Transition metal chalcogenide nanosheet material and preparation method thereof, battery anode material, secondary battery and application thereof

A transition metal and chalcogenide technology, applied in secondary batteries, metal selenide/telluride, battery electrodes, etc., can solve the problems of dangerous operation, great harm to human body, complicated operation, etc., to alleviate the volume expansion pulverization, The effect of excellent cycle performance and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] According to a first aspect of the present invention, a method for preparing a transition metal chalcogenide nanosheet material is provided, comprising the following steps:

[0072] Dissolving the raw materials in an aqueous solution of soluble salts, removing water to obtain a solid, then sintering the solid, and washing with water to obtain a transition metal chalcogenide nanosheet material;

[0073] Wherein, the raw materials include chalcogen precursors and transition metal precursors.

[0074] The preparation method adopts soluble salt as template agent, is cheap, environment-friendly, easy to remove in post-treatment, and the obtained transition metal chalcogenide nano-sheet material has thinner sheet thickness. Compared with the traditional silica template method and hydrothermal method, the preparation method greatly shortens the synthesis cycle, has the characteristics of simplicity, controllability, high yield, simple experimental operation, and is suitable fo...

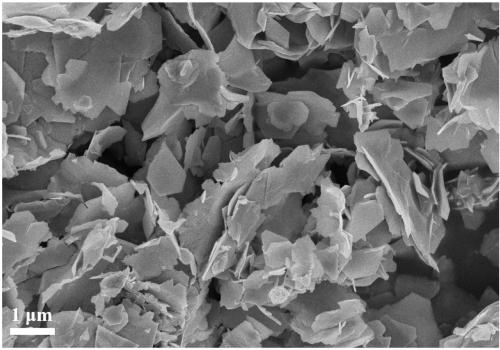

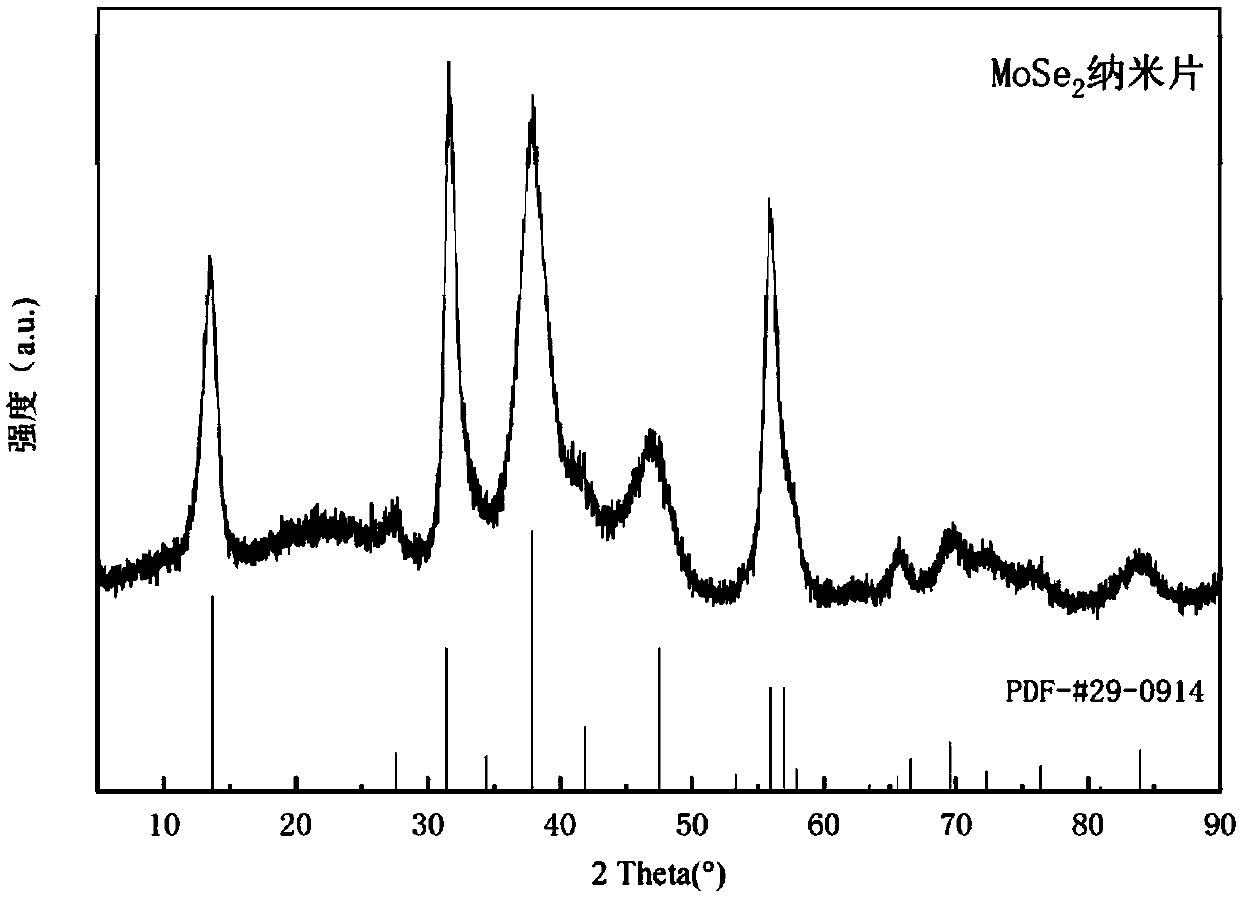

Embodiment 1

[0130] 1. A preparation method of a transition metal chalcogenide nanosheet material, comprising the following steps:

[0131] (1) Disperse 2mmol of selenium powder in 8mL of hydrazine hydrate and heat to 85°C for 1 hour to fully dissolve the selenium powder.

[0132] Ammonium heptamolybdate tetrahydrate (molybdenum element in the ammonium tetrahydrate ammonium heptamolybdate is 1mmol) is dissolved in the water of 10mL, then adds in the above-mentioned selenium powder solution.

[0133] Add 50ml of saturated brine (25°C) to the solution, stir and heat until the liquid evaporates to dryness.

[0134] (2) In the tube furnace, the mixed solid containing selenium-hydrazine hydrate, ammonium molybdate, and NaCl was placed in an alumina porcelain boat, and placed in the middle of the heating zone of the tube furnace.

[0135] (3) Before heating, first pass Ar / H into the tube furnace 2 Mix the gas and remove the air in the tube. Then the temperature was raised to 600° C. at a heat...

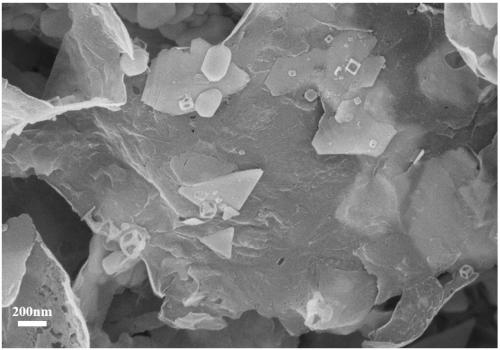

Embodiment 2

[0141] A preparation method of a transition metal chalcogenide nanosheet material, comprising the following steps:

[0142] (1) Disperse 2mmol of selenium powder in 8mL of hydrazine hydrate and heat to 85°C for 1 hour to fully dissolve the selenium powder.

[0143] Ammonium heptamolybdate tetrahydrate (molybdenum element in the ammonium tetrahydrate ammonium heptamolybdate is 1mmol) is dissolved in the water of 10mL, then adds in the above-mentioned selenium powder solution.

[0144] Glucose (the molar mass of element C is 8 mmol) was added to the solution, and 50 ml of saturated saline (25° C.) was continuously added to the solution, stirred and heated until the liquid evaporated to dryness.

[0145] (2) In the tube furnace, put the mixed solid containing selenium-hydrazine hydrate, ammonium molybdate, glucose, and NaCl in an alumina porcelain boat, and place it in the middle of the heating zone of the tube furnace.

[0146] (3) Before heating, first pass Ar / H into the tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com