Fan air-cooled automatic tool change electric spindle used for carpentry carving and milling

A technology of automatic tool change and electric spindle, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of wood pollution, inability to use machine tools, high heat generated by high-frequency built-in motors, etc., to improve the heat dissipation effect and solve the impact , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

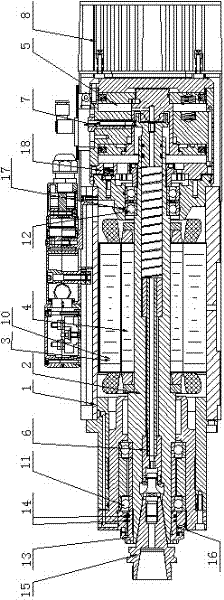

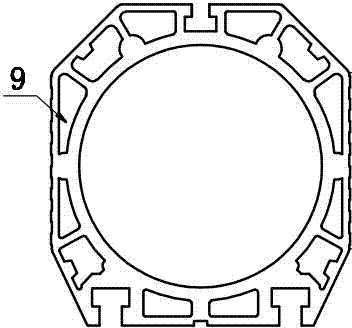

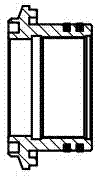

[0017] Such as figure 1 It is a structural schematic diagram of the present invention, a kind of air-cooled automatic tool-changing electric spindle for woodworking engraving and milling, including a casing 1, a rotor shaft 2, a stator component 3 and a rotor component 4 arranged in the casing 1, and respectively The front bearing 11 and the rear bearing 12 at both ends of the rotor shaft 2, the casing 1 is an integral square and has an air duct 9, and the two ends of the casing 1 are provided with a knife handle 15 and an independent fan 8, the independent The fan 8 is a seven-blade fan blade. The rotor shaft 2 is provided with an automatic tool change mechanism 6 , a cylinder 5 and a detection device 7 for the automatic tool change mechanism. The front end of the casing 1 is provided with a sealing cover 13 . The casing 1 is integrally formed by aluminum profiles. Such as figure 2 As shown, the casing 1 adopts an integrated square design with ventilation channels, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com