Patents

Literature

835results about How to "Guaranteed decentralization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear-resistant thermoplastic elastomer and preparation method thereof

The invention discloses a wear-resistant thermoplastic elastomer, which is prepared from the following raw materials in percentage by weight: 10 to 80 percent of matrix resin, 10 to 60 percent of master batch, 0 to 42 percent of extending oil, 0 to 20 percent of thermoplastic resin, 0 to 30 percent of mineral filler, 0 to 1.5 percent of coupling agent, 0.1 to 2 percent of processing aid and 0.1 to 2 percent of stabilizing agent. The invention also discloses a method for preparing the wear-resistant thermoplastic elastomer. SBS, SEBS and the like are adopted as the matrix resin, and the problem of poor wear resistance of SBC thermoplastic elastomers is solved through improvement of a mixing formular and a process; the prepared thermoplastic elastomer has good wear resistance; compared with the TPU products with good wear resistance, the thermoplastic elastomer has low cost; in the whole process of modifying and producing the material, chemical solvents are not used, the influence on the environment is small, the halogen is free and the environment is protected; and the leftover material of the thermoplastic elastomer can be repeatedly used.

Owner:CGN JUNER NEW MATERIALS +1

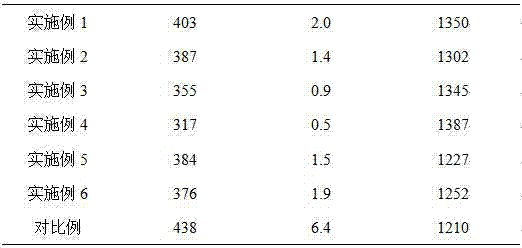

Controlled/slow release polycarboxylate water reducing agent for inhabiting aggregate mud content influence and preparation method thereof

InactiveCN101798197ARich microporous structureLarge specific surface areaCarboxylic acidWater reducer

The invention relates to a controlled / slow release polycarboxylate water reducing agent for inhabiting the aggregate mud content influence, which is characterized in that the controlled / slow release polycarboxylate water reducing agent comprises the following ingredients by weight parts: 75 to 95 parts of polycarboxylate water reducing agents, 2 to 5 parts of retarders and 5 to 25 parts of slow release agents. Because natural zeolite powder has the characteristics of microporous structure, large specific surface area and strong surface absorption capability, the natural zeolite powder can be used as the slow release agents. The invention utilizes the natural zeolite powder as the slow release agents, and the surface of the natural zeolite powder can absorb a large number of polycarboxylate water reducing agents and a small number of retarders after the natural zeolite powder is mixed with the polycarboxylate water reducing agents and the retarder. Clay can preferentially absorb the natural zeolite powder with strong surface absorption capability when the natural zeolite powder is doped into concrete to be stirred with gelled materials, aggregates and water, and the excessive absorption of the polycarboxylate water reducing agent by the clay is avoided, so the absorption of the polycarboxylate water reducing agents on cement grains and the dispersing effect taking are ensured.

Owner:NANCHANG UNIV

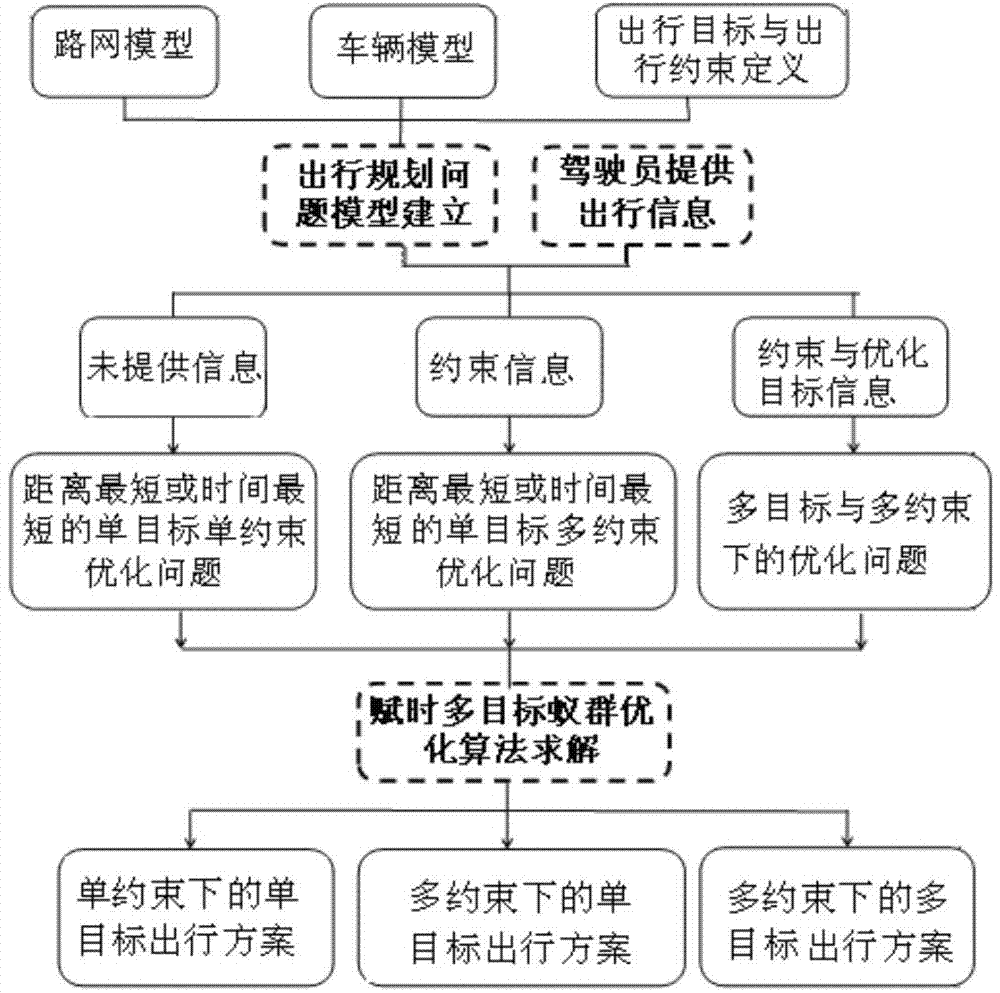

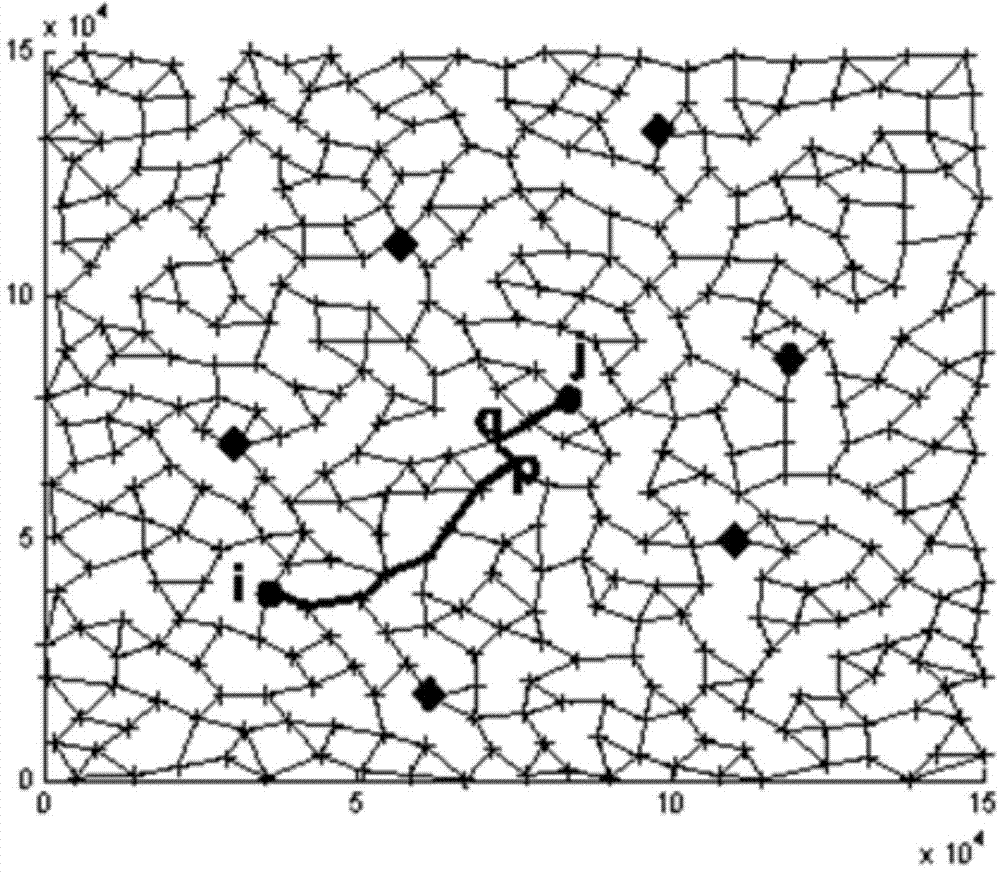

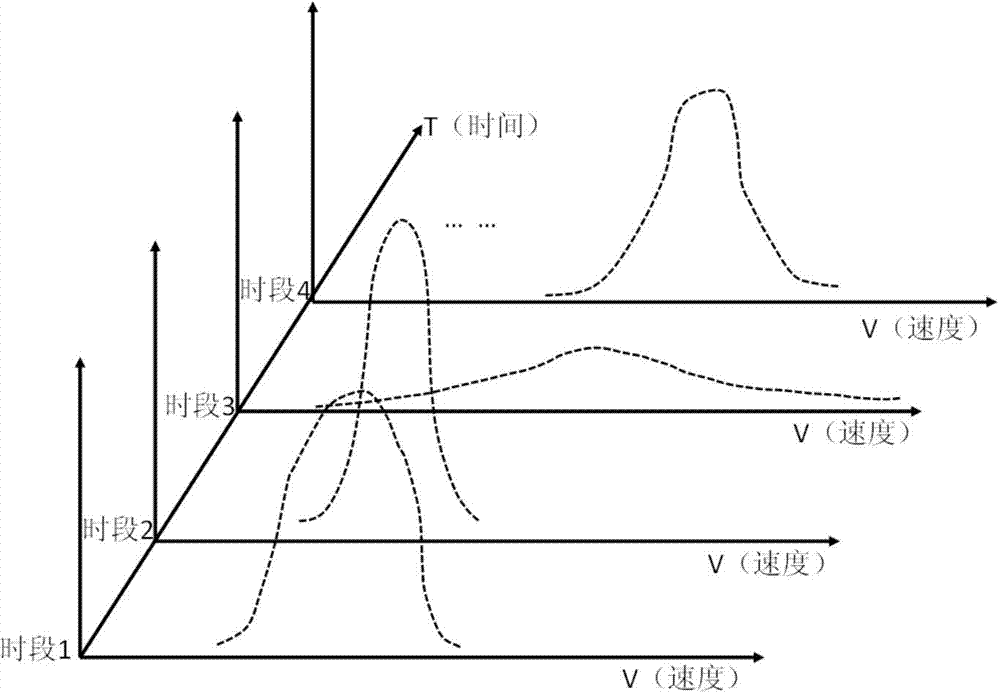

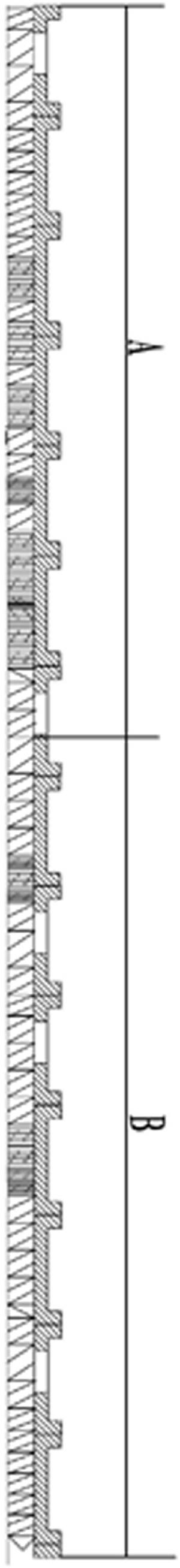

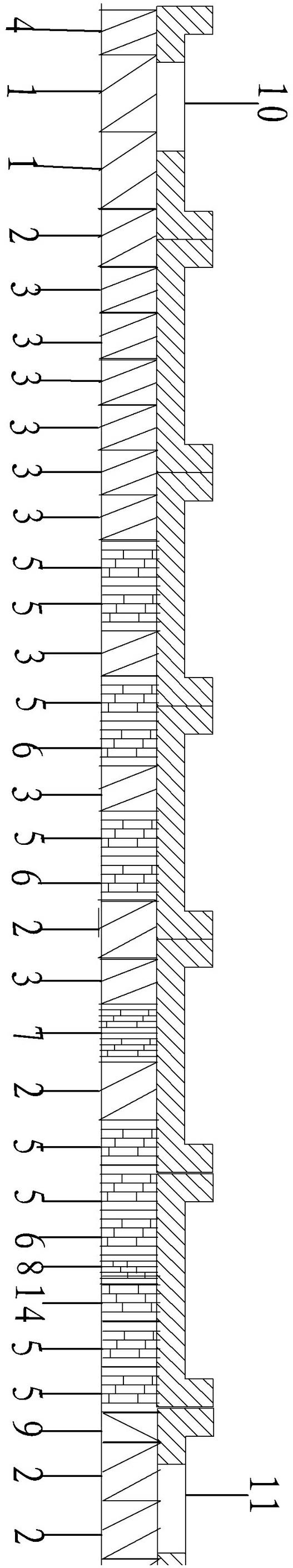

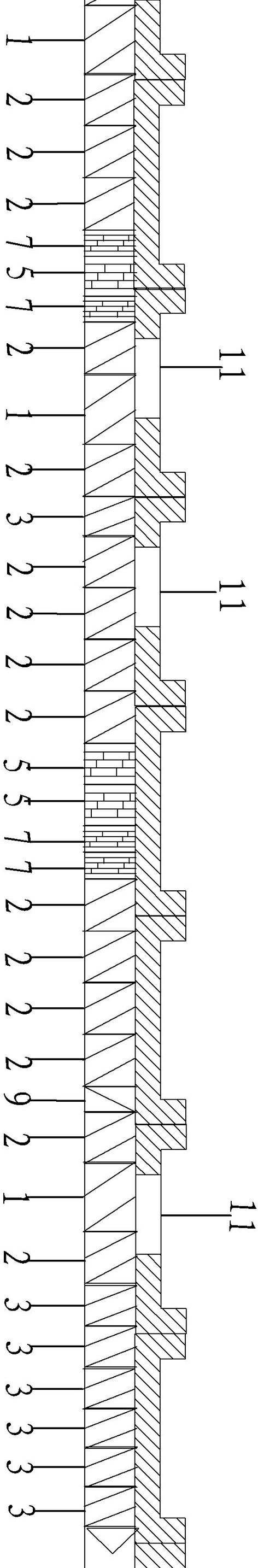

Electric vehicle travel planning method based on multi-target optimization

ActiveCN104331743AOptimization solution setGuaranteed decentralizationForecastingArtificial lifeTransfer probabilityRoad networks

The invention discloses an electric vehicle travel planning method based on multi-target optimization, generally comprising the following steps: (1) a travel planning problem model is established; (2) drivers provide travel information; and (3) an optimal scheme is solved based on a timed multi-target ant colony optimization algorithm. The problem model comprises a road network model, a vehicle model, and travel target and travel constraint definition. Travel information includes: not providing any information, providing constraint information, and providing optimization goal and constraint information. The ant colony optimization algorithm includes the steps of pheromone initialization, route transfer probability calculation, travel scheme search, air conditioner use determining, travel scheme ranking, pheromone updating, and loop optimization. A dynamic stochastic road network model is used to describe the traffic environment and plan the travel of electric vehicles, and target characteristics corresponding to different travel schemes can be reflected. The ant colony optimization algorithm ensures that a multi-target and multi-constraint optimized electric vehicle travel scheme is generated as the number of iterations increases.

Owner:TSINGHUA UNIV

Method for preparing high-dispersion white carbon black/rubber nano composite material

The invention relates to a method for preparing a high-dispersion white carbon black / rubber nano composite material. According to the invention, by means of mixing rubber latex and white carbon black water slurry to obtain a uniform mixed solution and forming a great amount of micro droplets of the mixed solution by utilizing a spray drying atomization process, the specific surface area of the mixed solution is obviously increased, so that the moisture in the mixed solution is rapidly removed in a drying medium of a spray drying device; and by means of introducing a gasified flocculating agent into spray drying carrier gas and combining the spray drying process with a flocculation process, the processes of ion flocculation, rapid dehydration and the like are carried out at the same time and the speed and the efficiency of the conversion process of the white carbon black / rubber mixed solution from a liquid phase to a solid phase are improved, so that the high-dispersion white carbon black / rubber nano composite material is prepared. The method is simple to operate, is energy-saving, has low cost and wide application range and is easy for industrialization. The white carbon black / rubber nano composite material product prepared with the method has excellent comprehensive performances.

Owner:BEIJING UNIV OF CHEM TECH

Heat-preservation hard composite carbon fiber felt and preparation method thereof

The invention discloses a heat-preservation hard composite carbon fiber felt and a preparation method thereof. The preparation method comprises the following steps: forming a carbon fiber vacuum filtration layer, compositing a viscose-based carbon fiber felt or polyacrylonitrile-based carbon fiber felt, soaking a binding agent, needling, coating an upper surface processing layer, forming and postprocessing. The heat-preservation hard composite carbon fiber felt and the preparation method thereof provided by the invention have the advantages that the cost performance optimization design is carried out on a product according to a specific operating environment, the designability of the density of the whole felt is high, the density of an organic padding is relatively low, a high density fiber stacking structure which is corresponding to a high temperature surface is effectively formed, a heat insulation effect is excellent, a low density fiber stacking structure which is corresponding to a low temperature surface is effectively formed, and the cost is economic.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

Preparation method of graphene/metal composite panel

InactiveCN103935103AGuaranteed decentralizationEvenly dispersedArmourLamination ancillary operationsAviationDispersity

The invention relates to a preparation method of a graphene / metal composite panel. The preparation method comprises the steps of firstly uniformly mixing a monodispersed graphene solution with a polyvinyl alcohol solution to prepare graphene / polyvinyl alcohol mixed slurry, spraying the graphene / polyvinyl alcohol mixed slurry to the upper and lower surfaces of a plurality of metal panels, heating to remove polyvinyl alcohol in a coating, and finally laminating the metal panels to prepare the graphene / metal composite panel in a hot rolling manner. The preparation method has the beneficial effects that by compositing the graphene / polyvinyl alcohol mixed slurry with the metal panels, the dispersity of graphene can be guaranteed; by utilizing a hot rolling process, the graphene can be beneficially dispersed into matrixes of the panels so as to play a strengthening effect; the molecular association between the graphene and the metal panels is realized in the premise of well preserving intrinsic physical properties of the graphene and a metal material; the process is simple, the large-batch and large-size graphene composite panels are easily prepared, the production cost is lowered, and the preparation method has excellent engineering application prospects in the fields of light armor materials, aviation, spaceflight and the like.

Owner:BEIJING GRAPHENE TECH RES INST CO LTD

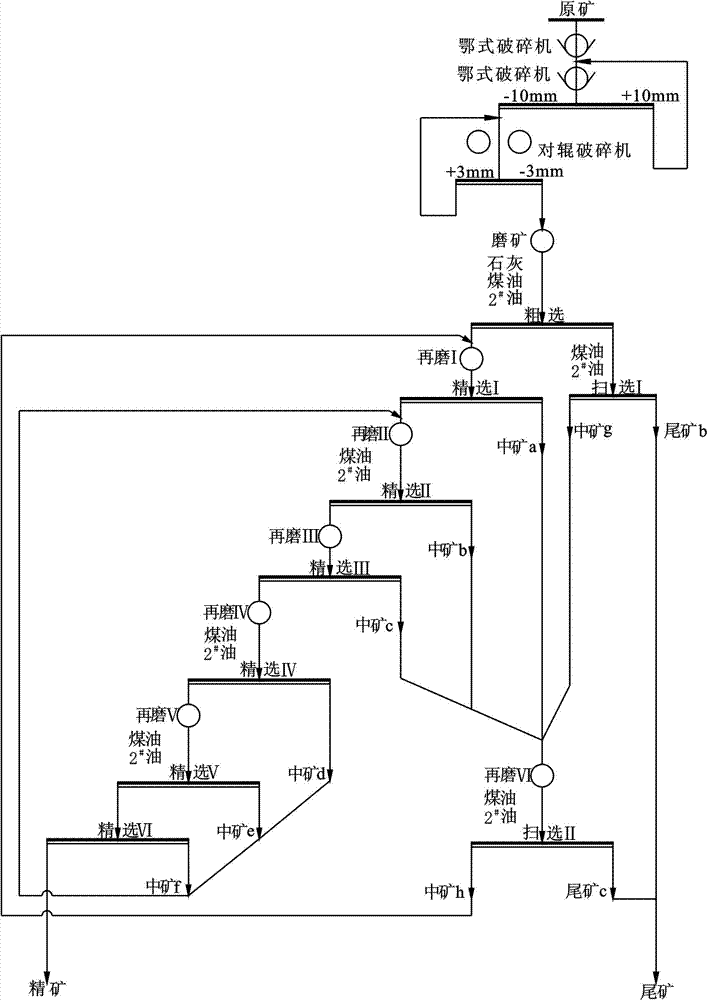

Fine flaky-cryptocrystalline mixed graphite separation technique

The invention discloses a fine flaky-cryptocrystalline mixed graphite separation technique which comprises the following steps: primary rough grinding and rough separation, quintic regrinding and sextic concentrating, and middling centralized processing. According to the technique, in the rough separation step, the grinding fineness is -0.074mm, and the content is 90-95%; in the concentrating step, the regrinding fineness is -0.045mm, and the content is 90-95%; and thus, the graphite monomer is sufficiently dissociated, thereby sufficiently ensuring the fixed carbon content and recovery rate of the concentrated concentrate. The technique adopts gradually decreased low concentrating concentrations in multiple concentrating process to ensure the dispersity of ore slurry, thereby solving thesevere problem of entrapped impurities in floatation foam; and thus, in the final concentrate, the fixed carbon content is 91.35%, and the recovery rate is 91.30%, thereby solving the problems of lowtechnical indexes, low grade, low recovery rate and high cost in the fine flaky-cryptocrystalline mixed graphite concentrate separation, so that the fine flaky-cryptocrystalline mixed graphite ores are utilized in an efficient, economical and reasonable way.

Owner:SICHUAN PILOT GRAPHITE PROD

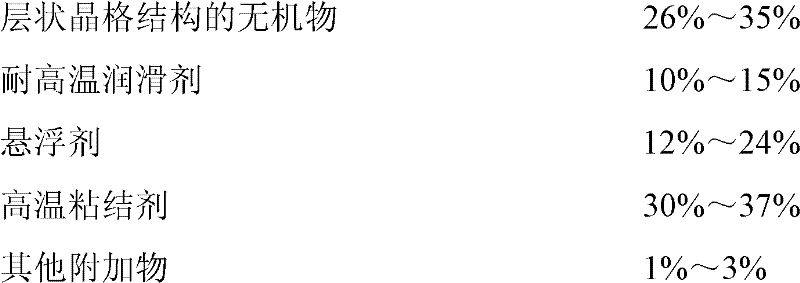

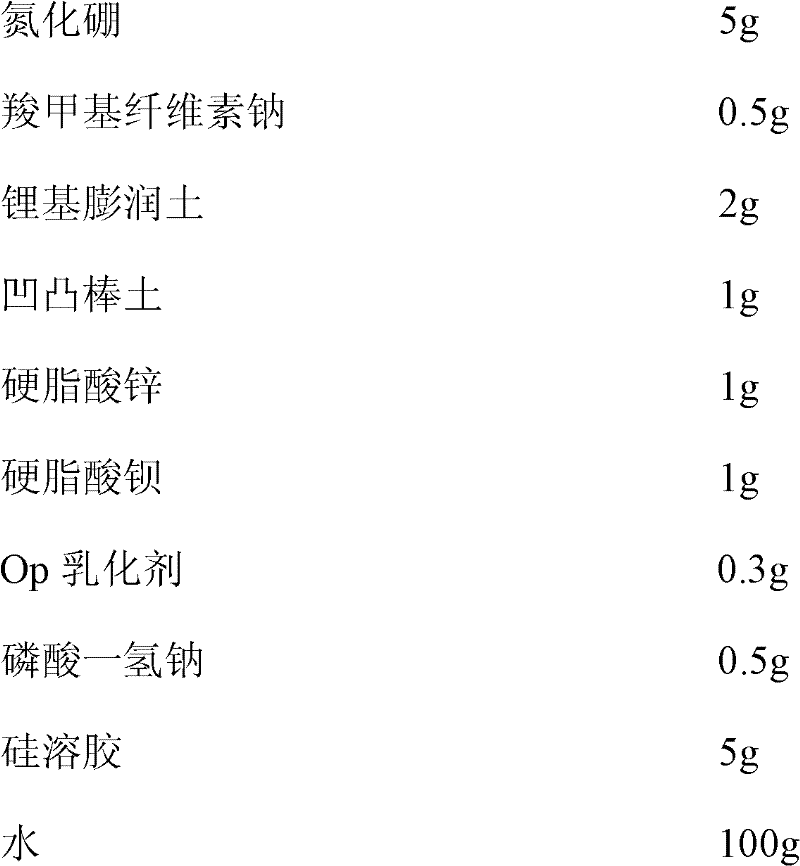

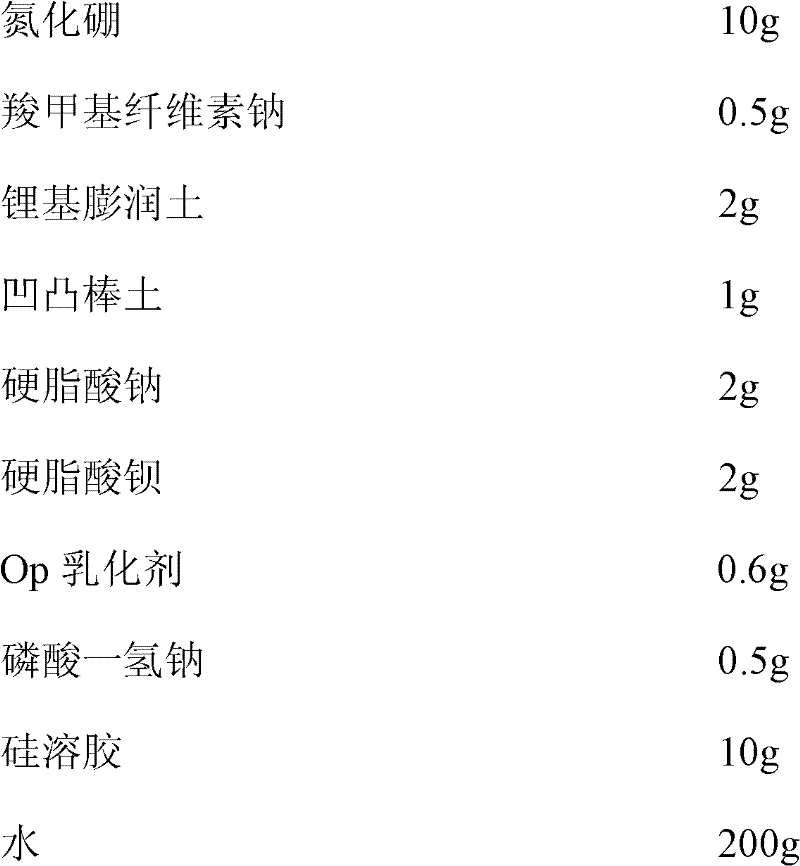

Non-graphite type lubricant for hot die forging of metal and preparation method of non-graphite type lubricant

The invention discloses a water-based non-graphite type lubricant, which is characterized by comprising the following ingredients in percentage by weight: 26%-35% of inorganic substance with layered lattice structures, 10%-15% of high-temperature-resistant lubricant, 12%-24% of suspending agent, 30%-47% of high-temperature adhesive and 1%-3% of adjuvant. The water-based non-graphite type lubricant is an environment-friendly lubricant for hot die forging, can replace a graphite type lubricant, and is especially suitable for the hot die forging of metal, in particular, for the hot die forging of large-sized aluminum pieces. The invention further discloses a preparation method of the water-based non-graphite type lubricant. The preparation method has the advantages of simple preparation process and excellent film-forming performance.

Owner:HUAZHONG UNIV OF SCI & TECH

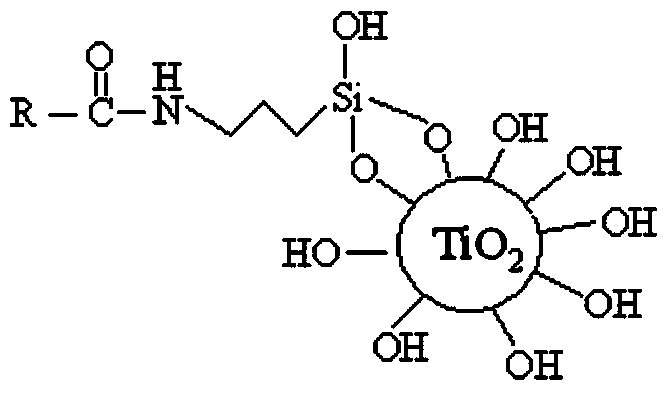

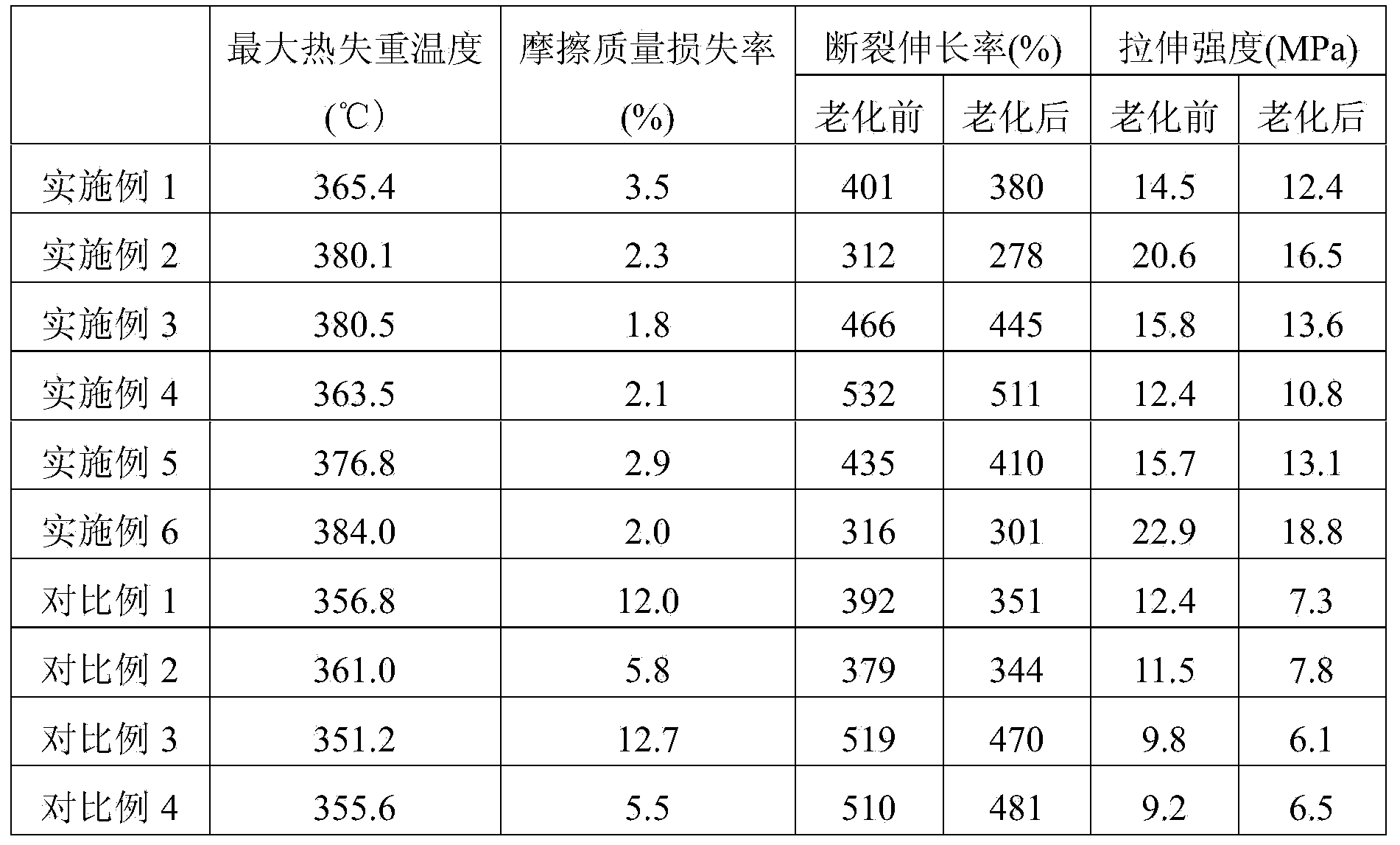

Water-based polyurethane paint containing polyether glycol/nano TiO2 hybrid material

ActiveCN104403548AGood thermal propertiesImprove mechanical propertiesPolyurea/polyurethane coatingsWater basedOrganometallic catalysis

The invention belongs to the technical field of water-based polyurethane paints, and discloses a water-based polyurethane paint containing a polyether glycol / nano TiO2 hybrid material, and a preparation method and application thereof. The paint comprises the following components in parts by mass: 25-75 parts of polyether glycol / nano titanium dioxide hybrid material, 15-65 parts of diisocyanate, 100 parts of polyether glycol, 8-16 parts of polyhydroxy-carboxylic acid, 0.05-0.5 part of organo-metallic catalyst, 0.5-10 parts of crosslinking agent, 6.2-12.4 parts of neutralizer, 1-8 parts of chain extender and 0.2-2.0 parts of defoaming agent. The paint enhances the compatibility between the nano titanium dioxide and polyurethane base, has the advantages of favorable thermal properties, favorable mechanical properties, favorable wear resistance and excellent ultraviolet resistance, and can be widely used in the fields of architectural paints, automobile paints, wood paints, electrodeposition paints, paper conditioning paints, glass fiber paints, electrophoretic paints and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

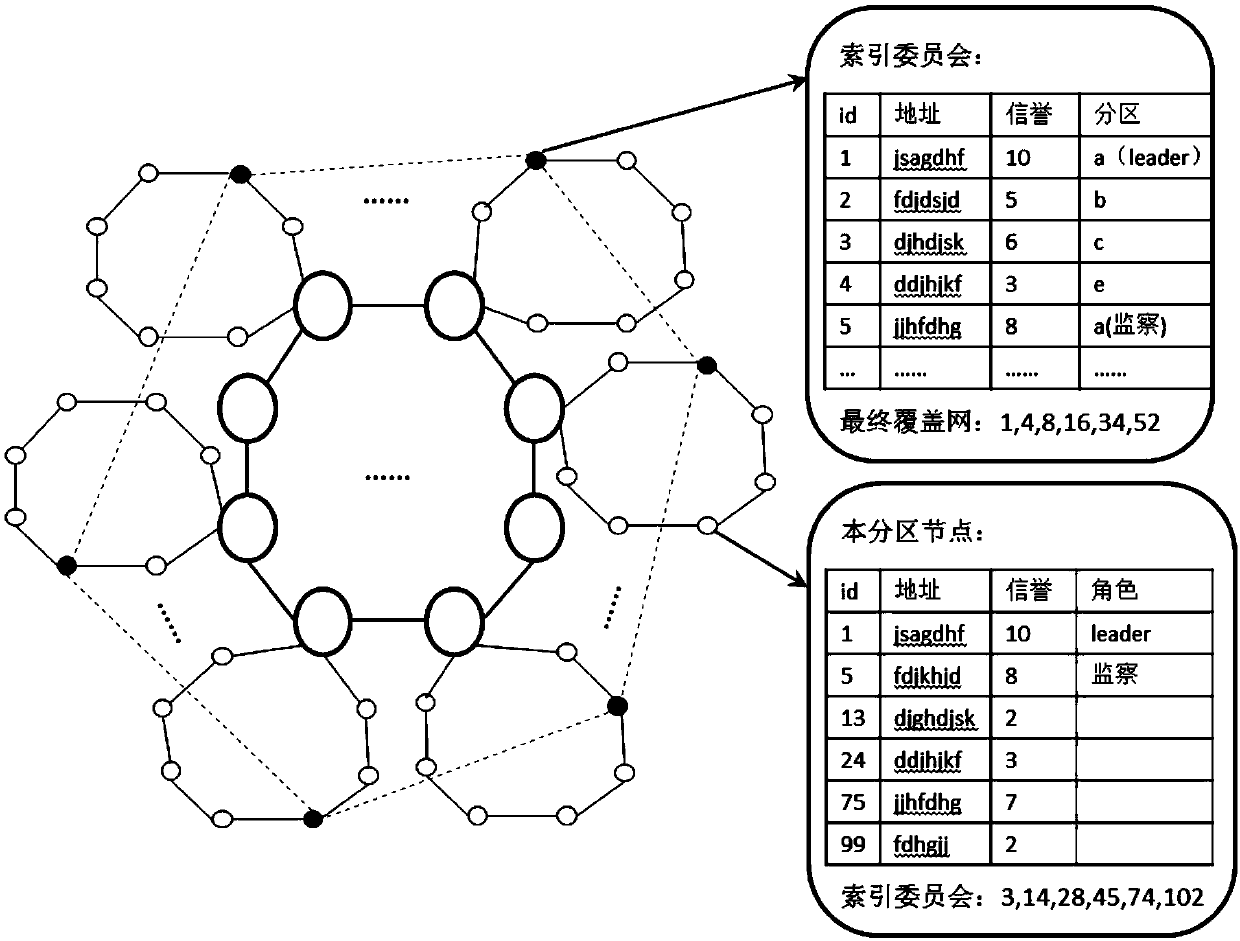

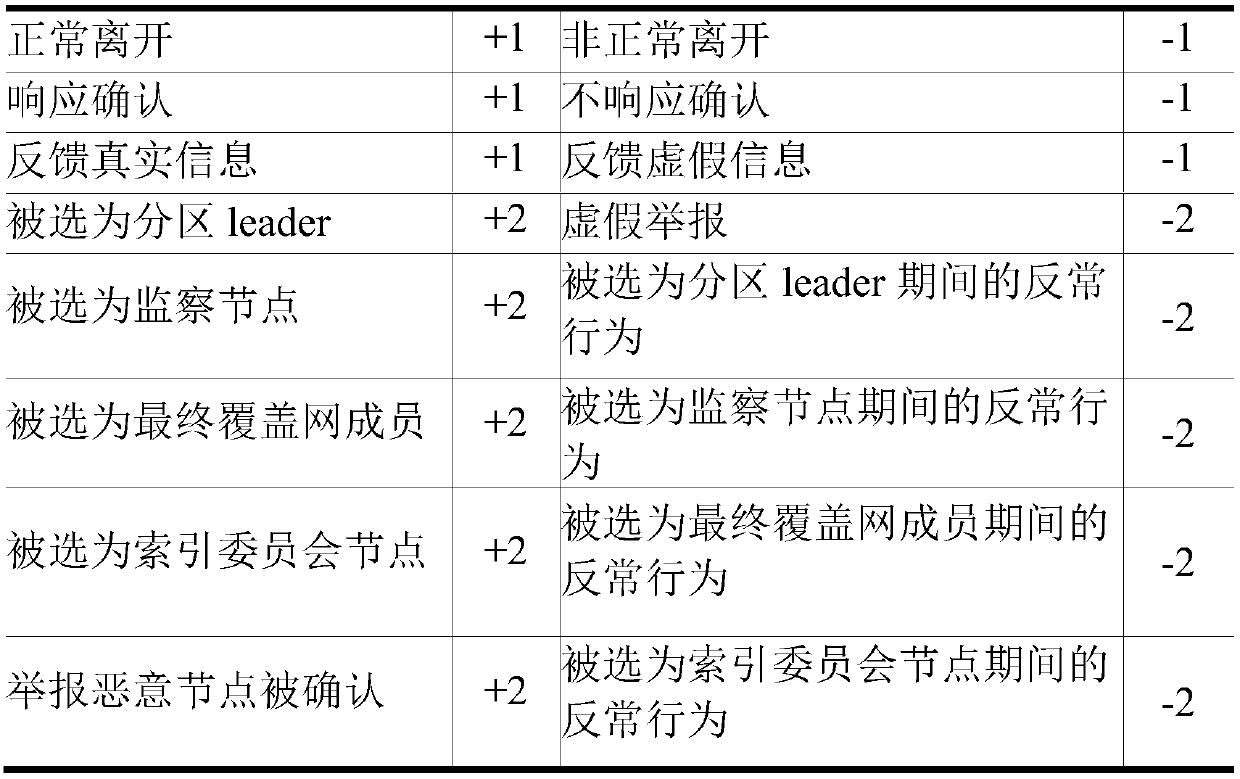

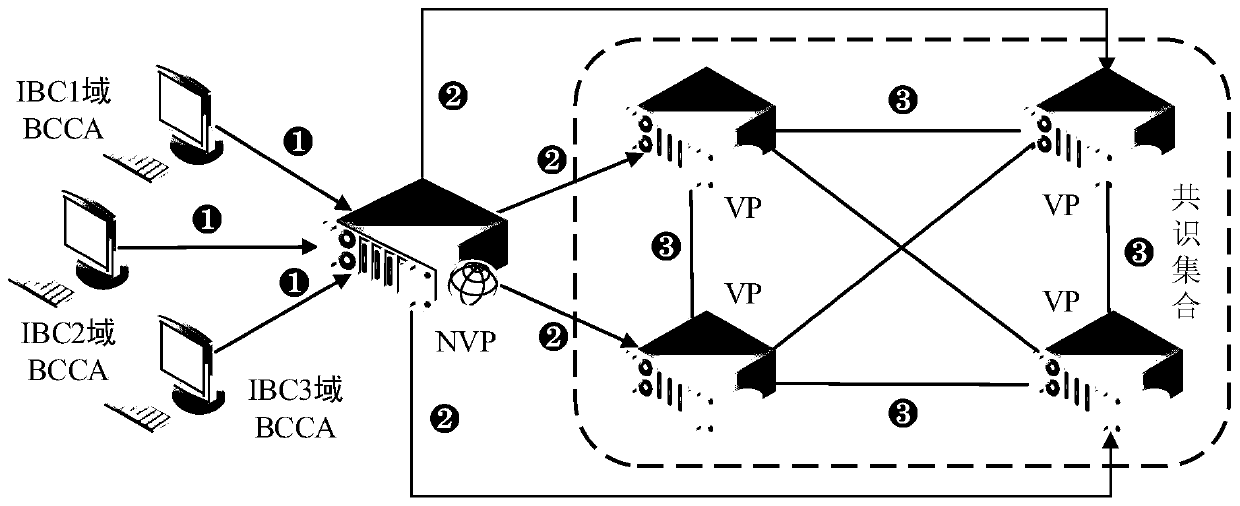

Partition fast consensus method based on reputation mechanism in blockchain

ActiveCN109547527AGuaranteed scalabilityBreak through the limitation of the number of nodesFinanceTransmissionFault toleranceContact method

The invention discloses a partition fast consensus method based on a reputation mechanism in a blockchain. The basic idea of the partition fast consensus method based on the reputation mechanism in the blockchain is divided into two stages: the first stage is to divide a large number of nodes in a global public chain into a plurality of small partitions, introduce the reputation mechanism in the P2P technology inside the partition, and realize local consensus using a Raft algorithm, which can achieve fault tolerance of malicious nodes; and the second stage is to further construct a global overlay network on top of the partitions to achieve the consensus of the entire public chain; in order to facilitate connections among nodes, an index committee is also constructed, which is mainly used to store the contact information and reputation values of all nodes in the whole chain; and all nodes can contact the index committee to find other nodes to establish a connection.

Owner:GUANGXI NORMAL UNIV

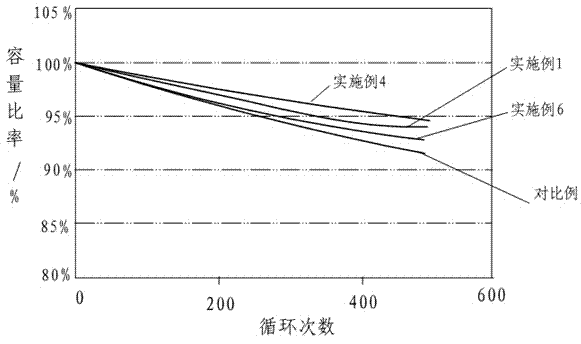

Composite lithium ion battery diaphragm and preparation method thereof

ActiveCN104269505AImprove uniformityGood dispersionCell component detailsPolymer adhesivePore distribution

The invention relates to a composite lithium ion battery diaphragm and a preparation method thereof. The composite lithium ion battery diaphragm comprises a base film and a coating (s) coated on the single side or the two sides of the base film; the coating is obtained by coating and drying slurry, the slurry contains 20-60 percent of a base material by weight percentage, and the balance is deionized water; the base material comprises the following substances in parts by weight: 0.2-4 parts of thickening agent, 0.2-3 parts of inorganic nanometer dispersing agent, 1-5 parts of polymer adhesive and 88-98 parts of nano alumina and nano barium sulfate, wherein the mass ratio of the nano alumina to the nano barium sulfate is 1: (1-10). The composite lithium ion battery diaphragm provided by the invention has the benefits that the coating uniformity is good, the bonding strength is high and the process is good; the abrasion of mechanical equipment can be reduced on the basis of ensuring uniform pore distribution, excellent air permeability and good foreign body puncture resistance, and continuous and stable mass production is facilitated.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

Light armored armor and preparation method thereof

ActiveCN104848748AGuaranteed decentralizationImprove bindingLaminationLamination apparatusHigh intensityGraphene

The invention discloses a light armored armor and a preparation method thereof. The armored armor is in a sandwich structure; a core plate is made of novel aluminum matrix composite of composite enhancing silicon carbide and graphene; a face plate and a back plate are made of 5083 and 7A21 high-intensity aluminum alloy; the core plate, the face plate and the back plate are glued through metallic glue; the composite of the core plate is graphene or silicon carbide enhanced aluminum matrix composite and prepared through the pressure infiltration technology; an infiltration framework is silicon carbide and graphene cold pressing block which are uniformly mixed. According to the light armored armor and the preparation method thereof, the core plate is obtained due to infiltration of aluminum alloy through the silicon carbide and graphene composite framework, the silicon carbide enhancement is used, the enhancement and toughening functions to the aluminum alloy from the graphene are fully played, the ballistic performance of the core plate is improved, and the light armored armor having a good application prospect is finally obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Double-foaming cellular concrete and production method thereof

The invention discloses double-foaming cellular concrete and a site production construction method thereof. The volume weight of the double-foaming cellular concrete ranges from 100 KG / M<3> to 400 KG / M<3>; the heat conduction coefficient is as little as 0.020 W / M.DEG C, and the intensity is up to 5 MPa. The double-foaming cellular concrete can be widely applied to the production of light-weight heat preservation materials such as roof heat preservation materials and external wall heat preservation materials and hanging pieces such as light-weight building hanging beams, and has the purposes of the filling of light-weight hollow bricks and hollow building covers; more importantly, the double-foaming cellular concrete can be applied to the construction of underwater facilities. The site production construction method for the double-foaming cellular concrete is simple in technology and simple and convenient to operate; by special equipment, full-automatic integrated productions, such as automatic foaming, metering and proportioning, are effectively realized; upon automatic control, the production construction of the double-foaming cellular concrete is finished highly efficiently at low cost.

Owner:河南华泰新材科技股份有限公司

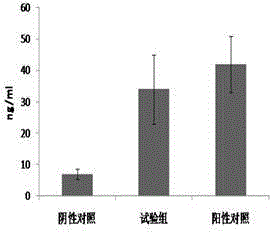

Cell preparation for treating osteoarthritis and preparation method thereof

InactiveCN104958320AGood reliefEasily damagedSkeletal disorderMammal material medical ingredientsJoint cavityMesenchymal stem cell

The invention provides a cell preparation for treating osteoarthritis and a preparation method thereof. The cell preparation mainly comprises mesenchymal stem cells, differentiation-induced stem cells, platelet-rich plasma and dispersion media thereof. Compared with the prior art, the cell preparation for treating osteoarthritis has the advantages that the mesenchymal stem cells are mixed with the differentiation-induced stem cells and compounded with the platelet-rich plasma and can be dispersed in the joint cavity, so that the immune regulation function of the mesenchymal stem cells can be exerted, the microenvironment of the whole joint cavity can be improved, and inflammation remission and injury repair are facilitated; tissues can be repaired after the differentiated mesenchymal stem cells are implanted into the body, so that the repair process is shortened.

Owner:广东佰鸿干细胞再生医学有限公司

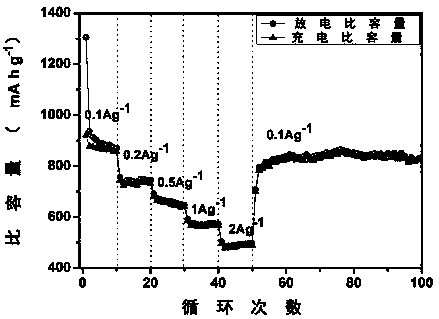

Lithium ion battery negative electrode material and preparation method thereof

InactiveCN108321358AImproved magnification performanceImprove electrochemical performanceCell electrodesCarbon compositesHigh rate

The invention provides a tin-based alloy / carbon composite material for a lithium ion battery negative electrode material and a preparation method thereof. Metal salt and organic ligands are stirred and dissolved in a solvent according to a certain proportion; normal temperature or solvent heat reaction is performed for preparing a porous MOF (metal-organic framework); tin salt is added into the MOF, so that the tin salt is fully adsorbed; MOF precursor powder containing the tin salt is calcined in air; carbonization is performed in inert gas to obtain a nanometer tin cobalt alloy / carbon composite material. The appearance of the prepared nanometer tin cobalt alloy / carbon composite material is a regular polyhedral spherical shape; the nanometer tin alloy size is smaller than 10nm; the material is uniformly dispersed in a porous polyhedral carbon base body. When the material is used for a lithium ion battery negative electrode, high reversible capacity, good cycling stability and high-rate performance are realized.

Owner:BEIJING UNIV OF CHEM TECH

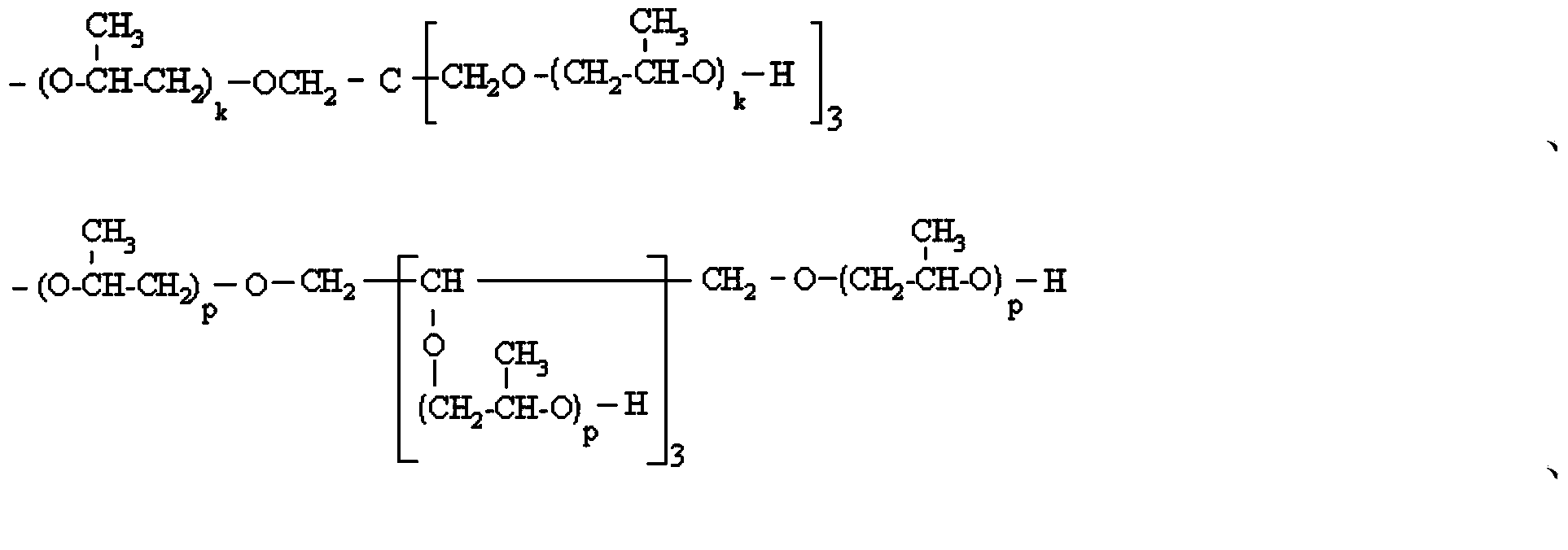

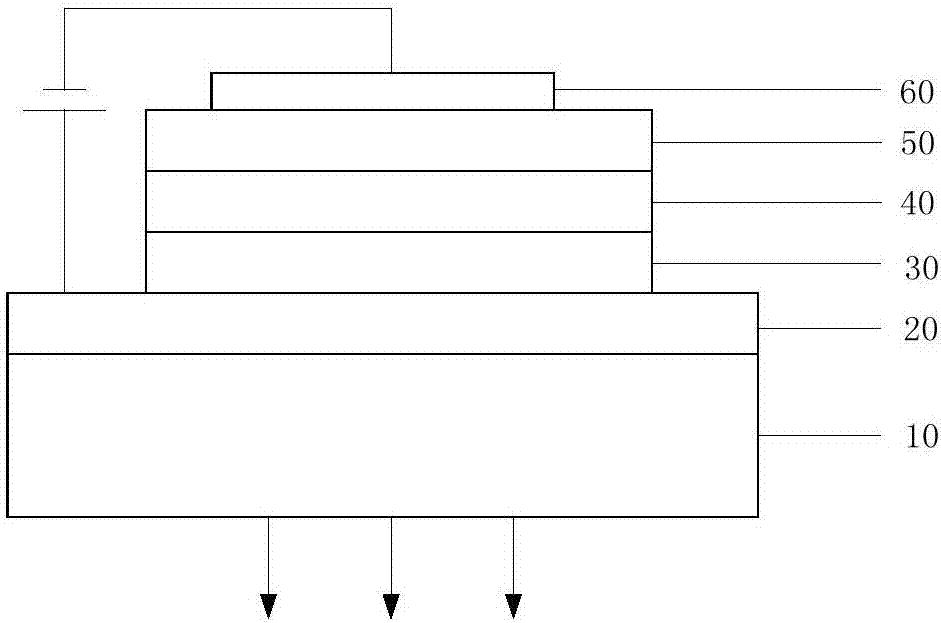

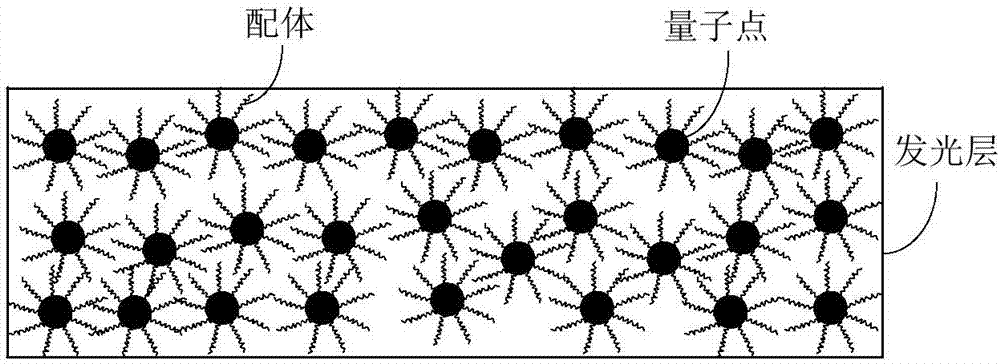

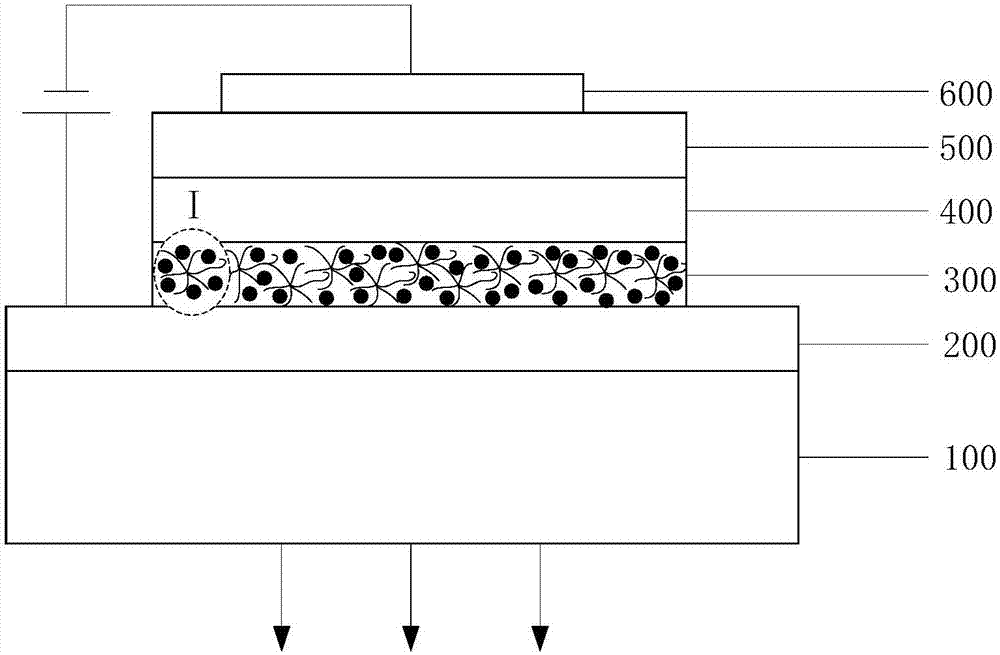

QLED, preparation method and display apparatus

ActiveCN107359264AImprove luminous efficiencyIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingDispersityQuantum yield

The invention provides a QLED, a preparation method and a display apparatus. The QLED comprises a substrate, a positive electrode, a hole transport layer, a light emitting layer, an electron transport layer and a negative electrode in sequence; the light emitting layer comprises quantum dots and a dispersing agent with a dendritic molecular structure; and the quantum dots are dispersed among side chains of the dendritic molecules. Compared with long-chain ligands on the surfaces of the quantum dots, an insulating layer is not formed on the surfaces of the quantum dots in the dendritic molecular structure, so that charge injection potential barrier of impedance, holes and electrons to the quantum dots on the surfaces of the quantum dots can be greatly lowered; in addition, the spacings between the quantum dot molecules, between quantum dots and the electron transport layer, and between the quantum dots and the hole transport layer can be closer, thereby improving the concentration of the quantum dots in the light emitting layer, and the exciton energy transfer efficiency; and by virtue of the OLED, the dispersity and yield of the quantum dots can be ensured while the current carrier energy transfer validity can be reinforced, thereby enhancing the light emitting efficiency of the OLED and the luminance of the OLED display apparatus.

Owner:HISENSE VISUAL TECH CO LTD

Amylum category complete biodegradable material and preparation method thereof

The invention discloses an amylum category complete biodegradable material and a preparation method thereof. The amylum category complete biodegradable material comprises, by weight, the long-chain branch aliphatic polyester or long-chain branch aliphatic series- aromatic copolyesters 50-70%, the starch 20-30%, the chain extender 0.1-3% and the balance chain extender 9-17%. The preparation method comprises the steps of enabling all components to be mixed in a high speed mixer, feeding in a twin-screw extruder after accurate measurement by means of a measurement scale, and extruding and prilling by adjusting a built-up sequence of a screw and designing different exhaust ports. The amylum category complete biodegradable material and the preparation method of the amylum category complete biodegradable material solve the problems of dispersing, plasticizing and exhausting of starch filler in the twin-screw extruder, and obtained amylum complete biodegradation material not only has complete biodegradation performance, but also has excellent mechanical property and good extrusion molding working quality.

Owner:KINGFA SCI & TECH CO LTD +2

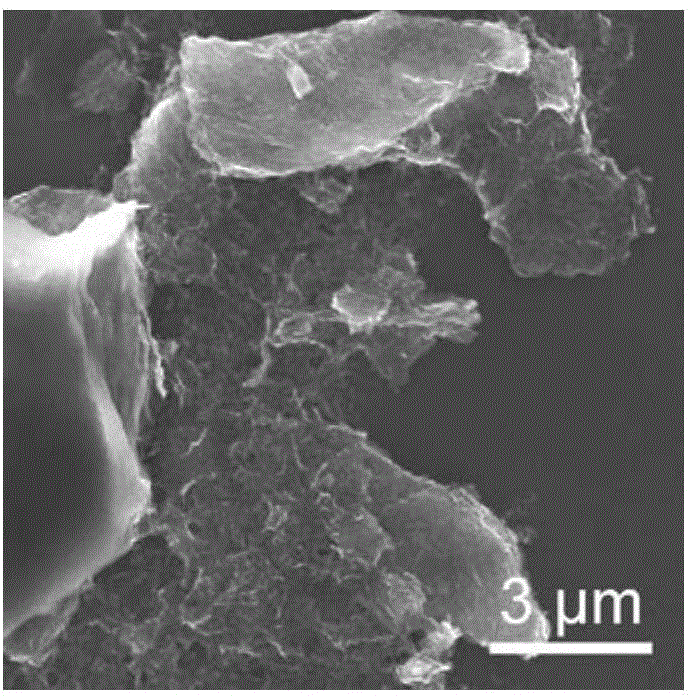

Preparation method for doped graphene foams

The invention discloses a preparation method for doped graphene foams. The preparation method comprises the following steps: adopting the hydrothermal method to enable nano particles to dope with and generate on oxidized graphene sheets to obtain oxidized graphene aerogel; reducing the oxidized graphene aerogel doped with the nano particles in a controllable manner at the low-temperature gaseous phase condition to obtain the doped graphene foams. According to the preparation method, a reductant is not used in the growing process of the nano particles, and liquid is not introduced into the reaction system, so that excessive overlap of the graphene layers is avoided, porosity of the graphene foams is maintained, polyporous shrinkage caused by surface stress is prevented, and the uniformly doped graphene foam material with the controllable appearance is obtained. The preparation method is convenient to operate, uniform in doping, controllable in product size, economical and fast, is adopted as the novel technology for the large-scale preparation of the doped graphene foam material, and is expected to provide novel materials for graphene adsorbents, graphene capacitors, graphene catalysts and the like.

Owner:四川烯城环保科技有限公司

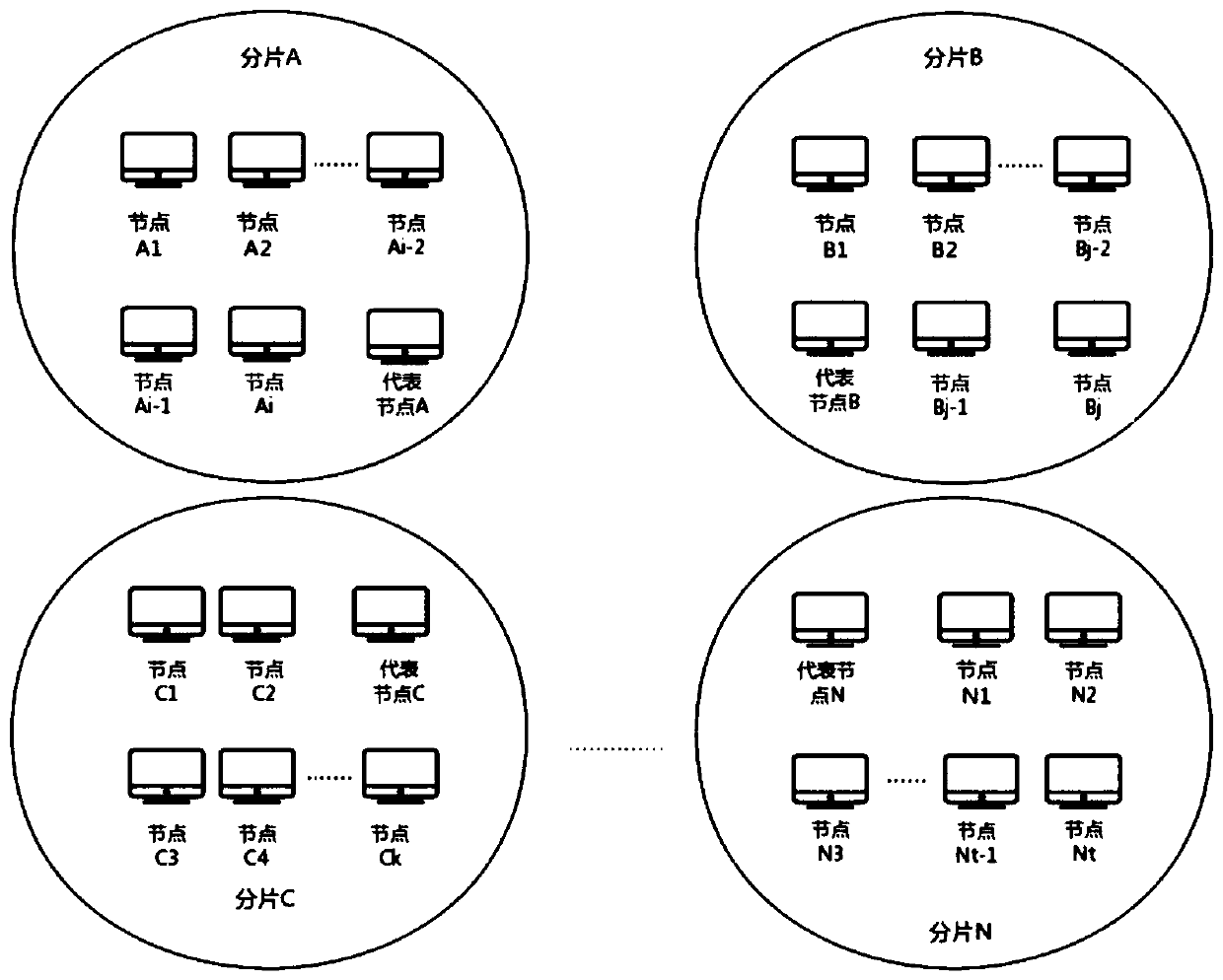

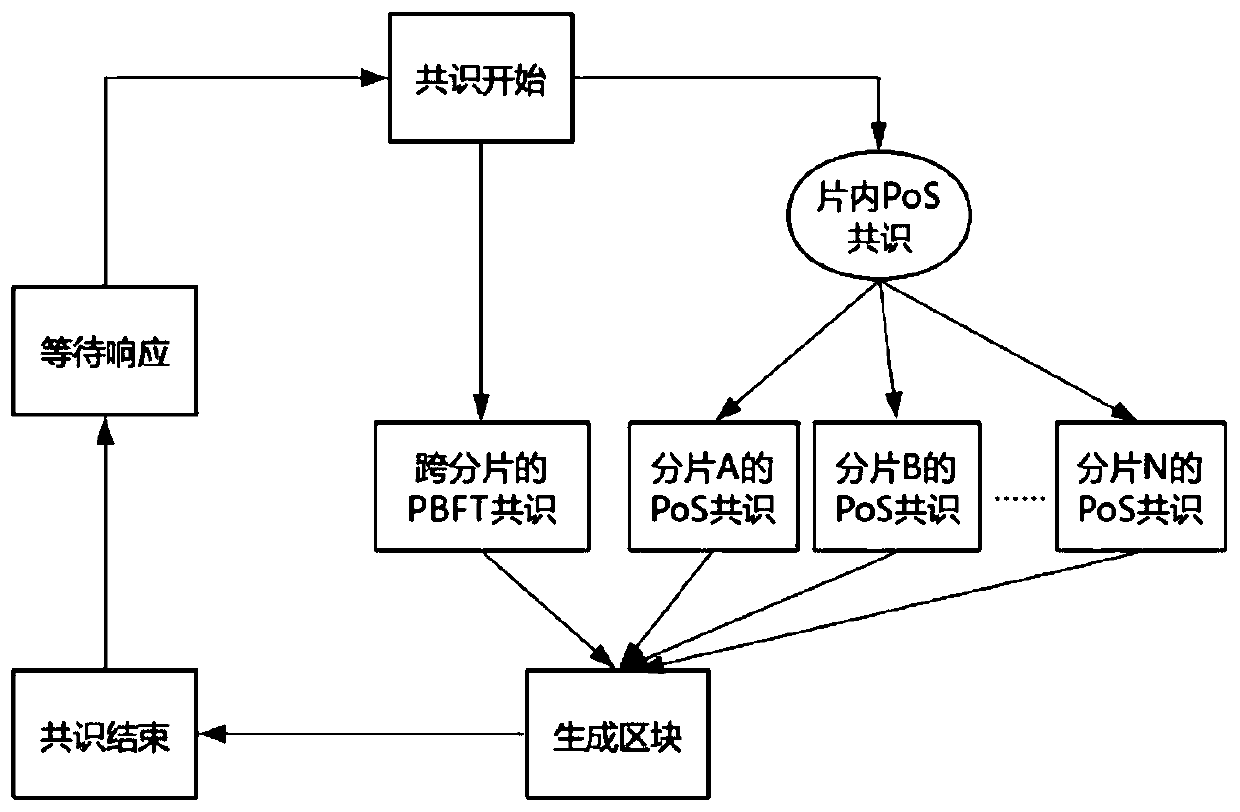

Hybrid consensus method based on fragmentation technology

ActiveCN110570202AGuaranteed decentralizationEnsure safetyFinanceDatabase distribution/replicationNODALChain system

The invention discloses a hybrid consensus method based on fragmentation technology. According to the method, fragmentation technology applied to a block chain system is designed. All nodes and transaction addresses are divided into a plurality of fragments. A common node in each fragment records a slave chain; wherein the representative nodes record the main chain and divide the consensus process into two layers, the first layer is consensus carried out in fragments, the consensus result is recorded in the slave chain and submitted to the main chain through the representative nodes of the fragments, and the second layer is 3% > 7 consensus carried out across the fragments and mainly processes, verifies and records transactions across the fragments. The consensus method is based on the fragmentation technology, and can improve the expandability of the blockchain system while ensuring the decentralization and security of the blockchain.

Owner:HANGZHOU QULIAN TECH CO LTD

Preparing method of copper-base electric contact material enhanced by in-situ grown graphene

InactiveCN105483641AImprove mechanical propertiesExcellent thermalTransportation and packagingMetal-working apparatusMethane gasPlasma chemistry

The invention discloses a preparing method of a copper-base electric contact material enhanced by in-situ grown grapheme, relates to the preparing method of the copper-base electric contact material, solves the problems that a conventional silver-base electric contact composite material is high in cost and low in cost performance, and overcomes the defect that when a copper-base composite material with high performance replaces metal silver, grapheme is dispersed in copper nonuniformly. The method comprises the following steps: placing copper powder in a plasma enhanced chemical vapor deposition vacuum device, introducing hydrogen, insulating at a high temperature, introducing methane gas for deposition, stopping introducing methane gas after the deposition is finished, and finally cooling to be below the room temperature to obtain grapheme / copper composite powder.

Owner:HARBIN INST OF TECH

Zinc oxide whisker compound germicide composition

InactiveCN1531852AAvoid the difficulty of dispersion and the problem of secondary reunionGuaranteed decentralizationBiocideAnimal repellantsWhiskersColor changes

The zinc oxide whisker compound germicide composition contains: four-needle shaped zinc oxide whisker 50-80 weight portions, nano zinc oxide 5-25 weight portions, nano titanium oxide 5-25 weight portions, and sodium silicate carrier 10-40 weight portions. It has the advantages of high germicidal effect, capacity of being reused, stable effect, no color change, no need of photocatalyst, convenient use, etc.

Owner:SOUTHWEST JIAOTONG UNIV +1

Preparation method of two-dimension nitrogen- and phosphorus-doped graphene

The invention discloses a preparation method of two-dimension nitrogen- and phosphorus-doped graphene. The preparation method particularly includes following steps: adding hydrotalcite to a proper amount of a sodium butyrate solution, stirring the mixture, aging the mixture, adding 4-dimethyl aminopyridine and n-butyl phosphate, stirring the mixture in a constant-temperature water bath at 60-70 DEG C for 6-8 h, separating a precipitation from liquid, washing the precipitation with deionized water for 2-3 times, drying and grinding the precipitation, sieving the precipitation through a sieve being 20-40 in meshes to obtain modified hydrotalcite powder, heating the modified hydrotalcite powder in a vacuum tubular furnace to 400-600 DEG C under a vacuum condition for calcining the powder for 2-4 h, adding the calcined powder to a hydrochloric acid solution, separating the precipitation and finally heating the precipitation to 2000-2500 DEG C under the vacuum condition to perform heat treatment for 3-6 h, and cooling a product to obtain the two-dimension nitrogen- and phosphorus-doped graphene. The preparation method is simple in raw materials and is mild in conditions.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

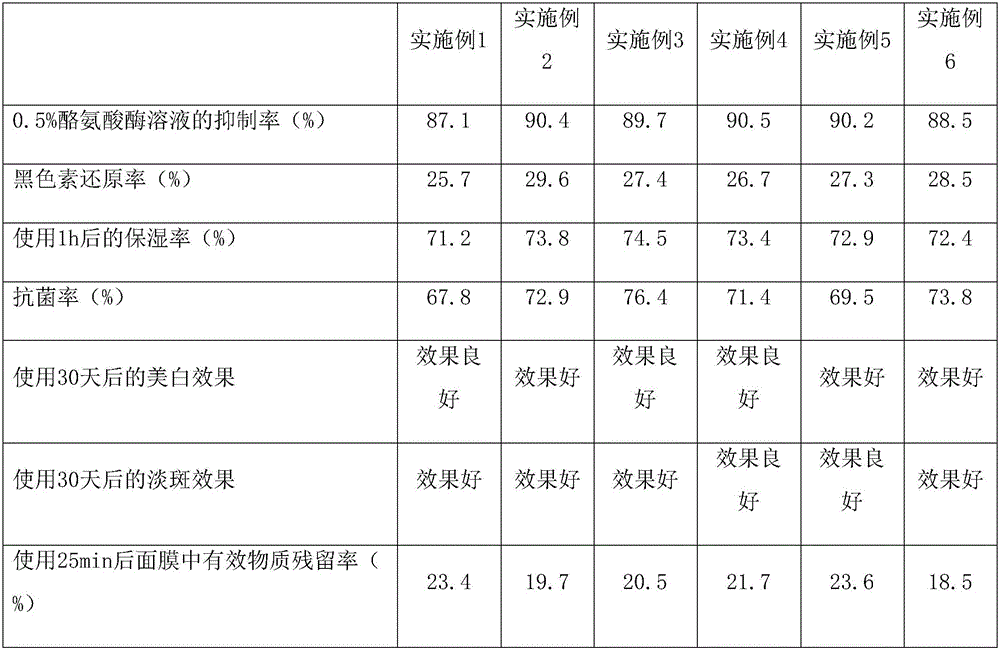

Apple facial mask based on traditional Chinese medicine formula

ActiveCN105769652AImprove antioxidant capacityStop chain reactionCosmetic preparationsToilet preparationsBetaineTremella

The invention provides an apple facial mask based on a traditional Chinese medicine formula.The apple mask comprises a silk matrix and a water-soluble substance.The water-soluble substance comprises apple extract, traditional Chinese medicine extract, seaweed extract, sodium hyaluronate, beta-glucan and assistant.The traditional Chinese medicine extract comprises tremella extract, centella asiatica extract, polygonum cuspidatum root extract, scutellaria root extract, tea extract, glycyrrhiza glabra root extract, chamomilla recutita flower extract, rosmarinus officinalis leaf extract and purslane herb extract.The seaweed extract contains chondrus crispus and bio-saccharide gum-1.The assistant comprises butanediol, propylene glycol, diglycerol, polyethylene glycol-400, Carbomer, hydroxyethyl cellulose, urea, allantoin, glycine betaine, nicotinamide, sodium glutamate, triethanolamine, 1,2-hexanediol, decoyl hydroximic acid, 1,3-propylene glycol, hexanediol and deionized water.The apple mask has the effects that stability is good, dispersibility is high, nutrients are proper in quantity and balanced, antibiosis and anticorrosion effects are achieved, and moisturizing, skin whitening and stain lightening are achieved.

Owner:珠海市雅莎医疗器械有限公司

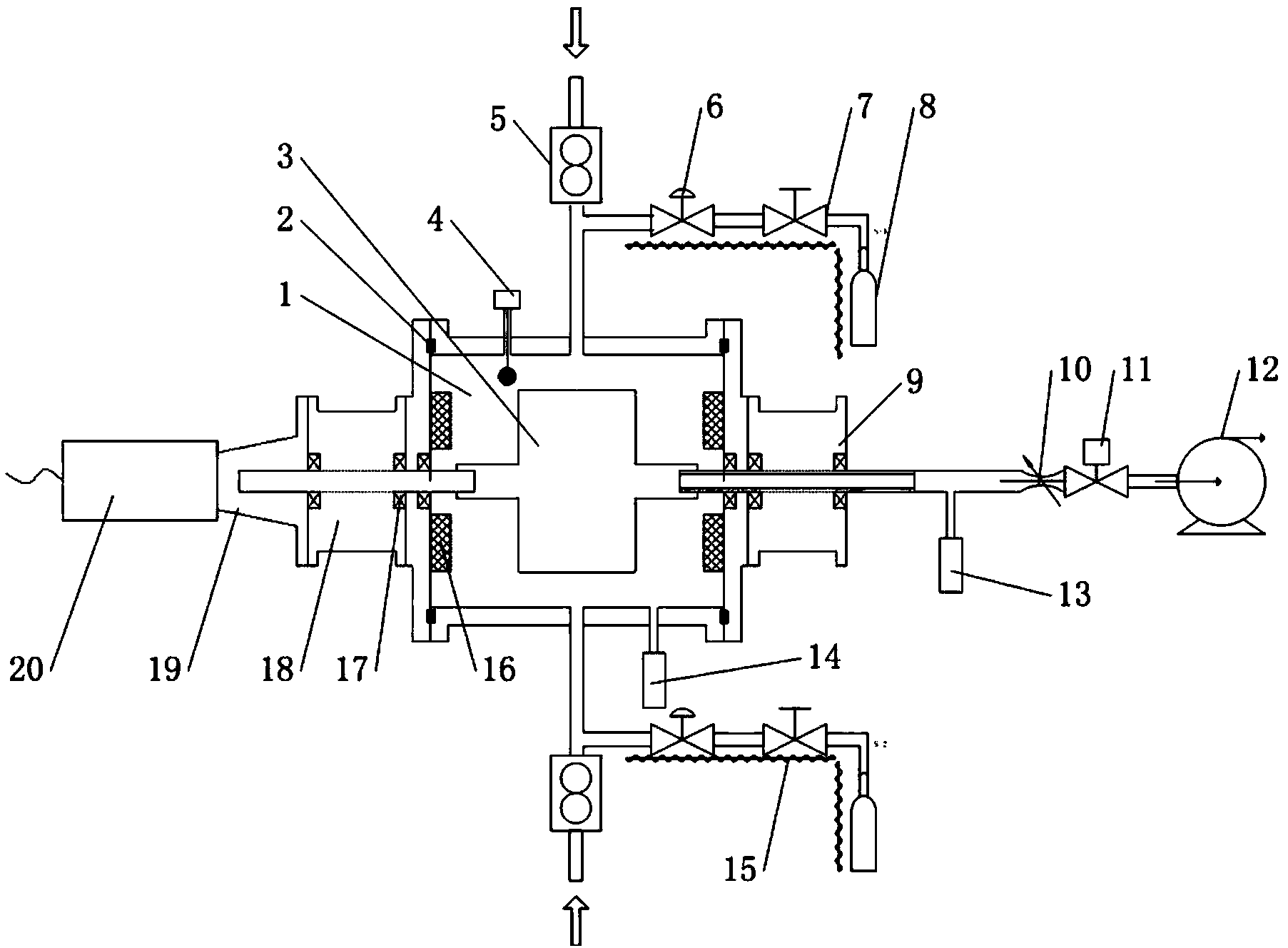

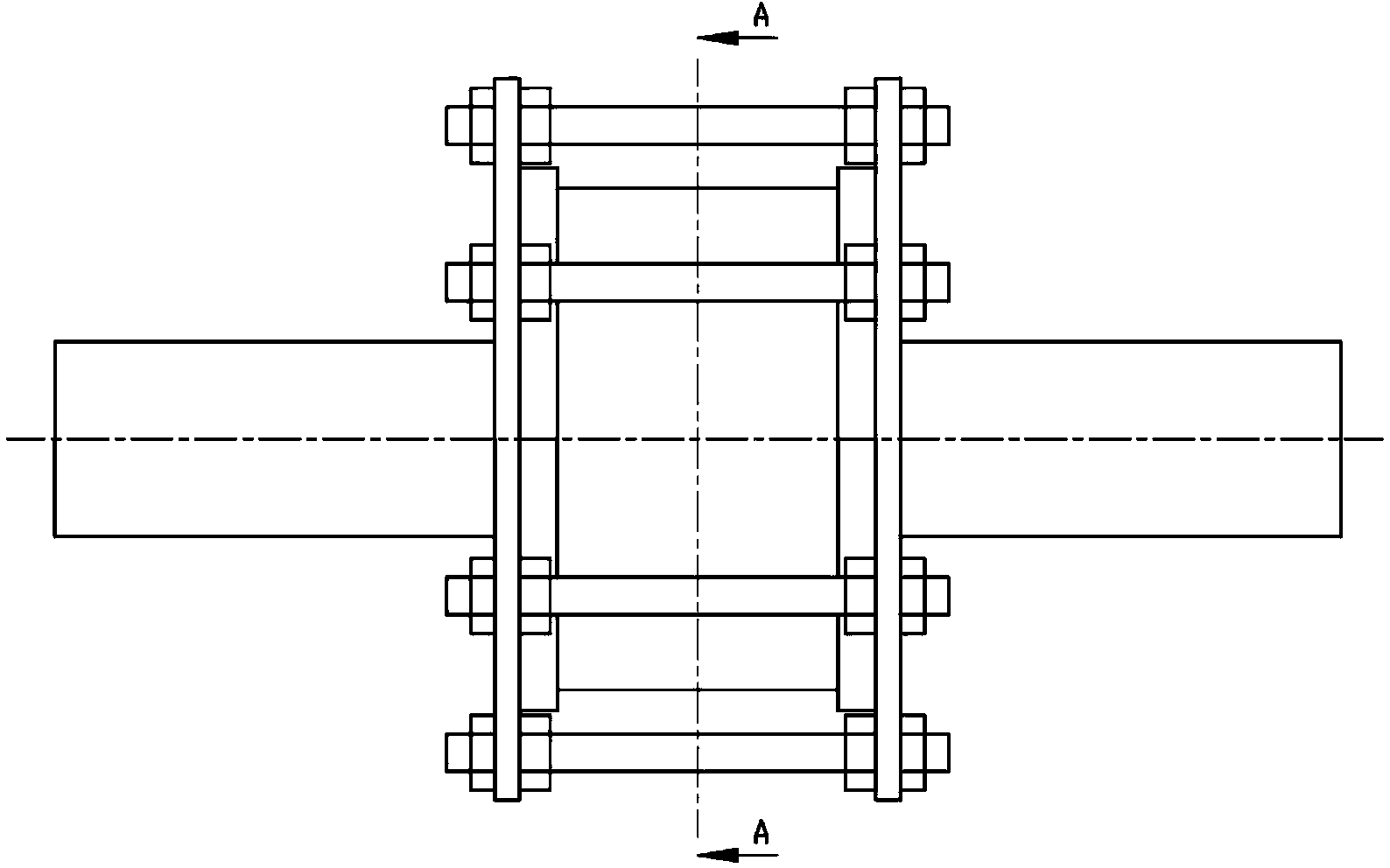

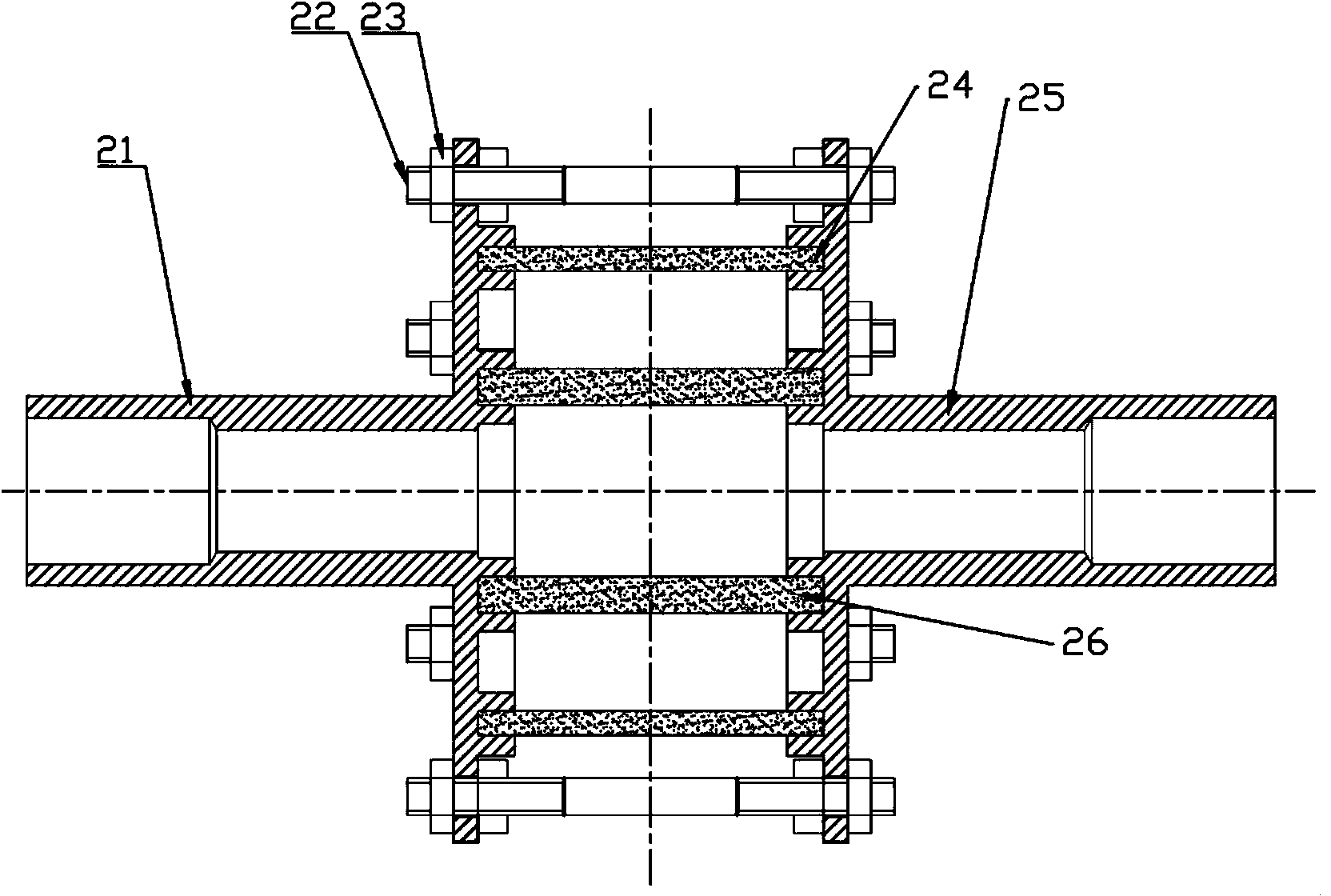

Device and method for surface modification of micro-nano particles

ActiveCN104046958ASufficient and uniform adsorptionIncrease profitMaterial nanotechnologyChemical vapor deposition coatingMicro nanoMicro nanoparticles

The invention discloses a device for surface modification of micro-nano particles. The device comprises a reaction cavity, a plurality of precursor supply devices, a carrier gas conveying system and a powder particle loading device, wherein a cavity formed inside the reaction cavity is used as a reaction space of precursors and the micro-nano particles; the plurality of precursor supply devices are respectively communicated with the reaction cavity by virtue of pipelines to provide different precursors; the precursors are conveyed to the reaction cavity by virtue of carrier gas output by the carrier gas conveying system; the powder particle loading device is used for loading the micro-nano particles to be modified; the precursors are alternately conveyed to the reaction cavity by virtue of the plurality of precursor supply devices respectively, and enter the rotary powder particle loading device so as to be in contact with the surfaces of the micro-nano particles to perform an atomic layer deposition reaction, thus forming a coating thin film on the surfaces of the micro-nano particles and realizing surface modification. The invention also discloses a method for performing surface modification on the micro-nano particles by using the device. The device and method disclosed by the invention can be used for obtaining a coating layer with high particle surface uniformity and improving the overall coating rate of the powder particles and the utilization rate of the precursors.

Owner:HUAZHONG UNIV OF SCI & TECH

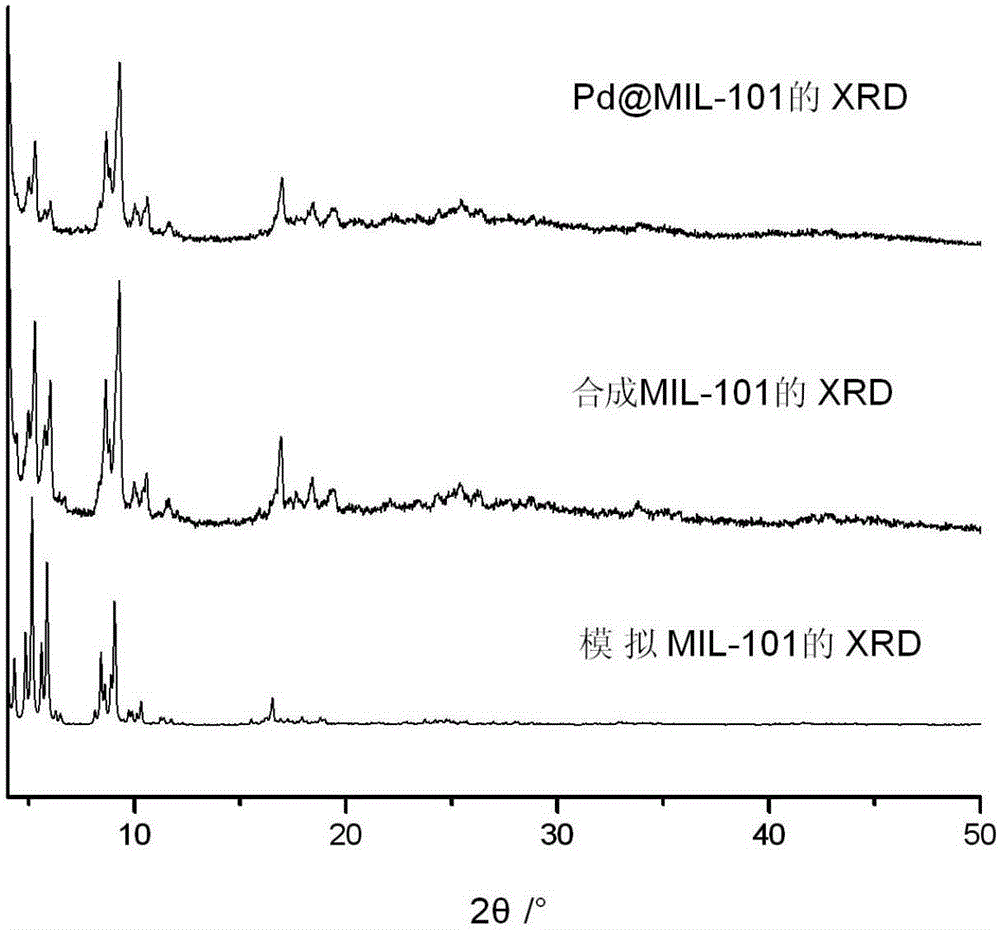

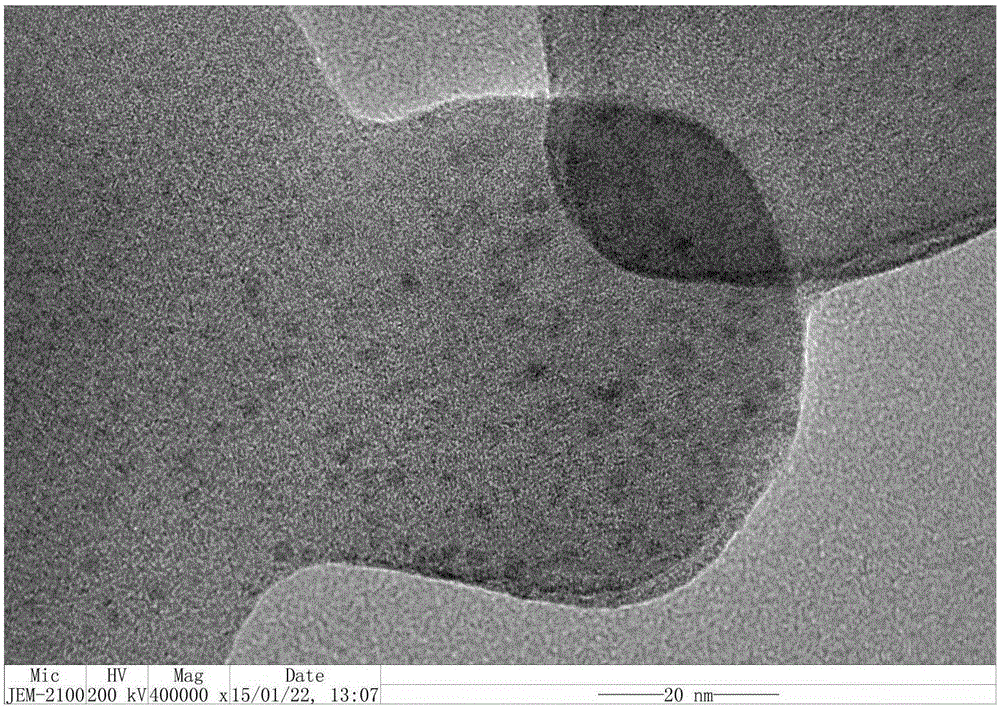

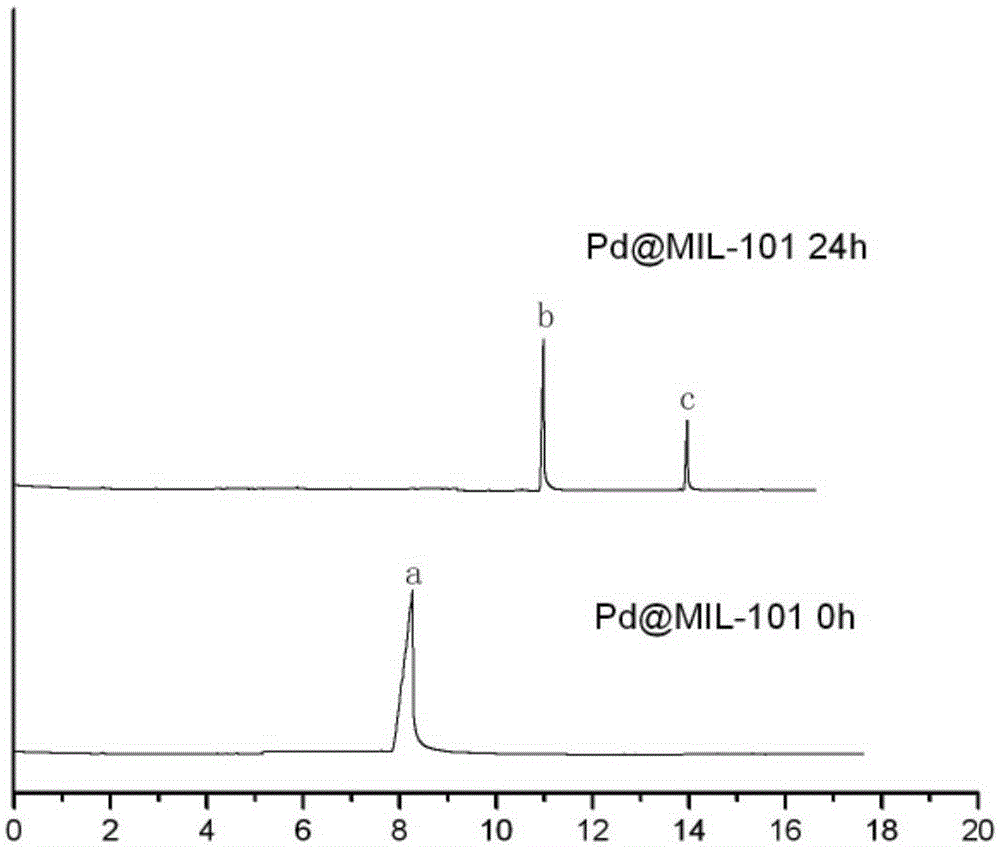

Pd @MIL-101 composite and preparation method and application thereof

ActiveCN105233872AEasy to separate and purifyHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsIce water1,4-Dibromobenzene

The invention relates to a Pd @MIL-101 composite and a preparation method and application thereof. According to the adopted technical scheme, palladium chloride is added to methyl alcohol while sodium chloride is added, ultrasonic dispersion is conducted, stirring is conducted for 10-20 hours, and sodium tetrachloropalladate is obtained; a sodium tetrachloropalladate solution is dropwise added into MIL-101 crystals slowly, pd<2+>@MIL-101 is obtained; a methanol solution of asaturated sodium borohydride is added to the pd<2+>@MIL-101, reduction is conducted under the condition of ice-water bath, and the Pd @MIL-101 composite is obtained. The synthesized Pd @MIL-101 composite has special selectivity catalytic activity for phenylboronic acid and 1,4-dibromo-benzene in a suzuki reaction, and the yield of an intermediate product 4-bromobiphenyl is effectively raised.

Owner:芜湖数字信息产业园有限公司

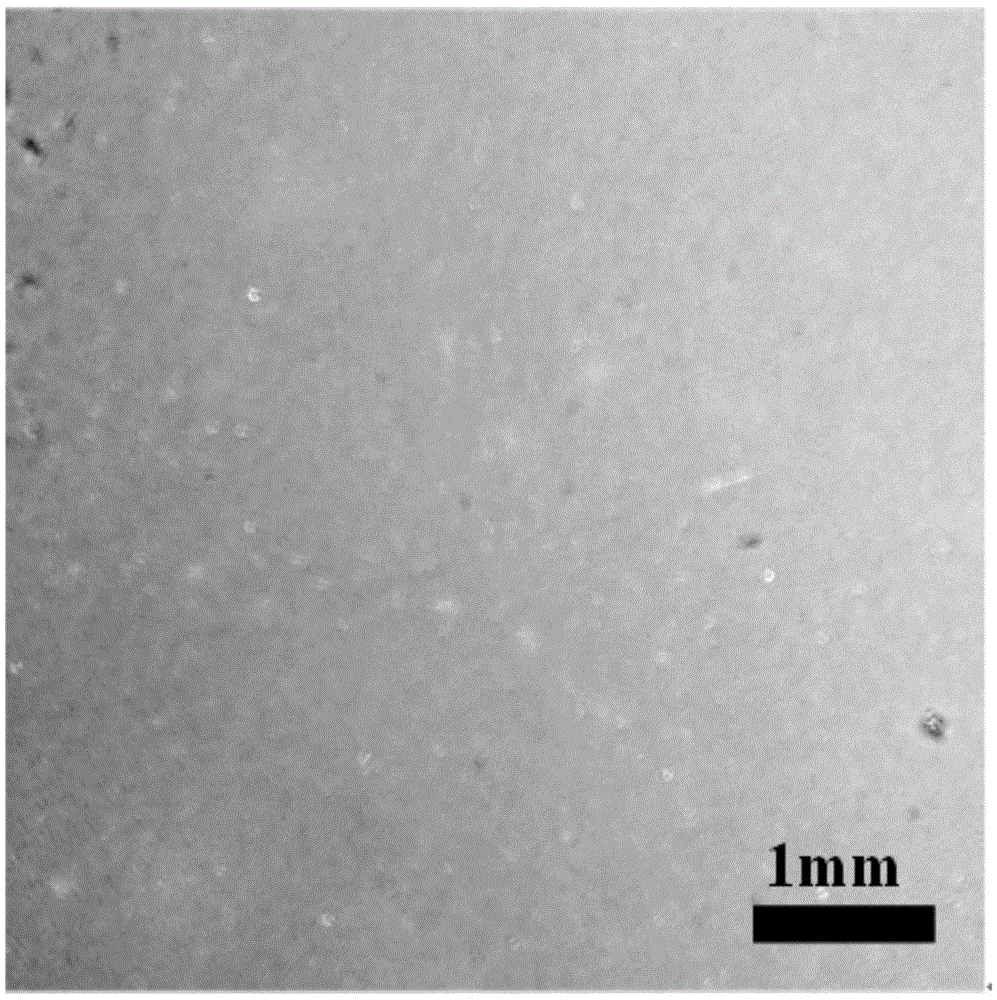

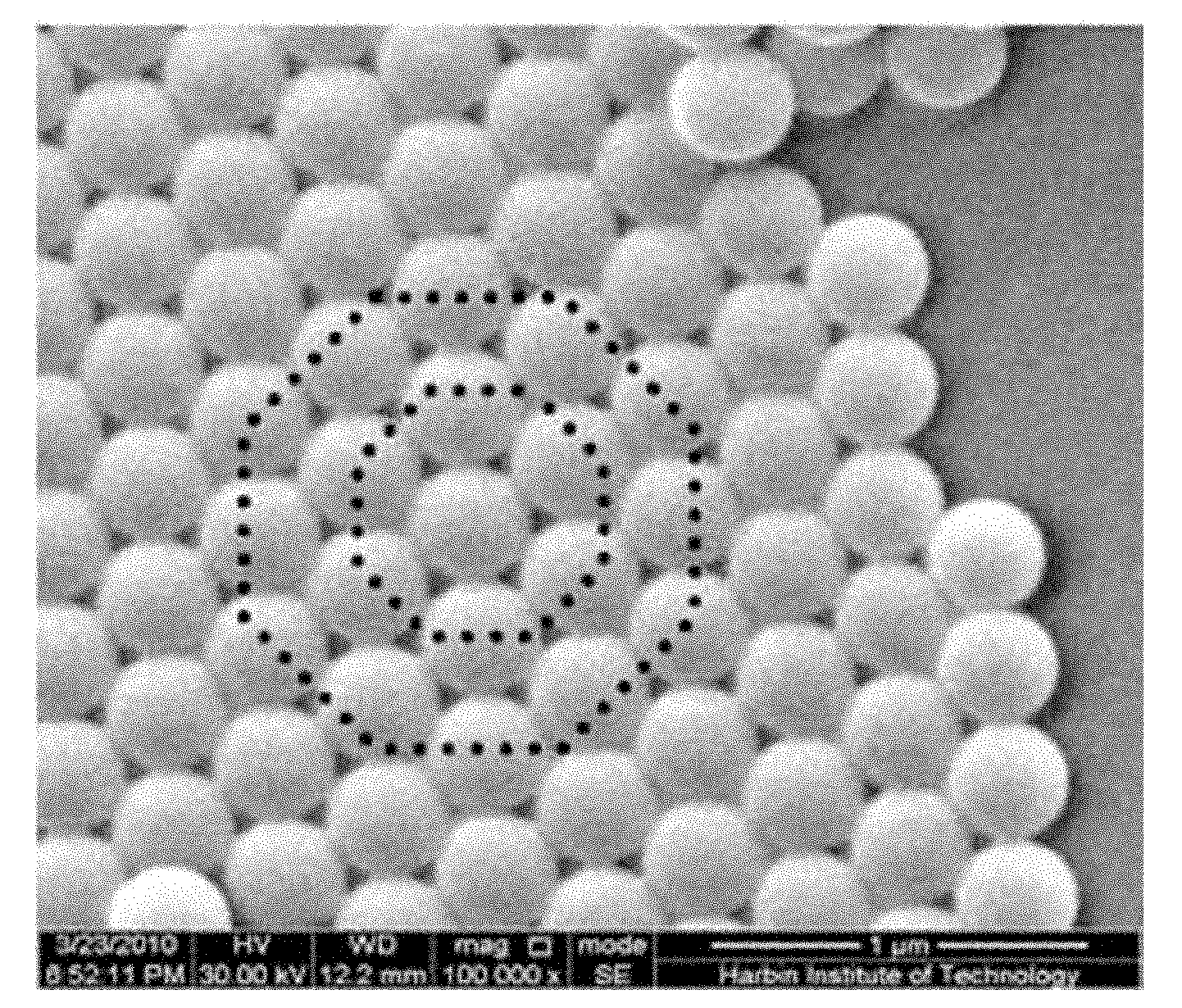

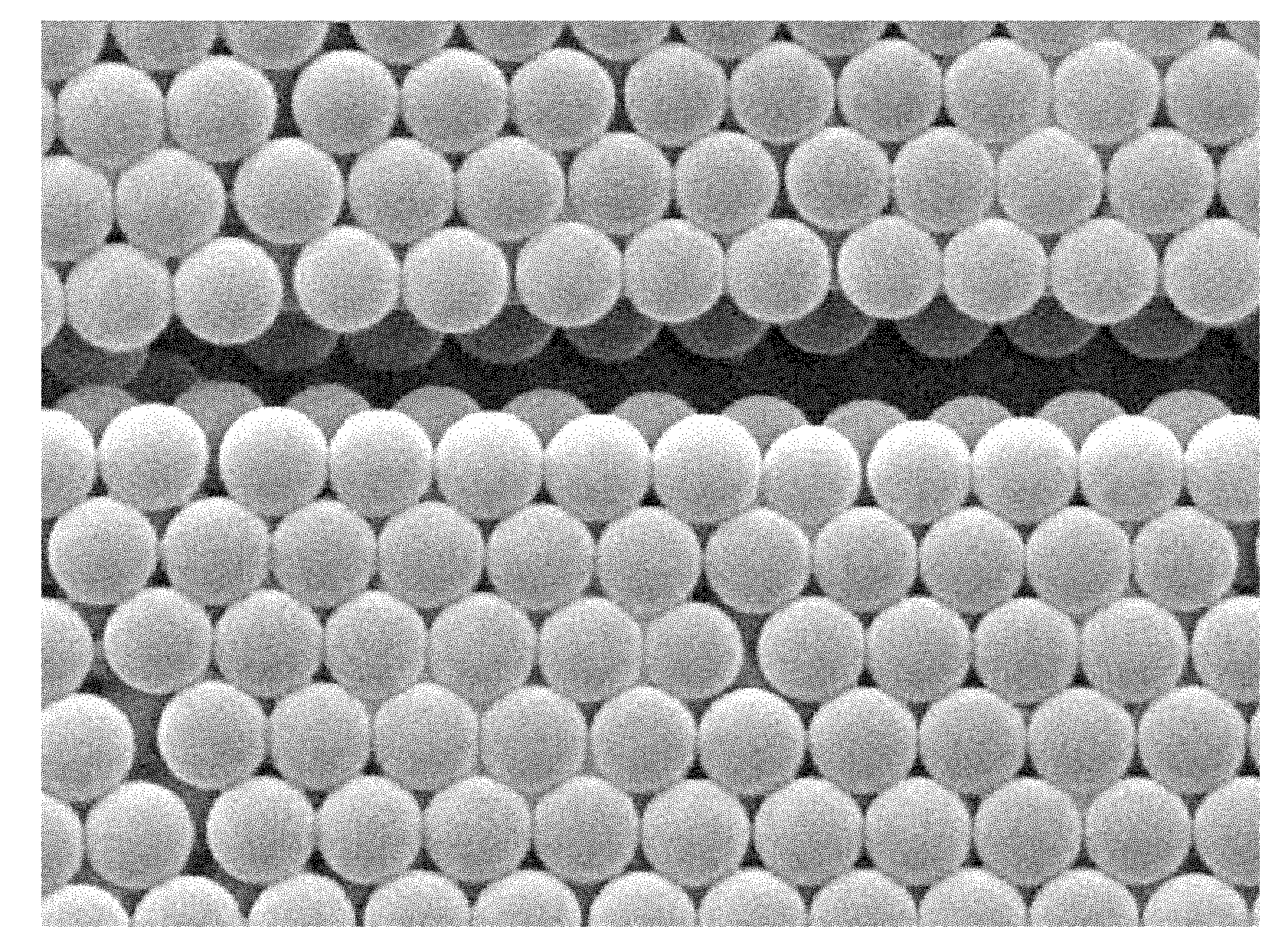

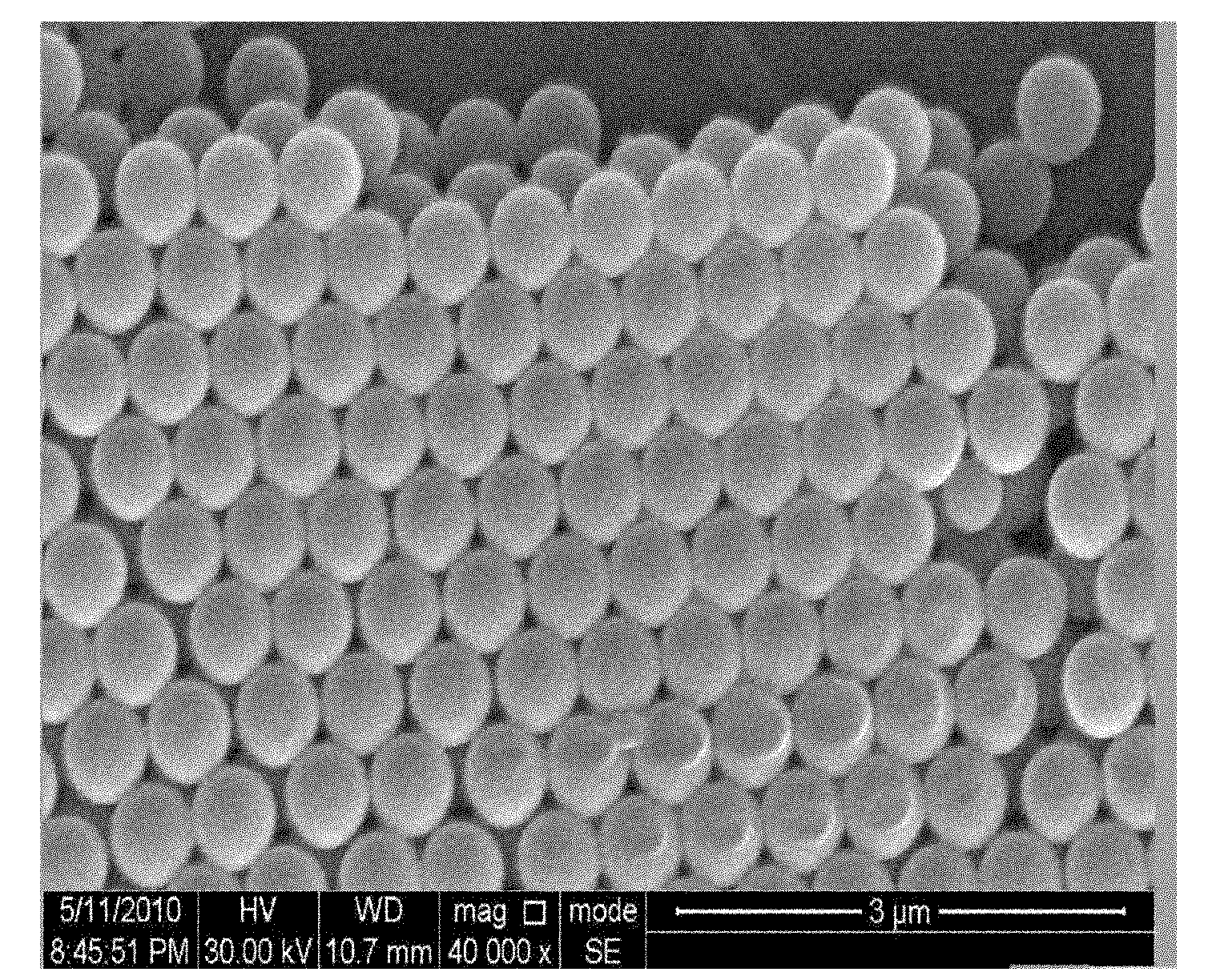

Self-assembling growth method of layer-controllable colloidal crystal

ActiveCN101934211AThe number of layers is controllableOvercoming the problem of poor orderPolycrystalline material growthColloidal chemistry detailsOptical propertyPhotonic crystal

The invention provides a self-assembling growth method of a layer-controllable colloidal crystal, which relates to a self-assembling growth method of a colloidal crystal and solves the problems that the traditional preparation method of colloidal crystal is more complicated, not easy to control and difficult to obtain the layer-controllable colloidal crystal. The method comprises the following steps of: 1. carrying out cleaning processing on a substrate, 2. preparing a colloidal particle suspension; and 3. inserting the substrate processed in the step 1 into the colloidal particle suspension prepared in the step 2, and placing into a constant-temperature incubator for 2-3 days. The method has the advantages of simple process, high efficiency, easy control and good repeatability and solvesthe problems of difficult layer number control of the self-assembling growing colloidal crystal and lower order degree of the obtained colloidal crystal of a traditional method and can be used for growing the colloidal crystals with large areas, ordered height and controllable layer number. The layer-controllable colloidal crystal obtained through self-assembly supplies a material for intensivelystudying the structure and the optical property of photonic crystals and simultaneously supplies a more rational and accurate template for three-dimensional ordered macroporous materials.

Owner:HARBIN INST OF TECH

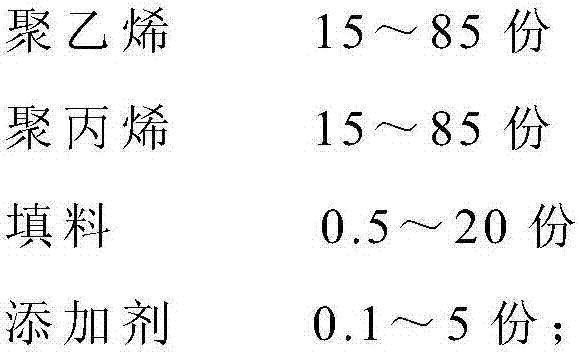

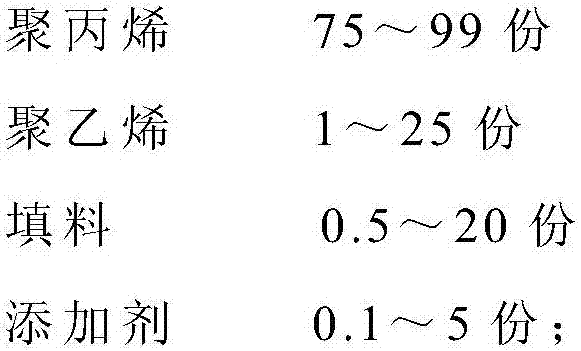

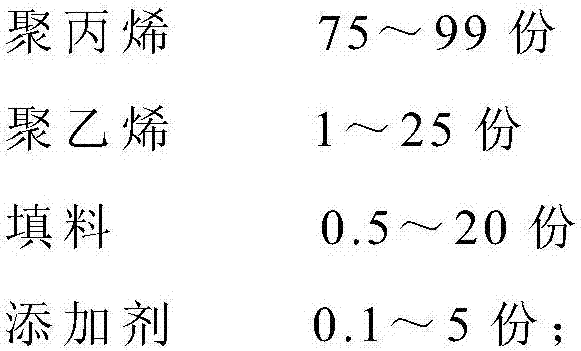

Extrusion type solar energy backboard and manufacturing method thereof

InactiveCN107275429AGuaranteed bonding performanceImprove adhesionSynthetic resin layered productsElectrical equipmentEngineeringSilica gel

The invention discloses an extrusion type solar energy backboard. The extrusion type solar energy backboard sequentially comprises an inner layer, a middle layer and an outer layer from inside to outside, wherein mass ratios of the inner layer, the middle layer and the outer layer are respectively 10-40:40-80:10-40, and total thickness of the extrusion type solar energy backboard is 0.1-0.6mm. The extrusion type solar energy backboard is advantaged in that polypropylene having relatively large rigidity is added to the inner layer, not only can adhesion stress between the backboard and a glue film be guaranteed, but also interlayer adhesion force between the inner layer and the middle-layer polypropylene material is further improved, moreover, polyethylene or copolymer of the polyethylene is added between the middle layer and the outer layer material, excellent adhesion with polyethylene of the inner-layer material can be realized, and interlayer adhesion force and low temperature impact strength of the backboard are further improved; the grafting material is added, uniformity and interlayer adhesion stress of products can be improved, surface tension of the backboard after corona processing can be improved, adhesion force between the backboard and sealing silica gel employed during solar energy cell frame sealing can be enhanced, and sealing performance is better.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

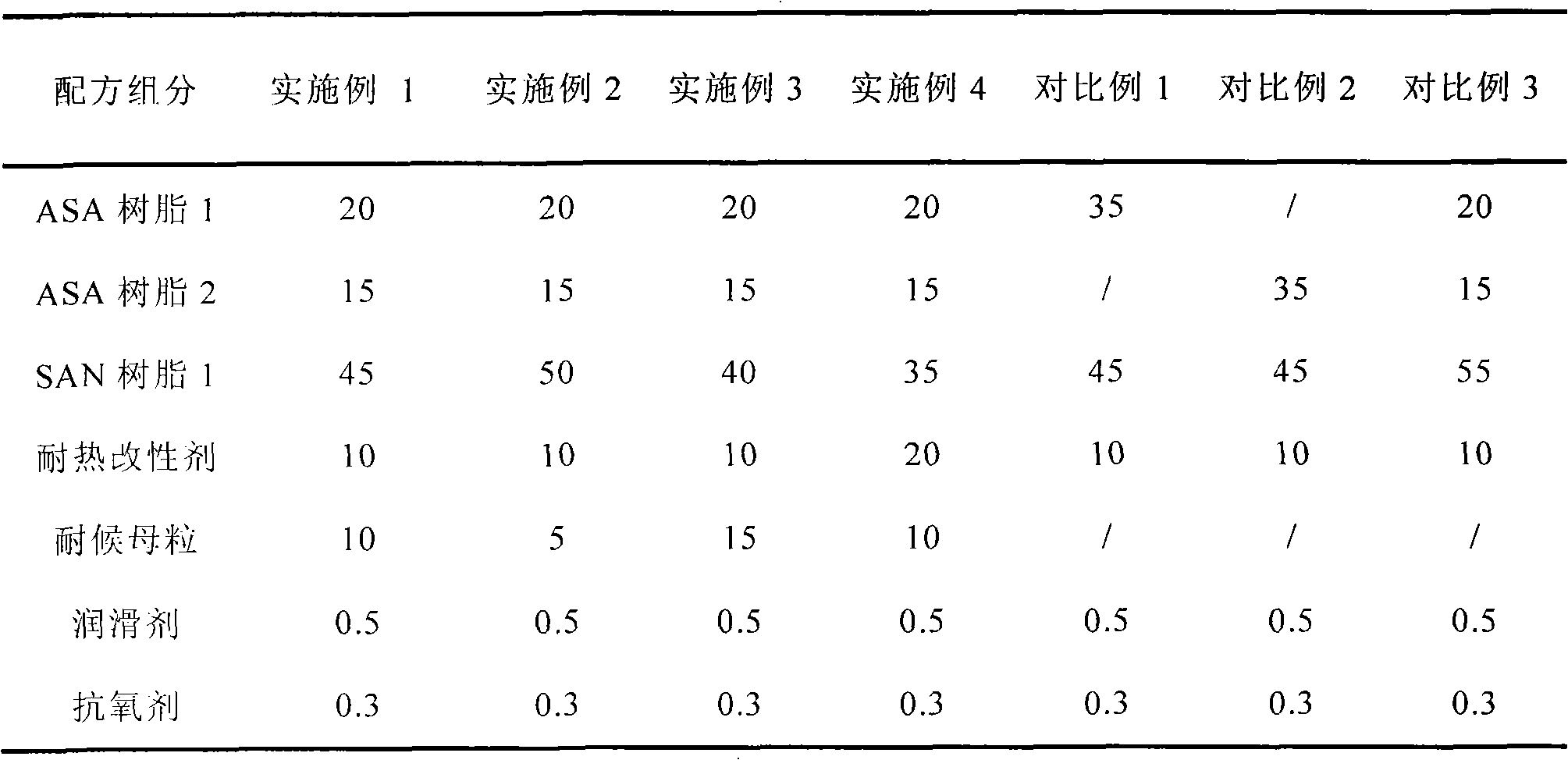

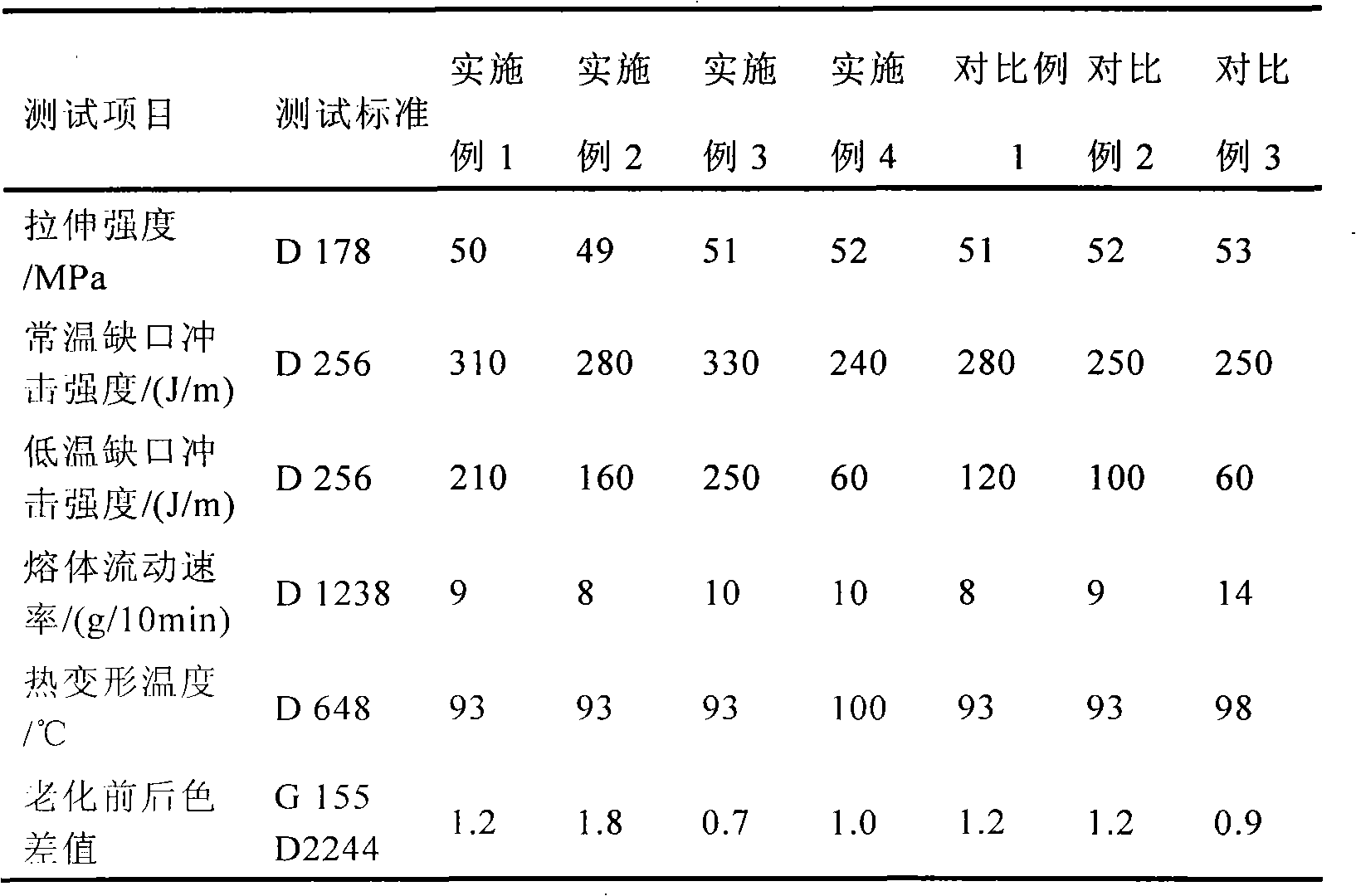

High-weather-resistance acrylate resin composition and preparation method thereof

The invention relates to a high-weather-resistance acrylate resin composition and a preparation method thereof. The raw materials of the high-weather-resistance acrylate resin composition comprise the following components in part by weight: 10 to 30 parts of acrylate rubber powder 1, 10 to 30 parts of acrylate rubber powder 2, 30 to 60 parts of SAN resin 1, 5 to 20 parts of heat-resistant modifier, 5 to 15 parts of weather-resistant master batch, 0.3 to 3 parts of lubricant and 0.05 to 0.5 part of antioxidant. The preparation method comprises the following steps of: stirring the raw materials except the weather-resistant master batch to obtain a mixture; adding the mixture from a main feed inlet of a double-screw extruder, and adding the weather-resistant master batch from a side feed inlet; and extruding and pelleting the raw materials by the double-screw extruder to obtain a sample. The high-weather-resistance acrylate resin composition prepared by the method has higher heat resistance, low-temperature impact resistance, weather resistance, excellent size stability and processing property, and is particularly suitable for automobile exterior trim parts, such as radiator grilles, rear-view mirrors, license plates, central pillar plates, outdoor triangular blocks and the like, with high requirements on weather resistance, heat resistance and low-temperature impact resistance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

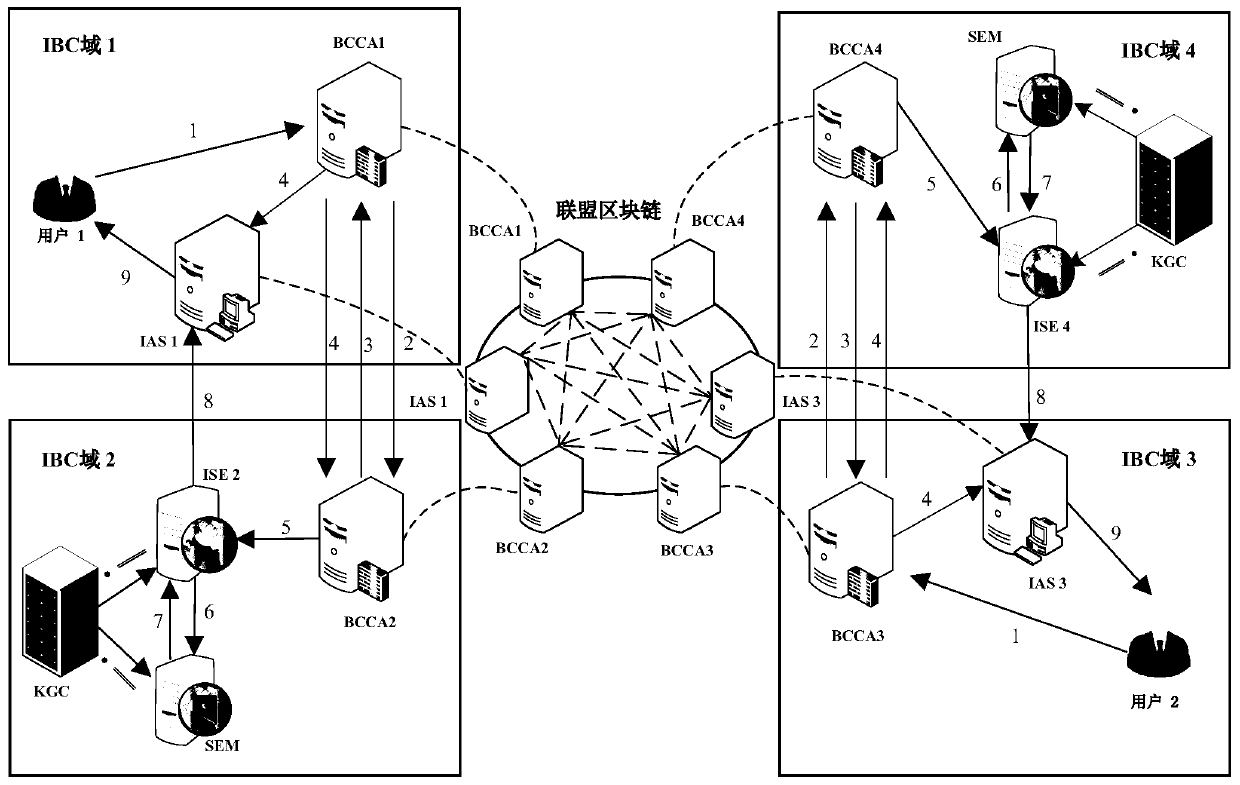

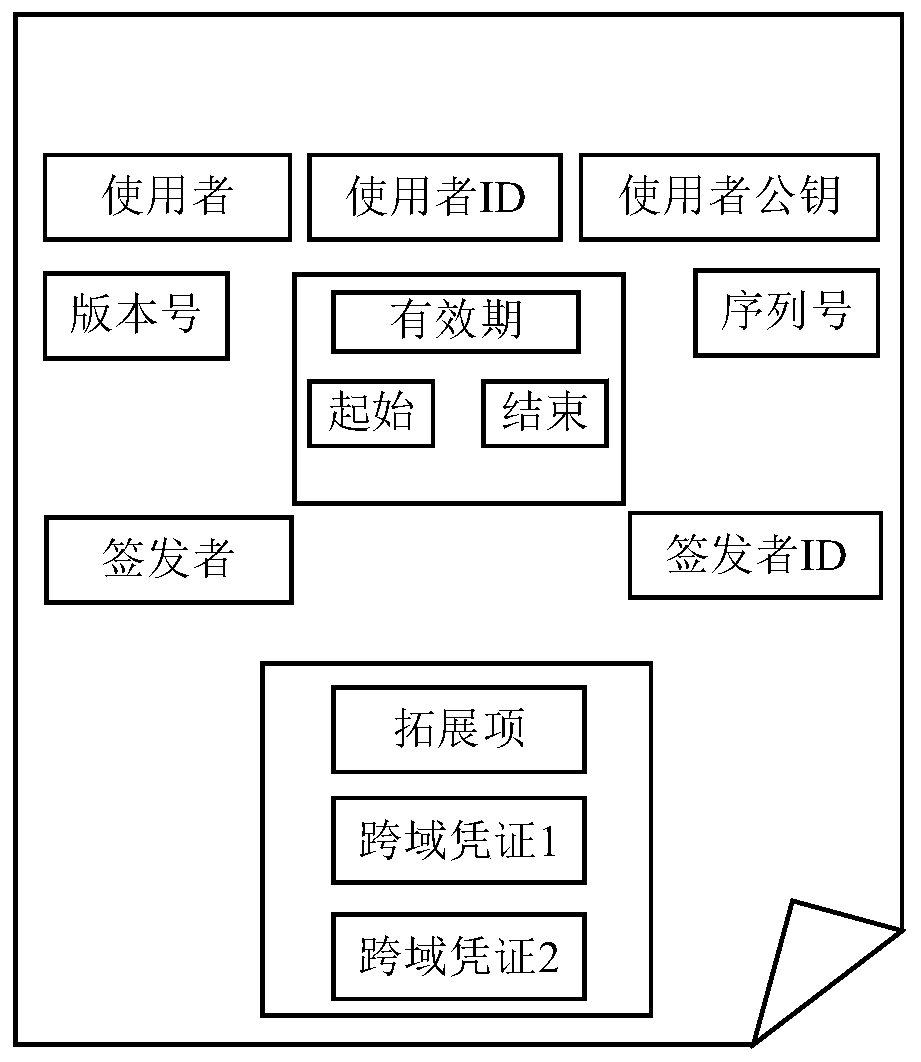

Credible identity authentication method based on block chain

InactiveCN110958229AGuaranteed decentralizationImprove securityUser identity/authority verificationCommunications serverBlockchain

The invention discloses a trusted identity authentication method based on a block chain. A blockchain certificate server transmits trust through a cross-domain model based on a block chain and realizes an authentication process of a client and an information service entity in different trust domains, and the information service entity obtains a complete signature through an arbitration entity communication server and realizes authentication of the complete signature through an identity authentication server. Only partial keys are stored in the information service entity; the rest secret keys are stored in the arbitration entity communication server; the information service entity obtains a complete signature of the message through the arbitration entity communication server; according to the invention, the capability of revoking the decryption or signature of the arbitration entity communication server can be realized by stopping sending signaling through the arbitration entity communication serve , the problem that the entity identity in the IBC system is difficult to cancel is solved, the problems of many certificate checking times, low cross-domain authentication and the like are also solved, and the decentralization and higher security of the block chain system are ensured.

Owner:NANJING UNIV OF SCI & TECH +1

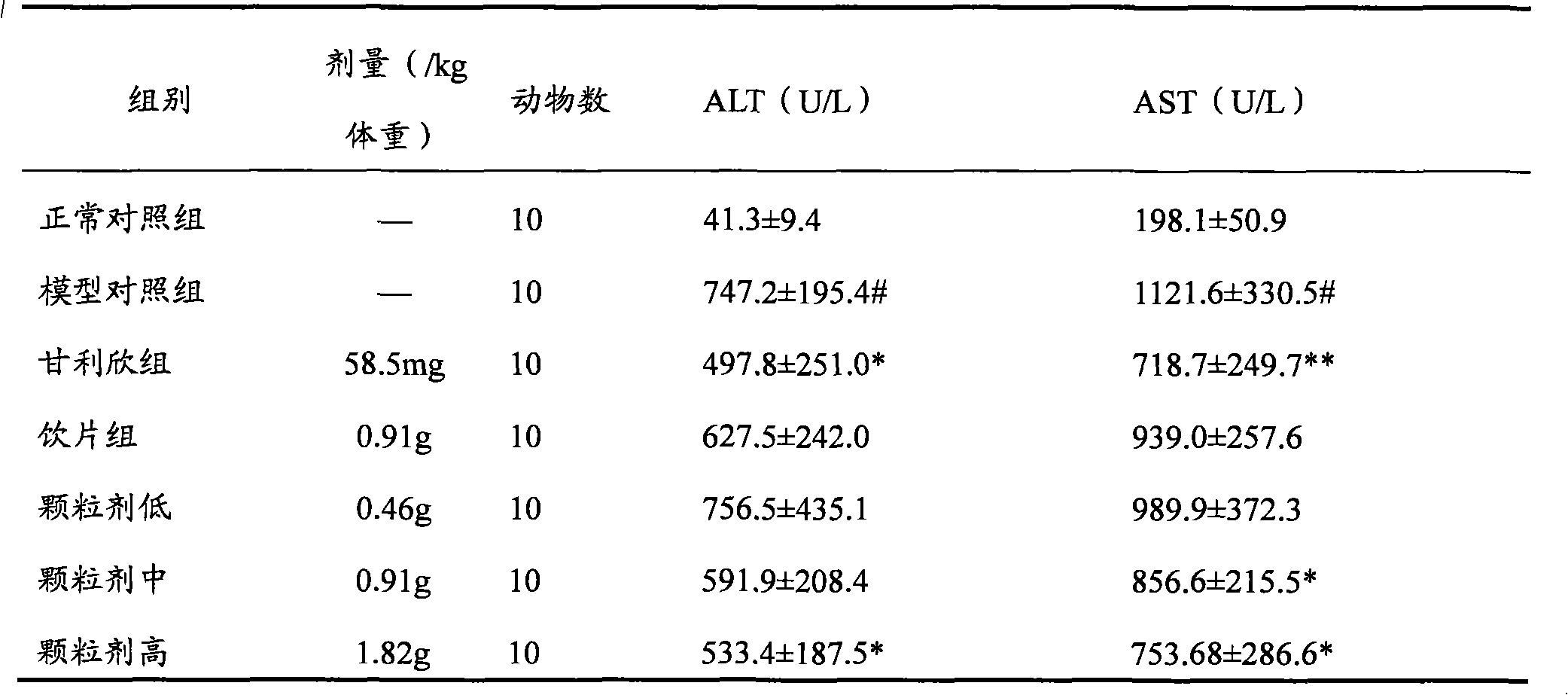

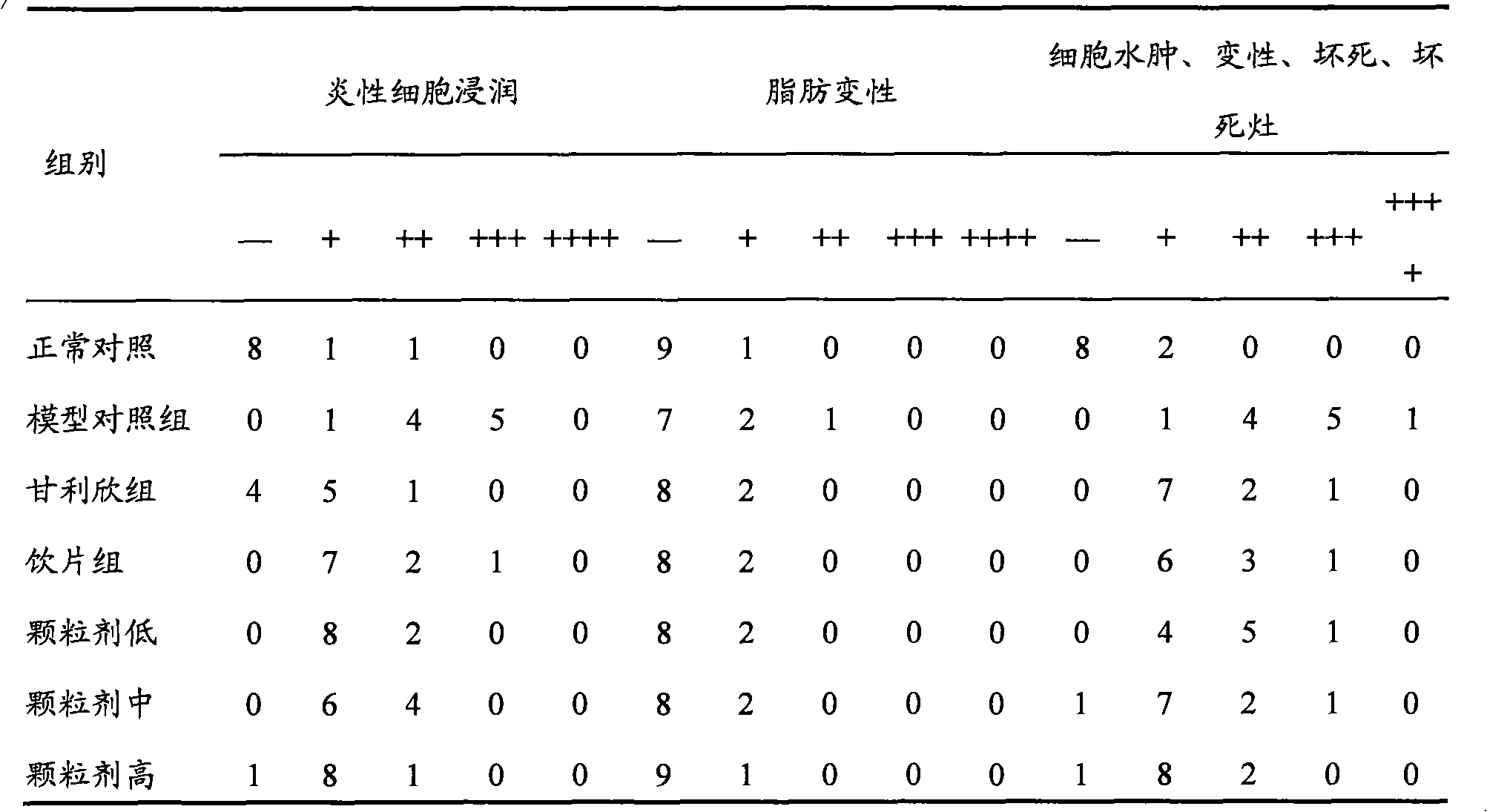

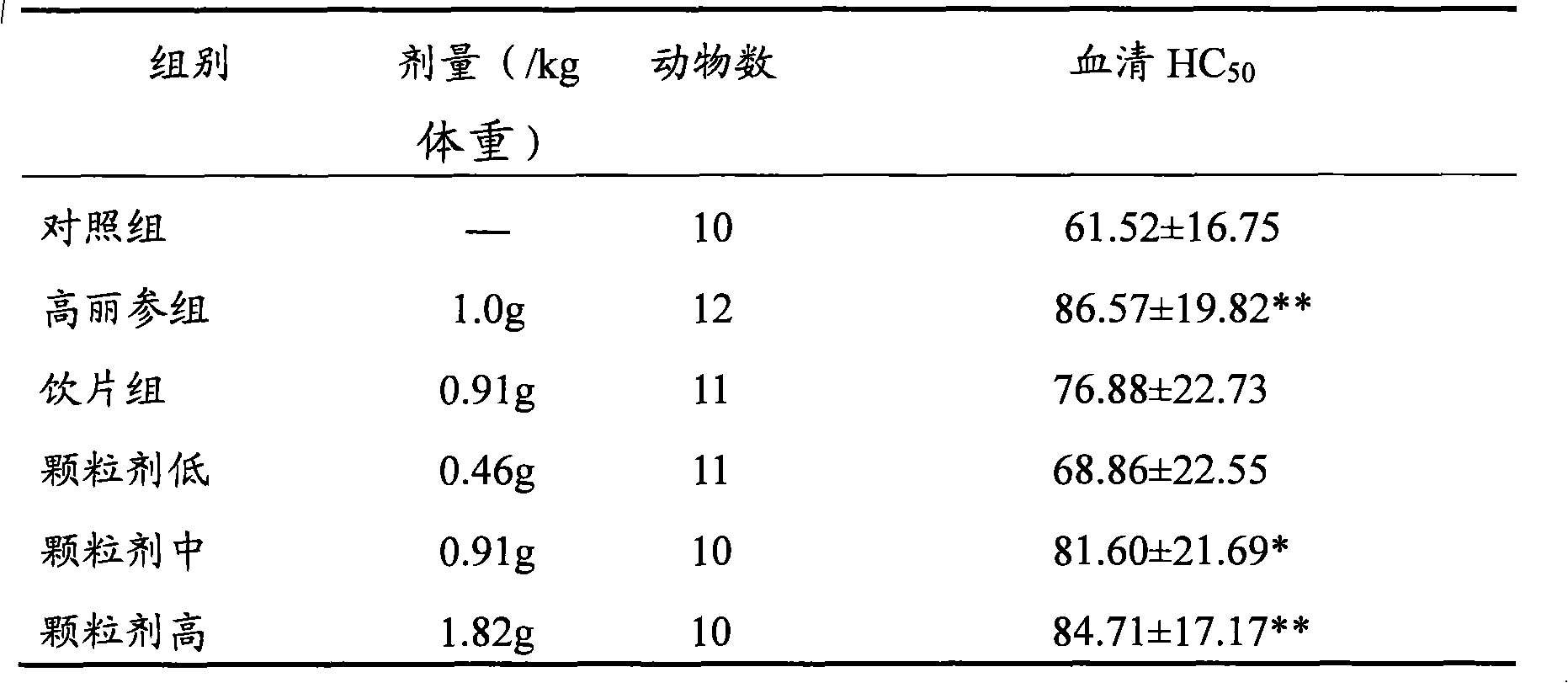

Chinese medicinal composition granules and preparation method thereof

ActiveCN101850066AGood effectSafe to takeAntinoxious agentsGranular deliveryDiseaseSalvia miltiorrhiza

The invention relates to Chinese medicinal composition granules and a preparation method thereof. The Chinese medicinal composition granules comprise the following ruptured powder in part by weight: 3 to 18 parts of American ginseng ruptured powder, 1 to 24 parts of pseudo-ginseng ruptured powder, 6 to 36 parts of dendrobium ruptured powder, and 9 to 45 parts of root of red-rooted salvia ruptured powder, wherein the granularity D90 of the ruptured powder is between 5 and 75 mu m. The invention also provides a method for preparing the Chinese medicinal composition granules. The method comprises the following steps of: uniformly mixing the American ginseng ruptured powder, pseudo-ginseng ruptured powder, dendrobium ruptured powder, and root of red-rooted salvia ruptured powder of which the D90 is between 5 and 75 mu m; preparing a soft material by adopting aqueous ethanol at the concentration of over 20 vol percent; and after granulating by using a granulator with 10 to 30 meshes, drying and finishing the granules to obtain the Chinese medicinal composition granules. The Chinese medicinal composition granules are applied to preventing and regulating human cardiac-cerebral vascular system diseases and sub-health state such as weak immunity and fatigability, have the obvious advantages of high medical effect, high quality uniformity, convenient carrying and administration, safety, reliability, and the like, and can meet the requirement on modern fast-paced lifestyle.

Owner:ZHONGSHAN ZHONGZHI PHARMA GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com