Patents

Literature

1727results about How to "Easy squeeze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorinated vinyl resin/cellulosic blends: composition, processes, composites, and articles therefrom

InactiveUS7030179B2High expansion rateEasy squeezeLavatory sanitoryRadiationCellulosePolymer science

Compositions and processes for preparing extrudable powder blends containing at least one vinyl chloride resin and a cellulosic material are provided. More specifically, compositions and processes for preparing extrudable free-flowing powder blends containing PVC and wood flour (WF) are also provided for preparing foamed or nonfoamed extrudates. The processes provided herein incorporate components which may contain up to a total of 25 weight percent water. Processes for preparing foamed extrudates are also provided wherein a cooling fluid is used to increase the expansion ratio of the foam. Finally provided are composites having an extrudable thermoplastic substrate and at least one capstock layer disposed thereon containing a PVC / WF composition.

Owner:ROHM & HAAS CO

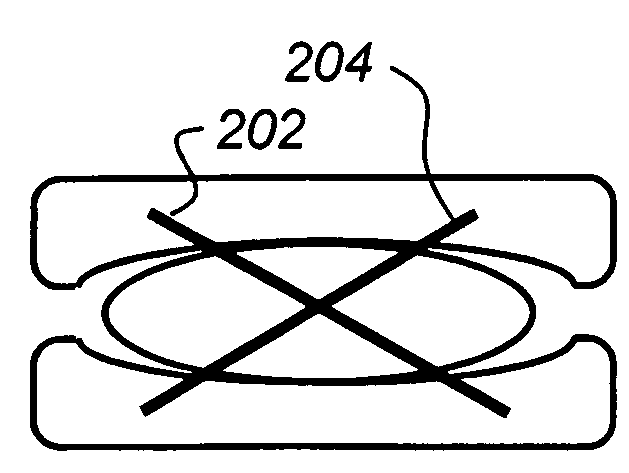

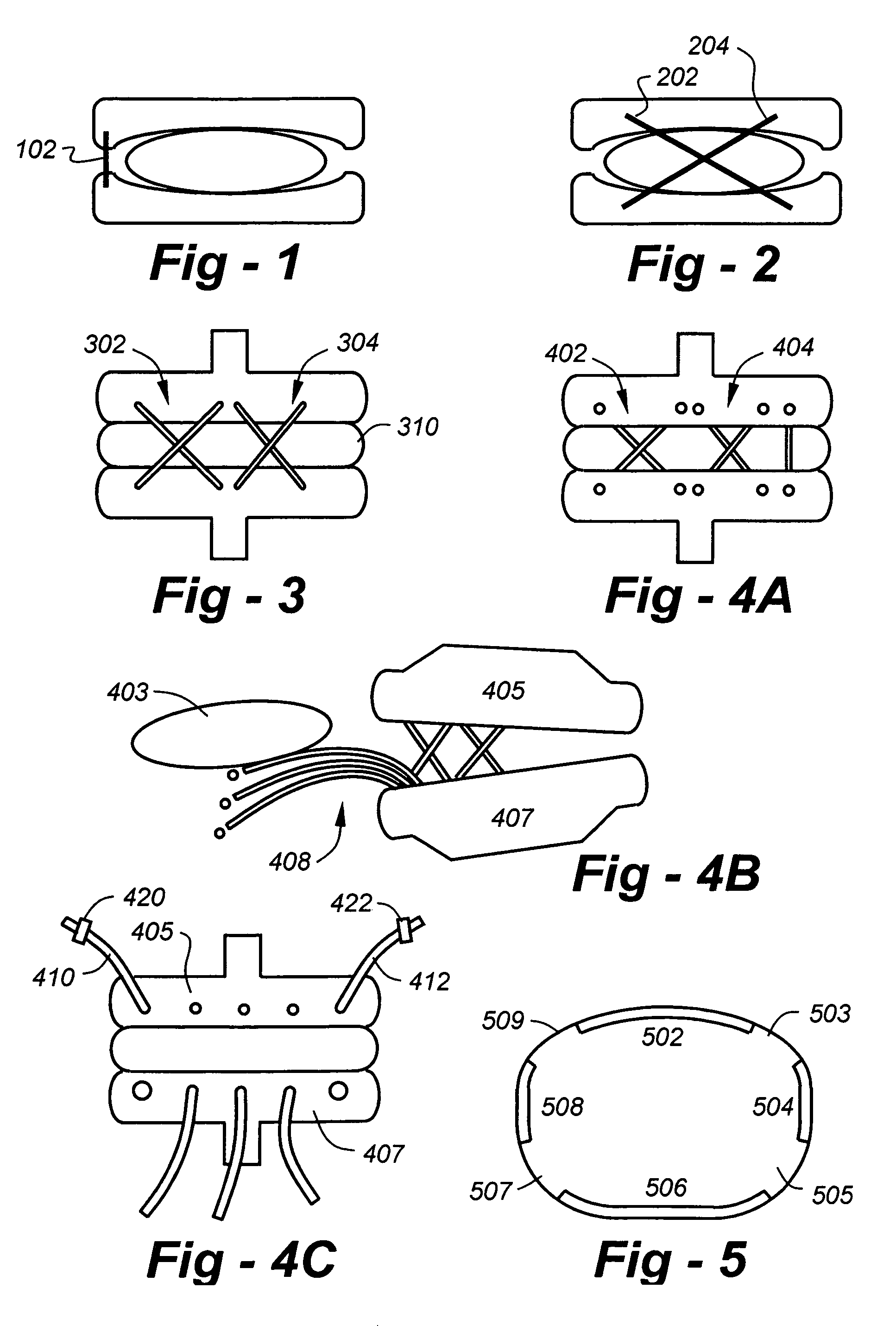

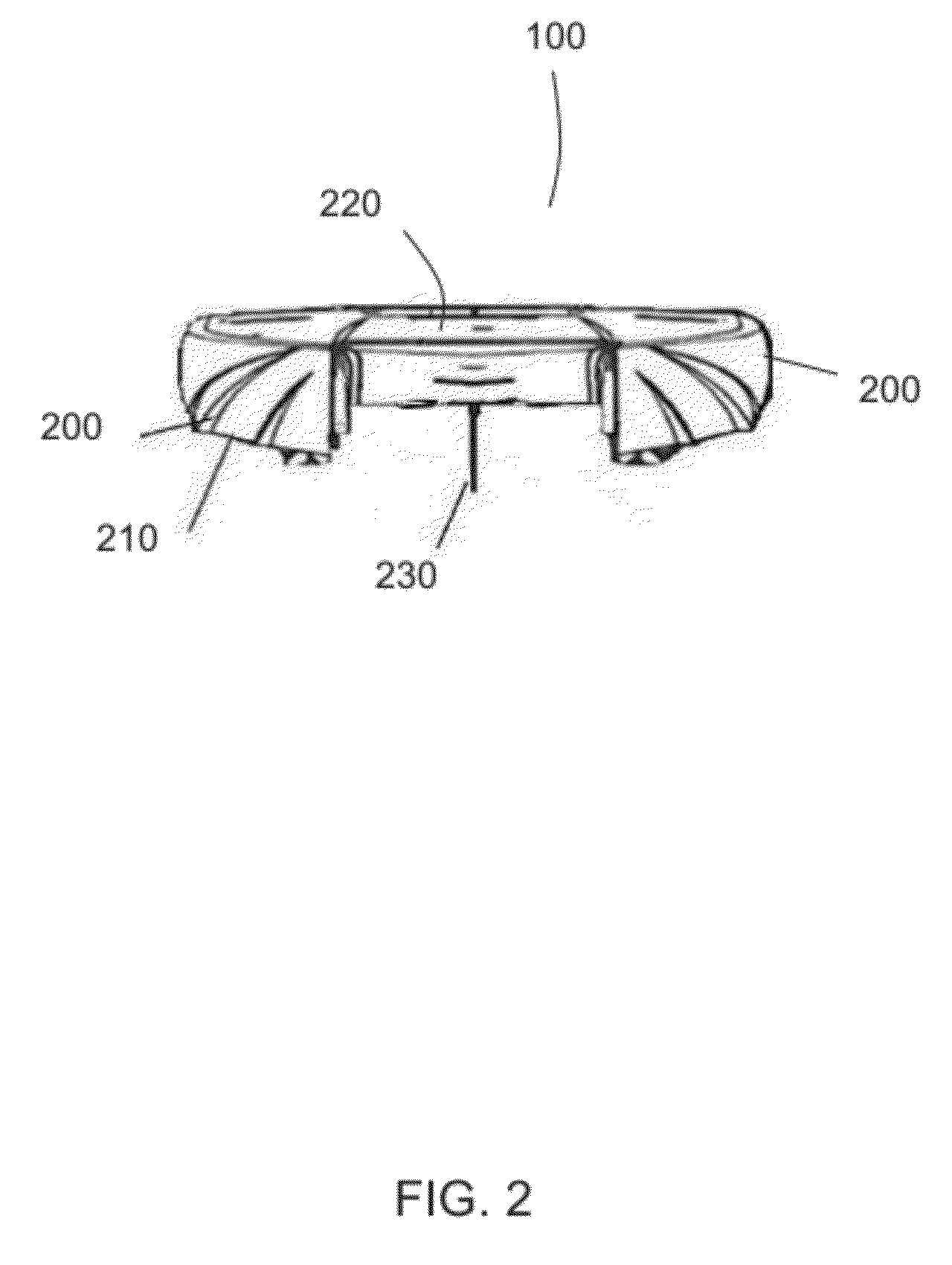

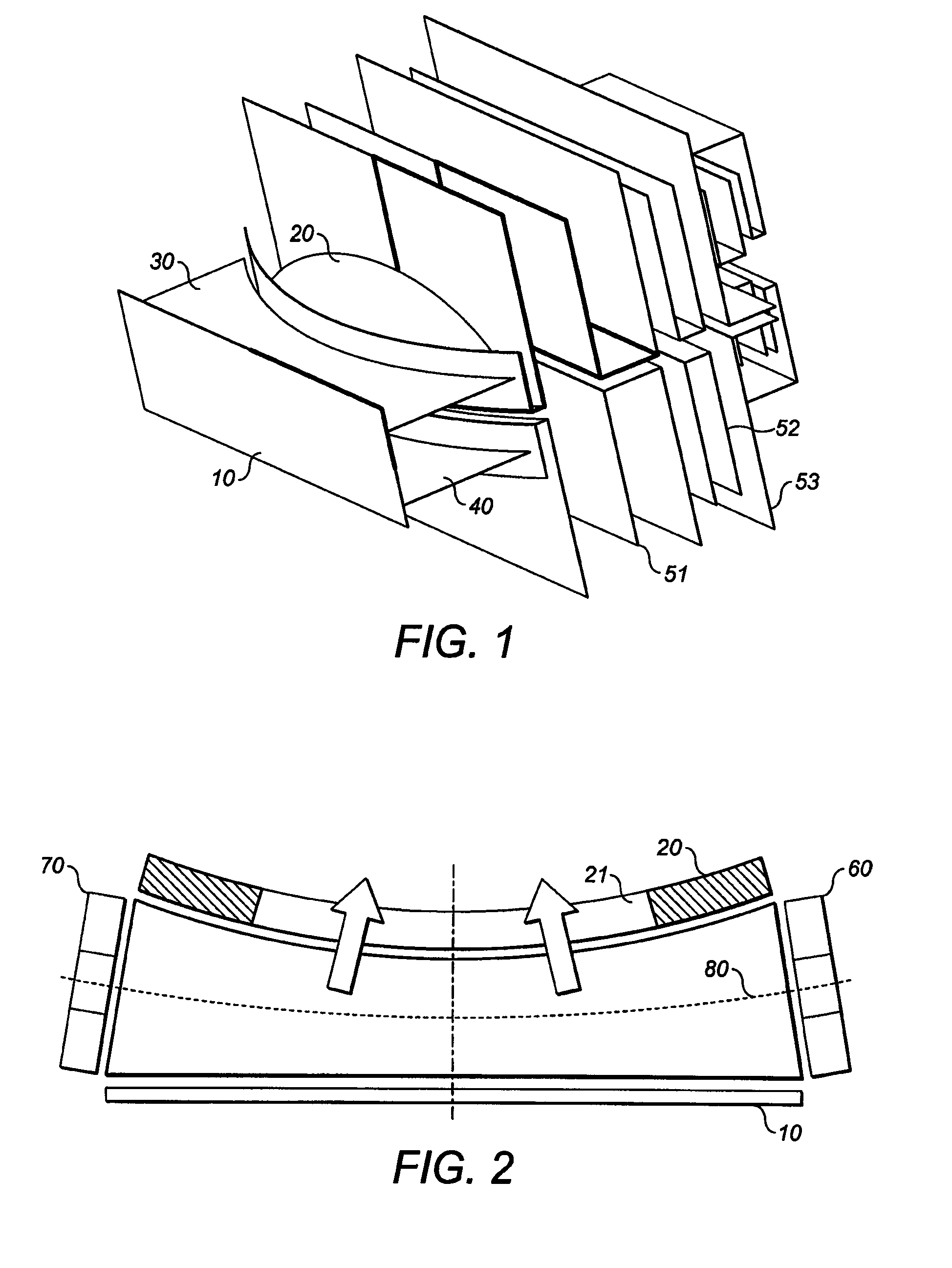

Check reins for artificial disc replacements

InactiveUS7156848B2Restore motion limiting functionPrevent excessive spinal motionInternal osteosythesisLigamentsAnterior longitudinal ligamentRange of motion

Check reins in the form of elongated members are used to limit the extreme range of motion which would otherwise be permitted by some ADR designs. The check reins serve two main purposes. First, they retain disc spacers, if present. Additionally, the wedge shape of ADRs and the removal of the Anterior Longitudinal Ligament (ALL) and a portion of the Annulus Fibrosus (AF) to insert the ADR from an anterior approach, favor anterior extrusion of disc spacers. In preferred embodiments the check reins are therefore limited to the anterior portion of the periphery of the ADR. Second, check reins serve to prevent excessive spinal motion. Again, although they may be helpful in other locations, anterior check reins help restore the motion limiting functions of the ALL and AF that were removed in anterior approaches to the spine.

Owner:FERREE BRET A

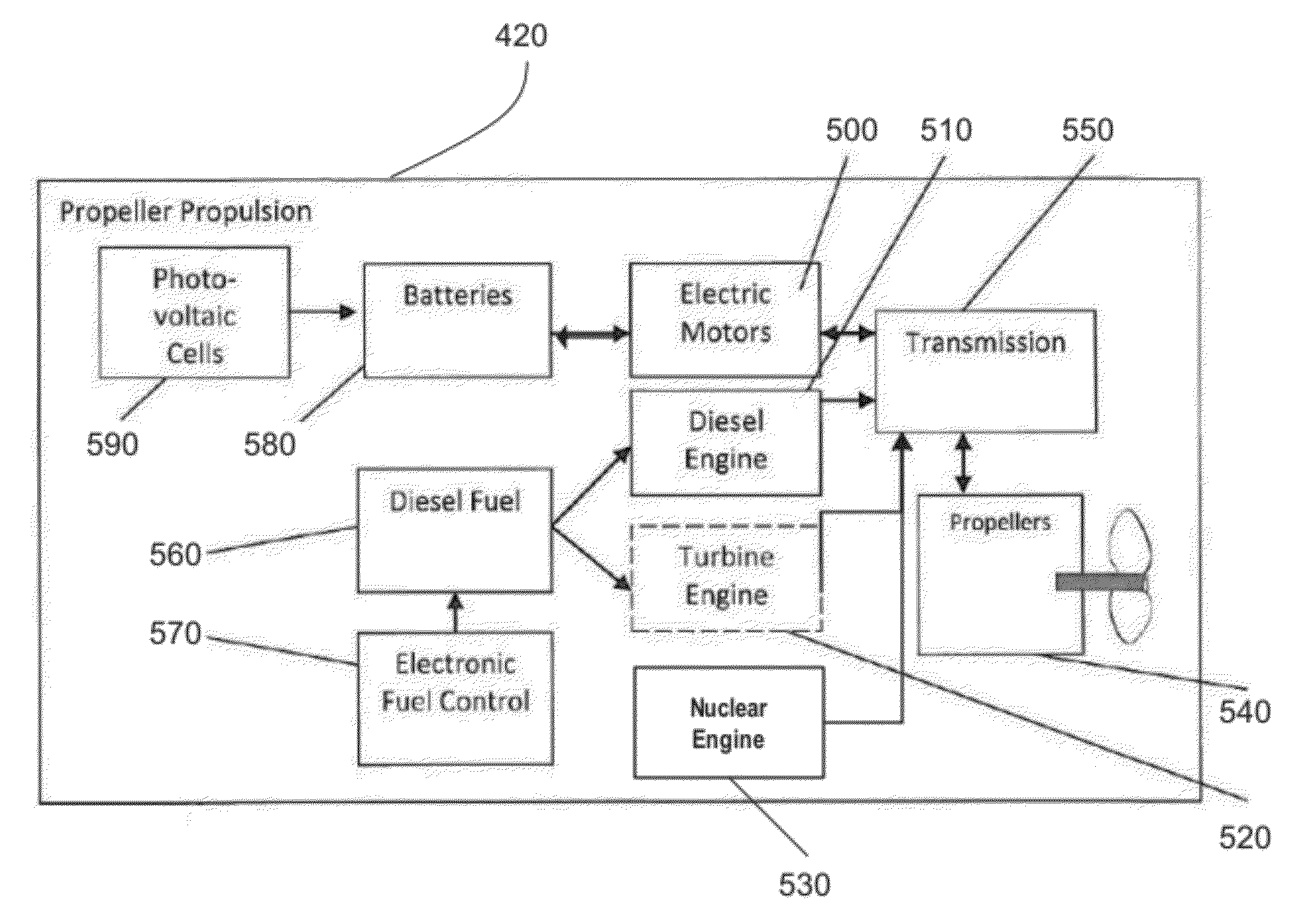

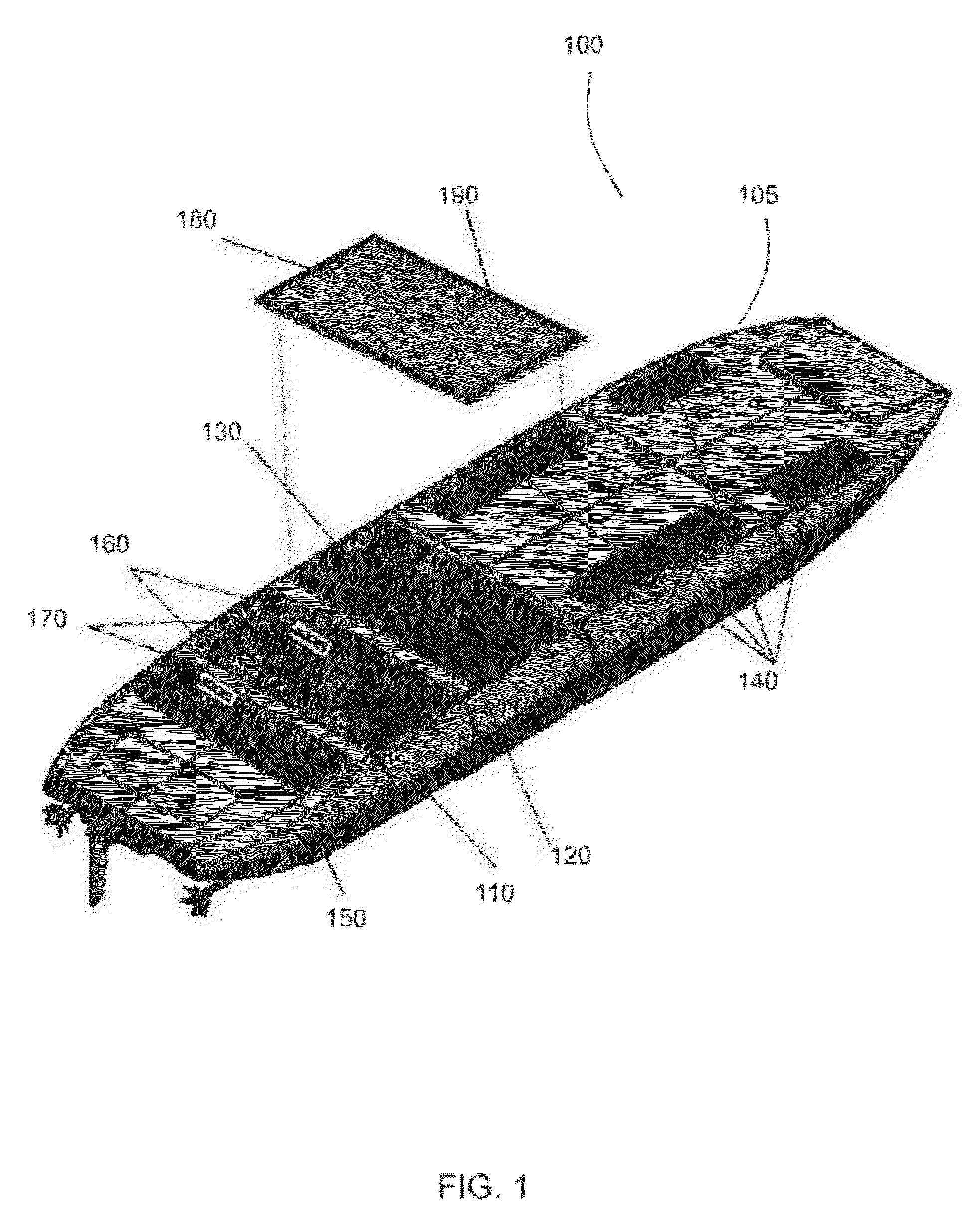

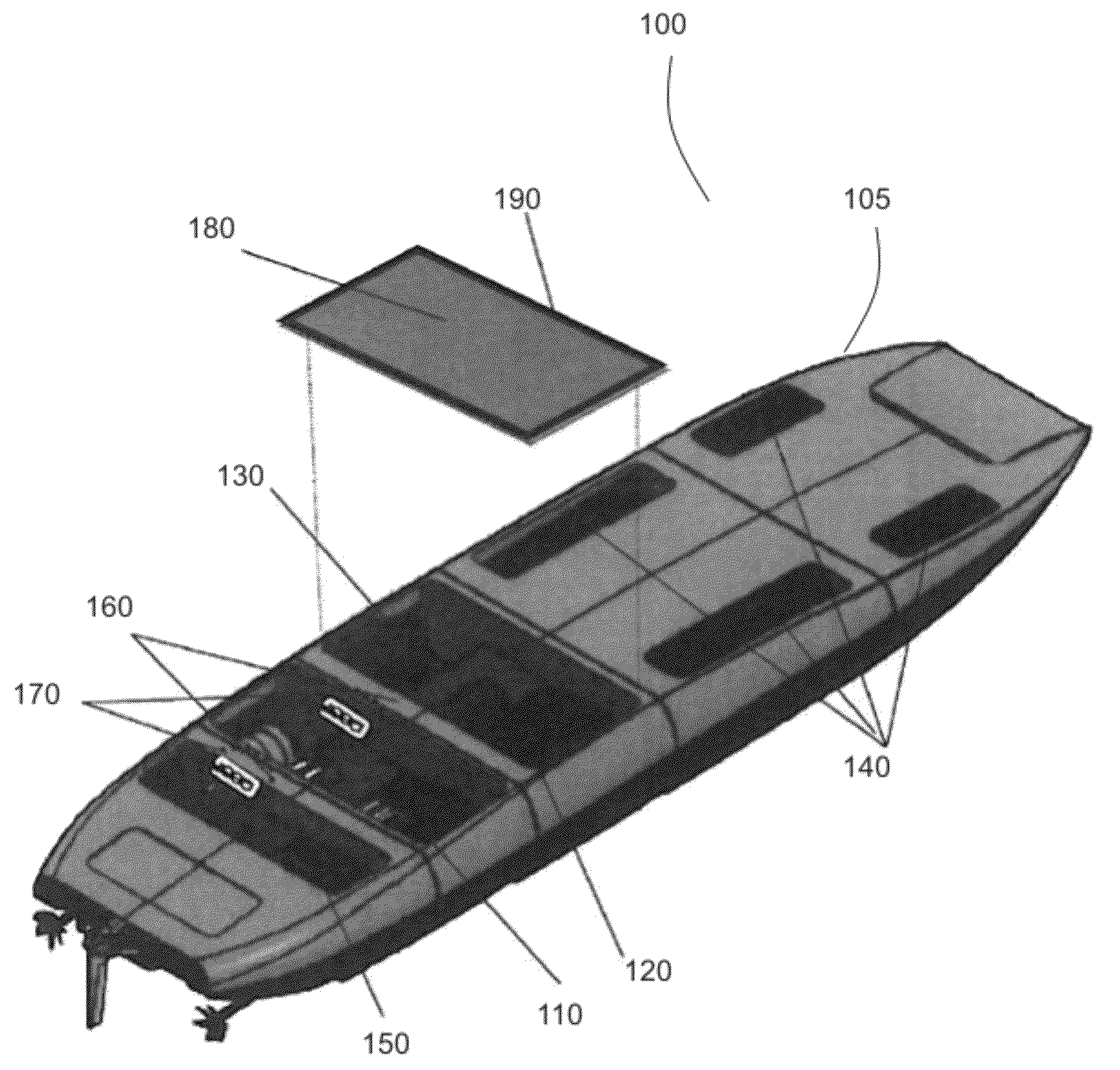

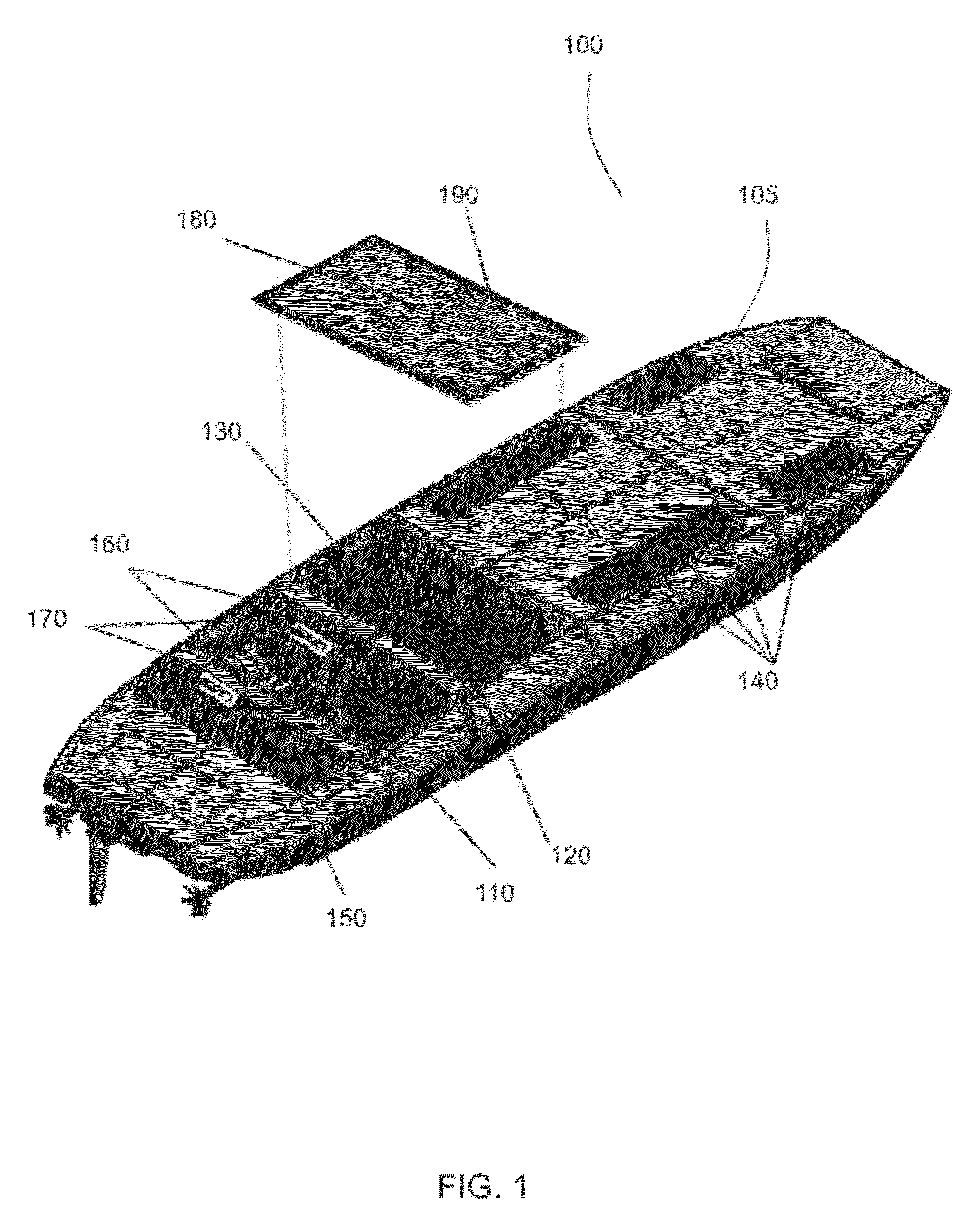

Multi-role unmanned vehicle system and associated methods

ActiveUS20120290164A1Improve operating characteristicsEasy to implementUnmanned aerial vehiclesConvertible vehiclesOn boardControl system

An unmanned vehicle may include a vehicle body that comprises an enclosed hull. The unmanned vehicle may include a propulsion, a ballast control system, a center of gravity system, a pressurization system, a control surface system, a navigation control system, and an on board master control system. The on board master control system may execute local control over operation of the various systems of the unmanned vehicle. The unmanned vehicle may also include a power supply carried by a portion of the vehicle body to provide power to the various systems. The various systems of the unmanned vehicle may be independently operable to support selective operation of the unmanned vehicle in the air, on the surface of the water, and below the surface of the water.

Owner:UNMANNED INNOVATION

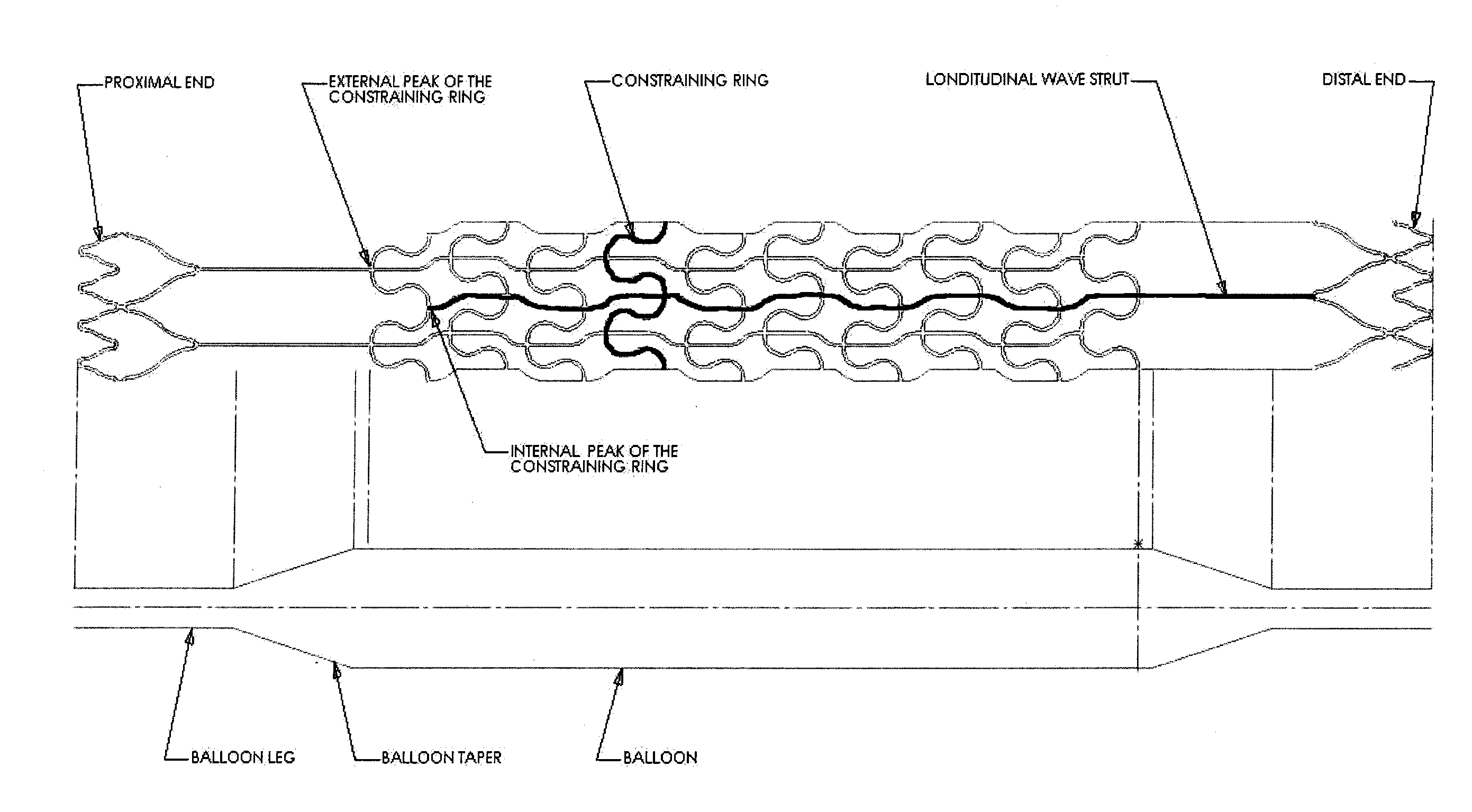

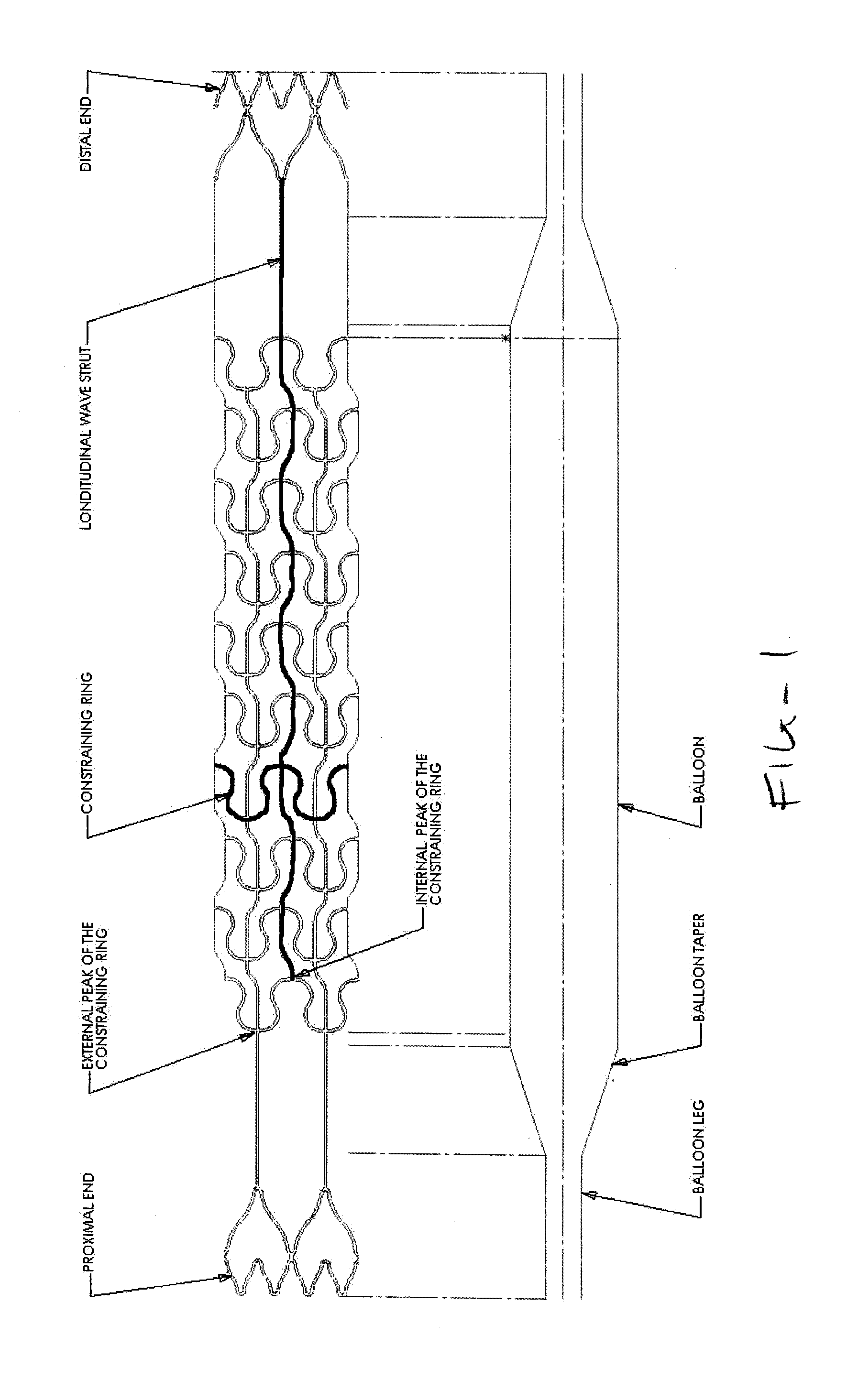

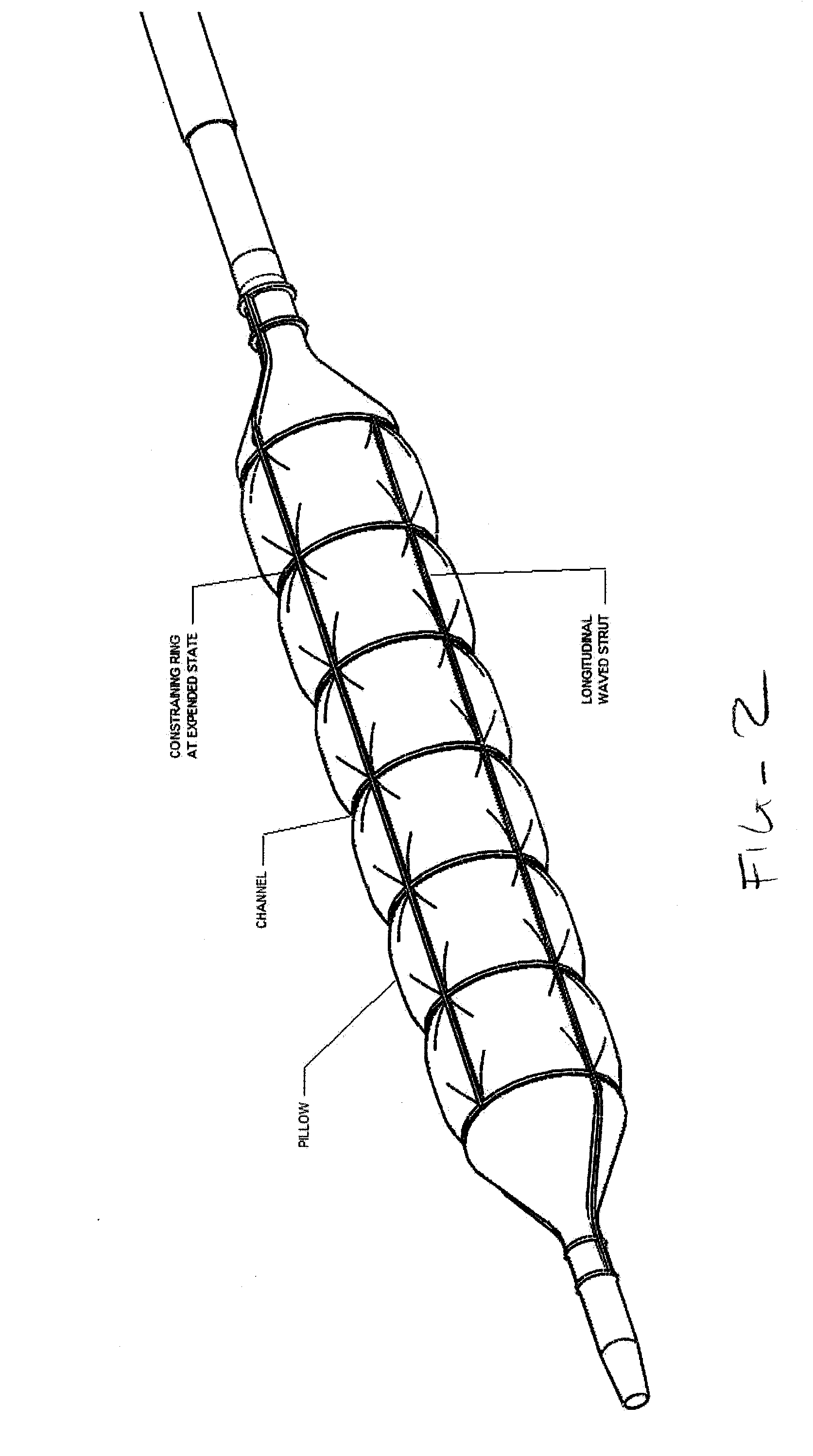

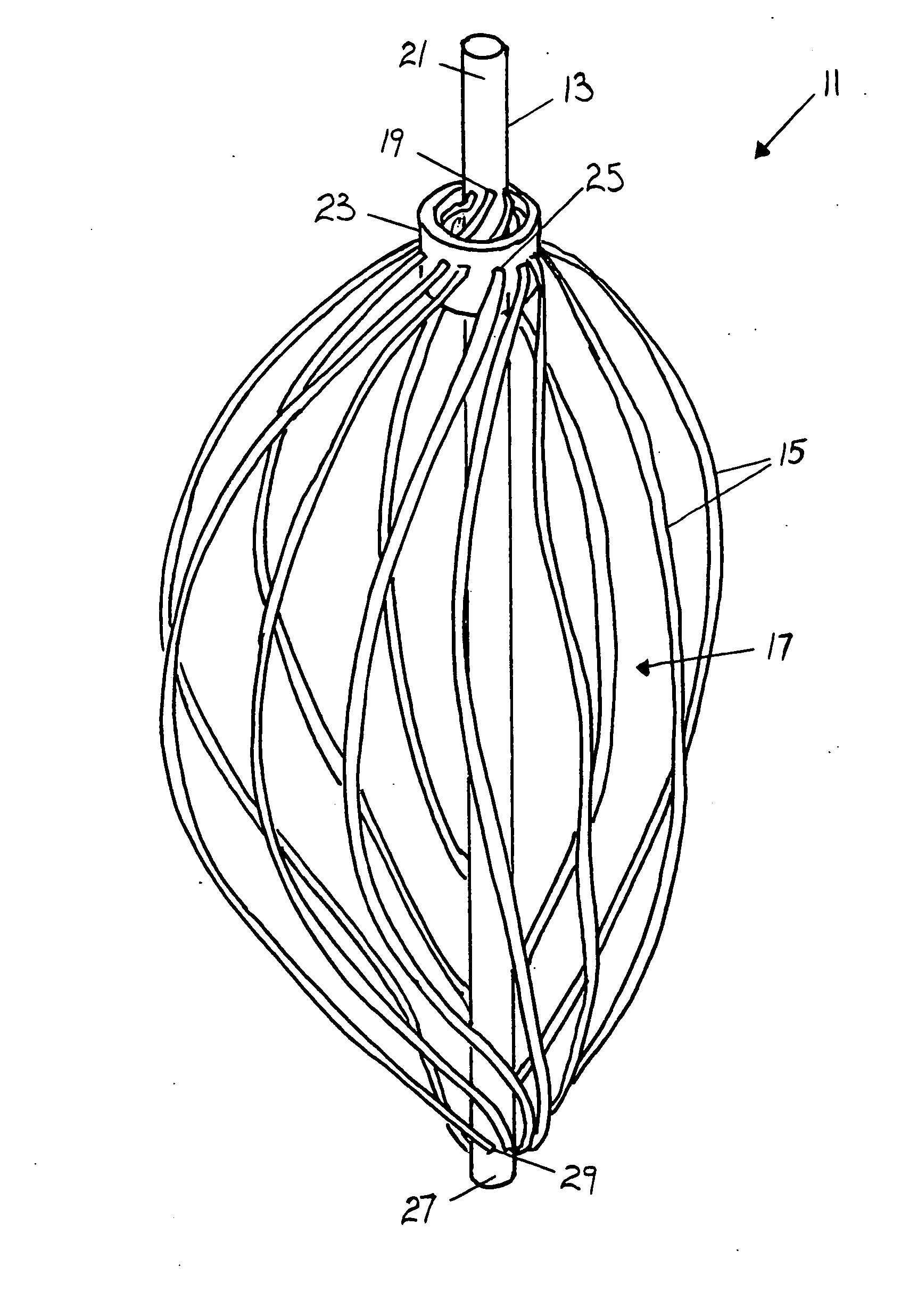

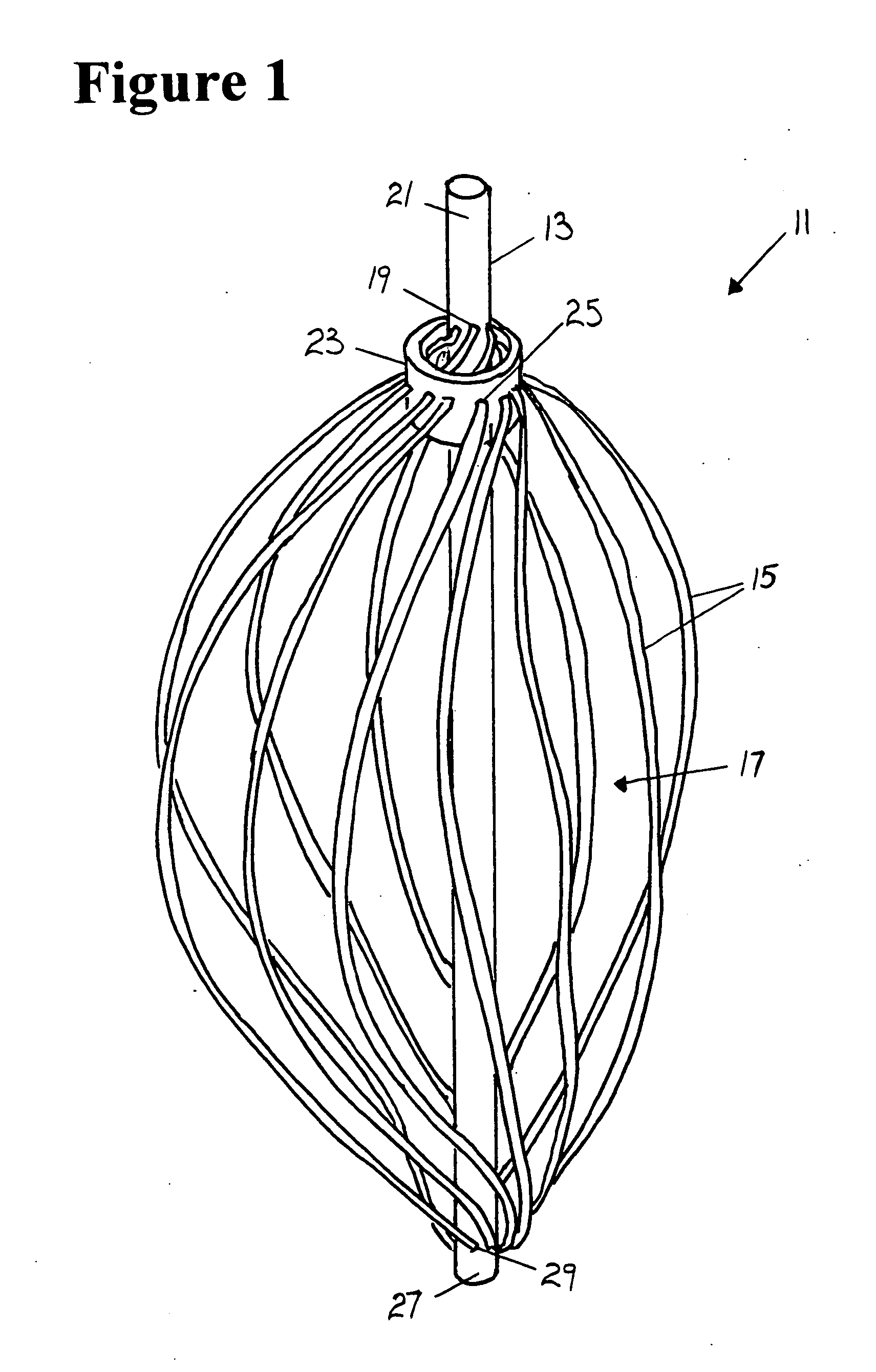

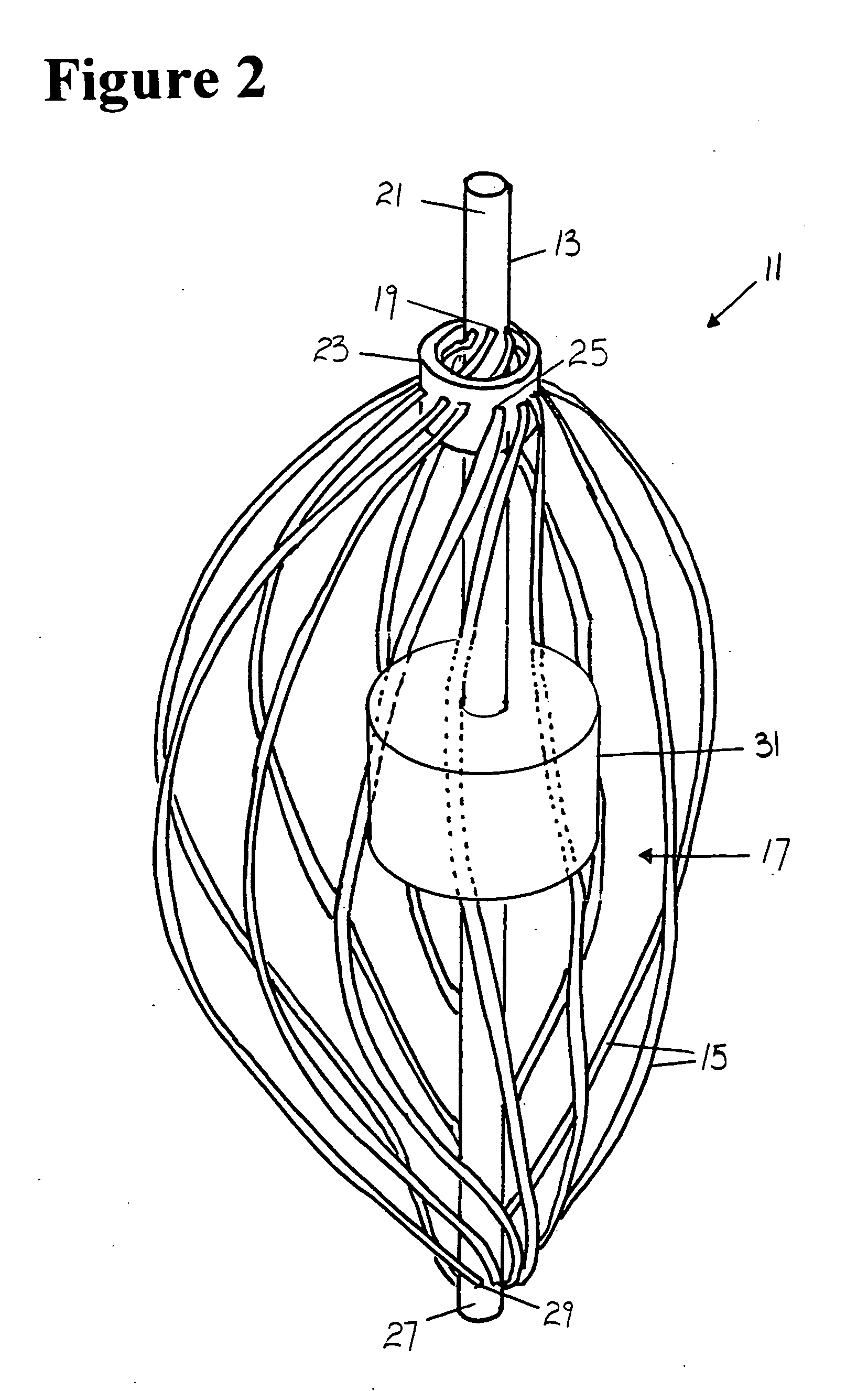

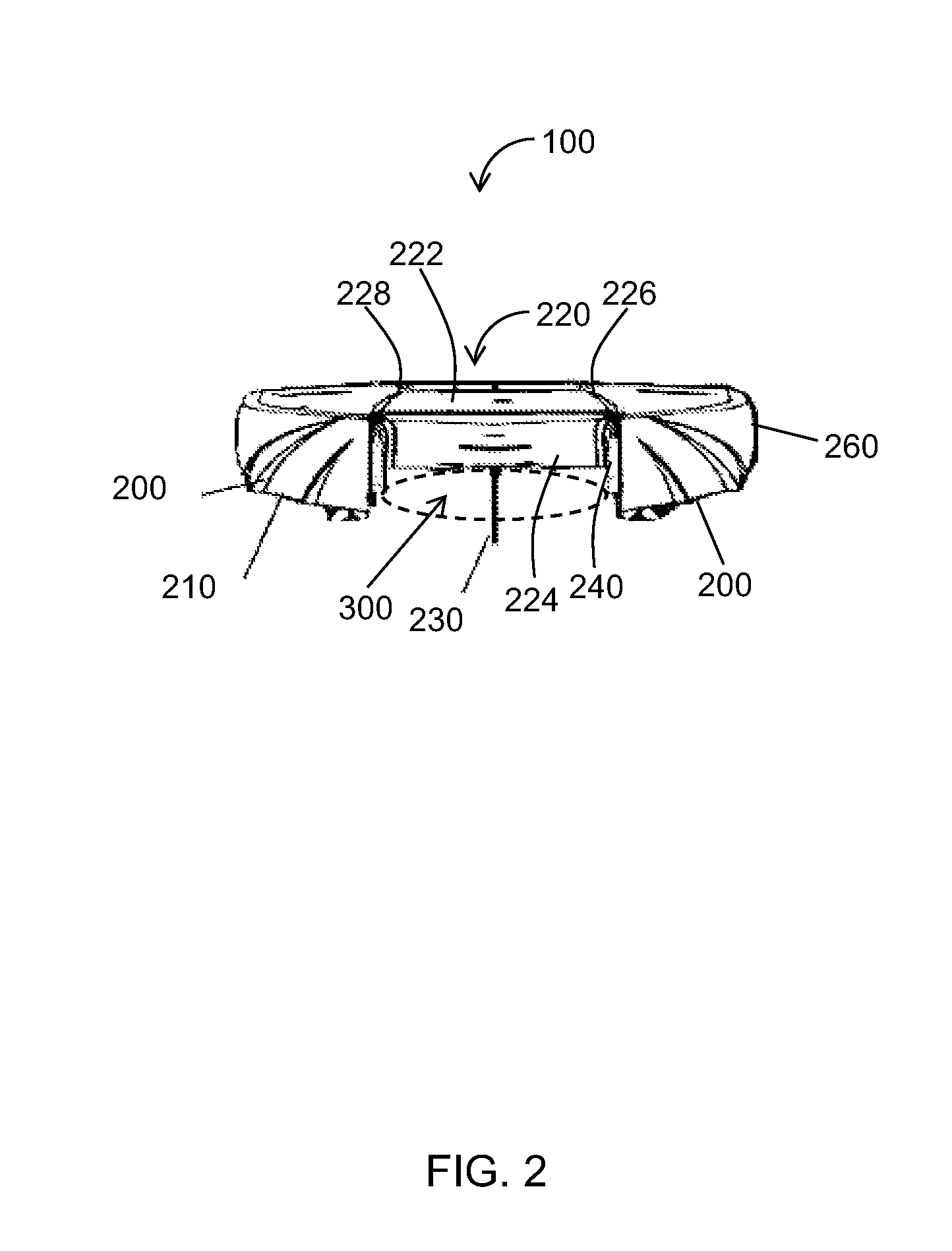

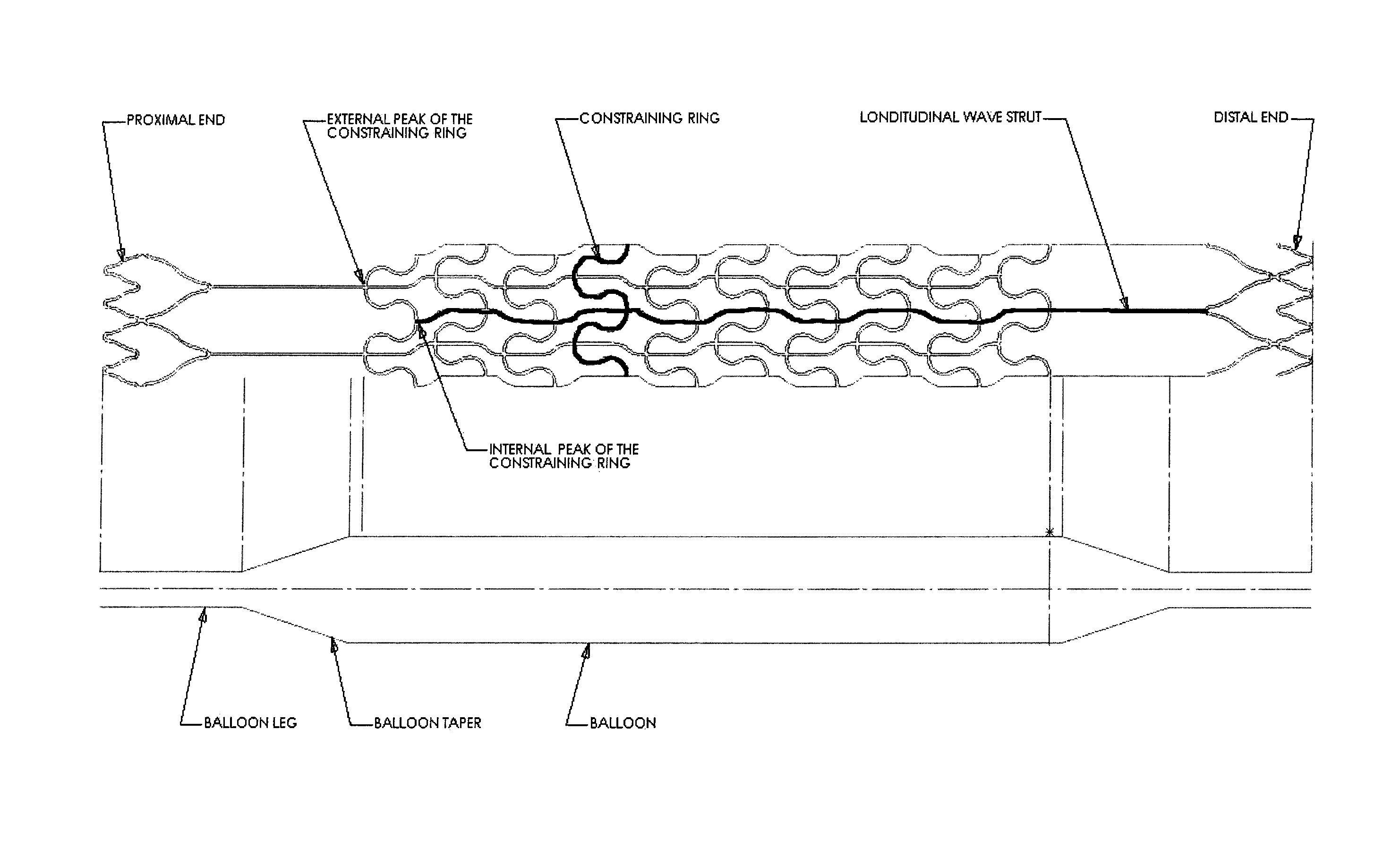

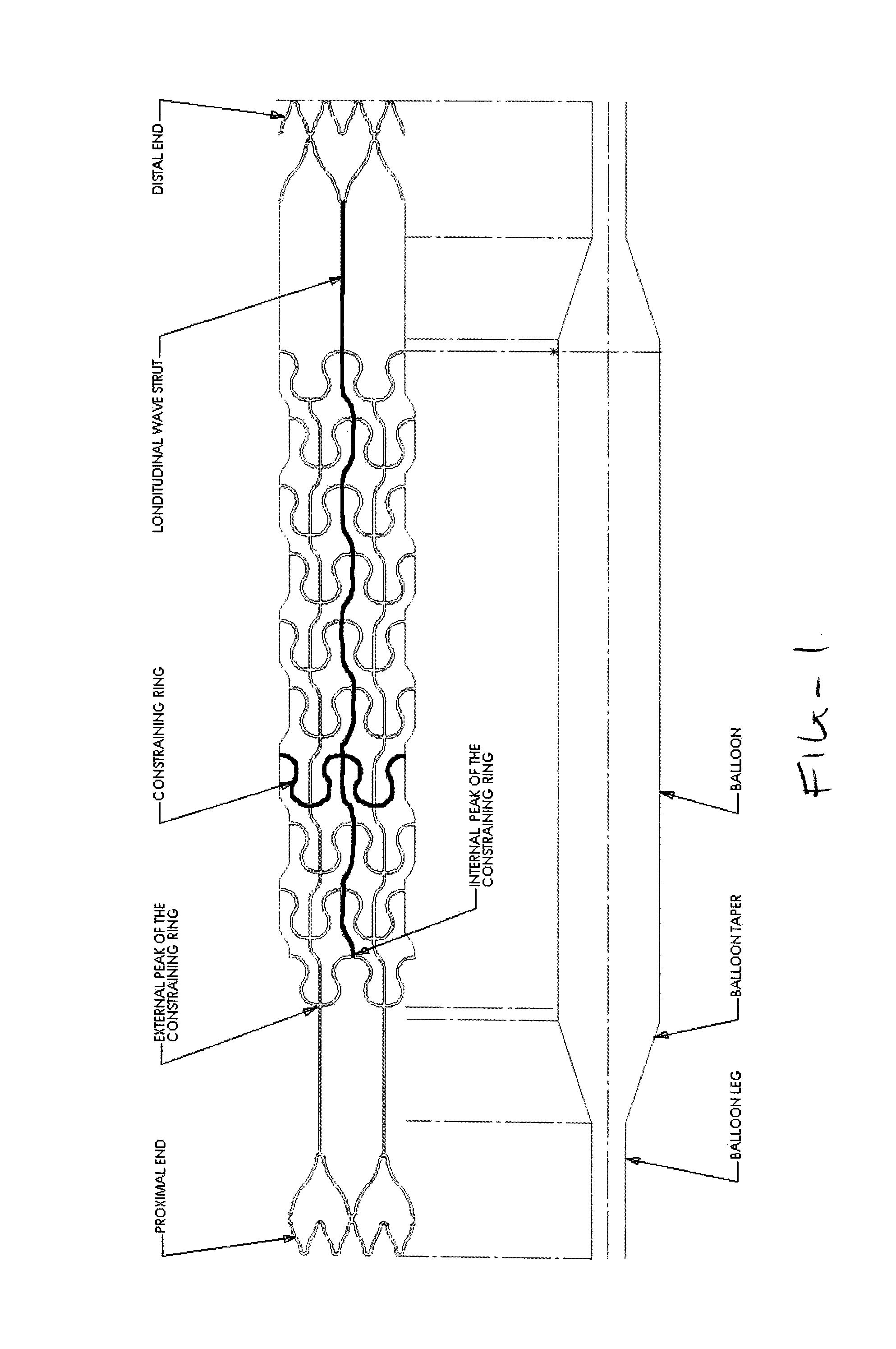

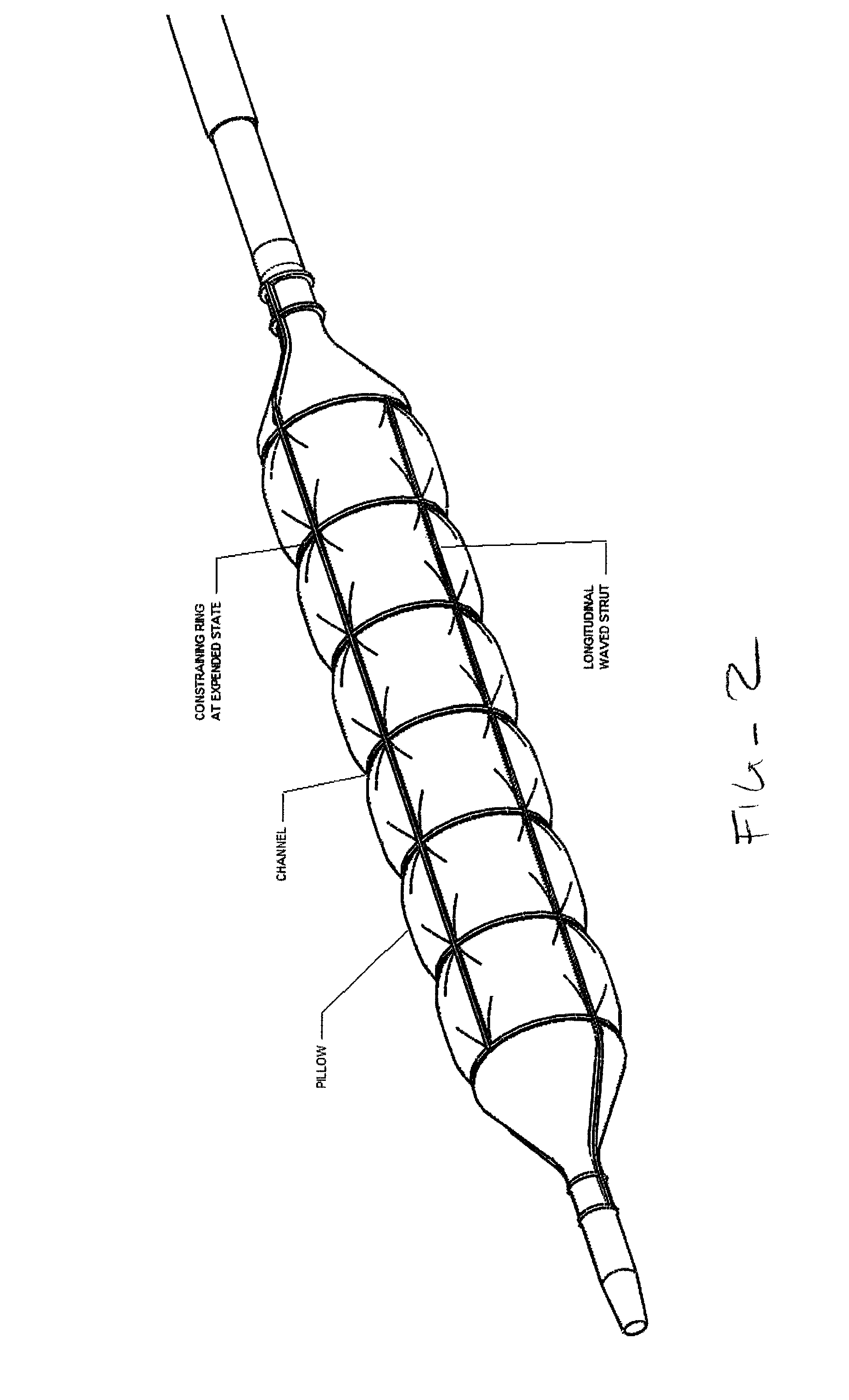

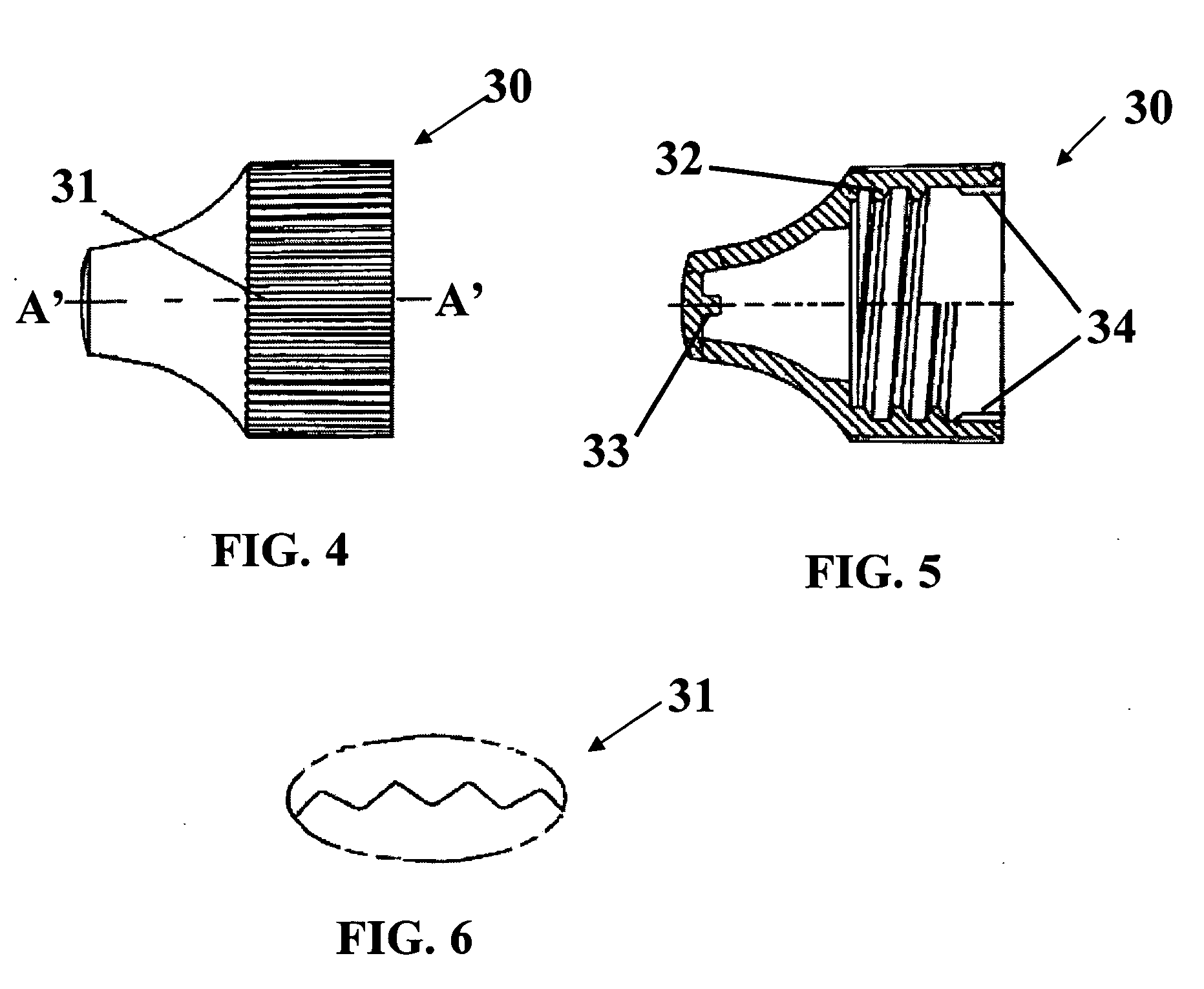

Constraining structure with non-linear axial struts

ActiveUS20130218181A1Facilitate plaque extrusionMinimize vessel traumaStentsBalloon catheterBalloon catheterSquare Window

A constraining structure for use with a balloon catheter can include multiple longitudinal struts and multiple, sinusoidal shaped radial rings. The constraining structure can expand to form a pattern of channels including substantially square windows. The constraining structure can modify, restrict, and control a shape and / or size of the balloon when inflated. Inflating the balloon catheter within the constraining structure can provide nonuniform pressure on a vessel wall adjacent the balloon.

Owner:TRIREME MEDICAL

Iolite cellular ceramic and preparation method

A high-porosity thin-wall cordierite-type cellular ceramics is prepared proportionally from LiO2, talc, kaolinite, calcined kaolinite, alpha-AlO, aluminum hydroxide, silicon powder, solid adhesive, and the liquid organic additive prepared from water, propanetriol, liquid adhesive, surfactant and lubricant. Its preparing process is also disclosed.

Owner:JIANGSU GAOCHUN CERAMICS +1

Disposable combined squeezer/stirrer/dispenser/brewer device

Owner:SAHA PAMELA

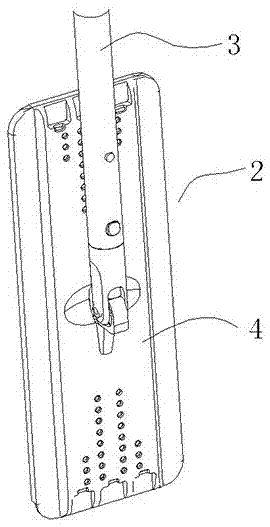

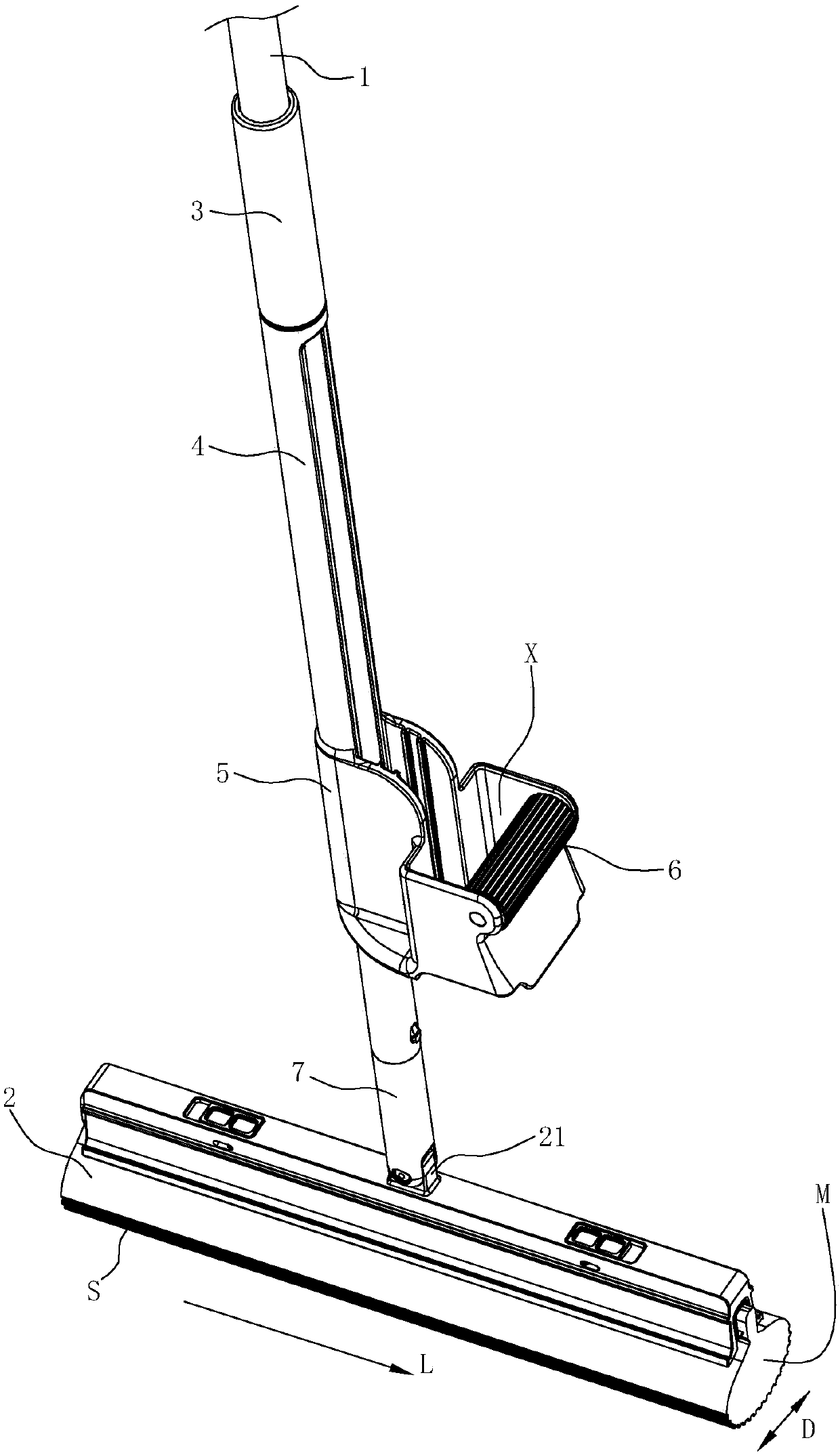

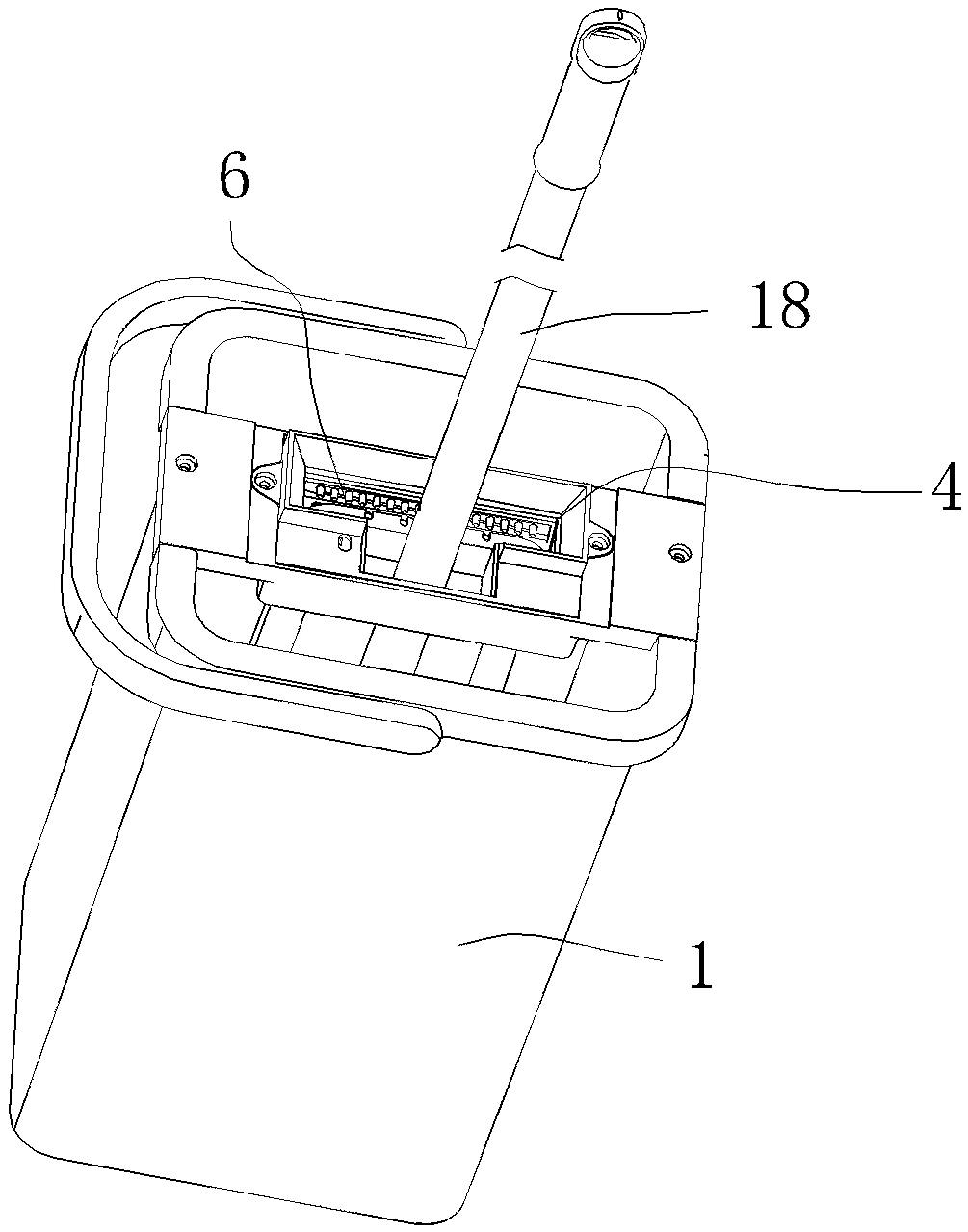

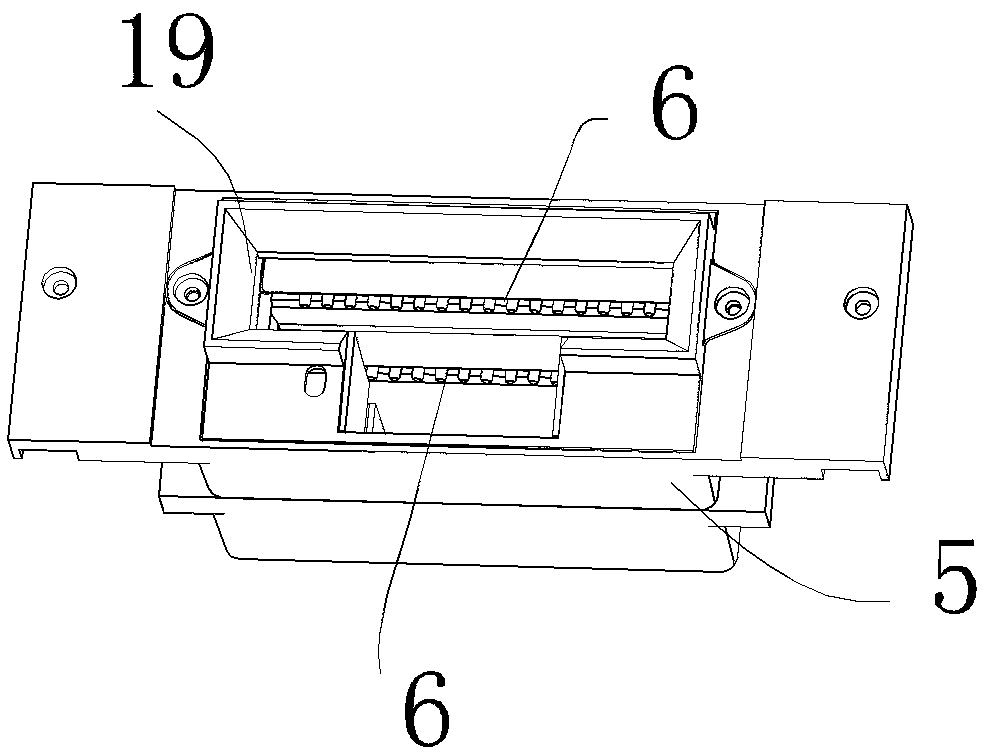

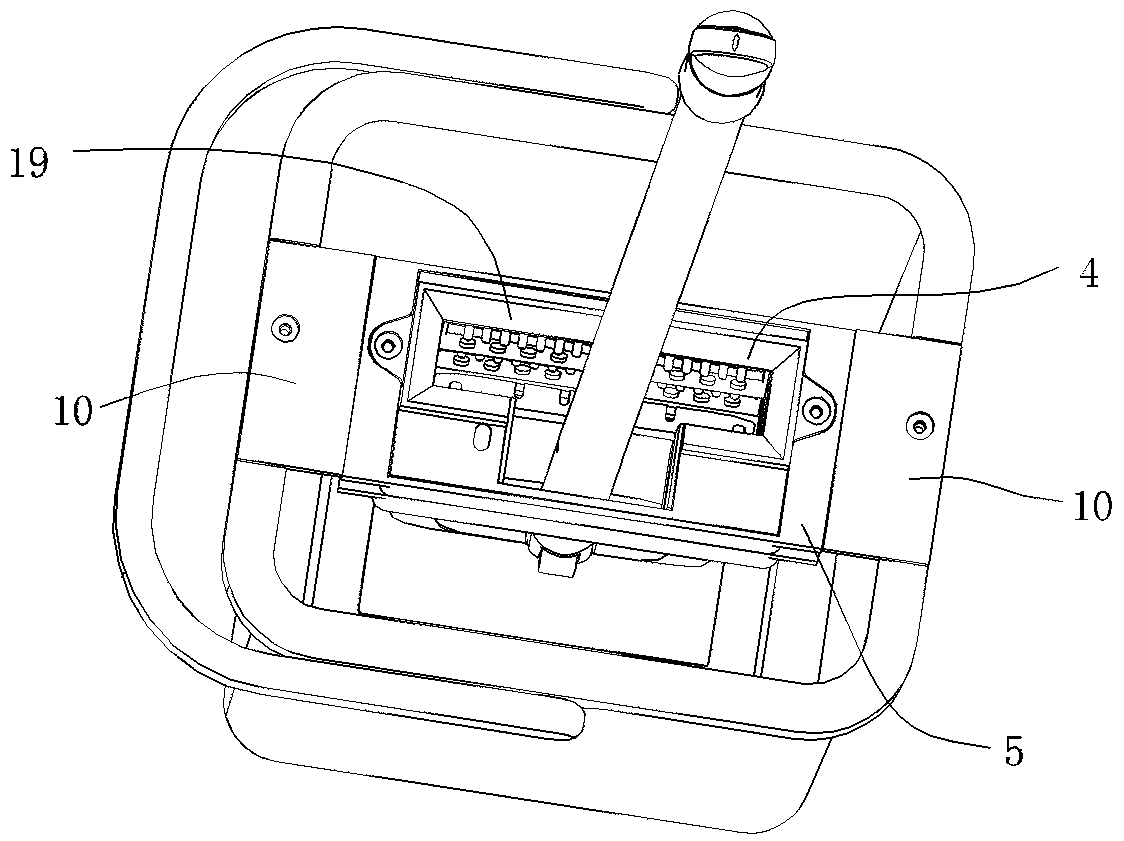

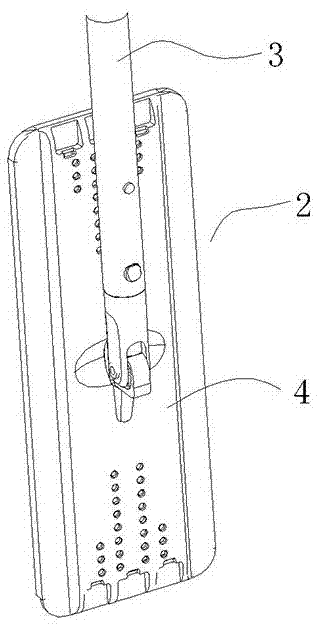

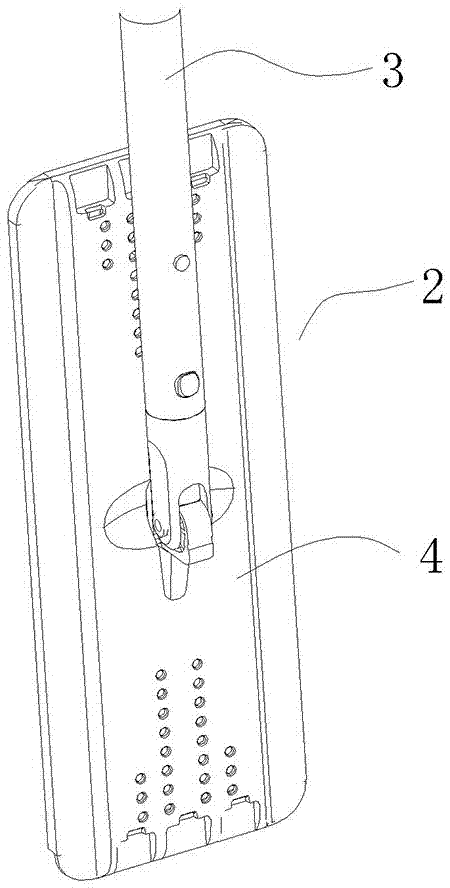

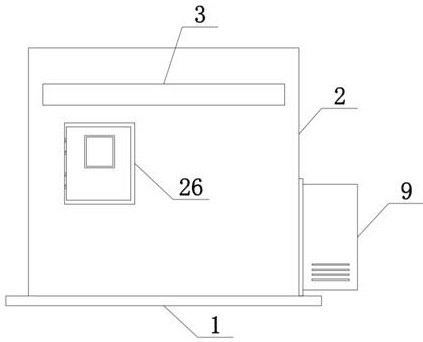

Extruding flat plate mop cleaning tool capable of being set upright

An extruding flat plate mop cleaning tool capable of being set upright comprises a mop barrel and a flat plate mop. The flat plate mop comprises a mop rod and a flat plate mop head, a wiping object is arranged on the flat plate mop head, and the mop barrel is provided with an independent cleaning region and an independent water extruding region; a stroking port extruding device is installed on the mop barrel, and the flat plate mop head is kept in a cleaning and water-extruding state through a positioning device between the flat plate mop head and the mop rod; during mopping, the flat plate mop head can be rotated to be in a floor-mopping state; during cleaning, the flat plate mop head moves between the cleaning region and the stroking port extruding device to perform extrusion, so that the wiping objected is moved to be extruded and cleaned, and during water extruding, the flat plate mop head moves between the water extruding region and the stroking port extruding device to perform extrusion, so that the wiping object is moved to be extruded and subjected to water extruding; after the flat plate mop is used, the flat plate mop can be inserted into the stroking port extruding device, so that the flat plate mop is set upright in the mop barrel. The stroking port extruding device is arranged on the mop barrel, so that using is more convenient.

Owner:CIXI BOSHENG PLASTIC PROD

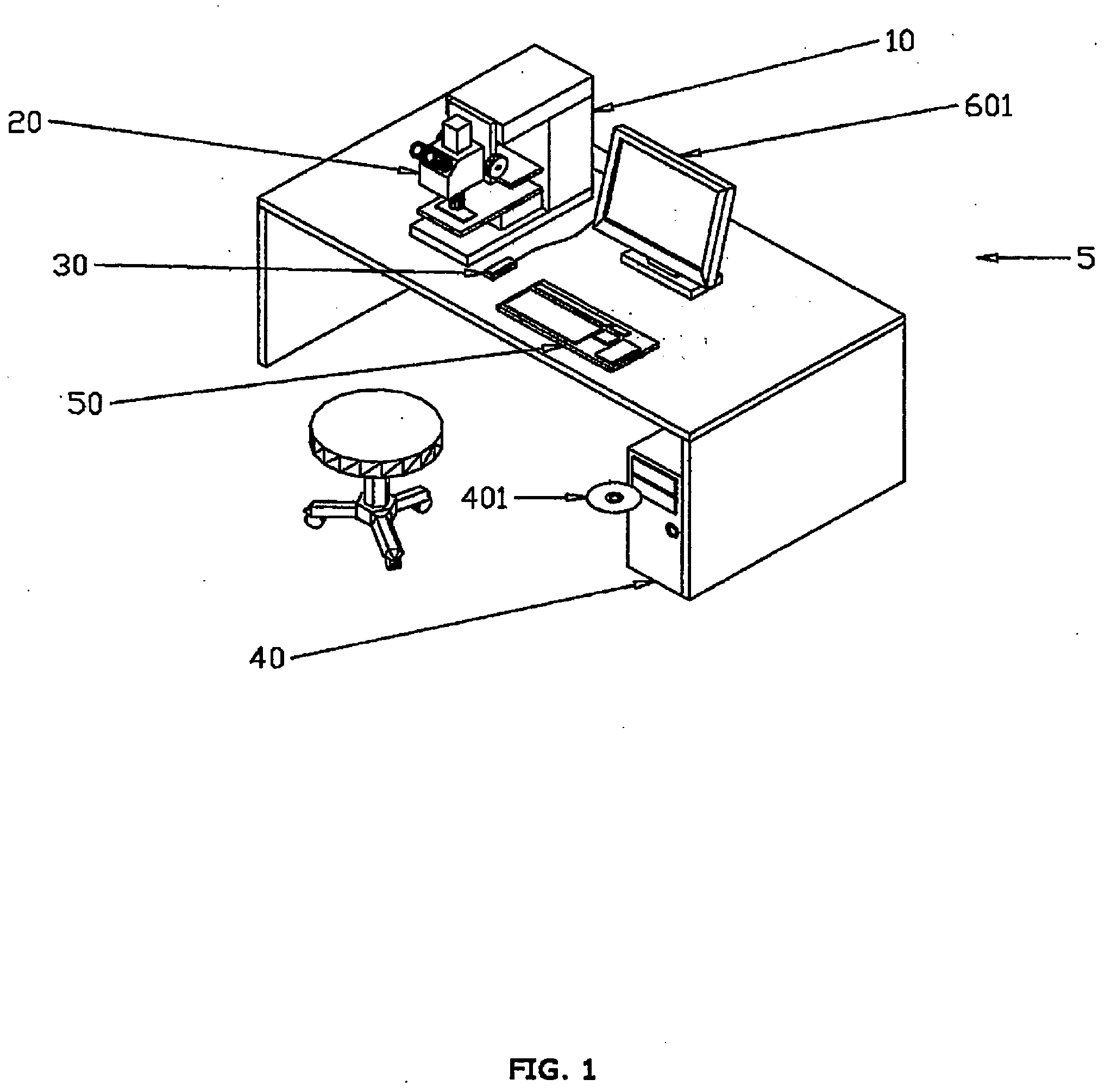

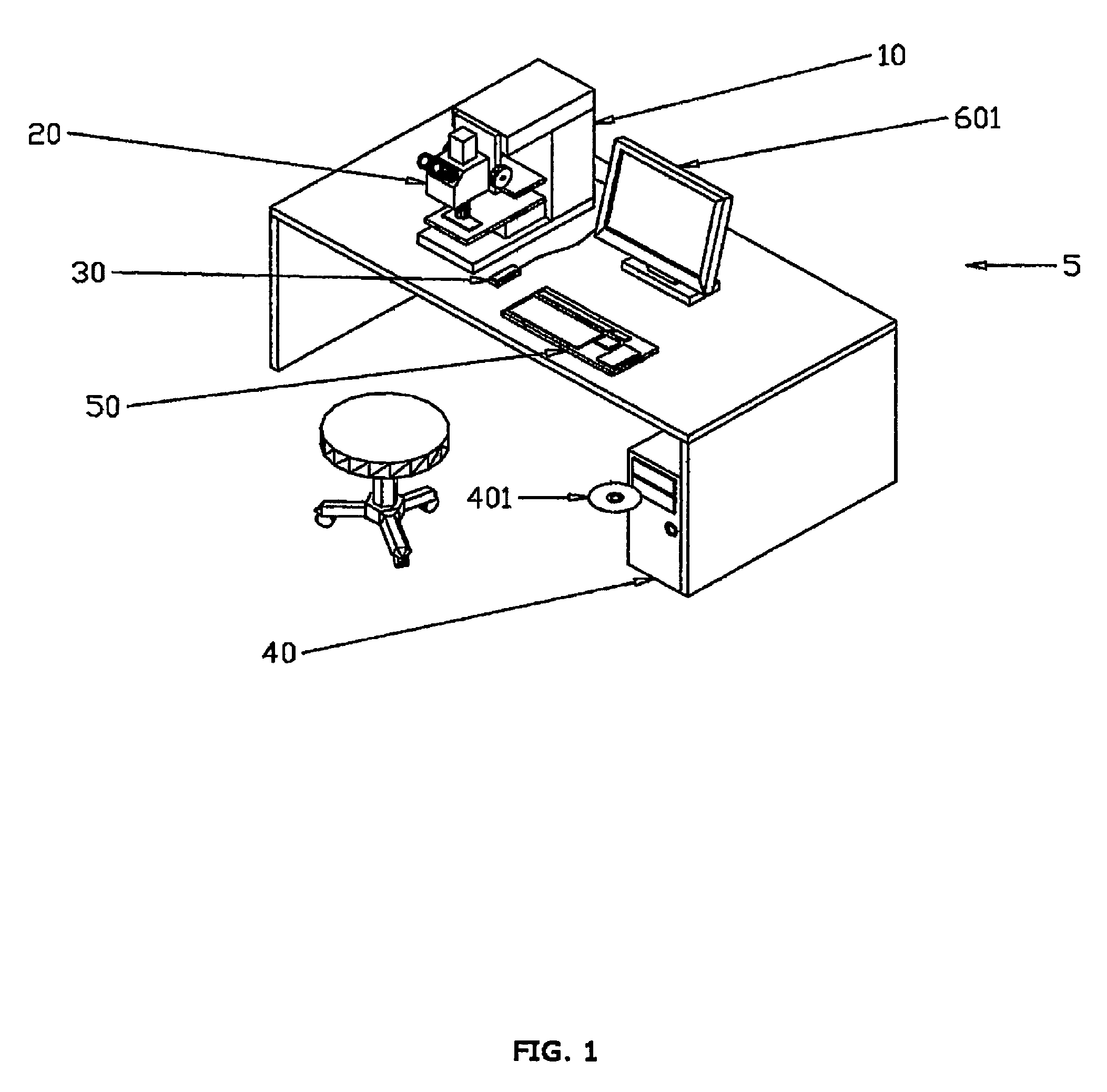

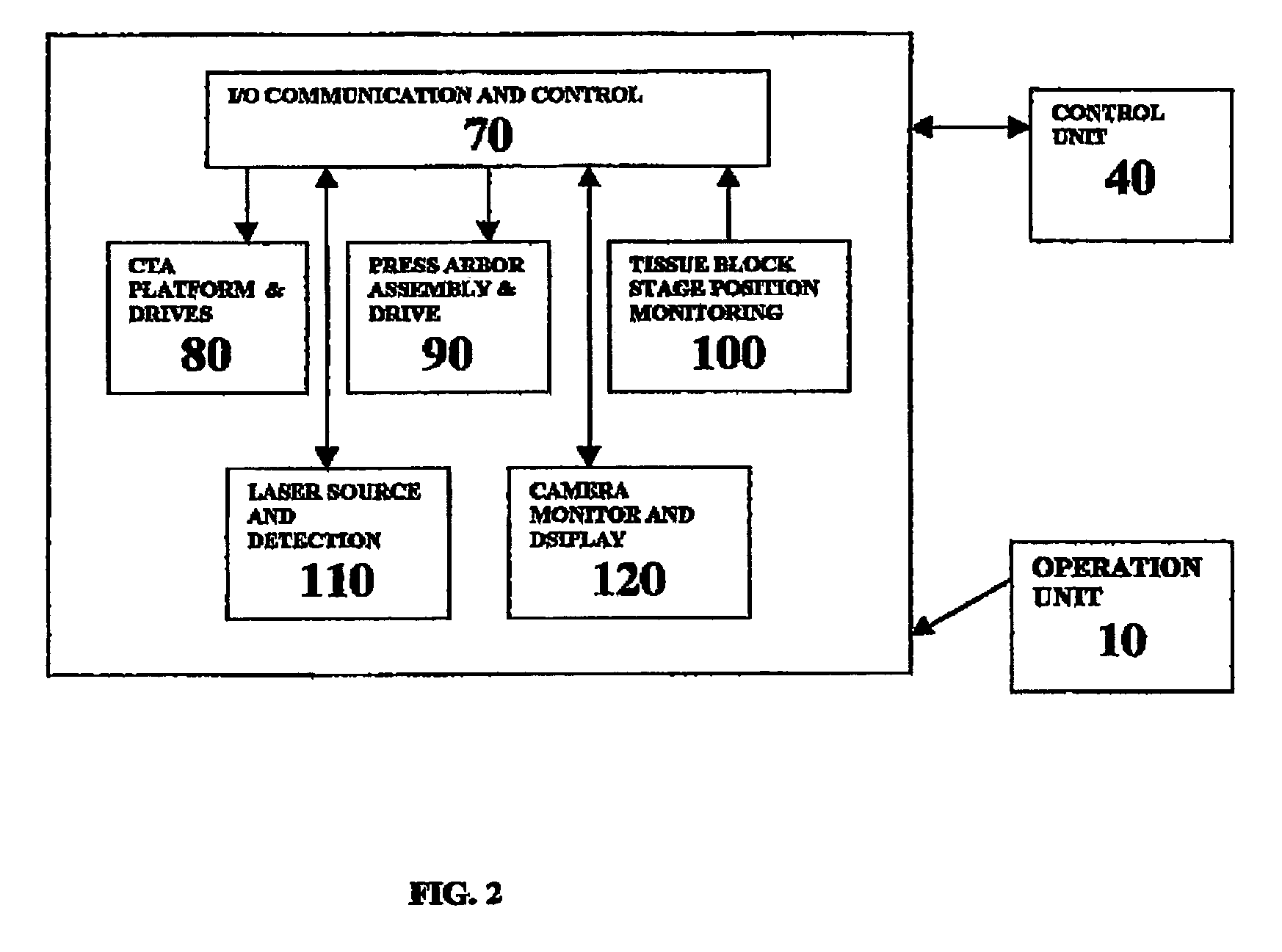

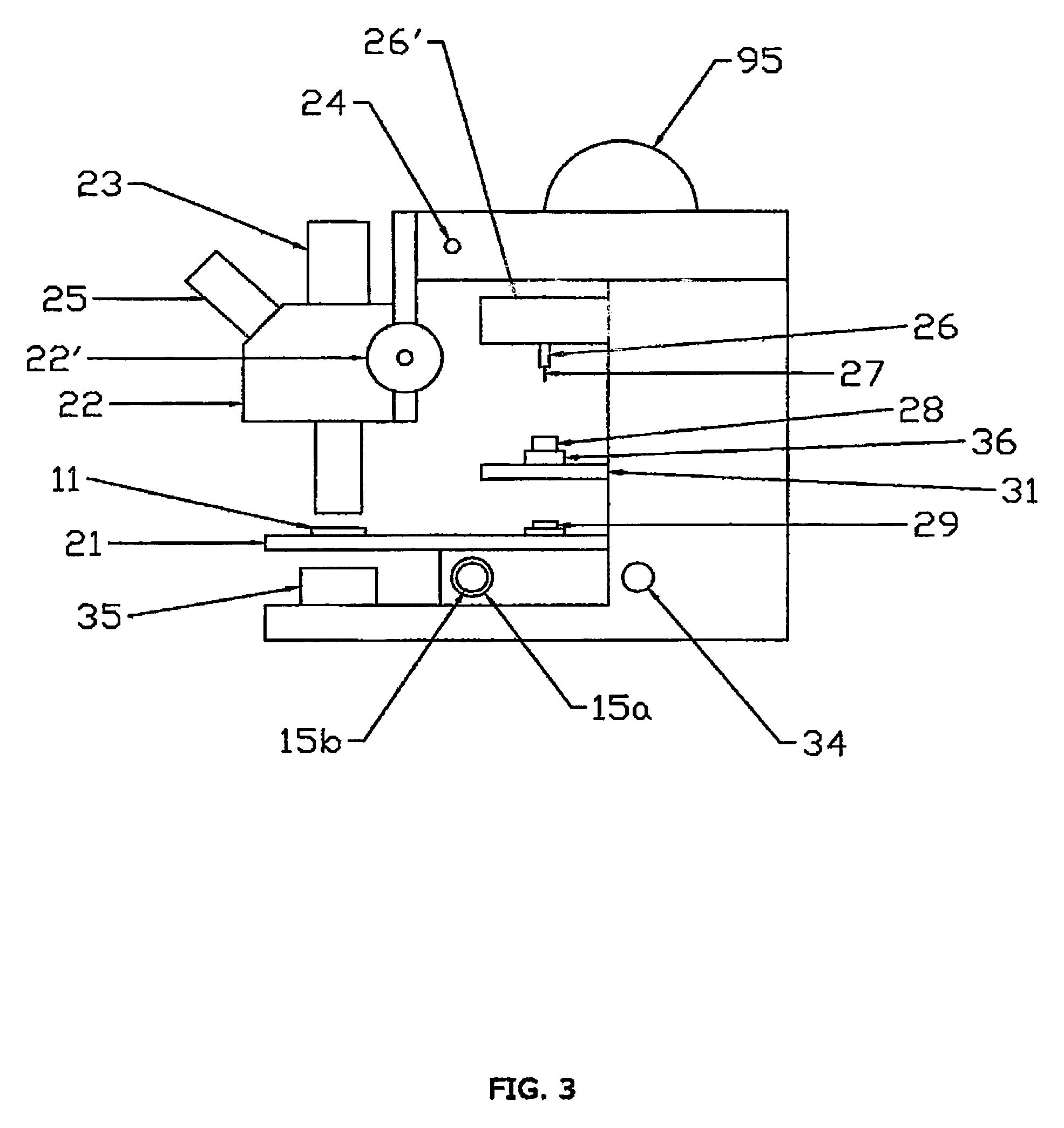

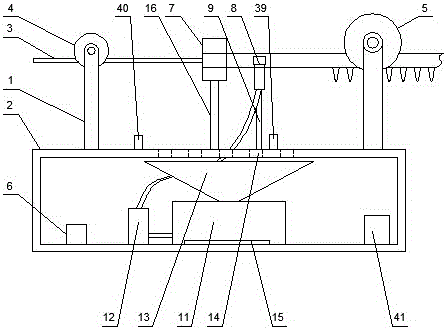

Tissue punch and tissue sample labeling methods and devices for microarray preparation, archiving and documentation

InactiveUS20060199169A1Avoid mistakesWaste of tissueBioreactor/fermenter combinationsBiological substance pretreatmentsVertical tubeTissue Arrays

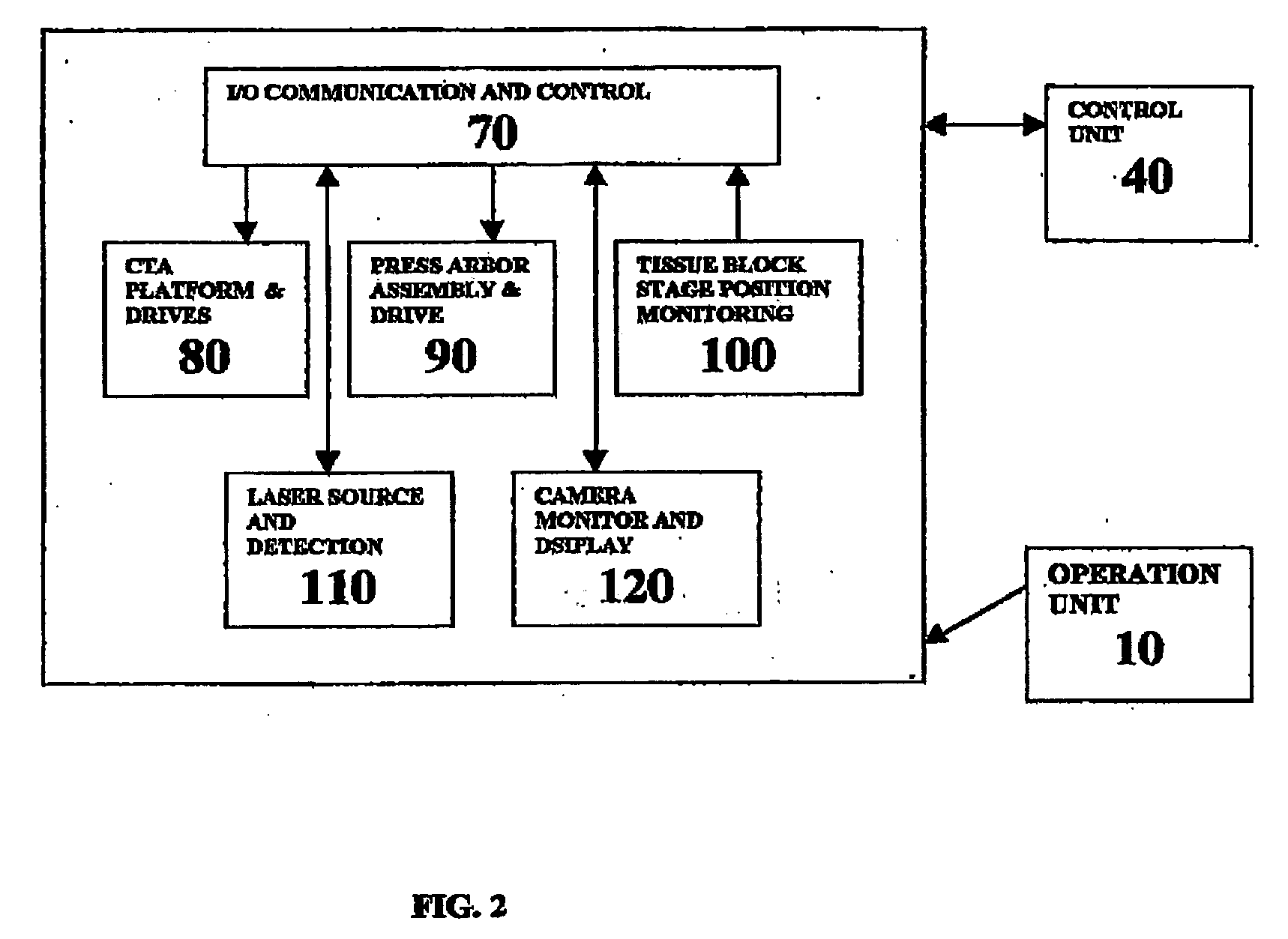

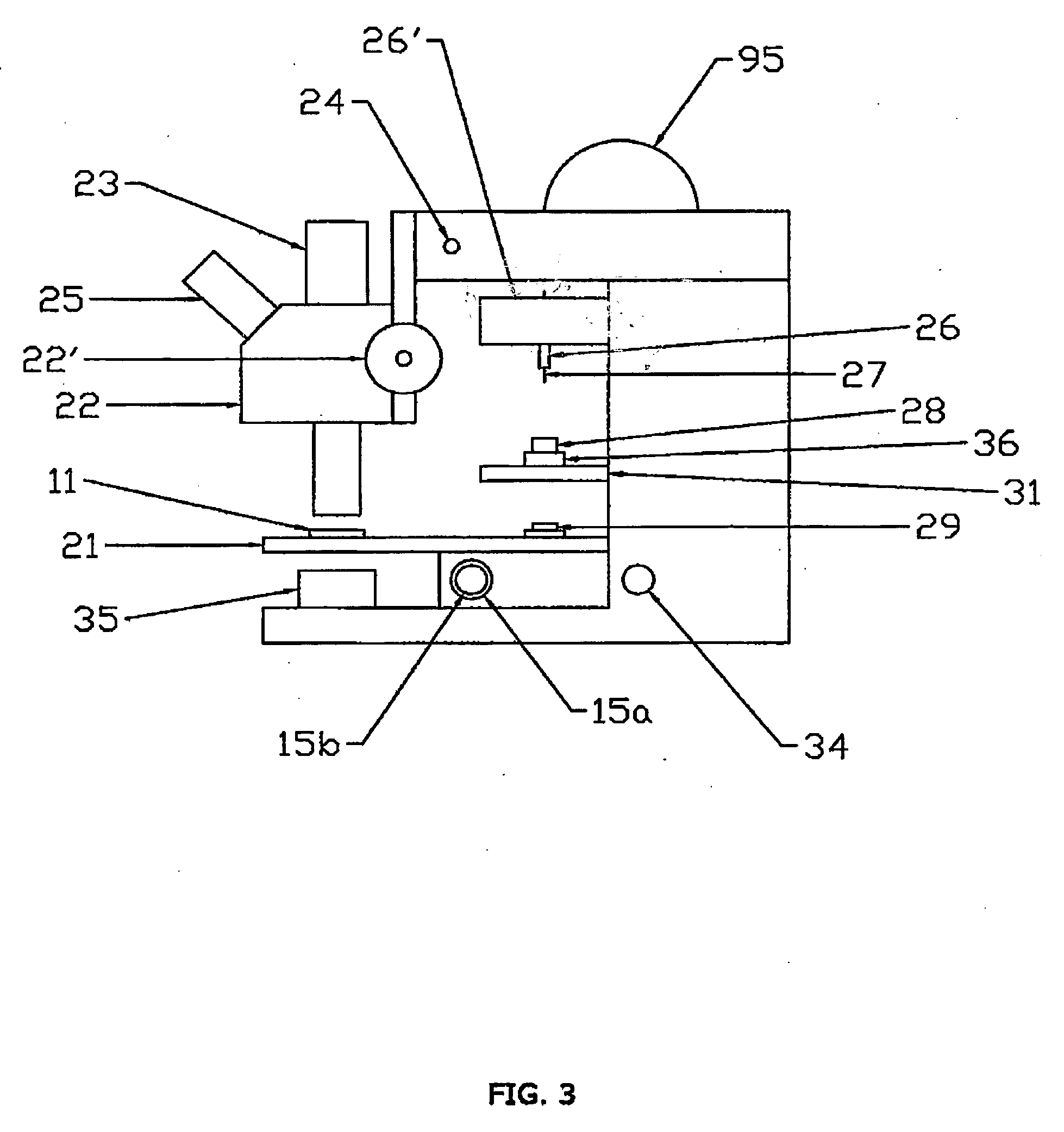

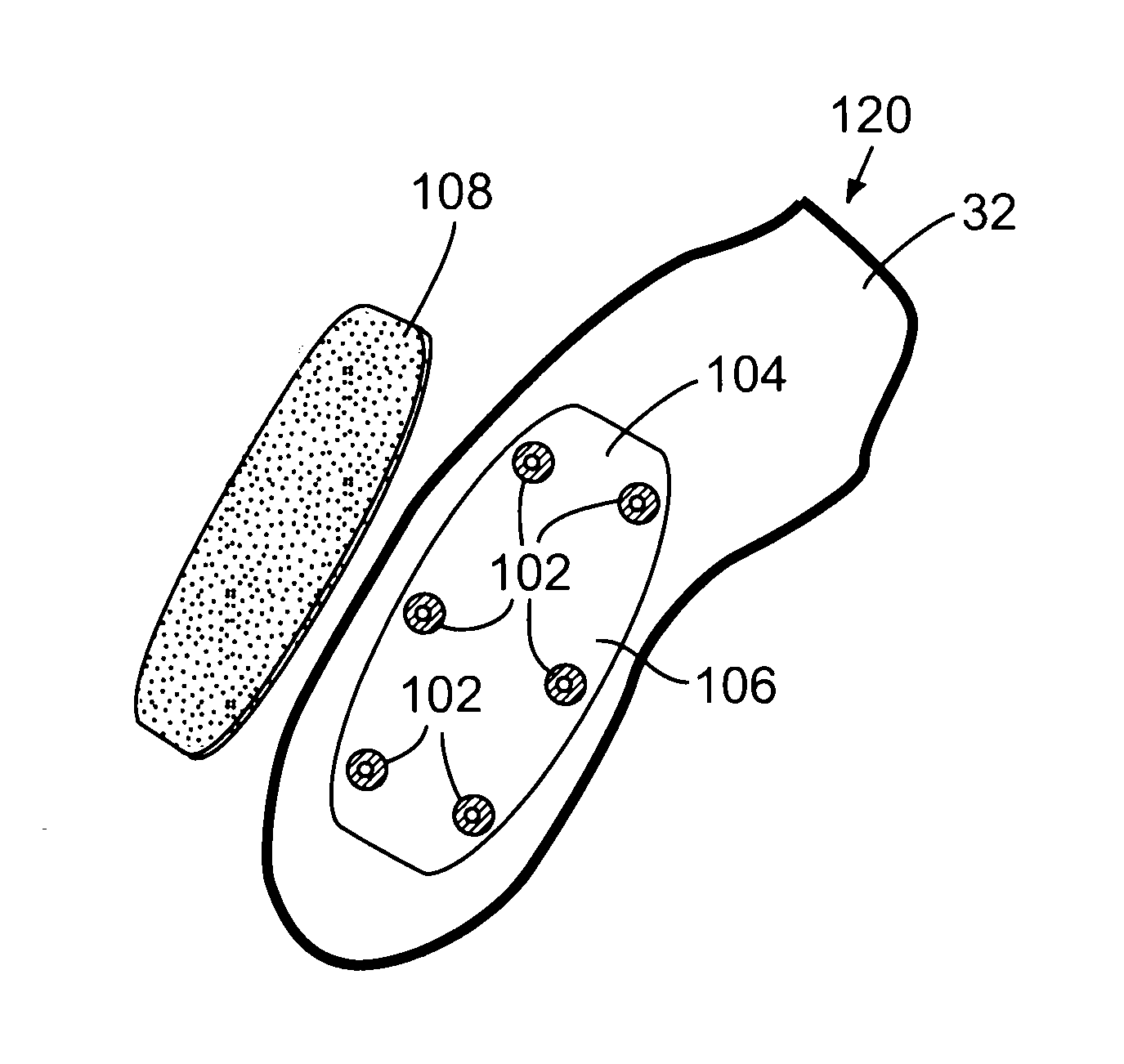

A workstation that provides an efficient method to collect biological tissues in a column tissue array format from blocks of embedded, frozen tissues, or fresh tissues. The workstation has a control unit for directing operations of the workstation and the operation unit for performing the production of the tissue column array. The operation unit comprises an array of vertical tubes in a platform, an arbor which engages and presses down the designated tube in the array, the embedded tissue block which is mounted directly below the designated tube, assemblies of motors responsive to the control unit for driving the platform and the tissue block, a light source block for generating an alignment signal, and a light detector block which measures the signal from the light source to determine the degree of alignment between the arbor, punch tubes, and the specimen block.

Owner:EXB TECH

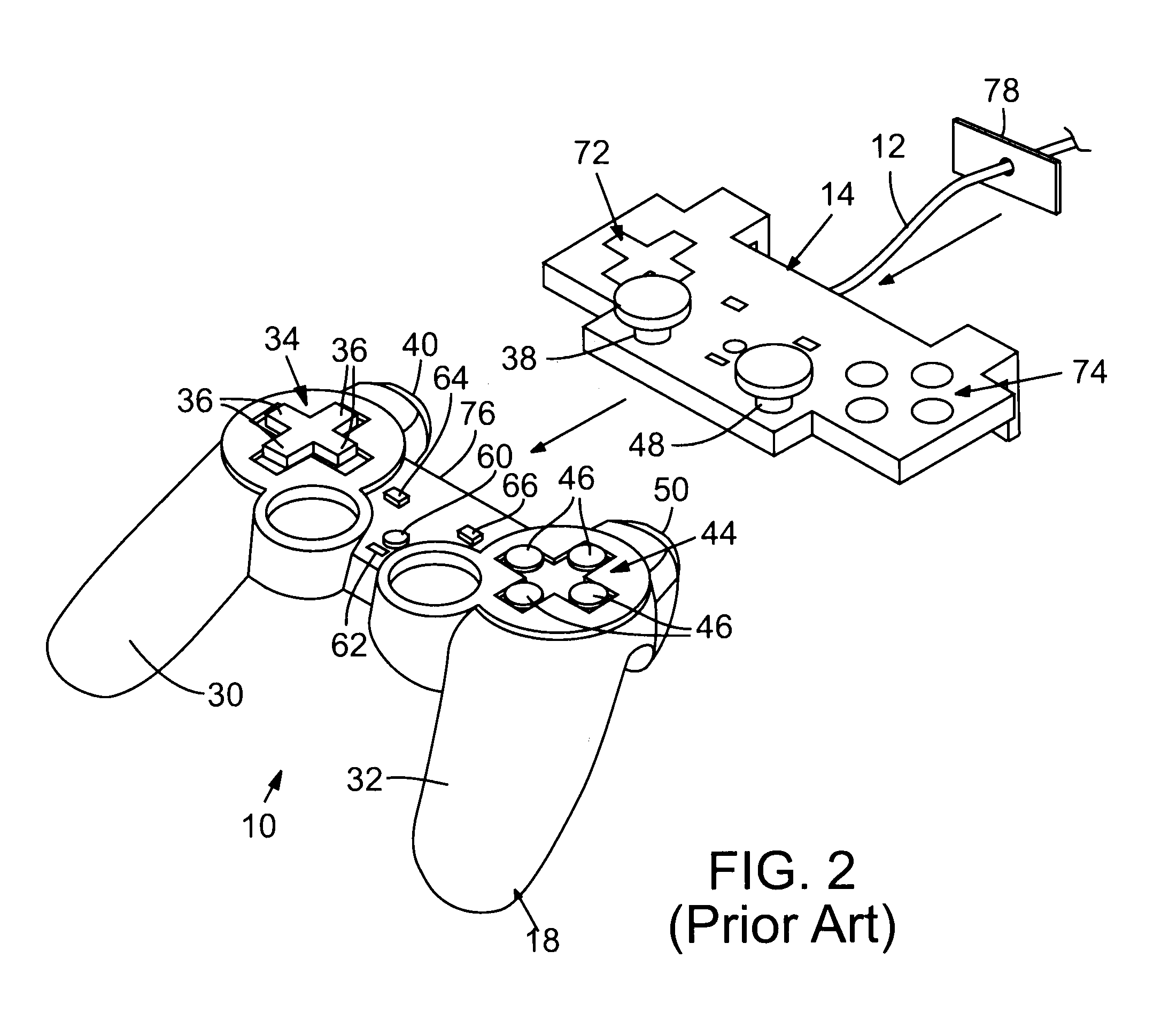

Pressure sensing controller

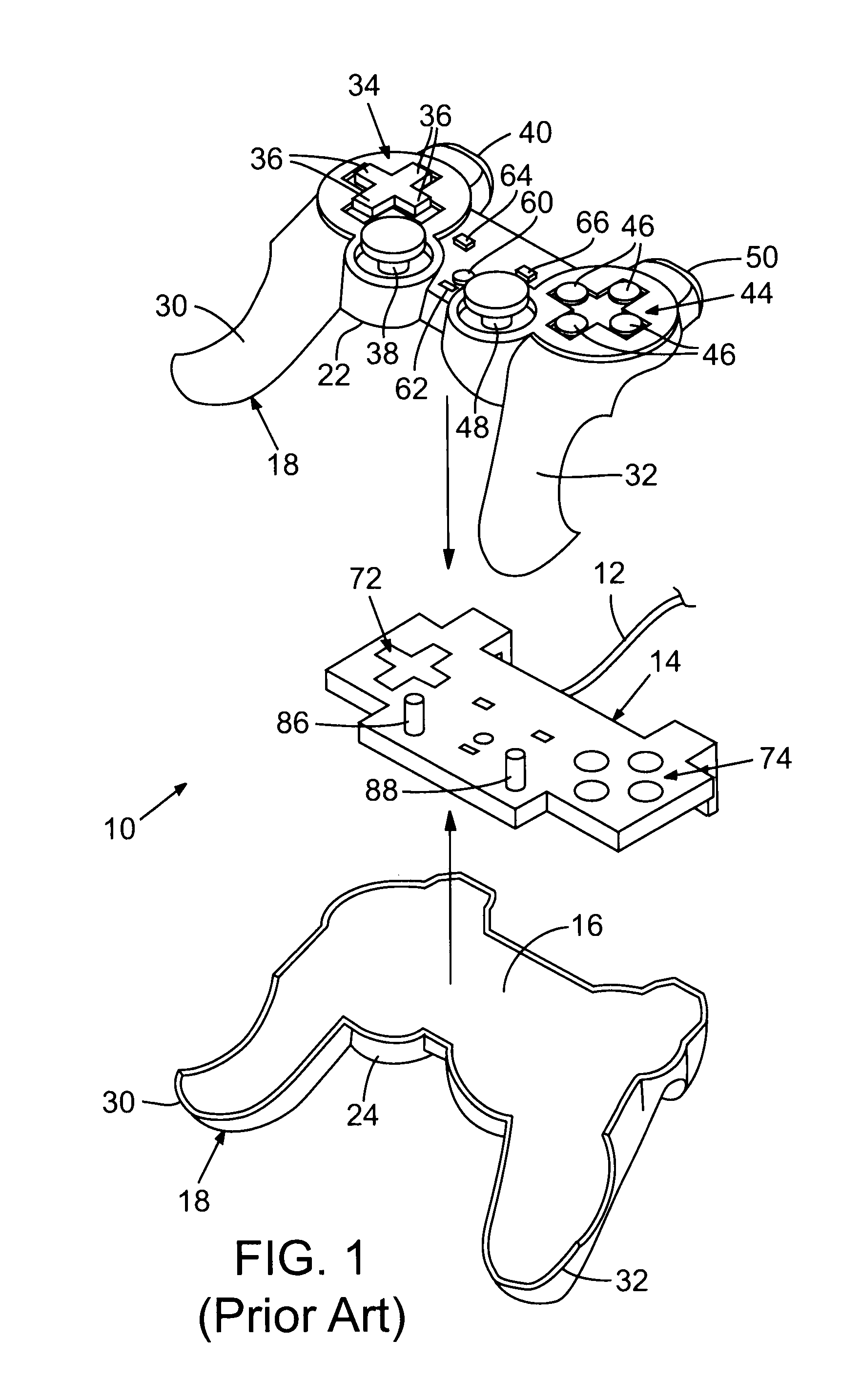

InactiveUS20100245239A1Facilitate user immersionFacilitates squeezeCathode-ray tube indicatorsVideo gamesInput controlControl equipment

Embodiments of a pressure sensing controller implement grip and pressure sensing, as well as standard input control actuation, to provide control input by a user. The disclosed grip and pressure sensing control can be implemented in hand-held game controllers, control devices for appliances, cellular telephones, and any other type of devices that require control input. In the case of an existing control device with predefined control output, user programming of input settings to define command extensions allows extended gripping and pressure control input to be combined within the capable existing control outputs of the device.

Owner:IPPASA

Multi-role unmanned vehicle system and associated methods

ActiveUS9096106B2Improve operating characteristicsEasy to implementUnmanned aerial vehiclesWatercraft hull designControl systemOn board

An unmanned vehicle may include a vehicle body that comprises an enclosed hull. The unmanned vehicle may include a propulsion, a ballast control system, a center of gravity system, a pressurization system, a control surface system, a navigation control system, and an on board master control system. The on board master control system may execute local control over operation of the various systems of the unmanned vehicle. The unmanned vehicle may also include a power supply carried by a portion of the vehicle body to provide power to the various systems. The various systems of the unmanned vehicle may be independently operable to support selective operation of the unmanned vehicle in the air, on the surface of the water, and below the surface of the water.

Owner:UNMANNED INNOVATION

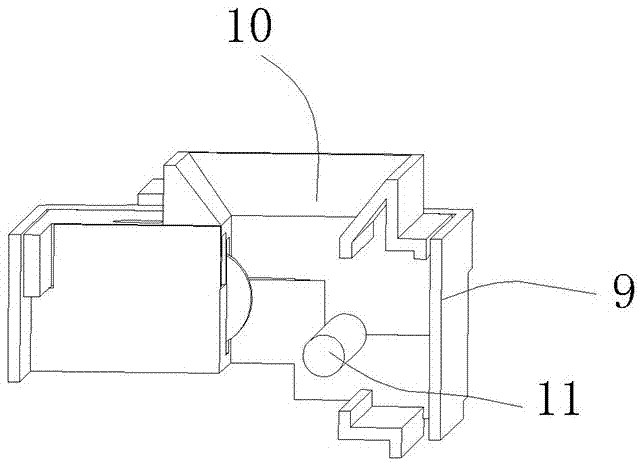

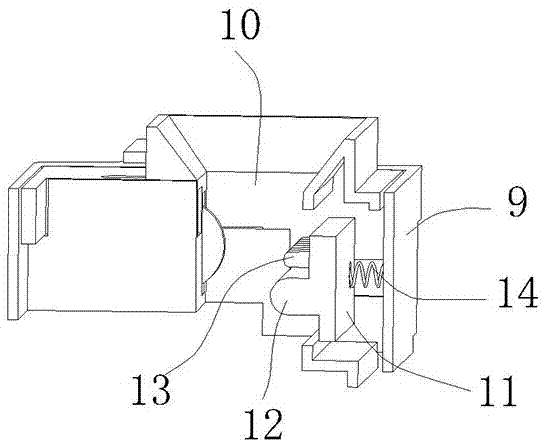

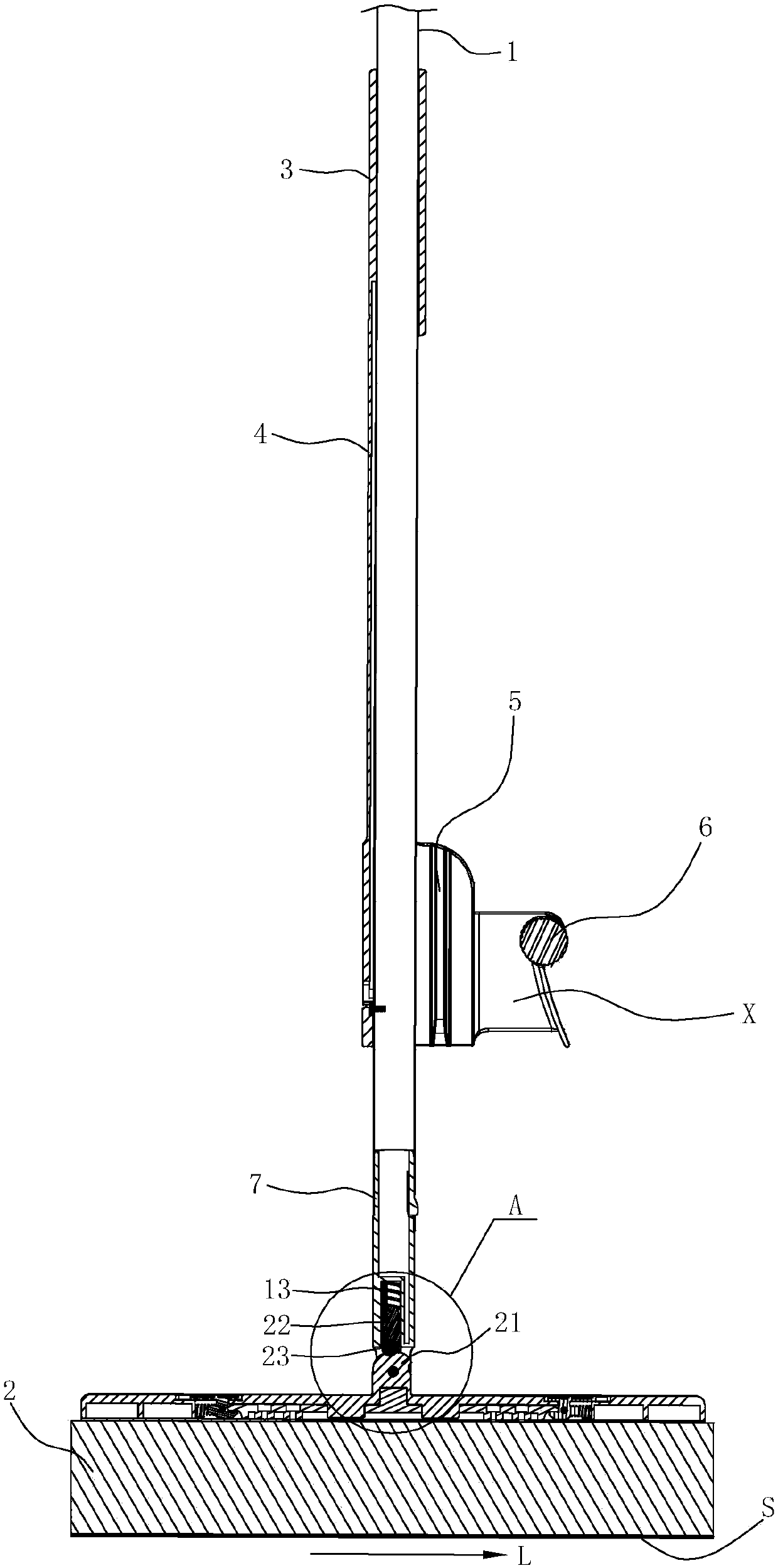

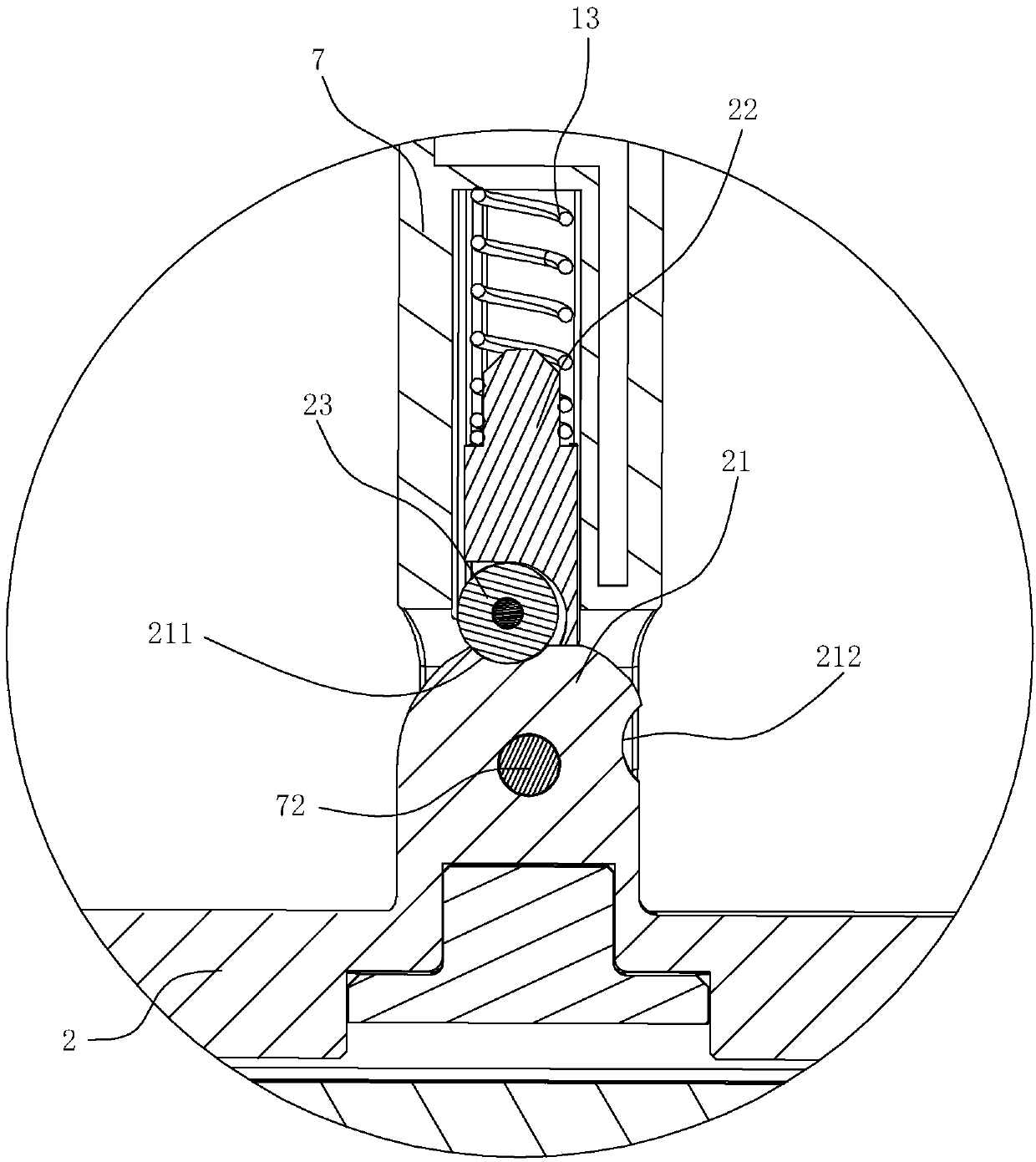

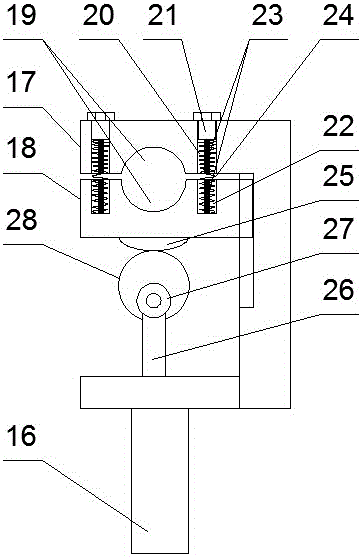

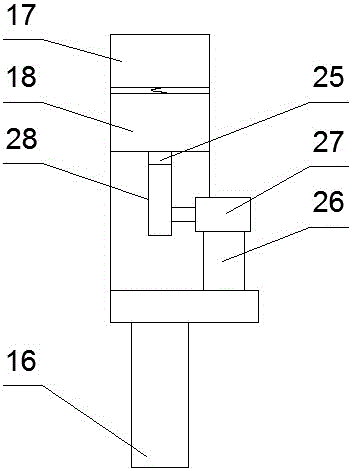

Foaming cotton head mop with improved water squeezing mode

ActiveCN107616764ASqueeze stroke is longShort contact distanceCarpet cleanersFloor cleanersCollodion CottonEngineering

The invention relates to a foaming cotton head mop with an improved water squeezing mode. The mop comprises a mop rod and a foaming cotton head. The mop is characterized in that the foaming cotton head is movably connected with the lower end of the mop rod, the mop rod is provided with a squeezing device which can slide up and down relative to the mop rod, and the foaming cotton head can rotate tothe length direction to be basically parallel to be mop rod and aligned to the water squeezing device; when water squeezing is conducted, the water squeezing device slides up and down in the length direction of the foaming cotton head and squeezes the bottom surface of the foaming cotton head to achieve water squeezing, and when mopping is conducted, the foaming cotton head is completely separated from the water squeezing device. The foaming cotton head mop changes a traditional collodion cotton mop water squeezing mode, can make the foaming cotton head freely rotate relative to the mop rod,meanwhile guarantees good water squeezing effect and saves labor in water squeezing operation.

Owner:NINGBO DERUNTANG INTELLIGENT TECH CO LTD

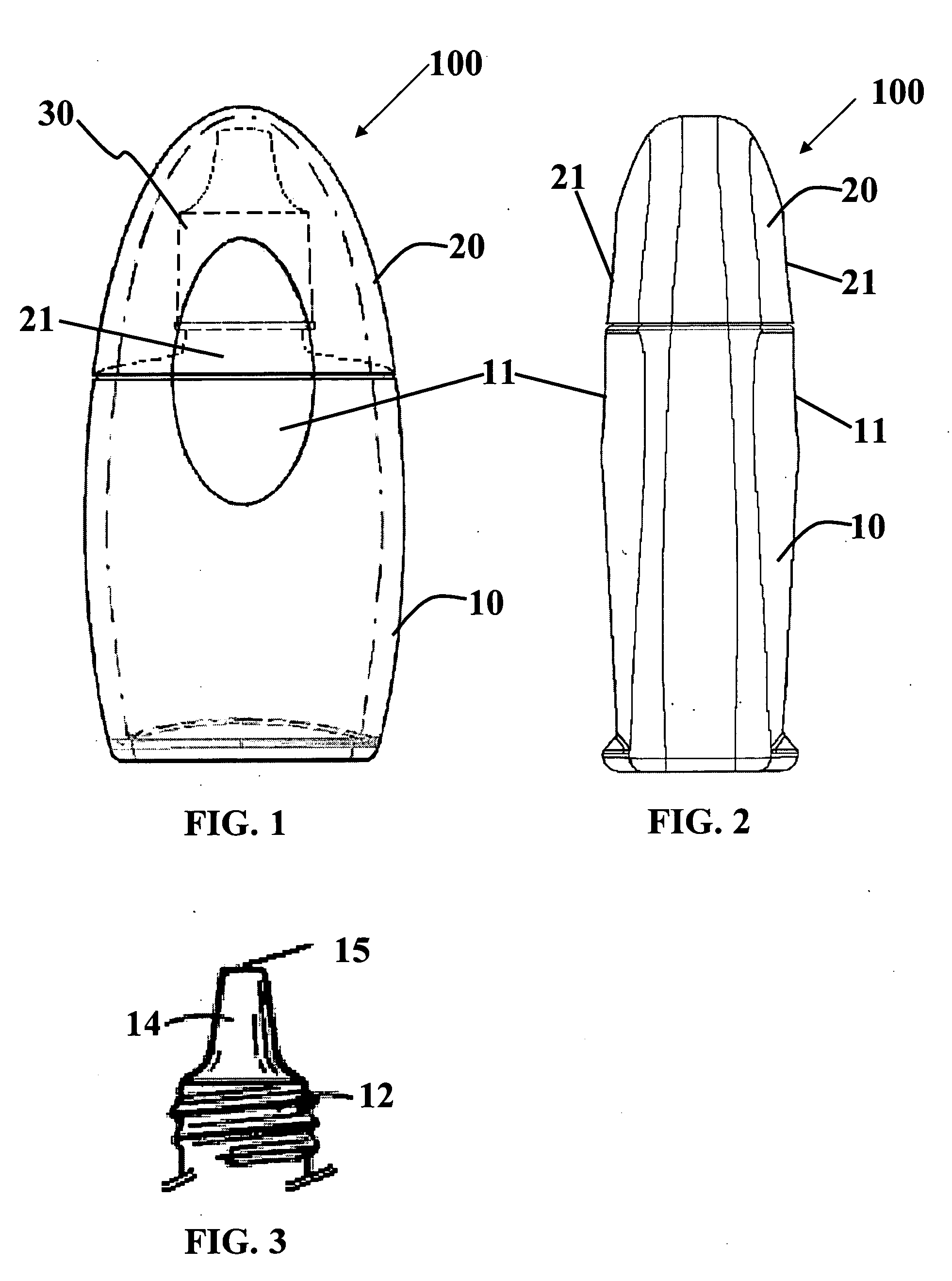

Ion trap

ActiveUS8017909B2Wide range of qualityEasy squeezeStability-of-path spectrometersTime-of-flight spectrometersIon beamIon trap

An ion trap comprises substantially elongate electrodes 10, 20 some of which are curved along their axis of elongation and which define a trapping volume between them. The sectional area of this trapping volume towards the extremities of the trap in the direction of elongation is different to the sectional area away from its extremities (eg towards the middle of the trap). In a preferred embodiment, the trap has a plurality of elongate electrodes, wherein opposed electrodes have different radii of curvature so that the trap splays towards its extremities. Thereby, a wider mass range of ions can be trapped and ejected, a higher space charge capacity (for a given trap length) is provided, and sharper ion beam focussing on ejection is possible.

Owner:THERMO FISHER SCI BREMEN

Constraining structure with non-linear axial struts

ActiveUS9179936B2Prevent longitudinal elongationEasy squeezeStentsBalloon catheterBalloon catheterSquare Window

A constraining structure for use with a balloon catheter can include multiple longitudinal struts and multiple, sinusoidal shaped radial rings. The constraining structure can expand to form a pattern of channels including substantially square windows. The constraining structure can modify, restrict, and control a shape and / or size of the balloon when inflated. Inflating the balloon catheter within the constraining structure can provide nonuniform pressure on a vessel wall adjacent the balloon.

Owner:TRIREME MEDICAL

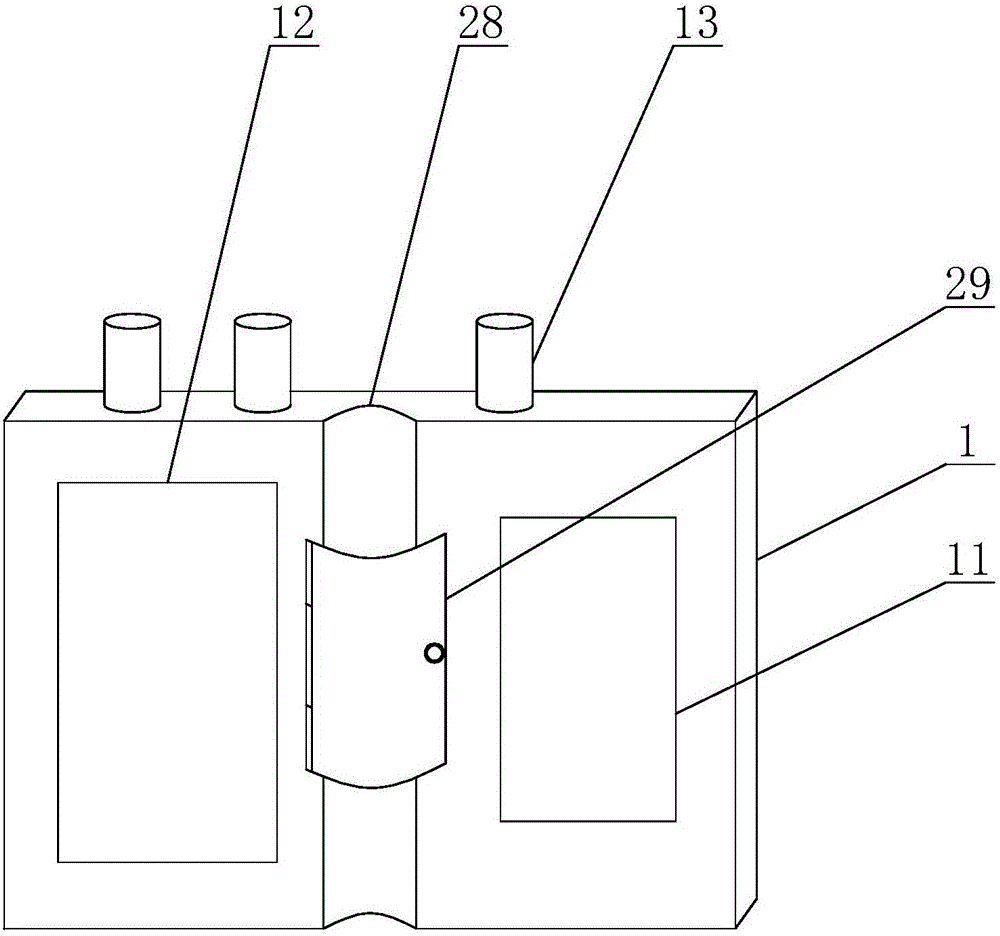

Single-bucket squeezing flat mop cleaning tool

PendingCN107692938AEasy to useSimple structureCarpet cleanersFloor cleanersMechanical engineeringEngineering

Owner:CIXI BOSHENG PLASTIC PROD

Dispensing pack and machine

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

Kitchen waste crushing and squeezing processor

The invention belongs to the field of environmental protection, and relates to a waste processing device, in particular to a kitchen waste crushing and squeezing processor. In order to overcome the defect of the lack of special kitchen waste processing equipment in the prior art, the invention provides a kitchen waste crushing and squeezing processor. The kitchen waste crushing and squeezing processor comprises a crushing part and a squeezing and dewatering part, wherein the crushing part comprises a roll type crushing mechanism, the roll type crushing mechanism comprises a driving shaft and a driven shaft, gears are arranged on the driving shaft and the driven shaft respectively, each gear comprises a gear ring and a gasket, gear teeth are arranged on the gear ring, the cutting gap between tooth surfaces of adjacent gears is 0.5mm, and the cutting gap between tip-shaped tops of the gear teeth and the gaskets is 0.5mm. The kitchen waste crushing and squeezing processor integrates crushing, squeezing and dewatering, and can be used for efficiently processing kitchen waste.

Owner:邢征

Petrol supply tube

InactiveUS6041826AReduce penetrationEasy squeezeDrying solid materials without heatHeat exhanger conduitsPolyamideGasoline

PCT No. PCT / FR94 / 00640 Sec. 371 Date Apr. 4, 1995 Sec. 102(e) Date Apr. 4, 1995 PCT Filed Jun. 1, 1994 PCT Pub. No. WO94 / 29626 PCT Pub. Date Dec. 22, 1994Polyamide-based petrol supply tube, especially for engines, characterized in that it comprises an outer layer of polyamide, a middle layer of fluoropolymer, preferably of PVDF, and an inner layer of polyamide, these layers being respectively bonded to each other by layers of adhesive bonding agent.

Owner:ELF ATOCHEM SA

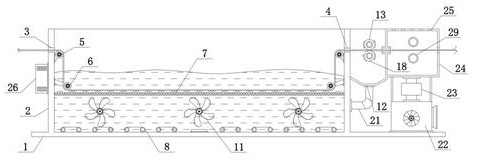

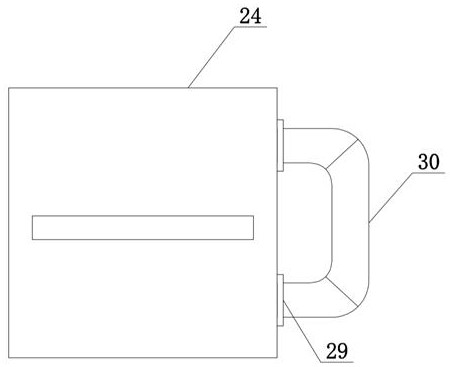

Detachable extruding flat plate mop cleaning tool

A detachable extruding flat plate mop cleaning tool comprises a mop barrel and a flat plate mop. The flat plate mop comprises a mop rod and a flat plate mop head, a wiping object is arranged on the flat plate mop head, and the mop barrel is provided with an independent cleaning region and an independent water extruding region; a stroking port extruding device is installed on the mop barrel, and the flat plate mop head is kept in a cleaning and water-extruding state through a positioning device between the flat plate mop head and the mop rod; during mopping, the flat plate mop head can be rotated to be in a floor-mopping state; during cleaning, the flat plate mop head moves between the cleaning region and the stroking port extruding device to perform extrusion, so that the wiping objected is moved to be extruded and cleaned, and during water extruding, the flat plate mop head moves between the water extruding region and the stroking port extruding device to perform extrusion, so that the wiping object is moved to be extruded and subjected to water extruding; the stroking port extruding device is detachably installed on the mop barrel. The stroking port extruding device is arranged on the mop barrel, so that using is more convenient.

Owner:CIXI BOSHENG PLASTIC PROD

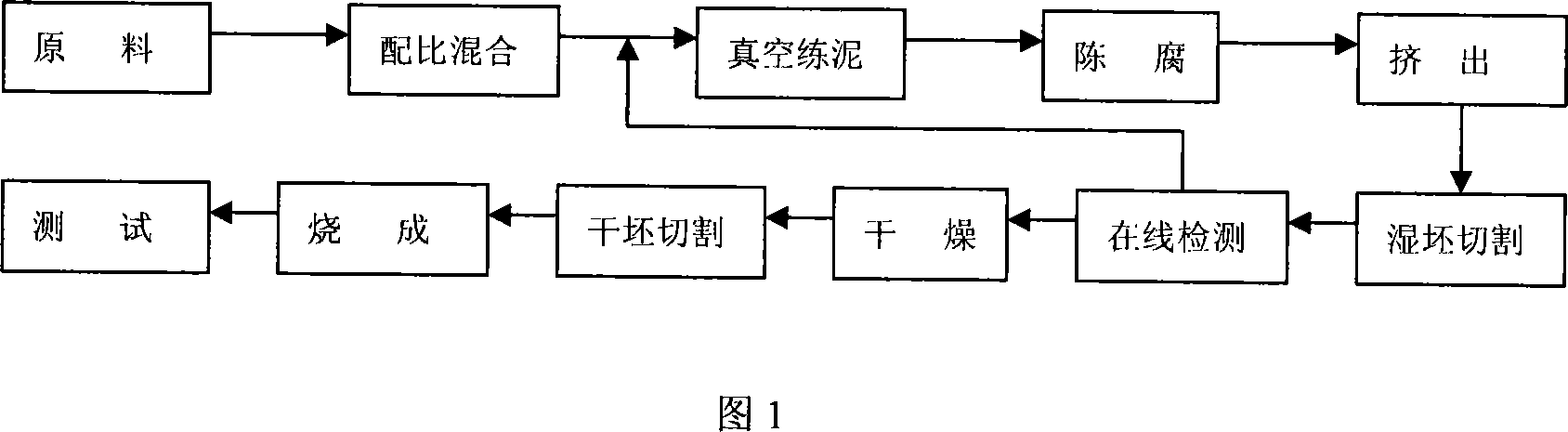

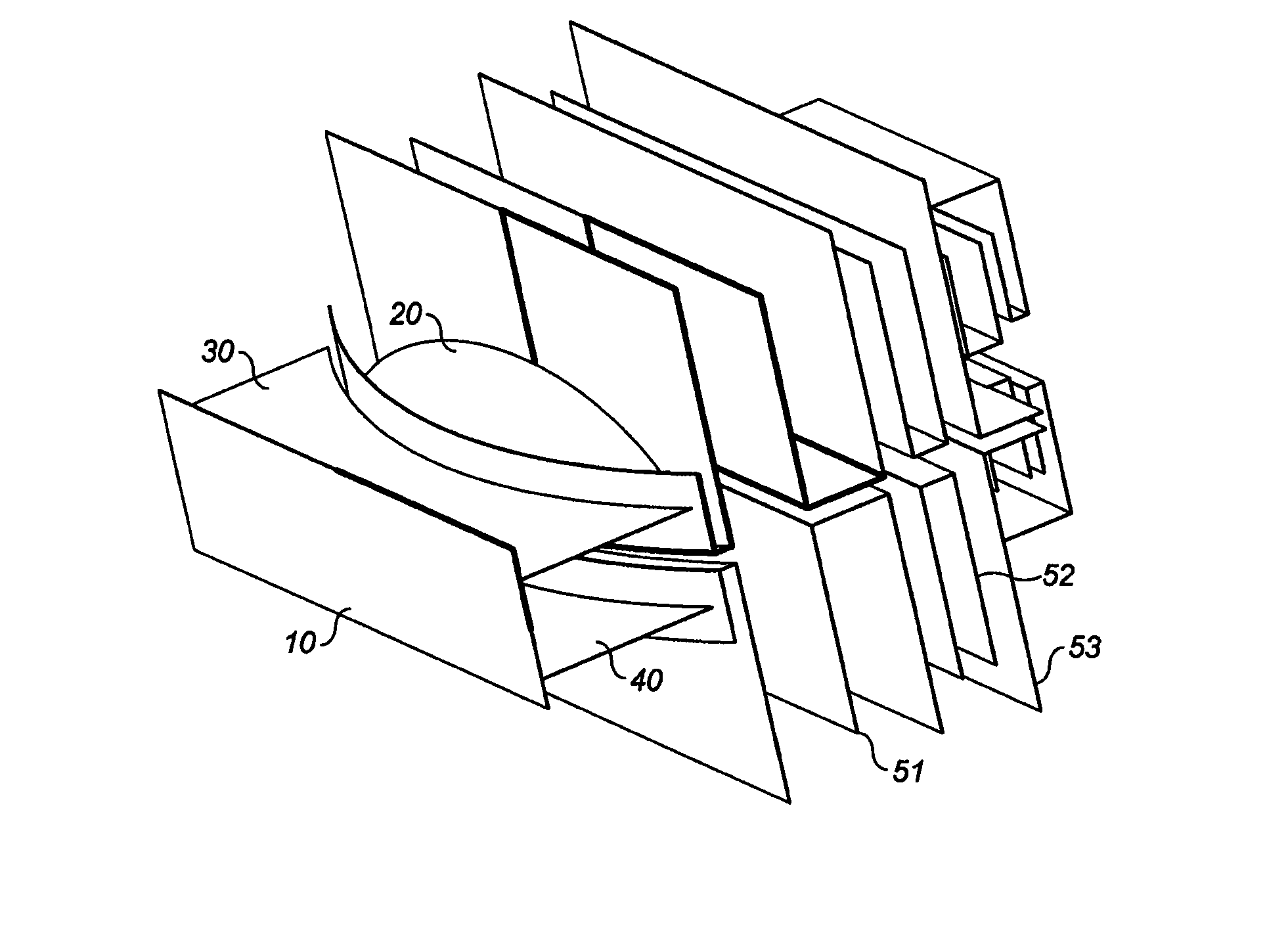

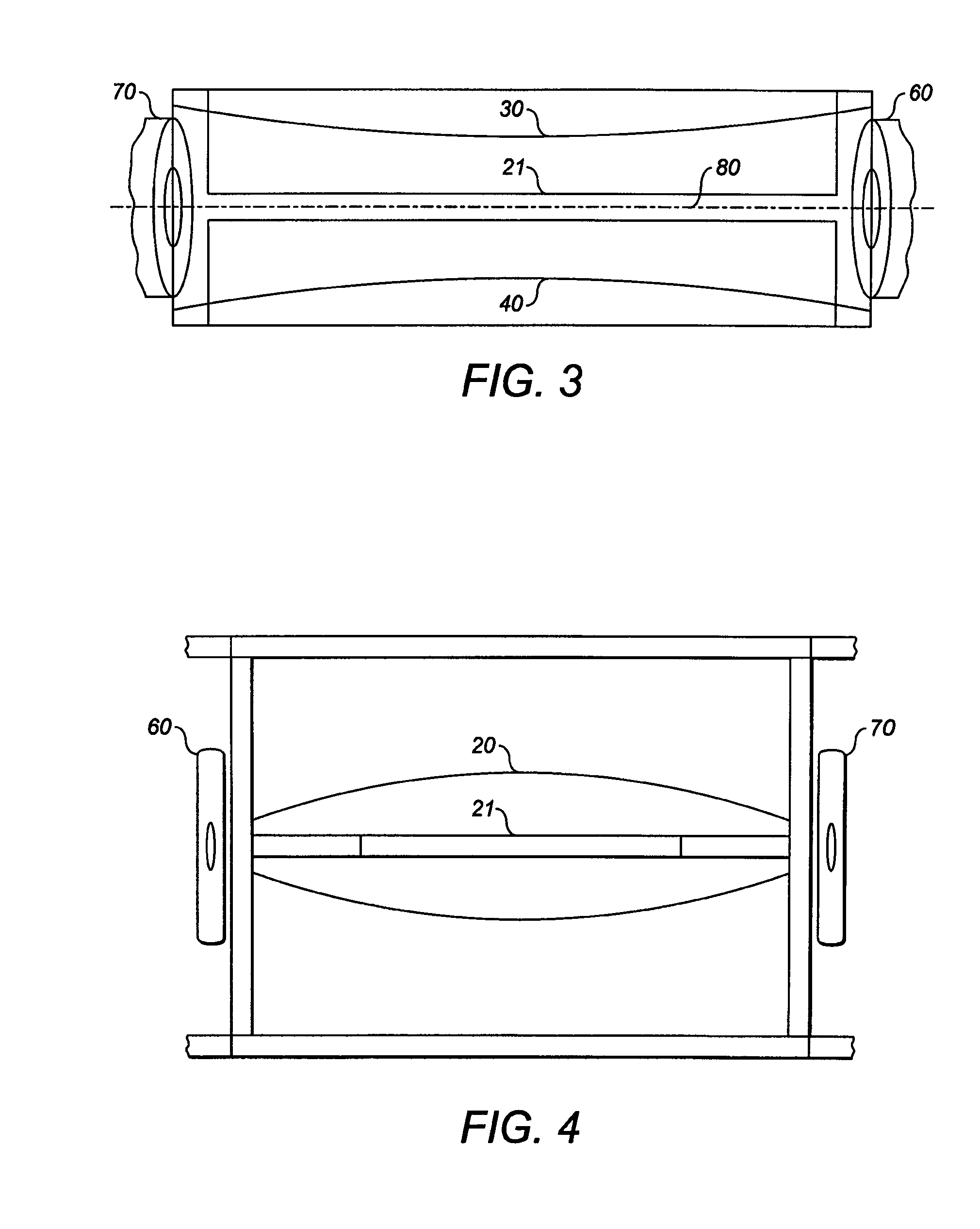

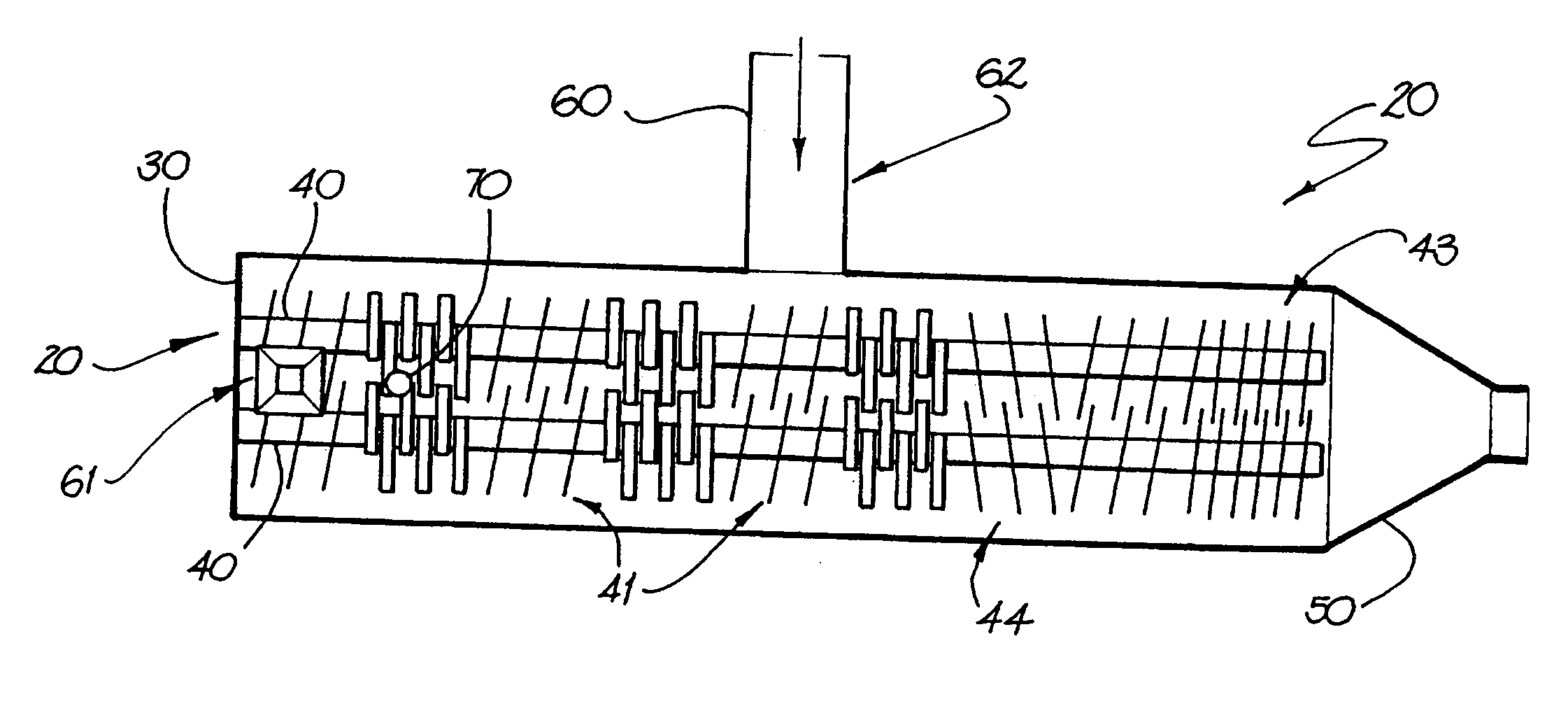

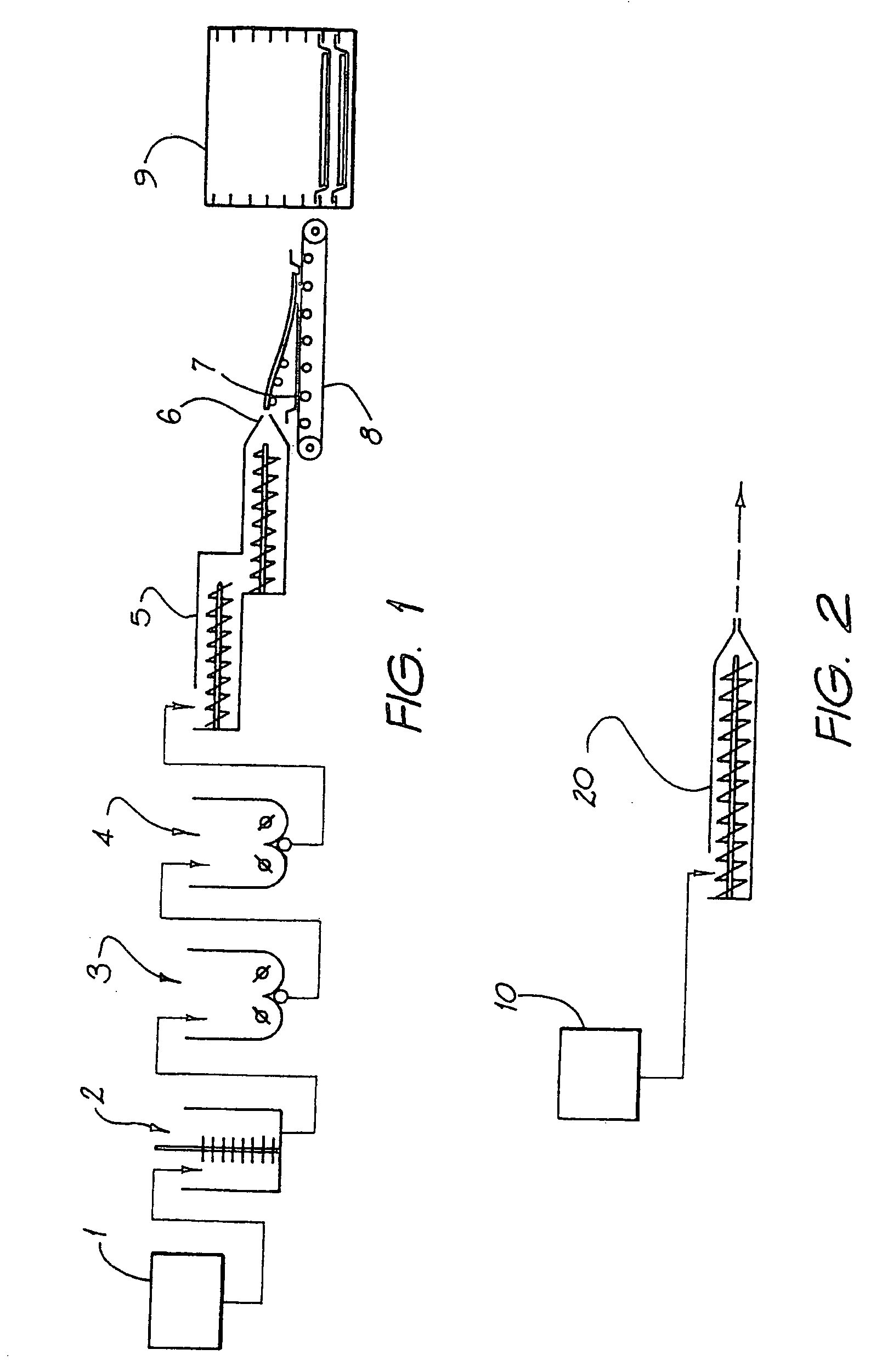

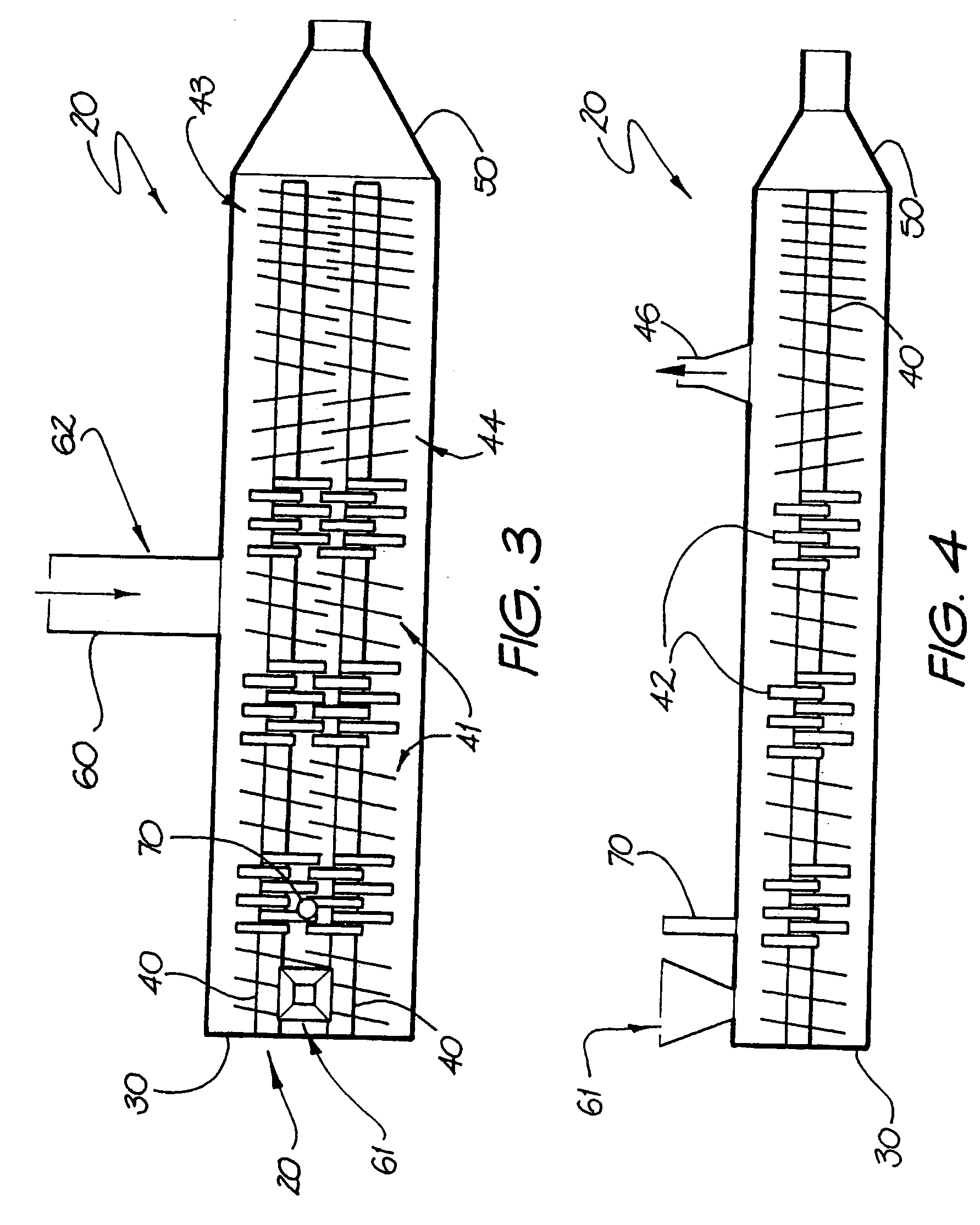

Method and apparatus for extruding cementitious articles

InactiveUS20060061007A1Quantity minimizationReduce clean up timeSolid waste managementAuxillary shaping apparatusMaterials scienceFibre cement

A method and apparatus (20) for extruding fibre cement. The extruder comprises a casing (30) with a pair of inter-meshing self-wiping screws (40) rotatably mounted therein. The screws continuously mix and or knead the components of the fibre cement provided through various feed means (61, 62) to form a substantially homogeneous paste and force the paste through a die (50) to form a green cementitious extrudate suitable for curing.

Owner:CHEN HONG +3

Tissue punch and tissue sample labeling methods and devices for microarray preparation, archiving and documentation

InactiveUS7405056B2Waste of tissueWaste of timeBioreactor/fermenter combinationsBiological substance pretreatmentsVertical tubeTissue Arrays

A workstation that provides an efficient method to collect biological tissues in a column tissue array format from blocks of embedded, frozen tissues, or fresh tissues. The workstation has a control unit for directing operations of the workstation and the operation unit for performing the production of the tissue column array. The operation unit comprises an array of vertical tubes in a platform, an arbor which engages and presses down the designated tube in the array, the embedded tissue block which is mounted directly below the designated tube, assemblies of motors responsive to the control unit for driving the platform and the tissue block, a light source block for generating an alignment signal, and a light detector block which measures the signal from the light source to determine the degree of alignment between the arbor, punch tubes, and the specimen block.

Owner:EXB TECH

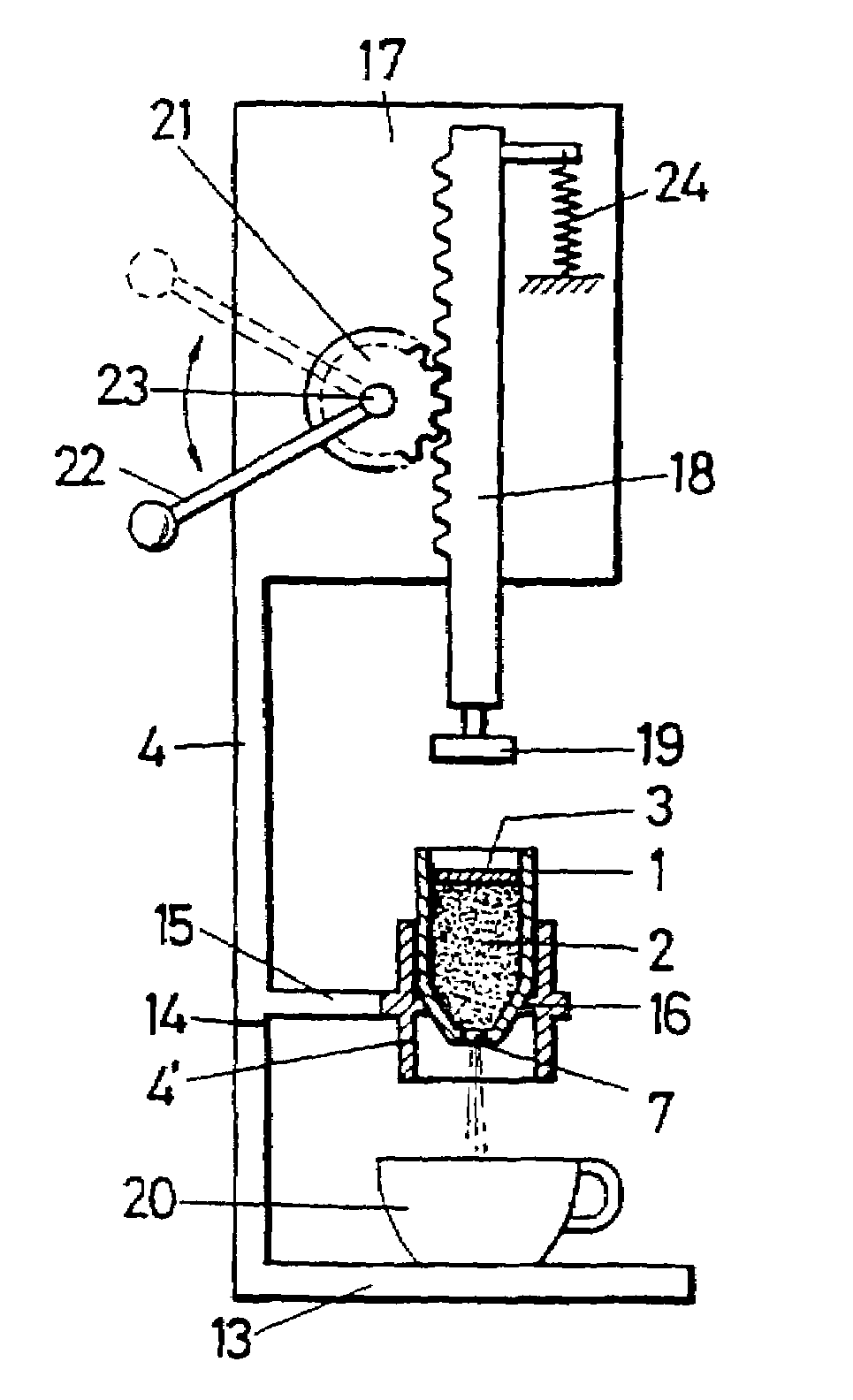

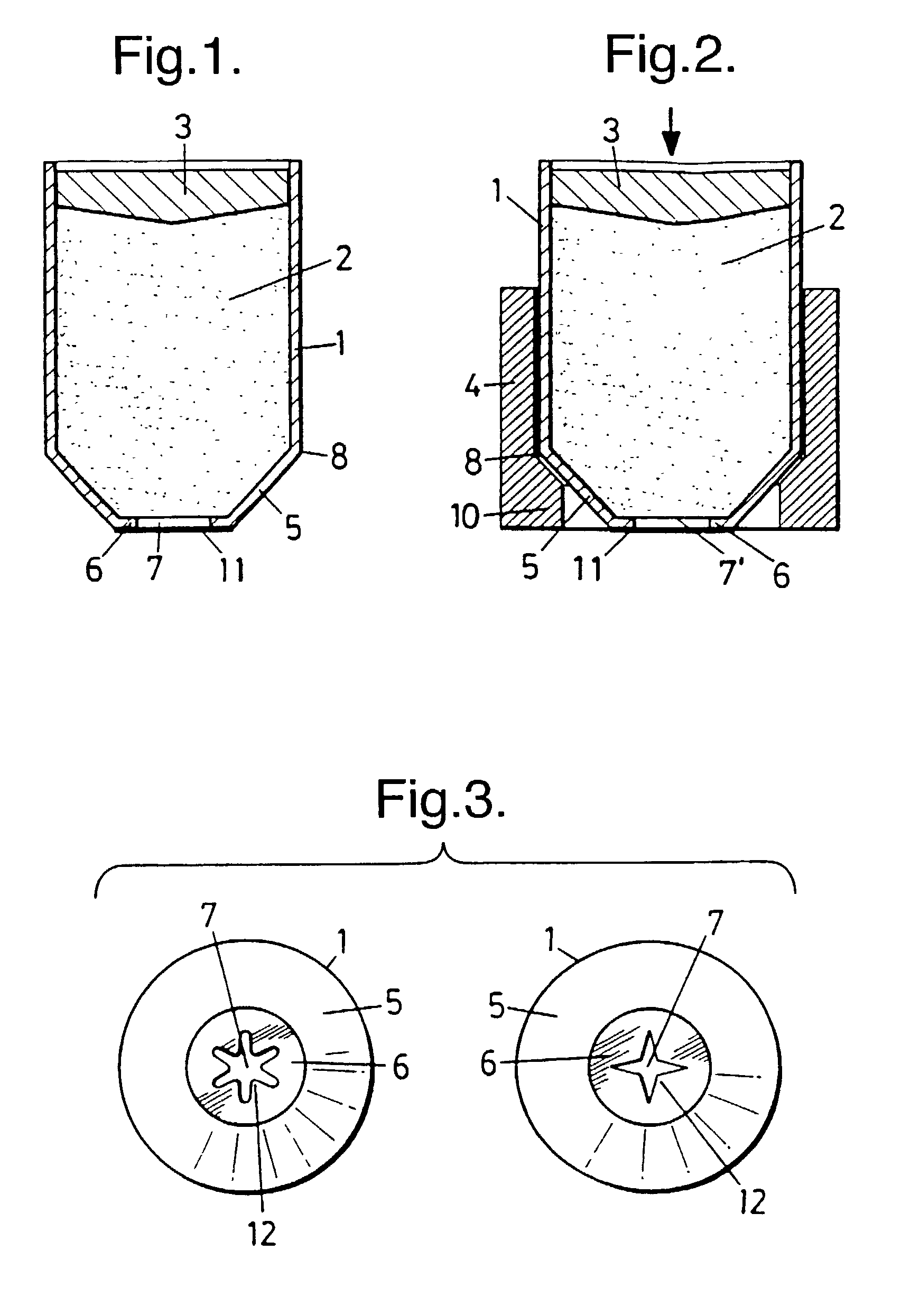

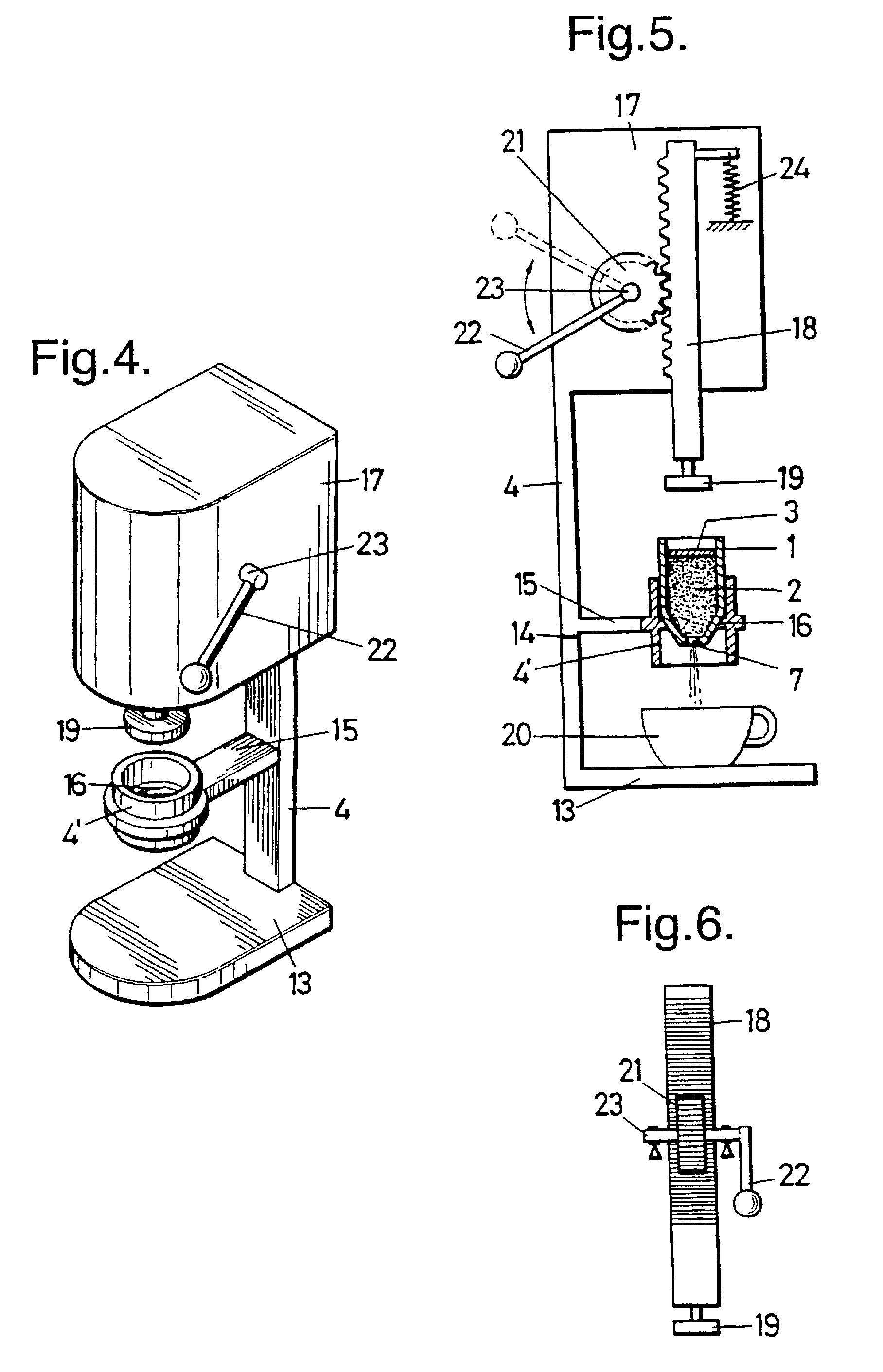

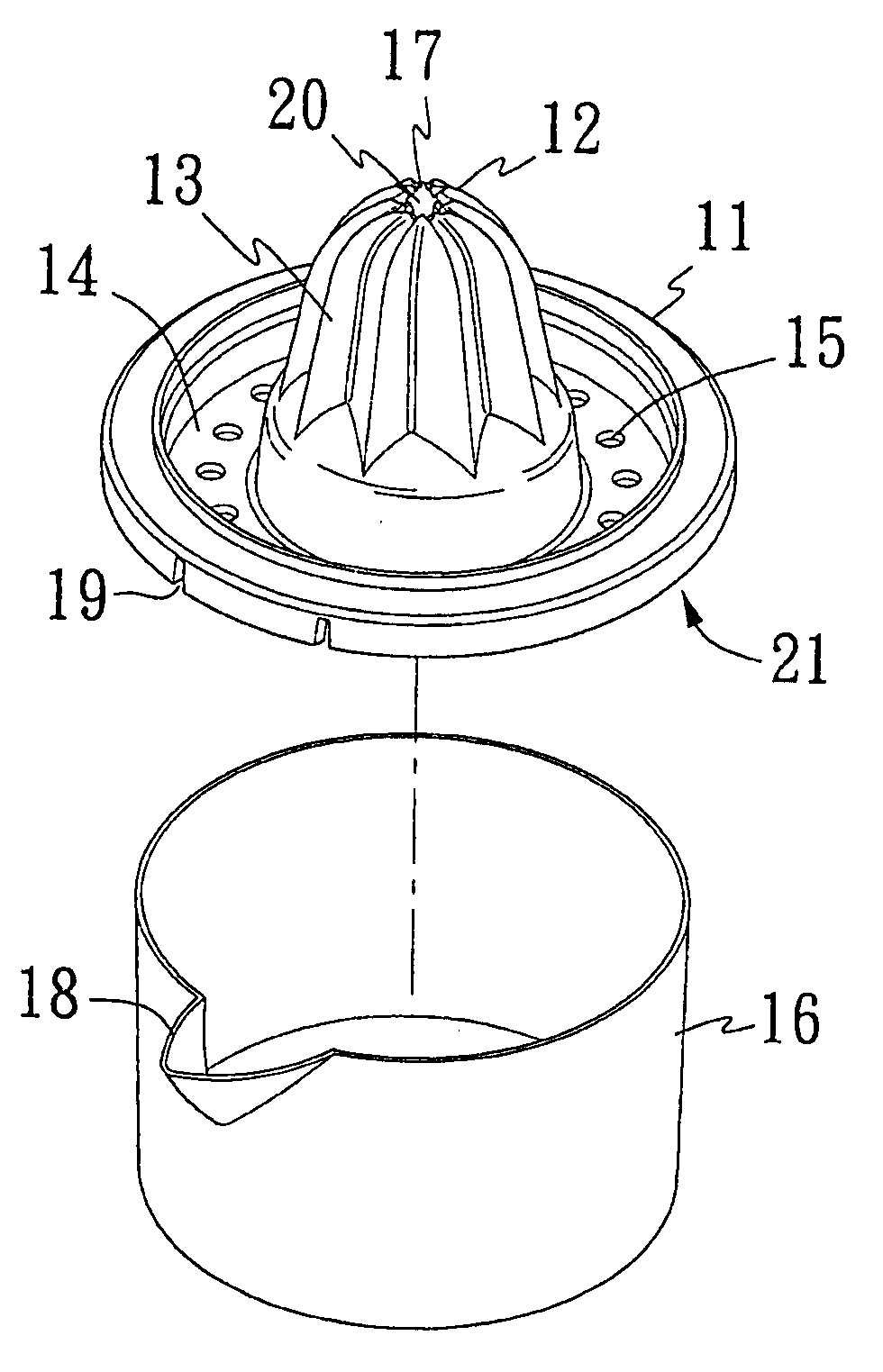

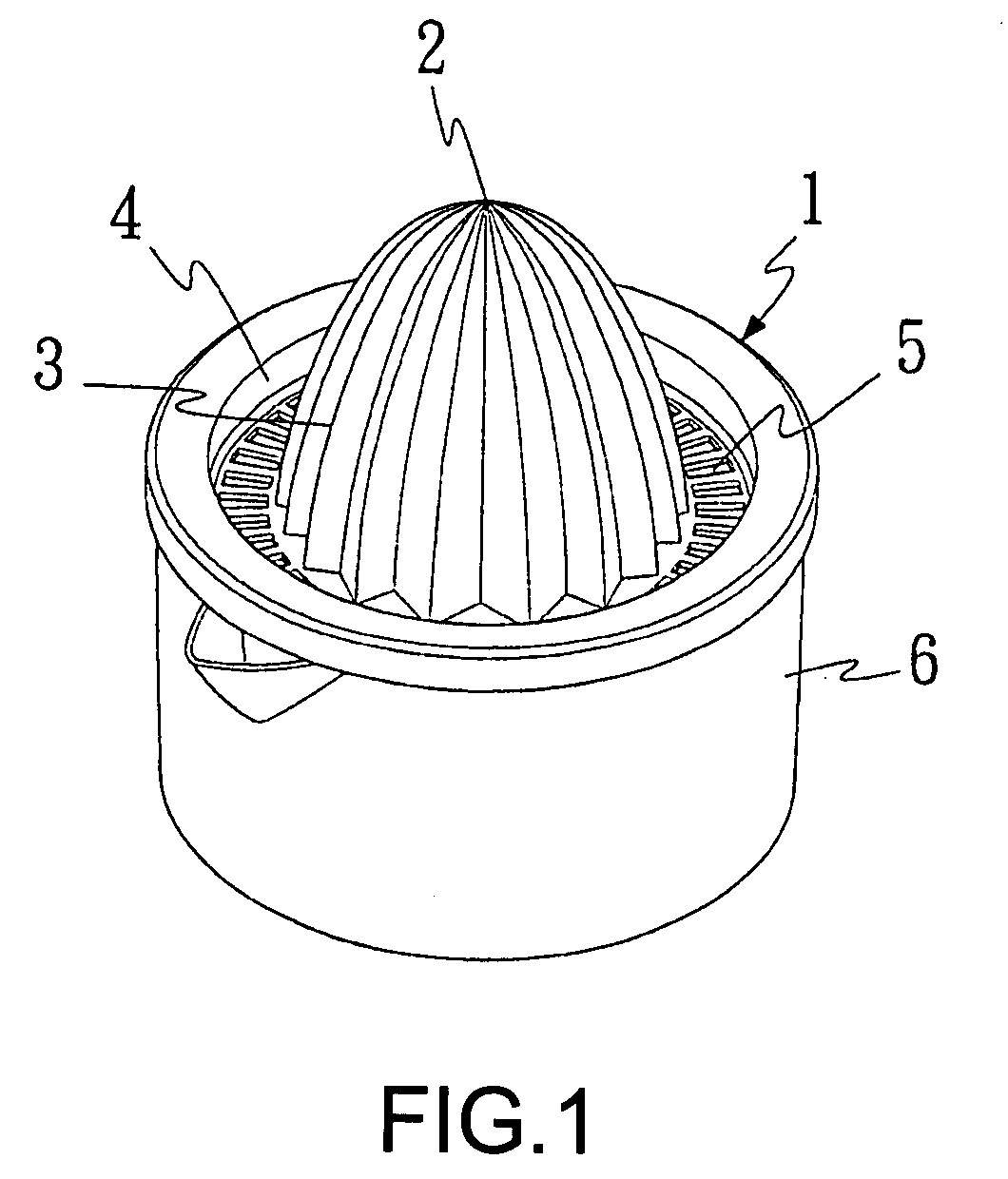

Manual juice extruder

InactiveUS20070272091A1Easy squeezeFacilitate to carry-out juice-extruding operationJuice extractionStrainersFruit juiceMechanical engineering

A manual juice extruder is used as a tool for extruding fruit juice and includes a juice-extruding tray. The central position of the juice-extruding tray has a raised portion that protrudes upwardly. The periphery of the raised portion has a plurality of protruding ribs. The center of the raised portion has an opening. The periphery of the opening has at least one skid-proof piercing portion that protrudes upwardly. Via this arrangement, when the user extrudes the juice manually, the fruit body can be fixed on the raised portion, which facilitates the extrusion of the juice.

Owner:HSIEN LAI CHENG

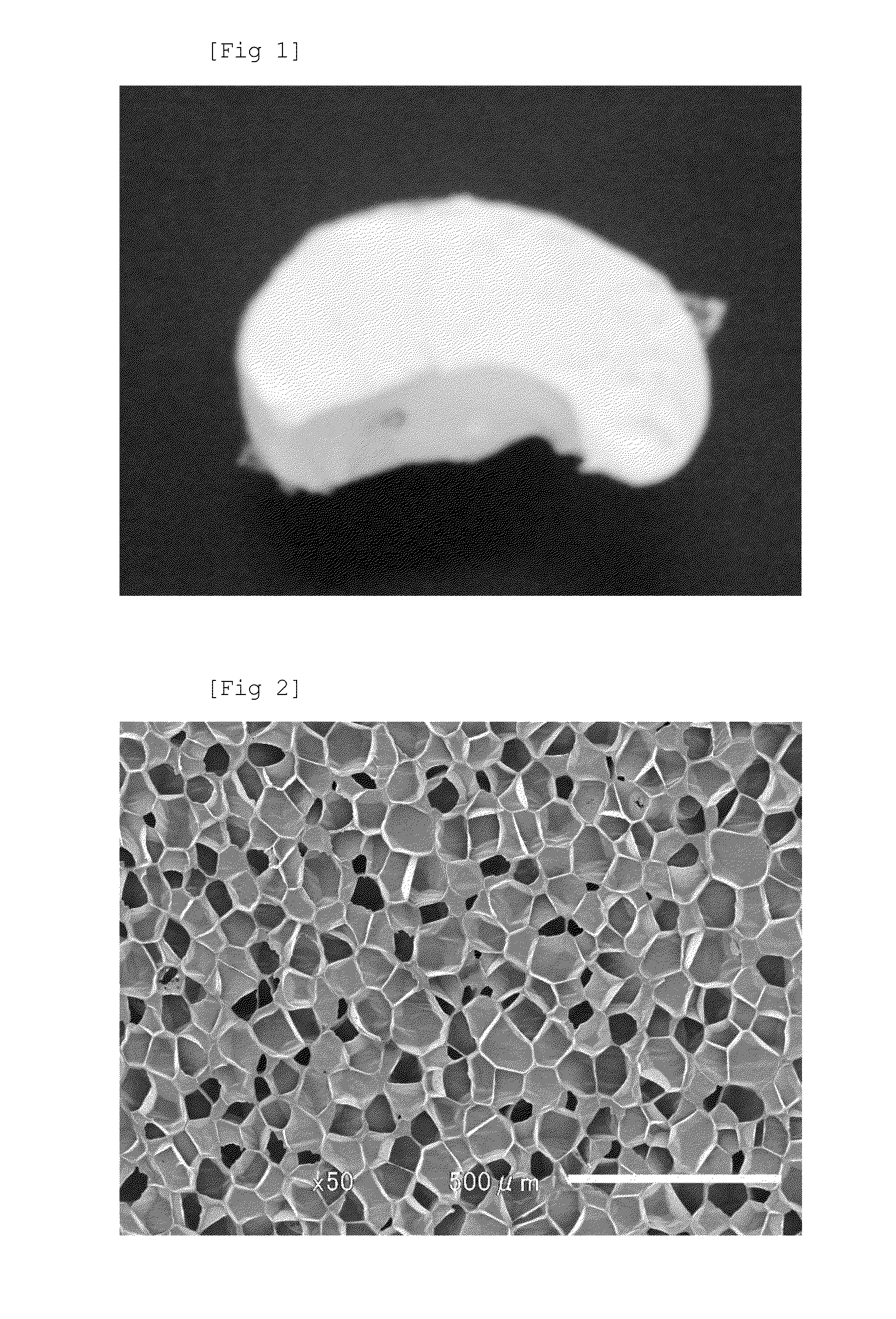

Propylene-based copolymer, propylene-based copolymer composition, molded product thereof and foamed product thereof, and production process therefor

ActiveUS20140088214A1Increase in melt tensionExcellent molding processabilityExpansion ratioVacuum forming

To provide a propylene-based copolymer and a propylene-based copolymer composition, each of which has a high melt tension because it has a long-chain branched structure, exhibits excellent molding processability during molding, such as inflation molding, extrusion molding, blow molding, injection molding or vacuum forming, and is capable of favorably providing a foamed product having an excellent expansion ratio and excellent cell uniformity in the foaming stage. The propylene-based copolymer (A) of the present invention comprises 50 to 95% by mol of constituent units [i] derived from propylene, 4.9 to 49.9% by mol of constituent units [ii] derived from an α-olefin of 2 to 10 carbon atoms other than propylene and 0.1 to 10% by mol of constituent units [iii] derived from a non-conjugated polyene (with the proviso that the total amount of the constituent units [i], [ii] and [iii] is 100% by mol), and is characterized by satisfying specific requirements (a) and (c).

Owner:MITSUI CHEM INC

Contact lens care product

InactiveUS20070045354A1Improve comfortEasy to holdLens cleaning compositionsClosuresContact lens careOptometry

Owner:NOVARTIS AG

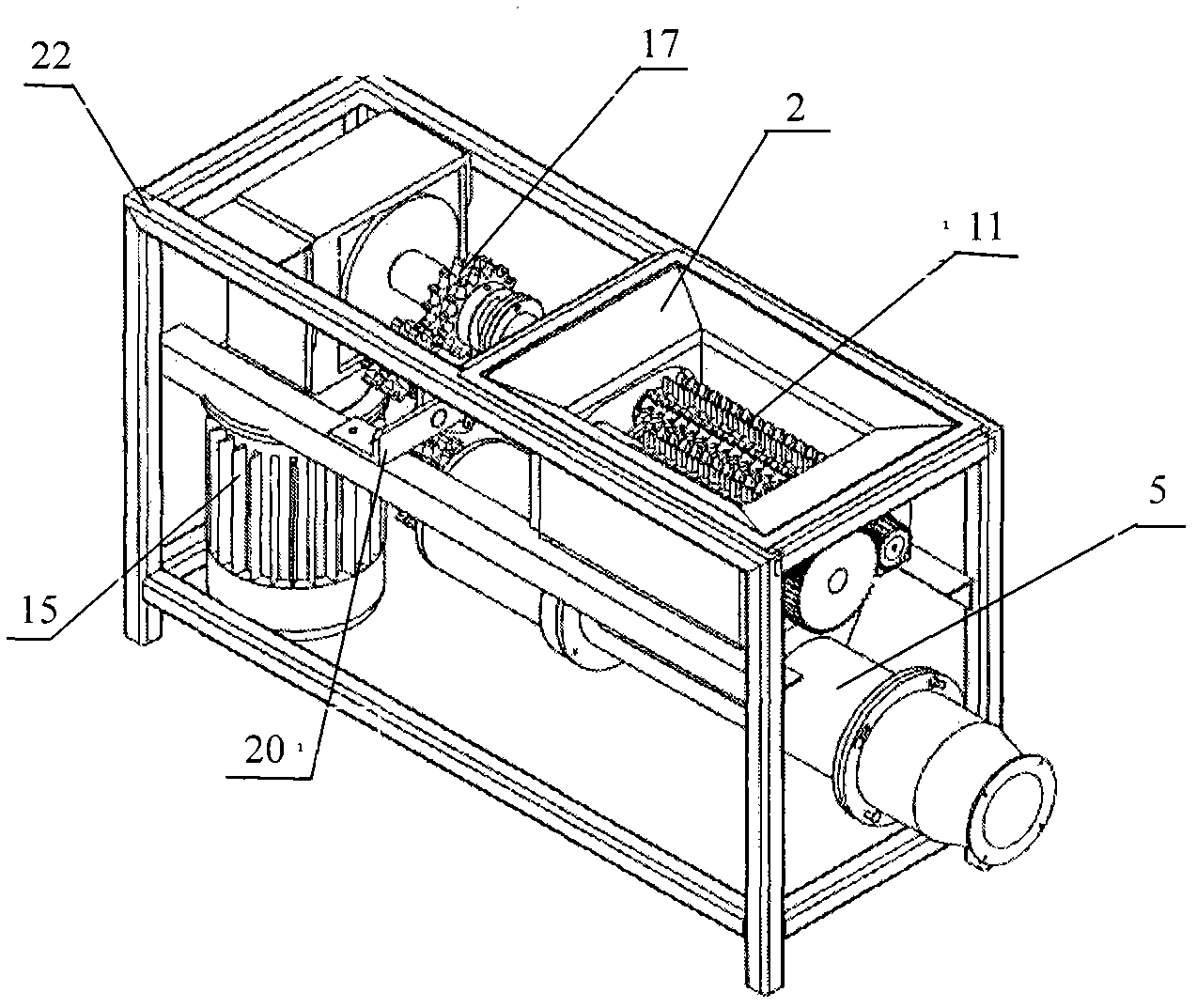

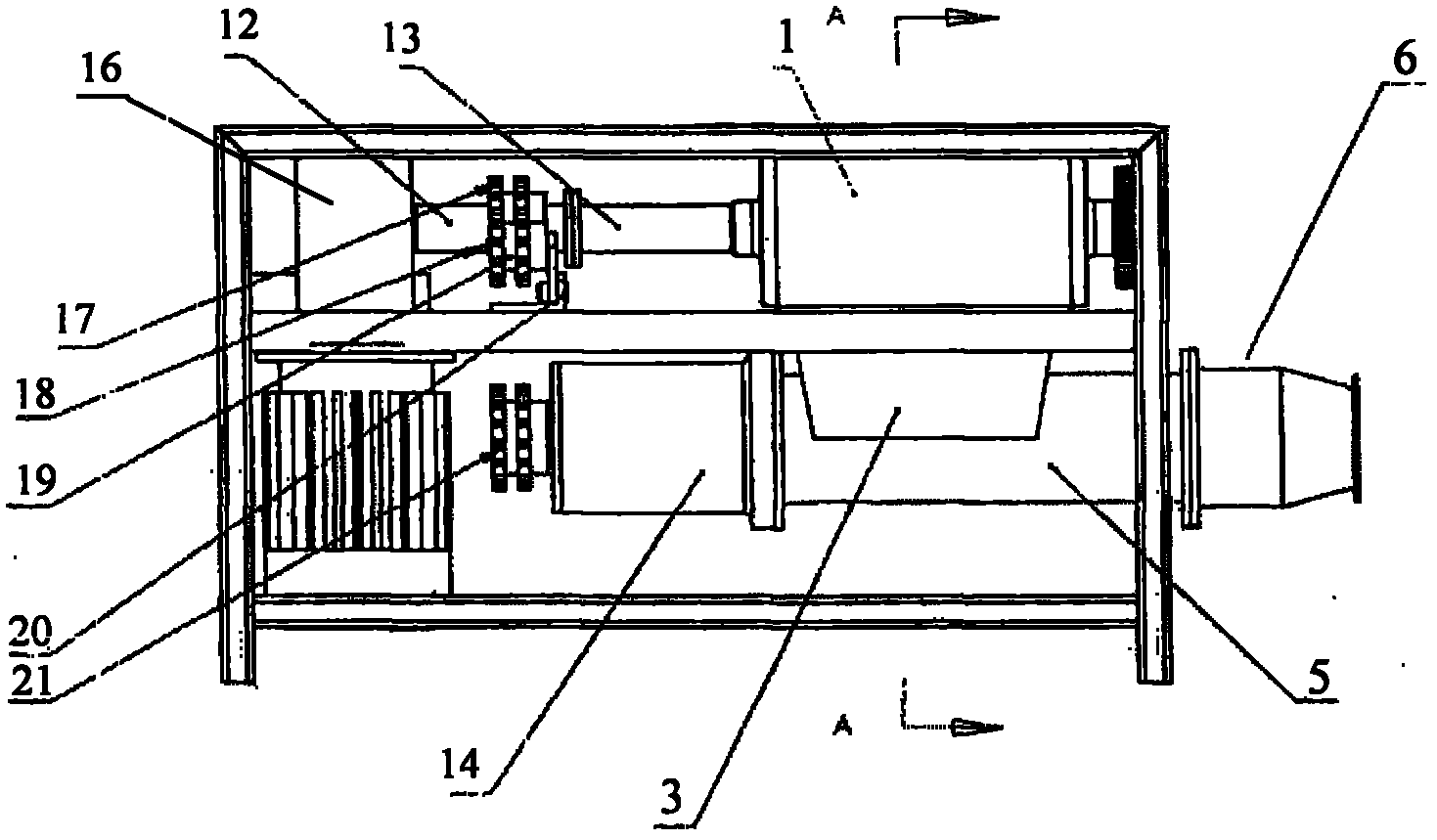

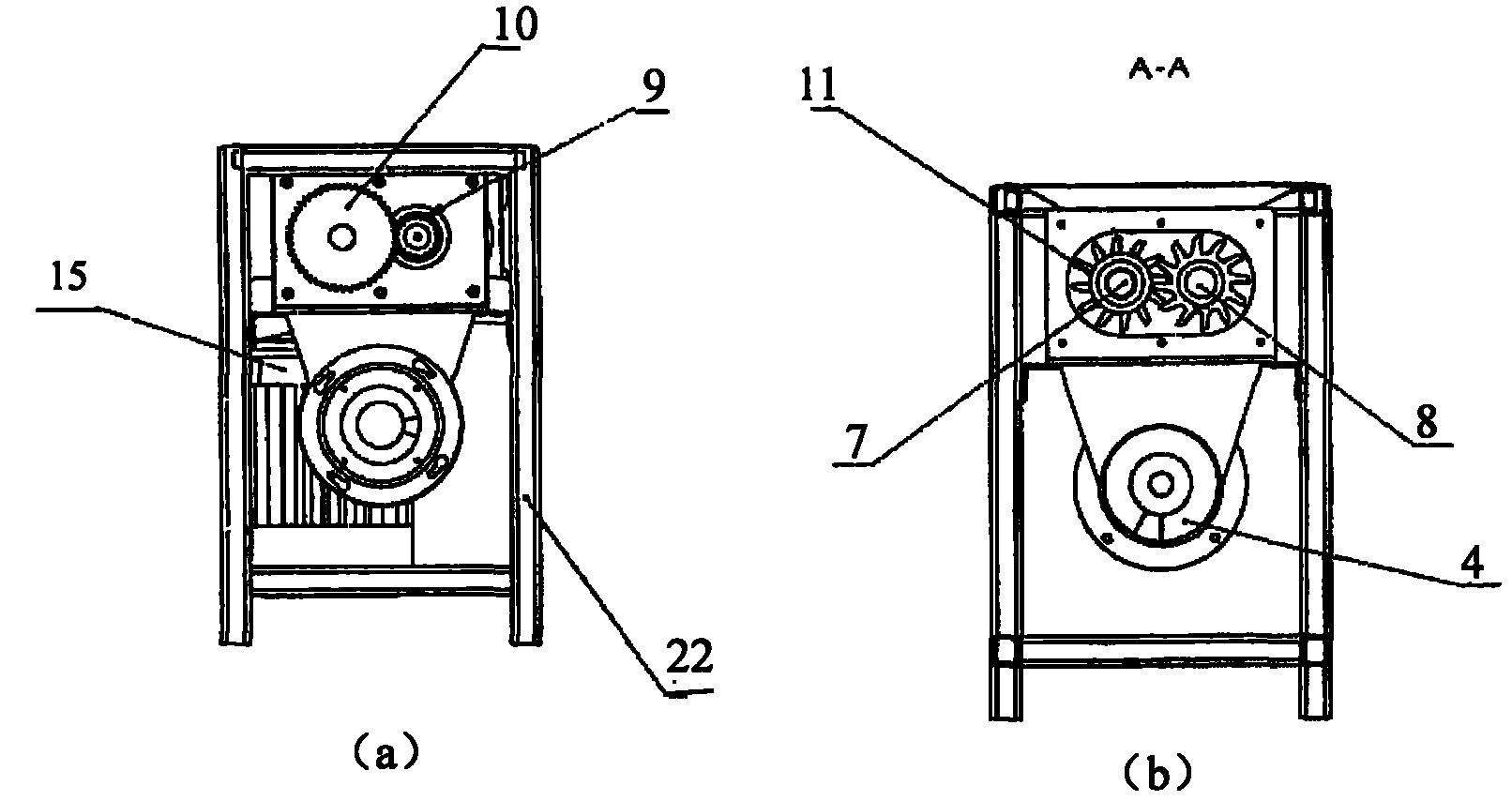

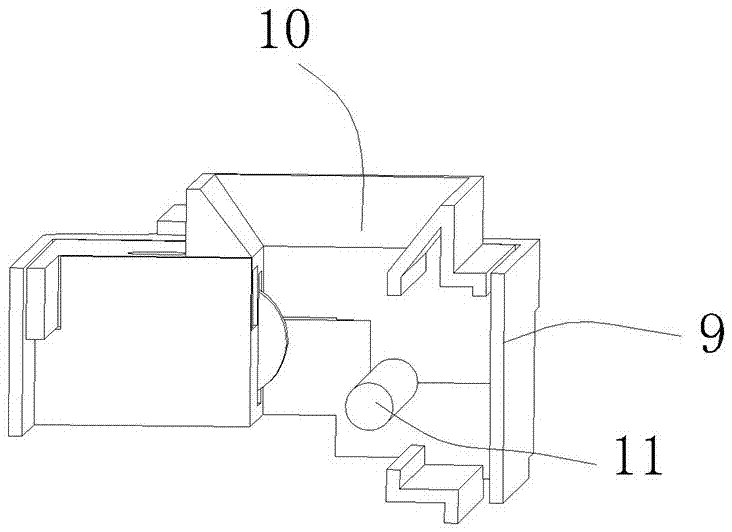

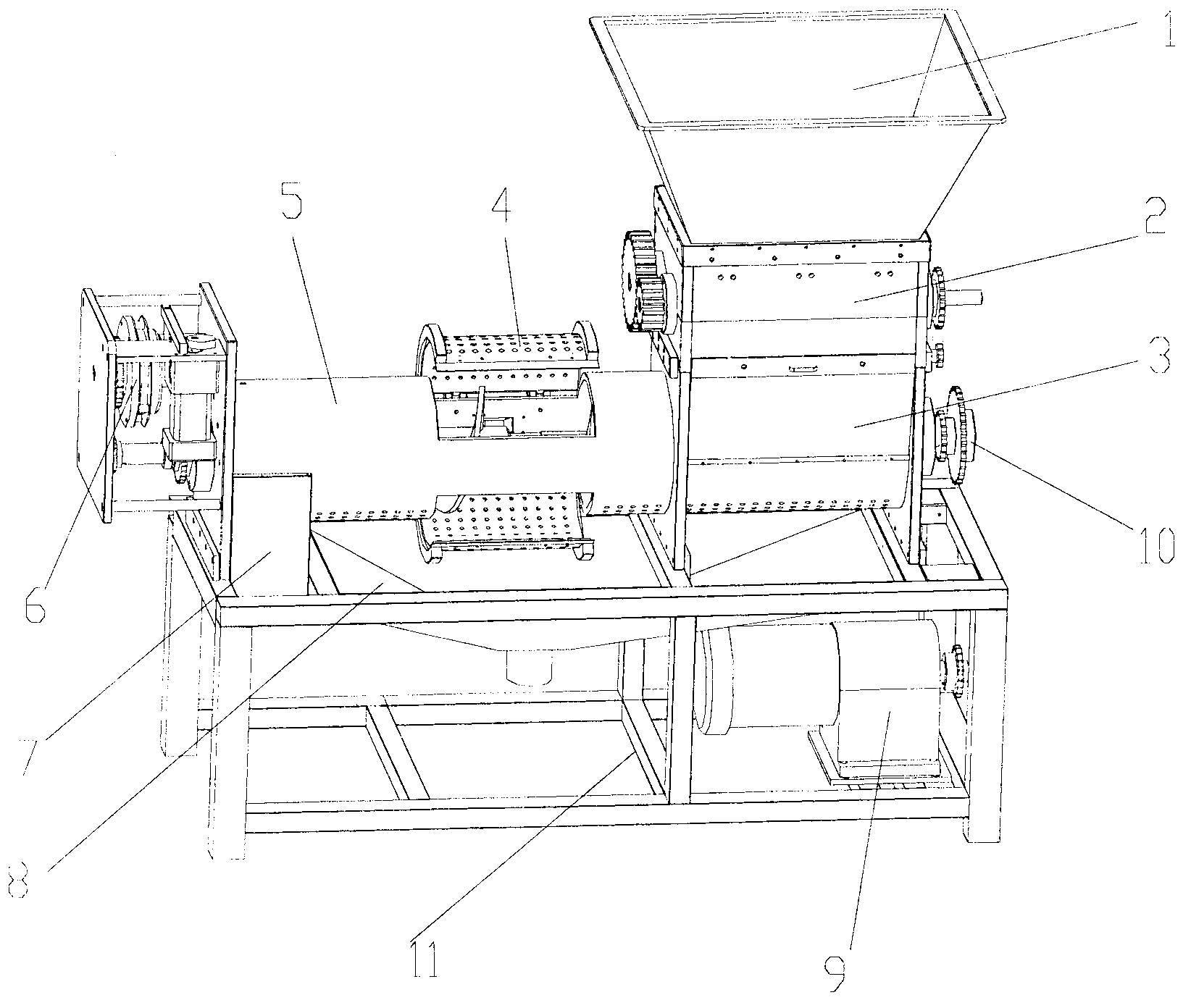

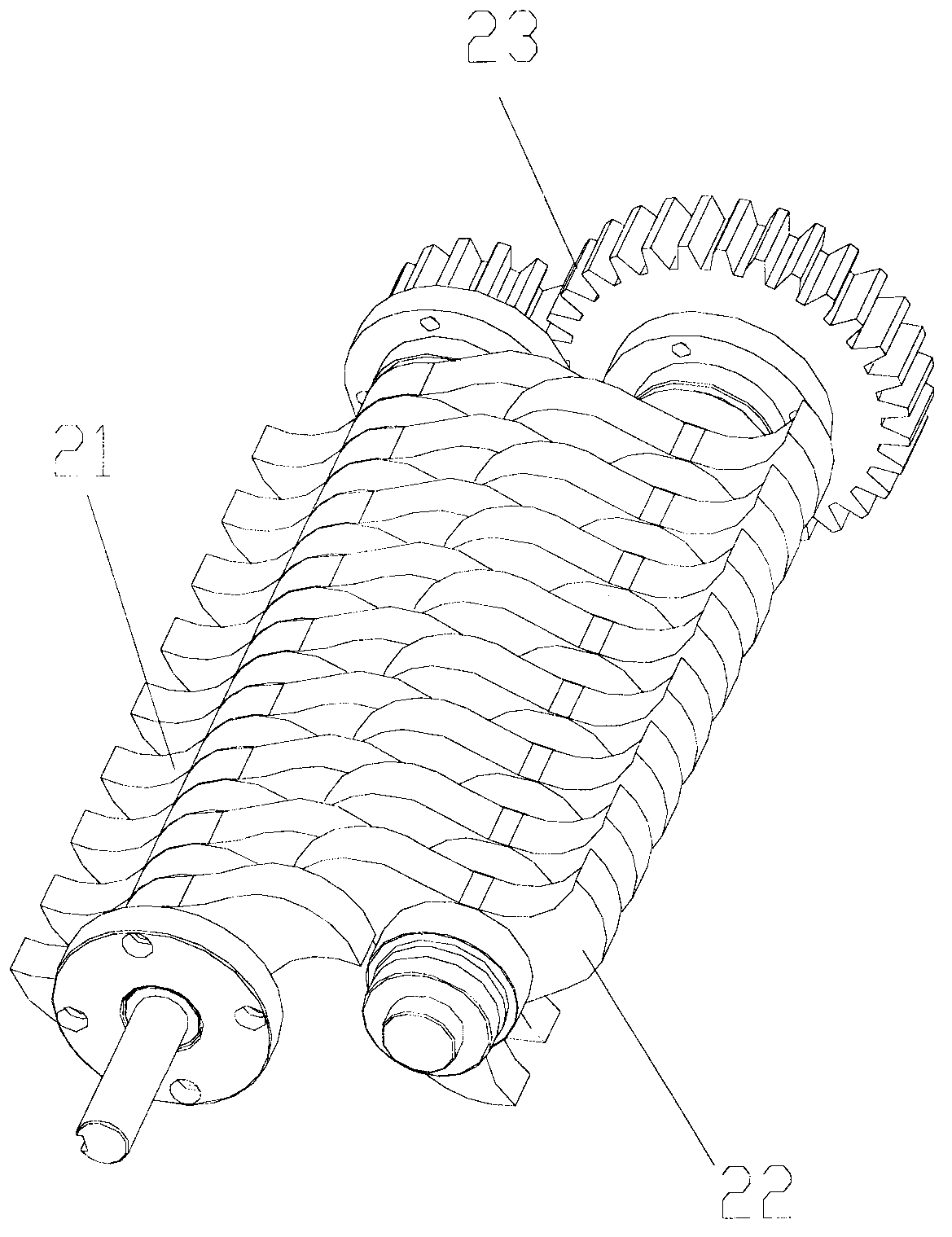

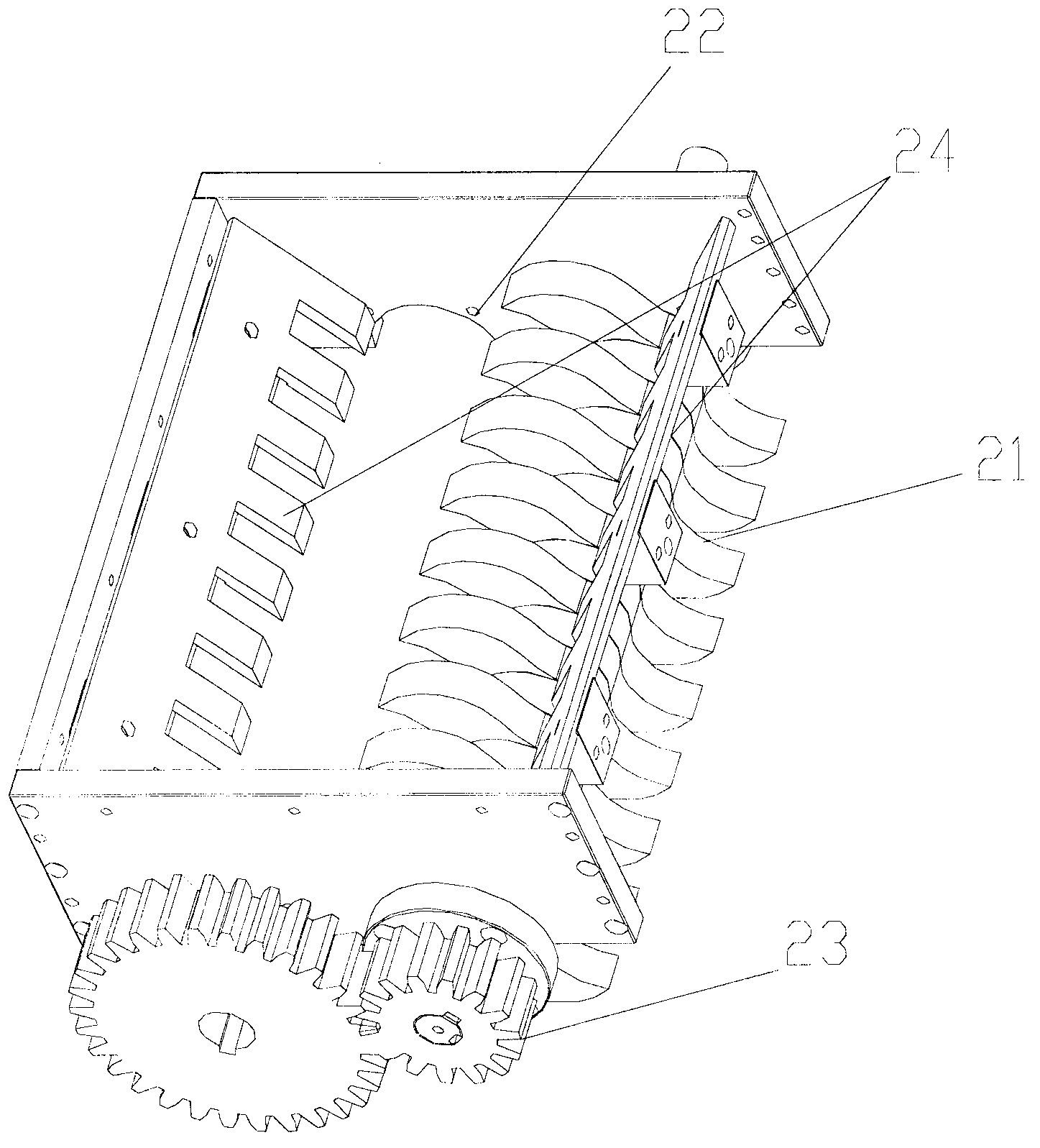

Automatic organic material crushing and dewatering machine and crushing and dewatering method

The invention discloses an automatic organic material crushing and dewatering machine which comprises a base frame, a feeding bucket, a hob crushing device, a driving chain wheel, a spiral feeding bin, an extruding dewatering bin, a spiral discharge bin, a discharge variable speed link group, a discharge port and a main motor, wherein the driving chain wheel, the spiral feeding bin, the extruding dewatering bin, the spiral discharge bin and the discharge variable speed link group are connected in sequence by screw rods; a water collecting bucket is arranged below the extruding dewatering bin; the hob crushing device is composed of a set of special crossed hobs with double blades and three blades and driven to operate by a pair of variable gears connected with the hobs; and screw rod structures are arranged in the spiral feeding bin and the spiral discharge bin, and spiral blade structures are arranged on screw rods to continuously push materials. The invention further discloses a crushing and dewatering method which uses the automatic organic material crushing and dewatering machine; different organic materials can be crushed and dewatered; the defects of the existing equipment available on the market are overcome; the automatic organic material crushing and dewatering machine has the advantages of simplicity and convenience in operation and maintenance; the service efficiency and the working efficiency of the equipment are improved; additionally, the operating environment is improved; and the wear of the equipment is reduced.

Owner:深圳市三盛环保科技有限公司

Novel squeezing flat mop cleaning tool

InactiveCN107456178ASimple structureEasy and labor-saving operationCarpet cleanersFloor cleanersEngineering

Owner:CIXI BOSHENG PLASTIC PROD

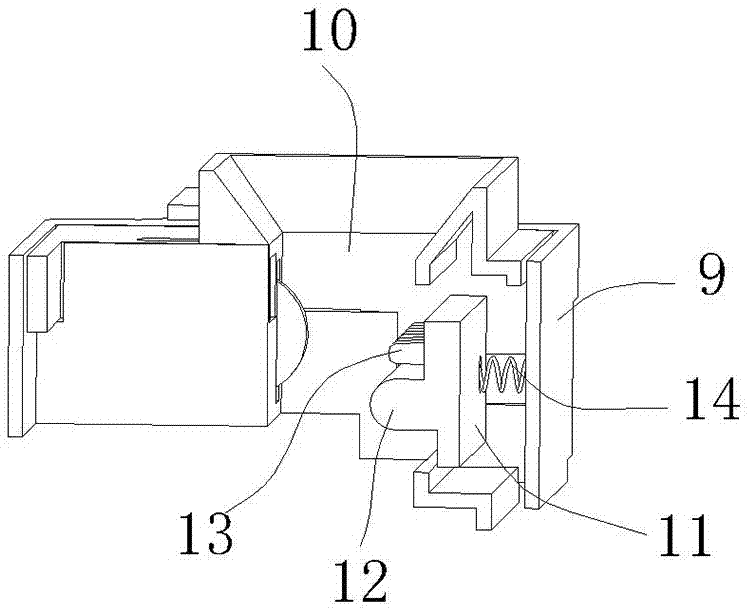

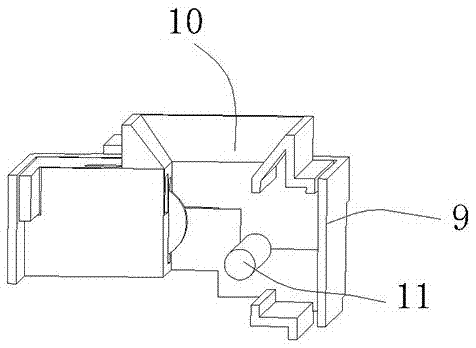

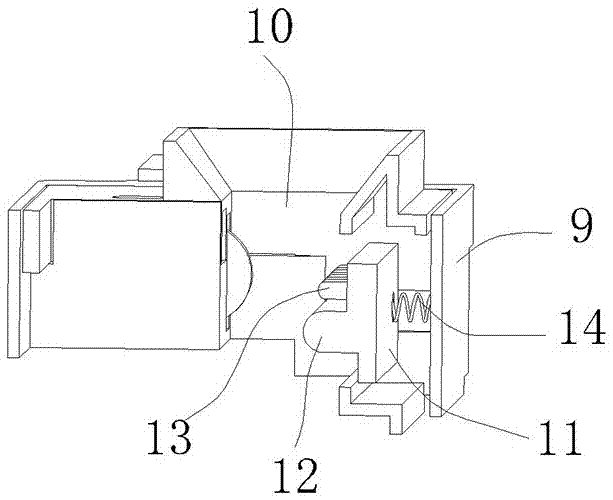

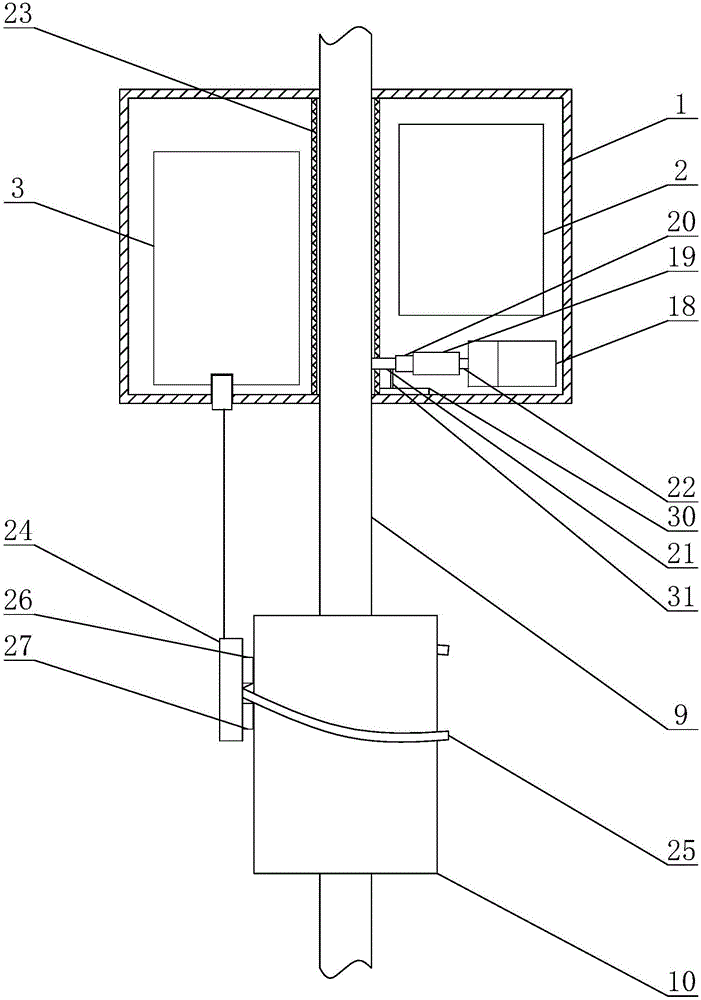

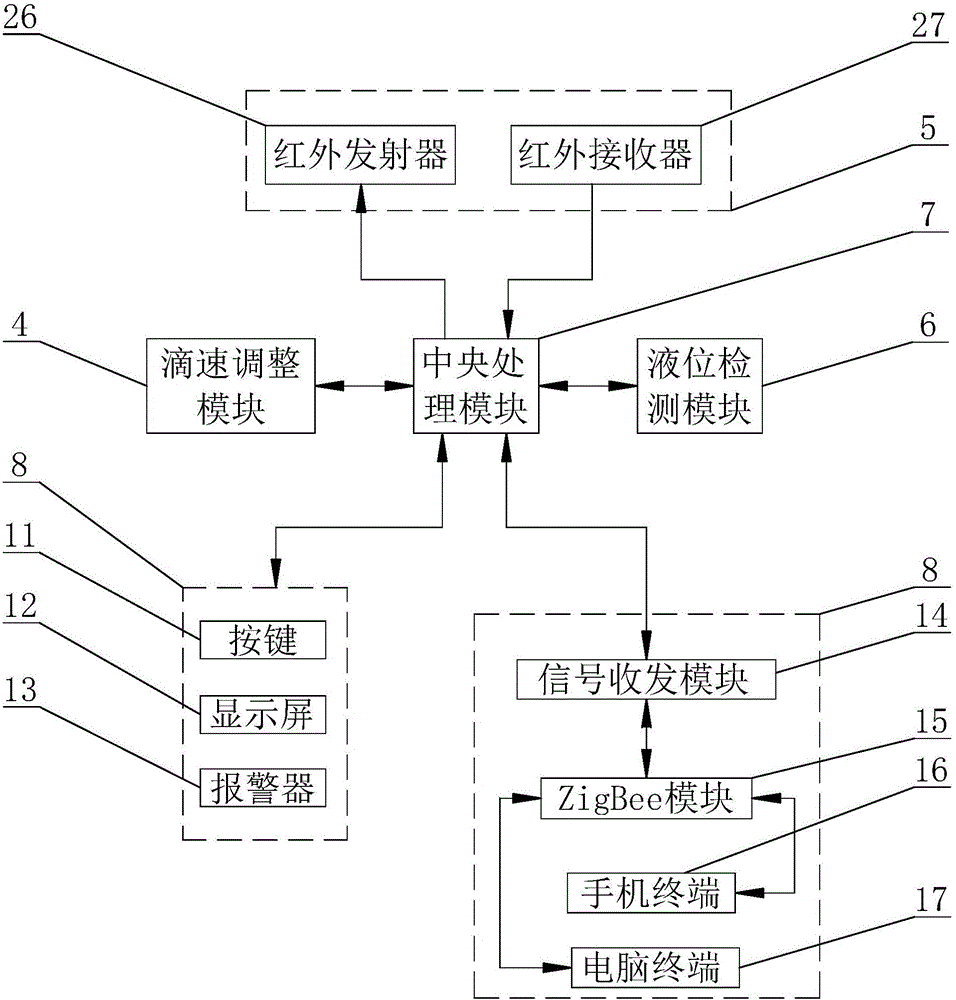

An infusion measuring and control device

InactiveCN105944181AEasy to monitor in real timeHigh degree of automationMedical devicesFlow monitorsElectricityEngineering

The invention provides an infusion measuring and control device comprising a shell, a battery, a circuit board, a dripping speed adjusting module, a dripping speed detection module, a liquid level detection module, a central processing module and a connector module. The shell is installed on an infusion hose on the upper side of a dripping cup; the battery provides power for the device and is installed in the shell; the dripping speed adjusting module, the dripping speed detection module, the liquid level detection module and the central processing module are electrically connected with the circuit board; the connector module is connected with the central processing module. The infusion measuring and control device facilitates the real-time monitoring of infusion, can adjust the dripping speed, can detect such conditions as blocking of the infusion hose, completion of infusion, and infusion exceptions timely, and enables people in charge of infusion to know the conditions timely through alarm signals, enables the people in charge of infusion to do preparation work timely, and thus enables infusion to be safe and reliable in an unattended state.

Owner:王中成 +1

Cloth soaking and coloring automatic equipment and operation method thereof

PendingCN111826853AUniform colorImprove production efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFuel tankElectric machinery

The invention discloses cloth soaking and coloring automation equipment and an operation method thereof, and belongs to cloth soaking and coloring automation equipment. The cloth soaking and coloringautomation equipment comprises a base, wherein the upper end of the base is fixedly connected with a dye box; and a feeding hole and a discharging hole are formed in the two sides of the upper end ofa fuel tank respectively. During cloth dyeing, driving motors in the motor box are started and drive a stirring paddle to rotate, and the stirring paddle stirs liquid in the dye box, so that the liquid in the dye box is always kept uniform; the uniform coloring of the cloth during dyeing can be ensured; and the situation of secondary processing of unqualified products is avoided. Moreover, an airbellow works to suck and blow external air flow into a heating box, the heating box heats and conveys the blown air into the drying box, and the hot air flow can dry the cloth in an accelerated manner, so that the cloth making efficiency can be improved, and the cloth can be dried more quickly.

Owner:常胜男

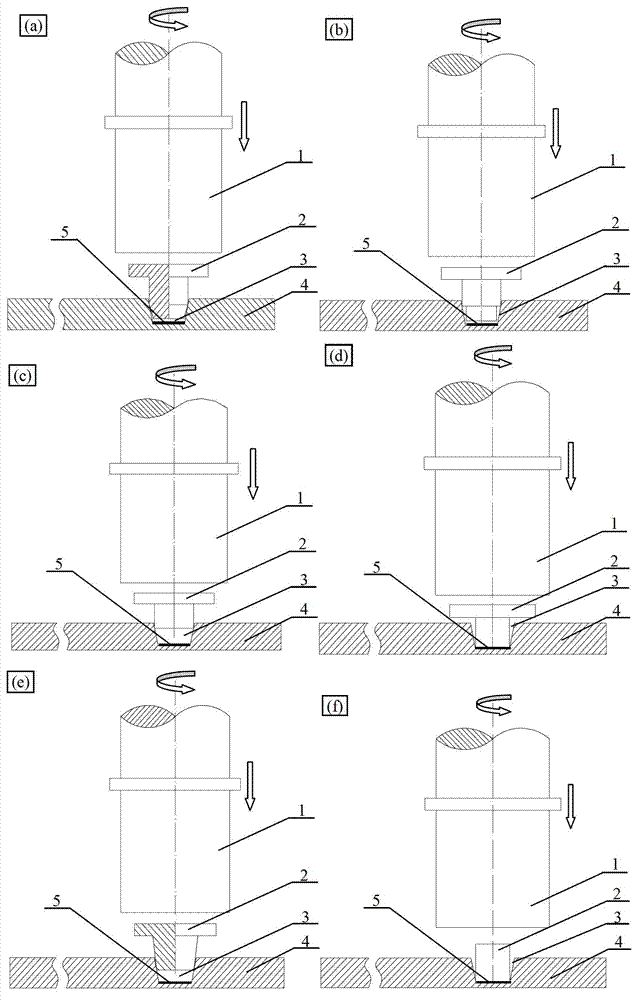

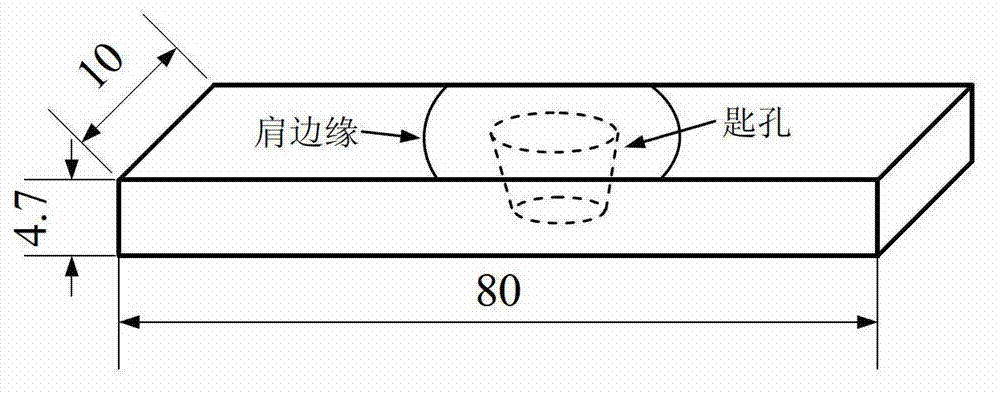

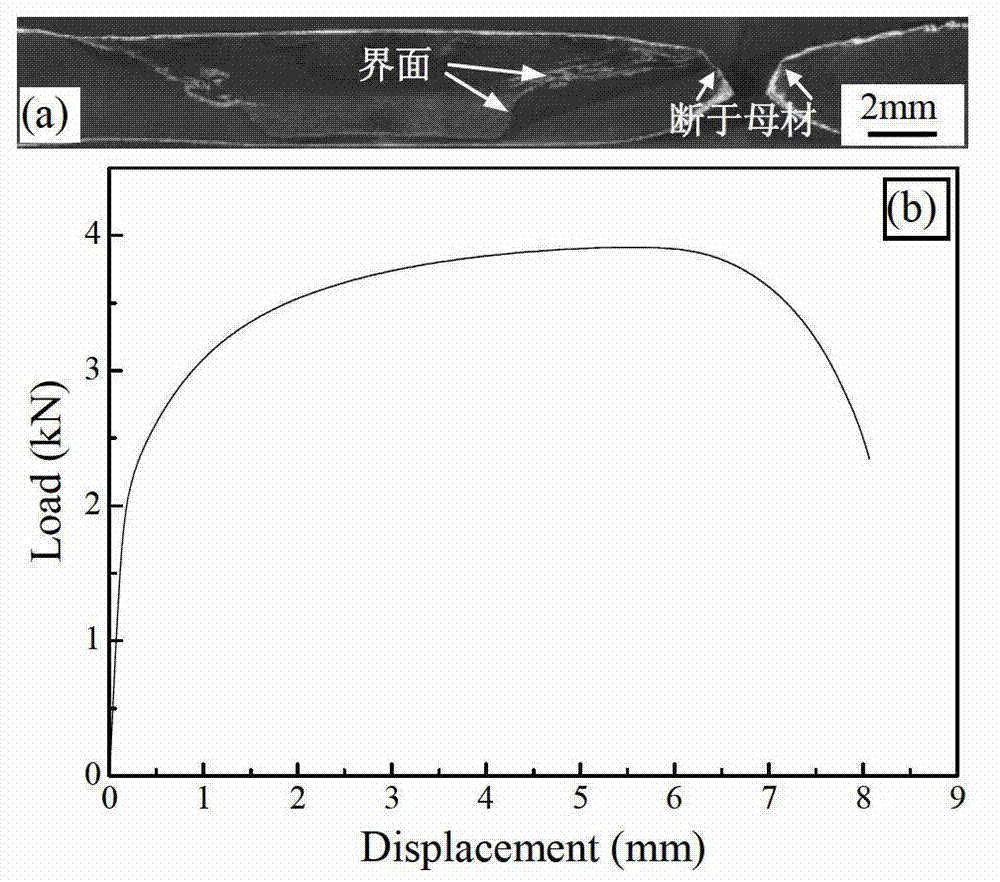

Method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of welding keyhole

InactiveCN103071911AAvoid smallImprove liquidityNon-electric welding apparatusFilling materialsBraze alloy

The invention discloses a method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of a welding keyhole. The method comprises the following steps that brazing alloy is preset in a keyhole, then a stuffing block is added in the keyhole, a T-typed stuffing block is subjected to rotation and friction through a needleless stirring head and is compressed down, the brazing alloy is heated to be softened, liquid brazing alloy is extruded and stirred by the stuffing block in an enclosed environment formed by the keyhole and the stuffing block, the liquid brazing alloy is stuffed in a driving and flowing way, and the liquid brazing alloy is enabled to be filled into a gap on the bottom of the keyhole; and due to the property of non-compression of the liquid brazing alloy, the liquid brazing alloy back flows along a side wall interface upward to stuff the remaining gap of the side wall, the side wall interface is dissolved, and compact alloying of the side wall and the bottom interface is realized. When the welding keyhole is repaired in batches, the replacement of tools is not needed, reduction of a welded keyhole does not exist or is extremely small, stuffing materials are saved, preset operation of the brazing alloy and the stuffing block is convenient, and the shaping of a surface of a stirring area is smooth.

Owner:XI AN JIAOTONG UNIV

Ice and snow removing apparatus for power transmission line

The invention discloses an ice and snow removing apparatus for a power transmission line. The ice and snow removing apparatus comprises a walking mechanism and a rack connected below the walking mechanism through mechanical arms, wherein the walking mechanism comprises a back walking wheel which is clamped at a part, where icing is removed, of the power transmission line, and a front walking wheel which is clamped at a part, where icing is not removed, of the power transmission line; the rack is provided with a de-icing mechanism; a wireless controller is arranged on the left side of the interior of the rack; the de-icing mechanism comprises an icing smashing module and a water jet cutter cutting module from left to right in sequence; an opening is formed in the top of a water tank; an ice and snow receiving funnel is arranged on the opening; notches are formed in a position, corresponding to the ice and snow receiving funnel, of the top of the rack, and used for collecting ice blocks falling from the power transmission line; and a heating module is arranged at the bottom of the water tank and is in electric signal connection with the wireless controller. Water pressure of the water jet cutter cutting module can be adjusted according to the detected thickness of an icing layer, so that efficient de-icing can be realized during cutting the surface icing without being affected by the thickness of the icing layer, and a line is not damaged either.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

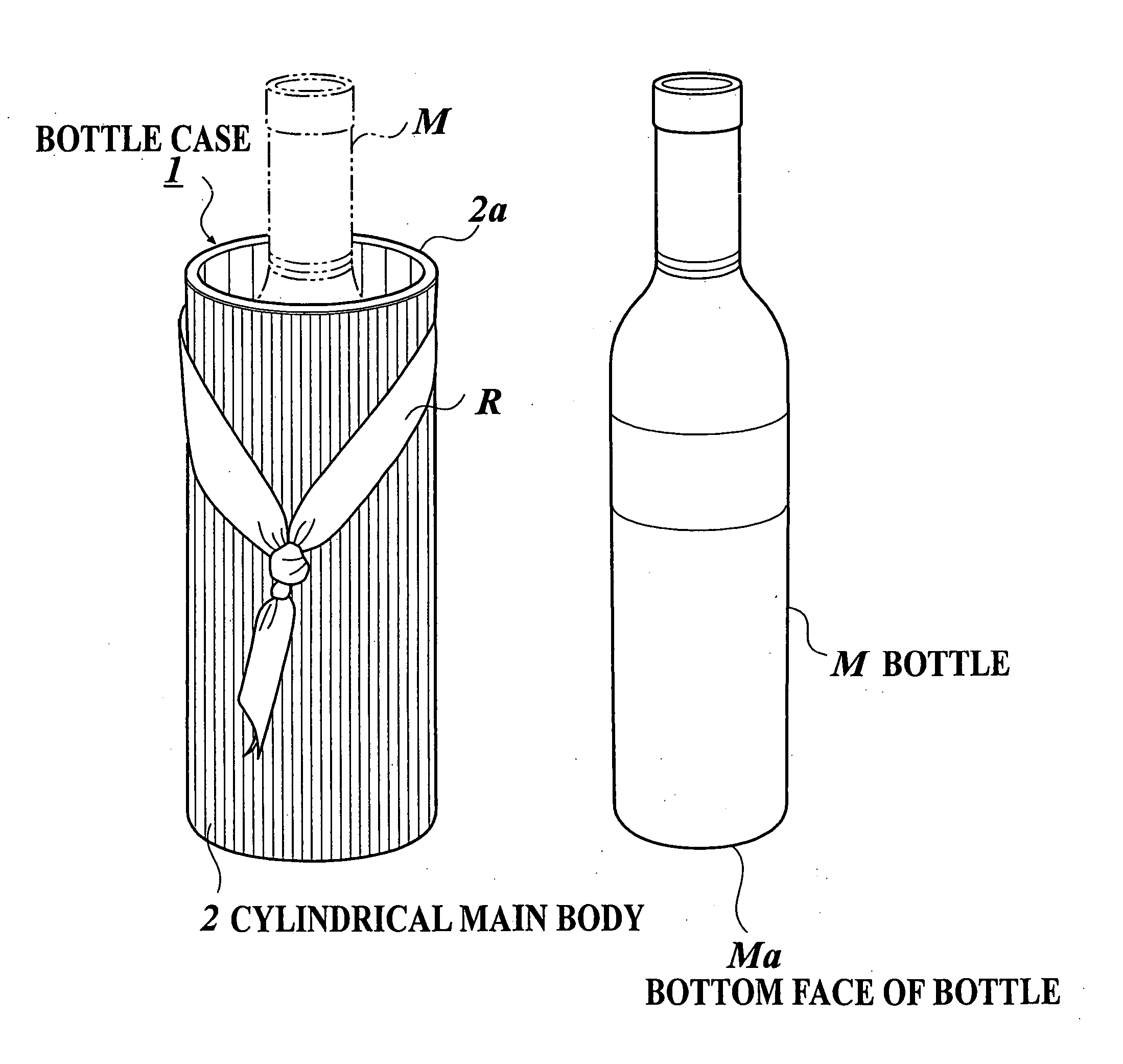

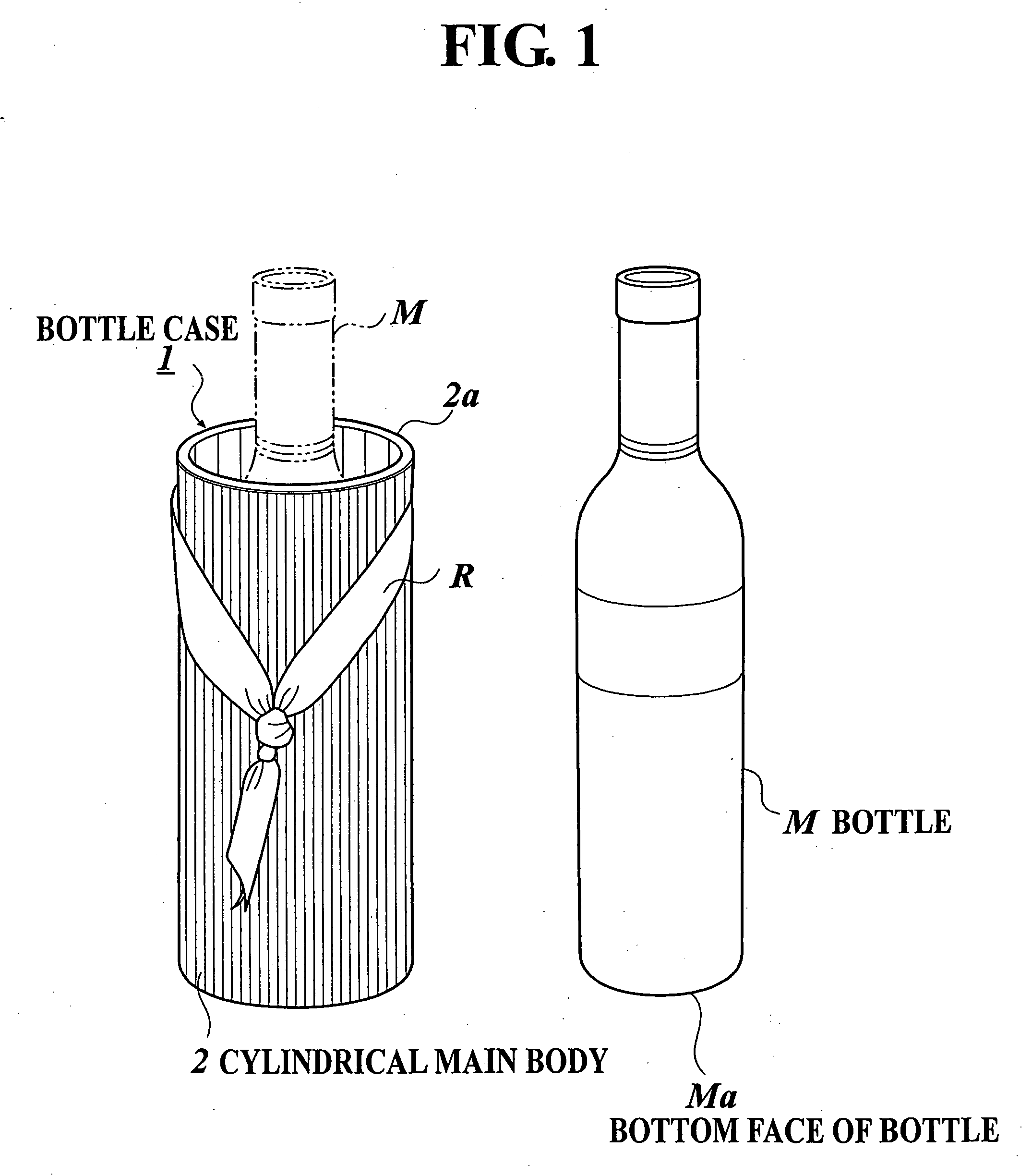

Woody molding, it's production system and production method

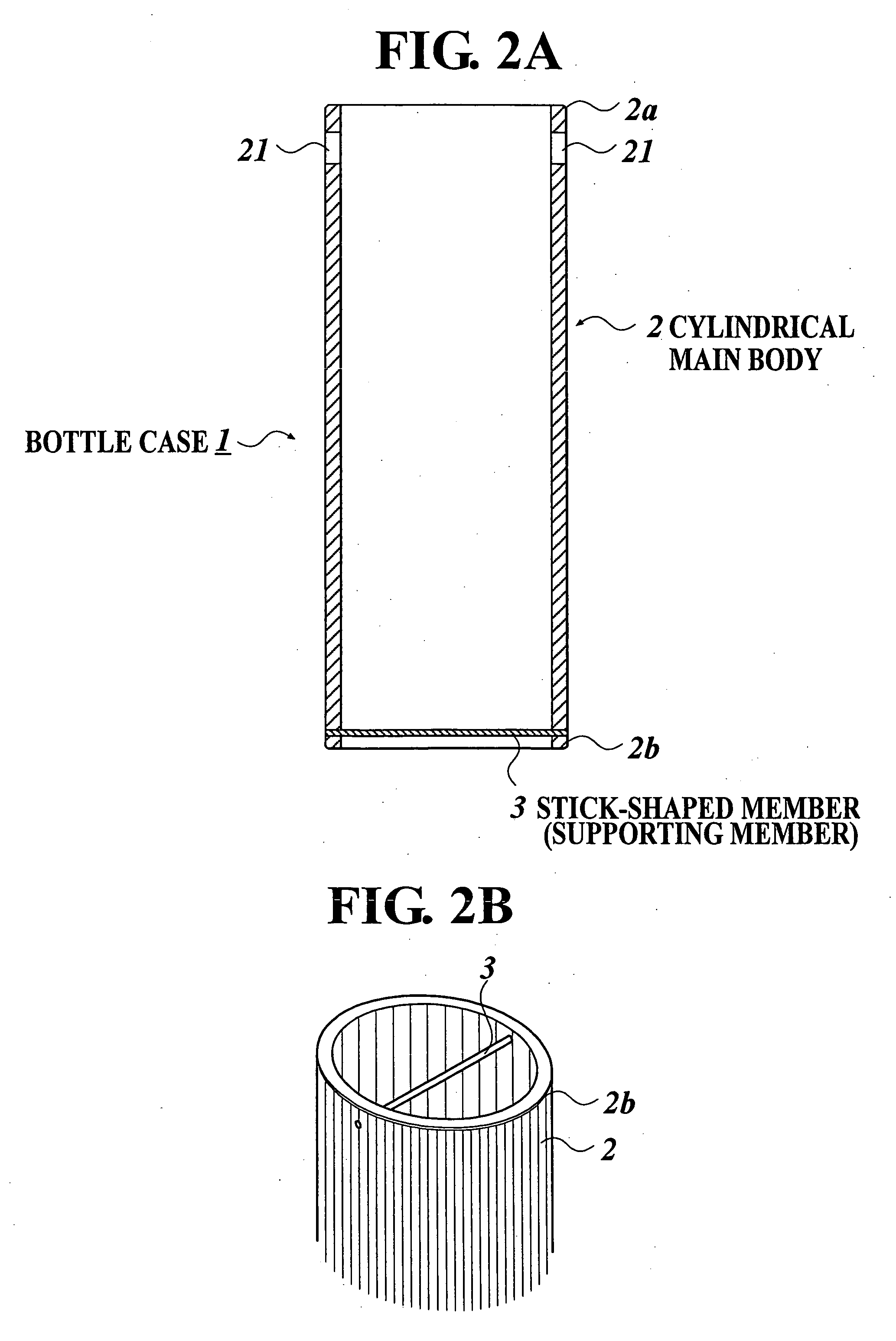

InactiveUS20060060592A1Favorable wood-like featureIncrease waste materialCandle holdersBottlesWine bottleEngineering

A wood-like molded product which is permitted to have wood-like features without using a natural wood material, and is usable as a bottle case to keep a wine bottle or the like inserted therein, and the like. The wood-like molded product includes: a cylindrical main body (2) which is made of a mixed material containing: fine cellulose powder particles (N) obtained from a wood material; and resin (P), and permits a bottle to be inserted thereinto; and a supporting member (3) provided in the cylindrical main body, to support a bottom face of the bottle inserted in the cylindrical main body.

Owner:MISAWA HOMES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com