Lithium ion battery and preparation method thereof

A lithium ion battery and a manufacturing method technology, applied in the field of lithium ion battery and its manufacturing, can solve problems such as the gram capacity cannot exceed 100, the safety cannot be satisfied, the low voltage and the compaction density, etc., to reduce the negative electrode rebound coefficient, The effect of increased speed, high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

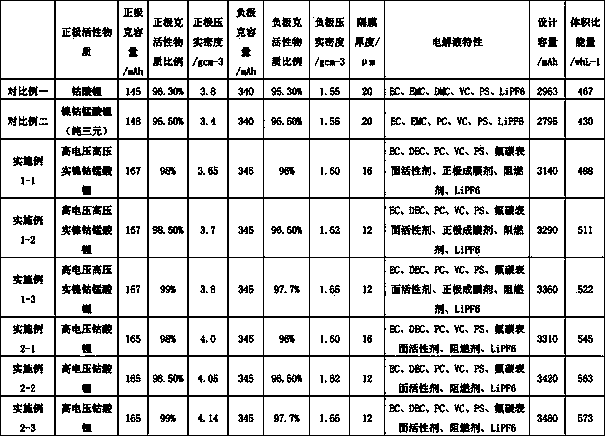

Examples

Embodiment 1

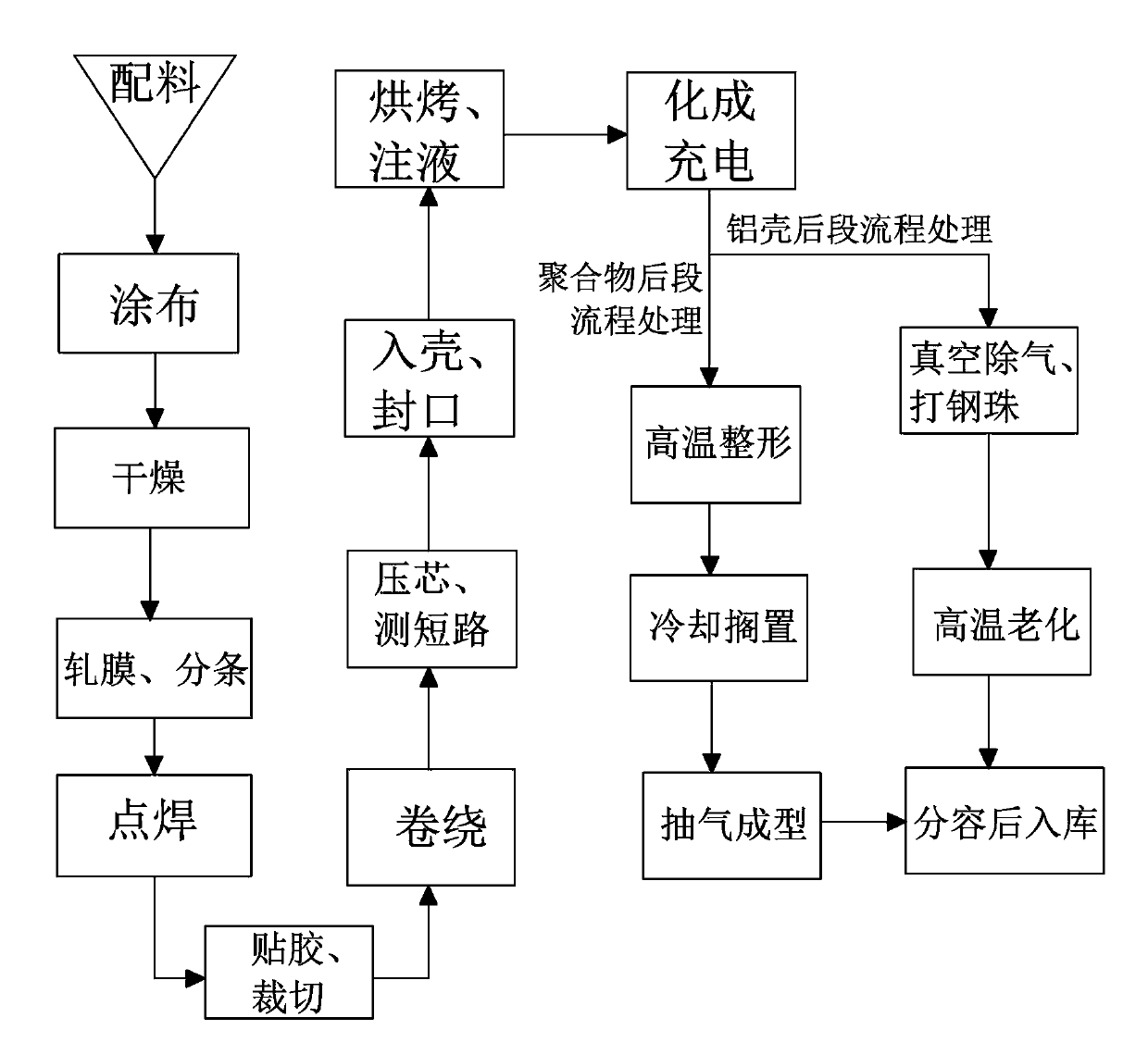

[0053] A method for manufacturing a polymer soft-packed lithium ion battery includes the following steps:

[0054] 1) The material of the positive electrode coating and the material of the negative electrode coating are respectively mixed at low speed under vacuum to prepare high uniformity positive electrode slurry and negative electrode slurry;

[0055] 2) The positive electrode slurry is uniformly coated on the positive electrode current collector by a coating machine and dried, and the negative electrode slurry is uniformly coated on the negative electrode current collector by a coating machine and dried, and the positive electrode film is prepared after drying Sheet and negative diaphragm;

[0056] 3) Roll the positive electrode film and the negative electrode film to the corresponding thickness, and then divide them into small rolls by a slitting machine, and then use a spot welding machine for spot welding, gluing and cutting to make the positive and negative sheets to be woun...

Embodiment 2

[0065] A manufacturing method of an aluminum shell lithium ion battery includes the following steps:

[0066] 1) The material of the positive electrode coating and the material of the negative electrode coating are respectively mixed at low speed under vacuum to prepare high uniformity positive electrode slurry and negative electrode slurry;

[0067] 2) The positive electrode slurry is uniformly coated on the positive electrode current collector by a coating machine and dried, and the negative electrode slurry is uniformly coated on the negative electrode current collector by a coating machine and dried, and the positive electrode film is prepared after drying Sheet and negative diaphragm;

[0068] 3) Roll the positive electrode film and the negative electrode film to the corresponding thickness, and then divide them into small rolls by a slitting machine, and then use a spot welding machine for spot welding, gluing and cutting to make the positive and negative sheets to be wound;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com