Nitrogen-doped hollow carbon ball loaded palladium-based catalyst and preparation method thereof, and alcohol fuel cell applying same

A technology of nitrogen doping and catalyst, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of high catalyst preparation cost, reduce catalyst production cost, complicated steps, etc., and achieve the promotion of large-scale production and commercial application, electric Improvement of catalytic performance and improvement of battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of Nitrogen-doped Hollow Carbon Spheres Supported Palladium Catalyst

[0053] (1) Synthesis of o-phenylenediamine polymer

[0054] Add 0.26g of o-phenylenediamine into a 50mL round bottom flask, disperse it in 30mL of secondary water and stir for 20 minutes, then place it in a 5°C water bath and stir for 40 minutes, then add 0.50g of ammonium persulfate, stir for 5 minutes, stop stirring, The flask was placed in a refrigerator at 5°C for 12 hours. Take out the suction filter, wash with 250mL ammonia water with a mass fraction of 5% and double distilled water until the filtrate is clear. The filtered solid was taken out and dried under vacuum at 50°C for 12 hours. The solid obtained by drying is o-phenylenediamine polymer.

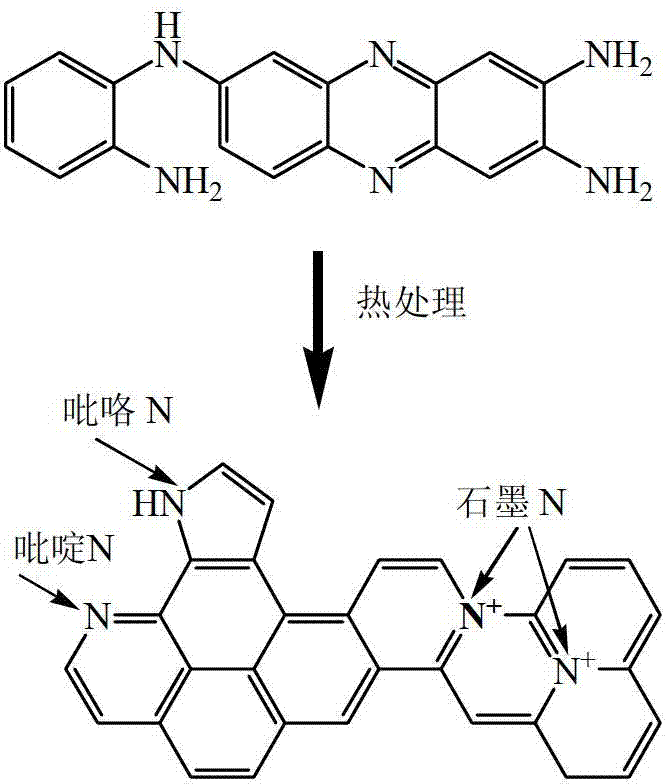

[0055] (2) Heat treatment of o-phenylenediamine polymer

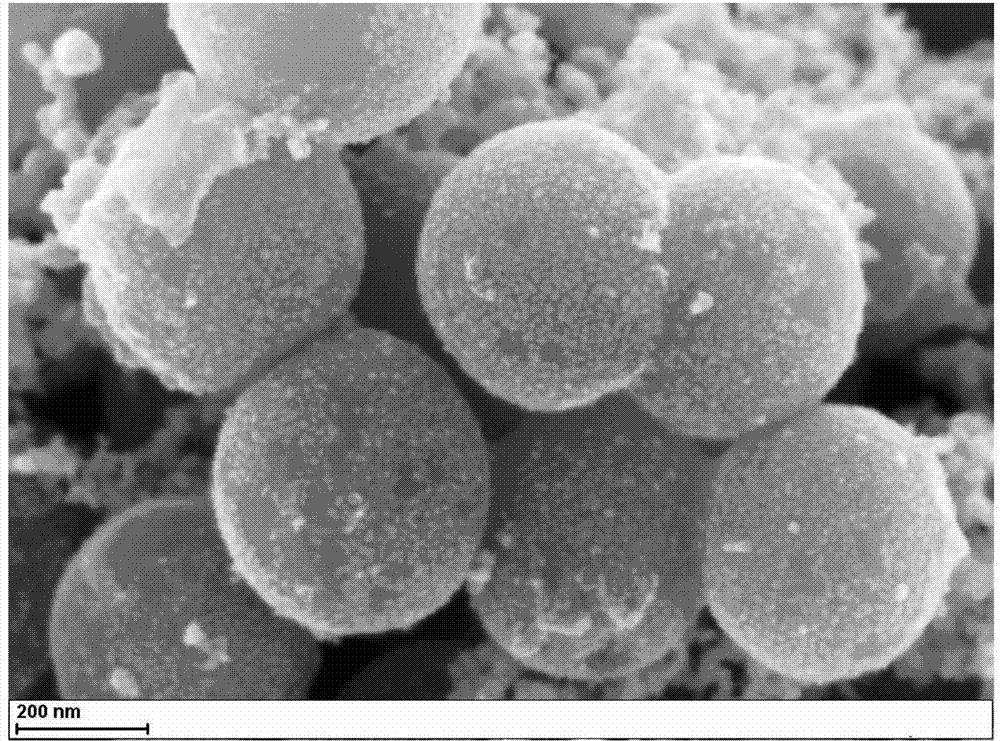

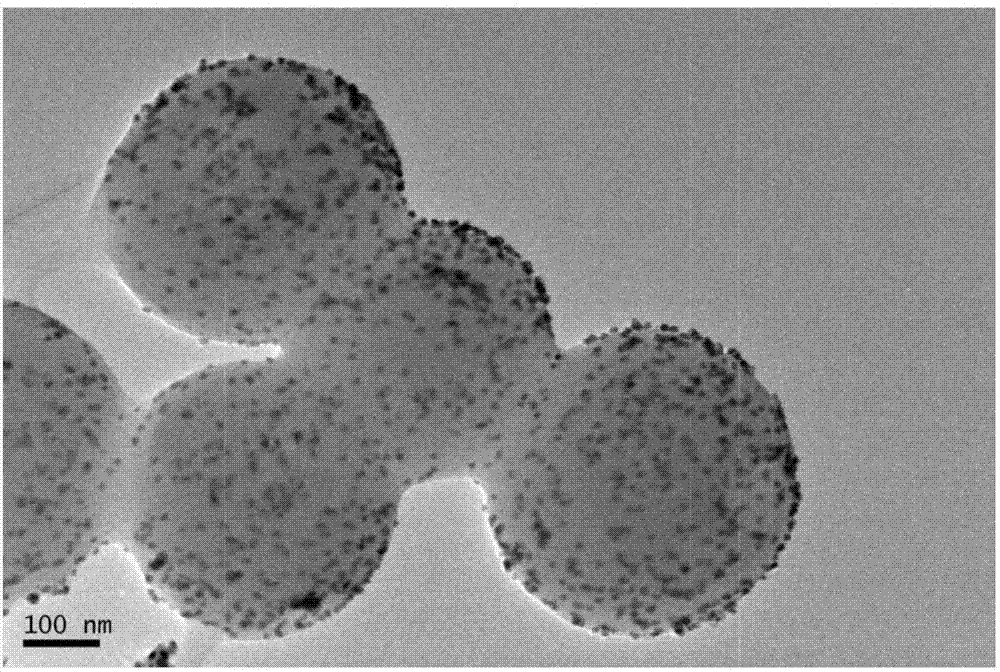

[0056] The o-phenylenediamine polymer was placed in a tube furnace, and under the protection of nitrogen, it was pyrolyzed at 850° C. for 4 hours to obtain nitrogen-doped hollo...

Embodiment 2 Embodiment 3

[0062] Take the same two parts of the o-phenylenediamine polymer obtained in the first step (1) of Example 1, place them in a tube furnace, and under the protection of nitrogen, pyrolyze them at 350°C and 550°C for 4 hours respectively , to obtain nitrogen-doped carbon spheres with a particle size of 400nm (Example 2) and 350nm (Example 3). (Particle size measured by SEM and TEM)

[0063] The nitrogen-doped hollow carbon spheres obtained in Example 2 and Example 3 were prepared according to the method and experimental conditions in step (3) of Example 1, respectively, to obtain nitrogen-doped hollow carbon sphere-supported palladium catalysts. According to elemental analysis and plasma inductively coupled spectroscopic analysis, as well as nitrogen adsorption and desorption curves:

[0064] For the palladium catalyst prepared in Example 2, the nitrogen doping ratio is 22.4% (mass), the metal loading is 40% (mass), and the specific surface area is 49.2m 2 / g;

[0065] The pa...

Embodiment 4

[0068] Preparation of Palladium and Cobalt Alloy Catalysts Supported by Nitrogen-doped Hollow Carbon Spheres

[0069] Add 0.26g of o-phenylenediamine to a 50mL round bottom flask, disperse in 30mL of secondary water and stir for 10 minutes, then place in a 5°C water bath and stir for 30 minutes, then add 0.50g of ammonium persulfate, stir for 5 minutes, stop stirring, The flask was placed in a refrigerator at 5° C. for 20 hours to react. Take out the suction filter, wash with 250mL ammonia water with a mass fraction of 5% and double distilled water until the filtrate is clear. The filtered solid was taken out and dried under vacuum at 50°C for 12 hours. The solid obtained by drying is o-phenylenediamine polymer.

[0070] The obtained o-phenylenediamine polymer was placed in a tube furnace, and under the protection of nitrogen, it was pyrolyzed at 850° C. for 4 hours to obtain nitrogen-doped carbon hollow spheres.

[0071] Disperse 100 mg of nitrogen-doped carbon hollow sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com