Patents

Literature

7338results about How to "Good film forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous emulsion polymerization of fluorinated monomers using a perfluoropolyether surfactant

The invention relates to an aqueous emulsion polymerization of fluorinated monomers using perfluoropolyethers of the following formula (I) or (II). In particular, the perfluoropolyether surfactants correspond to formula (I) or (II) CF3—(OCF2)m—O—CF2—X (I) wherein m has a value of 1 to 6 and X represents a carboxylic acid group or salt thereof, CF3—O—(CF2)3—(OCF(CF3)—CF2)z—O-L-Y (II) wherein z has a value of 0, 1, 2 or 3, L represents a divalent linking group selected from —CF(CF3)—, —CF2— and —CF2CF2— and Y represents a carboxylic acid group or salt thereof. The invention further relates to an aqueous dispersion of a fluoropolymer having the aforementioned perfluoropolyether surfactant(s).

Owner:3M INNOVATIVE PROPERTIES CO

Fluoropolymer dispersion containing no or little low molecular weight fluorinated surfactant

ActiveUS6861466B2Good film formingTransportation and packagingFibre treatmentPolymer scienceRoom temperature

In an aspect of the invention, a fluoropolymer dispersion, preferably a PTFE dispersion, is provided that comprises fluoropolymer particles having an average particle size of 10 to 400 nm dispersed in water whereby the dispersion has an amount of solids between 35 and 70% by weight. The dispersion is free of fluorinated surfactant having a molecular weight of less than 1000 g / mol (hereinafter called low molecular weight fluorinated surfactant) or contains the low molecular weight fluorinated surfactant in an amount of not more than 0.05% by weight based on the total weight solids of the dispersion. The dispersion further comprises a non-ionic non-fluorinated surfactant or mixture of non-ionic non-fluorinated surfactants and one or more non-fluorinated anionic surfactants. Through the use of a non-fluorinated anionic surfactant, a dispersion is obtained that has a low viscosity at room temperature (20° C.). The dispersion is further free of aromatic group containing non-ionic surfactants and is accordingly environmentally more friendly and can yield coatings that are less susceptible of discoloration. The amount and nature of the non-ionic non-fluorinated surfactant or mixture of non-ionic non-fluorinated surfactants is selected such that the Viscosity Transition Temperature (VTT) (measured as set forth in the examples) of the fluoropolymer dispersion is at least 26, preferably at least 28° C. In a further aspect of the invention, a method is provided to obtain the aforementioned dispersion.

Owner:3M INNOVATIVE PROPERTIES CO

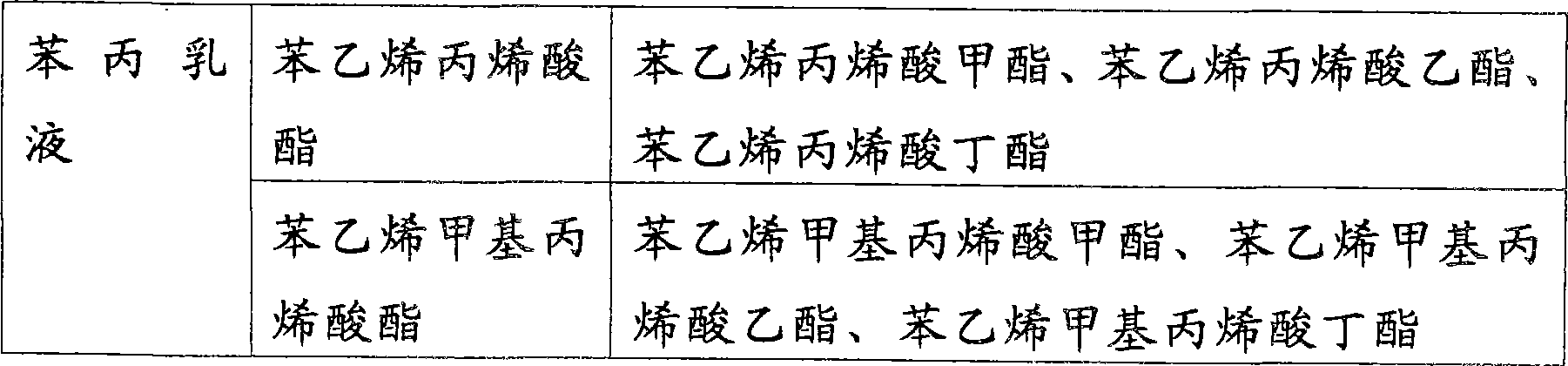

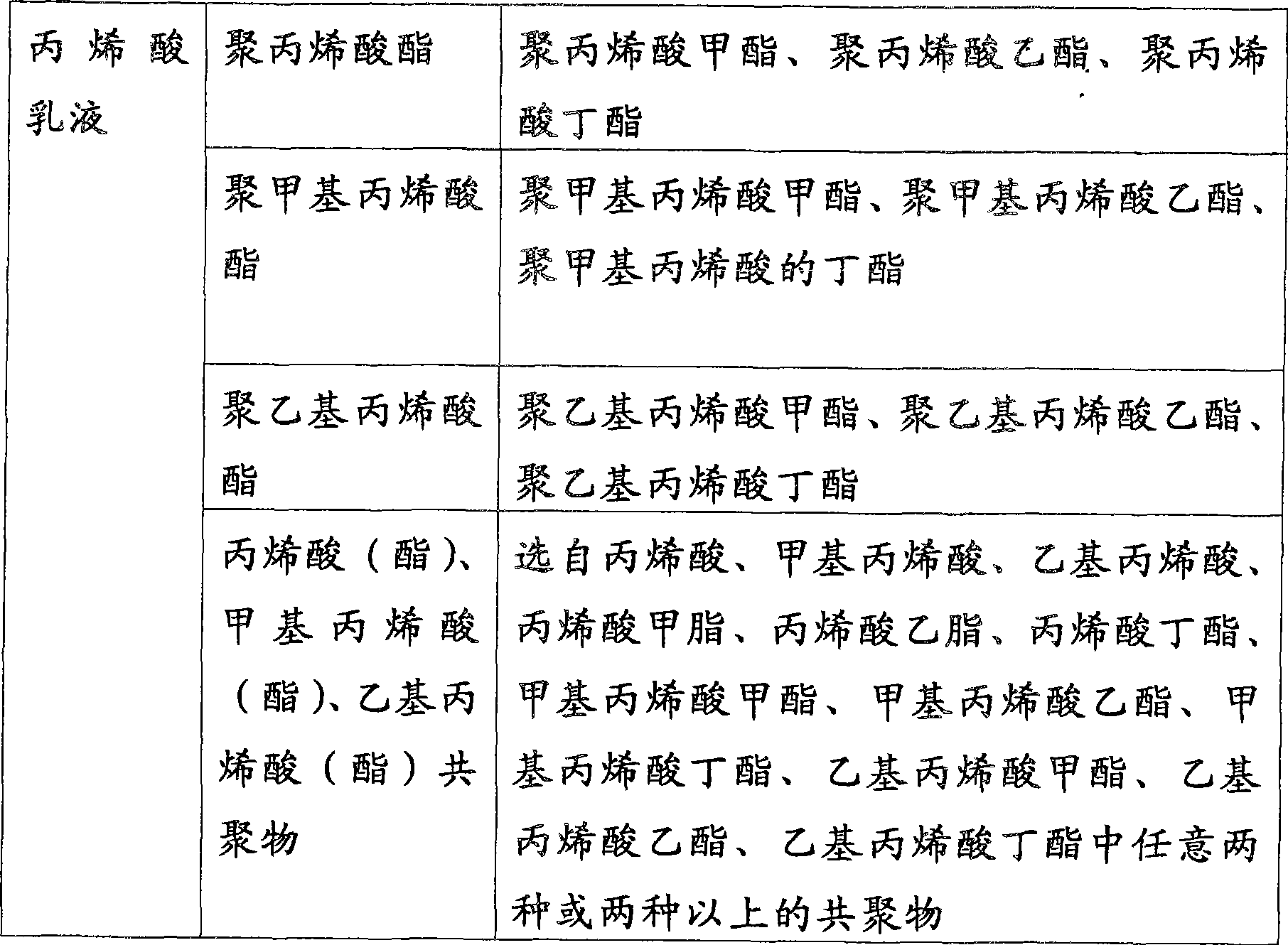

Multifunctional coatings and preparation method thereof

ActiveCN101386719AGood film formingImprove impermeabilityFireproof paintsLuminescent paintsFire retardantStorage garage

The invention relates to multifunctional paint with the functions of water and fire prevention, lighting, noise reduction, safe escape and decoration and a preparation method thereof. The multifunctional paint comprises a polymer emulsion, a filler, a flame retardant, a long afterglow luminescent material, an addition agent and water, and the paint comprises raw materials in weight percentage: 10 to 50 percent of the polymer emulsion, 5 to 30 percent of the filler, 10 to 30 percent of the flame retardant, 10 to 60 percent of the long afterglow luminescent material, 0.1 to 5 percent of the addition agent and 1 to 50 percent of the water. The multifunctional paint is applied to a highway tunnel, an underground garage, an underground urban traffic passage, a civil defence engineering, an underground fortification, an underground warehouse, an underground production workshop and other underground buildings, can well meet the requirements of waterproof and fireproof functions and has obvious energy-saving effect; and with the characteristic of the long afterglow of the luminescent paint, the multifunctional paint exerts the function of illumination after power failure and is used to guide personnel to safely evacuate the scene of an accident. In addition, the multifunctional paint also has certain functions of noise absorption and noise reduction.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD

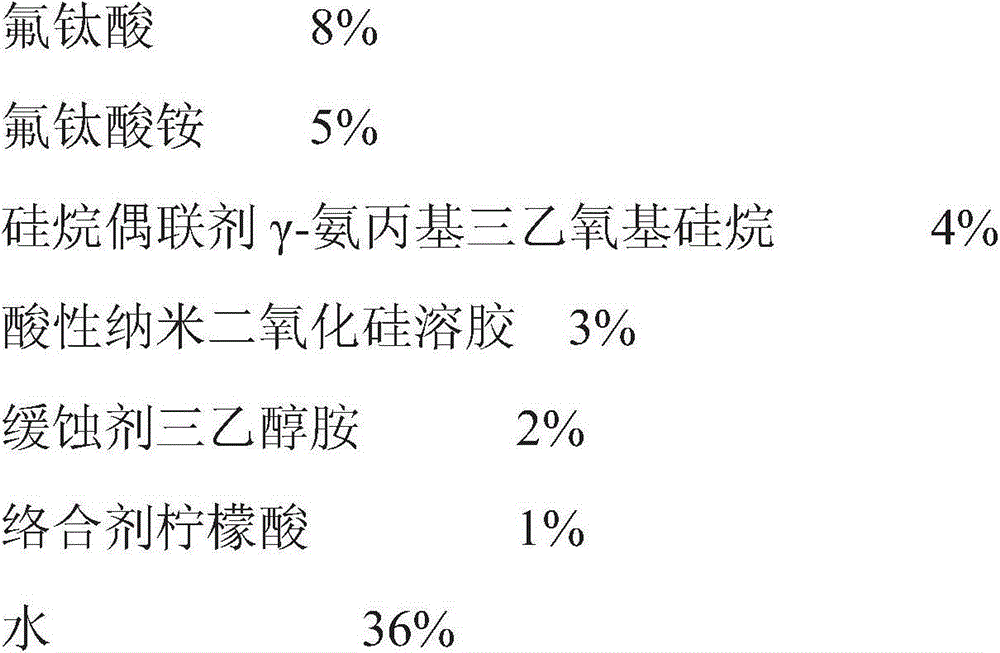

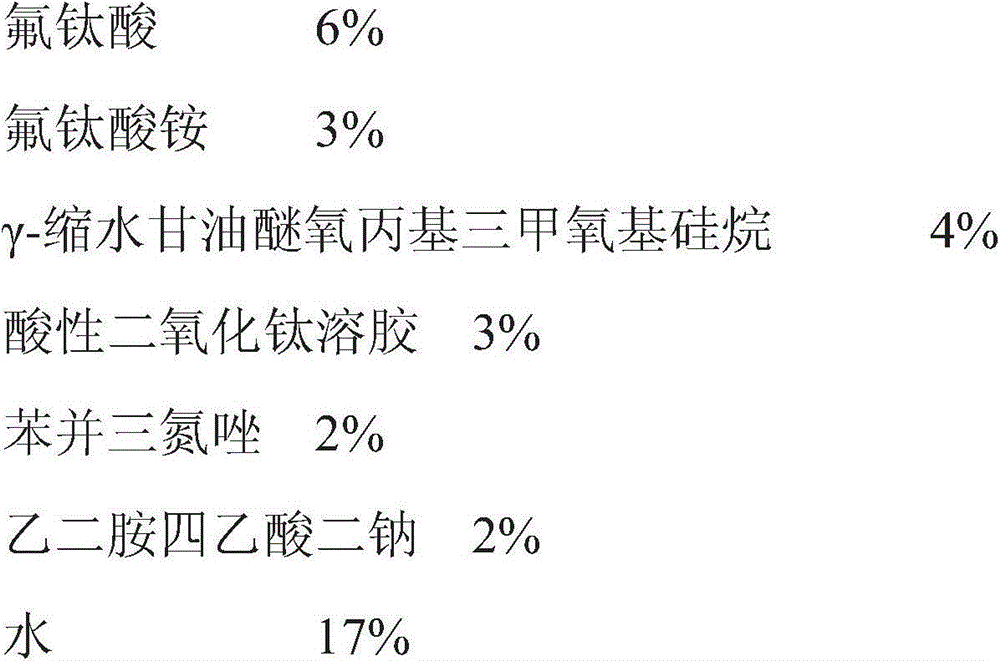

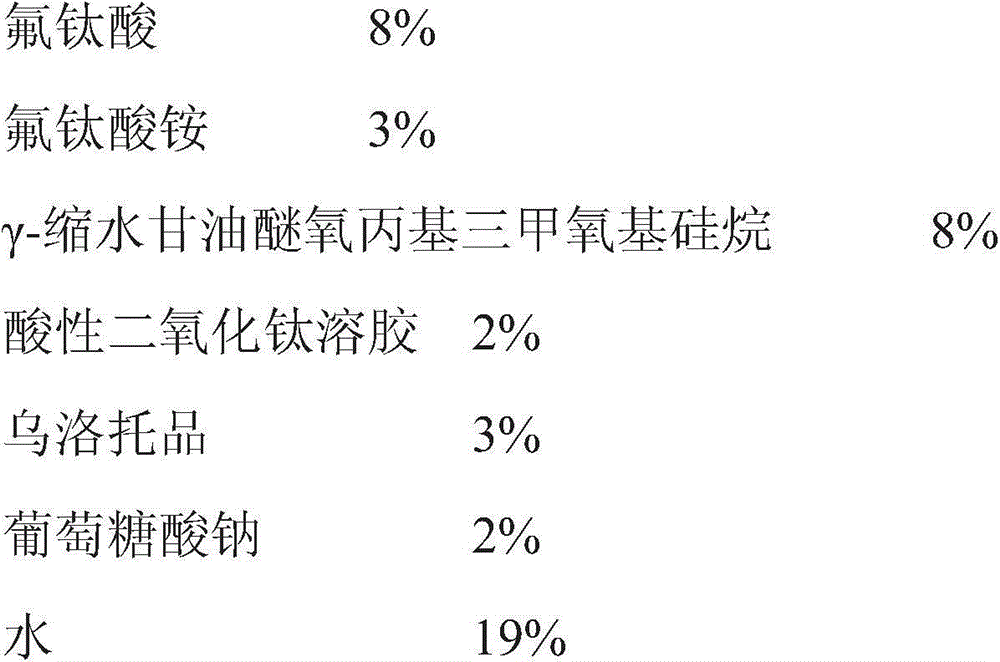

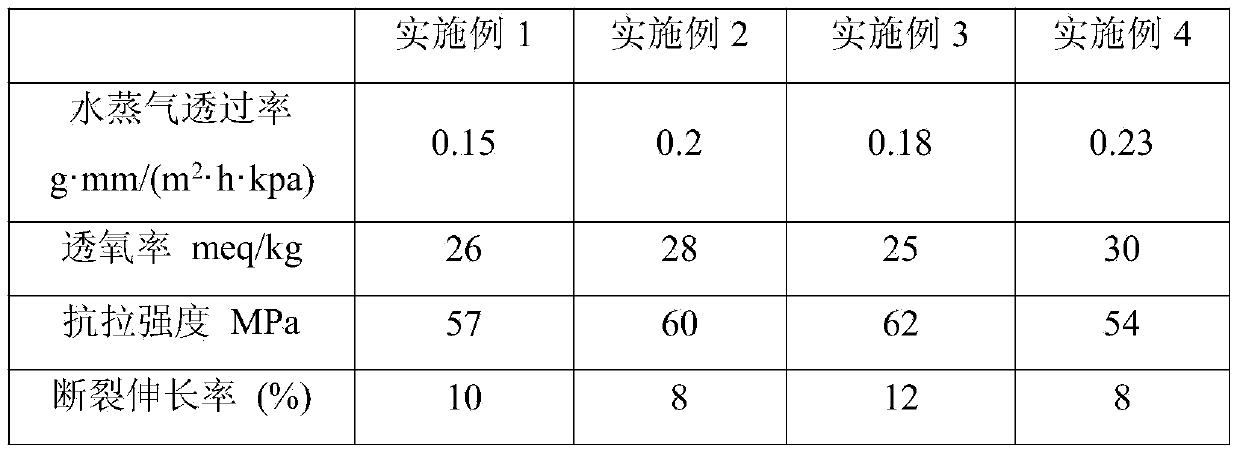

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

Edible biological preservative film and preparation method thereof

ActiveCN104194354AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersAntioxidantPlasticizer

The invention discloses an edible biological preservative film and a preparation method thereof. The edible biological preservative film comprises the following components in parts by weight: 30-60 parts of a film former, 1-10 parts of a natural antioxidant, 1-10 parts of a natural bacterial inhibitor, 1-4 parts of a plasticizer and 0.5-4 parts of an emulsifier. The preparation method comprises the following steps: mixing the components in proportion to form preservative film liquid, and preparing the preservative film by adopting a tape-casting process. According to the preservative film, excellent film forming performances of materials such as marine polysaccharides, chitosan, gelatin and the like are utilized, the natural antioxidant and the natural bacterial inhibitor are selected and used, and the modification process is carried out through the plasticizer, the emulsifier and the like, so that the prepared preservative film is good in mechanical property, delays the spoilage of an aquatic product and can effectively prolong the shelf life of the aquatic product.

Owner:MARINE BIOLOGY INST OF SHANDONG PROVINCE

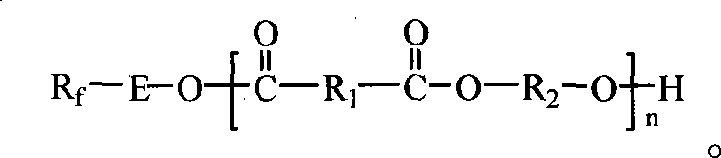

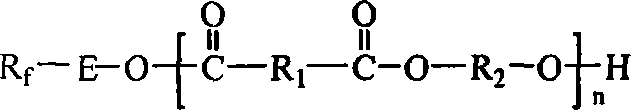

Fluorinated polyesters with low surface energy and preparation method thereof

The present invention belongs to the field of mnacromolecule, relating to the fluorine-containing polyester of low surface energy and the preparation method of the fluorine-containing polyester. The polyester has the following chemical structure (1): wherein R f C is the straight chain of 2 - 21 C or the branch-chain pseudo-perfluoroalkyl; R1, R2 is the alkyl, aryl, or naphthenic base of the C1-C8; E is -(CH2) m-; formula (3) or formula (4); R' is H or the straight chain or the branch-chain alkyl under C4; m is an integer between 0 or 10. The polyester preparation method is that dibasic acid or the correspondent diester, dihydric alcohol and perfluoroalkane, which are 0.05 percent to 10 percent of the total material weight, are fused and polymerized under vacuum condition. The polyester preparation method at the pseudo-perfluoroalkyl sealed end is simple, and is of good drainage and oil dredging properties. The present invention can be widely used in antifouling coatings, and is of important development and application value.

Owner:DALIAN UNIV OF TECH

Acrylic polyurethane copolymer emulsion, its preparation method and use

The invention refers to a kind of acrylic acid polyurethane copolymer latex, the making method and the application to carpentry dope. It adopts technique of seed-latex polymerization, selects end-sealing agent, and adopts self cross-linking acrylate monomer to make the excellent-capability epoxy cross-linked denaturing copolymer latex. The diameter of particles of the latex is small and distributes evenly. The painting film made of it has excelelnt water-resistant, solvent resistance, high rigidity and better appearance.

Owner:SOUTH CHINA UNIV OF TECH

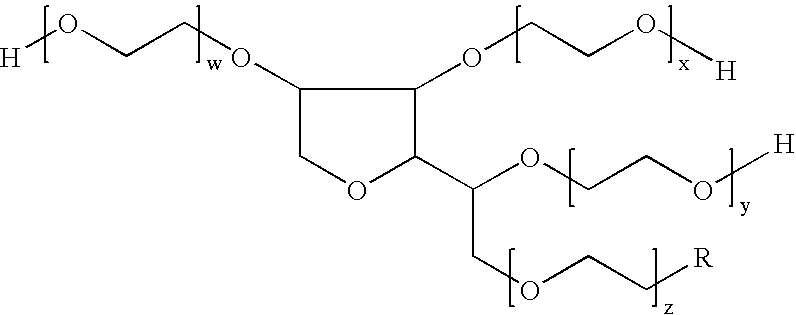

Artificial tear replacement solution

InactiveUS7001607B1Reduce wearGood film formingHalogenated hydrocarbon active ingredientsSenses disorderConjunctivaConjunctival sac

A tear replacement solution that contains at least one water-soluble fluorosurfactant, water and a non-polar component, preferably in gel form, and a method for the external treatment for the eye of an mammal by applying the tear replacement solution to the eye, preferably by placing in the conjunctival sac.

Owner:PHARMPUR

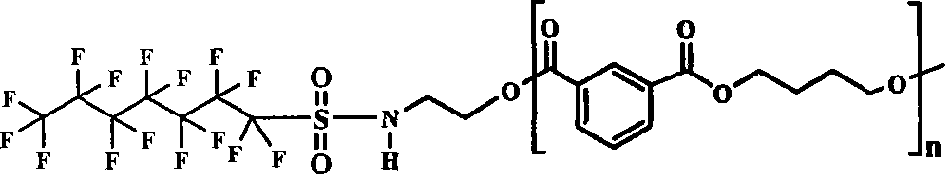

Method for preparing aromatic polybenzimidazole resin film

InactiveCN101456964AHigh molecular weightImprove thermal stabilitySemi-permeable membranesCell component detailsSolubilityNitrogen gas

The invention relates to a preparation method for aromatic series polybenzimidazole resin film, comprising: (1) under function of polyphosphoric acid / phosphorus pentoxide system, condensation polymerization reaction is carried out to aromatic series amine and aromatic series dicarboxylic acids mixed according to mol ratio of 1:1 in nitrogen atmosphere; (2) after cooling, polymer is poured into water and broken down into powder in a resin pulper and washed over and over again by distilled water and soaked for 48 hours in NaHCO3 solution and washed till pH value shows neutral and drawn and filtered for drying in vacuum; (3) the polymer dried is dissolved in even solution prepared by organic solvent with mass percent of 5 percent, and then is dried at temperature of 130 DEG C for 12 hours, and is soaked in hot water for boiling and striping, and is dried in vacuum at temperature of 100 DEG C for 5 hours and then is obtained. The polybenzimidazole prepared by the invention has the advantages of big molecule weight, stable thermal stability, fine solubility and film forming performance, etc. The preparation has simple technology, low cost, convenient operation and can be finished in common equipments through preparation procedure.

Owner:DONGHUA UNIV

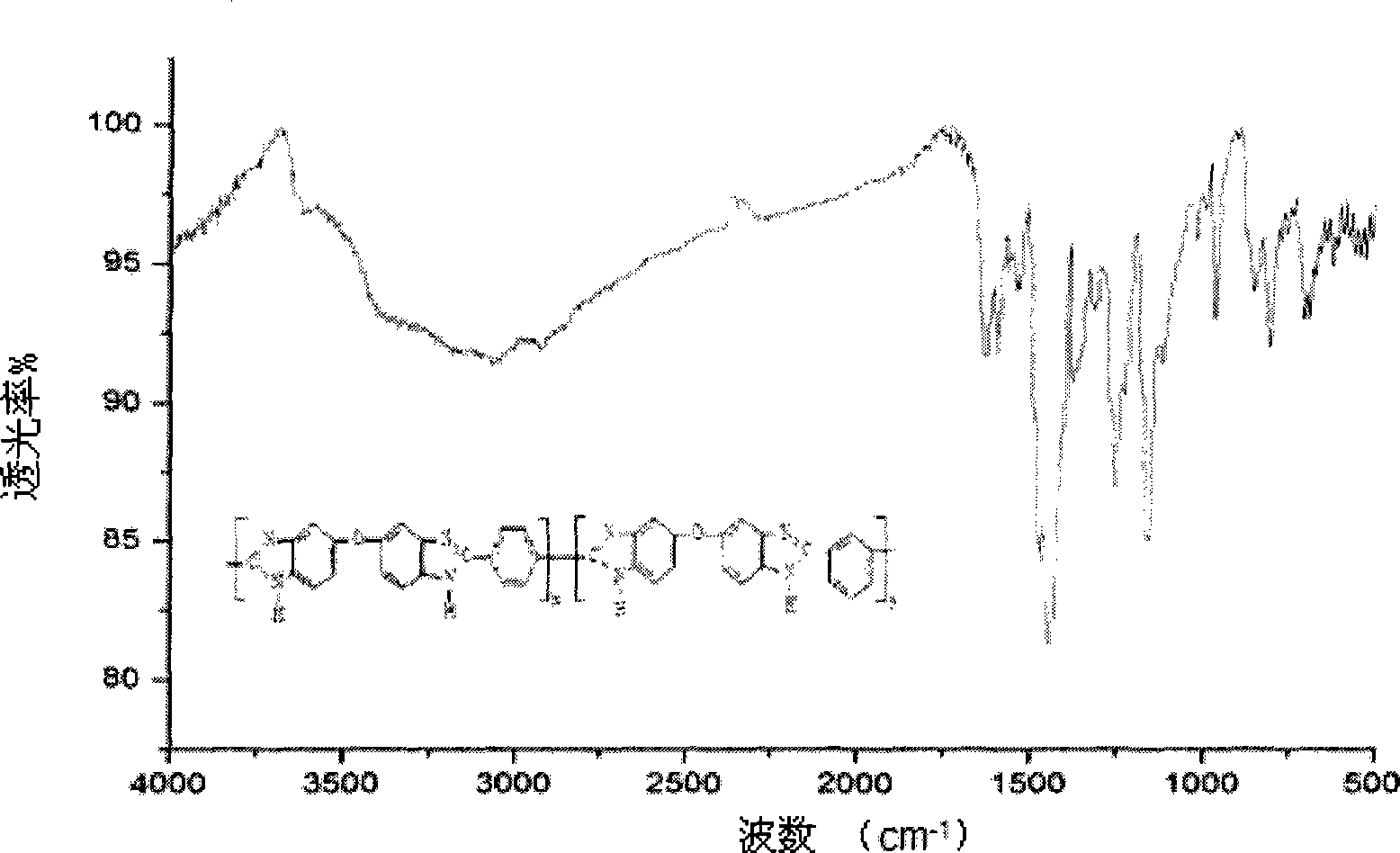

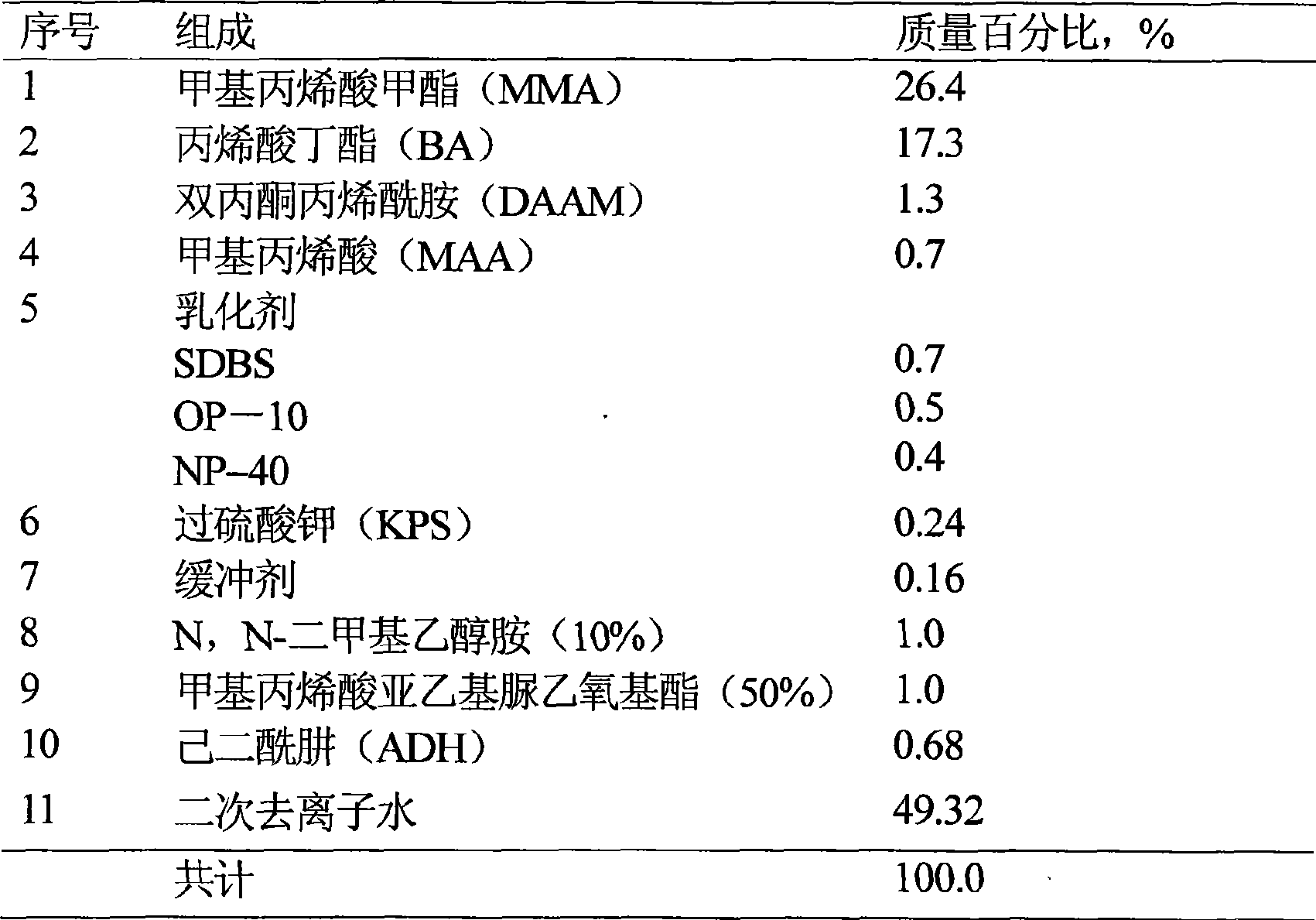

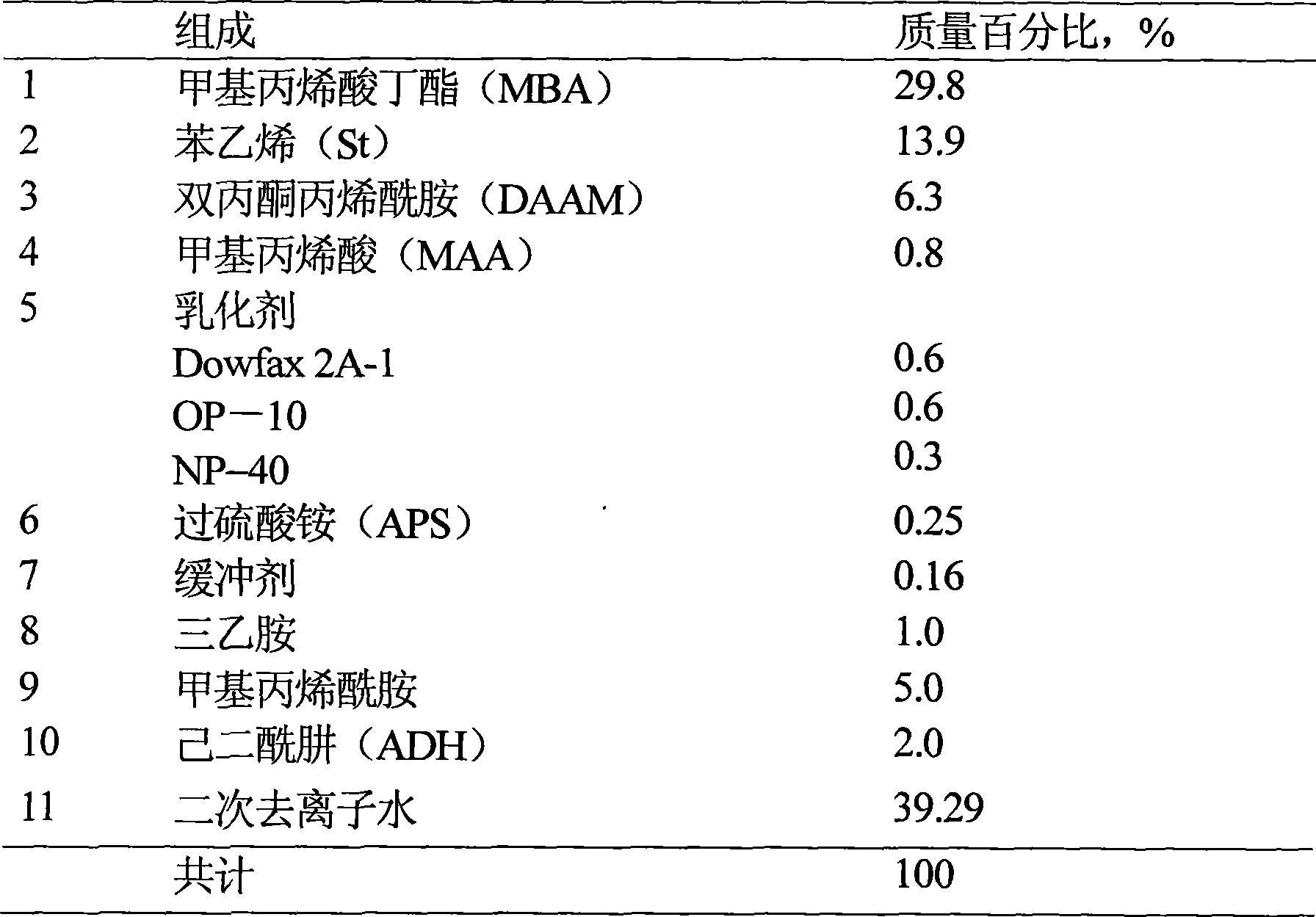

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

Graphene oxide/cellulose compound material as well as preparation method and application of same

ActiveCN102489259AImprove toughnessGood film formingOther chemical processesWater/sewage treatment by sorptionFiberCellulose compounds

The invention belongs to the field of material science and particularly relates to a graphene oxide / cellulose compound material as well as a preparation method and application of the material. The compound material is prepared by mixing graphene oxide suspension and alkaline solution of cellulose, and forming a compound structure of the graphene oxide and the cellulose under the action of mechanical stirring, shearing, ultrasonic or the like. In the preparation method, raw materials are cheap and easy to obtain, a water system is simple and free of pollution, equipment is simple and low in cost, and the industrial preparation is easy to realize; and the prepared compound material has the properties of fiber and the graphene oxide and is widely applied.

Owner:HENAN UNIVERSITY

Konjac jelly powder and method for making jellies by using same

InactiveCN102106495AGood physical and chemical propertiesImprove water holding capacityFood preparationLocust bean gumFiltration

The invention discloses konjac jelly powder. The konjac jelly powder comprises the following components in part by weight: 30 to 40 parts of konjac powder, 10 to 25 parts of carrageenin, 0 to 10 parts of xanthan gum, 0 to 15 parts of locust bean gum, 0 to 20 parts of guar gum, 5 to 12.5 parts of sodium citrate, 8 to 15 parts of potassium chloride, 0 to 7 parts of xylitol and 2 to 5 parts of citric acid. A method for preparing jellies by using the konjac jelly powder comprises the following steps of: mixing the konjac jelly powder and white granulated sugar uniformly; pouring the mixed white granulated sugar and konjac jelly powder into a stirred cold water proportioning cylinder; continuously adding the white granulated sugar or syrup, opening steam and heating; and performing filtration, packing and sterilization to obtain konjac jelly finished products. The konjac jelly powder provided by the invention has low production cost, adjustable taste and high dietary fiber content; the prepared konjac jellies do not need to be treated by alkali; and the method for preparing the jellies by using the konjac jelly powder has simple making process and low making cost.

Owner:HUBEI YIZHI KONJAC BIOTECH

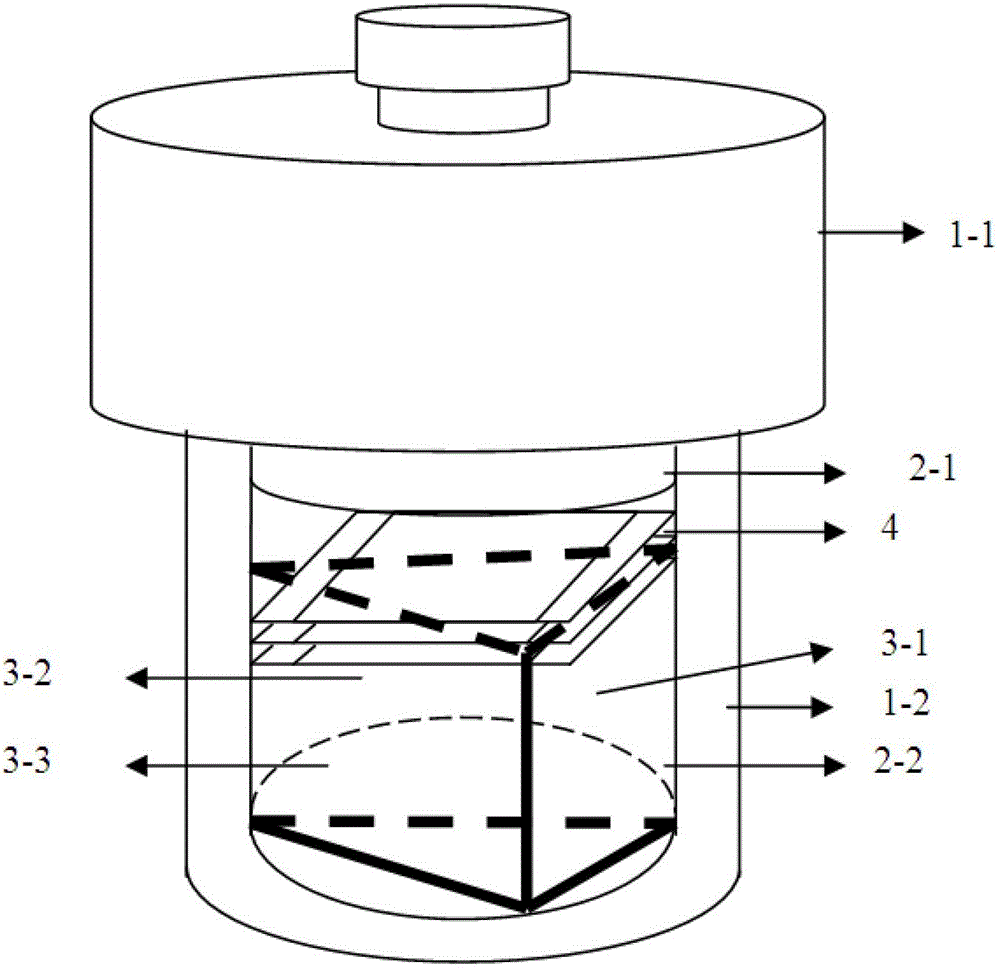

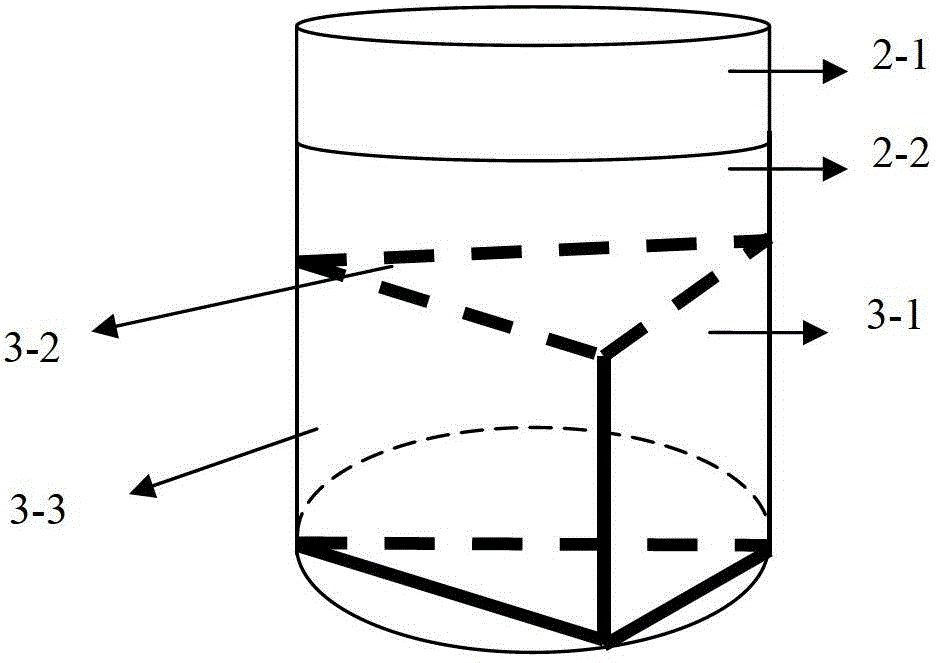

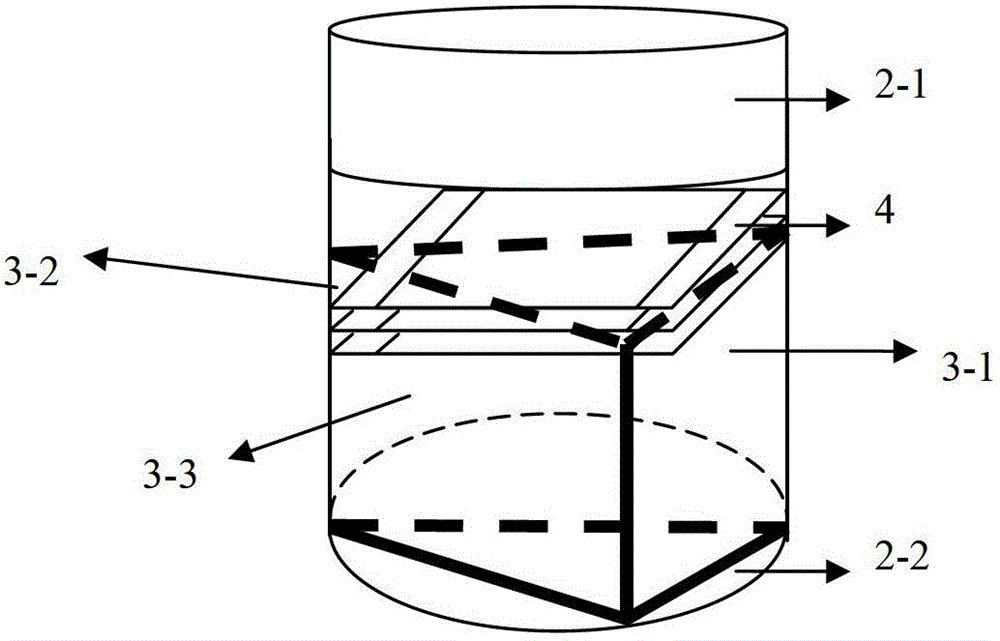

Polymer composite diaphragm and its preparing method

InactiveCN1851957AReduce the probability of short circuitImprove electrical performanceCell component detailsTextiles and paperPolymer compositesOrganic solvent

This invention discloses a polymer compound membrane and its preparation method, in which, the method includes: mixing strengthening bodies of a matrix film and inorganic nm materials in an organic solvent to get a uniform slurry to be coated on both sides of a non-woven cloth to get a polymer compound membrane, in which, said strengthening bodies are selected from the following three: 1, an organic monomer and its related initiator, 2, two or more than two polymers, 3, organic monomers and their related initiators and two or more than two polymers, 4, organic monomers and two or more than two polymers.

Owner:PEKING UNIV

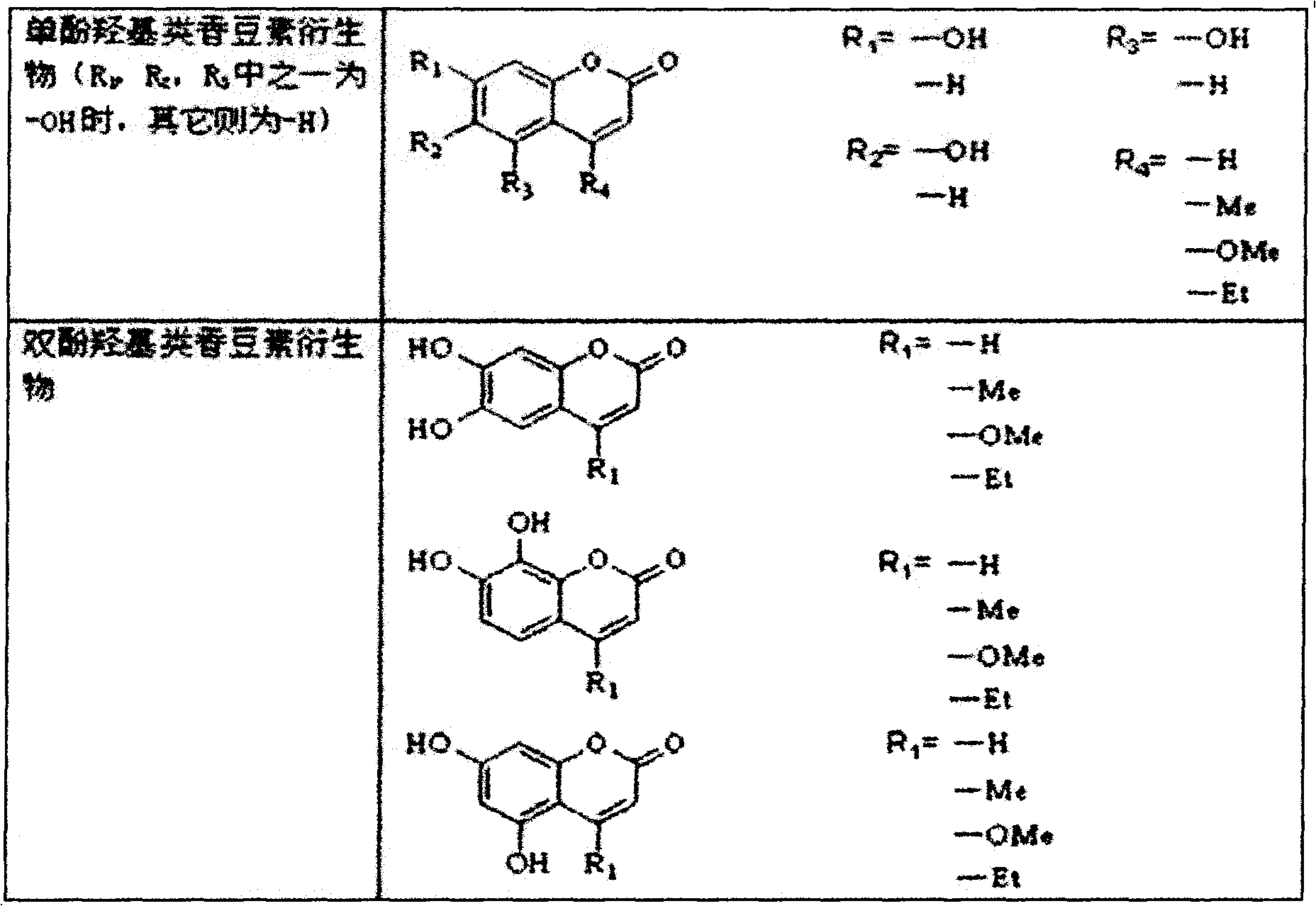

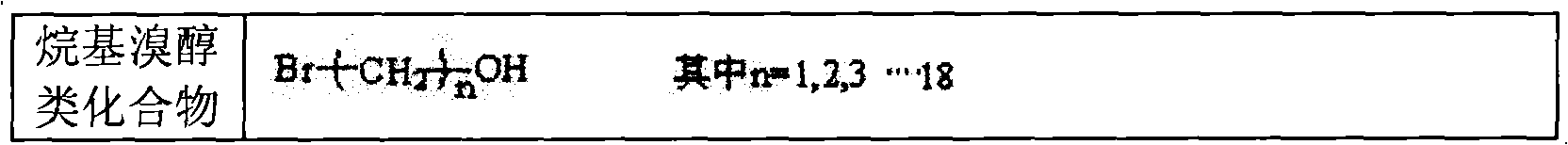

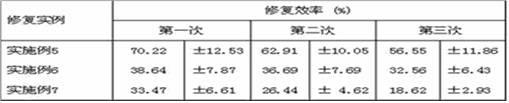

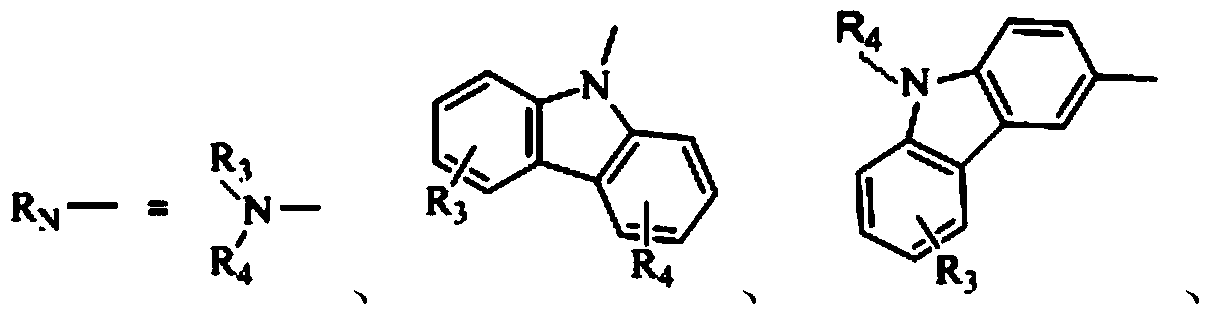

Photo-induced reversible self-repair polyurethane film and repair method

The invention relates to a photo-induced reversible self-repair polyurethane film and a preparation method and a repair method thereof. The polyurethane film mainly comprises 10 to 40 parts of phenolic hydroxyl coumarin derivative, 10 to 50 parts of alkyl bromal compound, 10 to 40 parts of polyisocyanate, and 10 to 30 parts of polyether polyol or polyester polyol. The preparation method comprises the following steps of: generating phenolic hydroxyl coumarin by using the phenolic hydroxyl coumarin derivative and the alkyl bromal compound under the action of absolute potassium carbonate; and reacting the phenolic hydroxyl coumarin, the polyisocyanate and the polyether polyol or the polyester polyol to obtain polyurethane solution, and performing cross linking under the irradiation of ultraviolet with wavelength of 350 nanometers after the film is formed to obtain the polyurethane film. The damaged surface is irradiated through the ultraviolet with wavelength of 254 to 350 nanometers, so that the reduced coumarin monomers are subjected to dimer cross linking reaction again and the purpose of repairing cracks is fulfilled. Compared with the prior art, the polyurethane film has the characteristics of good film forming property and high transparency; and the repair process is simple and has low cost.

Owner:SUN YAT SEN UNIV

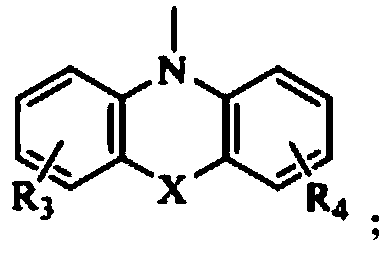

1,3,5-triazine derivative and application thereof in white organic electroluminescent light emitting diode

InactiveCN103435597AHigh color purityHigh fluorescence quantum yieldOrganic chemistrySolid-state devices1,3,5-TriazineTriplet state

The invention discloses a 1,3,5-triazine derivative. The derivative is a compound with a structure of a formula I. The compound of the formula I can emit high-efficiency blue fluorescence and meanwhile has higher triplet state energy; so that the compound of the formula 1 can sensitize green and red phosphorescent doped materials while emitting the high-efficiency blue fluorescence, so that the technological conditions for preparing WOLEDs (White Organic Light Emitting Diode) are met. Meanwhile, the invention also discloses a preparation method of the compound of the formula 1 and application in preparation of the white light organic electroluminescent diode.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of high-solid-content aqueous polyurethane for leather

The invention relates to the field of synthetic leather material polyurethane, in particular to a preparation method of high-solid-content aqueous polyurethane for leather. The method comprises the process steps of: prepolymerization reaction: reacting polyol, a hydrophilic chain extender and isocyanate monomer; monomer modification: adding polyhydroxy monomer to be modified together with polyurethane prepolymer; salt formation by neutralization: adding a neutralizing agent so that an emulsion forms salt ion groups; and chain extension subsequent to emulsification: dissolving an external emulsifying agent and a sulfonic acid chain extender in water to obtain a solution and adding the solution to the system for performing emulsification. In the invention, the emulsification property of theemulsion is improved by using carboxylic acid type and sulfonic acid type chain extenders, so that polyurethane and water are fully emulsified; simultaneously, due to the employment of the method in which self emulsification and external emulsification are combined, not only the stable emulsion can be synthesized, but also the solid content can be increased; in addition, the use of water as the solvent in emulsification is consistent with the requirement of clean production process; and the finally-synthesized emulsion has good film forming performance, high drying speed, no yellowing, excellent mechanical properties and short process flow, is suitable for the synthesis of leather substrates or surface materials, and can take the place of solvent-type products.

Owner:溧阳常大技术转移中心有限公司

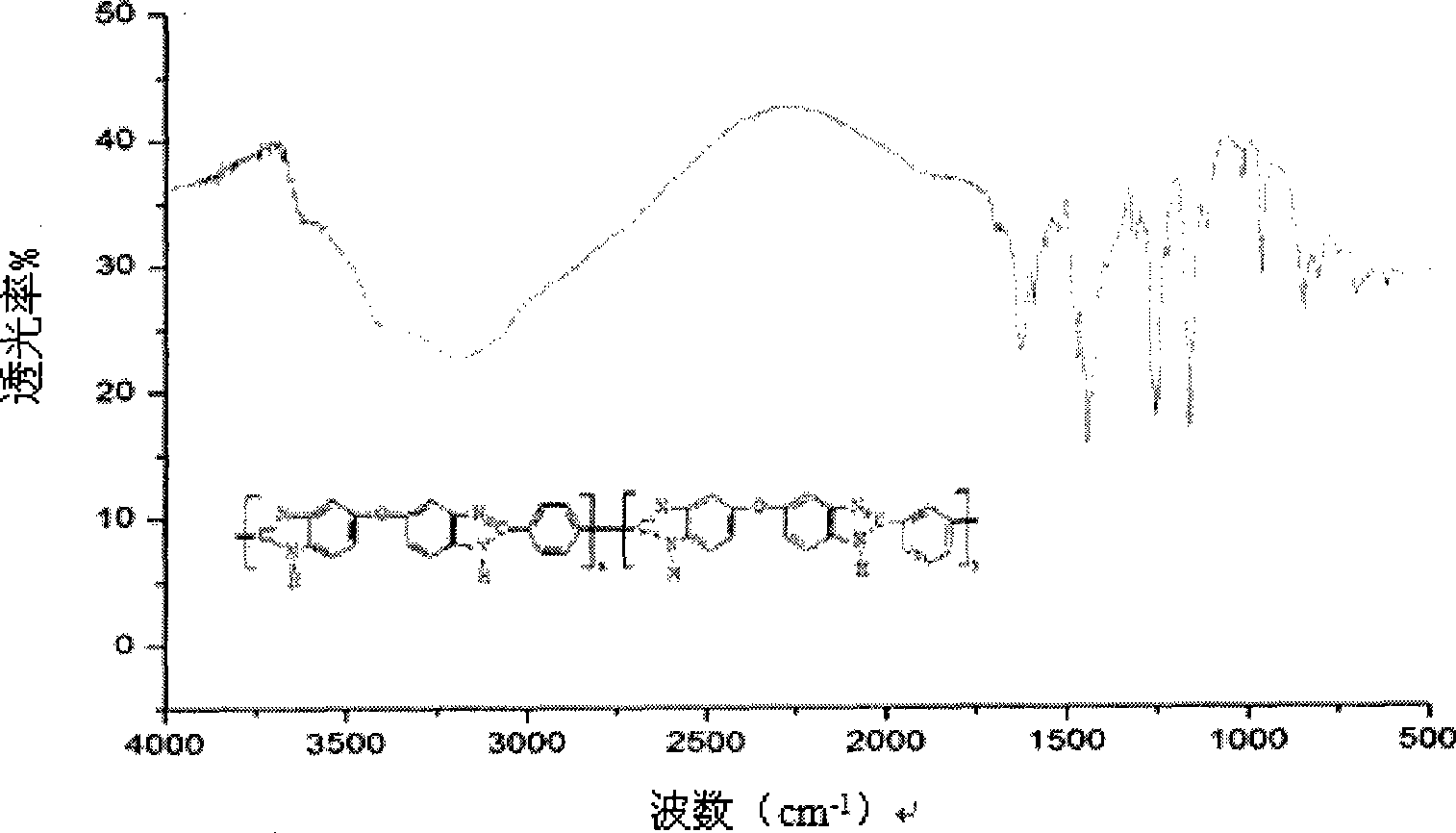

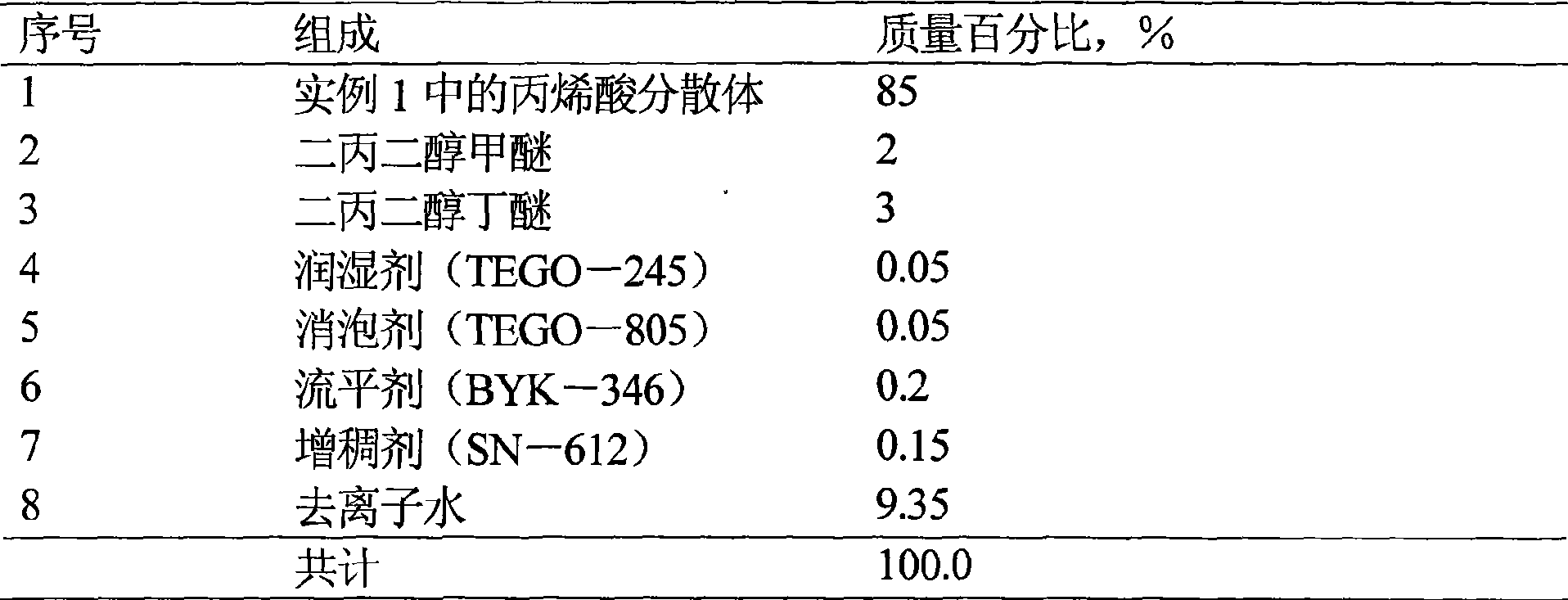

Acrylate micro-emulsion with high solid content, its preparation method and use

The invention refers to a high-solid content acrylate micro-latex, its making method and its application to carpentry dope. It adopts the technique of half-continuous starvation feeding, and is obtained by the polymerizing method of seed latex. It leads into cross-linking groups in the course of polymerization such as amidogen, acetoacetyl and amido, depends on the reaction of the groups of form film, gets painting film with cross-linking construction, and improves the water and solvent resistance of the painting film.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous compositions comprising polymeric duller particle

ActiveUS20070218291A1Improve clarityGood “hand feel”Liquid surface applicatorsLayered productsMeth-Single stage

The present invention provides aqueous matte coating compositions comprising a binder component B) and a polymeric duller component A) composed of particles of one or more multi-stage copolymer or single stage crosslinked (co)polymer, e.g. crosslinked t-butyl (meth)acrylate, the duller component particles A) having an average diameter of 1-20 μm. Components A) and B) are compatible. Preferably, the duller component A) is acrylic; more preferably, components A) and B) are acrylic. The aqueous compositions provide matte coatings having haptic or feel (soft touch) properties, film and appearance properties, including burnish resistance and low color loss.

Owner:ROHM & HAAS CO

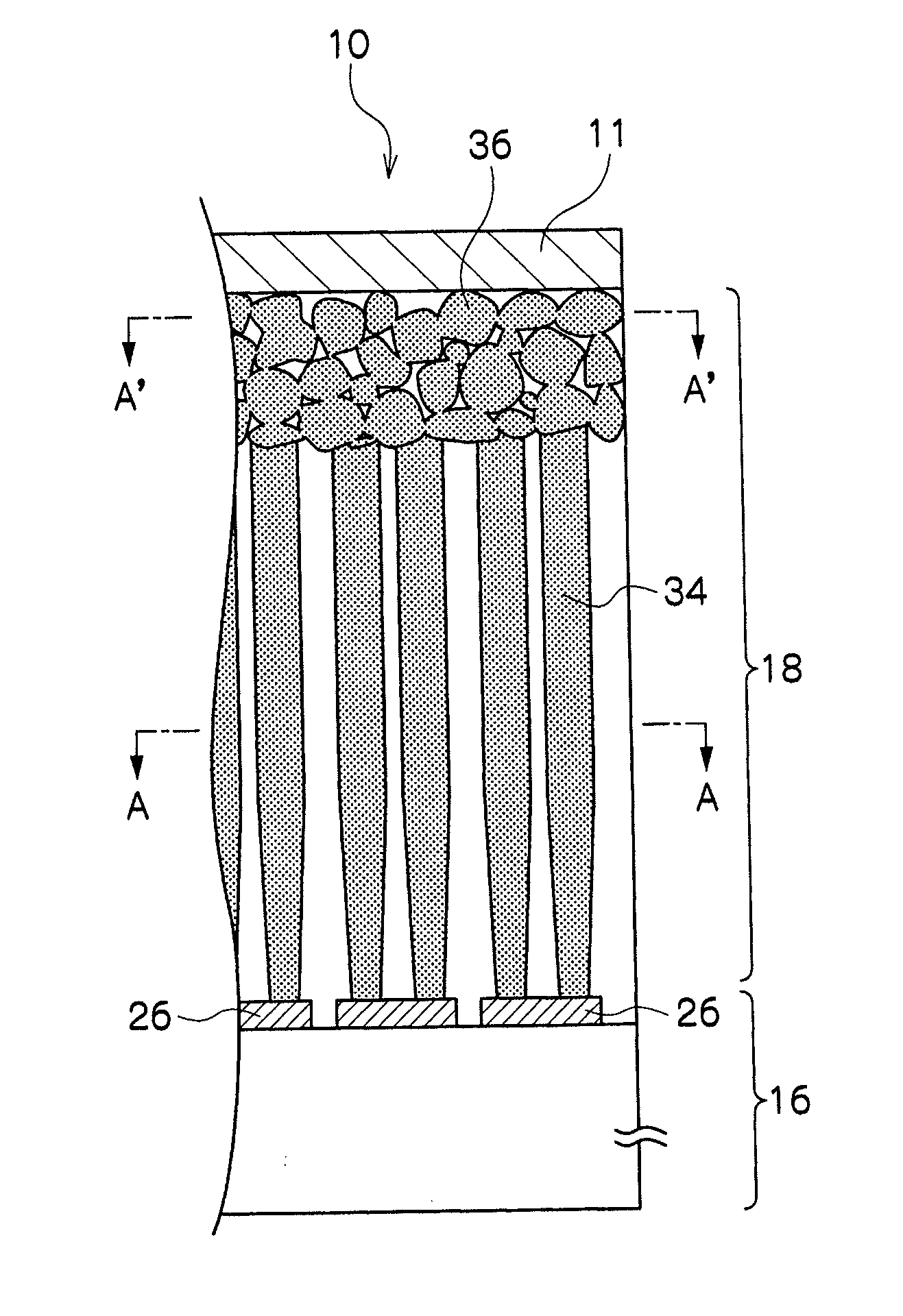

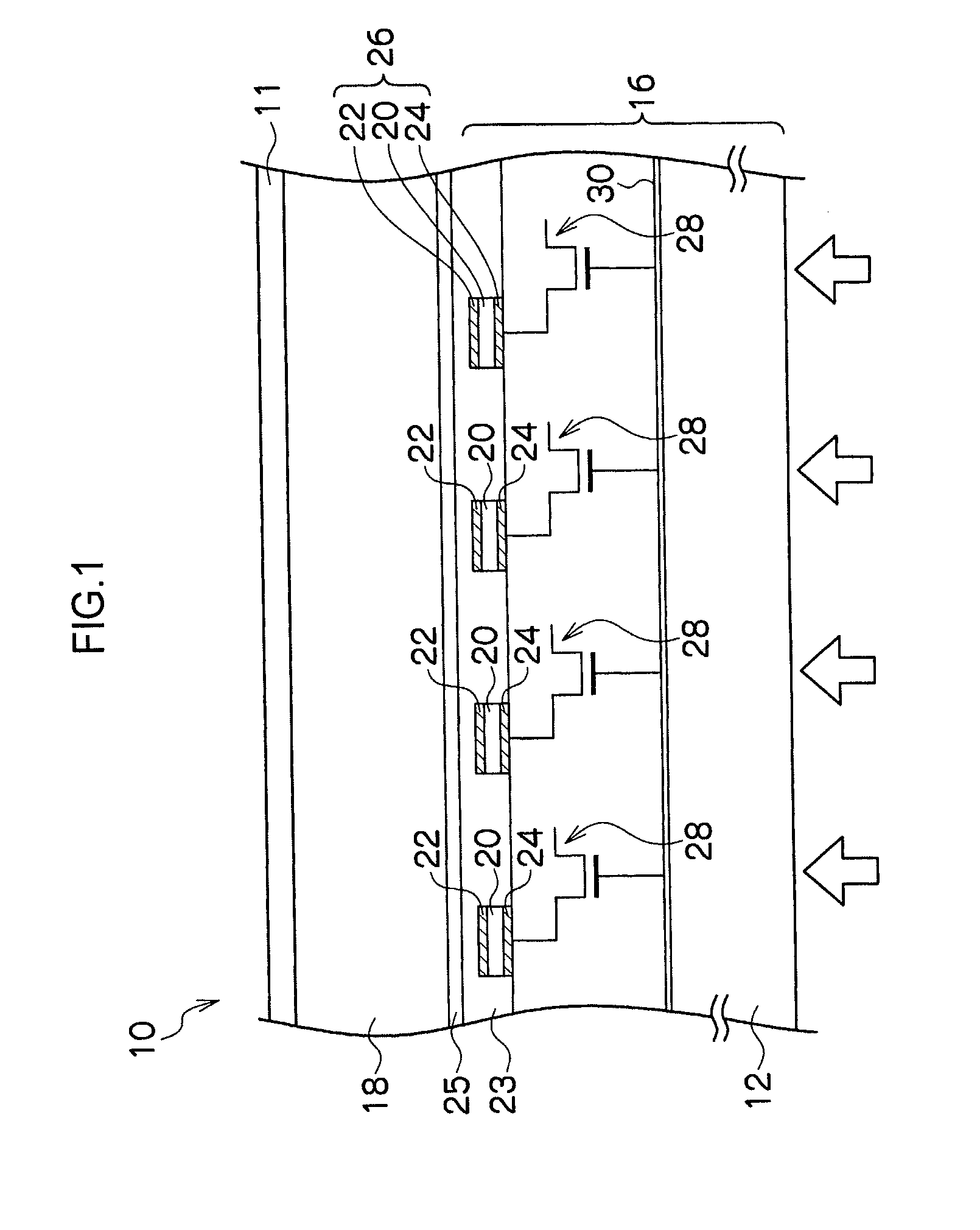

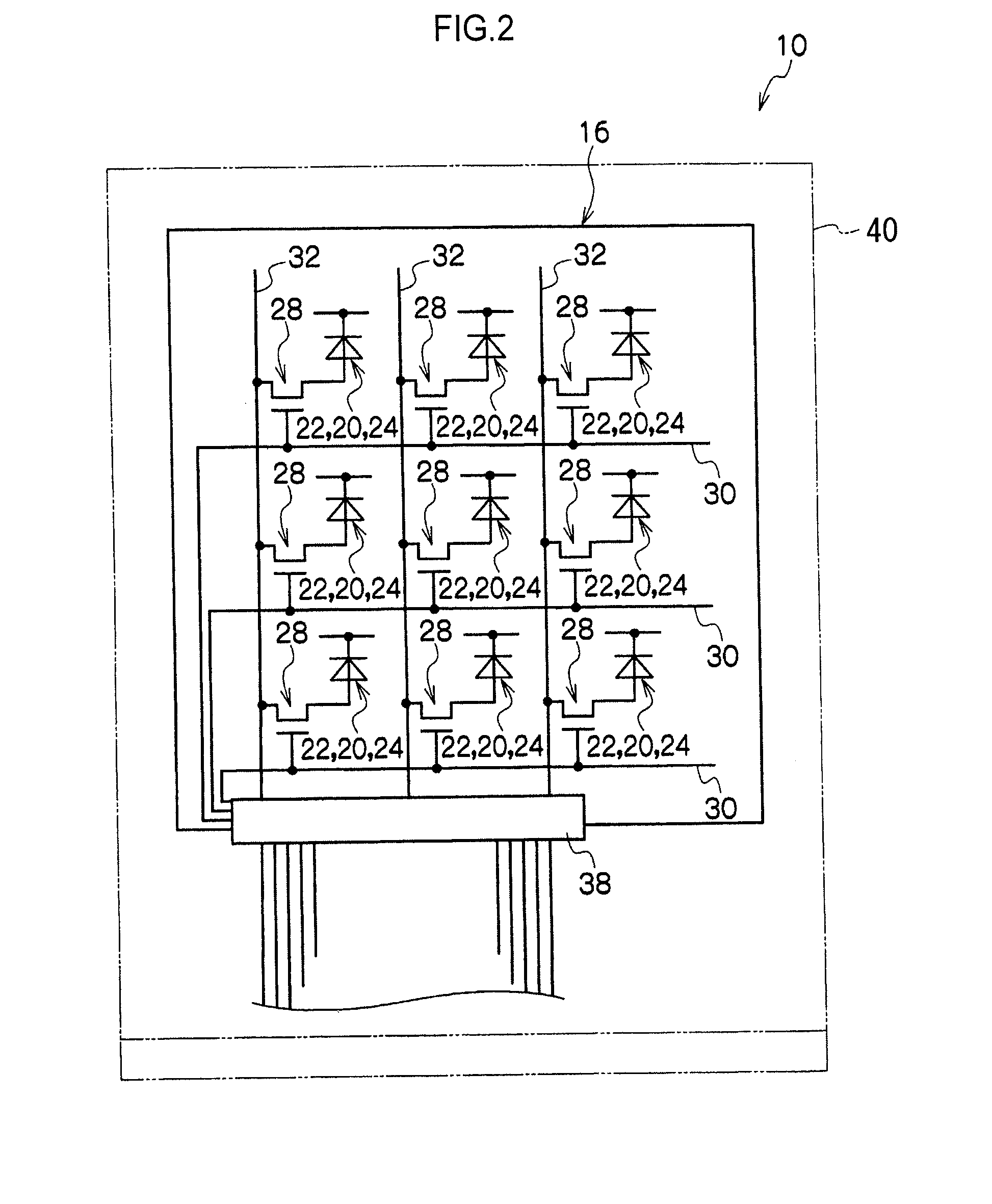

Radiation image detection apparatus and manufacturing method of the same

ActiveUS20110006213A1Reduce lightGood film formingMaterial analysis by optical meansChemical vapor deposition coatingImage detectionScintillator

A radiation image detection apparatus comprising a scintillator, which is configured to include columnar crystals and converts radiation into light when the radiation is irradiated thereon, and an optical detector, which converts the light, emitted from the scintillator into an electrical signal, the scintillator and the optical detector being arranged on a support such that the radiation is incident on the optical detector and the scintillator in this order, wherein a columnar crystal area is present at a radiation-incident side of the scintillator, and a non-columnar crystal area is present at a side of the scintillator opposite to the radiation-incident side; and a method for manufacturing the radiation image detection apparatus are provided.

Owner:FUJIFILM CORP

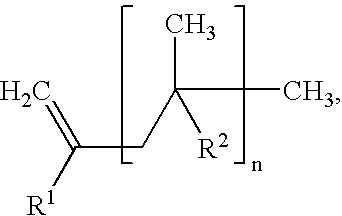

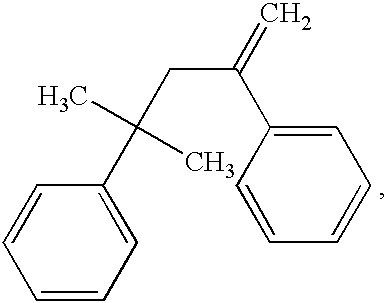

Cross-linkable polymer composition

The invention pertains to a polymer obtainable from the steps:polymerizing a mixture, that is substantially free or organic solvents, of ethylenically unsaturated monomers which consist for at least 70% of methacrylates, and which comprises specific chain transfer agents, α-methylstyrene dimer being preferred, to form a first polymer,aqueous emulsion polymerizing a mixture comprising ethylenically unsaturated monomers in the presence of the first polymer to form a dispersion of a water-insoluble second polymer, wherein these steps are preferably performed in the absence or the substantial absence of a surfactant.

Owner:NUPLEX RESINS BV

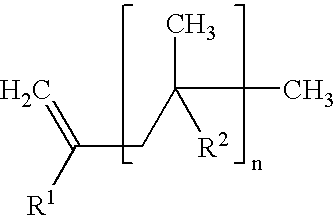

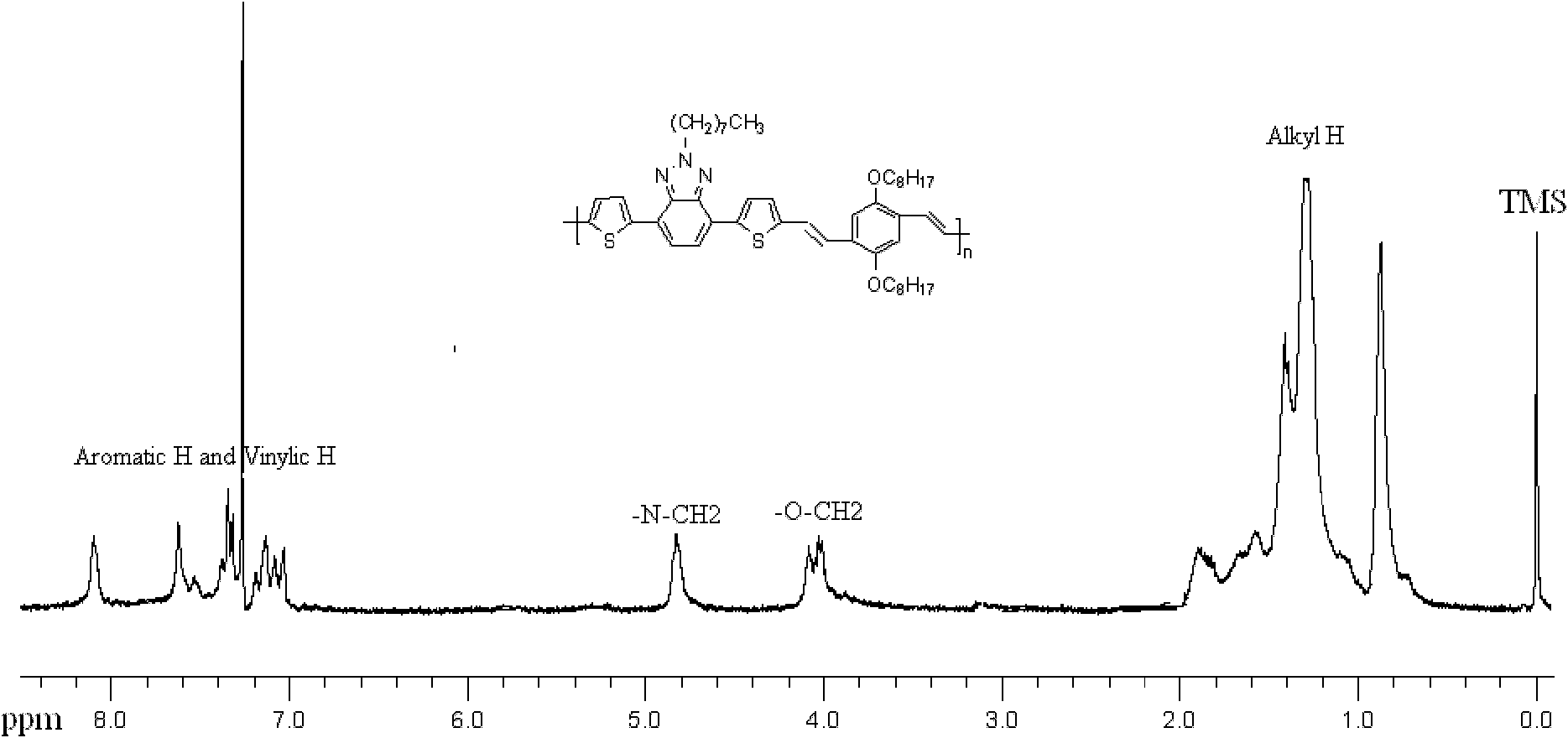

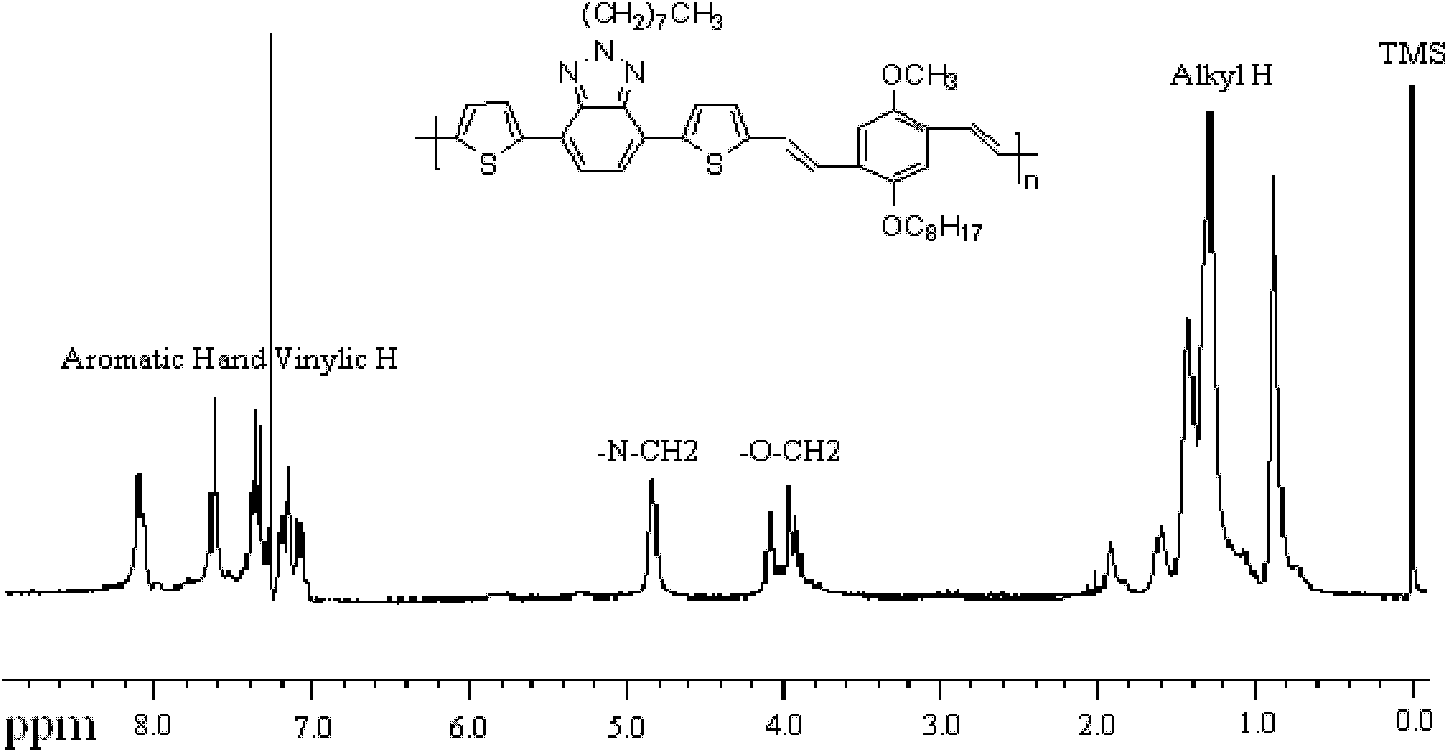

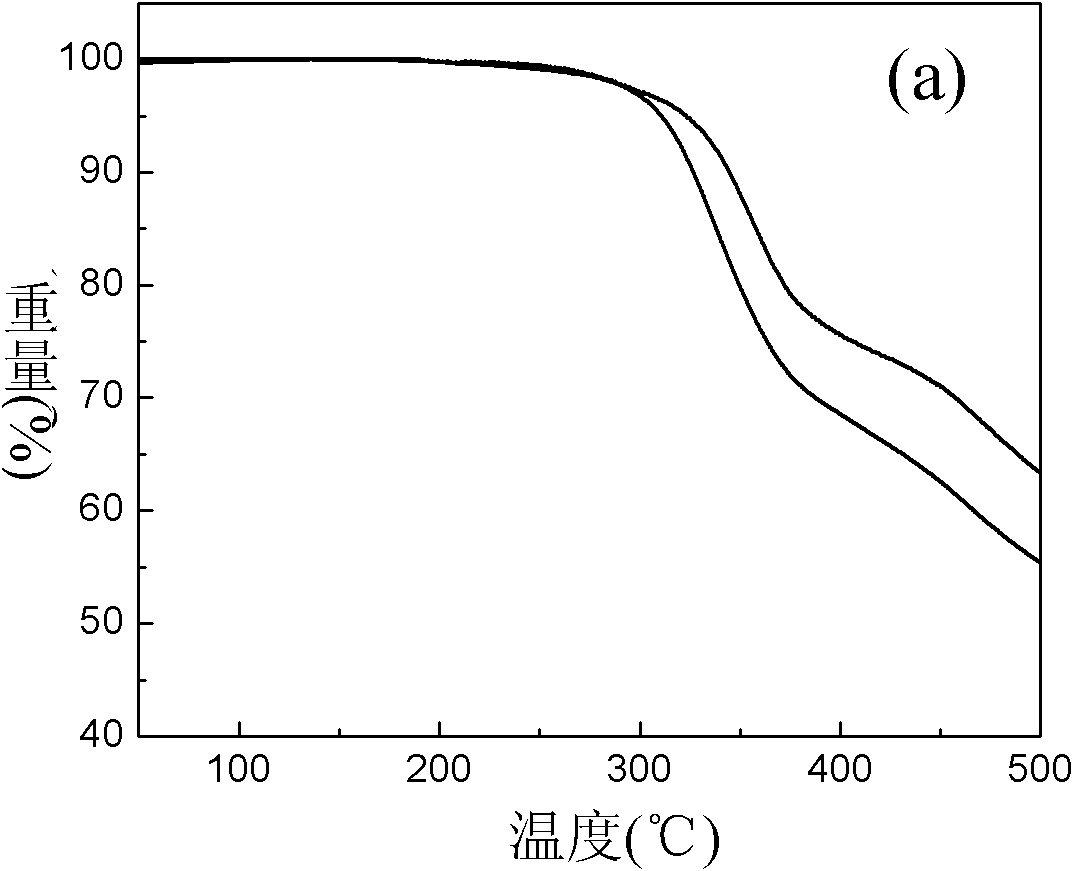

2-thiophene-benzotriazole-based polymer materials and photovoltaic application thereof

InactiveCN101935389ASolve solubilityUniform textureSolid-state devicesSemiconductor/solid-state device manufacturingDouble bondSingle bond

The invention discloses a series of 2-thiophene-benzotriazole-based polymer materials. In the invention, a 2-thiophene-benzotriazole unit is connected with another aromatic ring, aromatic heterocyclic ring or derivatives thereof by a carbon-carbon single bond or a carbon-carbon double bond to obtain the 2-thiophene-benzotriazole-based polymer materials. The series of 2-thiophene-benzotriazole-based polymer materials are applied to polymer solar cells and have good photoelectric conversion function. The application of the 2-thiophene-benzotriazole-based polymer materials has the following steps of: mixing the 2-thiophene-benzotriazole-based polymer materials with a C60 receptor; spreading on ITO (Indium Tin Oxide) glass to form a layer of semitransparent film; and finally evaporating a metal electrode on the polymers in a vacuum evaporating way to obtain a polymer solar cell device.

Owner:CENT SOUTH UNIV

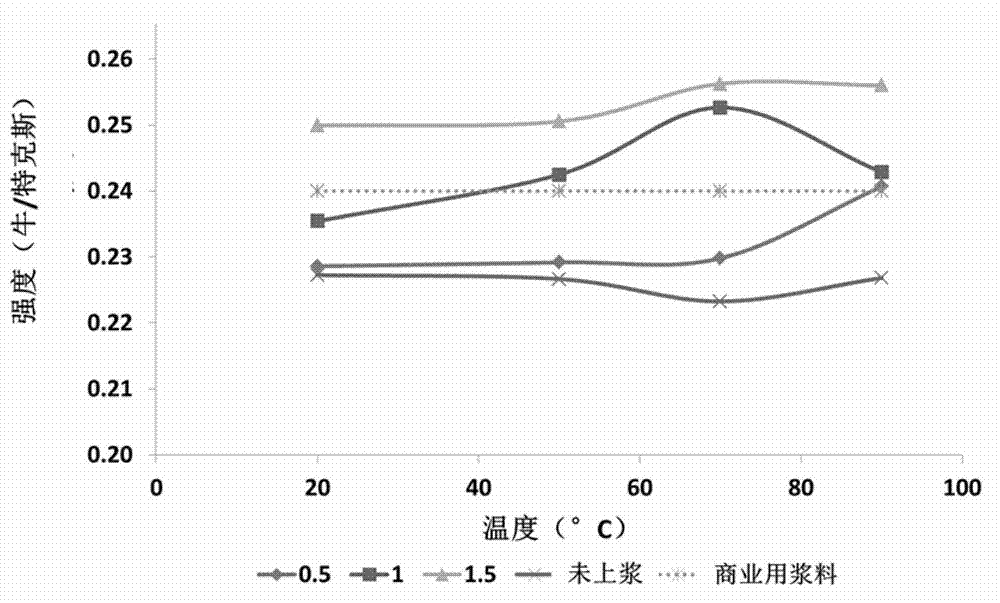

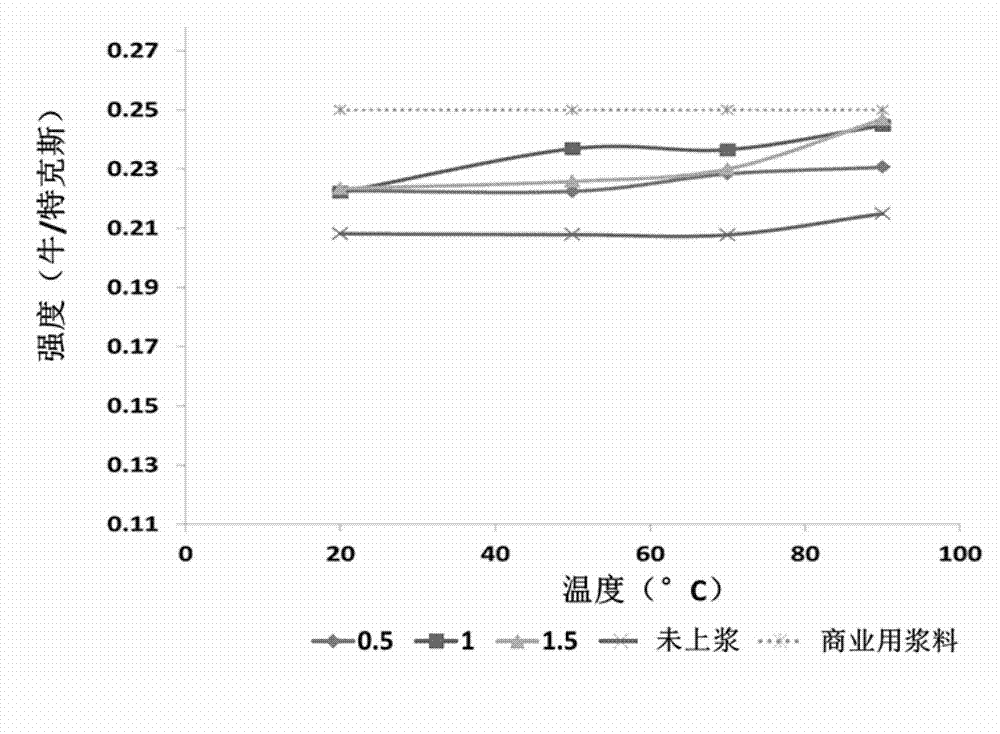

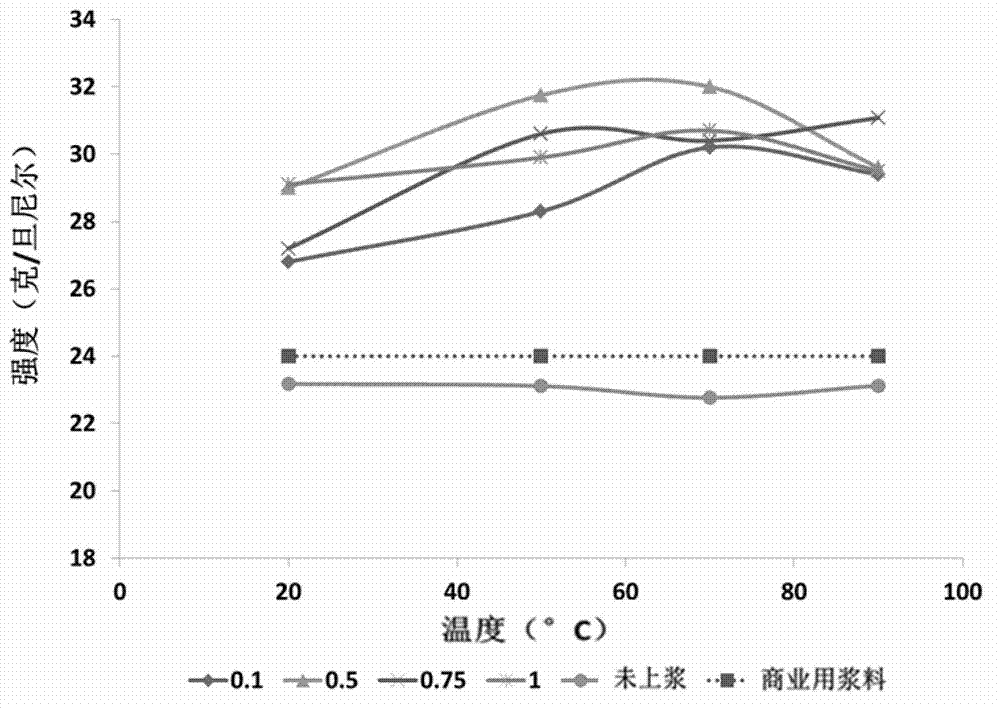

Preparation method of proteins and protein-based sizes for warp sizing

InactiveCN103087332AGood film formingGood mechanical propertiesFibre treatmentProtein proteinChemistry

The invention relates to a preparation method of proteins and protein-based sizes for warp sizing. The method comprises the following steps: (1) taking, putting the protein raw materials, such as plant proteins, animal proteins or animal-protein-based-materials, which are taken as size raw materials, into a sodium hydroxide solution or an alcohol solution, heating the obtained mixture for 30-60 minutes under the constant temperature condition of 20-90 DEG C, adjusting the pH value of the obtained mixture to be 7-8, removing undissolved precipitates through centrifugation or suction filtration, and eventually producing proteins or protein-based sizes; and (2) soaking thick yarns, spun yarns, fabrics or other textile materials into the sizes for 5-10 minutes at 20-90 DEG C, and after fabrics are soaked in the sizes, carrying out constant-speed rolling in the thickness direction of the fabrics. The proteins and the protein-based sizes prepared by using the method disclosed by the invention have good biodegradable properties, and can be directly applied to the sizing of cotton yarns, polyesters, polyester cotton blended yarns and other blended yarns, and the size preparation is low in cost and does not pollute the environment.

Owner:DONGHUA UNIV

Preparation method of graphene-titanium dioxide composite material

The invention discloses a preparation method of a graphene-titanium dioxide composite material, and relates to the graphene-titanium dioxide composite material. The preparation method of the graphene-titanium dioxide composite material is high-efficient and environment-friendly, and comprises following steps: 1) preparing a solution by dissolving a titanium iron-containing precursor into absolute ethyl alcohol, and adding oxidized graphene solution, so that titanium irons are adsorbed by the surface of oxidized grapheme, hydrolyzation is performed, and amorphous titanium hydroxide nano-particles are obtained; precipitating and drying an obtained oxidized graphene-titanium hydroxide composite material so as to obtain a oxidized graphene-amorphous titanium oxide composite material; 2) adding an aqueous solution into a sealed high-pressure hydrothermal reaction vessel, adding the oxidized graphene-amorphous titanium oxide composite material which is obtained in step 1) on the aqueous solution, and performing reduction reaction of oxidized graphene and crystallization reaction of amorphous titanium oxide so as to obtain the graphene-titanium dioxide composite material.

Owner:大正(江苏)微纳科技有限公司

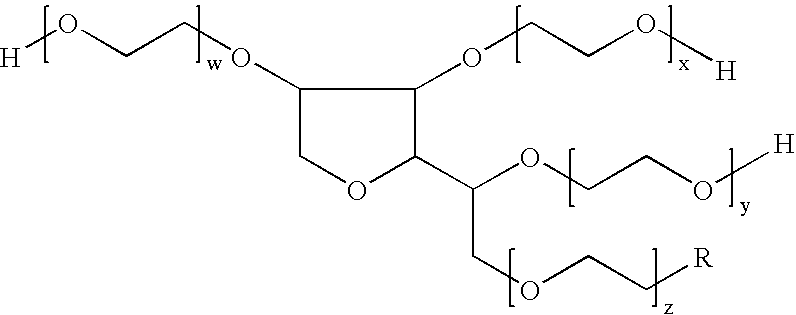

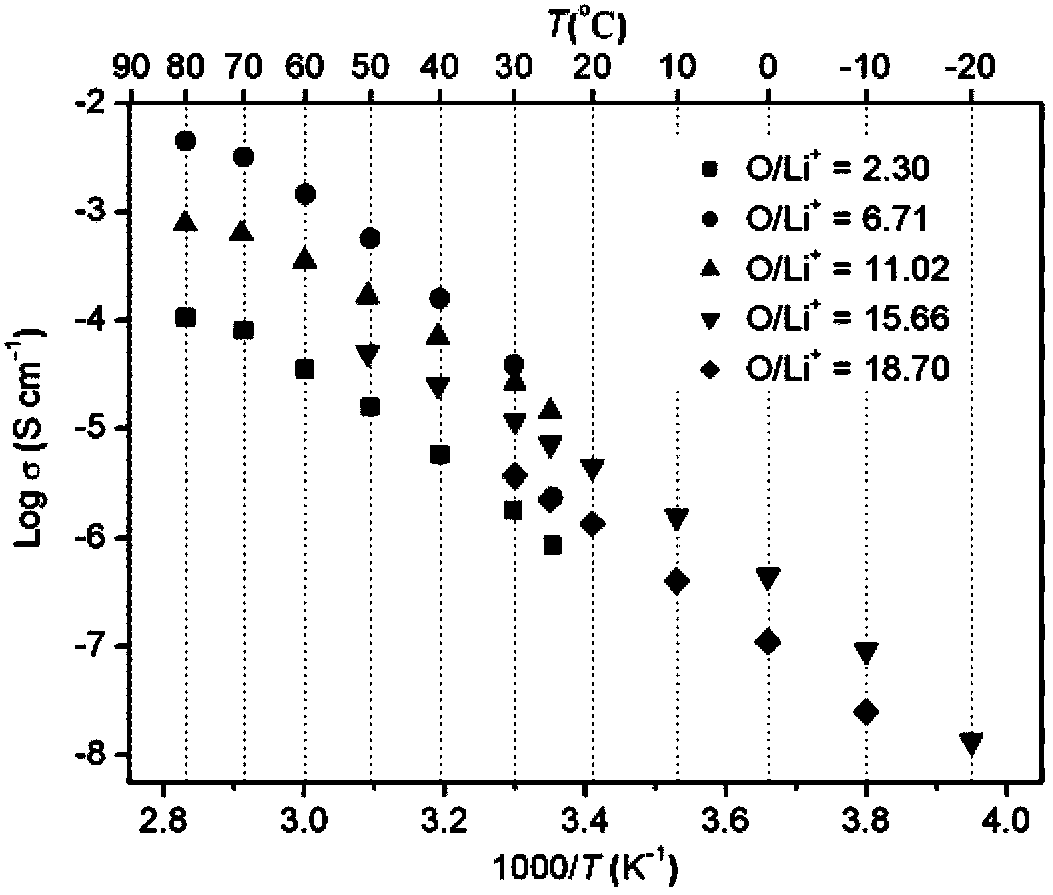

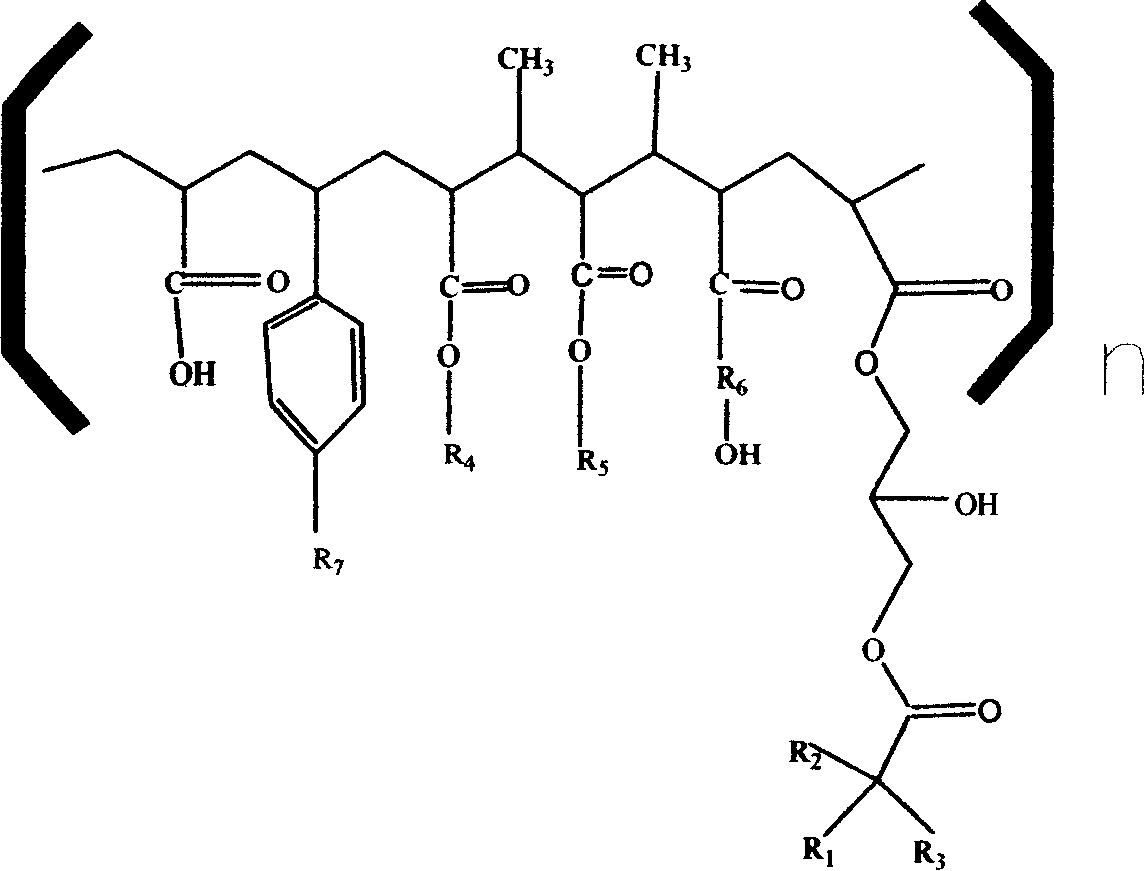

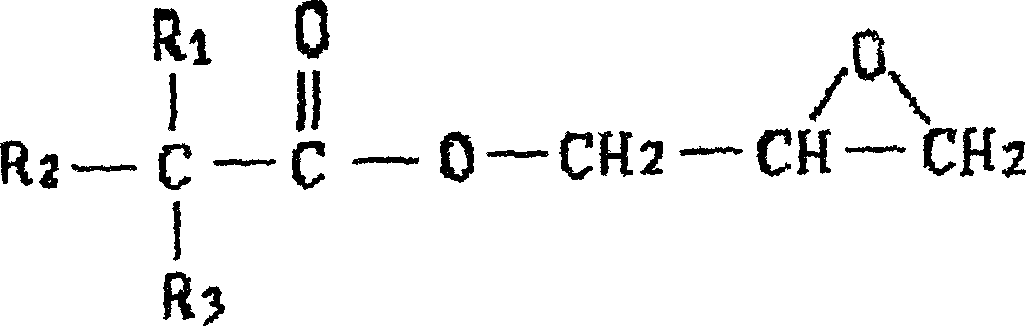

Polymer single-ion electrolyte and preparation method thereof

ActiveCN103509153AHigh conductivity at room temperatureReduce crystallinitySecondary cellsLithium imideCrystallinity

The invention discloses random copolymerization single-ion polymer electrolyte or block copolymerization single-ion polymer electrolyte which is obtained through copolymerization between a (p-vinyl phenylsulfonyl) (perfluoroalkyl sulfonyl) lithium imide monomer and a methoxyl polyethylene glycol acrylate monomer, and a preparation method of the electrolyte. The polymer single-ion electrolyte prepared by the method disclosed by the invention has the advantages of high room-temperature conductivity, high lithium ion transference number, low glass state temperature and degree of crystallinity, good mechanical strength and film-forming properties, wide electrochemical window, good thermal stability and the like, and has potential application values in the aspects of lithium (ion) batteries, carbon-based super-capacitors, solar batteries and the like.

Owner:武汉市瑞华新能源科技有限公司

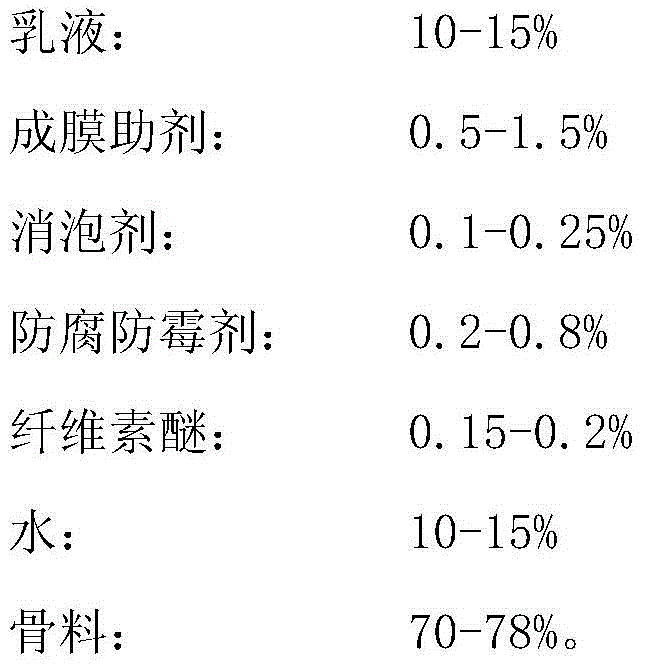

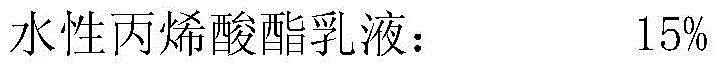

Stone-like paint and preparation method thereof

The invention relates to paint and a preparation method thereof, and specially relates to stone-like paint and a preparation method thereof. The stone-like paint mainly comprises an emulsion, cellulose ether and aggregate. The stone-like paint provided by the invention is good in film forming ability, does not crack, and has the prominent advantage that the stone-like paint is dried in a short period (2 h) during construction under the condition of low temperature (5-7 DEG C) and high humidity (70-80%) and is not whitened when meeting water; and the stone-like paint provided by the invention has excellent contamination resistance, excellent water whitening resistance and good in color retention and endurance, and is capable of overcoming rain print phenomenon.

Owner:JIANGMEN CRYSTONE PAINT

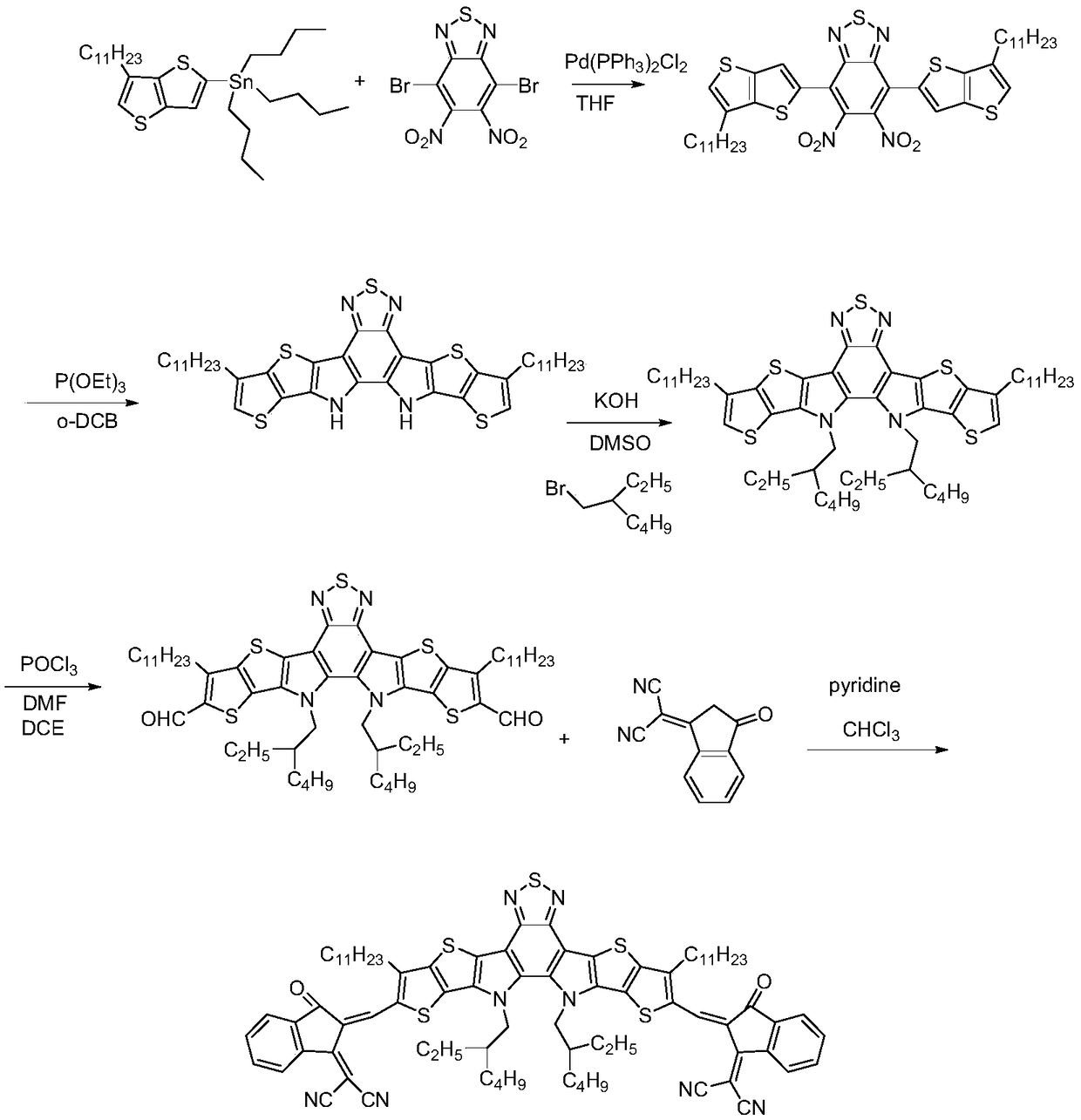

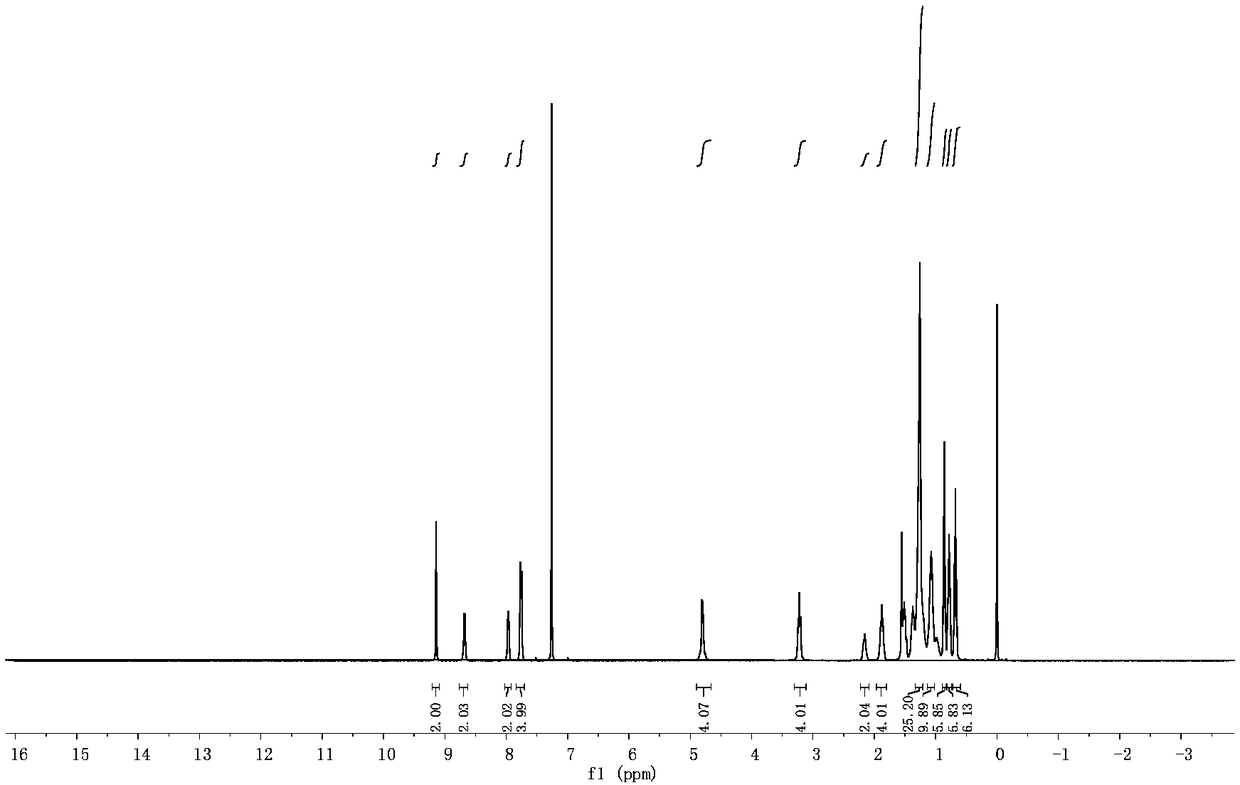

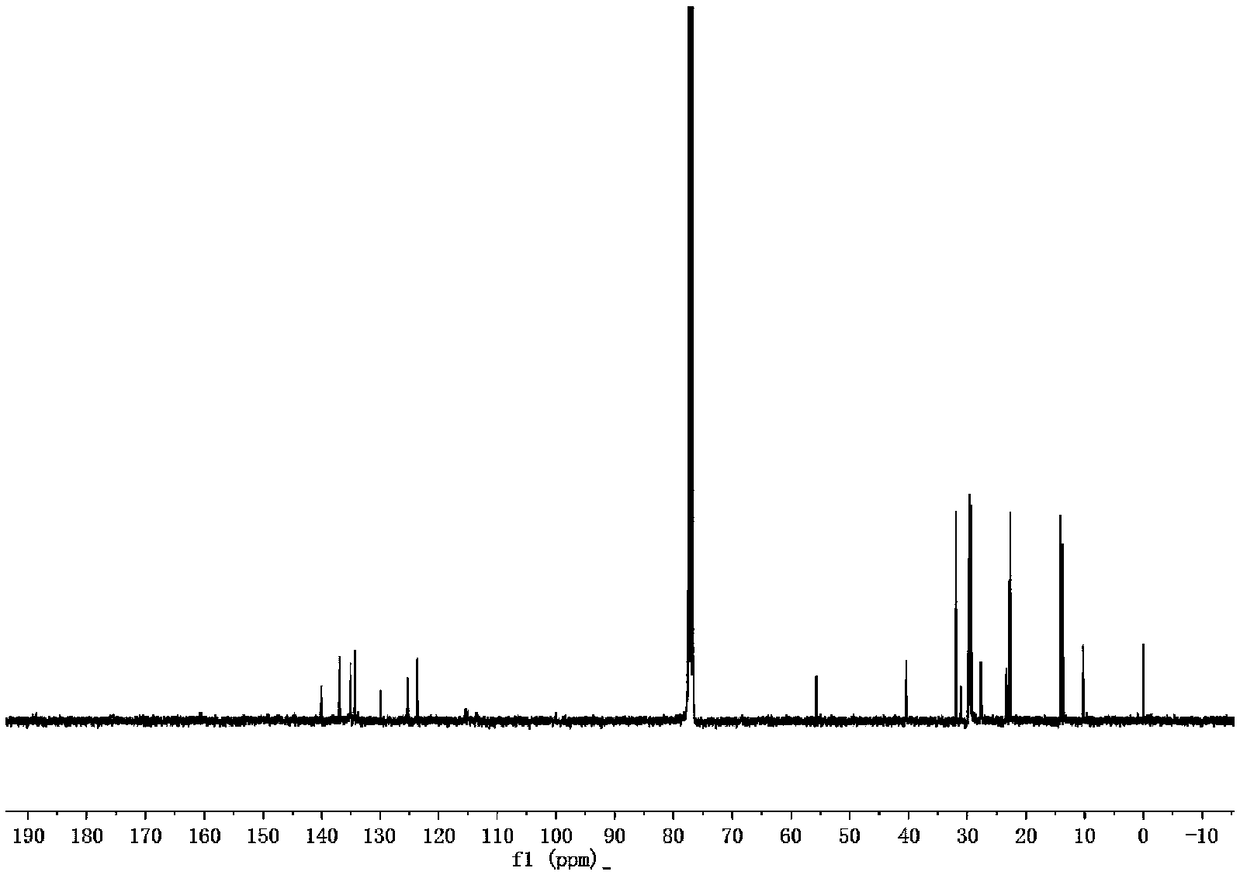

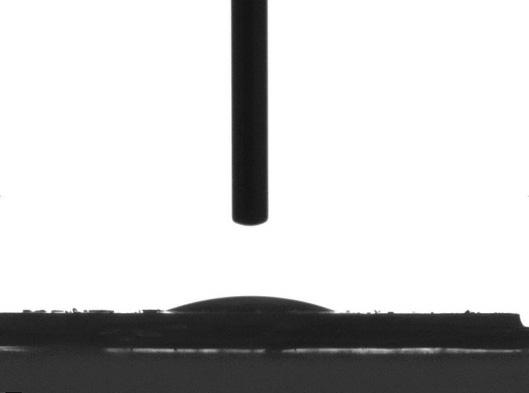

Polycyclic benzothiadiazole non-fullerene acceptor material, preparation method thereof and application of material

ActiveCN109134513AImprove solubilityPromote absorptionOrganic chemistrySolid-state devicesSolubilityOrganic solar cell

The invention discloses a polycyclic benzothiadiazole non-fullerene acceptor material, a preparation method thereof and an application of the material. The polycyclic benzothiadiazole non-fullerene acceptor material comprises a polycyclic benzothiadiazole center core and electrophilic end groups, the polycyclic benzothiadiazole center core is of a nitrogen bridge trapezoidal polycyclic structure,the electrophilic end groups are connected to two ends of the center core, 4, 7-dibromo-5, 6-binitro benzothiadiazole serves as a raw material in the preparation process, Stille coupling and Vilsmeier-Haack reaction are sequentially performed to obtain the polycyclic benzothiadiazole center core, and end-group structures are introduced by Knoevenagel reaction to obtain the polycyclic benzothiadiazole non-fullerene acceptor material. The acceptor material is good in solubility and easily processed into a film, has a good photoelectric conversion function and is used for preparing an organic solar battery device, and photoelectric conversion efficiency reaches nearly 16% of single battery conversion efficiency.

Owner:CENT SOUTH UNIV

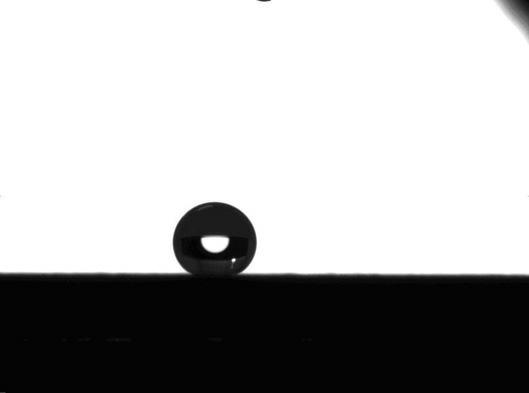

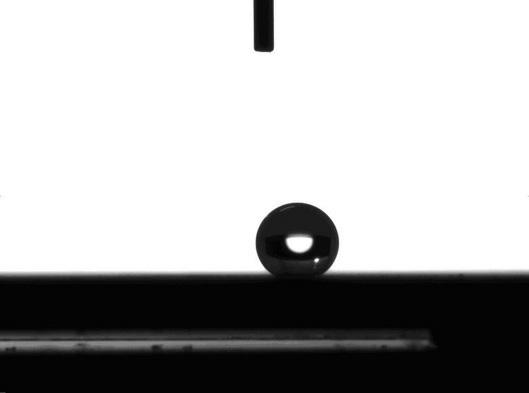

Preparation method for high-wave permeability super-hydrophobic moisture-proofing coating for antenna housing material

InactiveCN102492339AReduce porosityLow dielectricPretreated surfacesSpecial surfacesEpoxySilicon dioxide

The invention discloses a preparation method for high-wave permeability and super-hydrophobic moisture-proofing coating for an antenna housing material. The preparation method is characterized by comprising the following steps of: preparing hole-sealing emulsion; preparing super-hydrophobic moisture-proofing emulsion; coating the hole-sealing emulsion on the antenna housing material, surface-drying the film coating under a room temperature, and then curing the film coating under the temperature of 100 DEG C to 140 DEG C; cooling and immersing the film coating to the super-hydrophobic moisture-proofing emulsion; surface-drying the film coating under the room temperature, and curing the film coating under the temperature of 80 DEG C to 160 DEG C to acquire the high-wave permeability and super-hydrophobic moisture-proofing coating for the antenna housing material. Micron-level silicon dioxide and fluorine-containing polymer are used in the method to perform accumulating and hole-sealing;a micron surface structure with certain roughness is provided, and epoxy resin with good viscosity is added to the hole-sealed coating, so that the mechanical property of the hole-sealed coating is improved; a self-growth method is adopted for depositing micron-level fluorine-containing polymer, which is in-situ packaged by organic silicon resin and attached with hydrophobic nanometre silicon dioxide, to the surface of the hole-sealed coating, so that the high-wave permeability and super-hydrophobic moisture-proofing coating of the antenna housing material is prepared.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Fluoropolymer dispersion containing no or little low molecular weight fluorinated surfactant

ActiveUS20040171736A1Low viscosityLess susceptible of discolorationTransportation and packagingFibre treatmentPolymer scienceRoom temperature

In an aspect of the invention, a fluoropolymer dispersion, preferably a PTFE dispersion, is provided that comprises fluoropolymer particles having an average particle size of 10 to 400 nm dispersed in water whereby the dispersion has an amount of solids between 35 and 70% by weight. The dispersion is free of fluorinated surfactant having a molecular weight of less than 1000 g / mol (hereinafter called low molecular weight fluorinated surfactant) or contains the low molecular weight fluorinated surfactant in an amount of not more than 0.05% by weight based on the total weight solids of the dispersion. The dispersion further comprises a non-ionic non-fluorinated surfactant or mixture of non-ionic non-fluorinated surfactants and one or more non-fluorinated anionic surfactants. Through the use of a non-fluorinated anionic surfactant, a dispersion is obtained that has a low viscosity at room temperature (20° C.). The dispersion is further free of aromatic group containing non-ionic surfactants and is accordingly environmentally more friendly and can yield coatings that are less susceptible of discoloration. The amount and nature of the non-ionic non-fluorinated surfactant or mixture of non-ionic non-fluorinated surfactants is selected such that the Viscosity Transition Temperature (VTT) (measured as set forth in the examples) of the fluoropolymer dispersion is at least 26, preferably at least 28° C. In a further aspect of the invention, a method is provided to obtain the aforementioned dispersion.

Owner:3M INNOVATIVE PROPERTIES CO

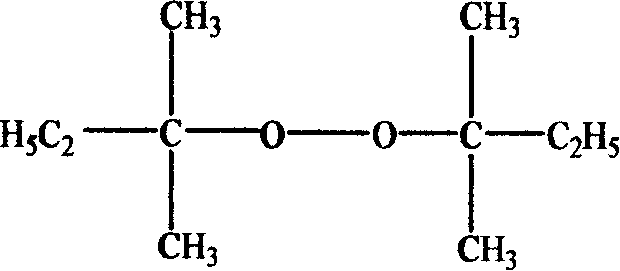

Water acrylic resin and preparing method thereof

The utility model relates to a water-based acrylic resin paintand the manufacturing method. The basic ray materials comprise acrylic monomer, styrene monomer, initiator, cosolvent, and active solvent. The utility model is characterized in that the acrylic monomer comprises acrylic derivative with hydroxyl; the cosolvent is ether alcohol solvent; the active solvent is butyl carbonate ethylene derivative active solvent; the initiator is peroxide initiator; and the neutralizer is Amine neutralizer. The resin is manufactured through two-step process. In the first step, water-based acrylic resin prepolymer is manufactured and is then manufactured into resin latex through inner emulsification on the second step. The product is of long storage time and is of no added emulsifier. Under the room temperature, the product can cross-link with water-based isocyanate curing agent to form membrane. The utility model is of excellent membrane, good water resistance, anti-scrubbing property, chemical resistance and sullying resistance.

Owner:上海市涂料研究所有限公司

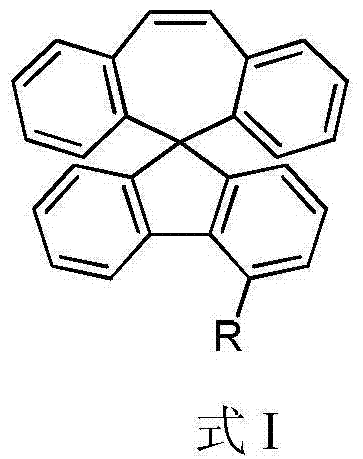

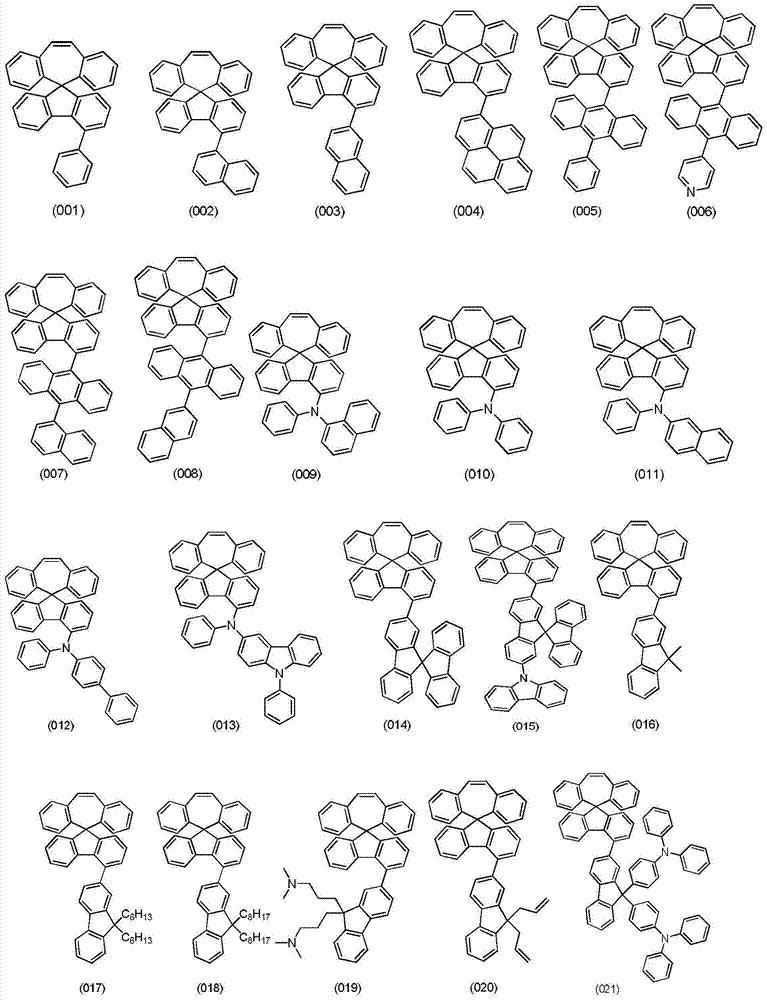

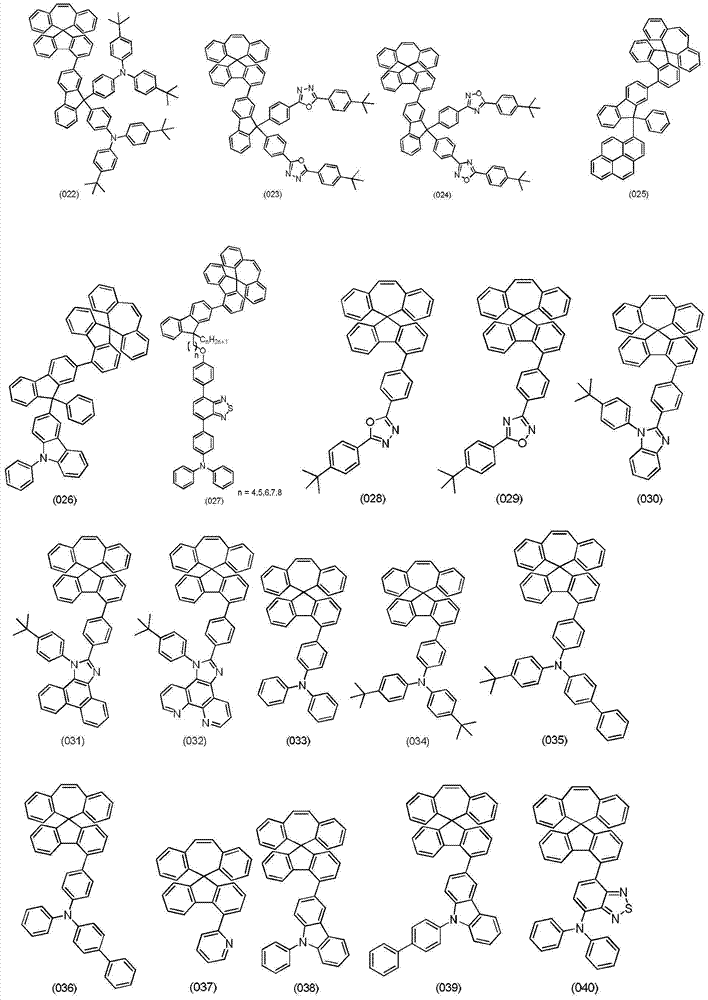

Organic electroluminescent materials, and preparation method and application thereof

ActiveCN103833507AHigh fluorescence quantum efficiencyGood film formingSilicon organic compoundsGroup 5/15 element organic compoundsOrganic electroluminescenceFluorescence

The invention discloses a series of organic electroluminescent materials, and a preparation method and an application thereof. A structural formula of the materials is shown as a formula I. The organic electroluminescent materials shown as the formula I have capacities of electron transportation and hole transportation. An organic electroluminescent device prepared by using the materials has a reduced starting voltage. The series of the materials have relatively good fluorescent quantum efficiency and electroluminescent efficiency, and relatively good film-forming property. Besides, the method for material synthesis and purification is simple and suitable for large-scale production. The organic electroluminescent materials are ideal selection for blue-light emitting materials of the organic electroluminescent device. Applications of the organic electroluminescent materials as luminescent materials independently or as main materials or doping dyes in luminescent layers are also in a protection range. The formula I is shown in the description.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com