Patents

Literature

1504results about How to "High nitrogen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

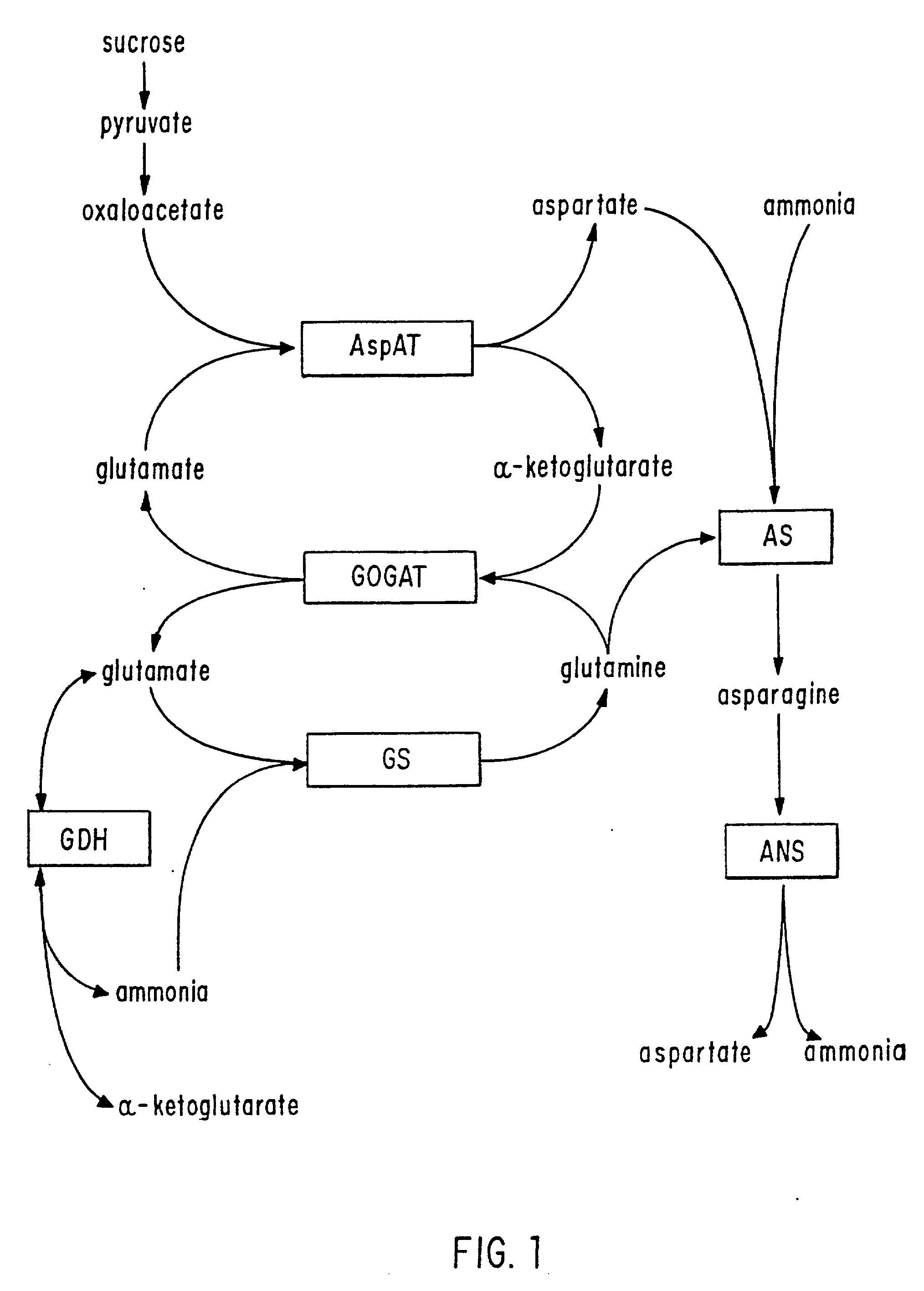

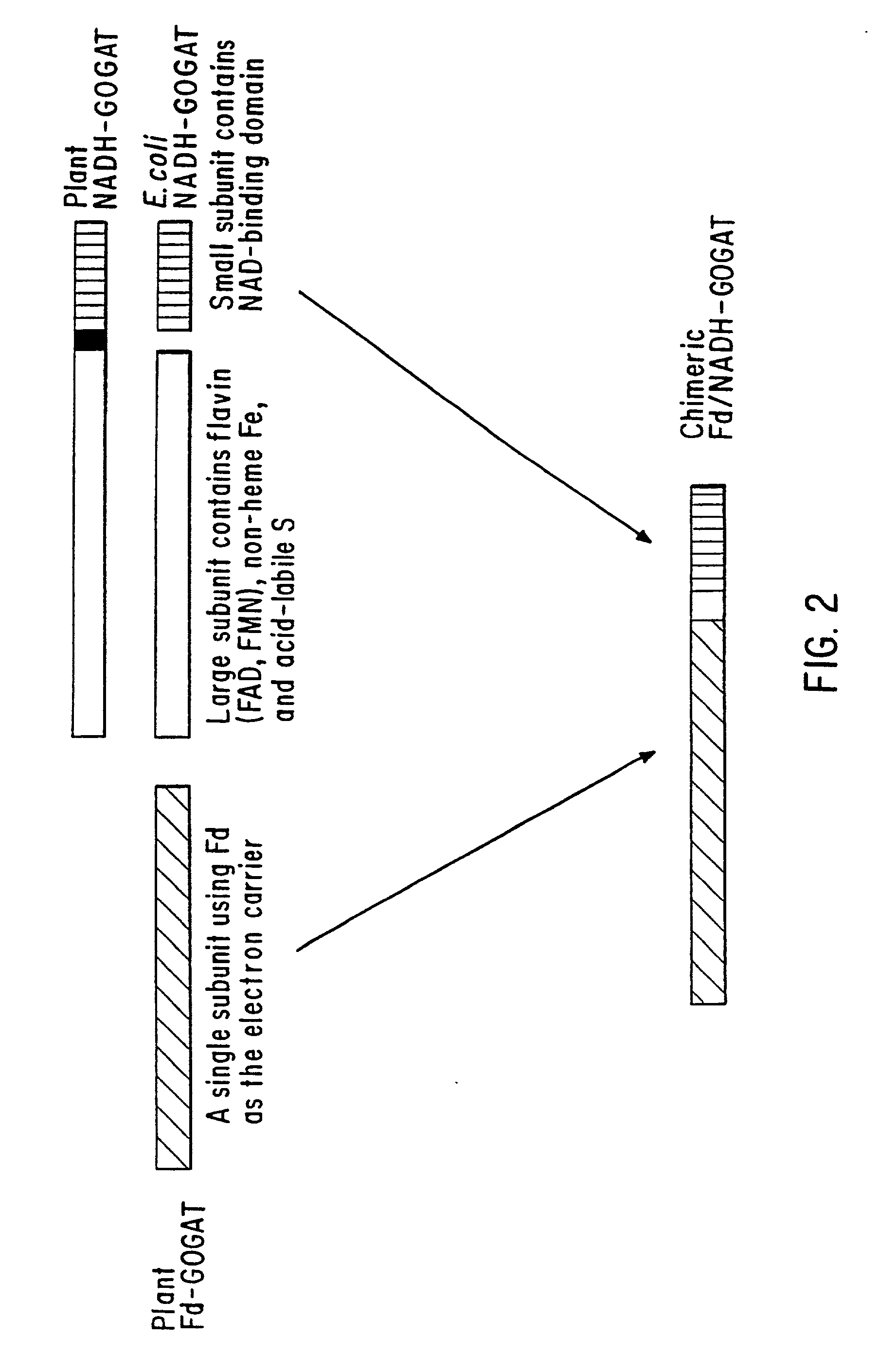

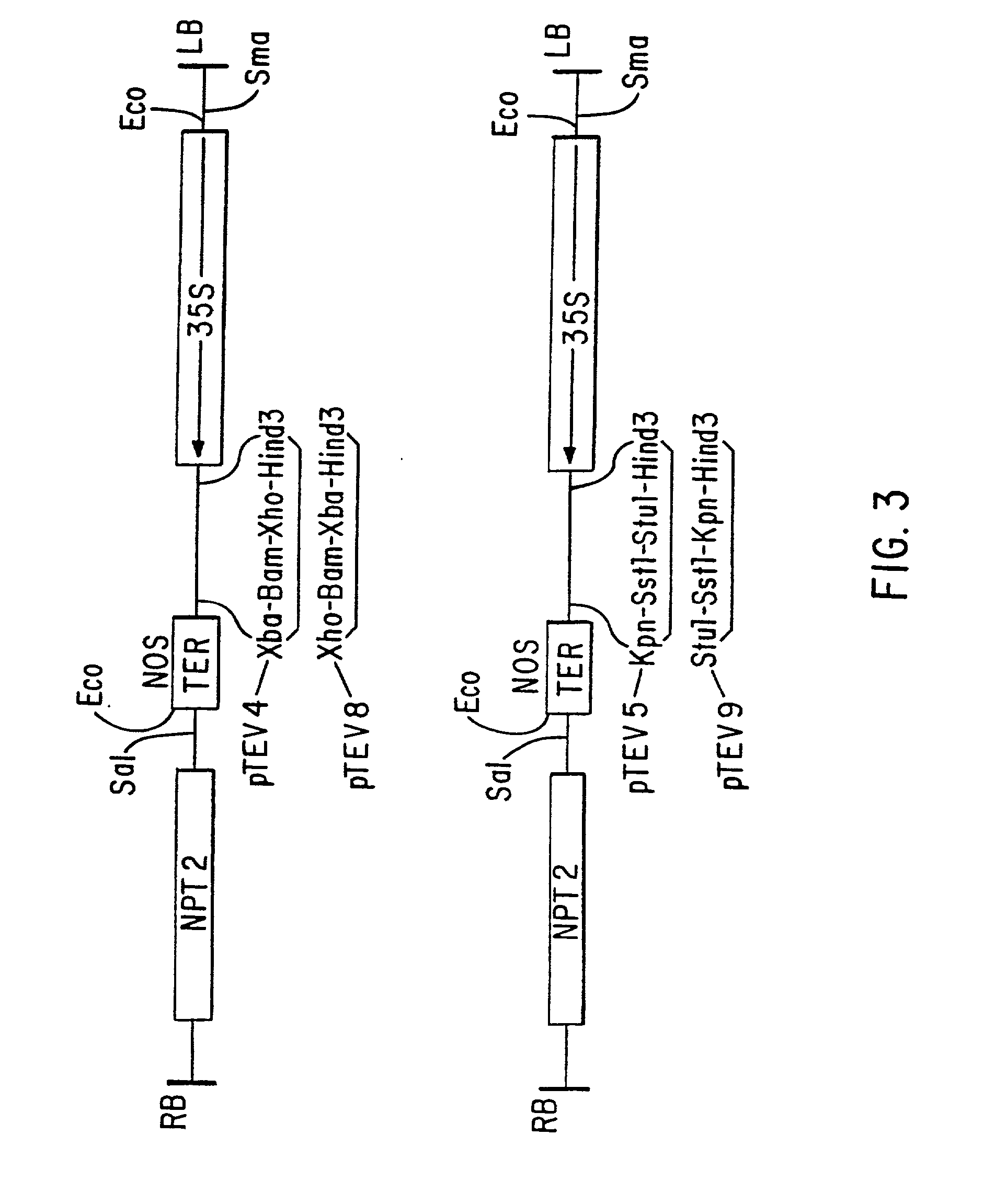

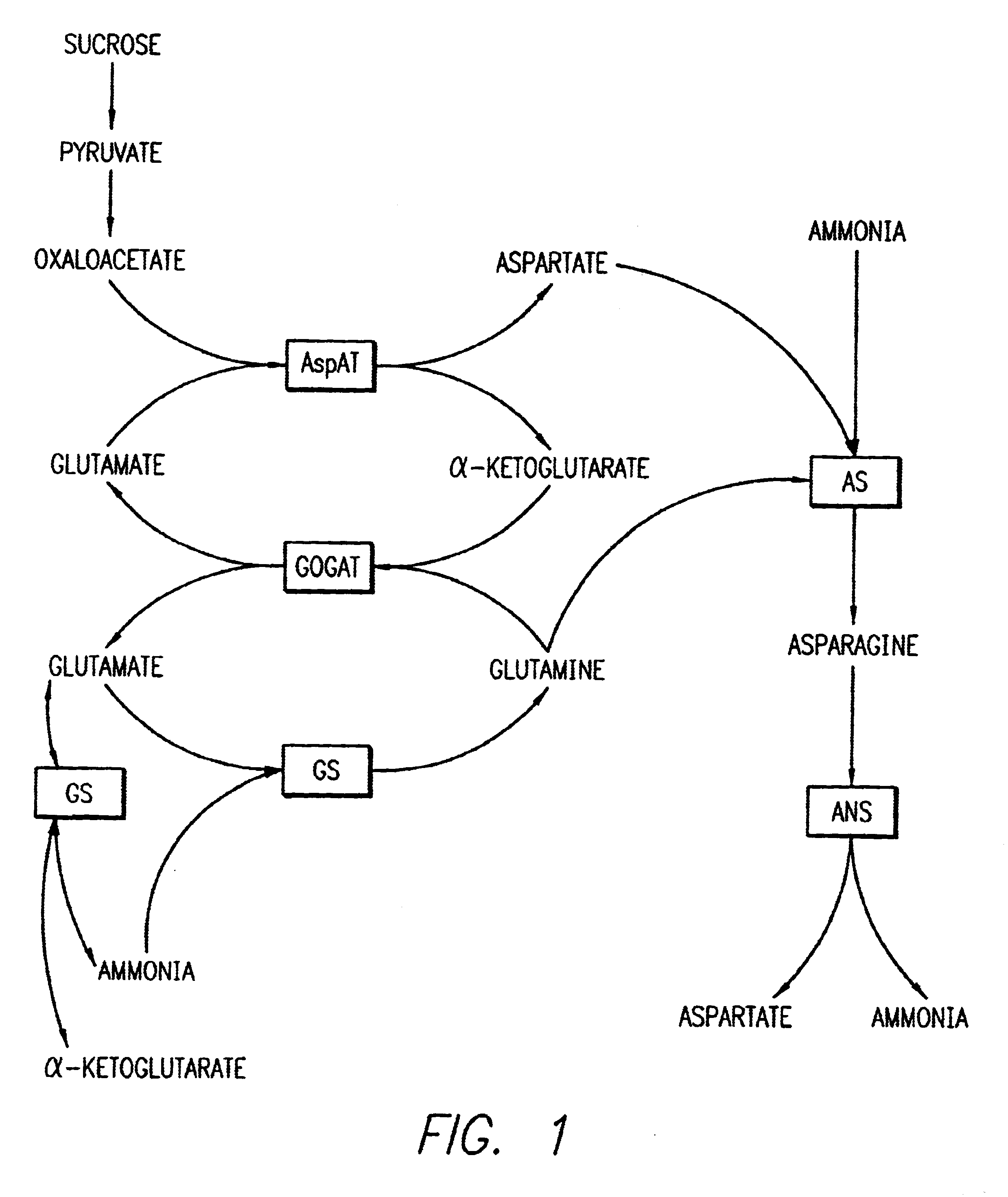

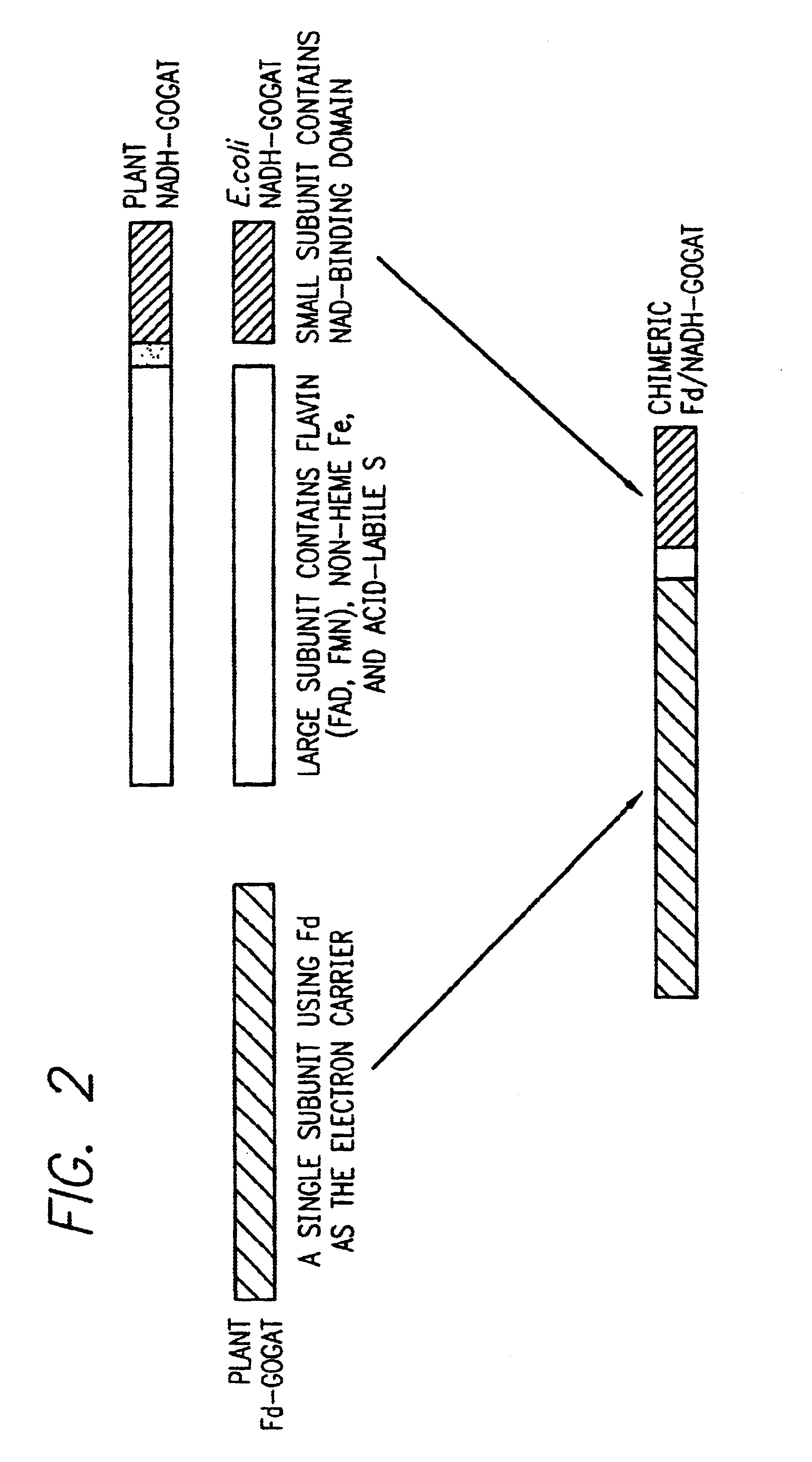

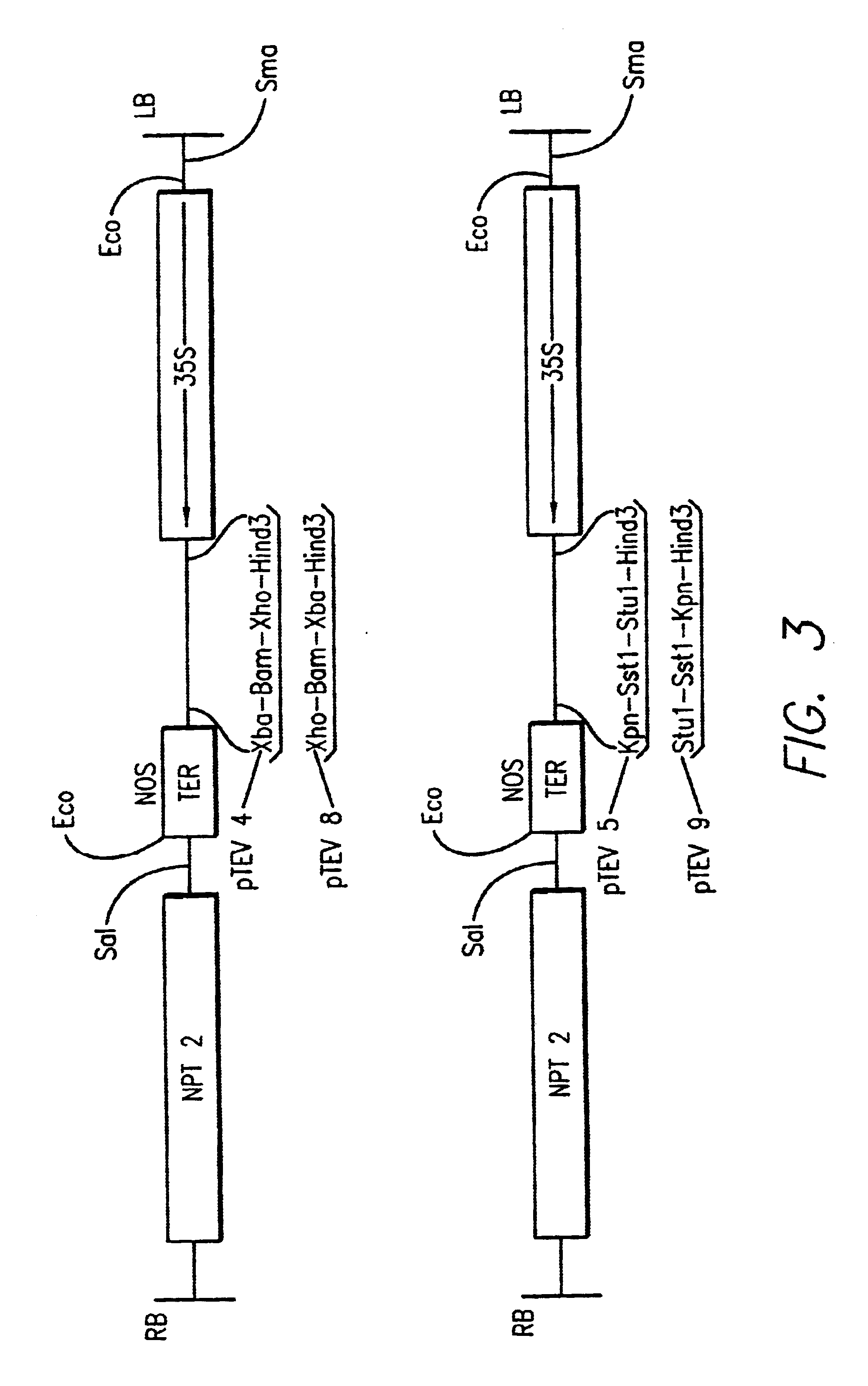

Transgenic plants that exhibit enhanced nitrogen assimilation

InactiveUS6107547AImprove featuresReduce investmentSugar derivativesOther foreign material introduction processesBiotechnologyNitrogen assimilation

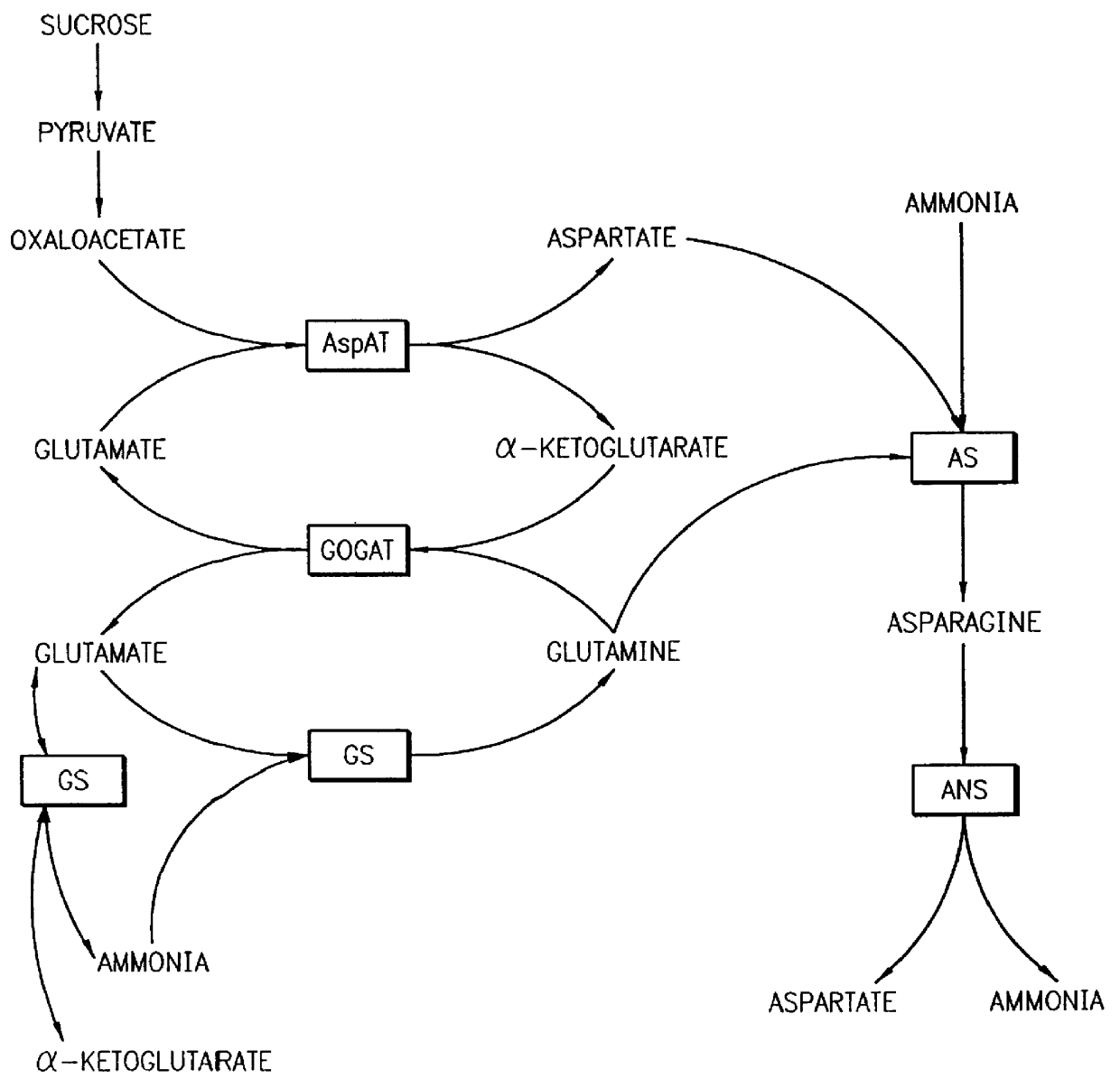

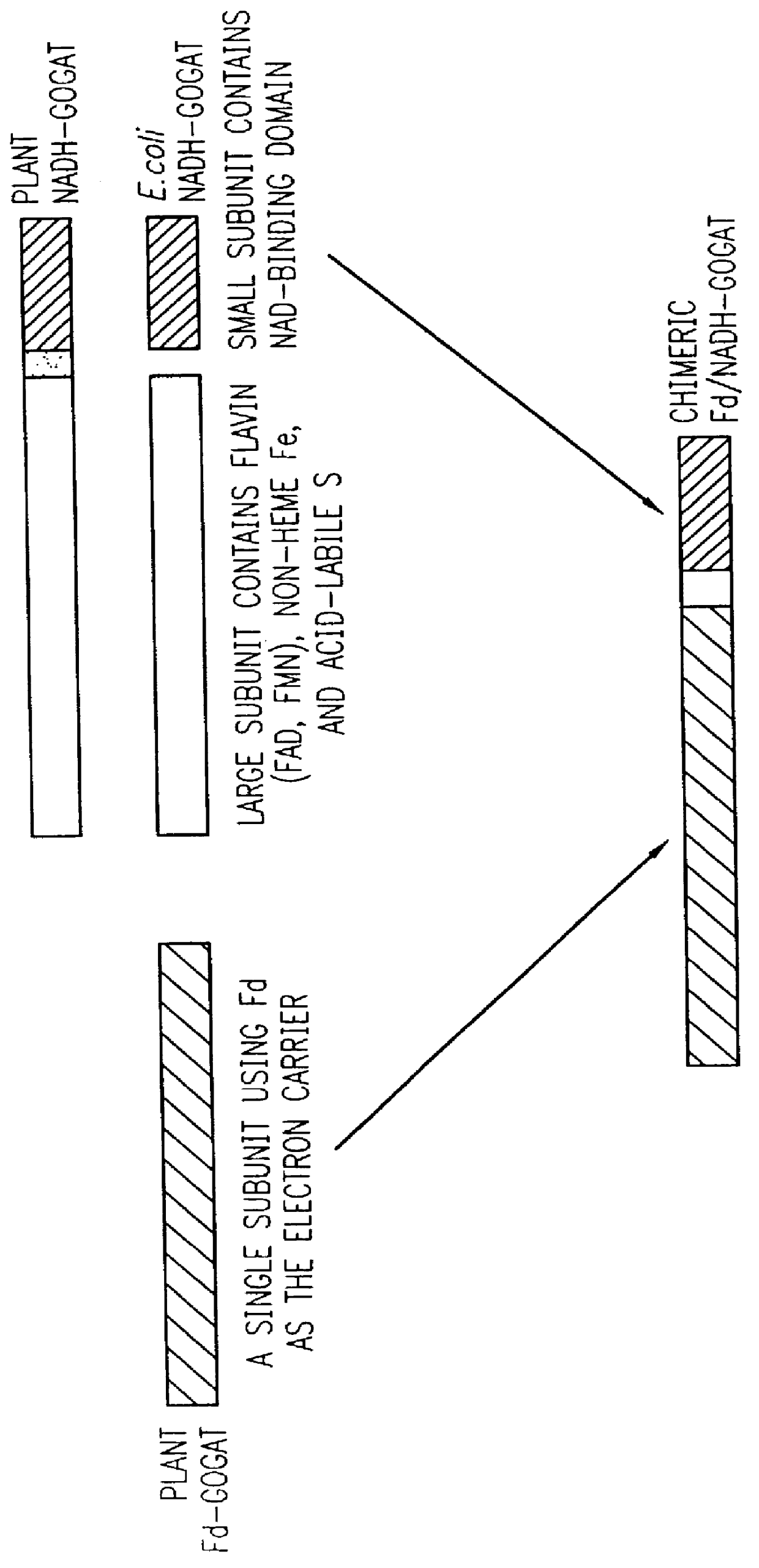

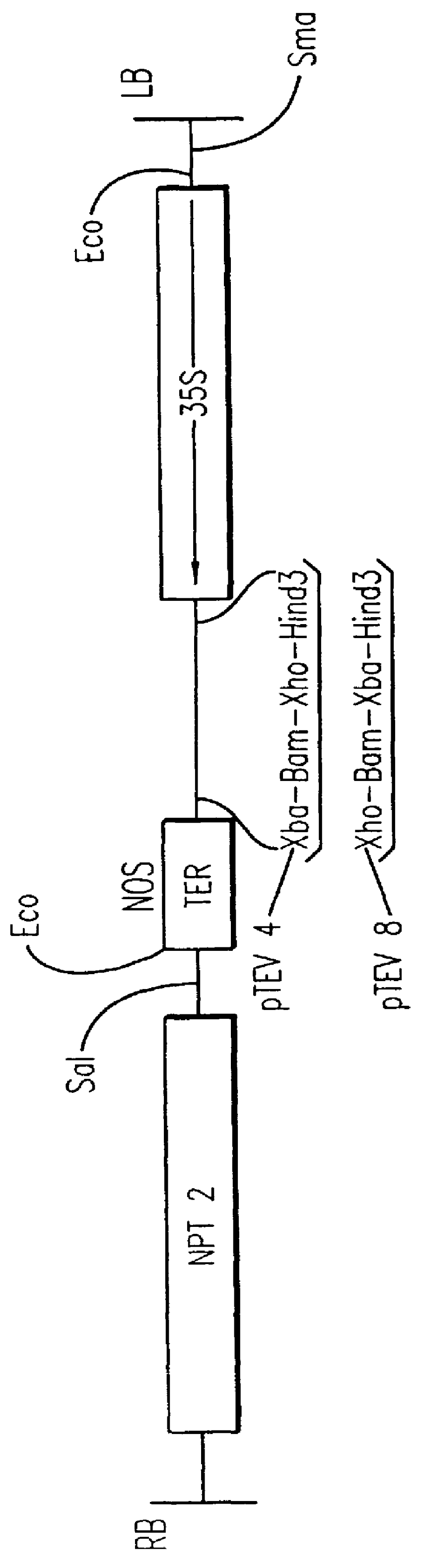

The present invention relates to a method for producing plants with improved agronomic and nutritional traits. Such traits include enhanced nitrogen assimilatory and utilization capacities, faster and more vigorous growth, greater vegetative and reproductive yields, and enriched or altered nitrogen content in vegetative and reproductive parts. More particularly, the invention relates to the engineering of plants modified to have altered expression of key enzymes in the nitrogen assimilation and utilization pathways. In one embodiment of the present invention, the desired altered expression is accomplished by engineering the plant for ectopic overexpression of one of more the native or modified nitrogen assimilatory enzymes. The invention also has a number of other embodiments, all of which are disclosed herein.

Owner:NEW YORK UNIV

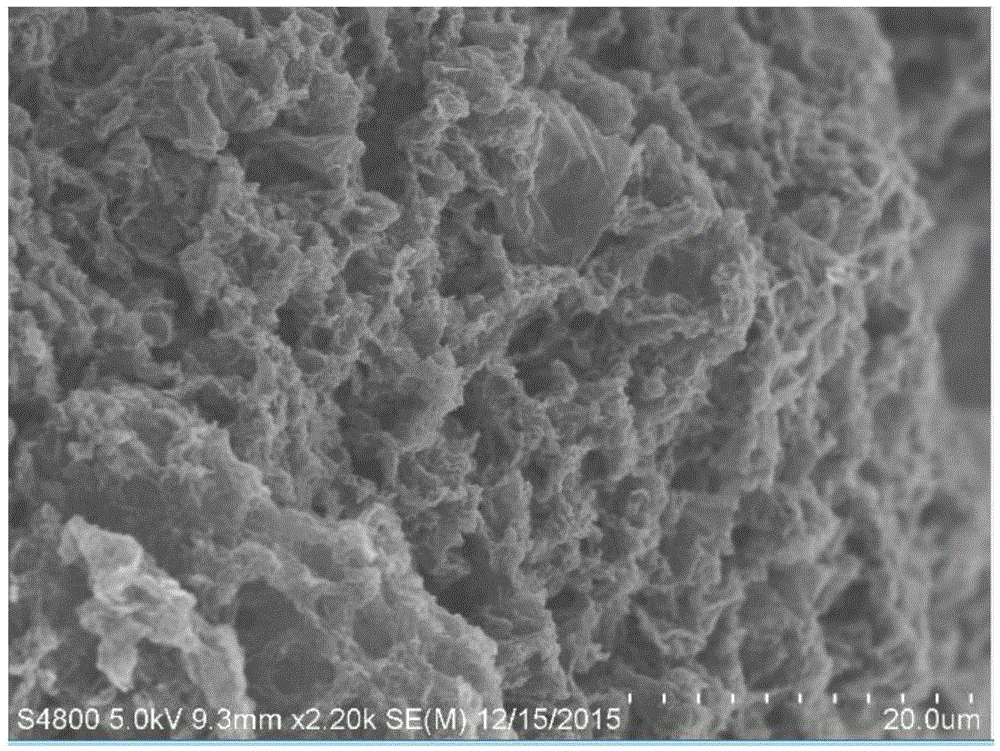

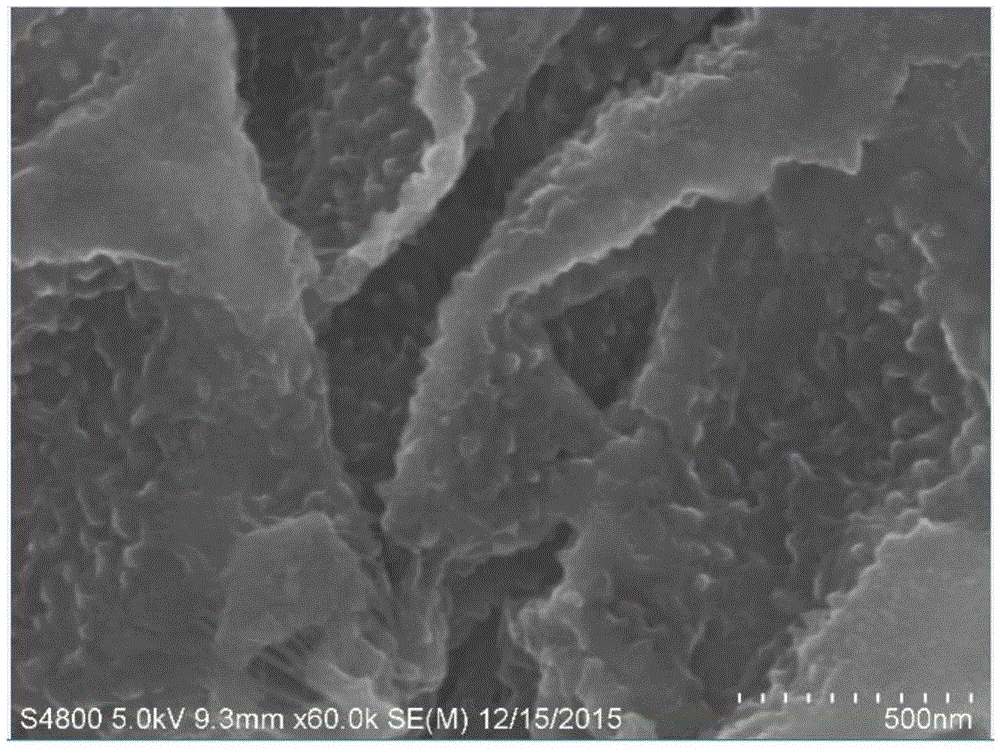

Method for preparing nitrogen-doped graphene material with hydrothermal process

The invention discloses a method for preparing a nitrogen-doped graphene material with a hydrothermal process, relating to a method for preparing the nitrogen-doped graphene material. The technical problems of lower nitrogen content, difficulty in control of nitrogen content, high production cost, complex structure of equipment required by reaction, rigorous reaction conditions, low yield, difficulty in industrialized production and the like in the traditional method for preparing the nitrogen-doped graphene material are solved in the invention. The method comprises the steps of: 1, dissolving graphite oxide in a solvent, adding a surfactant and uniformly mixing; 2, adding a nitrogen-containing compound, and uniformly mixing; and 3, after a hydro-thermal reaction, washing and drying to obtain the nitrogen-doped graphene material. The nitrogen-doped graphene material prepared in the invention has the advantages of higher nitrogen content, controllable nitrogen content, low production cost, simple structure of required equipment, high yield and easiness in realizing industrialized production.

Owner:HEILONGJIANG UNIV

Preparation method of nitrogen-doped porous-structure carbon material

ActiveCN103964412AImprove the reduction catalytic activityHigh nitrogen contentMaterial nanotechnologyPhysical/chemical process catalystsCapacitanceMetal particle

The invention discloses a preparation method of a nitrogen-doped porous-structure carbon material and belongs to the technical field of inorganic material preparation. The preparation method utilizes a micromolecular carbon-containing compound as a raw material and comprises the following steps of based on the weight of the raw material, adding 0-400wt% of an inorganic base, 0-400wt% of an organic nitrogen-containing compound and 0-50wt% of a metal or metal oxide or inorganic metal salt into the raw material, carrying out uniform dispersion, and carrying out a reaction process in an inert gas protective atmosphere at a temperature of 400-900 DEG C for 0.5-12h so that the nitrogen-doped porous-structure carbon material having micropores, mesopores and macropores is obtained. The preparation method has simple processes, can be controlled easily, and realizes one-step combination of porous structure, functionalization nitrogen doping and metal particle modification. The nitrogen-doped porous-structure carbon material having high nitrogen content has a large capacitance value and good cycle performances, can be used as an oxygen reduction reaction catalyst having high activity, high selectivity and high stability and has a very large application prospect.

Owner:BEIJING UNIV OF CHEM TECH

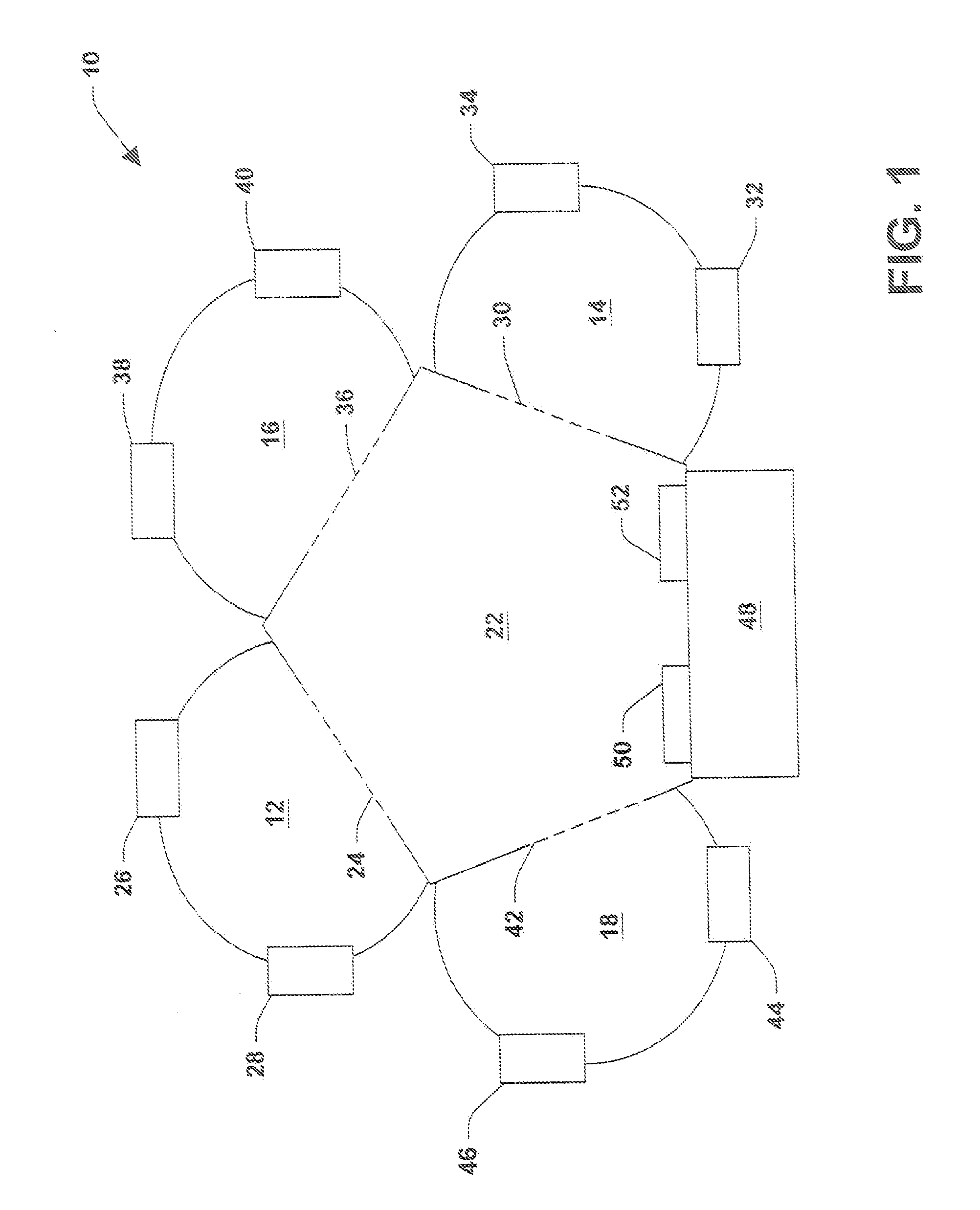

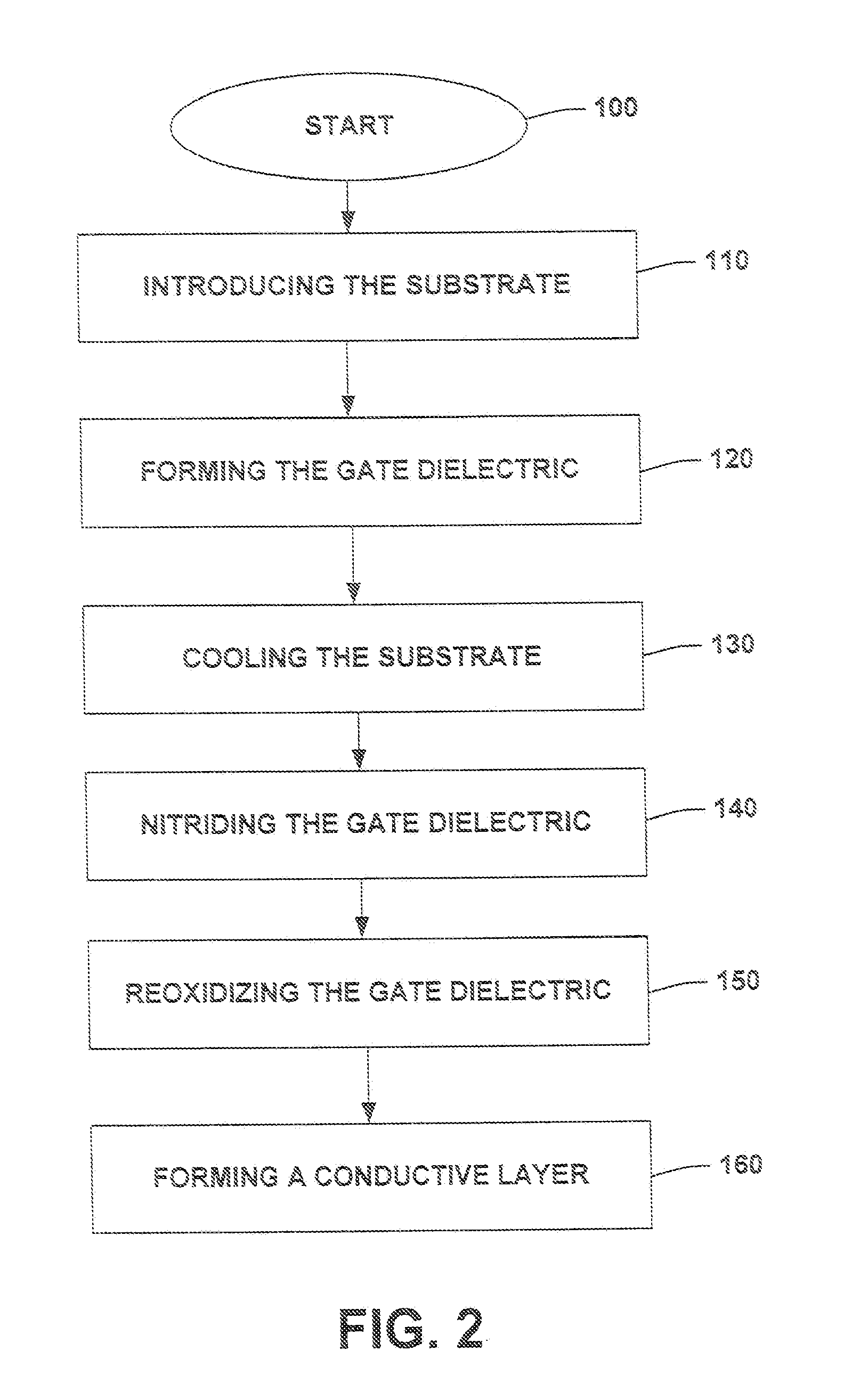

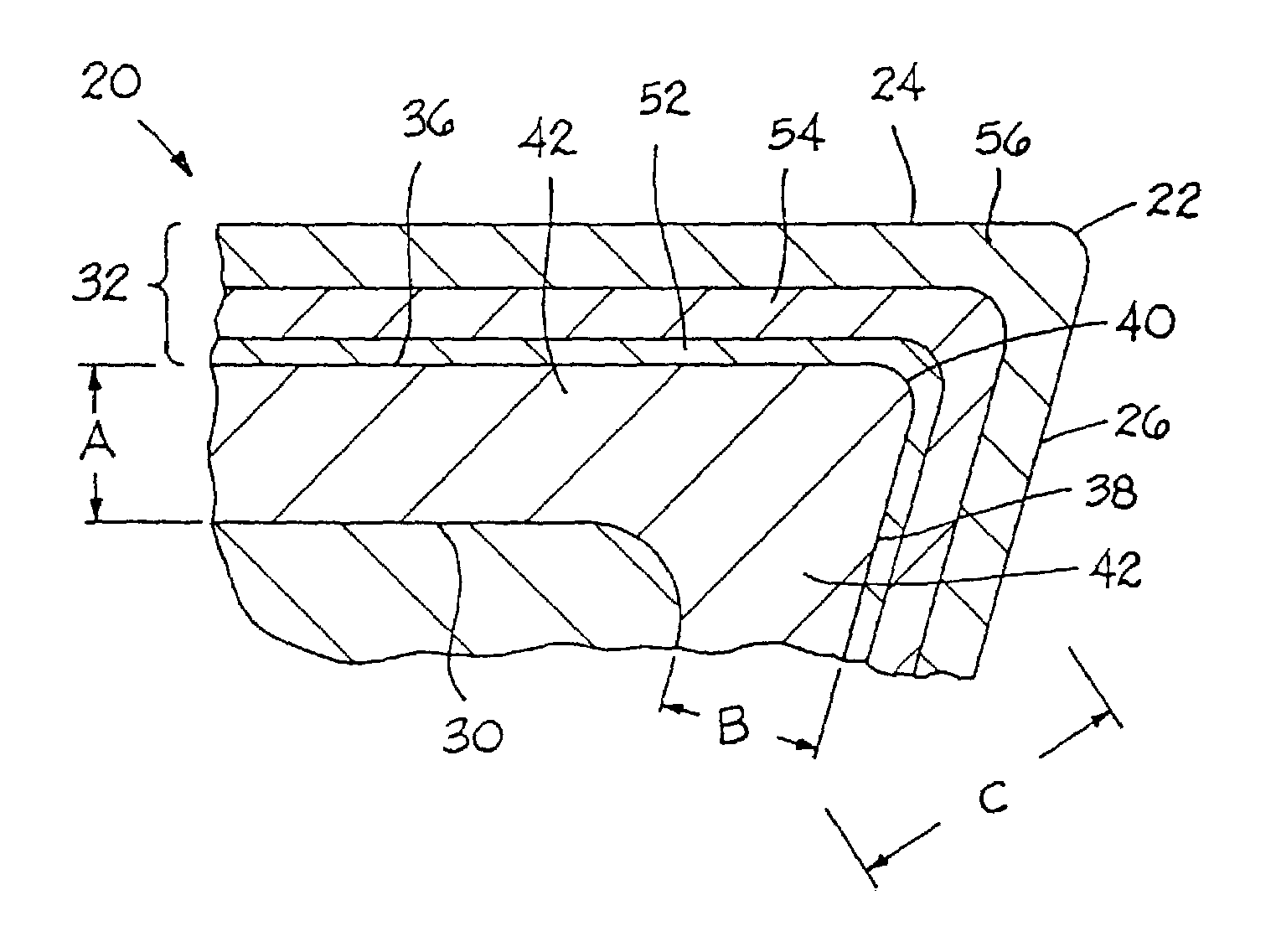

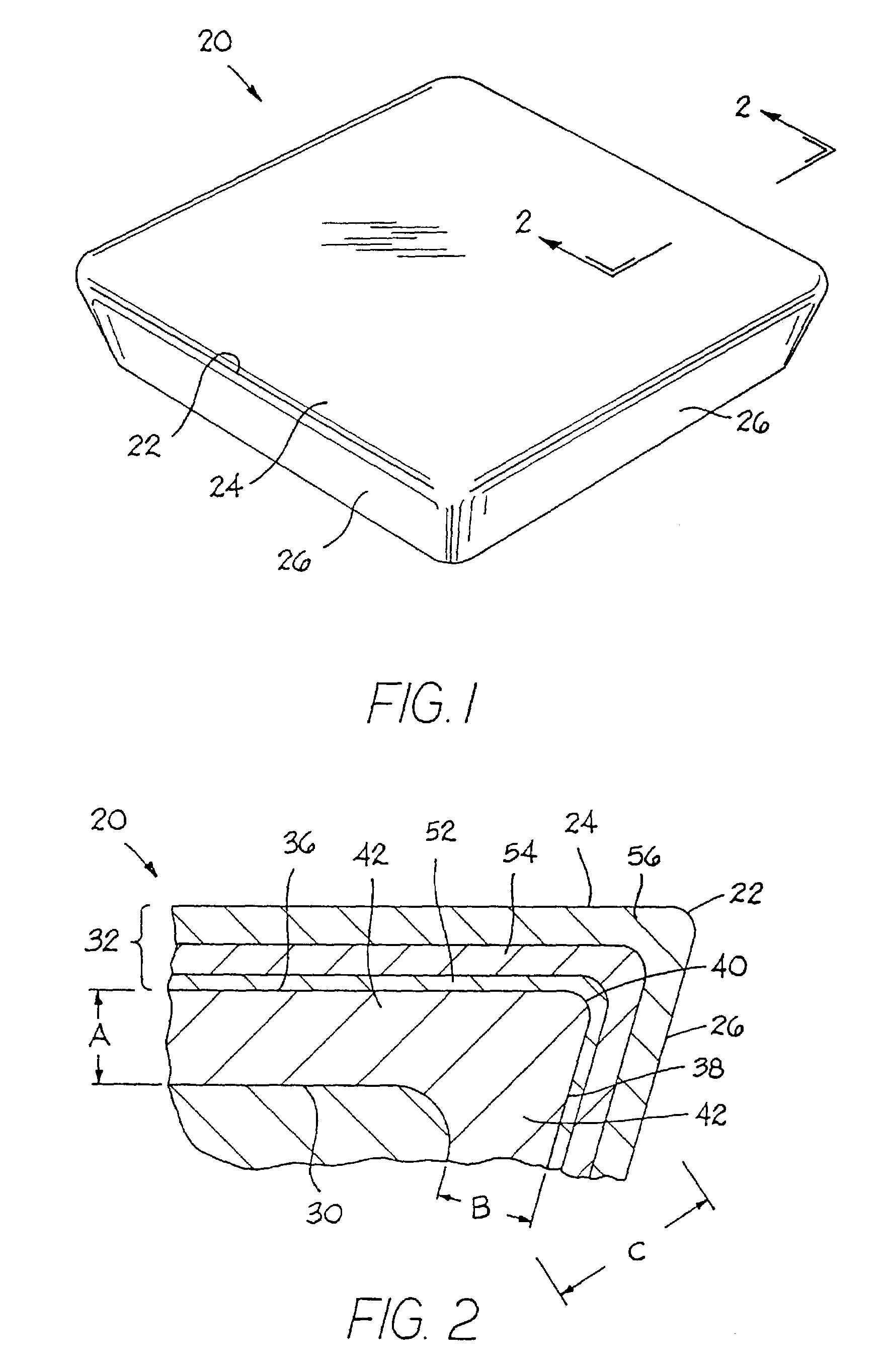

System and Method for Mitigating Oxide Growth in a Gate Dielectric

ActiveUS20080050882A1Promote growthImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingGate dielectricNitrogen

Oxide growth of a gate dielectric layer that occurs between processes used in the fabrication of a gate dielectric structure can be reduced. The reduction in oxide growth can be achieved by maintaining the gate dielectric layer in an ambient effective to mitigate oxide growth of the gate dielectric layer between at least two sequential process steps used in the fabrication the gate dielectric structure. Maintaining the gate dielectric layer in an ambient effective to mitigate oxide growth also improves the uniformity of nitrogen implanted in the gate dielectric.

Owner:TEXAS INSTR INC

Transgenic plants that exhibit enhanced nitrogen assimilation

InactiveUS20020069430A1Improve growth characteristicsImproved vegetativeClimate change adaptationOther foreign material introduction processesPlant cellThreonine

Transgenic plants containing free amino acids, particularly at least one amino acid selected from among glutamic acid, asparagine, aspartic acid, serine, threonine, alanine and histidine accumulated in a large amount, in edible parts thereof, and a method of producing them are provided. In this method, glutamate dehydrogenase (GDH) gene is introduced into a plant together with a regulator sequence suitable for over expressing the sequence encoding GDH gene in plant cells.

Owner:AJINOMOTO CO INC

Soil-improving bio-fertilizer and preparation method thereof

The invention relates to a soil-improving bio-fertilizer and a preparation method thereof. The soil-improving bio-fertilizer is prepared by mixing the following raw materials in parts by weight: 200-400 parts of grass carbon, 200-400 parts of an organic fertilizer, 100-400 parts of an inorganic fertilizer, 50-200 parts of a porous inorganic matter, 10-30 parts of trace elements, 50-80 parts of clay and 10-20 parts of a compound microbial agent. A plurality of microorganisms with the functions of fixing nitrogen, solubilizing phosphate and solubilizing potassium are added into the fertilizer, so that the nitrogen content of soil can be increased, the utilization ratio of a chemical fertilizer is increased, the soil structure is improved, the crop yield is increased, and the crop quality is enhanced.

Owner:DEZHOU YUANHE AGRI TECH DEVCO

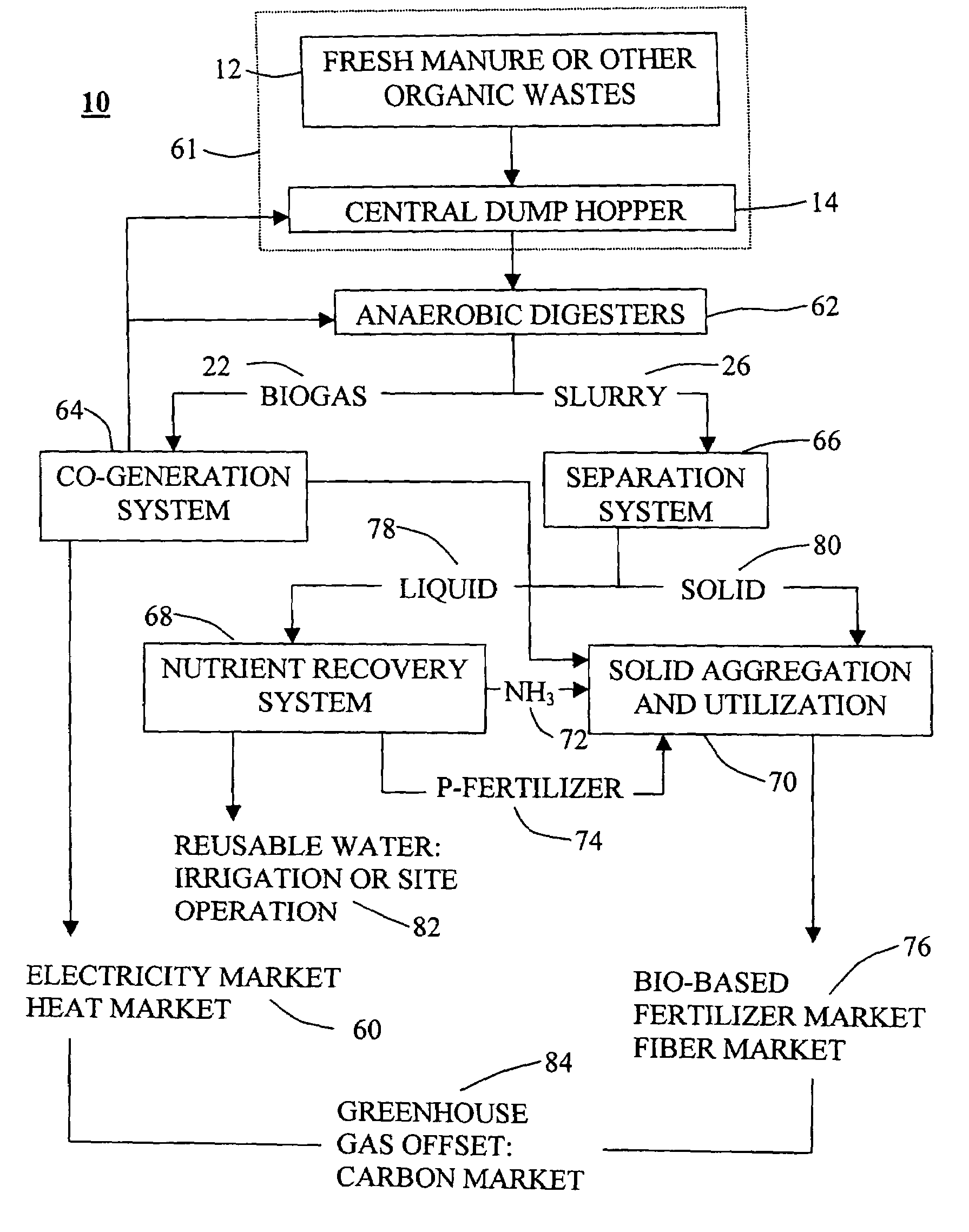

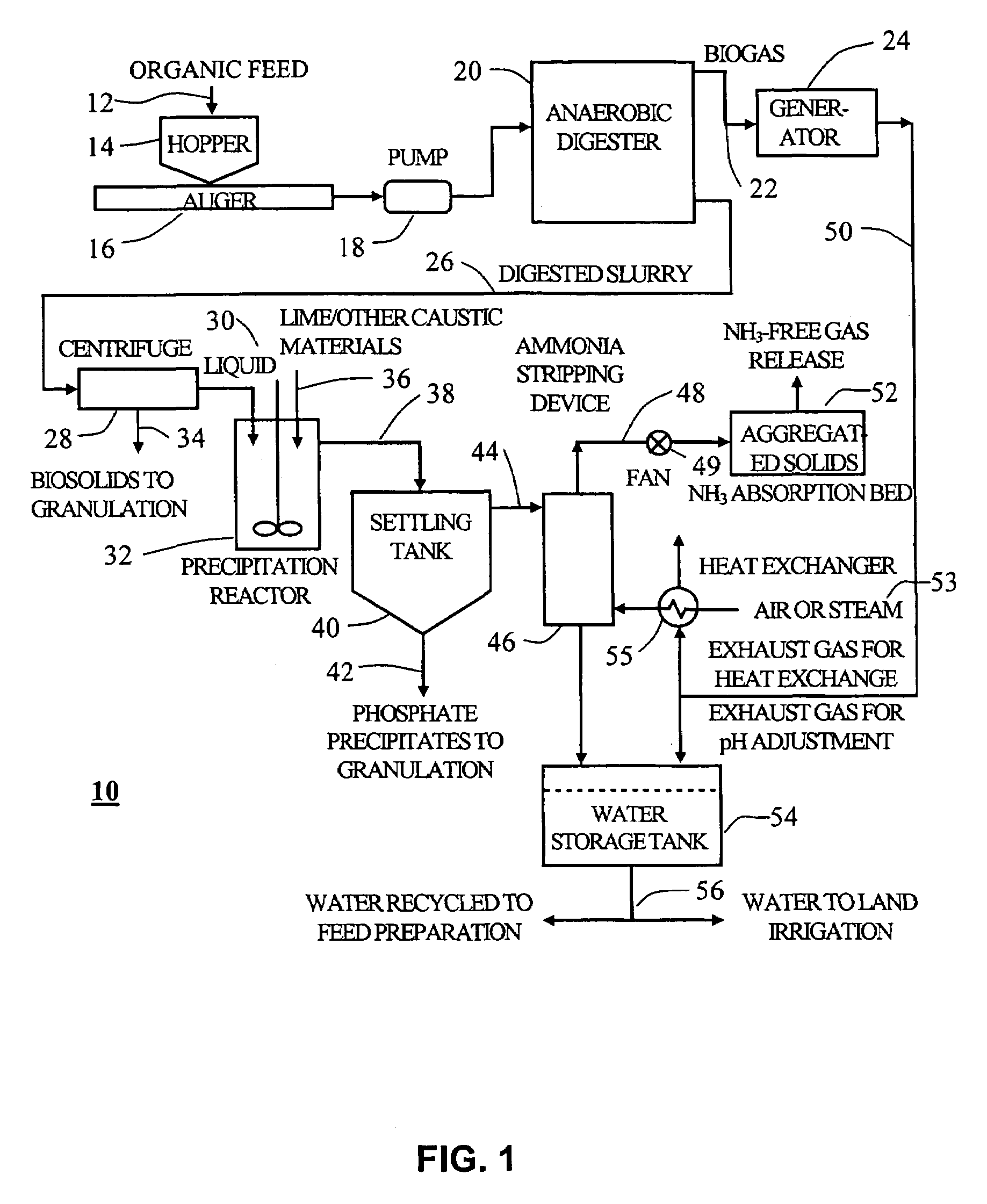

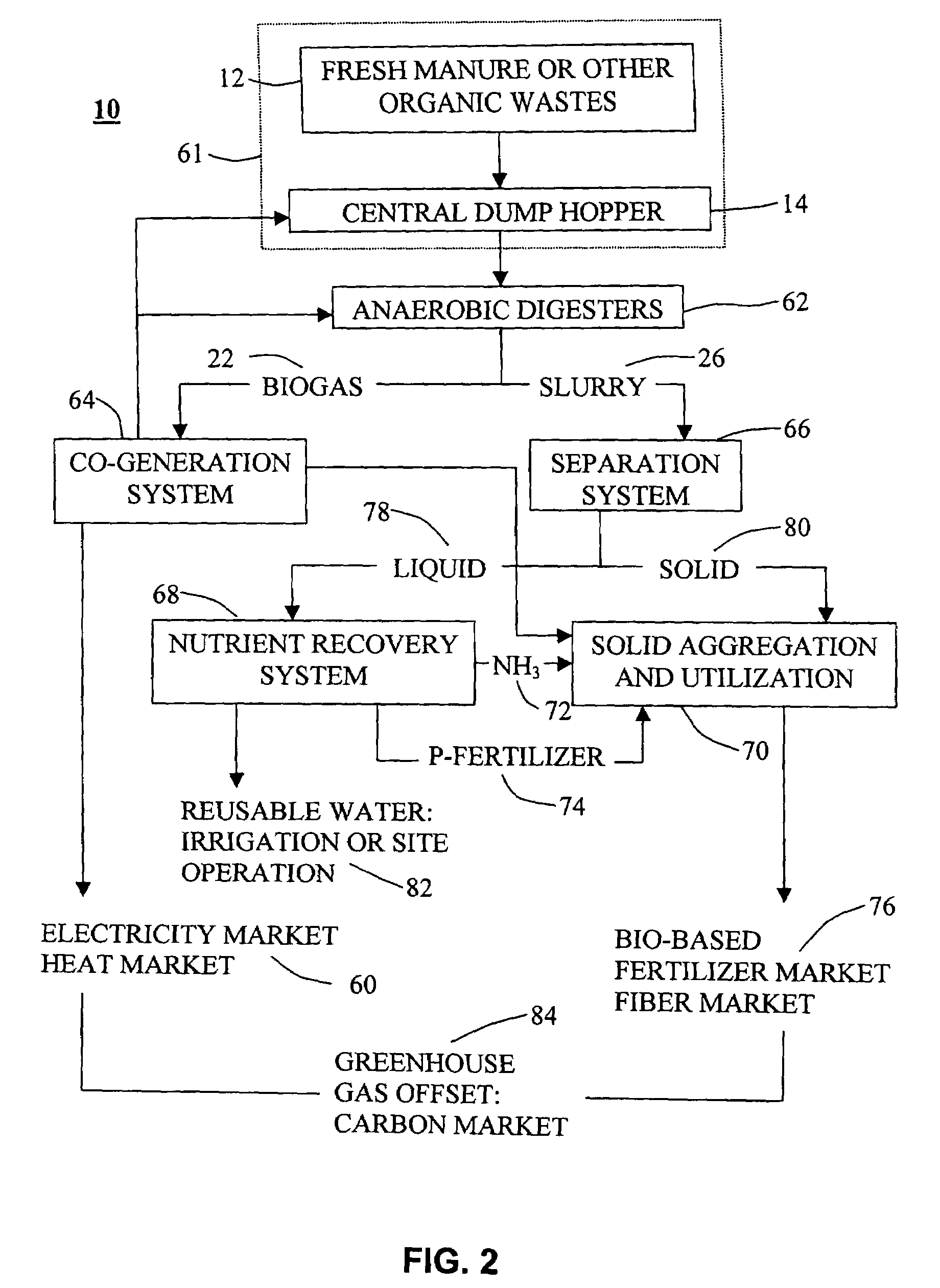

Process for removal and recovery of nutrients from digested manure or other organic wastes

InactiveUS7014768B2Eliminate the effects ofIncrease temperatureBioreactor/fermenter combinationsBio-organic fraction processingCogenerationNitrogen gas

A process for removal and recovery of nutrients and recycling of water from digested manure or other organic wastes. A first step involves separating waste from an anaerobic digester into digested liquids, digested solids, and biogas. A second step involves precipitating solids from the digested liquids. A third step involves stripping ammonia from the digested liquids. A fourth step involves injecting an exhaust stream of carbon dioxide drawn from the co-generator into the digested liquids to reduce the pH and raise the temperature of the digested liquid. A fifth step involves recycling the digested liquids back to the anaerobic digester for use in diluting in coming solid wastes. A sixth step involves passing the excess ammonia stripped from the digested liquid through the digested solids to recover nitrogen through aborption with the resultant digested solids being usable as a biofertilizer with a high nitrogen content. A seventh step involves capturing the biogas for use in a co-generation system.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

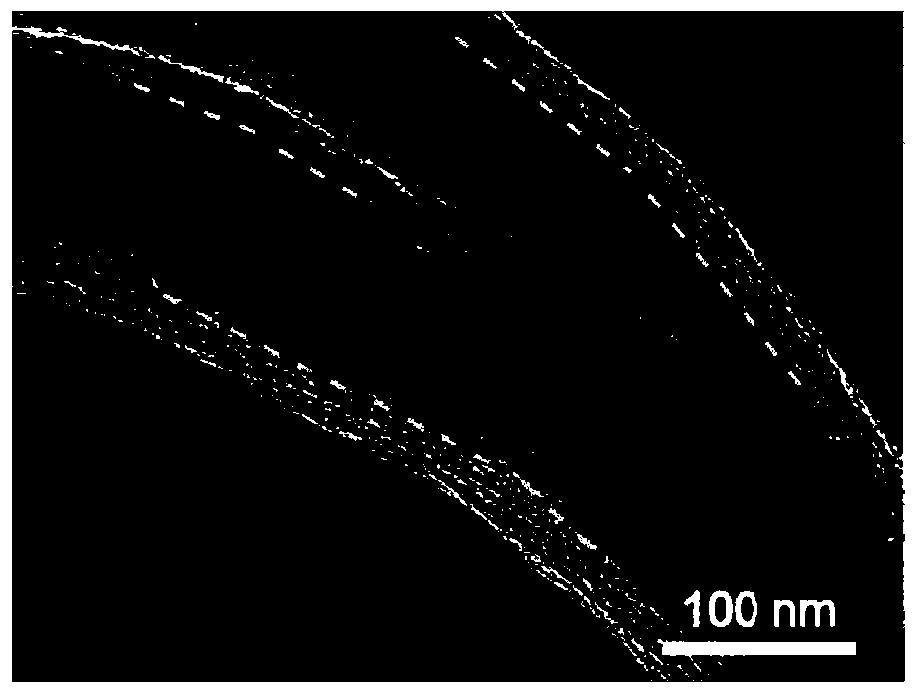

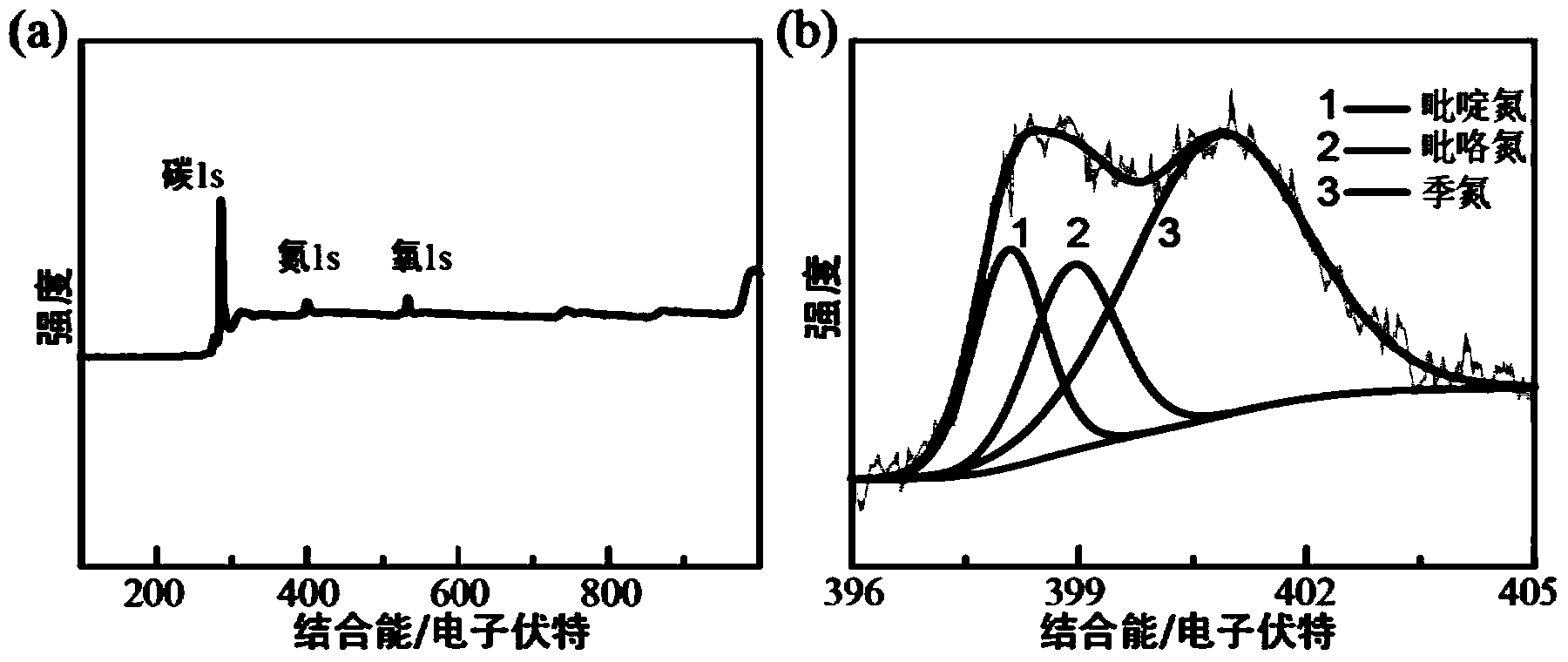

Composite material of nitrogen-doped porous carbon-wrapped carbon nano tube as well as preparation method and application of material

ActiveCN103706388AEasy to prepareEconomical method of preparationMaterial nanotechnologyPhysical/chemical process catalystsCarbon layerPorous carbon

The invention relates to a composite material of a nitrogen-doped porous carbon-wrapped carbon nano tube as well as a preparation method and an application of the composite material. The preparation method comprises the following steps: dispersing the carbon nano tube in water, adding a carbon source to obtain a reaction system, subsequently performing hydrothermal reaction, performing thermal treatment on the carbon nano tube wrapped with a carbon layer on the surface, and a nitrogen source at the high temperature so as to obtain the composite material of the nitrogen-doped porous carbon-wrapped carbon nano tube. According to the preparation method, the carbon source is polymerized under a hydrothermal reaction condition so as to obtain the carbon layer, the outer surface of the carbon nano tube is wrapped with the carbon layer, subsequently the carbon layer is carbonized and decomposed to generate a porous structure under high temperature treatment, and at the same time, the gasified nitrogen source is diffused to the carbon layer through ducts to be subjected to in-situ doping. The composite material provided by the invention can be used as a cathode oxidation reduction catalyst of a fuel battery, is excellent in catalysis, and is high in oxidation activity when being compared with other nitrogen-doped materials reported in documents. The preparation method provided by the invention is simple and economic in process, convenient to operate and easy to achieve the large-scale production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

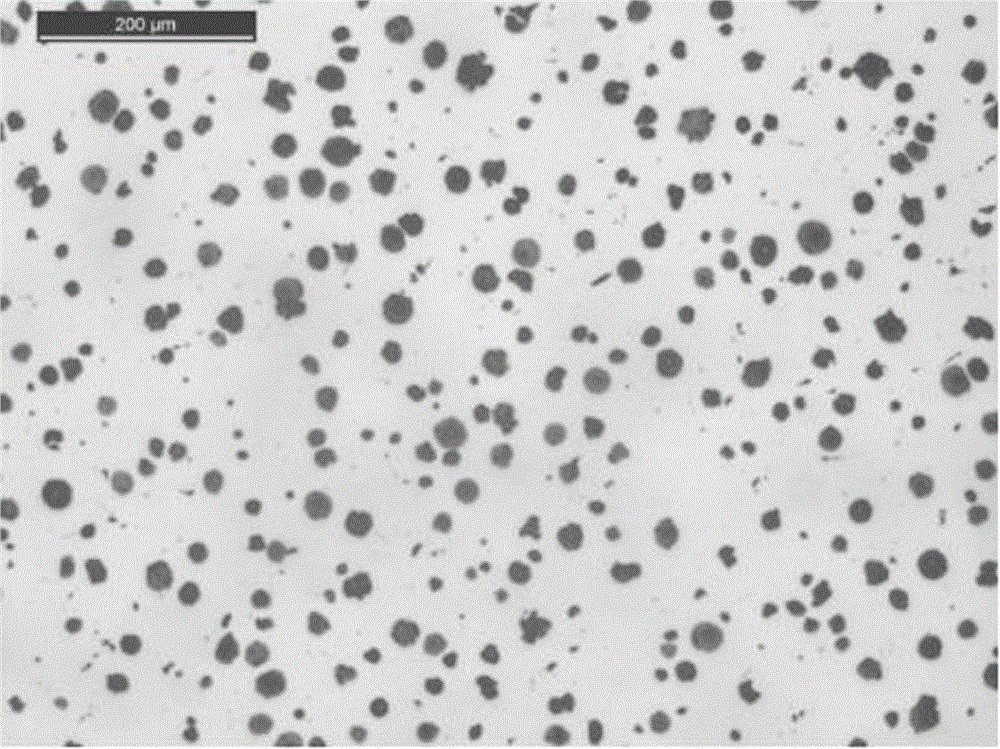

Nitrogen-containing nickel-free stainless steel and metallurgy forming process for powder thereof

The invention provides a nitrogenous nickel-free stainless steel and a powder-metallurgical molding technology, relating to the field of stainless steel production. Nitrogenous stainless steel powder and a prepared cementing agent are mixed evenly in a mixing machine and then crashed to injection molding feedstock; injection molding blanks with smooth surfaces and without macro defects are obtained by an injection molder under appropriate injection temperature and injection pressure; after degreasing by chlorylene solvent, thermal degreasing and presintering are carried out to the injection molding blanks, thermal degreasing blanks with certain strength and without defects are obtained; the thermal degreasing blanks are sintered and densified in nitrogen based atmosphere, therefore, products with higher density and more excellent performance can be obtained. The nitrogenous nickel-free stainless steel of the invention can solve the problems that resource price of the nickel-contained stainless steel is expensive and the contained nickel thereof is harmful to human health and the like, extends the application scope of nitrogenous austenitic stainless steel. The materials prepared by using the nitrogenous nickel-free stainless steel of the invention are better than traditionally smelted austenitic stainless steel in terms of performance and the nitrogenous nickel-free stainless steel of the invention is resource saving and environmentally friendly.

Owner:UNIV OF SCI & TECH BEIJING

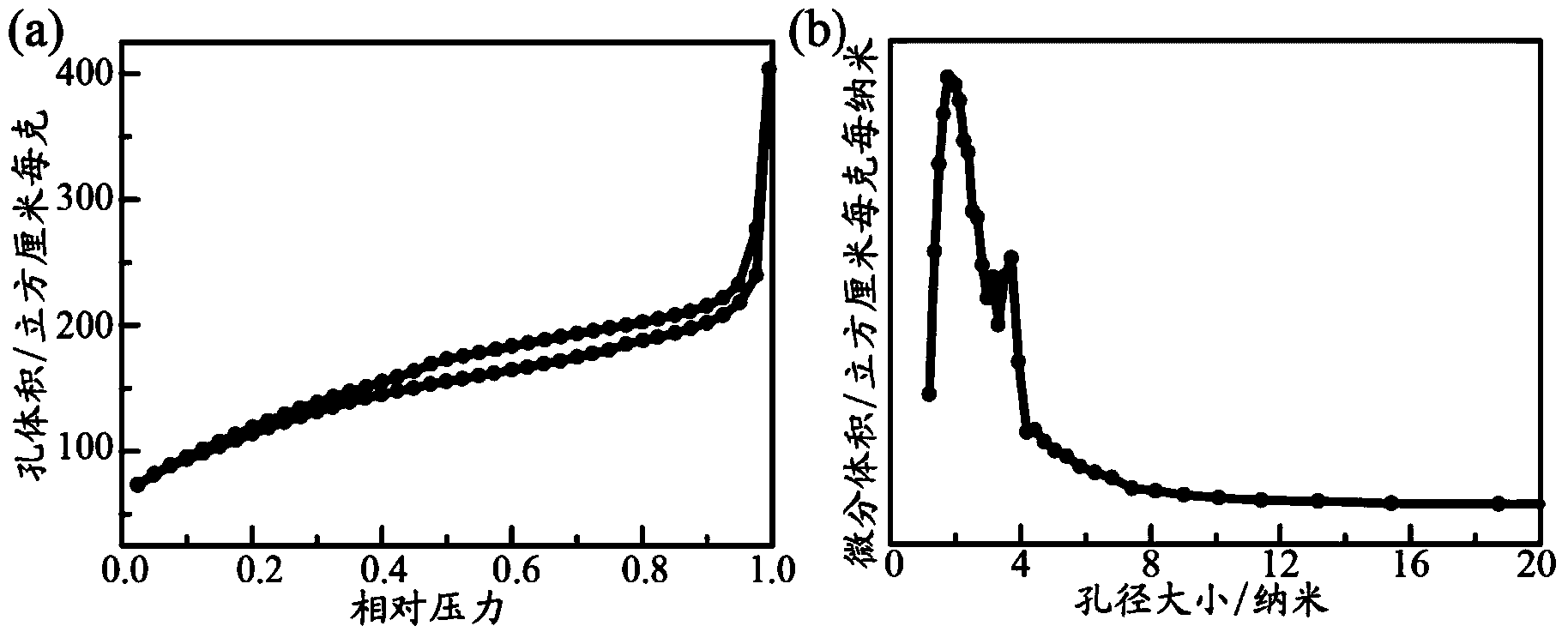

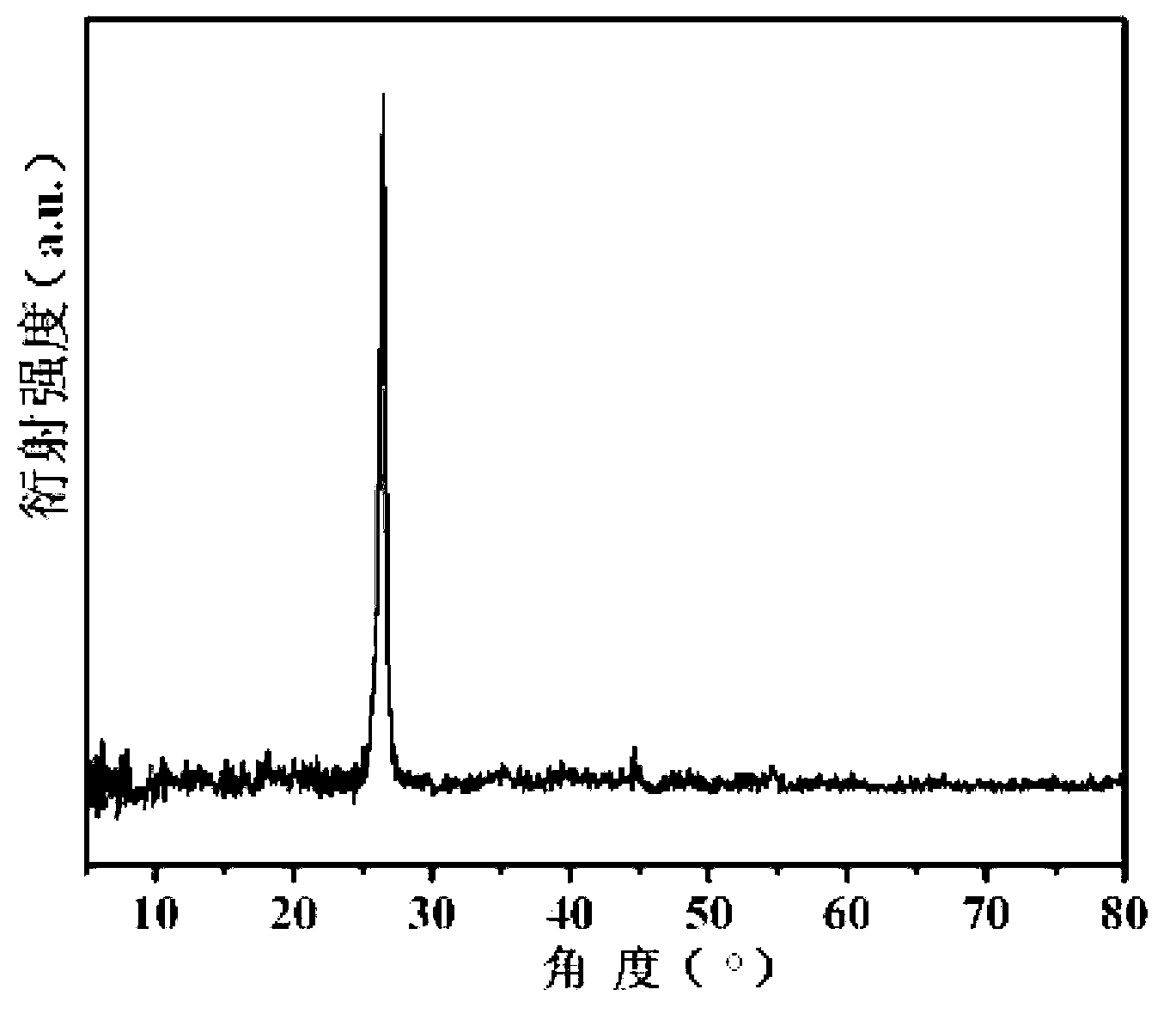

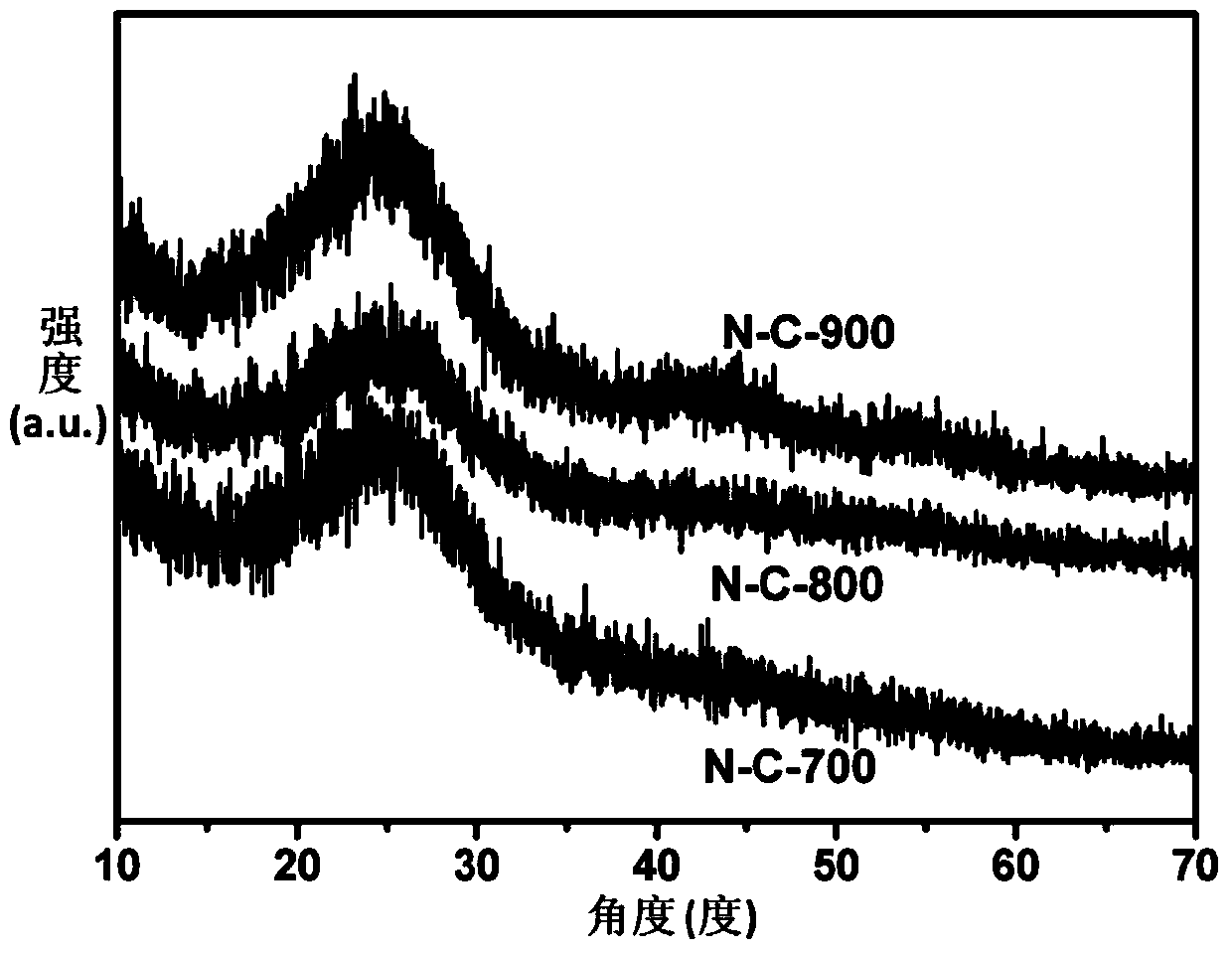

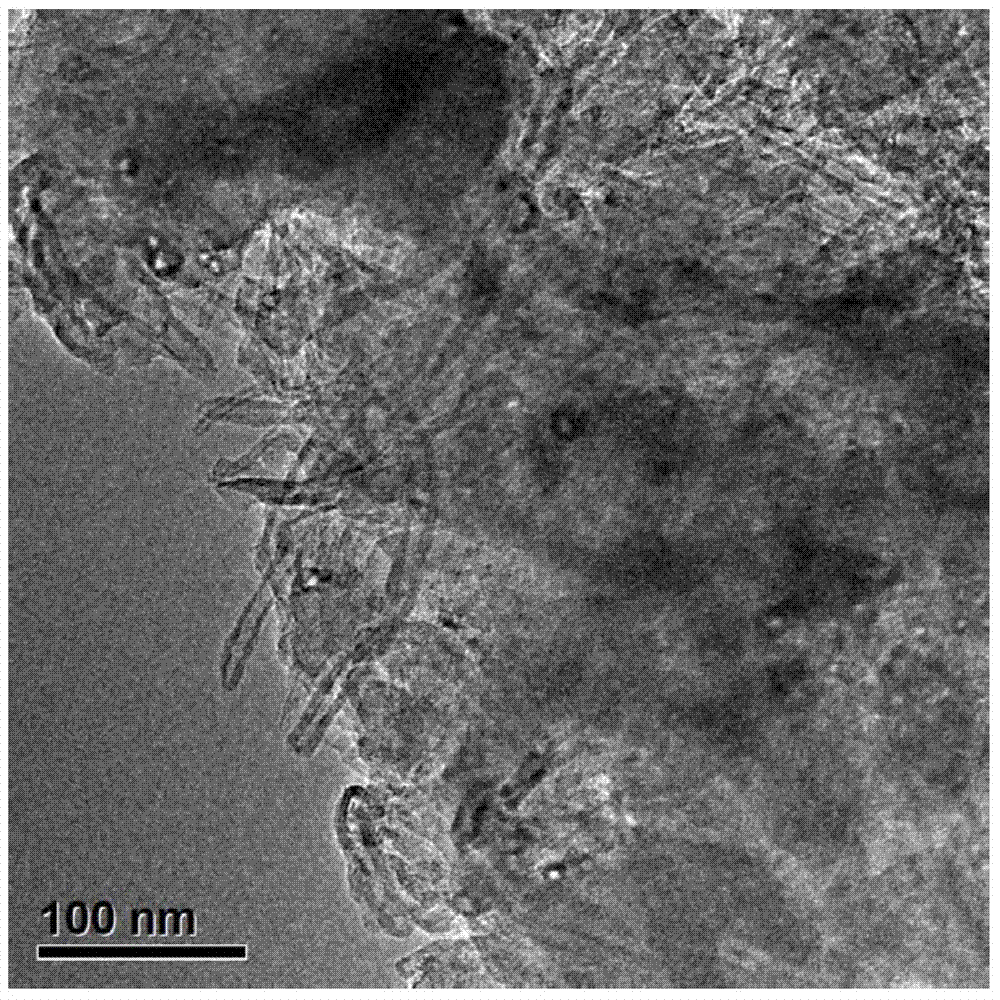

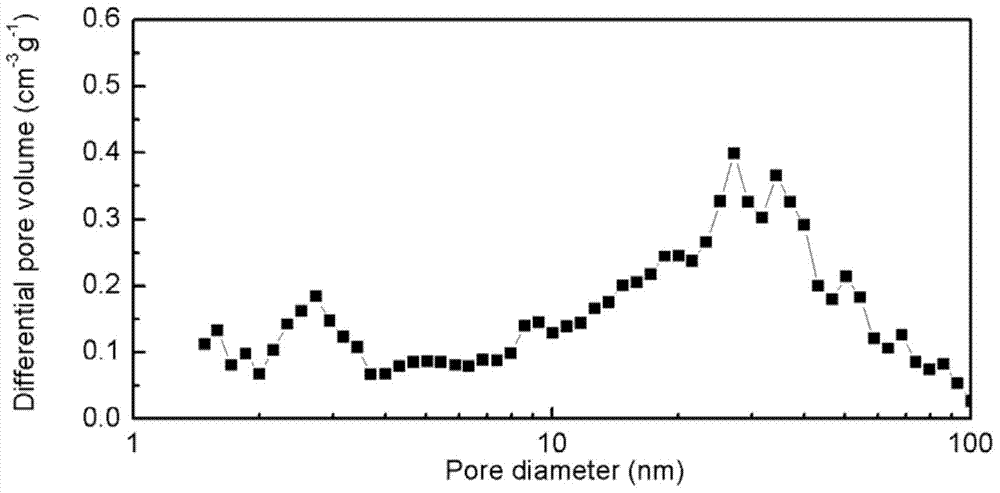

Preparation method of high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial

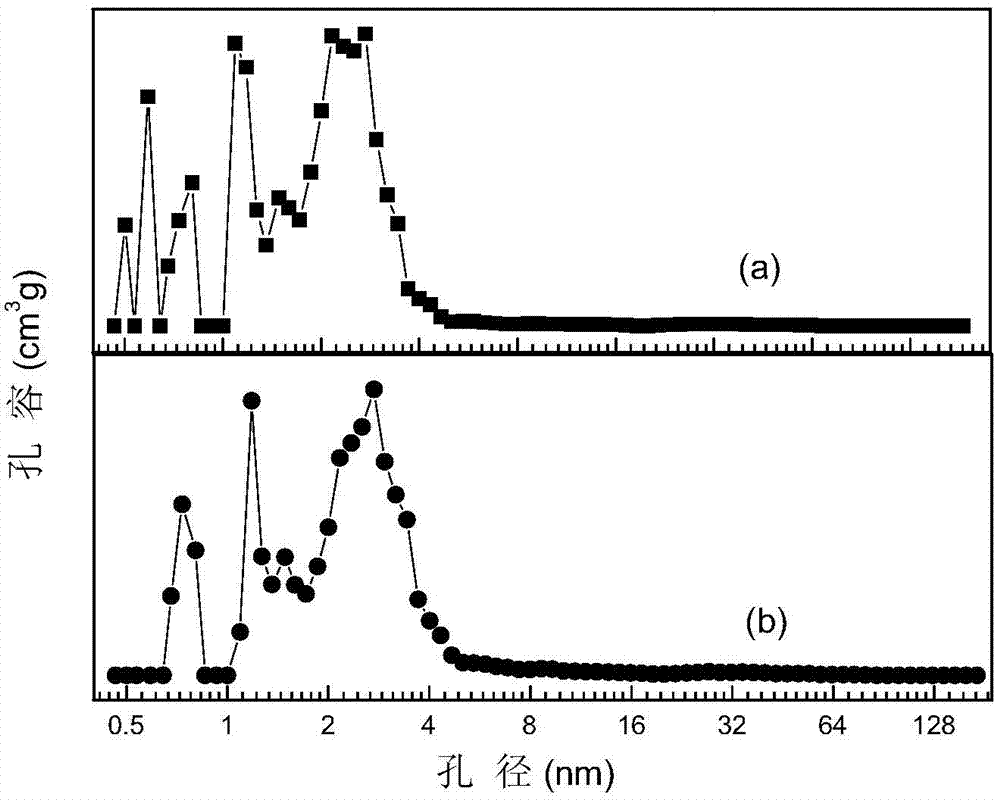

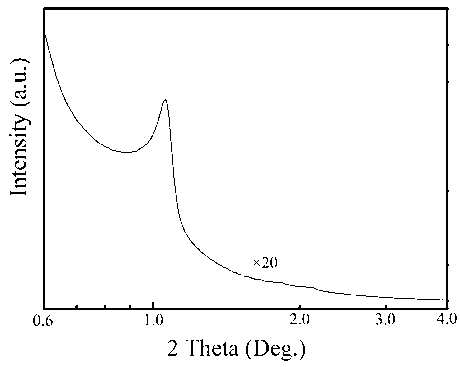

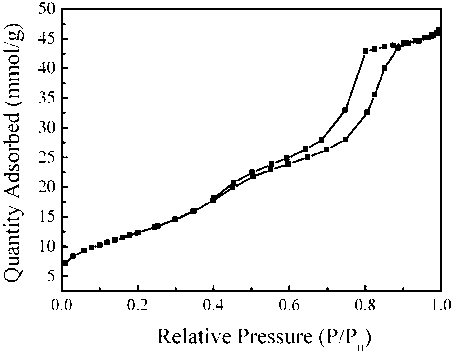

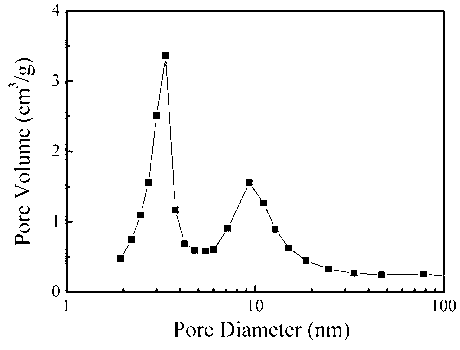

ActiveCN103303912AAchieve preparationHigh degree of graphitizationMaterial nanotechnologyNano-carbonLow nitrogenPore diameter

The invention discloses a preparation method of a high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial, relating to a preparation method of a carbon material and aiming at solving the problems of small specific surface area, low nitrogen content, low productivity, poor graphitizing degree and high cost of the nitrogen-doped graphitizing carbon nanomaterial prepared by the prior art. The preparation method comprises the steps of: I. preparing a complex; II. curing and carbonizing the complex; and III. carrying out acid leaching method treatment, and drying. Compared with an existing nitrogen-doped graphitizing carbon nanomaterial, the prepared high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has the advantages that the graphitizing degree is improved, the nitrogen content is increased, and the specific surface area is obviously increased, and the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has obvious pore diameter distribution. The preparation method is used for preparing the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial.

Owner:HEILONGJIANG UNIV

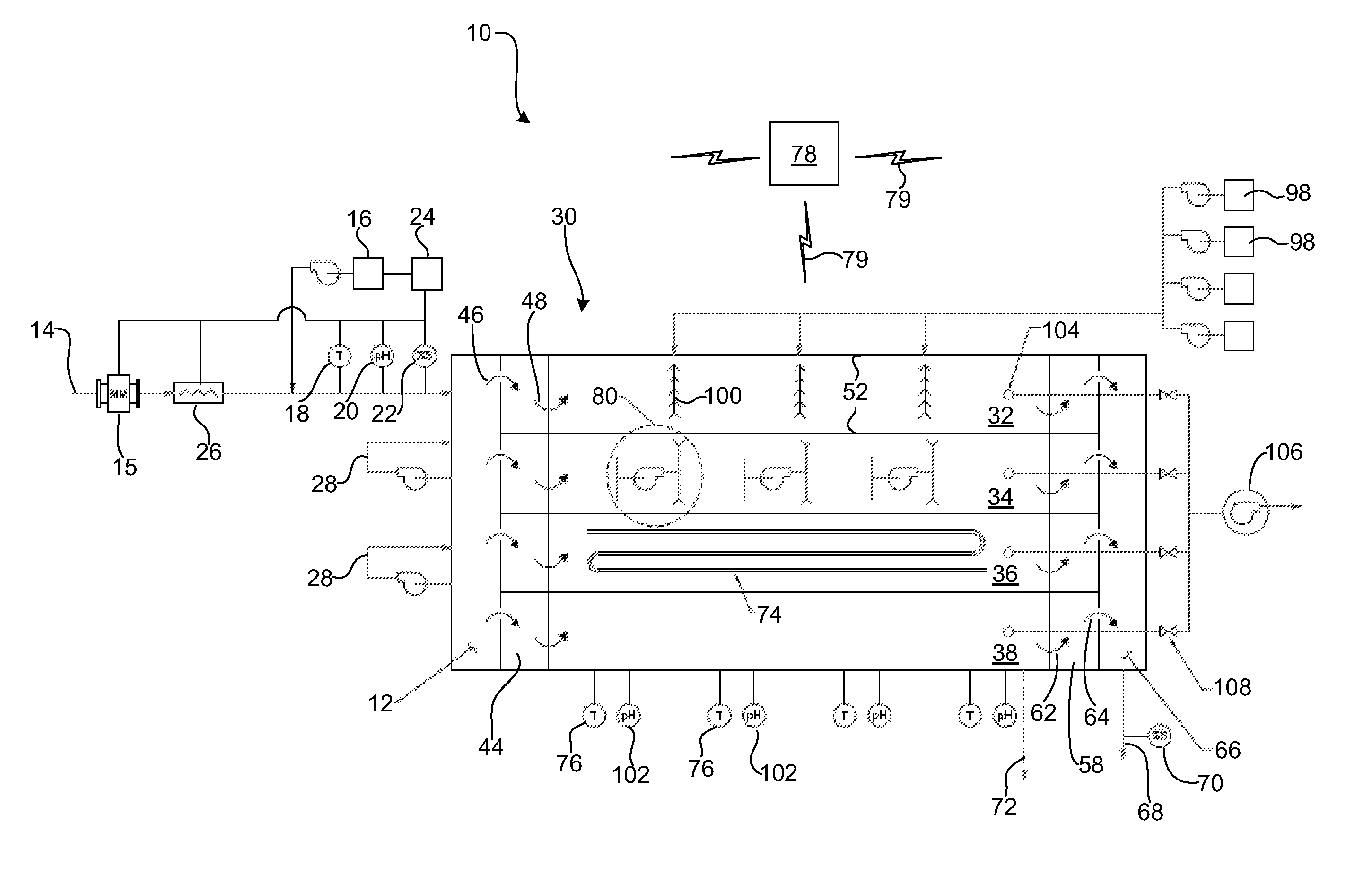

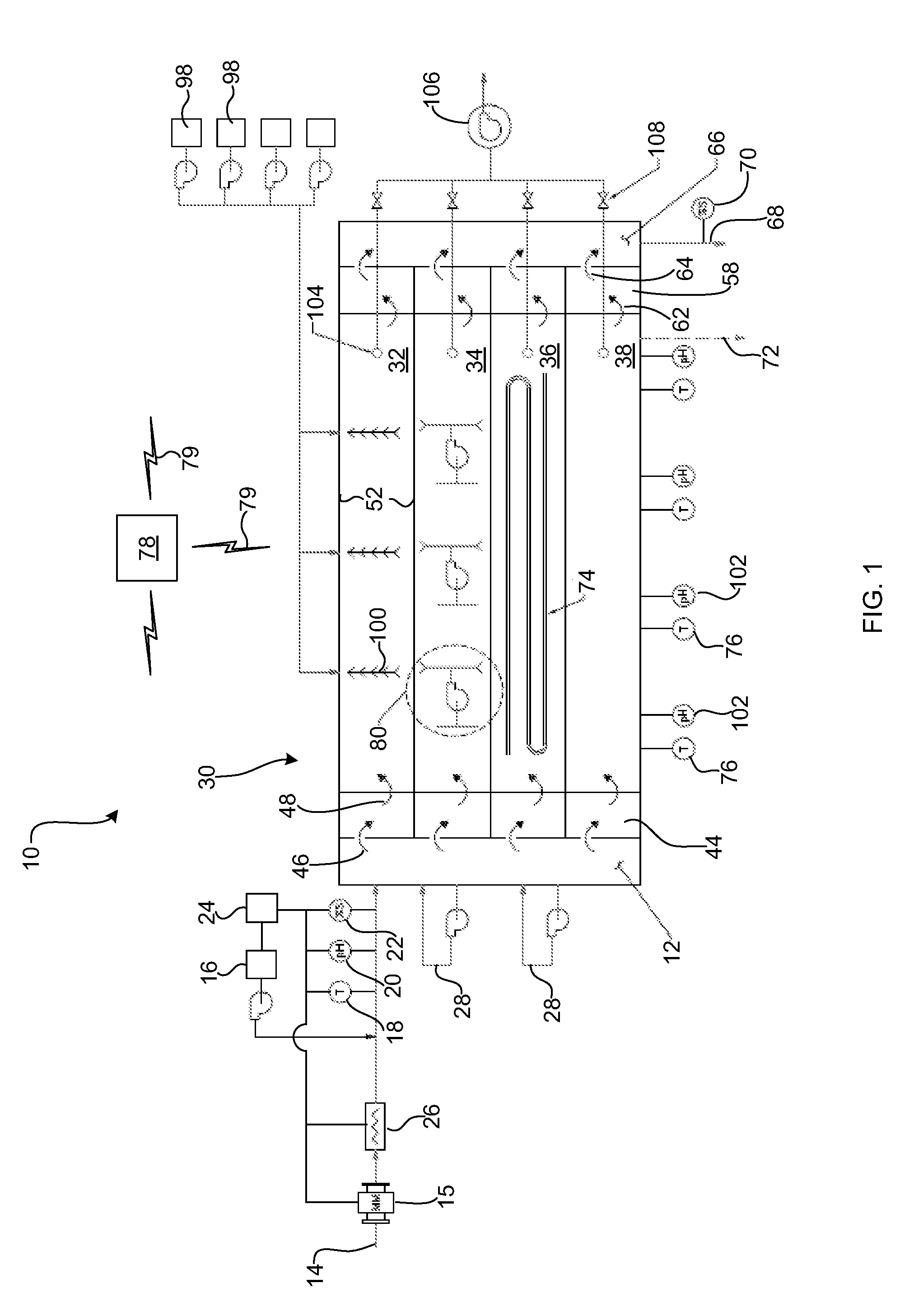

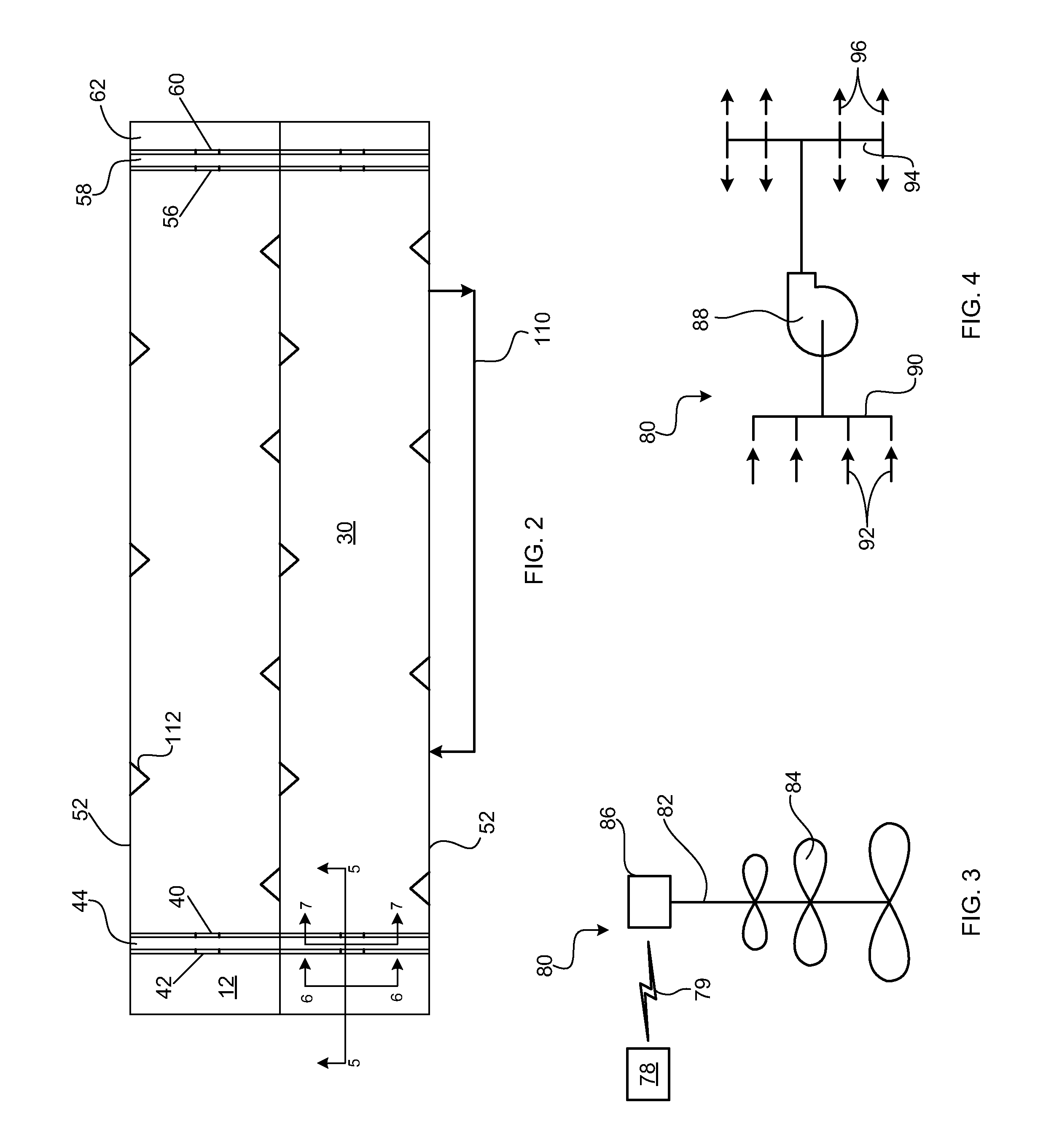

Anaerobic digester design and operation

ActiveUS20100032370A1High carbon contentHigh nitrogen contentBiological substance pretreatmentsIon-exchanger regenerationControl systemDigestion Treatment

An apparatus for the anaerobic digestion of solid waste is disclosed. The apparatus includes a pre-digestion treatment chamber and an anaerobic digester chamber coupled to the pre-digestion treatment chamber. A liquid suspension of solid waste is pretreated under aerobic conditions by heating to a desired pre-digestion temperature. One or more chemical or biological additives are added to the suspension of solid waste to improve the anaerobic digestibility of the solid waste. This may include enzymes to destruct poorly digestible solids and / or materials to provide a desired C:N ratio in the solid waste. The apparatus may include mixers, heaters, chemical or biological additives as needed, various sensors and probes, and a control system to monitor and control the anaerobic digestion process and maintain microbial health of the digester.

Owner:WATER SOLUTIONS TECH LLC

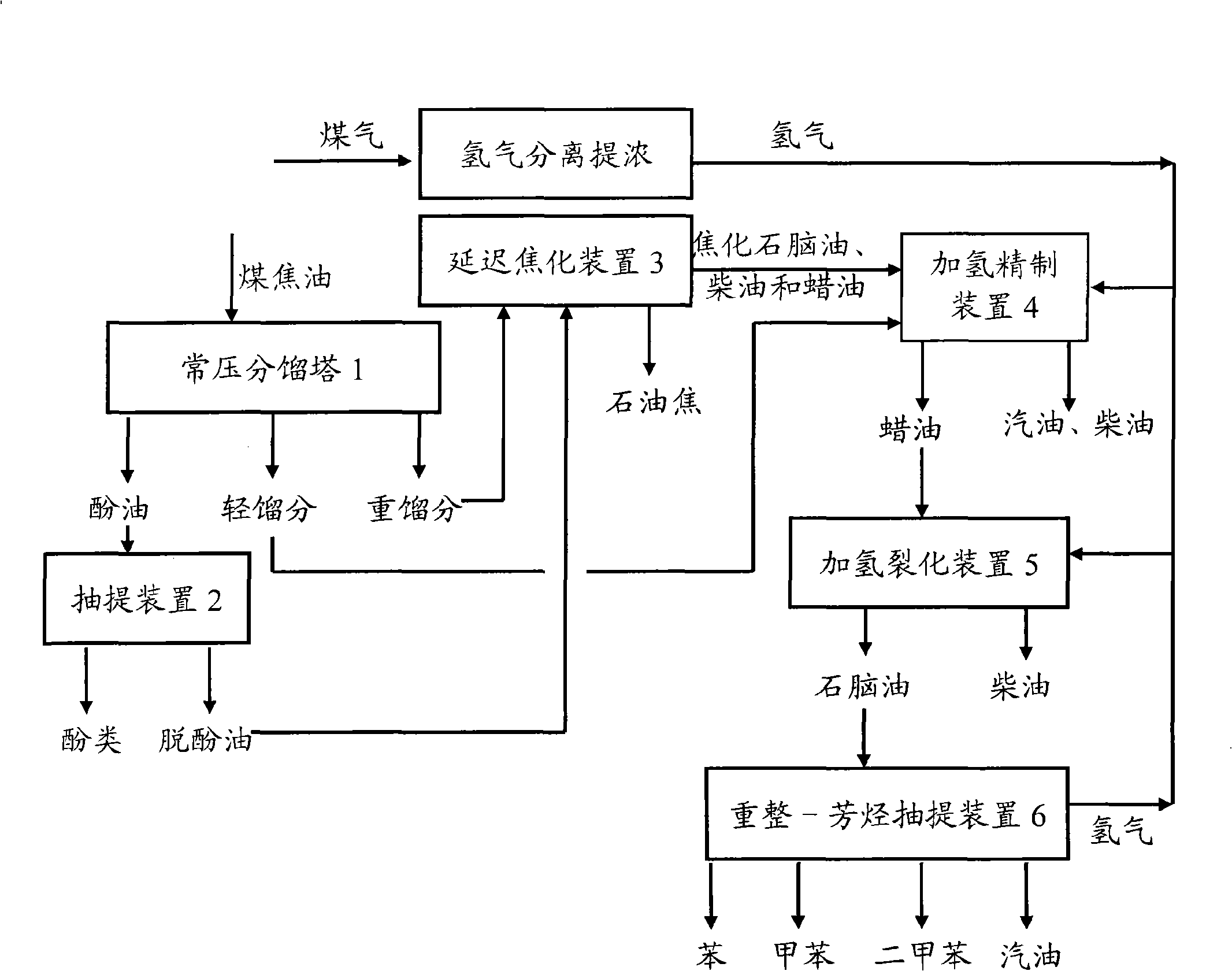

Medium and low temperature coal tar deep processing method

InactiveCN101538482AImprove performanceEfficient use ofThermal non-catalytic crackingCatalytic naphtha reformingCatalytic reformingFractionation

The invention discloses a medium and low temperature coal tar deep processing method. Medium and low temperature coke material is pretreated and fractionated to obtain light fraction, carbolic oil and heavy fraction, dephenolization treatment is carried out on the carbolic oil to obtain phenols product and dephenolized oil, the dephenolized oil and the above heavy fraction carry out pyrogenetic reaction jointly to obtain various carbonized products, wherein carbonized naphtha, at least one of carbonized diesel oil and carbonized wax oil is mixed with the light fraction obtained by material fractionation to carry out hydrofining and hydrocracking reaction, hydrogenated naphtha obtained by hydrocracking carries out catalytic reforming-aromatics extraction to obtain benzene, toluol, xylene, solvent oil and other products. Compared with the prior art, gasoline fraction and diesel oil fraction obtained by the inventive method are clean and stable in properties. In addition, the invention can produce a plurality of chemical products with high added value, truly realizes the effective utilization of medium and low temperature coal tar, and greatly improves the service life of devices.

Owner:胜帮科技股份有限公司

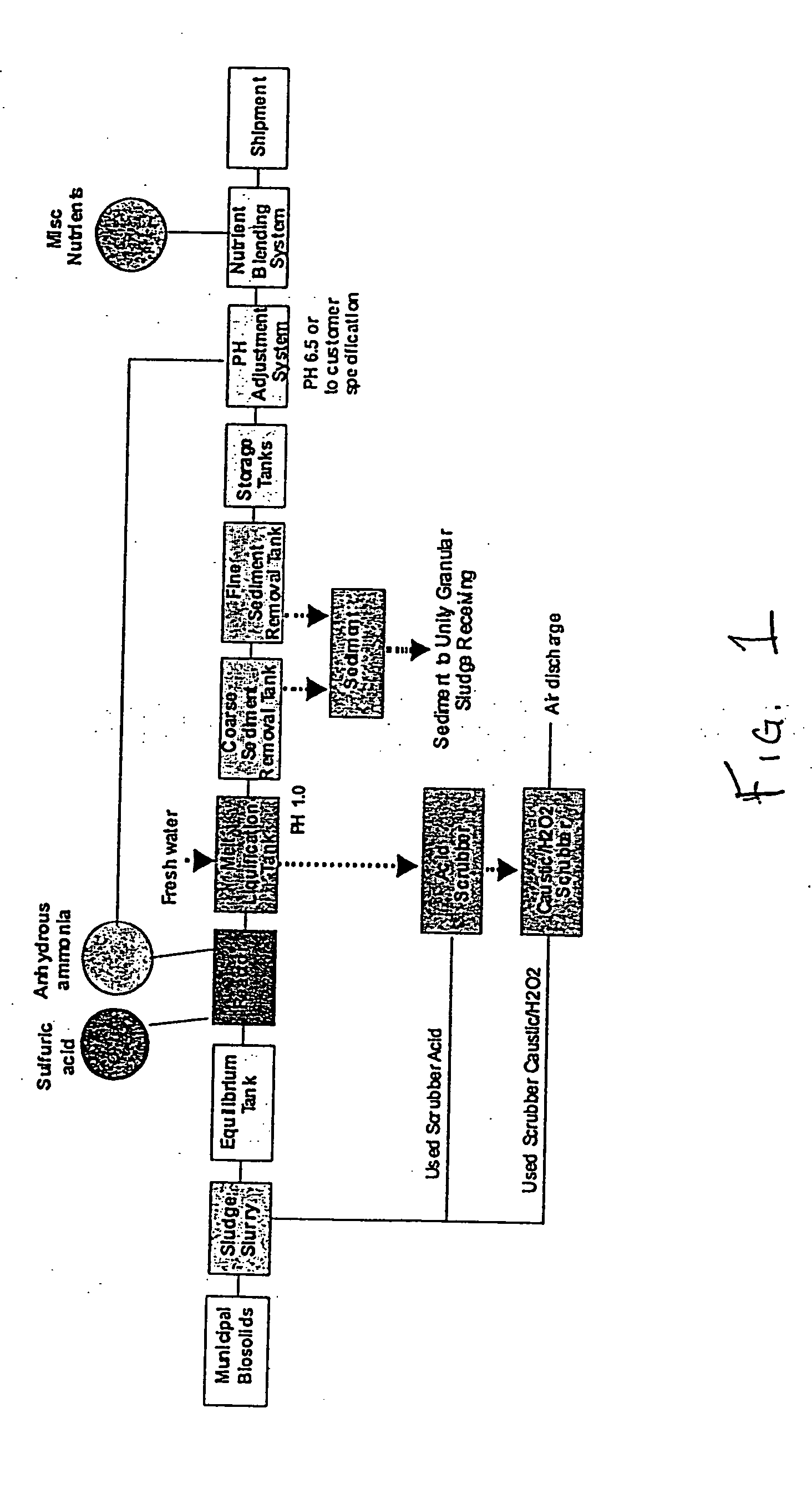

Liquid fertilizer incorporating biosolids and high concentrations of ammonium

InactiveUS20050005660A1High nitrogen contentEasy to transportBio-organic fraction processingAnimal corpse fertilisersHigh concentrationNitrogen

This invention is directed to a method of manufacturing a liquid agricultural fertilizer utilizing biosolids and high concentrations of nitrogen and other essential plant nutrients and the resulting products.

Owner:ENVIRONMENTAL TECH CAPITAL PARTNERS +1

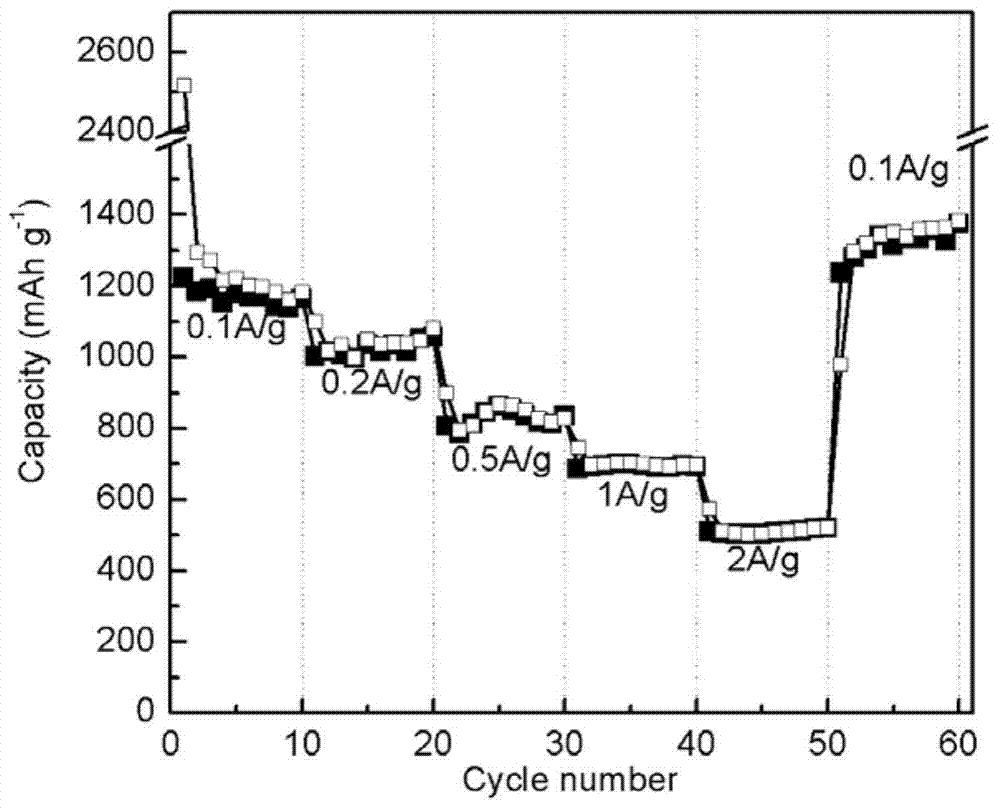

Preparation method of nitrogen-rich multimode beehive carbon-sulfur composite anode material

ActiveCN103746098ALarge specific surface areaHigh nitrogen contentPositive electrodesLi-accumulatorsArgon atmosphereOxide composite

The invention relates to a preparation method of a lithium sulphur battery composite anode material. The preparation method is as follows: preparing a mixed solution of carbon tetrachloride, a nitrogen source and carbonate, heating and flowing back to obtain a nitrogen-rich polymerization / carbonic acid salt compound; high temperature pyrolyzing in a nitrogen or argon atmosphere after drying the compound, so as to form the nitrogen-rich carbon / oxide compound; adding dilute acid to remove vestigial oxide, so as to form the nitrogen-rich multimode beehive carbon material of a multilevel porthole structure; uniformly mixing the nitrogen-rich multimode beehive carbon and sublimed sulfur, heat preserving under vacuum condition, injecting sulfur gas to the nitrogen-rich multimode beehive carbon material, so that the lithium sulphur battery composite positive material can be obtained. The composite anode material provided by the invention is alveolate, and has the advantages that portholes are abundant, sulfur content is high, sulfur particle can be distributed uniformly in the nitrogen-rich multimode beehive carbon material of the multilevel porthole structure, and the carbon sulfur particles can be combined more tightly, the material mechanical stability is high, discharge specific capacity is high, cycle performance is excellent, and technological process is simple, pollution is avoided, cost is low, and the method is liable to large scale production and application.

Owner:CENT SOUTH UNIV

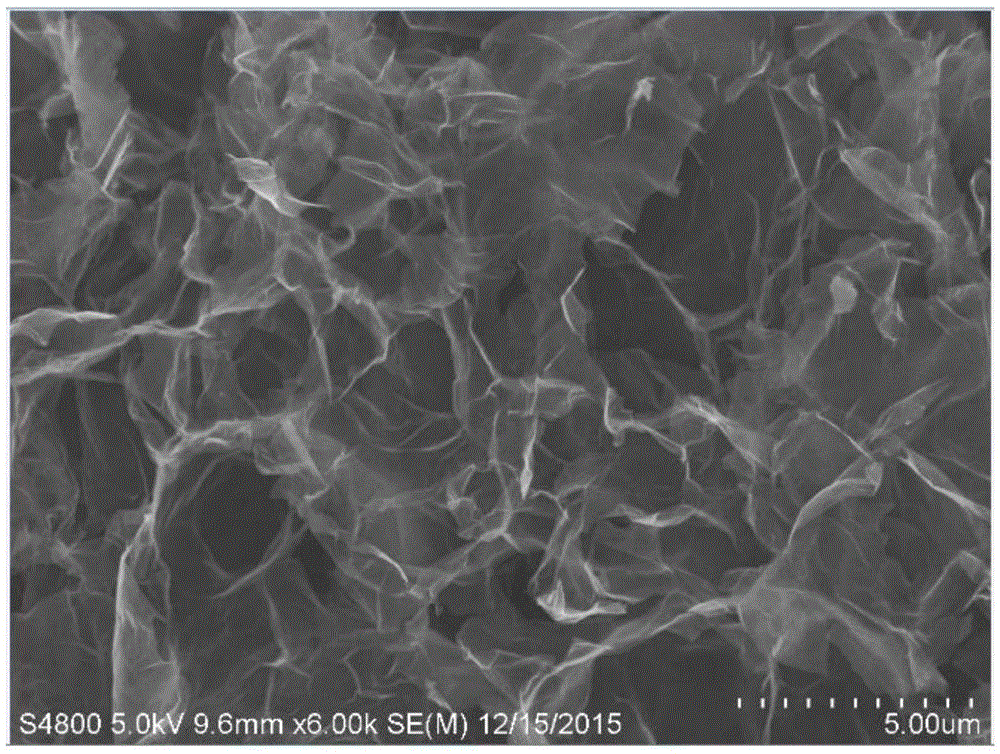

Preparation method of high-performance nitrogen-doped three-dimensional graphene

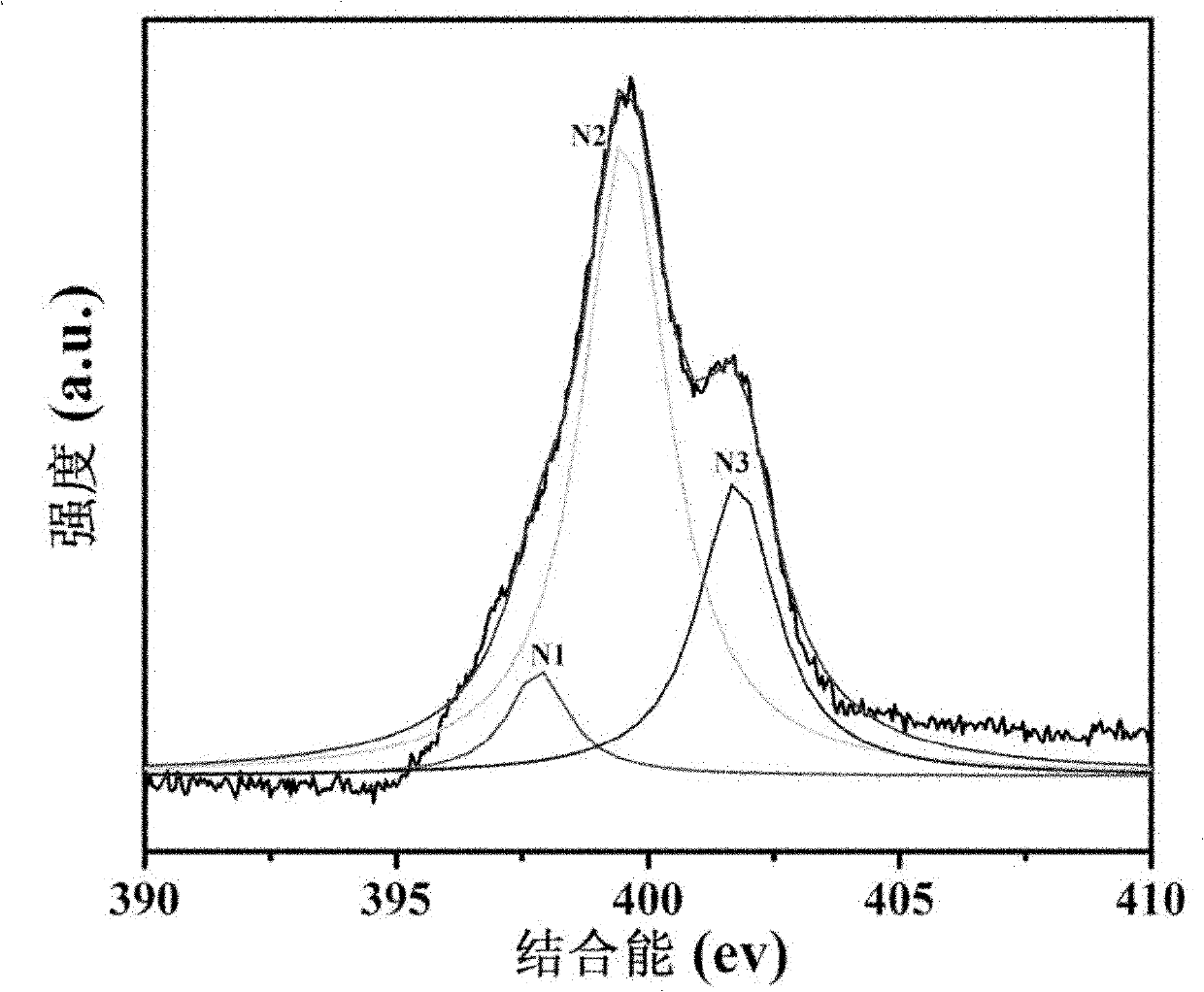

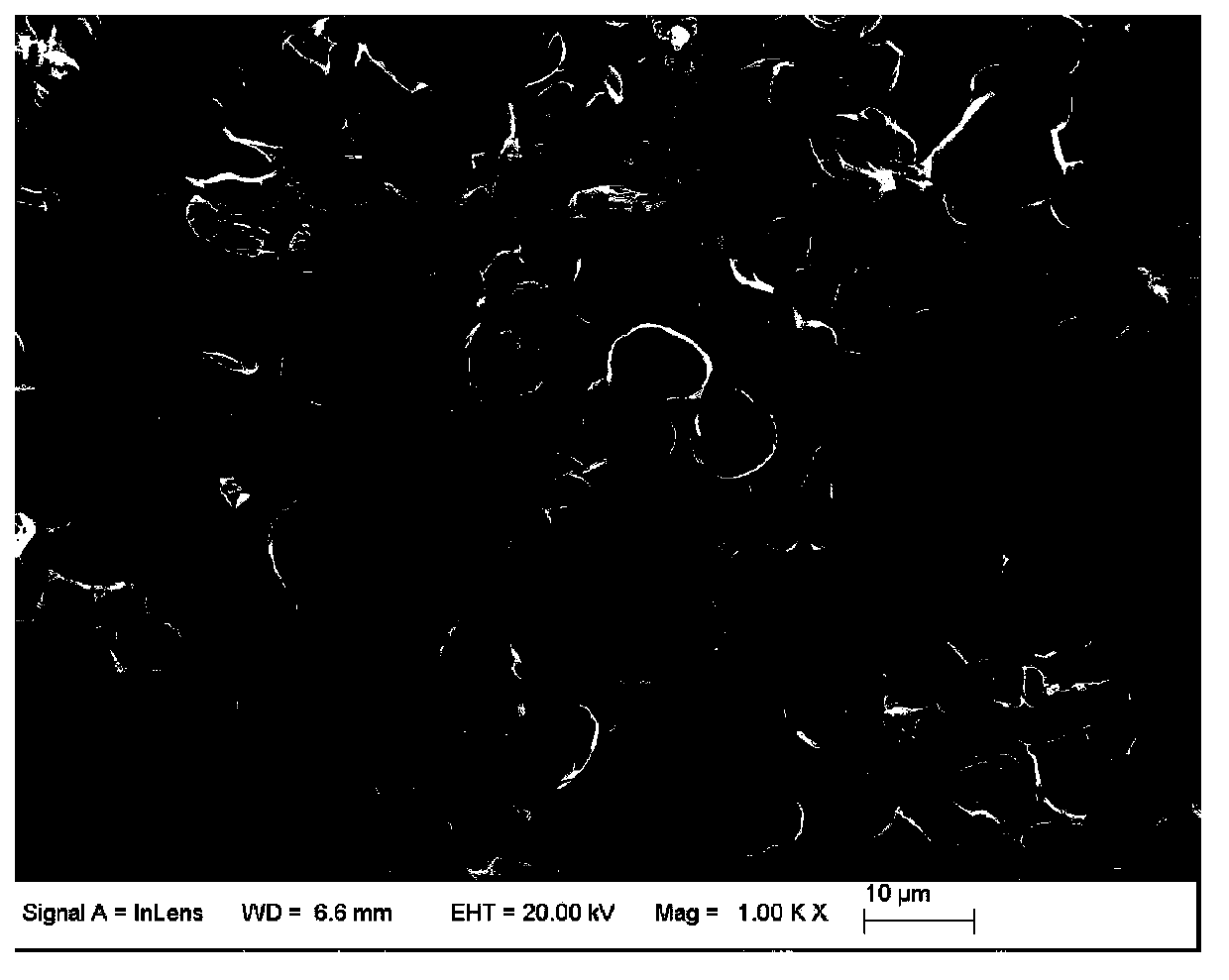

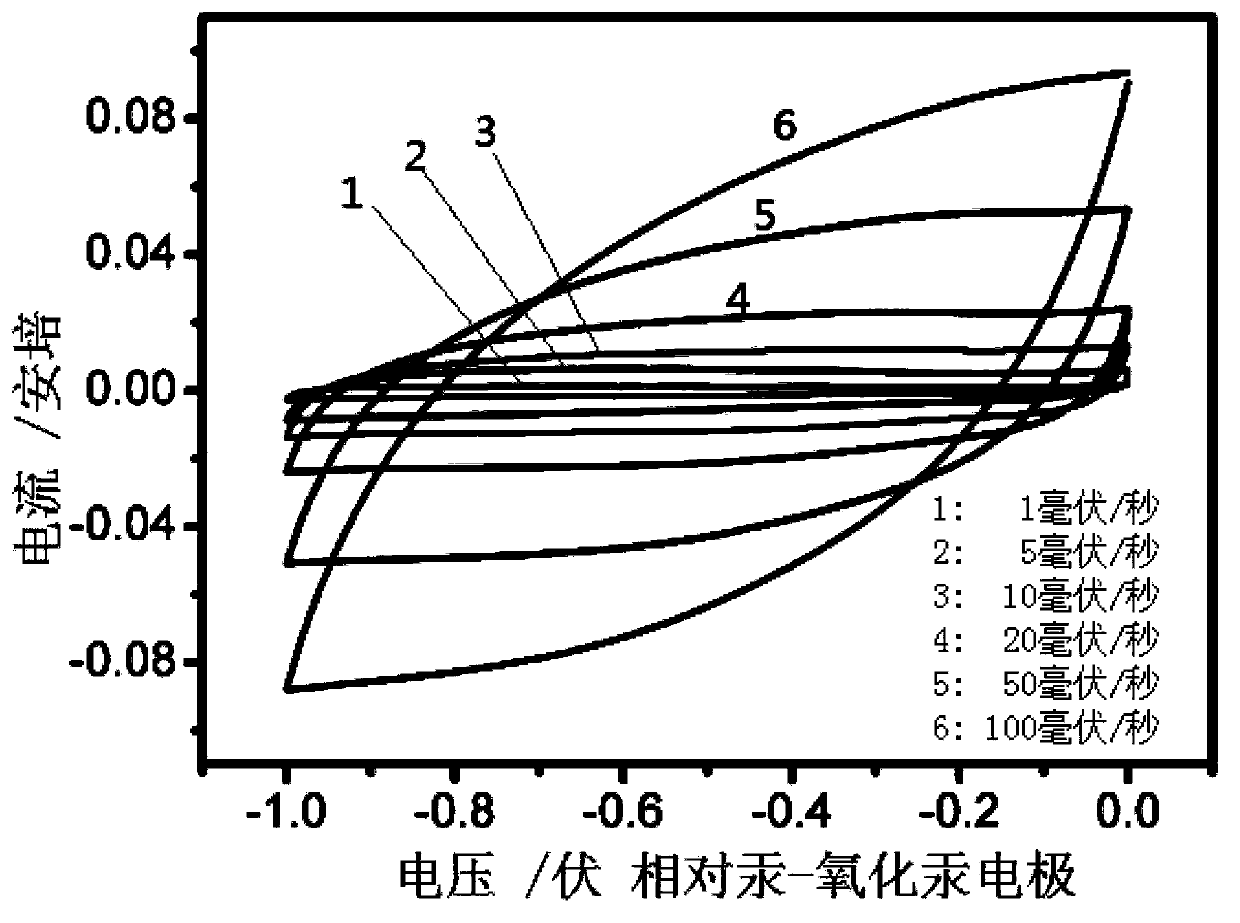

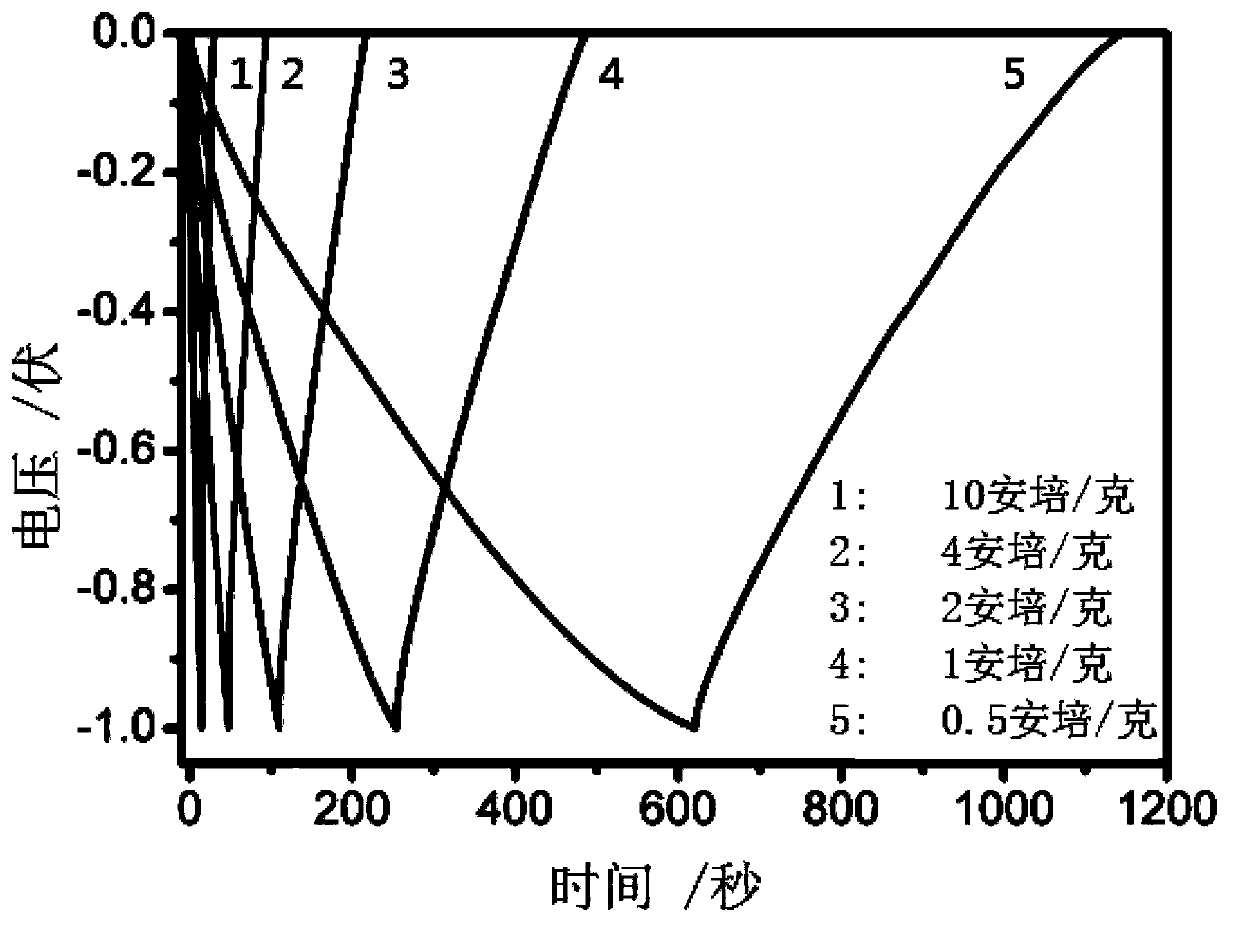

ActiveCN105645403AHigh nitrogen contentPlay a skeleton roleHybrid capacitor electrodesGrapheneNitrogen gasNitrogen doped graphene

The invention relates to the technical field of synthesizing of graphene materials and provides a preparation method of nitrogen-doped graphene. The preparation method includes: using an improved Hummers method to prepare continuous large-piece graphene oxide; using a hydrothermal method to prepare the graphene oxide into graphene of a porous three-dimensional structure; ultrasonically dispersing the graphene of the porous three-dimensional structure into an acid solution with the pH being 1-5, adding aniline, well mixing, adding ammonium persulfate, well mixing, and transferring the obtained mixed liquid into a teflon container for hydrothermal reaction so as to obtain a porous three-dimensional graphene-polyaniline compound; performing high-temperature treatment under nitrogen protection to allow polyaniline to decompose out nitrogen sources so as to obtain the nitrogen-doped porous three-dimensional graphene. The method has the advantages that the nitrogen-doped graphene with high nitrogen content can be prepared, the structure of the three-dimensional graphene can be kept, the obtained nitrogen-doped porous three-dimensional graphene is good in electrochemical performance and quite suitable for being used for producing a super capacitor, and the method is convenient to operate and beneficial to industrial popularization.

Owner:NANJING UNIV OF POSTS & TELECOMM

Direct drawing type waterless planographic original form plate

InactiveUS6096476AHigh nitrogen contentHigh degreePhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringHeat sensitive

PCT No. PCT / JP96 / 03296 Sec. 371 Date Oct. 27, 1997 Sec. 102(e) Date Oct. 27, 1997 PCT Filed Nov. 8, 1996 PCT Pub. No. WO97 / 17208 PCT Pub. Date May 15, 1997A directly imageable raw plate for waterless planographic printing plate, in which a heat insulating layer, heat sensitive layer and ink repellent layer are formed in this order on a substrate, comprising physical properties of 5 to 100 kgf / mm2 in initial elastic modulus and 0.05 to 5 kgf / mm2 in 5% stress as tensile properties of the heat sensitive layer or the heat insulating layer or the laminate consisting of both the layers. It can be suitably used also for large printing presses and web offset printing presses requiring high printing durability, and makes it possible to obtain an economically advantageous printing plate.

Owner:TORAY IND INC

Cemented carbide tool and method of making

InactiveUS6998173B2High nitrogen contentPigmenting treatmentOther chemical processesNitrogen partial pressureAlloy

A coated cemented carbide tool, and a method for making the same, wherein the as-sintered substrate is formed by sintering in an atmosphere having at least a partial pressure and for a part of the time a nitrogen partial pressure.

Owner:KENNAMETAL INC

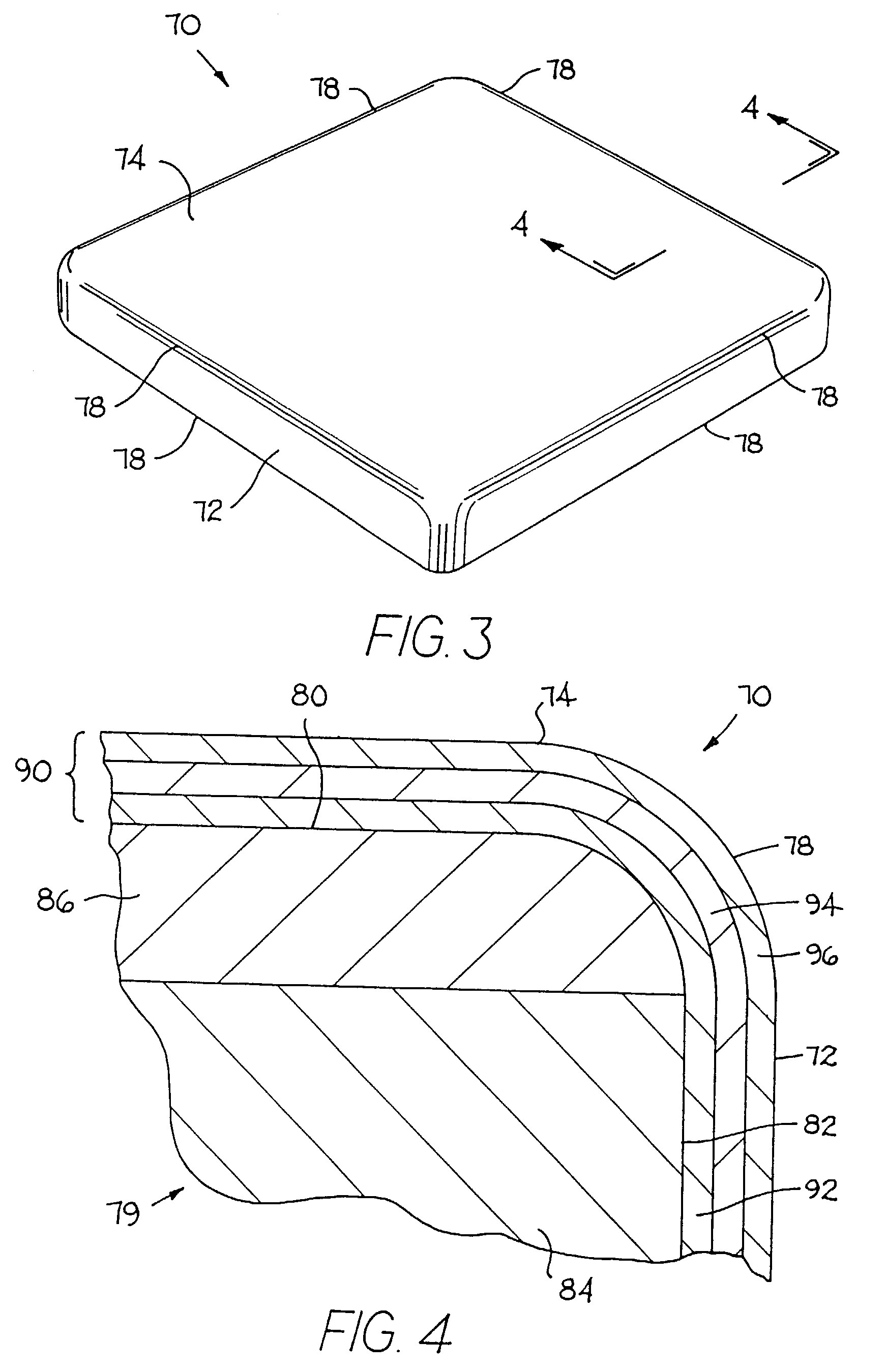

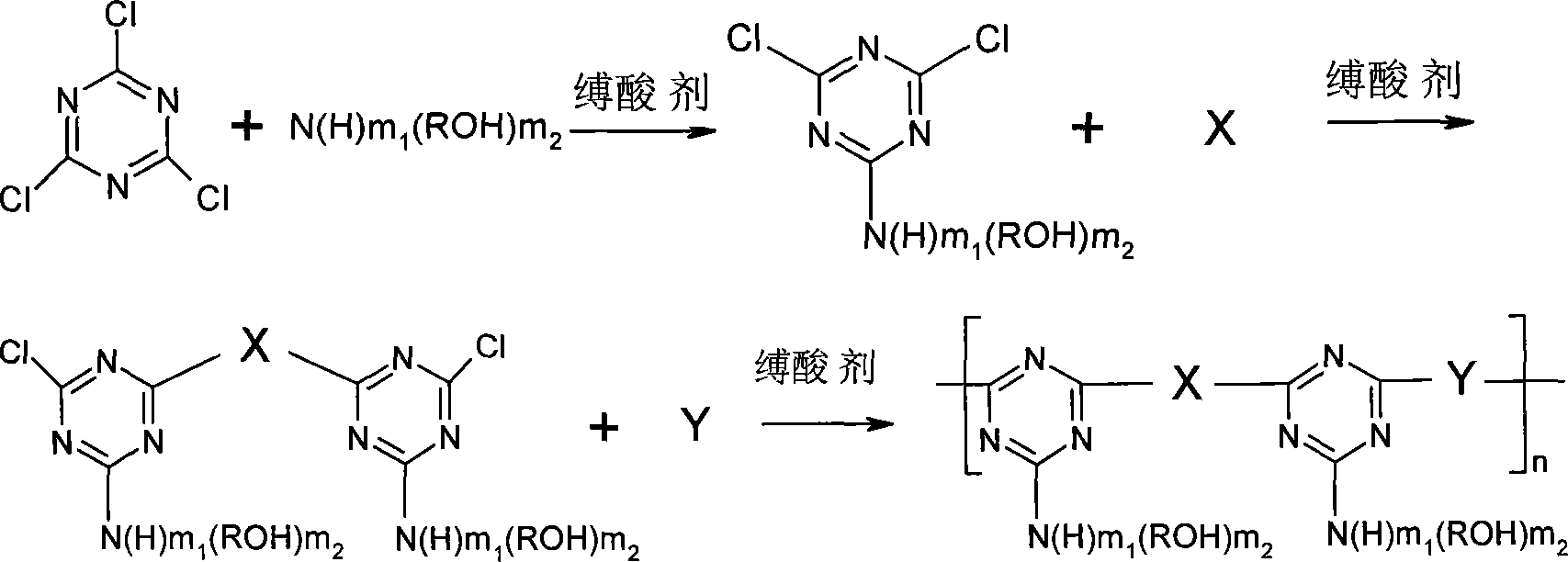

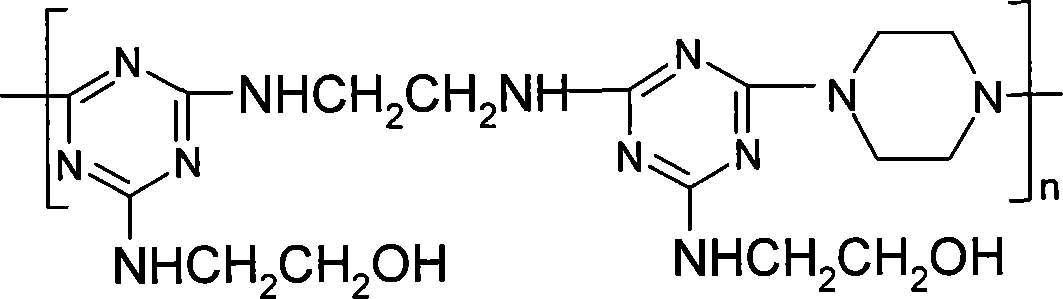

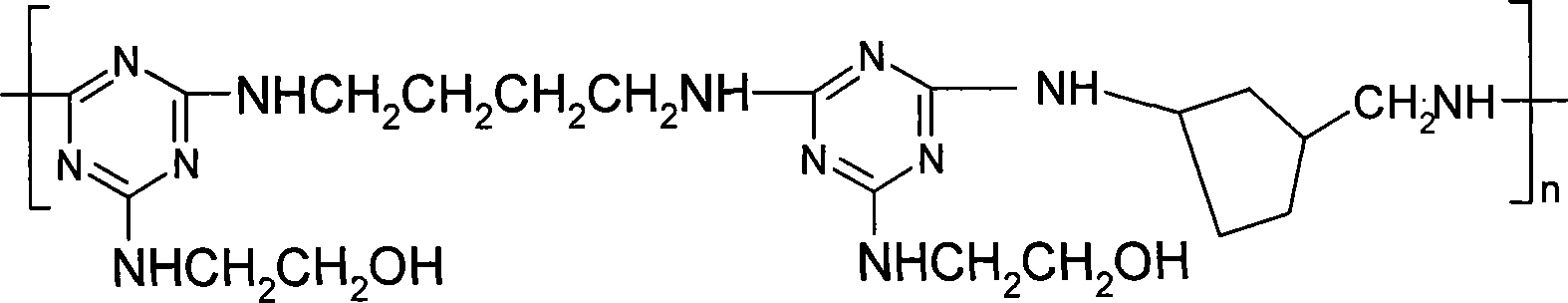

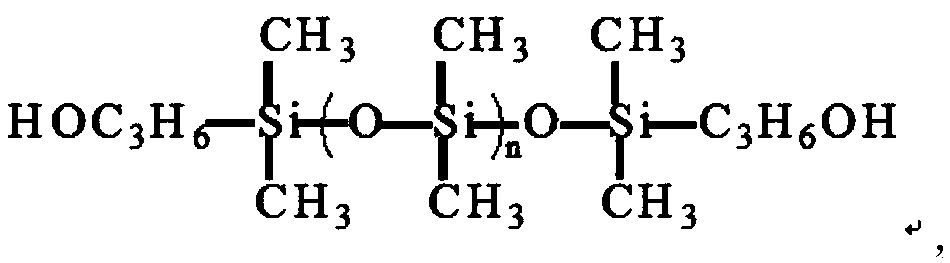

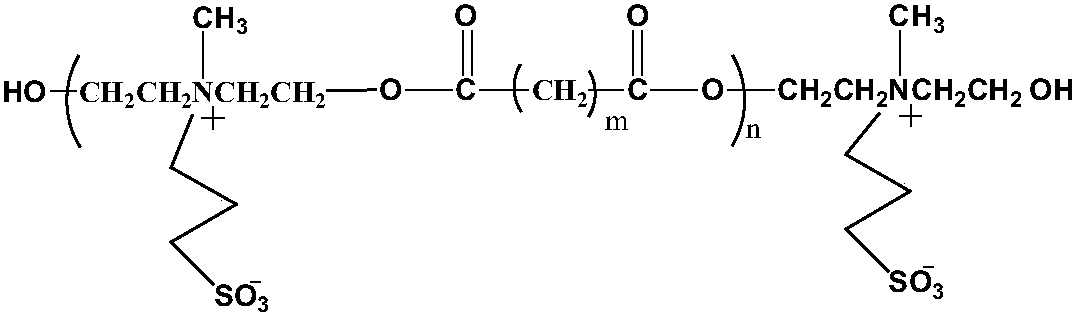

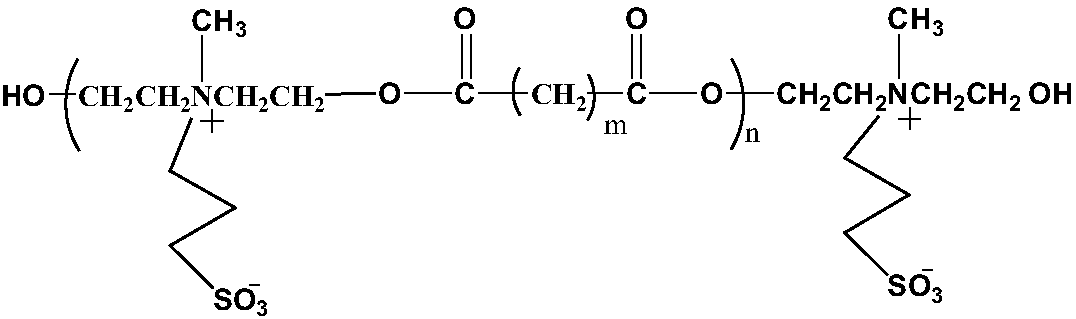

Triazine series oligomer and its synthesizing method

The invention relates to a triazine series oligomer and the compound method. The method has the following steps: adding solvent into cyanuric chloride, dropping alkylol amine and acid roping agent to gain substitute of cyanuric chloride; heating, dropping diamidogen and acid roping agent to gain the substitute of cyanuric chloride; adding diamidogen and acid roping agent into reaction solution, heating, pumping, washing, and drying to gain triazine series oligomer. The invention has strong charring and expanding ability, and good thermal stability. It has advantages of continuously reaction process, short reaction time, simple compounding technology, little organic solvent, and easy to recycle organic solvent.

Owner:NORTHEAST FORESTRY UNIVERSITY

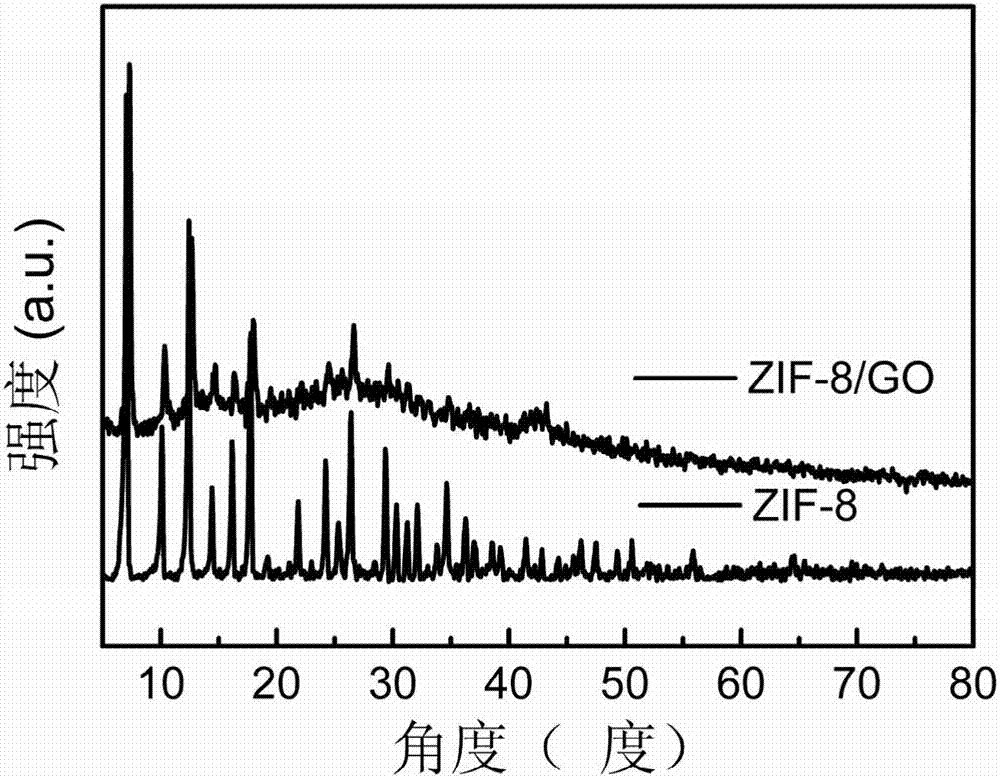

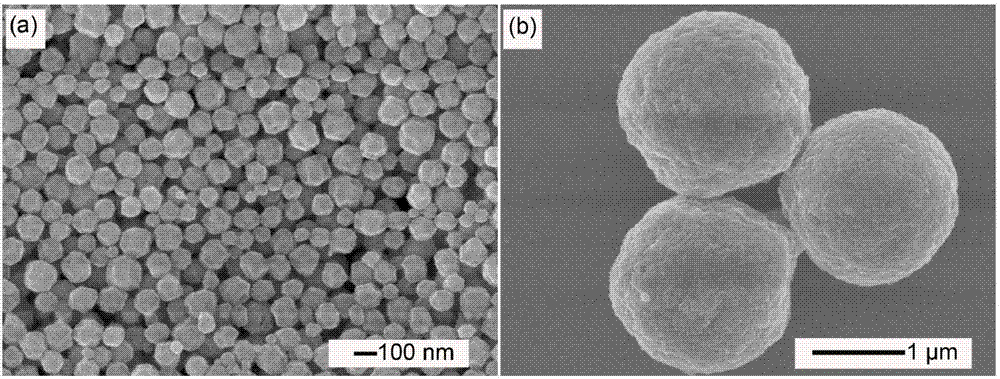

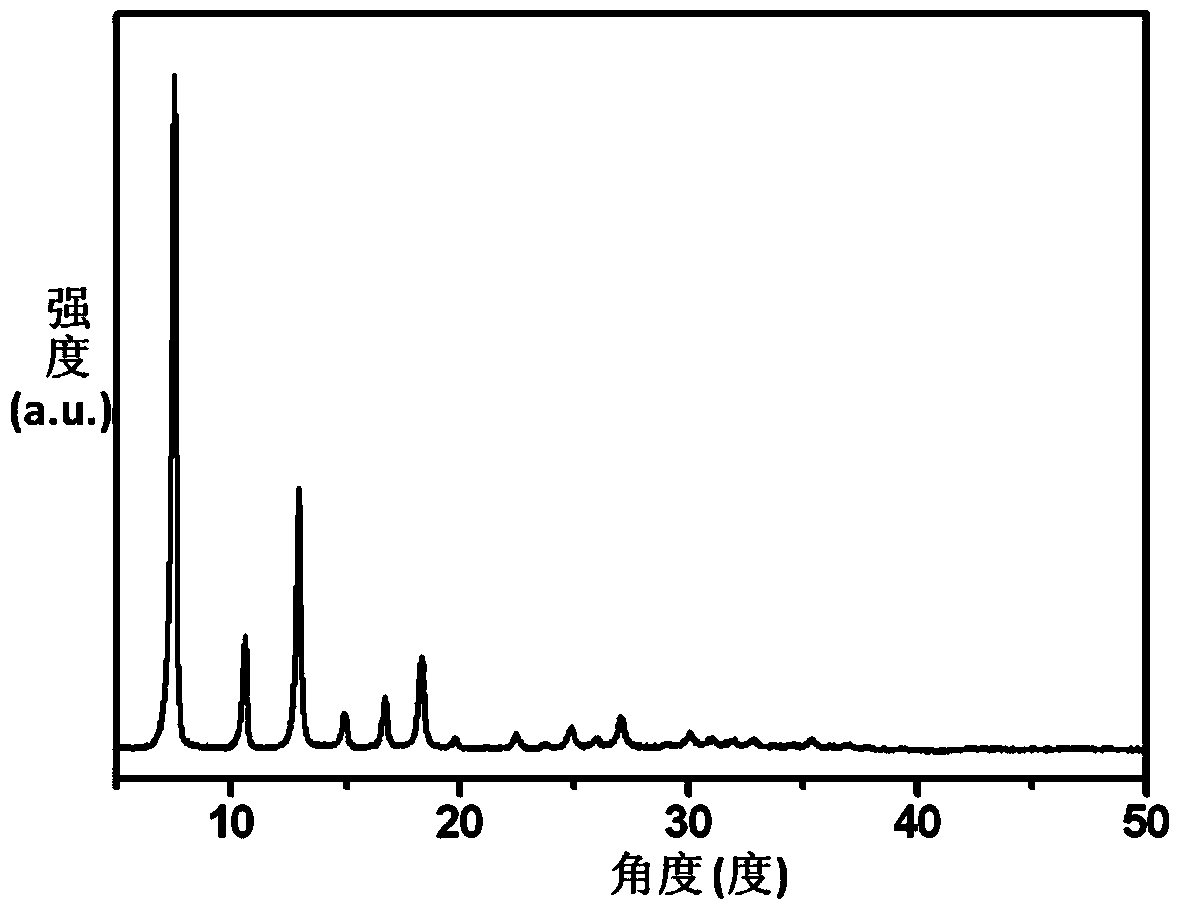

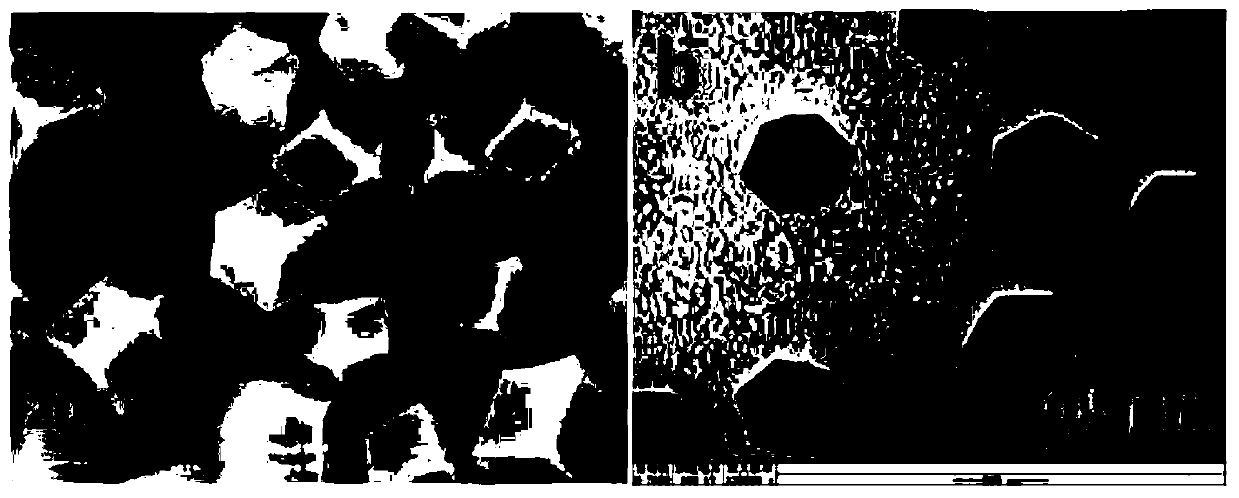

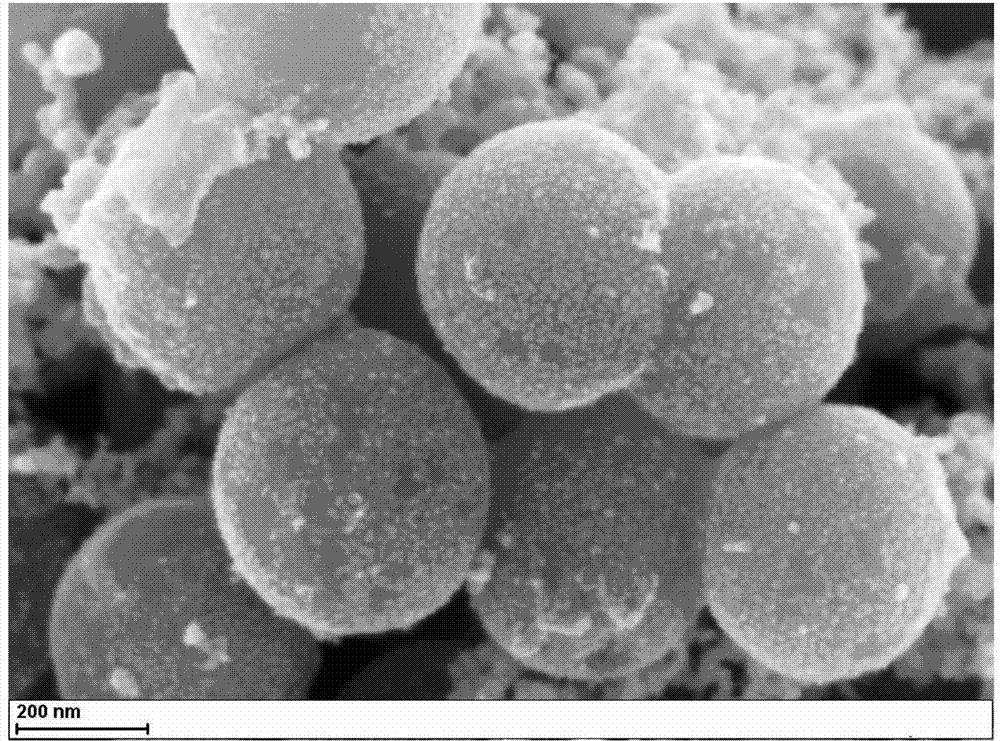

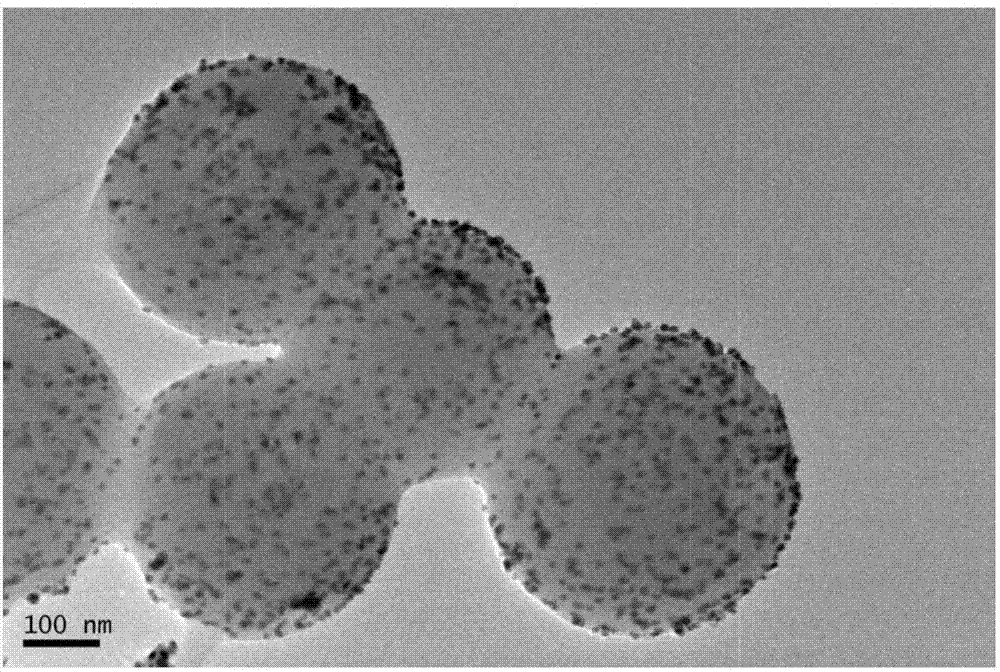

Preparation method of metal organic skeleton compound and oxidized graphene composite microspheres having uniform appearance

InactiveCN107497377AComposite uniformUniform sizeMicroballoon preparationMicrocapsule preparationMicrospherePorous carbon

The invention relates to a preparation method of metal organic skeleton compound and oxidized graphene composite microspheres having uniform appearance. The method comprises mixing a metal organic skeleton compound dispersion liquid with an oxidized graphene dispersion liquid, and performing spray drying to prepare composite microspheres. According to the spray drying method, the obtained microspheres are uniform in size and high in yield, and have the yield in a range of 70-85% and the average size at about 1.5 mum. To avoid agglomeration of oxidized graphene at a high temperature, ZIF-8 can be converted to nanometer porous carbon at a high temperature, and N-doped nanometer porous carbon and graphene composite microspheres having high specific surface area and nitrogen content. Through high-temperature carbonization treatment, the composite microspheres are improved in conductivity, and can be applied to aspects of CO2 adsorption, super capacitors, batteries, catalysis and separation.

Owner:SHANDONG UNIV

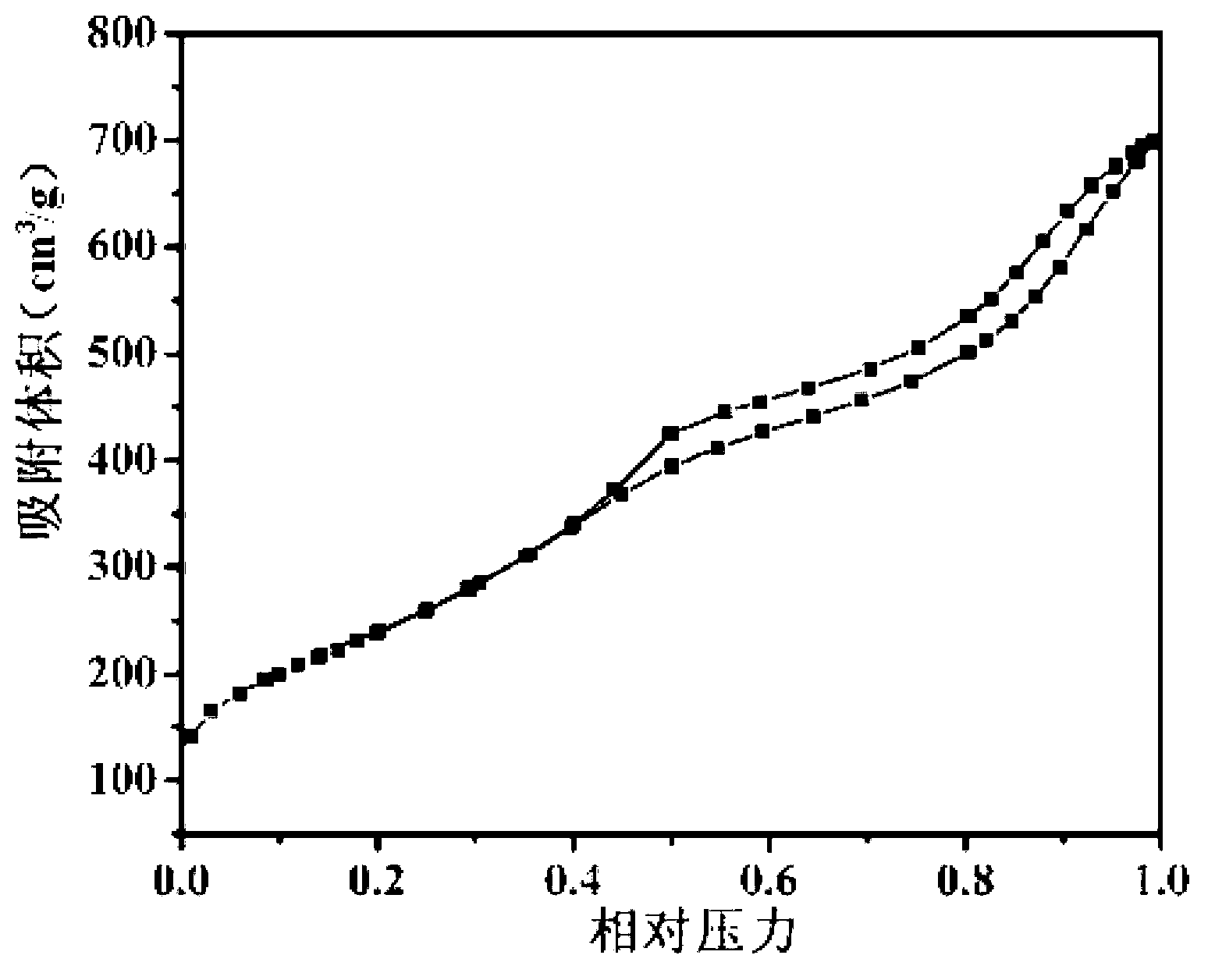

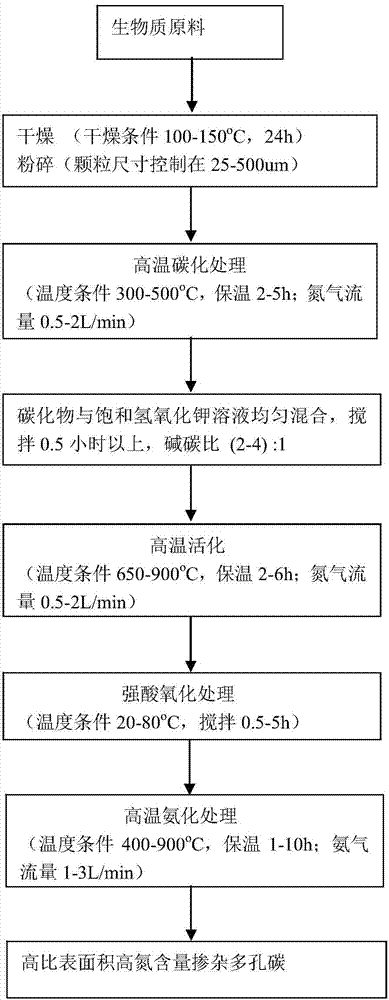

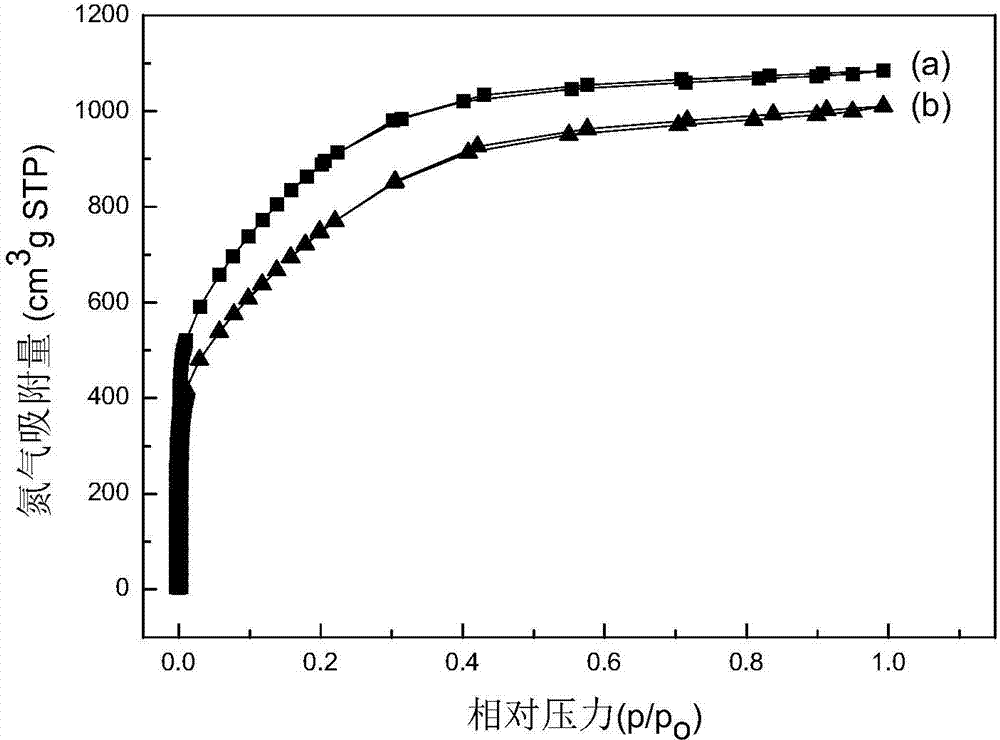

Preparation method of high nitrogen content-doped porous carbon with high specific surface area

ActiveCN103922305AHigh nitrogen contentNitrogen content controlCarbon preparation/purificationPorous carbonStrong acids

The invention discloses a preparation method of high nitrogen content-doped porous carbon with a high specific surface area. The preparation method comprises the following steps: drying and smashing a biomass raw material to obtain particles and carbonizing the particles in a nitrogen atmosphere at a high temperature to obtain carbide; then, dispersing the carbide in a potassium hydroxide solution, and stirring and drying to obtain an alkali and carbon mixture; activating the alkali and carbon mixture at the high temperature in the nitrogen atmosphere, and washing, filtering and drying to obtain the porous carbon material; uniformly dispersing the porous carbon material in a strong acid solution for oxidation treatment, and filtering, washing and drying to obtain an oxidized porous carbon material; and finally, ammonifying the oxidized porous carbon material at the high temperature in an ammonia atmosphere to obtain the high nitrogen content-doped porous carbon with the high specific surface area. The specific surface area of the doped porous carbon is 2500-3500<m2> / g, the pore diameter of the material is 0.5-6nm and the nitrogen content is 4-12%. The method disclosed by the invention is simple and effective, easy to operate, convenient for batch production on a large scale and suitable for application in industrial production.

Owner:TONGJI UNIV

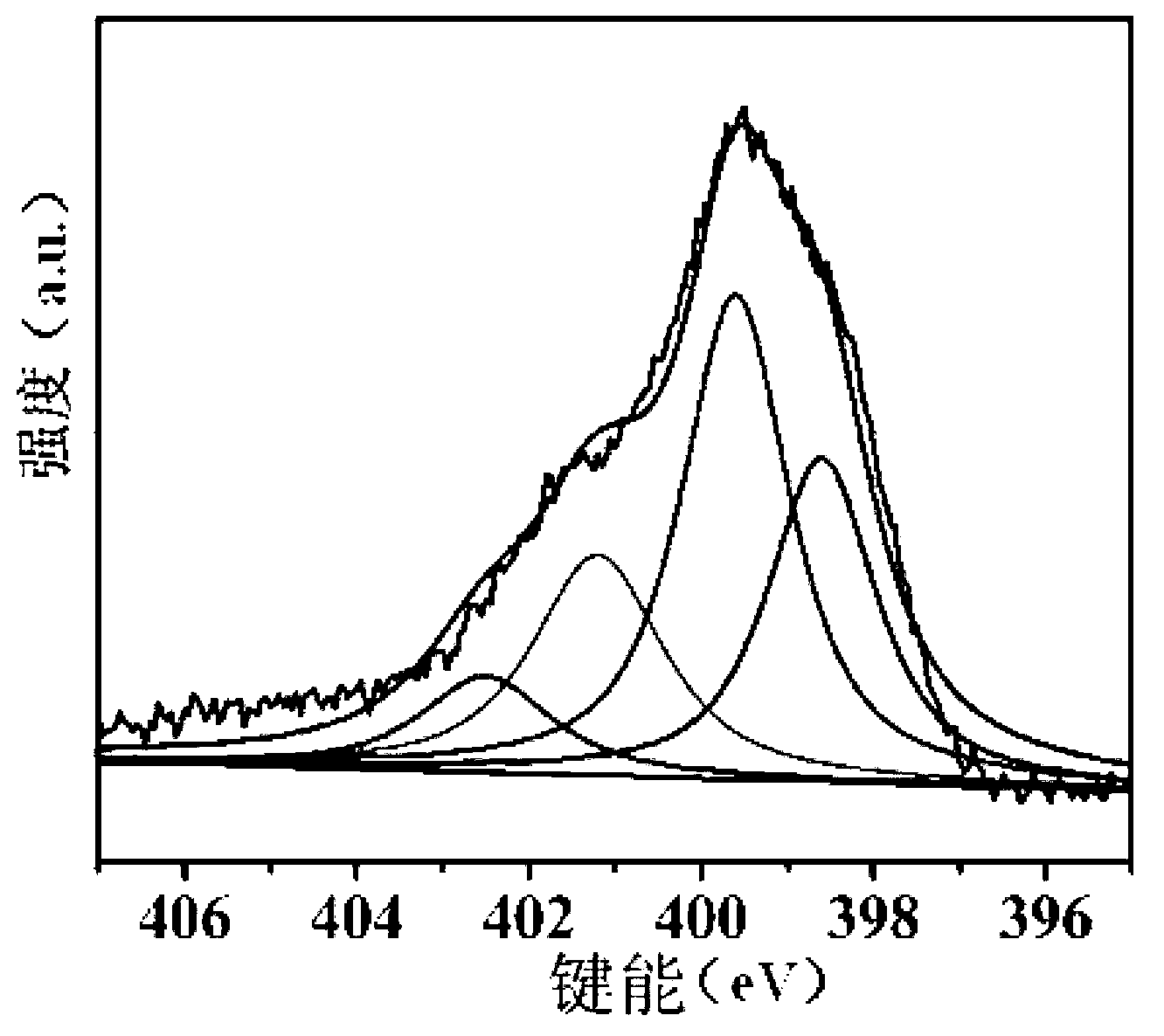

Preparation method of high-nitrogen-doped graphene nanoparticles and application of high-nitrogen-doped graphene nanoparticles as negative material of lithium ion battery

ActiveCN104201385AEasy to dopeHigh nitrogen contentMaterial nanotechnologyCell electrodesDoped grapheneZinc nitrate

The invention provides a preparation method of high-nitrogen-doped graphene nanoparticles and application of the high-nitrogen-doped graphene nanoparticles as a negative material of a lithium ion battery. The corresponding method comprises the following steps: slowly dropwise adding a preset quantity of zinc nitrate (Zn(NO3)) methanol solution into a methanol mixed solution which is prepared from a preset amount of 2-methylimidazole (C4H6N2) and a preset amount of polyvinylpyrrolidone (PVP), magnetically stirring and standing for preset time, carrying out centrifugal separation to obtain ZIF-8(a complex formed by zinc and 2-methylimidazole) nanoparticles; and putting the obtained ZIF-8 nanoparticles in a high-temperature furnace and calcining at 600-1,000 DEG C for preset time in the nitrogen atmosphere to obtain the high-nitrogen-doped graphene nanoparticles. The preparation process of the high-nitrogen-doped graphene nanoparticles is simple, and the high-nitrogen-doped graphene nanoparticles are uniform in shape, relatively large in specific surface and high in content of nitrogen, and have great application potentials in aspects of lithium ion batteries, electrochemical energy storage, catalysis and the like. The preparation method of the high-nitrogen-doped graphene nanoparticles is simple and efficient, safe and liable to implement, short in synthesis cycle, is capable of preparing a large quantity of high-nitrogen-doped graphene nanoparticles and is expected to be popularized and industrially applied.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of nitrogen-doping ordered mesoporous carbon materials

InactiveCN103072973AWell-ordered pore structureHigh dopingCarbon preparation/purificationMolecular sieveSpace group

The invention provides a preparation method of nitrogen-doping ordered mesoporous carbon materials. According to the method, rich-hydroxyl saccharide carbohydrate is used as carbon sources, ammonia water is used as nitrogen sources, amination reaction under the hydrothermal condition is adopted for preparing rich-nitrogen precursors, mesoporous silica molecular sieves SBA-15 (space group P6mm) are used as templates, and the nitrogen-doping ordered mesoporous carbon materials in two-dimensional orthohexagonal ordered mesostructures are prepared through multi-time wetting combined with the high-temperature themolysis technology.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

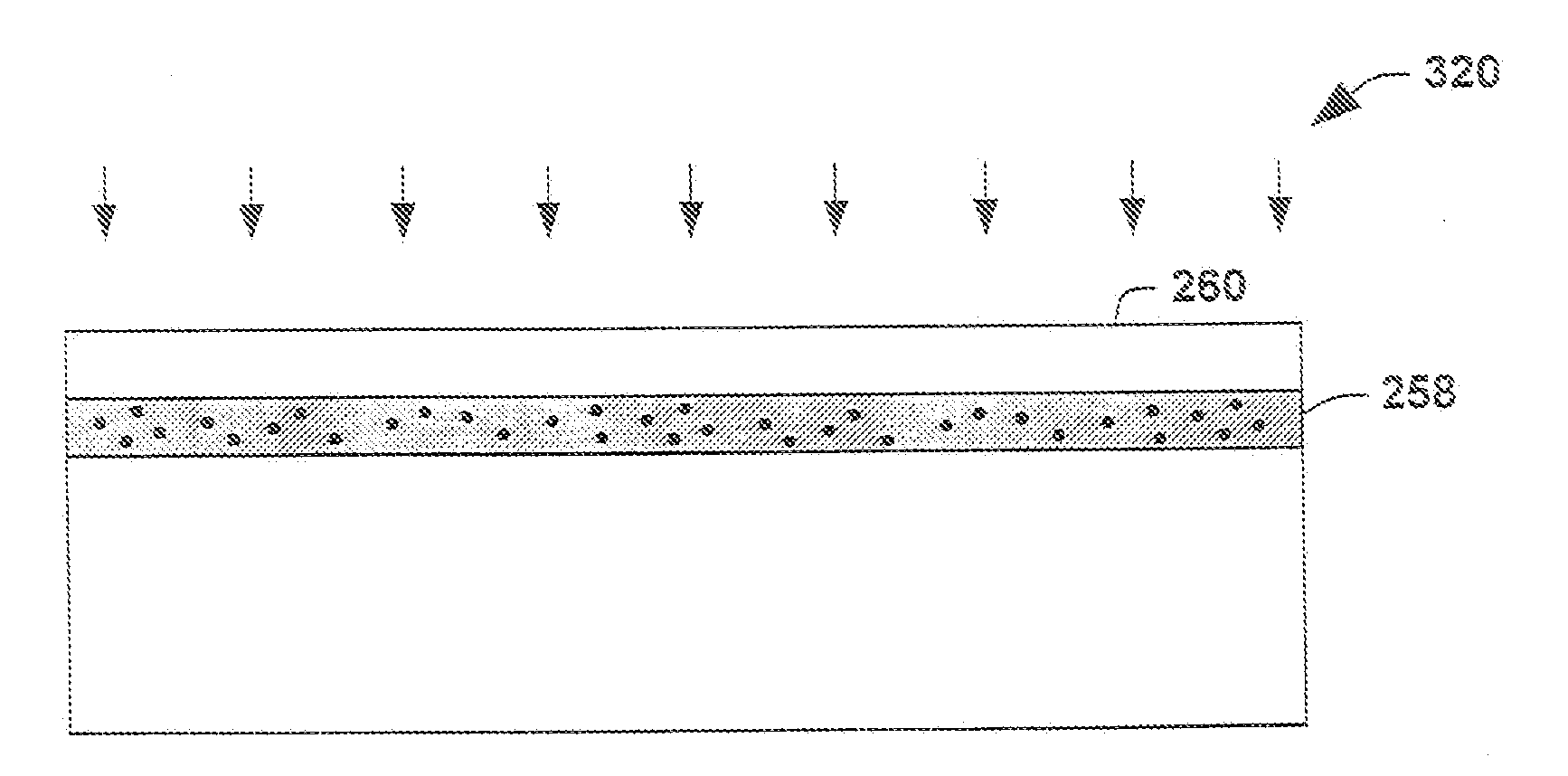

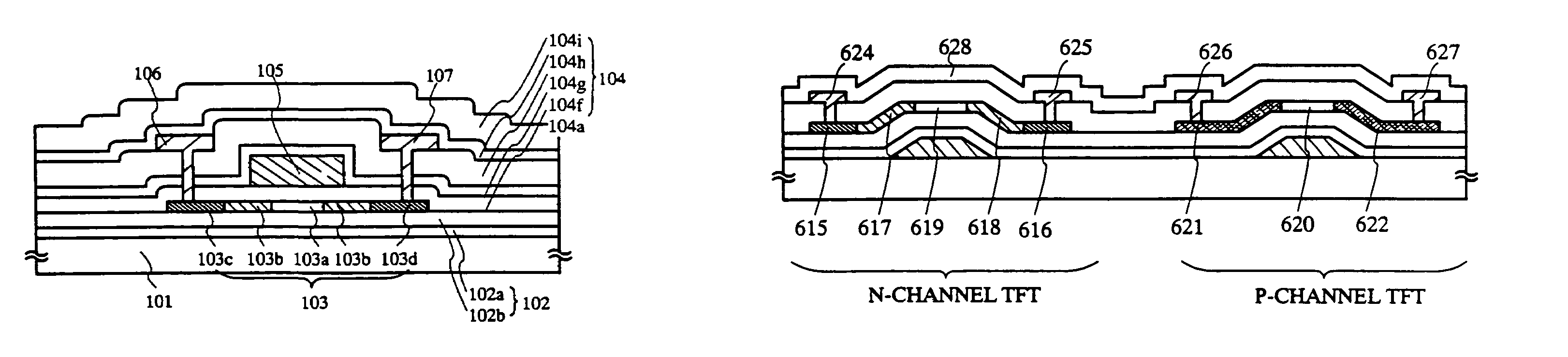

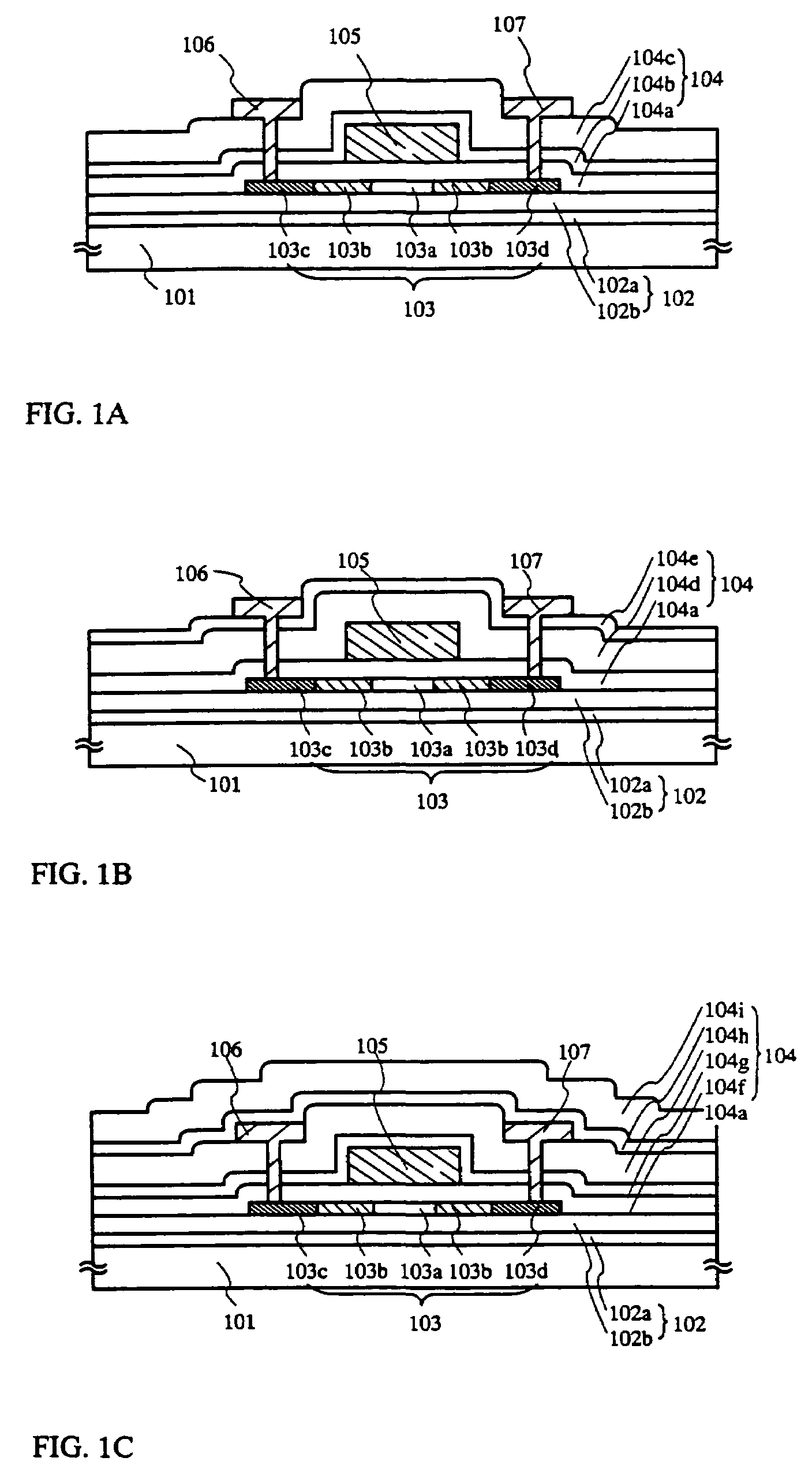

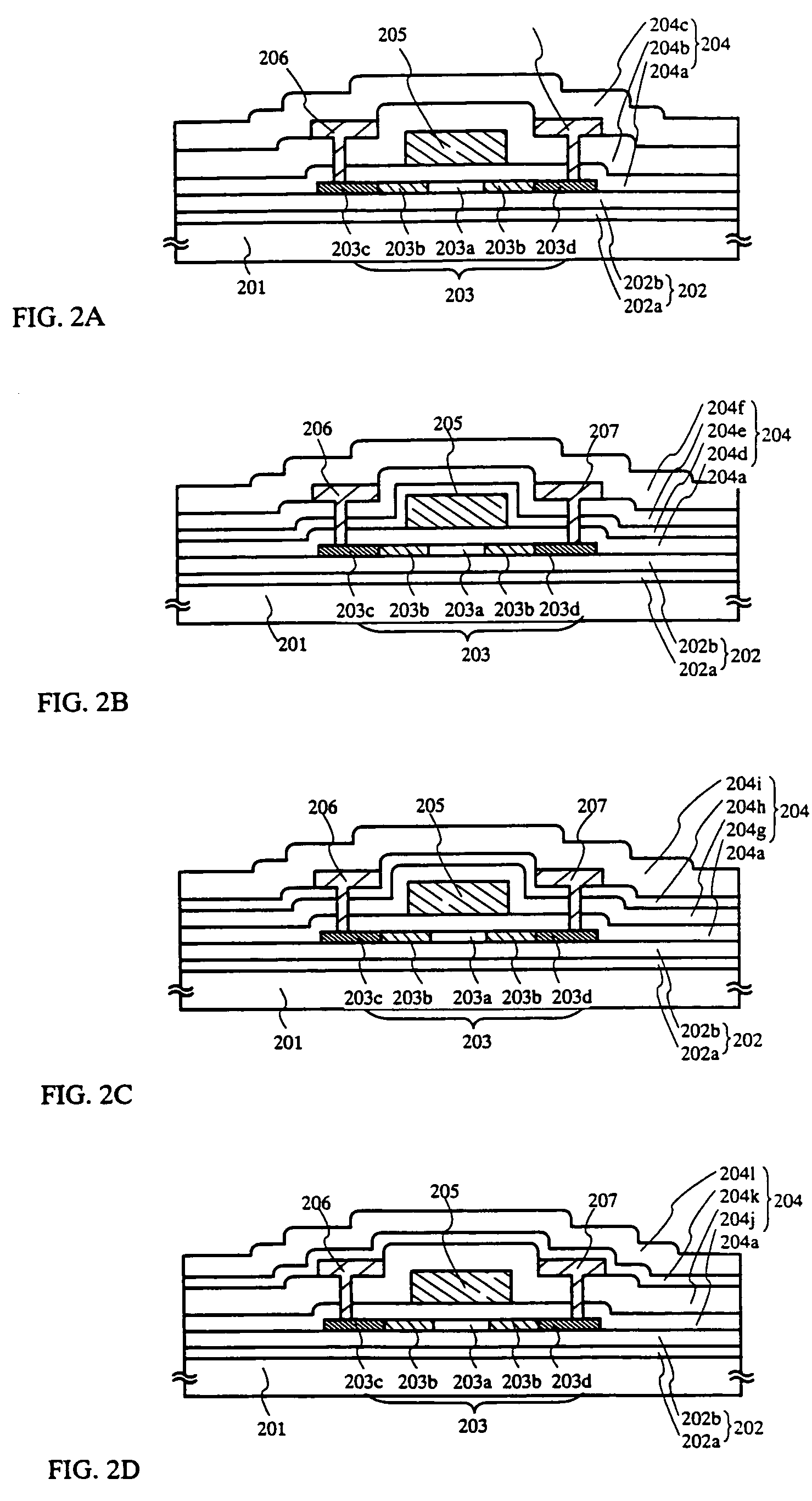

Semiconductor device and method of fabricating the same

InactiveUS7015505B2Bulk defect density interface defect densityReduce defect densityTransistorSolid-state devicesActive layerTension stress

In a semiconductor device including a laminate of a first insulating layer, a crystalline semiconductor layer, and a second insulating layer, characteristics of the device are improved by determining its structure in view of stress balance. In the semiconductor device including an active layer of the crystalline semiconductor layer having tensile stress on a substrate, tensile stress is given to the first insulating layer formed to be in close contact with a surface of the semiconductor layer at a substrate side, and compressive stress is given to the second insulating layer formed to be in close contact with a surface of the semiconductor layer at a side opposite to the substrate side.

Owner:SEMICON ENERGY LAB CO LTD

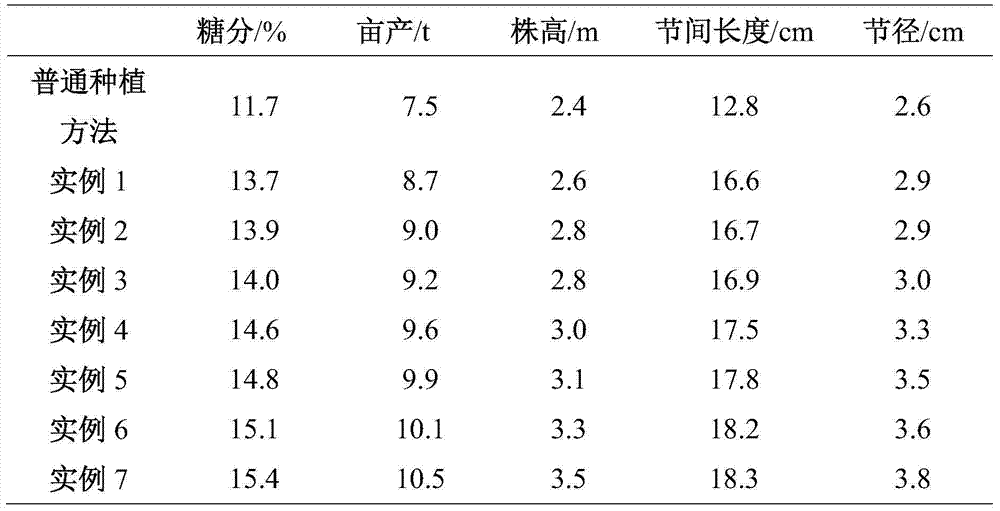

High-yield cultivation method for sugarcanes

InactiveCN104838869AEasy to killQuality improvementSuperphosphatesBio-organic fraction processingLactariusPlastic mulch

The invention provides a high-yield cultivation method for sugarcanes. The high-yield cultivation method includes directly applying raw materials of green manure into newly excavated sugarcane furrows; allowing the raw materials of the green manure to ferment under film covering closed conditions for 15-25 days; lifting each mulching film to a side of the corresponding sugarcane furrow after the raw materials ferment and become thoroughly decomposed; adding compound fertilizers into the sugarcane furrows; covering soil on the compound fertilizers; planting sugarcane seedlings. The raw materials of the green manure comprise, by weight, 300-500 parts of broken sugarcane leaves, 300-500 parts of silt from fish ponds, 200-300 parts of farmyard manure, 200-300 parts of bran hulls, 100-200 parts of sweet potato residues, 50-100 parts of yeasts and 20-50 parts of lactic acid bacteria. Sugarcane buds are soaked in mixed solution for 18-24h to obtain the sugarcane seedlings, and the mixed solution comprises 6-24 parts of quicklime, 1-1.5 parts of gibberellin missible oil and 800-1200 parts of water. The high-yield cultivation method for the sugarcanes has the advantages of high bud ratio, low fertilizer and pesticide consumption in planting procedures and capabilities of obviously increasing the yield of the sugarcanes and obviously improving the quality of the sugarcanes.

Owner:黄建军

Compound microbial fertilizer and preparation method thereof

ActiveCN102718603AHigh nitrogen contentSimple structureFertilizer mixturesAureobasidium sp.Metabolite

The invention relates to a compound microbial fertilizer and a preparation method thereof. The compound microbial fertilizer is prepared by mixing the following raw materials: yeast fermentation powder residues, an organic fertilizer, urea, K2SO4, NH4H2PO4, clay and a compound microbial agent; and the compound microbial agent is formed by fermentation of bacillus mucilaginosus, bacillus megaterium, bacillus cereus, bacillus thuringiensis, azotobacter chroococcum, pichia farinose and streptomyces microflavus. The compound microbial fertilizer disclosed by the invention has a variety of microbes with the effects of nitrogen fixation, phosphorus dissolution and potassium dissolution, can increase the nitrogen content in soil, improves the utilization rate of the chemical fertilizer, and is favorable for improving the structure of the soil and improving the yield and quality of crops; and simultaneously, the microbes in the fertilizer can produce a variety of metabolites, and the metabolites can effectively resist diseases and insect pests.

Owner:DEZHOU YUANHE AGRI TECH DEVCO

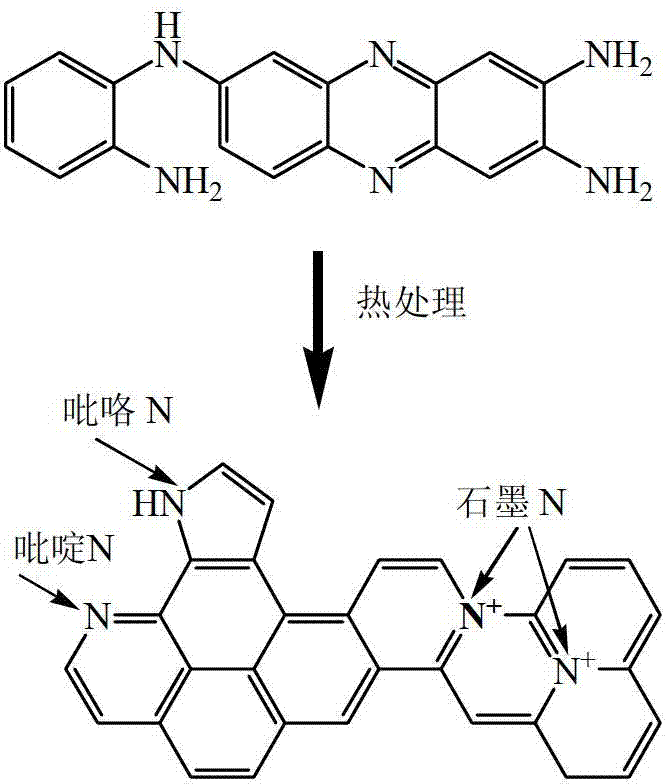

Nitrogen-doped hollow carbon ball loaded palladium-based catalyst and preparation method thereof, and alcohol fuel cell applying same

The invention relates to a preparation method of a nitrogen-doped hollow carbon ball loaded palladium-based catalyst, which comprises the following steps of: dispersing o-phenylenediamine in a solvent for being stirred at a low temperature, adding an initiator for reacting for 12-24h, then extracting and filtering, and drying in vacuum to obtain a poly(o-phenylenediamine) hollow ball; pyrolyzing an o-phenylenediamine polymer at a high temperature for 2-6h under the protection of an inert gas to obtain a nitrogen-doped hollow carbon ball; and dispersing the nitrogen-doped hollow carbon ball into water, adding a chloropalladic acid solution for ultrasonic treatment, adding a reducing agent for ultrasonic treatment, extracting and filtering after the reaction is completed, and drying in vacuum to obtain the nitrogen-doped hollow carbon ball loaded palladium-based catalyst. The nitrogen-doped hollow carbon ball loaded palladium-based catalyst prepared by adopting the preparation method has the nitrogen content of 10.4-22.4wt%, has the advantages of excellent oxidization reaction catalysis property to alcohol, stable performance, low preparation cost and simple preparation process, and is a novel high-performance catalyst for a low-temperature direct alcohol fuel cell anode.

Owner:NANJING COMM INST OF TECH

Transgenic plants that exhibit enhanced nitrogen assimilation

InactiveUS6864405B1Improve featuresReduce investmentBryophytesSugar derivativesBiotechnologyNitrogen assimilation

The present invention relates to a method for producing plants with improved agronomic and nutritional traits. Such traits include enhanced nitrogen assimilatory and utilization capacities, faster and more vigorous growth, greater vegetative and reproductive yields, and enriched or altered nitrogen content in vegetative and reproductive parts. More particularly, the invention relates to the engineering of plants modified to have altered expression of key enzymes in the nitrogen assimilation and utilization pathways. In one embodiment of the present invention, the desired altered expression is accomplished by engineering the plant for ectopic overexpression of one of more the native or modified nitrogen assimilatory enzymes. The invention also has a number of other embodiments, all of which are disclosed herein.

Owner:NEW YORK UNIV

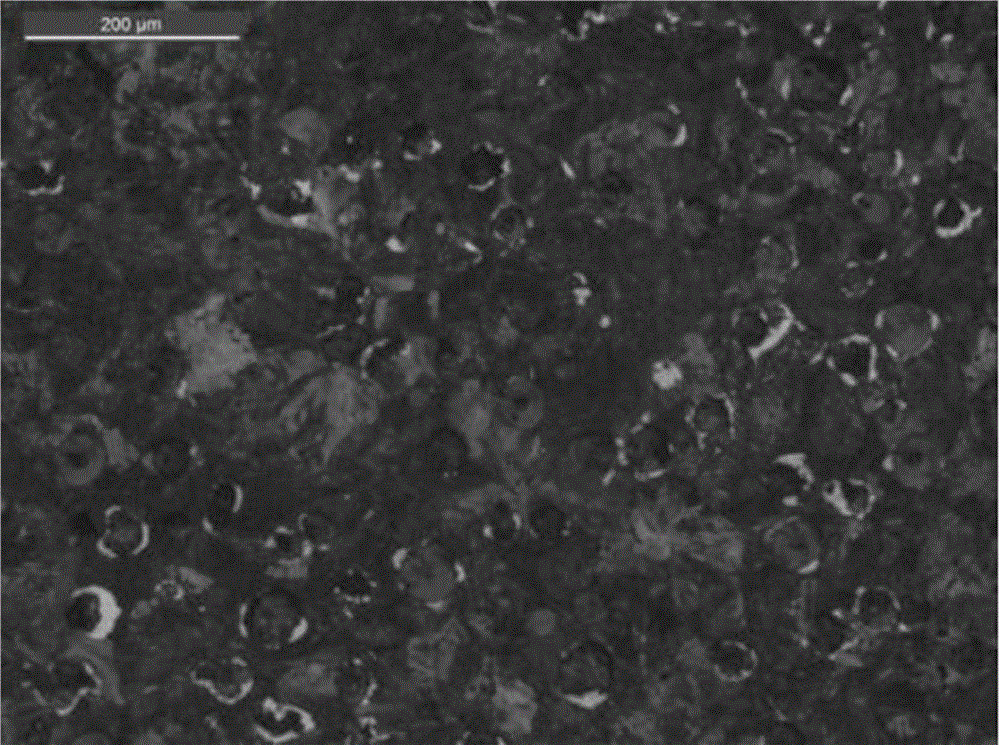

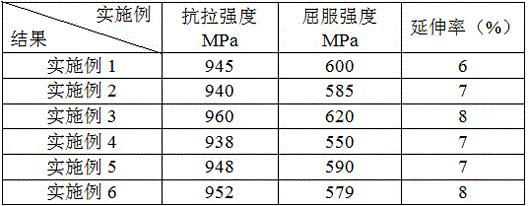

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

Nitrogen-enriched porous material/carbon nano structure composite material as well as preparation method and application thereof

ActiveCN104332596AEvenly dispersedDecentralized regulationCell electrodesNano structuringOrganic solvent

The invention provides a nitrogen-enriched porous material / carbon nano structure composite material as well as a preparation method and application thereof. The composite material is prepared from a nitrogen-enriched porous material and various carbon nano materials by compounding. The preparation method comprises the following steps: melamine, a polyformyl aromatic compound and the carbon nano materials are in contact in an organic solvent to obtain a product, and the contacted product is subjected to a series of processes including separation, heat treatment, washing, drying and the like to obtain the nitrogen-enriched porous material / carbon nano structure composite material. The prepared nitrogen-enriched porous material / carbon nano structure composite material has the high nitrogen content, abundant pore structures and uniformly-distributed carbon nano composite components. The composite material can be used as an electrode material and is applied to secondary batteries including lithium ion batteries and the like; and the composite material has the high capacity and the excellent circulating performance and rate capability, and can meet the requirements of the lithium ion batteries in the actual application.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Self-flame-retardant heat-preservation water-based polyurethane composition and foaming body, and preparation method of foaming body

InactiveCN108129628AImprove insulation effectImprove flame retardant performanceWater basedPolymer science

The invention discloses a self-flame-retardant heat-preservation water-based polyurethane composition and foaming body, and a preparation method of the foaming body. The invention can be applied to different fields such as artificial synthetic leather, heat preservation of water heaters, heat-insulation coatings and the like. According to the invention, an aerogel material is introduced into water-based foaming polyurethane, and the heat-insulation and heat-preservation properties of a resin water-based polyurethane foam base material can be improved. The foaming water-based polyurethane provided by the invention has a plurality of synergistic flame retardant mechanisms, and can endow the foaming polyurethane with excellent flame retardancy and low toxicity.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com