Lithium ion secondary battery negative pole and its preparing method and lithium secondary battery including said negative pole

A secondary battery and lithium-ion technology, applied in the direction of secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of low volume specific energy, small tap density, limiting specific capacity of lithium-ion secondary batteries, etc., to achieve improved The effect of volume specific energy, high tap density, and specific capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

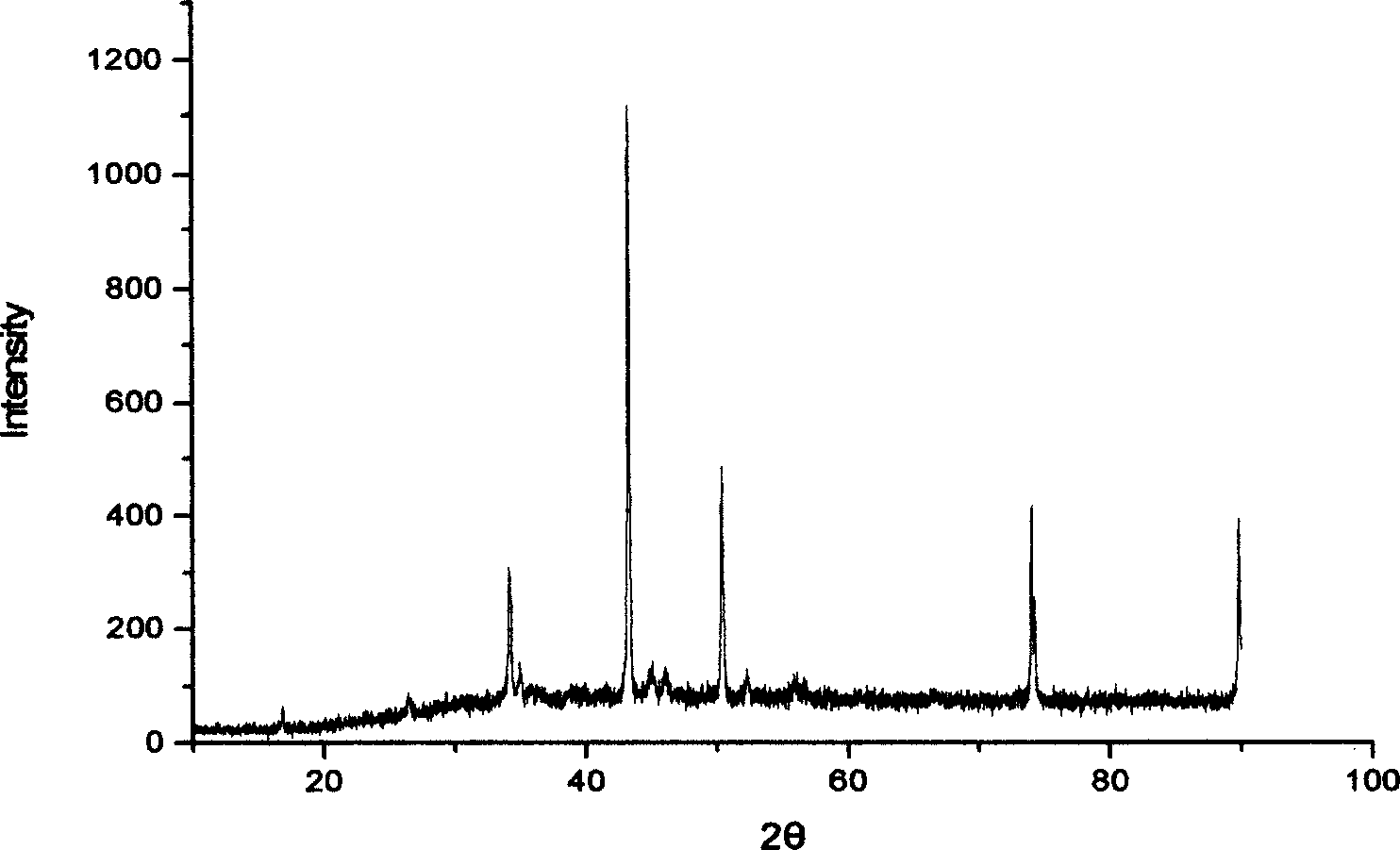

[0021] Put 5 grams of black phosphorus powder of 200 mesh sieves into 100 milliliters of strong oxidizing agent concentration and be 10% nitric acid (HNO 3 ) solution at room temperature for 10 hours, and then washed with distilled water, and then placed in a drying oven at 120 ° C for 12 hours to dry. Then take vinylidene fluoride as binder, N-methylpyrrolidone as organic solvent, and acetylene black as conductive agent, mix and stir the slurry evenly according to the ratio of black phosphorus: acetylene black: vinylidene fluoride=90:4:6 Coated on the current collector copper foil, and dried at 120°C for 16 hours. Then immerse in any ratio of lithium-containing compound n-butyllithium / ethane solution for 12 hours, then wash with dimethoxyethane, put it into a vacuum drying oven, heat up to 160°C, and keep it warm for 48 hours to get this product. Invention of the required lithium ion secondary battery negative electrode.

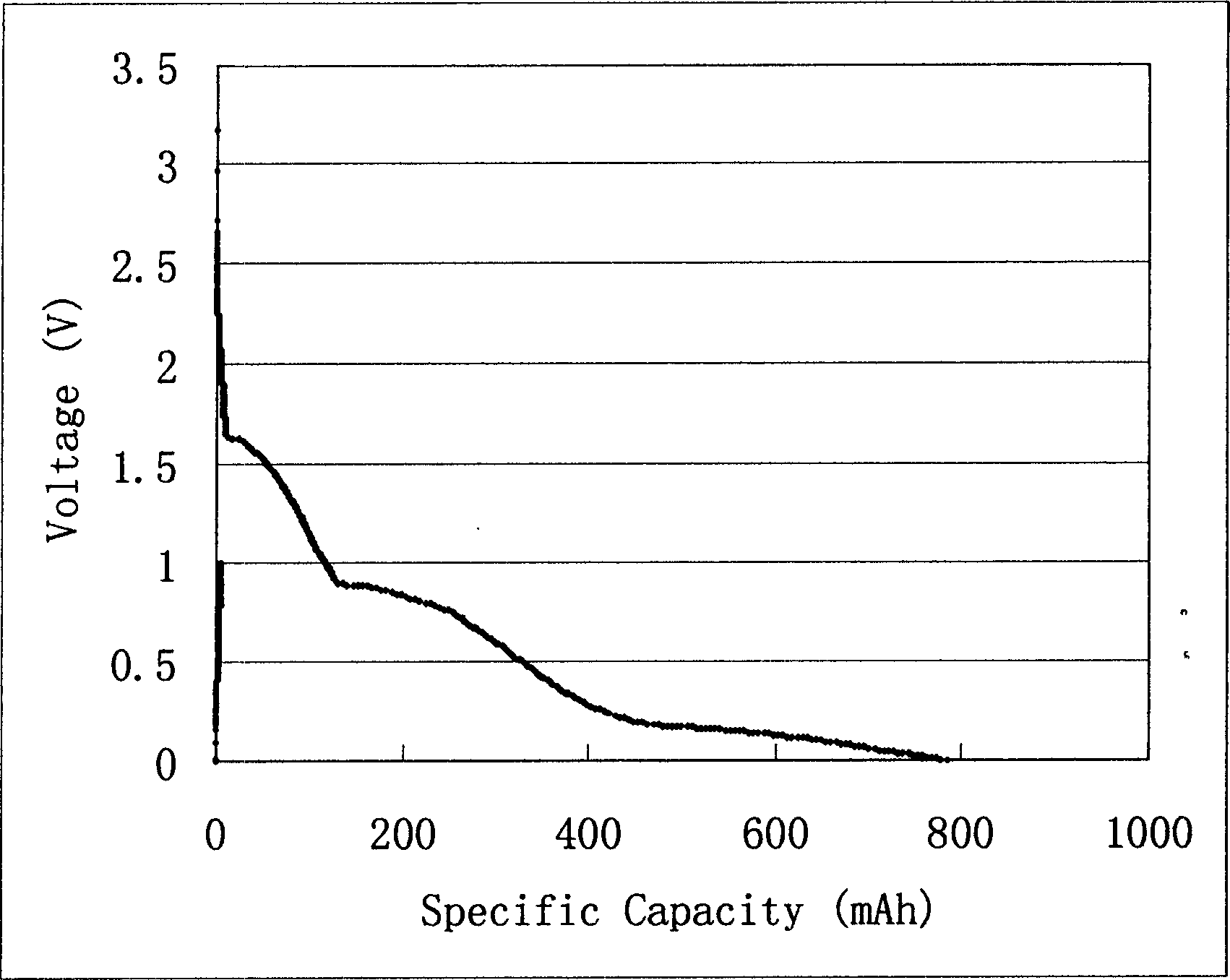

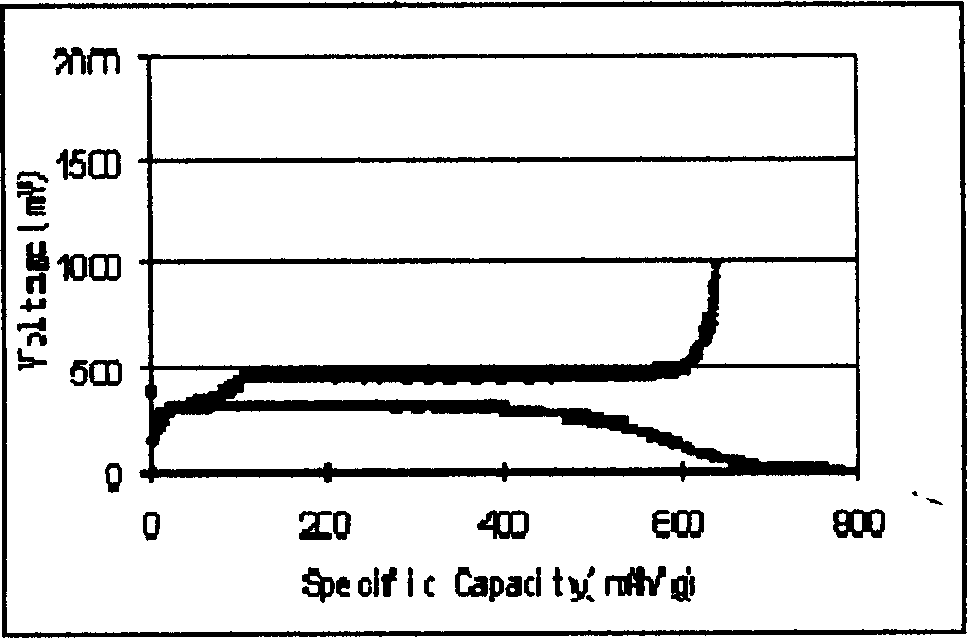

[0022] The lithium ion secondary battery negative e...

Embodiment 2

[0024] The negative electrode of the lithium ion secondary battery prepared above, the positive electrode material is lithium manganate, the electrolyte is lithium hexafluoroborate, the solvent is ethylene carbonate and diethyl carbonate with a volume ratio of 1:3, and the diaphragm is CeLgrd2300 microporous membrane , made of 063048 batteries. , The measured capacity of the battery is 1345mAh.

Embodiment 3

[0026] With the lithium ion secondary battery negative electrode that above-mentioned makes, anode material is lithium nickelate, electrolytic solution is lithium chlorate, solvent solvent is ethylene carbonate and diethyl carbonate, volume ratio is 1: 1, diaphragm is CeLgrd2300 micron The porous film is made into a 063048 battery, and the measured capacity of the battery is 1425mAh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com