Patents

Literature

748results about How to "Short synthesis cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

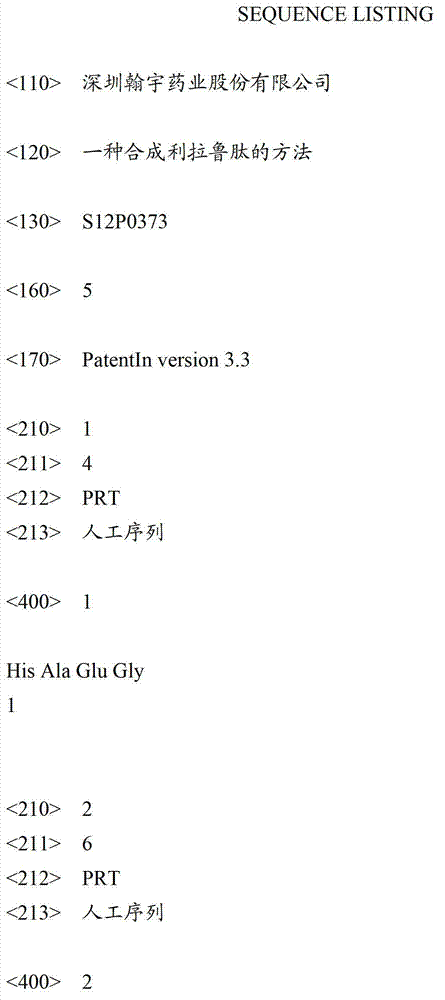

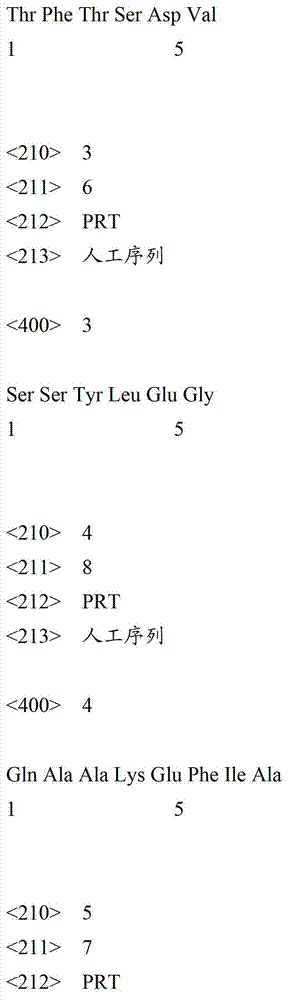

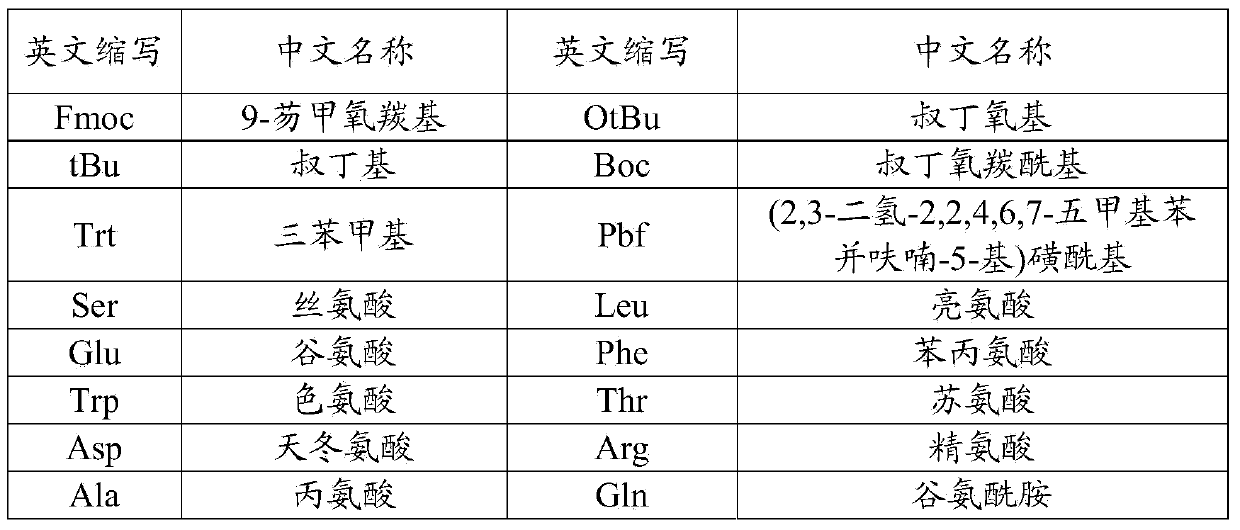

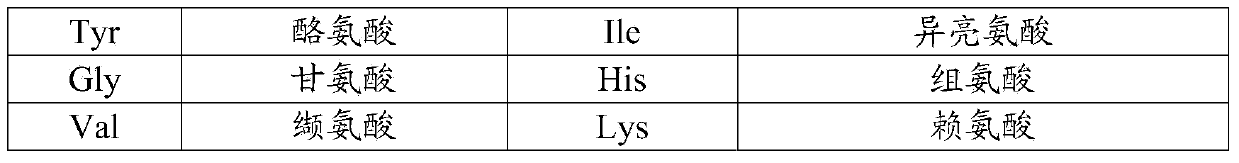

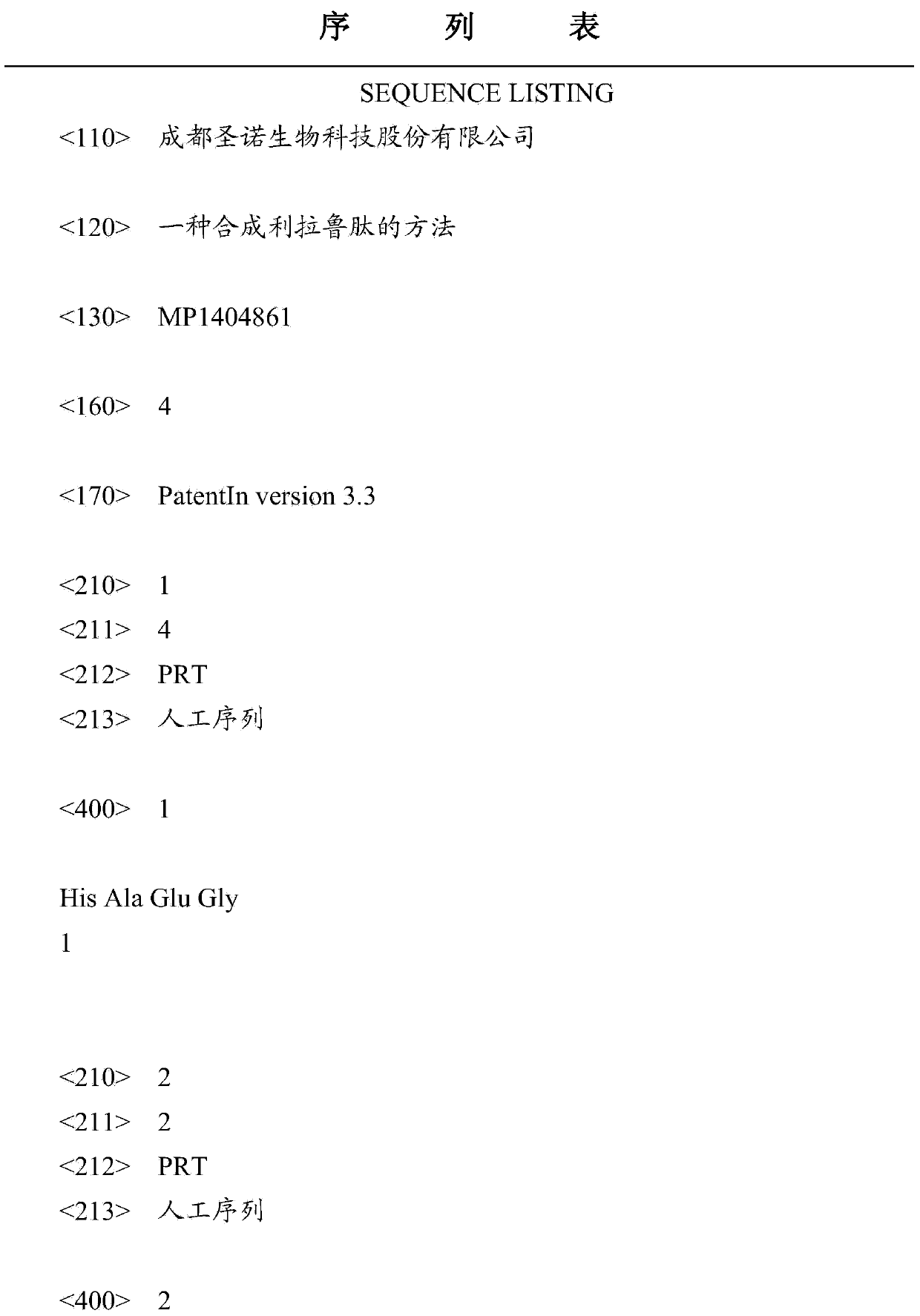

Method for synthesizing liraglutide

ActiveCN102875665AShort synthesis cycleImprove efficiencyPeptide preparation methodsBulk chemical productionLiraglutideAmino acid

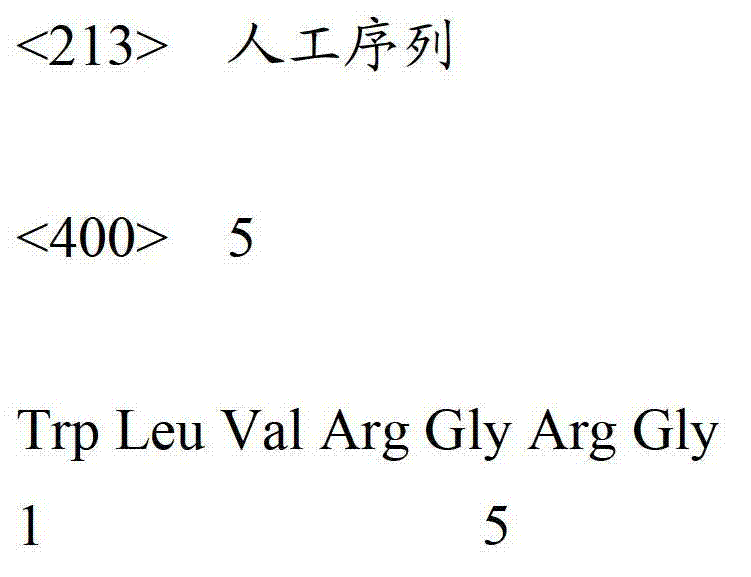

The invention relates the field of medical synthesis and discloses a method for synthesizing liraglutide. The method includes: firstly synthesizing five polypeptide fragments of amino acid from first to fourth, amino acid from fifth to tenth, amino acid from eleventh to sixteenth, amino acid from seventeenth to twenty-fourth, and amino acid from twenty-fifth to thirty first according to amino acid sequence of the liraglutide main chain from N end to C end, and coupling the five polypeptide fragments to synthesize the liraglutide. Synthesizing of the five fragments can be performed simultaneously, synthesizing cycle is shortened greatly, total yield of the liraglutide can be increased, and accordingly the method is better than existing synthesizing methods.

Owner:HYBIO PHARMA

Solid-phase synthesis method for liraglutide

ActiveCN103864918AShort synthesis cycleImprove efficiencyPeptide preparation methodsBulk chemical productionSynthesis methodsSide chain

The invention discloses a solid-phase synthesis method for liraglutide. The solid-phase synthesis method for liraglutide comprises the following steps: 1) firstly synthesizing first to tenth amino acid segments 3, eleventh to nineteenth amino acid segments 2, and twentieth to thirty-first amino acid segments 1, wherein the twentieth lysine adopts Fmoc-Lys(Mtt)-OH, and the first histidine adopts Boc-His(Trt)-OH; 2) synthesizing pal-Glu(OH)-Otbu by adopting a liquid phase synthesis method; 3) selectively removing the Mtt protecting group on the twentieth lysine by use of 5% TFA (Trifluoroacetic Acid), connecting pal-Glu(OH)-Otbu with the side chain of the twentieth lysine to obtain a segment 4; 4) sequentially connecting the segments 2, the segments 3 and the segments 4 to obtain peptide resin completely protected by liraglutide; 5) cracking, purifying, and lyophilizing to obtain the liraglutide product.

Owner:哈尔滨吉象隆生物技术有限公司

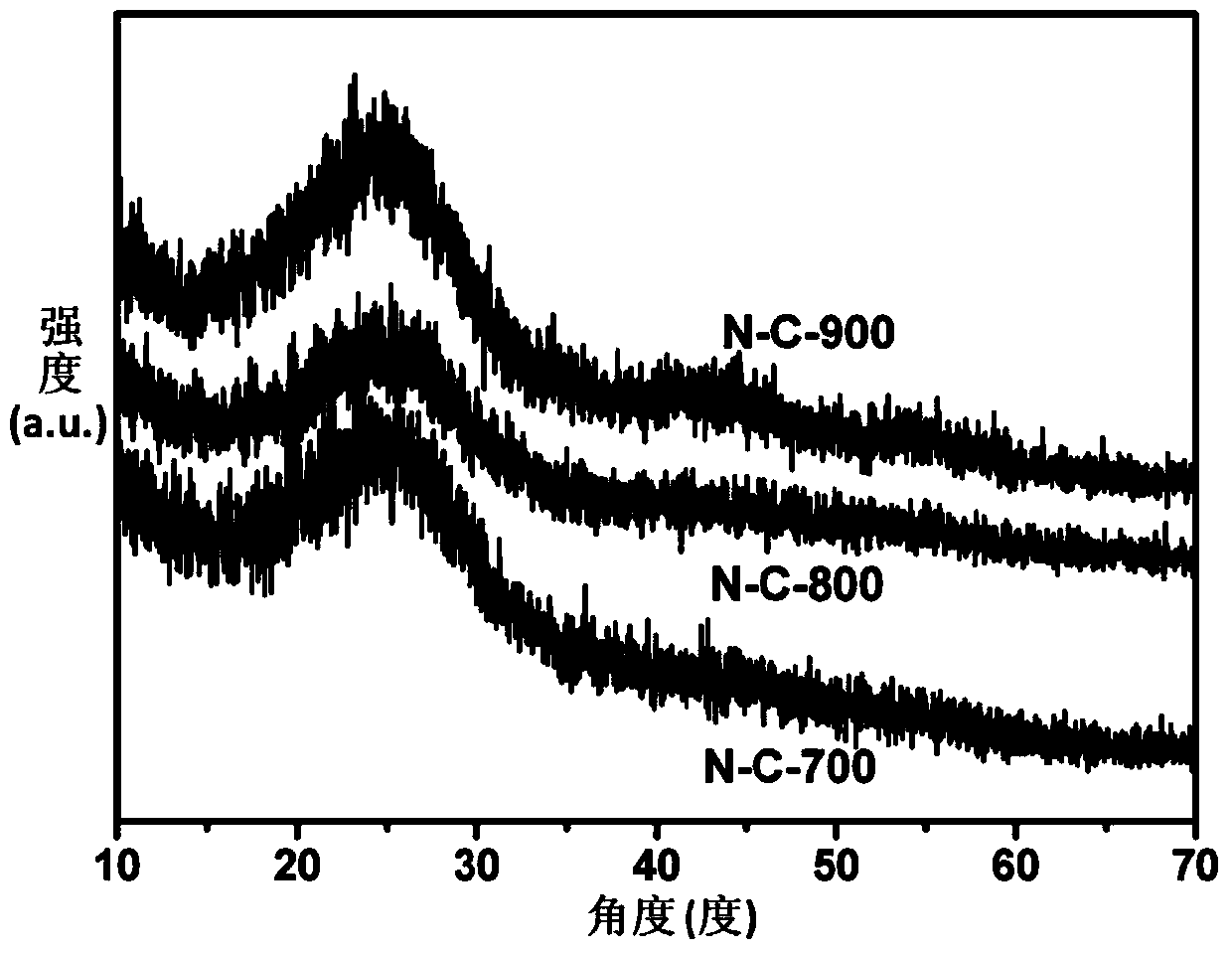

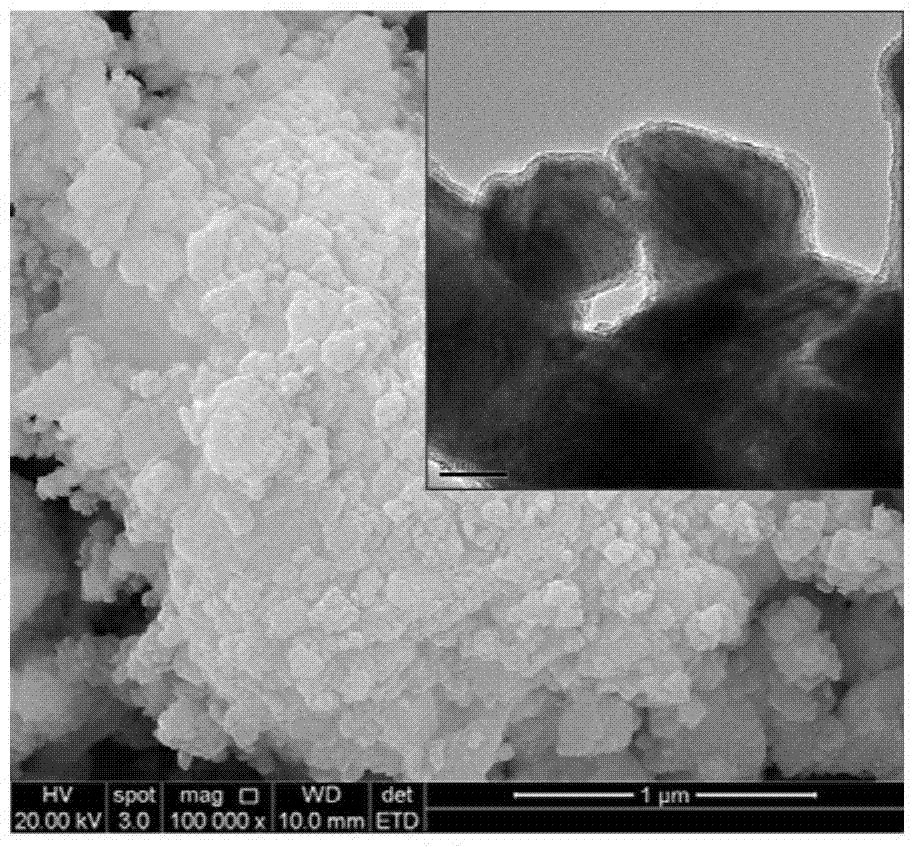

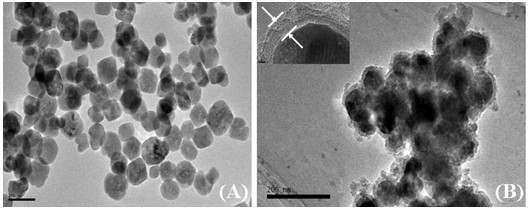

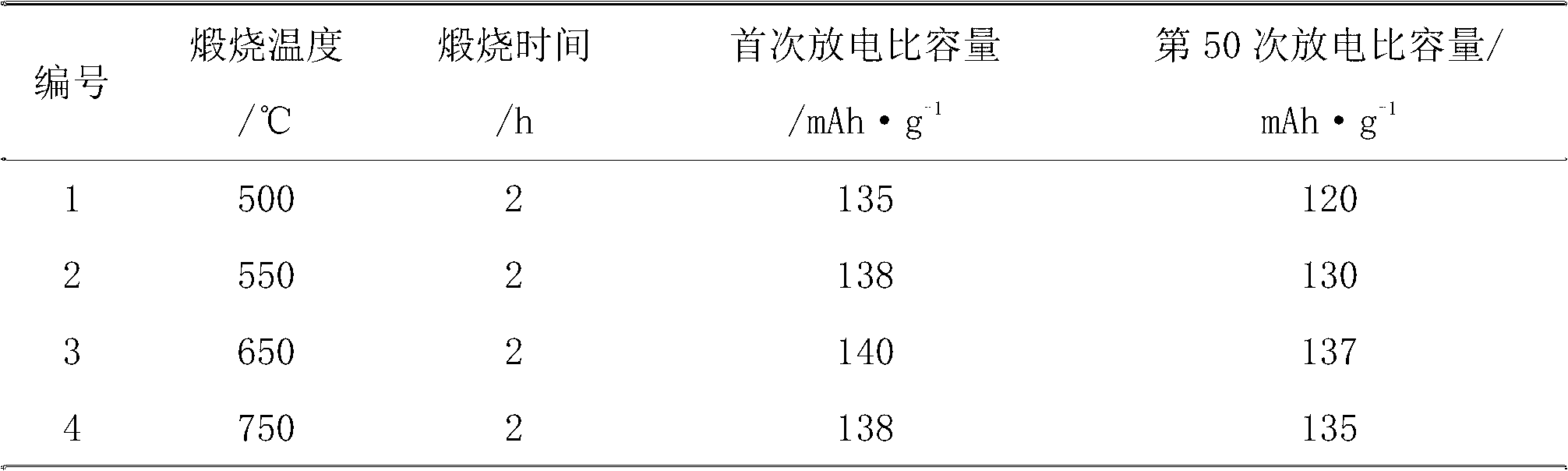

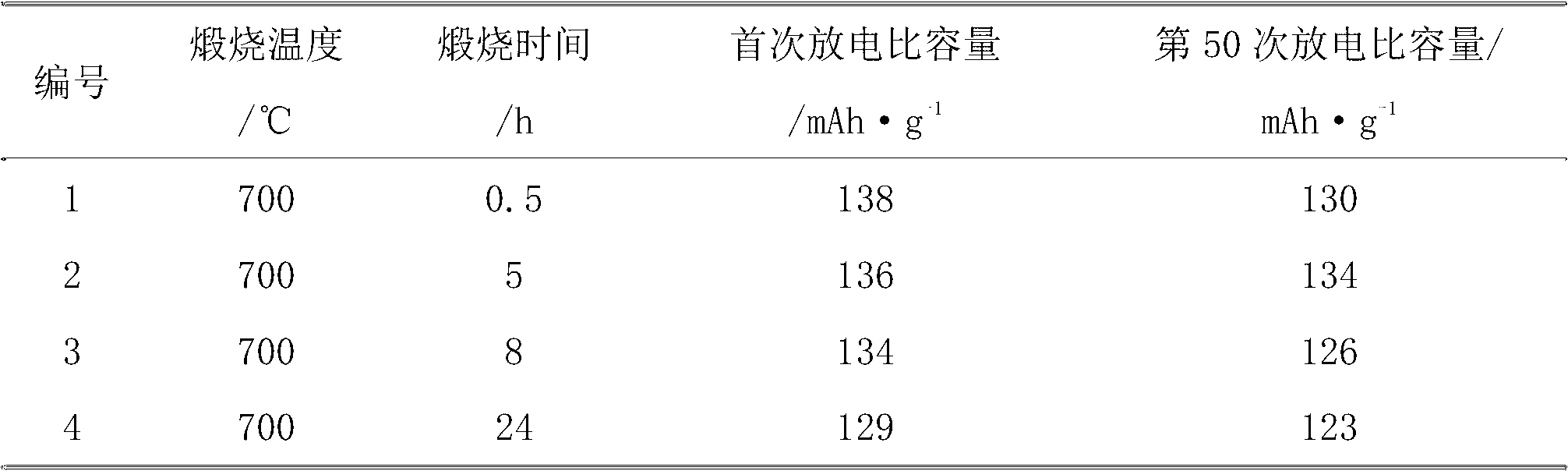

Preparation method of high-nitrogen-doped graphene nanoparticles and application of high-nitrogen-doped graphene nanoparticles as negative material of lithium ion battery

ActiveCN104201385AEasy to dopeHigh nitrogen contentMaterial nanotechnologyCell electrodesDoped grapheneZinc nitrate

The invention provides a preparation method of high-nitrogen-doped graphene nanoparticles and application of the high-nitrogen-doped graphene nanoparticles as a negative material of a lithium ion battery. The corresponding method comprises the following steps: slowly dropwise adding a preset quantity of zinc nitrate (Zn(NO3)) methanol solution into a methanol mixed solution which is prepared from a preset amount of 2-methylimidazole (C4H6N2) and a preset amount of polyvinylpyrrolidone (PVP), magnetically stirring and standing for preset time, carrying out centrifugal separation to obtain ZIF-8(a complex formed by zinc and 2-methylimidazole) nanoparticles; and putting the obtained ZIF-8 nanoparticles in a high-temperature furnace and calcining at 600-1,000 DEG C for preset time in the nitrogen atmosphere to obtain the high-nitrogen-doped graphene nanoparticles. The preparation process of the high-nitrogen-doped graphene nanoparticles is simple, and the high-nitrogen-doped graphene nanoparticles are uniform in shape, relatively large in specific surface and high in content of nitrogen, and have great application potentials in aspects of lithium ion batteries, electrochemical energy storage, catalysis and the like. The preparation method of the high-nitrogen-doped graphene nanoparticles is simple and efficient, safe and liable to implement, short in synthesis cycle, is capable of preparing a large quantity of high-nitrogen-doped graphene nanoparticles and is expected to be popularized and industrially applied.

Owner:UNIV OF SCI & TECH OF CHINA

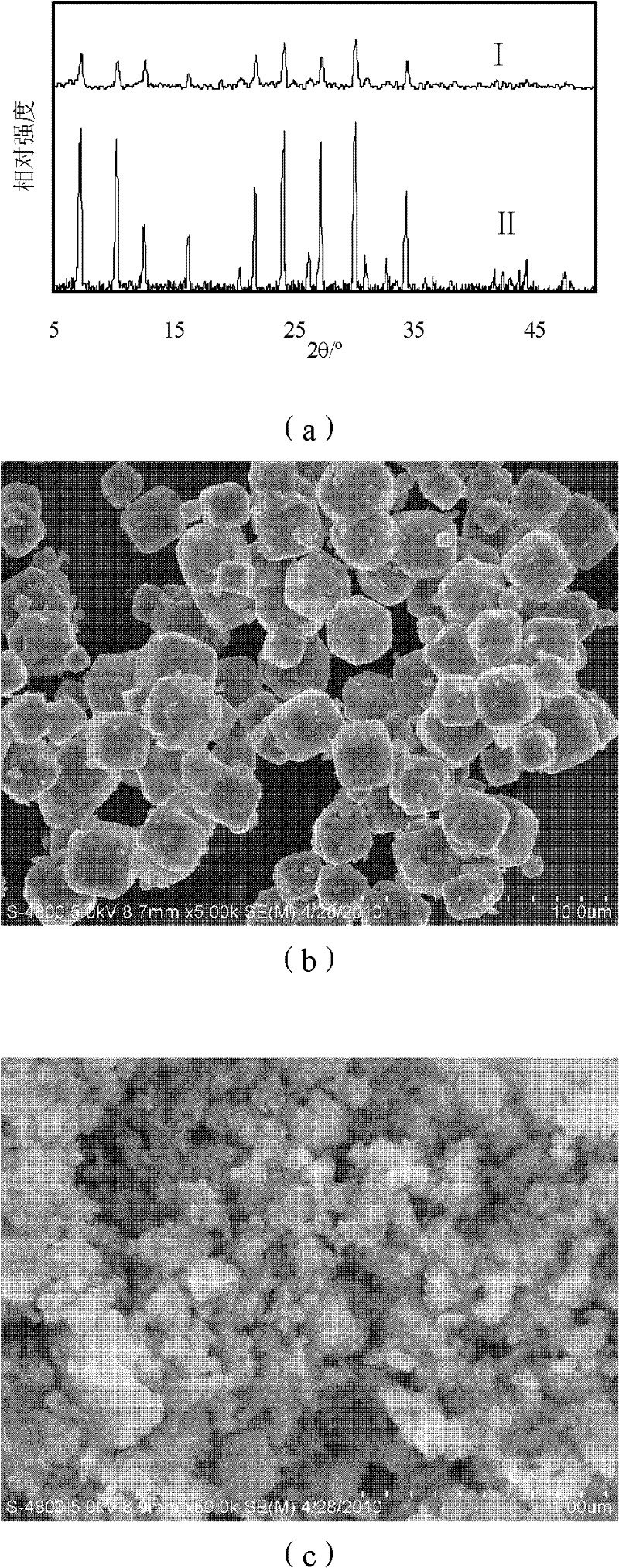

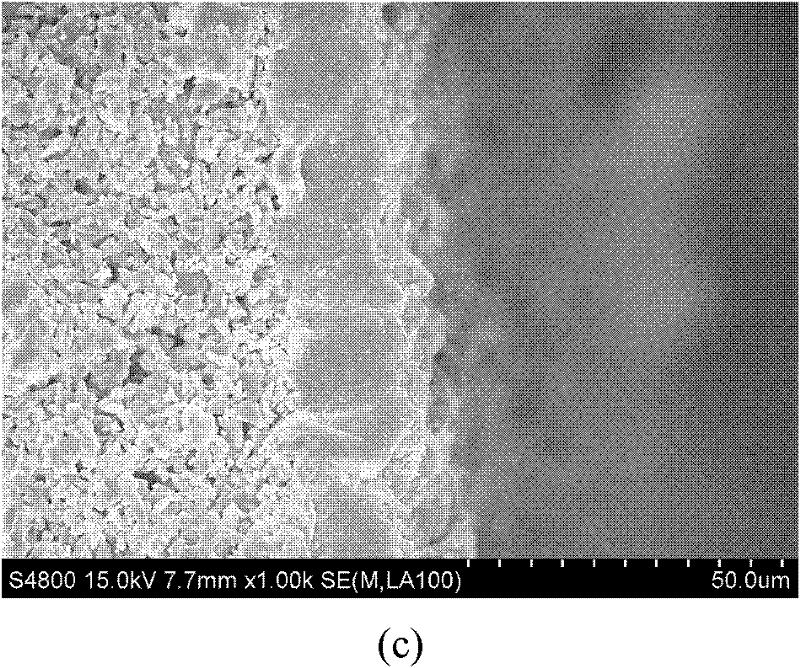

Method for preparing NaA molecular sieve membrane through induction of nanocrystal seeds

InactiveCN102247767AShort cycleSimple methodSemi-permeable membranesMolecular sieveHydrothermal synthesis

The invention relates to a method for preparing a NaA molecular sieve membrane through the induction of nanocrystal seeds, which comprises the following steps of: crushing NaA molecular sieve particles with a large size by using a ball mill to obtain nano-scale molecular sieve particles serving as the crystal seeds; and coating a crystal seed layer on the surface of a carrier, and preparing the NaA molecular sieve membrane by a hydrothermal synthesis method through induction. The NaA molecular sieve membrane synthesized by the method has high separating property, penetration flux and membrane formation repeatability, and a short synthesis period, and is suitable for mass scale-up production.

Owner:NANJING UNIV OF TECH

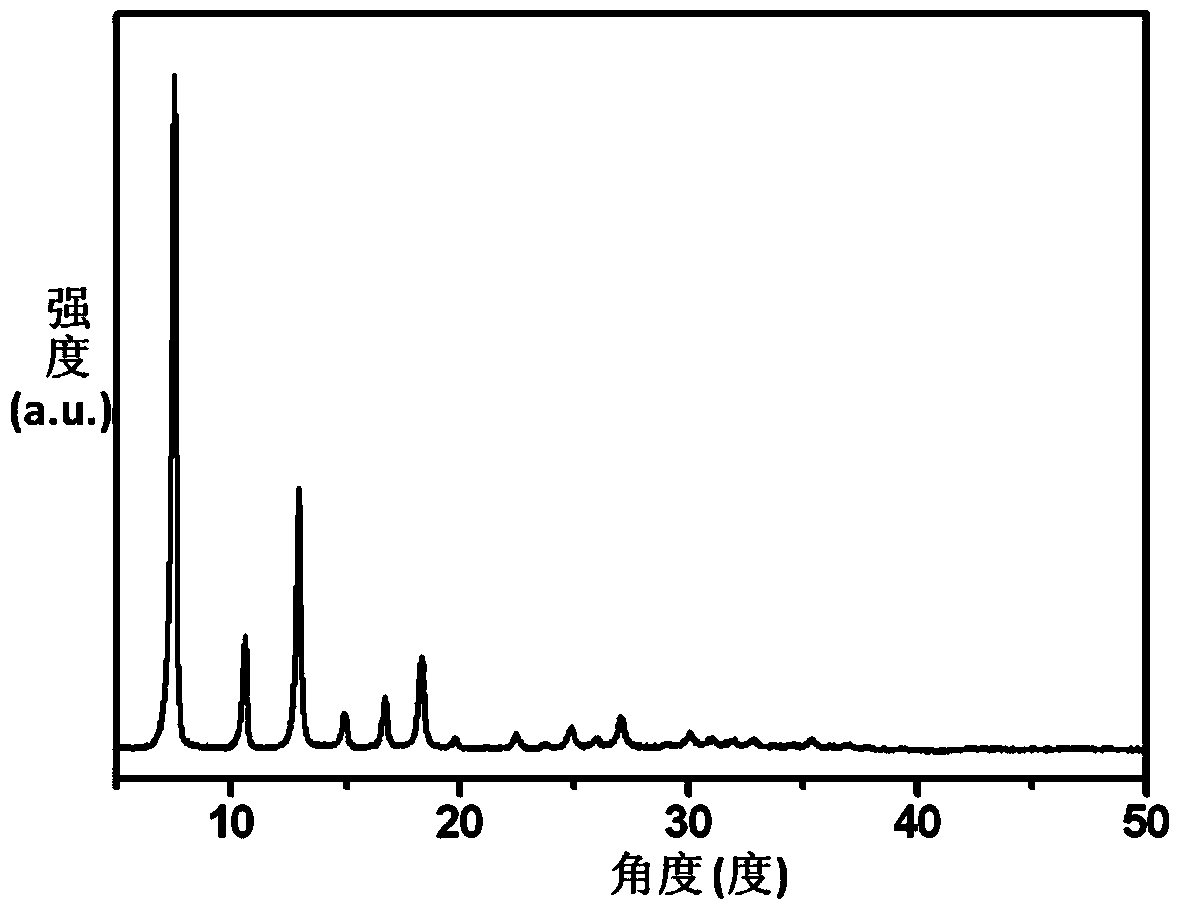

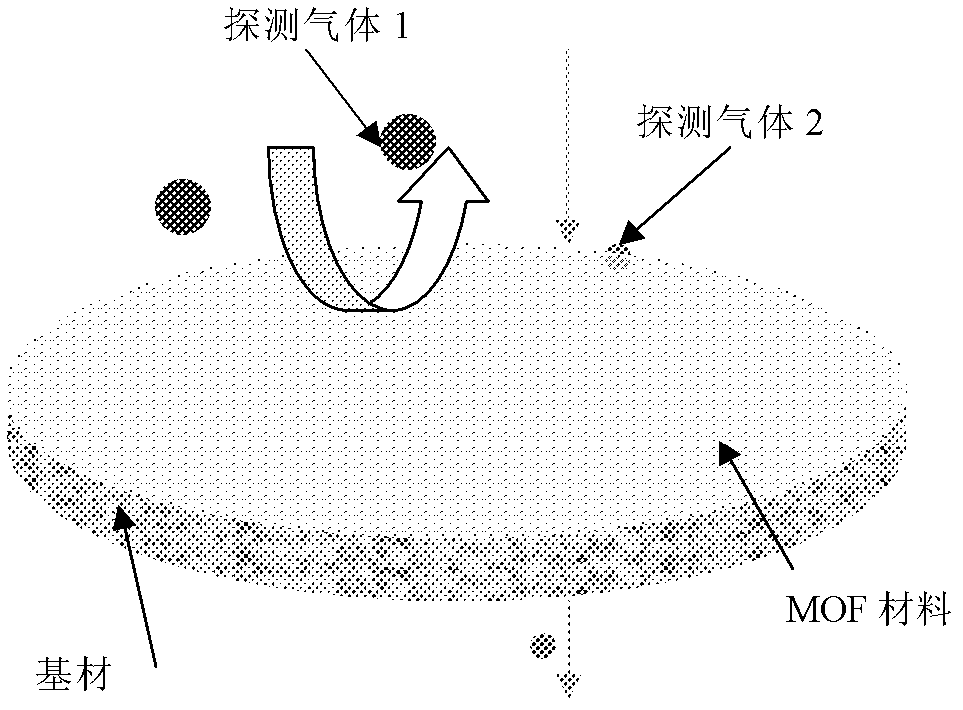

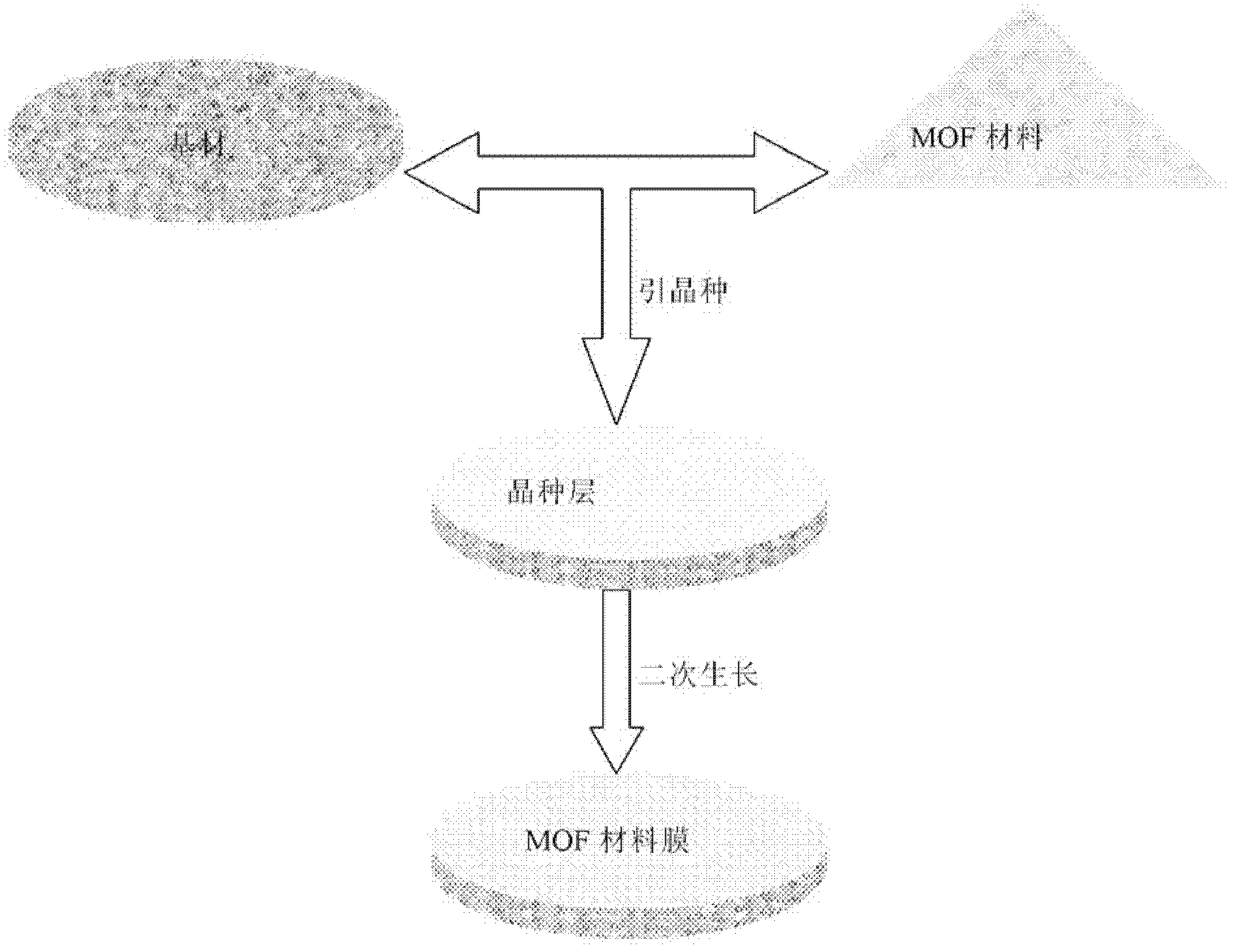

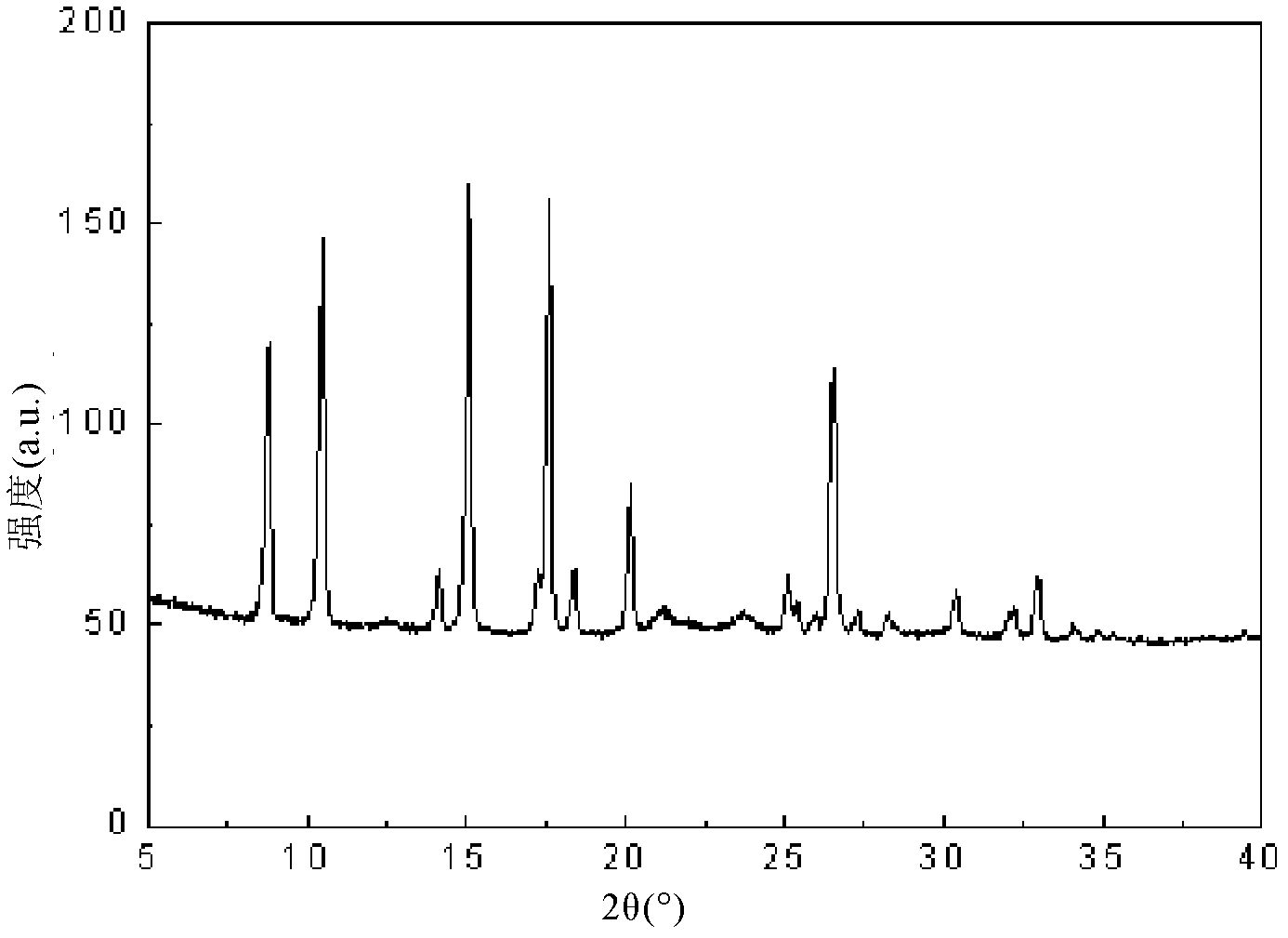

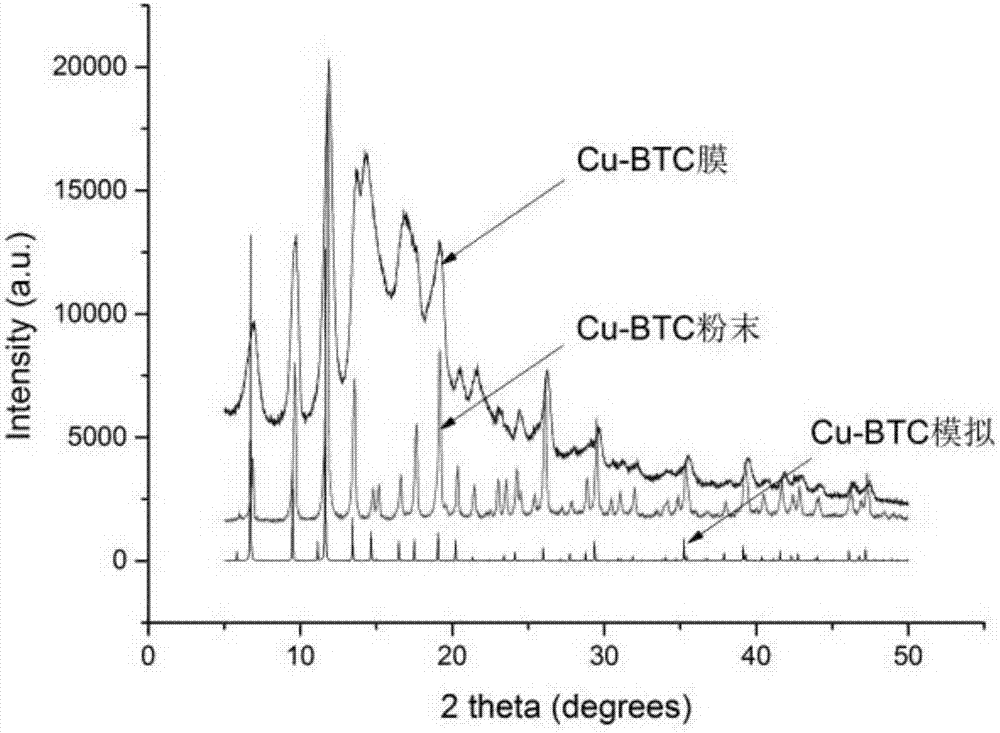

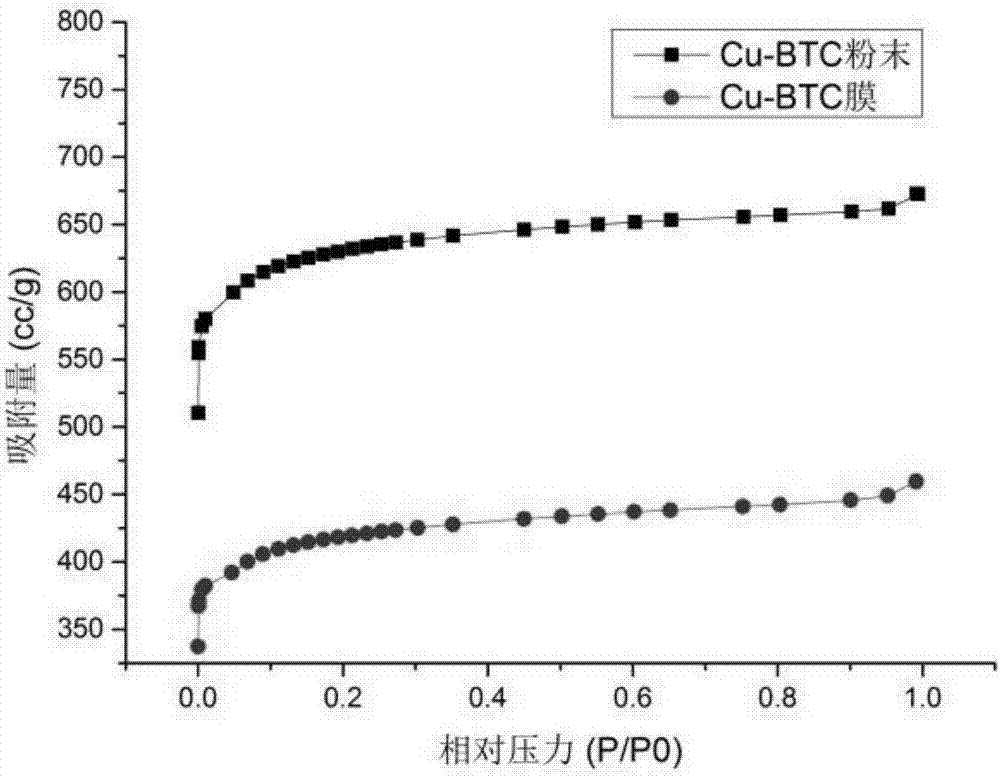

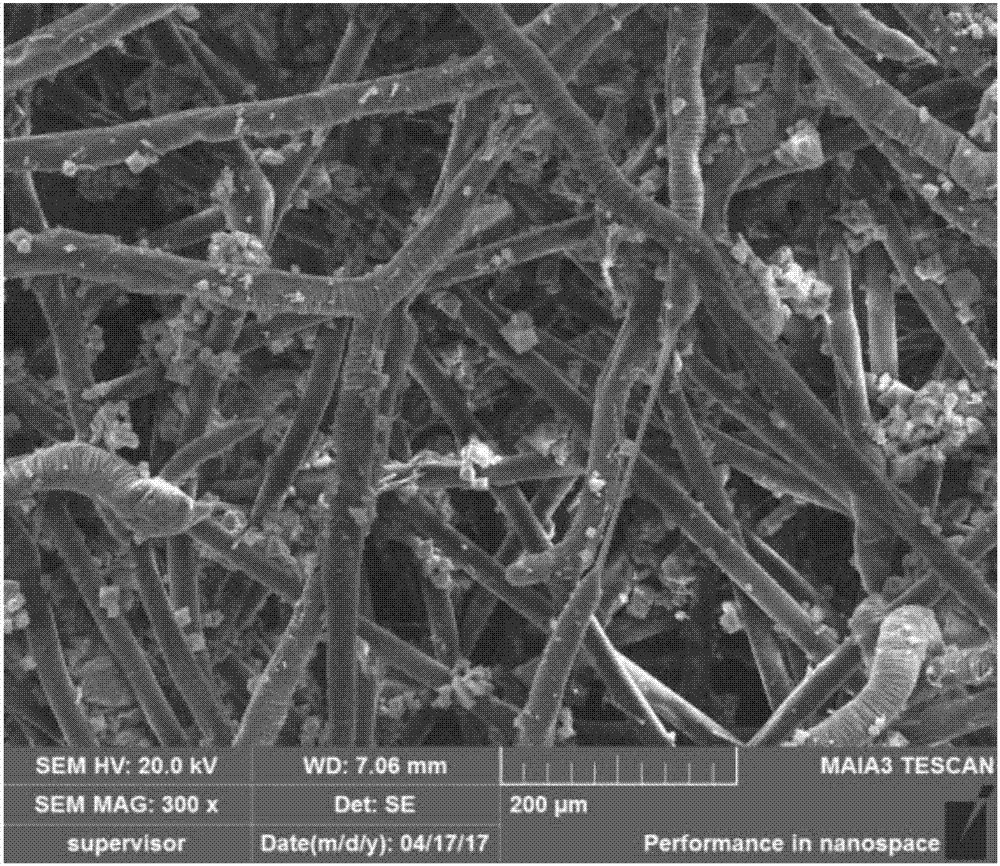

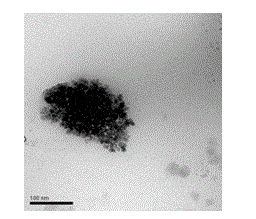

Metal-organic framework (MOF) material for permeating and separating gases and preparation method thereof

ActiveCN102489183AEasy to manufactureWell formedSemi-permeable membranesDispersed particle separationMetal-organic frameworkPermeation

The invention discloses a metal-organic framework (MOF) material for permeating and separating gases and a preparation method thereof. Specifically, an MOF film disclosed by the invention is provided with a functional group, which contributes to nucleating on a substrate, increase the nucleating density on the substrate and contributes to the growth of a dense film; and the functional group can coact with certain specific gases, so that selective permeation of gases is facilitated. Due to the adoption of a film preparation method disclosed by the invention, the growing process of the film is simplified, the structure and shape of the film are optimized simultaneously, and film permeating and separating performance is enhanced. The MOF film prepared with the method has the advantages of high permeation amount, high separating coefficient, low energy consumption and avoidance of secondary pollution, and is particularly suitable for permeating and separating gases such as H2, CO2, CH4 and the like.

Owner:宁波大膜科技有限公司

Complete solid-phase synthesis method for liraglutide

InactiveCN103145828AImprove reaction efficiencyHigh purityPeptide preparation methodsBulk chemical productionFreeze-dryingSide chain

The invention discloses a complete solid-phase synthesis method for liraglutide. 2-Cl-TrtResin is enabled to serve as a solid-phase carrier. DIC / HOBt is enabled to serve as a condensation agent. After processing of microwave reaction technology, reaction time is shortened, and condensation efficiency is improved. According to side chain modification, novel ivDde side chain protected lysine is adopted and side chain modification synthesis is carried out. During the process, 20% piperidine is adopted to get rid of Fmoc protection until linear chain polypeptide synthesis is finished. Then, after hydrazine hydrate is adopted to get rid of ivDde protection, a side chain modification reaction is carried out. Obtained liraglutide with complete protection on the solid phase carrier is processed by trifluoroacetic acid, and crude liraglutide is obtained. After purification and freeze-drying by a C18 column, pure liraglutide is obtained. After strong negative ion salt conversion and free-drying, acetic acid liraglutide acetate is obtained. The complete solid-phase synthesis method for the liraglutide is simple in operation, short in synthesis cycle, low in production cost, few in accessory substance, high in product yield and beneficial for mass production.

Owner:宁波瑞达医药科技有限公司

Method for preparing polypeptide used for treating osteoporosis

InactiveCN102731643AShort synthesis cycleEasy to purifyPeptide preparation methodsParathyroid hormonesPeptideSolid phases

The invention belongs to the pharmacochemistry technical field, and discloses a method for preparing polypeptide used for treating osteoporosis, concretely relates to a teriparatide preparation method. The preparation method is characterized by comprising the following steps: preparing each peptide resin fragment for forming teriparatide, gradually coupling each peptide resin fragment to teriparatide on a solid phase, then pyrolysizing to obtain the teriparatide crude product, and purifying to obtain the product teriparatide. Compared with the prior art, the preparation method has the advantages of simple operation, short synthesis cycle, low cost, less environmental pollution and high yield of teriparatide, and the total yield is 30%. The method of the invention is suitable for large-scale industrial production of teriparatide, and the prepared teriparatide has the advantages of high purity and less by-products, and has considerable economical and practical value as well as wide application prospect.

Owner:HYBIO PHARMA

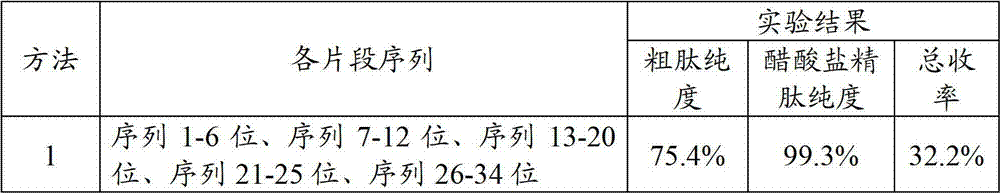

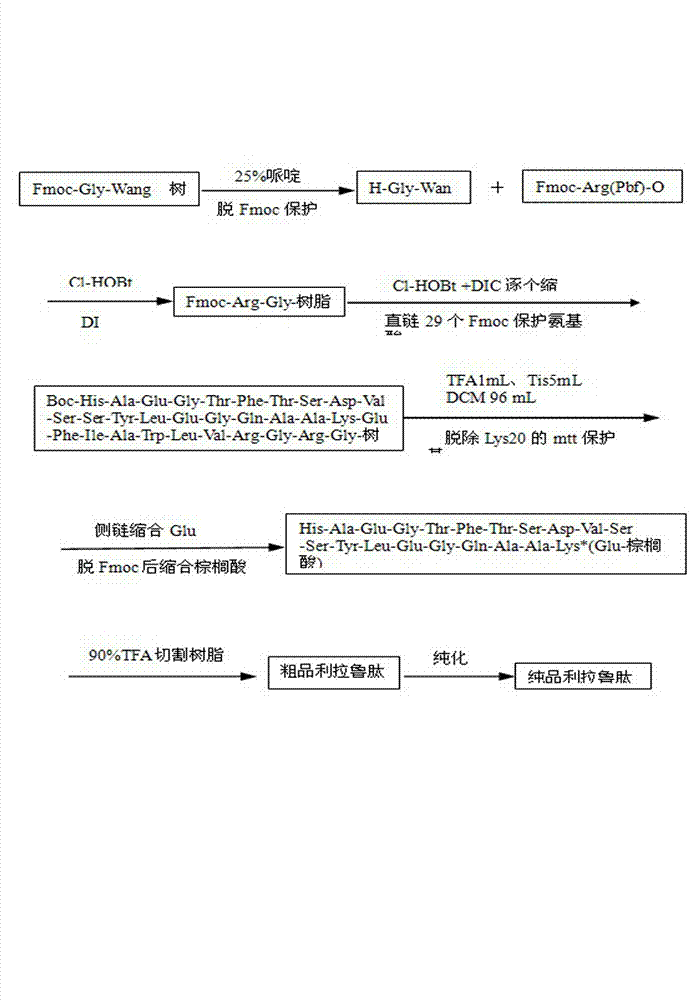

Solid-phase synthesis method of liraglutide

InactiveCN103087181ALess usableSmall quantityPeptide preparation methodsBulk chemical productionSide chainWang resin

The invention discloses a method for synthesizing liraglutide. The method comprises the following steps of: 1, selecting Fmoc-Gly-Wang resin and N terminal Fmoc protected and side chain protected amino acid as raw materials, wherein lysine on a 26th site adopts Fmoc-Lys(Mtt)-OH or Fmoc-Lys(Mmt)-OH, histidine on an N terminal adopts Boc-His(Trt)-OH or Boc-His(Boc)-OH; 2, selectively removing a Mtt or Mmt protecting group on the lysine by adopting 1 percent TFA (Trifluoroacetic Acid); 3, sequentially coupling one g-glutamic acid and palmitic acid on a side chain; and 4, cutting resin by the TFA to obtain a crude product of the liraglutide, and carrying out preparative liquid chromatography purification and lyophilization to obtain a pure product of the liraglutide. The method for synthesizing the liraglutide is simple in steps, saves time and labor, is less in difficult sequences in a coupling process, simple and easy to operate during side chain de-protection, less in byproducts and high in yield, and is suitable for industrialized production.

Owner:刘卫 +1

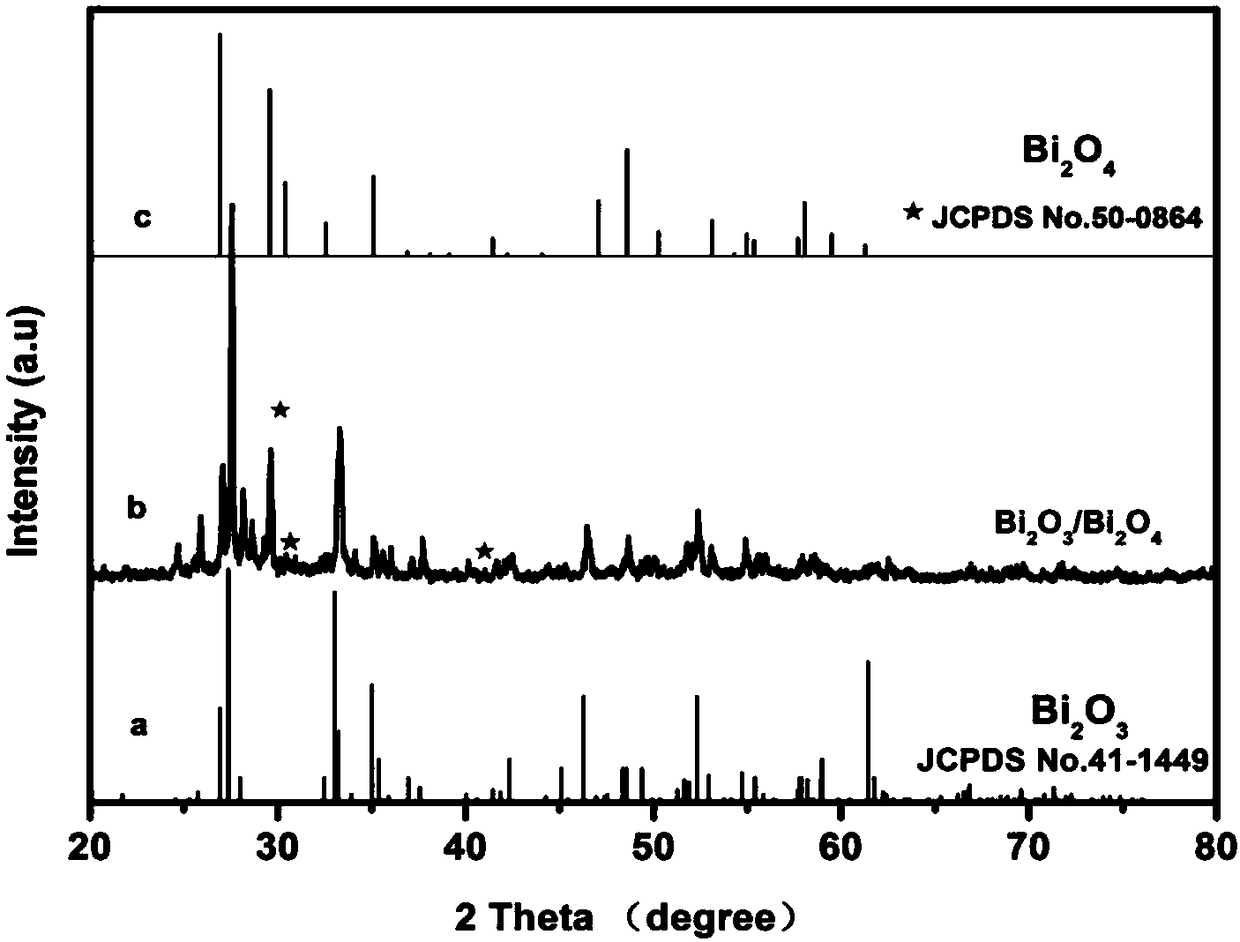

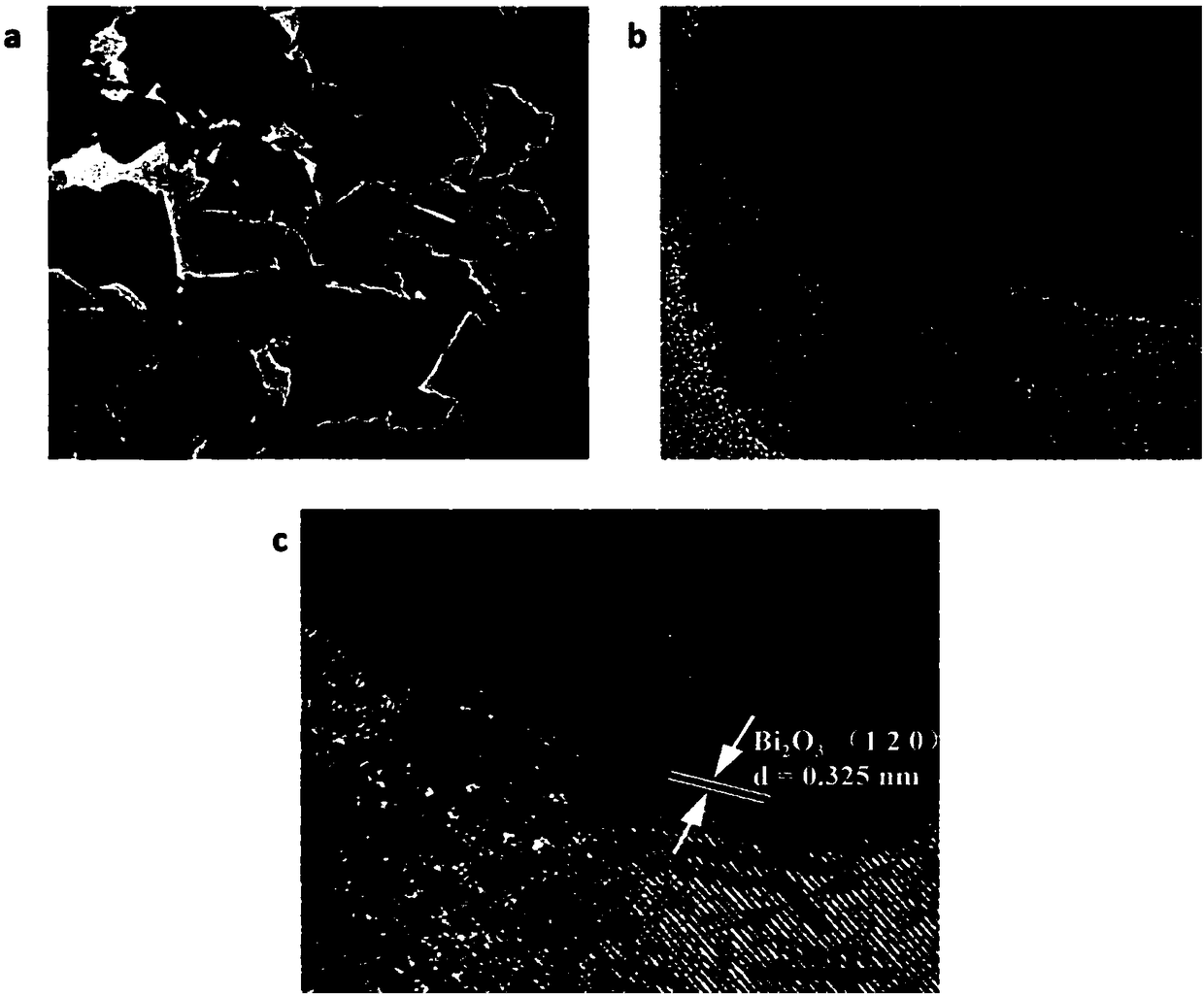

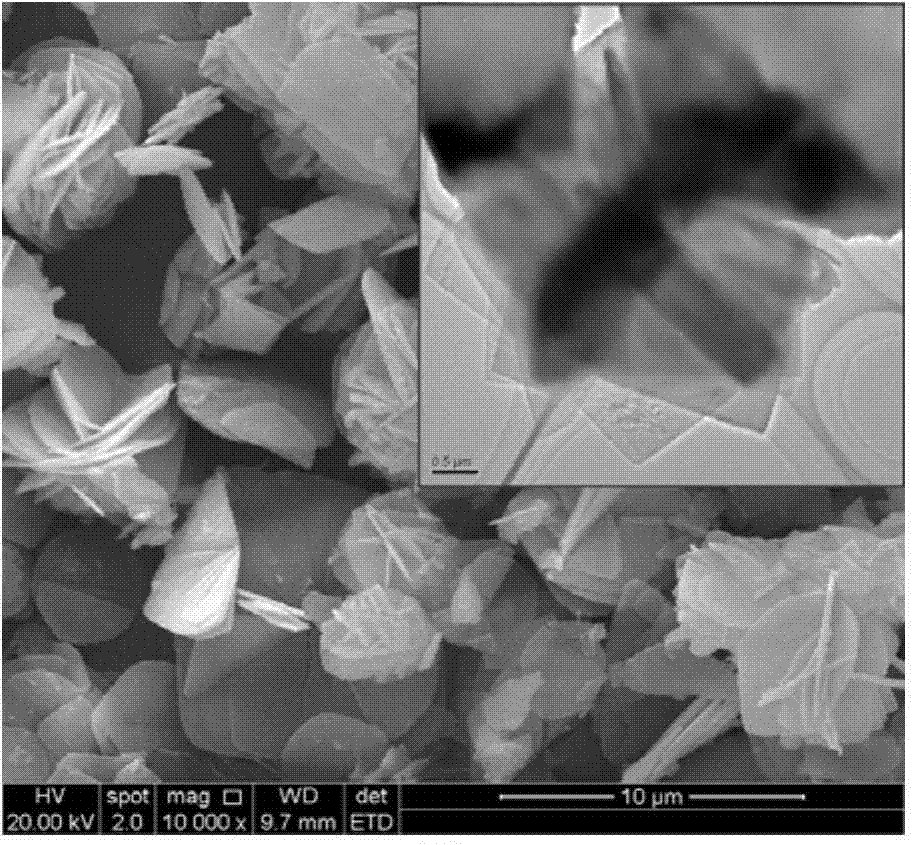

Bismuth oxide/bismuth tetraoxide heterojunction photocatalyst, preparation method and use thereof

ActiveCN108273492AOvercoming the disadvantage of low photocatalytic activityReduce typesWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionMuffle furnace

The invention provides a preparation method and use of a Bi2O3 / Bi2O4 phase heterojunction photocatalyst. The preparation method comprises the following steps: firstly, mixing 2.8 g of bismuth salt with 0-1.87 g of alkali uniformly to prepare a paste; then, placing a mixture into a muffle furnace and calcining at 100-450 DEG C for 0.5-4.0 h; washing a calcined substance with deionized water; and drying at 60 DEG C to obtain earthy yellow to reddish brown solids which are the Bi2O3 / Bi2O4 heterojunction photocatalyst. The Bi2O3 / Bi2O4 phase heterojunction photocatalyst prepared in the invention isused for degrading organic pollutants in water, and has higher visible light catalyzing activity than a commercial Bi2O3 photocatalyst.

Owner:YUNNAN UNIV

Nitrogen oxide storing catalyst with waterlike talc as precursor

InactiveCN101143327AThe synthesis process is simpleShort synthesis cycleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumTalc

The invention provides a nitrogen and oxygen storage catalyst with hydrotalcite-like compound as precursor. The formula of the catalyst is CoxM1-xAlyM'1-yOm. The compositions and contents (calculated according to weight percent) of each component are: cobalt oxide (CoO), 0 to 70 percent; and alumina Al2O3, 5 to 20 percent. 0M refers to magnesium oxide (MgO) or Calcium oxide (CaO); M` refers to lanthanum oxide La2O3 or other oxides of transition metal elements, such as copper, strontium, cerium, manganese, iron, zirconium or titanium. The invention adopts coprecipitation method or hydro-thermal method to prepare catalyst, so the cost is low and the preparation process is simple. The catalyst of the invention is used to store nitrogen oxide of lean-burn gasoline engine or diesel engine in oxygen rich atmosphere. The nitrogen dioxide is absorbed on the catalyst in the form of nitrate or nitrite to be stored. The catalyst still has relatively good storage performance of nitrogen dioxide in case of existence of carbon dioxide and water, and has great anti-oxidation performance and wide application prospects.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Process for solid-phase microwave synthesis of polypeptide

InactiveCN1699404AIncrease reaction rateLower activation energyPeptide preparation methodsBulk chemical productionCombinatorial chemistrySolvent

Disclosed is a process for solid-phase microwave synthesis of polypeptide comprising, (1) preparing amino acid and resin compound, (2) removing amino protecting group through microwave radiation, (3) condensating amino acid through microwave radiation, (4) replacing amino acids, repeating step (2) and (3) to synthesize the needed polypeptides, (5) preparing the polypeptides crude product.

Owner:NANJING UNIV OF TECH

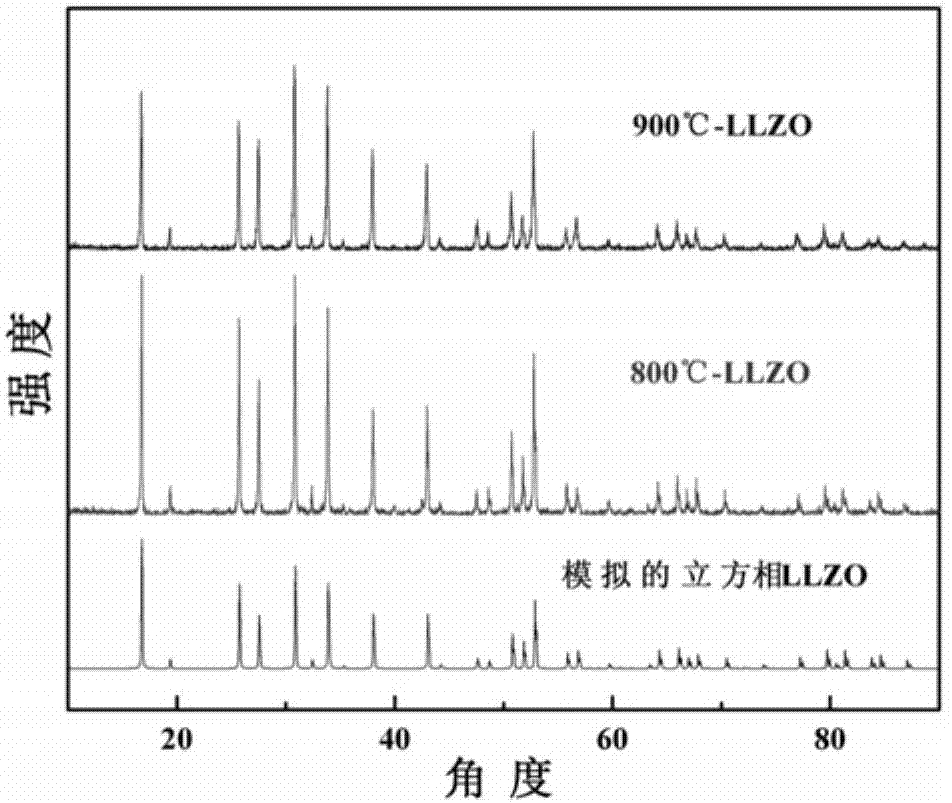

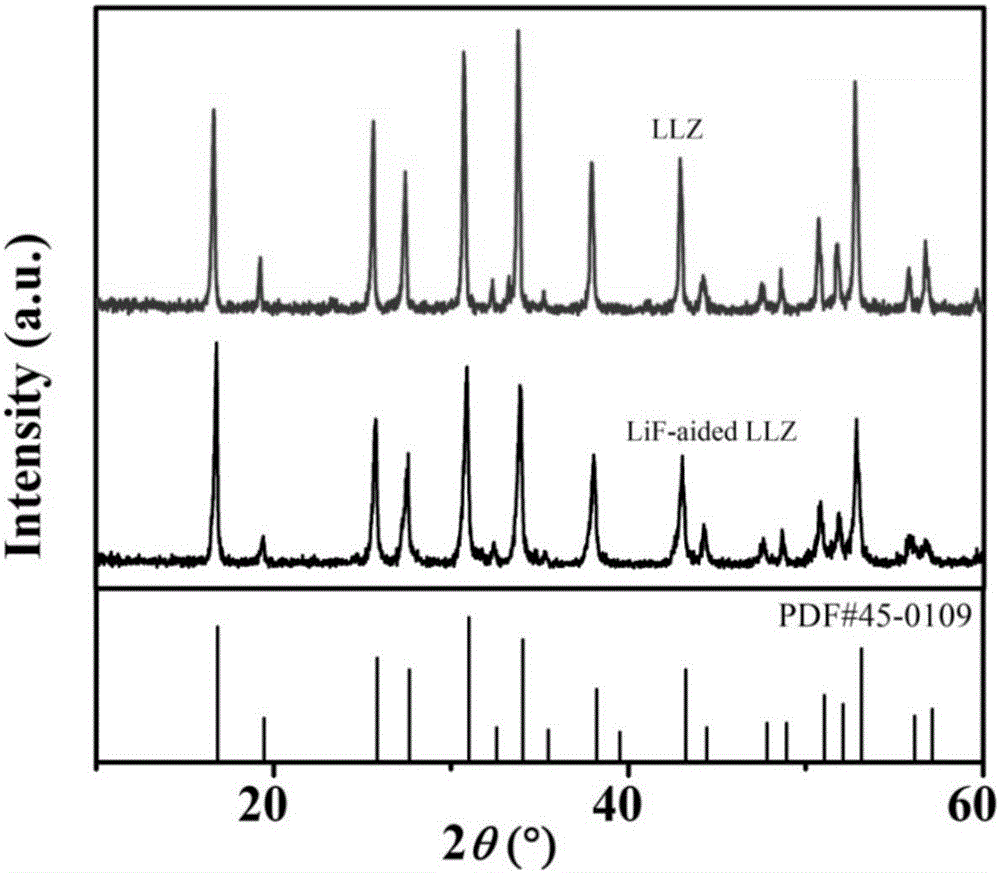

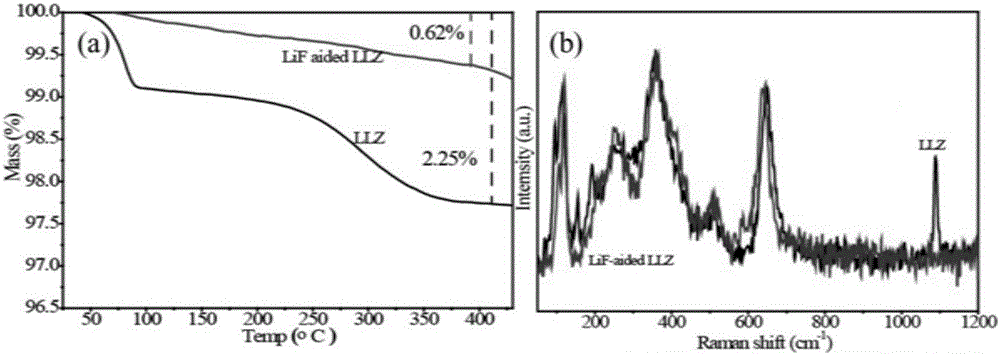

Method for preparing solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder

ActiveCN104124467ACalcination temperature is lowHigh sintering activitySecondary cellsElectrical batteryElectrochemistry

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

Fast synthesis process of high-crystallinity zeolite molecular sieve

InactiveCN1417116AShort synthesis cycleHigh crystallinityPentasil aluminosilicate zeoliteIon contentMolecular sieve

High-crystallinity H-type zeolite molecular sieve is synthesized through the fast process including: adding dropwise mixed solution B comprising Al2(SO4)3.18H2O, water and concentrated sulfuric acid to mixed solution A comprising water glass and deionized water while stirring drastically; adding fatty amine and inorganic ammonia solution to form gel mixture; sealing, ageing, crystallizing, cooling, solid-liquid separation, washing to filter cake pH value of 8-9, drying, calcining and HCl exchange. The process has the advantages of short synthesis period, high crystallinity, low organic template agent content in crystallized zeolite and low sodium ion content.

Owner:SYNFUELS CHINA TECH CO LTD

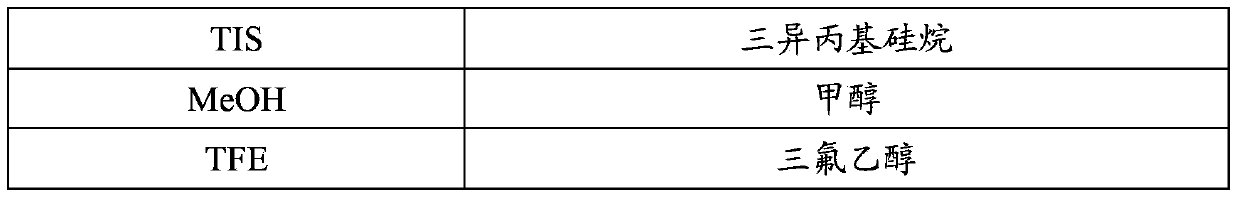

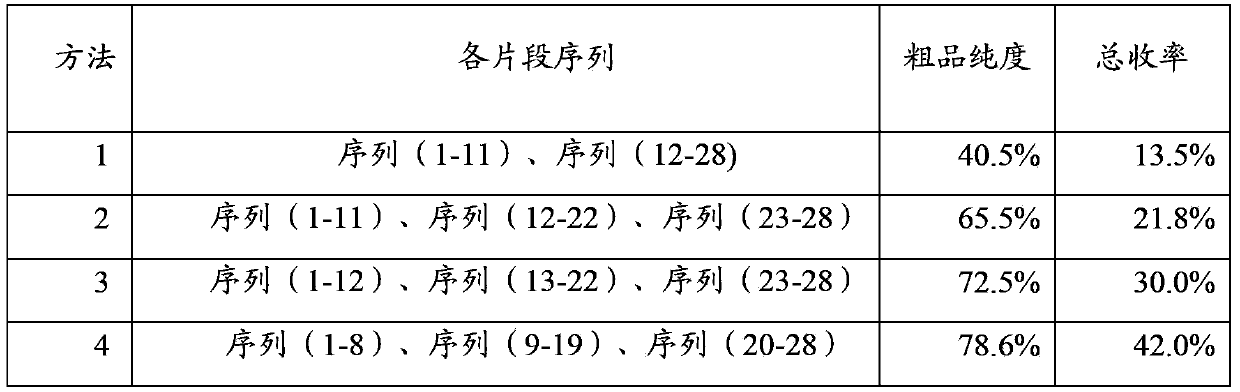

Method for synthesizing thymalfasin

ActiveCN103497245AEase of mass productionEasy to purifyThymosin peptidesPeptide preparation methodsThymalfasinCombinatorial chemistry

The invention relates to the field of medicine synthesis, and discloses a method for synthesizing thymalfasin. According to the method of the invention, based on the amino acid sequence from the C terminal to the N terminal of the thymalfasin peptide chain, fragments of 1-8, 9-19 and 20-28 are synthesized, and the three polypeptide fragments are coupled to obtain thymalfasin. According to the invention, a plurality of fragments are synthesized simultaneously; the synthetic period is reduced by 2 / 3; intermediates are easy to purify; the cost is low; the purity of the finished products is high; by-products are few; the product yield is high; and the method facilitates large-scale production of thymalfasin.

Owner:HYBIO PHARMA

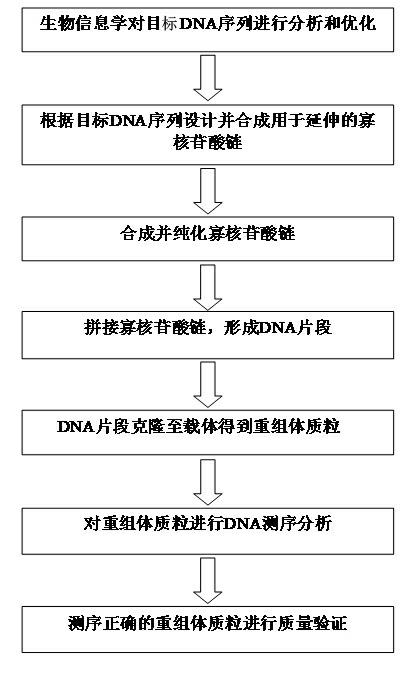

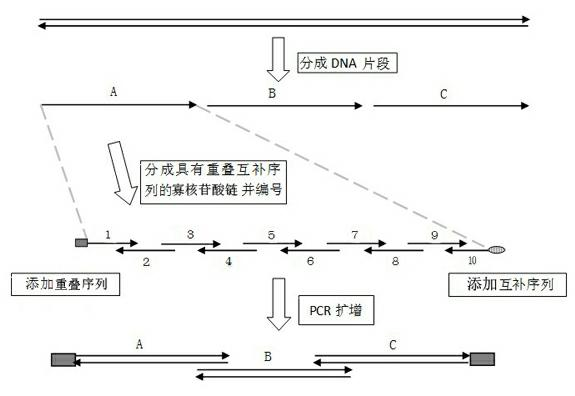

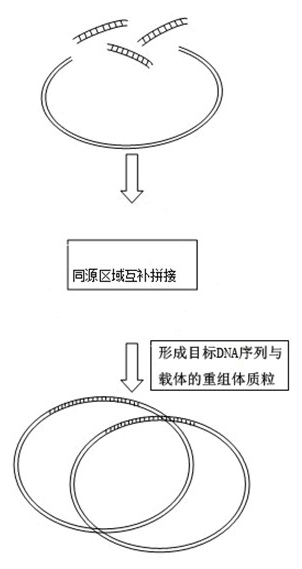

Industrialized gene synthesis method

The invention discloses an industrialized gene synthesis method. The industrialized gene synthesis method comprises the following steps of (1) analyzing and optimizing a DNA sequence for synthesis to obtain a target DNA sequence; (2) designing an oligodeoxynucleotide chain for extension according to the target DNA sequence; (3) synthesizing and purifying the oligodeoxynucleotide chain; (4) splicing the oligodeoxynucleotide chain to form a DNA fragment; (5) cloning the DNA fragment to a vector to obtain a recombinant plasmid; (6) carrying out sequencing analysis of the recombinant plasmid; and(7) carrying out a quality validation process on the recombinant plasmid with a correct sequence. The industrialized gene synthesis method has the characteristics of high success rate, high throughput, high speed, low cost, simple design, wide application scope and standardized operation. Therefore, the industrialized gene synthesis method has feasibility of industrial scale popularization, and is beneficial for reduction of costs, shortening of a synthesis cycle and improvement of synthesis quality.

Owner:GENEWIZ INC SZ

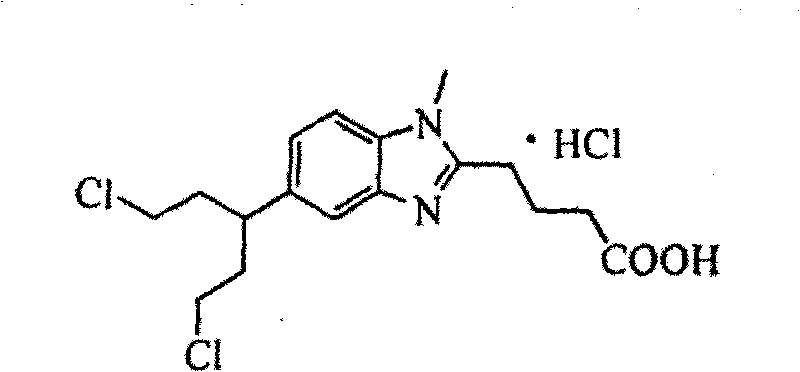

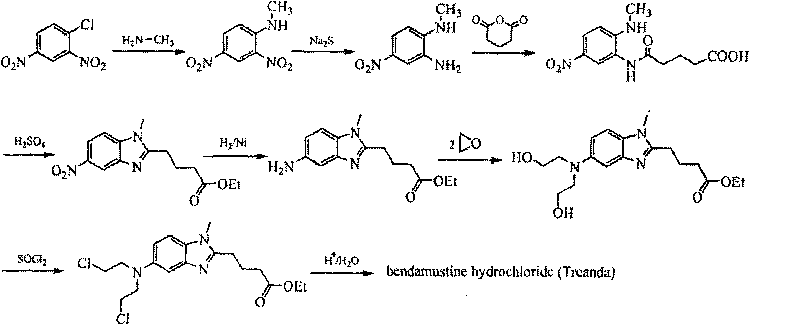

Method for synthesizing highly-pure bendamustine hydrochloride

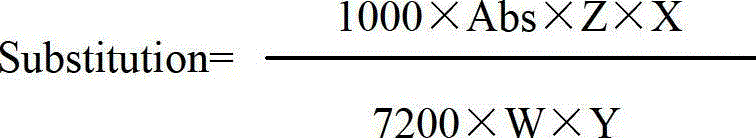

ActiveCN101691359AComply with drug quality standardsShort synthesis cycleOrganic chemistryBendamustine hydrochlorideEthylene oxide

The invention discloses a method for synthesizing highly-pure bendamustine hydrochloride, which comprises the following steps: taking [1-methy-2(4'-ethyl butyrate)-5-amino]-1H-benzimidazole as a raw material; and orderly reacting the [1-methy-2(4'-ethyl butyrate)-5-amino]-1H-benzimidazole with ethylene oxide and phosphorus oxychloride through the four steps of substitution, hydrolysis, salification and refinement so as to produce the bendamustine hydrochloride. The method in the invention is mild in condition, simple in operation, short in synthesis period and suitable for scaled-up industrial production; and the purity of the synthesized bendamustine hydrochloride is over 99.5 percent, while monomeric impurity is below 0.1 percent, which meet the quality standards of raw material medicament.

Owner:深圳万乐药业有限公司

Method for synthesizing liraglutide

ActiveCN104004083AReduce carrier usageAvoid couplingPeptide preparation methodsBulk chemical productionAmino acid synthesisCoupling

The invention relates to the field of medicine synthesis, and discloses a method for synthesizing liraglutide. The method includes the steps that three polypeptide fragments of the first to the fourth amino acid, the fifteenth to the sixteenth amino acid and the seventeenth to thirty-first amino acid are synthesized at first according to the amino acid sequence from N end to C end of a main chain of liraglutide, and then the three polypeptide fragments and the other amino acid are connected according to the sequence from the C end to the N end in a coupling mode to synthesize the liraglutide. According to the method, the three fragments can be synthesized simultaneously, coupling and acidolysis with much carrier resin are avoided, the use quantity of resin carriers is greatly reduced, the synthesis cycle is shortened, and the complexity level of synthetic process is simplified on the premise that high total recovery and purity are guaranteed.

Owner:CHENGDU SHENGNUO BIOTEC CO LTD

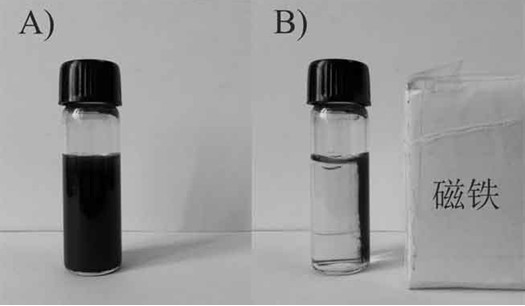

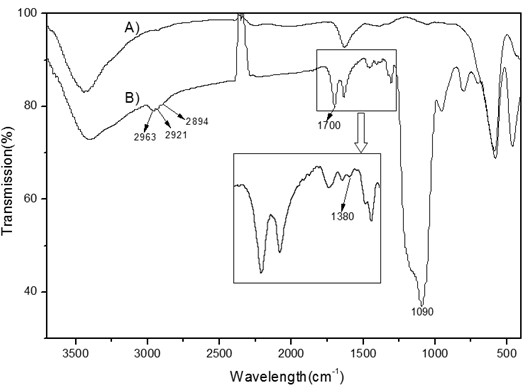

One-pot synthesis phenylboronic acid polymer magnetic nano composite material and preparation method and application thereof

InactiveCN102558463AGood core-shell morphologyStrong magnetismOrganic compounds purification/separation/stabilisationSugar derivativesPolymer scienceFunctional monomer

The invention provides one-pot synthesis phenylboronic acid polymer magnetic nano composite material and a preparation method and an application thereof. The preparation method comprises the following steps: dispersing ferroferric oxide nanoparticles in the alcohol containing a silane precursor and a catalyst through using a one-pot method, performing sol-gel reaction, and then continuously adding a phenylboronic acid type functional monomer, a cross-linking agent and an initiator to perform free radical polymerization in order to make synthesis phenylboronic acid polymer magnetic nano composite material. The synthesis method is simple, effective, high in yield and less in reagent consumption. The phenylboronic acid polymer magnetic nano composite material prepared has the advantages of good core-shell morphology, good magnetic field induction, strong specificity, high adsorption capacity, and good use value and application prospect in the fields such as proteomics and the like.

Owner:FUZHOU UNIV

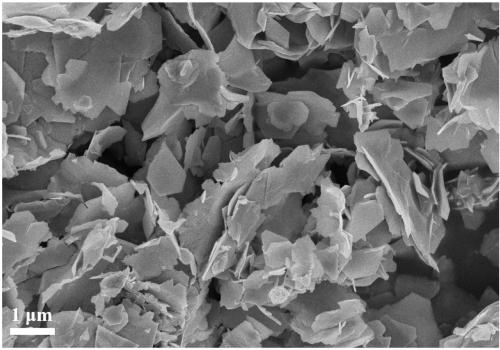

Transition metal chalcogenide nanosheet material and preparation method thereof, battery anode material, secondary battery and application thereof

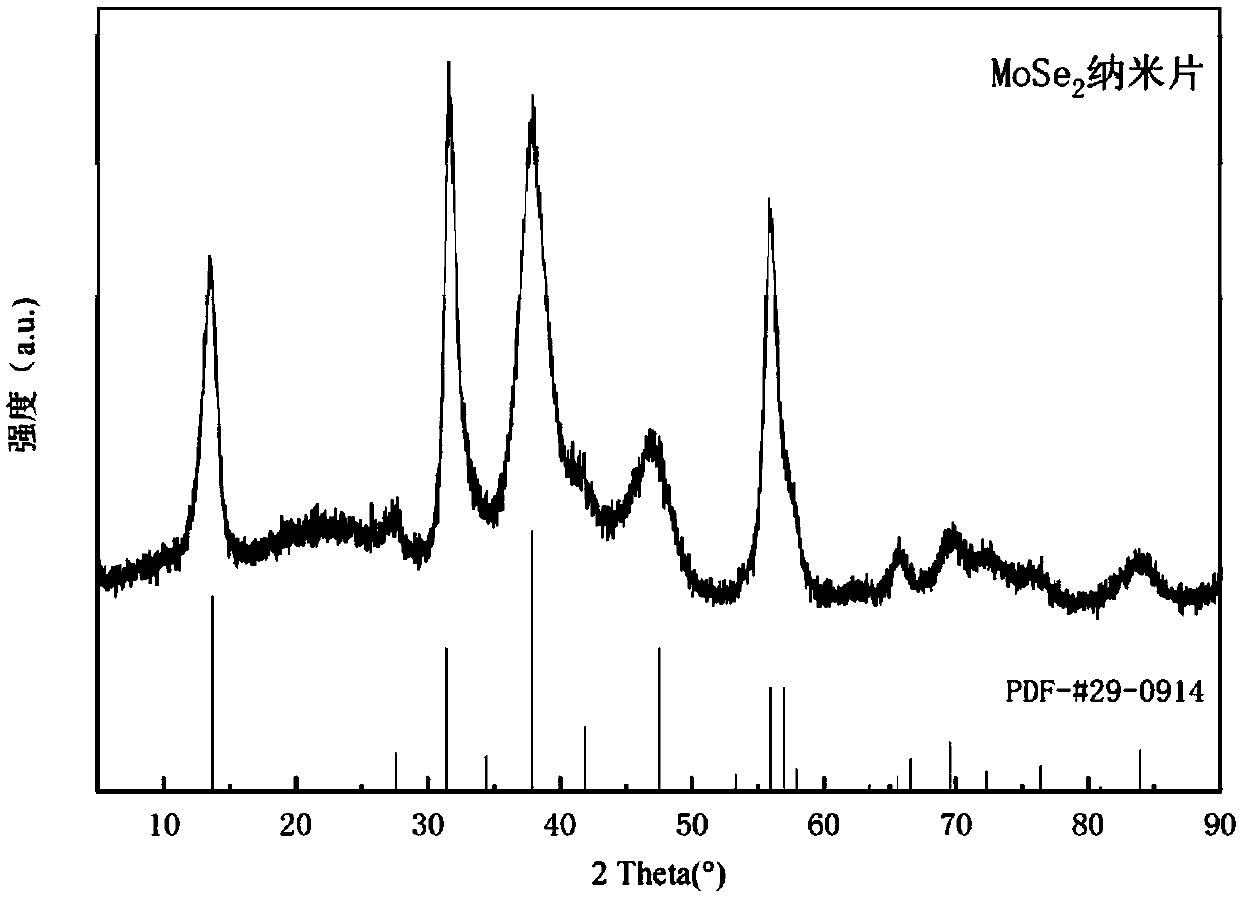

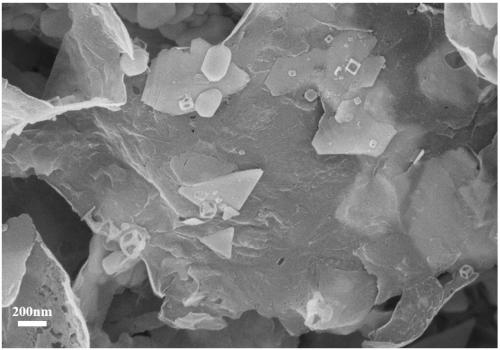

InactiveCN109650348AImprove performanceHigh specific capacityMaterial nanotechnologySecondary cellsSulfurSilicon dioxide

The invention provides a transition metal chalcogenide nanosheet material and a preparation method thereof, a battery anode material, a secondary battery and an application thereof, and belongs to thetechnical field of transition metal chalcogenides. The invention provides a preparation method of a transition metal chalcogenide nanosheet material, comprising the following steps: dissolving raw materials in an aqueous solution of soluble salt, removing moisture to obtain a solid, sintering the solid, and washing to obtain a transition metal chalcogenide nanosheet material, wherein the raw materials include a chalcogen precursor and a transition metal precursor. According to the preparation method, the soluble salt is used as a template, is inexpensive, is environmentally friendly and is easy to remove in post-treatment, and the obtained transition metal chalcogenide nanosheet material has a thinner sheet thickness. Compared with a traditional silica template method or a hydrothermal method, the preparation method of the invention greatly shortens the synthesis cycle, is simple and feasible, is controllable, has characteristics of high yield and simple experimental operation, and issuitable for large-scale production.

Owner:SHENZHEN INST OF ADVANCED TECH

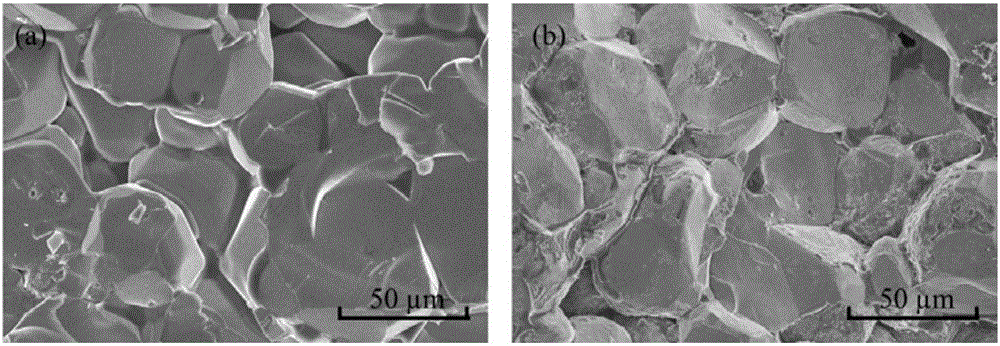

Solid electrolyte capable of lowering interface resistance on metal lithium electrode, and preparation method for solid electrolyte

ActiveCN106129466AReduce lossReduce time lossSecondary cellsElectrolyte immobilisation/gelificationSolid state electrolyteState of art

The invention relates to a solid electrolyte capable of lowering interface resistance on a metal lithium electrode, and a preparation method for the solid electrolyte. The preparation method comprises the steps of mixing lithium carbonate, lanthanum oxide and zirconium oxide, and uniformly grinding the mixture by a dry grinding method; then sintering the mixture in a muffle furnace, and grinding to obtain mother powder, and tabletting the mother powder; putting the tablet-shaped material into a crucible with a cover; then performing mother powder filling and sintering in the muffle furnace to obtain the compact ceramic sheet; and polishing the ceramic sheet until the surface of the ceramic sheet is smooth to obtain the solid electrolyte. Compared with the prior art, the electrolyte prepared by the method has the advantages of absence of impure phase on the surface, high relative density, low interface resistance on the metal lithium electrode, and the like.

Owner:SHANGHAI JIAO TONG UNIV

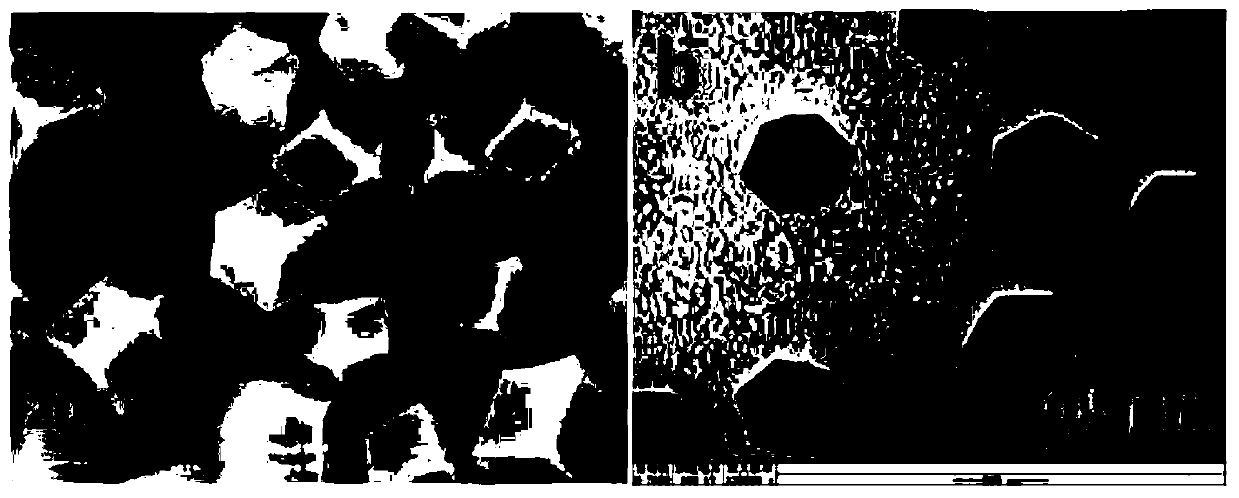

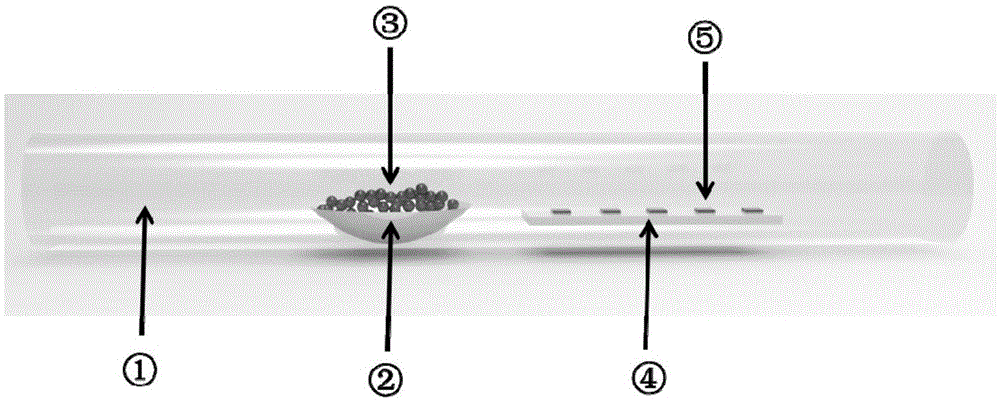

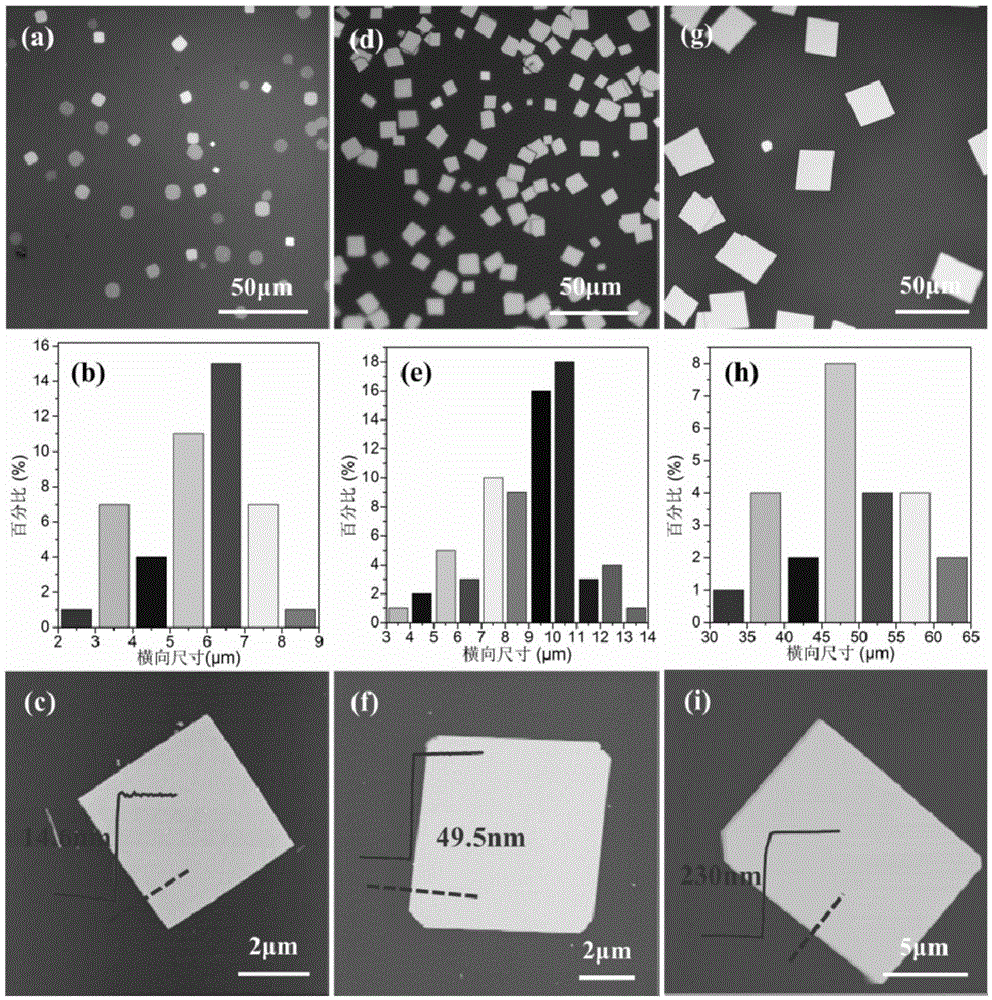

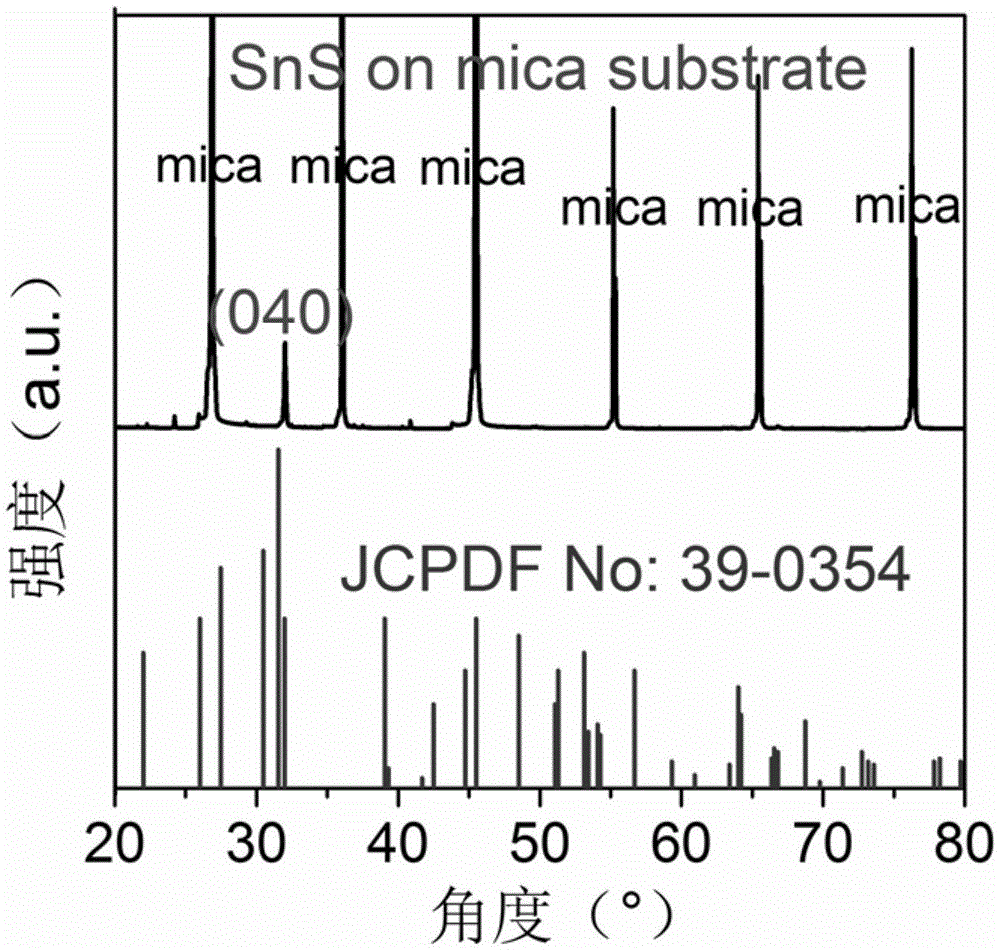

Controllable method for preparing orthogonal-phase stannous sulfide two-dimensional monocrystalline nanosheet

ActiveCN105420815AQuality improvementIncrease the areaPolycrystalline material growthFrom condensed vaporsPhotovoltaic detectorsHydrogen

The invention discloses a controllable method for preparing an orthogonal-phase stannous sulfide (SnS) two-dimensional monocrystalline nanosheet. The method includes the steps that a substrate is arranged on the downstream of a heating center of a horizontal tubular furnace and is 8-20 cm away from the heating center, SnS powder is placed in a high-temperature-resistant container, and the container is placed in the heating center of the horizontal tubular furnace; the tubular furnace is vaccumized, when the pressure intensity in the furnace is reduced to 0.1 Pa, inactive gas is injected into the furnace so that the pressure intensity in the tubular furnace can be 20-300 Torr again, and the flow speed of the gas is kept between 20 sccm to 200 sccm; the temperature of the heating center of the horizontal tubular furnace is raised to 600-800 DEG C, reaction time is 5-30 min, the substrate is taken out after the temperature in a cavity of the tubular furnace is naturally lowered to room temperature, and the stannous sulfide two-dimensional monocrystalline nanosheet grows on the surface of the substrate. The method is easy to operate, low in cost and high in controllability. Obtained SnS has the advantages of being large in size, good in uniformity and high in crystallinity, and the method has important research value and wide application prospects in the fields of field effect transistors, photoelectric detectors, photocatalytic hydrogen generation, lithium ion batteries and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Molded metal-organic framework material and molding method thereof

InactiveCN107029670AGood bonding performanceHigh strengthOther chemical processesDispersed particle separationMetal-organic frameworkOrganic solvent

The invention discloses a molded metal-organic framework material and a molding method thereof. The molding method comprises the following steps: preparing a binder solution with a proper concentration to allow the binder solution to minimally block holes in a metal-organic framework material while maintaining good bonding performance; then uniformly mixing the binder solution with a suspension of the metal-organic framework material; placing a substrate membrane in the mixed solution obtained in the previous step to allow the surface of the substrate membrane to be uniformly adhered by a layer of the metal-organic framework material; and then soaking the substrate membrane uniformly adhered by the metal-organic framework material in an organic solvent to allow water molecules in the pore channels of the metal-organic framework material to be displaced out so as to reinforce the strength of the metal-organic framework material adhered on a substrate, wherein the molded metal-organic framework material with a large specific surface area and high mechanical strength is eventually obtained. Thus, the molding method provided by the invention overcomes the technical problems of complex molding process, a long molding period, severe conditions, high cost, severe loss of specific surface areas and the like in the prior art.

Owner:HUAZHONG UNIV OF SCI & TECH

Modified starch magnetic nano compound and preparation method and application thereof

ActiveCN102716718ASmall particle sizeSmall specific surface areaOther chemical processesAlkali metal oxides/hydroxidesPhysical chemistryNanotechnology

The invention relates to a modified starch magnetic nano compound and a preparation method and application thereof. The modified starch magnetic nano compound is expressed as ES-Fe3O4 NPs. The invention further comprises the preparation method of the modified starch magnetic nano compound and the application of the modified starch magnetic nano compound to desorption of heavy metal ions in waste water. The magnetic particles of the modified starch magnetic nano compound have small particle diameters and large specific surface areas and are easy to combined with target substances; when the modified starch magnetic nano compound is utilized to desorb the heavy metal ions in the waste water, the speed is high, the extraction ratio is considerable, and the magnetic particles can be used repeatedly; separation is quick under the action of an external magnetic field, and centrifugal operation is not needed to facilitate the simplification and the automatization of the separation process; raw materials are cheap and easy to obtain, the synthesis steps are greatly simplified, and the synthesis cycle is short; no toxic substance is used in the synthesis process, so that safety and environmental friendliness are achieved; and the operation is simple, the time consumption is low, the efficiency is increased, and manual labor and energy sources are saved.

Owner:HUNAN NORMAL UNIVERSITY

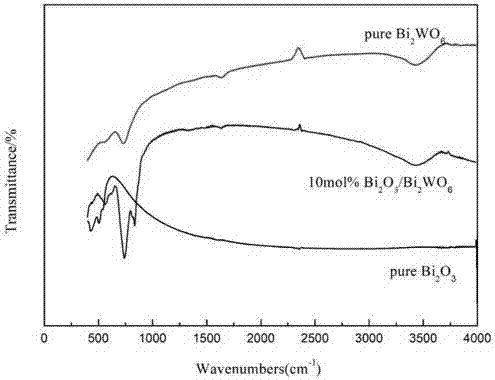

Bismuth trioxide-bismuth tungstate heterojunction photocatalyst and preparation method thereof

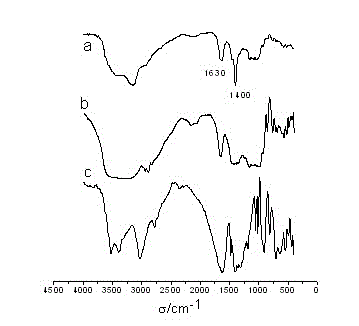

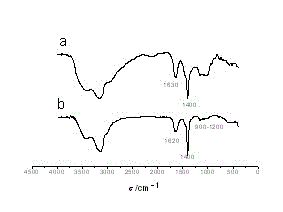

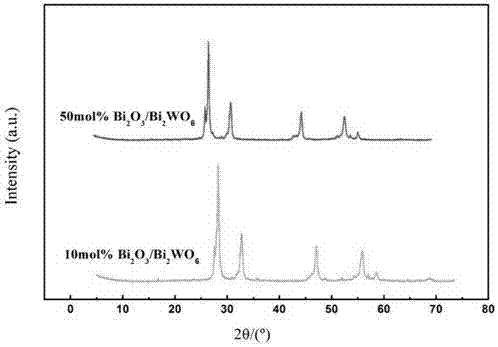

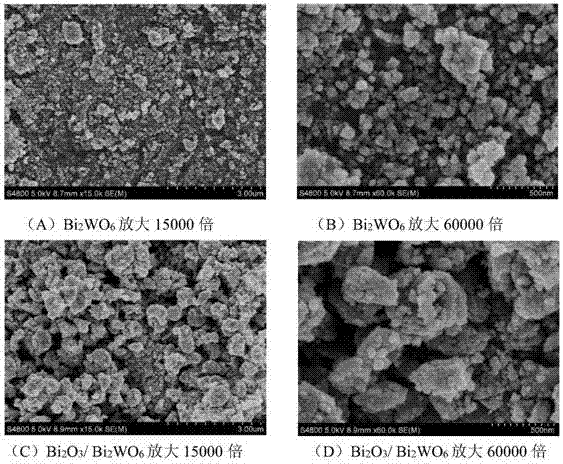

InactiveCN107486199AAchieve separationHigh activityWater/sewage treatment by irradiationWater contaminantsHeterojunctionSpectral response

The invention belongs to the field of semiconductor catalysis, and discloses a preparation method of a bismuth trioxide-bismuth tungstate heterojunction photocatalyst. The method comprises the steps of compounding bismuth trioxide and bismuth tungstate with the molar ratio being 0.1:1 to 0.5:1, so as to form a heterojunction structure, and ensuring that bismuth trioxide is loaded on the surface of bismuth tungstate. According to the method, bismuth nitrate and ammonium metatungsten are taken as raw materails, and the bismuth trioxide-bismuth tungstate heterojunction photocatalyst is formed by one step through a solvothermal method. The preparation method is simple, the synthesis period is short, and a formed sample is high in purity and has a typical p-n heterojunction structure, can effectively restrain the compounding of photo-induced electron and holes, promotes the separation of photon-generated carriers, has the characteristics of high activity and wide spectral response, and is of great importance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

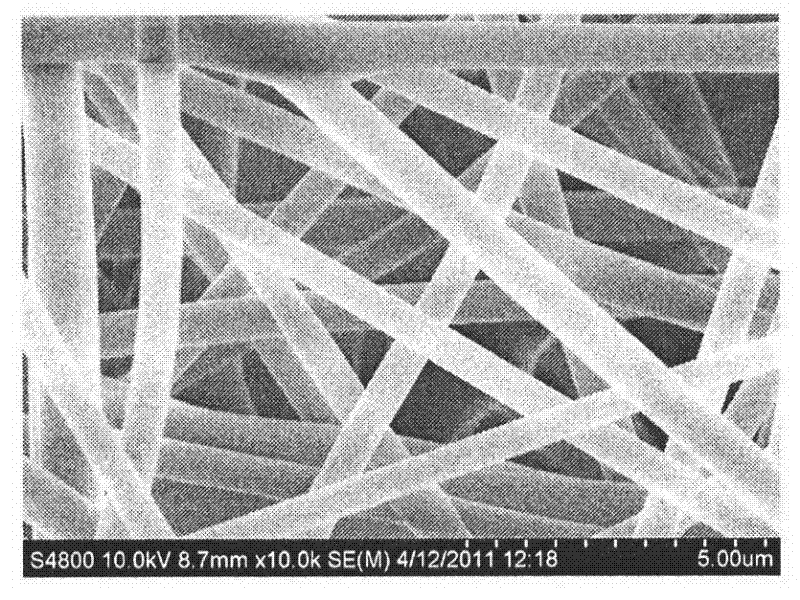

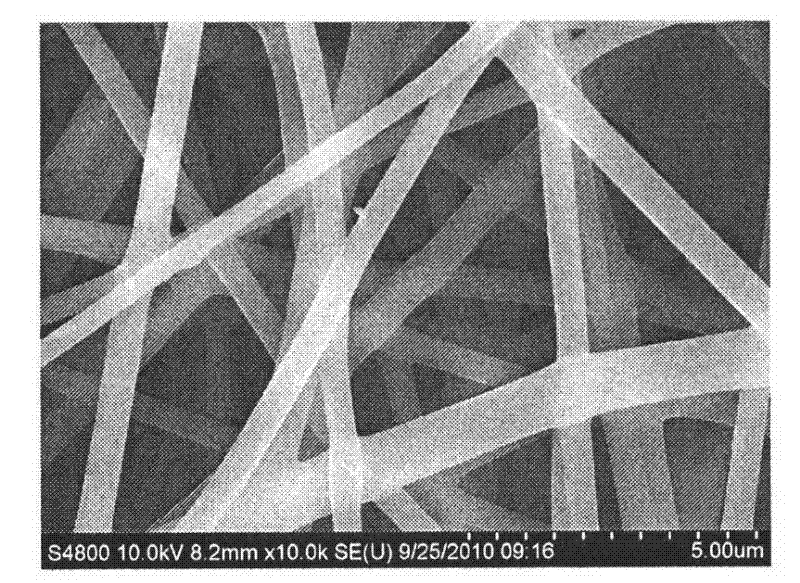

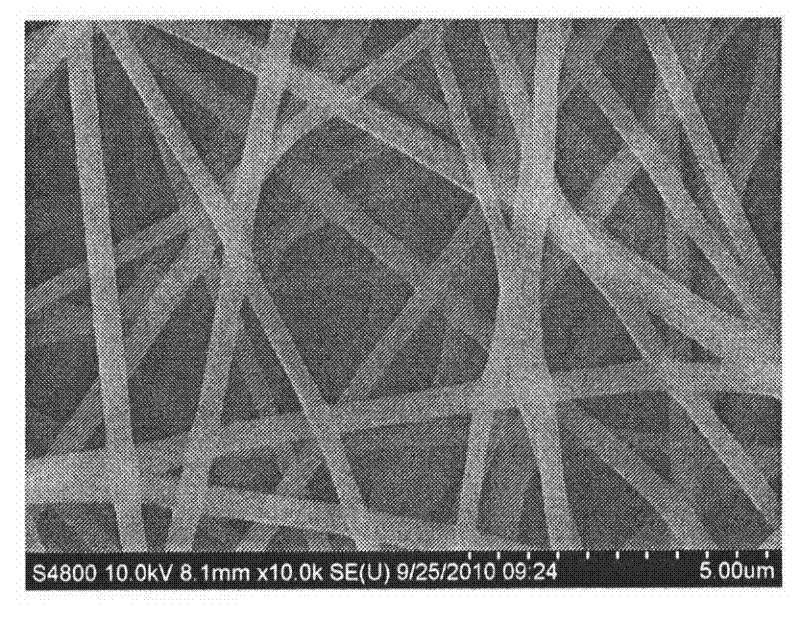

Stock solution for spinning phenolic fibers (PFs) and preparation method for stock solution

ActiveCN102532444AGood dispersionSynthetic conditions are mild and controllableMonocomponent synthetic polymer artificial filamentFiberTO-18

The invention relates to a stock solution for spinning phenolic fibers (PFs). The stock solution comprises the following raw materials: phenol, a 30 to 40 weight percent formaldehyde solution, a 6 to 18 weight percent polyvinyl alcohol (PVA) solution and a catalyst in a mass ratio of 100:(90-200):(40-250):(8-40). The stock solution has the advantages that: spinnability is high, the spinnable viscosity interval is wide, and the intrinsic properties of the PFs are not influenced by an additive.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

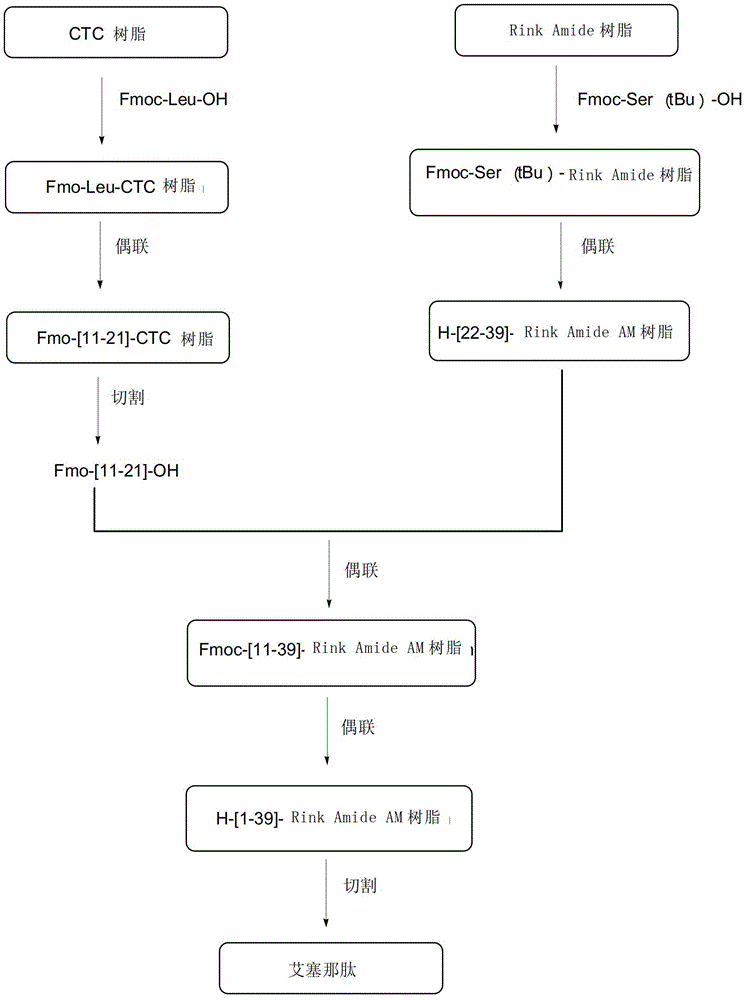

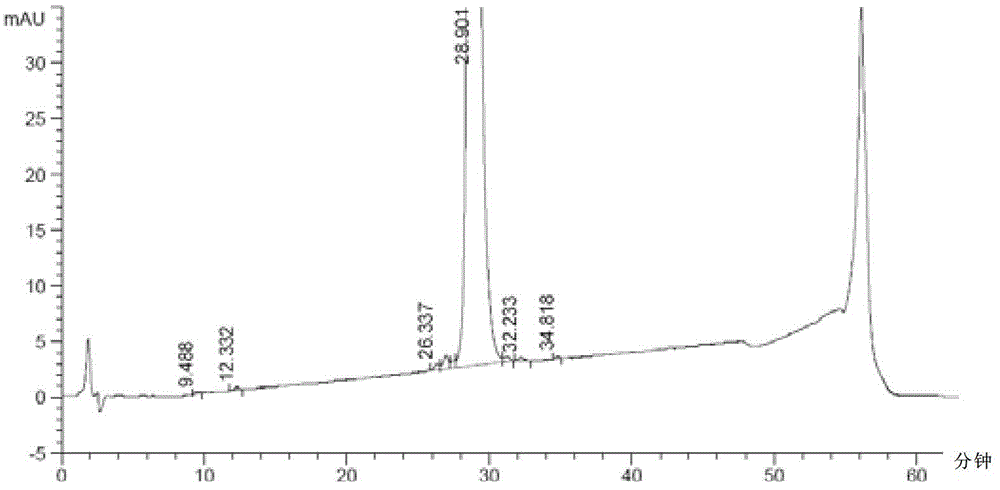

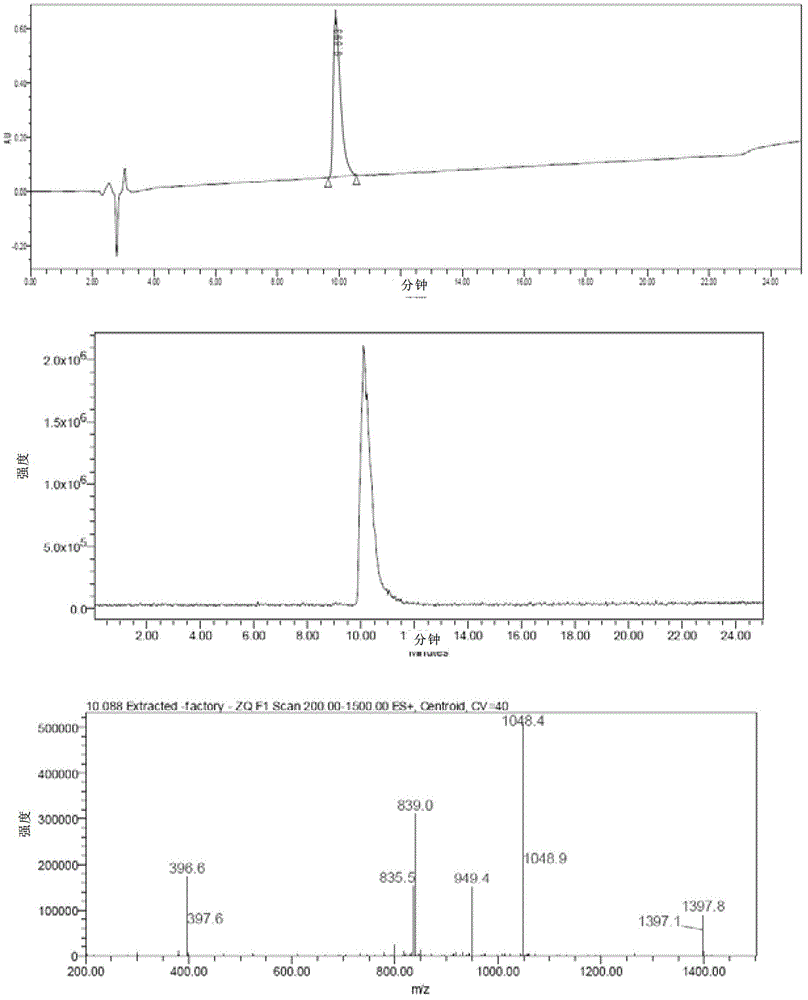

Synthesis of exenatide through solid phase fragment method

ActiveCN103333237AImprove efficiencyShort synthesis cycleHormone peptidesPeptide preparation methodsRink amide resinSide chain

The invention discloses a solid phase synthesis preparation method of exenatide represented by a formula I, wherein a Fmoc-resin and a deprotection agent are mixed to obtain a deprotection resin, a Fmoc-amino acid and a deprotection resin are subjected to condensation to obtain a Fmoc-amino acid-resin, and Fmoc protection removal and condensation of the polypeptides on the Fmoc-amino acid and the resin are repeated to carry out condensation of the amino acid and the polypeptide on the resin according to a C terminal-to-N-terminal sequence to form a polypeptide resin. The method is characterized by comprising the following steps: (1) respectively forming polypeptide resin fragments represented by a formula II and a formula III; (2) cutting the fragment represented by the formula III to obtain a polypeptide fragment with complete side chain protection and represented by a formula IV; (3) conjugating the polypeptide fragment with complete side chain protection and represented by the formula IV to the polypeptide resin fragment represented by the formula II, and removing Fmoc to obtain a polypeptide resin represented by a formula V; (4) sequentially conjugating the remaining 10 Fmoc-amino acids, and removing Fmoc to obtain an exenatide-Rink Amide resin represented by a formula VI; and (5) separating the polypeptide and the resin on the polypeptide resin represented by the formula VI to obtain the exenatide represented by the formula I.

Owner:HAINAN SHUANGCHENG PHARMA

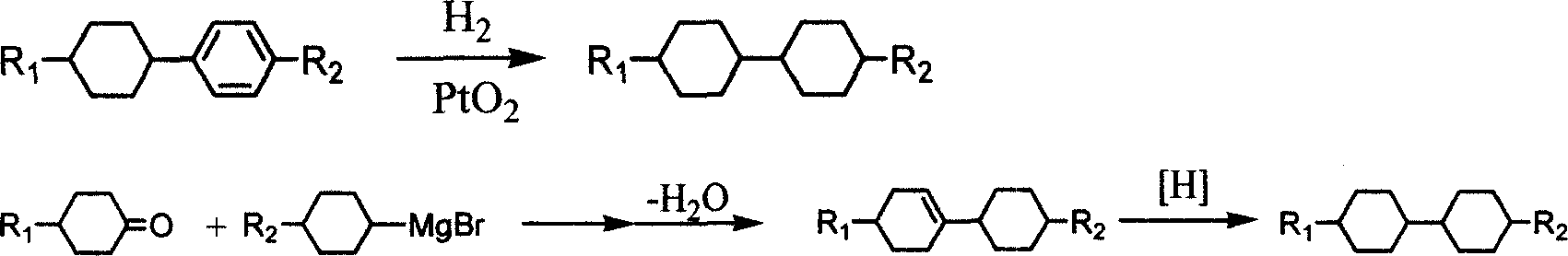

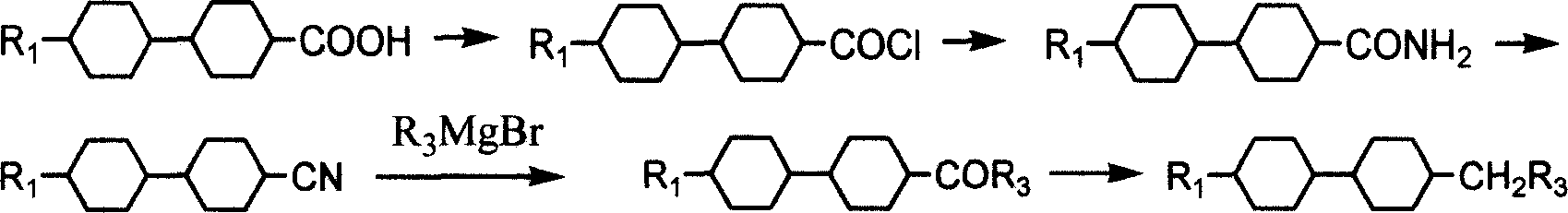

Method for preparing bis cyclohexane monomer liquid crystal using grignard reaction

InactiveCN1962580AAvoid drop in yieldLow costLiquid crystal compositionsHydrocarbon from oxygen organic compoundsGrignard reactionStructural formula

The invention discloses a preparing method of bicyclohexane monomer LCD in the monomer LCD preparing technical domain, which utilizes Grignard reaction to prepare the product with structural formula as graph I and synthetic feature route as graph II, wherein R1 and R2 is C2-C10; R3 is C1-C9 straight-chain alkyl; X is Cl or Br or I; A is C2H4 or cyclohexane; n is 0 or 1.

Owner:VALIANT CO LTD

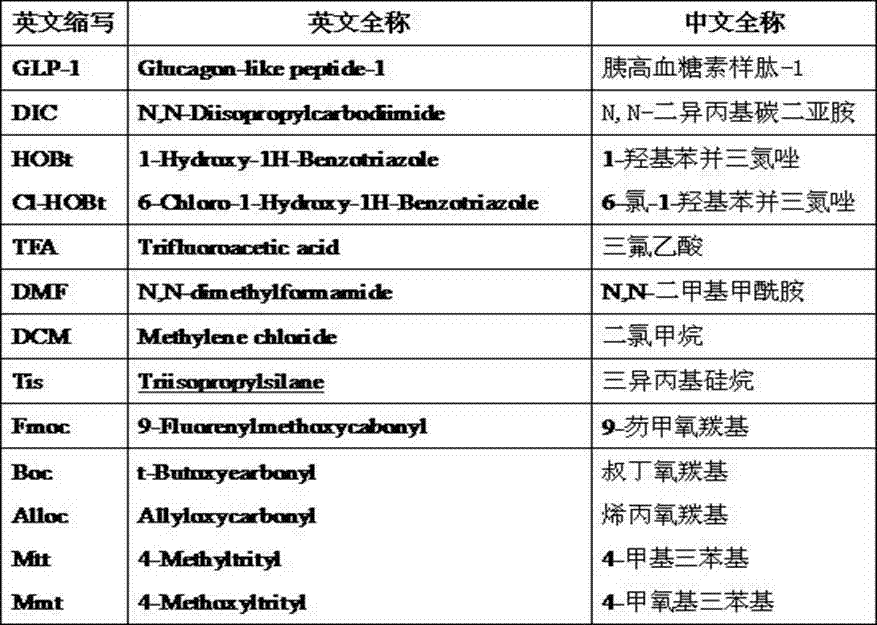

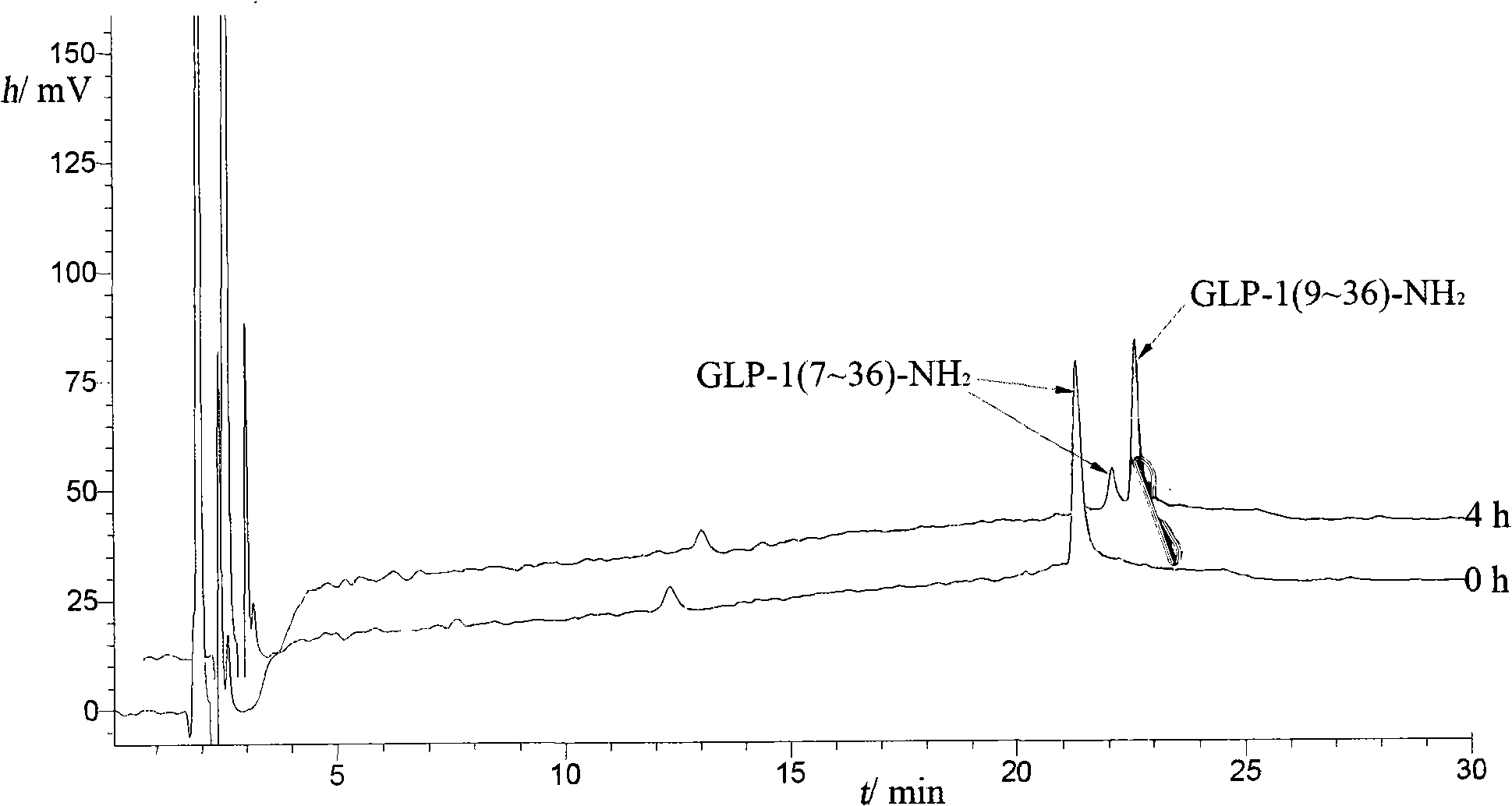

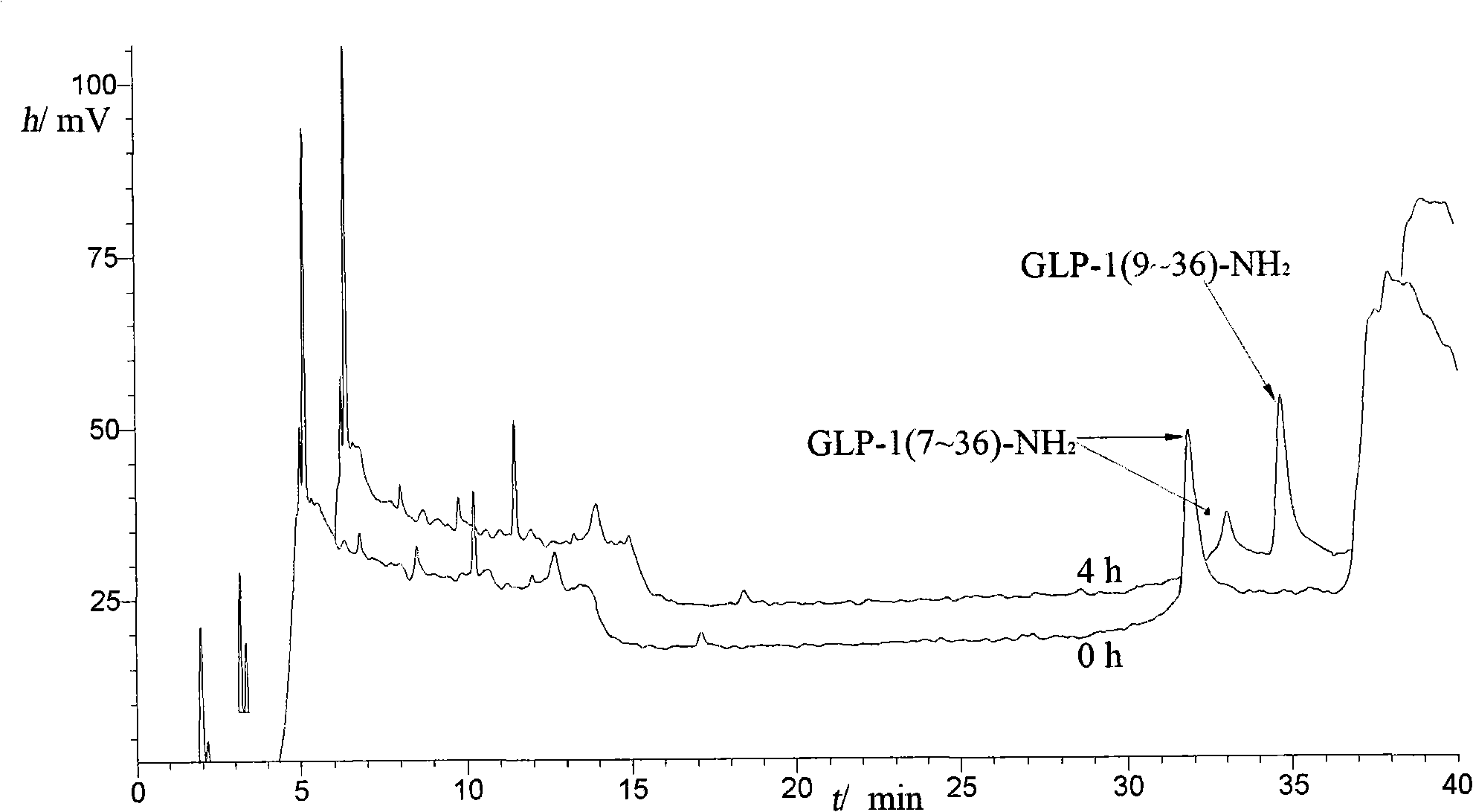

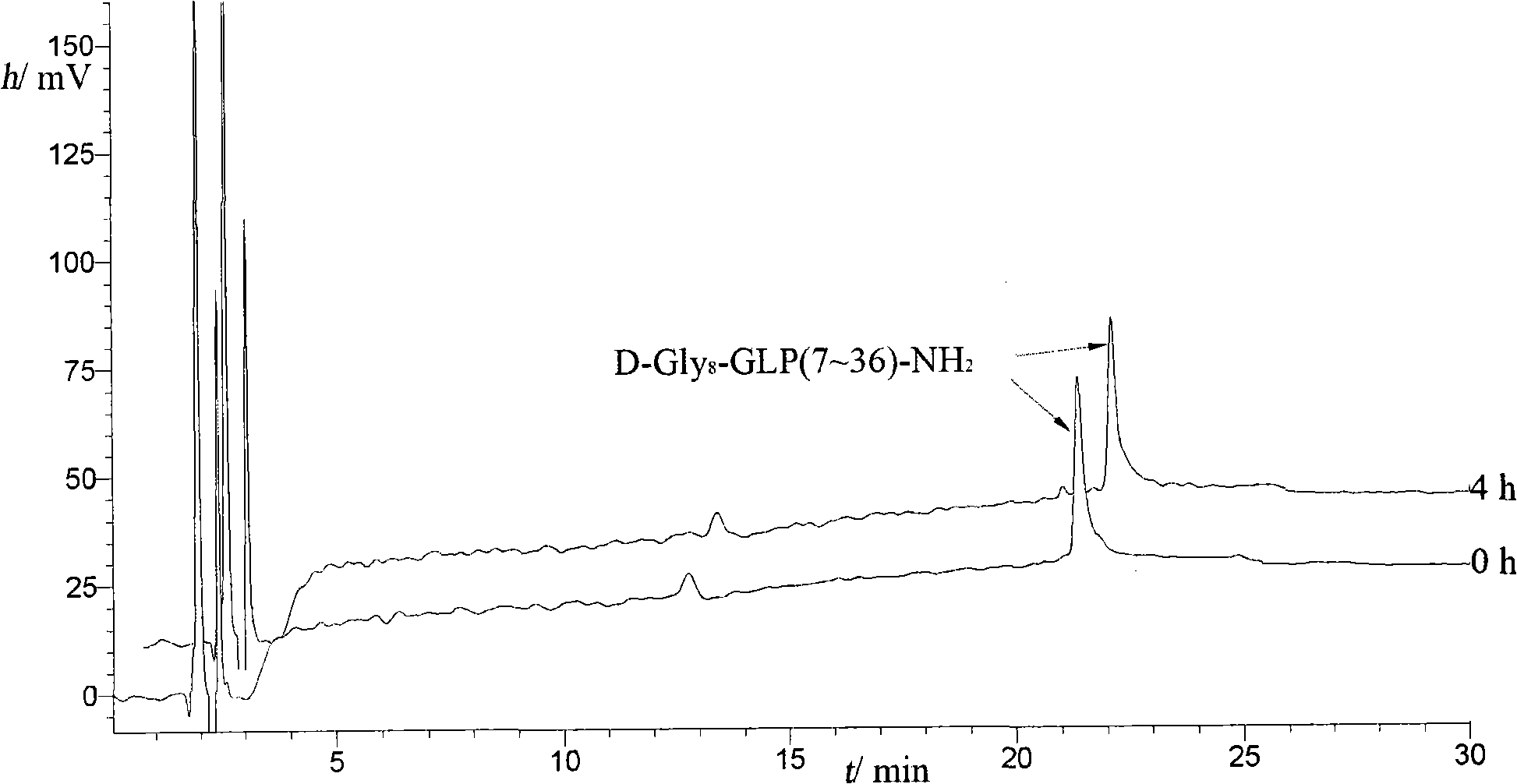

Micro-wave promoted solid-phase synthesis of glucagons-like peptide-1(GLP-1) analogue and uses thereof

InactiveCN101255191AImprove stabilityProlong the action timePeptide/protein ingredientsMetabolism disorderChemical synthesisMicrowave

The invention relates to new type GLP-1 analogues and a microwave promotive solid phase synthesis process of the same. GLP-1 analogues with longer pharmacological action time can be obtained by modifying 8, 9, 16, 22, 27 or 37 sites of natural GLP-1, the chemical synthesis is highly effectively and rapidly realized by microwave promotive solid phase synthesis process, the crude product is purified by highly effective liquid phase, and GLP-1 analogues is obtained after lyophilized.

Owner:CHINA PHARM UNIV

Preparation method of metal organic framework material and application of metal organic framework material in cyclohexyl hydroperoxide decomposition reaction

ActiveCN105712867AEasy to makeShort synthesis cycleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSodium acetateAlkali free

The invention discloses a preparation method of a metal organic framework material and application of the metal organic framework material in a cyclohexyl hydroperoxide decomposition reaction. Transition metal salt and terephthalic acid or a derivative thereof are subjected to a hydrothermal synthesis reaction in a sodium acetate solution to obtain the metal organic framework material, then the metal organic framework material serving as a catalyst is added into industrial cyclohexane uncatalysed oxidation liquid, the temperature is controlled to be 50-150 DEG C, the time is controlled to be 0.1-5 h, cyclohexyl hydroperoxide decomposition is carried out to obtain hexamethylene and cyclohexanone, the conversion rate of cyclohexyl hydroperoxide is larger than 95%, and the selectivity of alcohol ketone reaches up to 100%; the activity of the repeatedly-recycled catalyst is kept unchanged basically. Compared with other catalysts containing metal active components, the catalyst is high in catalytic efficiency, recyclable and stable in reusability; when the catalyst is applied to the cyclohexyl hydroperoxide decomposition reaction, the decomposition process is conducted under the alkali-free condition, the catalytic efficiency is very high, and pollution caused by waste alkali liquor to the environment is avoided.

Owner:XIANGTAN UNIV

Method for preparing sodium fluorophosphate vanadium for positive pole material of sodium-ion battery

InactiveCN103022490AEasy to achieve large-scale industrial preparationLow costCell electrodesSynthesis methodsSodium-ion battery

The invention discloses a method for preparing sodium fluorophosphate vanadium for a positive pole material of a sodium-ion battery. The method comprises the following steps of: taking a high-valence vanadium source compound, a phosphorus source compound, a sodium source compound, a fluorine source compound and a reductant as raw materials, and uniformly mixing the raw materials in a manner that the molar ratio of vanadium to phosphorus to sodium to fluorine is 1: 1: (1-1.05): 1; adding the reductant in a manner that the molar ratio of the reductant to the vanadium source compound is (1: 1) to (10: 1), carrying out mechanical activation for 0.5-24 hours, and producing small-particle amorphous sodium fluorophosphate vanadium under the conditions of normal temperature and normal pressure in a manner that high-valence vanadium is reduced by the reductant; and heating the amorphous sodium fluorophosphate vanadium to the temperature of 500-750 DEG C in a non-oxidizing atmosphere, and carrying out constant-temperature calcination for 0.5-24 hours, thereby obtaining crystalline-state sodium fluorophosphate vanadium powder. The method has the advantages that the synthesis temperature is low, the synthesis cycle is short, the synthesis method is simple, the quality of synthetic products is high, and the large-scale industrialized preparation of the sodium fluorophosphate vanadium for the positive pole material of the sodium-ion battery is easily realized.

Owner:广西地博矿业集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com