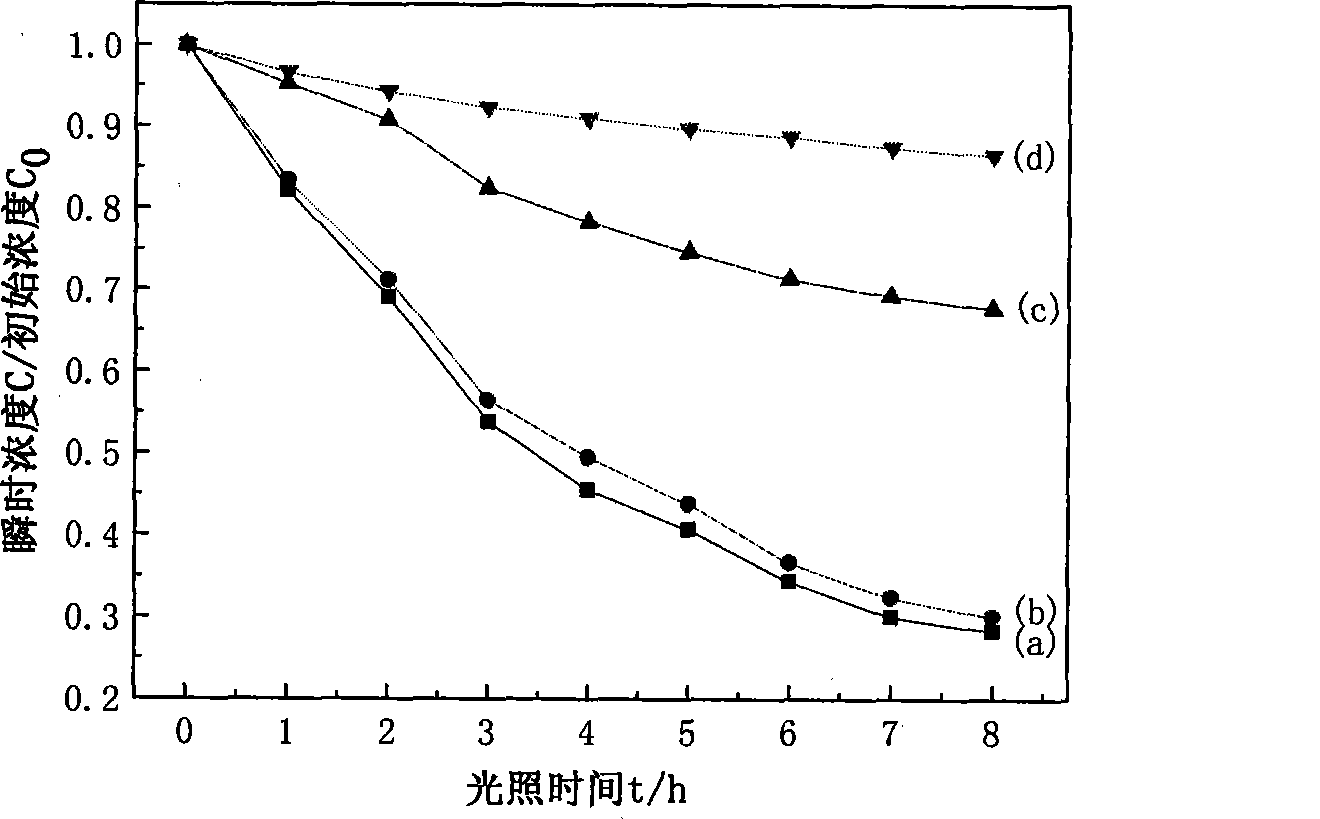

Nano-fibre supported titanium dioxide photocatalyst and preparation method thereof

InactiveCN101428209AImprove bindingImprove photocatalytic activityPhysical/chemical process catalystsFibre treatmentFiberElectrospun nanofibers

The invention provides a nanofiber load titanium dioxide photocatalyst and a preparation method thereof, which belong to the technical field of preparation of novel nanometer photocatalyst functional materials. The method comprises the following steps: preparing a homogeneous spinning solution with titanium precursor, a hydrolysis inhibitor, a polymer and an organic solvent; carrying out spinning according to a proper electrostatic spinning process to obtain a nanofiber felt / film; introducing hydroxyl groups into electrospun nanofiber, and immersing the electrospun nanofiber in an aqueous solution containing an ammoniation agent, so that hydrolysis and ammoniation reaction of titanium precursor occurs and produces titanium-ammino complex; and carrying out post treatment processes such as baking and the like to obtain the nanofiber load titanium dioxide photocatalyst. The catalyst has excellent photo-catalytic activity in response to ultraviolet light or visible light, and can effectively improve the bonding reliability of titanium dioxide with nanofiber with the help of the action of nitrogen bond.

Owner:BEIJING UNIV OF CHEM TECH

Concrete mortar stirring and mixing device for building construction

InactiveCN107053480AImprove the mixing effectImprove stirring efficiencyCement mixing apparatusLiquid ingredients supply apparatusHelical bladeArchitectural engineering

A concrete mortar mixing device for building construction, including a main body, a mixing bucket is arranged inside the main body, a limit spring is arranged between the mixing bucket and the main body, a number of auxiliary mixing blades and a number of auxiliary mixing blades and a number of Auxiliary cutting blade, the spur rack slides through the body, the left end of the spur rack is fixed with a limit plate, the limit plate is located outside the body, a first return spring is arranged between the limit plate and the body, and a piston is fixedly installed on the body The water-drawing sleeve, the left end of the piston rod is vertically fixed with a piston top plate, the cam is in contact with the right side of the transmission plate, and the cam is in contact with the left side of the piston top plate; the spiral blade arranged at the bottom of the stirring shaft in the present invention will move the bottom of the mixing tank The concrete mortar is turned upwards to make the mixing more complete. Driven by the wire rope, the mixing bucket vibrates up and down, making the concrete mortar shake up and down in the mixing bucket, which promotes the mixing effect of the concrete mortar.

Owner:长沙鼎成新材料科技有限公司

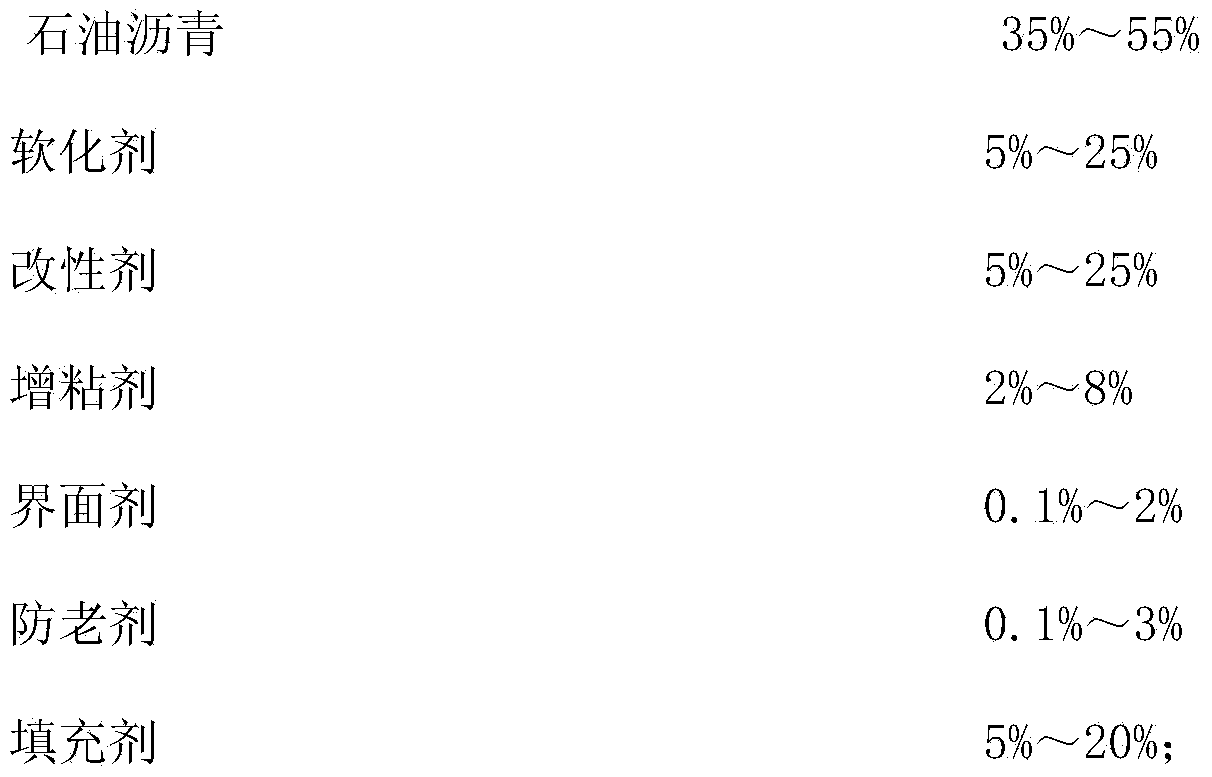

Creeping self-adhesive asphalt water-proof coiled material and preparation method thereof

InactiveCN104194719ASolve the leakExtended service lifeNon-macromolecular adhesive additivesBituminous material adhesivesAsphaltAnti ageing

The invention relates to a creeping self-adhesive asphalt water-proof coiled material and a preparation method thereof. An asphalt sizing material used for the creeping self-adhesive asphalt water-proof coiled material has good adhesive property and creeping property, and the asphalt sizing material is prepared from the following raw materials in percentage by weight: 35%-55% of petroleum asphalt, 5%-25% of softening agent, 5%-25% of modifying agent, 2%-8% of tackifying agent, 0.1%-2% of interface agent, 0.1%-3% of anti-aging agent and 5%-20% of filling agent. The self-adhesive asphalt water-proof coiled material disclosed by the invention has very good initial adhesion, can be well adhered with a base layer under the conditions of the wet base layer and lower temperature even if a little dust is positioned on the surface of the base layer, is difficult to strip after being adhered, and can ensure that a complete sizing material can be retained on the base layer after being stripped, thus meeting the requirement for water-proof property.

Owner:HUIZHOU ORIENTAL YUHONG BUILDING MATERIALS

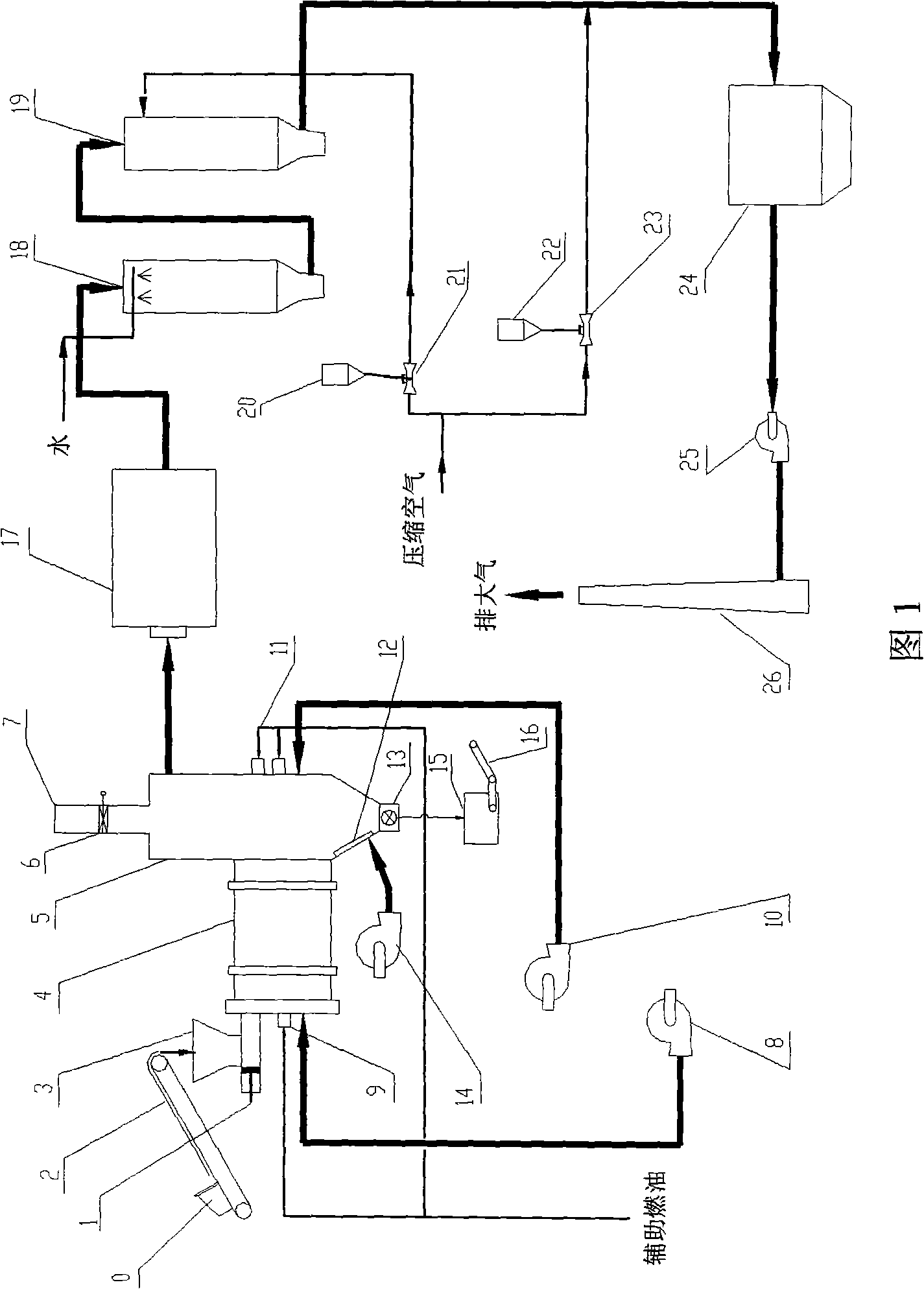

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

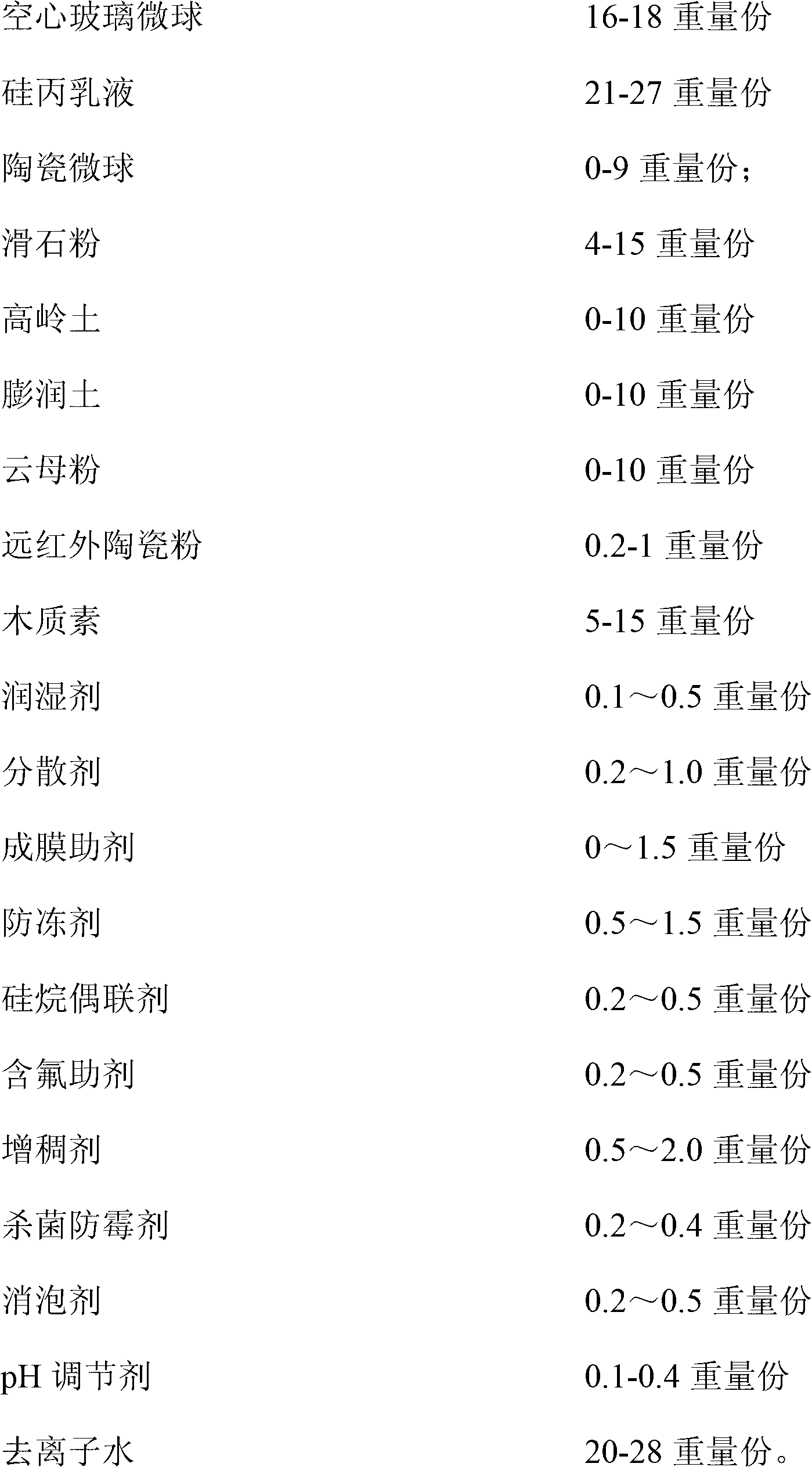

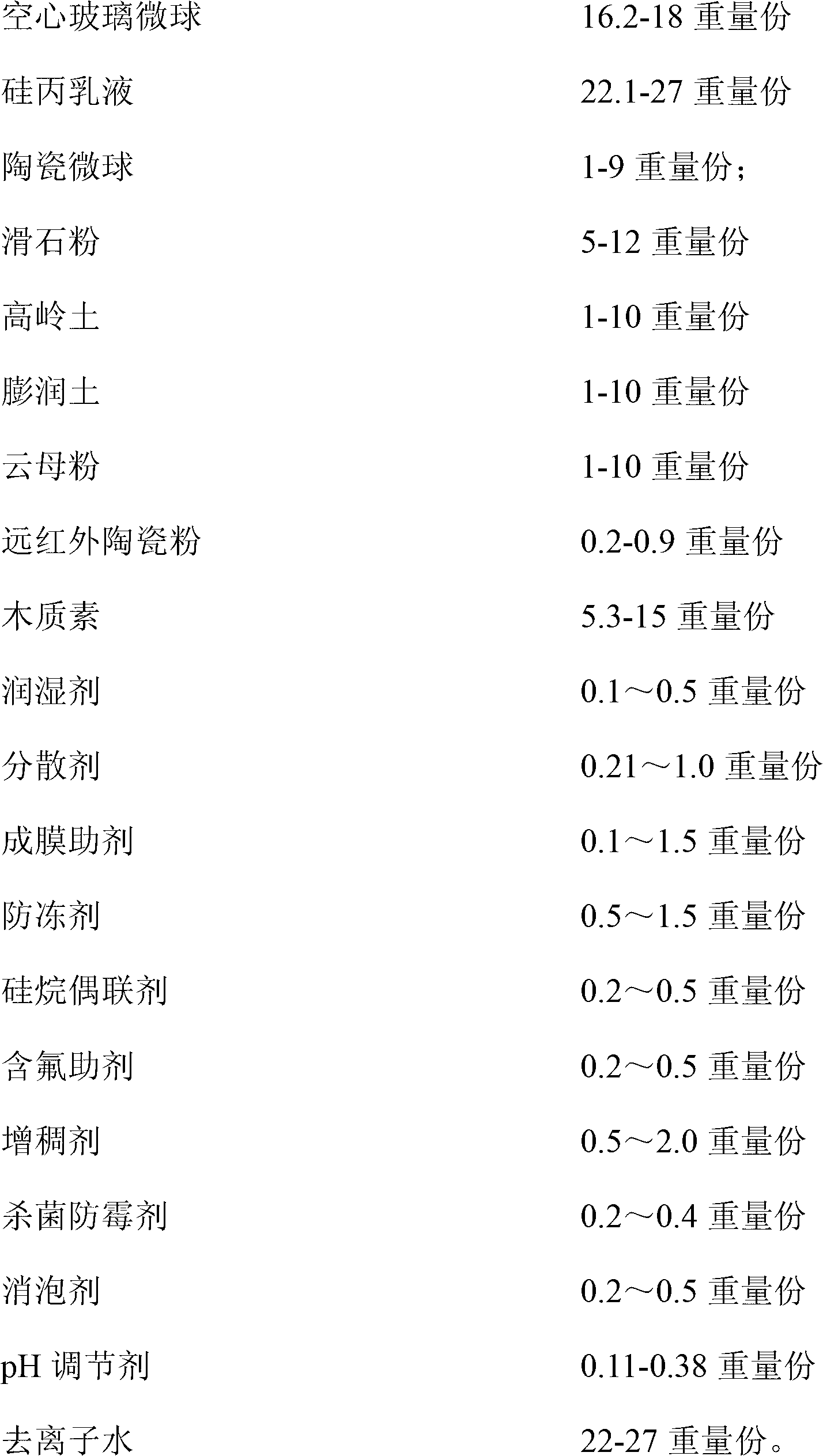

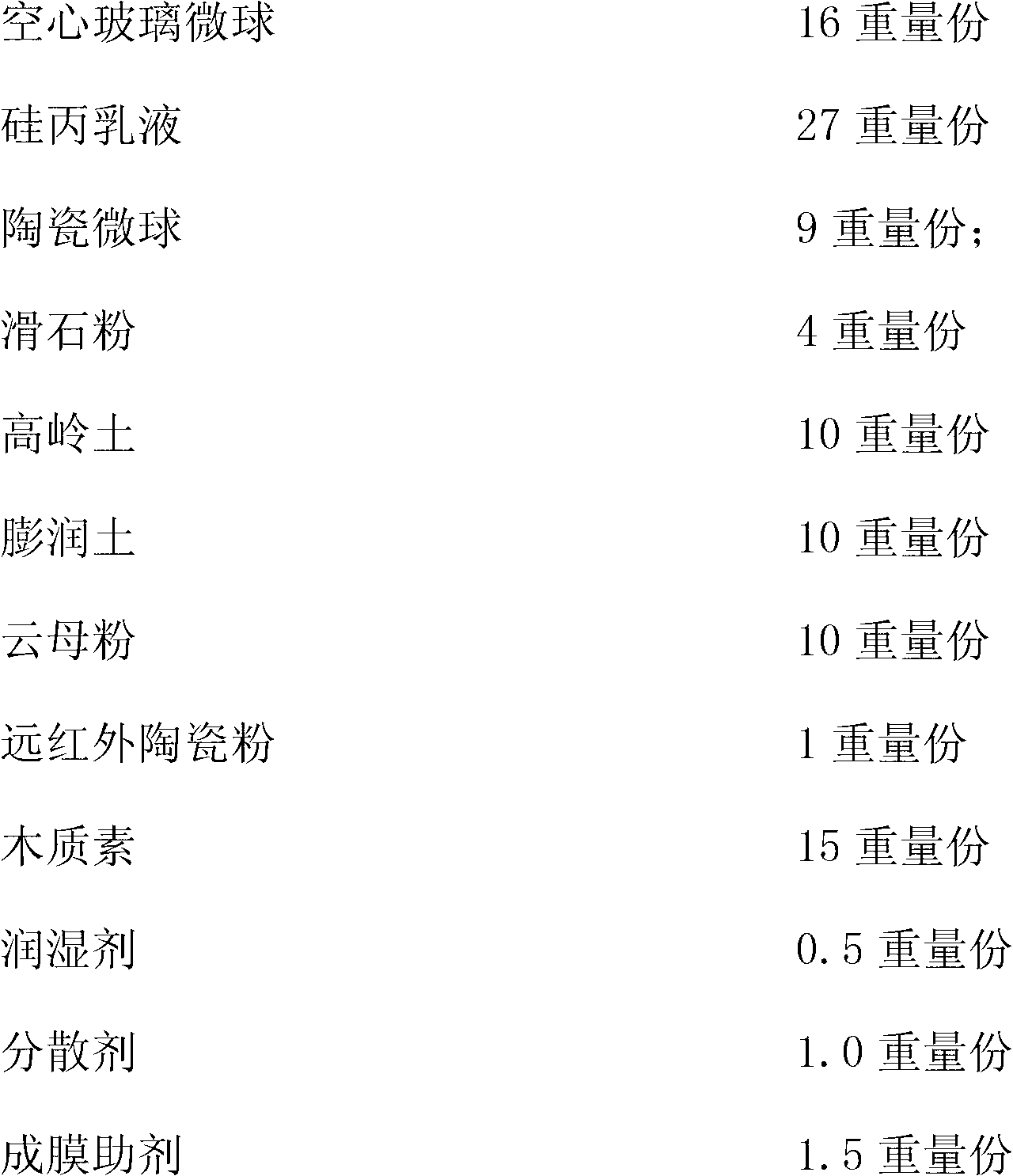

Waterproof thermal insulation coating composition and preparation method thereof

InactiveCN102702904AStir wellHigh solar reflectanceAntifouling/underwater paintsPaints with biocidesEmulsionThermal insulation

The invention relates to a waterproof thermal insulation coating composition, which comprises an aggregates, a substrate, an auxiliary filling and an assistant, and is characterized in that the aggregates are hollow glass microspheres, and the substrate is silicone acrylic emulsion; in the thermal insulation coating composition, 6-18 parts by mass of hollow glass microspheres and 21-27 parts by mass of silicone acrylic emulsion are provided. According to the invention, the silicon acrylic emulsion is selected, so that the thermal insulation coating has excellent thermal insulation property, and good waterproof and antifouling performance, and the waterproof and antifouling performance is more excellent for fluorine-containing silicone acrylic emulsion.

Owner:TIANCHANG JULONG TRAVEL PAINT

Method for increasing retention rate of calcium carbonate in paper-process reconstituted tobacco sheets

The invention relates to a method for increasing the retention rate of calcium carbonate in paper-process reconstituted tobacco sheets. The purpose of the invention is to solve the problems that: since the prior art directly adds calcium carbonate, the bonding force between the calcium carbonate and tobacco fibers is weak, as a result, loss is severe, the material utilization rate is low, the amount of waste water to be treated is large, and the treatment cost is high. The technical point is that: needed chemical constituents are extracted from tobacco material, residue is ground into pulp after extraction, and the concentration of the pulp is regulated between 3 percent and 25 percent; the solution of soluble carbonate accounting for 4 percent to 40 percent of the weight of dry fibers in the pulp is added into the pulp, and is fully stirred and uniformly mixed, and impregnation is then carried out for 20 to 150 minutes, so that the fibers of the pulp can be impregnated with the soluble carbonate; the solution of soluble calcium salt, the molar mass of which is approximately equal to the molar mass of the soluble carbonate, is added into the impregnated pulp, and is fully stirred and uniformly mixed, static reaction is then carried out for 30 to 180 minutes, and the reaction temperature is controlled at 5 DEG C to 50 DEG C; and after the static reaction, the pulp is made into reconstituted tobacco sheets by papermaking equipment.

Owner:GUANGDONG JINKE REFORGING TOBACCO LEAF CO LTD

Inorganic powder capillary crystalline waterproof coating material

InactiveCN101362867AImprove impermeabilityImprove permeabilityAntifouling/underwater paintsPaints with biocidesWater reducerQuartz

The invention discloses an inorganic powder infiltration crystalline water-proof material which consists of 45 to 55 portions of 600#silicate cement, 20 to 25 portions of ultra-thin quartz sands, 25 to 30 portions of master batches, 1 to 5 portions of effective retarding water reducers and 1 to 5 portions of macromolecular tougheners and is manufactured by feeding the materials into a stirrer to be uniformly stirred. The inorganic powder infiltration crystalline water-proof material is characterized by having the advantages of secondary anti-permeability capacity, durable water-proof performance, high sticking performance, acid resistance and alkali matter resistance; besides, the inorganic powder infiltration crystalline water-proof material have the capacity of growing an insoluble crystal in the pores and the micro cracks of a concrete substrate to plug the pores and the micro cracks, thereby improving the anti-permeability capacity of the concrete and achieving the goals of anti-permeability and anti-leakage. The inorganic powder infiltration crystalline water-proof material can be broadly applied to the water-proof projects of railways, roads, ports and docks, culverts, dams and pools as well as large underground projects.

Owner:天津市耀新科技发展有限公司

Underwater solventless epoxy anti-corrosive coating and preparation method thereof

InactiveCN101619189AGood flexibilityStrong adhesionAntifouling/underwater paintsPaints with biocidesEpoxyPliability

The invention relates to an underwater solventless epoxy anti-corrosive coating and a preparation method thereof. The coating contains A component and B component and comprises the following components by weight percent: 20-25% of epoxy resin E-51, 12-17% of epoxy resin E-44, 3-8% of epoxy active diluent, 3.5-5% of plasticizer, 10-16% of talcum powder, 10-15% of sericite powder, 1.0-1.6% of thixotropic agent, 2-4% of titanium dioxide, 0.5-1.0% of coupling agent, 0.5-1.2% of dispersant, 0.5-1.2% of defoaming agent, 0.1-0.5% of carbon black, 12-15% of 1085 curing agent and 5-8% of 810 curing agent; wherein, B component comprises 1085 curing agent and 810 curing agent and the remainder is A component. The preparation method comprises the following steps: separately preparing A component and B component and when using, mixing A component and B component in a weight ratio of 4:1 evenly to obtain the underwater solventless epoxy anti-corrosive coating. The invention has simple process, strong product adhesion, high mechanical strength and corrosion resistance; the coating can be especially used to coat members in water at a low temperature, has fast curing rate and good flexibility of coating film, and is hard to peel, thus being applicable to the protection of steel structures such as gates of hydroelectric power stations, sediment bottom sluices and the like and concrete structures.

Owner:QINGDAO PACIFIC OCEANEERING CO LTD

Organic silicon-modified water-based UV (ultraviolet) coating and preparation method thereof

ActiveCN103555192AStir wellFast curing ratePolyurea/polyurethane coatingsUrethane acrylateAcrylate ester

The invention relates to an organic silicon-modified water-based UV (ultraviolet) coating and a preparation method thereof, and belongs to the technical field of environment-friendly coatings. The organic silicon-modified water-based UV coating comprises the following components in percentage by mass: 30 to 55 percent of organic silicon-modified hyperbranched water-based urethane acrylate, 20 to 50 percent of filler, 1 to 10 percent of photoinitiator, 0 to 3 percent of auxiliaries and 5 to 30 percent of water. The preparation method comprises the following steps: fully grinding the organic silicon-modified hyperbranched water-based urethane acrylate, the filler and water in a proportion, performing dispersion for 1 to 2 hours at 40 to 50 DEG C at a rotating speed of 400 to 600rpm, adding the photoinitiator and the auxiliaries, and uniformly stirring and standing a mixture to obtain the water-based UV coating. The coating is environment-friendly, nontoxic, high in curing speed, stability, aging resistance, solvent resistance, adhesive power and abrasion resistance and suitable for a plurality of coating modes and production requirements, and can be widely applied to the surfaces of automobiles, electronic products, ships, furniture and packaging printing materials.

Owner:WUHAN UNIV

Green biological seedling raising matrix

InactiveCN102126877APromote differentiationNutritional diversityBio-organic fraction processingOrganic fertiliser preparationDiseaseNicotiana tabacum

The invention discloses a green biological seedling raising matrix, relating to the seedling raising matrix technology. The preparation method comprises the following steps of: mixing straw powder, organic fertilizer and nutrient soil to be uniform, adding water until the water content is 45-55%, adding compound bacteria and then mixing to be uniform, stacking for fermenting, turning when the temperature increases to 50 + / - 2 DEG C, turning and cooling for 1-2 days when the temperature is increased to 50 DEG C again, adding microelements and growth hormone, stirring to be uniform, and packaging. The invention has the beneficial effects that: (1) the matrix is rich in organic matters and beneficial biological germs, has comprehensive nutrition and is loose and soft; (2) the matrix is seed-saving and labour-saving and can shorten seedling raising period; (3) the matrix can be used to ensure uniform and strong seedlings and high sprout rate; (4) the matrix can protect roots and hold water and fertilizer and has good air permeability; (5) the matrix has the functions of promoting flower bud differentiation and improving the yield; and (6) the matrix has the effect of resisting soil diseases. The matrix disclosed by the invention is applicable to seedling raising of vegetable, melon and fruit, flower and plant, tea, tobacco and cotton.

Owner:徐贵阁

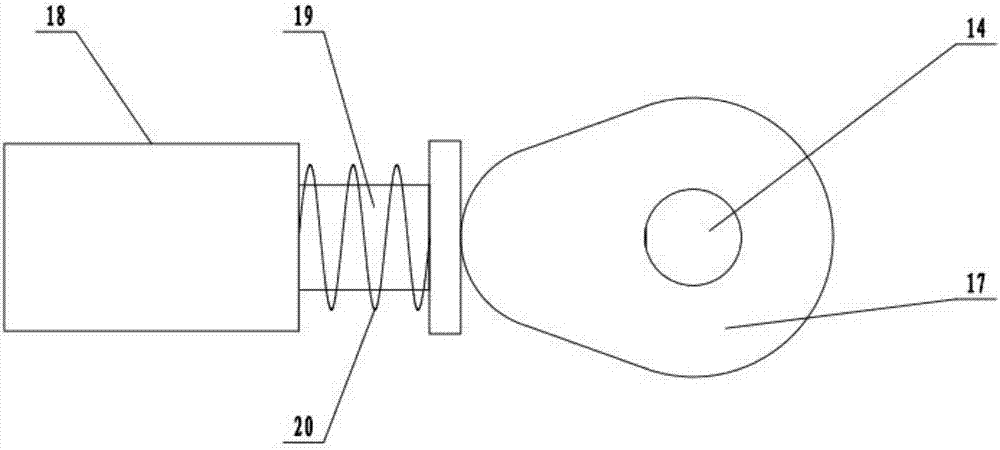

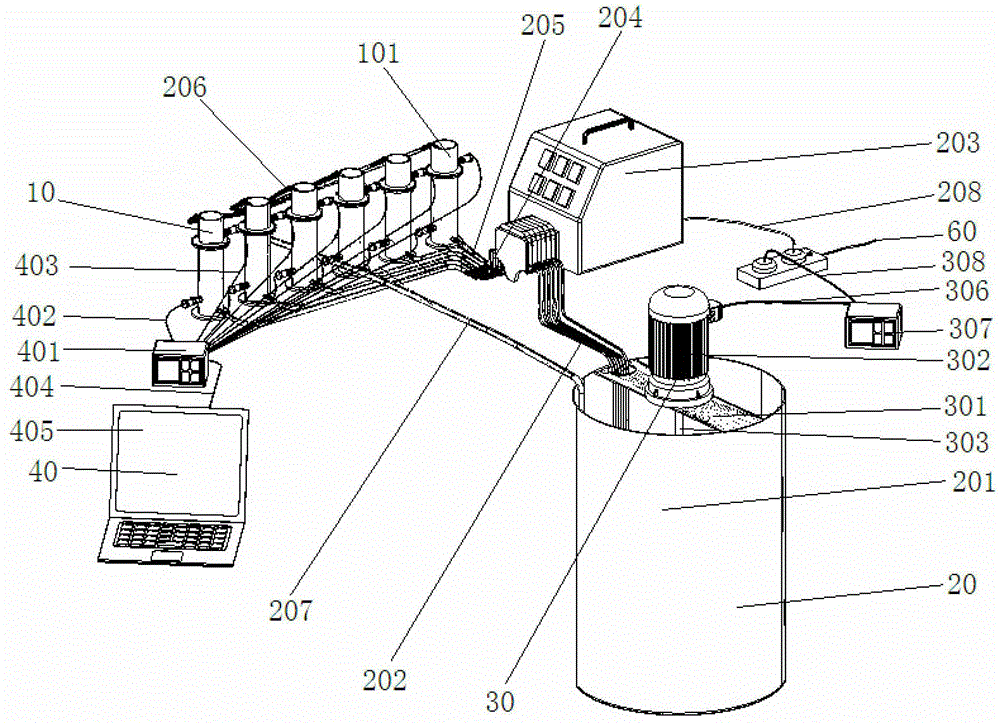

Porous medium biological clogging simulation test device and simulation test evaluation method

InactiveCN102866093AClogged true reflectionSatisfy automatic hydrodynamic conditionsPermeability/surface area analysisPeristaltic pumpPorous medium

The invention relates to a porous medium biological clogging simulation test device and a simulation test evaluation method. The porous medium biological clogging simulation test device is characterized by comprising a plurality of biological clogging simulation single bodies, wherein each biological clogging simulation single body comprises a first column body and a second column body; the first column body is provided with a water inlet and a water inlet pressure sensor; a first permeable plate is arranged inside the first column body; the junction of the first column body and the second column body is provided with a second permeable plate, and the second column body is provided with a water outlet pressure sensor and a water outlet; a circulating water supply device comprises a water storage tank, the inside of the water storage tank is connected with a peristaltic pump through a pipeline, and the peristaltic pump is connected with a water inlet on each first column body through a pipeline; a water outlet of each second column body is connected into the water storage tank through a pipeline; a stirring device comprises a motor which is arranged on the top of the water storage tank, the output end of the motor is connected with a stirring shaft which is plugged inside the water storage tank, and the stirring shaft is provided with a stirring blade; and a pressure collecting device comprises a pressure collection controller, the input end of the pressure collection controller is connected with each water inlet pressure sensor and each water outlet pressure sensor, and the output end of the pressure collection controller is connected with a computer.

Owner:CHINA AGRI UNIV

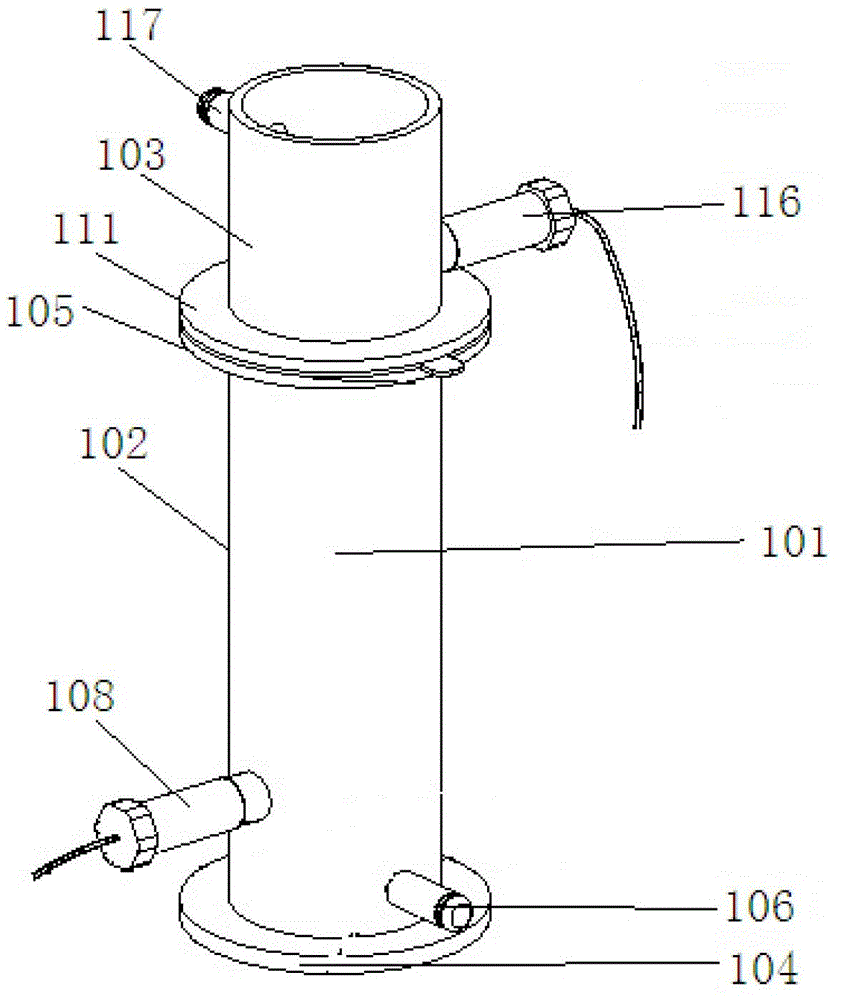

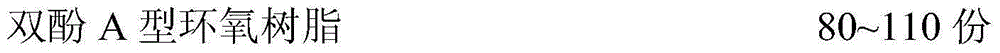

Double-component high-strength building epoxy structural adhesive and preparing method thereof

ActiveCN105062396AStir wellImprove toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberGlycidyl ethers

The invention provides double-component high-strength building epoxy structural adhesive and a preparing method thereof. The structural adhesive is mainly formed by mixing a component A and a component B at the weight ratio of 1.8-2.5:1. The component A is mainly composed of bisphenol A type epoxy resin, bisphenol F type epoxy resin, glycidyl ether diluent, a flexibilizer, a coupling agent, a thixotropic agent I and filler I. The component B is mainly composed of a complex-amine curing agent, an accelerator, hixotropic agent II and filler II. The epoxy structural adhesive is used for reinforcing construction of carbon fiber plates, and the carbon fiber plates are light in mass, convenient to bond in construction (the structural adhesive does not flow) and high in strength. Compared with a steel bonding construction method, the procedures of welding, polishing, pressurizing and the like are not needed in the method. The complex-amine curing agent is adopted in the developed component B, and the curing object is high in bonding strength, good in water resistance and good in toughness. The epoxy resin adhesive component A is free of crystallization, easy to smear and convenient to construct.

Owner:CARBON TECH CO LTD

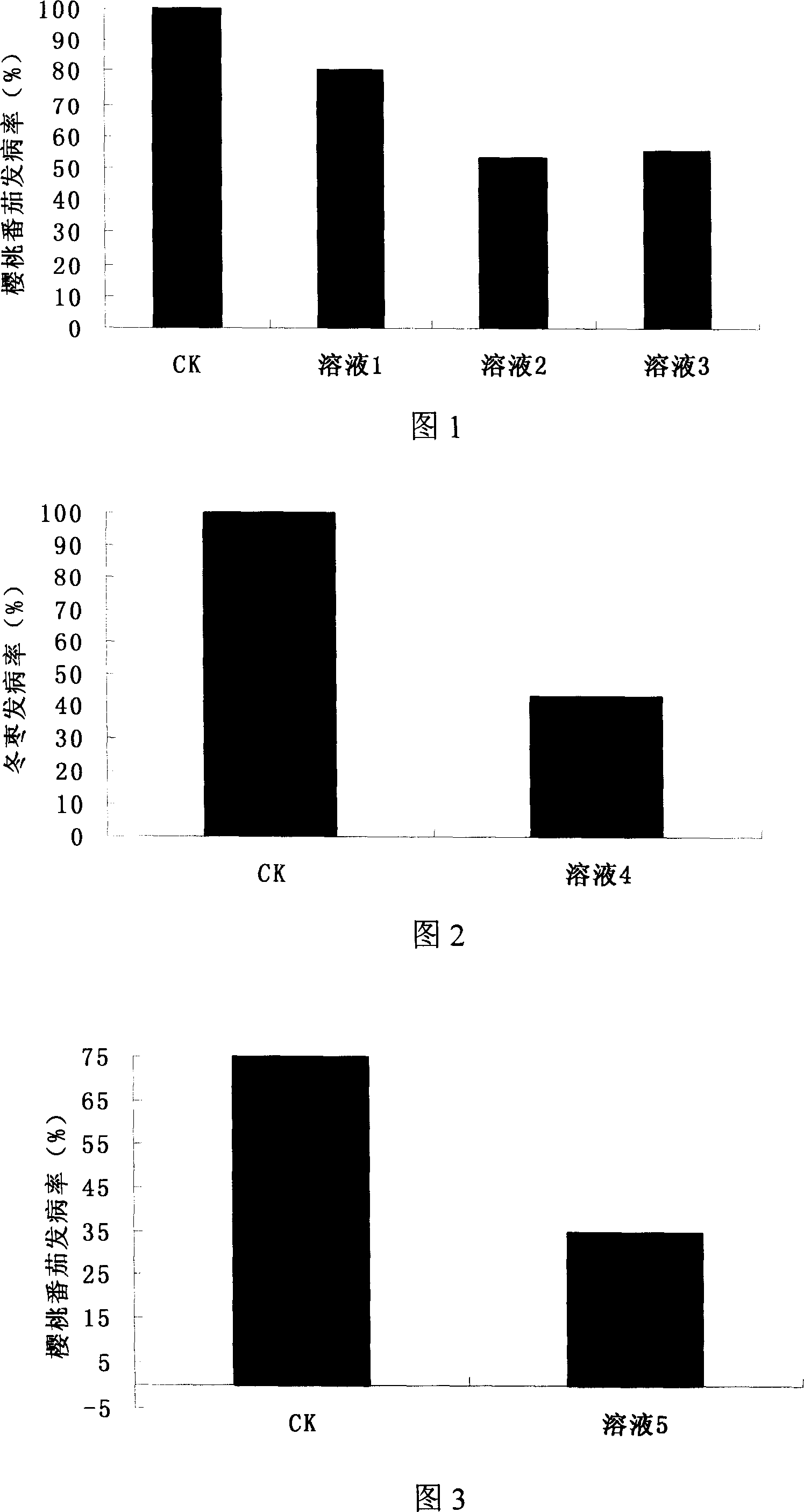

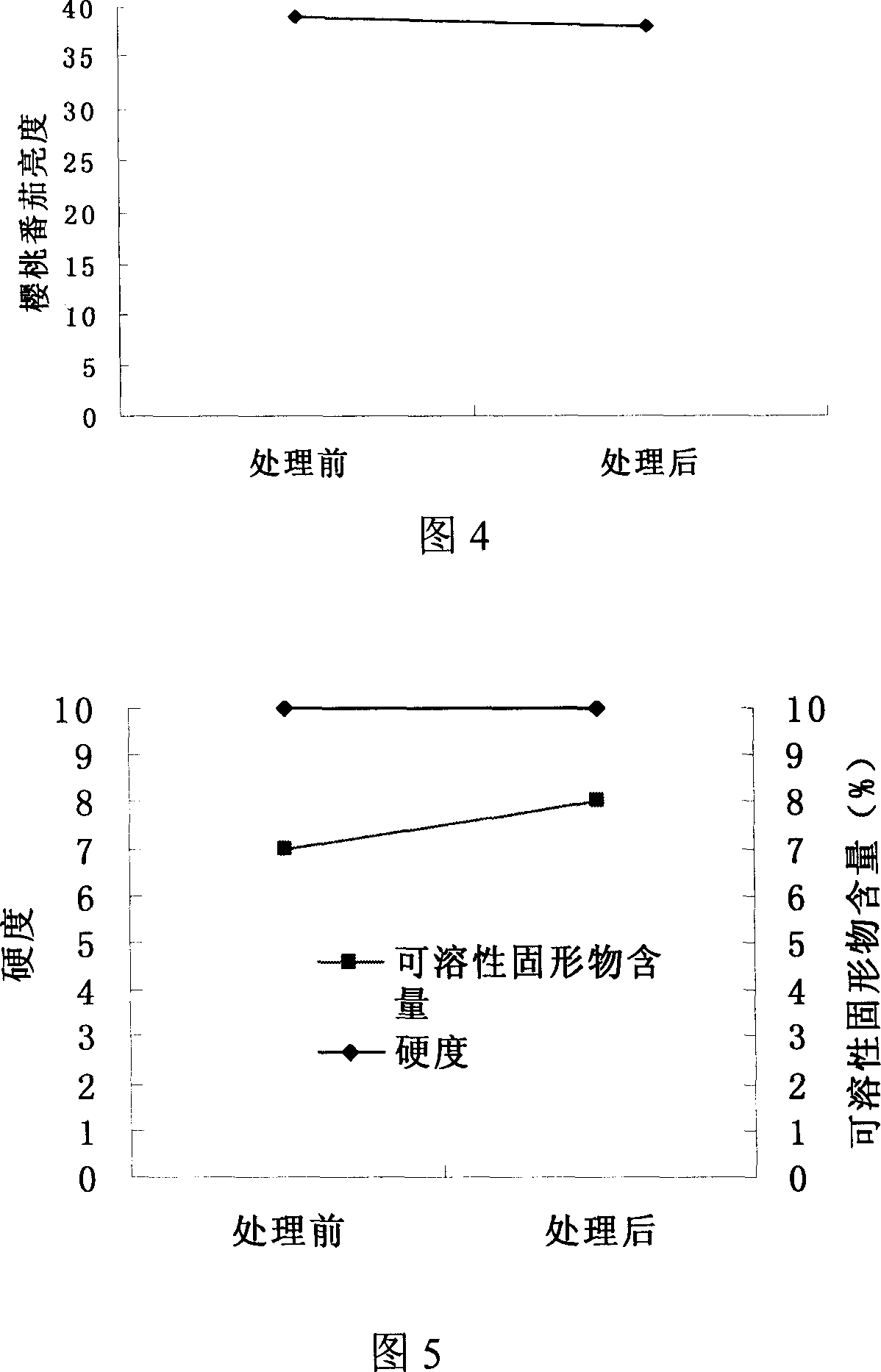

Biological preservative for fruits and vegetable and its prepn

InactiveCN101019572AImprove securityReduce rotFungiFruit and vegetables preservationYeastPreservative

The present invention discloses one kind of biological bactericide for fruits and vegetable and its preparation process. The biological bactericide consists of 10<8>-10<11> CFU / ml concentration Tallman yeast cell suspension 100-1000 ml, and sodium ethyl hydroxyl benzoate 0.6-1.2 g or sodium butyl hydroxyl benzoate 0.6-1.2 g. The preparation process includes the following steps: 1. inoculating the saccharommycete to NYDB culture medium inside a flask, culturing at 26-28 deg.c and 150-200 rpm for 18-30 hr, centrifuging the fermented liquid at 2000-3000 rpm for 5-10 min to collect thallus, twice washing with abacterial water, counting with a blood counting chamber and regulating the concentration of the suspension to 10<8>-10<11> CFU / ml; and 2. mixing the suspension, sodium hydroxyl benzoate and water in the ratio of 100 to 1 to 105-100 to 1 to 106 via stirring.

Owner:ZHEJIANG UNIV

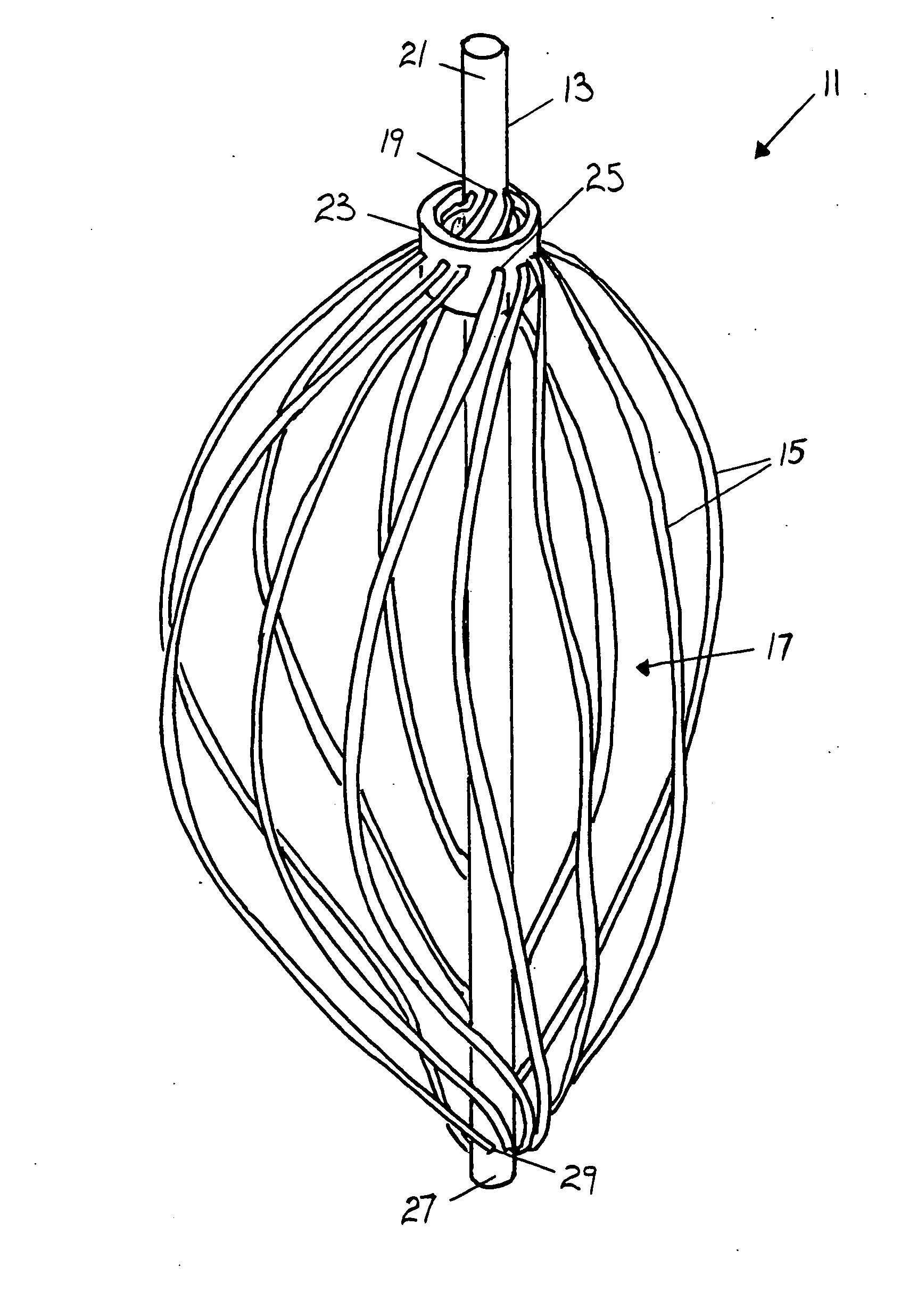

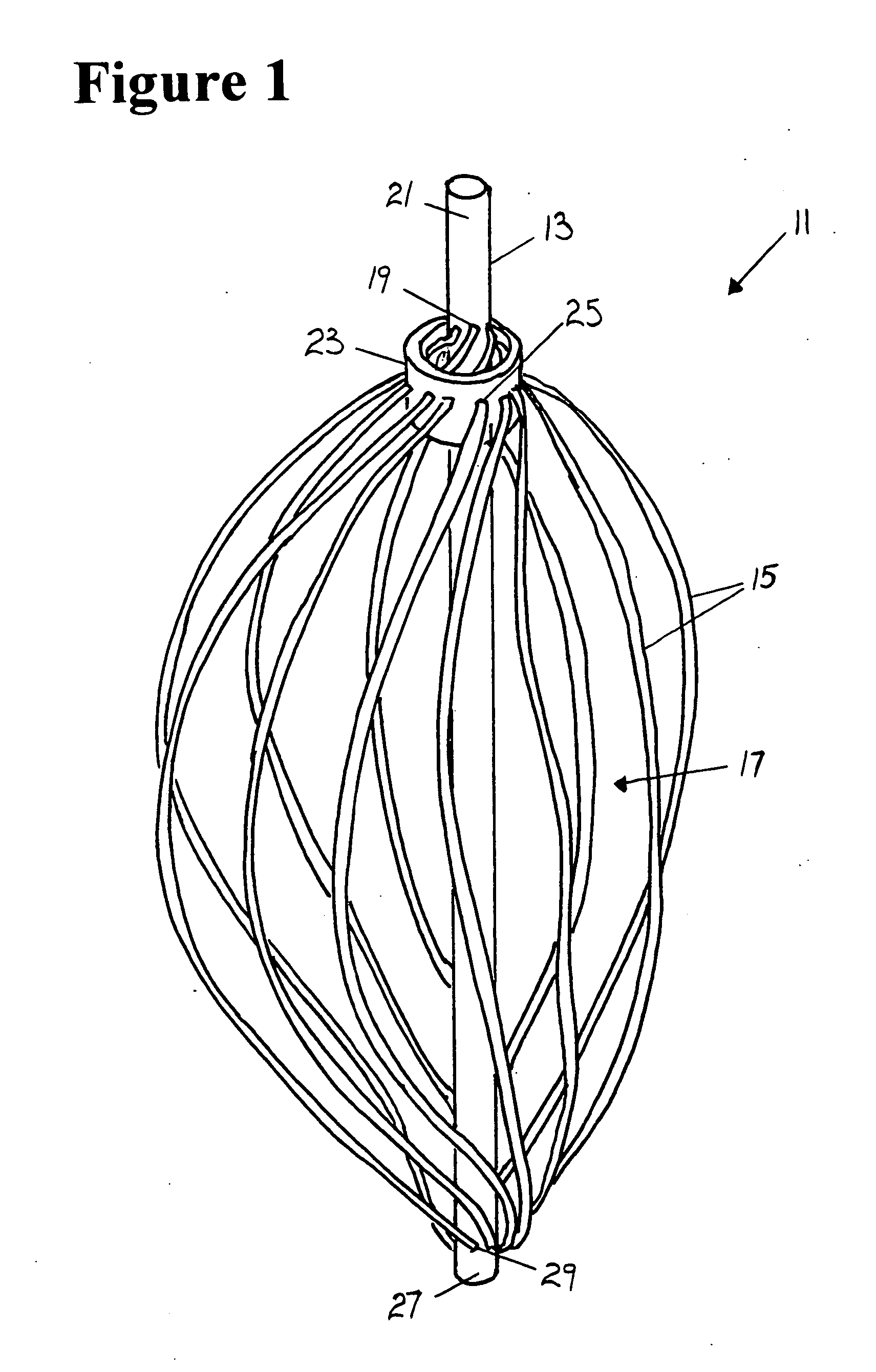

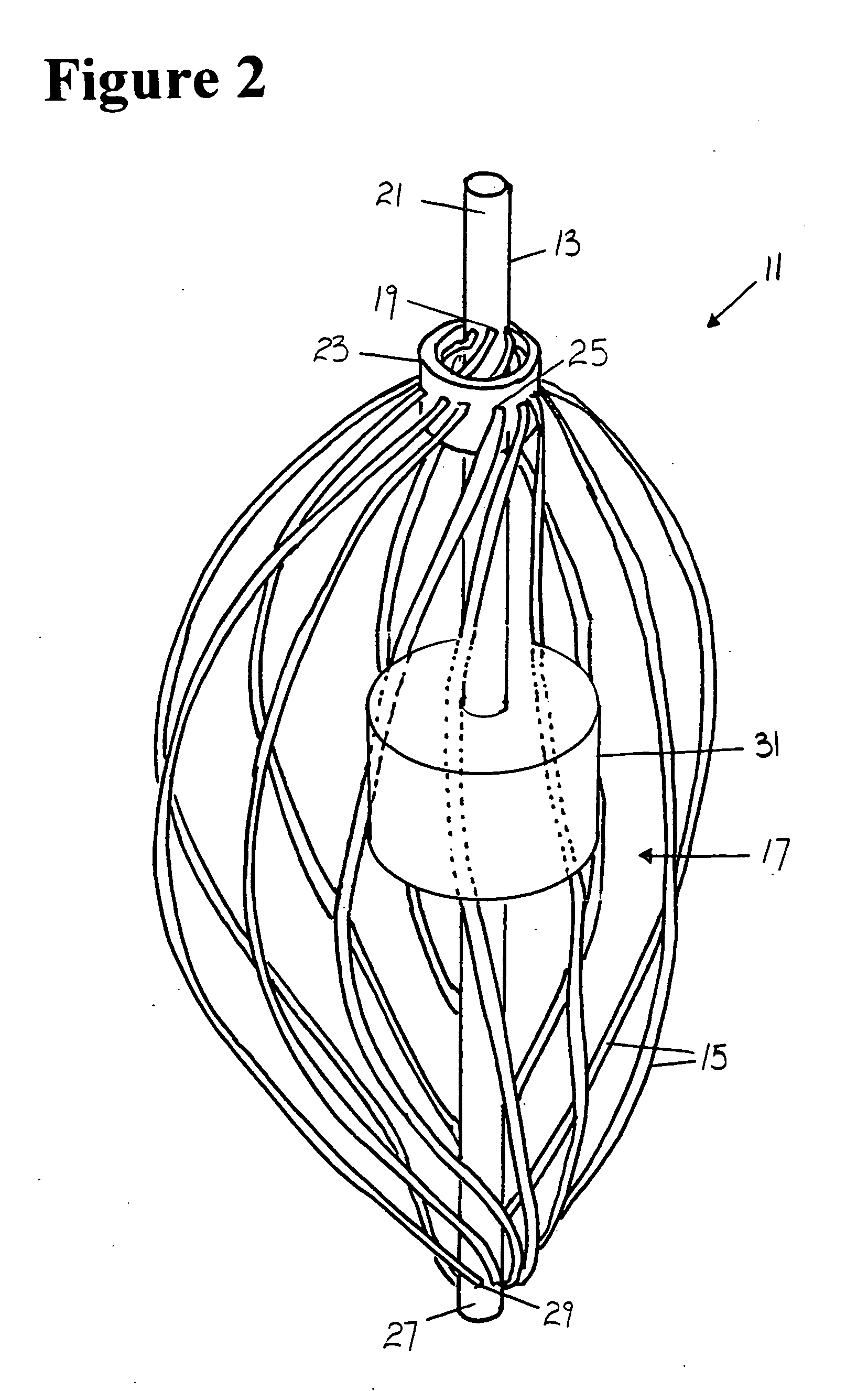

Disposable combined squeezer/stirrer/dispenser/brewer device

Owner:SAHA PAMELA

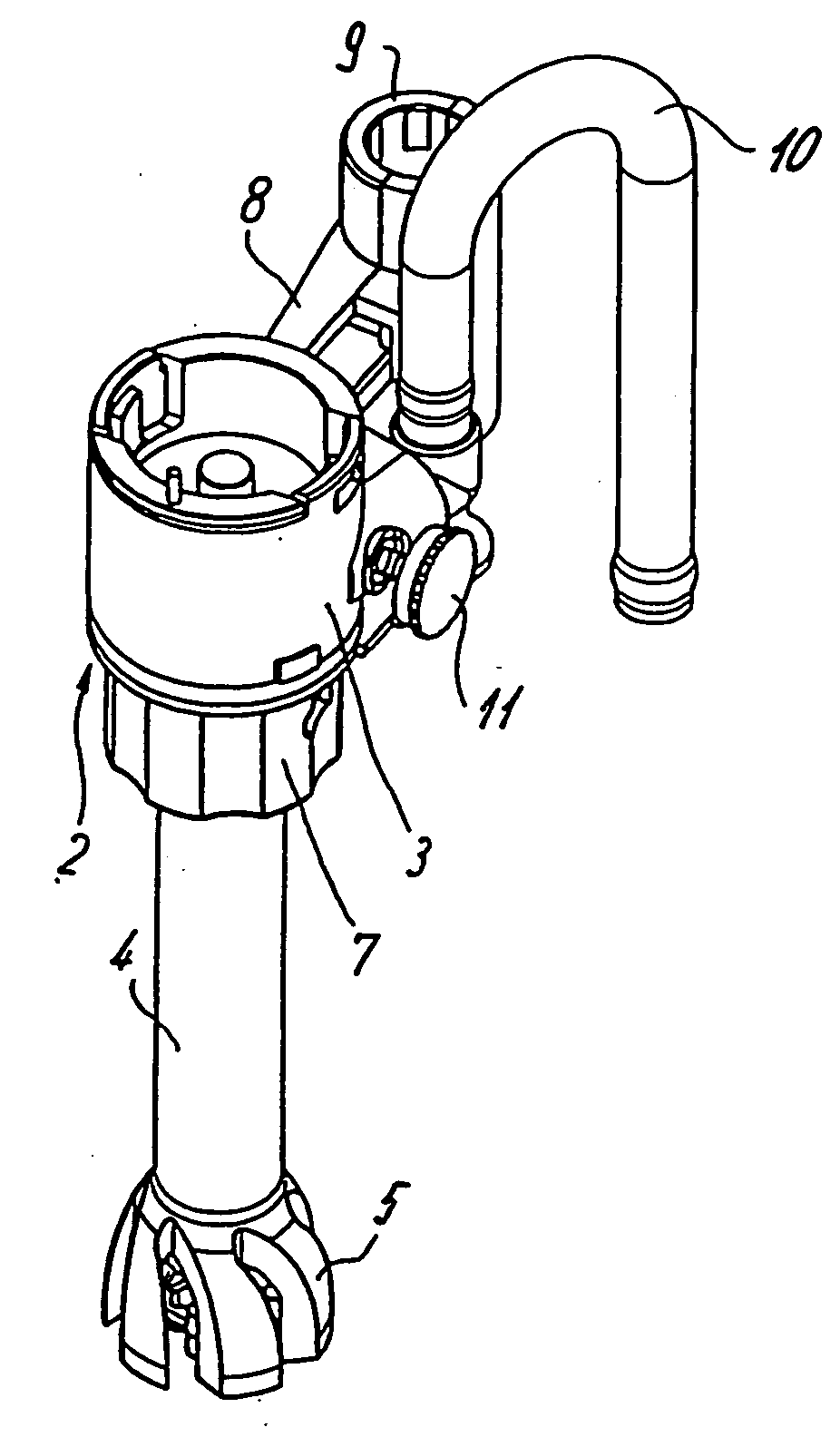

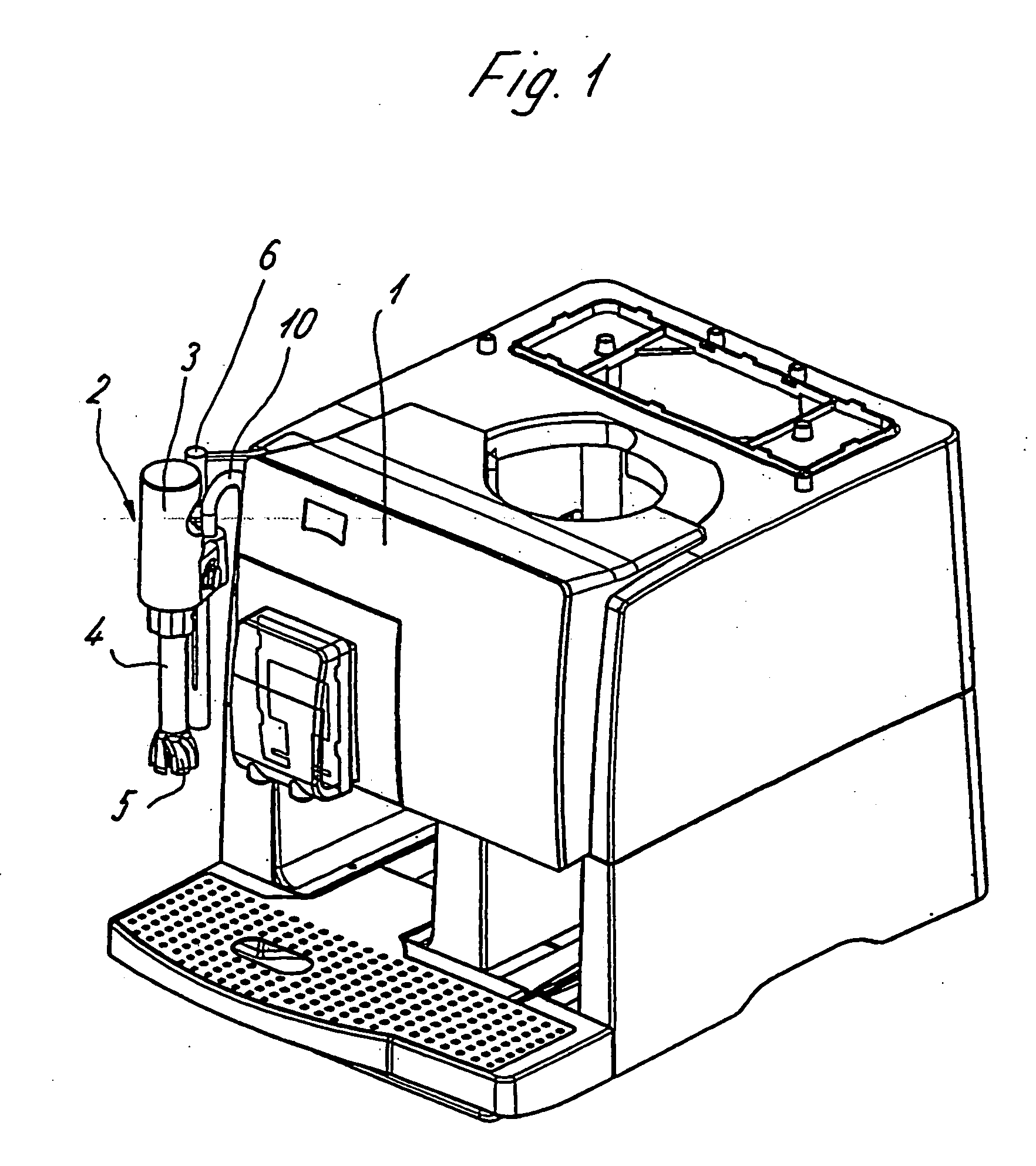

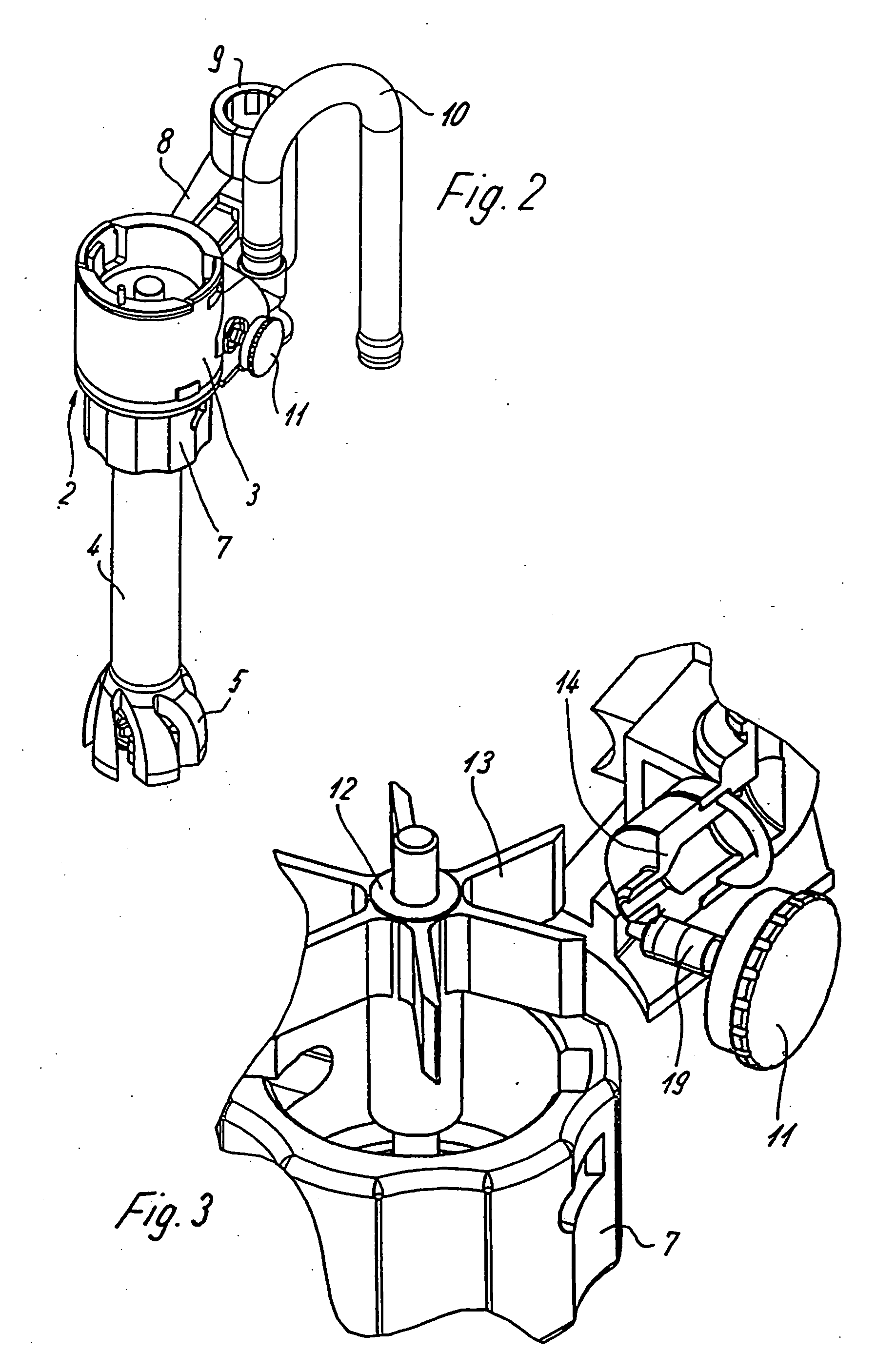

Device for foaming a liquid

ActiveUS20050259508A1Simple designEasy to cleanLighting and heating apparatusUsing liquid separation agentProcess engineeringTurbine

A device for foaming a liquid includes a casing with a turbine arranged inside the casing. A shaft connects an agitator with the turbine. An air supply nozzle is coupled to the casing and a tube is coupled to the casing for conducting a steam supply to drive the turbine. A pipe is connected between the agitator and the turbine to introduce a steam-air mixture to a region of the agitator. The steam-air mixture is whirled together with the liquid when the agitator is immersed in the liquid.

Owner:MELITTA EUROPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com