Patents

Literature

52 results about "Carpentry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carpentry is a skilled trade and a craft in which the primary work performed is the cutting, shaping and installation of building materials during the construction of buildings, ships, timber bridges, concrete formwork, etc. Carpenters traditionally worked with natural wood and did the rougher work such as framing, but today many other materials are also used and sometimes the finer trades of cabinetmaking and furniture building are considered carpentry. In the United States, 98.5% of carpenters are male, and it was the fourth most male-dominated occupation in the country in 1999. In 2006 in the United States, there were about 1.5 million carpentry positions. Carpenters are usually the first tradesmen on a job and the last to leave. Carpenters normally framed post-and-beam buildings until the end of the 19th century; now this old fashioned carpentry is called timber framing. Carpenters learn this trade by being employed through an apprenticeship training—normally 4 years—and qualify by successfully completing that country's competence test in places such as the United Kingdom, the United States, Canada, Switzerland, Australia and South Africa. It is also common that the skill can be learned by gaining work experience other than a formal training program, which may be the case in many places.

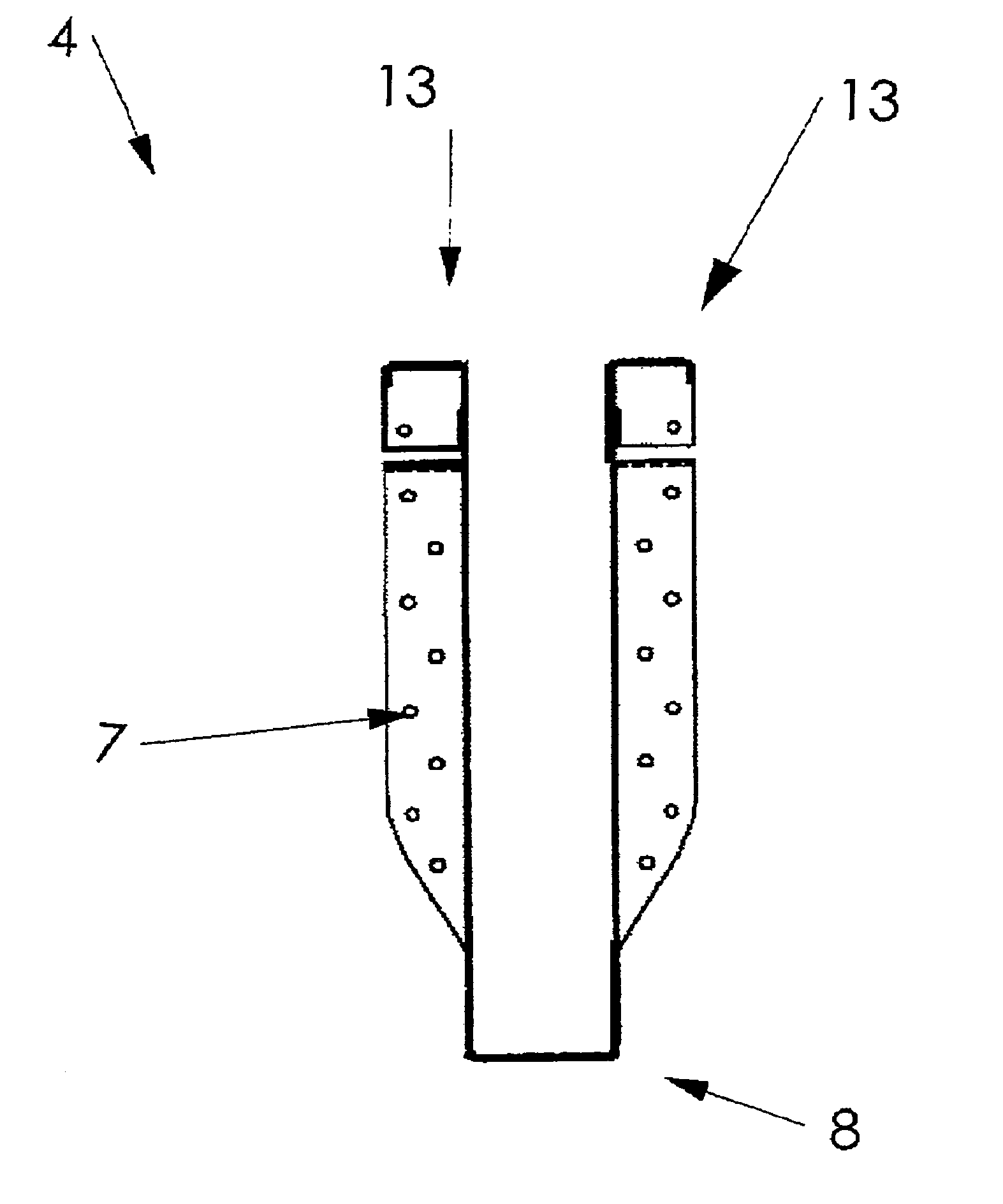

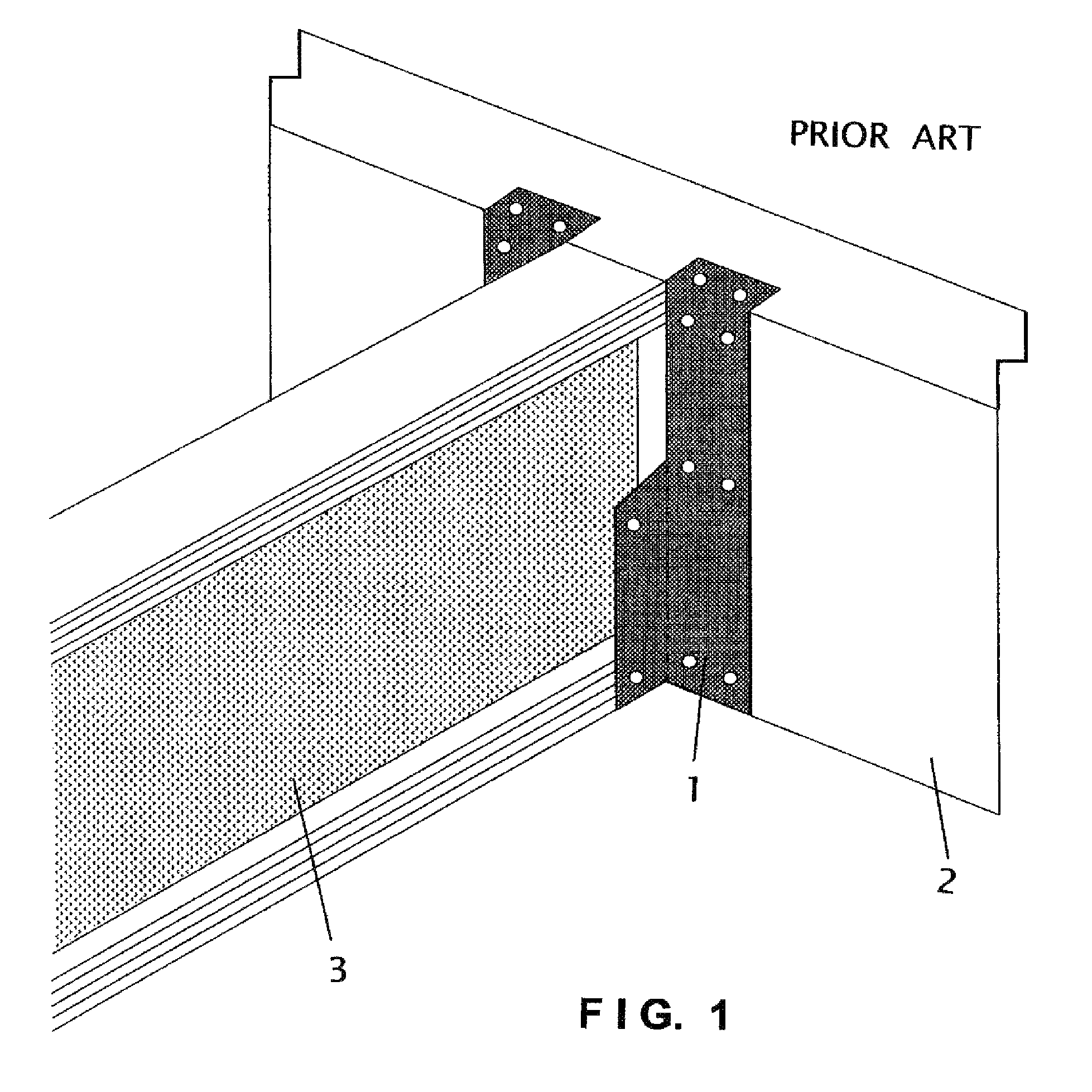

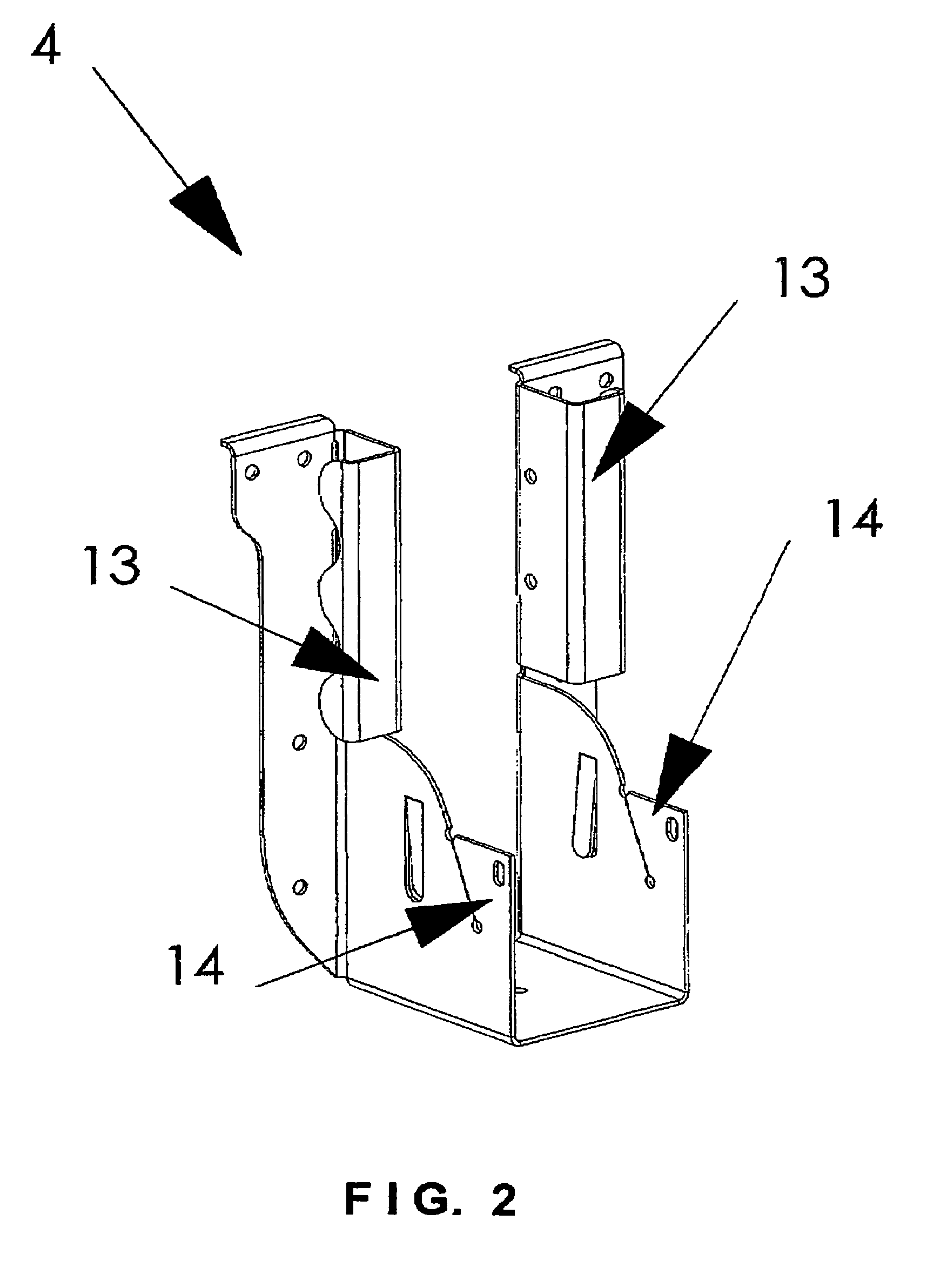

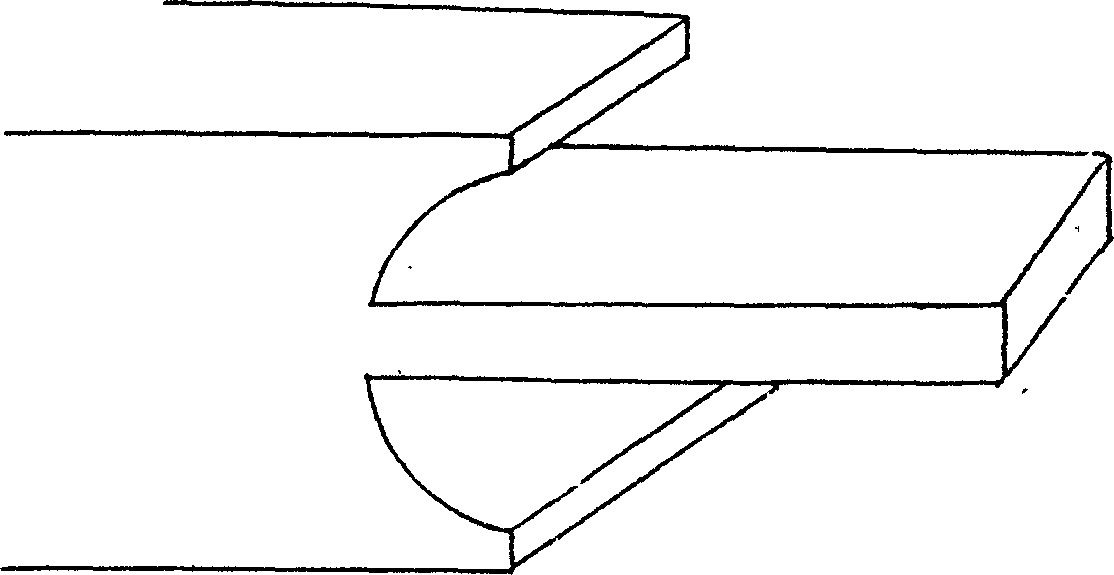

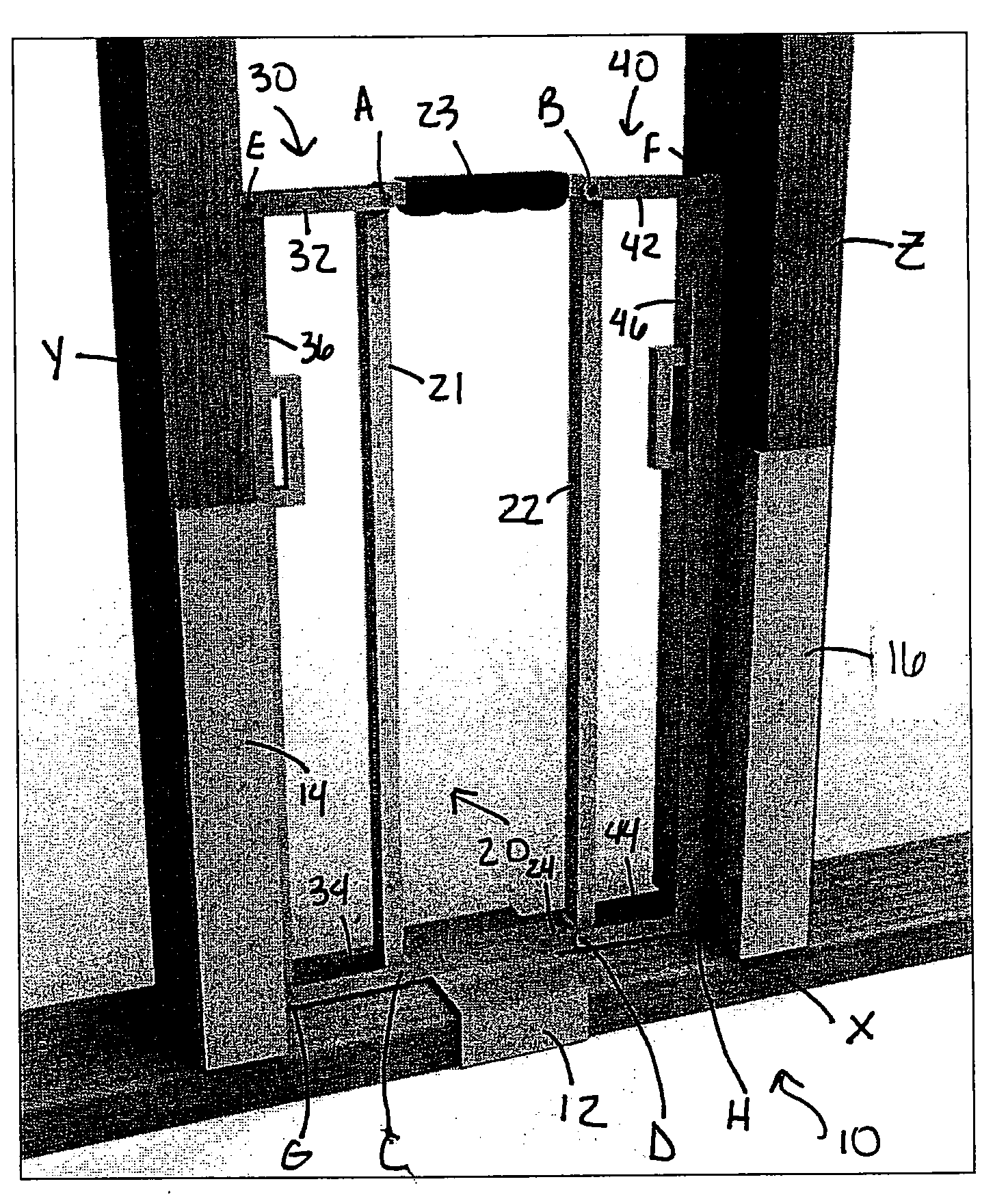

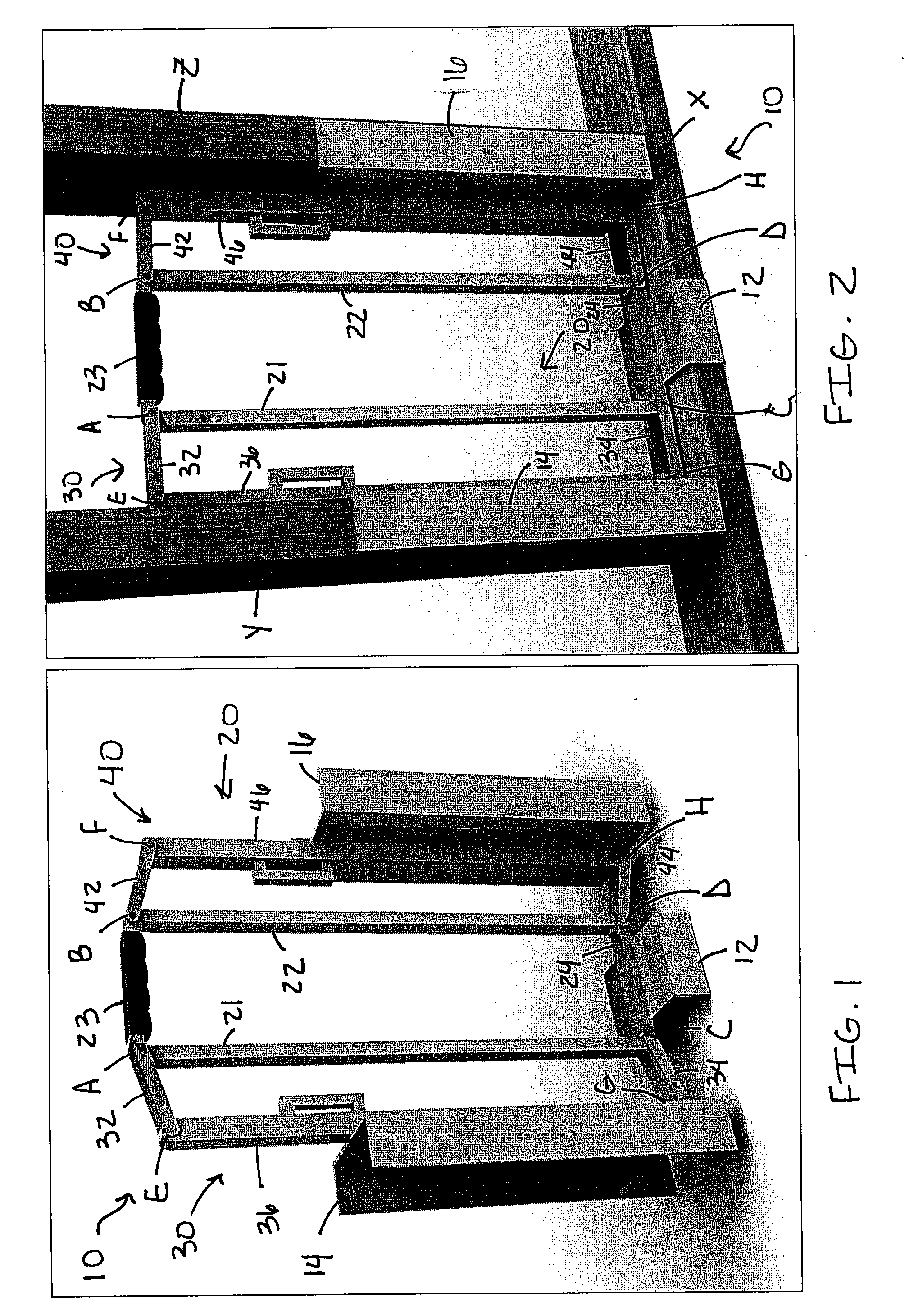

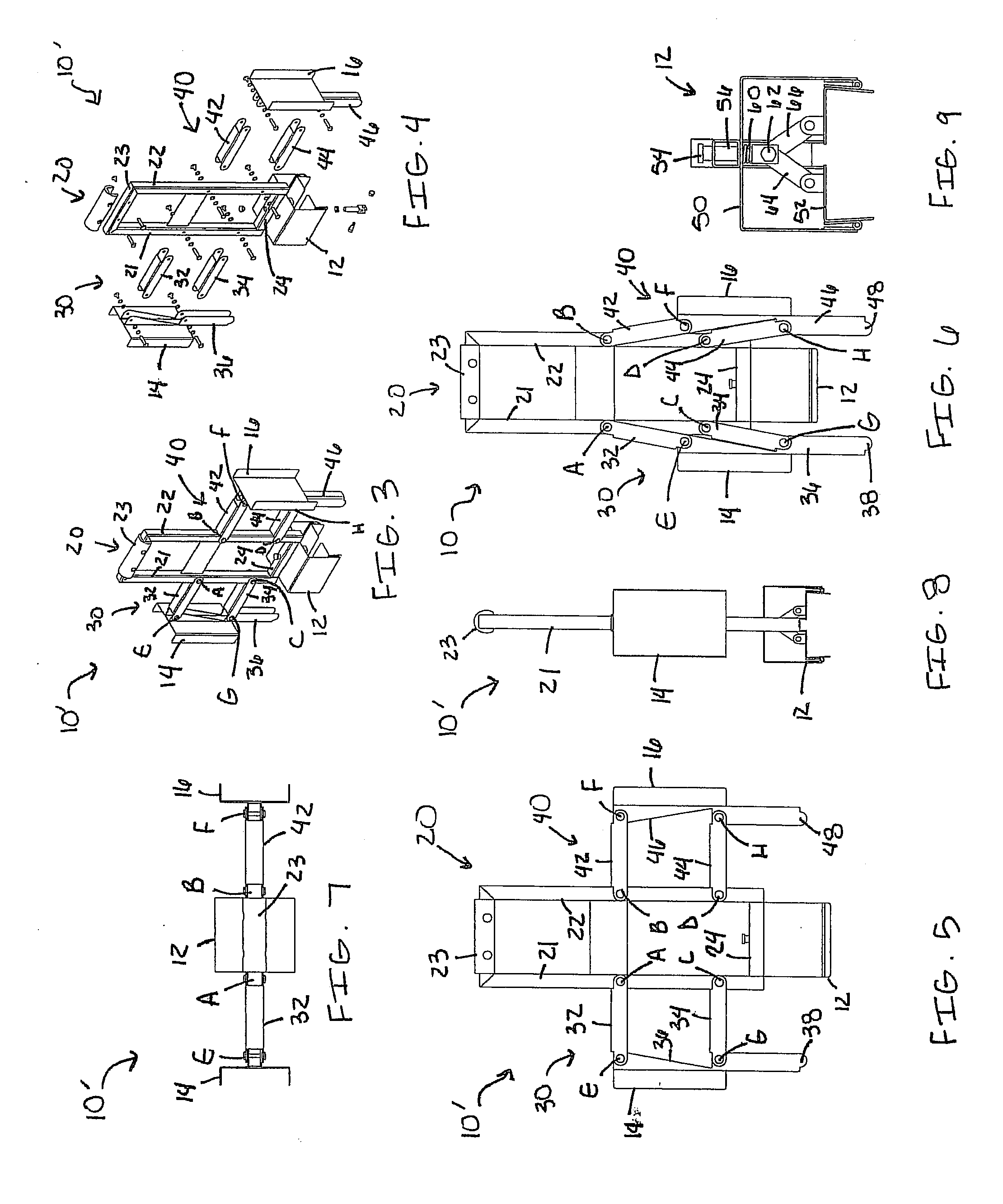

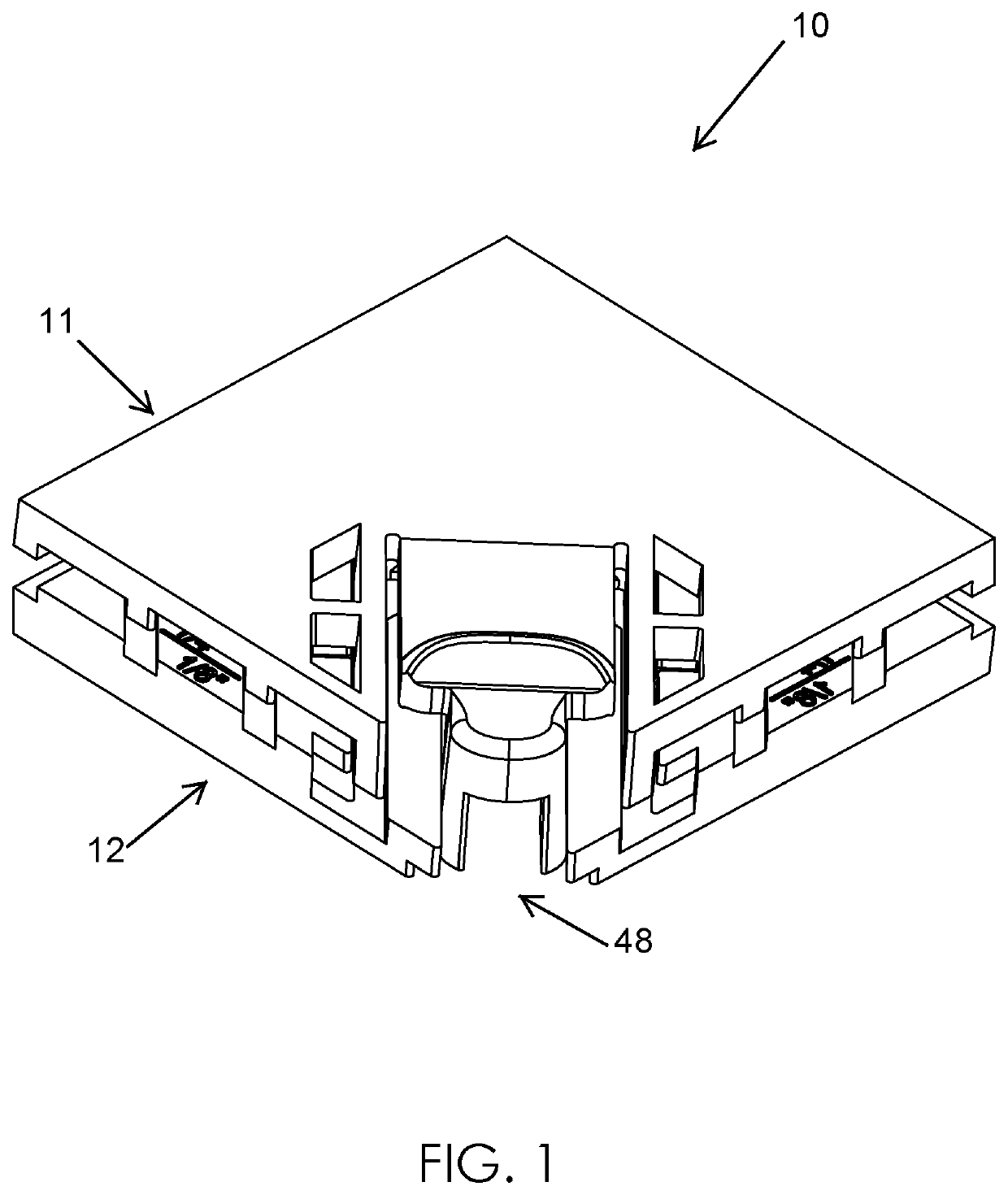

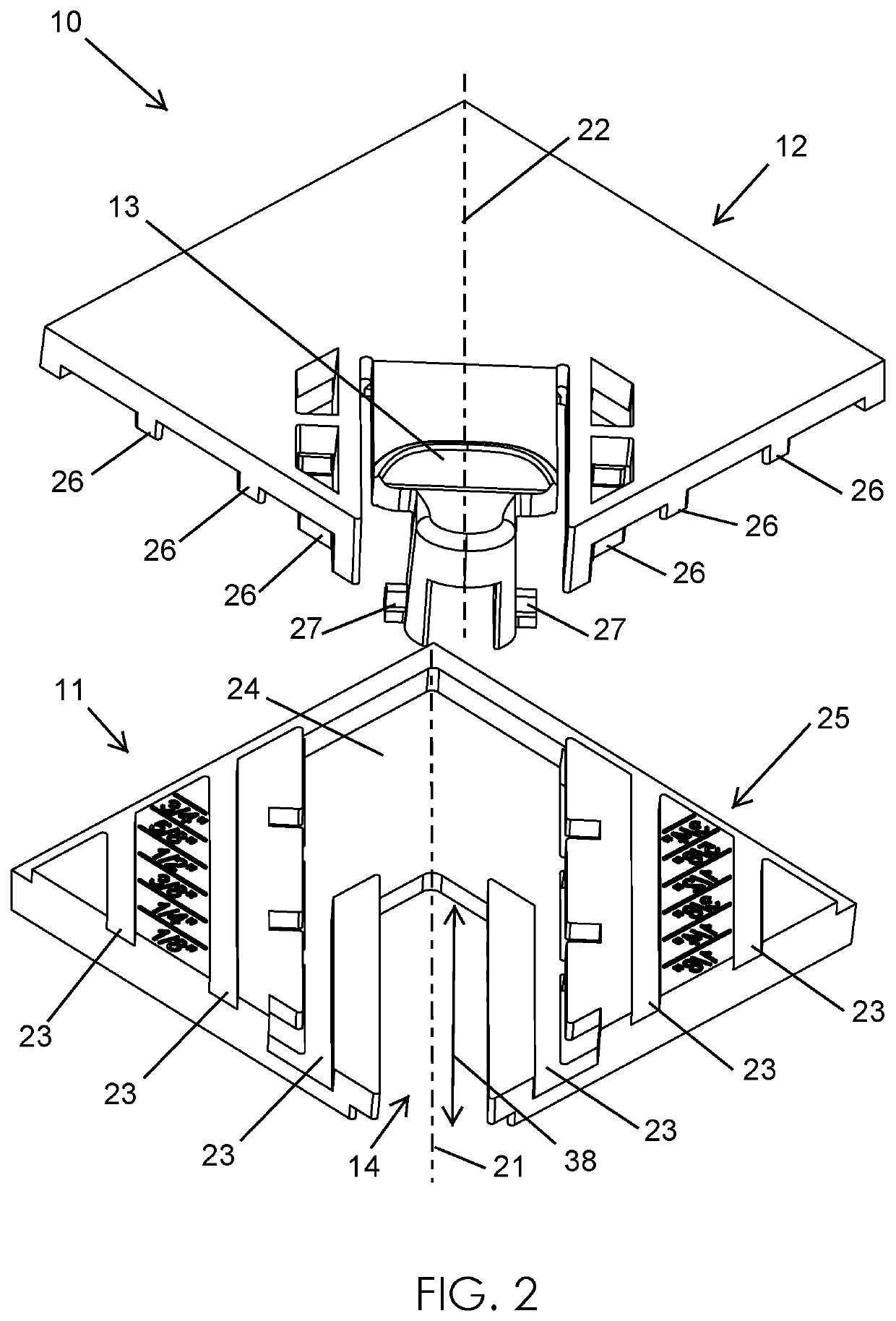

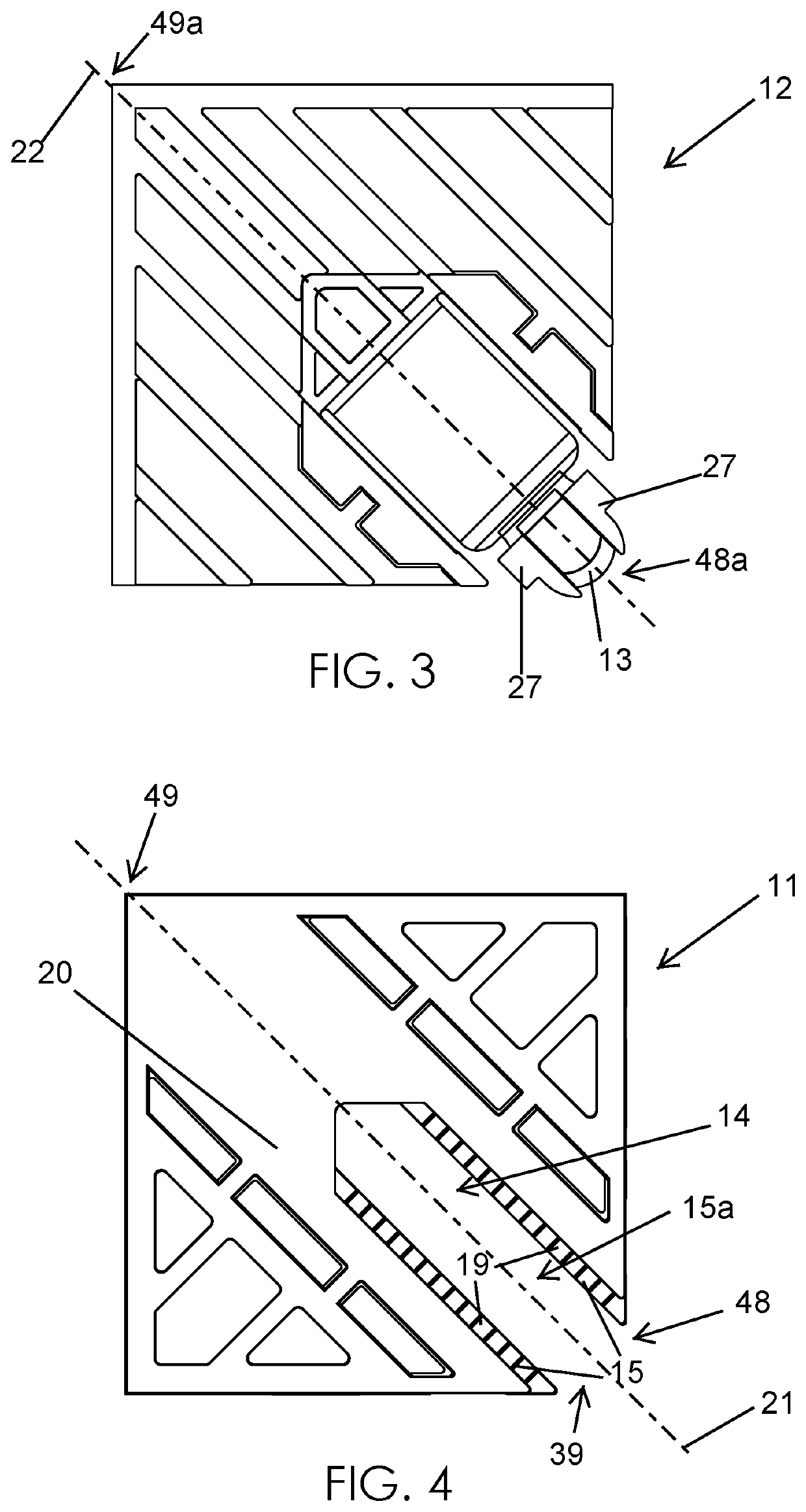

Method and system of framing components and hangers used in a structural interface

A system and method used in residential and commercial construction of floors, ceilings and roofs, where a beam and hanger together support a joist / rafter to which sheathing is applied. Hanger design features include bendable stiffeners that provide pinching structural support for opposing sides of an engineered wood I-joist web after the joist / rafter is seated into the bridge of the hanger, providing a superior structural interface connection, less material cost, and no contact between the hanger and sheathing which reduces unwanted noise in finished construction. Additional strengthening of the structural / load-bearing interface between the joist / rafter and beam may include selected horizontally-extending dato, groove, cut, or other detail formed in the support beams during their manufacture / milling and rearwardly-extending protections on the hanger configured to engage the detail.

Owner:ROBELL GLENN

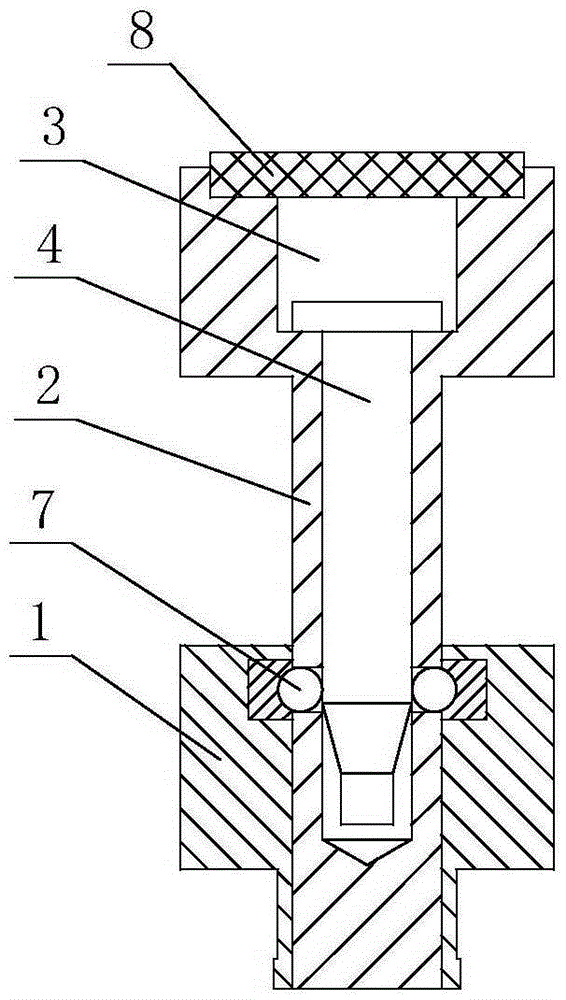

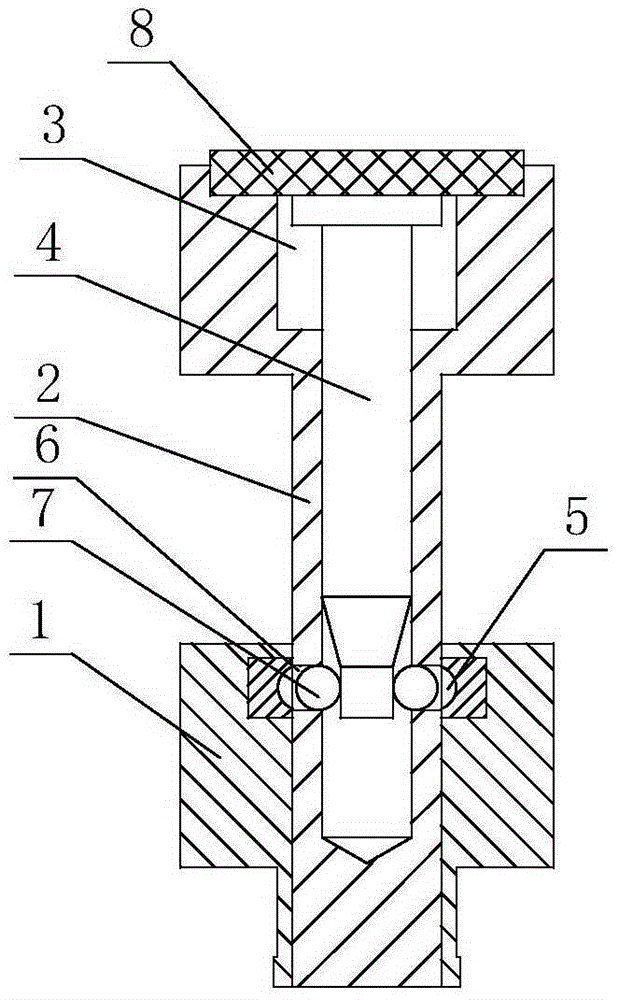

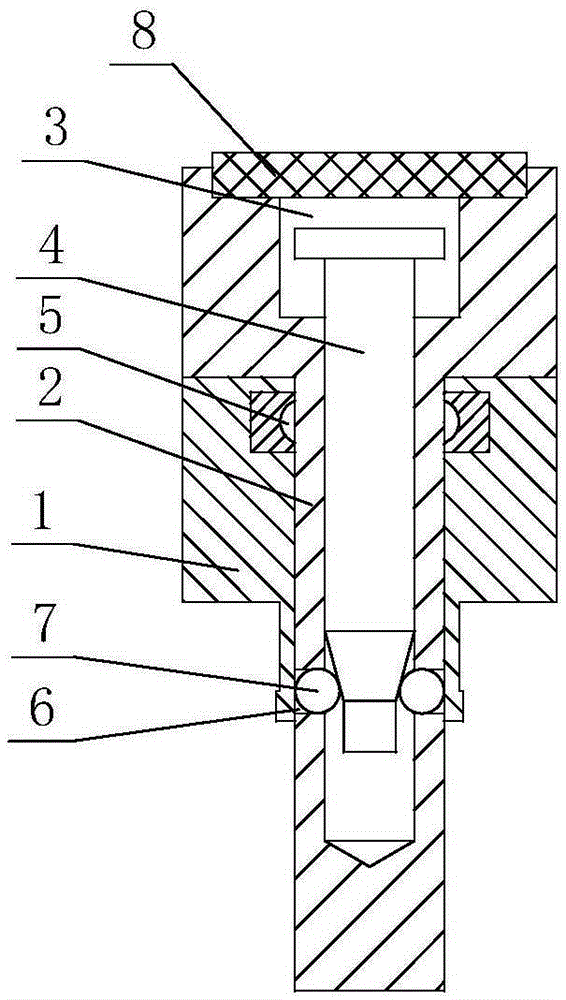

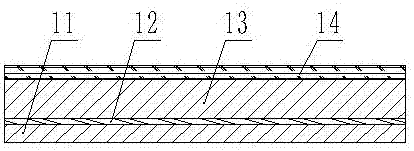

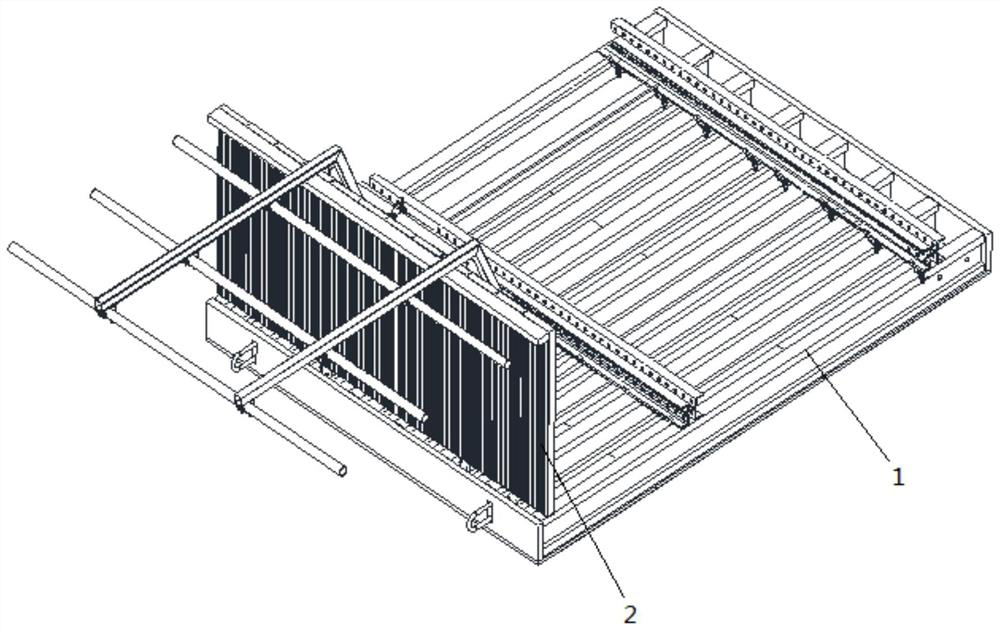

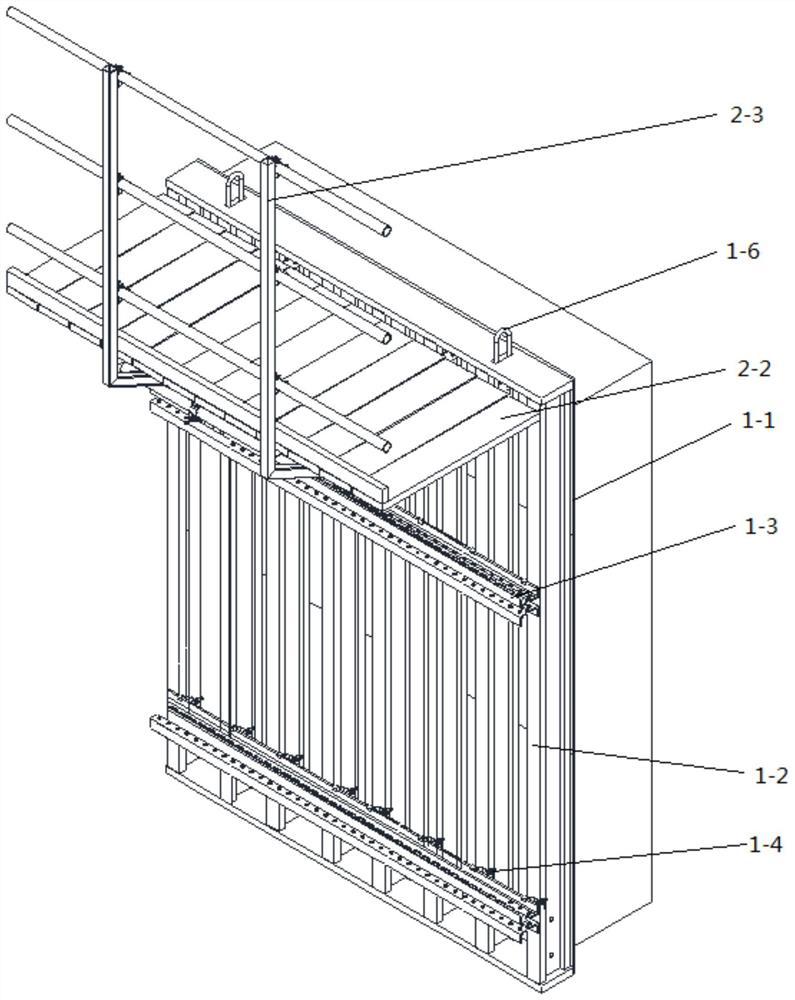

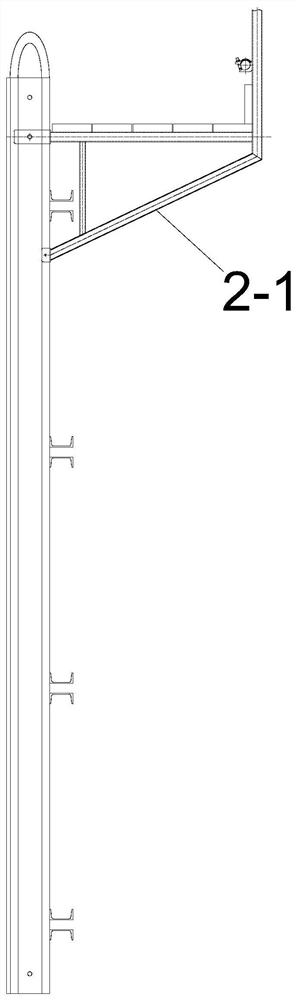

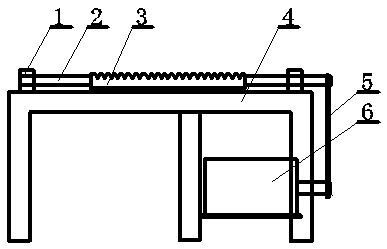

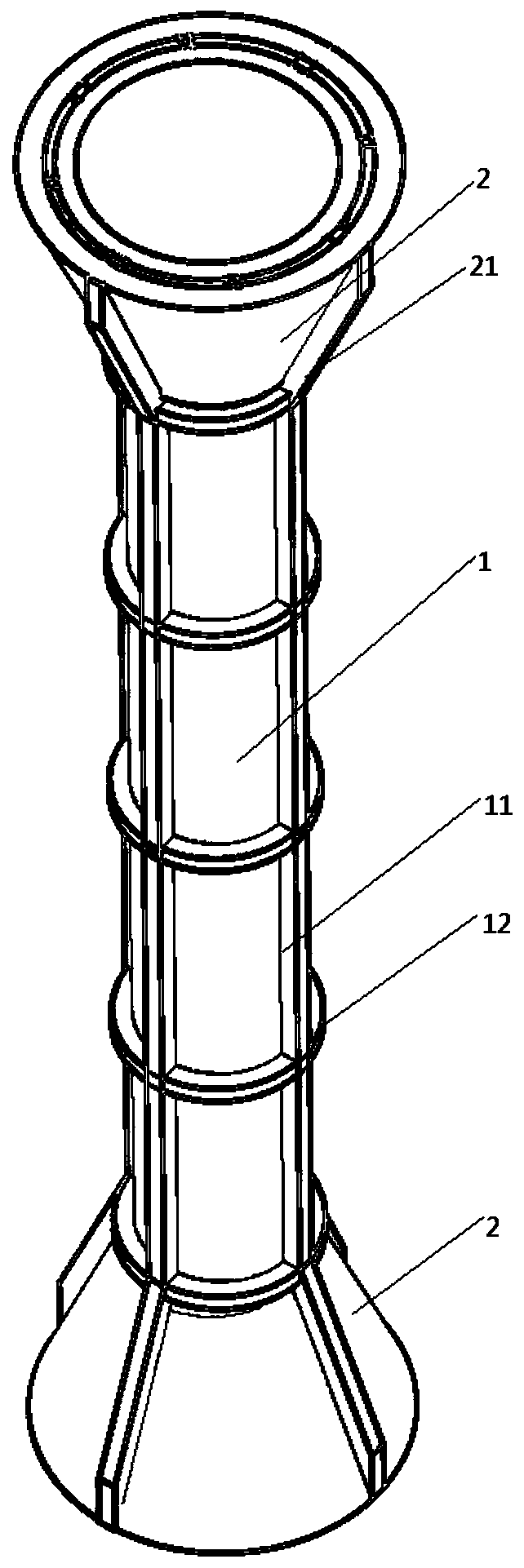

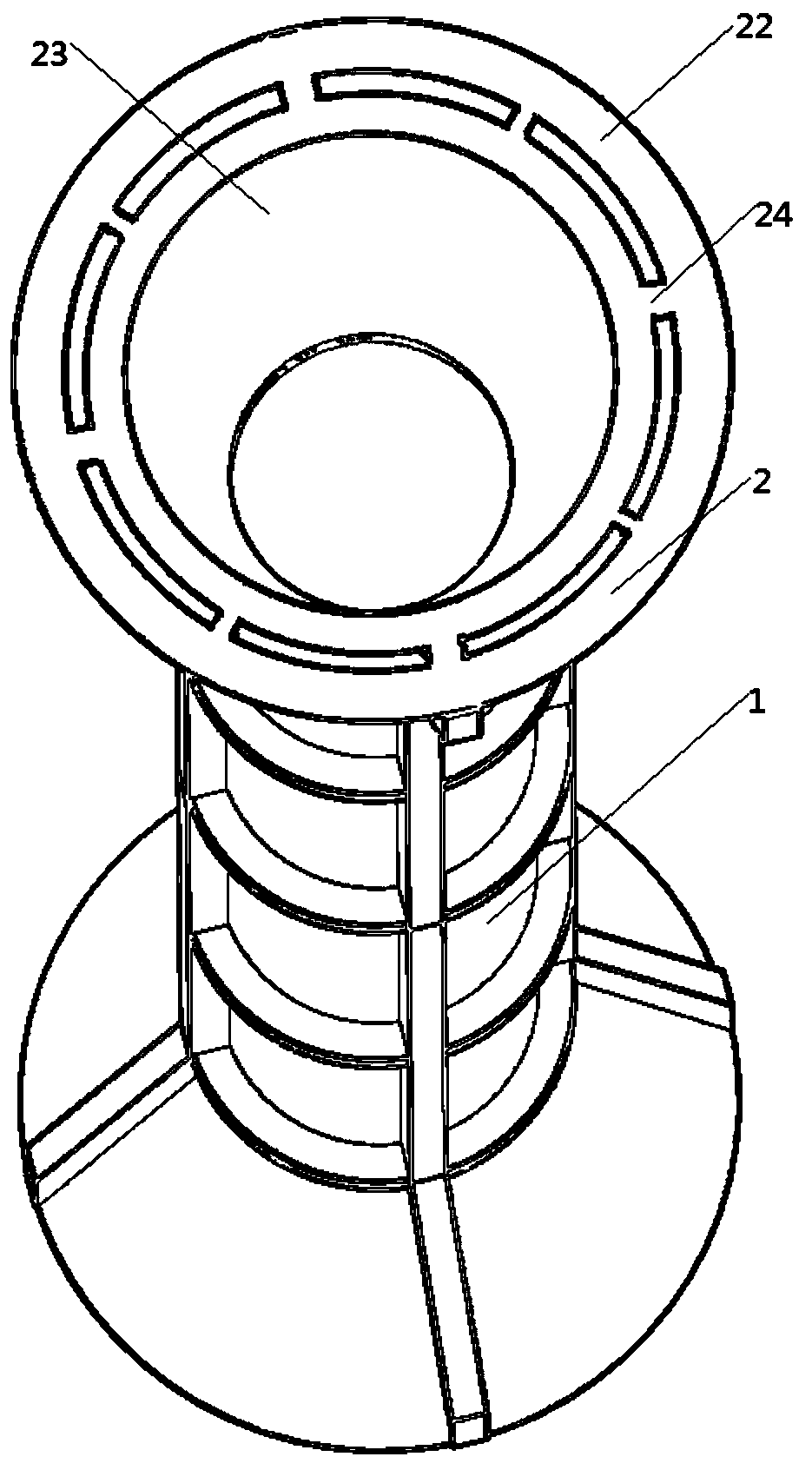

Workbench lifting cushion block of three-dimensional (3D) laminating machine for carpenters

ActiveCN105235347AReasonable structural designReduce labor intensityLaminationLamination apparatusSteel ballEngineering

The invention discloses a workbench lifting cushion block of a three-dimensional (3D) laminating machine for carpenters, which comprises a base, wherein a vertical portion of a top rod with a T-shaped cross section is movably inserted into the base, a cavity is arranged in the top rod along the length direction of the vertical portion, a moving shaft which can up and down lift along the inner wall of the cavity under the action of magnetic force is arranged in the cavity, the bottom portion of the moving shaft is of a funnel shape, a plurality of arc-shaped grooves are arranged on the inner wall of the base along the circumferential direction, steel ball mounting holes are respectively arranged on the vertical portion of the top rod corresponding to the positions of each arc-shaped grooves, and steel balls are respectively arranged in each steel ball mounting holes. A plurality of cushion blocks which can up and down lift under the action of magnetic force are uniformly arranged on a workbench of a 3D laminating machine, then plates to be laminated are placed on the lifting cushion blocks, and enable the adjacent cushion blocks which are arranged on the periphery of the plates to be laminated to sink through the magnetic force when working, thereby enabling four side surfaces of the plates to be laminated to hang in the air, replacing spliced base plates ago, reducing labor strength, and greatly improving work efficiency.

Owner:济南展鸿图机械设备有限公司

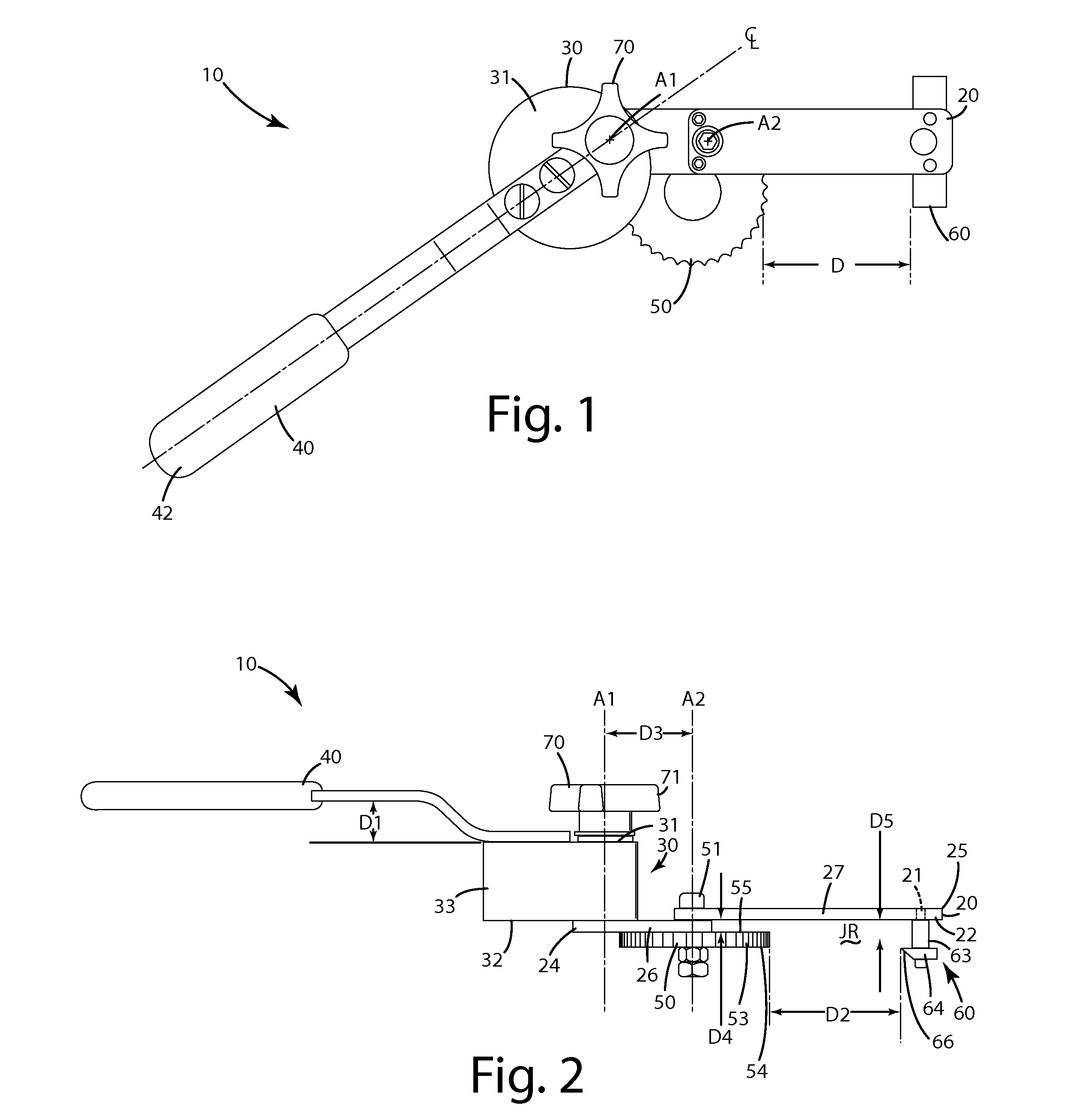

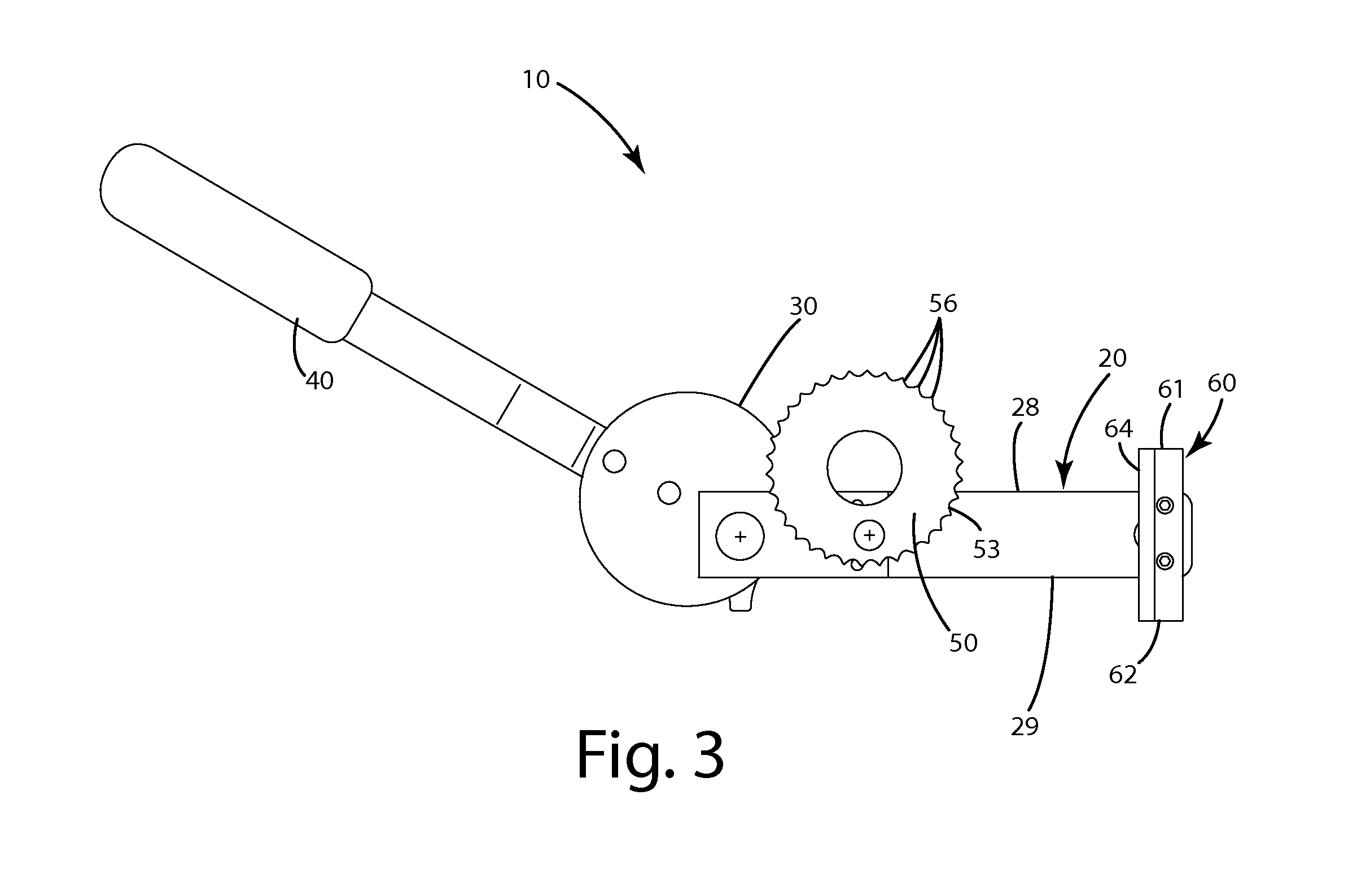

Adjustable carpenters square and method of use

An adjustable carpenters square has a handle and first and second blades extending from the handle in a substantially perpendicular relationship. The first blade is fixed in the handle and the second blade is pivotally mounted on the handle to enable it to be adjustable with respect to the fixed first blade to ensure that it is at a true 90° to the first blade. A cam mechanism is mounted in the handle and engageable with the second blade to pivot the second blade with respect to the first blade. The cam mechanism includes a one-piece cam having a cylindrical base and a cam portion offset therefrom. This cam mechanism enables the method of the present invention of adjusting the perpendicular relationship between the two blades to be achieved with a high degree of accuracy.

Owner:WOODPECKERS LLC

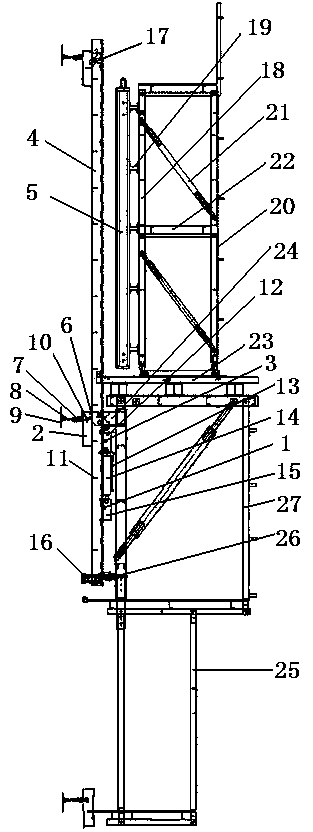

Coastal environment high pier hydraulic self-creeping formwork construction method

PendingCN111119060AEasy to operateImprove securityBridge structural detailsBridge erection/assemblyPurlinShaped beam

The invention discloses a coastal environment high pier hydraulic self-creeping formwork construction method. The method comprises the steps of tower column starting section construction, tower columnfirst section construction, hydraulic creeping formwork installation, tower column second section construction, tower column remaining section construction and creeping formwork removal, the hydraulic creeping formwork comprises an embedded part mechanism embedded in a high pier wall, and a frame body mechanism comprises a lower hanging bracket and a bearing frame; the formwork installation comprises a formwork consisting of a panel, a woodworking I-shaped beam and a steel enclosing purlin, a movable template bracket and a backward moving device; a hydraulic power mechanism comprises an upperreversing box, a lower reversing box, a hydraulic pump and a hydraulic oil cylinder which are connected with the guide rail in a sliding manner; the guide rail is composed of two steel channels and guide rail stair stops, and the upper reversing pawl of the upper reversing box and the lower reversing pawl of the lower reversing box are arranged between the guide rail stair stops. The constructionmethod is convenient to operate, high in safety and convenient to construct, working hours and construction sites are saved, and formwork bumping damage is reduced; and the formwork is recycled, theworkload of hoisting machinery is greatly reduced, and the construction process is stable, synchronous and safe.

Owner:YANJIAN GRP CO LTD +1

Multifunctional single side tenon-making machine for carpenter

InactiveCN1803417AReasonable layoutEasy to useWood mortising machinesWood slotting machinesEngineeringMachine tool

The invention discloses a multifunctional carpentry single-sided tenon-making machine, which comprises the following parts: machine body, working bench and clamp device on the machine body board, wherein the end saw, tenon knife rack, level knife shaft and vertical knife shaft are assembled on the front and back of machine body.

Owner:何沛佳

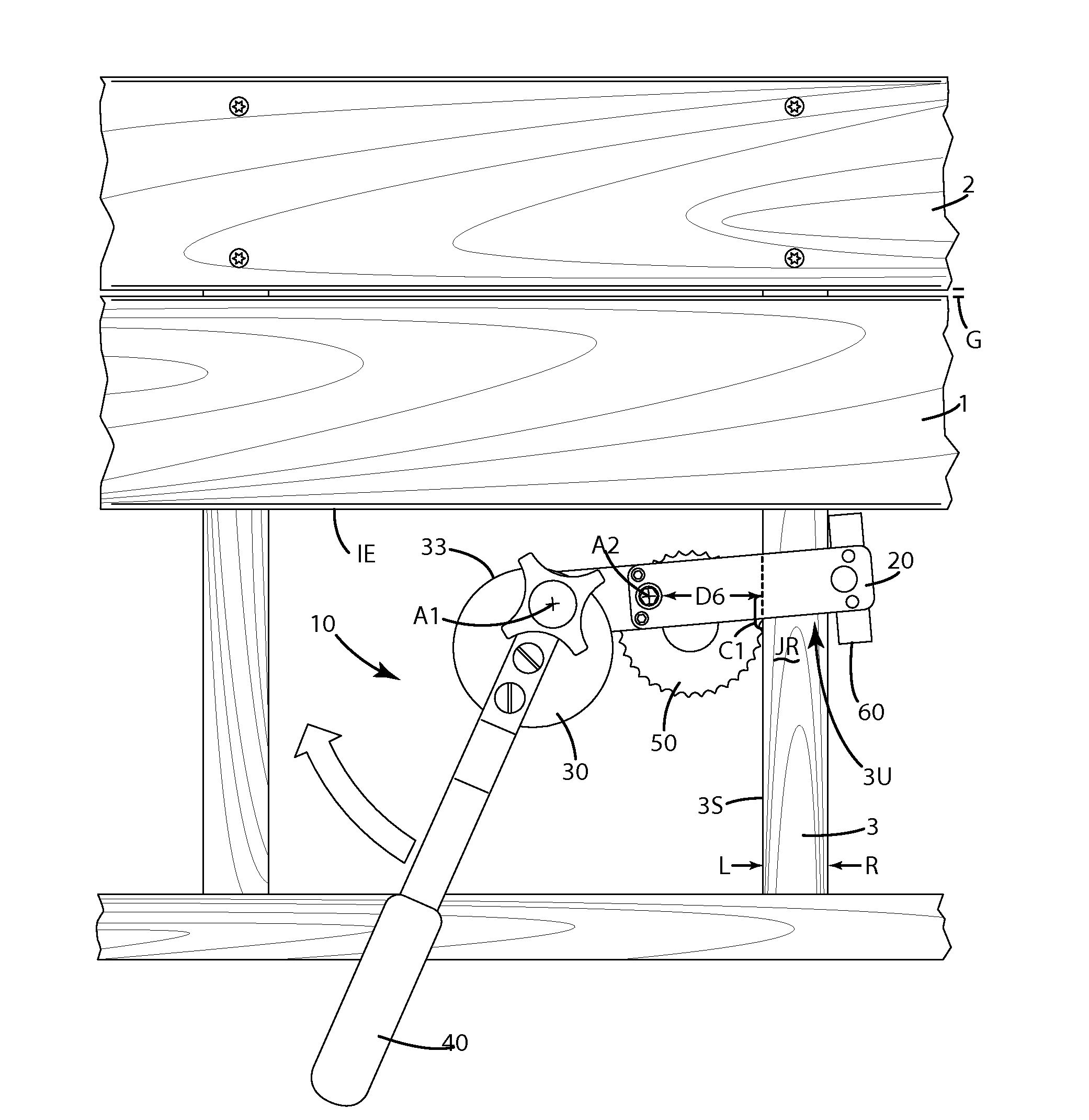

Carpentry tool

ActiveUS20150345156A1Effective clampingEffective gripLifting devicesBuilding constructionsJoistEngineering

A carpentry tool for pushing deck, flooring or other boards toward one another on a joist or underlying substructure. The tool can be operated with one hand, leaving the other hand free for installation of a fastener. The tool can leave an area adjacent the joist and board exposed so that a fastener can be installed in the board and joist in that area. The tool can include a pusher cam rotatably joined with a base, and fixedly joined with a lever. A joist cam and joist blade can be joined with the base, disposed opposite one another across a variable width joist recess. The pusher cam and joist cam can be mechanically coupled to the base so that rotation of the pusher cam urges rotation of the joist cam, thereby causing the joist cam to dynamically grip the joist and prevent the tool from rocking and / or moving away from the pushed board.

Owner:NAT NAIL

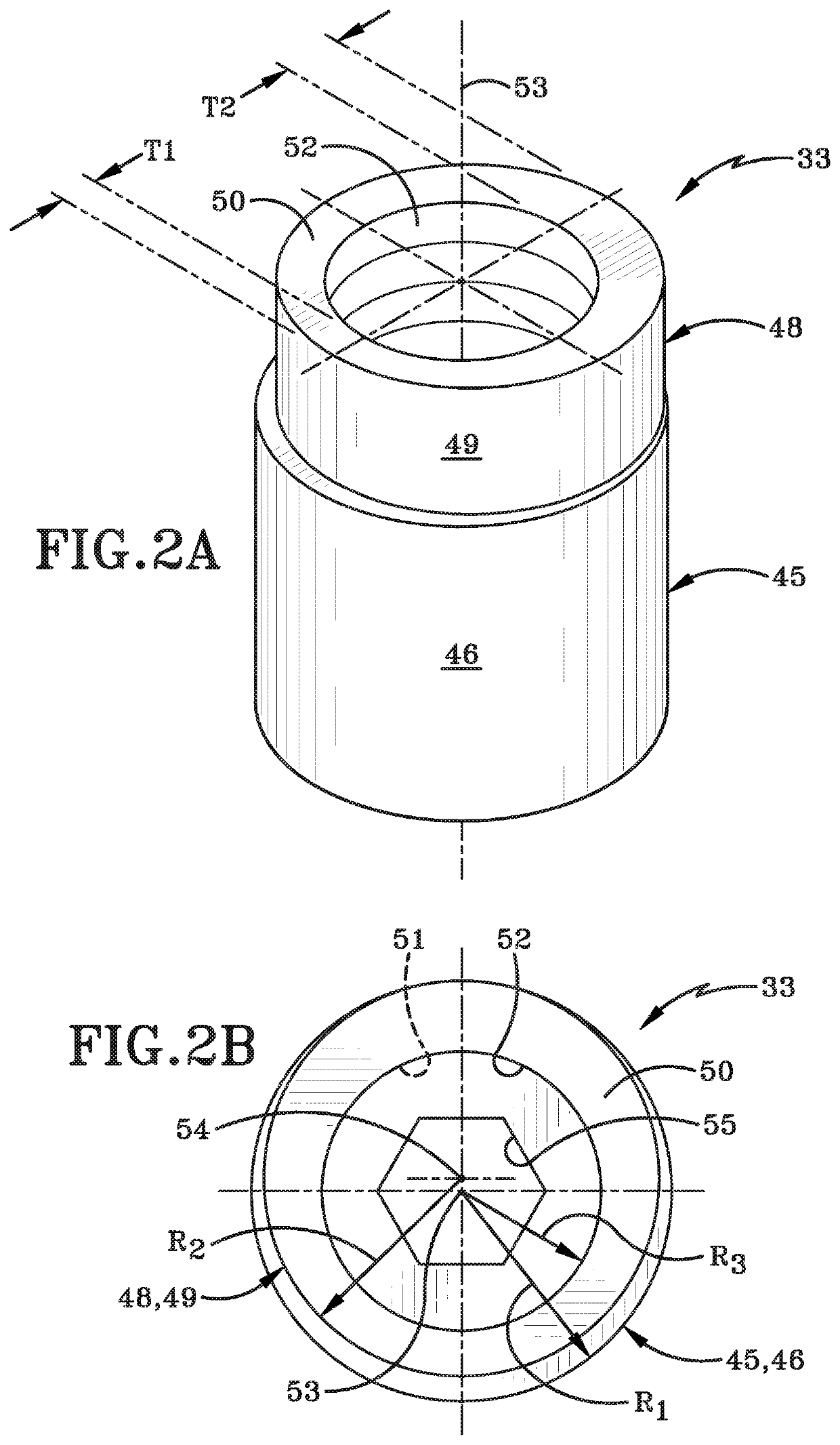

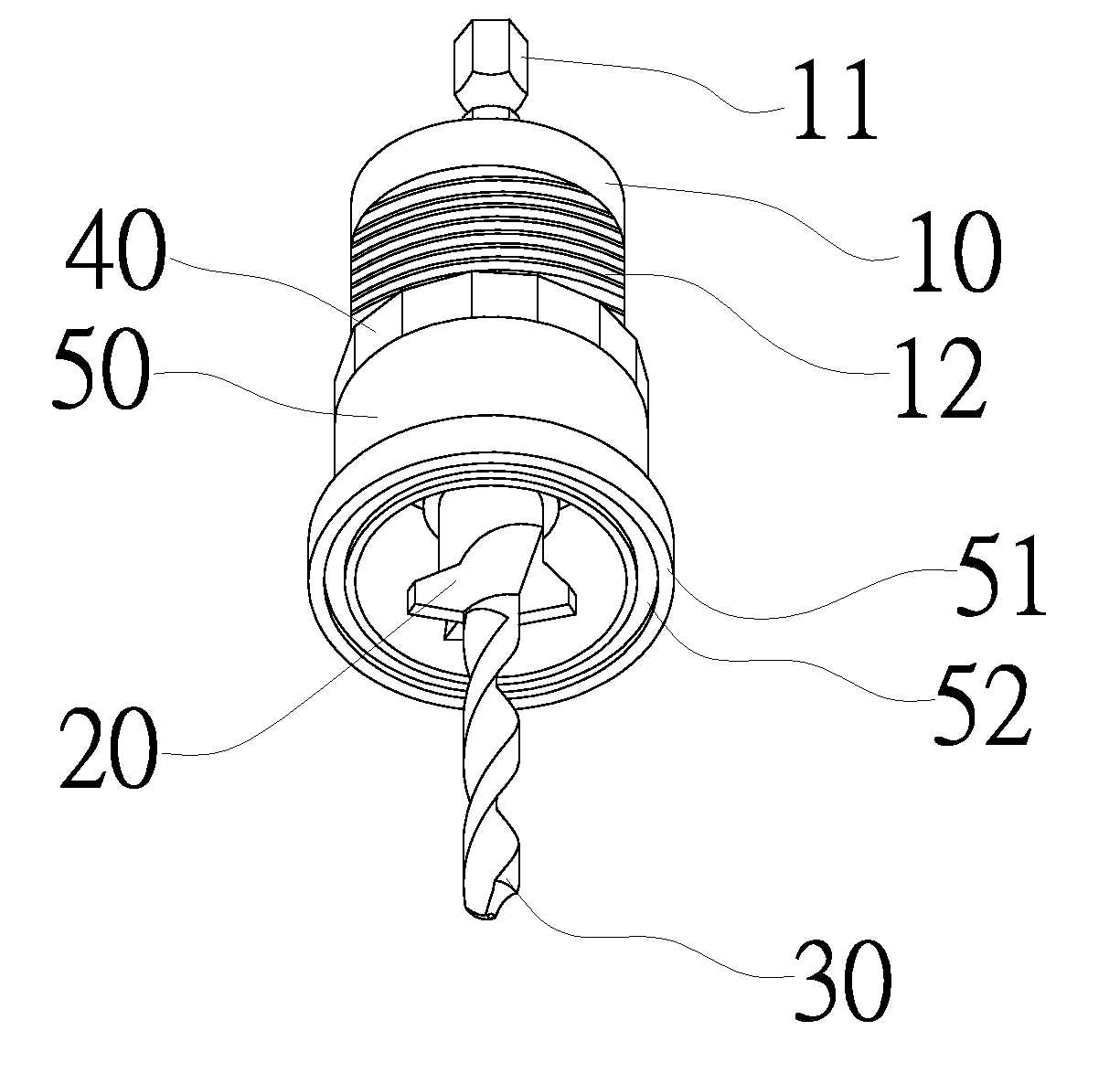

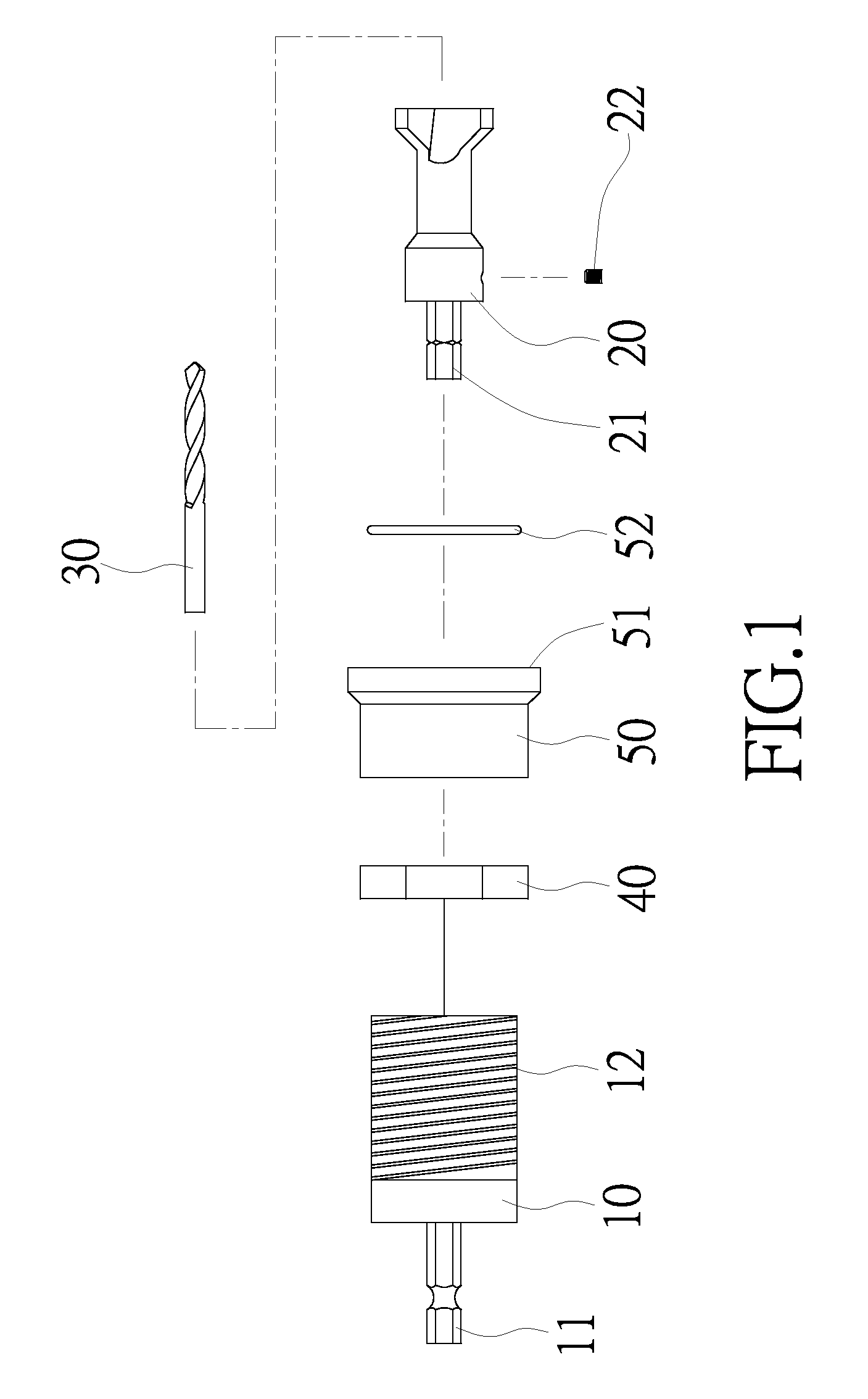

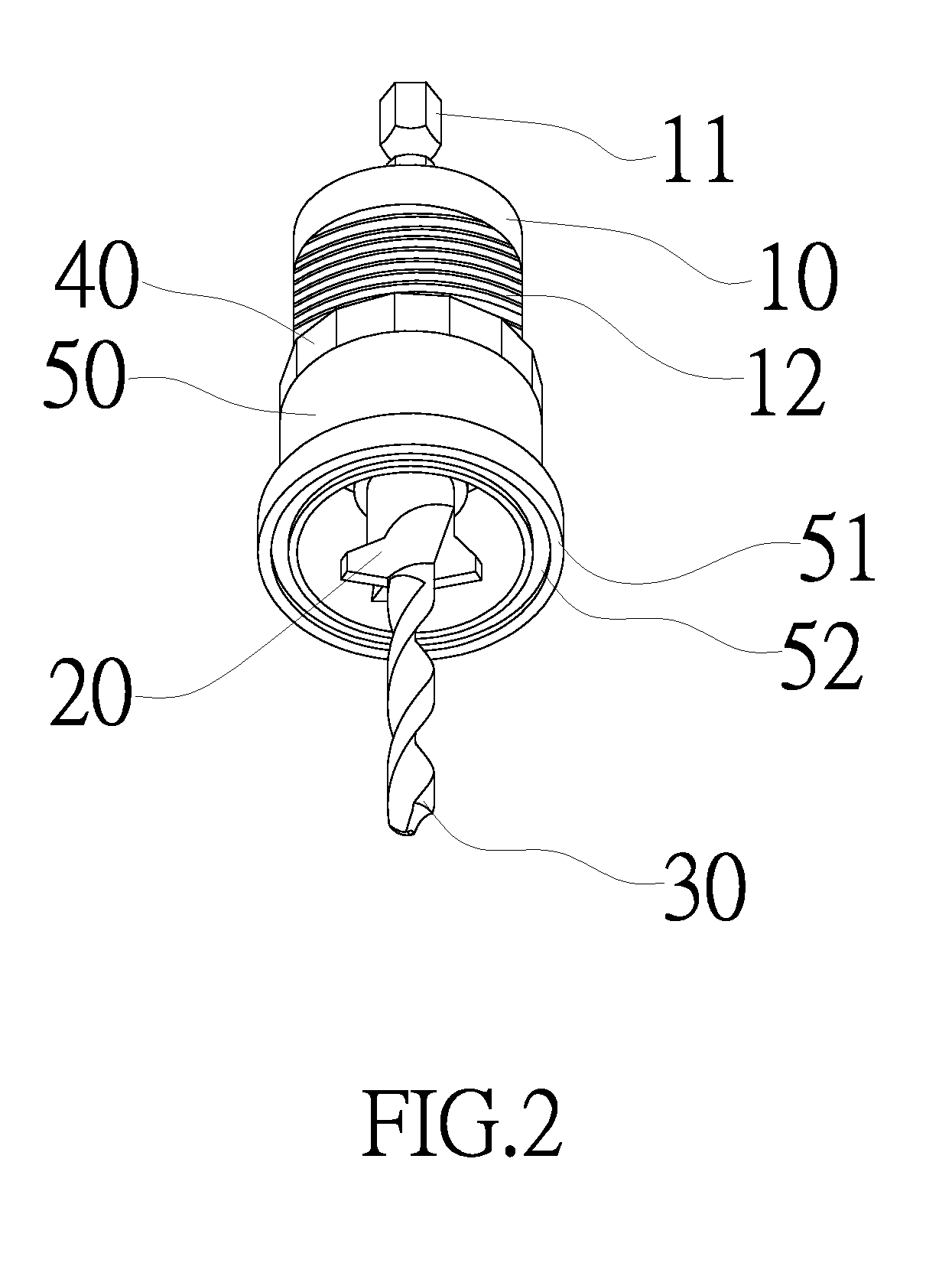

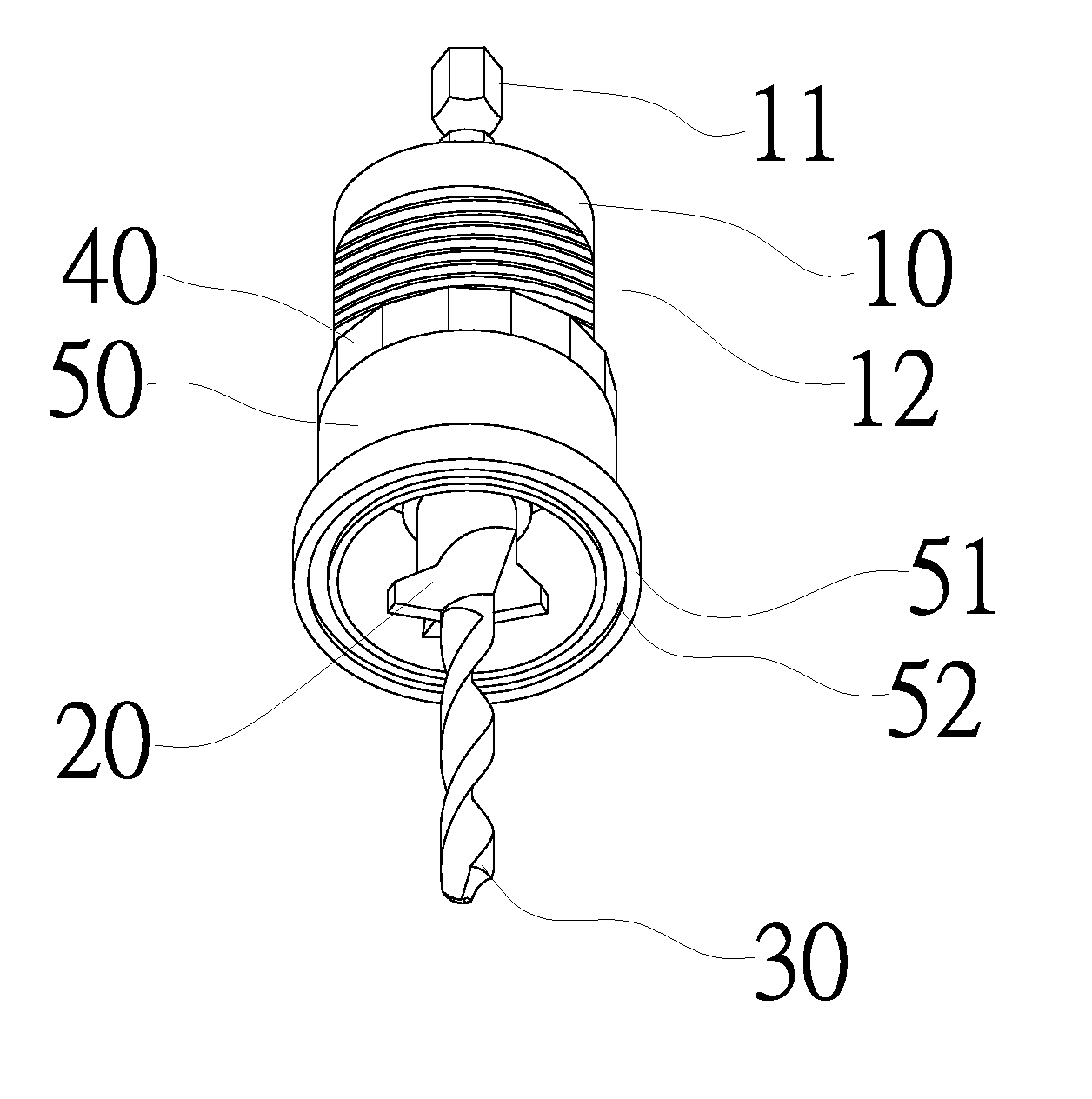

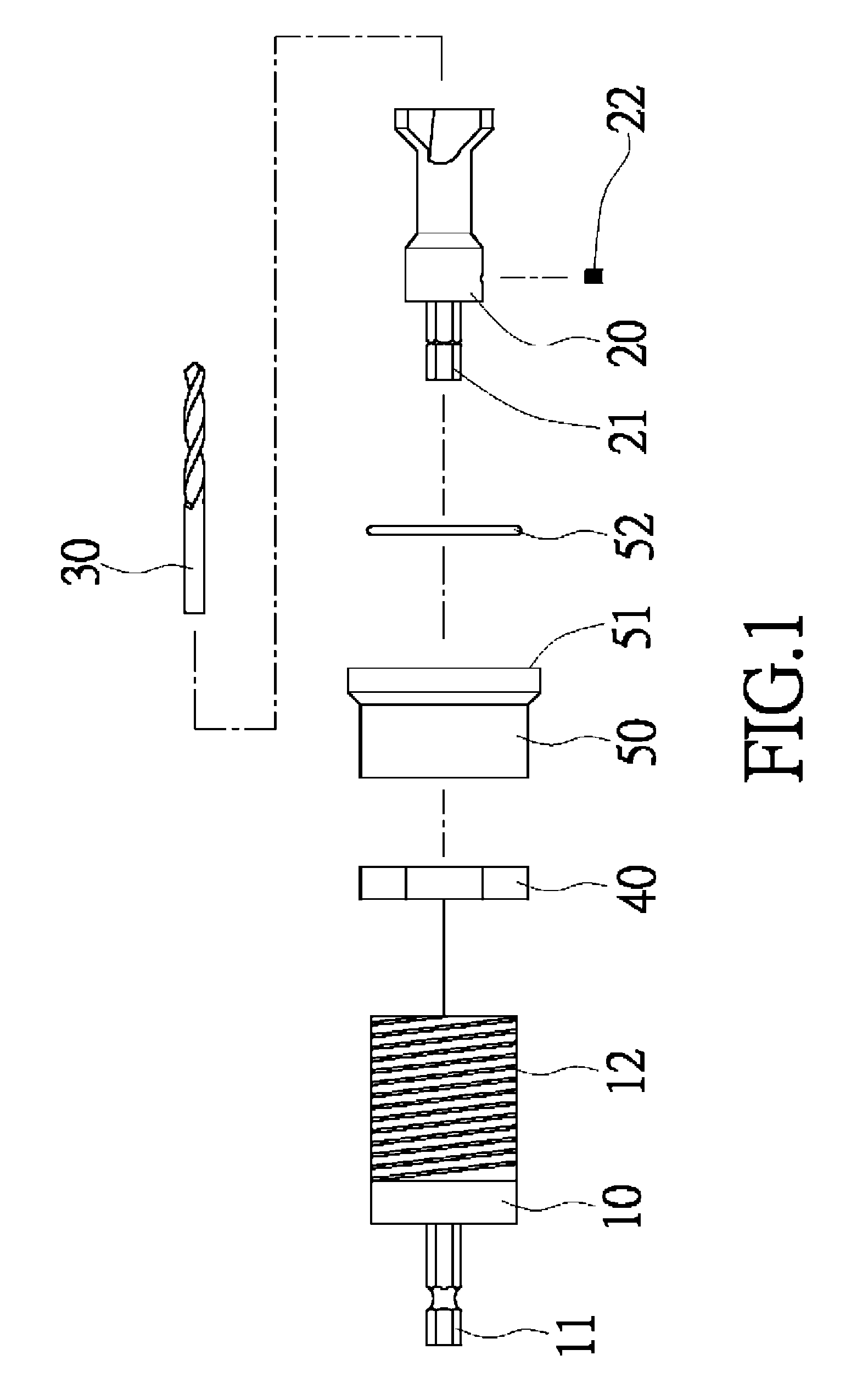

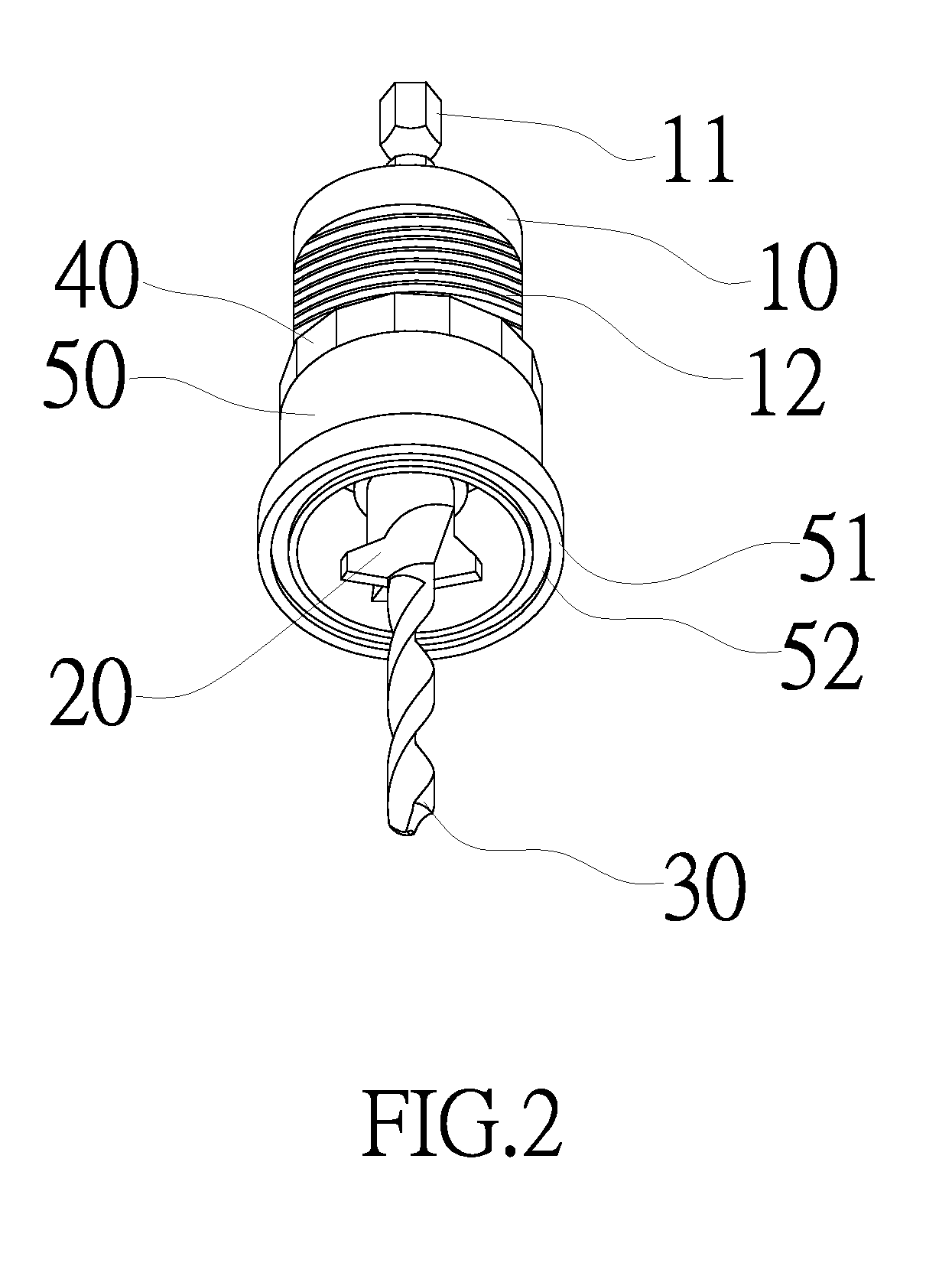

Drilling bit with the depth-limiting and angle-leading function for the carpenter's work

InactiveUS20110110740A1Enhancing real valueImprove operational convenienceThread cutting toolsDrilling/boring measurement devicesDrive shaftEngineering

Owner:LIU TSAI FA

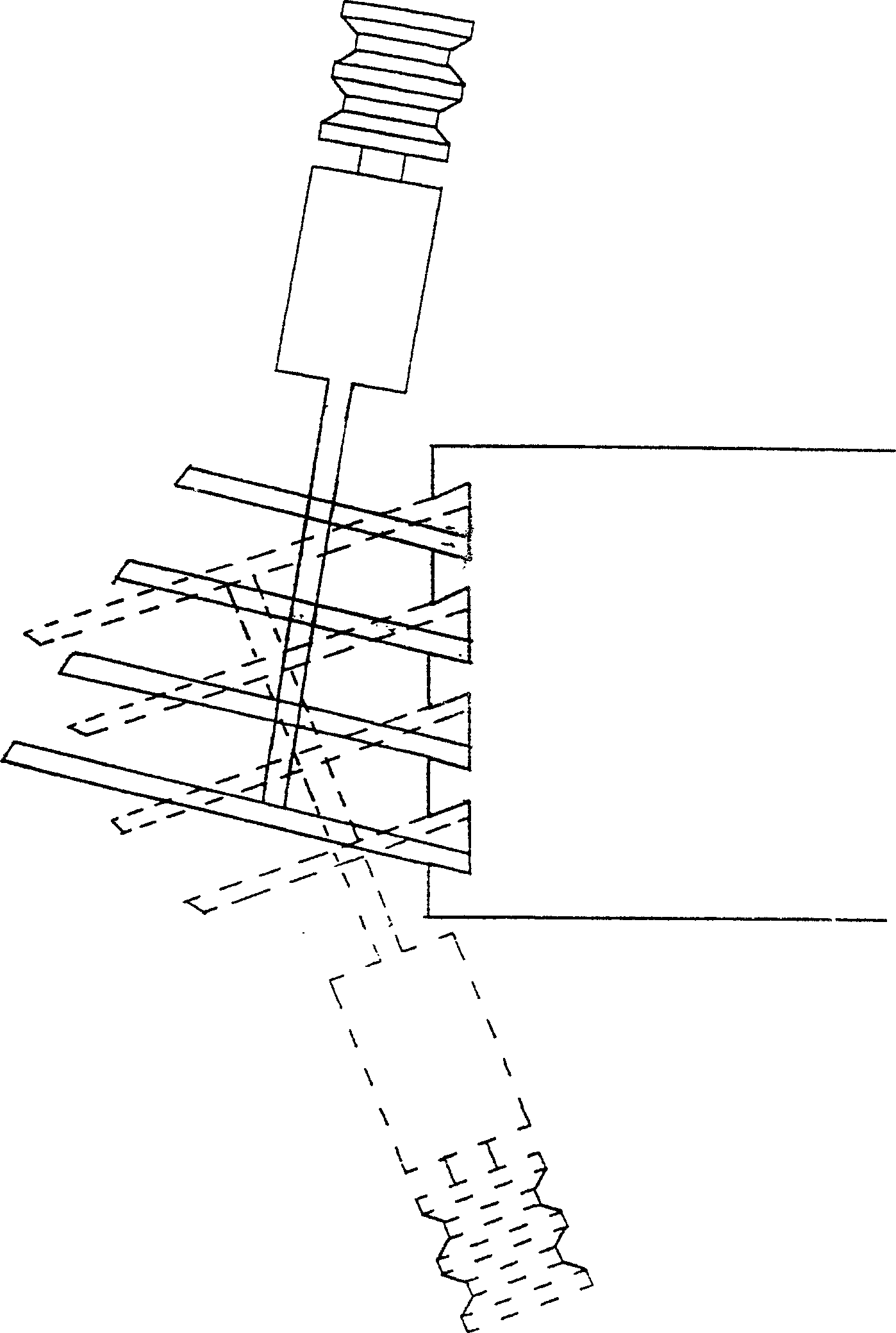

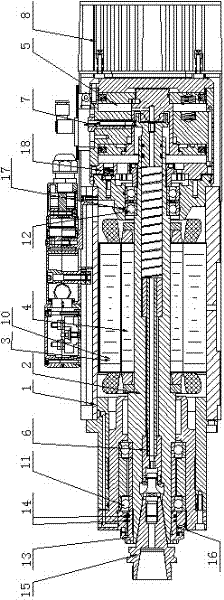

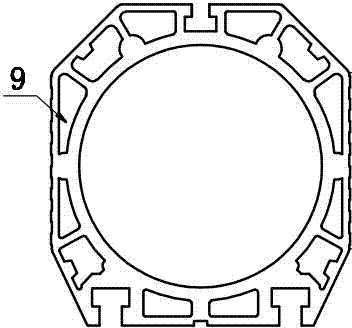

Fan air-cooled automatic tool change electric spindle used for carpentry carving and milling

InactiveCN102394529AExtended service lifeAvoid stickingCooling/ventillation arrangementSupports/enclosures/casingsEngineeringFan blade

The invention relates to the electric spindle technology field, and especially relating to a fan air-cooled automatic tool change electric spindle used for carpentry carving and milling. The fan air-cooled automatic tool change electric spindle comprises a shell which is provided with a rotor shaft, a stator part and a rotor part, and a front bearing and a rear bearing which are provided at two ends of the rotor shaft. The shell is a one-body cuboid and has a wind channel. Two ends of the shell are provided with a tool shank and an independent fan. The independent fan has seven fan blades. The rotor shaft is provided with an automatic tool changer, a cylinder and a detection apparatus of the automatic tool changer. A front end of the shell is provided with a seal cover. According to the invention, a heat radiation effect of the electric spindle is substantially raised, a usage scope of the electric spindle is enlarged, and a service life of the bearing is prolonged.

Owner:常州市翰琪电机有限公司

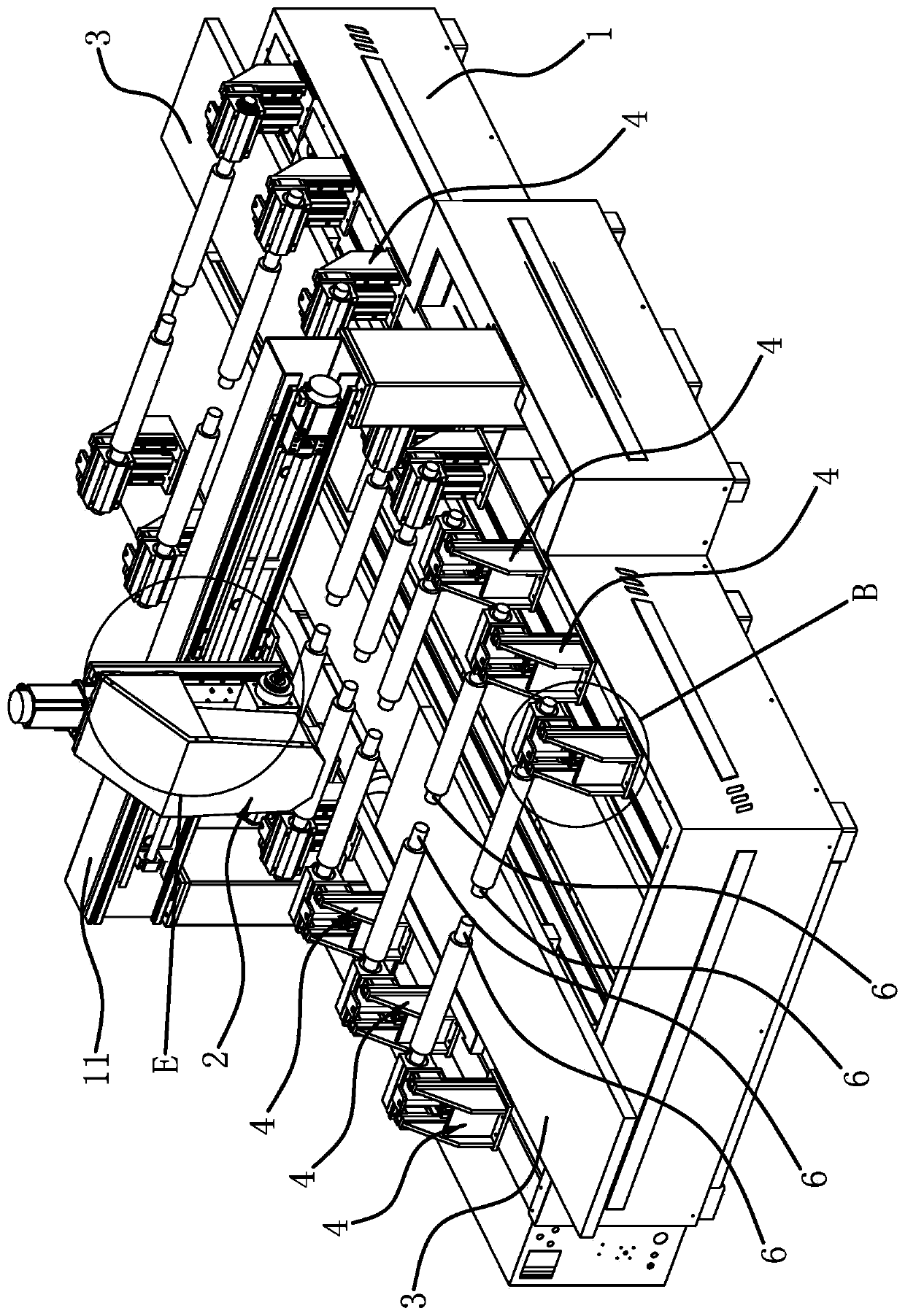

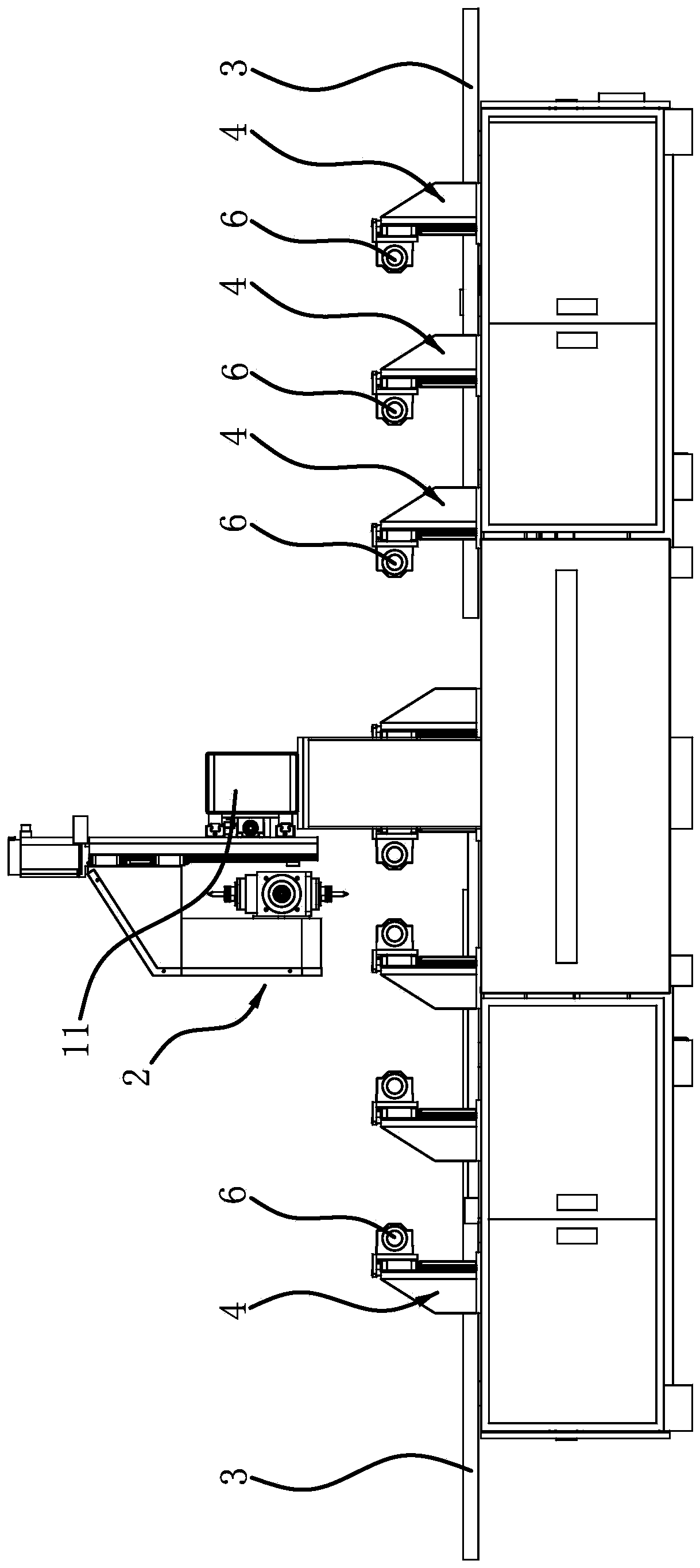

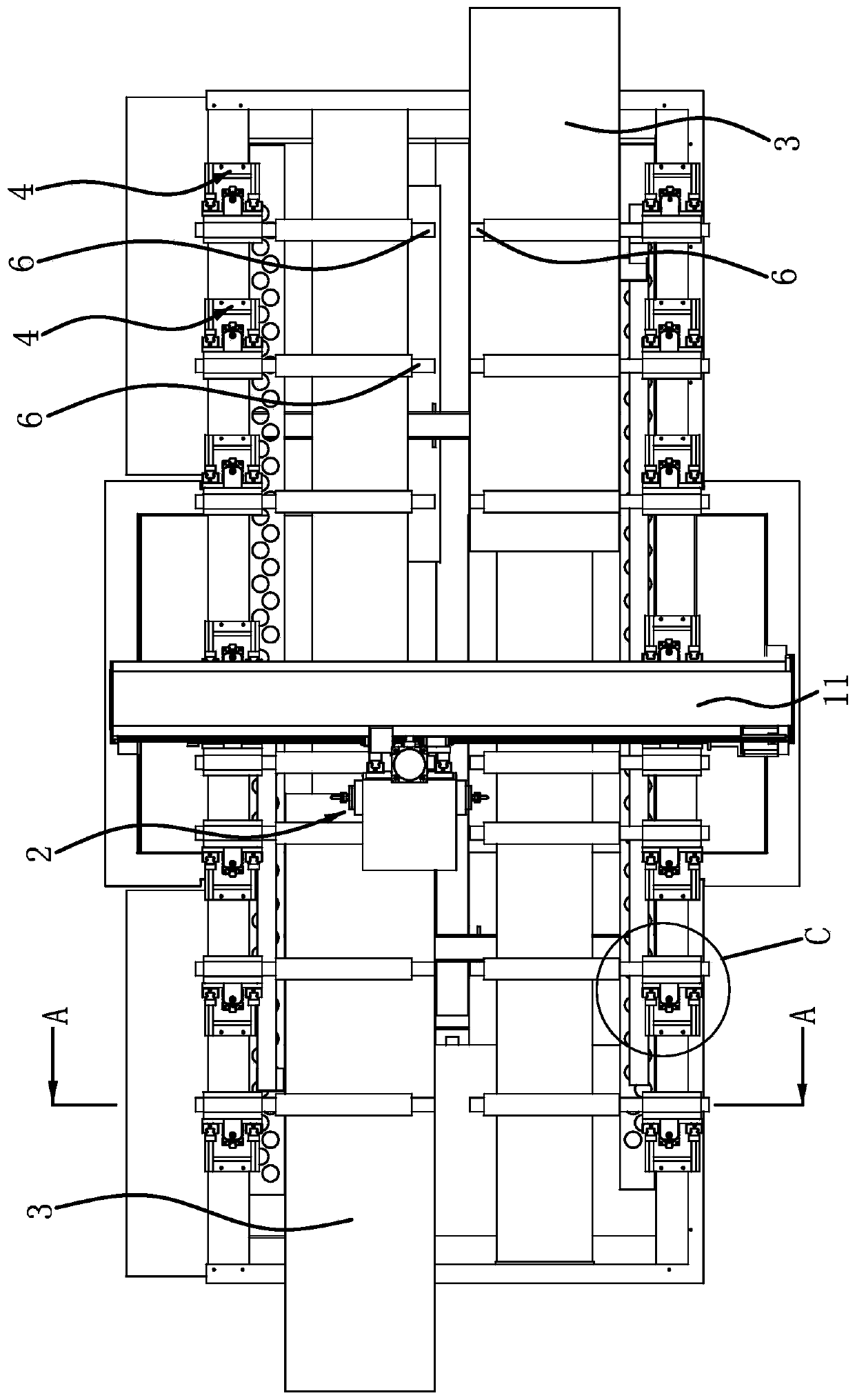

Positioning structure of carpentry machining center

ActiveCN111391038AImprove positional stabilityThere will be no phenomenon of uneven forceMulti-purpose machinesProfiling/shaping machinesMachineCarpentry

The invention provides a positioning structure of a carpentry machining center and belongs to the technical field of machining equipment. The problem that the positioning stability of irregular-shapedworkpieces by an existing carpentry machining center is poor is solved. The carpentry machining center of the positioning structure comprises a machine frame and a transverse beam which is fixed to the machine frame; a machining assembly is disposed on the transverse beam; and a machining platform is slideably disposed on the machine frame in the horizontal direction. The positioning structure comprises a plurality of installing seats which are arranged on the machine frame; positioning pressure rollers are horizontally disposed on the installing seats correspondingly; the plurality of installing seats are arranged in two rows; lifting seats are slideably connected to the installing seats in the vertical direction correspondingly; one ends of the positioning pressure rollers are connectedto the lifting seats, and the other ends of the two rows of positioning pressure rollers face the inner side of the machine frame; when the lifting seats ascend, the other ends of the two rows of positioning pressure rollers can be located above the machining platform; and each installing seat is provided with a driving part. The positioning stability of the irregular-shaped workpieces by the carpentry machining center is higher.

Owner:吴善旺

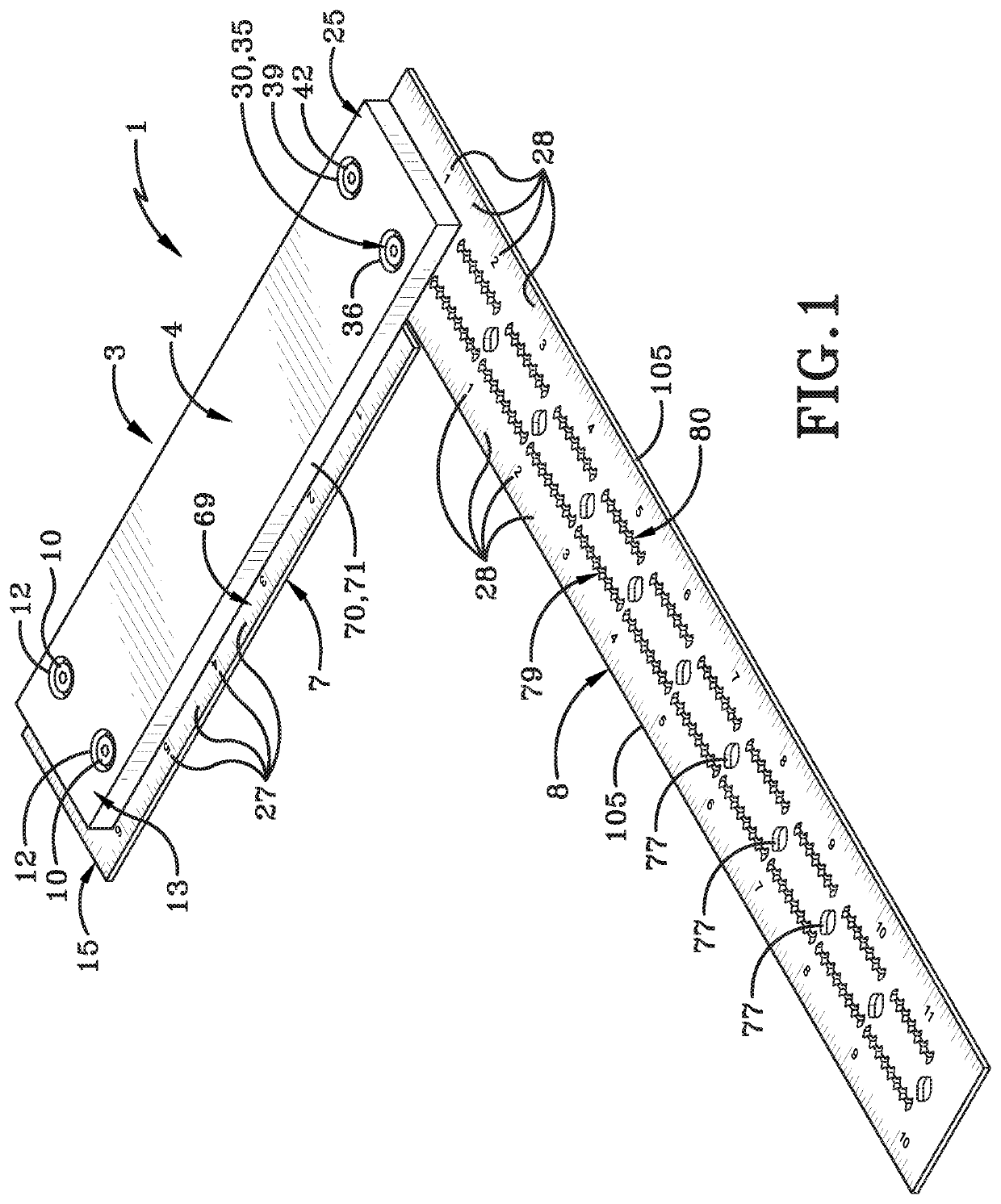

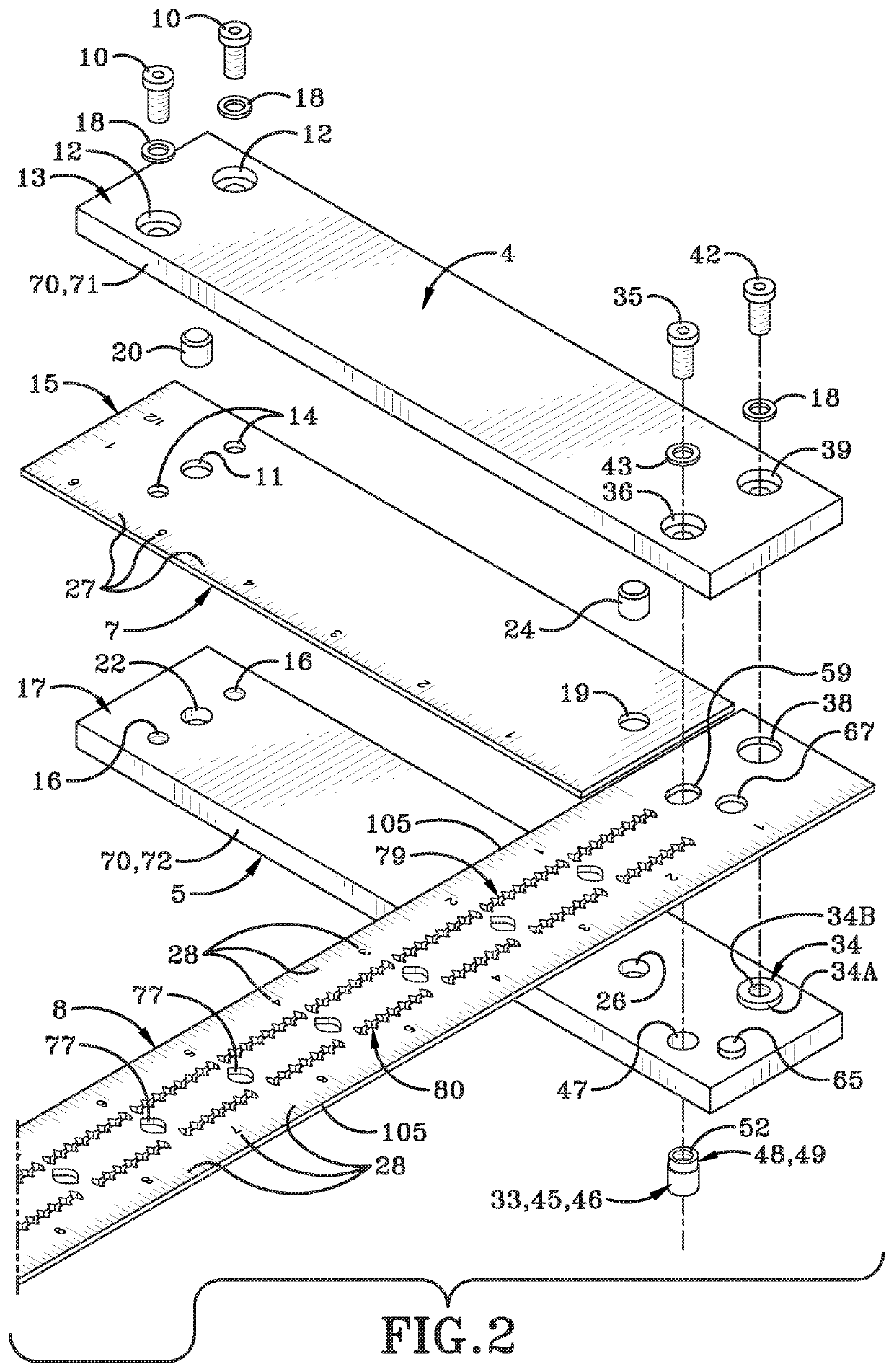

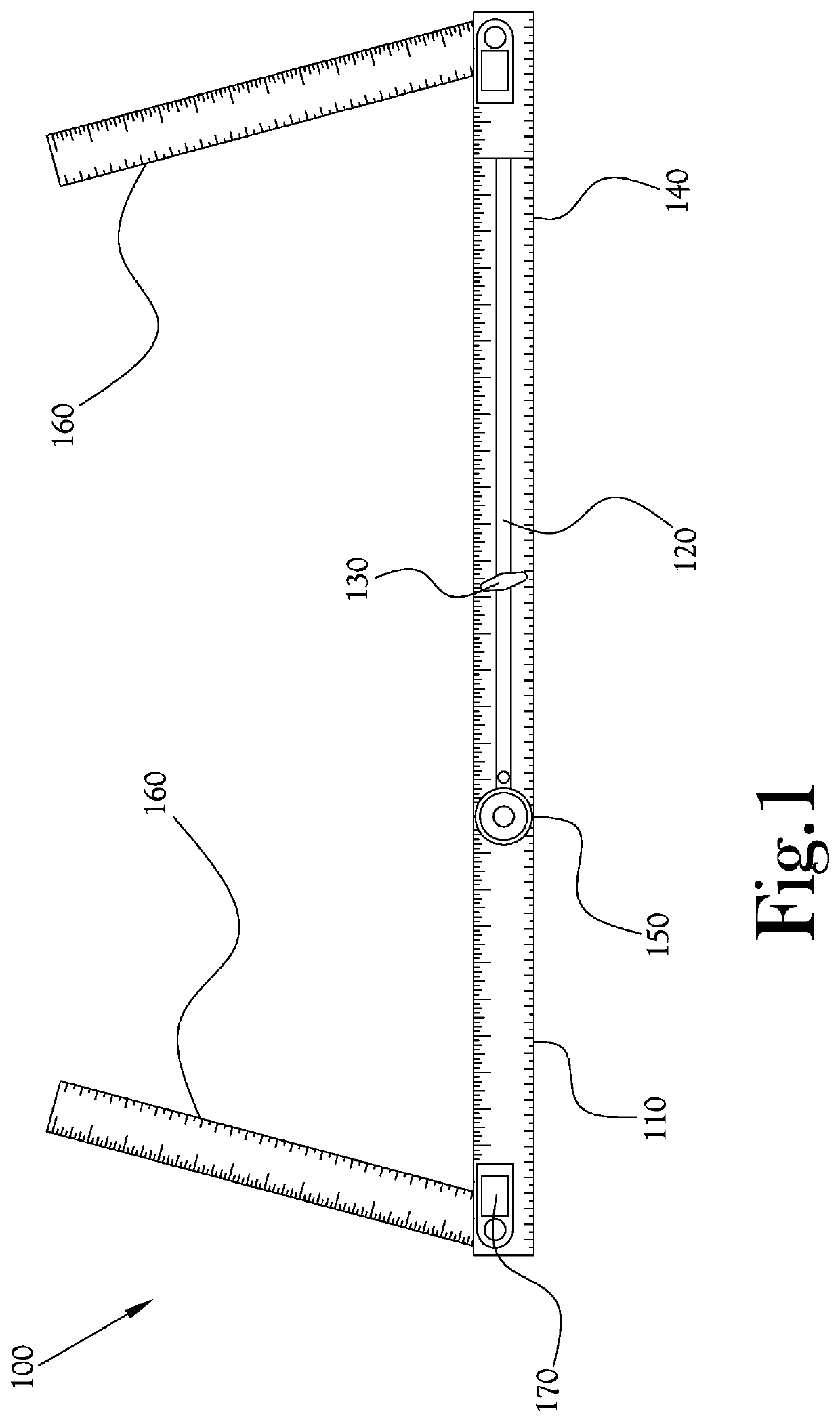

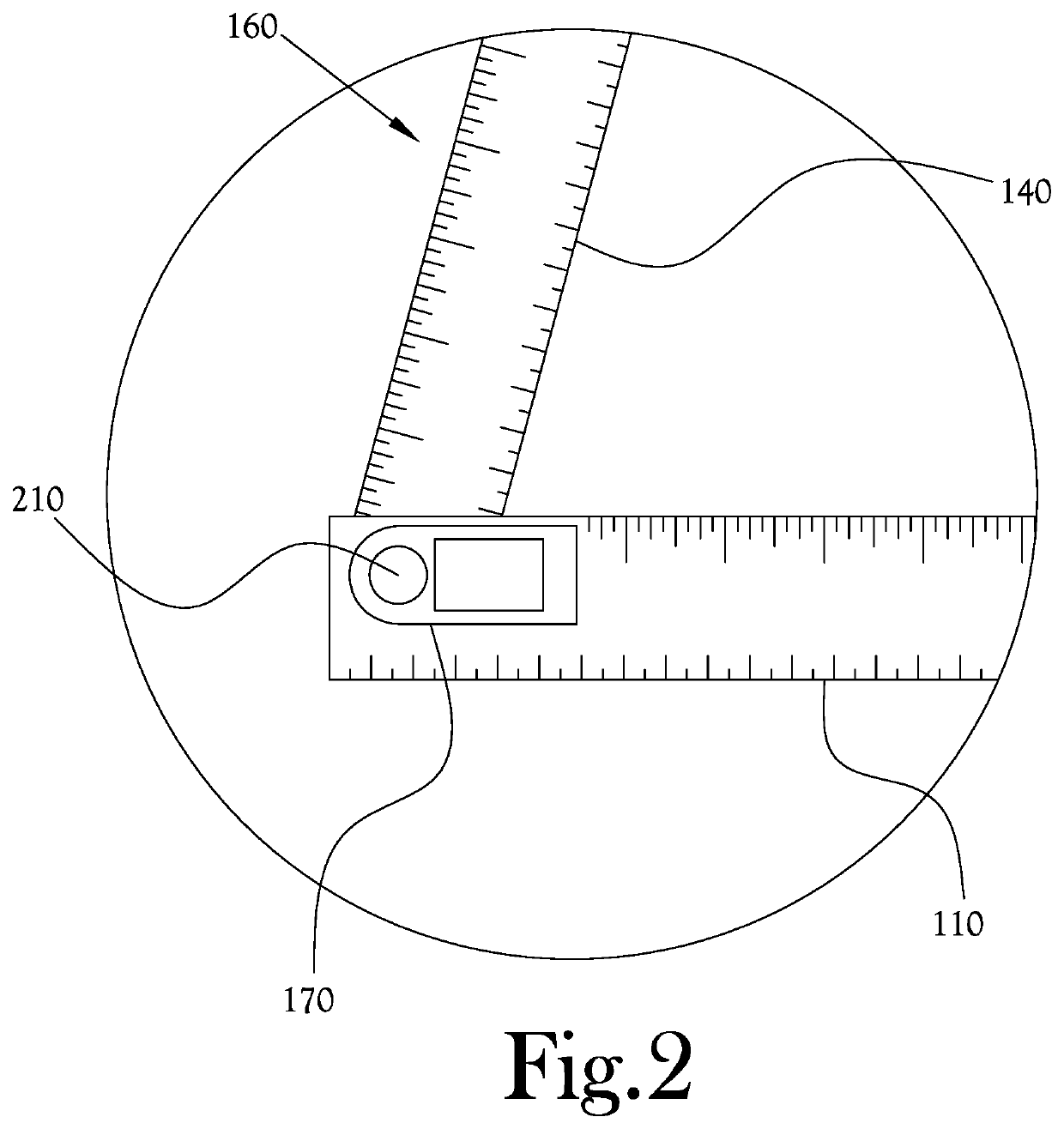

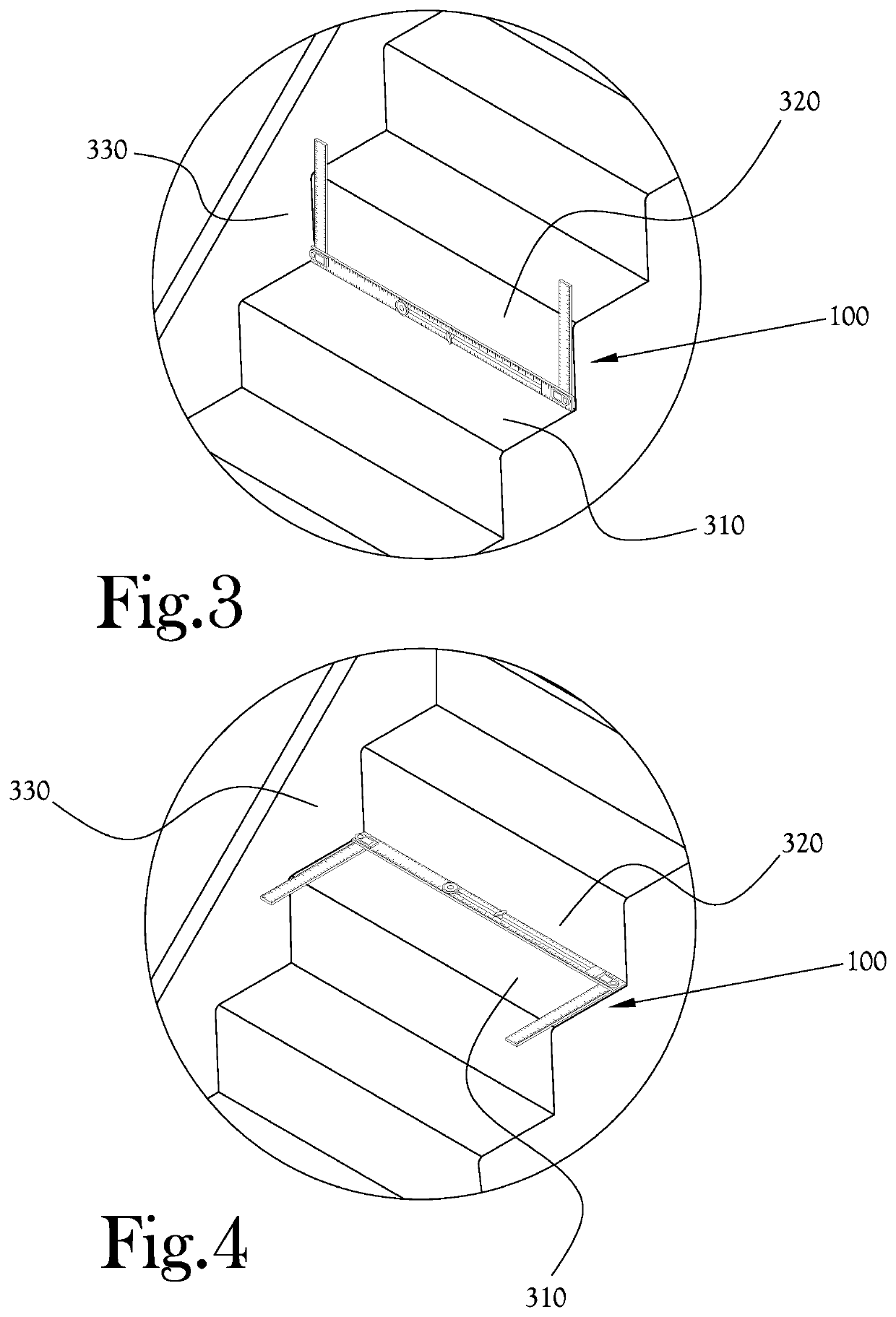

Digital Step Square

InactiveUS20200149856A1Accurate measurementRulers for direct readingIncline measurementEngineeringComputer science

A carpentry device including a main arm having a width and length configured to measure distances of an object. The main arm can include indicia markings on a face of the main arm for measuring distances of an object. The main arm can be formed from one or more sections configured to extend or retract in a longitudinal direction, including at least one supplemental arm extending from at least one connection point at an end of the main arm such that the at least one supplemental arm can rotate about the at least one connection point. A digital angle finder can be attached to the at least one connection point to display an angle between the at least one connection point and the main arm. A bubble level can be attached to the face of the main arm.

Owner:MILLER DONALD

Water-based highly-filled glaze for carpentry, preparation method of water-based highly-filled glaze and construction process

The invention belongs to the field of coatings, and relates to water-based highly-filled glaze for carpentry, a preparation method of the water-based highly-filled glaze and a construction process. The water-based highly-filled glaze for the carpentry comprises, in weight percentage, 15%-25% of water-base resin, 0.5%-2% of bentonite, 40%-60% of powder materials, 1%-10% of water, 1%-10% of water-based color paste color powder and 10.6%-22.5% of other functional additives. The glaze has good filling functions without affecting coloring and is good in anti-settling effect, various water-based primers can effectively adhere, and delaminating is avoided.

Owner:AODA KOALA PAINT HUIZHOU

Ultraviolet-cured transparent finishing coat with high colouring capacity for carpentry

InactiveCN104559748AIncrease dosageConvenient and quick escapePolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolHigh concentration

The technical scheme for realizing the objective of the invention is as follows: an ultraviolet-cured transparent finishing coat with high colouring capacity for carpentry is composed of the following ingredients in parts by weight: 15-25 parts of urethane acrylate, 10-15 parts of epoxy acrylate, 5-10 parts of tripropylene glycol diacrylate, 5-10 parts of trimethylolpropane triacrylate, 5-15 parts of pentaerythritol triacrylate, 5-10 parts of a photoinitiator, 5-10 parts of active amine, 0.5-1.0 part of a dispersant, 0.5-1.0 part of a defoamer, 0.5-1.0 part of a leveller, 3-5 parts of wear-resistant powder, 3-5 parts of matt powder and 10-20 parts of an oily dye. The high-concentration oily dye is used in the ultraviolet-cured transparent finishing coat disclosed by the invention as a breakthrough, meanwhile, the dosage of active amine is increased in a formula, thus greatly solving the problem of achieving the high colouring capacity in one step, ensuring the adhesion force of the finishing coat, achieving the purpose of curing a coating film, and increasing the production efficiency.

Owner:FUJIAN DEZHIXIAN ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

Drilling bit with the depth-limiting and angle-leading function for the carpenter's work

InactiveUS8465234B2Improve convenienceIncrease valueThread cutting toolsDrilling/boring measurement devicesDrive shaftDrill bit

Owner:LIU TSAI FA

Bergamot pear wooden bead and manufacturing method thereof

InactiveCN104742211ASolve technical problemsMuch lovedWood working apparatusJewelleryTool bitPunching

The invention discloses a bergamot pear wooden bead, a manufacturing method of the bergamot pear wooden bead and a bead string, and belongs to the field of jewelry accessories. The method for manufacturing the wooden bead through Korla pear wood includes the steps that first, the Korla pear wood of more than five years old is selected for use; second, the selected wood is manufactured into square bars, a common carpentry milling machine is used for manufacturing the wood into balls, and the rotating speed of a chuck and the rotating speed of a tool bit are adjusted and selected according to the hardness of the wood; third, coarse grinding is conducted, a carpentry polishing machine tool is used, wood abrasive paper of 60-180 meshes is selected for use, the rotating speed is 600-2100 turns per minute, and the using time is 80-140 minutes; fourth, accurate grinding is conducted, the carpentry polishing machine tool is used, wood abrasive paper of 120-2500 meshes is selected for use according to the hardness of the wood and the polished part, the rotating speed is 200-1200 turns per minute, grinding is conducted twice, the time used by the abrasive paper is 60-120 minutes for the first time, and the time used by the abrasive paper is 30-60 minutes for the second time; fifth, punching is carried out, and the rotating speed is 1000-2200 turns per minute. According to the bergamot pear wooden bead and the manufacturing method thereof, a new material for manufacturing the wooden bead is provided, and the manufactured bergamot pear wooden bead and the bead string win warm praise from customers.

Owner:张建新

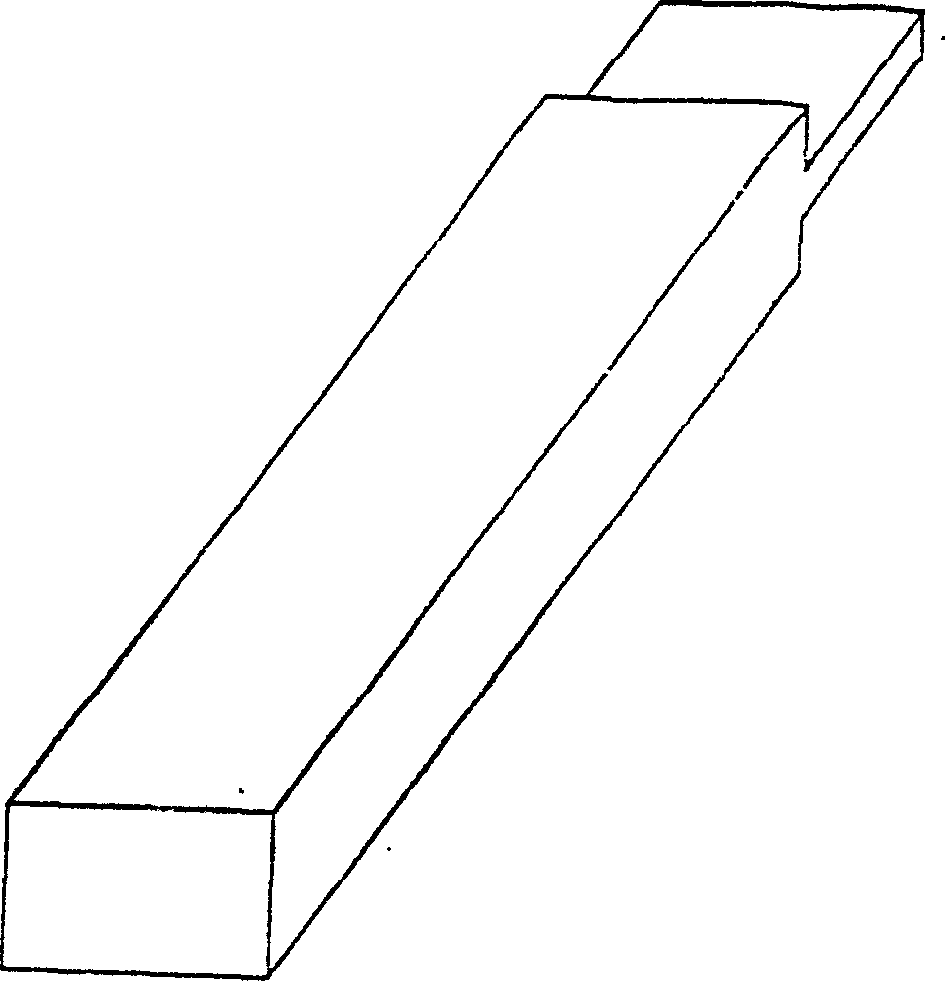

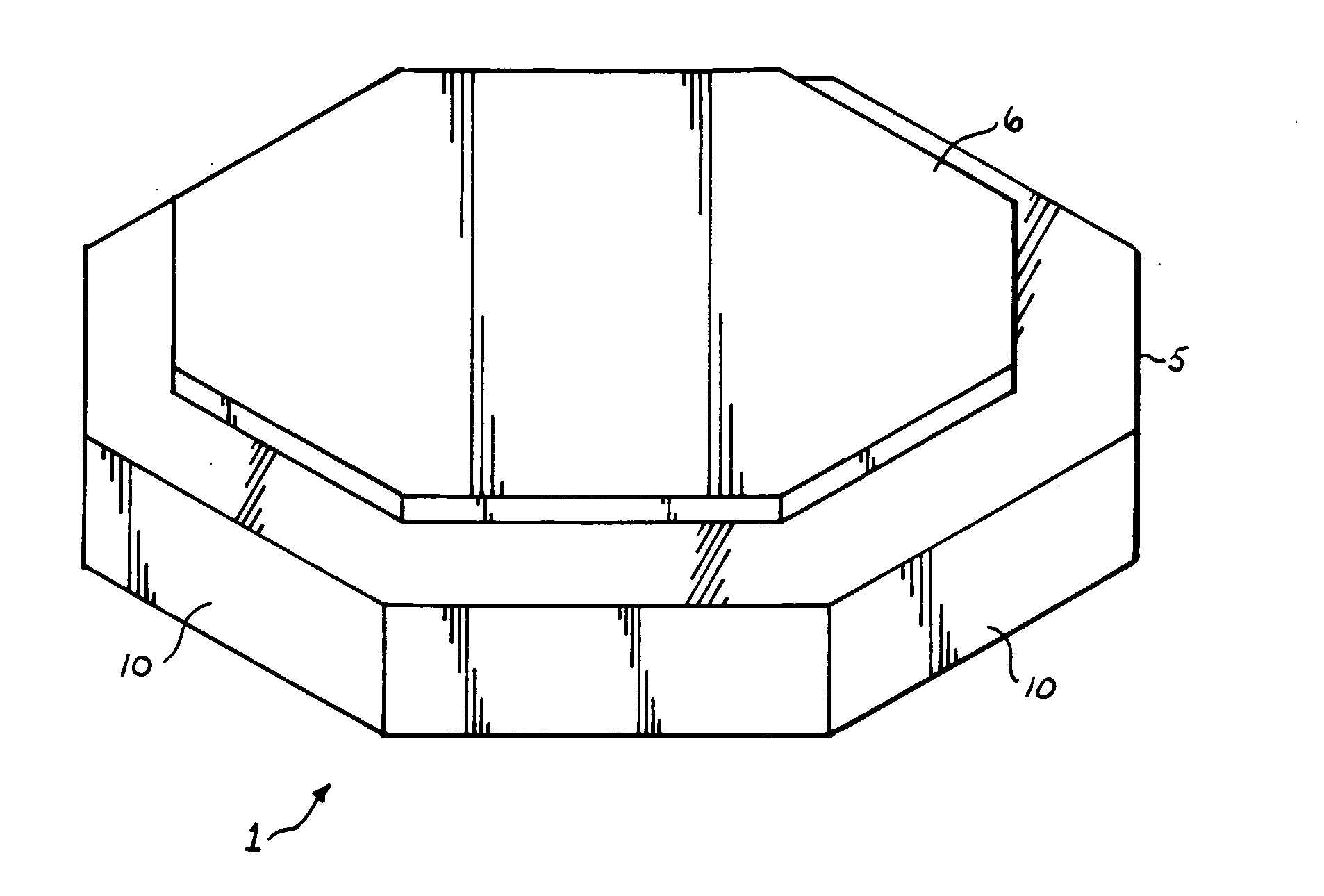

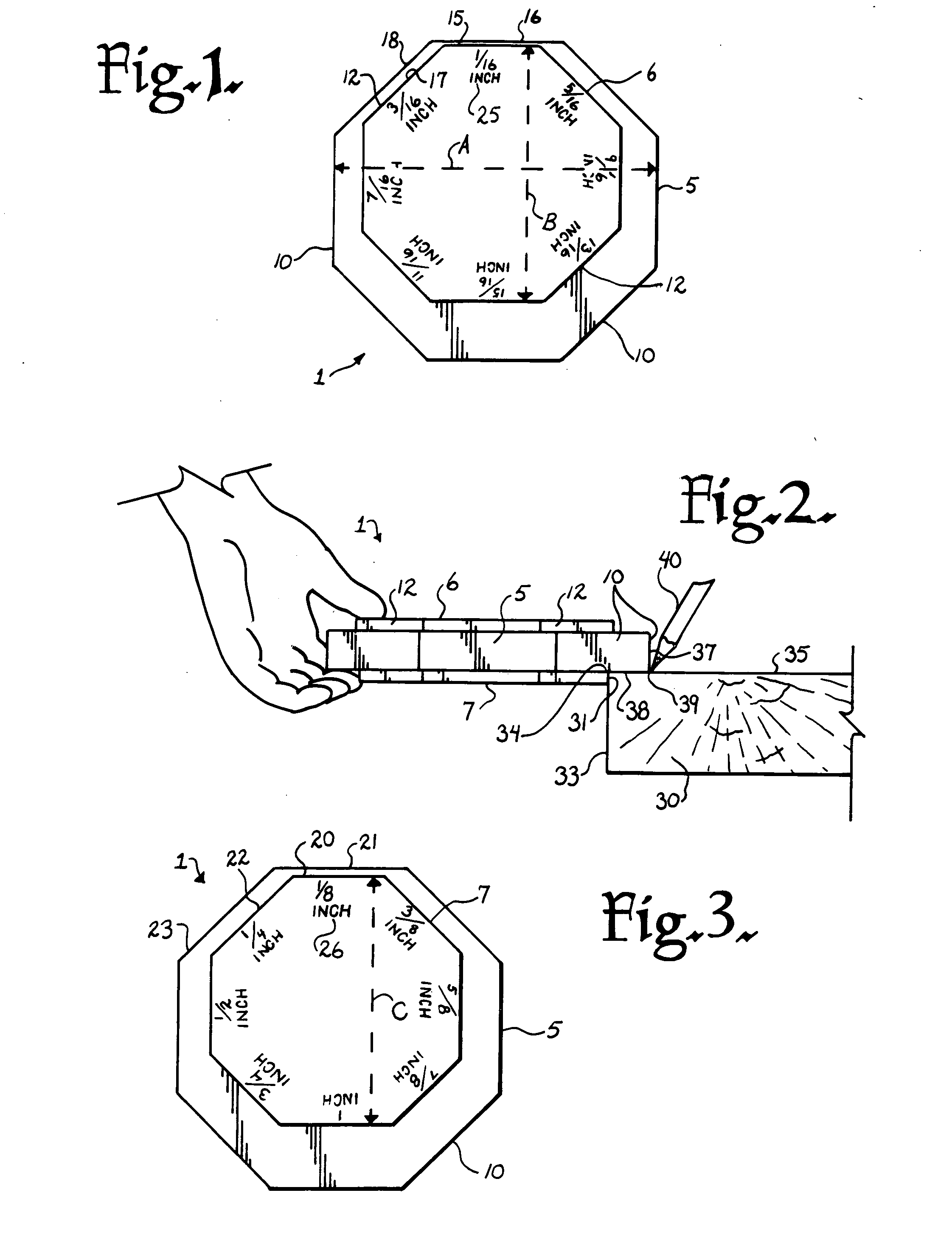

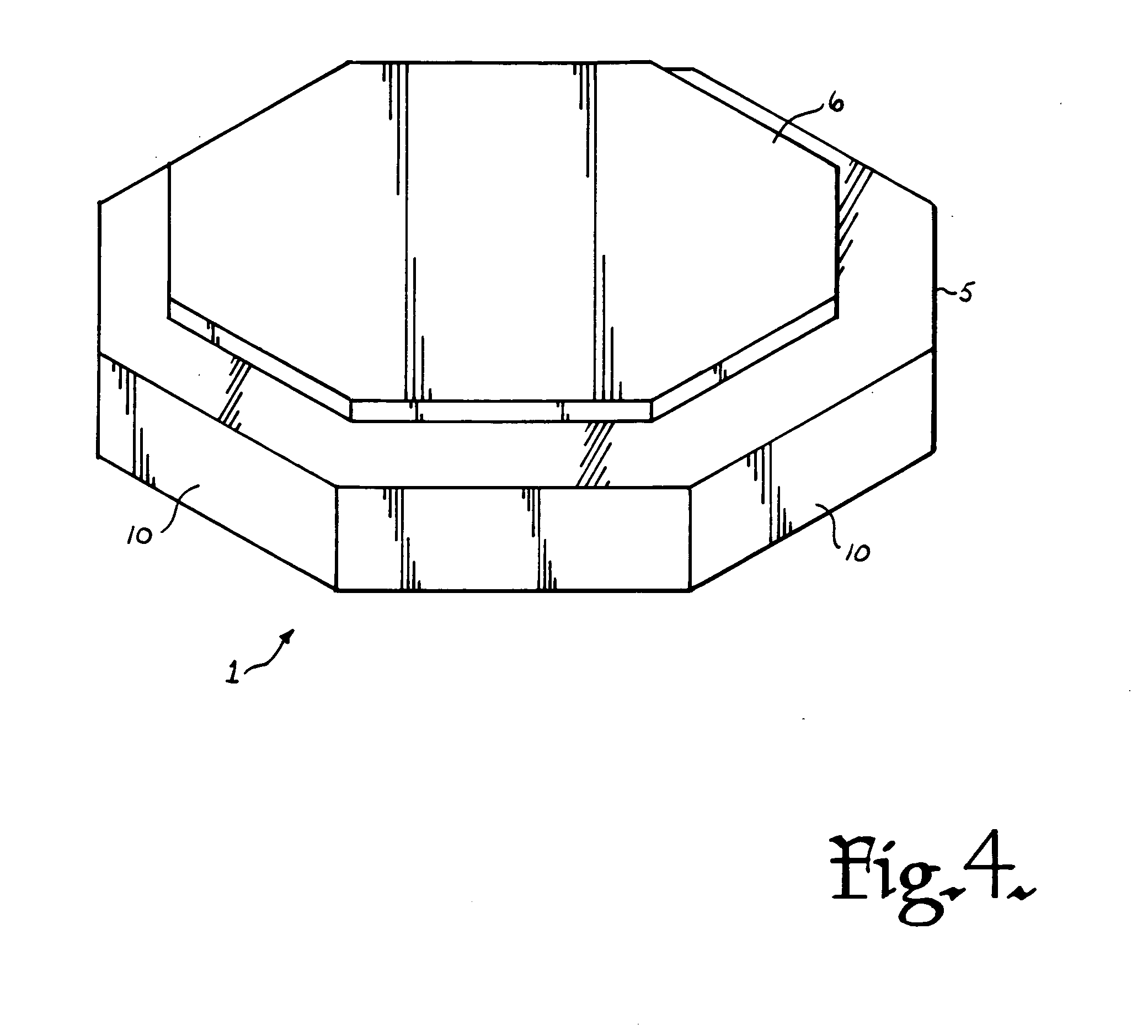

Carpentry stud spacer

An apparatus for spacing studs on a plate is provided. The apparatus includes a frame, a bottom jaw, and first and second side jaws. The frame includes first and second parallelogram linkages at first and second ends thereof, and the first and second side jaws are connected to outer ends of the first and second parallelogram linkages, respectively. The bottom jaw is capable of engaging a plate, and the first and second side jaws are capable of engaging first and second studs for securing the first stud to the plate at a predetermined distance from the second stud.

Owner:PIANETTO NICHOLAS

Carpentry marking tool

Owner:WILLIAMS GARY E

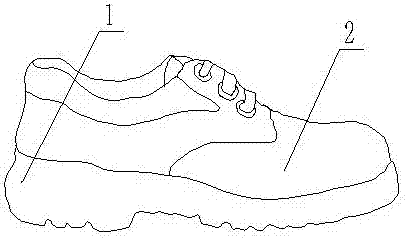

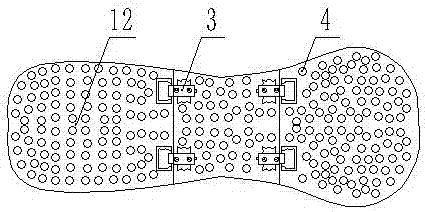

Safety protective shoes

The invention relates to a pair of safety protective shoes for carpenters and construction workers, and belongs to the technical field of labor protection articles. Each safety protective shoe comprises a sole 1 and a shoe body 2, wherein the sole 1 comprises a bottom rubber layer 11, a middle protective layer 12, an upper rubber layer 13 and a surface elastic cushion layer 14; the middle protective layer 12 is a steel hinge pad which is formed by connecting at least two steel sheets by virtue of a hinge 3; and a plurality of screen meshes 4 are formed in the middle protective layer 12. According to the safety protective shoes provided by the invention, by virtue of the steel hinge pad protective layers which are sandwiched between the bottom rubber layers and the upper rubber layers and are provided with the screen meshes, foot bottoms can be protected from getting wounded in the case that the soles are pierced by such articles as a nail, a reinforcing steel bar and the like, and moreover, since the protective layers are connected by virtue of the hinges, feet can bend flexibly, so that blood circulation is promoted and human body health is guaranteed; and in addition, by virtue of the screen meshes, the bottom rubber layers and the upper rubber layers are connected more firmly.

Owner:姜学明

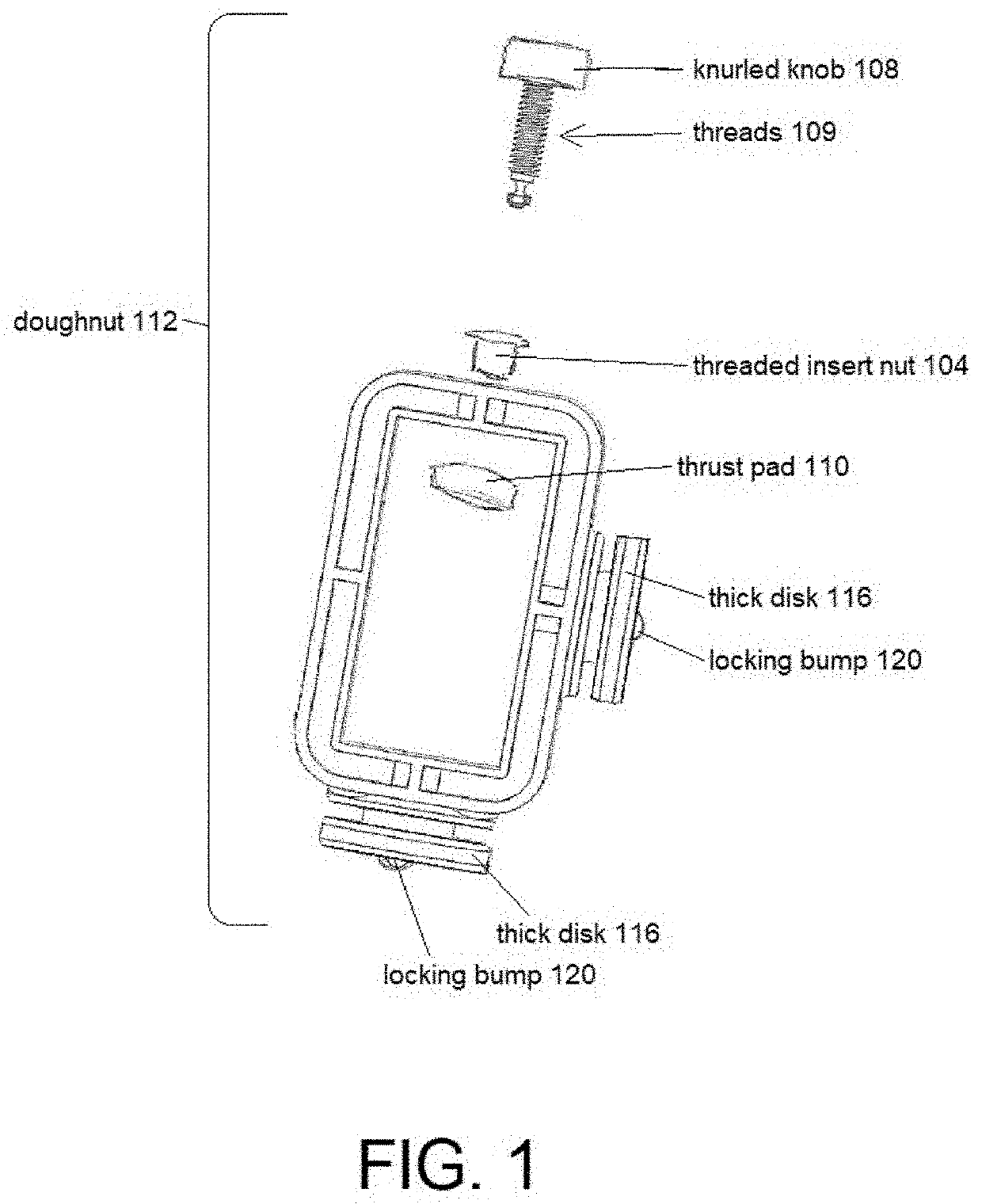

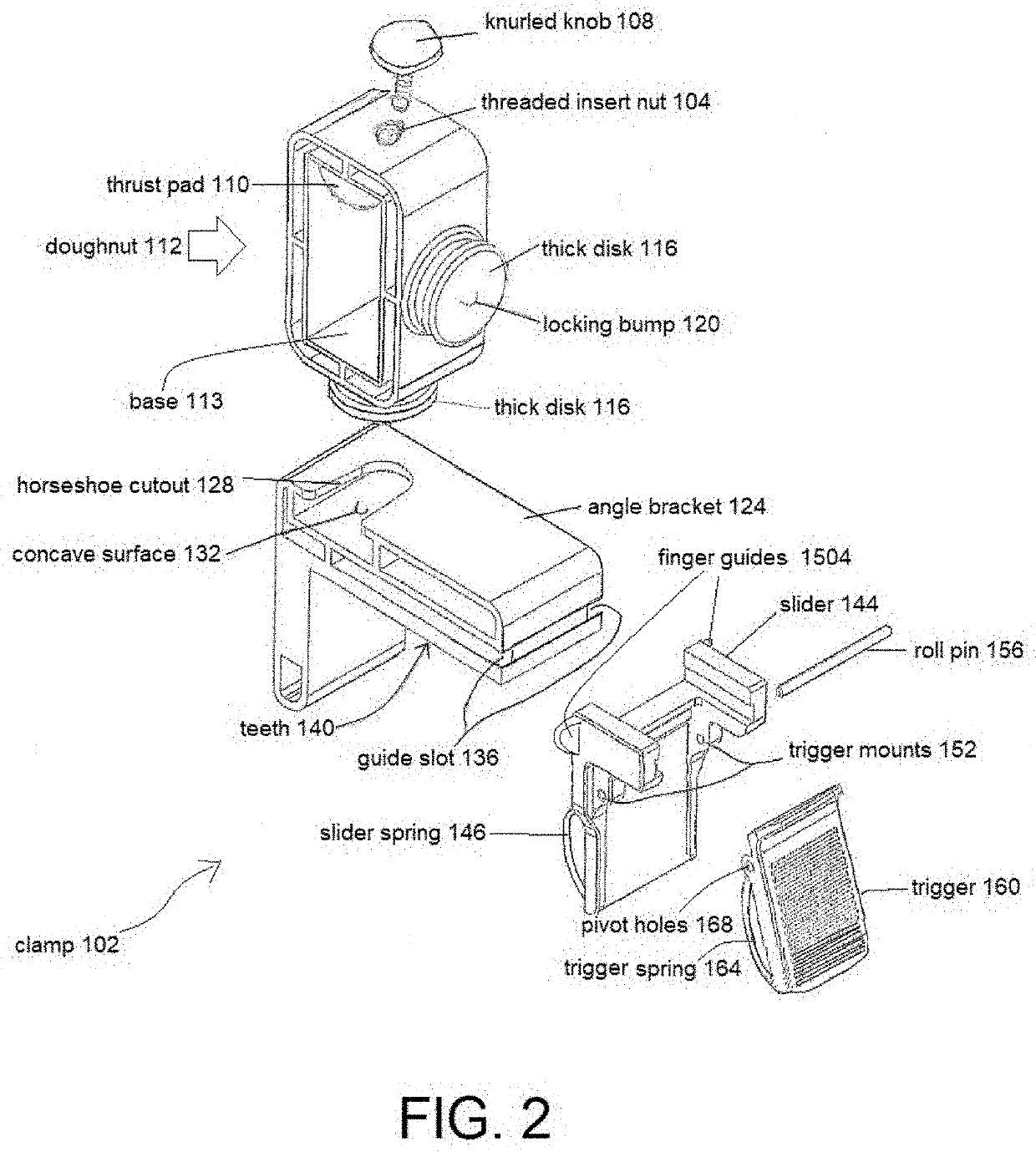

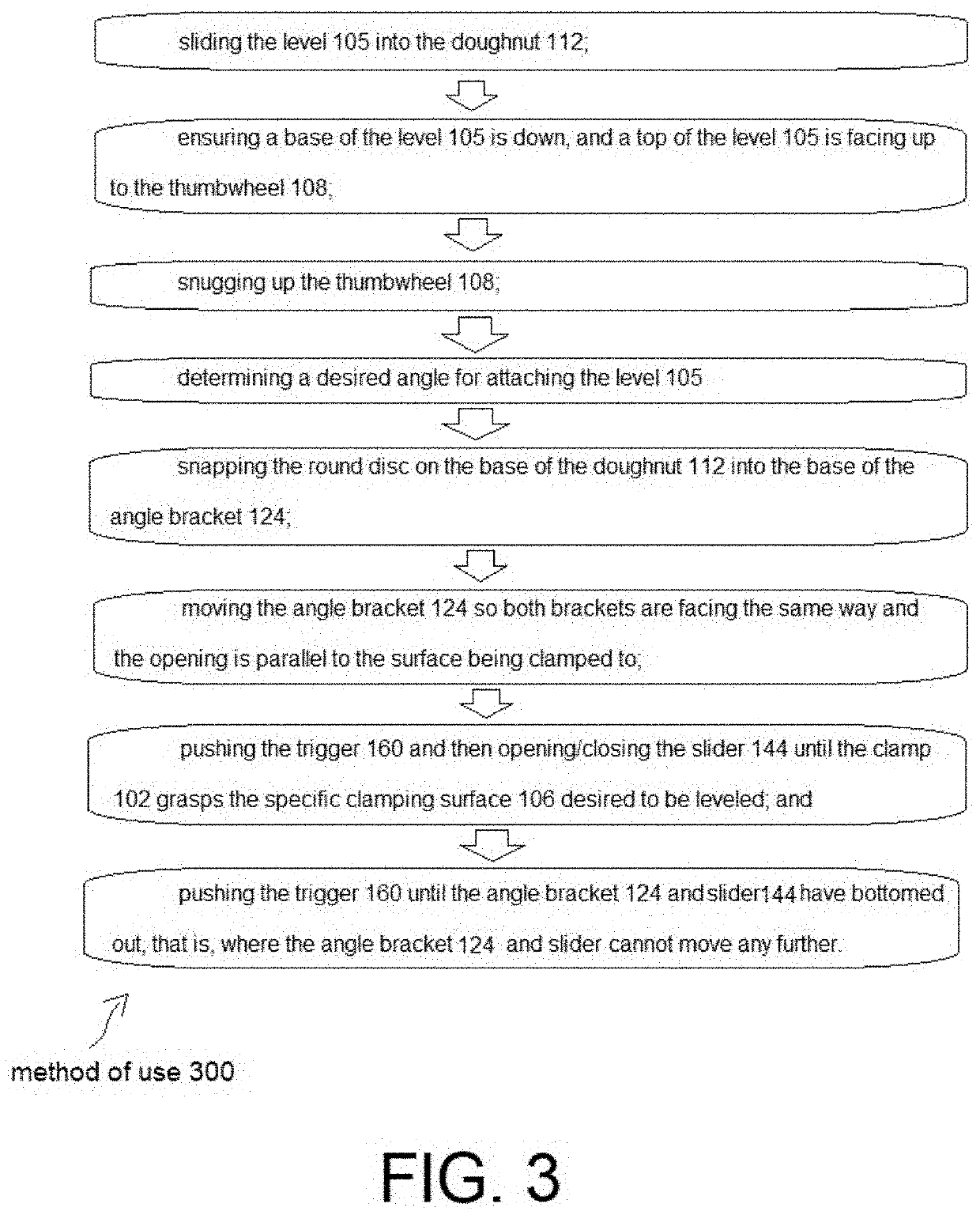

System and Method for Mounting Carpenter Levels

ActiveUS20200130144A1Work benchesFriction grip releasable fasteningsEngineeringMechanical engineering

An improved system and method for clamping of carpenter levels is disclosed. Within the system, it is not necessary to re-size and re-adjust the clamps over and over again as they are re-located. As such, time-consuming repetitive steps are reduced. Additionally, the system can be applied to a variety of clamping surfaces, and can be swiveled to fit at unusual angles.

Owner:HANDY TOOLS LLC

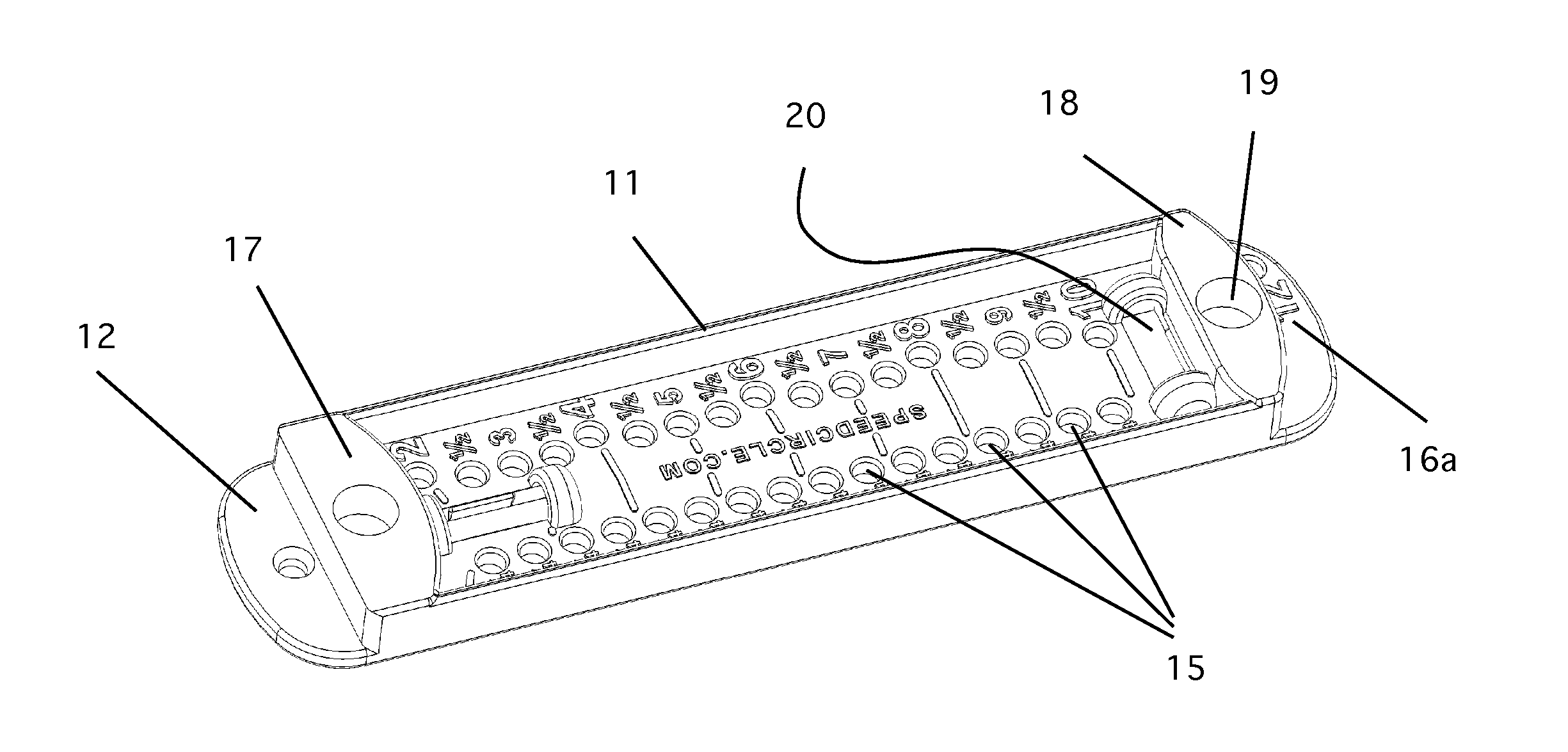

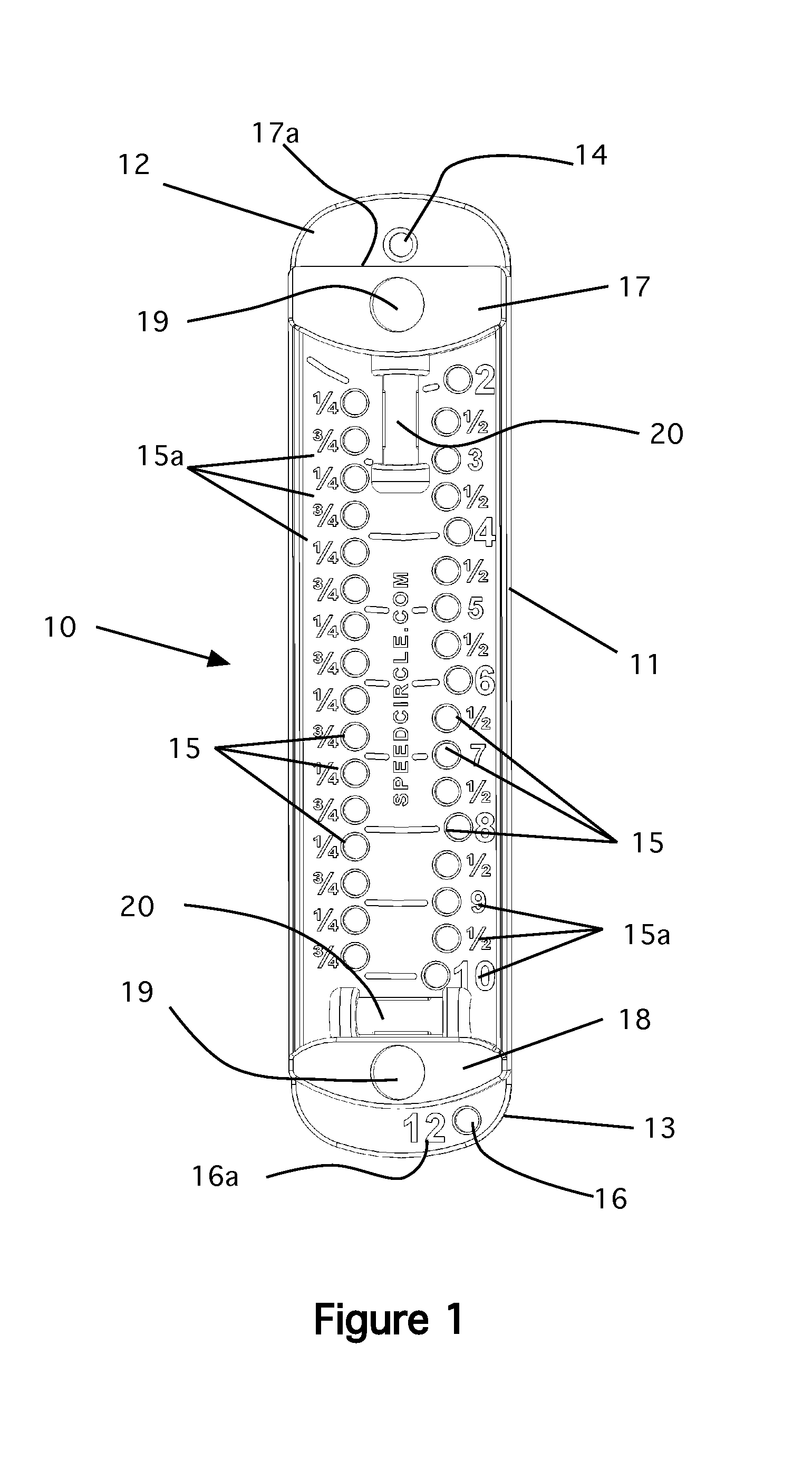

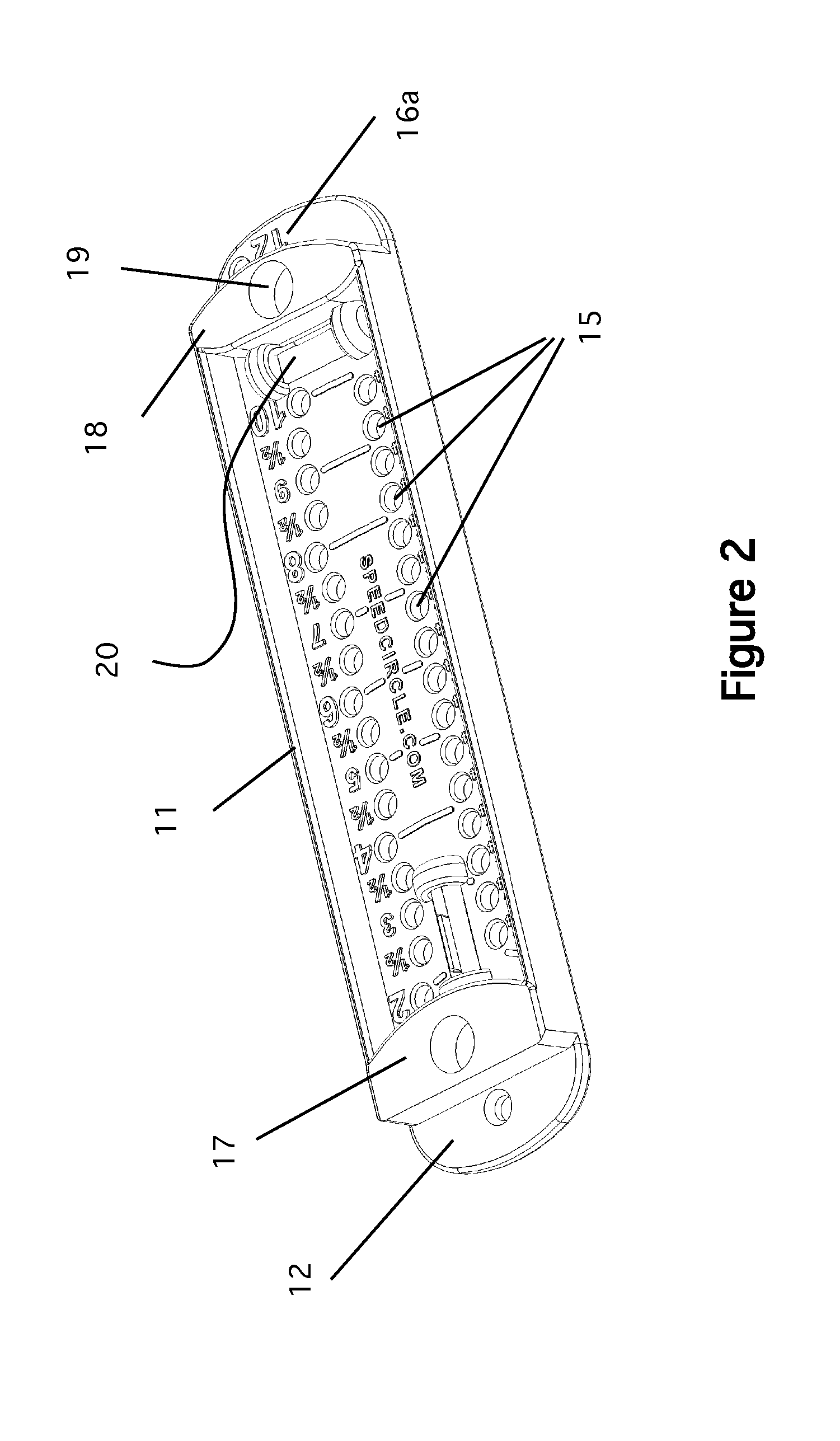

Circle making tool

A tool for carpentry that when used with a nail, a pencil, and a tape measure can draw circles and arcs from a radius of 1 inch up to that of the length of the tape measure. It can also easily make circles or arcs with a radius of 2 inches up to 12 inches using pencil guide holes that are staggered down the length of the device at one eighth-inch intervals. The tool has two rare earth magnets that hold the tape measure to the tool during use. The magnets can be used also to hold a nail on the tool for storage purposes. In that way, a nail is always available when a circle is needed. For more convenience, one or more bubble levels can be added to the tool making the tool not only a circle tool but a torpedo level as well.

Owner:SPEEDY CIRCLE MFG

Resin for carpentry paint and carpentry paint

The invention provides resin for carpentry paint. The resin is prepared from the following components in parts by weight: 5-9 parts of n-butyl acrylate, 12-20 parts of methyl methacrylate, 7-12 parts of n-butyl methacrylate, 1-3 parts of styrene, 0.5-1 part of methacrylic acid, 1.5-4 parts of a cross-linking agent, 0.5-1 part of an initiator, 0.5-1 part of a fluorinated surfactant, 1.5-4.5 parts of an emulsifying agent and 1-2 parts of ammonia water. The resin for the carpentry paint is low in film-formation temperature, and can realize self-crosslinking at room temperature and low temperature; an obtained paint film is high in hardness, strong in adhesion and good in toughness; the paint film is maintained not to crack when the volume of wood is changed. Experimental results prove that the hardness of the carpentry paint can reach 2H in the fourth day after the carpentry paint is sprayed. The invention also provides the carpentry paint.

Owner:深圳市长辉新材料科技有限公司

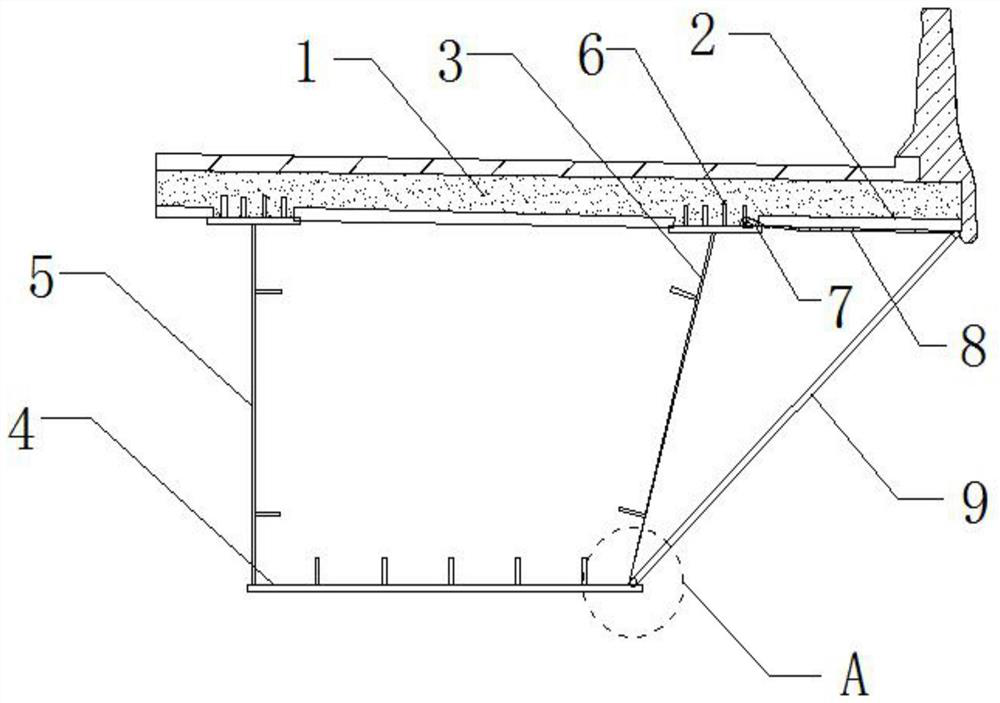

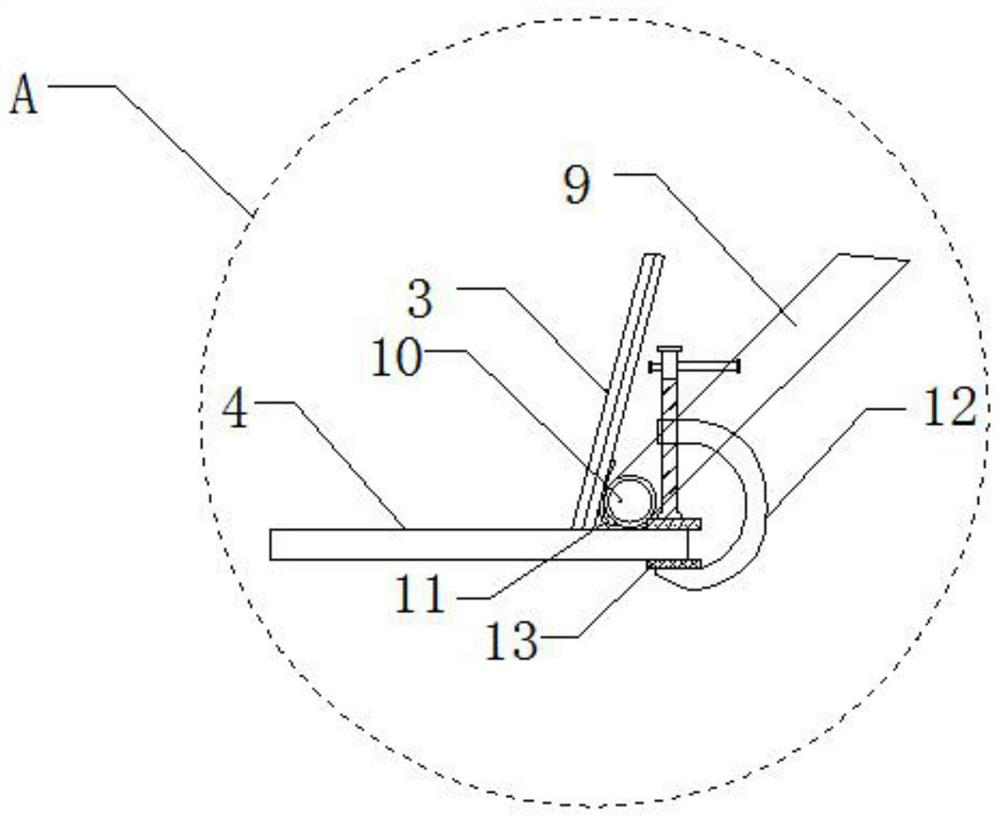

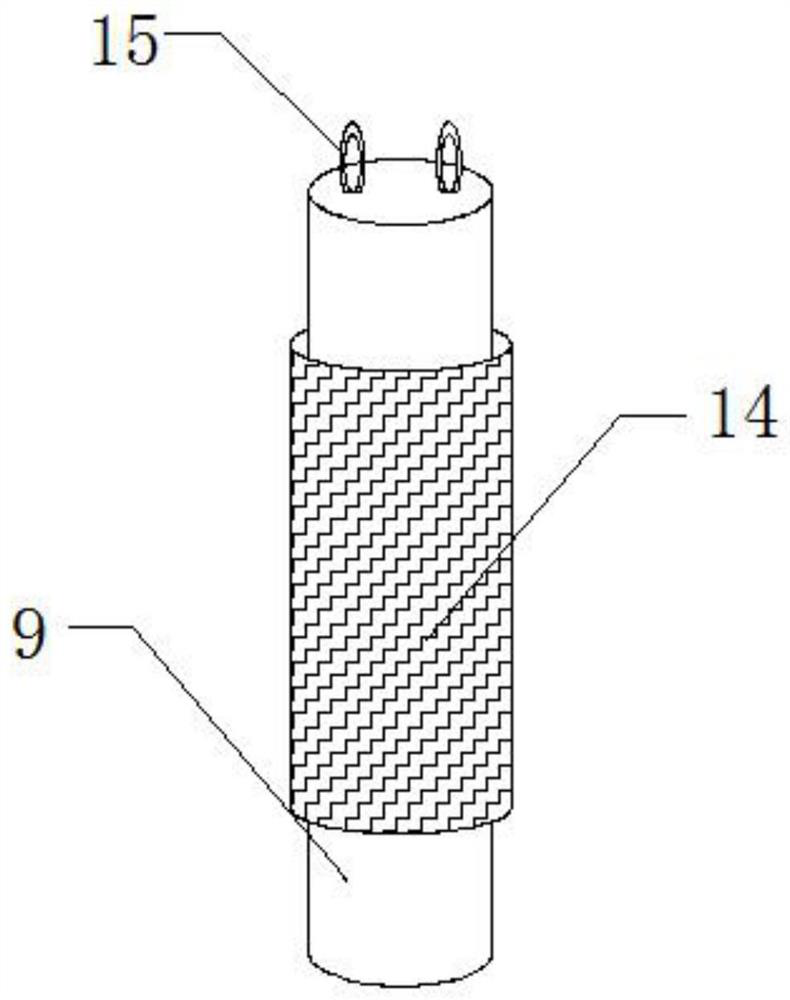

Steel-concrete composite beam bridge deck slab supporting mechanism

PendingCN112695615AFast constructionImprove linearityBridge structural detailsBridge deckEngineering

The invention discloses a steel-concrete composite beam bridge deck slab supporting mechanism which comprises a cast-in-place bridge deck slab, an opening type profiled steel sheet is fixedly installed at the bottom of the cast-in-place bridge deck slab, one side of the bottom of the opening type profiled steel sheet is fixedly connected with the top of a steel beam inclined web, and a fixing column is fixedly connected to one side of the middle of the opening type profiled steel sheet. The bottom of the fixing column is sleeved with a hose, one side of the hose is in winding connection with one end of a steel wire rope, the other end of the steel wire rope is in winding connection with the top of an inclined supporting steel pipe, and an inclined supporting frame bottom longitudinal beam is connected to the top end of the steel beam bottom plate. One side of the inclined supporting frame bottom longitudinal beam is connected with bottom of an inclined supporting steel pipe through a carpenter clamp. According to the steel-concrete composite beam bridge deck slab supporting mechanism, the inclined supporting steel pipes, the steel wire ropes, the woodworking clamps and the inclined supporting frame bottom longitudinal beams are arranged, so that a whole support system is not welded, a support is detachable and reusable, the construction speed of a construction method is high, the linearity of a bridge deck slab at a cantilever is good, no welding point exists on a steel box girder, and secondary cutting does not exist.

Owner:LANZHOU RAILWAY SURVEY & DESIGN INST

Water-based carpentry putty

The invention discloses water-based carpentry putty which comprises the following components by mass percent: 10-15% of water, 20-25% of zinc stearate emulsion, 20-25% of heavy calcium, 25-30% of light calcium, 5% of talcum powder, 2% of propylene glycol, 1% of a defoamer, 1-1.5% of a film former, a proper amount of a leveler and a proper amount of a thickener. The water-based carpentry putty is fine and smooth in surface, good in grindability and very good in heat resistance; the situation that a coating film is softened and adhered to abrasive paper or an abrasive wheel due to temperature rise during grinding of the abrasive paper or mechanical grinding of the abrasive wheel can be avoided; moreover, the water-based carpentry putty is good in transparence, difficult to precipitate and yellowing-resistant, can well protect wood after being applied, and prolongs the service life of carpentry.

Owner:QINGDAO DEGU BUILDING MATERIAL

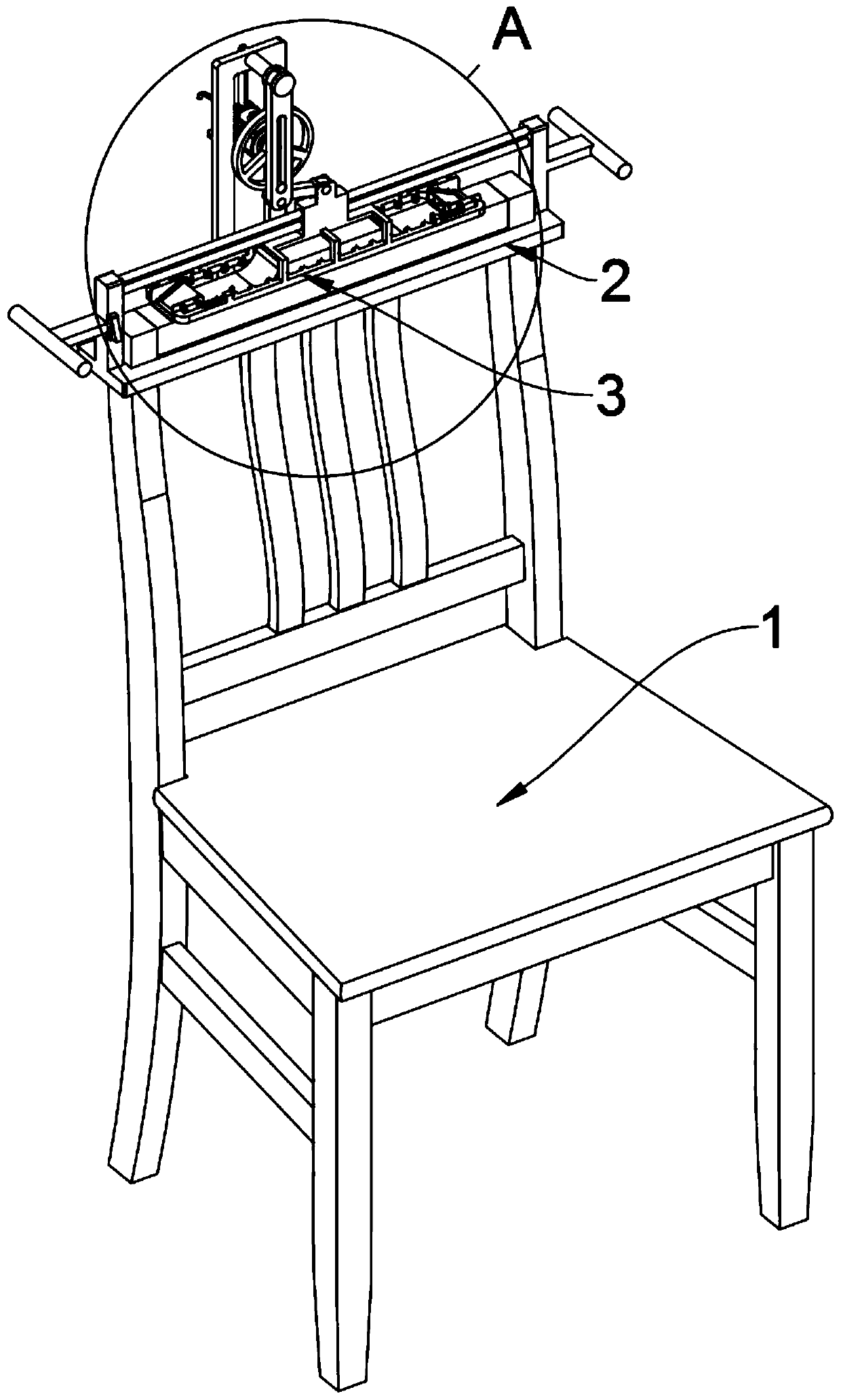

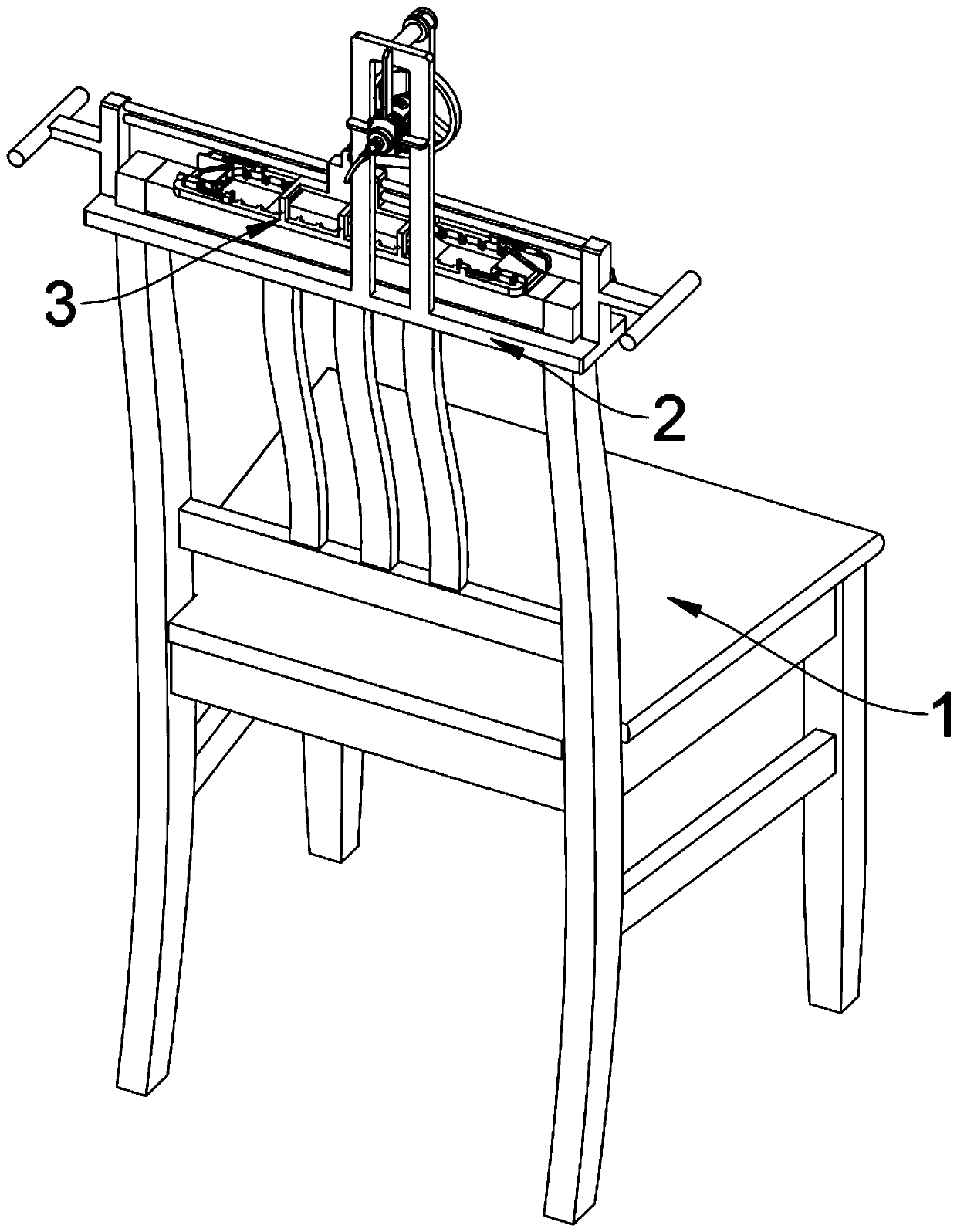

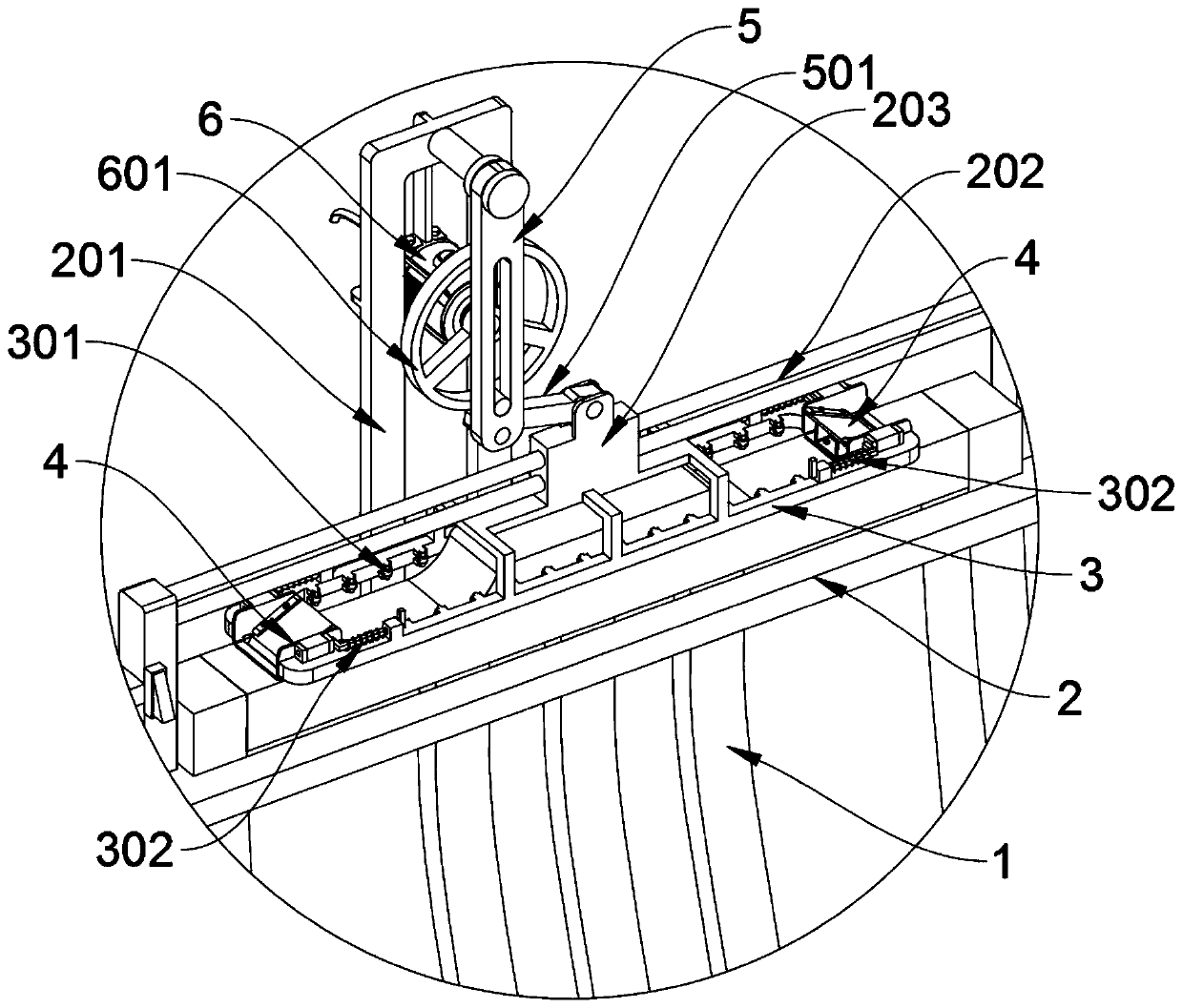

Wooden chair top end transverse plate scraping device

InactiveCN111113620AEasy to removeEasy to implement and maintainFlat surfacing machinesToggle switchElectric machinery

The invention discloses a wooden chair top end transverse plate scraping device, relates to the technical field of carpentry scraping appliances, and solves the problems that the existing scraping device planes and scrapes the two ends of the top rod of a cross brace step by step instead of synchronous operation, is more tedious in planing and scraping process and is low in operating efficiency. The wooden chair top end transverse plate comprises a sliding scraping frame, a swing rod, a motor and a T-shaped handle rod, wherein two carpenter's planes are symmetrically welded at the left and right ends of the sliding scraping frame; a sliding chute is formed in the swing rod in a penetrating manner; the motor is locked and hoisted at the top end of the middle of the rear side of a positioning frame; the positioning frame is arranged at the top end of the wooden chair backrest of the positioning frame in a clamping and sleeving manner; and a toggle switch is arranged on the middle sectionof the mounting rod of the vertical brace of the T-shaped handle rod on the left side and is in electric control connection with the motor. The positioning frame can arrange the entire wooden chair top end transverse plate scraping device on the top rod of the cross brace of the top end of the wooden chair backrest in a sleeving, inserting, clamping and positioning manner and provides conveniencefor integral clamping installation and application of the device.

Owner:冯妶英

Adjustable scribe and associated use therefore

An adjustable carpentry reveal tool includes a base member, and a sliding member slidably engaged to the base member wherein the sliding member is configured to be selectively displaced along predetermined linear increments relative to the base member without becoming detached from the base member. Advantageously, the sliding member is configured to simultaneously mark a pair of adjustable reveals along the x-axis and the y-axis of the trim corner of the frame opening without having to fasten the base member to the trim corner of the frame opening. Notably, in this manner, the adjustable reveals are defined between an outermost periphery of the base member and an outermost periphery of the sliding member.

Owner:SCRIBE IT LLC

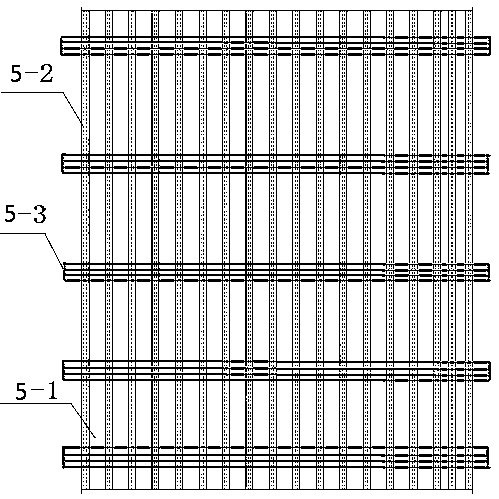

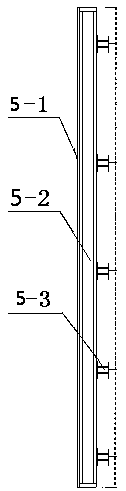

Variable-section cantilever formwork suitable for rapid construction and construction method adopting variable-section cantilever formwork

PendingCN111648255ARealize processingImprove securityBridge erection/assemblyShaped beamArchitectural engineering

The invention relates to a variable-section cantilever formwork suitable for rapid construction. The variable-section cantilever formwork comprises a formwork system, an operating platform and a connecting system. The formwork system comprises a plurality of formwork units, and each formwork unit comprises a panel, a wood I-shaped beam, channel steel, a connecting claw, a bolt, a steel nail and alifting hook. Each template unit is provided with an operation platform; the connecting system comprises a core belt, a core belt pin, a cable-stayed seat and a pull rod; the adjacent template units arranged on the same surface are connected through a core belt and a core belt pin; the two formwork units arranged at the corners are connected through pull rods and cable-stayed seats, and the cable-stayed seats and the formwork units are connected through core belts and core belt pins. The invention further relates to a construction method adopting the variable-section cantilever formwork. The method is suitable for industrialized and standardized production, high-altitude operation rapid construction and installation standardized operation, efficient bridge construction is achieved, and themethod belongs to the technical field of bridge construction structures.

Owner:广州市市政工程机械施工有限公司

Nail removing device

InactiveCN109202816ASimple structureSafe and convenient exclusionNail extractorsPulp and paper industryReducer

A nail removing device is characterized in that a transverse roller shaft is mounted on a cuboid-shaped bottom frame, wherein an axial rack is mounted on the roller shaft; two ends of the roller shaftare connected to the bottom frame through a shaft seat; a speed reducer is mounted at the lower part of the bottom frame; and a transmission belt is mounted between the speed reducer and the roller shaft. The device solves the problems of high working intensity and low efficiency in the operation of manually removing wasted nails through tongs or a claw hammer; and the device is widely applied toprocessing of carpentry.

Owner:刘成其

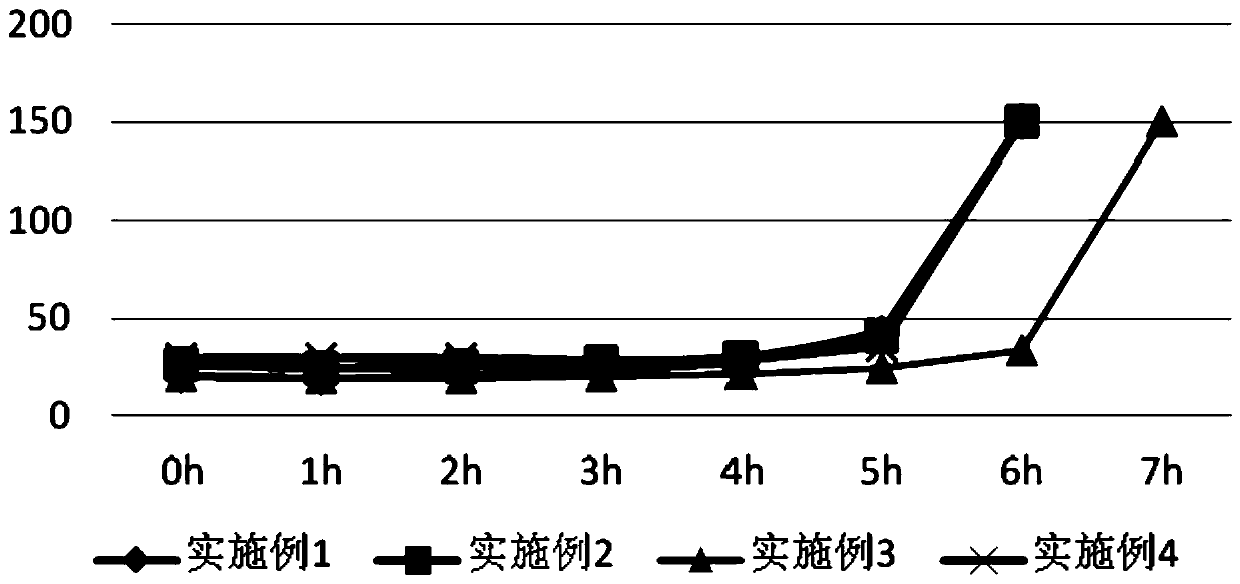

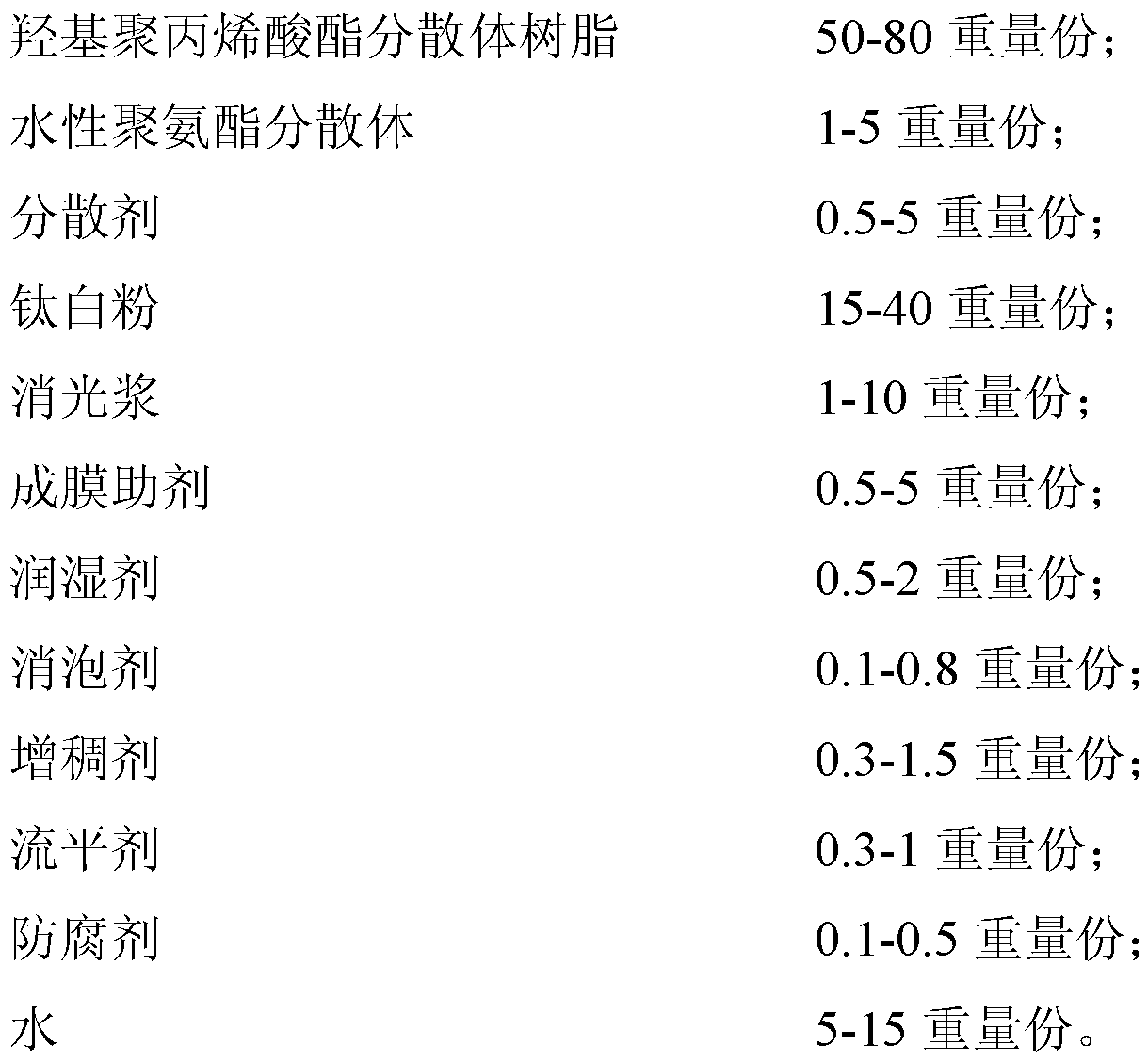

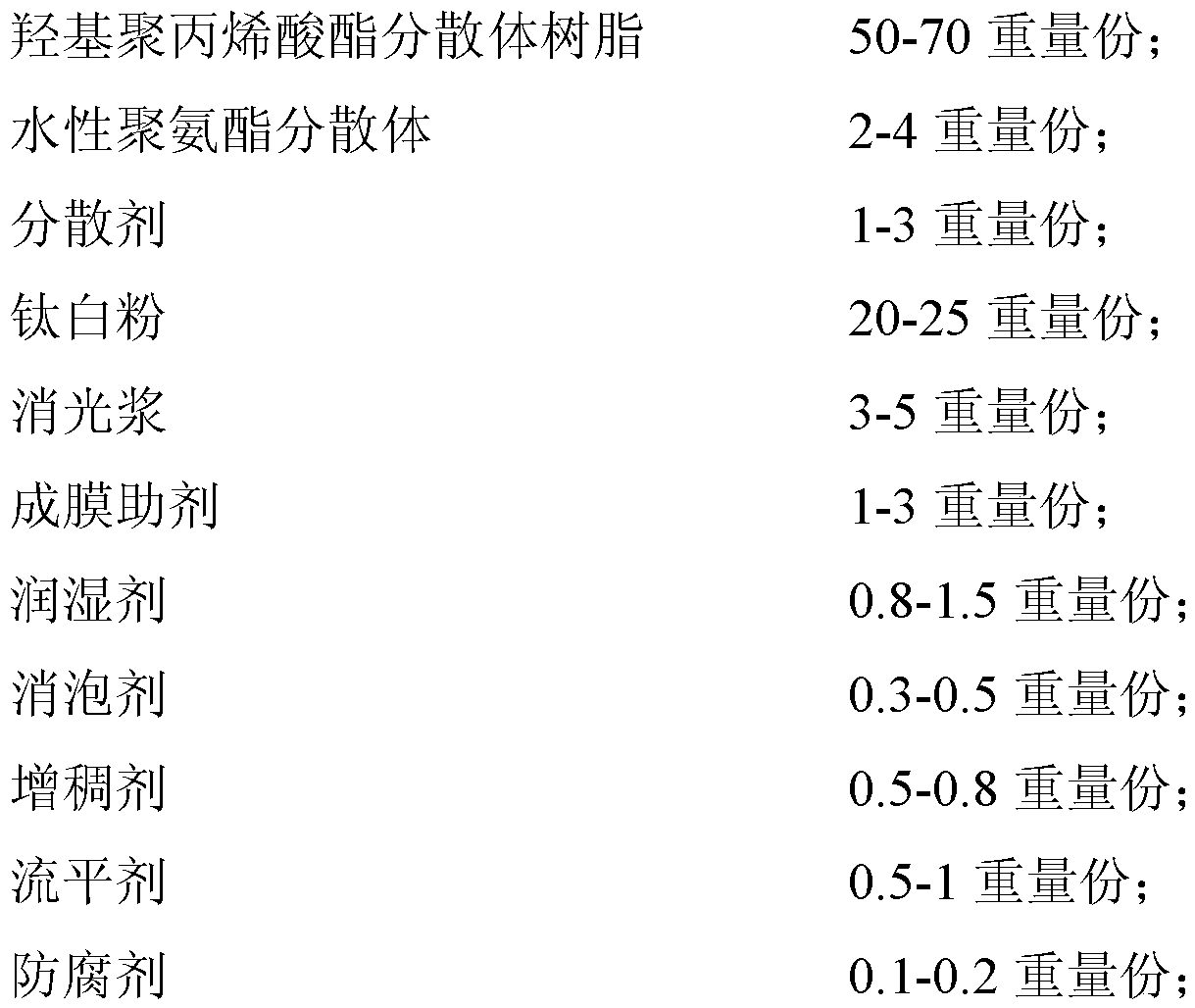

A polyurethane composition for woodware with visible gelling characteristics and its preparation method

The invention discloses a polyurethane composition with a visual gelling feature for carpentry and a preparation method. The polyurethane composition is prepared from the following components in parts by weight according to the claims and specification: hydroxyl polyacrylate dispersion resin, a waterborne polyurethane dispersion, a dispersing agent, titanium dioxide, flatting pulp, a film forming aid, a wetting agent, an antifoaming agent, a thickening agent, a leveling agent, a preservative and water. A white paint prepared from the components serves as a main paint and is mixed with a curing agent for more than an activation period; the liquid paint is gelled to remind a constructor in time, and the construction quality is ensured; the polyurethane composition has a remarkably high market practical value.

Owner:NIPPON PAINT CHINA

Paint for carpentry furniture

The invention relates to the technical field of paint for furniture, in particular to paint for carpentry furniture. The paint comprises the following raw materials in parts by weight: 20-40 parts of acrylic resin containing hydroxyl, 10-20 parts of amine resin, 1-5 parts of zinc stearate, 0-0.3 parts of a dispersing agent, 0-0.5 parts of a handfeel smoothing agent, 0-0.2 parts of antifoaming agents, 5-30 parts of color paste, 0-0.3 parts of a flatting agent and 0.5-1 part of a wetting agent. The invention aims to provide the paint for the carpentry furniture which is environment-friendly and reasonable in component match.

Owner:戴留庆

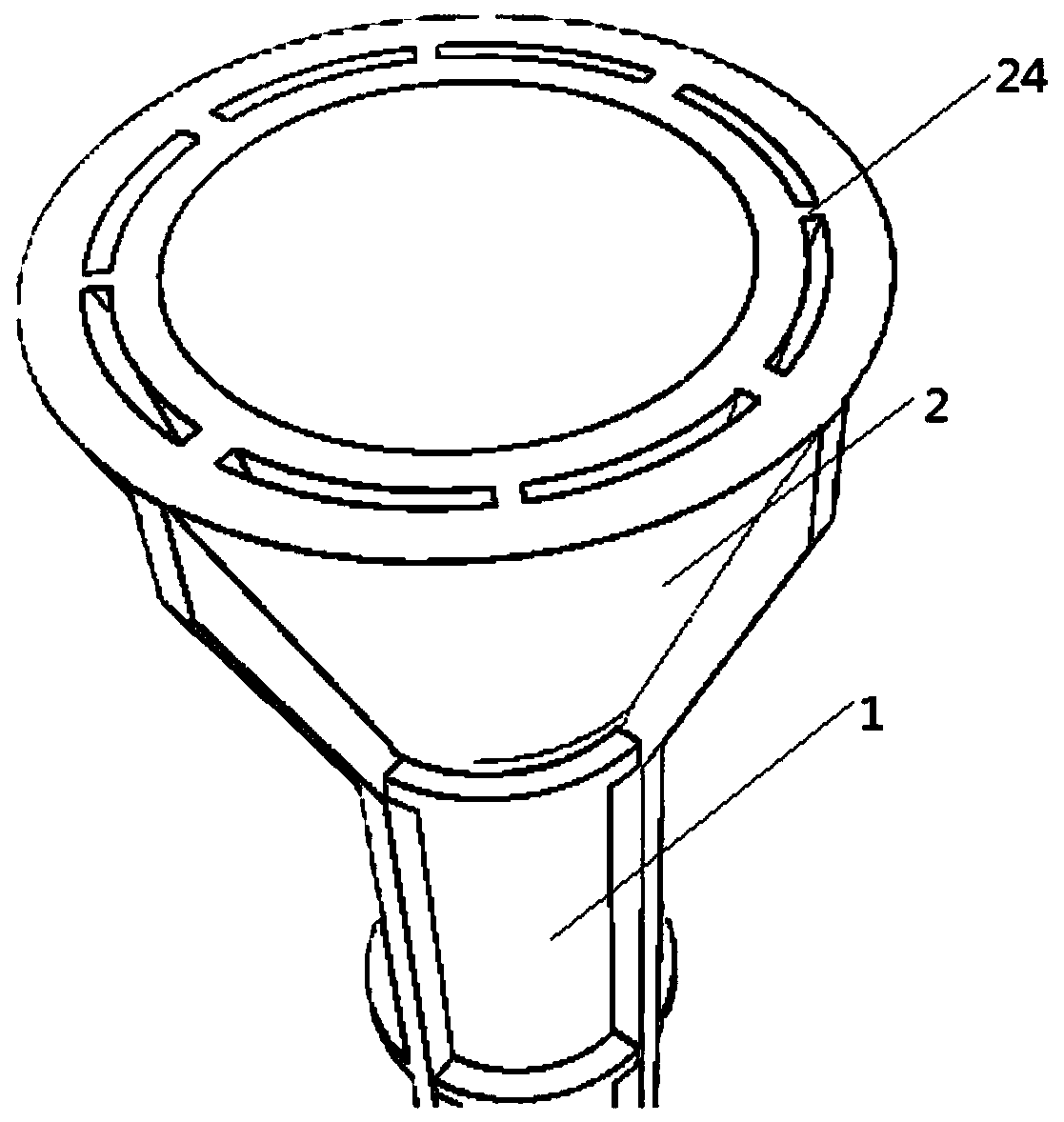

Wall-penetrating screw sleeve with internal supporting effect for construction carpenter

PendingCN110847605ALabor savingLow costAuxillary members of forms/shuttering/falseworksPlate pressureConstruction carpenter

The invention discloses a wall-penetrating screw sleeve with an internal supporting effect for a construction carpenter. A sleeve body is of a hollow cylinder structure. First reinforcing ribs are arranged on the sleeve body. Second reinforcing ribs are arranged between the first reinforcing ribs. Seal rings are arranged at the two ends of the sleeve body correspondingly. Third reinforcing ribs are arranged on the outer side walls of the seal rings. Each seal ring comprises an outer wall ring and an inner wall ring. Fourth reinforcing ribs are arranged between the outer wall rings and the inner wall rings. By designing the horn-mouth-shaped multi-layer seal rings at the two ends, concrete grout is effectively prevented from entering a pipe cavity, the protection range of drilled holes of timber formworks is enlarged, meanwhile if sealing is not tight, concrete mortar can be effectively prevented from entering an inner cavity, the error rate of pores of the formworks on the two sides isincreased, and a screw can be better drawn out; and meanwhile, the longitudinal reinforcing ribs and the annular reinforcing ribs are designed in the device, so the longitudinal formwork pressure resistance and transverse concrete impact force resistance are effectively improved, and the strength of a pipe wall is increased.

Owner:杨红

Carpentry cleaner

InactiveCN106350299ASelf-cleaningNo harmBiocidePhysical/chemical process catalystsSodium silicateCarpentry

The invention refers to cleaning area, especially the carpentry cleaner, the raw material comprises of the carpentry cleaner, by weight: 100 parts of water, 1 - 1.5 parts of sodium silicate, 0.5 - 1.5 parts of natural camphor oil, 1.5 - 3.5 parts of nano titanium dioxide, 1.5 - 3 parts of onion juice, 0.5 - 2 parts of ethanol, 0 - 1.5 parts of plant aromatic essential oil. The carpentry cleaner could effectively clean the carpentry and make the carpentry own good self-cleaning function to prevent bacteria from growing efficiently.

Owner:四川达文西科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com