Patents

Literature

1279 results about "Halloysite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

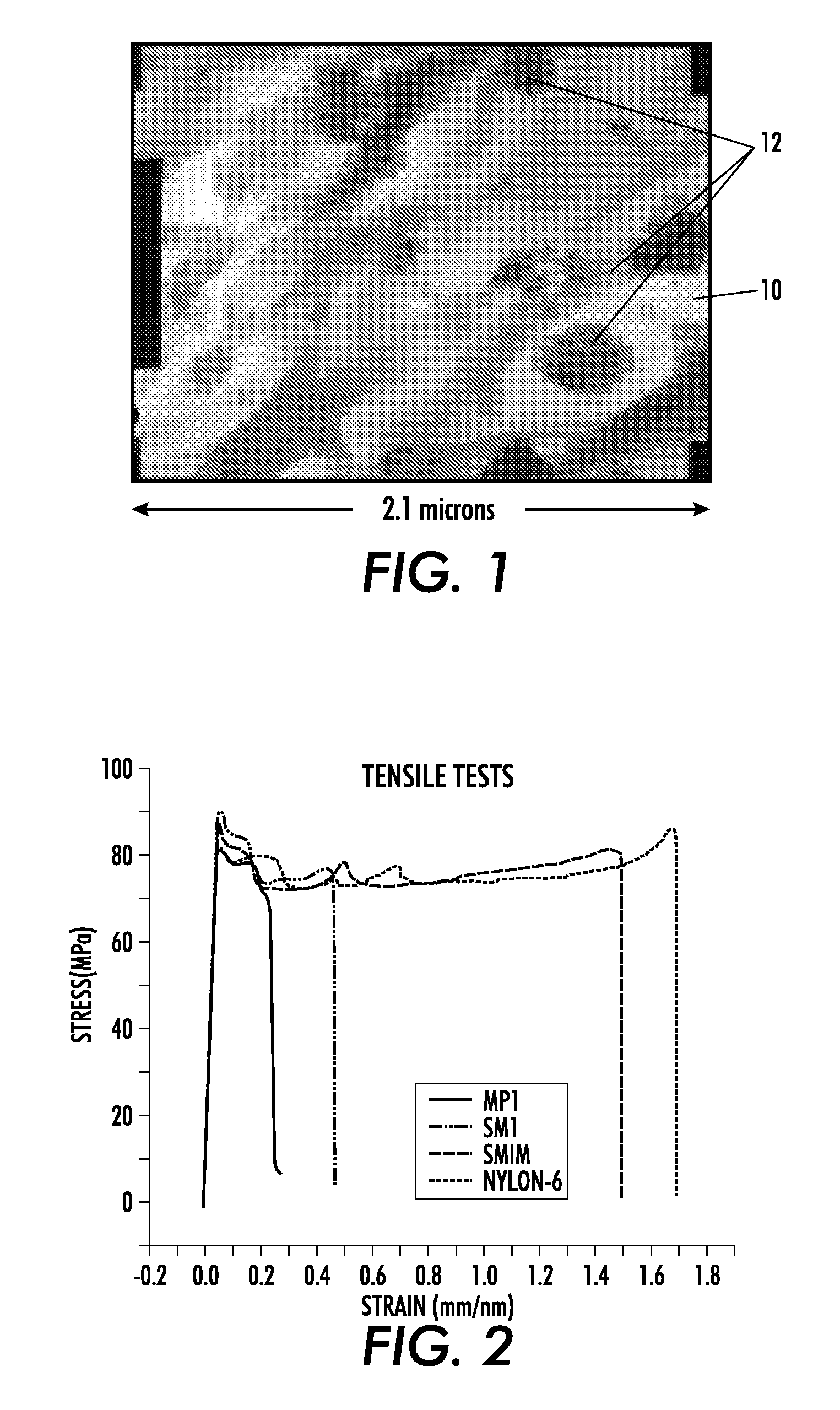

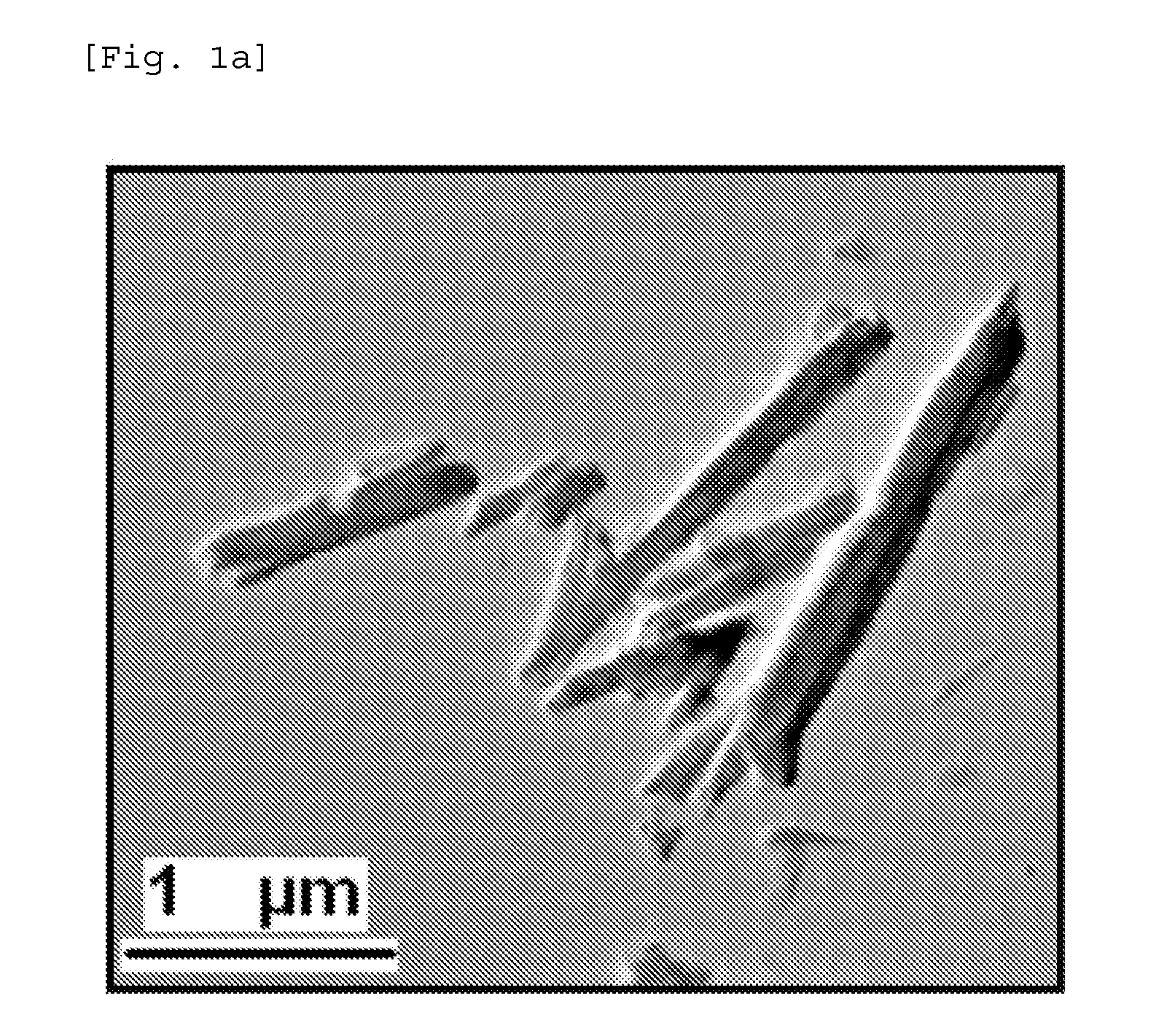

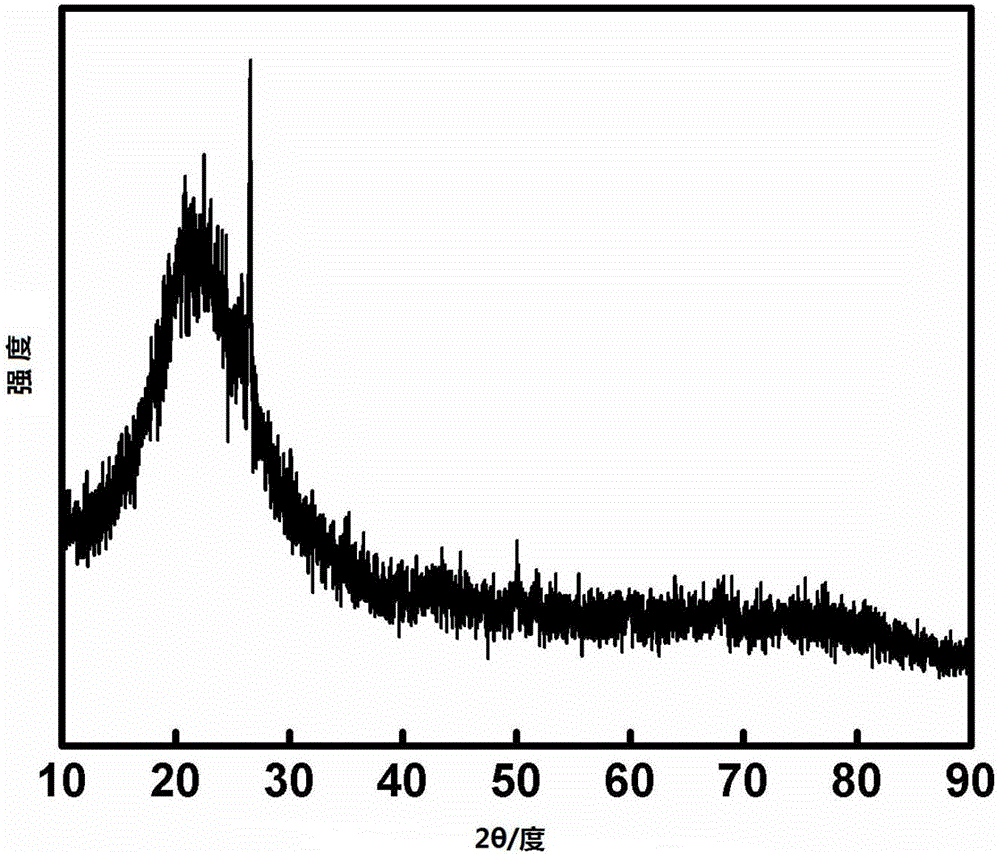

Halloysite is an aluminosilicate clay mineral with the empirical formula Al₂Si₂O₅(OH)₄. Its main constituents are aluminium (20.90%), silicon (21.76%) and hydrogen (1.56%). Halloysite typically forms by hydrothermal alteration of alumino-silicate minerals. It can occur intermixed with dickite, kaolinite, montmorillonite and other clay minerals. X-ray diffraction studies are required for positive identification. It was first described in 1826 and named after the Belgian geologist Omalius d'Halloy.

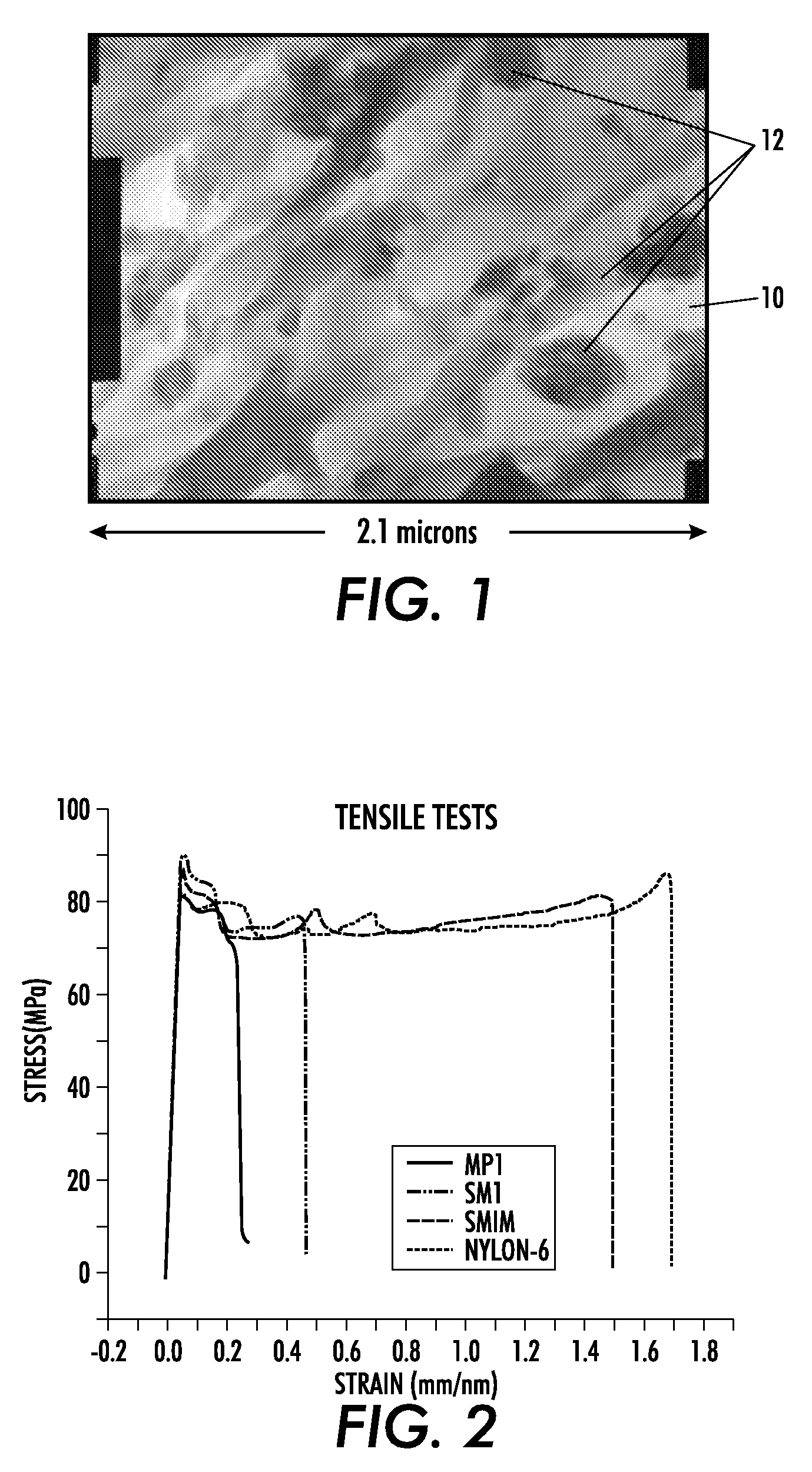

Polymeric composite including nanoparticle filler

InactiveUS20070106006A1Increase potential environmental impactReduce load levelHalloysiteNanoparticle

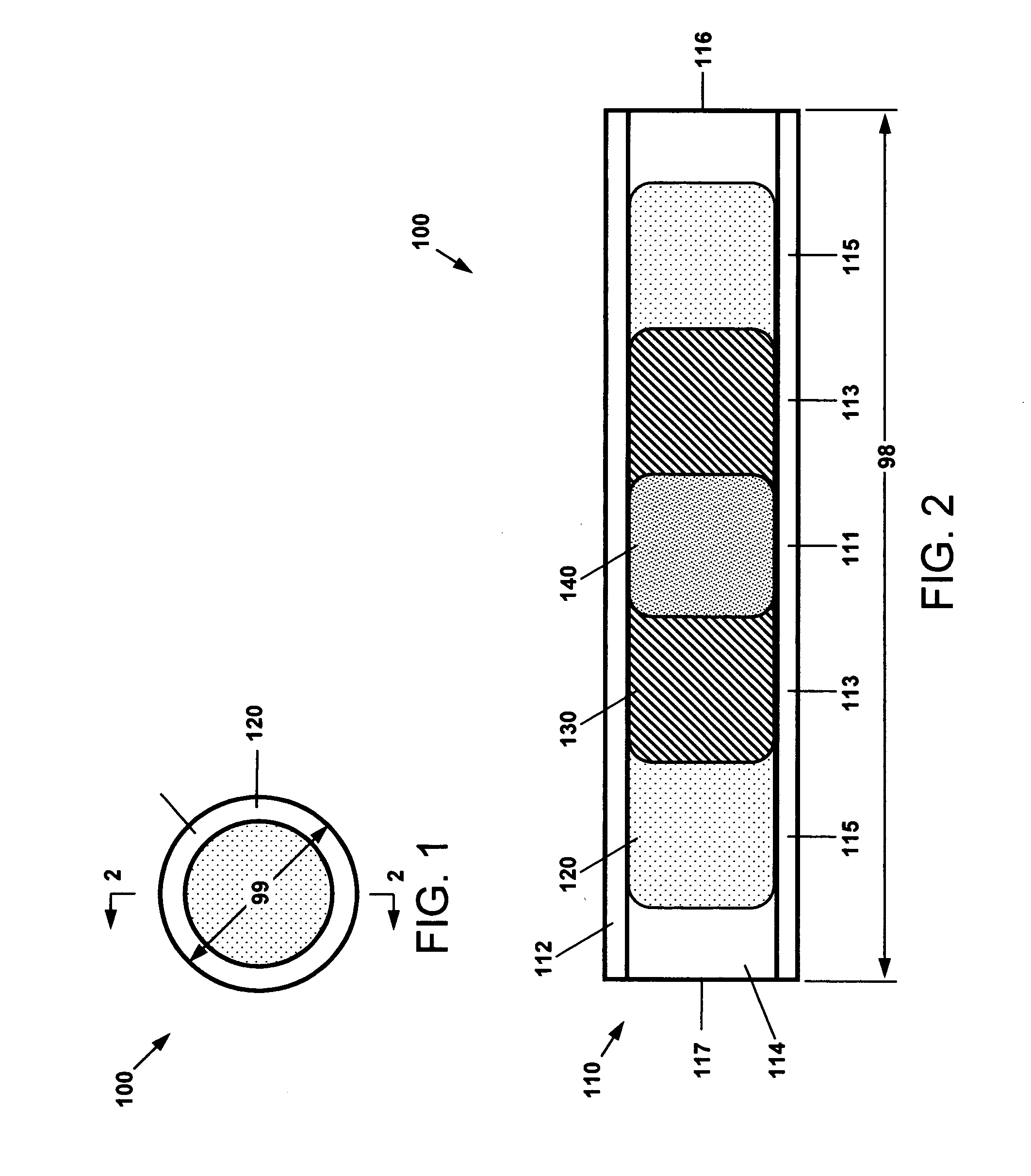

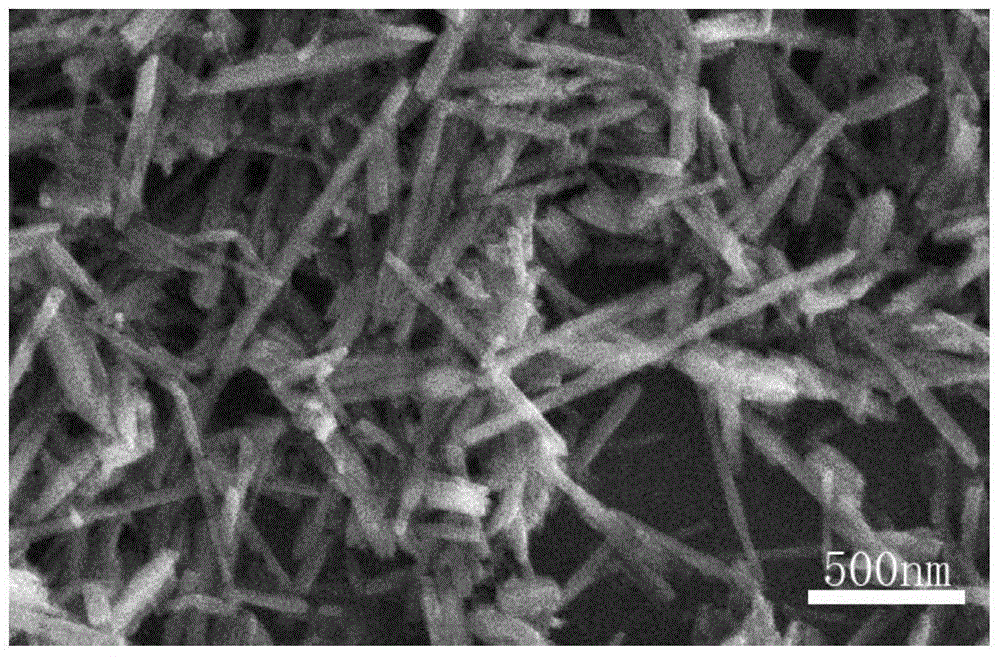

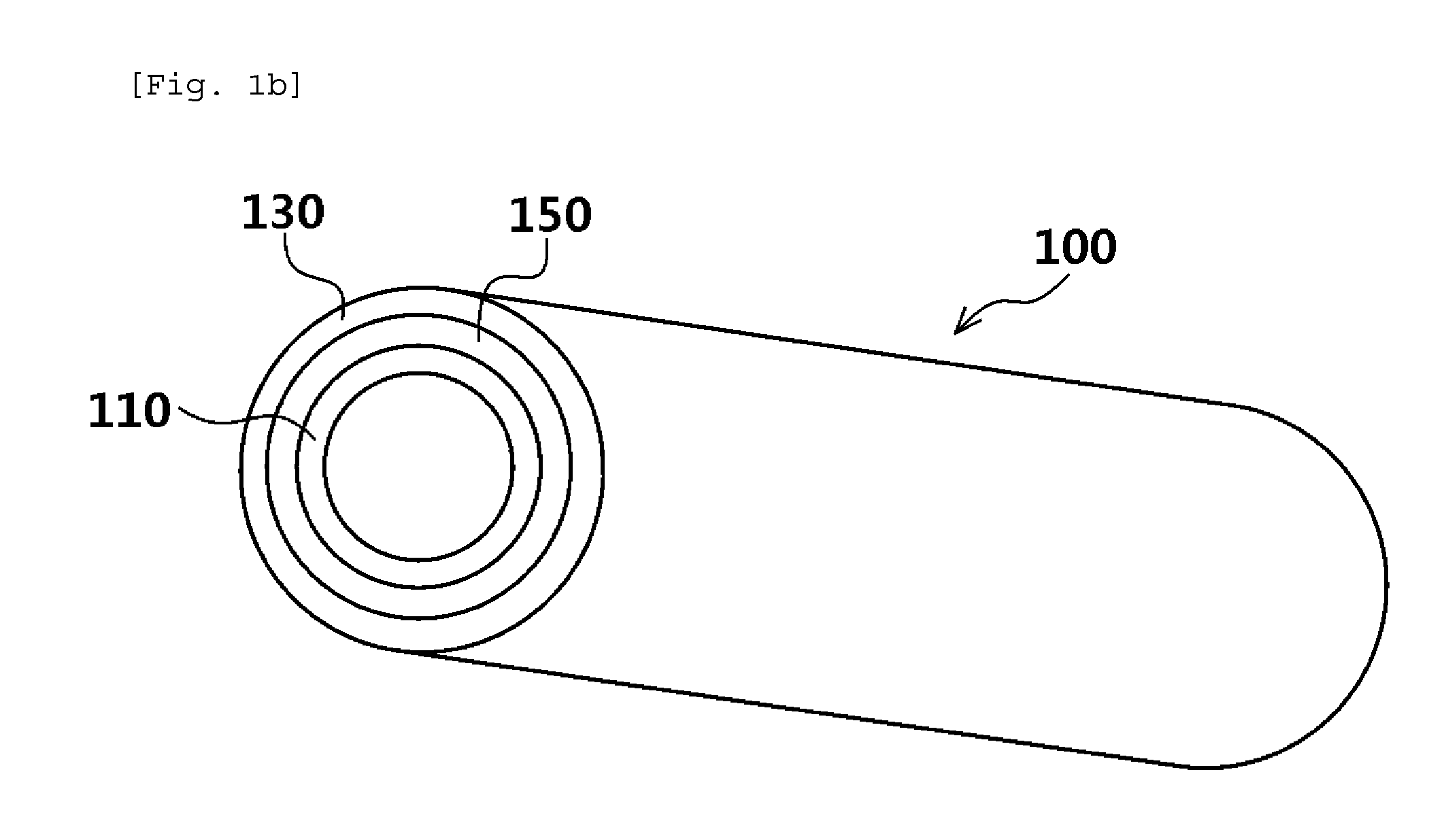

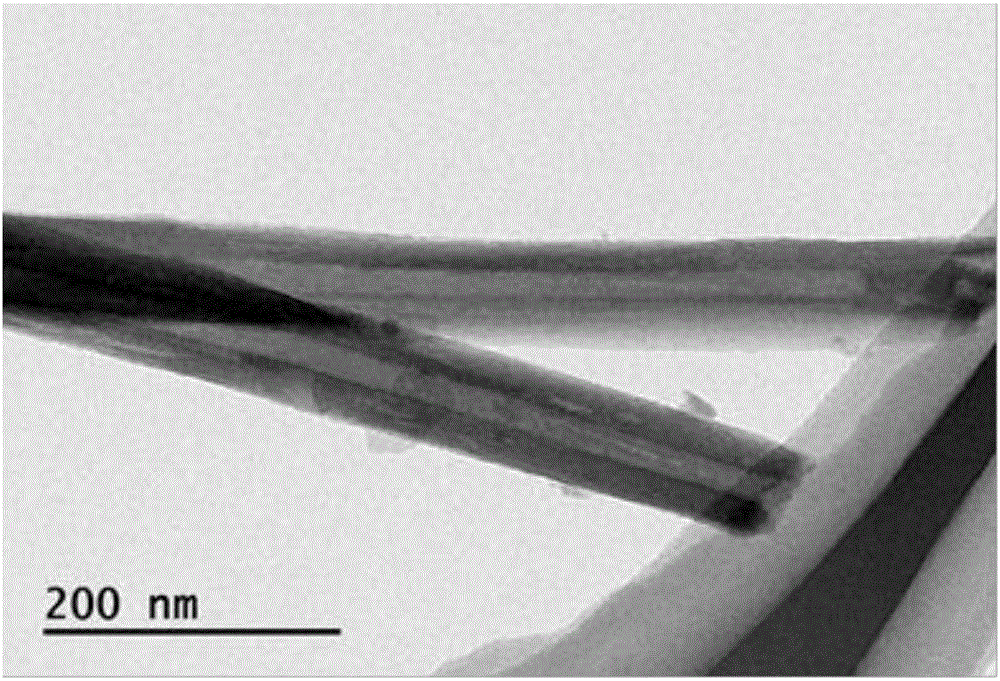

Disclosed is a novel polymeric composite including a nanoparticle filler and method for the production thereof. More particularly, the present invention provides a novel halloysite nanoparticle filler which has the generally cylindrical or tubular (e.g. rolled scroll-like shape), in which the mean outer diameter of the filler particle is typically less than about 500 nm. The filler is effectively employed in a polymer composite in which the advantages of the tubular nanoparticle filler are provided (e.g., reinforcement, flame retardant, chemical agent elution, etc.) with improved or equivalent mechanical performance of the composite (e.g., strength and ductility).

Owner:NATURALNANO CORP

Halloysite microtubule processes, structures, and compositions

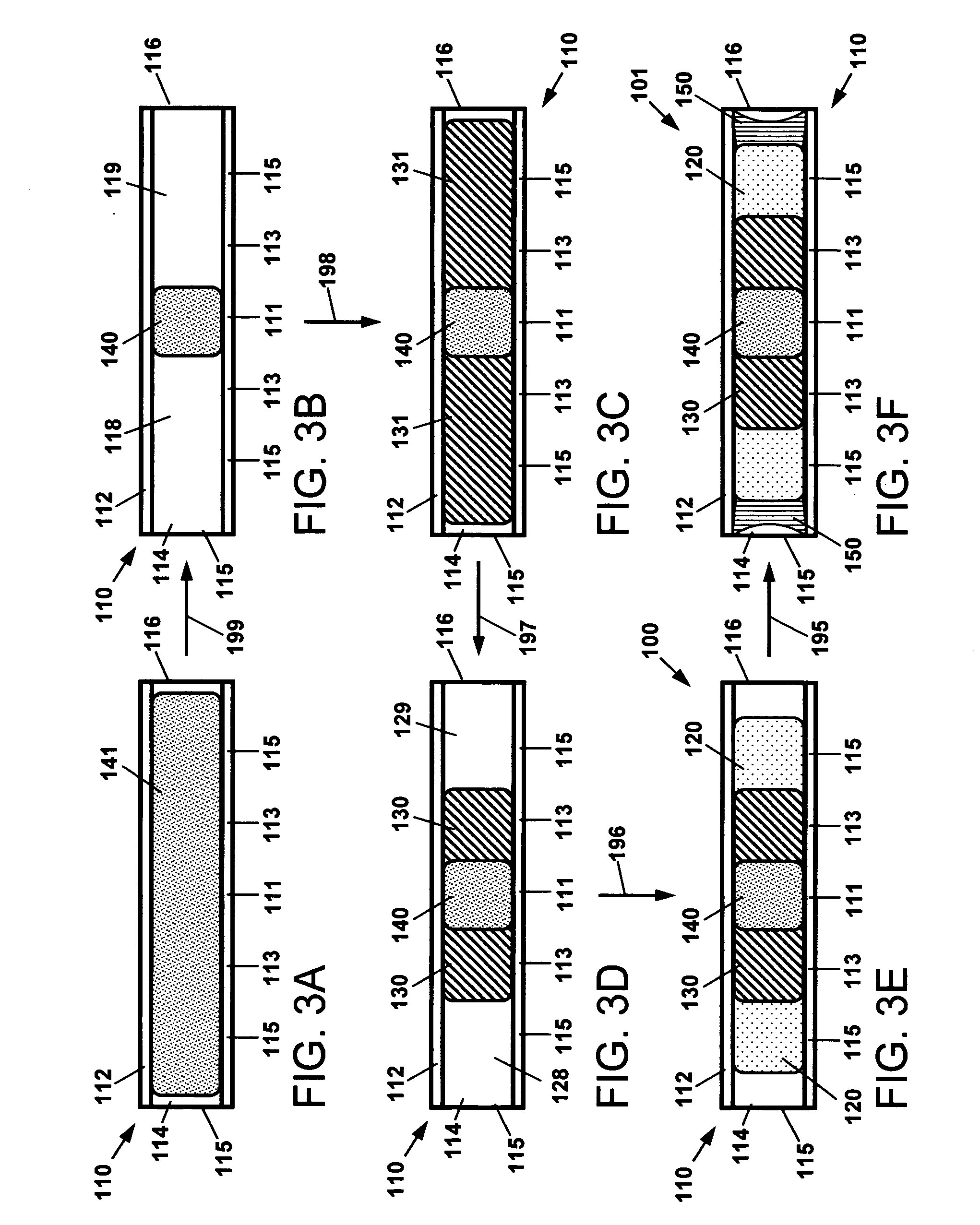

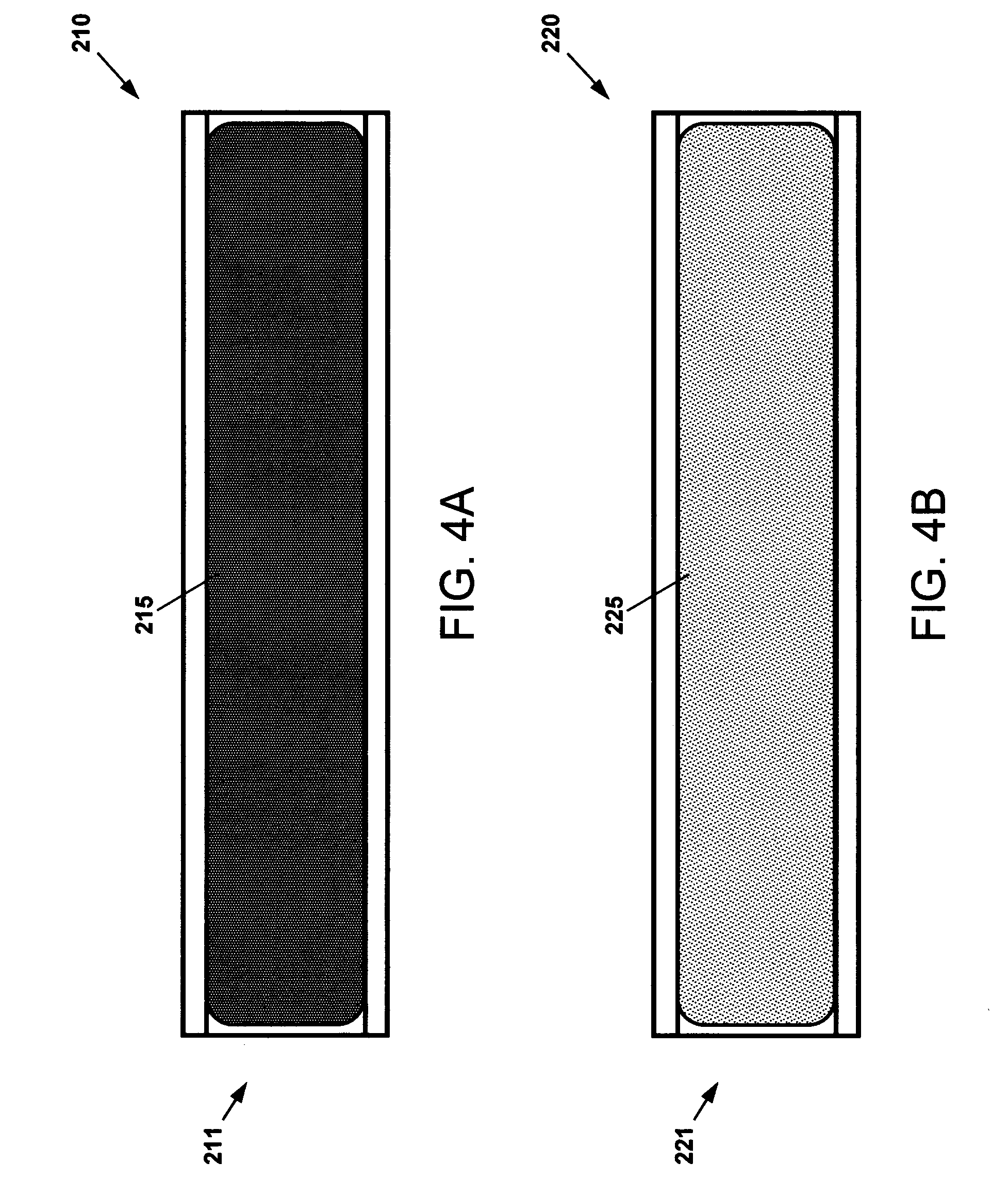

A composition for use in the delivery of a first active agent and a second active agent, the first active agent being sequentially deliverable after the second active agent, the composition comprising hollow mineral microtubules, each of the hollow mineral microtubules having a length, and opposing ends; and including a cylindrical wall, and a hollow lumen; and a central region, an intermediate region, and an outer region along the length; and within the microtubules, the first active agent disposed within the lumen in the central region of the microtubules, and the second active agent disposed within the lumen in the intermediate region of the microtubules. The composition may also be provided for the delivery of three or more active agents in sequence. There is further provided methods for making the compositions of the present invention.

Owner:NATURALNANO RES

Polymeric coatings including nanoparticle filler

InactiveUS20080248201A1Reduce load levelIncreases potential for homogeneous dispersionPretreated surfacesSpecial surfacesHalloysiteNanoparticle

Disclosed is a novel polymeric composite coating including a nanoparticle filler, where the filler may be suitable to alter one or more characteristics of the coating. More particularly, one embodiment of the present invention provides a novel halloysite nanoparticle filler which has the general configuration of a cylinder or a rolled scroll-like shape, and a polymer protective coating containing the halloysite nanoparticle or equivalent nanotubular filler.

Owner:NATURALNANO RES

High-strength high-thermal-insulation silica aerogel and preparation method thereof

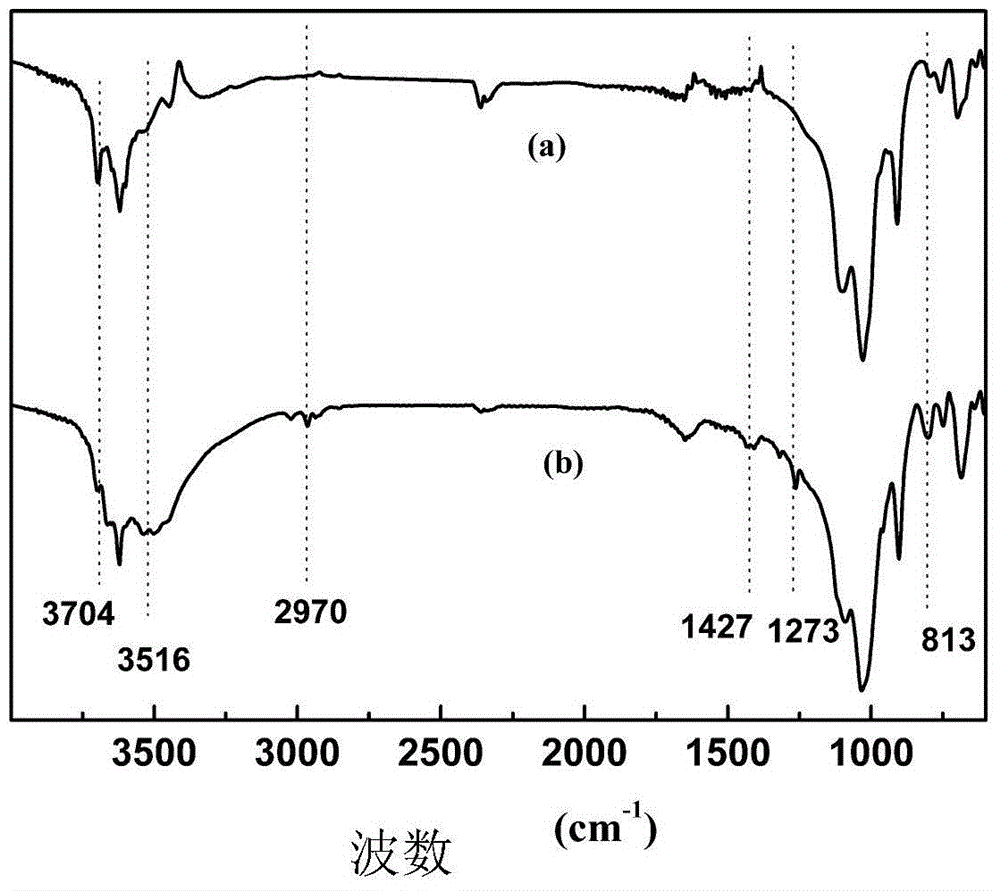

The invention discloses high-strength high-thermal-insulation silica aerogel and a preparation method thereof. The preparation method comprises the following steps: modifying halloysite with amino-terminated polysiloxane; adding ethyl orthosilicate, absolute ethyl alcohol, hydrochloric acid, dimethyl formamide and ammonium hydroxide to ensure a reaction and obtain gel; finally, carrying out carbon dioxide supercritical extraction to obtain the silica aerogel. As hollow natural clay fiber halloysite which is high in mechanical strength, low in thermal conductivity and high in thermal stability is taken as a reinforcing phase, the silica aerogel prepared according to the preparation method is relatively high in porosity, relatively low in density, excellent in mechanical property, favorable in heat-insulating property and relatively high in heat resistance.

Owner:TIANJIN CHENGJIAN UNIV

Polymeric adhesive including nanoparticle filler

InactiveUS20080249221A1Increase potential for homogeneous dispersionReduce load levelMaterial nanotechnologyNon-macromolecular adhesive additivesHalloysiteAdhesive

Disclosed is a novel polymeric nanoparticle adhesive composite including a nanoparticle filler and method for the production thereof. More particularly, the disclosure describes the use of nanoparticle fillers, including a novel halloysite nanoparticle filler which utilizes generally cylindrical or tubular nanoparticles (e.g. rolled scroll-like shape). The filler is effectively employed in a polymer nanoparticle adhesive composite, containing the halloysite nanoparticle or other equivalent naturally occurring nanotubular filler, in which the advantages of the nanoparticle filler are provided (e.g., reinforcement, flame retardant, etc.) while maintaining or improving mechanical performance of the adhesive composite (e.g., adhesive strength and tack)

Owner:NATURALNANO RES

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

Halloysite microtubule processes, structures, and compositions

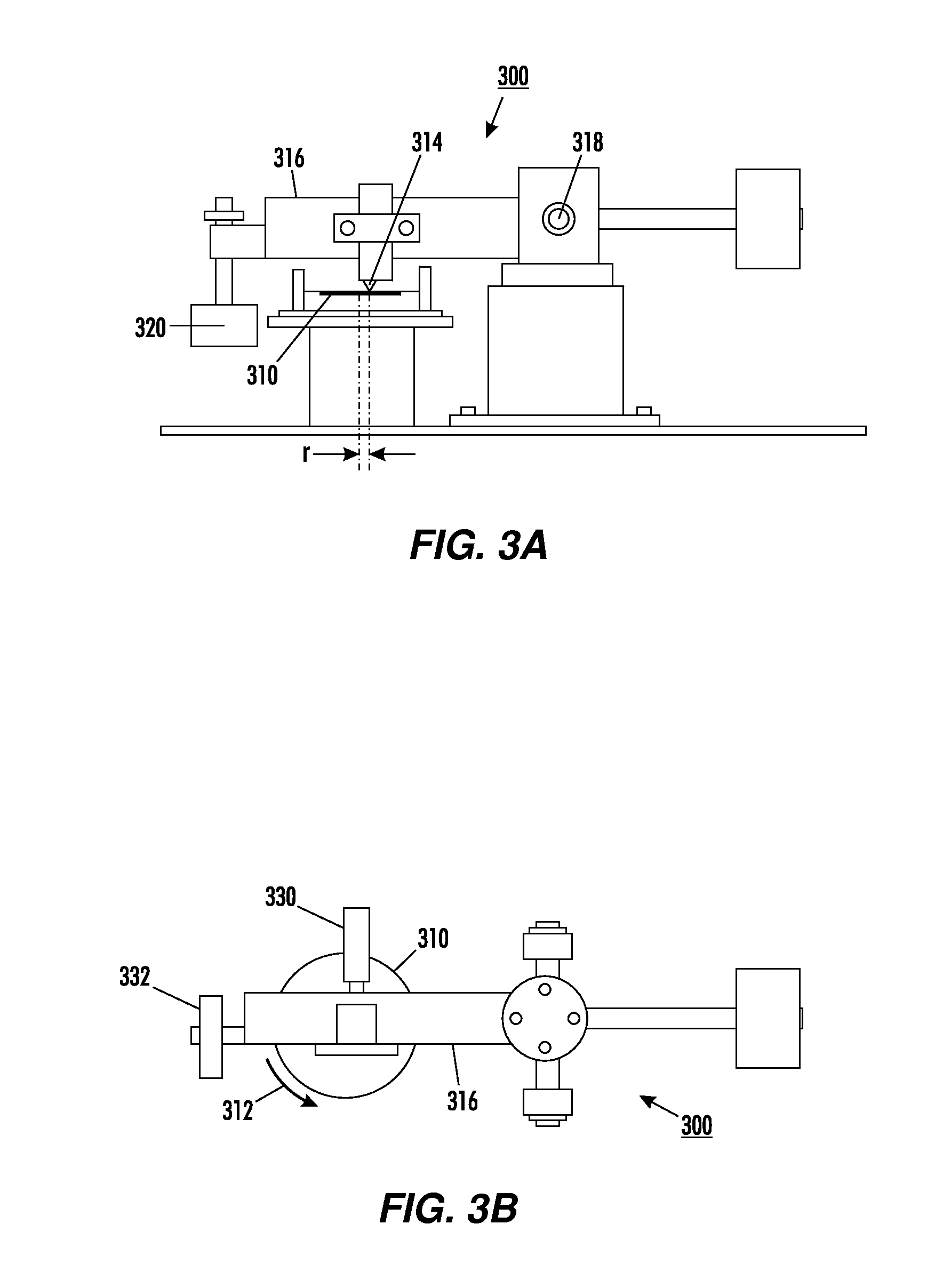

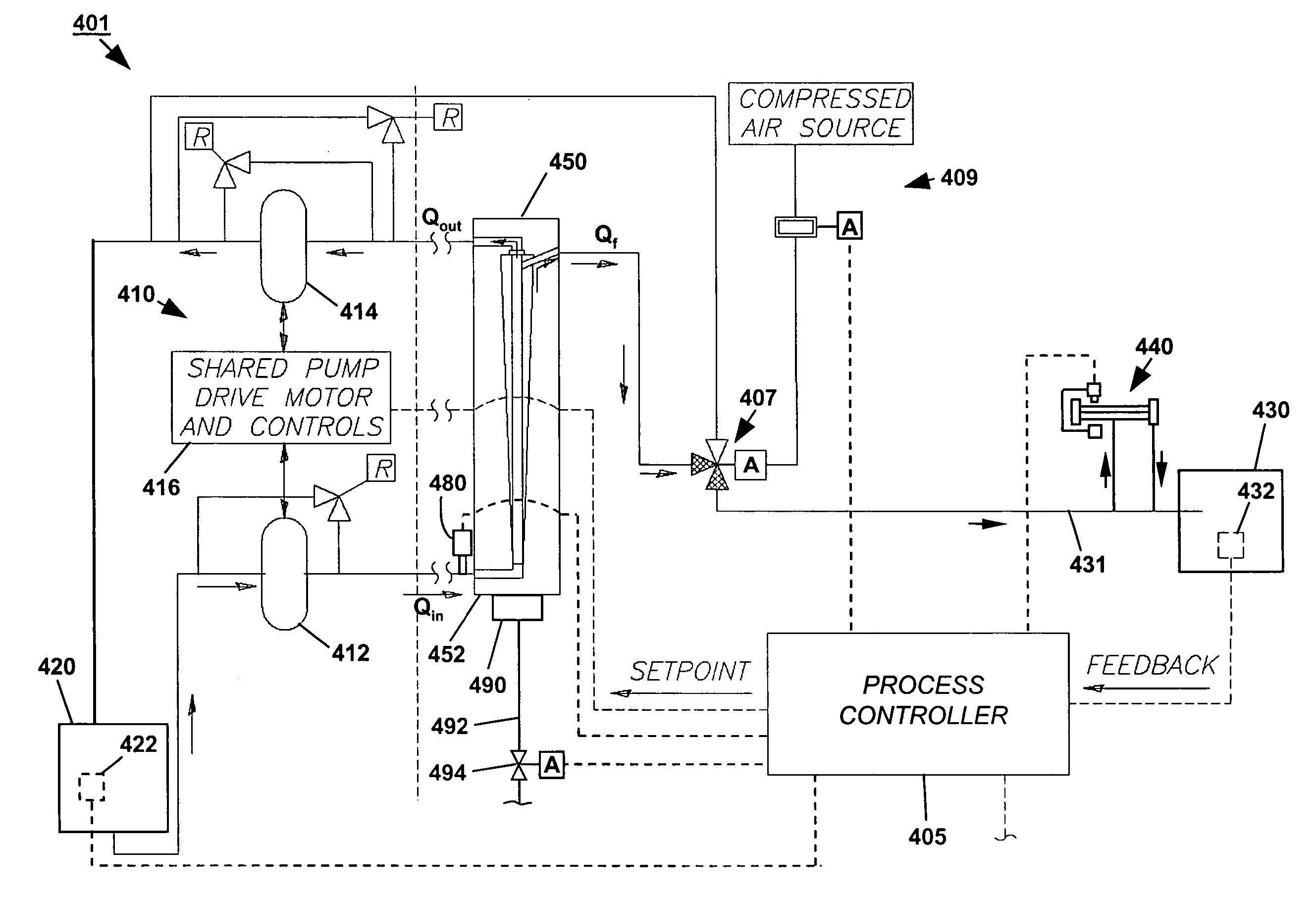

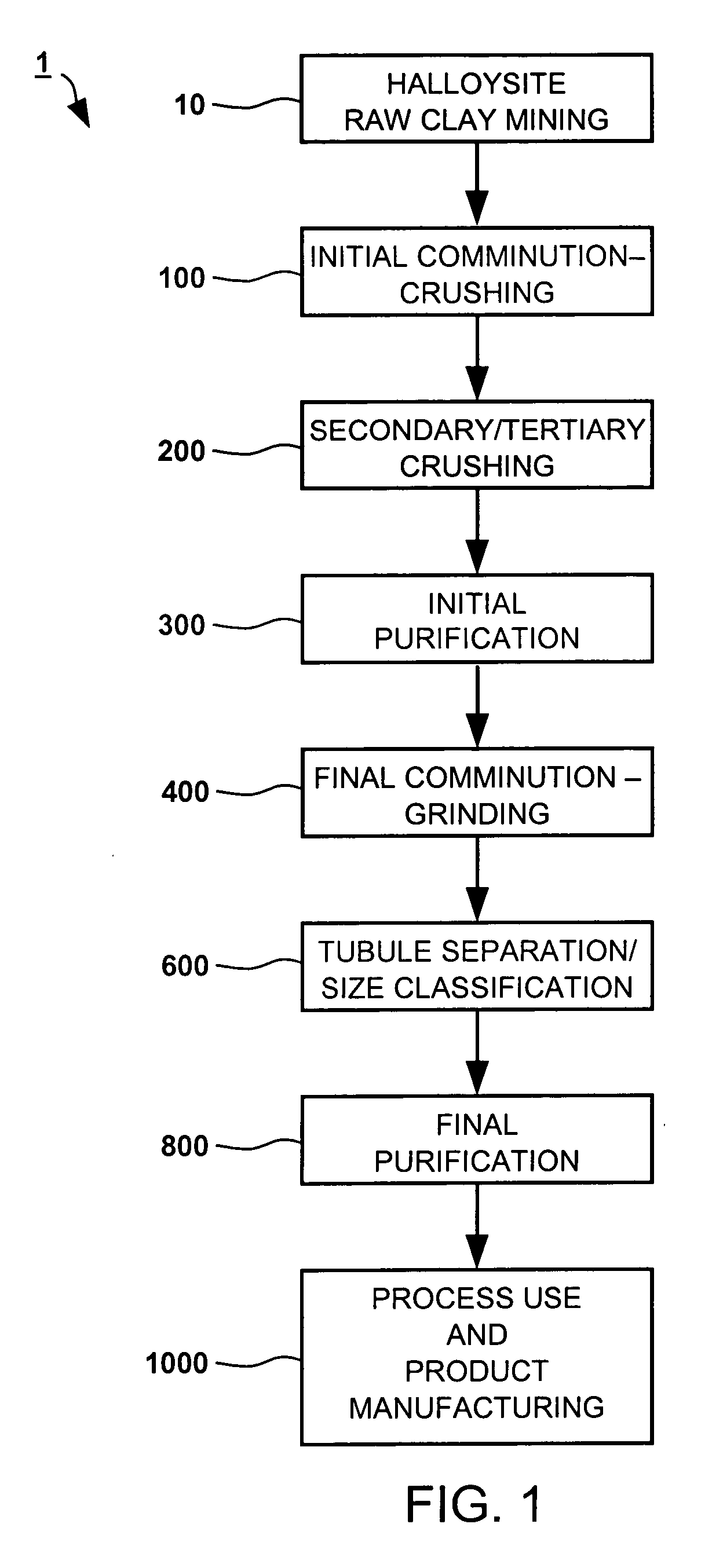

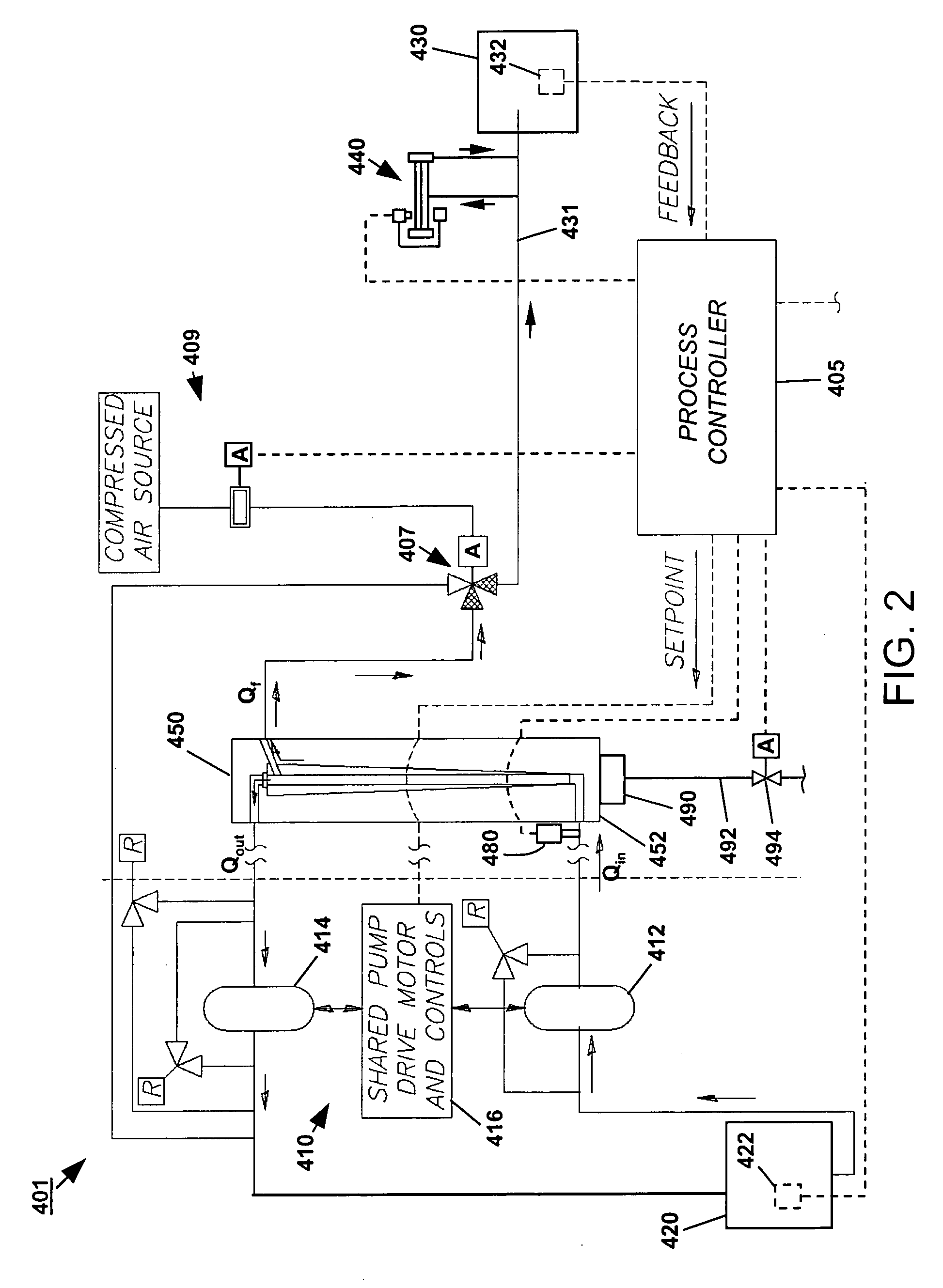

A processes for the separation and purification of microtubules of halloysite clay by separating an inlet stream of a liquid slurry of suspended clay particles flowing into a cross-flow filter into a decantate stream and a filtrate stream, the filtrate stream having a higher concentration of microtubular particles than the inlet stream. Also disclosed are subsequent preparations of novel structures and compositions of matter that include microtubules of halloysite clay.

Owner:NATURALNANO RES

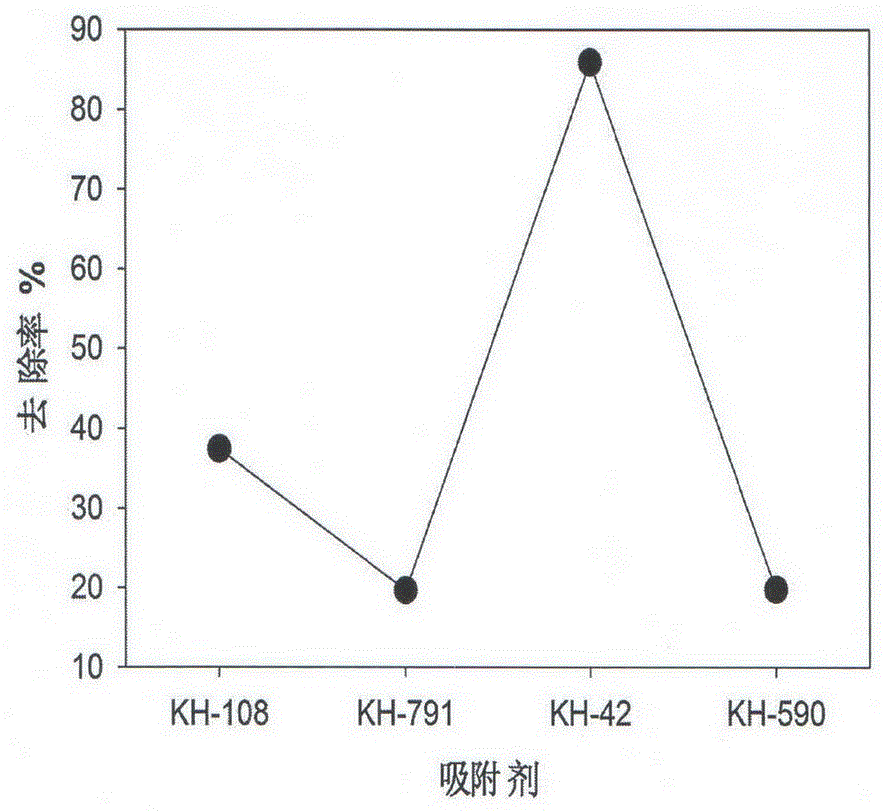

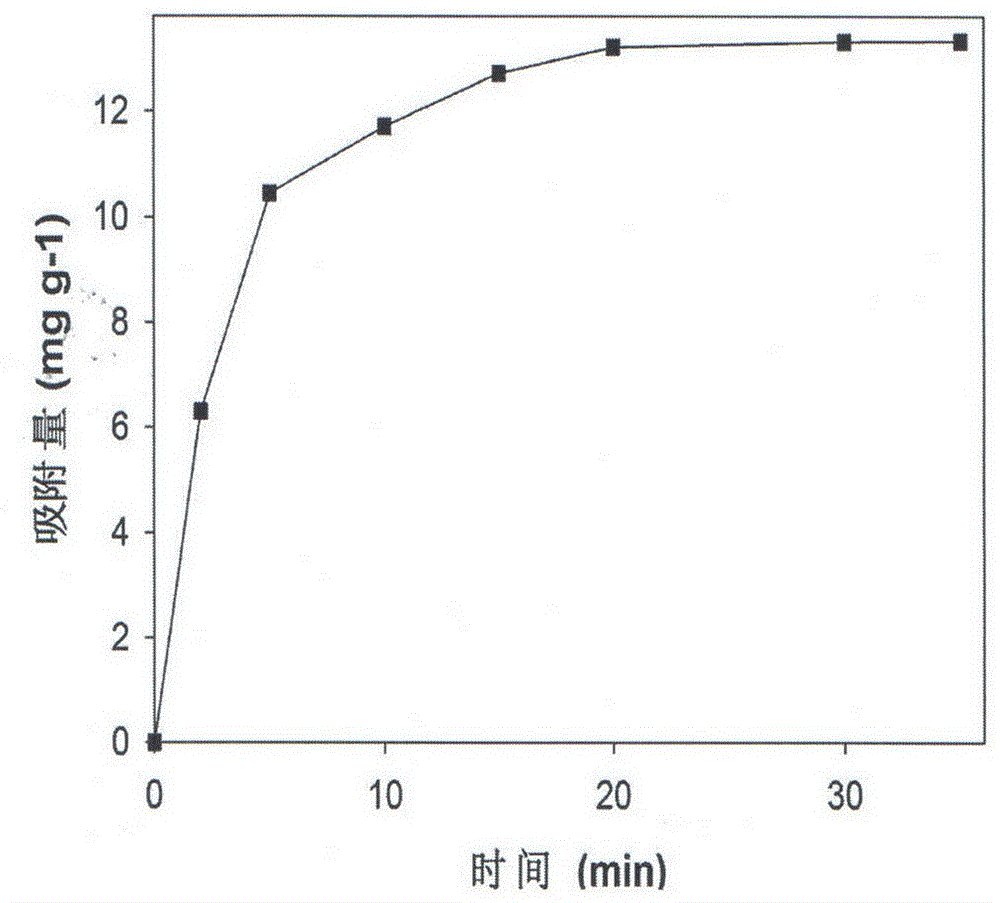

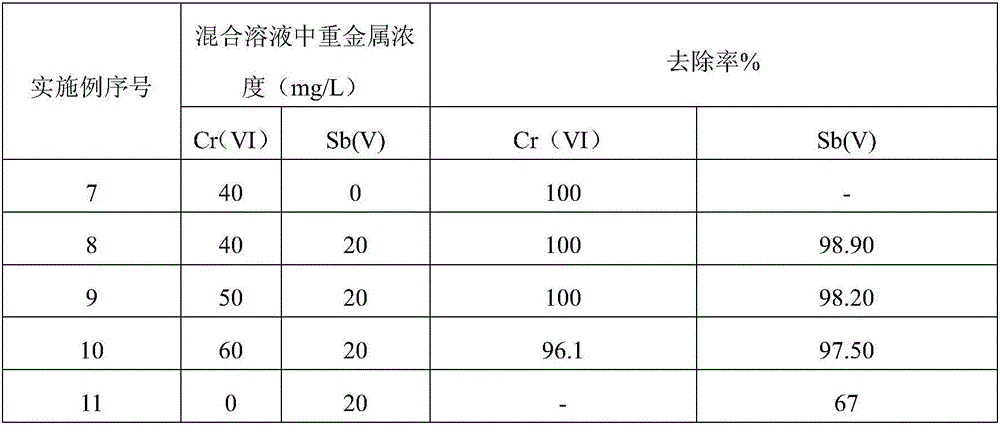

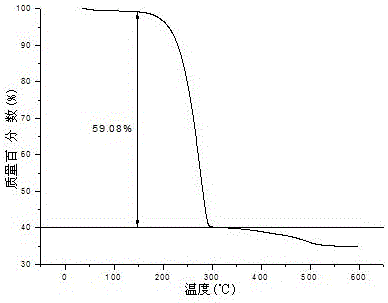

Preparation method and application of silane coupling agent modified magnetic halloysite material

InactiveCN106111067AImprove separation efficiencyEasy to separateOther chemical processesWater contaminantsHalloysiteSorbent

The invention belongs to the field of water treatment material preparation and in particular relates to a preparation method and application of a silane coupling agent modified magnetic halloysite material. The method is characterized by taking halloysite as a template and adhering Fe3O4 particles to the surface of a halloysite nanotube by an in-situ synthesis method; mixing a silane coupling agent with halloysite / Fe3O4 and grafting the silane coupling agent onto the surface of halloysite through reaction. The method has the beneficial effects that the raw materials are cheap and accessible; a functional group on the surface of the silane coupling agent modified magnetic halloysite material obtained by the method is bonded with a matrix via chemical bonds, so the material has strong bonding force; the material has high thermal stability, is convenient and fast to separate and recover, can be recycled multiple times, can serve as an adsorbent for eliminating heavy metal pollution of printing and dyeing wastewater and enables that the treated printing and dyeing wastewater can reach the national wastewater discharge standards.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

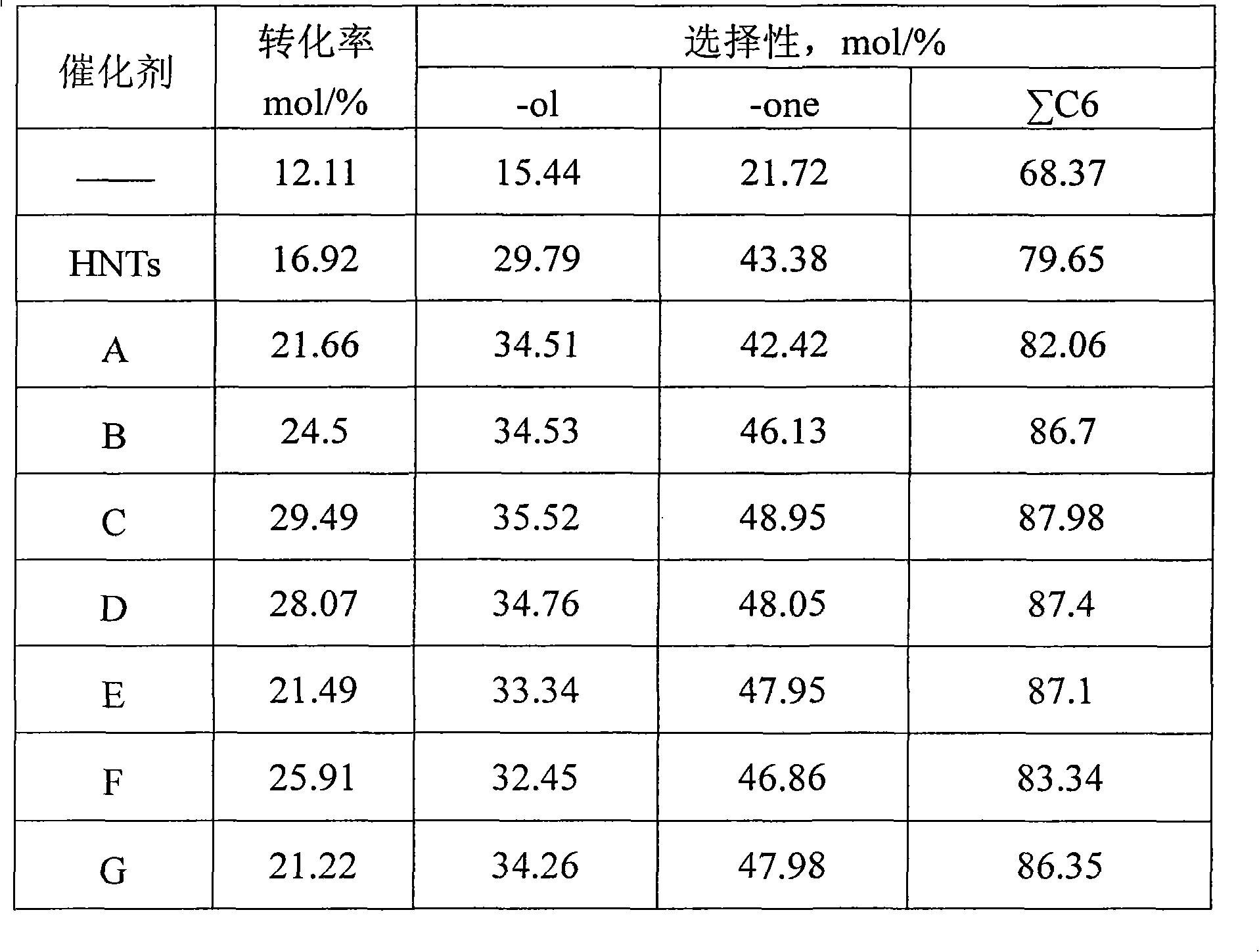

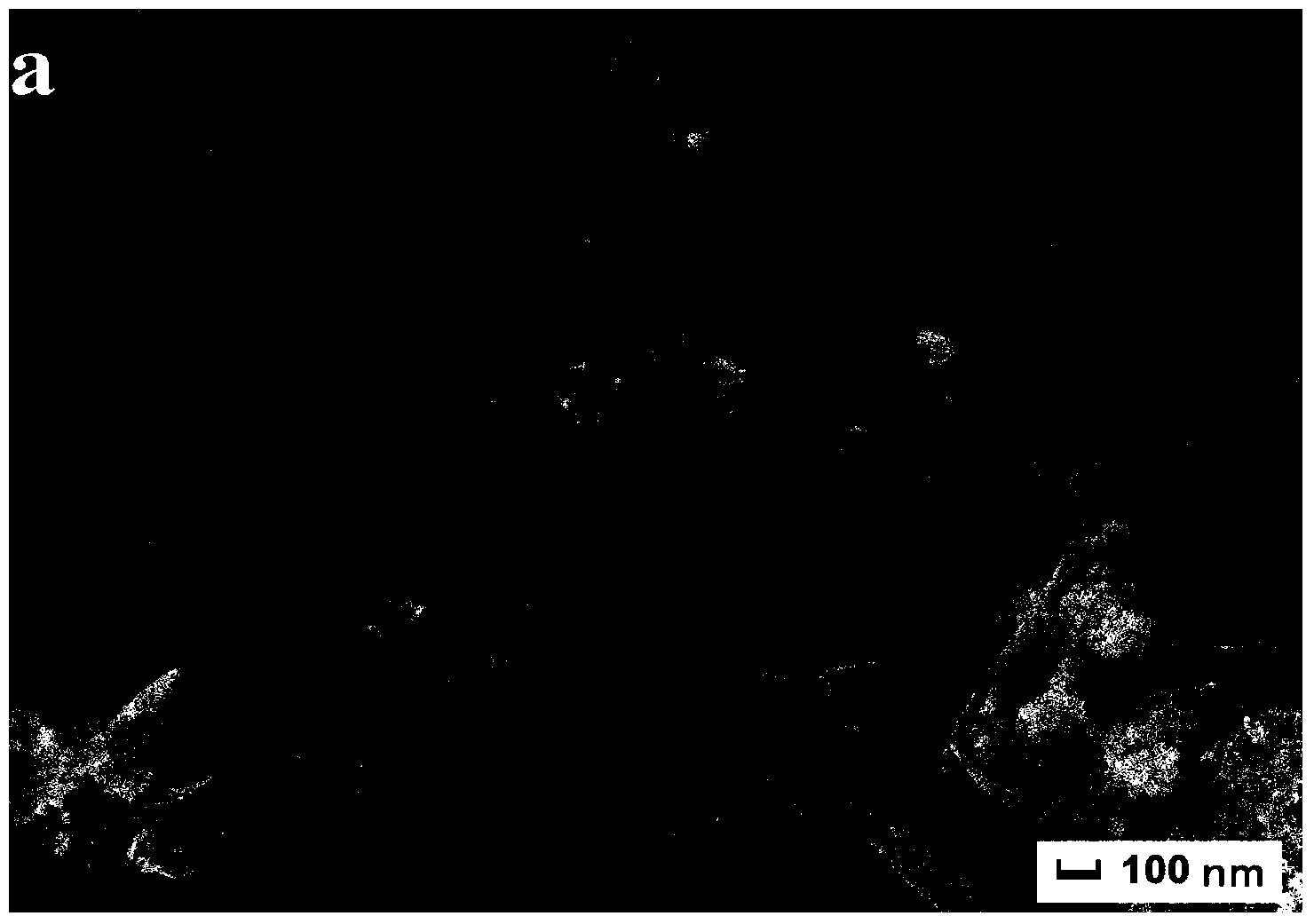

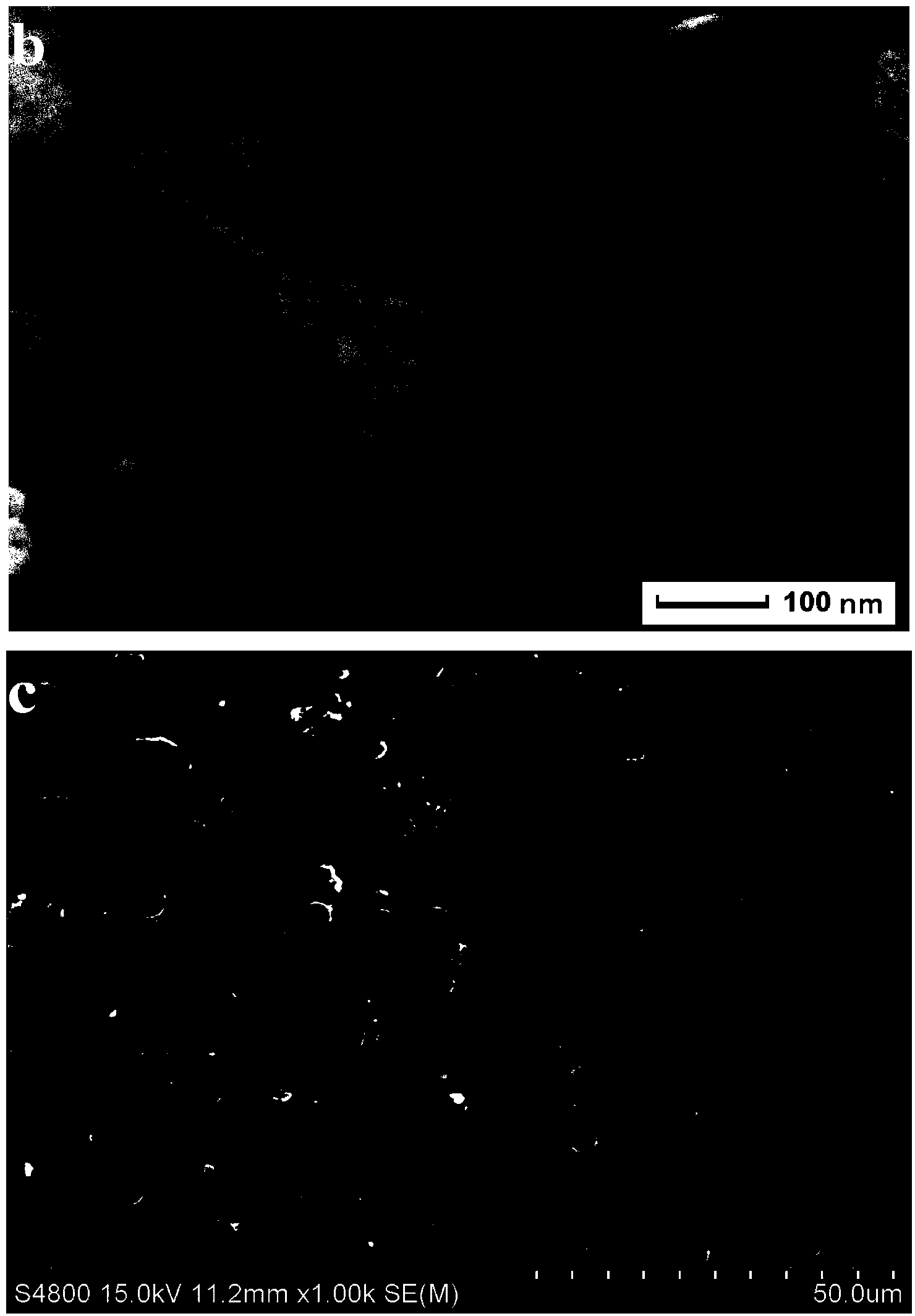

Preparation method and application of load type nano-gold catalyst

InactiveCN101829567AImprove loading efficiencyEasy to operatePreparation by oxidation reactionsCarbonyl compound preparation by oxidationHalloysiteGold particles

The invention discloses a preparation method and an application of a load type nano-gold catalyst. The preparation method comprises the following steps of: (1) adding 2.0g of halloysite nanotube carrier, 2.05 to 6.15mL of chlorogold acid solution with a concentration of 10g / L and 40 to 120mL of deionized water to a 250mL flask with three necks; (2) putting the flask into an oil bath with the temperature of 60 DEG C; adjusting the pH of the solution to 8 to 12 by using 4.0M ammonia water; then carrying out stirring reflux at 95 DEG C-105 DEG C for 1 hour; filtering; rinsing for 5 minutes by using 10 to 20mL of 4.0M ammonia water; washing twice with 15 to 20mL of hot water; drying for 1 to 2 hours at 100 DEG C; and finally roasting for 3 to 4 hours in air at 300 DEG C to obtain the load type nano-gold catalyst. The invention has the advantages of simple and convenient preparation method, uniformly dispersed gold particles and high loading efficiency. The catalyst provided by the invention can be used for cyclohexene oxidation of cyclonene and cyclohexenol, with the advantages of mild reaction condition, good activity and selectivity and less catalyst utilization quantity.

Owner:ZHEJIANG UNIV

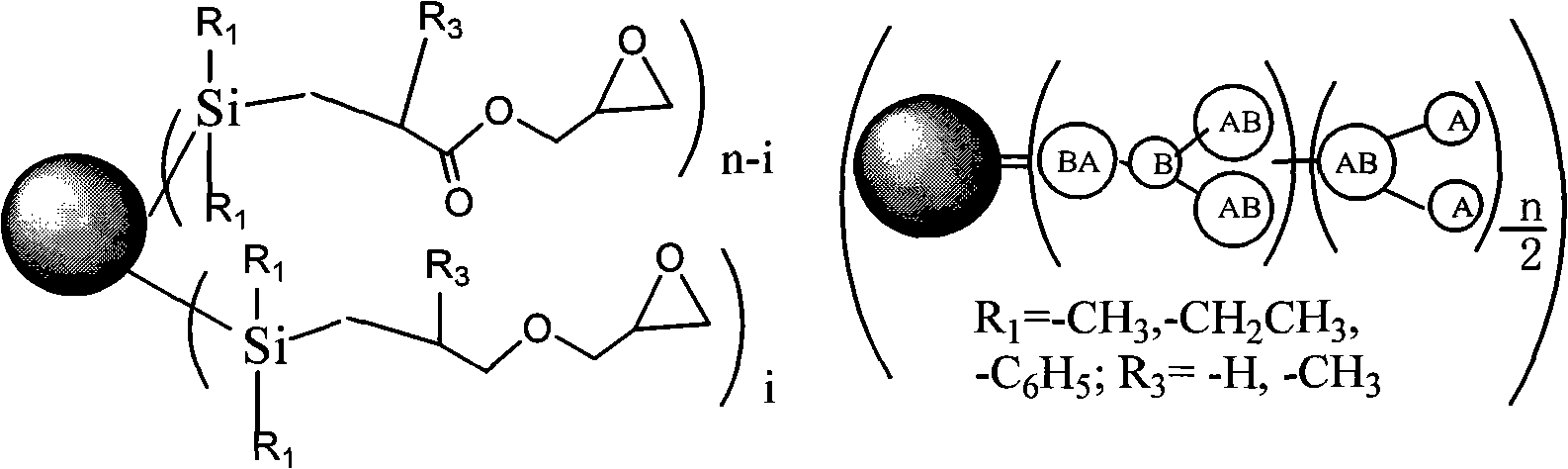

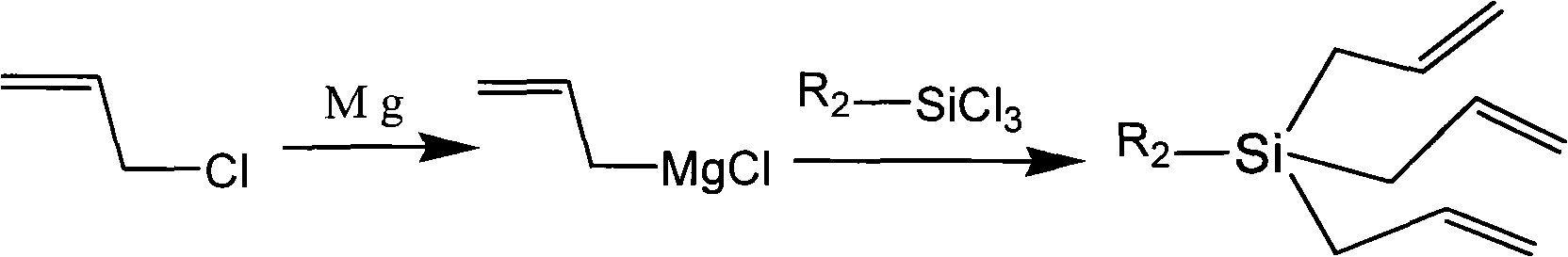

Silicon framework hyperbranched epoxy resin and preparation method thereof

ActiveCN101880374ALow viscosityLow heat resistanceEpoxy resin adhesivesEpoxy resin coatingsHalloysiteEpoxy

The invention discloses a silicon framework hyperbranched epoxy resin and a preparation method thereof. Firstly, compound A containing two moles of silicon-hydrogen bond, compound B containing three moles of double bond and self-made halloysite supported platinum catalyst are uniformly mixed, and are stirred under the temperature of 30DEG C to 100DEG C to react for 5 to 10 hours, so that the double bond can fully reacts, and thereby hyperbranched organic silicon resin, the end group of which is the silicon-hydrogen bond, is obtained; then, compound C containing a epoxy group is added in the hyperbranched organic silicon resin, and is stirred under the temperature of 60DEG C to 120DEG C to react for 10 to 15 hours until the silicon-hydrogen bond fully reacts, hydroquinone as polymerization inhibitor is then added, and after vacuumization, the silicon framework hyperbranched epoxy resin is obtained. The method has the advantages of simple technique and easily obtained materials, and does need organic solvent and processes such as washing, thus avoiding environment pollution caused by conventional organic solvent and washing for preparing organic silicon resin, and the obtained product is expected to be applied to fields such as the strengthening and toughening of epoxy resin and solventless, low-volatility epoxy resin coating.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Halloysite composite flame retardant masterbatch

Owner:SHENZHEN KEJU NEW MATERIAL

Preparation method for novel magnetic chitosan composite microsphere antibiotic adsorbent

InactiveCN103801267AEasy to makeImprove thermal stabilityOther chemical processesAlkali metal oxides/hydroxidesHalloysitePolymer science

Owner:JIANGSU UNIV

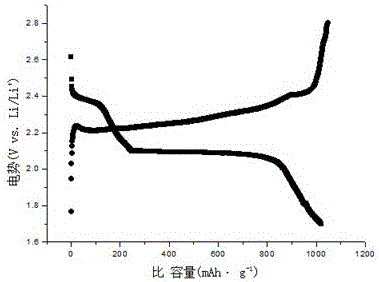

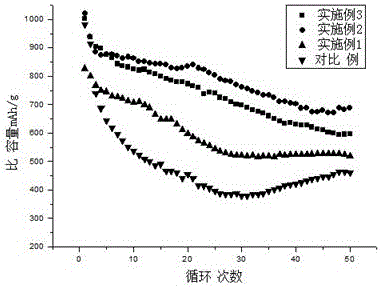

Halloysite-based positive electrode material of lithium-sulfur battery and preparation method for positive electrode material

ActiveCN105932235AIncrease inner diameterImprove fill rateMaterial nanotechnologyCell electrodesAcid etchingHalloysite

The invention relates to a positive electrode material of a lithium-sulfur battery and a preparation method for the positive electrode material, wherein the positive electrode material takes halloysite as a sulfur carrier; the preparation method comprises the steps of enlarging the inner diameter of the tube cavity of the halloysite by acid etching; then filling the tube cavity of the halloysite with sulfur by a liquid phase chemical deposition method and a thermal processing two-step method to form a halloysite / sulfur composite material; and then preparing and obtaining the halloysite-based lithium-sulfur battery positive plate. The halloysite is large in specific surface area, high in adsorption capacity and unique in the micropore structure, so that polysulfide generated in the charging-discharging process of the lithium-sulfur battery can be limited in the tube cavity of the halloysite, the volume expansion of sulfur in the charging-discharging process is restrained, and the capacity and the cycling stability of the battery are greatly improved; in addition, the preparation process is simple; and in addition, the halloysite nanotube is a natural environment-friendly material, low in cost and easily available, so that the industrial production of the lithium-sulfur battery can be realized conveniently.

Owner:BEIJING UNIV OF CHEM TECH

Polymeric composite including nanoparticle filler

InactiveUS7888419B2Improved and equivalent mechanical performance of compositeHalloysiteNanoparticle

Disclosed is a novel polymeric composite including a nanoparticle filler and method for the production thereof. More particularly, the present invention provides a novel halloysite nanoparticle filler which has the generally cylindrical or tubular (e.g. rolled scroll-like shape), in which the mean outer diameter of the filler particle is typically less than about 500 nm. The filler is effectively employed in a polymer composite in which the advantages of the tubular nanoparticle filler are provided (e.g., reinforcement, flame retardant, chemical agent elution, etc.) with improved or equivalent mechanical performance of the composite (e.g., strength and ductility).

Owner:NATURALNANO CORP

Chinese medicine external-use preparation medicament for treating surgery wound infection and method for producing the same

InactiveCN101543565ALess medicinal propertiesLess varietyHeavy metal active ingredientsHydroxy compound active ingredientsHalloysiteSide effect

A Chinese medicine external-use preparation medicament for treating surgery wound infection and a method for producing the same. The medicament has the raw materials of pangolin scales, dragon's blood, notoginseng, red halloysite, frank incense, myrrh, artificial mercuric sulphide, black catechu, pearl powder, drgon's bones, calomelas, borneol and gingelly oil. The medicament is mild in temperament, has no toxicity and side effect and is easy for dressing change. The prescription activates blood and resolves stasis, regenerates tissue, tonifies qi, benefits blood, takes temporary solution and effects a permanent cure. The producing method need simple facilities, saves energy and water, has short production period, low cost and no pollution and solves the adverse reaction in the surgery usual wound infection treatment due to frequently externally changing applied medicament and frequently removing necrosis infection tissue.

Owner:卜继武

Titanium dioxide nano antibacterial agent taking halloysite as carrier and preparation method thereof

InactiveCN101983569ASimple production processReduce manufacturing costBiocidePhysical/chemical process catalystsHalloysiteAmmonium hydroxide

The invention provides a titanium dioxide antibacterial agent taking hallyoysite as carrier and a preparation method thereof. The preparation method includes the following steps: halloysite is activated; titanium tetrachloride solution is prepared; the activated hylloysite is mixed with the titanium tetrachloride solution, thus obtaining suspension; ammonia solution is slowly dropwise added into the suspension until pH value of system is stabilized to be 6-7, and stirring is carried out for 30-60min; and reaction products are filtered, washed, dried and calcined, thus obtaining the titanium dioxide nano antibacterial agent taking halloysite as carrier. The preparation method is simple, and preparation cost is low, thus being applicable to mass production. The prepared product has good stability, firm antibacterial agent load, high photochemical catalysis efficiency, long service life, high antibacterial efficiency and broad spectrum, has good killing and inhibiting effects on various bacteria and moulds and produces no pollution to the environment.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

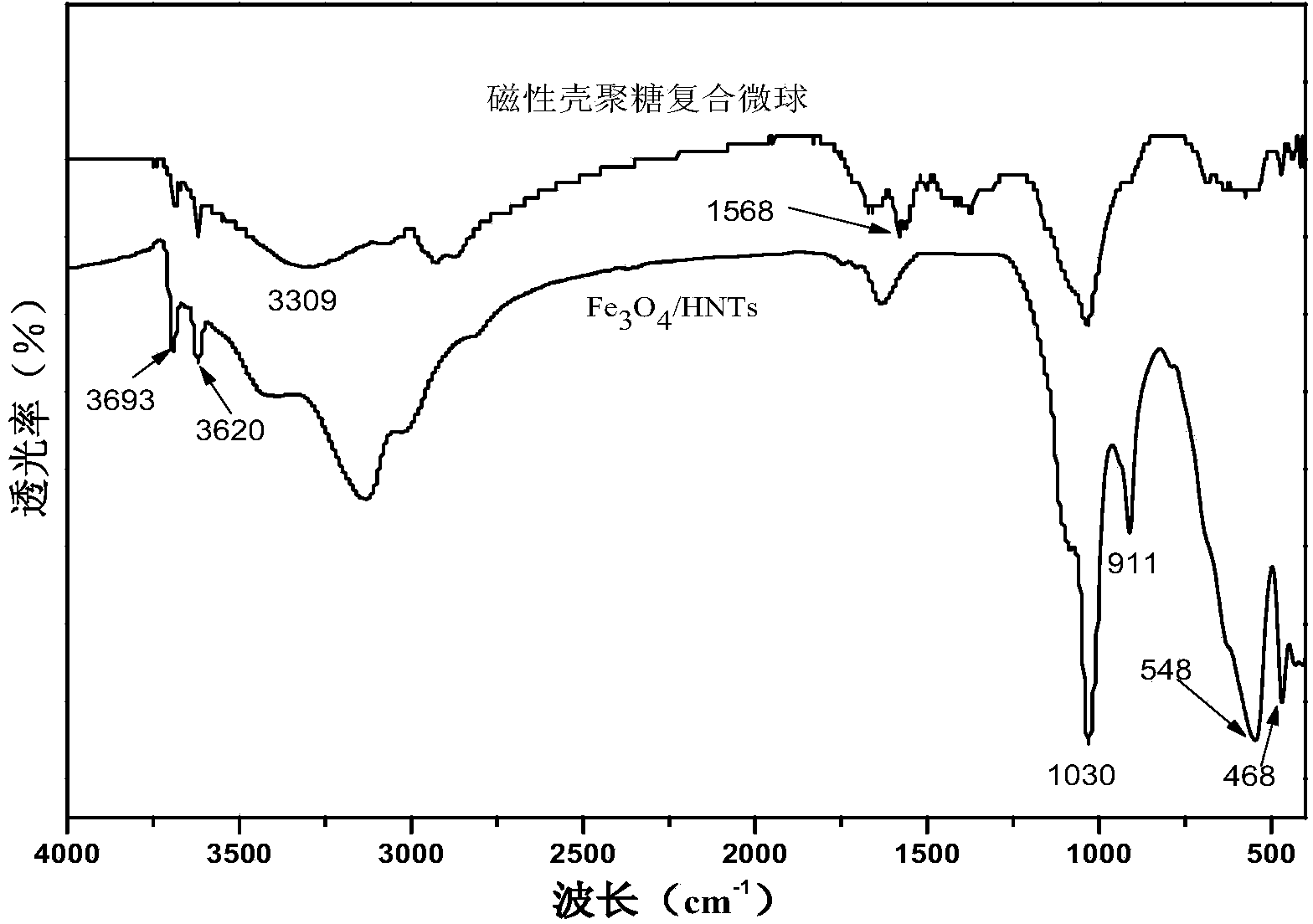

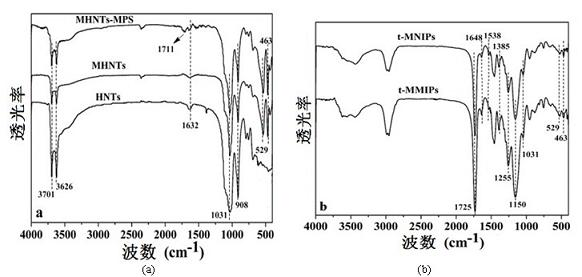

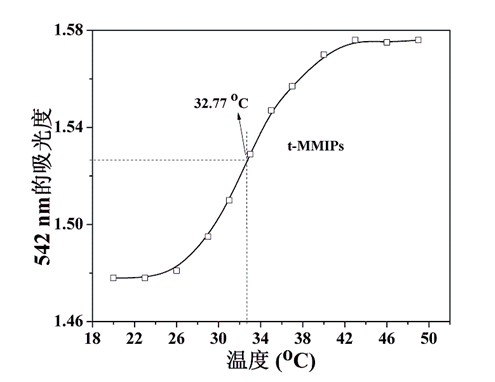

Preparation method of temperature sensitive adsorbent of halloysite magnetic composite material surface blotting

InactiveCN102580696AHigh mechanical strengthImprove adsorption capacityOther chemical processesComponent separationMolecular identificationHalloysite

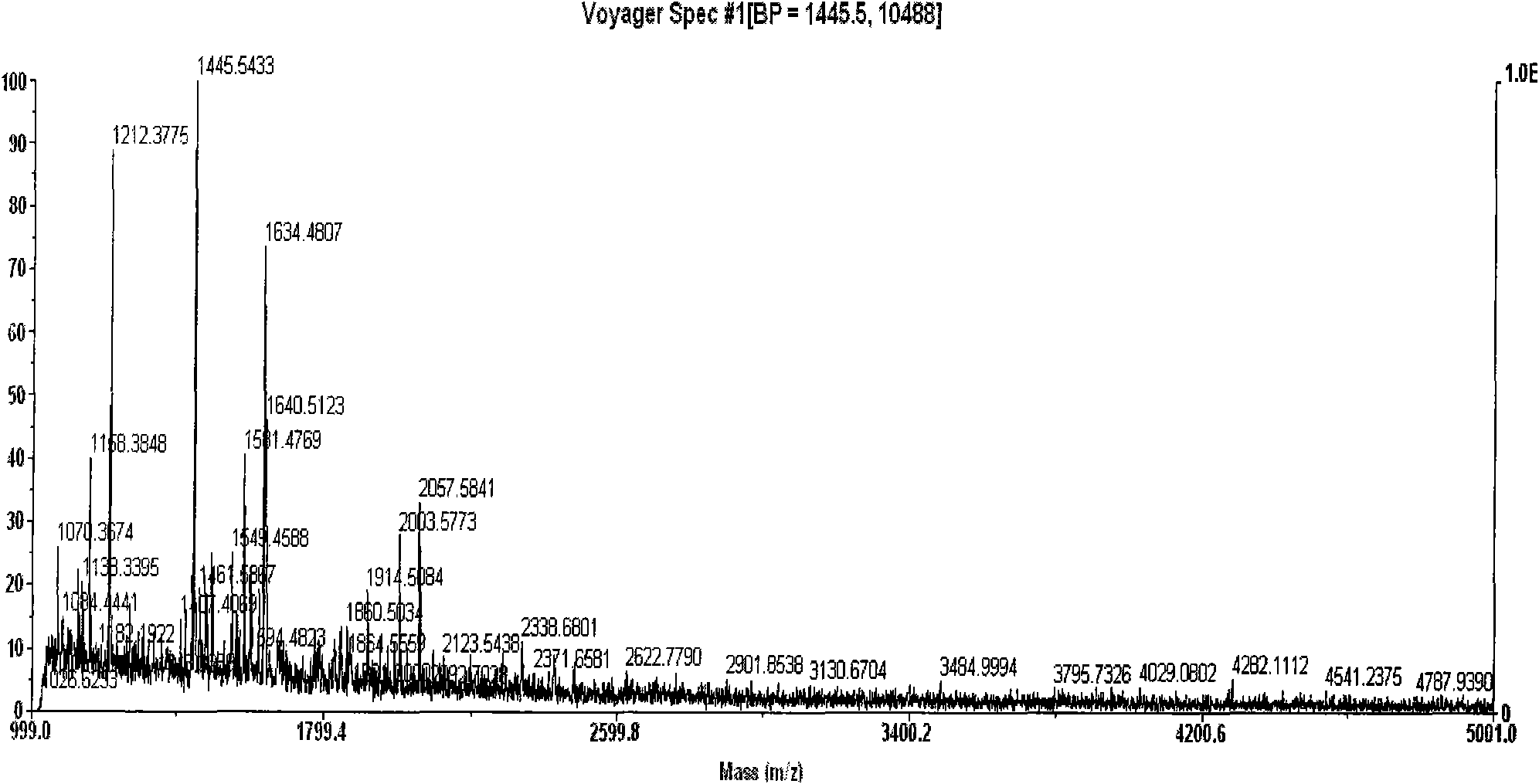

The invention discloses a preparation method of a temperature sensitive adsorbent of halloysite magnetic composite material surface blotting, belonging to the technical field of environment functional material preparation. The preparation method comprises the following steps: preparing a ferroferric oxide / halloysite nanotube (Fe3O4 / HNTs) magnetic composite material through a simple and effective solvent thermosynthesis method; and then, performing ethylene modification on the magnetic composite material; and preparing the temperature sensitive adsorbent of halloysite nanotube magnetic composite material surface blotting through a radical polymerization process, and utilizing the adsorbent in selective identification and separation of 2,4,5-trichlorophenol in aqueous solution. The prepared temperature sensitive blotting adsorbent has excellent thermal and magnetic stability, sensitive magnetic and thermal induction effect, high adsorption capacity, excellent reversible adsorption / release function with temperature and obvious TCP molecular identification performance.

Owner:JIANGSU UNIV

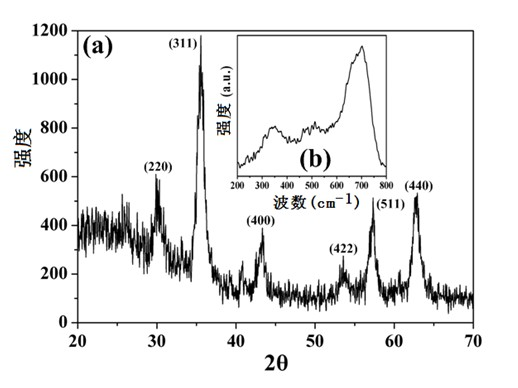

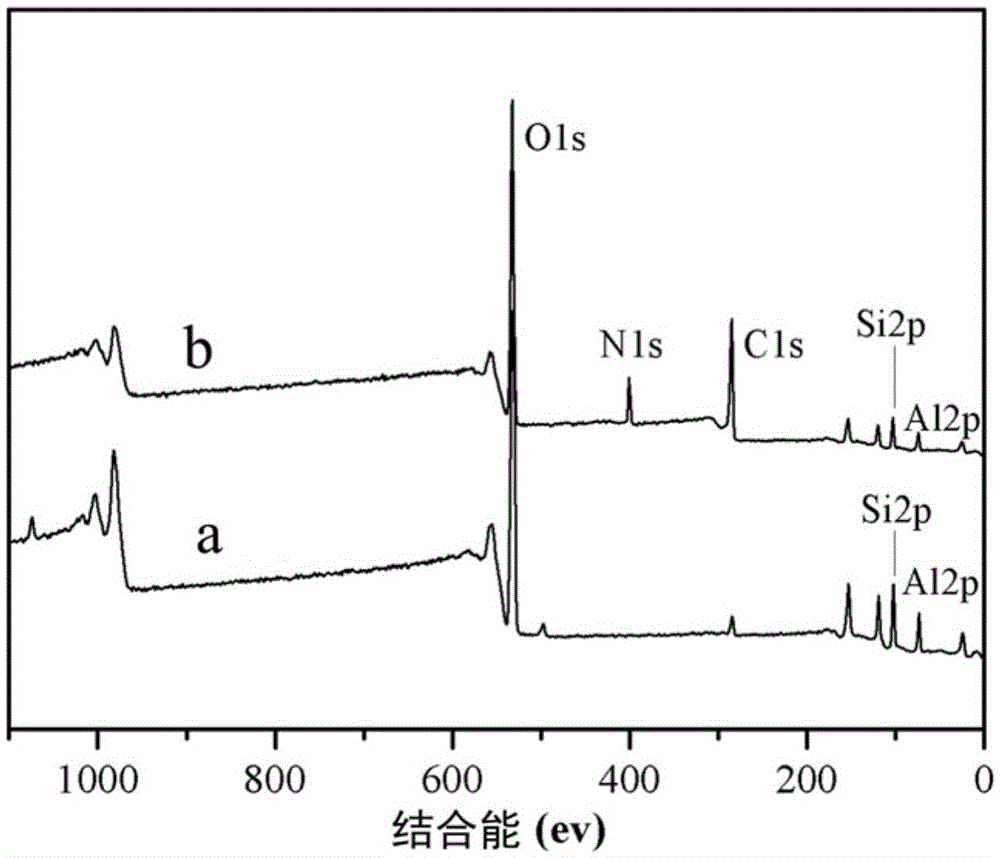

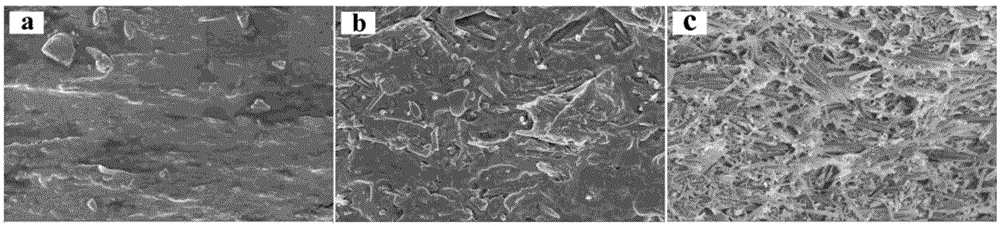

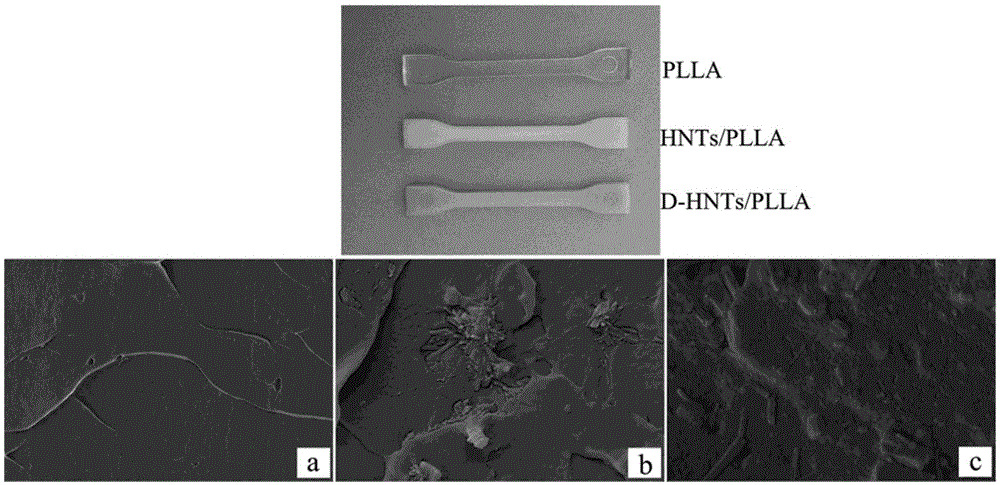

Polydopamine-modified halloysite nanotube / polylactic acid composite material and preparation and application thereof

ActiveCN105566872ASolving Dispersion ProblemsSolve interface compatibility issuesMonocomponent polyesters artificial filamentArtifical filament manufactureHydroxyapatite crystalNanotube

The present invention discloses a polydopamine-modified halloysite nanotube / polylactic acid composite material and preparation and application thereof. The polydopamine-modified halloysite nanotube / polylactic acid composite material comprises 0.05 to 60% by mass of polydopamine-modified halloysite nanotubes and 40 to 99.95% by mass of polylactic acid. By surface modification of the halloysite nanotubes, dispersion of the halloysite nanotubes in a polylactic acid matrix and interface compatibility of the halloysite nanotubes and the polylactic acid matrix can be solved, and the polylactic acid matrix can be effectively enhanced by the halloysite nanotubes; excellent cell affinity and osteogenic activity can be given to the polydopamine-modified halloysite nanotube / polylactic acid composite material, and more significantly, by the use of biological mineralization of a polydopamine layer on the surface of the halloysite nanotubes for formation of hydroxyapatite crystals, eventually good osteo inductivity can be given to the polydopamine-modified halloysite nanotube / polylactic acid composite material. The polydopamine-modified halloysite nanotube / polylactic acid composite material is simple in preparation method, mild in reaction conditions, low in price, and suitable for industrial production.

Owner:JINAN UNIVERSITY

Halloysite nano tube silver-carried monomer antibacterial agent and preparation method thereof

The invention belongs to the technical field of inorganic nonmetallic materials, and particularly relates to a halloysite nano tube silver-carried monomer antibacterial agent and a preparation method thereof. Silane coupling agent modified halloysite nano tubes are used as carriers in the antibacterial agent, and silver monomers are carried on the carriers. The antibacterial agent has the advantages of easily obtained raw materials, low cost, simple operation, wide condition, low energy consumption, environmental friendliness, wide application range and strong antibacterial activity.

Owner:ZHENGZHOU UNIV

Catalyst for preparing yellow phosphorus through catalytic decomposition of phosphine gas and preparation method thereof

InactiveCN102935371ALow costReduced activityPhosphorus compoundsMetal/metal-oxides/metal-hydroxide catalystsHalloysiteNickel salt

The invention discloses a catalyst for preparing yellow phosphorus through catalytic decomposition of phosphine gas and a preparation method thereof, and belongs to the technical fields of the discharge control technique for industrial tail gas pollutants and phosphine tail gas resource comprehensive utilization. The catalyst is characterized in that the catalyst takes fe-ni alloy containing M element or free of the M element (the M is boron or phosphorus) as an active component, takes a natural halloysite nanotube as a carrier, and has the advantages of being low in cost, high in activity, good in selectivity and the like. The preparation method includes taking soluble ferric salt and nickel salt, the natural halloysite nanotube, the compound containing the M element or free of the M element as the raw materials; and generating active components which are evenly loaded on the carrier in a nano particle form after processes of impregnation, evaporation, drying, calcinations, hydrogen reduction and the like. The preparation method is simple in process, low in cost, mild in conditions and free of pollution. According to the catalyst and the method, phosphine gas can be subjected to catalytic decomposition with a high efficiency and a low cost, and remarkable environmental and economical benefits are provided.

Owner:NANKAI UNIV

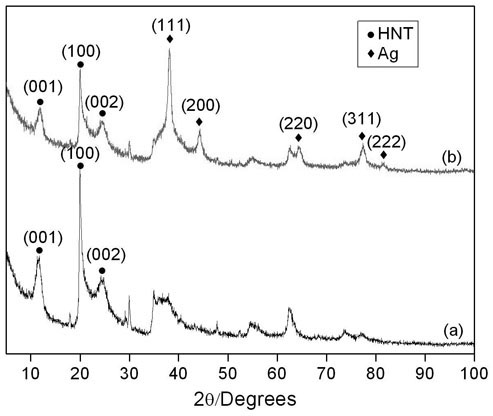

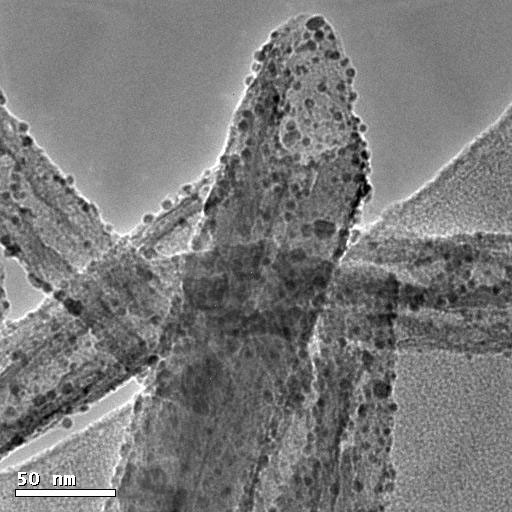

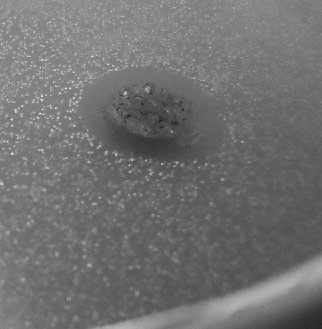

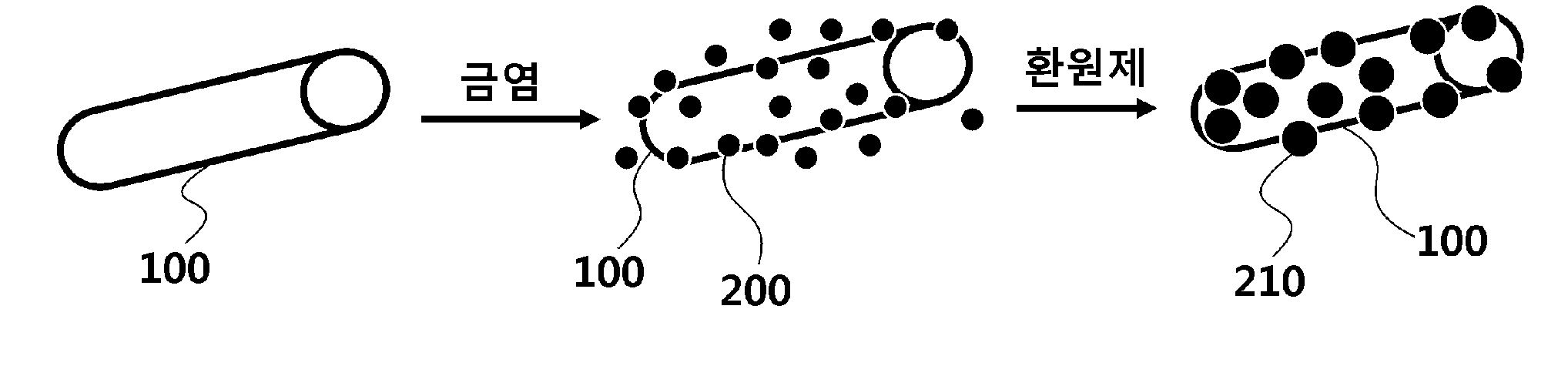

Gold nanoparticle-halloysite nanotube and method of forming the same

InactiveUS20090092836A1Wider surface areaLiquid surface applicatorsGlass/slag layered productsHalloysiteNanoparticle

A gold nanoparticle-halloysite nanotube, on a surface of which a gold nanoparticle is formed, and a method for forming the same are disclosed. In order to form the gold nanoparticle on a surface of the halloysite nanotube, a gold salt is added to an agitated suspension solution. By the gold salt, a gold ion is formed on the surface of the halloysite nanotube. If the reducing agent is added to the halloysite nanotube on which the gold ion is formed, the gold ion is reduced into the gold nanoparticles. The formed gold nanoparticle has the very small size, and distributed on the surface of the halloysite nanotube. Accordingly, without the separate protective agent or the surface reformation, the gold nanoparticle may be easily formed.

Owner:GWANGJU INST OF SCI & TECH

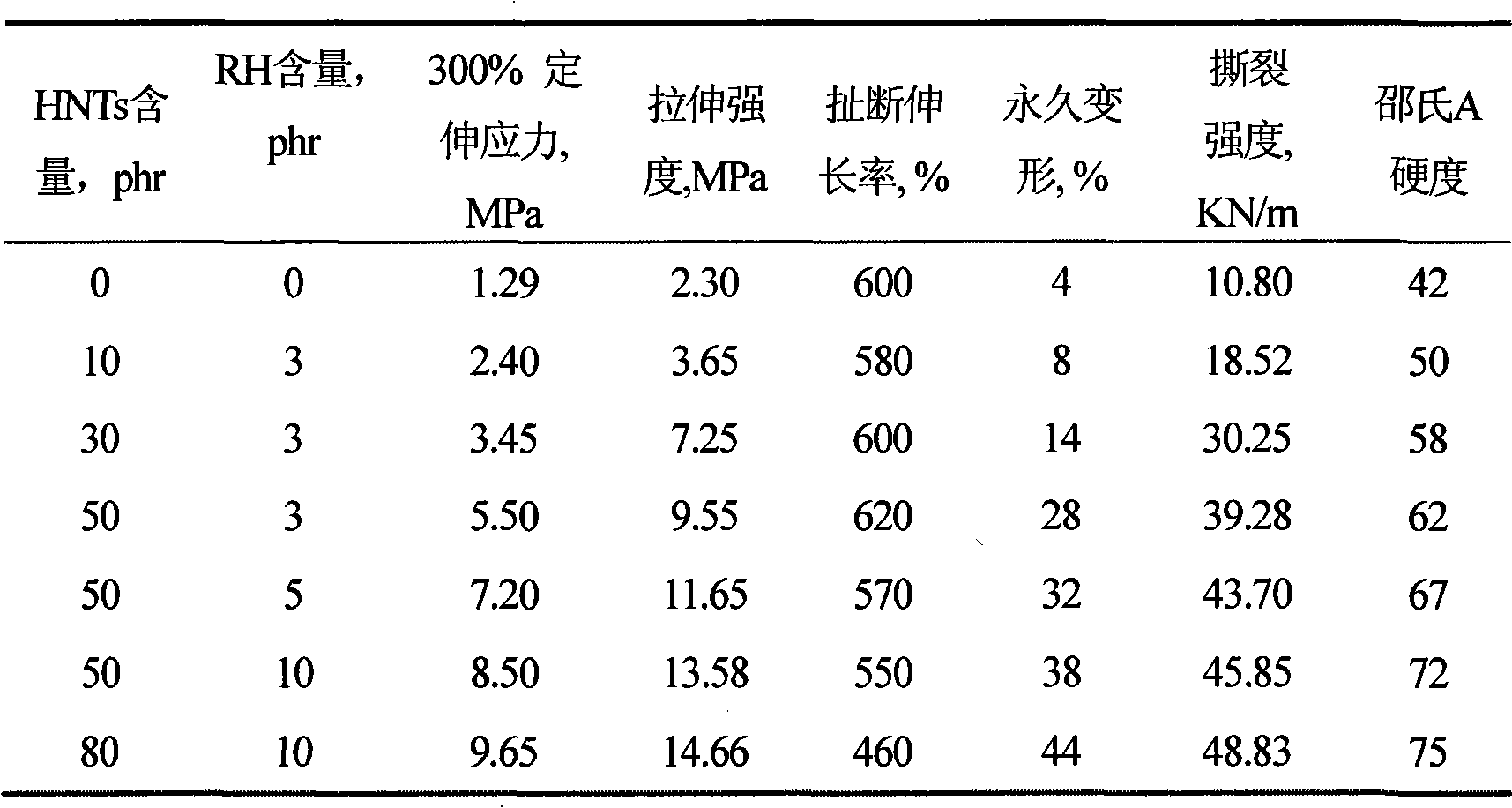

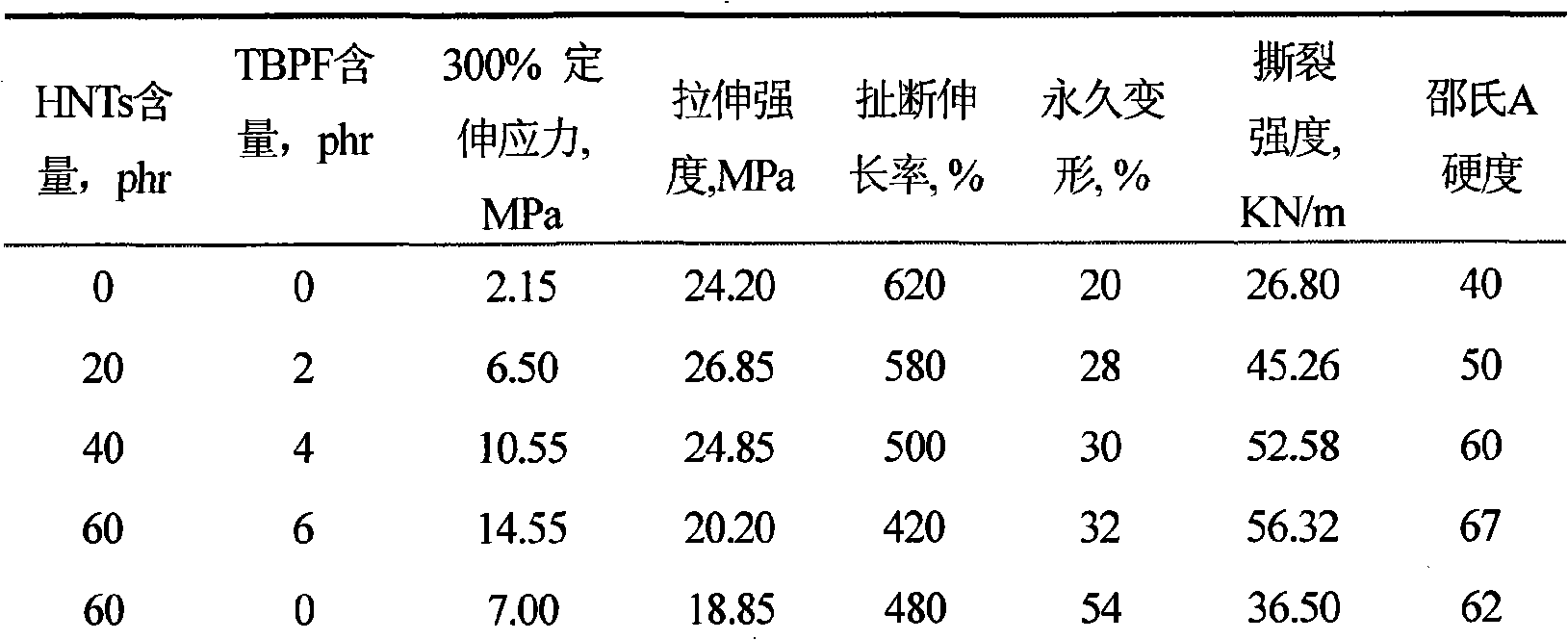

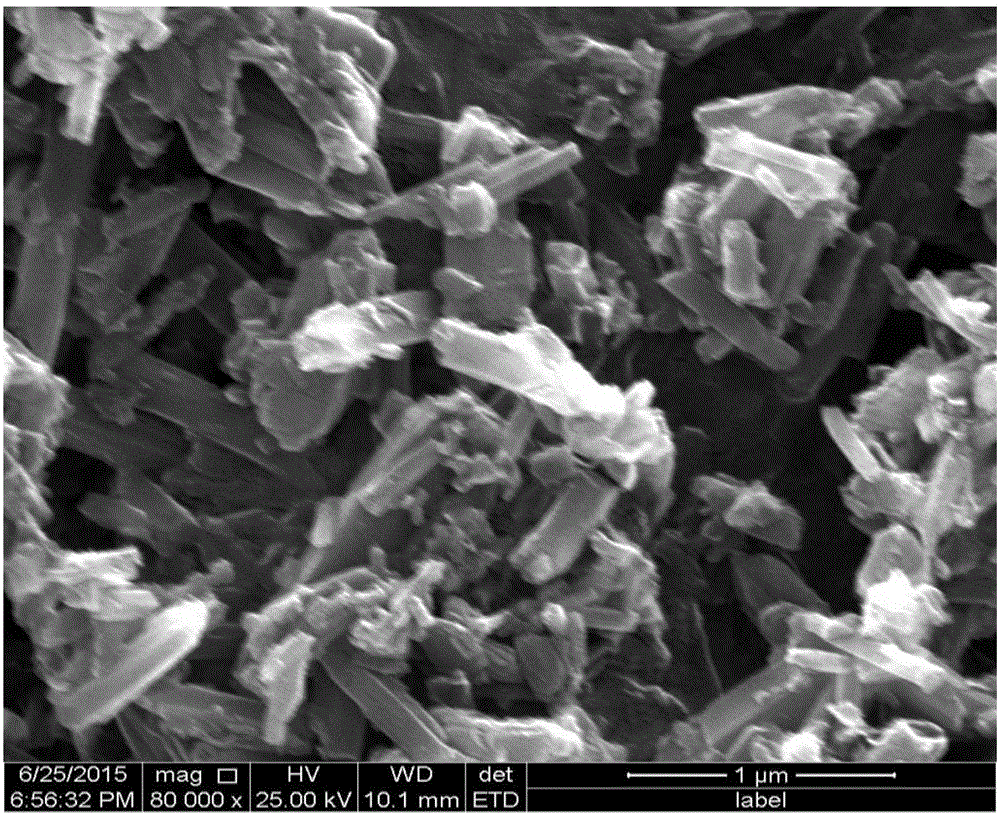

Preparation method for rubber/keramite nano-tube nano-composite material

The invention relates to preparation method of rubber / halloysite nanotube nano-composite material, the invention adopts the preparation method that the rubber, the halloysite nanotube and modifying agent are mixed according to the mass ratio of 100:5 to 100 : 0.5-20 through the ordinary rubber pugging equipment and technique, then the sulphation is performed through the ordinary sulphidizing process and equipment to realize the in-situ modification, and finally, the rubber / halloysite nanotube nano-composite material with nano-dispersion, good interfacial bonding and good performance. Wherein, the modifying agent comprises compound in-situ generated phenolic resin, alkyl phenolic resin, modified rubber, methacrylic acid metal salt and one or more than one mixture (s) in the sulfur-containing organosilane coupling agent. The preparation method of rubber / halloysite nanotube nano-composite material has the advantages that the defects that the rubber / halloysite nanotube nano-composite material is difficult to be dispersed, the interfacial bonding is not good, the performance can not be improved observably can be overcome, and the preparation method can be applied in a variety of rubber products, rubber toughening plastics and binding agents and the like.

Owner:SOUTH CHINA UNIV OF TECH

Silicon dioxide carbon composite negative electrode material, modified silicon dioxide carbon composite negative electrode material and preparation methods and application of silicon dioxide carbon composite negative electrode material and modified silicon dioxide carbon composite negative electrode material

ActiveCN105789575AImprove performance and stabilityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCarbon compositesHalloysite

The invention relates to the field of preparation of a lithium ion battery, and particularly discloses a preparation method of a silicon dioxide carbon composite negative electrode material. The method comprises the following steps of (1) mixing halloysite with an organic carbon source in the presence of a solvent, and removing the solvent to acquire a solid product; and (2) roasting the solid product in an inertia atmosphere. The invention also provides a carbon nanotube / nitrogen modification method of the silicon dioxide carbon composite negative electrode material. The silicon dioxide carbon composite negative electrode material and the carbon nanotube / nitrogen modified silicon dioxide carbon composite negative electrode material, obtained according to the preparation methods provided by the invention, have relatively high cycle stability and discharge specific capacity, and are expected to be novel negative electrode materials used at a large scale.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

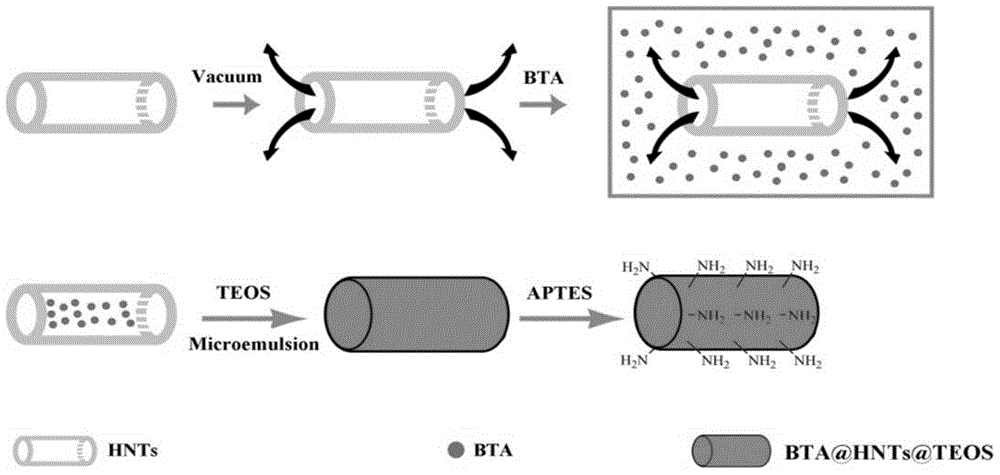

Method for preparing halloysite/epoxy composite coating capable of controlling release of corrosion inhibitor by pH response

ActiveCN105111888AGood dispersionImprove thermal stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyHalloysite

The invention discloses a method for preparing a halloysite / epoxy composite coating capable of controlling release of a corrosion inhibitor by pH response. The method comprises the following steps: (1), loading the corrosion inhibitor: performing ultrasonic dispersion on HNTs and a benzotriazole (BTA) solution for 30 min according to the weight ratio of HNTs to the BTA solution being 1:(1-1.5), so as to obtain suspension liquid and then concentrating the suspension liquid; (2), encapsulating the corrosion inhibitor: reacting distilled water, 25% aqueous ammonia, the suspension liquid with tetraethyl orthosilicate (TEOS) for 12 h; (3), modifying halloysite nanotubes: dropwise adding 3-triethoxysilylpropylamine, reacting at room temperature for 24 h, filtering, washing and drying; (4), preparing a functional coating: dispersing 3wt% of modified halloysite nanotubes in epoxy resin, and finally spraying onto steel discs for curing. According to the method for preparing the halloysite / epoxy composite coating capable of controlling release of the corrosion inhibitor by pH response, provided by the invention, the operation is simple, the prepared modified halloysite nanotubes are uniformly dispersed in epoxy resin, therefore both the toughness and the corrosion resistance of the composite material are improved.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of hydrophilic magnetic halloysite surface molecularly-imprinted nano composite material

InactiveCN103509161AUniform sizeEvenly distributedOther chemical processesWater contaminantsHalloysitePolymer science

The invention relates to a preparation method of a hydrophilic magnetic halloysite surface molecularly-imprinted nano composite material and belongs to the technical field of preparation of an environment functional material. Magnetic halloysite is synthesized by an impregnation method and a high temperature reducing method, and magnetic nano particles have a uniform size and are uniformly distributed; an initiator is grafted to the surface of the magnetic halloysite by the surface amination and amidation reaction and a molecularly-imprinted polymerization layer grafted to the surface of the magnetic halloysite is controlled in the nanoscale by surface atom transfer radical polymerization; due to existence of a tail-end ATRP (atom transfer radical polymerization) active group, the hydrophilic magnetic halloysite surface molecularly-imprinted nano composite material is successfully grafted with a hydrophilic polymer brush, is successfully applied to high-efficiency selective removal and rapid magnetic separation of sulfamethazine in the water environment and has excellent regenerability.

Owner:JIANGSU UNIV

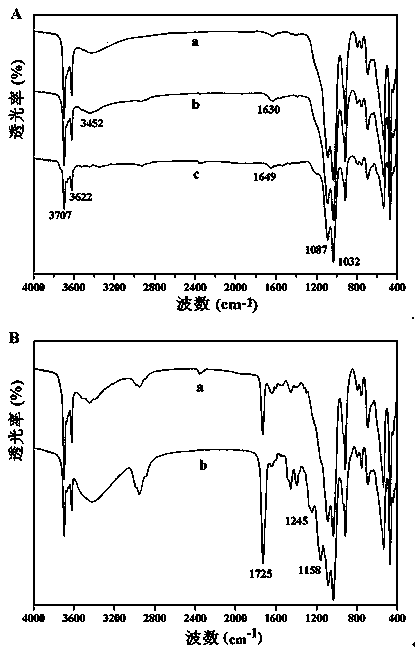

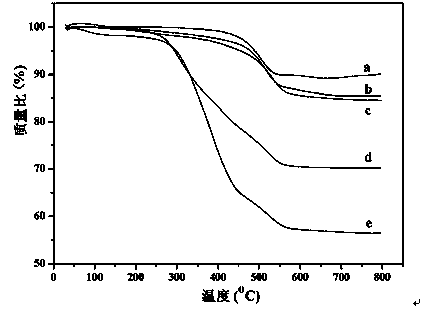

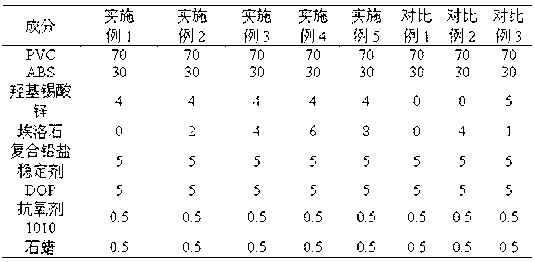

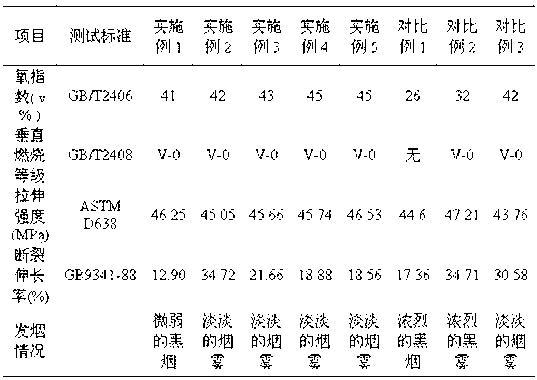

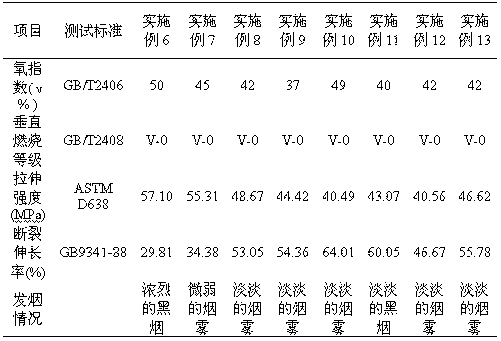

Flame-retardant PVC (polyvinyl chloride) composite material and preparation method thereof

The invention relates to PVC (polyvinyl chloride) and specifically relates to a flame-retardant composite material and a preparation method thereof, in particular to a flame-retardant PVC composite material with synergy of halloysite and zinc hydroxystannate and a preparation method thereof. The flame-retardant PVC composite material comprises the following components in parts by weight: 50-90 parts of PVC, 10-50 parts of acrylonitrile butadiene styrene (ABS), 2-8 parts of zinc hydroxystannate, 2-8 parts of halloysite, 3-5 parts of stabilizer, 5-10 parts of plasticizer, 0.5-1 part of antioxidant and 0.5-1 part of paraffin wax. An environment-friendly and economic flame-retardant composite material with excellent mechanical properties, thermal stability and flame retardance is prepared by utilizing the zinc hydroxystannate and the halloysite to realize synergic flame retardance.

Owner:CHANGZHOU UNIV

Preparation method of halloysite loading phosphoric acid Silverlight catalyst

ActiveCN103934008AFully contactedHigh light transmittancePhysical/chemical process catalystsHalloysiteFiltration

The invention discloses a preparation method of a halloysite loading phosphoric acid Silverlight catalyst. The preparation method comprises the following specific steps of adding halloysite in a salpeter solution so as to obtain the halloysite after acid treatment, placing the 4-8g halloysite after acid treatment into a vacuum filtration bottle, mixing the halloysite and a silver nitrate ethanol solution under a vacuum state, enabling the silver nitrate to fully enter a halloysite pipe, sequentially stirring 2-5h, carrying out solid-liquid separation, and vacuum drying at 70-80 DEG C; adding the obtained product after drying in a 50 mL of sodium dihydrogen phosphate solution the concentration of which is 0.5-1.5mol / L, stirring for 4-5h, carrying out solid-liquid separation, washing, drying at 100-105 DEG C so as to obtain the halloysite loading phosphoric acid Silverlight catalyst. The preparation method provided by the invention has the advantages that the air and moisture in a halloysite pipeline are discharged, the silver nitrate enters a pipeline, an aluminum oxide of the inner wall of the halloysite is removed, the effects of increasing light penetrating degree and aperture property action can be achieved, the obtained silver phosphate particles are arranged in a halloysite pipe and are prevented from birdnesting and falling.

Owner:江阴智产汇知识产权运营有限公司

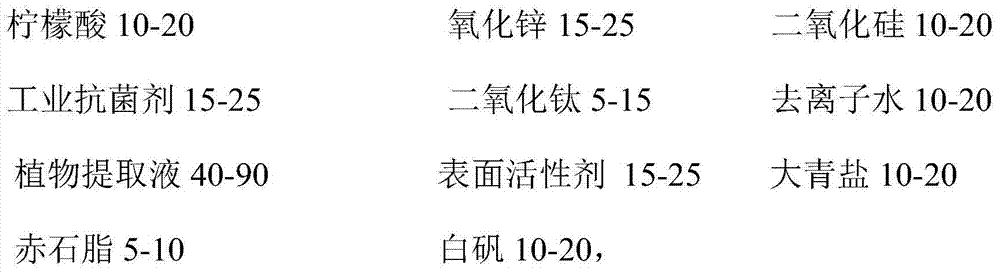

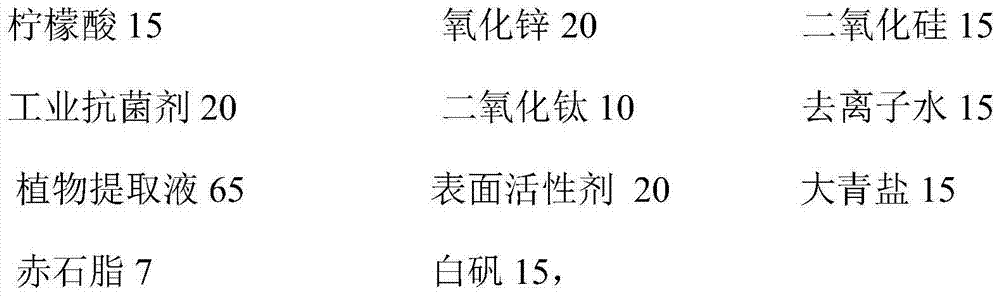

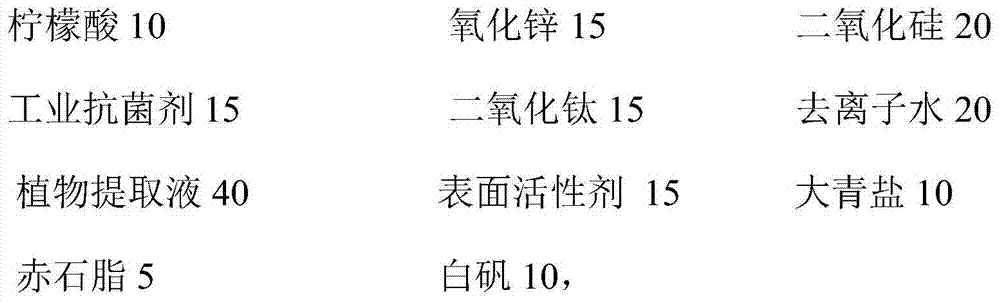

Benzaldehyde scavenger

The invention discloses a benzaldehyde scavenger, which is composed of citric acid, zinc oxide, silicon dioxide, an industrial antibacterial agent, titanium dioxide, deionized water, a plant extracting solution, a surfactant, halite, red halloysite and alum. According to the benzaldehyde scavenger disclosed by the invention, the raw materials are high in degree of safety and non-toxic, are not added with toxic ingredients, and do not contain industrial product ingredients, so that high safety can be ensured, harmful gas such as formaldehyde and benzene can be directly removed without lighting, and the benzaldehyde scavenger is safe, reliable, non-toxic, harmless, free of secondary pollution and really environment-friendly.

Owner:BEIJING ZHONGTIAN GUOHONG ENVIRONMENTAL PROTECTION SCI & TECH

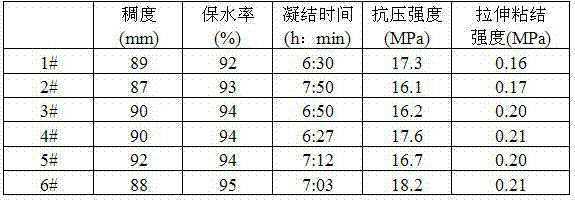

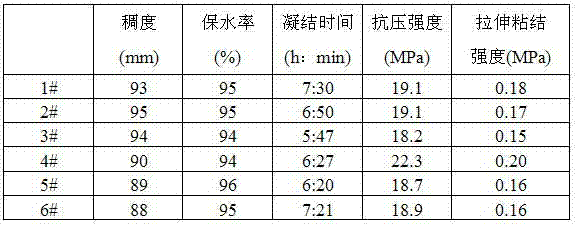

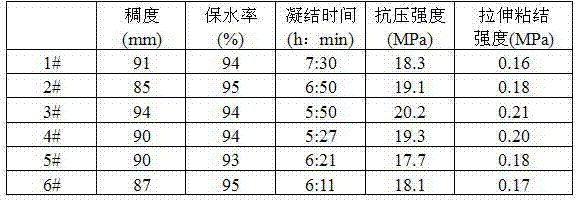

Reinforced premix mortar moisture-retention thickening agent and preparation method thereof

The invention discloses a reinforced premix mortar moisture-retention thickening agent and a preparation method thereof. The reinforced premix mortar moisture-retention thickening agent is prepared from montmorillonite, kaolin, halloysite, attapulgite clay, fly ash, other admixtures, surfactant and modifier. The preparation method adopts a double grinding method and comprises the following steps: carrying out drying pretreatment on the raw materials; pregrinding the surfactant and the montmorillonite; and carrying out secondary grinding on the other raw materials and the primary grinding raw materials according to parts by mass, thereby obtaining the reinforced premix mortar moisture-retention thickening agent. The invention can obviously improve the workability and water retention property of mortar, greatly lower the cement consumption and effectively enhance the cost performance of the mortar.

Owner:广东广业检测有限公司 +2

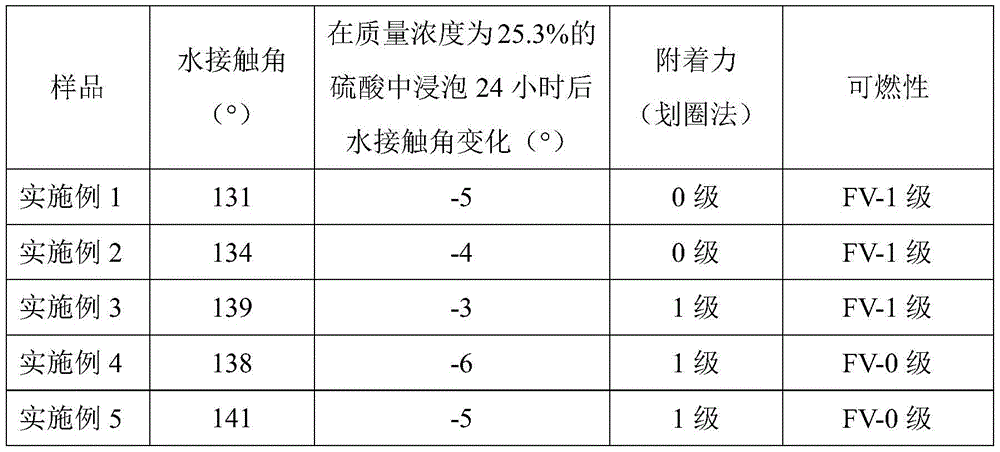

Silicone rubber hydrophobic coating used for insulator and preparation method thereof

ActiveCN105623503ASimple preparation processImprove adhesionFireproof paintsInsulatorsHalloysitePolymer science

The invention belongs to the technical field of coatings, and particularly discloses a silicone rubber hydrophobic coating used for an insulator and a preparation method thereof. The silicone rubber hydrophobic coating comprises hydroxy-terminated poly-dimethylsiloxane, fluoroalkyl silane modified halloysite nanotubes, tetraethyl orthosilicate, dibutyltin dilaurate and cyclohexane; the preparation method comprises the steps of mixing all the components for stirring uniformly at room temperature to prepare a viscous solution, then coating the surface of a composite insulator with the viscous solution, leaving to stand for curing at room temperature, so as to obtain the silicone rubber hydrophobic coating after the solvent naturally volatiles. The silicone rubber hydrophobic coating used for the insulator, provided by the invention, has the advantages that the preparation process is simple, the hydrophobic nature is good, the adhesive force is strong, the fire resistance is good, and the using requirements of an insulator on the external insulating coating material are met.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

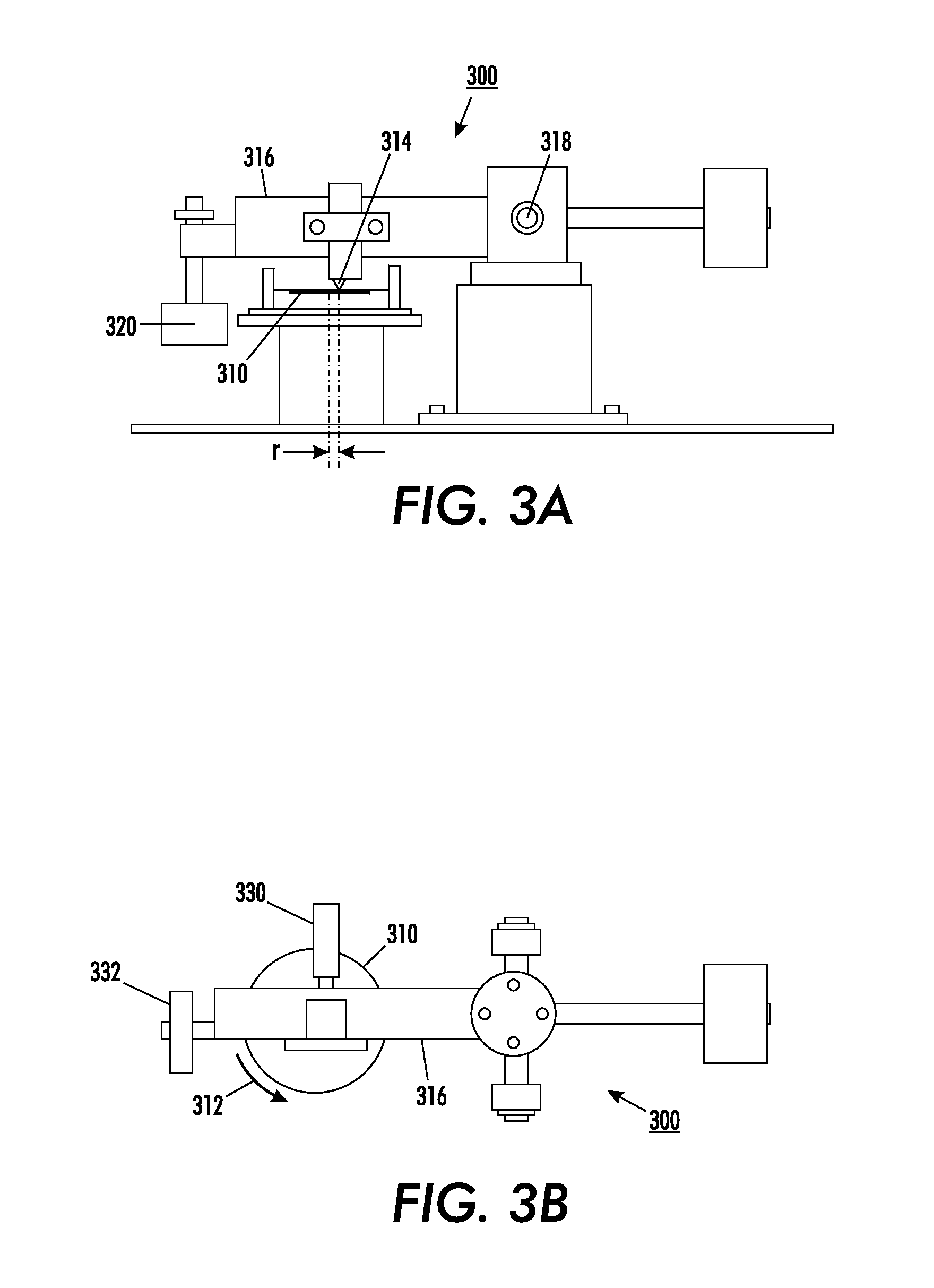

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com