Patents

Literature

95results about How to "Increase volume specific energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

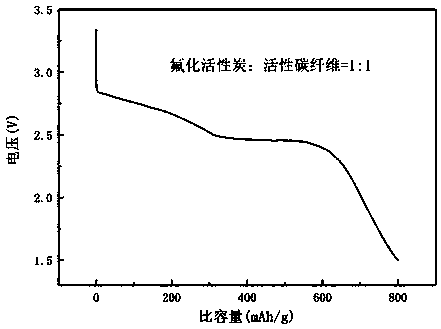

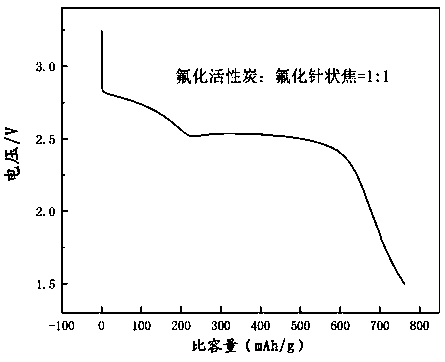

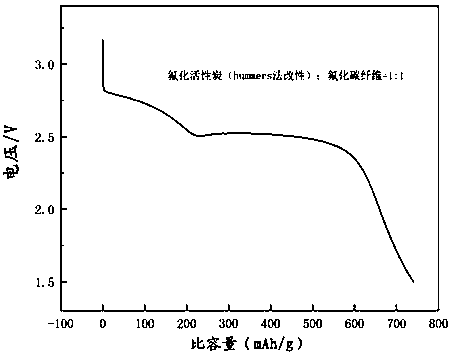

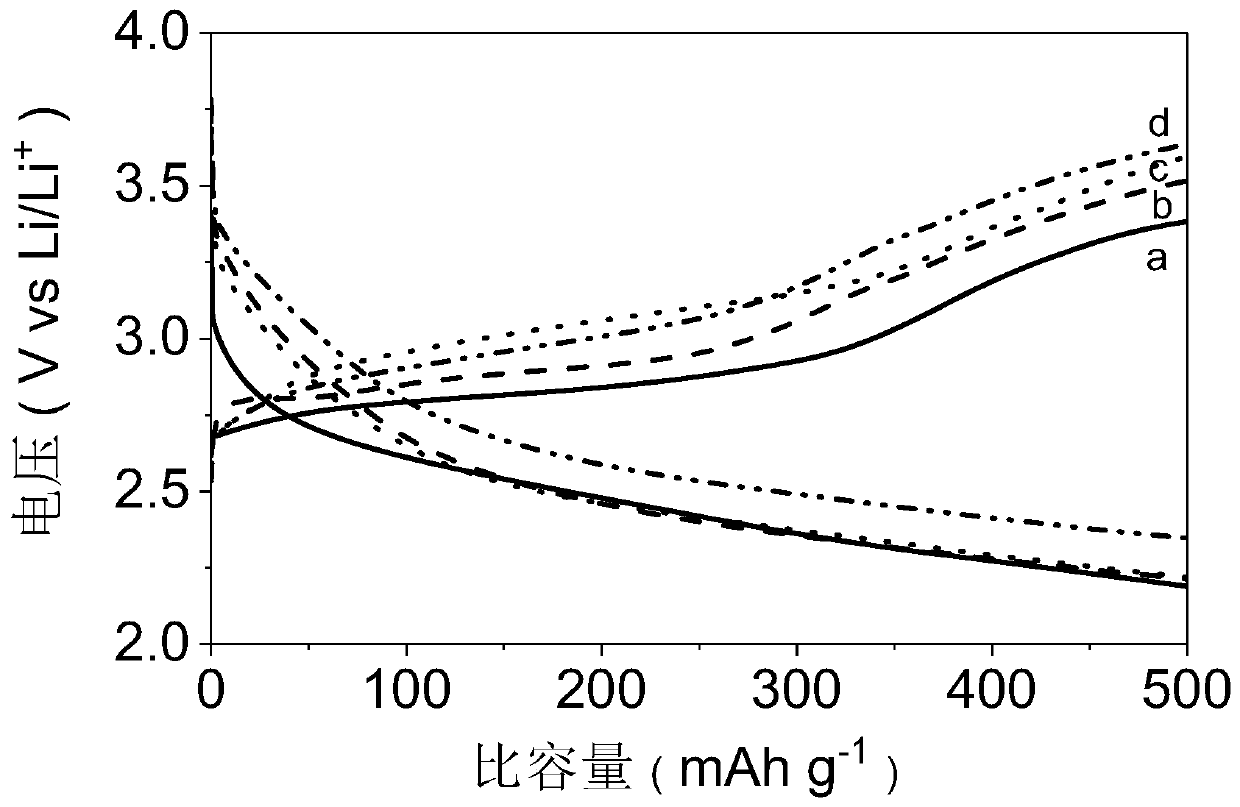

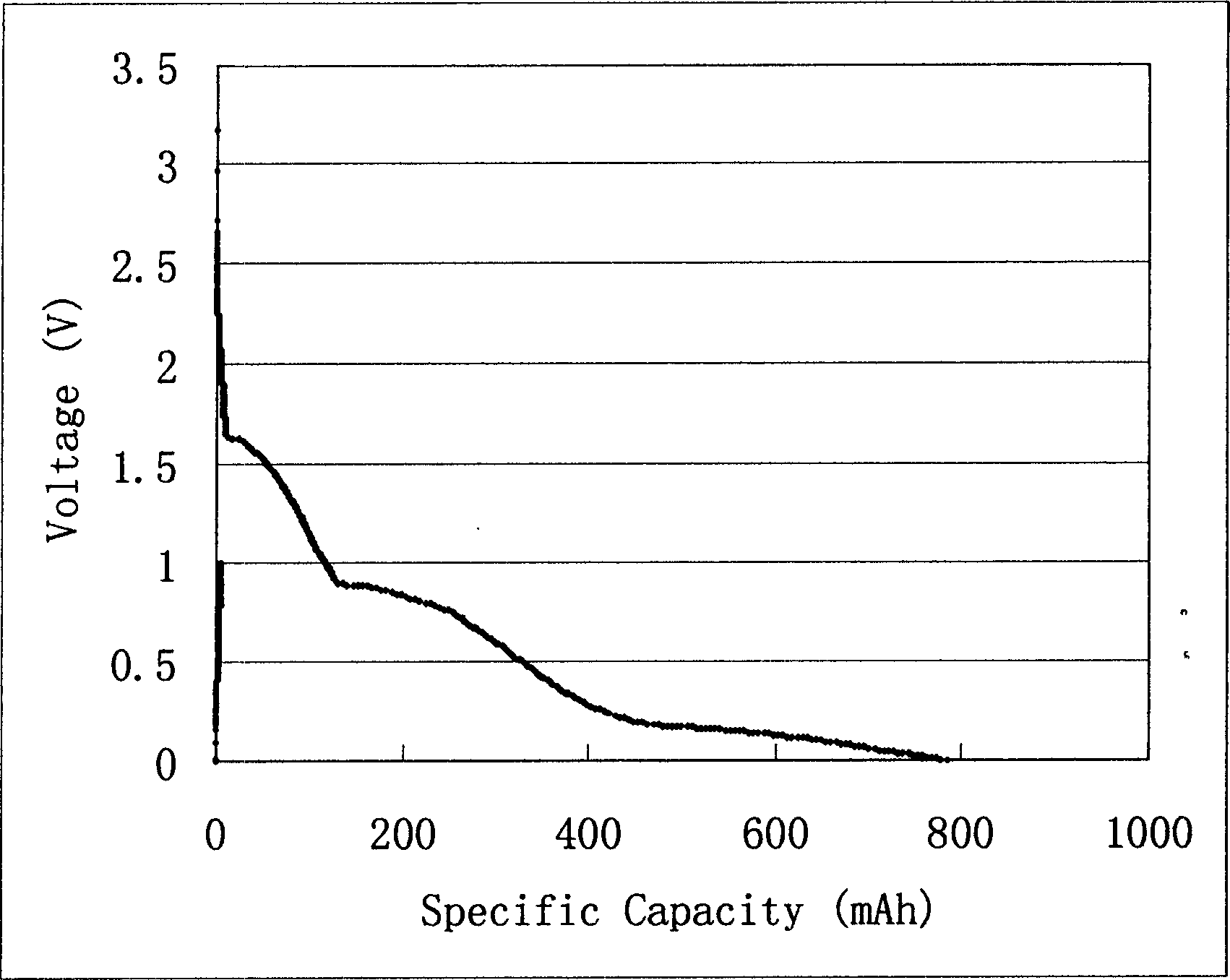

Composite carbon fluoride cathode material for lithium primary battery, preparation method and application thereof

ActiveCN109461923AHigh specific capacityHigh capacity densityCell electrodesNon-aqueous electrolyte cellsMass ratioPorous carbon

The invention belongs to the technical field of a cathode material for a lithium primary battery, particularly relates to the field of preparation of the cathode material for a fluorocarbon battery, and in particular to a composite carbon fluoride cathode material for the lithium primary battery, a preparation method and an application thereof. The material is a composite material prepared by ballmilling and mixing a porous carbon fluoride material having a high tap density and a carbon fluoride material having a high graphitization degree and then fluorinating the mixture. The composite material has a carbon content of 38-60%, a fluorine content of 40-62% and a tap density of greater than 0.8g / ml; the mixing mass ratio is in the range of 1:0.1-1:10; and the composite material has high specific surface area, high tap density and high graphitization degree. Due to the high tap density of the material, the overall high volumetric specific energy of the material is guaranteed; through anion diffusion channel composed of porous carbon fluorides, the voltage hysteresis phenomenon at the initial stage of the battery discharge is effectively improved and the overall discharge performance of the material is improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

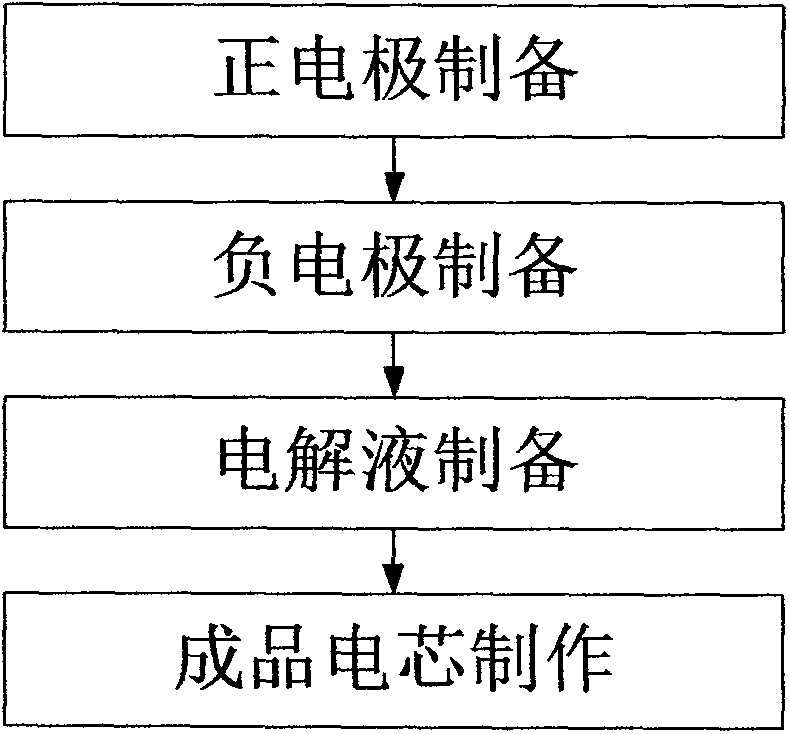

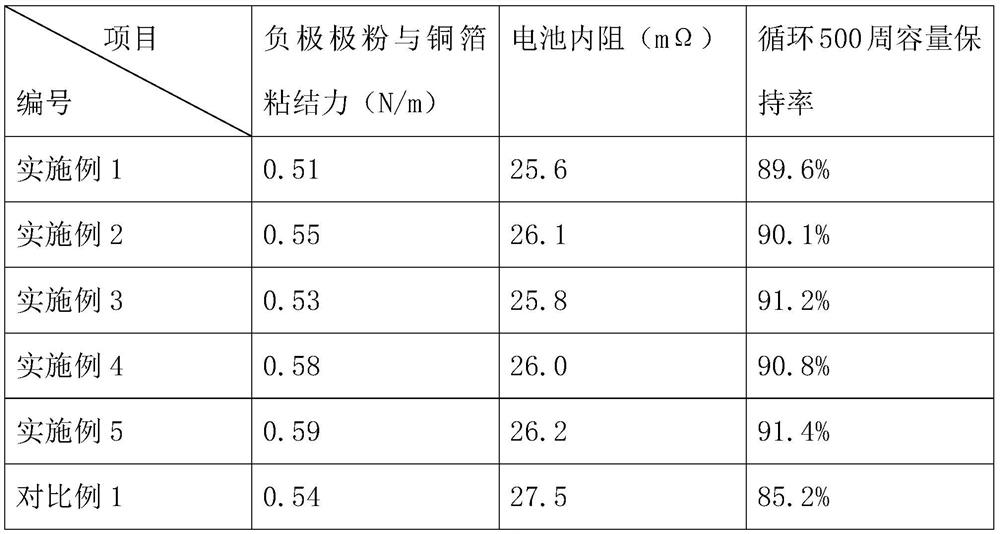

Water-soluble three-dimensional network type electrode binding agent and preparation method thereof, electrode piece and preparation method thereof, and electrochemical devices

ActiveCN102142560ANo pollution in the processAdhesive retentionElectrode manufacturing processesElectrical batteryCross linker

The invention discloses a water-soluble three-dimensional network type electrode binding agent, comprising a water-soluble polymer polyelectrolyte. Molecular chains of the polyelectrolyte contain active groups; the molecular chains of the polyelectrolyte are cross-linked and bridged by a cross-linking agent to form a three-dimensional network type molecular structure. The invention also disclosesa preparation method of the binding agent, an electrode piece prepared by utilizing the binding agent, and electrochemical devices. In the water-soluble three-dimensional network type electrode binding agent disclosed by the invention, the water solubility is good, the viscosity is adjustable, and the tensile strength and the Young modulus are controllable; in the carbon electrode piece prepared by the electrode binding agent, the mechanical property is good, the phenomenon of common material falling of the electrode piece can be avoided, the irreversible capacity is low in the first chargingprocess, the reversible capacity is high, and electrochemical devices such as lithium-ion batteries and super capacitors and the like with excellent circulating performance can be manufactured.

Owner:SHENZHEN CAPCHEM TECH CO LTD

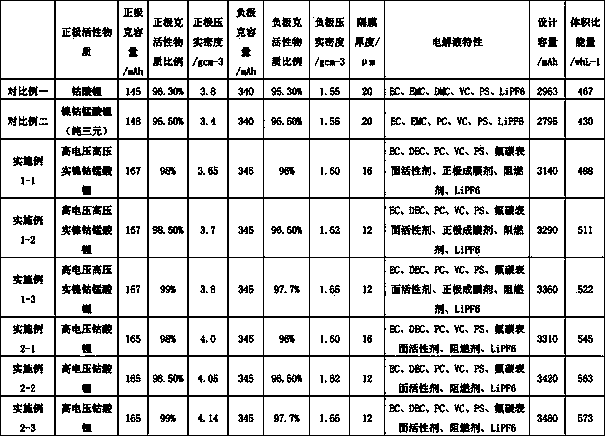

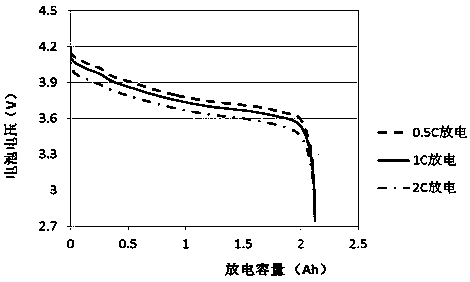

Lithium ion battery and preparation method thereof

InactiveCN103779602AIncrease volume specific energyImprove performanceCell electrodesFinal product manufactureEngineeringLithium-ion battery

The invention discloses a lithium ion battery which comprises a roll, an electrolyte and a shell, wherein the roll comprises a positive plate, a diagram and a negative plate which are sequentially stacked. The positive plate comprises a positive pole current collector and positive pole coatings coated on both sides of the positive pole current collector, and the negative plate comprises a negative pole current collector and negative pole coatings coated on both sides of the negative pole current collector. The positive pole coating comprises a positive pole active matter, a positive pole conductive agent and a positive pole binder at a weight ratio of (98-99%):(0.4-1%):(0.6-1%). The negative pole coating comprises a negative pole active matter, a negative pole thickener, a negative pole binder and a negative pole conductive agent at a weight ratio of (96-97.7%):(0.7-1.2%):(1.3-2.2%):(0.3-0.6%). The invention provides the lithium ion battery which is high in volumetric specific energy by changing the proportion of a negative pole formula and a positive pole formula and adopting matters by virtue of an optimized technological process.

Owner:DONGGUAN ADF BATTERY

Method for preparing lithium nickel manganese oxide anode material

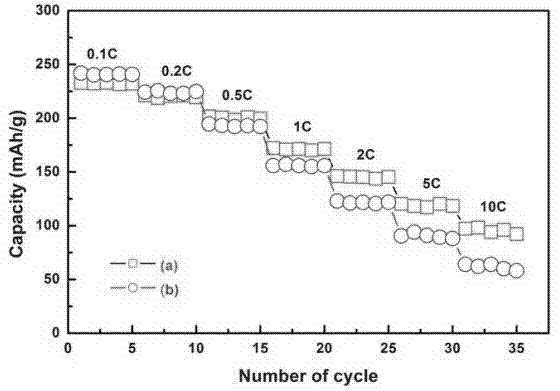

InactiveCN105118983AIncrease specific energyHigh specific powerCell electrodesSecondary cellsLithium compoundPolytetrafluoroethylene

The invention discloses a method for preparing a lithium nickel manganese oxide anode material. The method includes the steps that A, divalent nickel salt, divalent manganese salt and Li<+> compounds are evenly mixed and grinded, and a nickel, manganese and lithium mixture is obtained; B, persulfate with the molar weight larger than the sum of the molar weight of the divalent nickel salt and the molar weight of the divalent manganese salt and the mixture obtained in the step A are mixed and grinded, and a reaction mixture is obtained; C, the reaction mixture obtained in the step B is transferred into a polytetrafluoroethylene reaction kettle, water is added, a cover and a stainless steel reaction-kettle outer bush are arranged for sealing, the reaction temperature is controlled and kept, and reactants are obtained; D, the reactants obtained in the step C are taken out and washed with water till no sulfate radical is detected, suction filtration is carried out, and brown or black solid is obtained; E, the brown or black solid is transferred into a crucible, in the atmosphere environment, roasting is carried out, natural cooling is carried out, and the lithium nickel manganese oxide anode material is obtained. The raw materials are abundant, the price is low, environment pollution is avoided, and a brand new easy and convenient solid-liquid film phase reaction method with the easily-controlled conditions and the simple devices is adopted.

Owner:HUBEI UEE ENERGY TECH CO LTD +1

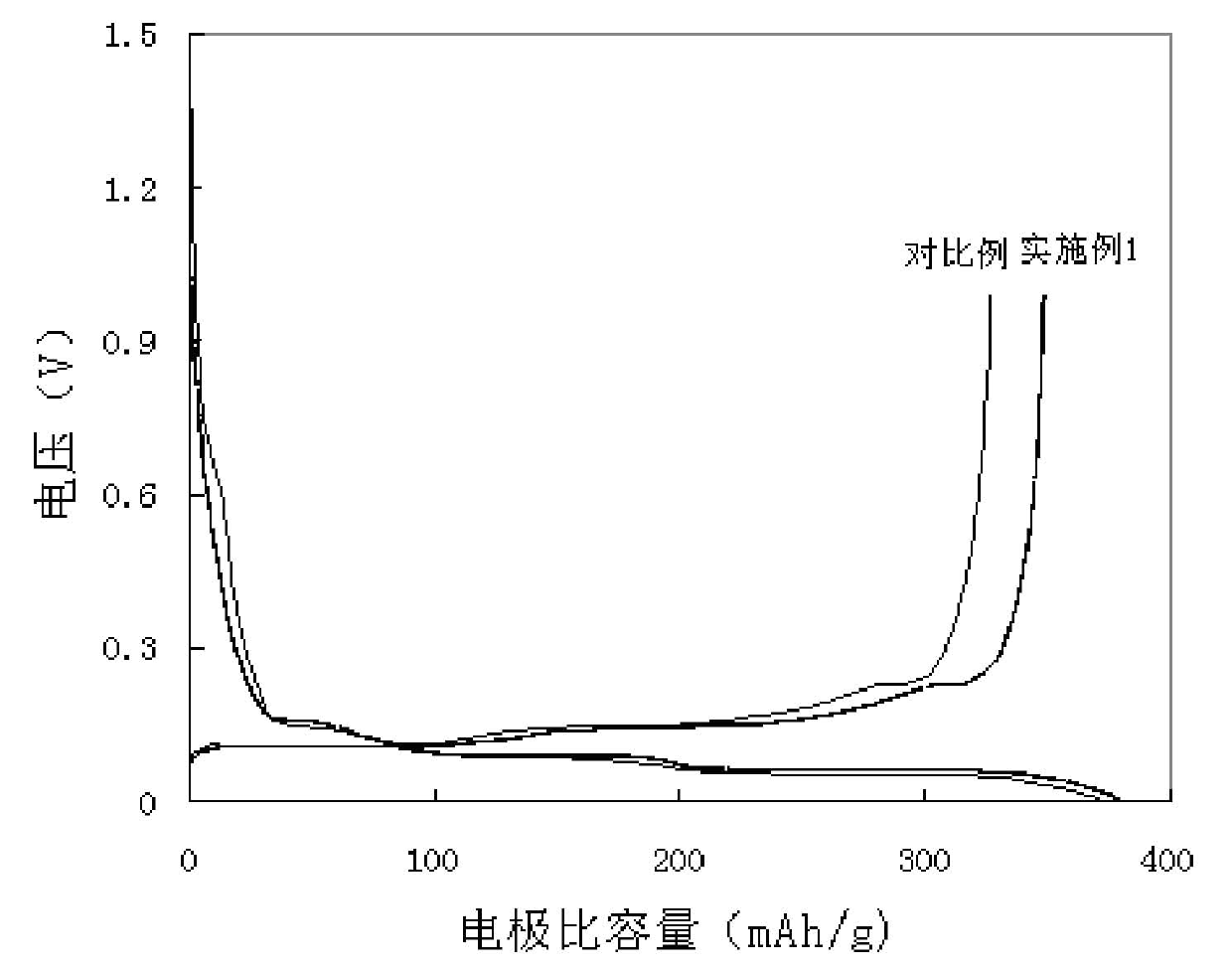

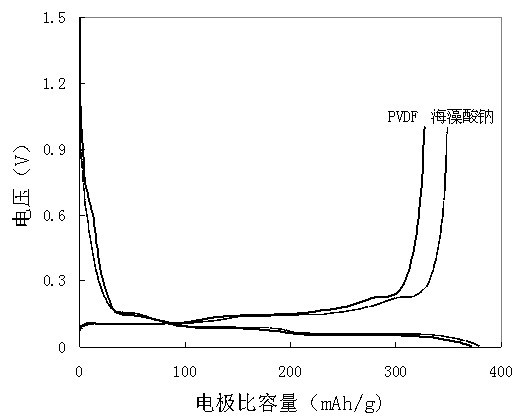

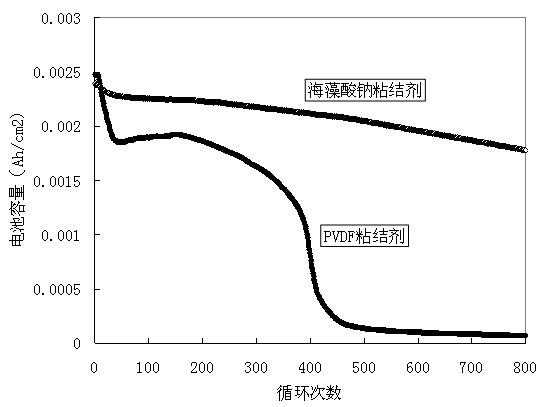

Application of alginate as a binder in the preparation of electrode sheets

InactiveCN102280642AIncrease specific energyIncrease volume specific energyCell electrodesHigh energyWater soluble

The invention discloses the application of alginate as a binder in preparing electrode sheets. In the present invention, alginate is used as a binder to prepare electrode sheets. The binder has good water solubility and good bonding effect, and the carbon negative electrode sheet prepared by it has good mechanical properties, low initial irreversible capacity, and high reversible capacity. The specific energy is high, and the cycle stability of the electrode is good.

Owner:SUZHOU UNIV

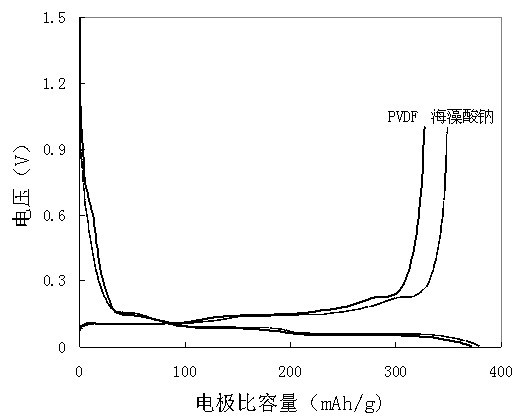

Liquid flexible packaged lithium-ion cell and manufacture method thereof

InactiveCN103367812AImprove permeabilityIncrease volume specific energyFinal product manufactureElectrolyte accumulators manufactureLithiumCopper foil

The invention discloses a liquid flexible packaged lithium-ion cell and a manufacture method thereof. The liquid flexible packaged lithium-ion cell comprises a positive electrode, a negative electrode, a diaphragm and an electrolyte, wherein an active medium of the positive electrode is lithium cobalt oxide LiCoO2, an active medium of the positive electrode is synthetic graphite, and the electrolyte is an electrolyte in which an impregnating compound, a stabilizing agent and a high-temperature additive are added. The manufacture method comprises the following steps of: preparing the positive electrode, namely, the lithium cobalt oxide, a conductive agent and a macromolecule binding agent form a mixture and then the mixture is uniformly coated on the surface of a metal aluminum foil; preparing the negative electrode, namely, the synthetic graphite, the conductive agent and the binding agent form a mixture, and the mixture is uniformly coated on the surface of a metal copper foil; and preparing the electrolyte, namely, the impregnating agent, the stabilizing agent and the high-temperature additive are blended into the electrolyte. According to the manufacture method, the volumetric specific energy of the lithium-ion cell can be remarkably improved, and the final battery cell is good in electrochemical performance.

Owner:SHENZHEN SONGDING TECH

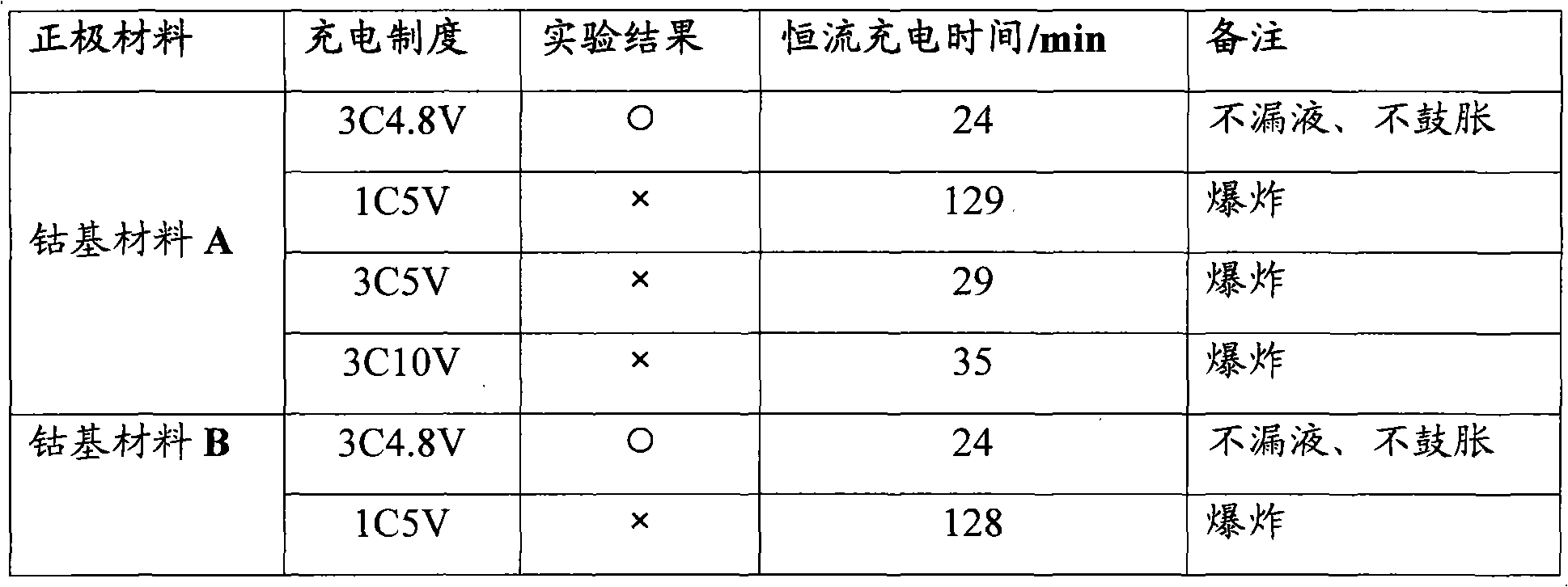

Compound lithium cobaltate cathode material, preparing method and application thereof

InactiveCN101587952AIncrease volume specific energyImprove cycle performanceElectrode manufacturing processesFinal product manufactureHigh energyPhysical chemistry

The present invention relates to a compound lithium cobaltate cathode material, a preparing method thereof and a lithium ion secondary battery. The chemical formula of the cathode material is xLiNi1 / 3Mn1 / 3Co1 / 3O2-LiCoO2, wherein the numerical value of x is 0.005-0.05. The compound lithium cobaltate disclosed by the invention not only can satisfy the requirement of high energy density, but also can cause that the lithium ion battery has excellent electrochemical property. The problem of electrochemical property of large-particle lithium cobaltate is effectively settled. The compound lithium cobaltate cathode material has the characteristics of high volumetric specific energy and excellent circulating performance.

Owner:TIANJIN UNIV

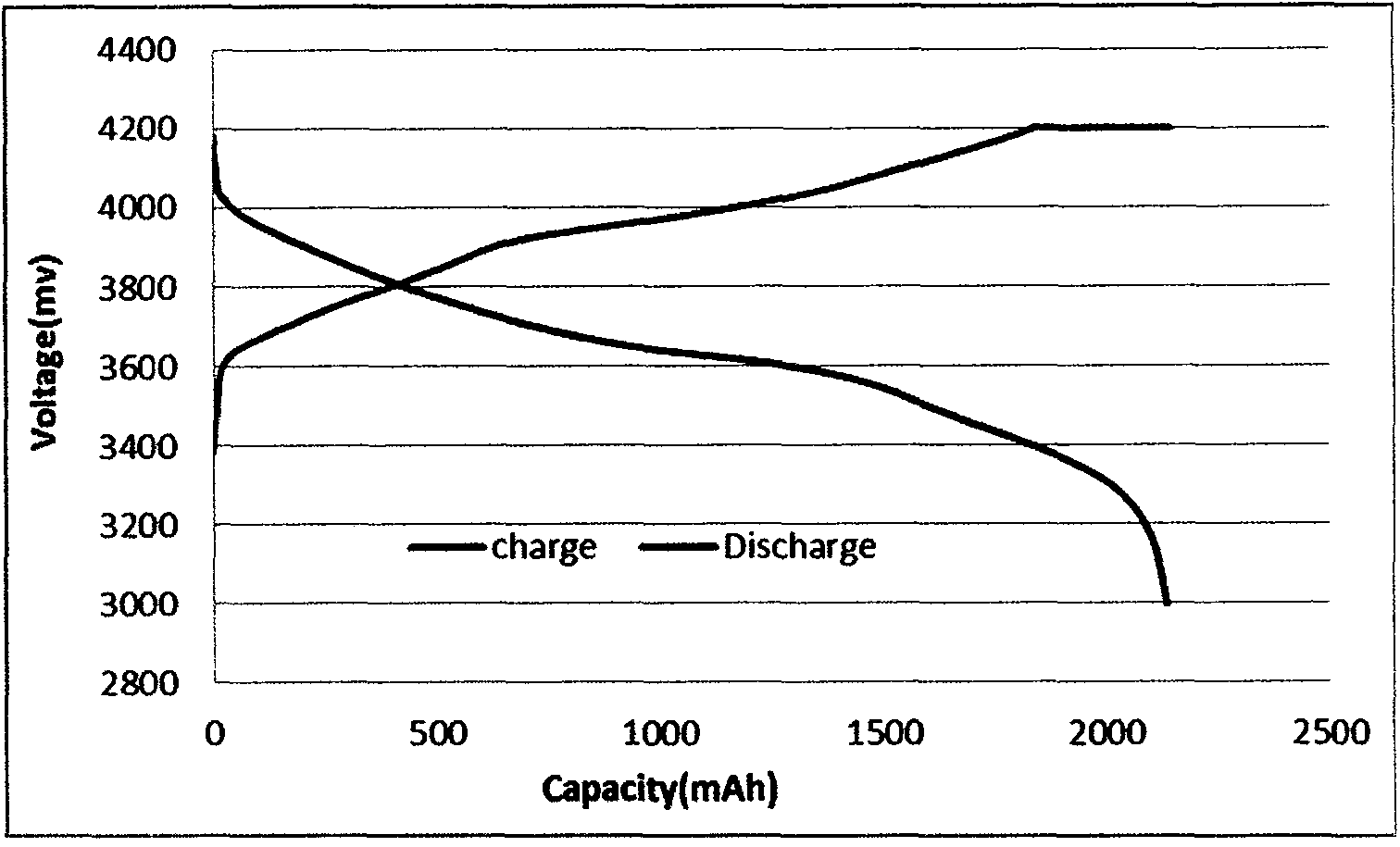

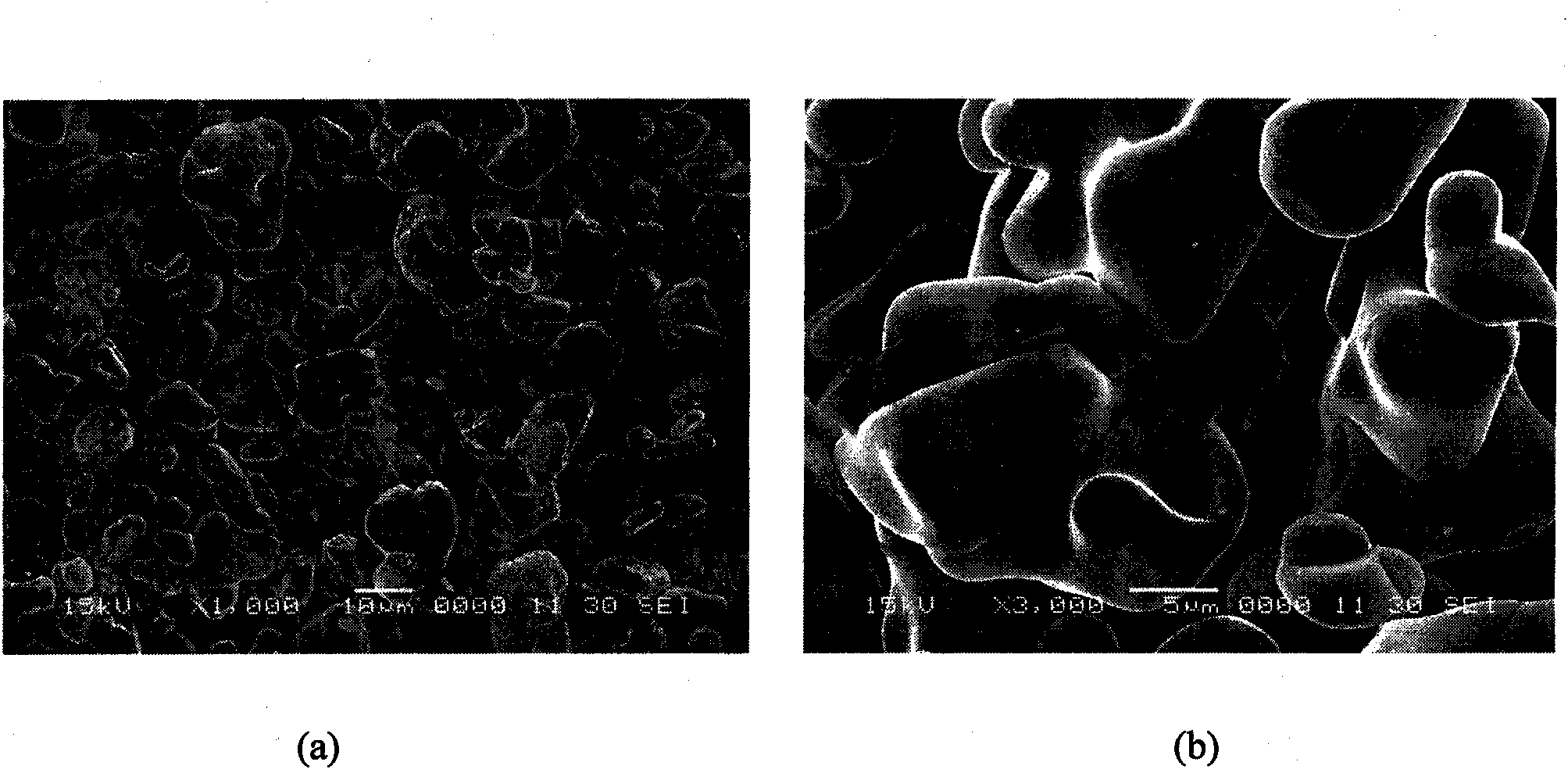

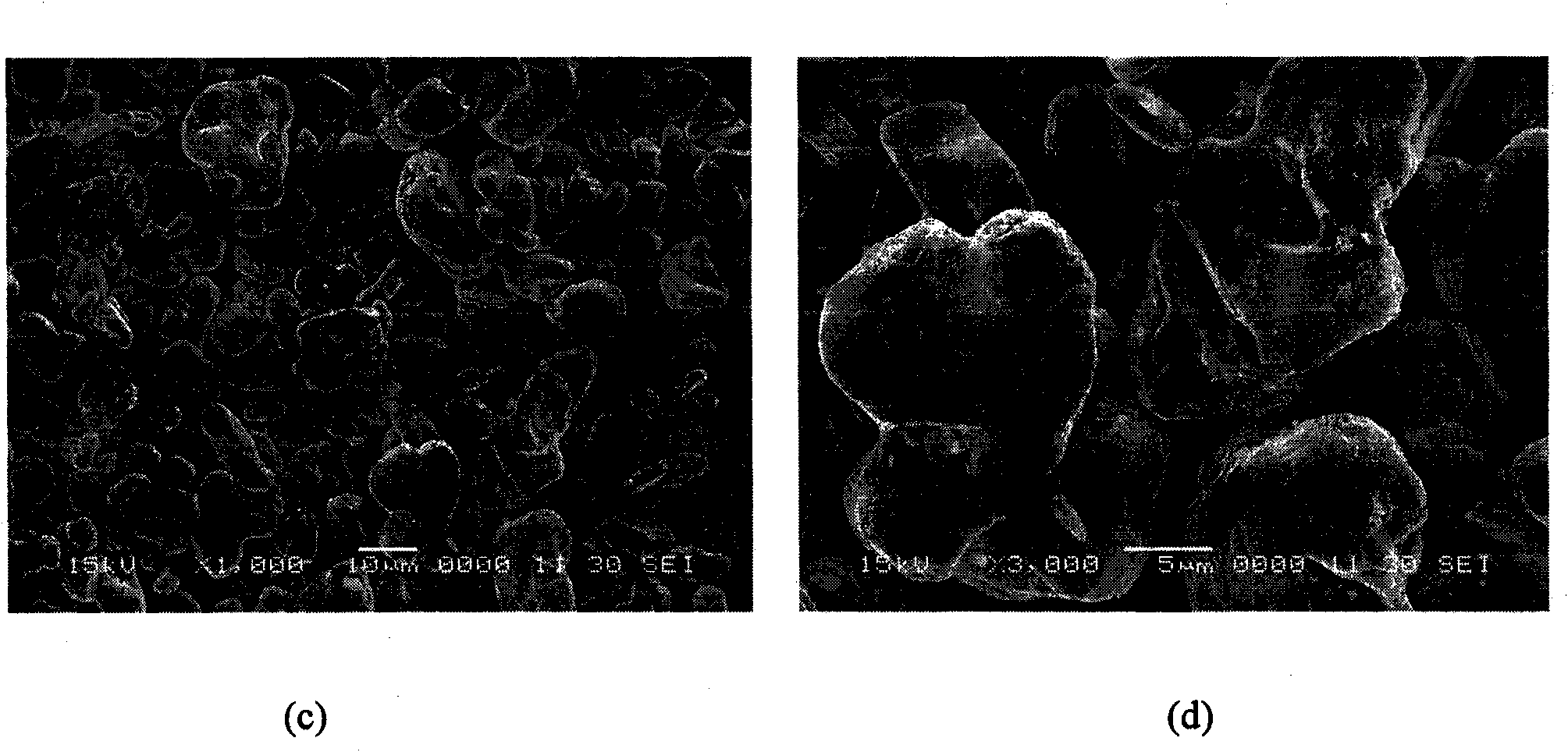

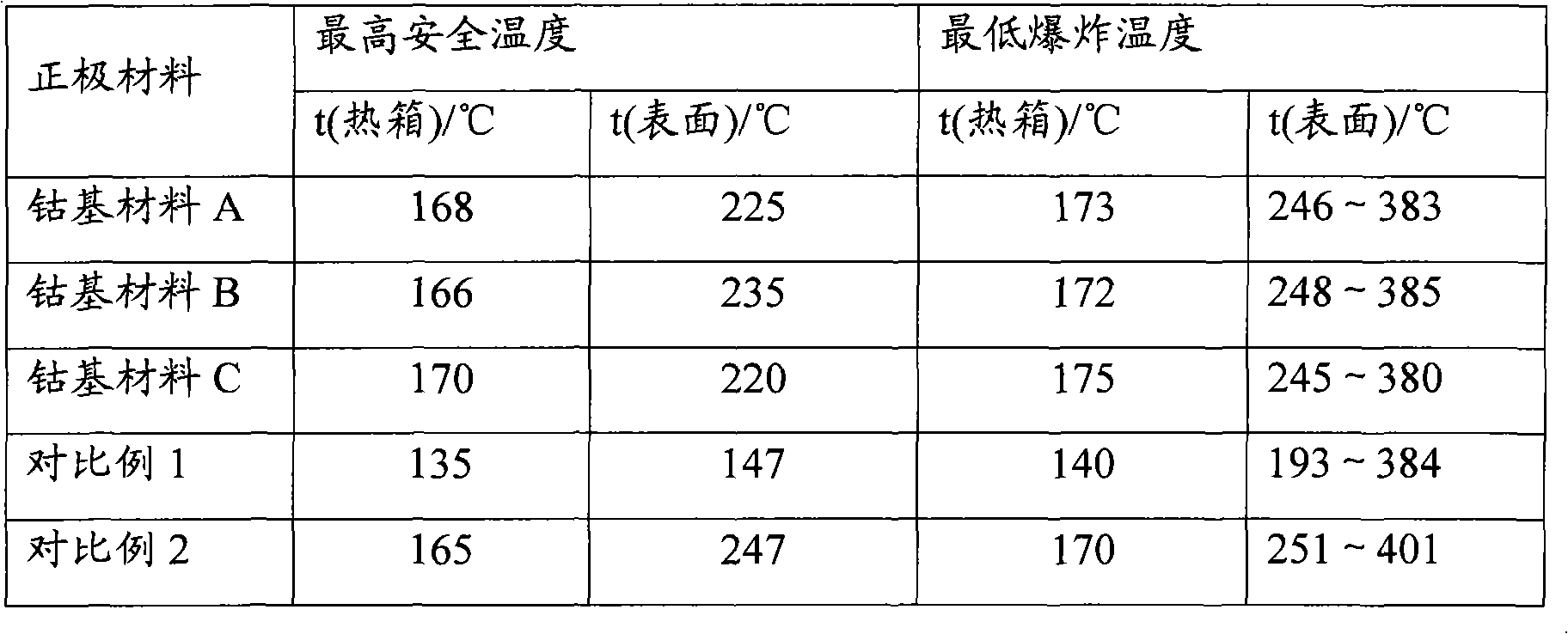

Preparation method of cobalt-based material

ActiveCN101944599AImprove discharge capacityGood high temperature performanceCell electrodesCobalt(II,III) oxideHeat stability

The invention discloses a preparation method of a cobalt-based material for the positive poles of lithium batteries, which comprises the following steps of: coating a nickel-cobalt-manganese hydroxide on the outer surface of spherical cobaltosic oxide and sintering to form the cobalt-based material of LiCo0.6Mn0.2Ni0.2O2. The cobalt-based material prepared by using the preparation method only not maintains the characteristics of lithium cobaltate materials of high volumetric specific energy and high discharge platform, but also has higher heat stability compared with lithium cobaltate, also reduces the cost of the lithium cobaltate materials and is the substitute of the next generation lithium cobaltate positive pole materials.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

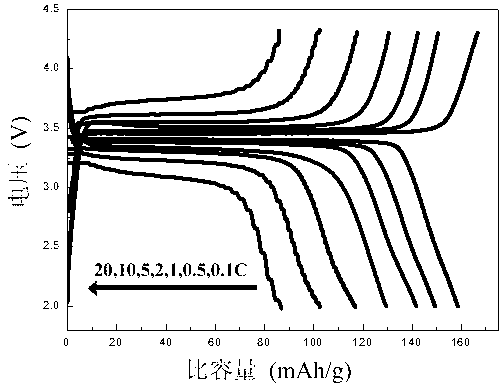

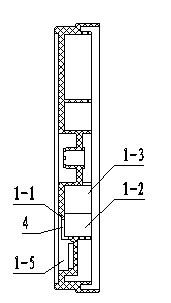

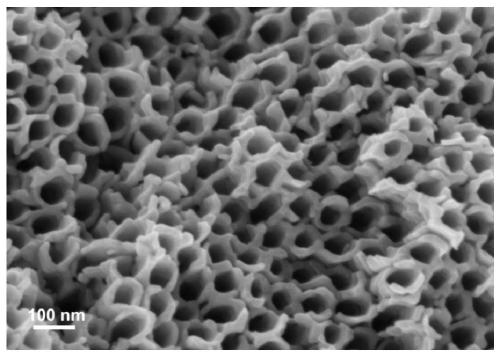

Porous lithium iron phosphate/carbon composite microspheres and preparation method thereof

InactiveCN103078114ALarge specific surface areaHigh tap densityCell electrodesPhosphorus compoundsCarbon compositesIron salts

The invention provides porous lithium iron phosphate / carbon composite microspheres and a preparation method thereof. The porous lithium iron phosphate / carbon composite microspheres and the preparation method thereof are characterized in that iron phosphate oxalate is used as a precursor and the preparation method comprises the following steps: (1) dispersing solution of iron salt and phosphate solution into a precipitating agent ethanol, adding lithium salt, carrying out ultrasonic stirring to enable the solution of iron salt, the phosphate solution and the lithium salt to be totally dissolved, and adding a certain quantity of oxalic ethanol solution into the obtained solution; (2) placing the obtained mixture into an oven to dry at a certain temperature so as to obtain a yellow jelly iron phosphate oxalate precursor; and (3) after mixing a carbon source and the iron phosphate oxalate precursor, calcining to obtain the porous lithium iron phosphate / carbon composite microspheres. The preparation method provided by the invention is low in cost and is simple and easy to operate; the pH does not need to be regulated; the products have high purity, high tap density and good repeatability; the products are spherical particles formed by self-assembling disk nano-scale particles, and thus, the specific surface area is large; and moreover, the diffusion path of lithium ions is greatly shortened, so that the porous lithium iron phosphate / carbon composite microspheres have excellent electrochemical property and are suitable for large-scale production.

Owner:QINGDAO UNIV OF SCI & TECH

Method for uniform carbon coating on lithium iron phosphate surface

InactiveCN105655548AStabilized carbon coating effectAvoid uneven coatingCell electrodesCarbon compositesPhosphoric acid

Belonging to the technical field of lithium ion battery anode materials, the invention relates to a method for uniform carbon coating on a lithium iron phosphate surface. The method includes the steps of: (1) preparation of an emulsion: preparing an organic carbon source and water into an aqueous solution, conducting heating to 50-100DEG C, adding an additive, and performing stirring to form an emulsion; (2) coating of the lithium iron phosphate surface with the organic carbon source: adding spherical iron phosphate into the emulsion, performing mixing for 0.5-8h to obtain a rheological body, and conducting drying to obtain iron phosphate powder; and (3) preparation of a lithium iron phosphate / carbon composite cathode material: mixing iron phosphate powder with a lithium source according to a Fe-Li mole ratio of 1:1-1:1.2, placing the mixture into an argon protective atmosphere sintering furnace, conducting heat preservation at 250-400DEG C for 2-6h, then raising the temperature to 550-700DEG C and performing heat preservation for 6-16h, and carrying out furnace cooling and sieving so as to obtain the lithium iron phosphate / carbon composite cathode material. The method provided by the invention has the advantages of stable process, simplicity and easy control, low cost, safety and environmental protection, high utilization ratio of the organic carbon source, high volumetric specific energy of the material, and easy industrialization, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

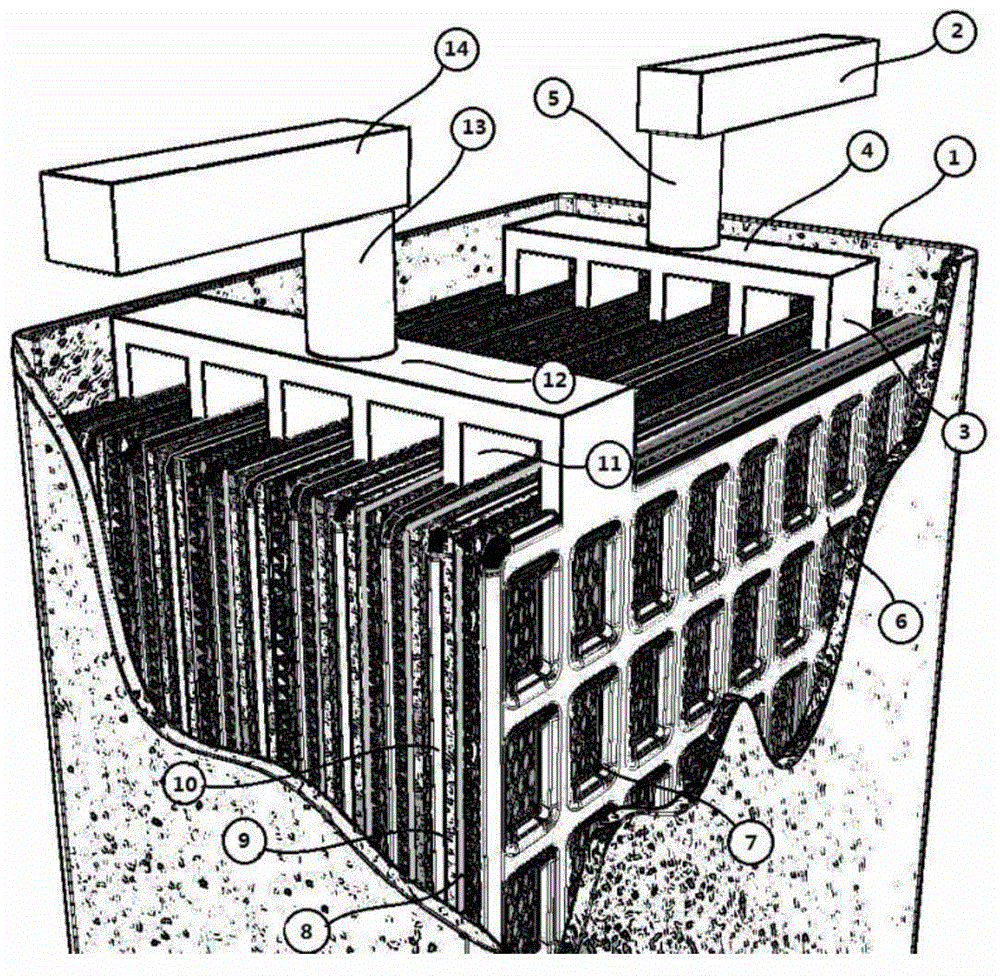

Cathode for whole vanadium oxide reduction flow battery and preparation method thereof

InactiveCN1694282AIncrease volume specific energyImprove voltage efficiencyElectrode manufacturing processesVanadium redox batteryMetal foil

This invention relates to an electrode used in V oxide liquid flow battery, which takes a metal foil / net as the collector deposited with Ir, Ta, Mg, Co, Ag, Ru, Mn and Fe on the surface. The electrode has high mechanical strength, high non-corrodibility against strong acid and keeps high electrochemical activation. When it has the same thickness with that of carbon conduction plastics, or even thinner, it has even better tensile strength and bending strength, suitable for increasing the volume ratio energy of the battery. Charge, discharge experiment in 2M V electrolyte is carried out taking this invented electrode as the positive, graphite electrode as the negative, N-115 Nafion as the membranes when the current density is set, the voltage efficiency is increased by 10% to that of carbon electrodes.

Owner:CENT SOUTH UNIV +1

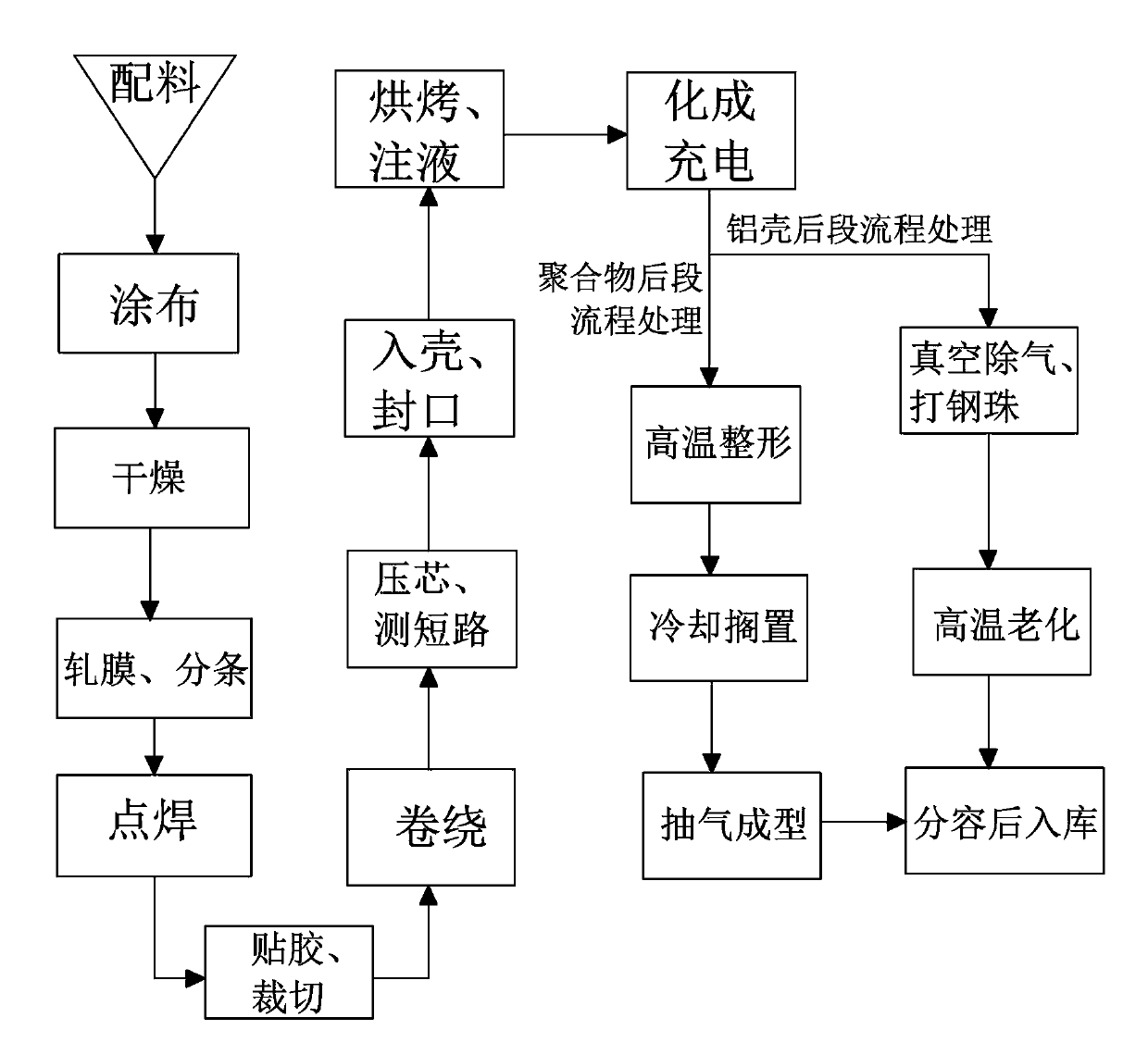

Method for manufacturing square power polymer lithium ion battery

InactiveCN104409781AReduce feverReduce design costFinal product manufactureWound/folded electrode electrodesHigh rateElectrical battery

The invention discloses a method for manufacturing a square power polymer lithium ion battery. The method comprises the steps of compounding, coating, continuous rolling of positive and negative electrodes, preparing electrode pieces of multiple lugs of the positive and negative electrodes, dividing a positive and negative electrode piece coil with the multiple lugs into two coils through a continuous dividing and cutting machine, accomplishing piece manufacturing process, coiling, performing super welding on a positive electrode aluminum lug and a negative electrode nickel lug, top side packaging, injecting electrolyte, forming, high-temperature ageing, secondary packaging and performing volume distributing. The method has the advantages that the internal resistance of the manufactured battery is low, the battery emits a small amount of heat during operation, can continuously discharge electricity at a high rate, thermal design is not required during the assembly of the discharge battery, the design cost of a power battery pack can be reduced, the volumetric specific energy of the power battery pack can be improved, and the safety performance of the power battery pack can be improved.

Owner:新余英泰能科技有限公司

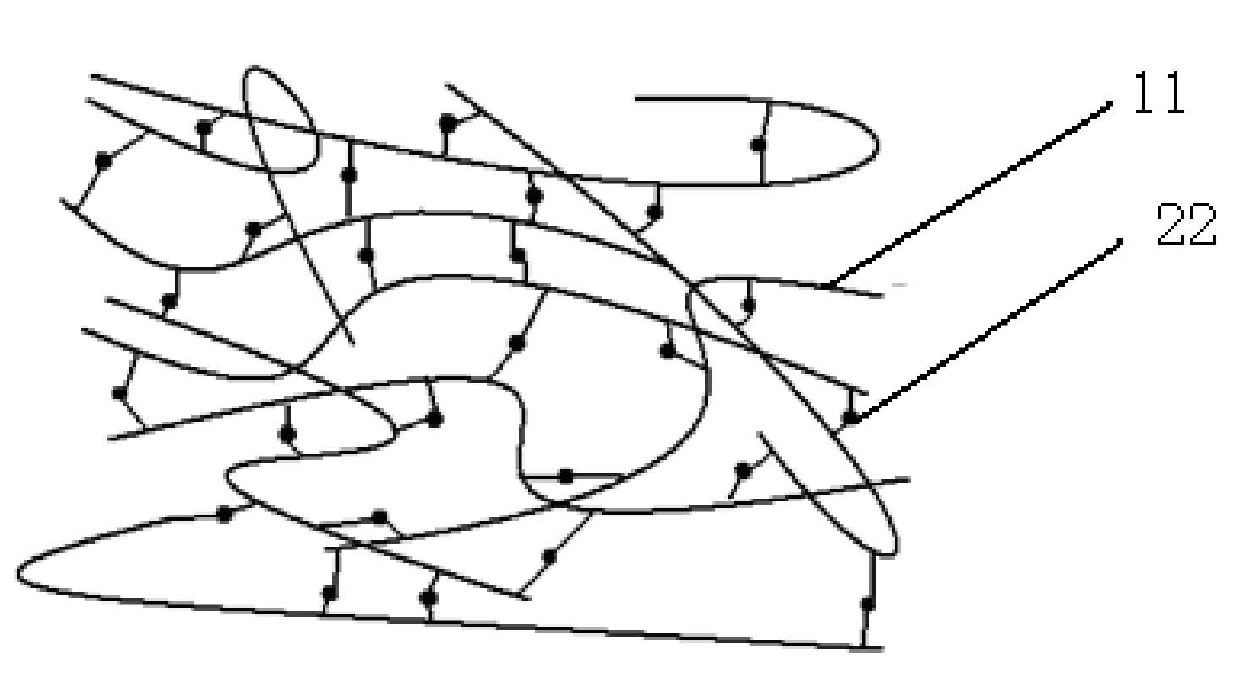

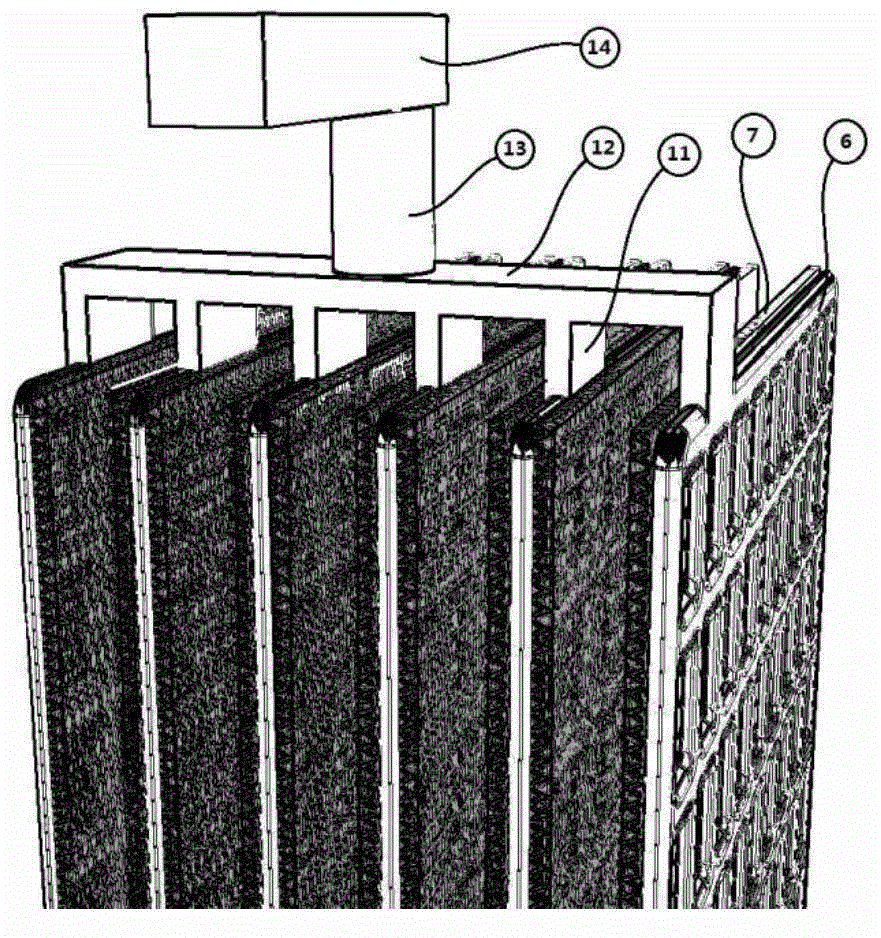

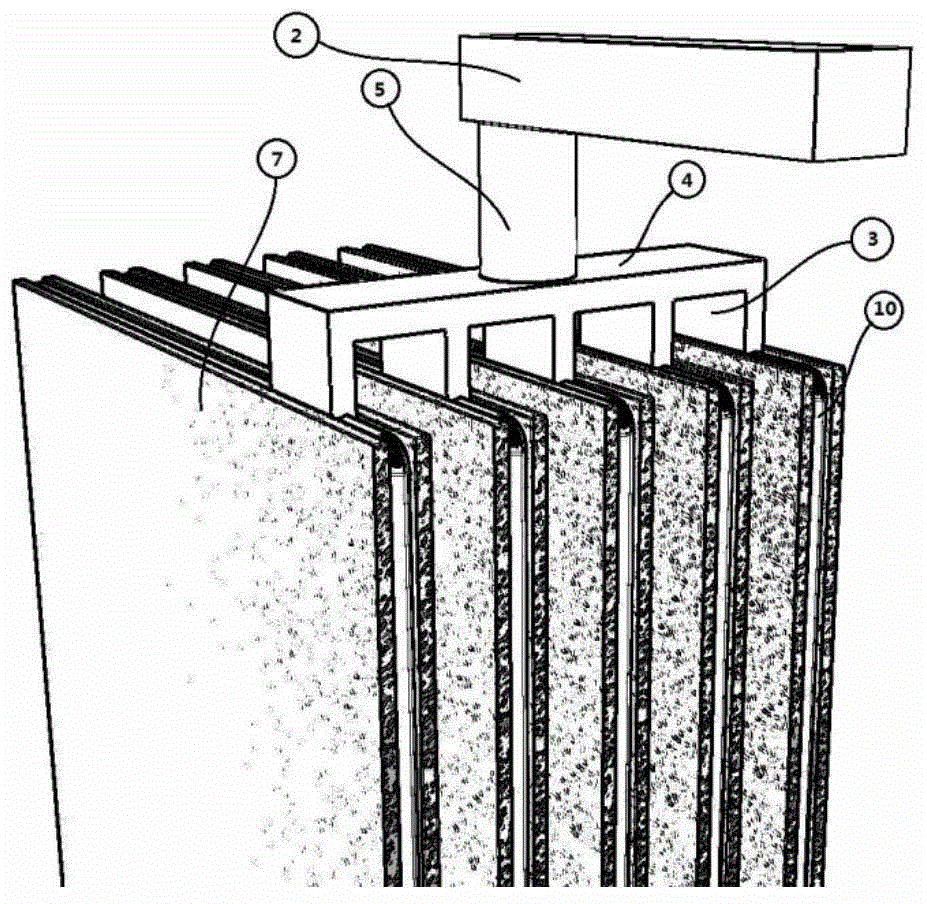

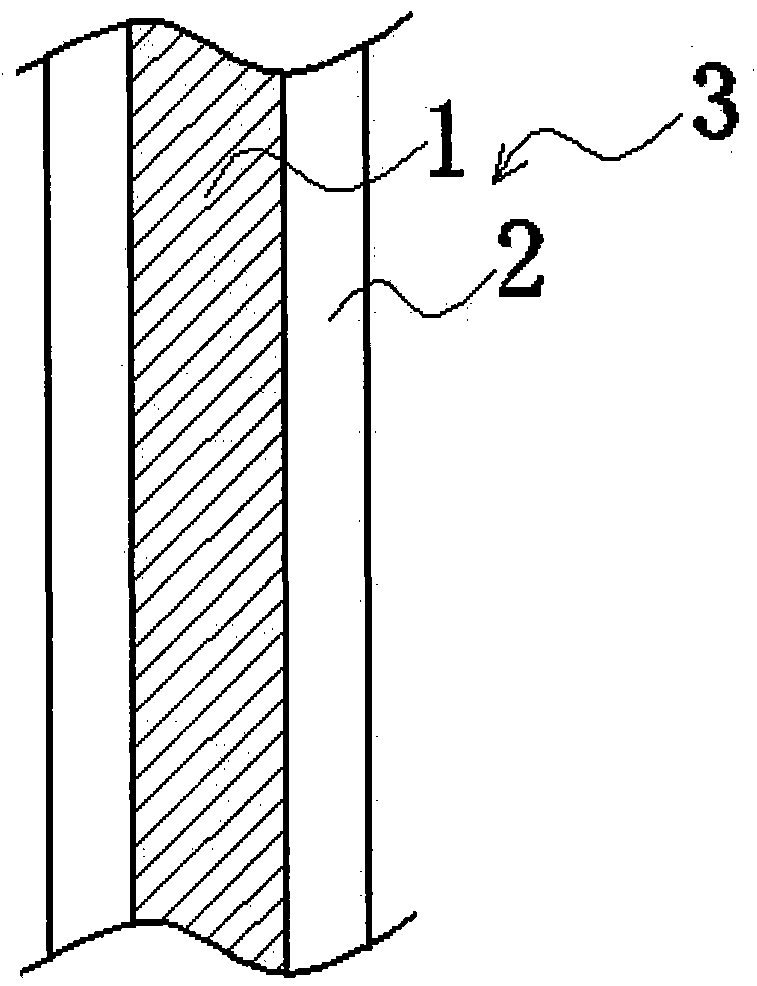

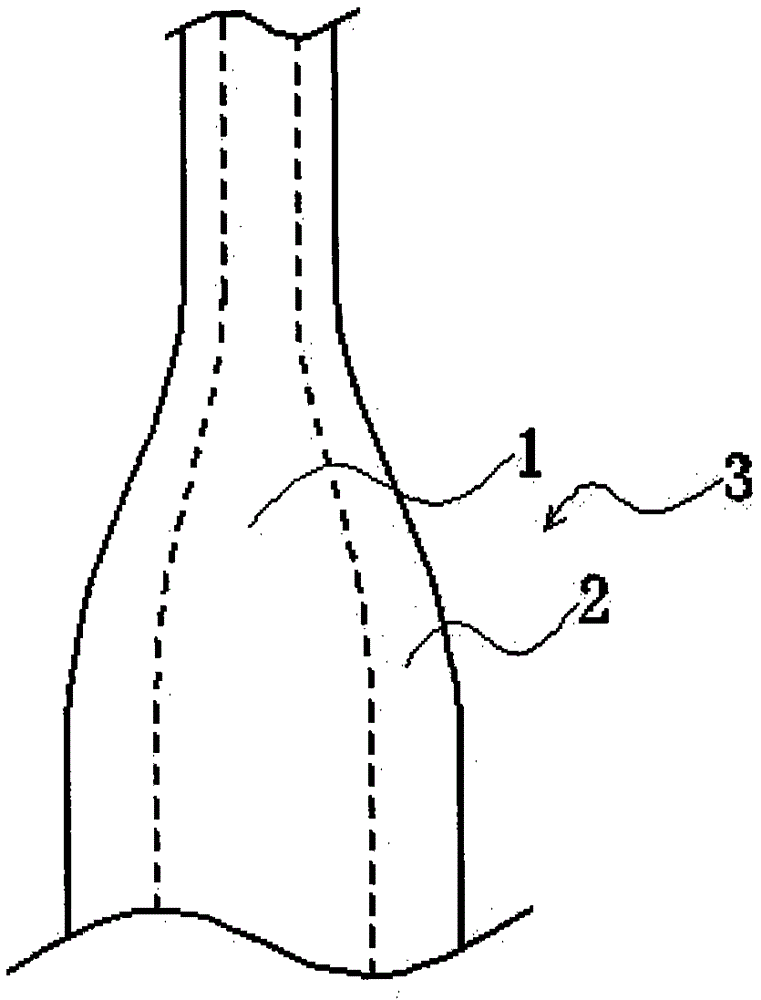

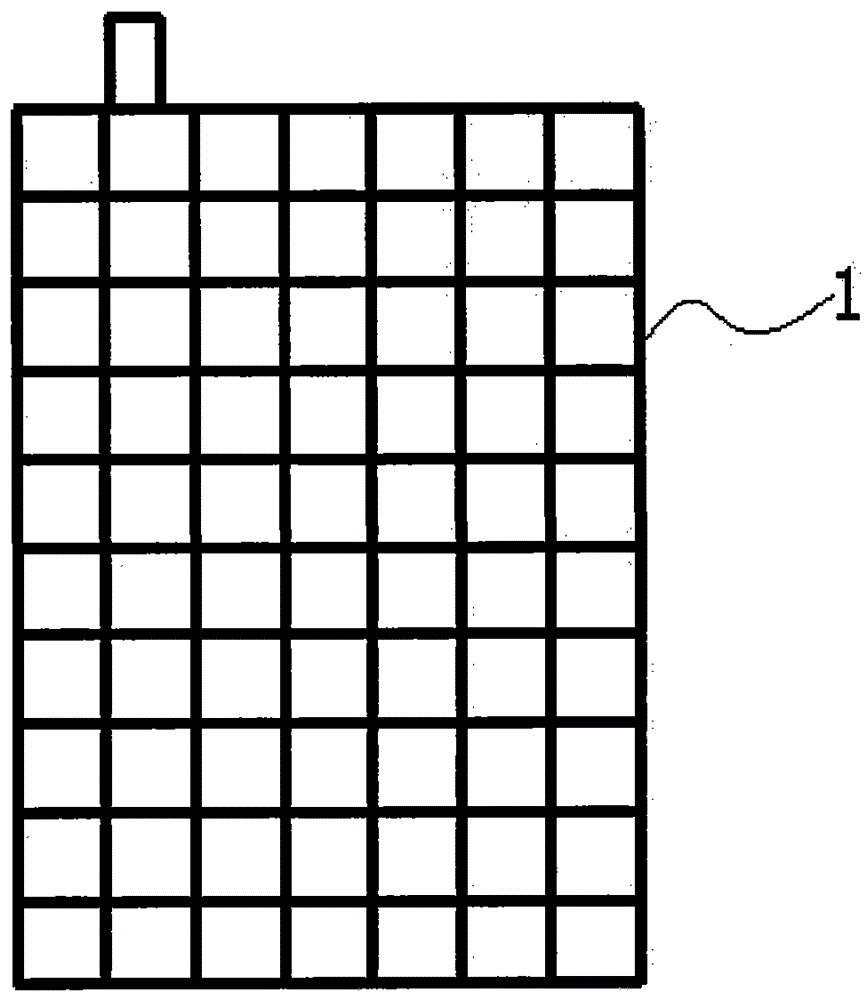

Three-dimensional netted graphite foam or netted glassy carbon bipolar plate of all-vanadium redox flow battery

InactiveCN103545539AIncrease volume specific energyIncrease the effective surface areaCell electrodesFuel cell detailsRedoxGraphite

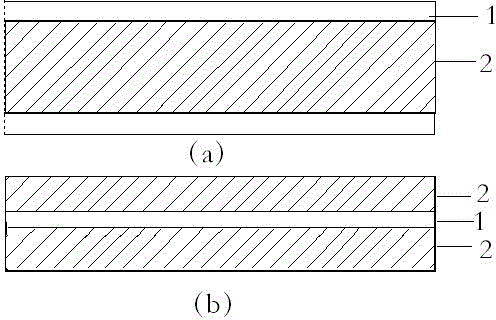

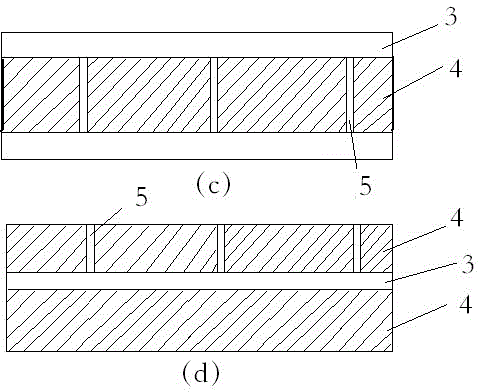

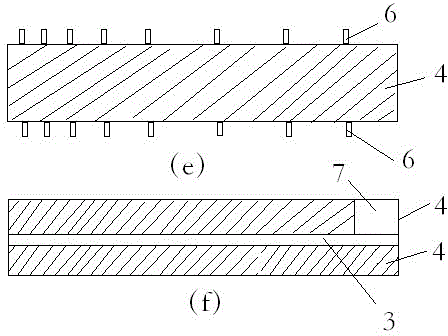

The invention discloses a three-dimensional netted graphite foam or netted glassy carbon bipolar plate of an all-vanadium redox flow battery, which can improve the active material utilization of battery electrodes by increasing the specific surface area. According to the technical scheme, the bipolar plate comprises three-dimensional netted graphite foam or netted glassy carbon (1), and is characterized in that the three-dimensional netted graphite foam or netted glassy carbon (1) is provided with holes communicated with each other, and the carbon content of the three-dimensional netted graphite foam or netted glassy carbon (1) is 10%-100%; one or more graphite current collectors (2) are arranged on one or two sides or in the middle of the three-dimensional netted graphite foam or netted glassy carbon (1), and the carbon content of the graphite current collector (2) is 10%-100%.

Owner:QINGDAO ADVANCED GRAPHITE MATERIALS CO LTD

Manufacturing method of high-capacity high-magnification high-safety lithium ion battery

InactiveCN103199262AUniform current densityIncrease capacityFinal product manufactureElectrode carriers/collectorsIonPolyvinylidene fluoride

The invention discloses a manufacturing method of a high-capacity high-magnification high-safety lithium ion battery. A positive pole material, a netty current collector, a negative pole material, a diaphragm and an electrolyte are adopted, and the positive pole material and the negative pole material are applied to the current collector to prepare a pole piece and prepare the battery. The preparation method of the current collector comprises the following steps of: (1) in an agitator kettle, dissolving PVDF (polyvinylidene fluoride) or PTFE (polytetrafluoroethylene) into NMP (N-methylpyrrolidone), or dissolving CMC into deionized water, then adding SBR (styrene butadiene rubber), stirring for 3-6hours, then adding a power mixture of one or more of silicon dioxide and aluminum oxide, with a concentration of 0.5-2%, and stirring so that powder is uniformly dispersed in the PVDF solution; and (2) applying a glue solution of the powder to the netty current collector by using a coater, and baking with an oven, so that the thickness of the powder on the current collector is 0.5-3mu m. The manufacturing method of the high-capacity high-magnification high-safety lithium ion battery has the beneficial effects of being simple in preparation, easy for production, and suitable for large-scale popularization and application.

Owner:SHANDONG REALFORCE ENTERPRISES

Manufacturing method of lithium ion battery high-compaction density pole plate

InactiveCN109473623AIncrease compaction densityLower internal resistanceElectrode rolling/calenderingSecondary cellsInternal resistanceSlurry

The invention discloses a manufacturing method of a lithium ion battery high-compaction density pole plate. The pole plate comprises a metal current collector and a conducting mixed slurry; the conductive mixed slurry is coated on the metal current collector at twice or multiple times, the pole plate is dried and rolled after the first coating, and the plate is dried and then rolled after the second coating, the coating, the drying, and the rolling are orderly performed until the conducting mixed slurry is completely coated. The thickness of the conducting mixed slurry wet coating layer through twice or multiple coating is thinner than that of once coating process, the drying load is educed, the drying time is shortened, the single rolling load is reduced, the roll coating is hard to occurunder high rolling pressure, the coating uniformity and precision are improved, the compaction density of the pole plate is increased, so that the volumetric specific energy is increased, the internal resistance of the pole plate is reduced, the polarization is reduced, the discharge capacity is increased, the battery energy density is increased, the cost is reduced, the flexibility of the pole plate is guaranteed, and the phenomena that the surface is curly uneven and even the plate is broken or crisp are avoided.

Owner:HUIZHOU WES NEW ENERGY LIMITED

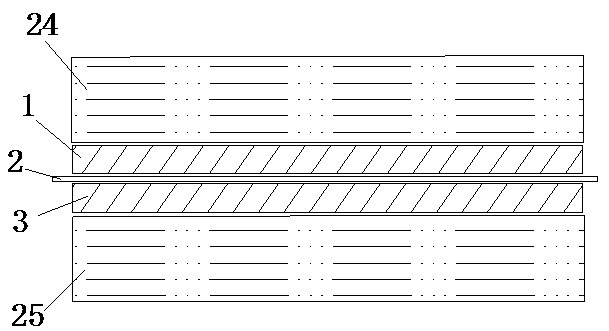

Bipolar-plate type unit high-energy lead-acid battery, high-voltage battery pack formed from same and package method of high-voltage battery pack

ActiveCN106207193AImprove resource utilizationSimple processFinal product manufactureElectrode carriers/collectorsElectrical conductorHigh energy

The invention relates to a lead-acid storage battery, in particular to a bipolar-plate type unit high-energy lead-acid battery, a high-voltage battery pack formed from the same and a package method of the high-voltage battery pack. The unit high-energy lead-acid battery comprises an electronic conductor bipolar plate, wherein a positive active material layer and a negative active material layer are respectively coated on two surfaces of the electronic conductor bipolar plate and are the same active material prepared by taking lead sulfate as main, and a batter partition plate is laid on the active material layer on one surface. After the unit battery disclosed by the invention is adopted to package batteries stacked in series, the battery with high voltage, low internal resistance and long cycle lifetime is easy to achieve, meanwhile, the production process of the battery is simplified, and the production cost is reduced.

Owner:曾碚凯

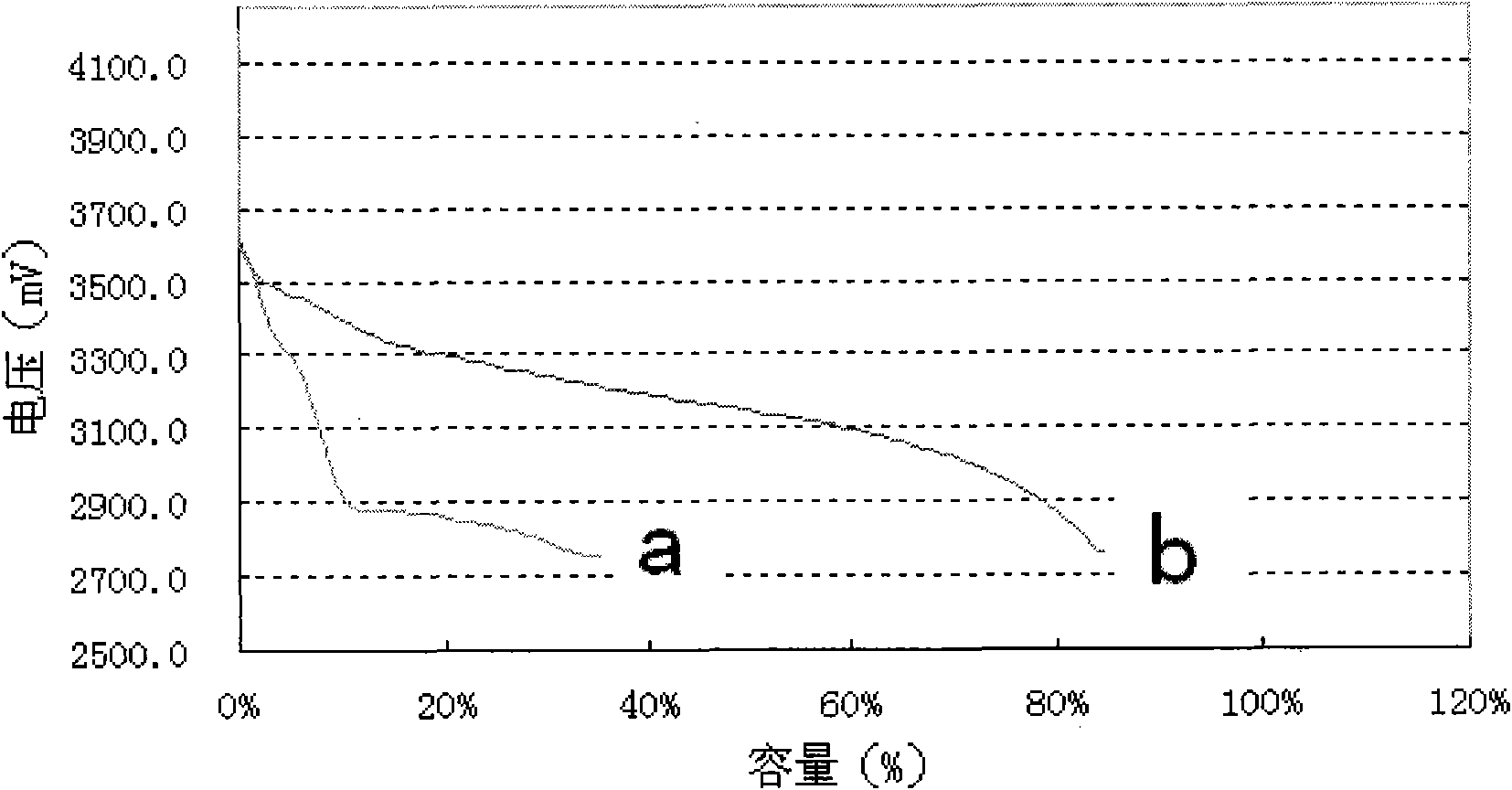

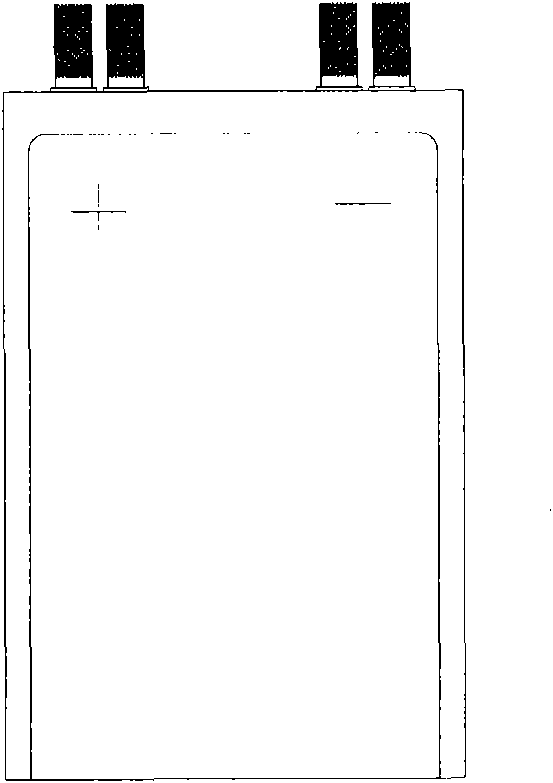

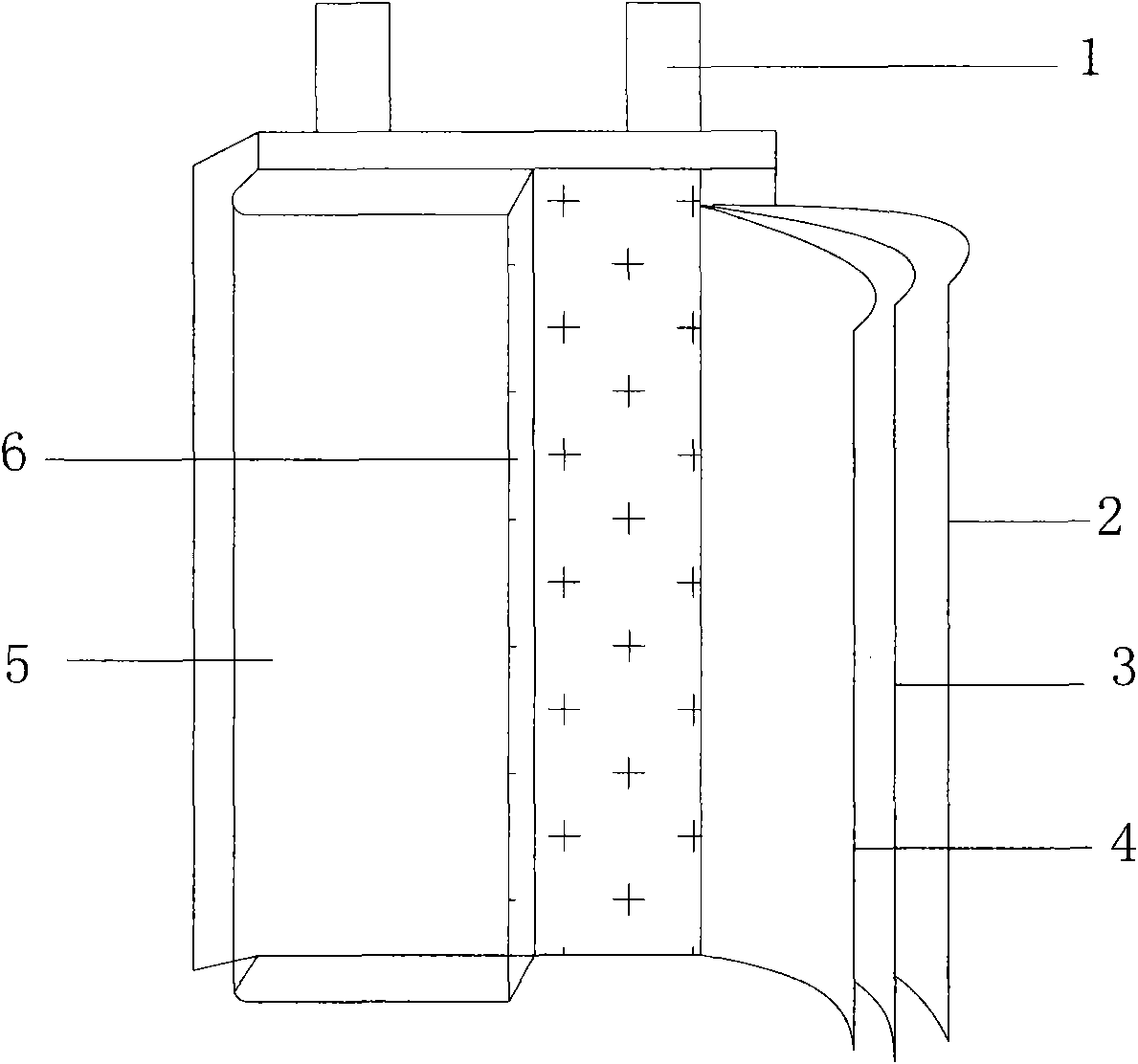

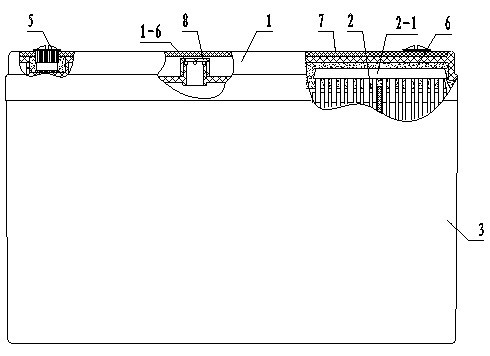

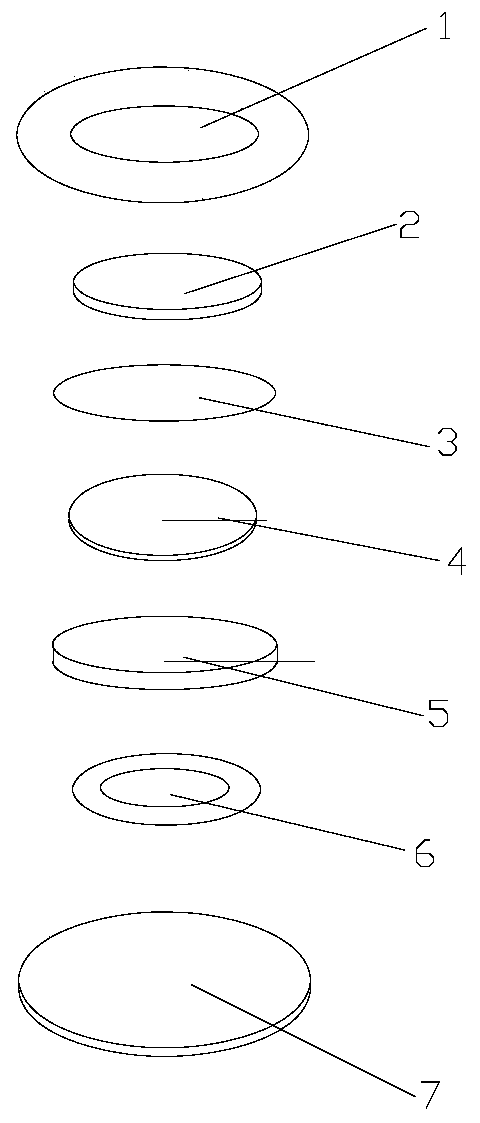

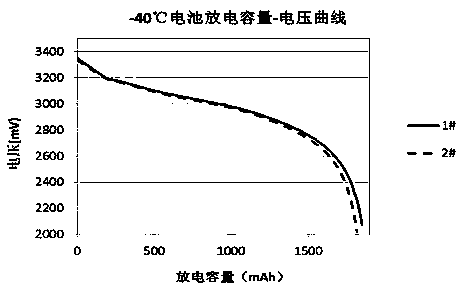

Lithium ion power low temperature cell

ActiveCN101615698AProduct performance is stableIncrease volume specific energyFinal product manufactureSecondary cellsPhysicsHigh energy

A lithium ion power low temperature cell comprises a tab (1), an anode plate (2), a cathode plate (4), a diaphragm (3), electrolyte (6) and an aluminum plastic die (5), and the invention adopts special proportioning and structure in the anode plate, the cathode plate and the electrolyte. The lithium ion power low temperature cell of the invention overcomes the defects that conventional products only can discharge under the environment of minus 20 DEG C to 60 DEG C, and has short discharging time or incapability of discharging under the condition of below minus 20 DEG C; the invention features stable performance, high energy of volume ratio, good safety and can satisfy high power discharging; the low temperature environment can satisfy normal work under the condition of minus 40 DEG C, and can discharge more than or equal to 70% of initial volume.

Owner:湖北中聚能源有限公司

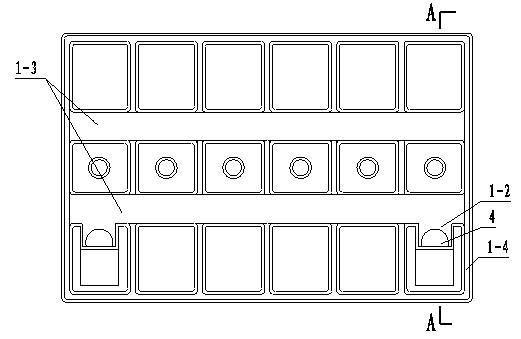

High volumetric specific energy valve-controlled sealed storage battery and preparing method thereof

ActiveCN102610780AIncrease volume specific energyMaximize capacityFinal product manufactureSecondary cells manufactureElectrical batteryEngineering

A volumetric specific energy valve-controlled sealed storage battery and a preparing method of the storage battery are disclosed to solve the problems in limited capacity and low volumetric specific energy of the storage battery. The storage battery comprises a storage battery groove, a storage battery cover, a big sealing cover, pole groups and a terminal, wherein the storage battery groove is provided with six single battery grooves side by side; the pole group is arranged in each of the single battery groups; the storage battery is characterized in that: the upper parts of the pole groups are higher than the single battery grooves; the pole groups in two adjacent single battery grooves are connected in series through a bus bar; terminal bus bars are arranged on the upper parts of the pole groups located in the single battery grooves at the two ends; and the terminal bus bars are provided with a terminal welding platform. The invention further provides a preparing method of the storage battery. In the preparing method of the invention, under the condition of an effective space, the height of a grid is maximized by cancelling a traditional structure that a middle pole is in bridged connection with a single battery, so that capacity maximization of the valve-controlled sealed battery within an effective volume is realized, and the volumetric specific energy of the storage battery is increased.

Owner:FENGFAN

Manufacturing method of lithium iron phosphate anode

ActiveCN102610797AIncrease volume specific energyImprove performanceCell electrodesCarboxymethyl celluloseEmulsion

The invention relates to a manufacturing method of a lithium iron phosphate anode. The manufacturing method comprises the following steps: adding a polytetrafluoroethylene emulsion to an aqueous carboxymethyl cellulose solution, stirring, adding lithium iron phosphate and a conductive agent, stirring, adding water to form a slurry, shaping by coating the slurry, drying, and sintering in an inert atmosphere, and compacting by a roller press. By using the manufacturing method provided in the invention and utilizing an aqueous solution system to manufacture the anode of a cell, the pollution of NMP (N-methyl pyrrolidone) to the environment and harms of the NMP to human bodies are avoided, and the volumetric specific energy of the cell is increased.

Owner:山西鼎能启源新能源科技有限公司

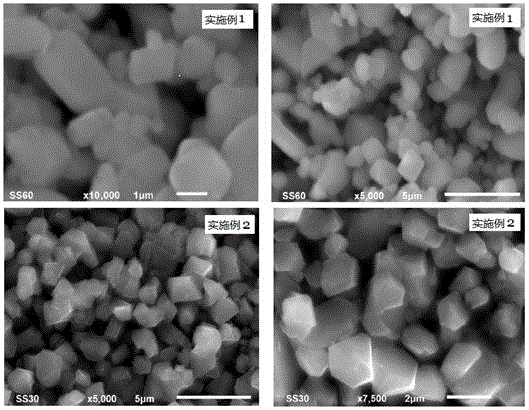

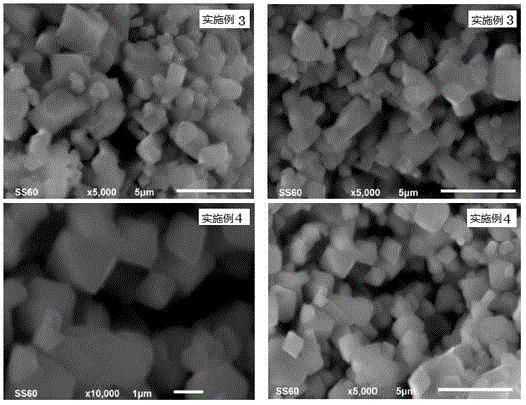

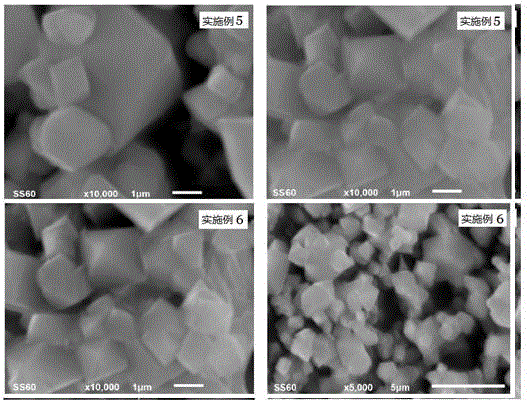

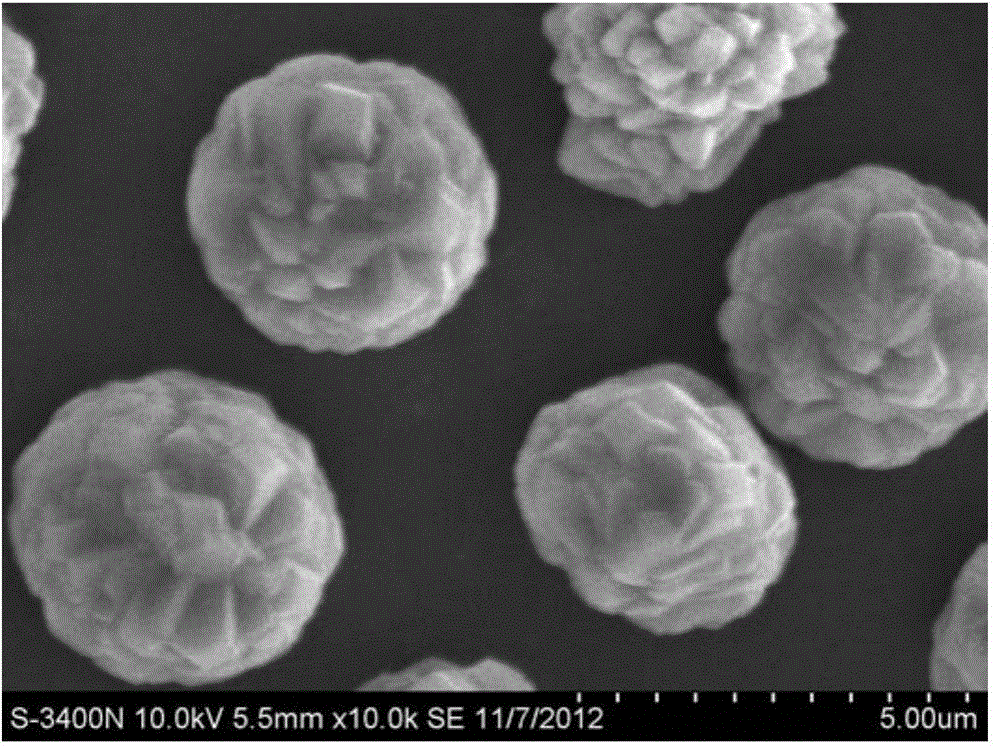

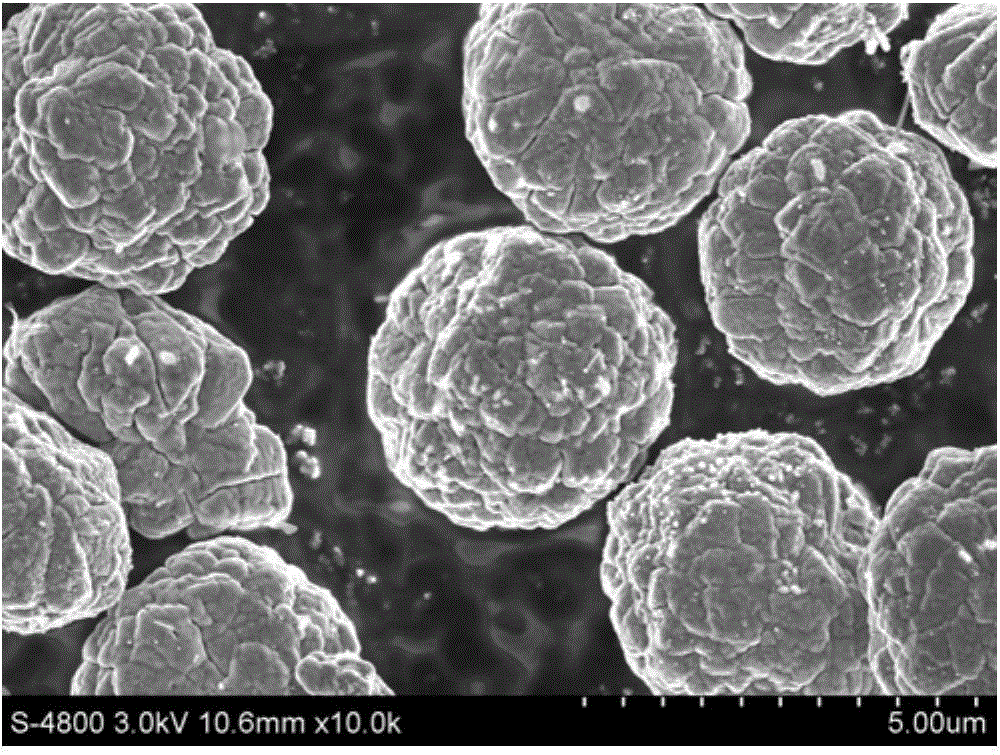

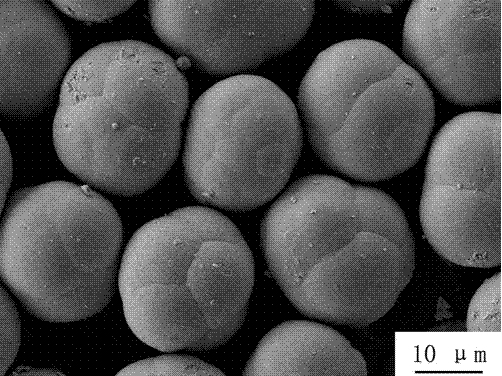

Preparation method of lithium ion batteries cathode material solid solution with core-shell structure

InactiveCN104716315AHigh tap densityIncrease volume specific energyCell electrodesNickel saltCoprecipitation

The invention relates to a preparation method of a lithium ion batteries cathode material solid solution with a core-shell structure. The solid solution is prepared by a two-step coprecipitation method, a molecular formula of the core-shell structure is Li1+y[(Mn1 / 3Ni1 / 3Co1 / 3)x(Ni1 / 4Mn3 / 4)1-x]1-yO2. The method comprises the following steps: spherical [Mn1 / 3Ni1 / 3Co1 / 3]CO3 is synthesized in a stirring reactor through the coprecipitation method, then nickel salt and manganese salt are placed in a reactor according to mol ratio of 1: 3, then a [Mn1 / 3Ni1 / 3Co1 / 3]CO3 precursor with the core-shell structure is obtained through a secondary coprecipitation method, and the precursor and the lithium salt are mixed for calcination to obtain the lithium ion batteries cathode material solid solution with the core-shell structure. The obtained product has excellent electrochemistry property, the preparation method is simple, and is suitable for large scale industrial production.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

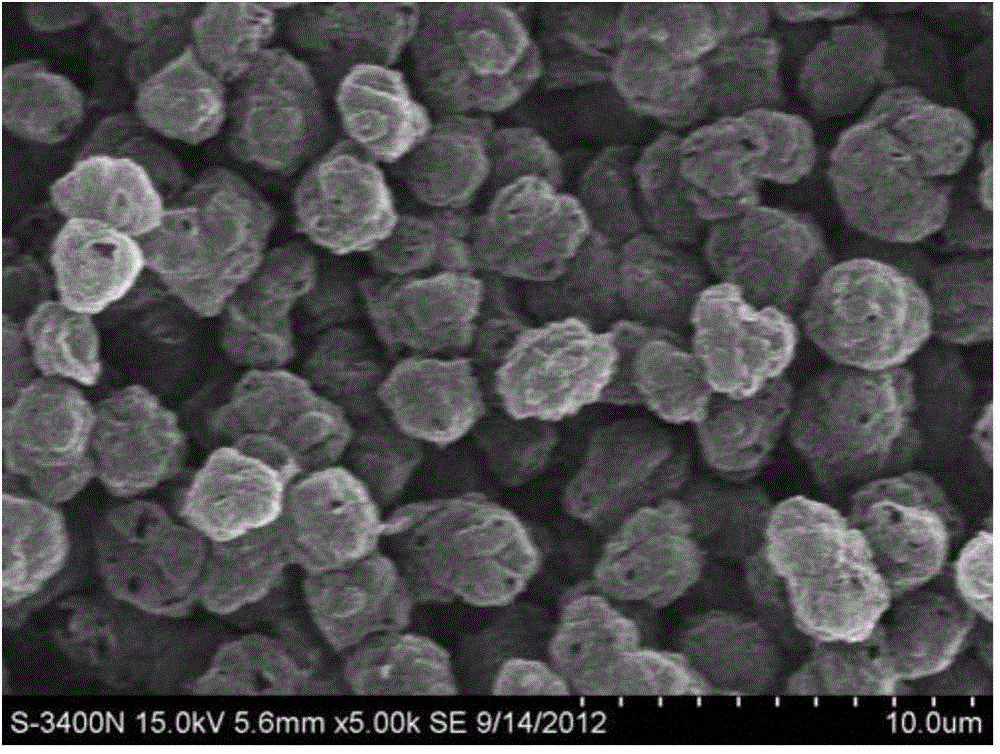

Method for synthesizing high-density lithium iron phosphate material

InactiveCN102205954AHigh bulk densityIncrease volume specific energyCell electrodesPhosphorus compoundsCarbon layerCooking & baking

The invention relates to a method for synthesizing a high-density lithium iron phosphate material, belonging to the technical field of cathode materials of lithium ion batteries. The method for synthesizing the high-density lithium iron phosphate material comprises the following technical steps of: 1, synthesizing pure-phase lithium iron phosphate: firstly, drying and dehydrating iron phosphate for 1-10 hours at the temperature of 200-700 DEG C, and uniformly mixing the dehydrated iron phosphate with metal lithium powder in the atmosphere of dry air or inert gas; and applying the pressure of 0.1-10MPa to the surface of an iron phosphate and lithium powder mixed material, and heating for 1-5 hours at the temperature of 300-400 DEG C in an air isolation way; 2, cladding a thin carbon layer: crushing lithium iron phosphate, and then immersing into a polyvinyl butyral / ethanol solution, wherein the concentration of the polyvinyl butyral is 1-20%, and the weight ratio of the lithium iron phosphate to the solution is 1:(1-10); and 3, baking and calcining: baking at the temperature of 100-120 DEG C, and calcining for 1-10 hours at the temperature of 500-600 DEG C. The method provided by the invention has the advantages of simple process and convenience for operation, and the high-density lithium iron phosphate material has the advantages of stable quality, high material packing density, low carbon content, high gram capacity, high energy density per unit volume and the like.

Owner:天津恒普科技发展有限公司

Housing of cylindrical lithium ion battery pack

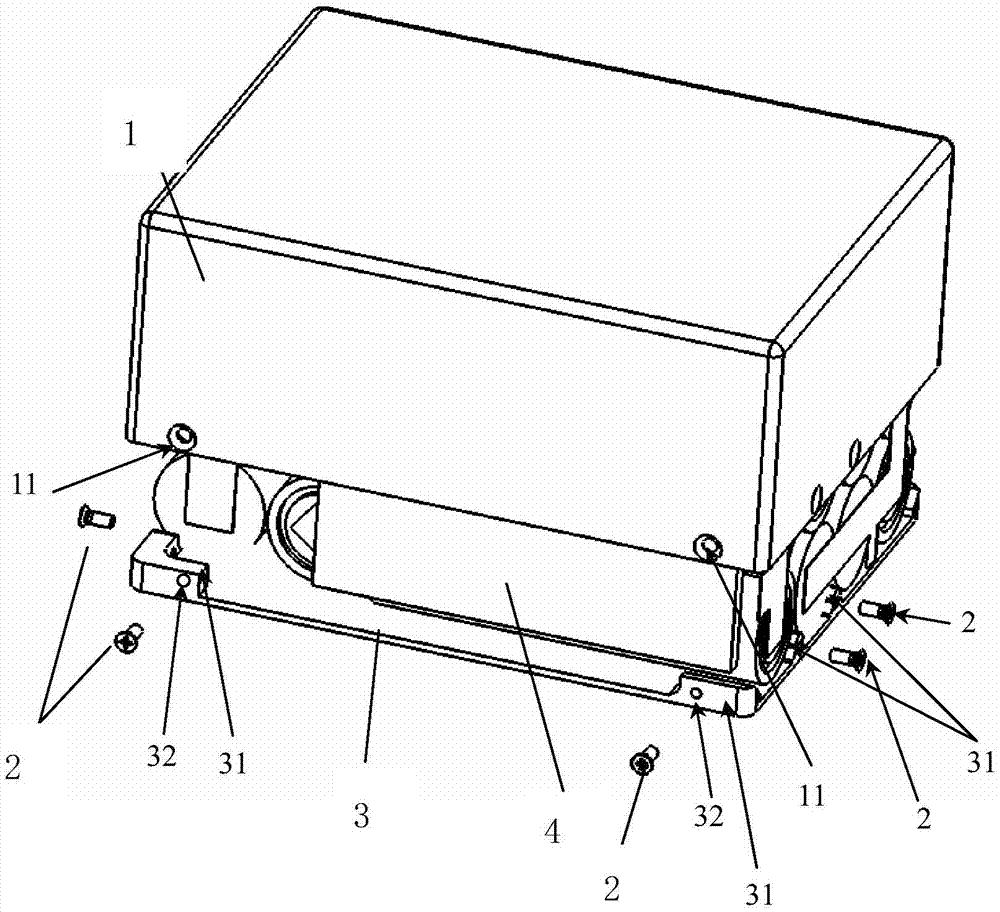

InactiveCN105449138AGuarantee security protectionSave volume and spaceCell component detailsElectrical batteryEngineering

The invention discloses a housing of a cylindrical lithium ion battery pack. The housing comprises a lower cover (3), wherein the cylindrical lithium ion battery pack (4) is arranged at the top of the lower cover (3) and covered by a hollow upper housing (1); the bottom of the upper housing (1) is open; the upper housing (1) and the lower cover (3) are fastened; a plurality of connecting bumps (31) are arranged at intervals on the peripheral edge of the top of the lower cover (3); a threaded hole (32) is formed in the outer side surface of each connecting bump (31); a plurality of screw through holes (11) are formed in the positions, corresponding to the threaded holes (32), of the upper housing (1); a countersunk screw (2) is arranged in each screw through hole (11) in a penetration manner; and the countersunk screws (2) are in threaded connection with the threaded holes (32). According to the housing, a gap formed when cylindrical batteries are combined can be fully utilized, the volume of the assembly structure of the screws is reduced, and the volume space of the battery pack is saved.

Owner:天津蓝天特种电源科技股份公司

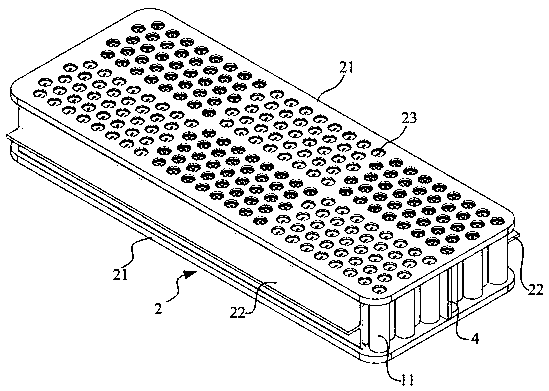

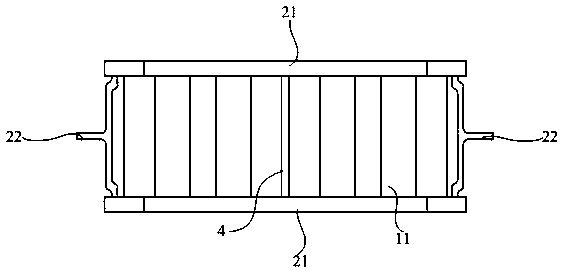

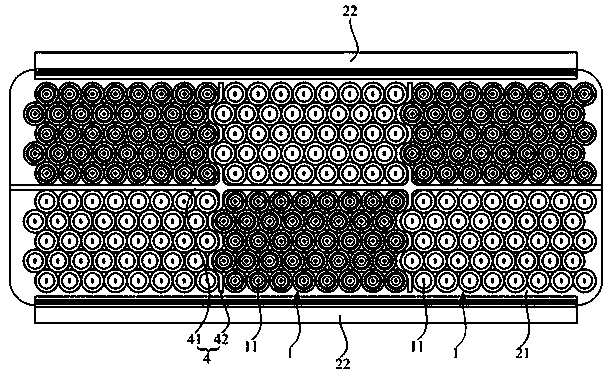

Novel power battery module and assembly process thereof

InactiveCN108923099AReduce space occupancyIncrease volume specific energyFinal product manufactureCylindrical casing cells/batteryPower batteryHeat conducting

The invention discloses a novel power battery module and an assembly process thereof. The novel power battery module comprises a module and a fixing bracket. The module comprises a plurality of battery core strings, and the battery core strings comprise a plurality of battery cores in interveined arrangement. The outer walls of adjacent battery cores of the core strings are connected to each other; the fixing bracket comprises insulating heat conducting plates at both ends of the module and fixing lugs on both sides of the width direction of the module, and the fixing lugs are respectively connected with the two insulating heat conducting plates. The sidewalls between two adjacent battery cores of the same battery core string are connected to increase the volumetric specific energy of themodule; heat at battery core lugs are transferred to the insulating heat conducting plates, the heat is taken away by an air cooling form, the temperature difference problem between the battery coresdue to the thermal aggregation effect between the battery cores can be reduced, and the consistency of the temperature of the battery cores can be improved. Compared with the prior art, the novel power battery module can improve volume specific energy and can solve the problem of the heat accumulation effect between the battery cores.

Owner:SUN YAT SEN UNIV +1

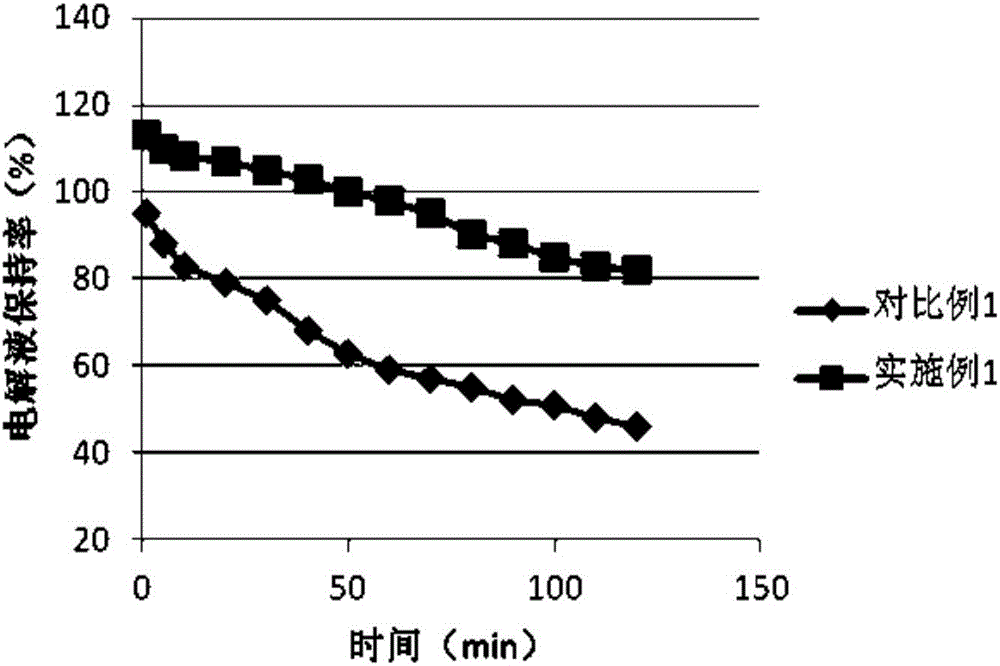

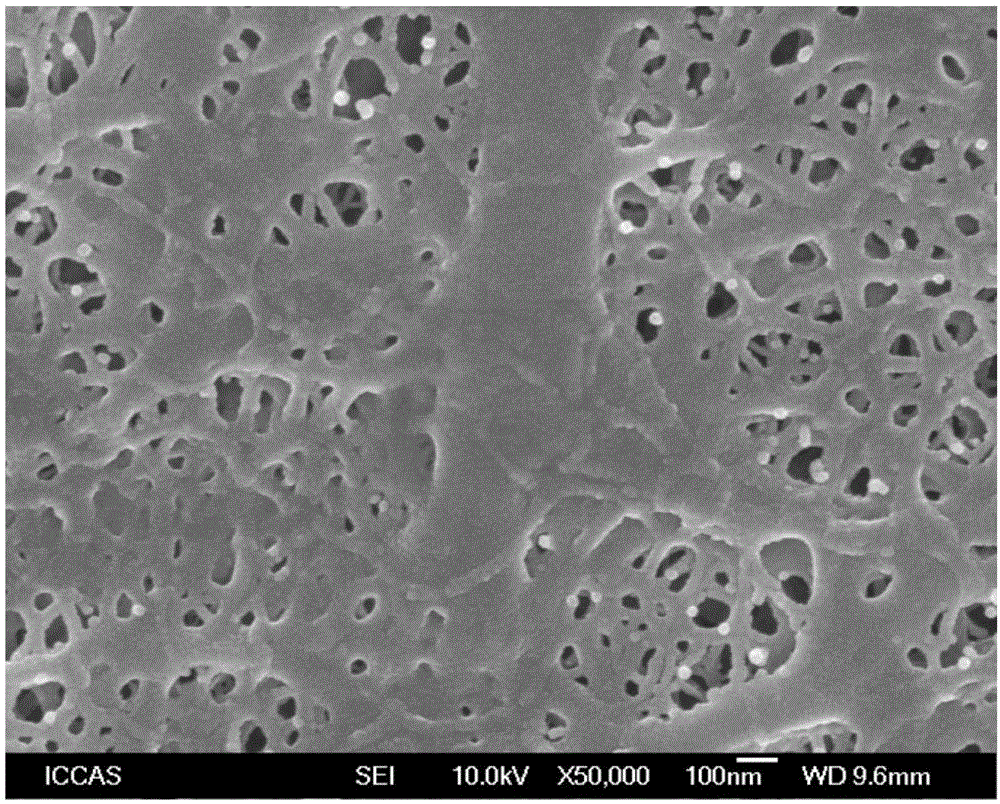

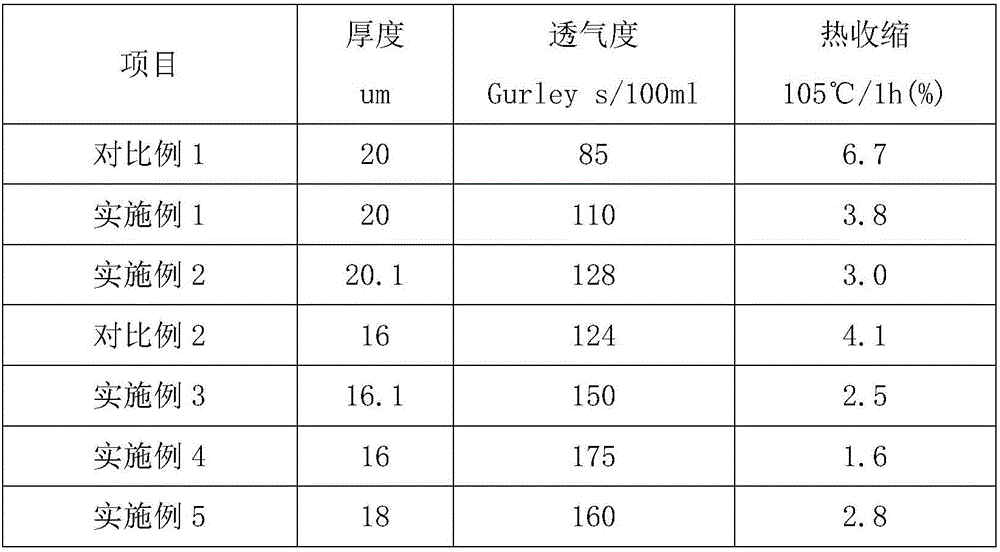

Preparation method of lithium battery membrane

InactiveCN106299199AImprove wettabilityIncreasing the thicknessCell component detailsElectrolytic agentPhysical chemistry

The invention provides a preparation method of a lithium battery membrane. The preparation method includes: adding a precursor compound, a structure directing agent and hydrochloric acid into a first mixed solution, stirring, and allowing alcoholysis reaction to obtain sol; coating the sol on the surface of a porous membrane, washing, and using hot air to dry to obtain the lithium battery membrane. The porous membrane is used as a base membrane, tetraethoxysilane, tetramethyl orthosilicate, silicon tetrachloride, titanium tetrachloride and tetrabutyl titanate are used as precursors, segmented copolymer is used as the structure directing agent, and an inorganic compound resistant to high temperature is coated among pores of the porous membrane, so that heat resistance of the membrane is improved effectively. Wettability of the membrane coated among the pores to electrolyte is improved obviously, and liquid absorbing and retaining performance is improved greatly; increase in thickness and weight of the lithium battery membrane prepared by utilizing an inter-porous coating method is small, and increasing of volumetric specific energy of batteries is facilitated. Experiment results show that the lithium battery membrane has high heat resistance and wettability to the electrolyte and is small in thickness.

Owner:SHENZHEN SENIOR TECH MATERIAL

Positive electrode material of metal-air battery, and preparation method thereof

ActiveCN111370706AImprove efficiencyImprove cycle lifeMaterial nanotechnologyFuel and secondary cellsElectrical batteryPhoto catalysis

The invention relates to the field of metal-air batteries, particularly to a positive electrode material of a metal-air battery, a preparation method of the positive electrode material, the metal-airbattery and a preparation method of the metal-air battery. The positive electrode material of the metal-air battery comprises a metal mesh structure substrate, a photocatalytic active material layer covering the surface of the metal mesh structure substrate, and cocatalyst nanoparticles loaded on the photocatalytic active material layer. The metal-air battery and the positive electrode material thereof provided by the invention have the advantages of good stability, high battery efficiency, low charging overpotential, low battery cost, high volumetric specific energy and the like under the conditions of the same capacity and energy density, and are easy to realize combination of solar energy and an energy storage system.

Owner:金华高等研究院

Preparation process of lithium ion low-temperature battery

InactiveCN108832181AImprove performanceIncrease volume specific energyCell electrodesFinal product manufactureCarbon nanotubeMethyl acetate

The invention discloses a preparation process of a lithium ion low-temperature battery. (1) A positive plate comprises a lithium cobalt oxide active substance, a binder PVDF, a conductive agent SP anda carbon nano tube; (2) a negative electrode slice comprises negative active material graphite, a thickening agent CMC or HPMC, an adhesive SBR, a conductive agent SP and a carbon nano tube, (3) a positive electrode and a negative electrode are wound to form a roll core, then a battery is manufactured through assembling, (4) an added electrolyte is a low-temperature electrolyte, wherein the fluxadopted by the electrolyte is PC (propylene carbonate) ), EC (ethylene carbonate), DMC (dimethyl carbonate) and MA (methyl acetate) ), wherein the electrolyte adopts LiPF<6>, wherein the concentrationof the electrolyte is 1.0-1.2M / L. The preparation process has the following advantages that the material variety and proportion of the battery are changed, so that the performance of the battery is stable, the volume ratio is high, and the work is stable under a low-temperature condition.

Owner:河南新太行电源股份有限公司

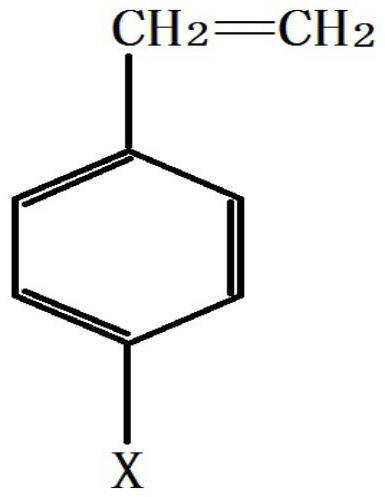

Negative electrode binder for lithium-ion battery, preparation method of negative electrode binder and lithium-ion battery containing negative electrode binder

PendingCN112151802AIncrease polarityImprove adhesionCell electrodesSecondary cellsButadiene DioxideElectrical battery

The invention discloses a negative electrode binder for a lithium-ion battery, the negative electrode binder comprises the following components in parts by weight: 100 parts of halogenated styrene, 80-110 parts of 1,3-butadiene, 170-220 parts of deionized water, 0.4-1.5 parts of an emulsifier 1, 0.4-1.5 parts of an emulsifier 2, 0.8-3 parts of an initiator 1, 20-30 parts of a seed emulsion, 1-9 parts of a carboxylic acid monomer 1, 0.5-2 parts of a molecular weight regulator 1 and 0.1-2.7 parts of an alkaline substance. Compared with the prior art, a halogenated styrene-butadiene rubber emulsion binder for the negative electrode of the lithium-ion battery is prepared by polymerizing the halogenated styrene and the 1,3-butadiene to form a main body and matching the main body with other components, the polarity of a high polymer is improved and the cohesiveness is enhanced due to the existence of halogen atoms on a benzene ring; and thus, the binder has favorable mechanical properties and electrochemical stability.

Owner:宜昌虎柏新能源有限公司

Lithium ion secondary battery negative pole and its preparing method and lithium secondary battery including said negative pole

InactiveCN1750296AHigh tap densityHigh specific capacityElectrode manufacturing processesActive material electrodesBlack phosphorusGraphite

This invention discloses the negative of a Li ionic secondary battery, its preparation method and the battery containing said negative, among which, the negative includes: rhombic black phosphorus with orthogonal structure applied by an inorganic solid electrolyte crystal film in 20-5000 artificially

Owner:陈冠宗 +2

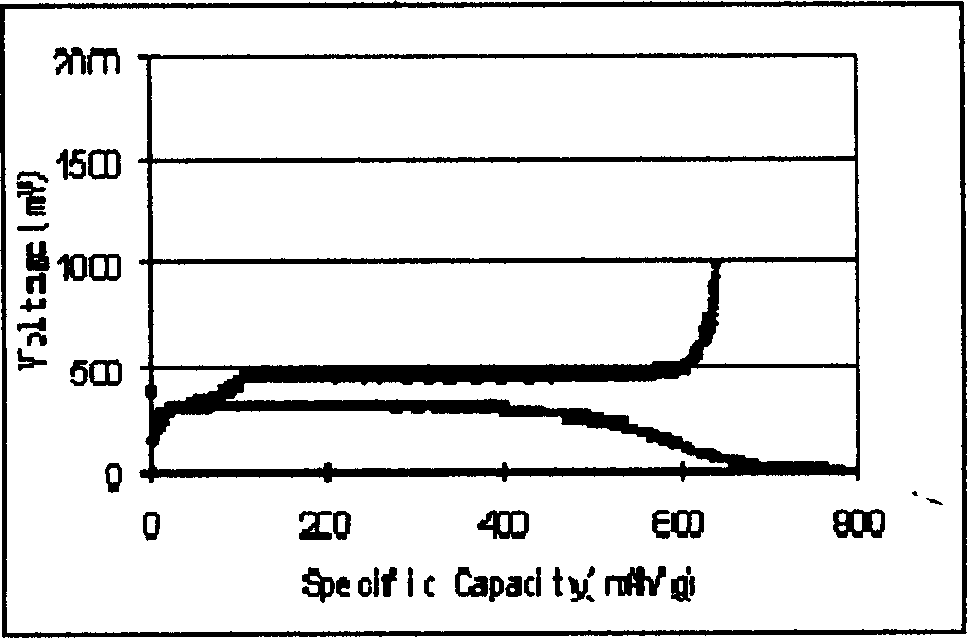

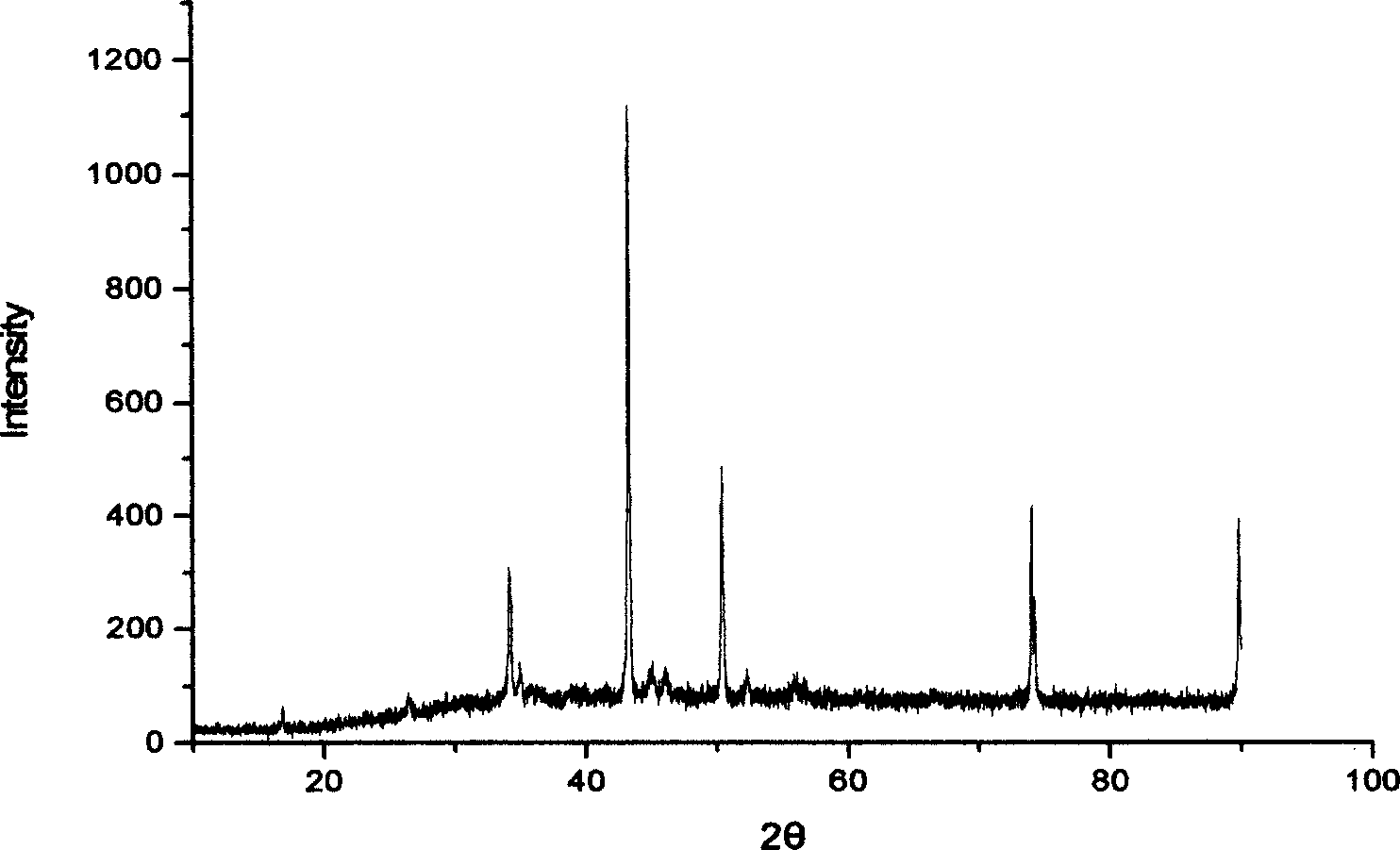

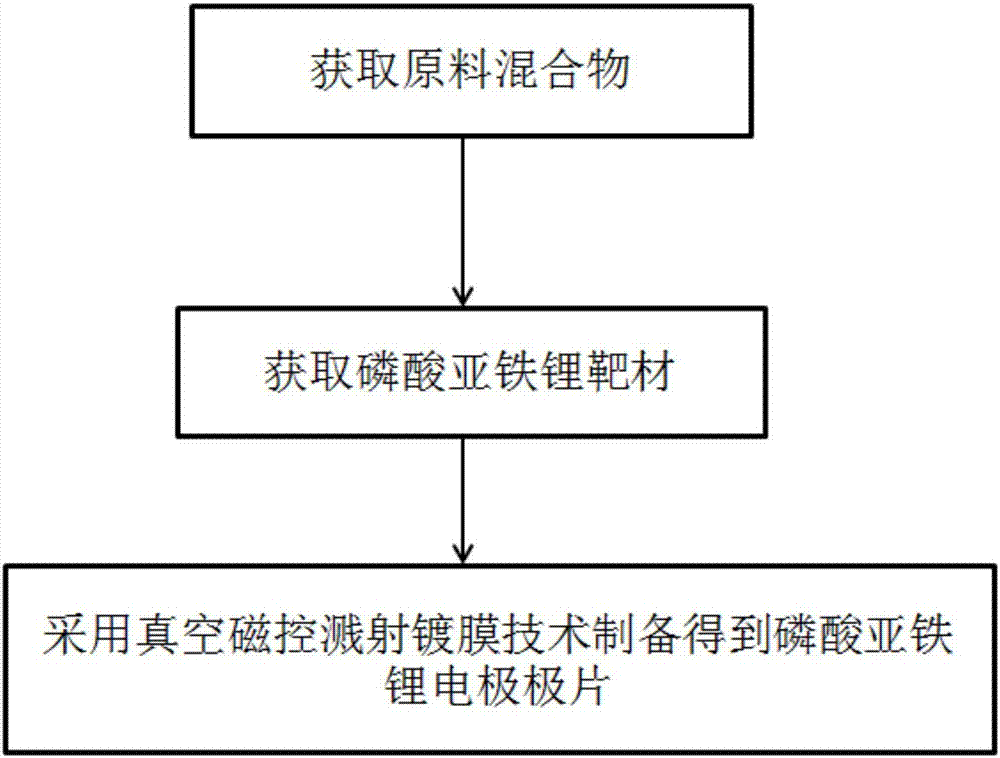

Preparation method of lithium iron phosphate cathode material pole piece

InactiveCN106898733ASimple structureEasy to manufactureVapour deposition manufacturingOxalateLithium iron phosphate

The invention discloses a preparation method of a lithium iron phosphate cathode material pole piece. The method comprises the following steps: (1) taking lithium carbonate, ferrous oxalate and ammonium dihydrogen phosphate as raw materials, mixing evenly to obtain a mixture of the raw materials; (2) presintering the mixture of the raw materials at high temperature and preparing presintered raw material mixture powder by adopting the grinding method, pressing the presintered raw material mixture powder into a green body, sintering the green body at high temperature and preparing a lithium iron phosphate target material by adopting an annealing technology; and (3) using a vacuum magnetron sputtering film coating technique, regulating the parameters of the vacuum magnetron sputtering film coating process, and directly preparing a lithium iron phosphate electrode pole piece from the prepared lithium iron phosphate target material and a conductive agent. The preparation method has the advantages that the preparation method of the lithium iron phosphate cathode material pole piece which is simple in structure, convenient in manufacturing, higher in volumetric specific energy and excellent in electrochemical performances is provided.

Owner:ANQING NORMAL UNIV

Lead-coated carbon composite material and application thereof

InactiveCN104377362AReduce quality problemsReduce pollutionElectrode carriers/collectorsCarbon compositesElectrochemistry

The invention relates to a lead-coated carbon composite material and an application thereof. The lead-coated carbon composite material is characterized in that lead (2) is used for coating the surrounding of a powder-form or rod-form carbon-based material (1) for extrusion moulding, or the powder-form carbon-based material (1) is compressed to a carbon-based grid or is wound to obtain the carbon-based grid after being made to a filament state, and then a lead sheath is used for coating on an outer layer of the carbon-based grid. The lead-coated carbon composite material can be used for making the grid for a storage battery electrode plate, volume ratio energy and discharge capacity of a storage battery can be effectively increased; the carbon-based material with light weight and strong conductivity can be taken as a conductive inner core, a lead layer with strong corrosion resistance and electrochemistry performance is used for coating outer part, so that lead amount is reduced, grid weight is greatly reduced, cell weight is greatly reduced, and environmental pollution can be mitigated.

Owner:JIANGSU JINDING AUTOMOBILE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com