Polydopamine-modified halloysite nanotube / polylactic acid composite material and preparation and application thereof

A technology of halloysite nanotubes and polydopamine, which is applied in the manufacture of rayon, single-component polyester rayon, and fiber chemical characteristics, can solve the problem of lack of ability to promote bone tissue healing and limited cell affinity , cumbersome graft modification methods, etc., to achieve excellent cell affinity and osteogenic activity, good cell affinity, and good biological functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of polydopamine modified halloysite nanotubes comprises the following steps:

[0035] Prepare a tris aqueous solution with a concentration of 0.5g / L, and adjust its pH value to 8.5 with hydrochloric acid, dissolve dopamine in this buffer solution, and the concentration of dopamine in the solution is 0.5g / L; Tubes (HNTs) were uniformly added to the dopamine solution, wherein the mass ratio of halloysite nanotubes to dopamine was 2:1; the reaction system was magnetically stirred at room temperature for 12 hours; the mixture was transferred to a centrifuge tube, and the Centrifuge until the upper layer solution is transparent, remove the lower layer of solid, and vacuum-dry at 50° C. for 48 hours to obtain polydopamine-modified halloysite nanotubes (D-HNTs).

Embodiment 2

[0037] The preparation of polydopamine modified halloysite nanotubes comprises the following steps:

[0038] Configuration concentration is the tris aqueous solution of 1g / L, and its pH value is adjusted to 9 with hydrochloric acid, and dopamine is dissolved in this buffer solution, and dopamine concentration is 2g / L in the solution; 2g halloysite nanotube ( HNTs) were evenly mixed into the dopamine solution, wherein the mass ratio of halloysite nanotubes to dopamine was 0.5:1; the reaction system was magnetically stirred at room temperature for 24 hours; the mixture was transferred to a centrifuge tube, and centrifuged at 1500r / min to The solution in the upper layer was transparent, and the solid in the lower layer was removed, and dried in vacuum at 50° C. for 48 hours to obtain polydopamine-modified halloysite nanotubes (D-HNTs).

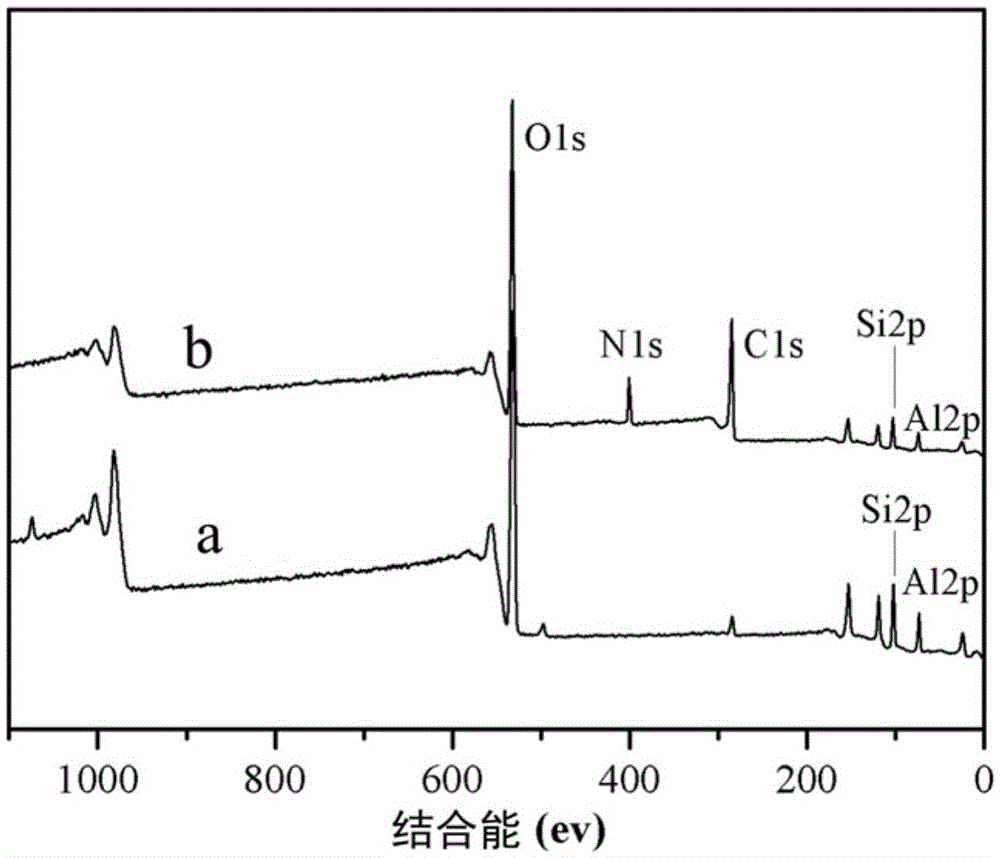

[0039] figure 1 Is HNTs in embodiment 2 ( figure 1 a) and D-HNTs ( figure 1 X-ray photoelectron spectroscopy in b). From figure 1 It can be...

Embodiment 3

[0041] The preparation of polydopamine modified halloysite nanotubes comprises the following steps:

[0042] The tris aqueous solution with a concentration of 1.5g / L is configured, and its pH value is adjusted to 8.5 with hydrochloric acid. Dopamine is dissolved in this buffer solution, and the concentration of dopamine in the solution is 5.0g / L; 5g halloysite nano Tubes (HNTs) were uniformly mixed into the dopamine solution, wherein the mass ratio of halloysite nanotubes to dopamine was 2:1; the reaction system was magnetically stirred at room temperature for 36 hours; the mixture was transferred to a centrifuge tube, and the Centrifuge until the upper layer solution is transparent, remove the lower layer of solid, and vacuum-dry at 50°C for 48 hours to obtain polydopamine-modified halloysite nanotubes; soak 1 g of polydopamine-modified halloysite nanotubes in 80 mL of simulated body fluid, simulate body fluid Composed of: Na + , 142.0mmol / L; K + , 5.5mmol / L; Mg 2+ , 1.5mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com