Molded metal-organic framework material and molding method thereof

A metal-organic framework and molding method technology, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of loss of specific surface area, complex molding process, high cost, etc., and achieve good bonding performance and large specific surface area , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

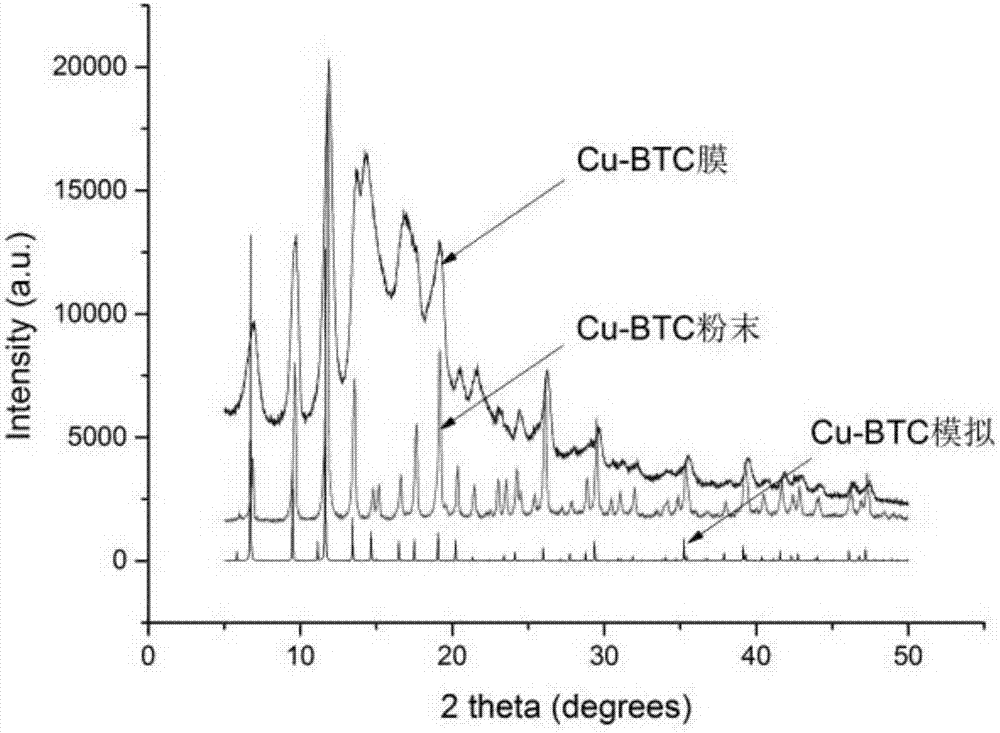

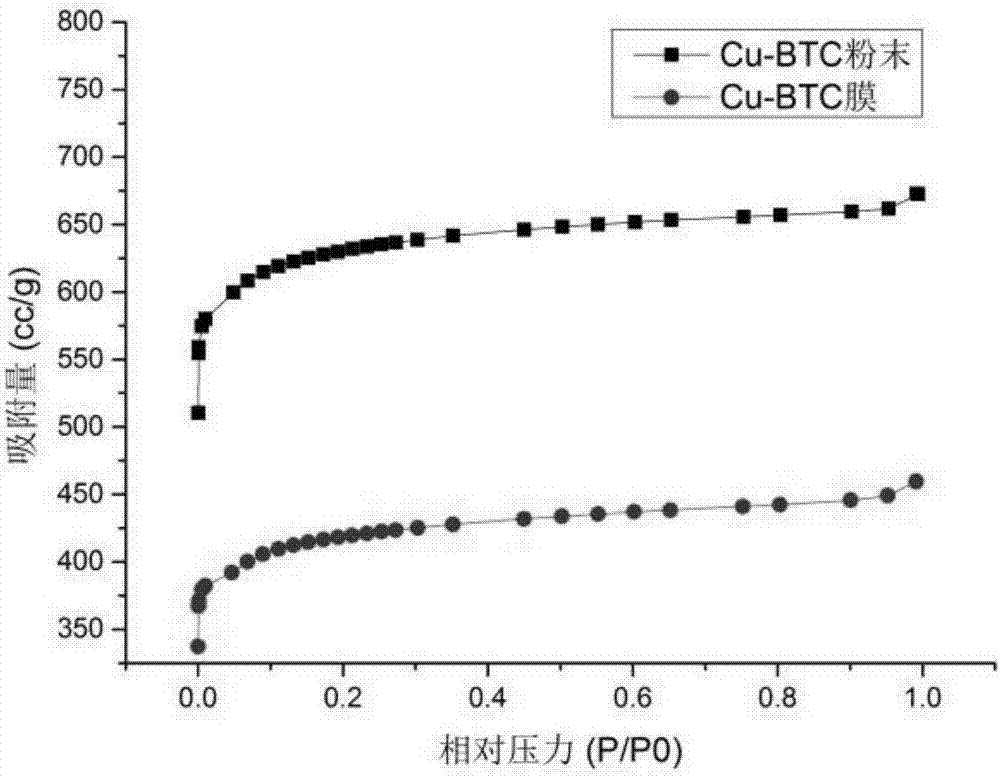

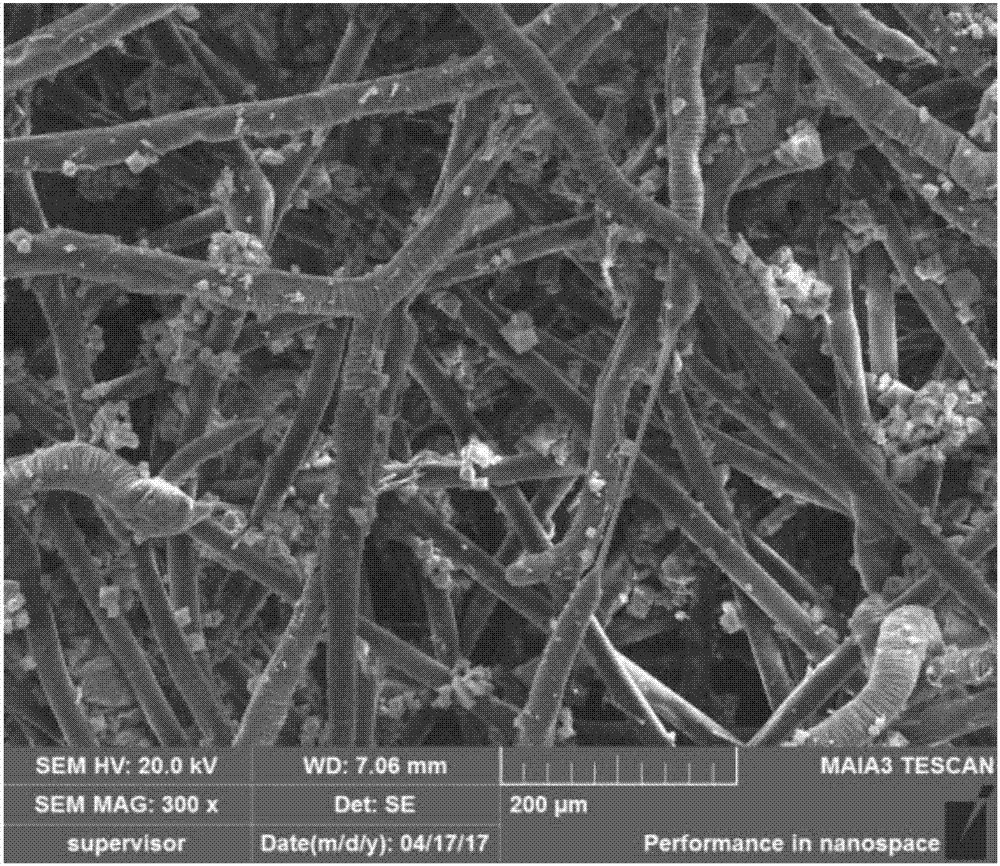

[0049] The substrate is polyethylene non-woven fabric, the metal-organic framework material is Cu-BTC, and the synthesized metal-organic framework material is non-woven fabric / Cu-BTC molding material.

[0050] Preparation:

[0051] (1) Synthesis of Cu-BTC: Dissolve copper acetate monohydrate (1.75g, 8.76mmol) and trimesic acid (0.84g, 4.06mmol) in ethanol (50ml), stir at room temperature for 48h, and filter to obtain a solid After that, it was washed once with ethanol and deionized water, and dried in vacuum at 100°C for 12 hours to obtain a Cu-BTC sample for future use.

[0052] (2) Preparation of Cu-BTC / cellulose suspension: put the Cu-BTC sample (0.5g) obtained in step (1) into deionized water (10ml), stir at 500rpm for 60min and then add to the prepared cellulose solution (20ml), then stirred at 25°C for 10 minutes at a speed of 500 rpm, and ultrasonically oscillated for 5 minutes to obtain a Cu-BTC / cellulose suspension for subsequent use; wherein the cellulose solution w...

Embodiment 2

[0056] The substrate is polyethylene non-woven fabric, the metal-organic framework material is UiO-66, and the synthesized metal-organic framework material is non-woven fabric / UiO-66 molding material.

[0057] Preparation:

[0058] (1) Synthesis of UiO-66: zirconium tetrachloride (5.83g, 0.025mol), terephthalic acid (4.15g, 0.025mol), hydrochloric acid solution (2ml, mass fraction is 37%), N,N- Dimethylformamide (150ml) was placed in a polytetrafluoroethylene-lined reaction kettle (750ml), reacted at 120°C for 24h, and the resulting solid was washed with N,N-dimethylformamide and methanol respectively, and dried at room temperature to obtain a UiO-66 sample for future use.

[0059] (2) Preparation of UiO-66 / polyvinyl alcohol suspension: put the UiO-66 sample (0.5g) obtained in step (1) into deionized water (10ml), stir at 500rpm for 60min and then add to the preparation In a good polyvinyl alcohol solution (20ml), stir again at 25°C for 10 min at 500 rpm, and ultrasonically ...

Embodiment 3

[0063] The substrate is polyethylene non-woven fabric, the metal-organic framework material is ZIF-8, and the synthesized metal-organic framework material is non-woven fabric / ZIF-8 molding material.

[0064] Preparation:

[0065] (1) Synthesis of ZIF-8: Zinc nitrate hexahydrate (0.796g, 2.68mmol) and 2-methylimidazole (0.2g, 2.44mmol) were dissolved in N,N-dimethylformamide (60ml), Stir at room temperature for 10 minutes, seal the reaction vessel, react at 140°C for 24 hours, after cooling down to room temperature, add chloroform, collect the upper layer product, then soak in methanol for 3 days, replace the solvent once a day, and then remove the product Gas treatment, first at room temperature for 3 hours, and then at 300 ° C for 2 hours to obtain a ZIF-8 sample for future use.

[0066] (2) Preparation of ZIF-8 / povidone suspension: the ZIF-8 sample (0.5g) obtained in step (1) is put into deionized water (10ml), and added to the preparation after stirring at 500rpm for 60min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com