Patents

Literature

711results about How to "No gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

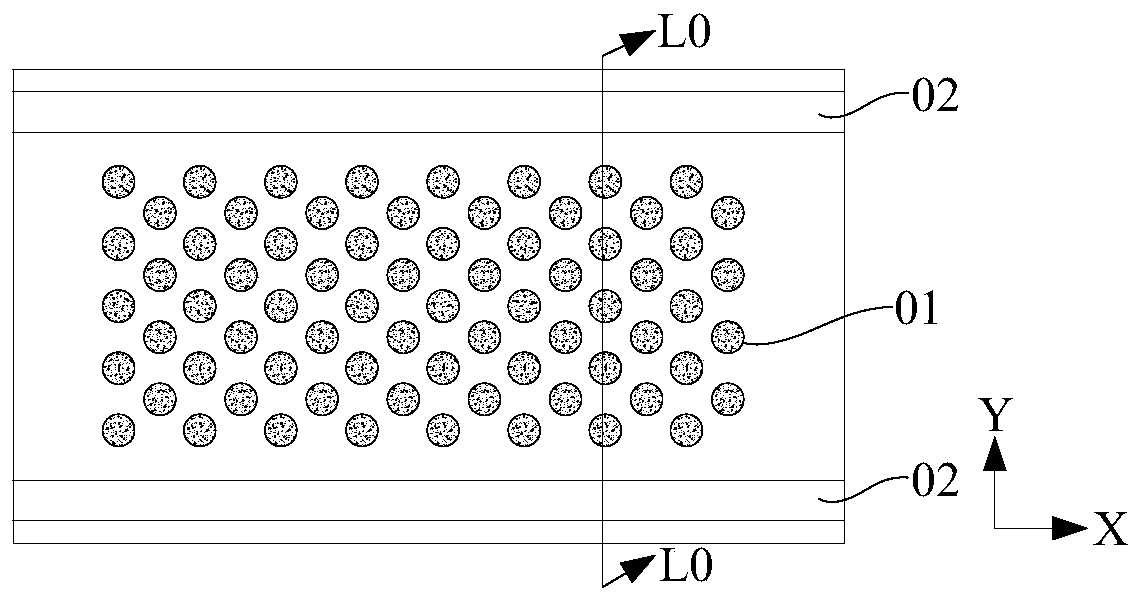

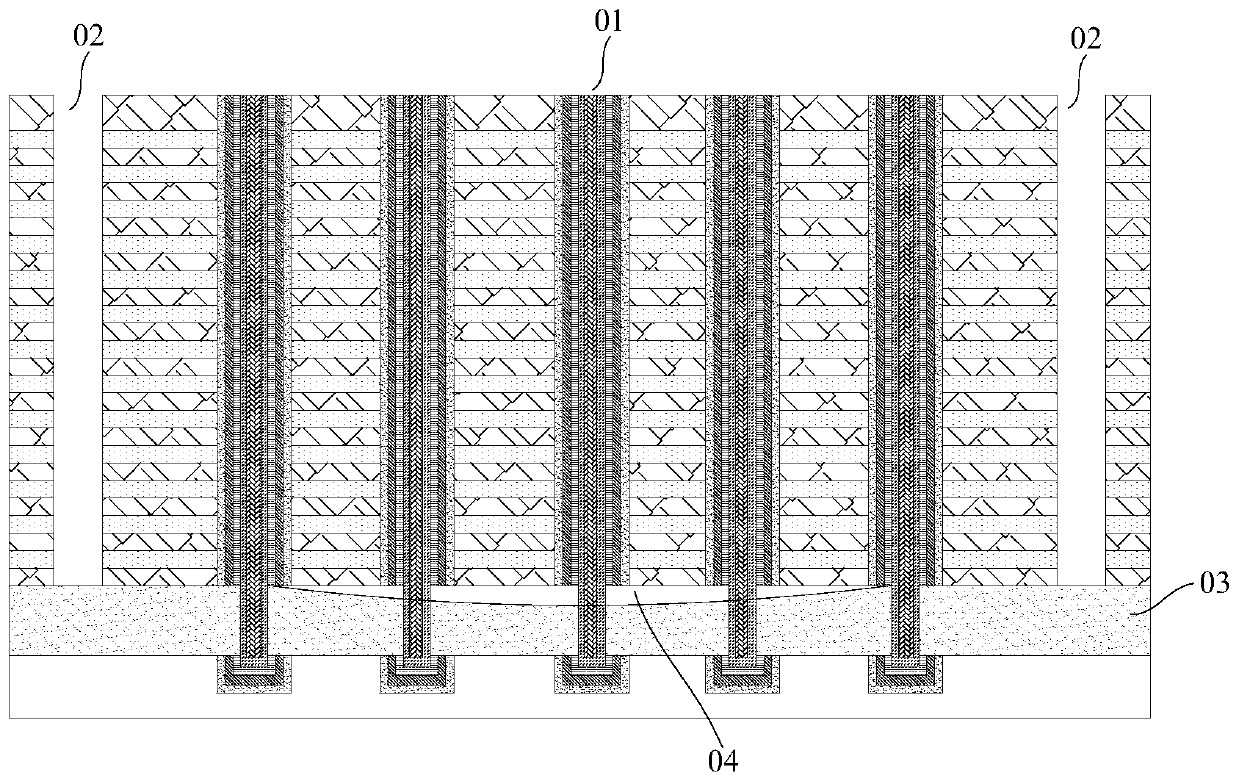

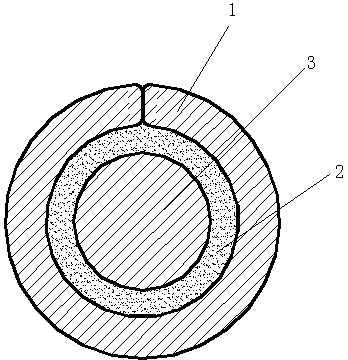

Air positive electrode constructed by conductive gel particles and lithium air battery

ActiveCN104659375AEasy and quick passFast deliveryFuel and primary cellsCell electrodesSolid structureLithium–air battery

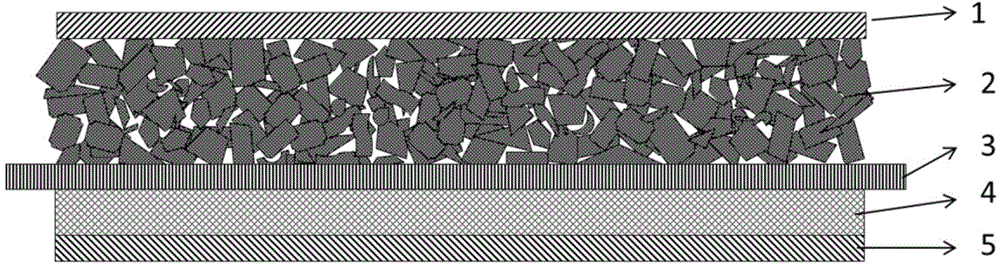

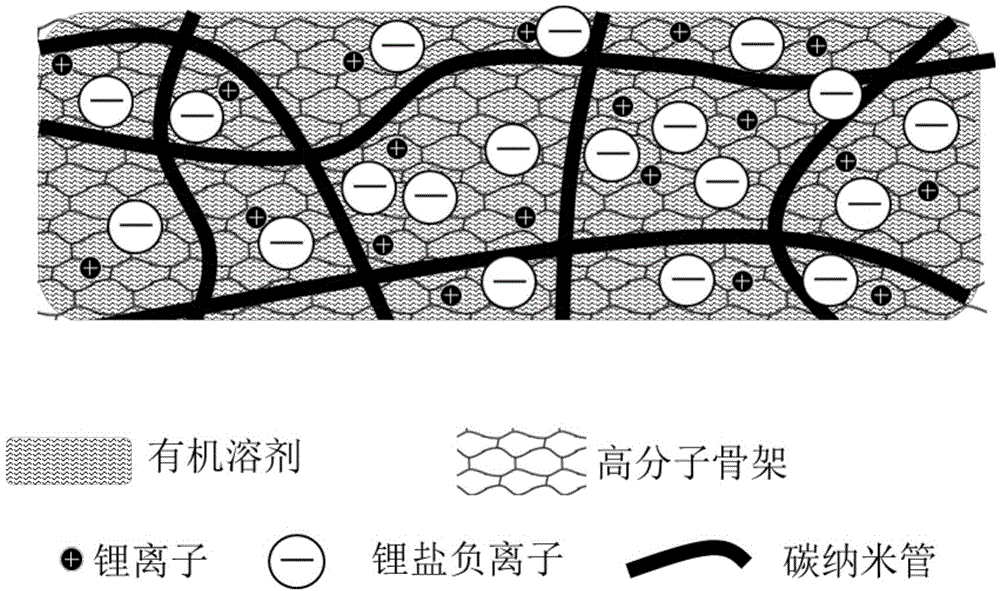

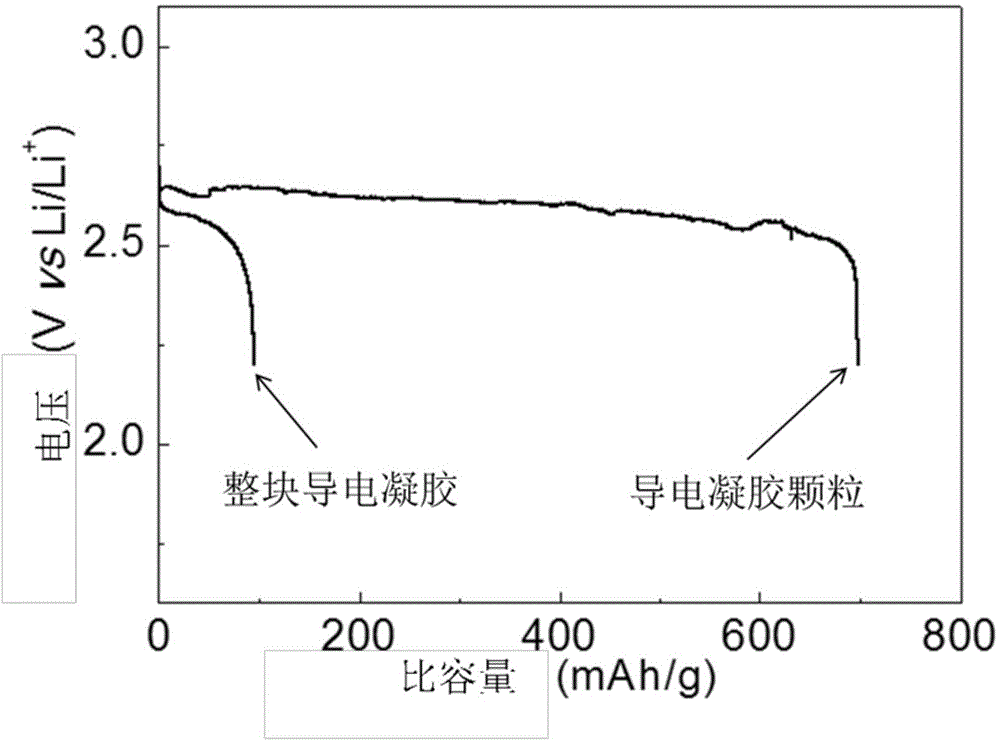

The invention discloses an air positive electrode constructed by conductive gel particles and a lithium air battery. The air positive electrode is characterized by being of a full-solid structure and comprising particles with arbitrary shapes, wherein the particles are prepared from conductive gel, gaps are formed among the particles, electrons and ions can be simultaneously conducted by conductive gel, and the size range of the particle sizes of the particles is 10-500 microns; the particles are stacked to form a laminated structure, and the thickness of the laminated structure is 50 microns to 5 millimeters. A battery cell of the lithium air battery is of a multi-layer winding type structure or a multi-layer laminating type structure and is formed by winding and laminating a plurality of repetitive units, and each repetitive unit comprises the air positive electrode. A rapid gas dispersion channel is formed in the air positive electrode and can be prepared to be relatively thick, so that the problem that oxygen is difficult to diffuse is effectively solved, and the air positive electrode can be truly input into actual application.

Owner:HUAZHONG UNIV OF SCI & TECH

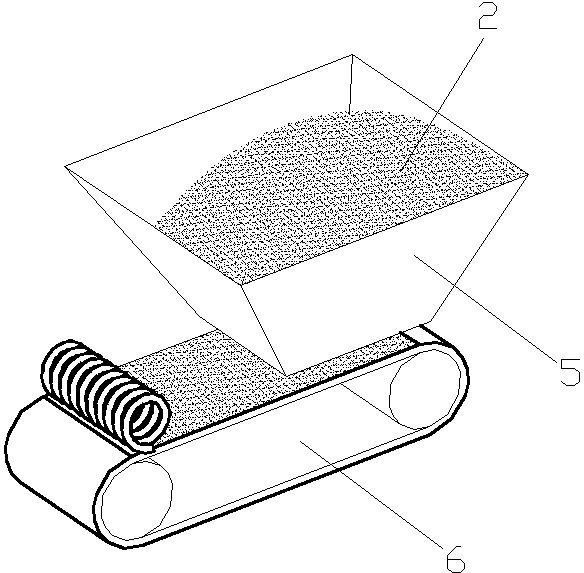

Spinning process of bamboo-like flat filaments produced by semi-continuous high-speed spinning machine

ActiveCN103290495AEasy maintenanceLow cost of spinningArtificial thread manufacturing machinesArtificial filaments from viscoseFrequency changerPolymer science

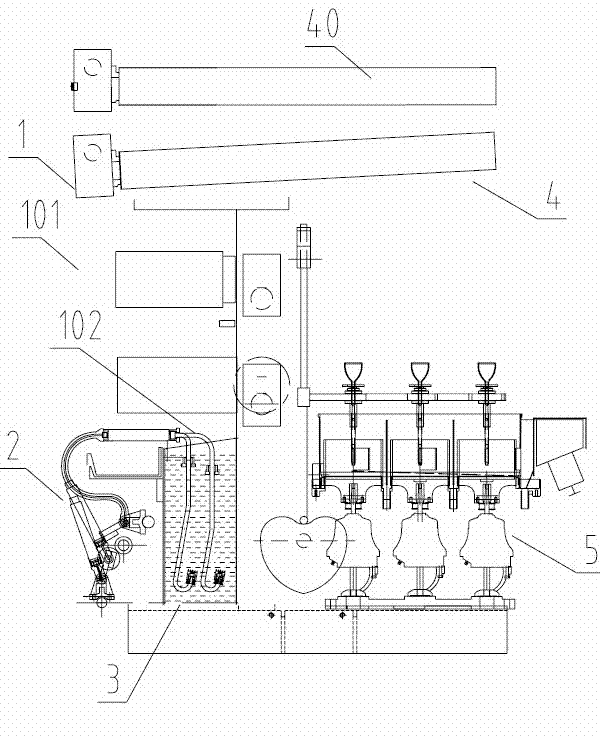

The invention relates to a spinning process of bamboo-like flat filaments produced by a semi-continuous high-speed spinning machine and belongs to the technical field of spinning of semi-continuous spinning machines. The spinning process comprises glue supply, filament strip forming, spinning and winding. The spinning process is characterized in that the glue supply is achieved through a glue supply device which comprises a metering pump, a glue supply tube and a filter; the metering pump is connected with a frequency converter which is used for controlling the amount of the glue supply of the metering pump; the frequency converter controls the metering pump to perform intermittent glue supply; the spinning is achieved through a spinning device which comprises at least one spinning roller which is horizontally arranged relative to an operating surface of a spinning surface; and filament strips surround the spinning roller to achieve drafting, solidification and deacidification in the spinning processes under the rotation of the spinning roller. The spinning process of the bamboo-like flat filaments produced by the semi-continuous high-speed spinning machine has the advantages of solving the problems that the filament strips of the semi-continuous spinning machines are inadequate in response, so that the spinning speed cannot be improved and the production efficiency and product quality cannot be integrated, enabling the arrangement direction of the spinning roller to be changed to enable the spinning speed of the spinning machine to be improved and enabling the high quality bamboo-like flat filaments to be spun out.

Owner:YIBIN HIEST FIBER +2

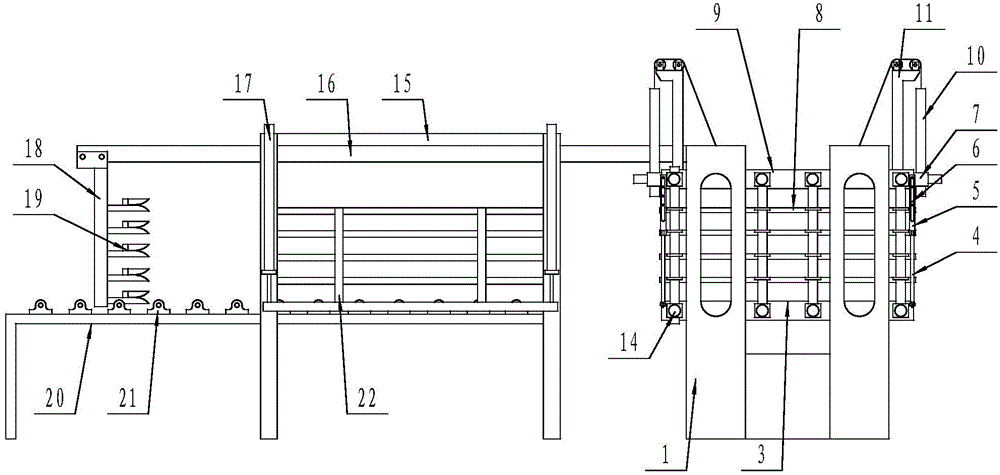

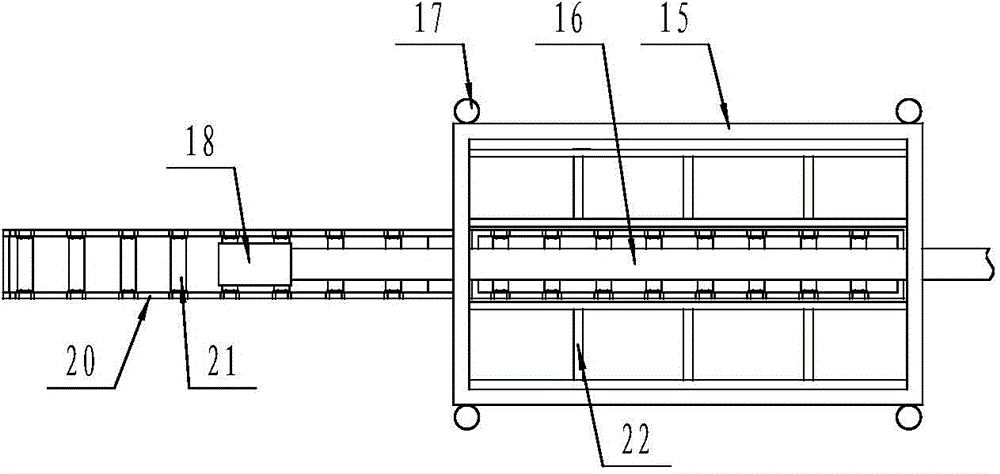

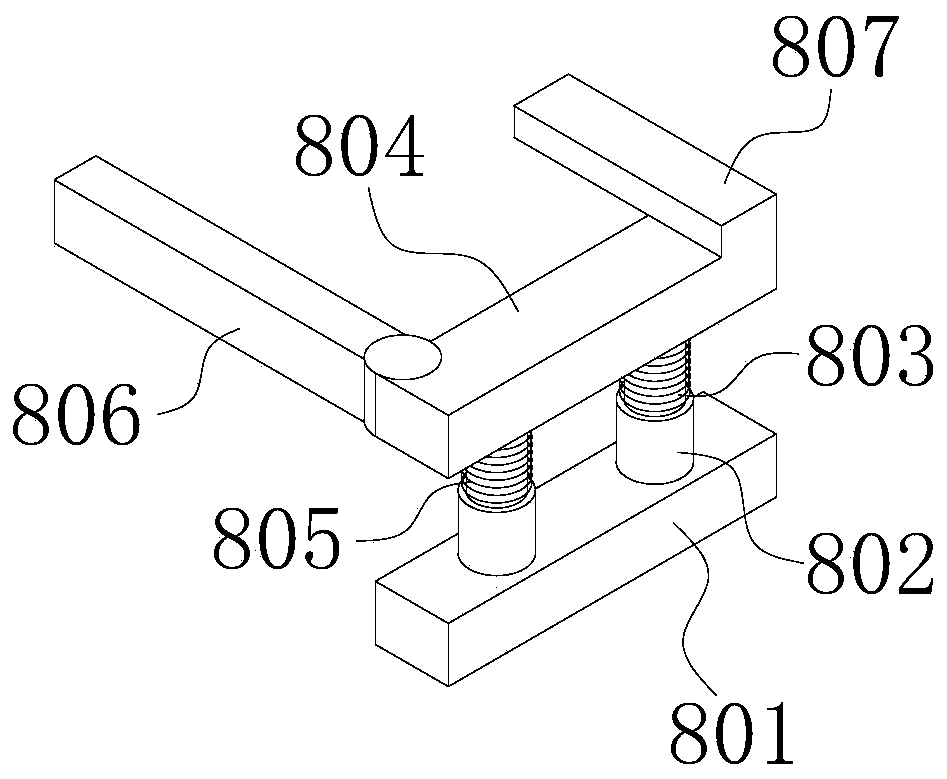

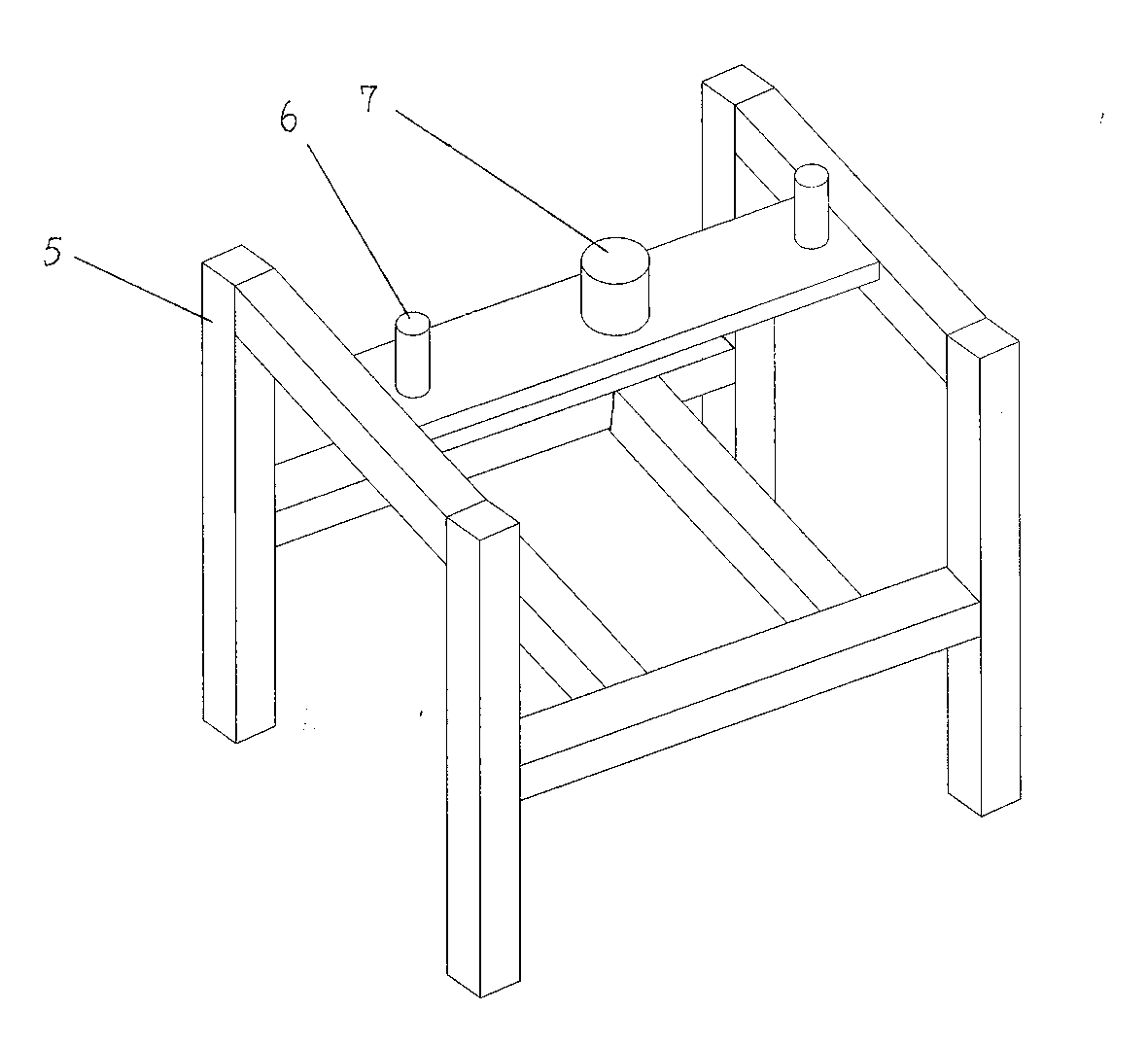

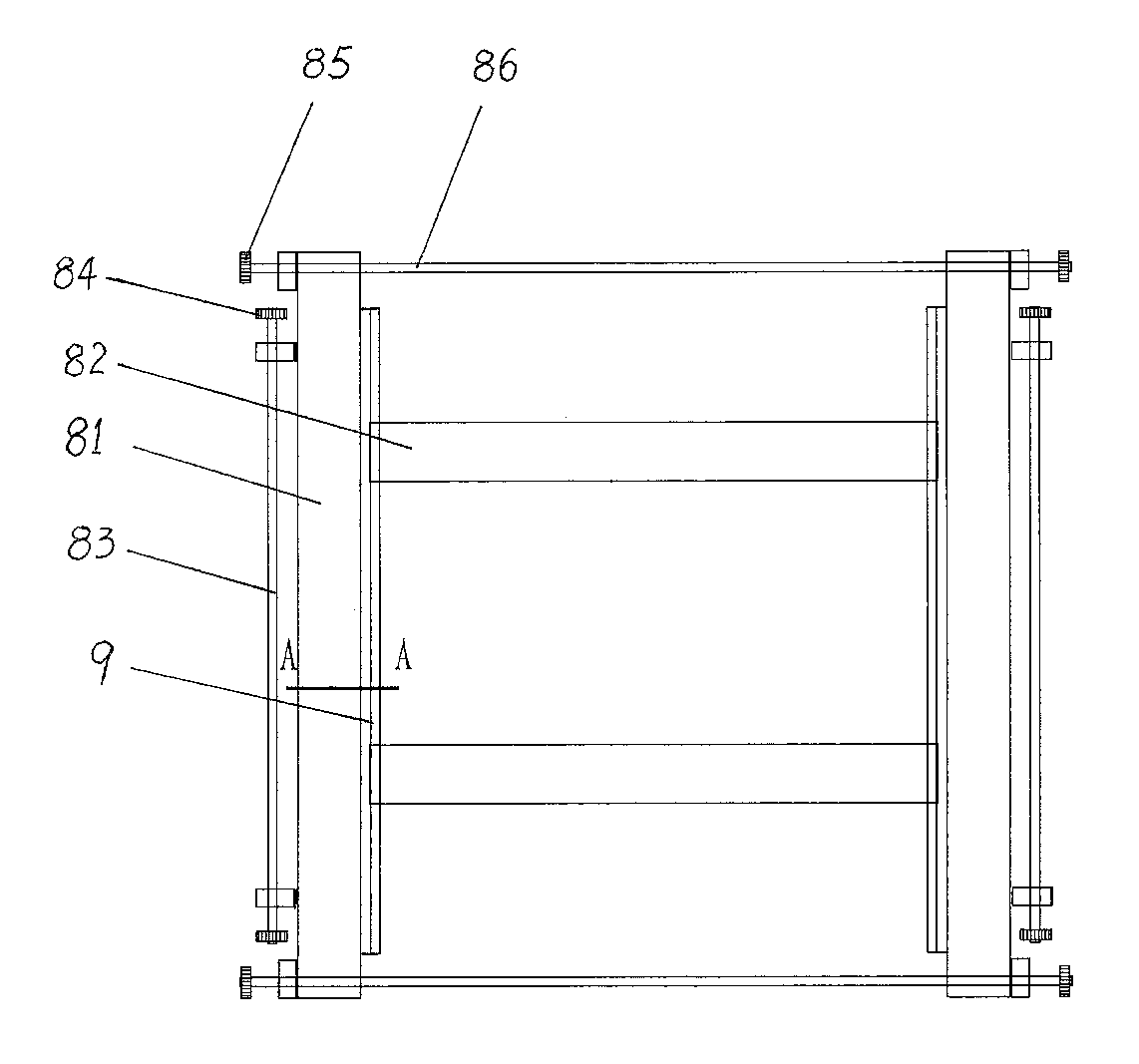

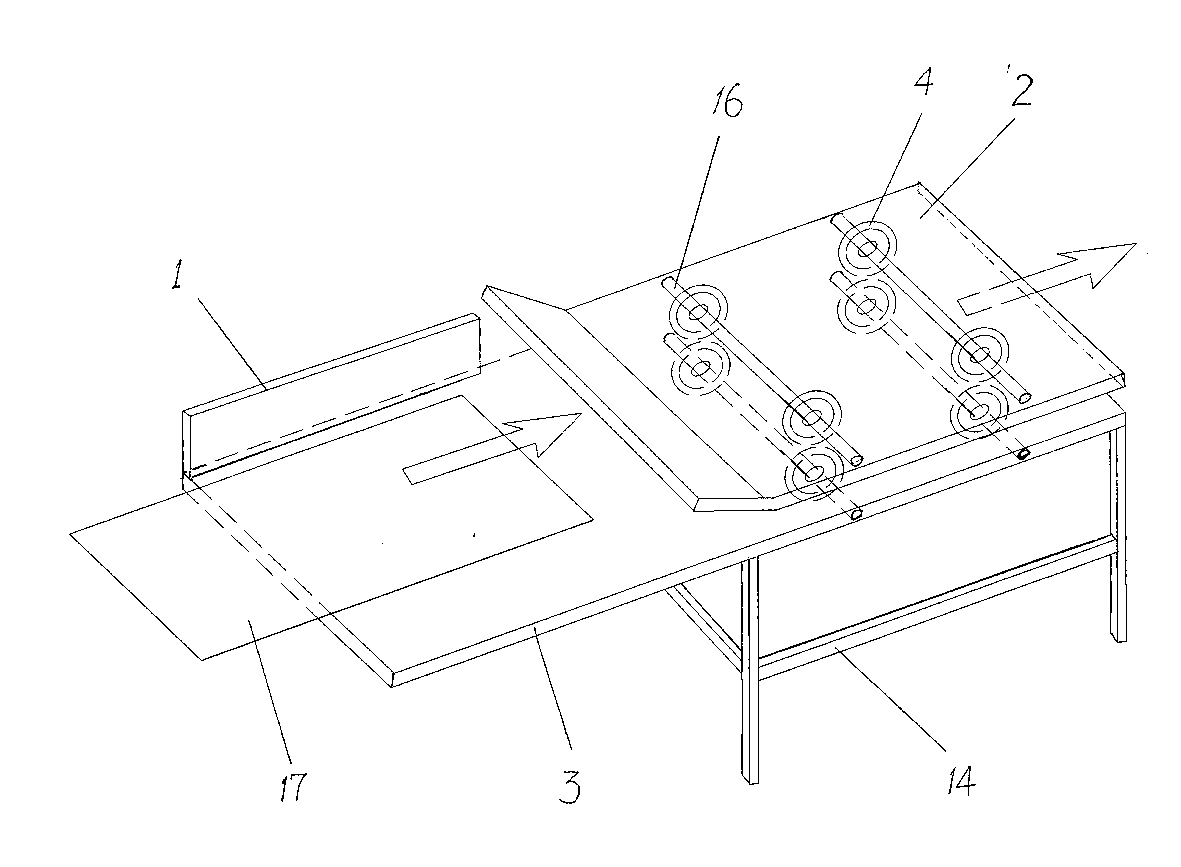

Multilayer thermal press for sheet material

InactiveCN104589432AIncrease productivityNo gapsPlywood pressesVeneer pressesThermal compressionEngineering

The invention discloses a multilayer thermal press for a sheet material and belongs to the field of sheet material machining. The multilayer thermal press comprises a rack, a press plate oil cylinder, an upper pressing plate, a plurality of carrier plates, a lower pressing plate, side locating rods, a suspending locating rod and a hot gas pipeline, wherein the press plate oil cylinder is connected with the lower pressing plate, and the carrier plates are arranged between the upper pressing plate and the lower pressing plate. The multilayer thermal press further comprises a synchronous closing device, wherein the synchronous closing device comprises two synchronous link mechanisms which are symmetrically distributed at the two sides of the rack, each synchronous link mechanism comprises an upper link, a lower link and a plurality of middle links, one end of each upper link is hinged to the upper pressing plate, a plurality of insertion holes are formed in each upper link, one end of each lower link is hinged to the lower pressing plate, the other end of each upper link is hinged to the other end of the corresponding lower link, one end of each middle link is hinged to the corresponding carrier plate, and the other end of each middle link is inserted into the corresponding insertion hole of the corresponding upper link and is always parallel to the corresponding lower link. The multilayer thermal press is applied to a thermal press procedure of a woodworking board machining process and has the advantages of high degree of automation, high production efficiency and high machined woodworking board quality.

Owner:王雨琪

Tomato grafting method capable of improving survival rate

InactiveCN104303851APrevent the occurrence of virusesImprove survival rateGraftingTomato graftingRootstock

The invention discloses a tomato grafting method capable of improving the survival rate. The tomato grafting method comprises the steps of variety selecting, strong stock culturing, scion forming, grafting and managing after grafting. High-quality seeds are selected and sterilized, a strong stock and scion are cultured, a W-shaped staggered grafting way is adopted, the contact area is enlarged, the rigorous and scientific later period maintenance is conducted, the resistance of a plant is improved, the cell division is promoted, the wound healing is accelerated, and the grafted young plant can recover and grow quickly. The survival rate of the grafted tomato young plant cultured according to the grafting method reaches more than 98%.

Owner:定远县金胜农业开发有限公司

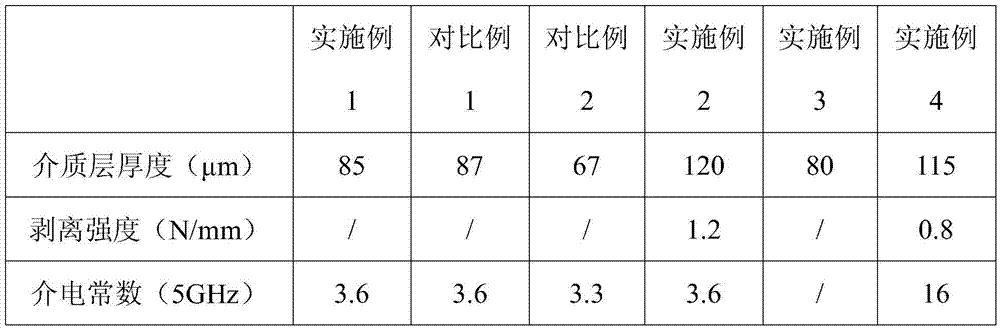

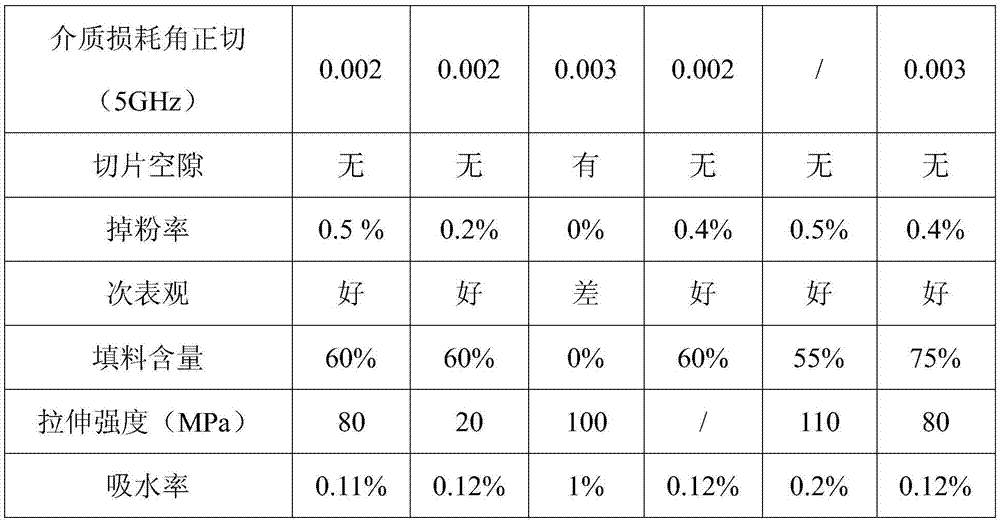

Packing contained composite material, sheet and circuit board containing same

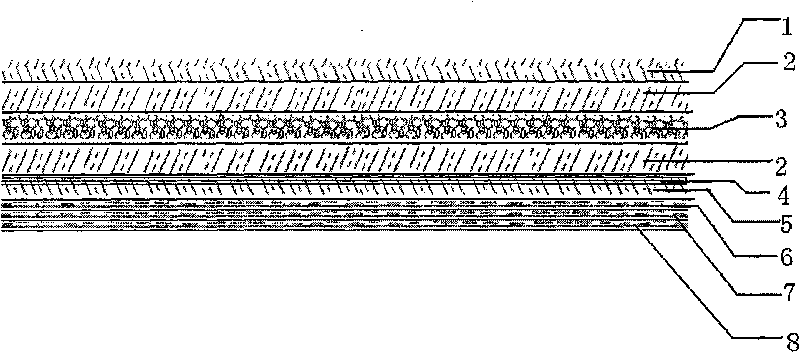

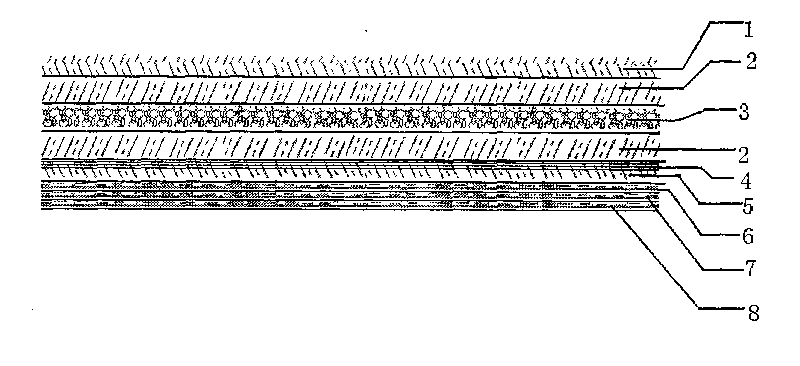

ActiveCN106928660ALow dielectric constantLow dielectric lossSynthetic resin layered productsLaminationFiberDielectric loss

The invention belongs to the technical field of copper-clad plates and relates to a packing contained thermoplastic liquid crystal polymer composite material, a prepreg and a circuit board. The packing contained composite material includes a three-dimensional net-structure material and packing spread in pores of the three-dimensional net-structure material, and the three-dimensional net-structure material is mainly formed by mutual lapping or adhering of thermoplastic liquid crystal polymer fibers. By the arrangement of the packing contained composite material, the prepreg and the circuit board which are obtained are isotropic in X and Y directions in dielectric constant, low in the dielectric constant and dielectric loss and good mechanical performance.

Owner:GUANGDONG SHENGYI SCI TECH

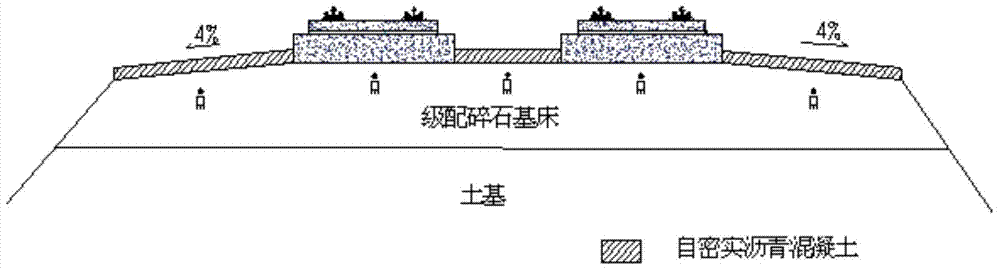

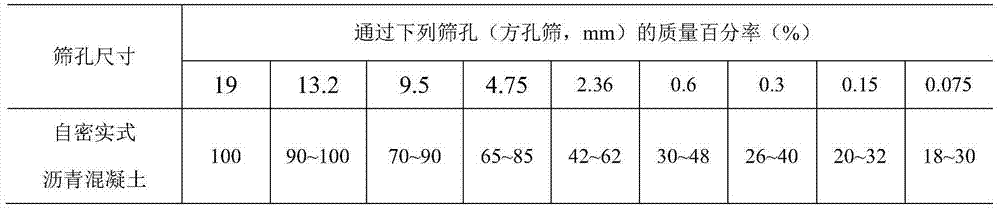

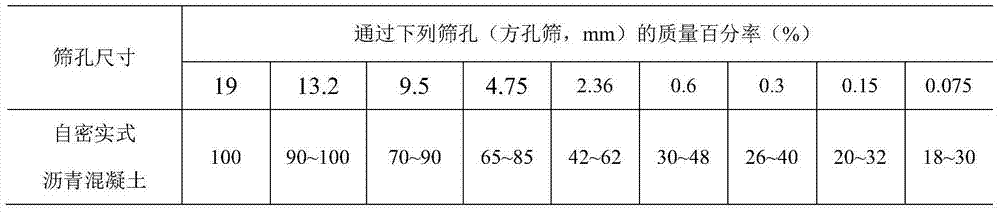

Self-compacting bituminous concrete waterproof seal and construction method thereof

ActiveCN104278598ANo crackGood deformation complianceRoadwaysRailway tracksFreeze thawingBituminous concrete

The invention relates to a self-compacting bituminous concrete waterproof seal and a construction method thereof. The self-compacting bituminous concrete waterproof seal is especially applicable to local waterproof sealing of high-speed railway or dedicated passenger line road beds in high and cold areas. Compared with the prior art, the self-compacting bituminous concrete waterproof seal and the construction method thereof have the advantages that the advantages such as good impermeability, freeze-thawing resistance, ageing resistance, deformation adaptability and high seal-healing capacity in the self-compacting bituminous concrete are given to full play, the road bed water controlling and drainage problems are solved by the use of the super-compact material structure, and water is prevented from permeating to damage the road beds; the waterproof seal is manually paved, thickness of the waterproof seal is determined through the use of wooden or steel forms, compacting by self-mobility is allowed, no compressing is required, constructing is simple and convenient, the requirement on environment is low, and the waterproof seal is suitable for structures, having small but abundant working faces, such as supports of overhead contact systems for high-speed railway road beds; the waterproof seal has ultra-long service life, less maintenance is required during using of the waterproof seal, the waterproof is easy to maintain, and a scheme about the ideal long-acting railway road bed waterproof seal is provided.

Owner:SOUTHEAST UNIV +3

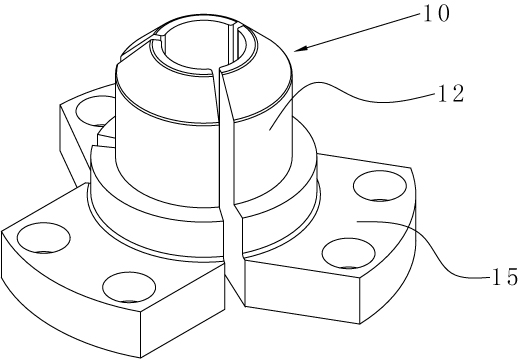

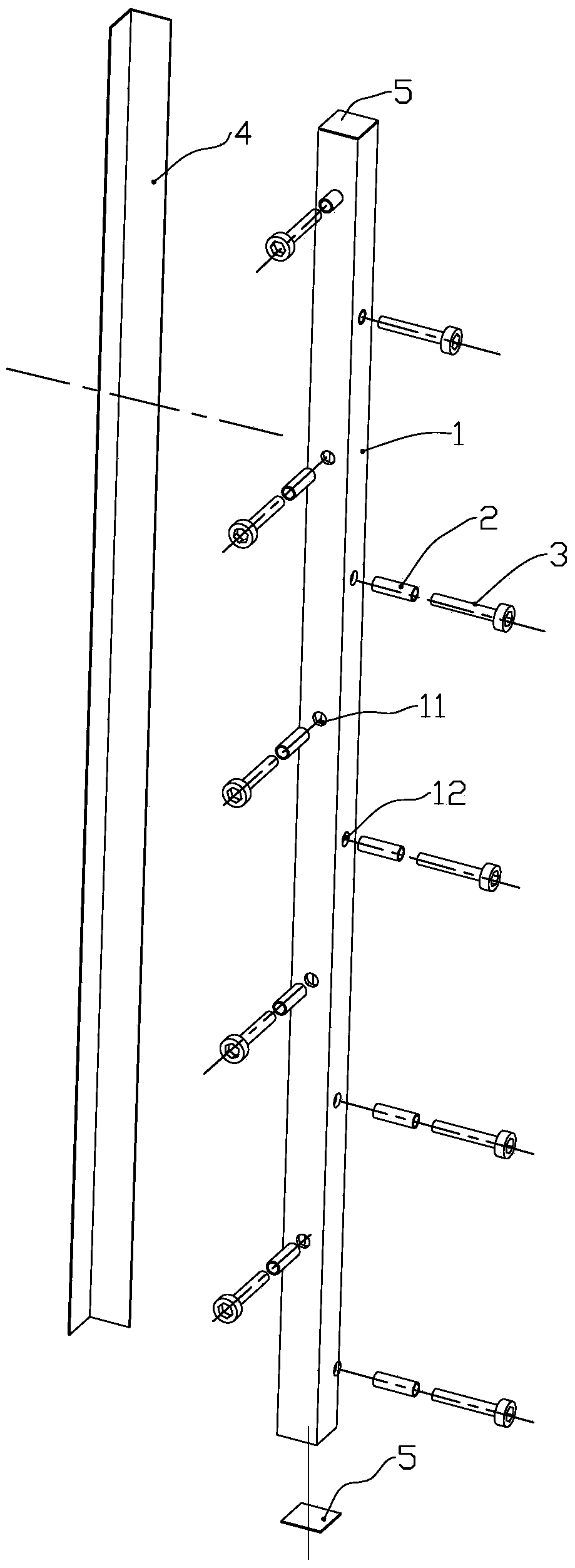

Round pin-inserted positioning device and tensioning and positioning round pin thereof

ActiveCN102121496AGuaranteed positioning accuracyGuaranteed positional stabilityWelding/cutting auxillary devicesBoltsEngineeringCar door

Owner:GUANGQI HONDA

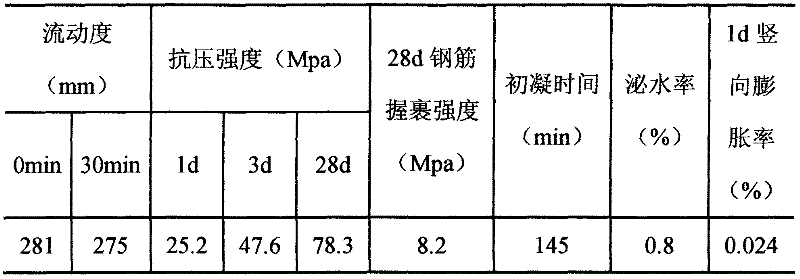

Cement-based shrinkage-free grouting mortar

The invention discloses a cement-based shrinkage-free grouting mortar which is characterized by comprising the following components in percentage by weight: 35%-42% of silicate cement, 5%-12% of aluminate cement, 6%-10% of gypsum, 40%-50% of aggregate, 0.8%-1.4% of high-efficiency water reducing agent, 0.05%-0.2% of coagulation-regulating agent, 0.4%-1.0% of defoamer and 1%-3% of bleeding resisting agent. The cement-based shrinkage-free grouting mortar is a gelled material which is prepared from the silicate cement, the aluminate cement and the gypsum and has stable performance, and the flow degree, coagulation time and expansion rate of the grouting mortar can be regulated according to the requirement of a user. After mixed with water, the grouting mortar has a good self-flowing property, no sedimentation and no bleeding; the grouting mortar has the characteristics of plastic micro-expansion property, no gap, high early strength, no contracted later strength, good durability, impermeability, freezing resistance and vibration resistance, low material price and wide raw material sources; and the grouting mortar is flexible to operate and is simple to use.

Owner:JIANGSU MINGHE GRP

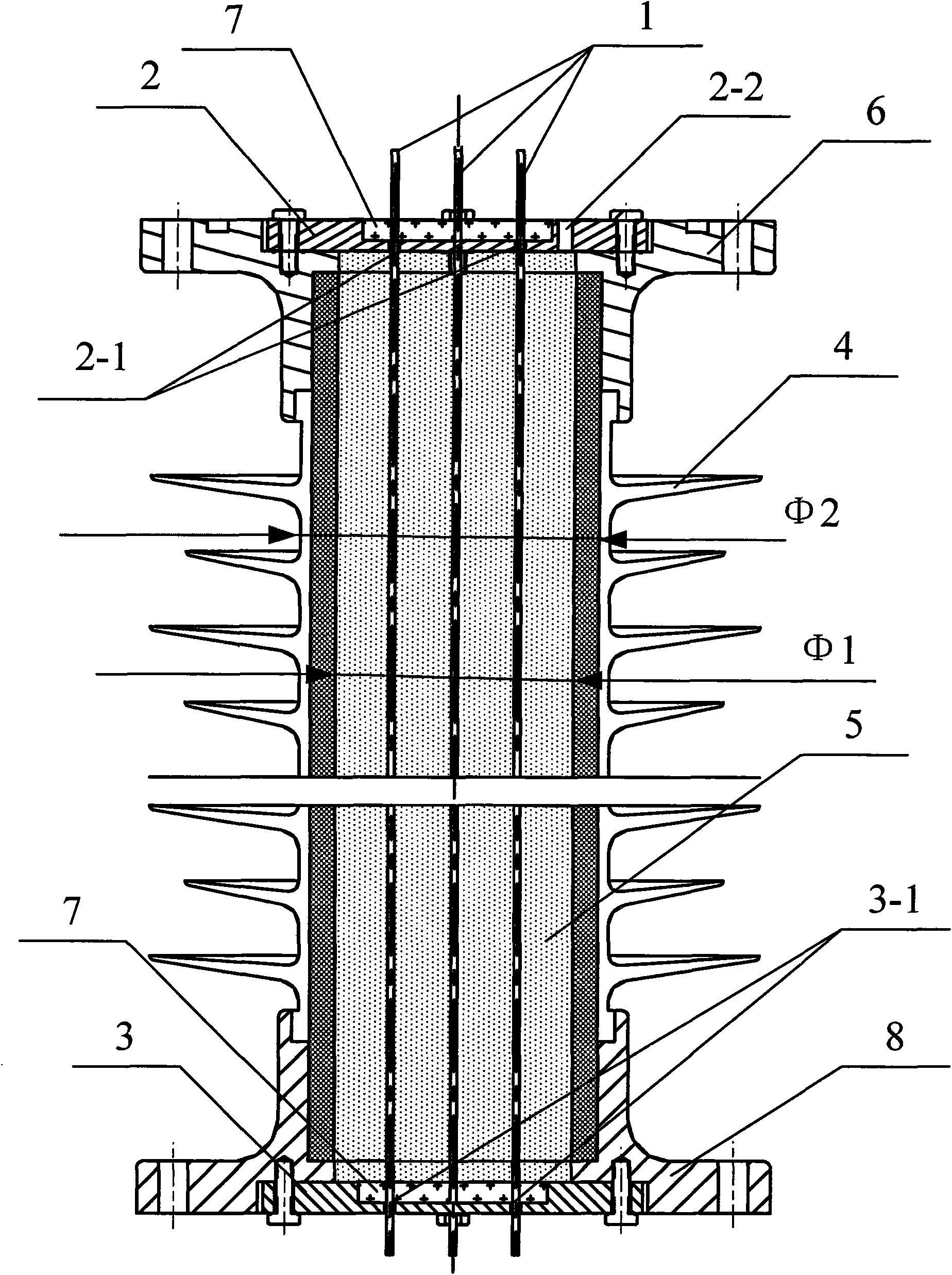

Soft insulating optical fiber insulator

A soft insulating optical fiber insulator relates to an insulating optical fiber insulator. The soft insulating optical fiber insulator of the invention settles the problems of inferior insulating property, large optical loss, complex processing, low finished product rate and short service lifetime existing in the prior optical fiber insulator. The upper end of the hollow insulator of the invention is fixedly connected with an upper metal end cap through the upper metal flange. The lower end of the hollow insulator is fixedly connected with the lower metal end cap through a lower metal flange. The upper metal end cap is provided with a plurality of through holes and one glue injection hole. The lower metal end cap is provided with a plurality of through holes. A plurality of optical fiber jumper wires run through the inner chamber of the hollow insulator. The interfaces between the plurality of optical fiber jumper wires and the upper metal end cap and the lower metal end cap are respectively provided with one layer of sealant. The soft glue is injected into the inner chamber of the hollow insulator through a glue injection opening on the upper metal end cap. The soft insulating optical fiber insulator of the invention has the advantages of increasing the insulating property and service lifetime of the optical fiber insulator, greatly reducing the optical loss, simplifying the processing technique and increasing the finished product rate of the product.

Owner:HARBIN INST OF TECH +1

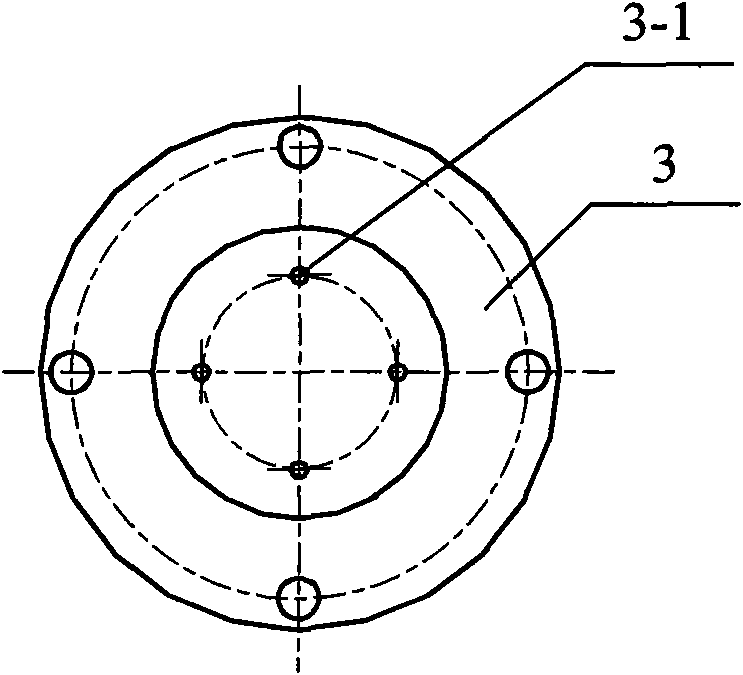

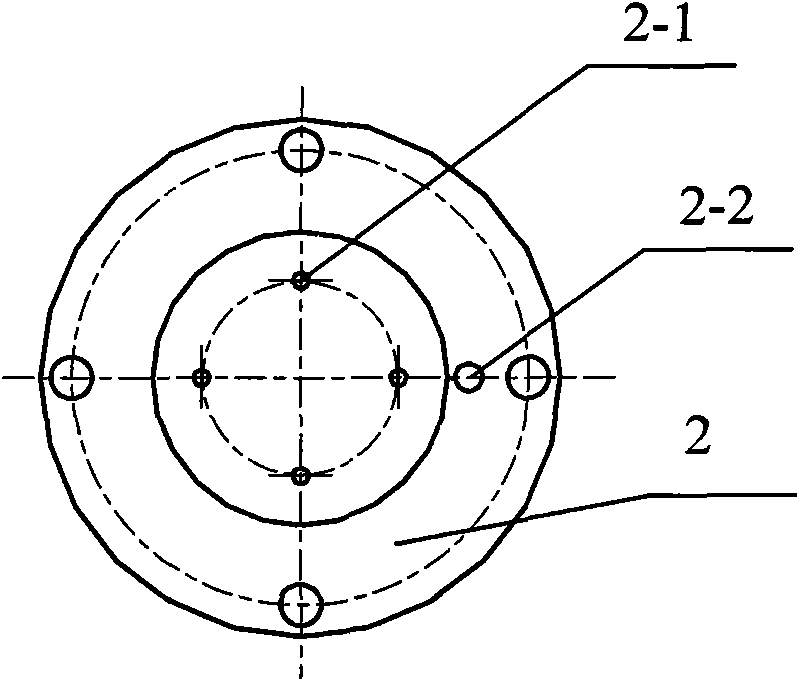

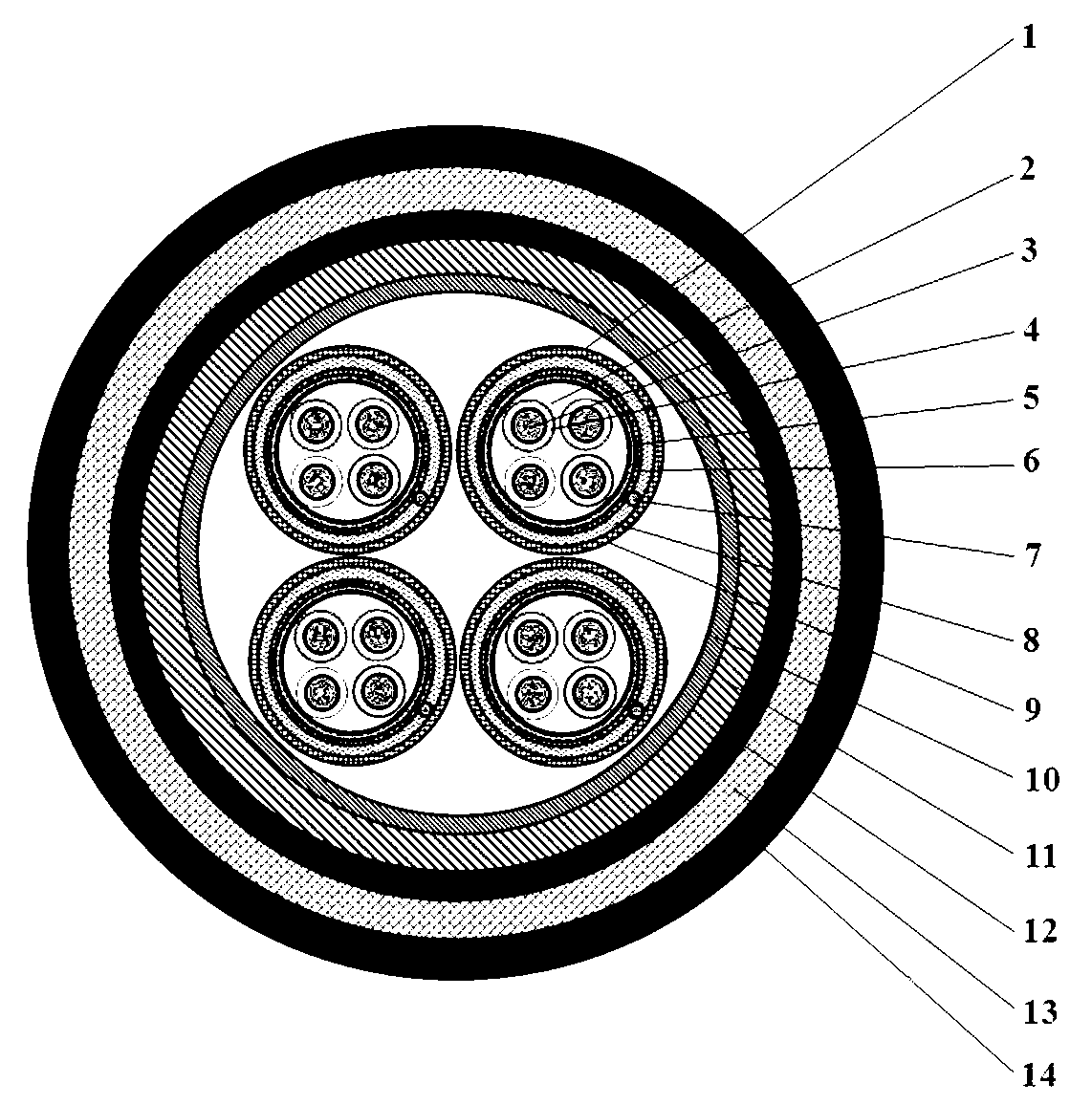

Copper strip welded embossing type internal shielding railway digital signal cable

ActiveCN102800398AImprove shielding effectHigh tensile strengthInsulated cablesInsulated conductorsCopper conductorSteel belt

The invention relates to a copper strip welded embossing type internal shielding railway digital signal cable, which comprises a cable core and a protective layer coating the cable core, wherein the cable core comprises at least one shielding quad; the shielding quad comprises four stranded insulating single lines in different colors; each insulating single line comprises a copper conductor and an insulating layer coating the copper conductor; wrapping is wrapped around the insulating single lines; an inner non-moisture-absorbent insulating layer, a copper strip welded embossing shielding layer and an outer non-moisture-absorbent insulating layer are sequentially arranged outside the wrapping; and the protective layer comprises a PET strip lapped layer, an aluminum sheath, a polyethylene adhesive protective layer, a galvanized steel strip gap lapped armoured layer and an outer sheath sequentially from inside to outside.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

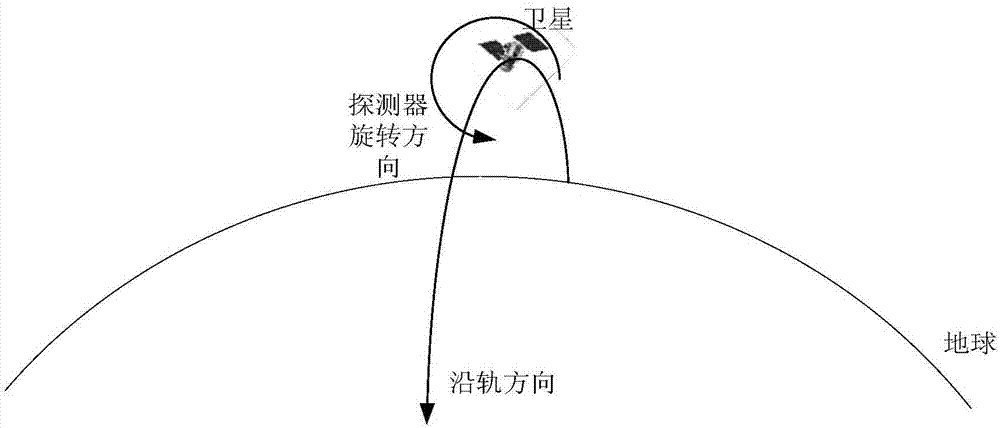

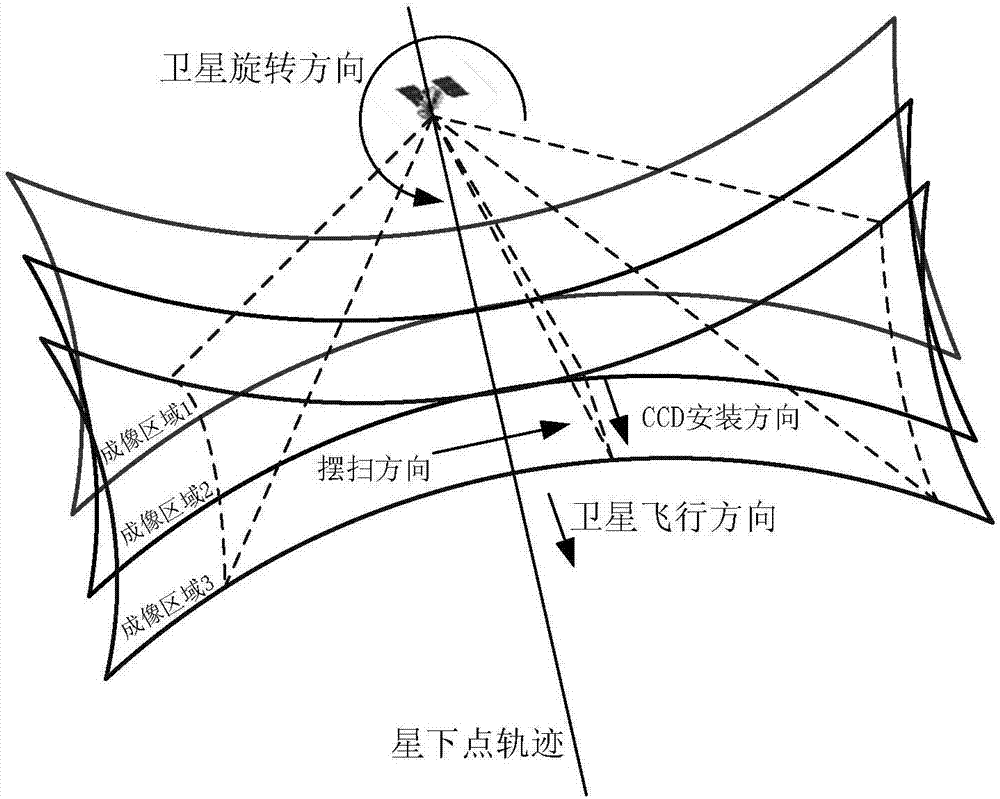

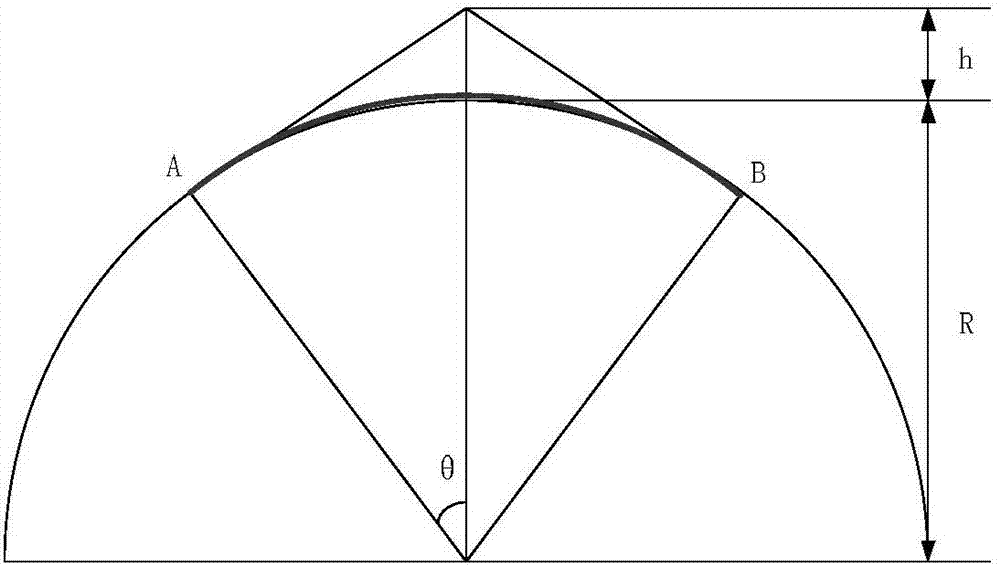

Quick rotary ultra-width pendular satellite imaging method

ActiveCN107152926ARealize ultra-large width swing-scan imagingIncrease coverageCosmonautic vehiclesCosmonautic partsFlight directionImage resolution

The invention discloses a quick rotary ultra-width pendular satellite imaging method, and relates to ultra-width pendular imaging methods. By the aid of the quick rotary ultra-width pendular satellite imaging method, the problems of incapability of meeting ultra-width imaging requirements on ground regions by conventional imaging methods and incapability of carrying out seamless splicing imaging on imaging regions of two adjacent orbits of a single satellite can be solved. The quick rotary ultra-width pendular satellite imaging method includes steps of firstly, computing the widths L<5> perpendicular to orbits; secondly, computing the widths L<1> in flight directions; thirdly, determining whether critical values of distances L2 of the centers of the optical axes of detectors on tracks of sub-satellite points on earth surfaces are the widths L<1> of the flight directions or not; fourthly, computing the spinning speeds of the detectors along the directions of the orbits; fifthly, computing corresponding resolution ratios A<c> of the detectors during ultra-width imaging under various orbit conditions; sixthly, computing horizontal frequencies F of CCD (charge coupled devices); seventhly, computing superposition distances L<6> among imaging regions of every two corresponding orbits and the like. The quick rotary ultra-width pendular satellite imaging method has the advantage that the quick rotary ultra-width pendular satellite imaging method can be applied to the field of ultra-width pendular imaging.

Owner:HARBIN INST OF TECH

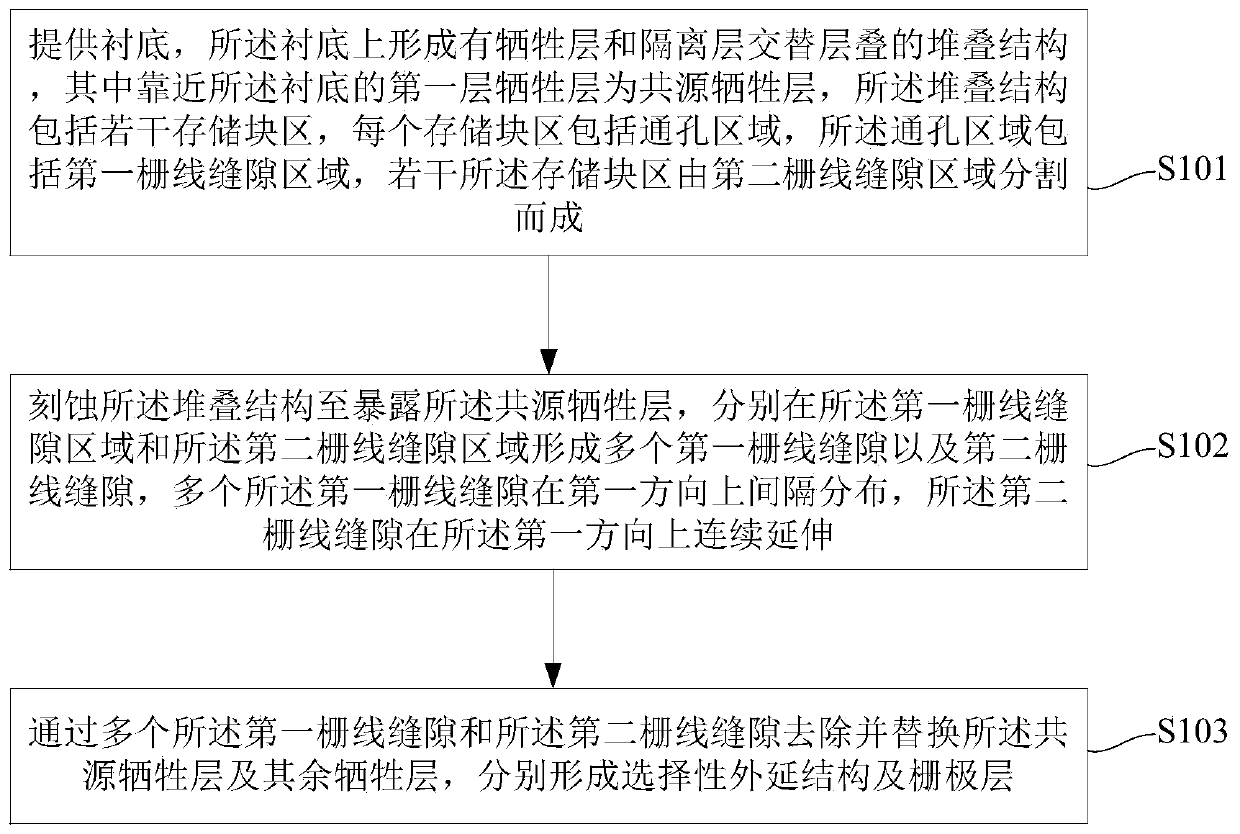

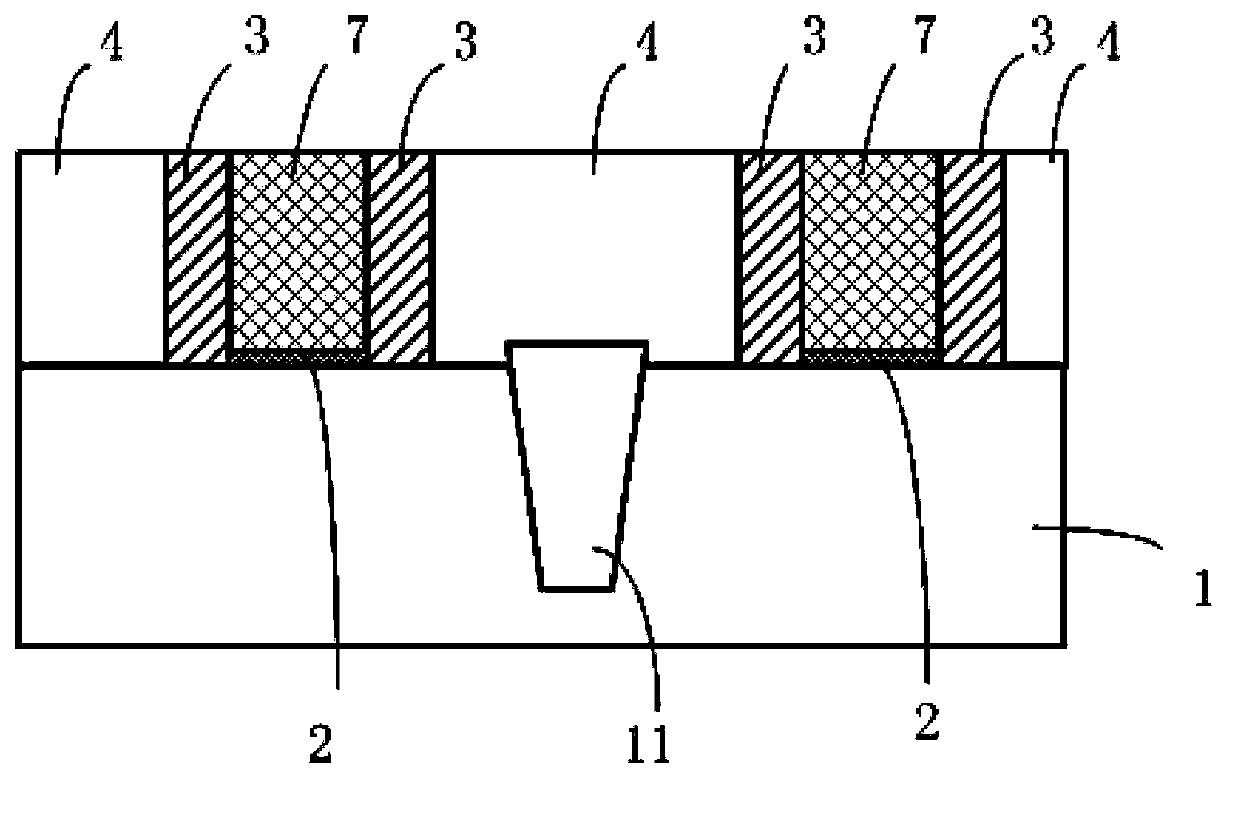

3D NAND memory and manufacturing method thereof

ActiveCN111223872AShorten the timePromote formationSolid-state devicesEnergy efficient computingConductive materialsMechanical engineering

Owner:YANGTZE MEMORY TECH CO LTD

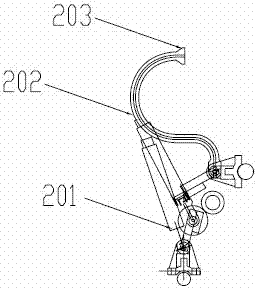

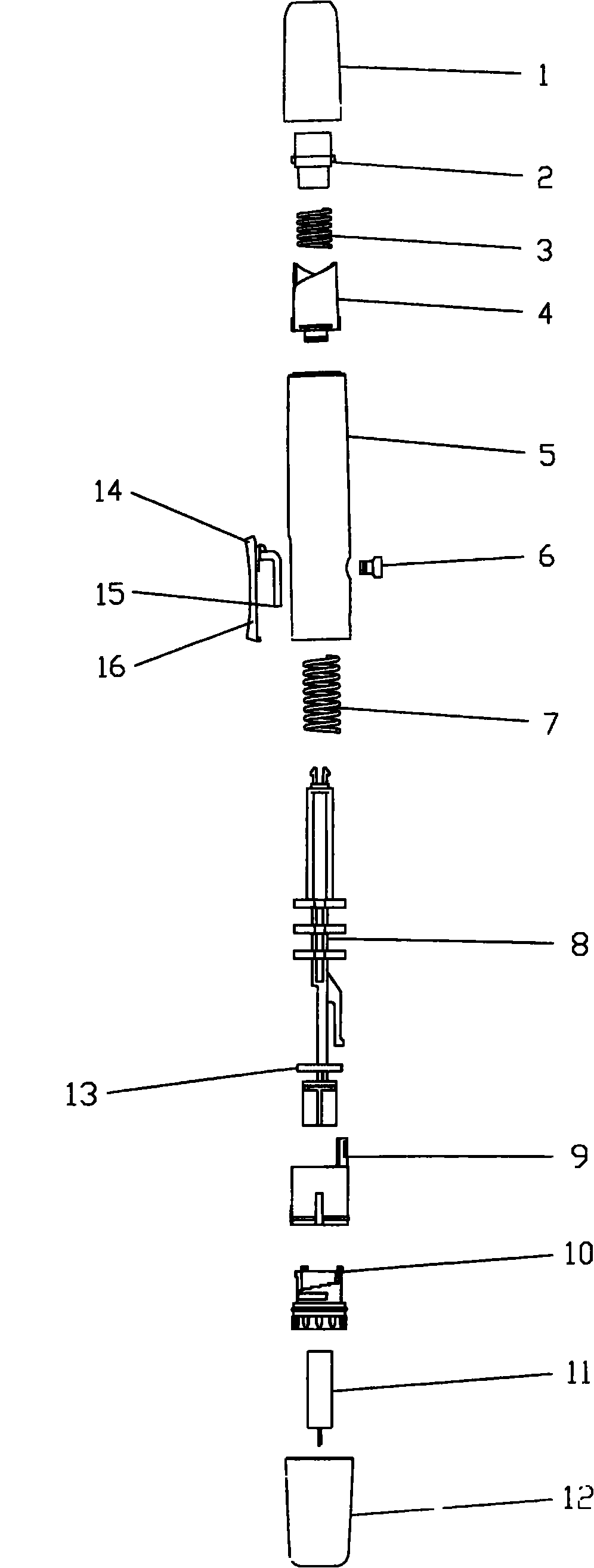

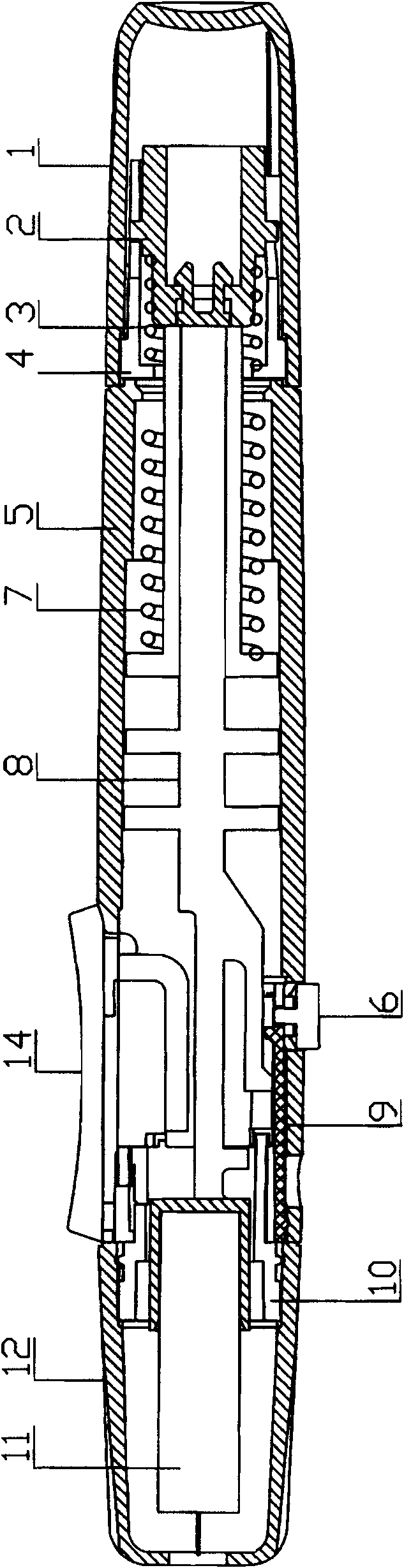

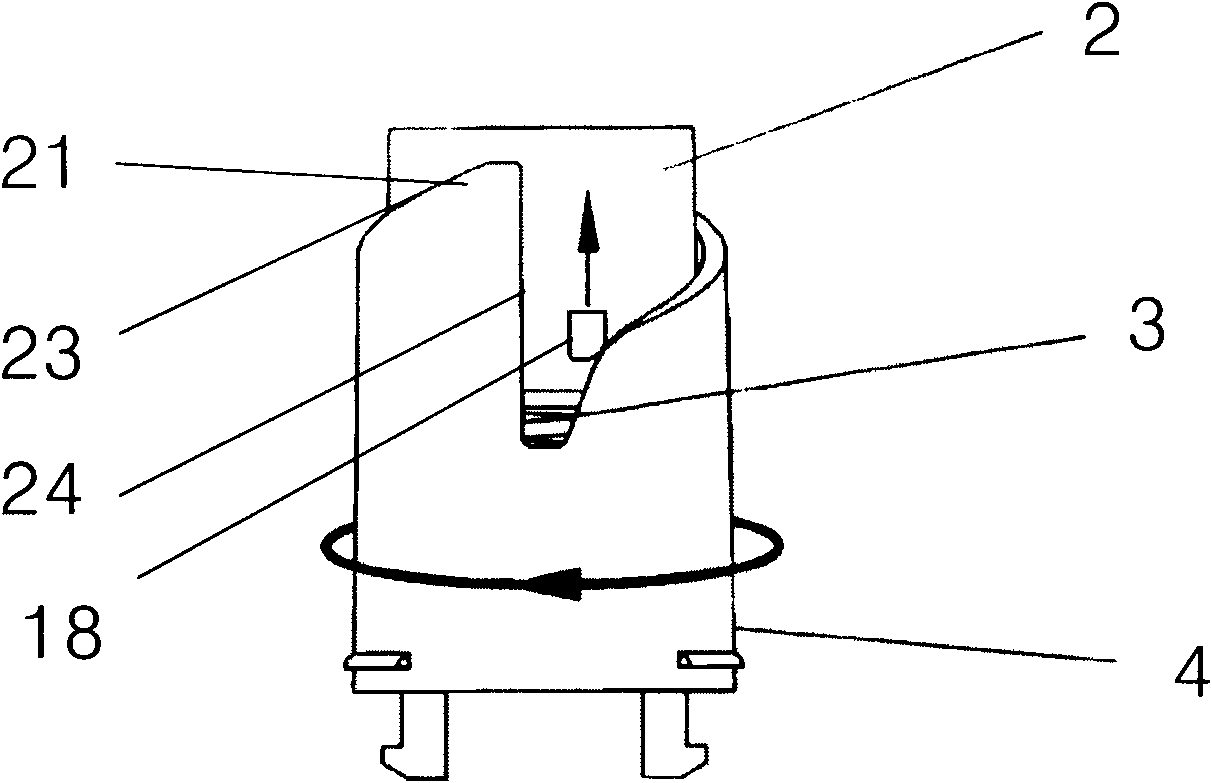

Blood drawing pen

ActiveCN102178538AEasy to operateImprove stabilityDiagnostic recording/measuringSensorsBlood drawingHIT device

The invention discloses a blood drawing pen capable of rotatably returning a needle, which comprises a needle returning device, a hitting device and a depth regulating device, wherein the hitting device comprises a pen holder with an inner cavity and a needle rod capable of sliding in the inner cavity, one end of the hitting device is connected with the needle returning device used for applying apre-ejection force, and the other end of the hitting device is connected with the depth regulating device used for regulating the ejection depth. The blood drawing pen is characterized in that the needle returning device comprises a rotating member with an inner cavity and a transmission member capable of sliding in the inner cavity of the rotating member, one end of the needle rod is sleeved with an ejection spring which passes through the inner cavity of the pen holder and the inner cavity of the rotating member to be fixedly connected with the transmission member, wherein one end of the rotating member and the pen holder are connected and can rotate relatively, the other end of the rotating member is provided with an incline rail formed by adopting an incline, and the outer wall of thetransmission member is provided with a lug boss capable of sliding on the incline rail. The blood drawing pen is simple in operation; and parts of the whole blood drawing pen are connected in a convex and concave matching manner without gaps and exposed parts, and are easy to assemble, therefore, production cost is effectively lowered.

Owner:ANDON HEALTH +1

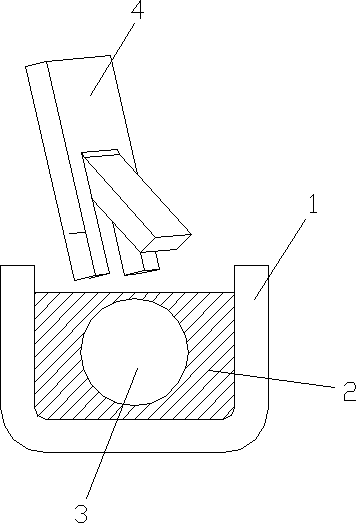

Brass strip core flux-cored welding ring and preparation method thereof

ActiveCN104384758AEnough fillingBrazing process is simpleWelding/cutting media/materialsWelding/soldering/cutting articlesSolderingMachining

The invention relates to a preparation method of a brass strip core flux-cored welding ring. The preparation method is characterized by comprising the following steps: preparing a brass rod material into a thin strip, curling the thin strip through a roller to form a U-shaped strip with an opening facing upwards, arranging a solid brass welding wire in the middle part of the U-shaped strip, conveying brass soldering flux to a gap between the U-shaped strip and the solid brass welding wire through a belt pulley, compressing the brass soldering flux by utilizing a pressing plate, pressing the U-shaped strip by utilizing a roller to enable the opening end of the U-shaped strip to be abutted to form a flux-cored welding wire of a tubular structure, cleaning the surface of the flux-cored welding wire by utilizing a brush wheel and a brush, and molding the flux-cored welding wire into a brass strip core flux-cored welding ring in a low-temperature resistance heating way or a cold machining way. By adopting the flux-cored soldering flux, the soldering efficiency and quality can be greatly improved, the soldering flux is tightly wrapped by a soldering flux skin, no notch exists, the content is stable, the welding performance is good, the production efficiency is high, the process is simple, and by adopting the design for wrapping the solid core with the soldering flux skin, the welding wire is convenient to machine into a ring shape.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

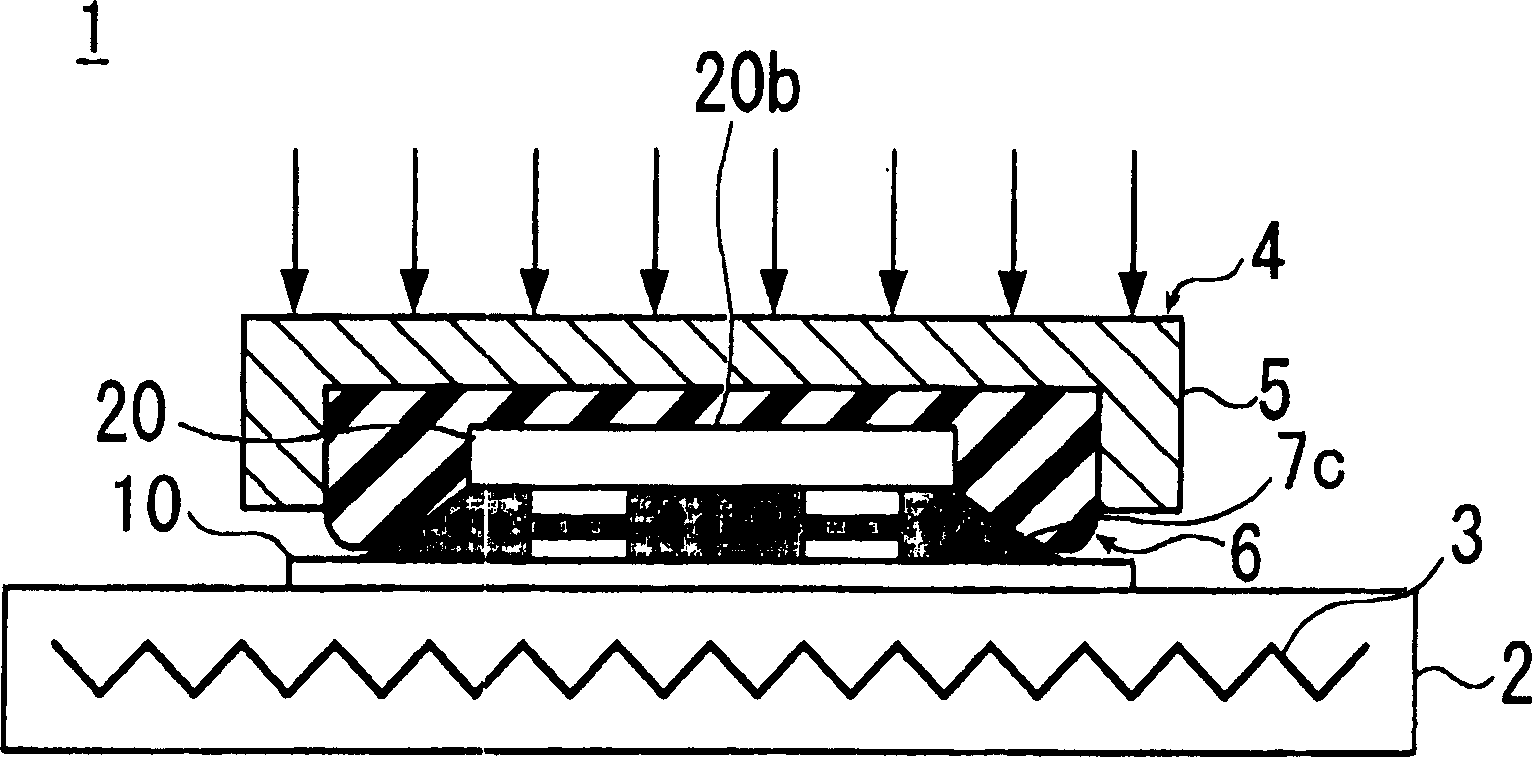

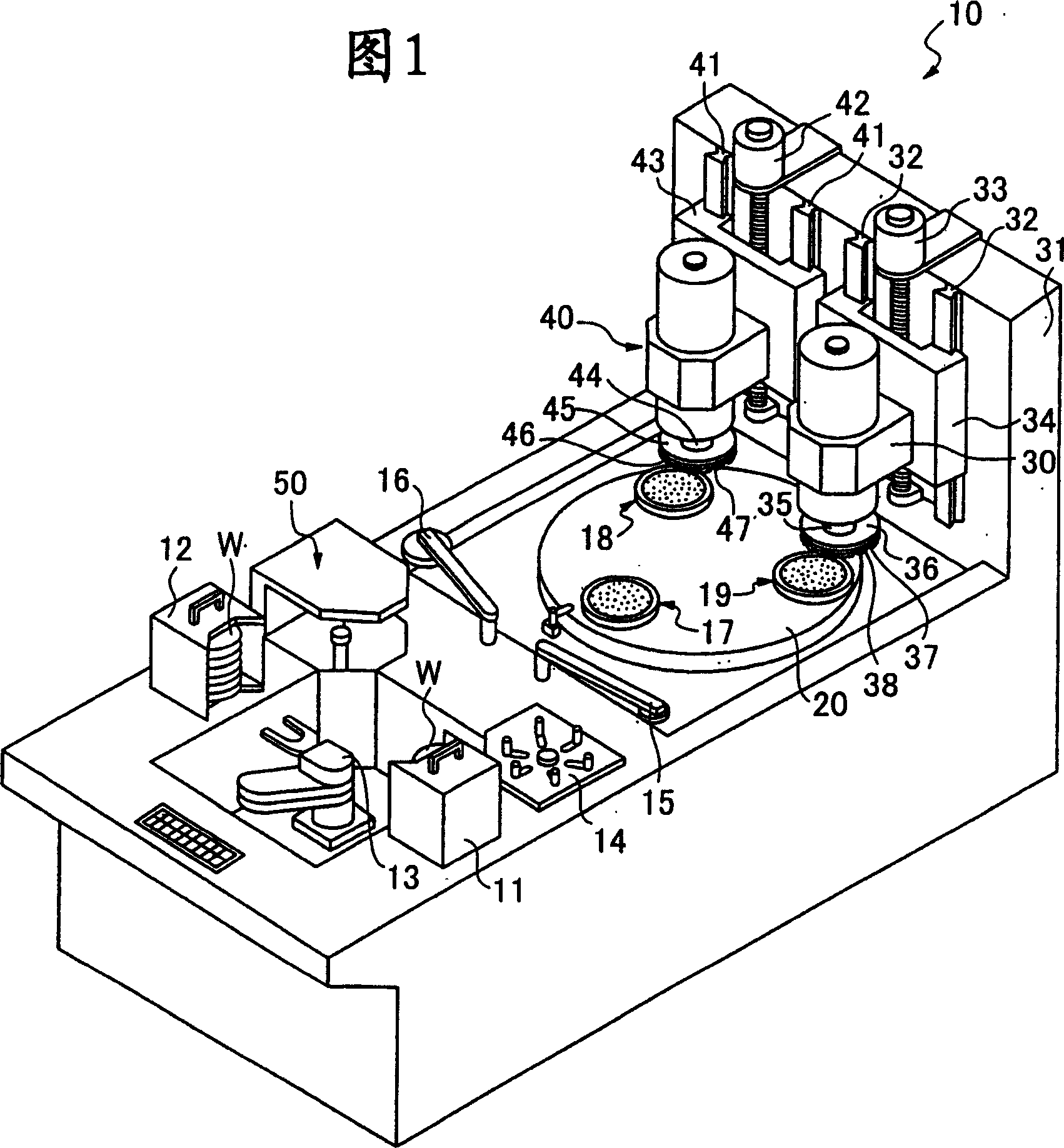

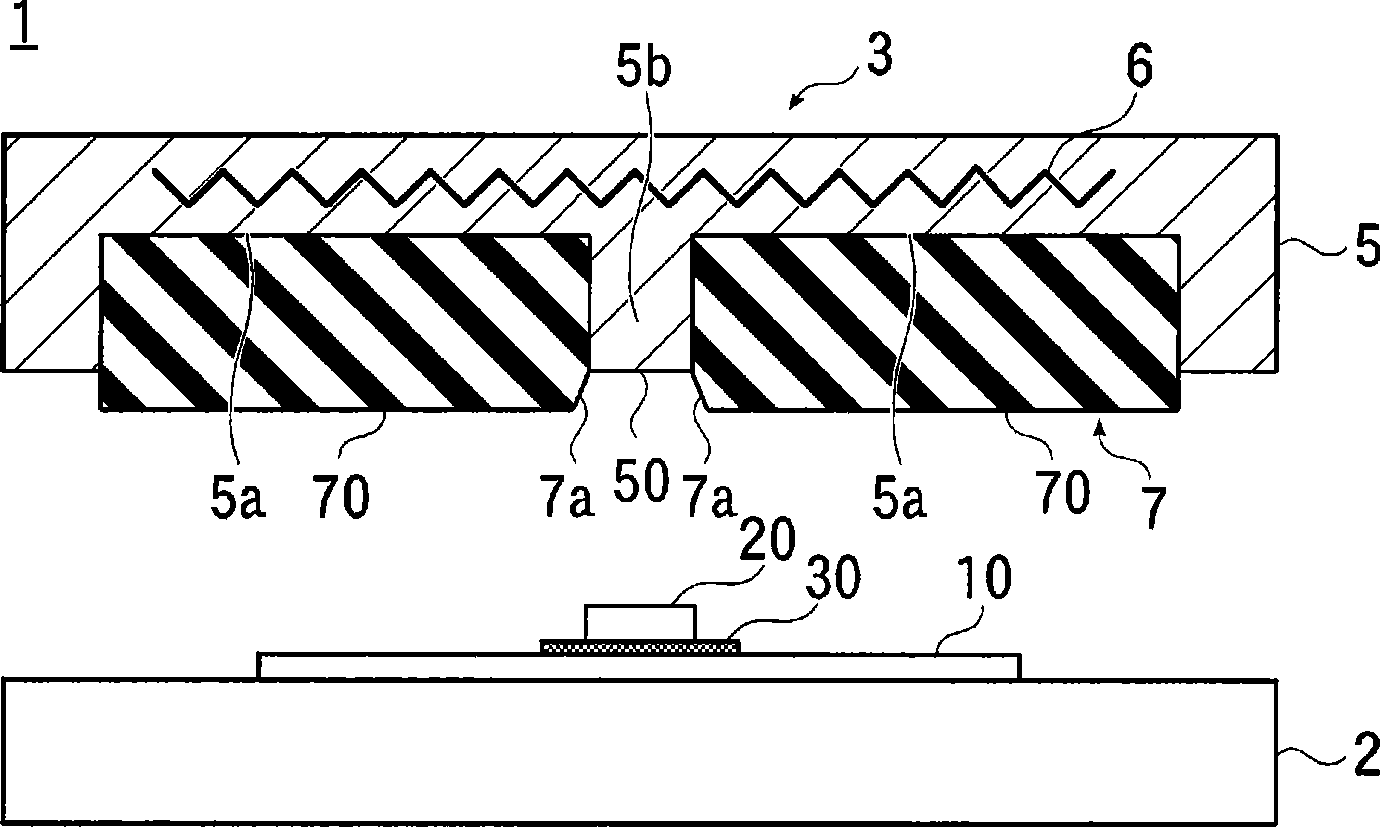

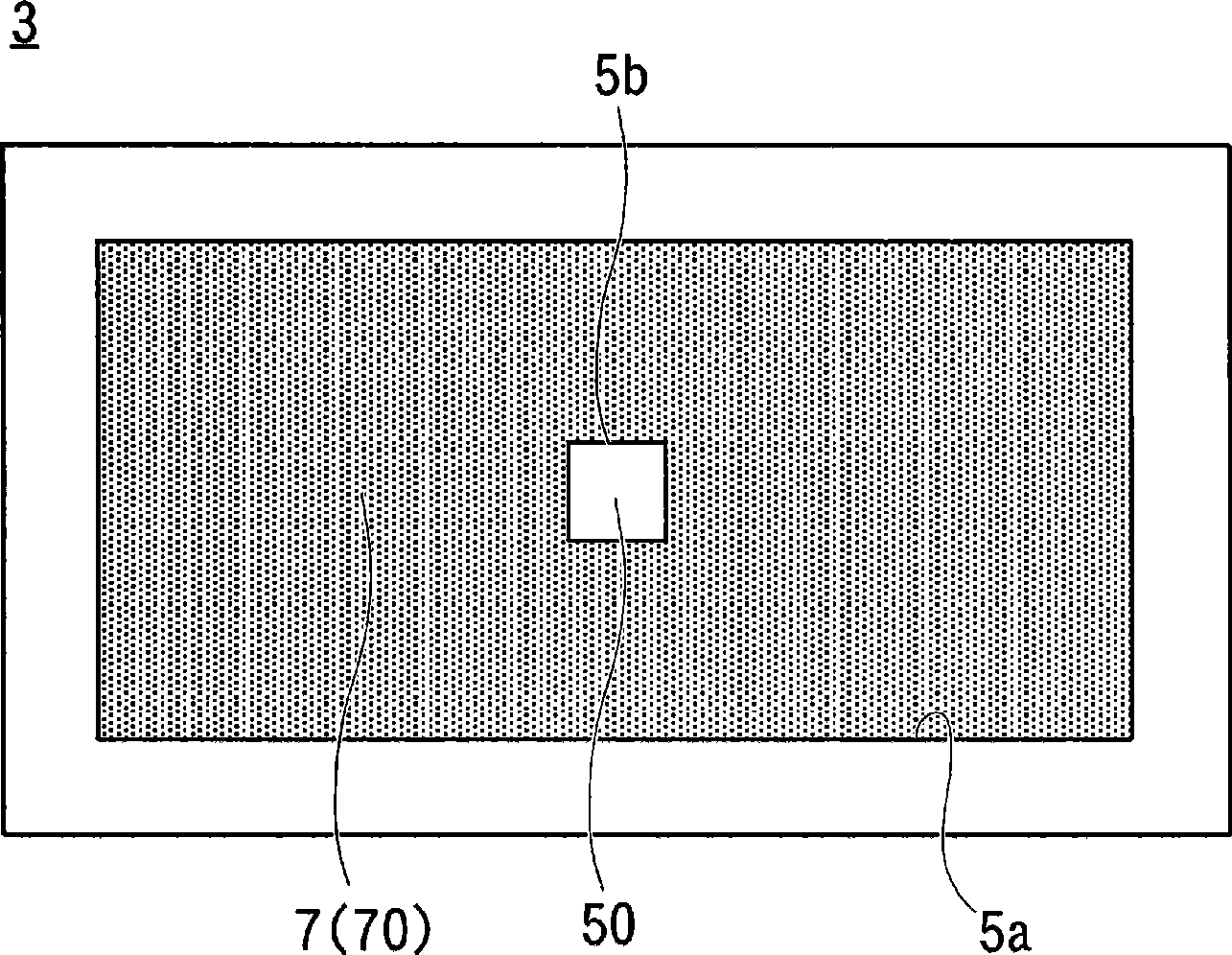

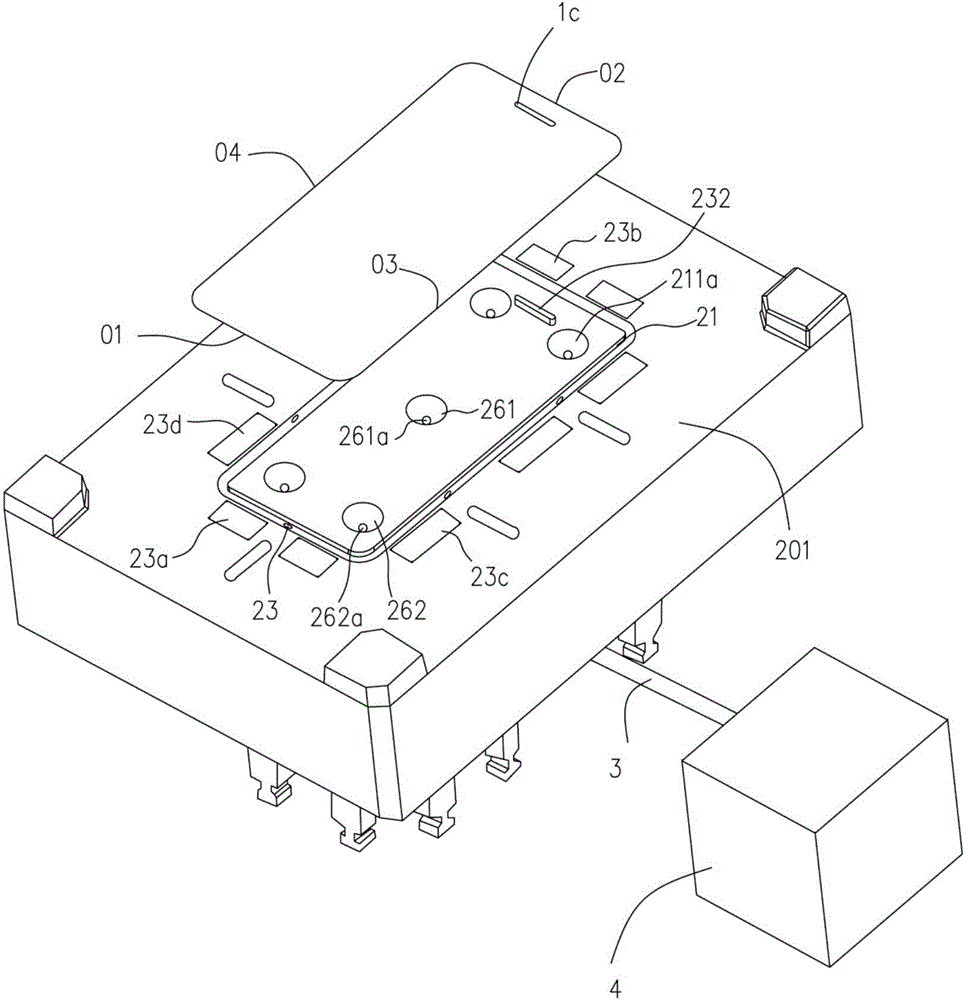

Packaging method and system of electric component

ActiveCN1823409AEasy to pressurizeReliable exclusionPrinted circuit assemblingSolid-state devicesAnisotropic conductive filmElastomer

A mounting method and a mounting device are provided, which can mount an electric component with high reliability by using an adhesive. The present invention is a mounting method including the step of thermocompression bonding an IC chip 20 onto a wiring board 10 by using an anisotropic conductive adhesive film 7. During the thermocompression bonding, a top region of the IC chip 20 is pressed against the wiring board 10 with a predetermined pressure, and a side region of the IC chip 20 is pressed with a pressure smaller than the pressure applied to the top region of the IC chip 20. An elastomer having rubber hardness of 40 or more and 80 or less is used for a compression bonding portion 6 of a thermocompression bonding head 4. The anisotropic conductive adhesive film 7 contains a binding resin 7b having melting viscosity of 1.0 x 10 2 mPa · s or more and 1.0 x 10 5 mPa·s or less.

Owner:DEXERIALS CORP

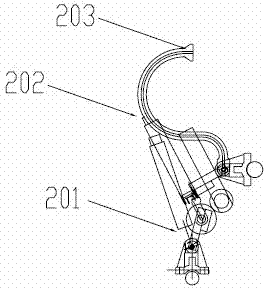

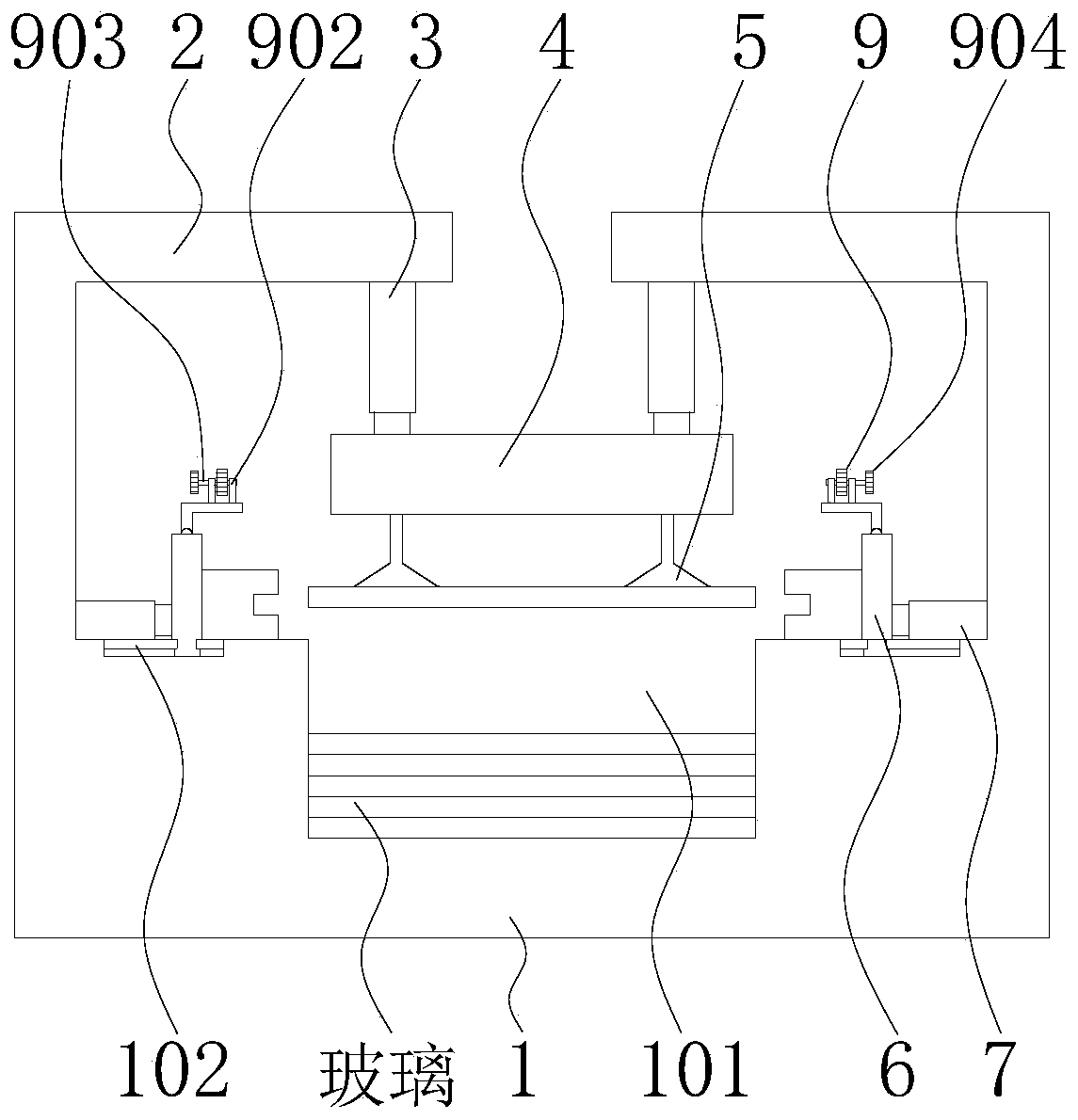

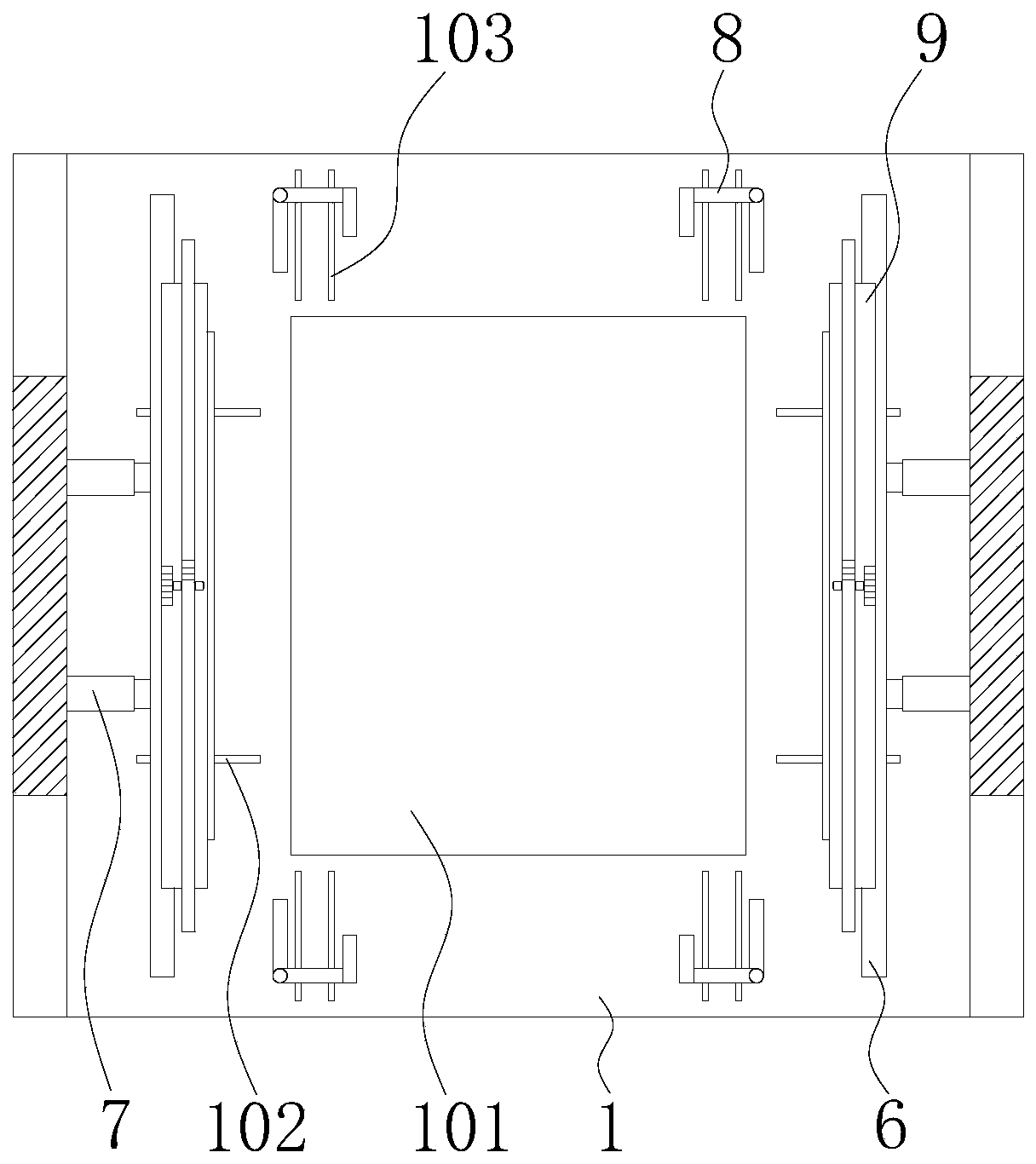

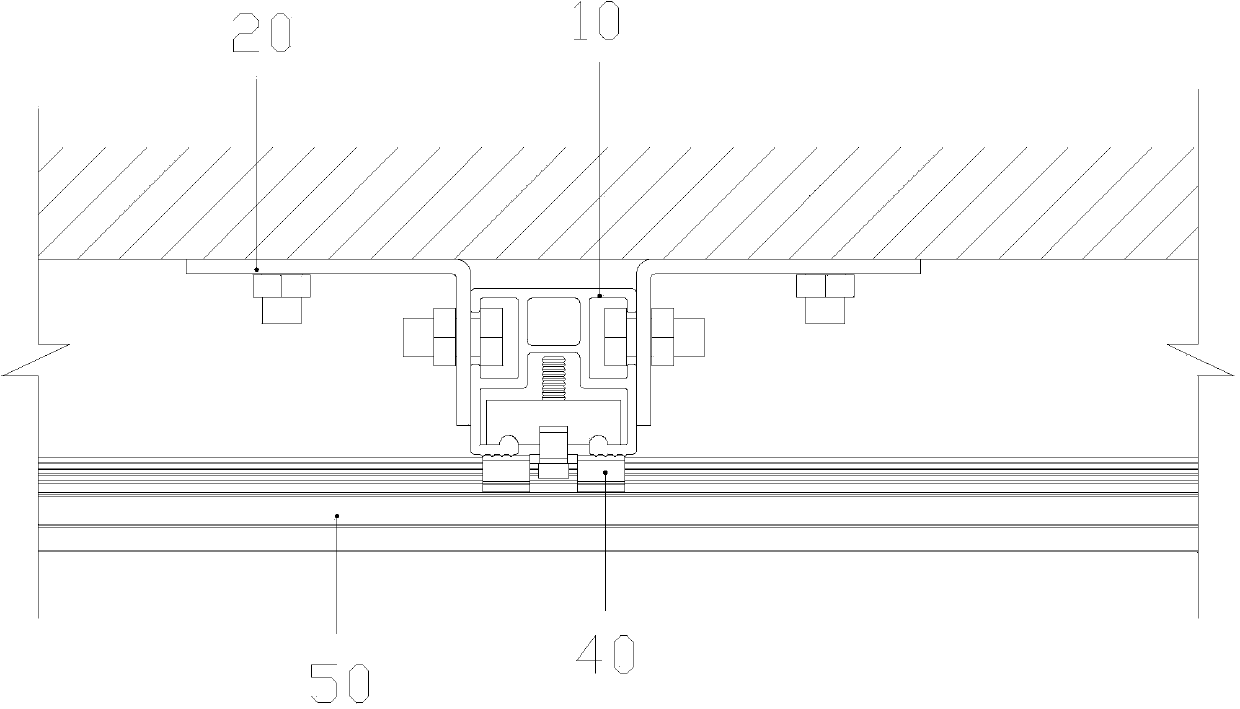

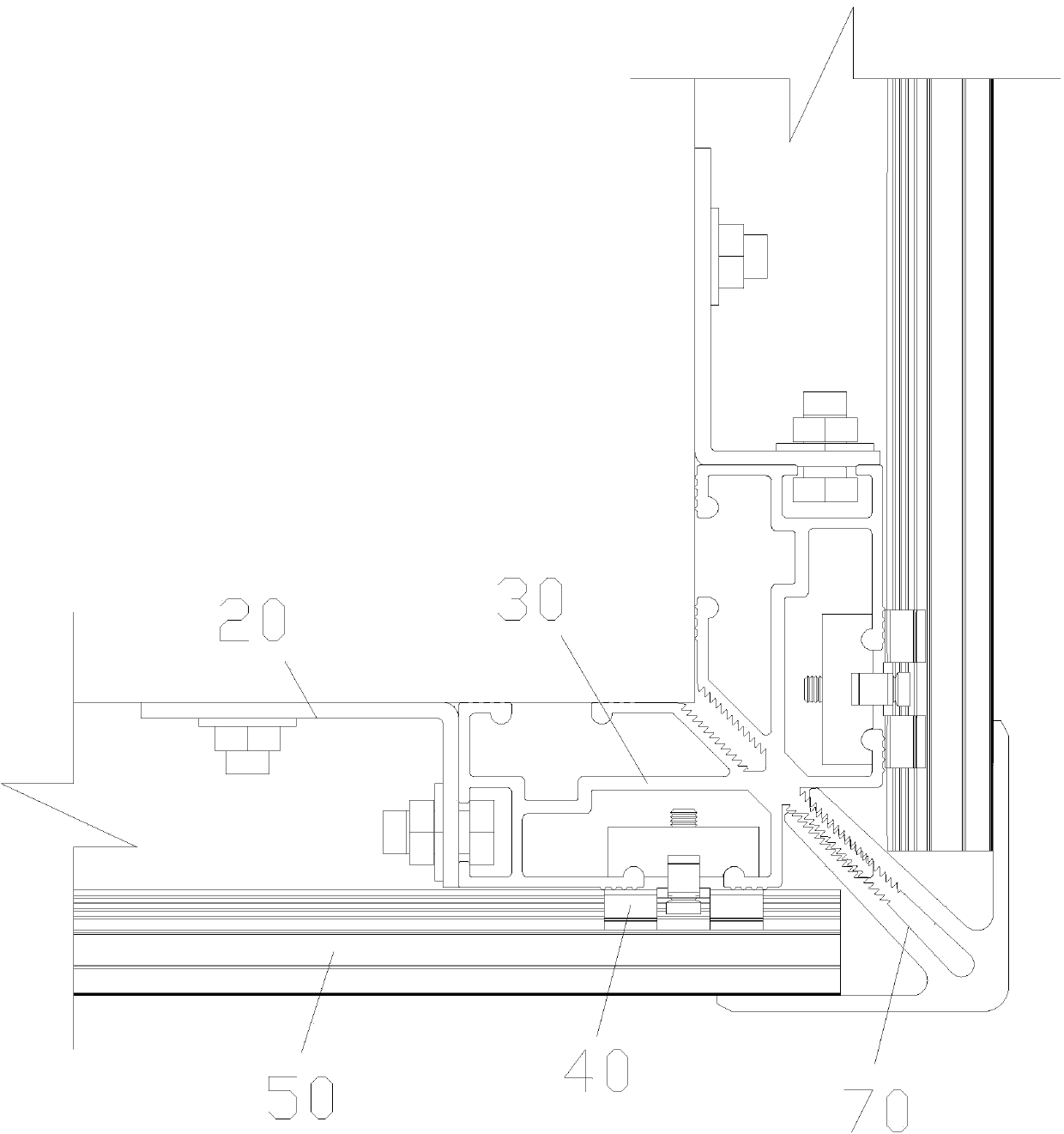

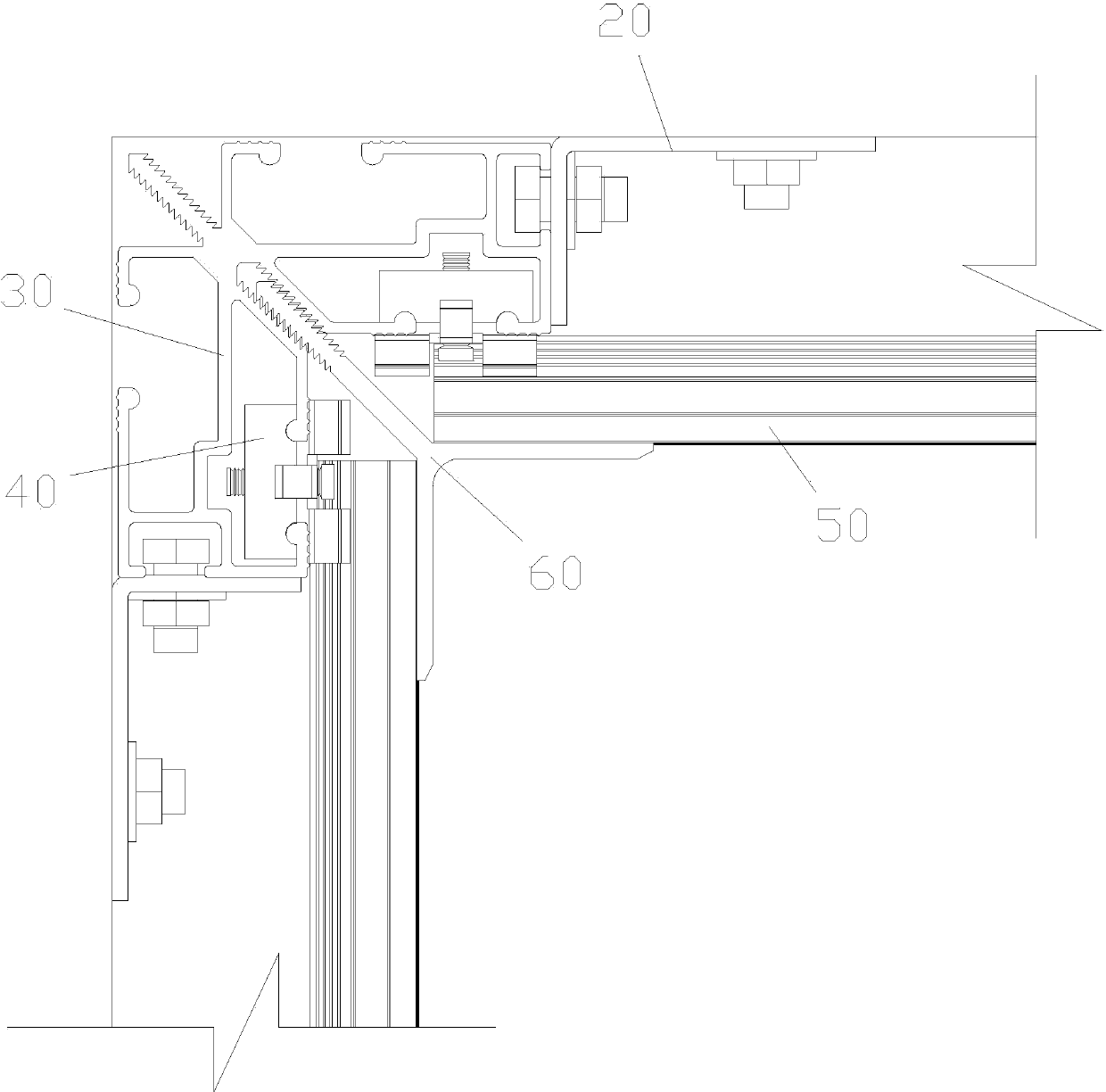

Automatic assembling machine and method for plastic-steel glass door and window

The invention belongs to the technical field of door and window manufacturing, and particularly relates to an automatic assembling machine and method for a plastic-steel glass door and window. The automatic assembling machine for the plastic-steel glass door and window comprises a base, an accommodating cavity is formed in the middle of the base, the two sides of the base are fixedly connected with supports, a first air cylinder is fixed on the bottom surface of the tops of the supports, the end part of a piston rod of the first air cylinder is fixedly connected with a rectangular mounting plate, and a suction cup is mounted on the bottom surface of the rectangular mounting plate. The upper surface of the base is provided with a first sliding groove. The interior of the first sliding groove is in sliding fit with a first push plate, the upper surface of the base is provided with a second air cylinder, the upper surface of the base is provided with a second sliding groove, the interiorof the second sliding groove is in sliding fit with a first adjusting mechanism, and the top of the first push plate is hinged with a second adjusting mechanism. When the plastic-steel glass door andwindow is assembled, no gap is generated between a door and window frame and glass and between door and window frames, and the assembled door and window has good sealing performance; when the plastic-steel glass door and window is assembled, the situation that the glass and the frame are rubbed and extruded cannot occur, and damage to the glass and the frame is avoided.

Owner:芜湖旭日节能门窗有限公司

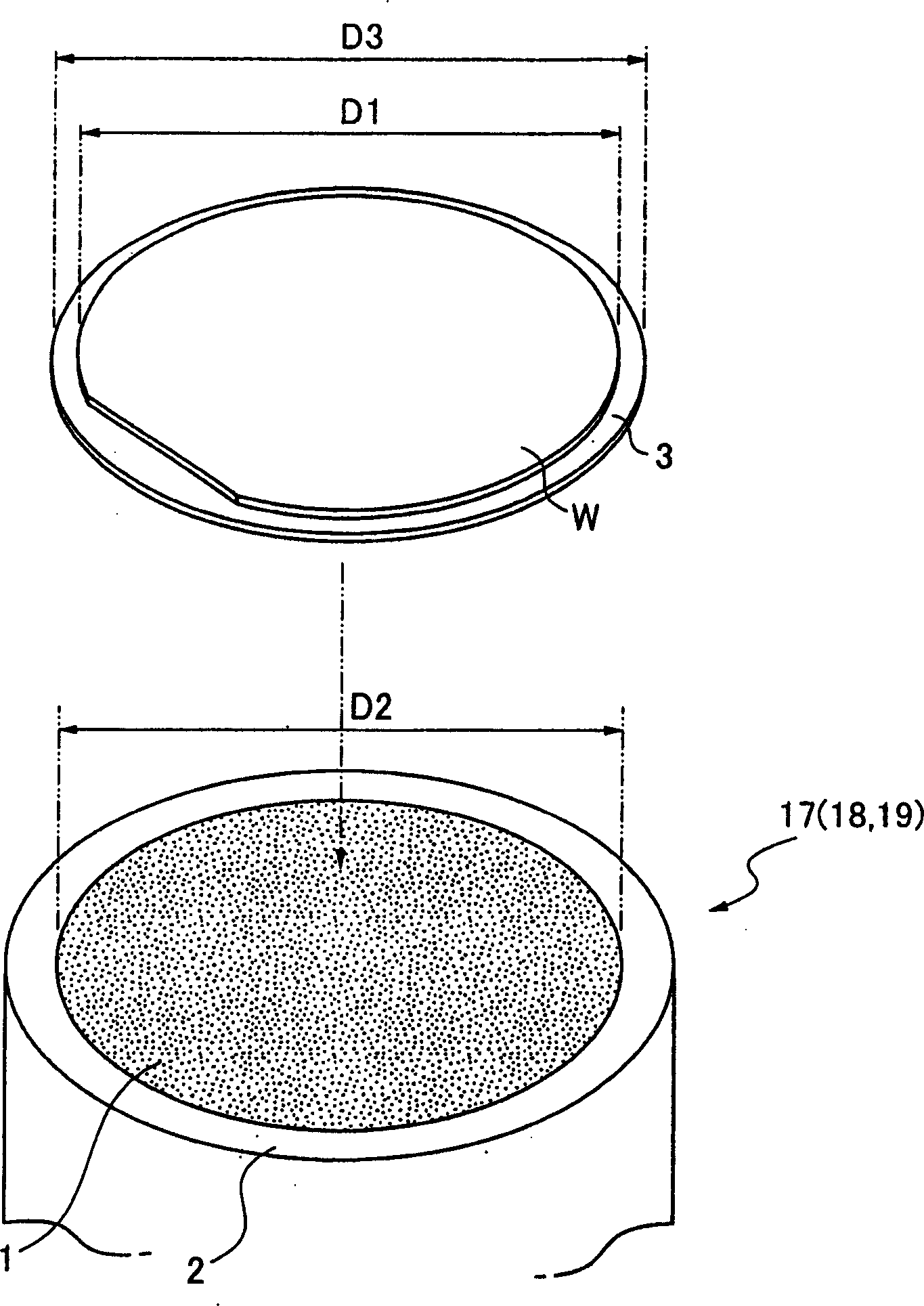

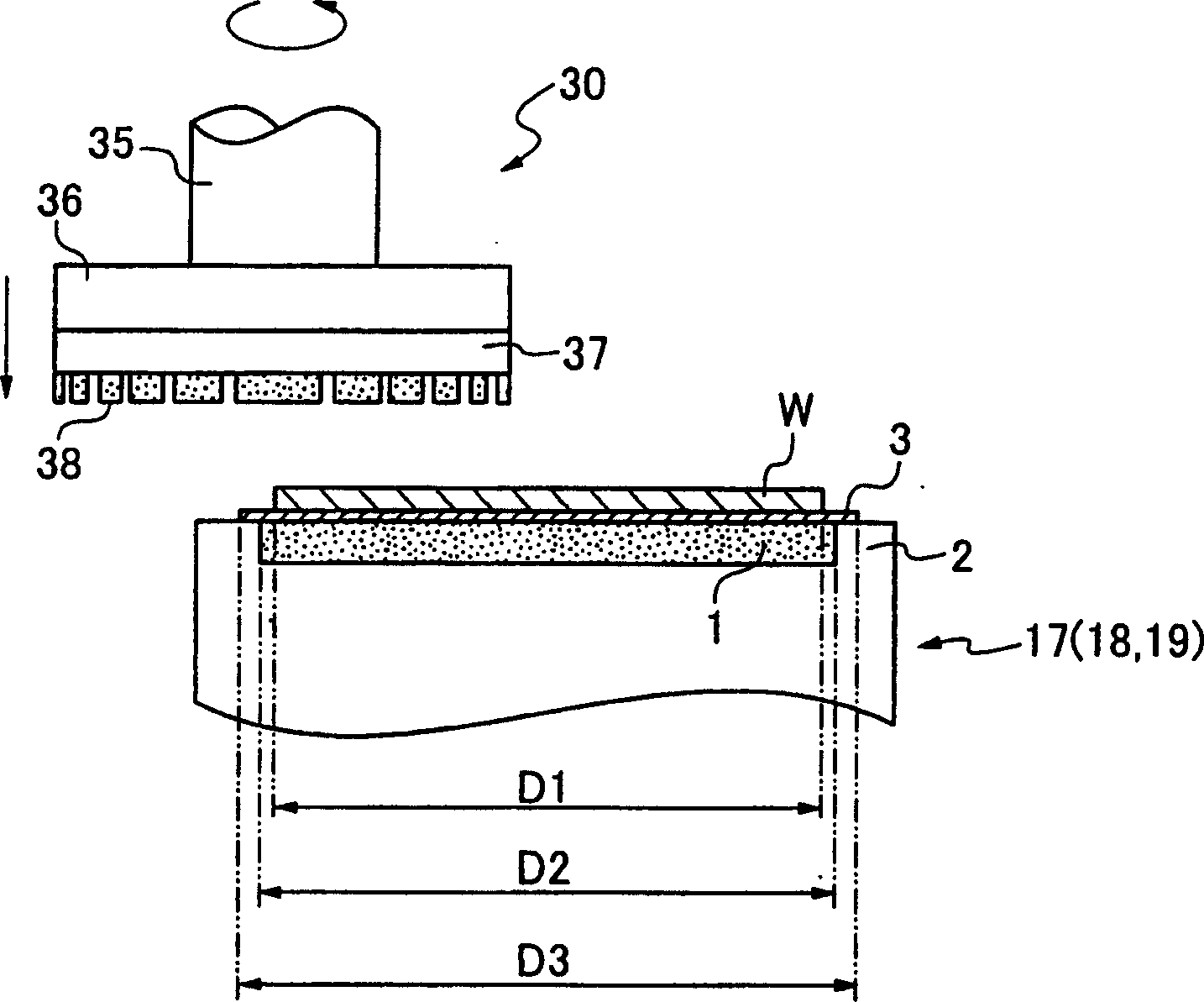

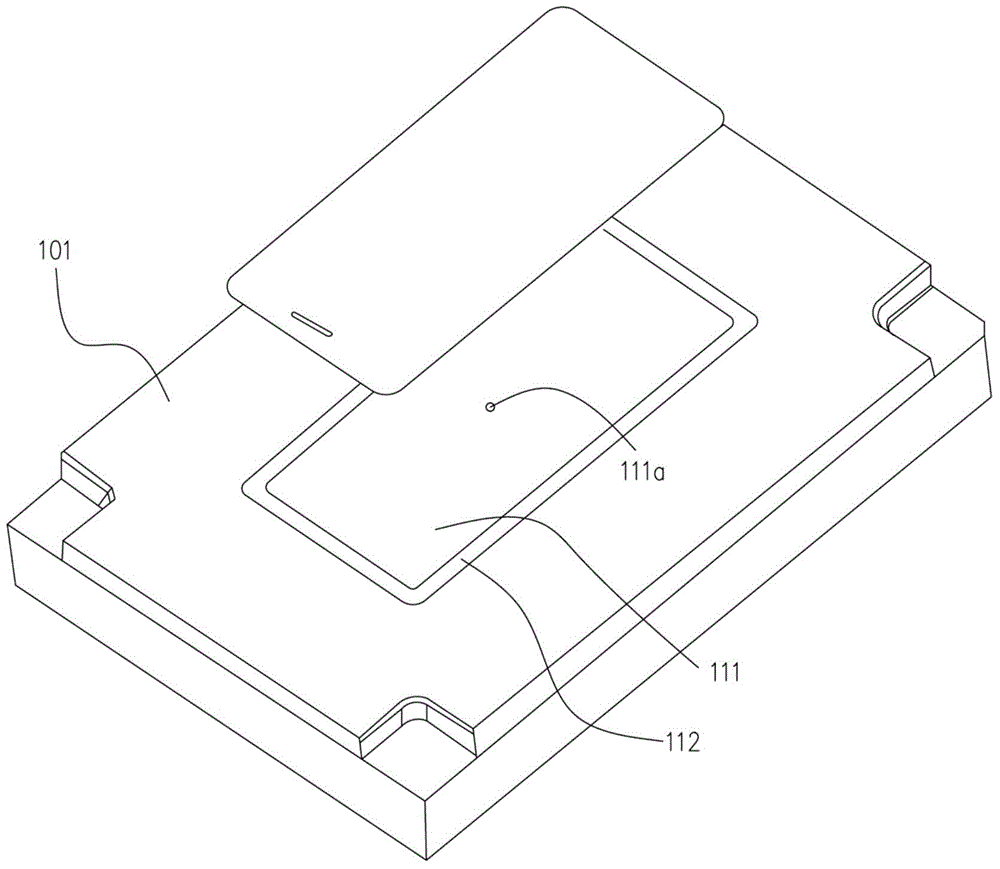

Semiconductor wafer protective member and semiconductor wafer grinding method

InactiveCN1496581ANo crackNo gapsFilm/foil adhesivesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A grinder composed of at least a chuck table (17) having a suction region (1) and a frame (2) and grinding means (30) for grinding a semiconductor wafer (W) held on the chuck table (17) is used. When a semiconductor wafer (W) having an outside diameter Dl smaller than that of the suction region (1) is ground, a semiconductor wafer (W) protective member (3) having an outside diameter D3 larger than the outside diameter Dl of the semiconductor wafer and larger than the diameter D2 of the suction region (1) is stuck on the side not to be ground of the semiconductor wafer (W). The whole surface of the semiconductor wafer (W) is held on the suction region (1), with the semiconductor wafer protective member (3) down. The exposed surface of the held semiconductor wafer (W) is ground by the grinding means (30). Thus the edge of the semiconductor wafer (W) is prevented from breaking, chipping and cracking.

Owner:DISCO CORP

General insulation composite material for exterior wall and application method

InactiveCN101691800AImprove insulation performanceGood heat insulationCovering/liningsInsulation layerMicrosphere

The invention relates to an insulation composite material for an exterior wall and an application method. The composite material is characterized in that the interior and exterior surface layers of a rigid polyurethane layer are combined with inorganic hollow microsphere polymer composite insulation layers, an anti-crack mortar layer is arranged on the exterior inorganic hollow microsphere polymer composite insulation layer and a wall decoration layer is combined with the exterior surface layer of the anti-crack mortar layer. The application method is as follows: the exterior wall to be treated is sequentially coated with the interior hollow microsphere polymer composite insulation layer, rigid polyurethane and the exterior hollow microsphere polymer composite insulation layer, the anti-crack mortar layer is coated on the exterior hollow microsphere polymer composite insulation layer and the wall decoration surface layer is coated on the exterior surface layer of the anti-crack mortar layer. The composite material has good heat insulation property and quick construction method, is strongly adaptive to main structures, reaches higher flame retardant level, is energy-saving and environment-friendly, is suitable for insulation of various walls, especially exterior walls, and is applicable to floors.

Owner:东营丰力输送带有限公司

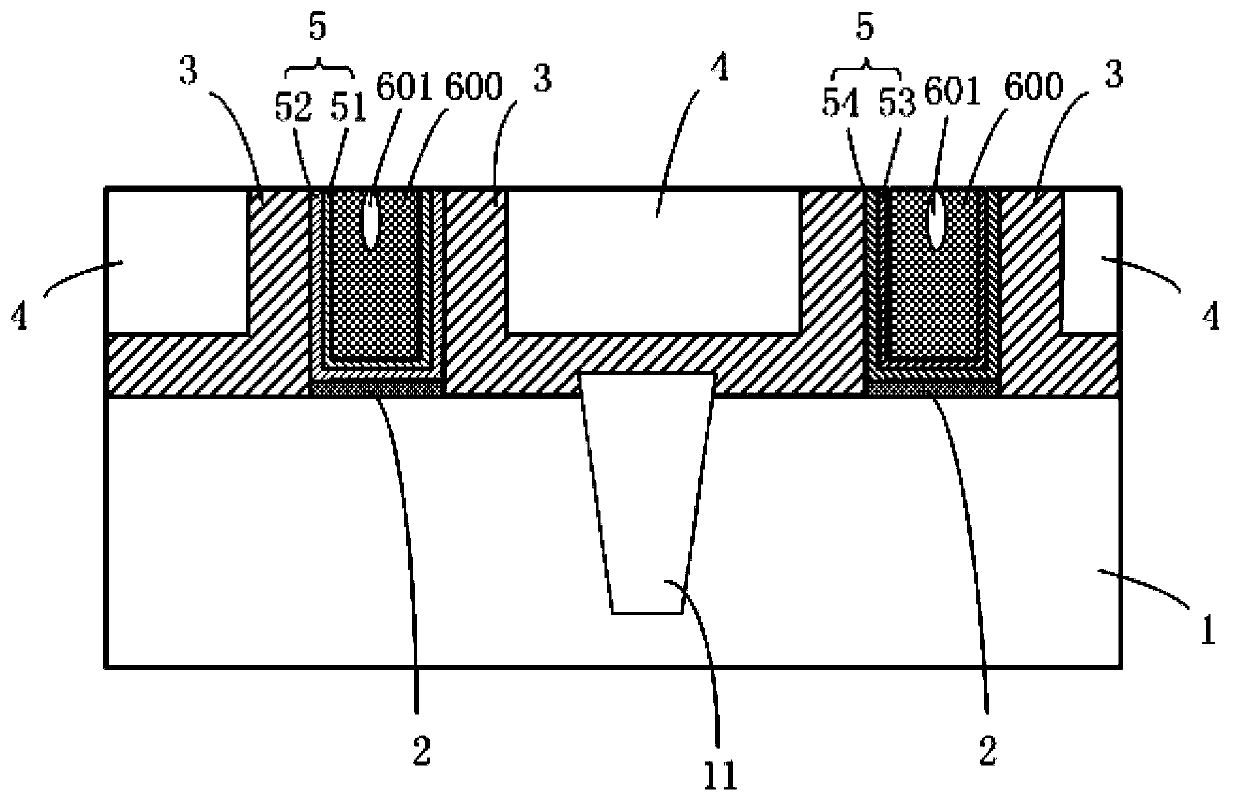

Forming method for metal gate

ActiveCN103871856ALower resistanceSolve the problem of production processSemiconductor/solid-state device manufacturingSemiconductor devicesWork functionMetal

The invention provides a forming method for a metal gate. The forming method comprises the following steps of forming a pseudo gate layer on a substrate, and forming sidewalls on the two sides of the pseudo gate layer; removing the pseudo gate layer to form a gate trench between the sidewalls; depositing work function metal to form work function metal layers on the bottom of the gate trench and the sidewalls, and enclosing a groove by using the work function metal layers on the bottom of the gate trench and the sidewalls; forming a protective layer to fill the groove, and performing flattening; etching the work function metal layer on the sidewalls of the gate trench to form a recess; removing the protective layer to connect the groove with the recess to form a nick; depositing a metal material to fill the nick. According to the forming method for the metal gate, an opening filled with the metal gate material is enlarged by a corresponding process step, so that gaps in the formed metal gate are avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

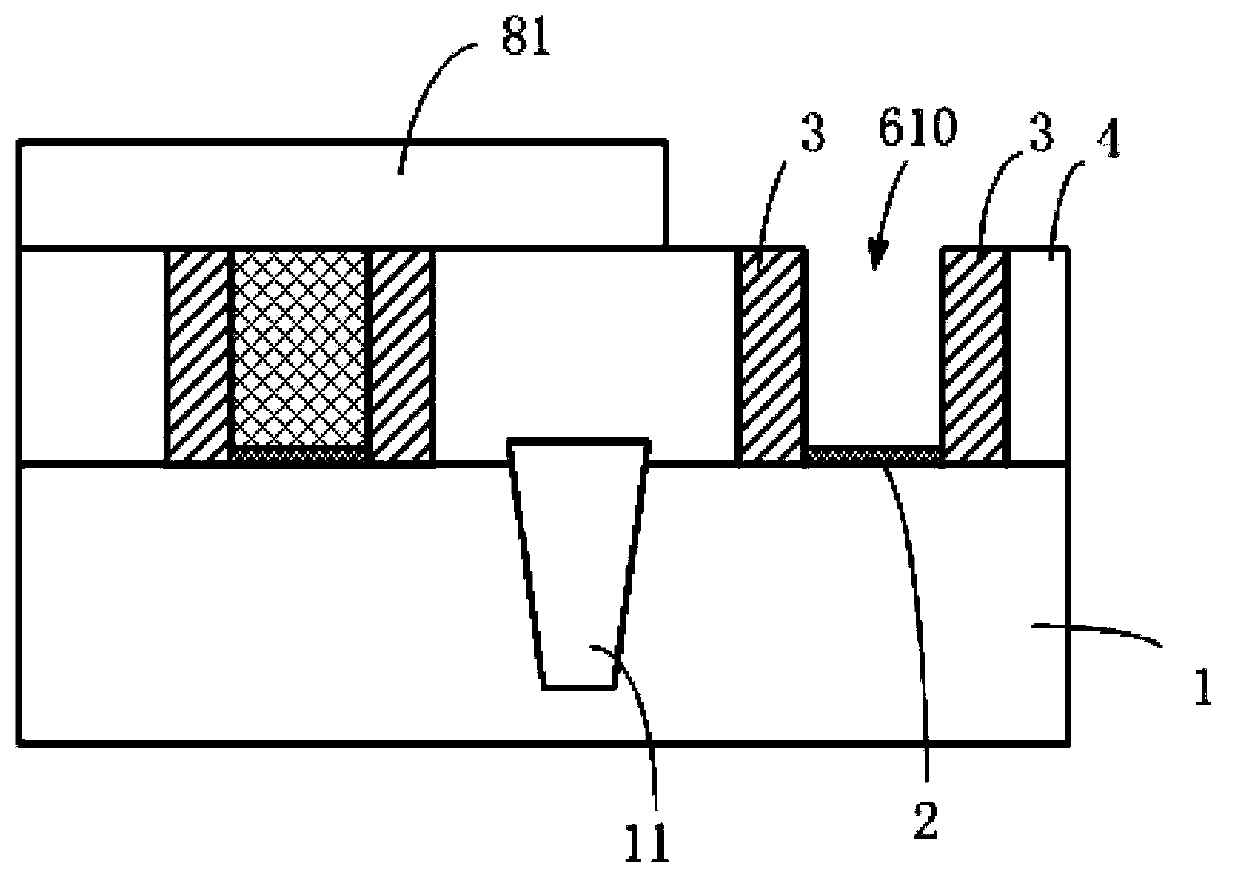

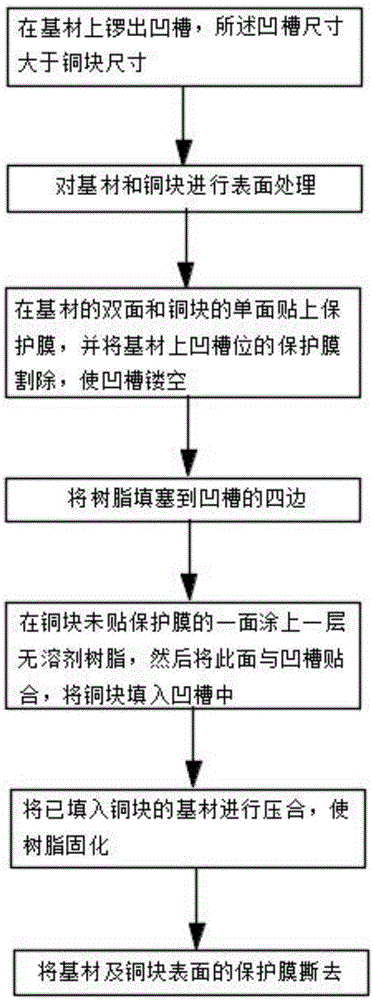

Copper block burying method of printed circuit board

ActiveCN106132089AImprove bindingNo delaminationInsulating substrate metal adhesion improvementPrinted circuit aspectsTectorial membraneSolvent free

The invention relates to the field of production and manufacturing of printed circuit boards, in particular to a copper block burying method of a printed circuit board. The method comprises the following steps: forming a groove in a substrate, wherein the size of the groove is larger than the size of a copper block; carrying out surface treatment on the substrate; adhering a protective film to each of two sides of the substrate and adhering a protective film to one side of the copper block and cutting off the protective film from the groove position on the substrate to hollow the groove; filling the four sides of the groove with resin; smearing a layer of solvent-free resin on the side, without the protective film, of the copper block and adhering the side to the groove; pressing the substrate in which the copper block is buried and curing the resin; and removing the protective films from the surfaces of the substrate and the copper block.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

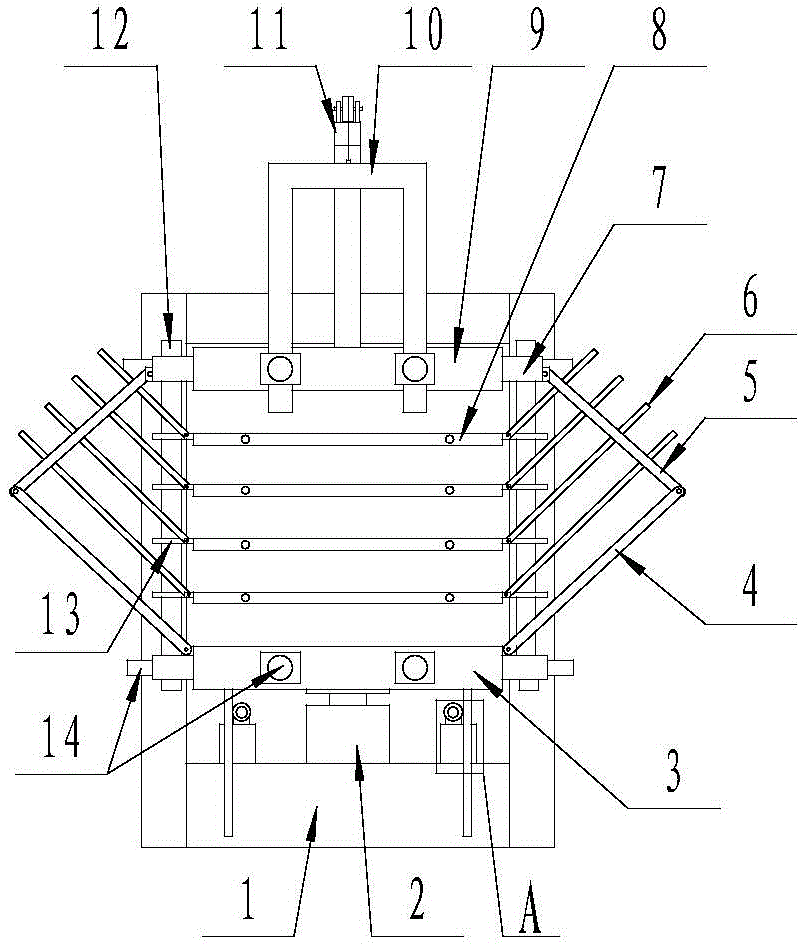

Four-edge board cutting machine for cutting carpentry veneer and four-edge cutting method of carpentry veneer

InactiveCN103009439AImprove finished product qualityNo gapsProfiling/shaping machinesEngineeringEnergy consumption

The invention relates to a four-edge board cutting machine for cutting a carpentry veneer, and a four-edge cutting method of the carpentry veneer. The four-edge board cutting machine comprises a rack, a rectangular bearing platform used for supporting the carpentry veneer, a rectangular bottom press bench used for implementing a flatting action on the supported carpentry veneer, a movable knife rest encircling the outside of the bottom press bench, cutting knifes fixedly mounted on an inner side wall at the periphery of the movable knife rest, a roller oppositely-grinding type veneer conveying mechanism used for conveying the carpentry veneer, a bottom press bench lifting control mechanism, a movable knife rest lifting control mechanism and a veneer feeding mechanism. According to the four-edge board cutting machine, a full frame of the carpentry veneer is compressed and flatted firstly, and then the four edges of the carpentry veneer are cut at the same time, so that joint opening or lamination of butting edges of the four cutting edges of the carpentry veneer are avoided in subsequent links such as assembling and prepressing, and the production efficiency of a core-board or a plywood is improved; the energy consumption is reduced; and the quality of a finished product is ensured.

Owner:河北北方绿野居住环境发展有限公司

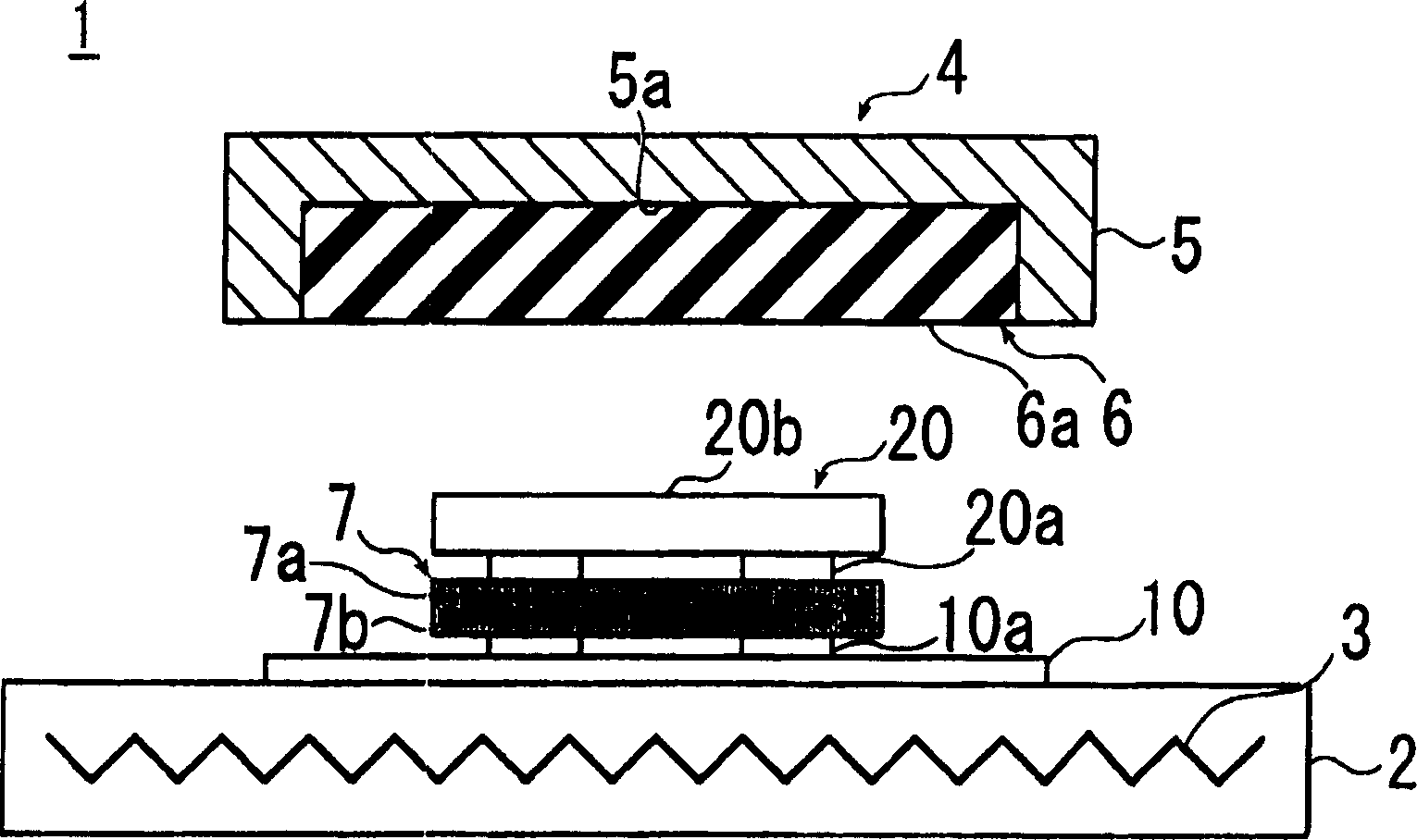

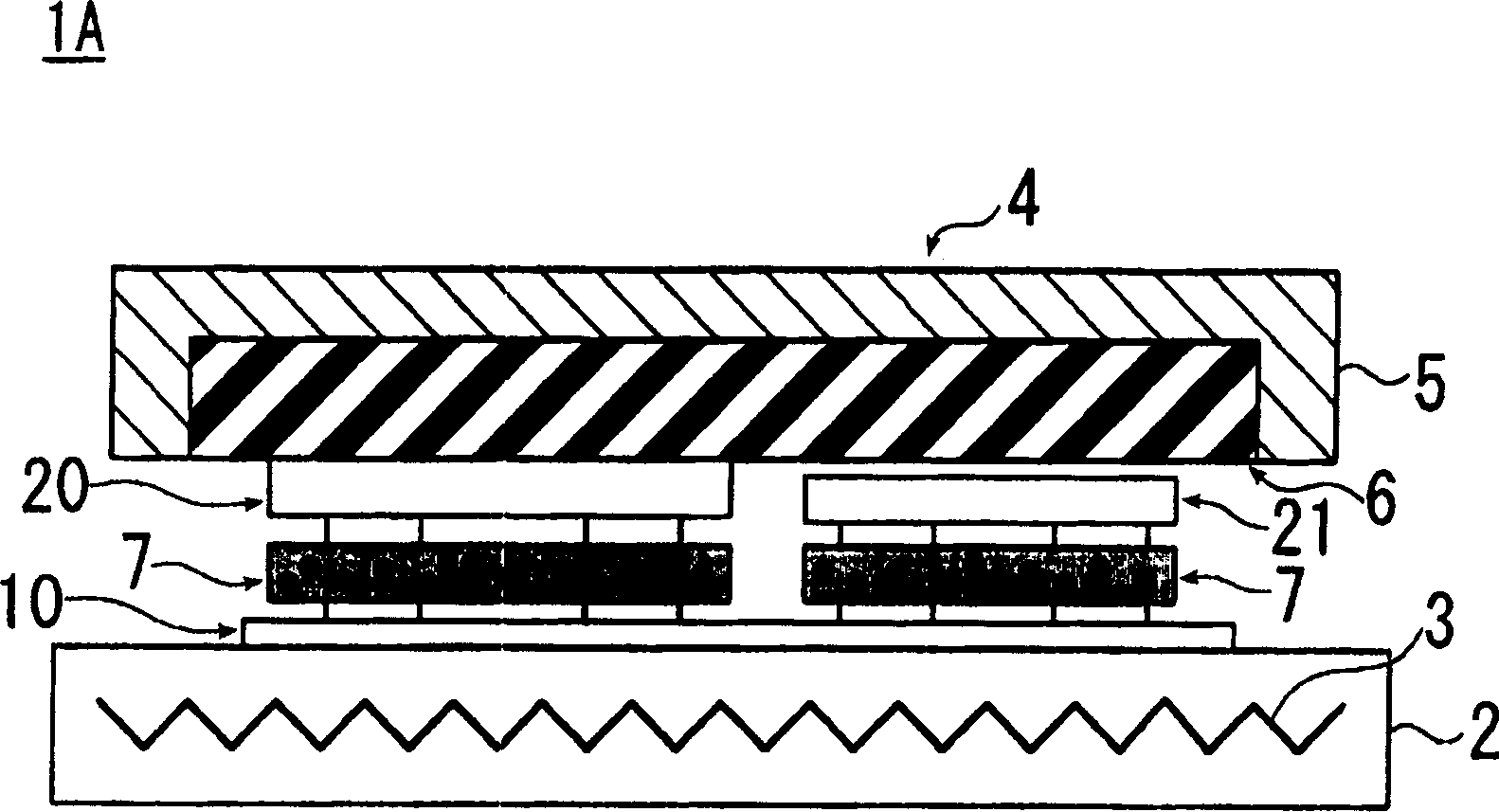

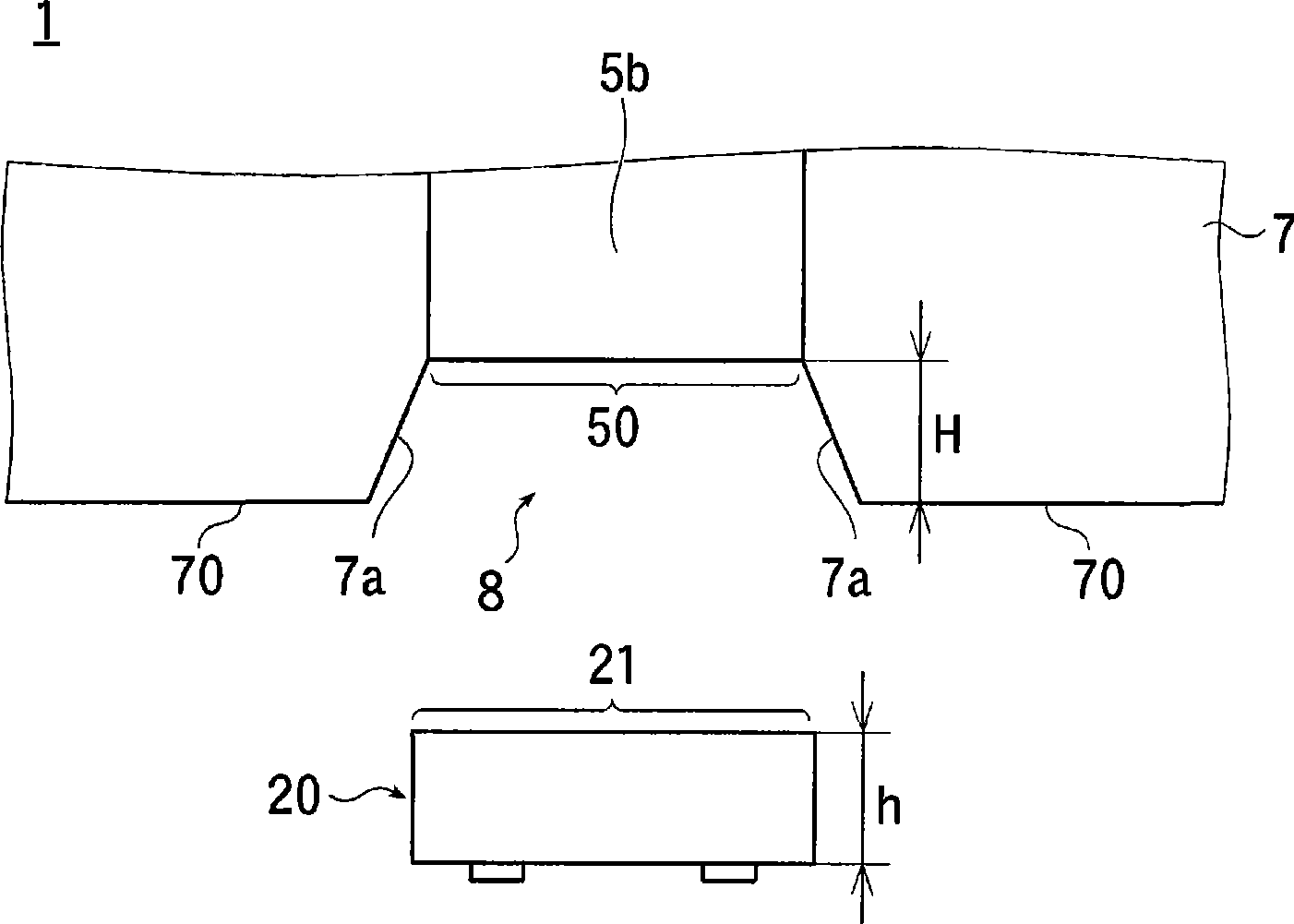

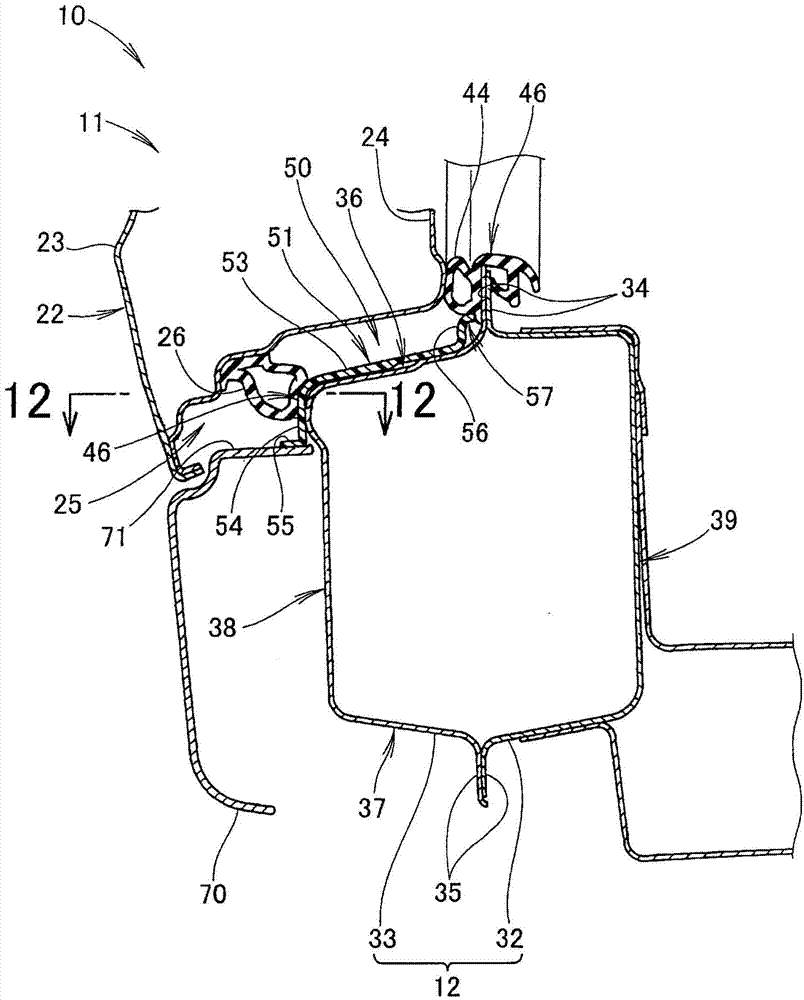

Mounting method using thermocompression head

InactiveCN101490831AImprove reliabilityNo gapsPrinted circuit assemblingPrinted circuit aspectsElastomerEngineering

Provided is a mounting method using a thermocompression head which can mount an electric component in a short time with high connection reliability. The method is provided for mounting an electronic component (20) on a wiring board (10) by using a thermocompression head (3) having an elastic pressure bonding member (7) composed of an elastomer on a heatable metal head main body (5). In the method, after arranging an adhesive on a mounting region on the wiring board (10), an electric component (20) is arranged on a mounting region, and the electric component (20) is bonded on the wiring board (10) by thermocompression by using the thermocompression head (3). At the time of performing thermocompression bonding, while pressing a top region (21) of the electric component (20) by a metal portion of the head main body (5), an adhesive (30) in the vicinity of a side portion region (22) of the electric component (20) is pressed by a taper section (7a) of the elastic adhesive member (7).

Owner:DEXERIALS CORP

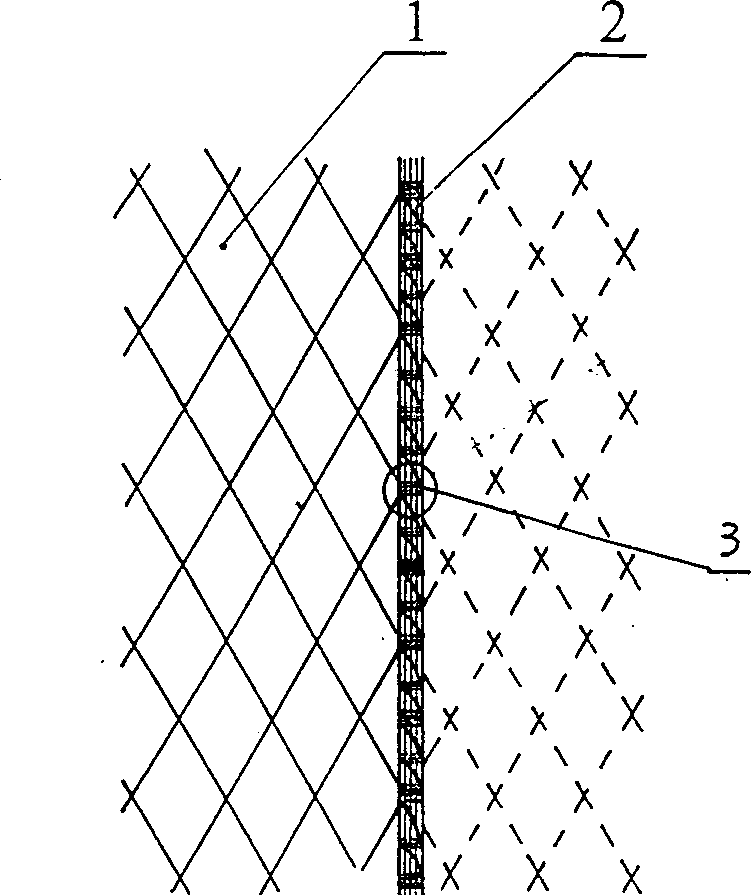

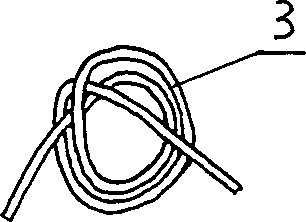

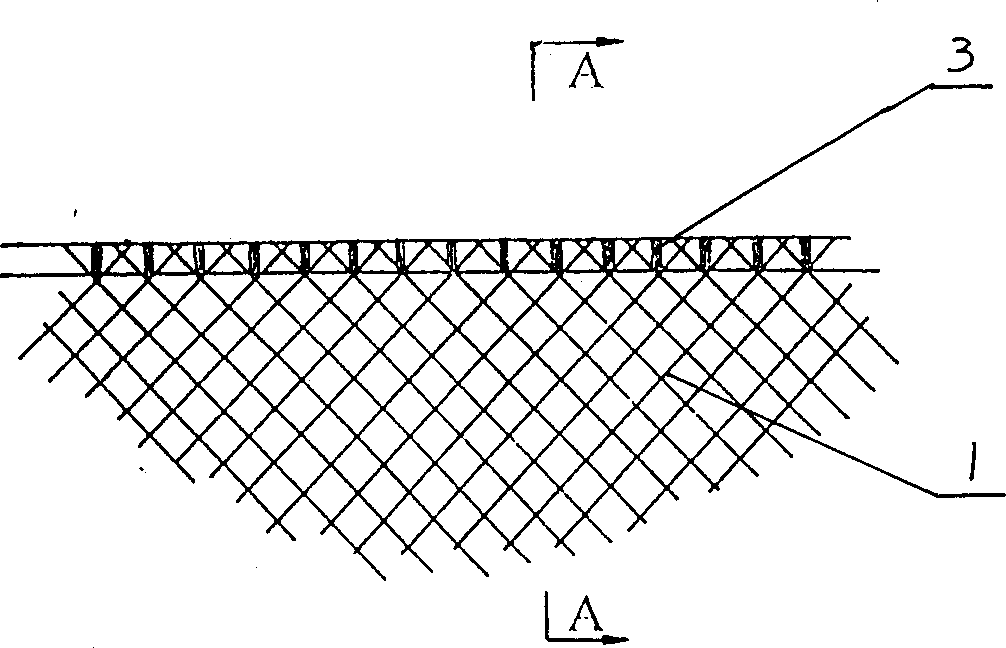

Technology for binding fish-culturing net or netted appliance

InactiveCN1354976AImprove the forceAvoid breakingClimate change adaptationKnottingEngineeringUltimate tensile strength

A technology for binding the netted appliance for culturing fish in deep sea includes such steps as cutting the netted fabric to needed shapes and sizes, sewing and binding with ropes, and features its additional edge-binding step. Its advantages include high strength, uniform stress, and not deforming or not being damaged by waves easily.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

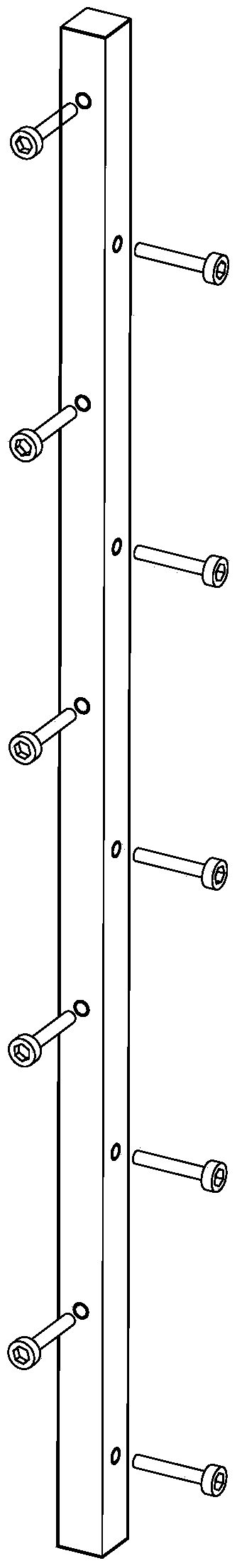

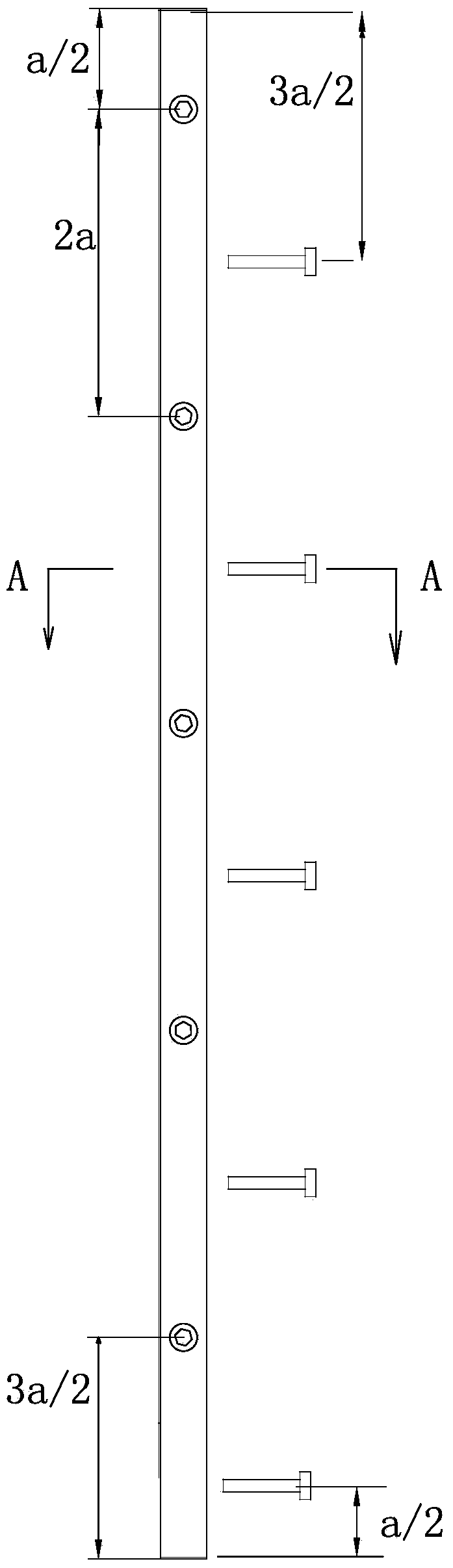

Adapter coupling piece dedicated for internal and external corner molds and internal and external corner mold structures

InactiveCN104234421ASolve the problem that there is no special adapter for male and female angle moldsQuick disassemblyAuxillary members of forms/shuttering/falseworksForming/stuttering elementsHigh surfaceEngineering

The invention discloses an adapter coupling piece dedicated for internal and external corner molds and an internal and external corner mold structure. The adapter coupling piece comprises a columnar body formed by a hollow square pipe, wherein two adjacent surfaces of the columnar body are respectively provided with a first through hole array and a second through hole array, and the first through hole array and the second through hole array are respectively vertical to respective surface and are mutually staggered; a thread bushing is respectively embedded and fixed in each through hole, and a bolt is screwed in each thread bushing. The invention also discloses the internal and external corner mold structure which uses the adapter coupling piece. Two steel templates are respectively fixedly arranged on two sides of the adapter coupling piece by the bolts and are respectively positioned in an inner side and an outer side to form an external corner mold or an internal corner mold. The adapter coupling piece is applied between the two steel templates to form the external corner mold and the internal corner mold which are in seamless connection, the problem that no adapter coupling pieces dedicated for the internal and external corner molds are in the presence in the traditional technical field of templates can be favorably solved, a quick assembling and disassembling effect is provided, and internal corners and external corners manufactured by the adapter coupling piece have high surface quality.

Owner:刘红艳

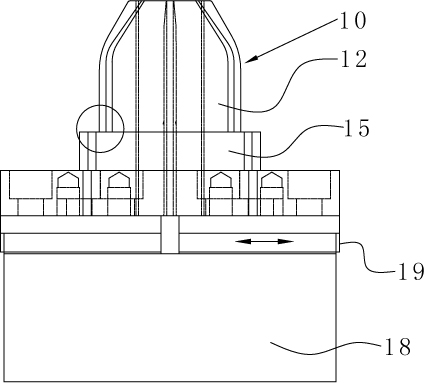

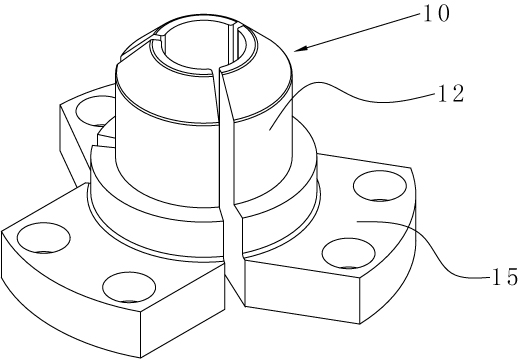

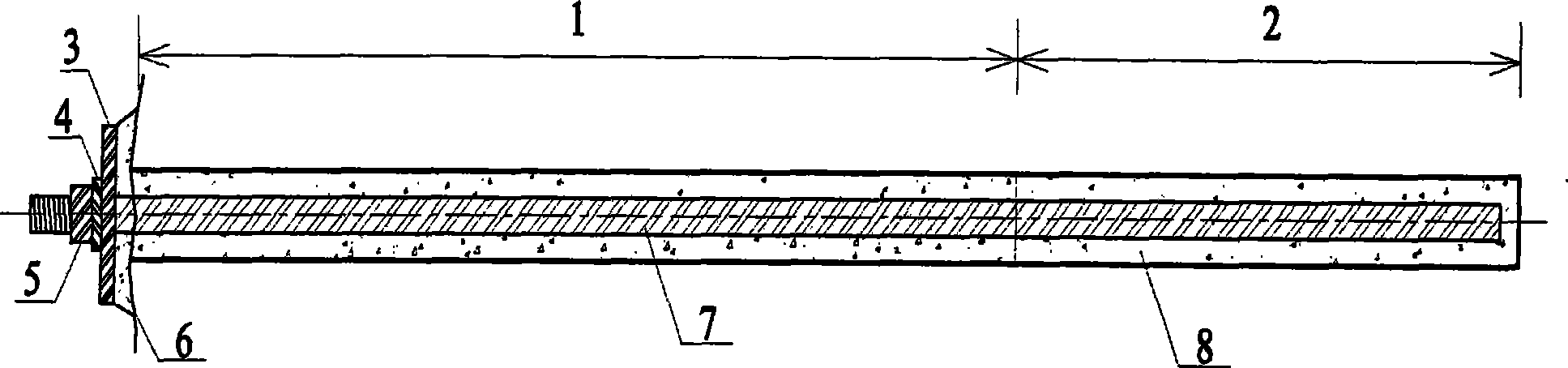

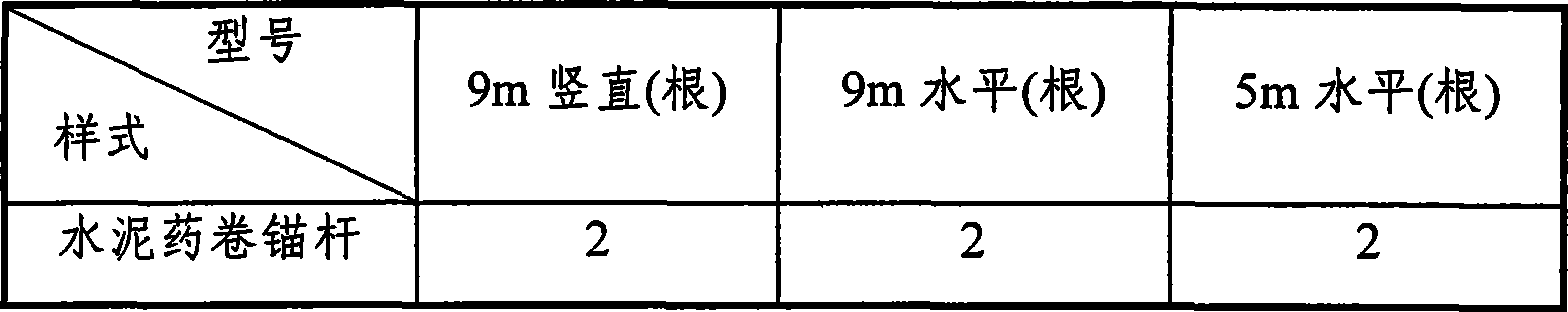

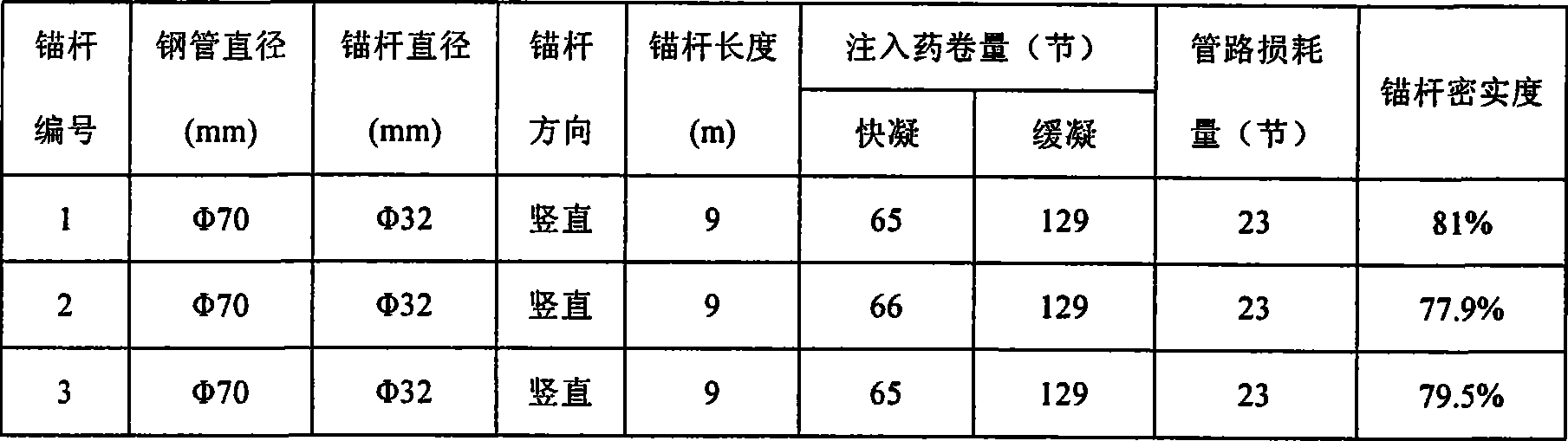

Injecting and mounting method of stretching anchor rod

The invention discloses a grouting method for a stretch-draw anchor rod, wherein a fast-setting anchoring agent and a slow-setting anchoring agent are grouted into an anchor rod hole respectively by adoption of an extruding grouter by means of fast setting first and slow setting subsequently; a grout pipe is extruded by grouting pressure and smoothly withdrawn until the anchor rod hole is filled with serum; and stretch-draw locking of the anchor rod is performed before initial setting of the slow-setting anchoring agent and after final setting of the fast-setting anchoring agent when the anchor rod is arranged in place and the strength required is reached. The grouting is uniform and continuous, the grout pipe is slowly extruded by the serum and is not influenced by artificial influence, so that no gap can occur and the compactness can be fully guaranteed; grouting equipment only needs power supply, so that a complex blast pipe line is saved; and the grouting method has the advantages of simple and convenient technology, high construction efficiency and good application prospect, and safety and reliability.

Owner:SINOHYDRO BUREAU 14 CO LTD

Wood-plastic wallboard laying structure

The invention provides a wood-plastic wallboard laying structure and relates to the technical field of building. The wood-plastic wallboard laying structure comprises main keels, L-shaped connecting parts, corner keels, clamping keys and a wallboard, wherein one side of the L-shaped connecting part is fixed on the main keel through a bolt, the other side of the L-shaped connecting part is fixed on the wall through a bolt, the main keels are installed on the wall at intervals and installed on the wallboard through the clamping keys, the corner keels are installed at internal corners and external corners of the wall and fixed on the wall through the L-shaped connecting parts, the corner keels are connected with the wallboard through the clamping keys, and the internal corners and the external corners are respectively provided with internal corner sealing edges and external corner sealing edges. The internal corner sealing edges and the external corner sealing edges are respectively connected onto the corner keels, the wallboard is laid from down to top, an upper closing-up part is arranged between the upmost end of the wallboard and the wall, a lower closing-up part is arranged at the downmost end, and further integral wallboard laying is achieved. The wood-plastic wallboard laying structure is simple, novel in design, convenient to install and capable of conveniently achieving installation of the wallboard the wall, gaps are not produced, standardized production can be achieved, and economic benefit is good.

Owner:ANHUI SENTAI WPC GRP CO LTD

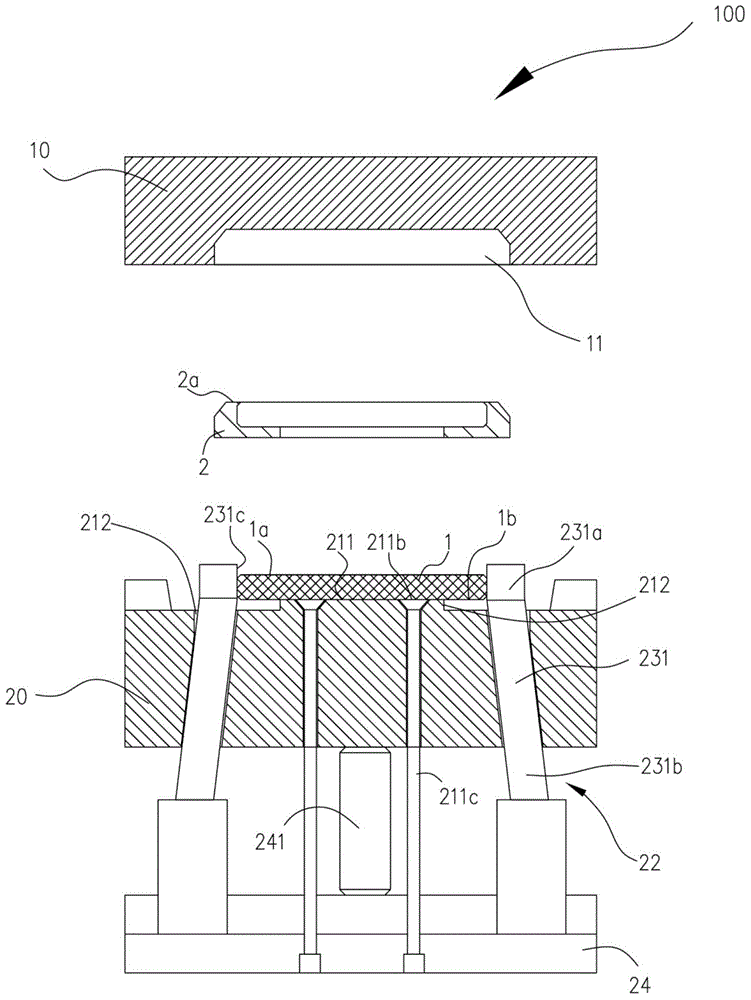

Forming mold of terminal front cover and manufacturing method of forming mold

The invention discloses a forming mold of a terminal front cover. The forming mold of the terminal front cover is used for integrally forming a glass plate and a frame enclosing the glass plate; the forming mold of the terminal front cover comprises a fixed mold and a movable mold, wherein the fixed mold is provided with a mold cavity, the inner surface of the mold cavity comprises a matching surface and a forming surface which is smoothly connected with the peripheral side of the matching surface, the matching surface is used for adhering to an appearance surface of the glass plate, the forming surface is used for forming an appearance surface of the frame, the movable mold is provided with a mold core, a sucking disc is arranged on the end surface of the top end of the mold core, the sucking disc is used for sucking a connecting surface of the glass plate depart from the appearance surface, a positioning mechanism is arranged on the movable mold, the positioning mechanism is used for positioning the glass plate so as to ensure that the appearance surface of the glass plate is aligned to the matching surface in a sliding direction of the movable mold, and an injection opening is formed in the movable mold and is used for injecting a frame raw material into the mold cavity.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

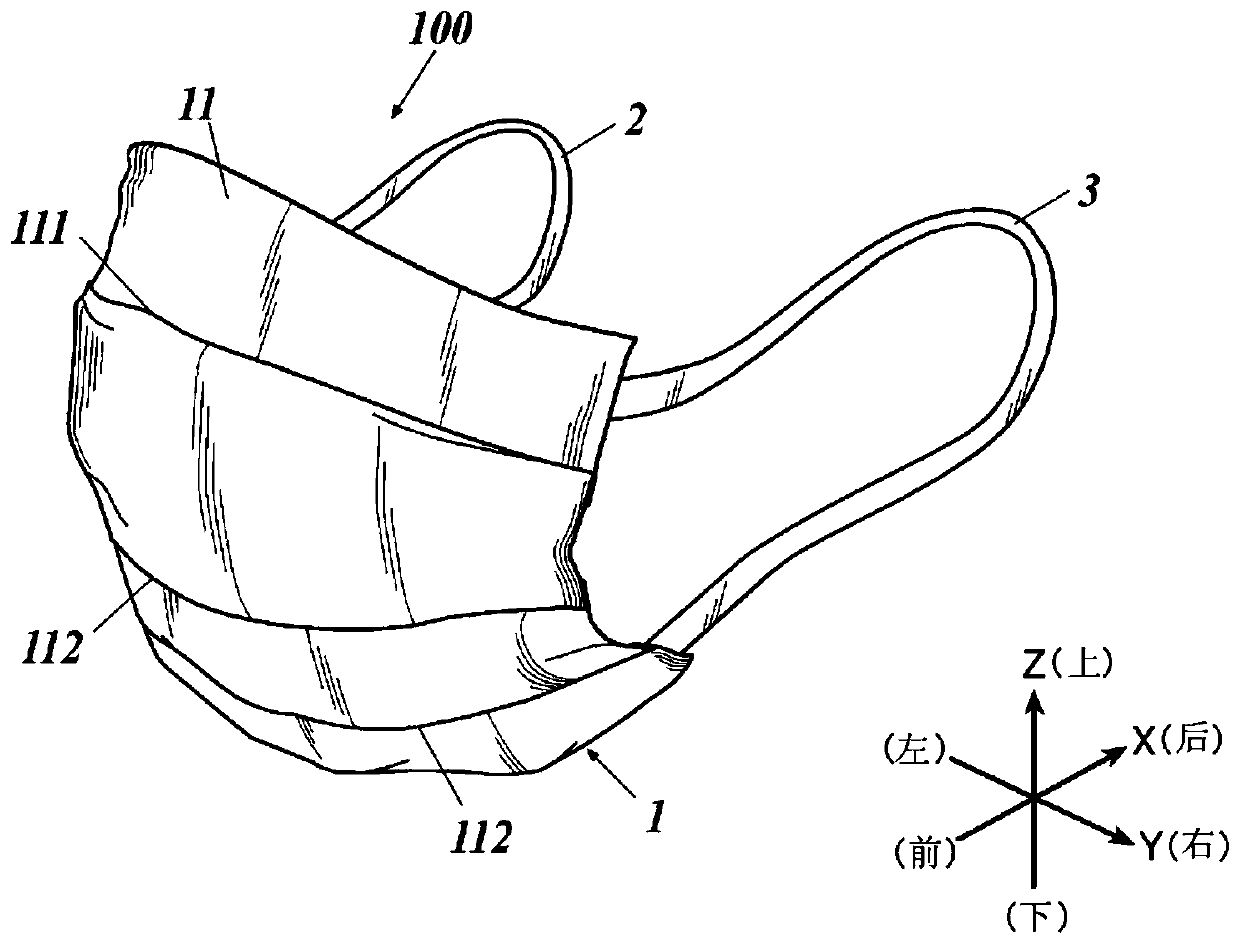

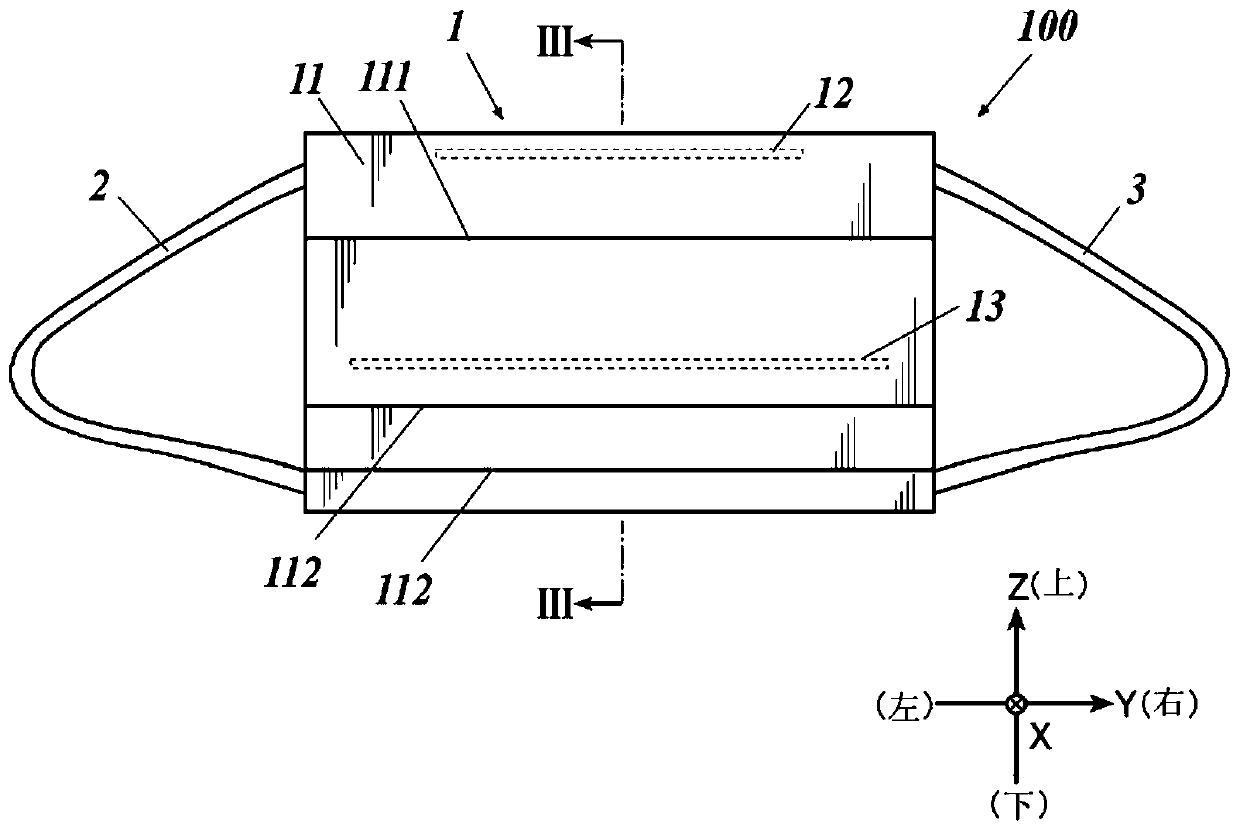

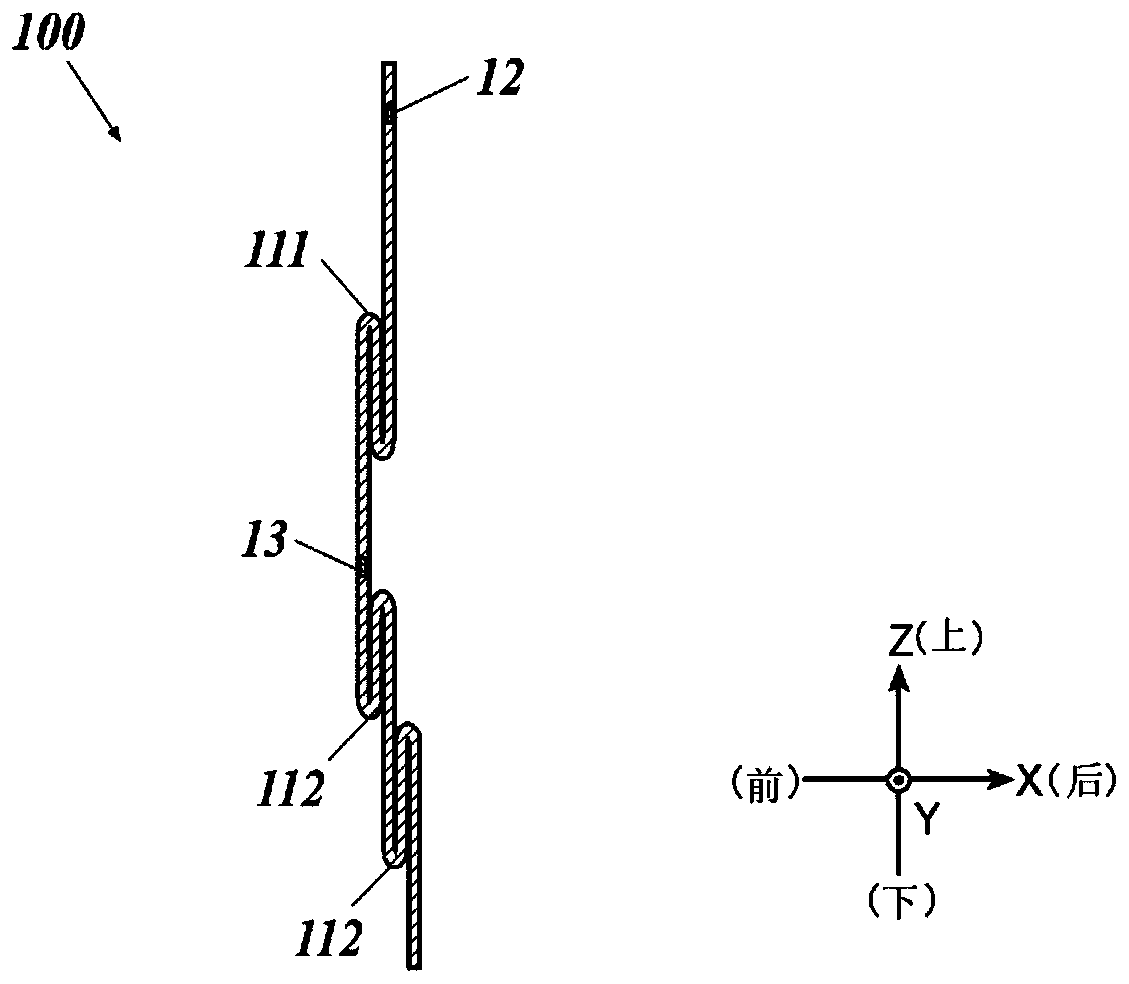

Mask

InactiveCN110381761ASecure spaceEasy to secure spaceProtective garmentRespiratorBiomedical engineering

A mask (100) with a main mask body section (1) that covers the target area of a wearer's face, and a right ear loop (2) and a left ear loop to fasten the main mask body section (1) to the wearer's ears, wherein the main body section (1) has a mouth area-reinforcing member (13) for procuring space between the wearer's mouth and the main mask body section. The mouth area-reinforcing member (13) is provided below the vertical middle of the main mask body section (1). As a result, it is possible to procure sufficient space around the lower lip area.

Owner:DAIO PAPER CORP

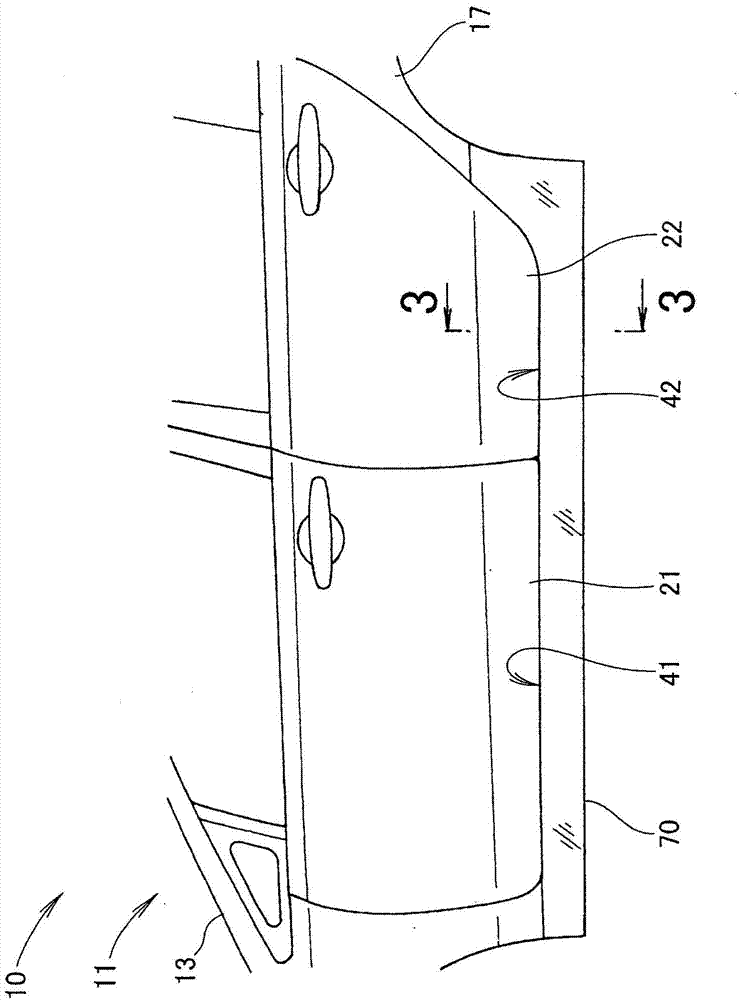

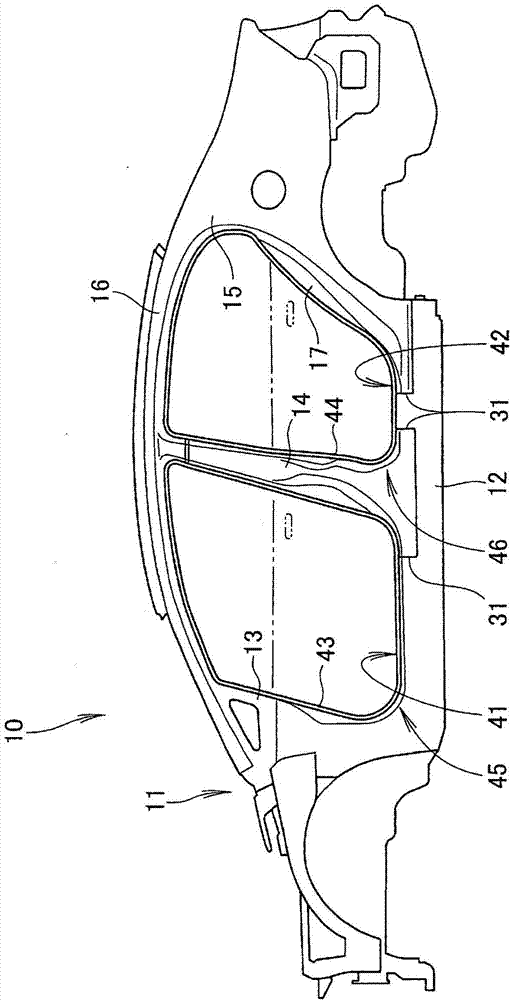

Structure for vehicle body lateral section

ActiveCN104334409AGood lookingImprove rigiditySuperstructure subunitsSteps arrangementEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

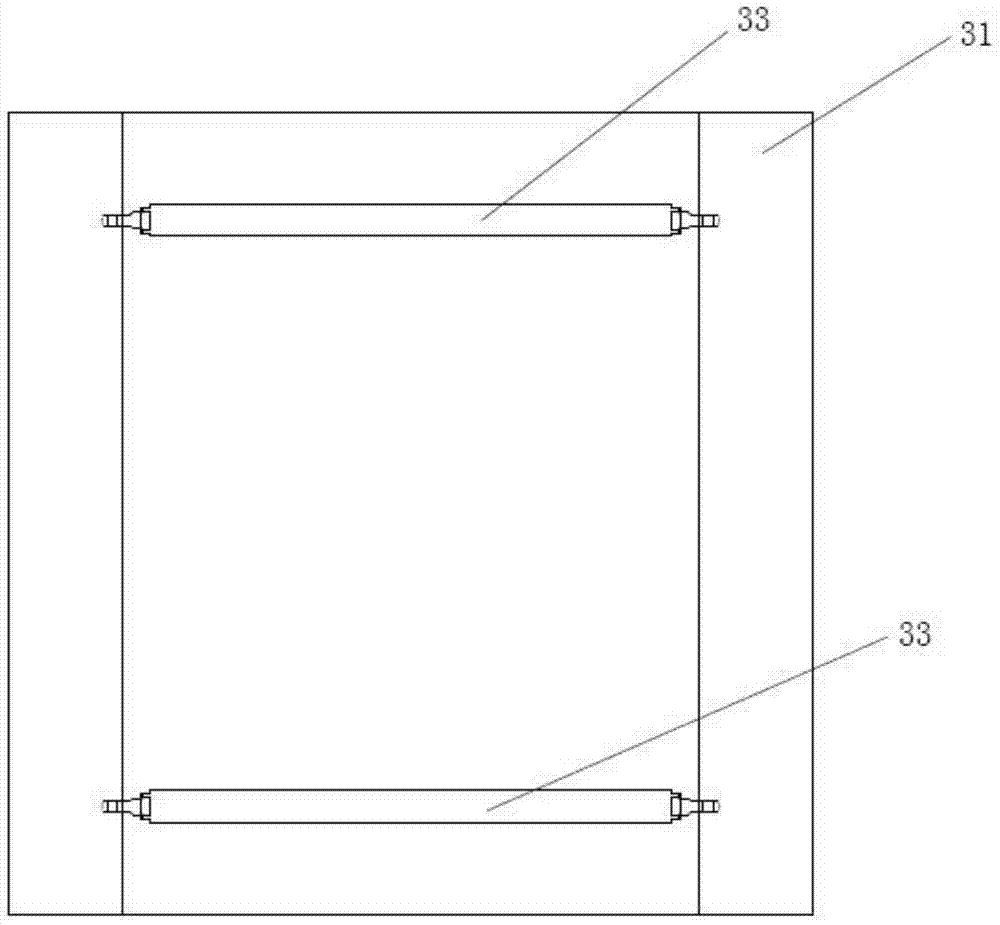

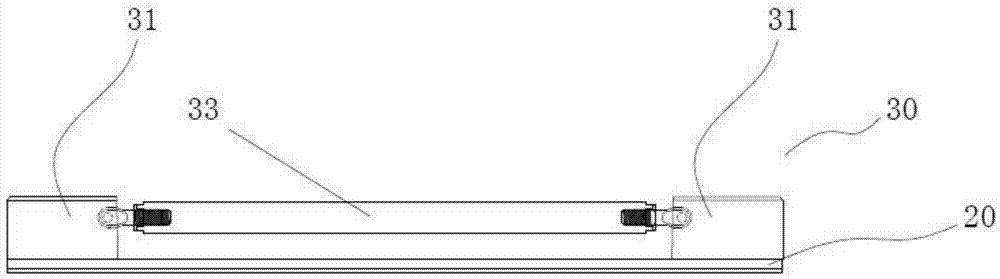

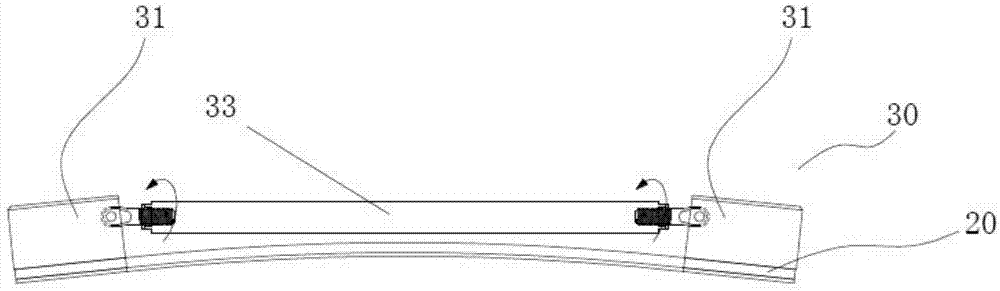

Bendable LED (light emitting diode) module, circular LED module and wavy LED module

ActiveCN104332114ANo gapsImprove the display effectElectric lightingLight fasteningsEngineeringLight-emitting diode

The invention discloses a bendable LED (light emitting diode) module, which comprises an elastic part layer (20) and an adjusting part (30), wherein a plurality of light emitting assemblies are arranged on the elastic part layer (20), the adjusting part (30) is arranged at the back part of the elastic part layer (20), and is tensioned or supported at the two sides of the elastic part layer (20), and the elastic part layer (20) is bent in an inner arc or outer arc way. The bendable LED module has the advantage that after the elastic part layer (20) is bent and deformed, a larger clearance or gap between the light emitting assemblies is avoided, so the display effect is better.

Owner:GLUX VISUAL EFFECTS TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com