Iolite cellular ceramic and preparation method

A technology of cordierite honeycomb and ceramics, which is applied in ceramic products, applications, household appliances, etc., and can solve the problems of enterprise-scale preparation processes and large gaps in product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

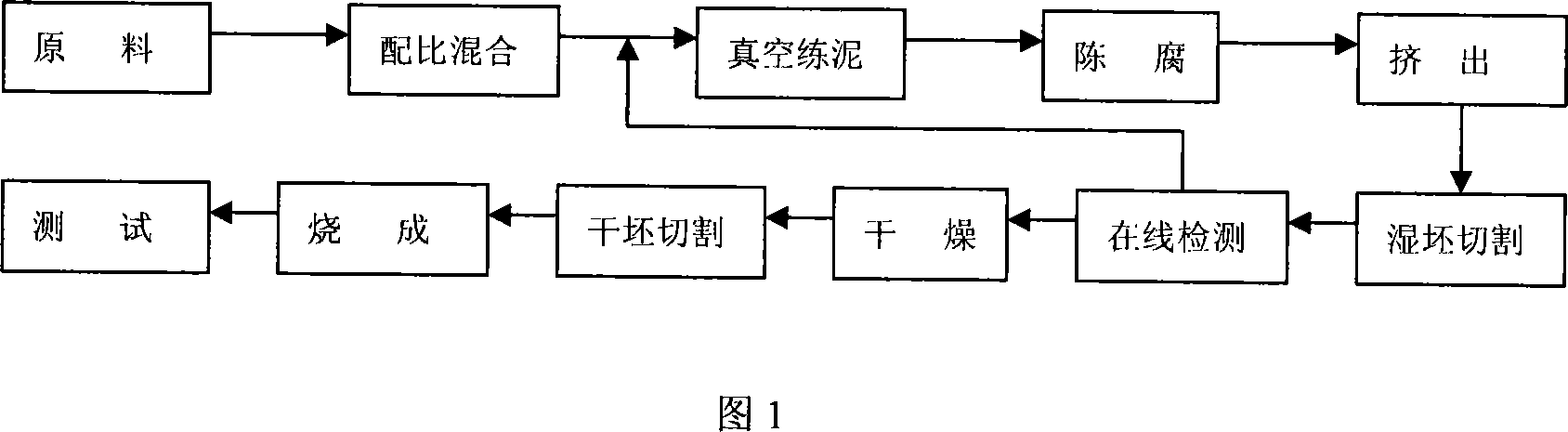

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Preparation of cordierite honeycomb ceramics with low thermal expansion and thermal shock resistance

[0019] First, mix water, glycerin, and acrylate multi-polymer in a ratio of 21-23:3-4:1-2 to obtain liquid A; mix polyoxyethylene laurate-2, oleic acid, and linseed oil 1. Light mineral oil is mixed according to the ratio of 1-2:2-3:3-4:2-3 to obtain liquid B; then liquid B is added to liquid A and stirred to obtain a liquid organic raw material additive.

[0020] Preparation of raw meal components: LiO 2 2.0-4% (weight ratio, the same below), talc 37.0% to 41.0% (average particle size 12μm), kaolin 12.0% to 16.0% (particle size ≤ 2μm), calcined kaolin 9.0% to 11.0% (particle size ≤ 2 μm), α-alumina 10.0% to 14.0% (particle size ≤ 2 μm), aluminum hydroxide 13.0% to 15.0% (particle size ≤ 2 μm), silica powder 8.0% to 10.0% (average particle size 9 μm), etc.

[0021] Typically LiO 22.% (weight ratio, the same below), talc 39.0%, average particle size 12 μm,...

Embodiment 2

[0027] Example 2: Preparation of cordierite honeycomb ceramics with high pore density

[0028] The preparation of liquid organic raw material additives, raw material mixing, vacuum mud refining, wet cutting, microwave drying, dry cutting, high-temperature firing, and detection methods are all the same as in Example 1. The differences are as follows:

[0029] The inorganic material for making honeycomb is clinker, and the typical formula of its chemical composition is: LiO 2 2.0 (weight ratio, the same below), SiO 2 50.0%, Al 2 o 3 360%, MgO 13.0%, Fe 2 o 3 0.4%, CaO 0.3%, K 2 O and Na 2 O is 0.09% and the average particle size is 7-9 μm. The composition change area of the present invention is relatively narrow, and the change in the range has no significant change in performance, wherein SiO 2 52.0%, Al 2 o 3 35.0%, MgO 12.0%, and the rest of the ingredients remain unchanged, with no significant changes.

[0030] After the plastic clay is stale for 24 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section diameter | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com