Patents

Literature

376results about How to "Improve rate discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

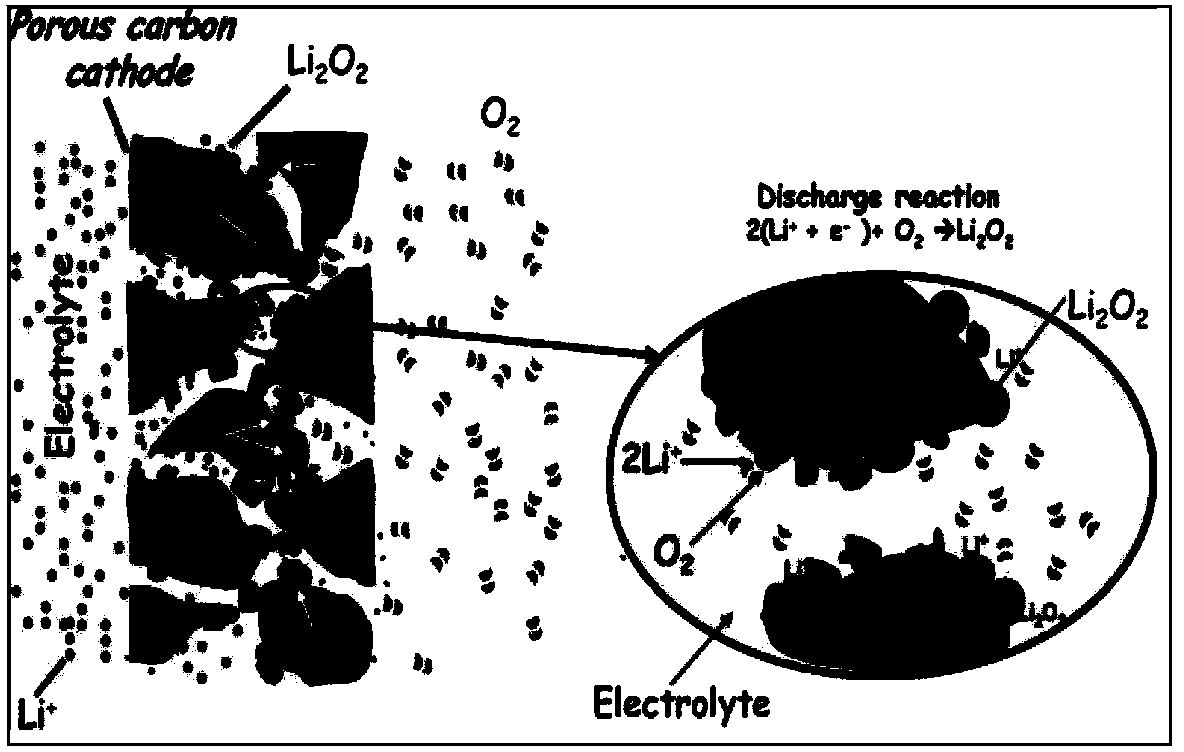

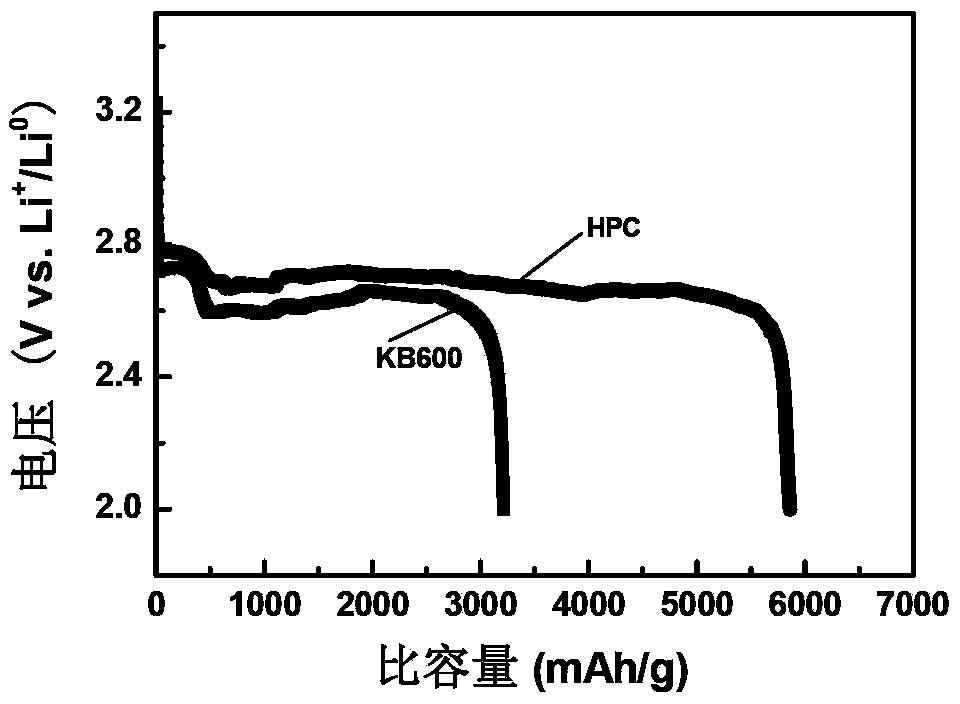

Nitrogen-doped porous carbon material for lithium-air battery positive electrode

ActiveCN103855366AHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesPorous carbonCharge discharge

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode, wherein the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Active substance of positive electrode and nonaqueous electrolyte battery containing the same

ActiveUS20050019659A1Increase energy densityImprove high rate discharge performanceSecondary cellsAlkali metal oxidesHigh rateHigh energy

A positive active material is provided which can give a battery having a high energy density and excellent high-rate discharge performance and inhibited from decreasing in battery, performance even in the case of high-temperature charge. Also provided is a non-aqueous electrolyte battery employing the positive active material. The positive active material contains a composite oxide which is constituted of at least lithium (Li), manganese (Mn), nickel (Ni), cobalt (Co), and oxygen (O) and is represented by the following chemical composition formula: LiaMnbNicCodOe (wherein 0<a≦1.3, |b−c|≦0.05, 0.6≦d<1, 1.7≦e≦2.3, and b+c+d=1). The non-aqueous electrolyte battery has a positive electrode containing the positive active material, a negative electrode, and a non-aqueous electrolyte.

Owner:GS YUASA INT LTD

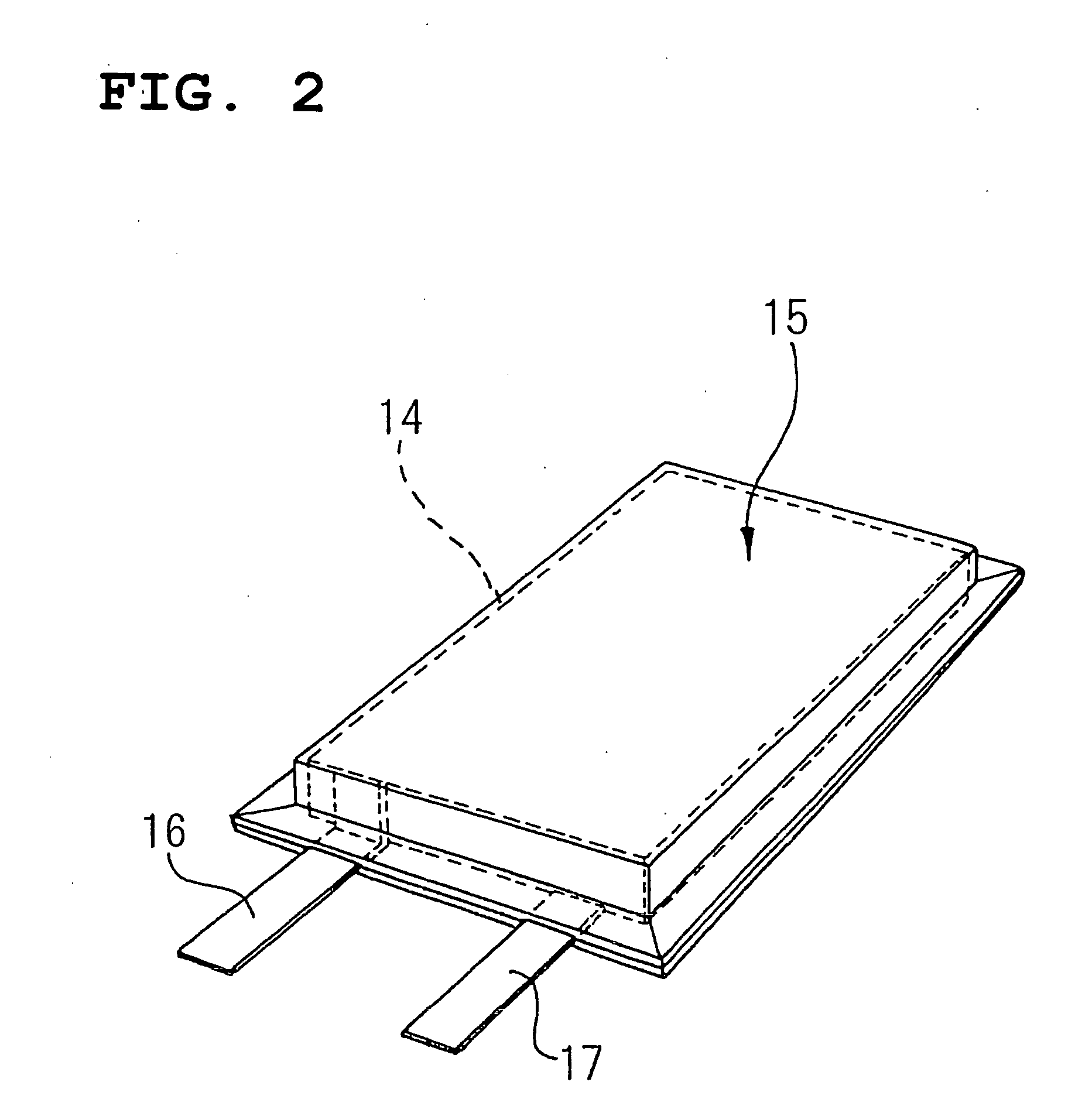

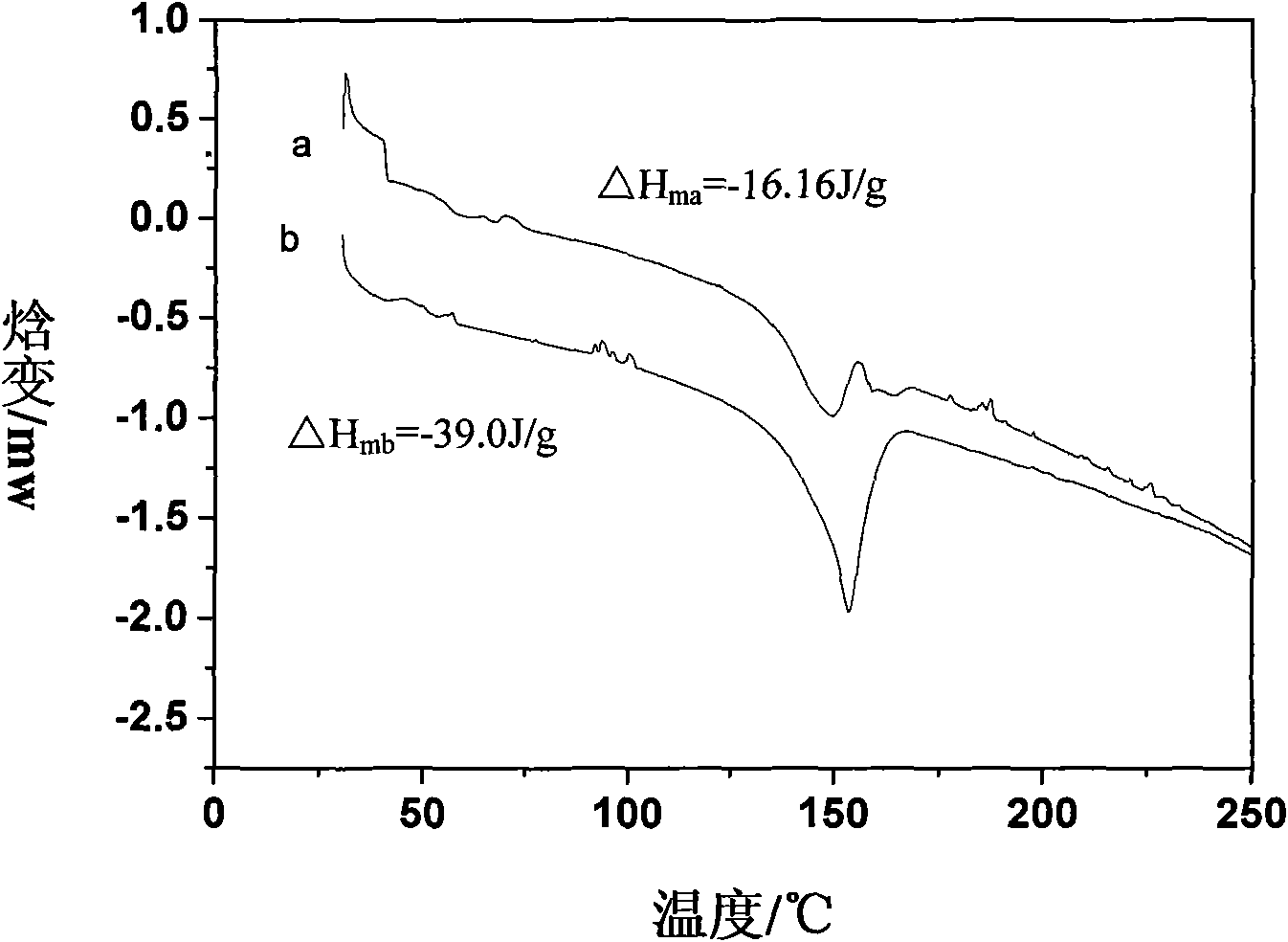

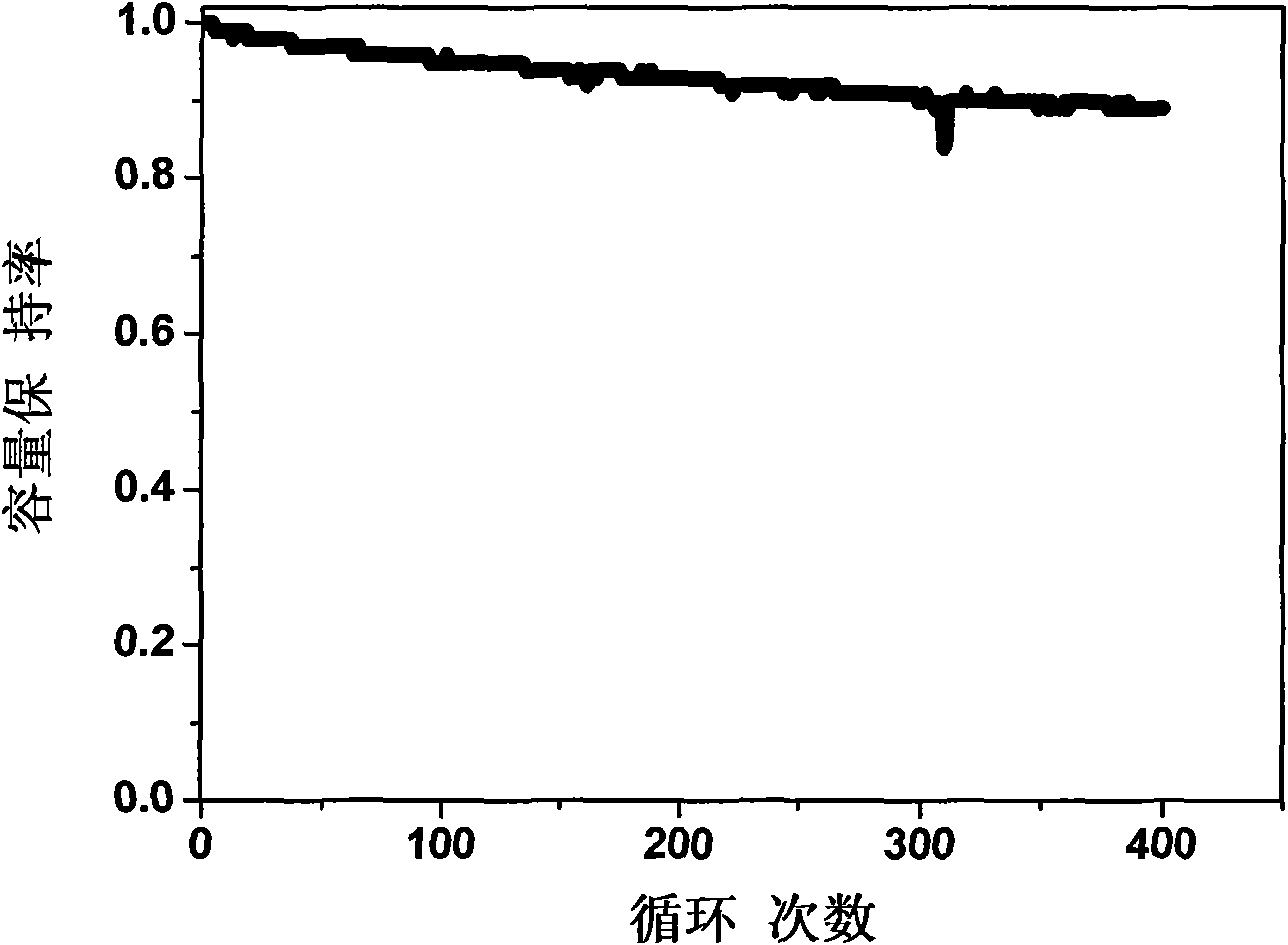

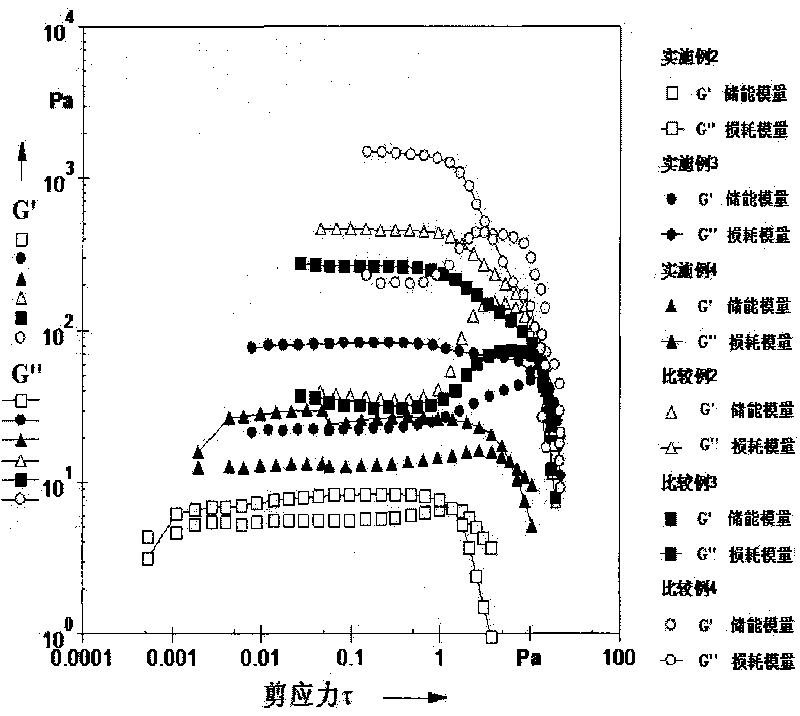

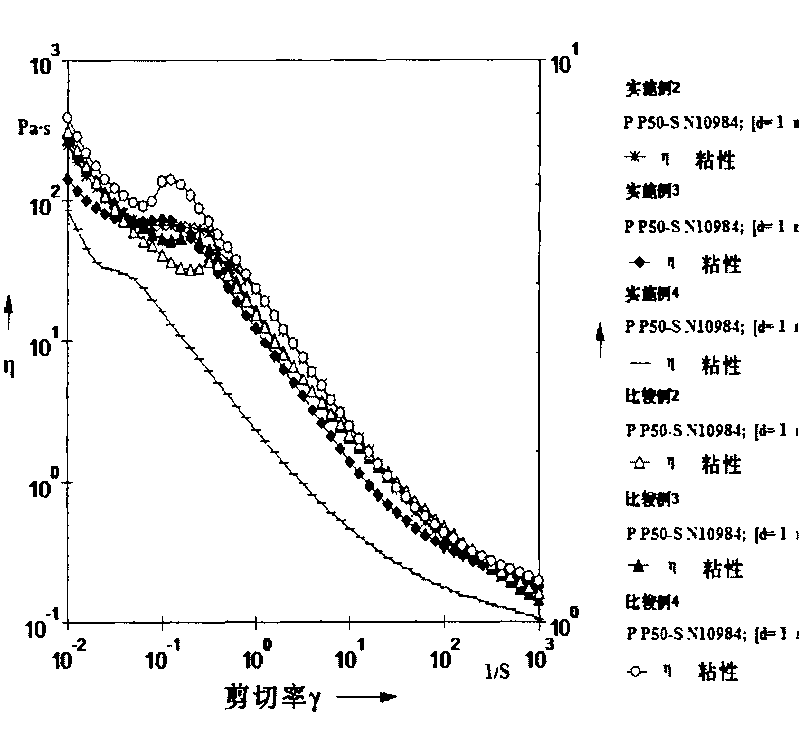

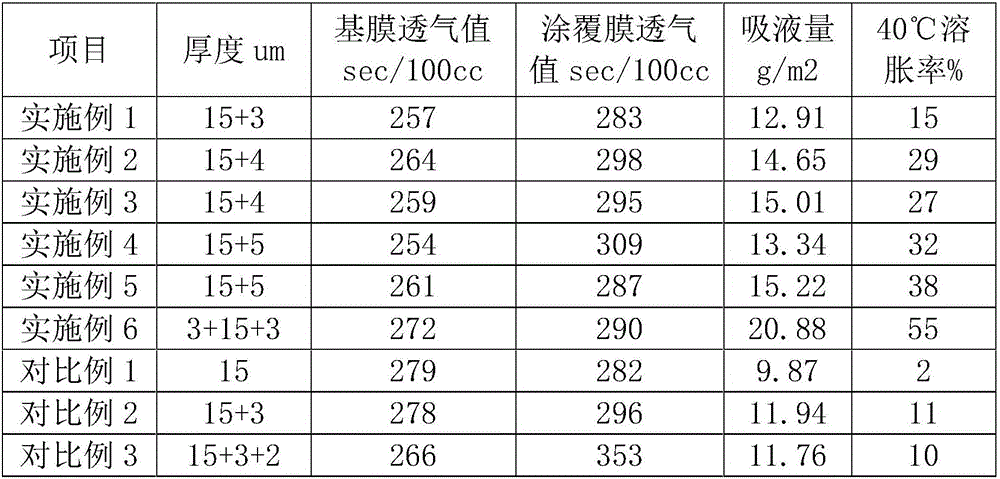

Polymer porous membrane, preparation method thereof, polymer electrolyte, polymer battery and preparation method of battery

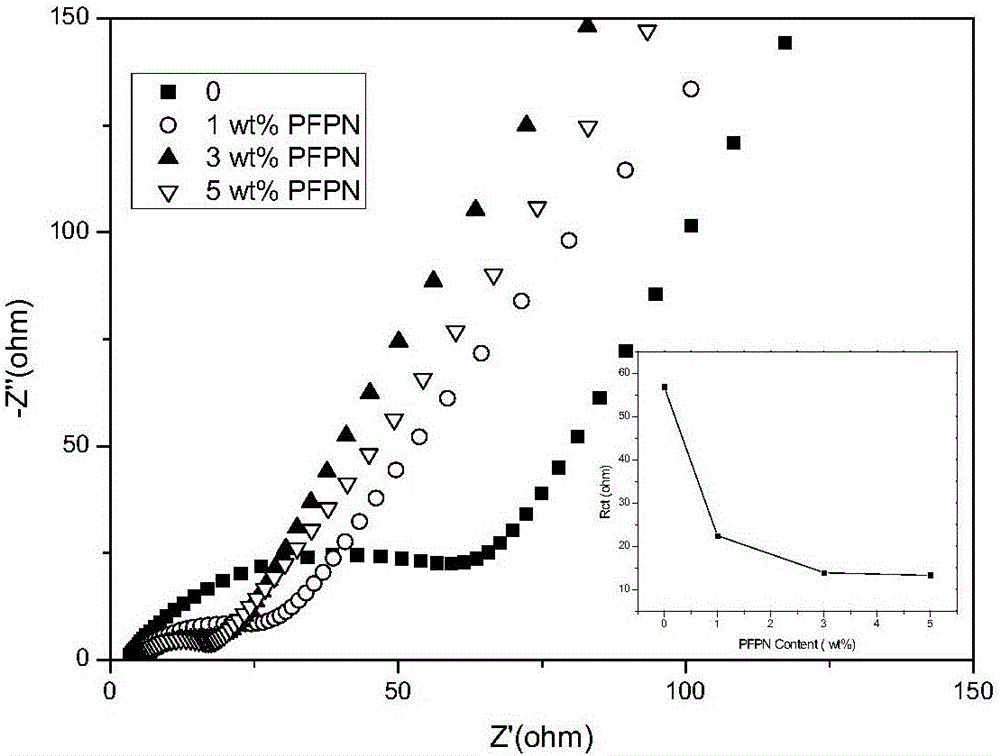

ActiveCN102035043AImprove rate discharge performanceImprove cycle performanceFinal product manufactureSynthetic resin layered productsPolymer electrolytesPolymer science

The invention provides a polymer porous membrane, a preparation method of the polymer porous membrane, a polymer electrolyte, a polymer battery and a preparation method of the polymer battery. A carbon material is dispersed in the polymer porous membrane, so that the degree of crystallization of a polymer which constitutes the polymer porous membrane is lowered and the liquid absorption of the polymer porous membrane is increased; the liquid absorption rate, liquid holding capability and ionic conductivity of the polymer porous membrane are increased; interface impedance is reduced, battery magnification discharging performance and the circulating performance of the battery are enhanced; simultaneously, the battery prepared by the method has excellent high temperature circulation and storage performance and low expansion ratio at a high temperature and further meets the development requirement of the polymer battery. Simultaneously, the preparation method is simple and is easy to implement and the prepared battery has high performance.

Owner:SHANGHAI BYD

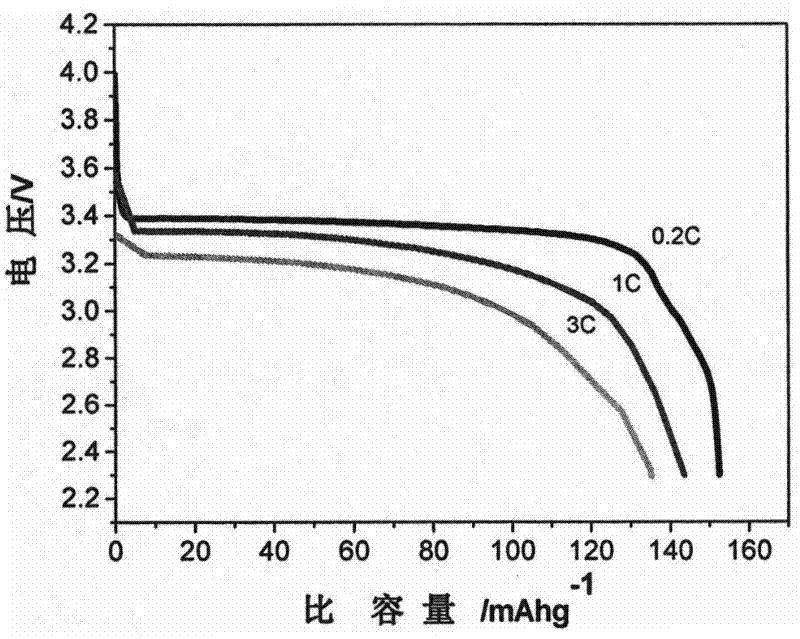

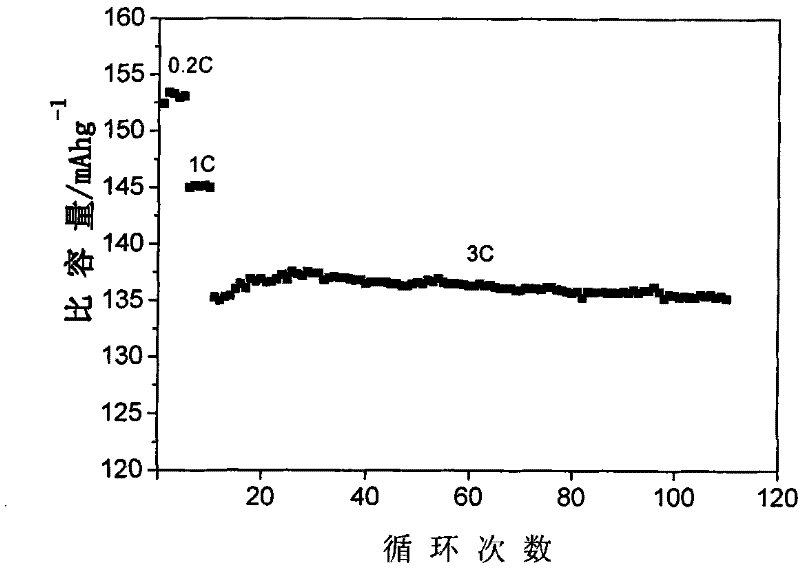

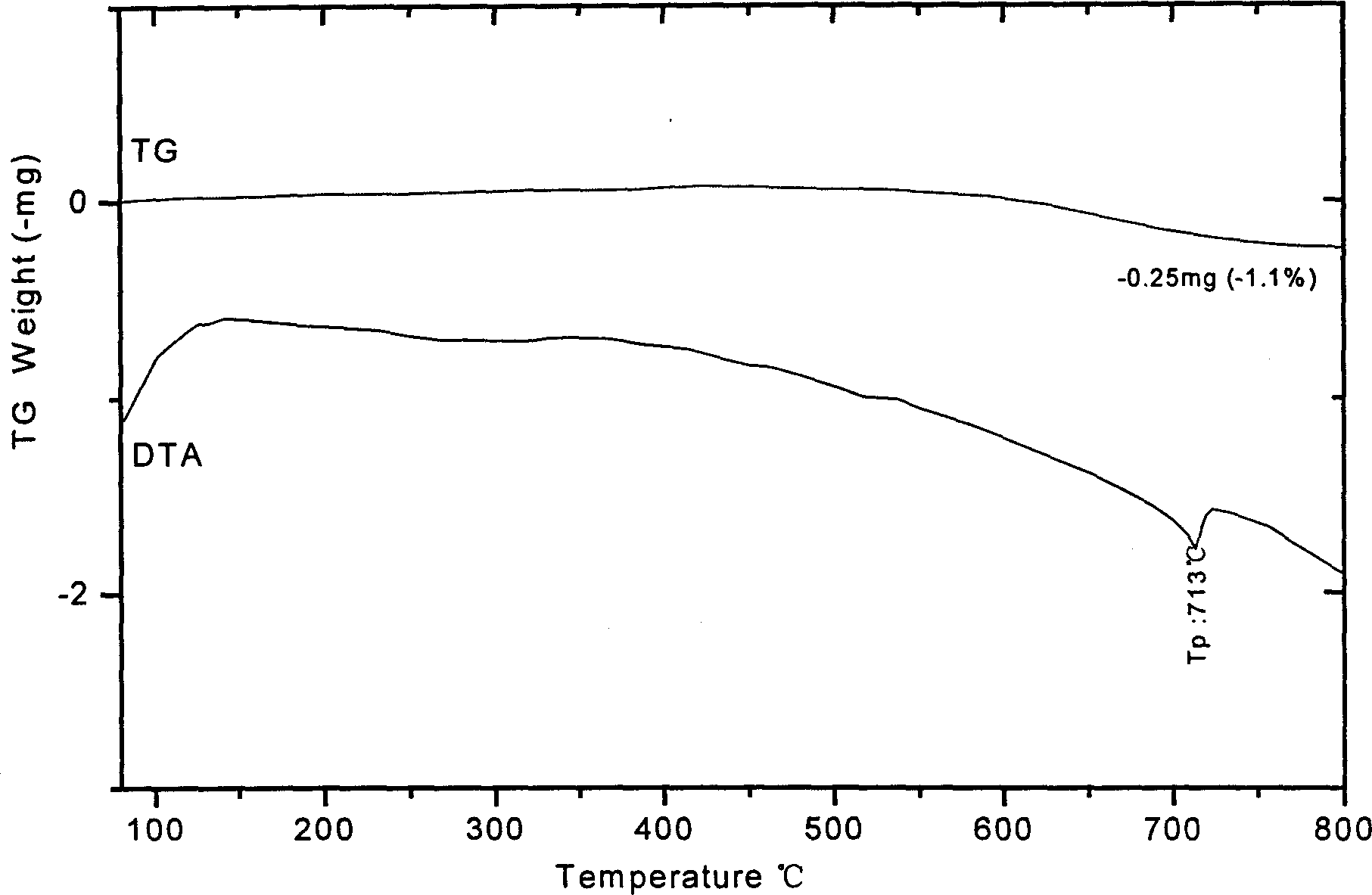

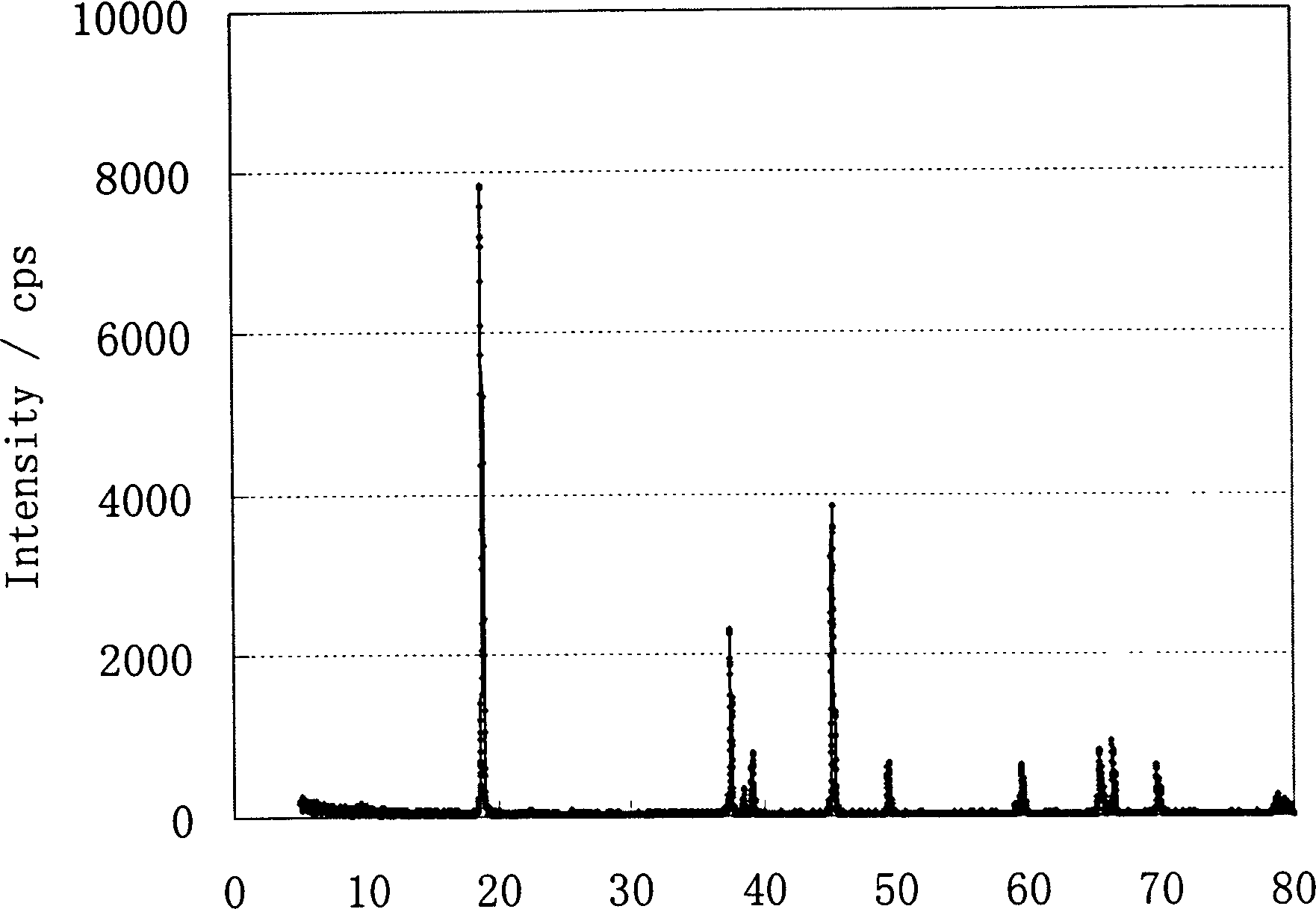

Nanoscale lithium titanate compound and preparation method thereof

ActiveCN101630732AEnabling molecular-scale mixingHigh purityElectrode manufacturing processesActive material electrodesLithium compoundCharge and discharge

The invention relates to a nanoscale lithium titanate compound and a preparation method thereof. The nanoscale lithium titanate compound is prepared by following steps: a lithium compound, a titanium compound and a doped element compound are mixed according to a molar ratio of 0.75-0.80:1:0:0.05 of Li to Ti to doped elements so as to form a mixture A; the mixture A and a complexing agent are mixed according to a weight ratio of 1:0.1-10 and dissolved in water to form a mixture B; and the mixture B and a carbon nanotube dispersion C are mixed to form the nanoscale lithium titanate compound coated by carbon nanotubes with a nanoscale grain size. The preparation method comprises the following steps: mixing the mixture B and the carbon nanotube dispersion C; heating an obtained mixture in nitrogen at 100-200 DEG C for 1-2 hours to obtain gel; and sintering the obtained gel in inert atmosphere at 500-1,000 DEG C for 5-48 hours to obtain the powdered lithium titanate compound. The lithium titanate compound is nanoscale lithium titanate coated by the carbon nanotubes, has fine and even grain and high purity and has the characteristics of higher charge and discharge capacity, good rate discharge performance, good cycle performance and good safety performance, and the like, thus the lithium titanate compound is an ideal anode material for manufacturing a lithium ion battery.

Owner:SHENZHEN DYNANONIC

Polymer electrolyte for lithium battery and manufacturing method of battery thereof

InactiveCN101826635ASimple manufacturing processEasy to manufactureFinal product manufactureLi-accumulatorsTO-18Polymer electrolytes

The invention discloses polymer electrolyte for a lithium ion battery and a manufacturing method of a battery thereof. The electrolyte is formed by dissolving 0.5 to 15 percent of electrochemical inert polymer with the molecular weight of 5000 to 120000, 6 to 18 percent of lithium salt and various functional additives into a non-aqueous solvent. The additives comprise a film forming additive, an overcharging prevention additive, a flame-retardant additive, a lithium salt stabilizer and a surfactant for enhancing the soaking performance of the electrolyte. In order to solve the preparation difficulty and the performance defect of a polymer battery at present, the invention selects a polymer with proper molecular weight and other functional components of the electrolyte creatively. By the electrolyte, the battery can have the characteristics of a traditional polymer battery and a traditional liquid-state battery, the safety performance, the service life, the high / low-temperature performance and the magnification performance of the battery are comprehensively enhanced, and the preparation of the battery is simple and easy.

Owner:GUANGZHOU TINCI MATERIALS TECH

Nano lithium iron phosphate material and preparation method thereof

InactiveCN101546830ASolve the real problemSmall particlesElectrode manufacturing processesChemical/physical/physico-chemical processesChemical compositionLithium iron phosphate

The invention relates to a nano lithium iron phosphate material and a preparation method thereof. A lithium source, an iron source, a phosphate radical source and a doped element compound are dissolved in water solution containing a complexing agent according to a stoichimetric proportion and added with high-conductive carbon nano tubes scattered by assistant to form a cladding material, the obtained solution is sintered in an inert atmosphere furnace, the reaction temperature is between 500 and 900 DEG C, and the reaction time is 3 to 16 hours. The method effectively controls the chemical components, phase components and grain diameters of LiFePO4; and the obtained lithium iron phosphate is the nano lithium iron phosphate clad by the carbon nano tubes, has fine and even grains with high purity, high charge / discharge capacity, good multiplying power performance and good cycle performance, and is an ideal material for manufacturing lithium ion batteries.

Owner:SHENZHEN DYNANONIC

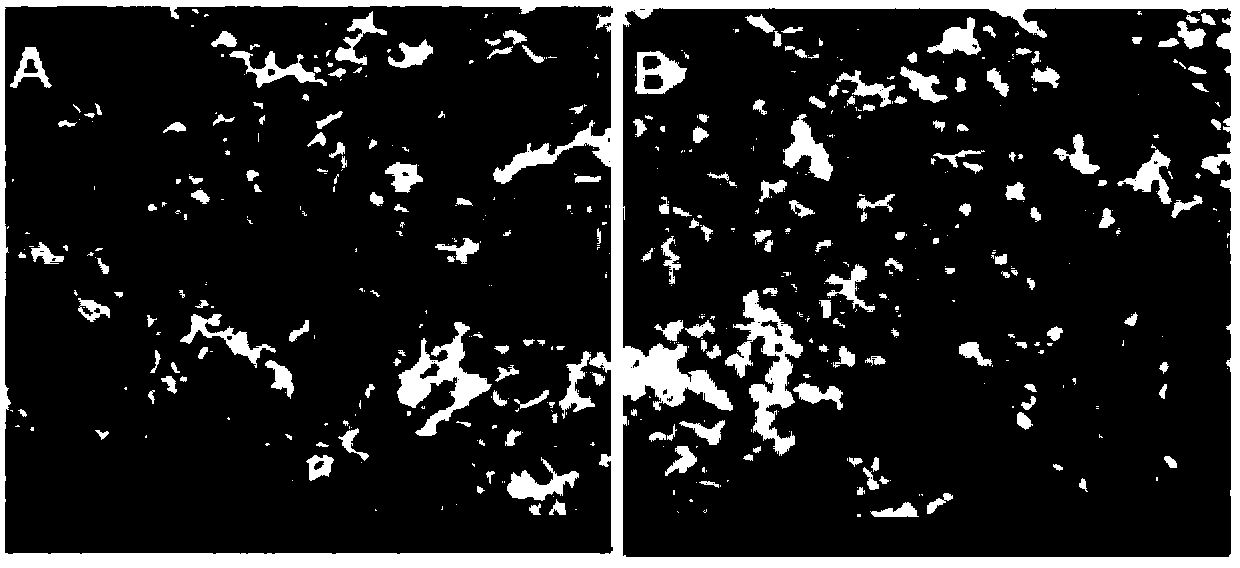

Porous carbon material used for lithium-air cell anode

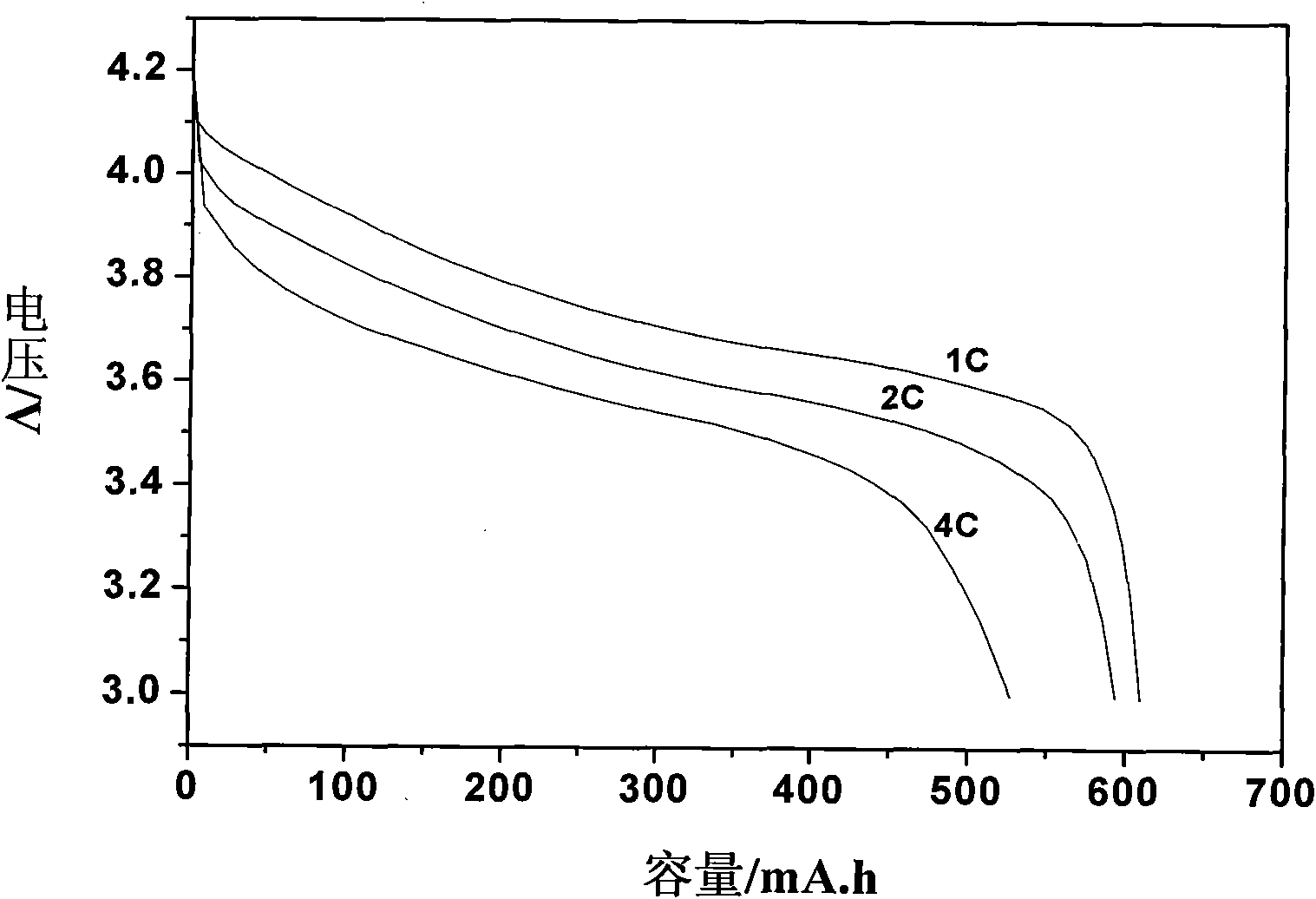

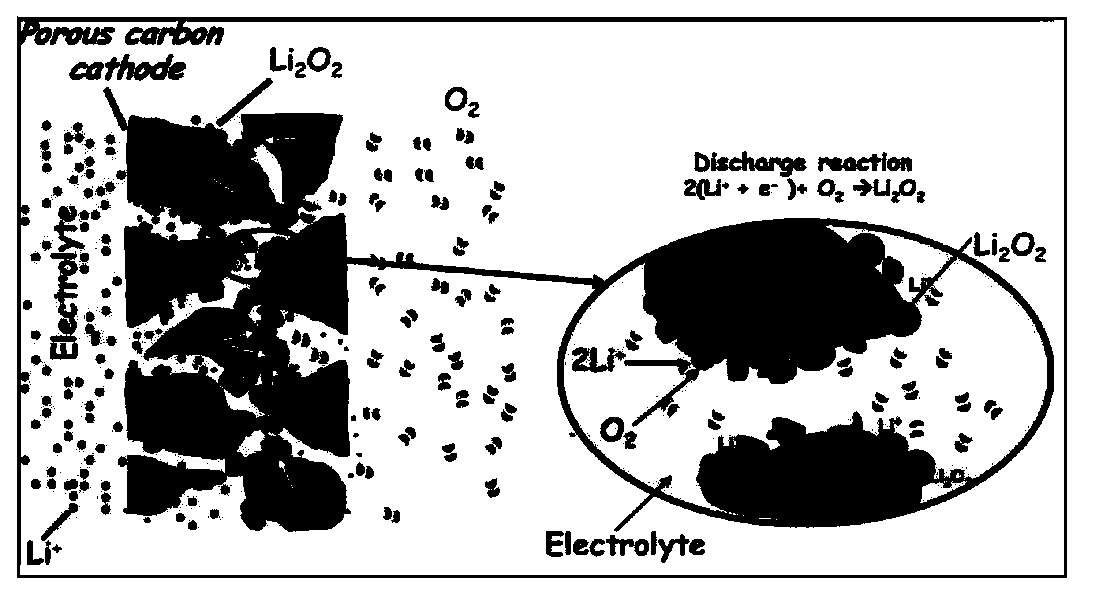

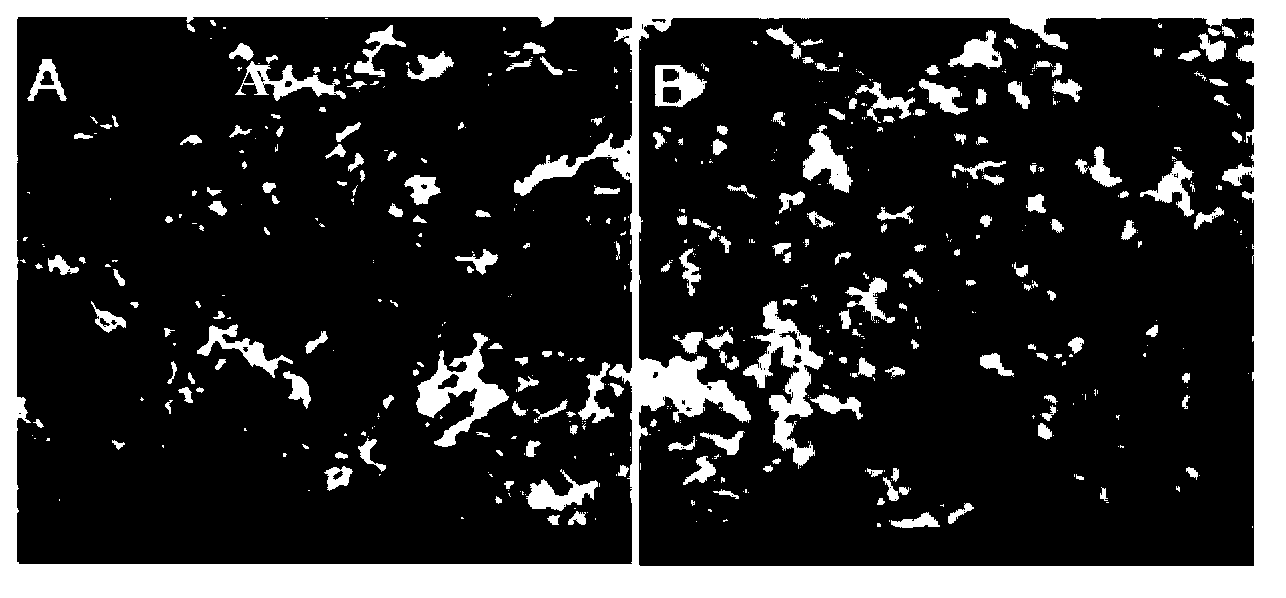

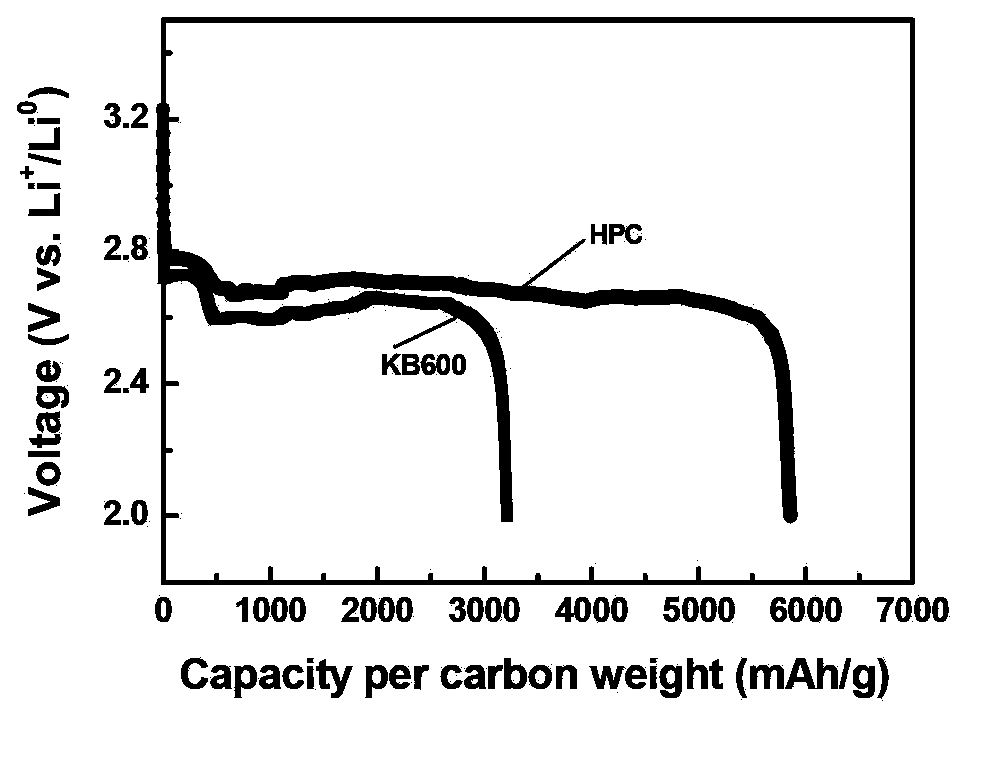

ActiveCN103855413AShorten the diffusion distanceImprove space utilizationFuel and secondary cellsCell electrodesPorous carbonAir cell

The invention relates to an application of a porous carbon material with a grading pore structure in a lithium-air cell anode, and is characterized in that the carbon material has mutually communicated grading pore structure distribution which has a mesoporous structure for depositing the discharge products and a macroporous structure suitable for transmission of oxygen and an electrolyte. When the carbon material is taken as a material of the lithium-air cell anode, the space utilization rate of carbon material can be increased at maximum limitation during a charge and discharge process, specific discharge capacity, voltage platform and multiplying power discharge capability of the cell can be effectively increased, so that the energy density and power density of the lithium-air cell can be increased. The porous carbon material has the advantages that the preparation technology is simple, the material source is wide, the grading pore carbon material pore structure enables regulation and control, the regulation and control modes are various, and the doping of metal / metal oxide can be easily and simultaneously realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

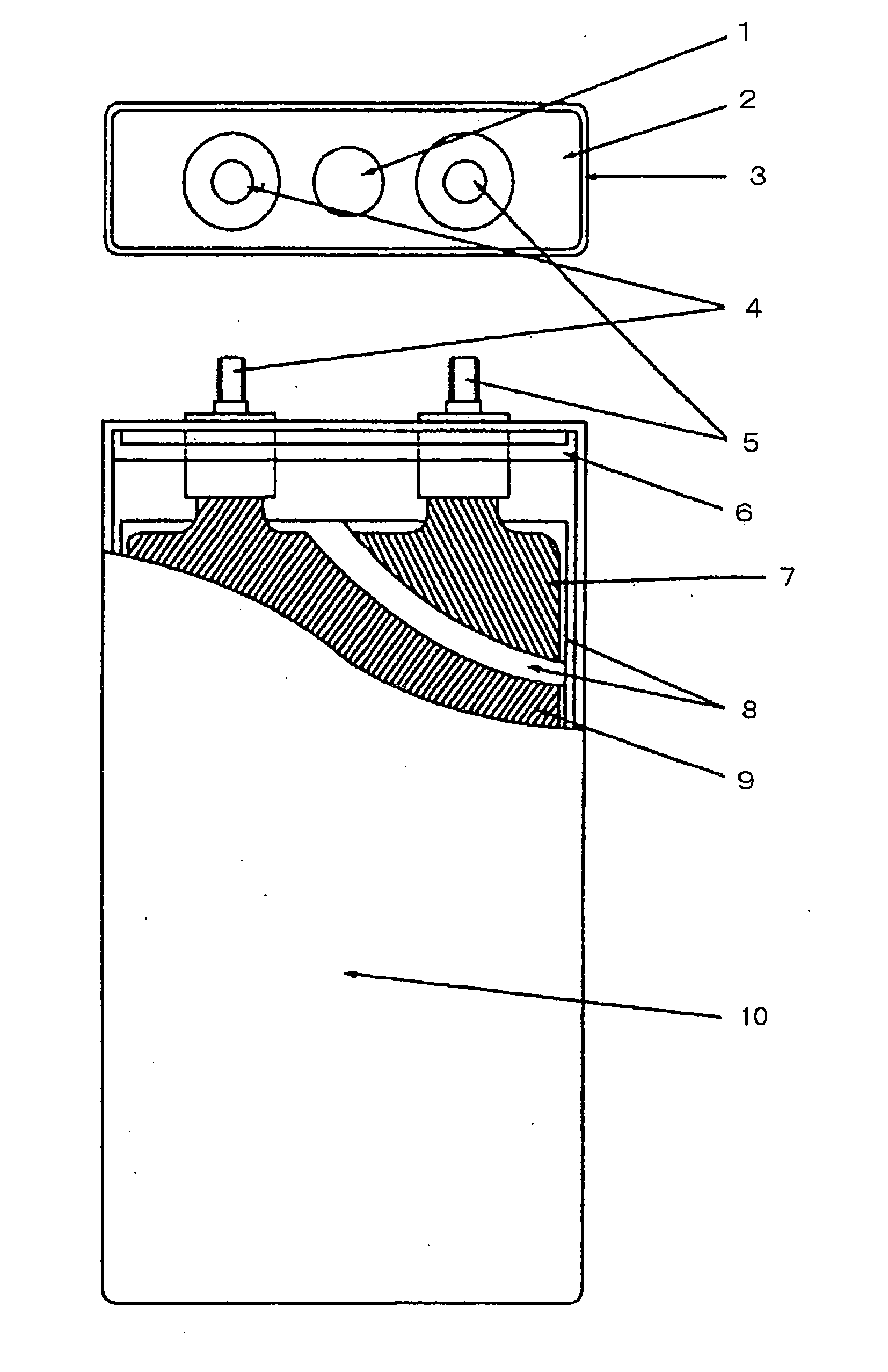

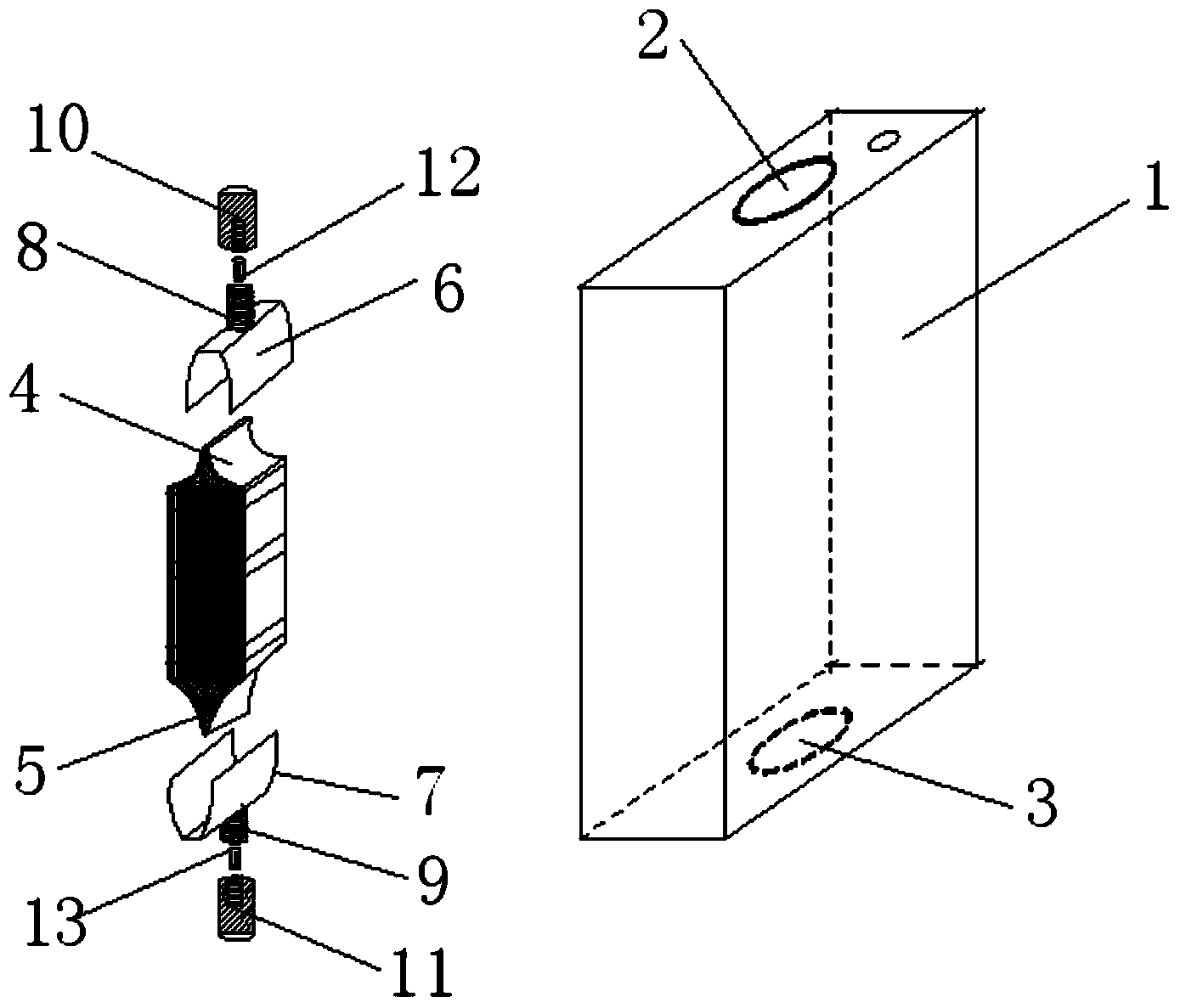

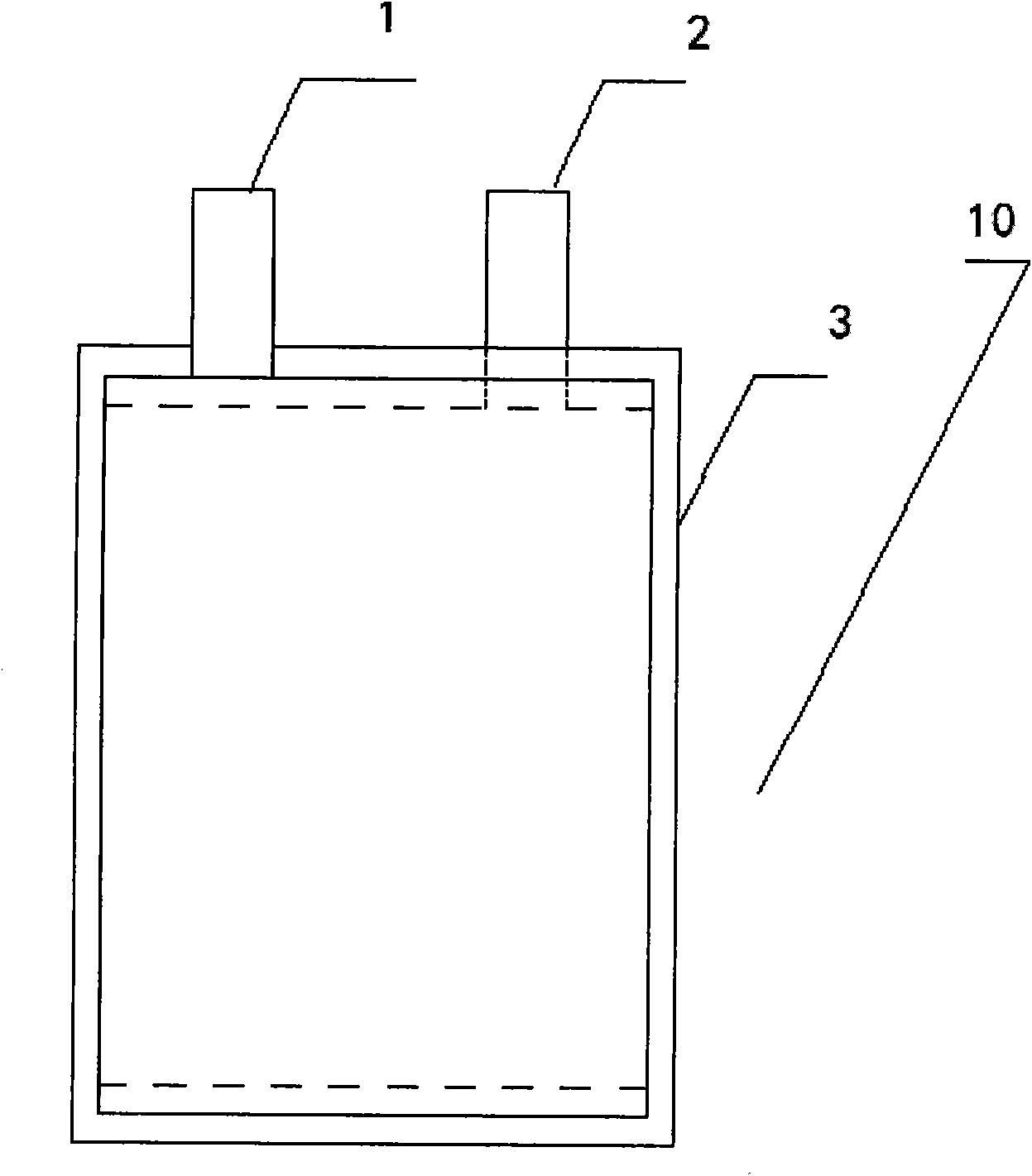

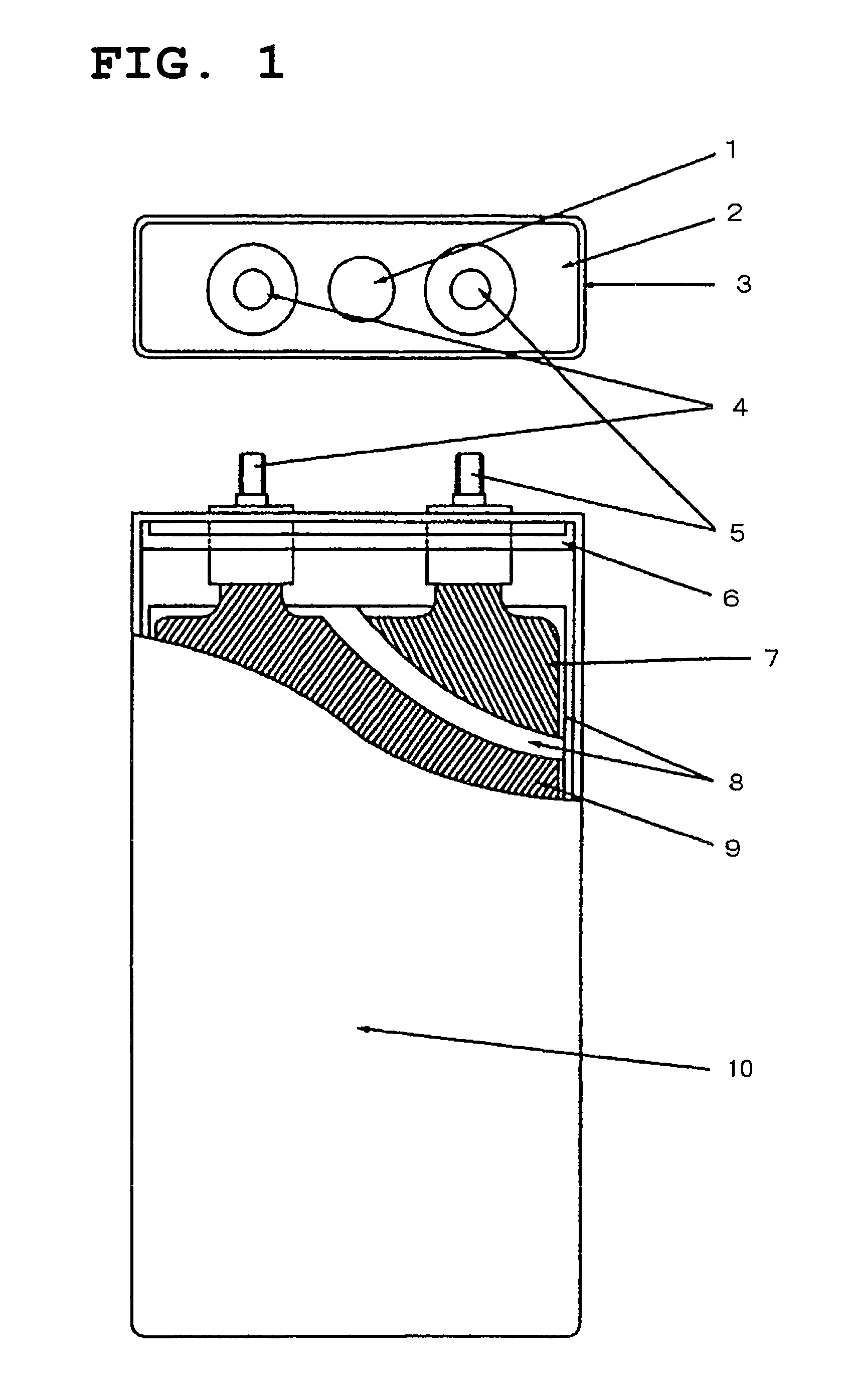

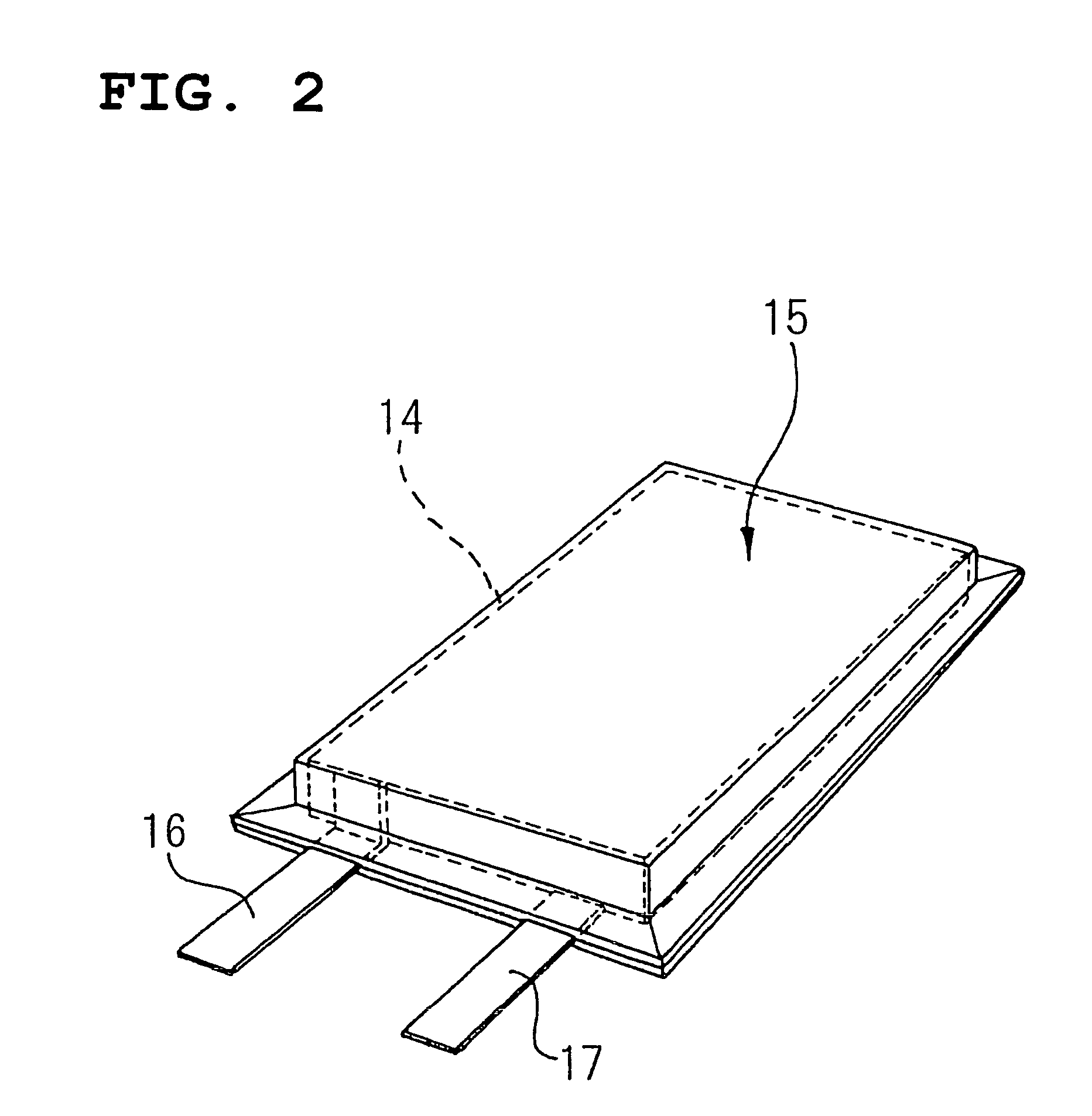

Lithium-ion battery with high rate discharge performance

ActiveCN103730625AImprove rate discharge performanceImprove securitySecondary cellsCell component detailsHigh rateEngineering

The invention discloses a lithium-ion battery with high rate discharge performance. The lithium-ion battery comprises a cover, a battery core in the cover, an upper cover plate, and a lower cover plate, wherein the battery core is prepared either by winding or laminating a positive pole piece with a positive pole ear, a negative pole piece with a negative pole ear and a diaphragm. The lithium-ion battery is characterized in that a positive pole piece clamping mechanism and a negative pole piece clamping mechanism are also arranged; the positive pole ear is packed and fixed inside of the positive pole piece clamping mechanism and a positive pole stud is arranged on the outside of the positive pole piece clamping mechanism and is in detachable connection with the upper cover plate; the negative pole ear is packed and fixed inside of the negative pole piece clamping mechanism and a negative pole stud is arranged on the outside of the negative pole piece clamping mechanism and is in detachable connection with the lower cover plate. The lithium-ion battery is particularly applicable to the fields of electrical motorcycles, electrical taxies and electrical buses, and the like, and can meet the requirements for high rate discharge performance of batteries when the vehicles are in the bad circumstances such as climbing, instantaneous starting and instantaneous accelerating.

Owner:安徽金鑫宏运新能源科技有限公司

Novel modified non-woven fabric lithium-ion battery diaphragm and preparation method thereof

ActiveCN103928649AEnsuring Winding ProcessabilityEnsuring satisfactory winding processabilityFinal product manufactureSecondary cellsElectrical batteryPhysical chemistry

The invention relates to a novel modified non-woven fabric lithium-ion battery diaphragm. The diaphragm comprises a modified non-woven fabric base material and a filling agent compounded on the modified non-woven fabric base material, wherein the modified non-woven fabric base material comprises a low-smelting-point material and a high-smelting-point material; the low-smelting-point material is subjected to melt crystallization treatment and the weight of the high-smelting point material accounts for 85-99.9% of the total weight of the base material; the residual amount is the low-smelting point material; the filling agent compounded on the modified non-woven fabric base material comprises organic polymer, a first filling material and / or a second filling material. The invention further relates to a preparation method of the battery diaphragm. The preparation method sequentially comprises the following steps: manufacturing a non-woven fabric fiber layer; manufacturing the modified non-woven fabric base material; preparing filling agent slurry; filling; removing a solvent; and carrying out post-treatment. The method is simple in operation and low in cost; a prepared product is low in water content, good in chemical stability and high in mechanical strength; the finished product rate of a battery is increased, the service life is prolonged and the safety is improved.

Owner:河南惠强新能源材料科技股份有限公司

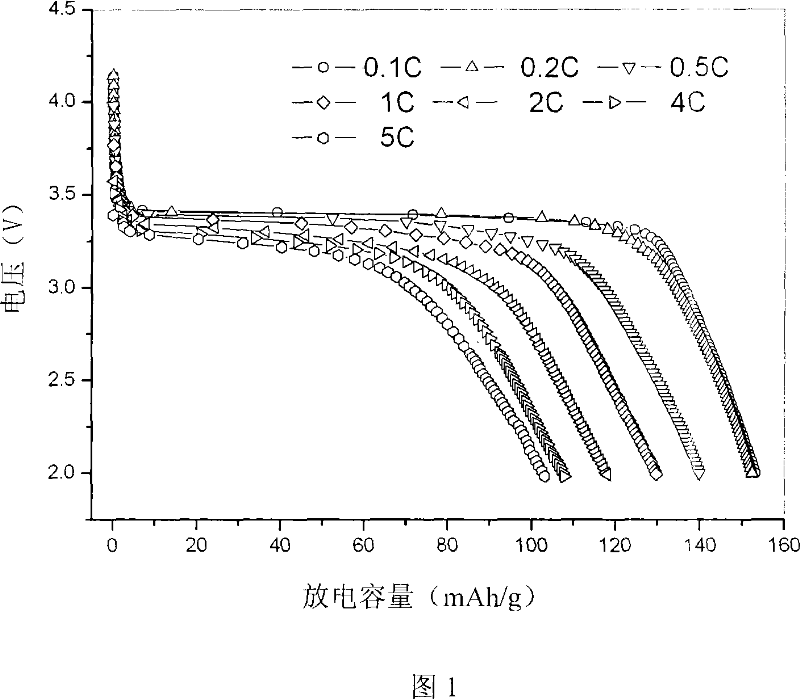

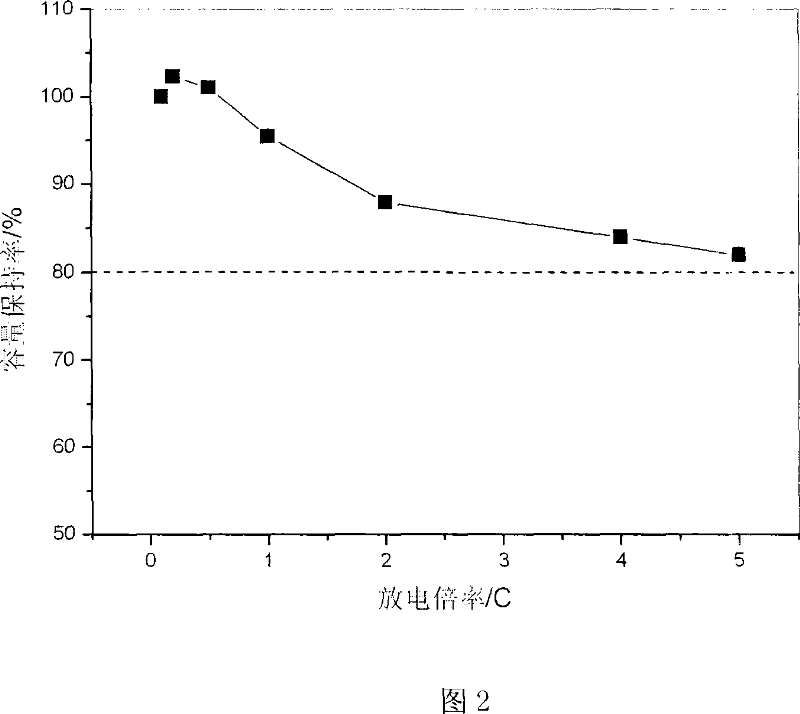

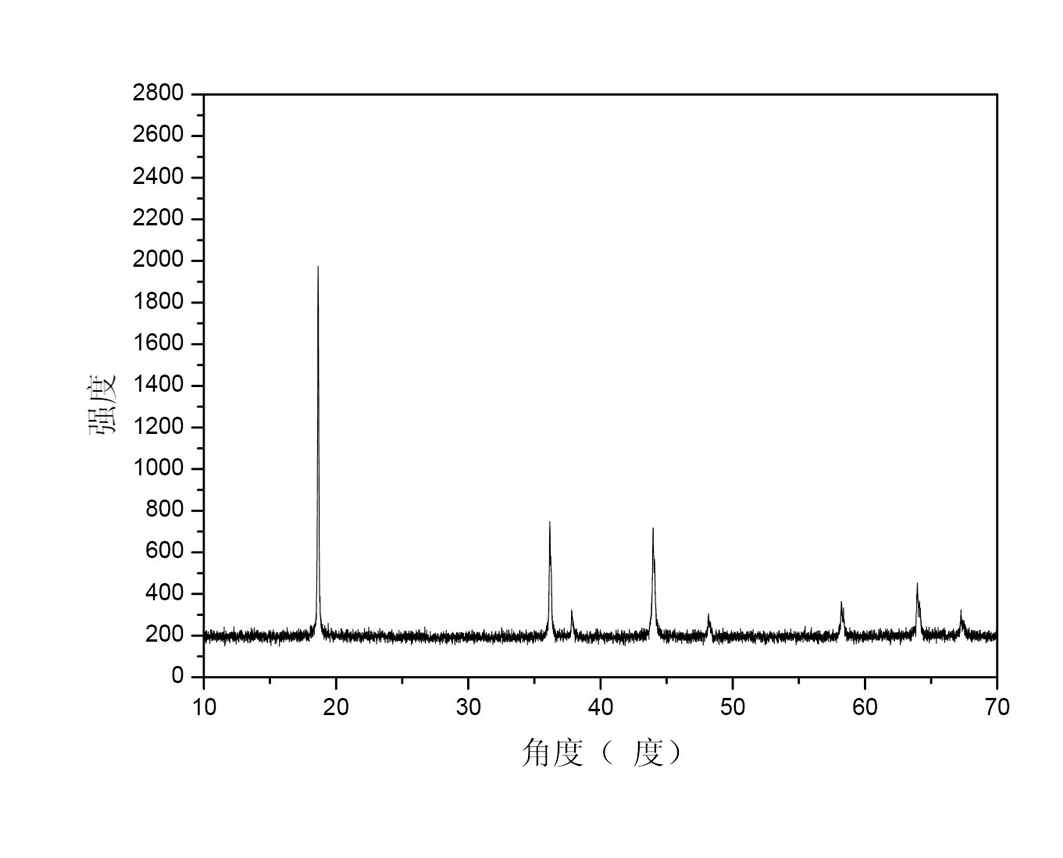

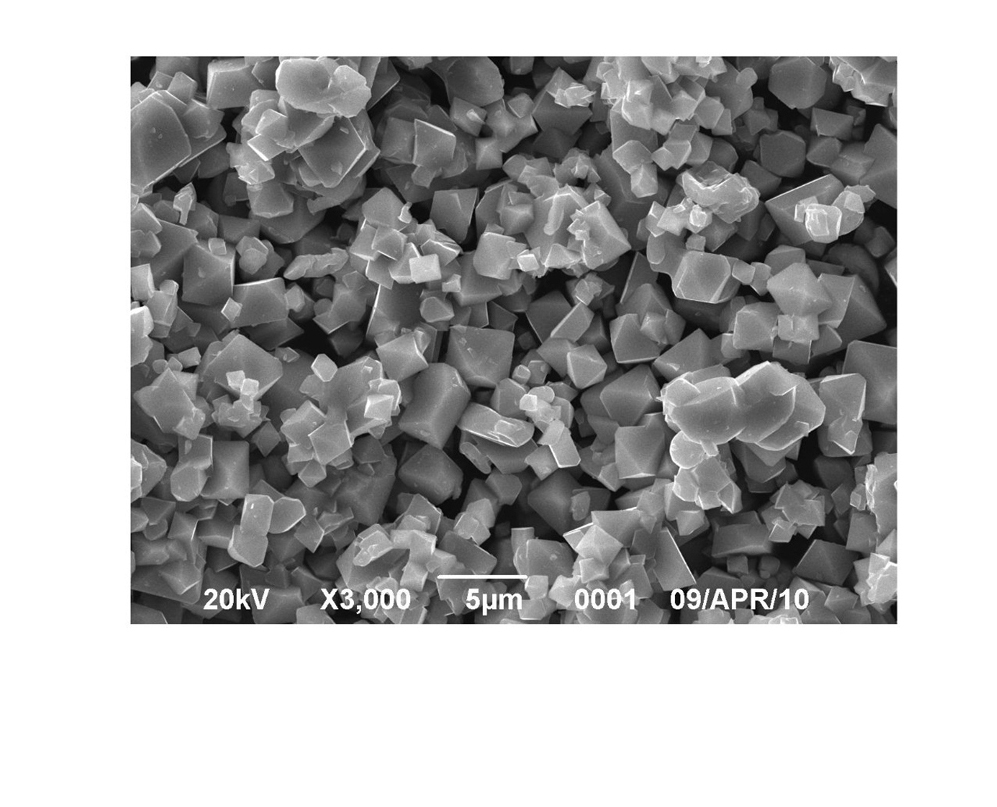

LiFePO4 cathode material based on P site doped and preparation method thereof

InactiveCN101037195AImprove rate discharge performanceImprove discharge capacityCell electrodesPhosphorus compoundsPhosphateFiltration

Disclosed is a phosphorus-doped lithium iron phosphate positive electrode material and a preparation method of the same, which relates to a positive electrode materials of lithium ion batteries. The present invention provides a phosphorus-doped lithium iron phosphate positive electrode material of lithium ion batteries with higher charge-discharge capacity, excellent multiplying power performance and cycle performance, and a preparation method of the same. The positive electrode material has a formula of LiyFe(P1-xMx)O4, wherein M is doping element of Ge, Sn, Se, Te or Bi. The preparation method comprises the steps of mixing the ferrite and phosphate with dopant; adding at least one of the water, alcohol, acetone serving as ball mill solvent; scrubbing and filtrating after ball milling; vacuum drying the filtration product to obtain the intermediate product which is mixed with lithium salt; adding ball mill solvent to ball mill again; drying the product and then heating calcining in the presence of inert gas or reducing atmosphere to obtain doping type lithium iron phosphate LiyFe(P1-xMx)O4 powder.

Owner:XIAMEN UNIV

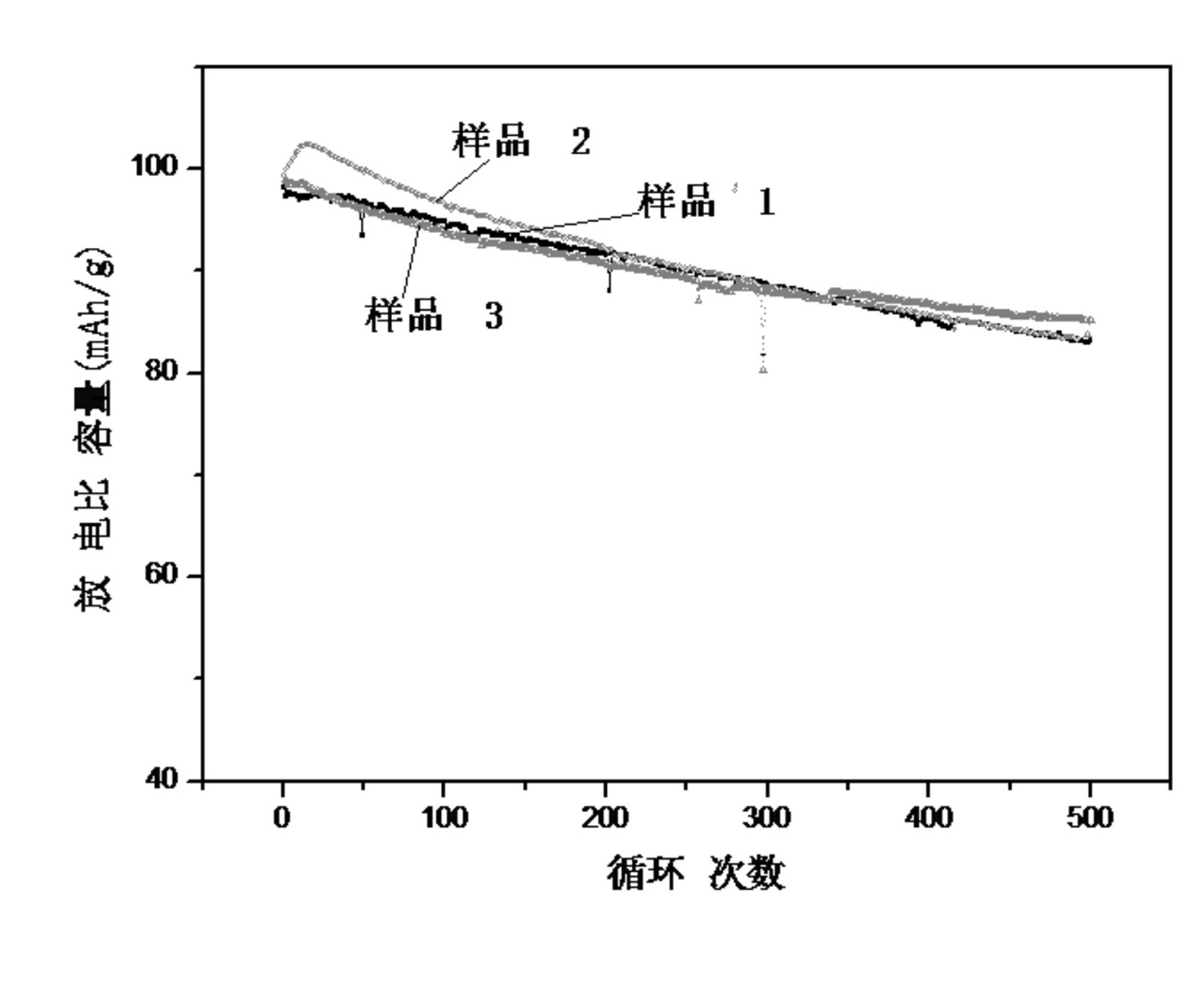

Preparation method of lithium ion battery anode material lithium manganate and automobile lithium ion battery

InactiveCN101964416AUniform bulkGood crystallizationCell electrodesSecondary cellsElectrical batteryManganate

The invention relates to a preparation technology of a battery anode material and a related automobile battery and particularly discloses a preparation method of lithium ion battery anode material lithium manganate. The method comprises the following steps: using lithium source, Mn3O4 and nanoscale doping metal additive as raw materials for proportioning, then presintering Mn3O4 or the Mn3O4 processed by ball milling, mixing the presintered Mn3O4 with the mixture of lithium source and metal additive; performing the first sintering and second sintering to the mixed raw material; and finally classifying and screening the sintering product to obtain the spinel lithium manganate product with the required grain size. The invention also discloses an automobile lithium ion battery which is assembled by using the spinel lithium manganate prepared by the method of the invention as anode and using graphite as cathode. The preparation method of the invention has simple operation and environmental friend; and the prepared lithium manganate product has excellent product performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

Conductive agent dispersion liquid, electrode slurry, electrode, battery, and preparation methods thereof

InactiveCN101752548AEvenly dispersedSmall diameterElectrode manufacturing processesActive material electrodesSolubilityCapacitance

The invention discloses a conductive agent dispersion liquid and a preparation method thereof. The conductive agent dispersion liquid contains a conductive agent, a solvent and a dispersion agent, wherein the dispersion agent contains aromatic rings and can be bound with the surface of the conductive agent by Van der Waals force among molecules and pi-pi action force between planes; and the solubility in the first solvent at the temperature of 25 DEG C is not smaller than 10wt%. The invention also discloses an electrode slurry and a preparation method thereof, and a battery electrode prepared from the electrode slurry and a battery. As using the matter which contains the aromatic rings and can be bound with the surface of the conductive agent by Van der Waals force among molecules and pi-pi action force between planes as the dispersion agent of the conductive agent, the battery capacitance, the charging and discharging capacitance and the rate discharge property are effectively enhanced.

Owner:BYD CO LTD

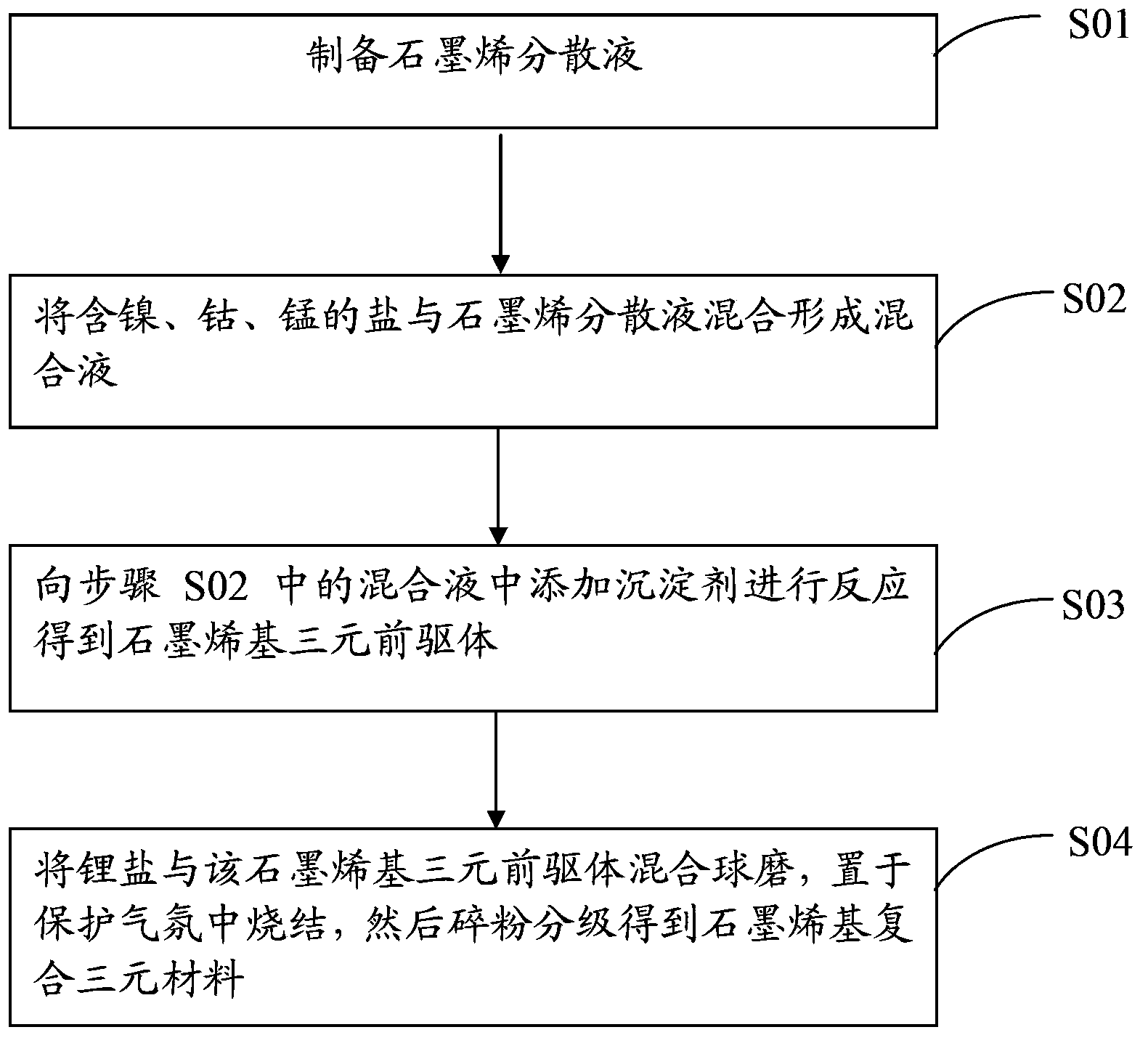

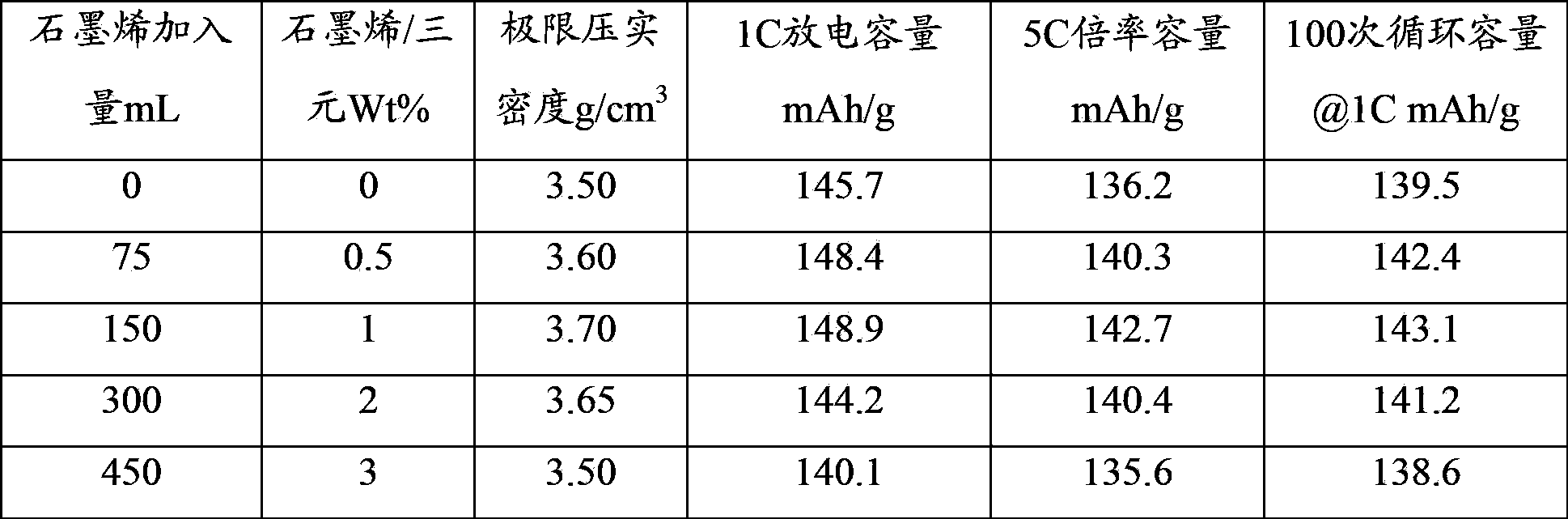

Graphene-based composite ternary material, preparation method thereof, and lithium ion battery

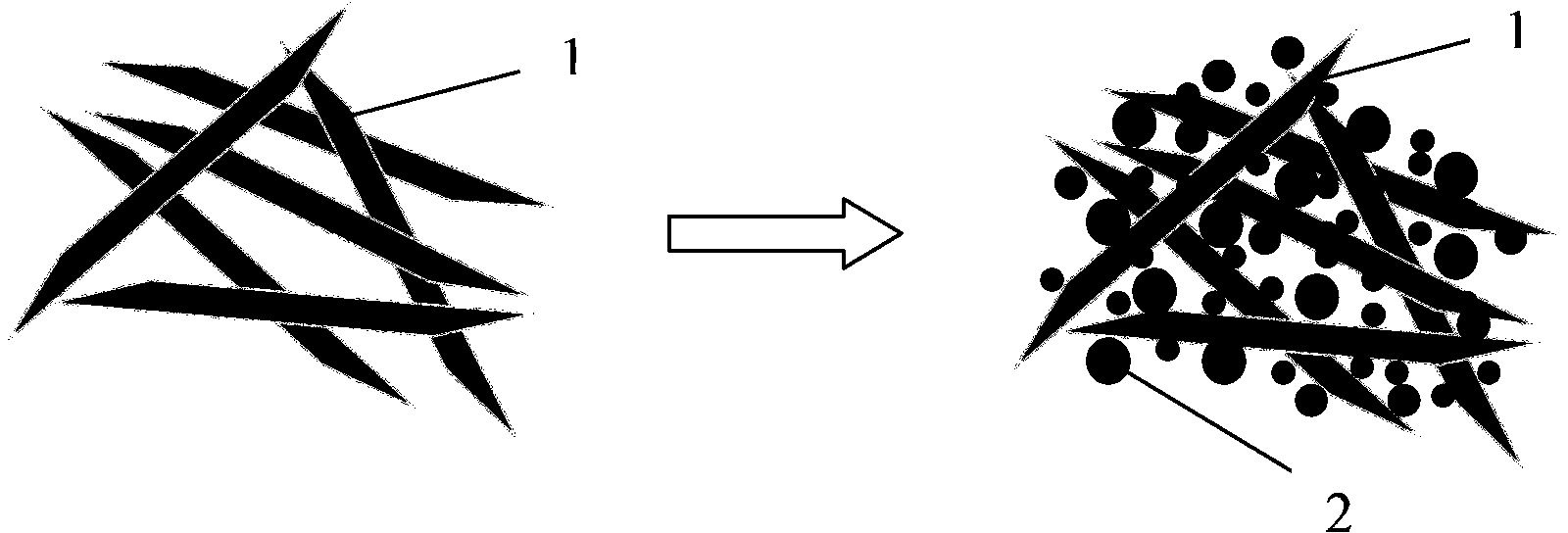

ActiveCN103904330AIncrease compaction densityReduce breakageMaterial nanotechnologyCell electrodesManganeseCobalt

The invention provides a graphene-based composite ternary material. The ternary material comprises graphene and a nickel-cobalt-manganese ternary material, wherein the graphene is prepared by sintering oxidized graphene, is composed of single-layered graphene slices or multi-layered graphene slices whose layer number is less than 10, and accounts for 0.1% to 10.0% of the total weight of the composite ternary material; and the nickel-cobalt-manganese ternary material has a primary particle structure or a secondary particle structure, has a molecular formula of Li(Ni<x>Co<y>Mn<z>)O2, wherein the sum of x, y, and z is equal to 1, and x, y, and z are all in a range of 0 to 1, and accounts for 90.0% to 99.9% of the total weight of the composite ternary material. The graphene slices are freely stacked in the graphene, thus conductive nets and cavities are formed, and the nickel-cobalt-manganese ternary material particles are embedded into the cavities between the nano graphene layers through a chemical precipitation method. The invention also provides a preparation method of the graphene-based composite ternary material.

Owner:HUAWEI TECH CO LTD

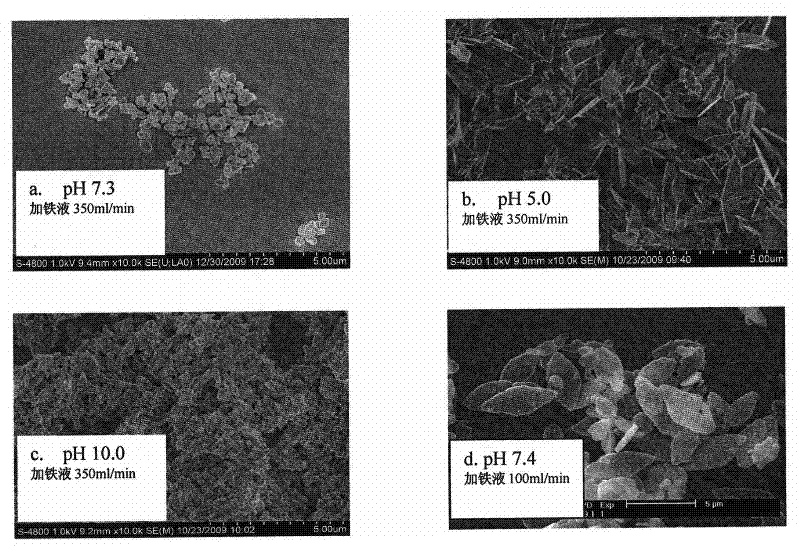

Hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure

InactiveCN101752564AImprove rate discharge performancePromote environmental protectionCell electrodesPhosphorus compoundsLithium hydroxidePhosphoric acid

The invention discloses a hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure, which comprises the steps of: 1. respectively adding lithium hydroxide solution and phosphoric acid, evenly adding iron source solution with a certain speed, wherein the molar ratio of the proportion of the added materials Li: Fe: P is 3.0:1.0:1.0-1.15, stirring 10-30 for minutes, adding pH value adjusting agent, leading the initial pH value of a reaction system to be 6.5-8.0, and reacting for 60-480 minutes at 40-180 DEG C; 2. filtering, washing and drying resultant; and 3. packing carbon. The hydrothermal synthesis method can take raw material solution for generating ferrous sulfate as iron source, produces a product with good performance by adjusting the pH value of the reaction system and controlling the feeding speed, eliminates working procedures for crystallizing and drying the ferrous sulfate and the like, is good for reducing water electricity consumption, and has less equipment investment, simple and controllable technology and good batch stability of the product.

Owner:HEBEI UNIV OF TECH

Nanometer ferrous silicate lithium material and preparation method thereof

ActiveCN101546828AHigh purityHigh charge and discharge capacityElectrode manufacturing processesPhosphorus compoundsCarbon nanotubeReaction temperature

The invention relates to a nano ferrous silicate lithium material and a preparation method thereof. The preparation method comprises the following steps: a lithium source, an iron source, a silicate source and a doping element compound are dissolved into a water solution which contains a complexing agent according to a certain stoichiometric ratio, a high-conductivity carbon nano tube dispersed by an auxiliary agent is added into the water solution and used as a wrapping material, an obtained solution is heated under the temperature of 100-200 DEG C for 1-3 hours to obtain gelatin, the obtained gelatin is sintered in an inert atmosphere furnace, the reaction temperature is 600-900 DEG C, and the reaction time is 3-16 hours. The invention effectively controls the chemical composition, the phase composition and the grain diameter of ferrous silicate lithium, and the obtained ferrous silicate lithium is nano ferrous silicate lithium wrapped by the carbon nano tube and has small and uniform grains with high purity quotient, higher charge-discharge capacity and good multiplying power property and circulation property, thus the ferrous silicate lithium is an ideal material for producing lithium ion batteries.

Owner:SHENZHEN DYNANONIC

Preparation method for microporous diaphragm and microporous diaphragm

ActiveCN103633272AImprove longitudinal strengthUniform structureCell component detailsPolyolefinPolymer science

The invention relates to the field of the processing of lithium-ion battery diaphragms, and discloses a preparation method for a microporous diaphragm. The preparation method for the microporous diaphragm includes the following steps: 1) a principal polyolefin resin and an auxiliary additive are uniformly stirred through a stirring mixer to obtain a mixture I; 2) the obtained mixture I is added into an extruder to be uniformly melted and plasticized into a melt; 3) an intermediate diaphragm is prepared from a cast piece of the melt extruded from a die head; 4) annealing treatment is performed on the intermediate diaphragm under bi-directional micro-tension; 5) the annealed intermediate diaphragm is stretched longitudinally to prepare the diaphragm with a microporous structure. The invention further discloses the microporous diaphragm prepared through the method, which consists of the principal polyolefin resin with a weight percentage of 75 to 99.9 percent and the auxiliary additive with a weight percentage of 25 to 0.1 percent. The preparation method disclosed by the invention has the advantage that the lithium-ion battery diaphragm with a uniform structure, the specific microporous structure and high safety performance can be prepared.

Owner:SHENZHEN SENIOR TECH MATERIAL

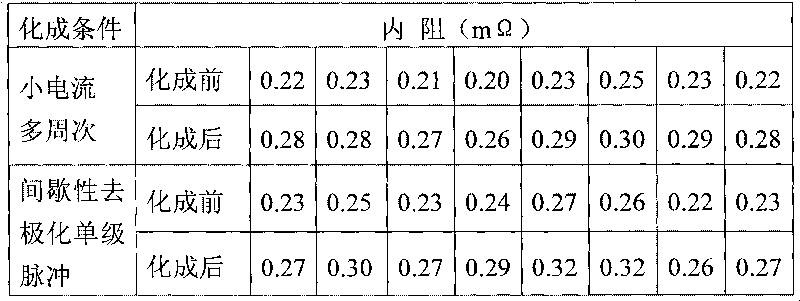

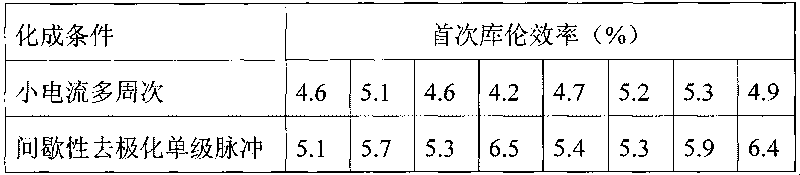

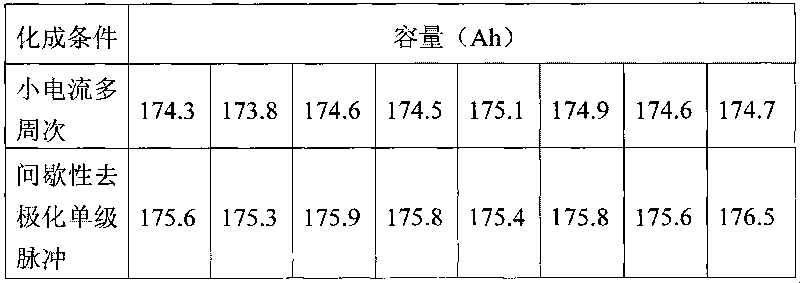

Rapid forming method of lithium ion power battery

InactiveCN101728579ALower impedanceImprove performanceFinal product manufactureSecondary cells charging/dischargingInternal resistanceElectrolyte

The invention discloses a rapid forming method of a lithium ion power battery, which is characterized by comprising the following steps of: 1. precharging; 2. settling and aging; and 3. charging by adopting an intermittent depolarized single-stage impulse charging mode until charge is finished. Because the forming process of the invention adopts the intermittent depolarized single-stage impulse charging mode, the impedance of an SEI (Solid Electrolyte Interface) membrane is lowered, thereby reducing the internal resistance of the battery and improving the rate discharge performance of the lithium ion power battery. Because the forming process of the invention adopts an impulse current with a lower frequency, the battery can be naturally depolarized within the impulse-off time, thereby lowering the polarizing effect, stabilizing the charging voltage, improving the charging efficiency, simultaneously avoiding the high requirement brought by a high frequency impulse current charging mode for equipment, improving the utilization efficiency of electric energy and greatly lowering the production cost. The step of precharge is adopted to facilitate the formation of the stable SEI membrane, thereby improving the performance of the battery.

Owner:SKY ENERGY LUOYANG

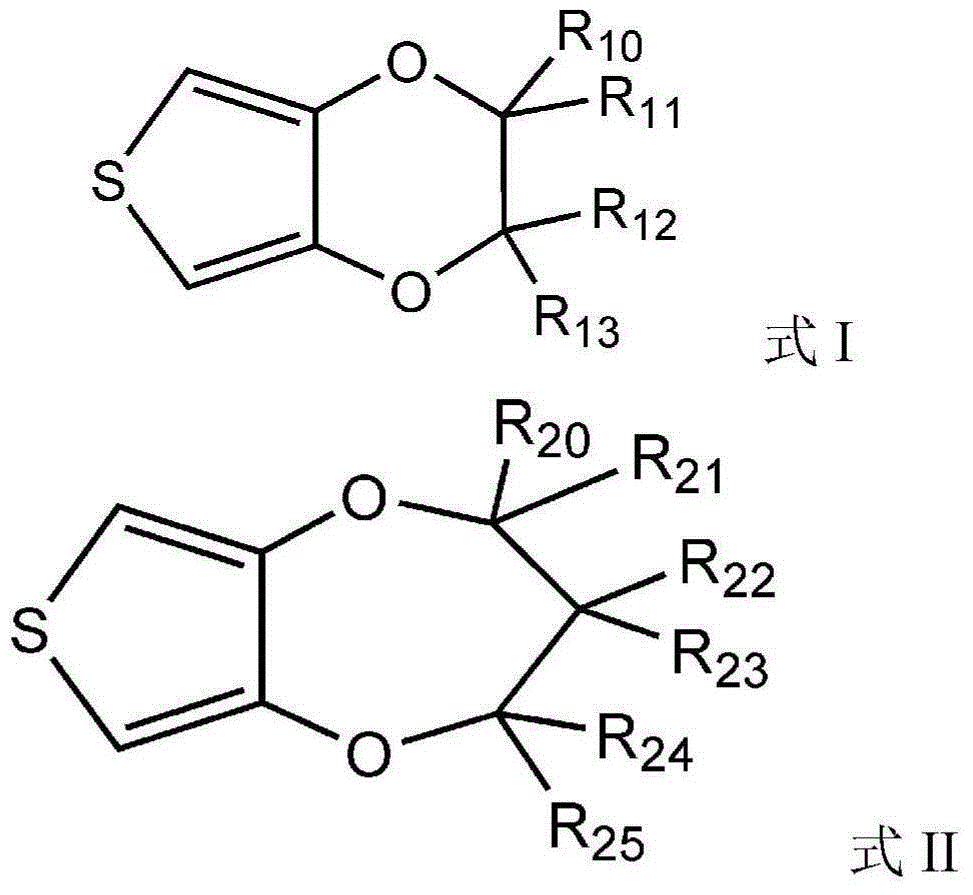

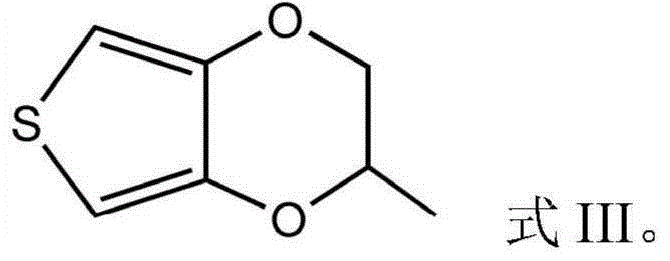

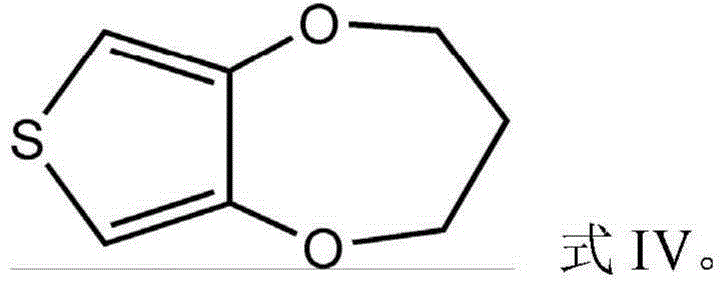

Electrolyte additive and application thereof

InactiveCN104577200AImprove cycle stabilityImprove securityOrganic chemistrySecondary cellsPower flowPhysical chemistry

The invention discloses an electrolyte additive and an apparition thereof. The additive contains a thiophene compound. The additive, which is used for a lithium ion battery, is capable of inhibiting the continuous electrochemical oxidation reaction of the electrolyte and the anode material, improving the electric conductivity of the anode material, improving the cycle performance and the high current discharge performance of the battery, and improving the safety performance and the rate performance of the battery.

Owner:NINGDE AMPEREX TECH

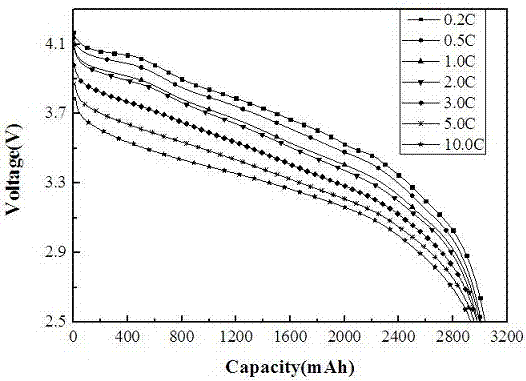

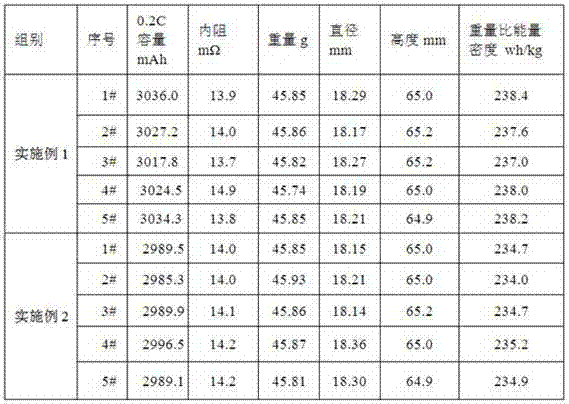

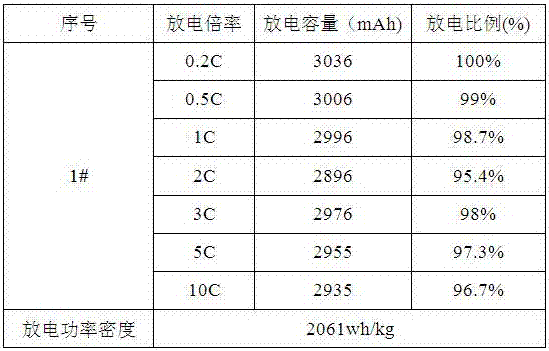

Novel lithium ion battery with high power and high energy density

InactiveCN107248592AIncrease gram capacityIncrease energy densityCell electrodesSecondary cellsHigh energyCarbon nanotube

The invention provides a novel lithium ion battery with high power and high energy density. The novel lithium ion battery comprises a positive plate, a negative plate, a diaphragm, electrolyte, a lug and a shell; the negative plate is mixed by negative electrode active materials, a negative electrode conductive agent and a negative electrode binder; the negative electrode active materials are composed of SiO, soft carbon and / or artificial graphite; the negative electrode conductive agent is at least one of superconductive carbon black and a single-walled carbon nanotube; and the negative electrode binder is at least two combinations of styrene butadiene rubber, acrylate and sodium carboxymethyl cellulose. The battery provided by the invention has excellent rate discharge capacity and high energy density; and besides, the weight specific energy density reaches 230wh / kg, the volume specific energy density is above 650wh / L, the power density is above 1,500w / kg, the rate discharge performance reaches 10C, and the cycle performance can reach more than 500 times.

Owner:鹤壁市诺信电子有限公司

Preparation method of waterborne PVDF (Polyvinylidene Fluoride)- PVDF copolymer composite coating membrane

ActiveCN106784532AReduce crystallinityLower internal resistanceCell seperators/membranes/diaphragms/spacersSwelling ratioInternal resistance

The invention provides a preparation method of a waterborne PVDF (Polyvinylidene Fluoride)-PVDF copolymer composite coating membrane. The method comprises the following steps: 1) preparation of PVDF-PVDF copolymer-ceramic mixed slurry: mixing and stirring deionized water, PVDF and a PVDF copolymer to obtain a uniform solution, adding a dispersing agent, mixing with mixed ceramic powder, uniformly stirring at the temperature of 30 to 50 DEG C, and performing ball milling for 0.5 to 2 hours to obtain the PVDF-PVDF copolymer-ceramic mixed slurry; (2) coating: coating one side or two sides of a base membrane with the PVDF-PVDF copolymer-ceramic mixed slurry prepared in the step 1) to form a waterborne coating, and drying in a three-stage drying oven at the temperature of 40 to 90 DEG C to obtain the waterborne PVDF-PVDF copolymer composite coating membrane. The preparation method has the beneficial effects that the swelling ratio of the membrane in electrolyte is increased, the electric conductivity of a lithium battery is increased, the internal resistance of the lithium battery is lowered, and the rate discharge performance and cycle performance of the lithium battery are improved.

Owner:广东卓高新材料科技有限公司

Electrolytic solution of lithium ion secondary battery and battery containing the electrolytic solution

ActiveCN101202353AImprove rate discharge performanceImprove securityFinal product manufactureSecondary cells manufactureHigh temperature storageLithium

The invention provides an electrolyte of a li-ion secondary battery and a li-ion secondary battery which is provided with the electrolyte. The electrolyte comprises non-aqueous solvent and electrolyte which is mixed lithium salt; wherein, the mixed lithium salt comprises lithium salt A, lithium salt B and lithium salt C; the lithium salt A is LiBOB; the lithium salt B is LiCF3SO3 and / or Li (CF3SO2)2N; the lithium salt C is one or more than one chosen out of LiPF6, LiBF4, LiCIO4, LiAsF6 and lithium halide. By adopting the electrolyte and the battery provided by the invention, the high-temperature storage performance, the high-temperature circulation performance, discharging performance in different ratios and safety performance are all obviously improved.

Owner:SHANGHAI BYD

High power lithium ion battery and method for preparing amorphous carbon coated anode material

InactiveCN1790799AImprove rate discharge performanceImprove electronic conductivitySecondary cellsNon-aqueous electrolyte accumulator electrodesLithium electrodeAmorphous carbon

The invention relates to a method for high-power lithium ion cell and amorphous-carbon to coat positive material. Wherein, the cell positive shell comprises a positive active material with shell-nucleus structure; the shell structure has amorphous material while the nucleus is spherical material with D50 size less than 10ª–m; the negative electrode comprises active material and carbon fiber, and the dual-surface coating weight for positive and negative active materials is 10-30mg / cm2 and 4.8-14.5mg / cm2 respectively. The method for amorphous-carbon comprises: 1) dipping the positive material into sweet water; 2) stirring, filtering; 3) drying; 4) carbonizing in inert gas atmosphere at 600-1000Deg; 5) breaking and screening. This invention reduces internal resistance of electrode, increases discharge property of cell, and economical to process.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

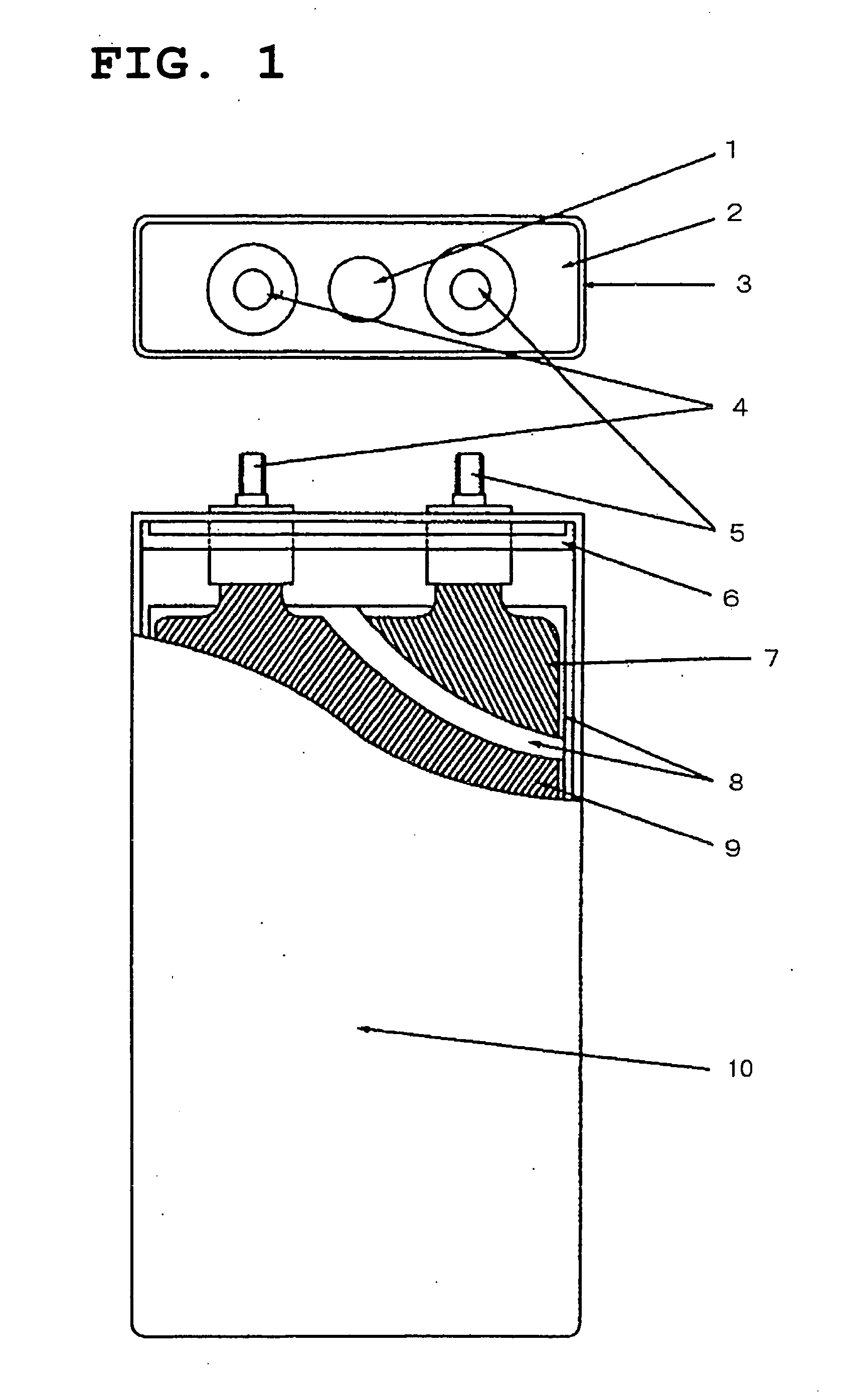

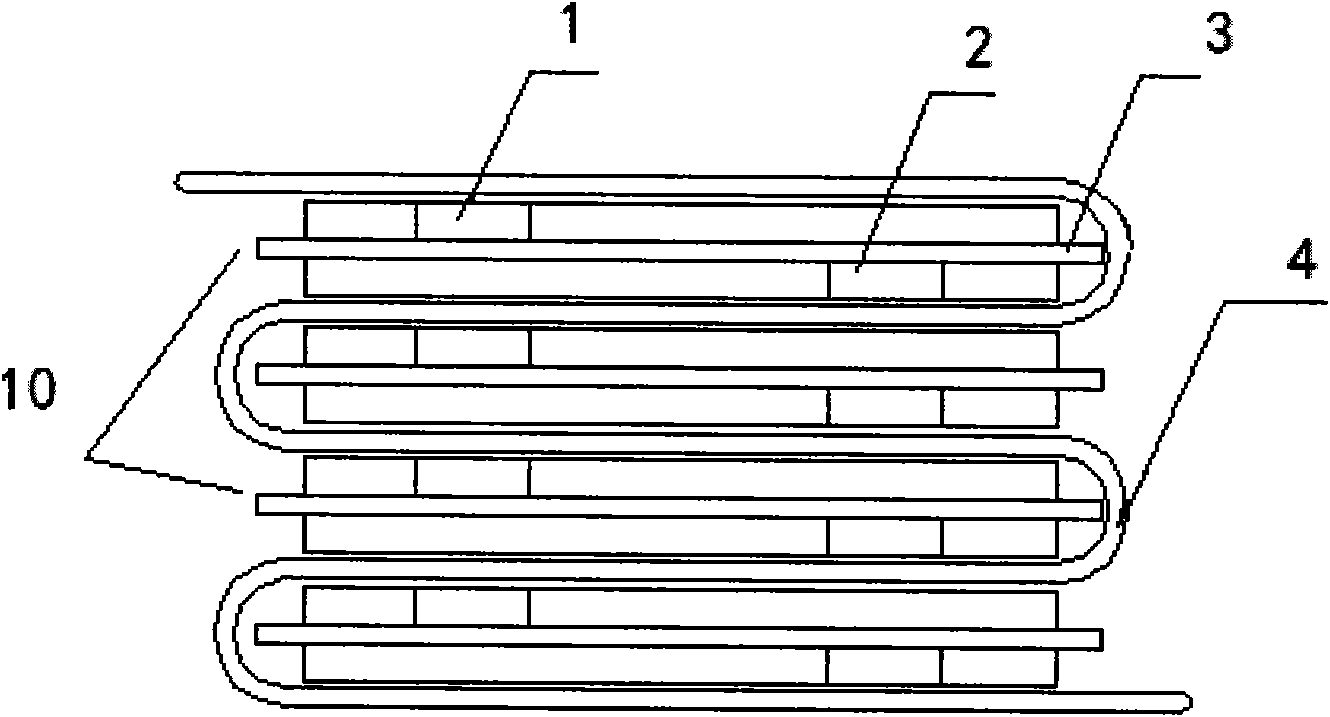

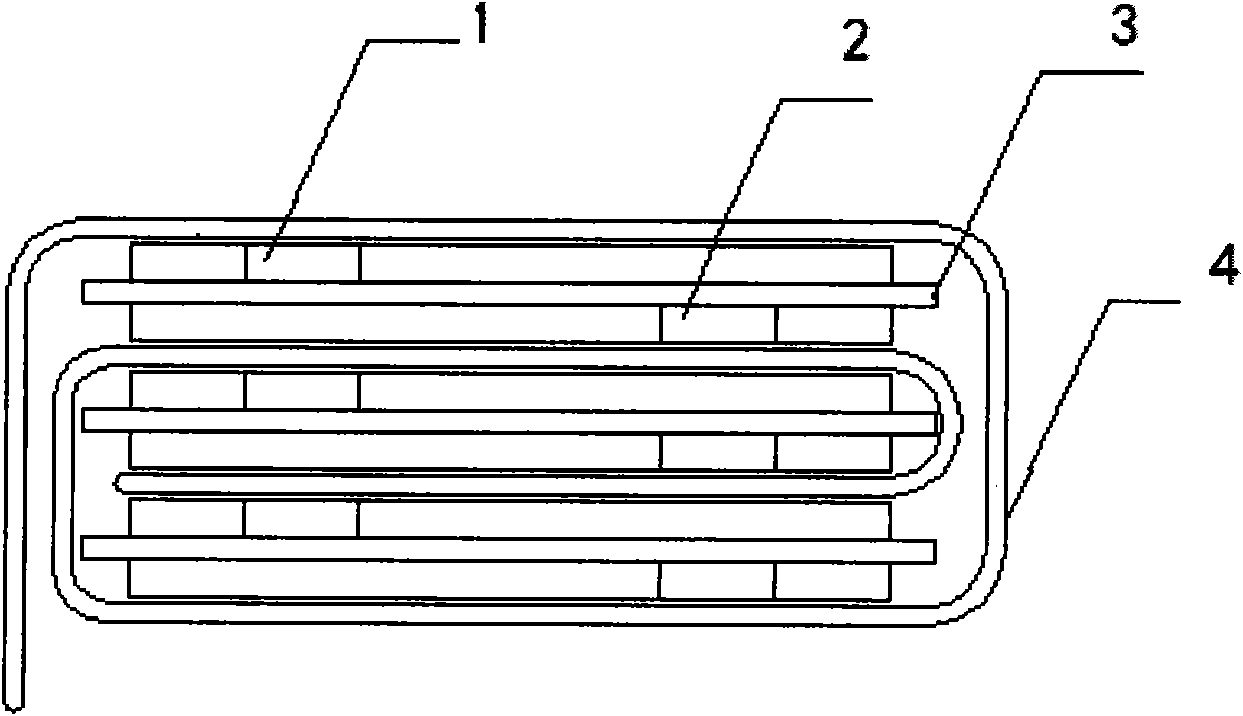

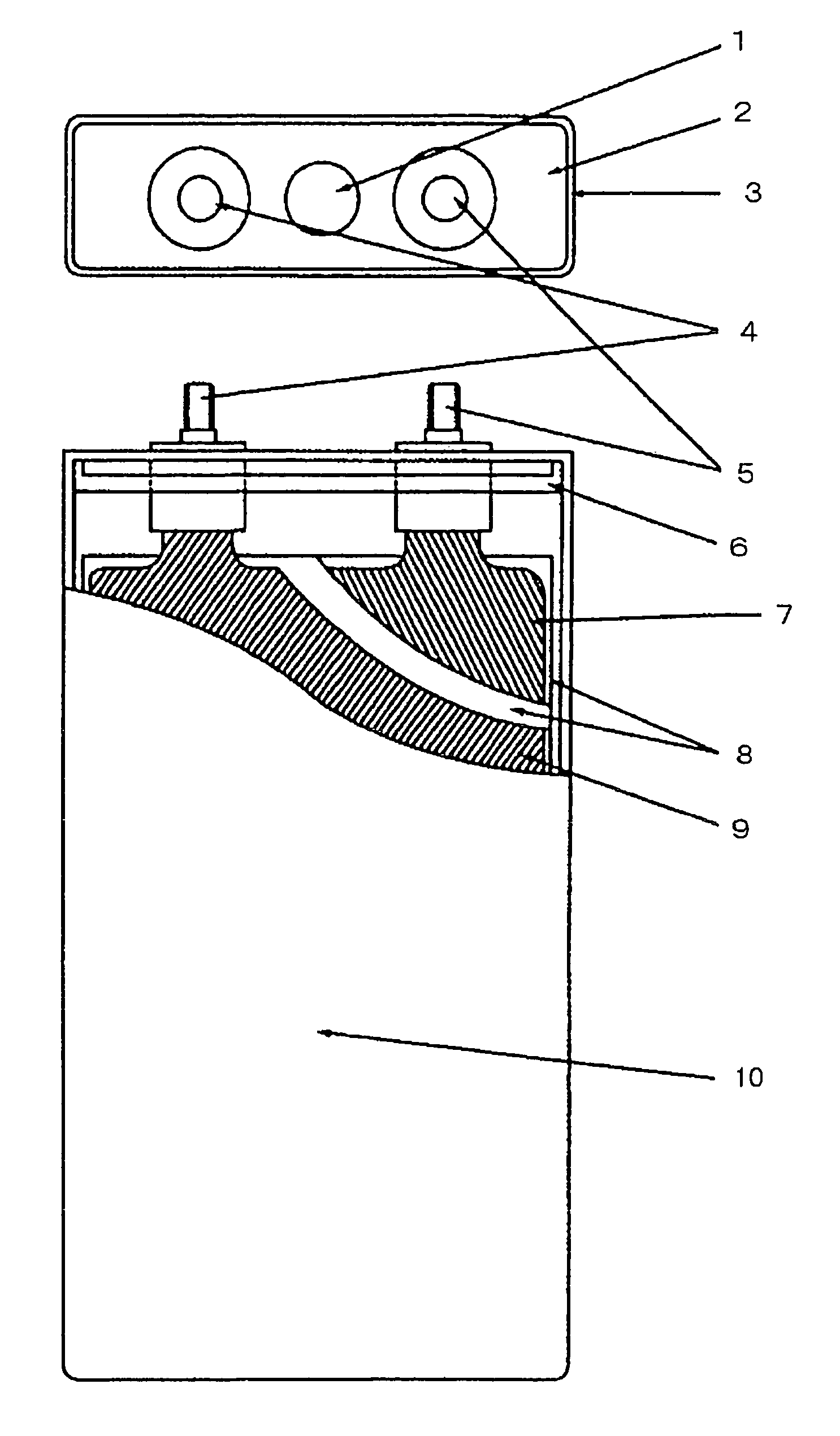

Core structure of lithium ion battery

InactiveCN101630757ALower internal resistanceImprove interface structureFinal product manufactureSecondary cellsInternal resistanceLithium-ion battery

The invention relates to a core structure of a lithium ion battery. In the core structure of the lithium ion battery, a core is formed by laminating and winding core monomers by means of a core septum; the core monomer is pressed by correspondingly laminating an anode sheet and a cathode sheet on two sides of the septum; and an anode ear of the anode sheet and a cathode ear of the cathode sheet are separated and positioned on two sides of the same side of the core monomer. The core septum wound with a plurality of the laminated core monomers can wind along the same direction and can also have a Z-shaped winding structure. The core is formed by laminating and winding the core monomers with the anode ears and the cathode ears by means of the core septum; the lithium battery with the core structure can effectively improve an interface structure between the core inner sheet formed by the laminated sheets and the septum, reduce the internal resistance of the core, improve the circulation performance and the rate discharge performance and can also prevent potential safety hazard triggered by misplacement of the anode sheet and the cathode sheet in the assembling process.

Owner:TCL CORPORATION

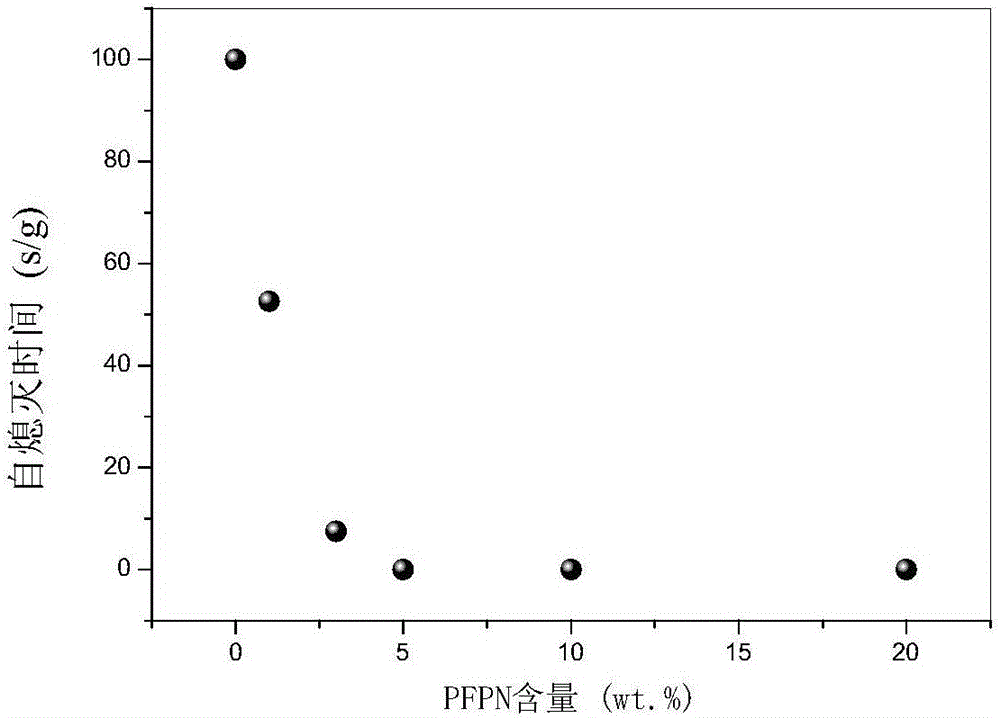

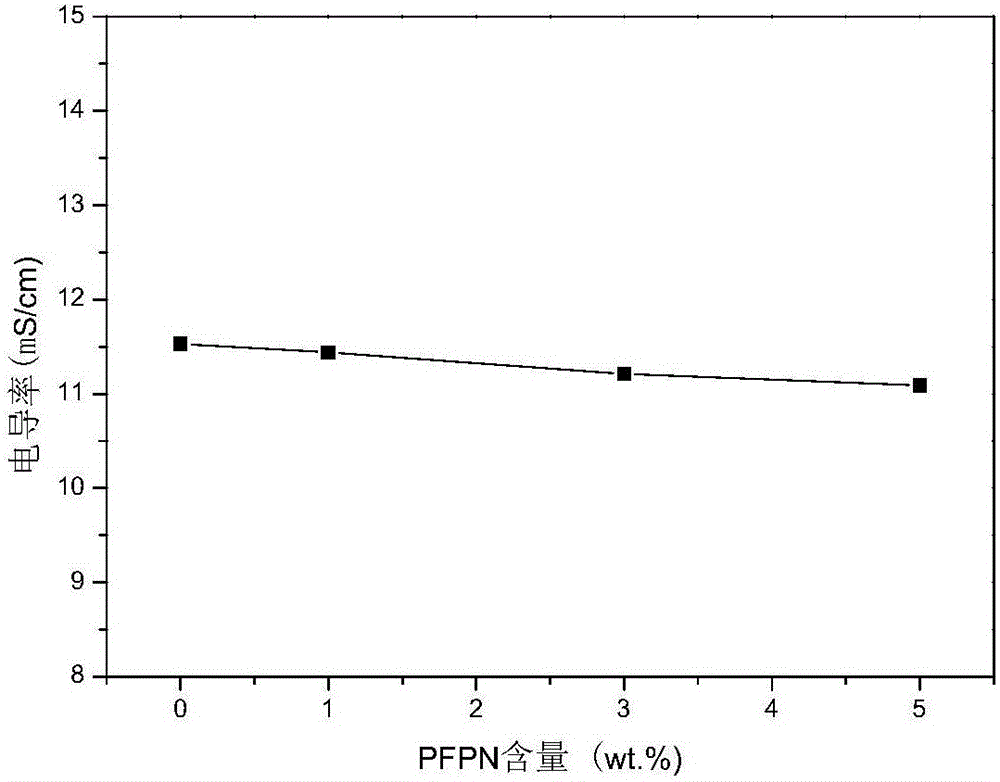

Flame-retardant electrolyte for secondary lithium-sulfur battery and preparation method for flame-retardant electrolyte

InactiveCN105977533AReduce flammabilityImprove electrochemical performanceFinal product manufactureSecondary cells servicing/maintenanceOrganic solventLithium–sulfur battery

The invention relates to a flame-retardant electrolyte for a secondary lithium-sulfur battery and a preparation method for the flame-retardant electrolyte. The flame-retardant electrolyte comprises a lithium salt, an organic solvent and a fire retardant, wherein the concentration of the lithium salt is 0.5-5mol / L in the electrolyte; the fire retardant is phosphonitrile fluoride fire retardant, which accounts for 0.1-20% of the total flame-retardant electrolyte based on mass percentage; the lithium salt is added to the organic solvent to be uniformly stirred to prepare the electrolyte; and then the fire retardant is added to the electrolyte to be continuously stirred and uniformly mixed to obtain the flame-retardant electrolyte for the secondary lithium-sulfur battery. Compared with the prior art, the flammability of the electrolyte added with the phosphonitrile fluoride additive is greatly lowered, and the influence on the conductivity is relatively low; according to the secondary lithium-sulfur battery assembled by the electrolyte containing the phosphonitrile fluoride fire retardant, the electrochemical performance of the secondary lithium-sulfur battery is obviously improved, and an effect of giving consideration to both of the flame-retardant effect and the electrochemical performance can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

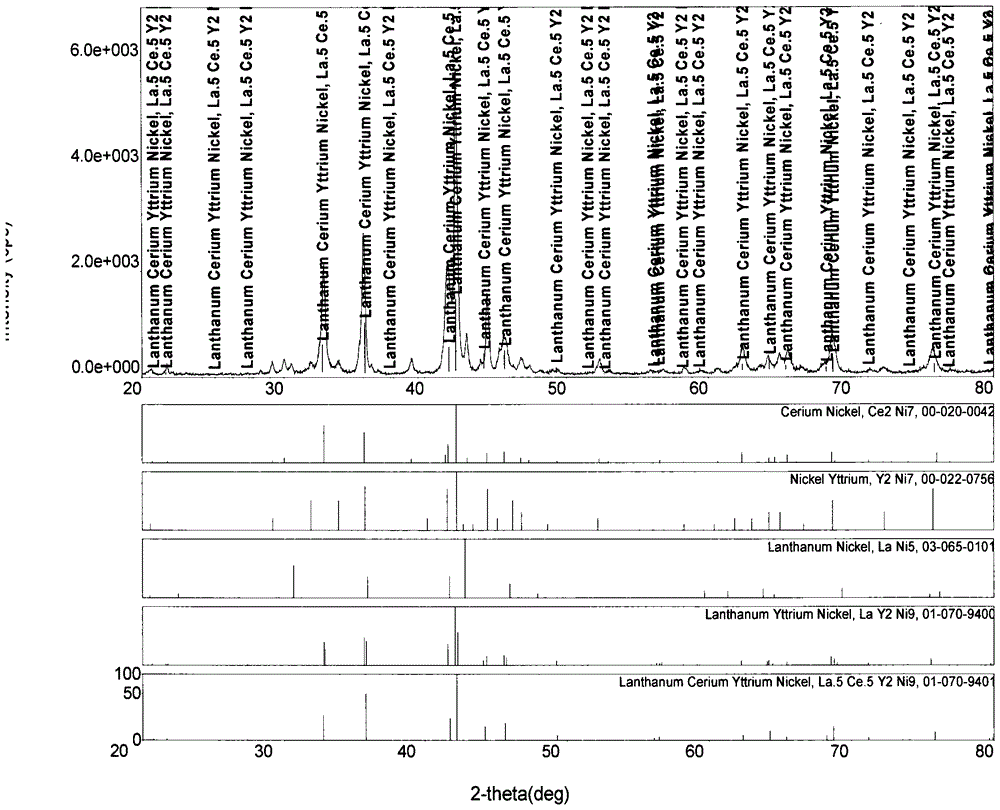

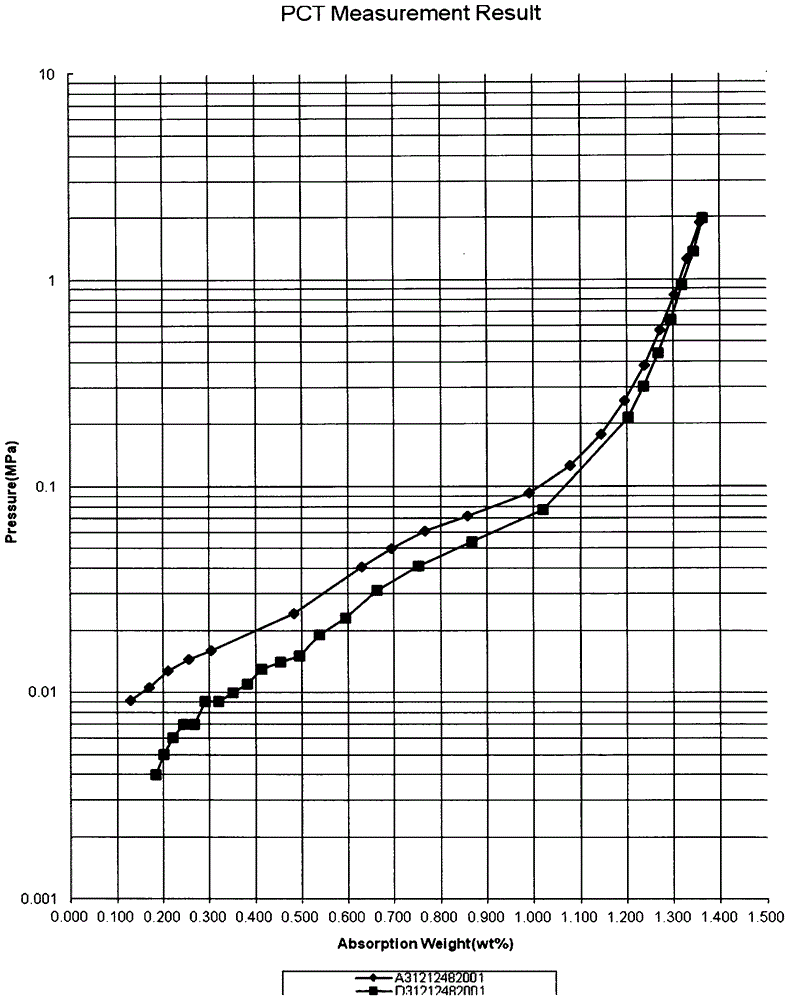

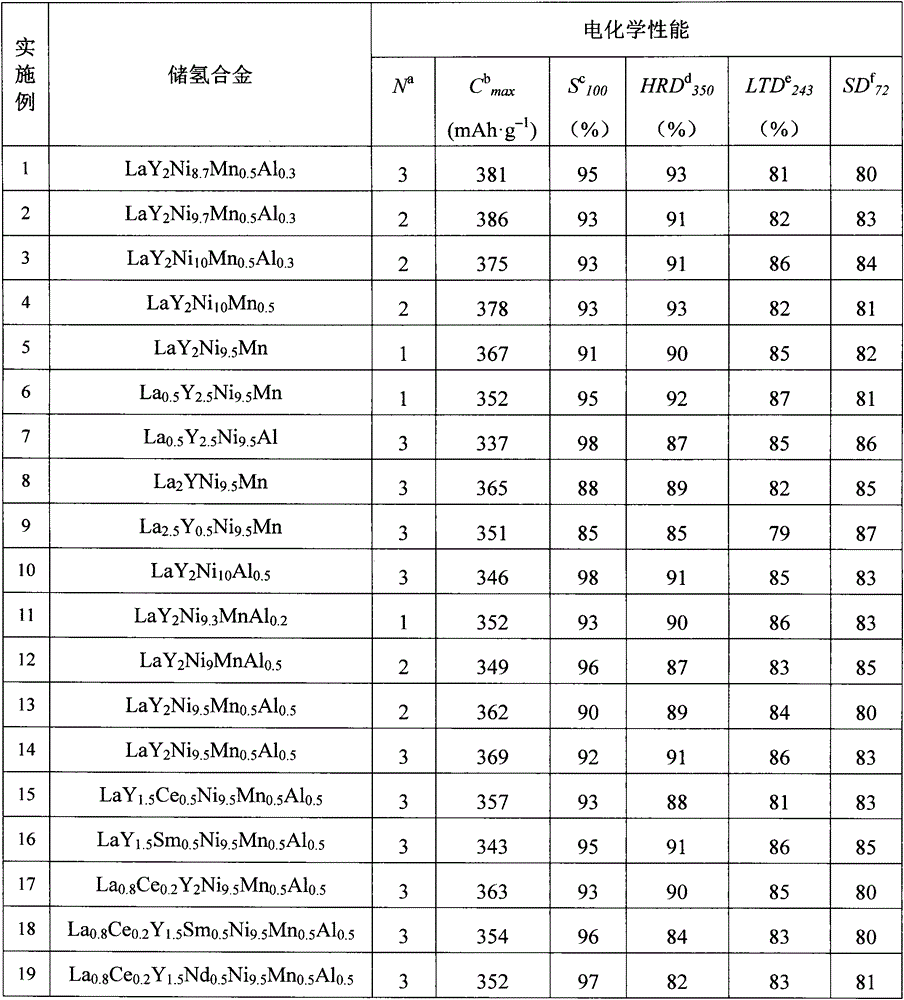

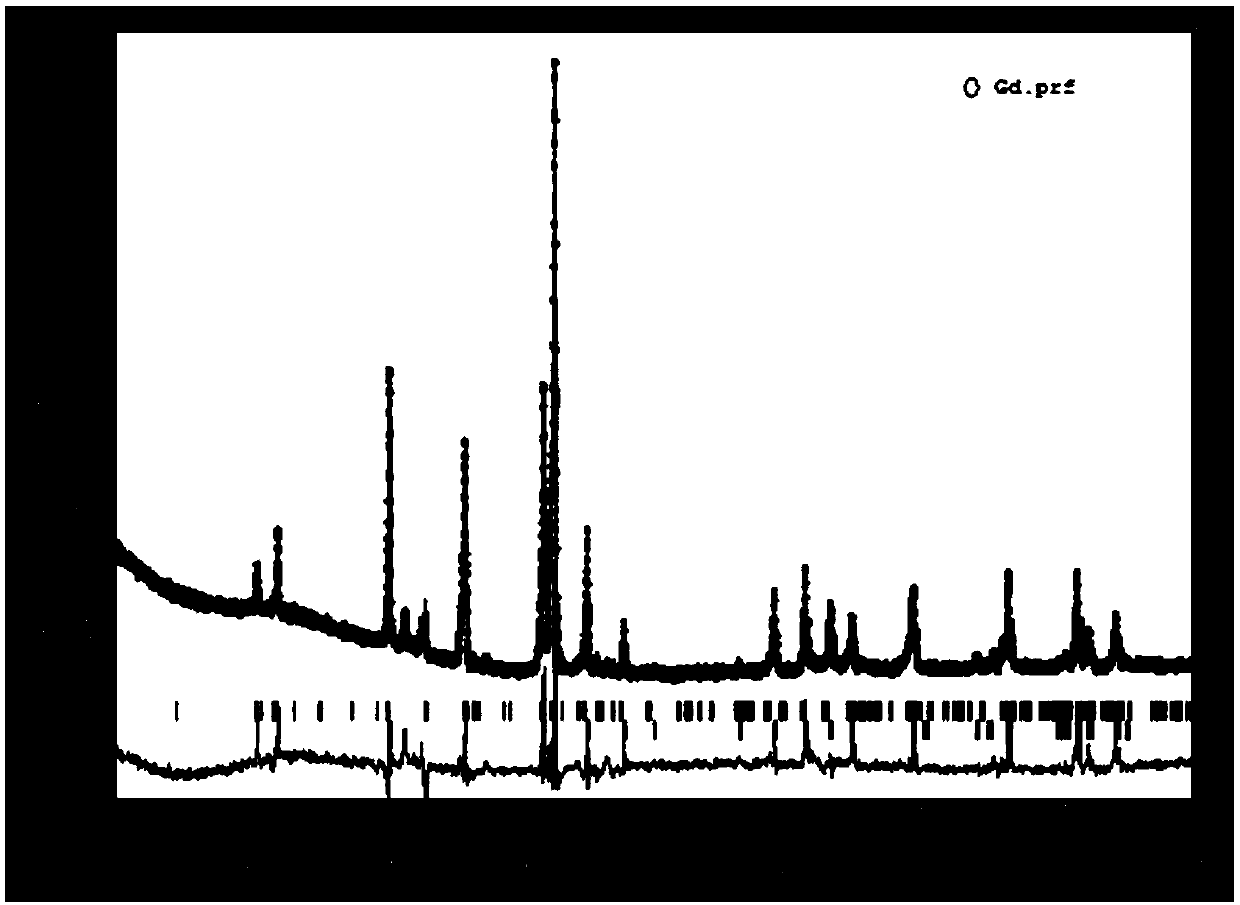

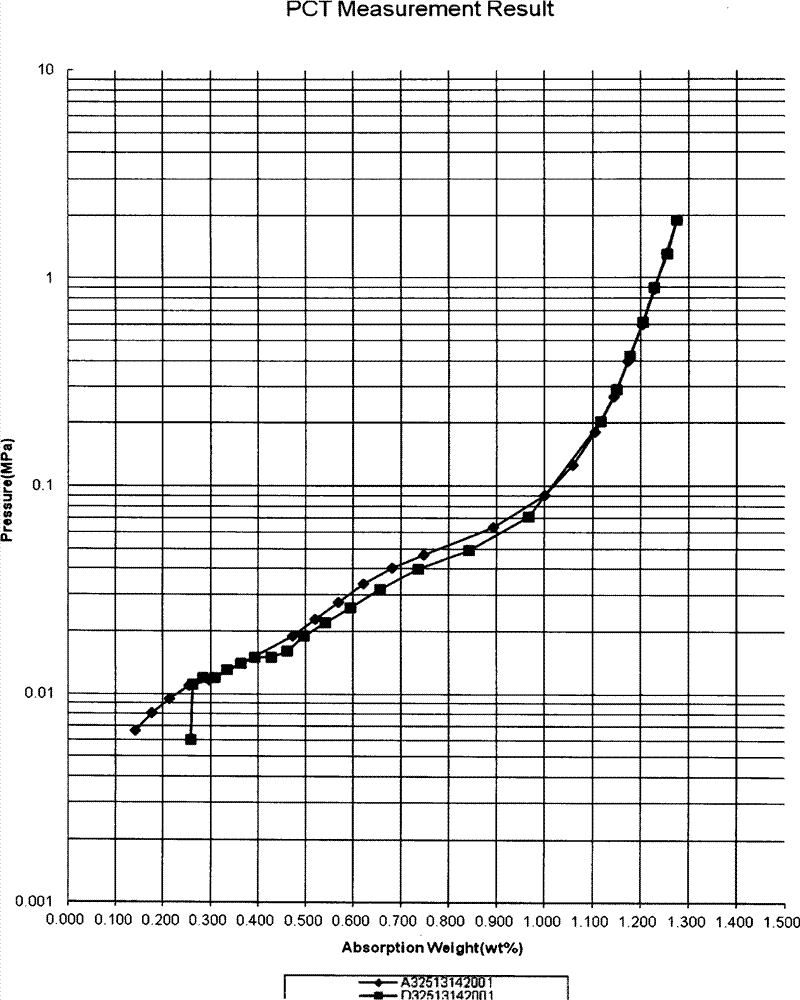

Yttrium-nickel rare earth-based hydrogen storage alloy

ActiveCN104532095AStructural stress reliefEliminate component segregationAlkaline accumulator electrodesGas phaseRare earth

The invention relates to A2B7 type RExYnNiz-a-bMnaAlb hydrogen storage alloy. The alloy is good in pressure-composition-isothermality, and has a maximum hydrogen storage amount of up to more than 1.36 wt.% under usual conditions. The alloy of the invention has better electrochemical performance as a hydrogen storage electrode and better gas-phase hydrogen absorption and desorption performance as a hydrogen storage material than traditional LaNi5 type hydrogen storage alloy; the alloy contains no magnesium element in the composition, so the preparation method of the alloy is simple and safe when compared with that of traditional rare earth-magnesium-nickel-based A2B7 type hydrogen storage alloy.

Owner:BAOTOU RES INST OF RARE EARTHS +2

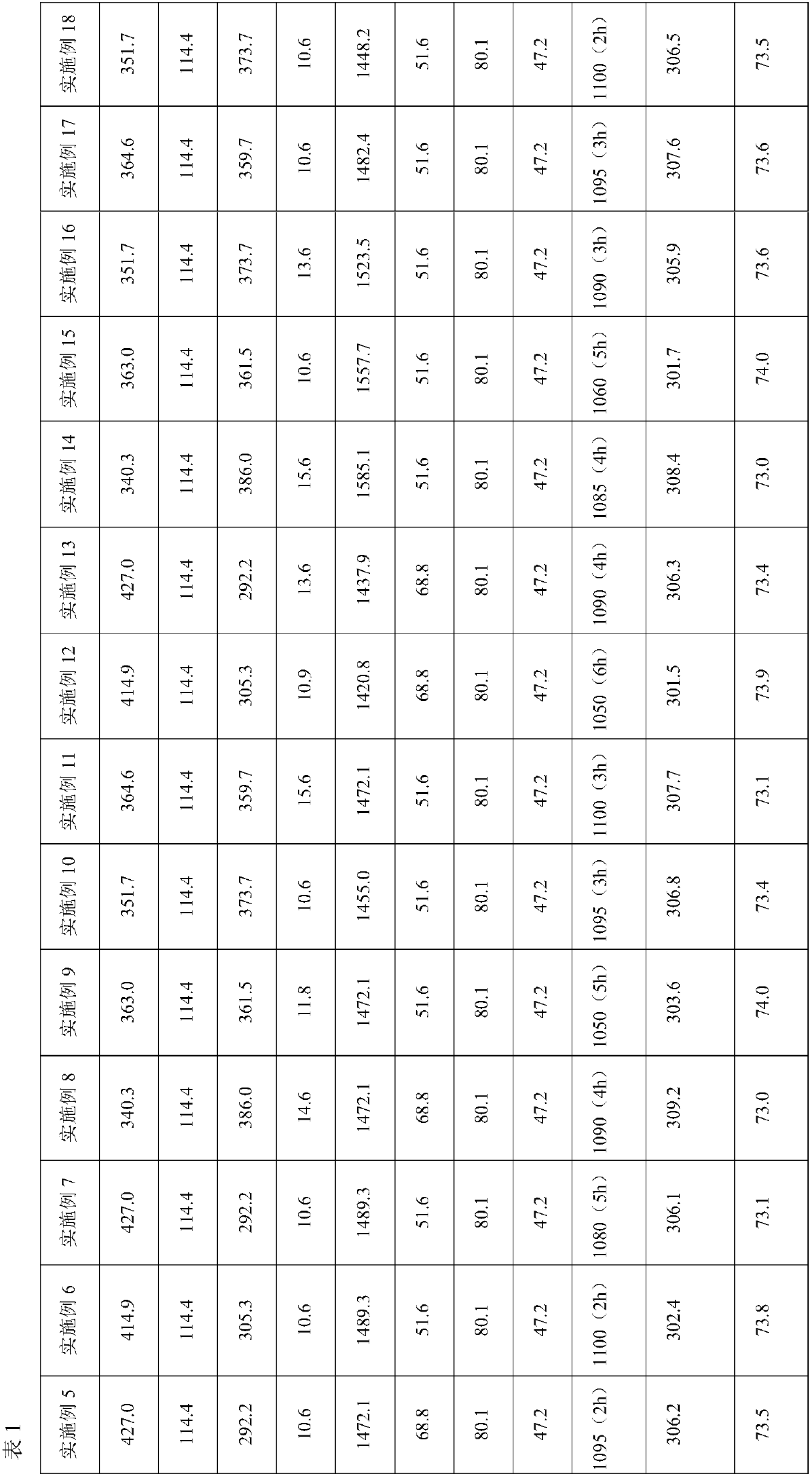

AB5-base hydrogen storage alloy, electrode for Ni-MH battery, secondary battery and method for preparing hydrogen storage alloy

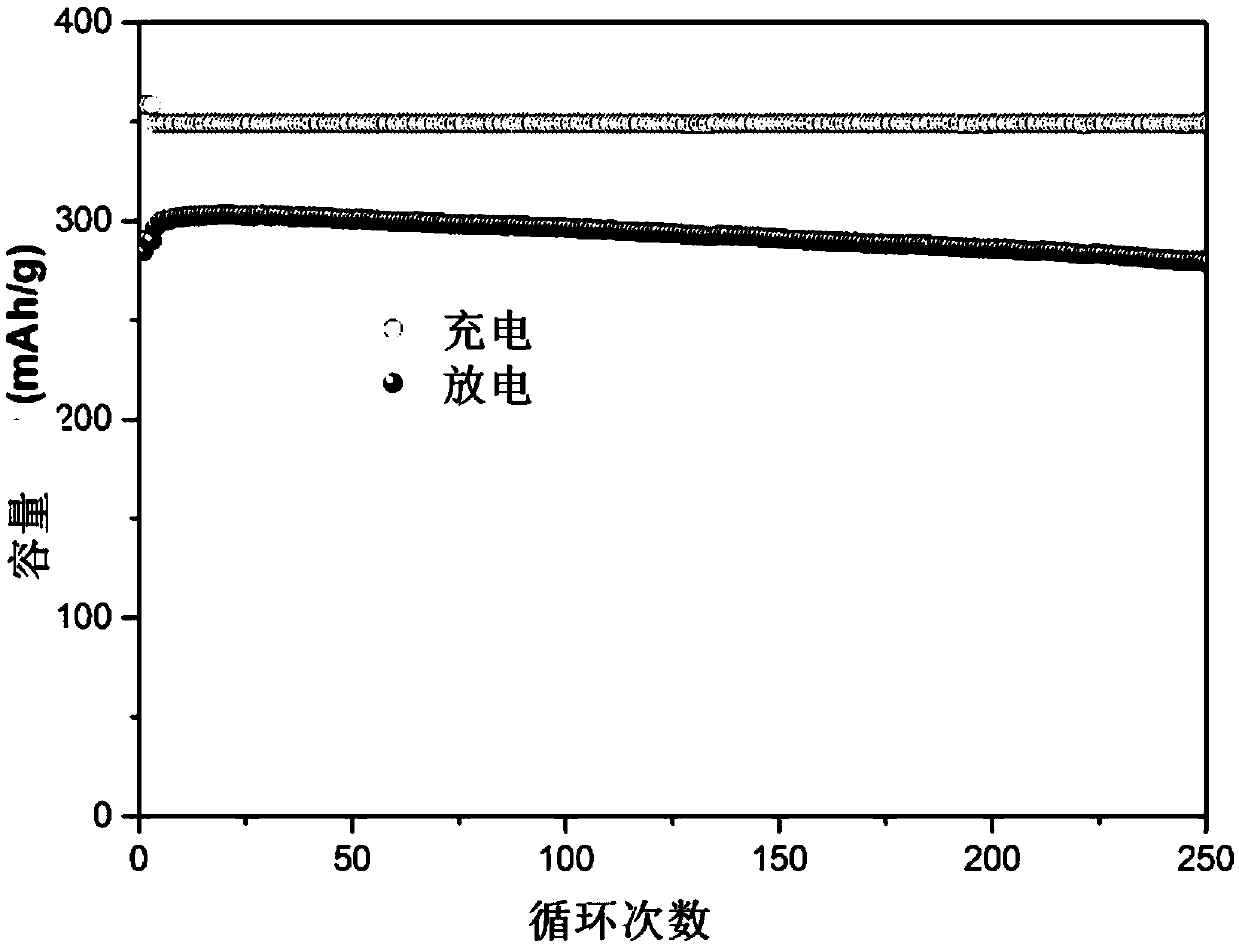

ActiveCN109585790AMeet overcharge performanceSatisfy the charging and discharging dynamic performanceNegative electrodesAlkaline accumulator electrodesHigh rateCerium

The invention relates to a hydrogen storage alloy, an electrode for a Ni-MH battery, a secondary battery and a method for preparing the hydrogen storage alloy. The chemical composition of the hydrogenstorage alloy is represented by the general formula La(3.0-3.2)x CexZrySm (1- (4.0~4.2)x-y)NizCouMnvAlw, wherein x, y, z, u, v, w are molar ratios; 0.14 <= x <= 0.17; 0.02 <= y <= 0 .03; 4.60 <= z +u + v + w <= 5.33; 0.10 <= u <= 0.20; 0.25 <= v <= 0.30; and 0.30 <= w <= 0.40. The overcharge performance of the electrode material is satisfied by fixing a ratio of lanthanum (La) to cerium (Ce) to3.0 - 3.2. A large number of samarium (Sm) elements on a side A are replaced, namely, the ratio of Sm atoms accounts for 25.6 to 42% of the side A to overcome a decrease in service life caused by lowcobalt (Co). The equilibrium pressure is adjusted by changing the ratios of Sm and La to Ce in order to satisfy the charge and discharge dynamics performance of the electrode material. The nucleationrate of a solidification process is increased by adding zirconium (Zr) having an atomic ratio of 2 to 3% relative to the elements at the side A to the elements at the side A. The Ni-MH battery anode material obtained by using the hydrogen storage alloy has high overcharge resistance, high rate discharge performance and good cycle stability.

Owner:SOUTH CHINA UNIV OF TECH +2

Gel polymer electrolyte, polymer battery and preparing method

ActiveCN101747642AImprove conductivityPrevent crystallizationSecondary cellsPolymer electrolytesLithium sulphate

The present invention provides a gel polymer electrolyte. The gel polymer electrolyte comprises a polymer, an electrolyte, an organic solvent and inorganic fillers. The electrolyte, the organic solvent and the inorganic fillers are dispersed in the polymer. The inorganic fillers are lithium sulfate and / or lithium bisulfate. The present invention also provides a polymer battery containing the gel polymer electrolyte and a preparing method thereof. The preparing method of the polymer battery comprises the steps: mixed solution containing the electrolyte, the inorganic fillers, a polymerizable monomer and the organic solvent is added between the positive pole and the negative pole of the battery, the polymerizable monomer in the mixed solution is then polymerized under polymerization conditions, and a substance in a gel state is obtained. As lithium sulfate and / or lithium bisulfate are used as the inorganic fillers in the gel polymer electrolyte, the conductivity of the gel polymer electrolyte and the rate discharge performance of the battery containing the gel polymer electrolyte are obviously improved.

Owner:BYD CO LTD

Lithium ion cell, anode therefor and preparing method thereof

ActiveCN1949561AGood dispersionImprove cycle performanceElectrode manufacturing processesFinal product manufactureLithiumAdhesive

The invention is an Li ion battery anode, comprising collector and coated and / or filled anode material on the collector, where the anode material comprises anode active matter, conducting agent and adhesive, the adhesive contains charcoal black which has a specific surface area above 500m2 / g obtained by nitrogen absorption, where the anode material also comprises dispersant. And a Li ion battery using the anode has good circulating performance and multiplying discharging performance.

Owner:BYD CO LTD

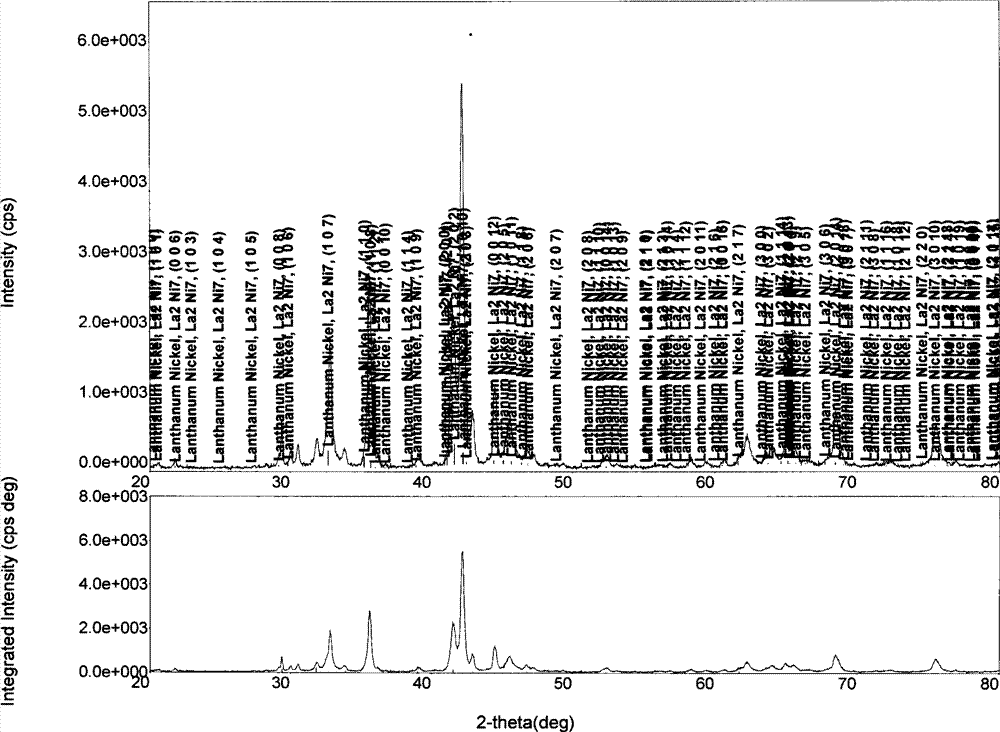

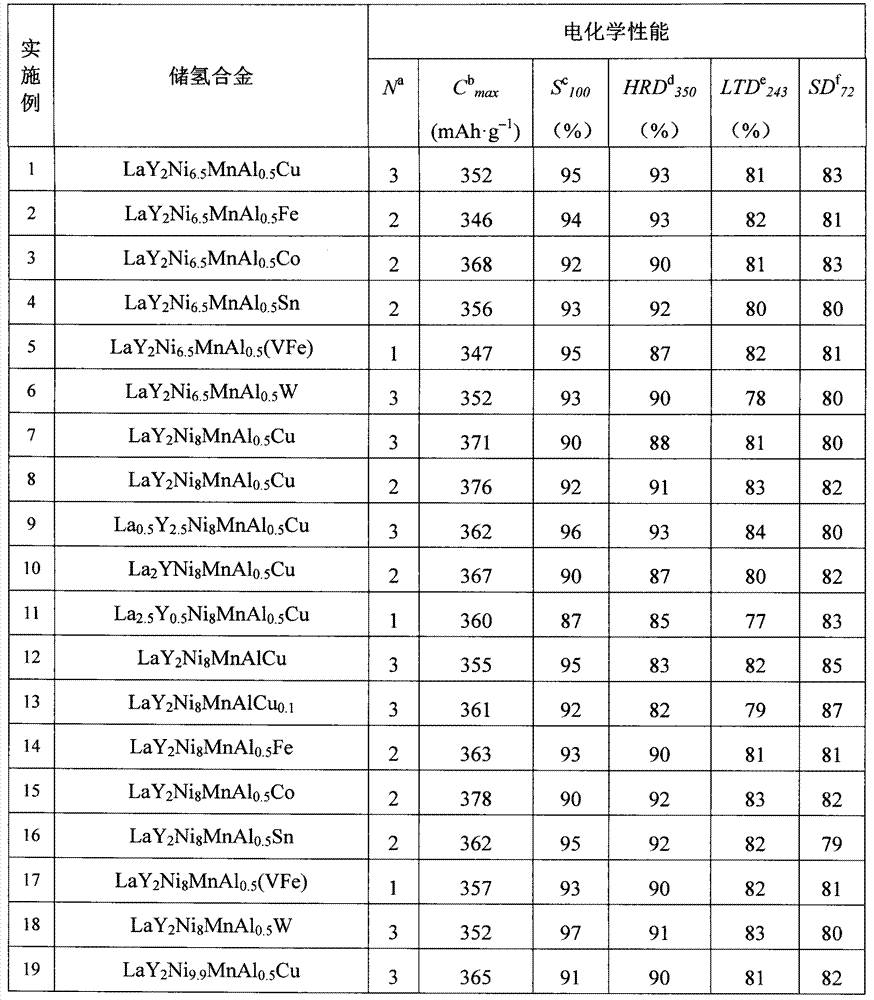

Rare earth-yttrium-nickel family hydrogen storage alloy, and secondary battery containing hydrogen storage alloy

ActiveCN104518204AIncrease capacityThe manufacturing method is simple and safeAlkaline accumulator electrodesNickel accumulatorsAlkaline earth metalRare earth

The invention relates to a rare earth family hydrogen storage alloy with the general formula of RExYyNiz-a-b-cMnaAlbMc. The alloy treats the rare earth Y as one of main components, contains Mn and Al elements or one of Mn and Al, also contains one or more of Cu, Fe, Co, Sn, V and W, contains no alkali earth metals, and is simple and safe to produce. The hydrogen storage alloy has a good compression-composition-isothermal characteristic and a large hydrogen storage amount reaching above 1.28wt% under usual conditions; the highest capacity of the above hydrogen storage alloy electrode is higher than that of LaNi5 type hydrogen storage alloy; and the rare earth family hydrogen storage alloy has good activation performances, rate discharge ability, and charge and discharge or hydrogen absorption and desorption cycle stability, can be used in a wide temperature range, and has small self discharge.

Owner:BAOTOU RES INST OF RARE EARTHS +2

Active substance of positive electrode and non-aqueous electrolyte battery containing the same

ActiveUS7691535B2Increase energy densityImprove high rate discharge performanceSecondary cellsAlkali metal oxidesHigh energyPhysical chemistry

A positive active material is provided which can give a battery having a high energy density and excellent high-rate discharge performance and inhibited from decreasing in battery performance even in the case of high-temperature charge. Also provided is a non-aqueous electrolyte battery employing the positive active material. The positive active material contains a composite oxide which is constituted of at least lithium (Li), manganese (Mn), nickel (Ni), cobalt (Co), and oxygen (O) and is represented by the following chemical composition formula: LiaMnbNicCodOe (wherein 0<a≦1.3, |b−c|≦0.05, 0.6≦d<1, 1.7≦e≦2.3, and b+c+d=1). The non-aqueous electrolyte battery has a positive electrode containing the positive active material, a negative electrode, and a non-aqueous electrolyte.

Owner:GS YUASA INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com