980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel and manufacturing method thereof

A technology of high hole-expanding steel and a manufacturing method, which is applied in the field of hot-rolled high-strength steel, can solve the problem that products without mass production are available, the mechanical properties are difficult to be greatly improved, and there is no hot-rolled high-strength, high-plasticity and high-hole expansion. Performance of ultra-high-strength steel and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with embodiment.

[0047] Table 1 is the composition of the steel of the embodiment of the present invention, Table 2 is the manufacturing process parameters of the steel of the embodiment of the present invention, and Table 3 is the performance of the steel of the embodiment of the present invention.

[0048] The process flow of the embodiment of the present invention is: converter or electric furnace smelting→vacuum furnace secondary refining→slab casting or ingot casting→slab (ingot) heating→hot rolling+cooling after rolling→steel coil, wherein the key process parameters are shown in Table 2.

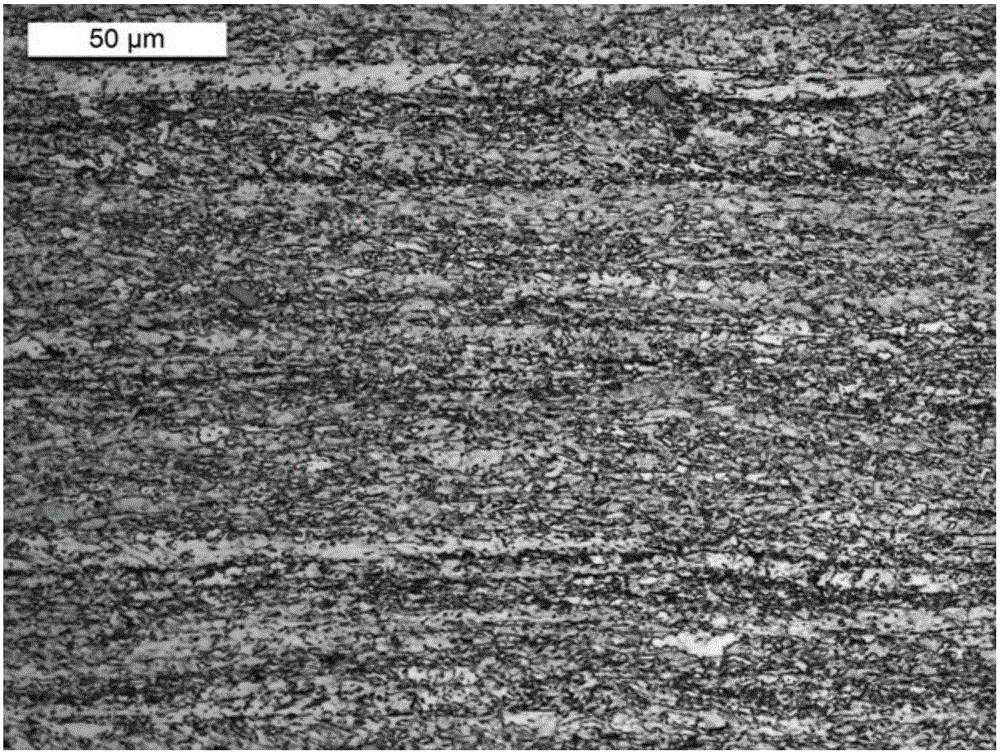

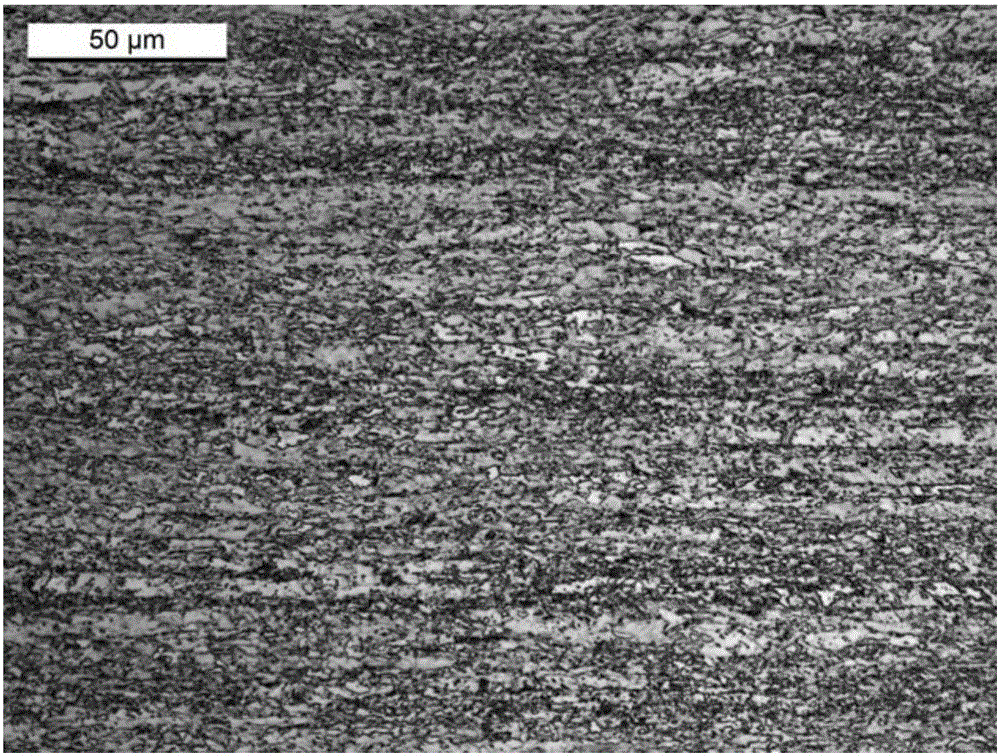

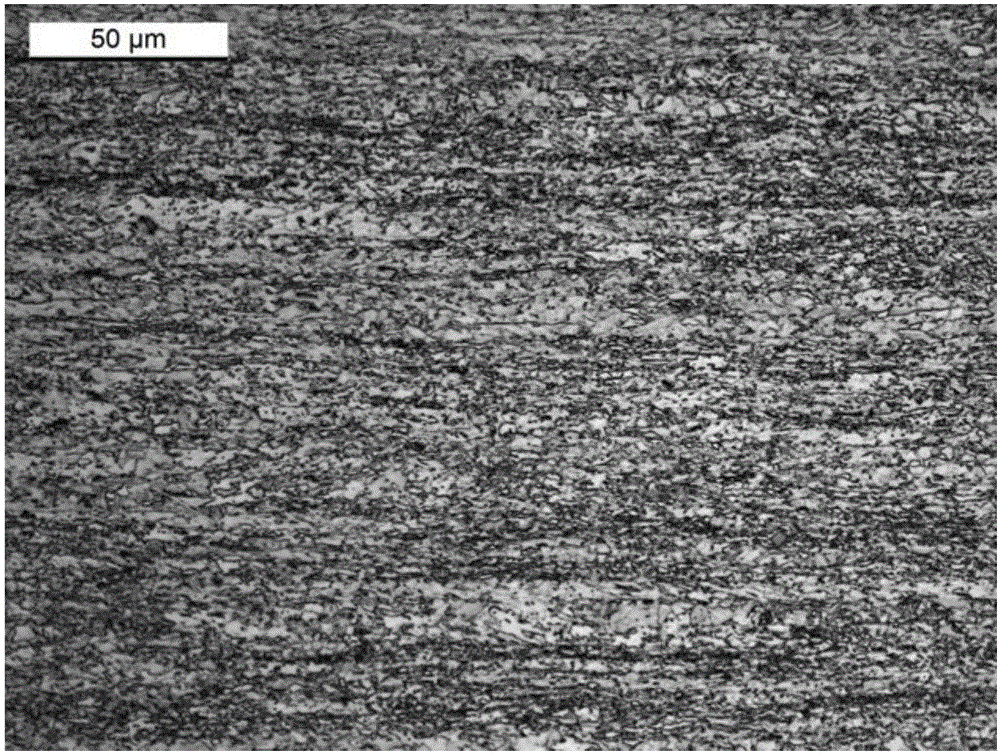

[0049] Figure 1-Figure 3 Respectively are the typical metallographic photographs of the steels tested in Examples 1, 3 and 5. From Figure 1-Figure 3 It can be seen that the microstructure of the steel plate of the present invention is that the microstructure of the steel plate is all fine bainite and a sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com