Patents

Literature

385 results about "Micro nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

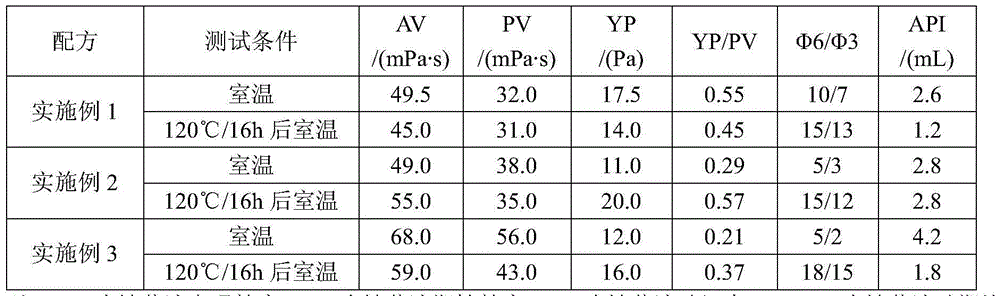

Water-based drilling fluid of shale gas horizontal well reinforced well wall and application thereof

ActiveCN104694092AImprove stabilityGood dispersionDrilling compositionBorehole/well accessoriesMicro nanoWater based

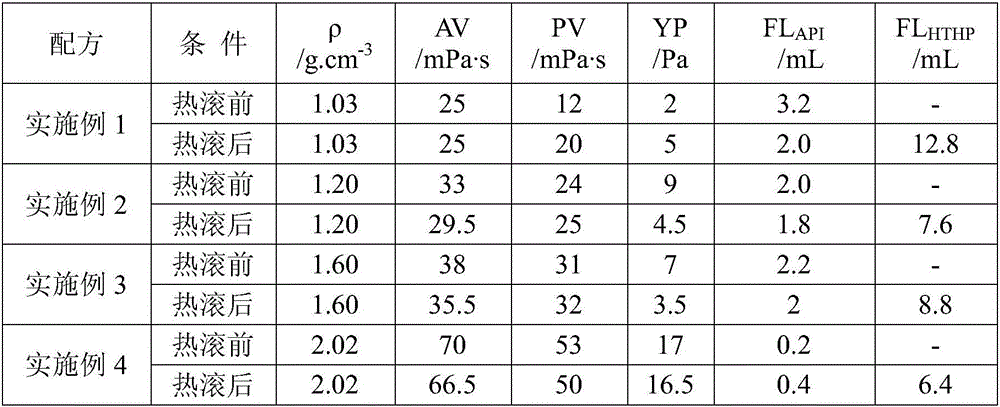

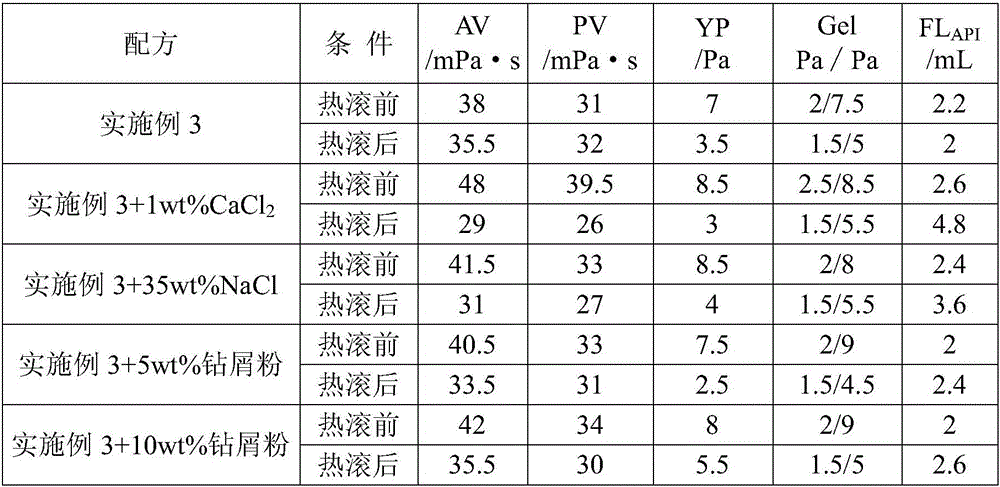

The invention relates to a water-based drilling fluid of a shale gas horizontal well reinforced well wall and an application thereof. The water-based drilling fluid comprises, by weight, 100 parts of water, 0-5 parts of clay, 0.5-3 parts of micro-nano particle blocking agents, 0.5-3 parts of chemical blocking agents, 0.1-2 parts of tackifier, 1-5 parts offiltrate reducer, 0.05-2 parts of encapsulating inhibiting agents, 0.1-3 parts of polyamine inhibiting agents, 1-5 parts of lubricant, 0.1-1 part of alkalinity regulator, 2-25 parts of inorganic salt, and 0-200 parts of weighting agents. The micro-nano particle blocking agents and the chemical blocking agents in the water-based drilling fluid of the shale gas horizontal well reinforced well wall have the effect of reinforcing the well wall in a cooperative mode, can effectively block micropore seams of shale to hinder pressure transmission, can further obviously improve the membrane efficiency of the shale, and facilitates the balance anti-collapse function of chemical activity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

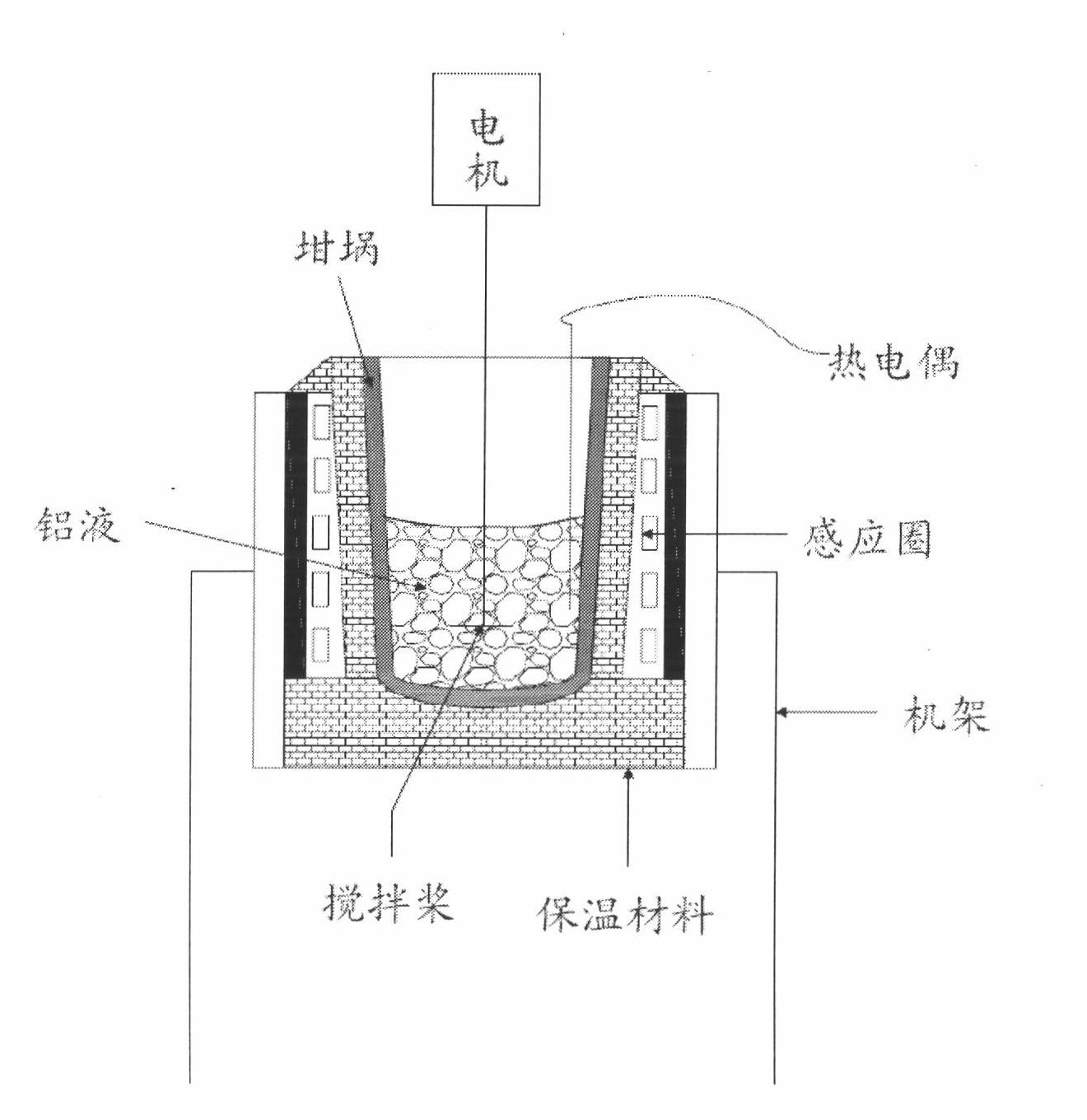

Method for diffusely distributing micro-nano particle reinforced phase in composite material

A method for diffusely distributing a micro-nano particle reinforced phase in a composite material is characterized in that the method comprises the following steps: 1, ball-milling the micro-nano particle reinforced phase and matrix powder by adopting a mechanical ball-milling process in order to improve the wettability of the micro-nano particle enhanced wetting phase and a metal melt; 2, melting the metal melt, adding the molten metal melt to the ball-milled mixed powder, and processing the obtained melt by utilizing an ultrasonic field or an ultrasonic and electromagnetic compound fieldt; and 3, carrying out cooling molding or casting molding to prepared a micro-nano particle reinforced phase diffusely distributed metal matrix composite material. The method realizes the diffusive distribution of one or more of ceramic particles of SiC, WC, Al4C3, B4C, ZrB2, TiB, Al2O3 and AlN in metal materials of aluminum alloy, magnesium alloy and the like, and the high-quality metal matrix composite material with good compactness and uniform performances can be obtained through the method.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

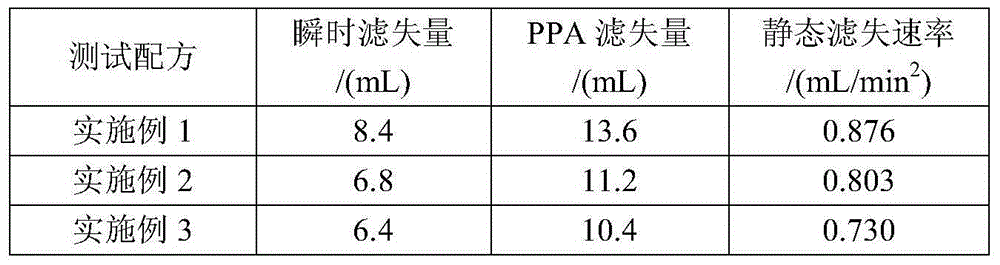

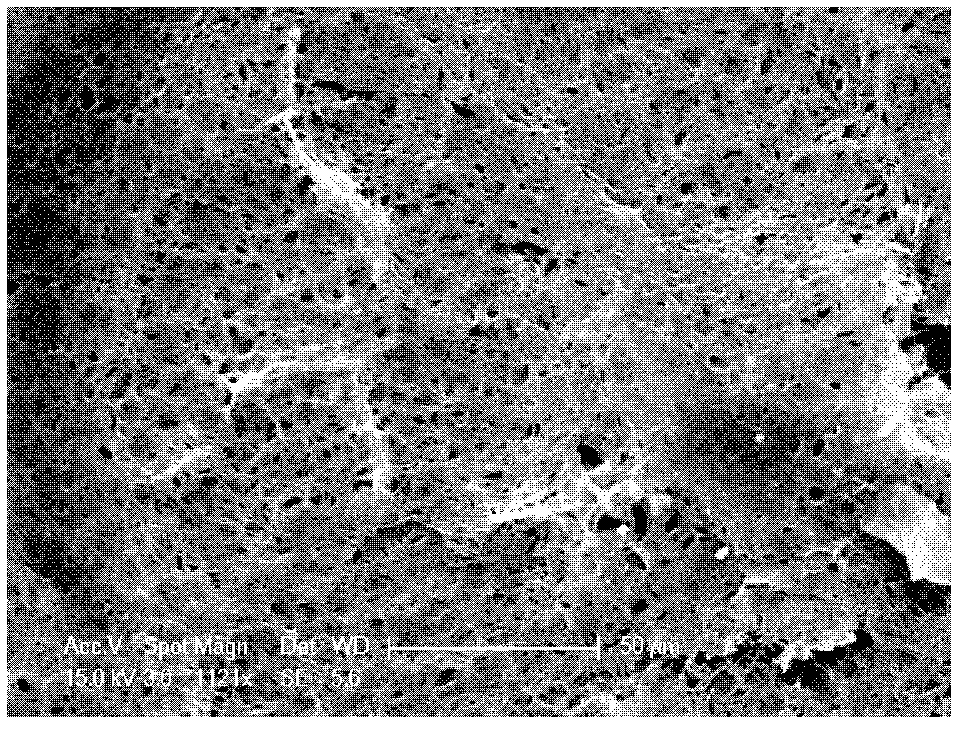

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

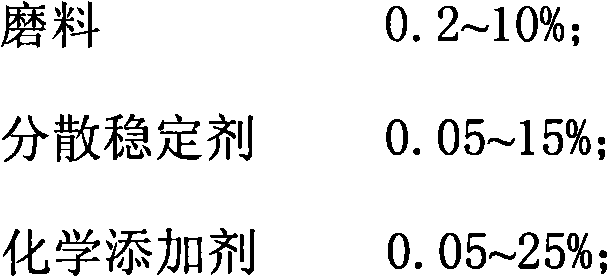

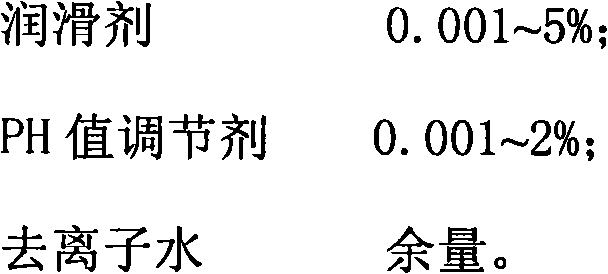

Water-based 6H-SiC monocrystalline substrate chemical mechanical polishing (CMP) solution and preparation method thereof

InactiveCN102337082AHigh removal rateNo damagePolishing compositions with abrasivesMicro nanoWater based

The invention discloses a 6H-SiC single chip global planar chemical mechanical polishing (CMP) solution. In the solution, spherical micro-nano particles are taken as grinding materials. The solution comprises the following components in percentage by weight: 0.2-10 percent of 1-3 types of spherical particles of 10-250 nanometers serving as grinding materials, 0.05-15 percent of dispersion stabilizer, 0.05-25 percent of additive having a chemical function, 0.001-5 percent of lubricating, a pH regulator for regulating the pH value to 9.5-13.5 and the balance of high-purity deionized water. The polishing solution has the advantages of controllable removing rate, no damage to a chip after polishing, high flatness, low price and low cost, and can be applied to the CMP process of hard and brittle crystal materials and precision CMP of other optical materials.

Owner:HENAN INST OF SCI & TECH

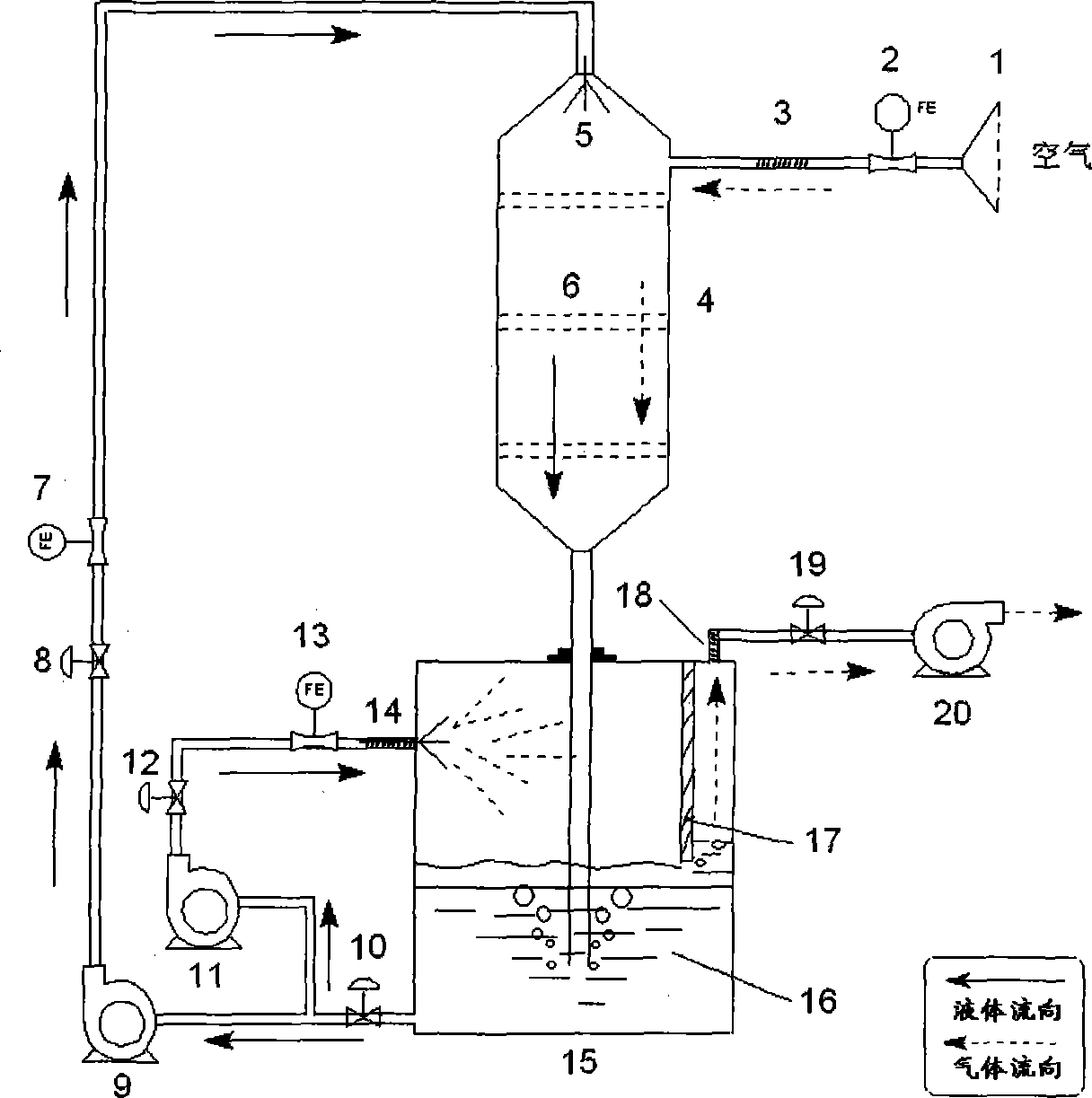

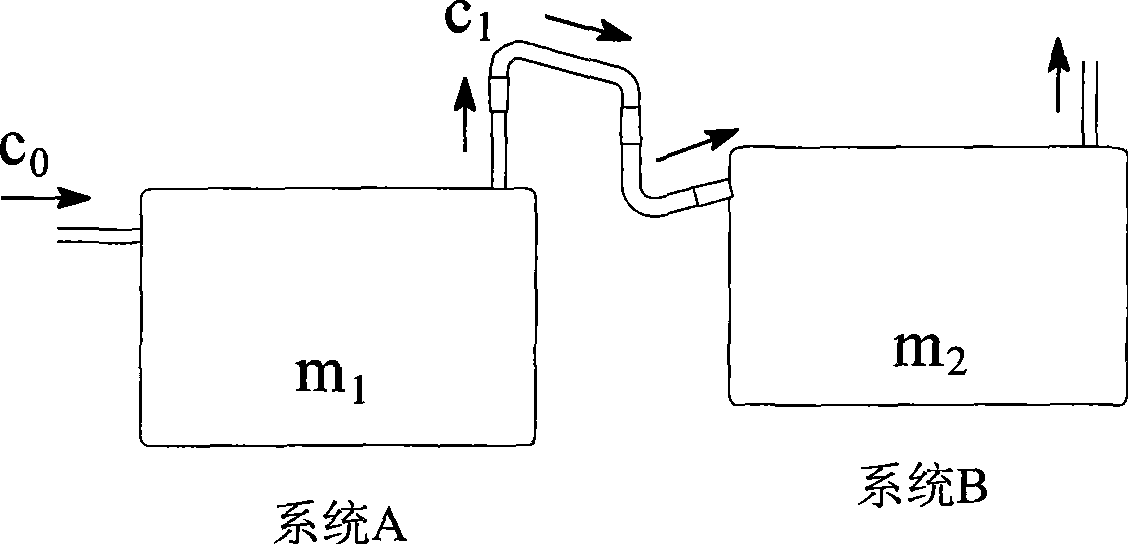

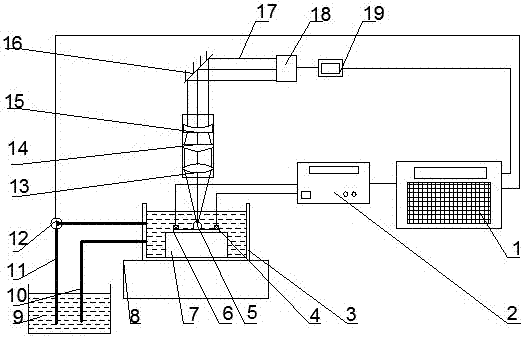

High-efficient trapping system for micro-nano powder dust in air

InactiveCN101502735AEfficient captureImprove wettabilityCombination devicesUsing liquid separation agentMicro nanoFiber

The invention discloses an efficient trapping system of micro-nanometer dust in the air. The invention comprises an air trapping opening, a filter core, a sprayer, a big and small flow micro pump, an atomizing nozzle, a liquid storage chamber, trapping liquid, a baffle and a vacuum pump, which construct an air flow route and a liquid circulation route, the system designs the air containing dust and the trapping liquid to experience four different absorption and trapping processes continuously, so as to realize efficient trapping of the micrometer and nanometer dust composed of various grains. By changing the variety of the trapping liquid or adjusting the hydrophile-lipophile balance (HLB) value of the trapping liquid, and improving the wettability of the trapping liquid and the nano dust in the air, micro nanometer fiber, thin sheet dust and other solid dust particles of various forms, containing micro-nano particles, can be efficiently trapped. The invention designs a plurality of air-liquid continuous contact processes, the air containing dust and the trapping liquid are only mixed and absorbed in the system, thus efficiently trapping nano dust in various dust density environment air including occupation workplaces.

Owner:NANJING UNIV OF SCI & TECH

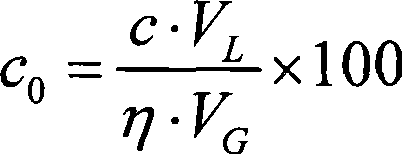

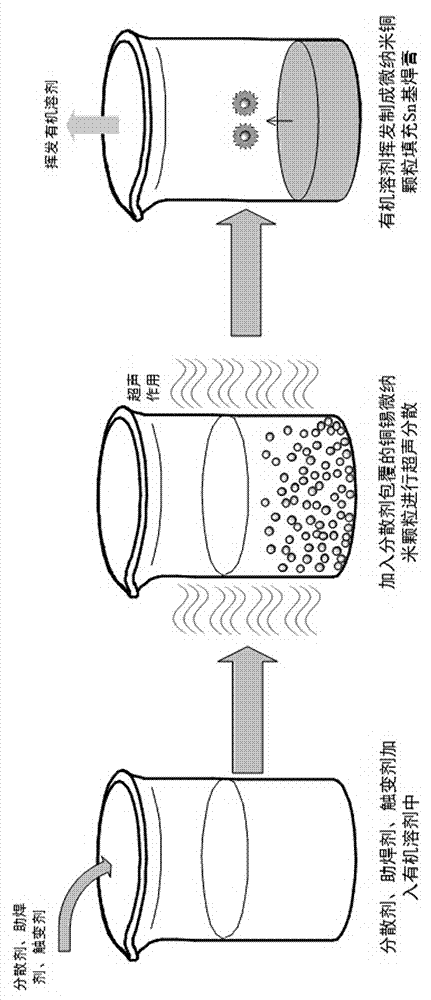

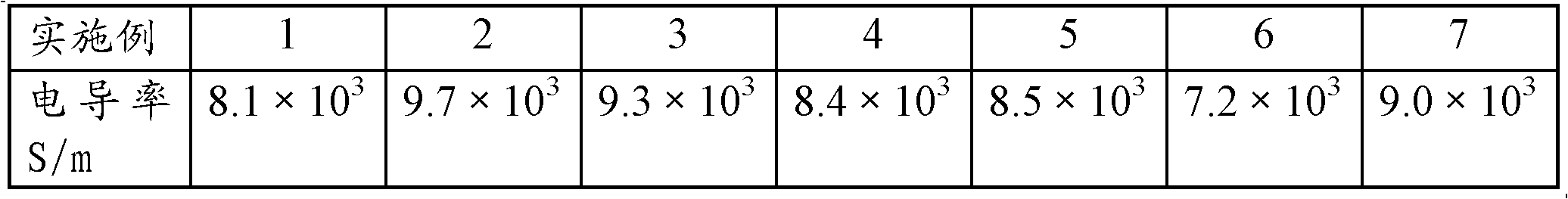

Micro-nano copper particle filled Sn based soldering paste for high-temperature packaging of electronic module and preparation method of soldering paste

ActiveCN104741821ALower interconnect temperatureImprove High Temperature Package ReliabilityWelding/cutting media/materialsSoldering mediaMicro nanoMicro nanoparticles

The invention discloses a micro-nano copper particle filled Sn based soldering paste for high-temperature packaging of an electronic module and a preparation method of soldering paste. The micro-nano copper particle filled Sn based soldering paste is prepared from the following components in parts by mass: 80 to 90 parts of copper tin micro-nano particles, 2 to 8 parts of dispersing agent, 2 to 8 parts of soldering flux, and 2 to 8 parts of thixotropic agent; the micro-nano copper and micro-nano tin are sequentially reduced by the direct liquid phase multi-element sequential controllable reduction method; meanwhile, the copper tin micro-nano particles are highly uniformly mixed; the prepared mixed copper tin micro-nano particles are mixed with the dispersing agent, the soldering flux and the thixotropic agent and then prepared into the soldering paste by the mixed loading dispersing process. According to the method, the micro-nano copper particles are prepared by the direct liquid phase multi-element sequential controllable reduction method; the method of directly secondarily preparing the micro-nano tin particles in the copper particle containing reacting liquid is utilized to prepare the micro-nano copper particle filled Sn based soldering paste; the method has the advantages of being simple, high in production efficiency, wide in applicable process range, controllable of copper and tin of the soldering paste, and matching with the traditional packaging process.

Owner:HARBIN INST OF TECH

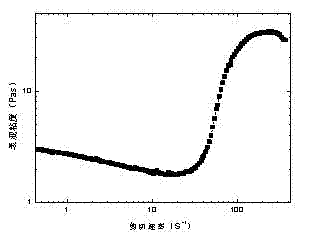

Preparation method and use of shear thickening fluid

The invention relates to the technical field of organic silicon polymer application and provides a preparation method of a shear thickening fluid. The preparation method realizes compatible matching of micro / nano-particles and a dispersion medium and improves system shear thickening effects and system storage stability. The shear thickening fluid is prepared by mixing micro / nano-particles and an organic silicon polymer, wherein a mass ratio of the micro / nano-particles to the organic silicon polymer is (1-3): (2-4). The preparation method is simple and has short preparation time. The shear thickening fluid obtained by the preparation method has stable quality, can be mass-produced easily, has low energy consumption, produces less three wastes and has a low cost. The invention also provides a use of the shear thickening fluid in a liquid protection composite material. The liquid protection composite material prepared from the shear thickening fluid has no toxicity and no pollution and is suitable for a human body and industrial production.

Owner:HANGZHOU NORMAL UNIVERSITY

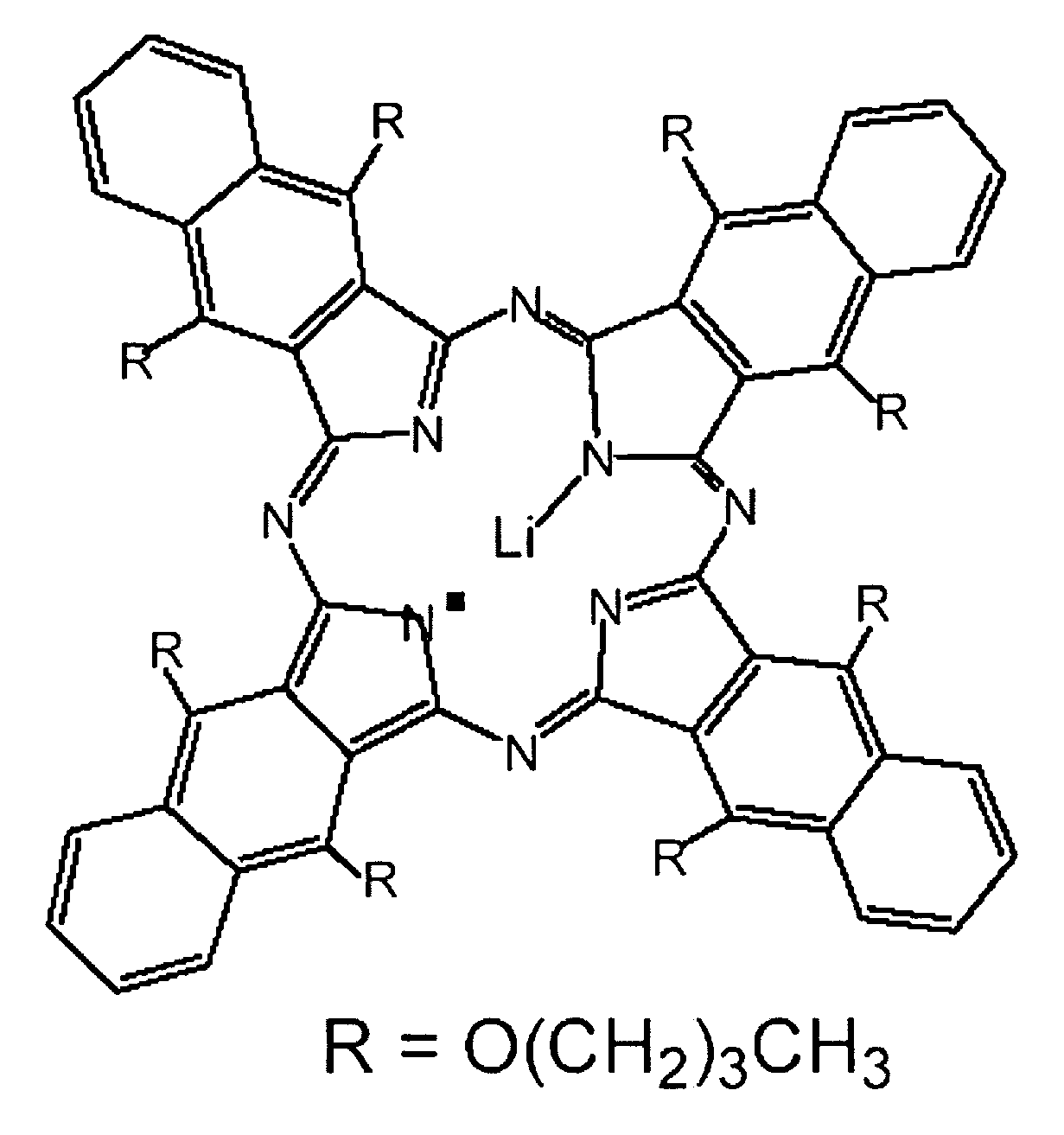

Nanoparticulate probe for in vivo monitoring of tissue oxygenation

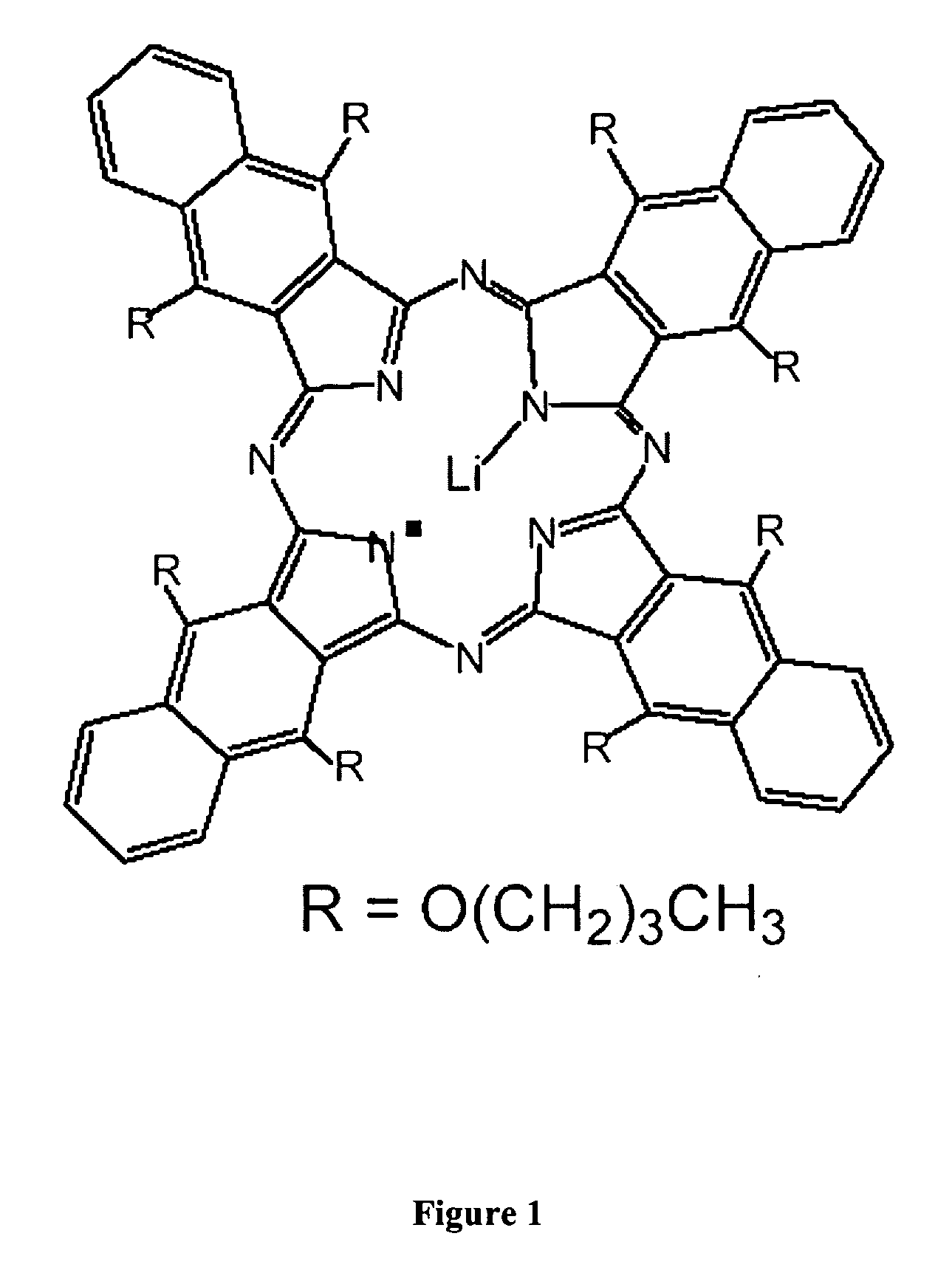

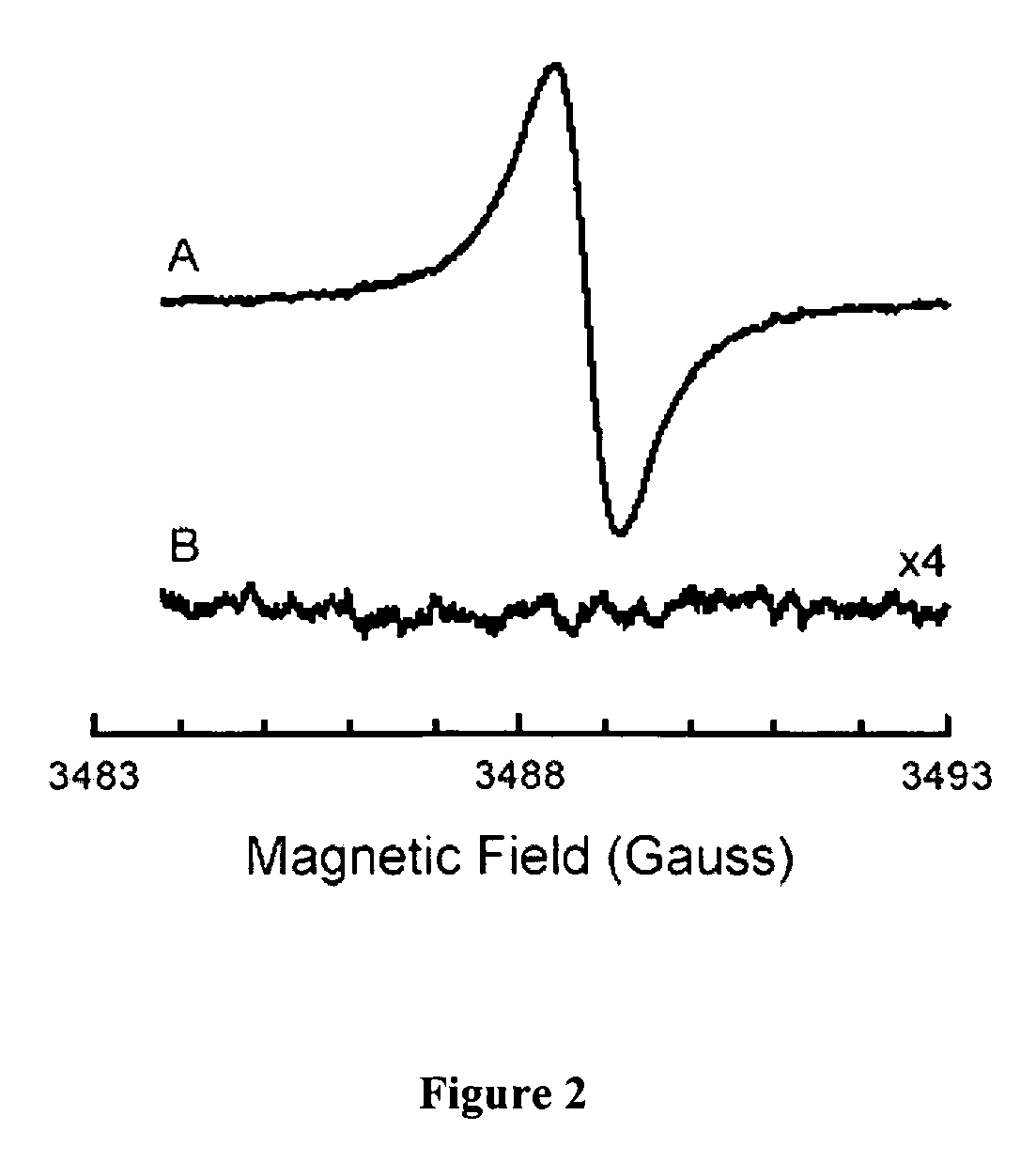

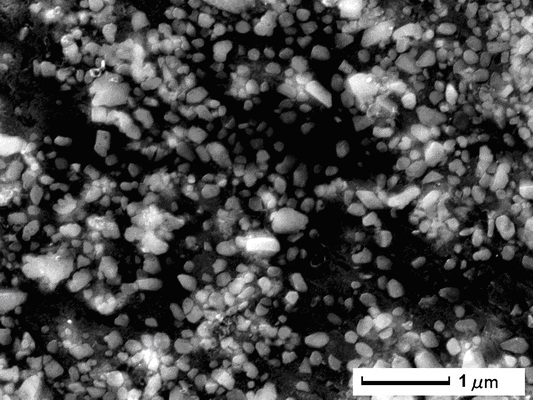

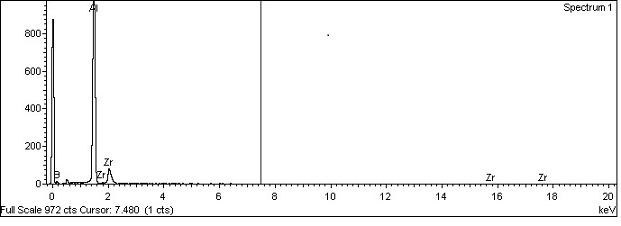

ActiveUS20070041909A1Organic chemistryMicrobiological testing/measurementPhthalocyanine derivativesMicro nanoparticles

A new class of micro- and nano-particulate paramagnetic spin probes useful for magnetic resonance imaging techniques, including electron paramagnetic resonance (EPR) and magnetic resonance imaging (MRI). The probes are lithium phthalocyanine derivative compounds. Also provided are suspensions and emulsions comprising lithium phthalocyanine derivative probes. Also provided are noninvasive methods for measuring noninvasive methods of measuring oxygen concentration, oxygen partial pressure, oxygen metabolism, and nitric oxide concentration in a specific tissue, organ, or cell in vivo or in vitro.

Owner:THE OHIO STATE UNIV RES FOUND

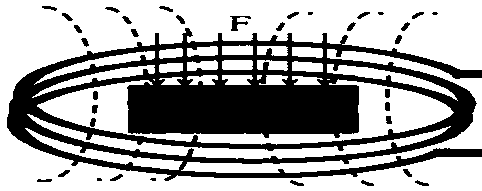

Method for synthesizing particle reinforced aluminum-based composite under high-intensity ultrasonic field and pulsed electric field

The invention relates to the technical field of the preparation of the particle reinforced metal-based composite, in particular to a method for synthesizing a particle reinforced aluminum-based composite under a high-intensity ultrasonic field and a pulsed electric field. The method is mainly characterized in that when the melt direct reaction method is adopted to perform the in-situ reaction of the particle reinforced aluminum-based composite, the high-intensity ultrasonic field and pulsed electric field are both applied on the reaction melt. The parameters of the high-intensity ultrasonic field are as follows: the frequency is 22-30kHz and the intensity is 1-10W / cm<2>. The parameters of the pulsed electric field are as follows: the peak density of current is 0.1-10A / cm<2> and the pulse frequency is 0.1-10Hz. The method has the significant advantage of the coupling of the high-intensity ultrasonic field and the pulsed electric field, thus the thermodynamics and kinetics of the in-situ particle formation reaction can be improved, the mixing of the reactant and the melt can be improved and the shape and size of particles in micron-scale / nanoscale can be controlled; and the dispersion effect of particles in the melt can be controlled, and the method is suitable for the preparation of the high performance micron-nano particle reinforced composite.

Owner:NANTONG UNIVERSITY

Environment-friendly water-based drilling fluid and preparation method thereof

ActiveCN106675535AImprove rheologyGood filter loss reduction effectDrilling compositionWater basedFiltration

The invention provides environment-friendly water-based drilling fluid and a preparation method thereof. The water-based drilling fluid is prepared from the following raw materials in parts by weight: 100 parts of water, 1-5 parts of bentonite, 0.05-0.4 part of sodium carbonate, 0.5-3 parts of a filtrate reducer A, 0.2-3 parts of a filtrate reducer B, 0.1-1 part of a viscosity / yield boosting agent, 0.5-4 parts of an inhibitor, 1-5 parts of a lubricant, 2-6 parts of a micro / nano particle plugging agent and 0-200 parts of weighting materials. The preparation method of the drilling fluid comprises the steps of adding bentonite and sodium carbonate into water; sequentially adding the filtrate reducer A, the filtrate reducer B, the viscosity / yield boosting agent, the inhibitor, the lubricant and the micro / nano particle plugging agent; adjusting the pH value by using sodium carbonate; selectively adding the weighting materials until the density reaches the drilling requirements. The resisting temperature of the drilling fluid can reach 150 DEG C, EC50 is greater than 3.0*10<4>mg / L, and the drilling fluid is nontoxic and environmentally friendly and has good rheological property, filtration reducing property, rejection capability, lubricating property, pollution resistance and reservoir protection effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

Device and method for realizing laser cavitating cleaning micro-nano-particles on surface of material

InactiveCN107470276AReduce dispersionImprove processing efficiencyCleaning processes and apparatusShock waveMicro nano

The invention relates to a device and method for realizing laser cavitating cleaning micro-nano-particles on the surface of a material. The device comprises a water box and a loading table located in the water box. The water box is arranged on a three-dimensional movable working table. A laser cavitating device is installed above the water box. The laser caviating device and the three-dimensional movable working table are connected with a computer. A voltage sensor detecting device is installed on the material. The voltage sensor detecting device is connected with the computer through a data processing device. When laser beams and water produce a cavitation effect, cavitation bubbles are induced to be produced, high pressure shock waves and micro jet produced after cavitation bubbles collapse can produce actionof cleaningthe micro-nano-particles on the surface of the material on a workpiece; and meanwhile, a pressure gradient is formed on the surfaces of the cavitation bubbles, the pressure gradient can drive the cavitation bubbles to move a target material, so that pressure changes are produced on the surface of the material. According to the device for realizing laser cavitating cleaning the micro-nano-particles on the surface of the material, the pressure changes of the surface the workpiece are used as characteristic parameters to judge the effect of laser cavitating cleaning the micro-nano-particles on the surface of the material, so that the measurement result is more convenient and accurate.

Owner:JIANGSU UNIV

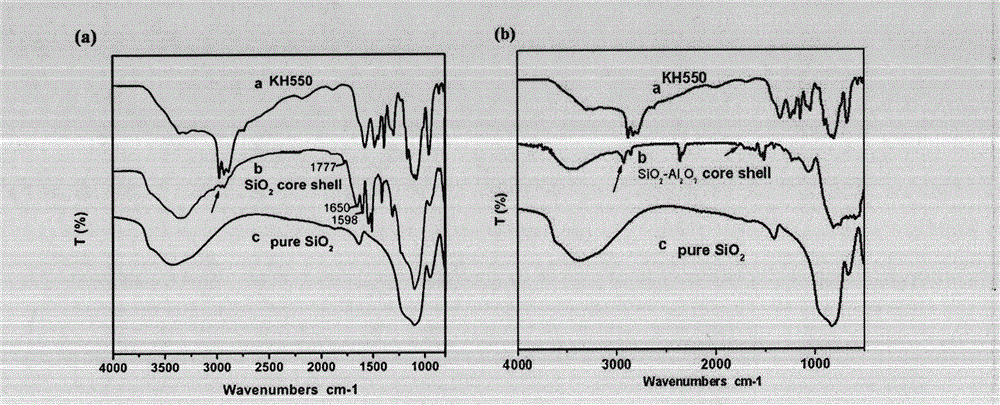

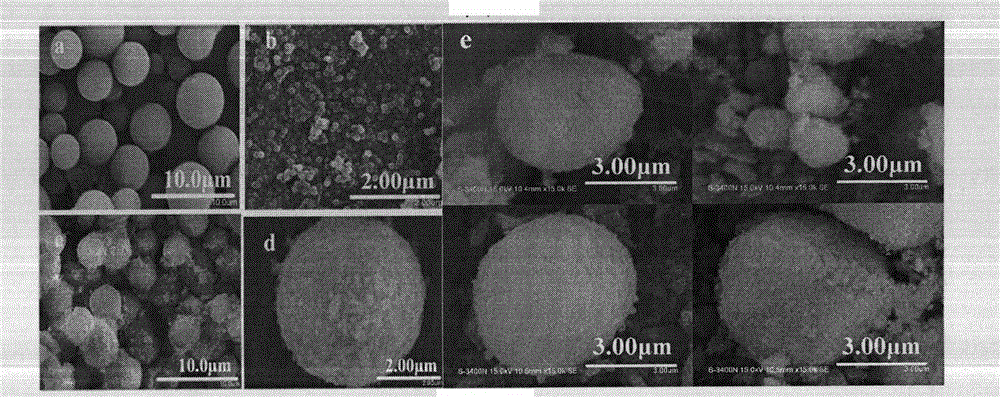

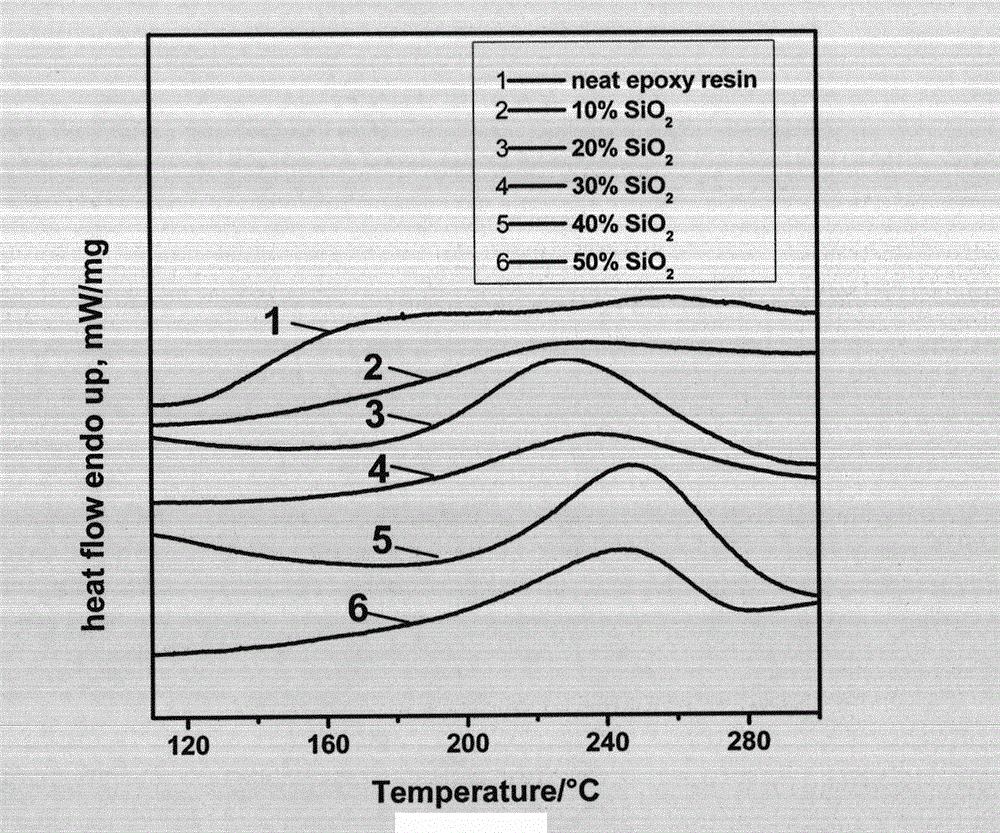

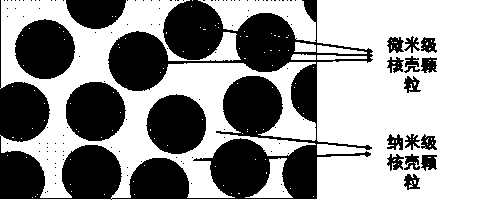

Method for preparing lyophobic heat conduction material with micro-nano core-shell structure

ActiveCN103146197AReduce the amount requiredHigh thermal conductivitySilicaOther chemical processesMicro nanoEpoxy

The invention discloses a method for preparing a lyophobic heat conduction material with a micro-nano core-shell structure. The method comprises the following steps of: preparing micro-nano particles with different particle sizes by adopting a colloidal sol method at first; utilizing organic matters containing special functional groups to wrap the nano particles on microparticles because nano particle surfaces comprise hydroxyls, and thus obtaining composite particles with core-shell structures; and filling the composite particles into epoxy resin or organic silicon resin so as to prepare a packaging material with high thermal conductivity, super hydrophobicity, good heat resistance and thermal mechanical performance. Compared with a conventional particle filling packaging material or thermal interface material, the material has more excellent performances.

Owner:东莞市维赛实业有限公司

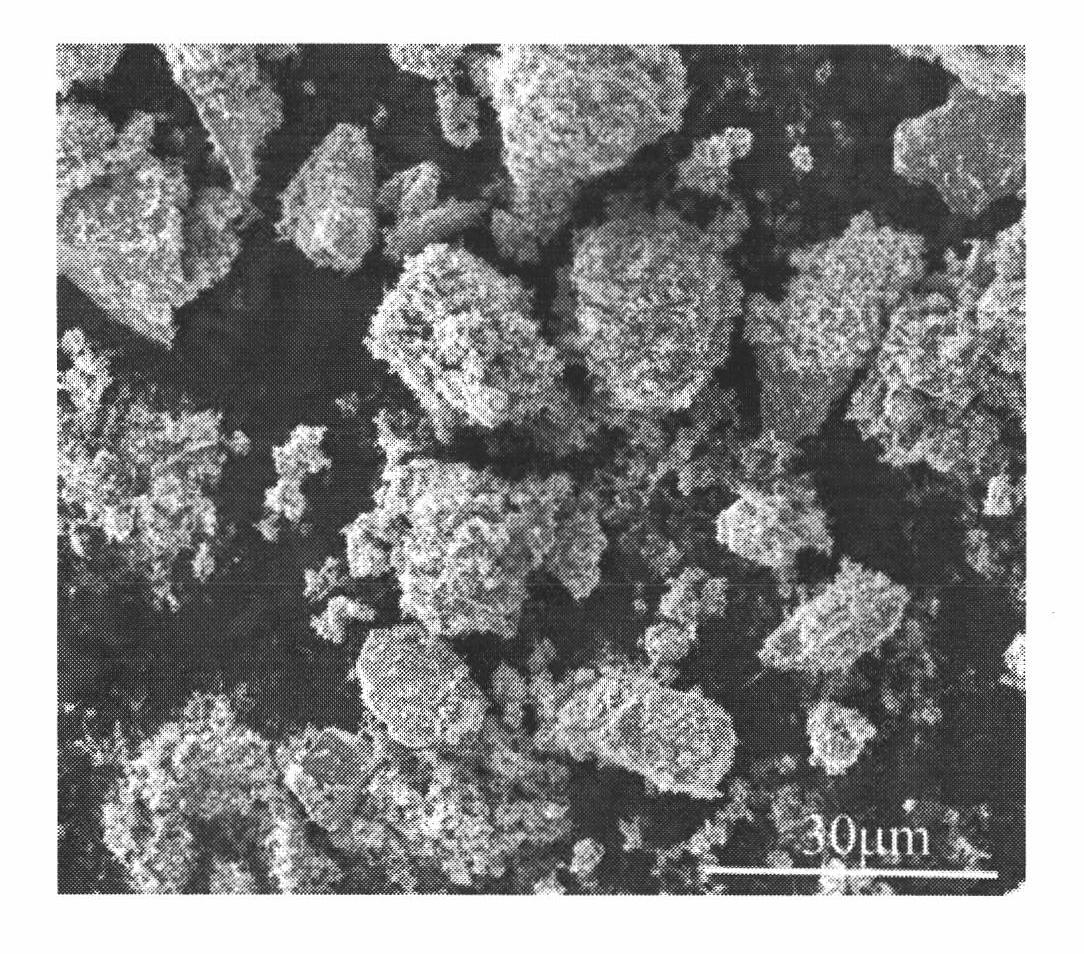

Micro-nano particle reinforced aluminum-based composite material and preparation method thereof

The invention relates to a micro-nano particle reinforced aluminum-based composite material and a preparation method thereof. The aluminum-based composite material takes aluminum or an aluminum alloy as a substrate material; micron-scale silicon carbide particles and nano alumina particles are uniformly dispersed in the substrate material; and the nano alumina particles are generated by undergoing a thermit reaction on nano copper oxide particles and a substrate alloy on the surfaces of the silicon carbide particles, so that a micron silicon carbide / nano alumina reinforced aluminum-based composite material is formed. The preparation method of the aluminum-based composite material comprises the following steps of: undergoing a reaction on micron-scale silicon carbide powder and soluble copper salt in an alkaline solution; filtering, baking and grinding to obtain silicon carbide / copper oxide composite powder; and undergoing a thermit reaction on the composite powder and an aluminum melt, and casting and molding to obtain a target product. By adopting the method, composite reinforcement of the substrate is realized by particles of multiple scales and multiple types, the obtained aluminum-based composite material has the advantages of high intensity, high wear resistance and the like, the bending resistance and Brinell hardness of the aluminum-based composite material are increased by over 50 percent and 73 percent compared with those of the conventional aluminum alloy respectively, and the friction coefficient is lowered by over 25 percent.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Poly-d-lactic acid micro-nano particle as cosmetic and plastic filler and preparation method thereof

The invention discloses a micron and nanoscale cosmetic and plastic filling particle made of poly-d-lactic acid macromolecule resin and a preparation method thereof. The size of the particle is 50-0.45micron. The freeze-dried powder of the particle is suspended in water, and then is injected into a loose or wrinkled facial tissue by an injector so as to achieve the purpose of plastic surgery. The particle contains compound amino acid and is prepared by a mechanical method or an emulsification method. The mechanical method comprises the following steps: suspending the amino acid into a polymer solution, removing a mixture of the dried solvent, extruding into strips, and smashing at low temperature into micro-nano particles; and the emulsification method comprises the following steps: emulsifying an amino acid water solution into a polymer organic solution to form a first emulsion, then emulsifying the emulsion into another water solution so as to obtain a multiple emulsion, and removing the organic solvent to obtain micro-nano particles. The micro-nano particle containing compound amino acid prepared by the two methods is sieved and then suspended in the water solution with a frozen support again, and after freeze drying is finished, the product is obtained.

Owner:吴学森

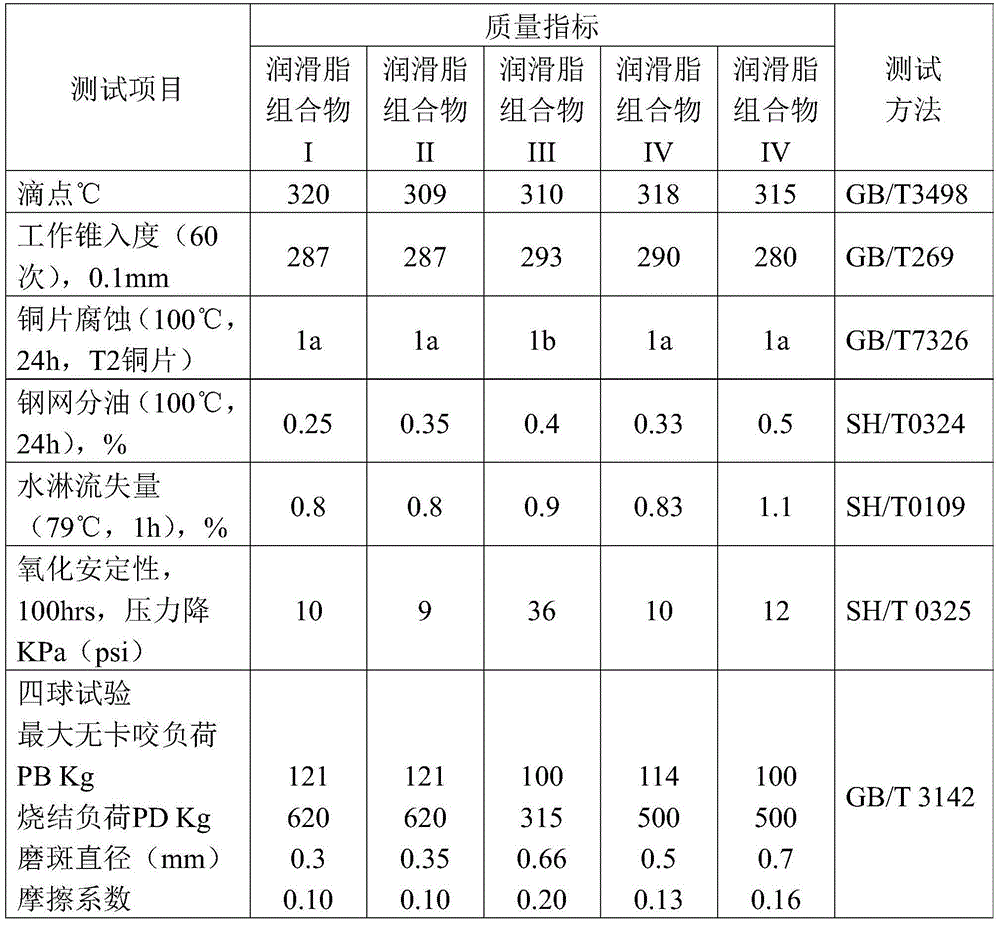

Lubrication grease composition and preparation method thereof

The invention provides a lubrication grease composition and a preparation method thereof. The lubrication grease composition comprises the following components: (a) polturea-based grease; (b) an antiwear agent; (c) an antioxidant; (d) a thickening agent; (e) a micro-nano granular additive. By taking the weight percentage of the polturea-based grease (a) as 100%, the addition amount of the antiwear agent (b) is 0.5-5wt%, the addition amount of the antioxidant (c) is 0.1-3wt%, the addition amount of the thickening agent (d) is 1-8wt%; the addition amount of the micro-nano granular additive (e) is 2-10wt%. The lubrication grease composition is excellent in comprehensive performance, can be used as lubricants of machines which operate in poor conditions with high temperature, severe abrasion, heavy load, humidity and high corrosion, and can be used for lubricating high-speed or ultrahigh-speed operation.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

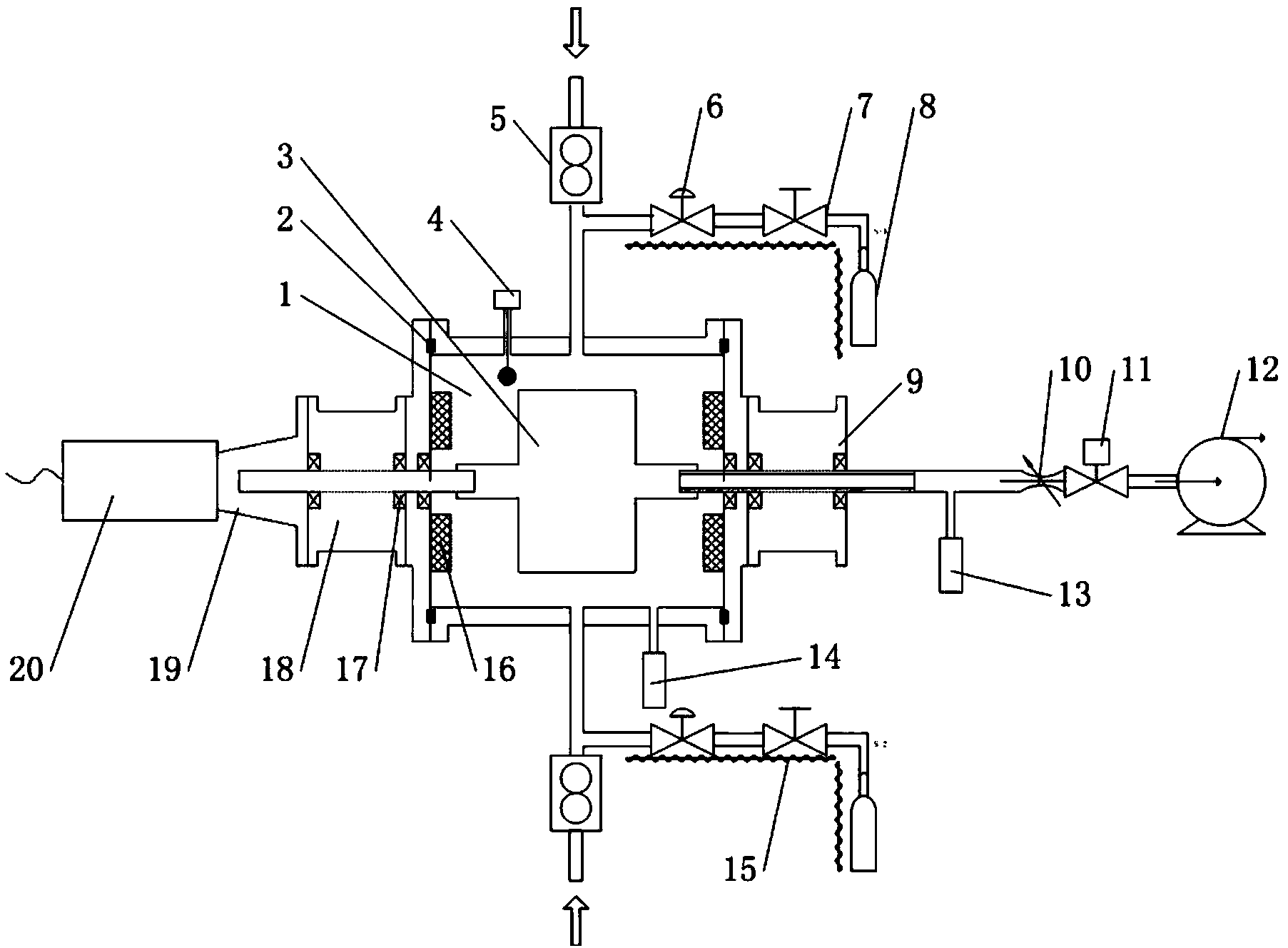

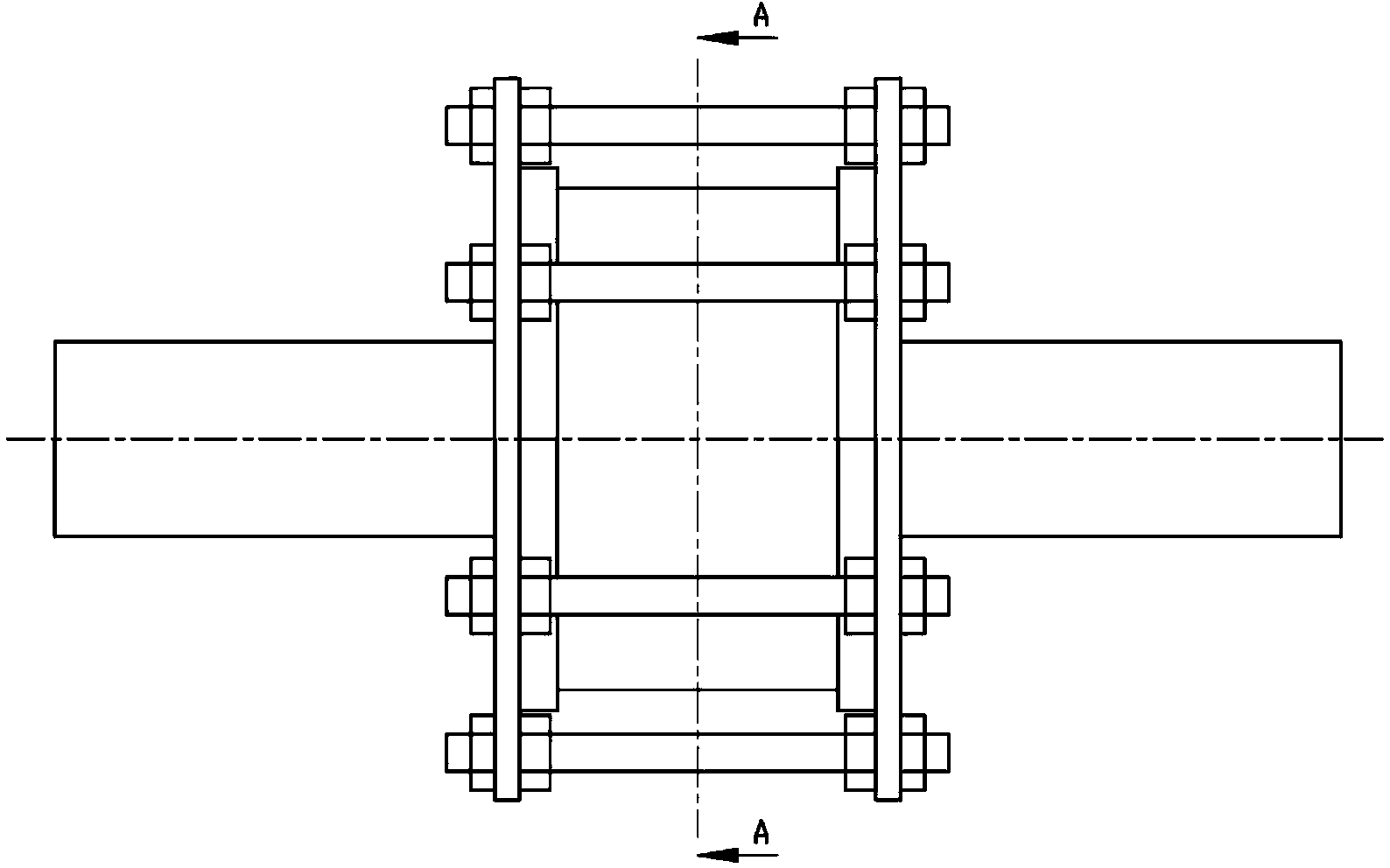

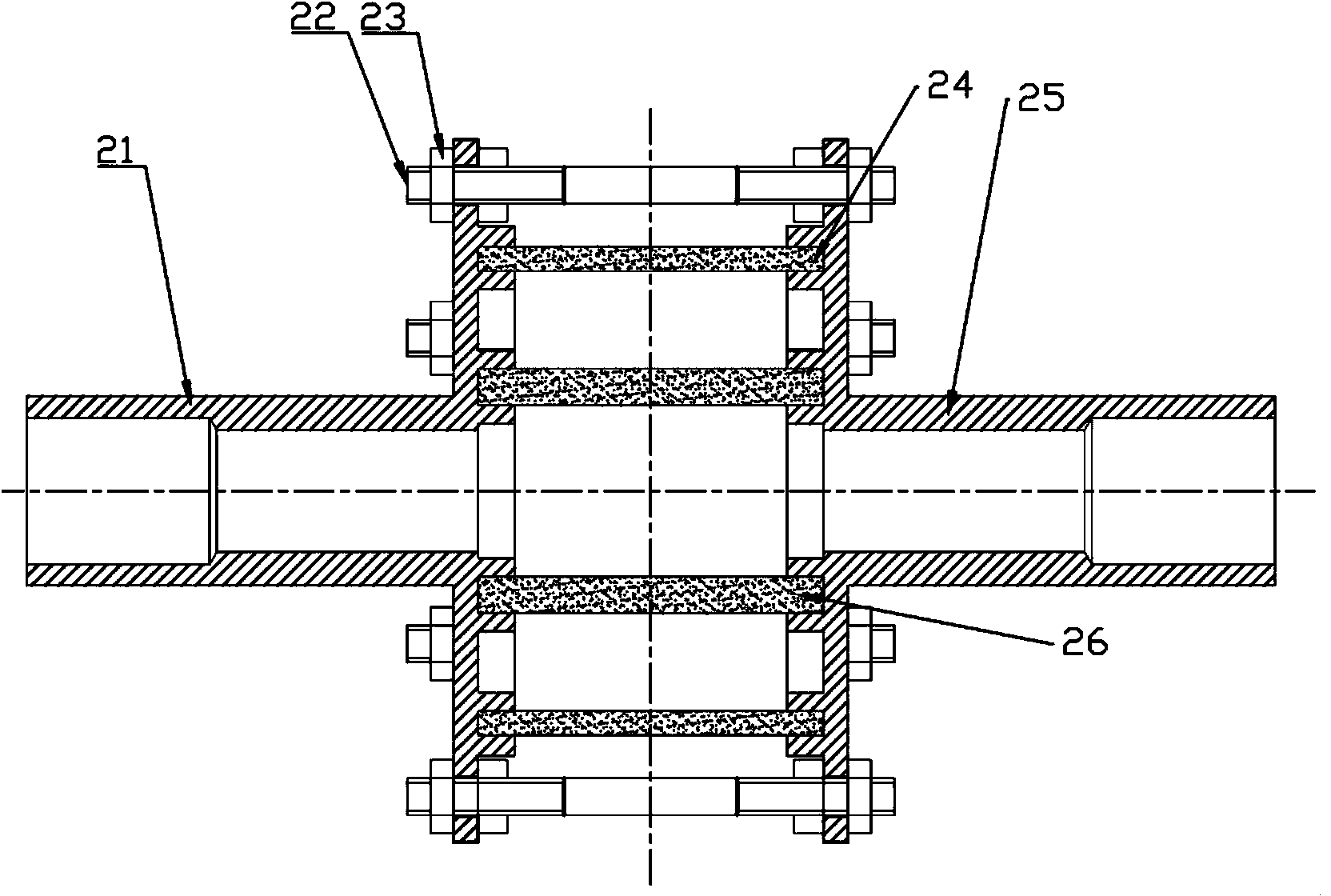

Device and method for surface modification of micro-nano particles

ActiveCN104046958ASufficient and uniform adsorptionIncrease profitMaterial nanotechnologyChemical vapor deposition coatingMicro nanoMicro nanoparticles

The invention discloses a device for surface modification of micro-nano particles. The device comprises a reaction cavity, a plurality of precursor supply devices, a carrier gas conveying system and a powder particle loading device, wherein a cavity formed inside the reaction cavity is used as a reaction space of precursors and the micro-nano particles; the plurality of precursor supply devices are respectively communicated with the reaction cavity by virtue of pipelines to provide different precursors; the precursors are conveyed to the reaction cavity by virtue of carrier gas output by the carrier gas conveying system; the powder particle loading device is used for loading the micro-nano particles to be modified; the precursors are alternately conveyed to the reaction cavity by virtue of the plurality of precursor supply devices respectively, and enter the rotary powder particle loading device so as to be in contact with the surfaces of the micro-nano particles to perform an atomic layer deposition reaction, thus forming a coating thin film on the surfaces of the micro-nano particles and realizing surface modification. The invention also discloses a method for performing surface modification on the micro-nano particles by using the device. The device and method disclosed by the invention can be used for obtaining a coating layer with high particle surface uniformity and improving the overall coating rate of the powder particles and the utilization rate of the precursors.

Owner:HUAZHONG UNIV OF SCI & TECH

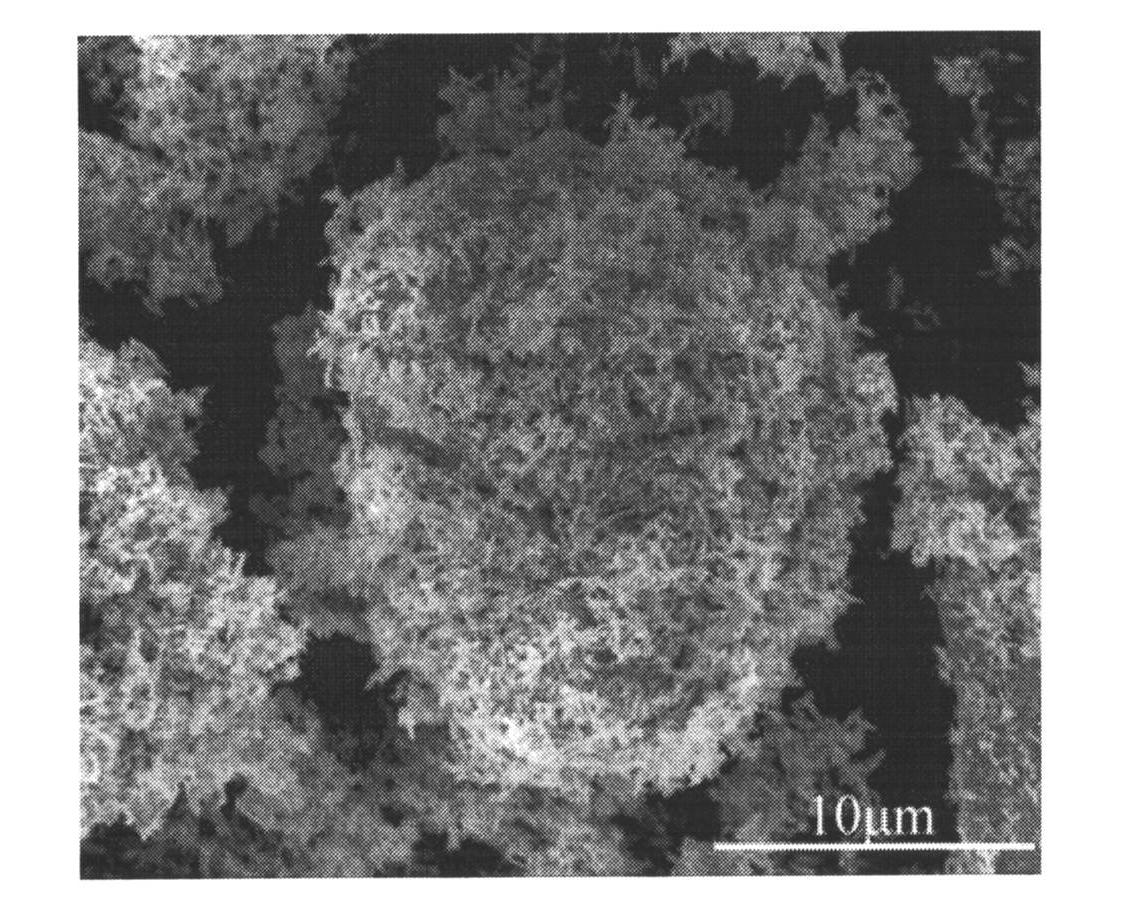

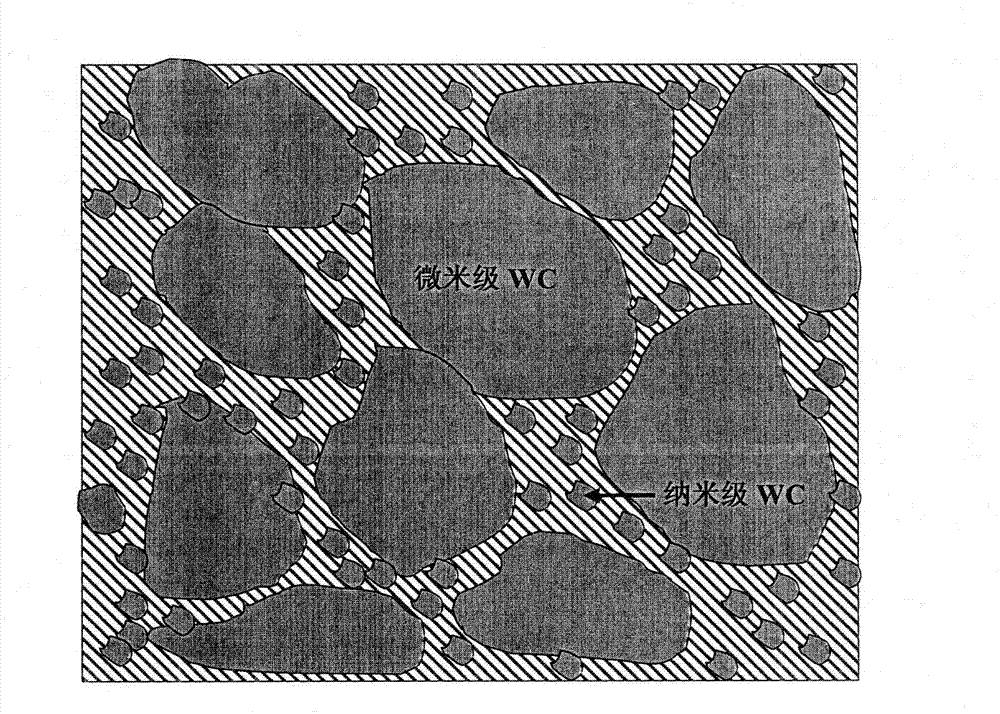

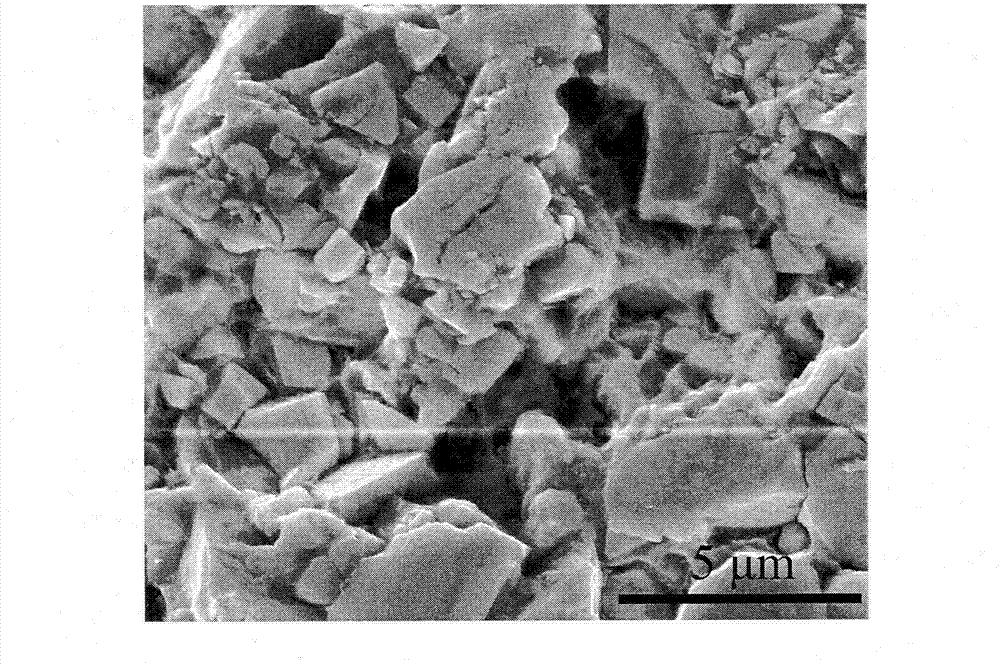

Micron-nano WC-Co hard alloy, preparation process and application thereof

The invention discloses a micron-nano WC-Co hard alloy, a preparation process and application thereof. According to the hard alloy, micron scale WC particles and nano scale WC particles serve as hard phase raw materials and account for 80-95 wt.%, micron scale WC particles and nano scale WC particles can be in any proportion, 0.01-5 wt.% of VC serves as a grain growth inhibitor, and 3-20 wt.% of Co serves as a binder phase. The preparation process comprises procedures such as ball milling, drying, pelleting, press forming and vacuum sintering which are conducted sequentially. According to the hard alloy, the preparation process and the application, a traditional powder metallurgy process is adopted, the harmonious enhancement function of micron-nano particles of different scales is used, the hard alloy has performance characteristics of both micron coarse-grain hard alloys and ultra-fine grain and nanocrystalline hard alloys, both the strength and the toughness are considered, and good comprehensive performance such as strength, hardness, shock resistance and wearing resistance is represented. Combinations of micron-nano particles can be designed according to requirements of different application areas, regulation and control of performance are achieved, and good modification and improvement of traditional hard alloy products are achieved.

Owner:王永富

Method for dispersing liquid metal to micro nano-particles

The invention relates to the field of liquid metal, in particular to a method for dispersing liquid metal to micro nano-particles. The method comprises the specific steps that high molecular polymer is dissolved in N,N-dimethylformamide (DMF), and a polymer solution is obtained; the liquid metal is dripped into the polymer solution, stirring is conducted, and the metal liquid is dispersed to the micro nano-particles. By means of the method for dispersing the liquid metal to the micro nano-particles, the liquid metal can be dispersed to the micro nano-particles without obvious agglomeration and sediment within 50 h; the liquid metal can be efficiently dispersed within a short time, and a method for preparing base materials is provided for printing the liquid metal.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of micro-nano particle reinforced aluminium matrix composite

The invention provides a preparation method of a micro-nano particle reinforced aluminium matrix composite and belongs to the field of an aluminium matrix composite preparation technology. The method comprises the following steps: carrying out high-energy ball milling on powdery aluminium base alloy and reinforcement powder; carrying out vacuum drying on the prepared composite powder after the end of ball milling and sieving; and carrying out supersonic vibration on the dried and sieved composite powder and carrying out pressureless sintering on the dispersible powder by controlling sintering atmosphere so as to prepare a fully-densified powder metallurgy aluminum matrix composite blank, and carrying out hot working such as extrusion, rolling, die forging and the like on the blank so as to obtain the required aluminium matrix composite. By a brand-new activated sintering densification technology, the composite powder directly undergoes supersonic vibration and densification sintering under atmosphere protection without pressing so as to prepare the fully-densified micro-nano particle reinforced aluminium matrix composite blank. The prepared aluminium matrix composite has uniform reinforcement phase distribution and excellent product performance. The method has no limit in size and shape of the product, is low-cost and is suitable for large-scale production.

Owner:天津海力特新材料有限公司

Silicon alloy and graphene composite material and preparation method thereof

The invention discloses a silicon alloy and graphene composite material. The silicon alloy and graphene composite material comprises graphene-coated silicon alloy micro-nano particles and graphene, wherein the graphene-coated silicon alloy micro-nano particles and the graphene are uniformly mixed in the mass ratio of (5:1) to (1:20), and the mass fraction of the silicon alloy micro-nano particles in the silicon alloy and graphene composite material is 0.1%-20%. According to the silicon alloy and graphene composite material, the ordinary carbon material is replaced with a graphene material which has good electrical conductivity and void distribution as well as high mechanical properties, so that the specific volume is higher compared with that of the traditional silicon-based materials. The invention further provides a preparation method of the silicon alloy and graphene composite material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

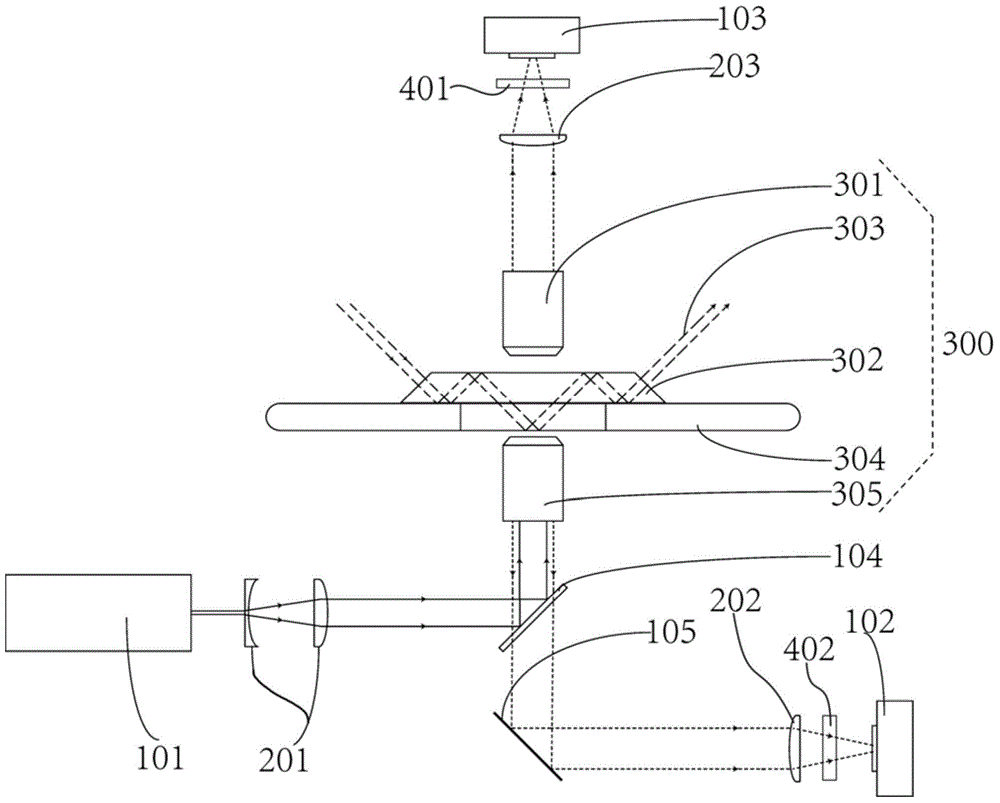

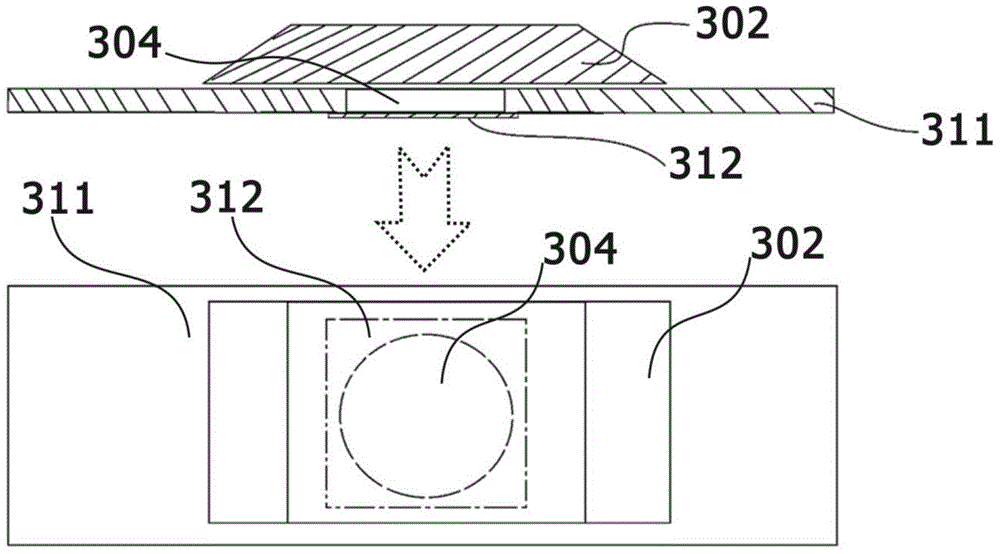

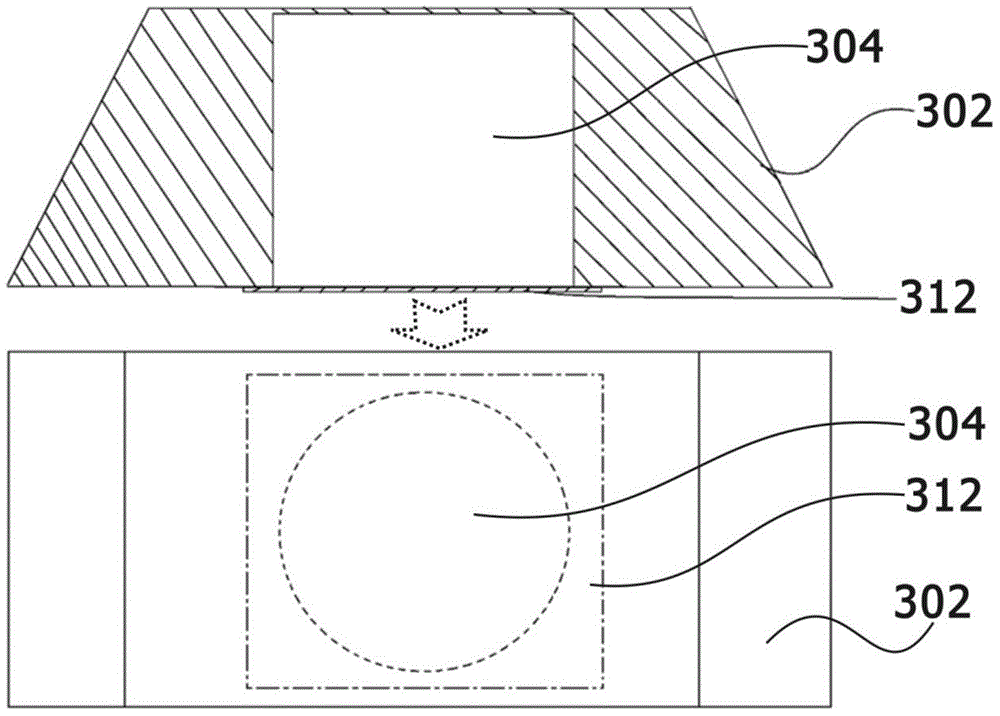

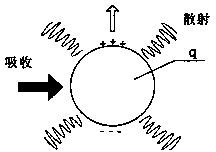

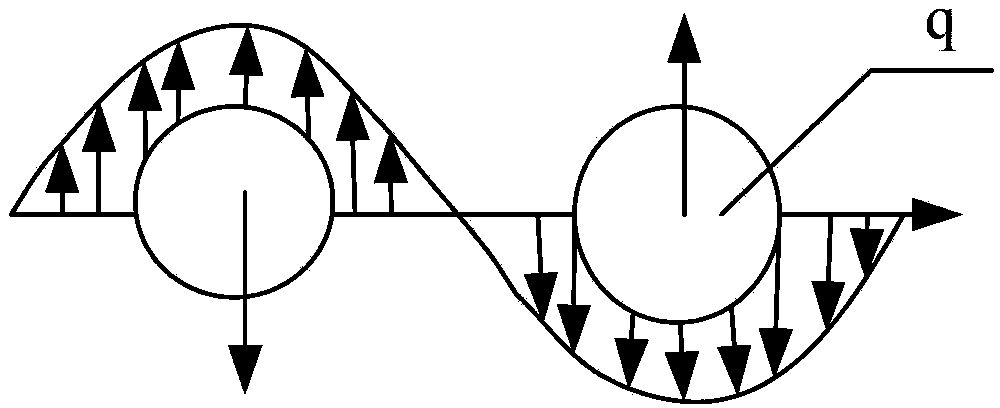

Dark field illumination method based on total internal reflection

InactiveCN104568886AAchieve lightingSimple structureFluorescence/phosphorescenceBiological cellMicro nanoparticles

The invention discloses a dark field illumination method based on total internal reflection. The dark field illumination method can be applied to optical microscopic imaging studies on micro / nano-particles, biological samples and the like. Dark field illumination on the sample is achieved on the basis of total internal reflection of illuminating light; scattered light or fluorescent light of the sample is utilized as a signal for optical imaging and detection, thus observation and measurement on micro / nano-scale samples are achieved; and the dark field illumination method has good applicability and compatibility on existing imaging devices such as microscopes. The illuminating light is subjected to total internal reflection for once or a plurality of times in a total internal reflection prism or a sample pool by the total internal reflection to form total internal reflection dark field illumination; and the dark field illumination method can be applied to the fields of studies on nano materials, biological cells, interaction between light and materials, and the like.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI +1

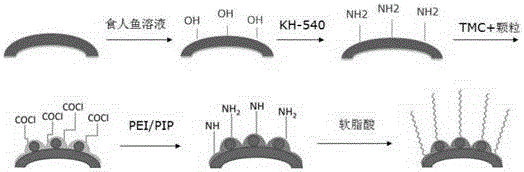

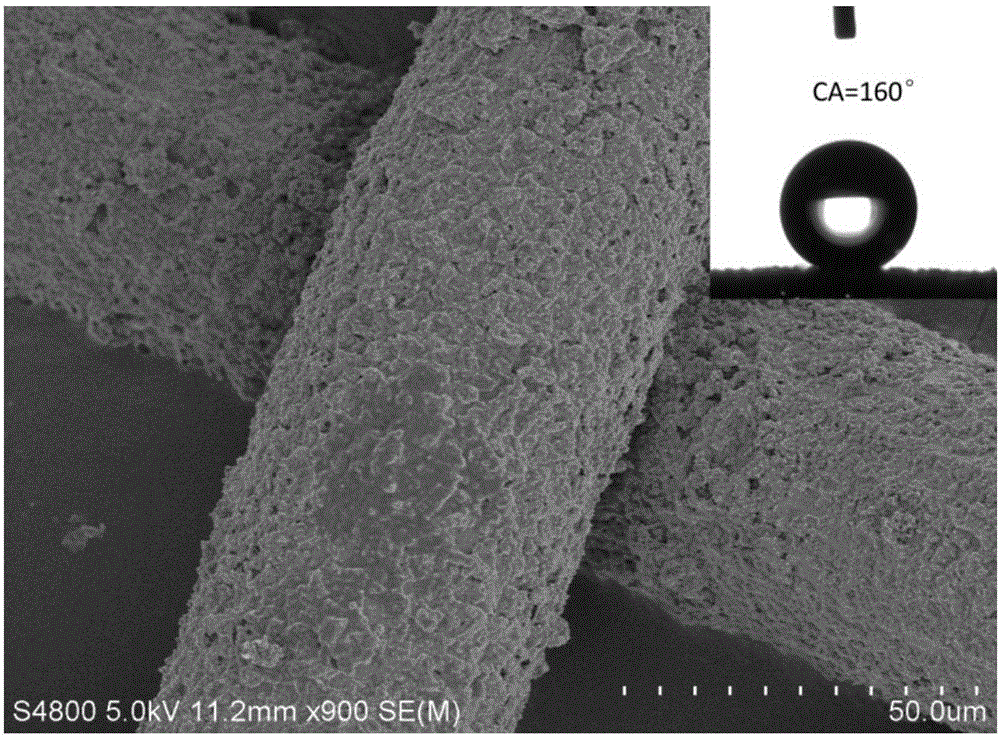

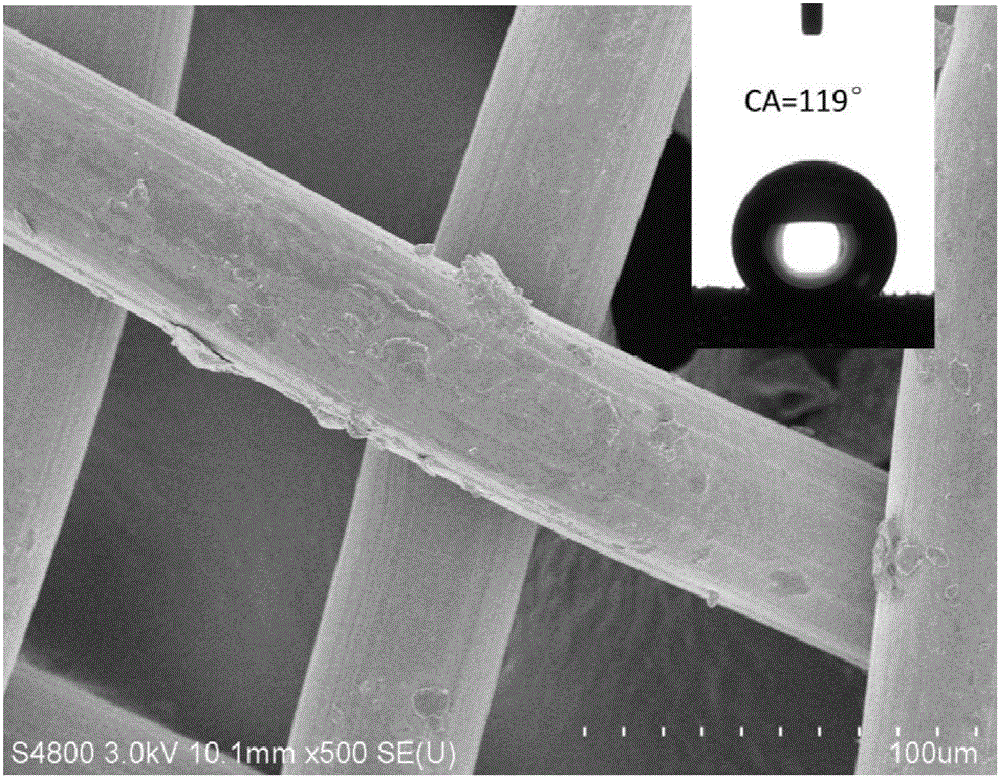

Super-hydrophobic wire mesh and preparation method thereof

ActiveCN106422423ASimple preparation processReduce manufacturing costLiquid separationMicro nanoparticlesRaw material

The invention relates to a super-hydrophobic wire mesh and a preparation method thereof. The preparation method is characterized in that a wire mesh is modified through interfacial polymerization and unimolecular layer adsorption so as to obtain the super-hydrophobic wire mesh, in other words, by means of polycondensation, a layer of polymeric membrane is formed on the interface or one side of an interfacial organic phase of two solutions which are dissoluble mutually and dissolved with two monomers to fix micro-nano particles to create a rough surface, and then monolayer low-surface-energy substances are grafted on the polymeric membrane through covalent bonds so as to obtain the super-hydrophobic wire mesh. The super-hydrophobic wire mesh has the advantages that the super-hydrophobic wire mesh is of super-hydrophobicity, high oil absorption capability, reusability and durability; good mechanical performance is achieved, the substances for forming the rough surface are connected by the chemical bonds, super-hydrophobicity remains unchanged after ultrasonic treatment, and the super-hydrophobic wire mesh can be used for oil-water separation continuously as compared with other oil-water separation materials. The preparation method is simple in technology, mild in condition, implementable at a room temperature without special instrument and equipment, easily available to modified raw materials, cheap in modified raw materials and low in material preparation cost.

Owner:TIANJIN UNIV

Graphite spheroidization method and production system thereby

The invention discloses a graphite spheroidization method and a production system thereby. The method comprises the following three steps of: (1) ultra-fine pulverizing, namely pulverizing graphite to a proper granularity by utilizing an ultra-fine high-energy pulverizer; (2) reshaping treatment, namely performing reshaping treatment on the pulverized graphite by utilizing a batch-type or continuous reshaping system consisting of one or more special reshaping devices and a micro-nano particle reshaping cladding system; and (3) ultra-fine multilevel classification, namely performing high-precision multilevel series classification on the graphite subjected to reshaping treatment by utilizing an ultra-fin multilevel classification system, so as to obtain narrow granular spherical graphite with the D50 of 3-35mu m. The method and the system haves the following advantages: the product spheroidization effect is good, the tap density is large, the yield of finished products is high, a favorable reshaping effect can be achieved for artificial graphite which is difficult to reshape, the preparation period is short, the processing equipment is compact, and the method is safe and environmentally-friendly.

Owner:WUHU ZHEXIN NEW ENERGY

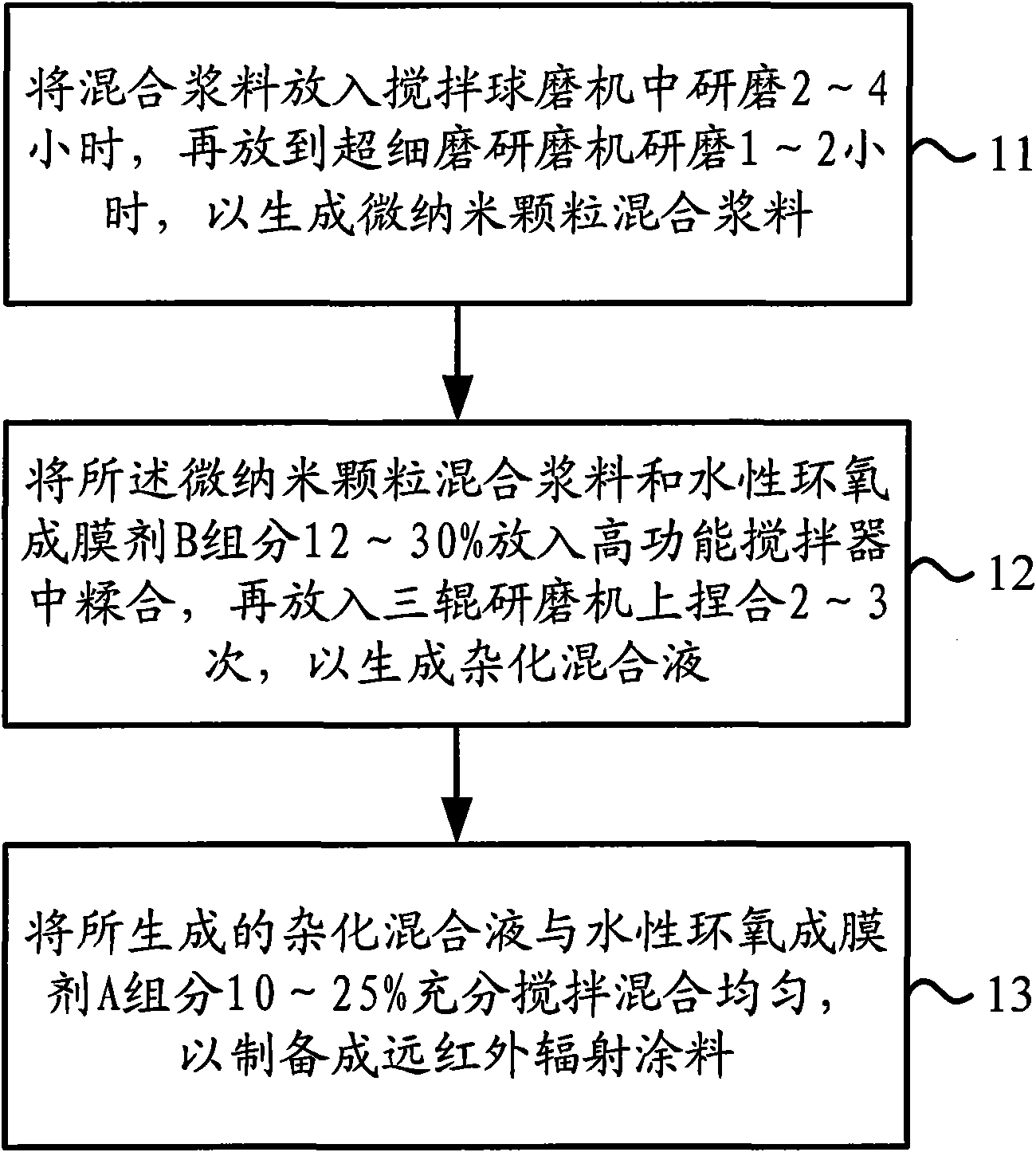

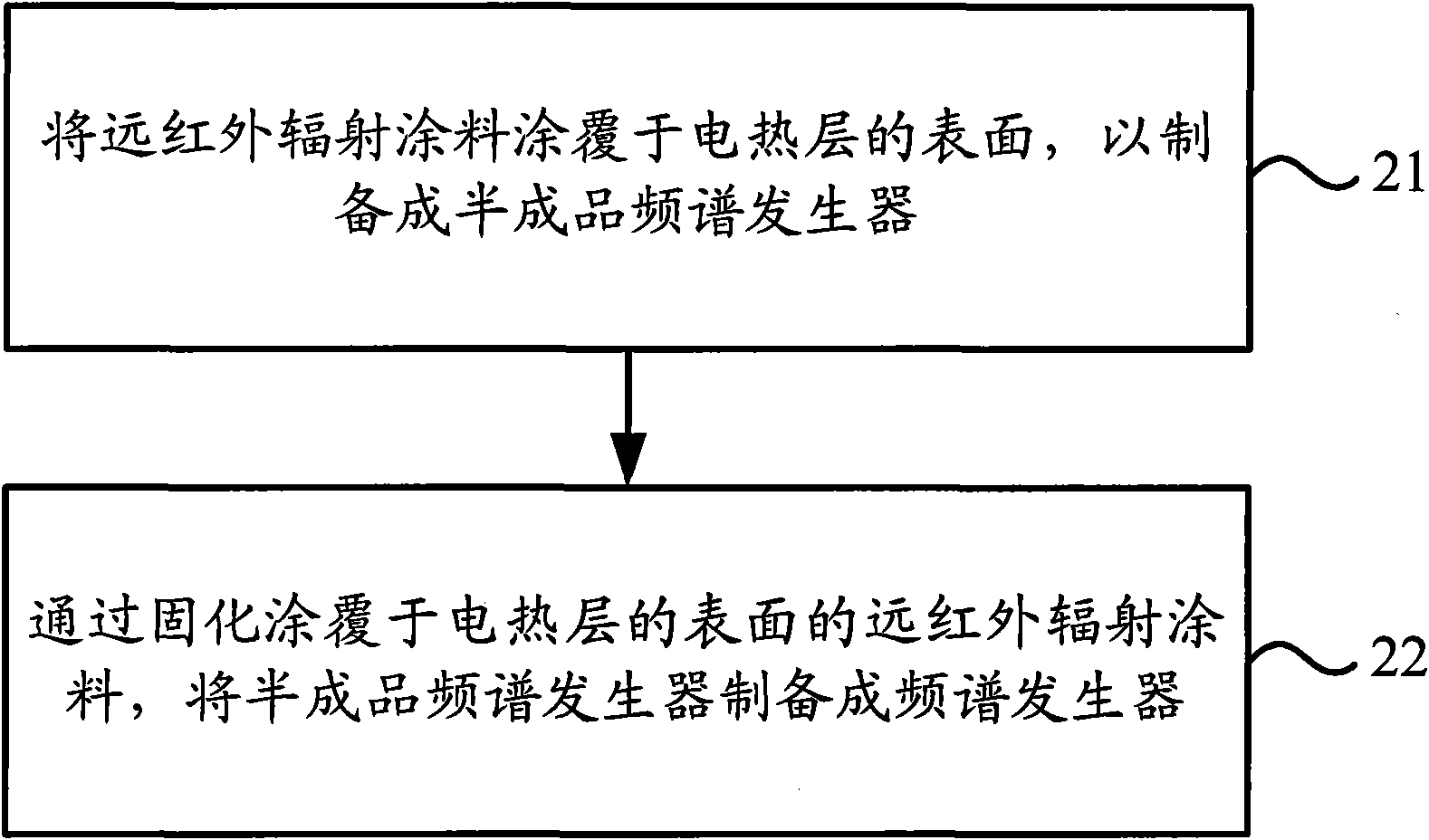

Spectrum generator, preparation method thereof and preparation method of far-infrared radiant coating

ActiveCN102031051ASimple structureThe generation process is simpleOhmic-resistance heatingLight therapyEpoxyMicro nano

The invention discloses a spectrum generator, a preparation method thereof and a preparation method of a far-infrared radiant coating. The preparation method of the far-infrared radiant coating comprises the following steps: putting a mixed slurry into a ball-stirring mill, grinding for 2-4 hours, then putting the slurry into an ultra-fine grinding machine, and grinding for 1-2 hours, so as to generate a mixed slurry of micro-nano particles; putting the mixed slurry of micro-nano particles and 12-30% of a component B of a water borne epoxy film-forming agent into a high-function stirrer for mixing, and putting the mixture into a three-roll grinder for kneading 2-3 times, so as to generate a hybrid mixed solution, wherein the component B of the water borne epoxy film-forming agent is a water borne epoxy curing agent; stirring and mixing the generated hybrid mixed solution and 10-25% of a component A of the water borne epoxy film-forming agent thoroughly and uniformly, so as to prepare the far-infrared radiant coating, wherein the component A of the water borne epoxy film-forming agent is epoxy resin or a epoxy resin mixture. By utilizing the method provided by the invention, the aims that the far-infrared radiant coating is prepared with a simple process and the radiant wavelength of the coating matches well with the best absorption wavelength of human body are realized.

Owner:GUANGDONG JUNFENG BFS TECH

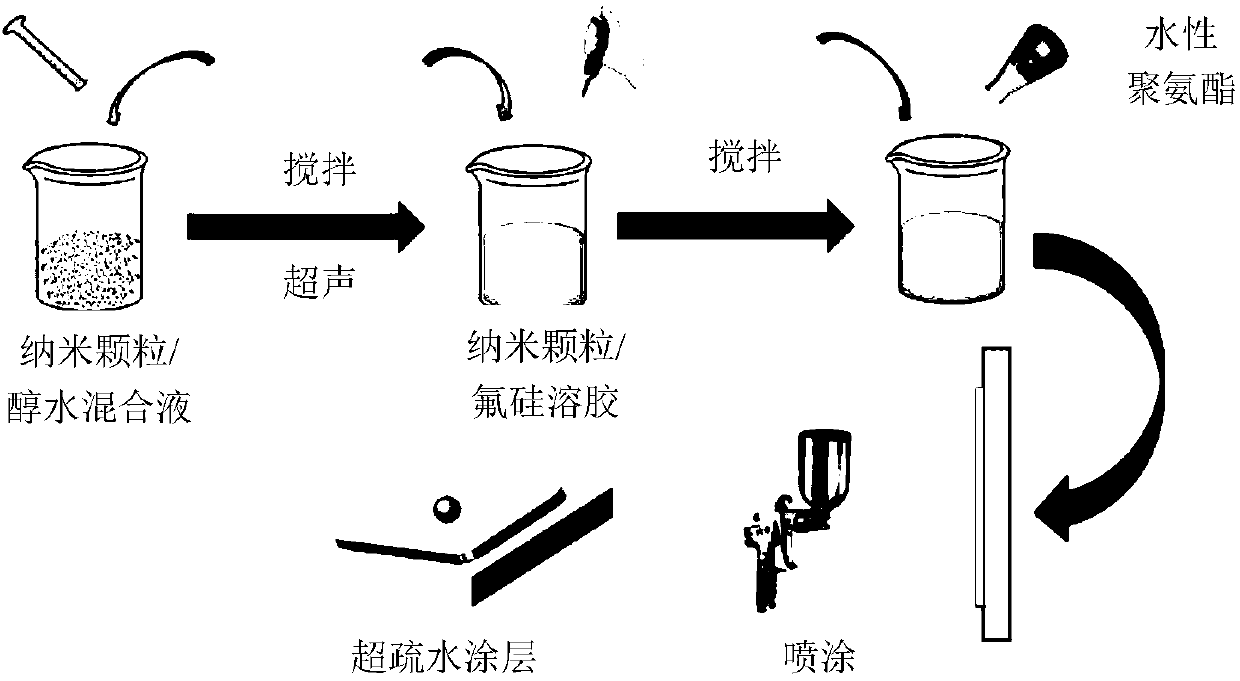

Waterborne polyurethane super-hydrophobic coating and preparation method thereof

InactiveCN108047916ADoes not affect the feelLiquid repellent fibresGrip property fibresMicro nanoMicro nanoparticles

The invention discloses a waterborne polyurethane super-hydrophobic coating and a preparation method thereof. The method comprises the steps that ethyl alcohol, deionized water and inorganic micro-nano particles are mixed to be uniform, ultrasonic treatment is performed for 5-20 min, a mixing solution is obtained, hybridized siloxane and fluorine-containing siloxane are added into the mixing solution, 25 v% ammonium hydroxide is adopted for slowly adjusting the pH value to 9-11, a stirring reaction is performed under the room temperature for 15-60 min, and then mixed sol is obtained; the obtained mixed sol and waterborne polyurethane (WPU) emulsion are mixed, a reaction is performed for 0.5-1 h under the temperature of 20-30 DEG C, and the waterborne polyurethane super-hydrophobic coatingcontaining inorganic nano-particles is obtained. Due to the simple and economical mode, the flexible super-hydrophobic coating can be manufactured, the coating is particularly applicable to textile super-hydrophobic treatment, and the touch of the textile is not affected due to the fact that polyurethane (PU) is flexible.

Owner:ZHEJIANG UNIV OF TECH

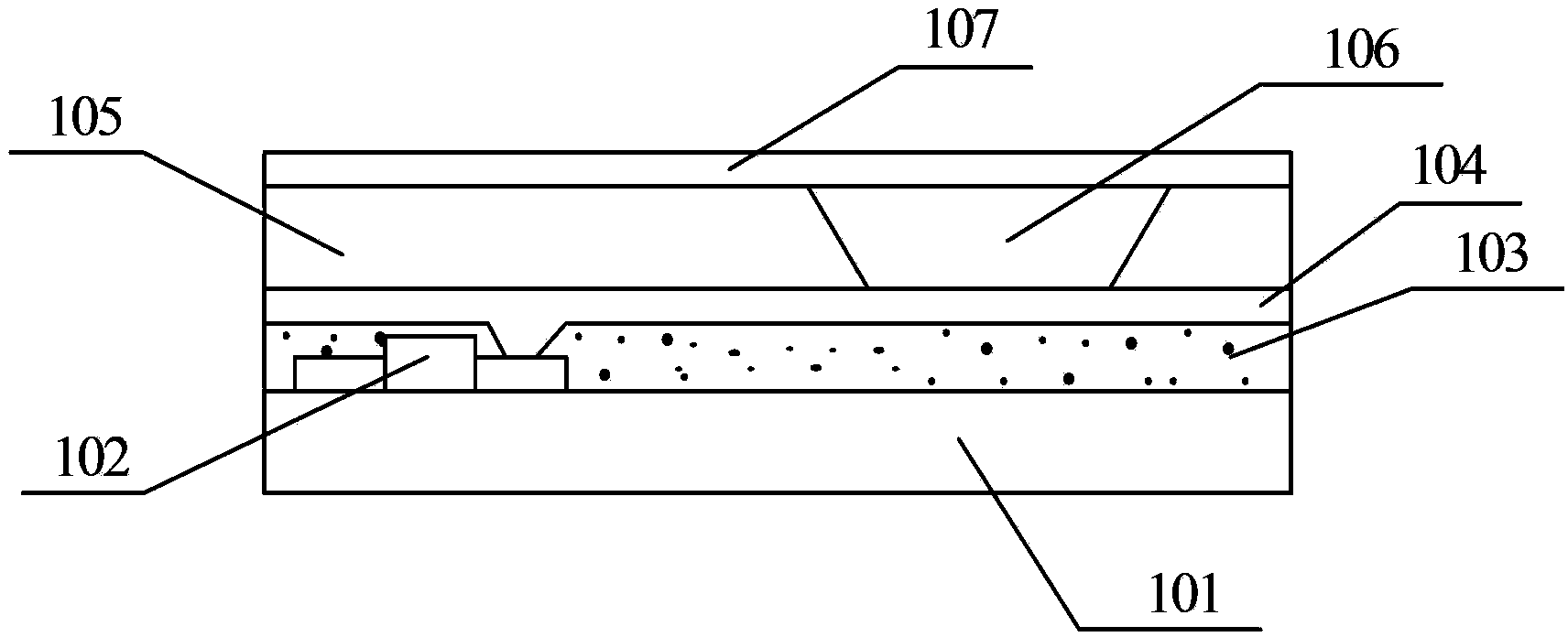

Array substrate, manufacturing method of array substrate, and display device

ActiveCN103441138AImprove light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingMicro nanoDisplay device

The invention provides an array substrate, a manufacturing method of the array substrate, and a display device and belongs to the technical field of organic electroluminescence display. The array substrate, the manufacturing method of the array substrate, and the display device can solve the problem that an existing array substrate is low in light out-coupling efficiency. The array substrate comprises an organic electroluminescence device, wherein the organic electroluminescence device comprises a first electrode layer, a second electrode layer, and a luminescent layer arranged between the first electrode layer and the second electrode layer, and the first electrode layer is a transparent electrode layer and is arranged on a planarization layer mingled with metal micro-nano particles.

Owner:BOE TECH GRP CO LTD

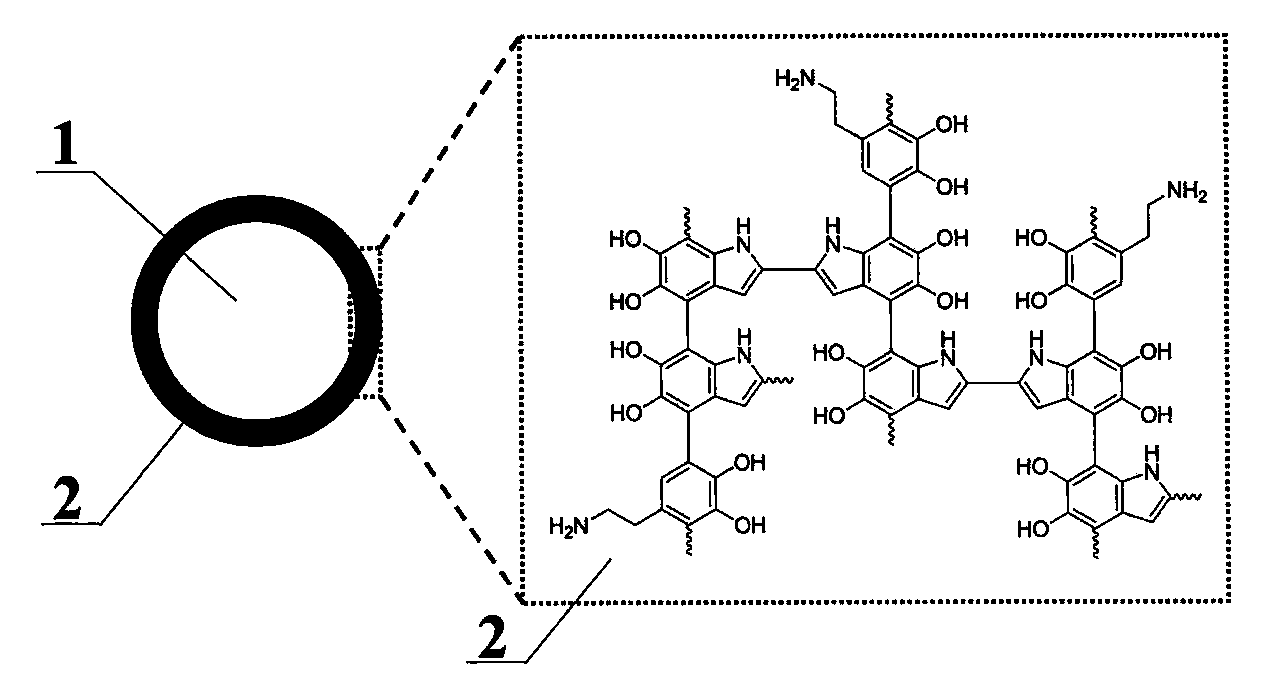

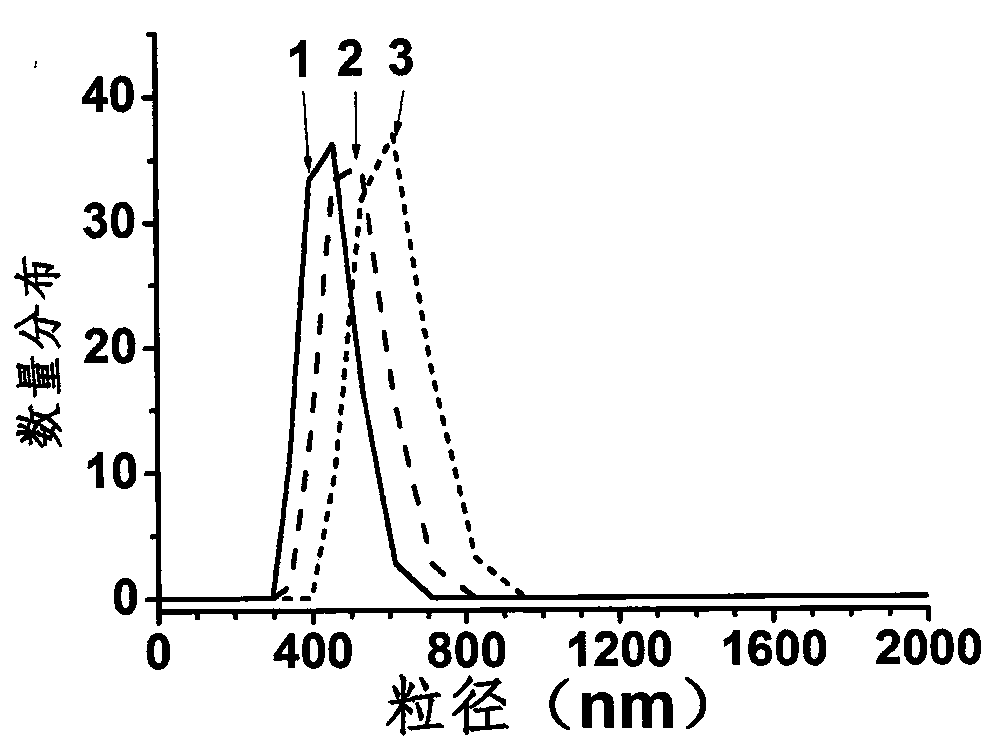

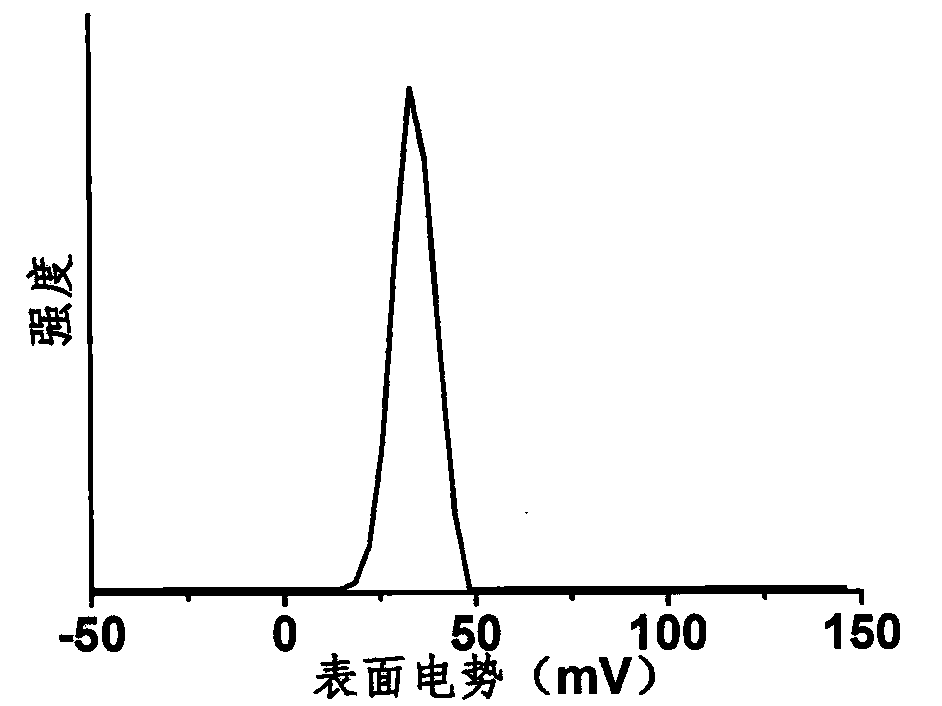

Application of poly-dopamine composite magnetic micro-nano particles in oily sewage treatment

InactiveCN104098156AEfficient separationFatty/oily/floating substances removal devicesWater/sewage treatment by magnetic/electric fieldsMicro nanoMicro nanoparticles

The invention belongs to the technical field of intersection of micro-nano materials and environmental engineering and relates to application of poly-dopamine composite magnetic micro-nano particles in oily sewage treatment. Poly-dopamine similar to the glossopodium component of a mussel is used as the surface modifier of magnetic ferroferric oxide micro-nano particles to prepare core-shell-shaped bionic composite magnetic micro-nano particles, and the composite magnetic micro-nano particles are used as oil-water separation materials for treating oily sewage. Due to the super-high bionic adhesion capacity, the composite magnetic micro-nano particles have super-high capacity of capturing oil drops in the oily sewage, so that an extremely high oil-water separation effect is realized. The raw materials are available, the method is simple and environmental friendly, the reaction is mild and the reaction speed is high; the operation of oil water separation is simple, the cost is low, the oil water separation effect is good, and industrial implementation is facilitated; the technical problem that oily sewage, particularly sewage produced during oil production for three times is difficult to treat is solved, and the poly-dopamine composite magnetic micro-nano particles have extremely important practical significance on resource conservation and environment protection.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

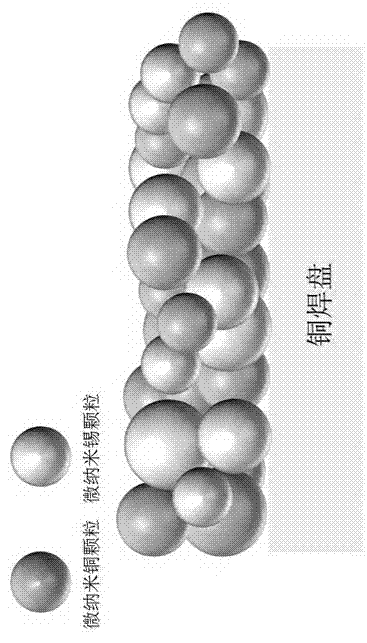

Multi-scale micro-nano particle composite soldering paste for field of electronic packaging and preparation method of multi-scale micro-nano particle composite soldering paste

ActiveCN109664049ASolve the disadvantages of poor oxidation resistance and difficulty in preservationSolve uneven distributionWelding/cutting media/materialsSoldering mediaMicro nanoActive agent

The invention provides the multi-scale micro-nano particle composite soldering paste for the field of electronic packaging and a preparation method and an application process of the multi-scale micro-nano particle composite soldering paste. The novel composite soldering paste is formed by mixing metal powder and a soldering flux, the metal powder is composed of 30 to 70 nm in particle size and 3 to 7 microns, 15 to 25 microns of Cu @ Ag particles, 40 to 60 nm of Ni @Ag particles and 1 to 2 microns of Ag particles, the scaling powder is composed of solvent isopropanol, an active agent stearicacid, a film-forming agent mixed rosin, polyethylene glycol, a modifier triethanolamine and a surfactant octylphenol polyoxyethylene ether, the existence of Cu @ Ag particles in the composite solder paste is reduced relative to the cost of the nano-silver solder paste, the electromigration resistance can be improved, the Ag particles can protect the integrity of the Cu @ Ag core-shell structure, under a high-frequency induction process condition, the magnetism of the Ni @ Ag particles ni enables the particle distribution to be more uniform, the density is improved, and the electric conductionheat conduction performance is improved. The method is low in cost, simple and controllable in process and high in efficiency, the problems that an existing device pasting material is high in cost, low in service temperature, long in process time and the like are solved.

Owner:哈尔滨景成创业投资管理有限公司

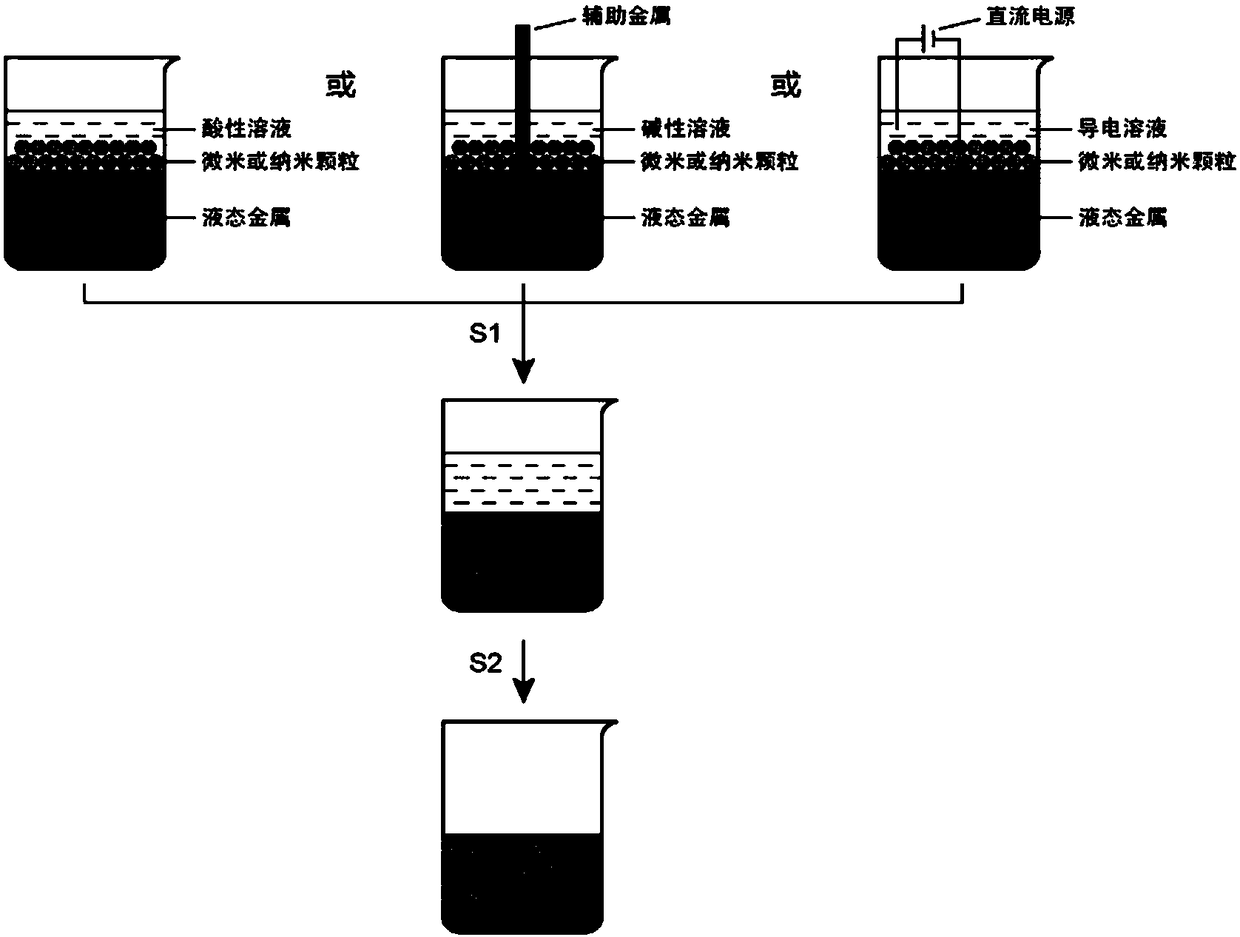

Method for doping micro nanoparticles into liquid metal and application of liquid metal-micro nanoparticle mixture

ActiveCN108085519AImprove and enhance existing propertiesImprove liquidityMagnetic liquidsHeat-exchange elementsLiquid metalMicro nanoparticles

The invention belongs to the field of liquid metallic materials, and particularly relates to a method for doping micro nanoparticles into liquid metal and application of a liquid metal-micro nanoparticle mixture. The method comprises the steps that the micro nanoparticles and the liquid metal with the mass ratio of the micro nanoparticles to the liquid metal being 1:(9-19) are added into an acidic, alkaline or conductive solution, and stirring is conducted, so that the micro nanoparticles are doped into the liquid metal, then the acidic, alkaline or conductive solution is removed. The invention further provides the liquid metal-micro nanoparticle mixture prepared through the method and application of the liquid metal-micro nanoparticle mixture in the aspect of preparing a high-thermal-conductivity liquid metal-micro nanoparticle mixing fluid or paste mixture, or in the aspect of preparing a magnetic-liquid liquid metal-micro nanoparticle mixing fluid or paste mixture. According to themethod for doping the micro nanoparticles into the liquid metal, the process is simple, properties of the liquid metal and the micro nanoparticles can be organically combined, original properties of the liquid metal can also be maintained, the functions of liquid metal materials are enriched, and the application field of the liquid metal is expanded.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD +1

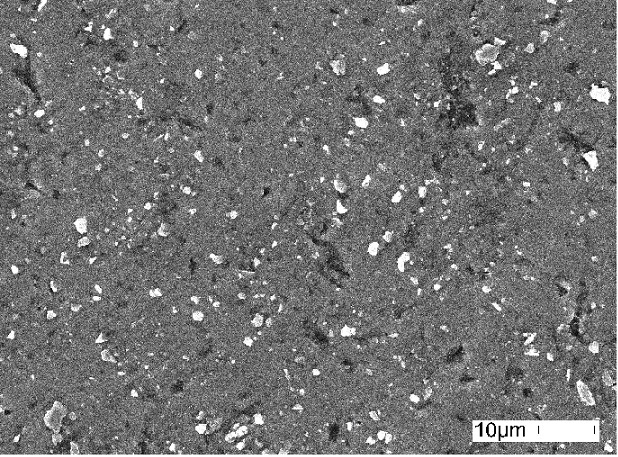

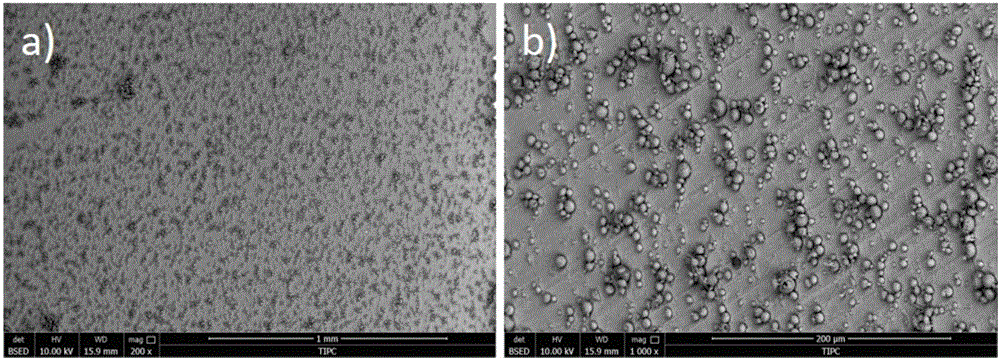

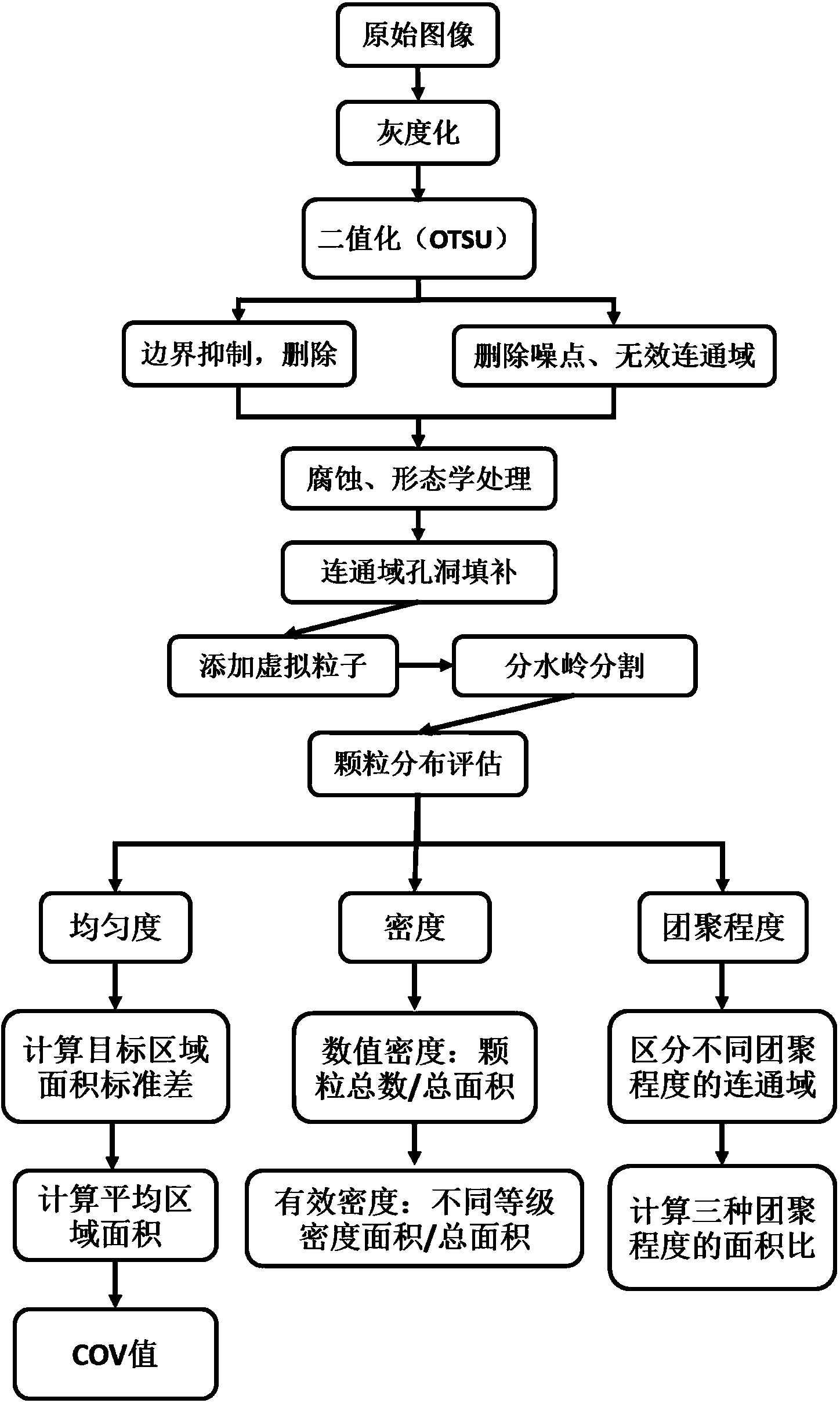

Method for analyzing and evaluating micro-nano particle dispersion and distribution

The invention provides a method for analyzing and evaluating micro-nano particle dispersion and distribution. The method includes the following steps of firstly, collecting a micro-nano particle microscopic image, and graying the image; secondly, conducting binaryzation on the image through an OTSU method, and removing impure points and ineffective communication domains in the image; thirdly, separating the connected communication domains through the morphological algorithm, and filling holes in the communication domains; fourthly, adding virtual particles, segmenting the image through the watershed algorithm, and obtaining segmented characteristic communication domains; fifthly, calculating related data of the characteristic communication domains; sixthly, evaluating micro-nano particle dispersion and distribution. By means of the method, the more accurate result can be obtained; a large number of micro-nano particle distribution microscopic images can be rapidly processed in a batched mode; the micro-nano particle distribution condition can be analyzed and evaluated comprehensively from the aspects of uniformity, density and clustering degree.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com