Patents

Literature

133 results about "Ship's carpenter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ship's carpenter specializes in shipbuilding, maintenance, repair techniques and carpentry specific to nautical needs in addition to many other on-board tasks; usually the term refers to a carpenter who has a post on a specific ship.

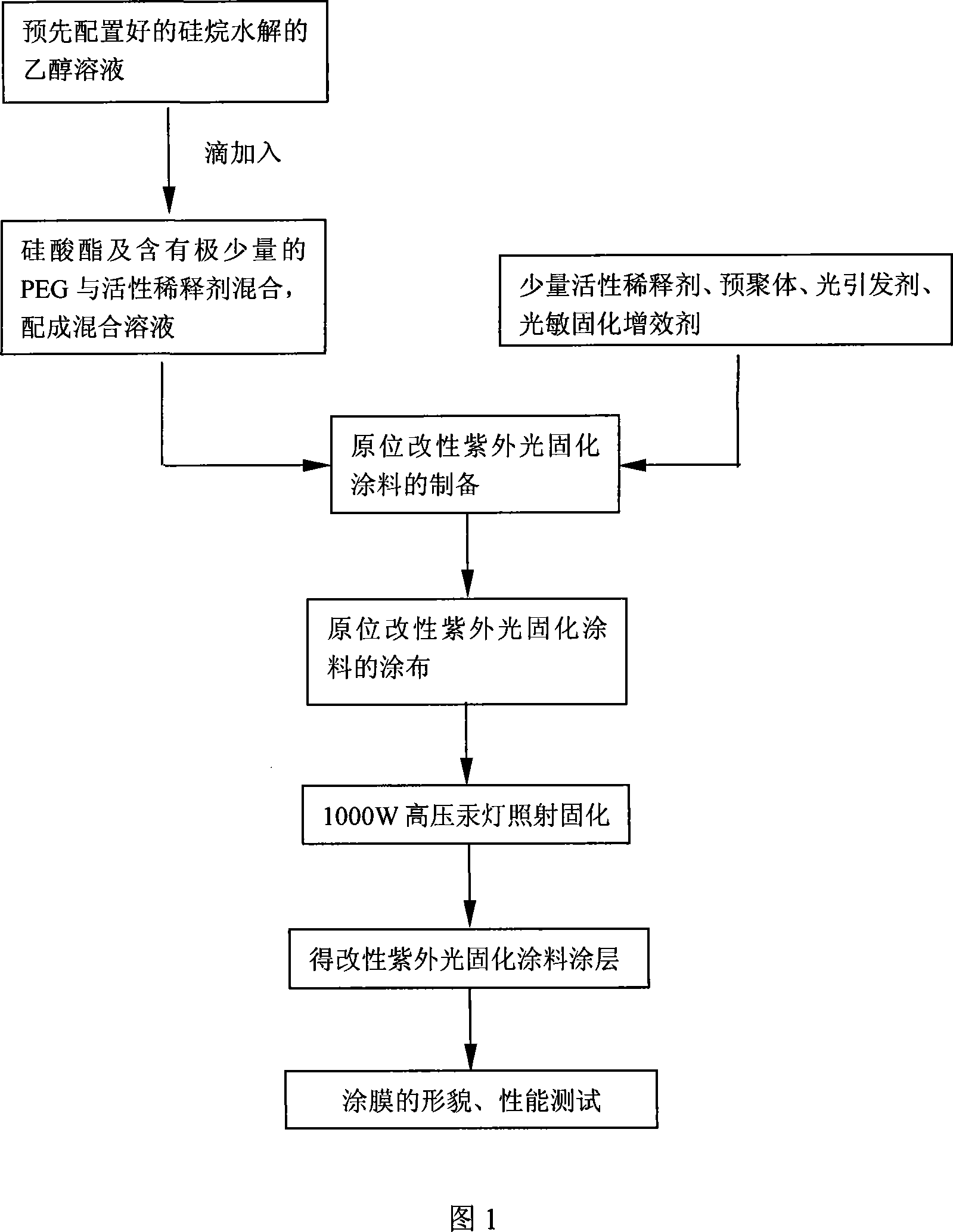

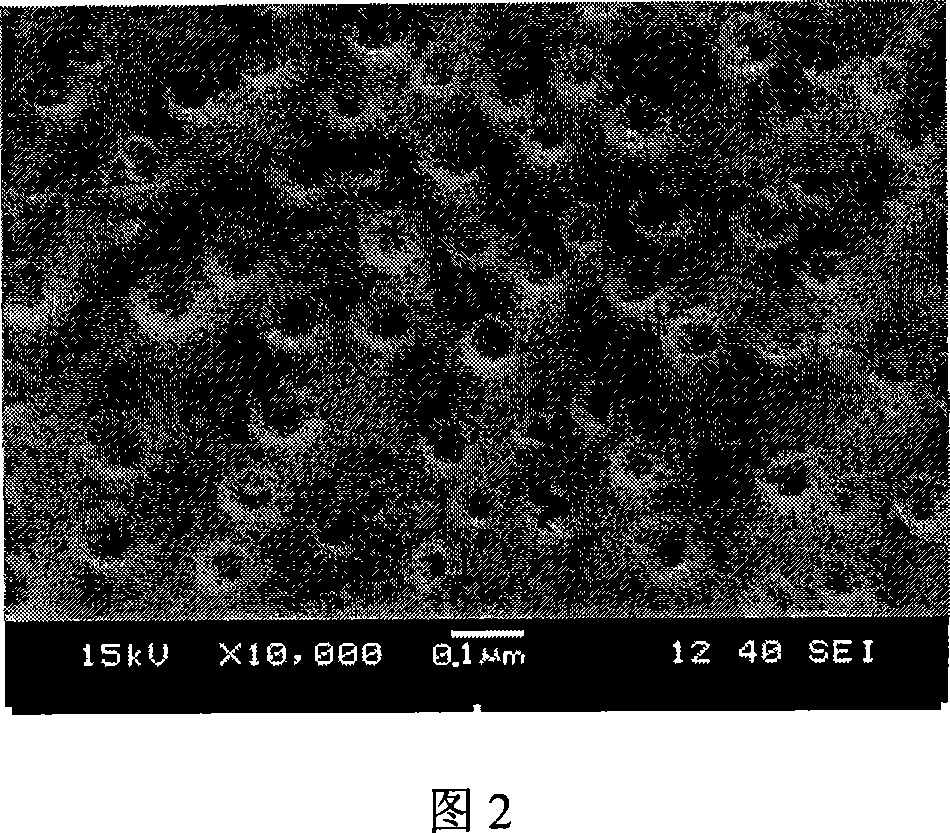

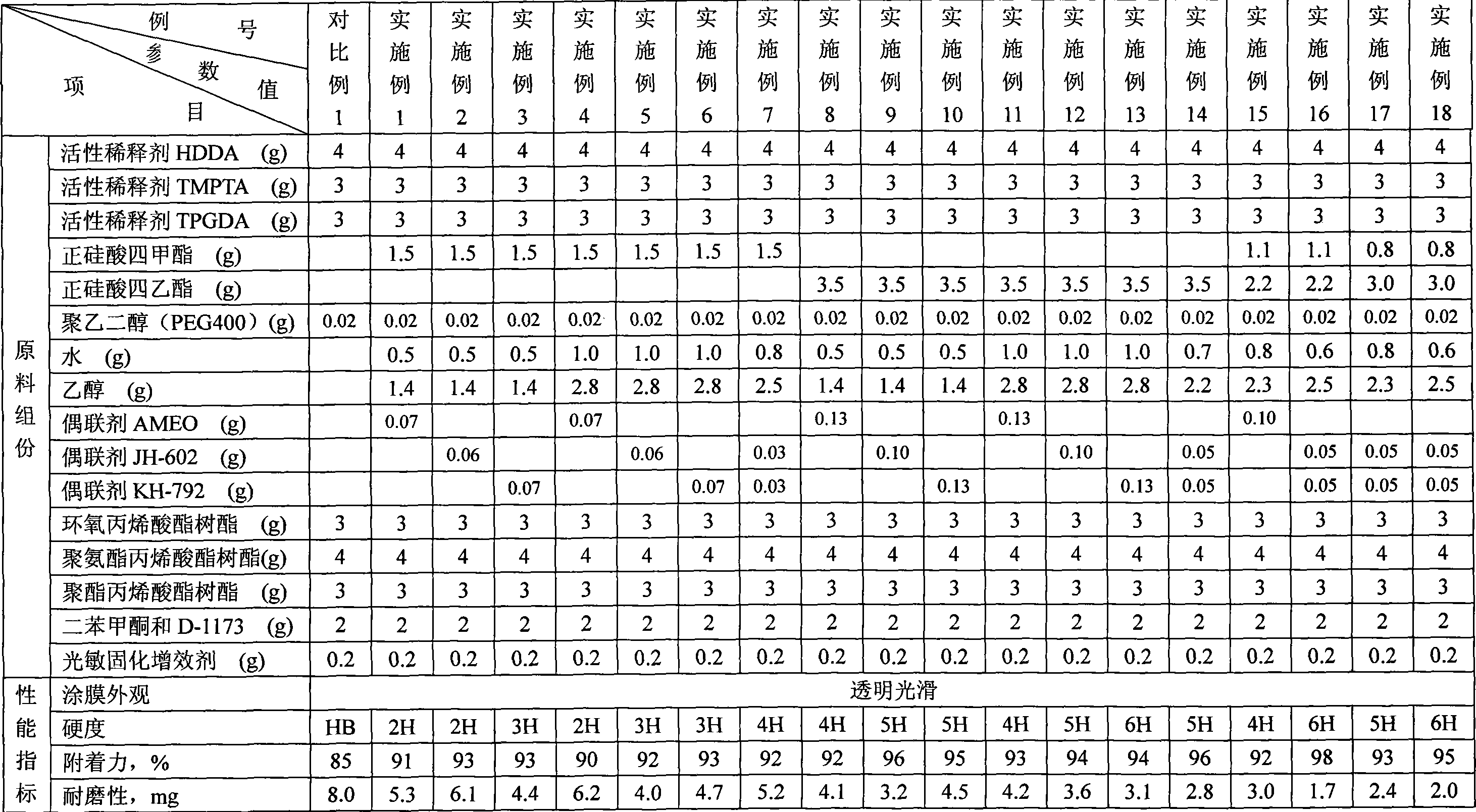

Preparation metod of modified ultroviolet light solidified wooden articles paint by in-situ method

ActiveCN101045833ASolve reunionInhibition dispersionLiquid surface applicatorsPolyurea/polyurethane coatingsSilicic acidUltraviolet lights

This invention relates to preparation method of in situ modified ultraviolet light curing carpentry dope. It selects one or more kinds of acrylate resin kind reactive diluents that has lower viscosity as in situ reactive basal body, adopts silicic acid ester as precursor, takes silane coupling agent with amino amino as catalyzer and surface conditioning agent, one-step complete preparation and surface treatment of nanometer materials, gain ultraviolet light curing dope. This film coating is transparence, rigidity reach 6H, adhesion reach 98%, wearability 1.7 mg . nanometer particle distribute uniformity in dope, particle size is between 60 to 80 nm, efficiently solve problem of nanometer particle agglomeration, advance wearability and rigidity and so on performance of film coating.

Owner:溧阳常大技术转移中心有限公司

Water anti-flaming carpentry paint

InactiveCN101143988AWith flame retardant effectDoes not affect the decorative effectLiquid surface applicatorsPolyurea/polyurethane coatingsWaxEmulsion

The invention relates to a coating, in particular to an aqueous flame retardant fireproof woodenware paint, which includes base material, flame retardant, water, wetting agent, film forming additive , flow agent, preservative, wax emulsion, and thickener, wherein the base material is organosilicone acrylic acid polymer and includes 75-80 percent of base material emulsion, 8-15 percent of flame retardant, 4-6 percent of water, 0.05-0.2 percent of wetting agent, 4-6 percent of film forming additive, 0.1-0.2 percent of flow agent, 0.05-0.2 percent of preservative, 1-3 percent of wax emulsion, and 0.1-0.3 percent of thickener, the woodenware paint has great flame retardant efficacy and good painting decoration effect.

Owner:刘炳义

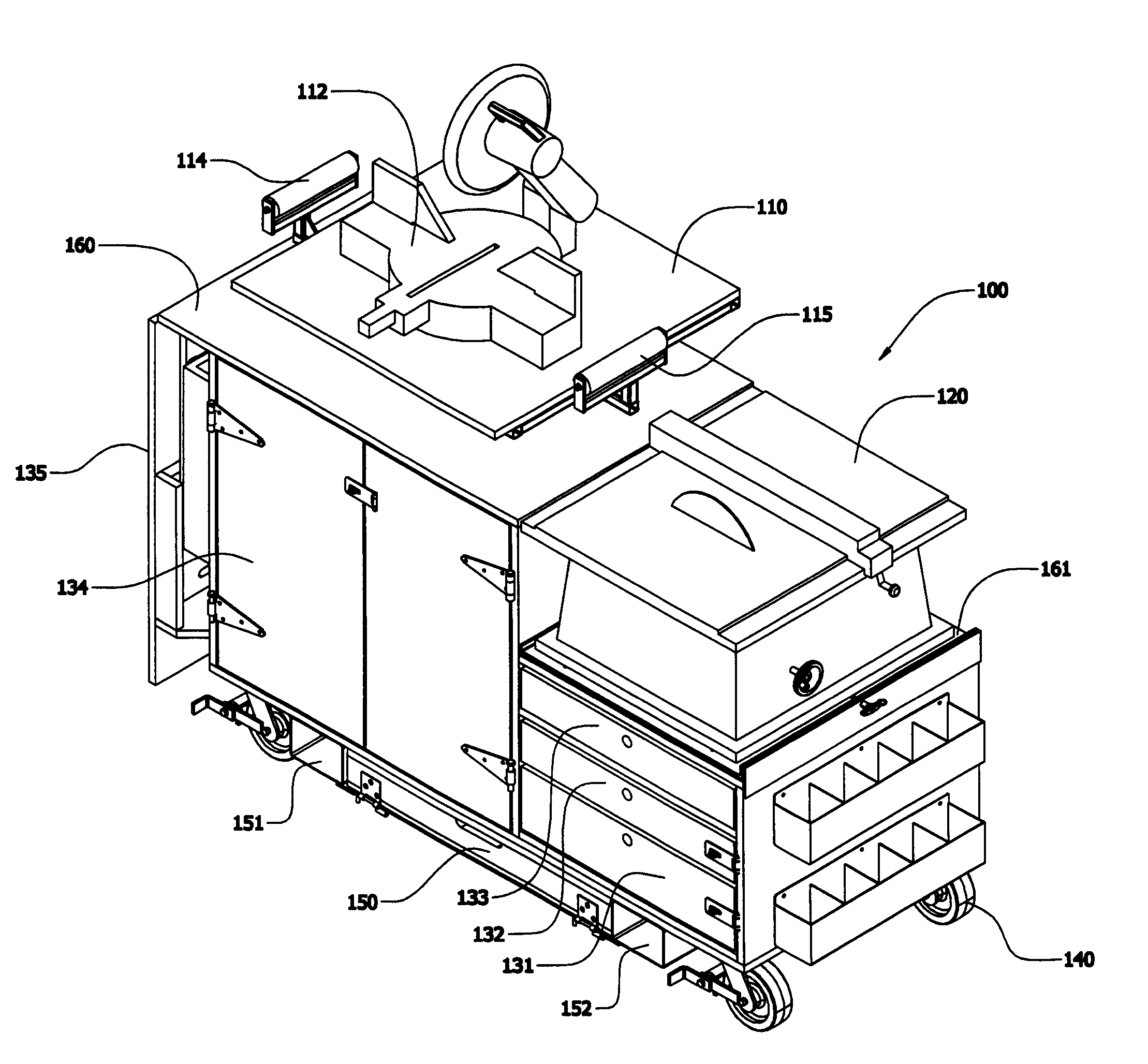

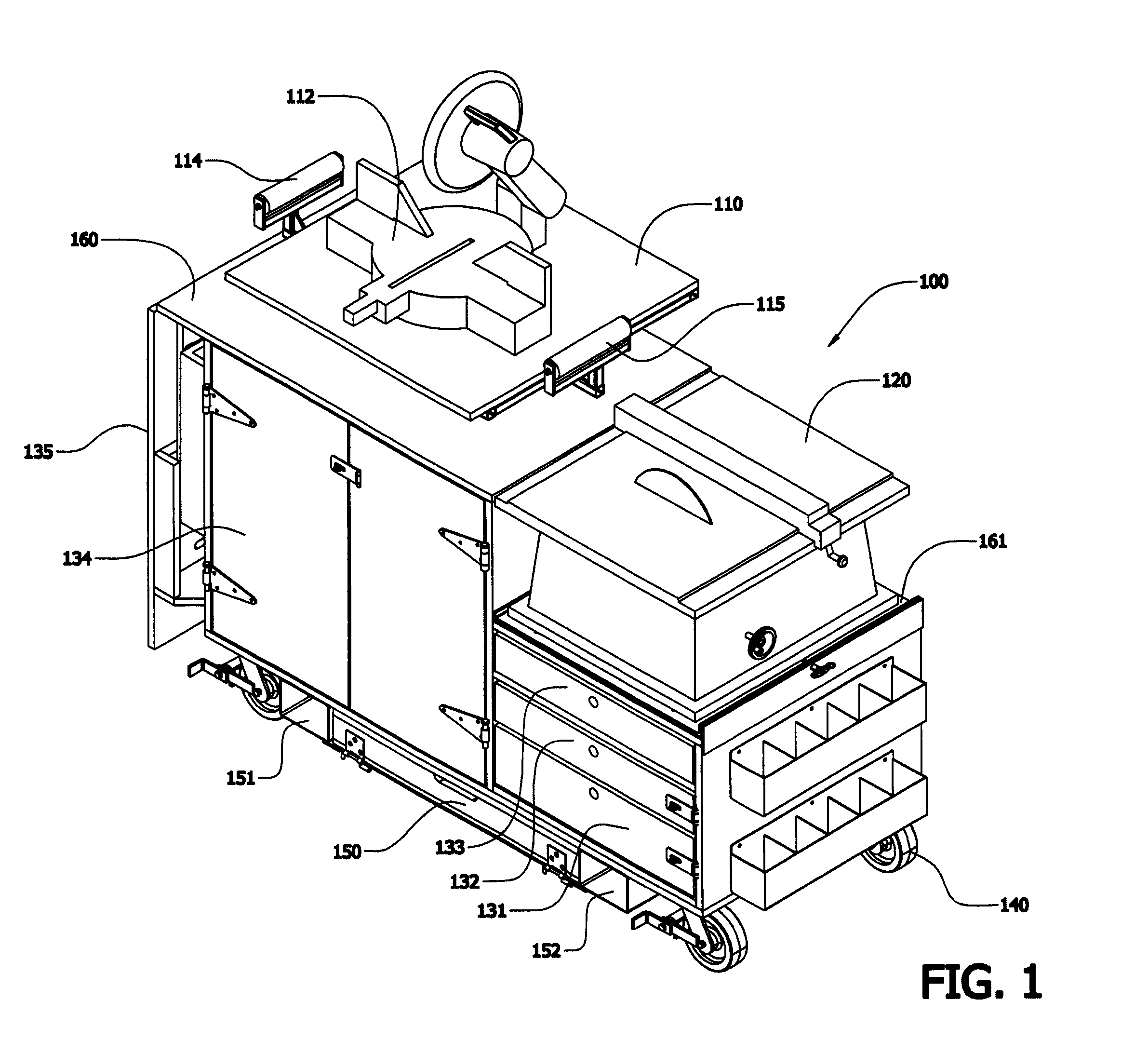

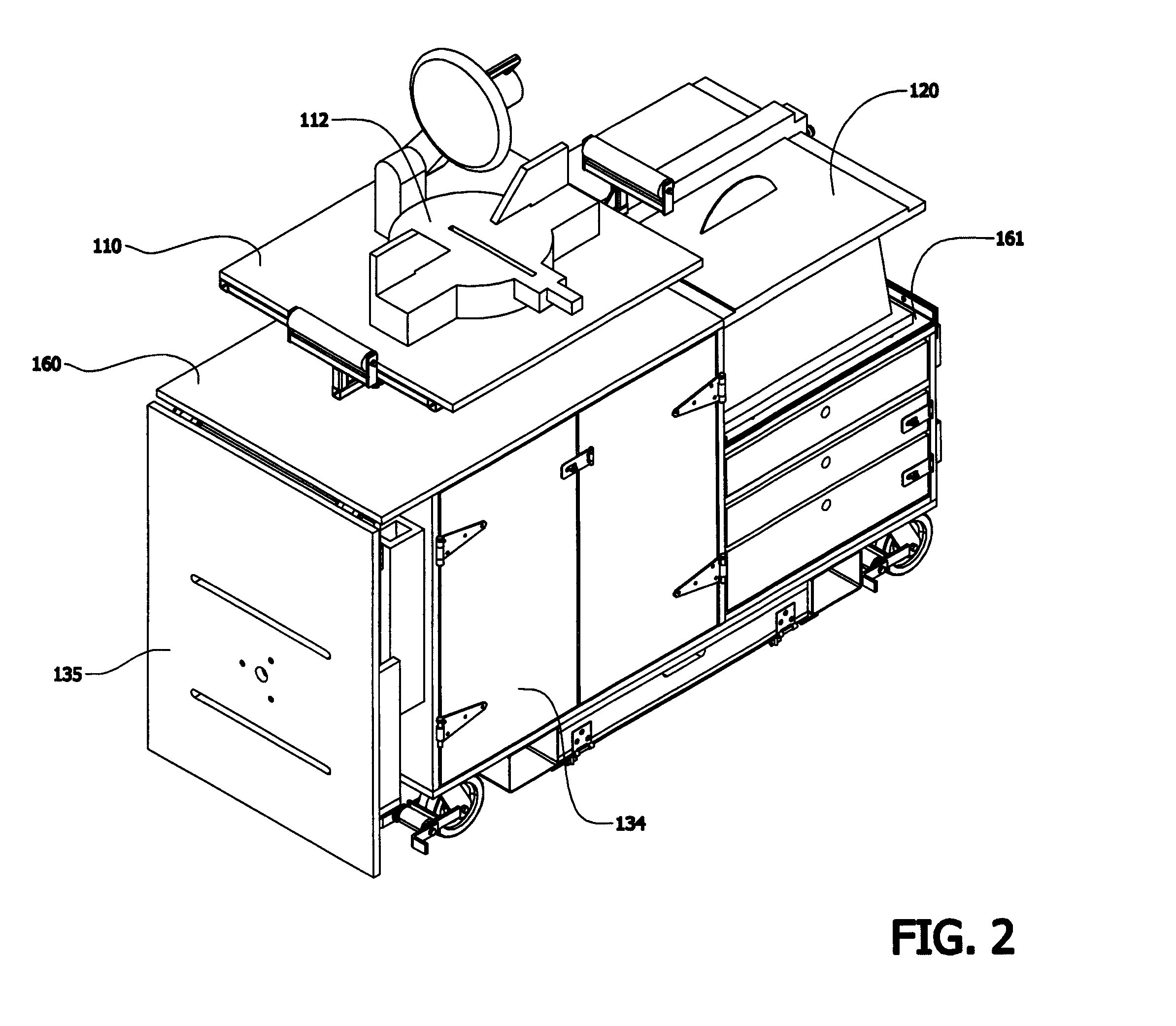

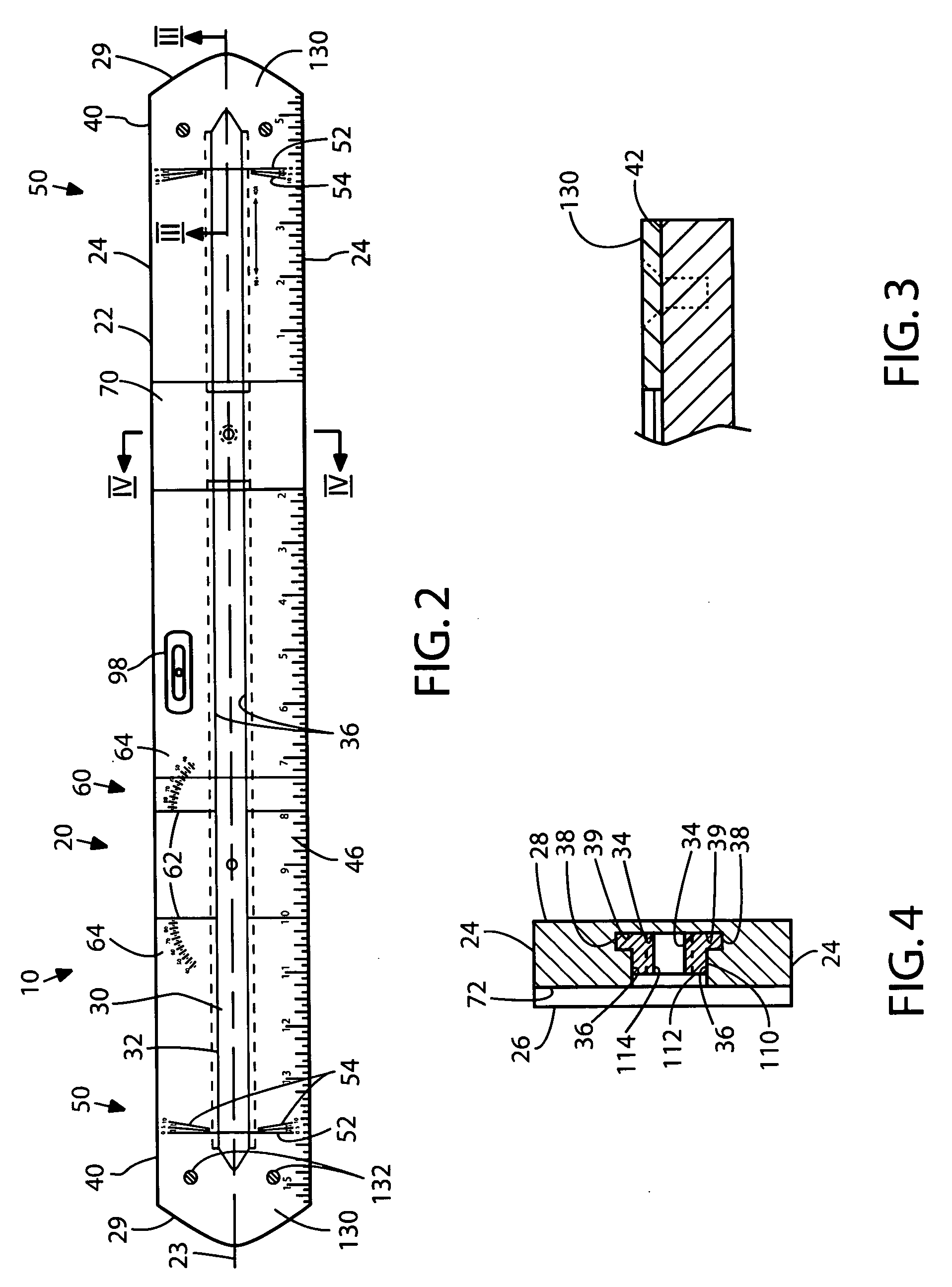

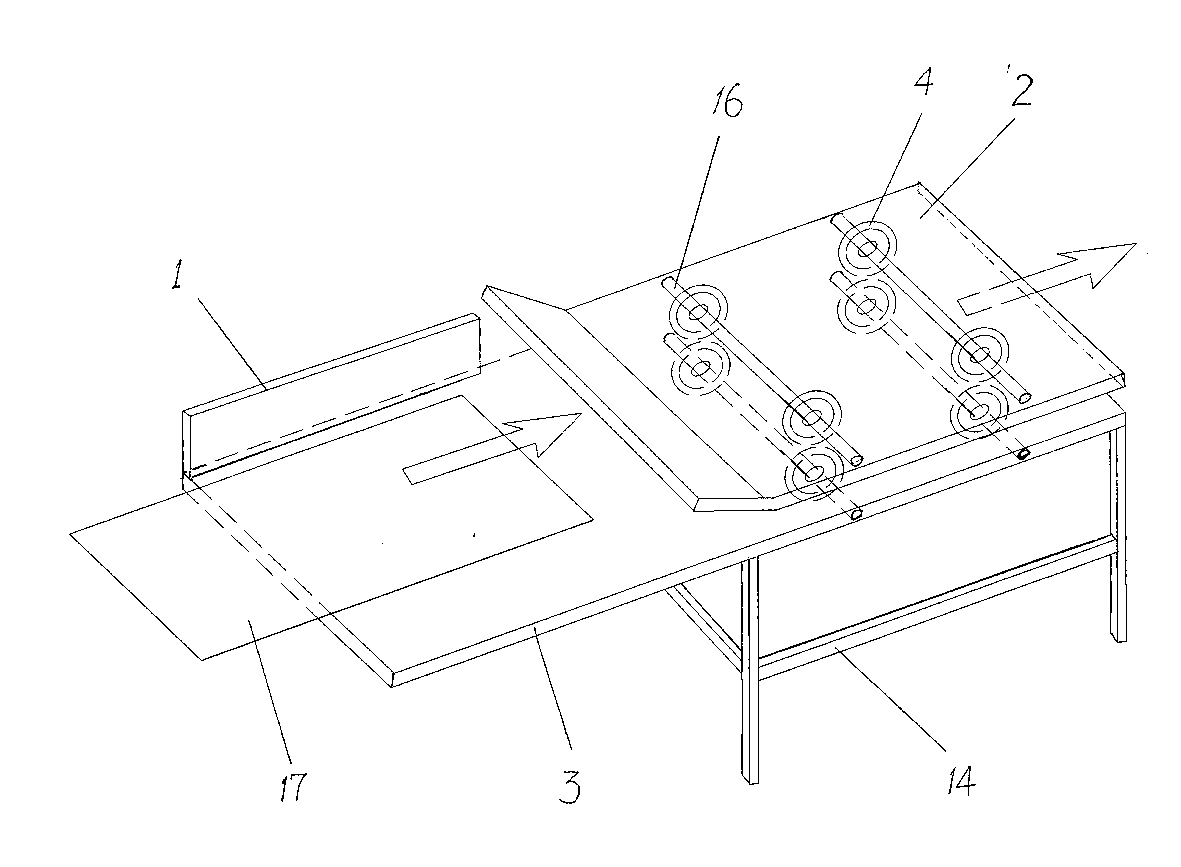

Portable carpentry workshop

InactiveUS7647956B1Easy to transportImprove mobilityGuide fencesShearing machinesEngineeringPower tool

A portable rolling carpentry workshop includes a table saw mounted on a sliding means to allow the blade of the saw to be shifted to the left or to the right of the longitudinal centerline of the workshop so that more supporting surface is available on either side of the blade to allow cutting large workpieces on a relatively narrow tabletop surface. The workshop of the invention is sized to allow easy maneuvering through the narrow hallways of apartment buildings but affords the functionality of larger worktables due to this unique ability to slide the table saw. Also provided is an extendable miter saw table located above the main tabletop surface and allowing passing of the longer workpieces underneath thereof when ripping with table saw. Therefore the use of both the table saw and the miter saw can be accomplished at the same time without the need to rearrange the configuration of the power tools on the workshop.

Owner:CONA FRED MR

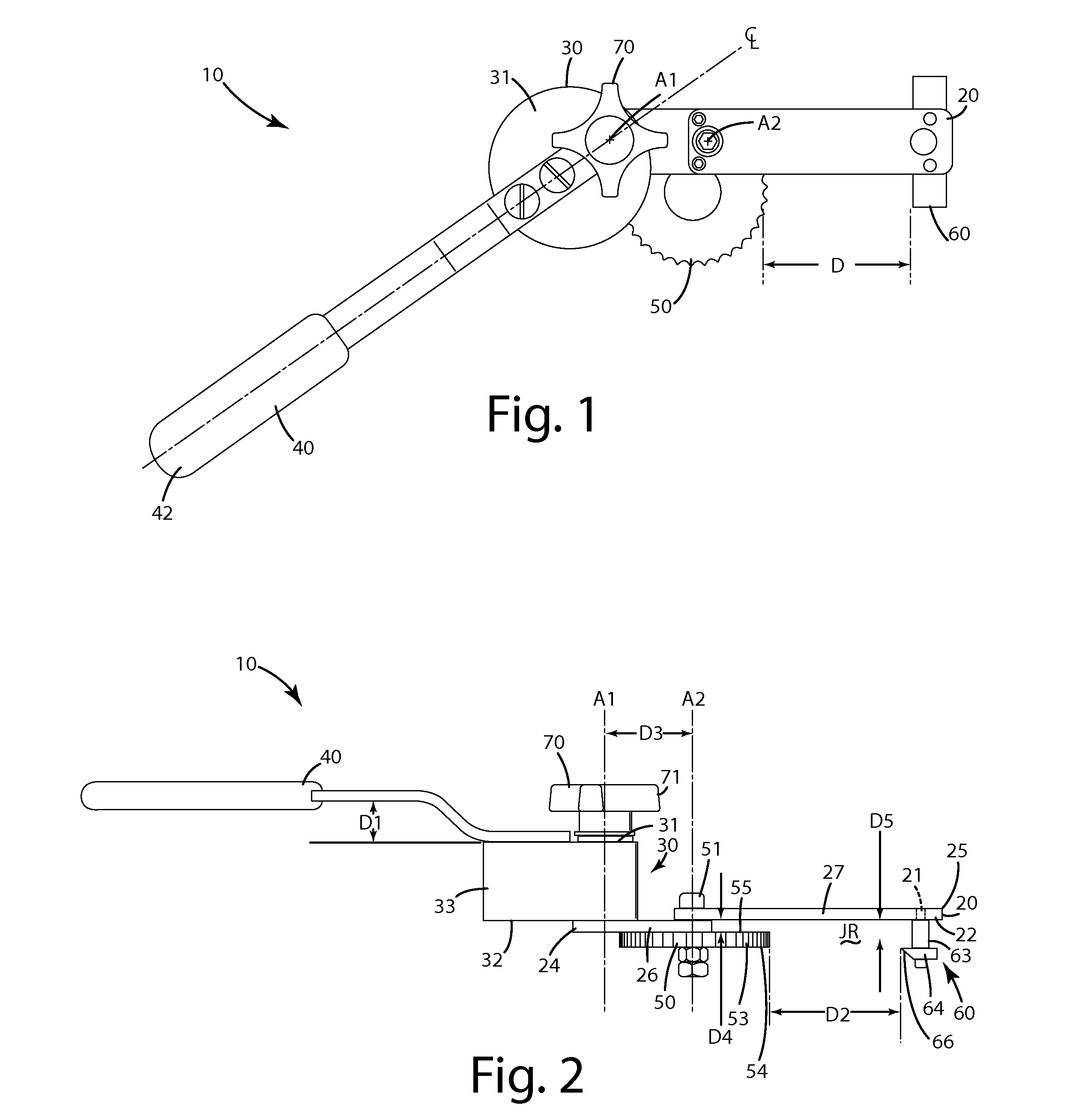

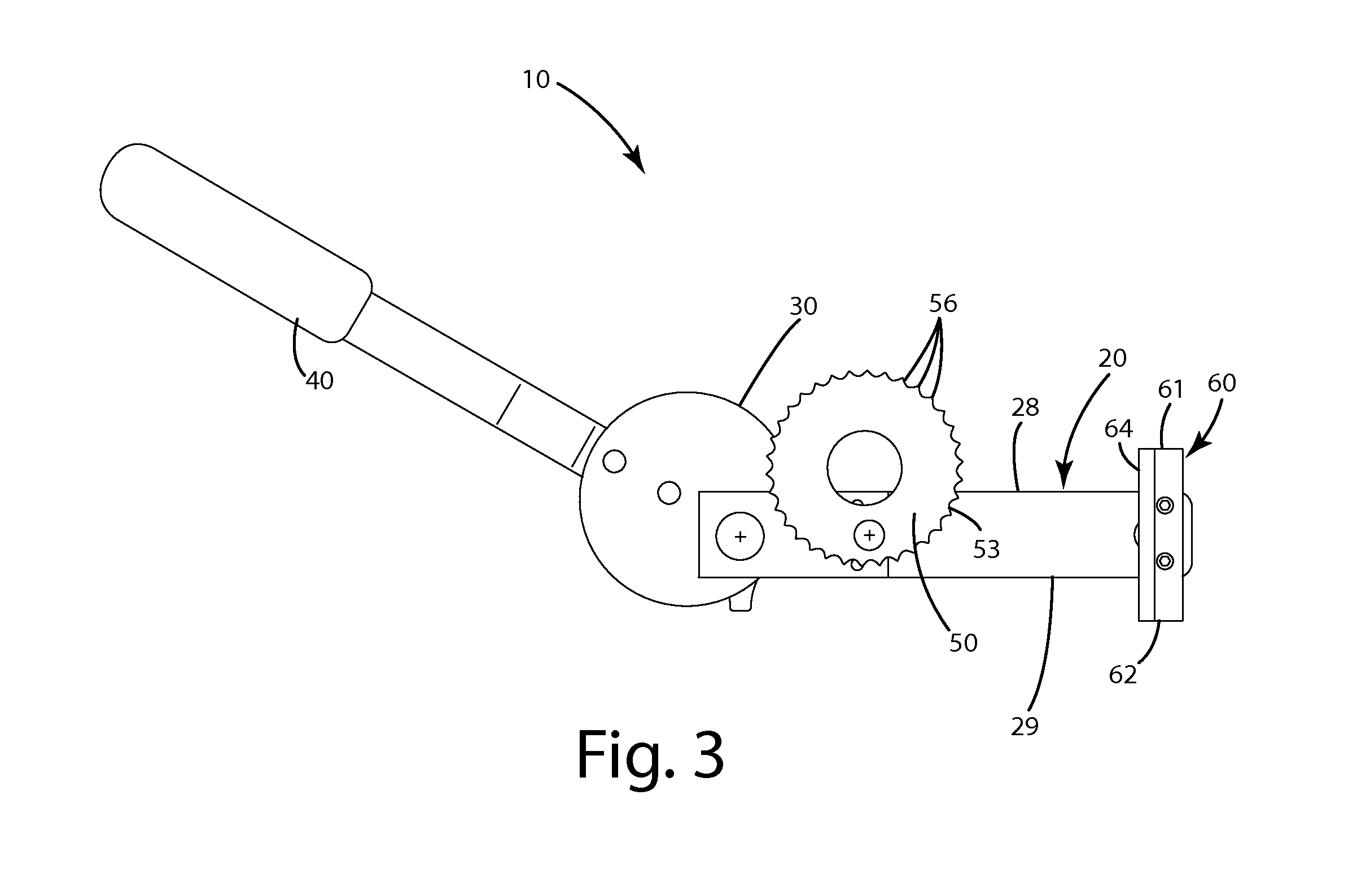

Adjustable angle carpentry apparatus

Owner:QUICK ANGLE

Preparation method for scratch-resistant and yellowing-resistant polyurethane carpentry matte white finish

The invention relates to a preparation method for scratch-resistant and yellowing-resistant polyurethane carpentry matte white finish. The finish comprises a component A of resin paint and a component B of curing agent; the weight proportioning of the component A and the component B is 1:0.5; the component A of resin paint comprises alkyd resin, titanium dioxide, extinction powder, coarse whiting powder, dispersant, light stabilizer, flatting agent, defoaming agent, anti-settling agent and solvent; and the component B of curing agent comprises TDI-HDI mixed tripolymer or TDI / TMP addition product, HDI tripolymer and solvent. The scratch-resistant polyurethane carpentry matte white finish, produced by the method, has no precipitate during storing, takes a high-solid and low-viscosity shape, and has the advantages of good leveling property, large thickness of once formed films without generating sags, mild hand feel, fullness, fineness, smoothness, coexistence of hardness and softness, and plump decoration effect as mirror face, gives elegant and comfortable feelings to people, adapts to the modern aesthetic view, is popularized in markets, and is favored by clients. The paint is widely applied in the surface of a product, such as carpentry, metal, plastic and the like, and is used as protection decoration.

Owner:UNION FOSHAN CHEM +1

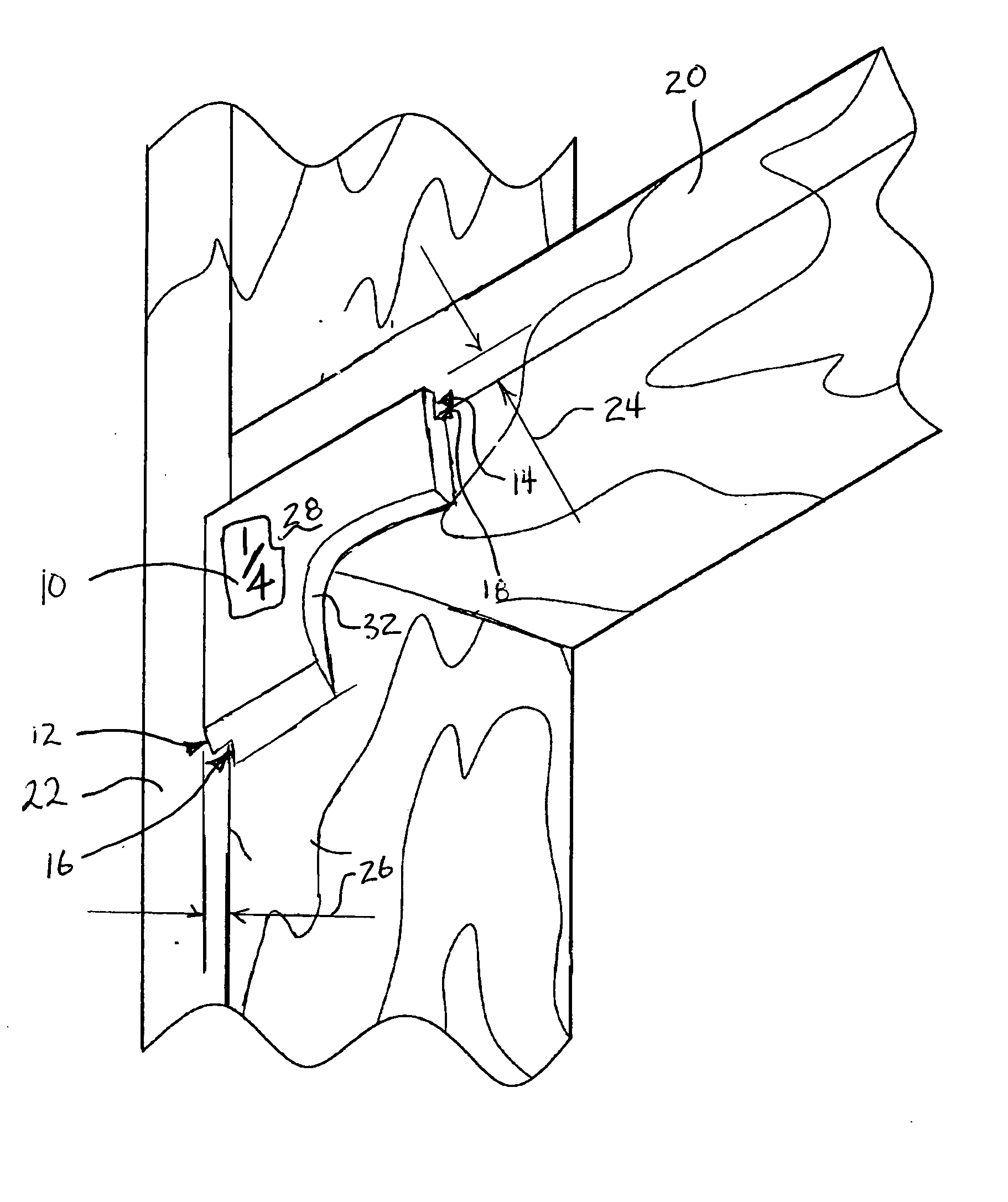

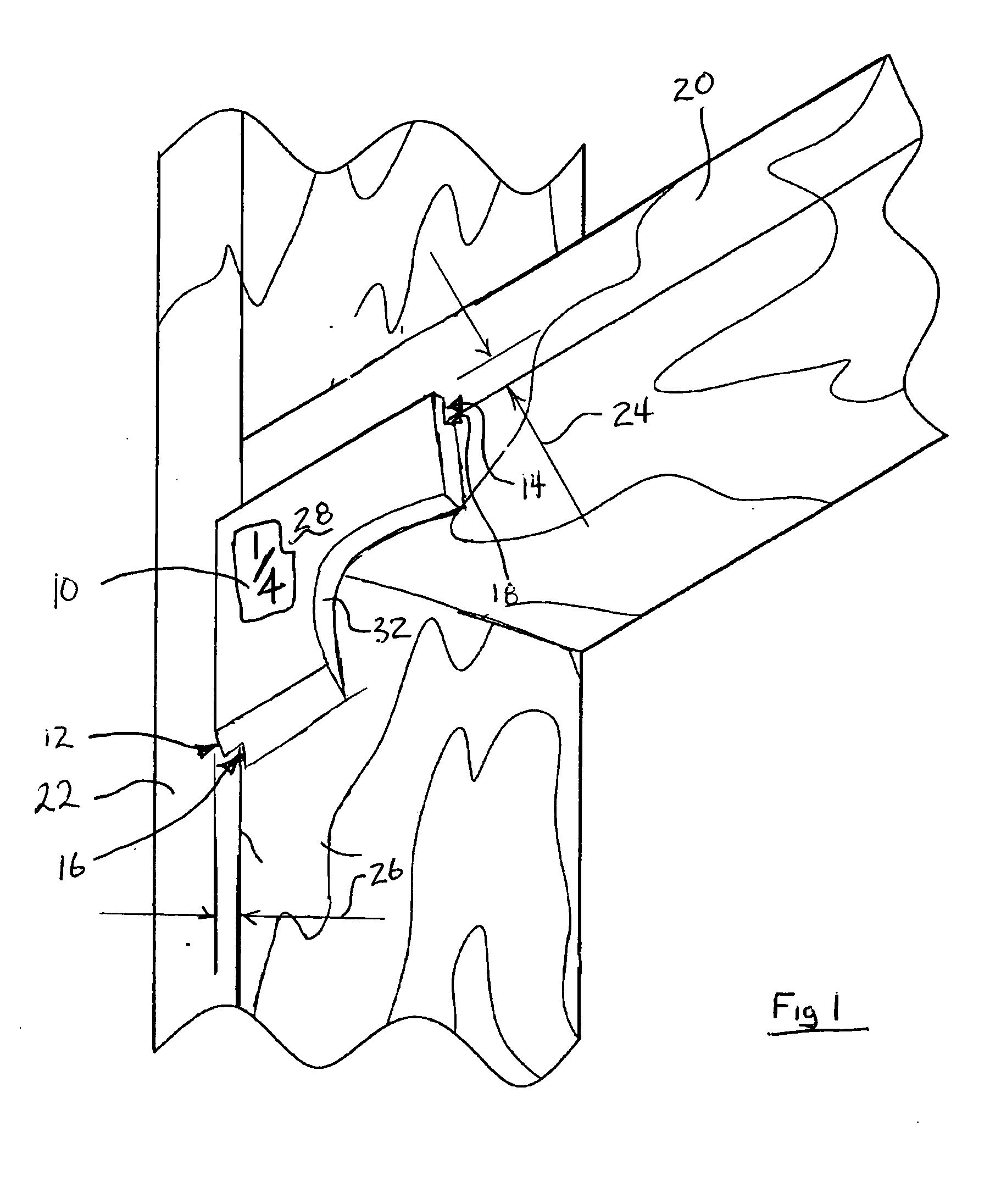

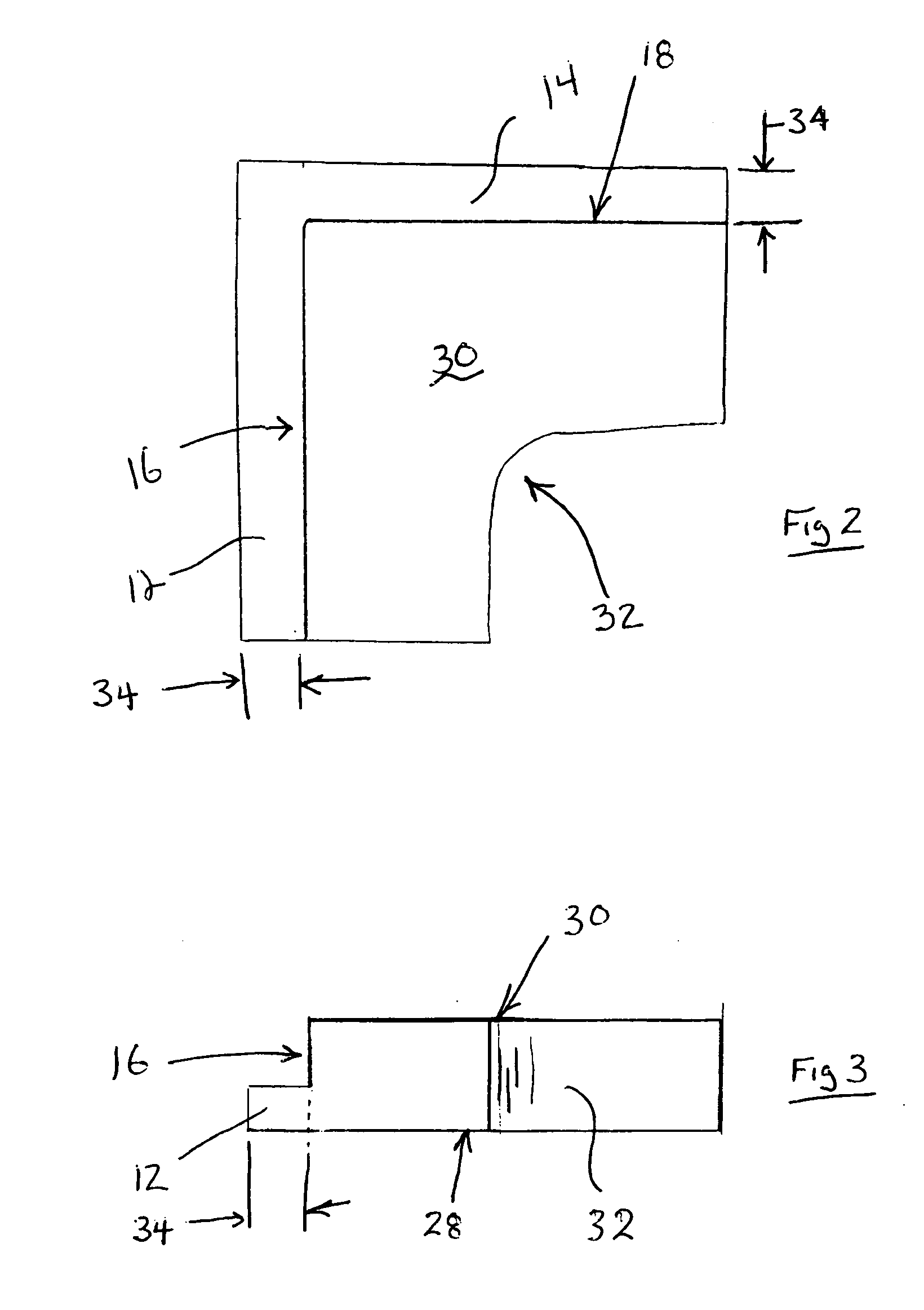

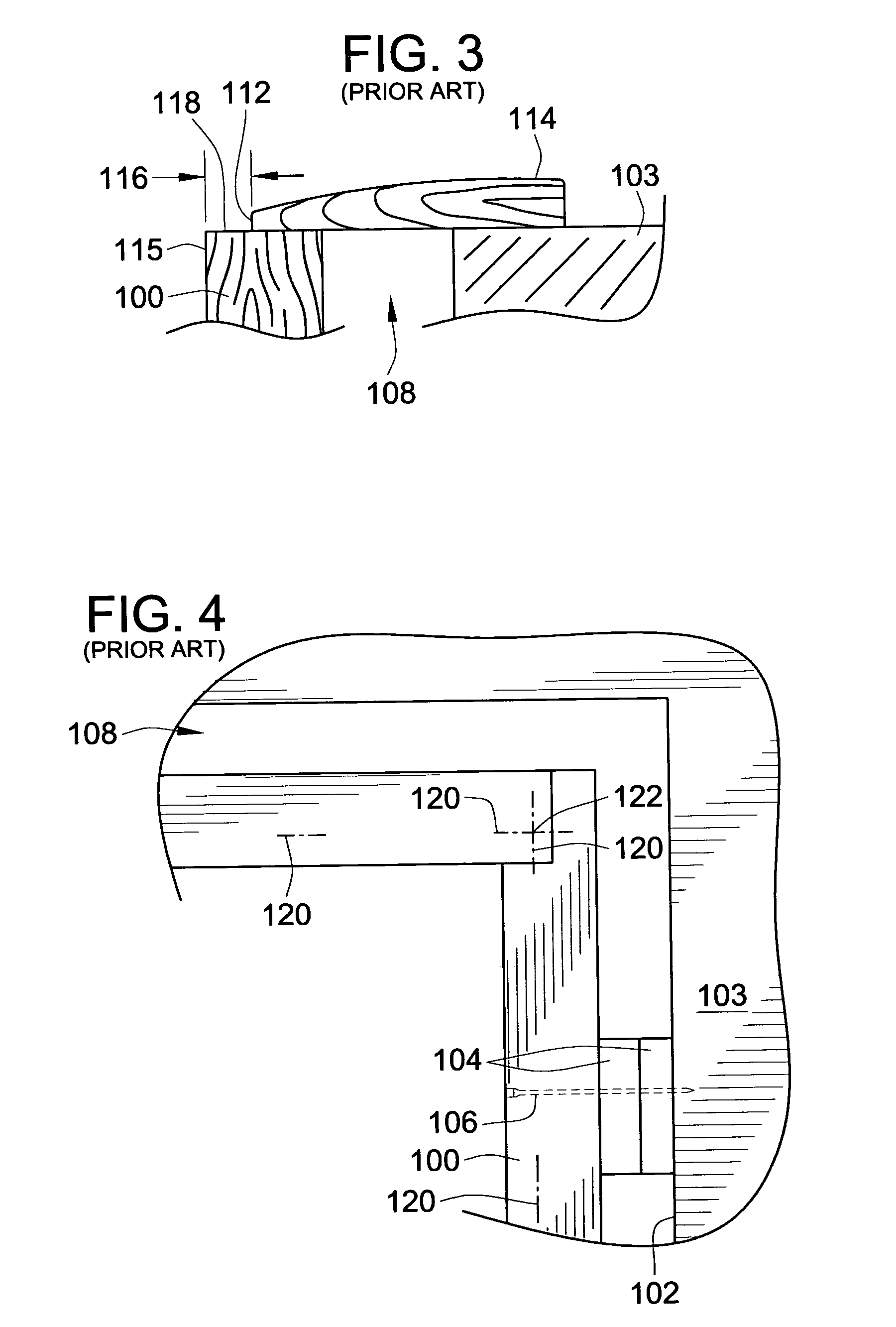

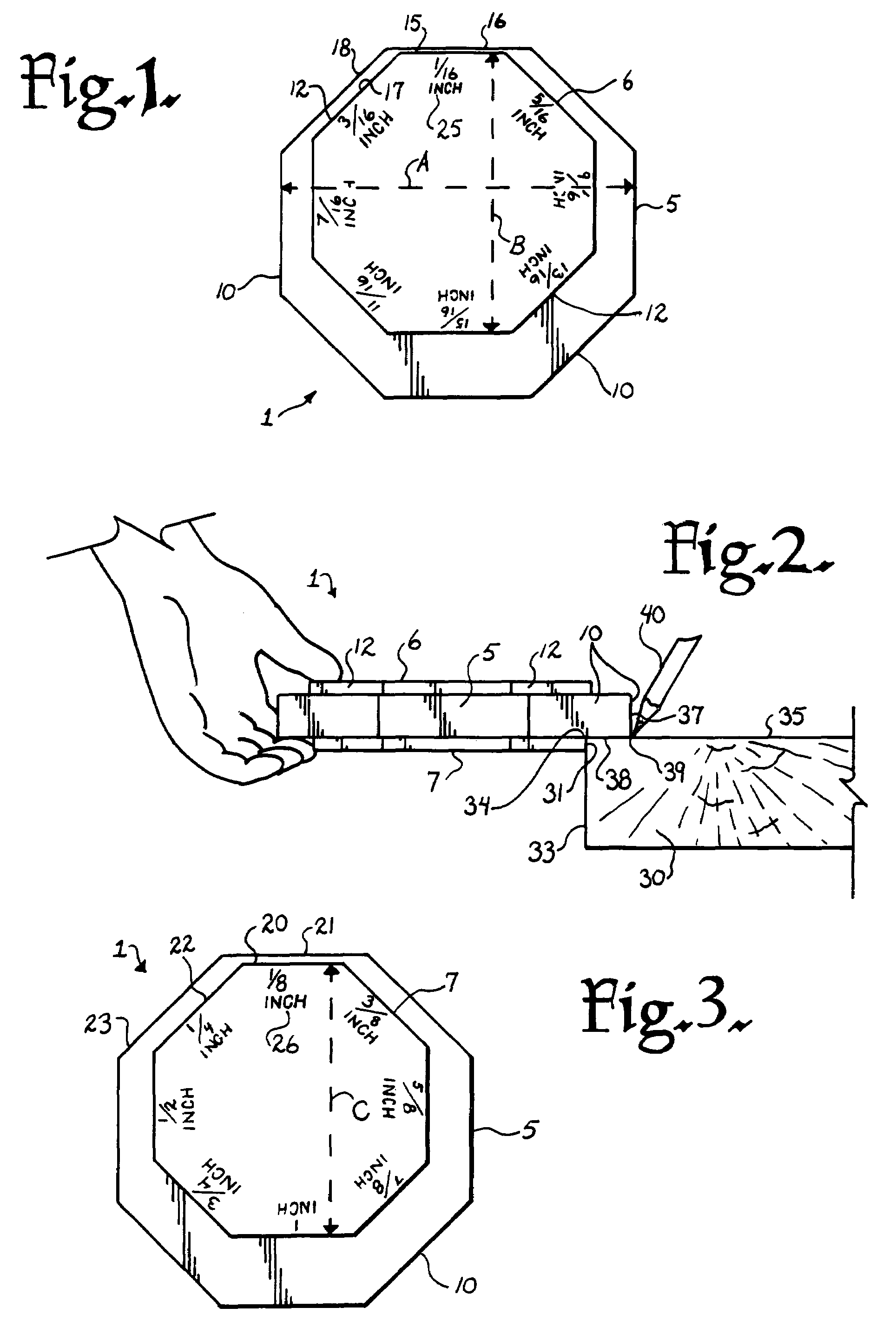

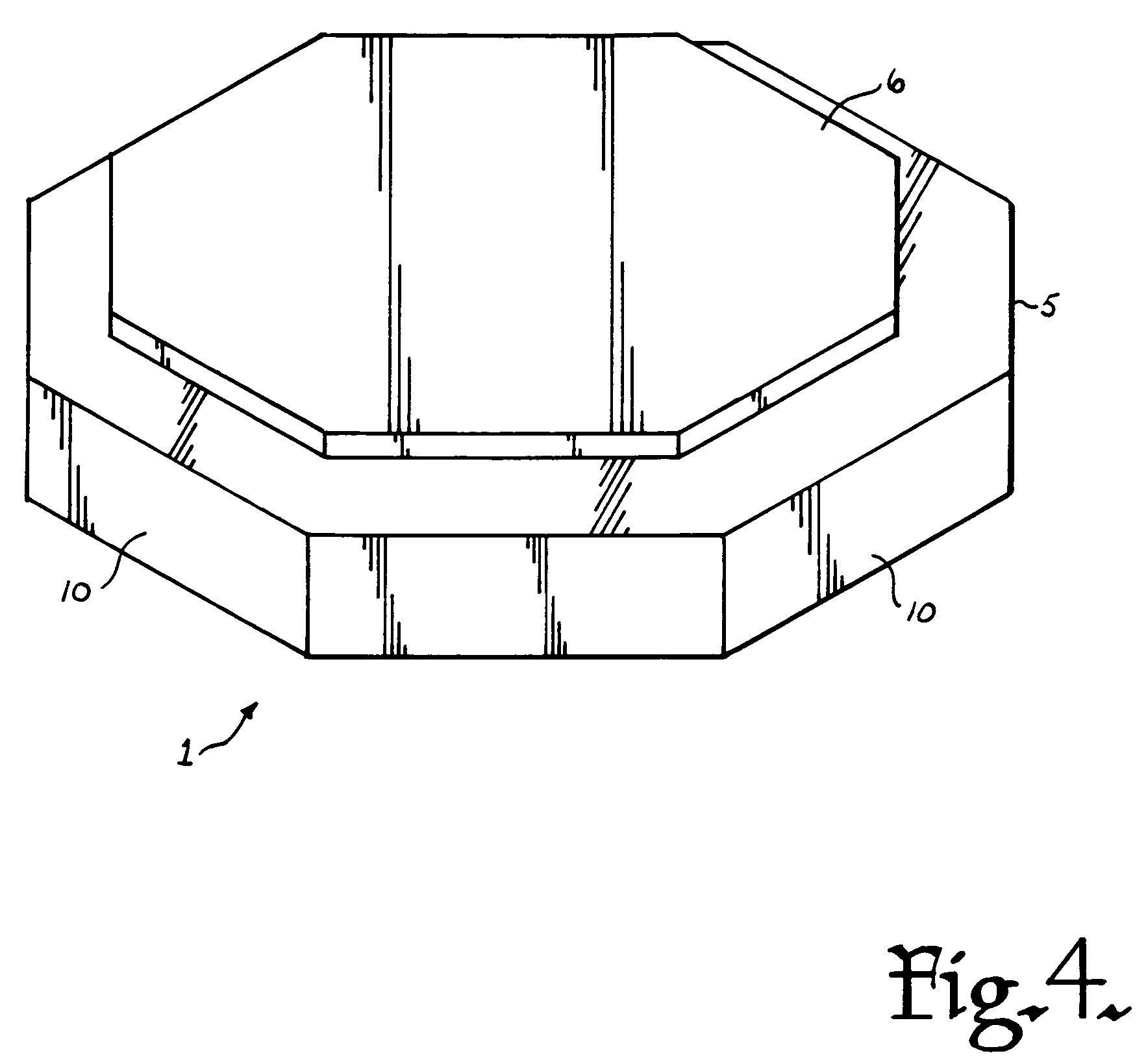

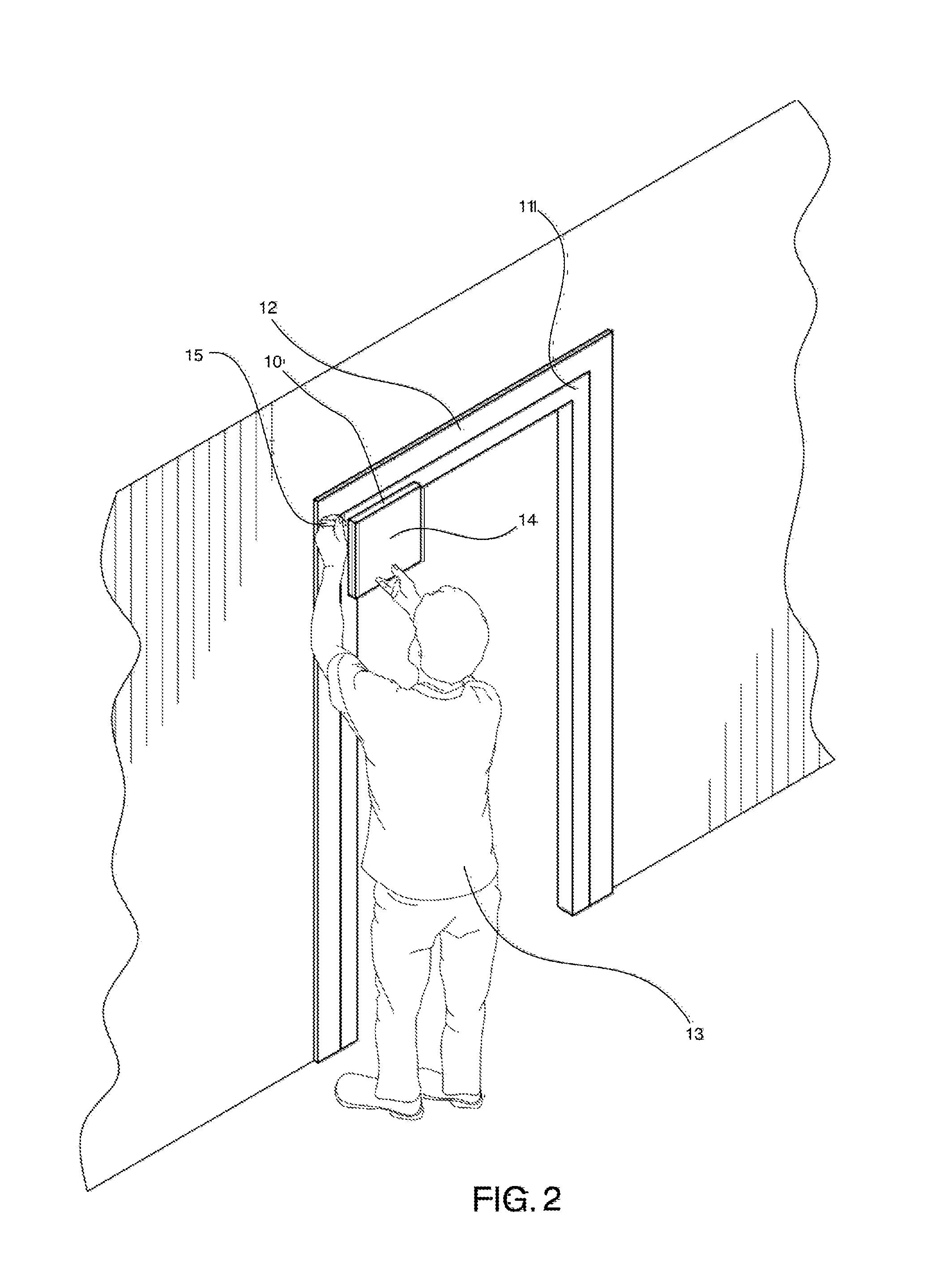

Finish carpentry trim gauge

InactiveUS20050022397A1Easy to carryEasy to placeMeasurement devicesDoors/windowsEngineeringConfusion

A carpentry gauge of this invention includes a first and second face surface that abut interior surfaces of vertical and horizontal frame members for the window or door opening. Extending from those faces are the lip portions. The lip portions overlap the outer surface of the vertical and horizontal members of the doorframe and provide the correct distance for a desired setback. The carpentry gauge of this invention is small, compact and easily placed and carried within a shirt pocket. No adjustments are required to be made to the gauge and only one dimension is provided in each gauge eliminating possible confusion during marking for a specific window or doorframe.

Owner:NEBLO RODNEY

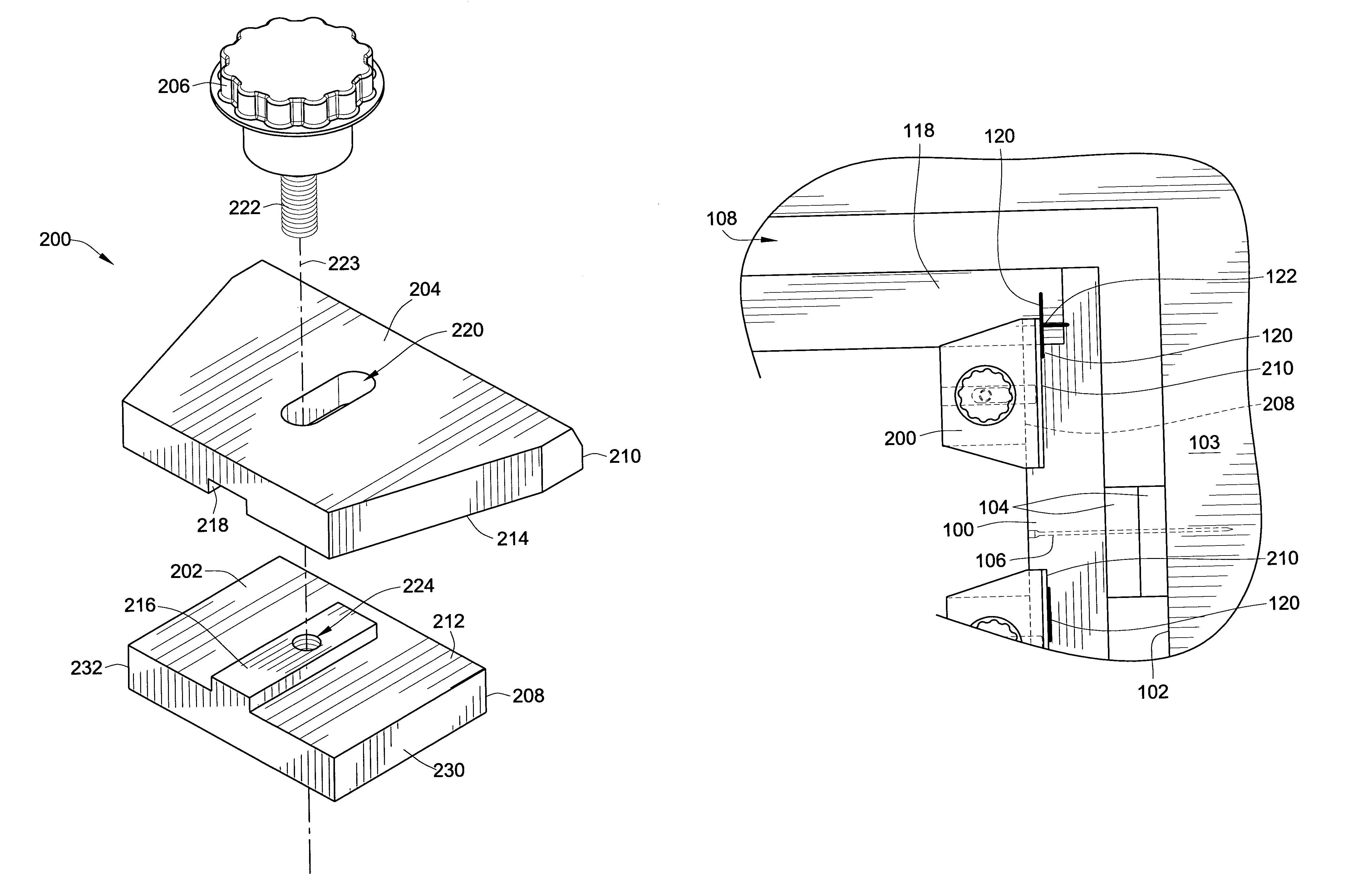

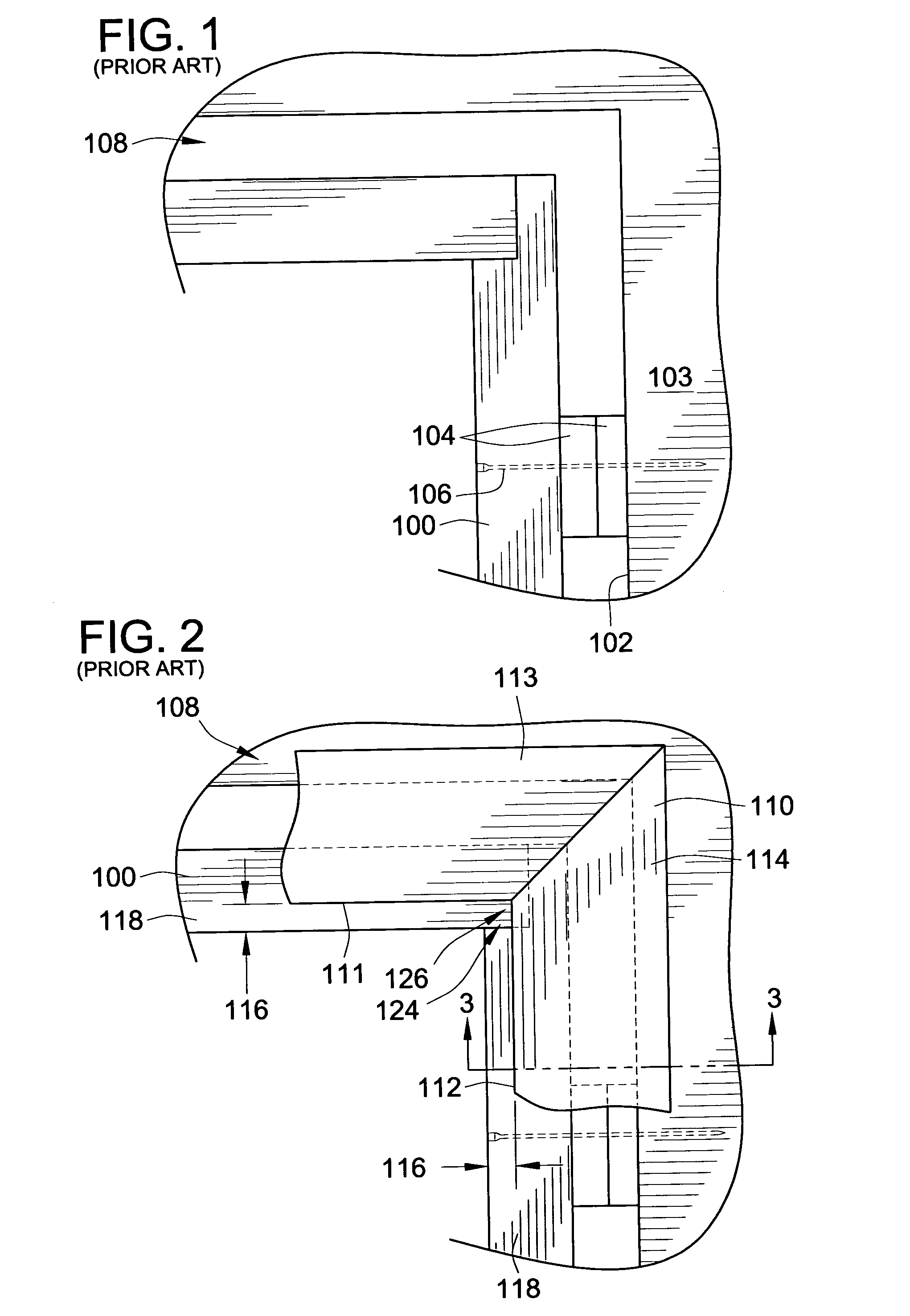

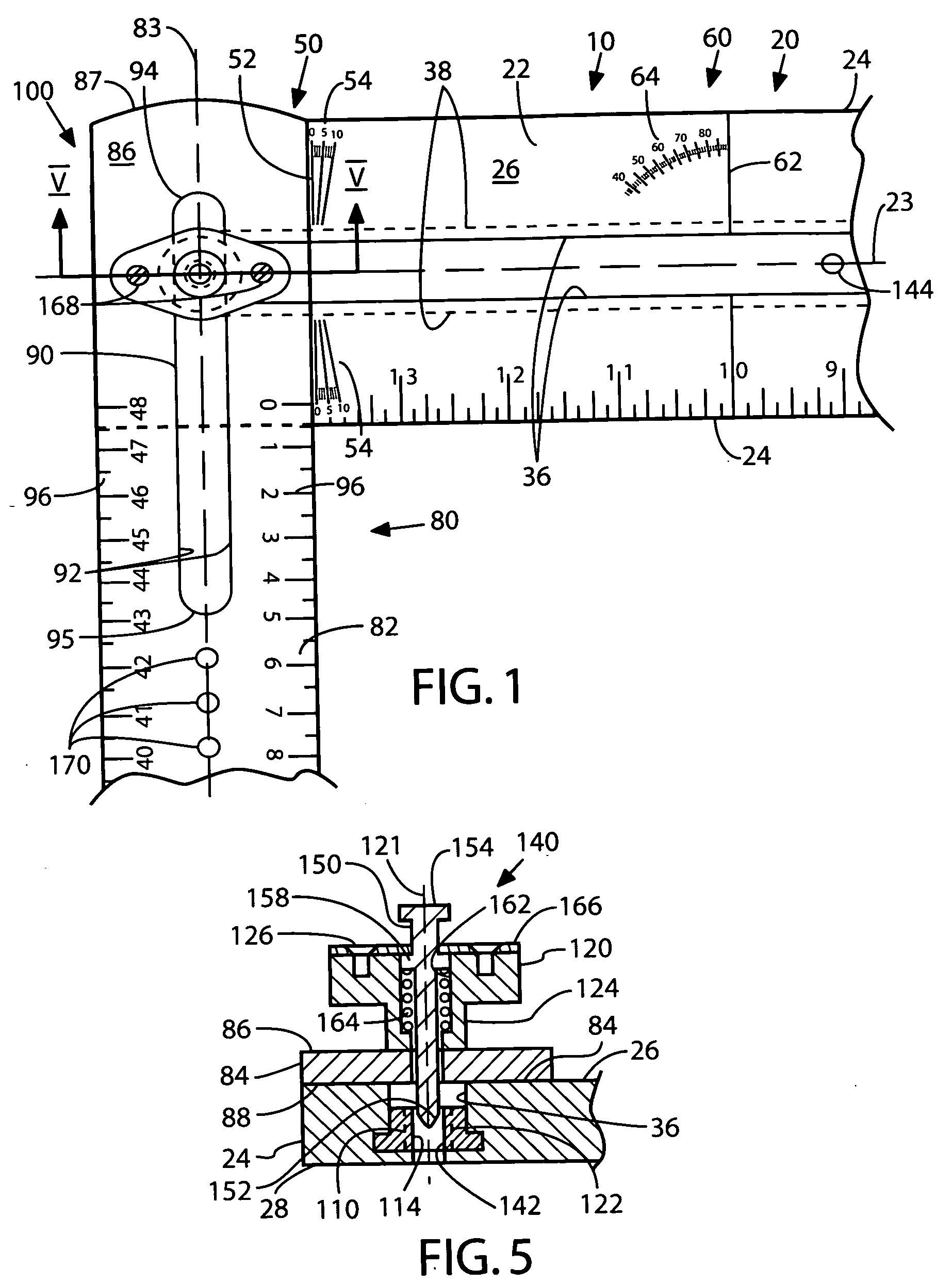

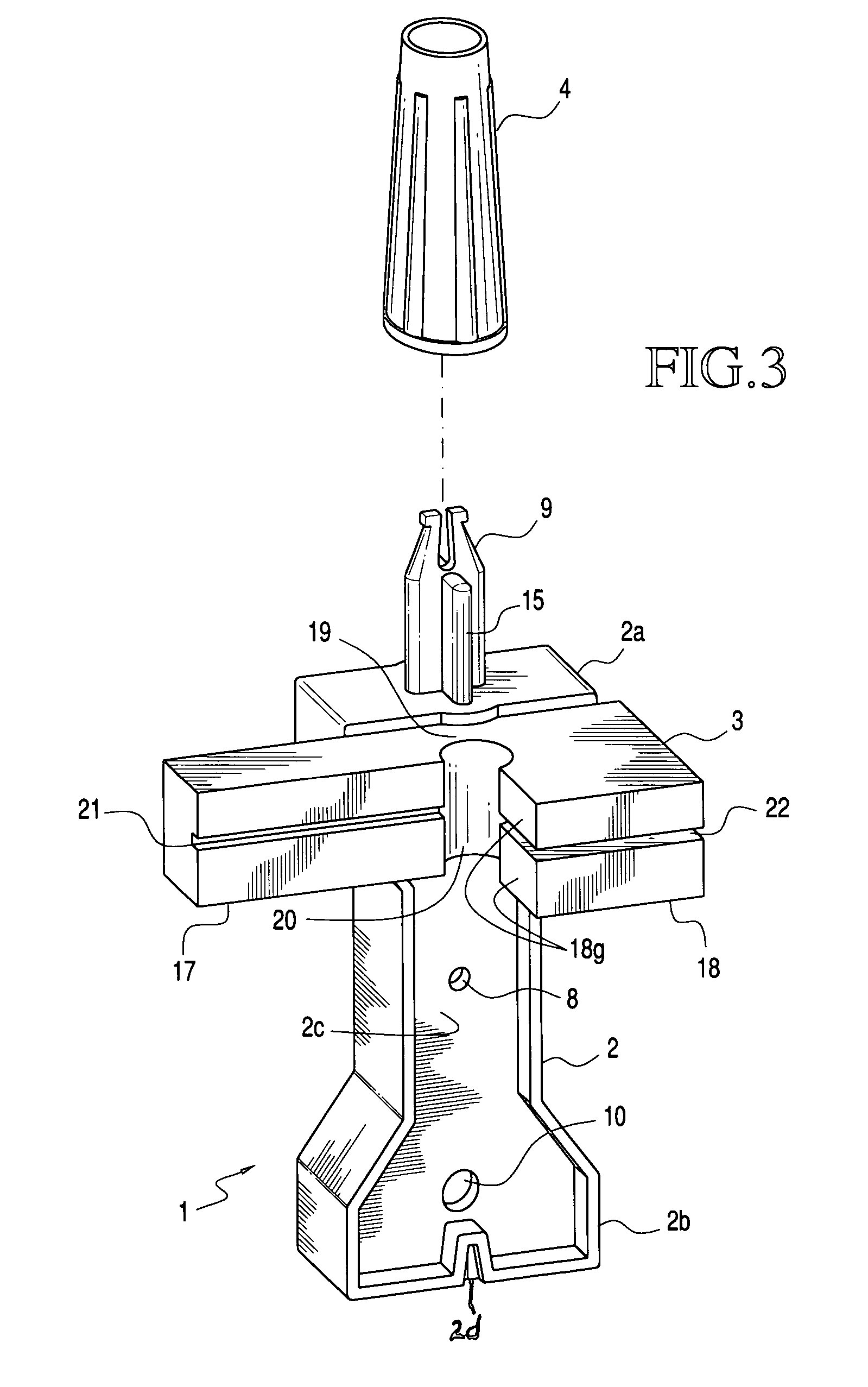

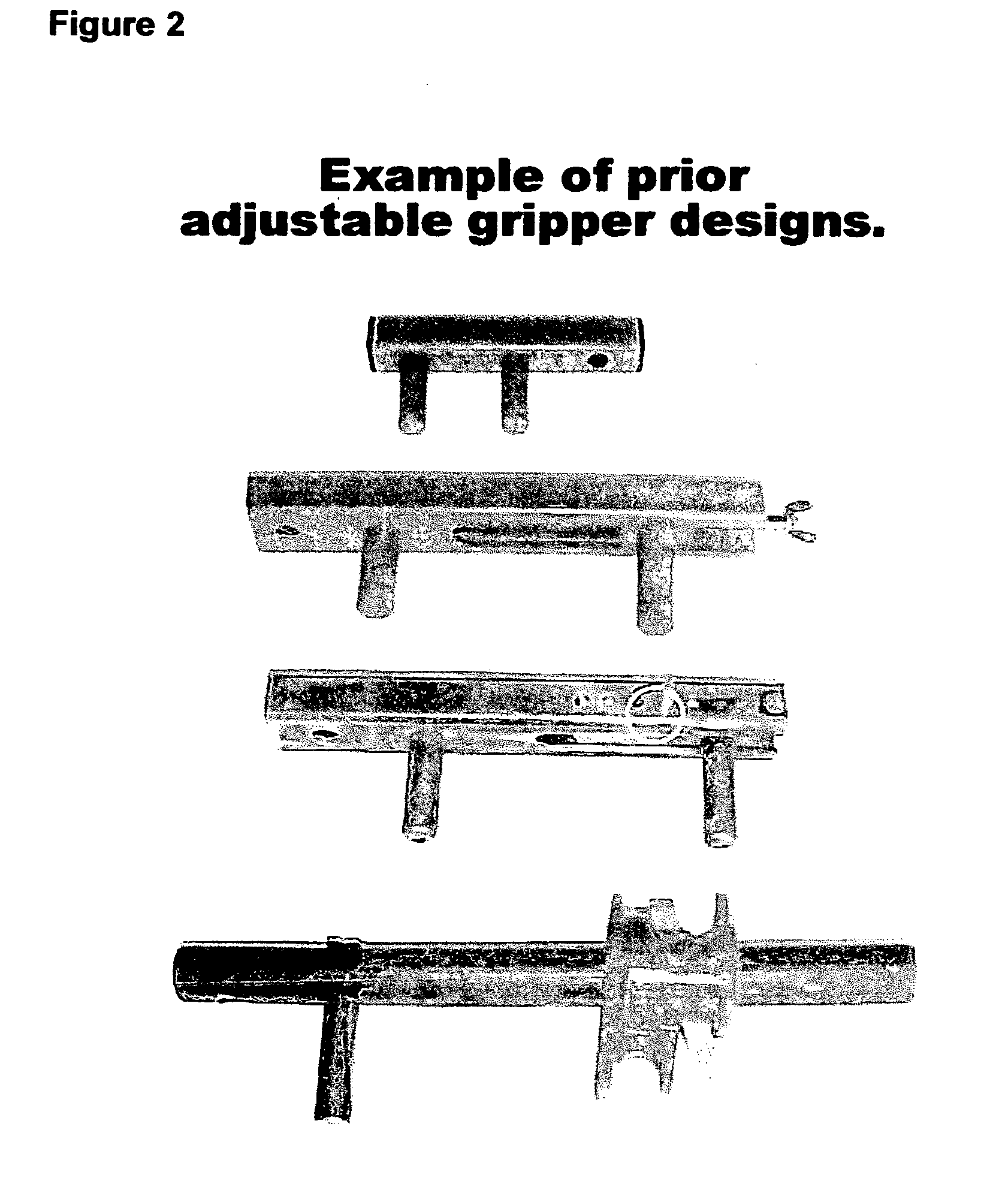

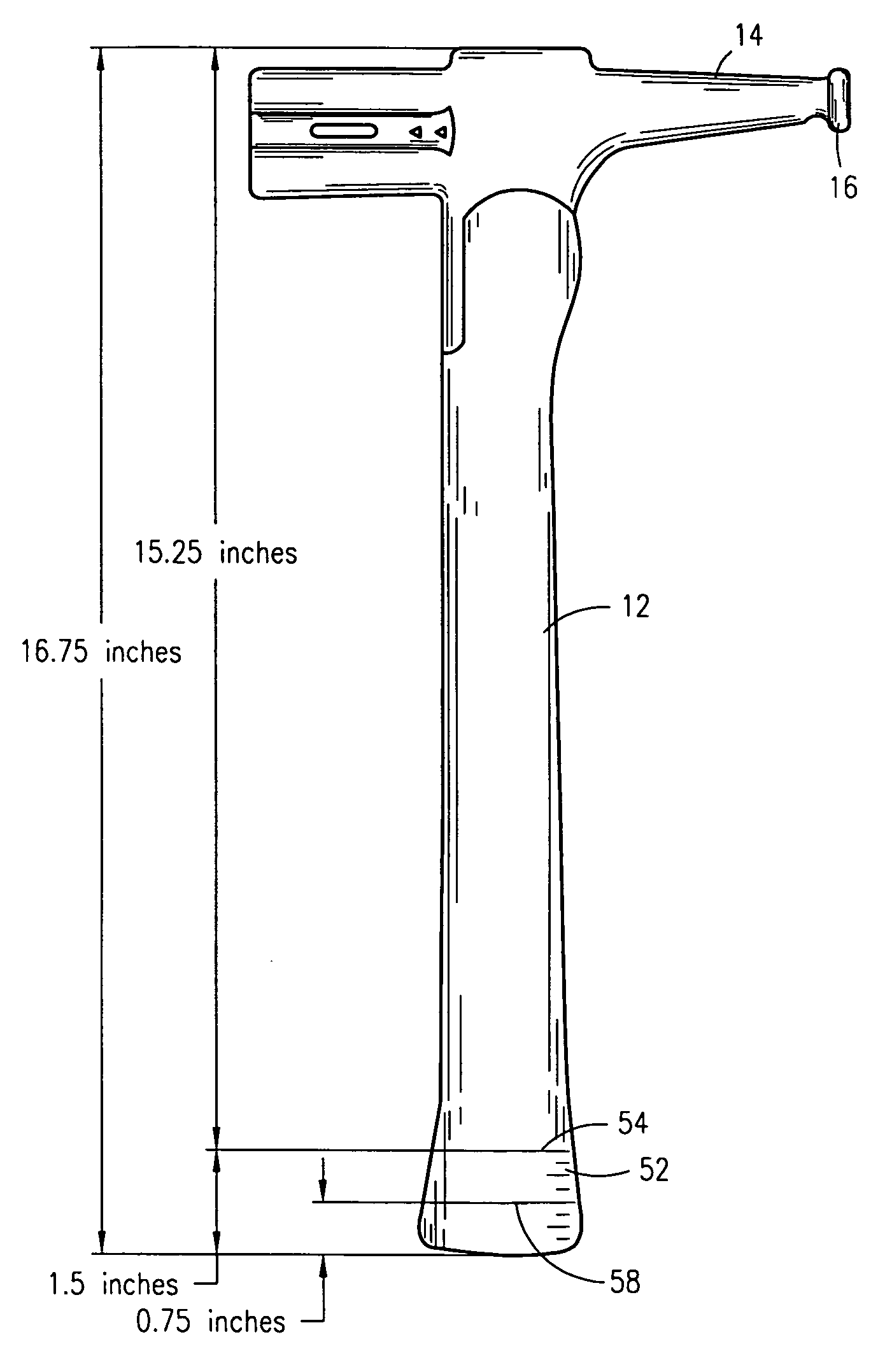

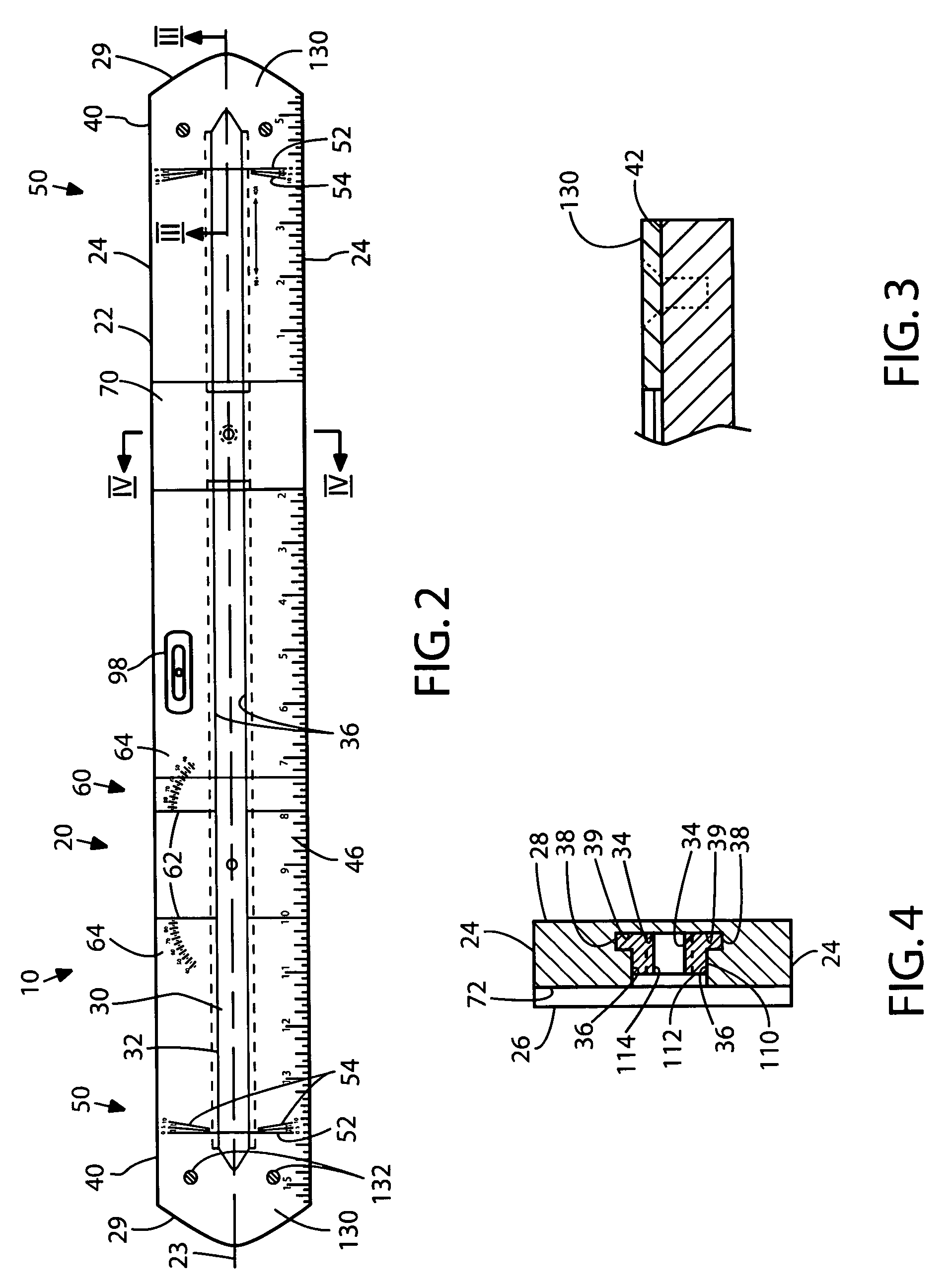

Carpentry trim marking gage

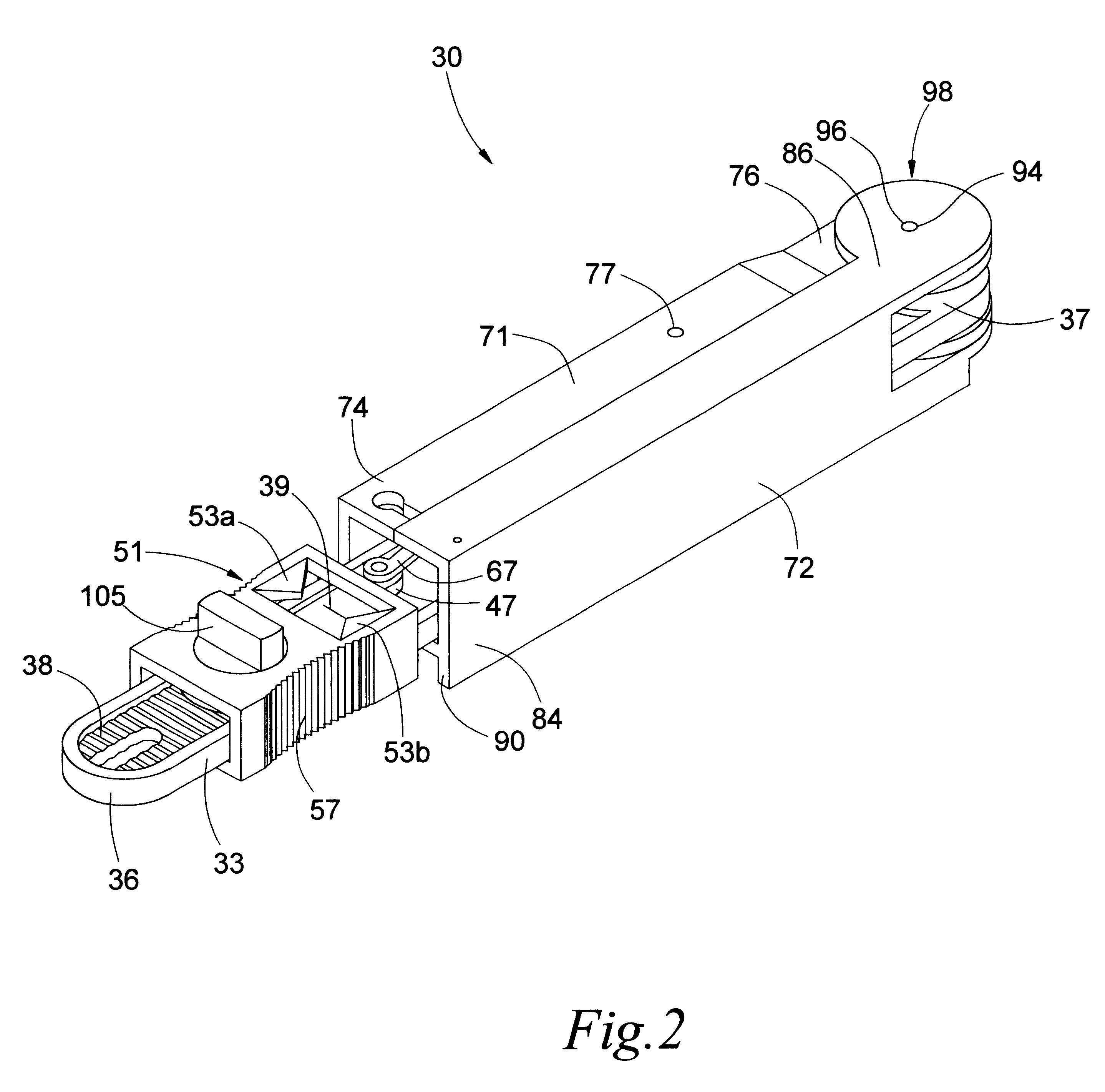

InactiveUS7240435B1Easy to installEasy to manufactureDoors/windowsMechanical clearance measurementsEngineeringWoodworking

An adjustable carpentry trim gage includes a scribing block adjustably attached to a guide block. The guide block includes a guide surface, adapted to be placed against a jamb. The scribing block includes a scribing surface along which a scribing instrument, such as a pencil or an awl, can be drawn to mark guidelines on the jamb, to facilitate installation of a casing on the jamb. The position of the guide block with respect to the scribing block is adjustable to allow the position of the scribing surface on the scribing block, with respect to the guide surface on the guide block, to be set in such a manner that the scribing surface will be placed to indicate a desired reveal on the jamb, when the guide surface is bearing against the jamb. The scribing surface extends beyond the maximum reveal setting of the gage, in a direction parallel to the face of the jamb against which the guide surface is bearing, to facilitate making intersecting guidelines indicating corners of the casing.

Owner:DOWDAKIN WILLIAM J

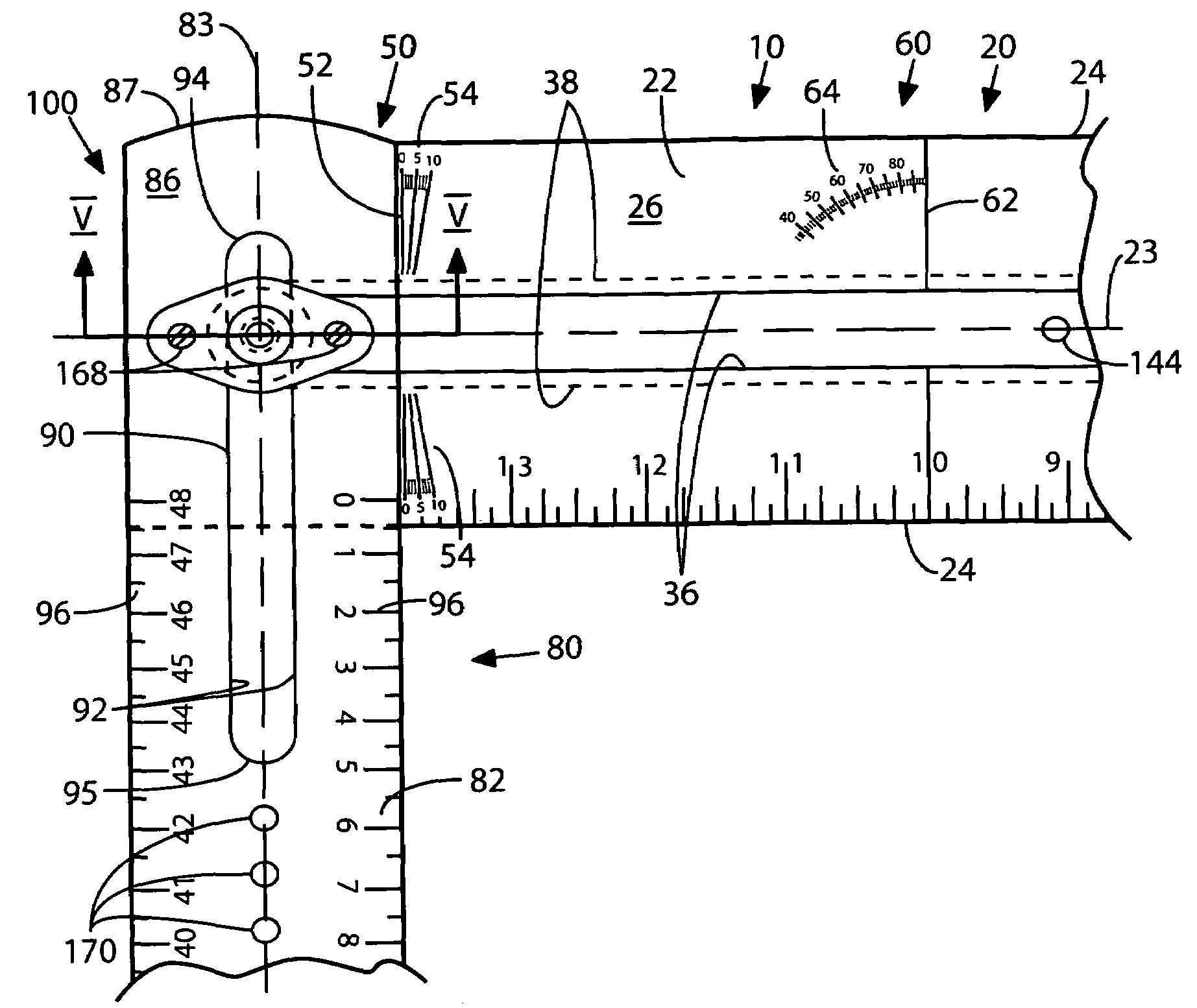

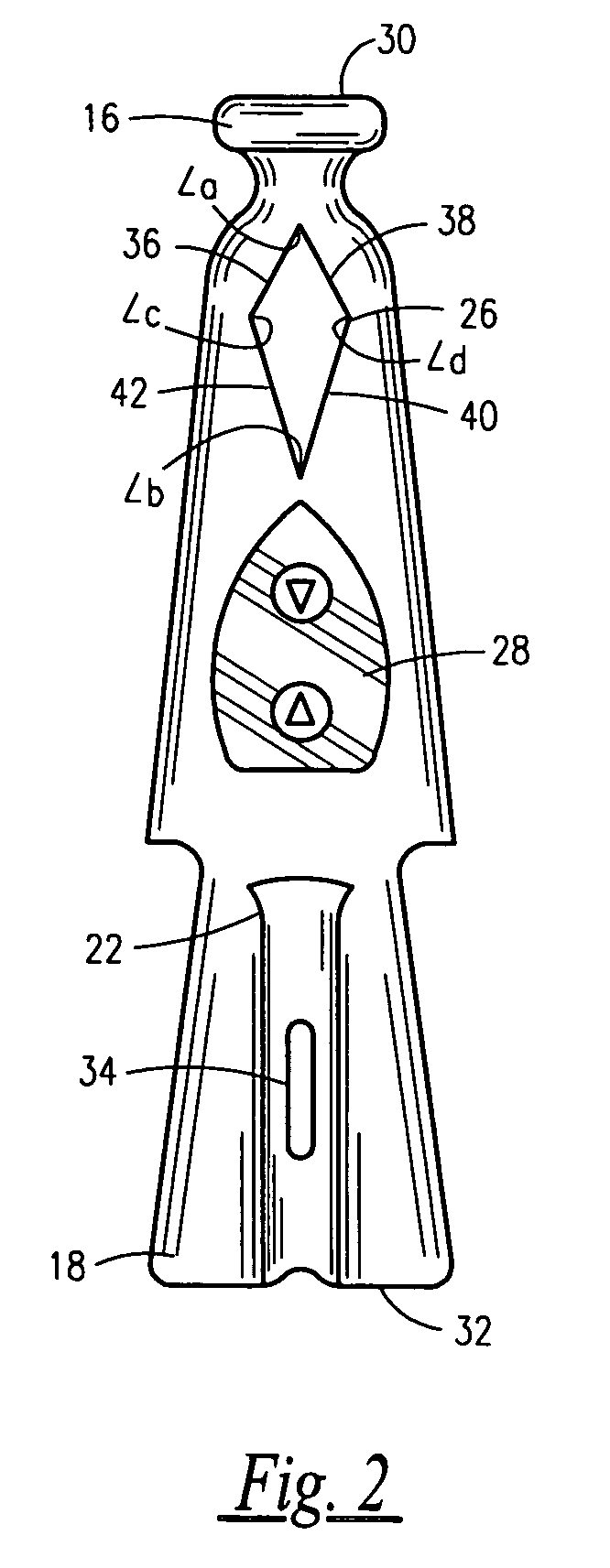

Multi-functional carpentry tool

InactiveUS20090193670A1Reduce weightCircular curve drawing instrumentsStraightedgesWoodworkingShip's carpenter

A multi-functional carpentry tool includes a base member having a longitudinal T-shaped groove formed therewithin and a rule member. A T-shaped slide member is positioned within the groove and has a threaded aperture formed therewithin. A knob has a threaded stem operatively received within the threaded aperture for selectively securing the base member and the rule member together in frictional engagement maintaining the base member and the rule member in selected positions relative to one another and permitting each of a sliding and pivoting movement of the rule member relative to the base member. Linear measuring scale indicia is provided in each of the base and rule members. Angular measuring scale indicia and a squaring groove is also provided within the base member. A spring biased pin is movably mounted within the knob for defining pivot axis and facilitating arc scribing effort.

Owner:FERNANDES PATRICK

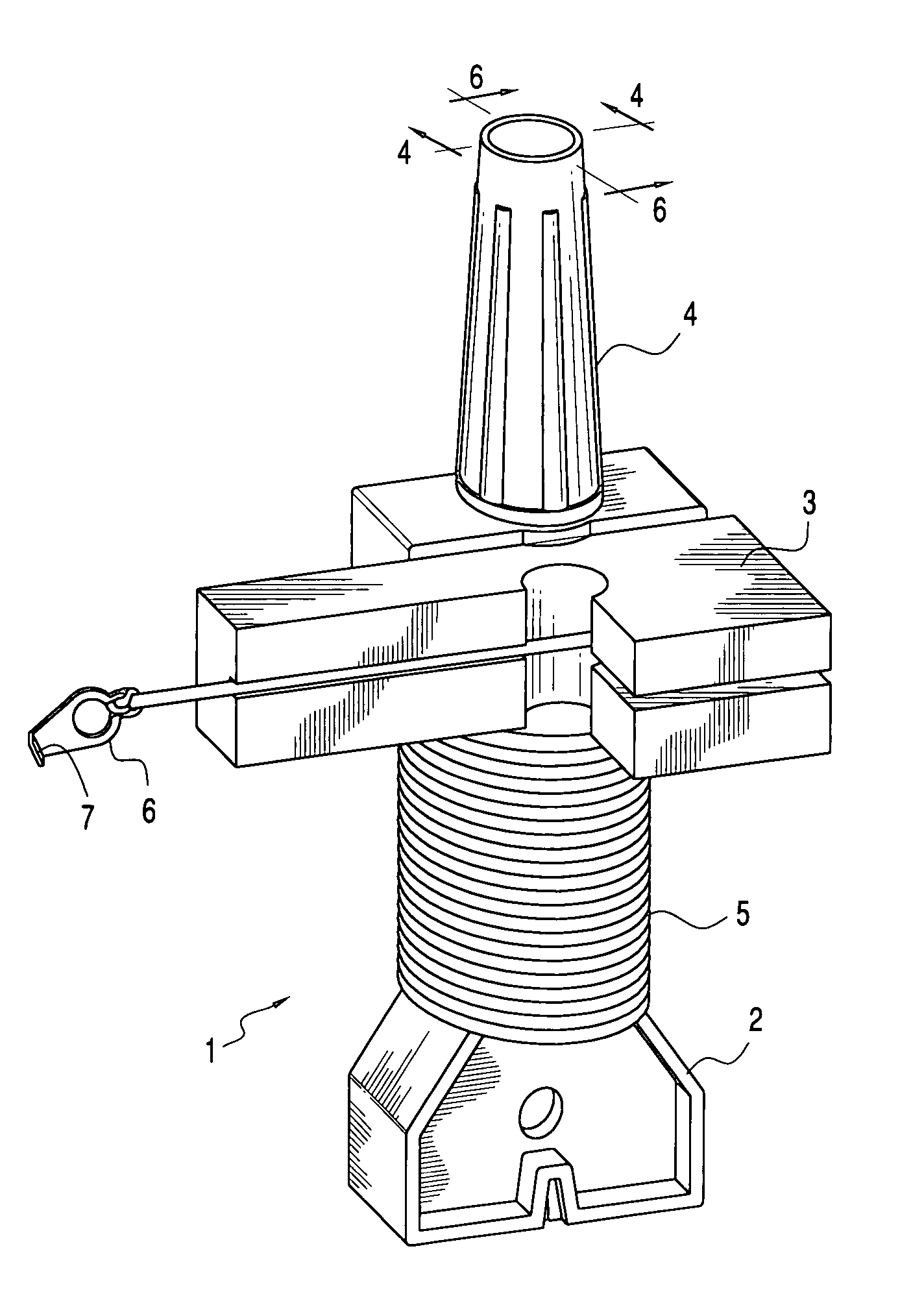

Self supporting string line reel-line block tool

InactiveUS7409771B2Easy to operateEasy alignmentSurveyor's staffsMovable markersEngineeringShip's carpenter

A string line tool having a string line support and an integral line block for using a string line under tension in alignment work for carpentry, masonry and general construction work. The string line tool of this invention is self supporting due to maintaining the string line under tension between the string line tool at one end of a string line and a fastening means at the opposite end of the string line via the intermediary of a grooved line block.

Owner:BOND WILLIAM RALPH

Finish carpentry nailing guard

A finish carpentry nailing guard adapted for use in protecting workpiece surfaces from damage by hammers while driving nails and / or from nail pulling devices when removing nails, the guard comprising a unitary block having a centrally located aperture and / or slots. In its preferred embodiment the guard is transparent and fabricated from lexan or other hard plastic.

Owner:GILDROY GRANT

Electrochemical aluminium gold-stamped water decal paper, and its production process and use

InactiveCN1851121AProduction Process SpecializationSpecial visual effect coatingsFlexible coversPulp and paper industryWater transfer

The invention discloses an anodized aluminum, metallized, water decal paper producing process, comprising the steps of: (A) using water transfer base paper as carrier, and printing or coating bonding layer; (B) printing or coating isolating layer; (C) thermoprinting anodized aluminum graphics and texts; (D) printing or coating closing layer; (E) printing or coating locating film. And the product can be transferred onto a substrate by water transfer process. And the invention can make multicolor metallized, water decal papers and can be applied to plural fields, such as lamp decoration, vessels, brand metallization decoration, and applied to substrates, such as glass, ceramic, metal, plastics, carpentry, etc, and largely enlarge the application range of the anodized aluminum metallization technique.

Owner:麦秀莲

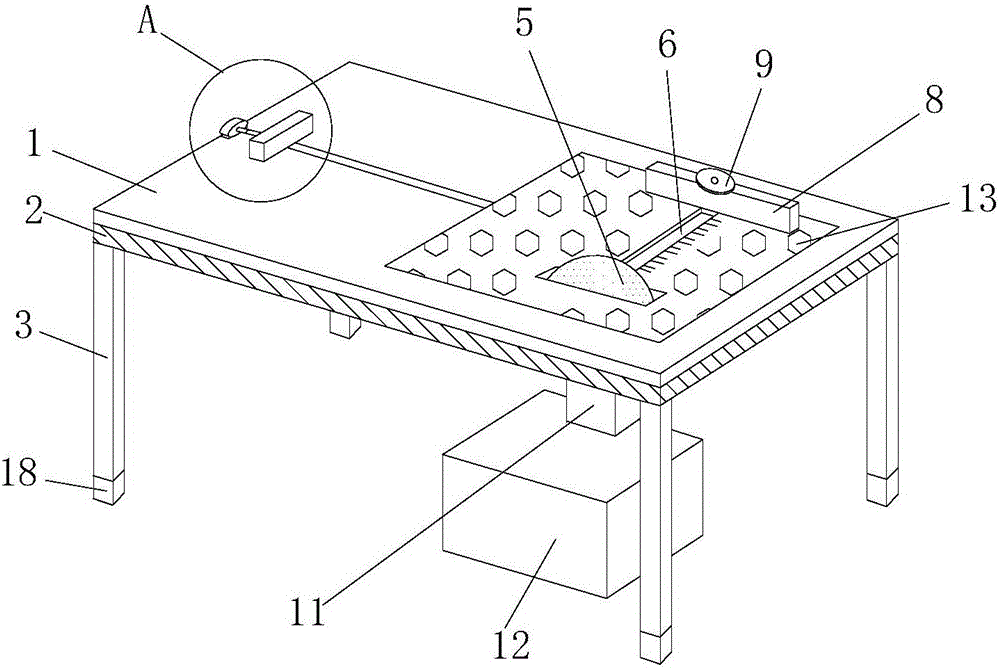

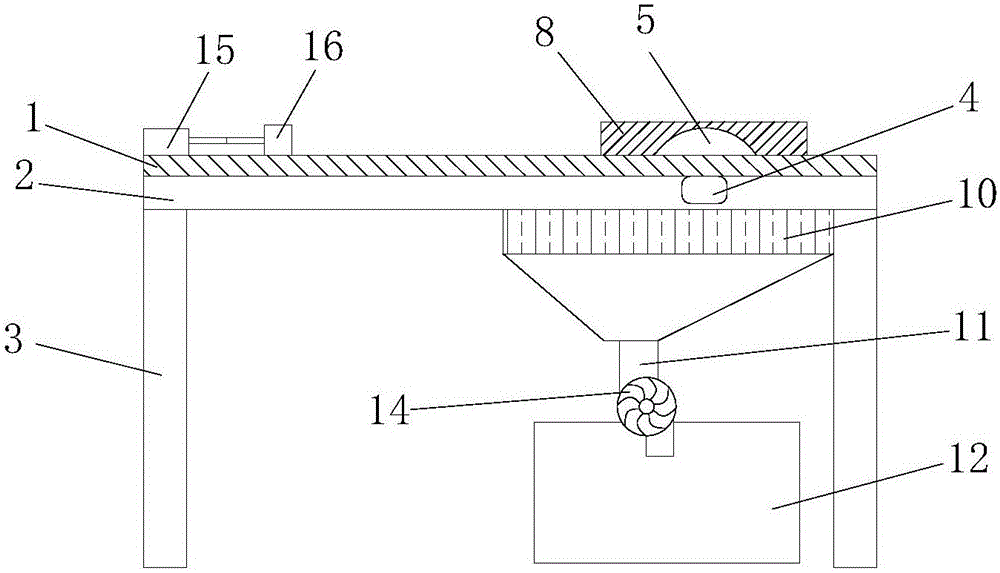

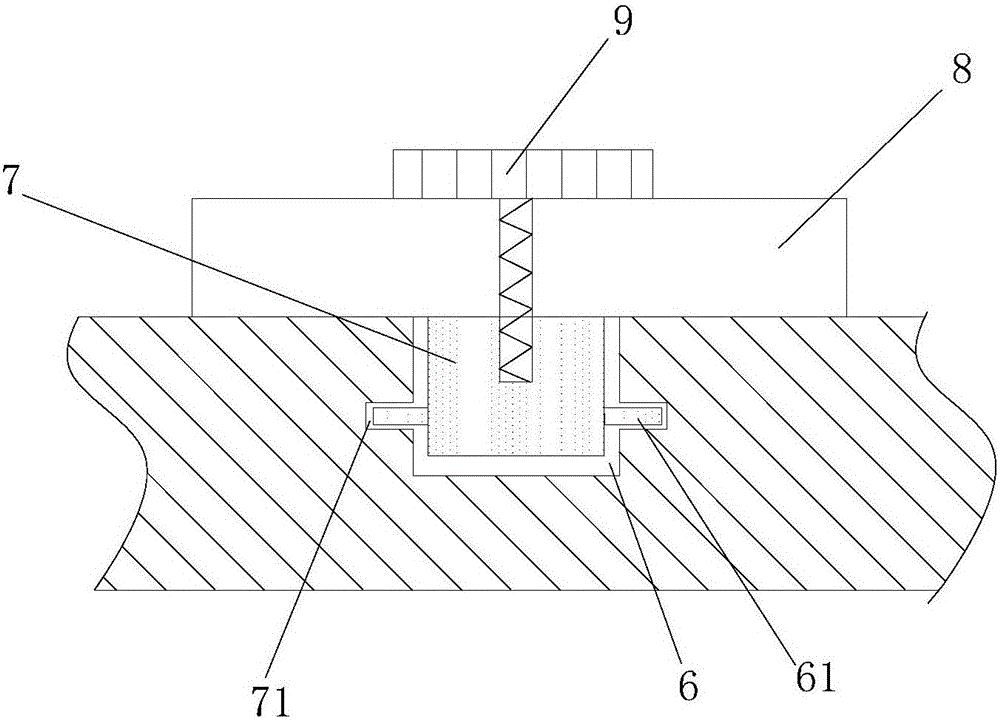

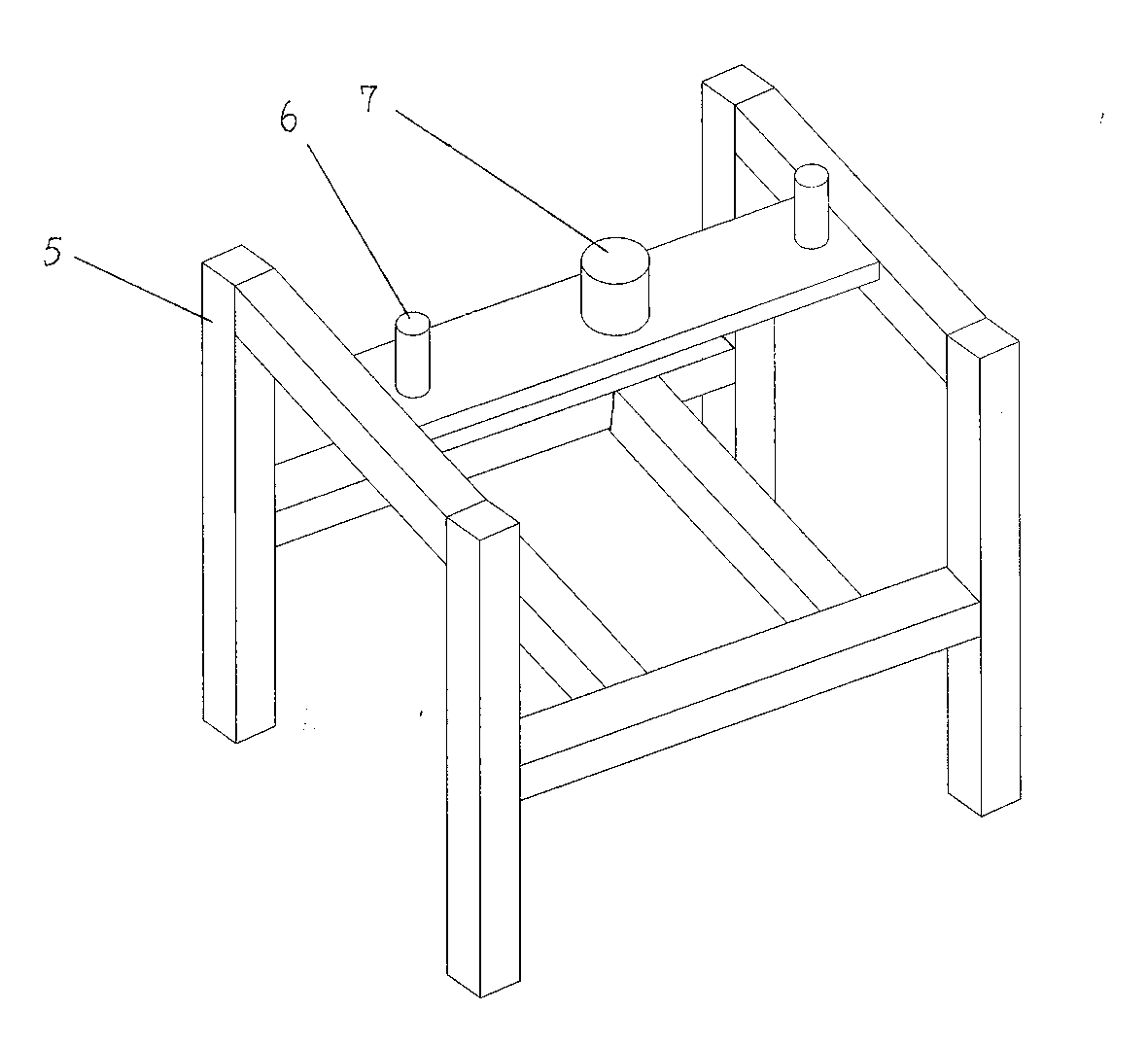

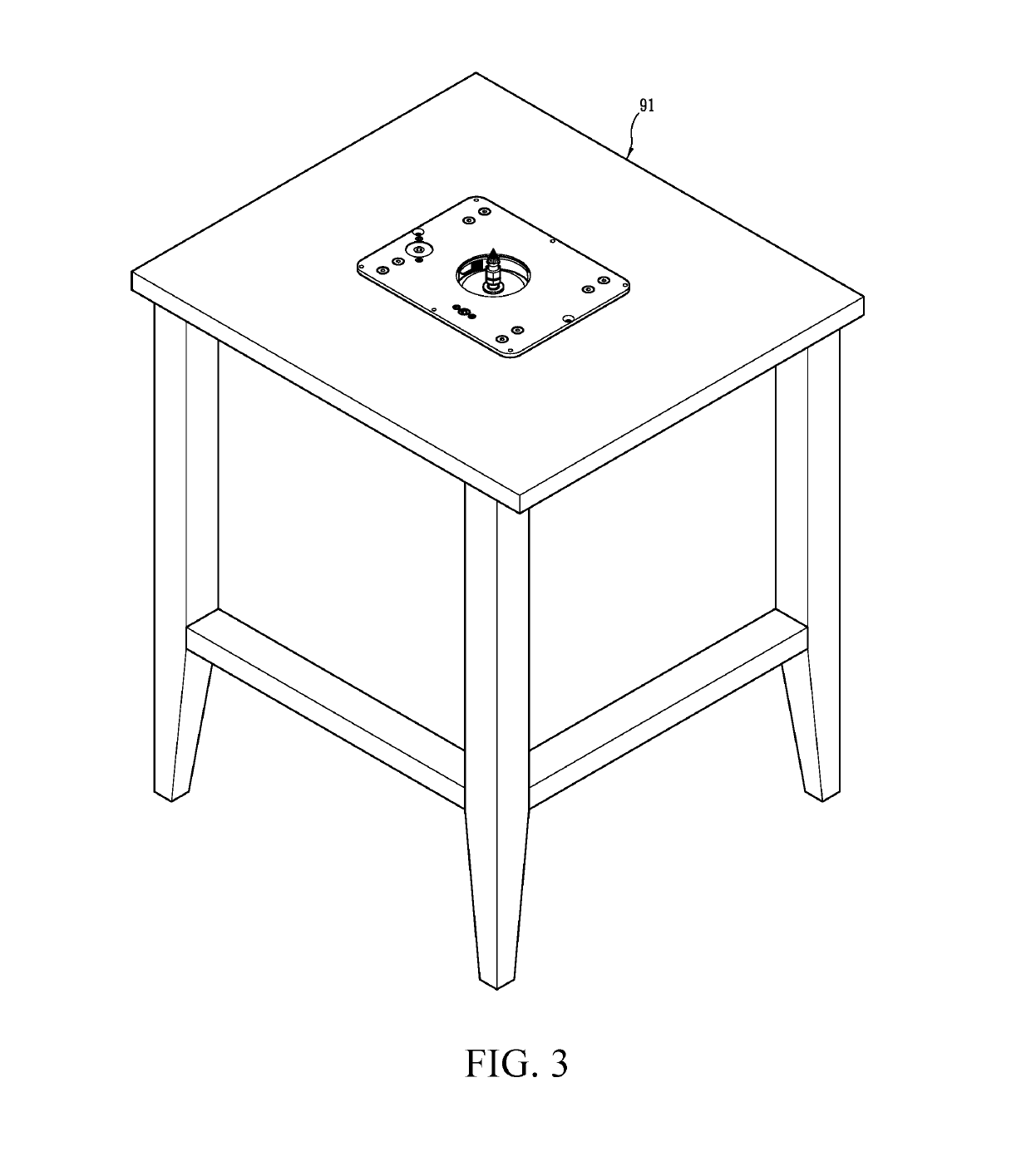

Carpentry worktable

The invention discloses a carpentry worktable. The worktable comprises a worktable surface. Horizontal beams are located under the worktable surface. The bottom of the horizontal beam is provided with support bars. The lower surface of the worktable surface is provided with a motor. One end of the motor is connected with a cutting blade through a transmission shaft. One side of the upper surface of the worktable surface is provided with a first slide rail. The surface of the first slide rail is provided with a buckle hole. The upper end of the first slide rail is connected slidingly with a slide block. The slide block surface is provided with a buckle block. The upper end of the slide block is fixedly connected with a stop plate. The upper end of the stop plate is provided with a positioning bolt which passes through the stop plate into the slide block. The other side of the worktable surface is provided with a motor telescopic rod. One end of the motor telescopic rod is connected with a push board. The push board is connected slidingly with a second slide rail located under the push board. The lower surface of the worktable surface is provided with a dust absorption cover. The lower end of the dust absorption cover passes through a dust discharge tube. The lower end of the dust discharge tube is provided with a fan. The lower end of the fan is connected with a dust collection filtration box.

Owner:ANHUI RUIZHIXIN INFORMATION TECH CO LTD

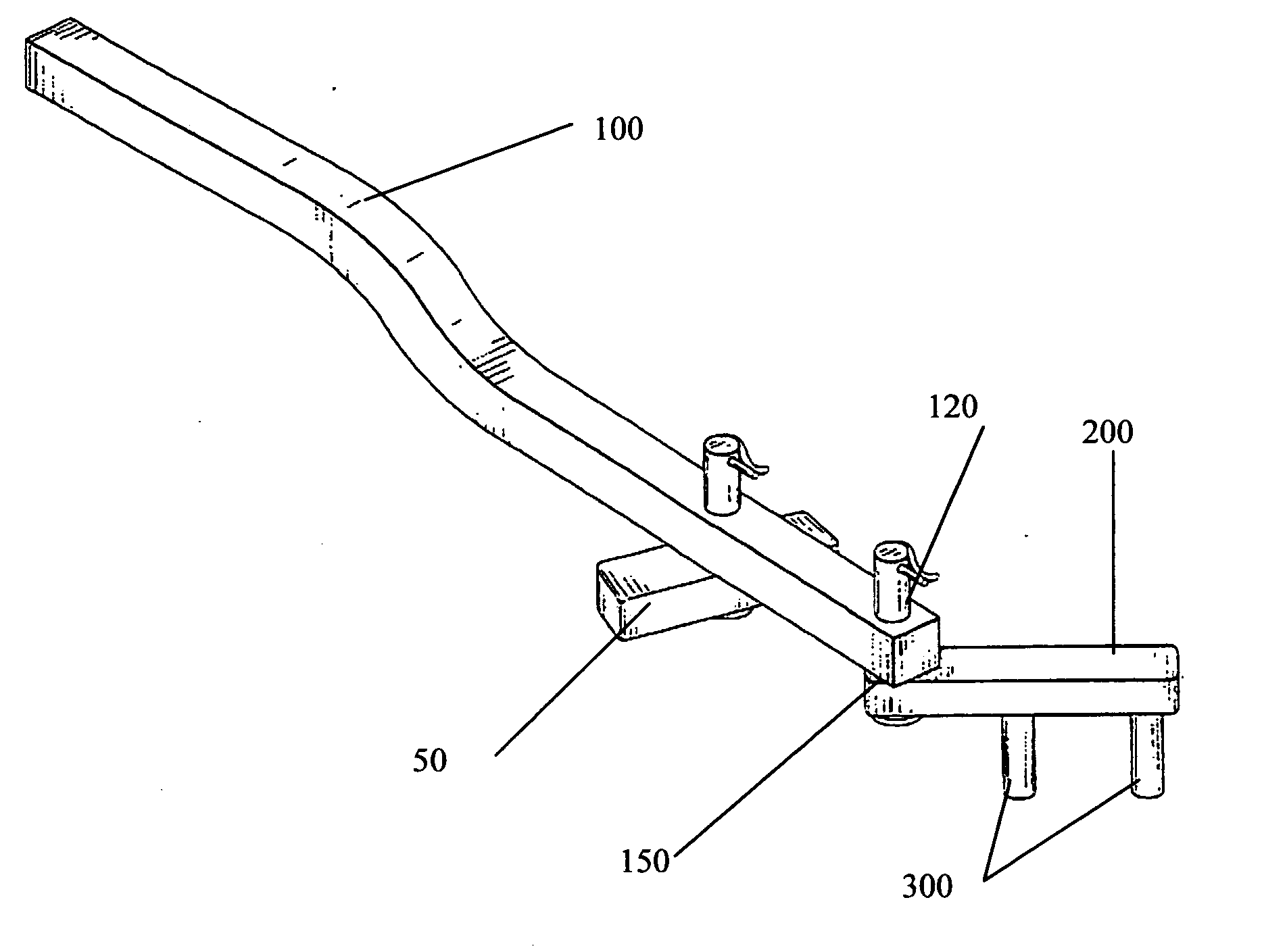

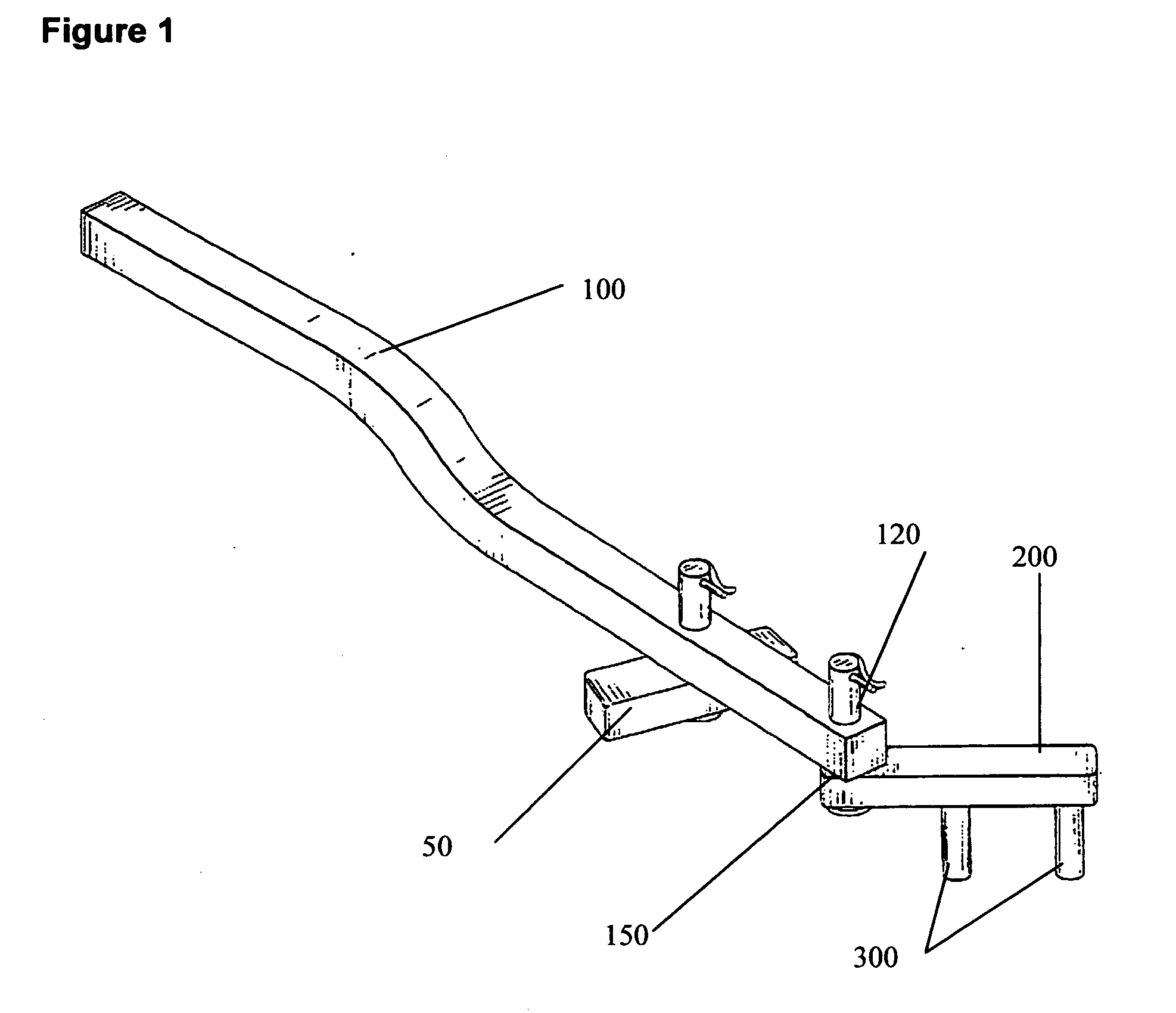

Adjustable joist gripper

A carpentry tool for the installation of parallel boards includes an elongated lever having a rotatable cam pivotally affixed adjacent to a distal end of the lever, a gripper body pivotally affixed at a distal end of the lever, the gripper body having two lugs or brackets extending downward from the lower end of the gripper body, wherein the gripper body includes a two-piece telescopic section having an outer tubing member and an inner tubing member in slidable engagement, the inner tubing member including a first lug or bracket on a lower face thereof, the outer tubing member including a second lug or bracket on a lower face thereof, opposing the first bracket, and a spindle extending from an upper face thereof, and a mechanism for reversibly affixing the sliding inner and outer tubing members at predetermined points. Further disclosed are novel adjustable joist grippers for use with the apparatus.

Owner:RES Q JACK

High transparency high-filled environment-friendly polyurethane carpentry paint

InactiveCN101613566AGood filling effectReduce the number of coatsPolyurea/polyurethane coatingsDiluentZinc stearate

The invention relates to an environment-friendly paint, in particular to the paint which is used in carpentry transparent coating technique, can be used for protecting and decorating, has the advantages of high transparency and good filling property, improves the coating efficiency and reduces the loss of film coating. A preparation technique of the paint comprises the steps: first, short-oil alkyd resin, diluent, dispersing agent and antifoaming agent are sequentially added and evenly dispersed at intermediate speed; then, talcum powder, transparent filler and zinc stearate are added and dispersed at high speed to have the fineness of less than or equal to 50mu m; finally, the diluent, drier and leveling agent are added and evenly stirred at intermediate speed; after being detected to be qualified, the product is filtered and packed, so that the high transparency high-filled environment-friendly polyurethane carpentry paint is obtained.

Owner:SKSHU PAINT

Carpentry marking tool

Owner:WILLIAMS GARY E

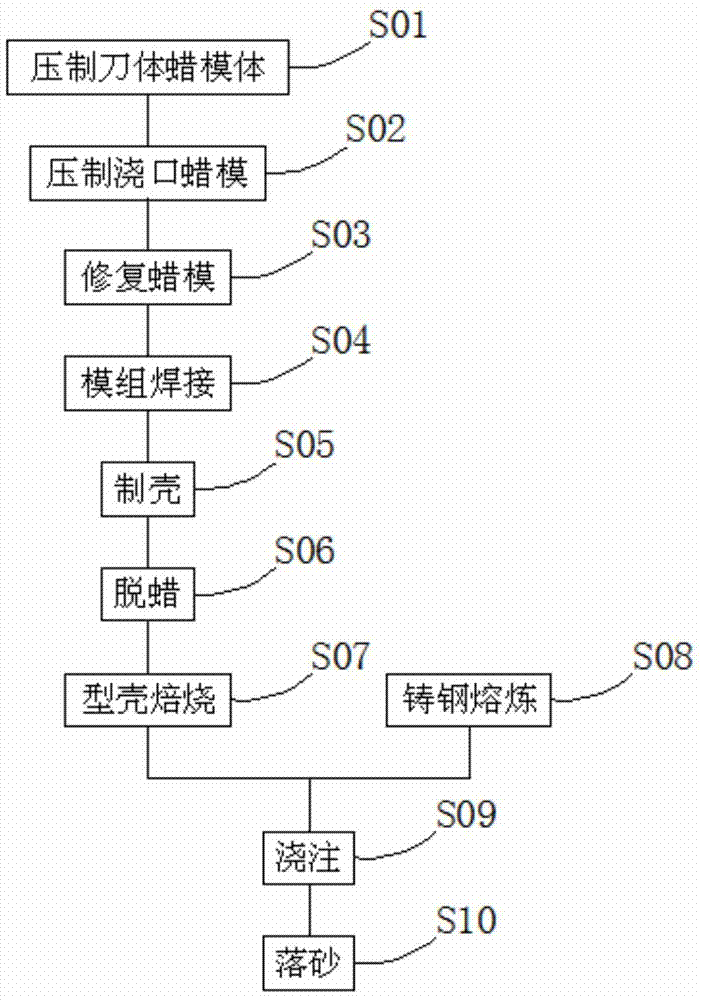

Carpentry cutter body manufacturing process

The invention relates to a carpentry cutter body manufacturing process comprises the steps of cutter body wax mold body pressing, gate wax mold pressing, wax mold repairing, module welding, shell manufacturing, de-waxing, mold shell roasting, cast steel smelting, casting, and shakeout. The carpentry cutter body manufacturing process provided by the invention has the advantages that: with the carpentry cutter body manufacturing process, carpentry cutter body with high hardness, high toughness, high-temperature resistance, and high cutter body casting size precision can be manufactured. Also, large amount of machine tool equipment and processing time can be saved, and also metal raw materials can be greatly saved.

Owner:付绍森

Four-edge board cutting machine for cutting carpentry veneer and four-edge cutting method of carpentry veneer

InactiveCN103009439AImprove finished product qualityNo gapsProfiling/shaping machinesEngineeringEnergy consumption

The invention relates to a four-edge board cutting machine for cutting a carpentry veneer, and a four-edge cutting method of the carpentry veneer. The four-edge board cutting machine comprises a rack, a rectangular bearing platform used for supporting the carpentry veneer, a rectangular bottom press bench used for implementing a flatting action on the supported carpentry veneer, a movable knife rest encircling the outside of the bottom press bench, cutting knifes fixedly mounted on an inner side wall at the periphery of the movable knife rest, a roller oppositely-grinding type veneer conveying mechanism used for conveying the carpentry veneer, a bottom press bench lifting control mechanism, a movable knife rest lifting control mechanism and a veneer feeding mechanism. According to the four-edge board cutting machine, a full frame of the carpentry veneer is compressed and flatted firstly, and then the four edges of the carpentry veneer are cut at the same time, so that joint opening or lamination of butting edges of the four cutting edges of the carpentry veneer are avoided in subsequent links such as assembling and prepressing, and the production efficiency of a core-board or a plywood is improved; the energy consumption is reduced; and the quality of a finished product is ensured.

Owner:河北北方绿野居住环境发展有限公司

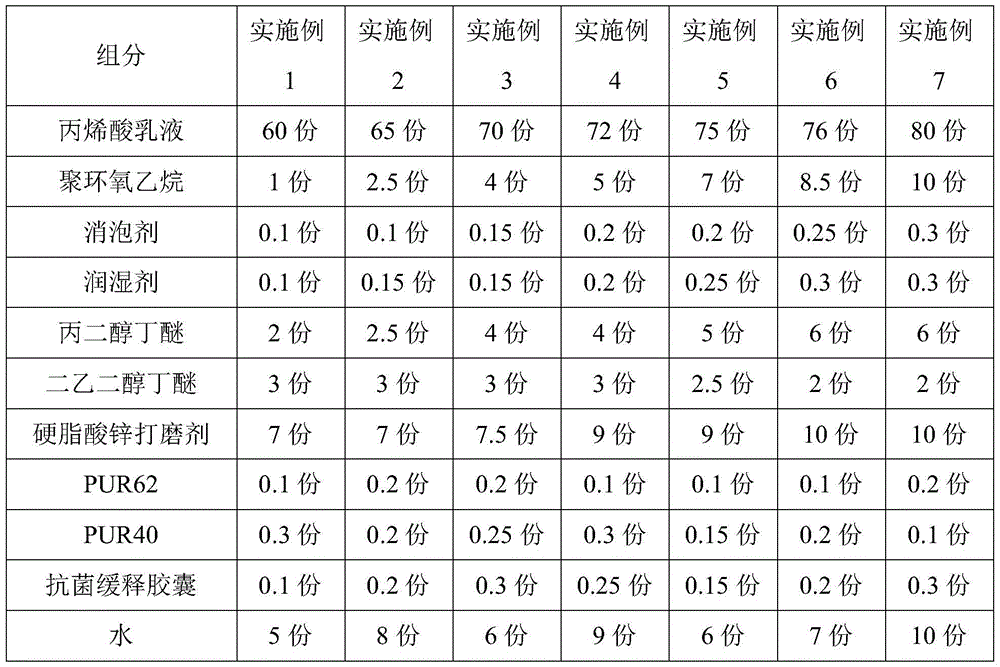

Carpentry water paint suitable for high pressure airless spraying and preparation method thereof

The invention discloses carpentry water paint suitable for high pressure airless spraying and a preparation method thereof and relates to the technical field of paint composition. The carpentry water paint is prepared in proportion by the following raw materials including, calculated by weight percentage, 70-80% of water-based self-crosslinking acrylic emulsion, 10-20% of deionized water, 0.1-0.3% of pH conditioning agent, 0.1-0.5% of wetting agent, 0.2-0.6% of defoaming agent, 1-5% of coalescing agent, 0-2% of extinction powder, 0.5-1% of thickening agent, 0.1-0.3% of light stabilizer, 0.1-0.3% of light absorber and 0.3-0.8% of flatting agent; the carpentry water paint suitable for the high pressure airless spraying is prepared by uniformly mixing and stirring the above raw materials. The carpentry water paint has the advantages of being healthy, environmentally friendly, capable of being coated in a thick mode, strong in adhesive force and fast in dryness; the superstrong weather resistance and the superstrong water resistance are achieved; the construction is convenient and fast, the thickness can be achieved rapidly, the paint film is level and smooth, the hand feeling is also good, and the cost is low.

Owner:刘善江

Two-component epoxy type termide-proof and insect-proof putty and its application

This invention discloses a two-component epoxy termite-proof and bug-proof putty and its application. The filming matter(liquid epoxy resin), special bug proof agent(such as insect control chrysanthemum ester style or other bug proof agent), coating auxiliary agent, quartz powder, talcum powder, disintagrated chalk, curing agent in the receipt are used in painting dressing process of furniture and plank floor to form termite and bug proof putty film to prevent termite and other bristletail to erode carpentry. Its efficiency is high, decorating effect is good, and execution is convenient, it can be used to carpentry processing of modern wood furniture painting and home decoration.

Owner:上海展辰涂料有限公司 +1

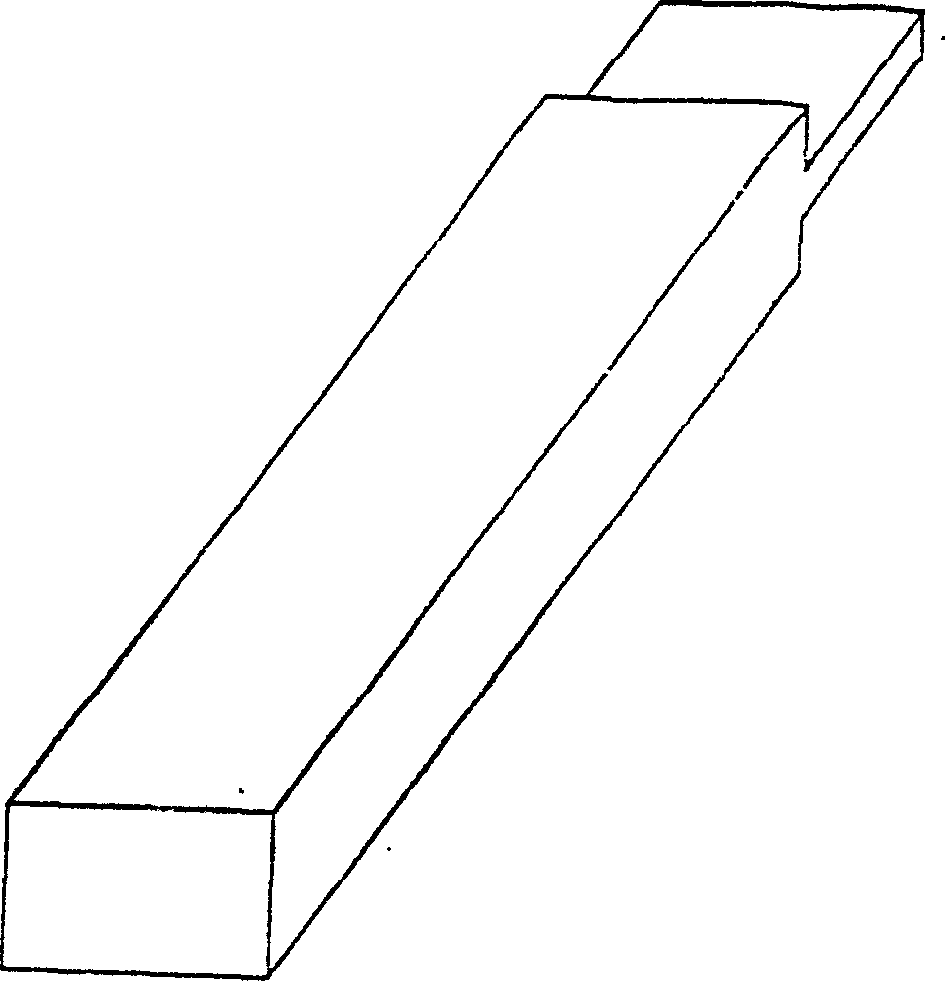

Carpentry guide tool for making consistent reveals

A carpentry guide tool for ensuring precise and accurate measurements with regard to offsets and reveals commonly used in carpentry, particularly in the context of trim and molding around a door or window, is now disclosed. More specifically, the now disclosed carpentry tool is capable of use simultaneously in two orthogonal directions for the accurate measurement of reveals in the corner of a framed threshold and is designed for both ease of use and ease of manufacture. The now disclosed carpentry tool is of fixed dimension and static manufacture, mitigating the possibility that human error yields inconsistencies in measurement. The preferred embodiment is two concentric square prisms of differing sizes wherein every edge of one prism is congruent and parallel to an edge of the second prism, creating a reveal defined by the size differential between the two prisms.

Owner:PARKIN SIMON P

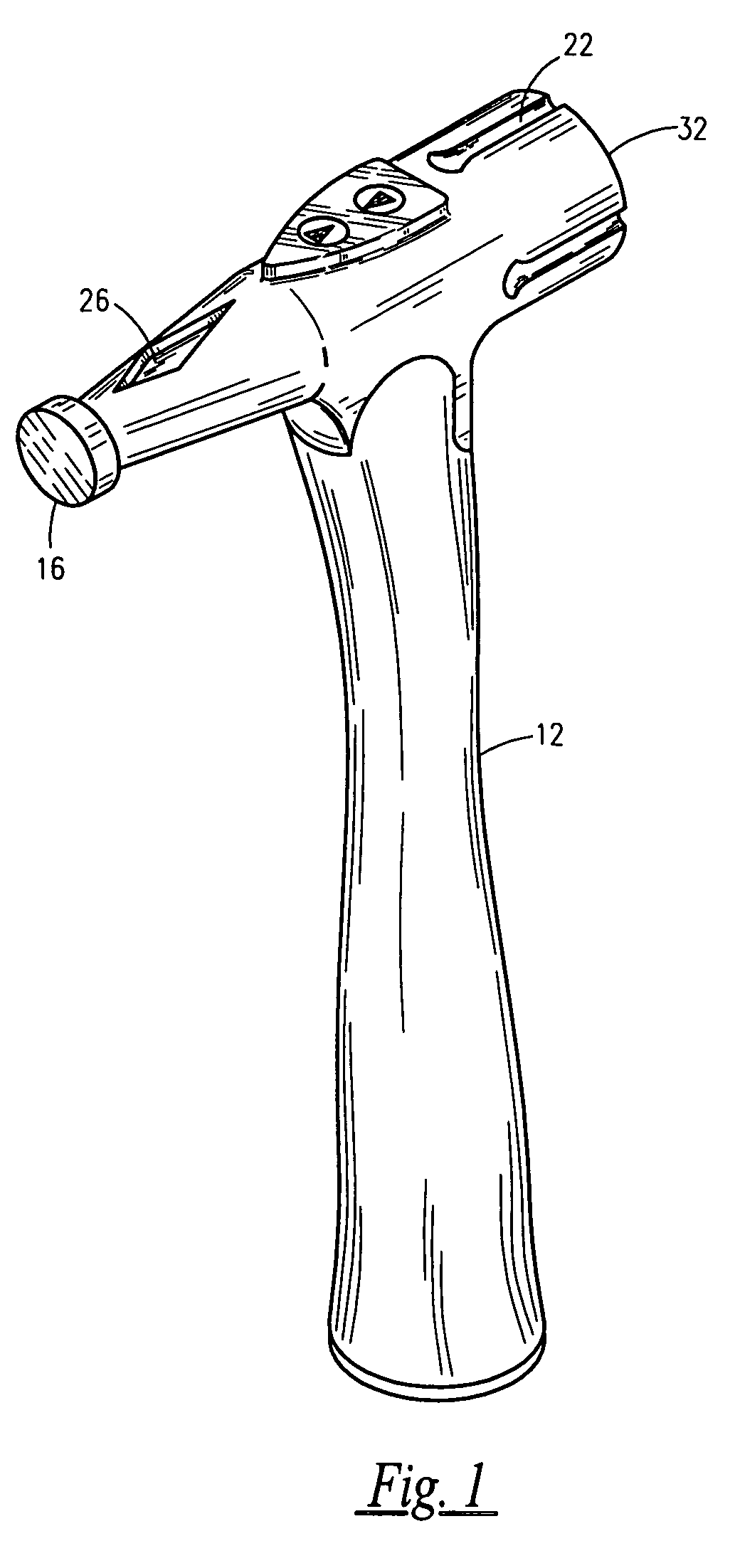

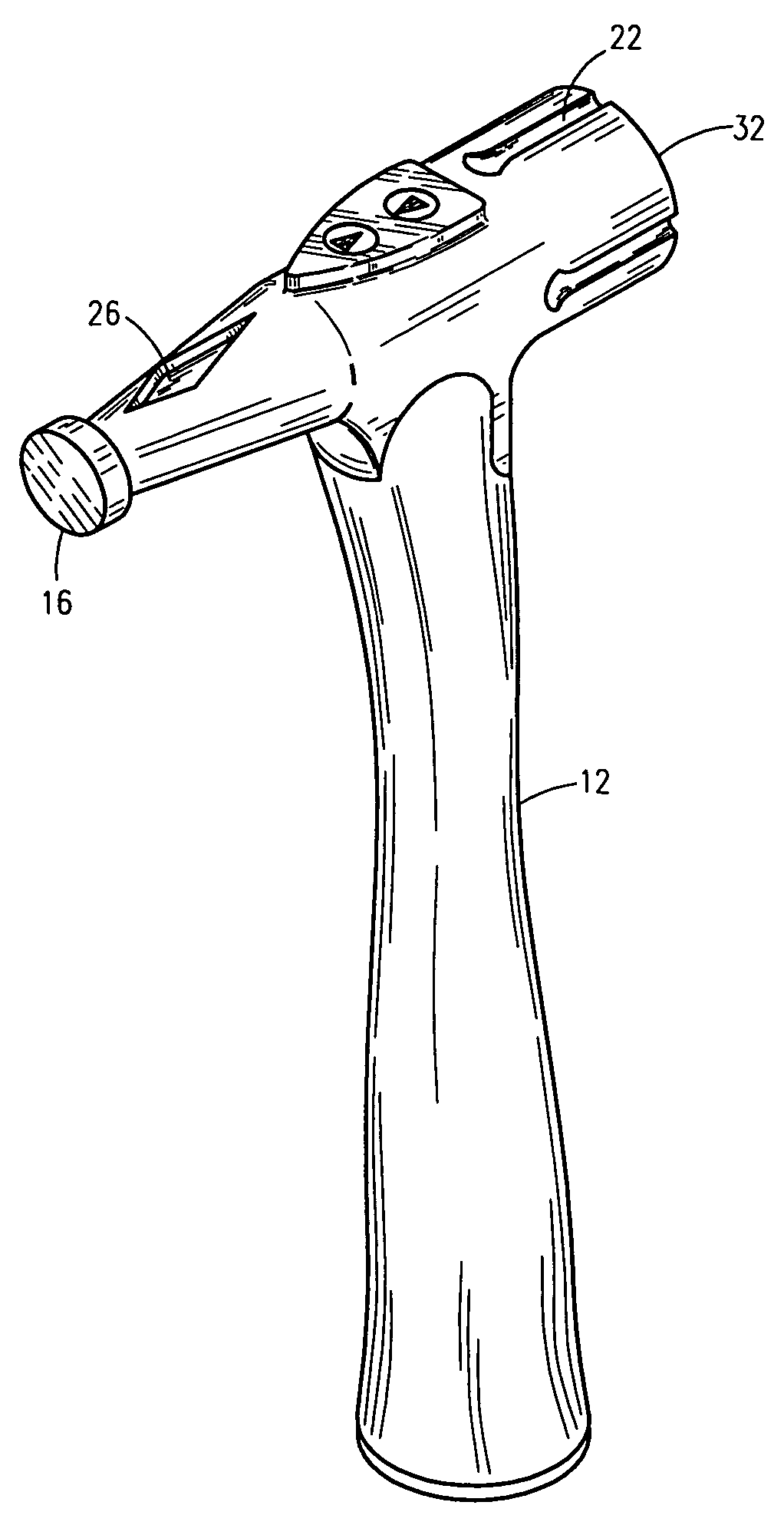

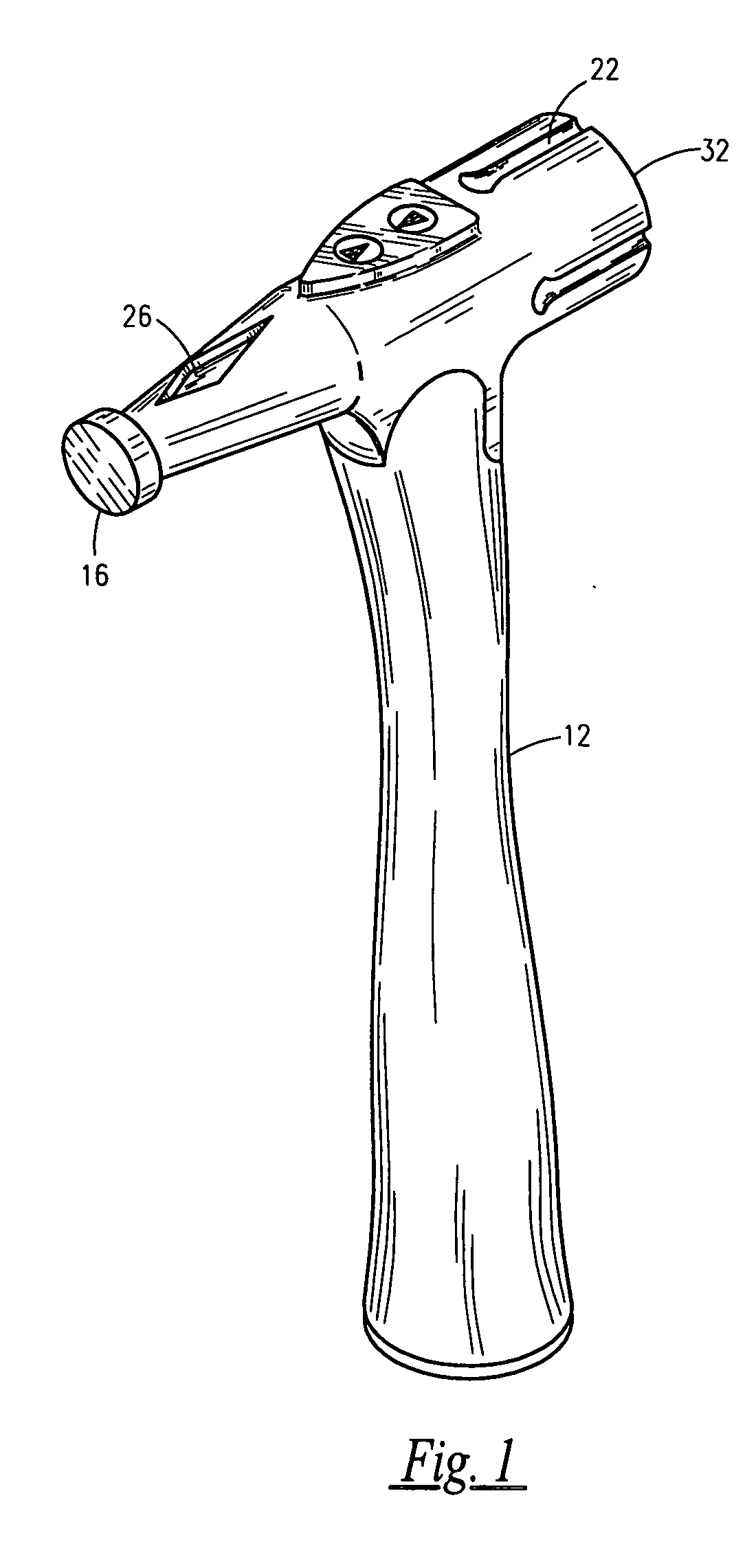

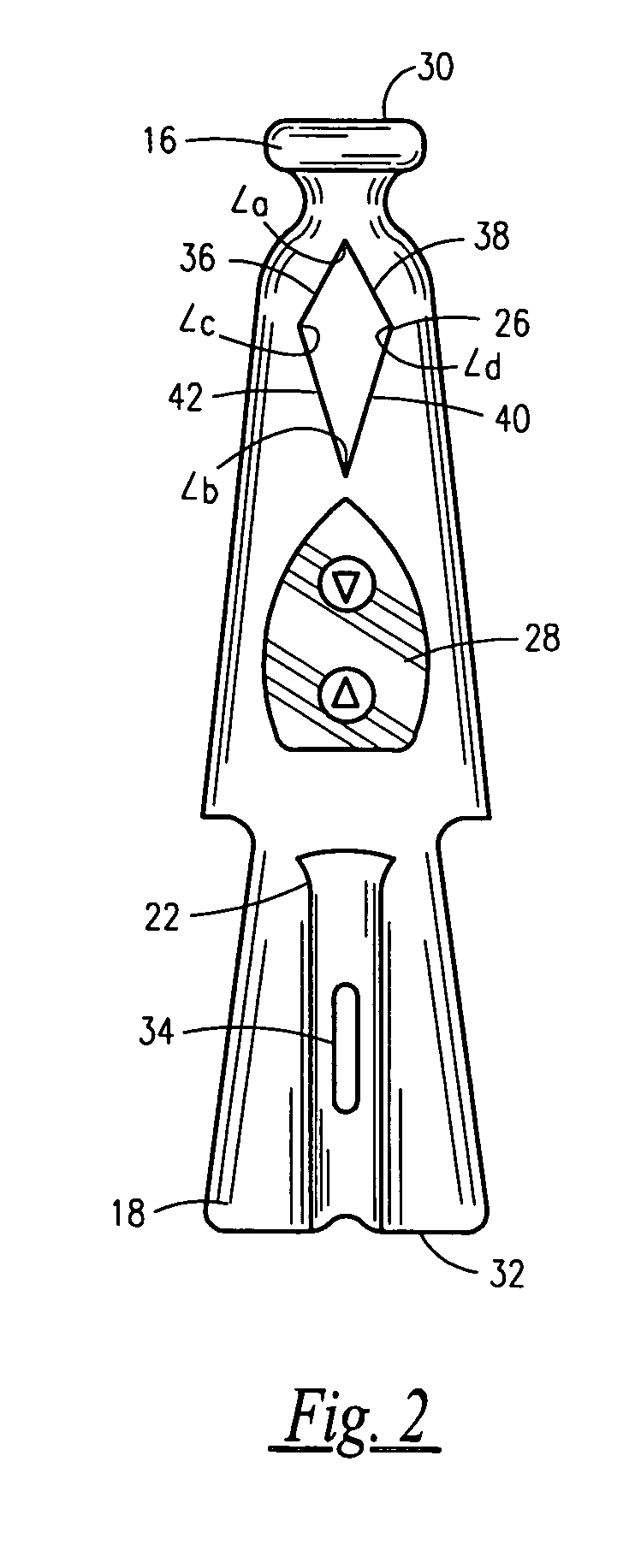

Dual headed hammer

InactiveUS7168339B2Accurate measurementMark accuratelyHand hammersMulti-purpose toolsEngineeringWoodworking

A dual headed hammer is a hammer with special features for framing and finishing applications. A first head of the hammer has a smaller head and face for finish carpentry applications, and may have a gridded-face to prevent nail slippage. A nail-extractor is located midway between the head and the handle. The opposite end of the hammer has a larger second head for framing applications. Additionally, the larger second head has a plurality of nail holders, complete with magnets, on the top and lateral sides of the second head. The handle is sized such that the total length of the invention is exactly 17.5 inches to aid in construction of walls that use 2×4 studs, 16 inches on center.

Owner:NAU TEVITA T

Multifunctional single side tenon-making machine for carpenter

InactiveCN1803417AReasonable layoutEasy to useWood mortising machinesWood slotting machinesEngineeringMachine tool

The invention discloses a multifunctional carpentry single-sided tenon-making machine, which comprises the following parts: machine body, working bench and clamp device on the machine body board, wherein the end saw, tenon knife rack, level knife shaft and vertical knife shaft are assembled on the front and back of machine body.

Owner:何沛佳

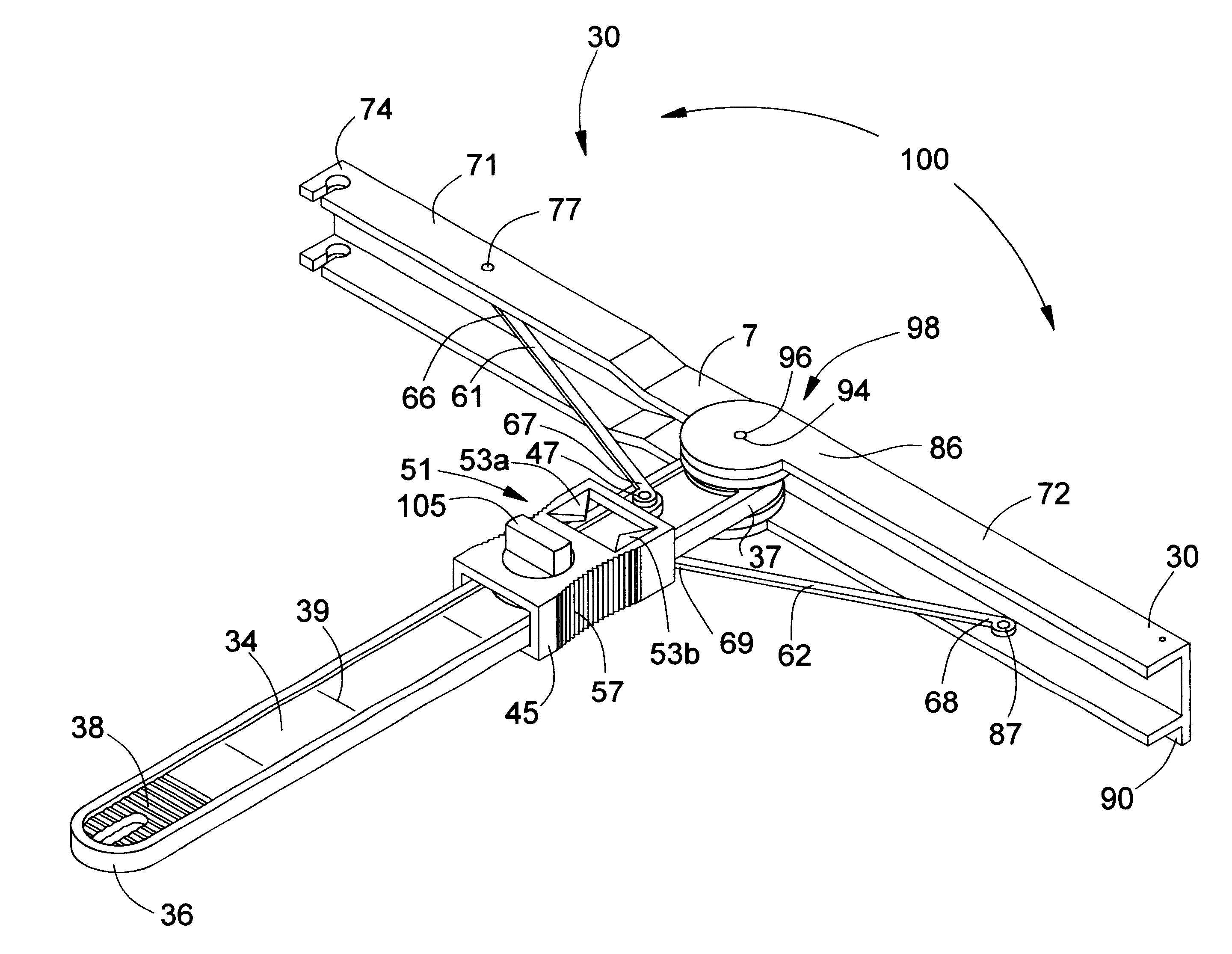

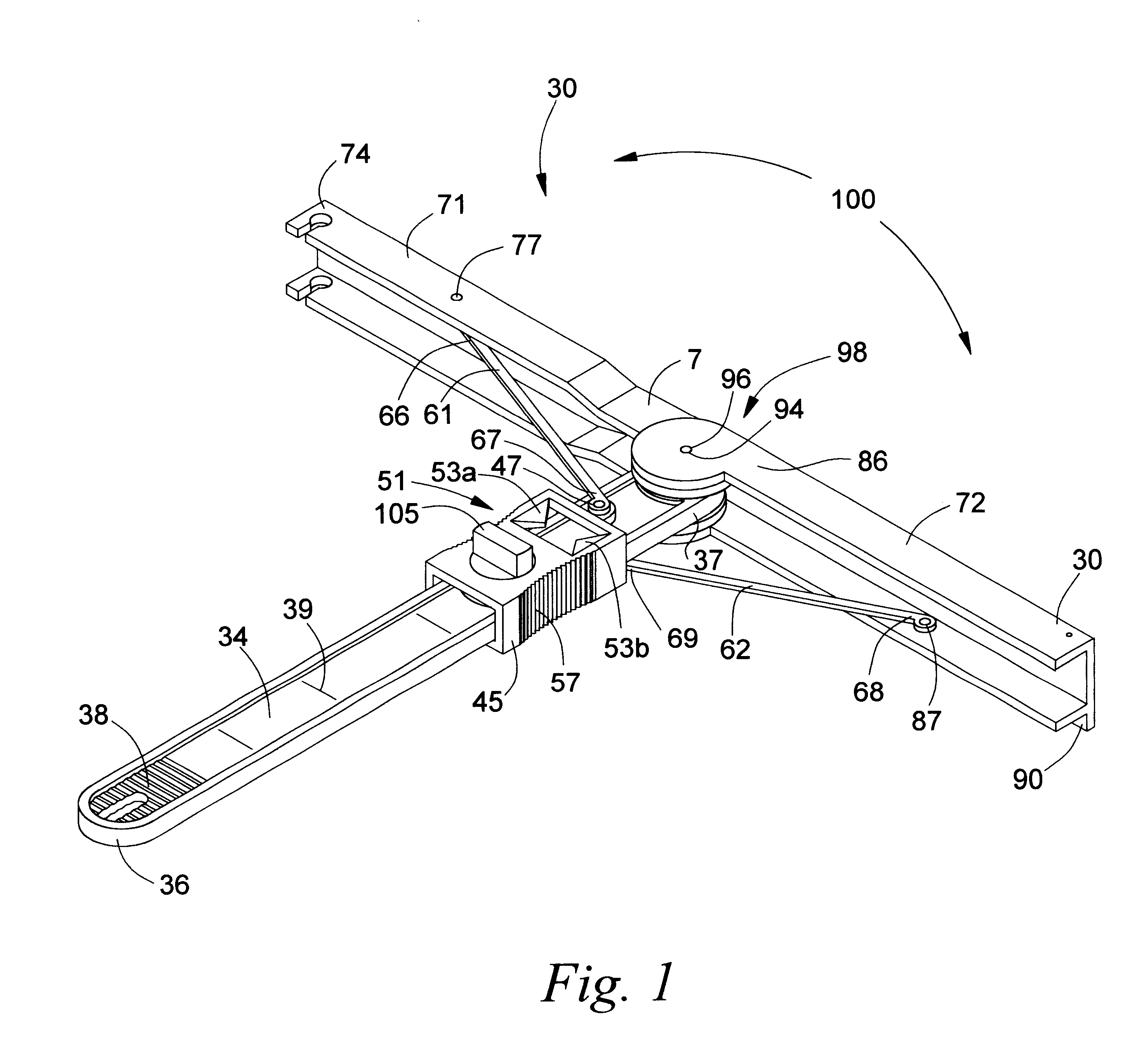

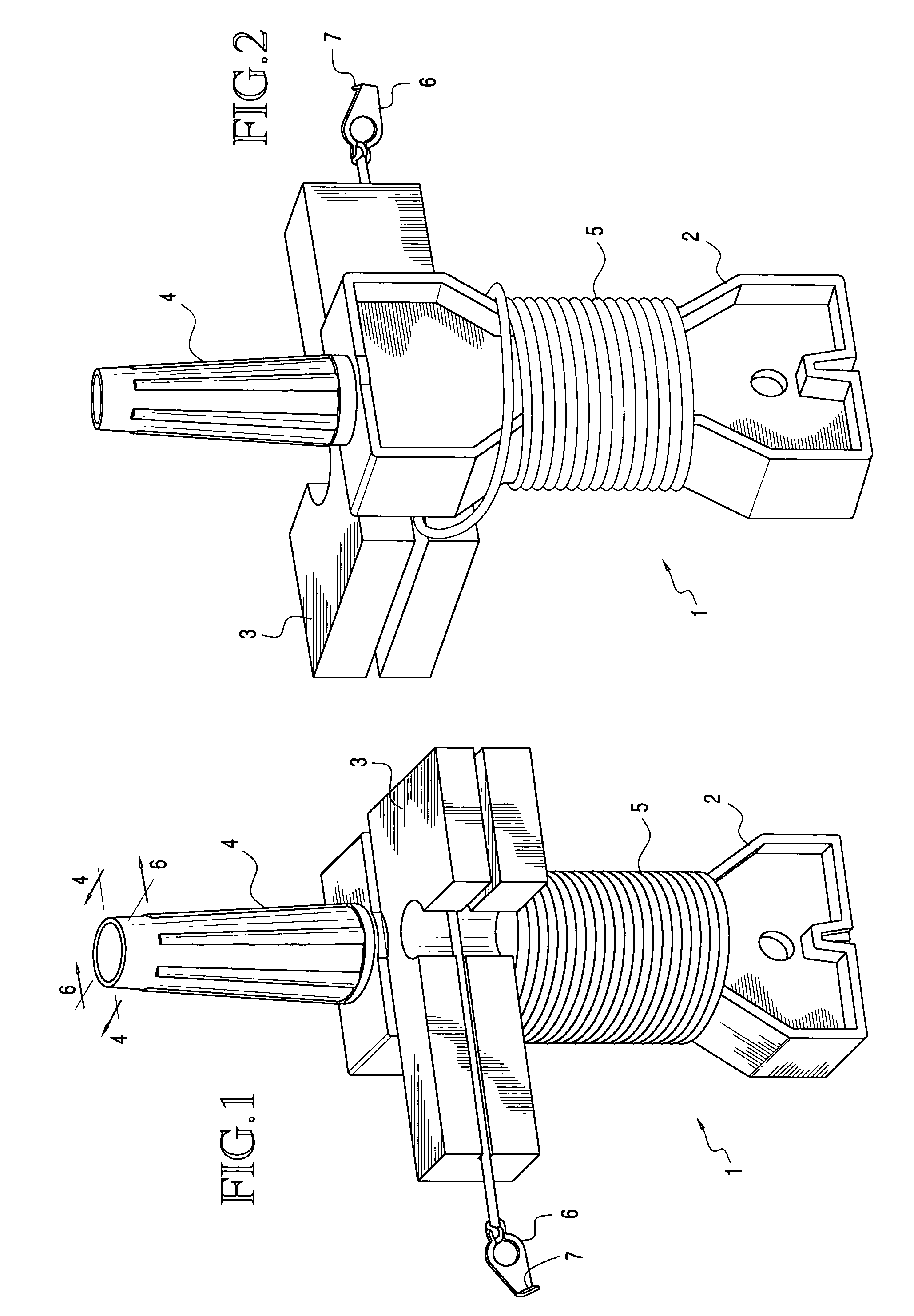

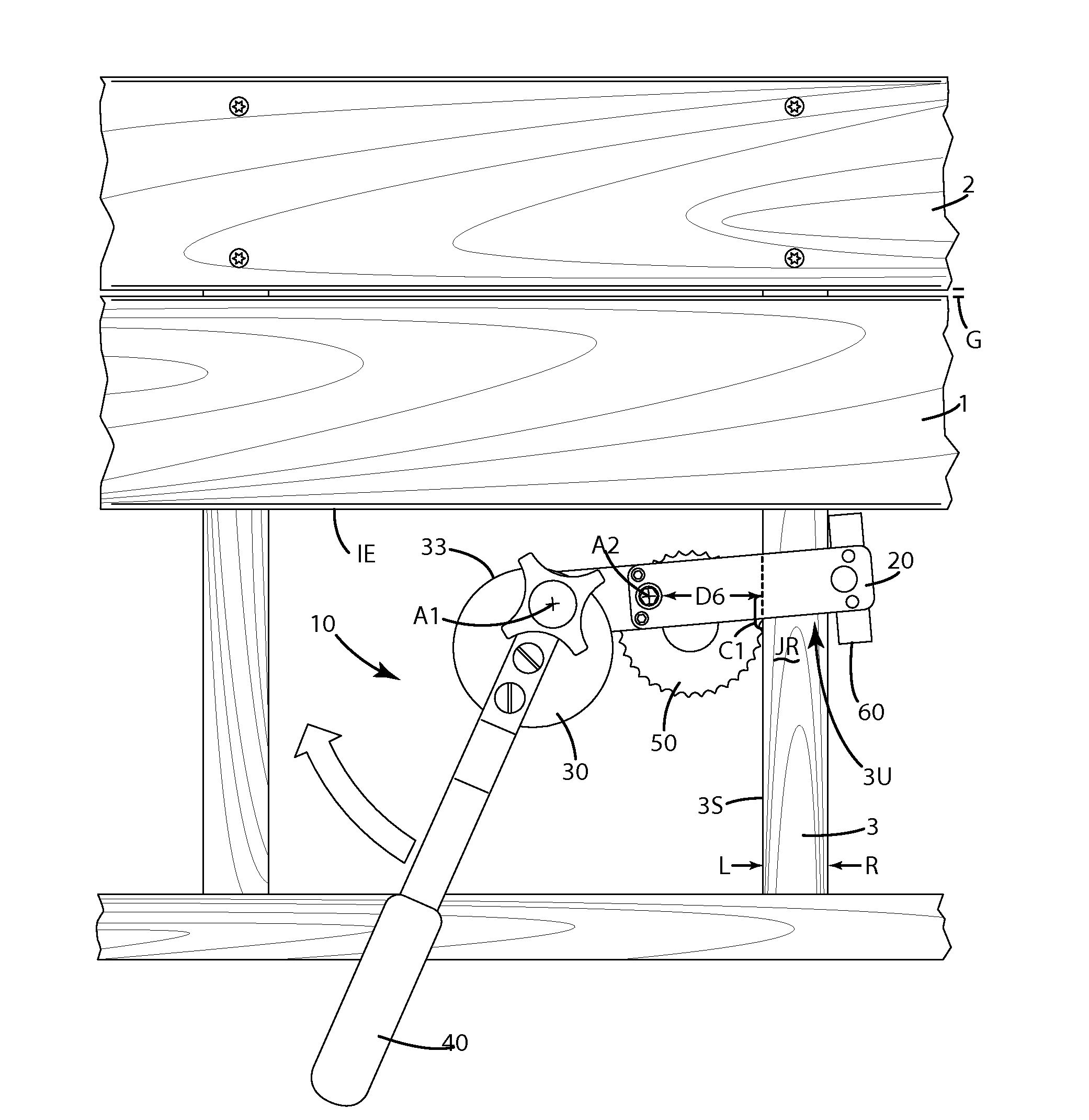

Carpentry tool

ActiveUS20150345156A1Effective clampingEffective gripLifting devicesBuilding constructionsJoistEngineering

A carpentry tool for pushing deck, flooring or other boards toward one another on a joist or underlying substructure. The tool can be operated with one hand, leaving the other hand free for installation of a fastener. The tool can leave an area adjacent the joist and board exposed so that a fastener can be installed in the board and joist in that area. The tool can include a pusher cam rotatably joined with a base, and fixedly joined with a lever. A joist cam and joist blade can be joined with the base, disposed opposite one another across a variable width joist recess. The pusher cam and joist cam can be mechanically coupled to the base so that rotation of the pusher cam urges rotation of the joist cam, thereby causing the joist cam to dynamically grip the joist and prevent the tool from rocking and / or moving away from the pushed board.

Owner:NAT NAIL

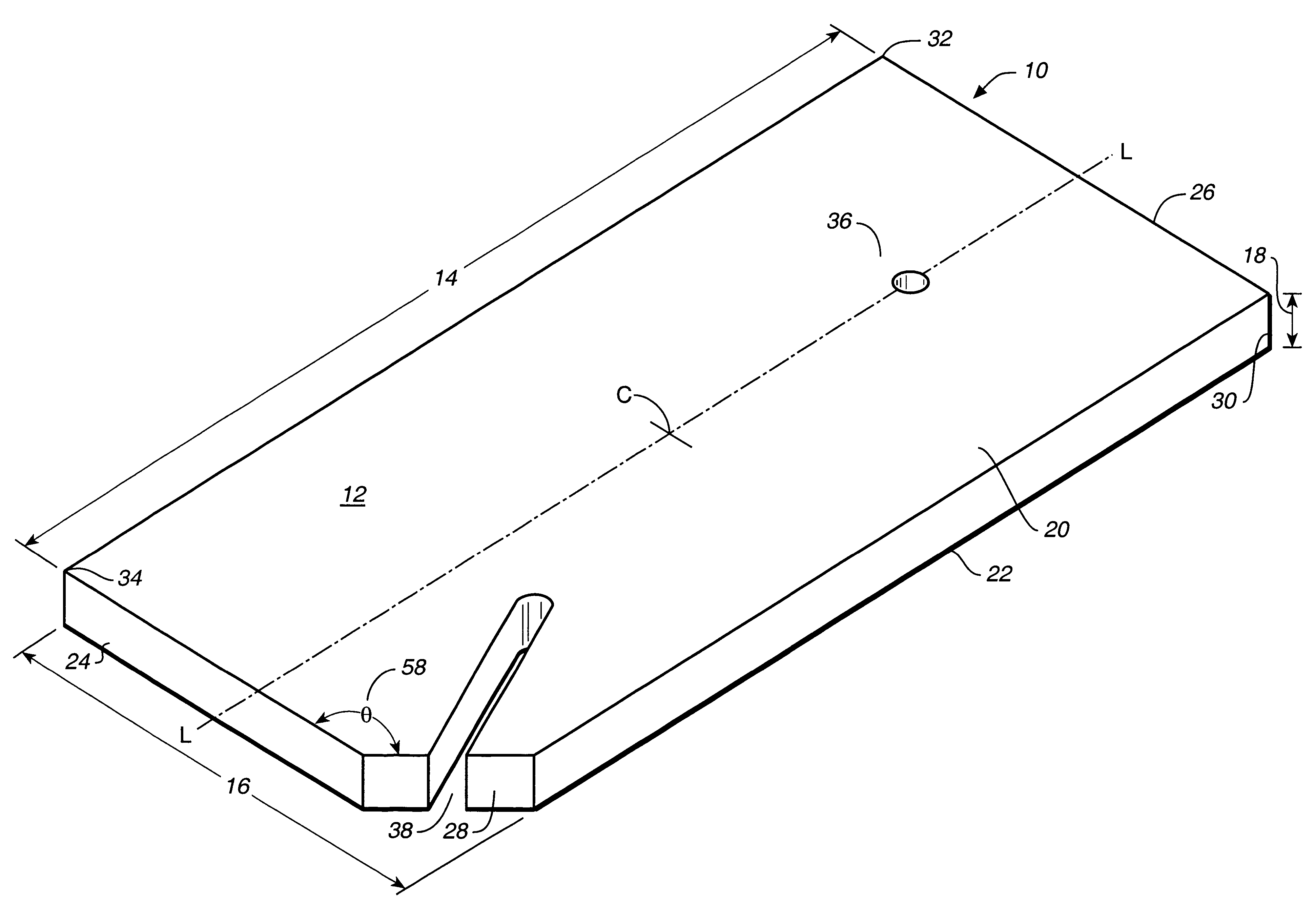

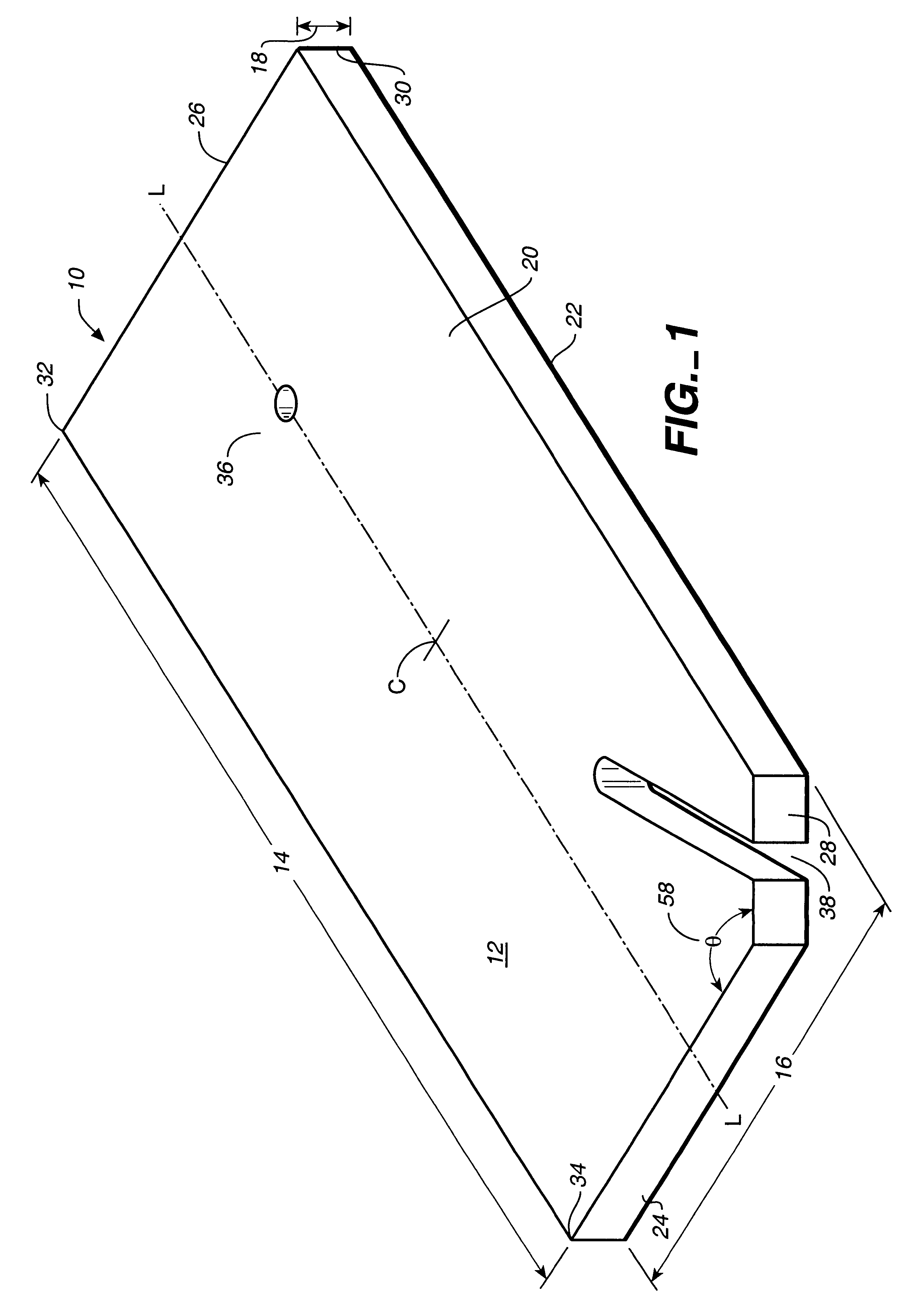

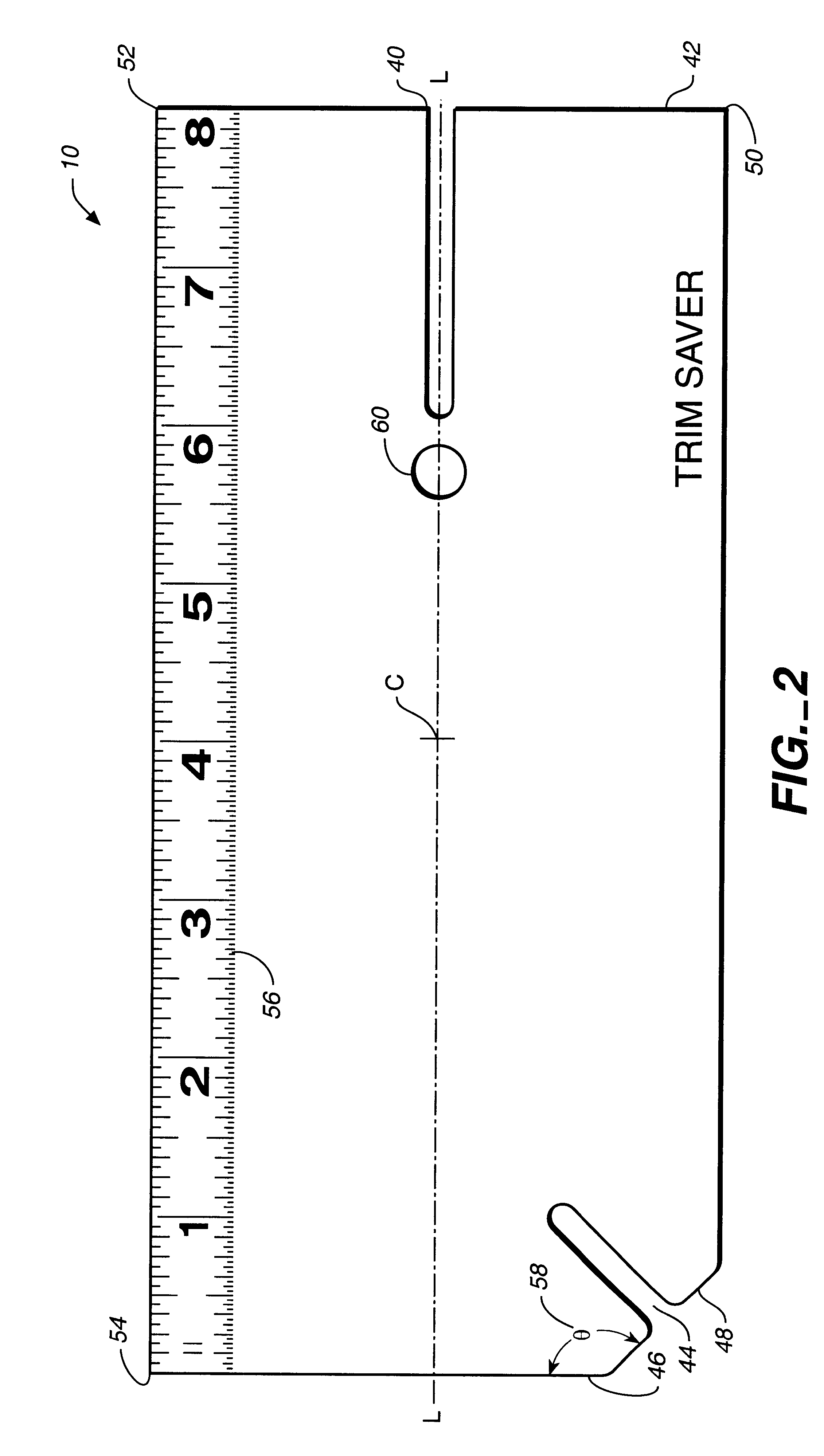

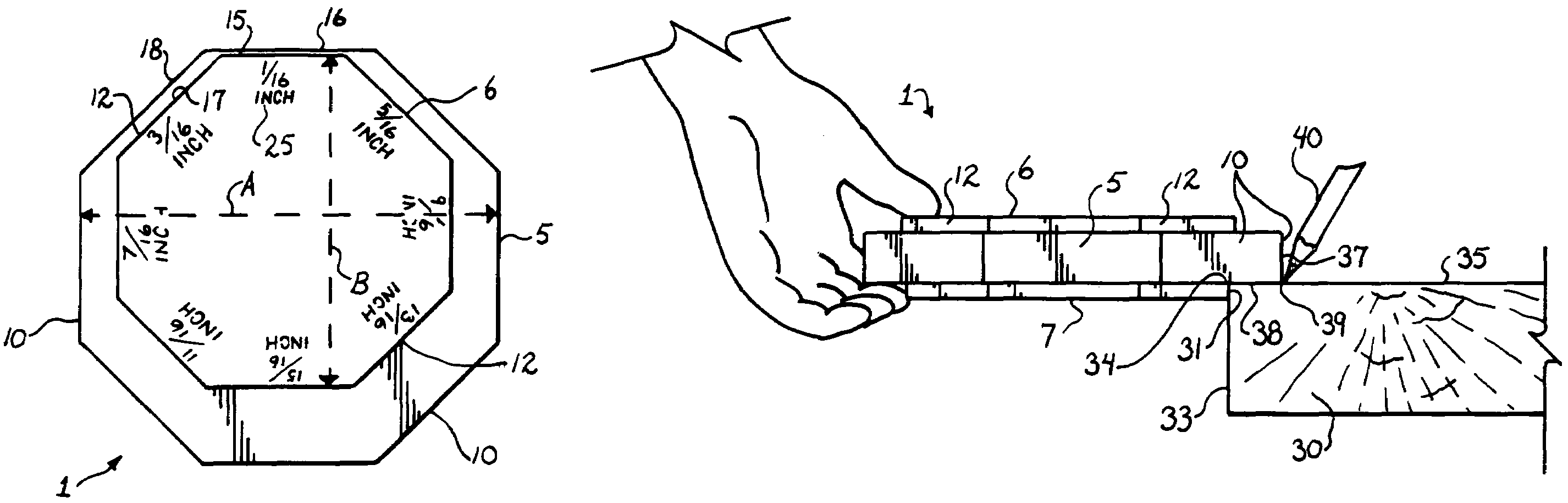

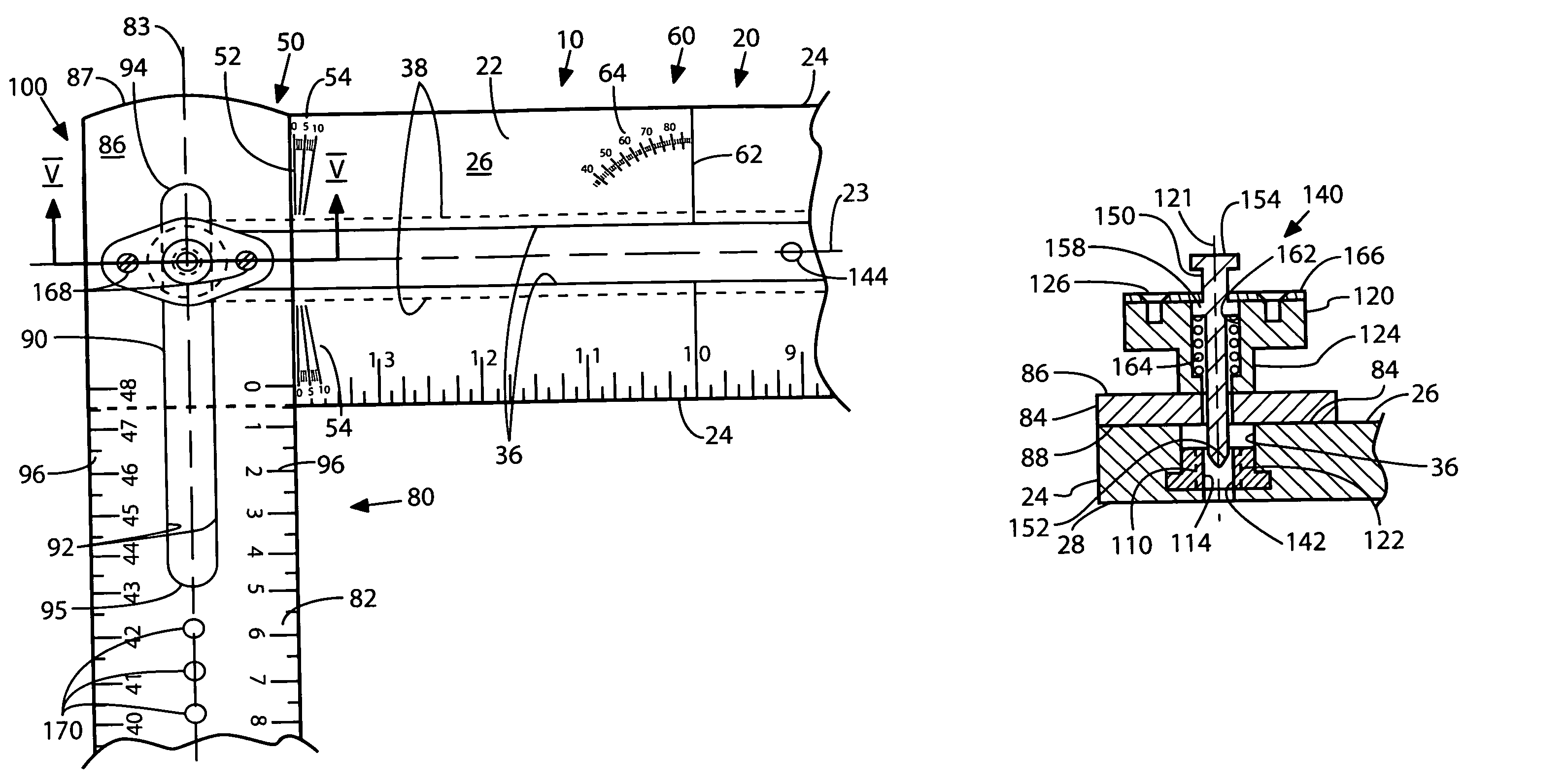

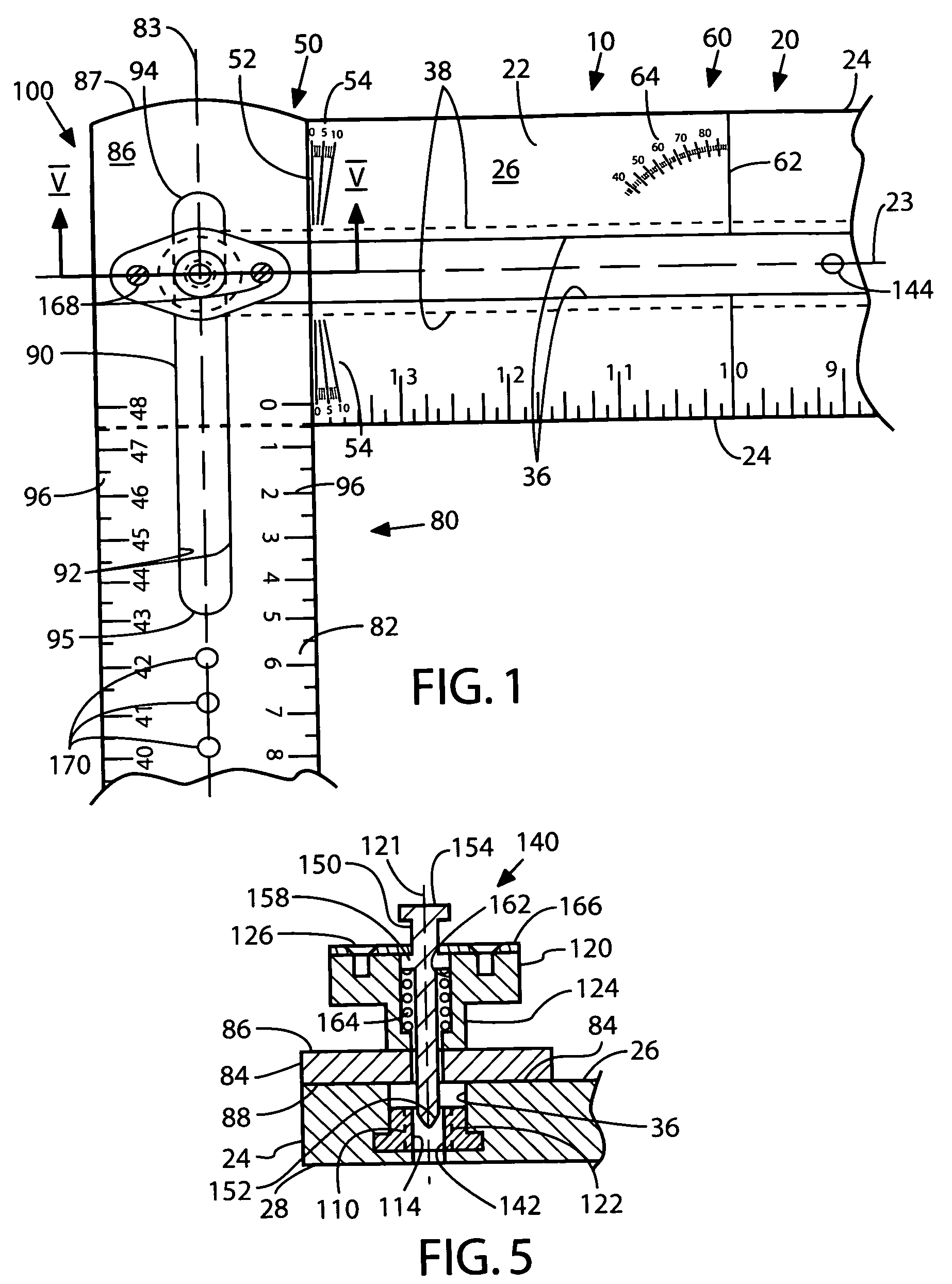

Multi-functional carpentry tool

InactiveUS7797842B2Reduce weightCircular curve drawing instrumentsStraightedgesEngineeringWoodworking

A multi-functional carpentry tool includes a base member having a longitudinal T-shaped groove formed therewithin and a rule member. A T-shaped slide member is positioned within the groove and has a threaded aperture formed therewithin. A knob has a threaded stem operatively received within the threaded aperture for selectively securing the base member and the rule member together in frictional engagement maintaining the base member and the rule member in selected positions relative to one another and permitting each of a sliding and pivoting movement of the rule member relative to the base member. Linear measuring scale indicia is provided in each of the base and rule members. Angular measuring scale indicia and a squaring groove is also provided within the base member. A spring biased pin is movably mounted within the knob for defining pivot axis and facilitating arc scribing effort.

Owner:FERNANDES PATRICK

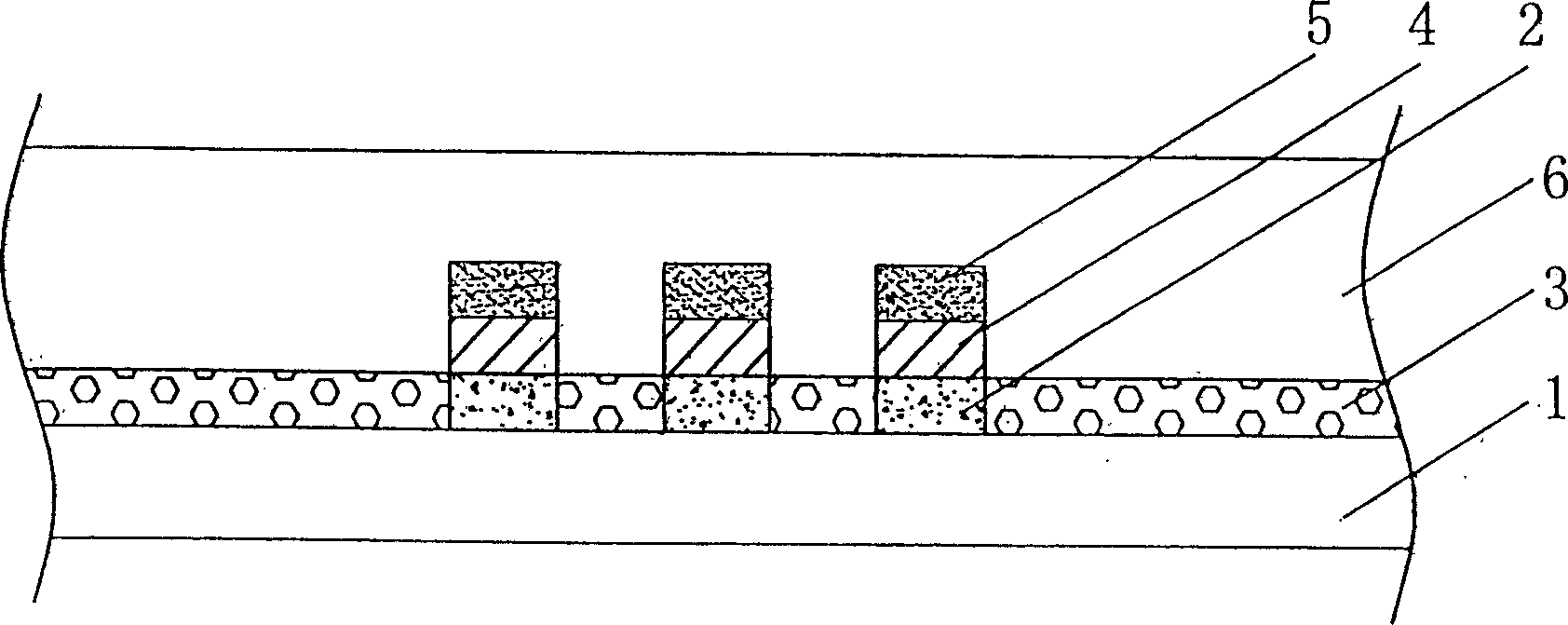

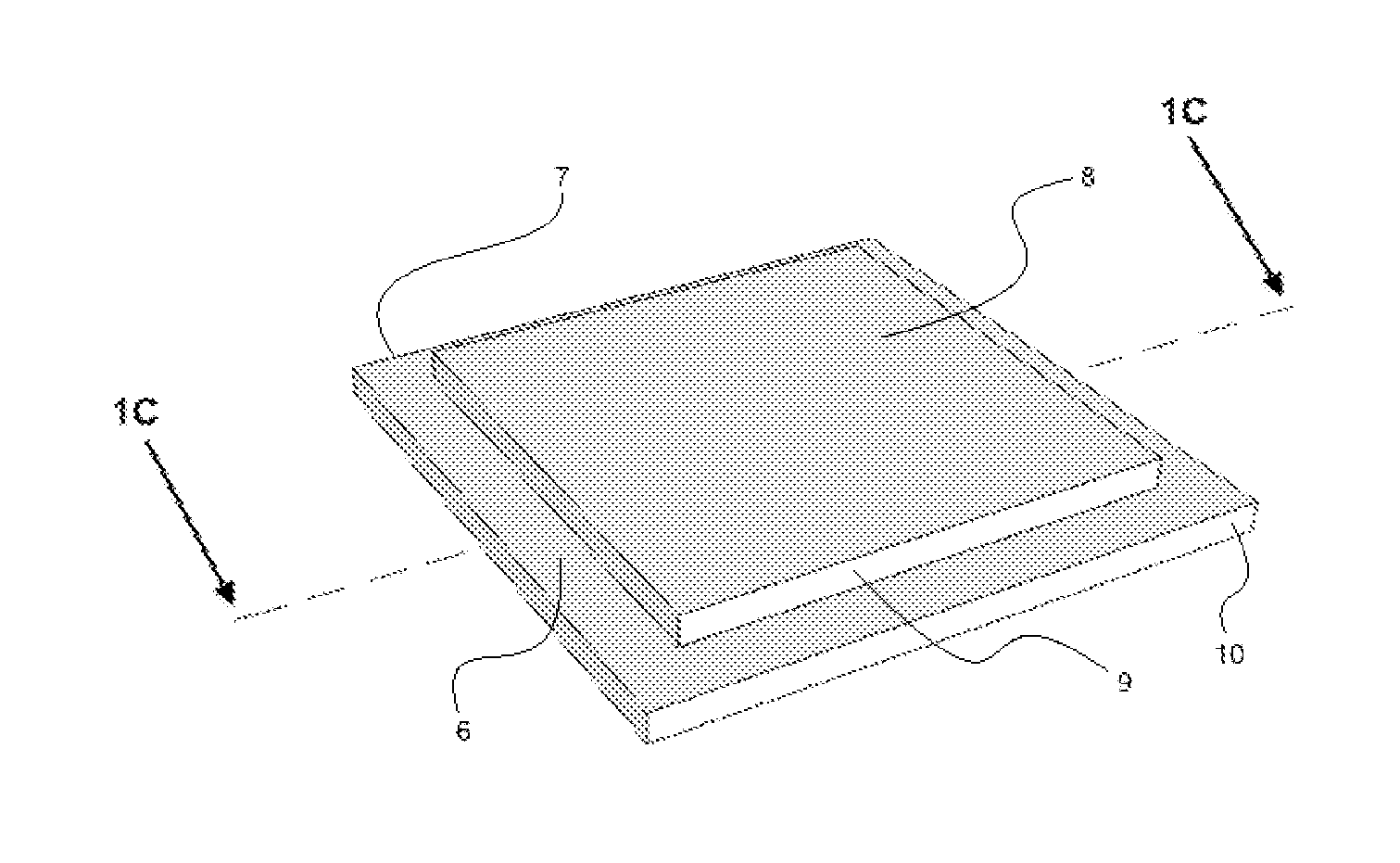

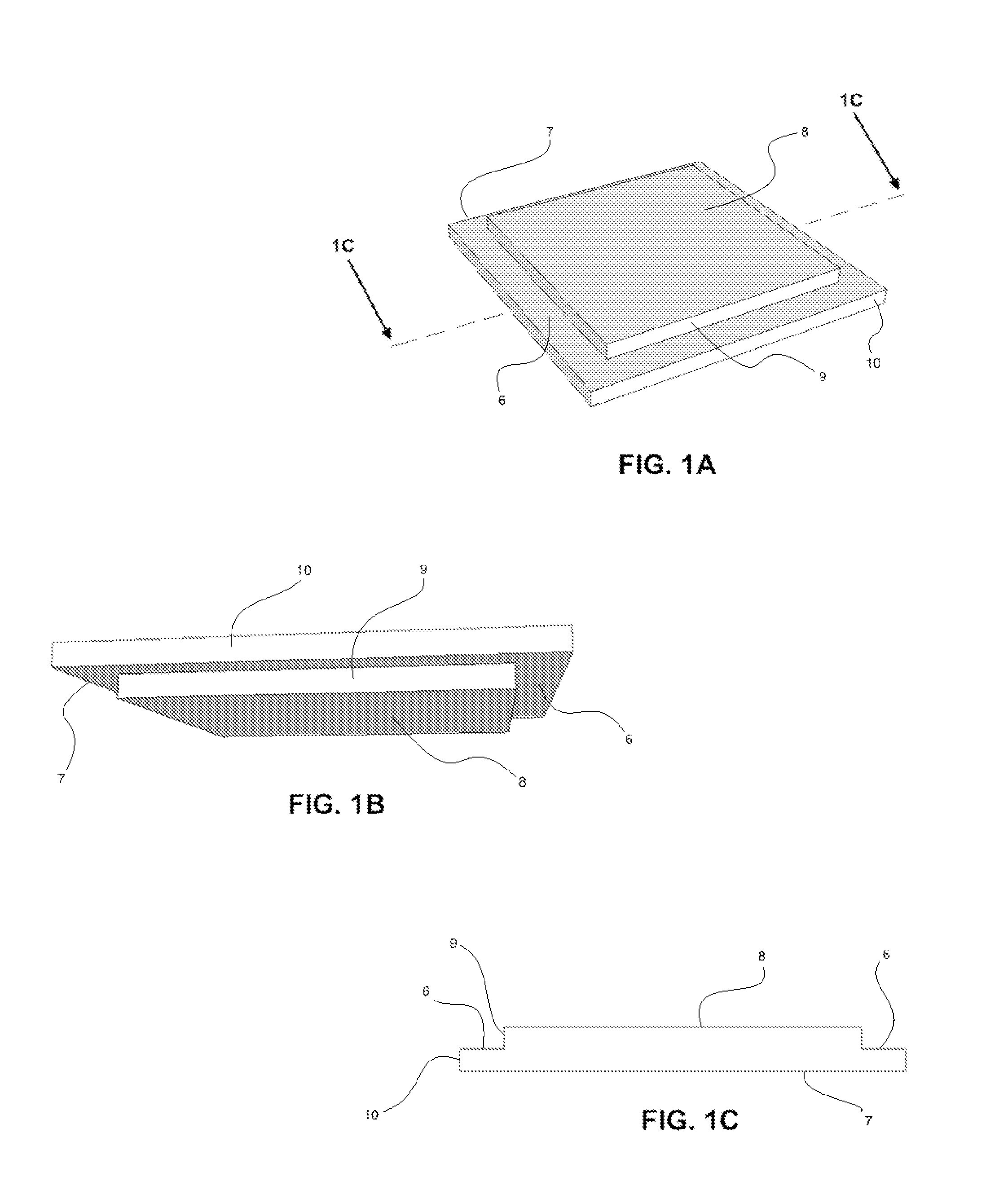

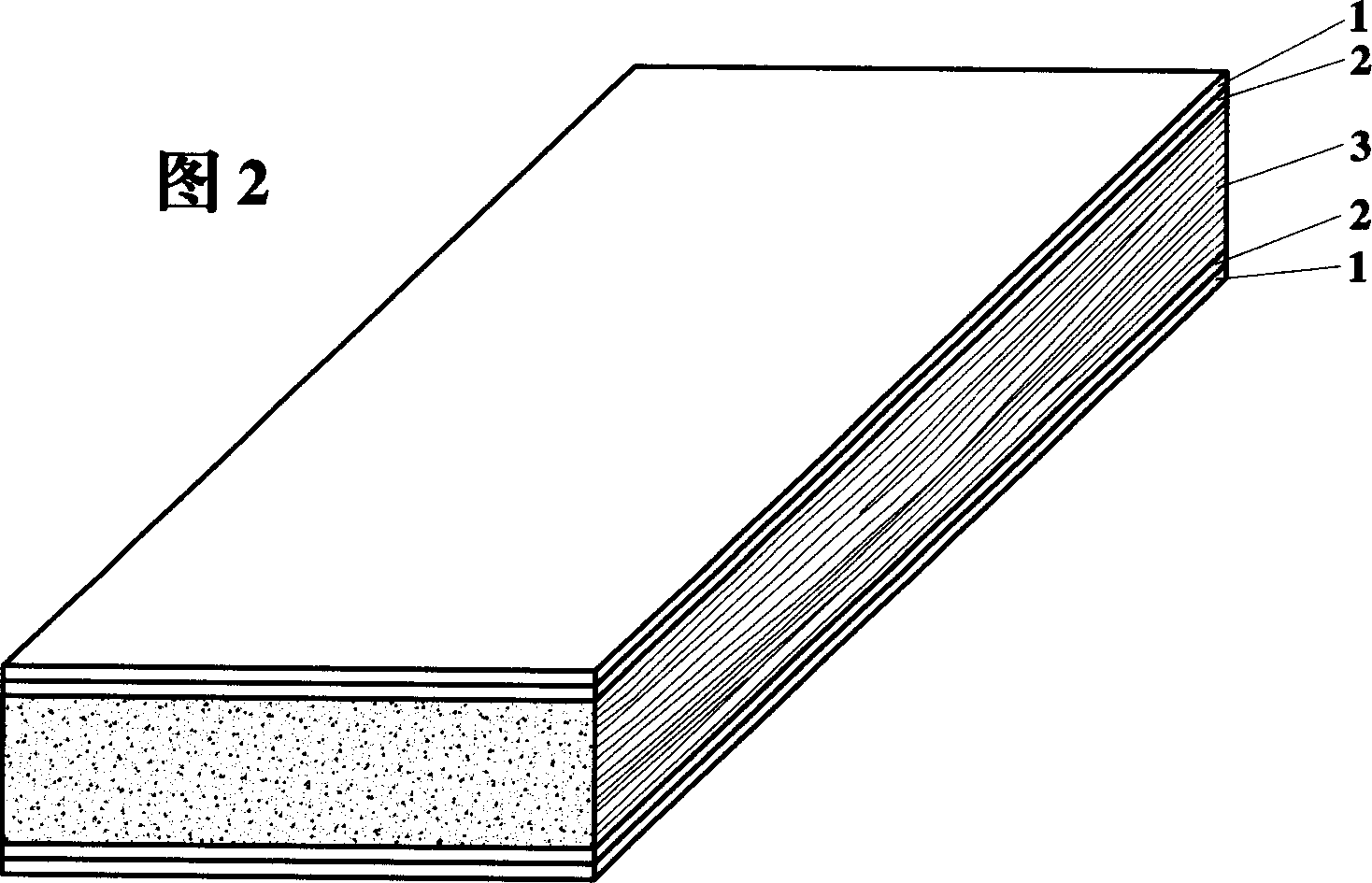

Improved type fine carpentry wood core plate and making method

InactiveCN1410236AReasonable workmanshipIncrease profitWood veneer joiningDomestic articlesEngineeringShip's carpenter

A core board of veneered strip-glued board is made up of the small-diameter raw material, thinning out tree, or branch through preparing raw material, rolling, longitudinal separation, transverse cutting, drying, applying glue, spreading and hot pressing. Its advantages are high productivity and utilization rate of wood, low cost and high quality.

Owner:ZHEJIANG FORESTRY UNIVERSITY

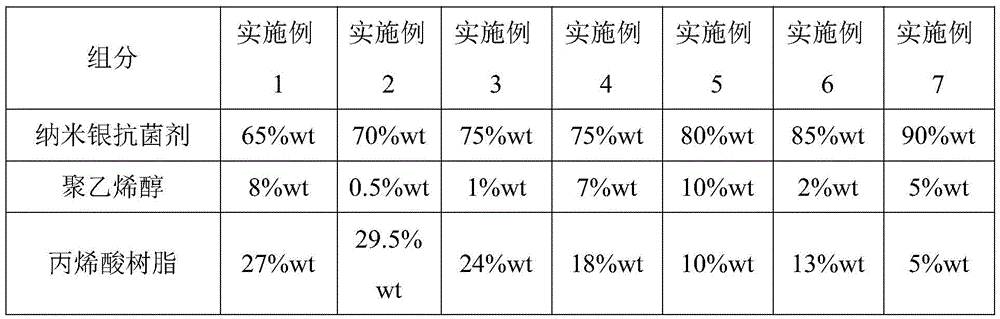

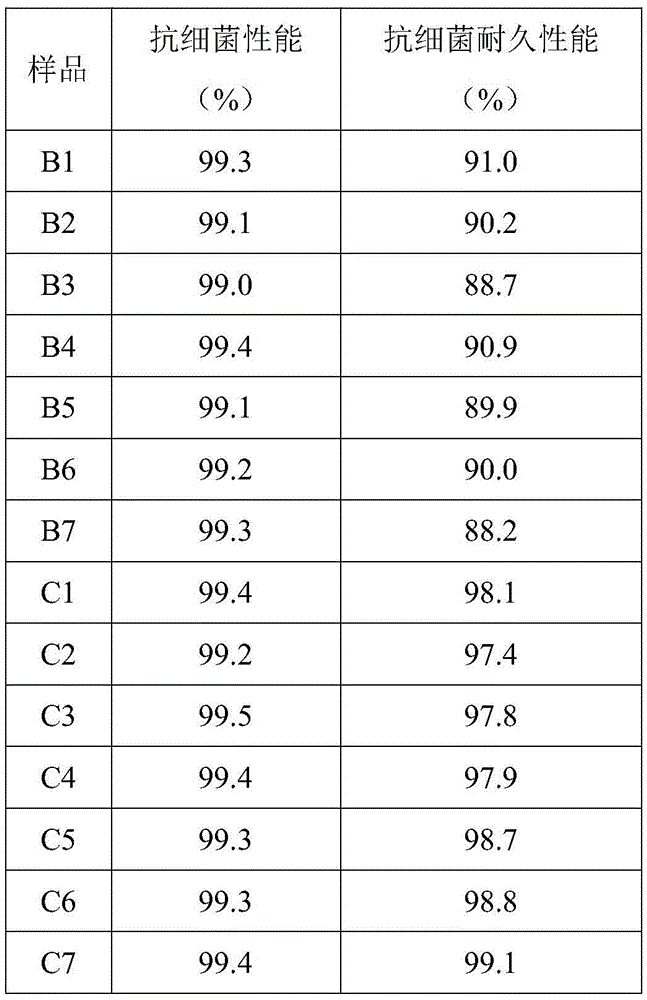

Waterborne carpentry paint

InactiveCN105567030ALong effective timeSolve the problem that sterilization and pest control cannot last for a long timeAntifouling/underwater paintsPaints with biocidesEmulsionSustained Release Capsule

The invention discloses a waterborne carpentry paint including an acrylic emulsion, antibacterial sustained-release capsules, and an auxiliary agent acceptable in the waterborne carpentry paint. An antibacterial agent is externally coated with a layer of sustained-release material, to achieve a purpose of slow release of the antibacterial agent and ultimately meet the durable antibacterial insect-prevention effects. The invention aims to provide the durable antibacterial insect-prevention waterborne carpentry paint.

Owner:BEIJING JINZHIQIAO TECH DEV CO LTD

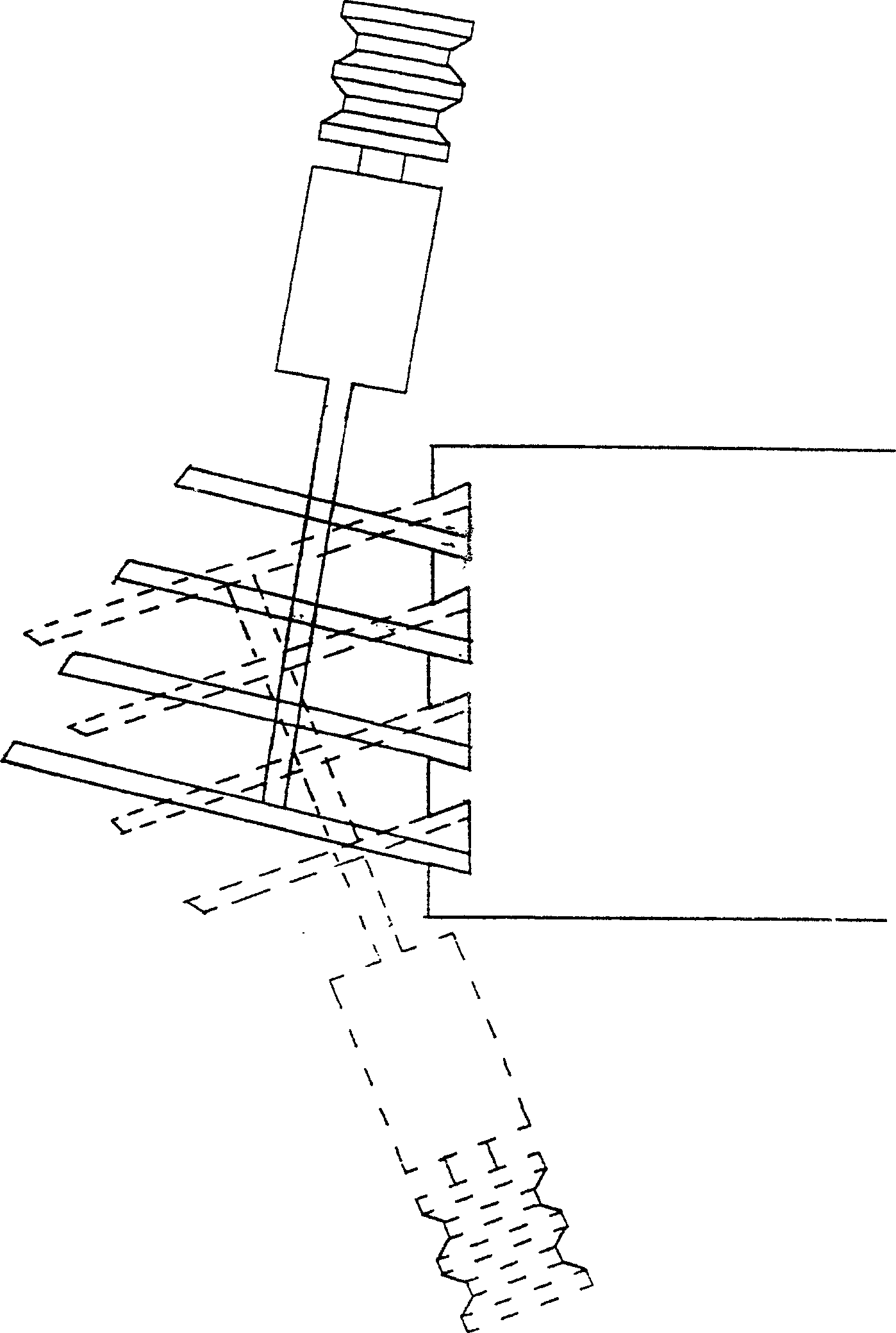

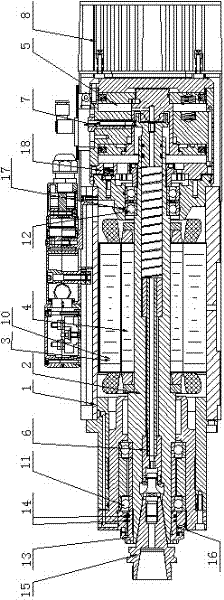

Fan air-cooled automatic tool change electric spindle used for carpentry carving and milling

InactiveCN102394529AExtended service lifeAvoid stickingCooling/ventillation arrangementSupports/enclosures/casingsEngineeringFan blade

The invention relates to the electric spindle technology field, and especially relating to a fan air-cooled automatic tool change electric spindle used for carpentry carving and milling. The fan air-cooled automatic tool change electric spindle comprises a shell which is provided with a rotor shaft, a stator part and a rotor part, and a front bearing and a rear bearing which are provided at two ends of the rotor shaft. The shell is a one-body cuboid and has a wind channel. Two ends of the shell are provided with a tool shank and an independent fan. The independent fan has seven fan blades. The rotor shaft is provided with an automatic tool changer, a cylinder and a detection apparatus of the automatic tool changer. A front end of the shell is provided with a seal cover. According to the invention, a heat radiation effect of the electric spindle is substantially raised, a usage scope of the electric spindle is enlarged, and a service life of the bearing is prolonged.

Owner:常州市翰琪电机有限公司

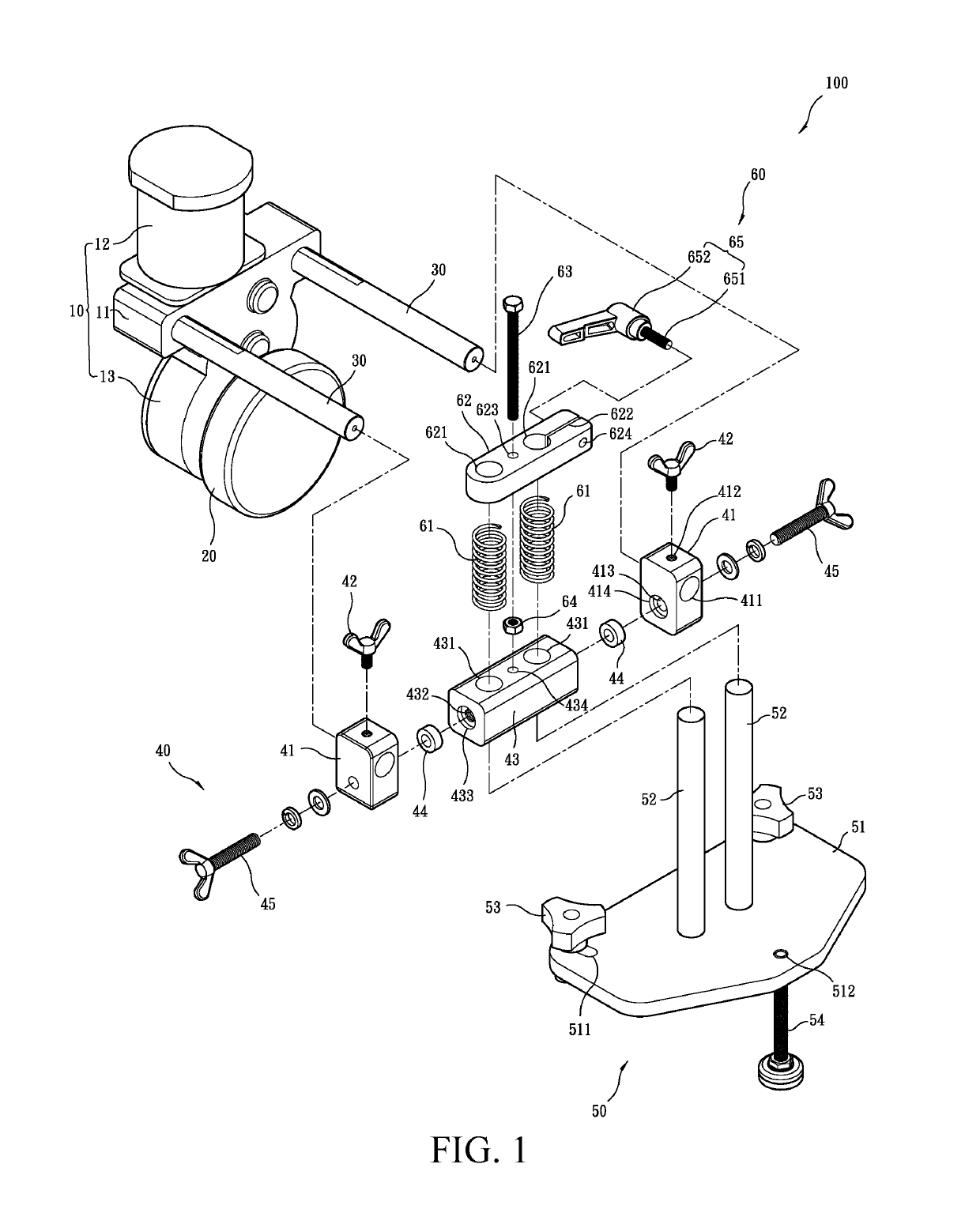

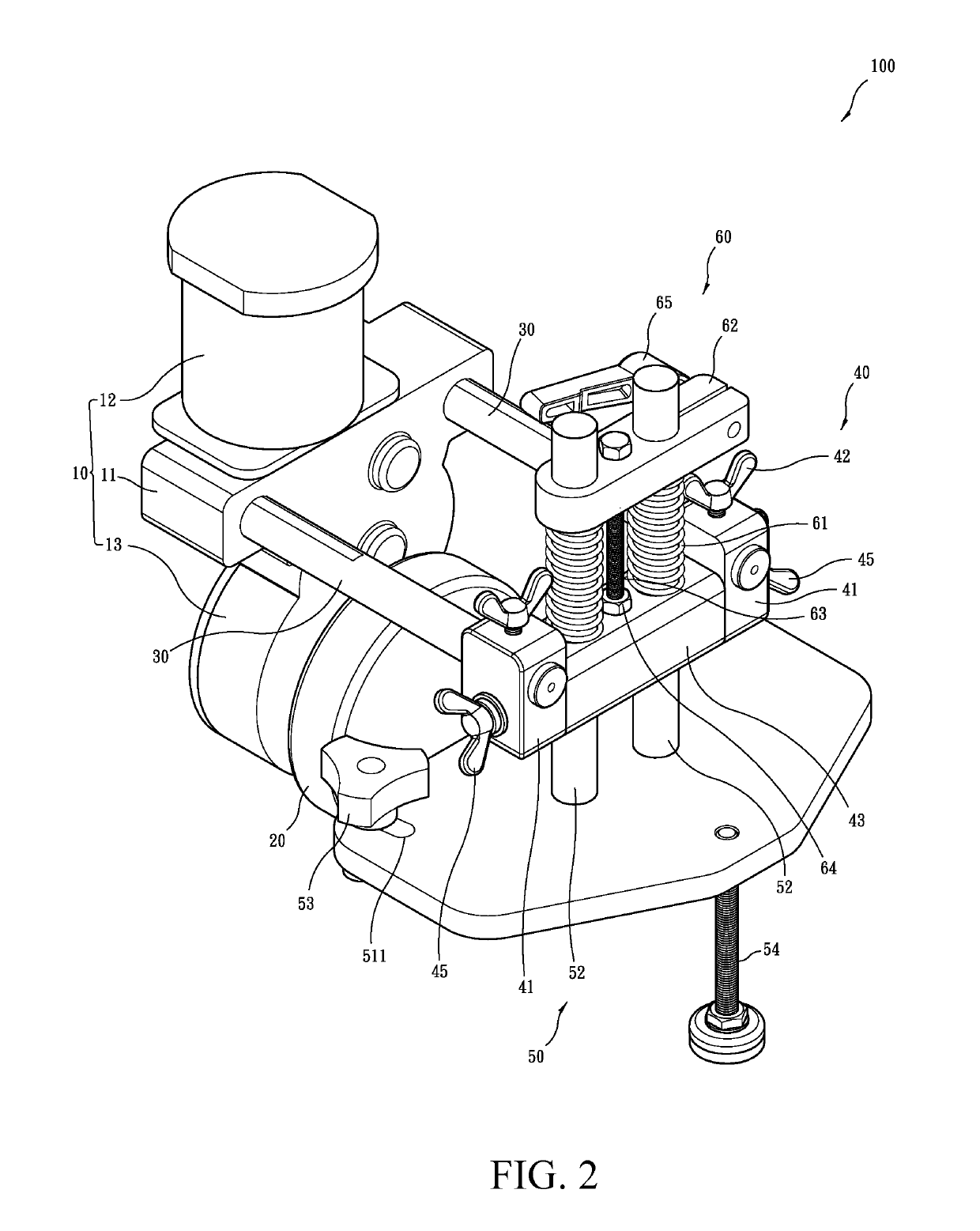

Structure of power carpentry feeder machine

ActiveUS20190210243A1Improve adaptabilityMaterial safetyWood feeding arangementsGuide fencesElectric powerWoodworking

A power carpentry feeder machine includes a power source; a rotary wheel operatively coupled to the power source; horizontal guide rods horizontally coupled to the power source; a horizontal movement unit including two movable blocks having horizontal guide holes to receive the horizontal guide rods therein, locking members attached to the movable blocks, a connection block interposed between the two movable blocks and including vertical guide holes, and jointing members jointing the movable blocks to the connection block; a mounting base including a base board and vertical guide rods vertically coupled to the base board and extending through the vertical guide holes; and a vertical movement unit including springs encompassing the vertical guide rods to set the connection block under the springs and a clamp block having clamping holes to receive the vertical guide rods to extend therethrough so as to set the clamp block on the springs.

Owner:YU BEN

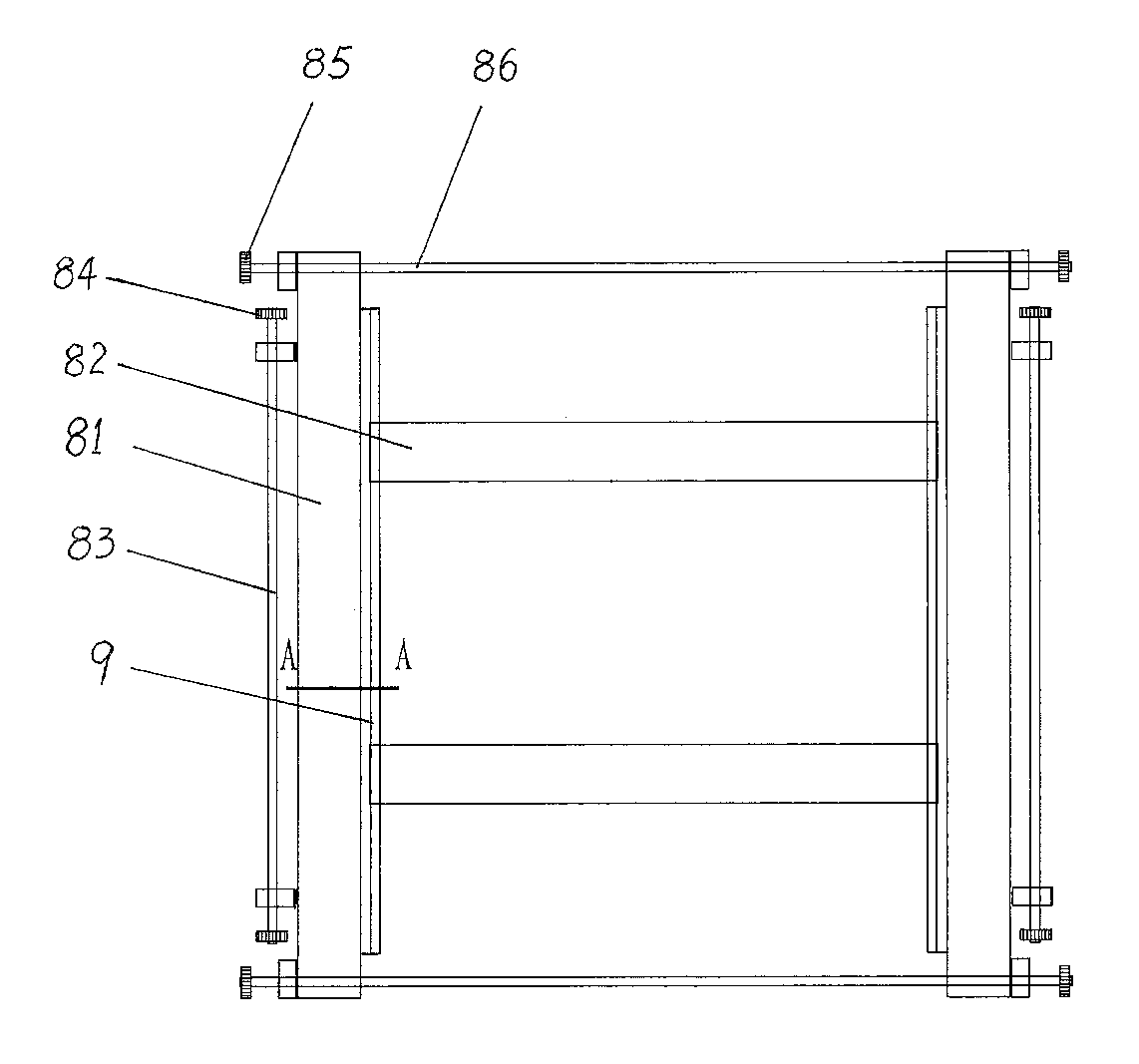

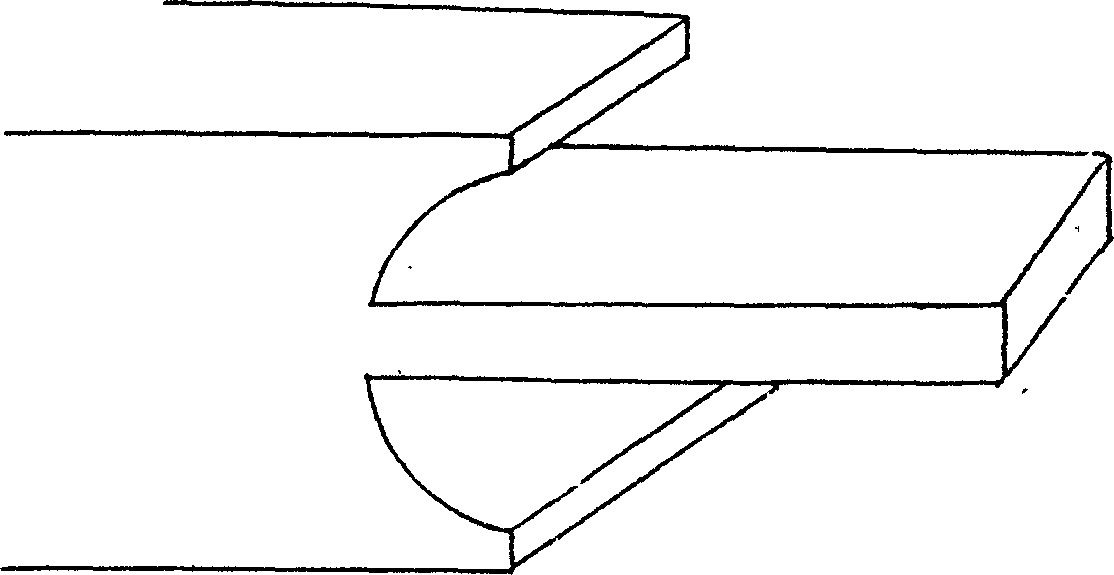

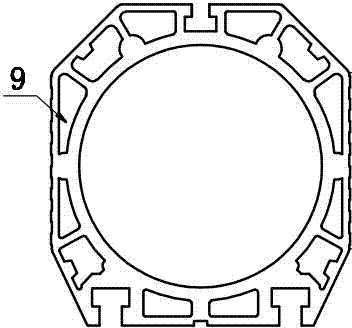

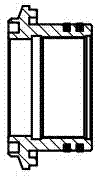

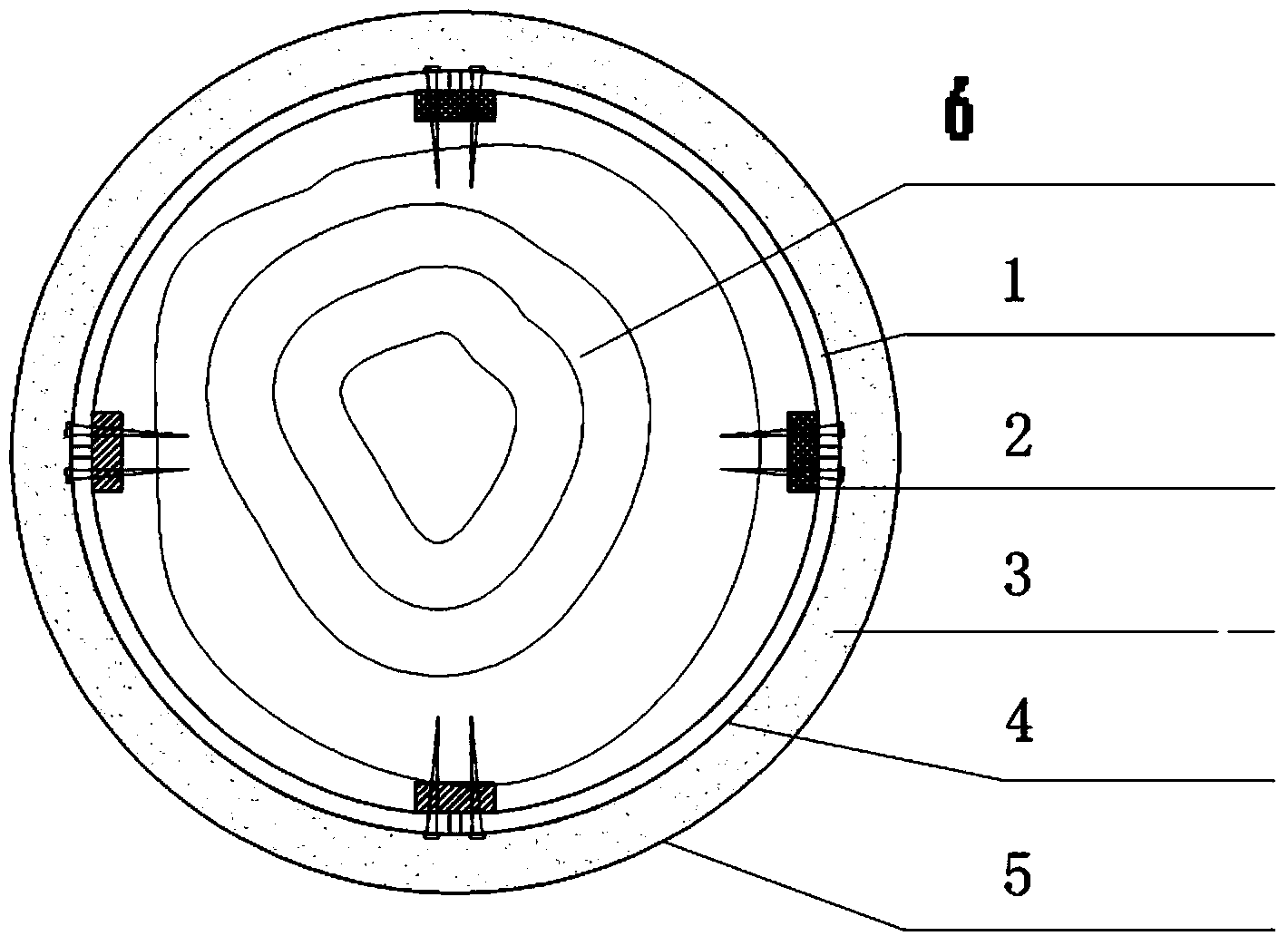

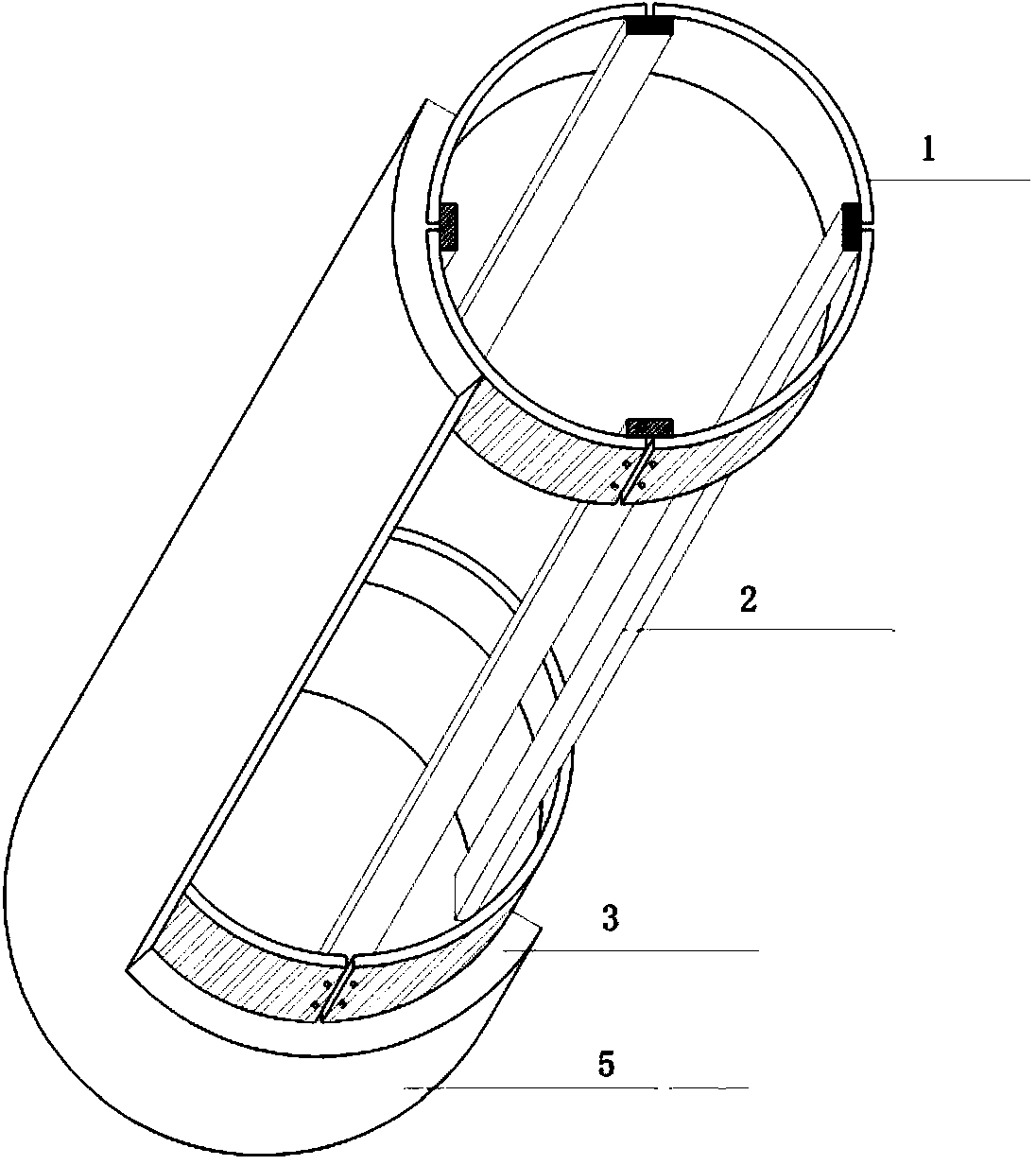

Historic-building carpentry reinforcing member and method

ActiveCN103726671AImprove mechanical performancePlay the role of structural reinforcement and reinforcementBuilding repairsCross connectionInorganic materials

The invention discloses a historic-building carpentry reinforcing member and method, and belongs to the technical field of traditional-building carpentry structure reinforcing. The historic-building carpentry reinforcing member comprises a metal structure frame composed of parallel steel hoops (1) and vertical metal ribs (2) longitudinally connected with the steel hoops (1). A filling layer (3) made of inorganic materials is arranged on the outer side of the metal structure frame, and a sealing layer (5) is arranged on the outer surface of the historic-building carpentry reinforcing member. According to the historic-building carpentry reinforcing member, the horizontal metal components and the vertical metal components are perpendicularly connected in an intersected mode to form the reinforcing frame structure which is tightly connected with an original carpentry structure, meanwhile, the inorganic jelling materials are filled, finally an overall structure is formed by the historic-building carpentry reinforcing member and the original carpentry structure, the carpentry overall stress capacity is greatly improved, and the structure reinforcing and enhancing effects are achieved.

Owner:北京大禹工坊建筑科技有限公司 +1

Dual headed hammer

InactiveUS20050115365A1Suitable for useAccurate measurementHand hammersMulti-purpose toolsEngineeringWoodworking

A dual headed hammer is a hammer with special features for framing and finishing applications. A first head of the hammer has a smaller head and face for finish carpentry applications, and may have a gridded-face to prevent nail slippage. A nail-extractor is located midway between the head and the handle. The opposite end of the hammer has a larger second head for framing applications. Additionally, the larger second head has a plurality of nail holders, complete with magnets, on the top and lateral sides of the second head. The handle is sized such that the total length of the invention is exactly 17.5 inches to aid in construction of walls that use 2×4 studs, 16 inches on center.

Owner:NAU TEVITA T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com