Patents

Literature

334results about How to "Avoid thickening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

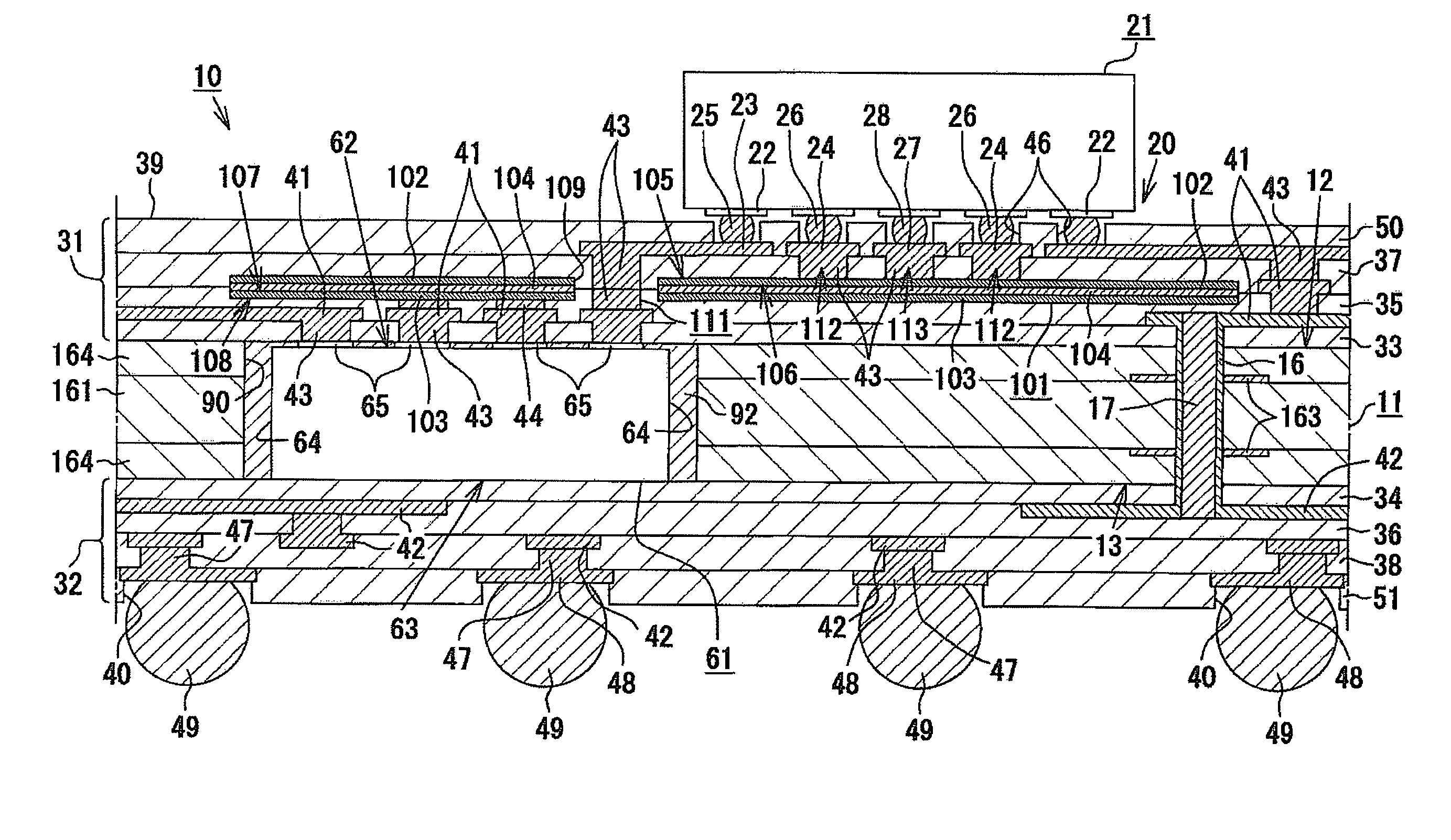

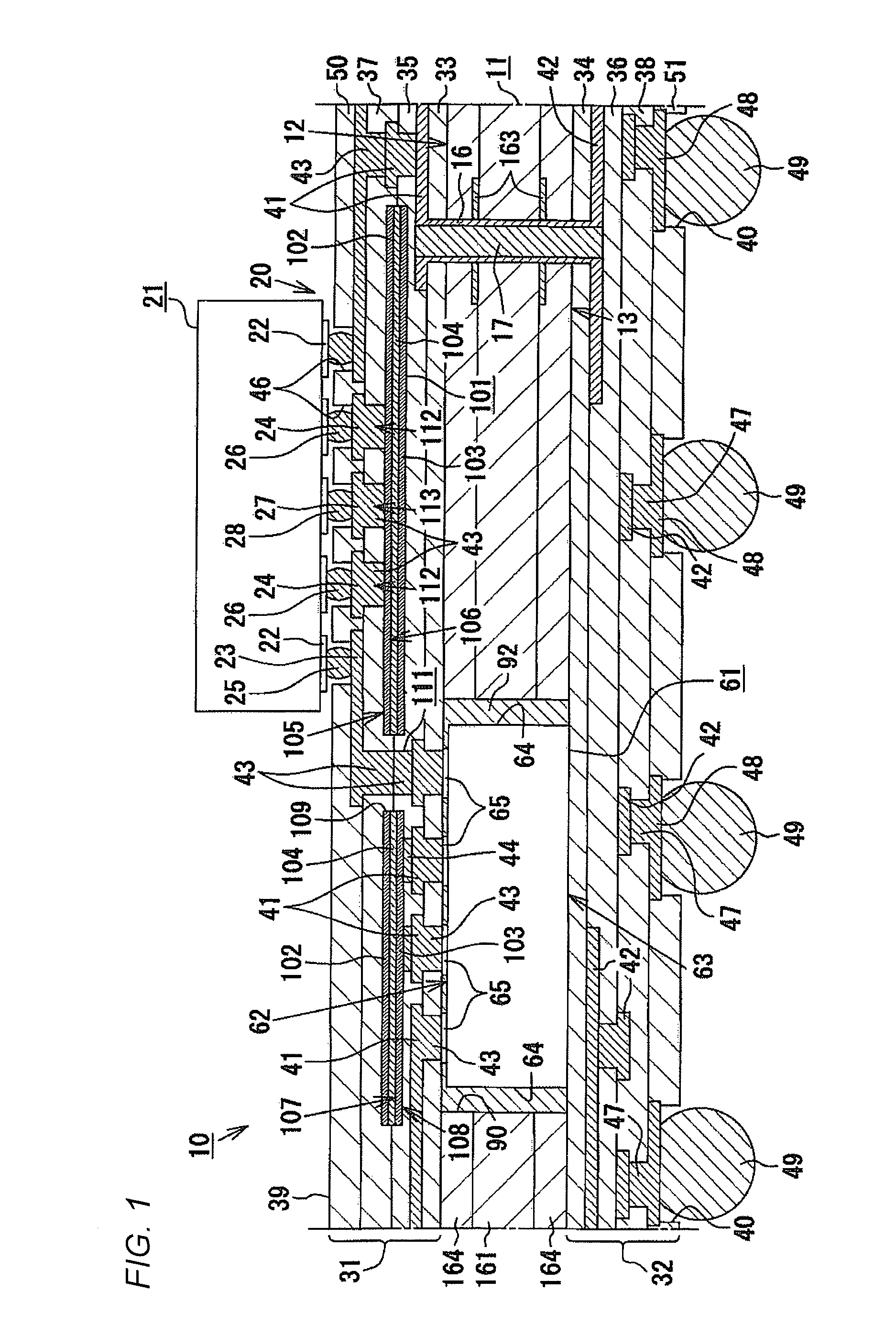

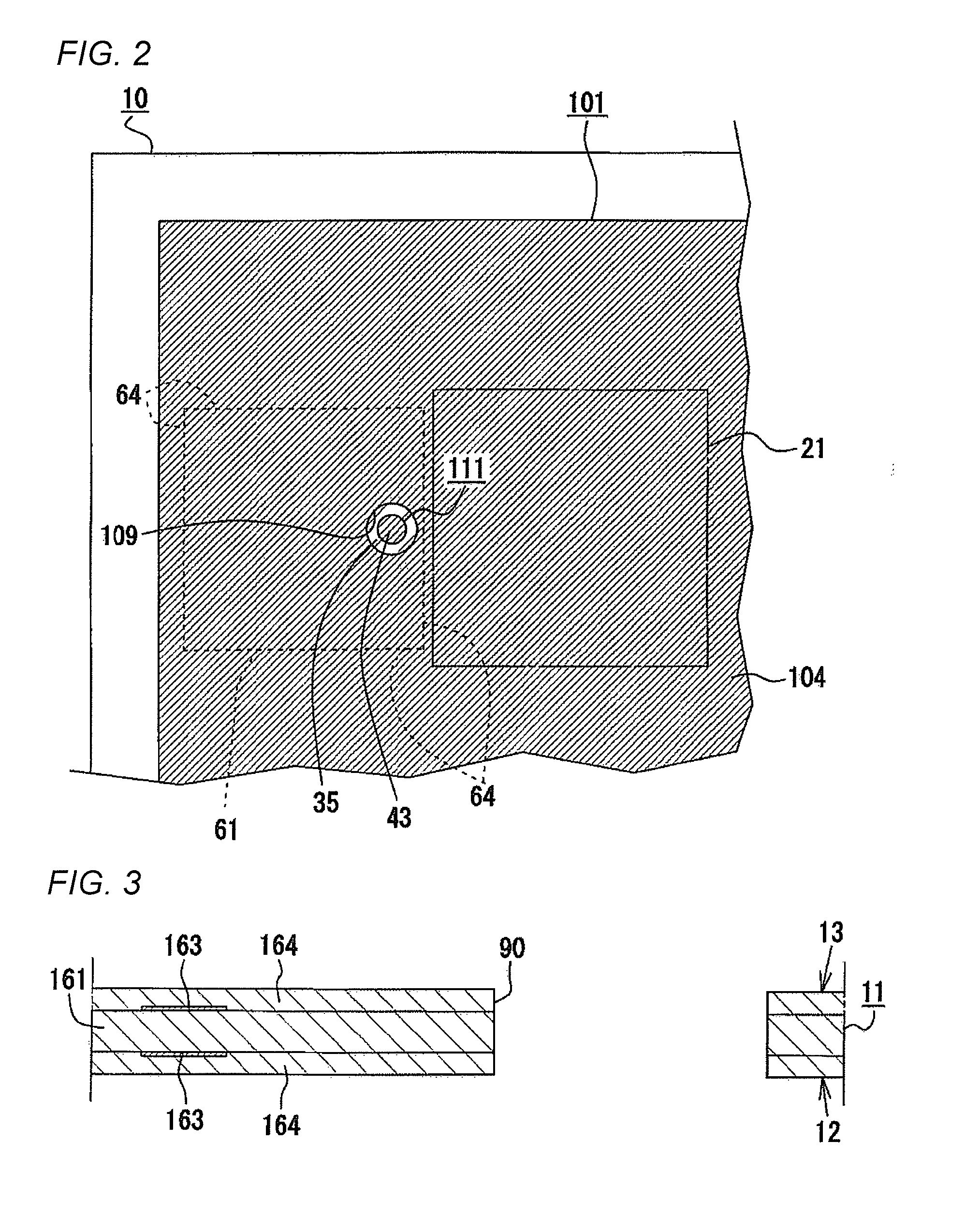

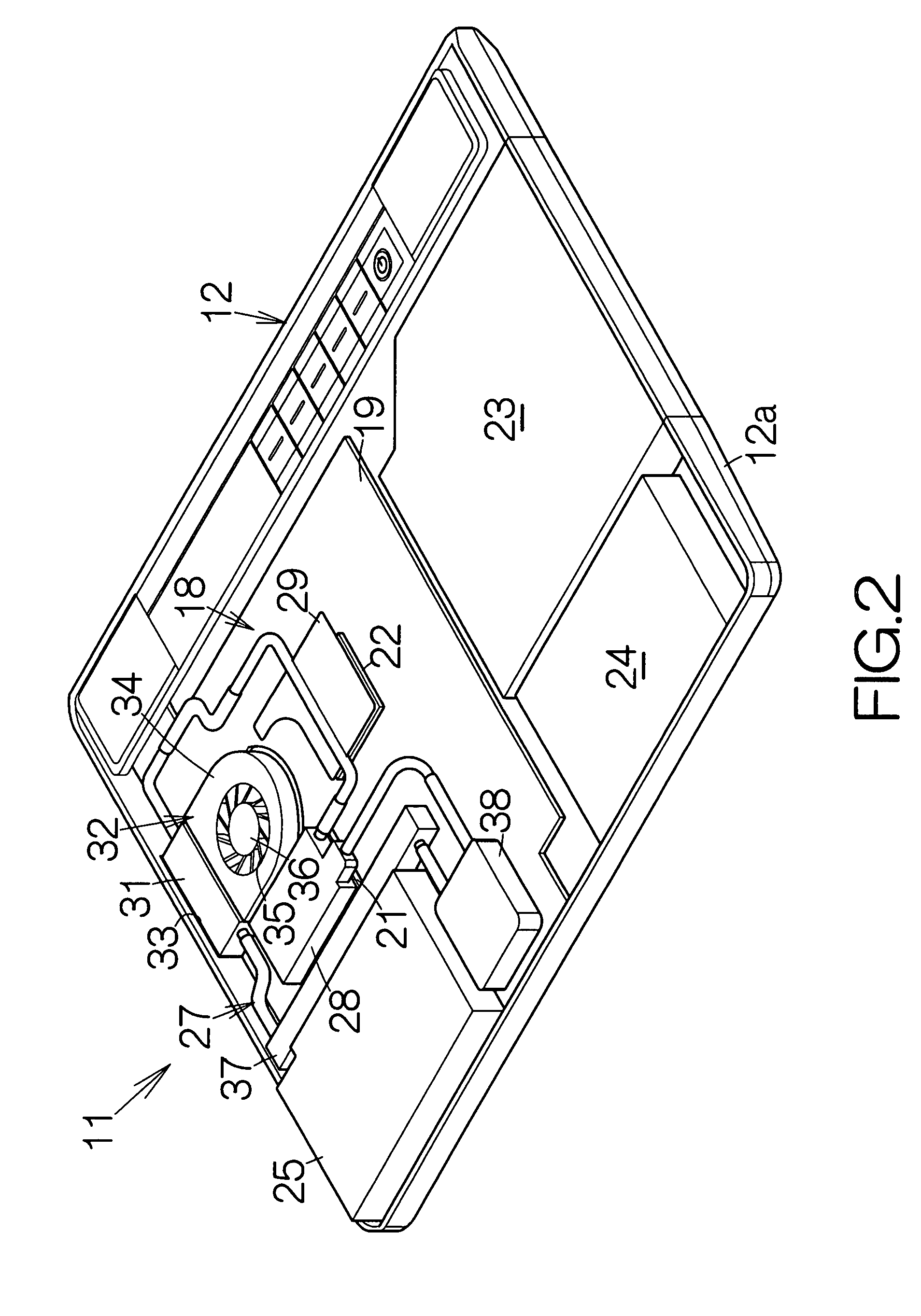

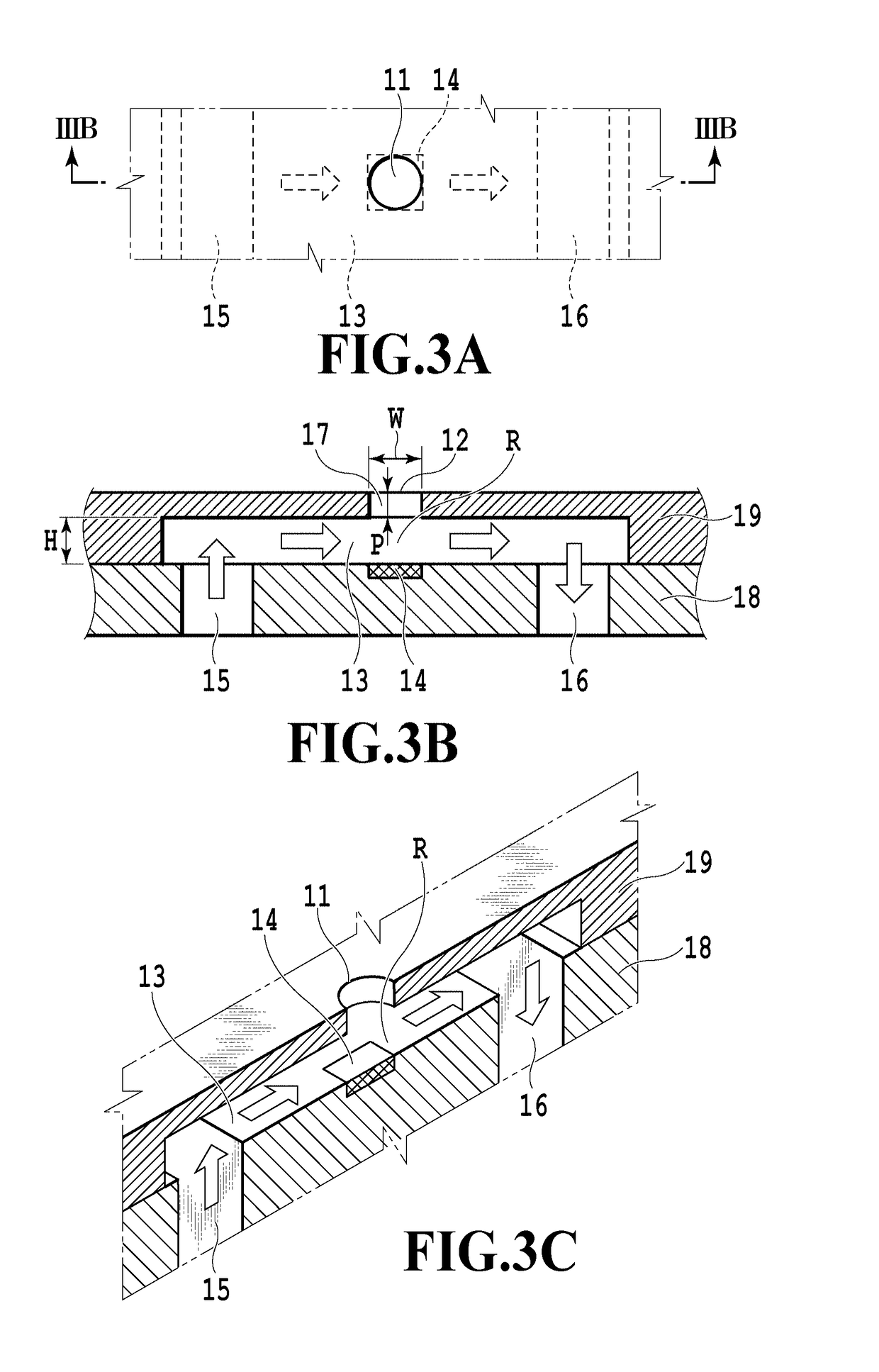

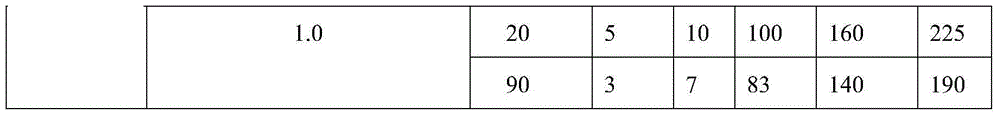

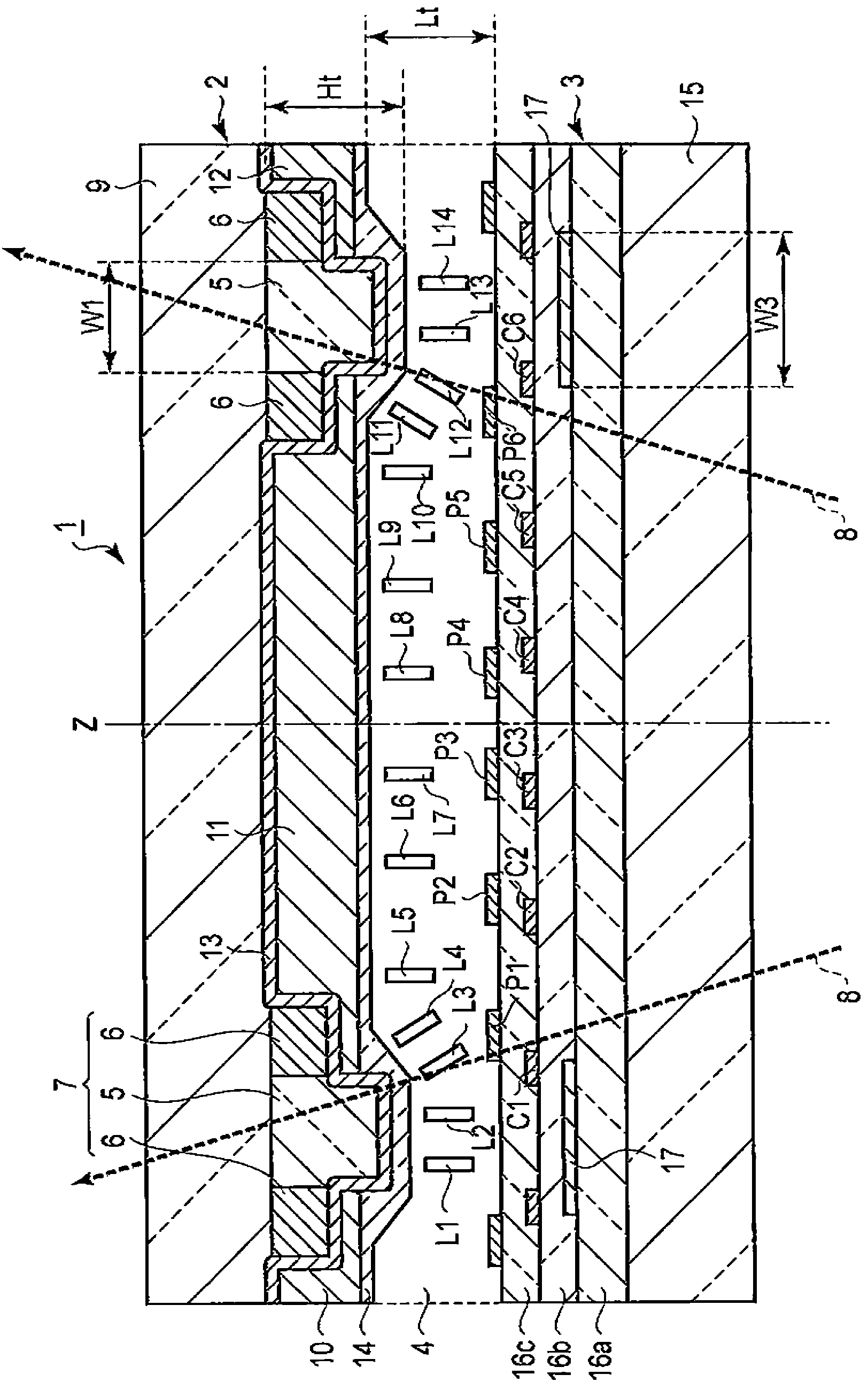

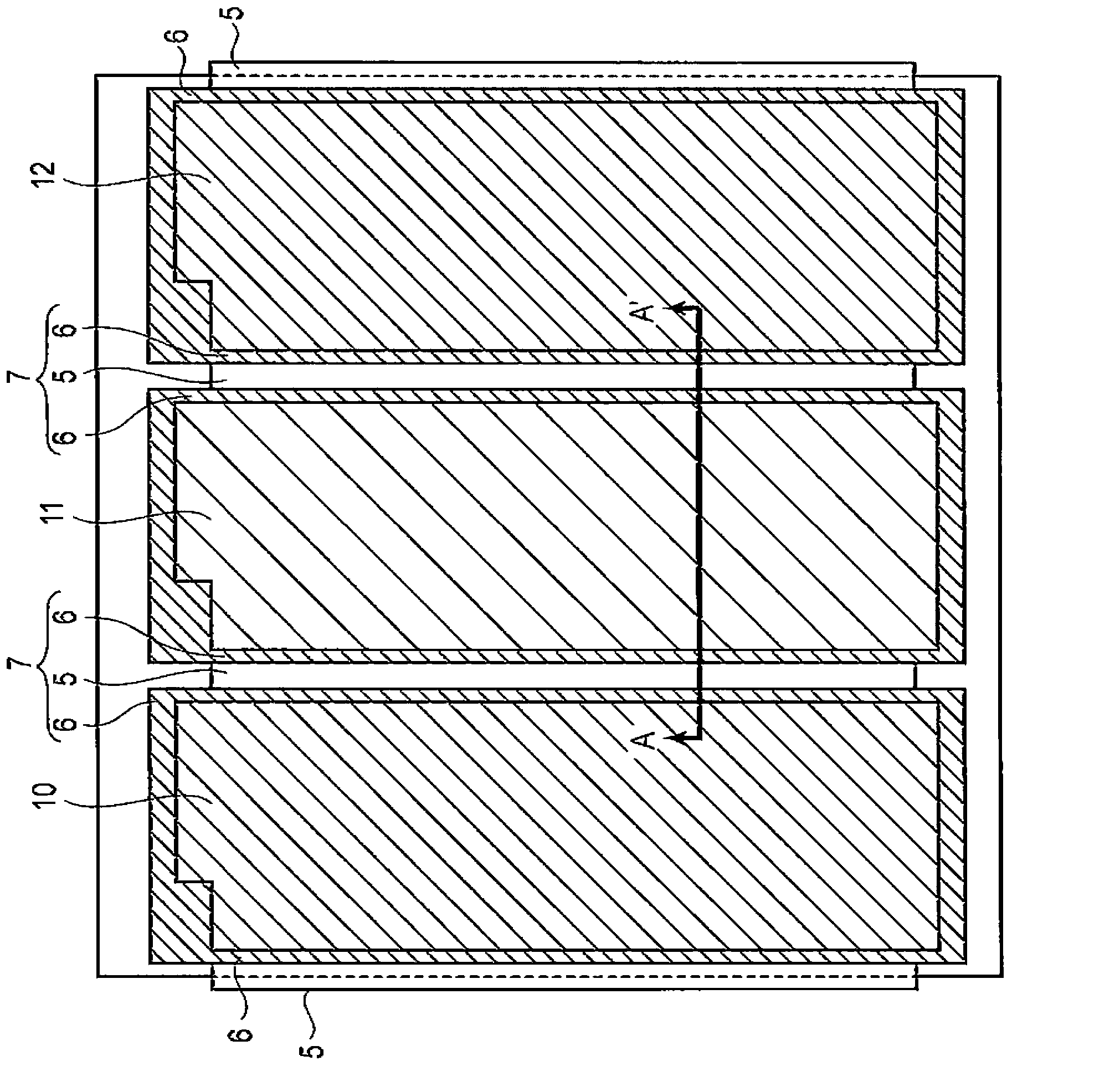

Component built-in wiring board

ActiveUS20090237900A1High densitySmall sizeElectrolytic capacitorsSemiconductor/solid-state device detailsEngineeringDielectric layer

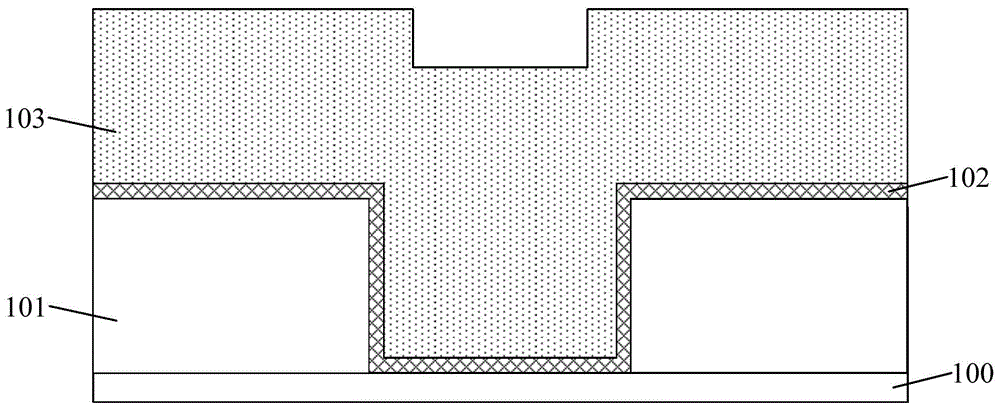

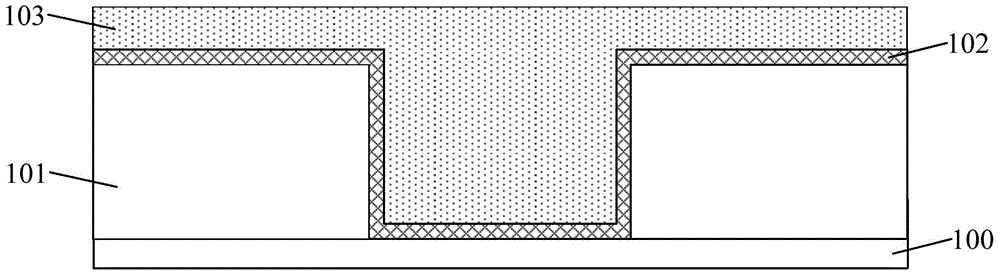

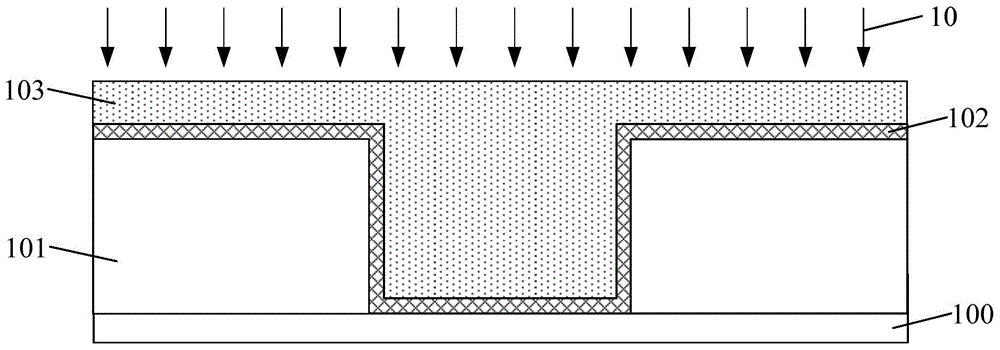

A component built-in wiring board is provided. The component built-in wiring board 10 includes a core substrate 11, a first component 61, a first built-up layer 31 and a capacitor 101. The core substrate 11 has a housing hole 90 and the first component 61 is housed in the housing hole 90. A component mounting region 20 capable of mounting a second component 21 is provided in a surface 39 of the first built-up layer 31. The capacitor 101 has electrode layers 102 and 103 and a dielectric layer 104. The capacitor 101 is embedded in the first built-up layer 31 such that a first front surface 105 and a second front surface 106 in the electrode layer 102 and a first front surface 107 and a second front surface 108 in the electrode layer 103 are disposed in parallel with the surface 39 of the first built-up layer 31.

Owner:NGK SPARK PLUG CO LTD

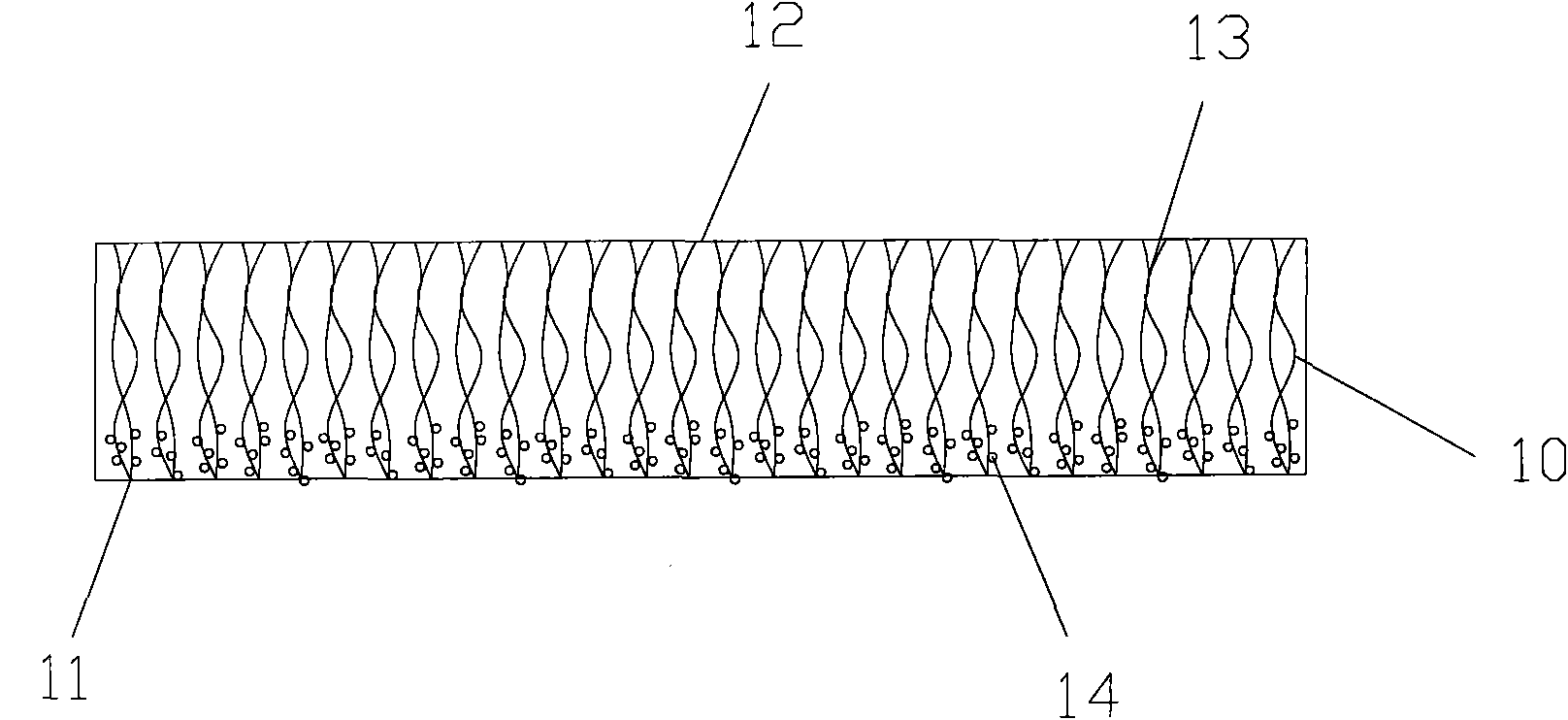

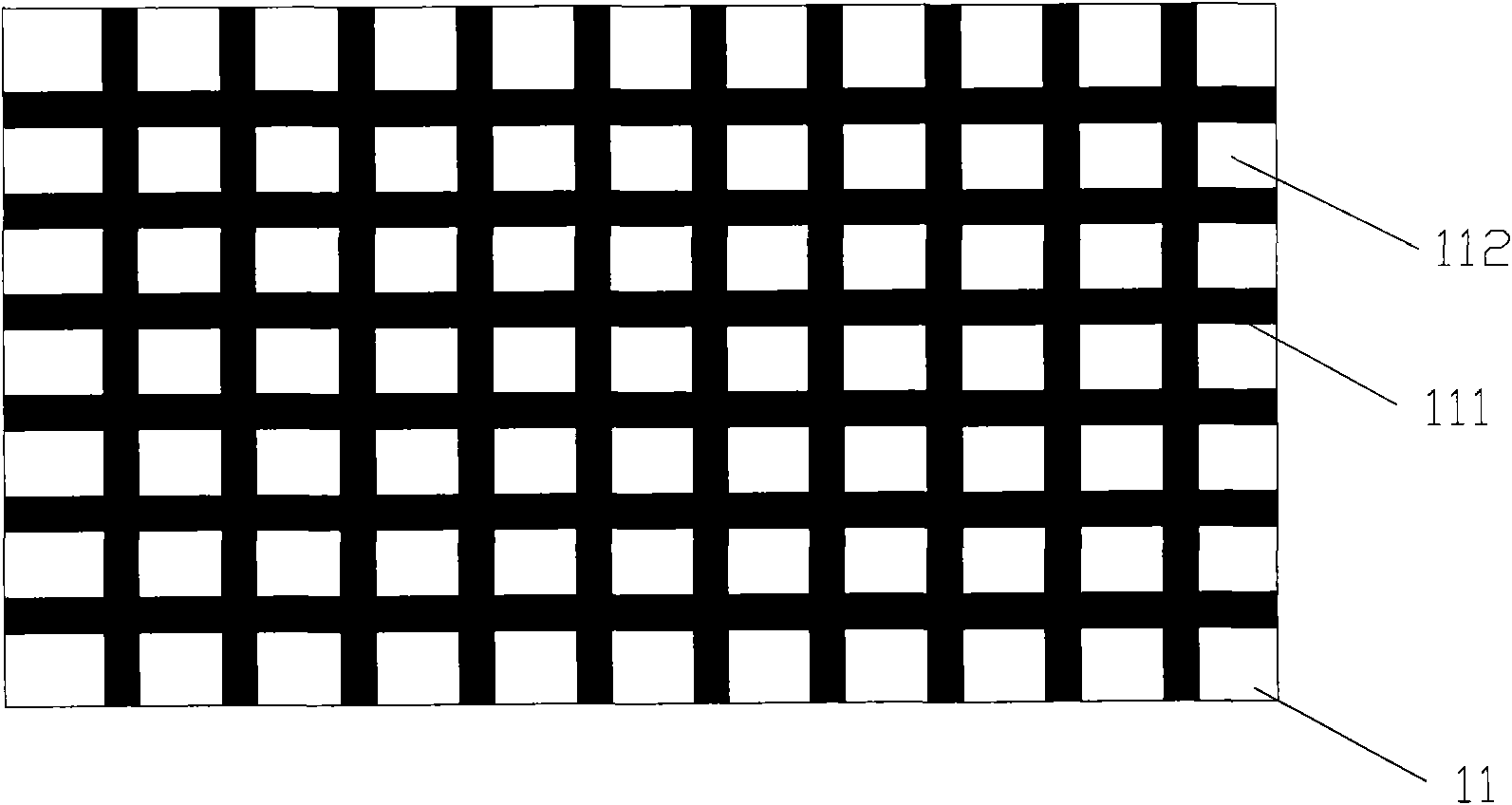

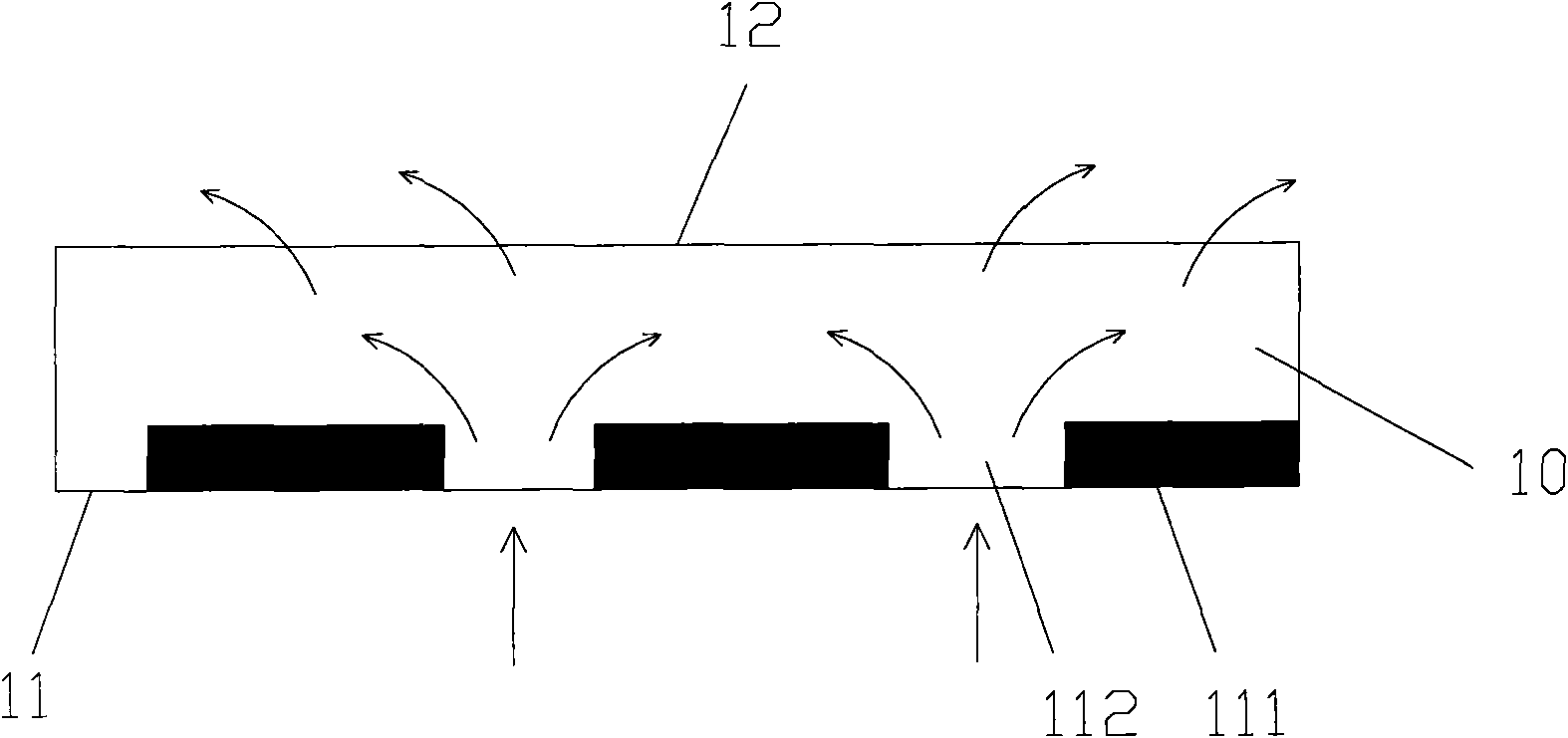

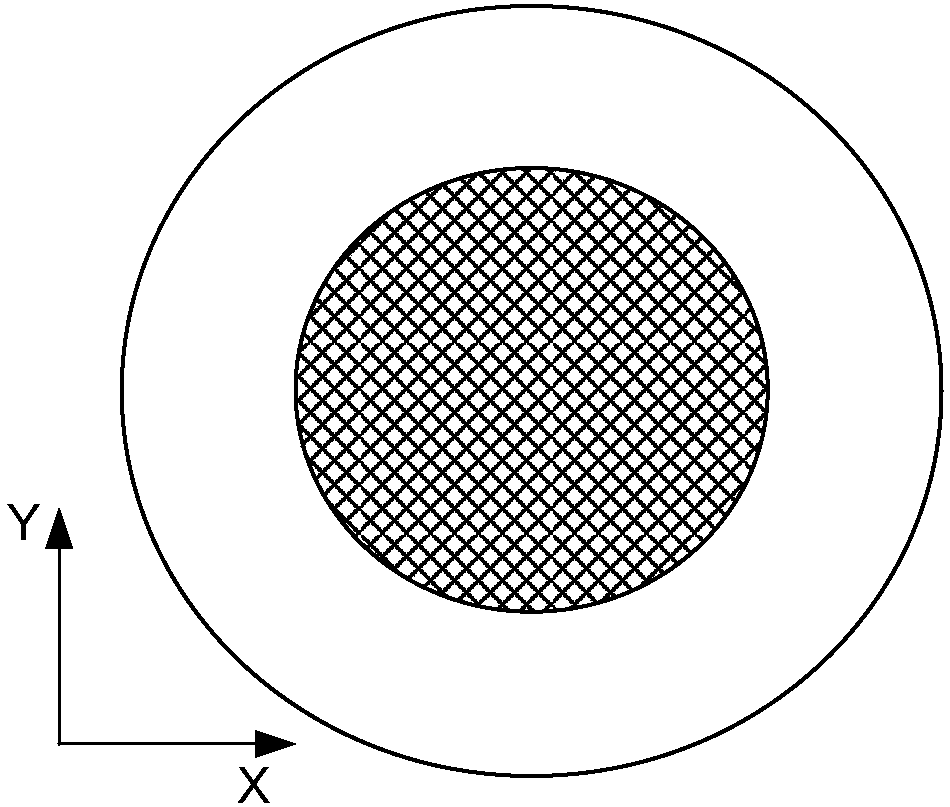

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

One-way moisture-transfer all-cotton spunlaced nonwoven as well as product and preparation method thereof

ActiveCN101775701AExcellent unidirectional moisture transfer performanceEffective absorptionNon-woven fabricsVegetal fibresSubstance useNonwoven fabric

The invention discloses a one-way moisture-transfer all-cotton spunlaced nonwoven and as well as a product and a preparation method thereof. The all-cotton spunlaced nonwoven comprises an all-cotton spunlaced nonwoven matrix, the all-cotton spunlaced nonwoven matrix comprises a hydrophobic surface and a hydrophilic surface, wherein the hydrophobic surface contains hydrophobic substances used for transferring moisture from the hydrophobic surface to the hydrophilic surface. The one-way moisture-transfer all-cotton spunlaced nonwoven selects an all-cotton material, has light and soft texture and good one-way moisture-transfer effect and can effectively absorb and permeate the moisture and prevent the moisture from reversely flowing, thereby enabling the hydrophobic surface directly contacting with the skin of a human body to keep dry and bringing about more comfortable feeling for a user of a one-way moisture-transfer product.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

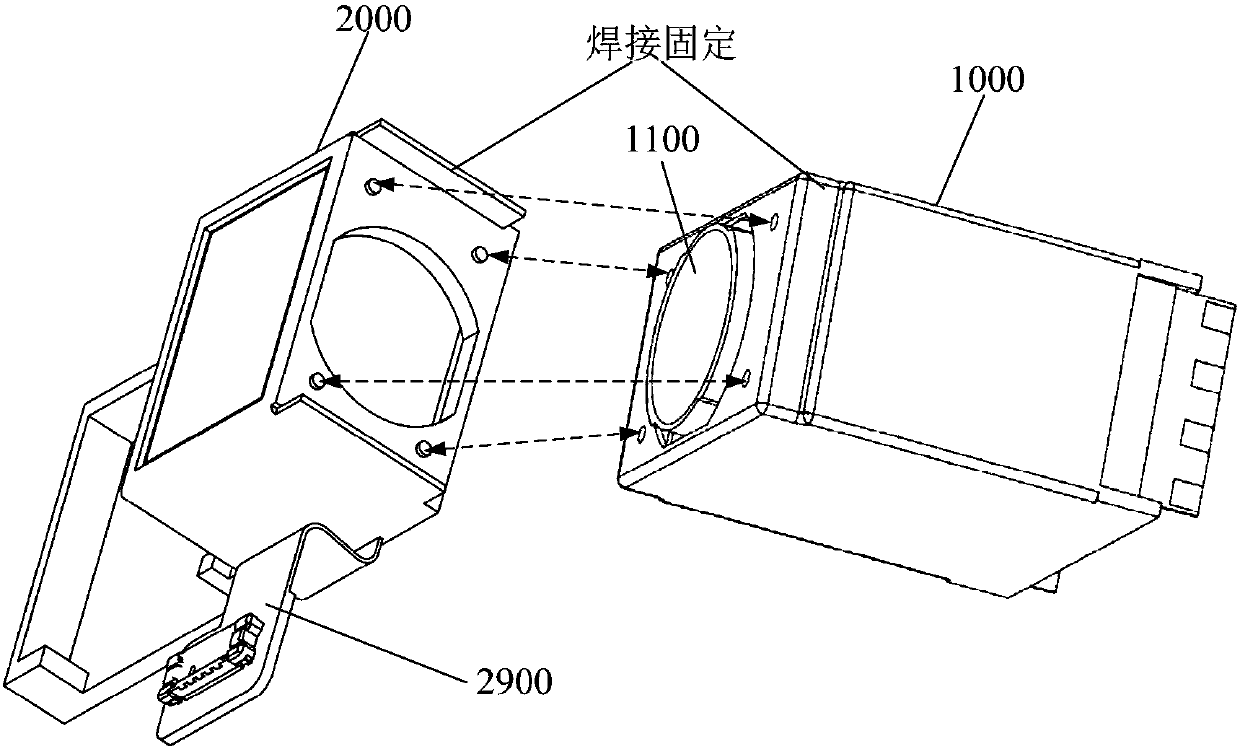

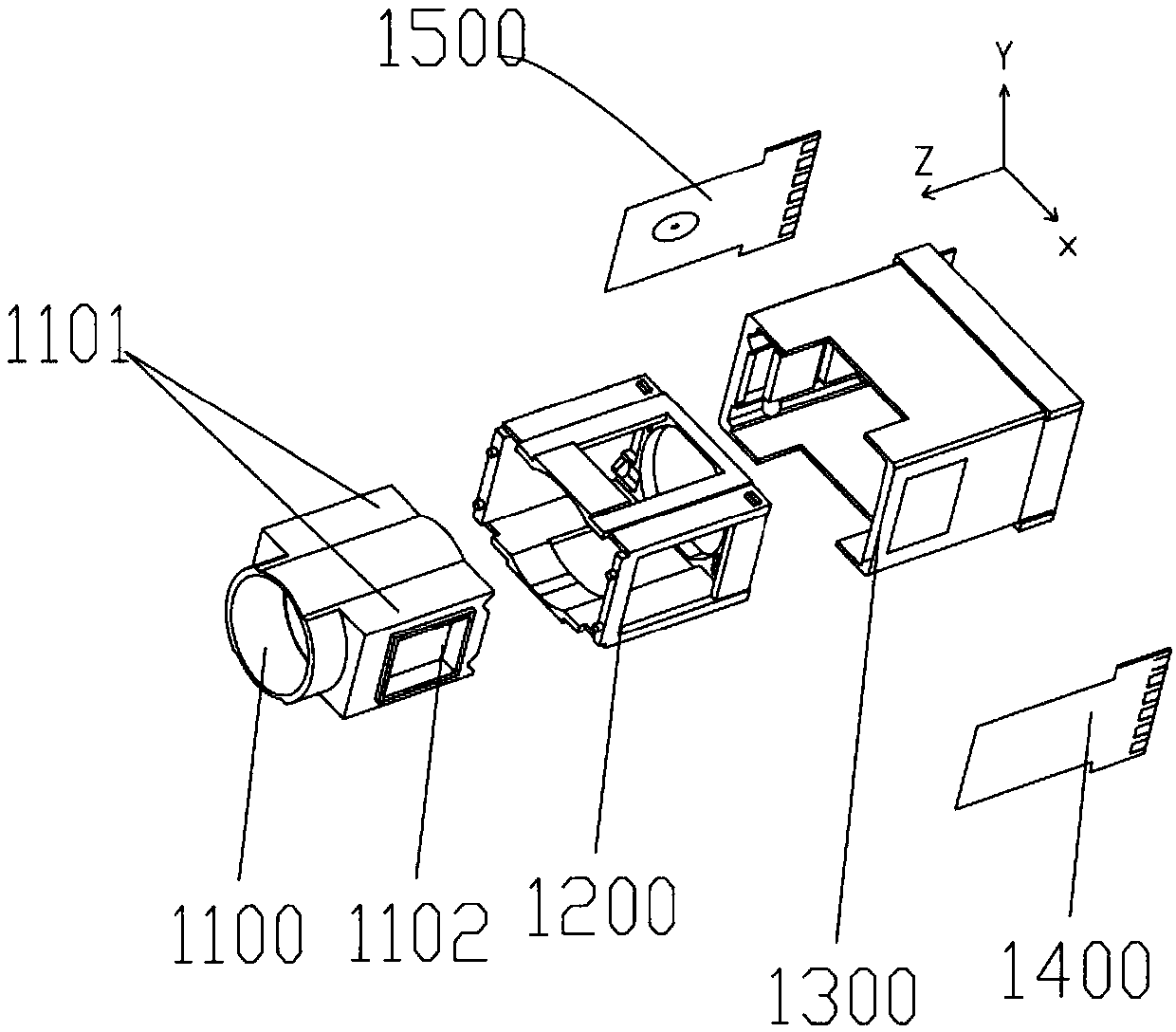

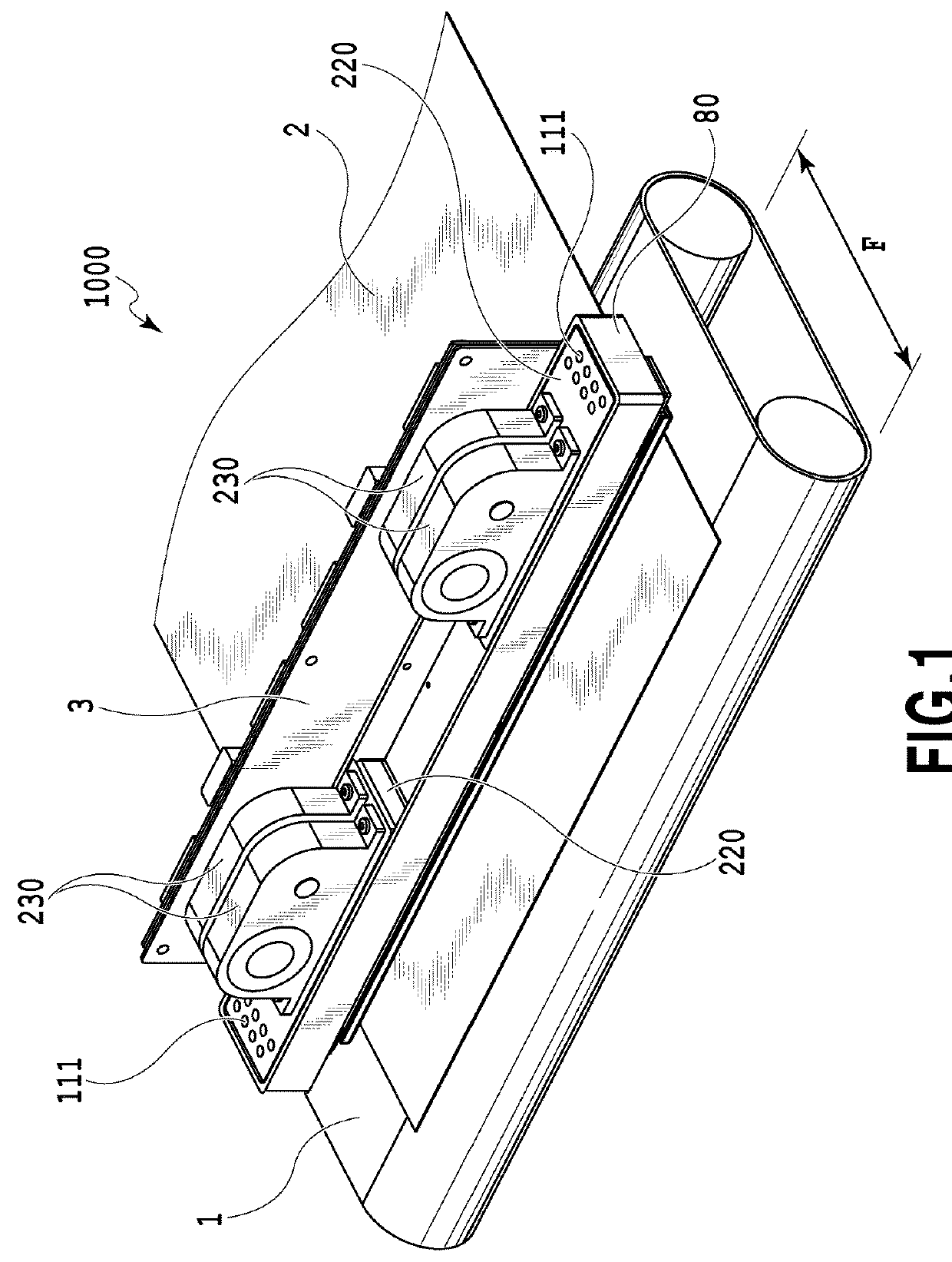

Periscopic shooting module

ActiveCN107783243AStable supportChange the direction of the outgoing lightTelevision system detailsPrintersCamera lensOptical axis

The invention discloses a periscope camera module. The periscope camera module comprises a light steering mechanism, a lens mechanism and a photosensitive chip, wherein the light steering mechanism ismounted at a light incident side of the lens mechanism, the photosensitive chip is mounted at a light exit side of the lens mechanism, the light steering mechanism comprises a prism, a prism holder,a support shaft and a base, the prism holder is arranged in the base, the prism holder has a support surface opposite to the prism, the prism holder is further provided with a shaft seat, the shaft seat is arranged at the other side of the support surface opposite to the prism, the shaft seat is provided with a through shaft hole, the support shaft is rotatably arranged in the shaft hole, the support shaft is perpendicular to an optical axis of an optical lens in the lens mechanism, the support surface has two side walls, and the intersection portion of the support surface and the side walls is provided with a support table which projects in the direction away from the support surface and extends along an intersection line of the support surface and the side walls. The periscope camera module is advantaged in that the prism holder and the support shaft are adopted, the anti-shake effect can be achieved through the rotatable prism, the structure is simpler, and manufacturing and maintenance are easy.

Owner:NINGBO SUNNY OPOTECH CO LTD

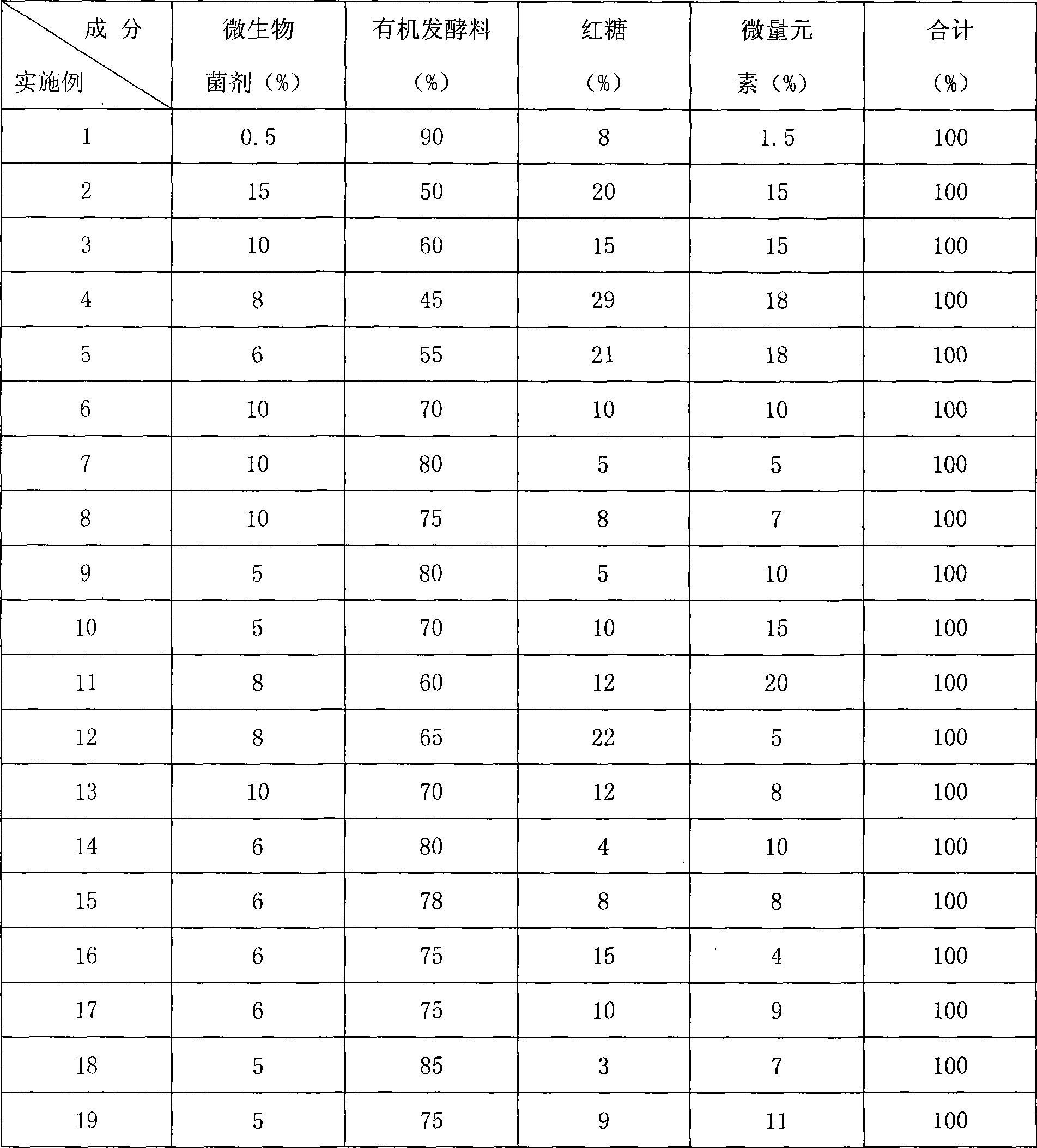

Composite microorganism formulation for controlling excessive multiplication of blue-green algae and preparation method thereof

InactiveCN101367581AIncrease oxygen contentIncrease oxygen content and improve water clarityBiological water/sewage treatmentMicrobial agentBlue green algae

The invention discloses a compound microbiological preparation and a preparation method for controlling the excessive reproduction of blue-green algae. The preparation comprises the following compounds with a certain weight proportion of microbial agents, organic fermentation agents, brown sugar and micro elements. The preparation steps are as follows: A. the preparation of the microbial agent, B. the preparation of the organic fermentation agent, and then the microbial agent\ fermentation agent, brown sugar and the micro elements are mixed based on a certain weight proportion, and finally, the compound microbiological preparation can be prepared. The preparation has reasonable formulation, is convenient to be used, has no pollution to the water, has high control rate and low cost, and is easy and convenient to be operated.

Owner:武汉合缘绿色生物股份有限公司

Backlight assembly and liquid crystal display apparatus having the same

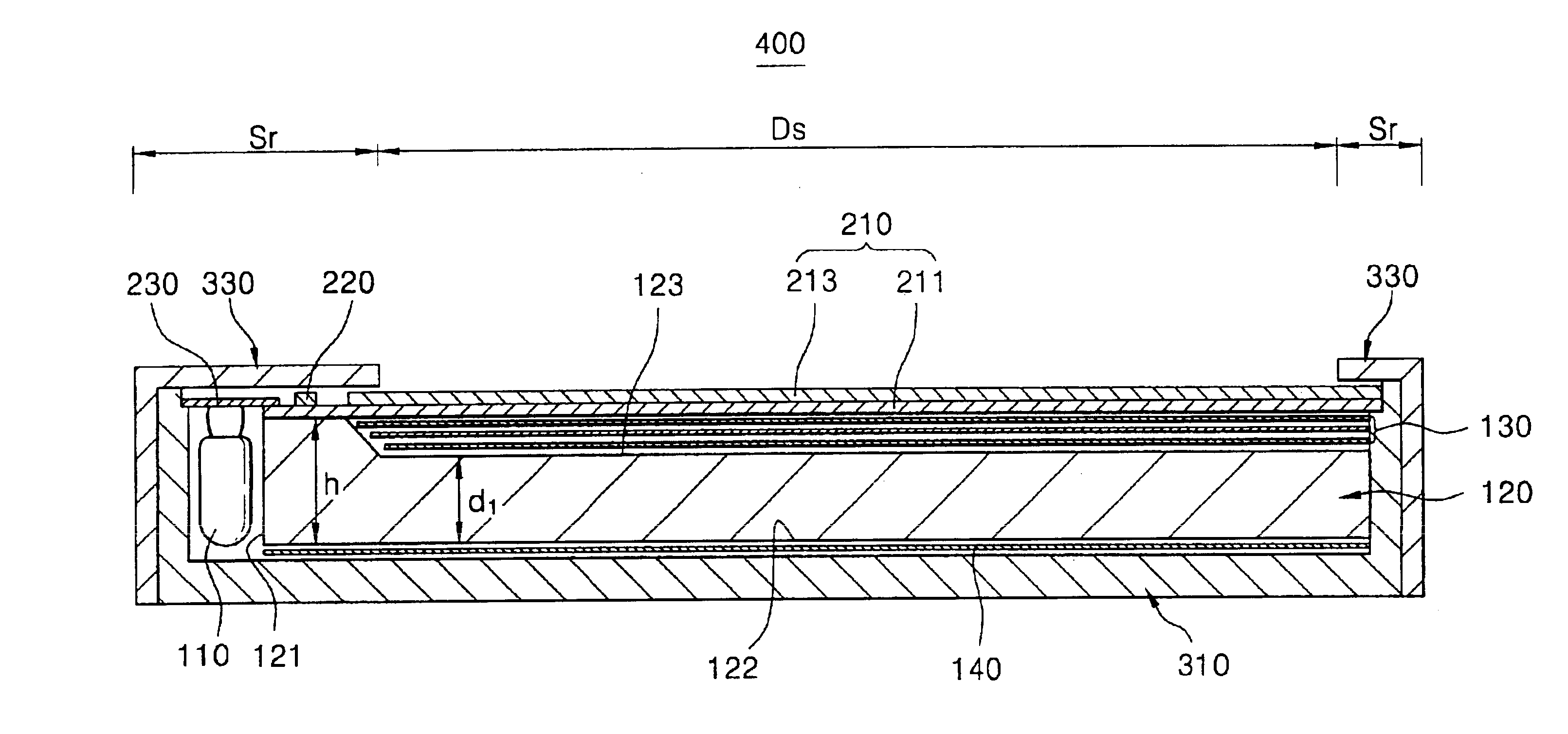

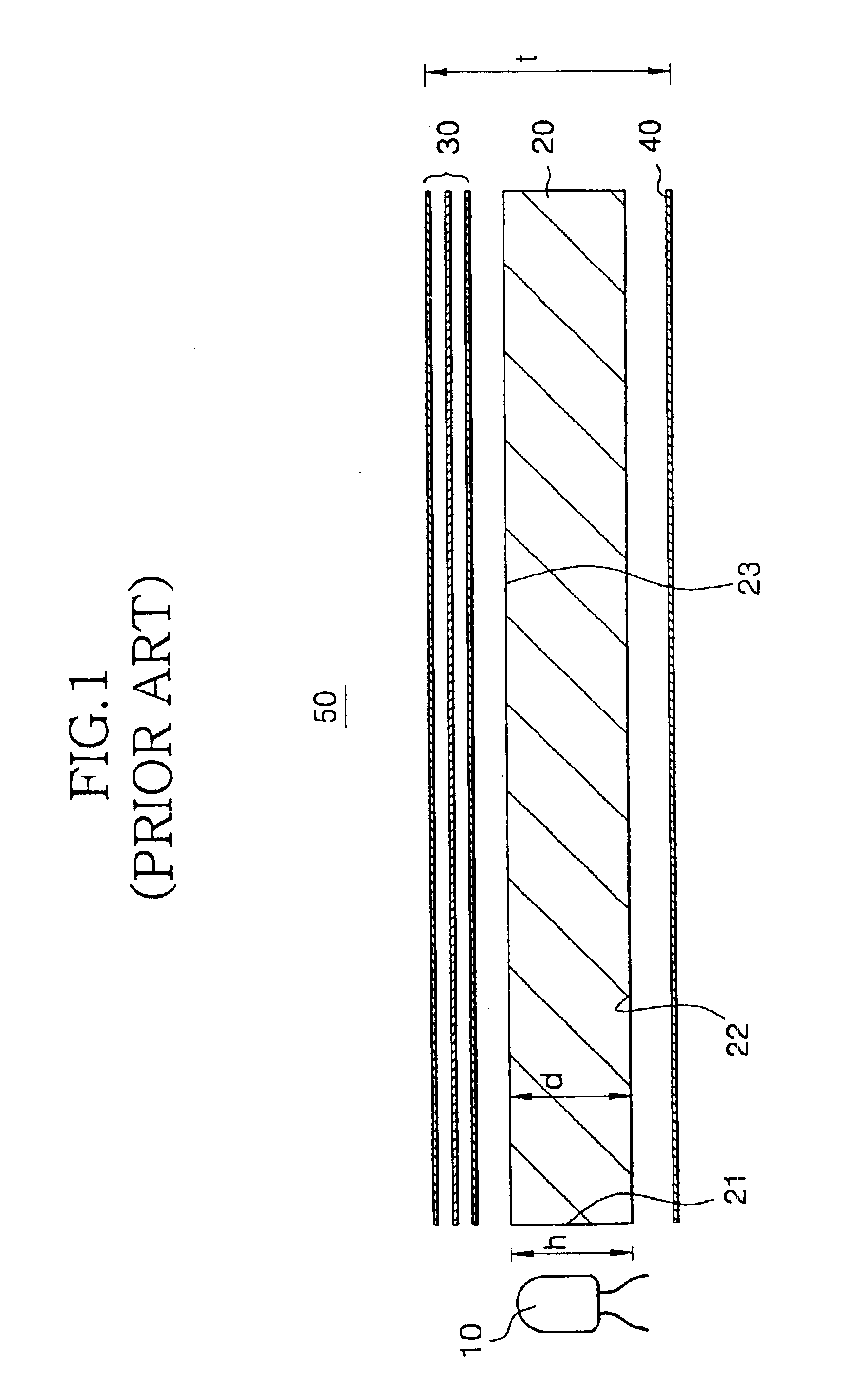

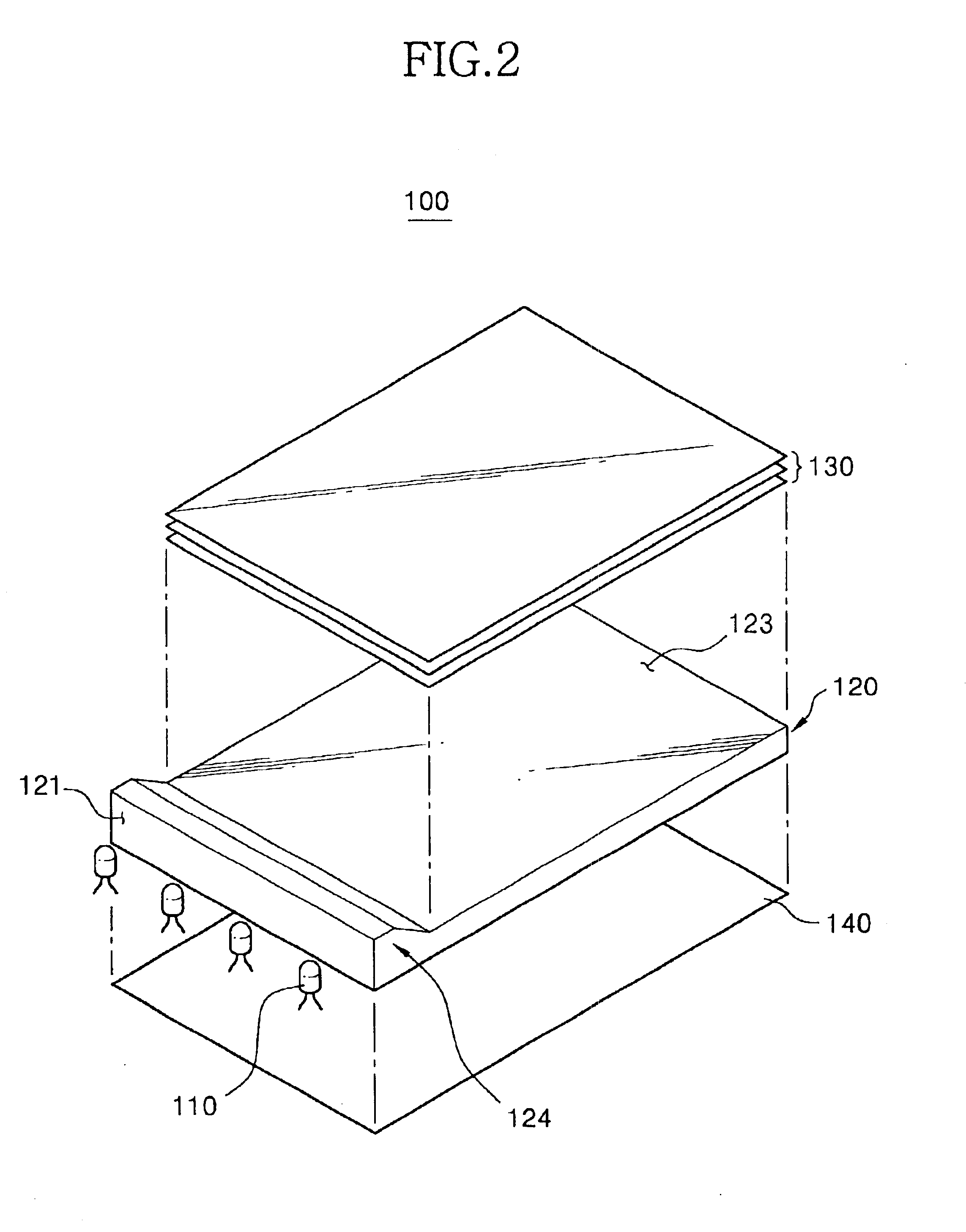

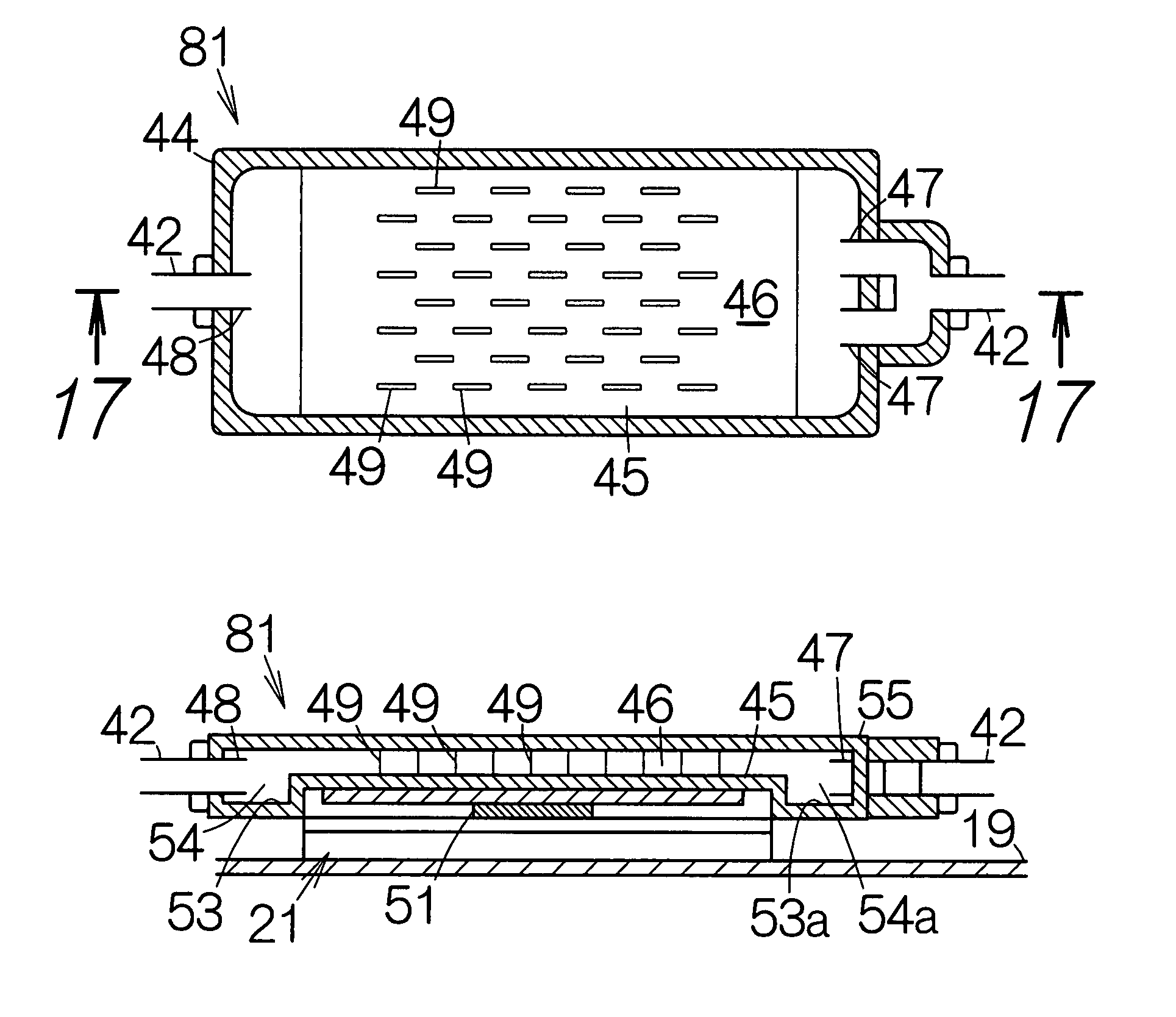

InactiveUS6942374B2Improve lighting efficiencyEfficient light emissionShow cabinetsMechanical apparatusLiquid-crystal displayLight guide

In an LCD apparatus having a backlight assembly, a light guide plate includes an incident surface for receiving light, a reflecting surface for reflecting the light and an emitting surface for emitting the light. A linear distance between the reflecting and emitting surfaces is smaller than a height of the incident surface. An optical sheet is positioned at the emitting surface having a height lower than the height of the incident surface. Accordingly, although the height of the incident surface increases, the linear distance between the reflecting and emitting surfaces does not increase. Therefore, the light guide plate can obtain an area of the incident surface appropriate to efficiently receive the light, thereby improving a light efficiency of the backlight assembly and preventing an increase in a thickness of the backlight assembly.

Owner:SAMSUNG DISPLAY CO LTD

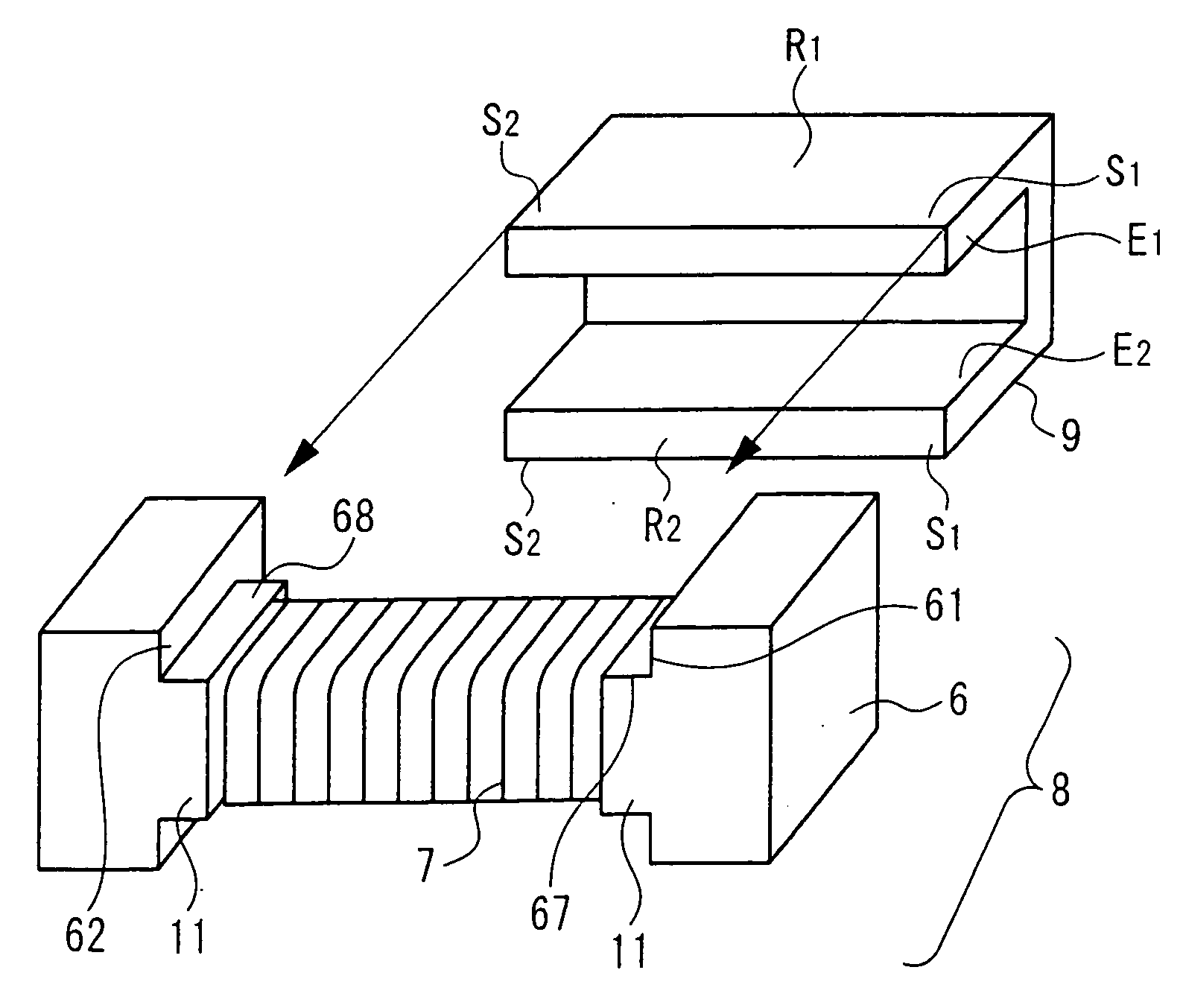

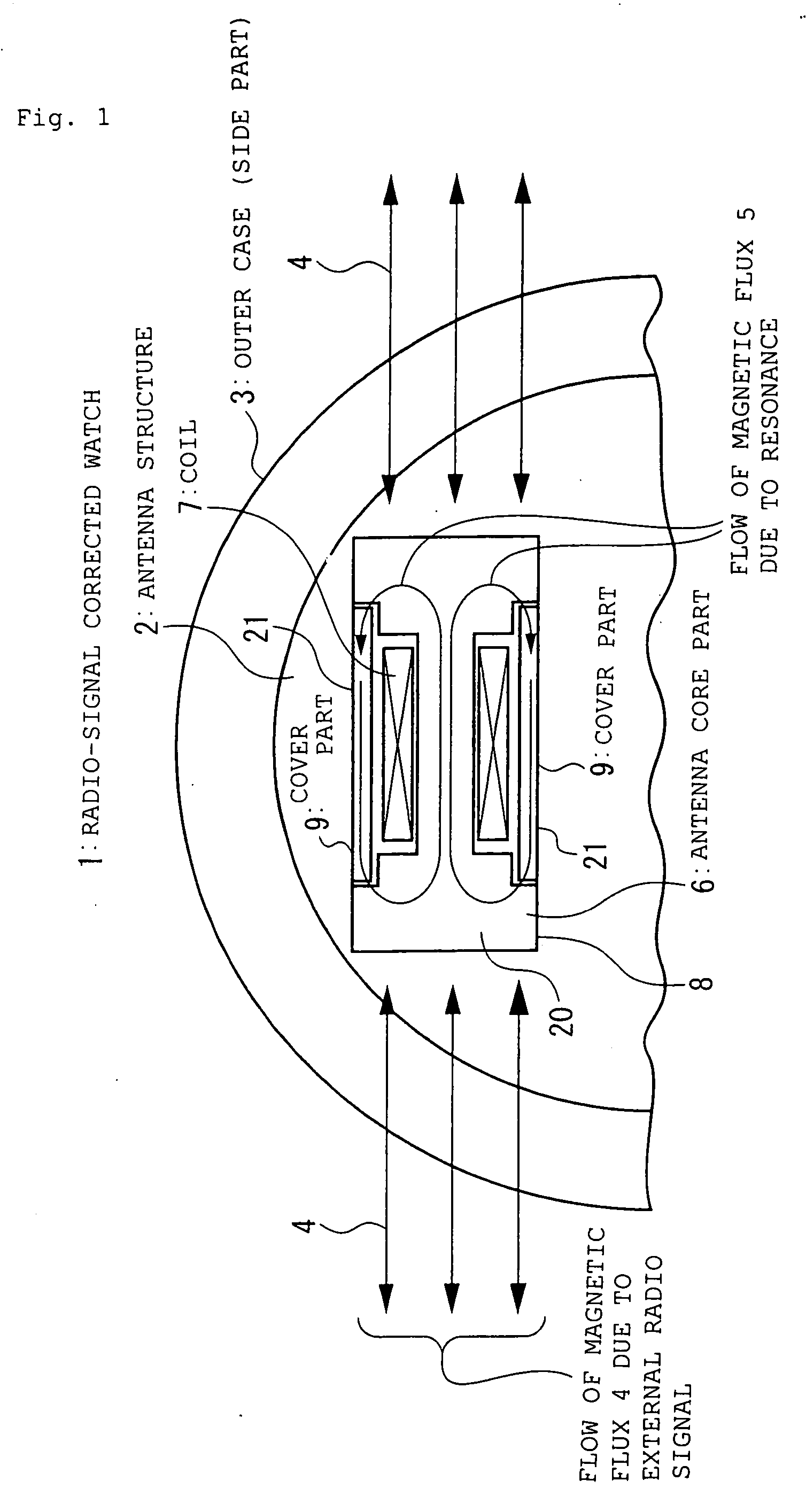

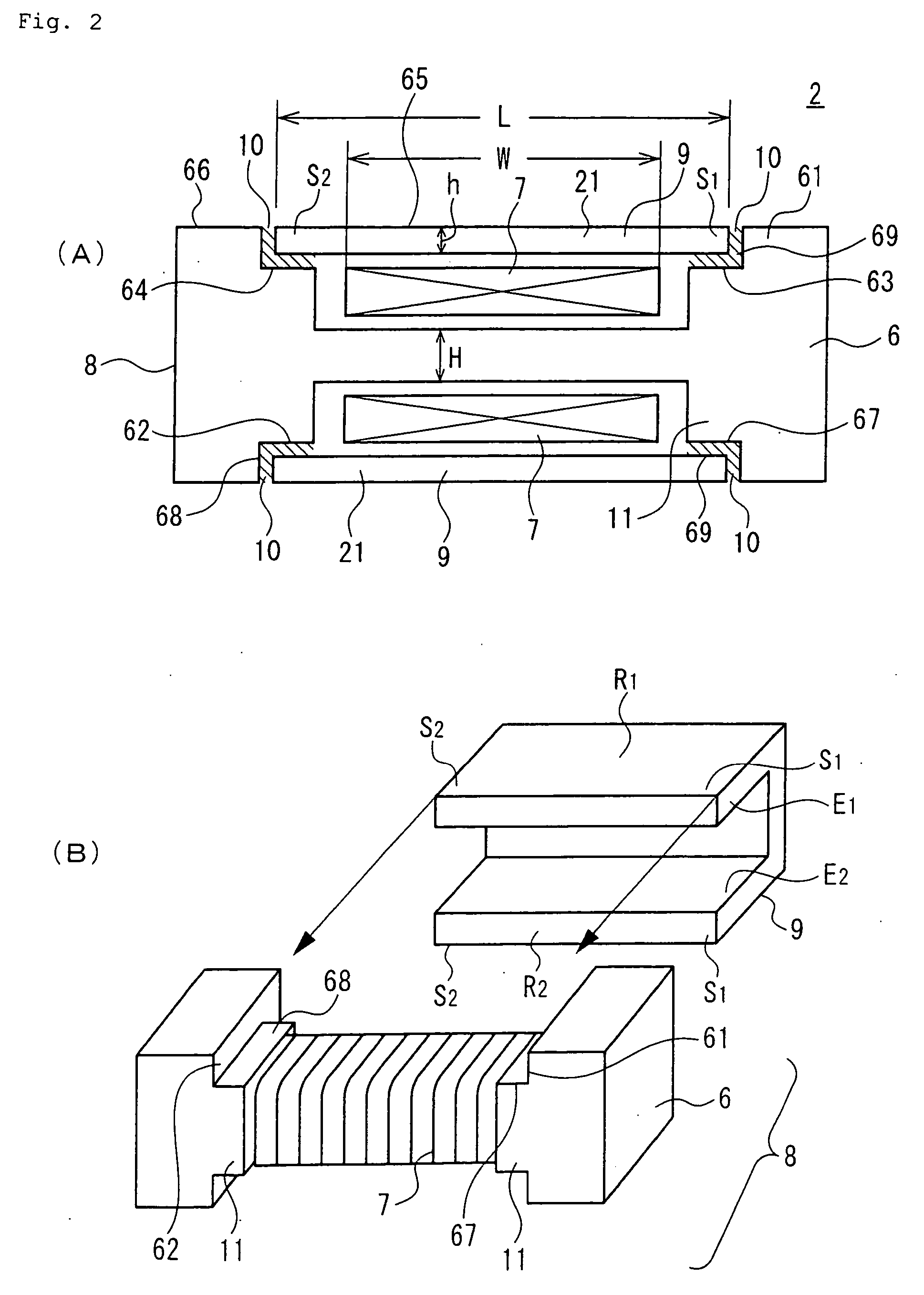

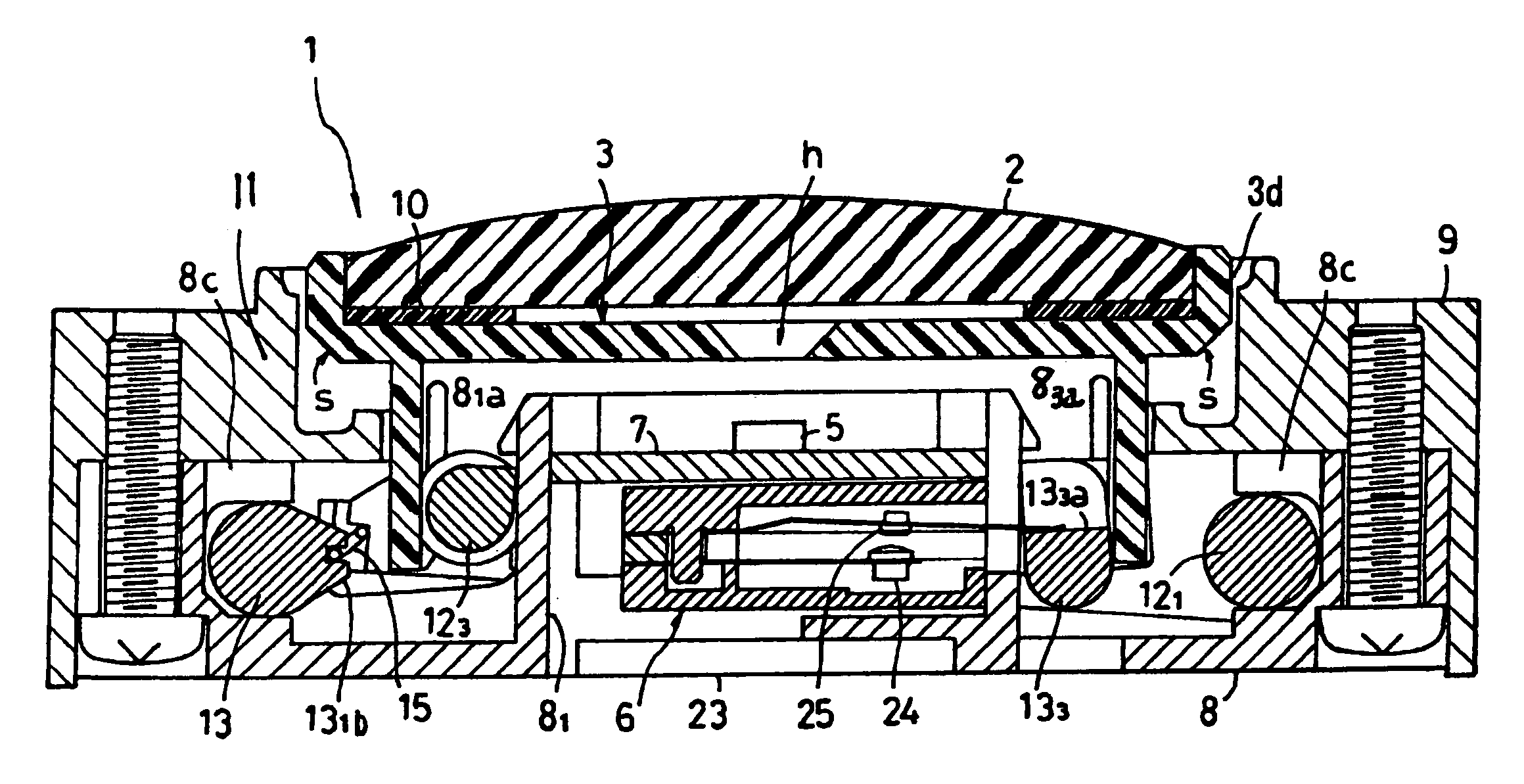

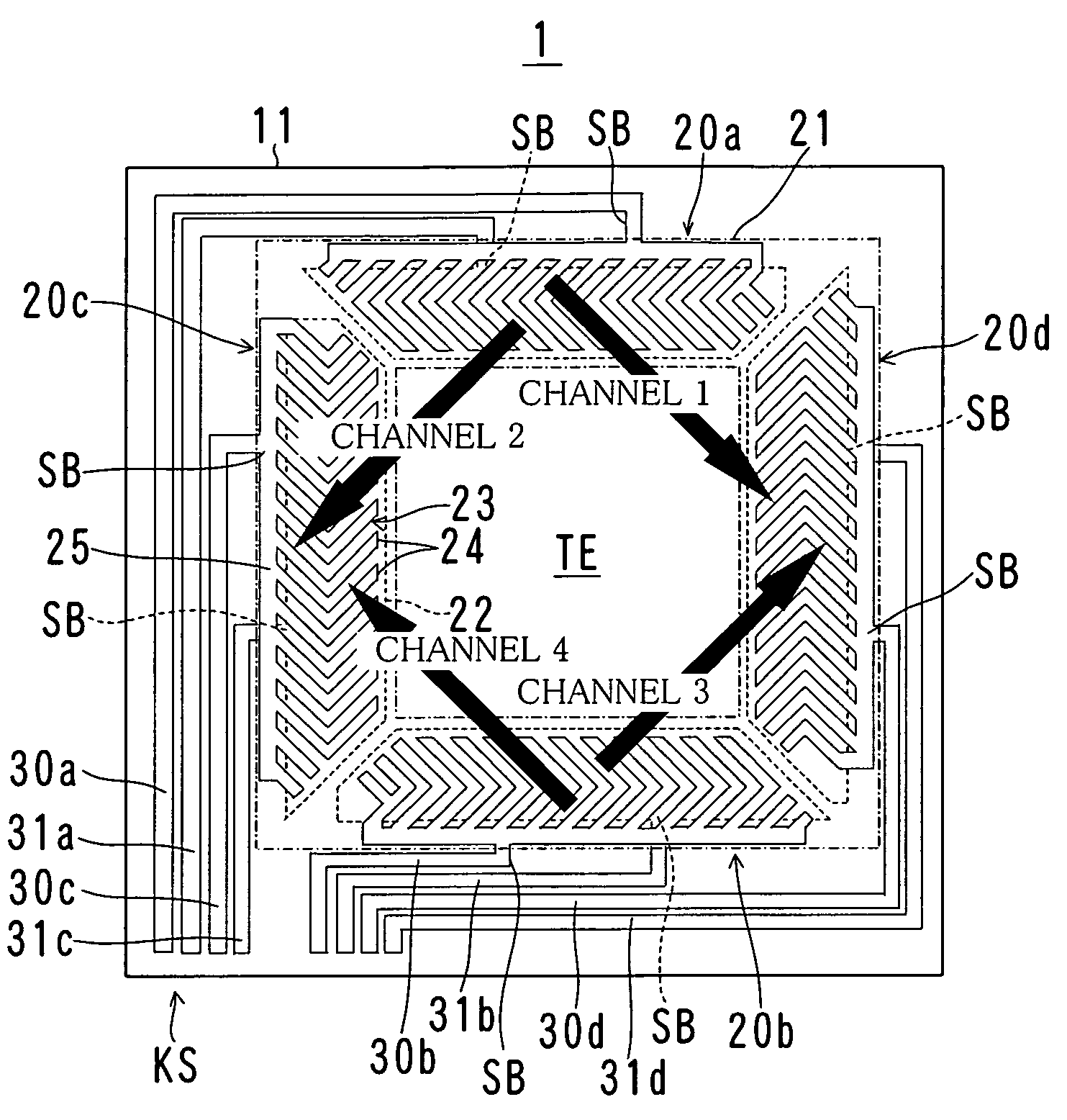

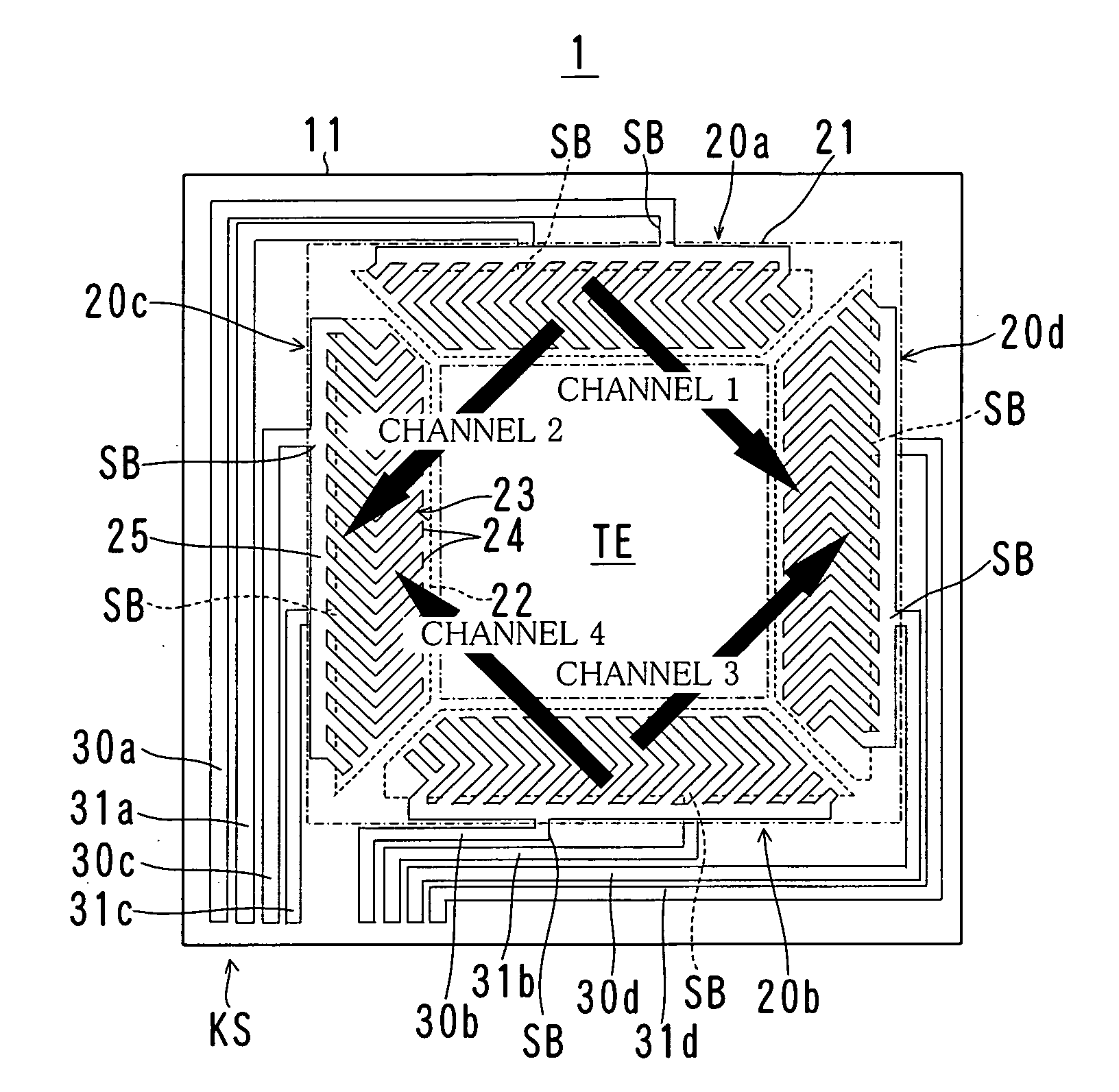

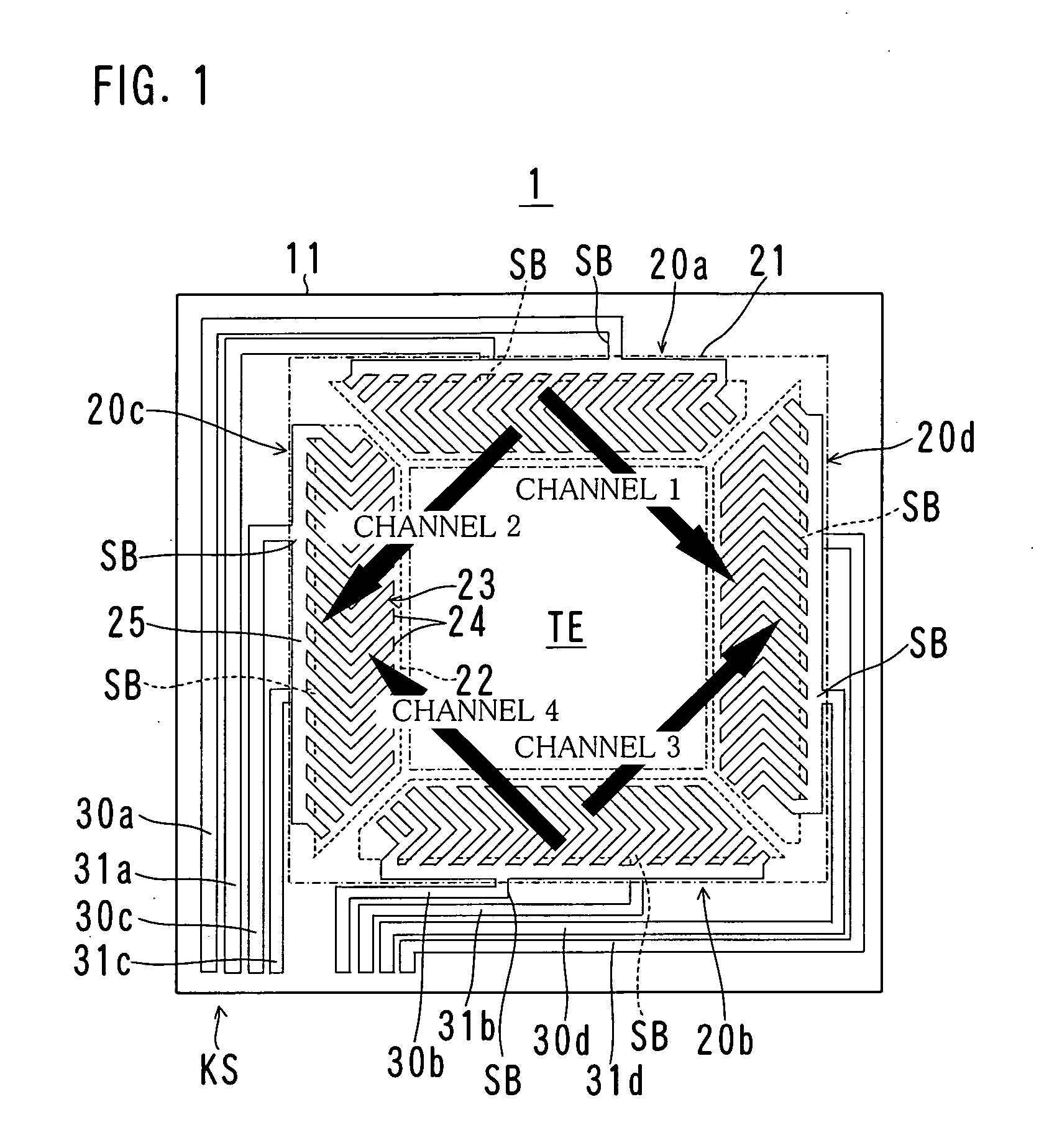

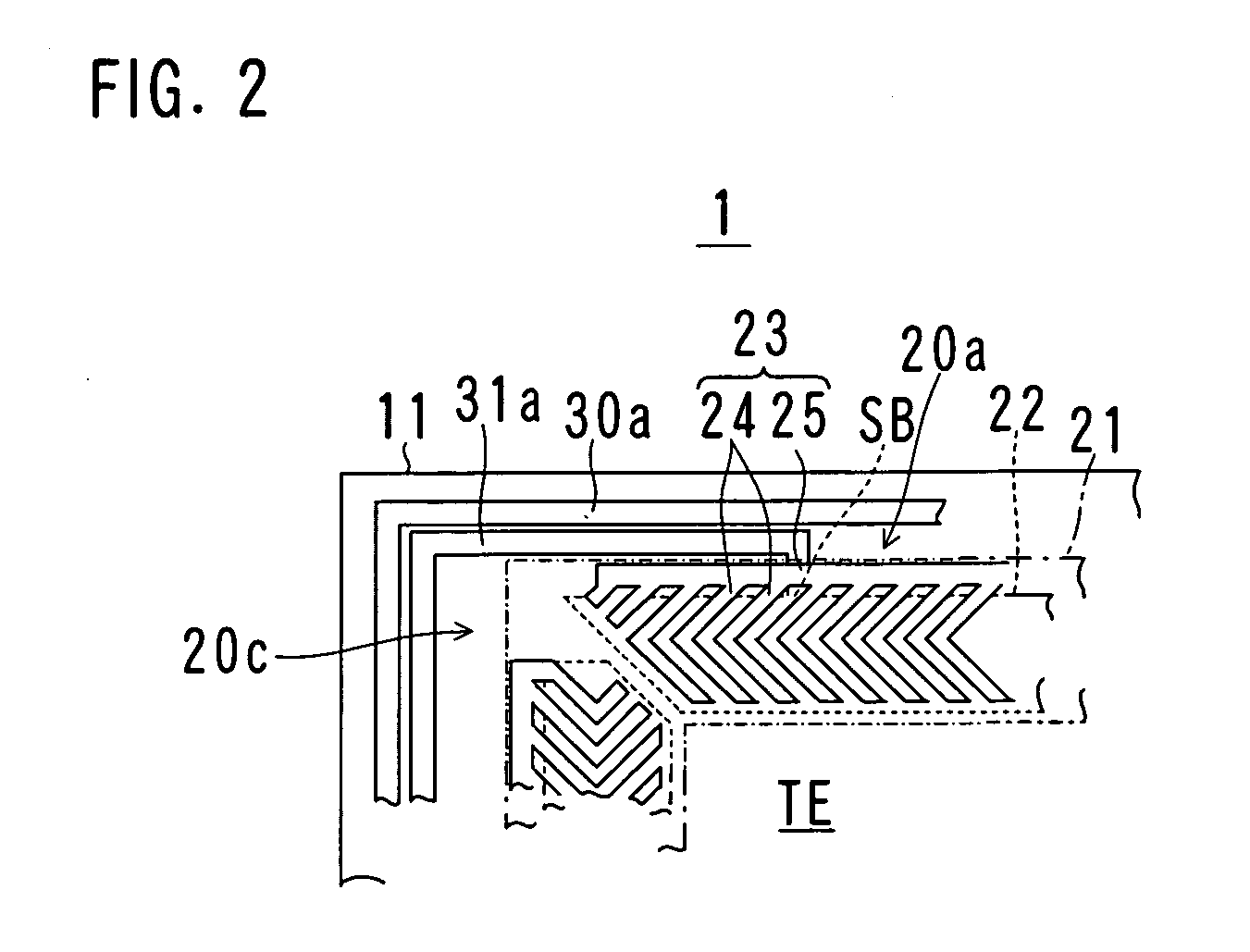

Antenna structure and radio-controlled timepiece

ActiveUS20070120758A1Good radio signal receiving performanceImprove reception performanceLoop antennas with ferromagnetic coreLogperiodic antennasResonanceEngineering

An antenna structure capable of receiving an external radio signal has a structure that enables reception of magnetic flux caused by an external radio signal, but has a magnetic path that makes it difficult for magnetic flux generated by resonance to leak to said outside of said antenna structure, said magnetic path being formed minimally by an antenna part, which is formed by at least one antenna core part and a coil part formed by winding of a conductive wire around said antenna core part, and a cover part disposed in a vicinity of said antenna part and covering at least a part of said antenna part, said antenna core part and cover part being made of a soft magnetic material, and also said cover part being joined to said antenna part at both ends of said antenna core part of said antenna part.

Owner:CITIZEN WATCH CO LTD

Health-care rice flour, rice and wheat flour, and prepn. method therefor

ActiveCN1559289APrevent hardeningAvoid breakingUnknown materialsFood preparationPolygonum fagopyrumAdditive ingredient

A health-care rice flour, or simulative rice, or noodle is prepared from corn, tartarian buckwheat, buckwheat, oats, soybean, sorghum and long-grained non-glutinous rice through proportionally mixing, grinding, proportionally mixing with pumpkin powder, carrot powder and ginkgo powder to obtain said rice flour, and shaping rice grains or noodles. It has high dietotherapeutic effect to orteriosclerosis, hypertension, hyperglycermia, hyperlipemia, and cardiovascular and cerebrovascular diseases.

Owner:北京益善康科技有限公司

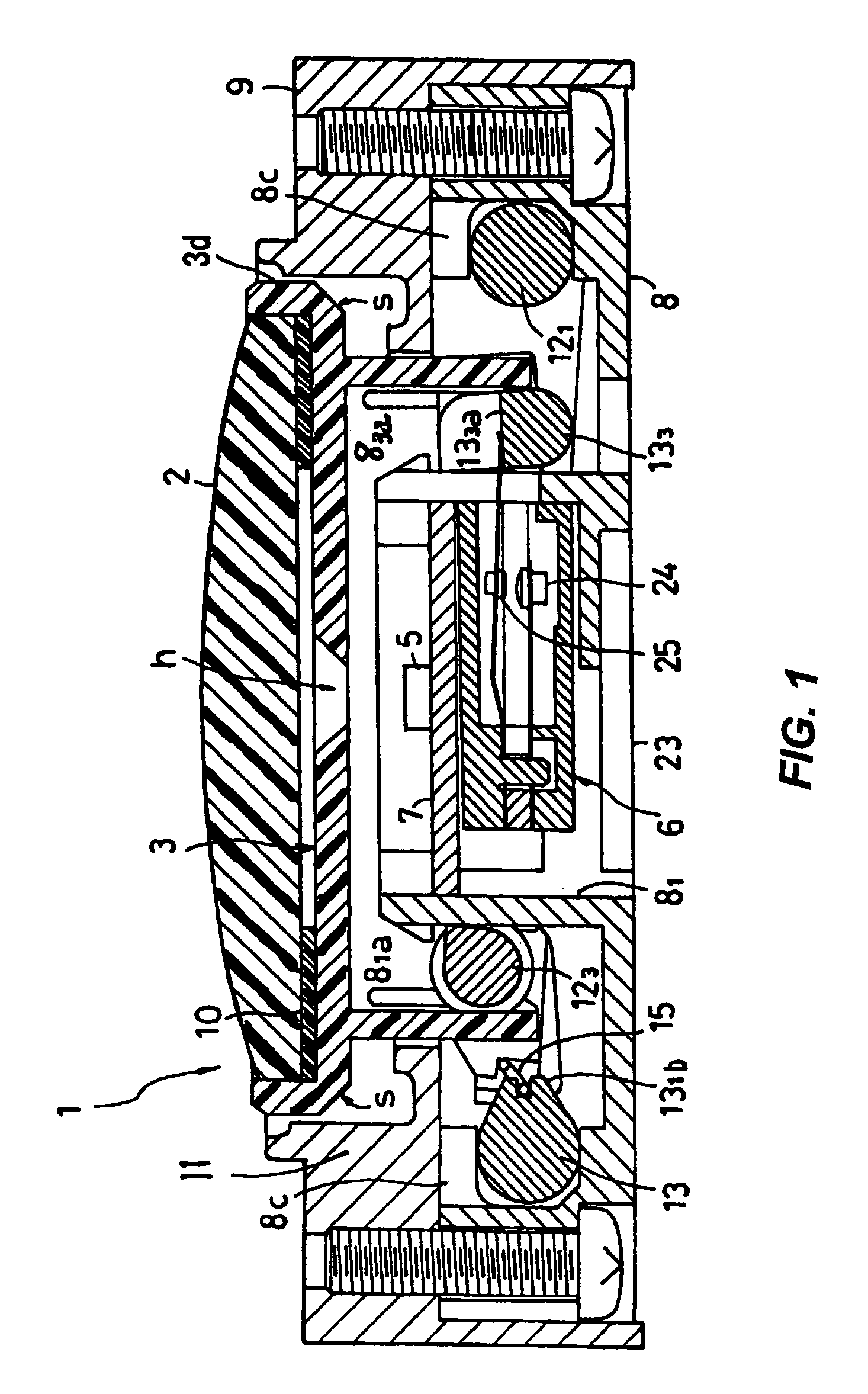

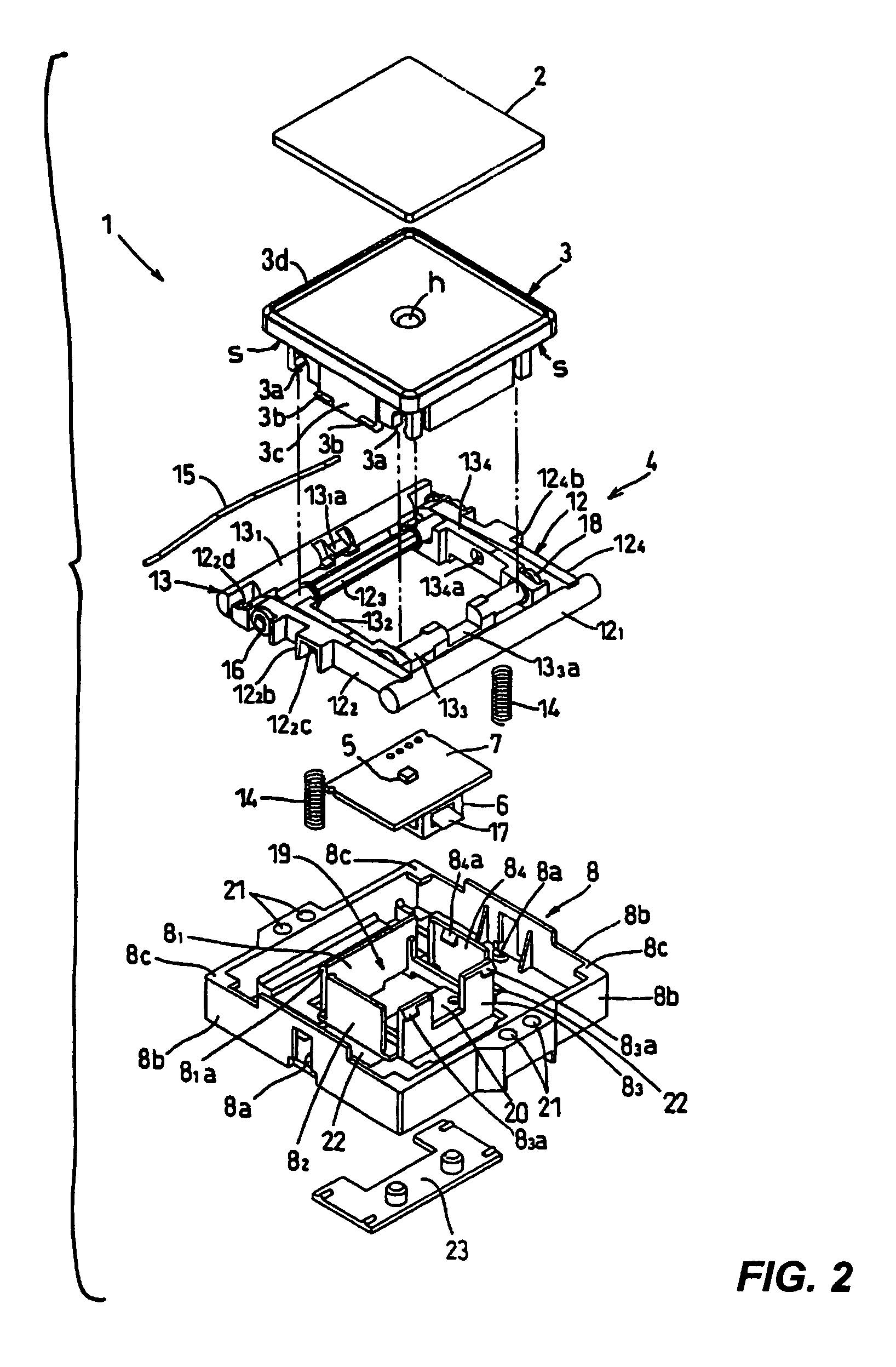

Push-button switch

A push-button switch has a plunger to be pressed so as to activate its main body supported by a base member. A cap serving as a pressing member is on an outer edge portion of the plunger. The outer periphery of the cap is surrounded by a frame part of a lens member made of a transparent resin material such that the light from a light source disposed near the center of the plunger is guided to the upper edge part of the frame part.

Owner:ORMON CORP +1

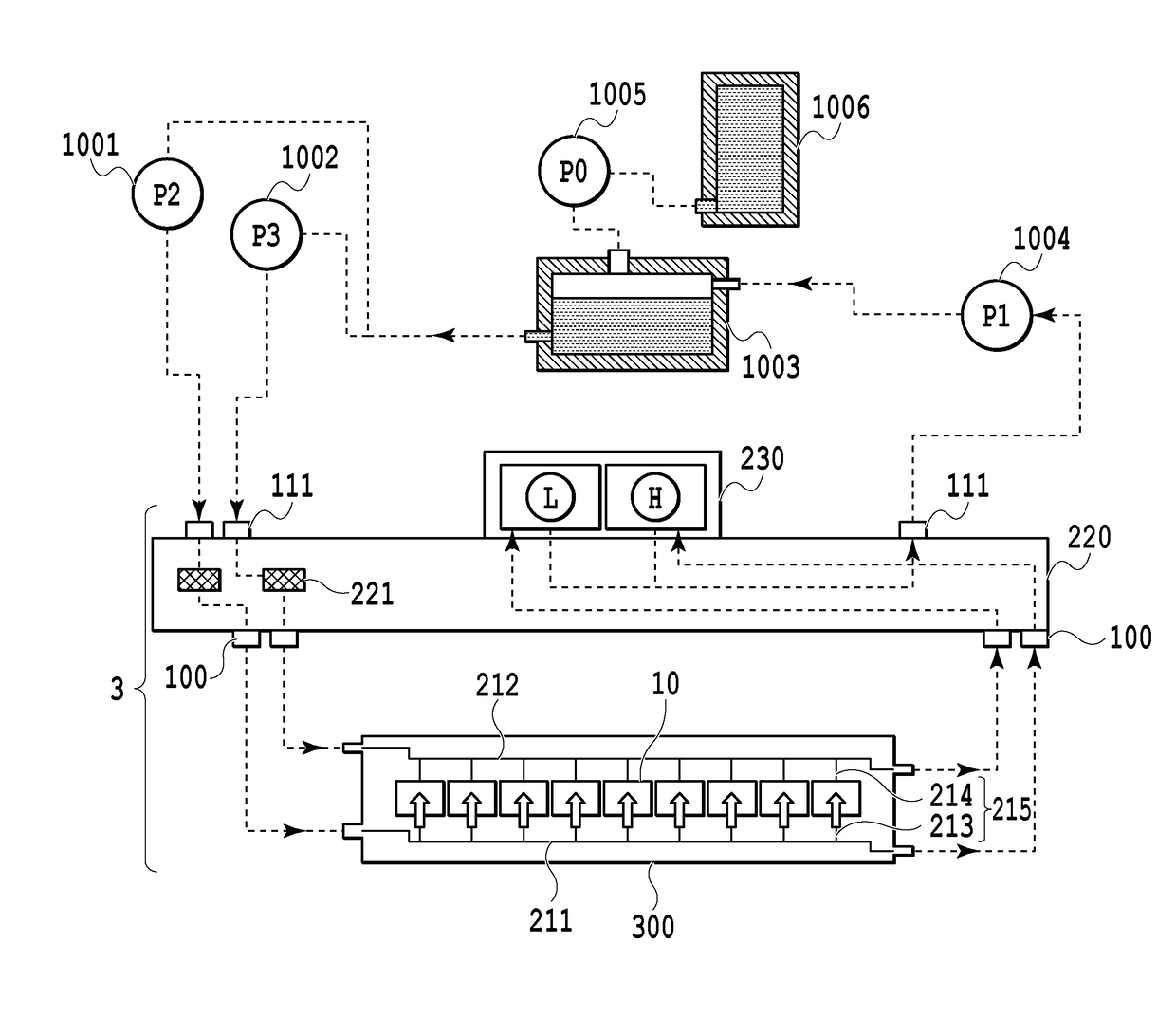

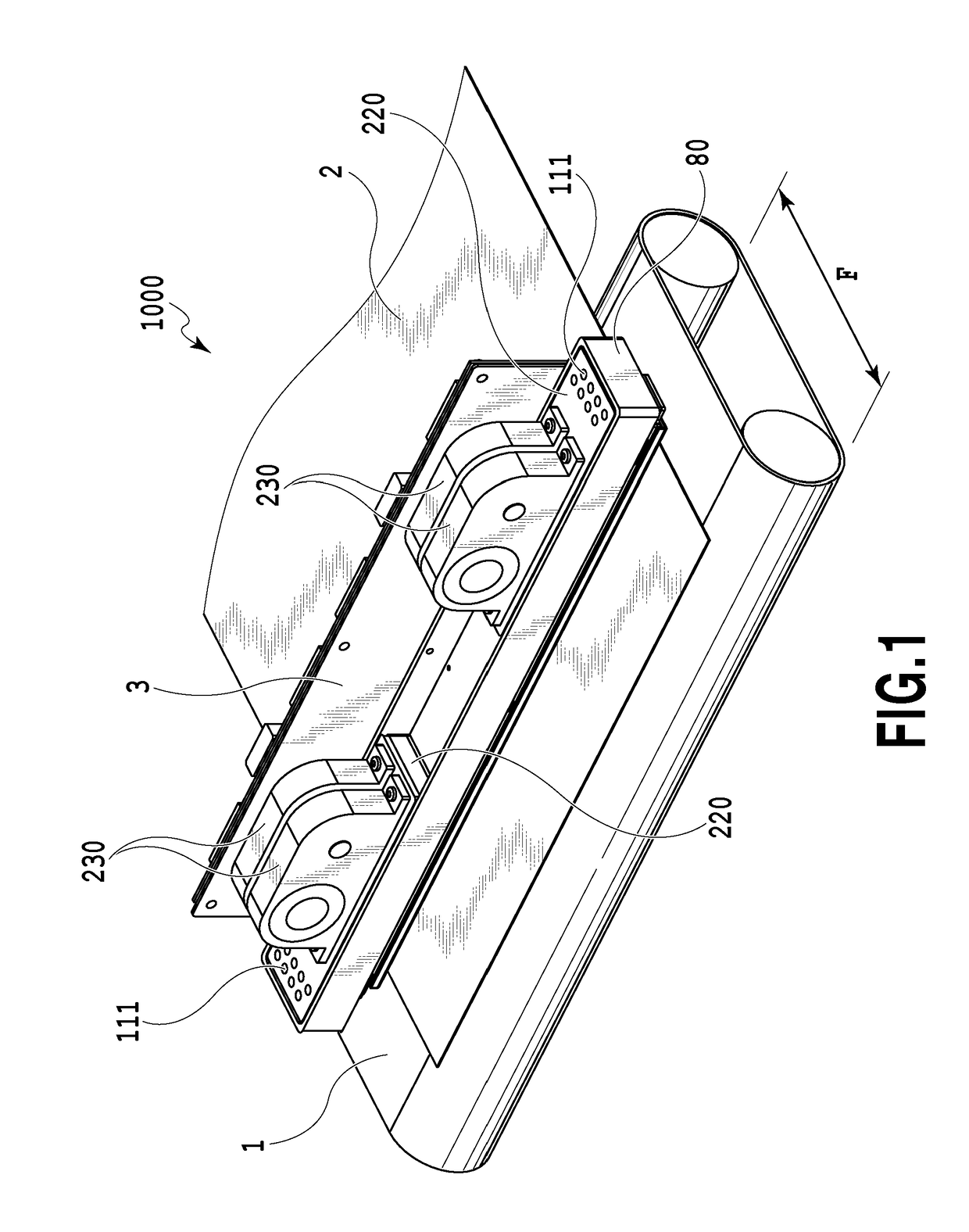

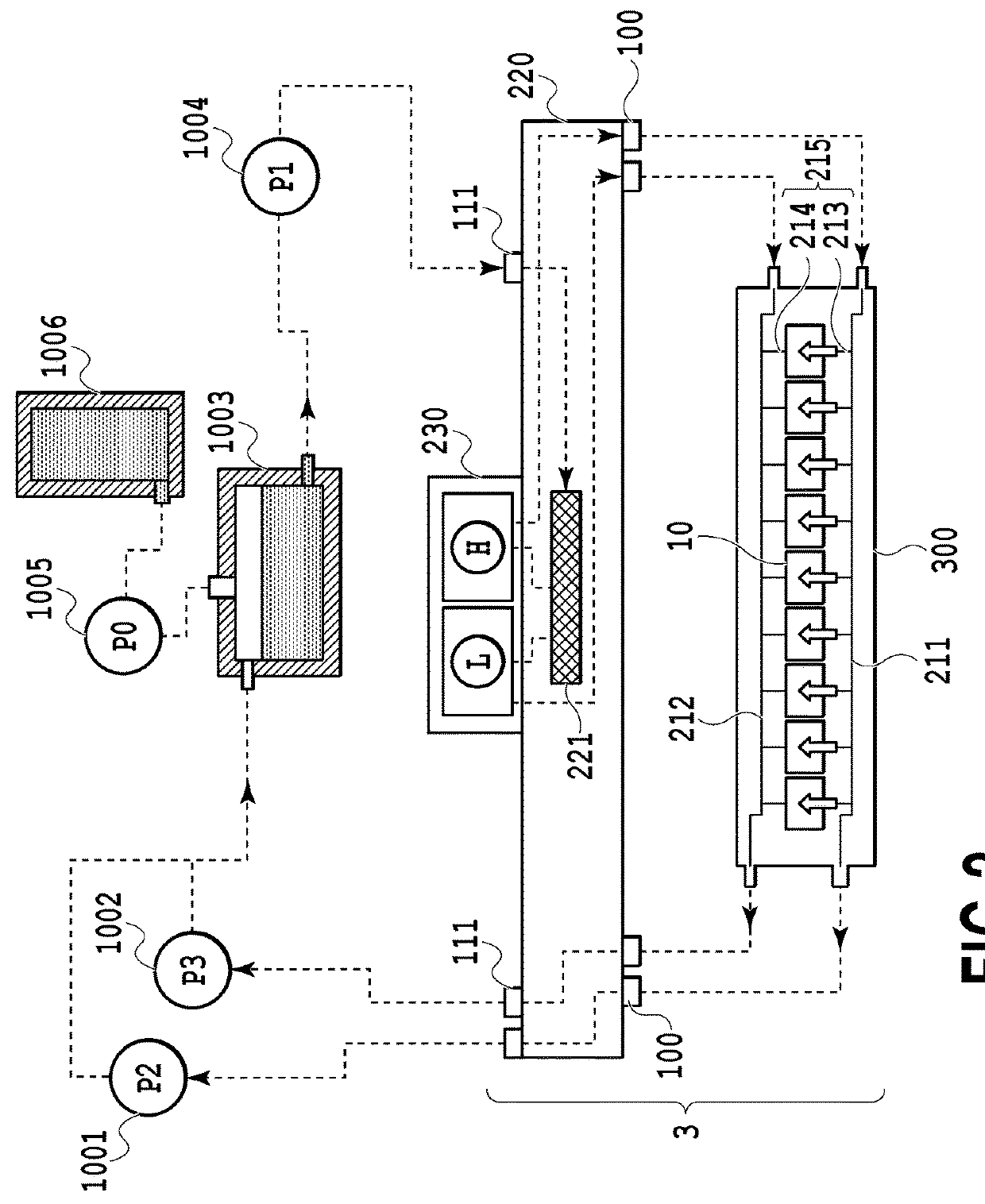

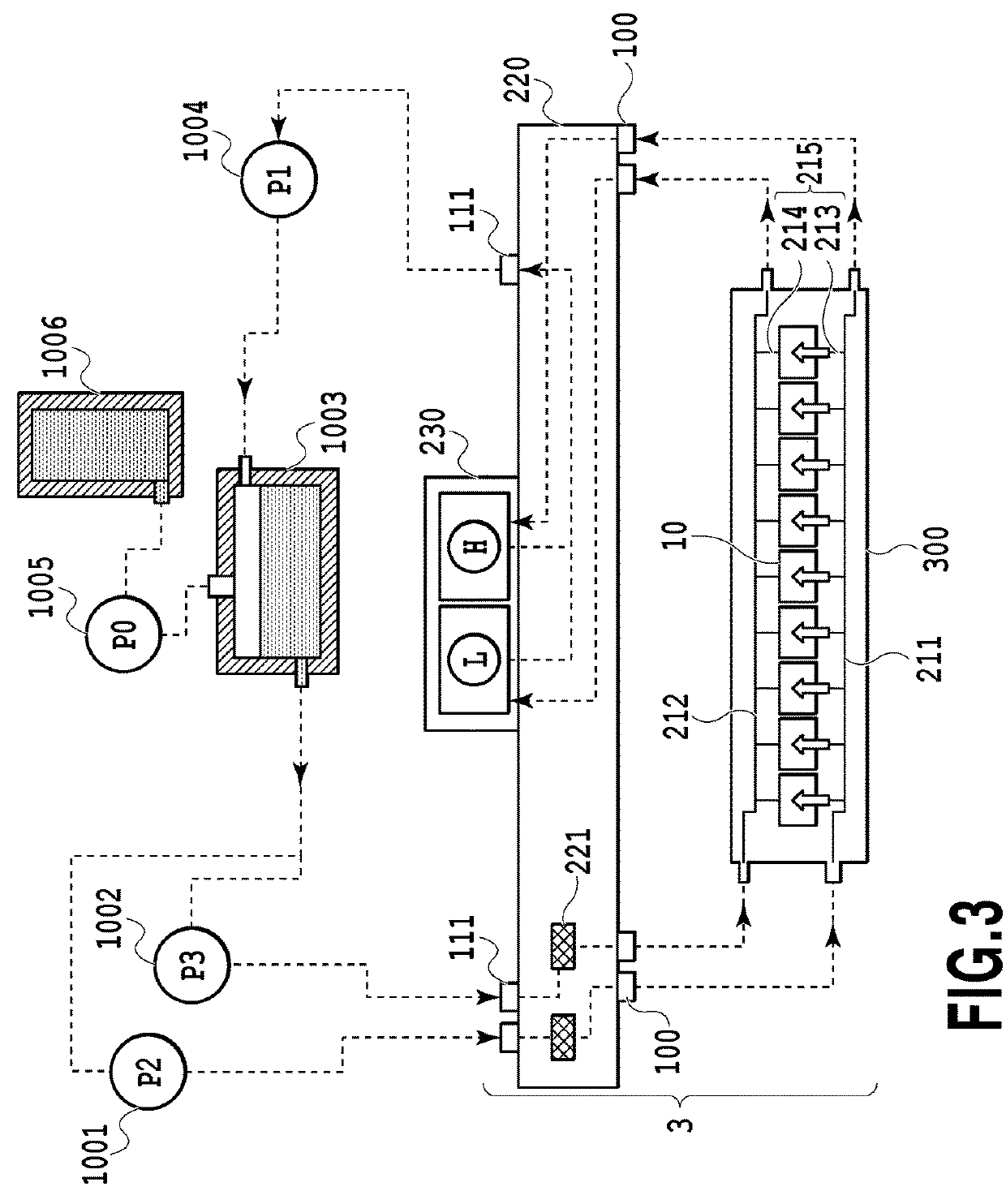

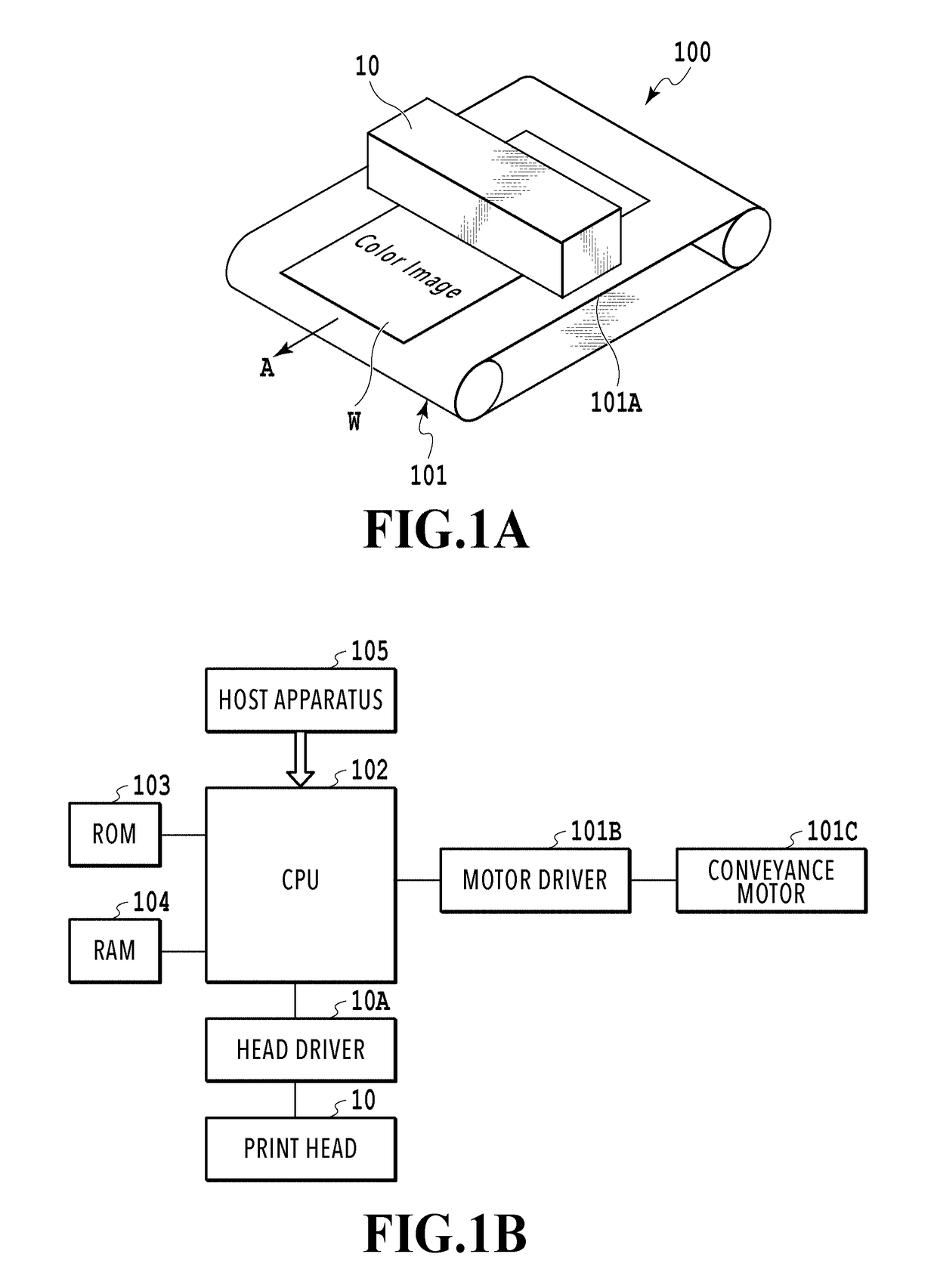

Liquid ejection head, liquid ejection apparatus, and method of supplying liquid

ActiveUS20170197419A1Change qualitySuppress change qualityInking apparatusEngineeringEnergy analysis

Owner:CANON KK

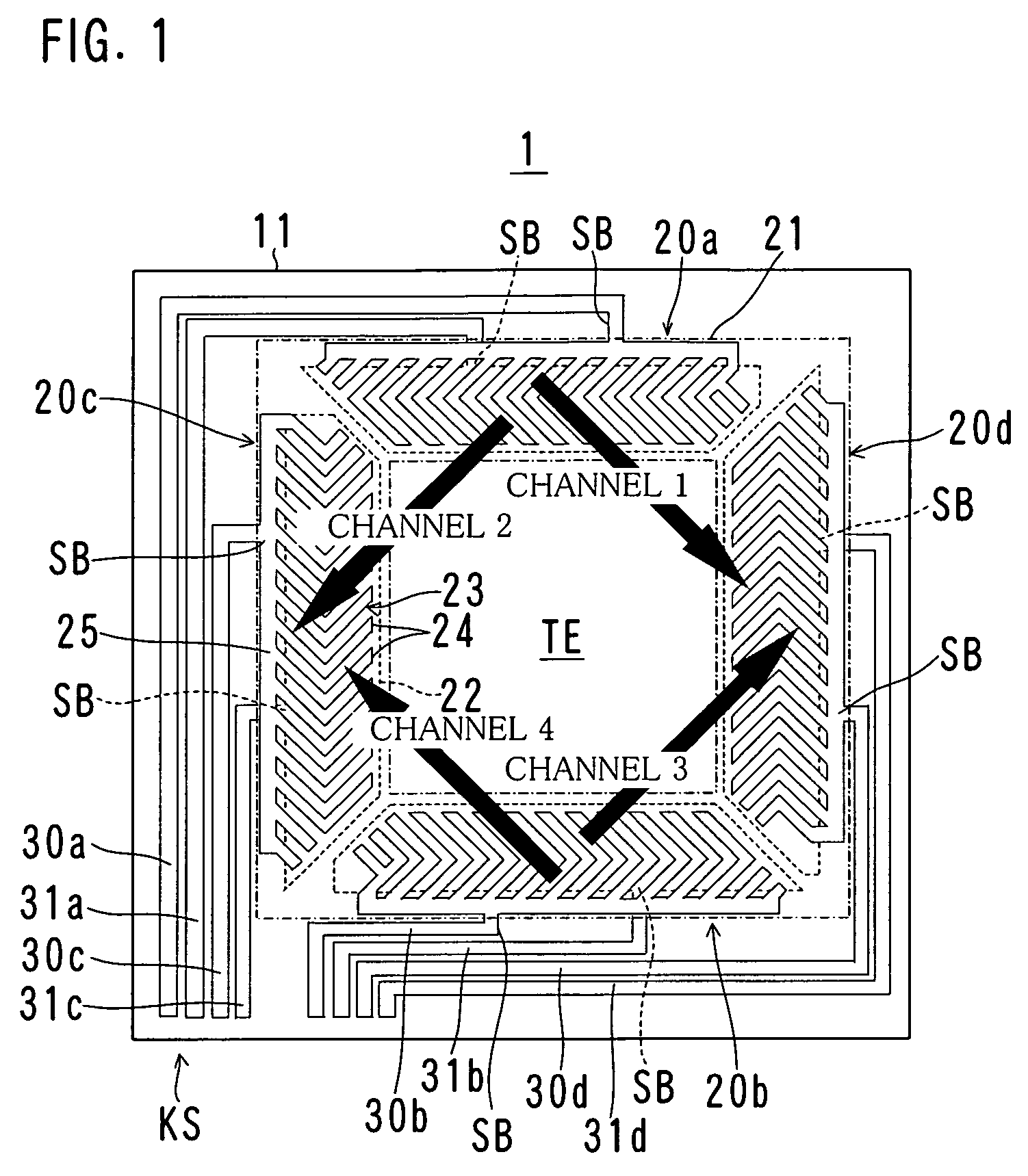

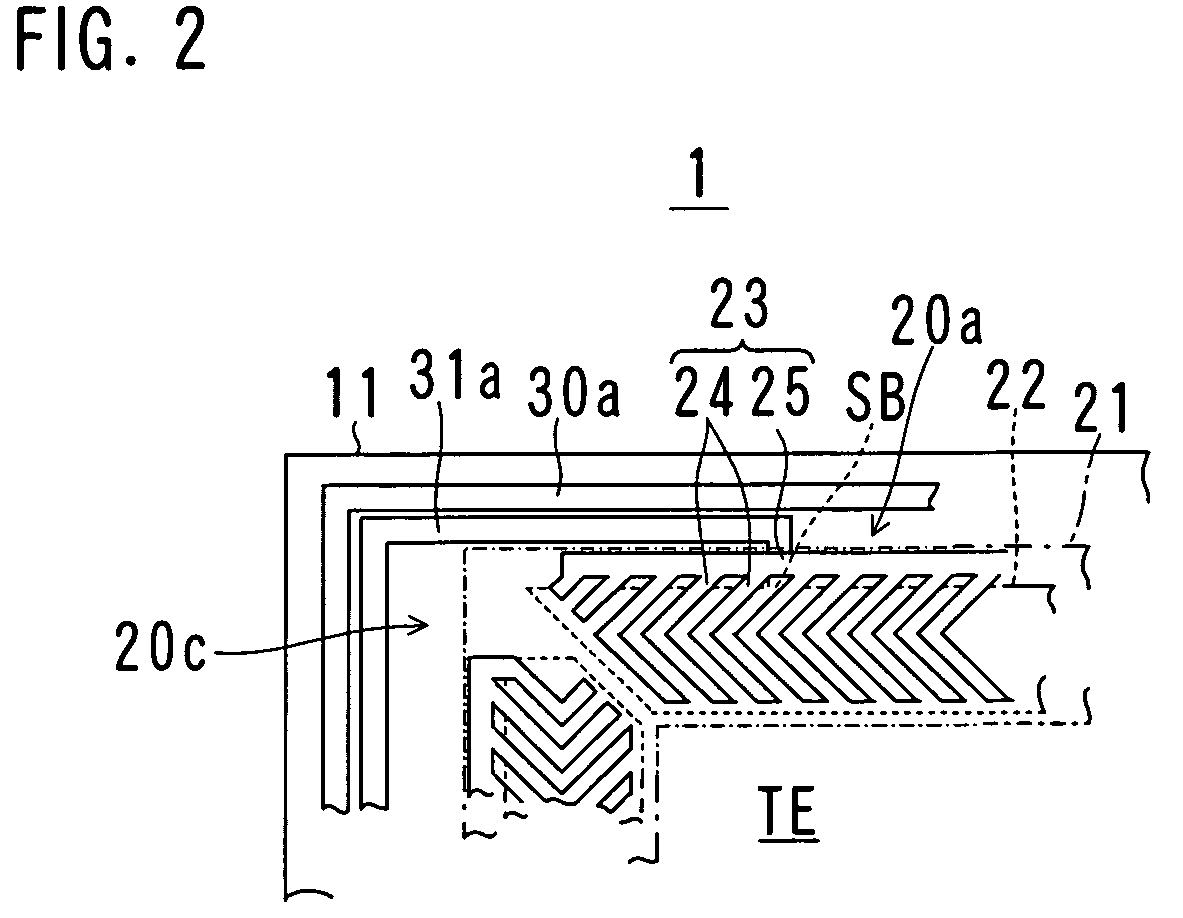

Touch panel device and method for manufacturing touch panel devices

ActiveUS7423636B2Avoid thickeningReduce border widthInput/output for user-computer interactionCathode-ray tube indicatorsSilver pasteTransducer

Each of transducers of a touch panel device includes a piezoelectric thin film, a plate electrode disposed at one surface of the piezoelectric thin film and a comb-like electrode disposed at the other surface of the piezoelectric thin film. The comb-like electrode has a plurality of comb-like electrode fingers and a linear bus electrode to which one end of each of the plural comb-like electrode fingers is connected. A plurality of wiring electrodes is provided at the outer side of any of the transducers in parallel with the bus electrode of the transducer and is connected to the bus electrode and the plate electrode of any of the transducers. Each of the wiring electrodes includes an electrode base portion formed by printing silver paste containing fine particles on the substrate and an electrode main body formed by printing silver paste containing large particles and fine particles in a mixed manner on the electrode base portion.

Owner:FUJITSU LTD

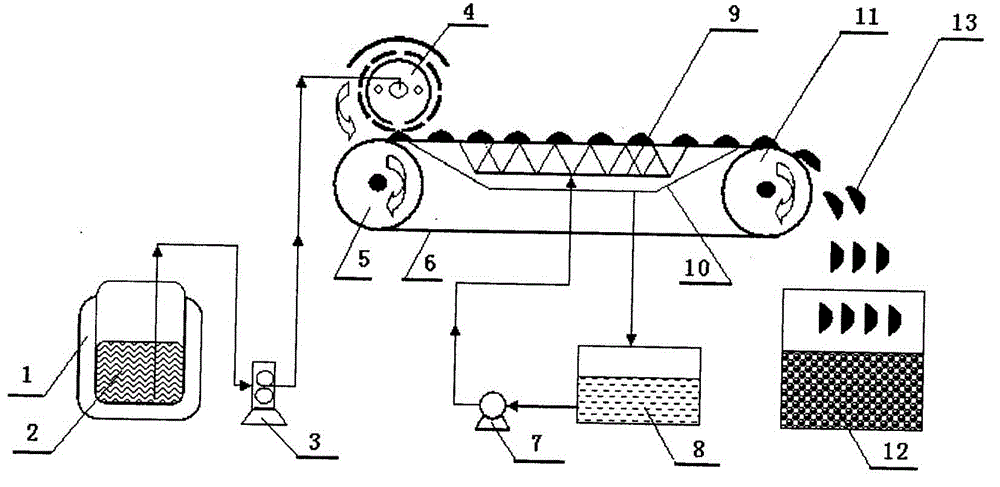

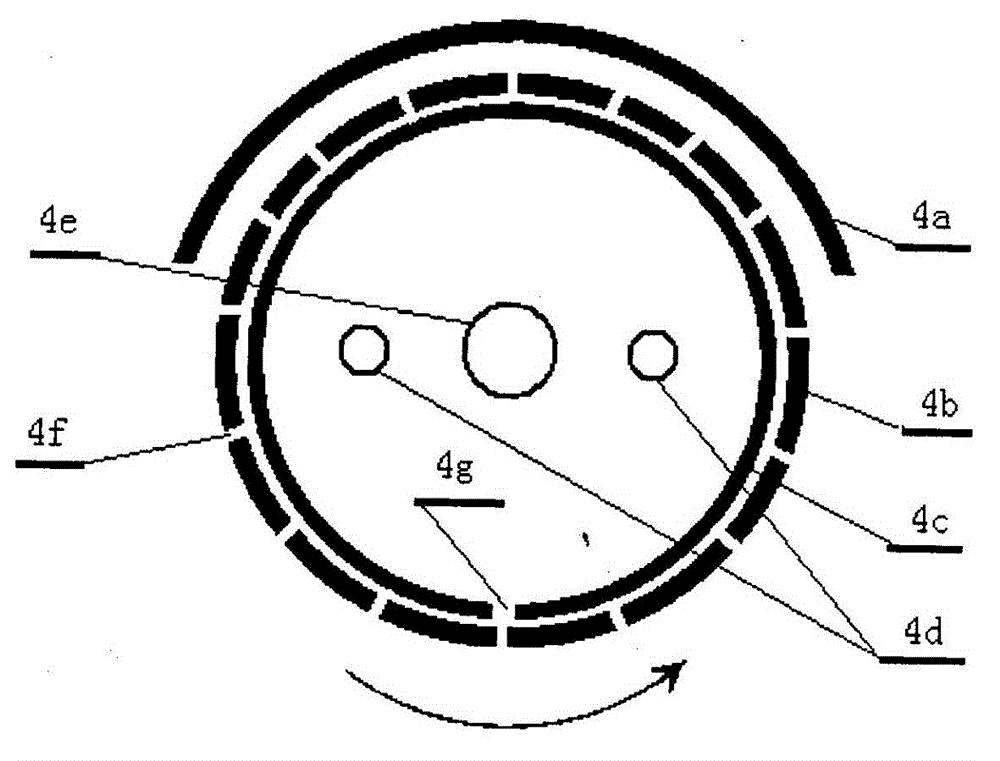

Hard asphalt granulation method and device thereof

InactiveCN102876345AImprove adaptabilityAdaptableWorking-up pitch/asphalt/bitumen by solidifying/disintegratingEngineeringAsphalt

The invention relates to a hard asphalt granulation method and a device thereof. The method comprises the following steps: heating hard asphalt to a molten state, delivering the hard asphalt in the molten state to a distributing device capable of adjusting fluid falling speed, evenly distributing the hard asphalt onto a rotary steel belt in a dropwise state, and carrying out forced cooling on the steel belt with a cooling water spraying system arranged below the rotary steel belt, so that cured asphalt granules are separated and fall off from the steel belt at the rotary end of the rotary steel belt. The method has the advantages of simple technical process, low pressure grade, low operating cost, high production efficiency and small pollution, can conveniently adjust the size of the hard asphalt granules, and has strong adaptability to hard asphalts with different softening points (viscosities). The produced asphalt granules have the advantages of uniform size and beautiful appearance, do not directly contact the cooling medium, and can obviously reduce the smoke dust and water pollution in the production process.

Owner:CHINA PETROLEUM & CHEM CORP

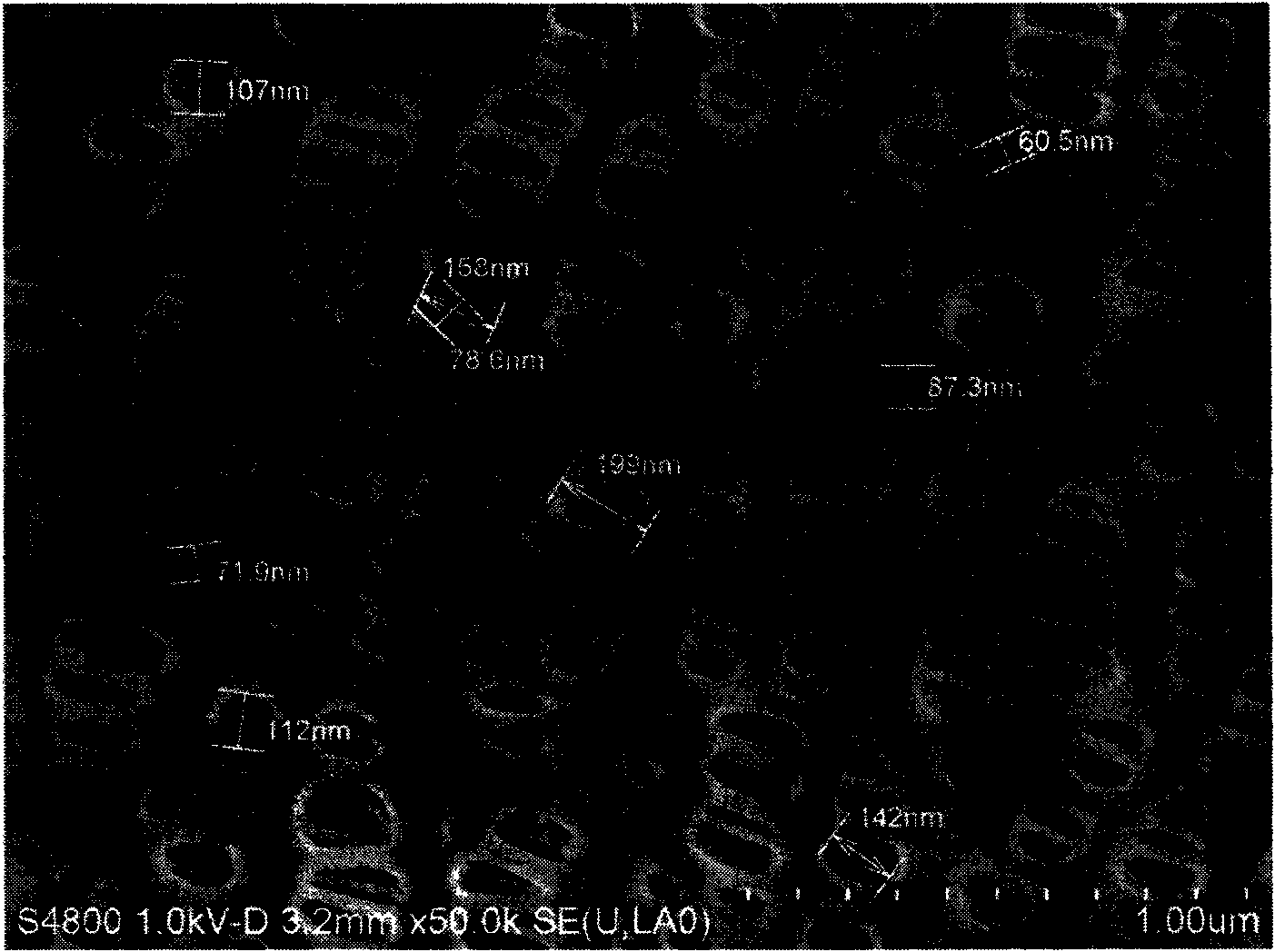

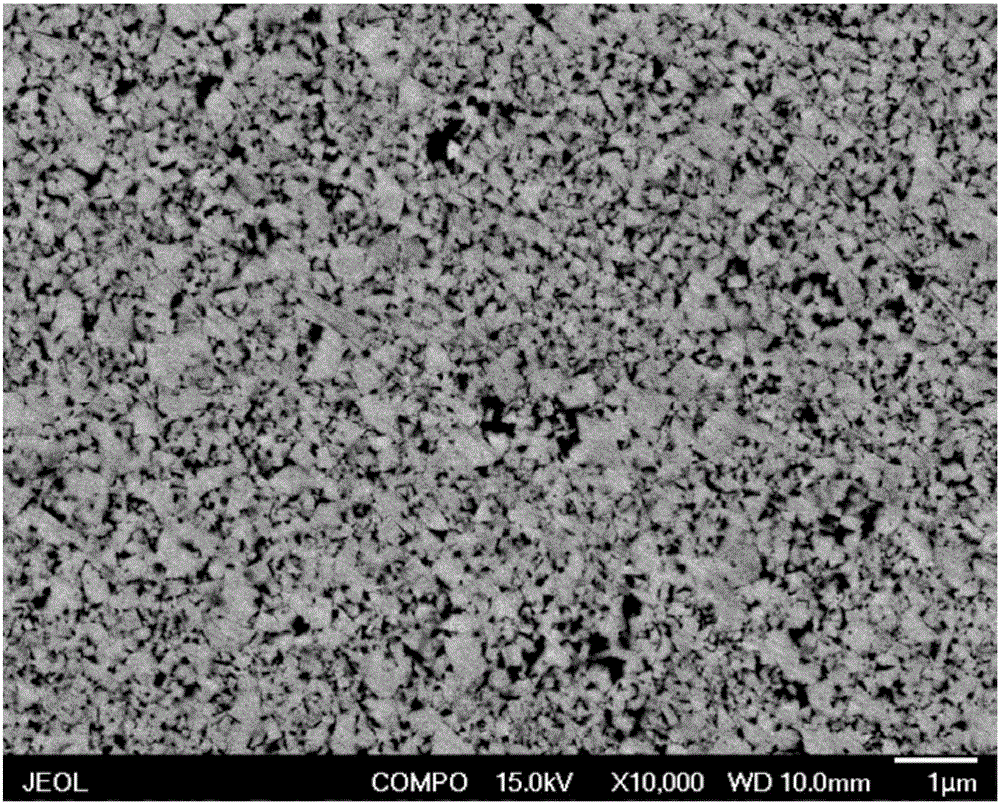

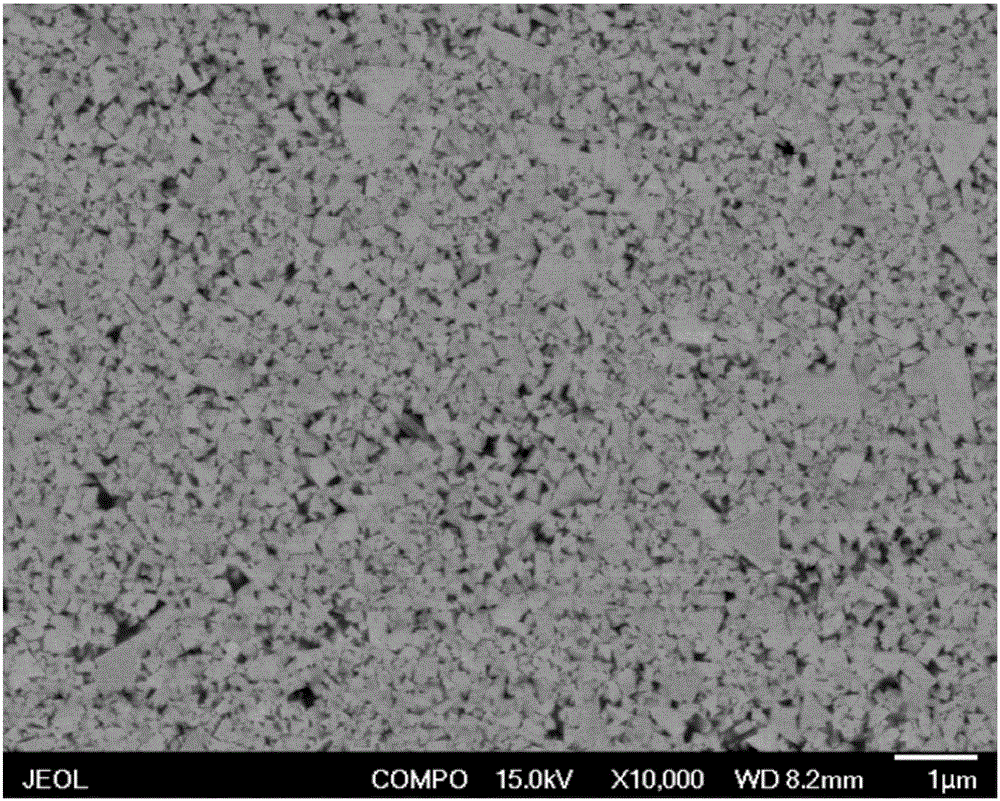

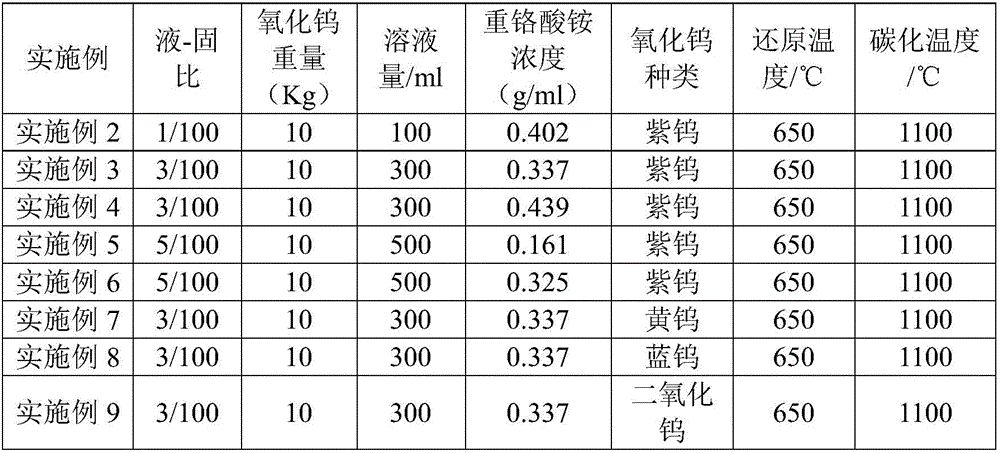

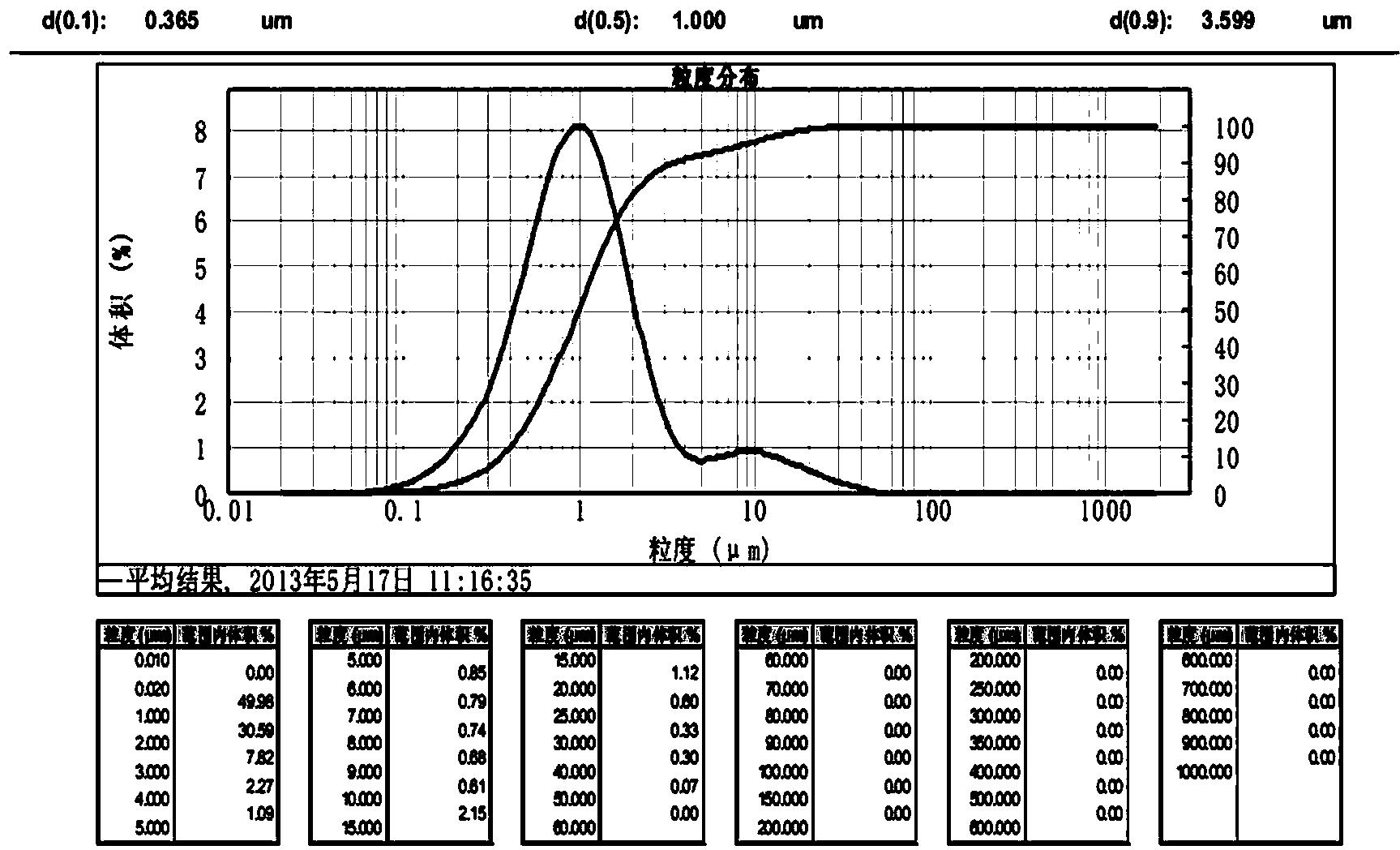

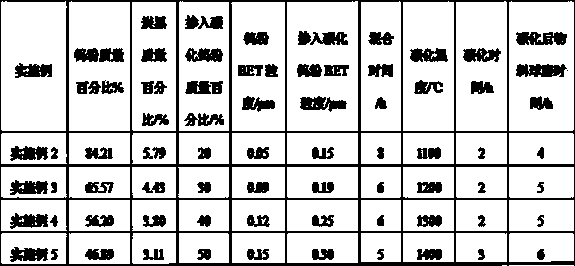

Method of preparing chromium-containing ultrafine WC powder through solid-liquid doping method

The invention discloses a method of preparing a chromium-containing ultrafine WC powder through a solid-liquid doping method. The method successively includes the steps of: preparing an ammonium dichromate solution; adding a certain amount of the ammonium dichromate solution to tungsten oxide powder, mixing the components to achieve solid-liquid mixing doping; performing hydrogen reduction, carbon blending, carbonization, cooling, ball milling and sieving to obtain the chromium-containing ultrafine WC powder. The method solves technical problems of non-uniform distribution, large granularity and unsatisfactory effect of inhibiting increase of granularity of WC grains of distribution of Cr3C2 in ultrafine WC powder and hard alloy. When the mixed powder is used for preparing the ultrafine hard alloy, the Cr3C2 has more significant effect of inhibiting the increase of granularity of carbonization grains than a conventional method.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Touch panel device and method for manufacturing touch panel devices

ActiveUS20060038792A1Prevent migrationReduce bezel widthInput/output for user-computer interactionCathode-ray tube indicatorsTouch panelEngineering

Each of transducers of a touch panel device includes a piezoelectric thin film, a plate electrode disposed at one surface of the piezoelectric thin film and a comb-like electrode disposed at the other surface of the piezoelectric thin film. The comb-like electrode has a plurality of comb-like electrode fingers and a linear bus electrode to which one end of each of the plural comb-like electrode fingers is connected. A plurality of wiring electrodes is provided at the outer side of any of the transducers in parallel with the bus electrode of the transducer and is connected to the bus electrode and the plate electrode of any of the transducers. Each of the wiring electrodes includes an electrode base portion formed by printing silver paste containing fine particles on the substrate and an electrode main body formed by printing silver paste containing large particles and fine particles in a mixed manner on the electrode base portion.

Owner:FUJITSU LTD

Nano-calcium phosphate biological active ceramic material containing silicon dioxide and preparation method thereof

InactiveCN101401950AIncrease biological reactivityAvoid thickeningProsthesisCalcium biphosphateBiological body

The invention provides a nanometer calcium phosphate bioactive ceramic material containing silicon dioxide and a method for preparing the same. The method for preparing the nanometer calcium phosphate bioactive ceramic material containing the silicon dioxide comprises the following steps: firstly, synthesizing an aqueous dispersion liquid of nanometer calcium phosphate by a liquid phase method; secondly, catalyzing and hydrolyzing ortho silicate ester compounds in the aqueous dispersion liquid, and performing gelatination to generate the silicon dioxide coating on the surface of the nanometer calcium phosphate; and thirdly, performing drying and high temperature calcination to obtain the nanometer calcium phosphate bioactive ceramic material containing the silicon dioxide. The direct agglomeration in the nanometer calcium phosphate is avoided in the process of drying and calcining after the surfaces of nanometer calcium phosphate particles are coated with the silicon dioxide, thus the original nanometer scale structure is kept; at the same time, the silicon dioxide coated on the surfaces of the calcium phosphate particles endows the ceramic material with better biological reactivity in organisms in comparison with the common nanometer calcium phosphate.

Owner:KUNMING UNIV OF SCI & TECH

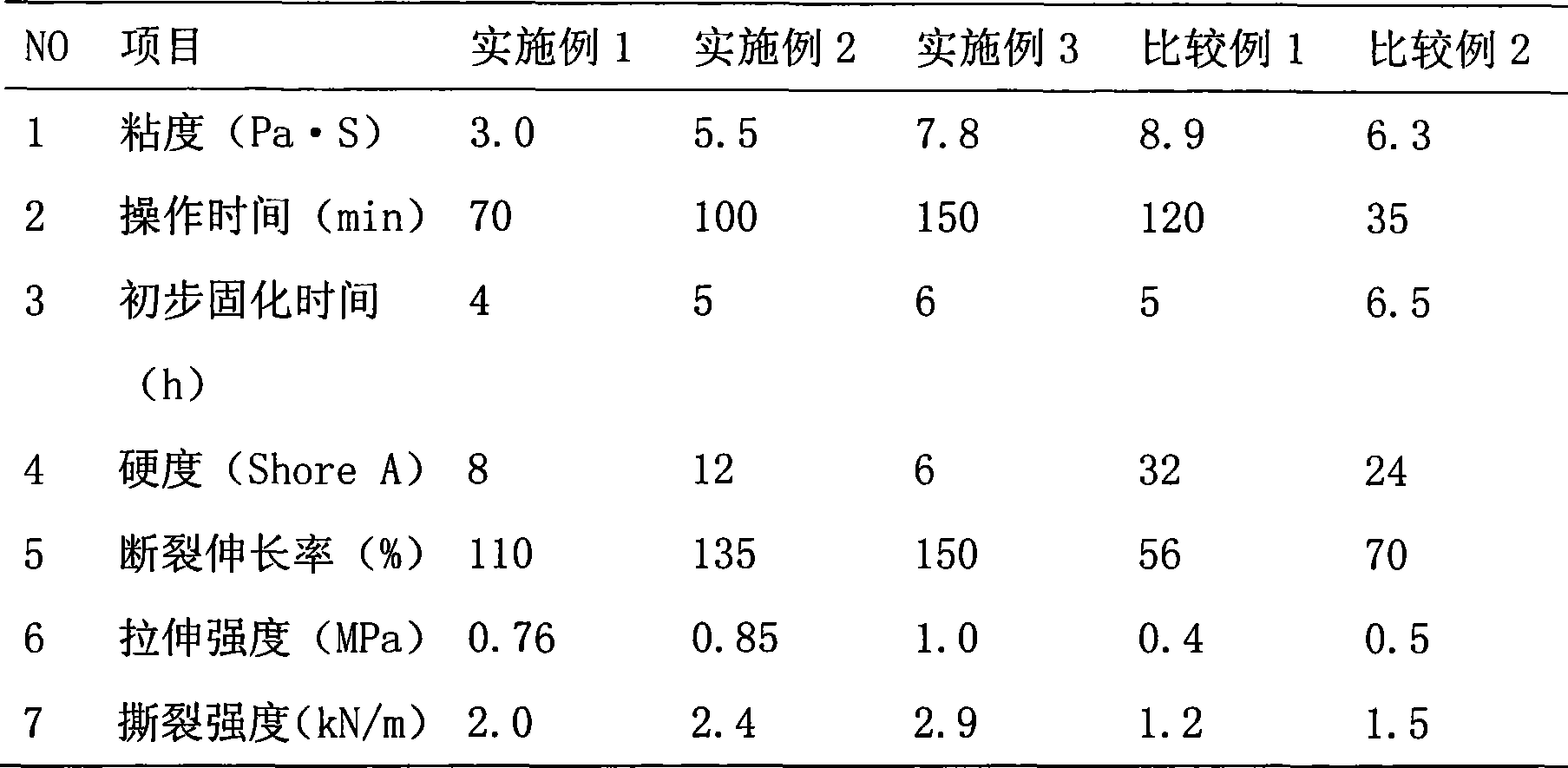

Bi-component silicone pouring sealant for LED photoelectric display device and method for manufacturing same

ActiveCN101544881AAvoid thickeningSimple processOther chemical processesSemiconductor/solid-state device manufacturingHydroxylamineDisplay device

The invention relates to a bi-component silicone pouring sealant for an LED optoelectronic display device and a method for manufacturing the same. The bi-component silicone pouring sealant is characterized in that the sealant is obtained through the reaction of components A and B by using alpha,omega-dihydroxy polydimethylsiloxane of which the structural formula shown on the right as a main material. The component A is prepared from the following components by weight portion through mixing: 100 portions of the alpha,omega-dihydroxy polydimethylsiloxane, 10 to 35 portions of organosilicon based gel, 0 to 50 portions of stuffing, and 10 to 30 portions of plasticizer; and the component B is prepared from the following components in portion by weight through mixing: 5 to 10 portions of cross-linking agent, 0.3 to 3 portions of coupling agent, 0.1 to 0.5 portion of titanate complex, 0.1 to 0.5 portion of diethyl hydroxylamine, 0.01 to 0.1 portion of dibutyltin dilaurate catalyst, and 2 to 10 portions of plasticizer. The silicone pouring sealant prepared by the method has the advantages of simple process flow, good adhesive property, excellent temperature and weather resistant properties, and good flow property, and can be widely applicable for embedding electronic devices such as the LED optoelectronic display device and the like.

Owner:CHENGDU GUIBAO SCI & TECH

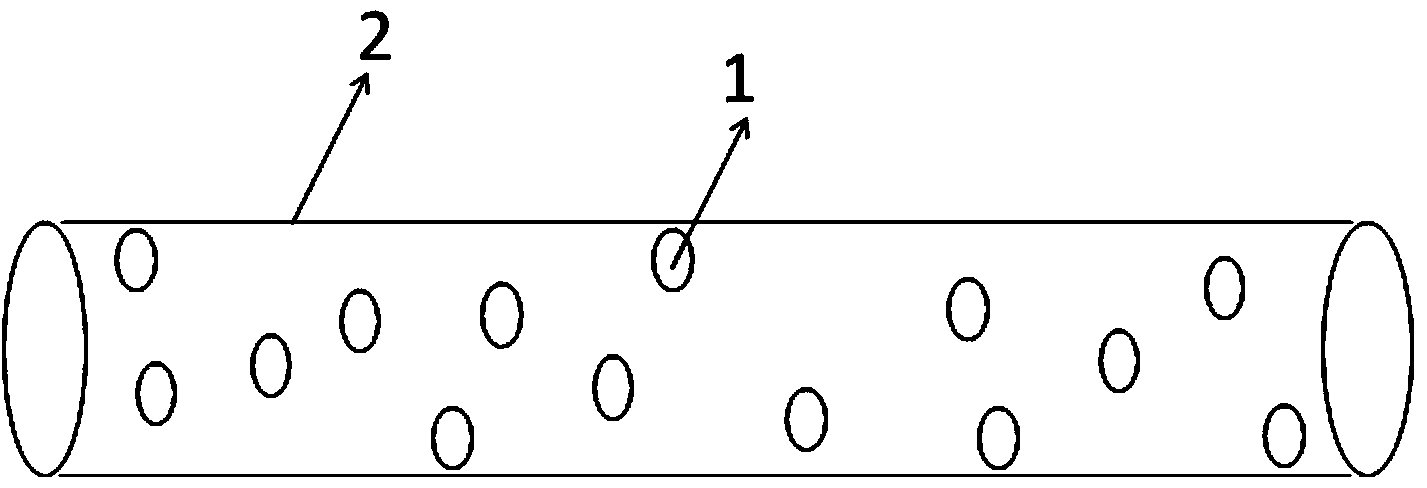

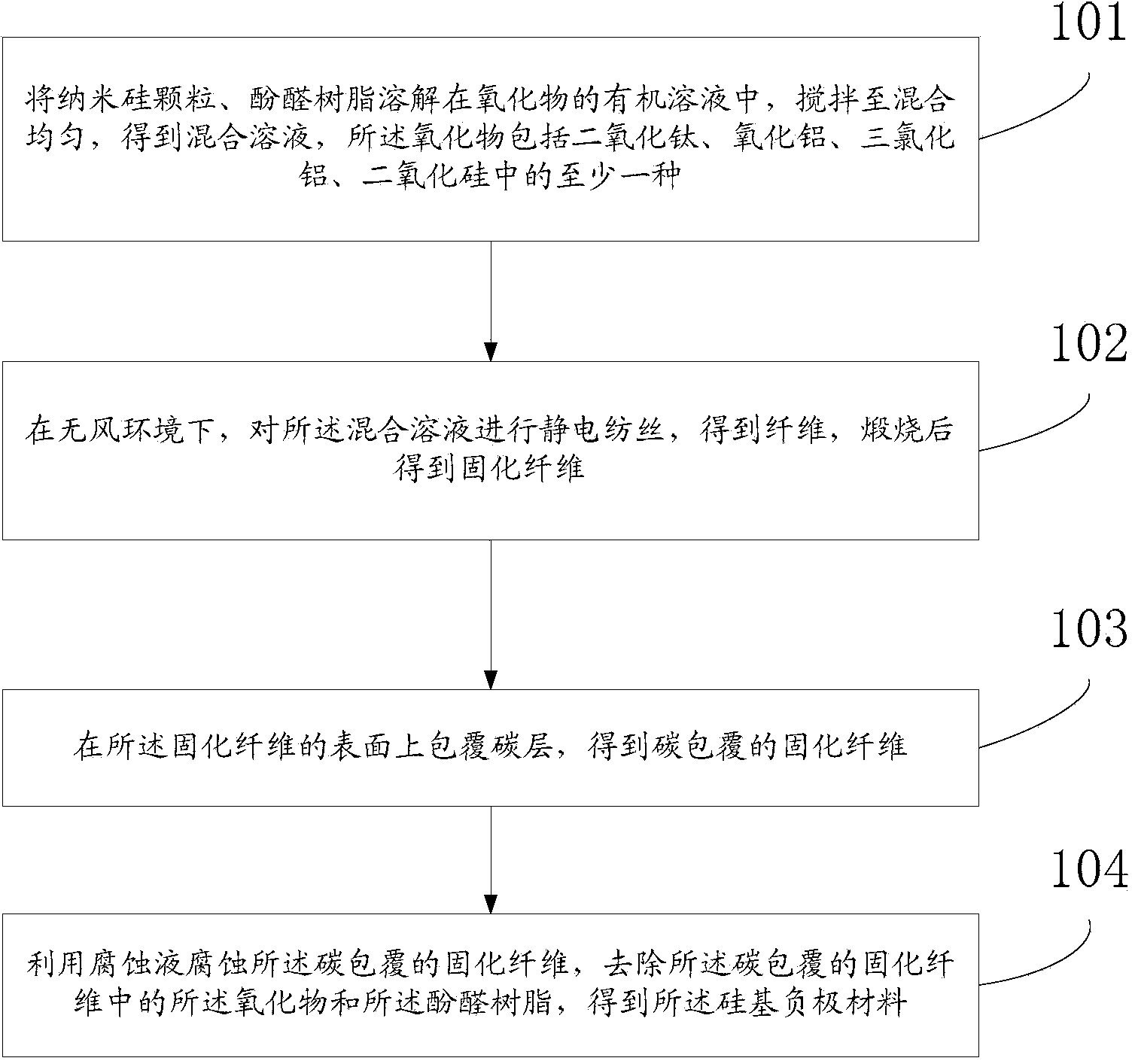

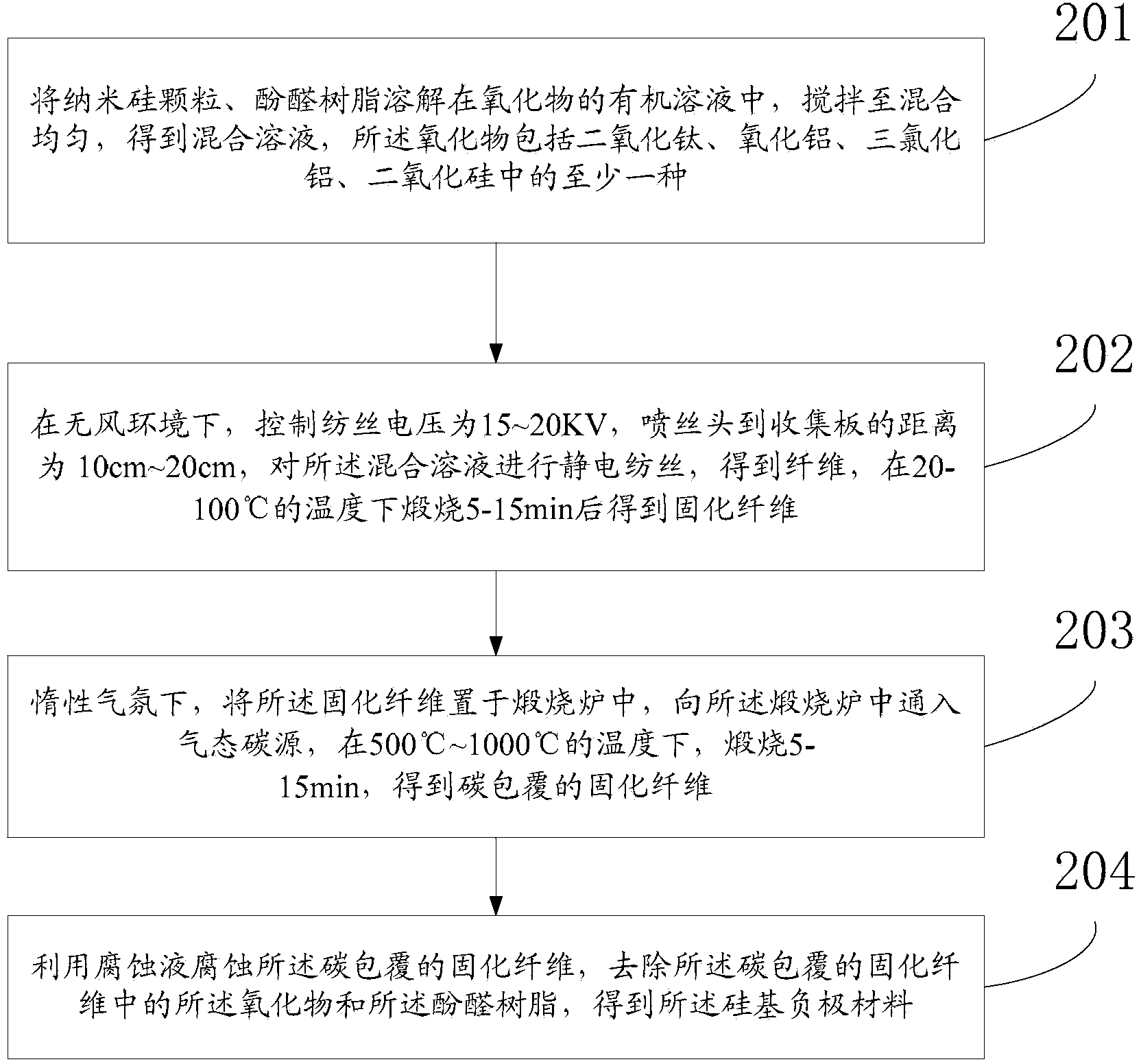

Silicon-based negative electrode material and method thereof

ActiveCN104112847AAvoid thickeningIncrease capacity and cycle performanceCell electrodesSecondary cellsSilicon particleElectrical battery

The invention discloses a silicon-based negative electrode material and a preparation method thereof, belonging to the field of negative electrode materials of lithium ion batteries. The silicon-based negative electrode material comprises a carbon tube and nanometer silicon particles in the carbon tube. Since gaps exist in the carbon tube, the silicon particles can be fixed in the limited space in the carbon tube, which enables volume expansion or shrinkage of the silicon particles to be in the limited space; thus, influence on electron transport performance between an active material and a current collector is avoided, thickening of an SEI membrane is prevented, and the capacity and cycle performance of a lithium battery are improved.

Owner:CHERY AUTOMOBILE CO LTD

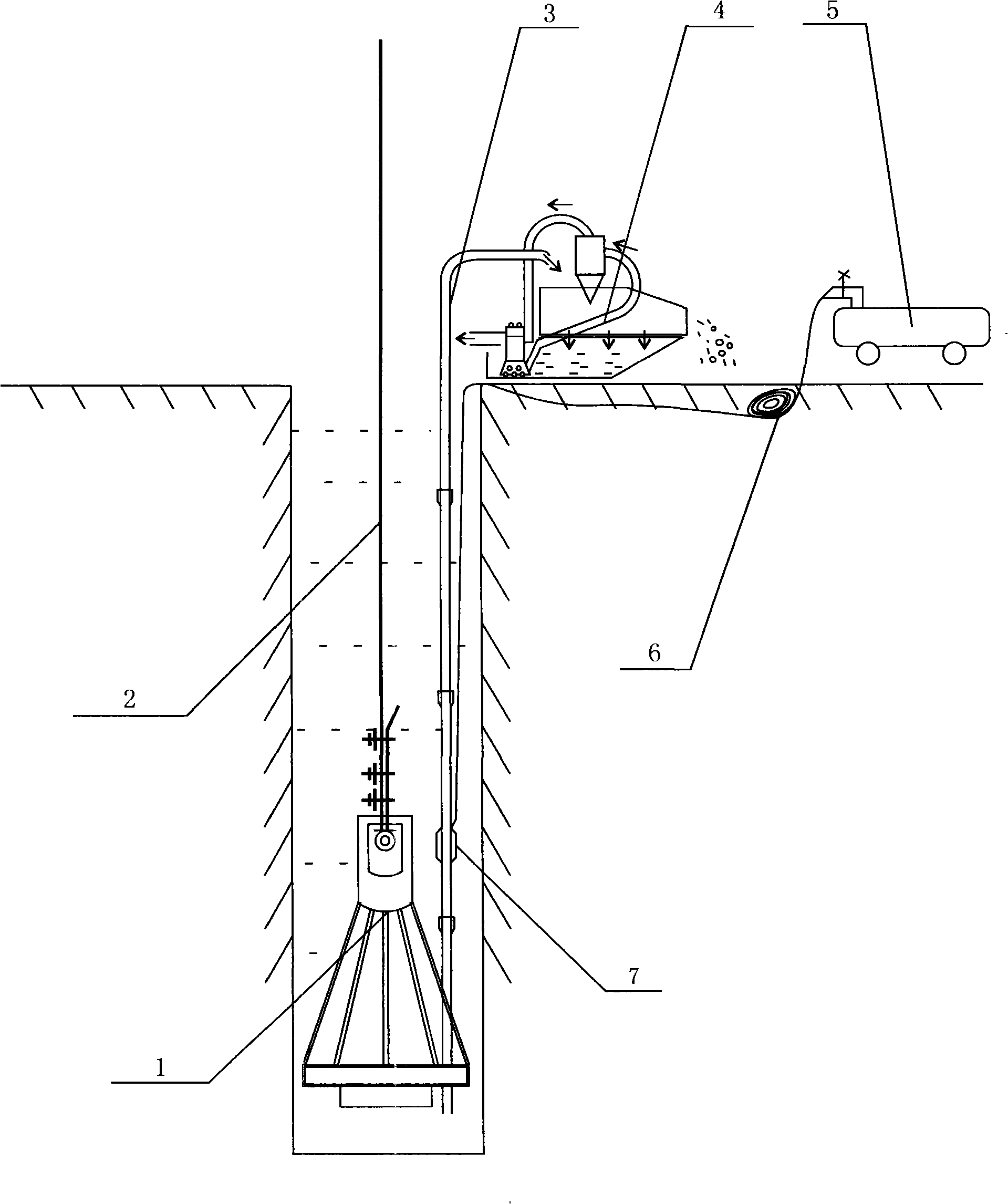

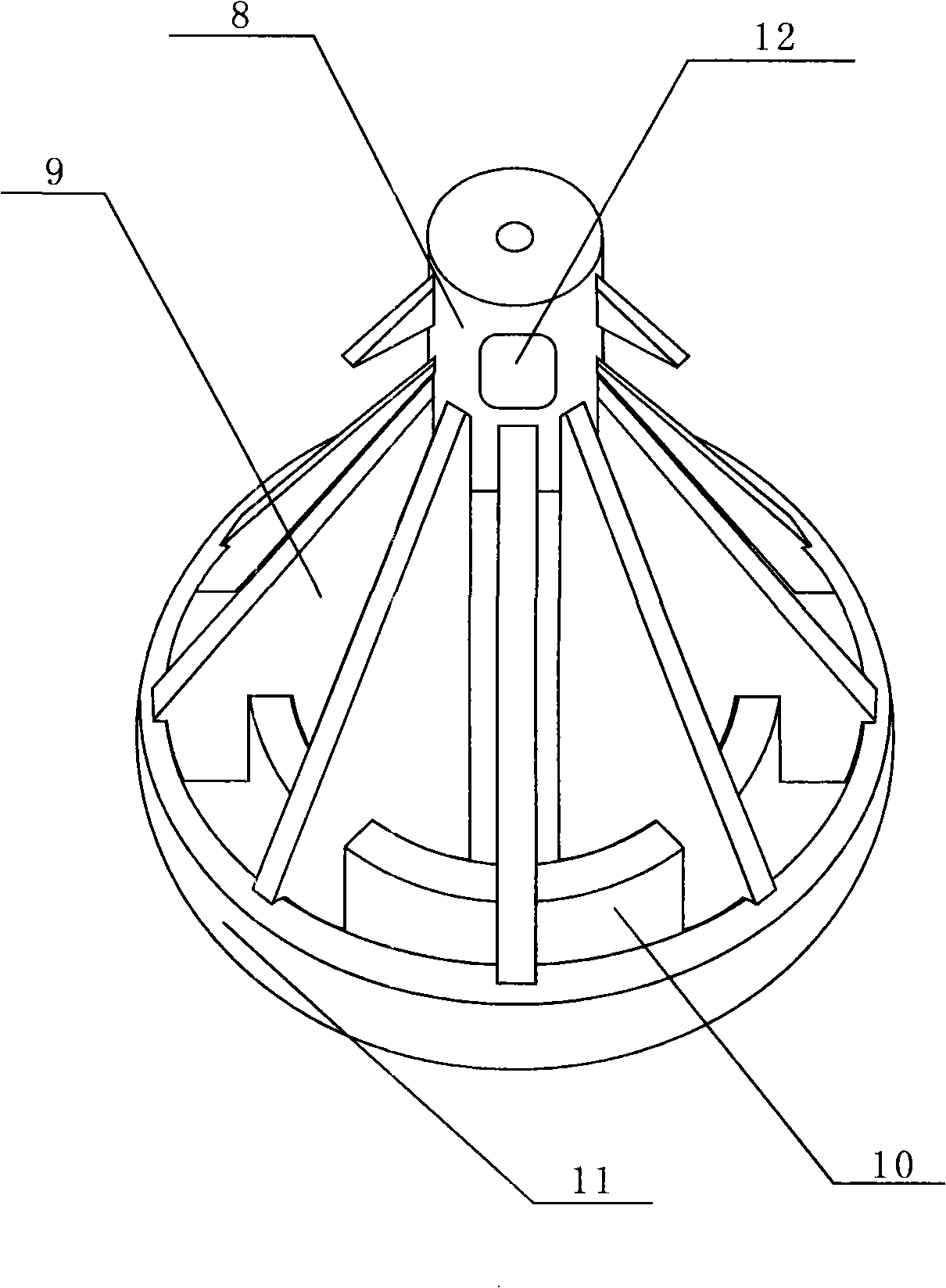

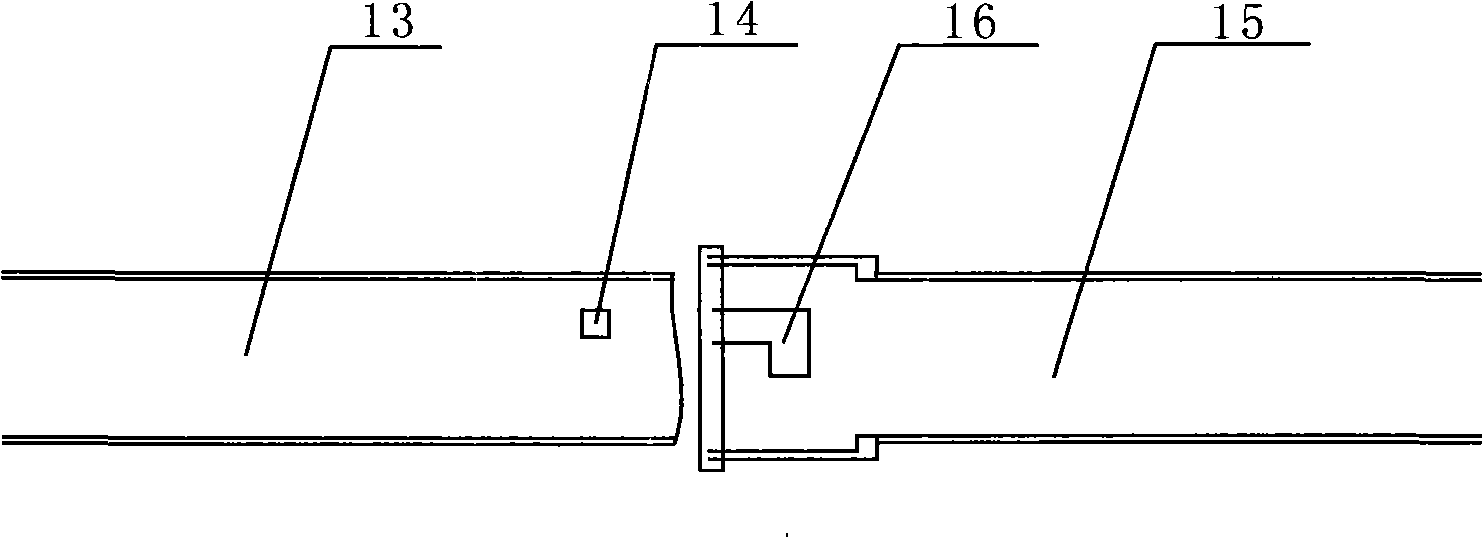

Reverse circulation construction technique and apparatus of single rope impact drill

InactiveCN101275458ARotation does not generateAvoid entanglementConstructionsReciprocating drilling machinesSlagEngineering

The invention discloses a process and a device for the reverse circulation execution of a single rope impact drill, the reverse circulation execution device comprises a percussion drill, a slurry pumping pipe at the hole bottom and a slurry purifier at the hole mouth, the drill bit is composed of a drill bit body and a cutting blade, the drill bit body is composed of a hammer body, corner boards and a base, the upper end of the hammer body is provided with a connecting hold connected with a non-rotating rope, the corner boards are distributed in the same angle axially on the cylindrical or circular-tube-shaped hammer body, the base is composed of coaxial inner base and outer base, which are tube-shaped, the upper surfaces of the two base are in the same plane, the inner base is higher than the outer base, the lower ends of the corner boards are connected with the two bases, the hammer body, the corner plate and the base are integrated by welding, casting or riveting, the lower end of the base is evenly equipped with multiple cutting blades; pile types of various section shapes can be dilled by the drill bit, the reverse circulation process of hole bottom slag pumping is used when drilling, the execution process is fastened, the energy consumption is reduced, the slag is cleaned completely and clearly, the time for cleaning the hole is shortened.

Owner:张安禄

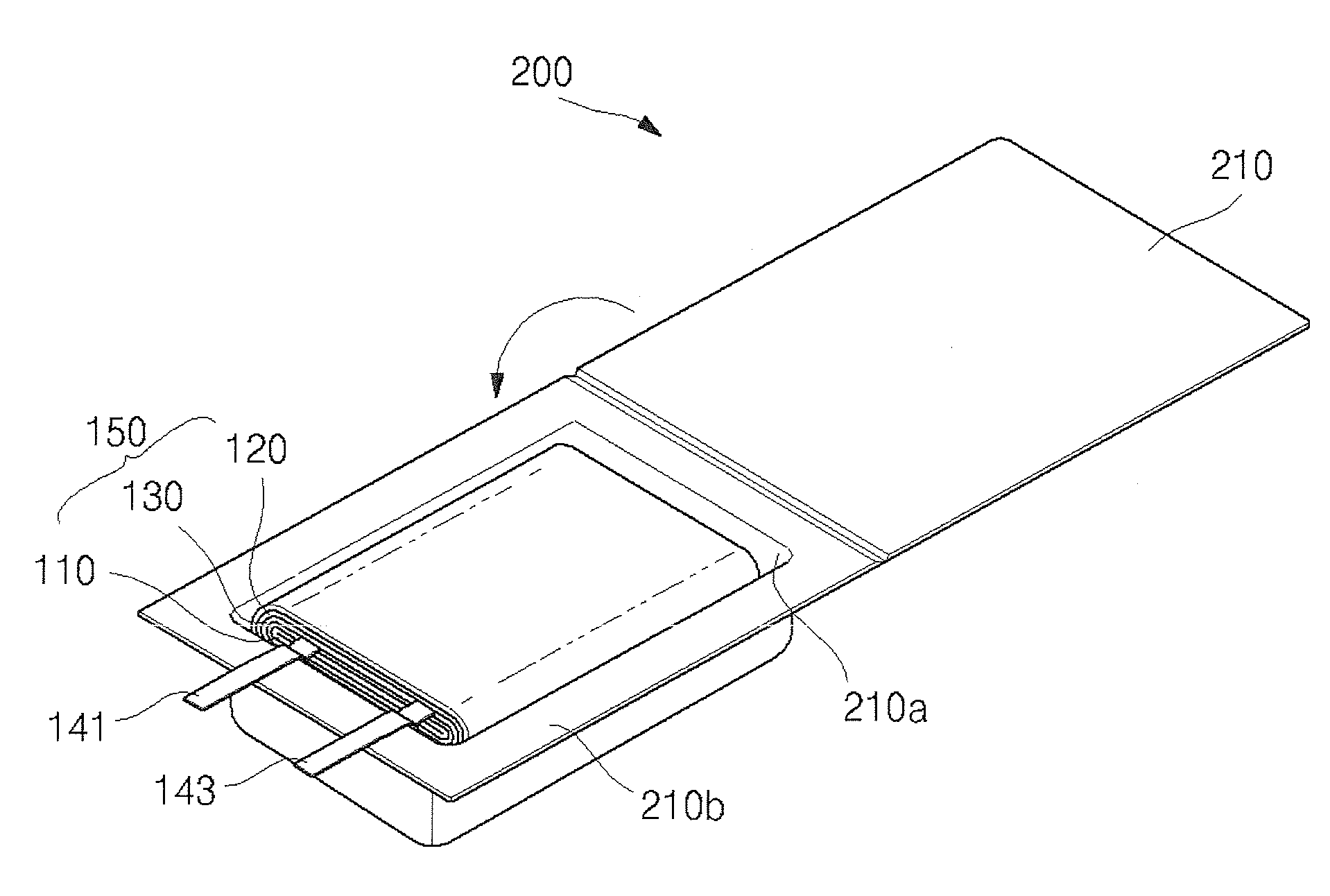

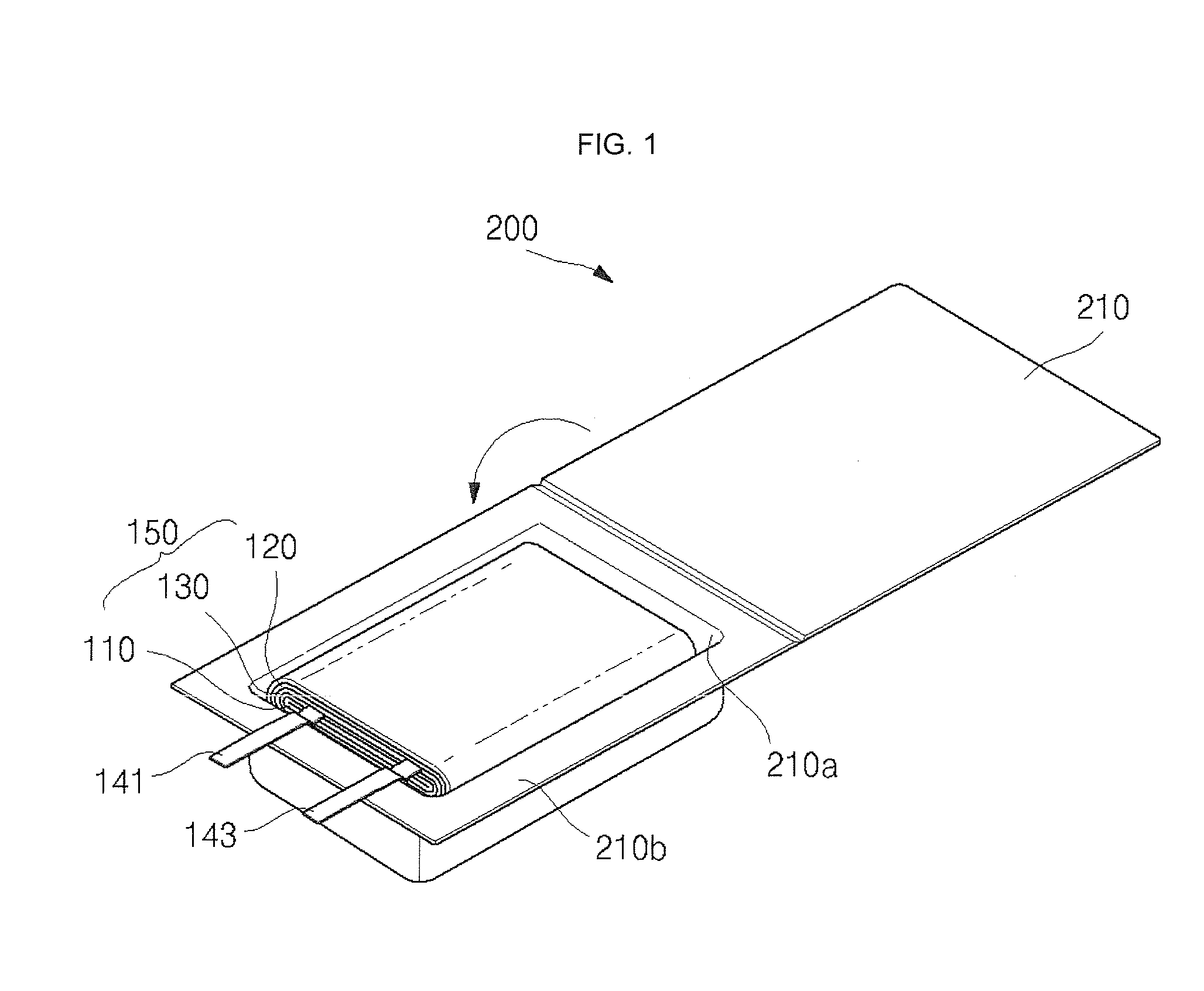

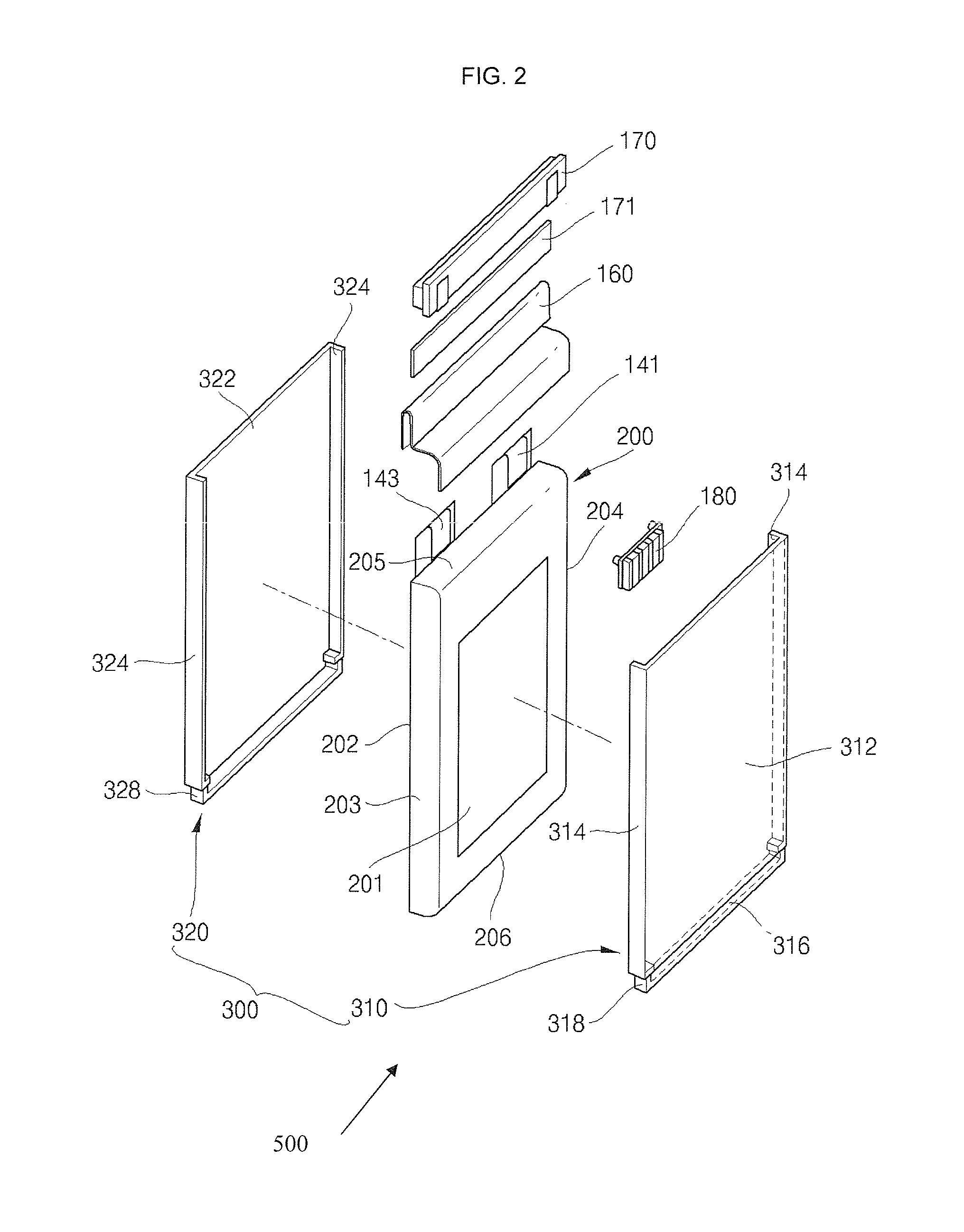

Battery Pack

InactiveUS20080096105A1Avoid thickeningPrevent materialSecondary cellsJackets/cases materialsEngineeringBattery pack

A battery pack including: a bare cell including an electrode assembly including first and second electrode plates and a separator interposed between the first and second electrode plates, a case to house the electrode assembly; an outer case to cover the bare cell and including a recessed portion; and a bottom cap disposed on the recessed portion.

Owner:SAMSUNG SDI CO LTD

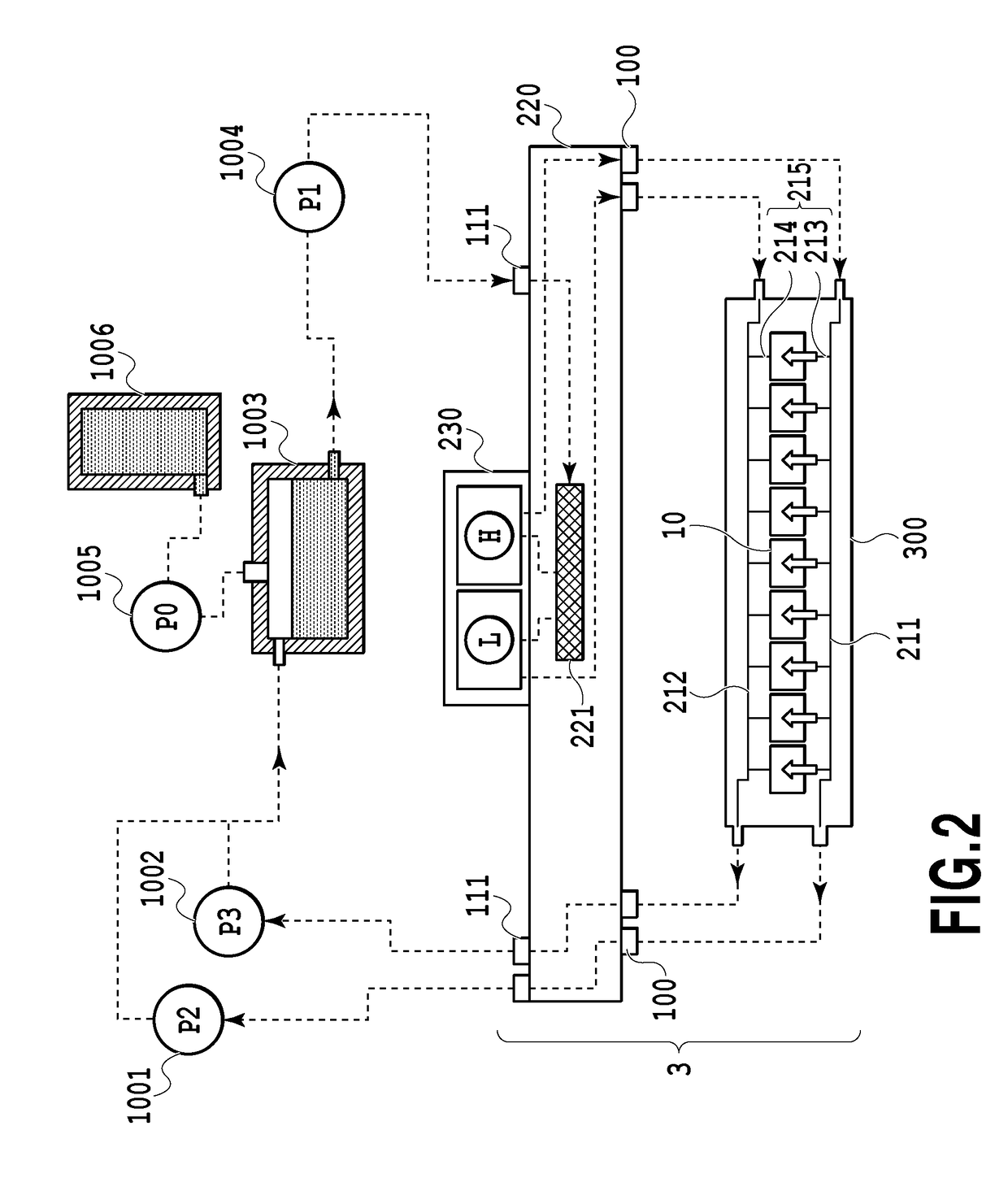

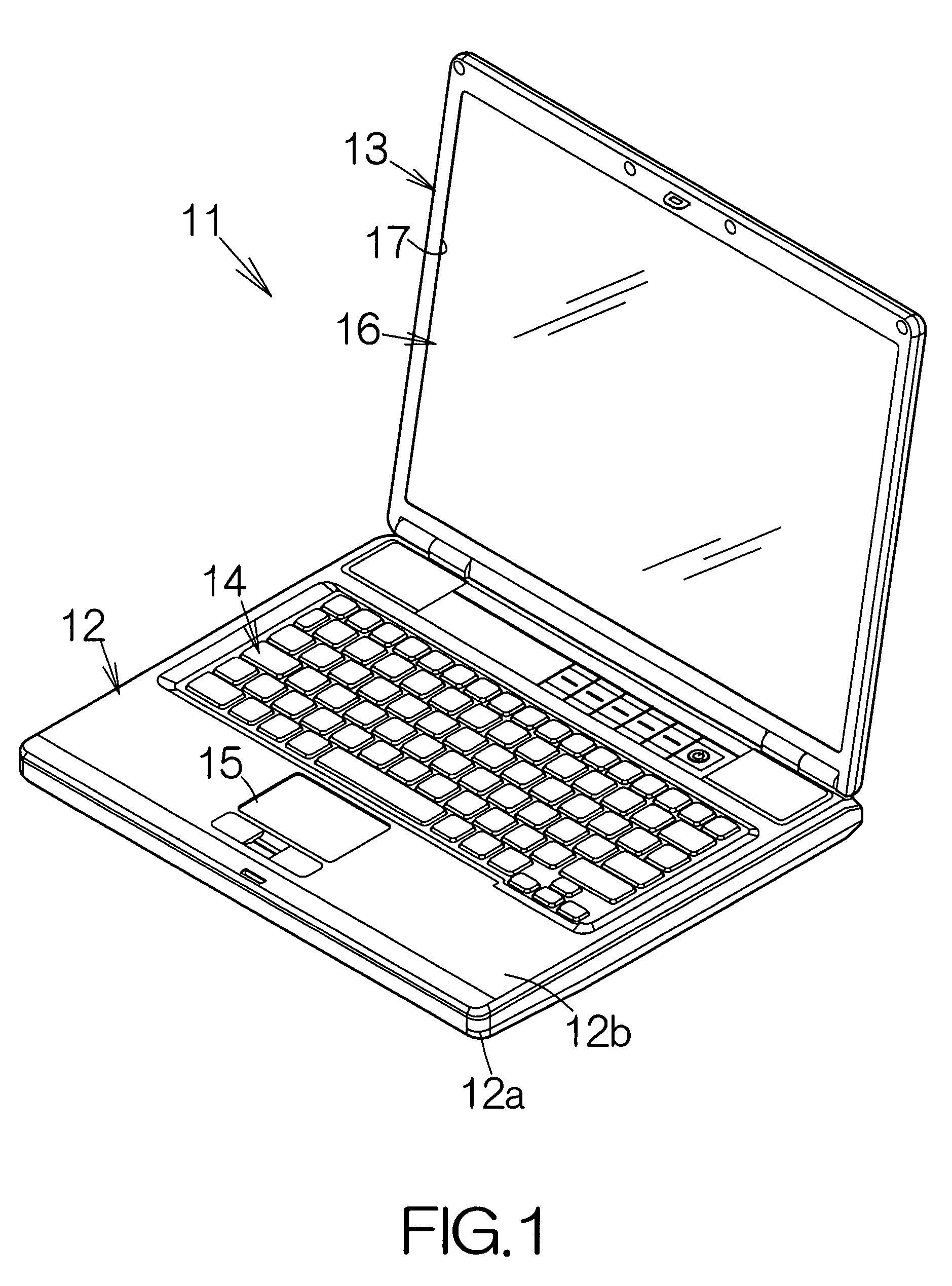

Liquid cooling unit and heat receiver therefor

ActiveUS8050036B2Avoid thickeningIncreasing the thicknessDigital data processing detailsSolid-state devicesEngineeringElectronic component

A heat receiver includes a casing defining a flow passage on a thermal conductive plate. The thermal conductive plate is received on an electronic component. An outflow nozzle has an inflow opening at the downstream end of the flow passage at a position outside the thermal conductive plate. Since the thermal conductive plate is received on the electronic component, the outflow nozzle is connected to the flow passage at a position outside the electronic component. This results in avoidance of increase in the thickness of the casing as compared with the case where the outflow nozzle directly extends into the flow passage on the thermal conductive plate.

Owner:FUJITSU LTD

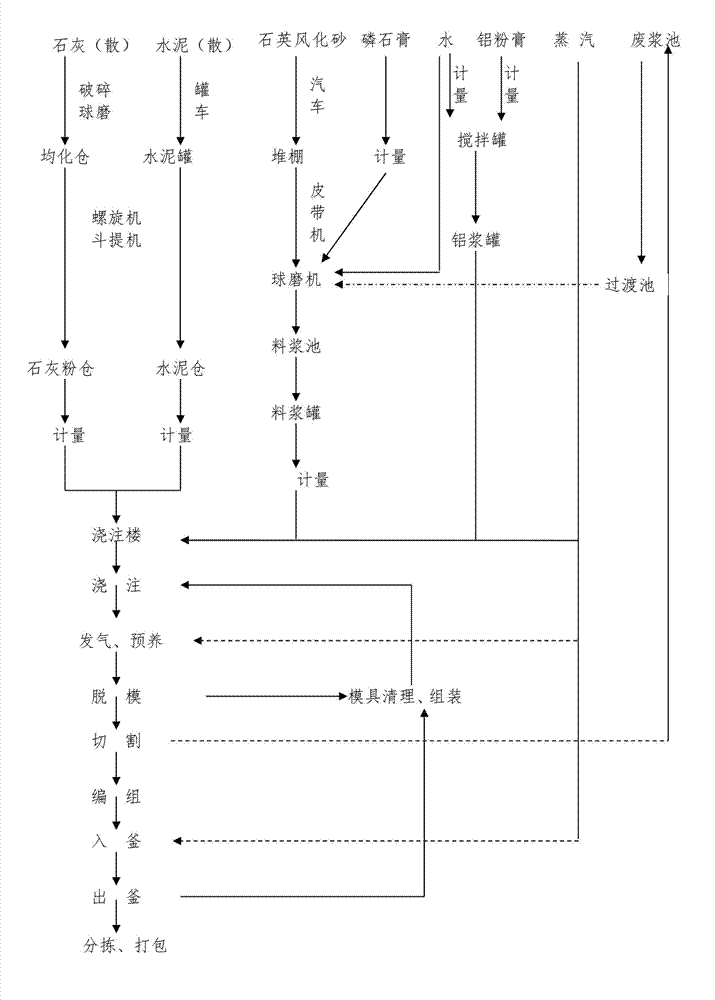

A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand and preparation method thereof

ActiveCN104774031AAlleviate the problem of comprehensive utilizationInhibits digestive reactionsCeramicwareEngineeringPhosphogypsum

The invention discloses an A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand. The A2.0 B04 grade high-performance autoclaved aerated concrete block is prepared from quartz eroded sand, cement, quick lime, industrial waste phosphogypsum, aluminum paste and water. The dry density of the concrete block is 415kg / m<3>, the cube crushing strength average value is 2.1 MPa, the single unit minimum value is 1.9 MPa, the ratio of splitting tensile is 0.19, the frost quality loss is 3.7%, the frost strength is 1.7 MPa, the heat conductivity coefficient (dry state) is 0.116 W / (m.K), the dry shrinkage value (standard value) is 0.22 mm / m and the percent of pass is greater than 98%. The raw material processing method is reasonable, the formula calculation is scientific, the production process is simple and the production waste can be recycled. The concrete block is a novel energy-saving and environmentally-friendly wall material and is suitable for industrial process.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Method for judging position of cohesive zone of blast furnace and position of cohesive zone of blast furnace

InactiveCN104915556APromote rational distributionGood technical and economic indicatorsBlast furnace componentsBlast furnace detailsEngineeringMechanical engineering

The invention relates to a method for judging a position of a cohesive zone of a blast furnace and the position of the cohesive zone of the blast furnace. The method is used for judging the position of the cohesive zone of the large-scale blast furnace of which the volume is 4000 to 5000 m<3>; a flat cold plate structure is adopted by a furnace body of the blast furnace; the furnace body totally comprises 53 layers of flat cold plates; a furnace bosh of the blast furnace is in 14th to 20th layers; the method comprises the judging steps of (I) measuring a thermal load valve of each part, and measuring a thermal load valve of the upper part of the furnace body; (II) comparing a ratio of the thermal load values of all parts according to the thermal load values of all the parts, wherein the thermal load value of a furnace bosh area during normal production of the large-scale blast furnace is (450 to 550)*10MJ / h, the ratio of the thermal load value of the furnace bosh area occupies 4.5% to 5,5% of the thermal load of the whole blast furnace, and the thermal load ratio of each flat cold plate layer is lowest; (III) judging that the position of the cohesive zone is in the furnace bosh. According to the method for judging the position of the cohesive zone of the blast furnace, disclosed by the invention, the position of the cohesive zone of the blast furnace during normal production can be clearly found; the temperature of the cohesive zone is controlled to be 50 to 60 DEG C after the position of the cohesive zone is determined, and a furnace wall can be prevented from getting thick.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

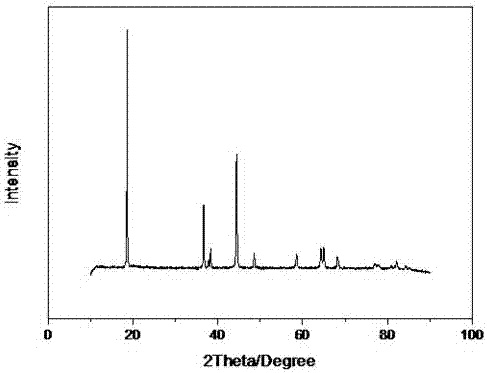

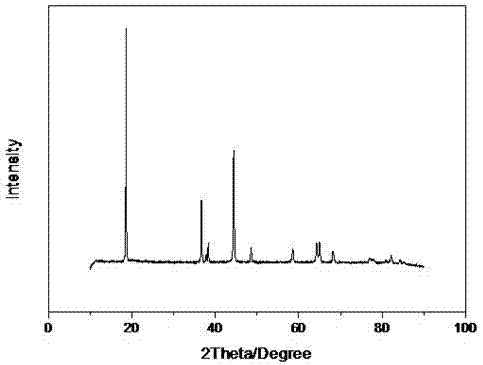

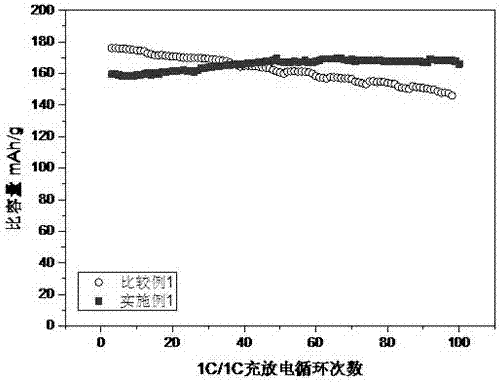

Lithium ion battery positive electrode active material and preparation method thereof

InactiveCN107342398AInhibit side effectsInhibit thickeningCell electrodesSecondary cellsOxygen atomMo element

The invention relates to the technical field of a lithium ion battery material, and particularly discloses a lithium ion battery positive electrode active material and a preparation method thereof. The lithium ion battery positive electrode active material is characterized in that the average constituent is Li<1+a>Ni<x>Co<1-x-y>Mn<y>MoO2, wherein 0.01<=a<=0.1, 0.6<=x<=0.9, 0.1<=y<=0.2, 0.1<=(x+y)<=0.2, and 0.005<=b<=0.03; and in particle of the positive active material, the concentration of Mo element is continuously and gradiently changed from inside to surface of the particle, and the Mo concentration is gradiently raised from a body phase to surface of the particle. By doping the Mo element into a ternary material in gradient distribution mode, the Mo element in the Li<1+a>Ni<x>Co<1-x-y>Mn<y>MoO2 particle is promoted to be gradiently raised from the body phase to the surface, and the bonding effect between a transition metal element and an oxygen atom is enhanced.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Liquid ejecting head and liquid ejecting apparatus

ActiveUS20180370230A1Suppress thickeningAvoid thickeningInking apparatusEngineeringMechanical engineering

In a circulating system which circulates liquid within a liquid ejecting head, thickening of liquid in the vicinity of an ejection port can be more securely suppressed. The ejection port includes a first ejection port disposed in an upstream side in an ejecting direction of ink and a second ejection port disposed in a downstream side in the ejecting direction. The second ejection port includes an enlarged diameter portion whose diameter is enlarged in a radially outward manner from at least a part of an opening edge portion of the first ejection port.

Owner:CANON KK

Preparation method of nano modified soaking agent used for basalt fiber

The invention discloses a preparation method of a nano modified soaking agent used for basalt fiber. The preparation method includes: adopting a mixed emulsion of the nano modified soaking agent prepared by film former, coupling agent, lubricant, modified nano SiO2 particle and water; taking the film former as a main material; using water to dilute binder; adding the coupling agent, the lubricant and the modified nano SiO2 particle; stirring after being fully mixed to obtain a finished nano modified soaking agent product. The nano modified soaking agent is mainly used for coating the basalt fiber, is high in impregnability and stability, has effect of improving clustering performance and wear resistance of the basalt fiber and can improve mechanical performance of the basalt fiber, and cracking strength, drawing performance and shearing strength are all improved.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

Preparation method of ultrafine tungsten carbide powder

ActiveCN103408015AImprove uniformityAvoid uneven mixingTungsten/molybdenum carbideTungstenCarbon black

The invention relates to a preparation method of ultrafine tungsten carbide powder. A mixture of ultrafine tungsten powder, carbon black and ultrafine tungsten carbide powder used as an initial reactant is subjected to carbonization reaction in a non-oxidizing atmosphere to prepare the ultrafine tungsten carbide powder. The ultrafine tungsten carbide powder prepared by the method has the advantages of small particle size, uniform particle size distribution, favorable dispersity, no pellet and high combined carbon content; and the production technique can easily control the quality and can implement mass production.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Chemical mechanical grinding method

InactiveCN105817991AAvoid scratchesAvoid thickeningSemiconductor/solid-state device manufacturingLapping machinesEngineeringGrinding process

The invention discloses a chemical mechanical grinding method which includes the following steps: a wafer to be ground is arranged on a first grinding pad; first grinding is conducted the wafer by first grinding liquid; the first grinding liquid has a first pH value, so the wafer to be ground can be separated from the first grinding pad; first cleaning liquid is sprayed on the surface of the wafer to be ground to conduct first cleaning; the first cleaning liquid has a second pH value; an absolute value of a difference between the first and second Ph values is no more than 1; after the first cleaning, the wafer to be ground is placed on a second grinding pad; second grinding is conducted to the wafer to be ground via second grinding liquid; the second grinding liquid has a third pH value; and an absolute value of a difference between the third pH value and the second pH value is no more than 1. Acid-base conflict can be prevented for the surface of the wafer to be ground, so plenty of microcosmic particles can be prevented from appearing on the surface of the wafer to be ground; and scraps to the surface of the wafer to be ground by the microcosmic particles during the second grinding can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

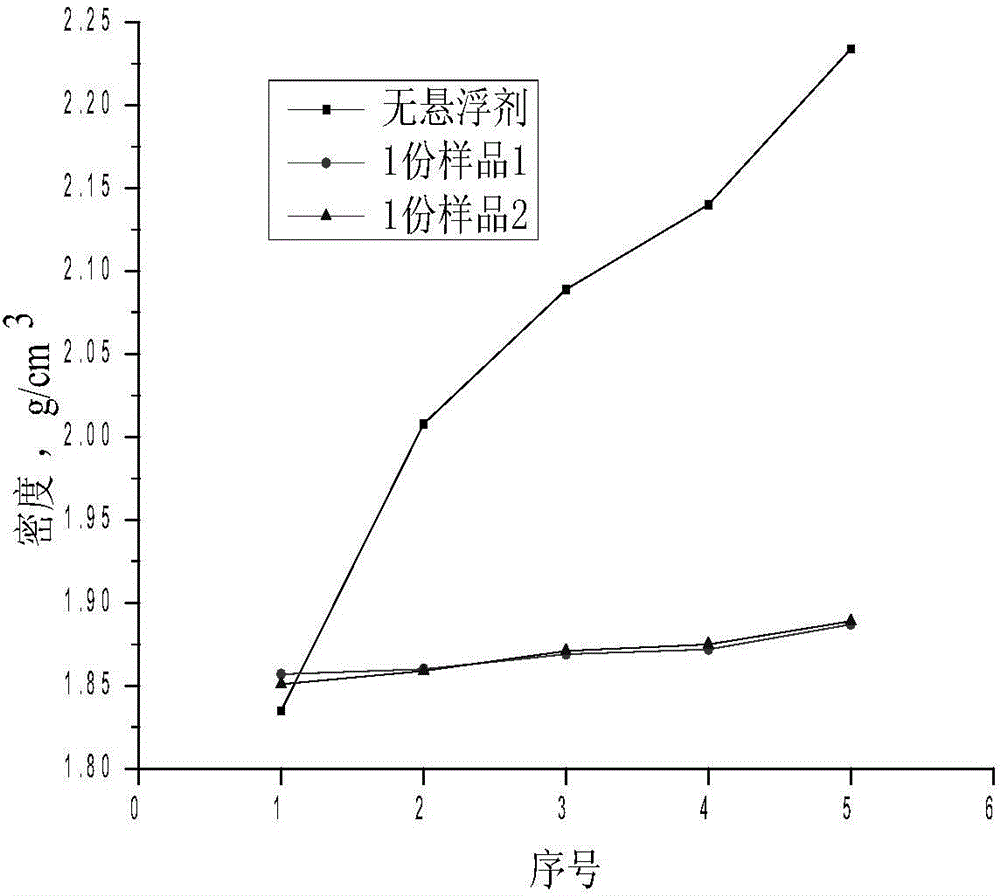

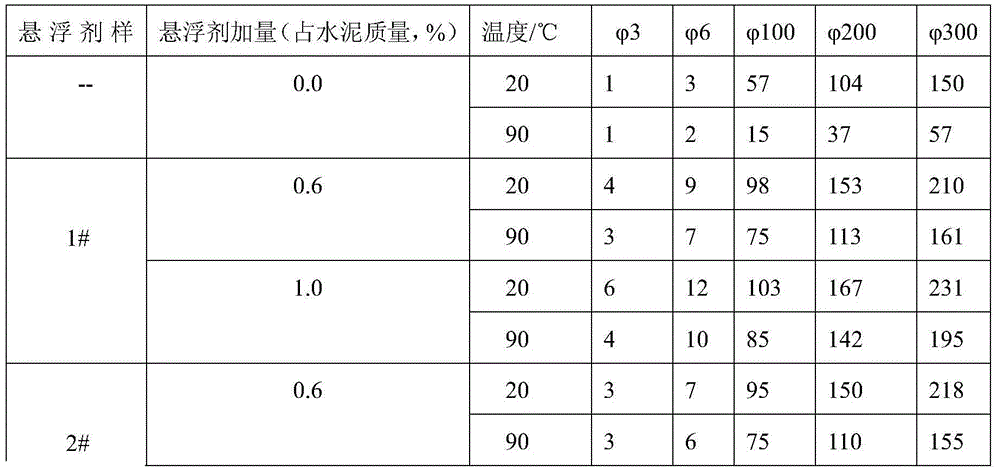

Oil well cement high temperature resistance suspending agent

ActiveCN105199690ASuspension stabilityImprove stabilityDrilling compositionSodium BentonitePolymer science

The invention relates to an oil well cement high temperature resistance suspending agent. The oil well cement high temperature resistance suspending agent is prepared from well drilling bentonite and a hydrophobic association water-soluble polymer on the basis that the mass ratio is 5:1. A hydrophobic associated compound is a quadripolymer synthetized by adopting the soap-free emulsion polymerization method. A polymerization monomer comprises, by mass, 35-80 parts of 2-acrylamide-2-methyl propyl sulfonic acid, 10-60 parts of acrylamide, 5-10 parts of N,N-dimethyl acrylamide and 5-20 parts of a monomer containing hydrophobic groups. The high temperature resistance suspending agent can resist the temperature of 170 DEG C, the stability of cement slurry can be effectively achieved, the oil well cement high temperature resistance suspending agent cannot be excessively thickened at low temperature and cannot be excessively diluted at high temperature, and the comprehensive performance is good.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Liquid crystal display substrate and liquid crystal display device

InactiveCN103339557APrevent getting heavyAvoid thickeningNon-linear opticsLiquid-crystal displayComputer science

A liquid crystal display substrate, the purpose of which is to prevent a liquid crystal display device from becoming heavy and thick, to prevent a reduction in the aperture ratio, and to perform effective field-of-vision control, and to do so by realizing effective visual control without using a vision controlling element or vision controlling pixels. The liquid crystal display substrate comprises polygonal pixels and polygonal sub-pixels, and a linear pattern (7). In a planar view, the polygonal pixels and the polygonal sub-pixels have parallel opposing sides, and the linear pattern (7) is provided on the parallel opposing sides of the polygonal pixels or the polygonal sub-pixels. Oblique light (8) passes through the linear pattern (7).

Owner:TOPPAN PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com