Patents

Literature

422results about How to "Increase gram capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

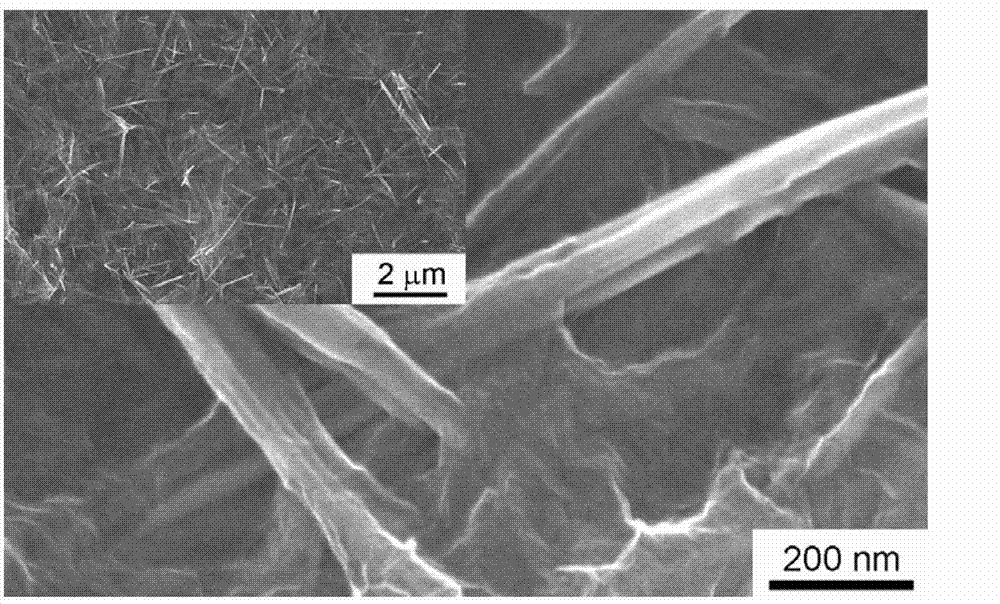

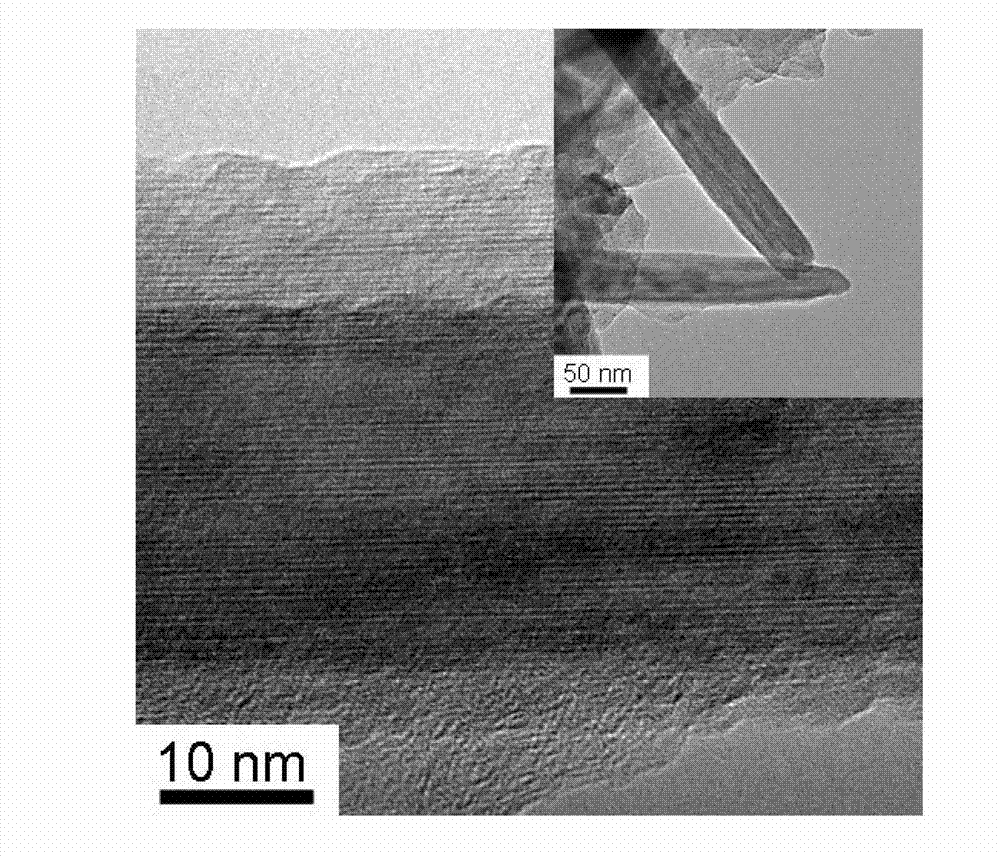

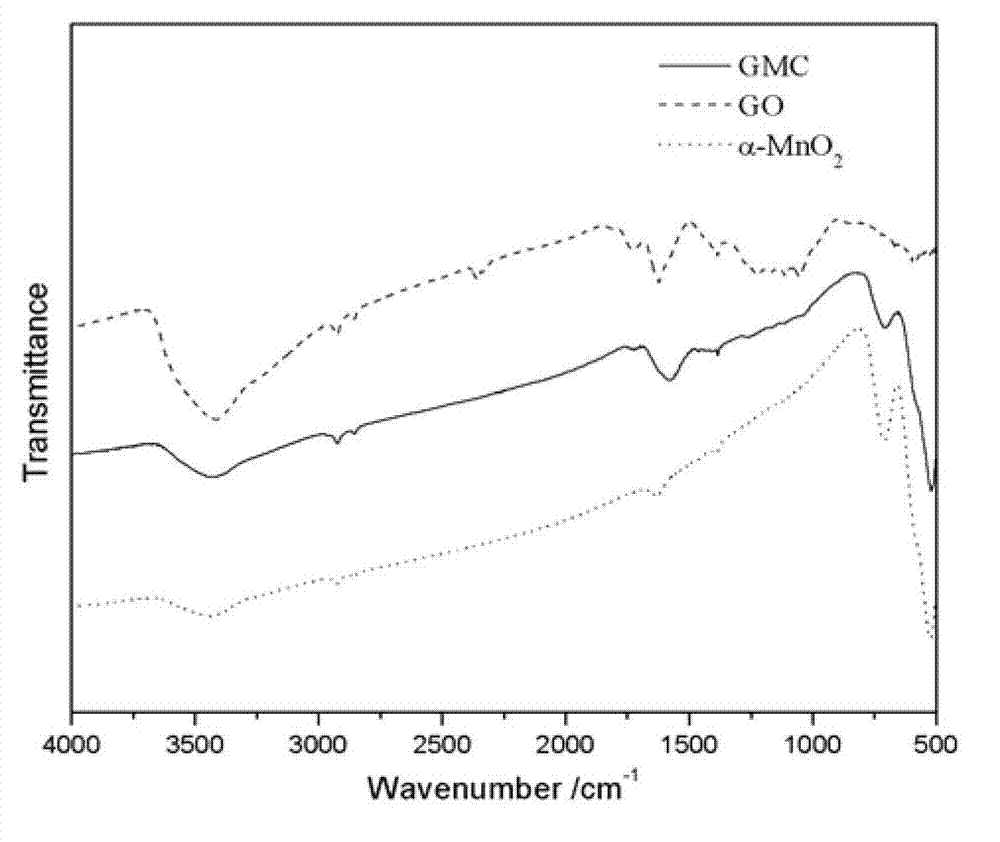

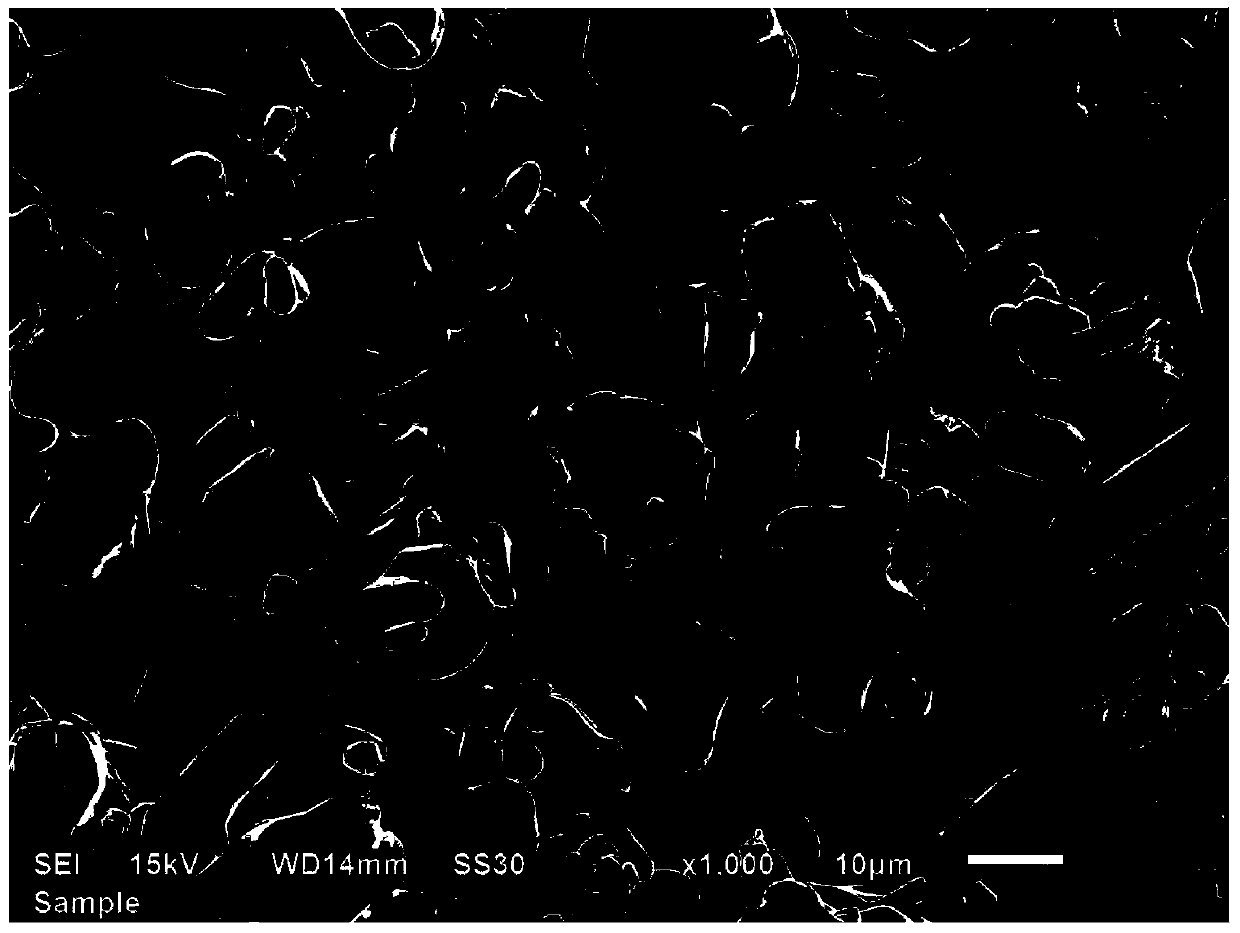

Method for compounding graphene and metallic oxide/metallic compound and composite material thereof

ActiveCN103094540AImprove cycle performanceImproved magnification performanceMaterial nanotechnologyCell electrodesSolubilityGram

The invention discloses a method for compounding graphene and a metallic oxide / metallic compound. The method comprises the following steps: a, dissolving graphene oxide in a dispersing agent, regulating the PH value of the solution to be 5-9, and preparing a graphene oxide solution; and b, adding the oxide / metallic compound into the graphene oxide solution, ultrasonically mixing, reacting at the temperature of 70-120 DEG C for 32-40 hours. According to the method for compounding graphene and the metallic oxide / metallic compound, a reducing agent is not used, the composite material is reduced by utilizing the reducing property of graphene oxide in a hydrothermal environment, and the final product forms the uniformly dispersed graphene and oxide / metallic compound composite material by utilizing the high water solubility of the graphene oxide; and moreover, according to the material, the cycle performance, rate capability and gram volume of the oxide which serves as an electrode of a lithium ion battery can be effectively improved, and the impendence is reduced.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

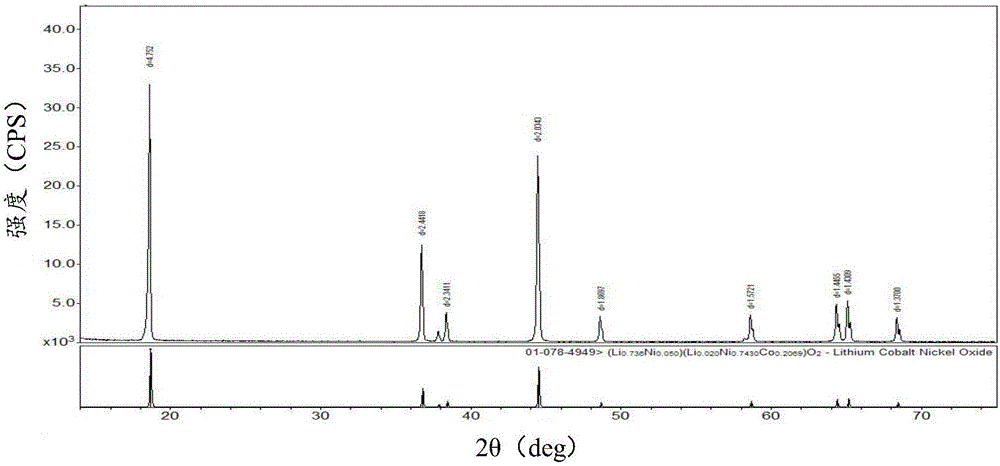

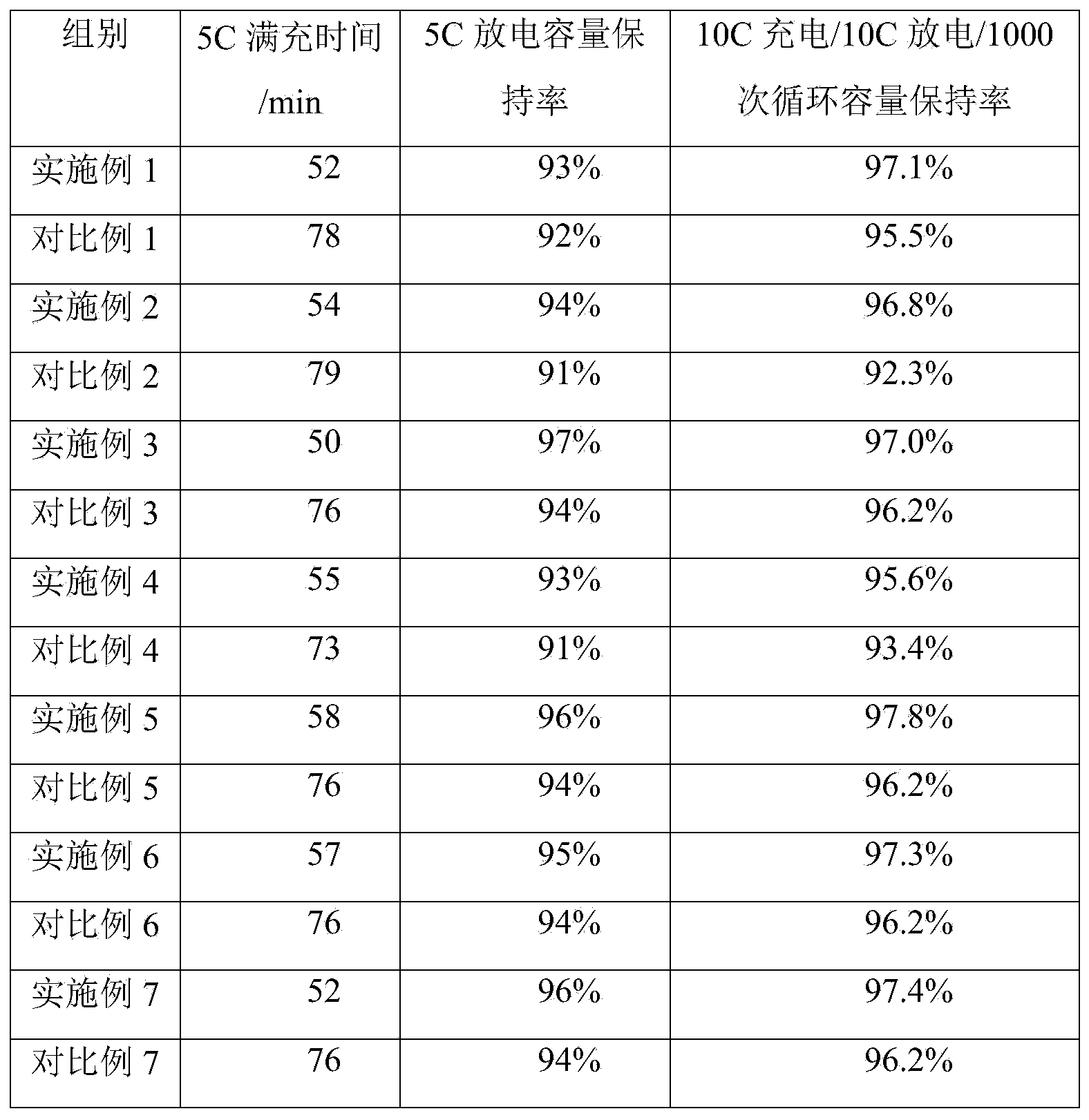

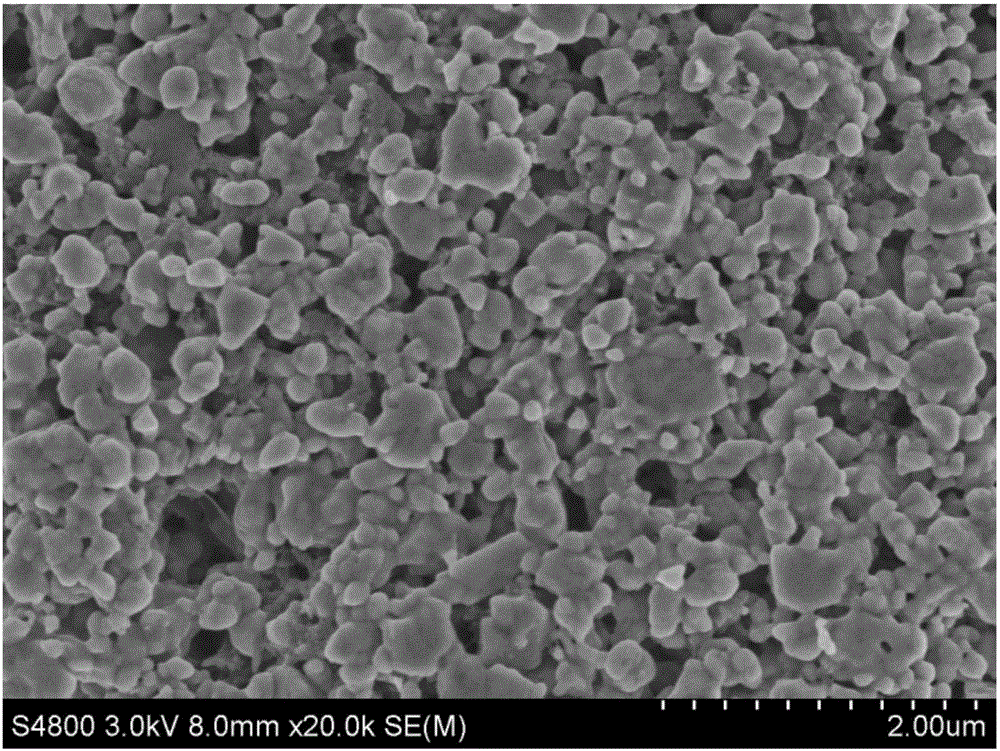

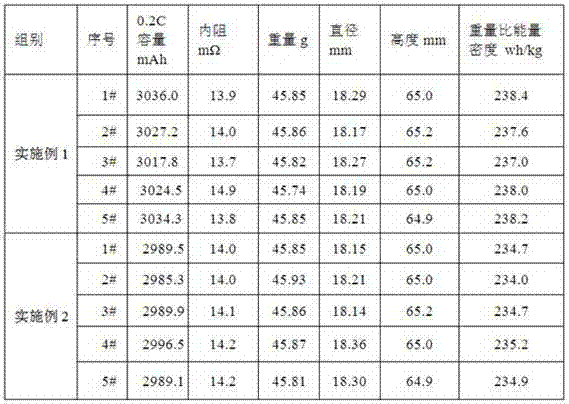

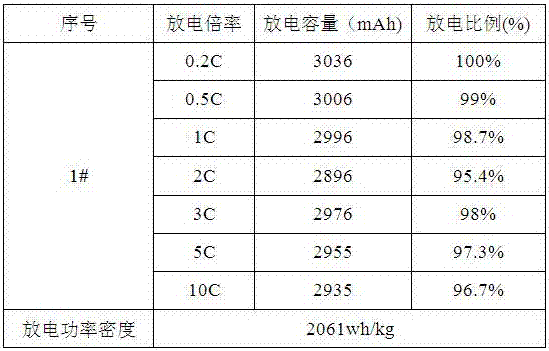

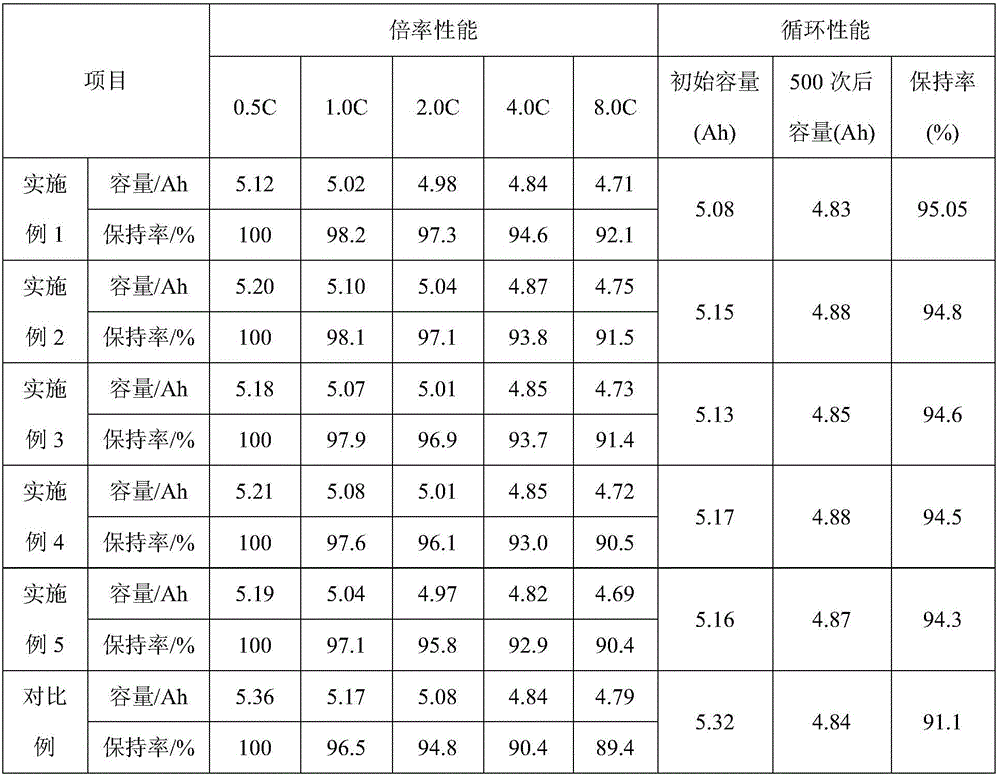

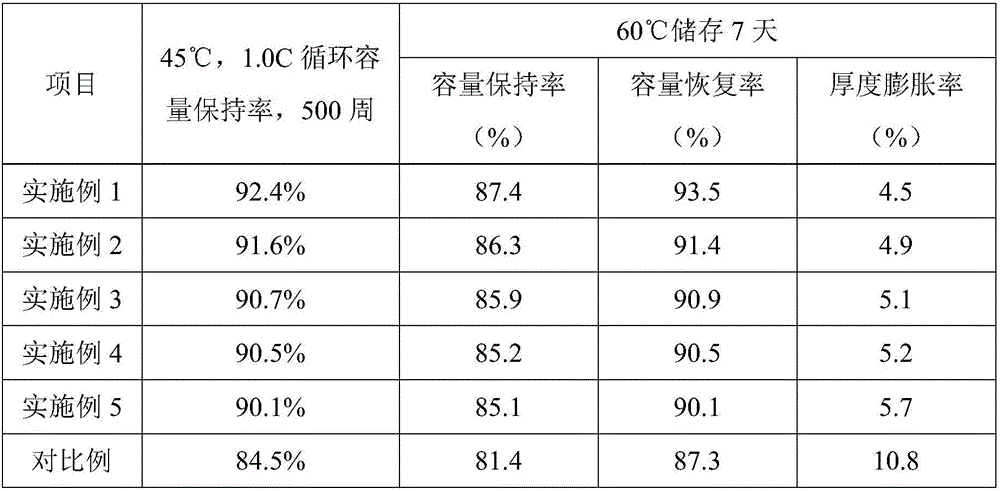

Single-crystal lithium nickel manganese cobalt positive electrode material, preparation method thereof and lithium ion battery

ActiveCN106505193AImproved magnification performanceIncrease gram capacityCell electrodesSecondary cellsElectrical conductorInternal resistance

The invention provides a single-crystal lithium nickel manganese cobalt positive electrode material. The single-crystal lithium nickel manganese cobalt positive electrode material comprises a substrate, wherein the substrate is a compound shown as a formula I of LiNi<x>Co<y>Mn<1-x-y>M<z>O<2>, x is more than or equal to 0.3 but less than or equal to 0.75, y is more than or equal to 0.2 but less than or equal to 0.3, z is more than or equal to 0 but less than or equal to 0.1, and a coating layer is coated on a surface of the substrate and is one or more of Li2ZrO3, Li2SnO3, LiNbO3, Li4Ti5O12 and LiAlO2. Compared with the prior art, a fast ion conductor is coated on the surface, thus, the rate performance of a single-crystal material is improved, the gram capacity of the single-crystal material is improved, the cycle performance of the material is further improved, the internal resistance can also be reduced, the polarization loss is reduced, and the cycle lifetime of a battery is prolonged; and meanwhile, the advantage of large compaction of a single-crystal ternary material is maintained, a particle broken phenomenon caused by rolling particles similar to secondary particles during battery fabrication can be prevented due to relatively high compaction, and the cycle performance is improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

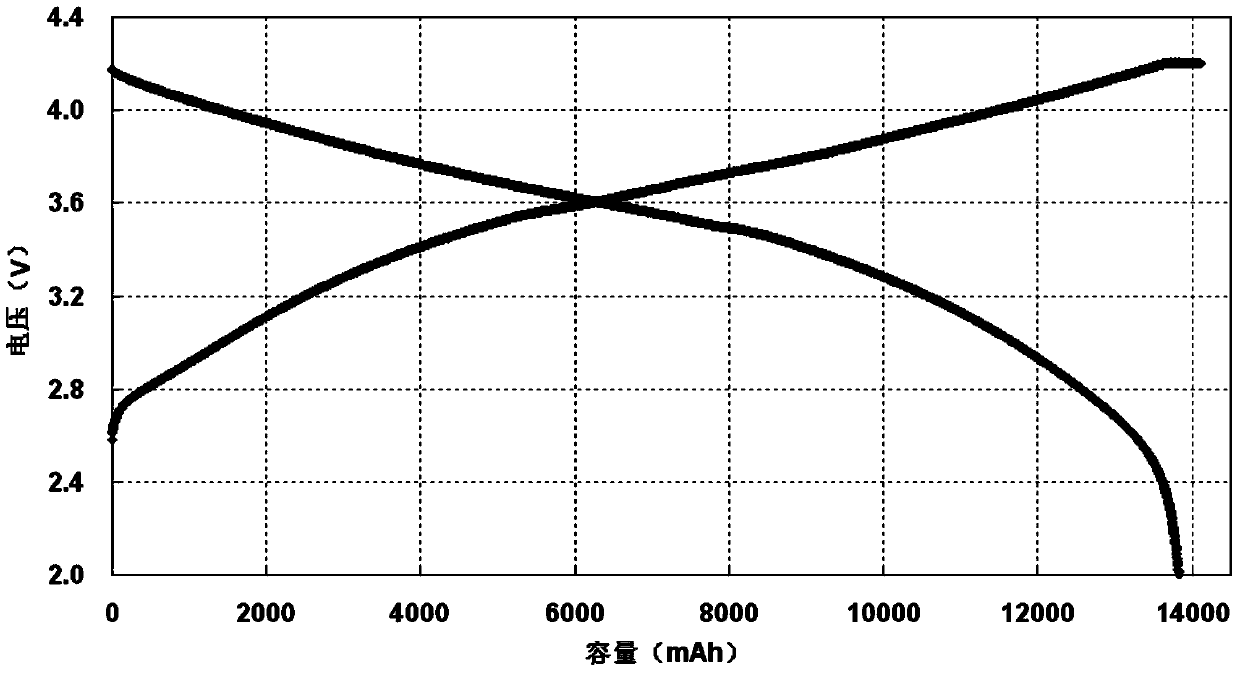

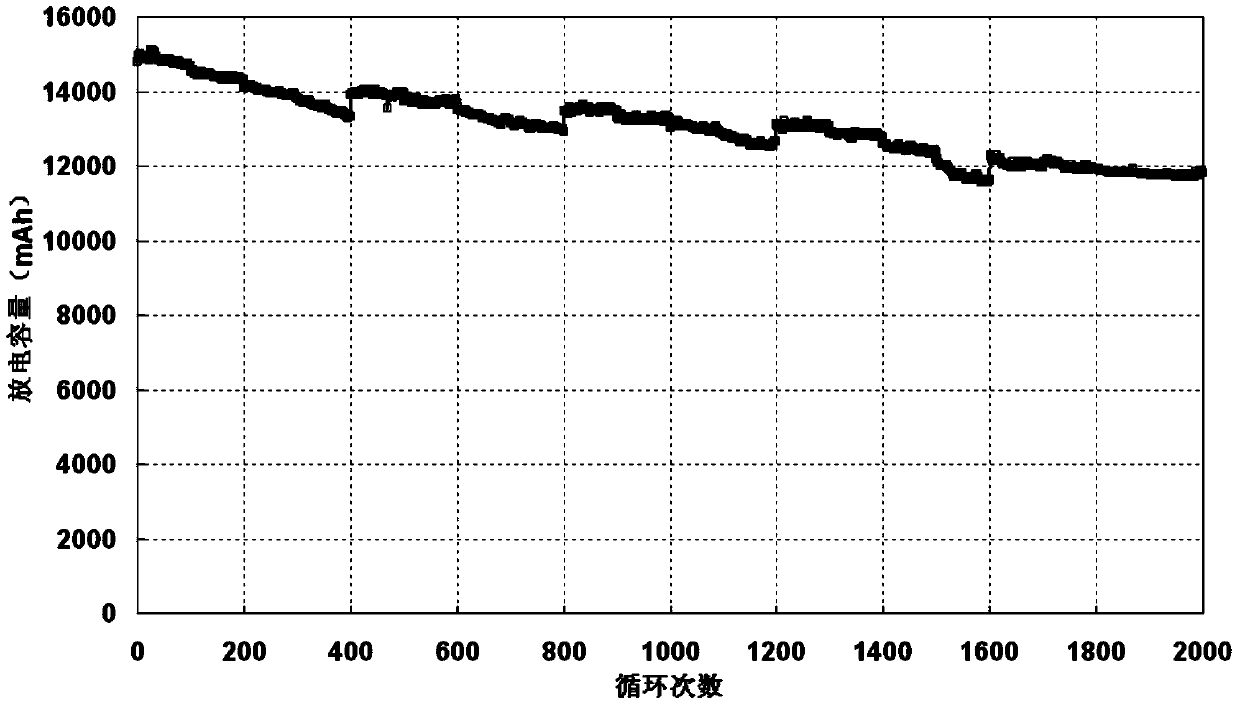

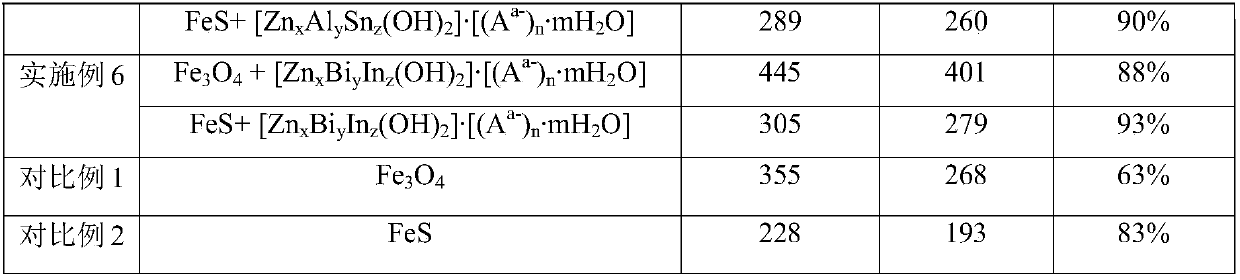

Power and energy storage lithium-ion battery and preparation method thereof

ActiveCN103441305AImproved gram capacity playIncrease capacityFinal product manufactureElectrolyte accumulators manufactureGramEngineering

The invention relates to a preparation method of a power and energy storage lithium-ion battery. A negative active substance of the power and energy storage lithium-ion battery comprises soft carbon, hard carbon, a mixed material of soft carbon and graphite and a mixed material of hard carbon and graphite. The designing method of the battery comprises the steps of designing the gram volume of the negative active substance as the primary lithium-embedding gram volume, designing the gram volume of the positive active substance as the primary lithium-removal gram volume, designing the ratio of the capacity of the positive electrode and the capacity of the negative electrode to be (1: 1) to (1.5: 1). By adopting the designing method, the capacity and comprehensive performance of the battery can be remarkably improved, and excellent lithium-embedding and lithium-removal capacity of the soft carbon material and the hard carbon material can be adequately exerted. Compared with the existing lithium battery technology, the prepared power lithium battery has long service life, high multiplying power, high safety performance and excellent low-temperature performance and can be widely applied to the fields such as electric tools, various portable devices, spaceflight, starting power supply and the like.

Owner:BTR NEW MATERIAL GRP CO LTD

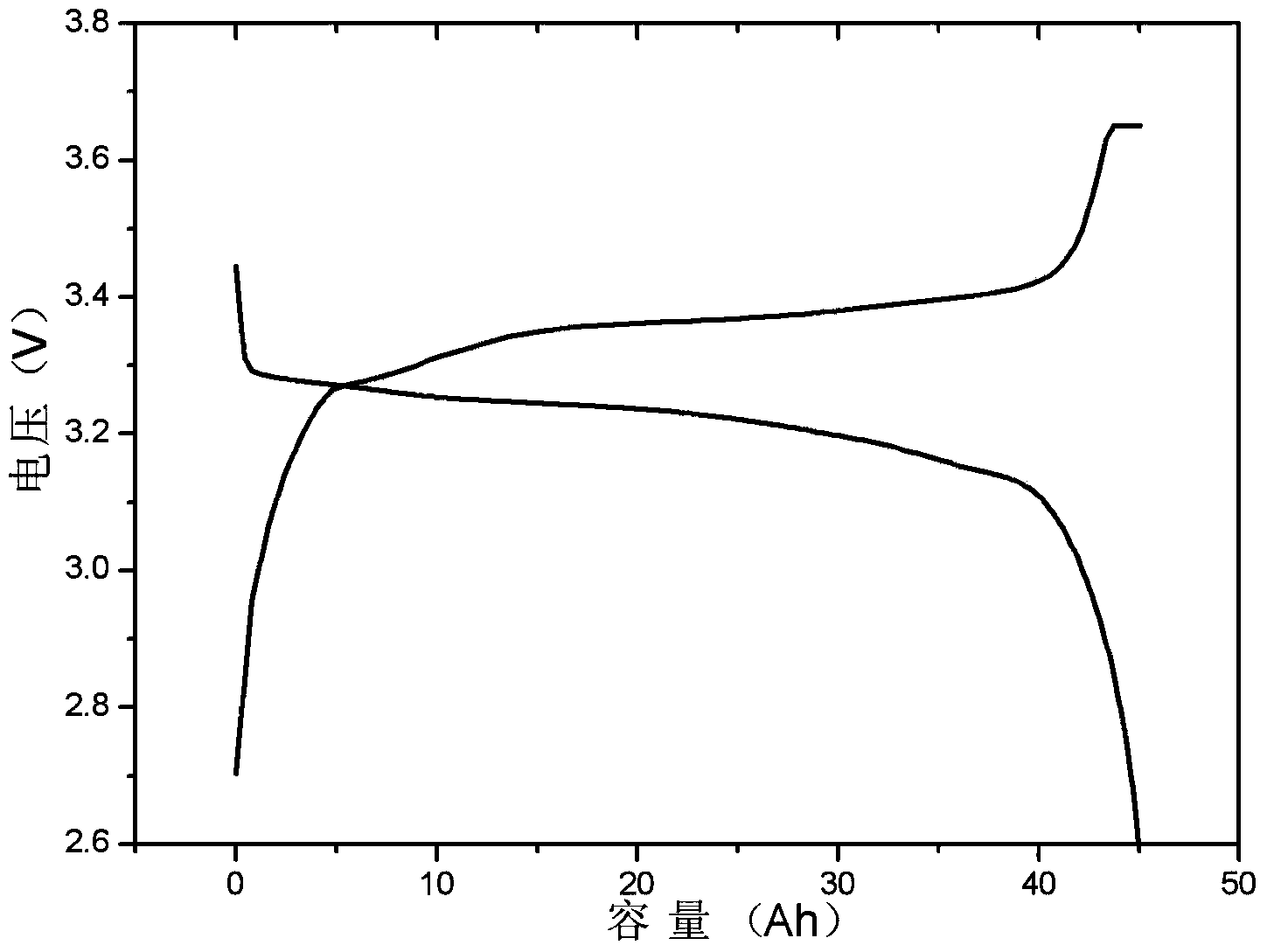

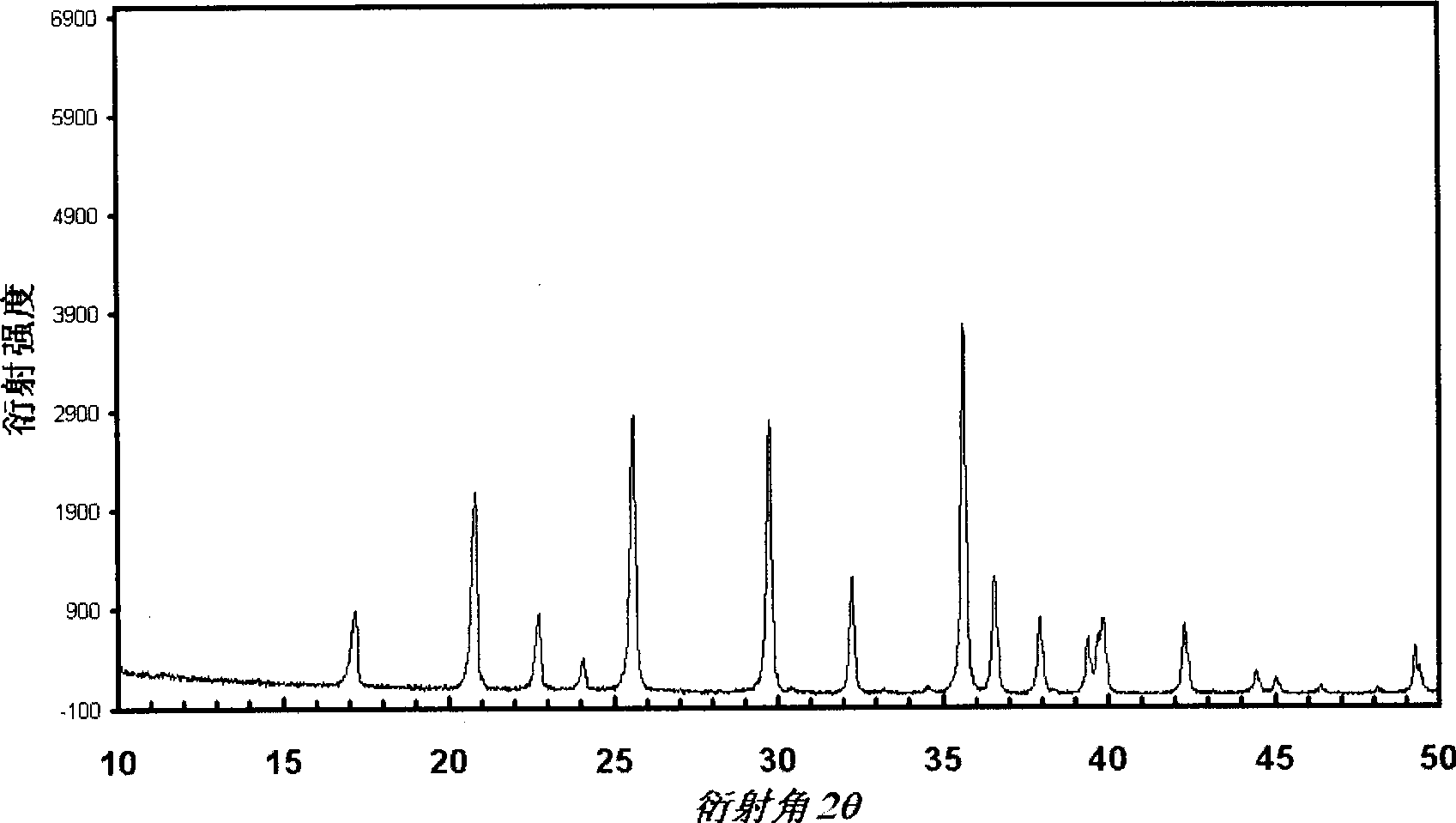

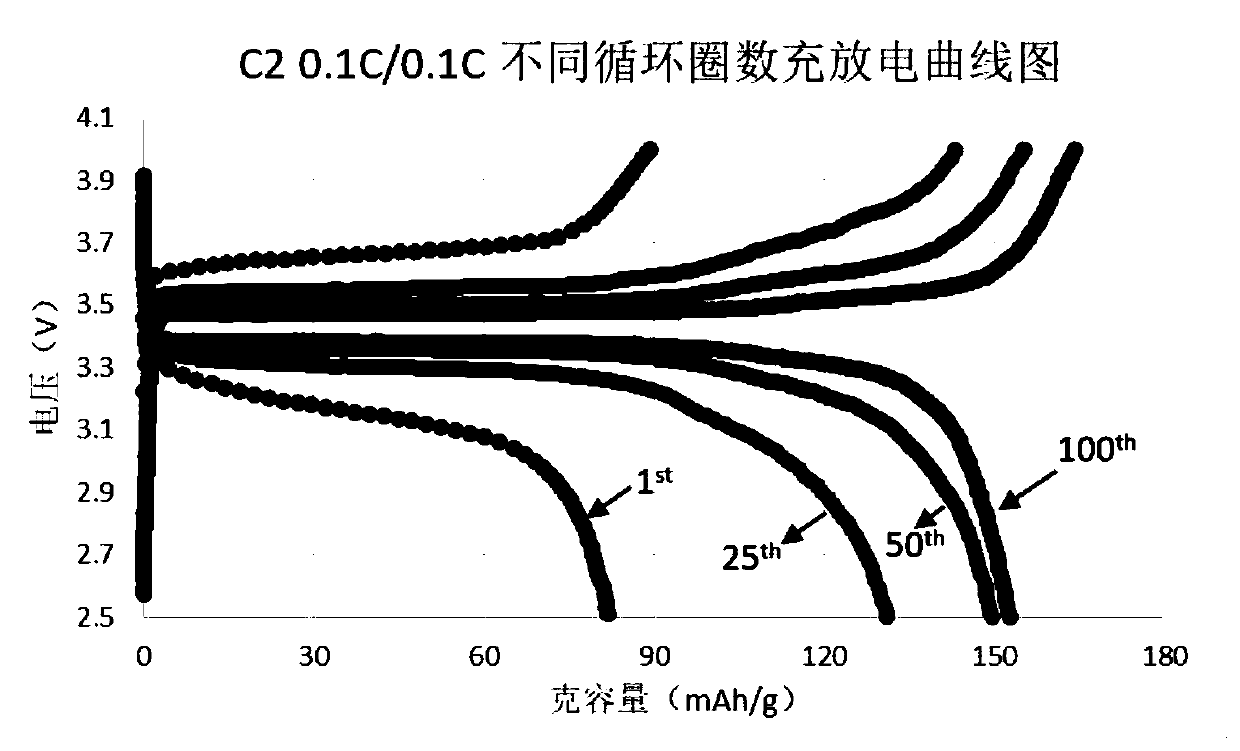

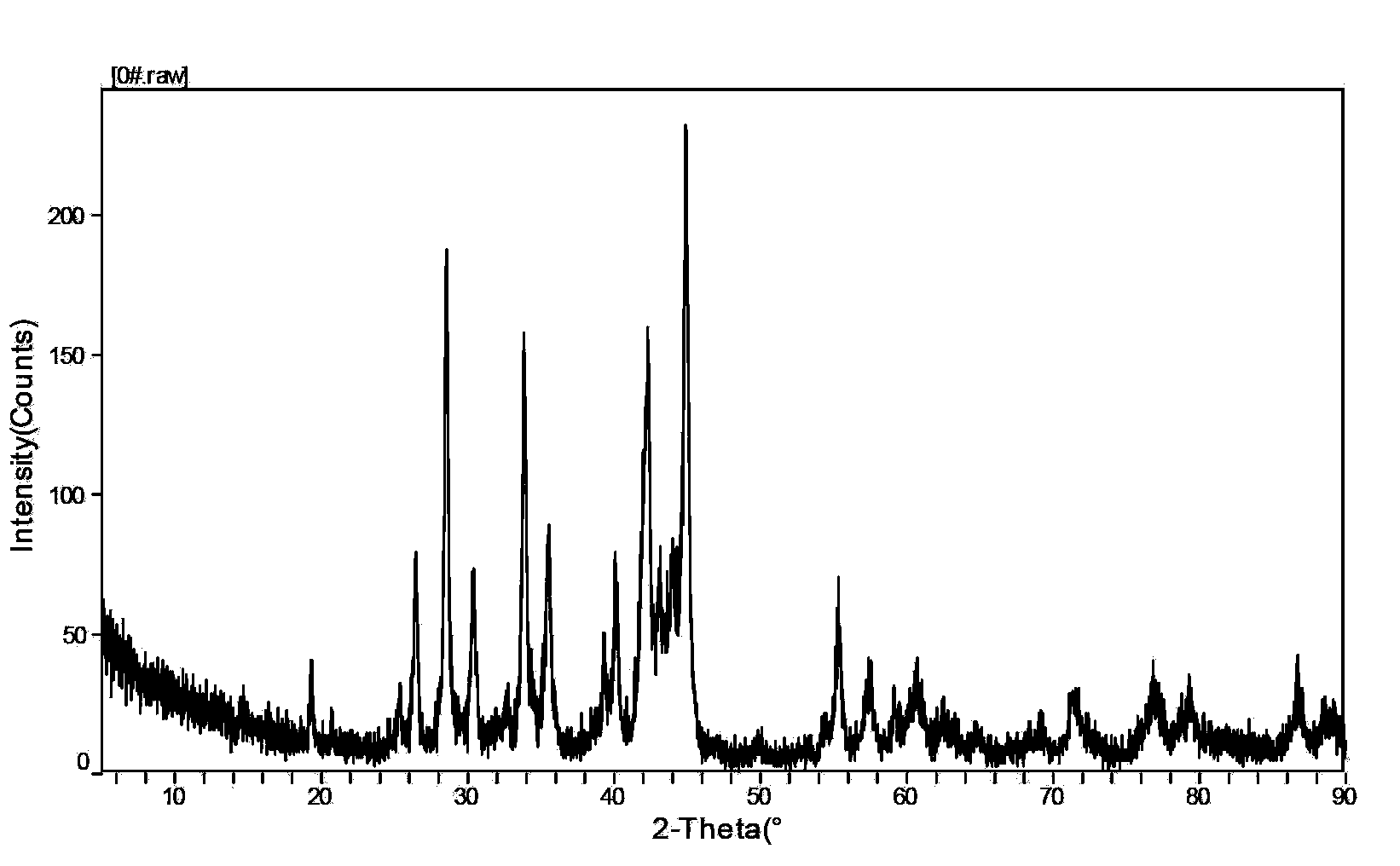

Method for recycling positive material from water-system waste lithium iron phosphate battery

InactiveCN103449395AIncrease gram capacityExcellent rate performanceWaste accumulators reclaimingPhosphorus compoundsChemistryCurrent collector

The invention discloses a method for recycling a positive material from a water-system waste lithium iron phosphate battery. The method comprises the following steps: elaborately disassembling fully-discharged waste lithium iron phosphate battery to obtain an undamaged positive plate, separating a positive active material from a current collector in a way of immersing through deionized water, and drying and ball-milling the active material to obtain a lithium iron phosphate positive material to be recycled; respectively testing carbon content and ratio of Li, Fe and P elements of the lithium iron phosphate positive material to be recycled, adding a lithium source and an iron source, adjusting a mole ratio of Li to Fe to P to be (1.0-1.1):1:1, further adding the lithium source, the ion source and the phosphate source according to a ratio of 1:1:1 and adjusting C content ratio in the material; and performing ball milling, low-temperature pre-sintering and high-temperature sintering on the material of which ratio of the elements is adjusted to obtain the recycled lithium iron phosphate positive material. The recycled material has the advantages that 0.1C discharging capability can reach up to 156mAh / g, 2C discharging capability can reach up to 120mAh / g, the retention ratio of 0.1C discharging capability after 50 times of recycling is greater than 99% and various electrochemical properties are excellent. The method disclosed by the invention is low in cost and simple in process; the secondary pollution is avoided.

Owner:UNIV OF SCI & TECH BEIJING

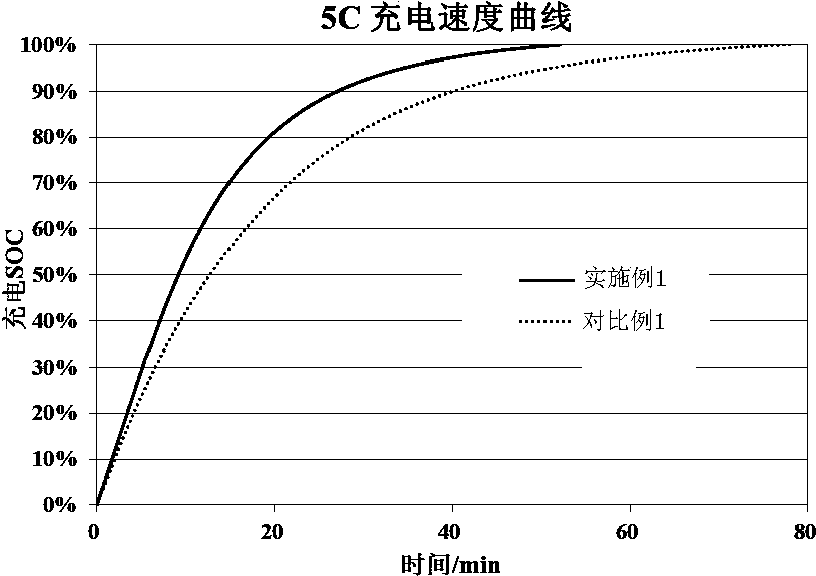

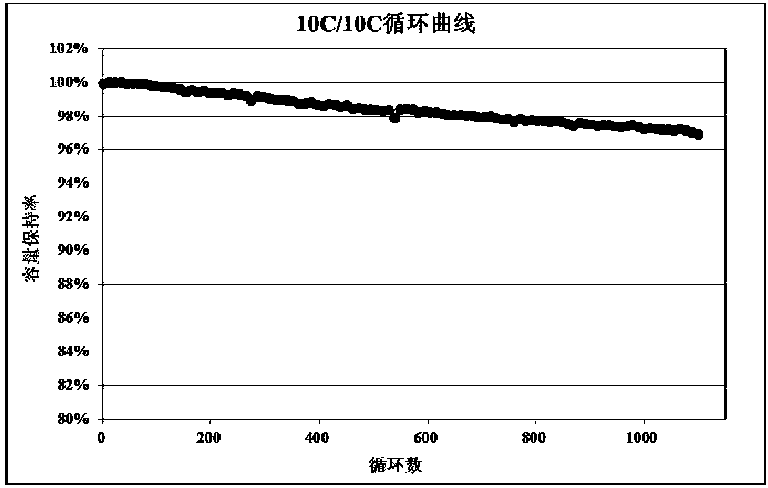

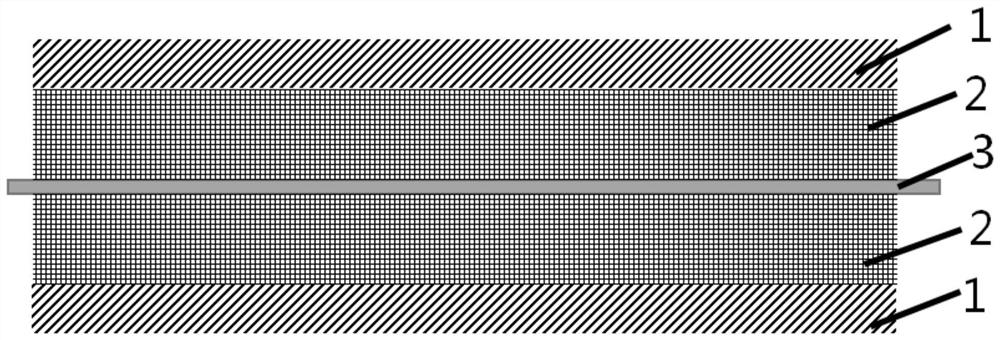

Lithium ion battery capable of quick charging

InactiveCN104347880AIncrease gram capacityImproved magnification performanceCell electrodesSecondary cellsLithium iron phosphateAdhesive

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery capable of quick charging. The battery includes a positive plate, a negative plate, isolating films arranged between the positive and negative plates at intervals, and electrolyte. The positive plate includes a positive current collector and a positive electrode active material layer arranged on the surface of the positive current collector. The positive electrode active material layer includes a positive electrode active material, a positive electrode conductive agent and a positive adhesive. The positive electrode active material includes components A and B. the component A is selected from at least one of nickel-cobalt lithium aluminate, nickel-cobalt lithium manganate, lithium manganate and lithium cobaltate. The component B is selected from at least one of lithium iron phosphate and lithium titanate. The mass percent of the component B in the positive electrode active material is 5-9 percent. In comparison with the prior art, the lithium ion battery has the advantages that the time of low voltage constant current charging can be prolonged due to use of the mixed positive electrode active material, and thus the charging speed is increased.

Owner:DONGGUAN AMPEREX TECH

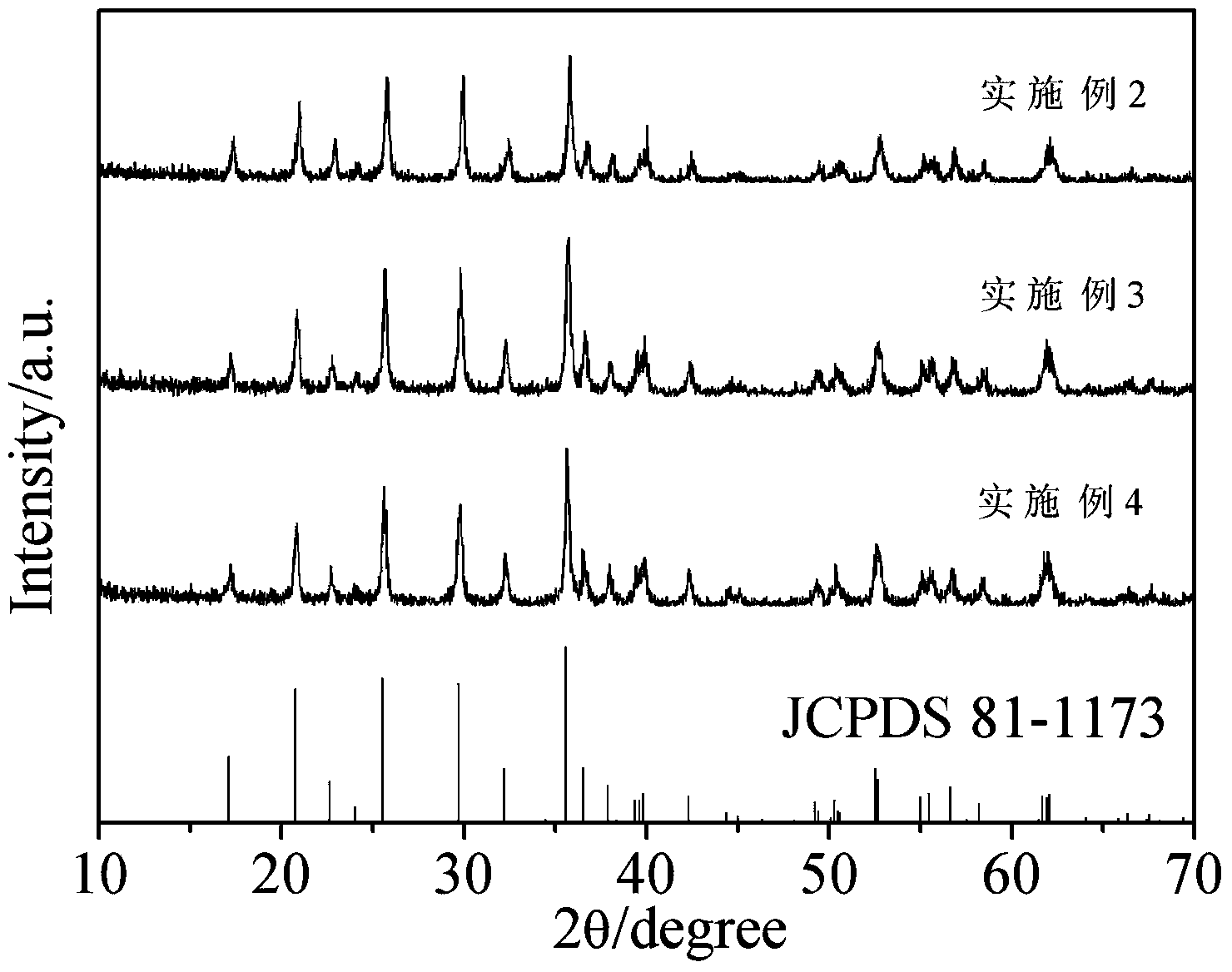

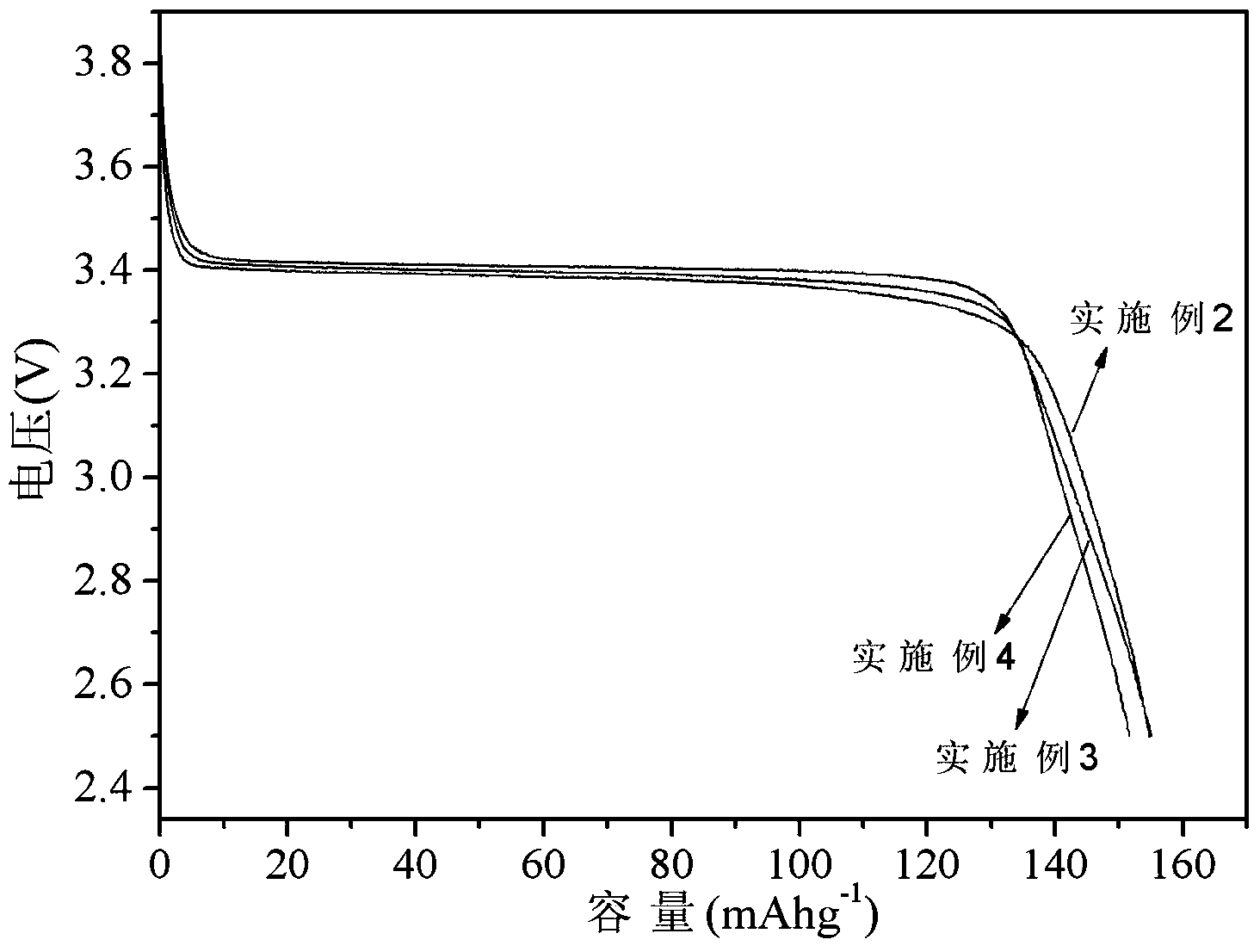

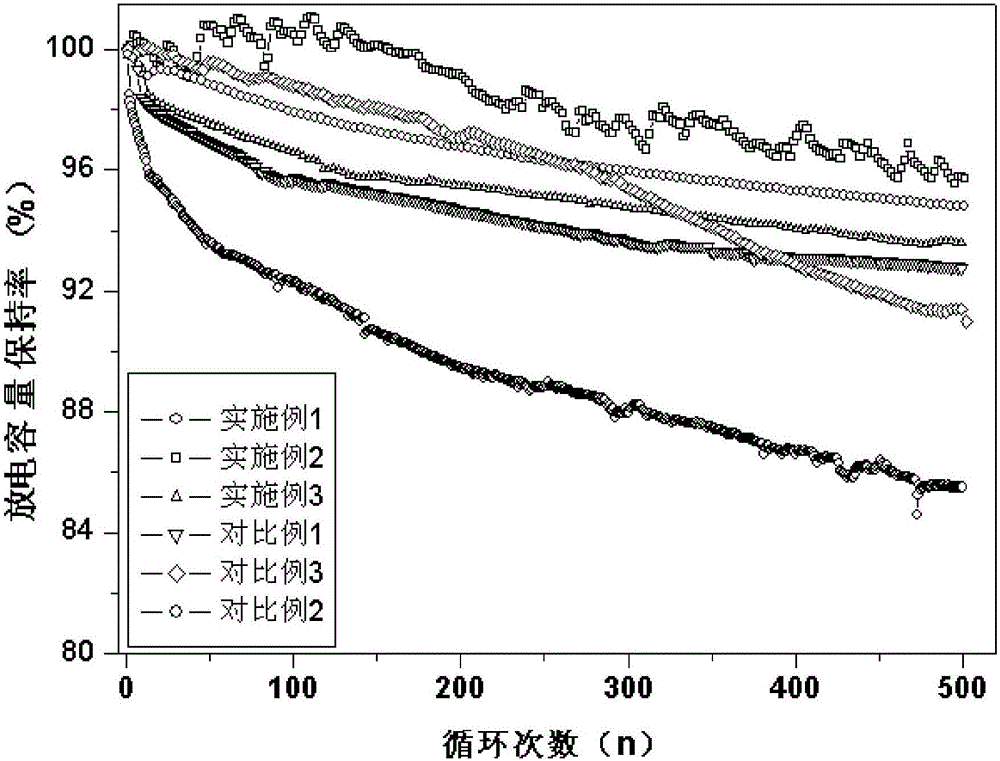

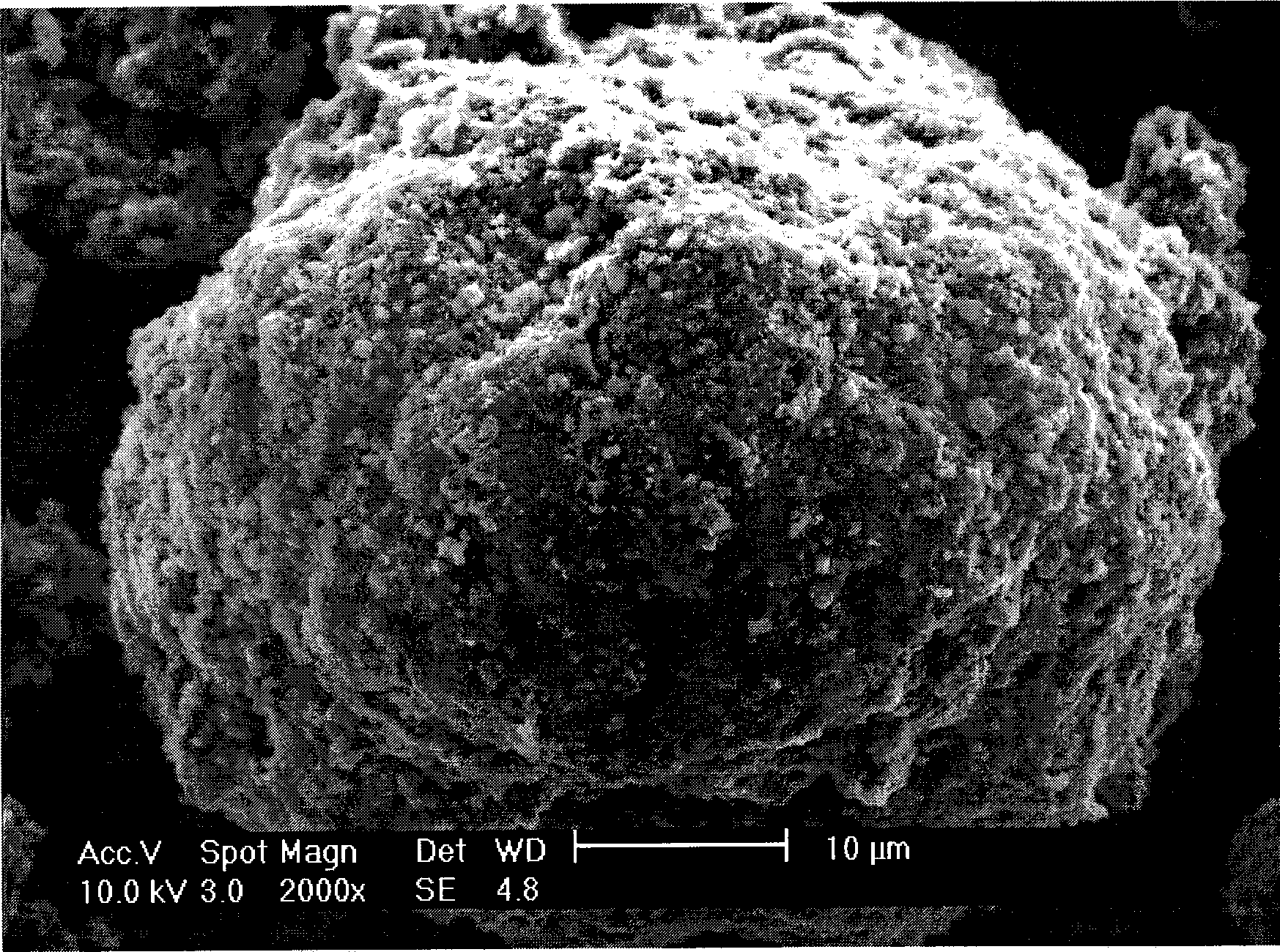

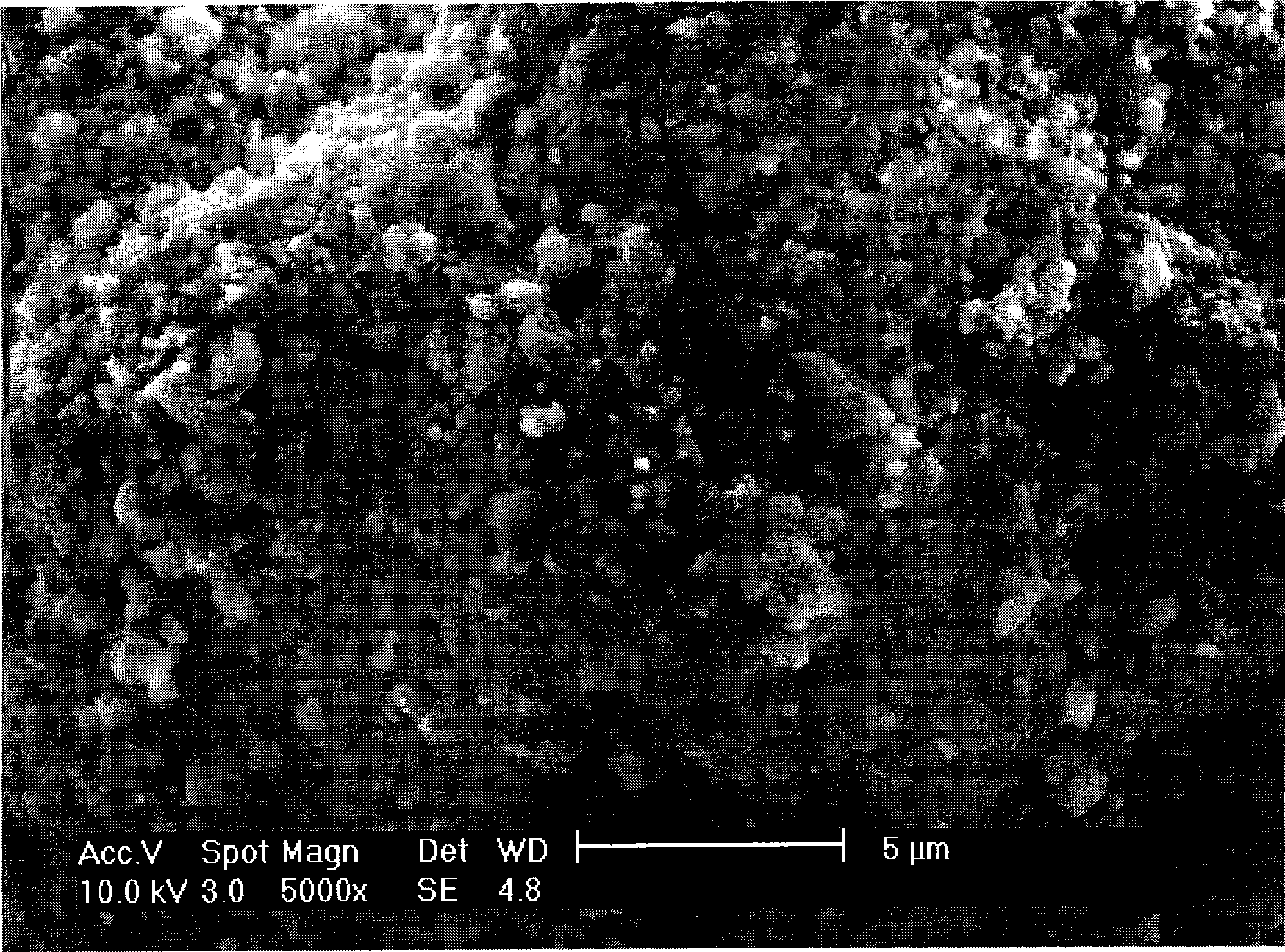

Sodium-titanium phosphate/carbon composite material and preparation method and use thereof

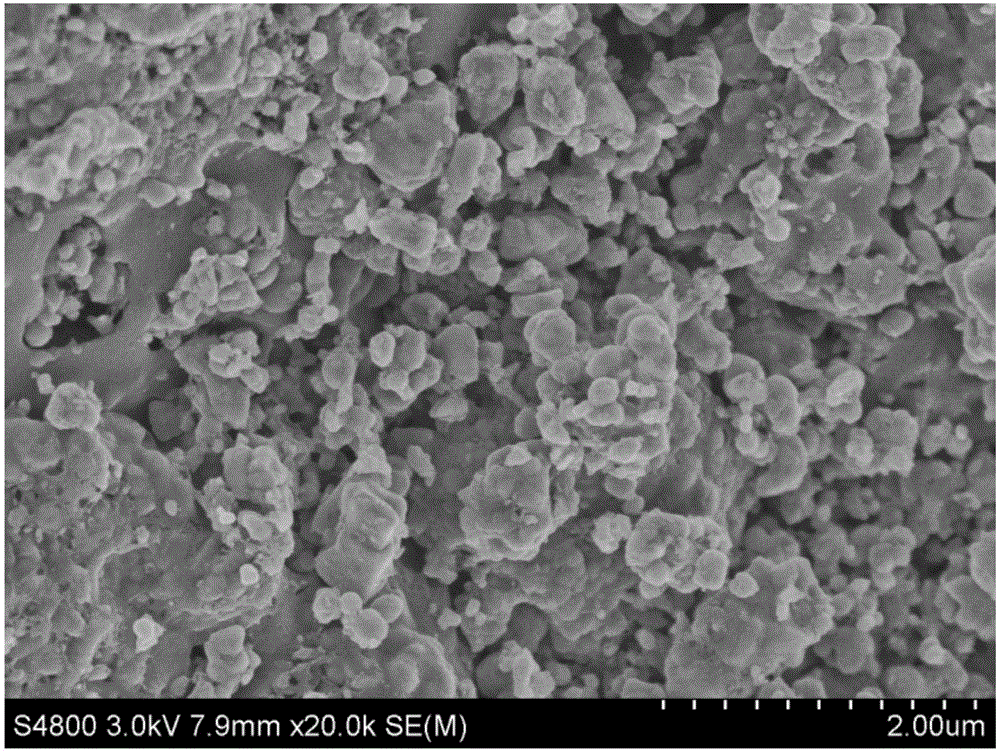

InactiveCN106784696AUneven solutionImprove uniformityCell electrodesSecondary cellsCarbon layerCarbon coating

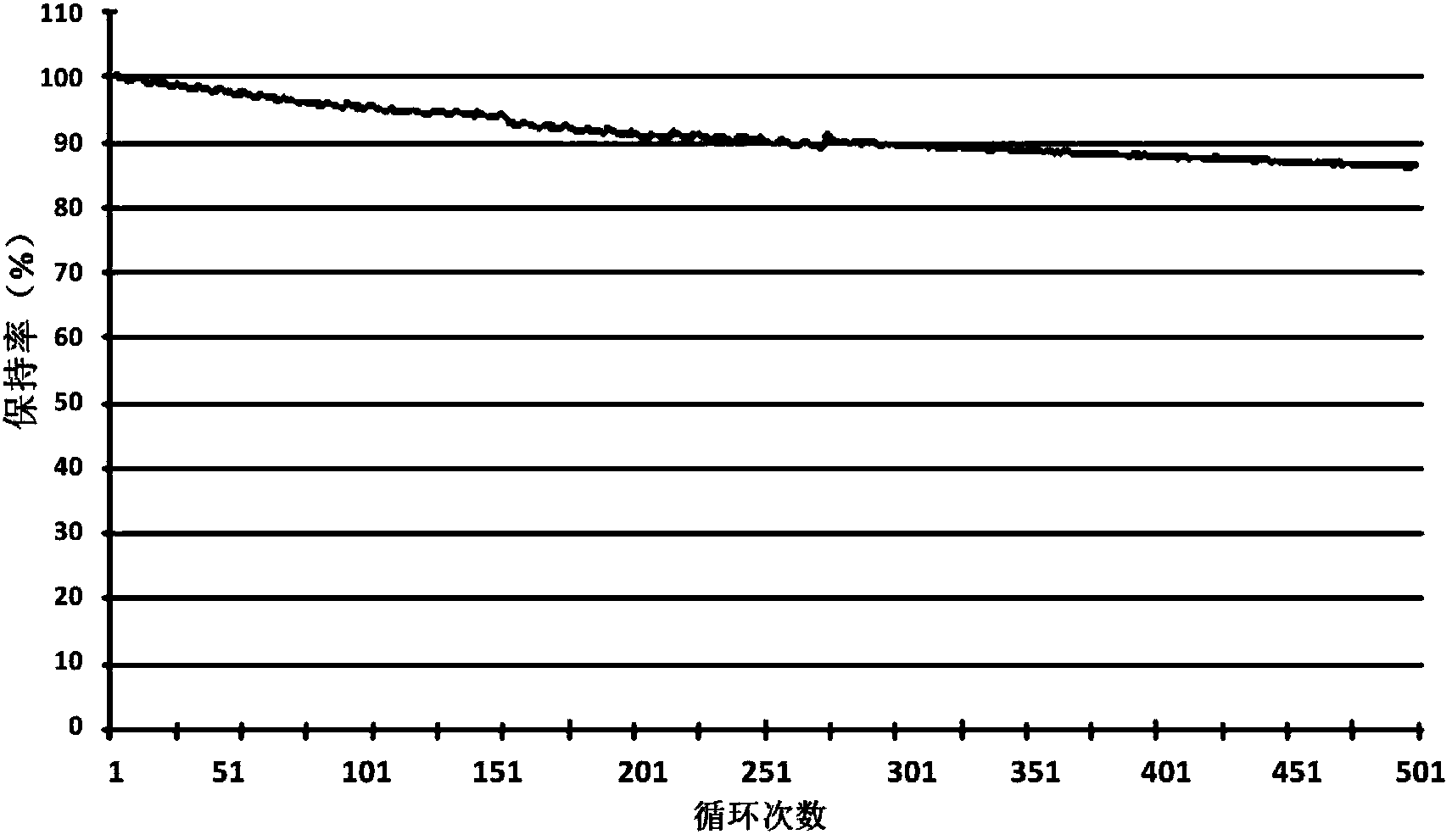

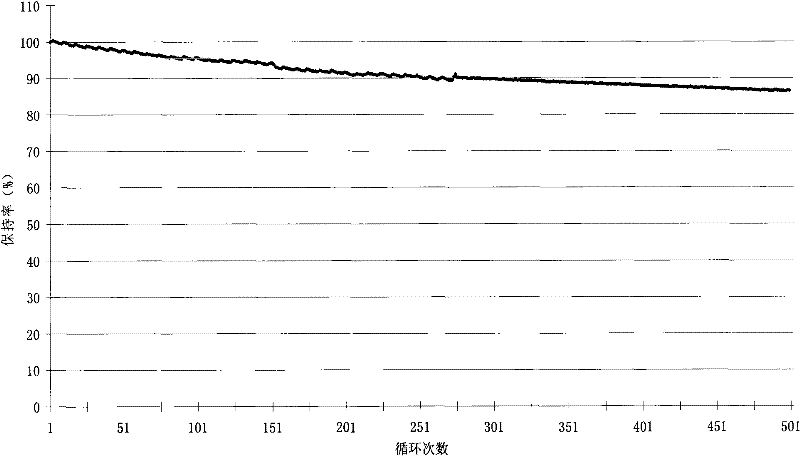

The invention belongs to the field of electrode material synthesis, and relates to a sodium-titanium phosphate / carbon composite material and a preparation method and use thereof. The sodium-titanium phosphate / carbon composite material comprises secondary particles formed by clustering primary particles, the primary particles comprise sodium-titanium phosphate particles and carbon layers coated on the surfaces of the sodium-titanium phosphate particles, and the carbon layers are prepared through two times of carbon coating. According to the sodium-titanium phosphate / carbon composite material and the preparation method and use thereof, by means of preparing a precursor of the sodium-titanium phosphate and then adopting a spray drying method to carry out primary carbon coating and secondary carbon coating, the sodium-titanium phosphate / carbon composite material having a uniform and compact coating carbon layer is prepared, and the problem that the coating carbon layer obtained by the primary carbon coating is not uniform is solved. The composite material is good in stability, electrodes prepared from the sodium-titanium phosphate / carbon composite material and assembled batteries have excellent electrochemical properties, the discharge capacity is above 115mAh / g, and the capacity retention ratio is above 95% after 500 weeks of circulation.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

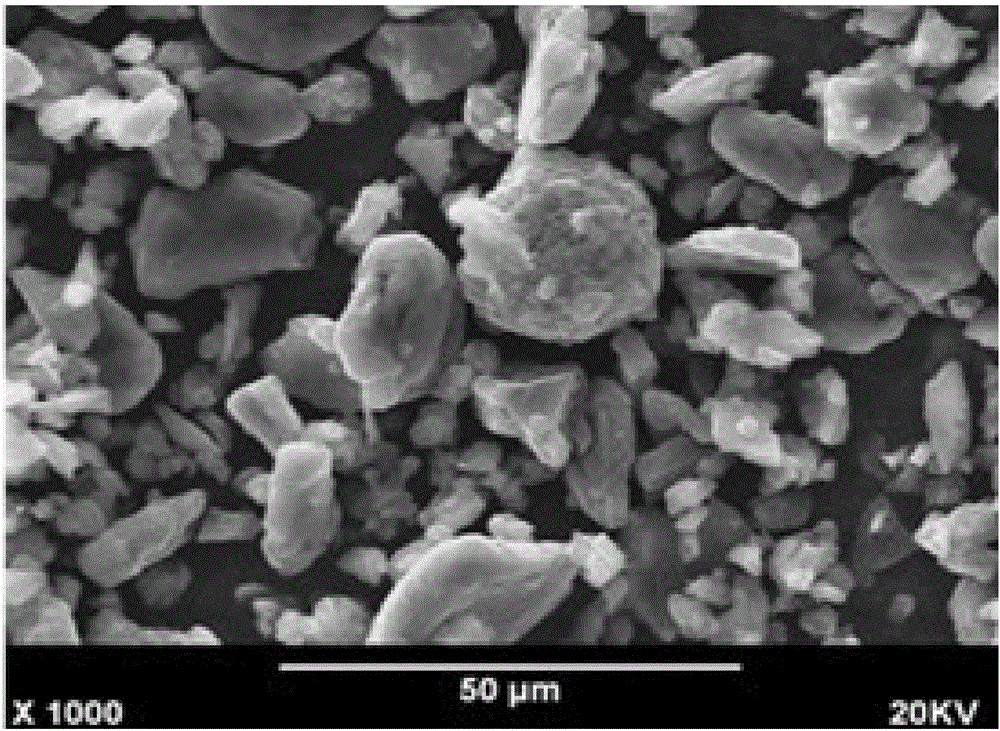

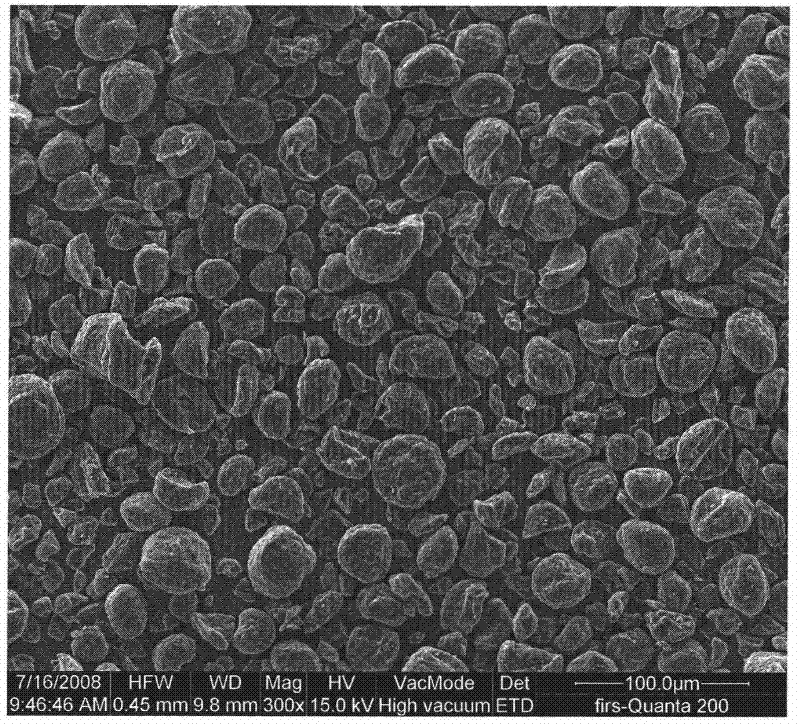

Artificial graphite lithium ion battery anode material and preparation method thereof

ActiveCN103887502AMaterial rigidity weakenedReduce rigidityCell electrodesSecondary cellsGraphiteSilicon dioxide

The invention discloses an artificial graphite lithium ion battery anode material and a preparation method thereof. The preparation method comprises the following steps: (1) mixing coal tar maltha with an additive according to a weight ratio of 5:1-50:1, well mixing, performing thermopolymerization reaction; (2) performing reduced pressure treatment of the reaction product; (3) performing carbonizing treatment, crushing, and grading treatment; (4) performing graphitization treatment. The additive is one or more of silicon, silica and silicon carbide. The artificial graphite lithium ion battery anode material has a high compaction density and first discharge capacity, and cells prepared by using the material as a lithium ion battery anode material have excellent comprehensive properties, stable structure, and good safety performance. The preparation method is simple and practical in process, wide in raw material source, and low in cost.

Owner:SHANGHAI SHANSHAN TECH CO LTD

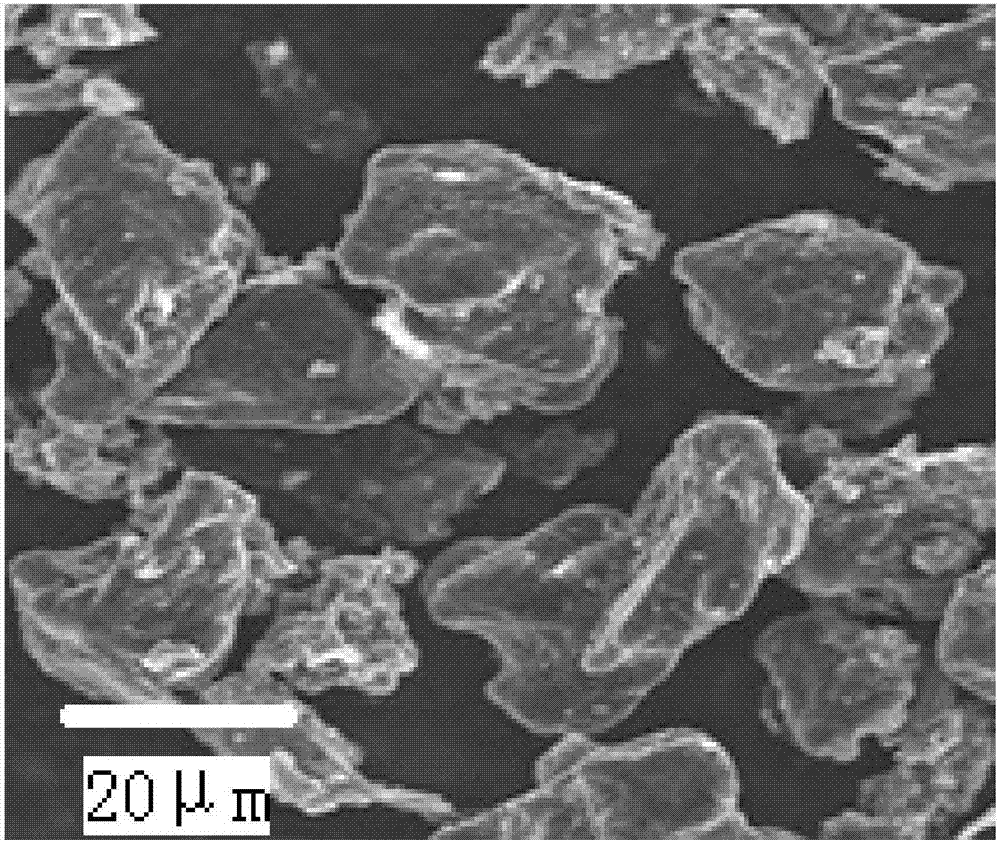

Lithium ion battery anode material and preparation method thereof

The invention discloses a lithium ion battery anode material which comprises graphite and a shell layer arranged outside the graphite, wherein the shell layer is an asphalt-based carbon material cladding layer with a porous structure. A preparation method of the lithium ion battery anode material comprises the steps of: 1, in the terms of the weight, uniformly mixing 100 parts of graphite particles with particle diameter of 5-50mum with 1-25 parts of asphalt monomers; 2, carrying out Friedel-Crafts cross-linking reaction; and 3, in an inert gas, thermally treating at 800-1500 DEG C for 1-12h,then cooling to be below 100 DEG C, taking out, crushing and sieving to prepare a composite asphalt material with the porous structure carbon material cladding layer. Due to the adoption of the invention, gram volume of the graphite material is greatly increased, reversible volume and coulomb efficiency are increased, and circulating stability of the anode material is greatly enhanced. Meanwhile,production cost is low.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Negative plate of secondary nickel-iron battery, preparation method of negative plate and secondary nickel-iron battery of using negative plate

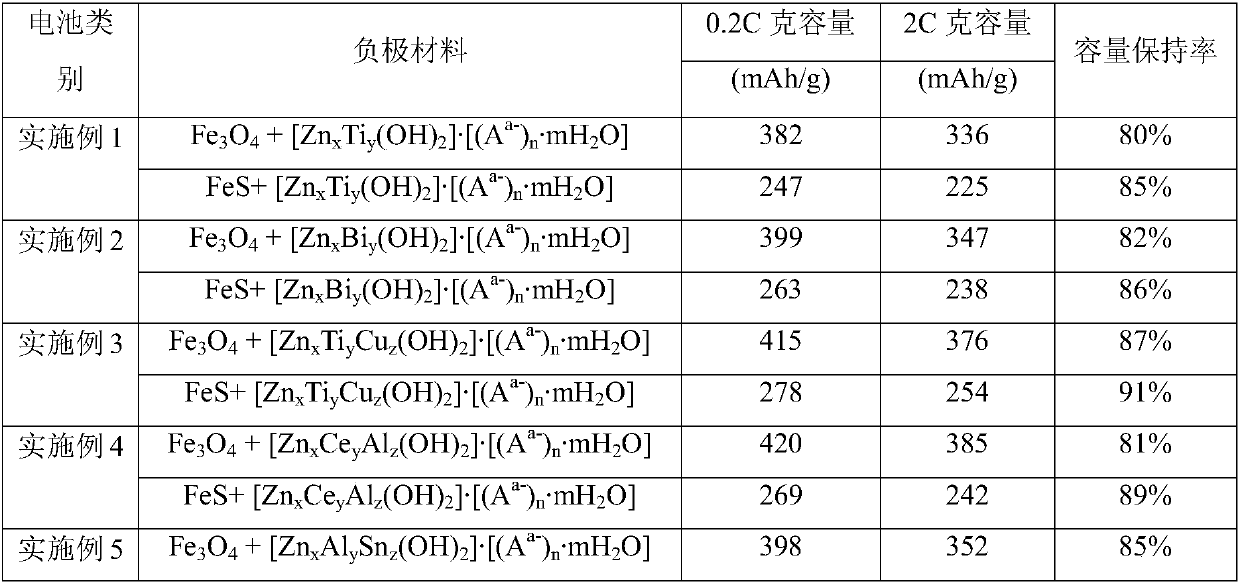

InactiveCN107681118AExcellent rate performanceImprove cycle performanceCell electrodesNickel accumulatorsEngineeringZinc

The invention discloses a negative plate of a secondary nickel-iron battery, a preparation method of the negative plate and a secondary nickel-iron battery of using the negative plate and belongs to the technical field of negative electrode materials for secondary nickel-iron batteries. According to the main points of the technical scheme, a negative active material in the negative plate of the secondary nickel-iron battery comprises an additive zinc-based multilayered hydroxide [ZnxMyM'z(OH)2].[(A<a->)n.mH2O]. The invention further particularly discloses a preparation method of the negative plate of the secondary nickel-iron battery and the secondary nickel-iron battery of using the negative plate. By adopting the novel negative plate of the secondary nickel-iron battery, the energy density and the rate capability of the secondary nickel-iron battery can be greatly improved and the cycle life of the secondary nickel-iron battery can be greatly prolonged.

Owner:HENAN NORMAL UNIV

Novel cathode material for lithium ion battery and preparation method thereof

ActiveCN102522532AIncrease gram capacityImprove efficiencyCell electrodesPetroleumCharge and discharge

The invention provides a novel cathode material for a lithium ion battery and a preparation method thereof. The material is compounded by natural graphite, oil coke and pitch. The compound process comprises mixing, pinching, rolling sheets, smashing, forming, carbonizing, graphitizing, spherizing and the like. By weight, the natural graphite is 35 to 55 parts, the oil coke is 25 to 45 parts, and the pitch is 15 to 25 parts. Compared with the prior art, the cathode material has the advantages of synthetic graphite and natural graphite and is large in volume, high in first efficiency and circulation efficiency and excellent in charging and discharging performance. Furthermore, the natural graphite adopts secondary products discharged and collected by a dust remover after natural crystalline flake graphite is smashed in spherical mode. Thus, secondary products are reasonably used, and production cost is remarkably reduced.

Owner:湖北联投恒达石墨有限公司

Novel lithium ion battery with high power and high energy density

InactiveCN107248592AIncrease gram capacityIncrease energy densityCell electrodesSecondary cellsHigh energyCarbon nanotube

The invention provides a novel lithium ion battery with high power and high energy density. The novel lithium ion battery comprises a positive plate, a negative plate, a diaphragm, electrolyte, a lug and a shell; the negative plate is mixed by negative electrode active materials, a negative electrode conductive agent and a negative electrode binder; the negative electrode active materials are composed of SiO, soft carbon and / or artificial graphite; the negative electrode conductive agent is at least one of superconductive carbon black and a single-walled carbon nanotube; and the negative electrode binder is at least two combinations of styrene butadiene rubber, acrylate and sodium carboxymethyl cellulose. The battery provided by the invention has excellent rate discharge capacity and high energy density; and besides, the weight specific energy density reaches 230wh / kg, the volume specific energy density is above 650wh / L, the power density is above 1,500w / kg, the rate discharge performance reaches 10C, and the cycle performance can reach more than 500 times.

Owner:鹤壁市诺信电子有限公司

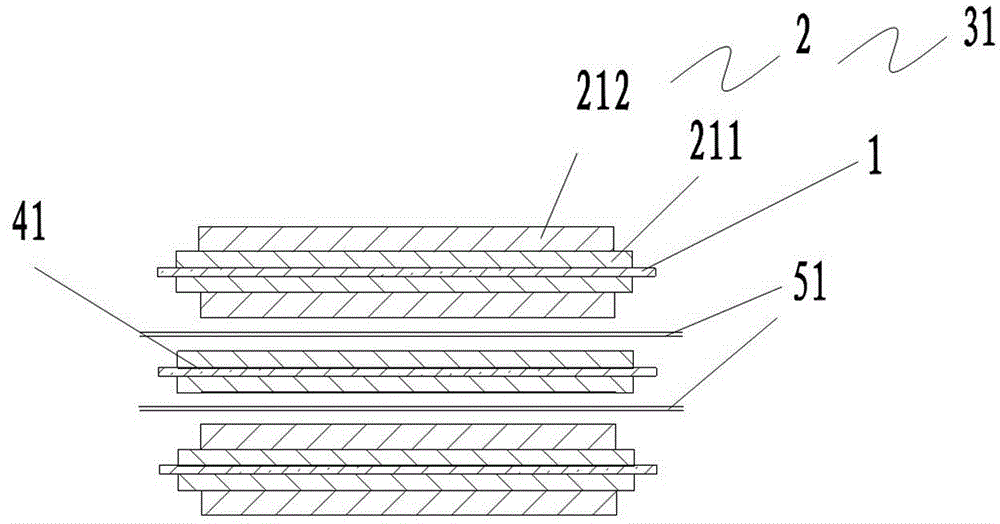

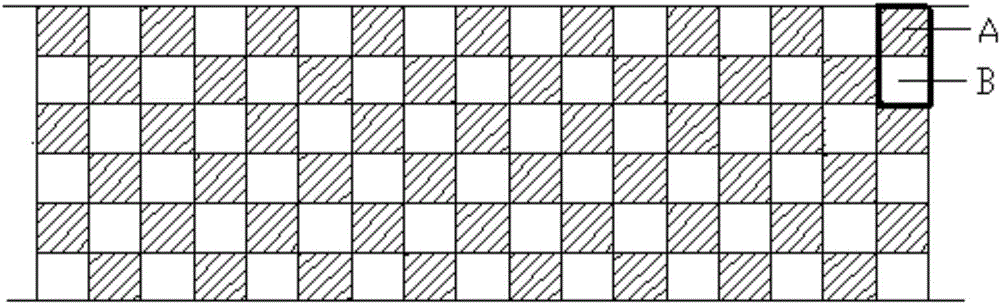

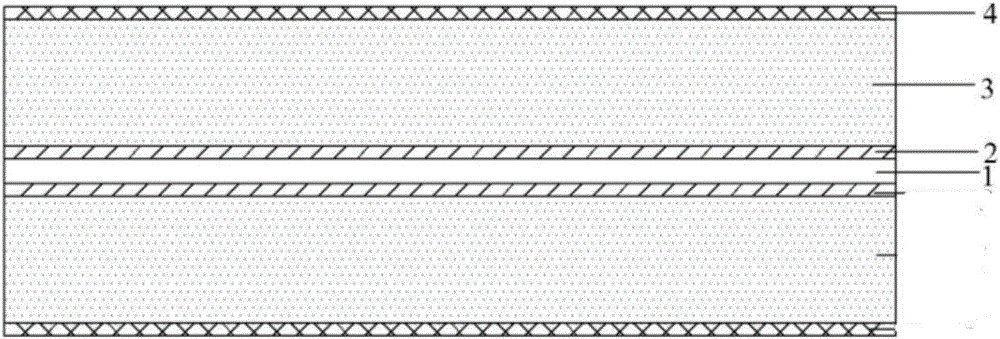

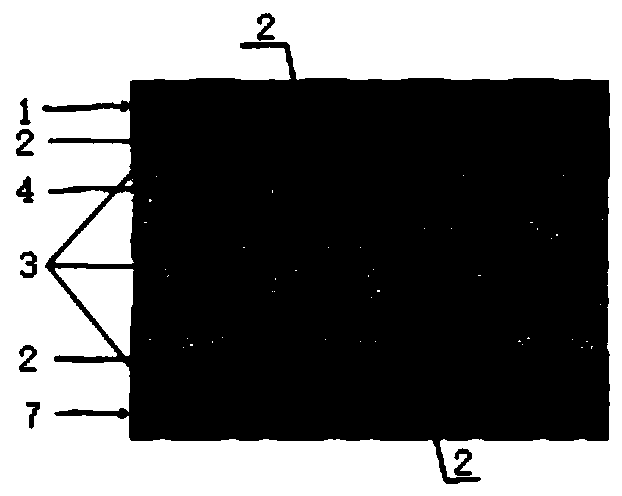

Multilayer positive plate, production method of positive plate and lithium ion battery

InactiveCN104600244AIncrease profitImprove securityCell electrodesSecondary cellsLithium-ion batterySizing

The invention discloses a multilayer positive plate. The multilayer positive plate comprises a current collector and an electrode material layer which is smeared on the surface of the current collector; the electrode material layer comprises one or more than one mixed sizing agent layer; the mixed sizing agent layer is gradually smeared on the surface of the current collector layer by layer. The invention discloses a production method of the multilayer positive plate. The invention also discloses a lithium ion battery. The positive plate adopts a multilayer structure, different layers can be made of identical or different electrode materials, so that the utilization rate of the positive active material can be increased, the utilization rate of the positive material can reach 95 to 98 percent, and the gram volume can be increased; by adding the active material coating with stable structure and good safety performance, the utilization rate of the material is increased, and the safety performance of the lithium ion battery also can be improved.

Owner:HUIZHOU HENGTAI TECH

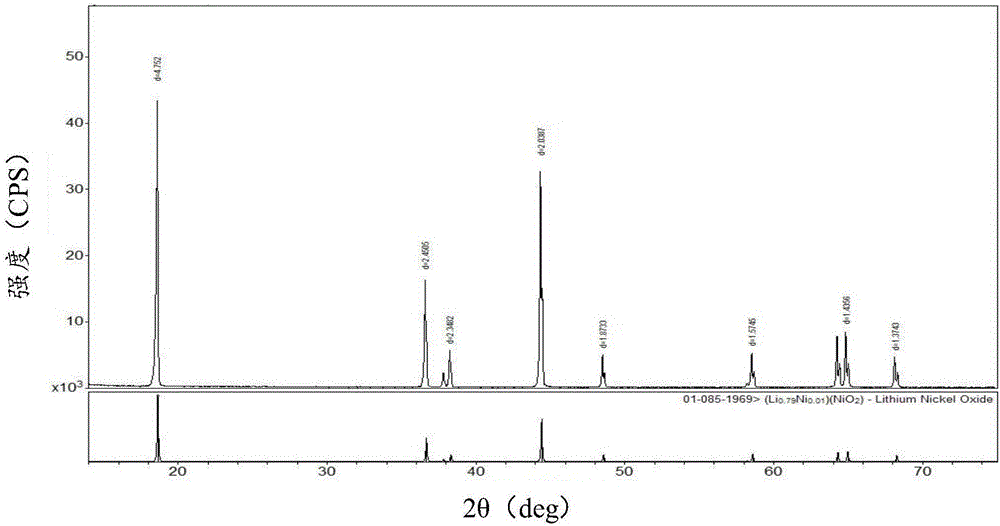

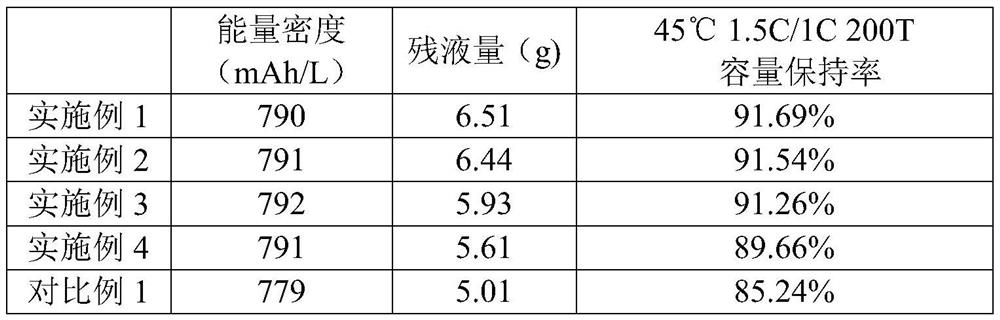

Nickel-based positive active material of lithium ion secondary battery and preparation method thereof

ActiveCN103943822AIncrease gram capacityIncrease working voltageCell electrodesSecondary cellsLithiumGram

The invention discloses a nickel-based positive active material of a lithium ion secondary battery. The nickel-based positive active material is subjected to wrapping treatment and is prepared from the following components in percentage by weight: 50%-99.5 percent of nickel-based material as a matrix and 0.05-50 percent of shell material. A general formula of the lithium ion secondary battery can be expressed as [Li(p)Ni(x)Co(y)Mn(z)O2][Li(q)Ni(a)Co(b)Mn(c)O2]. A preparation method of the nickel-based positive active material comprises the steps of preparing a precursor of the positive material of the lithium ion secondary battery; and preparing the positive material of the lithium ion secondary battery. According to the invention, as the gradient variation of nickel concentration between the matrix material and the shell material is realized by virtue of wrapping, the nickel-based positive active material has good electrochemical performance of high gram volume, high working voltage, good cycle performance and the like, and the safety and the machinability of the material are also ensured. In addition, the preparation method is high in the operability, is favorable for industrial production and has high application value.

Owner:NANTONG RESHINE NEW MATERIAL

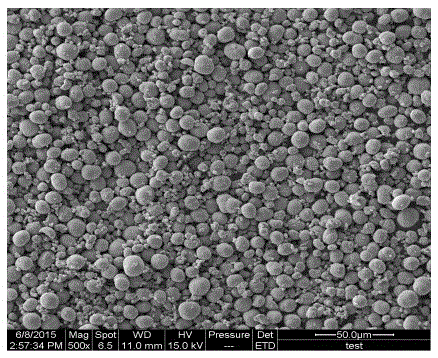

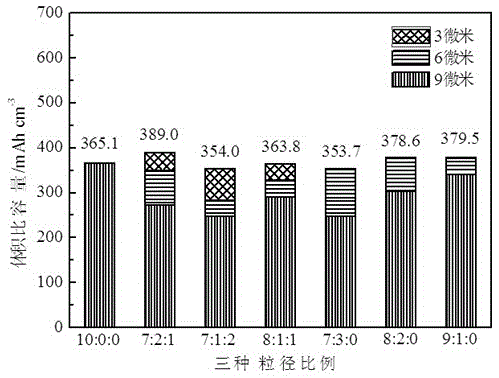

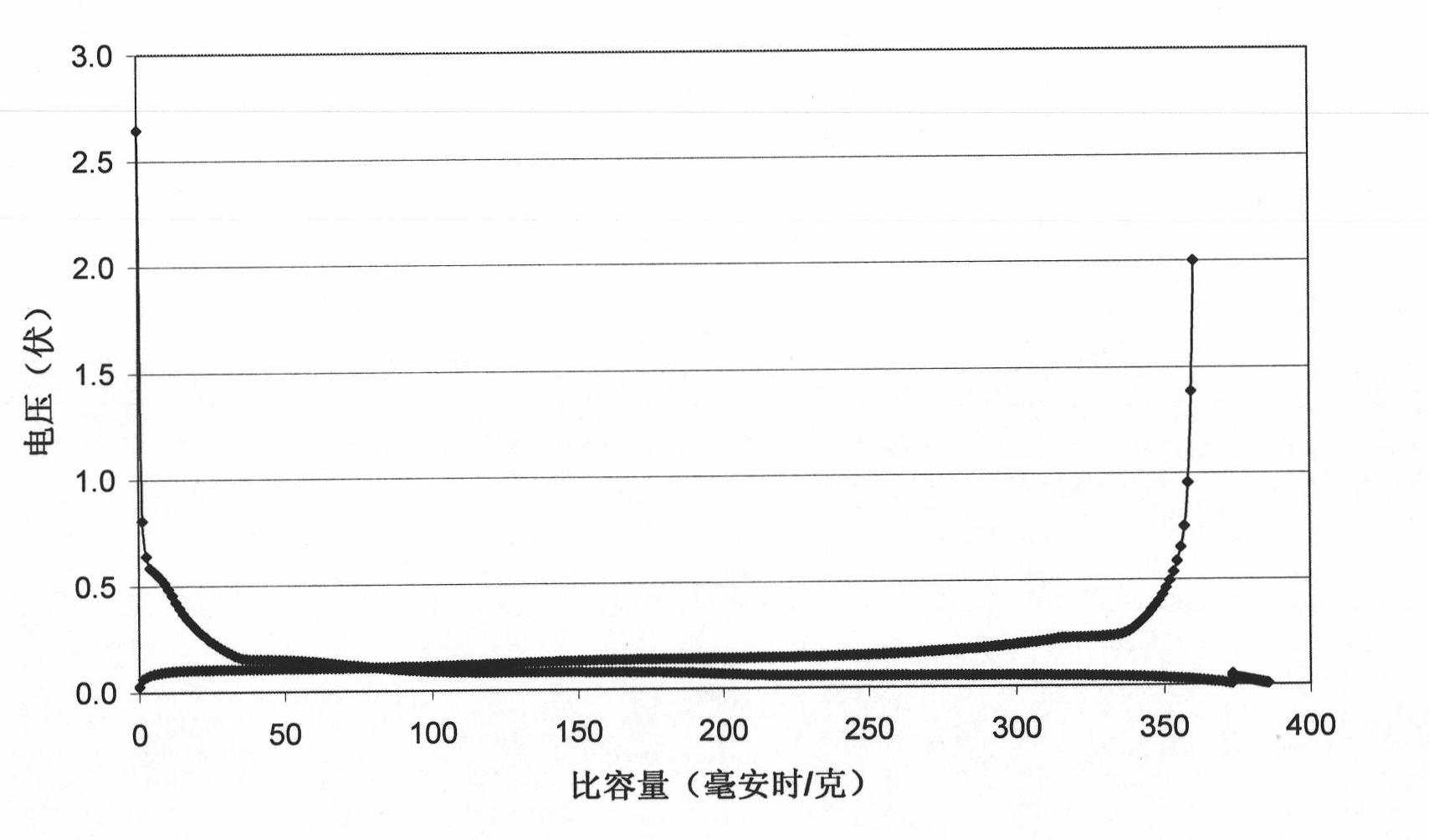

Method for improving tap density of ternary nickel-cobalt-manganese cathode material for lithium-ion battery

InactiveCN105489881AHigh tap densityIncrease volume capacitySecondary cellsPositive electrodesCyclic processManganese

The invention discloses a method for improving tap density of a ternary nickel-cobalt-manganese cathode material for a lithium-ion battery. The method comprises the following steps: (1) screening ternary material precursors Ni<x>Co<y>Mn<z>(OH)<2> with large, medium and small particle sizes; (2) carrying out ball-milling wet-mixing roasting on the ternary material precursors screened in the step (1) and a lithium salt respectively, so as to obtain ternary nickel-cobalt-manganese cathode materials with large, medium and small particle sizes; and (3) mixing the ternary nickel-cobalt-manganese cathode material with the large particle size obtained in the step (2) with the ternary nickel-cobalt-manganese cathode materials with the medium and / or small particle sizes, and then carrying out secondary low-temperature roasting to obtain the ternary nickel-cobalt-manganese cathode material with high tap density. According to the method, the tap density and the volumetric specific energy of the ternary nickel-cobalt-manganese cathode material for the lithium-ion battery can be improved; the gram volume of the material is improved on the basis of ensuring the stability of the material in the cyclic process; and the rate capability is improved.

Owner:HARBIN INST OF TECH

Graphite material at negative pole of lithium ion battery and preparation method thereof

ActiveCN102110813AImprove adaptabilityImprove performanceCell electrodesMicroballoon preparationMass ratioGraphite

The invention discloses a graphite material at the negative pole of a lithium ion battery, which comprises interphase graphite and artificial graphite in mass ratio of 90:10 to 20:80. The graphite material has the advantages of highly compacted density, small specific surface area, high discharge capacity, long circulating life, high charge-discharge efficiency and high product performance-price ratio. The invention also provides a method for preparing the graphite material, which has the advantages of simple, convenient and feasible technology, wide raw material sources and lower cost.

Owner:福建杉杉科技有限公司

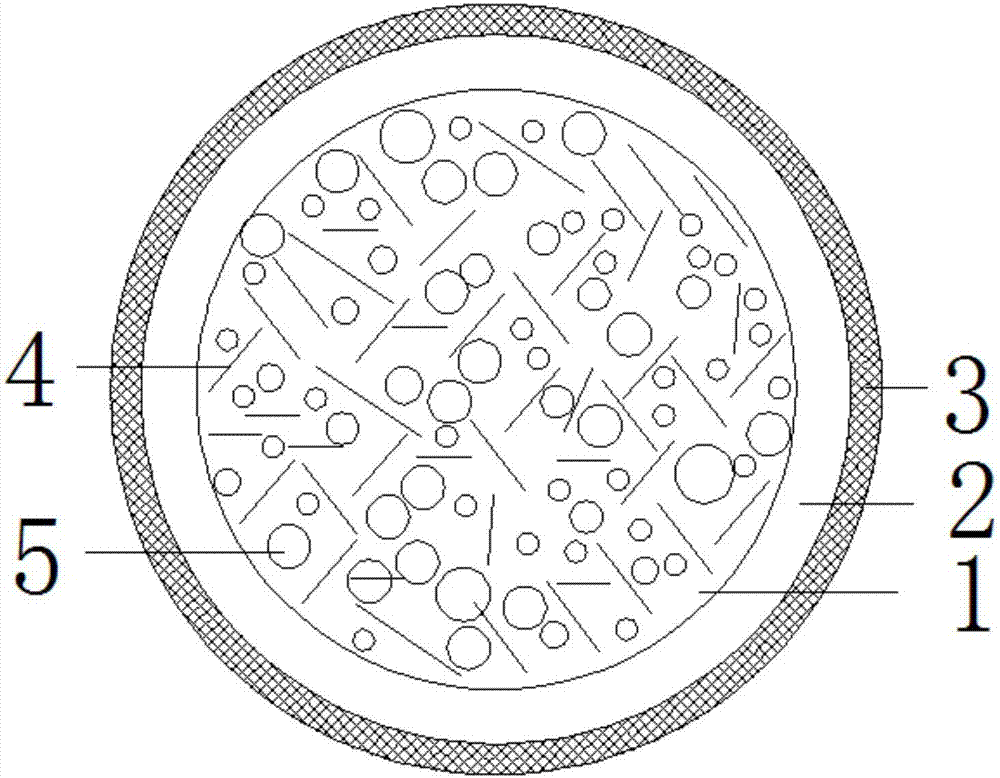

Nitrogen-doped graphene-silicon composite negative pole material, preparation method thereof, and lithium ion battery

ActiveCN106876689AIncrease gram capacityReduce expansionCell electrodesSecondary cellsOrganolithium compoundsNitrogen doped graphene

The invention relates to a nitrogen-doped graphene-silicon composite negative pole material, a preparation method thereof, and a lithium ion battery, and belongs to the field of lithium ion battery material preparation. The nitrogen-doped graphene-silicon composite negative pole material is of a core-shell structure, the core of the core-shell structure is the nitrogen-doped graphene-silicon composite material, the shell of the core-shell structure is of a double-layer structure, and the double-layer structure consists of a silane coupling agent layer and an organolithium compound layer in sequence from inside to outside; and the silane coupling agent layer is silane coupling agent. By use of the nitrogen-doped graphene-silicon composite negative pole material, the expansion rate of a nanometer silicon material can be lowered, a lithium ion transmission rate and the gram volume of the negative pole material can be improved, and the silane coupling agent layer covers the outer surface of the core to improve the tap density and the structure stability of the material so as to improve the cycle performance of the lithium ion battery of the nitrogen-doped graphene-silicon composite negative pole material; the initial efficiency of the material of the lithium ion battery can be improved by an original lithium compound layer out of the silane coupling agent layer, sufficient lithium ions are provided for a large multiplying power charging and discharging process of lithium ions, and multiplying power performance is improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

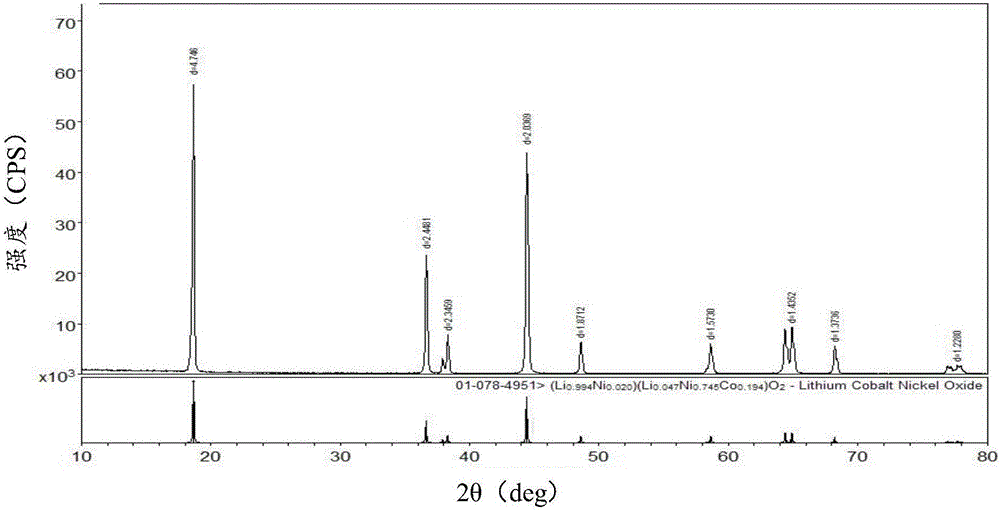

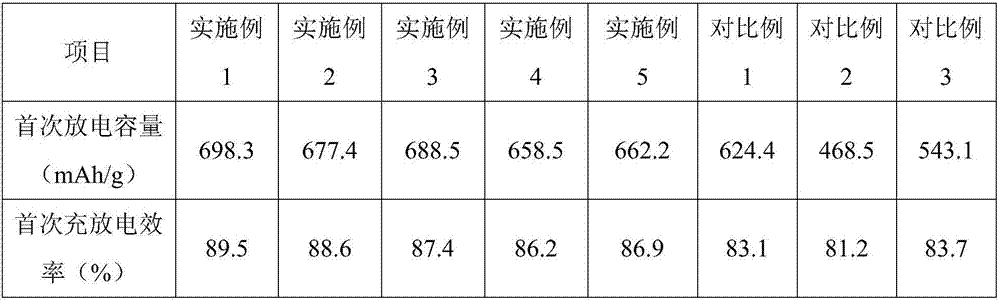

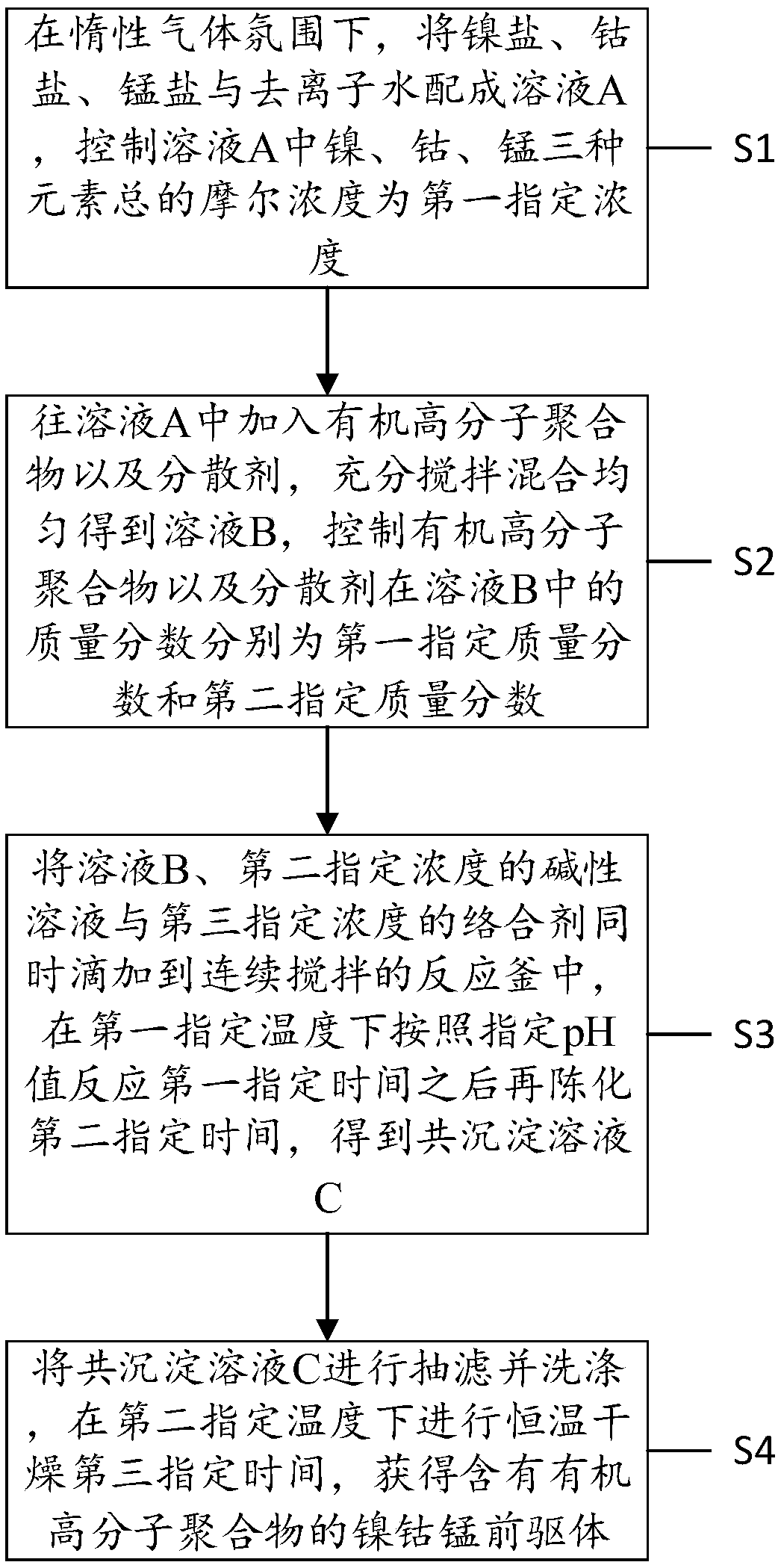

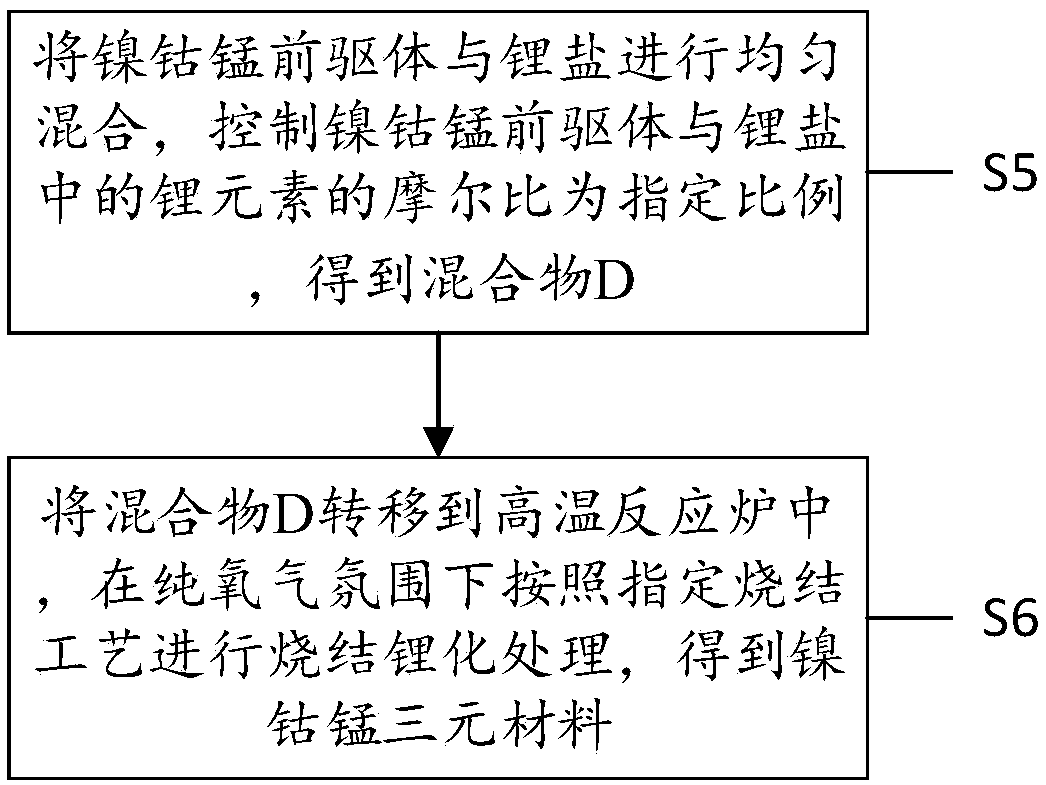

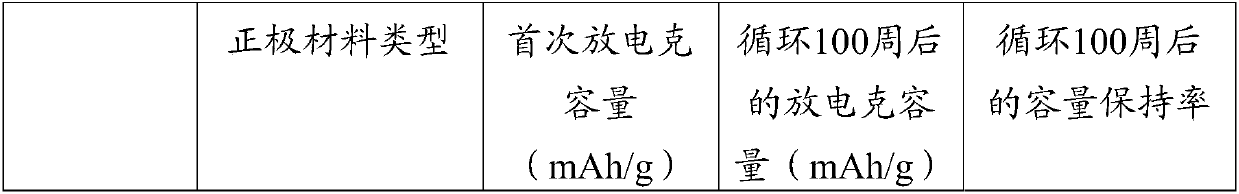

Nickel-cobalt-manganese precursor, preparation method of nickel-cobalt-manganese ternary material and lithium ion battery

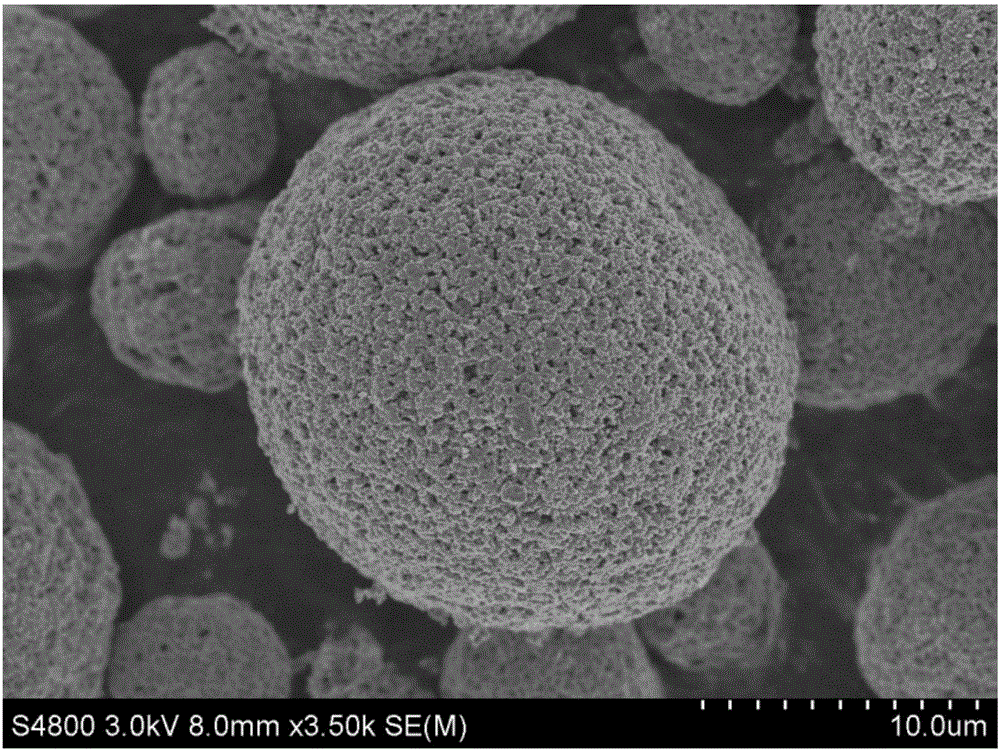

ActiveCN109616664AThe solution is simple and feasibleEase of mass industrializationSecondary cellsPositive electrodesChemistryLithium electrode

The invention provides a nickel-cobalt-manganese precursor, a preparation method of a nickel-cobalt-manganese ternary material and a lithium ion battery. Starting from the preparation of the precursorof the high nickel ternary material, the high nickel ternary positive electrode material with internal voids in the secondary particles and gradient layers of transition metal ions in the primary particles is prepared by using organic polymer particles as a pore-forming agent and its carbonized substance in lithium sintering as a reducing agent. A new method is developed to fabricate a porous high nickel ternary positive electrode material with the gradient layers of transition metal ions. The method is simple and feasible and easy to industrialize on a large scale. The gram capacity, cyclicstability and structural stability of the lithium ion battery using the porous high nickel ternary material containing transition metal ion gradient layers as the positive electrode material have beenimproved significantly.

Owner:SUNWODA ELECTRONICS

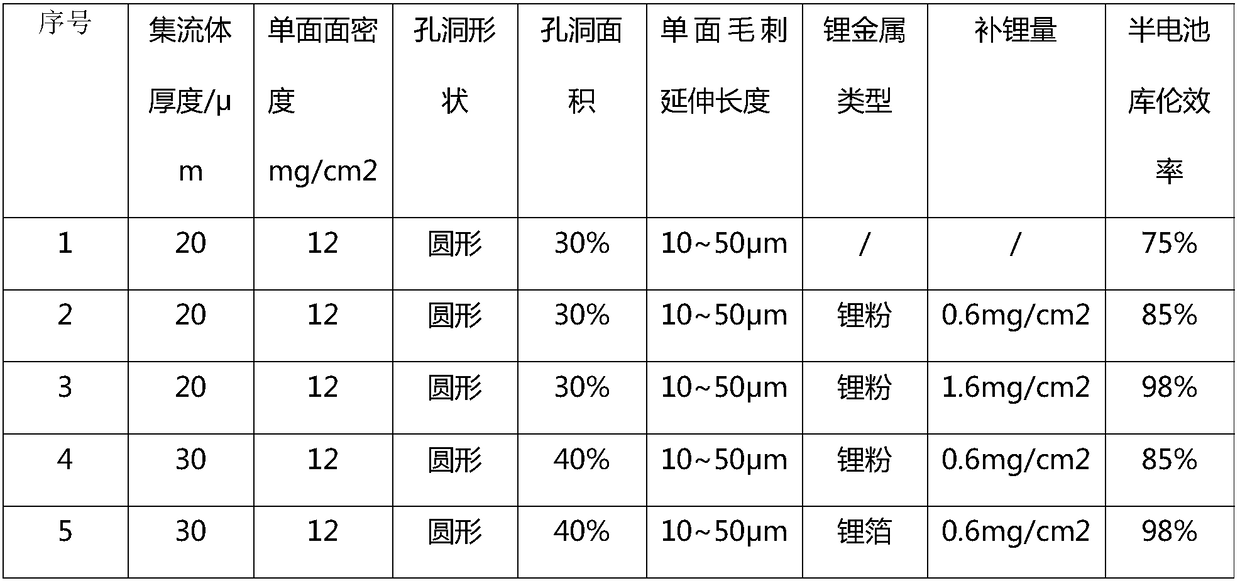

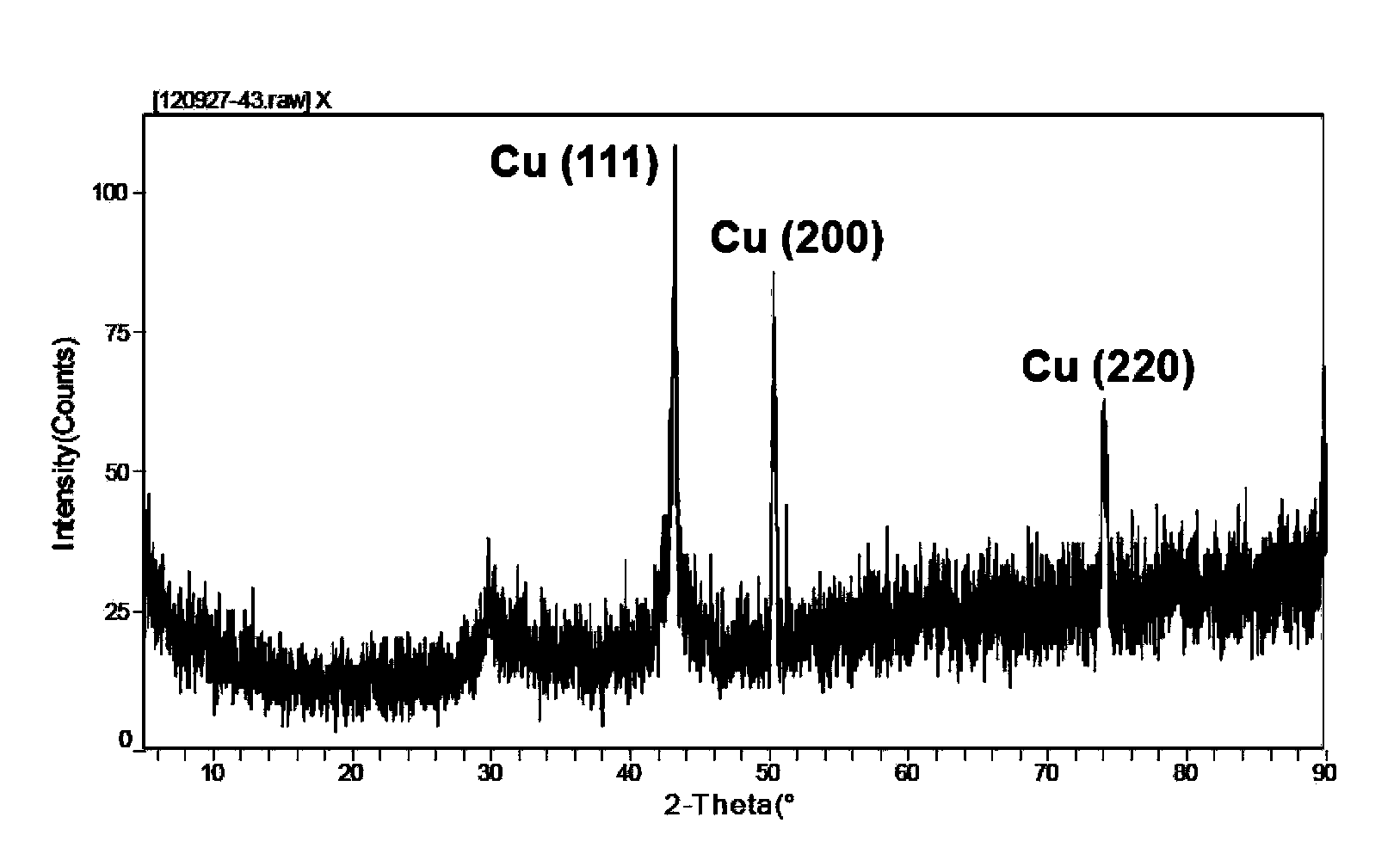

Lithium ion battery negative electrode single-side pre-lithiation method using three-dimensional foil

InactiveCN108550780AStrengthens the conductive networkIncrease gram capacityElectrode carriers/collectorsManufacture by sprayingGraphite electrodeLithium metal

The invention provides a lithium ion battery negative electrode single-side pre-lithiation method using a three-dimensional foil. The method comprises the following steps: 1, coating a three-dimensional current collector with a negative electrode slurry, and performing rolling to obtain a rolled electrode sheet; 2, performing pre-lithiation compounding on the electrode sheet: carrying the following two pre-lithiation processes according to the difference of lithium metal raw materials: uniformly spraying or coating one side of the rolled electrode sheet with lithium metal powder through a lithium metal powder pre-lithiation process or bonding and compounding one side of the rolled electrode sheet with a lithium foil under a certain pressure by adopting a lithium foil pre-lithiation process; and 3, assembling a positive electrode, a diaphragm and the negative electrode obtained after the pre-lithiation compounding is completed in order to form a battery cell, and performing electrolyteinjection and formation on the battery cell. The lithium ion battery negative electrode single-side pre-lithiation method using the three-dimensional foil solves the problems of swelling peeling, short life and low capacity of a silicon carbide / graphite electrode; and two-side pre-lithiation is simplified into single-side pre-lithiation, so the pre-lithiation efficiency is improved.

Owner:TIANJIN ENERGIES

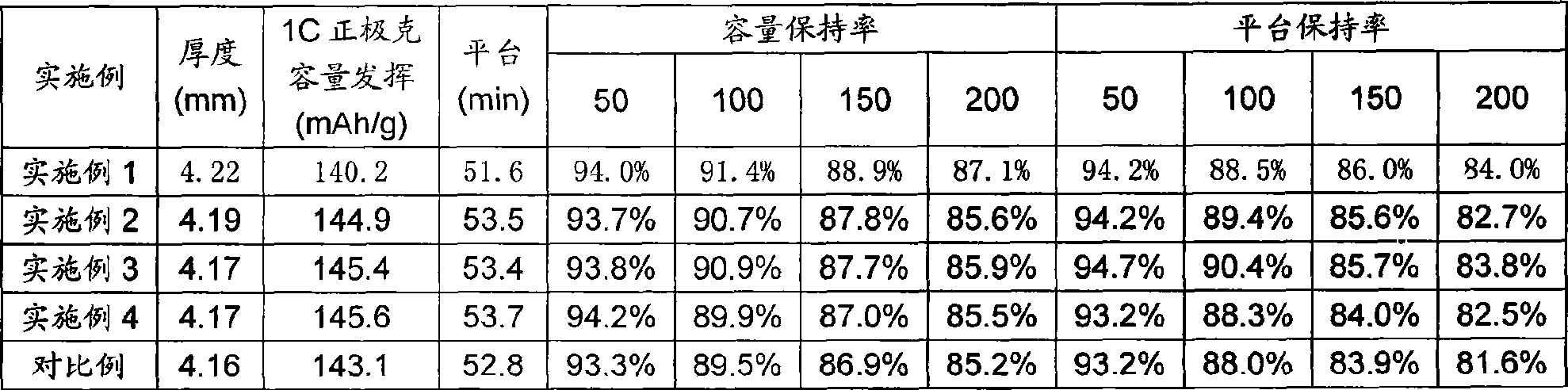

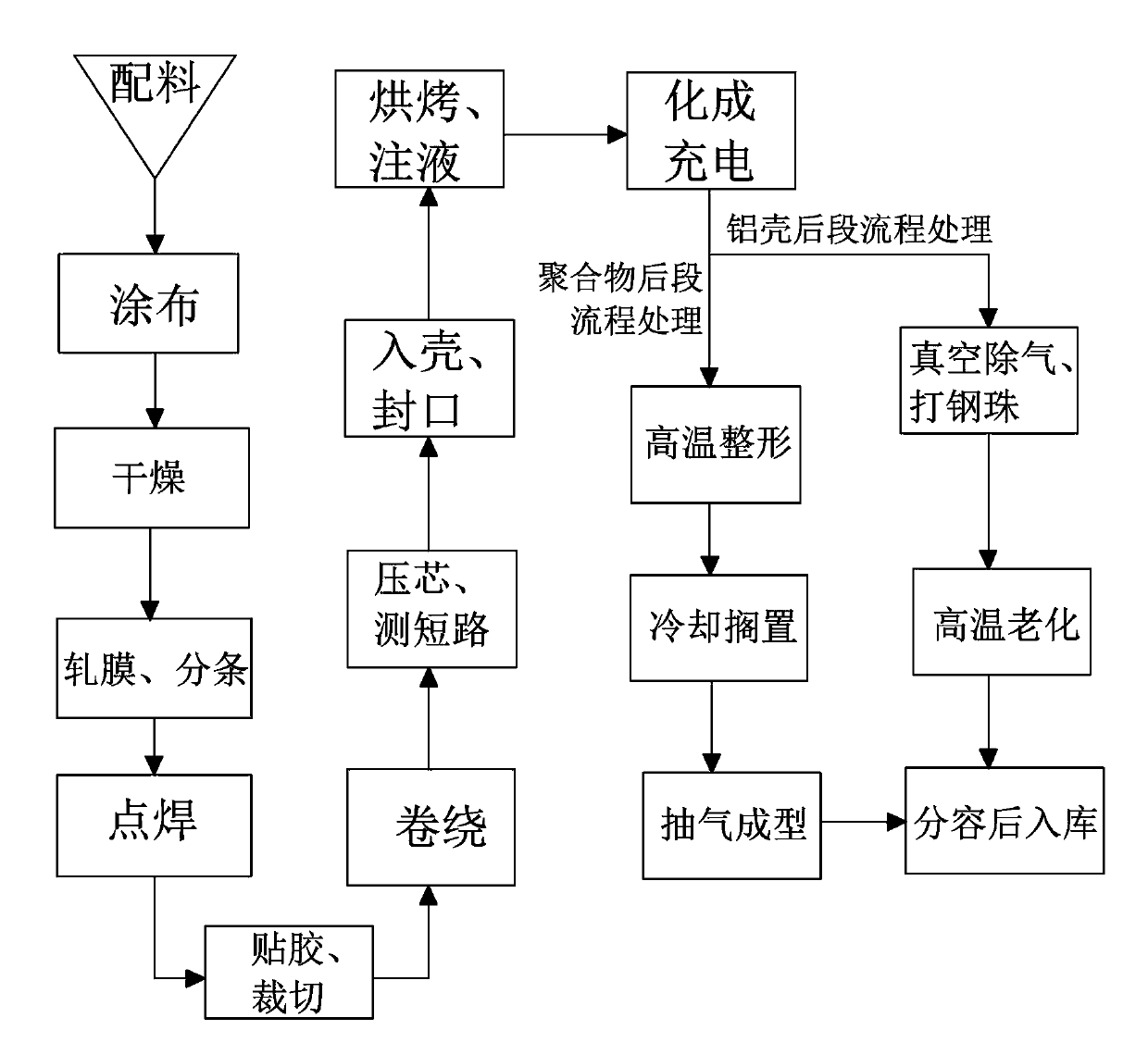

Liquid injection process for core of lithium ionic cell

InactiveCN101399328AImprove performanceImproved gram capacity playFinal product manufactureSecondary cellsVacuum pumpingGram

The invention relates to a liquid injection process of an electric core of a lithium-ion battery, the liquid injection process comprises: (S1) when in liquid injection of the electric core of the lithium-ion battery, 70-90 percent of the total amount of pre-determined electrolyte is firstly injected for being placed for 14-20 hours; (S2) the pre-charging is carried out on the electric core, the charging condition is that the charging is carried out for 210-1200 minutes at 0.06-0.2C; (S3) the residual electrolyte is injected in the electric core after the completion of the pre-charging under the vacuum pumping condition, and the sealing is carried out for the preparation. The process can improve the performance of the electric core, improve the gram capacity exertion of positive electrode material and improve the capacity of the electric core and the cycle retention rate of a platform; the electrolyte is saved, the production cost of the electric core is reduced, the environmental air is improved, and the service life of a device is prolonged.

Owner:SHENZHEN BAK BATTERY CO LTD

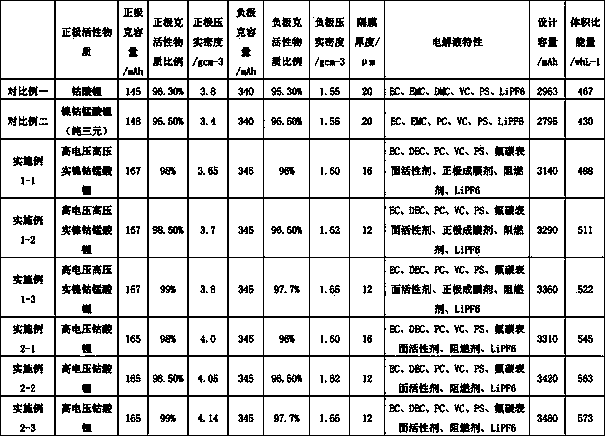

Lithium ion battery and preparation method thereof

InactiveCN103779602AIncrease volume specific energyImprove performanceCell electrodesFinal product manufactureEngineeringLithium-ion battery

The invention discloses a lithium ion battery which comprises a roll, an electrolyte and a shell, wherein the roll comprises a positive plate, a diagram and a negative plate which are sequentially stacked. The positive plate comprises a positive pole current collector and positive pole coatings coated on both sides of the positive pole current collector, and the negative plate comprises a negative pole current collector and negative pole coatings coated on both sides of the negative pole current collector. The positive pole coating comprises a positive pole active matter, a positive pole conductive agent and a positive pole binder at a weight ratio of (98-99%):(0.4-1%):(0.6-1%). The negative pole coating comprises a negative pole active matter, a negative pole thickener, a negative pole binder and a negative pole conductive agent at a weight ratio of (96-97.7%):(0.7-1.2%):(1.3-2.2%):(0.3-0.6%). The invention provides the lithium ion battery which is high in volumetric specific energy by changing the proportion of a negative pole formula and a positive pole formula and adopting matters by virtue of an optimized technological process.

Owner:DONGGUAN ADF BATTERY

High-capacity lithium ion battery negative electrode plate and preparation method thereof

InactiveCN106374081ABuffer volume effectImprove conductivitySecondary cellsElectrode collector coatingExpansion rateSilicon

The invention discloses a high-capacity lithium ion battery negative electrode plate and a preparation method thereof. The negative electrode plate comprises a negative electrode current collector, and a base coat, an active substance layer and a conductive composite layer which are coated on the surface of the negative electrode current collector. The negative electrode plate is characterized in that the base coat makes a silicon material and a carbon material deposit on the surface of the current collector to form unit cells in the staggered directions through a vapor deposition method, and the silicon material and the carbon material are arranged in the unit cells in a staggered mode. The silicon material and the carbon material deposit on the surface of the current collector through the vapor deposition method and are high in density and large in adhesive force with the current collector, and the process is controllable; meanwhile, the carbon material deposits on the periphery of the silicon material, the electric conductivity of the electrode plate is improved, the expansion rate of the electrode plate is decreased, and therefore the energy density and cycle performance of a lithium ion battery are improved.

Owner:XIAMEN RIZHEN POWER TECH CO LTD

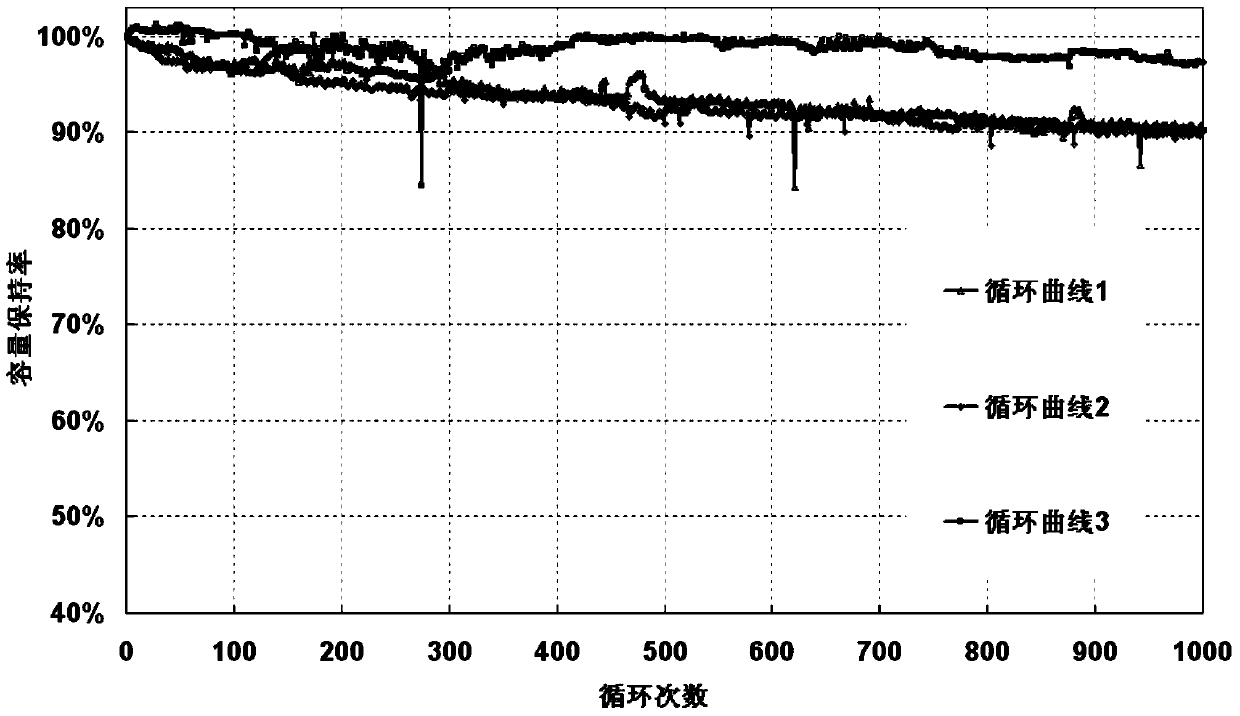

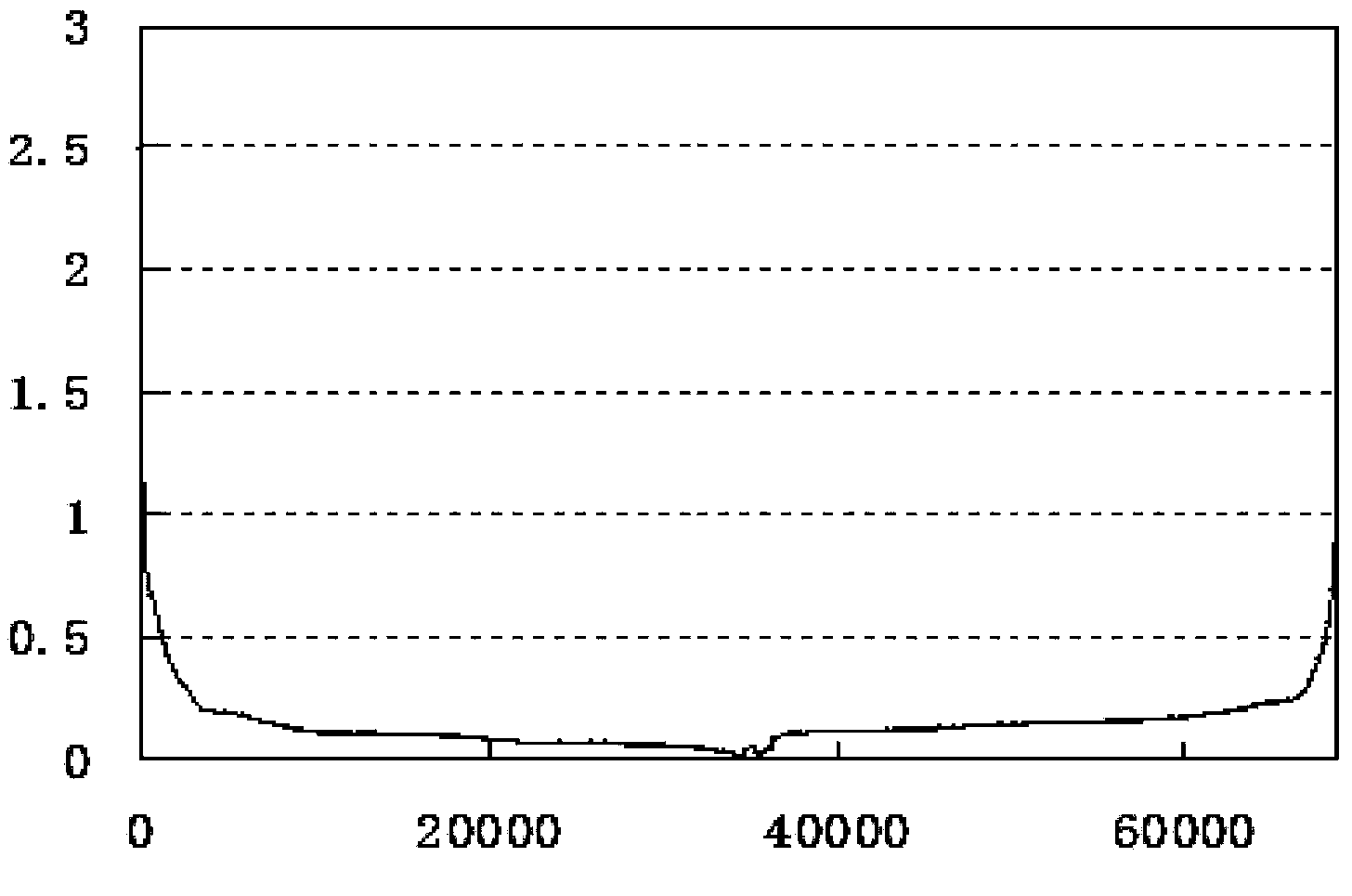

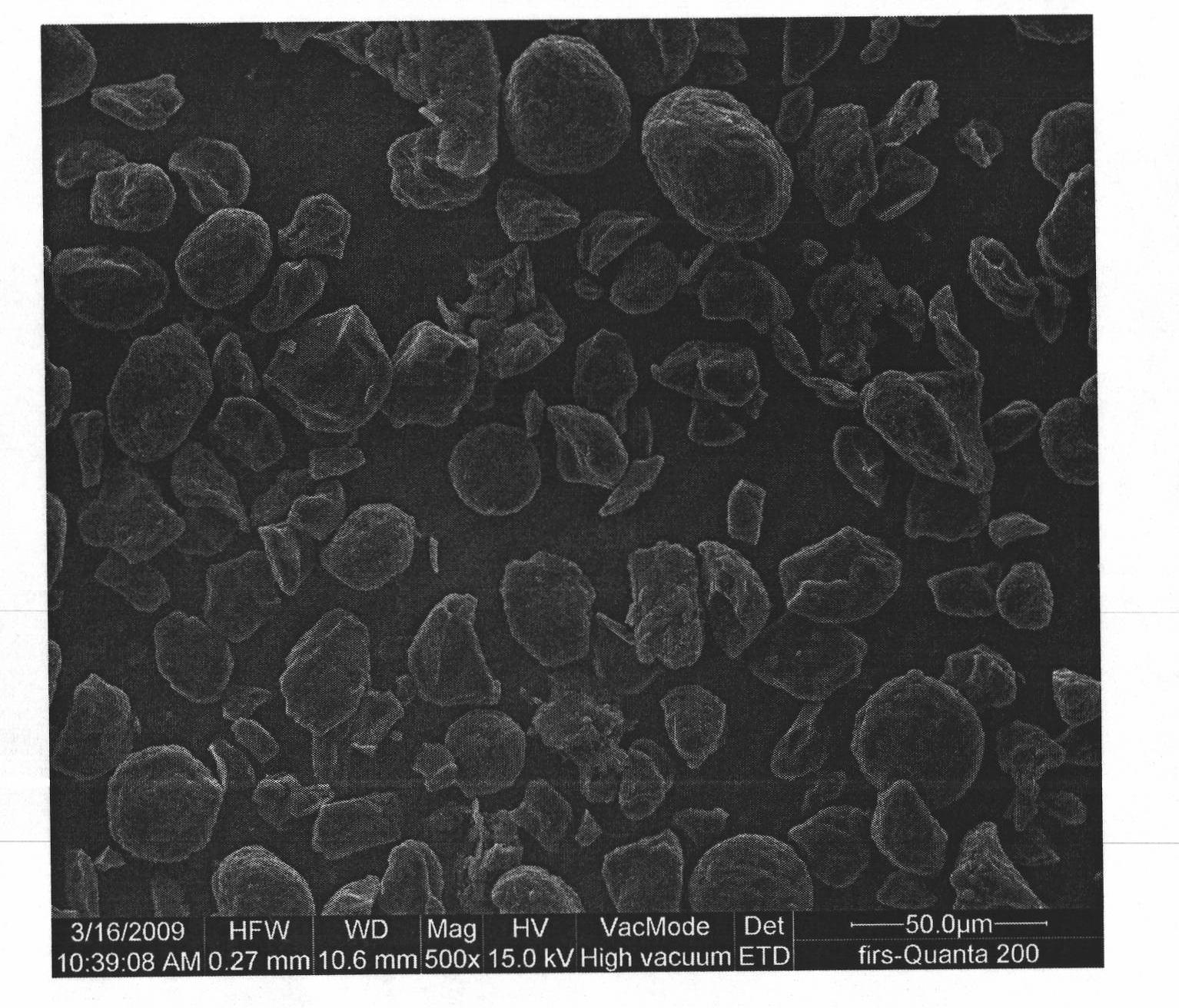

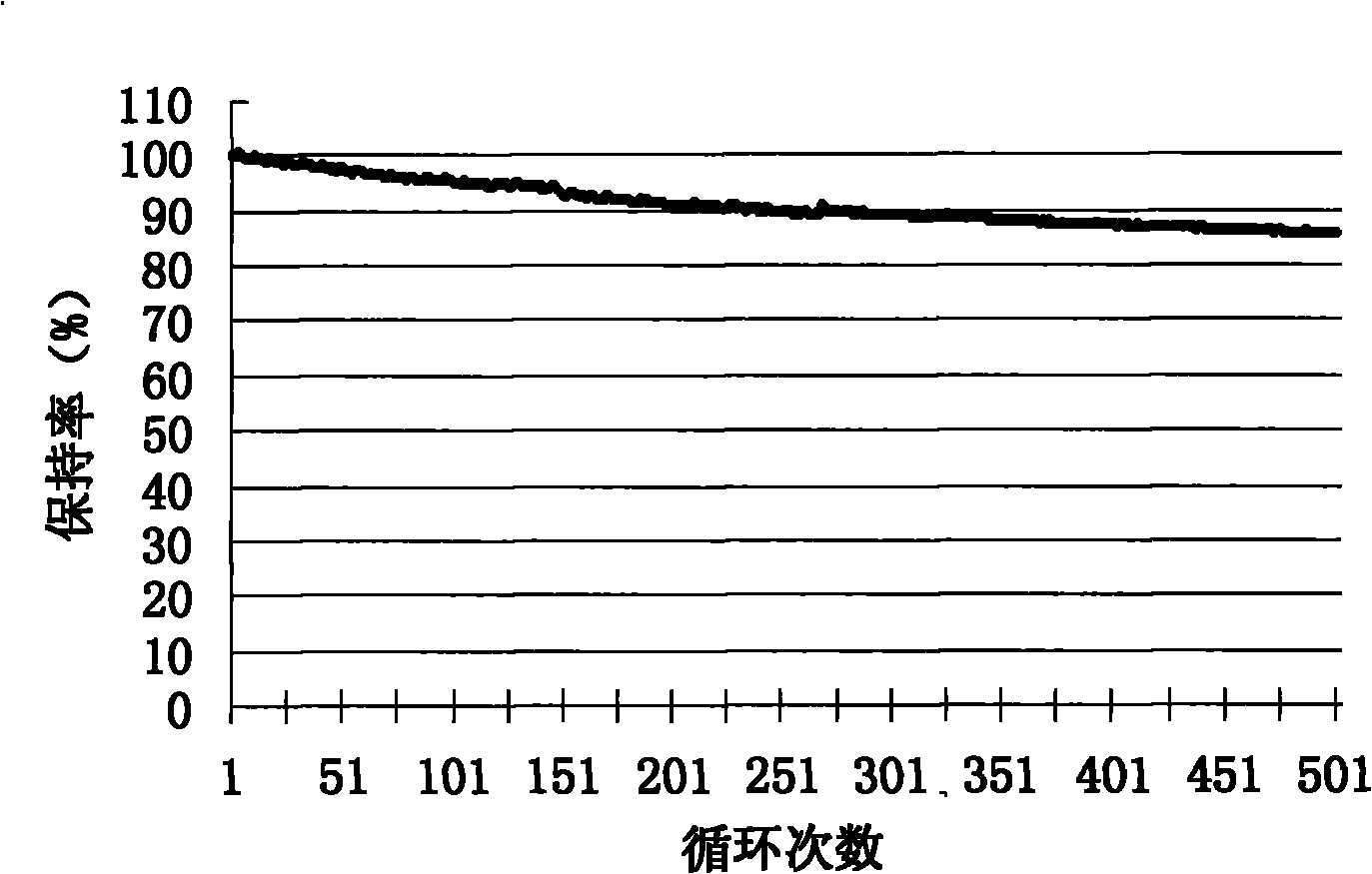

Pretreatment method of cobaltosic oxide for preparing high-voltage lithium cobalt oxide, high-voltage lithium cobalt oxides anode material and preparation method of high-voltage lithium cobalt oxide

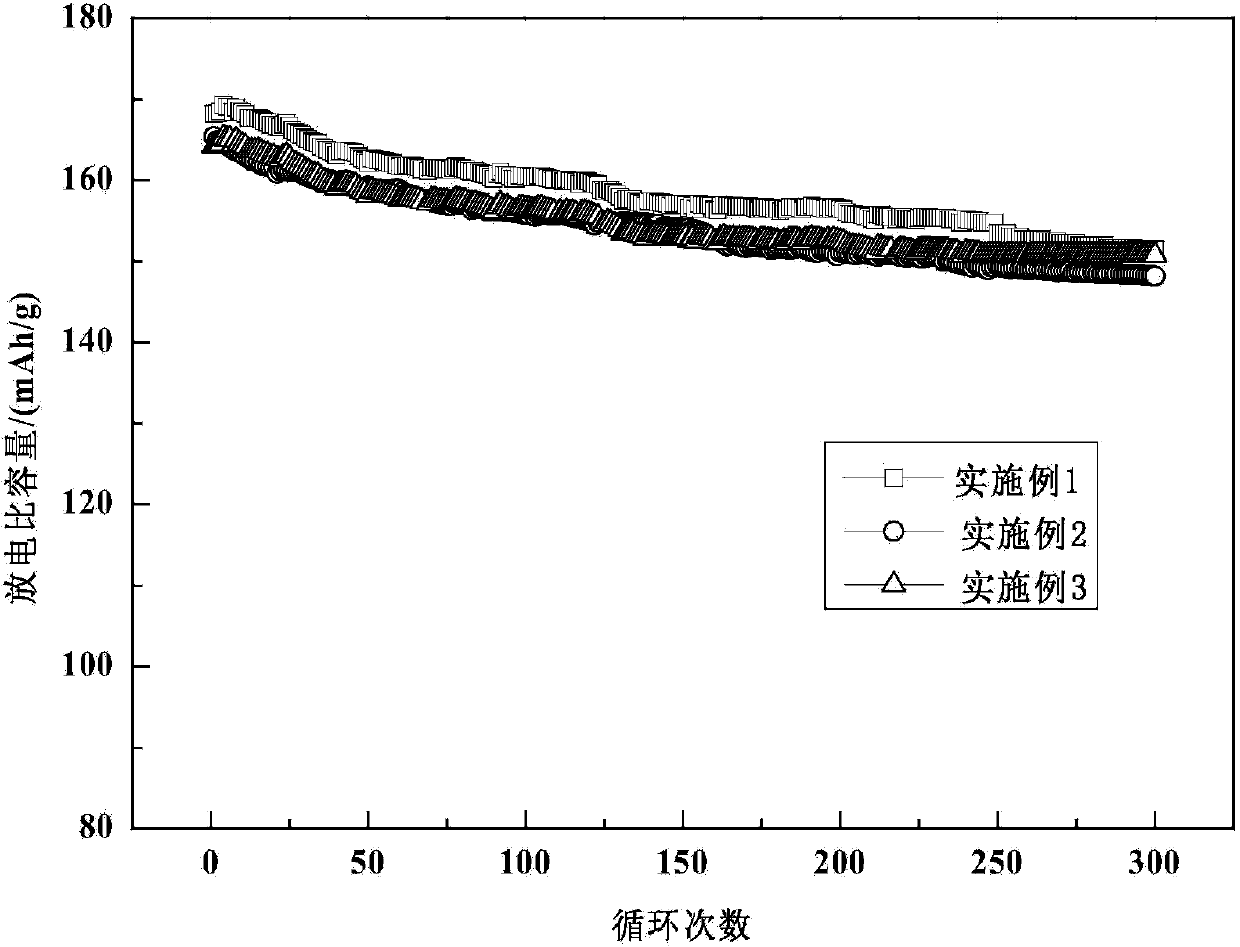

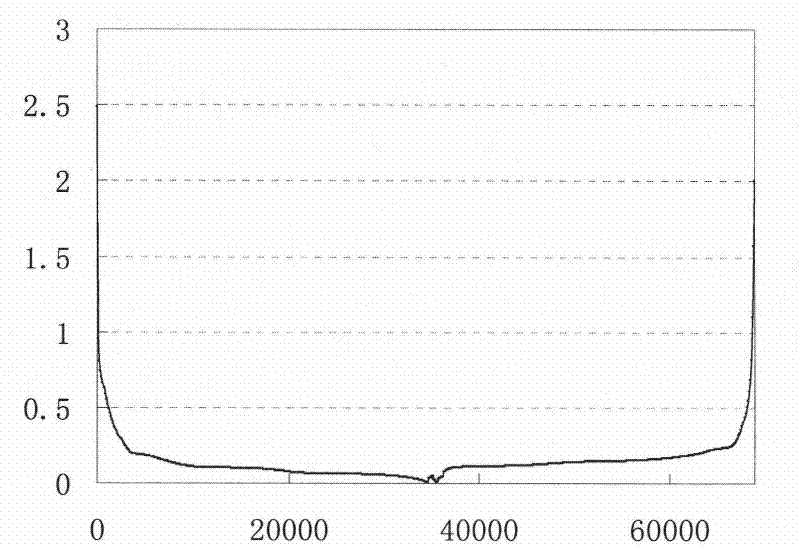

The invention discloses a pretreatment method of cobaltosic oxide. The method comprises the steps of mixing a titanium-containing organic matter with an organic solvent so as to obtain a mixed liquid; adding cobaltosic oxide powder into the mixed liquid under a stirring condition so as to form a turbid liquid, adding deionized water into the turbid liquid, adequately stirring the turbid liquid and the deionized water until a uniform pulp-shaped fluid material is formed, and drying the uniform pulp-shaped fluid material so as to obtain a cobaltosic oxide compound. The high-voltage lithium cobalt oxide can be obtained by adequately mixing the obtained cobaltosic oxide compound, a lithium source and a dopant to obtain a mixture, and performing solid sintering and covering on the mixture at a high temperature. The tap density of the prepared high-voltage lithium cobalt oxide is more than 3.0g / cm<3>, the compaction density is more than 4.2g / cm<3>, the primary discharge gram capacity in the range of 2.8V to 4.34V can reach more than 164mAh / g, and the circulating capacity retention rate in 300 weeks is more than 89 percent. The prepared high-voltage lithium cobalt oxide has the advantages of good processing performance, high tap density, good circulating performance, high specific capacity and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Low temperature electrolyte for lithium ion battery

InactiveCN101252207AExcellent low temperature charge and discharge performanceLow melting point boiling pointOrganic chemistrySecondary cellsDielectricAluminium-ion battery

The invention provides low temperature electrolyte for lithium ion batteries, consisting of basal solvent, low viscosity carbonic esters, low viscosity and low melting point addition agent and lithium salts, by studying on main parameters of the electrolyte such as the melting point, the boiling point, the viscosity and the dielectric constant, etc., proper components and rates of the solvent are selected, and the particular addition agent of the low temperature electrolyte is selected, which obtains the electrolyte having desirable high temperature and low temperature charge-discharge performances and low temperature multiplying factor performance. The low temperature electrolyte for lithium ion batteries has the advantages of reasonable ratios of components, desirable normal temperature and low temperature charge-discharge performances, good normal temperature cyclical stability and good low temperature multiplying factor performance, and is applied to the industrialized production and can also be used as a renewal product for the low temperature electrolyte of the prior lithium ion batteries.

Owner:CENT SOUTH UNIV

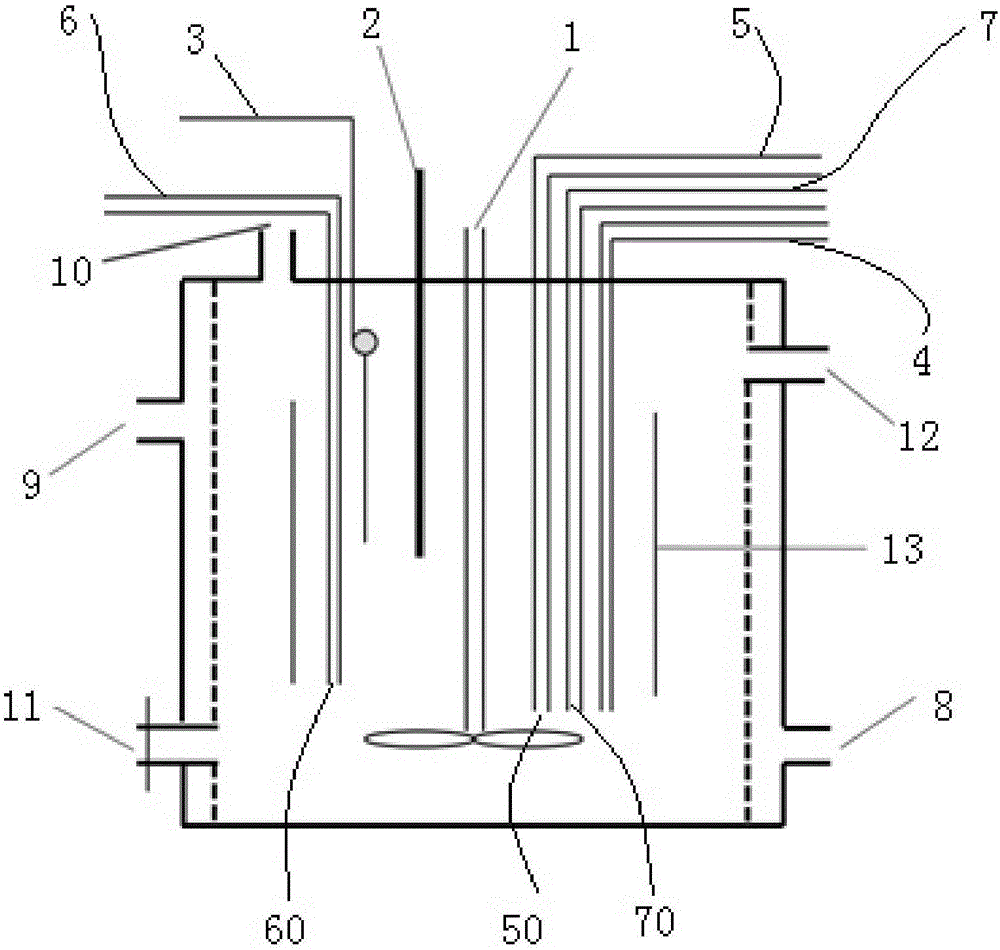

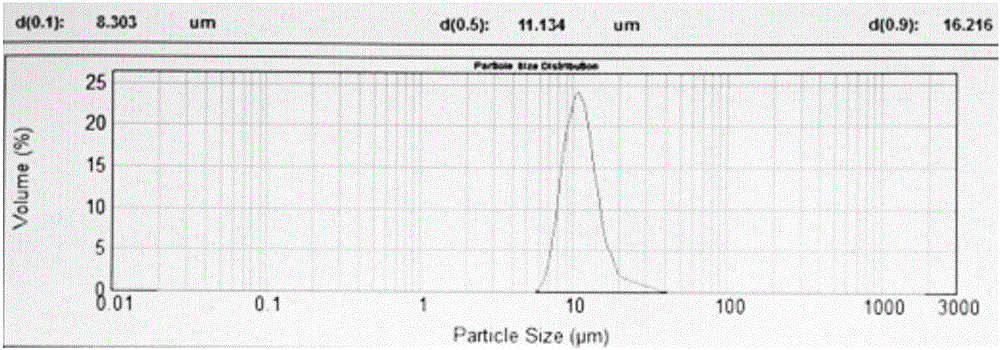

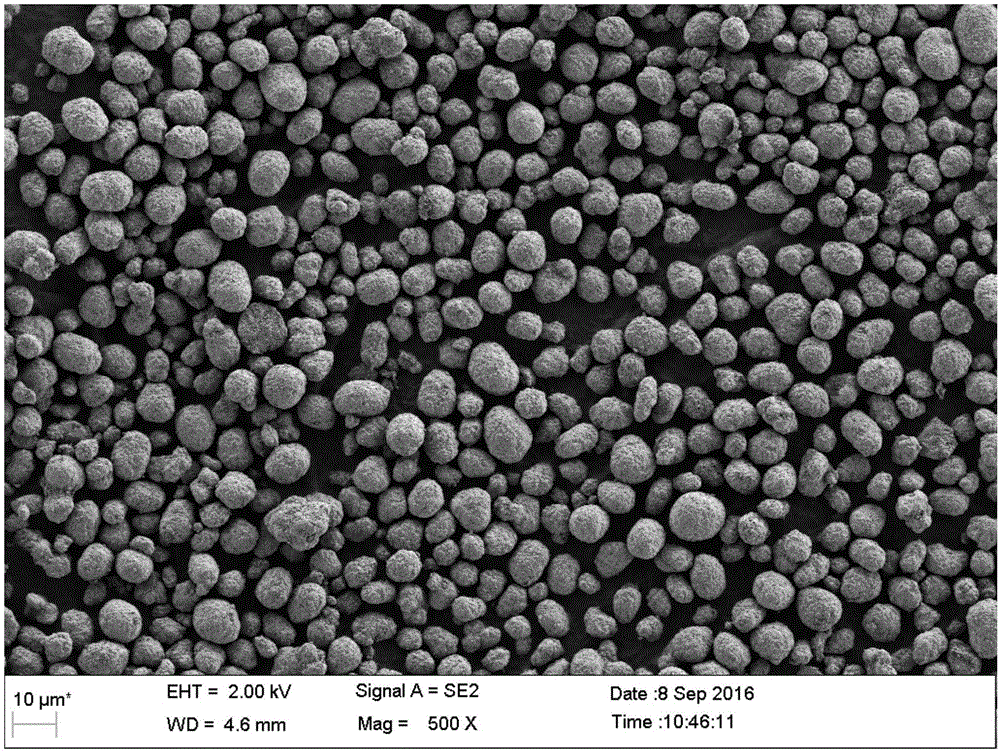

Preparation method for nickel-manganese-cobalt compound hydroxide and reaction kettle for preparing nickel-manganese-cobalt compound hydroxide

ActiveCN106549150AReduce supersaturationReduced particle size distribution widthProcess control/regulationCell electrodesNickel saltGranularity

The invention relates to a preparation method for nickel-manganese-cobalt compound hydroxide and a reaction kettle for preparing the nickel-manganese-cobalt compound hydroxide. The preparation method comprises the following steps: 1) dissolving a nickel salt, a manganese salt, a cobalt salt and an M-salt to obtain a multi-metal salt solution; and 2) introducing a complexing agent solution, an alkali solution and the multi-metal salt solution into the reaction kettle through a complexing agent tube, an alkali solution tube and a main salt solution tube respectively, heating, stirring, performing nucleation in a system in which pH is between 12.5 and 14, performing nucleus growth in a system in which the pH is between 10 and 12, and adjusting the flow proportion of a main salt solution tube to a branch salt solution tube if a granularity distribution width is detected to be over large in the nucleus growth process in order to control the granularity distribution width. In the preparation method for the nickel-manganese-cobalt compound hydroxide provided by the invention, a nucleating process and the nucleus growth process are separated through control of the two-segment pH values, and narrow-granularity distribution nickel-manganese-cobalt compound hydroxide is obtained finally through adjustment of new crystal nucleuses and a growth speed in the nucleus growth process.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

Graphite composite anode material and preparation method thereof

ActiveCN106450311AIncrease contentIncrease layer spacingCell electrodesSecondary cellsIonic liquidHigh magnification

The invention relates to a graphite composite anode material and a preparation method thereof. The graphite composite anode material is of a core-shell structure and comprises an inner core and an outer shell, wherein the inner core is graphite; the outer shell is a nitrogen and phosphorus-doped composite material layer; the nitrogen and phosphorus-doped composite material layer is formed by adding the graphite serving as a raw material into nitrogen-containing ionic liquid in which a phosphorus-containing organic compound, a surfactant and lithium salt are dispersed and sintering; the mass ratio of the phosphorus-containing organic compound to the surfactant to the lithium salt to the nitrogen-containing ionic liquid is (10-50):(1-5):(1-5):200. The graphite composite anode material provided by the invention has the advantages that the transmission rate of lithium ions under the condition of high magnification can be improved, and the compatibility of the graphite composite anode material with an electrolyte can also be improved, so that the cycle performance is improved; the lithium salt in the outer shell can provide sufficient lithium ions, so that the first-time efficiency and the cycle performance are improved.

Owner:陕西君和聚源科技有限公司

Method for preparing cathode material of lithium iron phosphate

InactiveCN101519198ANo impuritiesSingle structureCell electrodesPhosphorus compoundsLithium iron phosphatePhosphate

The invention discloses a method for preparing a cathode material of lithium iron phosphate for a lithium ion battery. The method comprises the following steps: firstly, adding a certain amount of deionized water into a ball mill, and adding lithium dihydrogen phosphate and ionic compound with good conductivity into the ball mill for stirring and ball milling at a high speed; secondly, adding iron oxide for stirring and ball milling at a high speed, and adding a certain amount of anhydrous ethanol as a dispersing agent; and finally, adding superfine conductive carbon black for full mixing and stirring to obtain evenly mixed powder by spray drying at a high speed, adding the powder into a mixing roll for mixing and granule crushing, and pressing the mixed powder into a block to improve the density of materials once again. After being preserved and sintered for 2 to 6 hours at 600 to 800 DEG C in a non-oxidizing sintering furnace and cooled below 50 DEG C, the materials after tablet pressing and granulation are discharged, crushed, refined and sifted, and the powder is dried so as to obtain lithium iron phosphate powder with no impurities, single structure and small granule size distribution. In addition, the preparation process method through improvement significantly reduces the cost for preparing the lithium iron phosphate and has little pollution.

Owner:丁建民

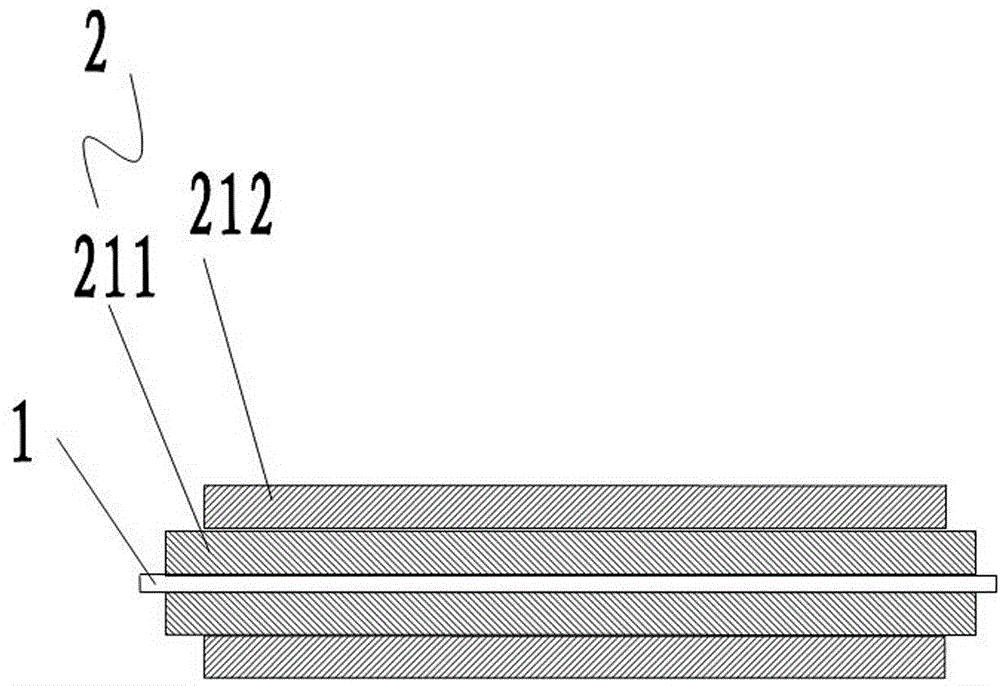

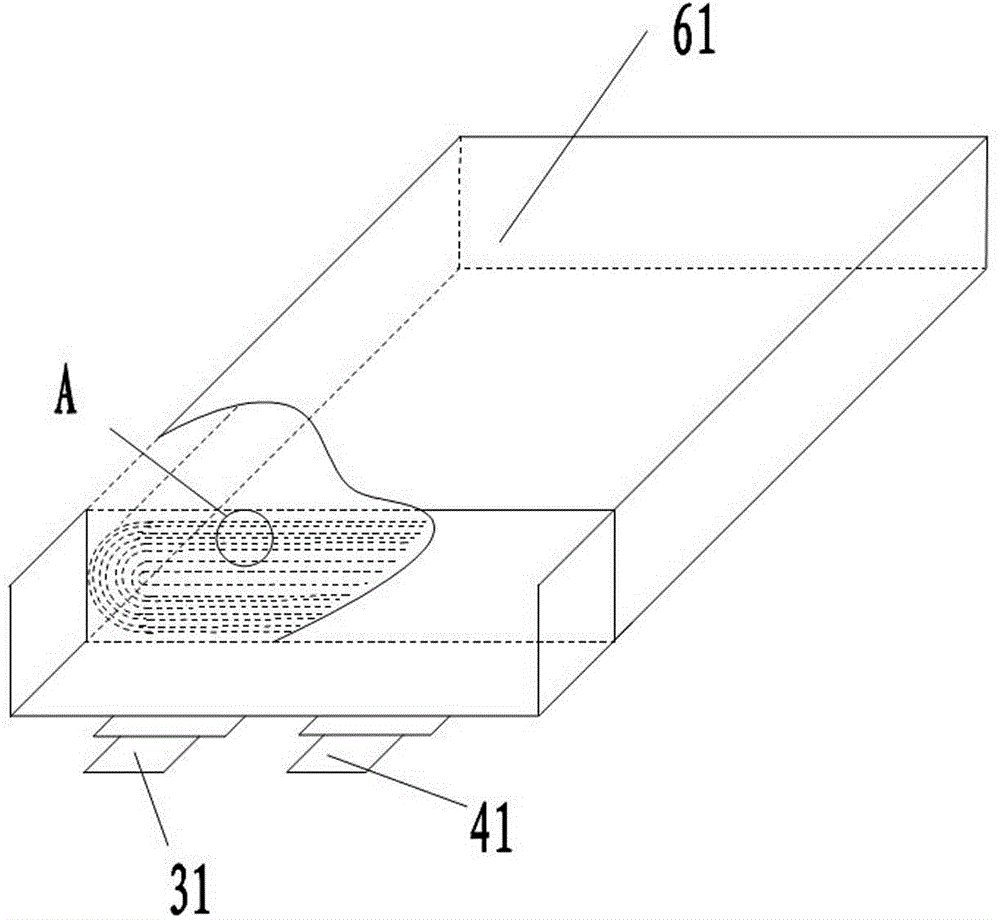

Preparation method of novel all-solid-state lithium ion battery

ActiveCN110233298AReduce interface impedanceWeaken polarizationCell electrodesFinal product manufactureSolid-state batteryChemistry

The invention relates to a preparation method of a novel all-solid-state lithium ion battery, belonging to the technical field of lithium ion batteries. The preparation method comprises the steps of:mixing and uniformly dispersing a cathode active substance, a conductive agent and Li3OX as a cathode ingredient; mixing and uniformly dispersing an anode active substance, the conductive agent and Li3OX as an anode ingredient; mixing and uniformly dispersing a main body solid electrolyte and Li3OX as a solid electrolyte layer ingredient; coating the cathode ingredient on a cathode current collector, coating the anode ingredient on the anode current collector, stacking the anode current collector, the anode ingredient, the solid electrolyte layer ingredient, the cathode ingredient and the cathode current collector in order layer by layer to form a solid battery laminated cell, performing sintering of the solid battery laminated cell at a temperature of 282-400 DEG C while applying the pressure to the solid battery laminated cell, packaging the sintered solid battery laminated cell by adopting a battery membrane shell to obtain a novel all-solid-state lithium ion battery. The preparation method is simple, friendly in preparation environment, and is suitable for large-scale production.

Owner:ZHUHAI COSMX BATTERY CO LTD

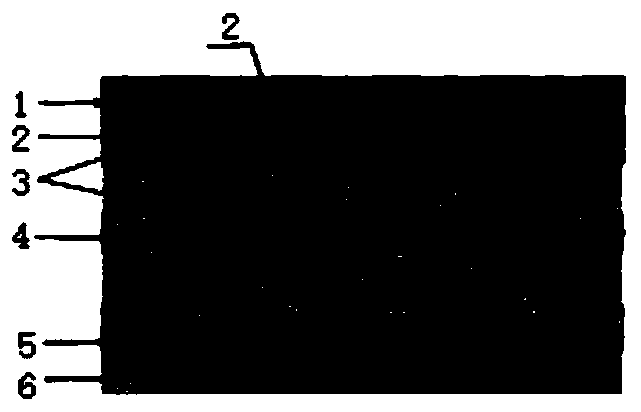

Silicon-containing negative plate and lithium ion battery comprising same

PendingCN112467079AIncrease fluid retentionIncrease gram capacityCell electrodesSecondary cellsSilicon oxygenPhysical chemistry

The invention discloses a silicon-containing negative plate and a lithium ion battery comprising the same. The negative plate comprises a current collector, a first active layer and a second active layer, wherein the second active layer is arranged between the current collector and the first active layer, active substances in the first active layer are a silicon-oxygen material and graphite, and the second active layer is arranged between the first active layer and the second active layer, and the active substance in the second active layer is graphite. a contact angle between the first activelayer active substance and the non-aqueous solvent is theta 1, the porosity of the first active layer active substance is a, the contact angle between the bottom active substance and the non-aqueoussolvent is theta 2, and the porosity of the bottom active substance is b, so 100 <theta1 / a<theta2 / b<450 is obtained, through the above specific structure, as the silicon expands greatly during the charging and discharging process, it is beneficial to improve the porosity of the surface electrode plate so as to improve the liquid retention of the battery. and meanwhile, the silica surface containsmore functional groups, and the particles are smaller than the graphite particles, so that the energy density, the liquid retention capacity and the cycle life of the battery can be remarkably improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Surface modified graphitized interphase carbon micro-powder and preparation method thereof

ActiveCN102195036AIncrease compaction densityIncrease gram capacityCell electrodesSecondary cellsCapacitancePre treatment

The invention provides surface modified graphitized interphase carbon micro-powder and a preparation method thereof. The method comprises the following steps of: (1) performing pretreatment to crush the raw material of the interphase carbon micro-powder; (2) adding an additive and fully mixing; (3) performing graphitization treatment; and (4) performing ball-grinding and shaping treatment. As an anode material of a lithium battery, the obtained surface modified graphitized interphase carbon micro-powder has the advantages of the conventional interphase carbon canoed materials, improves the compacted density and the first discharge capacitance, reduces the specific area, produces cells with high comprehensive performance and therefore is a new replacement product of the interphase anode material.

Owner:福建杉杉科技有限公司

Preparation method and application of high-capacity tin alloy sulfide negative electrode material suitable for industrialized mass production

ActiveCN103384005AImprove negative electrode capacityImprove cycle performanceCell electrodesIngotBattery cell

The invention discloses a preparation method for a high-capacity tin alloy sulfide negative electrode material suitable for industrialized mass production. The preparation method comprises the steps of smelting tin and other metals and nonmetals to obtain alloy uniform in ingredients, making alloy ingots into amorphous alloy powder, calcining the powder and a sulfur source, and obtaining the high-capacity tin alloy sulfide negative electrode material by preparation. The invention further discloses application of the high-capacity tin alloy sulfide negative electrode material in batteries. The preparation method is simple in reaction conditions, free of pollution, simple and convenient to operate, low in device requirements and good in product uniformity. The high-capacity tin alloy sulfide negative electrode material has extremely good gram volume and cycle performance in lithium-ion secondary batteries and is suitable for industrialized mass production.

Owner:ADVANCED ELECTRONICS ENERGY LIMITED GUANGDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com