Silicone rubber hydrophobic coating used for insulator and preparation method thereof

A hydrophobic coating, silicone rubber technology, applied in coatings, insulators, fire-retardant coatings, etc., can solve the problems of slow recovery of hydrophobicity, poor adhesion of hydrophobic coatings, poor hydrophobicity, etc., and achieve good adhesion and application range. Broad, excellent flame retardancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

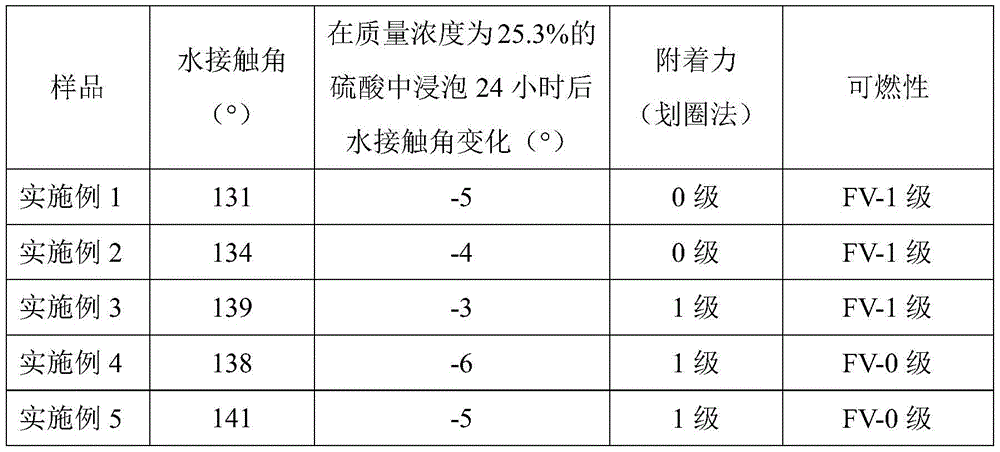

Examples

Embodiment 1

[0029] (1) Add 90~100g of halloysite nanotubes and 18~25g of perfluorooctyltriethoxysilane into 0.8~1.3L of ethanol aqueous solution with a mass concentration of 70%, stir in an oil bath at 80~100°C, Condensate and reflux, and react for 4 to 7 hours; after naturally cooling to room temperature, the above mixture is filtered, vacuum-dried, and pulverized to obtain halloysite nanotubes modified by perfluorooctyltriethoxysilane.

[0030] (2) 100 parts of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 20,000, 150 parts of halloysite nanotubes modified by perfluorooctyltriethoxysilane, 6 parts of ethyl orthosilicate, 0.2 parts Dibutyl tin dilaurate and 100 parts of cyclohexane were mixed and stirred evenly at room temperature to form a viscous solution; the above viscous solution was coated on the surface of a silicone rubber composite insulator, and left to cure at room temperature for 24 hours. After the solvent evaporates naturally, a silicone rubber hydroph...

Embodiment 2

[0032] (1) Add 90-100g of halloysite nanotubes and 18-25g of heptadecafluorotrimethoxyethoxysilane into 0.8-1.3L of ethanol aqueous solution with a mass concentration of 70%, and stir in an oil bath at 80-100°C , condensed and refluxed, and reacted for 4 to 7 hours; after naturally cooling to room temperature, the above mixture was filtered, vacuum-dried, and pulverized to obtain halloysite nanotubes modified by heptadecafluorotrimethoxyethoxysilane.

[0033] (2) 100 parts of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 15000, 180 parts of halloysite nanotubes modified by heptadecafluorotrimethoxyethoxysilane, 7 parts of ethyl orthosilicate, 0.3 1 part of dibutyltin dilaurate and 80 parts of cyclohexane, mixed and stirred evenly at room temperature to form a viscous solution; apply the above viscous solution on the surface of a silicone rubber composite insulator, and let it stand and cure for 24 hours at room temperature , after the solvent evaporates n...

Embodiment 3

[0035] (1) Add 90-100g of halloysite nanotubes and 18-25g of heptadecafluorodecyltrimethoxysilane into 0.8-1.3L of ethanol aqueous solution with a mass concentration of 70%, and stir in an oil bath at 80-100°C, Condensate and reflux, and react for 4 to 7 hours; after naturally cooling to room temperature, the above mixture is filtered, vacuum-dried, and pulverized to obtain halloysite nanotubes modified by heptadecafluorodecyltrimethoxysilane.

[0036] (2) 100 parts of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 11000, 210 parts of halloysite nanotubes modified by heptadecafluorodecyltrimethoxysilane, 8 parts of ethyl orthosilicate, 0.4 parts Dibutyltin dilaurate and 60 parts of cyclohexane were mixed and stirred evenly at room temperature to form a viscous solution; the above viscous solution was coated on the surface of ceramic insulators, and left to solidify at room temperature for 24 hours. After natural volatilization, a silicone rubber hydrophobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com