Method for preparation of multi-element composite lithium ion battery anode material by secondary sintering

A technology for lithium-ion batteries and composite materials, which is applied in the field of preparing multi-element composite lithium-ion battery cathode materials through secondary sintering, can solve problems such as poor safety and unsuitability, achieve high tap density, reduce battery internal resistance, and improve Effects of cycle performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

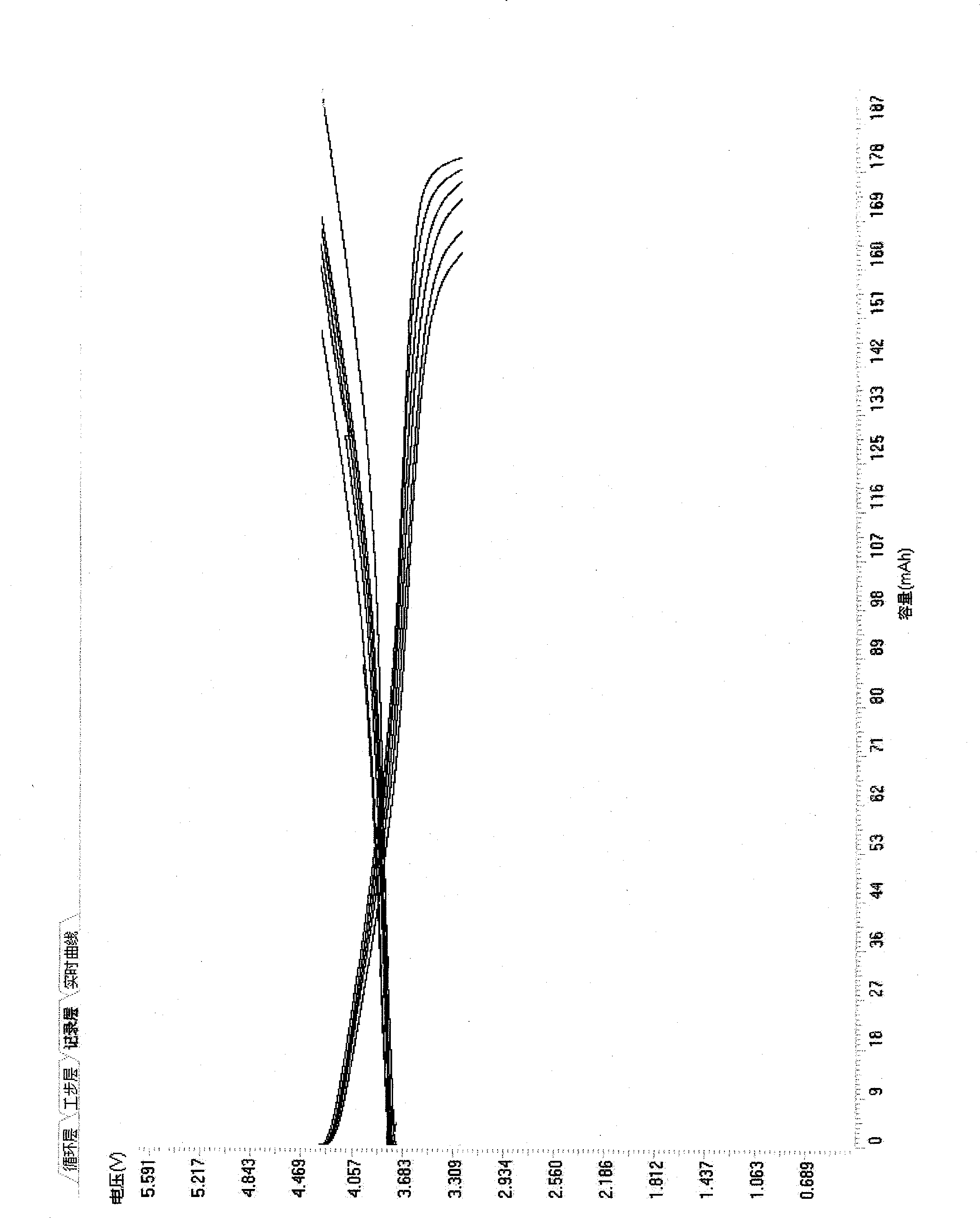

Image

Examples

Embodiment 1

[0028] Weigh a certain amount of nickel sulfate, cobalt sulfate, and manganese sulfate according to the molar ratio of Ni:Co:Mn=1:1:1, and weigh magnesium sulfate according to the molar ratio of Mg:(Ni+Co+Mn)=0.05:1 , add deionized water to make a 1mol / L standard mixed solution.

[0029] Under the protection of an inert atmosphere, add 3 mol / L ammonia solution and 5 mol / L sodium hydroxide solution to the mixed solution, keep the temperature in a water bath at 65°C, control the liquid addition rate to keep the pH value of the system at 12, and react for 2 hours. After filtering, washing and drying, spherical nickel-cobalt-manganese hydroxide doped with magnesium is obtained.

[0030] Li: (Ni+Co+Mn+Mg)=1.05:1 Molar ratio takes lithium carbonate and the spherical nickel-cobalt-manganese hydroxide doped with magnesium, adds in the ball mill, adds the zirconia ball of 3 times of amount simultaneously, Grind well and remove after 3 hours.

[0031] Put the resulting mixture into a ...

Embodiment 2

[0036] Weigh a certain amount of nickel sulfate, cobalt sulfate, manganese sulfate according to the molar ratio of Ni:Co:Mn=5:2:3, and weigh magnesium sulfate according to the molar ratio of Mg:(Ni+Co+Mn)=0.03:1 , add deionized water to make a 1mol / L standard mixed solution.

[0037] Under the protection of an inert atmosphere, add 3 mol / L ammonia solution and 5 mol / L sodium hydroxide solution to the mixed solution, keep the temperature in a water bath at 60°C, control the liquid addition rate to keep the pH value of the system at 11.5, and react for 2 hours. After filtering, washing and drying, spherical nickel-cobalt-manganese hydroxide doped with magnesium is obtained.

[0038] Weigh lithium carbonate and spherical nickel-cobalt-manganese hydroxide doped with magnesium at a molar ratio of Li:(Ni+Co+Mn+Mg)=1.08:1, add in the ball mill, and simultaneously add 3 times the amount of zirconia balls, Grind well and remove after 3 hours.

[0039] Put the resulting mixture into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com