Bi-component silicone pouring sealant for LED photoelectric display device and method for manufacturing same

A technology for LED displays and optoelectronic displays, applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, electrical components, etc., can solve problems such as stickiness, catalyst poisoning, and uncured surfaces of glue, to avoid damage and simplify the process. , conducive to the effect of potting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

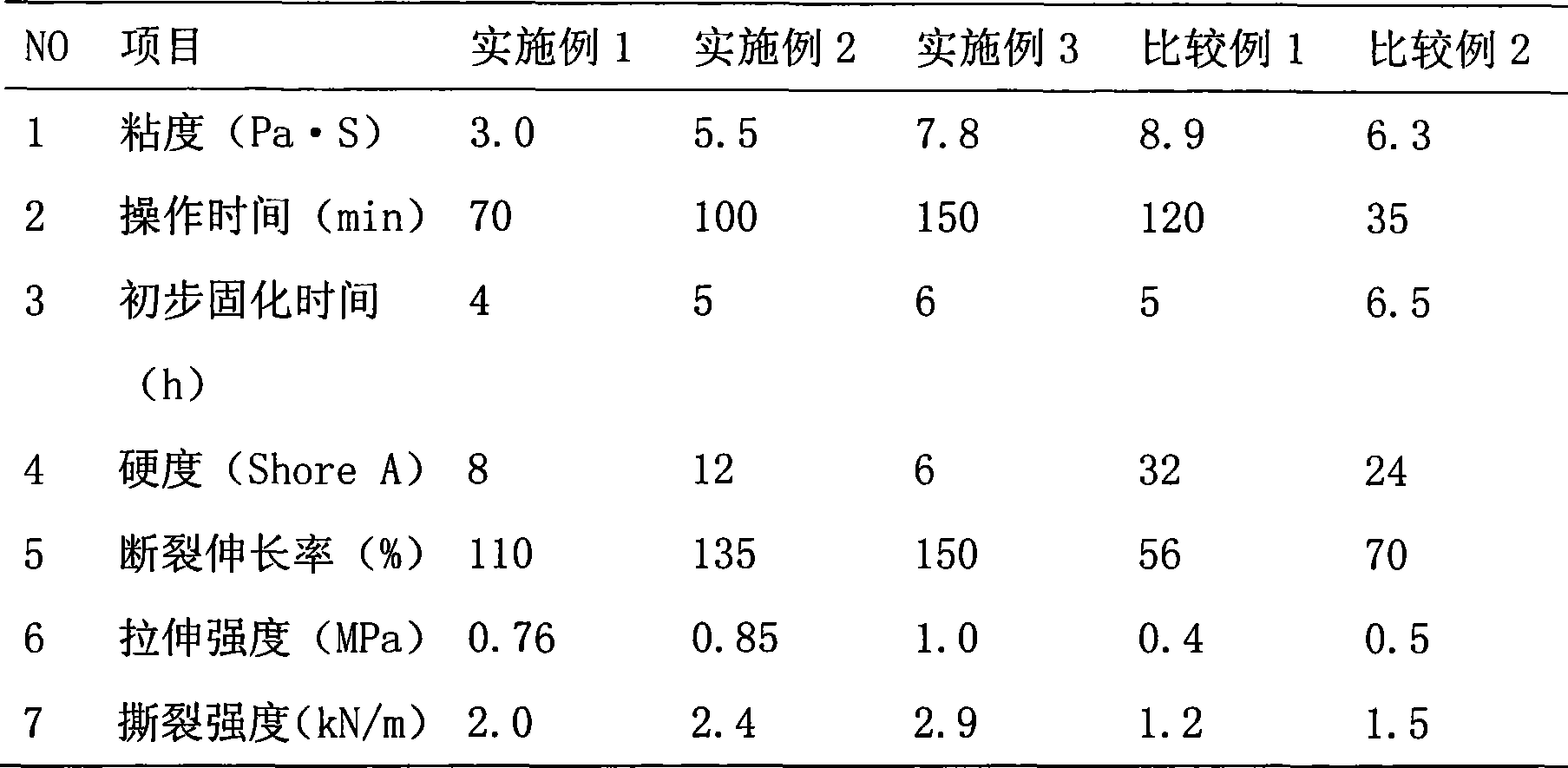

Examples

Embodiment 1

[0046] Put 100 parts of α, ω-dihydroxypolydimethylsiloxane and 5 parts of dimethyldimethoxysilane into the vacuum kneader, stir evenly, add 50 parts of precipitated white carbon black, knead at room temperature for 2 hours, Then kneading and blending at a temperature of 100° C. and a vacuum of 0.06 Mpa for 30 minutes to obtain a silicone-based rubber.

[0047]100 parts of α, ω-dihydroxy polydimethylsiloxane, 35 parts of silicone-based glue, 5 parts of α, ω-dimethyl polydimethylsiloxane, poly Add 5 parts of dimethylsiloxane into a mixer, and stir for 30 minutes under a vacuum of 0.06mpa to obtain component A. 8 parts of mixture of tetraethoxysilane and tetraethoxysilane hydrolyzate, 0.3 parts of mixture of γ-aminopropyltriethoxysilane and γ-(2,3-glycidoxy)propyltrimethoxysilane Parts, 0.5 part of diisopropoxytitanium bis(ethyl acetoacetate) chelate, 0.2 part of diethylhydroxylamine, 0.01 part of dibutyltin dilaurate catalyst, α, ω-dimethylpolydimethyl Add 2 parts of siloxane ...

Embodiment 2

[0049] Put 100 parts of α, ω-dihydroxy polydimethylsiloxane and 15 parts of hexamethyldisilazane into the vacuum kneader, after mixing thoroughly, add 150 parts of precipitated white carbon black, knead at room temperature for 4 hours, and then Kneading and blending for 200 minutes at a temperature of 150°C and a vacuum of 0.099Mpa to obtain a silicone-based rubber;

[0050] 100 parts of α, ω-dihydroxy polydimethylsiloxane, 20 parts of silicone-based glue, 40 parts of silicon powder, 10 parts of calcium carbonate, 10 parts of α, ω-dimethyl polydimethylsiloxane , 10 parts of polydimethylsiloxane with a hydroxyl group at one end and a methyl group at the other end were added to a blender, added to the blender, and stirred for 30 minutes under a vacuum degree of 0.08mpa to obtain component A. Mixture of tetraethoxysilane and tetraethoxysilane hydrolyzate 5 parts, mixture of γ-aminopropyltriethoxysilane and γ-(2,3-glycidoxy)propyltrimethoxysilane 1 Parts, 0.3 parts of diisopropox...

Embodiment 3

[0052] Put 100 parts of α, ω-dihydroxy polydimethylsiloxane and 10 parts of tetramethylammonium siloxanol and dimethyldiethoxysilane into the vacuum kneader, after mixing thoroughly, add 100 parts Precipitate white carbon black, knead at room temperature for 3 hours, then knead and blend at a temperature of 120° C. and a vacuum of 0.08 Mpa for 30 to 200 minutes to obtain a silicone-based rubber.

[0053] 100 parts of α, ω-dihydroxy polydimethylsiloxane, 10 parts of silicone-based glue, 30 parts of aluminum oxide, 15 parts of α, ω-dimethyl polydimethylsiloxane, one end is Add 15 parts of polydimethylsiloxane with a methyl group at one end of the hydroxyl group into the mixer, add it into the mixer, and stir for 30 minutes under a vacuum degree of 0.099mpa to obtain component A. 10 parts of a mixture of tetraethoxysilane and tetraethoxysilane hydrolyzate, a mixture of γ-aminopropyltriethoxysilane and γ-(2,3-glycidoxy)propyltrimethoxysilane 3 Parts, 0.1 part of diisopropoxytitan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com