Preparation method of high-nitrogen-doped graphene nanoparticles and application of high-nitrogen-doped graphene nanoparticles as negative material of lithium ion battery

A lithium-ion battery and nanoparticle technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of complex process, long reaction time, high temperature, etc., achieve simple and efficient preparation process, increase nitrogen doping amount, The effect of short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, prepare uniform ZIF-8 nanoparticles

[0025] At room temperature, 50mL containing 105mg zinc nitrate (Zn(NO 3 )) methanol solution was slowly dripped into 50mL containing 120mg of 2-methylimidazole (C 4 h 6 N 2 ) and 1.5 g of polyvinylpyrrolidone (PVP) in methanol solution, magnetically stirred and left to stand for 10 hours, centrifuged to obtain the precursor ZIF-8 (complex formed by zinc and 2-methylimidazole) nanoparticles.

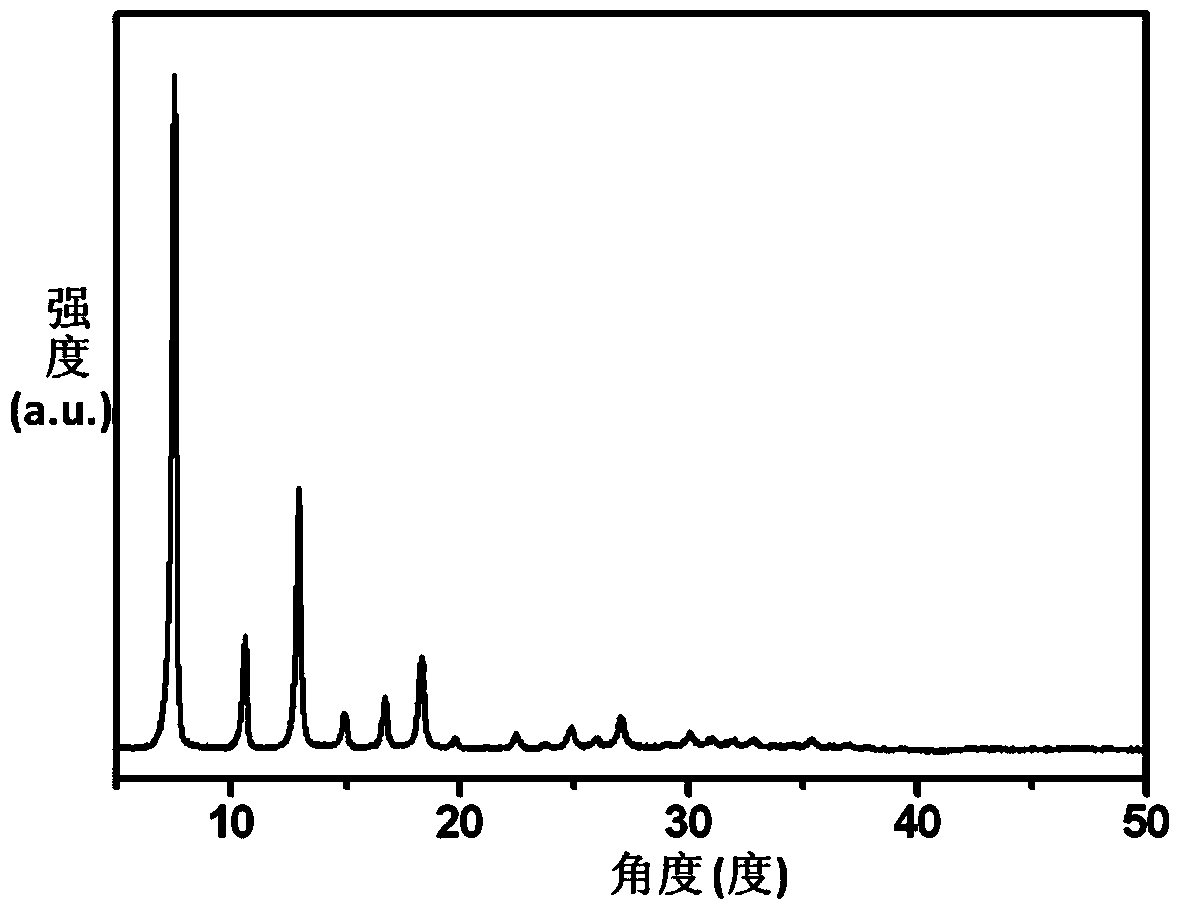

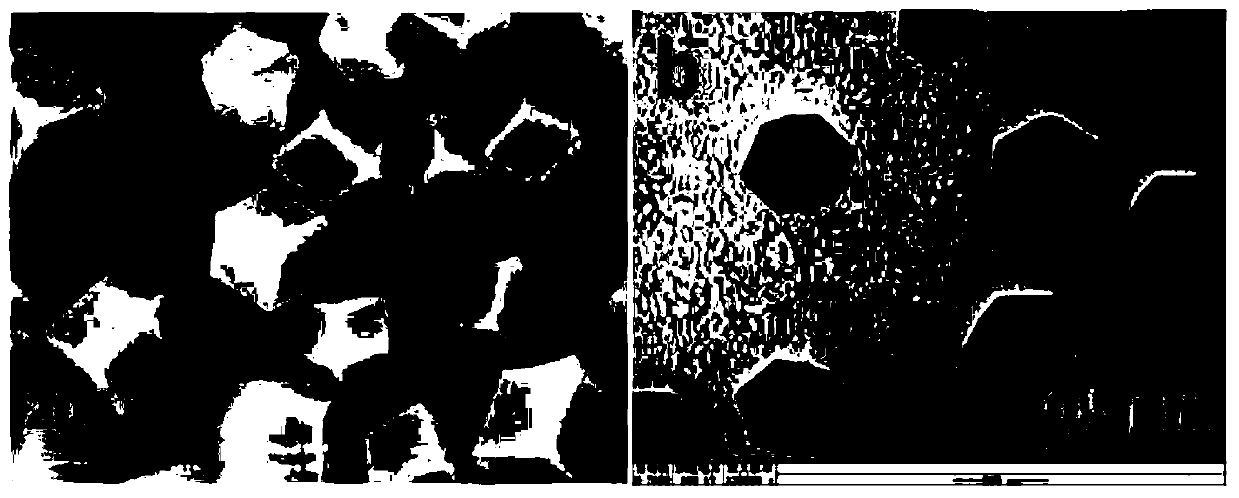

[0026] Such as figure 1 Shown, the X-ray diffraction of precursor ZIF-8 in the present embodiment ( ) figure, all diffraction peaks are consistent with the simulated ZIF-8 crystal data, showing that the product is ZIF-8 with good crystallinity. figure 2 are scanning electron microscope (SEM) photos and transmission electron microscope (TEM) photos of the product. From figure 2 (a) In the SEM image, it can be seen that ZIF-8 exists in the form of nanoparticles, and the particles have a uniform shape, a polyhedral shape, a...

Embodiment 2

[0027] Embodiment 2, preparation of high nitrogen-doped graphene-like nanoparticles

[0028]The precursor ZIF-8 nanoparticles obtained in Implementation 1 were placed in a crucible, and the temperature was raised to 800° C. at a rate of 5° C. / min in a nitrogen atmosphere, where the gas flow was 400 ml / min. Then calcining at this temperature for 8 hours, after naturally cooling to room temperature, immerse the obtained sample with 35% hydrochloric acid with a mass fraction to remove impurities such as zinc oxide remaining on the sample, then wash the obtained sample with water and ethanol successively for three times, Highly nitrogen-doped graphene-like nanoparticles (N-C-800) can be obtained.

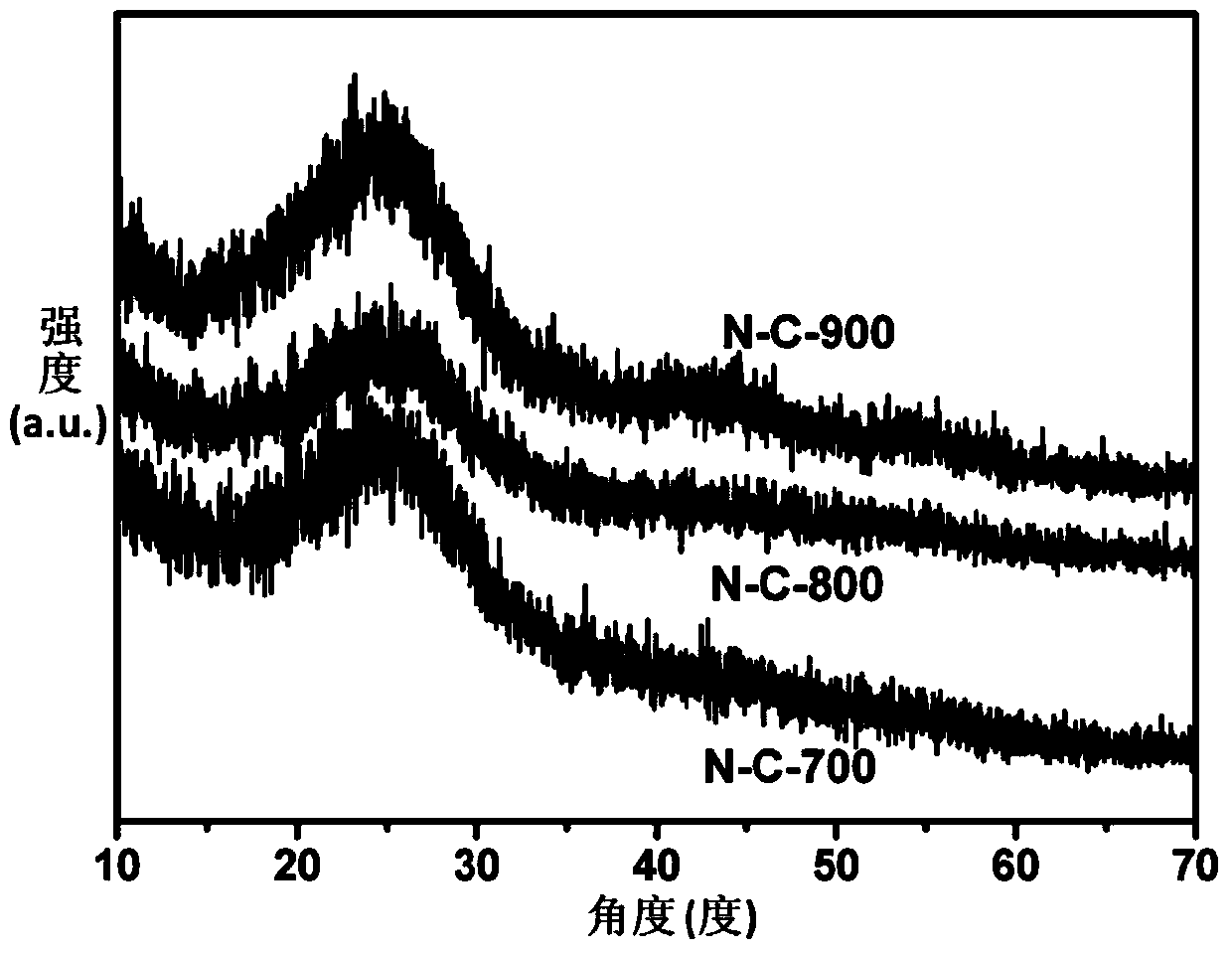

[0029] The chemical composition of the particles can be determined by X-ray diffraction. Such as image 3 Shown, the X-ray diffraction ( )picture. The broad front at around 24° corresponds to the (002) crystal plane of the graphite-type carbon material, indicating that the sample i...

Embodiment 3

[0033] Embodiment 3, the influence of calcining temperature on product

[0034] Same as other conditions in Example 2, the precursor ZIF-8 was calcined at 900°C and 700°C respectively to obtain black products N-C-900 and N-C-700. Like the sample calcined at 800°C, the broad front at around 24° corresponds to the (002) crystal plane of the graphite-type carbon material, indicating that the sample is a graphite-type carbon material with low crystallinity. Figure 6 middle Figure 6 (a) and Figure 6 (b) Scanning electron micrographs corresponding to N-C-900 and N-C-700, respectively, where the inset is the transmission electron micrograph of the corresponding sample. It can be seen from the figure that when the calcination temperature rises from 700 °C to 900 °C, the morphology of the product changes little. However, nitrogen adsorption and desorption data show (as shown in Table 1), the specific surface area from 730.1m 2 / g(N-C-700) becomes 657.2m 2 / g(N-C-900), the space...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com