Degradable mulching product and its production process

A technology of liquid mulch film and production method, which can be applied in the direction of plant protection cover, etc., can solve the problems of white soil pollution and harm to the natural environment, and achieve the effects of excellent film-forming performance and good adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 (by weight percentage)

[0016] 5000PPM activated chlorine dioxide (ClO 2 ) 20%

[0017] Ultrafine ore powder 30%

[0018] Starch 10%

[0019] Acacia gum powder (or mixed gum powder) 40%

Embodiment 2

[0020] Embodiment 2 (by weight percentage)

[0021] 5000PPM activated chlorine dioxide (ClO 2 ) 15%

[0022] Ultrafine ore powder 25%

[0023] Starch 15%

[0024] Acacia gum powder (or mixed gum powder) 45%

Embodiment 3

[0025] Embodiment 3 (by weight percentage)

[0026] 5000PPM activated chlorine dioxide (ClO 2 ) 10%

[0027] Ultrafine ore powder 20%

[0028] Starch 20%

[0029] Acacia gum powder (or mixed gum powder) 50%

[0030] The method of using this liquid mulch film is: you can first activate 5000PPM chlorine dioxide (ClO 2 ) is mixed with water into an aqueous solution of a certain concentration, and then this aqueous solution is used to prepare ultra-fine ore powder, starch-like substances, acacia gum powder (or mixed gum powder), and finally diluted to a certain multiple according to the type of different uses, Use after stirring well. According to the general experimental results: it is advisable to dilute 30 to 50 times. The dilution factor for planting vegetables on dry land can be higher, and the dilution factor for planting in sandy soil can be lower. After dilution, use a special spray machine to spray on the ground to form a film.

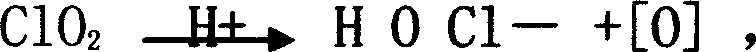

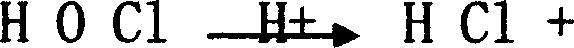

[0031] Mechanism analysis on the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com