Patents

Literature

640results about How to "Avoid delamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

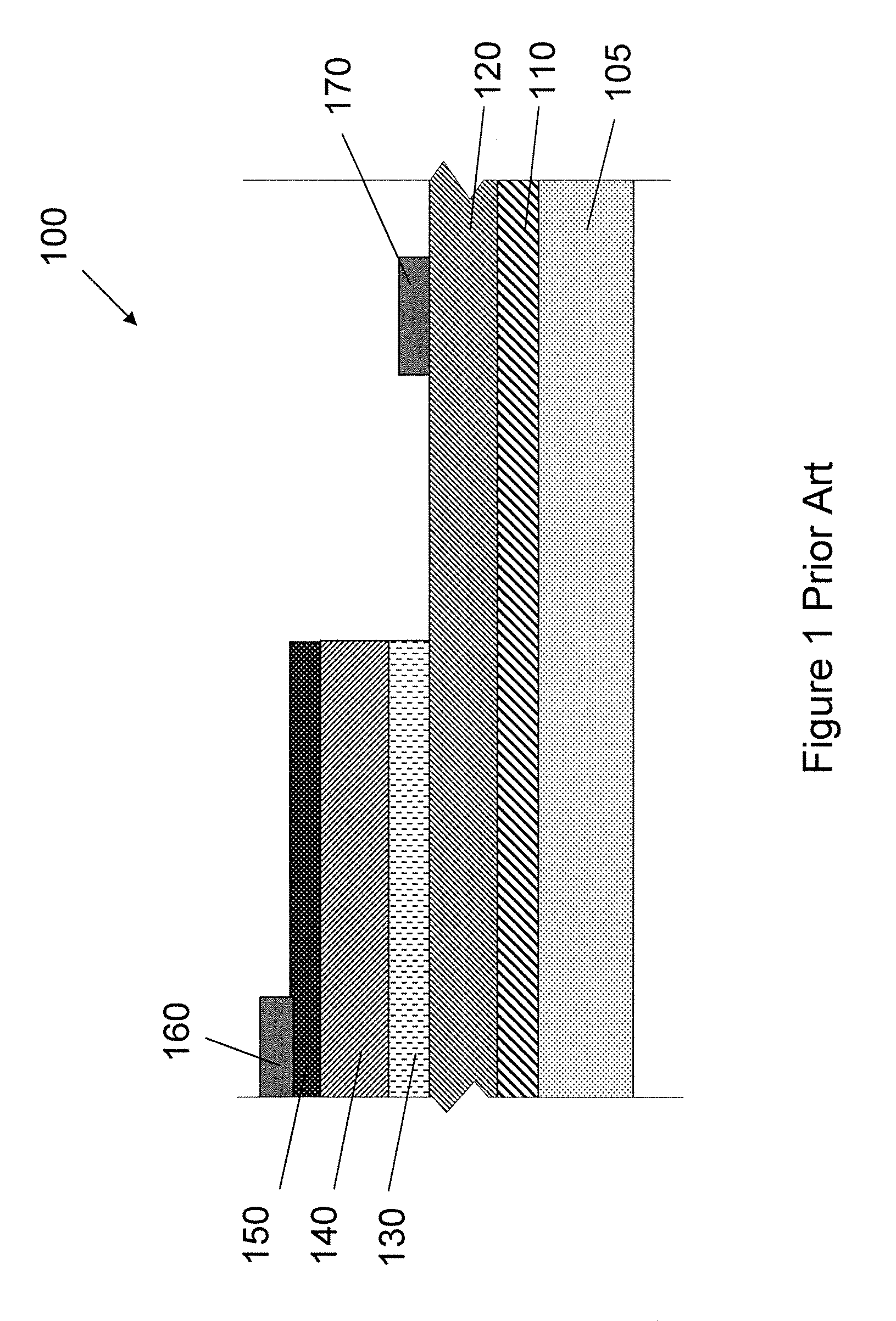

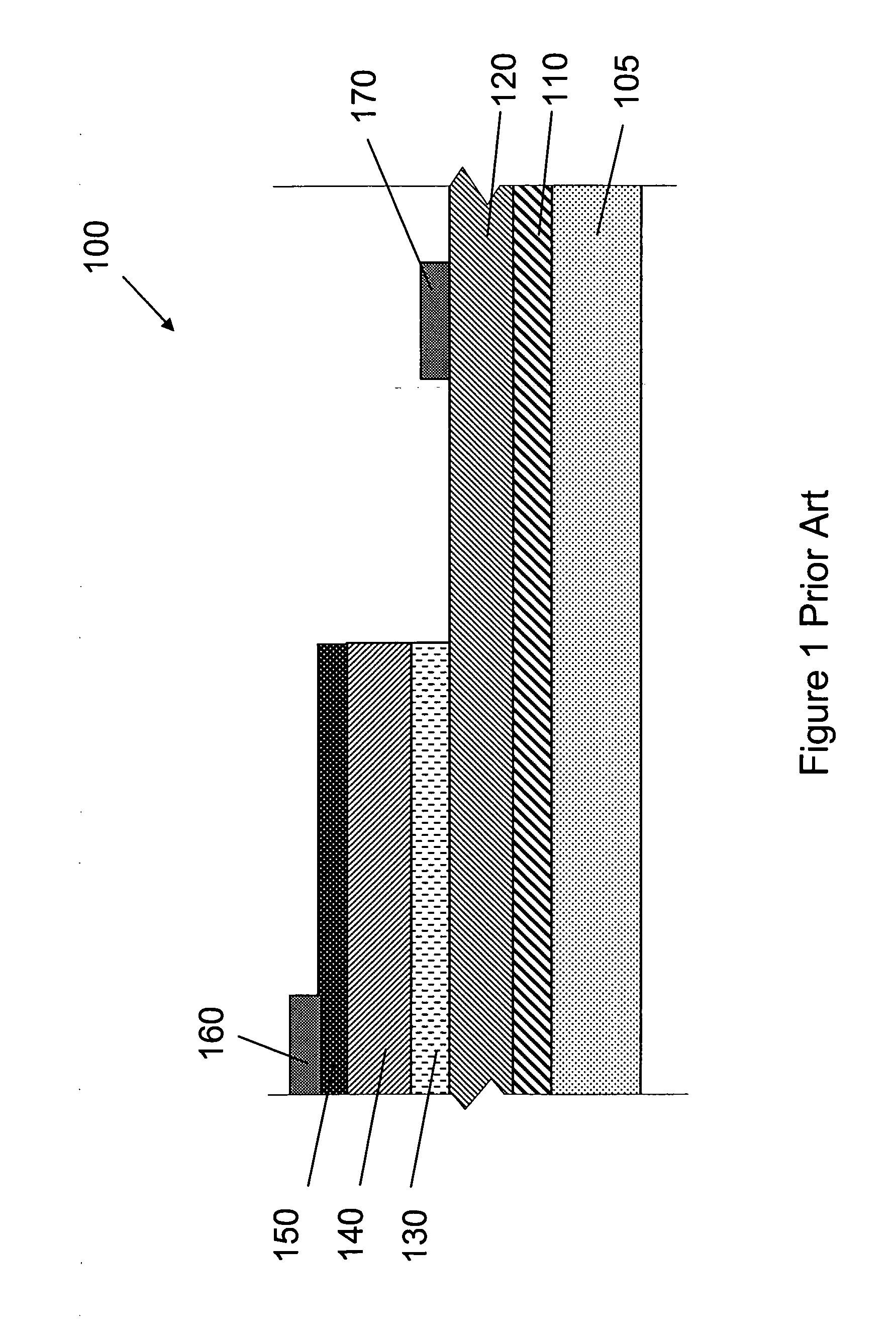

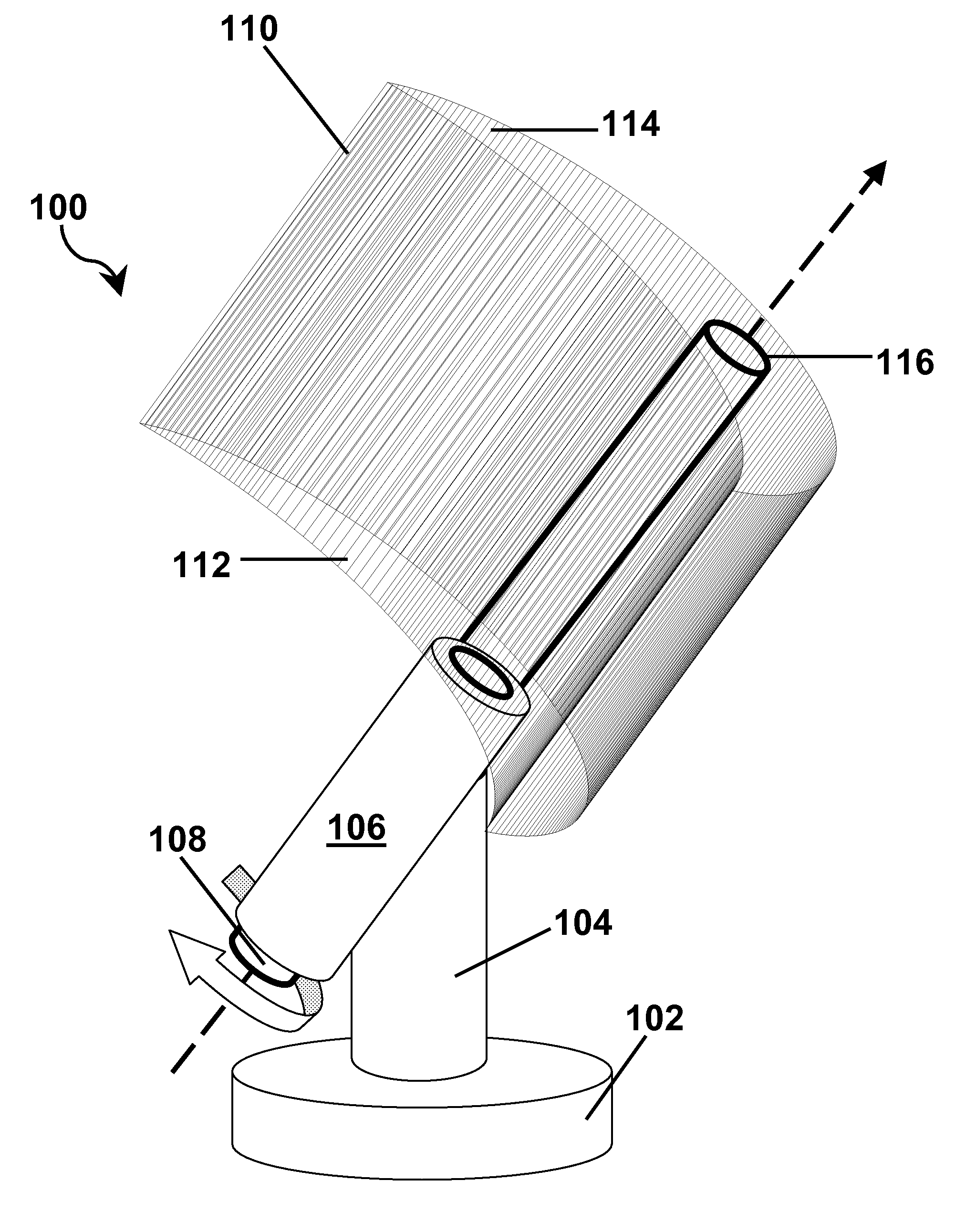

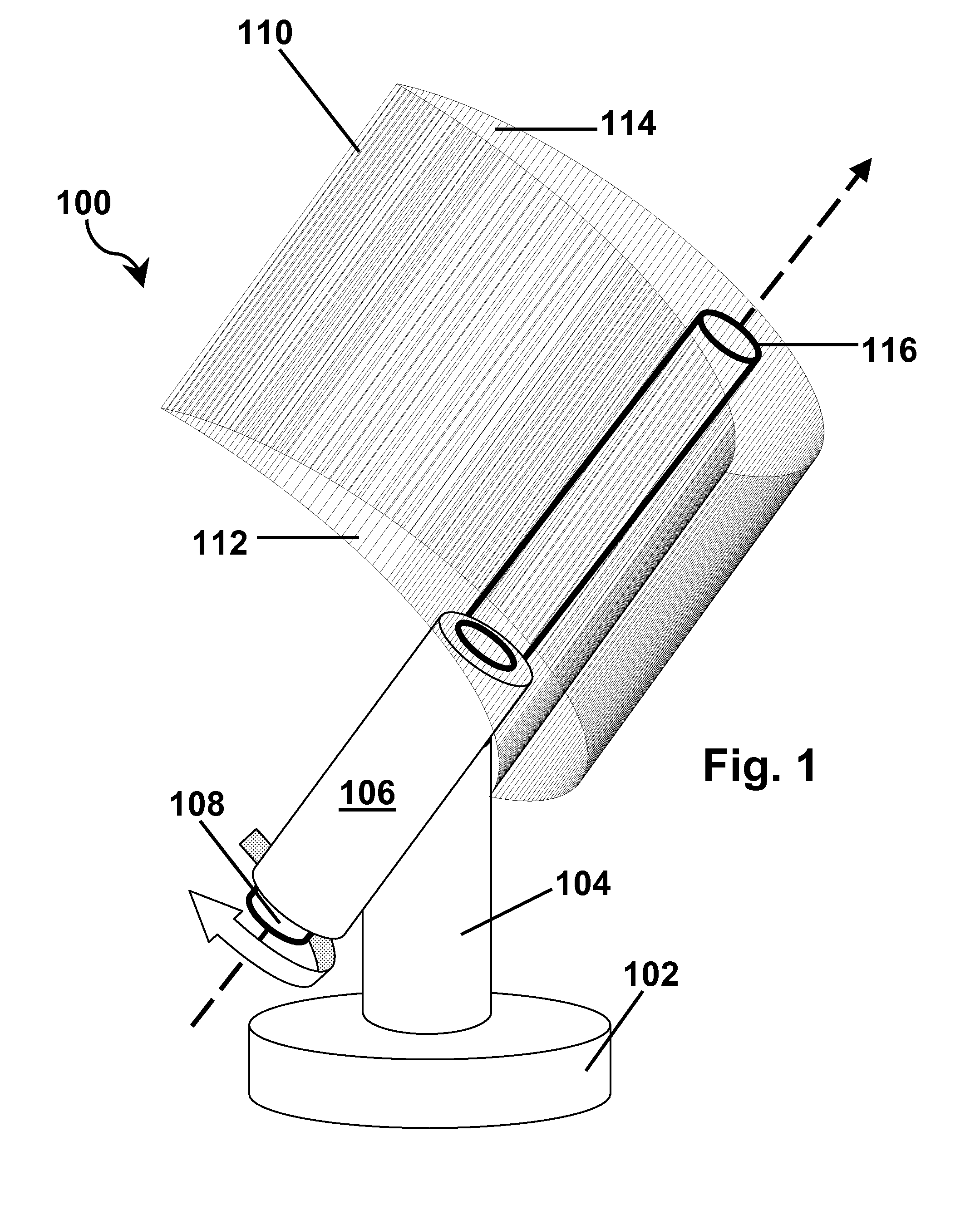

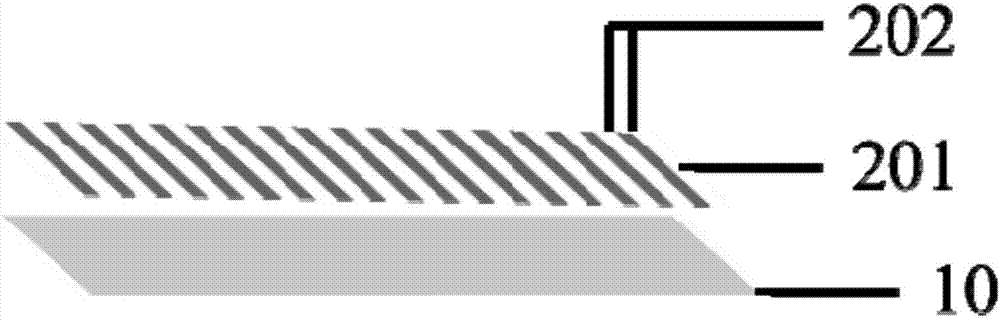

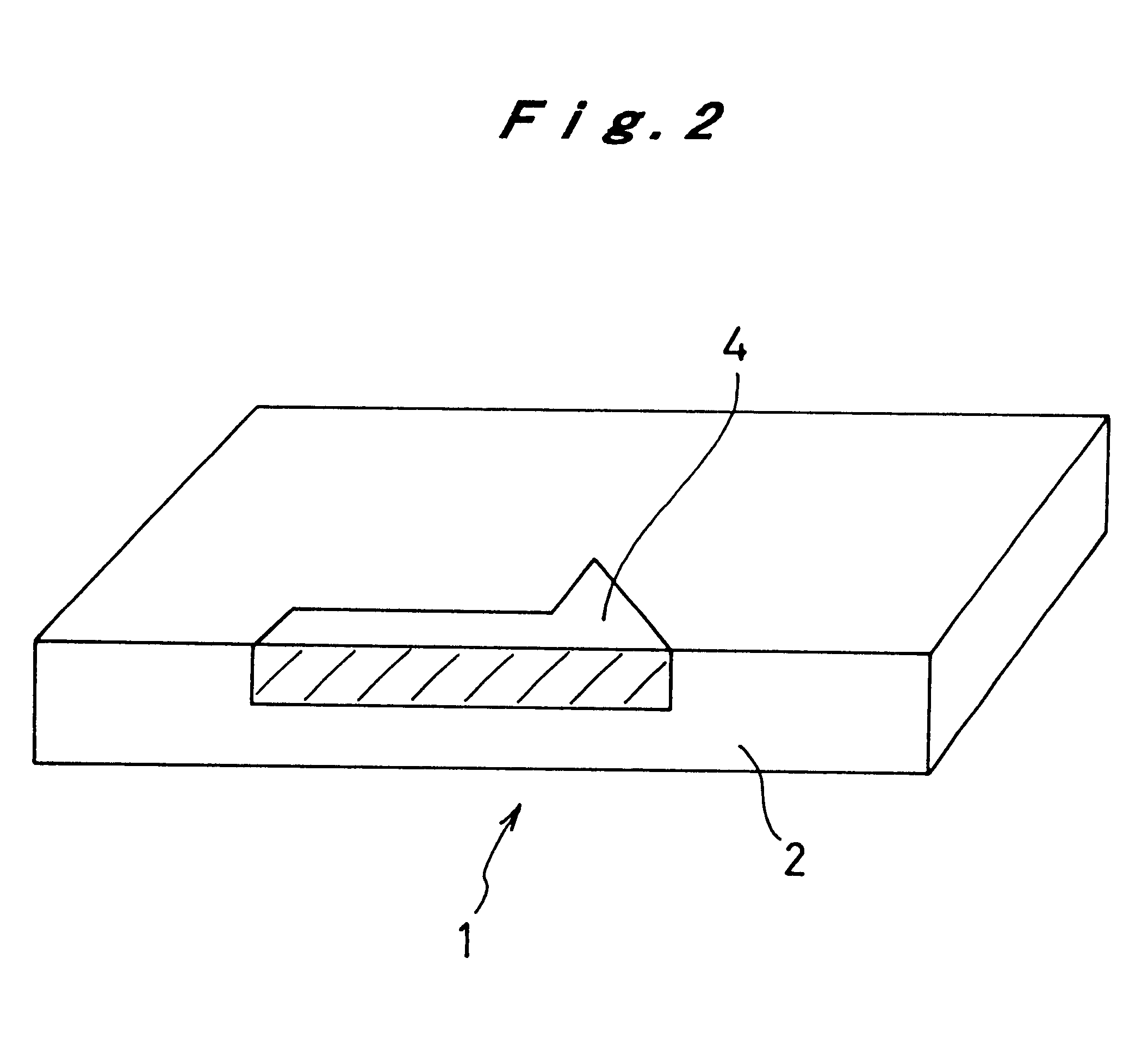

Light emitting device

InactiveUS20090032799A1High luminous intensityLarge luminous surfaceSemiconductor/solid-state device manufacturingSemiconductor devicesLight emitting deviceLight emission

A light emitting device includes a substrate having a first surface and a second surface not parallel to the first surface, and a light emission layer disposed over the second surface to emit light. The light emission layer has a light emission surface which is not parallel to the first surface.

Owner:SIPHOTON

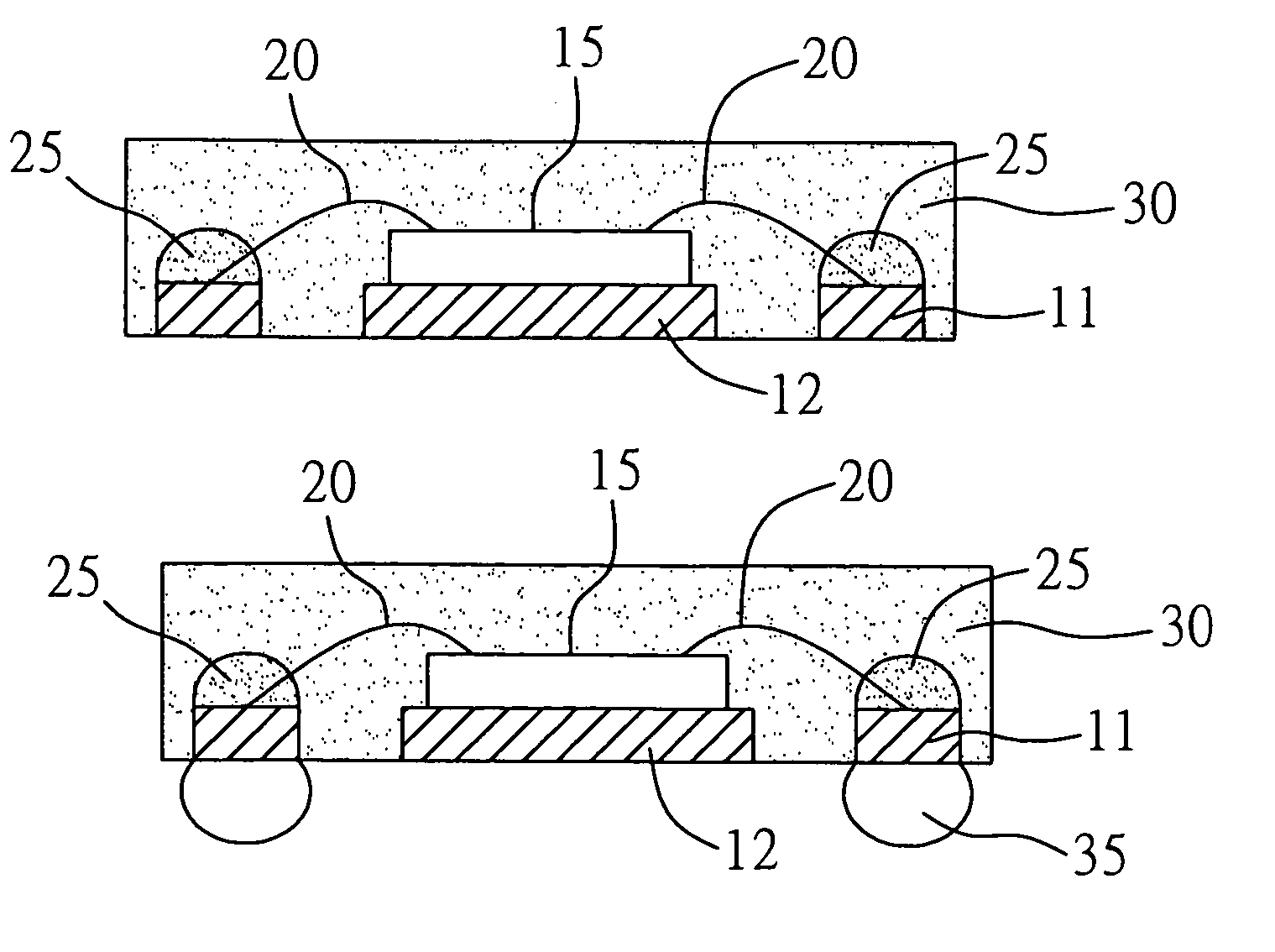

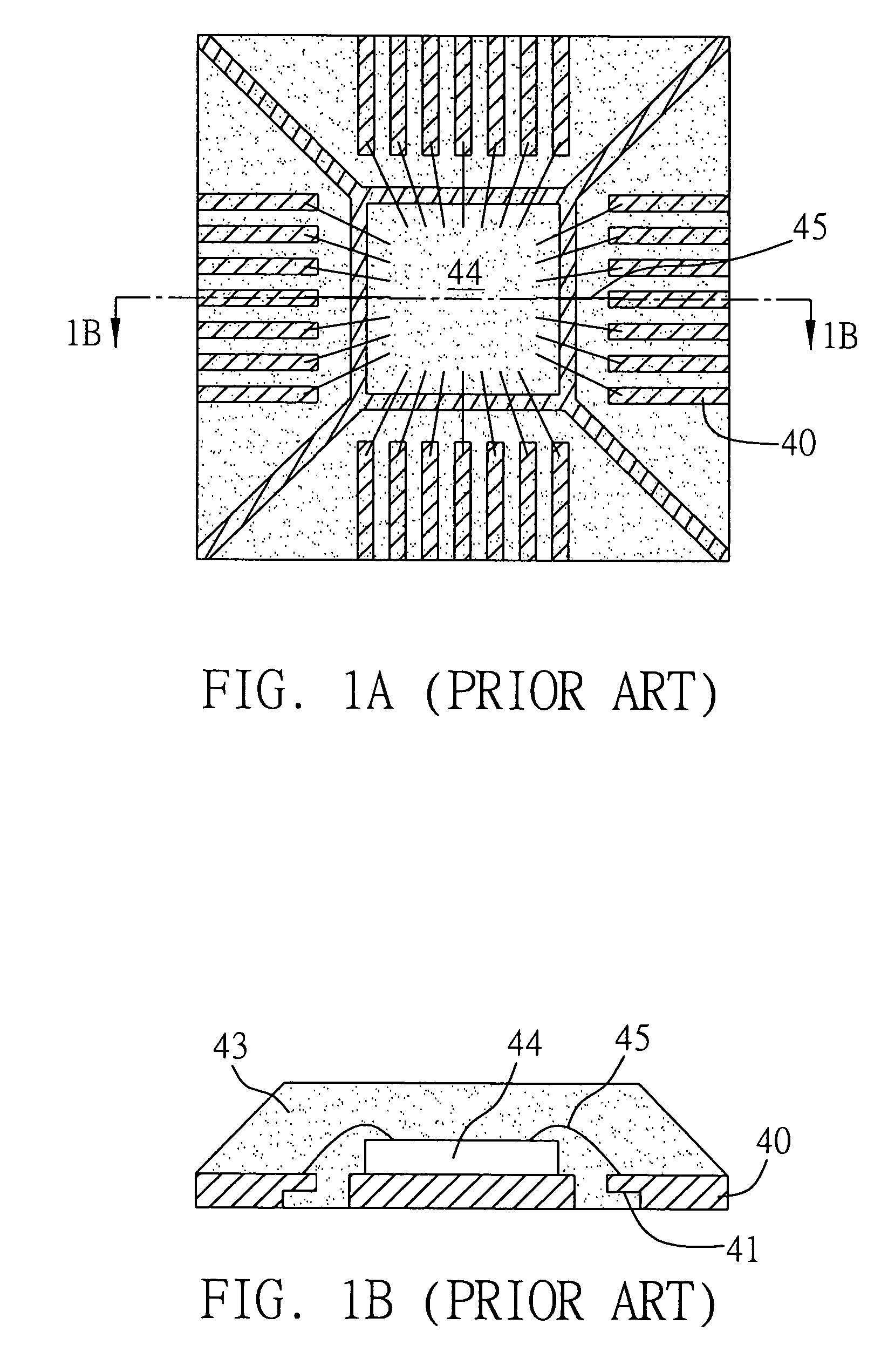

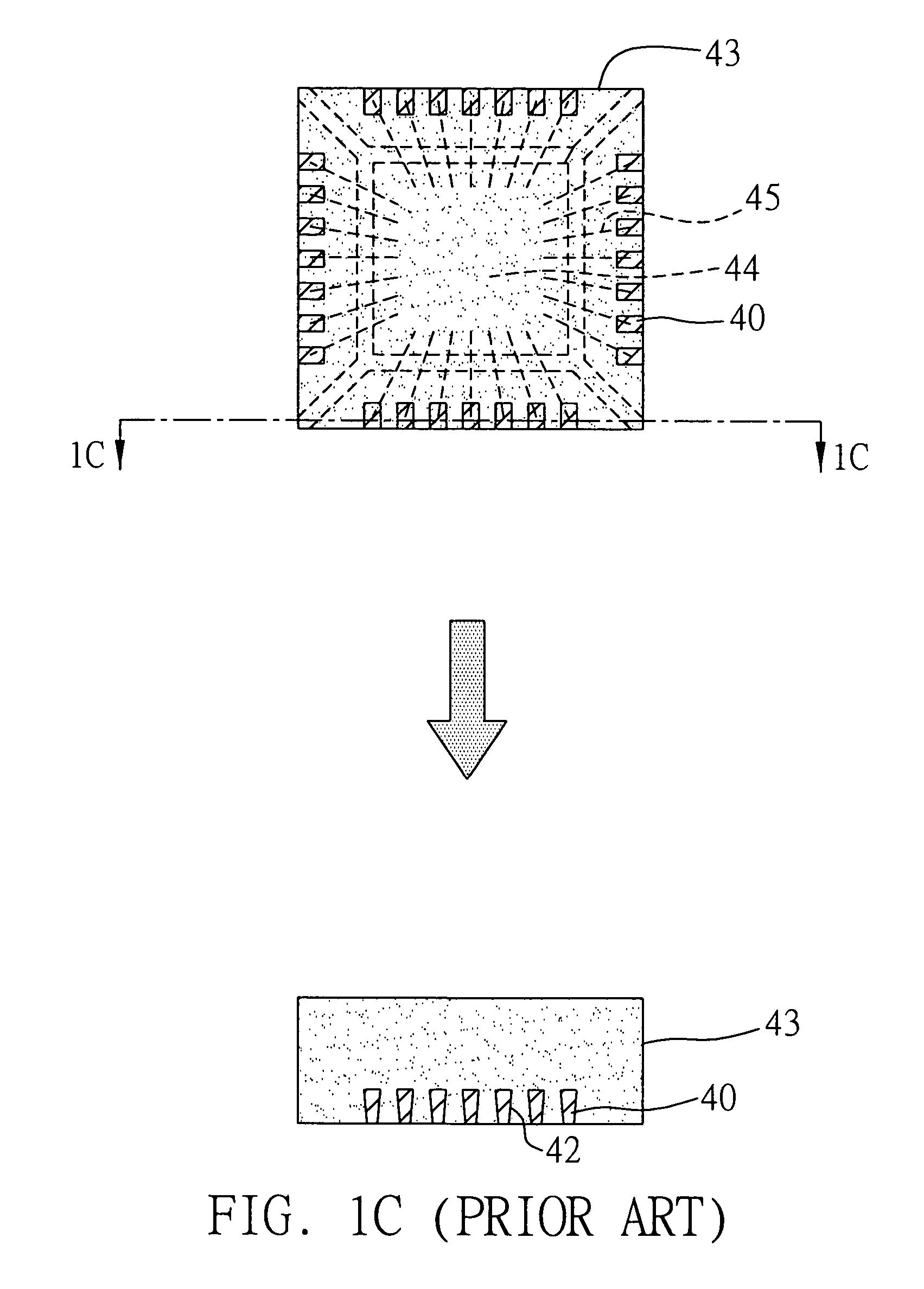

Carrier-free semiconductor package and fabrication method thereof

InactiveUS7314820B2Improve bond strengthAvoid delaminationSemiconductor/solid-state device detailsSolid-state devicesSealantCoating

A carrier-free semiconductor package and a fabrication method thereof are provided. The fabrication method includes the steps of: providing a carrier having a plurality of electrical contacts formed thereon; mounting at least one chip on the carrier; electrically connecting the chip to the electrical contacts via a plurality of bonding wires; forming a coating layer on each of the electrical contacts to encapsulate a bonded end of each of the bonding wires on the electrical contacts; performing a molding process to form an encapsulant for encapsulating the chip, the bonding wires and the electrical contacts; and removing the carrier, such that bottom surfaces of the electrical contacts are exposed from the encapsulant. This obtains a semiconductor package not having a carrier, and the coating layers can enhance adhesion between the electrical contacts and the encapsulant.

Owner:SILICONWARE PRECISION IND CO LTD

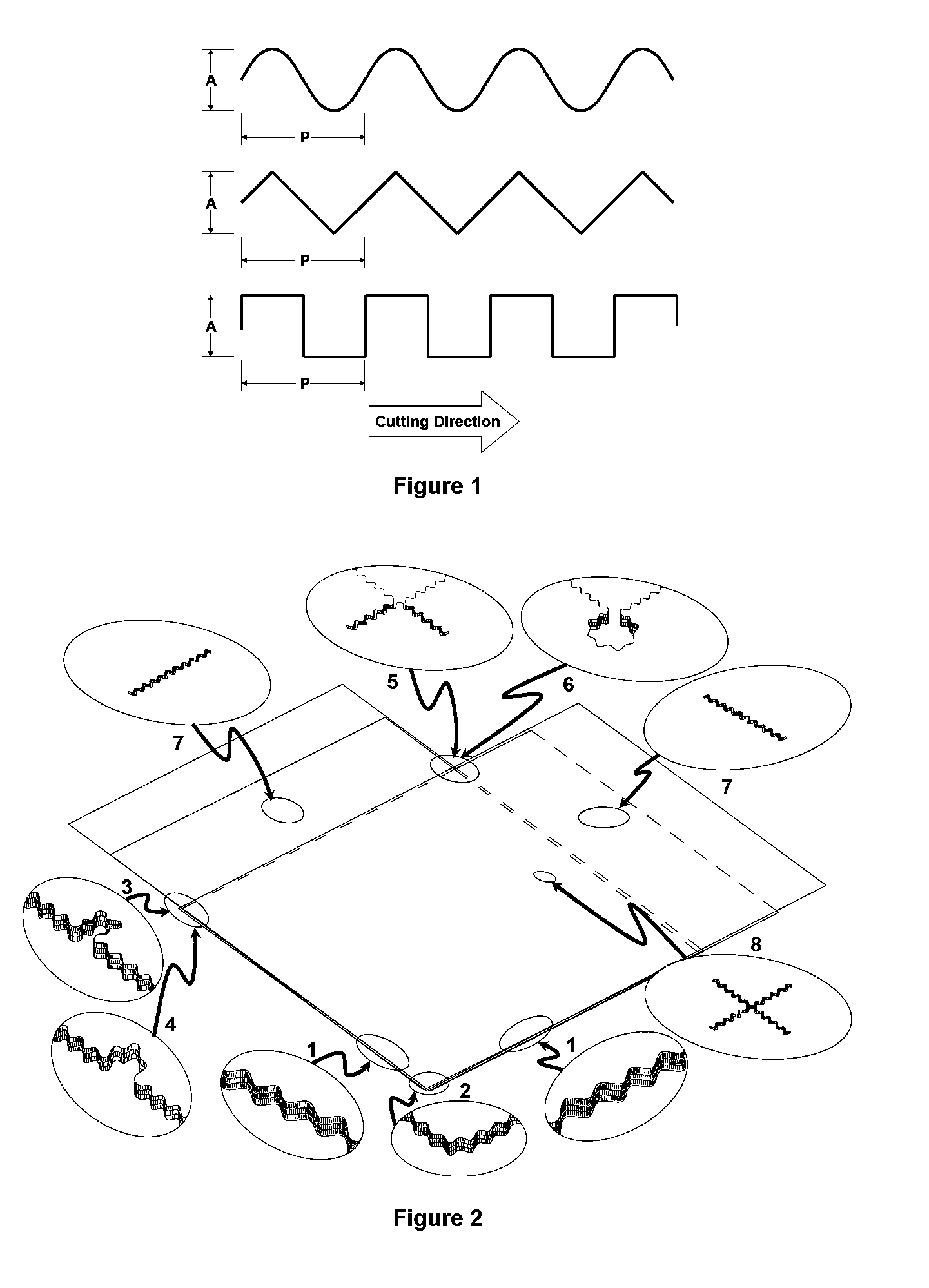

Composite cutting with optical ablation technique

InactiveUS20050077275A1Avoid delaminationAvoid thermal effectsWelding/soldering/cutting articlesLaser beam welding apparatusAudio power amplifierAblation Techniques

The present invention relates to methods and systems for dynamically controlled laser amplifier configuration for composite cutting includes the steps of generating an initial wavelength-swept-with-time optical pulse in an optical pulse generator, amplifying the initial optical pulse, compressing the amplified optical pulse to a duration of less than 10 picoseconds and applying the compressed optical pulse on the composite with an ablating energy density, to controllably remove a slice of material from the composite.

Owner:RAYDIANCE

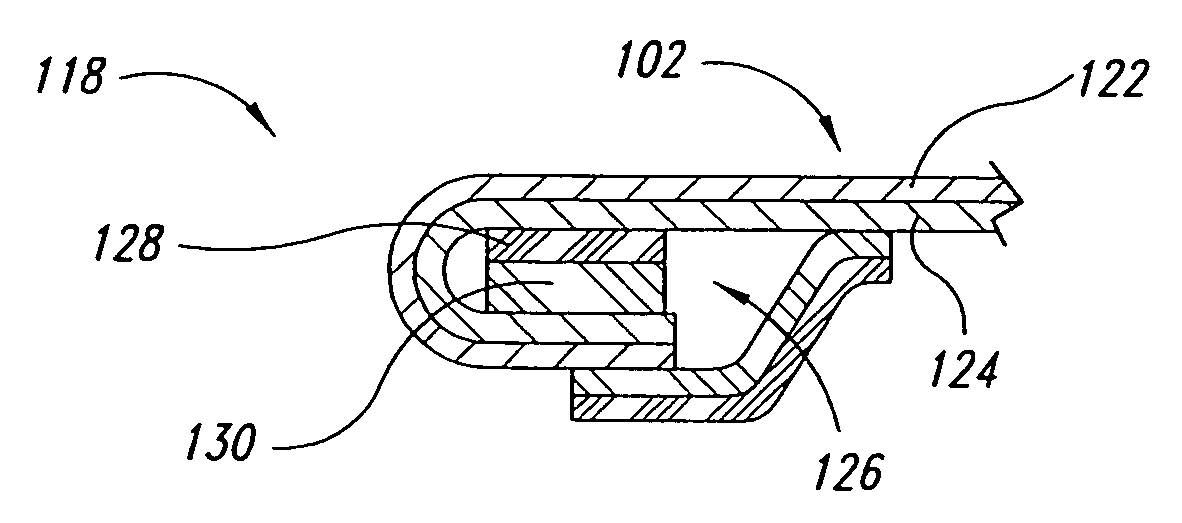

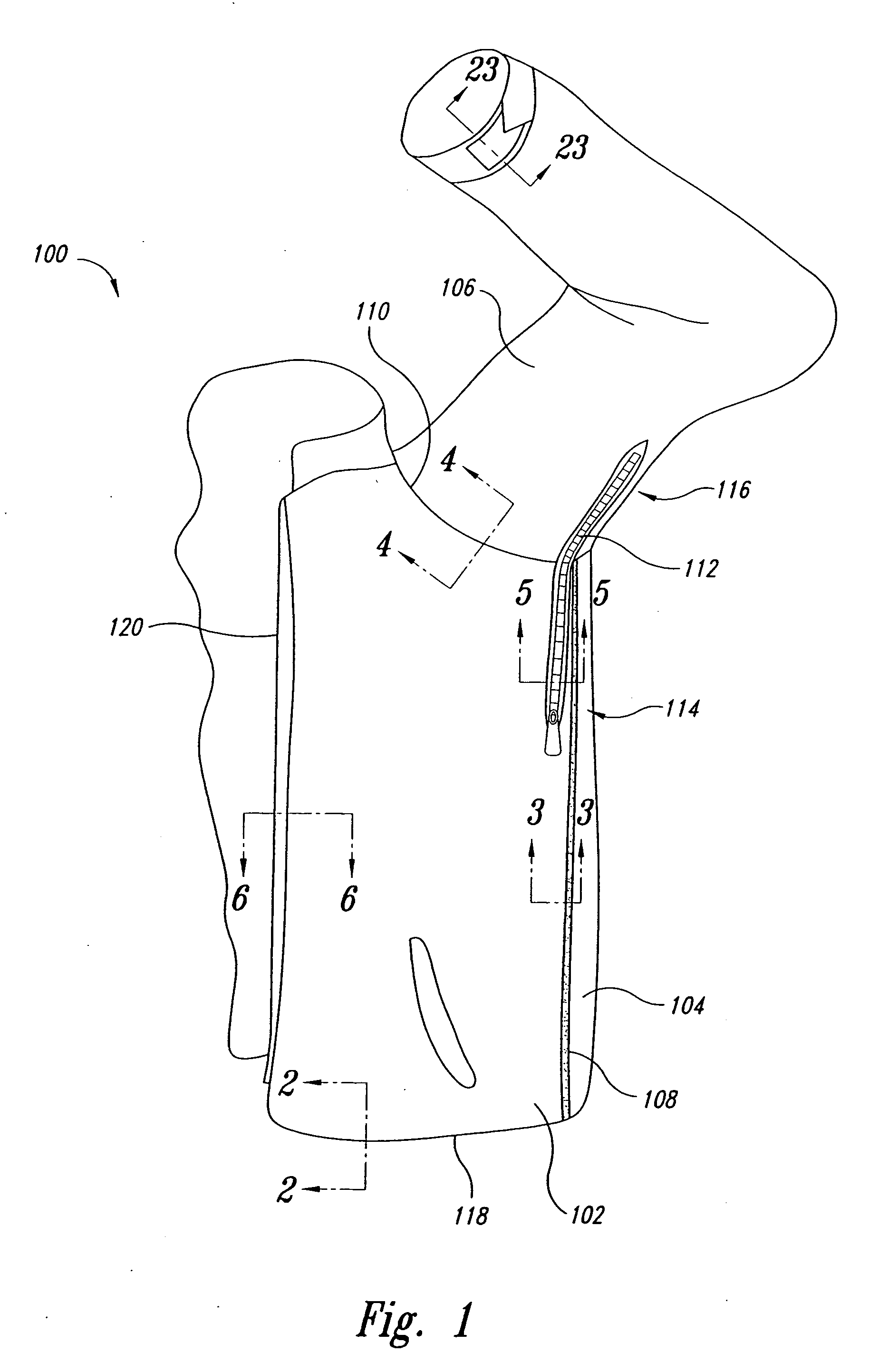

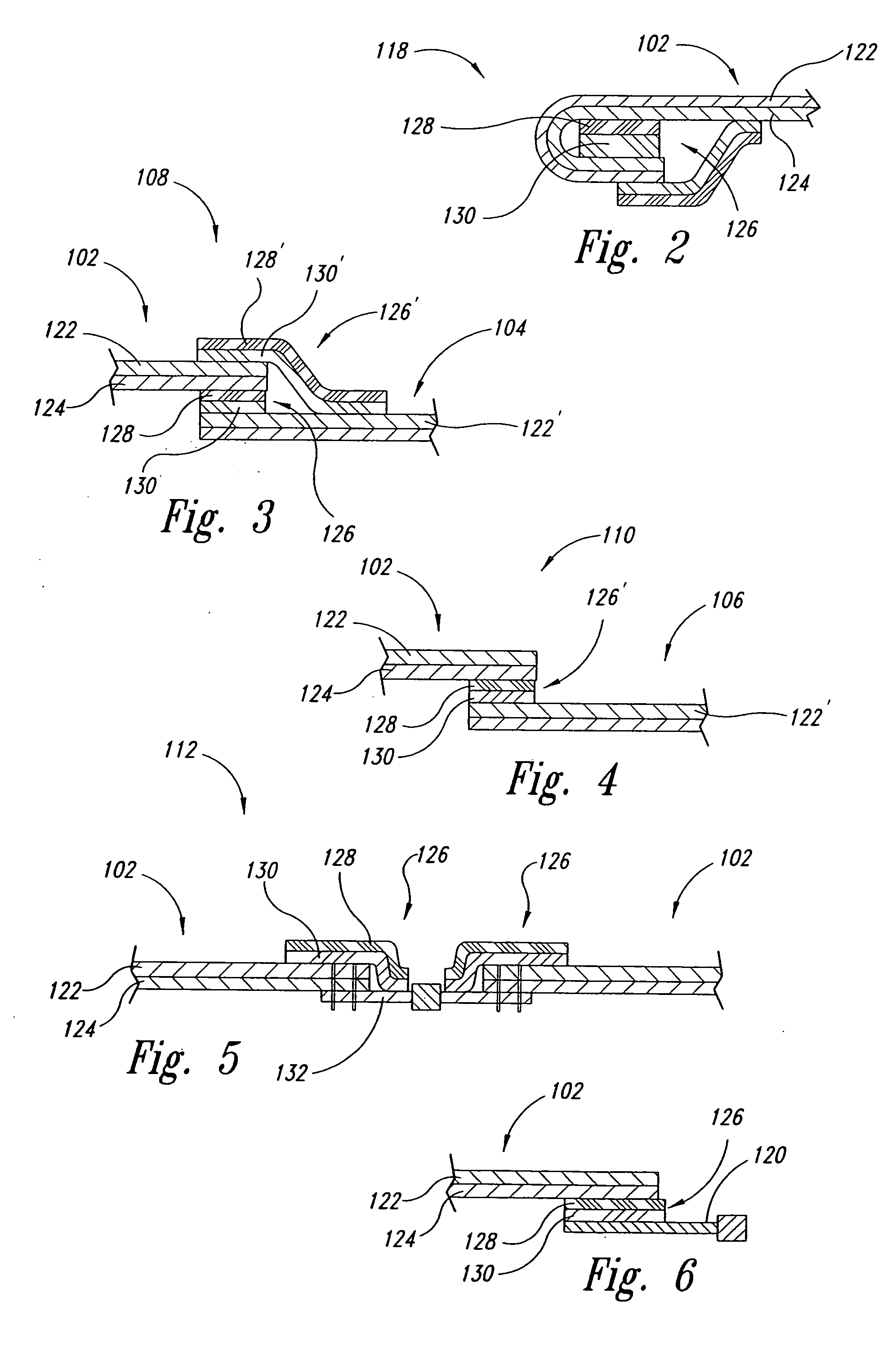

Hems, edges, patches and seams for durable, water repellant woven fabric, and methods for making the same

Edges, hems, patches and seams for woven fabric that has been treated for water repellency, and methods for making the same, are shown and described. In one particular embodiment of the invention, for example, a lapped seam between two pieces of water repellent fabric has an outer material at least partially overlapping an inner material, and a laminate strip positioned between the overlapping portions of the materials. The outer and inner materials, which are both oriented in the same direction, have an exterior layer of woven fabric that has been treated with water repellent and / or stain repellent chemicals, and an inner layer comprising a polymer membrane, such as polyurethane. The laminate strip has a bottom portion in contact with the outer layer of the inner material. The bottom portion has a low melt point, high flow rate adhesive system of one or more layers that penetrates and surrounds the fibers in the woven fiber of the outer layer of the inner piece of material. The laminate strip also has a top layer in contact with the inner layer of the outer piece of material. The top layer of the laminate is a thin, elastic, highly abrasion resistant material with a strong bonding affinity for polyurethane. The layers of the laminate strip bond to the adjacent layers of the overlapped material to create a strong lap seam.

Owner:FOWLER

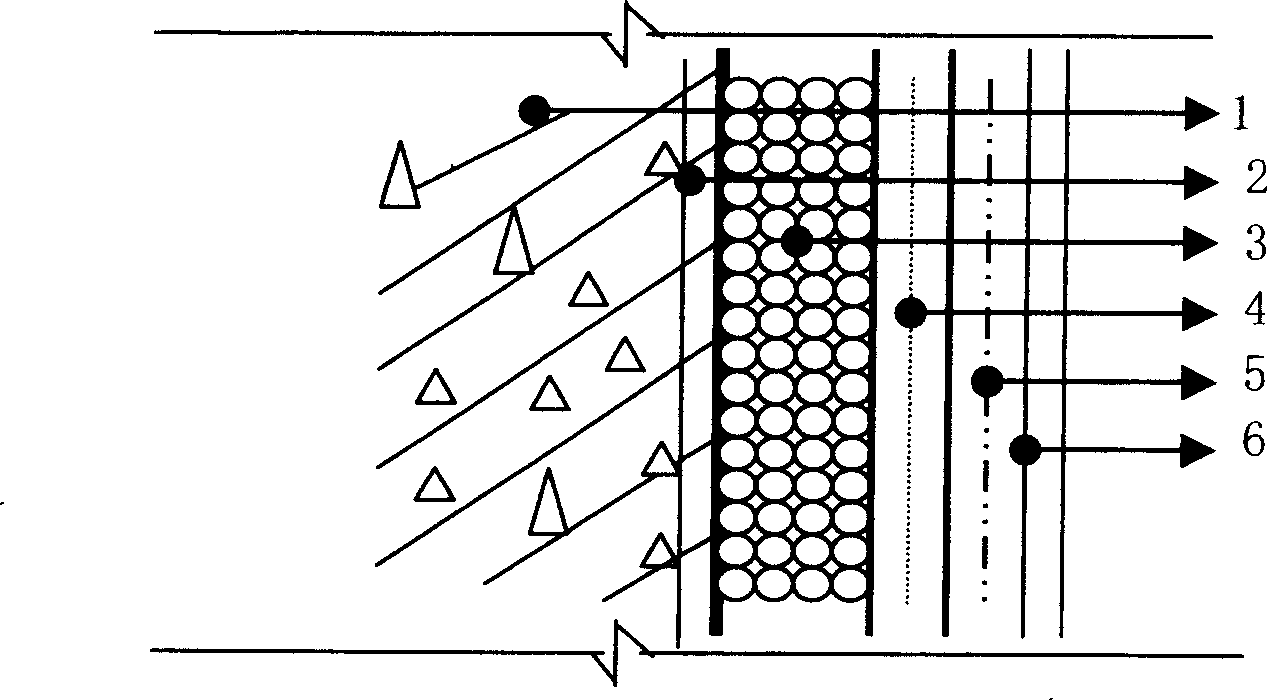

Polyurethane rigid foam material for external thermal insulation system of external wall

The invention provides a external thermal-insulated system material of polyurethane rigid foam, which is characterized in that: said system material comprises polyurethane dampproof bottom paint, polyurethane rigid foam material, surface agent, anti-break polymer cement sand pulp containing glass fiber grid cloth and a paint decorated surface. The invention can reach compatibility and balance between each layer of external thermal-insulated material to be an organic integration. The layers can flexibly release distortion stress to effectively reduce the generation of seams on said wall, and flatten the surface of polyurethane rigid foam, without concave-convex surface. And the layers have strong adhesive force, to avoid departure between them.

Owner:青岛金北洋工程材料有限公司

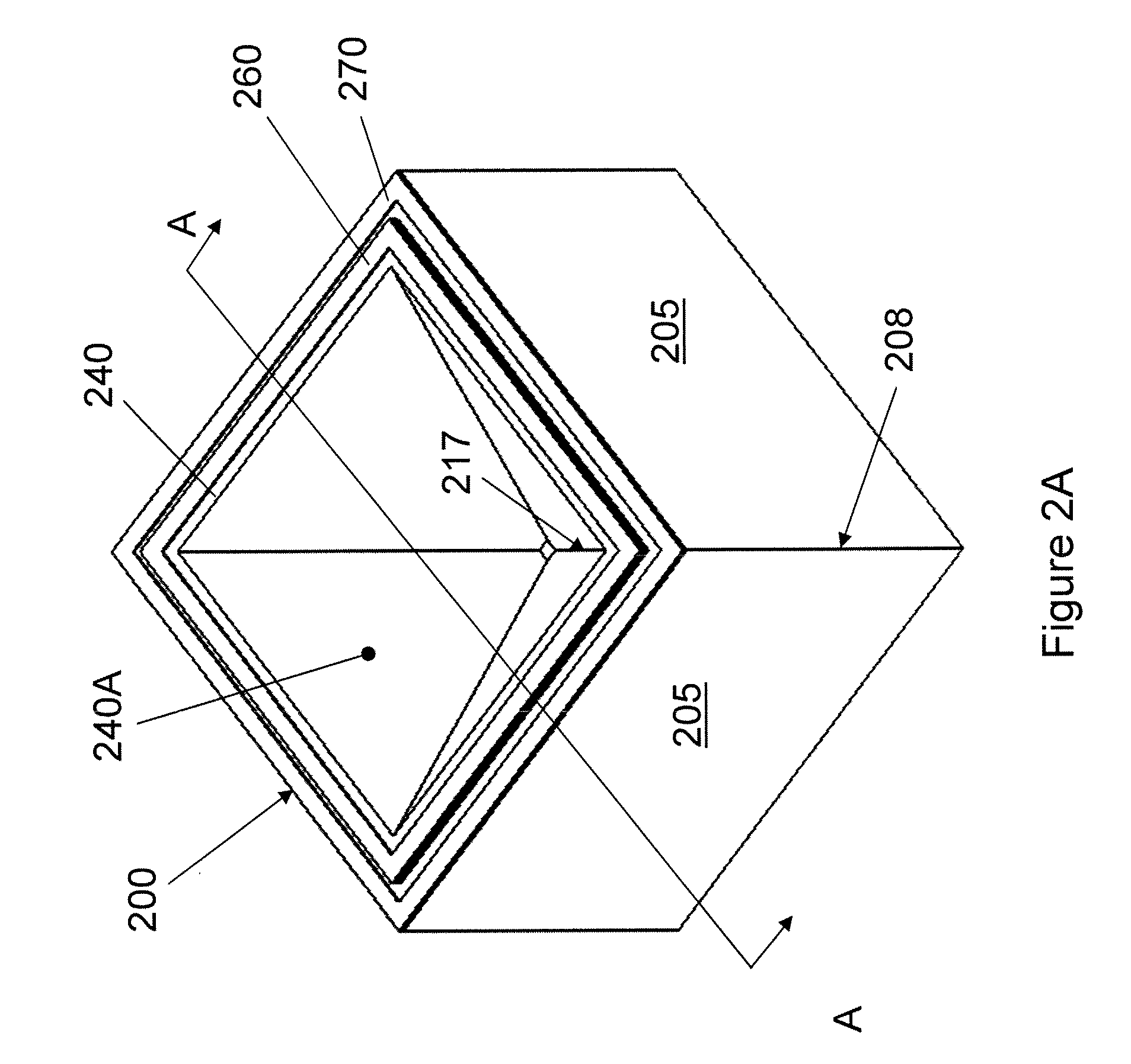

Light emitting device

InactiveUS20110114917A1High luminous intensityLarge luminous surfaceSolid-state devicesSemiconductor devicesLight emitting deviceLight emission

A light emitting device includes a substrate having a first surface and a second surface not parallel to the first surface, and a light emission layer disposed over the second surface to emit light. The light emission layer has a light emission surface which is not parallel to the first surface.

Owner:PAN SHAOHER X

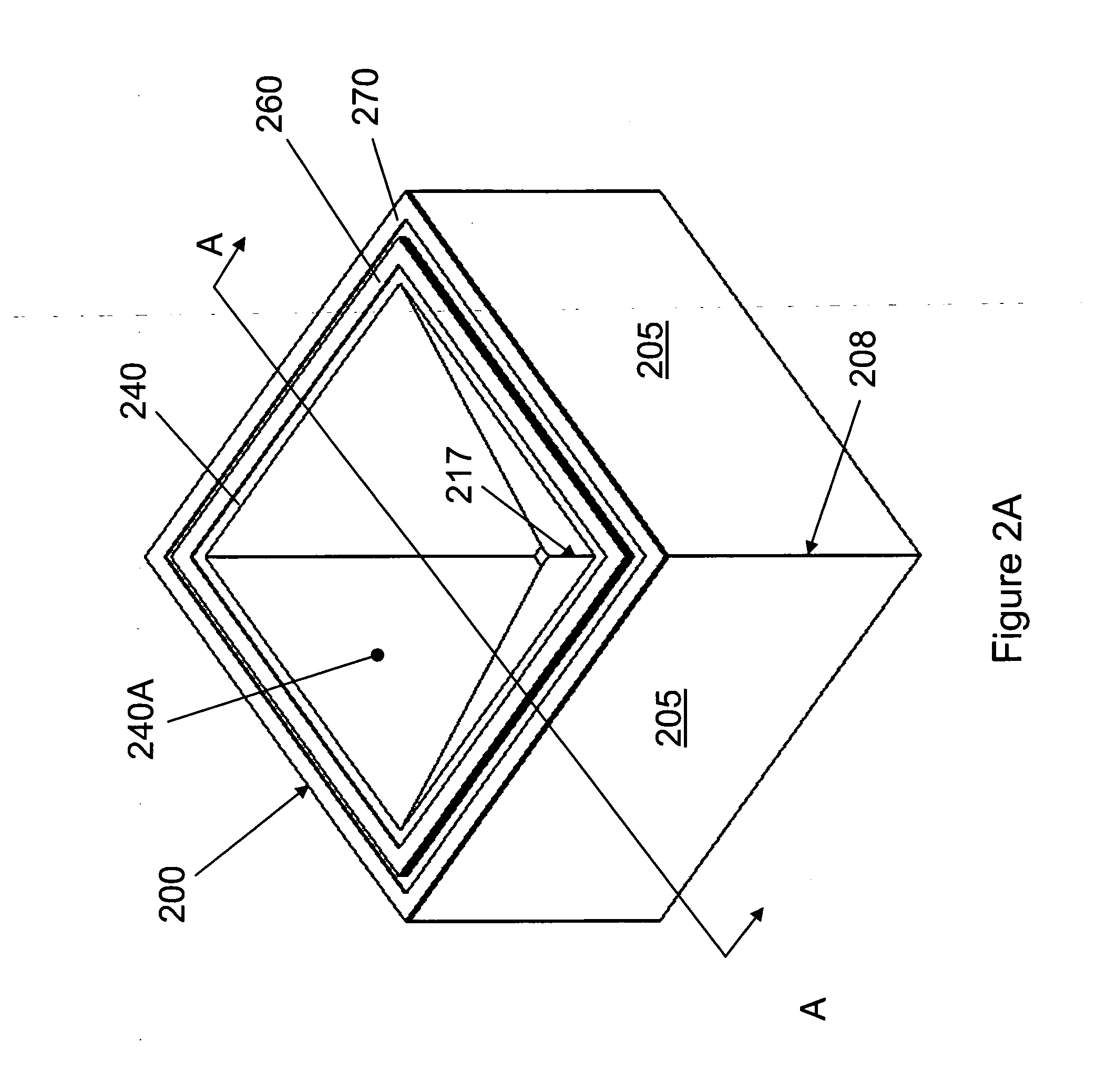

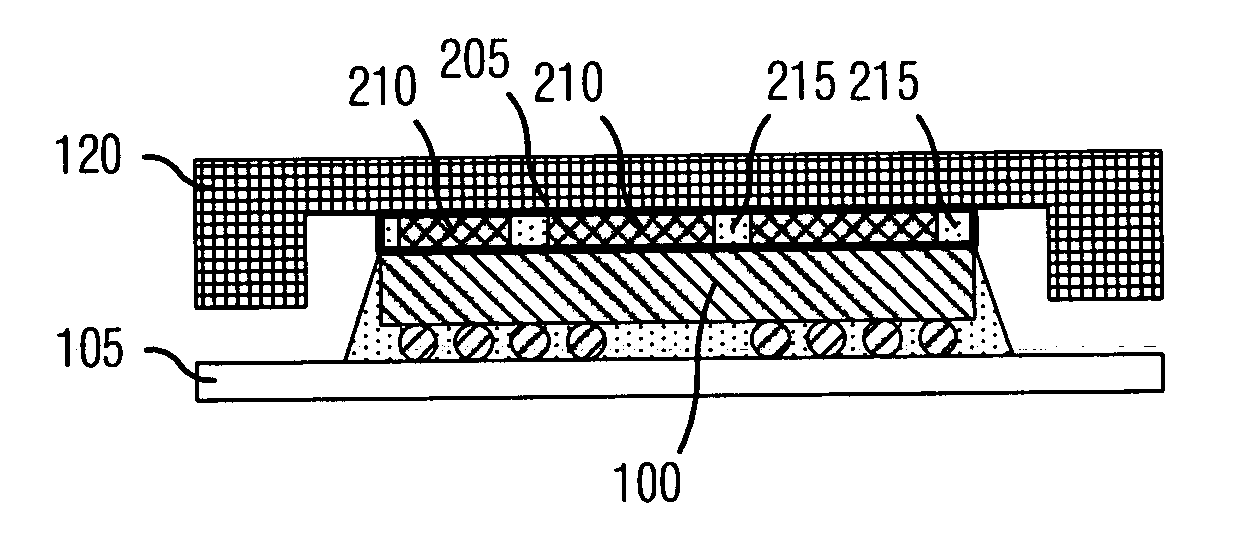

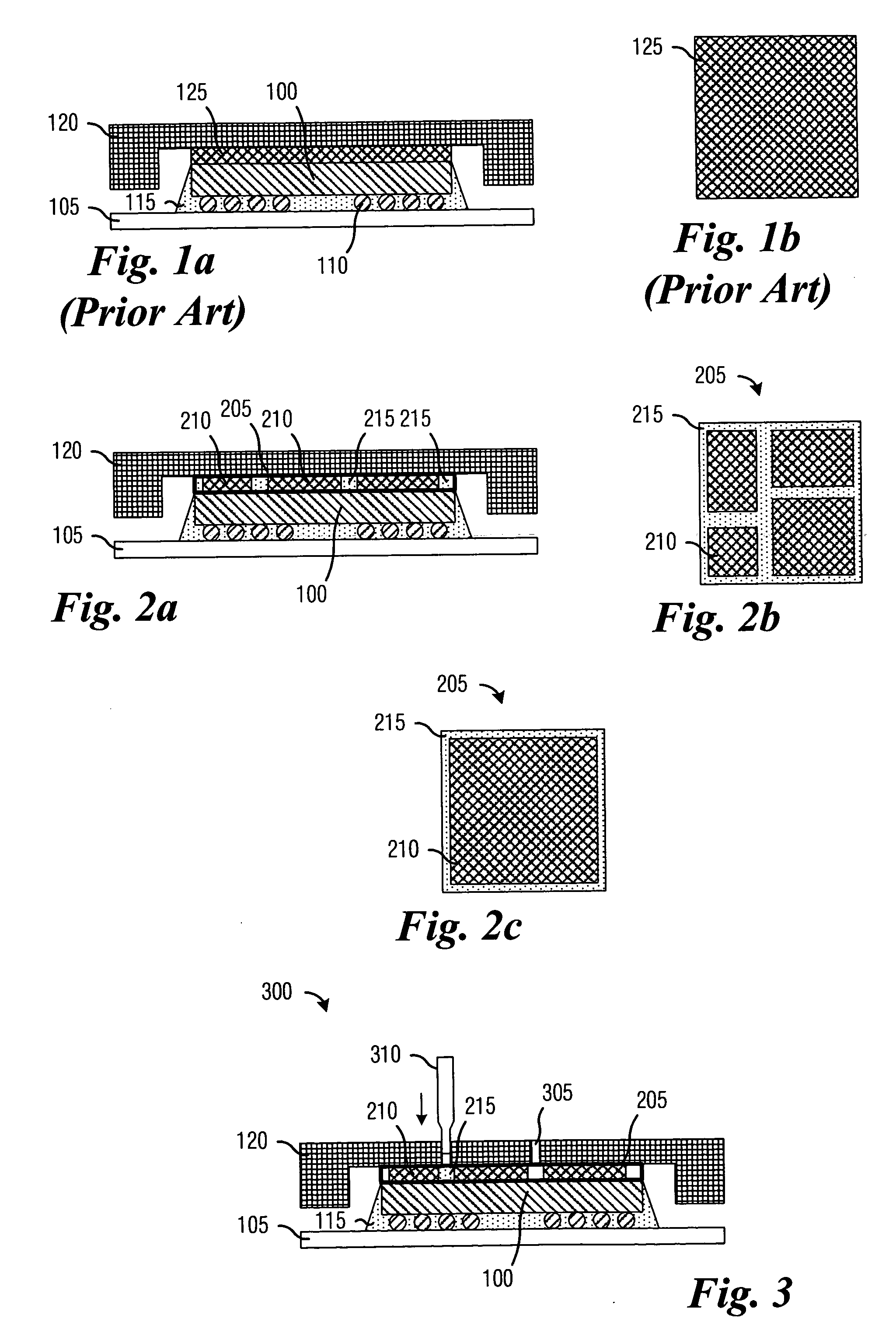

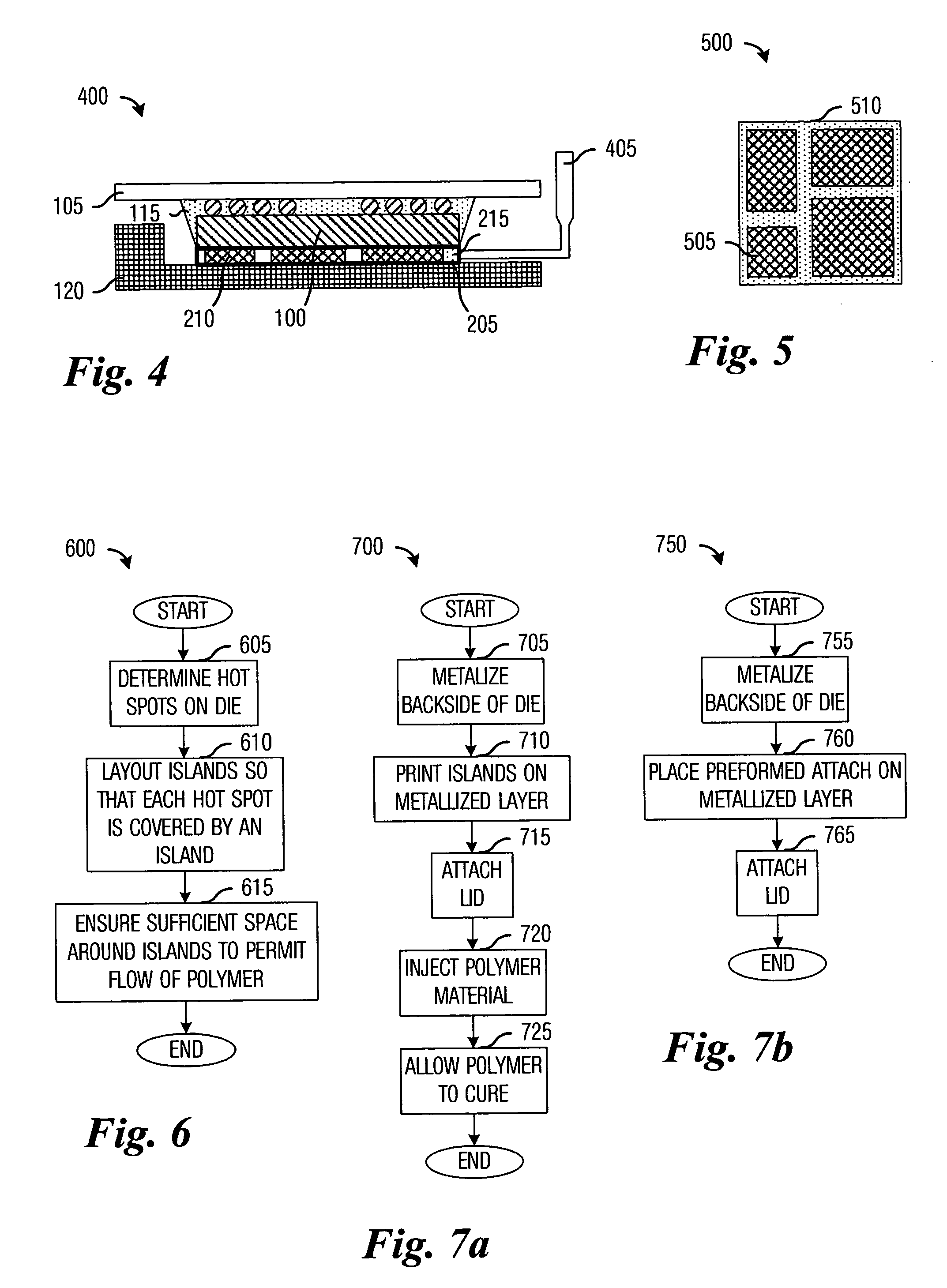

System and method for polymer encapsulated solder lid attach

InactiveUS20060270106A1Avoid delaminationAvoid separationSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceSealant

System and method for a polymer encapsulated solder lid attach. A preferred embodiment comprises one or more metallic islands distributed throughout the combination attach, wherein each metallic island overlays one or more heat producing portions of the integrated circuit die, and a polymer encapsulant to encircle each metallic island and to bind the one or more metallic islands in place. The one or more metallic islands, with their high thermal conductivity, can effectively dissipate large amounts of heat, while the polymer encapsulant binds the one or more metallic islands in place, preventing (or reducing) movement occurring during thermal cycles that can lead to delamination and separation.

Owner:TEXAS INSTR INC

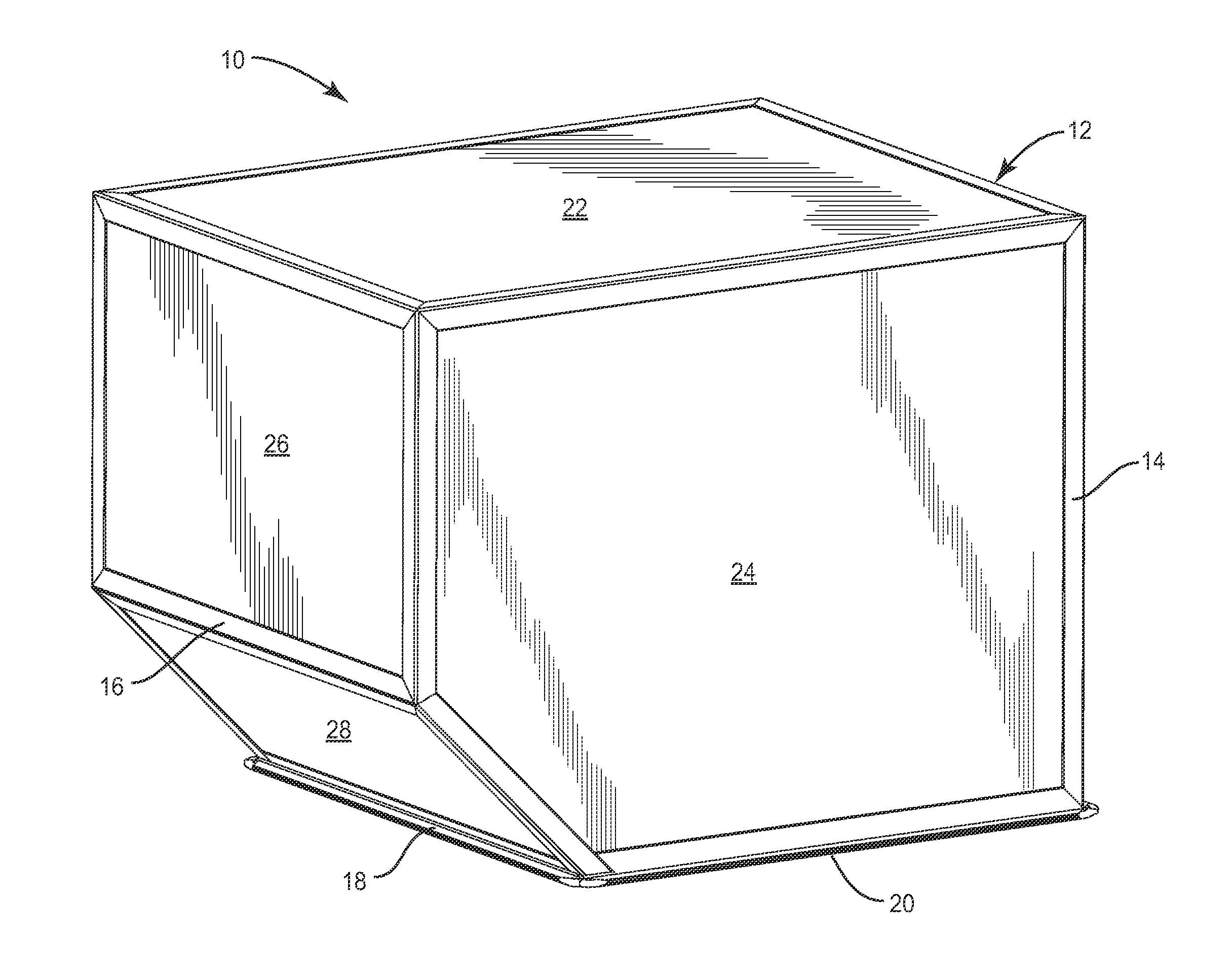

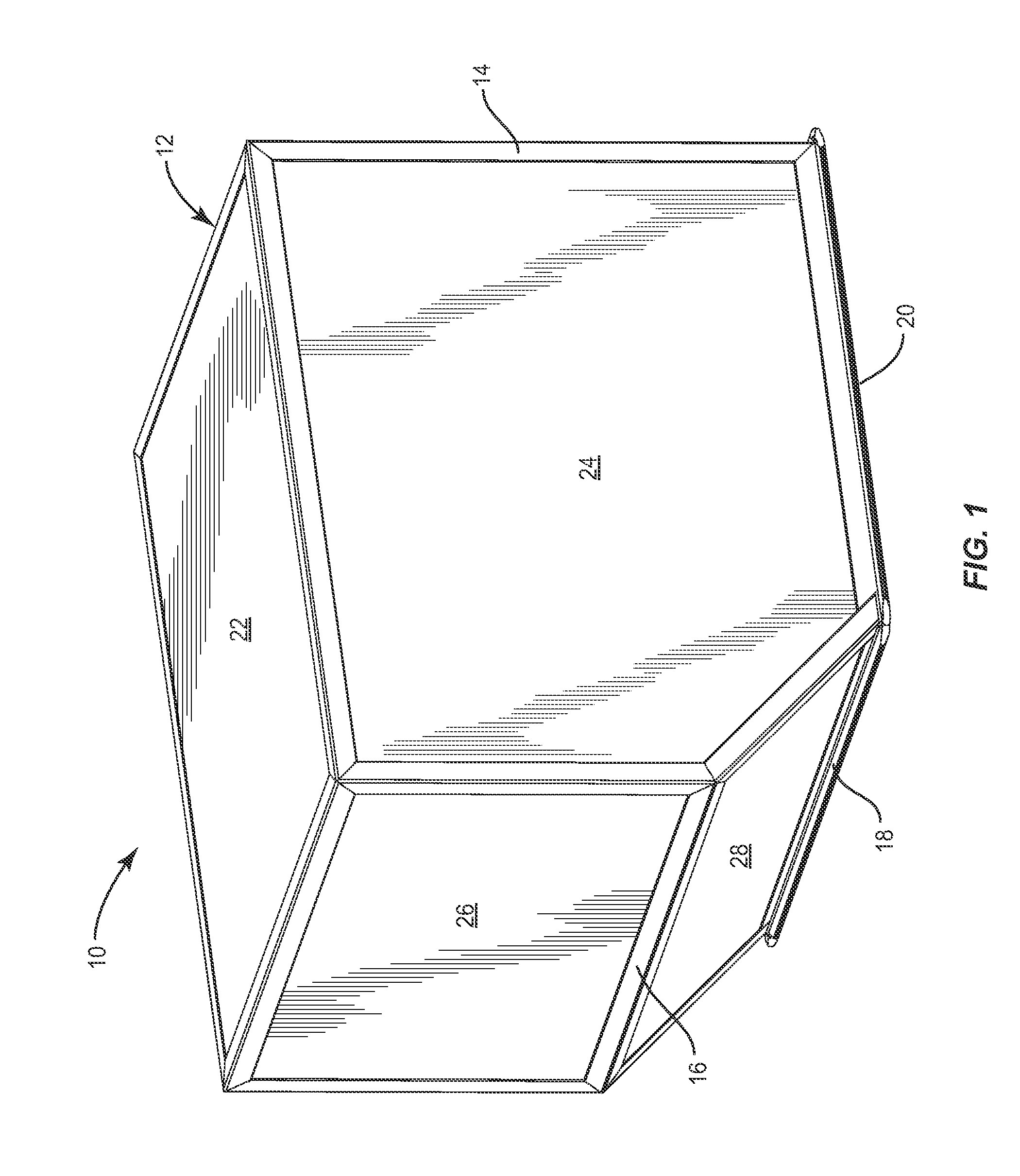

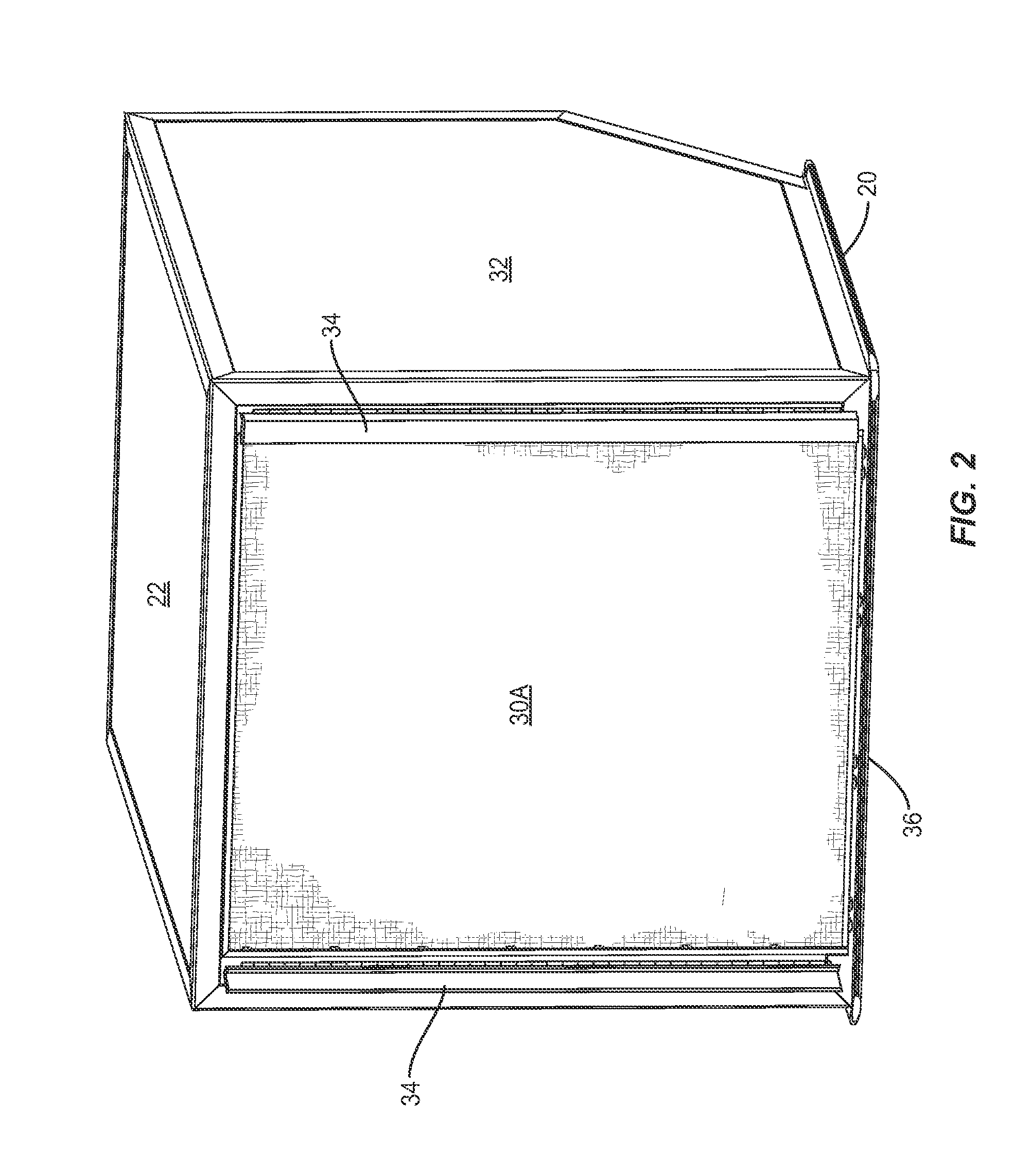

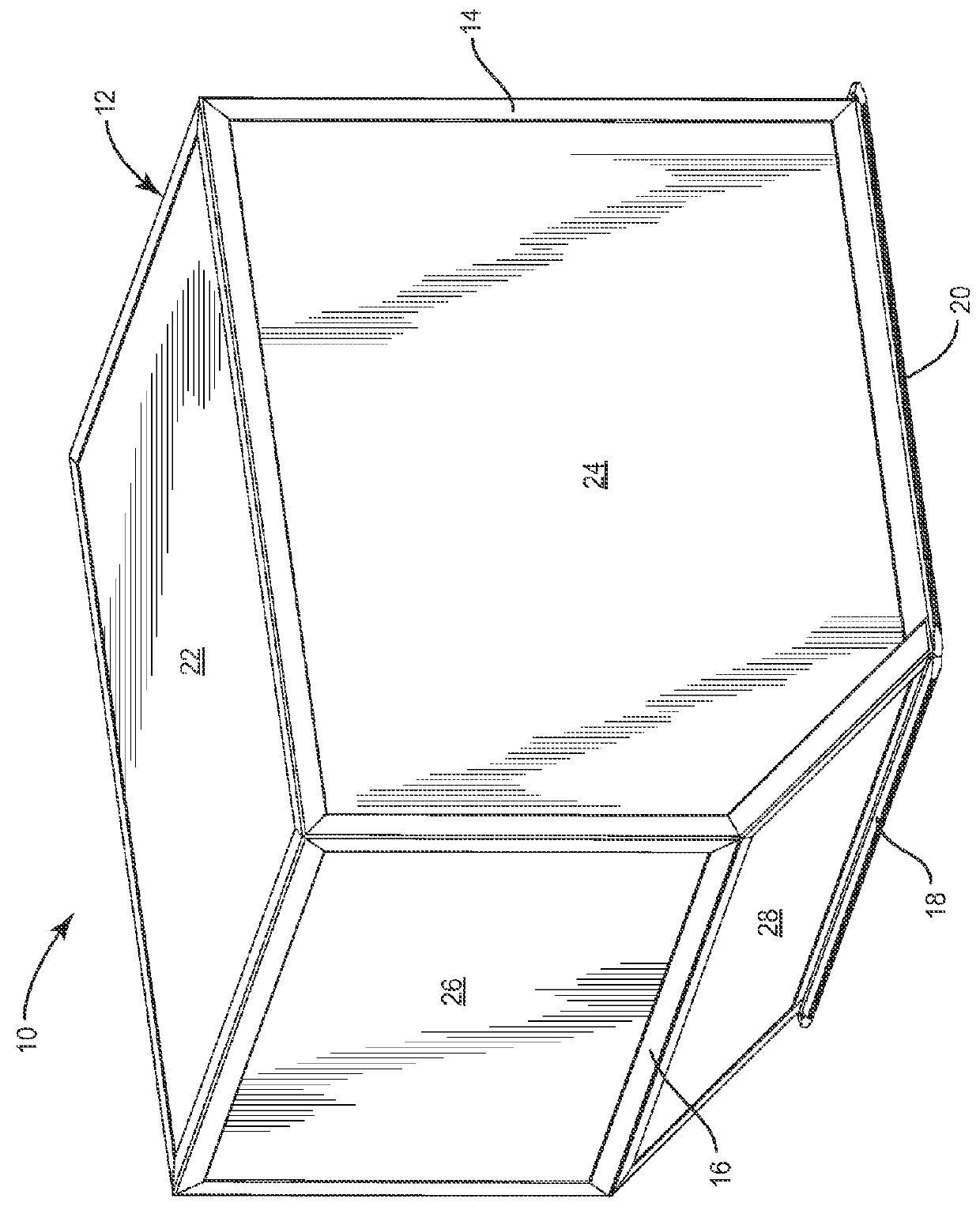

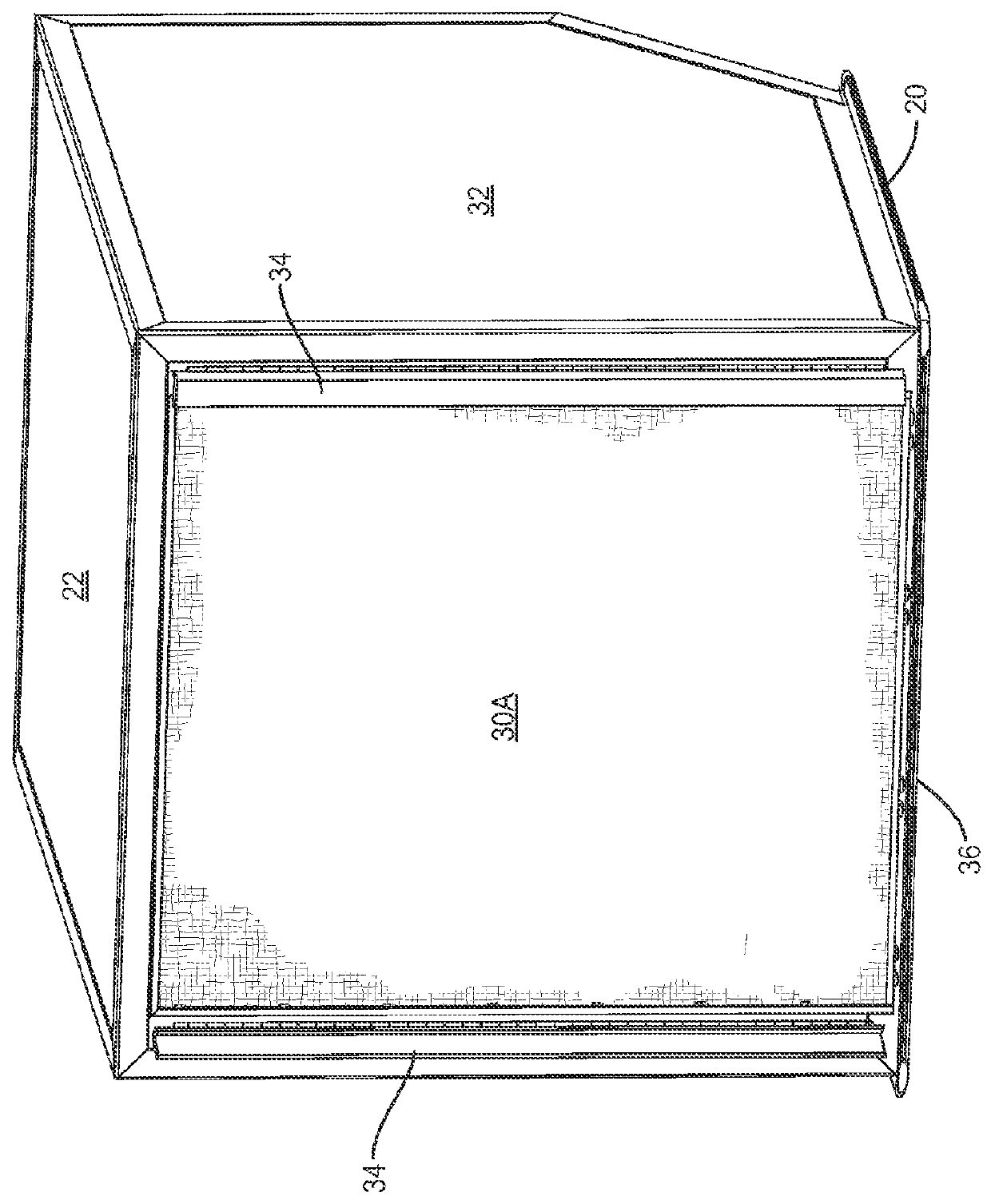

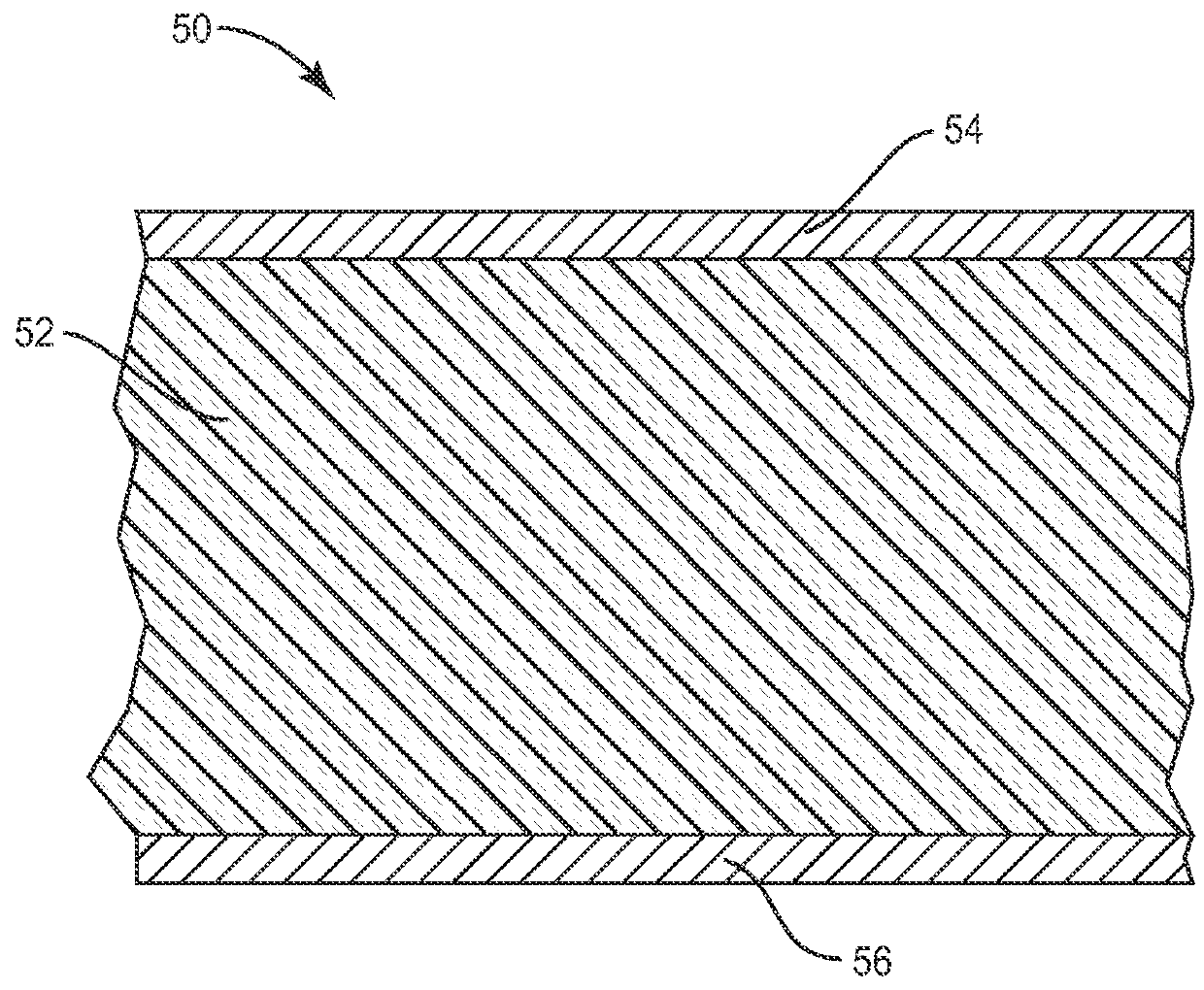

Air cargo container

ActiveUS20130161331A1Damage they withstandAvoid delaminationContainer filling methodsSynthetic resin layered productsFiberAir cargo

Composite panel for air cargo containers including a fire resistant, closed cell foam core, a skin attached to each surface of the core formed by fire resistant fibers in a matrix resin, wherein the panel will contain an internal fire with temperatures of up to 1500° F. for a period of at least 4 hours.

Owner:ADVANCED COMPOSITE STRUCTURES LTD

Gas barrier laminate film, method for producing the same and image display device utilizing the film

InactiveUS20050238846A1High yieldAvoid crackingSynthetic resin layered productsRecord information storageWrinkle skinRoll film

In a gas barrier laminate film comprising a gas barrier layer laminated on at least one surface of a support, the surface of the support on the side opposite to the surface laminated with the gas barrier layer is made to have an Ra value of 1 to 20 nm. A gas barrier laminate film that can prevent cracks generated by displacement of rolled film, slacks and wrinkles during rolling up and transportation in the production process of the film and thus can be produced with a high yield, a method for producing the same and an image display device utilizing the film are provided.

Owner:FUJIFILM CORP

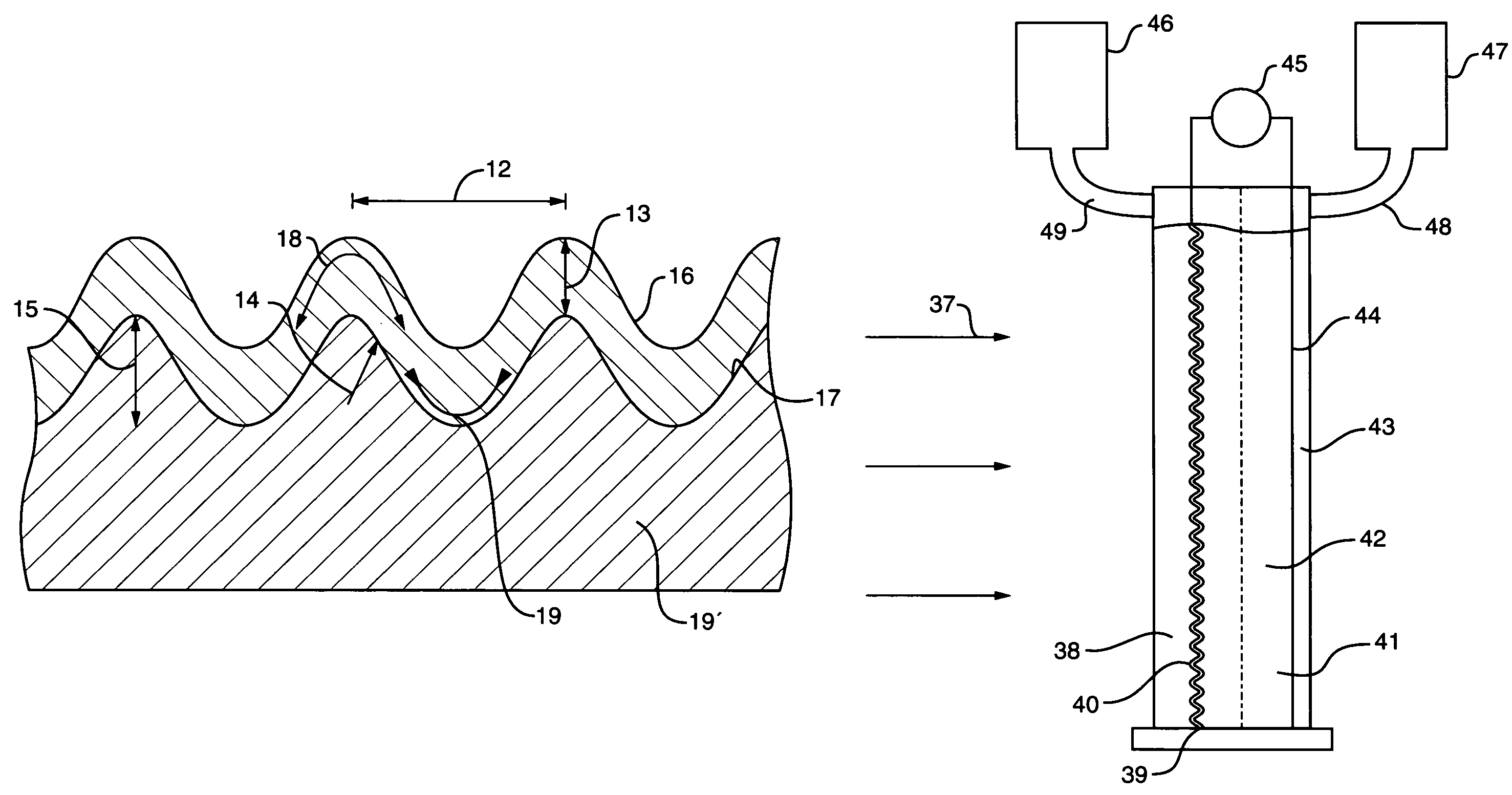

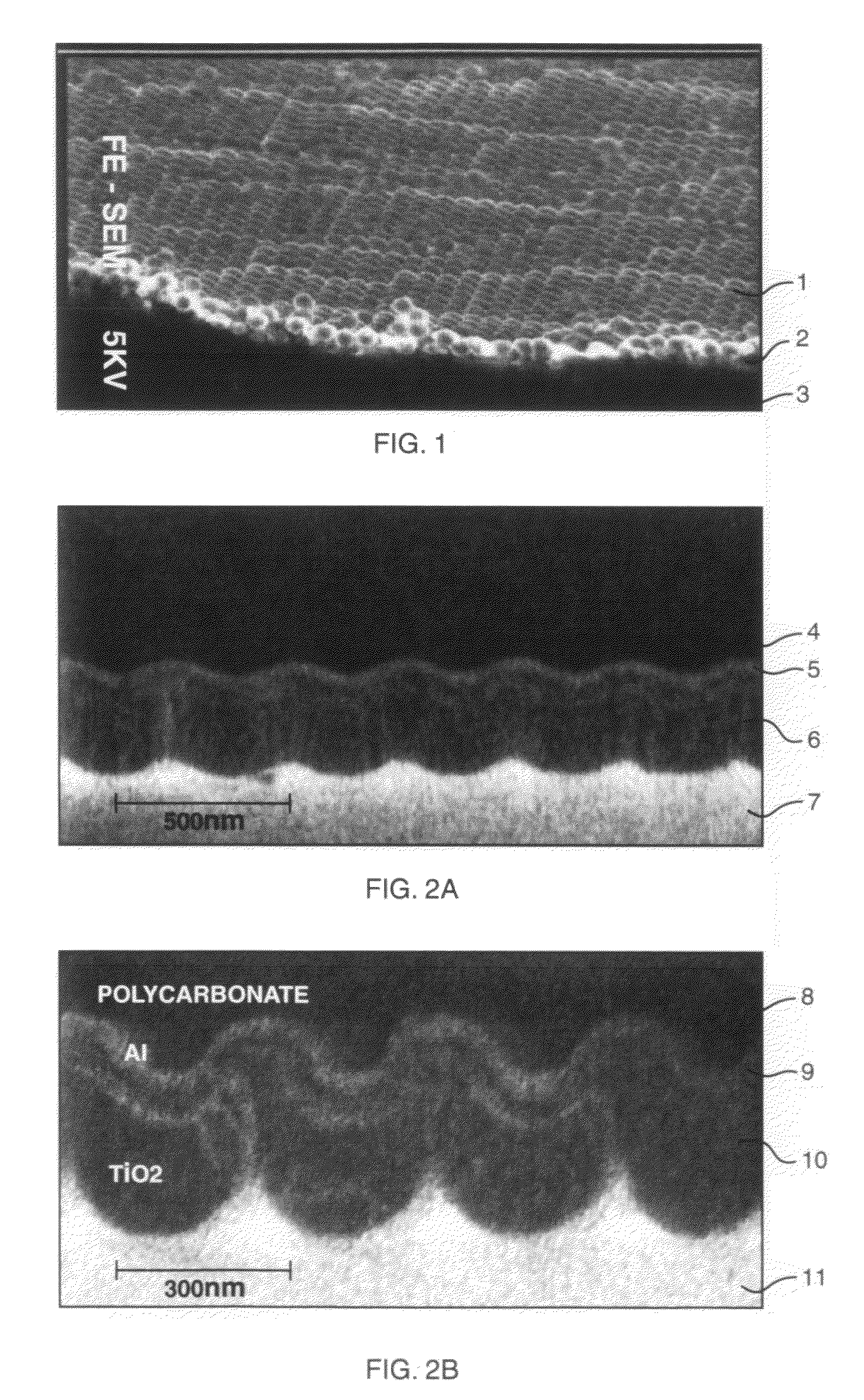

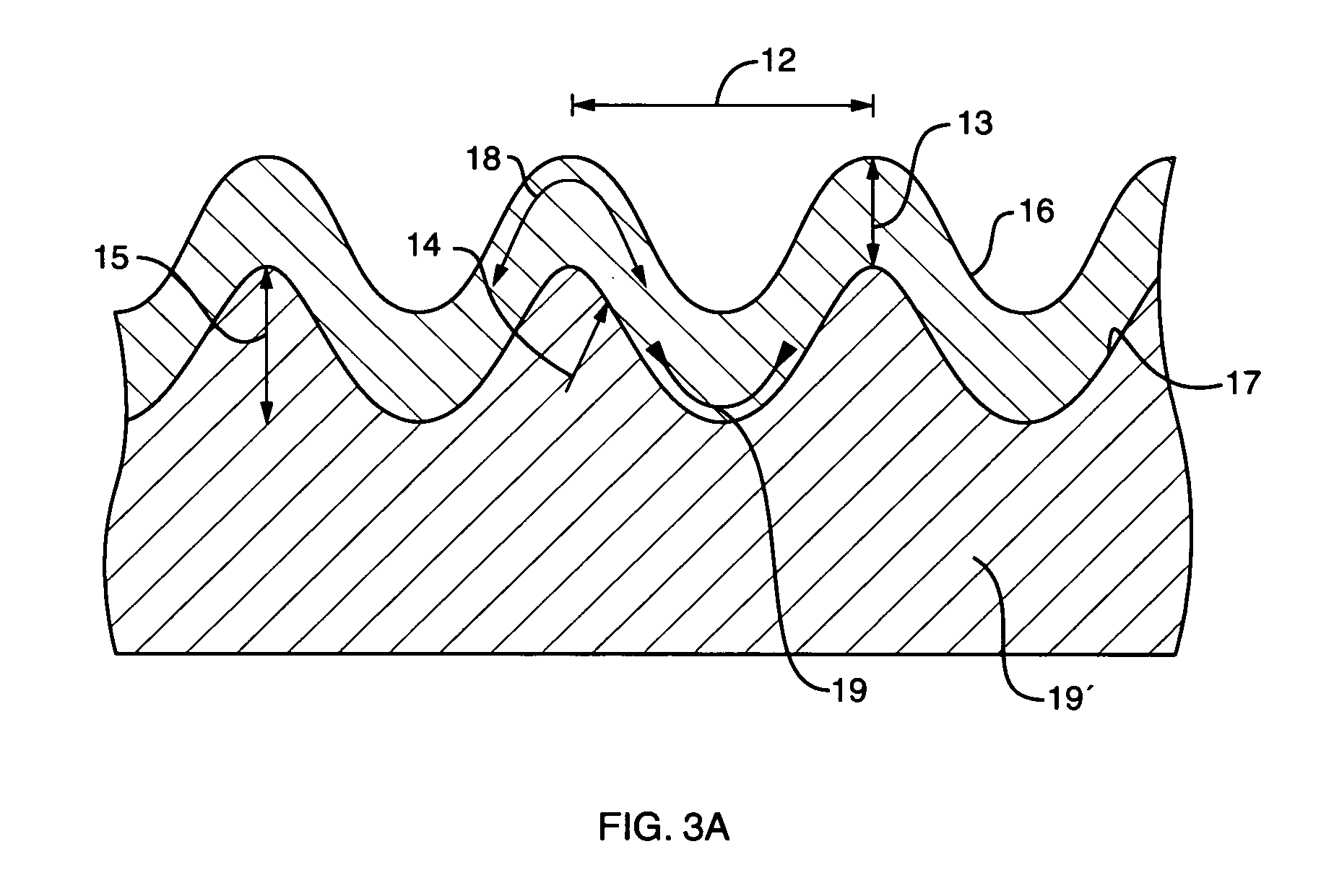

Stress-induced bandgap-shifted semiconductor photoelectrolytic/photocatalytic/photovoltaic surface and method for making same

ActiveUS7485799B2Improve efficiencyIncrease photocatalytic surface areaLight-sensitive devicesInternal combustion piston enginesStress inducedHydrogen

Titania is a semiconductor and photocatalyst that is also chemically inert. With its bandgap of 3.0, to activate the photocatalytic property of titania requires light of about 390 nm wavelength, which is in the ultra-violet (UV), where sunlight is very low in intensity. A method and devices are disclosed wherein stress is induced and managed in a thin film of titania in order to shift and lower the bandgap energy into the longer wavelengths that are more abundant in sunlight. Applications of this stress-induced bandgap-shifted titania photocatalytic surface include photoelectrolysis for production of hydrogen gas from water, photovoltaics for production of electricity, and photocatalysis for detoxification and disinfection.

Owner:NANOPTEK CORP

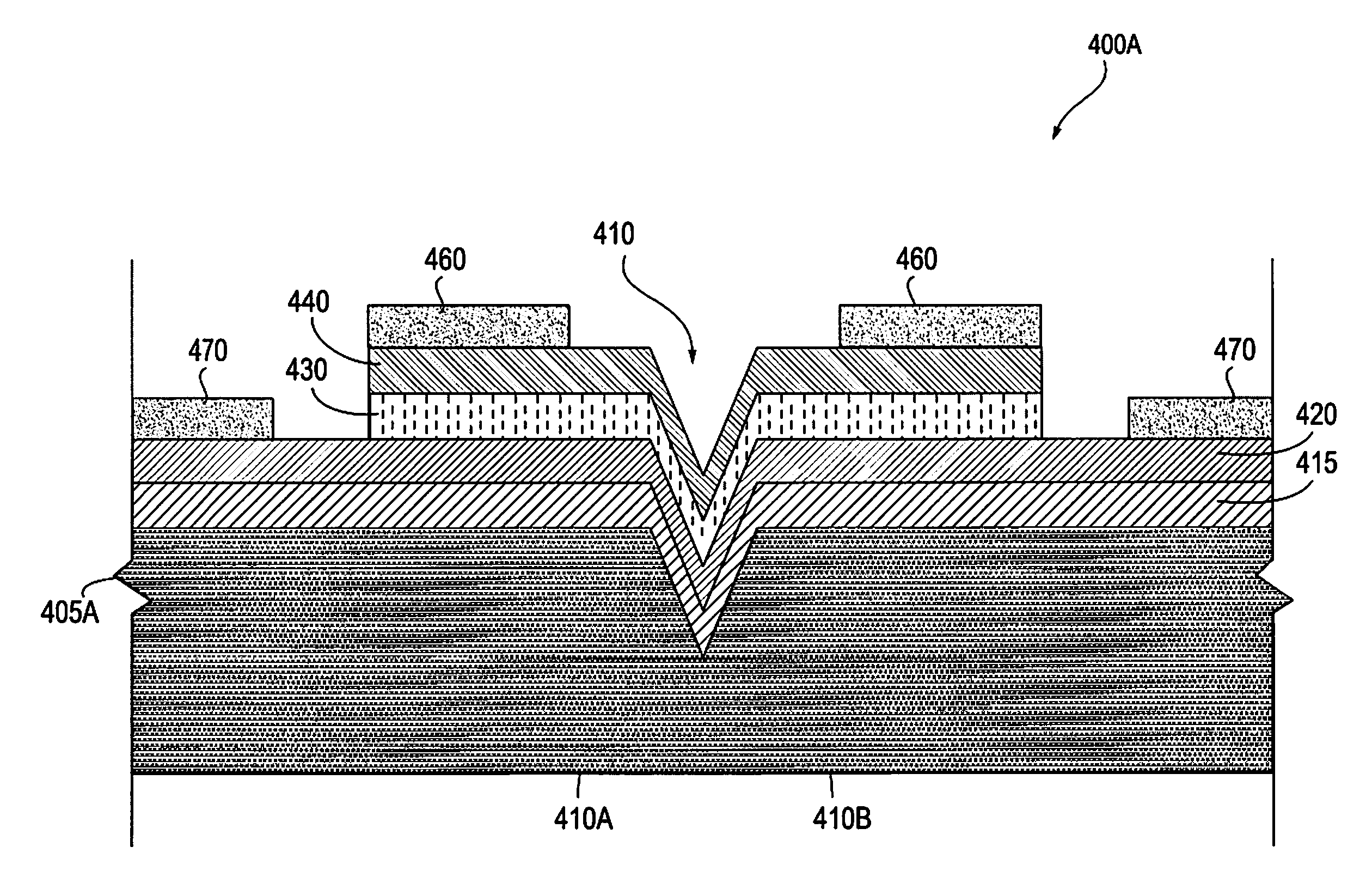

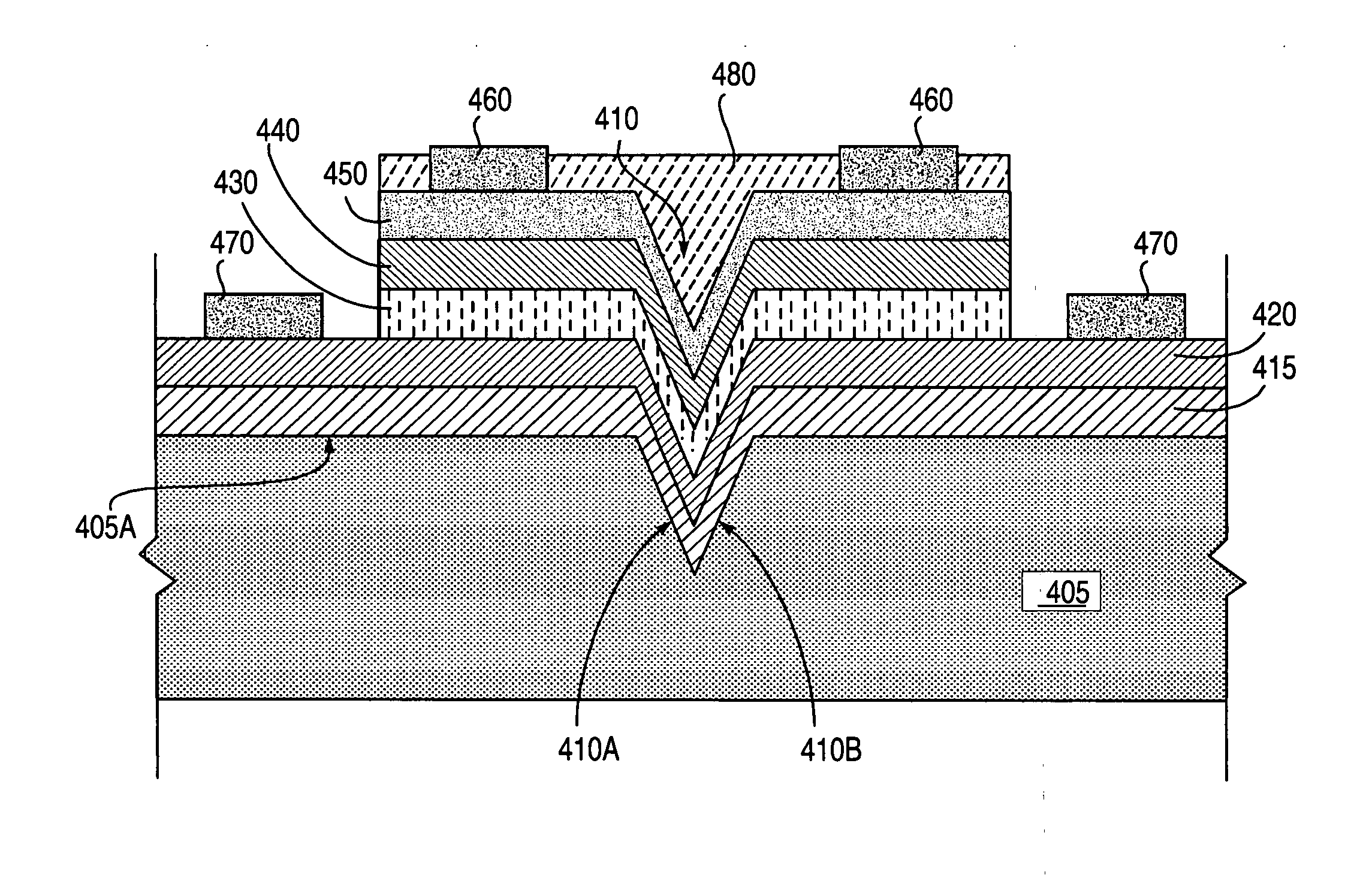

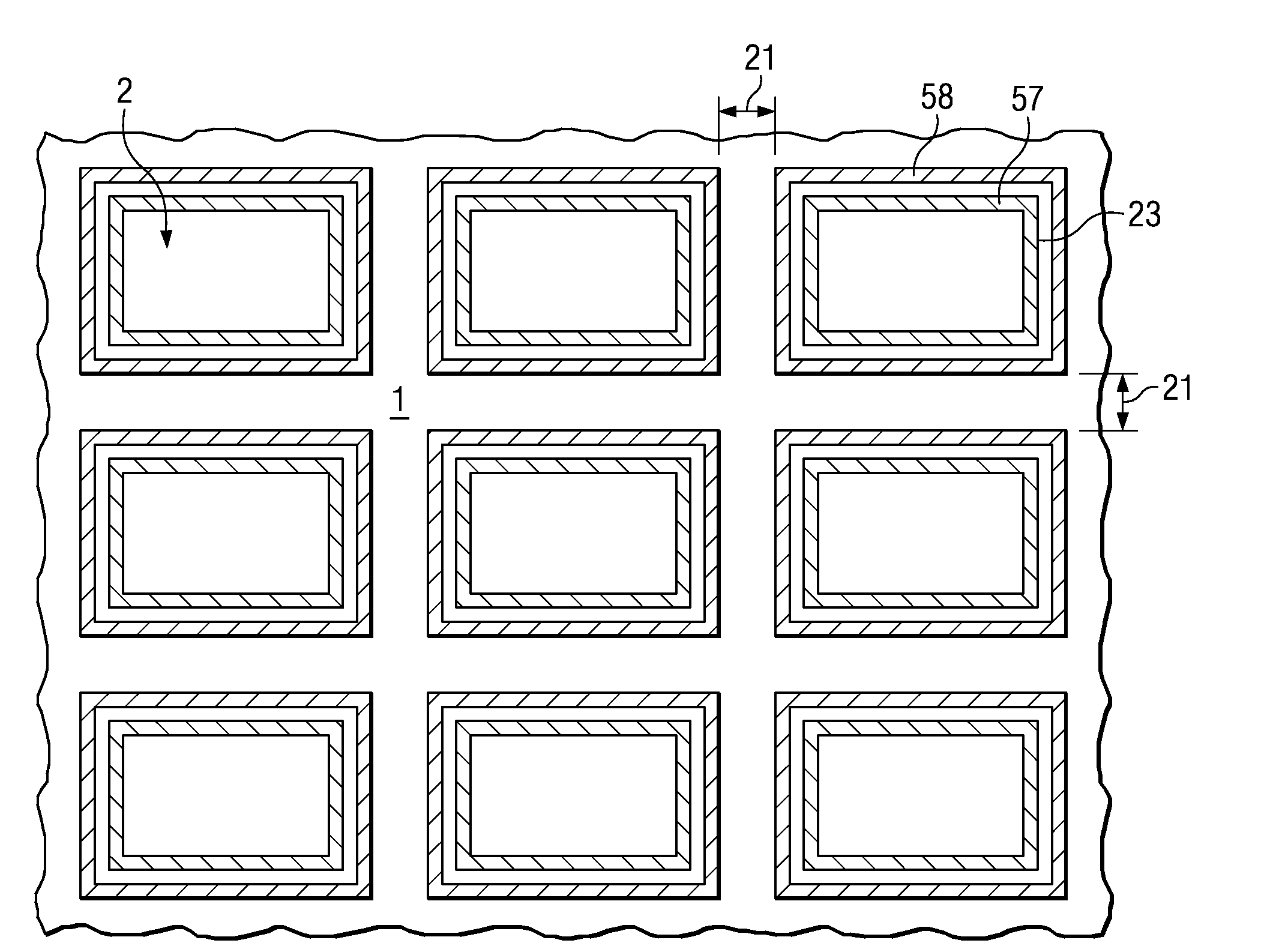

Crack Stop Trenches

ActiveUS20090203192A1Avoid delaminationPreventing other reliability issueSemiconductor/solid-state device detailsSolid-state devicesCell regionElectrical and Electronics engineering

Structures and methods of forming crack stop trenches are disclosed. The method includes forming active regions disposed in cell regions of a substrate, the cell regions separated by dicing channels, and forming back end of line (BEOL) layers over the substrate, the BEOL layers being formed over the cell regions and the dicing channels. Crack stop trenches are then formed encircling the cell regions by etching a portion of the BEOL layers surrounding the cell regions. The wafer is diced along the dicing channels.

Owner:INFINEON TECH AG

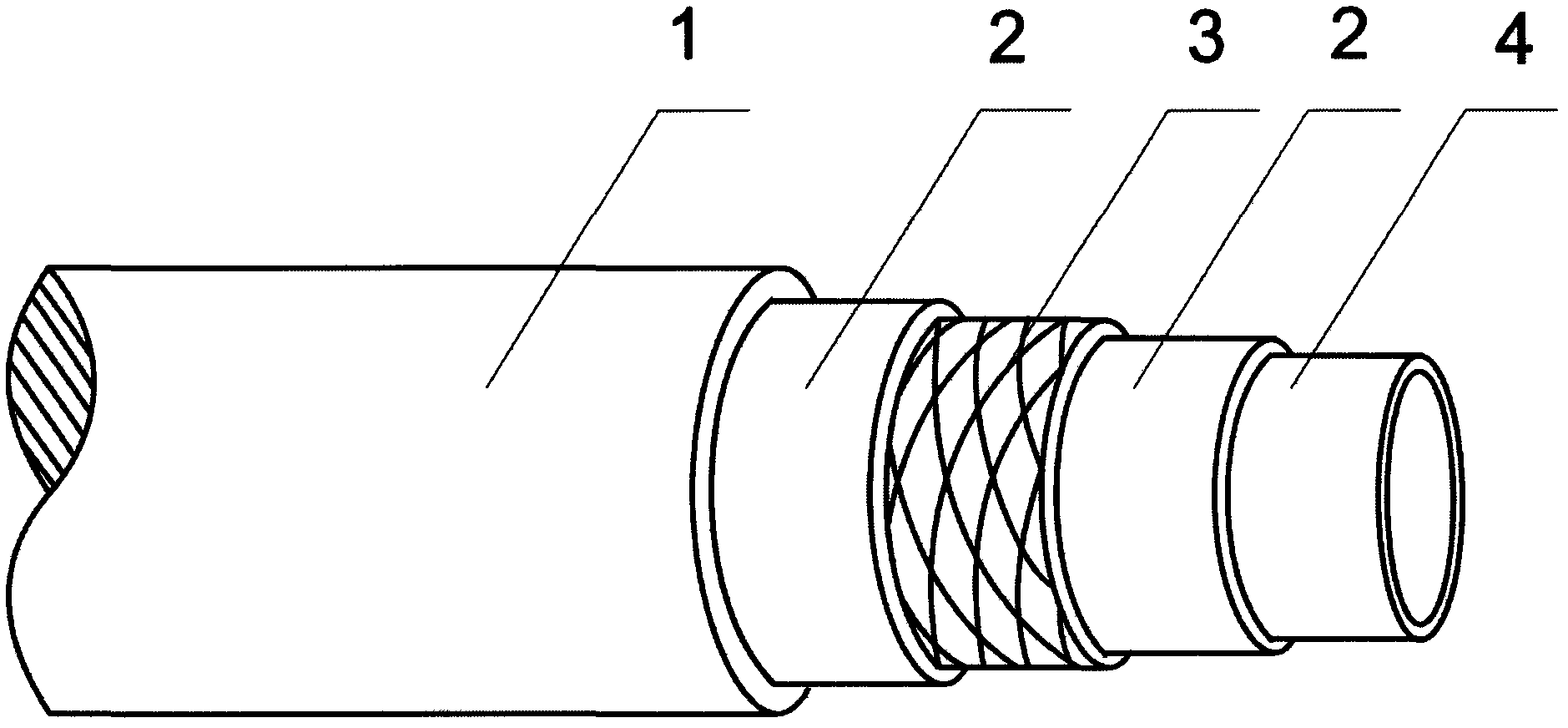

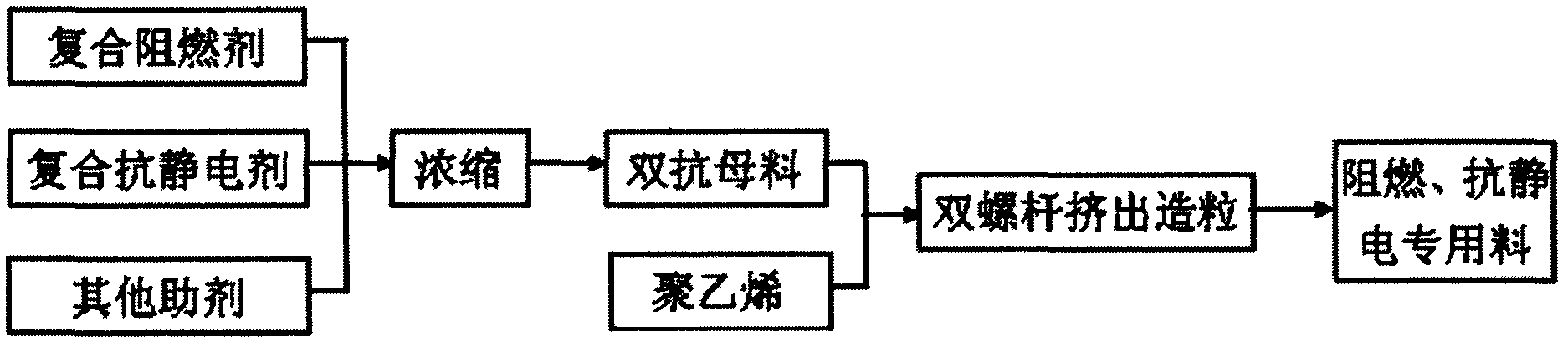

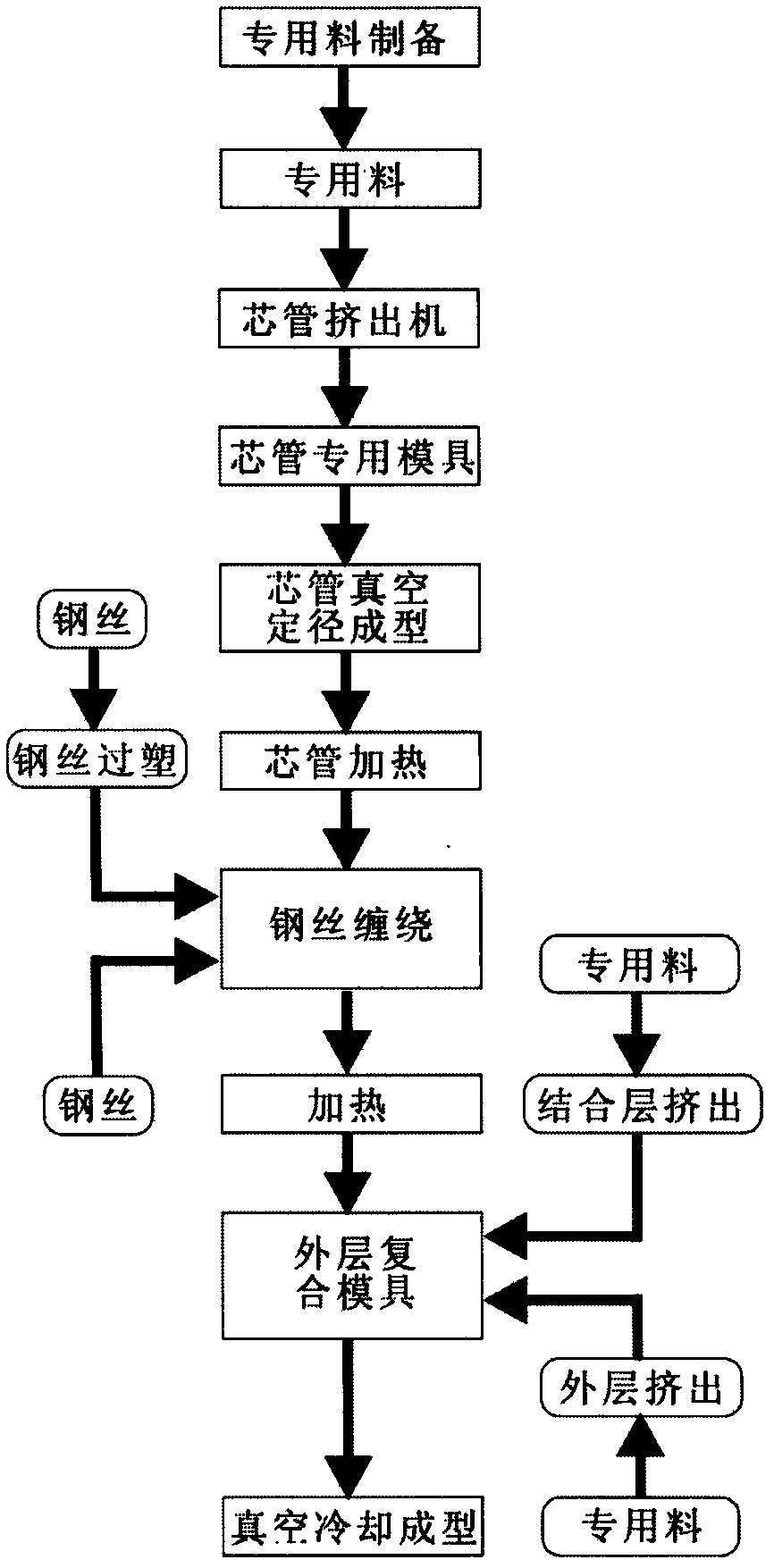

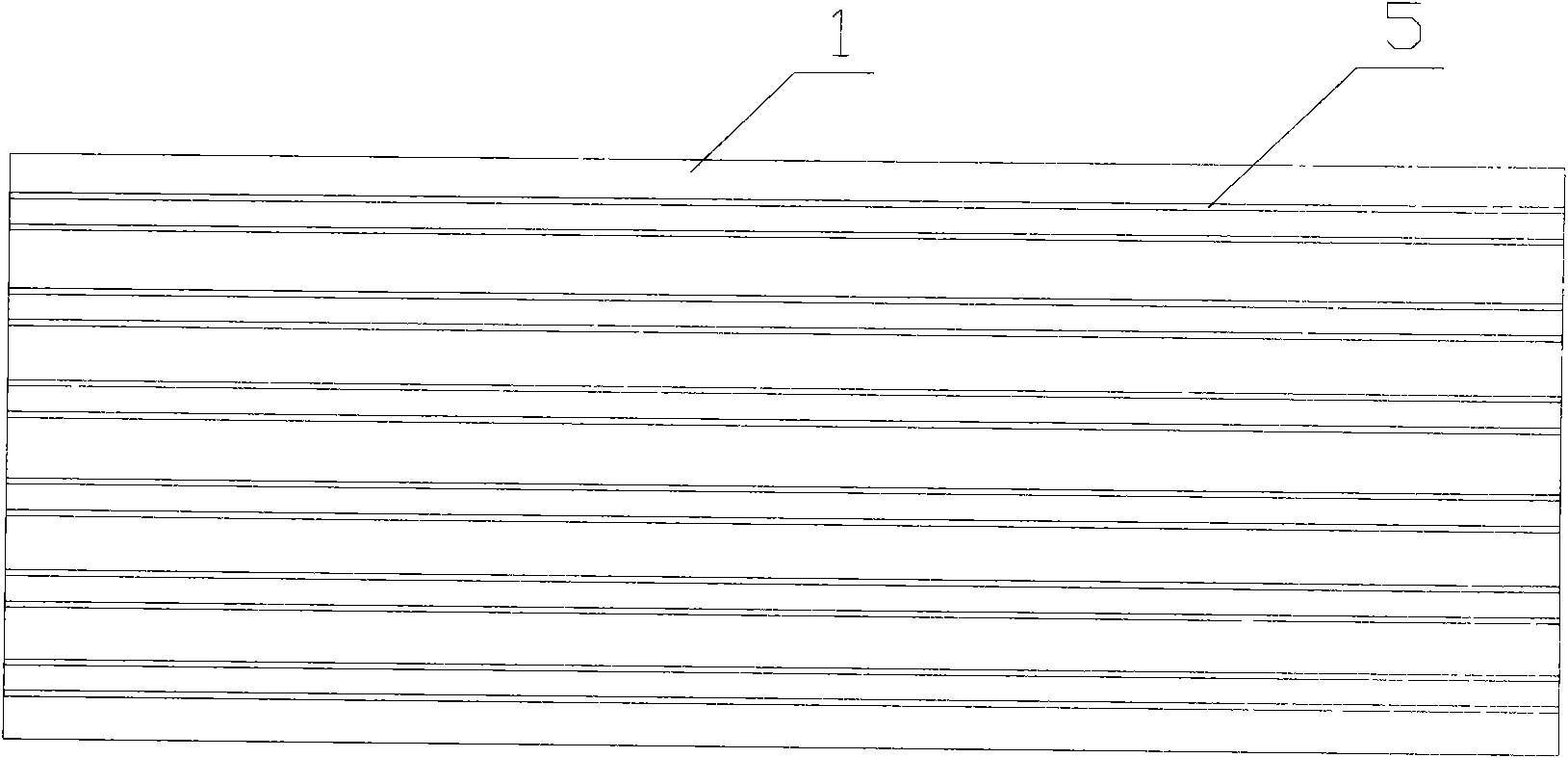

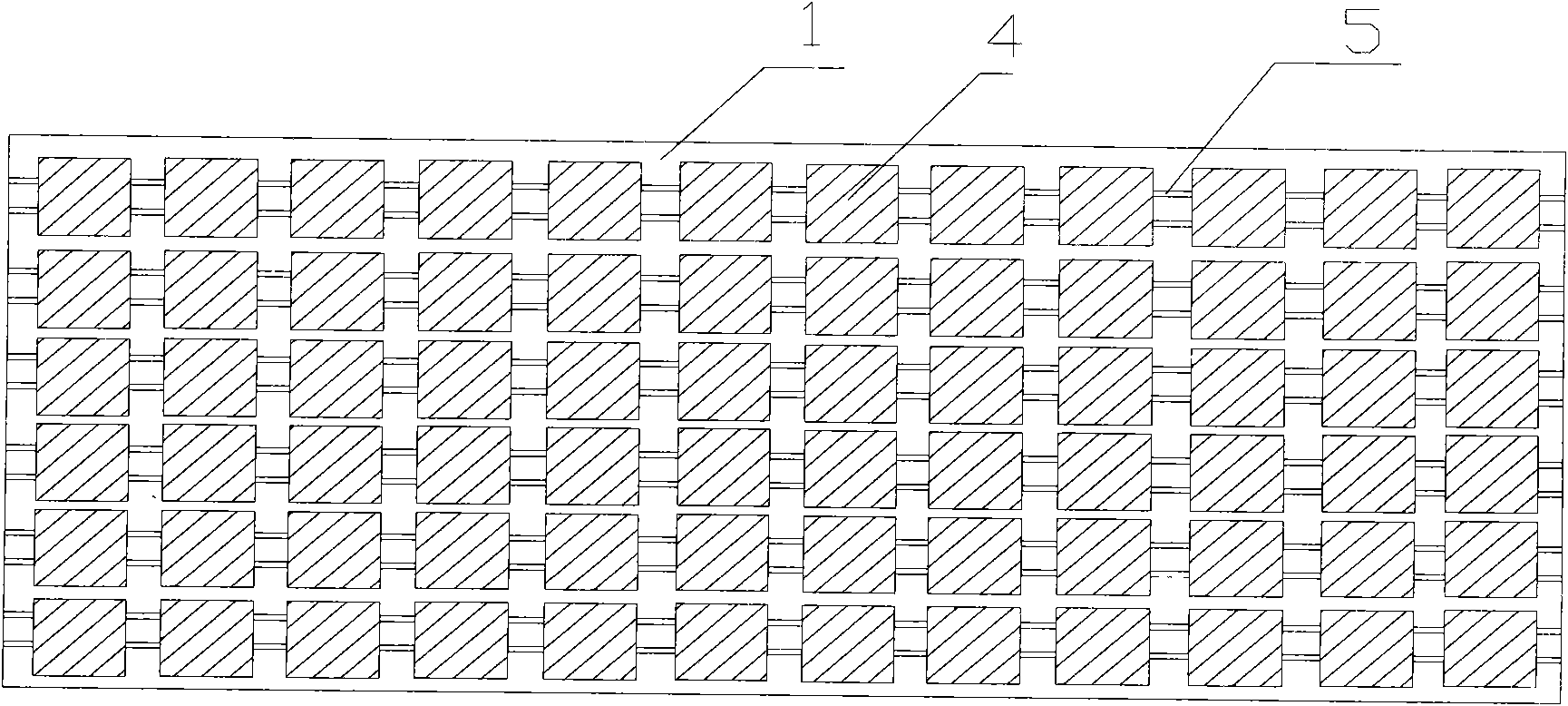

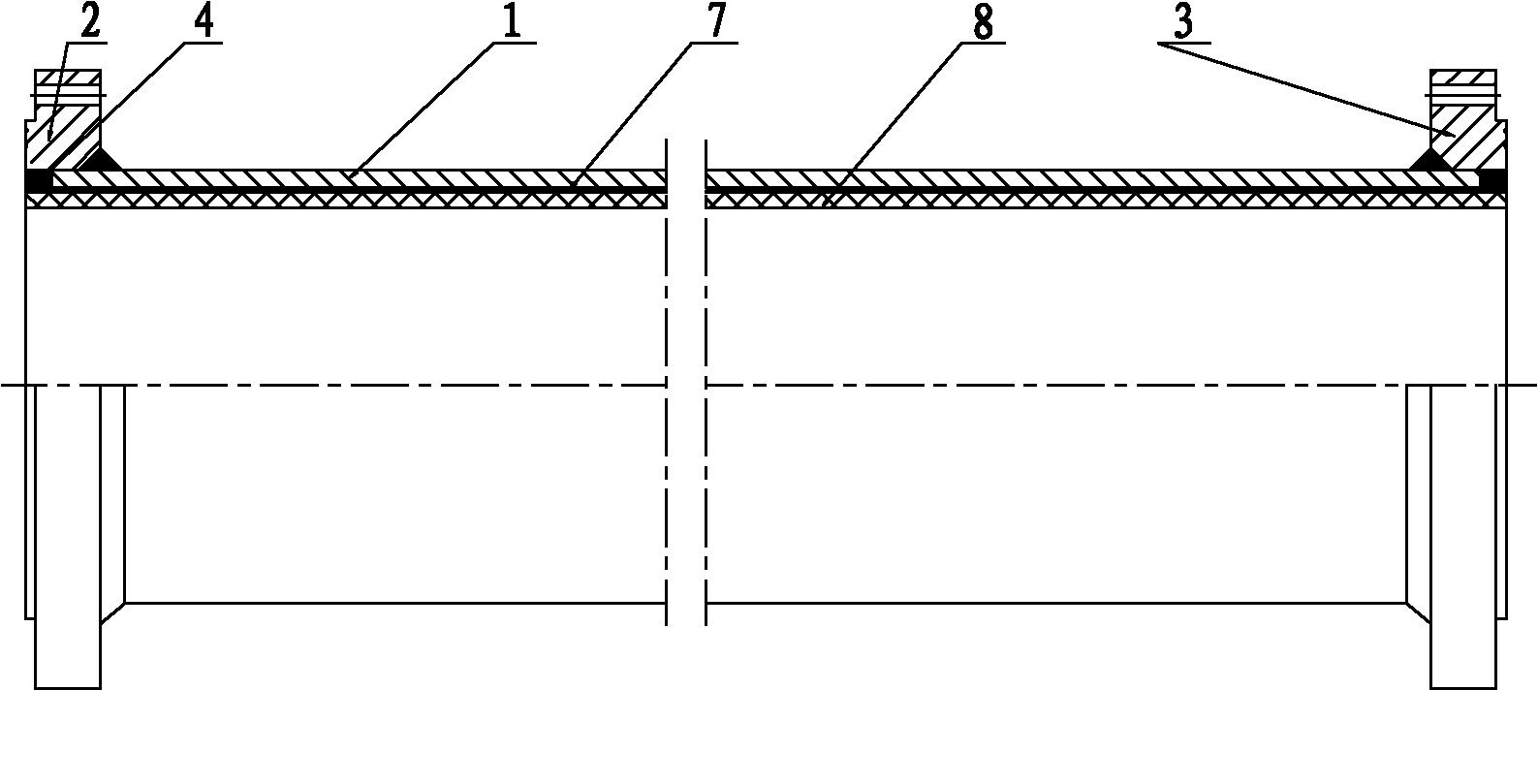

Flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and manufacturing method thereof

InactiveCN102359668AGuaranteed reliabilityGuaranteed uniformityRigid pipesPipe protection against damage/wearFire retardantCoal

The invention relates to a flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and a manufacturing method thereof. The method is characterized in that the polyethylene composite pipe is obtained by the manufacturing processes of subjecting dedicated composite modified polyethylene plastics to flame retarding and antistatic treatment in two steps, compositing the treated plastics with a high-strength steel mesh skeleton and a hot melt adhesive bond for several times, and heating and vacuuming the composite for several times. At least two layers of high-strength steel wires are wound to be reticulate in an oblique crossing manner, arranged between the outer wall of the inner layer and the inner wall of the outer layer as a skeleton, and tightly combined with the pipe body of the inner and outer layers into an integral whole by means of a hot melt adhesive, thus forming a composite pipe for underground coal mines, which is flame-retardant and antistatic and has relatively high mechanical strength and pressure resistance, long service life and other excellent properties. As the pipes are connected through welding by electric melting pipe fittings, the flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining has high overall properties and convenience in laying, is applicable to the coal mine industry with strict property requirements in all aspects, and is also applicable to water supply and drainage, fire protection and gas delivery in the municipality and construction.

Owner:GUANGDONG EAST PIPES

Solar module and manufacturing method thereof

ActiveCN101661964AImprove sealingGood weather resistancePhotovoltaic energy generationSemiconductor devicesSolar batterySealant

The invention relates to a solar module, which comprises a battery array, a glass model, a sealing material and a sealant, wherein the battery array is formed by connecting a plurality of solar battery pieces in series or in parallel through solder strips; the glass model is tabular and the inside of the glass model is provided with a cavity and a side opening; the battery array is placed in the cavity of the glass model; the sealing material is filled in the space beyond the battery array in the cavity; and the sealant is used for sealing the side opening of the glass model. The invention simultaneously discloses a manufacturing method for the solar module. The method adopts a scheme of the internal seal of the glass model with the side opening to improve the sealability, the weatherability and the photoelectric conversion efficiency of the solar module. Because a laminating method is not adopted, the phenomena of the displacement of the battery pieces, the generation of bubbles and even the crushing of the battery pieces are prevented, and the phenomena of layering stripping and ageing are prevented.

Owner:BYD CO LTD +2

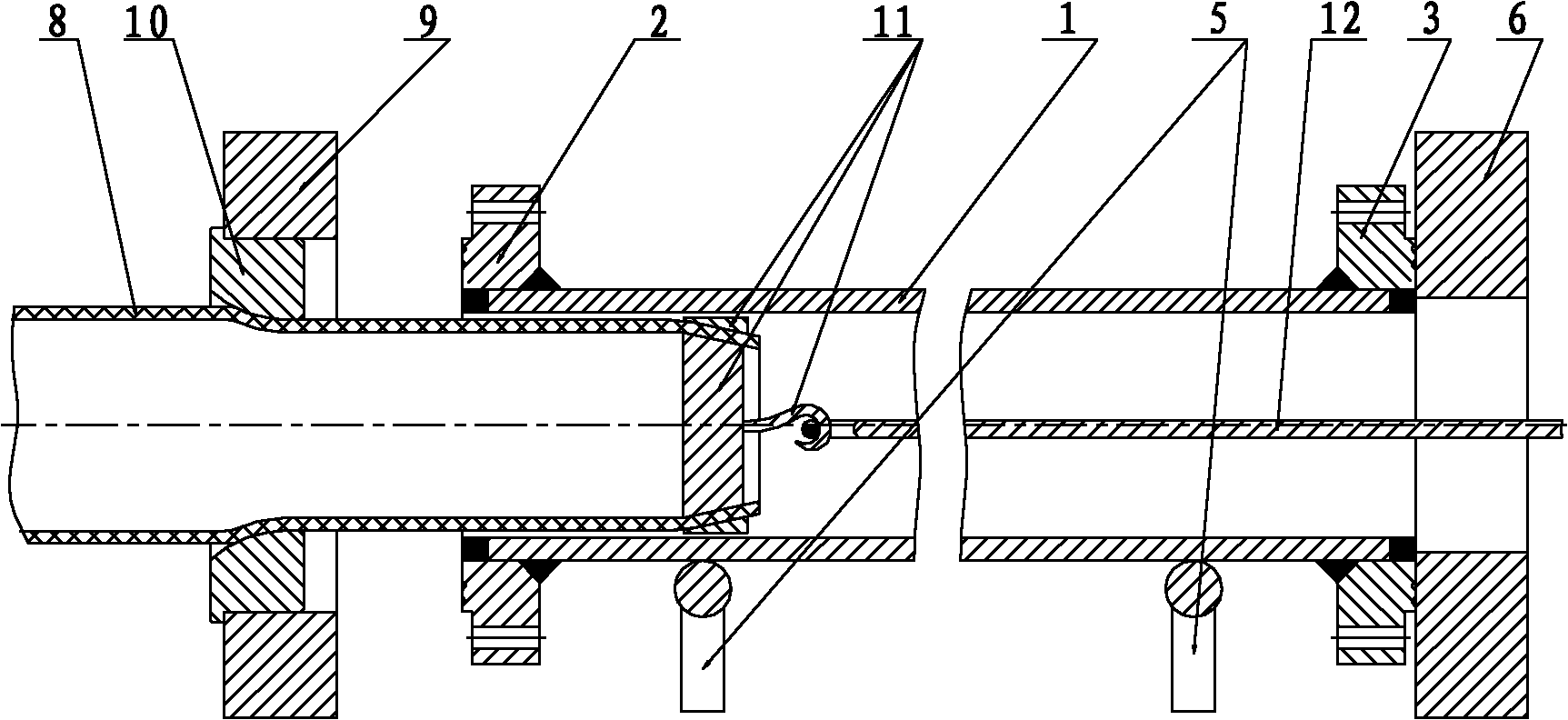

Method and equipment for producing flange type lining plastic compound steel pipe

ActiveCN101839375AFit tightlyAvoid delaminationLaminationLamination apparatusInterference fitMetallurgy

The invention discloses a method and equipment for producing a lining plastic compound steel pipe, and in particular relates to a method and equipment for producing a flange type lining plastic compound steel pipe. The technical problem to be solved by the invention is to provide the method and the equipment for producing the flange type lining plastic compound steel pipe which enables the inner walls of a plastic pipe and a steel pipe to be compounded into a whole through a hot melt adhesive, ensures no separation and delamination phenomena occurred between steel and plastics and has stable and reliable product quality, the plastic pipe is towed to penetrate into the steel pipe through a towing device, the plastic pipe clings to the steel pipe through compressed air, and then the hot melt adhesive on the outer wall of the plastic pipe is molten and bonded with the steel pipe through an electromagnetic induction heating device. The inside of the plastic pipe is pressurized by adopting compressed air, so that the plastic pipe is expanded to enable the plastic pipe and the steel pipe to be in the state of interference fit, and then the steel pipe is heated at the moment by adopting an induction heating ring, so that the plastic pipe and the steel pipe are compounded into a whole, the steel and plastic materials in the pipes are more tightly bonded, and the separation and delamination phenomena between the steel and the plastics can not occur.

Owner:成都共同制管有限公司

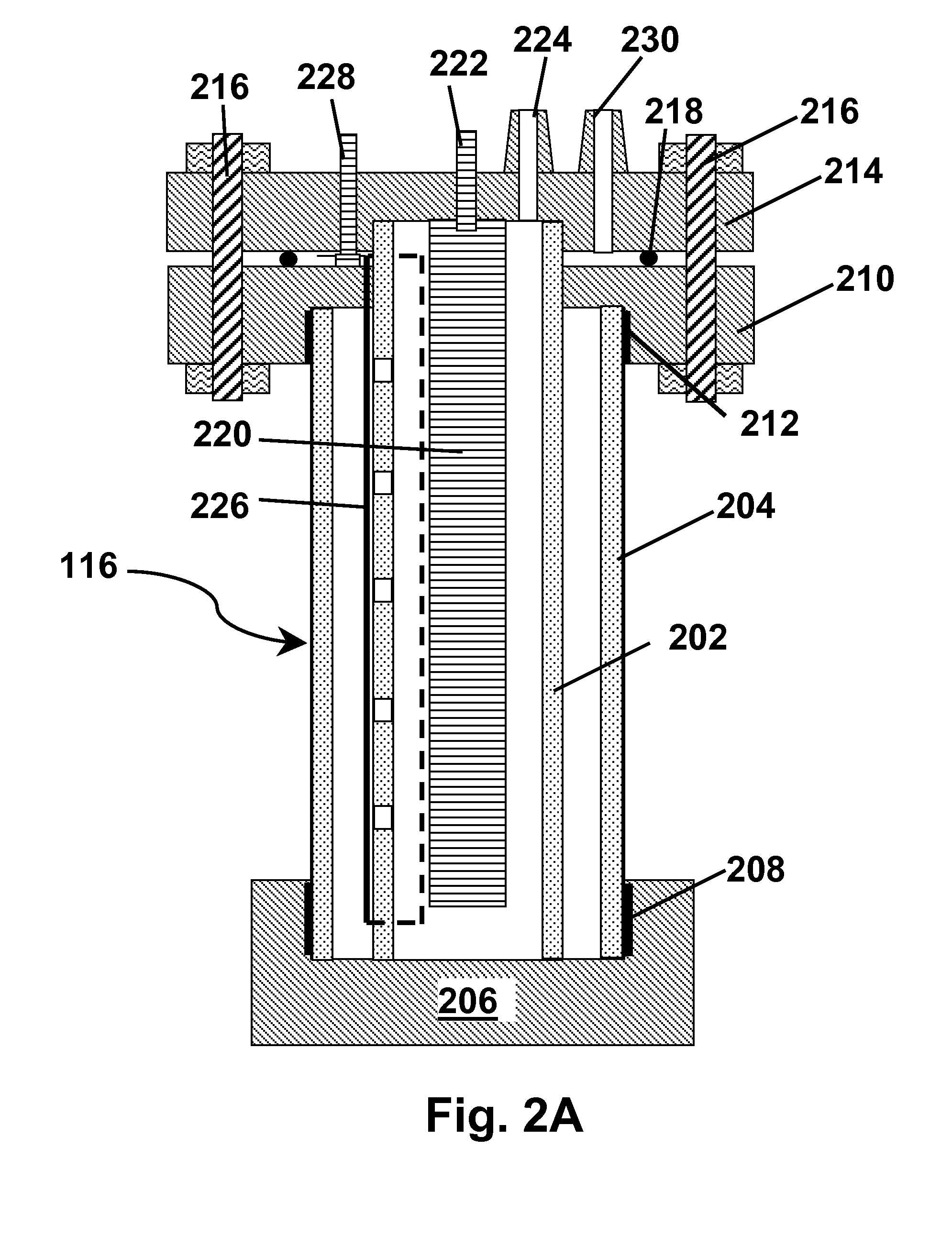

Bandgap-shifted semiconductor surface and method for making same, and apparatus for using same

InactiveUS20080283121A1Improve efficiencyIncrease photocatalytic surface areaElectrolysis componentsElectrostatic separatorsElectricityDirect radiation

Apparatus for generating electricity and for carrying out photo-induced reactions comprises: a primary reflector (610) or other optic which concentrates radiation to a primary focus; a secondary reflector at the primary focus to direct radiation to a secondary focus; a photovoltaic device (602) to convert radiation to electricity; and a photo-reactor (116) having a photoactive electrode, one of the photovoltaic device (602) and the photoactive electrode (116) lies at the primary focus, and the other at the secondary focus. Electric potential generated by the photovoltaic device (602) may be used to provide a bias or over-voltage between the photoactive electrode and a counter electrode. The apparatus may be used to photolyze water or to carry out other photochemical reactions.

Owner:NANOPTEK CORP

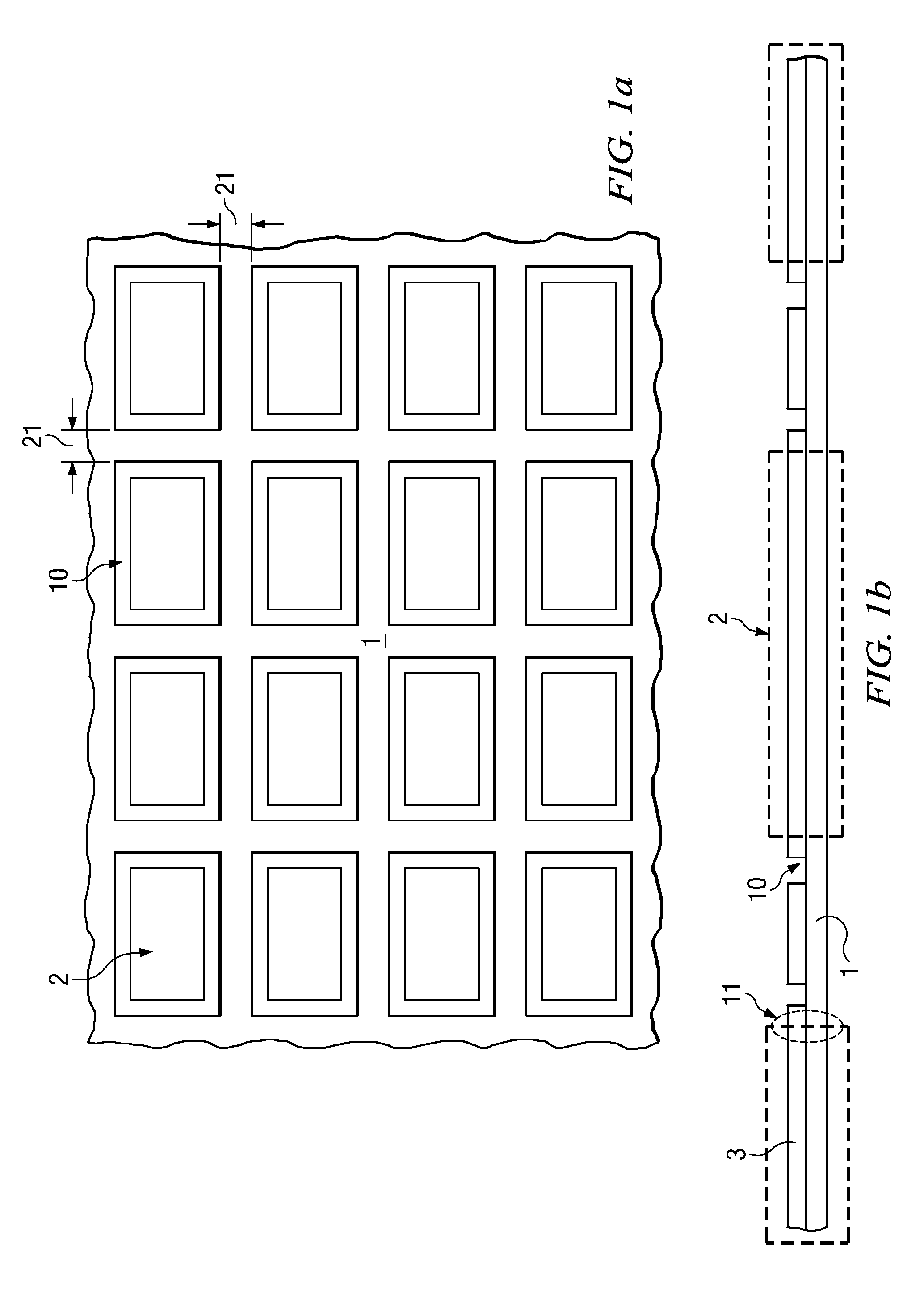

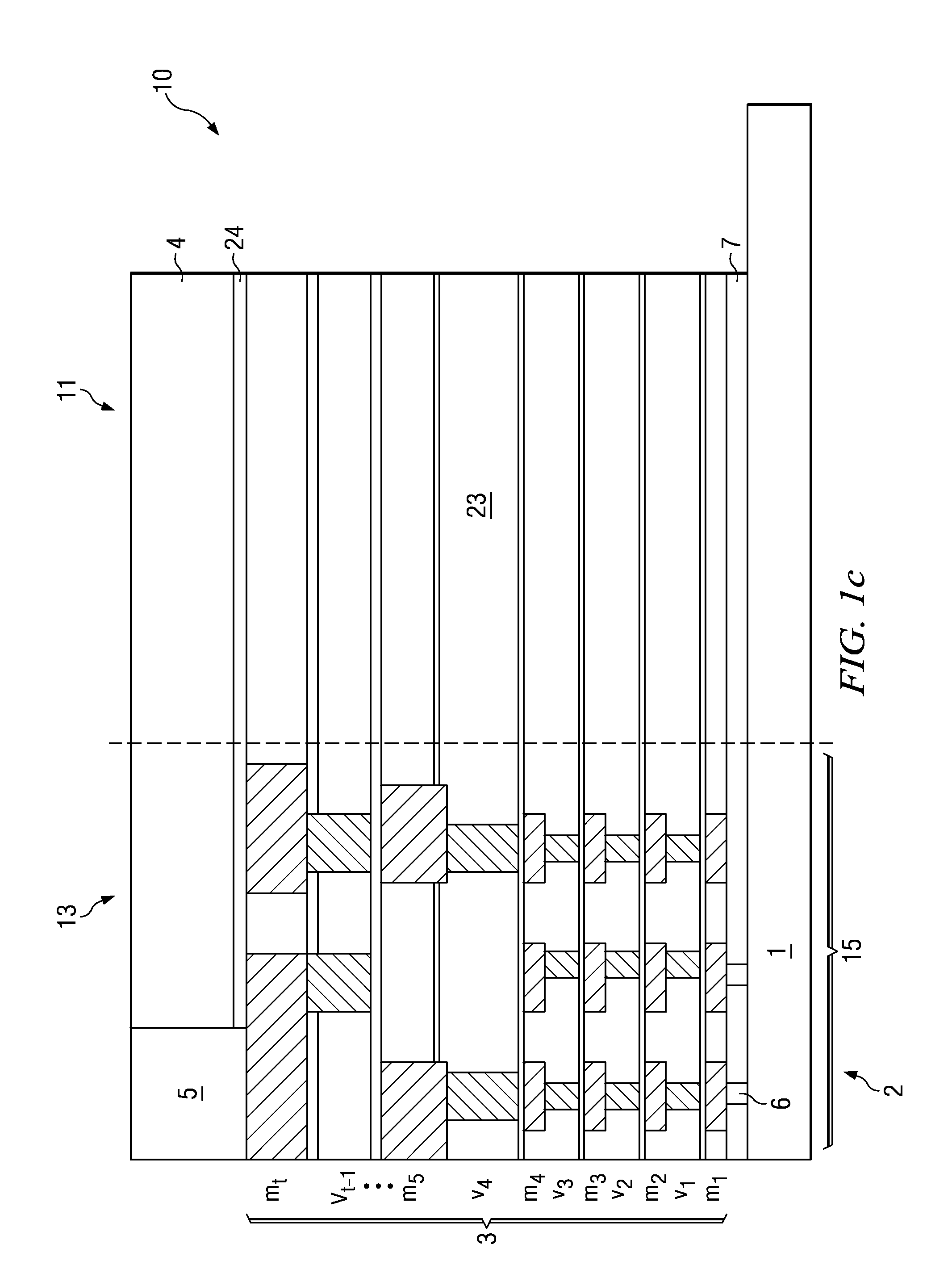

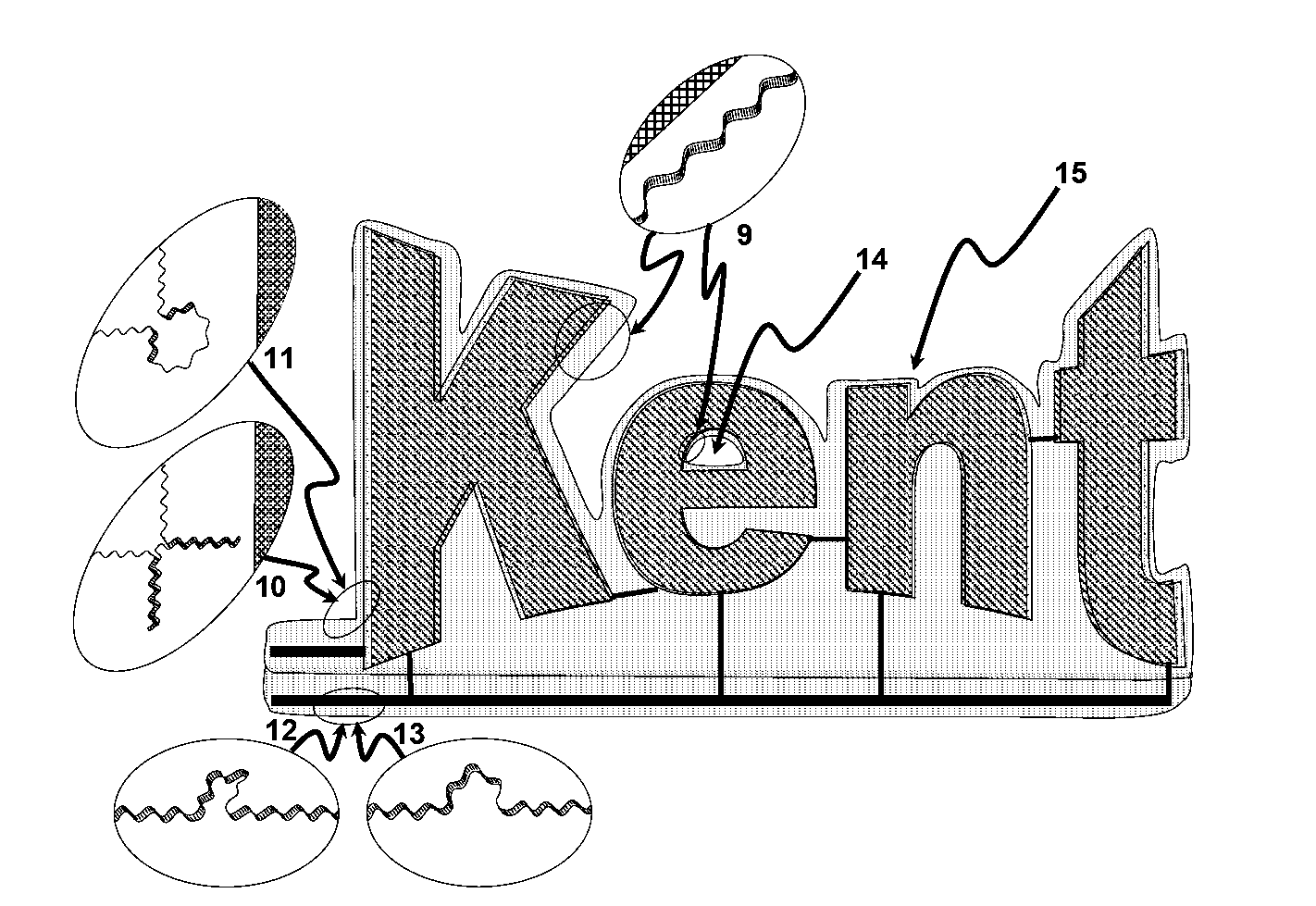

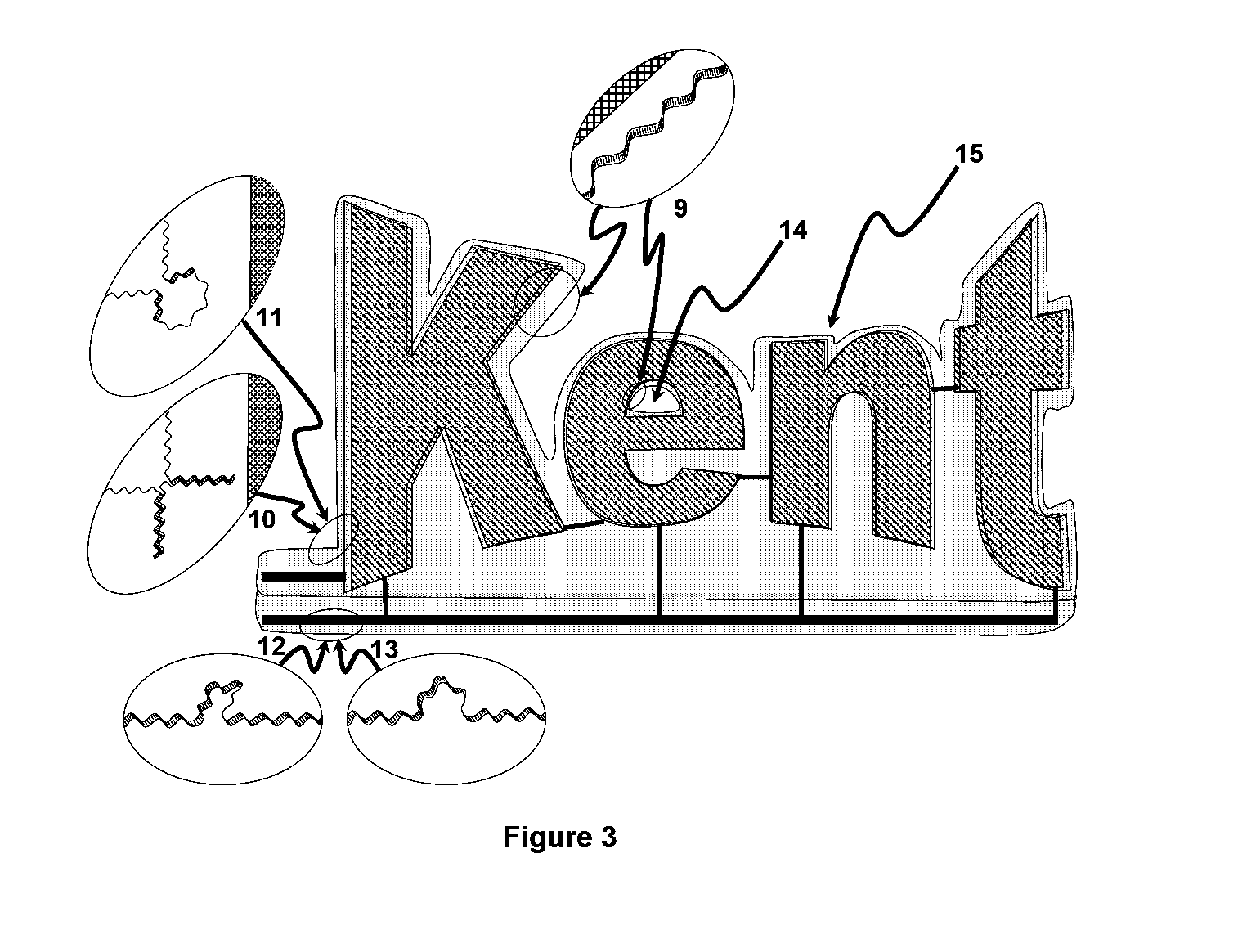

Method of simultaneous singulation and edge sealing of plastic displays

ActiveUS20070277659A1Unique electro-optical featureAvoids tendencyAdhesive processesAutomatic control devicesRoll-to-roll processingLiquid-crystal display

The production of liquid crystal displays (LCDS) on plastic substrates is desirable over glass substrates so that the finished product is thinner, lighter, and more robust. Plastic substrates can enable the use of new and different processing techniques which are not possible on glass such as roll-to-roll processing. This invention discusses an advancement which is laser cutting a plastic substrate and display layer. One aspect of the invention is laser cutting and welding together two or more plastic substrates and LCD layer therebetween from a larger sheet or roll of plastic LCDs.

Owner:KENT DISPLAY SYST

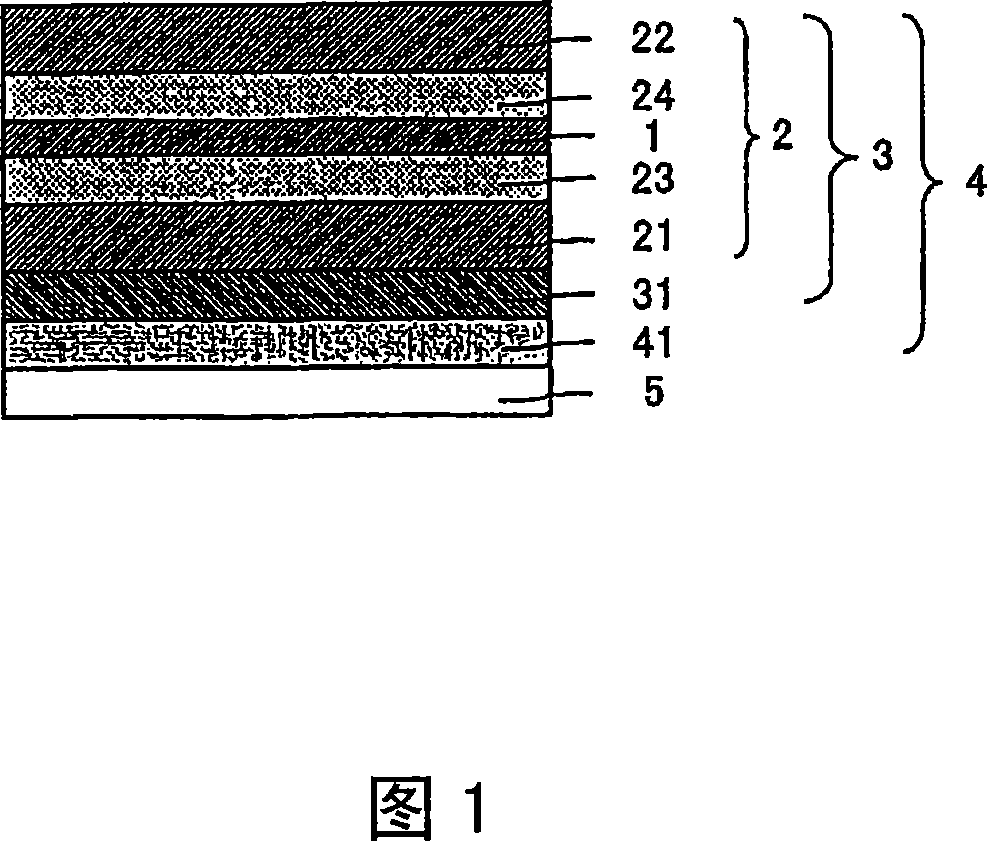

Pressure-sensitive adhesive type polarizer with retardation layer, process for producing the same, optical film, and image display

ActiveCN101080657AEasy to identifySuppresses changes in optical propertiesPolarising elementsAcid polymer adhesivesPolyvinyl alcoholPotassium

The present invention provides a pressure-sensitive adhesive type retardation-layer-possessing polarizer (4) obtained by forming a polarizer (2) comprising an iodine-containing polarizing element (1) and transparent protective films superposed respectively on both sides thereof, disposing a retardation layer on at least one of the transparent protective films of the polarizer (2) to produce a retardation-layer-possessing polarizer (3), and further superposing a pressure-sensitive acrylic adhesive layer on the retardation layer side. In the iodine-containing polarizing element (1), the ratio of the content of potassium (K) (wt.%) to the content of iodine (I) (wt.%), (K / I), is 0.200-0.235. In the polarizer (2), the iodine-containing polarizing element (1) has been laminated to the transparent protective films through an adhesive layer formed from a water-soluble adhesive comprising a polyvinyl alcohol resin having acetoacetyl groups and a crosslinking agent. The retardation-layer-possessing polarizer (3) has a degree of shrinkage in the absorption axis direction, as measured after 24-hour standing at 80 DEG C and expressed by the following equation, of 0.5% or lower. The pressure-sensitive adhesive type retardation-layer-possessing polarizer (4) by itself has a transmittance of 41.0-43.2%. This pressure-sensitive adhesive type retardation-layer-possessing polarizer can be inhibited from changing in optical properties even under high-temperature high-humidity conditions and can keep visibility high.

Owner:NITTO DENKO CORP

Li-ion secondary battery formation method

ActiveCN101212067AAvoid delaminationIncrease capacityFinal product manufactureSecondary cells charging/dischargingLithiumEngineering

The invention relates to a formation method of lithium iron secondary battery. The method comprises the processes: the battery is charged under the formation temperature of the lithium iron secondary battery; the charge process comprises the processes: the continuous current of a first current is used for charging to the first voltage; the continuous voltage of the first voltage is used for charging to the cutoff current; the continuous current of a second current is used for charging to the second voltage. The second voltage is higher than the first voltage and the second current is higher than the first current. As the battery is carried out the formation using the formation method of the invention, the battery has a good comprehensive electrical-chemical performance such as a higher capacity, high-temperature circulation performance and a discharge performance for big current.

Owner:SHANGHAI BYD

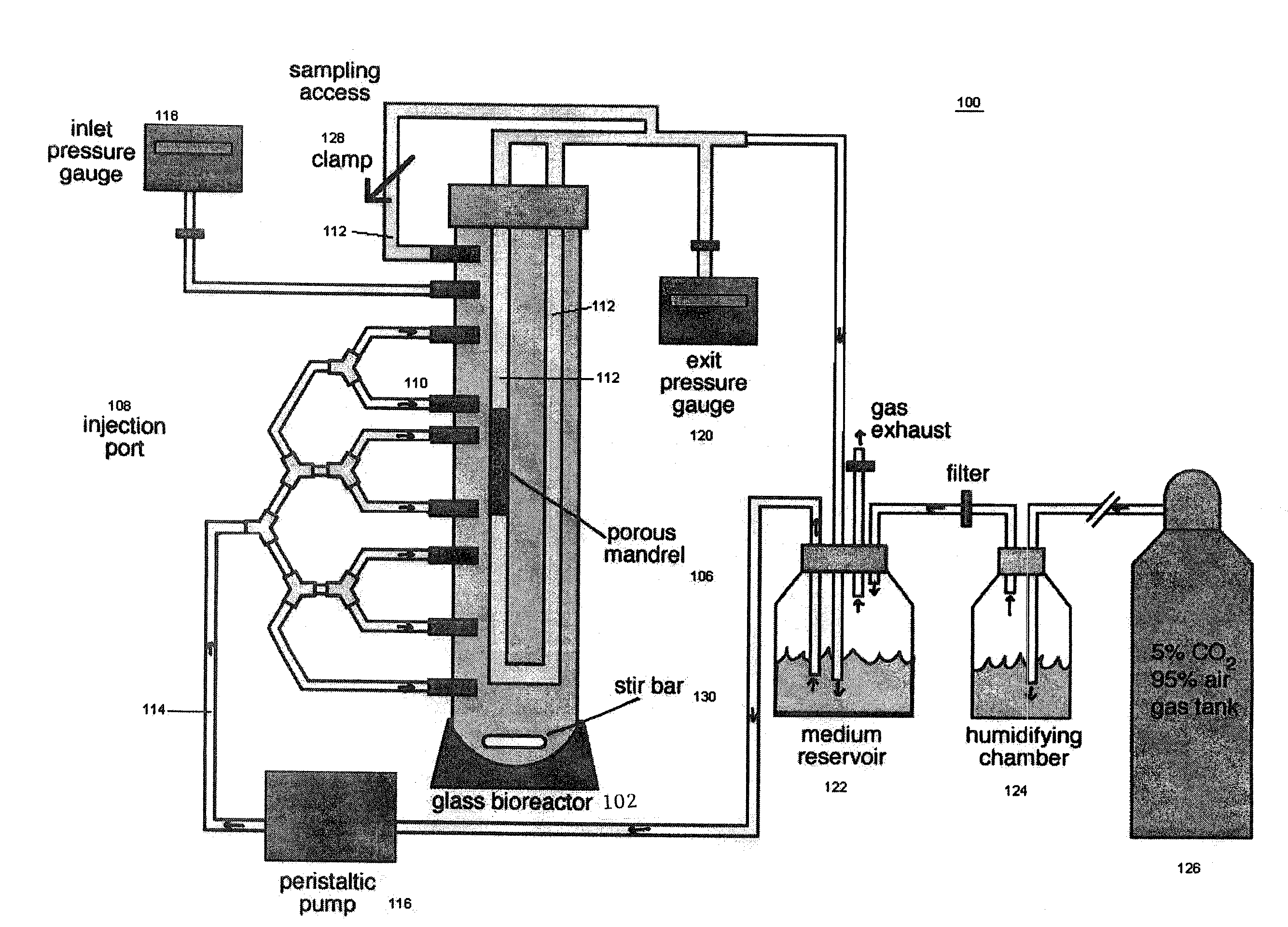

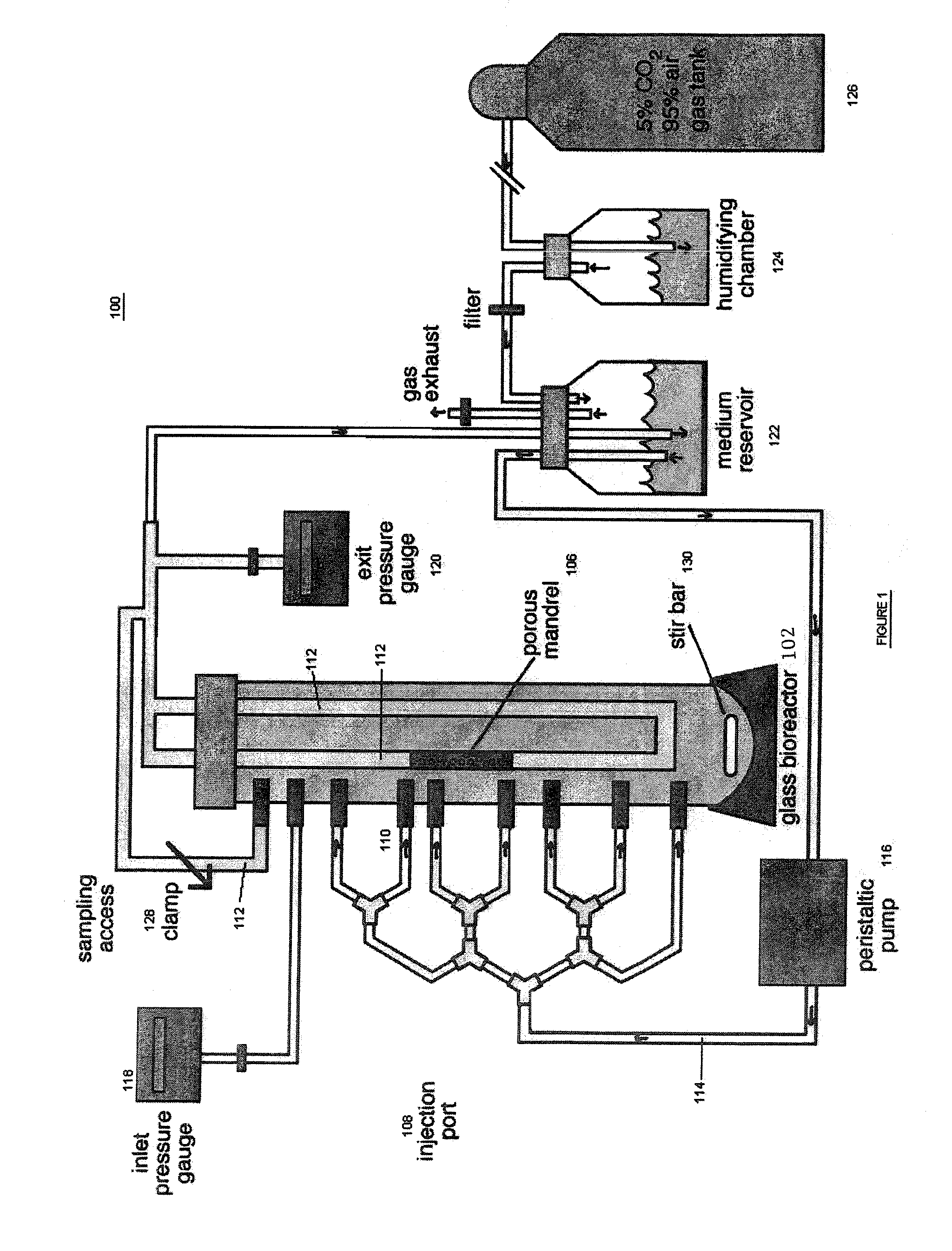

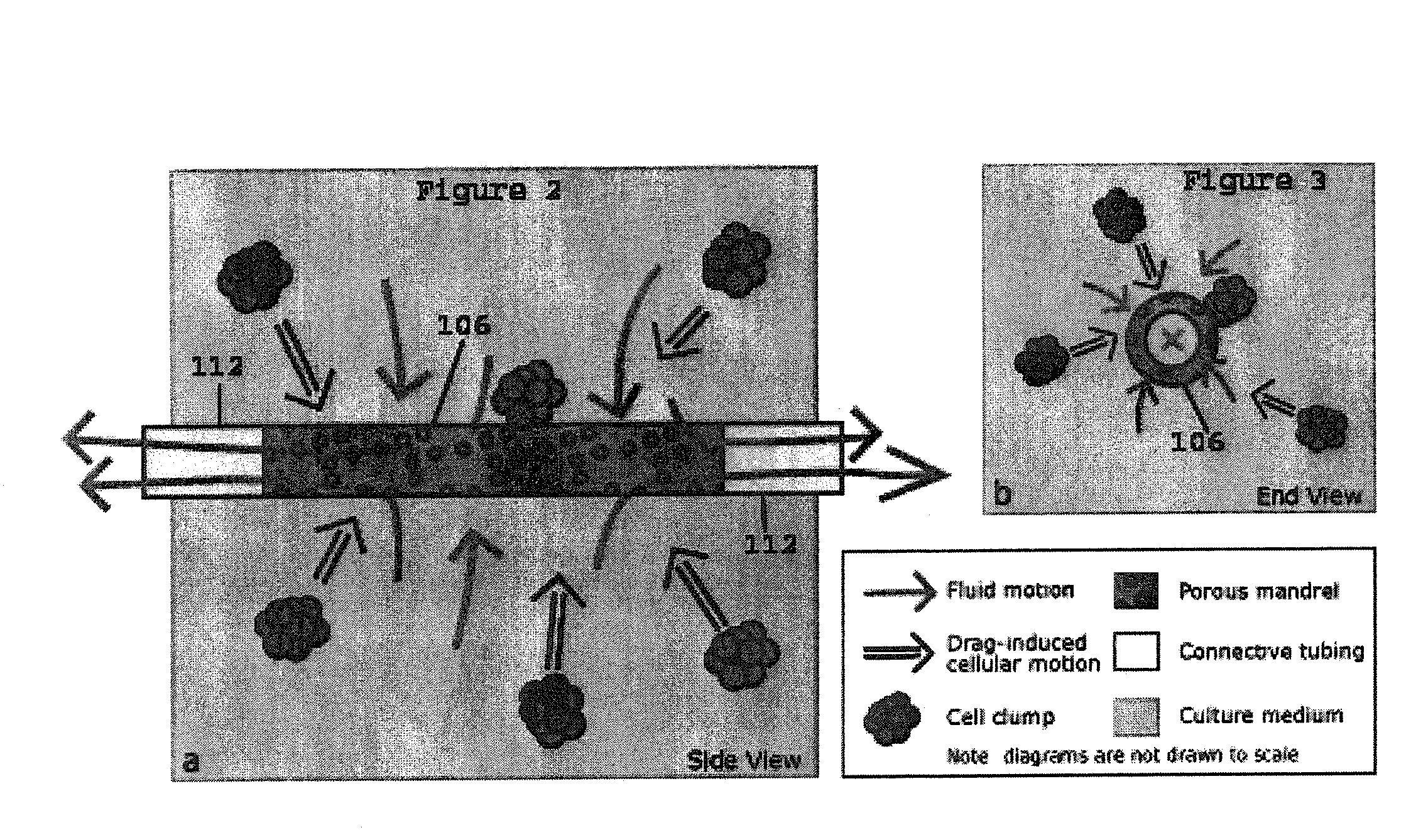

Convective flow tissue assembly

InactiveUS7439057B2Accurate tissue morphologyAvoid delaminationBioreactor/fermenter combinationsBiological substance pretreatmentsIn vivoBiology

The present invention provides for an improved in vitro tissue assembly system and related methods that includes and uses a bioreactor, a porous mandrel disposed in the bioreactor, and components that provide for the circulation of culture media and cell suspensions within the bioreactor and through the porous mandrel. The circulation of the culture media and cell suspensions within the bioreactor produces a radial, convective flow and drag forces that result in the deposition of cells on the mandrel to form a tissue construct. Upon completion of the culture and tissue formation process, the tissue construct may be removed from the mandrel for subsequent in vivo use.

Owner:LA JOLLA BIOENG INST

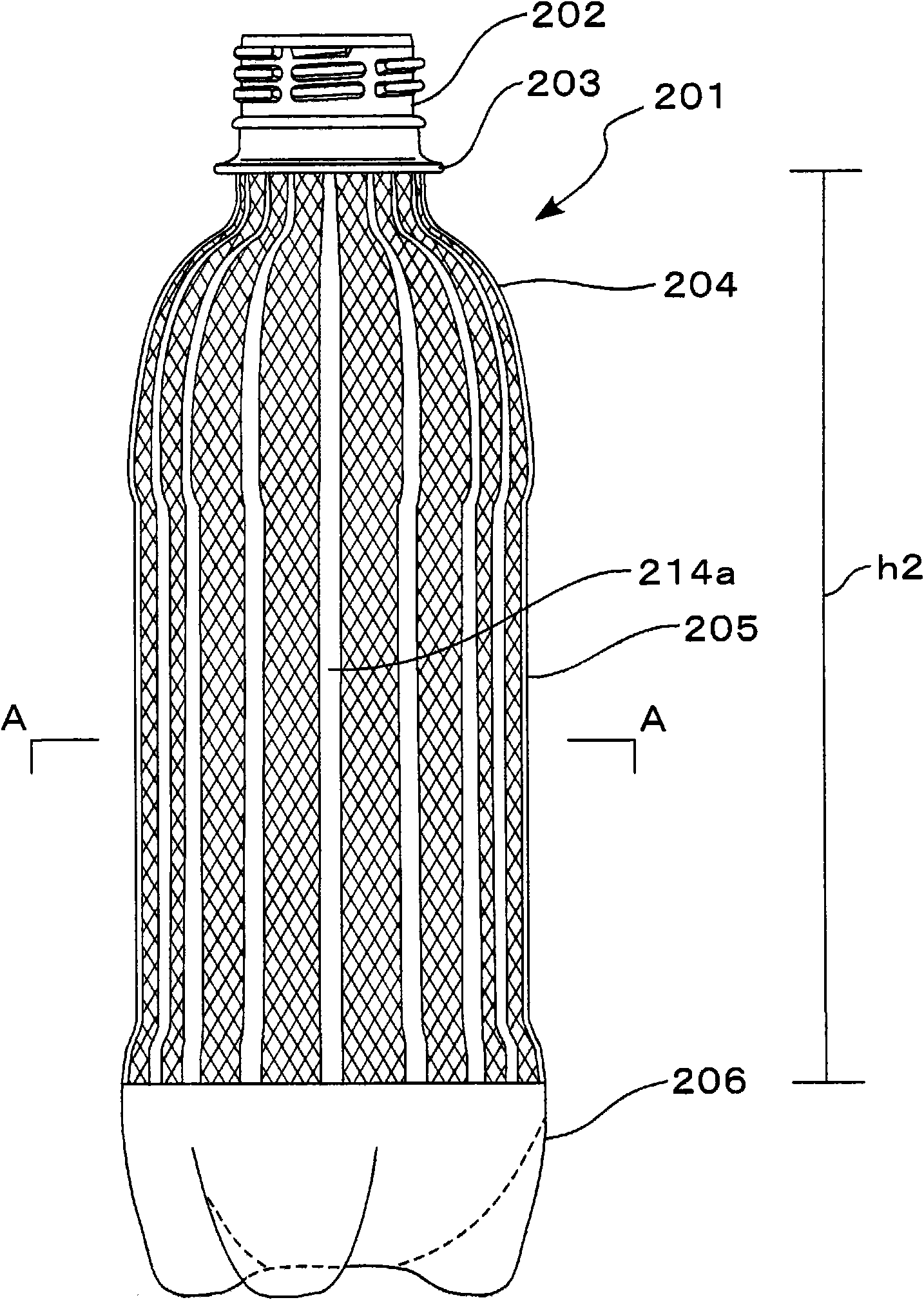

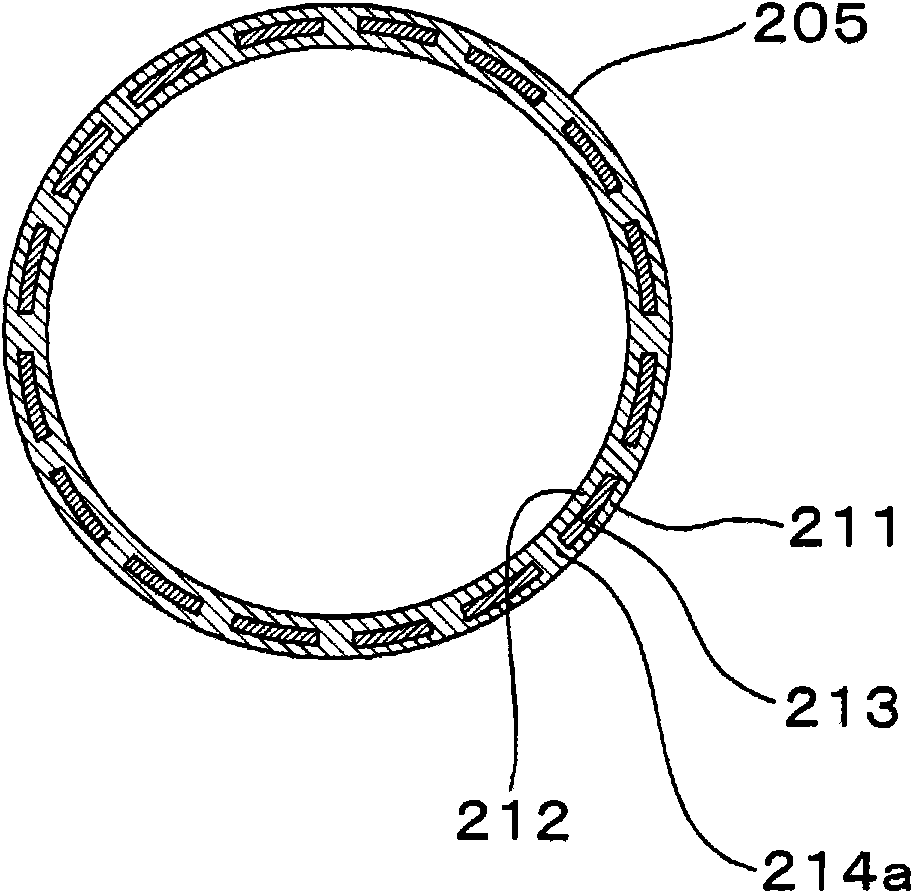

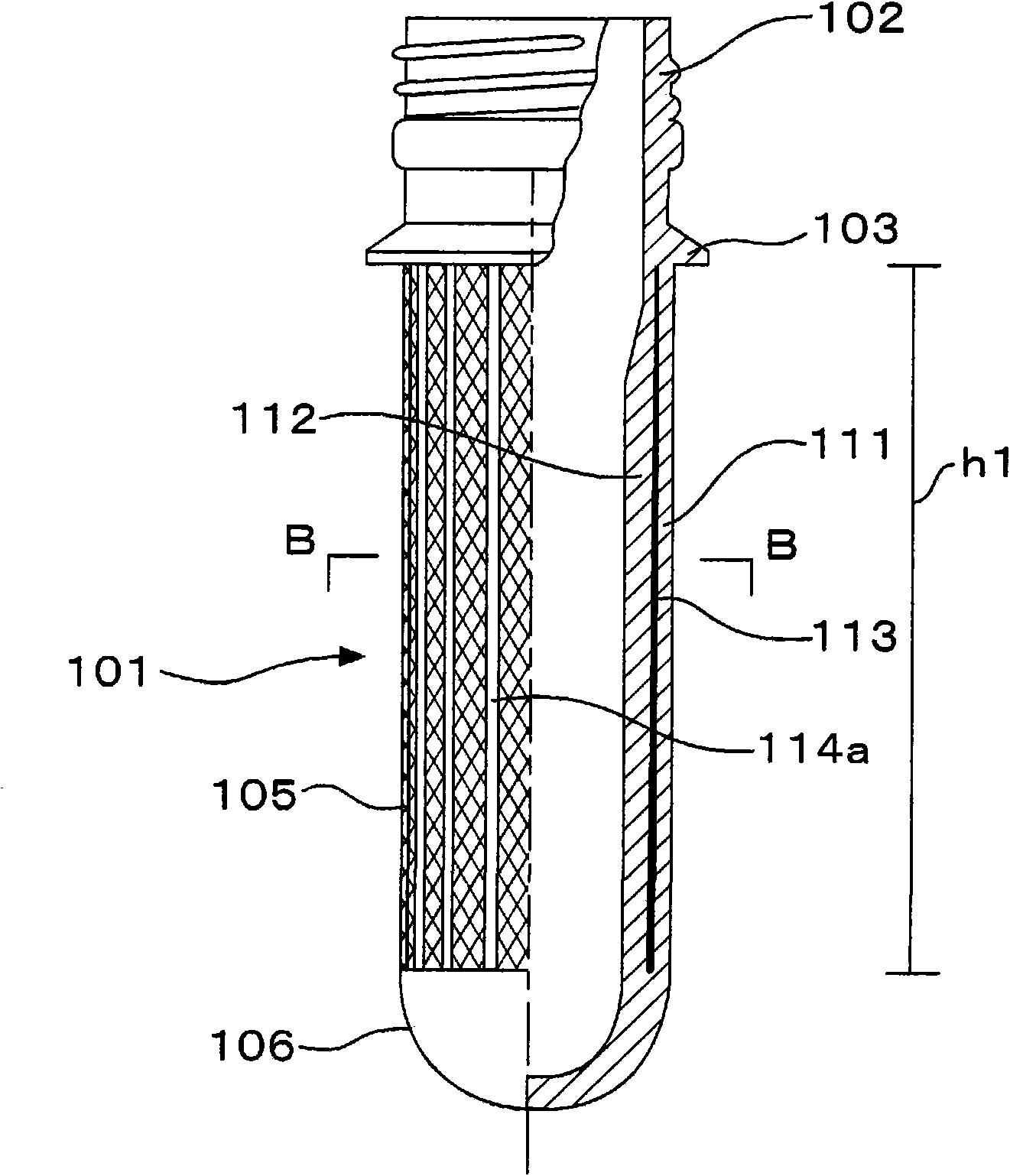

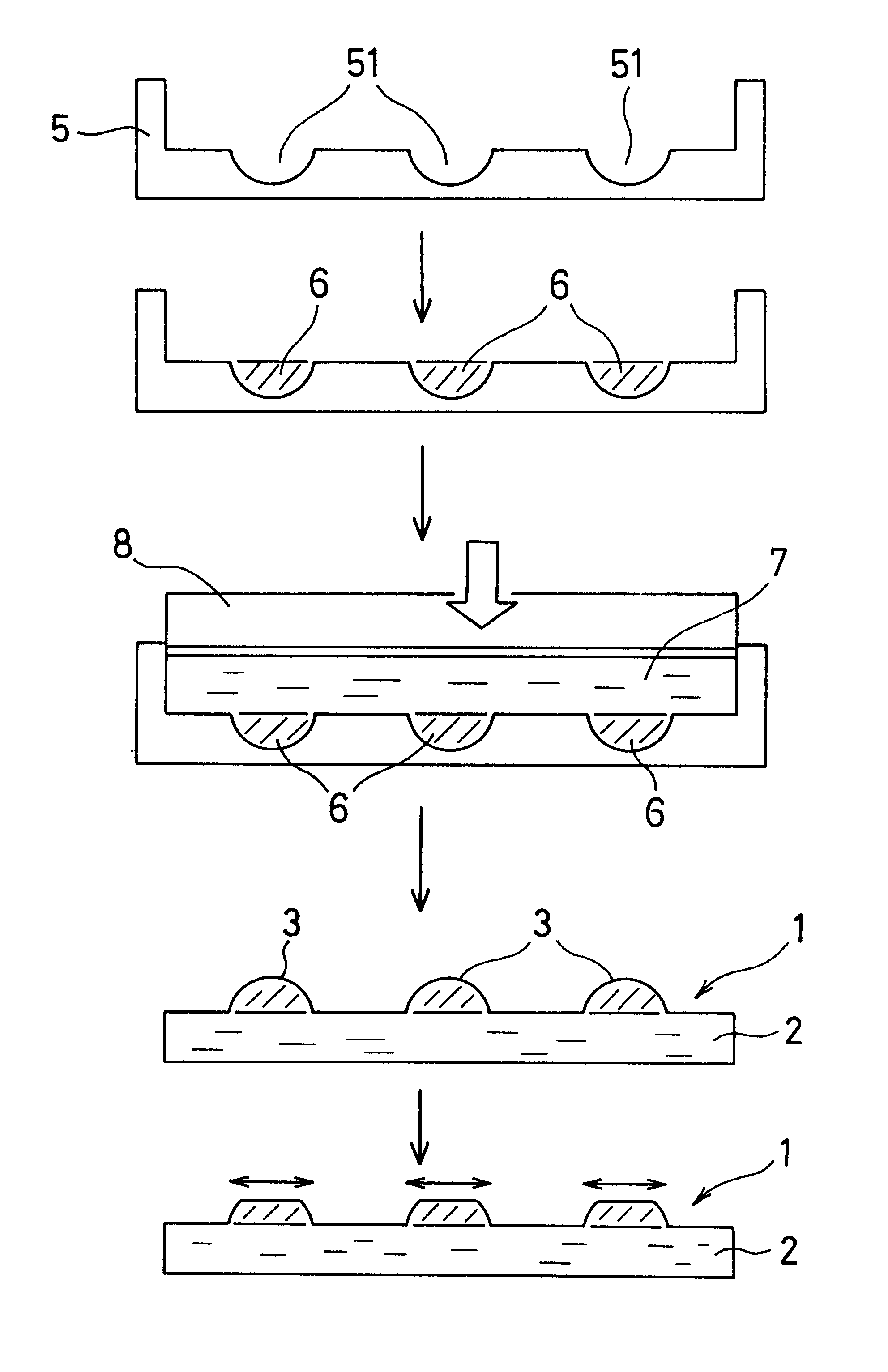

Synthetic-resin laminated bottle body, injection molding device and method for forming laminated preform

The invention provides a synthetic-resin laminated bottle body, an injection molding device and a method for forming laminated preform. To minimize delamination problem with a laminated bottle body produced by biaxial stretch blow molding. A principal method for solving the problem with the laminated bottle body, produced by biaxial stretch blow molding, comprises laminating an intermediate layer between base layers, extending a plurality of longitudinal strip coupling portions, where the base layers are laminated in a directly deposited state on the opposite sides of the intermediate layer, in a region with a predetermined height, in the direction of the central axis in parallel with each other in the circumferential direction, providing as required, a plurality of circumferential strip coupling portions, where the base layers are laminated in a directly deposited state on the top and bottom surfaces of the intermediate layer, in parallel with each other in the direction of the central axis, and dividing the intermediate layer by the longitudinal strip coupling portions and the circumferential strip coupling portions.

Owner:YOSHINO KOGYOSHO CO LTD

Air cargo container

ActiveUS9248958B2Avoid layeringRetain structureContainer filling methodsSynthetic resin layered productsFiberAir cargo

Composite panel for air cargo containers including a fire resistant, closed cell foam core, a skin attached to each surface of the core formed by fire resistant fibers in a matrix resin, wherein the panel will contain an internal fire with temperatures of up to 1500° F. for a period of at least 4 hours.

Owner:ADVANCED COMPOSITE STRUCTURES LTD

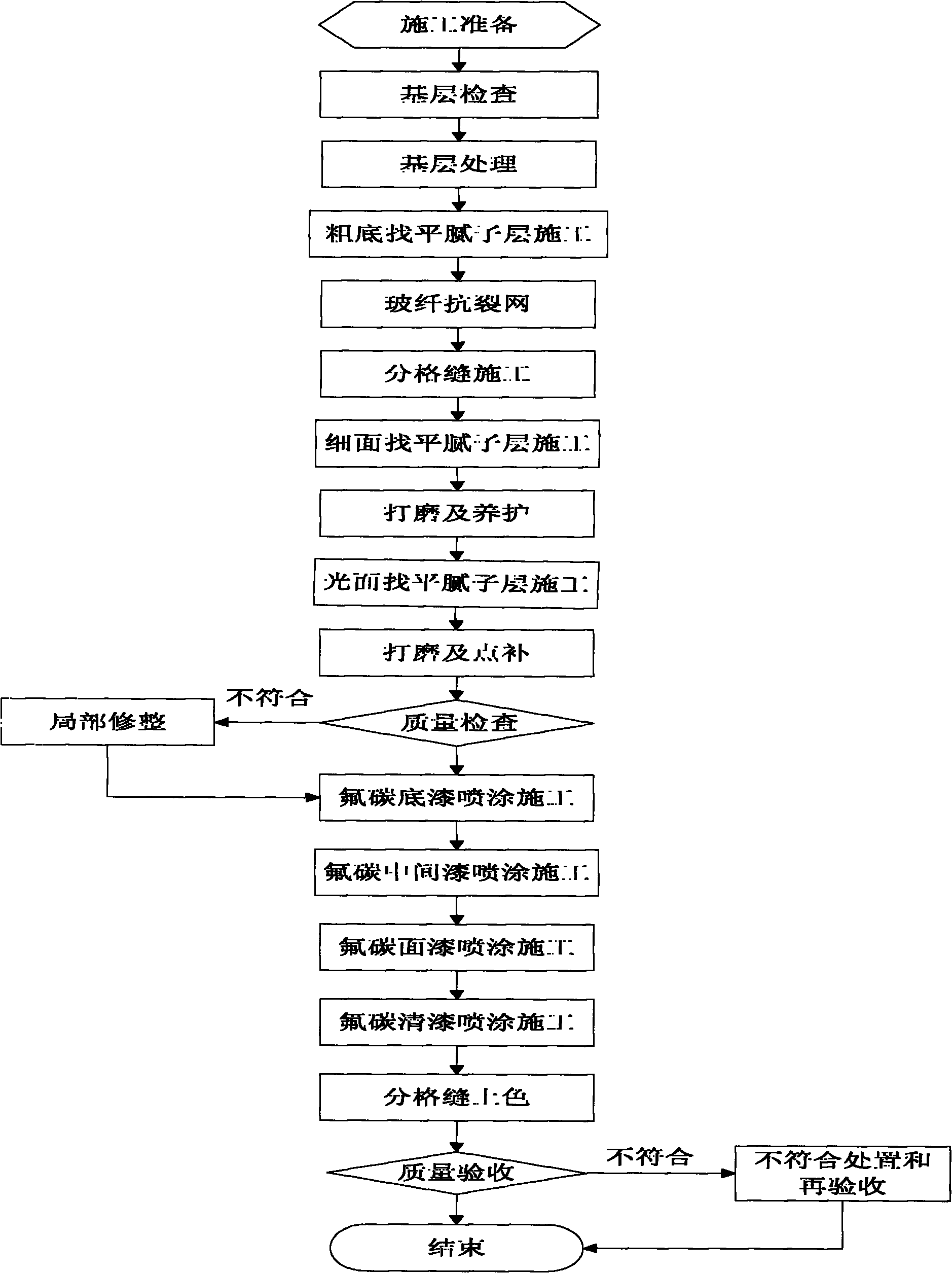

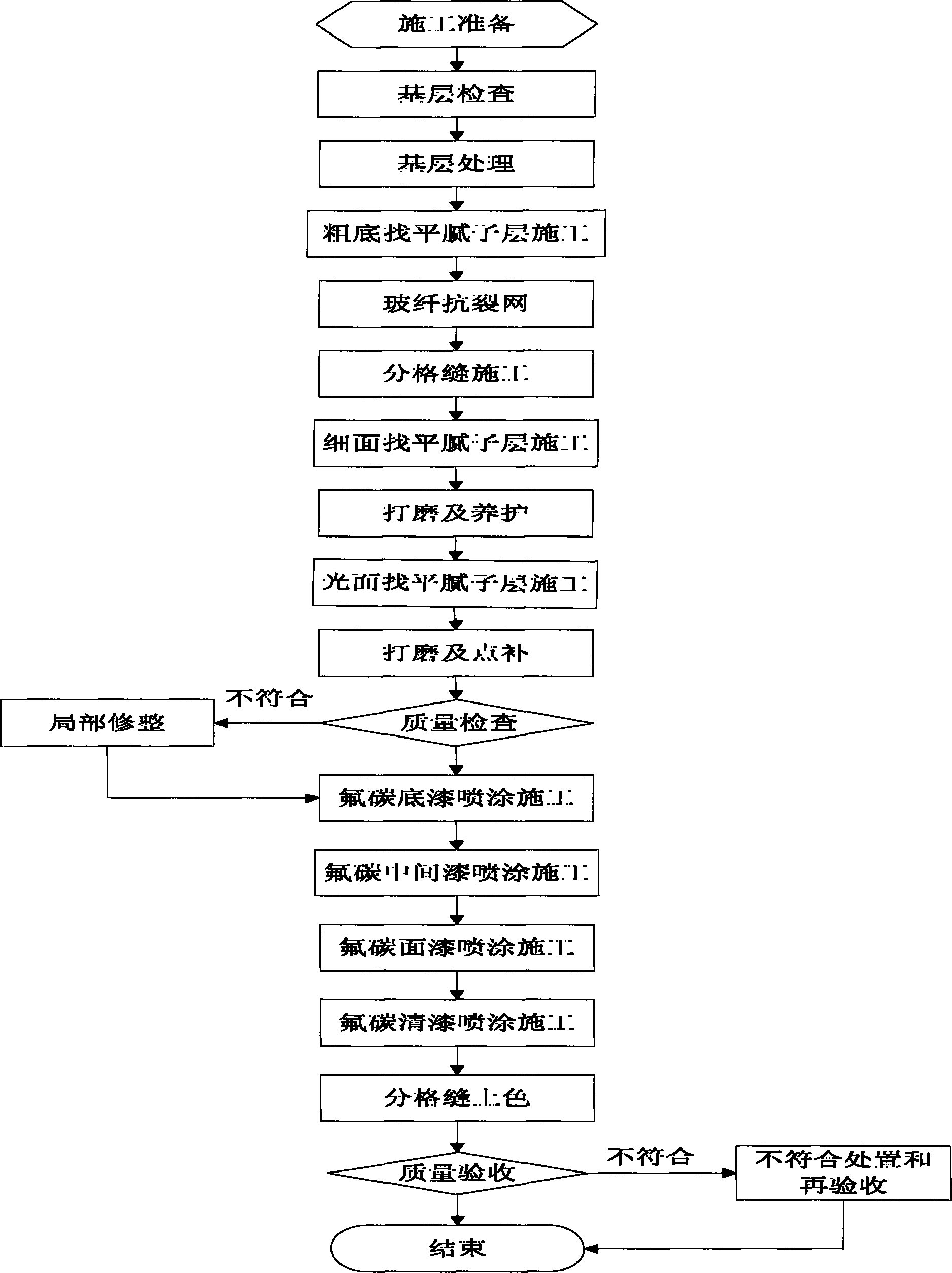

Construction process for outer wall metal fluorocarbon coating

InactiveCN101832015ASimplify construction stepsEasy to operateBuilding constructionsGlass fiberLacquer

The invention discloses a construction process for an outer wall metal fluorocarbon coating. The construction process comprises the following steps of: 1, checking a base layer; 2, treating the base layer; 3, performing coarse bottom leveling putty layer construction, wherein the used outer wall leveling coarse bottom putty is a finished putty special for the outer wall and a proper amount of quartz sand is added into the finished putty; 4, laying a glass fiber crack resistant net; 5, performing dividing joint construction; 6, performing fine surface leveling putty layer construction to ensure that the glass fiber crack resistant net is clamped between the coarse bottom leveling putty layer and the fine surface leveling putty layer; 7, polishing and maintaining; 8, performing polished side leveling putty layer construction; 9, performing fluorocarbon primer spraying construction; 10, performing fluorocarbon intermediate coating spraying construction; 11, performing fluorocarbon finish paint spraying construction; 12, performing fluorocarbon varnish spraying construction; and 13, coloring dividing joints. The construction process for the outer wall metal fluorocarbon coating has the advantages of simple construction steps, reasonable design, convenient operation, low construction cost, high construction quality, and excellent use efficiency, and can prevent the hollowness, delamination, crack and other quality defects on the surface of the outer wall metal fluorocarbon coating.

Owner:陕西建工第二建设集团有限公司

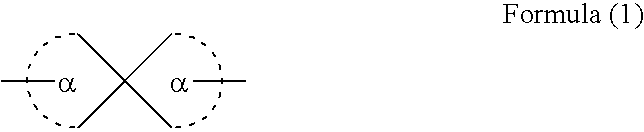

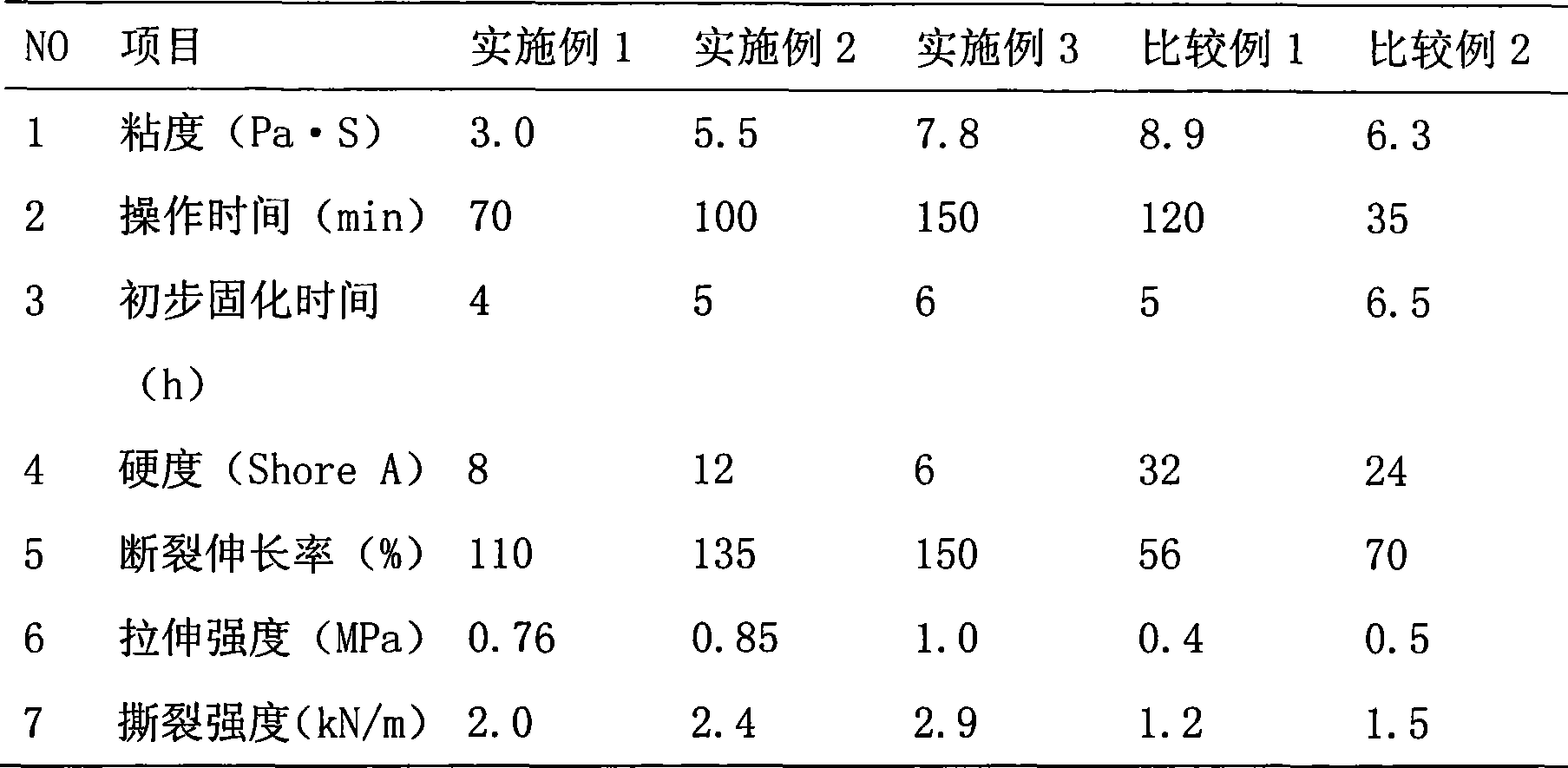

Bi-component silicone pouring sealant for LED photoelectric display device and method for manufacturing same

ActiveCN101544881AAvoid thickeningSimple processOther chemical processesSemiconductor/solid-state device manufacturingHydroxylamineDisplay device

The invention relates to a bi-component silicone pouring sealant for an LED optoelectronic display device and a method for manufacturing the same. The bi-component silicone pouring sealant is characterized in that the sealant is obtained through the reaction of components A and B by using alpha,omega-dihydroxy polydimethylsiloxane of which the structural formula shown on the right as a main material. The component A is prepared from the following components by weight portion through mixing: 100 portions of the alpha,omega-dihydroxy polydimethylsiloxane, 10 to 35 portions of organosilicon based gel, 0 to 50 portions of stuffing, and 10 to 30 portions of plasticizer; and the component B is prepared from the following components in portion by weight through mixing: 5 to 10 portions of cross-linking agent, 0.3 to 3 portions of coupling agent, 0.1 to 0.5 portion of titanate complex, 0.1 to 0.5 portion of diethyl hydroxylamine, 0.01 to 0.1 portion of dibutyltin dilaurate catalyst, and 2 to 10 portions of plasticizer. The silicone pouring sealant prepared by the method has the advantages of simple process flow, good adhesive property, excellent temperature and weather resistant properties, and good flow property, and can be widely applicable for embedding electronic devices such as the LED optoelectronic display device and the like.

Owner:CHENGDU GUIBAO SCI & TECH

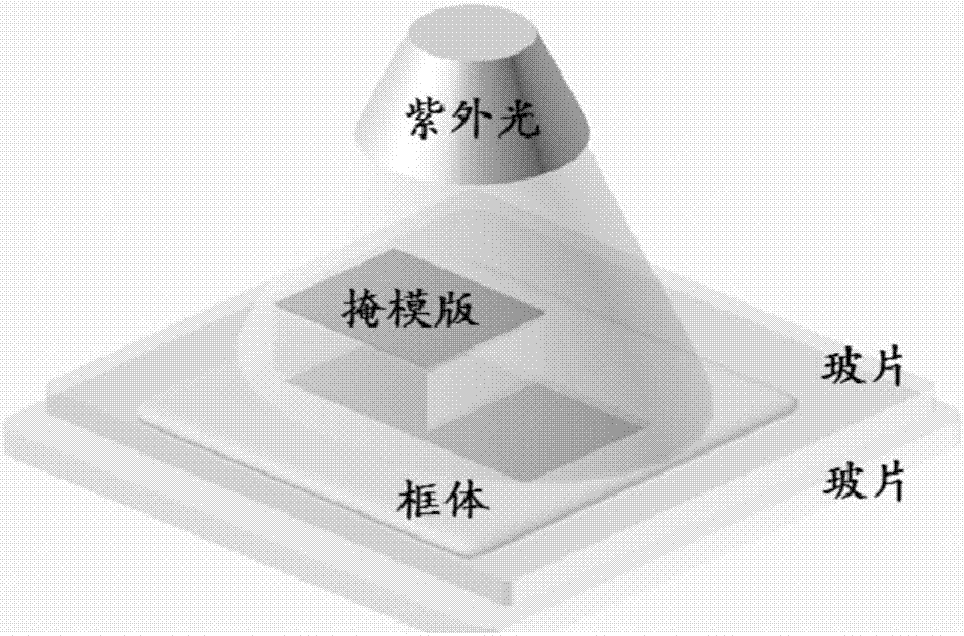

Deformable stimuli responsive material and preparation method thereof and stimuli responsive flexible microelectrode array

ActiveCN107033279AAchieve three-dimensional structural transformationImprove adhesionHead electrodesExternal electrodesElectricityStimuli responsive

The invention provides a deformable stimuli responsive material which has local Young modulus differences. The deformable stimuli responsive material is formed by at least one of a thermal response material, a photo-thermal response material, a magnetic thermal response material, an electric heating response material, a humidity response material and a pH response material. The deformable stimuli responsive material can be converted into a three-dimensional structure from a plane two-dimensional structure under one or more outside stimuli conditions of temperature, light, magnetism, electricity, humidity and pH. The material is modified to the back of a planar flexible microelectrode array, so that three-dimensional deformation of the flexible microelectrode array can be implemented through outside stimuli, and precise control over controllable shaping and curvature of the conventional planar flexible microelectrode array can be implemented by further regulating the thickness or crosslinking degree and the like of the stimuli responsive material. The invention further provides a method for preparing the deformable stimuli responsive material and a stimuli responsive flexible microelectrode array.

Owner:SHENZHEN INST OF ADVANCED TECH

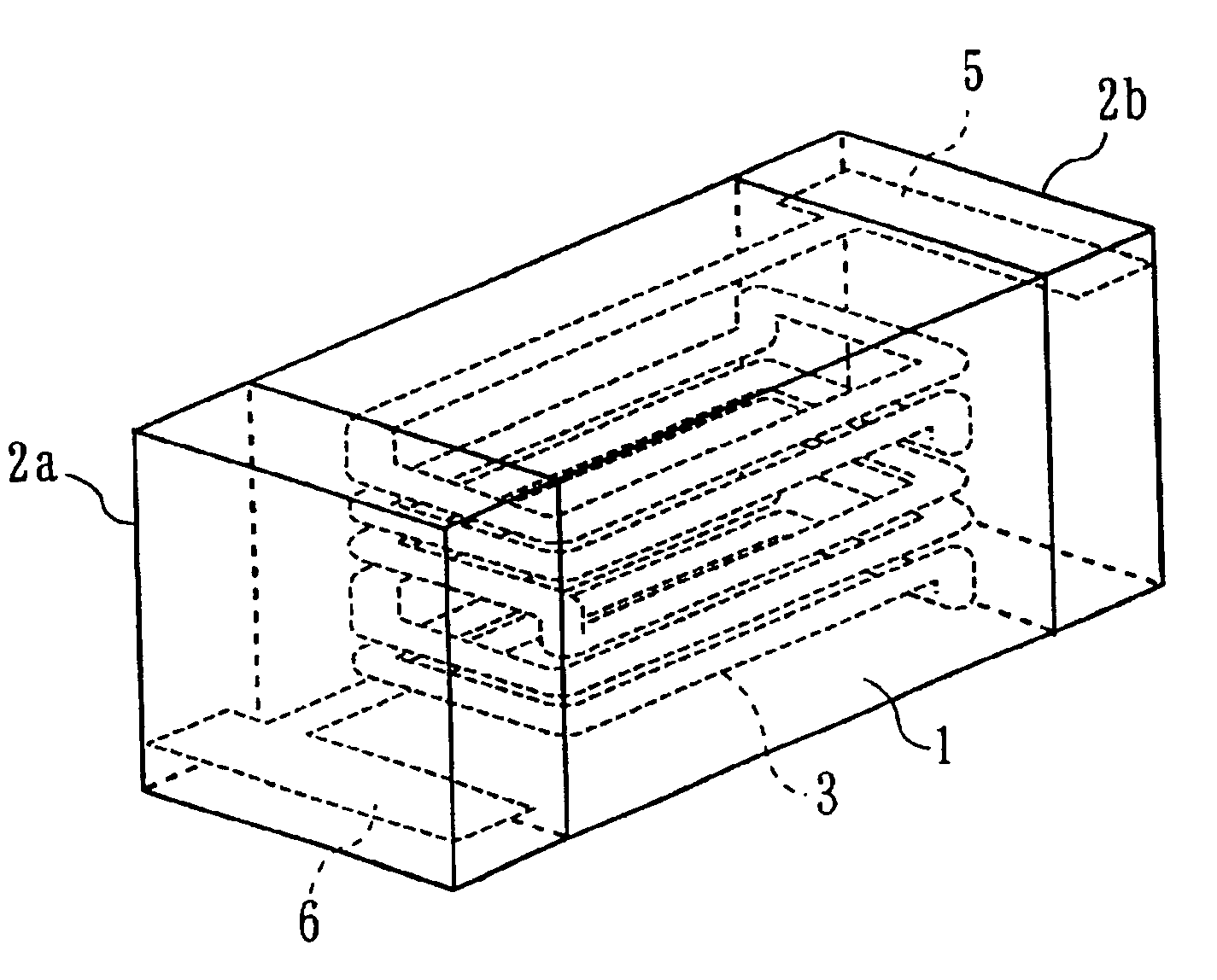

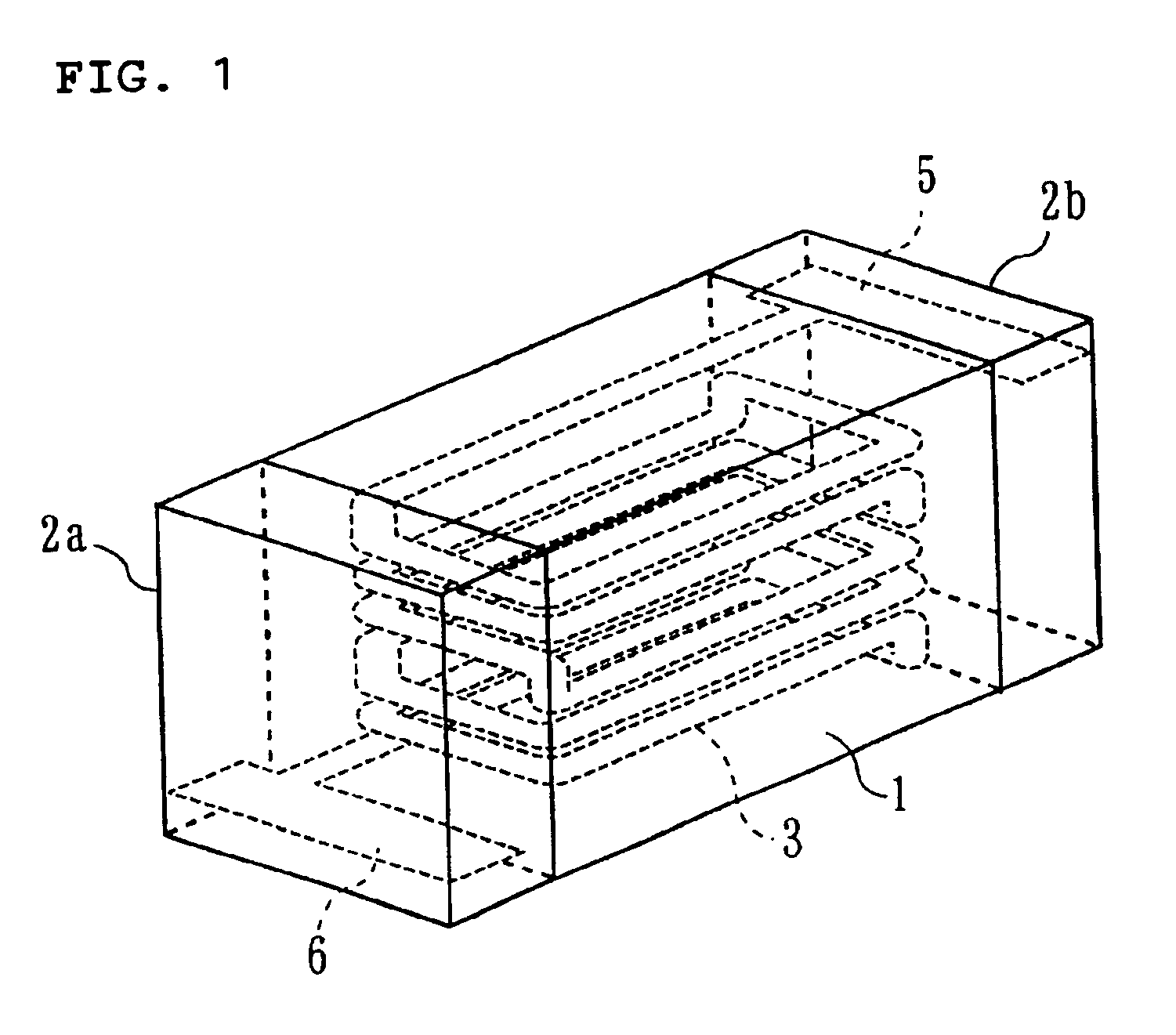

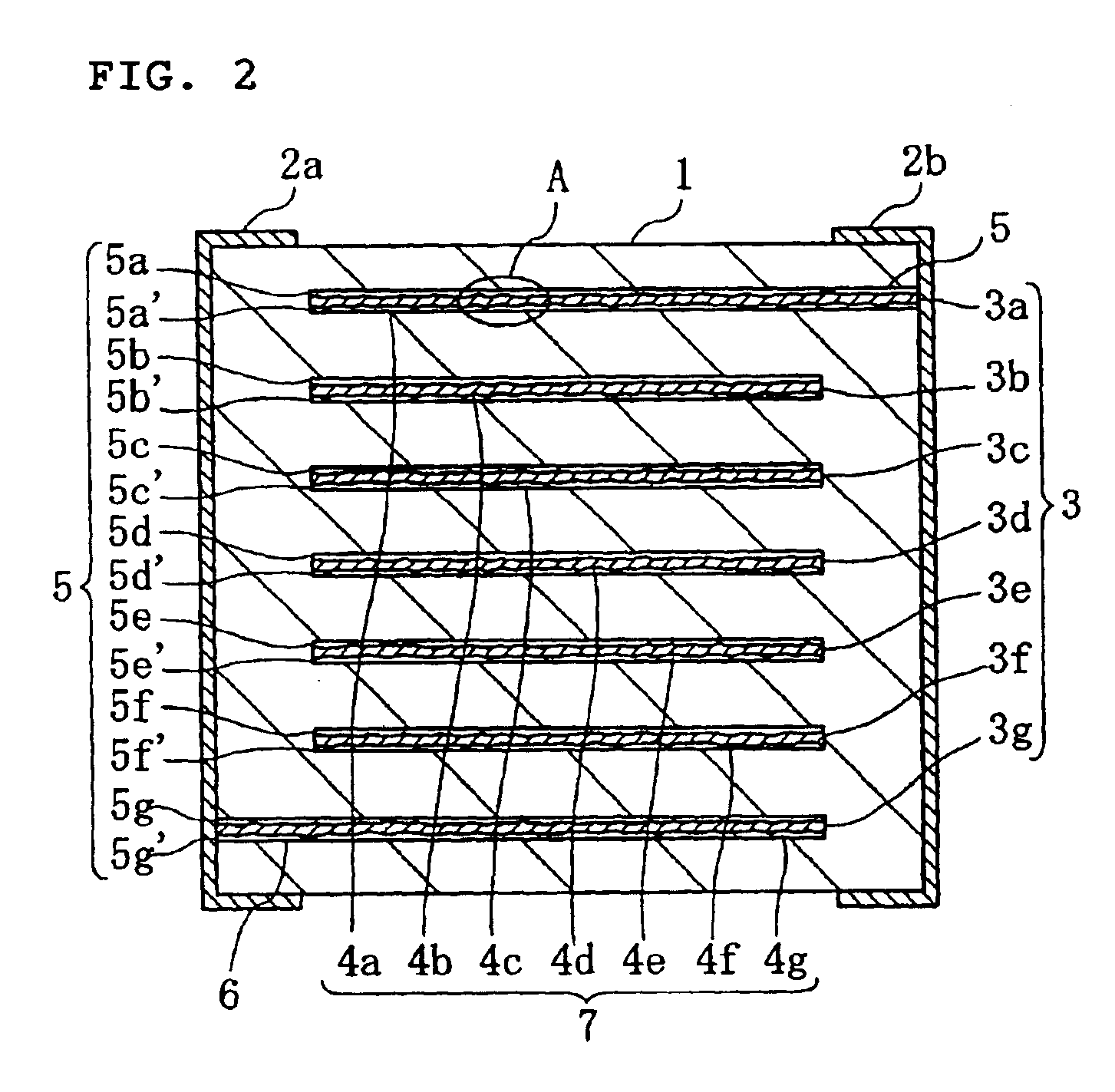

Method for manufacturing laminated multilayer electronic components

InactiveUS6855222B2Improve reliabilityGood anti-surge effectLayered product treatmentFixed capacitor electrodesConductive pasteElectronic component

A method for producing a laminated electronic component produces a laminated electronic component having a superior surge-proofing property, a sufficient resistance to a flux, and excellent electrical properties, without experience the occurrence of structural effects such as cracking, delamination, or other structural defects. Conductive paste is prepared to contain conductive particles and resin particles having a thermal decomposition-ability. The resin particles have an average particle size of about 0.25 to about 1.50 times the average particle size of the conductive particles. The volume ratio of the resin particles is in the range of about 0.5 to about 1.0 the volume of the conductive particles. The conductive paste is applied to the surface of a ceramic layer to form a conductor layer. The ceramic layers and the conductor layers are alternately laminated. The laminate is fired to form a ceramic sintered laminate. Thus, a laminated electronic component is produced.

Owner:MURATA MFG CO LTD

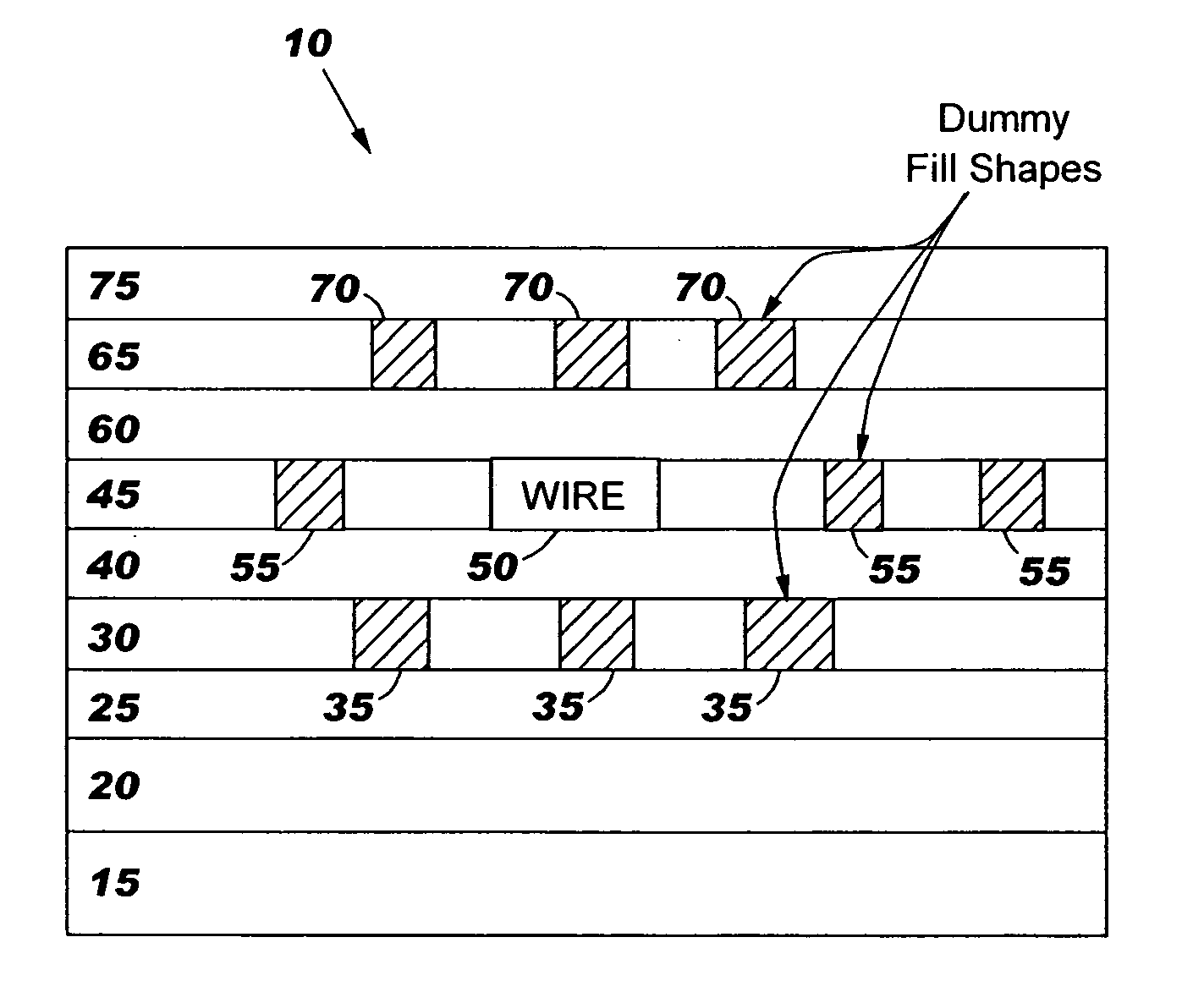

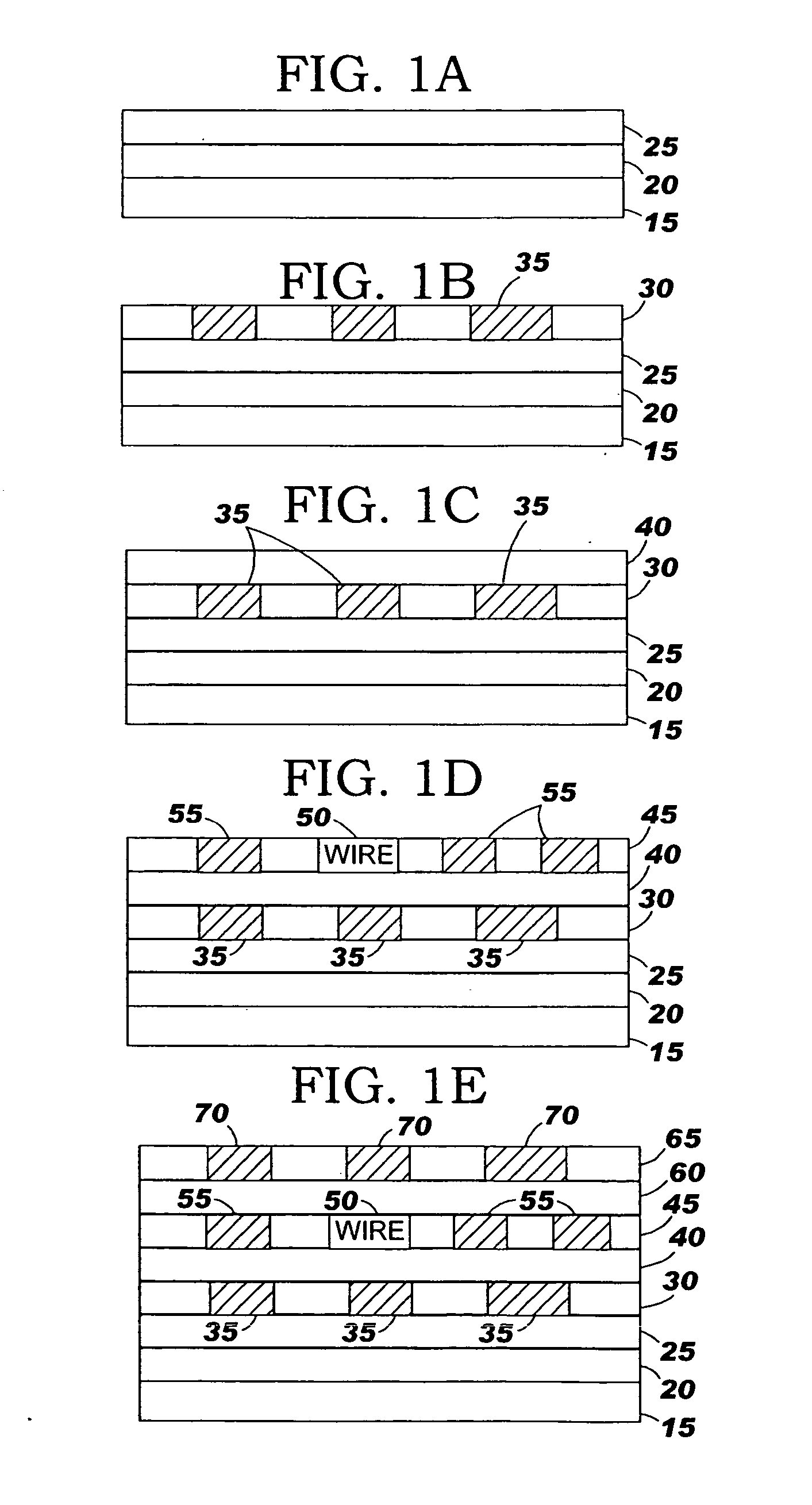

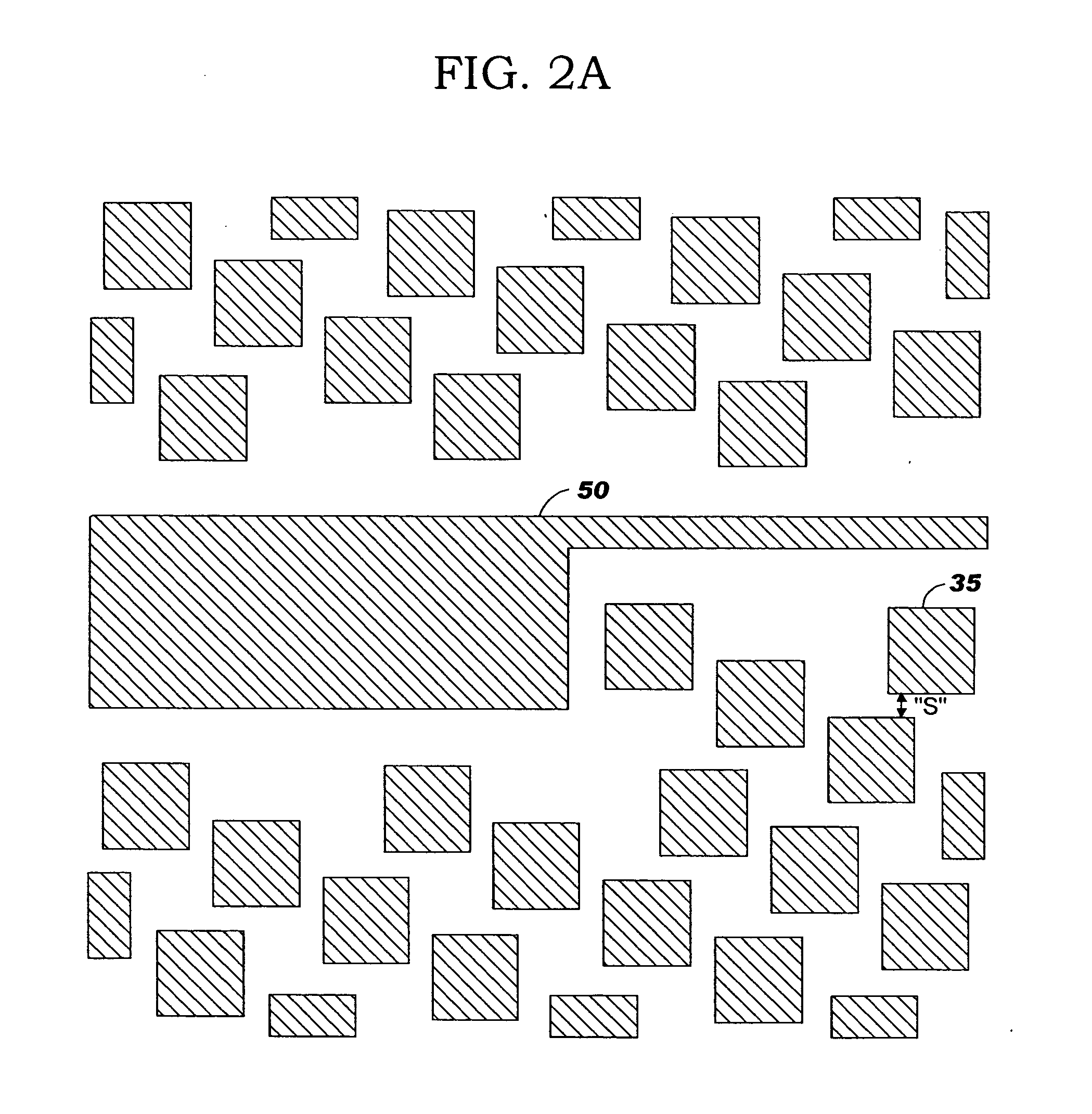

Dummy metal fill shapes for improved reliability of hybrid oxide/low-k dielectrics

InactiveUS20060118960A1Improve mechanical stabilityAvoid delaminationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMixed oxideSemiconductor structure

Semiconductor structure including a first rigid dielectric layer and a second rigid dielectric layer. A first non-rigid low-k dielectric layer is formed between the first and second rigid dielectric layer. A plurality of dummy fill shapes is formed in the first non-rigid layer which replace portions of the first non-rigid low-k dielectric layer with lower coefficient of thermal expansion (CTE) metal such that an overall CTE of the first non-rigid low-k dielectric layer and the plurality of dummy fill shapes matches a CTE of the first and second rigid dielectric layers more closely than that of the first non-rigid low-k dielectric layer alone.

Owner:GLOBALFOUNDRIES INC

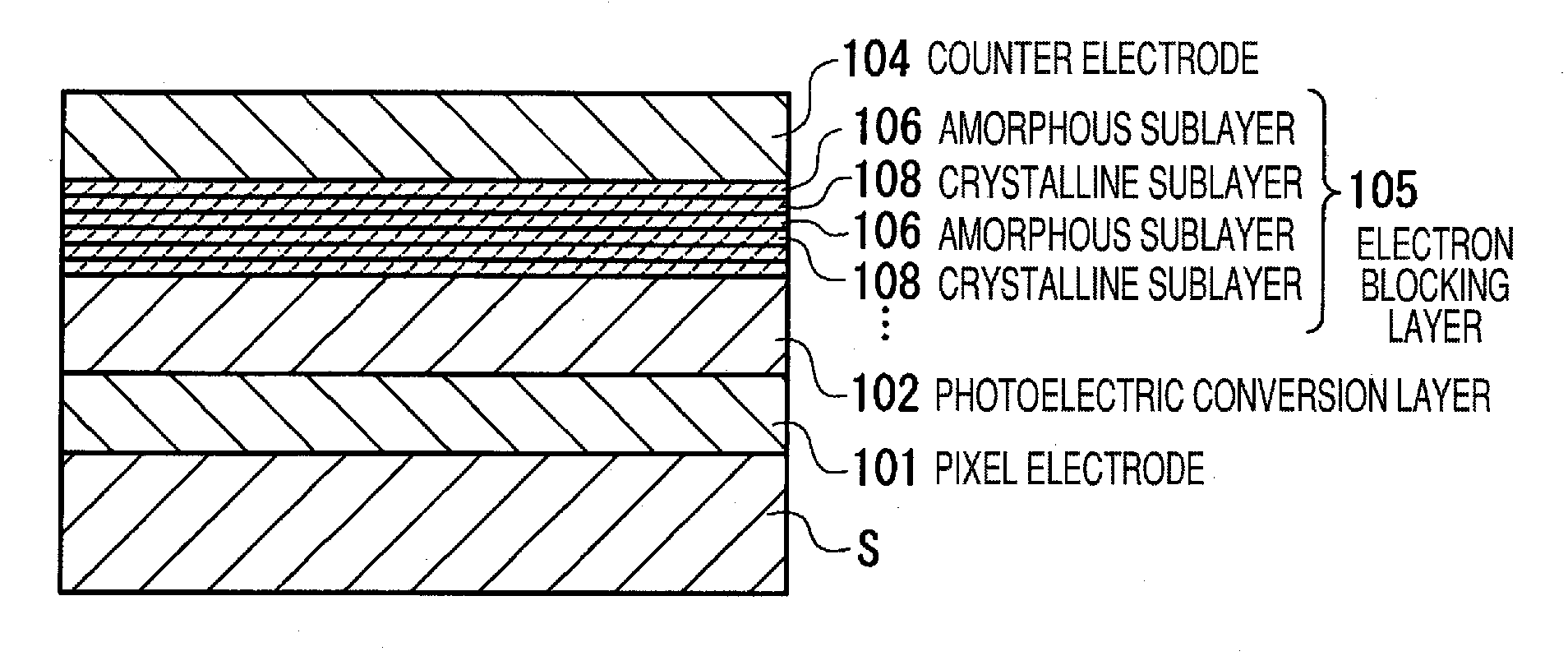

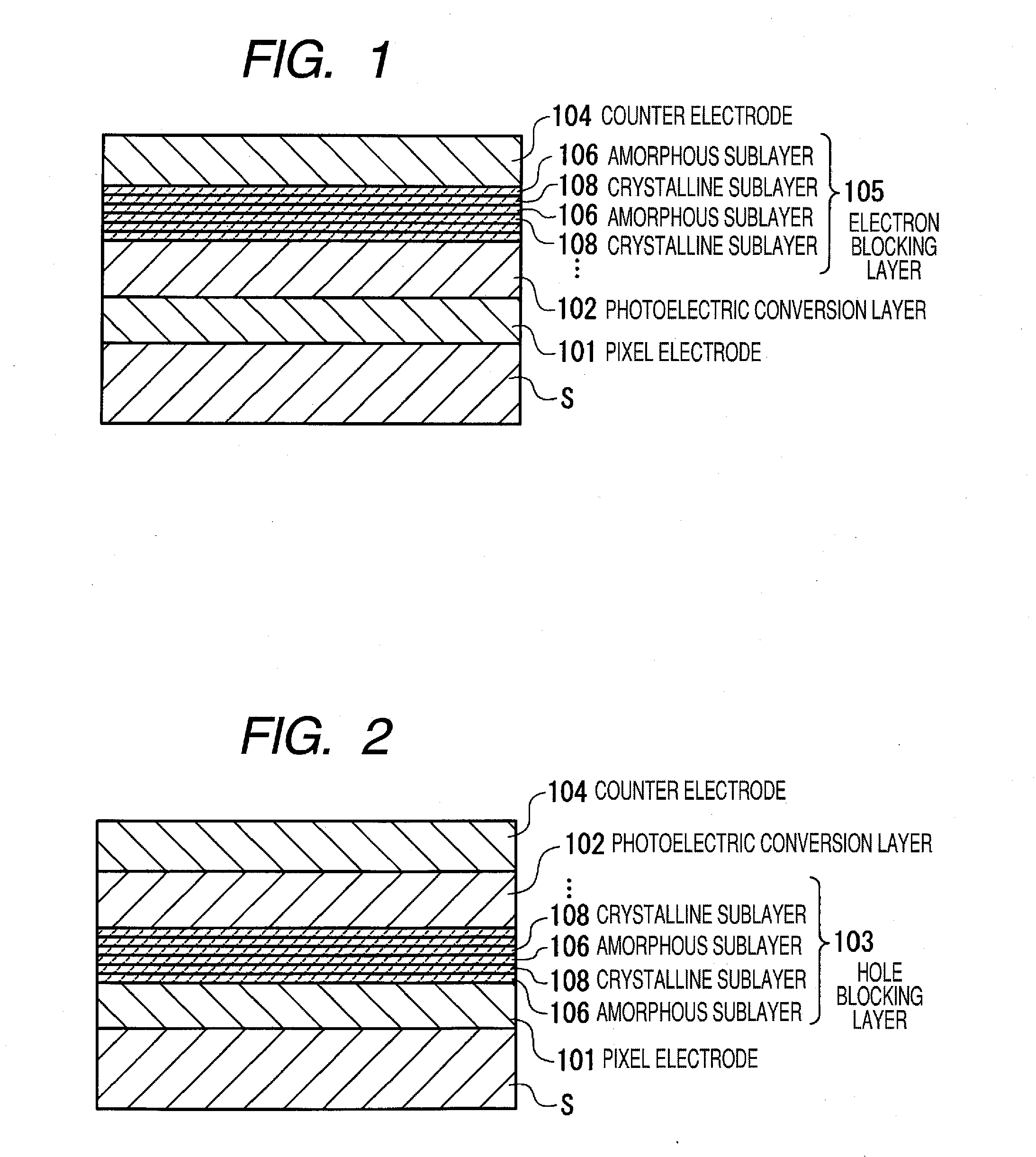

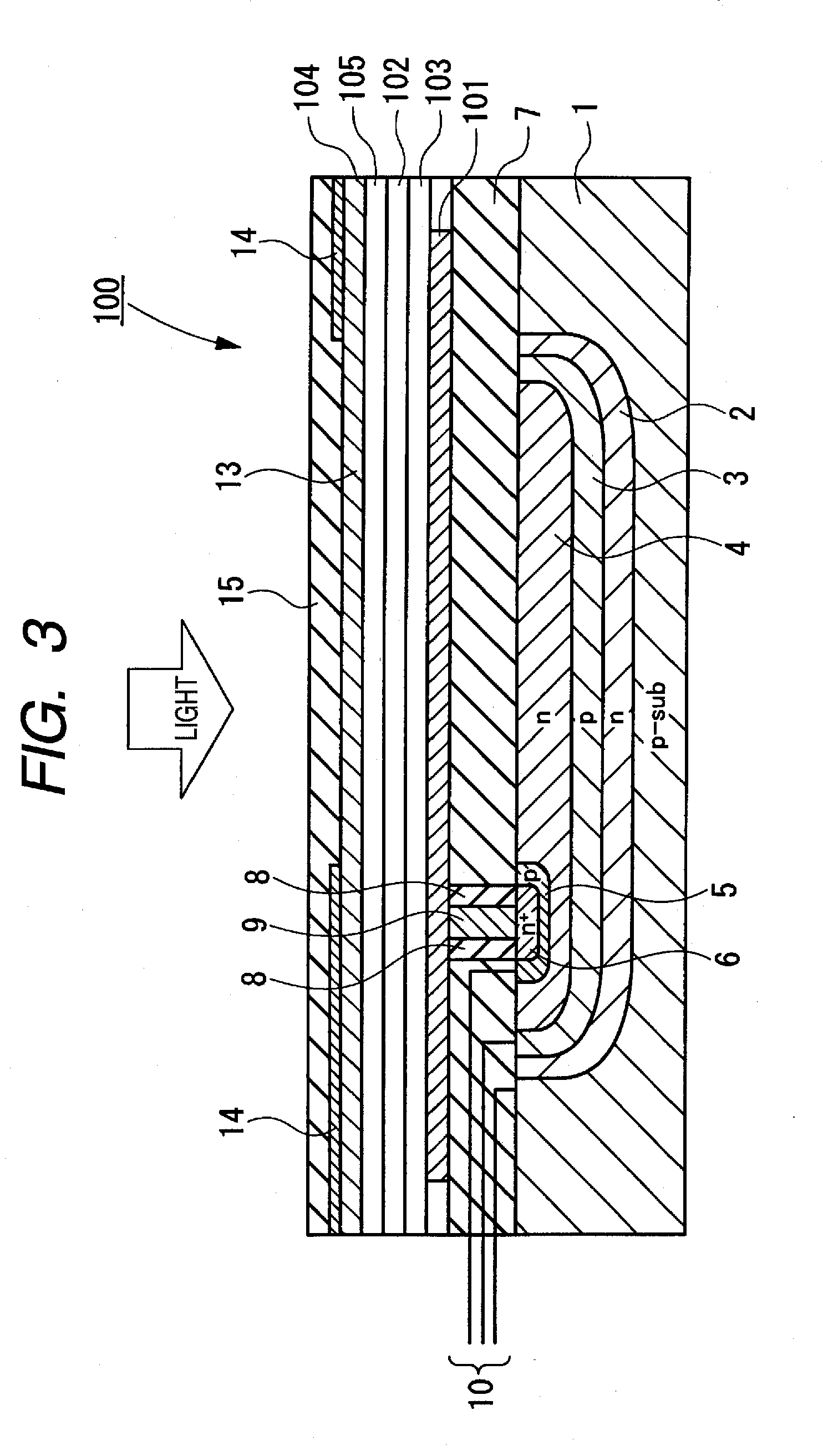

Photoelectric conversion element and solid-state imaging device

InactiveUS20090315136A1Relieve stressAvoid performanceSolid-state devicesDiodePhotoelectric conversionPhysics

A photoelectric conversion element includes a pair of electrodes, a photoelectric conversion layer provided between the pair of electrodes and a stress buffer layer provided between the photoelectric conversion layer and at least one of the electrodes, and the stress buffer layer has a stack structure comprising a crystalline sublayer.

Owner:FUJIFILM CORP

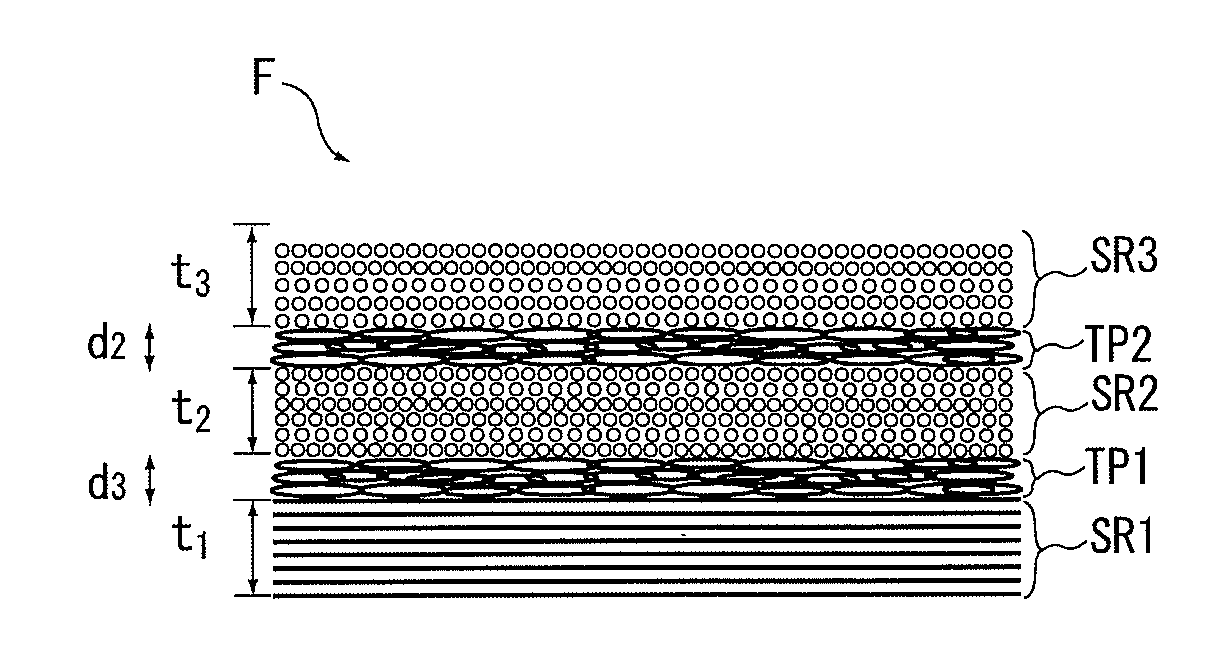

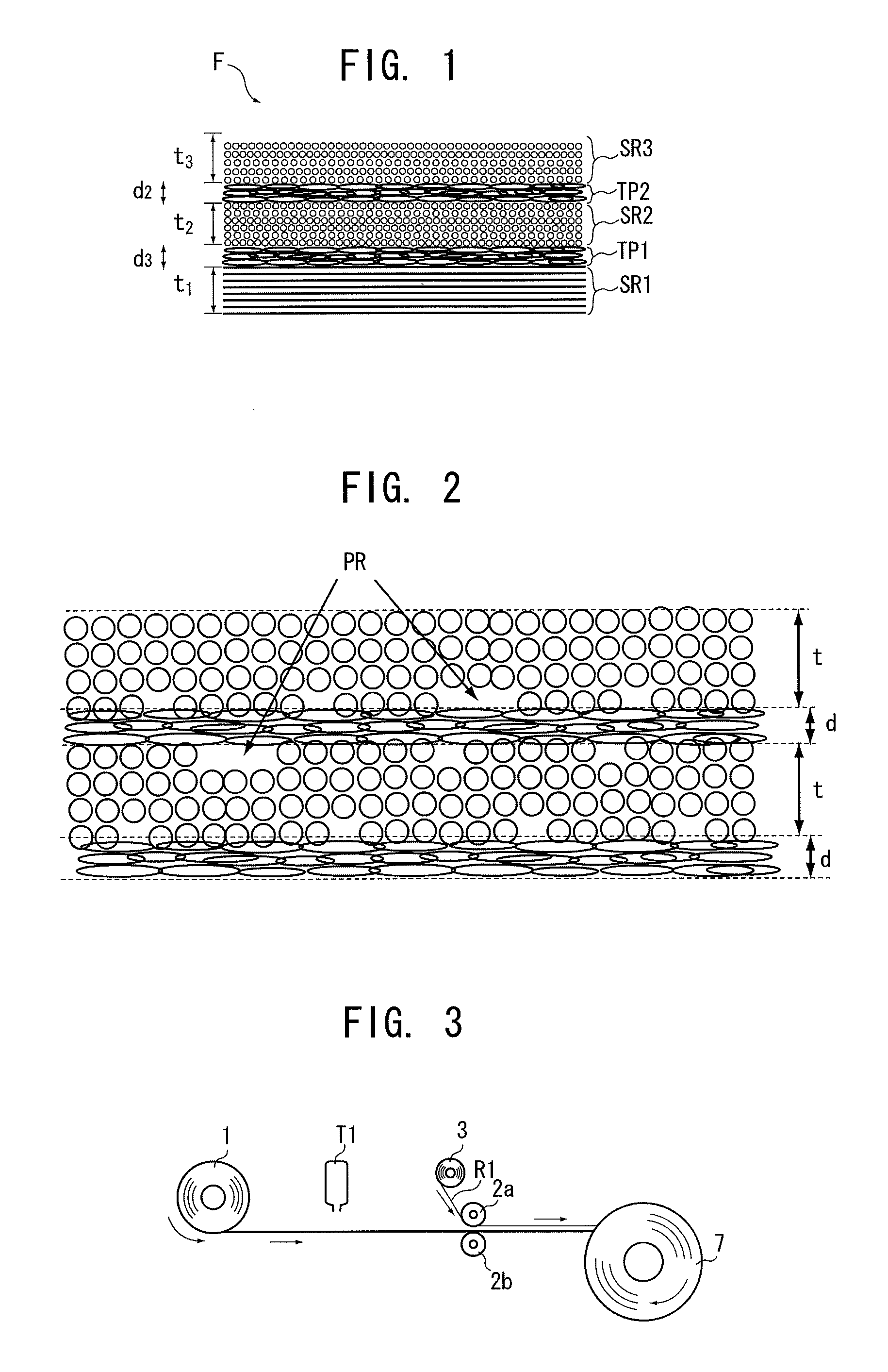

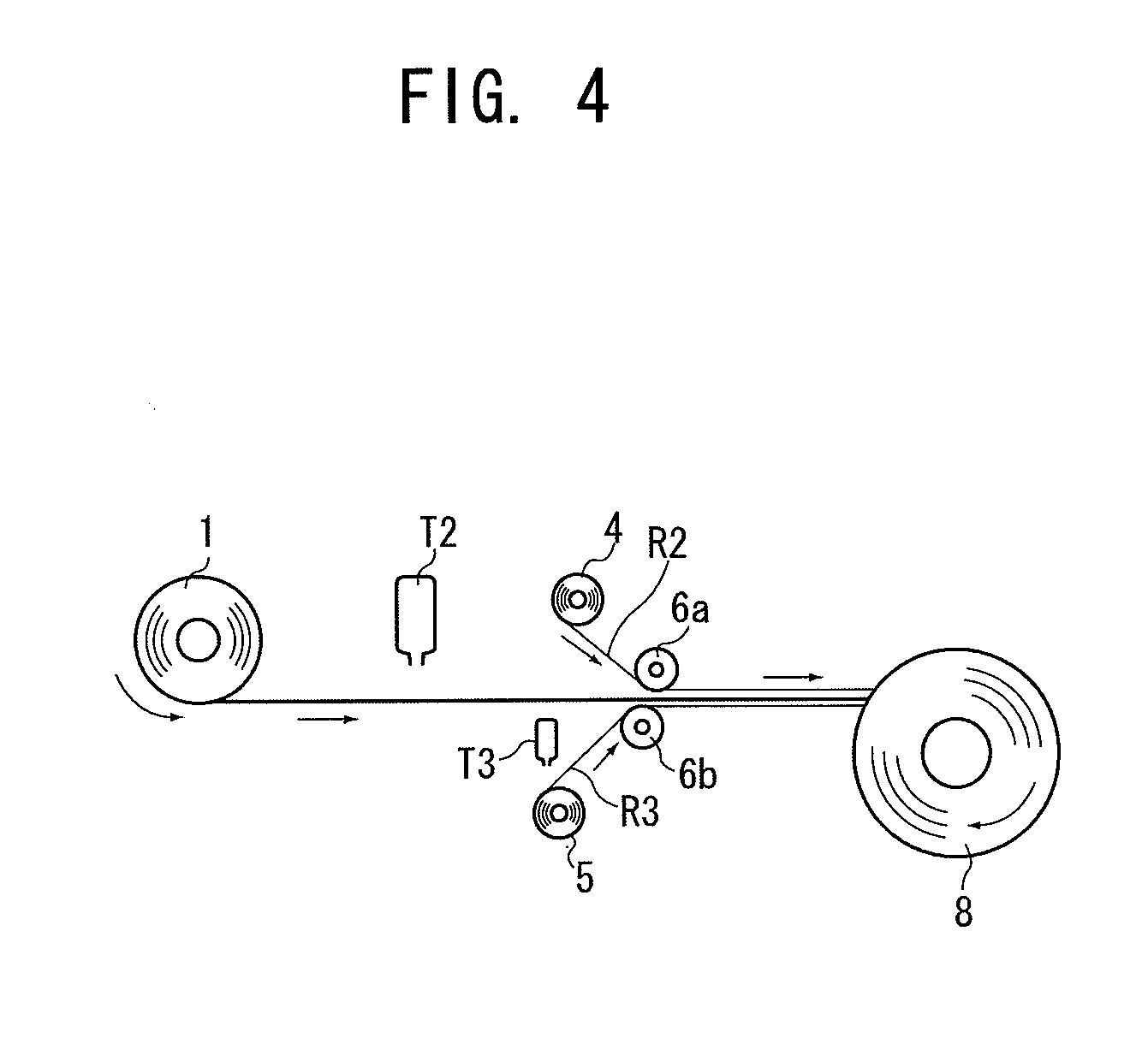

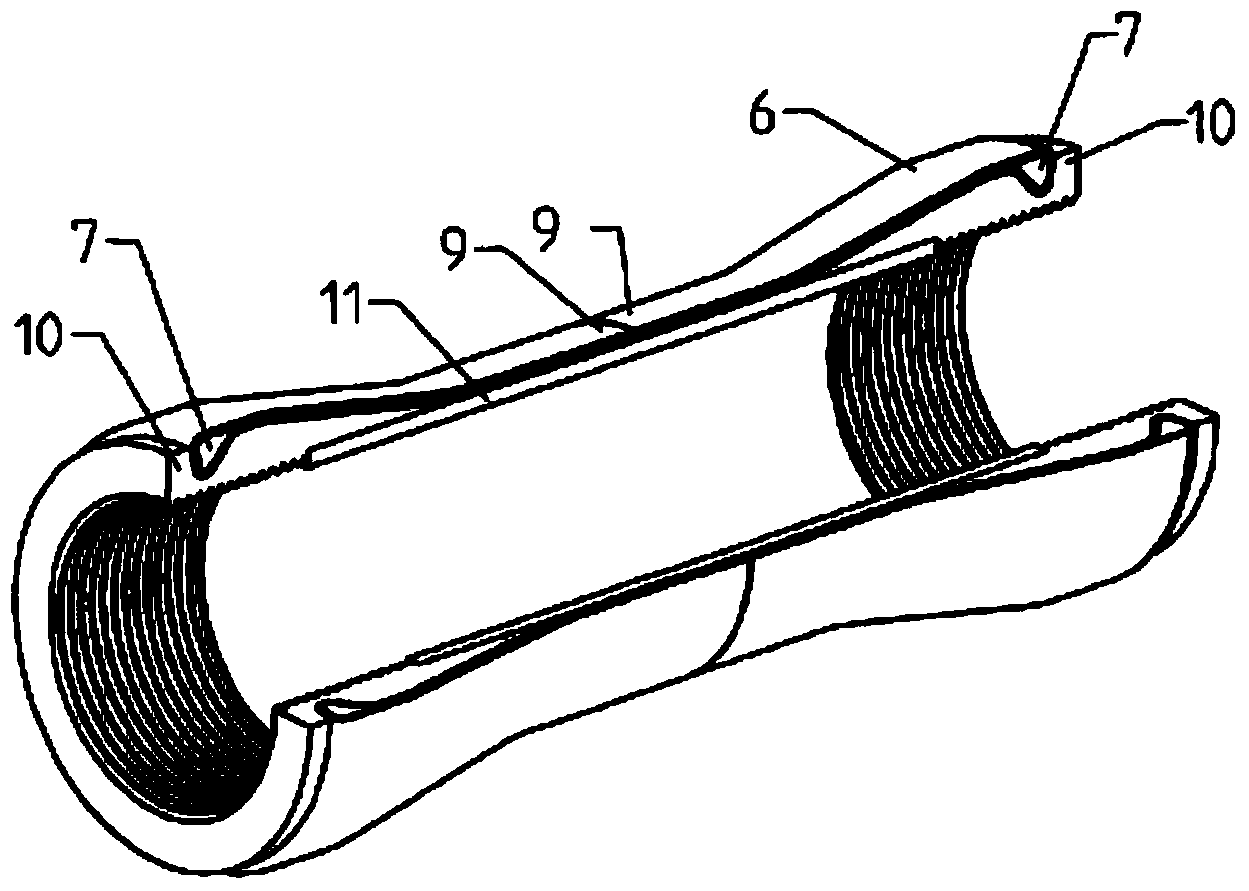

Multiaxially reinforced laminated moldings and process for production thereof

InactiveUS20090291278A1Avoid layeringReduce thicknessVehicle componentsGlass/slag layered productsHigh intensityPolyresin

An object of the present invention is to provide a laminated molding having high strength and reduced possibility of layer separation, a multiaxially reinforced laminated molding capable of reducing the production time and the production cost, and a method for producing the same. A multiaxially reinforced laminated molding (F) is formed of fiber-reinforced layers (SR1 to SR3), each including reinforcing fiber sheets stacked on top of each other such that reinforcing fibers of the reinforcing fiber sheets are oriented in three axial directions. Resin layers (TP1 and TP2) are disposed among the fiber-reinforced layers. The resin layers (TP1 and TP2) are formed of many particles of a thermoplastic resin material that are substantially uniformly distributed and heat-sealed together. The distributed thermoplastic resin material is adhered to the adjacent fiber-reinforced layer through heat-sealing. The thermoplastic resin material has many fine gaps and the entirety of the fiber-reinforced layers and the resin layers are thoroughly impregnated with the thermosetting resin material.

Owner:FUKUI PREFECTURE +1

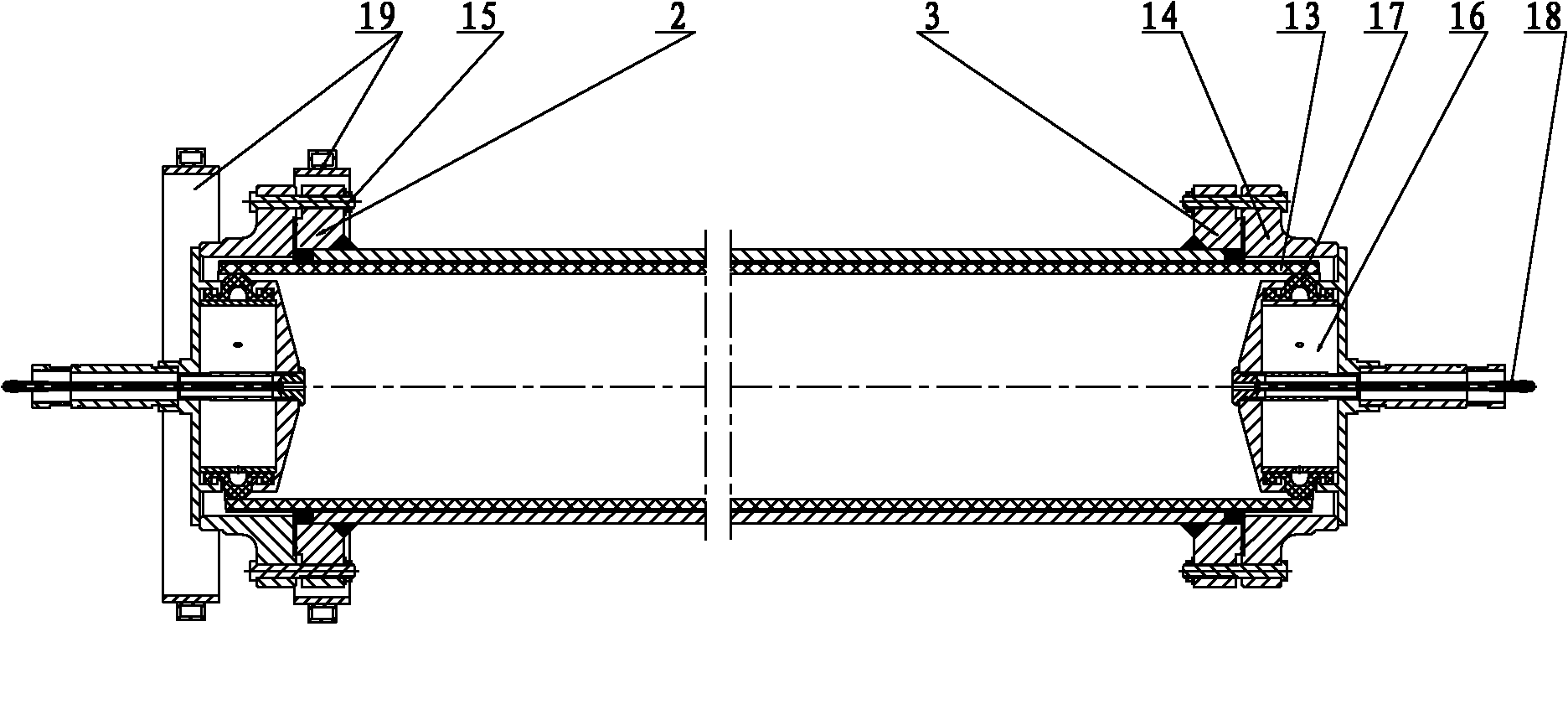

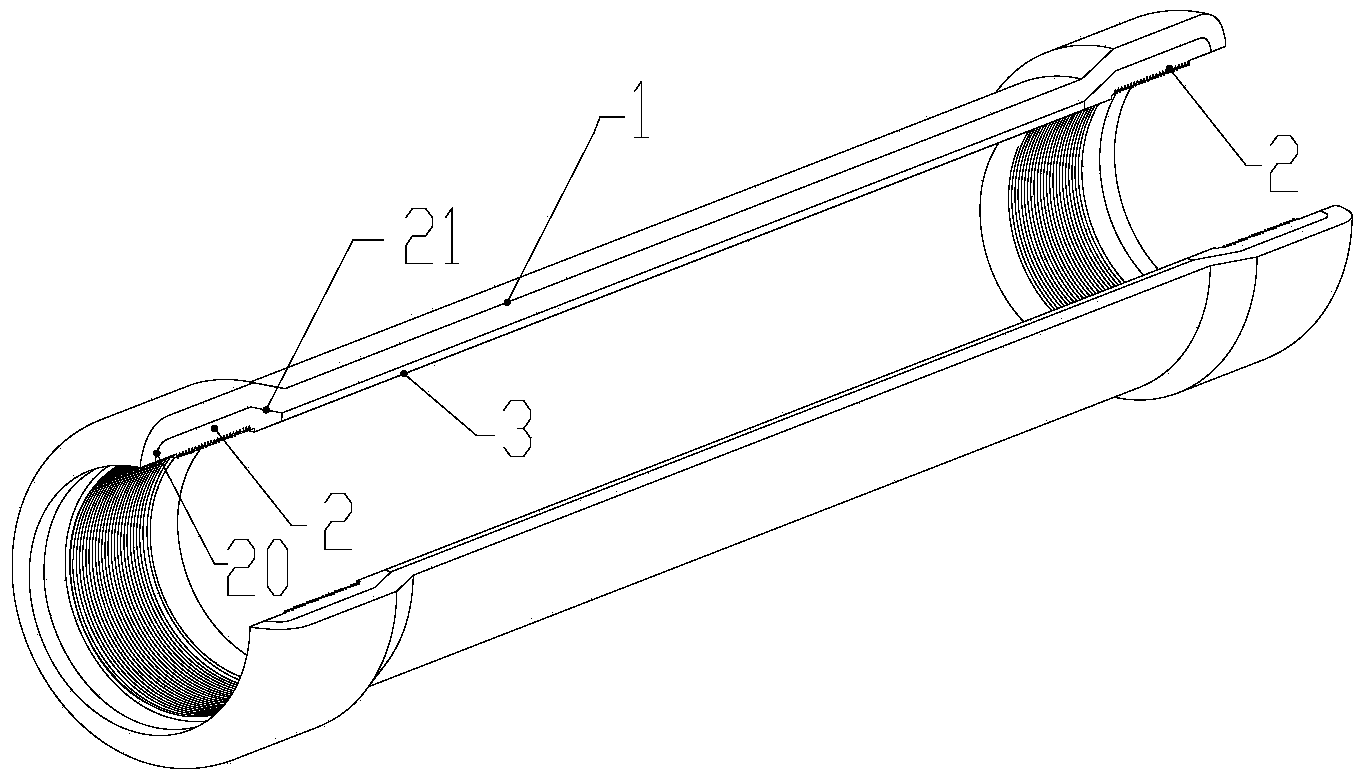

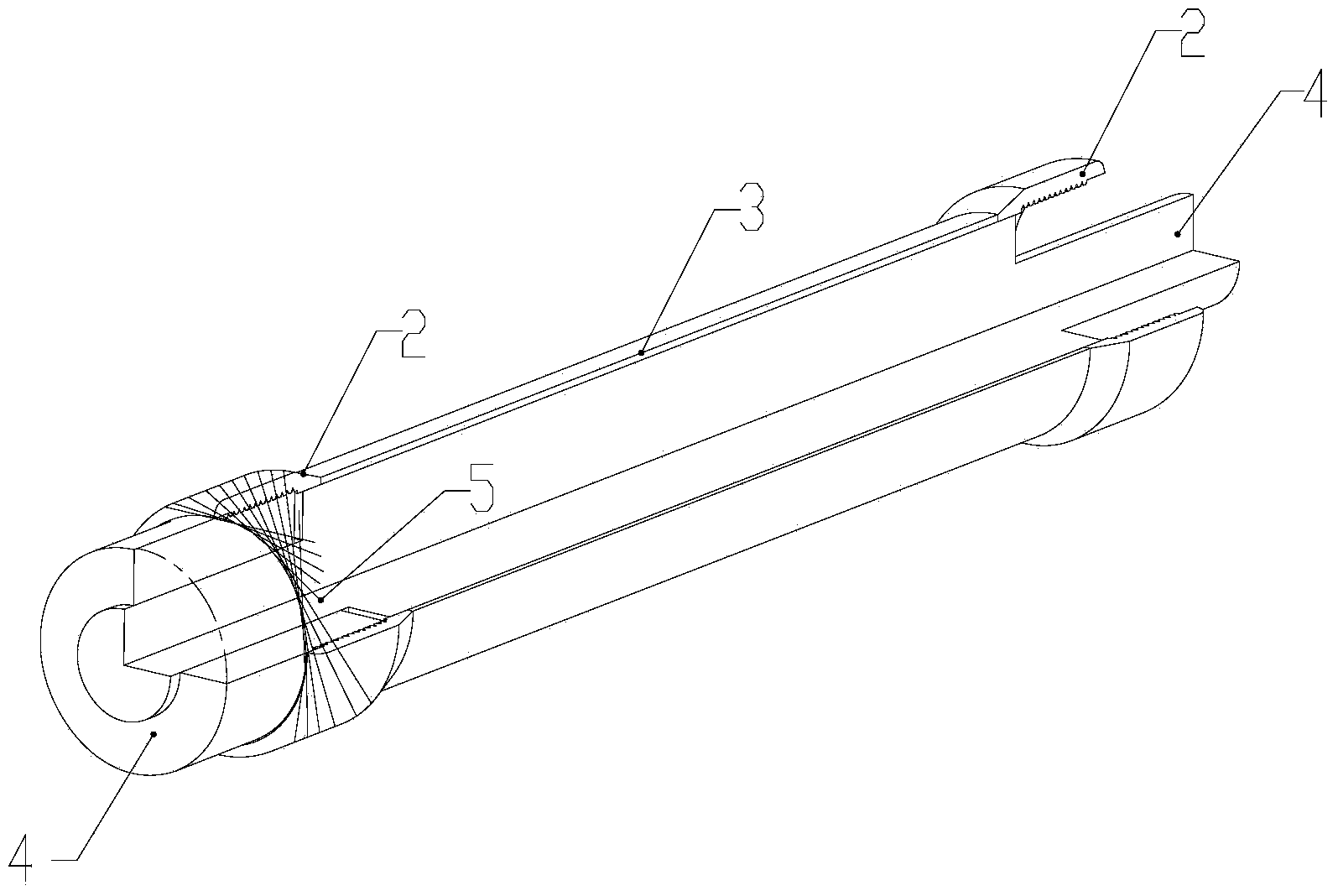

Composite-material tube, manufacturing method, hydraulic cylinder barrel and piston rod

InactiveCN103527549AAvoid interruptionImprove connection strengthFluid-pressure actuatorsHydraulic cylinderFiber

The invention discloses a composite-material tube. Two connecting rings are nested in inner holes in the two end portions of a tube body. The tube body comprises axial strengthening fibers, and the two connecting rings are wound and wrapped with the axial strengthening fibers in a continuous and reciprocating mode with the two ends of the tube body as poles. The invention further discloses a hydraulic cylinder barrel, a piston rod and a manufacturing method of the composite-material tube. According to the composite-material tube, the hydraulic cylinder barrel, the piston rod and the manufacturing method of the composite-material tube, the strength of connection between the connecting rings and the tube body is improved, large axial stretching and compressing loads can be borne, meanwhile, materials of the strengthening fibers are saved, the cost for manufacturing the hydraulic cylinder barrel is reduced, and the production efficiency is improved.

Owner:SANY AUTOMOBILE MFG CO LTD

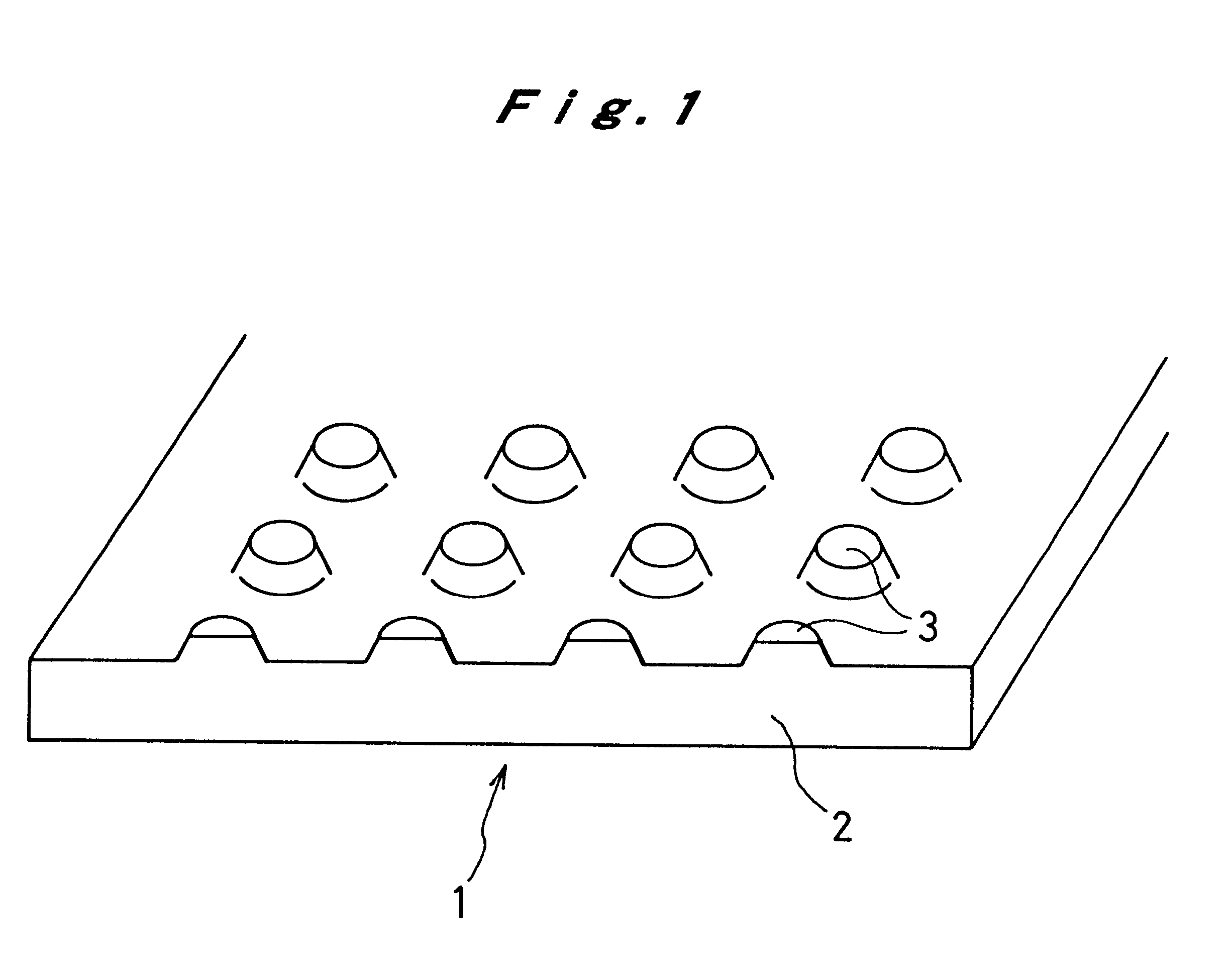

Artificial stone molded product

InactiveUS6500543B2Low costAvoid abrasionsOptical articlesPaving detailsUltravioletUltraviolet absorption

Provided is an artificial stone molded product in which protrusions or embedded grooves for a figure or a pattern are provided integrally on or in a flat surface of a substrate, and a main composition comprises an aggregate of an inorganic material and a resin, characterized in thatat least a part of the above-mentioned protrusions or embedded grooves are luminous or fluorescent, light-emitting portions which contain a luminous or fluorescent material having a luminescence or a luminousness accompanied by ultraviolet absorption and an aggregate of a transparent inorganic material, or an aggregate of a transparent inorganic material having a surface baked with the above-mentioned luminous or fluorescent material as at least a part of the aggregate of the inorganic material.

Owner:DOPPEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com