Patents

Literature

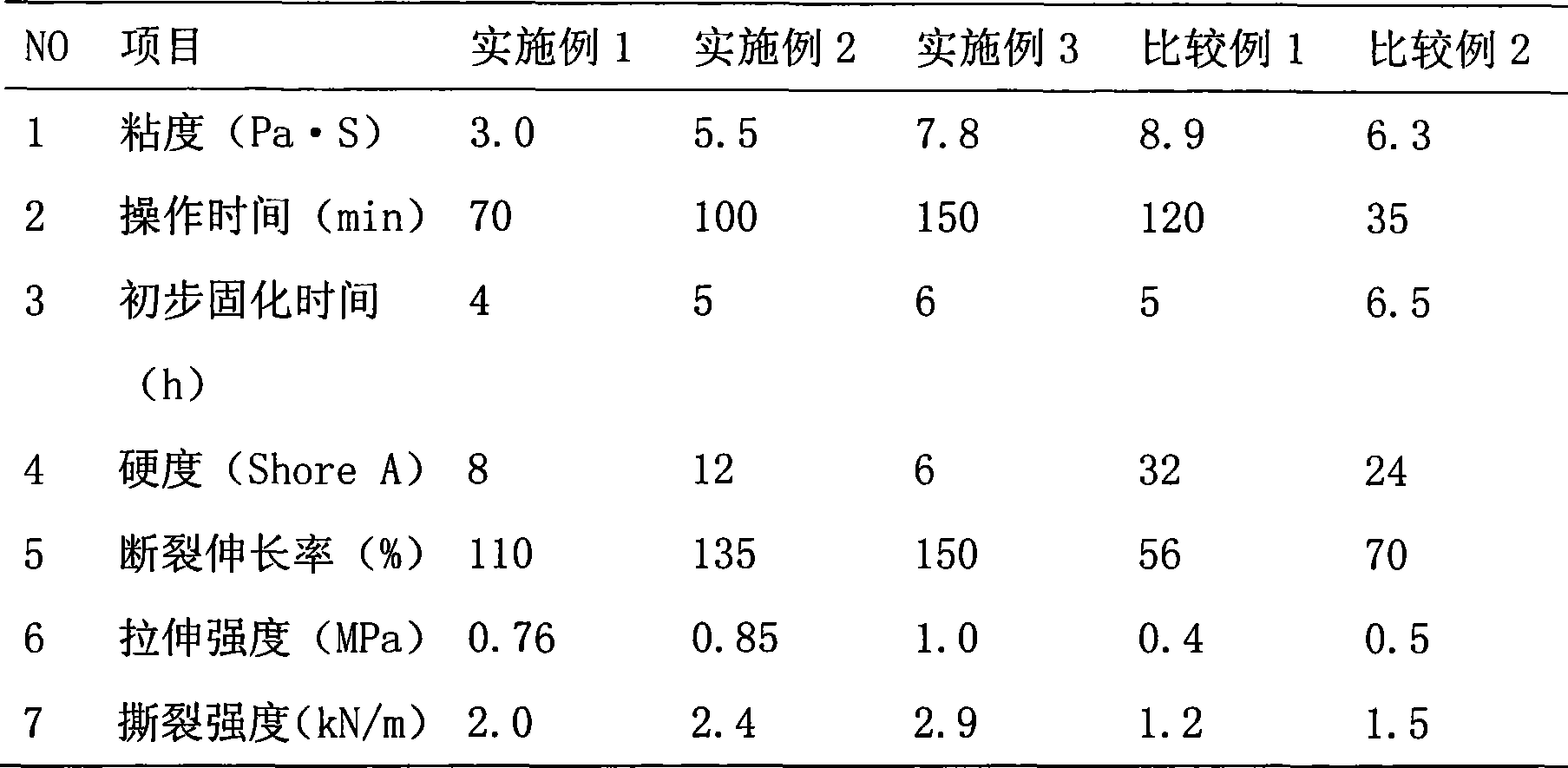

1799 results about "Dibutyltin dilaurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyltin dilaurate (Abbreviated: DBTDL), also called Dibutyltindilaurate or Butynorate, is an organotin compound that is used as a catalyst. It is a colourless oily liquid. In terms of its structure, the molecule consists of two laurate groups attached to a dibutyltin(IV) center.

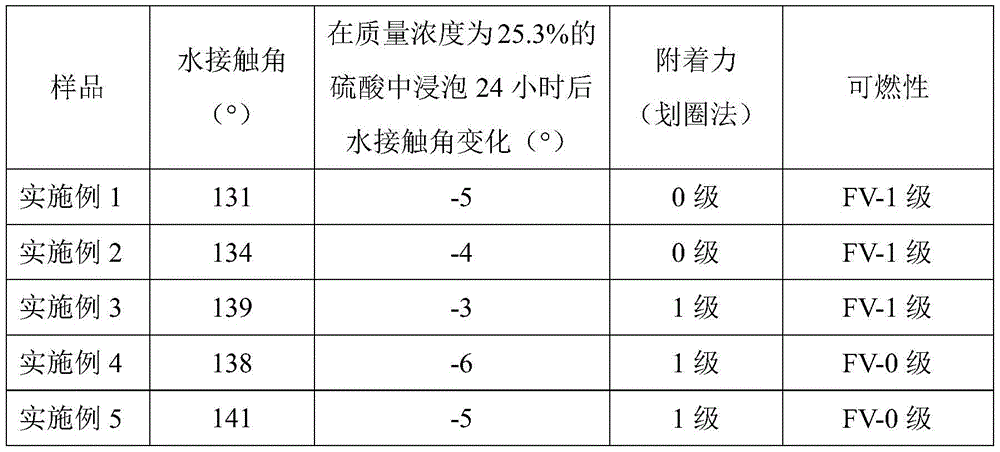

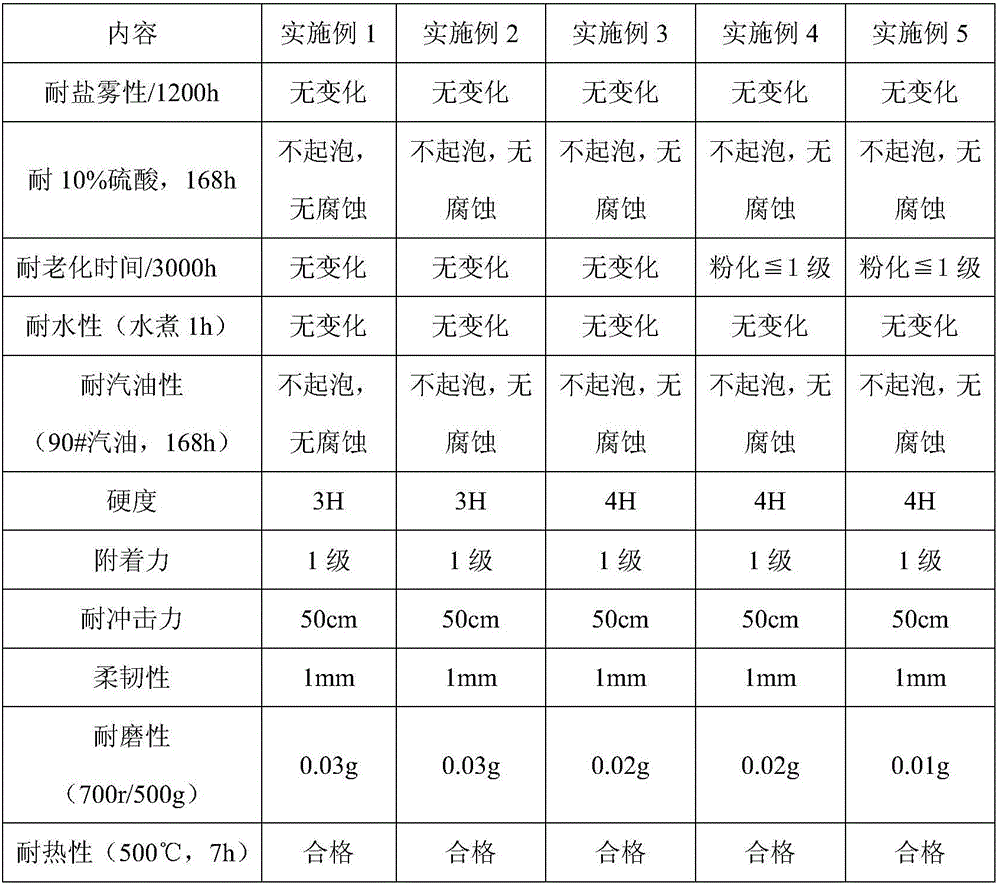

Anti-pollution flashover normal-temperature cured fluorocarbon resin coating and preparation method thereof

ActiveCN102010636AImprove hydrophobicityExcellent hydrophobic migrationAntifouling/underwater paintsSynthetic resin layered productsResin coatingDibutyltin dilaurate

The invention discloses a normal-temperature cured fluorocarbon resin coating, which consists of the following components in percentage by weight: 35 to 70 percent of tetrafluorochloroethylene-vinyl ester polymer, 5.5 to 12 percent of curing agent, 2 to 10 percent of coupling agent, 1 to 10 percent of pigment, 1 to 30 percent of hydrophobic particles, 0.03 to 3 percent of aid, 20 to 40 percent ofsolvent and 0.001 to 1 percent of catalyst, wherein the coupling agent is fluorosilane with a -CF3 group and a -CF2 group; the aid is a flatting agent, an antifoaming agent and a dispersing agent; the solvent is butyl acetate and methyl isobutyl ketone; the catalyst is dibutyltin dilaurate; and the curing agent is aliphatic diisocyanate. By adopting a specific coating formula, due to the combinedaction of the fluorosilane coupling agent and the hydrophobic particles, the anti-pollution flashover fluorocarbon resin coating has a static contact angle theta of 120 degrees, is excellent in hydrophobic performance and hydrophobic migration property, high in anti-pollution flashover performance, high in coating leveling property, smooth in surface, and high in self-cleanliness, chemicals resistance and hot-water resistance, and has an adhesive force reaching a zero level.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

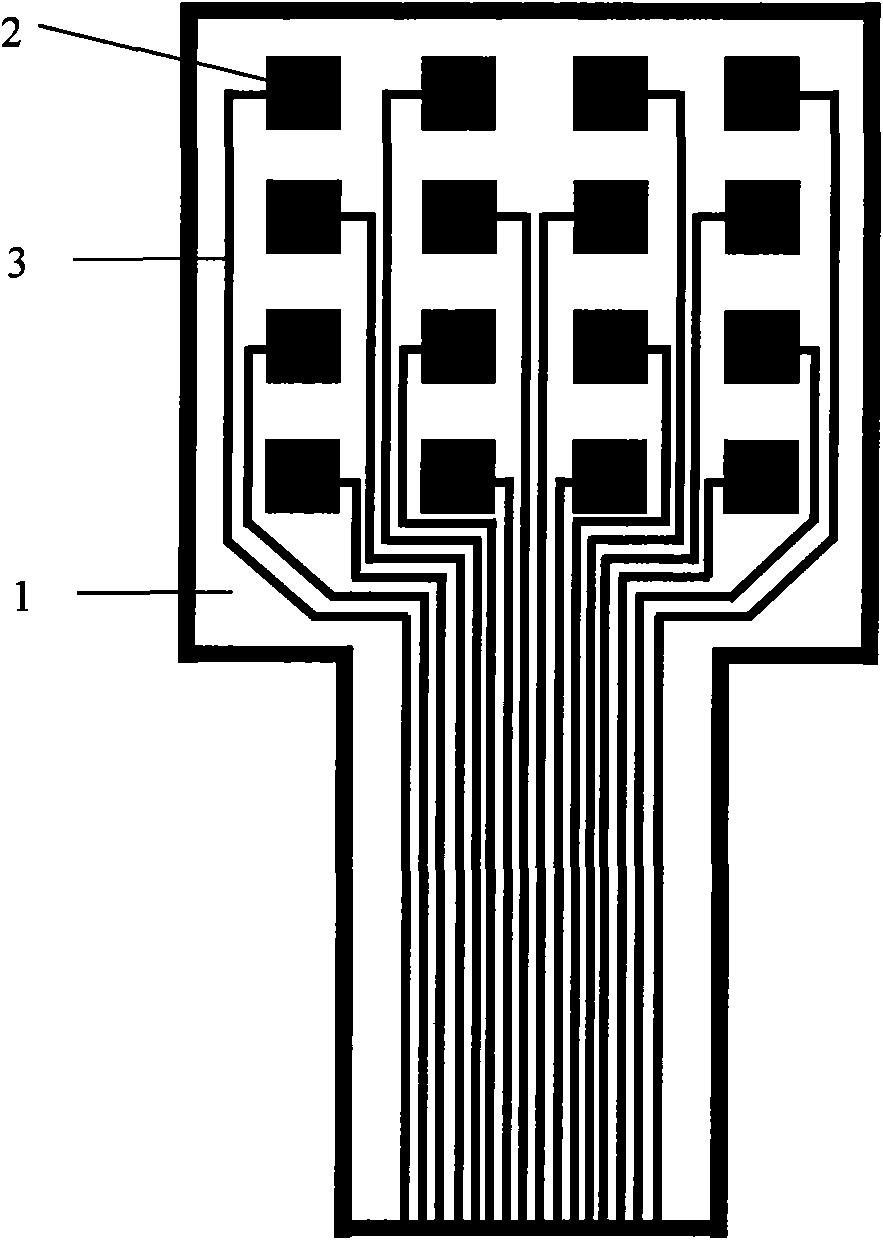

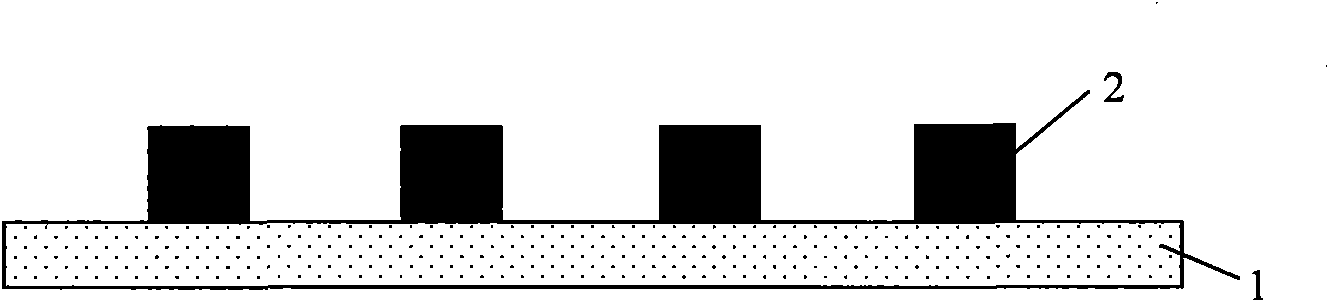

Development method of flexible pressure-sensitive element based on carbon nano-tube filled high polymer composite material

InactiveCN101885463ALarge aspect ratioHigh sensitivityDecorative surface effectsChemical vapor deposition coatingCarbon nanotubeCopper foil

The invention relates to a development method of a flexible pressure-sensitive element based on a carbon nano-tube filled high polymer composite material, which belongs to the technical field of sensors. The method comprises the following steps of: 1. pressure-sensitive material preparation: dispersing carbon nano-tubes into polydimethylsiloxane by utilizing ultrasonic vibration and mechanical stirring methods, and preparing a thin and flexible pressure-sensitive material by using tetraethoxysilane as a crosslinking agent and dibutyltin dilaurate as a catalyst with a spin coating method; 2. pressure-sensitive element packaging, wherein a two-stage sandwich structure is adopted, the first-stage sandwich structure comprises two layers of packaging films and the pressure-sensitive material positioned in the middle; and in the second-stage sandwich structure, each layer of packaging film comprises two layers of polyimide films as well as a copper foil electrode and a lead which are embedded in the two layers of polyimide films. The pressure-sensitive element developed by the invention has good flexibility, high precision, thin thickness, simple process and low cost and is applicable to the fields of pressure monitoring of structures between narrow curved surface layers in the fields of military industry and civil use and artificial electronic skin development and the like.

Owner:NORTHEASTERN UNIV

Polyurethane-polypeptide graft copolymer and preparation method thereof

The invention relates to a polyurethane-polypeptide graft copolymer and a preparation method thereof. The graft copolymer is a comb-shaped polymer, wherein the molecular weight of polyurethane is 10,000 to 100,000; and the molecular weight of the polypeptide chain segment is 500 to 5,000. The preparation method comprises the following steps of: 1) synthesis of polyurethane provided with lateral carboxyl on the molecular chain: adding diisocyanate, polypropylene glycol, polyethylene glycol, dibutyltin dilaurate catalyst and dimethyl formamide solvent into a dry reaction bottle, performing stirring reaction under inert atmosphere, adding dimethylolpropionic acid dissolved in dimethyl formamide to react, adding butanediol to react, finally adding butanol to react, and obtaining a target product; and 2) synthesis of the polyurethane-polypeptide graft copolymer: putting the polyurethane provided with lateral carboxyl on the molecular chain, a solvent and a condensation agent into a dry reactor, adding polypeptide homopolymer into the reactor, and performing stirring reaction under the inert atmosphere to obtain a target product with pH response.

Owner:SHANDONG UNIV OF TECH

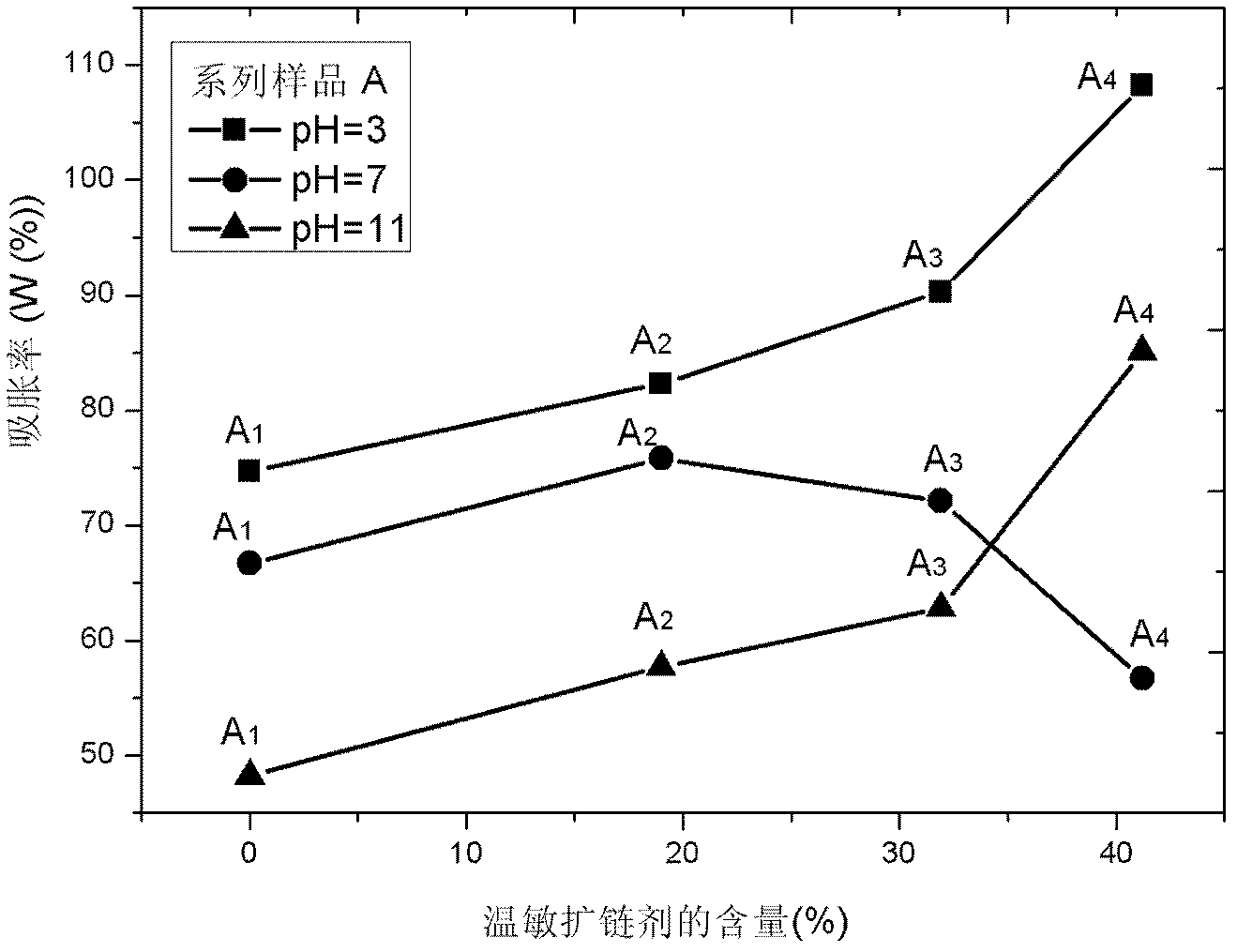

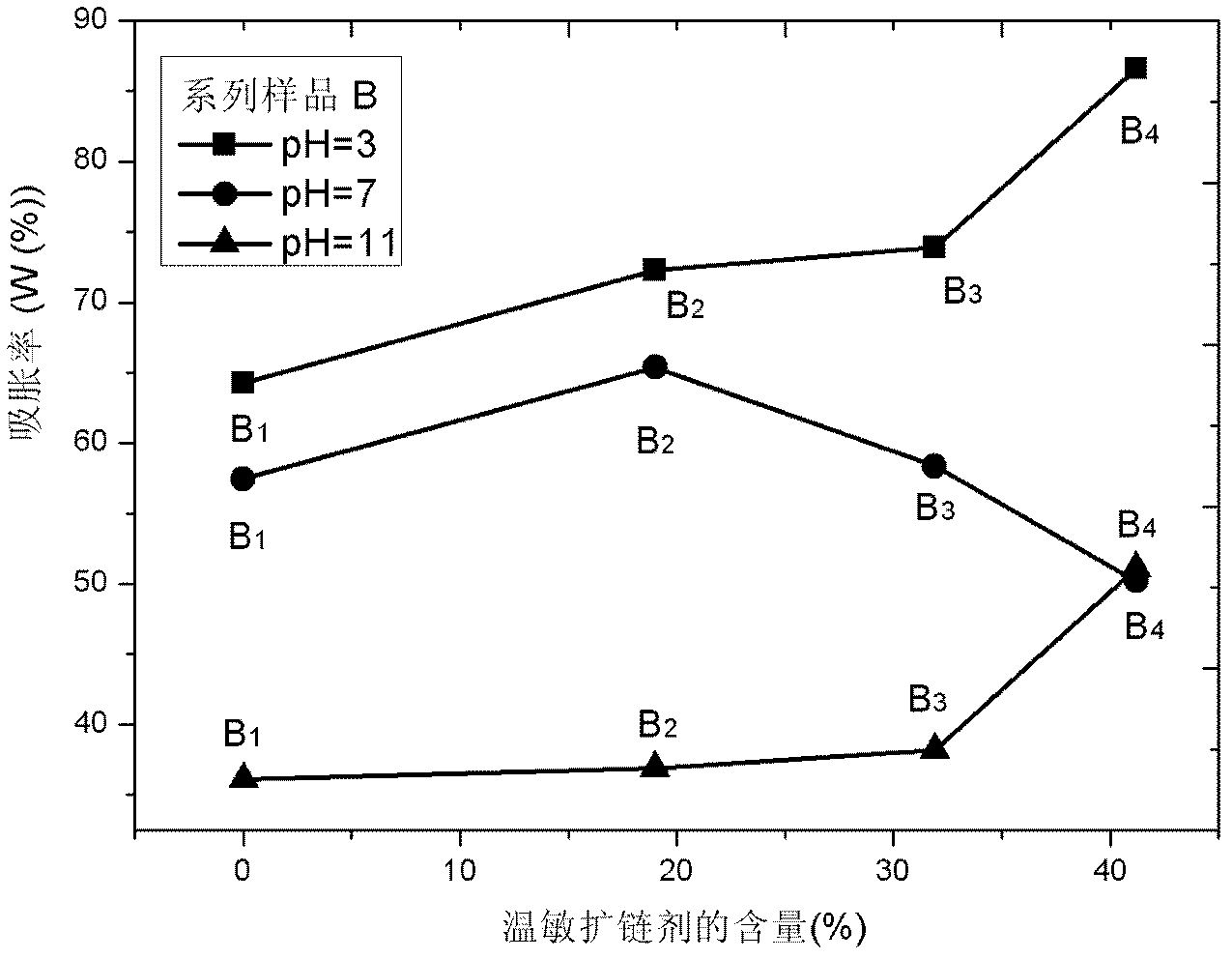

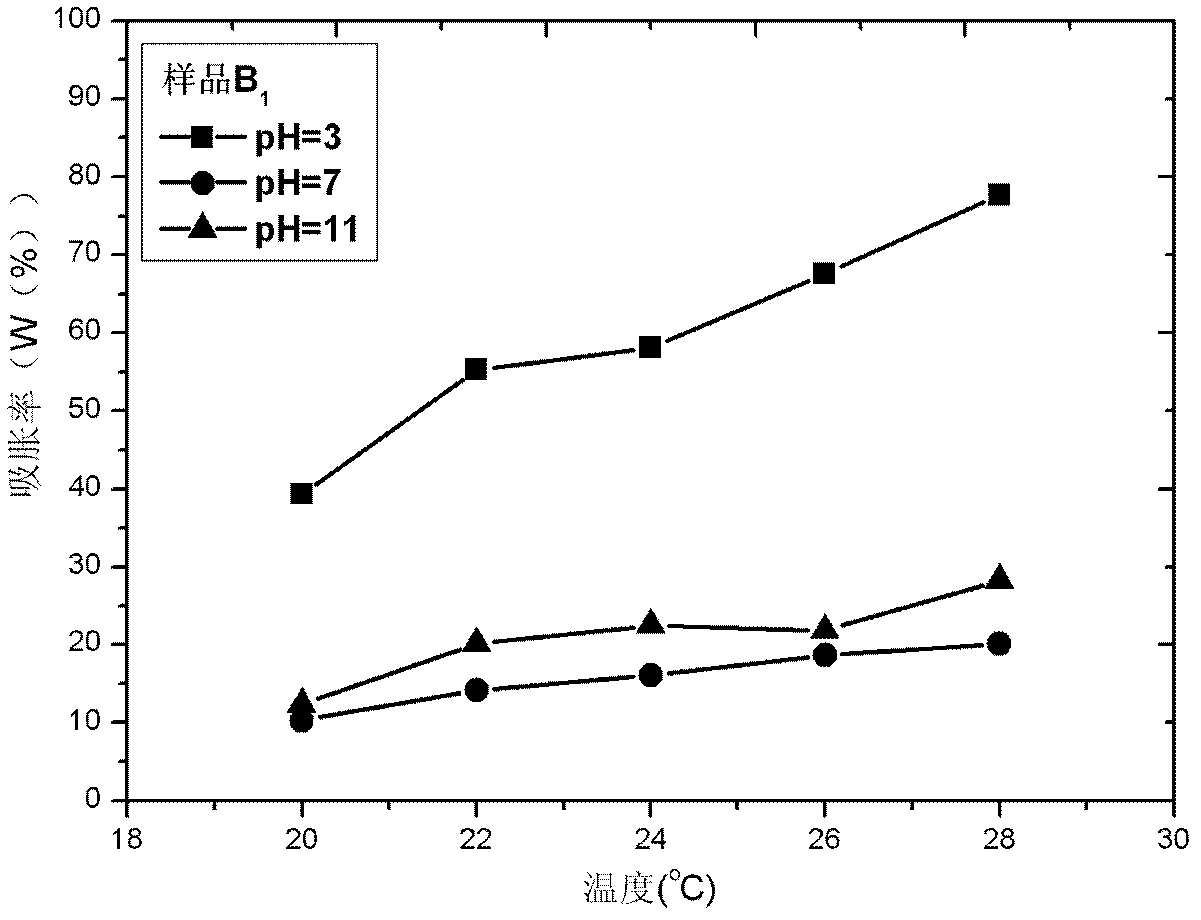

Thermo-sensitive chain extender and polyurethane hydrogel with double sensitivity of temperature and pH

The invention discloses a thermo-sensitive chain extender and polyurethane hydrogel with double sensitivity of temperature and pH. The hydrogel is prepared by the following methods: mixing 15-20.6 percent of polyethylene glycol, 6.7-9.2 percent of polyhydric carboxylic acid, 25.2-34.6 percent of multi-isocyanate and dibutyltin dilaurate used as a catalyst to perform pre-condensation polymerization reaction; adding organic solvent to stop reaction to obtain a pre-polymer; adding 15.3-36.5 percent of a thermo-sensitive chain extender to perform chain extension reaction; adding 3.1-4.3 percent of polyhydric alcohol amine stop end after the pre-polymer is subjected to the chain extension; and then, adding 11.6-19.4 percent of a curing crosslinking agent to perform crosslinking reaction to obtain polyurethane hydrogel with double sensitivity of temperature and pH. The thermo-sensitive chain extender is prepared by the method, and a method for introducing the thermo-sensitive chain extenderin polyurethane is provided, and the softness and hardness of the material are controlled in a post-crosslinking mode, so that the defects that introduction of groups and cross-linking solidity are carried out at the same time in the conventional way of excitation of double bonds are overcame, and the polyurethane hydrogel with double sensitivity of temperature and pH is prepared.

Owner:SOUTH CHINA UNIV OF TECH

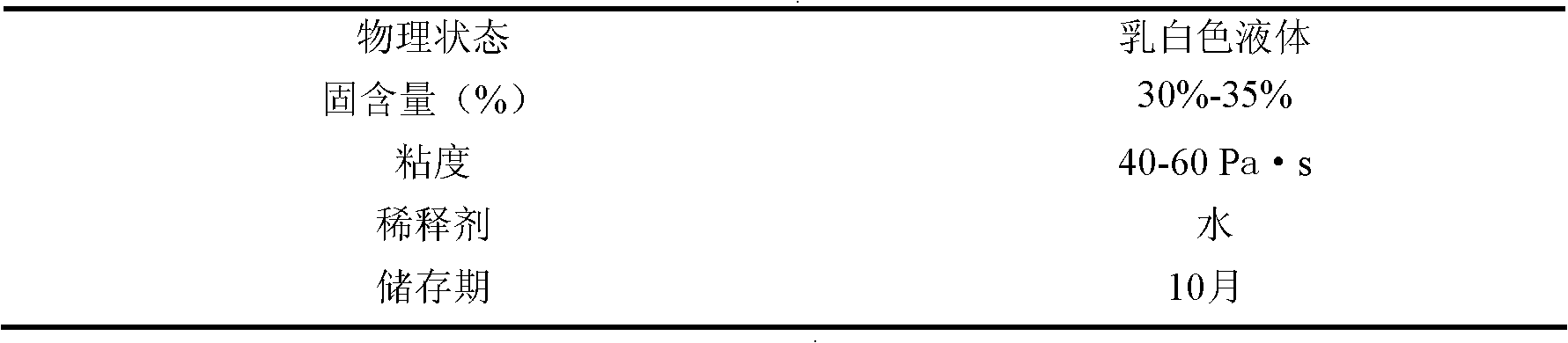

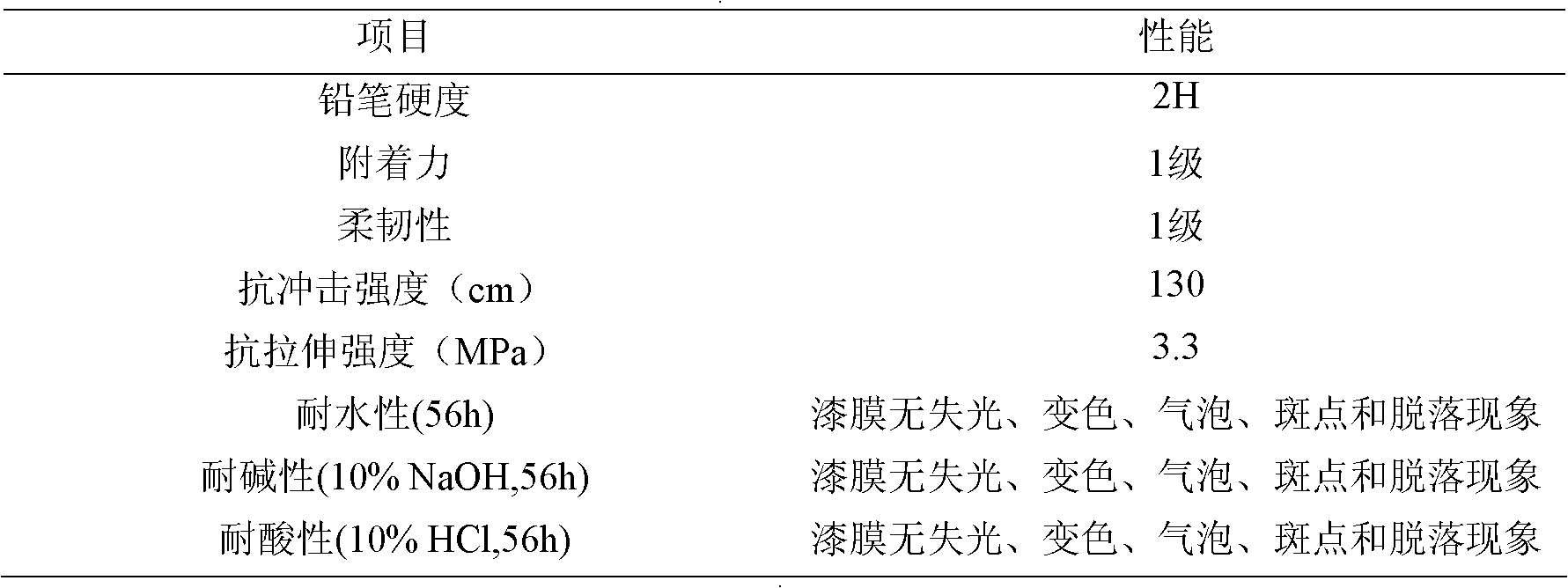

Aqueous fluorine-containing acrylate modified polyurethane coating, preparation method and application thereof

The present invention belongs to the field of polymer material synthesis, relates to aqueous polyurethane acrylate emulsion modification, and especially to an aqueous fluorine-containing acrylate modified polyurethane coating, a preparation method and an application thereof. The preparation method comprises: dissolving polyether polyol in an N-methyl pyrrolidone solution of dimethylol propionic acid; adding diisocyanate in a dropwise manner; adopting dibutyltin dilaurate as a catalyst, and adding hydroxyethyl methacrylate to carry out end capping; adding triethylamine to form a salt, then adding deionized water to prepare an aqueous polyurethane acrylate prepolymer emulsion; and finally adding hexafluorobutyl acrylate and azodiisobutyronitrile to prepare the aqueous fluorine-containing acrylate modified polyurethane coating. The synthesized emulsion of the present invention has the following advantages that: dispersion is uniform; stability is good; water resistance and mechanical property of the cured film are substantially improved; elasticity and mechanical property of polyurethane are provided; ultraviolet resistance, nuclear radiation resistance, flexibility, excellent surface properties, water resistance and corrosion resistance of the fluorine-containing material are provided; and the coating can be adopted as coatings for building and furniture.

Owner:BOMEX CHEM SHANGHAI

Prepn of stone material surface protecting agent

InactiveCN1506426AImprove breathabilityPrevent intrusionCoatingsStone-like material working toolsWater vaporSilanes

The present invention is the preparation process of stone material surface protecting agent. The preparation process includes adopting absolute ethyl alcohol as solvent, mixing with long chain alkyl alkoxy silane and hydrogenous methyl silicone oil at room temperature, and adding dibutyltin dilaurate as organic catalyst through stirring. When it is used, the stone material surface protecting agent is painted directly before letting stand for 24 hr and further construction without needing heating for crosslinking. It may be used in repairing fine holes and cracks without blocking the capillary tracts, and it can form excellent hydrophobic effect while not blocking inside water vapor to diffuse outwards.

Owner:曾繁杰 +1

Fireproof flame-retardant polyurethane external wall thermal-insulation system material

InactiveCN101851993AImprove fire and flame retardant performanceImprove heat resistanceFireproof paintsCovering/liningsFoaming agentPolyol

The invention relates to a fireproof flame-retardant polyurethane external wall thermal-insulation system material, which is characterized by comprising a moistureproof primer paint, a flame-retardant rigid polyurethane foam material, an interface agent, anti-crack mortar, a fireproof coating and a decorating coating which are arranged sequentially from inside to outside, wherein the flame-retardant rigid polyurethane foam material consists of an component A and a component B; the component A is prepared by mixing 80 to 50 parts by weight of phosphorous flame-retardant polyether polyol, 20 to 50 parts by weight of heterocyclic amine polyether polyol, 2 parts by weight of organic silicon foam stabilizer, 2 parts by weight of dimethylethanolamine catalyst, 1 part by weight of dibutyltin dilaurate catalyst, 20 to 50 parts by weight of flame retardant and 20 to 40 parts by weight of fluoro dichloroethane; the component B is a flame-retardant polyisocyanates curing agent; in the using process, the component A and the component B are mixed and foamed and an isocyanate index is between 1.05 and 1.10. The fireproof flame-retardant polyurethane external wall thermal-insulation system material of the invention has the advantage of having higher fireproof flame-retardant property.

Owner:SHANGHAI COLLODIN MATERIAL TECH DEV CO LTD

Method for preparing waterborne polyurethane taken as waterborne epoxy hardener

The invention relates to a method for preparing waterborne polyurethane taken as a waterborne epoxy hardener. The method comprises the following steps of: adding aliphatic polyisocyanate into low polymer polyalcohol; dissolving dimethylolpropionic acid taken as a hydrophilic chain extender in N-methylpyrrolidone; adding dibutyltin dilaurate taken as a catalyst into the mixture; stirring the mixture and raising the temperature to a certain extent to prepare a preformed polymer containing a terminated isocyanate group; cooling the prepared preformed polymer to room temperature; adding triethylamine into the preformed polymer to perform neutralization reaction for a certain period of time; and adding an appropriate amount of distilled water and violently stirring the mixture to emulsify the mixture; and adding a polyamine chain extender to perform chain extension reaction for a certain period of time to obtain amino-terminated waterborne polyurethane emulsion. The method has the advantages of preparing polyurethane emulsion which can be directly applied to curing epoxy resin, realizing a simple synthetic method and more easily controlled operation, enhancing the compatibility of epoxy resin emulsion with a curing agent, enabling a synthetized paint product to achieve the advantages of polyurethane and the epoxy resin and realizing high performance of paint.

Owner:TIANJIN UNIV

Preparation method of light-resistant waterborne polyurethane

The invention discloses a preparation method of light-resistant waterborne polyurethane, which comprises the steps of mixing polytetramethylene ether glycol with diisocyanate in the presence of a dibutyltin dilaurate catalyst, stirring at 70-90 DEG C for reaction for 2-4h, obtaining a polyurethane prepolymer, adding a hydrophilic chain extender, a polyhydroxyl compound and butanone into the polyurethane prepolymer, stirring at 70-90 DEG C for reaction for 1.0-3.5 h, adding triethylamine for neutralizing, stirring for reaction for 40-60min, adding water for emulsification to form hydrophilic polyurethane, adding a nano emulsion into a hydrophilic polyurethane system, shearing and stirring for 40-60min under the condition that a pH value is 7, and obtaining light-resistant waterborne polyurethane. Prepared light-resistant waterborne polyurethane is environment-friendly and low in price, and can meet the demand of a market on a property of light-resistant polyurethane.

Owner:上海力太化学有限公司

Method for preparing natural cross-linking halogen-free flame-retardant polyolefin thermal conductive foam

InactiveCN102010538ASimple structureImprove heat resistanceFloor carpetsLow-density polyethyleneCross-link

The invention provides a method for preparing natural cross-linking halogen-free flame retardant polyolefin thermal conductive foam. The method comprises the following steps of: kneading low-density polyethylene resin, vinyl tri-methoxysilane, white carbon black and an auxiliary agent, and discharging to prepare a cross-linking master batch A; kneading the low-density polyethylene resin, the ethylene-vinyl acetate copolymer, ethylene propylene diene monomer, the cross-linking master batch A and the auxiliary agent, banburying, and extruding by using a single screw to prepare a basic raw material B; kneading the low-density polyethylene resin, dibutyltin dilaurate and the auxiliary agent, and extruding by using the single screw to prepare a catalyst master batch C; kneading the low-density polyethylene resin, a foaming agent, sodium phosphate dibasic dehydrate and the auxiliary agent, and extruding by using the single screw to prepare a foam master batch D; and kneading the basic raw material B, the catalyst master batch C and the foam master batch D, extruding by using the single screw and foaming by using a foaming furnace to prepared the product. By the method, natural cross-linking effect is good, process is simple and production cost is low; and the product has good thermal conductive performance, strong flame retardant performance and good environmental protection effect.

Owner:HUBEI LEYUAN NEW MATERIAL TECH

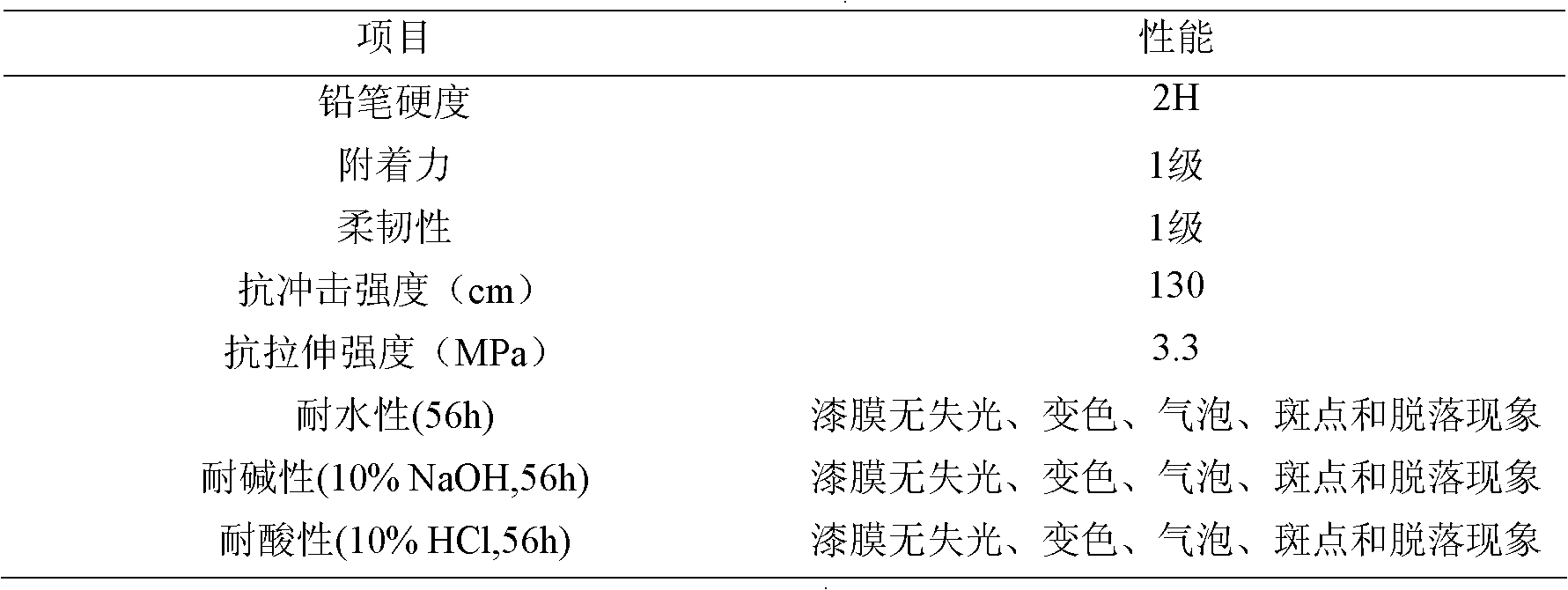

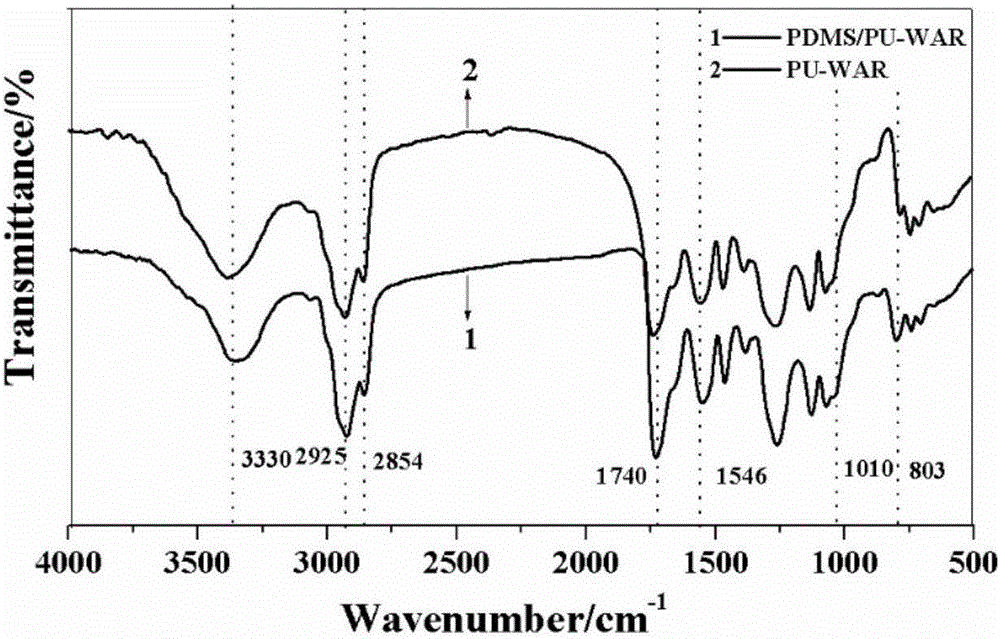

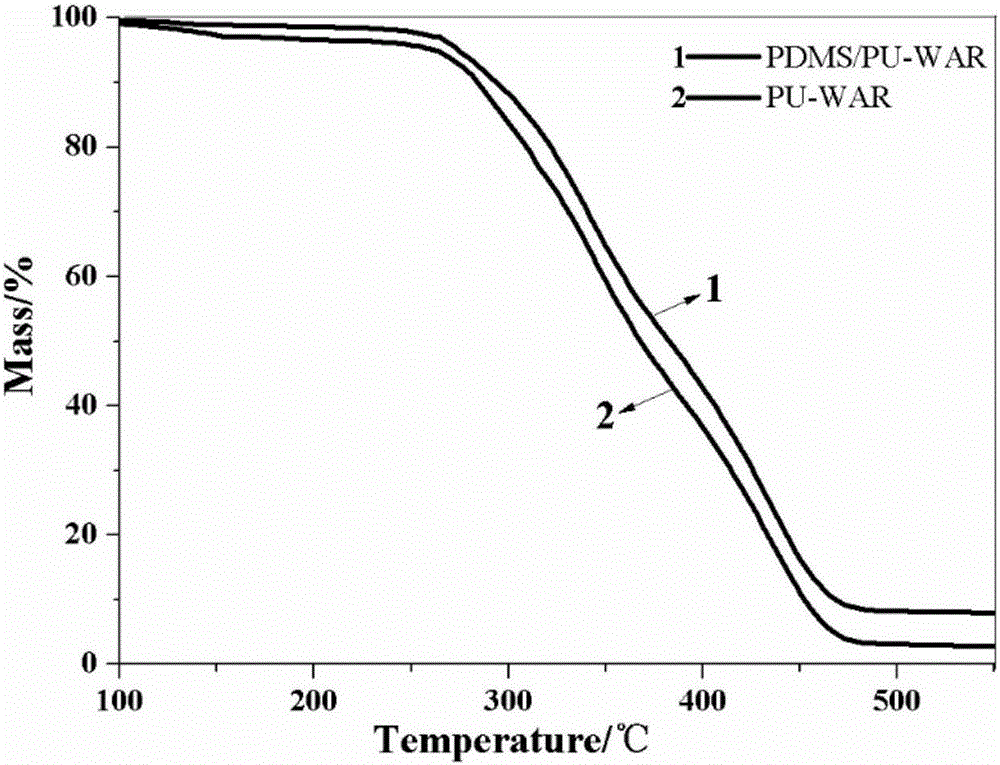

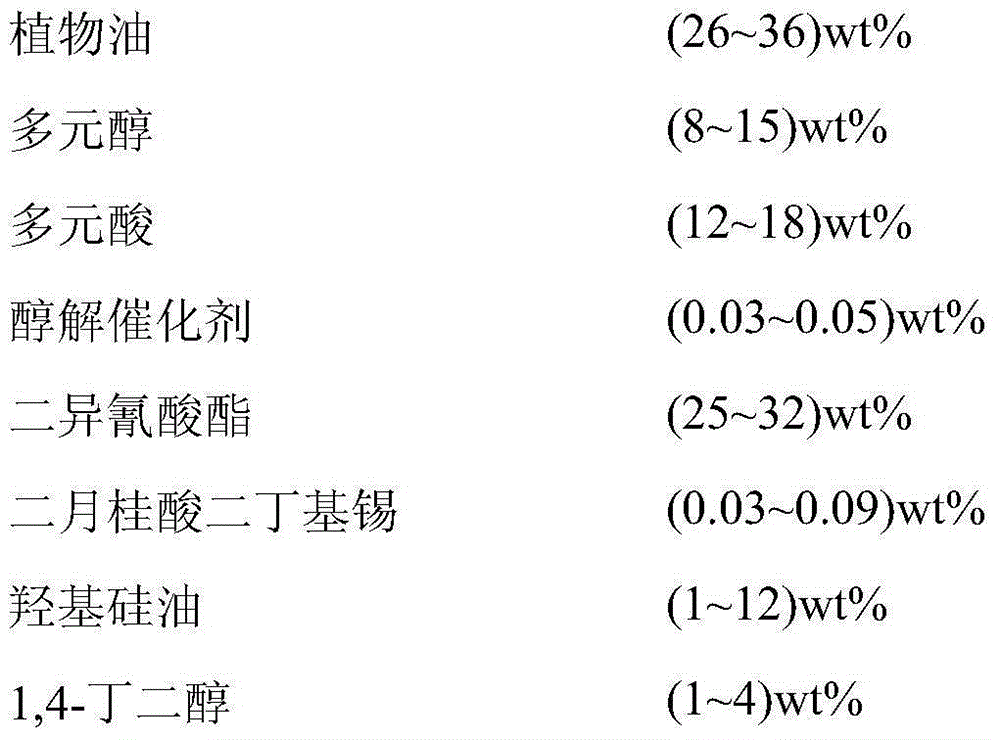

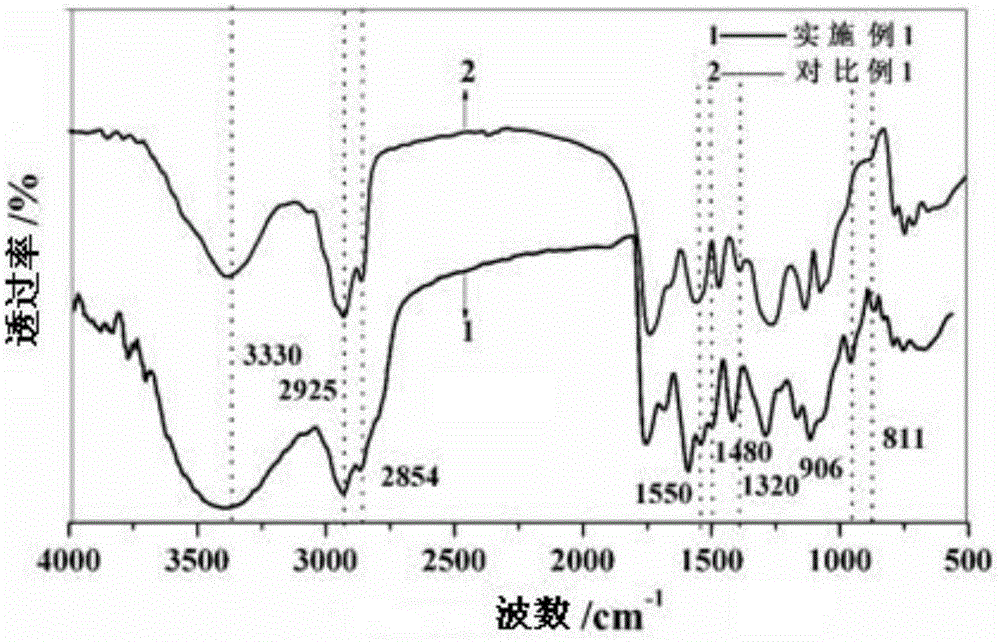

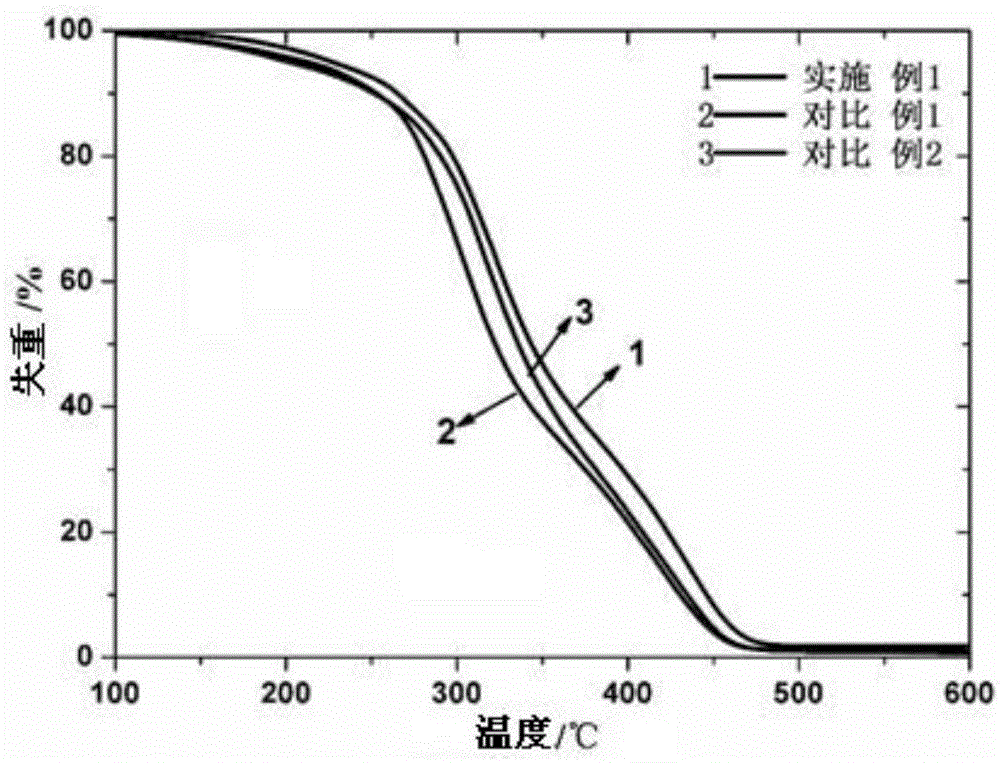

Polyurethane-organosilicon modified waterborne alkyd resin, and preparation method and application thereof

InactiveCN105218801AThe preparation process is stable and simpleGood storage stabilityPolyester coatingsPropanoic acidPolyol

The invention relates to the technical field of chemical engineering, and discloses polyurethane-organosilicon modified waterborne alkyd resin and a preparation method and an application thereof. The polyurethane-organosilicon modified waterborne alkyd resin is composed of the following components, by weight: 26-36 parts of vegetable oil, 8-15 parts of polyol, 12-18 parts of polyacid, 0.03-0.05 parts of an alcoholysis catalyst, 25-32 parts of diisocyanate, 0.03-0.09 parts of dibutyltin dilaurate, 1-12 parts of hydroxyl silicone oil, 1-4 parts of 1,4-butanediol, 3-7 parts of 2,2-dimethylol propionic acid, 2-6 parts of a neutralizing agent, and 1.2-1.9 parts of a small-molecular chain extender. The resin provided by the invention is used for preparing a paint film. The prepared paint film has the advantages of easy construction, high gloss, full paint film, good thermal stability, water resistance, low surface energy, and good mechanical performance.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of bi-component siloxane modified polyurethane sealant

InactiveCN101838513AGood adhesionImprove operational stabilityNon-macromolecular adhesive additivesOther chemical processesSealantMechanical property

The invention discloses a preparation method of a bi-component siloxane modified polyurethane sealant, which belongs to the technical field of sealants. The method comprises the following steps: preparing a polyurethane prepolymer; carrying out synthetic reaction to obtain the polyurethane prepolymer under certain conditions by using two-function polyether glycol, diphenylmethane diisocyanate, plasticizer and siloxane containing amino groups; using the prepared prepolymer, inorganic filler, plasticizer and organosilicon adhesion accelerant as the first component of the sealant; and using inorganic filler, diluter, curing agent, surfactant, and dibutyltin dilaurate or tertiary amine catalyst as the second component. By designing the structure of the end silane polyurethane prepolymer and adjusting the proportion of the inorganic filler, in cooperation with a proper curing system and catalysis system, the prepared sealant has the characteristics of high curing speed, good adhesion effect and the like. The sealant has the advantages of high mechanical properties, good elasticity, no toxicity, no irritative gas emission and outstanding weatherability.

Owner:BEIJING COMENS NEW MATERIALS

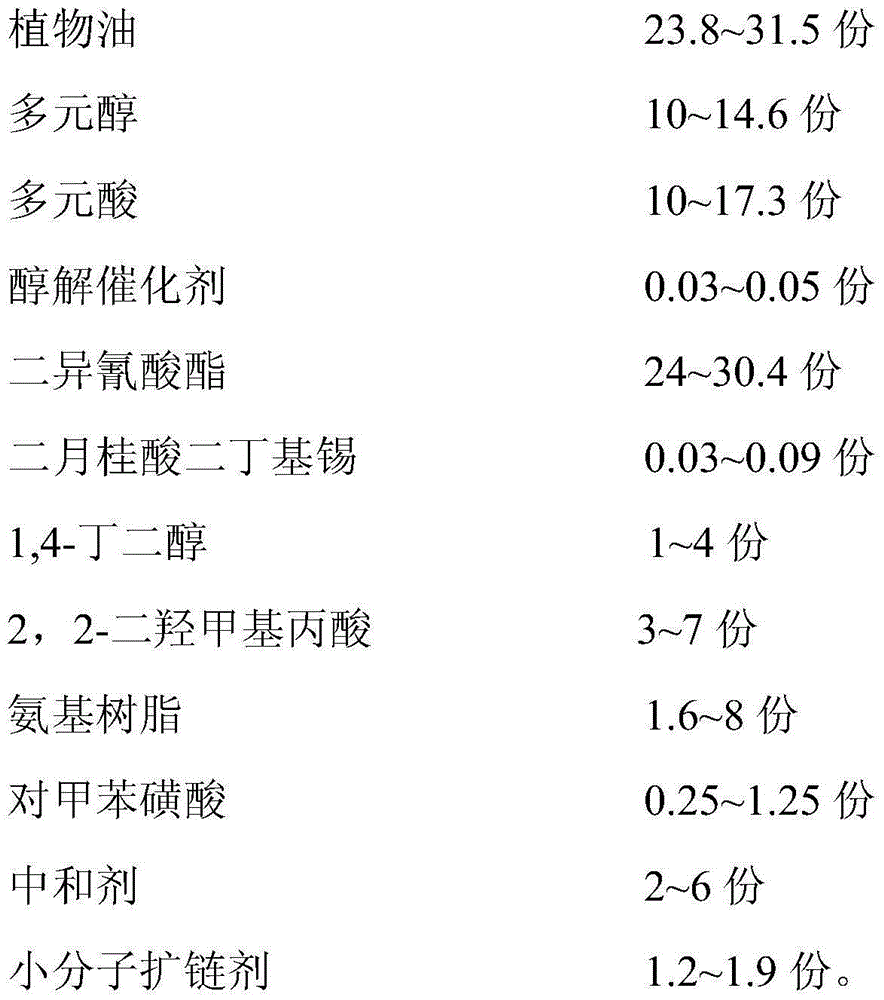

Polyurethane-amino resin modified waterborne alkyd resin and preparation and application thereof

InactiveCN105153387ALow priceIncrease the degree of cross-linkingPolyurea/polyurethane coatingsVegetable oilPropanoic acid

The invention belongs to the technical field of coatings, and discloses polyurethane-amino resin modified waterborne alkyd resin and preparation and application thereof. The resin is prepared from, by mass, 23.8-31.5 parts of vegetable oil, 10-14.6 parts of polyhydric alcohol, 10-17.3 parts of polyatomic acid, 0.03-0.05 part of alcoholysis catalyst, 24-30.4 parts of diisocyanate, 0.03-0.09 part of dibutyltin dilaurate, 1-4 parts of 1,4-butanediol, 3-7 parts of 2,2-dihydromethyl propionic acid, 1.6-8 parts of amino resin, 0.25-1.25 parts of p-toluenesulfonic acid, 2-6 parts of neutralizer and 1.2-1.9 parts of micromolecular chain extender. The vegetable oil is used as the raw material, and the amino resin is introduced through chemical modification, so that the obtained waterborne alkyd resin is low in cost, the hardness, water resistance, solvent resistance, heat resistance and tensile strength of a resin paint film are improved, and the application prospects are good.

Owner:SOUTH CHINA UNIV OF TECH

Water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and preparation method thereof

InactiveCN108342181AHigh strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and a preparation method thereof and relates to the technical field of polyurethane adhesives. The adhesive comprises, by weight, 30-40 parts of polytetrahydrofuran glycol, 15-22 parts of polycarbonate diol, 3-7 parts of poly-2,6-polyethylene naphthalate polyester glycol, 17-25 parts of diisocyanate, 2-5 parts of chain extender, 0.5-2 parts of silane coupling agent modified silicon dioxide nanoparticles, 0.1-0.6 part of dibutyltin dilaurate, 4-8 parts of acetone, 1-3 parts oftriethylamine, 0.05-0.1 part of sodium hydroxide and an appropriate amount of water. Polytetrahydrofuran and polycarbonate diol are adopted as oligomer polyhydric alcohols in raw materials for preparing polyurethane, and added poly-2,6-polyethylene naphthalate polyester glycol is introduced to a soft-segment part of polyurethane; by adding silane coupling agent modified silicon dioxide nanoparticles, the mechanical properties and heat resistance of the adhesive can be improved; the prepared adhesive is high in adhesive force and excellent in water resistance and high temperature resistance, and the application range of the adhesive is enlarged.

Owner:佛山市三水日邦化工有限公司

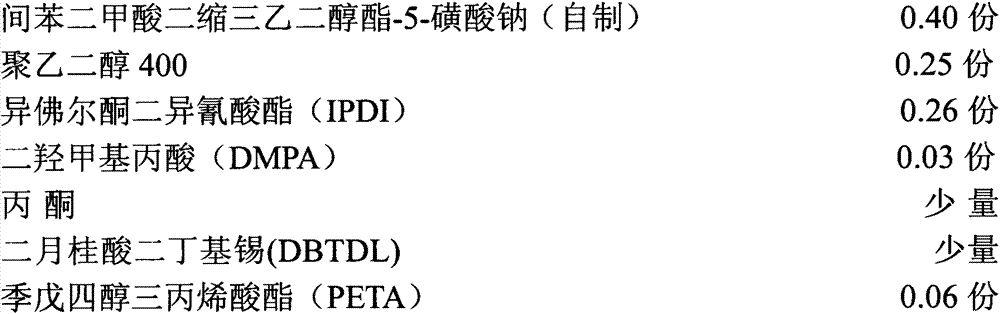

Preparation method for antifogging thin film coating with high light transmission

ActiveCN103709927APolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSolventDibutyltin dilaurate

Provided is a preparation method for an antifogging thin film coating with high light transmission. M-phthalic acid triethylene glycol ester-5-sodium sulfonate (self made), polyethylene glycol 400, isophorone diisocyanate and pentaerythritol triacrylate are employed as main raw materials, dibutyltin dilaurate is employed as a catalyst, dimethylolpropionic acid is employed as a chain extender, acetone is employed as a solvent, and hydrophilic UV prepolymers are prepared; ethyl orthosilicate is employed as a precursor, gamma-methacryloxy propyl trimethoxysilane is employed as a modifier, a sol-gel method is employed, and uniform and stable modified SiO2 sol is prepared; the hydrophilic UV prepolymers and the modified SiO2 sol are subjected to hybridization through a UV curing way, and a thin film coating is obtained. The prepared thin film coating has good hardness and adhesive force, water resistance and high light transmission and good antifogging effects, and can be used for antifog of surfaces of glass and eyeglass. The preparation technology of the thin film coating accords with green environmental protection concepts, curing and film forming are fast, and comprehensive performances are good. The antifogging thin film coating has good market prospect and is suitable for popularization and application.

Owner:JIANGNAN UNIV

Method of preparing fluorinated polyurethane paint and fluorinated polyurethane anticorrosive paint

InactiveCN104293158ALower surface energyExcellent water and oil repellencyAnti-corrosive paintsPolyurea/polyurethane coatingsPolyolMixed materials

The invention provides a method of preparing fluorinated polyurethane paint. The method is characterized by comprising the following steps: a step of preparing a component A, namely adding 15-60 parts of fluorinated polyether polyol and 0.01-0.03 part of dibutyltin dilaurate into a three-necked flask with a stirring rod in sequence, and stirring for 30 minutes to obtain the component A; a step of preparing a component B, namely adding 10-40 parts of 4,4-diphenyl methane diisocyanate and 0-30 parts of collaborative anticorrosive filler into 20-60 parts of a solvent system to stir and dissolve to obtain the component B; and a step of preparing fluorinated polyurethane anticorrosive paint, namely adding the component B into the three-necked flask filled with the component A, stirring for 8-10 minutes, grinding the mixed materials in the three-necked flask until fineness is 40-50 mu m after uniformly stirring, coating a metal sheet with the grinded mixed materials and curing for 24 hours to obtain the fluorinated polyurethane anticorrosive paint.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

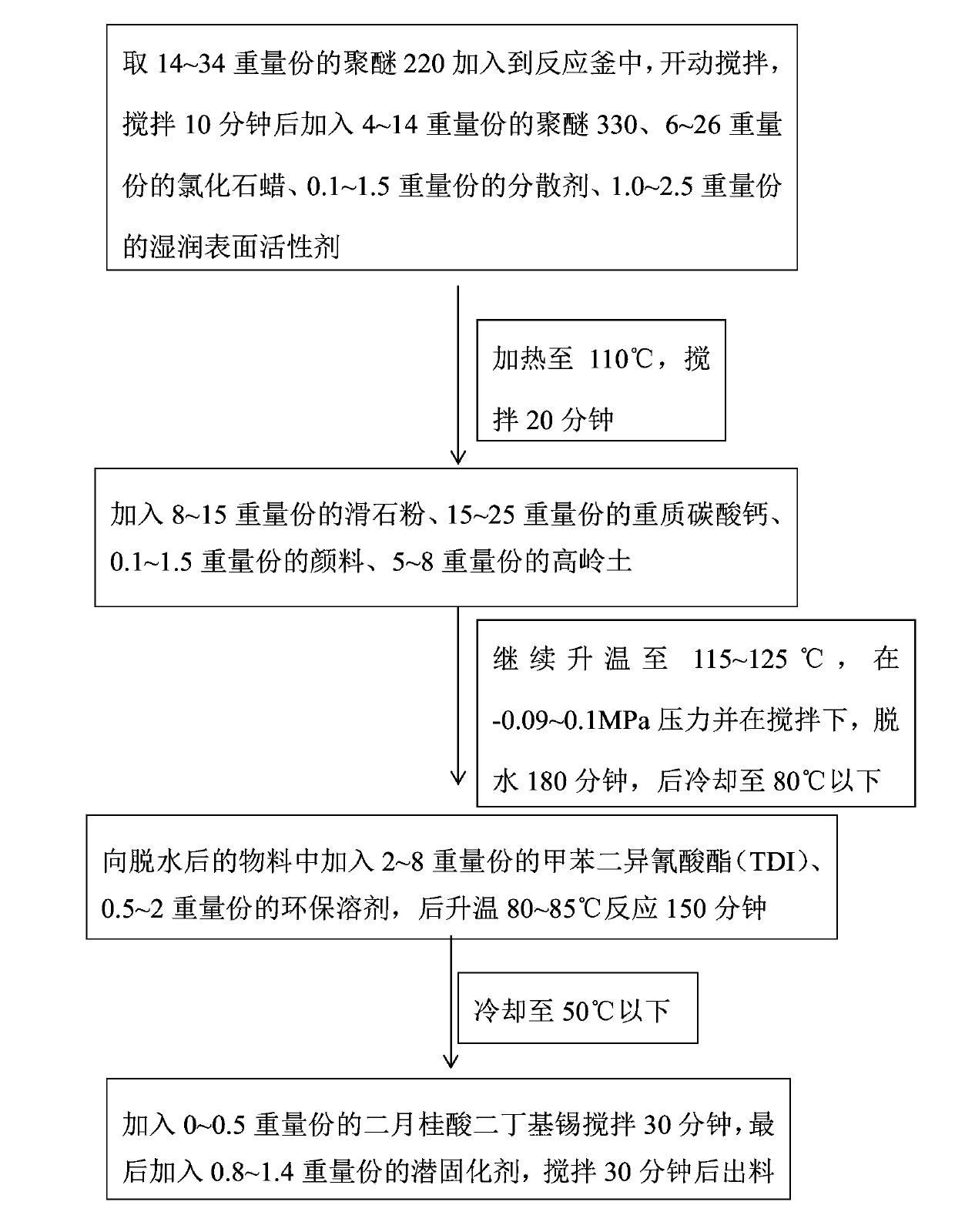

Single-component moisture curable polyurethane waterproof coating and preparation method thereof

InactiveCN103965765ASolve the problem that the construction quality is difficult to guaranteeGood storage stabilityPolyurea/polyurethane coatingsToluene diisocyanateChlorinated paraffins

The invention provides a single-component moisture curable polyurethane waterproof coating and a preparation method thereof. The single-component moisture curable polyurethane waterproof coating comprises the following raw materials by weight: 14-34 part of polyether 220, 4-14 parts of polyether 330, 6-26 parts of chlorinated paraffin, 0.1-1.5 parts of a dispersing agent, 1.0-2.5 parts of a wetting surfactant, 8-15 parts of talcum powder, 15-25 parts of heavy calcium carbonate, 0.1-1.5 parts of a pigment, 5-8 parts of kaolin, 2-8 parts of toluene diisocyanate (TDI), 0.5-2 parts of environment-friendly solvent, 0-0.5 part of dibutyltin dilaurate, and 0.8-1.4 parts of a latent curing agent. In the preparation process of the polyurethane coating, the wetting surfactant and the latent curing agent are added, so that even if a fundamental plane with a lot of dust is encountered in a construction process of the coating, sand holes and other problems cannot arise. Adding of the latent curing agent can prevent the coating from undergoing micro-foaming during construction.

Owner:YANTAI DONGJU WATERPROOF THERMAL INSULATION ENG CO LTD

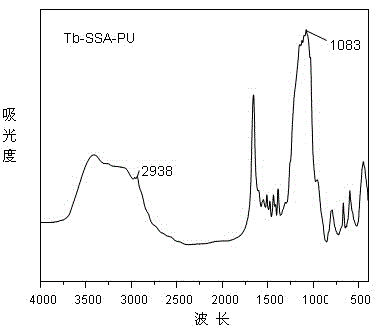

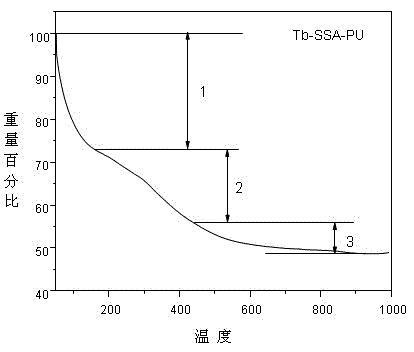

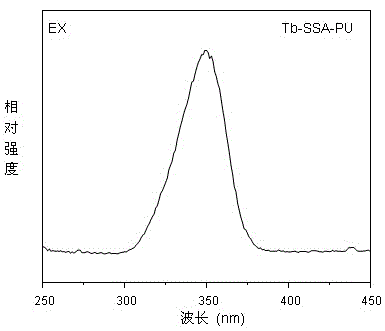

Rare-earth polyurethane high-polymer composite luminescent material and preparation method thereof

InactiveCN102876322AHigh Luminous Quantum EfficiencyImprove thermal stabilityLuminescent compositionsPolymer sciencePtru catalyst

The invention discloses a synthesis method of a rare-earth polyurethane high-polymer composite luminescent material, which comprises the following steps: after modifying a hydroxy-containing carboxylic acid organic ligand by a chemical method, and introducing rare-earth ions by a sol-gel method to obtain a binary rare-earth carboxylic acid hybrid material; and by using free hydroxy group in the hybrid material as active group and dibutyltin dilaurate (T12) as a catalyst, reacting with an organic substance diphenylmethane diisocyanate or toluene-2,4-diisocyanate with active group (isocyanate) to implement combination by a covalent bond, thereby obtaining the bonded rare-earth polyurethane high-polymer composite luminescent material which has the advantages of long fluorescence lifetime, high luminescent quantum efficiency and high heat stability. The preparation method of the rare-earth polyurethane high-polymer composite luminescent material has the characteristics of simple technique, mild reaction conditions, no need of any additive, low production cost and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method of antibacterial type soft polyurethane foaming plastic

InactiveCN103467702AGood antibacterial and bactericidal performanceStable heat resistancePolymer scienceButanediol

The invention discloses a preparation method of an antibacterial type soft polyurethane foaming plastic. The preparation method is characterized by comprising the following technical steps: a, adding metered polyether glycol N330 and 1,4-butanediol, a catalytic amount of dibutyltin dilaurate and tripolycyanamide to a reaction kettle, filling nitrogen or an inert gas into the reaction kettle for protection, heating at 40-60 DEG C, sufficiently stirring for 6-8 hours, and reducing temperature to 25 DEG C; b, adding polyisocyanate, silicone oil, triethylamine, nanometer zinc oxide and a right amount of water to a product obtained from the step a, and stirring at high speed till foaming; c, when a large quantity of white foams appear, immediately injecting the white foams into a mould, aging at 40-60 DEG C for 60-150 minutes, and demoulding to obtain a soft polyurethane foaming plastic product. The obtained polyurethane soft foaming plastic has the advantages of good antibacterial and bactericidal property, stability in heat-resistant property, no bactericide separation, safety, environment protection, simpleness and convenience for production process and suitability for industrialized production.

Owner:NANJING NIANJI REFRIGERATION FOOD

Silicone rubber hydrophobic coating used for insulator and preparation method thereof

ActiveCN105623503ASimple preparation processImprove adhesionFireproof paintsInsulatorsHalloysitePolymer science

The invention belongs to the technical field of coatings, and particularly discloses a silicone rubber hydrophobic coating used for an insulator and a preparation method thereof. The silicone rubber hydrophobic coating comprises hydroxy-terminated poly-dimethylsiloxane, fluoroalkyl silane modified halloysite nanotubes, tetraethyl orthosilicate, dibutyltin dilaurate and cyclohexane; the preparation method comprises the steps of mixing all the components for stirring uniformly at room temperature to prepare a viscous solution, then coating the surface of a composite insulator with the viscous solution, leaving to stand for curing at room temperature, so as to obtain the silicone rubber hydrophobic coating after the solvent naturally volatiles. The silicone rubber hydrophobic coating used for the insulator, provided by the invention, has the advantages that the preparation process is simple, the hydrophobic nature is good, the adhesive force is strong, the fire resistance is good, and the using requirements of an insulator on the external insulating coating material are met.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Epoxy polysiloxane graphene heavy-duty anticorrosion coating and preparation method

ActiveCN105860761AImprove aging resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsNitrogen gasSolvent

The invention discloses epoxy polysiloxane graphene heavy-duty anticorrosion coating, comprising component A and component B according to a weight ratio of 100:17-24; the component A includes: epoxy resin, epoxy polysiloxane and graphene; the component B includes: cashew nut shell oil-modified amine curing agent. A preparation method of this coating includes: (1), hydrogenated bisphenol A epoxy resin and epoxy polysiloxane into a reactor introduced with nitrogen, heating to 60-80 DEG C, and adding dibutyltin dilaurate; heating slowly to 125-135 DEG C, and reacting for 5-6 h; cooling to 55-60 DEG C, adding silane coupling agent, and continuing to react for 2 h; extracting with petroleum ether, and removing a solvent at 40 DEG C at low vacuum pressure of 0.08 MPa; (2), mixing the epoxy resin, the epoxy polysiloxane of step (1) and graphene, heating for dissolving, adding other materials, and mixing; the coating prepared herein has excellent properties such as aging resistance, water resistance, hardness, flexibility, and salt water resistance.

Owner:WUHAN HOSTS COATING MATERIAL CO LTD

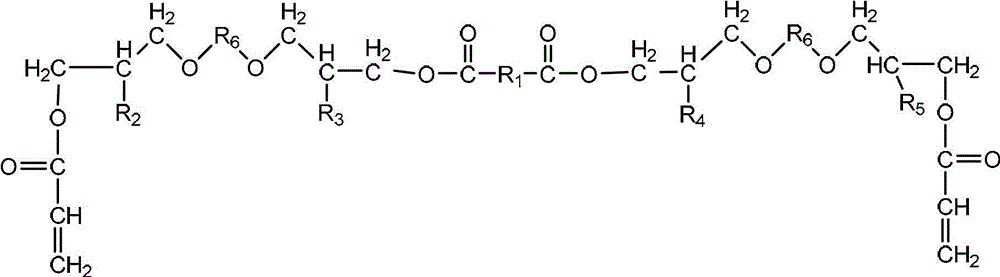

Bi-component silicone pouring sealant for LED photoelectric display device and method for manufacturing same

ActiveCN101544881AAvoid thickeningSimple processOther chemical processesSemiconductor/solid-state device manufacturingHydroxylamineDisplay device

The invention relates to a bi-component silicone pouring sealant for an LED optoelectronic display device and a method for manufacturing the same. The bi-component silicone pouring sealant is characterized in that the sealant is obtained through the reaction of components A and B by using alpha,omega-dihydroxy polydimethylsiloxane of which the structural formula shown on the right as a main material. The component A is prepared from the following components by weight portion through mixing: 100 portions of the alpha,omega-dihydroxy polydimethylsiloxane, 10 to 35 portions of organosilicon based gel, 0 to 50 portions of stuffing, and 10 to 30 portions of plasticizer; and the component B is prepared from the following components in portion by weight through mixing: 5 to 10 portions of cross-linking agent, 0.3 to 3 portions of coupling agent, 0.1 to 0.5 portion of titanate complex, 0.1 to 0.5 portion of diethyl hydroxylamine, 0.01 to 0.1 portion of dibutyltin dilaurate catalyst, and 2 to 10 portions of plasticizer. The silicone pouring sealant prepared by the method has the advantages of simple process flow, good adhesive property, excellent temperature and weather resistant properties, and good flow property, and can be widely applicable for embedding electronic devices such as the LED optoelectronic display device and the like.

Owner:CHENGDU GUIBAO SCI & TECH

Multifunctional urethane acrylate oligomer as well as synthesis method and application thereof

ActiveCN102911338AImprove brittlenessImprove toughnessPolyurea/polyurethane coatingsSynthesis methodsReaction temperature

The invention discloses a multifunctional urethane acrylate oligomer as well as a synthesis method and application thereof. The synthesis method comprises the following steps: synthesizing a modified glycidyl ether by adding a diglycidyl ether, a dibasic acid and a catalyst which is the triphenylphosphine into a reactor and subjecting the materials to reaction at 120-150 DEG C for 2.5-3.5 hours; synthesizing a semi-adduct by dropwise adding acrylic hydroxy ester and dibutyltin dilaurate into diisocyanate, and keeping the reaction temperature at 40-50 DEG C until the concentration of the isocyanate group is 48-52% of the initial concentration; and synthesizing a hydroxyl-group containing multifunctional urethane acrylate. In the process of synthesizing, by using the difference of raw materials and controlling the proportion of monomers for reaction, the soft and hard segments are introduced into the molecule structure so that the toughness is increased, and the brittleness of the coating film is improved. The hydroxyl groups are provided in the molecular structure design, which is helpful to the improvement of the adhesion of the coating film on the substrate in the later period.

Owner:CHANGXING PHOTOELECTRIC MATERIAL +1

Method for preparing fire-retarding aqueous polyurethane

The invention discloses a method for preparing fire-retarding aqueous polyurethane, which comprises the following steps of: reacting a polyhydroxyl phosphorus compound and hexamethylene diisocyanate in the presence of a dibutyltin dilaurate catalyst for 1 to 3h to obtain a polyurethane prepolymer; adding hydrophilic chain extender containing 1.5 to 3 percent by total weight of polyurethane prepolymer of carboxyl and a butanone solvent which is 10 to 20 percent by the total weight of polyurethane prepolymer into the polyurethane prepolymer, reacting for 2 to 3h, adding triethylamine, neutralizing the reaction solution for 20 to 40min, and adding water for emulsification to form hydrophilic polyurethane; and adding bentonite dispersion liquid and phospholipid into the hydrophilic polyurethane, and shearing and stirring for 30 to 80 minutes under a condition of a pH value of 7 to obtain the fire-retarding aqueous polyurethane. The polyurethane has greatly improved fire retardance and mechanical property.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

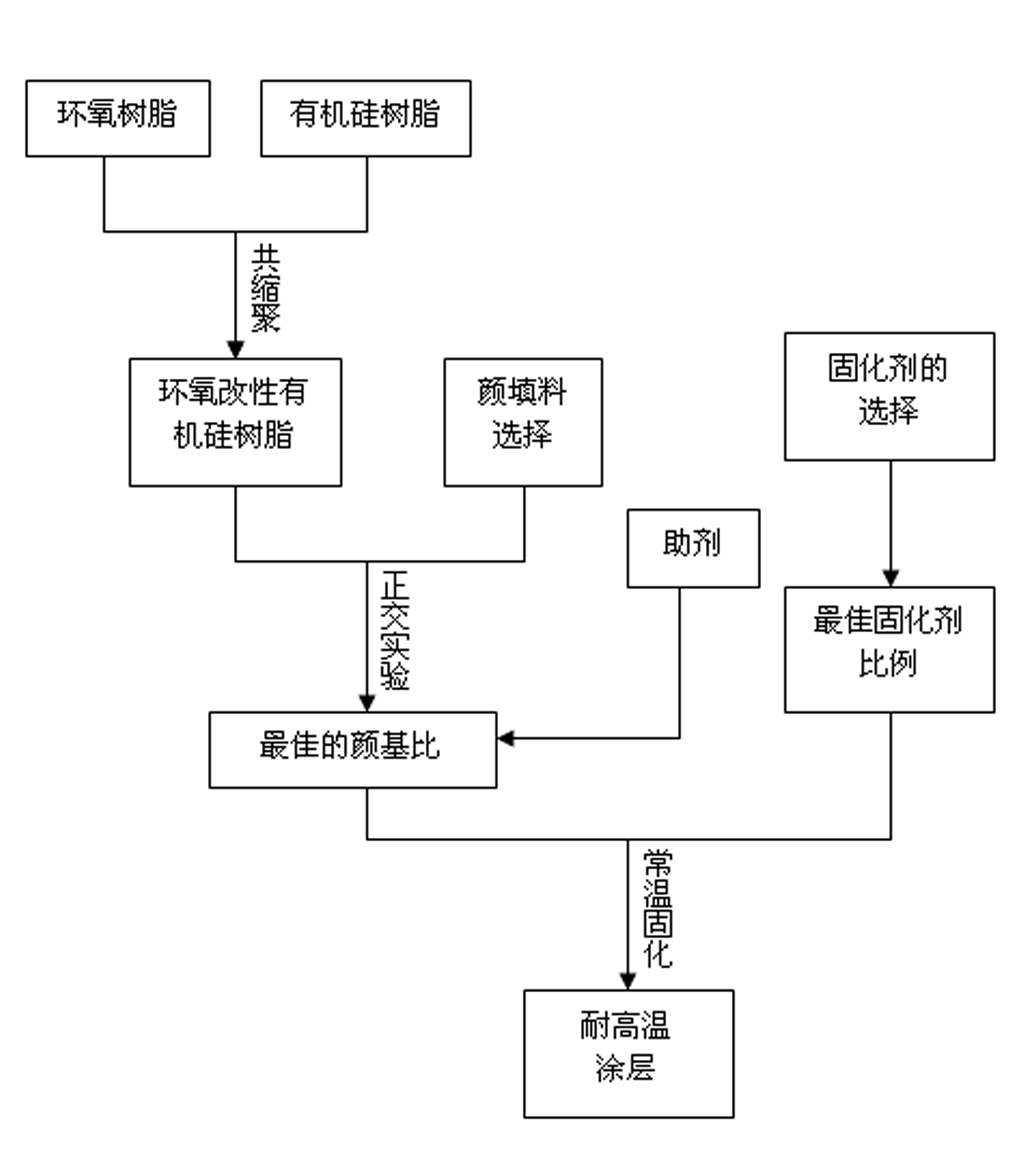

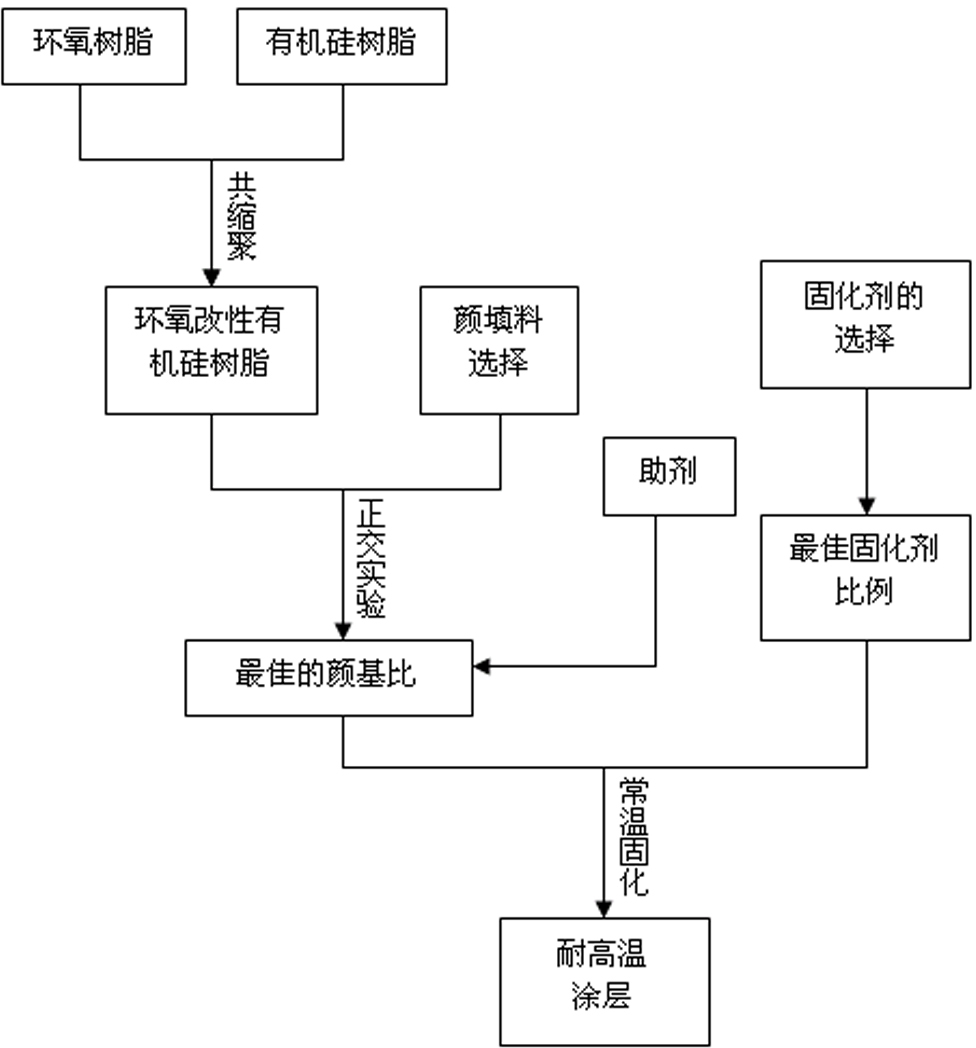

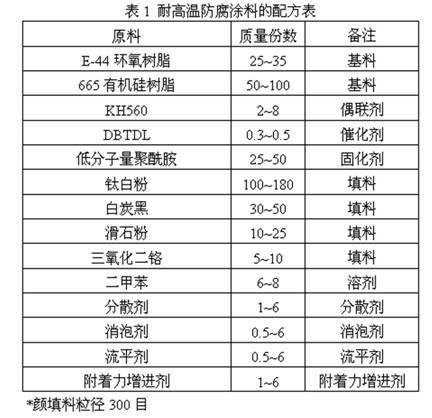

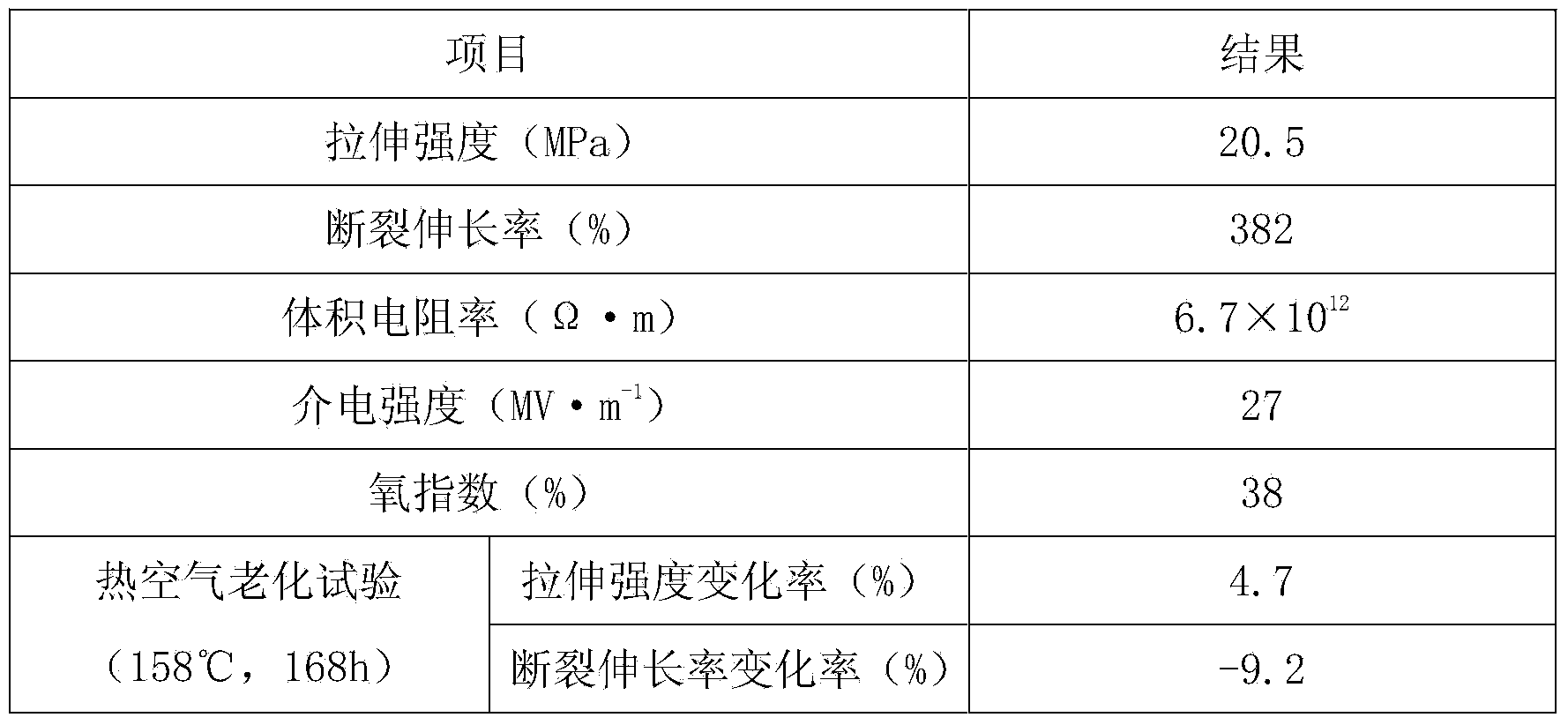

Epoxy modified high-temperature-resistant anticorrosive paint

InactiveCN101935497ASolve the shortcomings of poor cold and hot alternating performanceGood cold and hot alternating performanceAnti-corrosive paintsEpoxy resin coatingsChemical industryEpoxy

The invention discloses a high-temperature-resistant anticorrosive paint. The paint comprises a base material, a color filler, an auxiliary agent, a solvent and a curing agent, wherein the base material is prepared by mixing E-44 type epoxy resin and 665 type organic silicone resin in a mass ratio of 1 to 3, adding a coupling agent KH-560 which accounts for 2 to 3 mass percent of the resin system, adding dibutyltin dilaurate serving as a catalyst which accounts for 1 to 2 mass percent of the coupling agent and performing constant temperature reaction at the temperature of between 120 and 130 DEG C for 6 hours; and the mass ratio of the base material to the color filler to the auxiliary gent to the solvent to the curing agent is 100:120-180:3-10:2-20:10-30. The paint can be quickly cured at the normal temperature and has a heat-resistant temperature of 700 DEG C, high hot and cold alternation performance and high corrosion resistance; and a cured coating is not changed after being corroded for 60 days in salt water. The paint remains perfect in corrosion environment such as simulated seawater, acid water and alkaline water. The paint can be widely applied to the fields of chemical industry, power and energy and military and has broad application prospect and economic benefit.

Owner:NAT UNIV OF DEFENSE TECH

High-temperature-resistant cable sheath material and preparation method thereof

ActiveCN103524844AExtended service lifeImprove high temperature resistanceInsulated cablesInsulatorsPolymer sciencePhosphate

The invention discloses a high-temperature-resistant cable sheath material and a preparation method thereof. The sheath material comprises the following raw materials in parts by weight: 70-80 of high density polyethylene, 20-30 of ethylene-propylene-diene monomer, 10-15 of maleic anhydride grafted polyethylene, 5-10 of bisphenol A novolac epoxy resin, 8-12 of diphenyl tolyl phosphate, 4-8 of dioctyl maleate, 0.5-1 of di(tert-butylperoxyisopropyl)benzene, 2-3 of p-benzoquinone dioxime, 1-2 of triallyl isocyanurate, 3-5 of paraffin oil, 2-3 of active zinc oxide, 10-15 of magnesium hydroxide, 5-10 of aluminum hydroxide, 4-6 of talcum powder, 8-12 of fly ash, 5-10 of nano bauxite, 2-3 of dibutyltin dilaurate, 1-2 of an anti-aging agent MB, 1-2 of an anti-aging agent TPPD, and 4-6 of a composite filler. The sheath material prepared by the invention not only has good high temperature resistance and can be used in a 125 DEG C working environment for a long time, but also has good flame retardant effect, has the oxygen index of more than 35%, has non halogen and low smoke, and solves the problem of poor heat resistance of a high-flame-retardant sheath material.

Owner:滁州三界外信息科技有限公司

Method For Preparing Carbon Nanotubes Graphene Modified Aqueous Polyurethane Coatings and Adhesives

ActiveUS20170114248A1Improve fire resistanceImprove light resistancePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsBenzoic acidAdhesive

The present invention discloses a method for preparing carbon nanotubes graphene modified aqueous polyurethane coatings and adhesives: under the presence of dibutyltin dilaurate as catalysts, mixing polytetrahydrofuran ether glycol with isophorone diisocyanate, reacting at 60° C. to 80° C., adding 2-sulfobenzoic anhydride, carboxylated carbon nanotubes and graphene sheet into the mixture, reacting at 90° C. for 2 hours, and then polyurethane prepolymer A is obtained; adding chain extender and acetone into prepolymer A, reacting at 65° C. to 75° C., adding D-panthenol and 2,4,6-trihydroxy benzoic acid, reacting at 75° C. to 85° C. for 0.5 to 2 hours, adding triethylamine and benzamide for neutralization, reacting for 30-50 min, adding water for emulsification, and then carbon nanotubes graphene modified aqueous polyurethane coatings and adhesives are obtained. The prepared polyurethane is environment-friendly and low cost, can be wildly used as adhesives on plastic, glass, paper-making and textiles.

Owner:YANTAI UNIV

Preparation method of sulfonate amphoteric polyurethane emulsion

The invention relates to a preparation method of sulfonate amphoteric polyurethane emulsion, comprising the following steps: adding oligomer polyalcohol subject to vacuum dehydration and isocyanate into a reactor under the protection of dry nitrogen, mechanically stirring the oligomer polyalcohol and the isocyanate to react for 2h at 85-100 DEG C, reducing the system temperature to 40-60 DEG C, adding a micro-molecule chain extender, a solvent, a catalyst stannous octoate (T-9) and dibutyltin dilaurate (T-12), and maintaining the temperature to react for 2h at 55-75 DEG C; reducing the systemtemperature below 60 DEG C, and adding a positive ion chain extender and the solvent to control the temperature between 40 DEG C and 60 DEG C to react for 1h; adding the sulfonate and the solvent; adding water to carry out emulsion dispersion until the content of an isocyanate group can not change in a generated prepolymer to be reacted; and decompressing, distilling and desolventizing to obtain the sulfonate amphoteric polyurethane emulsion. The prepared sulfonate amphoteric polyurethane emulsion has a certain acidity-alkalinity resistance and can be used as an excellent carrier of a biological macromolecule and a more ideal protein model compound.

Owner:ANHUI UNIVERSITY

Preparation method of light-resistant water-based polyurethane coating

InactiveCN103436155AGood compatibilityGood light fastnessPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method of a light-resistant water-based polyurethane coating. The preparation method comprises the following steps of: mixing bisphenol S and diisocyanate in the presence of a dibutyltin dilaurate catalyst, and stirring to react at 60-85 DEG C for 1.5-3.5 hours to obtain a polyurethane prepolymer A; adding a hydrophilic chain extender with carboxyl content accounting for 1.2%-4.6% of the weight of A into A, then adding a solvent which accounts for 15%-35% of the weight of A, and stirring to react under the condition of 80-95 DEG C for 1.0-4.0 hours; adding triethylamine according to the condition that the mole ratio of COOH / NH2 is 0.6:(1-1.6):1 for neutralization, stirring to react for 30-70 minutes, and adding water for emulsification to form the light-resistant water-based polyurethane coating. The prepared light-resistant water-based polyurethane is environmentally-friendly and low in cost and can meet the requirement of the market on the property of light-resistant polyurethane.

Owner:HESHAN YIXIN CHEM CO LTD

Preparation method for waterborne polyurethane with improved fire resistance by virtue of nano materials

The invention discloses a preparation method for waterborne polyurethane with improved fire resistance by virtue of nano materials. Under the condition that a dibutyltin dilaurate catalyst exists, PTMG and IPDI (isophorone diisocyanate) are mixed for reaction at the temperature of 75-95 DEG C for 1.5-3.5 hours, so that polyurethane prepolymer can be obtained; a hydrophilic chain extender, of which the weight of carboxyl groups is 1.2-3.2 % of that of the polyurethane prepolymer, and an acetone solvent, of which the weight is 12-25% of that of the polyurethane prepolymer, are added into the polyurethane prepolymer for reaction at 65-85 DEG C for 1.5-3.5 hours, then, triethylamine is added for neutralization reaction for 30-50 minutes, and water is added for emulsification, so that polyurethane emulsion A can be formed; nano material emulsion, with the weight being 5-10% of that of the polyurethane emulsion A, is added into the polyurethane emulsion A, and the mixture of the nano material emulsion and the polyurethane emulsion A is subject to shear agitation for 20-50 minutes under the condition that the pH value is 7, as a result, the fire resistance waterborne polyurethane can be obtained. The prepared fire resistance polyurethane is environment-friendly and low is price, and can meet the low cost requirement on fire resistance leather products by the market.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com