Injecting and mounting method of stretching anchor rod

A bolt and tension technology, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of injury to construction personnel, short hardening time of cement rolls, and easy formation of gaps, etc., to speed up construction progress, The effect of saving the air pipe line and fast pulping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

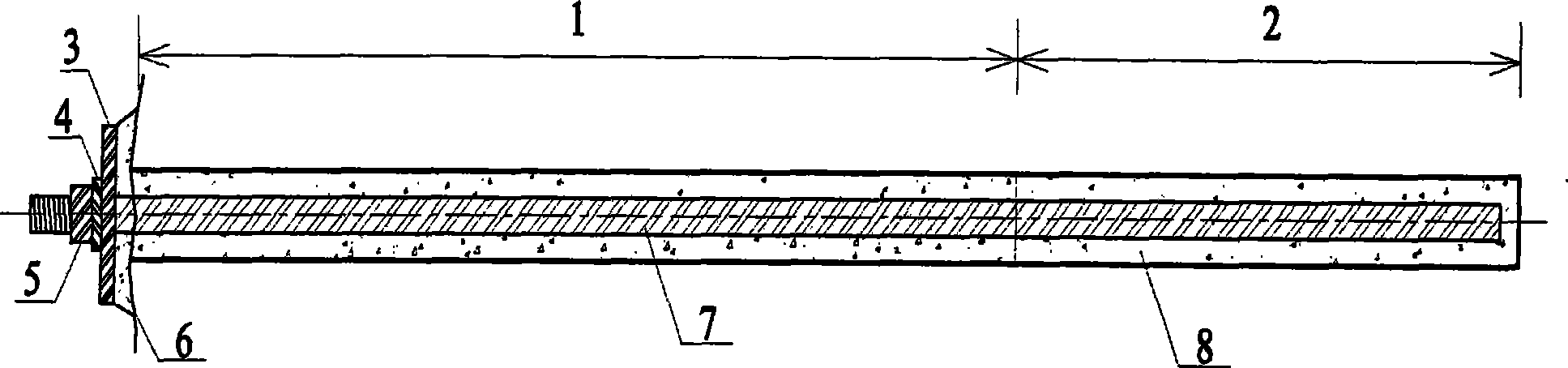

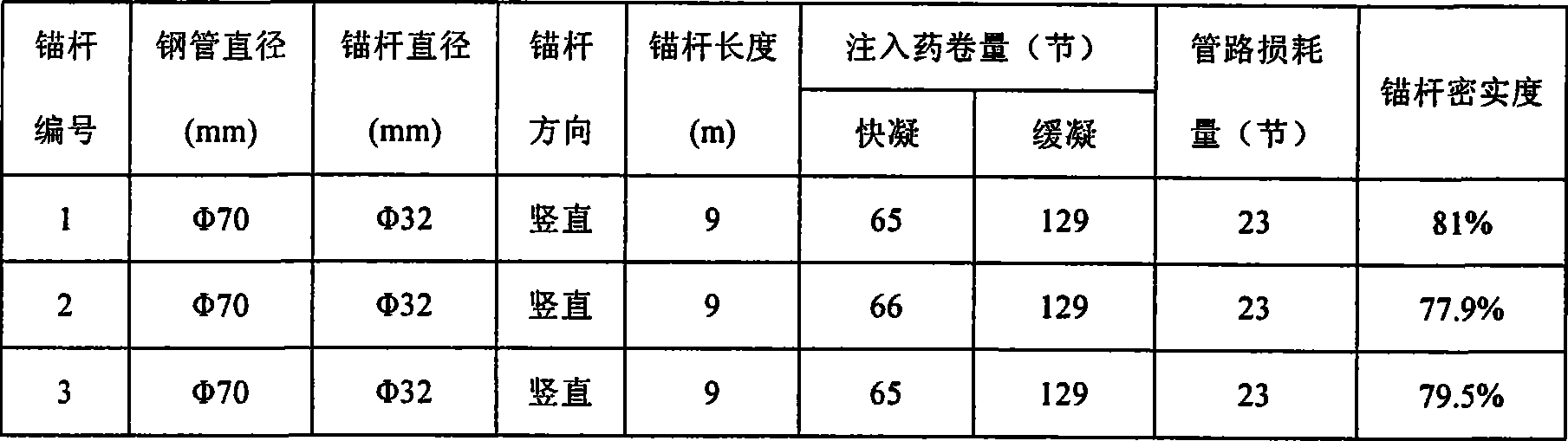

[0026] As shown in the accompanying drawing, when carrying out the construction of the horizontal hole in the side wall, at first, drill out the bolt hole 8 with a three-arm rock drilling jumbo on the rock wall, the hole depth is 12m, and the dust and sundries in the hole are cleaned, And check the depth of the hole to ensure the smooth installation of the anchor rod. Two kinds of fast-setting anchoring agent and retarding-setting anchoring agent are mixed respectively, the fast-setting anchoring agent adopts 8604-K3, and the retarding-setting anchoring agent adopts 8604-M1. The water-cement ratio of the two anchoring agents is 0.3. Mixing should be uniform, so as to avoid agglomeration entering the grouting pipe, causing blockage of the grouting pipe, or even bursting the pipe. Use a squeeze grouting machine for injection, insert the grouting pipe into the bottom of the anchor hole, and install a grout plugging device 3-5 mm smaller than the hole diameter of the anchor hole ...

Embodiment 2

[0028] Repeat Example 1 with the following differences: the tension locking period is 6 hours after the quick-setting anchoring agent is loaded.

Embodiment 3

[0030] Repeat Example 1 with the following differences: the tension locking period is 9 hours after the quick-setting anchoring agent is loaded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com