Thermoplastic polyurethane composition with low viscosity and high adhesive strength and preparation method thereof

A composition, polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of unsatisfactory and low bonding strength of polyurethane compositions, and achieve good bonding performance, low Melting point and effect of high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

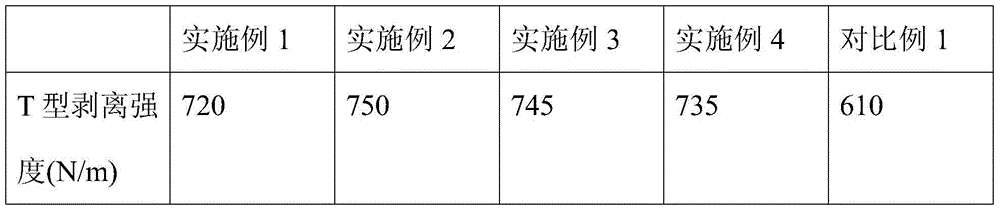

Examples

Embodiment 1

[0031] A polyurethane composition with low viscosity and high adhesive strength contains aliphatic polyester diol with a weight average molecular weight of 2000 and diisocyanate, wherein the molar ratio of diisocyanate to aliphatic polyester diol is 0.7.

[0032] The polyurethane composition also contains a chain extender, the chain extender is 1,4-butanediol with carbon atoms, and the amount of the chain extender is no more than 3% of the amount of the aliphatic polyester diol .

[0033] The polyurethane composition also contains accelerators and flame retardants.

[0034] The amount of the accelerator is no more than 3% of the amount of the aliphatic polyester diol.

[0035] The amount of the flame retardant is no more than 3% of the amount of the aliphatic polyester diol.

[0036] A kind of preparation method of a kind of low-viscosity high-bonding strength polyurethane composition as above, described method comprises the steps:

[0037] Mix aliphatic polyester diol and ...

Embodiment 2

[0039] A polyurethane composition with low viscosity and high adhesive strength contains aliphatic polyester diol with a weight average molecular weight of 6000 and diisocyanate, wherein the molar ratio of diisocyanate to aliphatic polyester diol is 0.95.

[0040] The polyurethane composition also contains a chain extender, the chain extender is 1,4-butanediol with carbon atoms, and the amount of the chain extender is no more than 5% of the amount of the aliphatic polyester diol .

[0041] The polyurethane composition also contains accelerators, flame retardants and plasticizers.

[0042] The amount of the accelerator is no more than 5% of the amount of the aliphatic polyester diol.

[0043] The amount of the flame retardant is no more than 5% of the amount of the aliphatic polyester diol.

[0044] The amount of the plasticizer is no more than 5% of the amount of the aliphatic polyester diol.

[0045] A kind of preparation method of a kind of low-viscosity high-bonding stre...

Embodiment 3

[0048] A polyurethane composition with low viscosity and high adhesive strength contains aliphatic polyester diol with a weight average molecular weight of 4000 and diisocyanate, wherein the molar ratio of diisocyanate to aliphatic polyester diol is 0.8.

[0049] The polyurethane composition also contains a chain extender, the chain extender is 1,4-butanediol with carbon atoms, and the amount of the chain extender is no more than 5% of the amount of the aliphatic polyester diol .

[0050] The polyurethane composition also contains accelerators, flame retardants, plasticizers, crystallization nucleating agents, catalysts and hydrolysis stabilizers.

[0051]The amount of the accelerator is no more than 5% of the amount of the aliphatic polyester diol.

[0052] The amount of the flame retardant is no more than 5% of the amount of the aliphatic polyester diol.

[0053] The amount of the plasticizer is no more than 5% of the amount of the aliphatic polyester diol.

[0054] The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com