Patents

Literature

931 results about "Expansion ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

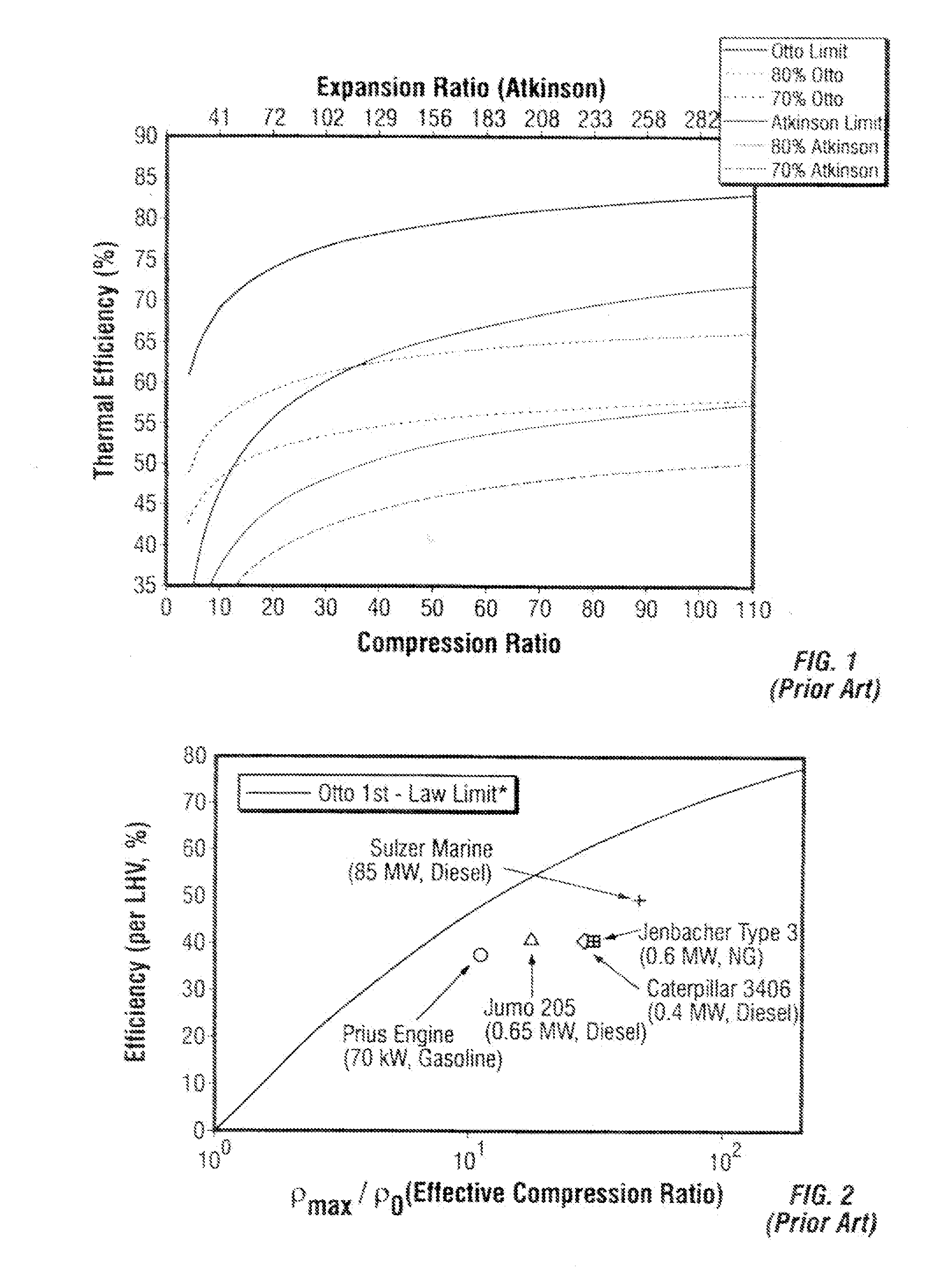

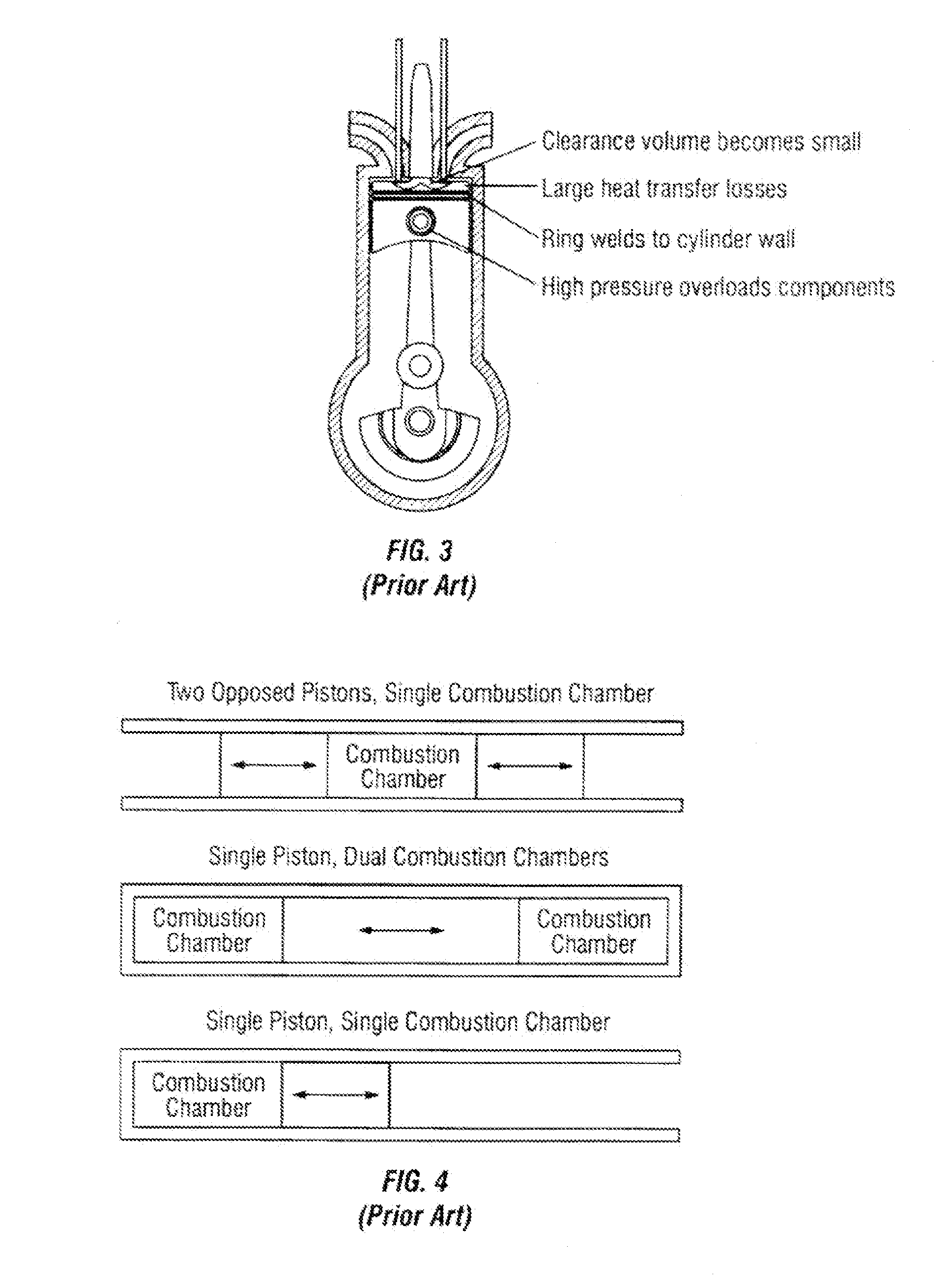

The expansion ratio of a liquefied and cryogenic substance is the volume of a given amount of that substance in liquid form compared to the volume of the same amount of substance in gaseous form, at room temperature and normal atmospheric pressure.

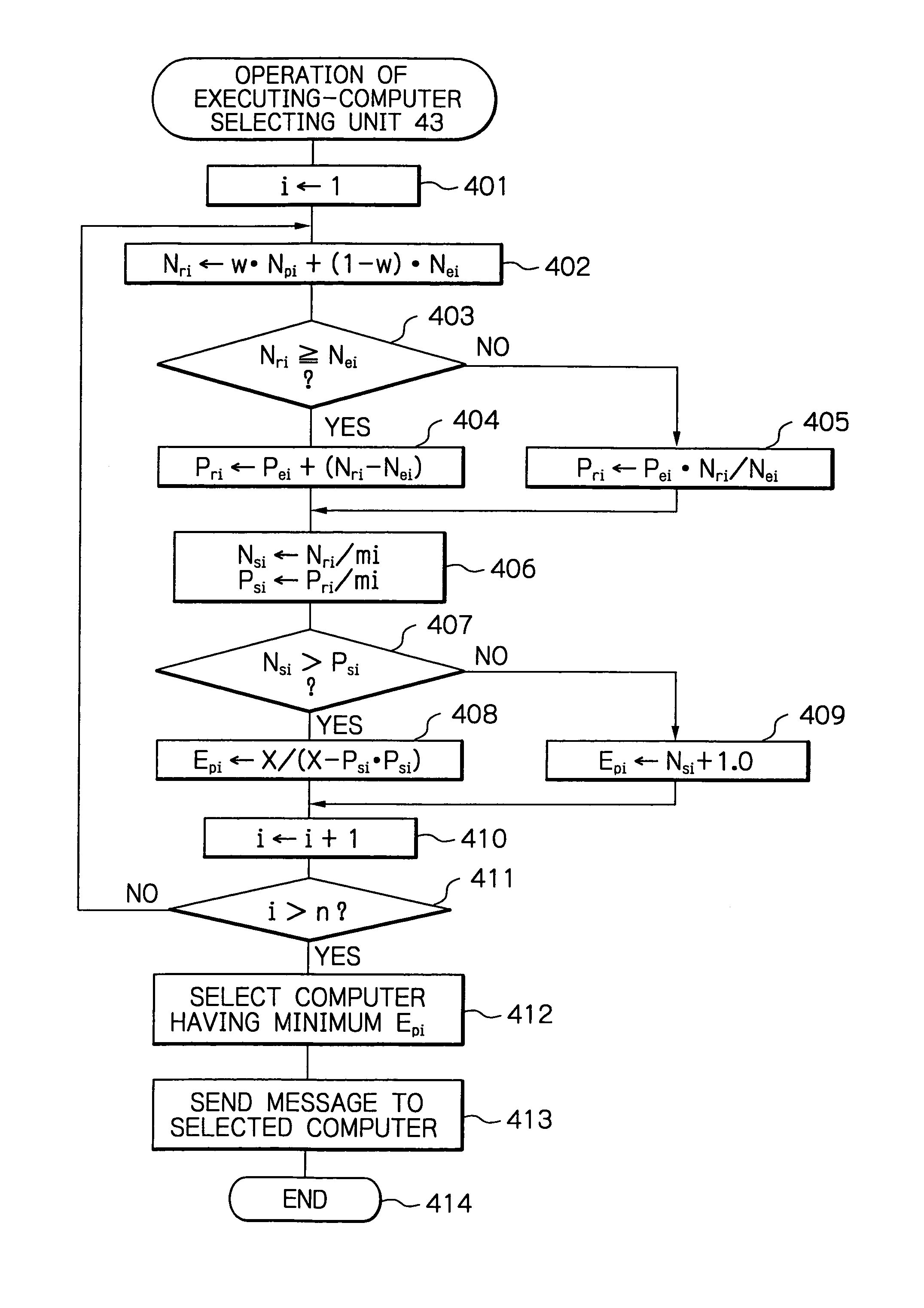

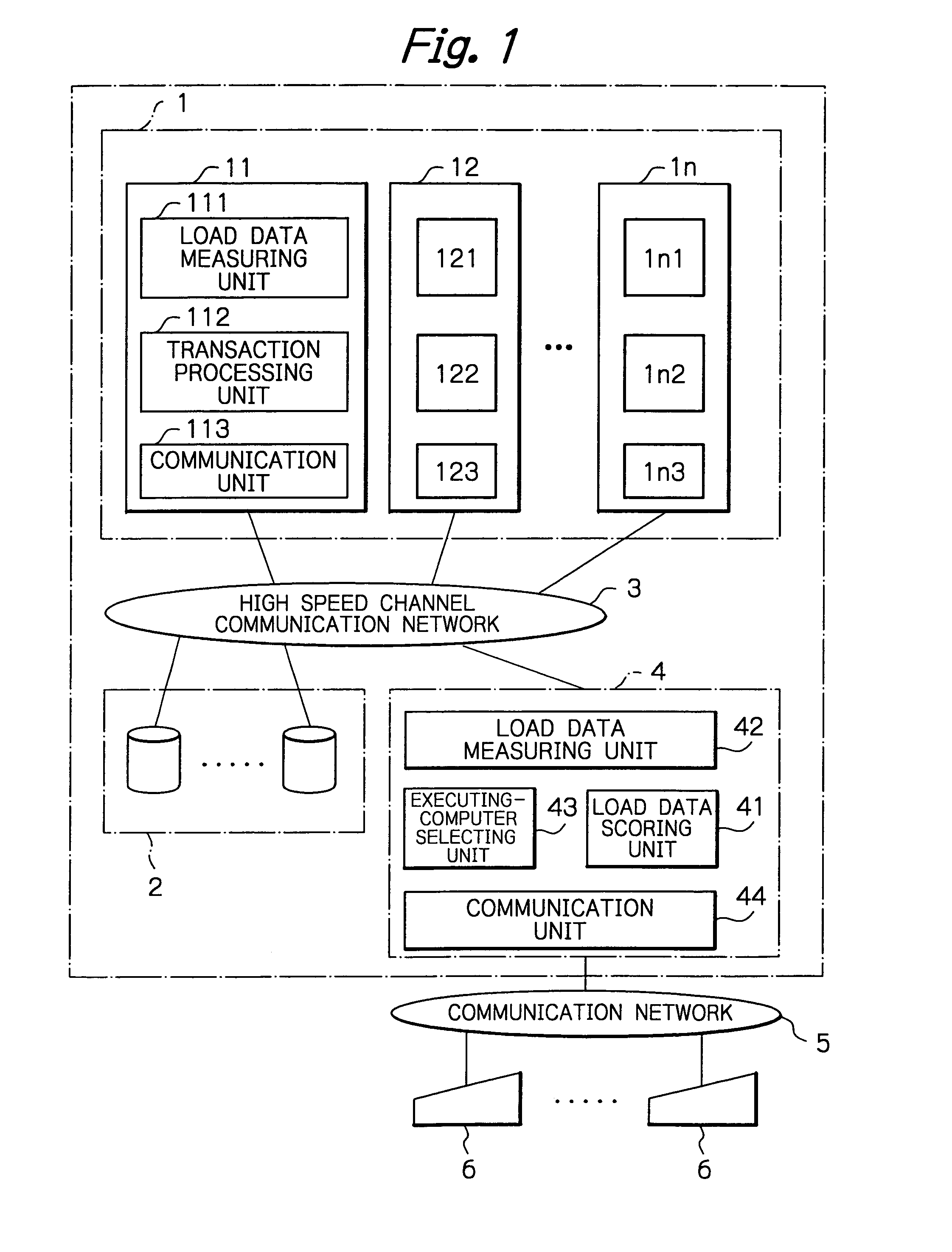

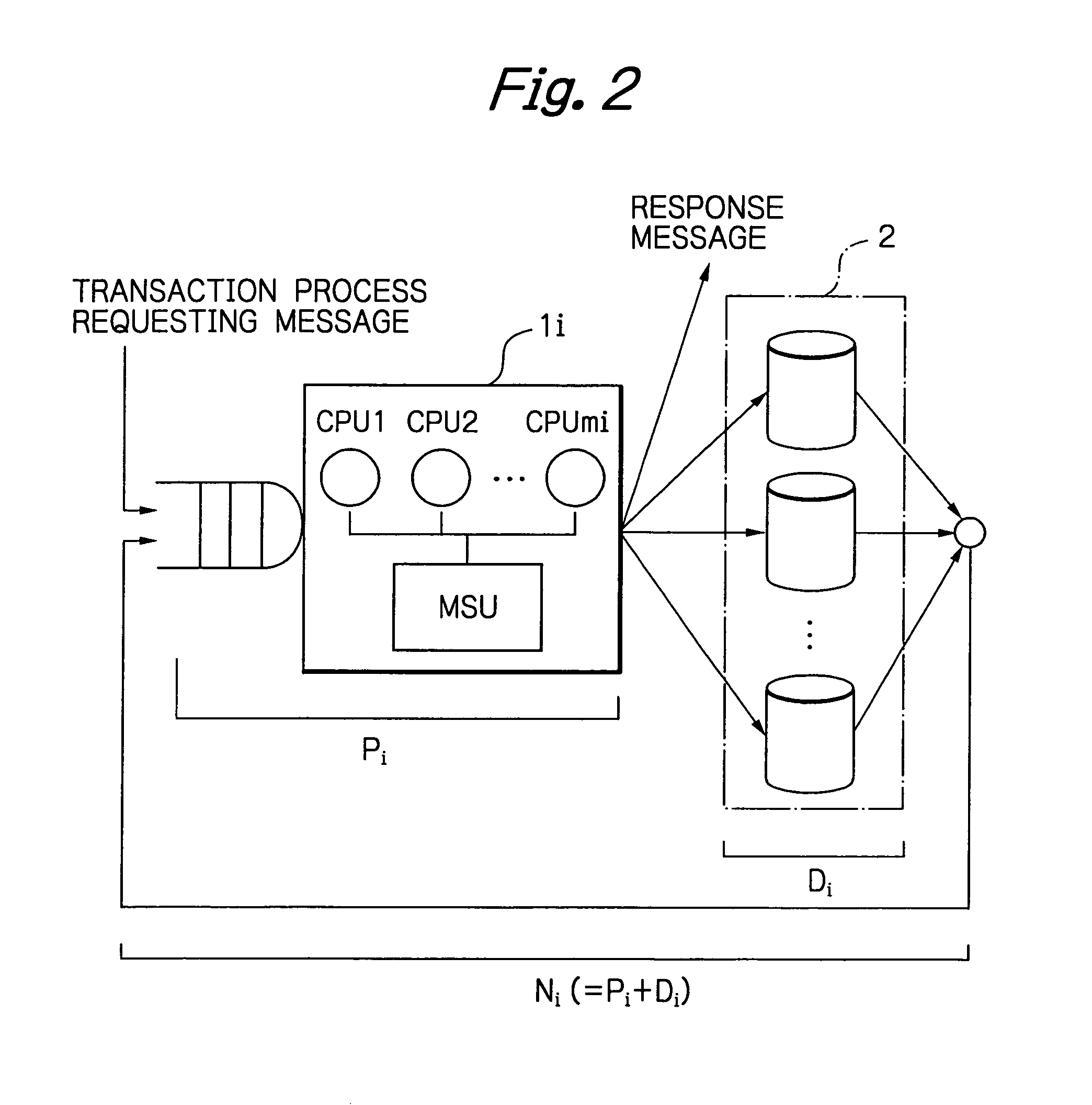

Dynamic load-distributed computer system using estimated expansion ratios and load-distributing method therefor

InactiveUS7062768B2Improve responsivenessResource allocationDigital computer detailsParallel computingSystem usage

In a method for distributing a transaction in a computer system including a plurality of computers each formed by processors, a plurality of estimated loads are calculated for the computers. Then, a plurality of estimated process time expansion ratios are calculated for the computers, in accordance with the estimated loads and the numbers of processors in the computers. Then, a plurality of load indexes one for each of the computers are calculated in accordance with the estimated process time expansion ratios. Finally, the transaction is distributed in accordance with the load indexes.

Owner:NEC CORP

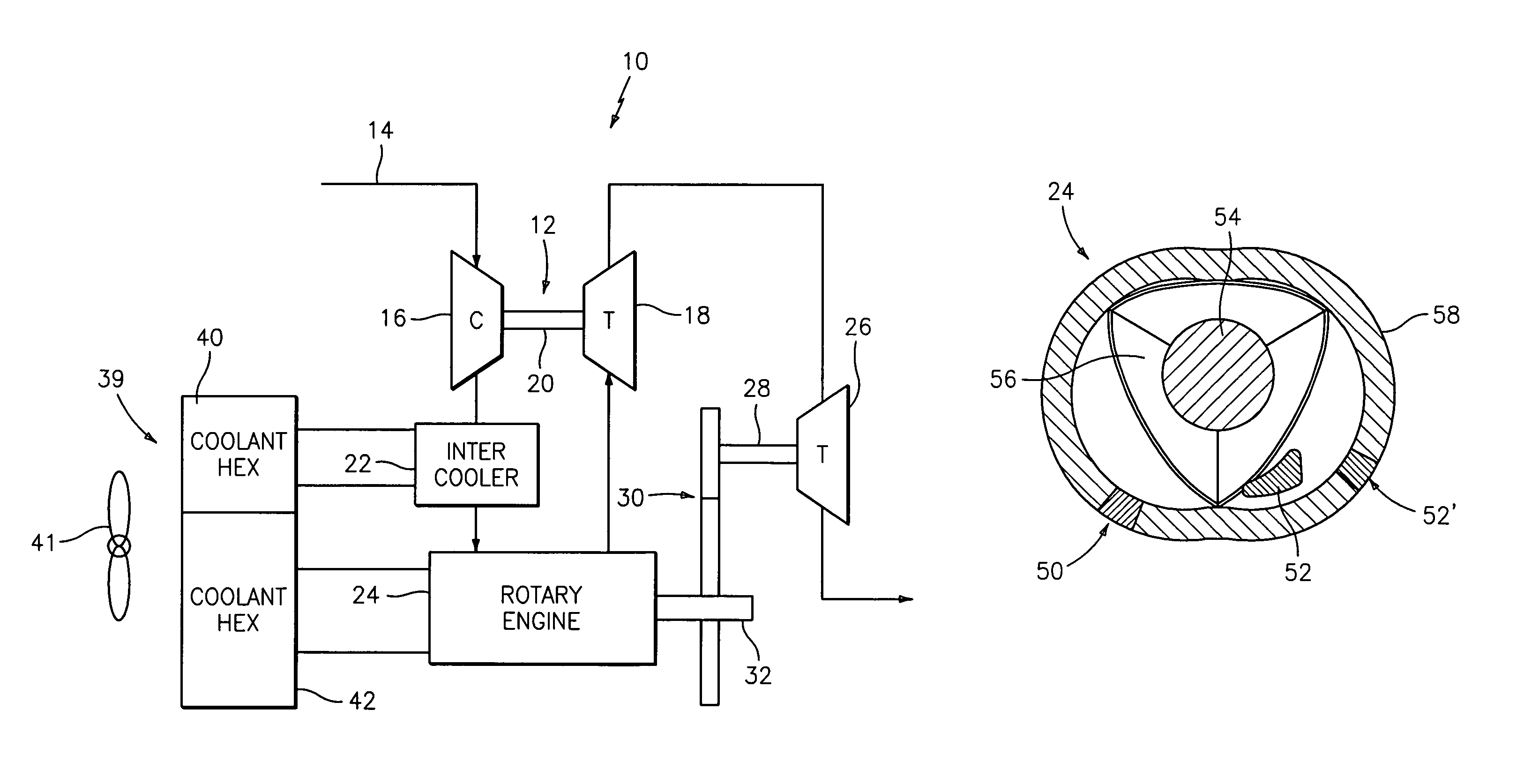

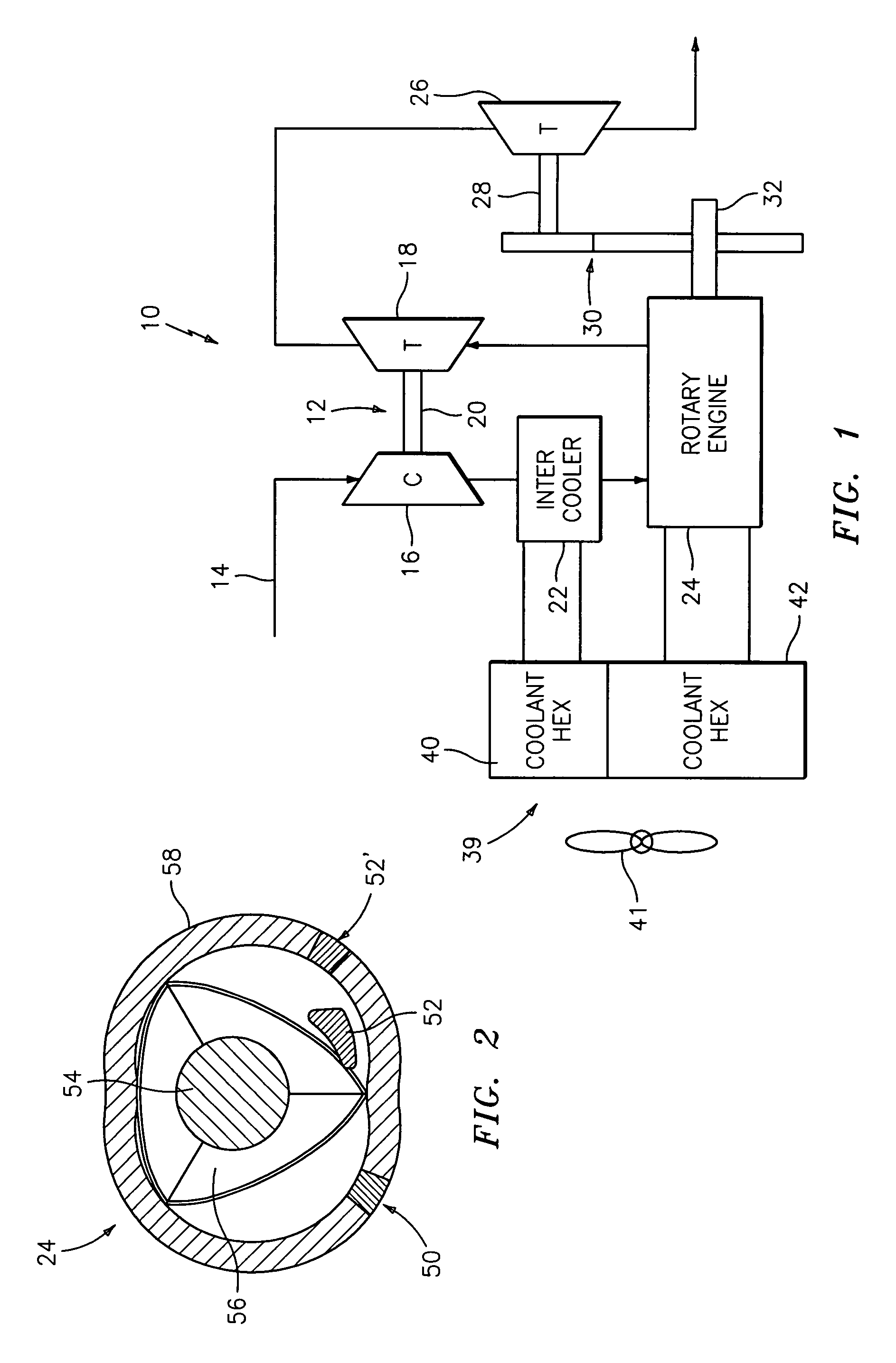

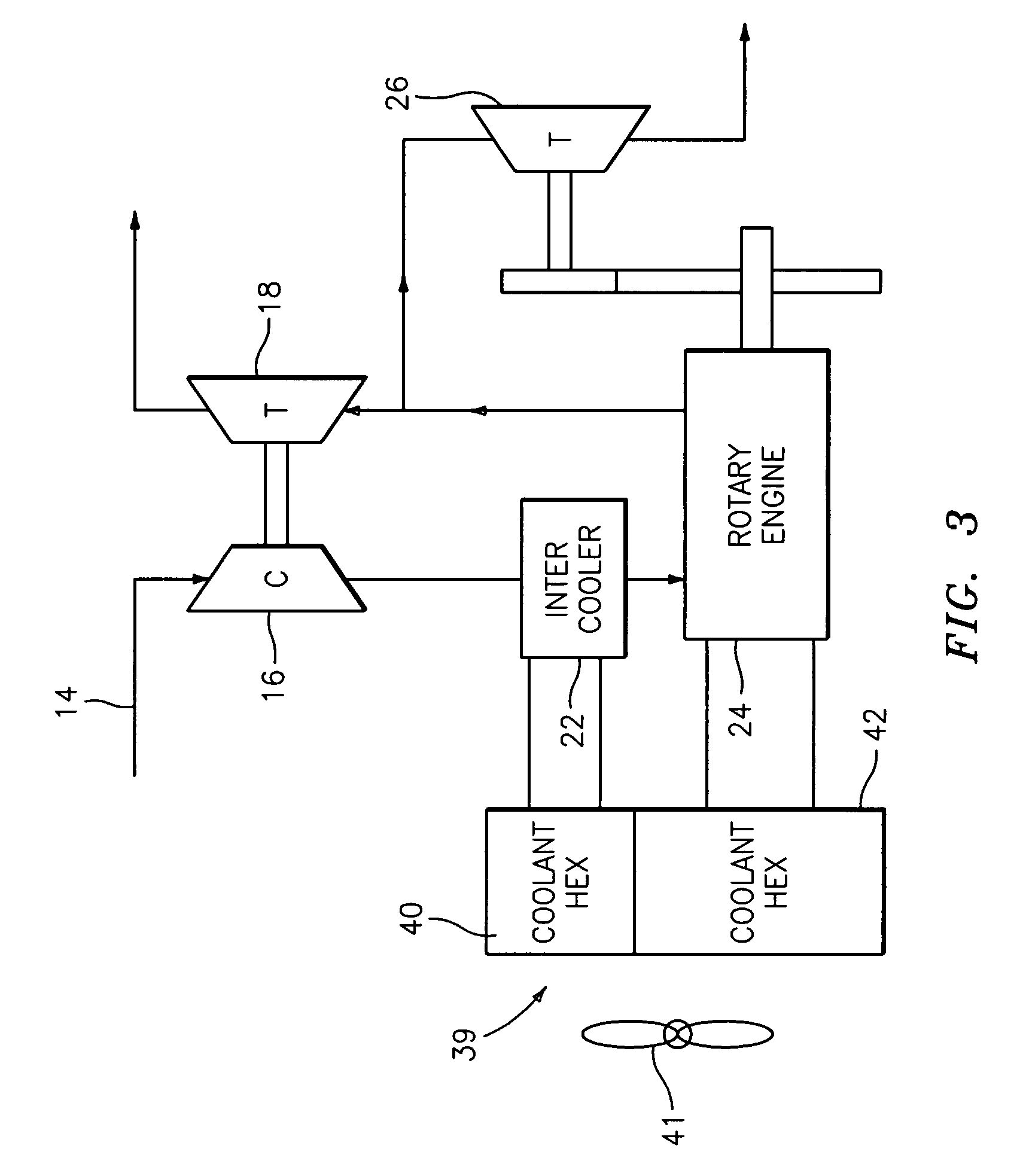

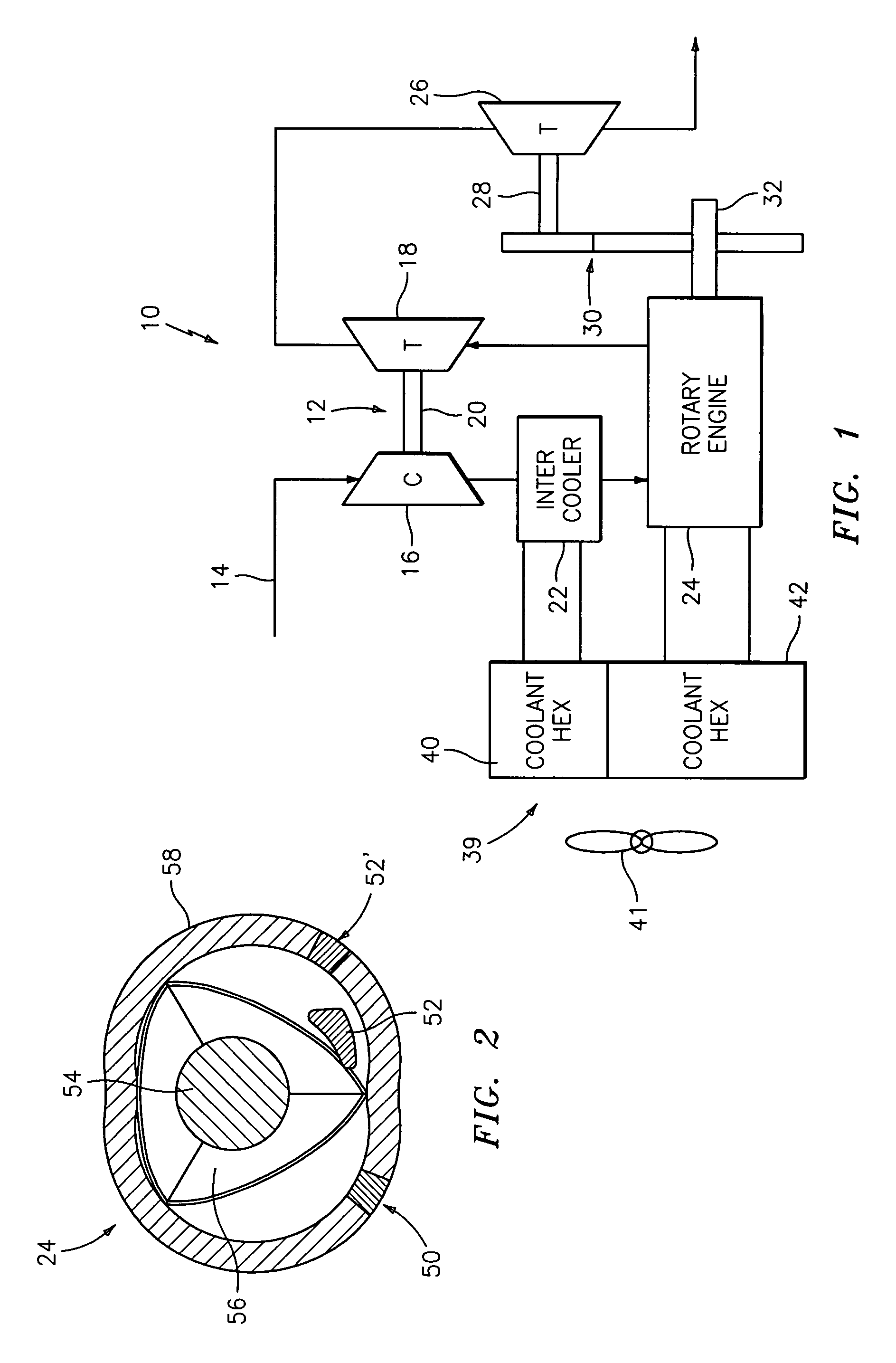

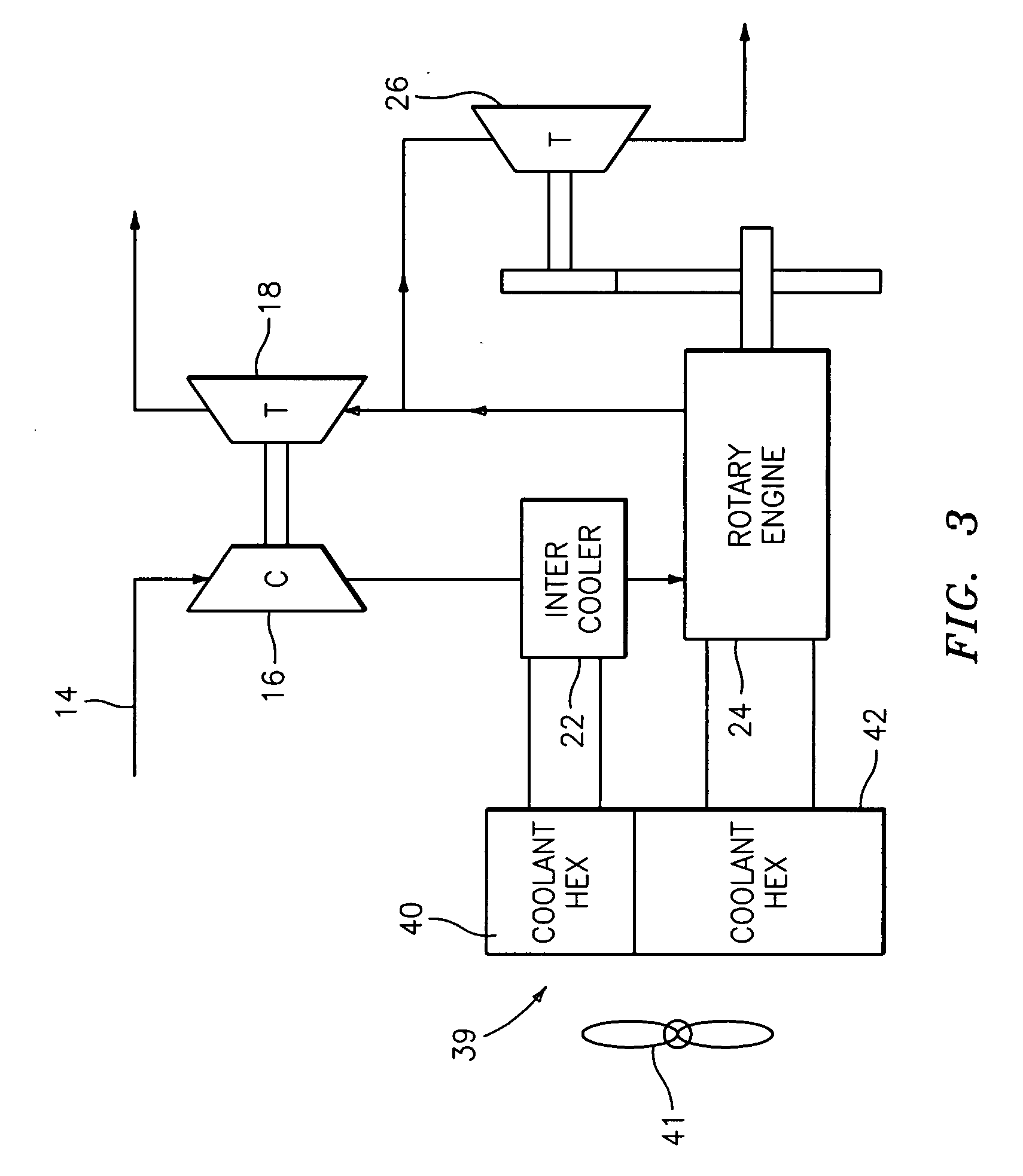

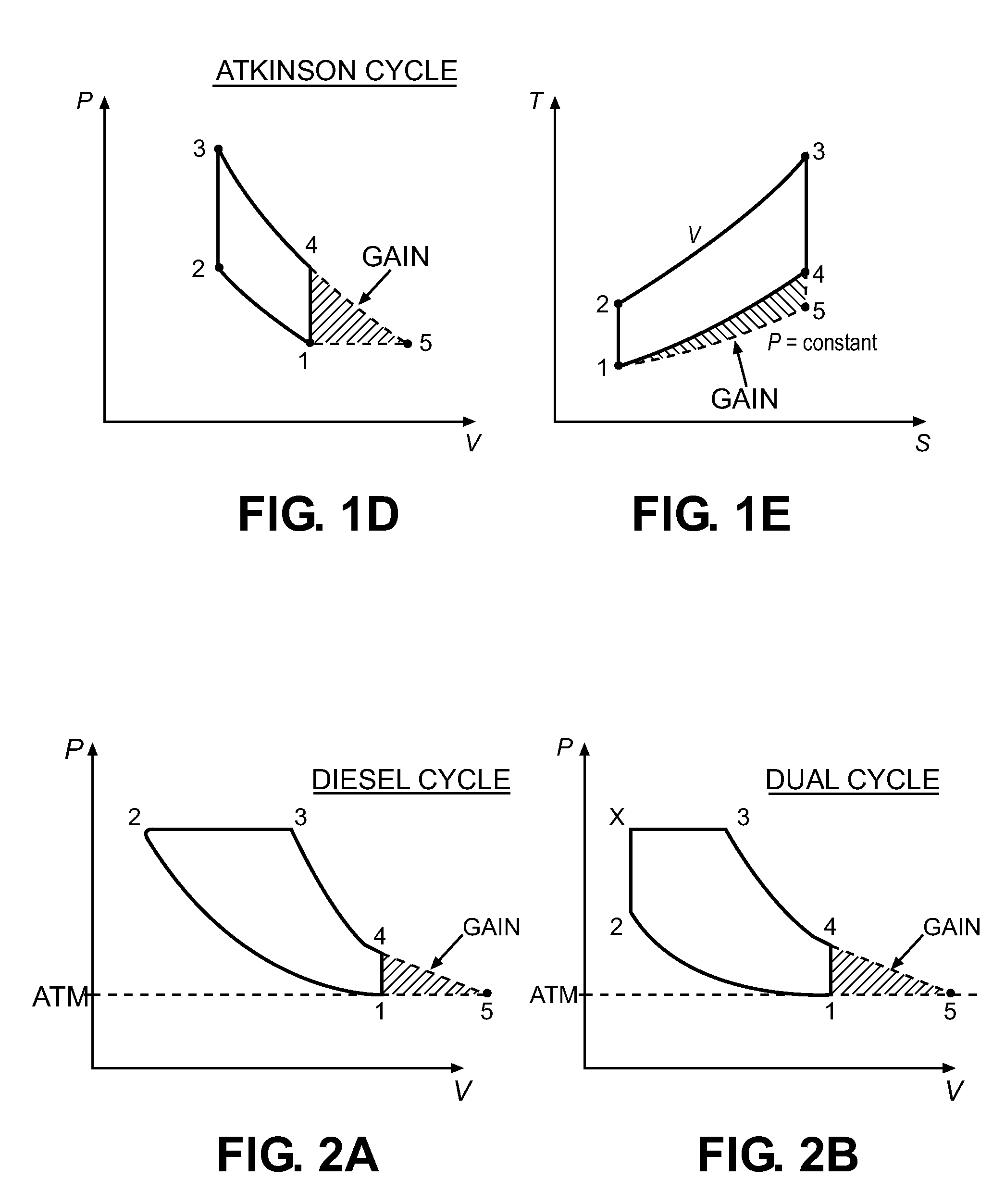

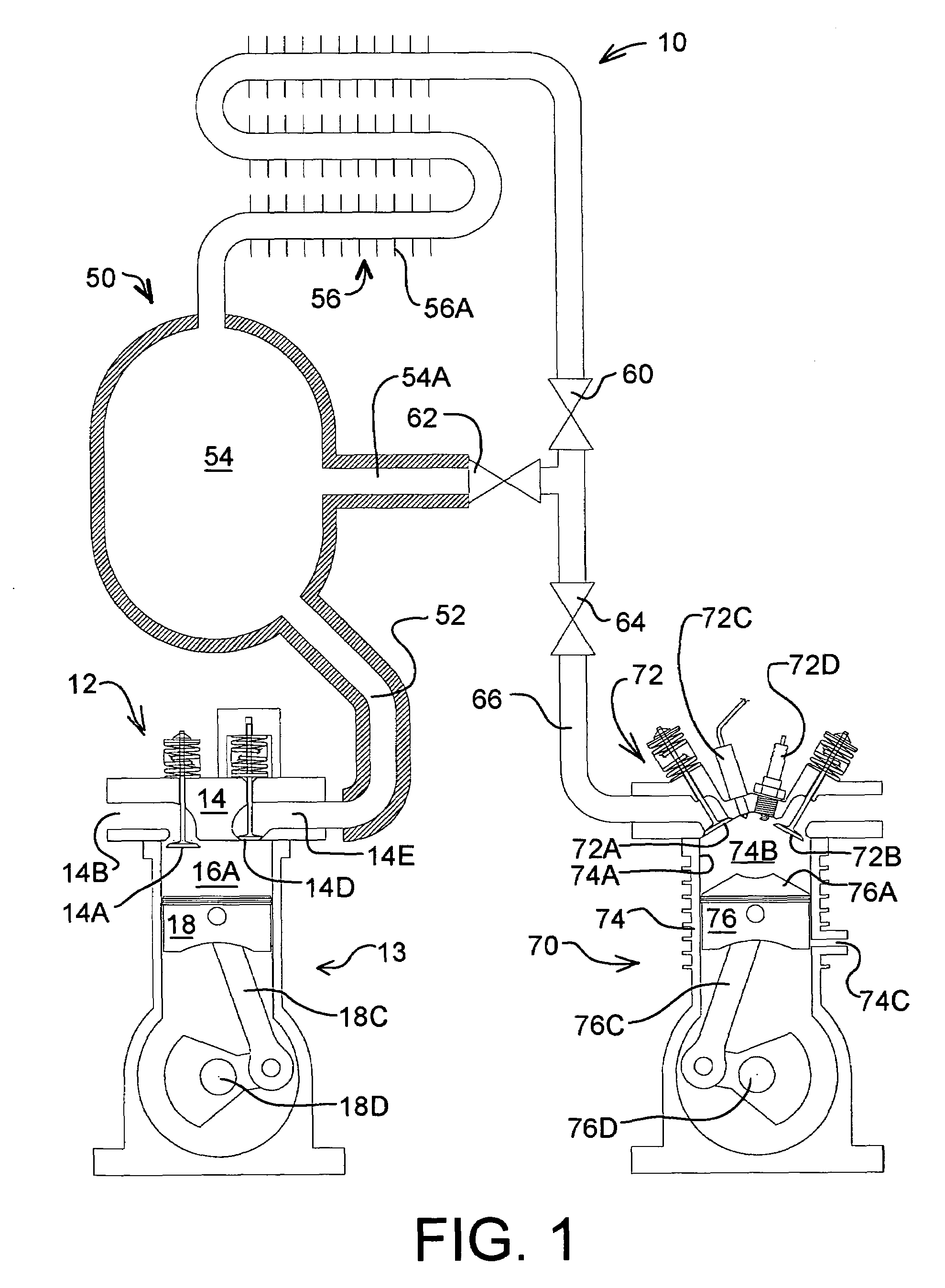

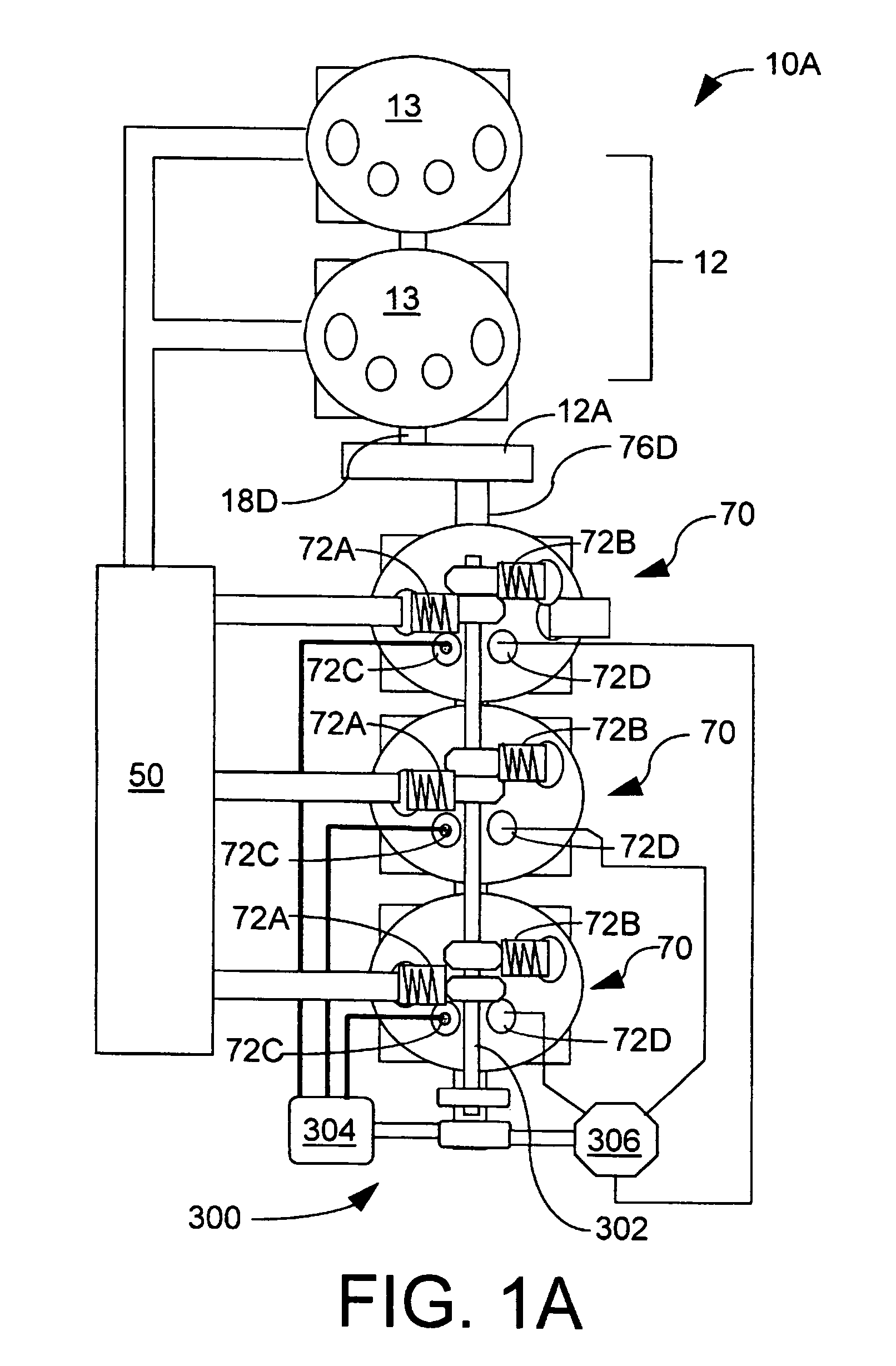

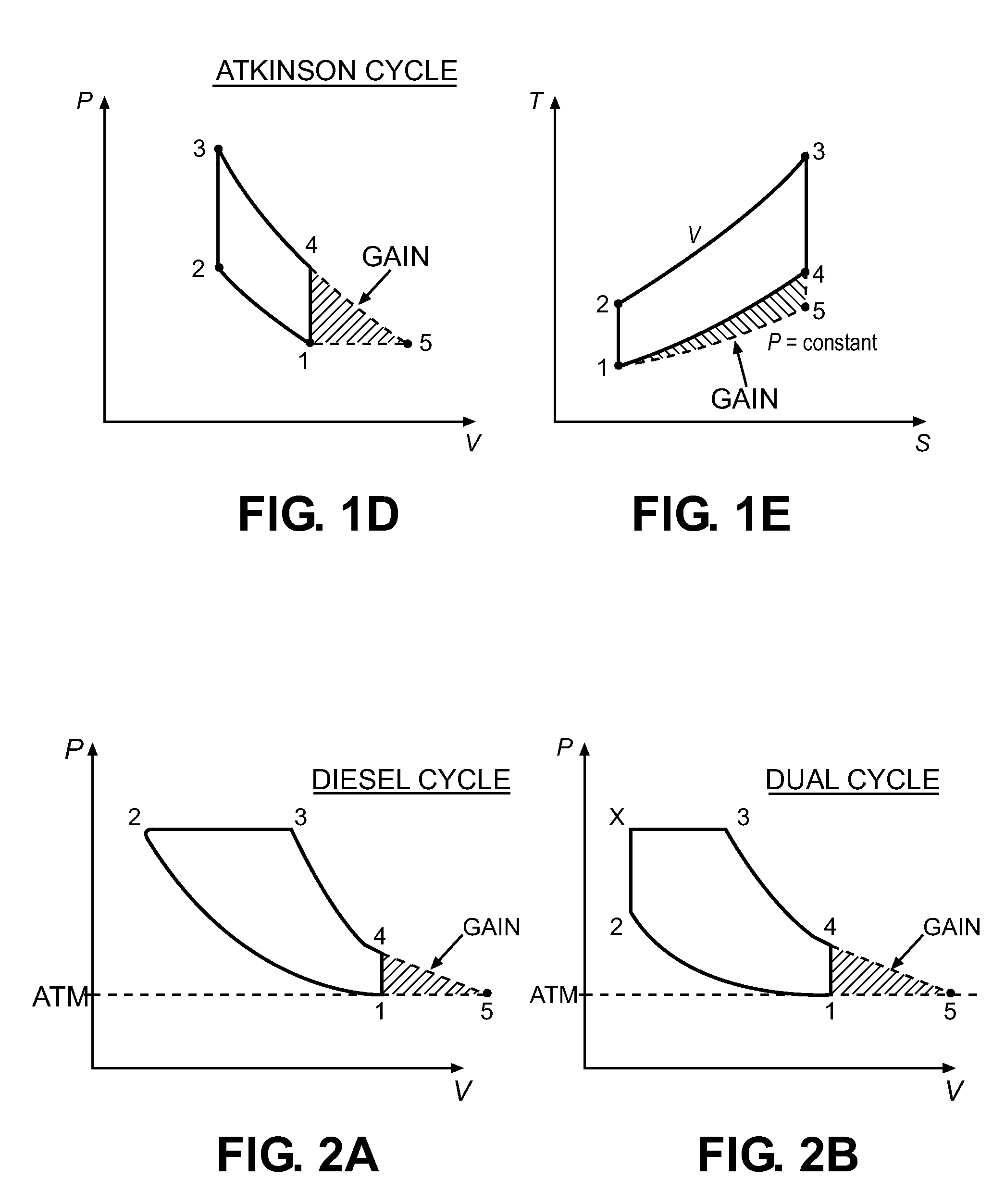

Compound cycle rotary engine

ActiveUS7753036B2High power to weightReduce fuel consumptionInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

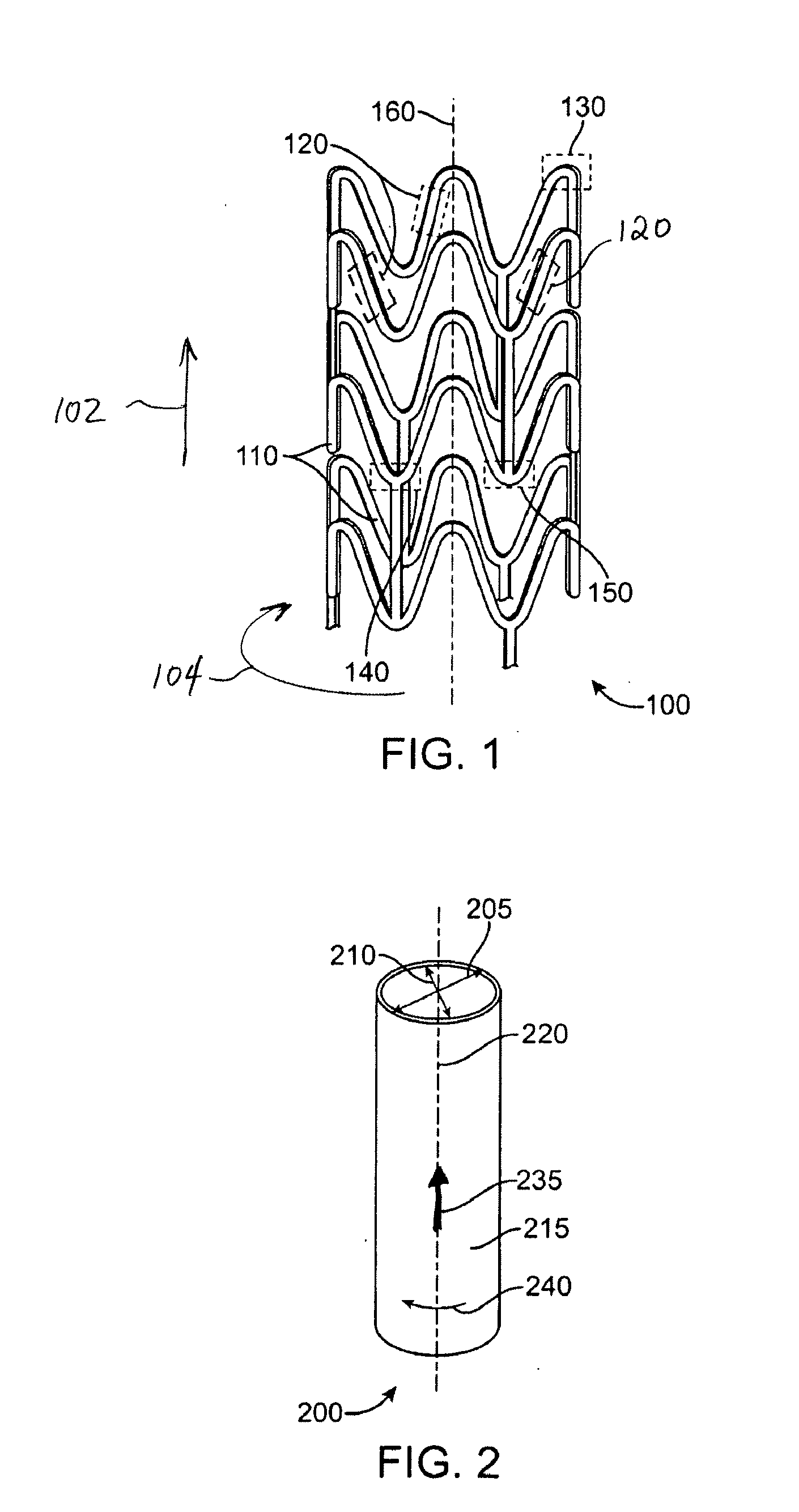

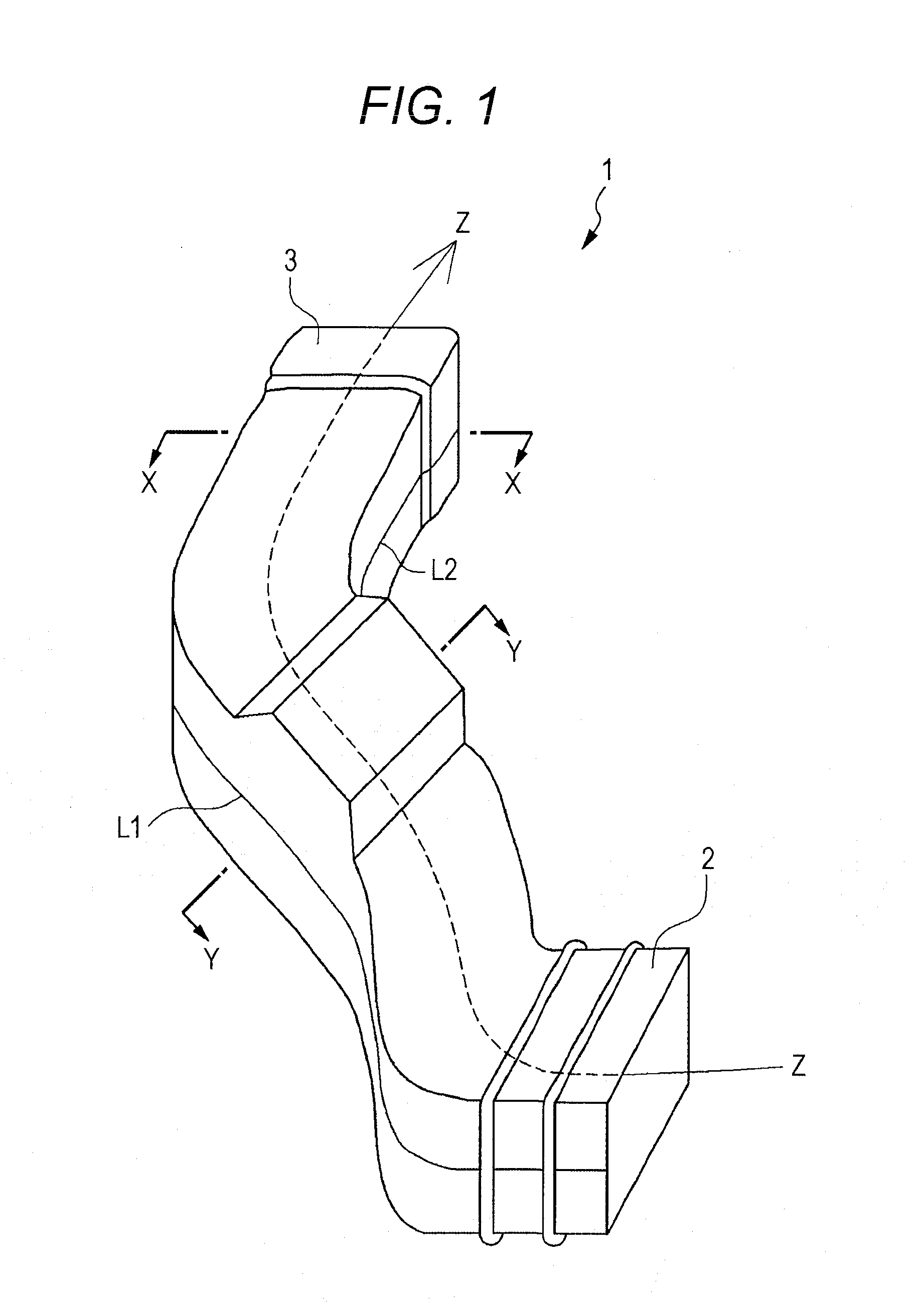

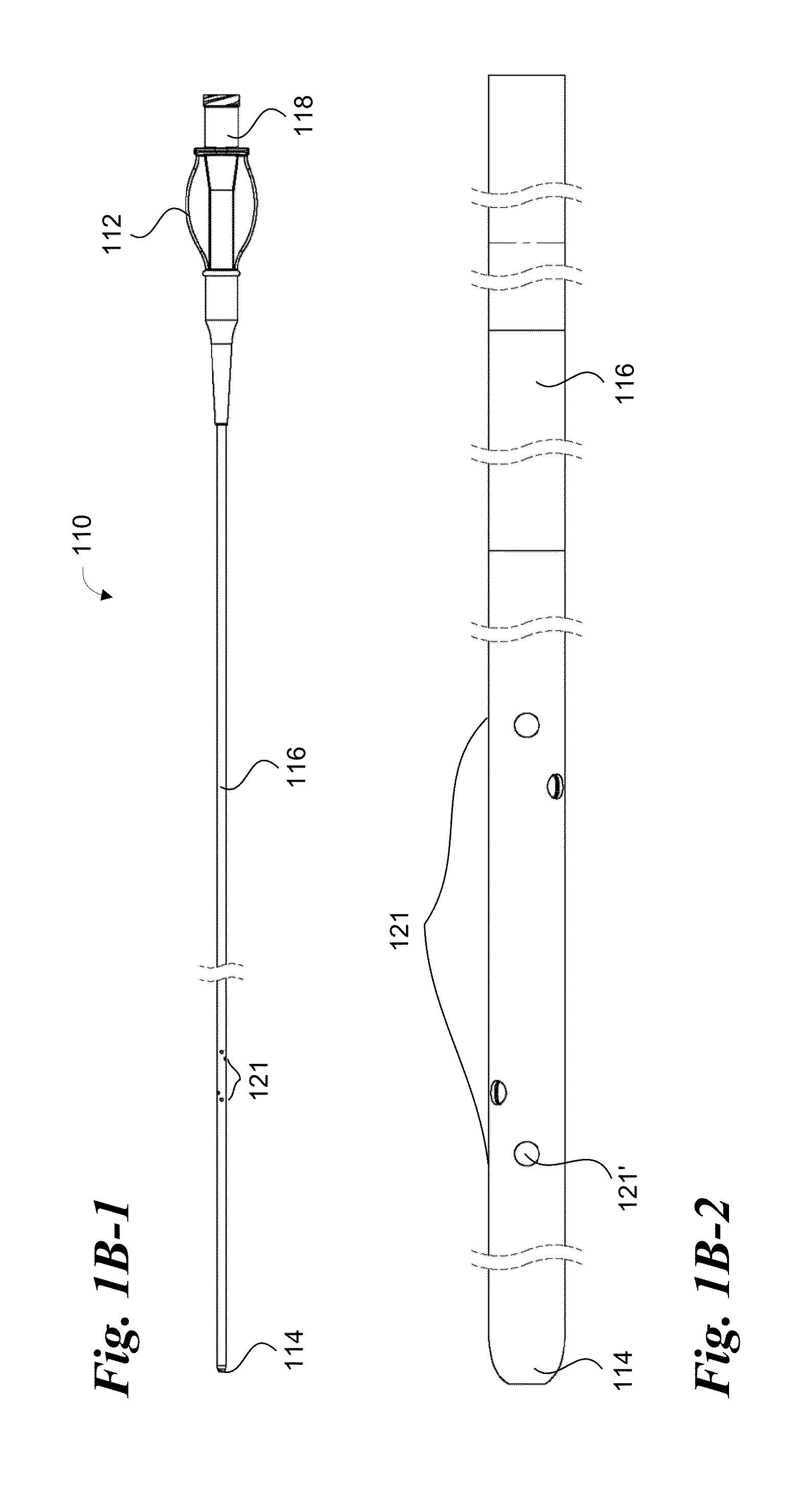

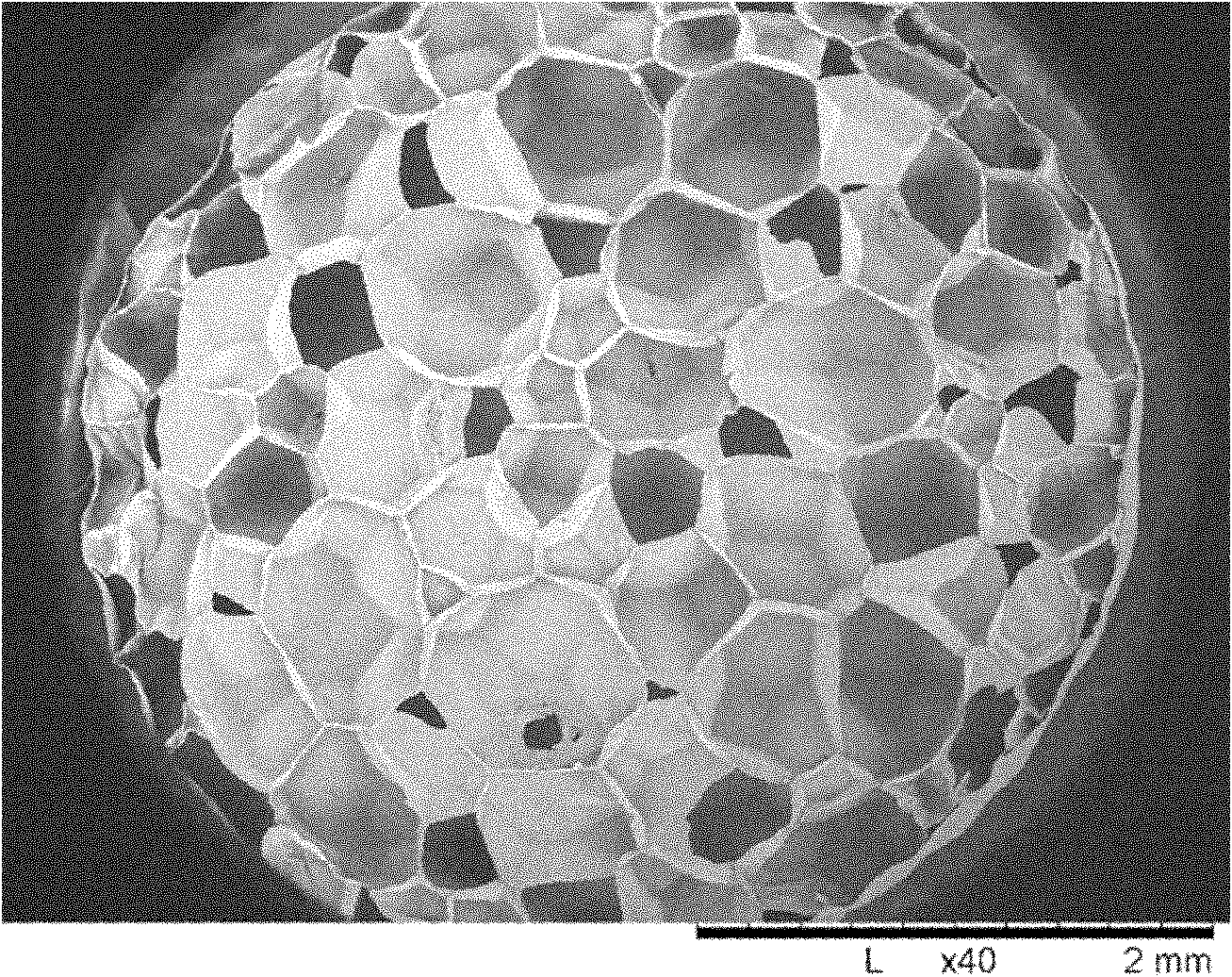

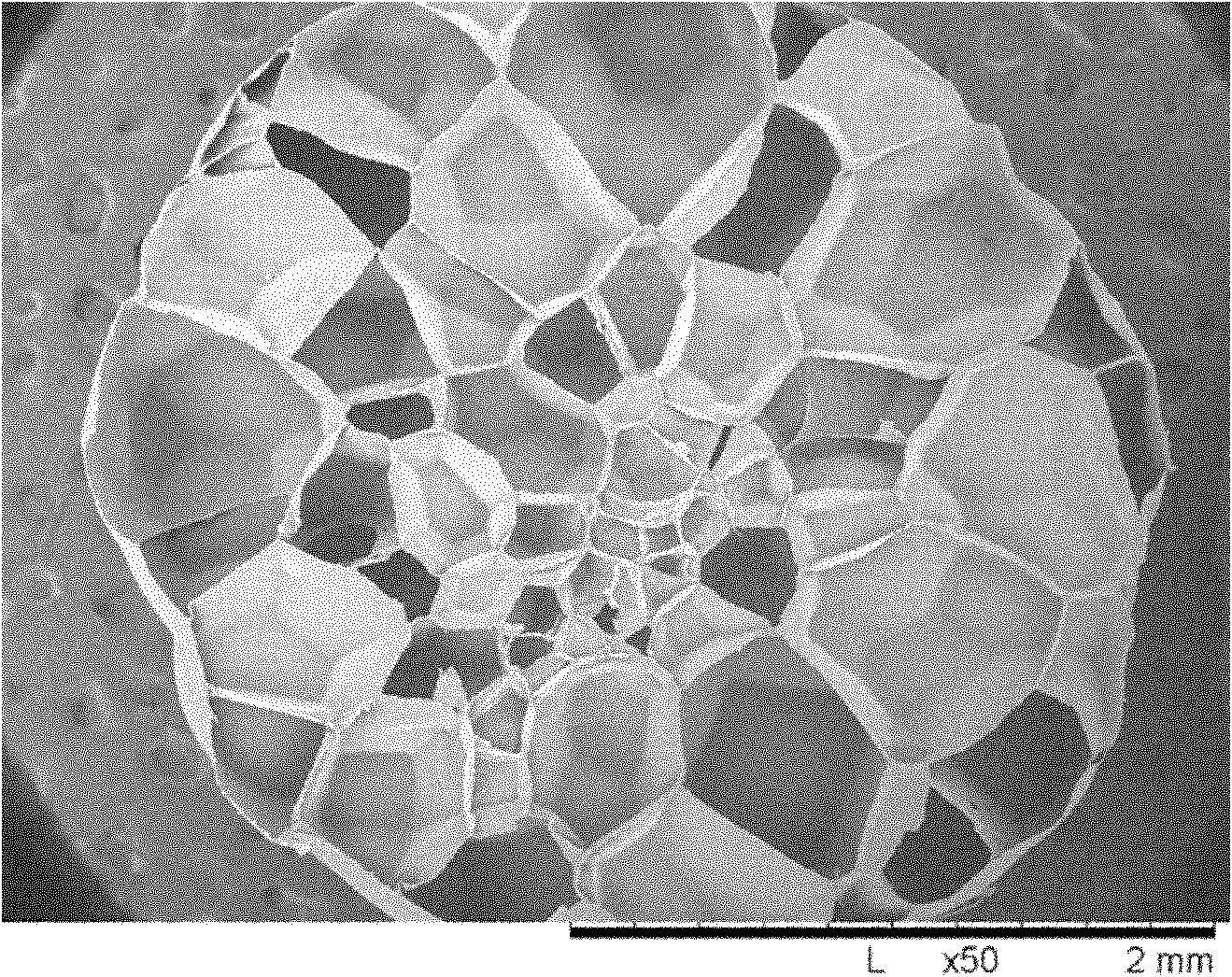

Polymeric Stent and Method of Making Same

A stent may be formed from a PLLA tubular polymer construct that is deformed in a blow mold. A desirable polymer morphology resulting in improved stent performance is obtained with a selected radial axial expansion ratio from about 20% to about 70%, a selected radial expansion ratio from about 400% to about 500%, a selected axial rate of deformation propagation at or about 0.3 mm / minute, a selected expansion pressure at or about 130 psi, and a selected expansion temperature that does not exceed 200 deg F. The tubular polymer construct may also be made of PLGA, PLLA-co-PDLA, PLLD / PDLA stereocomplex, and PLLA-based polyester block copolymer containing a rigid segment of PLLA or PLGA and a soft segment of PCL or PTMC.

Owner:ABBOTT CARDIOVASCULAR

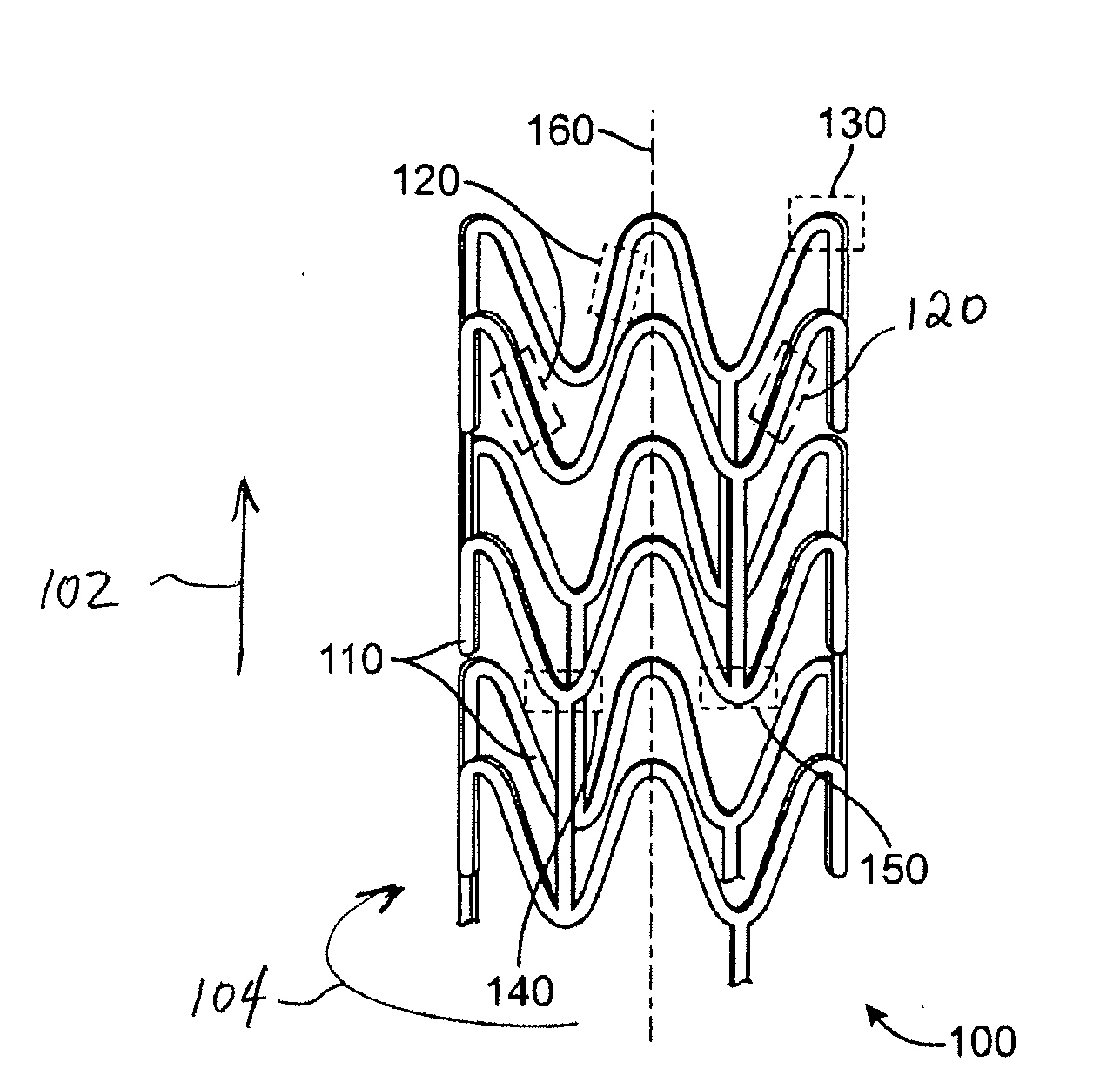

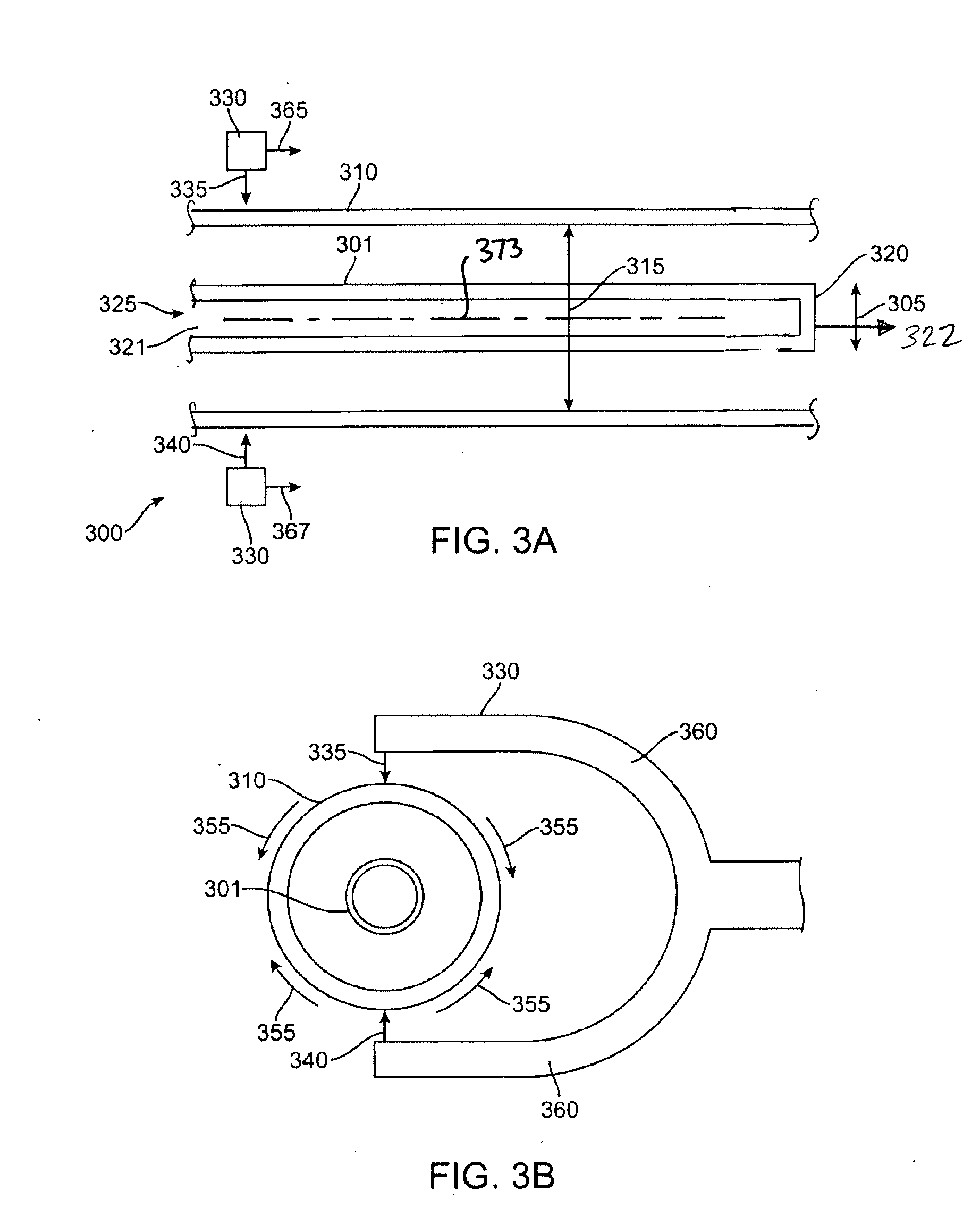

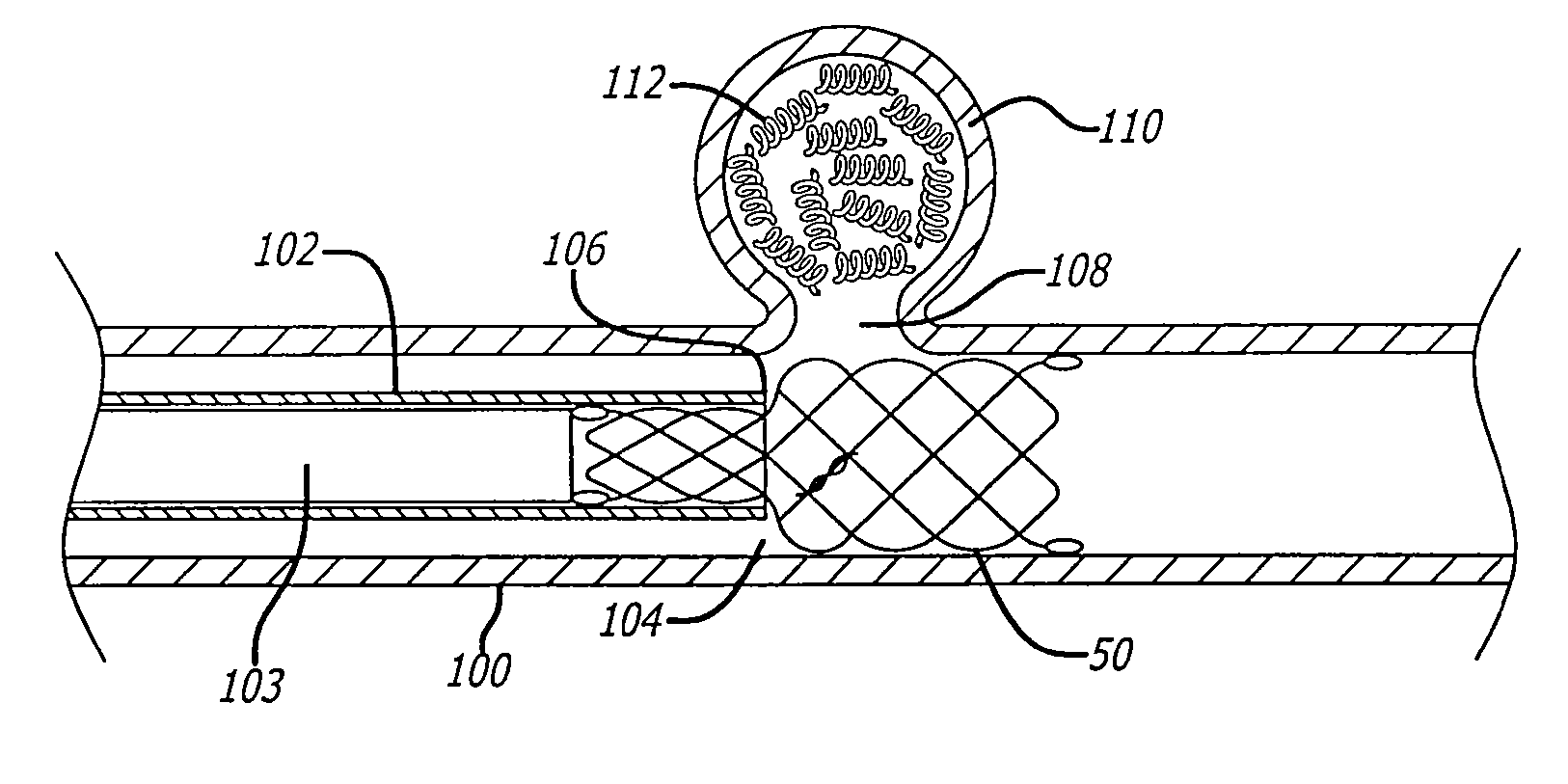

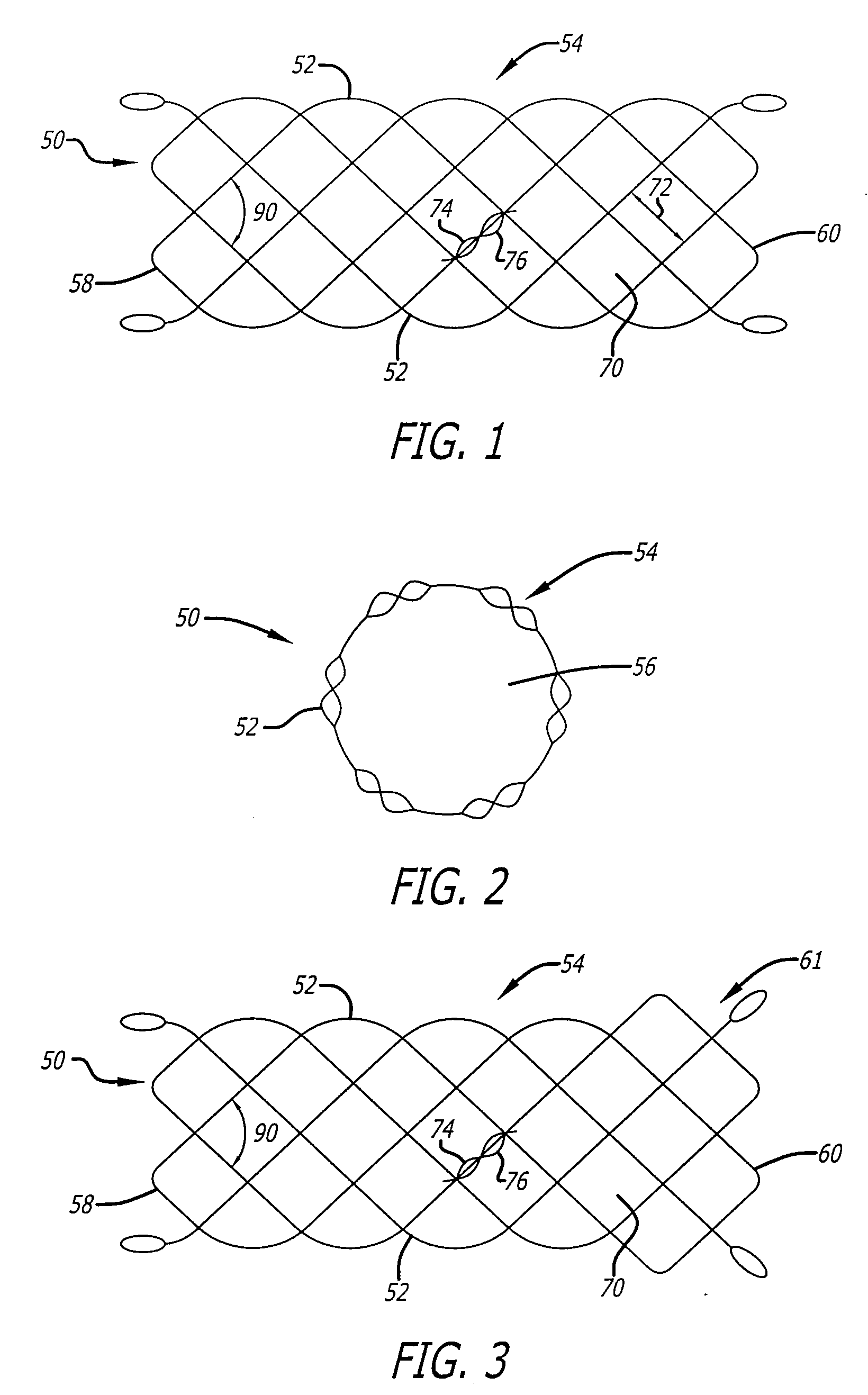

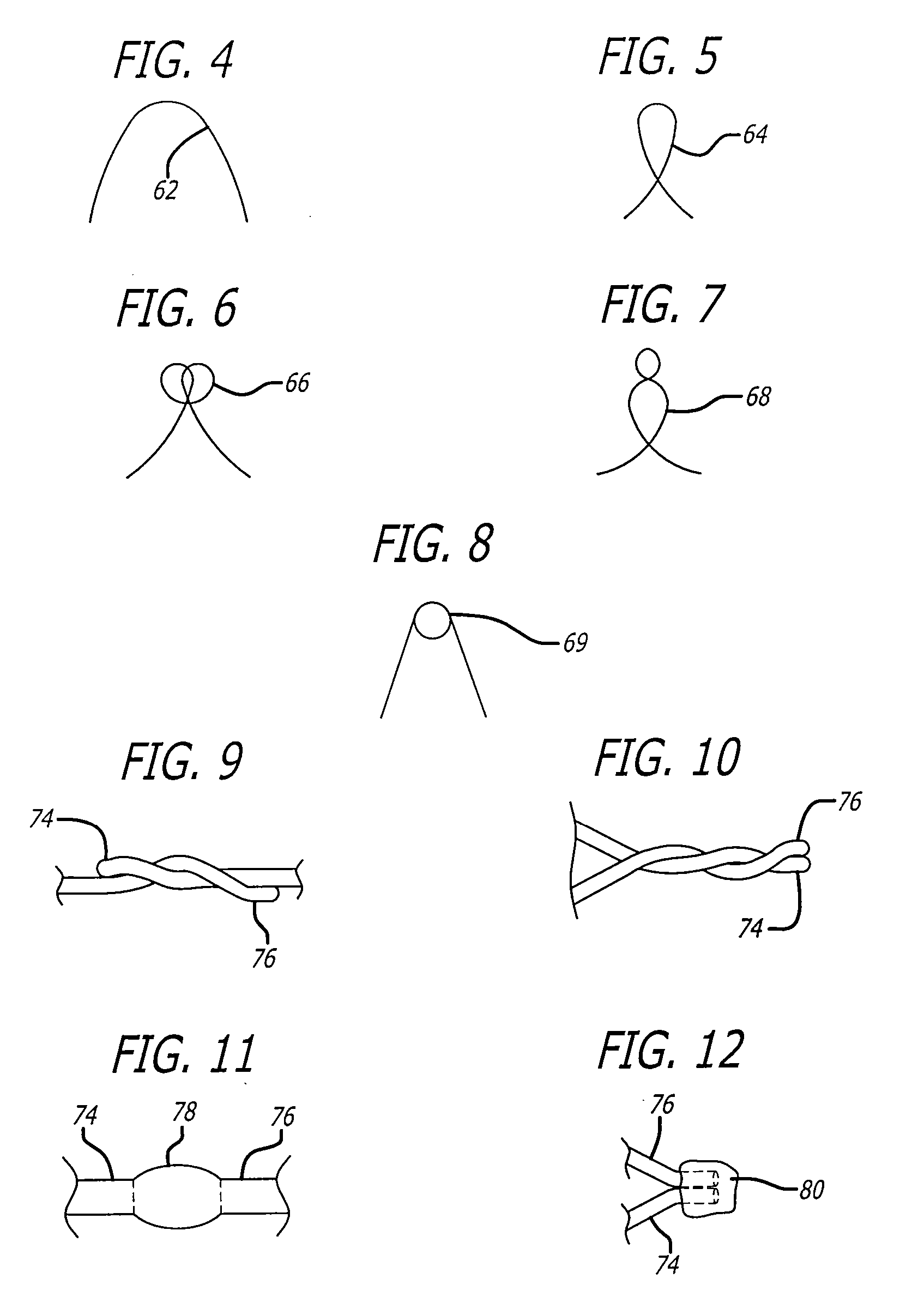

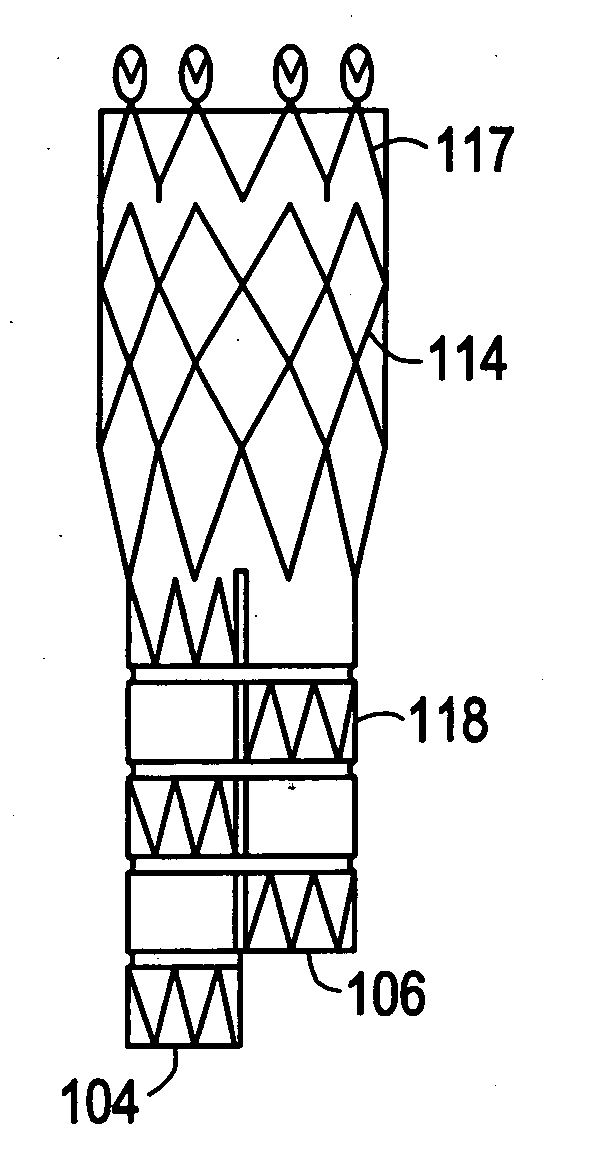

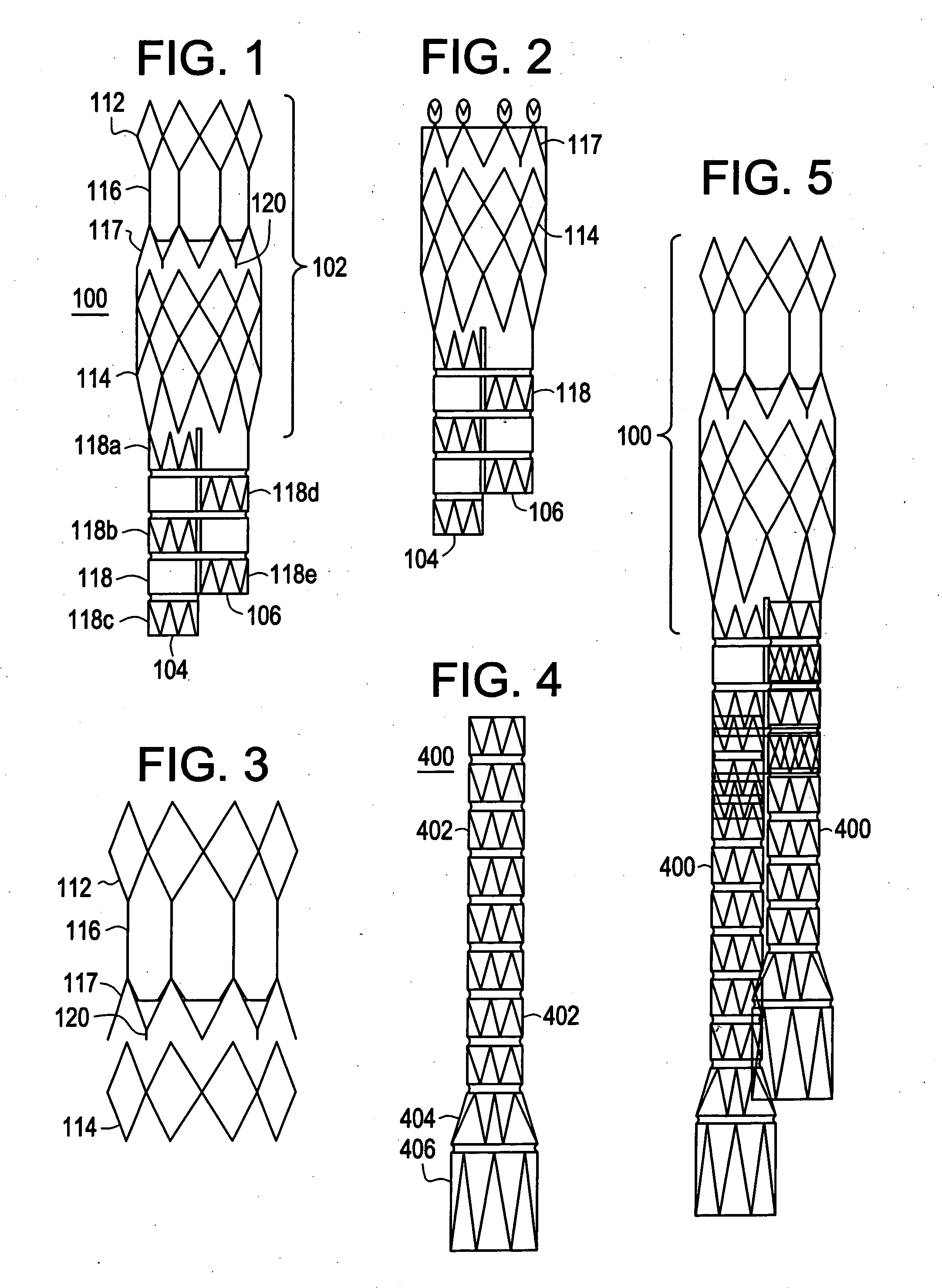

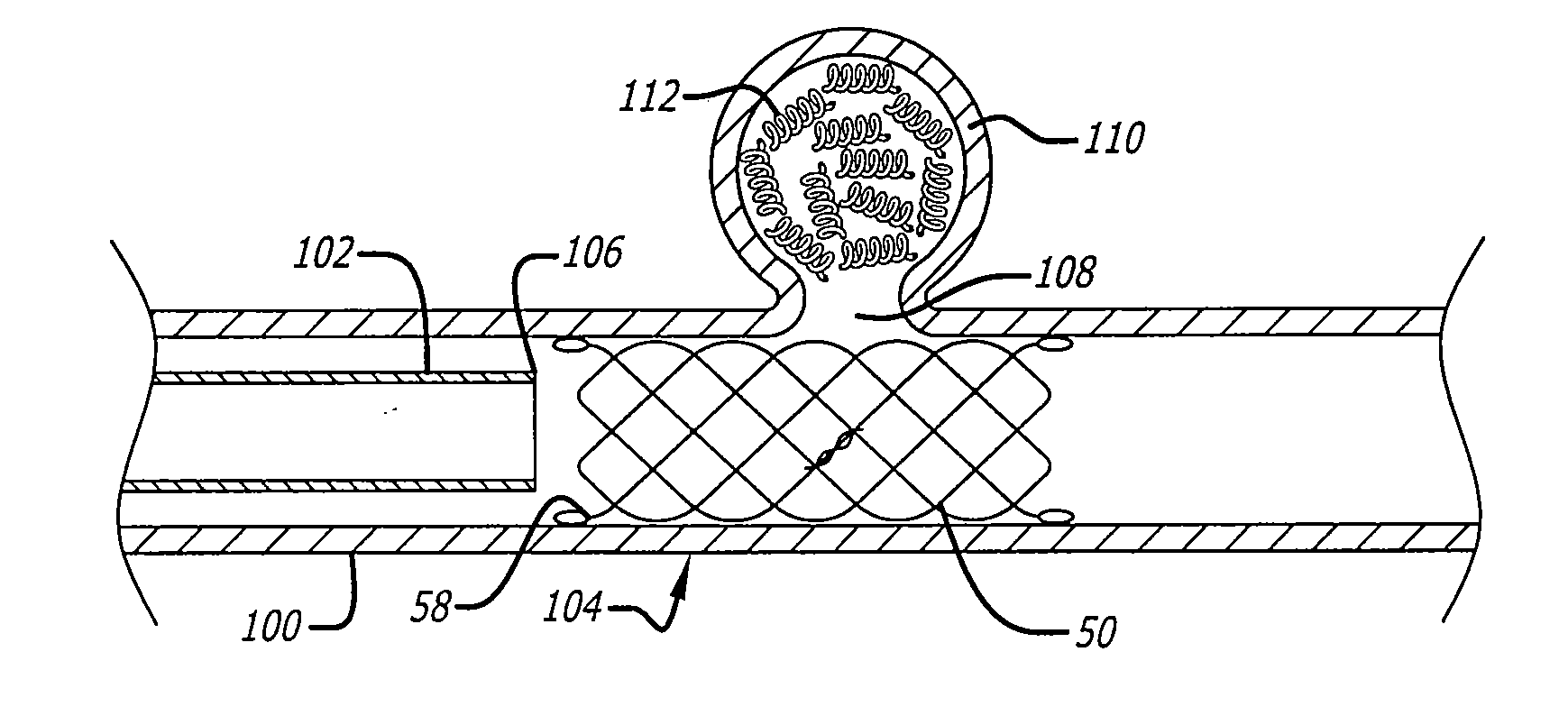

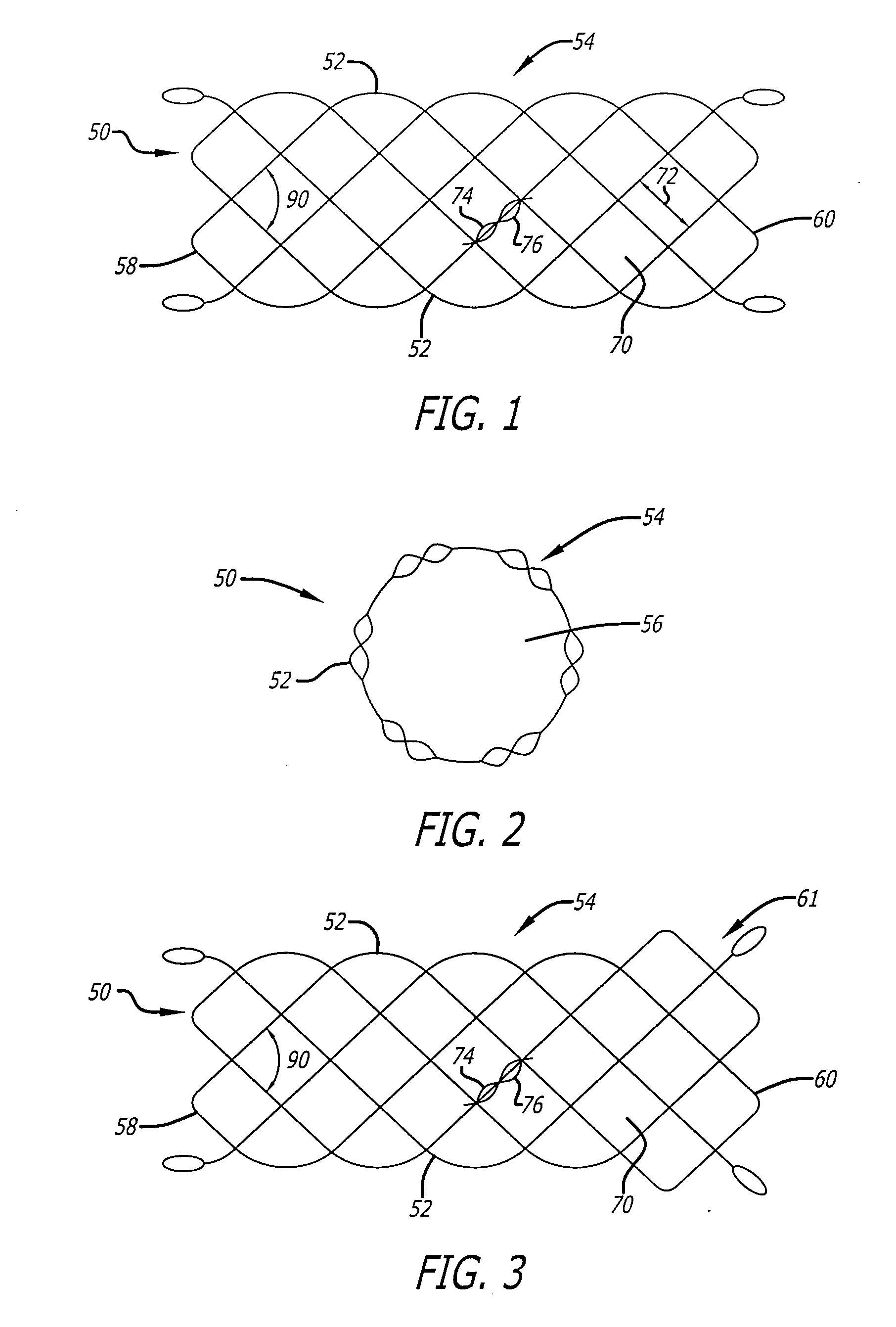

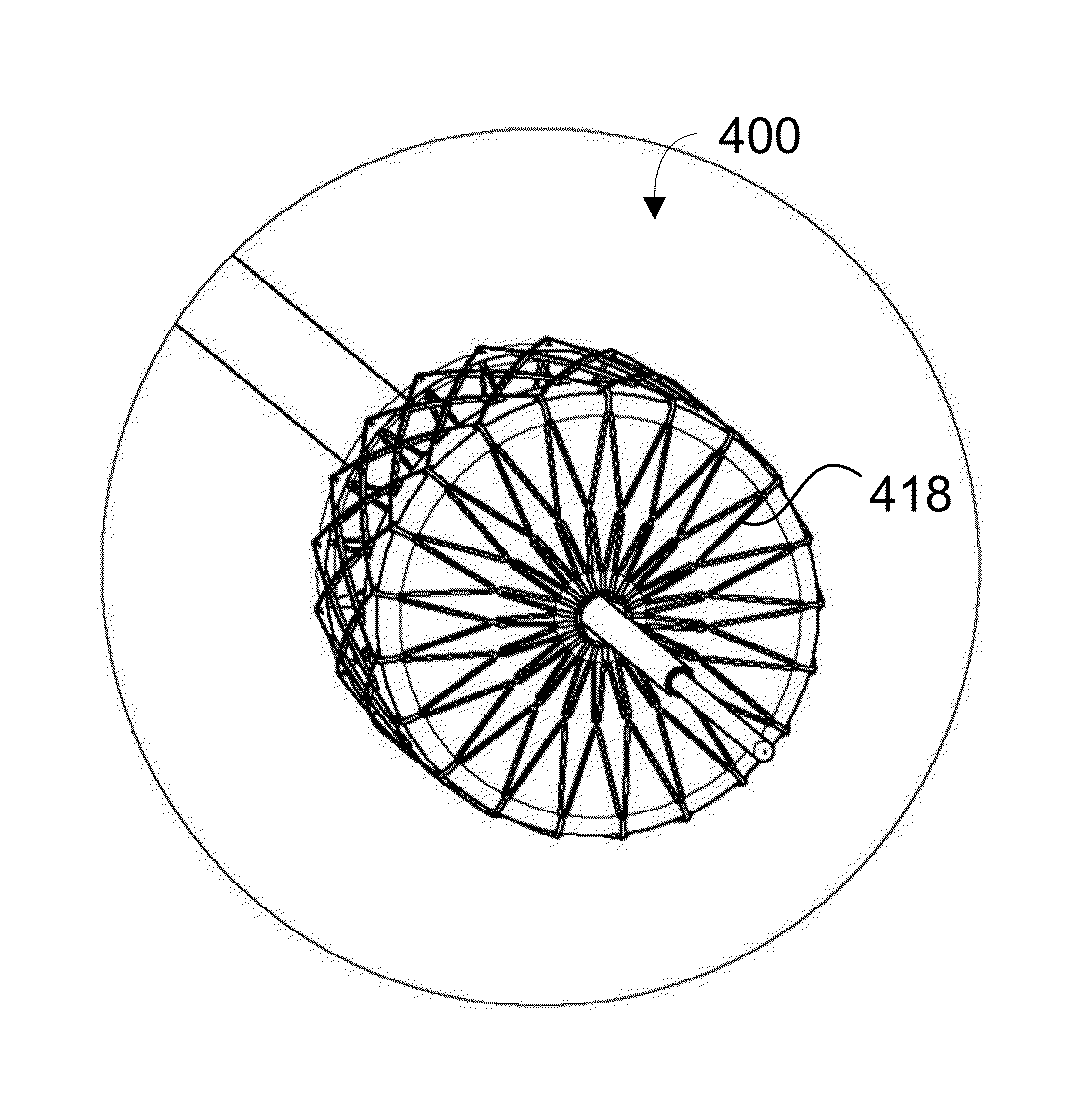

Self-expanding, pseudo-braided intravascular device

InactiveUS20080109063A1Large expansion ratioIncrease flexibilityStentsHand lacing/braidingThrombusTubular stenosis

A self-expanding, pseudo-braided device embodying a high expansion ratio and flexibility as well as comformability and improved radial force. The pseudo-braided device is particularly suited for advancement through and deployment within highly tortuous and very distal vasculature. Various forms of the pseudo-braided device are adapted for the repair of aneurysms and stenoses as well as for use in thrombectomies and embolic protection therapy.

Owner:ENDOVASCULAR TECH

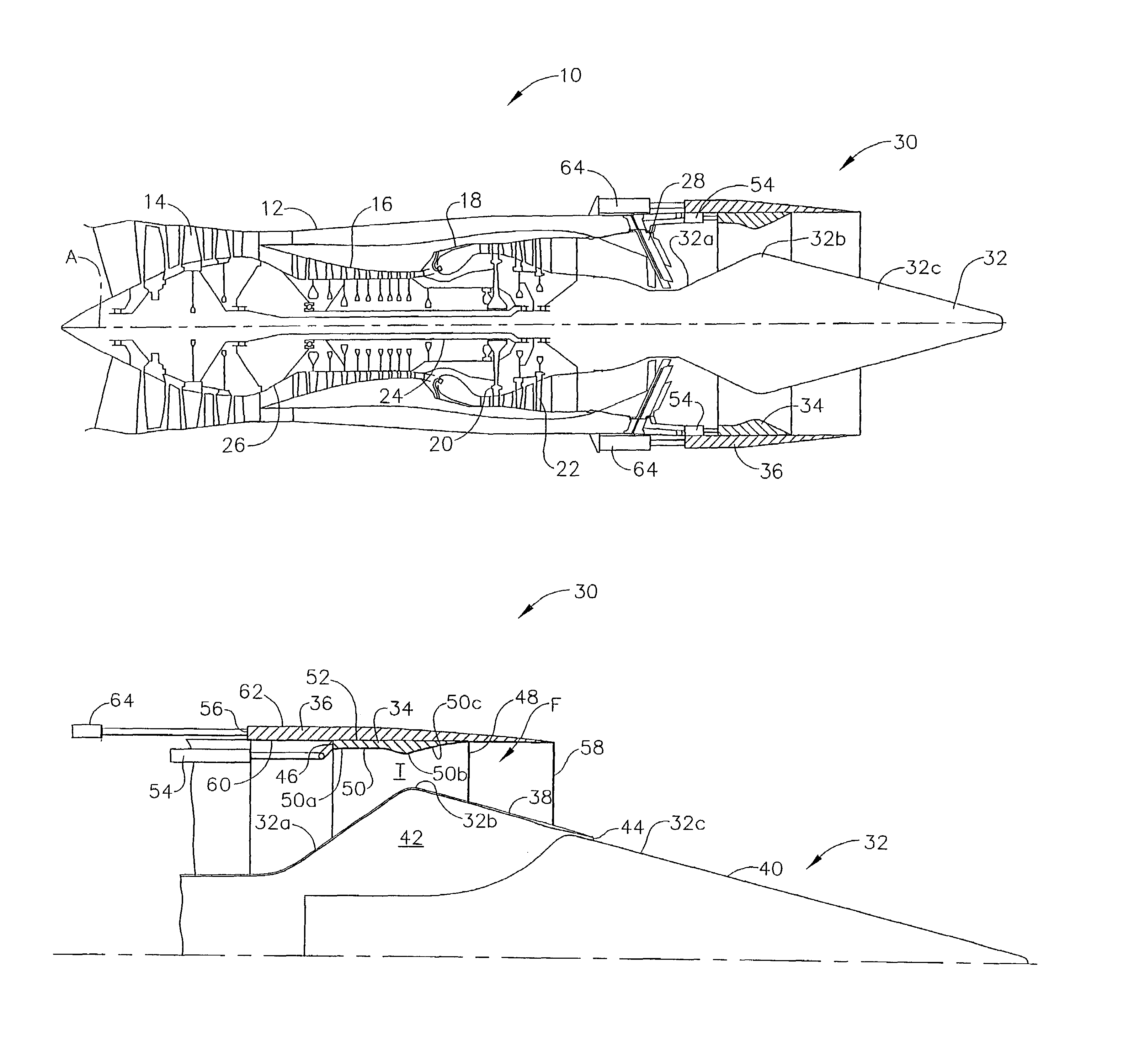

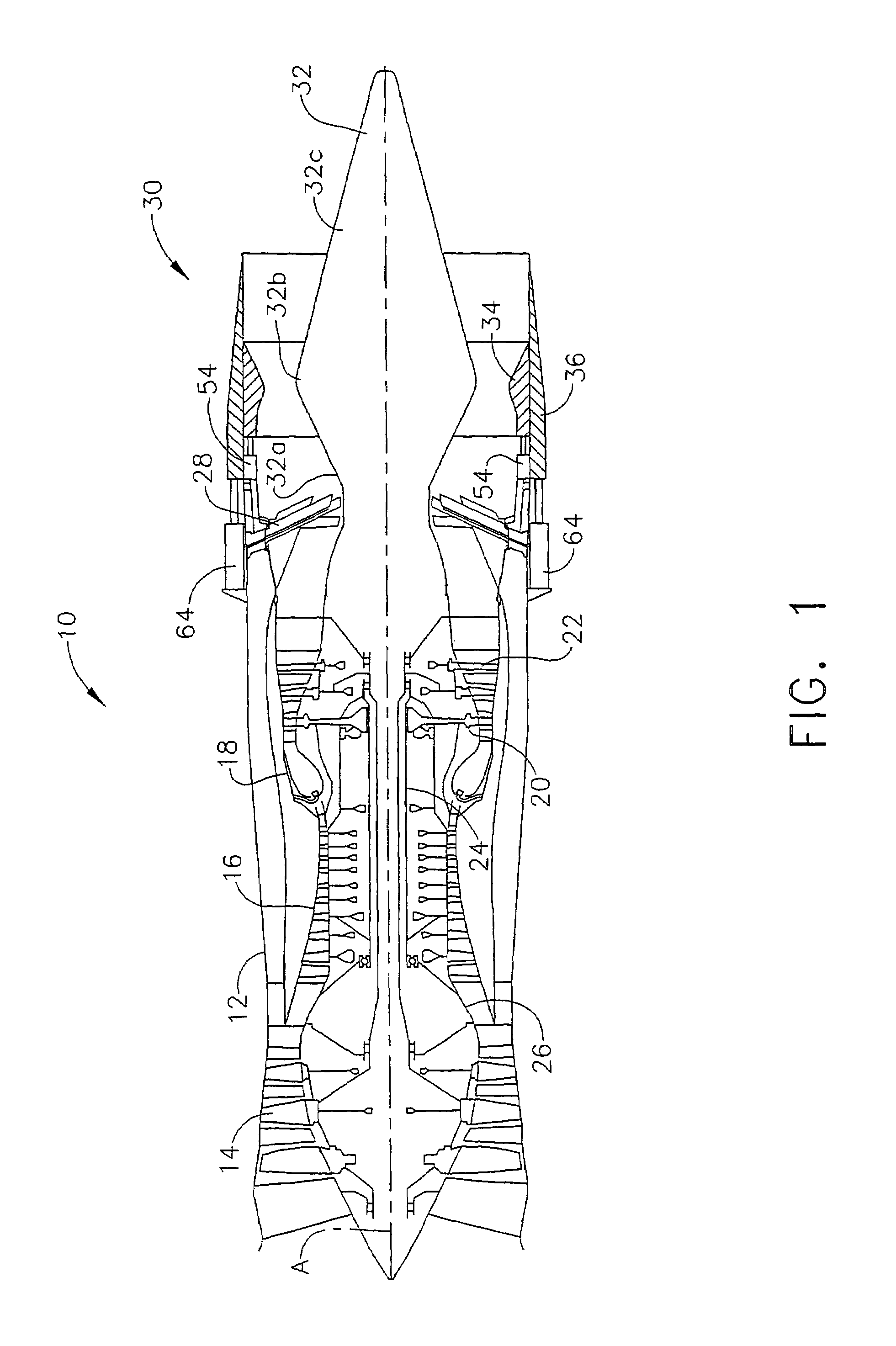

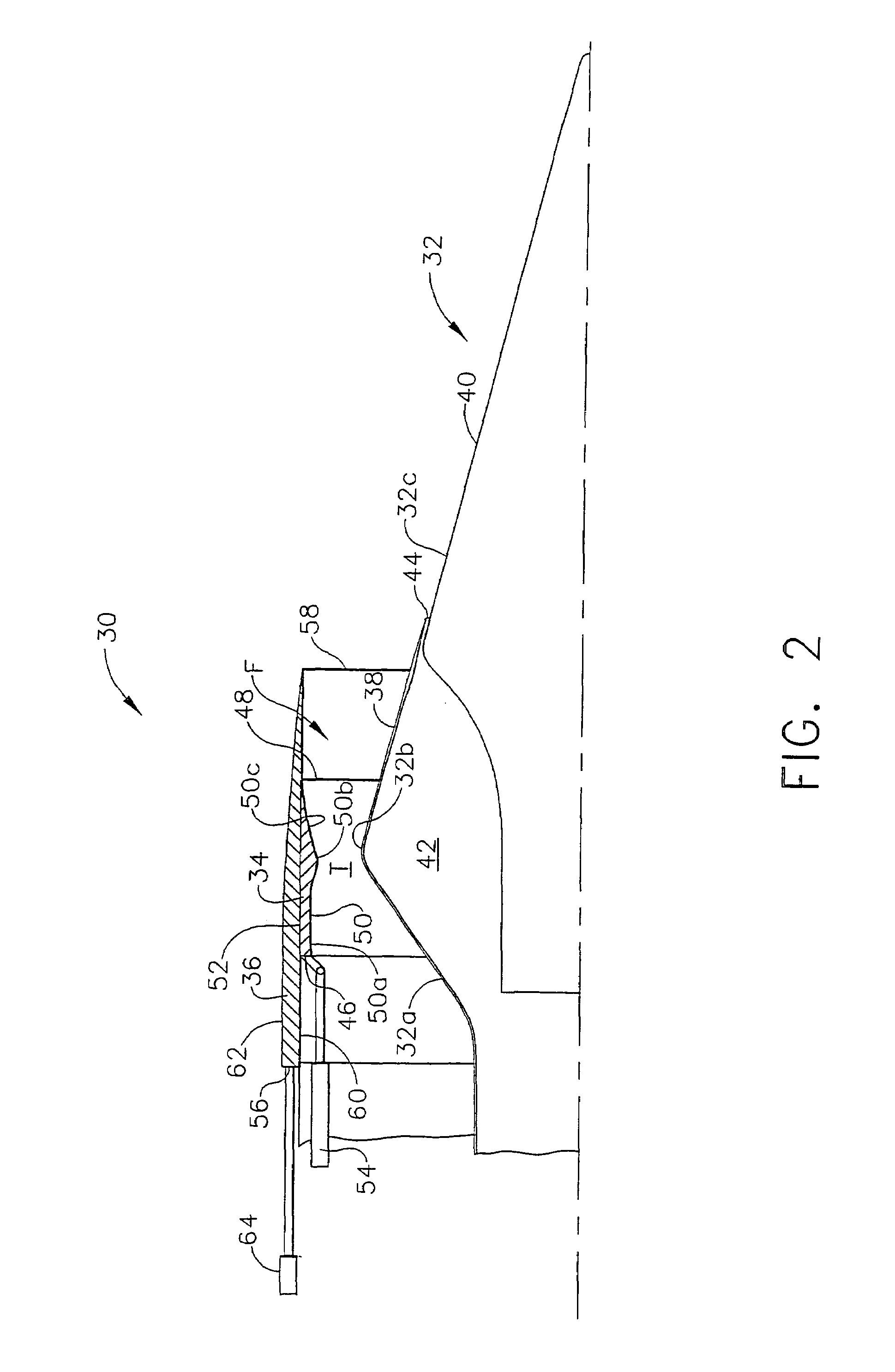

Split shroud exhaust nozzle

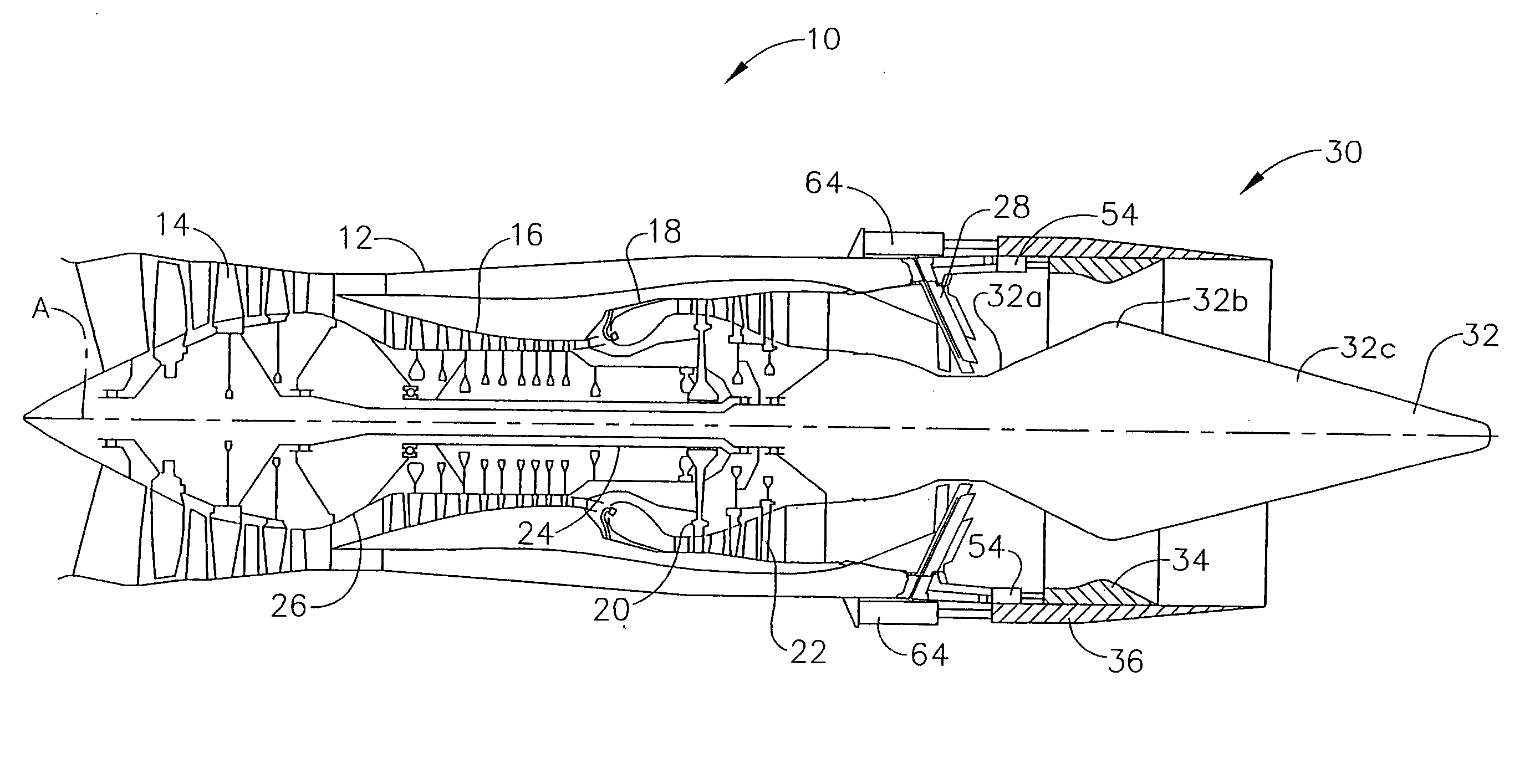

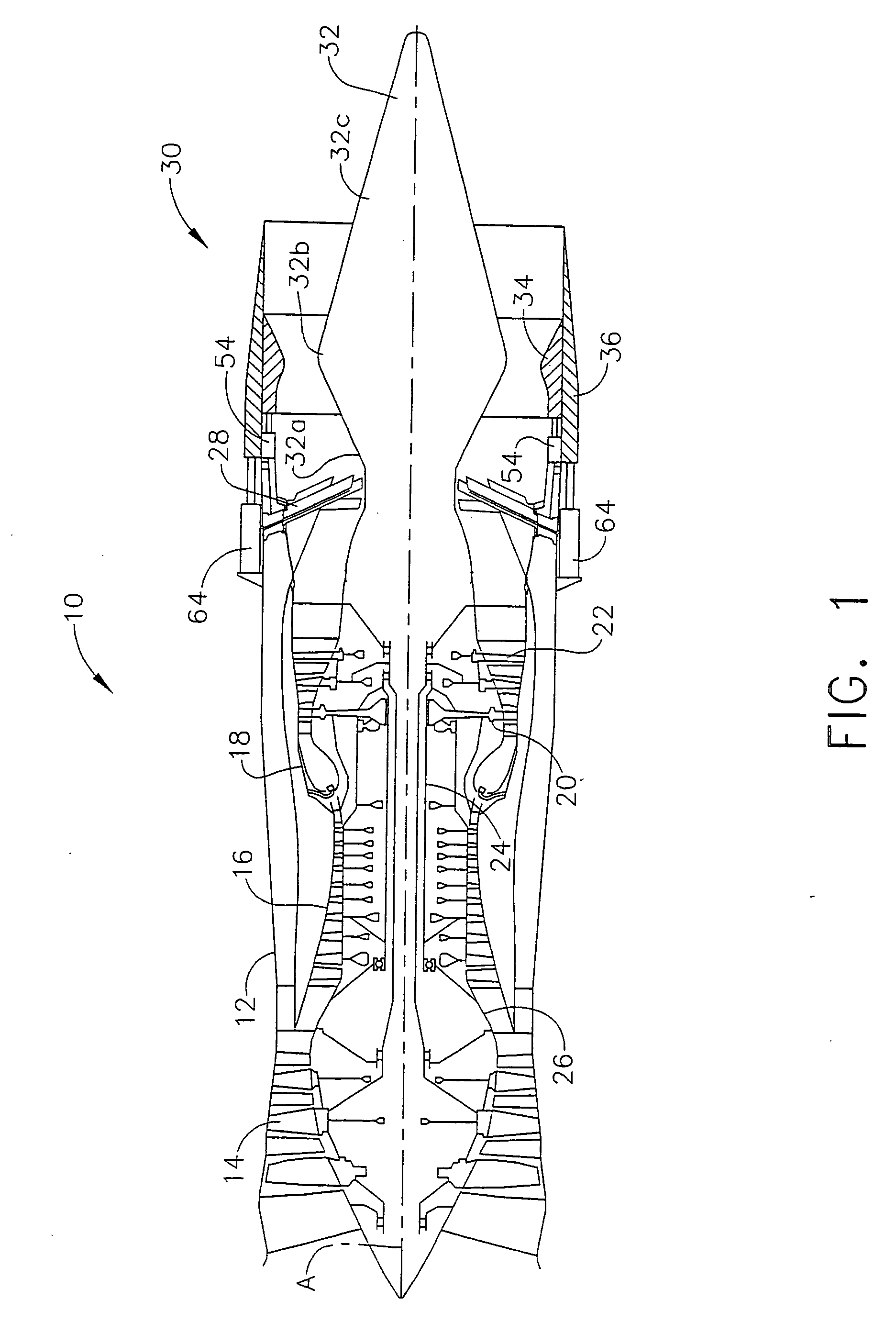

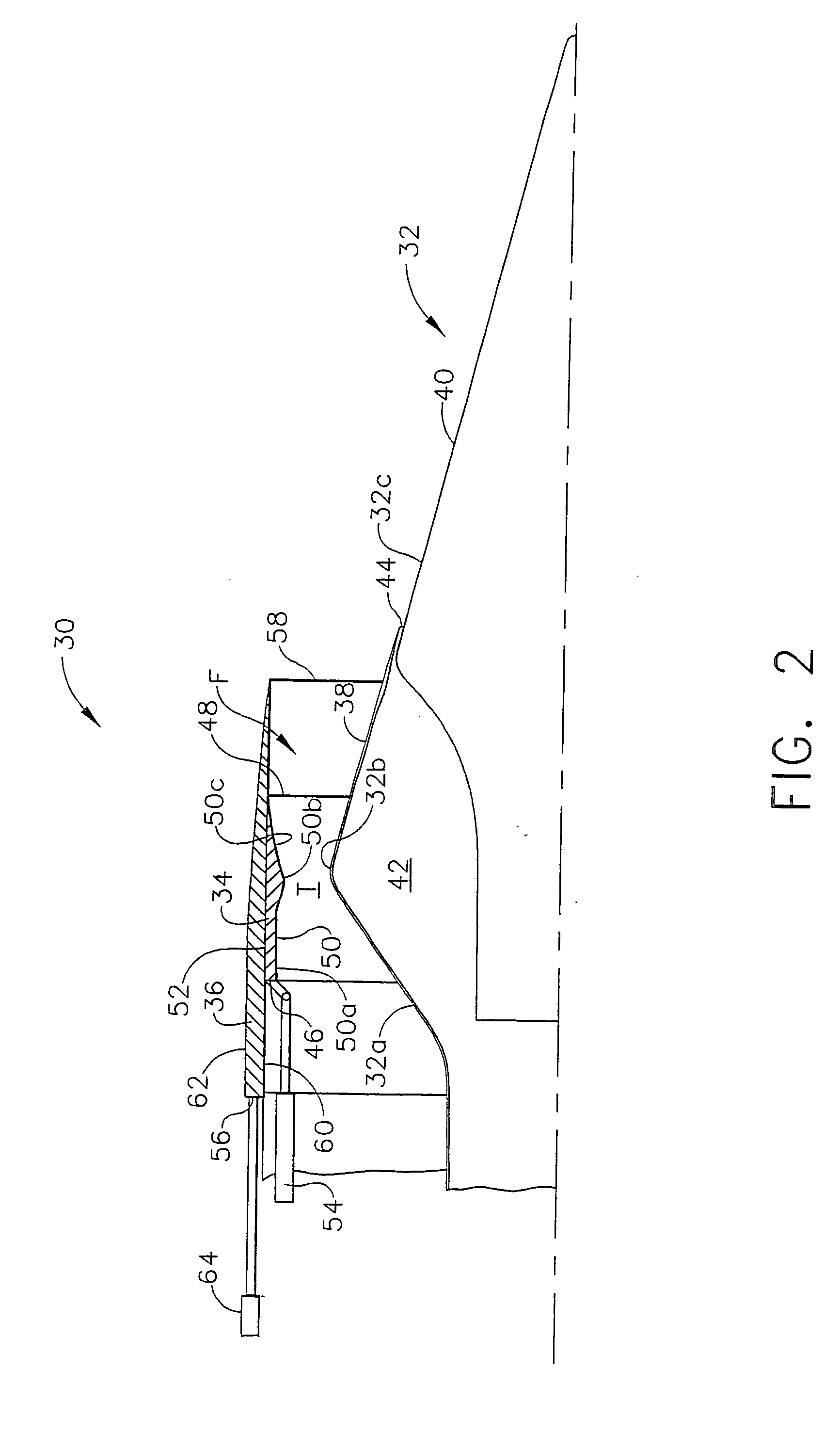

A variable geometry convergent-divergent nozzle for a gas turbine engine includes a centerbody extending rearward along a longitudinal axis of the engine which has a throat section of increased diameter. An inner shroud surrounds the centerbody and cooperates with the centerbody to define the throat of the nozzle. An outer shroud surrounds the inner shroud and cooperates with the centerbody to define the exit area of the nozzle. Both shrouds are independently translatable to provide independent control of the nozzle throat area and the nozzle expansion ratio.

Owner:GENERAL ELECTRIC CO

Chlorinated vinyl resin/cellulosic blends: composition, processes, composites, and articles therefrom

InactiveUS7030179B2High expansion rateEasy squeezeLavatory sanitoryRadiationCellulosePolymer science

Compositions and processes for preparing extrudable powder blends containing at least one vinyl chloride resin and a cellulosic material are provided. More specifically, compositions and processes for preparing extrudable free-flowing powder blends containing PVC and wood flour (WF) are also provided for preparing foamed or nonfoamed extrudates. The processes provided herein incorporate components which may contain up to a total of 25 weight percent water. Processes for preparing foamed extrudates are also provided wherein a cooling fluid is used to increase the expansion ratio of the foam. Finally provided are composites having an extrudable thermoplastic substrate and at least one capstock layer disposed thereon containing a PVC / WF composition.

Owner:ROHM & HAAS CO

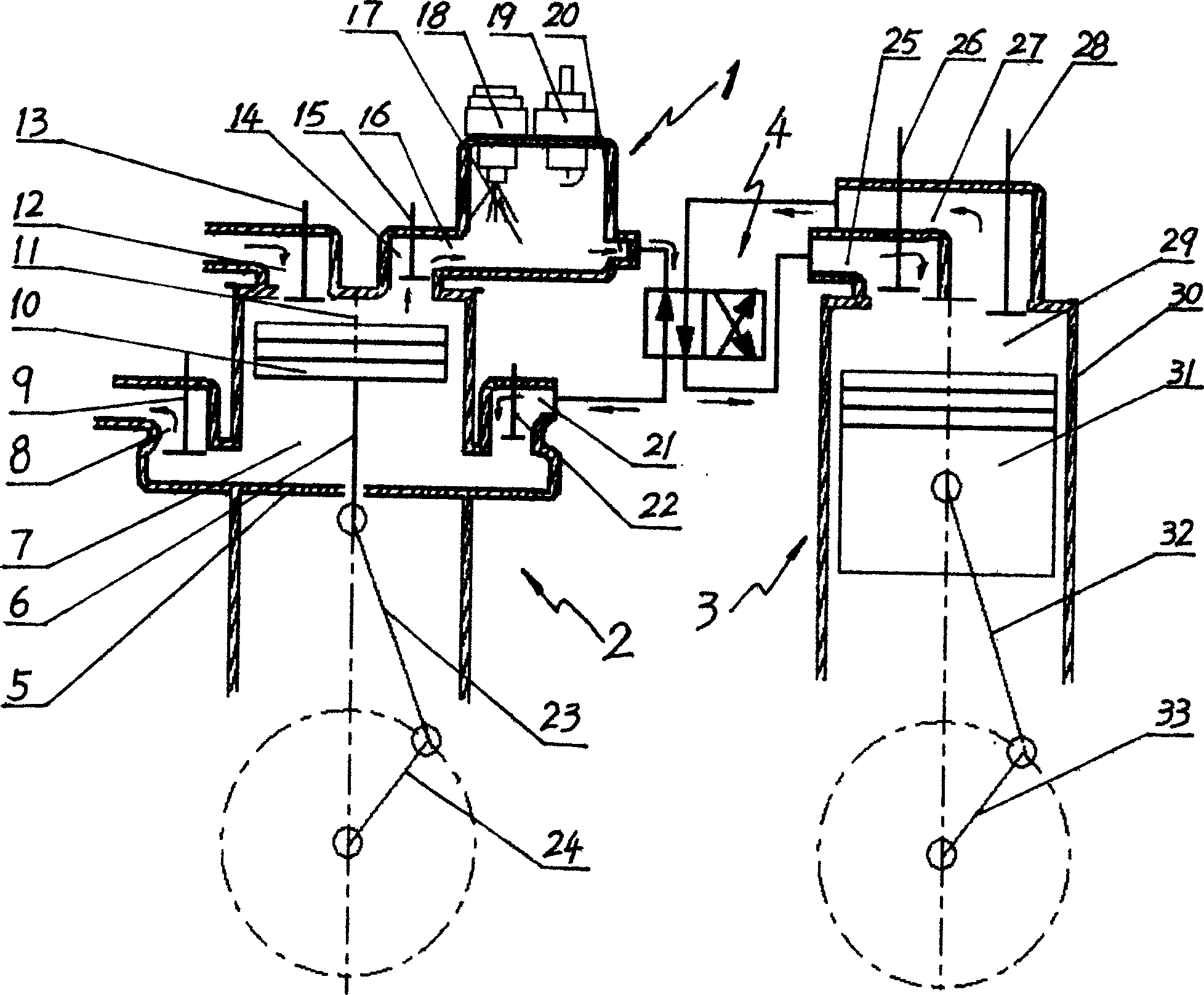

Compound cycle rotary engine

ActiveUS20090007882A1Reduce fuel consumptionHigh power to weightInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

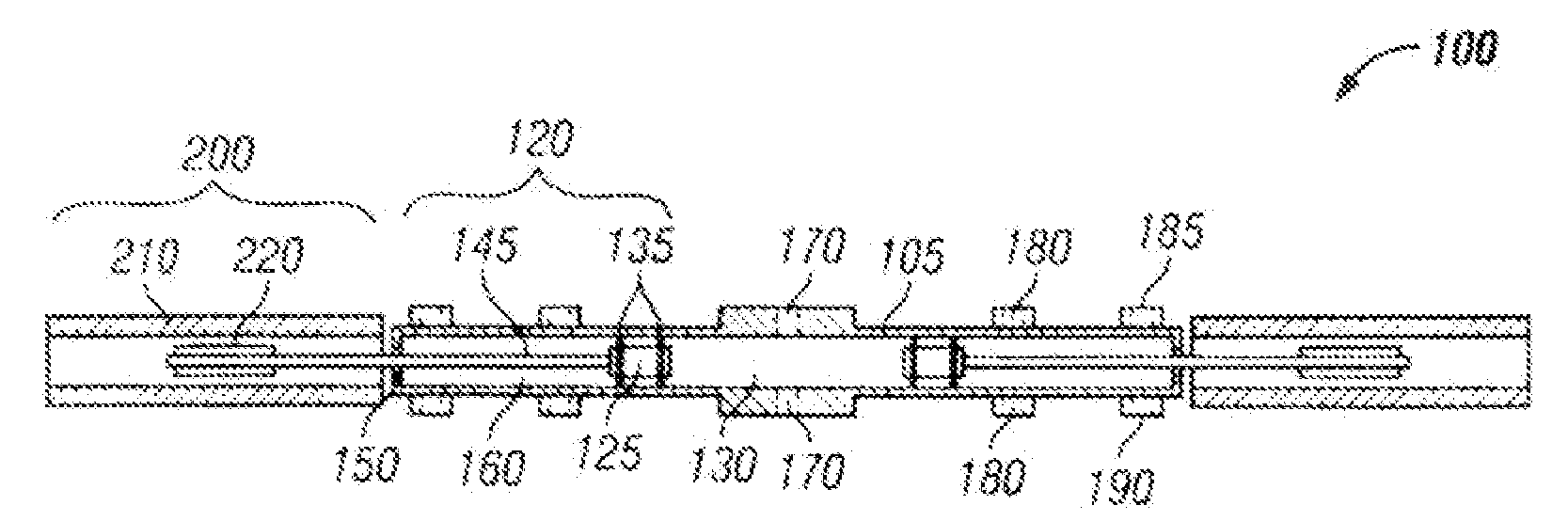

Reduced profile AAA device

An abdominal aortic aneurysm endoprosthesis having a reduced profile for percutaneous delivery of the endoprosthesis. The endoprosthesis provides a cranial section supported by a stent, and a bifurcated caudal section having at least two legs each of which are supported by individual stents. The individual stents of each leg of the caudal section are staggered so as not to line up with one another. Altering the lengths of the legs permits nesting of the endoprosthesis. Optimizing the expansion ratio and radial strength of the endoprosthesis is achieved by altering the dimensions of the starting material from which the stent segments are fabricated, by altering the final austentite temperature of the starting materials, or by changing the structural configuration of the stent segments. A graft material is attached to at least a portion of the cranial section and to all of the caudal section of the endoprosthesis.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

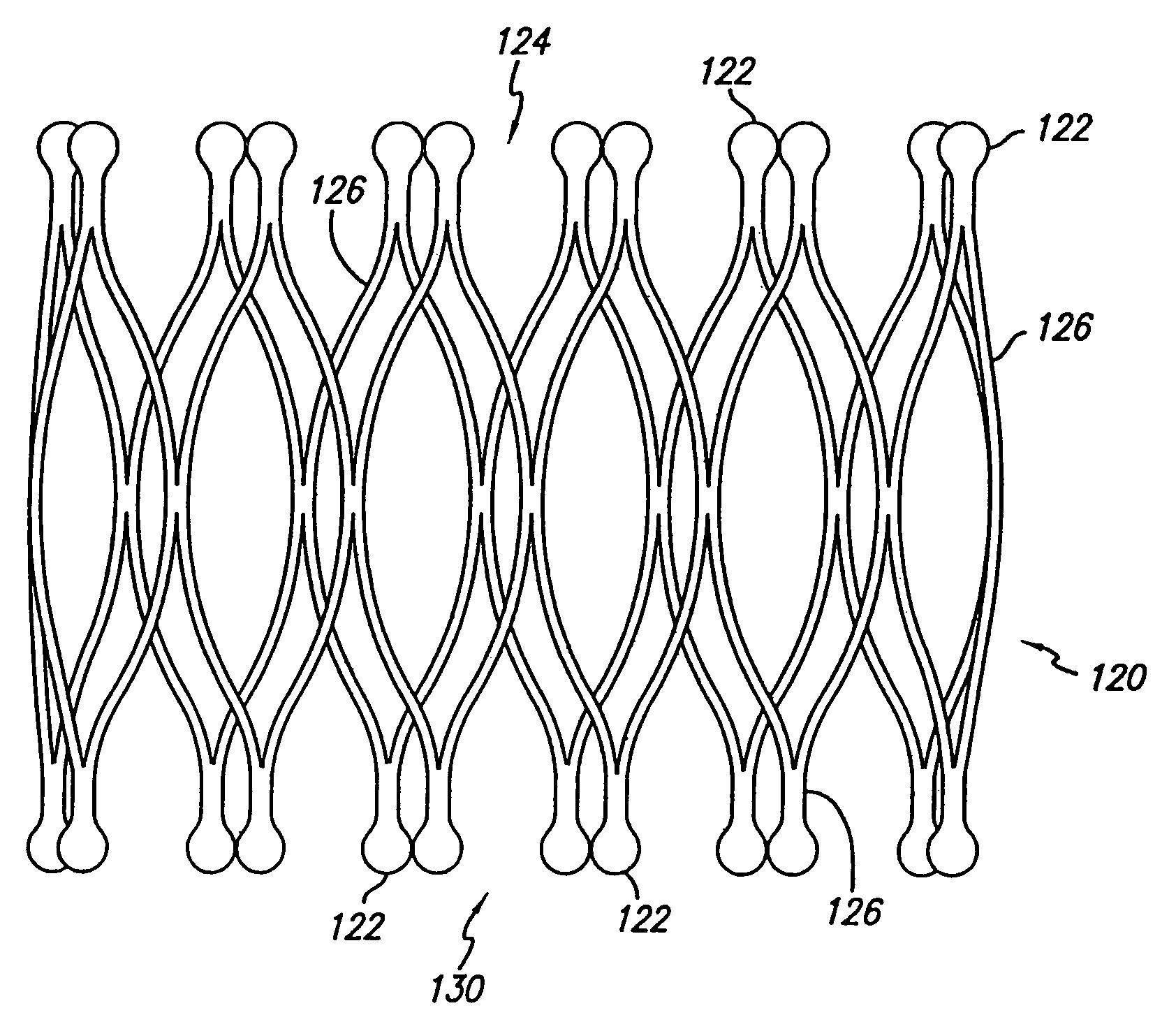

Self-expanding pseudo-braided intravascular device

InactiveUS20100004726A1Large expansion ratioIncrease flexibilityStentsHand lacing/braidingThrombusRepair aneurysm

A self-expanding, pseudo-braided device embodying a high expansion ratio and flexibility as well as comformability and improved radial force. The pseudo-braided device is particularly suited for advancement through and deployment within highly tortuous and very distal vasculature. Various forms of the pseudo-braided device are adapted for the repair of aneurysms and stenoses as well as for use in thrombectomies and embolic protection therapy.

Owner:ABBOTT CARDIOVASCULAR

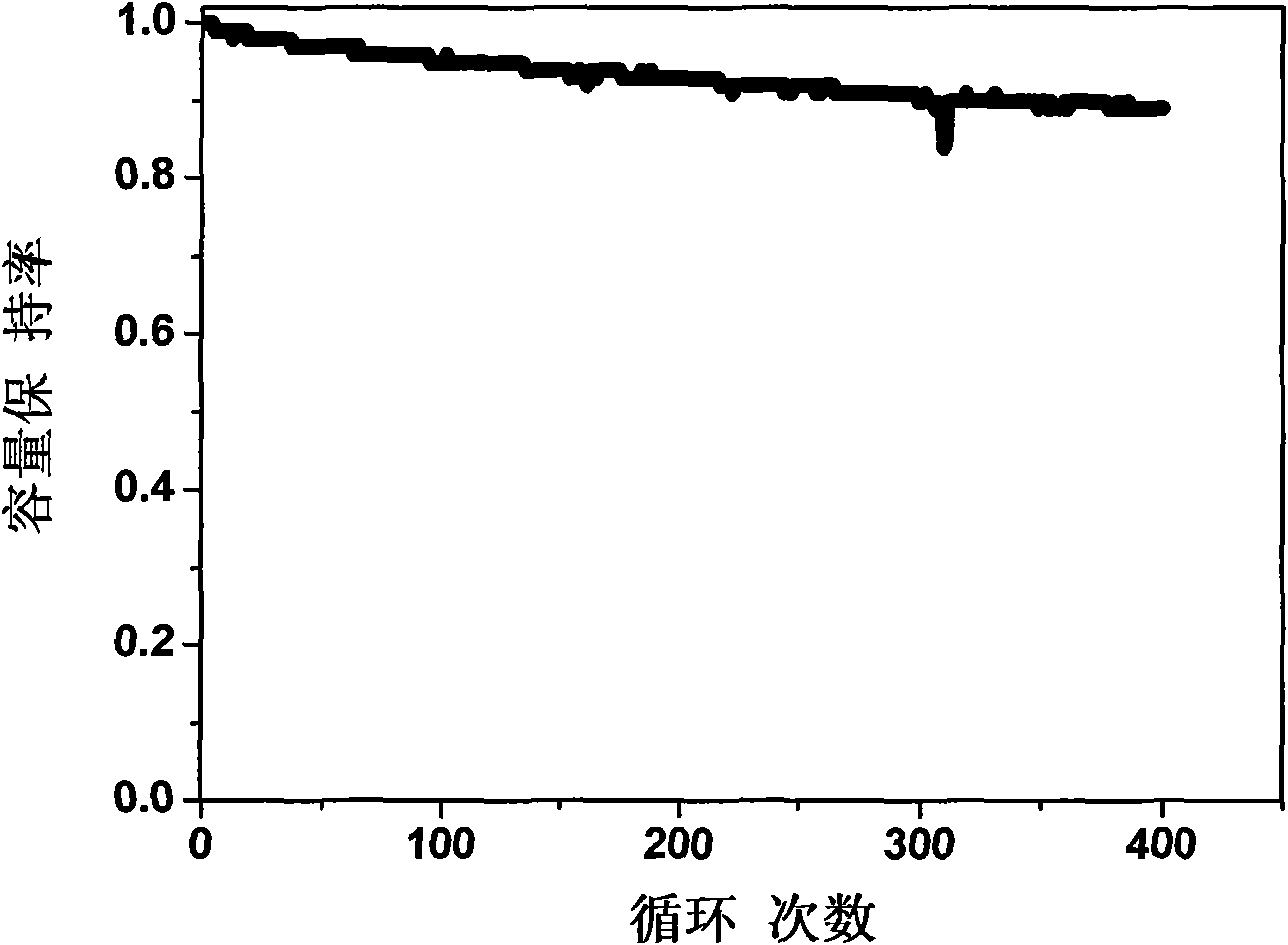

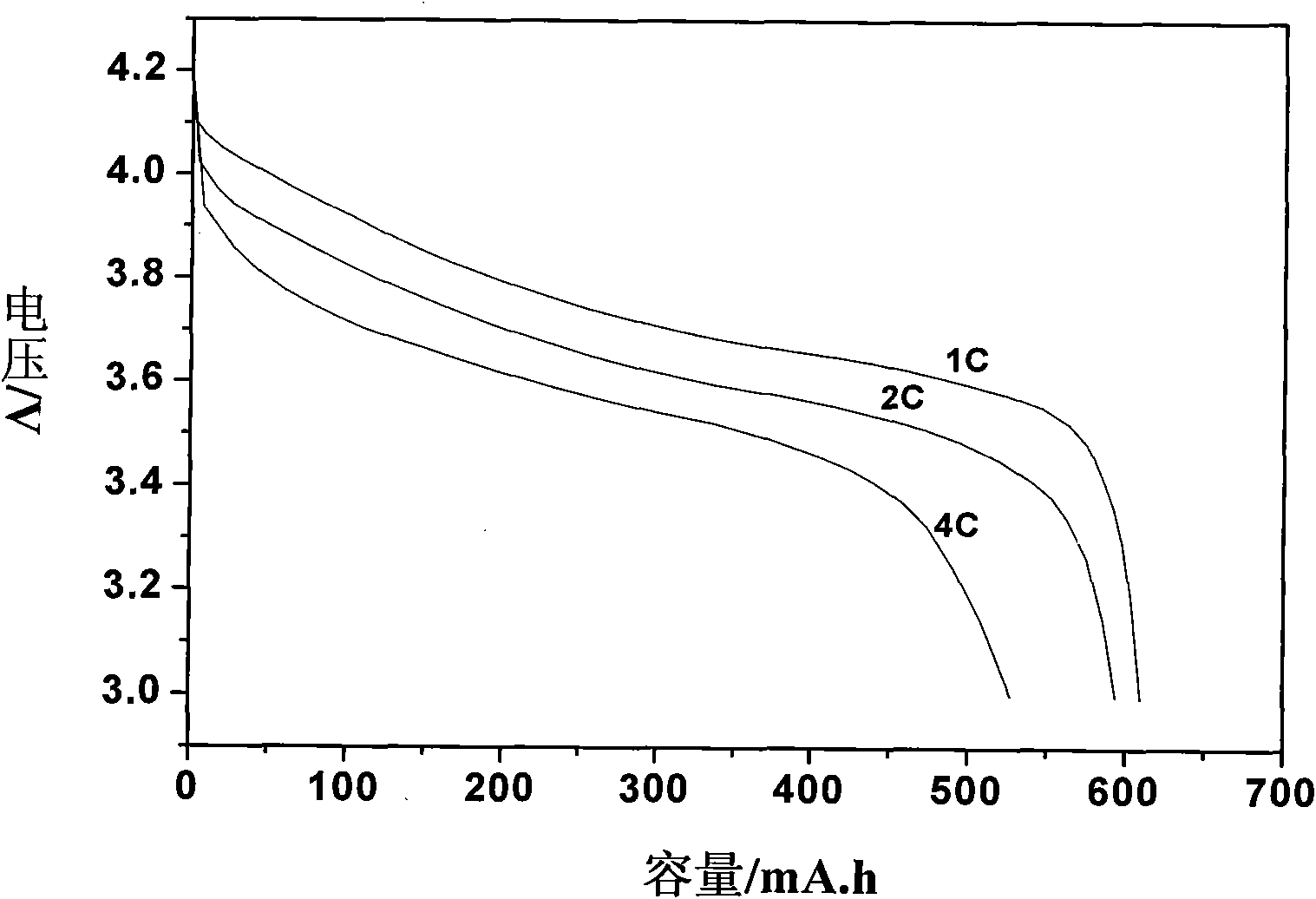

Polymer porous membrane, preparation method thereof, polymer electrolyte, polymer battery and preparation method of battery

ActiveCN102035043AImprove rate discharge performanceImprove cycle performanceFinal product manufactureSynthetic resin layered productsPolymer electrolytesPolymer science

The invention provides a polymer porous membrane, a preparation method of the polymer porous membrane, a polymer electrolyte, a polymer battery and a preparation method of the polymer battery. A carbon material is dispersed in the polymer porous membrane, so that the degree of crystallization of a polymer which constitutes the polymer porous membrane is lowered and the liquid absorption of the polymer porous membrane is increased; the liquid absorption rate, liquid holding capability and ionic conductivity of the polymer porous membrane are increased; interface impedance is reduced, battery magnification discharging performance and the circulating performance of the battery are enhanced; simultaneously, the battery prepared by the method has excellent high temperature circulation and storage performance and low expansion ratio at a high temperature and further meets the development requirement of the polymer battery. Simultaneously, the preparation method is simple and is easy to implement and the prepared battery has high performance.

Owner:SHANGHAI BYD

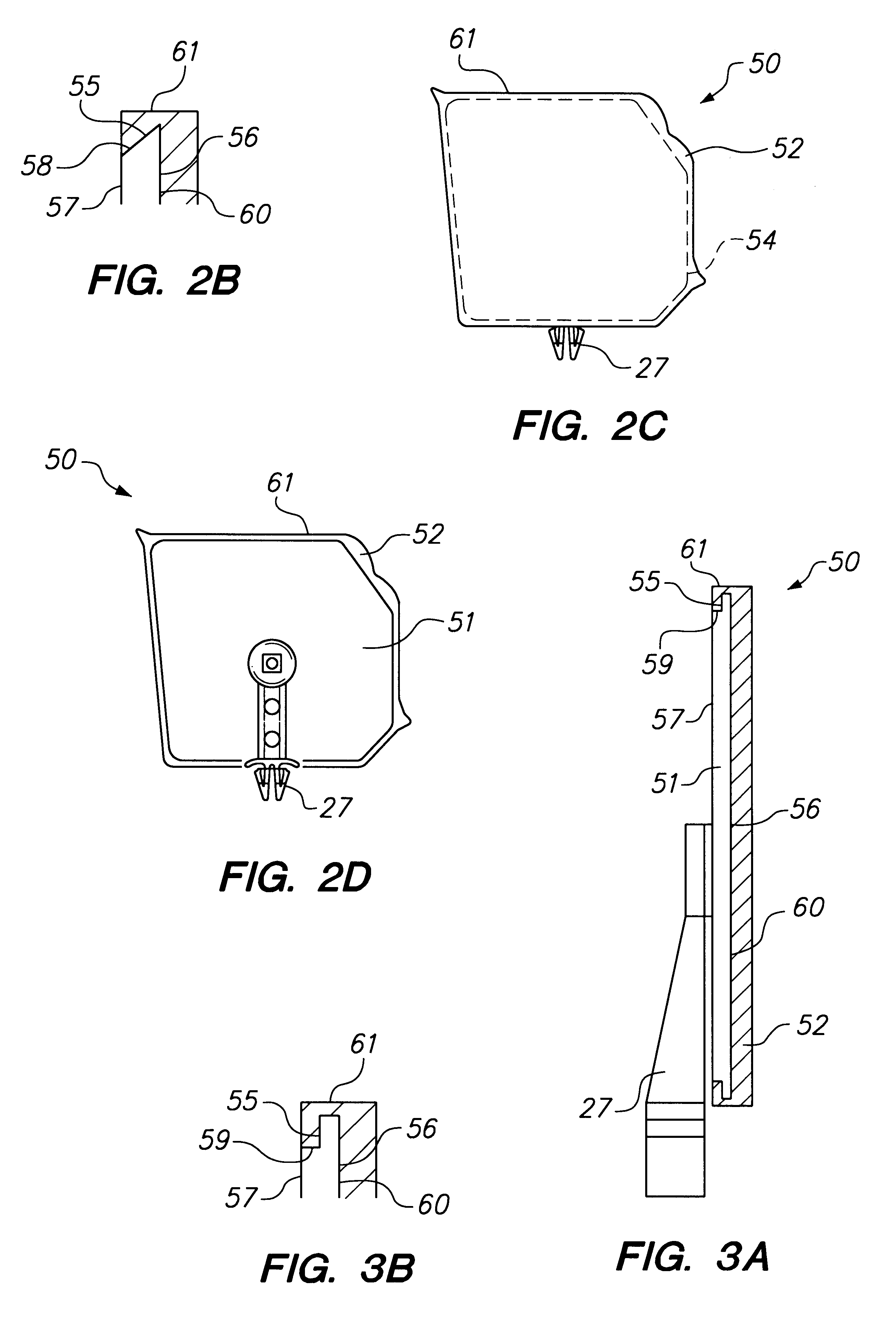

Cavity sealing article having improved sag resistance

Conventional foamable cavity sealing articles are susceptible to sagging when expanded in a vertical orientation with the foaming material facing downwards, because of gravitational drag on the molten material during expansion. The problem is particularly pronounced in foaming materials formulated to have high expansion ratios and low melt viscosities. A solution to the problem is presented in the form of a cavity sealing article having a planar holder and a foamable sealer, the foamable sealer circumscribing the edge of the support member. This construction creates a gripping effect which prevents sagging of the sealing member during expansion.

Owner:TYCO INT PA +2

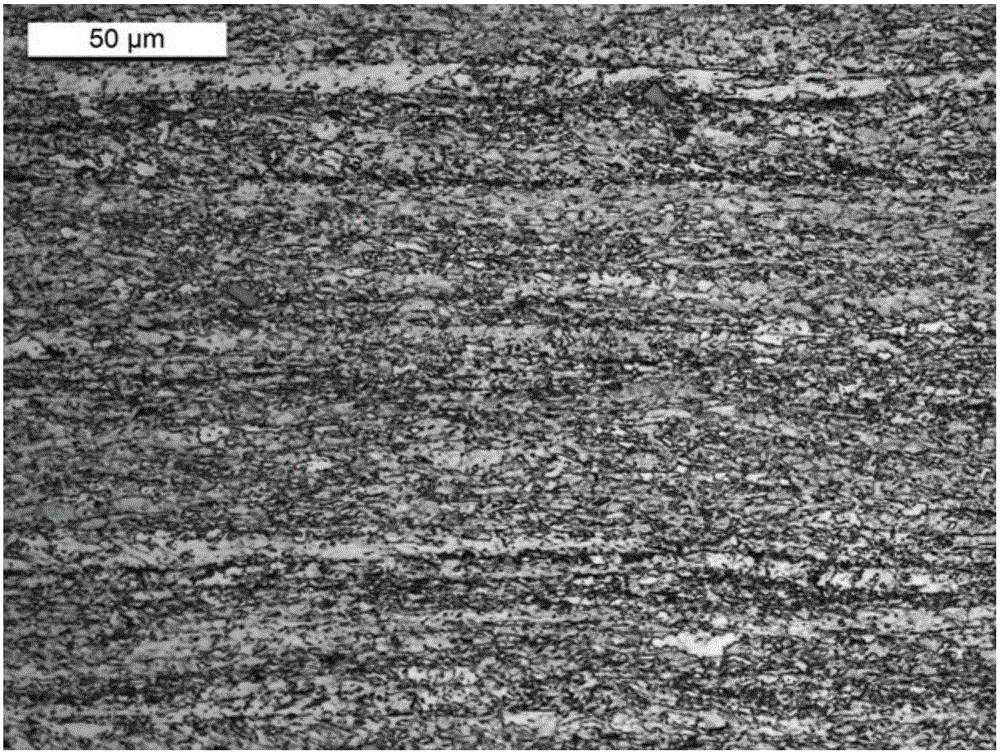

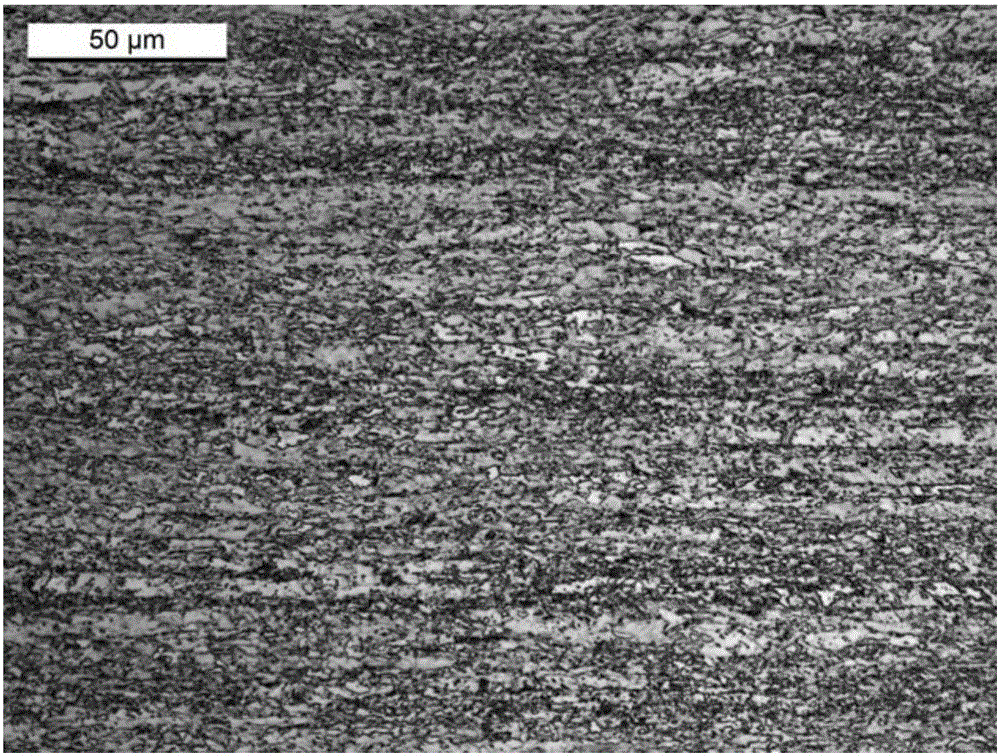

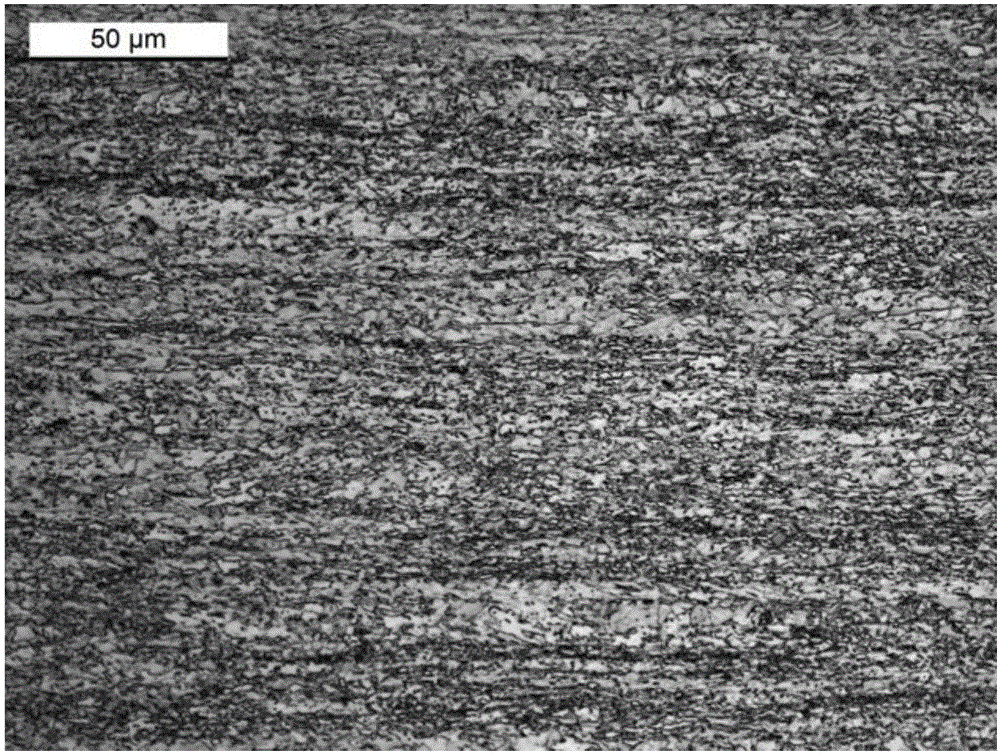

980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel and manufacturing method thereof

The invention provides 980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel and a manufacturing method thereof. The 980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel comprises, by weight, 0.05%-0.10% of C, 0.1%-0.8% of Si, 1.5% -2.5% of Mn, 0-0.015% of P, 0-0.005% of S, 0-0.003% of O, 0.02%-0.08% of Al, 0-0.005% of N, 0.05%-0.15% of Ti, 0.02%-0.06% of Nb, 0.1%-1.0% of Cr, 0.01%-0.10% of V, and the balance Fe and inevitable impurities, wherein the chemical components meet the relations that 0.15%<=Nb+Ti+V<=0.25%, and 0.01%<=(Ti-3.42N) / 4+V / 4.24<=0.06%. The microstructure of the steel is made of granular bainite and martensite; the yield strength of the steel is equal to or higher than 900 MPa, the tensile strength of the steel is equal to or higher than 980 MPa, the ductility of the steel is equal to or higher than 15%, and the hole expansion ratio of the steel is equal or higher than 50%; and the 980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel has excellent strength, ductility and hole expansion matching and can be widely applied to thinned high-strength complexly-formed components such as an automobile chassis, a crossbeam and a wheel.

Owner:BAOSHAN IRON & STEEL CO LTD

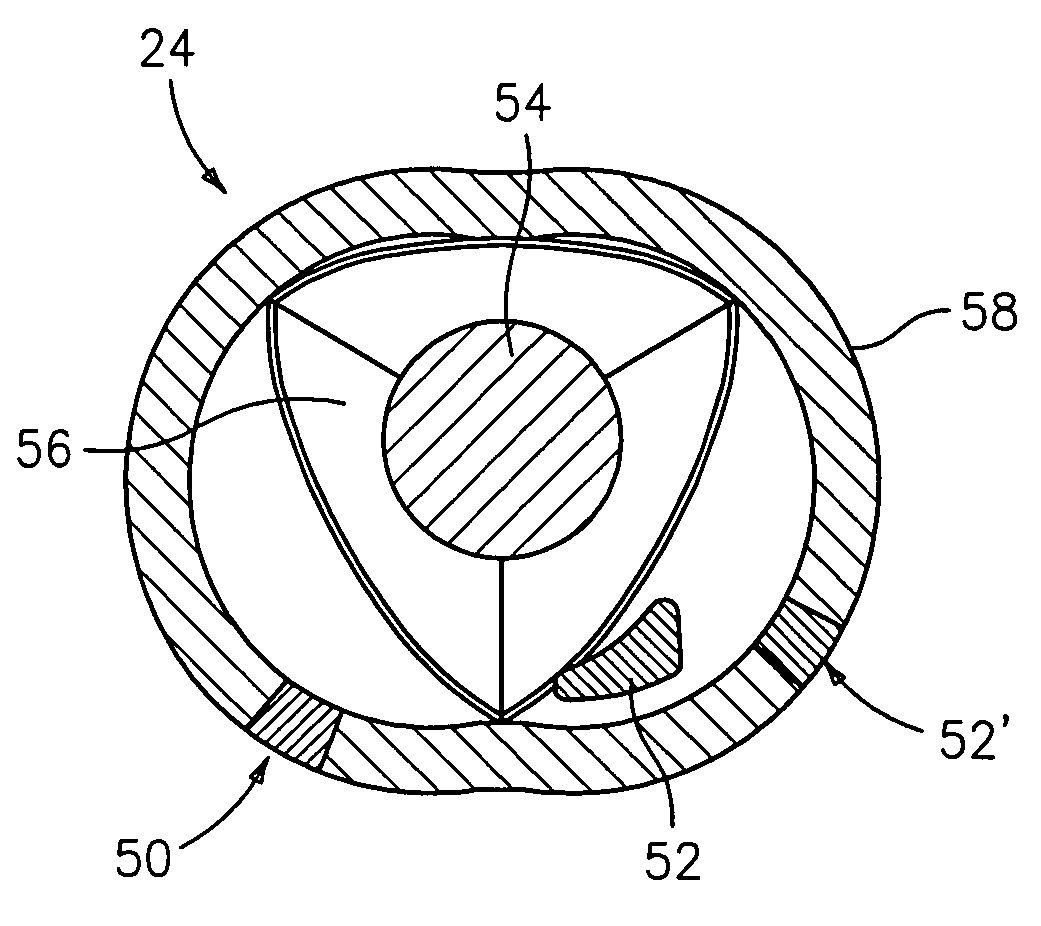

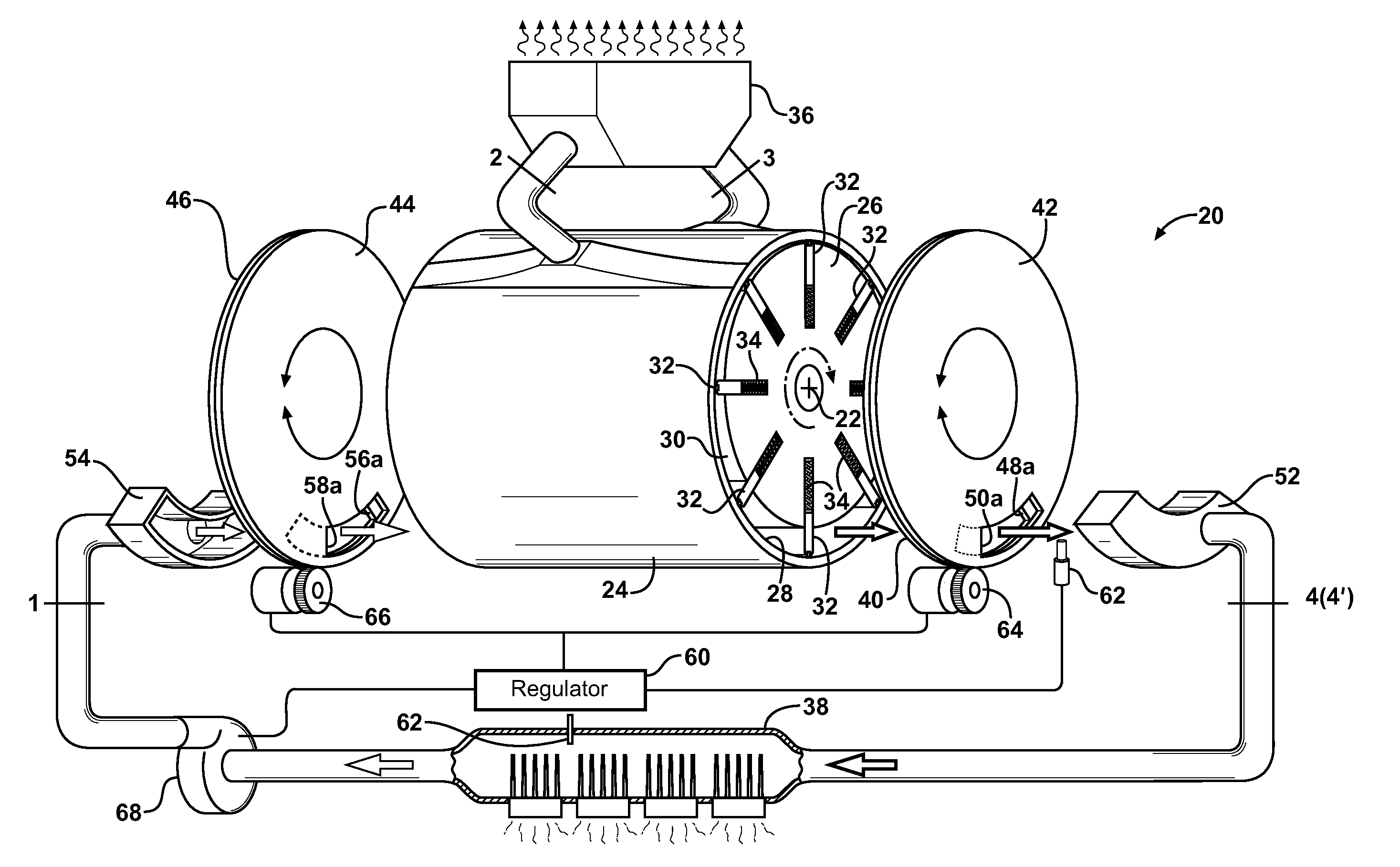

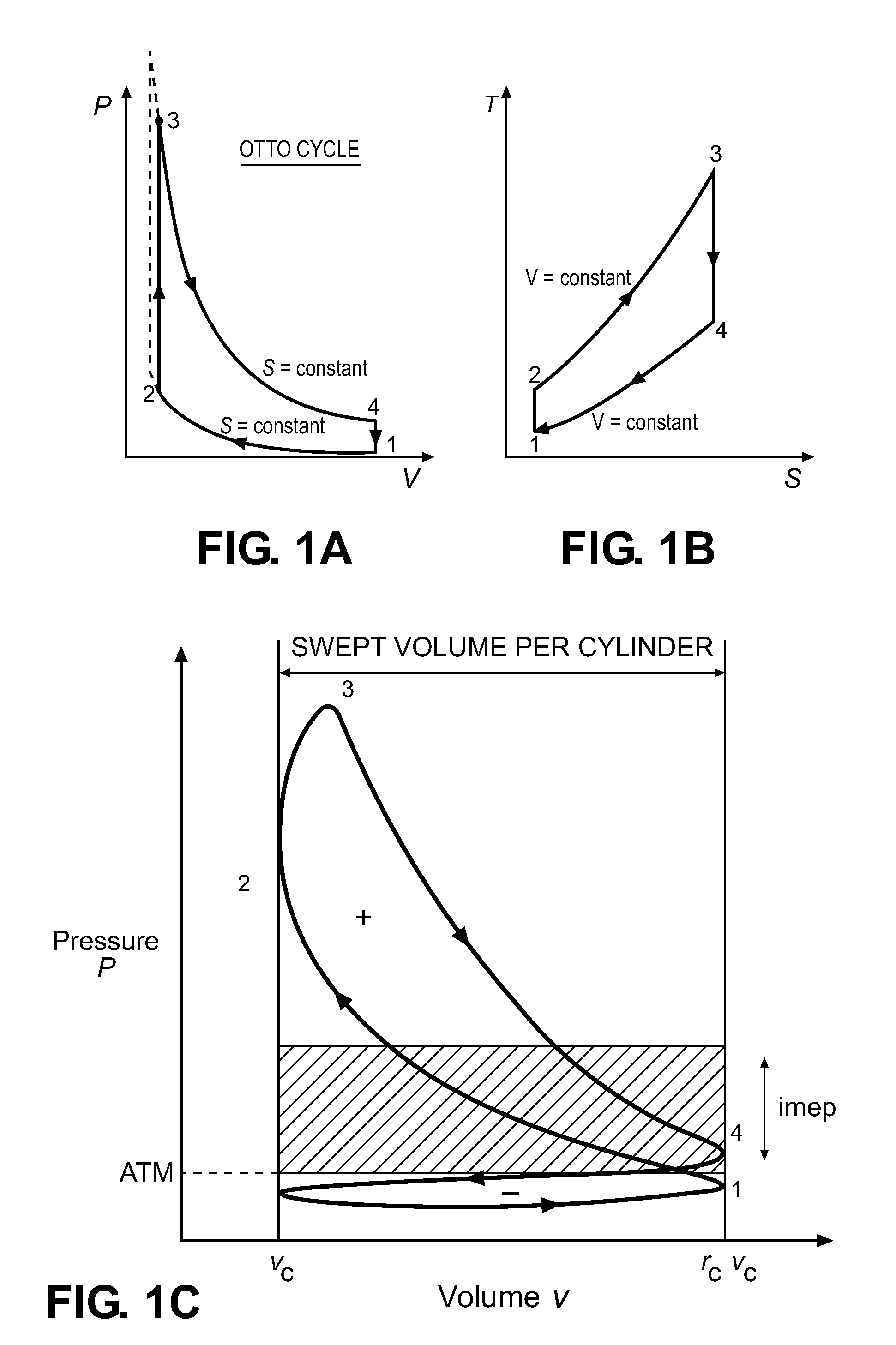

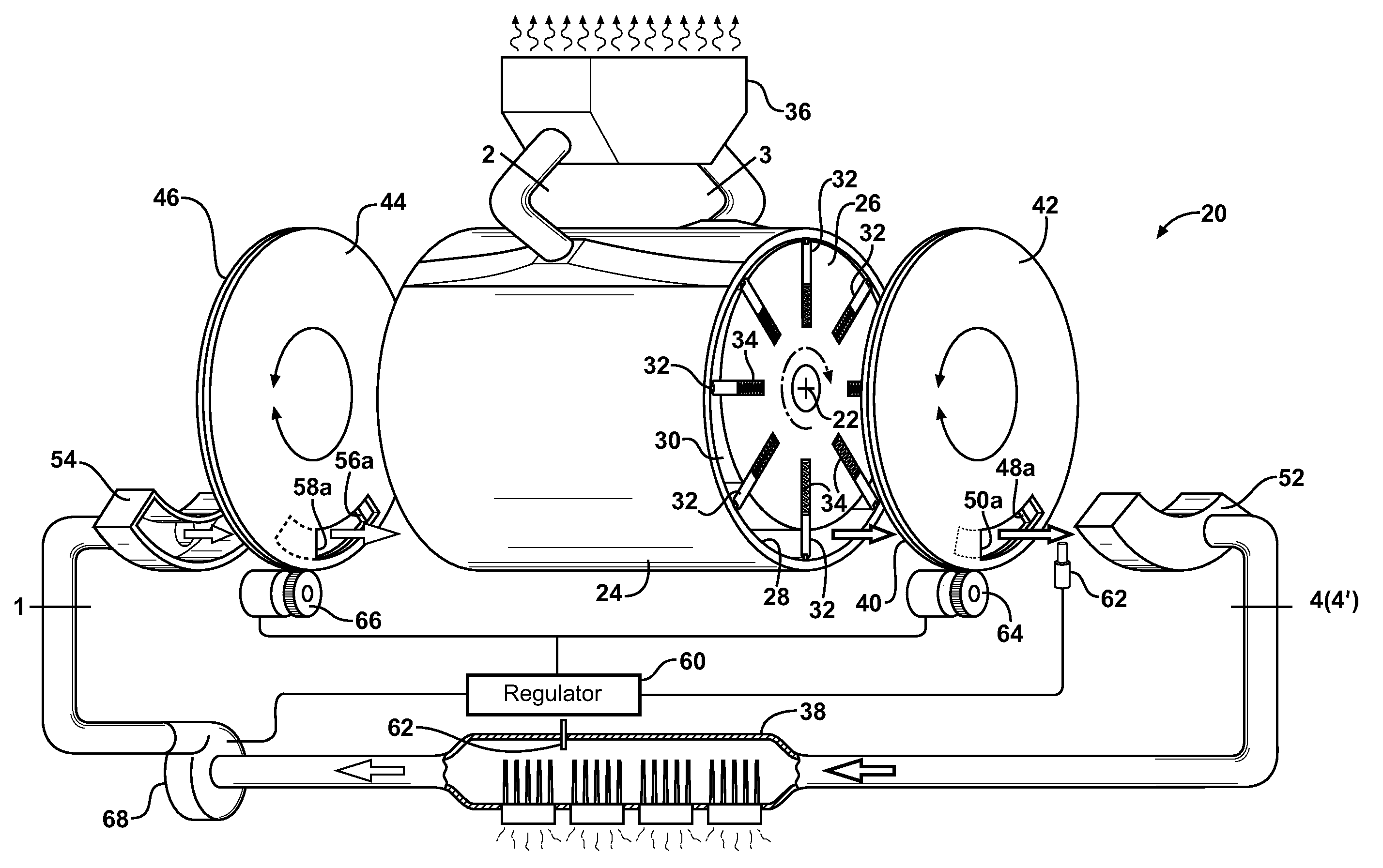

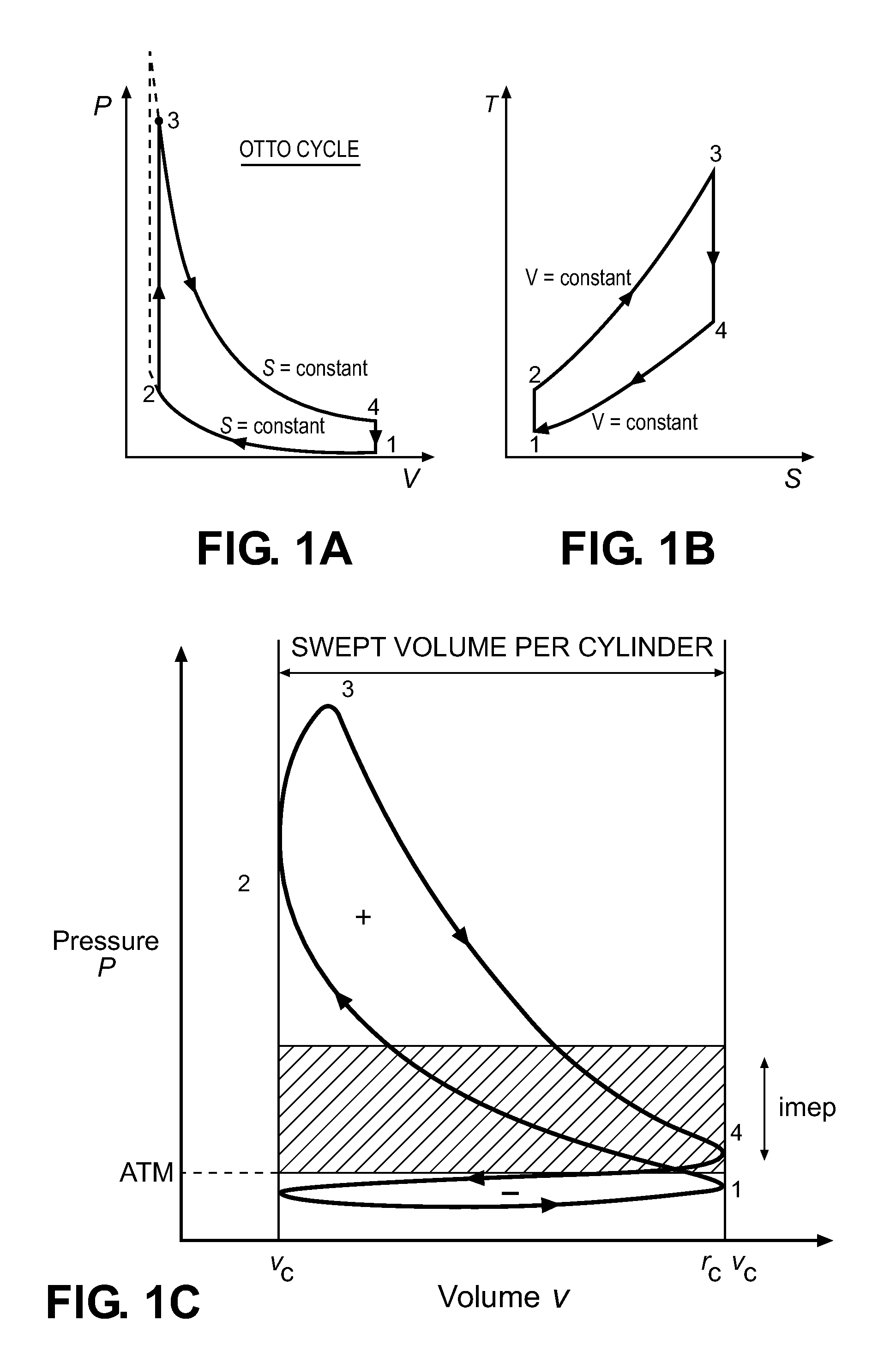

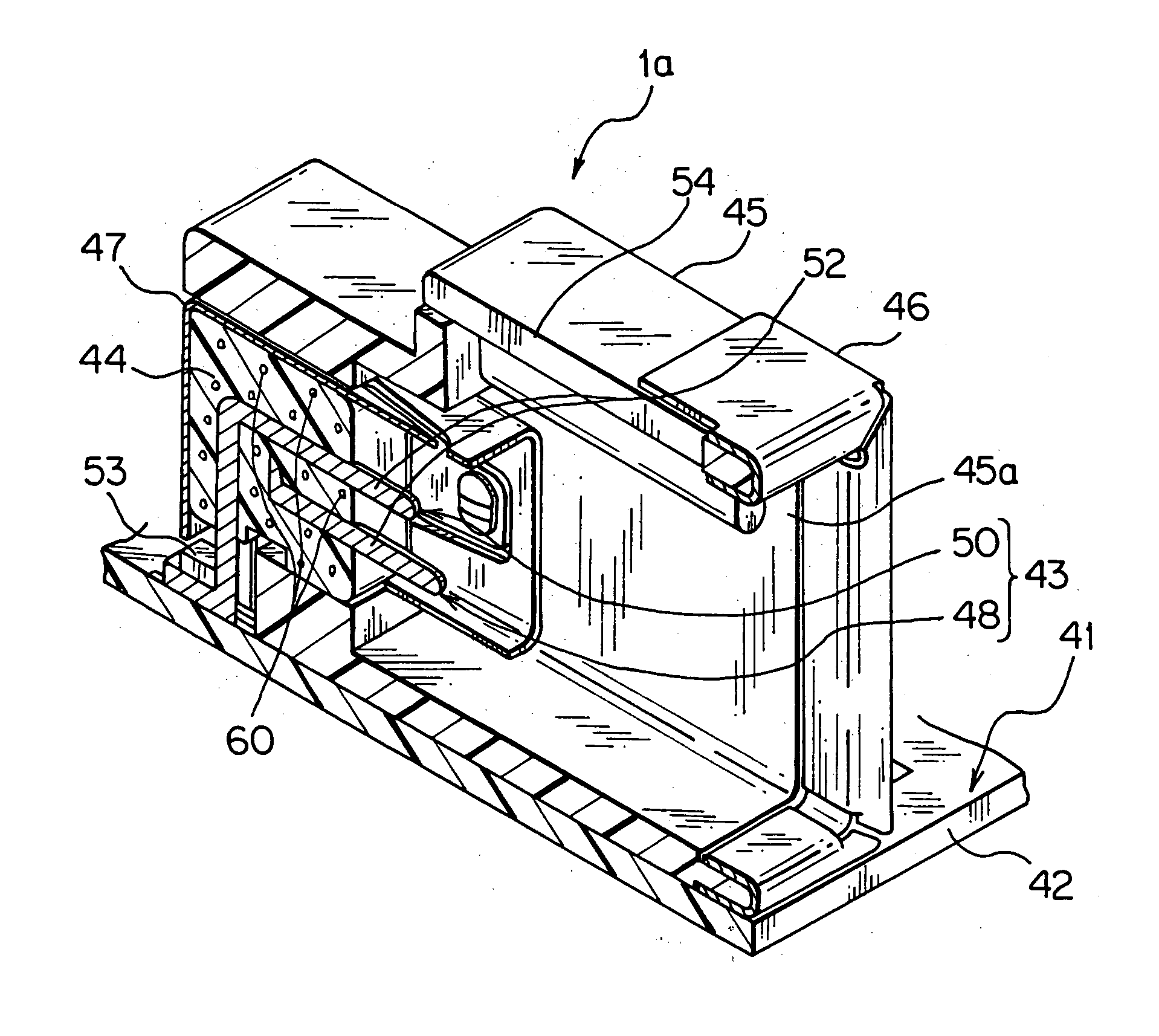

High efficiency positive displacement thermodynamic system

ActiveUS8424284B2Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

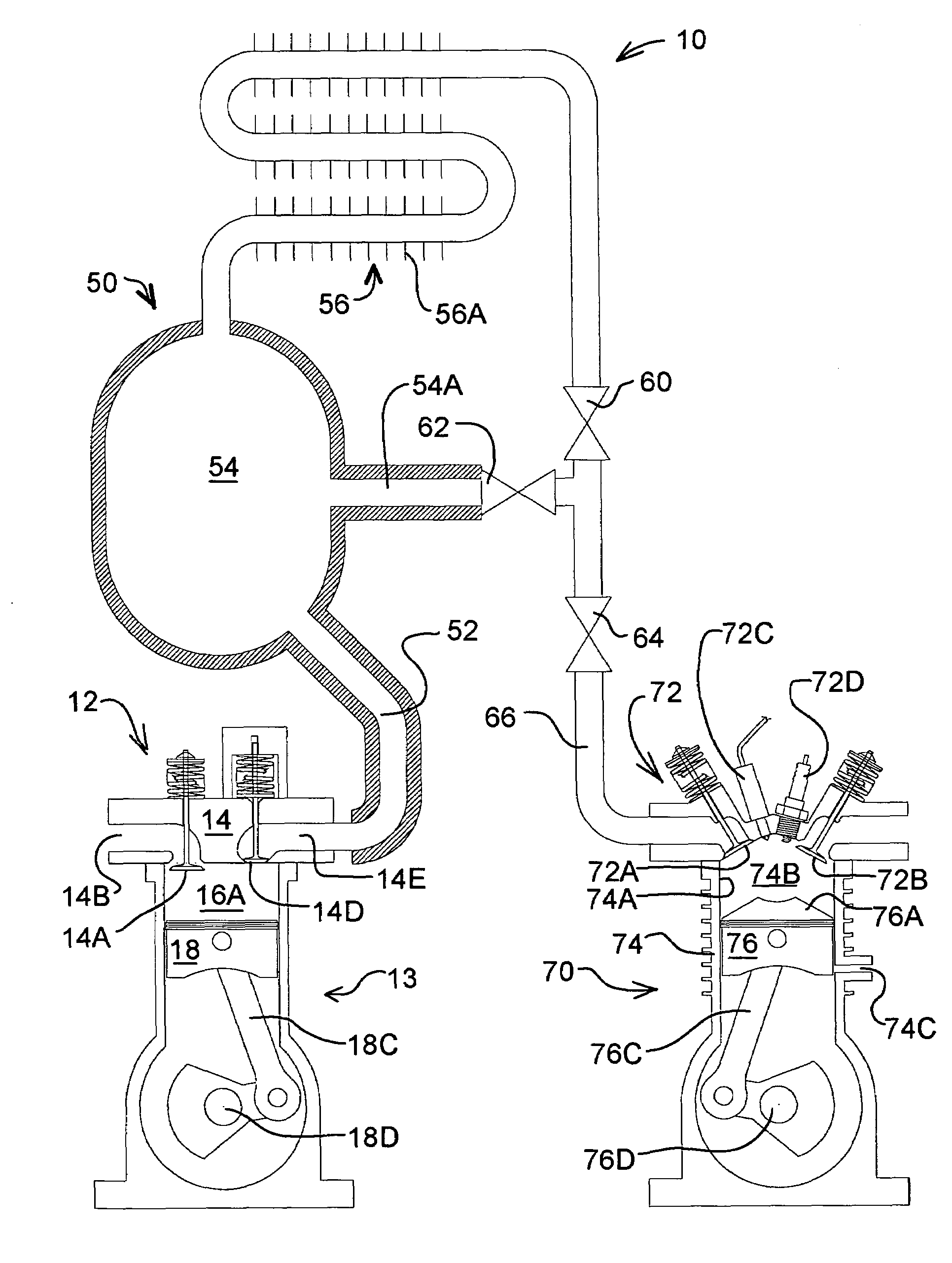

Air injection engine

InactiveUS7007639B1Improve power densityHigh expansion rateInternal combustion piston enginesOutput powerCombustionExternal combustion engine

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

Method for molding molded foam, and molded foam

ActiveUS20110104414A1High expansion rateReduce weightClosuresLayered productsFoaming agentPolypropylene

The invention provides a molded foam molding method capable of obtaining a molded foam in which pinholes may not be formed with ease even when a blow ratio is high and which has a high expansion ratio. The invention also provides a molded foam which includes no pinholes, is reduced in weight, and is excellent in heat insulating property. The molding method includes blending a polypropylene-based resin having an equilibrium compliance from 2.0 to 6.0 (10−3×Pa−1) with a foaming agent and kneading the blend in an extruder. The extruded foamed resin is molded so as to be fit along a mold by a pressurized fluid. Moreover, the molded foam is formed by the method described above, and has an expansion ratio from 1.5 to 5.0 times and an impact strength of not less than 30 kg·cm.

Owner:KYORAKU CO LTD

Continuous combustion constant power engine

InactiveCN1821557ATroubleshoot hard-to-start issuesEmission reductionInternal combustion piston enginesDetonationCombustor

The present invention relates to continuous combustion constant power engine. There are one independent continuous combustor outside the cylinder, two sets of link rod-piston mechanisms with gas compressing device and expansion device, and one gas exchange valve for connecting these two mechanisms to the continuous combustor, to constitute one complete thermal engine. The present invention can reach ideal low temperature multiple fuel clean combustion with less noise, no smoke and no combustion detonation, and has raised compression ratio, raised expansion ratio, high heat efficiency, and reduced exhaust of harmful gas. The independent combustor of the present invention can realize fast ignition and self starting without compression and in the condition of low temperature.

Owner:李岳

High Strength Hot Rolled Steel Sheet and Method for Manufacturing the Same

InactiveUS20060096678A1High strengthHigh elongationFurnace typesHeat treatment furnacesExpansion ratioHigh intensity

The present invention relates to a high strength hot rolled steel sheet consisting of 0.04 to 0.15% C, 1.5% or less Si, 0.5 to 1.6% Mn, 0.04% or less P, 0.005% or less S, 0.04% or less Al, 0.03 to 0.15% Ti, 0.03 to 0.5% Mo, by mass, and balance of Fe and inevitable impurities, and having a microstructure consisting of ferrite containing precipitates, second phase of bainite and / or martensite, and other phase, wherein the percentage of the ferrite containing precipitates is 40 to 95%, and the percentage of the other phase is 5% or less. For example, the high strength hot rolled steel sheet having a thickness of 1.4 mm shows a tensile strength of 780 MPa or higher, an elongation of 22% or higher elongation, and a hole expansion ratio of 60% or higher, thus the steel sheetis suitable for reinforcing members automobile cabin and crash worthiness members of automobile.

Owner:JFE STEEL CORP

Crosslinked olefin elastomer foam and elastomer composition therefor

A crosslinked olefin elastomer foam has a specific gravity of 0.05 to 0.2, an expansion ratio of 8 to 15, a compression set of 30 to 60% and a tear strength of 1.5 to 2.5 kg / cm. The crosslinked foam is obtained by heating an elastomer composition comprising a specific ethylene / alpha-olefin copolymer, an organic peroxide, a crosslinking auxiliary and a foaming agent. The crosslinked foam has a high expansion ratio, is free from surface roughening attributed to defoaming, realizes a soft touch, exhibits a low compression set and is excellent in mechanical strength (particularly tear strength) and heat resistance.

Owner:MITSUI CHEM INC

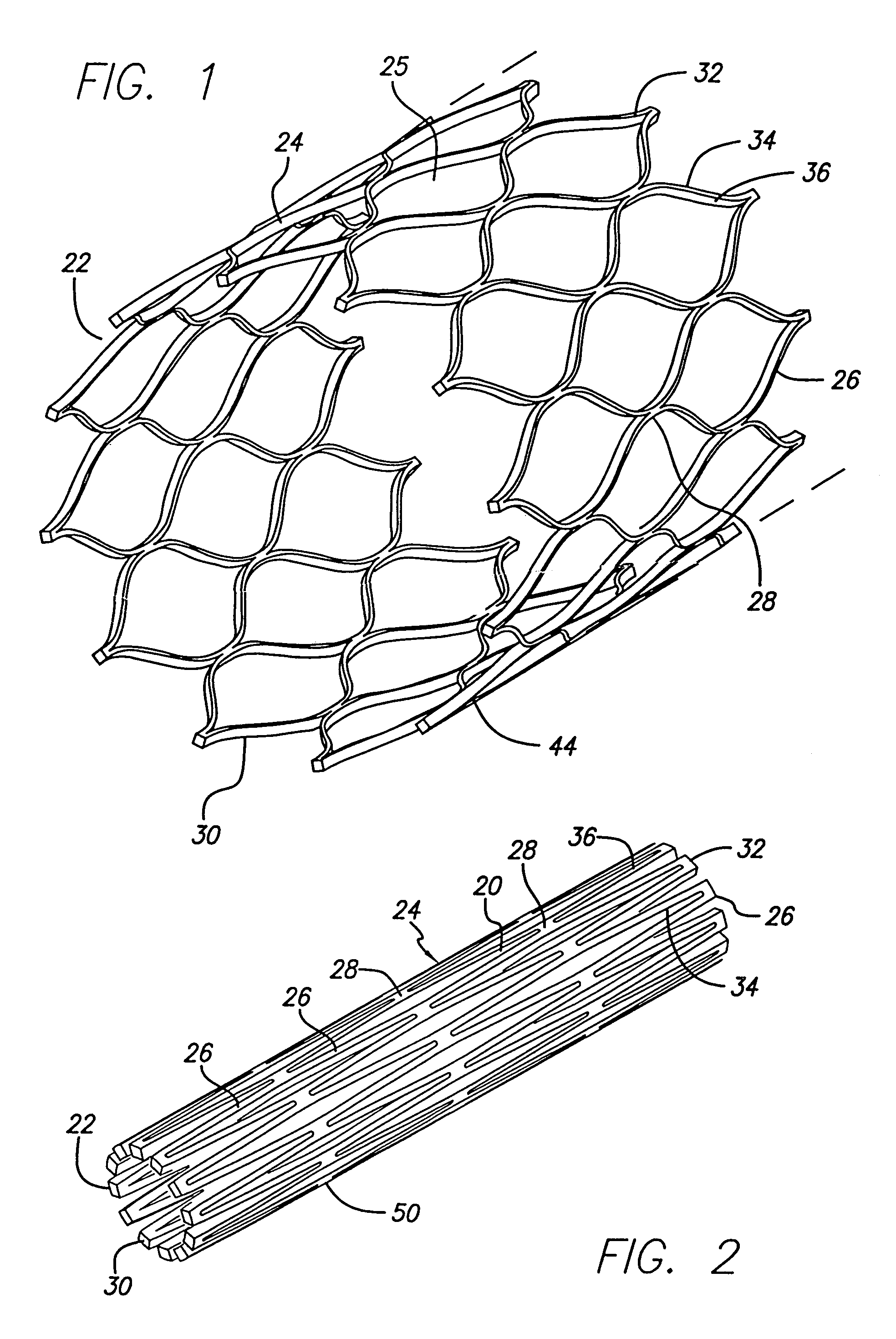

Single-piece endoprosthesis with high expansion ratios and atraumatic ends

A new endoluminal prosthesis for use in sealing a vascular graft to corporeal lumen provides for a flattened bulbous tail at the end of each cell of the prosthesis. The flattened bulbous tails reduce the amount of wear between the prosthesis and the softer material of the vascular grafts or corporeal lumen walls. A method of manufacturing a stent from a flat sheet of material is also included.

Owner:ENDOVASCULAR TECH

Split shroud exhaust nozzle

ActiveUS20060016171A1Increase the diameterReduce the overall diameterCosmonautic vehiclesEngine manufactureNozzle throatVariable geometry

A variable geometry convergent-divergent nozzle for a gas turbine engine includes a centerbody extending rearward along a longitudinal axis of the engine which has a throat section of increased diameter. An inner shroud surrounds the centerbody and cooperates with the centerbody to define the throat of the nozzle. An outer shroud surrounds the inner shroud and cooperates with the centerbody to define the exit area of the nozzle. Both shrouds are independently translatable to provide independent control of the nozzle throat area and the nozzle expansion ratio.

Owner:GENERAL ELECTRIC CO

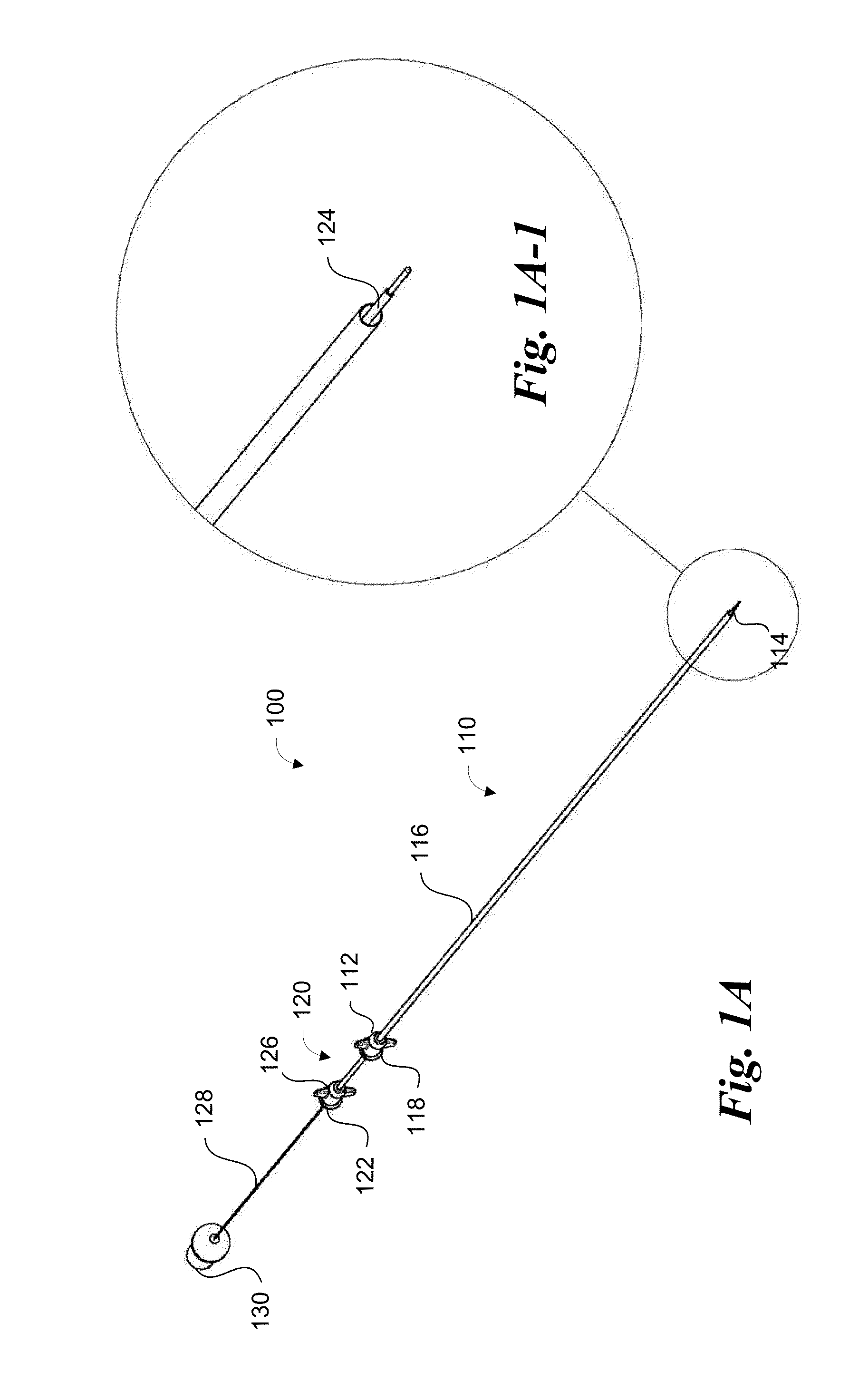

Methods and devices for endovascular embolization

The present disclosure describes an occlusion device and methods of delivering the occlusion device. The occlusion device can include an expandable structure configured to move between an unexpanded configuration and an expanded configuration. The expandable structure can be configured to have an expansion ratio of at least about 5:1. Further, the occlusion device can be configured to prevent substantially all fluid from flowing past the occlusion device when the occlusion device is in the expanded configuration in the vessel.

Owner:EMBOLIC ACCELERATION LLC

High-efficiency linear combustion engne

ActiveUS20120125288A1Improve thermal efficiencyRaise the ratioCombustion enginesEngine controllersCombustionGas spring

Various embodiments of the present invention are directed toward a linear combustion engine, comprising: a cylinder having a cylinder wall and a pair of ends, the cylinder including a combustion section disposed in a center portion of the cylinder; a pair of opposed piston assemblies adapted to move linearly within the cylinder, each piston assembly disposed on one side of the combustion section opposite the other piston assembly, each piston assembly including a spring rod and a piston comprising a solid front section adjacent the combustion section and a hollow back section comprising a gas spring that directly provides at least some compression work during a compression stroke of the engine; and a pair of linear electromagnetic machines adapted to directly convert kinetic energy of the piston assembly into electrical energy, and adapted to directly convert electrical energy into kinetic energy of the piston assembly for providing compression work during the compression stroke; wherein the engine includes a variable expansion ratio greater than 50:1.

Owner:MAINSPRING ENERGY INC

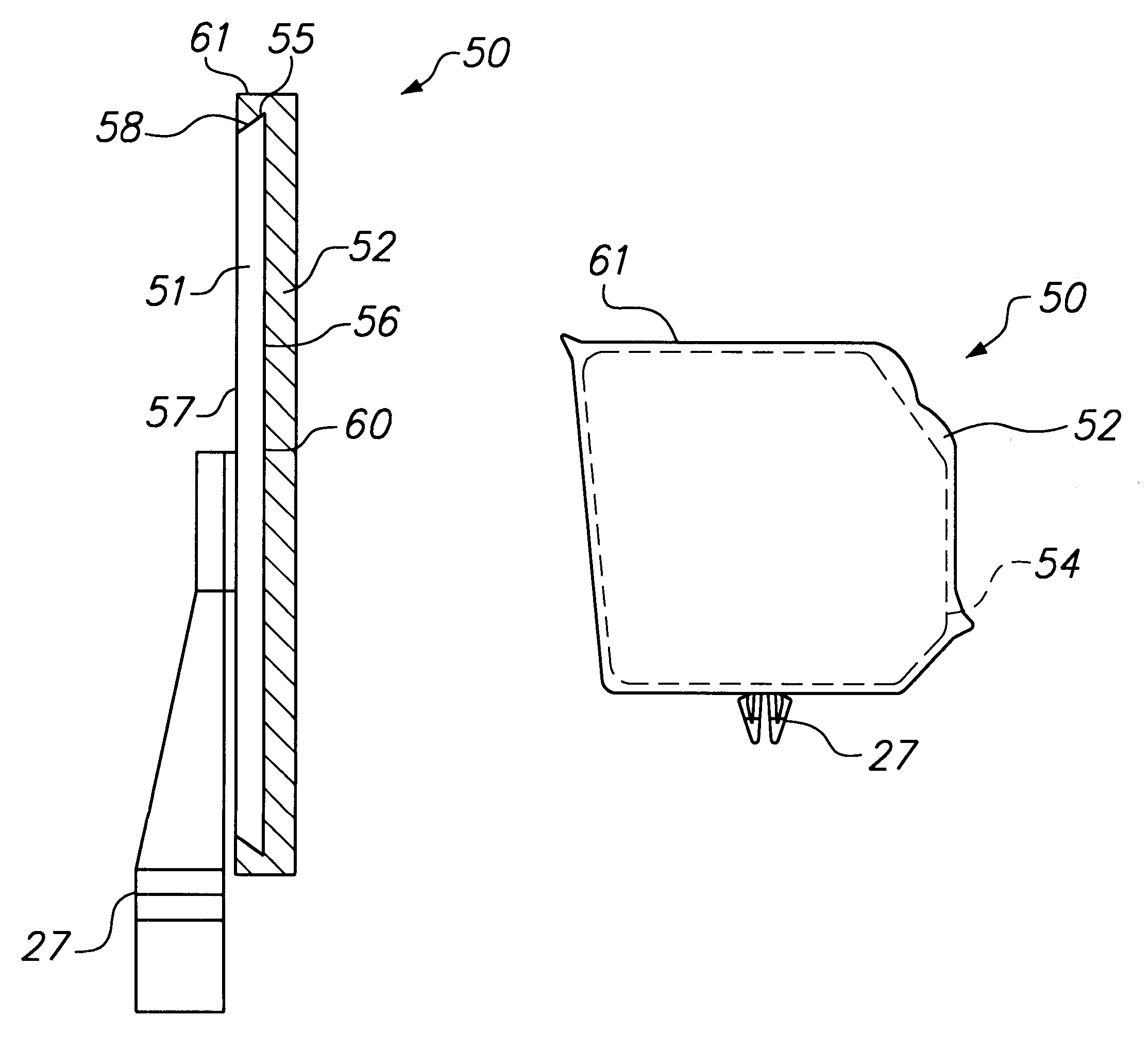

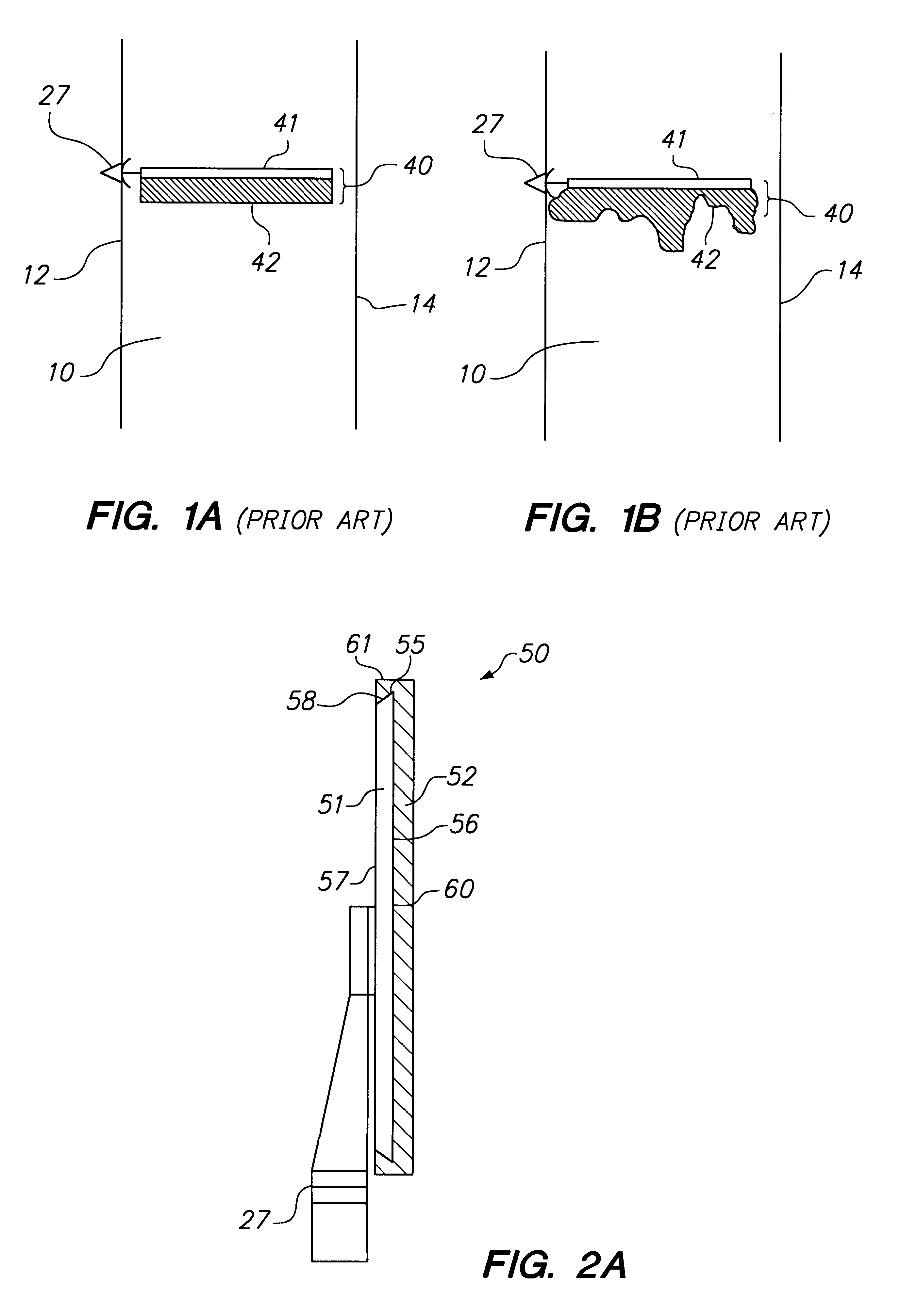

High efficiency positive displacement thermodynamic system

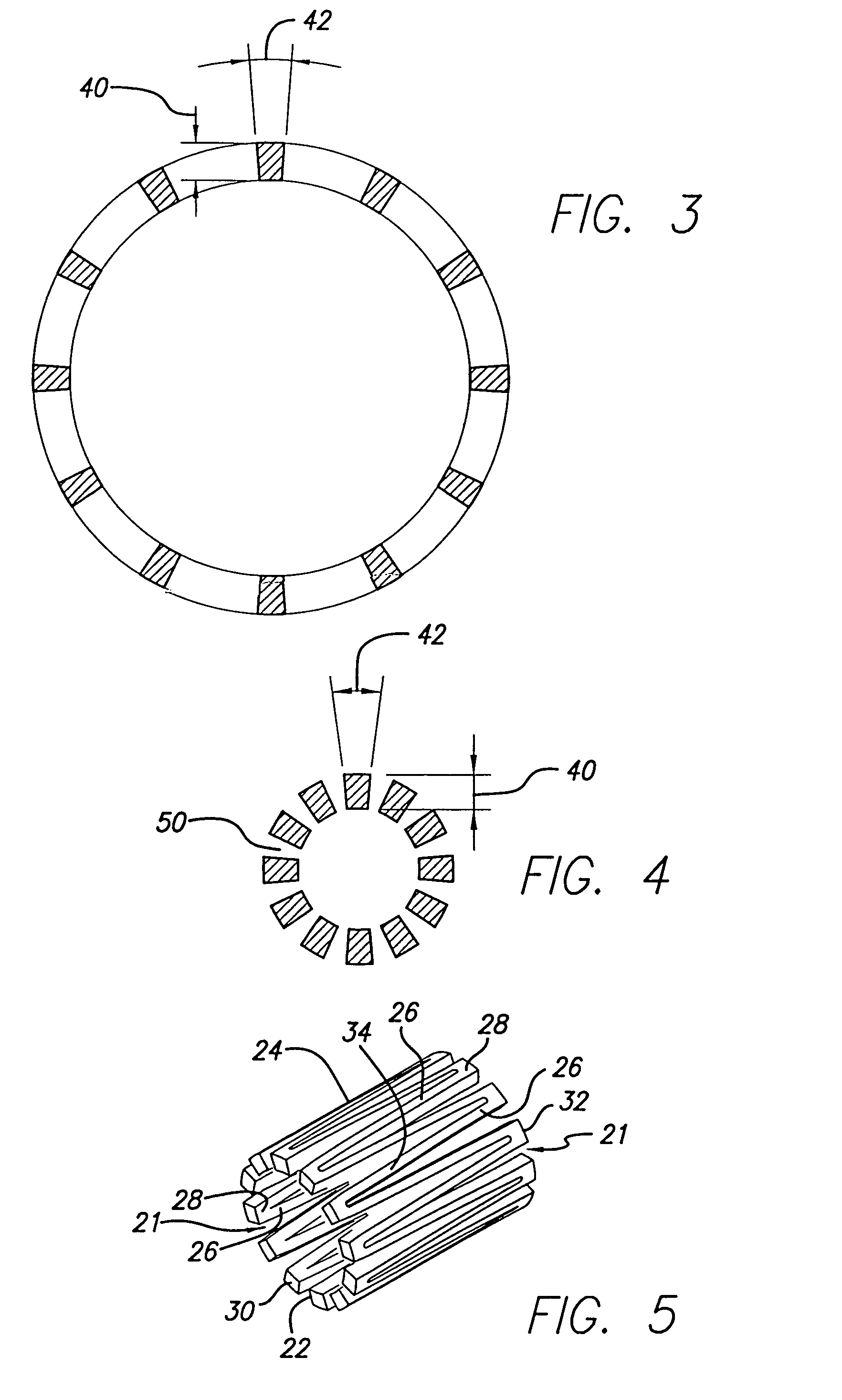

ActiveUS20100050628A1Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

Method for preparing polyurethane/rubber interpenetrating network type water-swellable rubber

The invention belongs to the technical field of sealing materials and relates to a method for preparing polyurethane / rubber interpenetrating network type water-swellable rubber. The method comprises the following steps: firstly, mixing rubber and super-absorbent resin for 10 to 40 minutes in an open mill; further adding solid softener, colorant, anti-ager and promoter to the open mill, and mixing for 10 to 40 minutes; then, adding zinc oxide, reinforcing agent and plasticizer to the open mill, and mixing for 10 to 50 minutes; further adding vulcanizer to the open mill, and mixing to obtain a mixture A; evenly mixing polyethylene glycol and MDI (methyl-di-p-phenylene isocyanate) by equal molar weight to obtain a mixture B; blending the mixture A and the mixture B in the open mill to obtain a product; and finally, vulcanizing the product in a mold on a plate vulcanization machine with the temperature and pressure being respectively controlled at 150 to 160 DEG C and at 10MPa to 15MPa, to obtain the interpenetrating network type water-swellable rubber. The method of the invention has the advantages of simple preparation process, high product expansion ratio, high ion resistance and controllable water absorption rate and mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

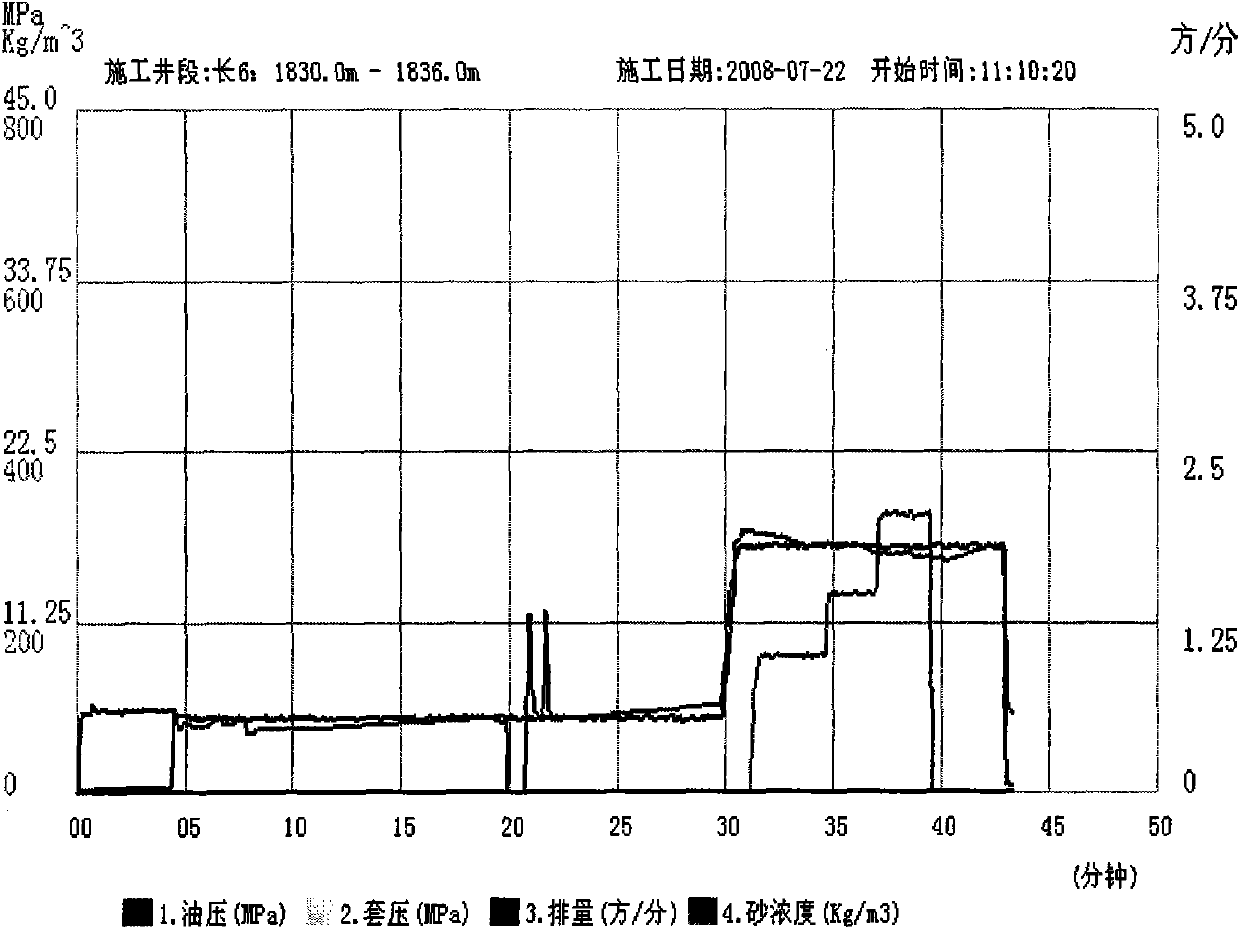

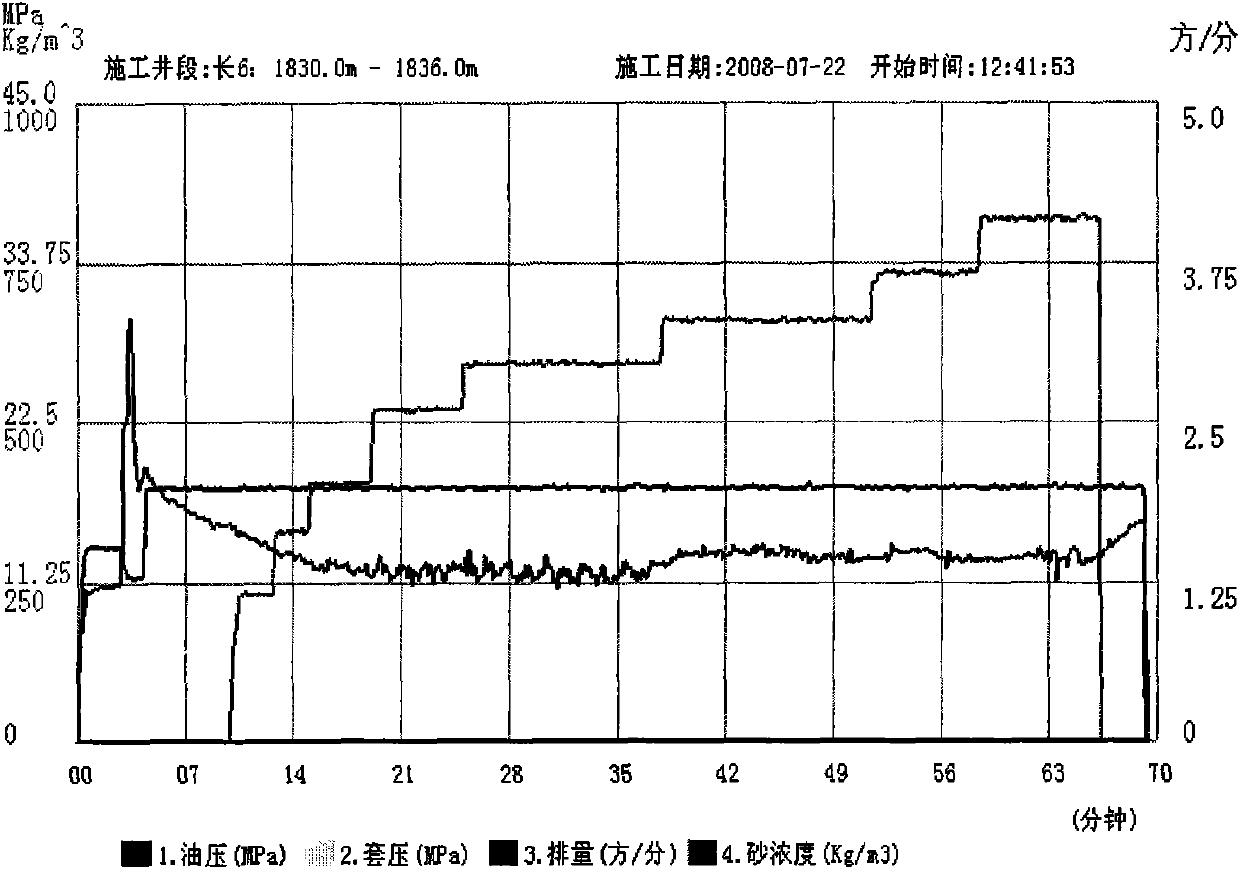

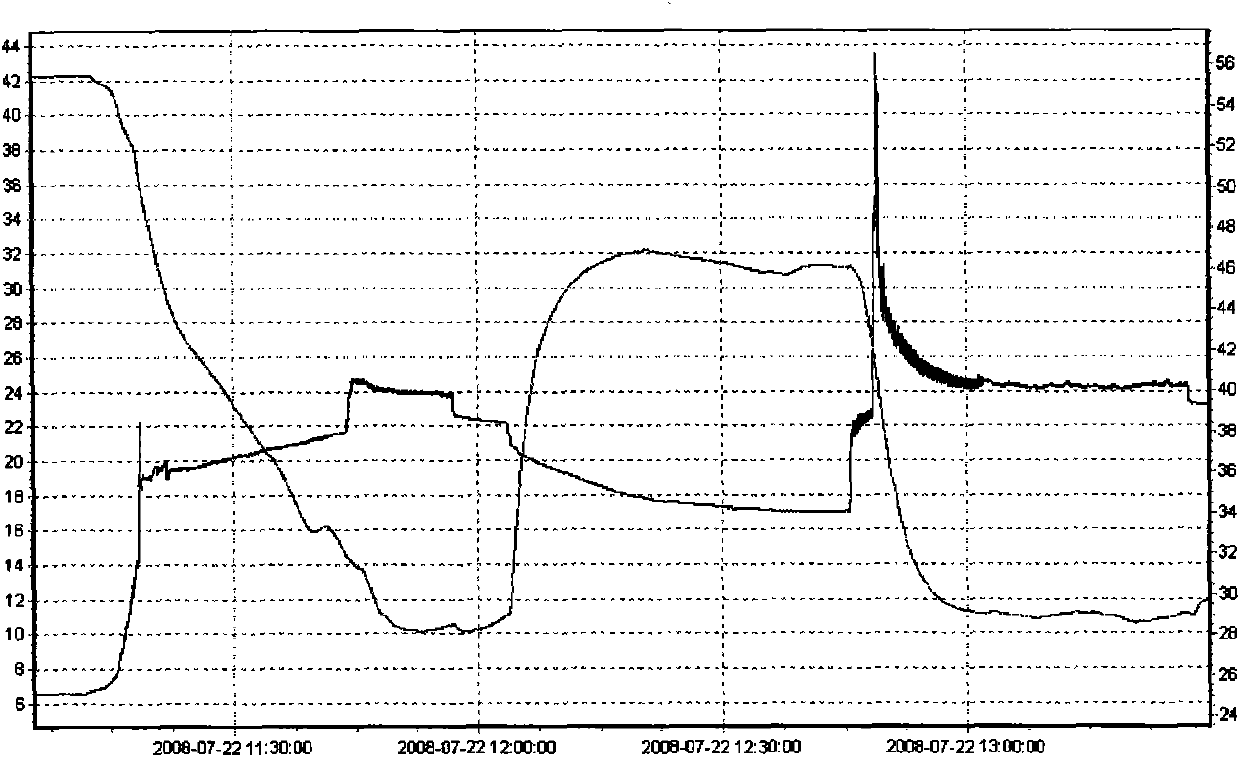

In-fissure diversion fracturing temporary blocking agent for low-permeability oilfield, and preparation method and application thereof

The invention relates to an in-fissure diversion fracturing temporary blocking agent for a low-permeability oilfield, and a preparation method and application thereof. The temporary blocking agent is prepared by the following steps of: mixing 92 mass percent of bone glue powder, 0.2 mass percent of benzoic acid, 5 mass percent of modified starch, 1.3 mass percent of hydroxyethyl cellulose, 1.0 mass percent of F-containing surfactant and 0.5 mass percent of cross-linking agent; adding polyoxyethylene diacrylate with concentration of between 5 and 100mg / L and an initiator with concentration of between 100 and 500mg / L and reacting at the temperature of 80 DEG C under the pressure of 1.2MPa for gelling; and granulating, applying oil and drying, wherein the maximum expansion ratio is 1.33; the agent has high temperature resistance stability and stable adhesion; the maximum elongation is 64 percent; the breakthrough pressure gradient reaches 30.0MPa / m; the viscosity is 35mPa.s after the agent is completely dissolved at the temperature of 60 DEG C; and the agent can be completely flowed back under the action of the carrying of fracturing liquid.

Owner:PETROCHINA CO LTD

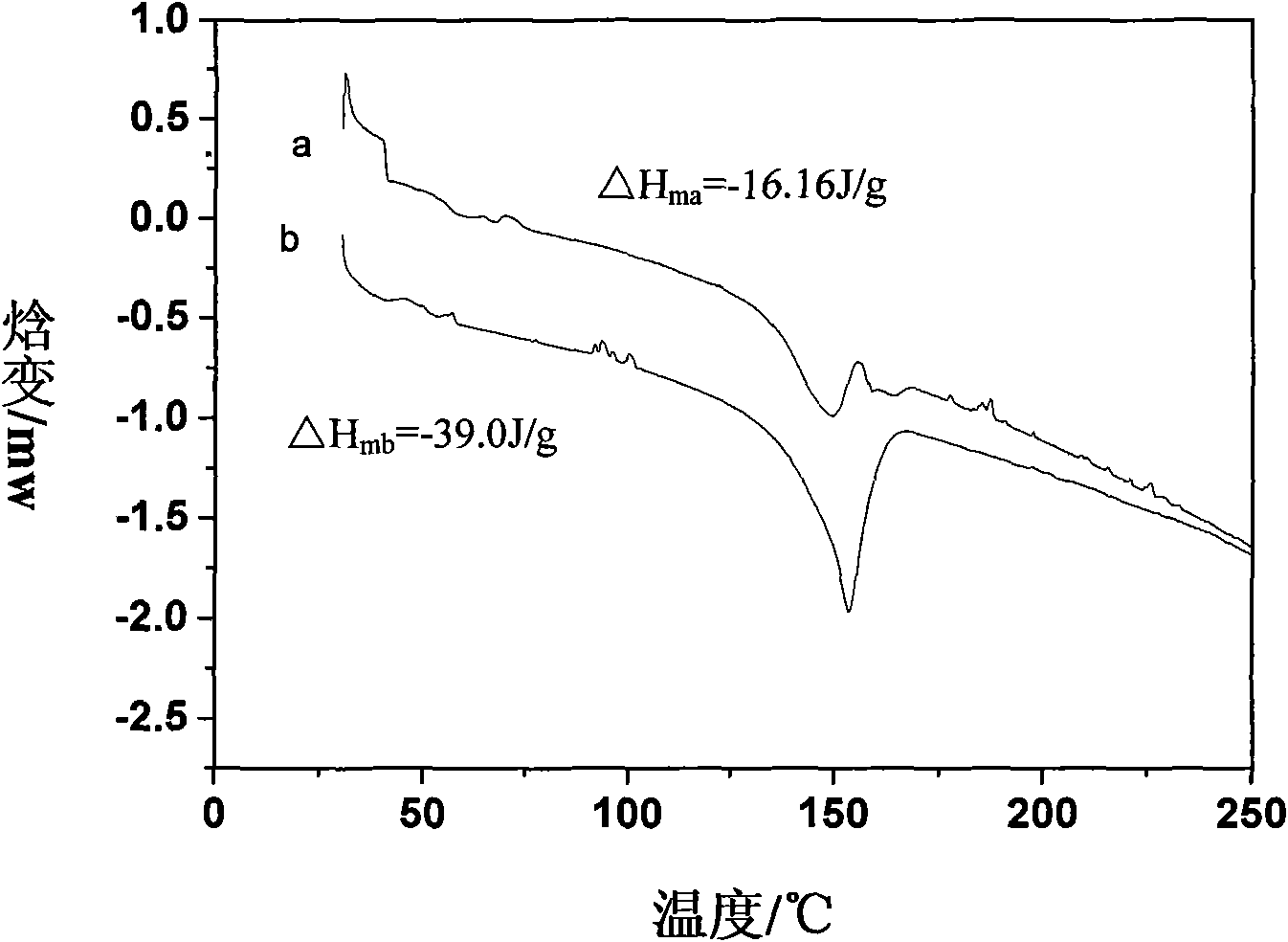

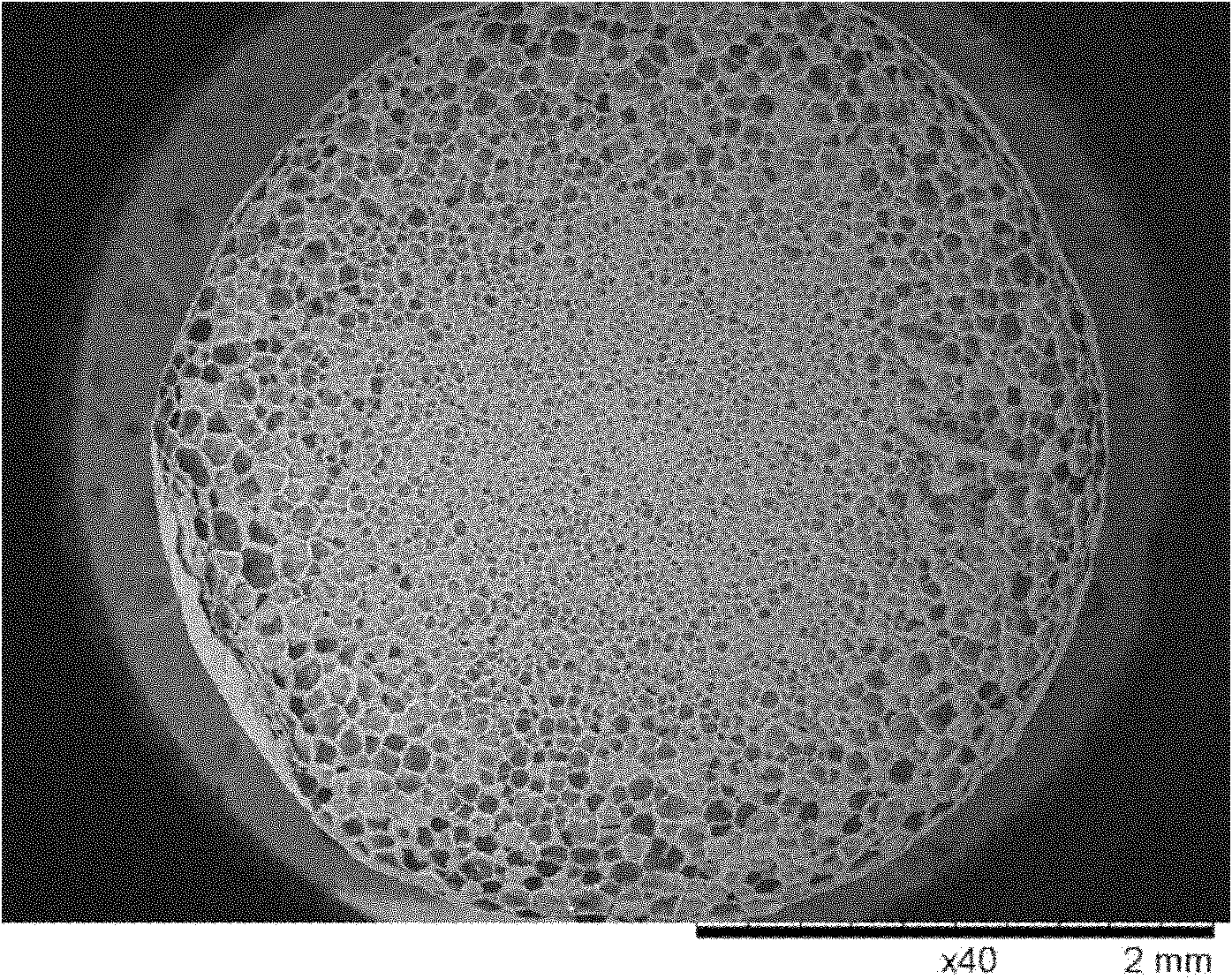

Preparation method of biodegradable polymer foamed particles

ActiveCN102127245AShort saturation timeEase of industrial implementationPolymer scienceHigh pressure

The invention discloses a preparation method of biodegradable polymer foamed particles, which comprises the following steps: (1) mixing polymer particles and a 0.5-8 MPa high-pressure fluid until the polymer particles are saturated, thereby obtaining the saturated polymer particles; and (2) putting the saturated polymer particles obtained in the step (1) in hot air with 60-150 DEG C, and foaming for 1-300 seconds, thereby obtaining the polymer foamed particles, wherein the polymer is polylactic acid, or a compound of polylactic acid and other polymers. The method is simple to operate, and can be easily used for industrial production; and the prepared foamed particles have the characteristics of high expansion ratio, smooth surface, high degree of crystallization, uniform foam pore structure, high foam pore density and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

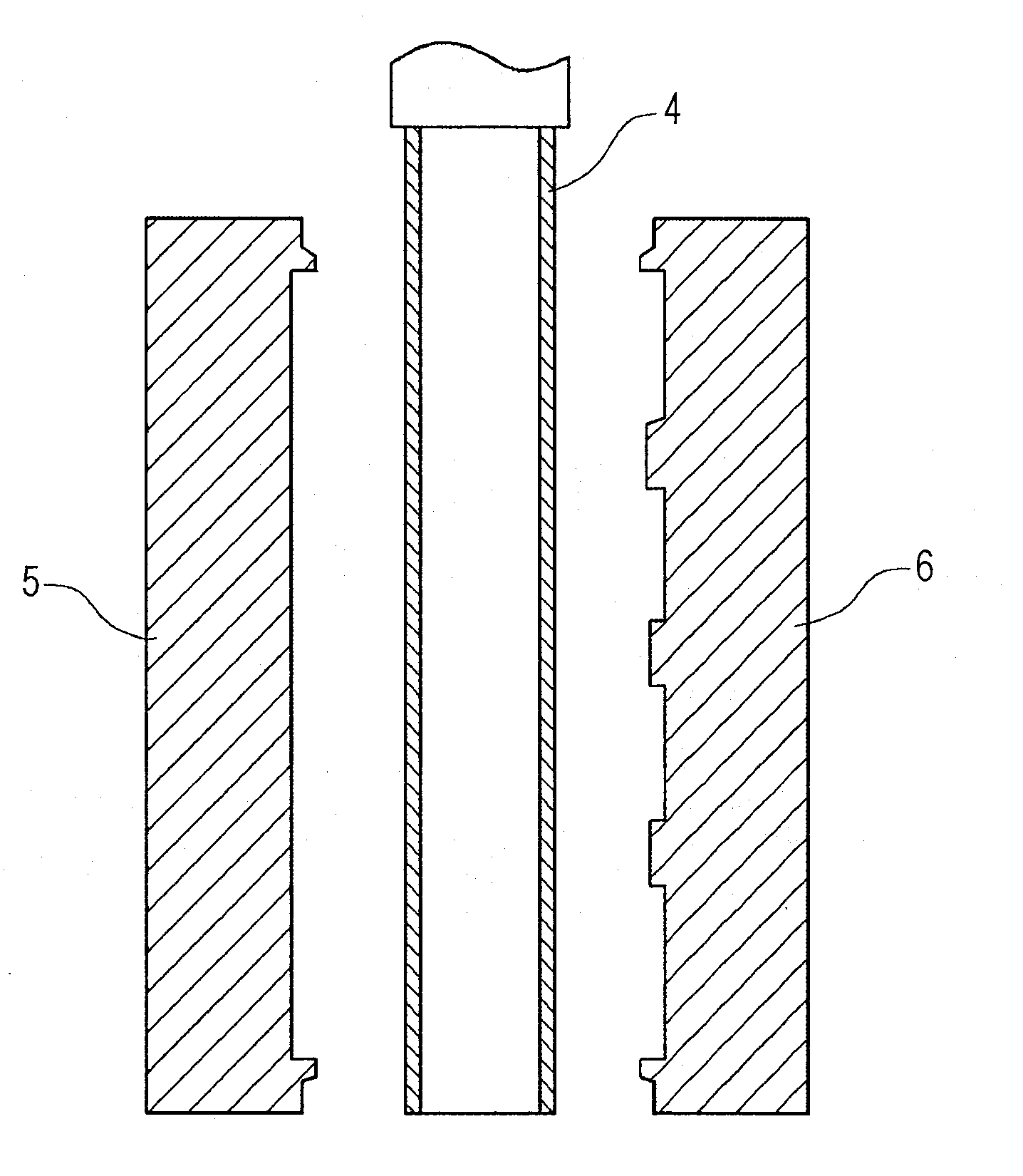

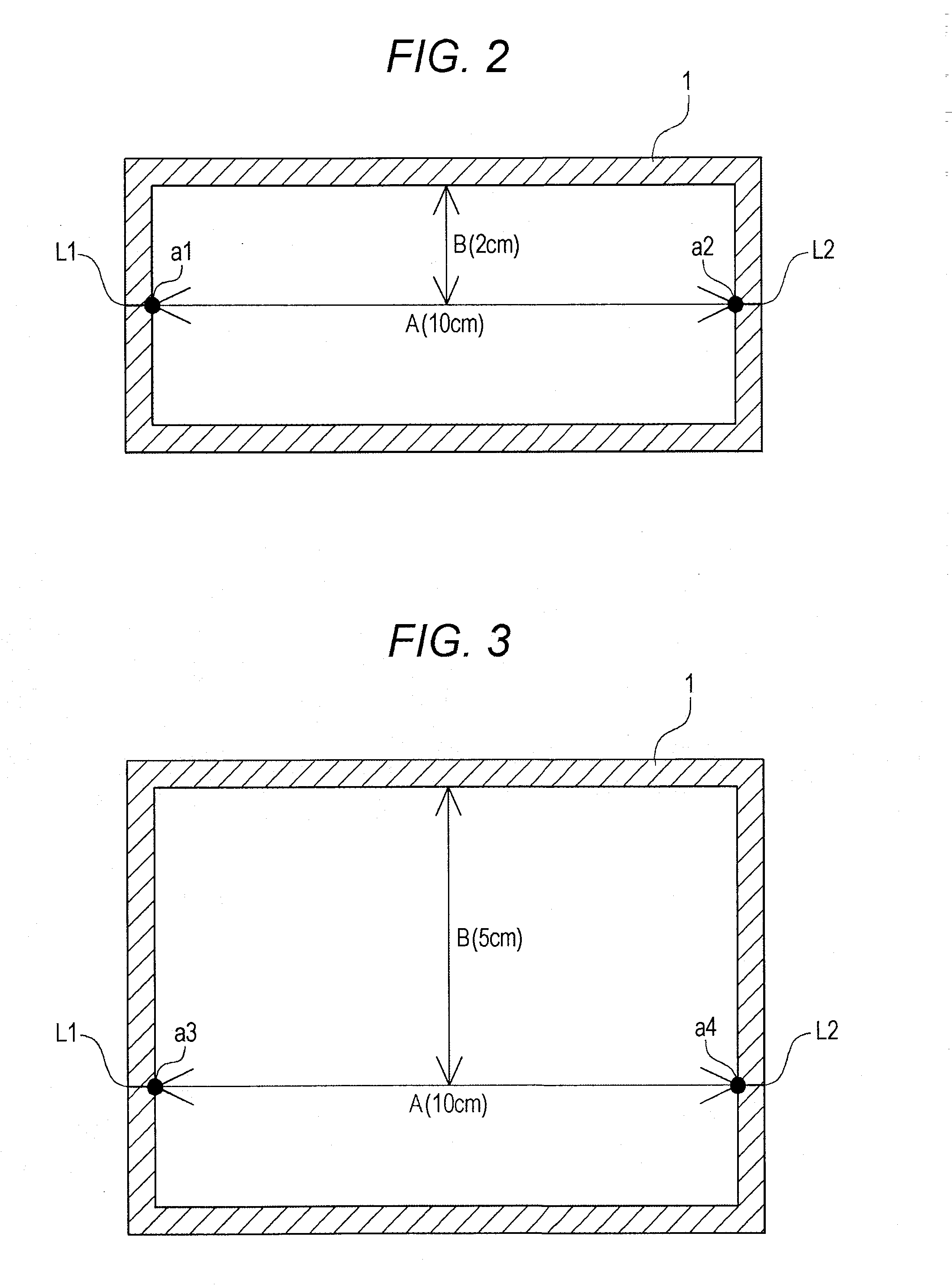

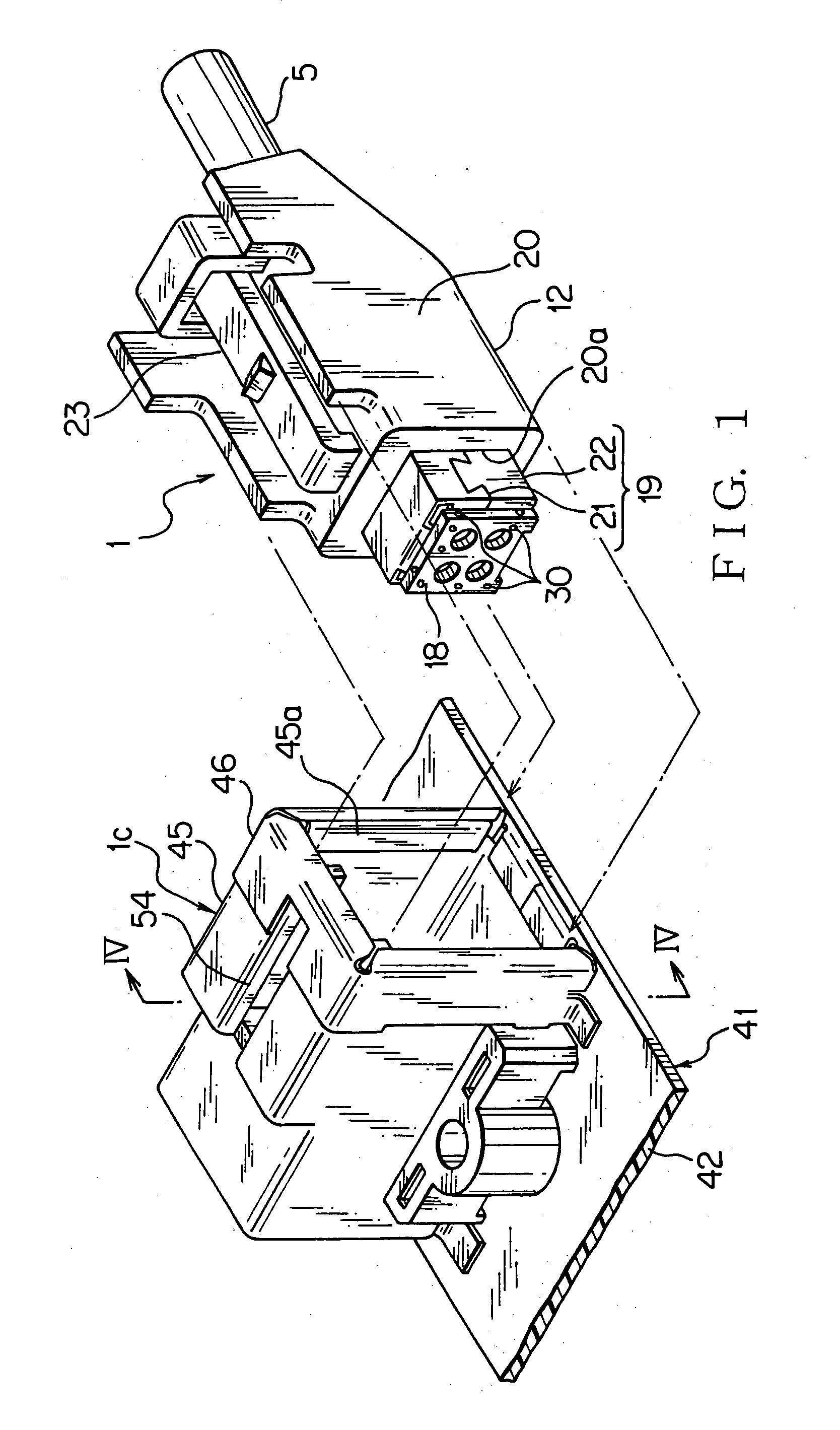

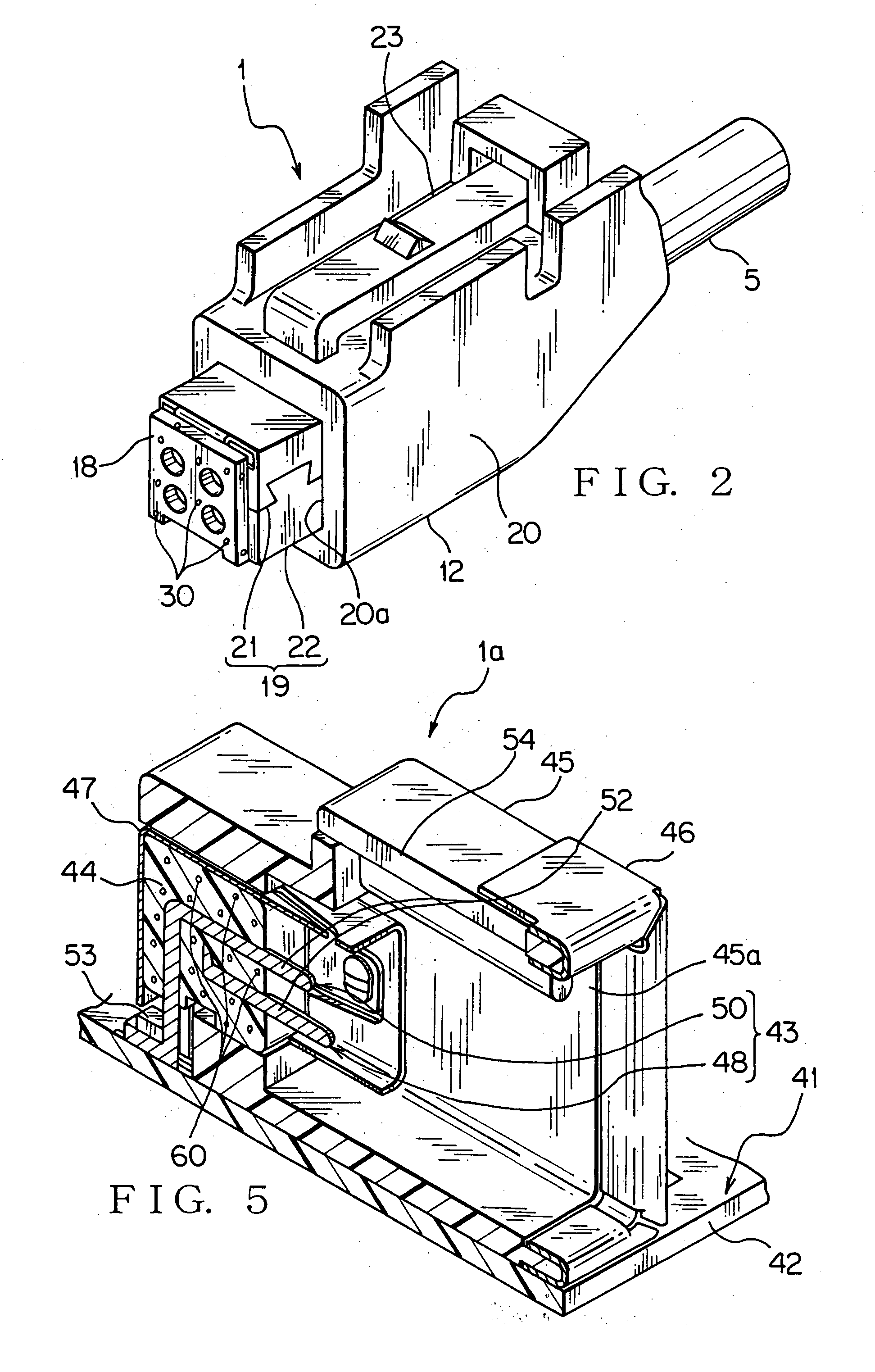

Connector and method of manufacturing the connector

ActiveUS20050101166A1Easy to changeLine/current collector detailsTwo pole connectionsMiniaturizationImpedance matching

A connector, which can have impedance matching between the connector and a cable or a mating connector even if the connector is miniaturized, and a manufacturing method thereof are provided. The connector is joined with an end of a cable 5. The connector has terminals, and a holder having an inner holder holding the terminals and an inner housing. The mating connector has terminals, and a holder holding the terminals. The holders are made of a foamed synthetic resin. Expansion ratio of the resin for the holder of the connector is adjusted to match the impedance with each wire of the cable 5. Expansion ratio of the resin for the holder of the mating connector is adjusted to match the impedance with the connector.

Owner:YAZAKI CORP

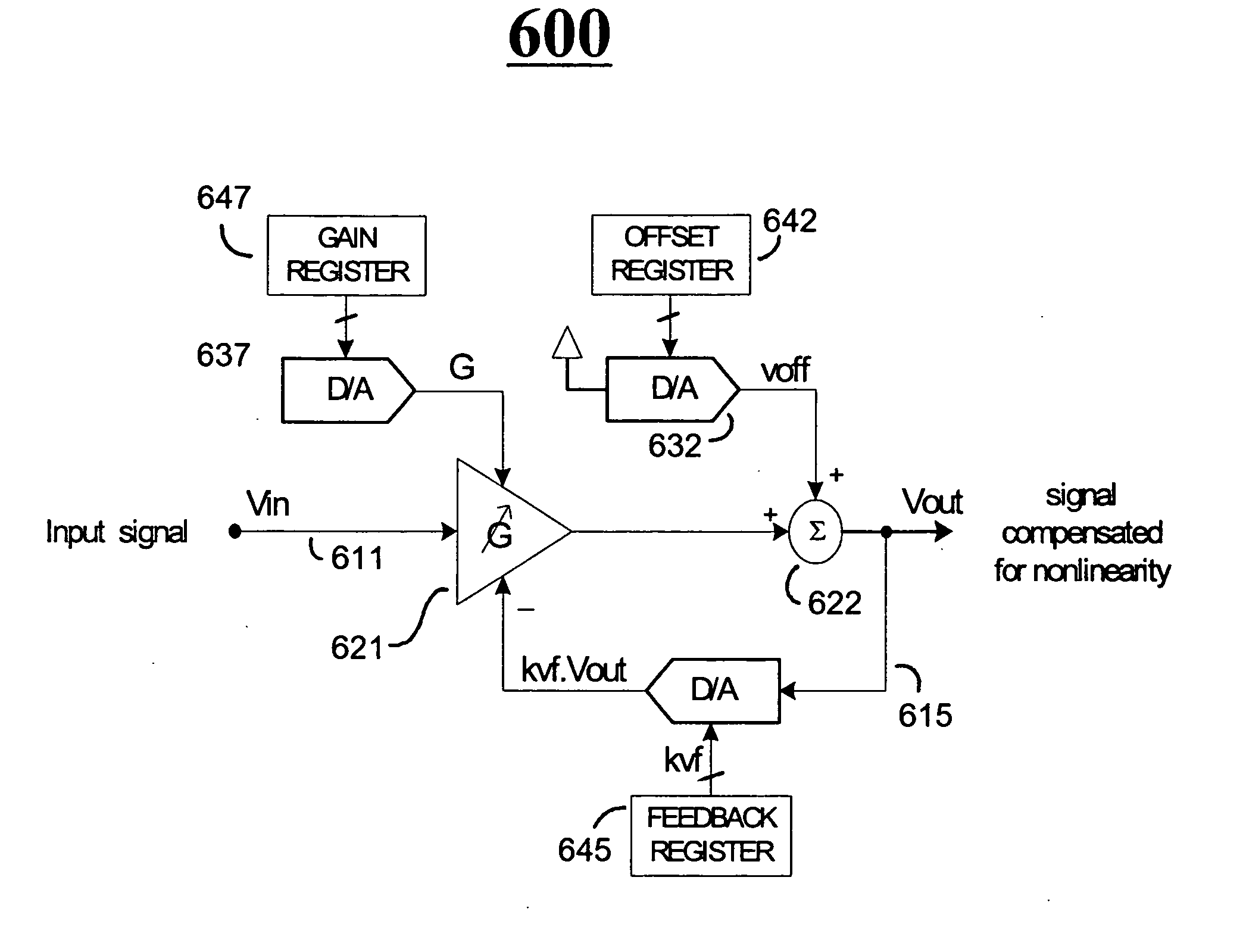

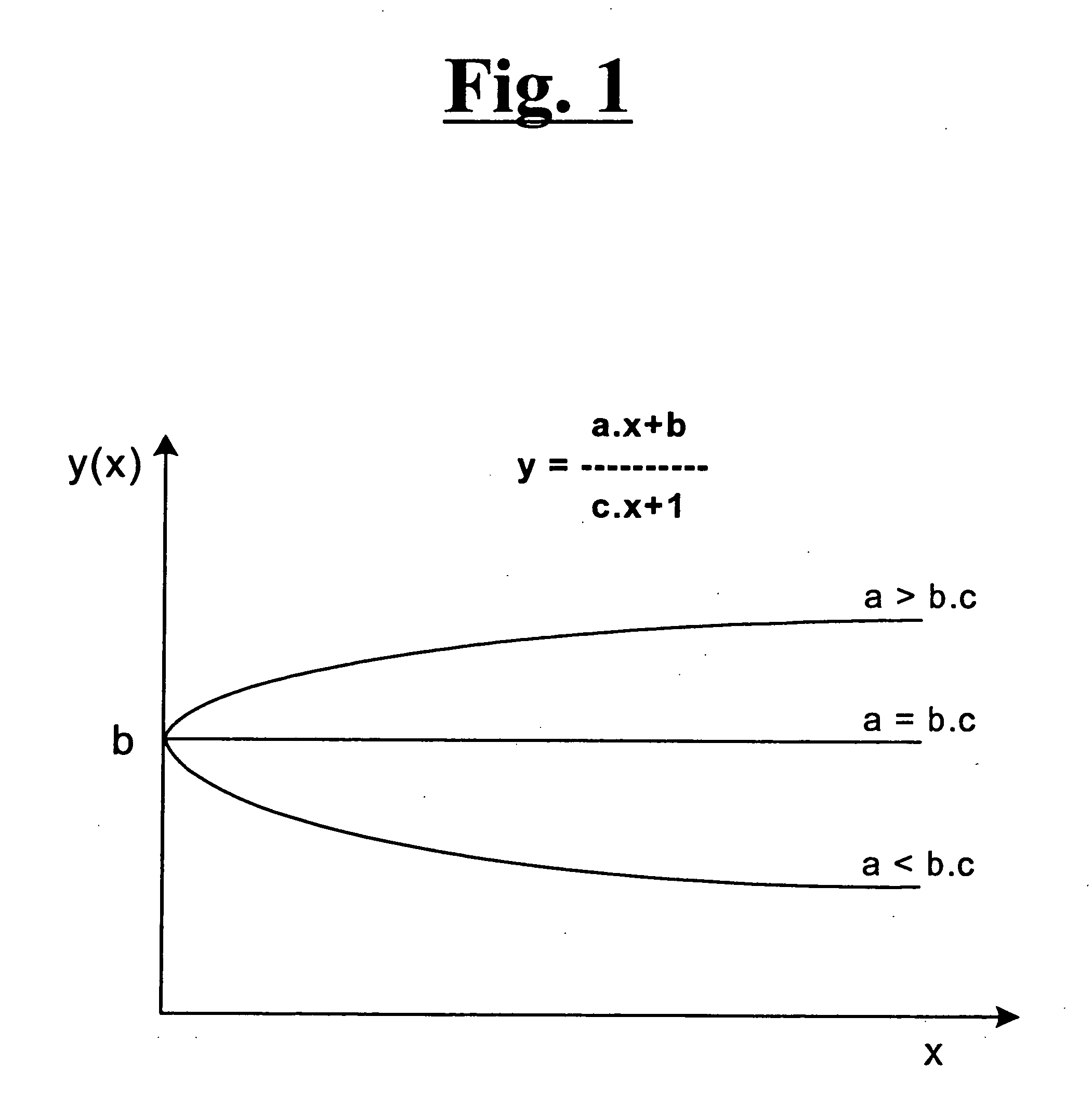

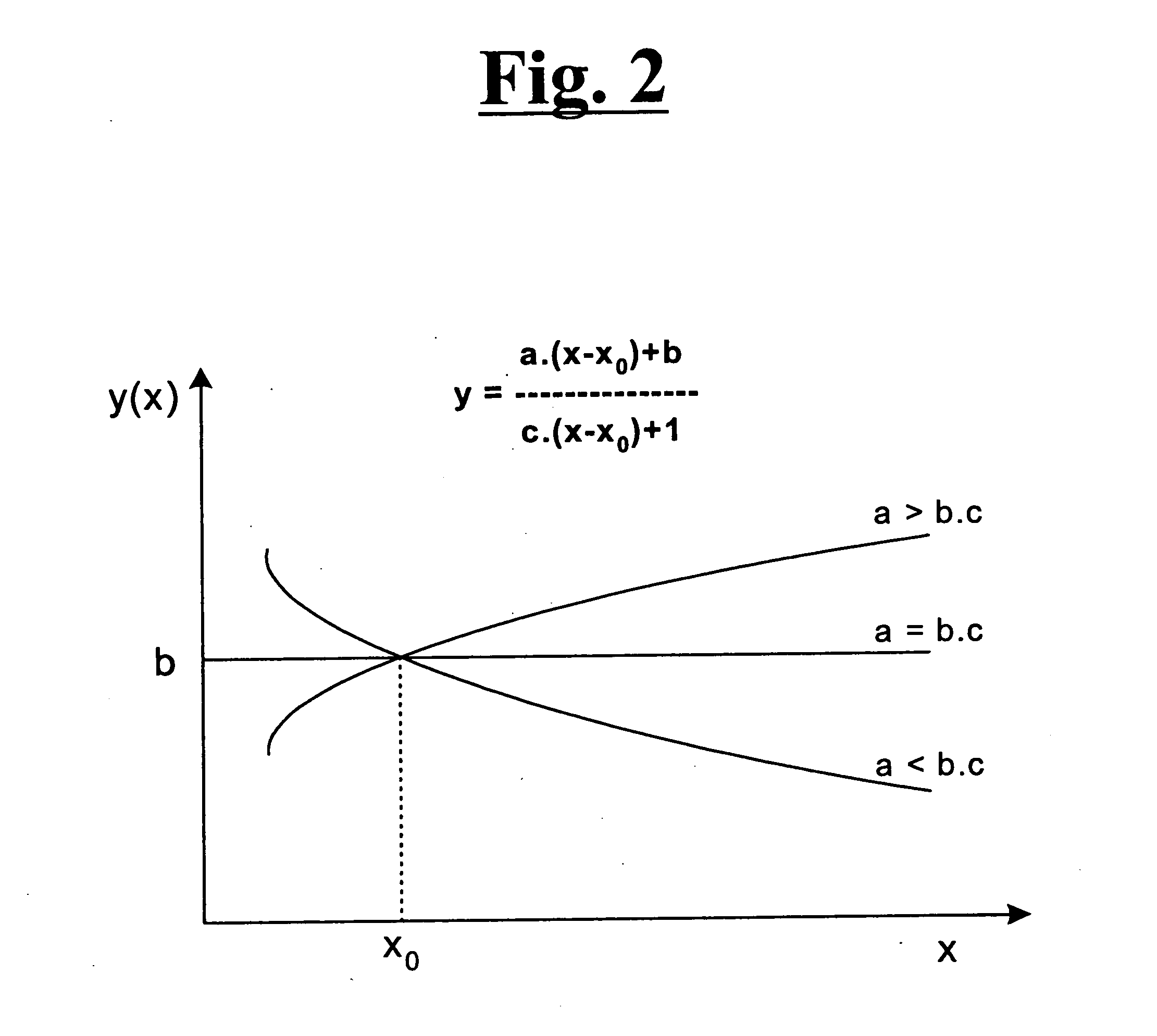

Pade' approximant based compensation for integrated sensor modules and the like

InactiveUS20050256660A1Improve accuracyProgrammably adjustedResistance/reactance/impedenceMitigation of undesired influencesAudio power amplifierVariable-gain amplifier

Methods and systems using Pade′ Approximant expansion ratios provide mappings between nonlinear sensors and a more linearized output domain. In one embodiment (a) a variable gain amplifier receives a supplied input signal, the amplifier has at least a first input terminal, an output terminal, and a gain control terminal; (b) a first summer coupled to the output terminal of the variable gain amplifier adds in a first offset signal; (c) a first multiplier coupled to an output of the first summer receives a proportional feedback factor signal and correspondingly generates a multiplied feedback; (d) a second summer coupled to an output terminal of the first multiplier adds in a corresponding second offset signal; and (e) a second multiplier coupled to an output of the second summer receives a gain factor signal and generates a multiplied gain signal; where the gain control terminal of the variable gain amplifier is operatively coupled to an output terminal of the second multiplier.

Owner:SEMICON COMPONENTS IND LLC

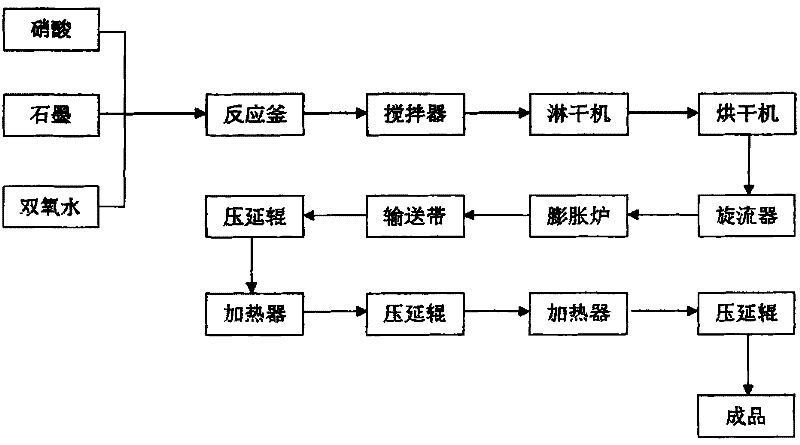

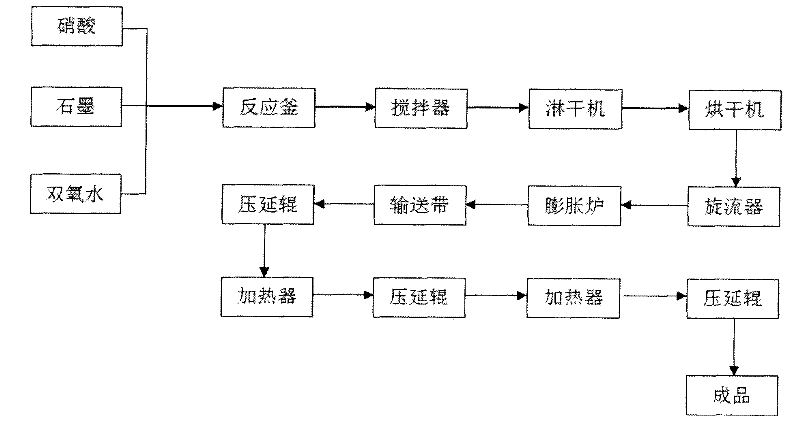

Ultrathin graphite paper radiating fin and manufacturing method thereof

The invention relates to a manufacturing method of an ultrathin graphite paper radiating fin. In the presence of nitric acid and hydrogen peroxide, graphite can stirred to be prepared into an expanded graphite product with the expansion ratio of 300 times, the expanded graphite product is dehydrated by a draining machine, dried by a drying oven and screened by a machine; the obtained graphite product is sent to an expansion furnace at a temperature of 950 DEG C for heating and expanding via a swirler, the expanded vermicular graphite is extracted from the expansion furnace and is sent to a stock bin; and according to different thickness requirements, vermicular graphite is subjected to repeated rolling until the thickness of final ultrathin graphite paper is reached. The thickness of the graphite paper radiating fin is equal to or greater than 0.04mm, the sulphur content is less than 1000ppm, and the thermal conductivity is more than 300W / moK. The invention, the obtained graphite paper radiating fin is thinnest, the miniaturization and ultra thin of the final product are realized, the service life of the product is improved, the problem of rapidly radiating at high temperature is solved, the cost of raw materials for producing the graphite paper radiating fin is lowered, rare graphite resources are protected and the uses of irregular shape products can be satisfied.

Owner:肖云凯

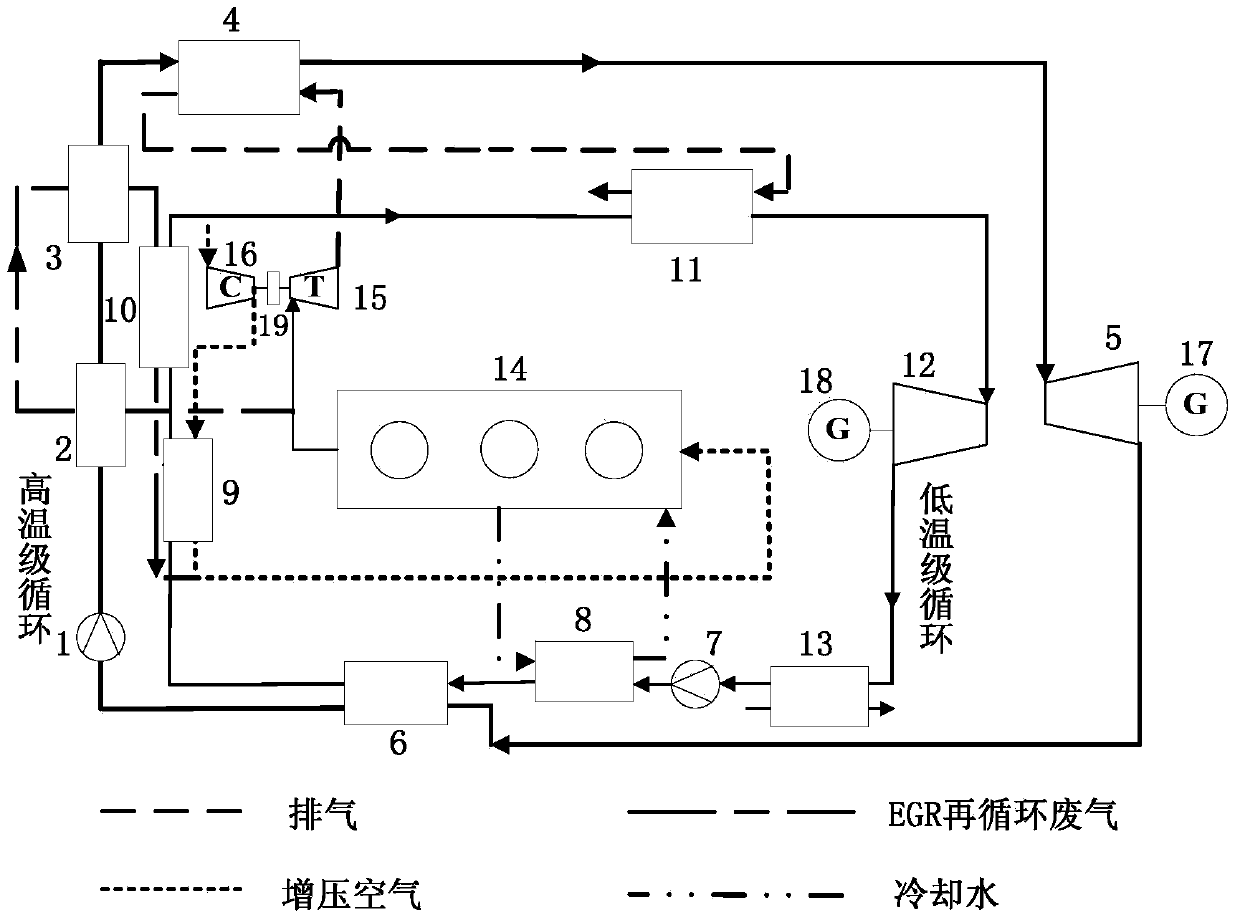

Combined-type diesel engine waste heat energy recycling system

InactiveCN104265502AMake up for the defect of small output powerReduce irreversible lossNon-fuel substance addition to fuelInternal combustion piston enginesOrganic Rankine cycleDiesel engine

The invention discloses a multi-grade waste heat energy cascade recycling system for a diesel engine, and particularly relates to a combined-type diesel engine waste heat energy recycling system. The waste heat energy recycling system is structurally characterized in that a high-temperature Rankine cycle system is composed of a working medium pump, a thermoelectric generator, an EGR heat exchanger, an exhaust heat exchanger, a steam turbine, a condenser and the like of a high-temperature system; a low-temperature Rankine cycle system is composed of a working medium pump, an EGR heat exchanger, an exhaust heat exchanger, the cylinder body cooling water heat exchanger, the supercharged air heat exchanger, a steam turbine, a condenser and the like of a low-temperature system. A middle electrical machine is arranged between a turbine motor and a supercharger; the waste heat of cooling water, supercharged air, exhausted gas, EGR recirculated waste gas and the like are utilized, and through the high-temperature and low-temperature organic Rankine cycles, thermoelectric power generation, turbine direct power generation and the like, heat exchange can be carried out between various kinds of waste heat generated by the diesel engine and working media sequentially according to the grade. Due to arrangement of the middle electrical machine, the expansion ratio of the exhausted gas can be improved, and excess pressure energy of the exhausted gas can be directly recycled. Full recycling of multi-grade waste heat energy of an internal combustion engine can be achieved, irreversible losses of the system are reduced, the fuel economical efficiency is effectively improved, and therefore the aims of saving energy and reducing emissions are achieved.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com