Patents

Literature

202results about How to "Toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

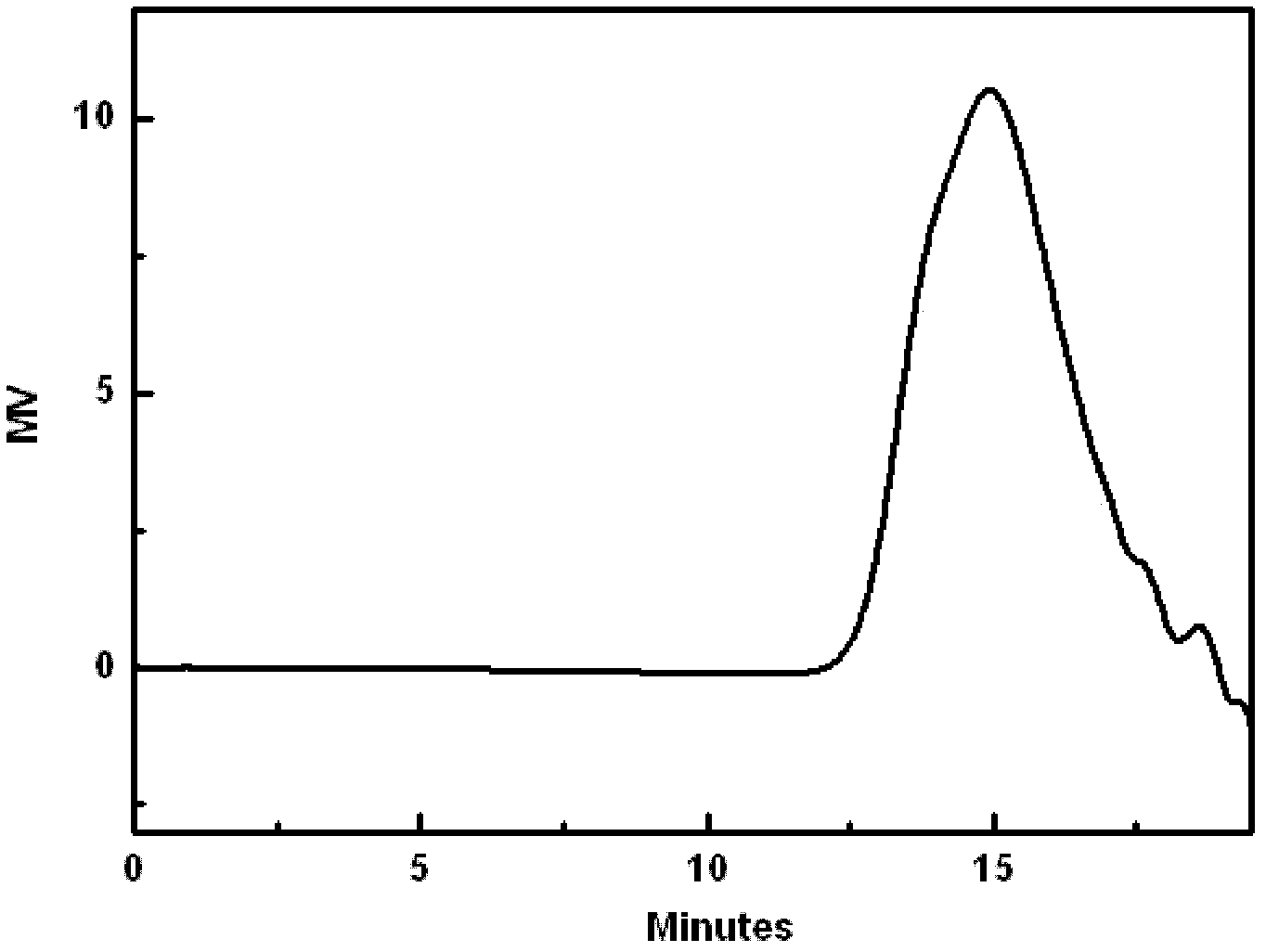

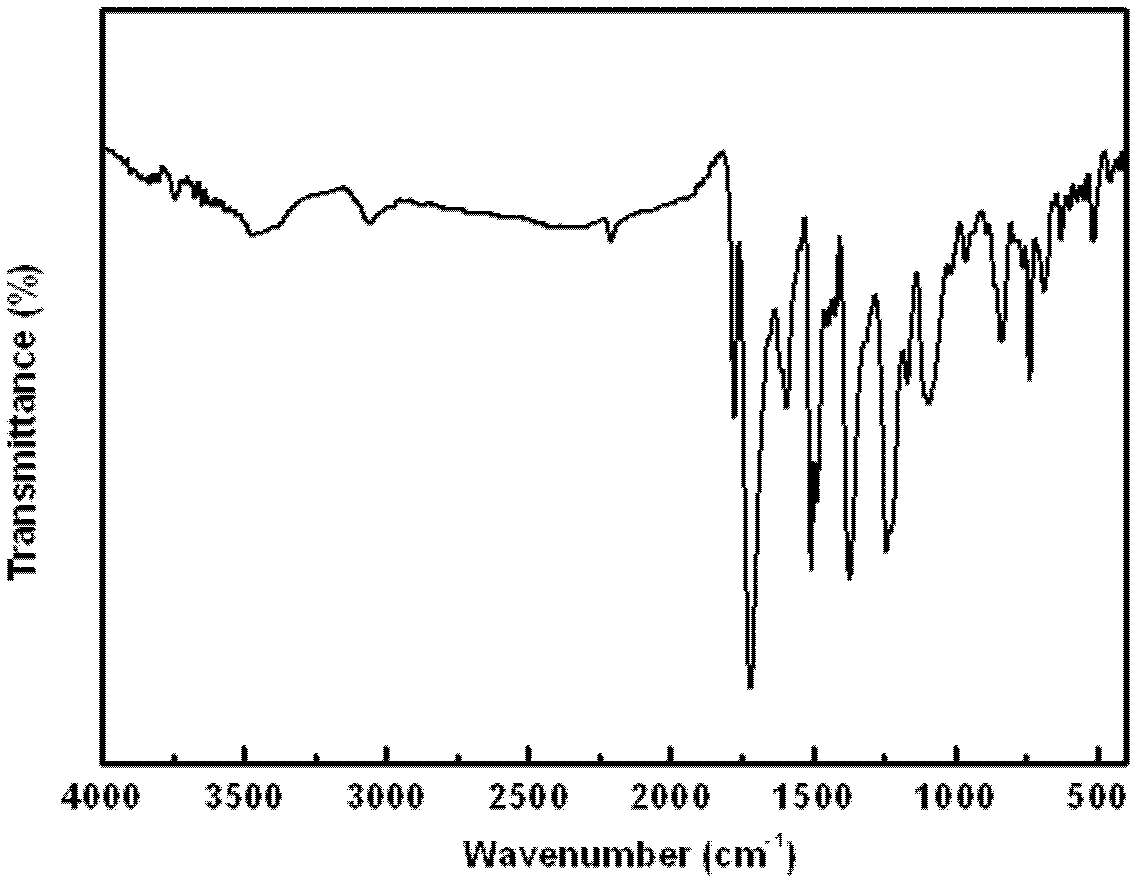

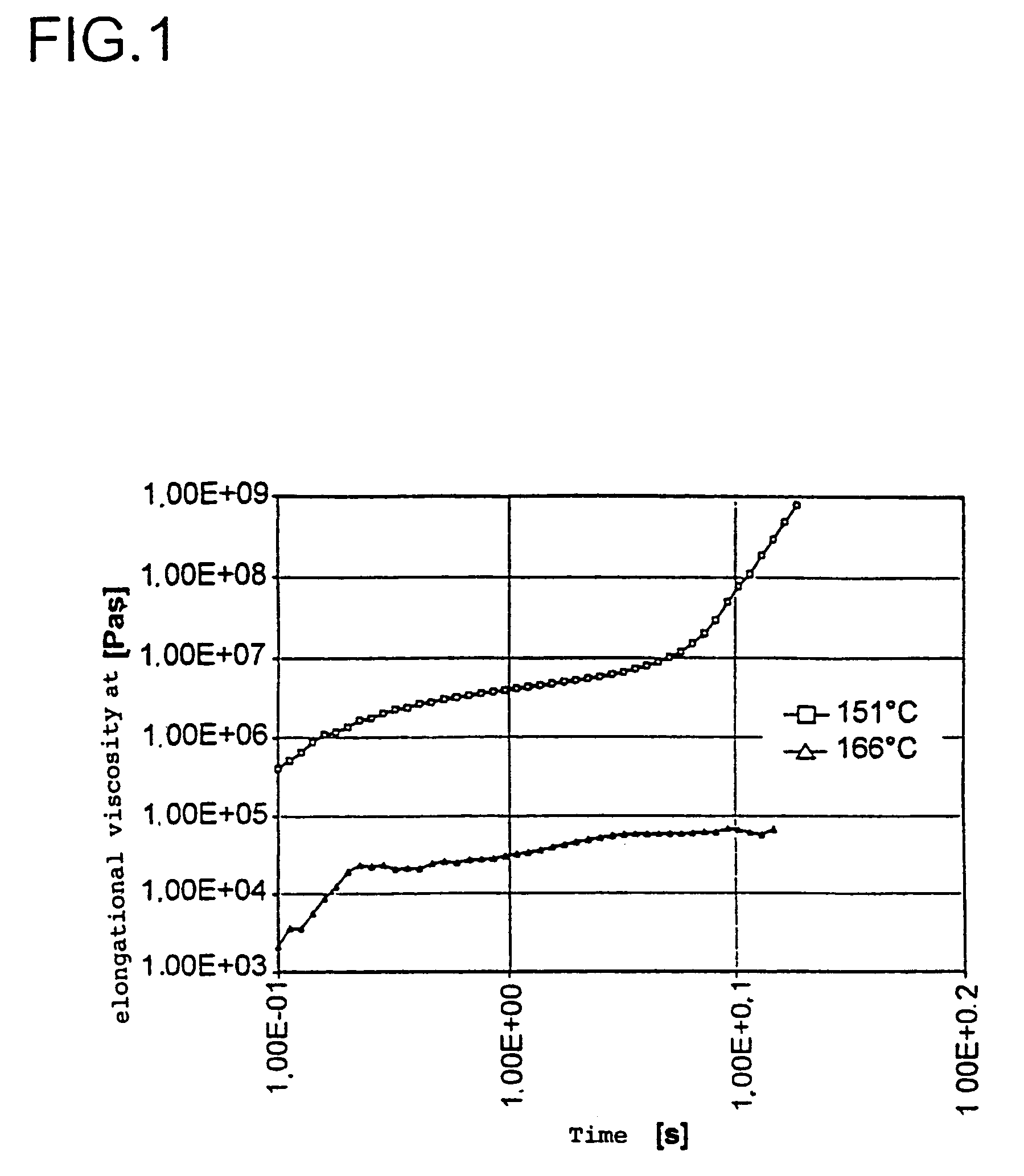

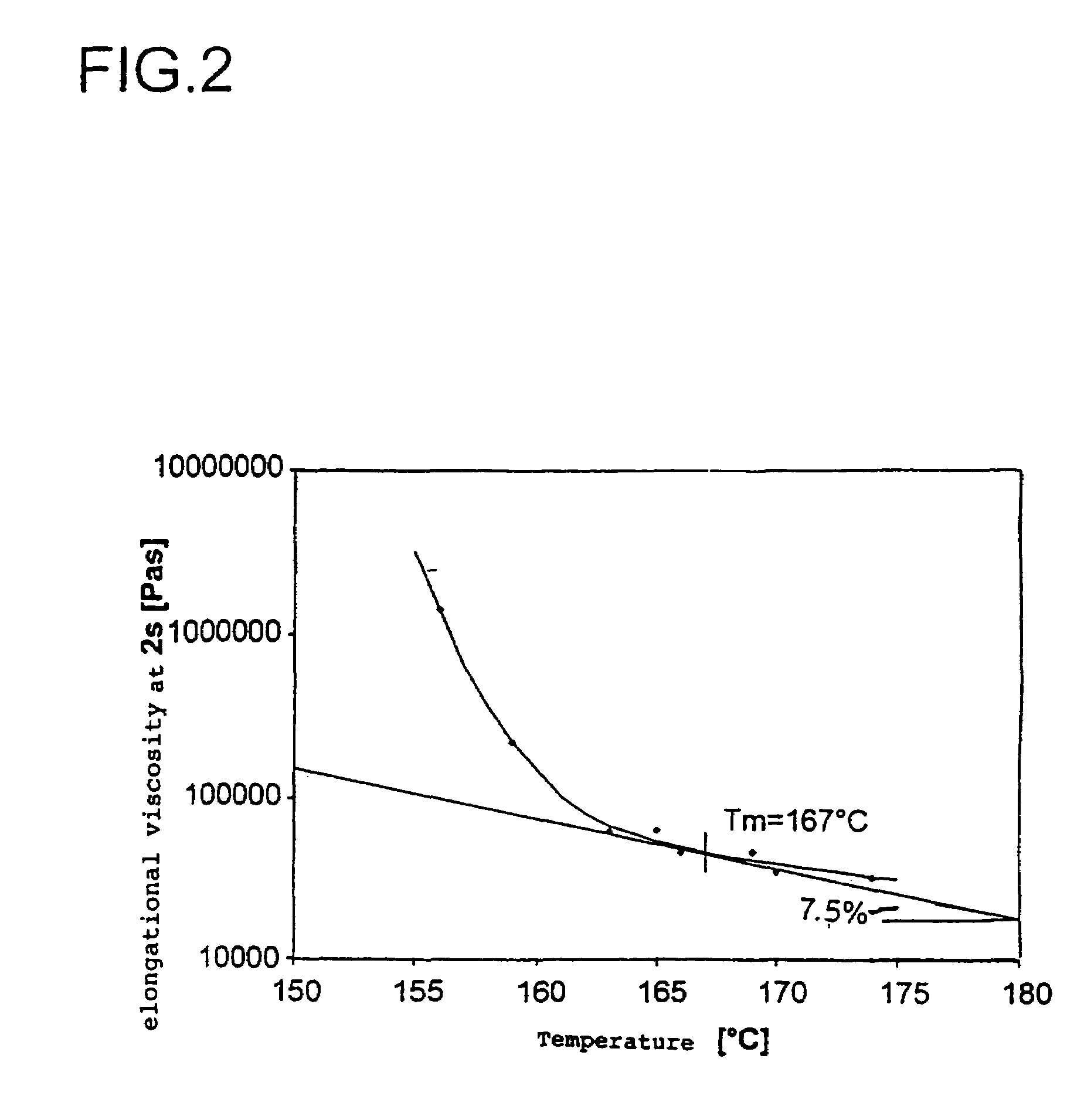

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene and a secondary polymer

InactiveUS7262251B2Broad processibilityImprove thermal stabilityOther chemical processesFilm/foil adhesivesWaxPlasticizer

Owner:ATO FINDLEY

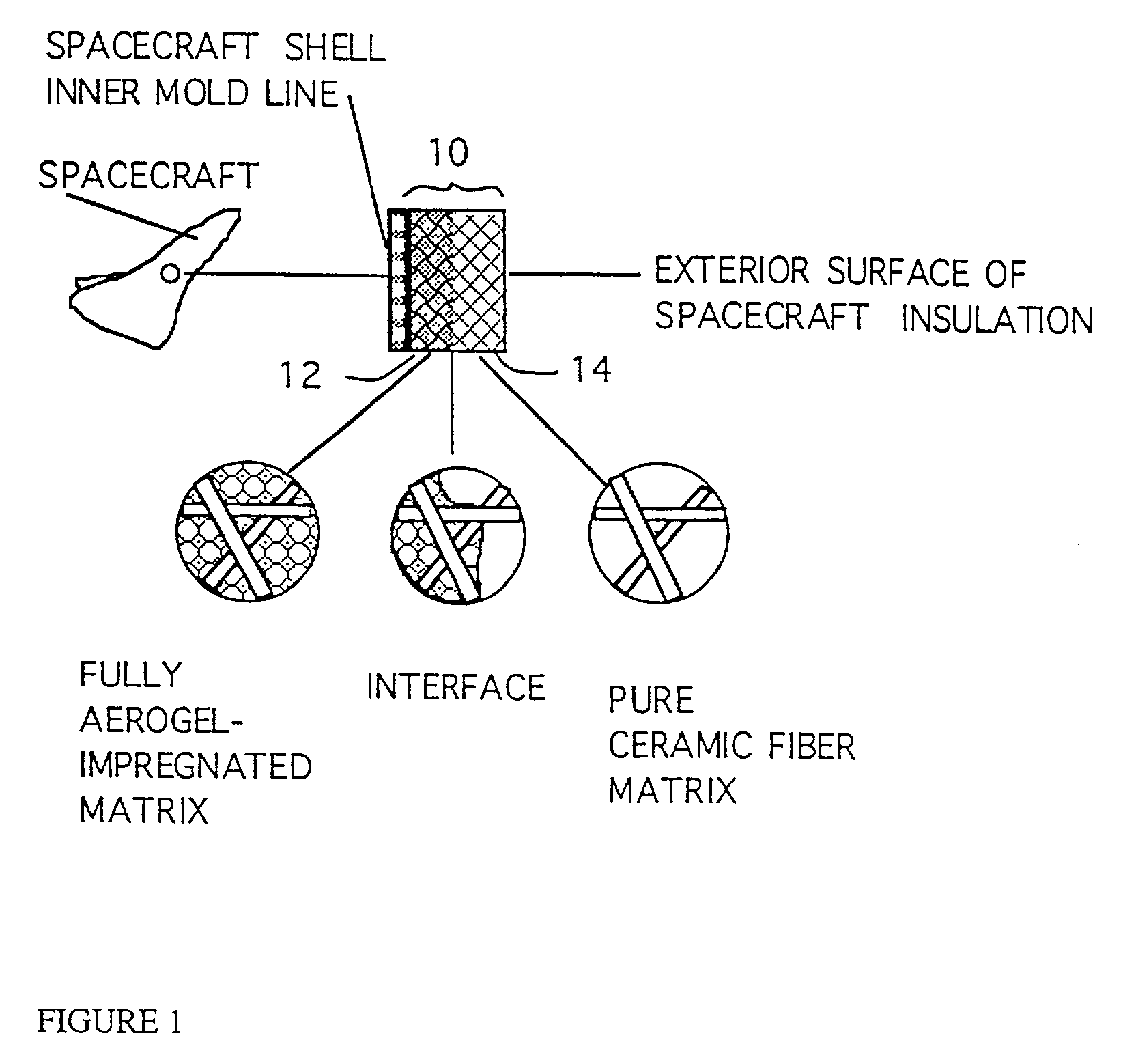

Aerogel loaded tile composite material

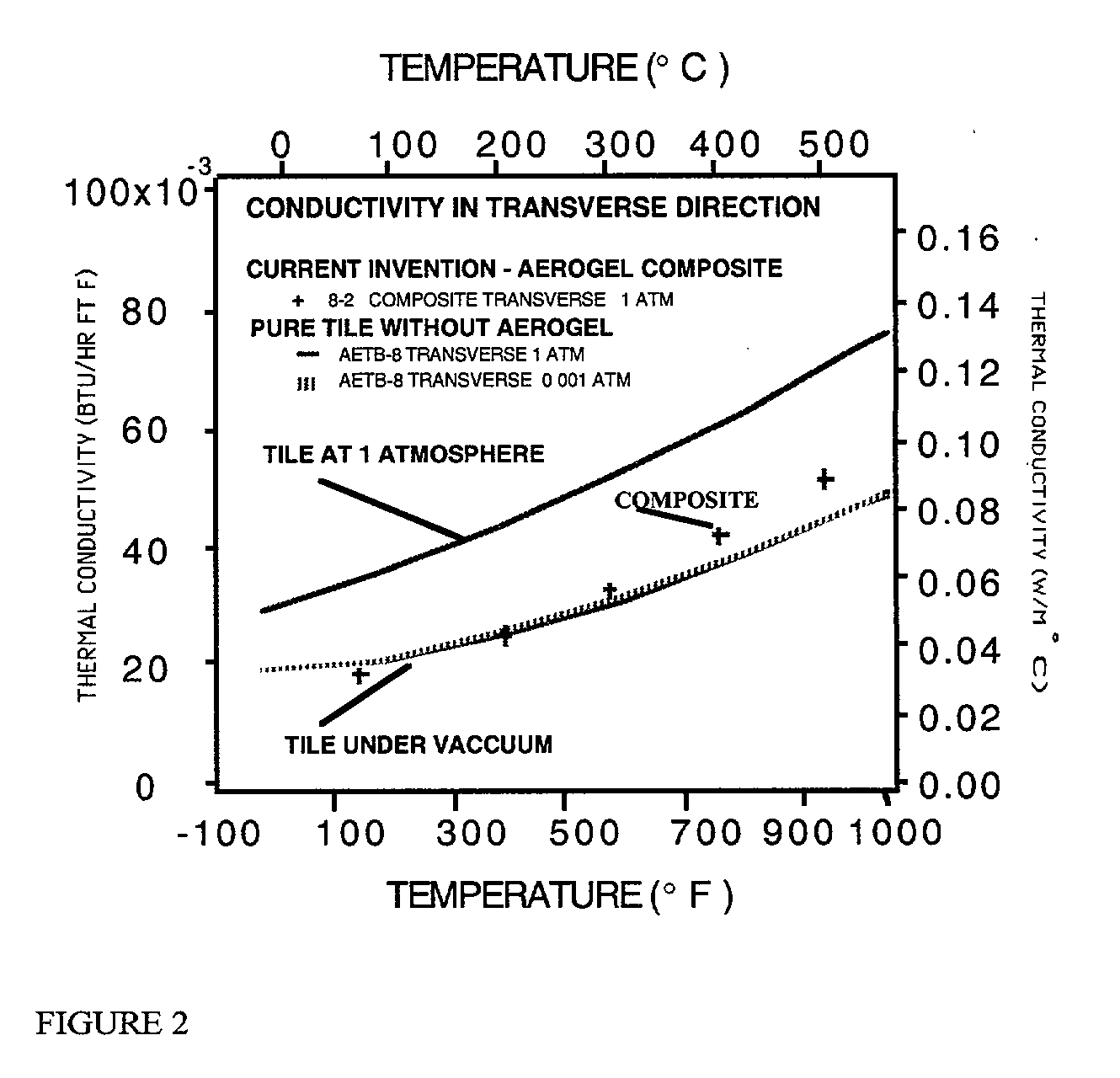

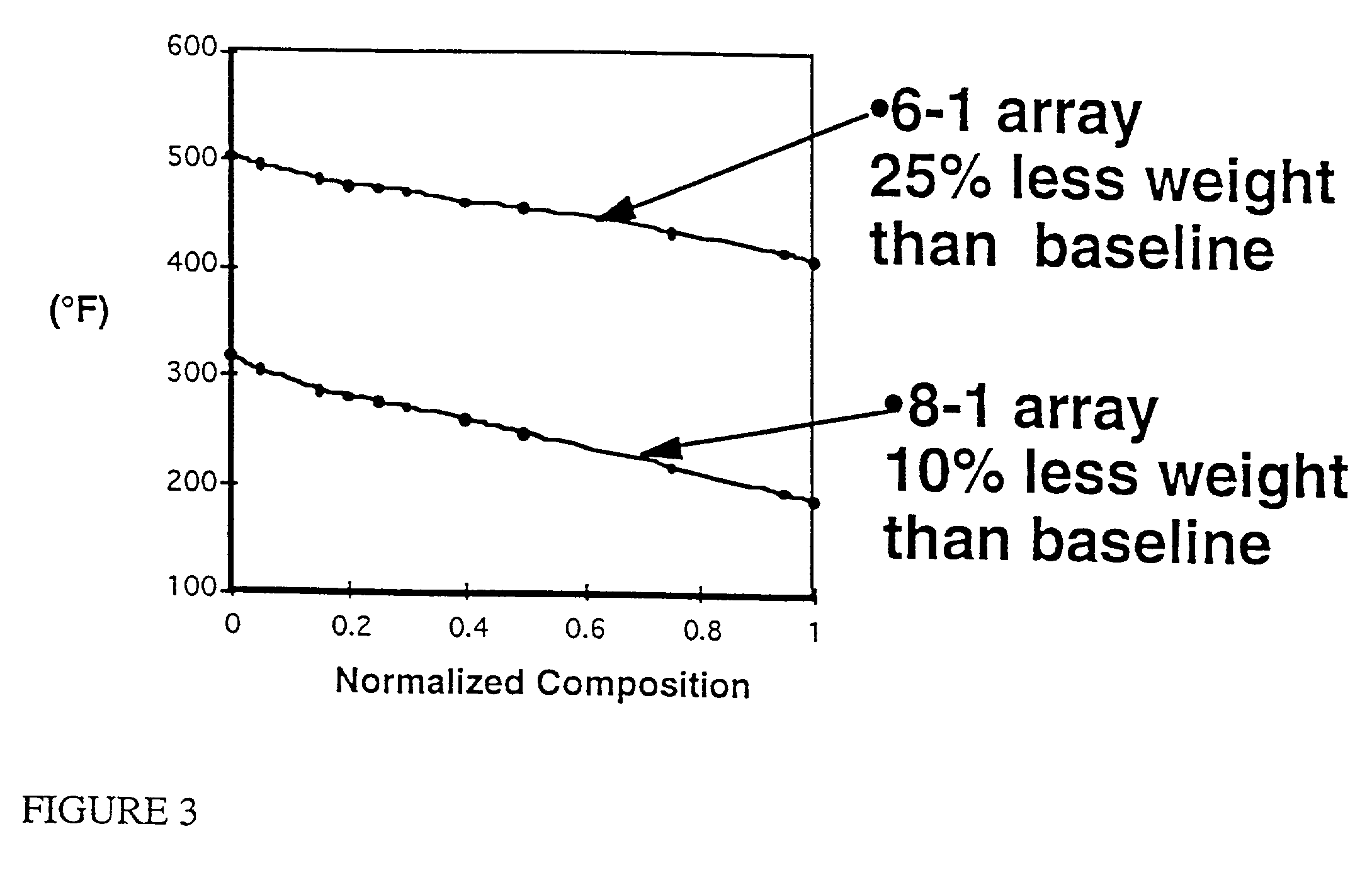

InactiveUS20020061396A1Avoid condensationImprove insulation performanceSynthetic resin layered productsCeramic layered productsTotal thicknessFiber matrix

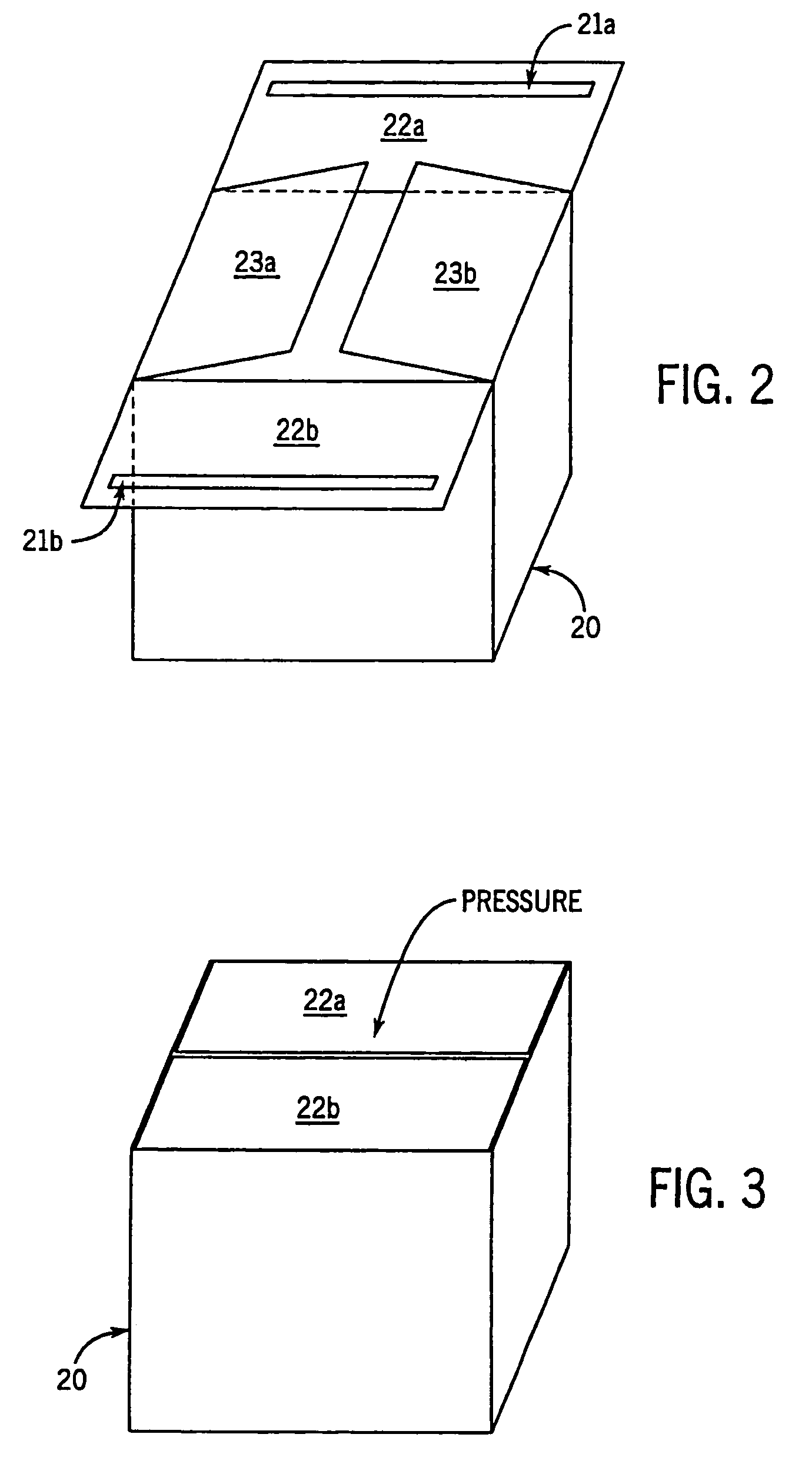

A composite material having a preferably rigid preformed ceramic fiber matrix at least partially impregnated with an aerogel and forming a multi-layered material. The matrix is impregnated with an aerogel material which forms a layer having a total thickness r where r is less than t or equal to t, where t is the thickness of the matrix, thus forming a single or multilayered composite material. The material may be formed with numerous layers s1, s2, S3, . . . snn where r=SIGMAsn and r is less than or equal to t. Thus, a multi-layered material is formed. Alternatively, the aerogel / fiber matrix composite has channels devoid of aerogel.

Owner:NASA

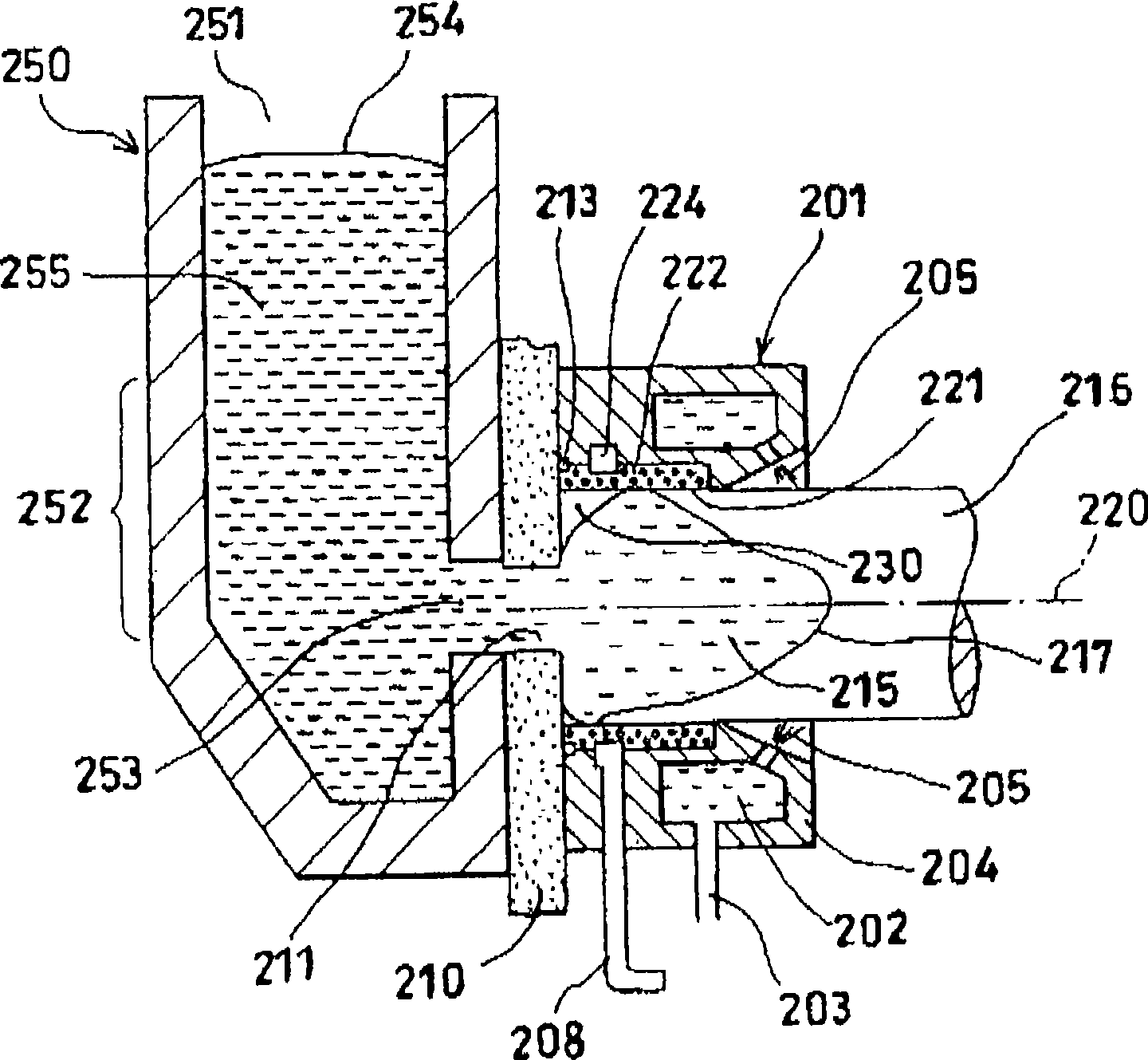

Siloxane-containing compositions curable by radiation to silicone elastomers

InactiveUS20030064232A1Fast curingAdvantage in of consumption costImpression capsLayered productsMethacrylatePolymer science

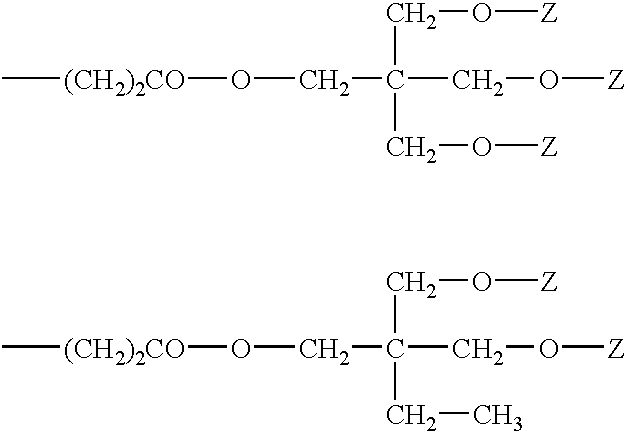

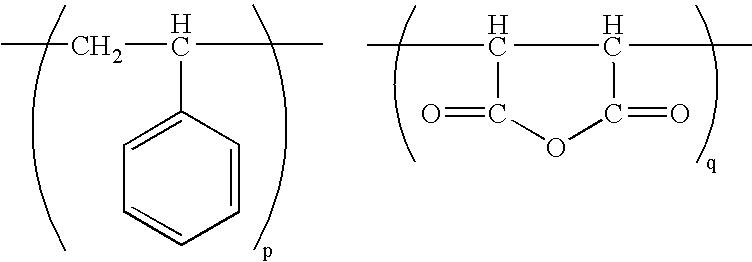

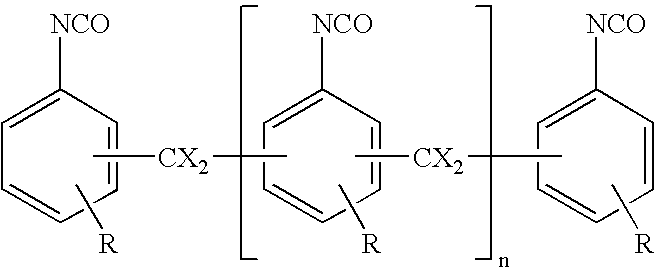

This invention provides for compositions, which can be crosslinked by radiation to give elastomeric coatings, which comprises: (a) high-molecular weight siloxanes with multiple (meth)acrylate functional groups; and (b) reinforcing fillers selected from the group consisting of silicone resins and silicone dioxide fillers, wherein the siloxanes (a) have the general structure: [R3SiO1 / 2]a[(Z)nG-Ym-R2SiO1 / 2]a'[R2SiO2 / 2]b[(Z)nG-Ym-RSiO2 / 2]b'[RSiO3 / 2]c[SiO4 / 2]d.

Owner:EVONIK GOLDSCHMIDT GMBH

Resin-polyester blend binder compositions, method of making same and articles made therefrom

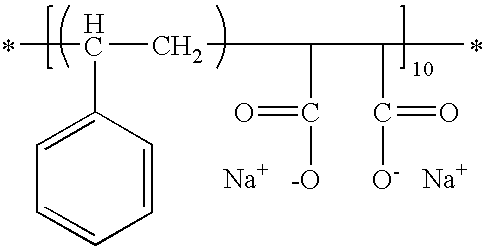

ActiveUS20080207833A1High tensile strengthMaintaining (or improving) asphalt coating characteristicsAbrasion apparatusPolyester coatingsFiberWater dispersible

An aqueous binder system including a mixture of urea-formaldehyde resin and water-dispersible polyester resin. A combination of the binder system applied to fiber insulation, a composite glass mat, glass / polyester mat, polyester mat, or substrate of a coated abrasive product. Fiber insulation, a composite glass mat, glass / polyester mat, polyester mat, or coated abrasive product with the binder system including urea-formaldehyde resin and water-dispersible polyester.

Owner:BAKELITE UK HLDG LTD

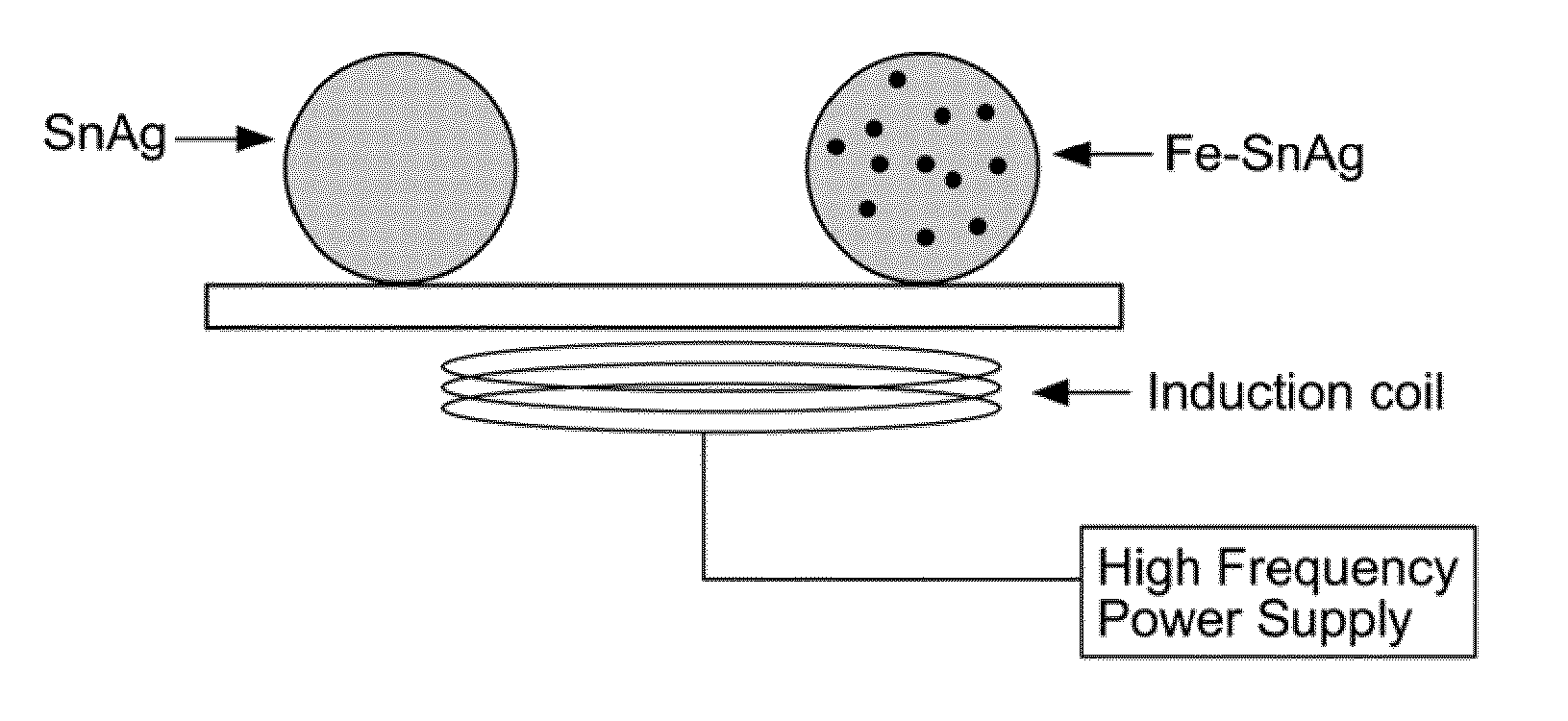

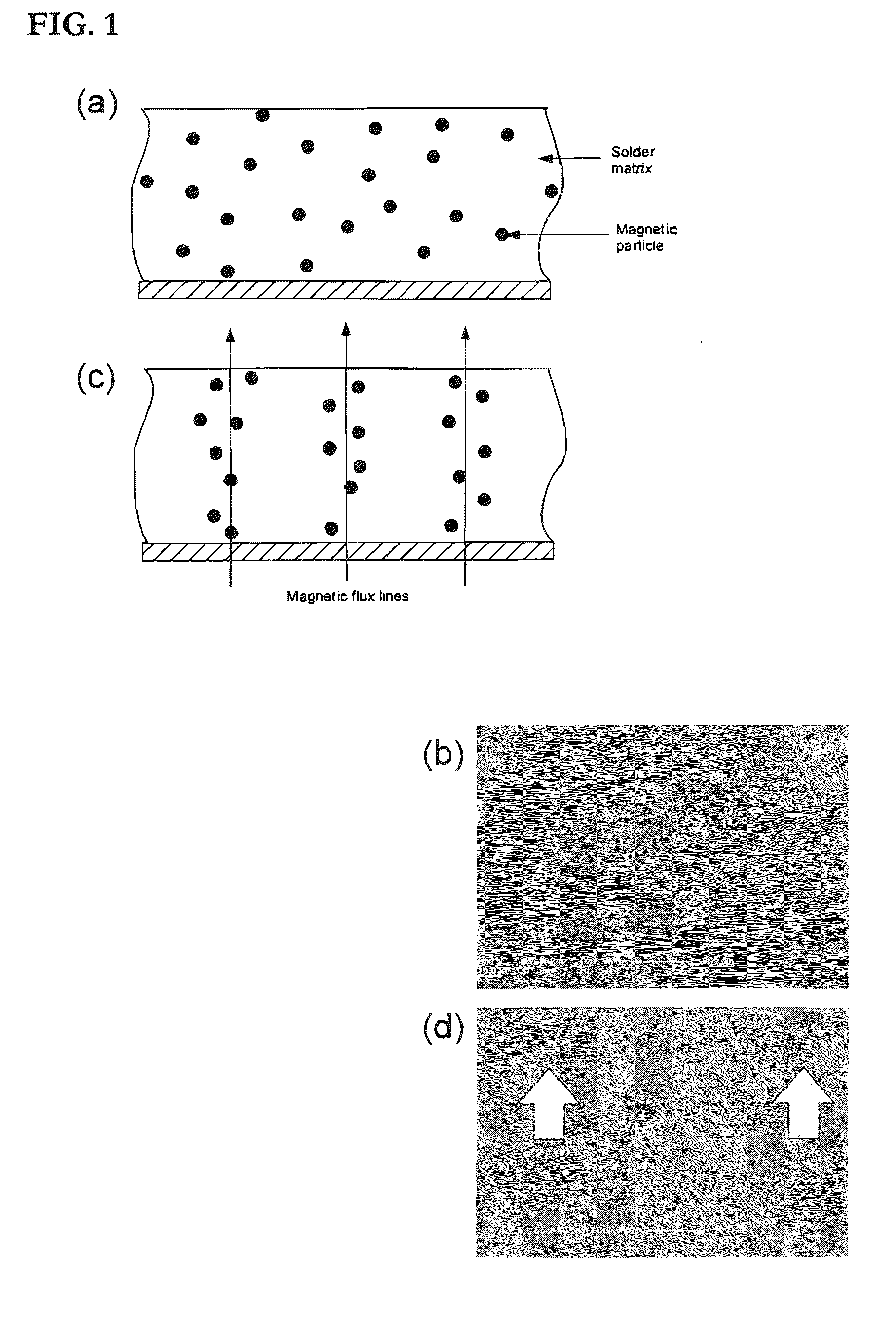

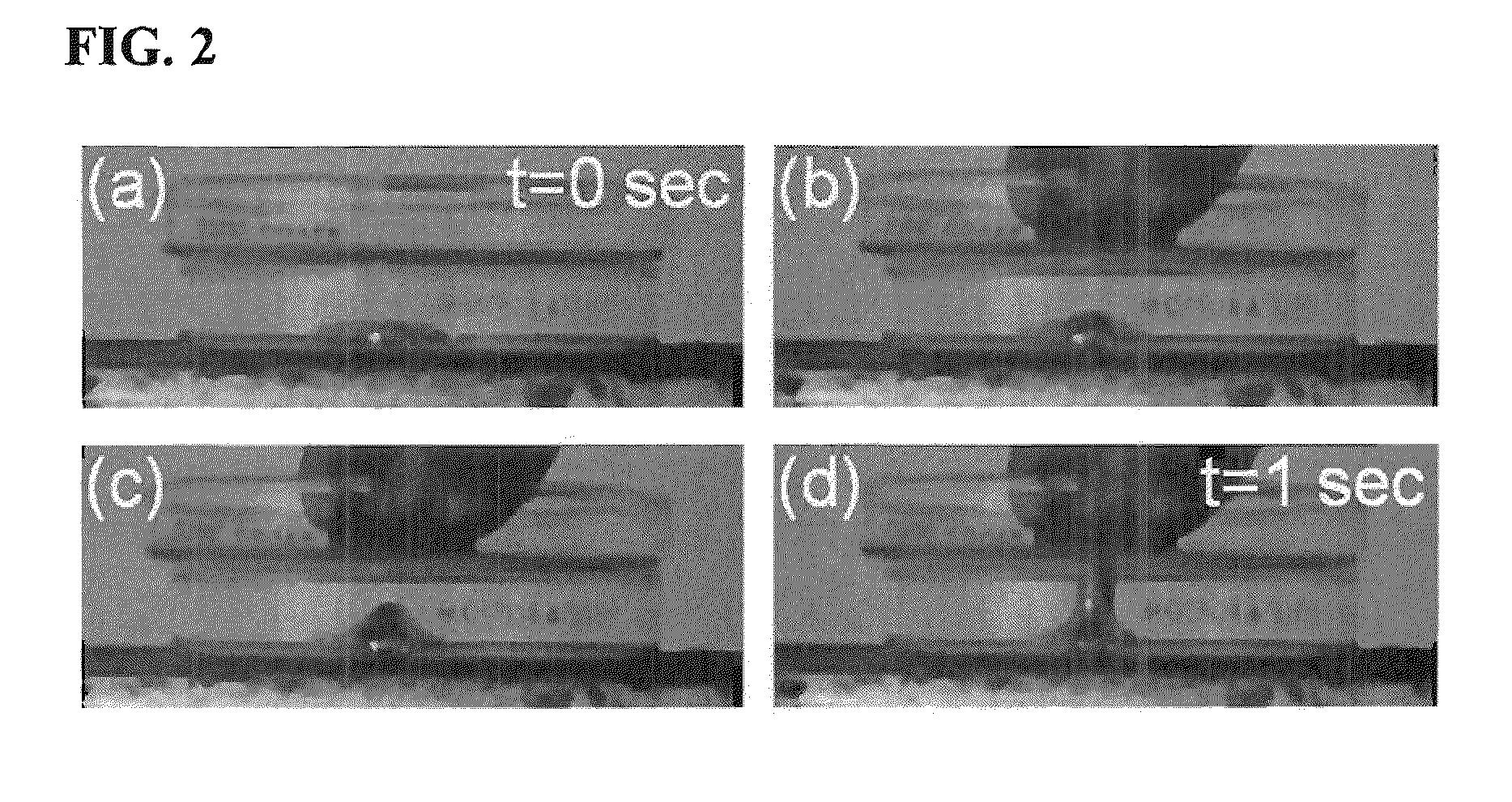

Low melting temperature alloys with magnetic dispersions

InactiveUS20110210283A1Enhanced mechanical propertyPromotes an increase in inductionNanomagnetismMagnetic liquidsMelting temperatureMelting point

A low melting temperature composite material including an alloy having about 0.1% by weight to about 99% by weight of tin and about 0.1% by weight to about 90% by weight of an element selected from the group consisting of silver and gold, and about 0.1% by weight to about 50% by weight of magnetic particles dispersed in the alloy. Method of heating such a composite material, remotely manipulating such a composite material with magnetic fields, enhancing the mechanical properties of such a material, and making such a material are also disclosed.

Owner:YALE UNIV

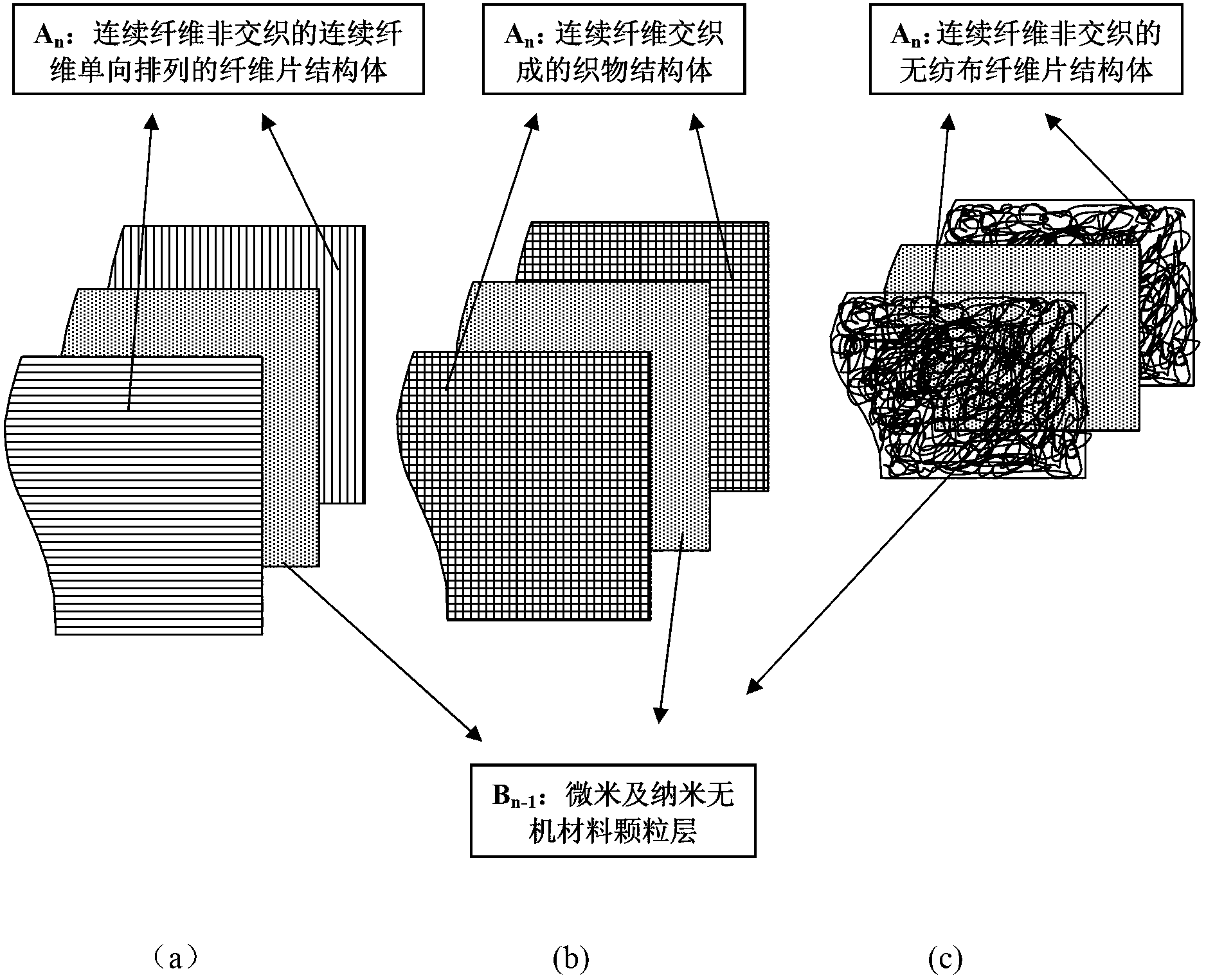

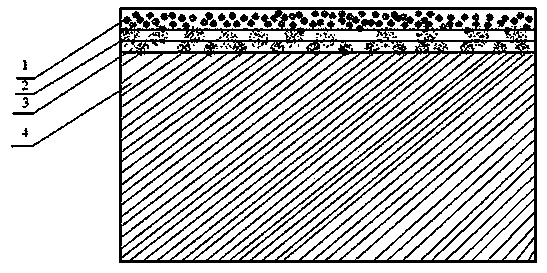

Micron and nano material-enhancing bionic layered composite material and manufacturing method thereof

ActiveCN102706219AImprove impact resistanceToughnessSynthetic resin layered productsLaminationBionicsUltimate tensile strength

The invention relates to the field of bionic layered composite materials, in particular to a micron and nano material-enhancing high-impact-resistance bionic layered composite material and a manufacturing method thereof. The material provided by the invention is formed in a manner that toughening structural material layers and enhancing material layers are composited at intervals layer by layer, and the outer layers on both faces of the bionic layered composite material are the enhancing material layers; and the toughening structural material layers are continuous fiber structural bodies formed through interweaving continuous fibers, or non-interweaved continuous fiber structural bodies formed by the continuous fibers, and the enhancing material layers are micron and nano inorganic material granular layers obtained in a manner that a mixture formed by mixing micron and nano inorganic material granules with thermoplastic macromolecular resin is coated on the toughening structural material layers. The material provided by the invention is a more-effective lightweight protective material, and some defects, such as low interlayer strength and too large load, caused by too thick composite layers, infirmness of interlayer bonding, and the like, in the prior art are overcome.

Owner:INST OF CHEM CHINESE ACAD OF SCI

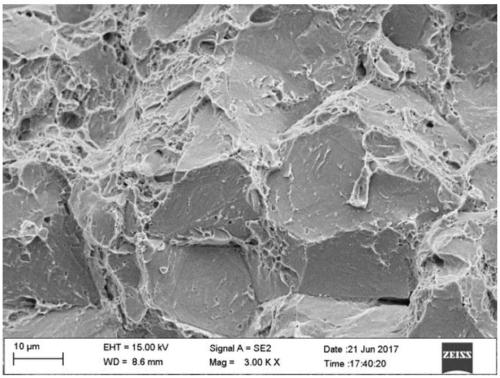

Low alloy steel, seamless steel oil country tubular goods, and method for producing seamless steel pipe

InactiveUS20090047166A1Improve the immunityToughnessFurnace typesHeat treatment process controlHardenabilityAlloy steel

A low alloy steel comprising, by mass %, C: 0.10 to 0.20%, Si: 0.05 to 1.0%, Mn: 0.05 to 1.5%, Cr: 1.0 to 2.0%, Mo: 0.05 to 2.0%, Al: 0.10 % or less and Ti: 0.002 to 0.05%, and with a Ceq value obtained by the following formula (1) of 0.65 or more, with the balance being Fe and impurities, wherein in the impurities, P is 0.025% or less, S is 0.010% or less, N is 0.007% or less, and B is less than 0.0003%, and the number per unit area of M23C6 type precipitates (M: a metal element) whose grain diameter is 1 μm or more is 0.1 / mm2 or less. This invention provides a low alloy steel possessing both hardenability and toughness and improves the resistance to sulfide stress corrosion cracking.Ceq=C+(Mn / 6)+(Cr+Mo+V) / 5 formula (1)where C, Mn, Cr, Mo and V in the formula (1) denote the mass % of respective elements.

Owner:SUMITOMO METAL IND LTD

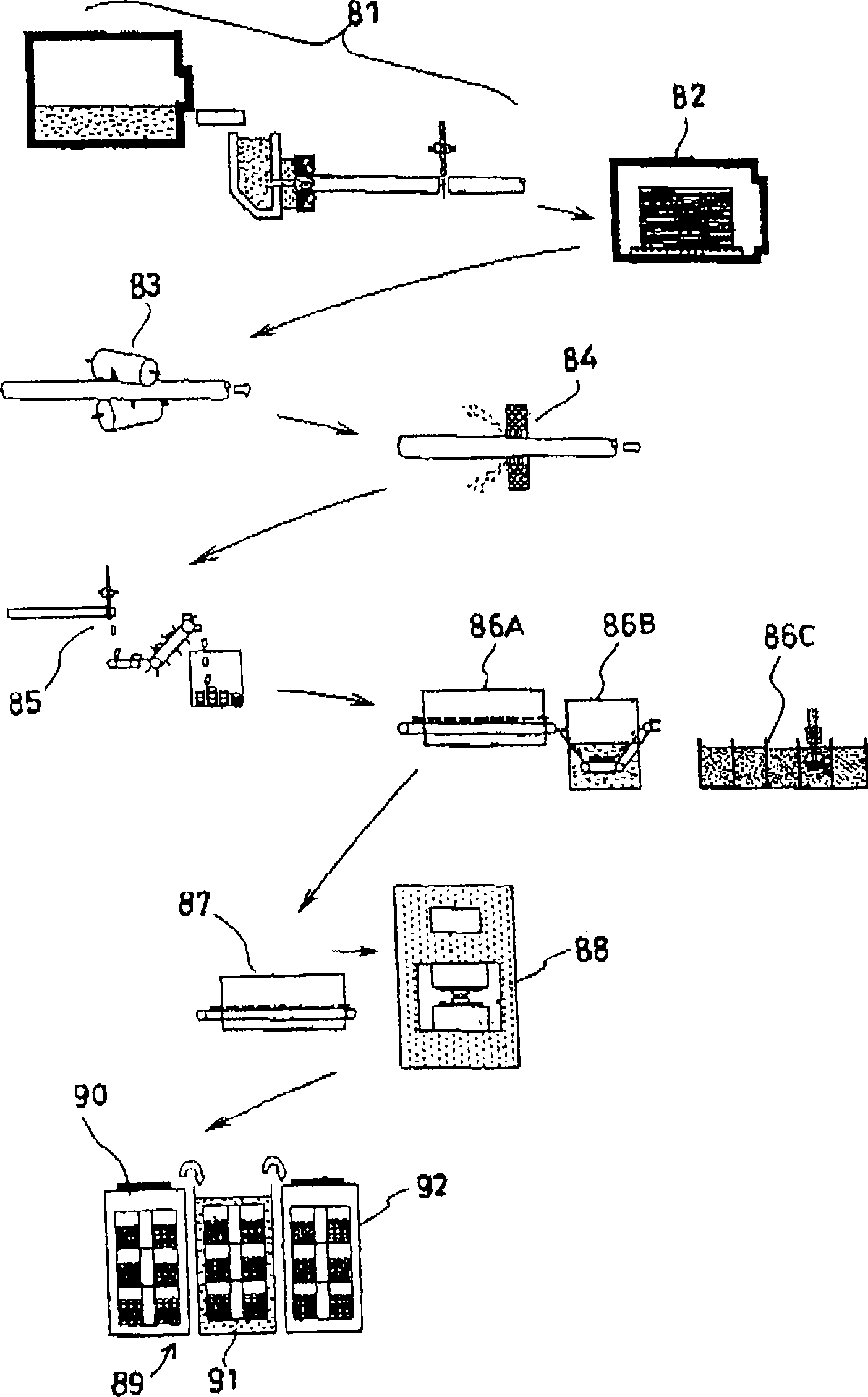

Process for production of aluminum alloy formings, aluminum alloy formings and production system

InactiveCN101522935ABoth ductilityToughnessMetal-working apparatusMachines/enginesUltimate tensile strengthMaterials science

The invention provides a process for production of aluminum alloy formings superior to conventional aluminum alloy forgings in mechanical strength at high temperature. A process for production of aluminum alloy formings by forging a stock consisting of a continuously cast rod made of an aluminum alloy, in which the aluminum alloy contains 10.5 to 13.5% by mass of Si, 2.5 to 6% by mass of Cu, 0.3 to 1.5% by mass of Mg, and 0.8 to 4% by mass of Ni and satisfies the relationship: Ni (% by mass) = [-0.68 OECu(% by mass) + 4.2(% by mass)] and which comprises the step (82) of preheat treatment of the stock, the heating step (87) of forging the stock, and the step (89) of postheat treatment of an aluminum alloy forming as the heat treatment / heating steps, with the step (82) involving the treatment of keeping the stock at -10 DEG C to 480 DEG C for 2 to 6 hours.

Owner:SHOWA DENKO KK

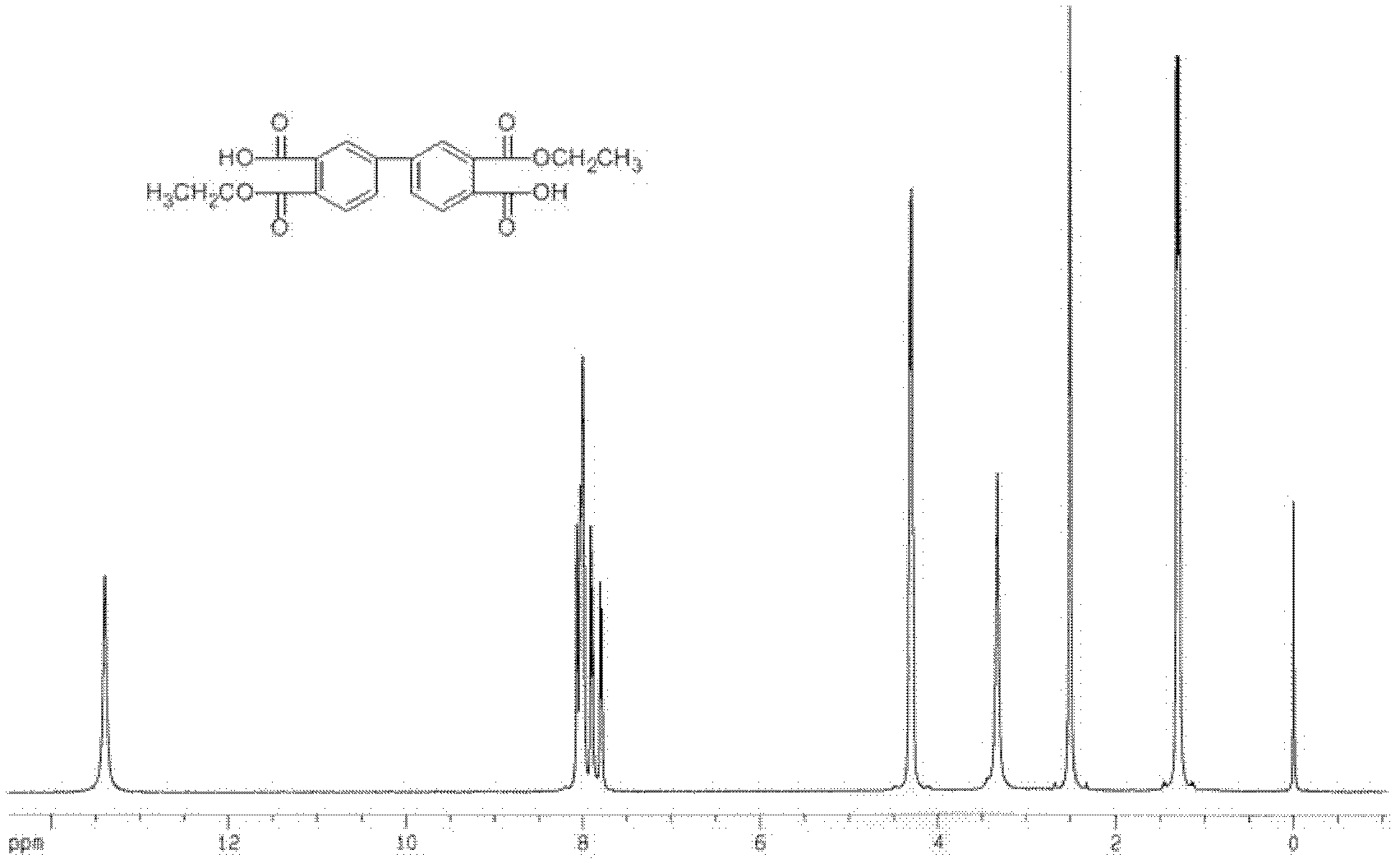

Polyimide resin as well as preparation method and application thereof

The invention discloses polyimide resin with low melt viscosity and high toughness as well as a preparation method of a composite material of the polyimide resin. The resin is high in solid content, low in solution viscosity and is easy to steep carbon fibers to prepare a high-quality carbon fiber prepreg (a belt or cloth); a melt resin formed by heating and melting the resin has the characteristics of low melt viscosity and wide melting temperature; a resin condensate formed by heating and solidifying is high in toughness and high in Tg (glass-transition temperature). The resin is suitable for steeping reinforced fibers to prepare prepregs, and a carbon fiber reinforced composite material prepared by the autoclave and the hot hubbing forming process is excellent in impact-resistant toughness, comprehensive mechanical property and high-temperature resistant performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

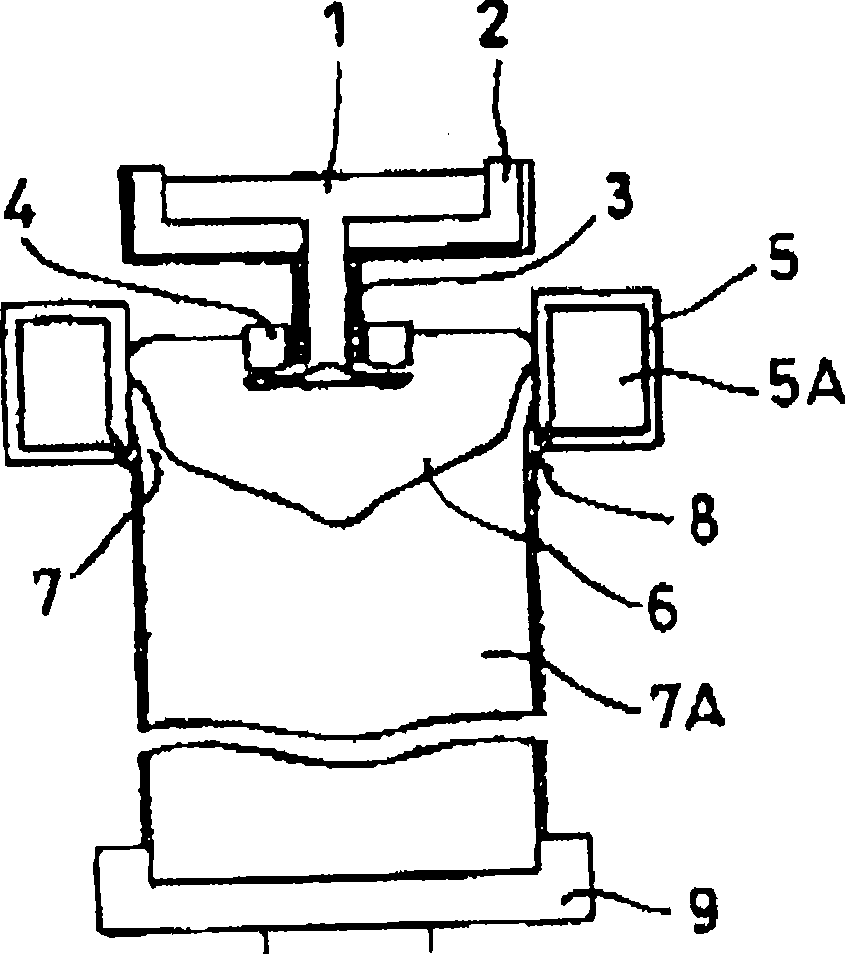

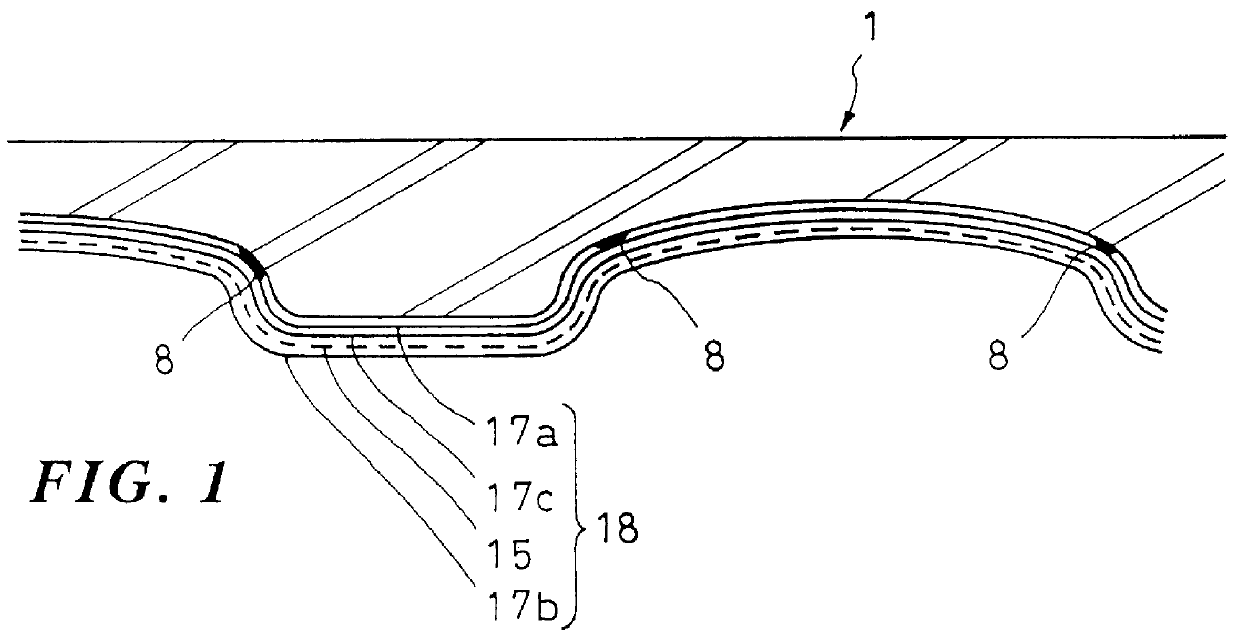

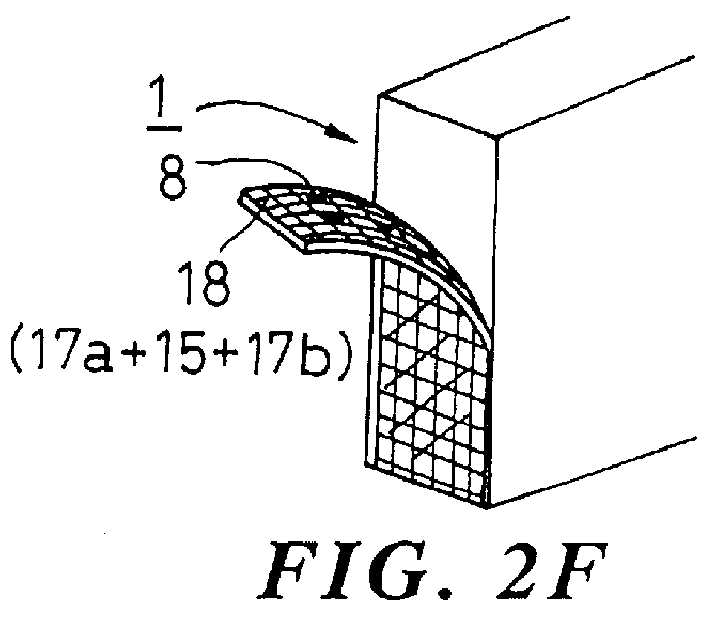

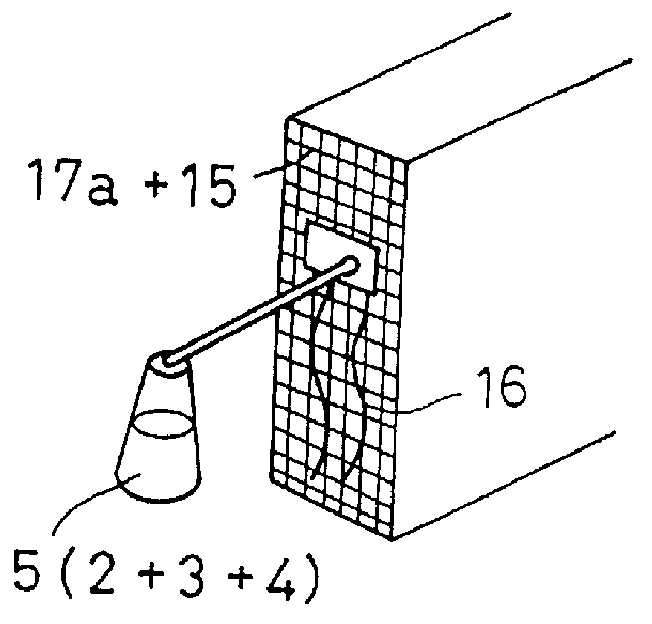

Method for cleaning structural surface

A method for cleaning structural surface 1 by forming a substratum membrane 17a thereon through application and drying of a thin layer 16 of aqueous solution 5 of membrane-forming polymer 2 on a structural surface, spreading a fibrous reinforcing member 15 on the thin layer 16 before drying or the substratum membrane 17a after dried, and applying the aqueous solution 5 on the outer surface of the reinforcing member 15 while wetting it in such a manner that, upon drying, an overlying membrane 17b integral with both the substratum membrane 17a and the reinforcing member 15 is formed so as to generate a multi-layer membrane 18 having the substratum and overlying membranes sandwiching the reinforcing member. After causing foreign matters on the structural surface 1 to adhere onto the substratum membrane 17a, the multi-layer membrane 18 is peeled off from the structural surface 1.

Owner:KAJIMA CORP

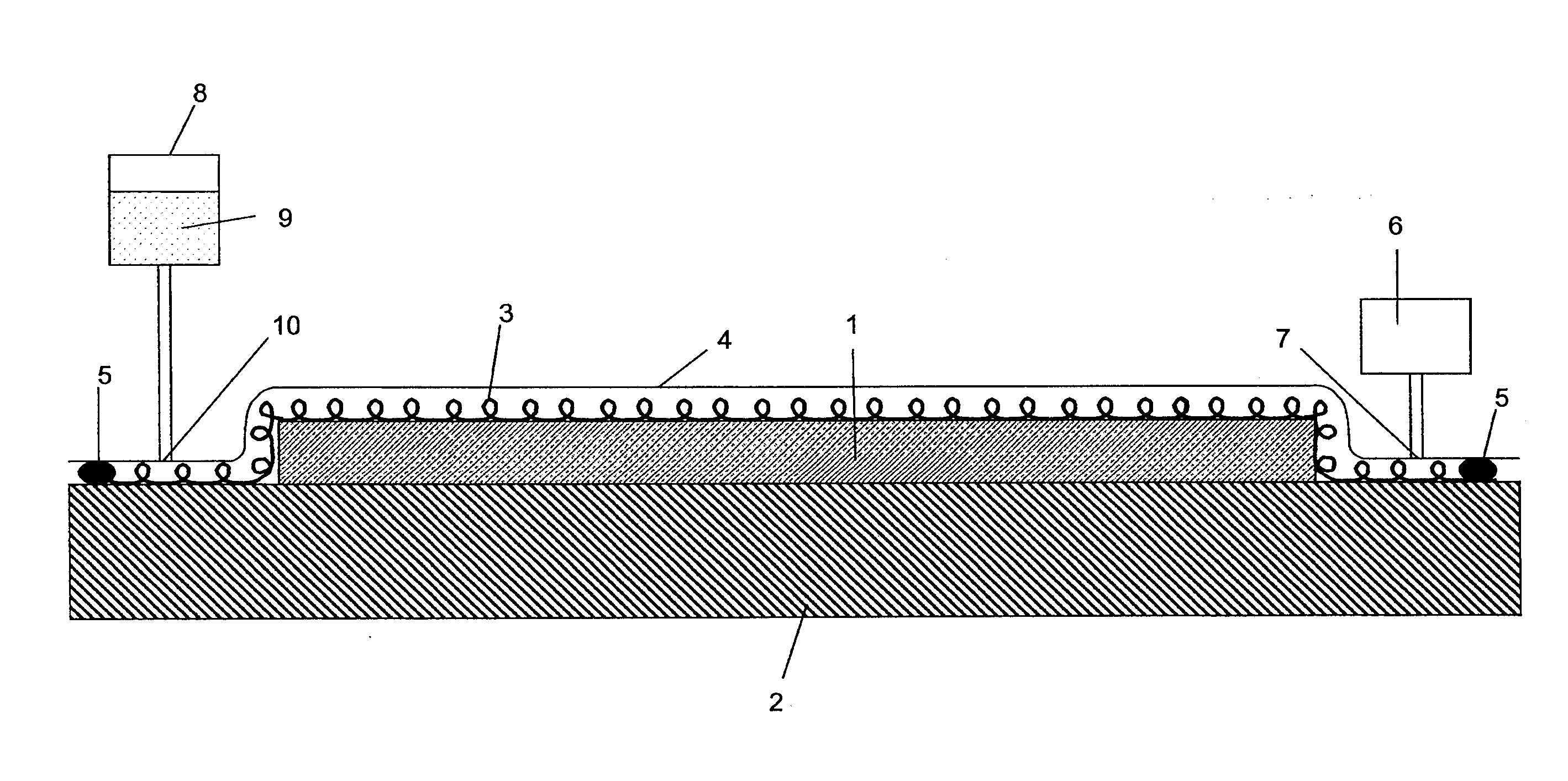

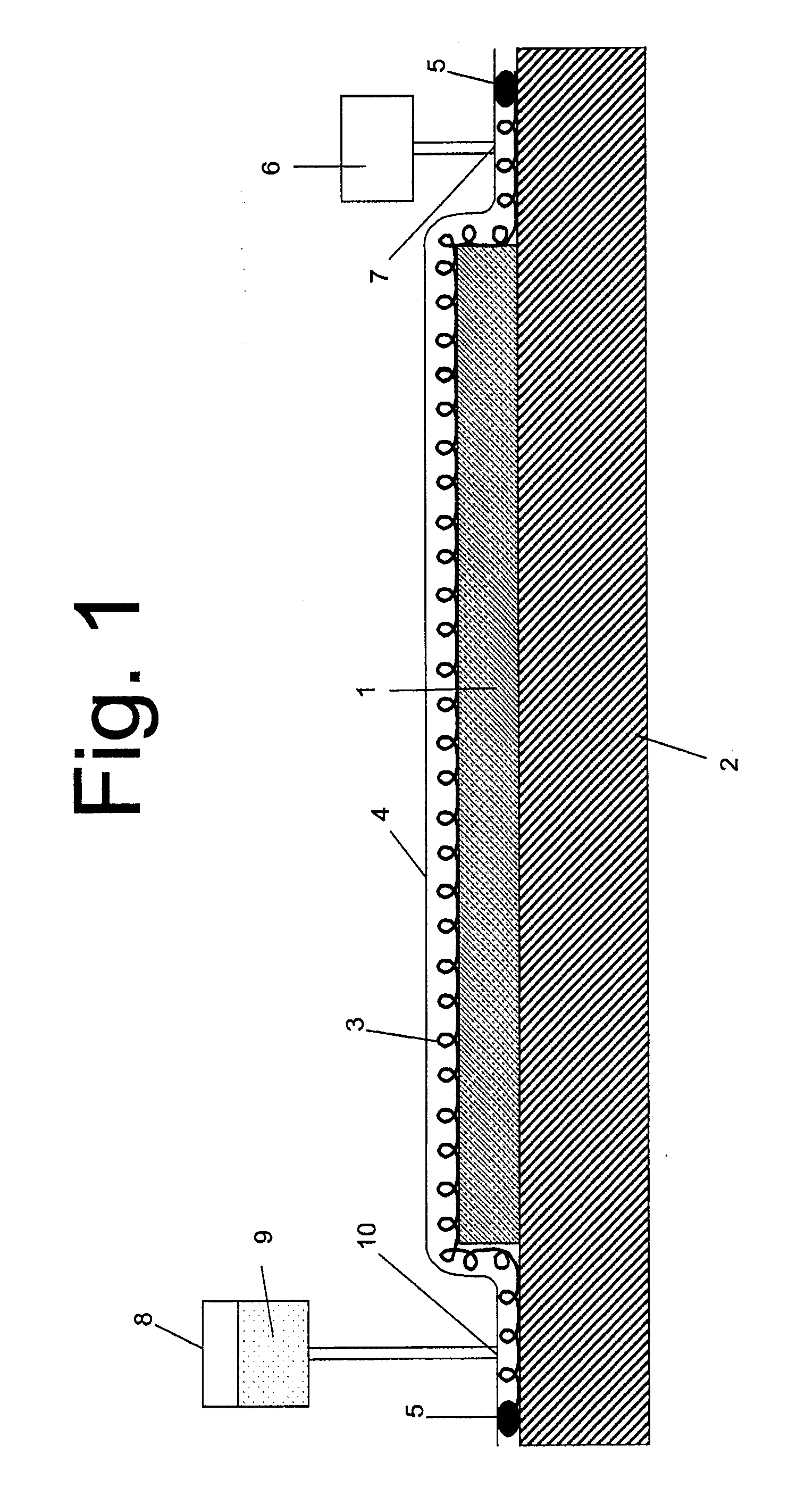

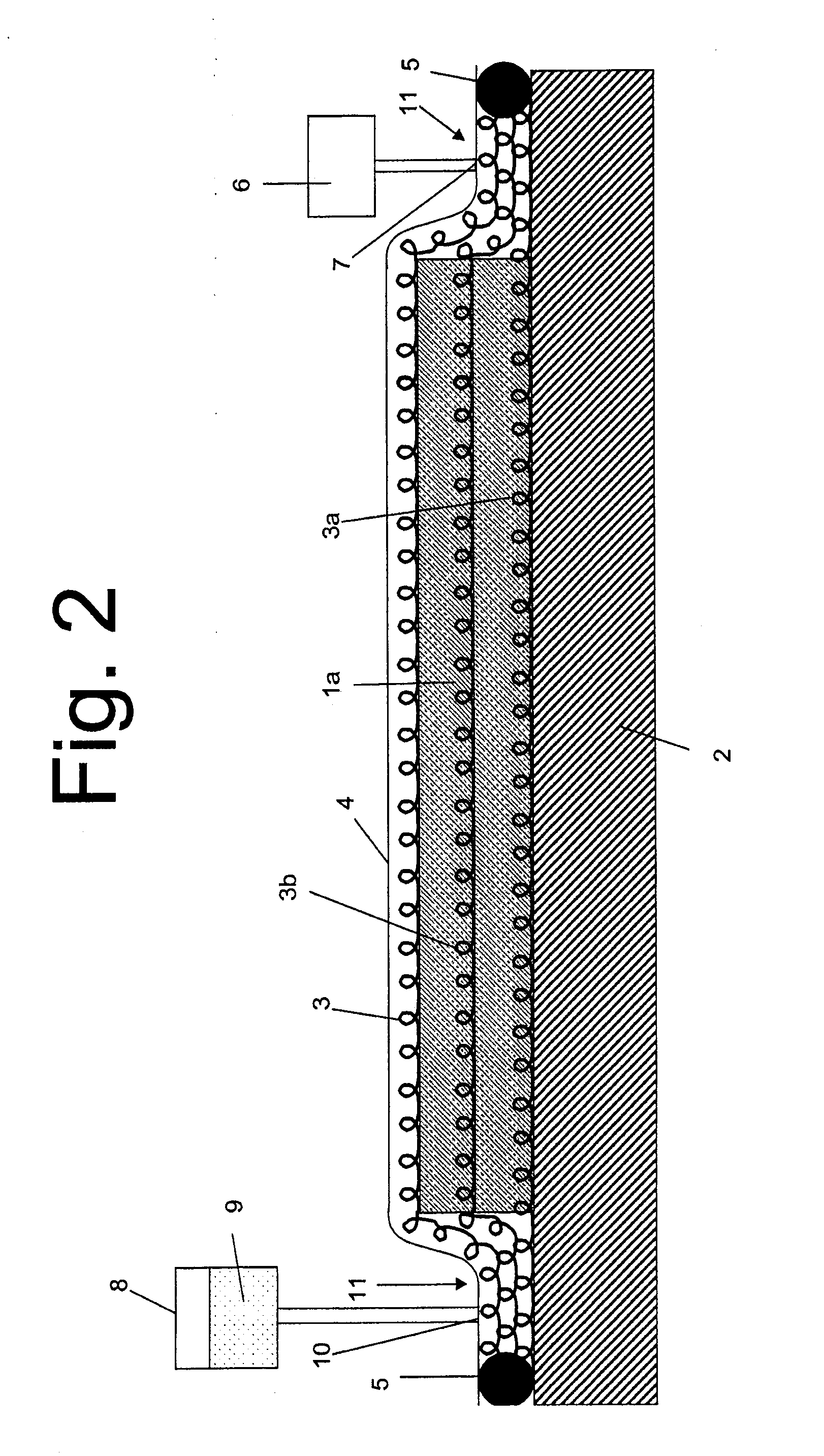

Method of processing a composite material

InactiveUS20100086765A1StrengthToughnessNatural cellulose pulp/paperSynthetic cellulose/non-cellulose material pulp/paperPorous layerMatrix diffusion

A method of processing a composite material comprising heating a porous layer in contact with the composite material above its melting point whereby it melts and becomes incorporated into the composite material. The material may be formed by a matrix diffusion process. In this case the porous layer acts as a distribution layer. Alternatively the material may be formed as a stack of prepregs. In this case the porous layer acts as a breather layer. The porous layer may comprise a polysulphone or polyethersulphone which increases the toughness of the material.

Owner:AIRBUS OPERATIONS LTD

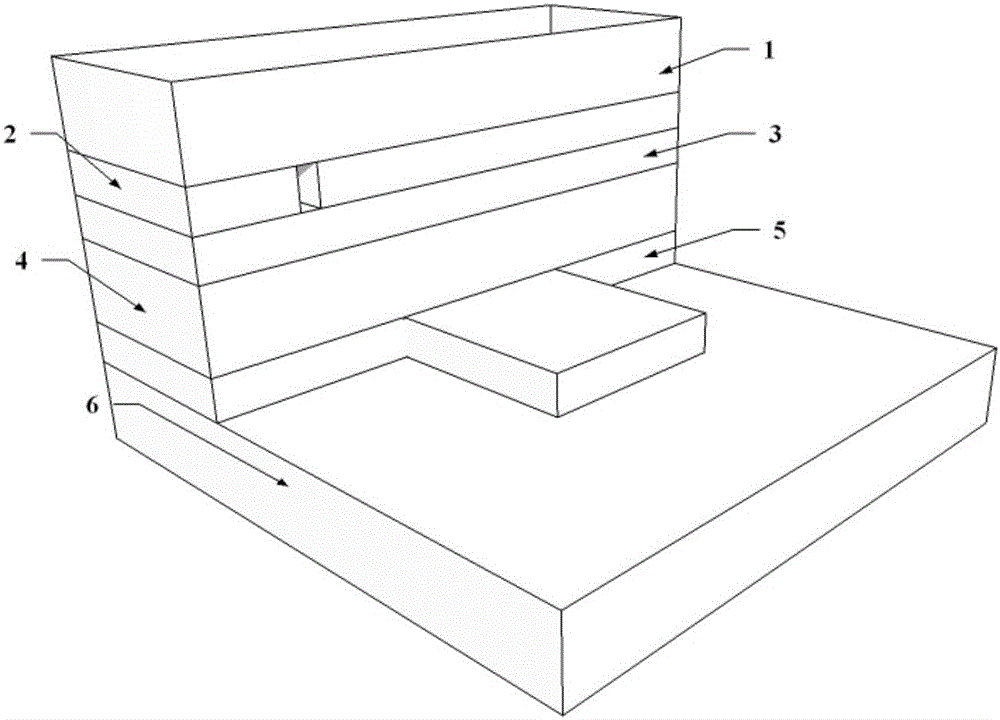

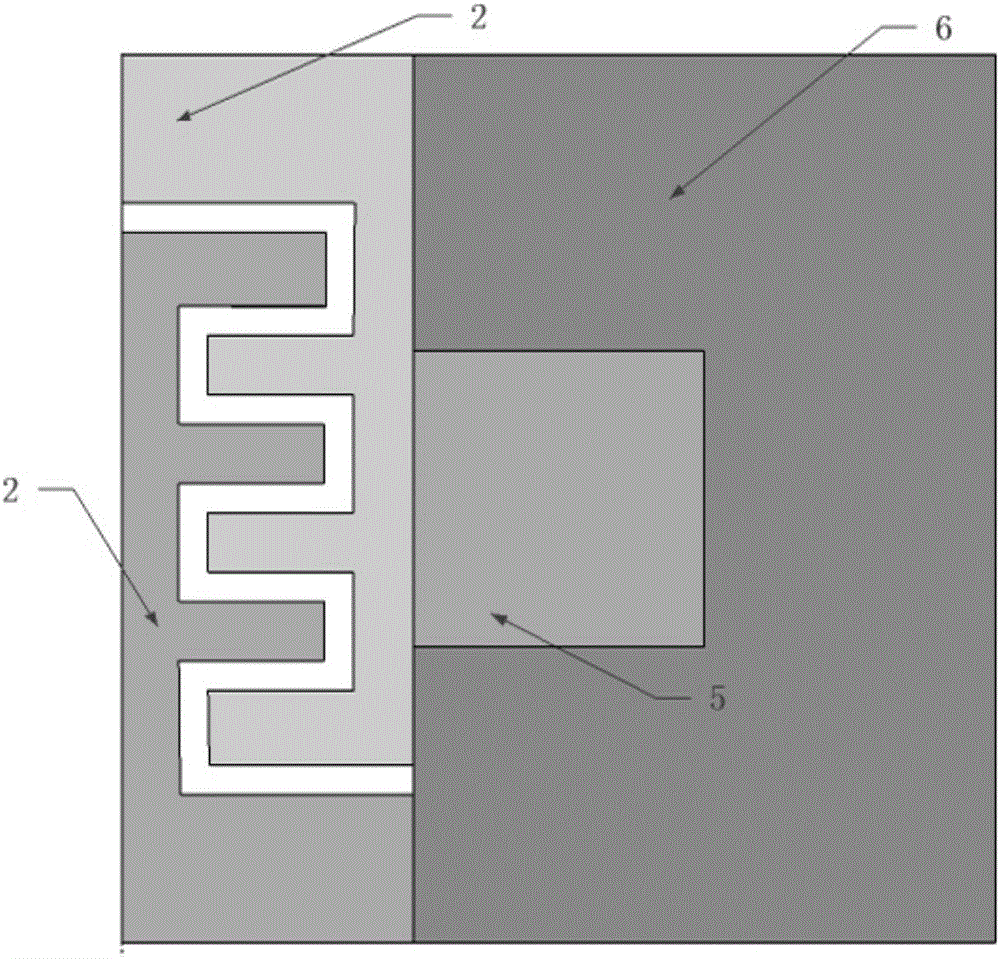

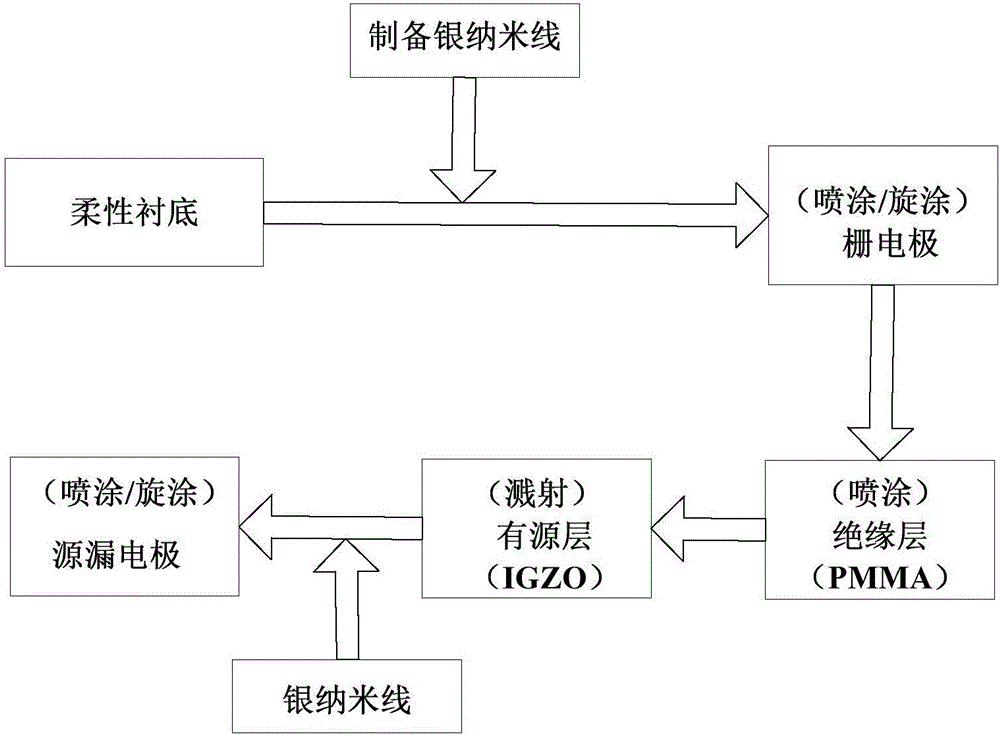

Novel bottom gate structured flexible thin film transistor and preparation method therefor

InactiveCN105742369AToughnessYoung's modulus is largeTransistorSemiconductor/solid-state device manufacturingBottom gateEngineering

The invention discloses a novel bottom gate structured flexible thin film transistor and a preparation method therefor, and belongs to the technical field of a semiconductor thin film transistor. The thin film transistor comprises a flexible substrate, a gate electrode, an insulating layer, an active layer, a source electrode and a drain electrode from the bottom up in sequence, wherein the gate electrode, the source electrode and the drain electrode adopt silver nanowire thin films; and the insulating layer adopts a PMMA thin film. The thin film transistor provided by the invention adopts the PMMA as the insulating layer, and takes the Ag nanowire thin films as the conductive electrode layer; the characteristics of bending resistance and high insulation of the PMMA thin film, and the characteristics of bending resistance and high conductivity of the Ag nanowire thin films are utilized, so that the shortcoming that the thin film transistor is damaged easily under a bending condition is overcome; and therefore, the novel bottom gate structured flexible thin film transistor can be applied to the fields of large-area flexible display, electronic paper, sensors and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

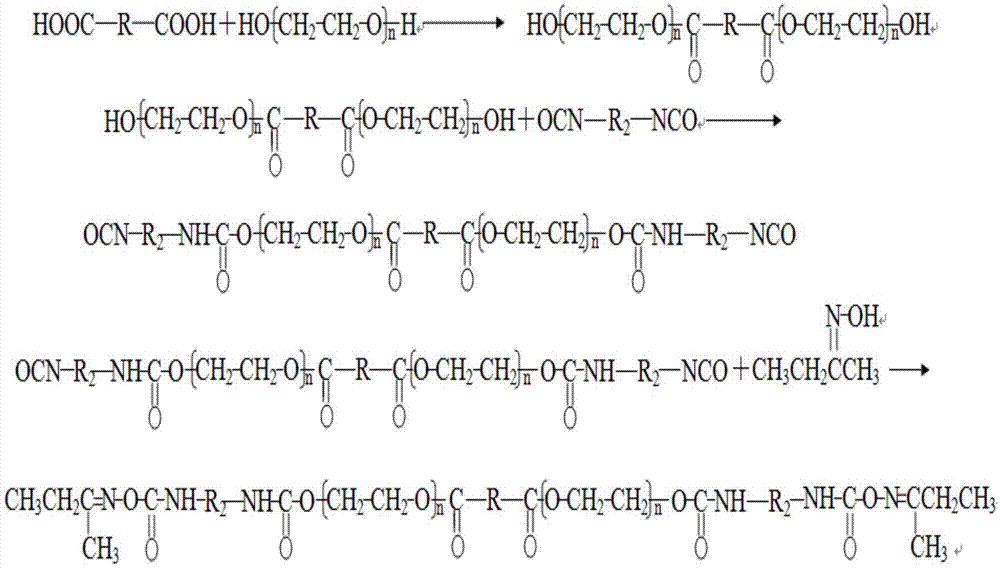

Water-borne epoxy composite-containing emulsified asphalt cold-recycling agent and preparation method thereof

The invention relates to a water-borne epoxy composite-containing emulsified asphalt cold-recycling agent and a preparation method thereof. The cold-recycling agent is prepared from the following components in parts by mass: 100 parts of emulsified asphalt and 10-20 parts of water-borne epoxy composite, wherein the water-borne epoxy composite comprises a component A and a component B, the component A is prepared from the following ingredients in parts by mass: 100 parts of water-borne epoxy emulsion, 10-25 parts of waterborne blocked polyurethane, 0.5-2 parts of associated thickener and 0.5-2 parts of coupler, and the component B is prepared from the following ingredients in parts by mass: 100 parts of an amine water-borne epoxy curing agent and 10-20 parts of accelerant. Compared with the prior art, the water-borne epoxy composite-containing emulsified asphalt cold-recycling agent belongs to a homogeneous system, has an excellent low-temperature flexibility, high-temperature stability, excellent water stability, good abrasion resistance and high early strength while the strength is improved, and the mixed material has excellent pavement performances and can be directly applied to the surface layer of pavement.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

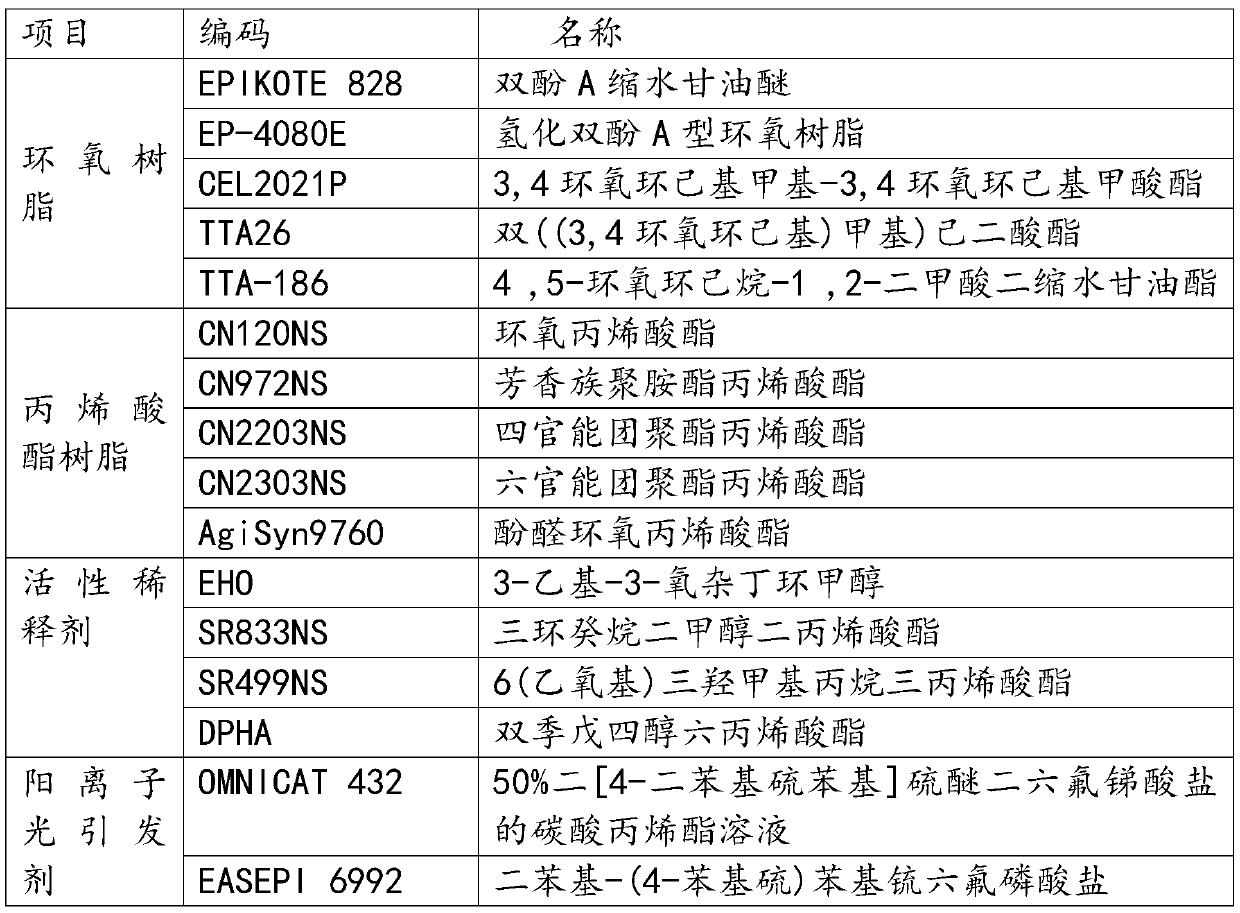

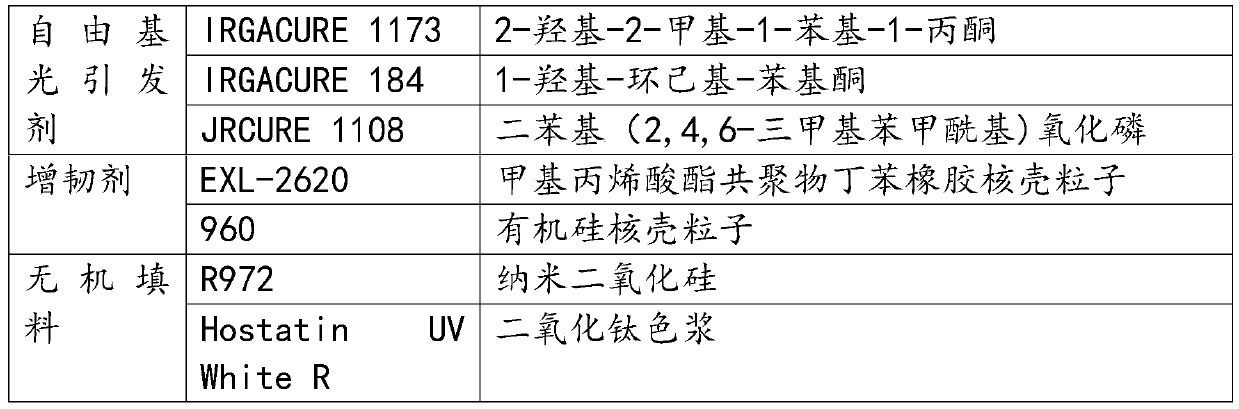

High-temperature-resistant light-cured resin and preparation method thereof

InactiveCN110724236APlay a synergistic roleLight curing reaction speed is fastAdditive manufacturing apparatusEpoxyPolymer science

The invention provides high-temperature-resistant light-cured resin and a preparation method thereof. The light-cured resin comprises the following components in percentage by mass: 40%-70% of epoxy resin, 5%-20% of acrylic resin, 10%-20% of an active diluent, 3%-6% of a cationic photoinitiator, 1%-3% of a free-radical photoinitiator, 5%-20% of a flexibilizer and 0.1%-3% of an inorganic filler. The high-temperature-resistant light-cured resin is high in curing reaction rate and has both toughness and strength.

Owner:威斯坦(厦门)实业有限公司

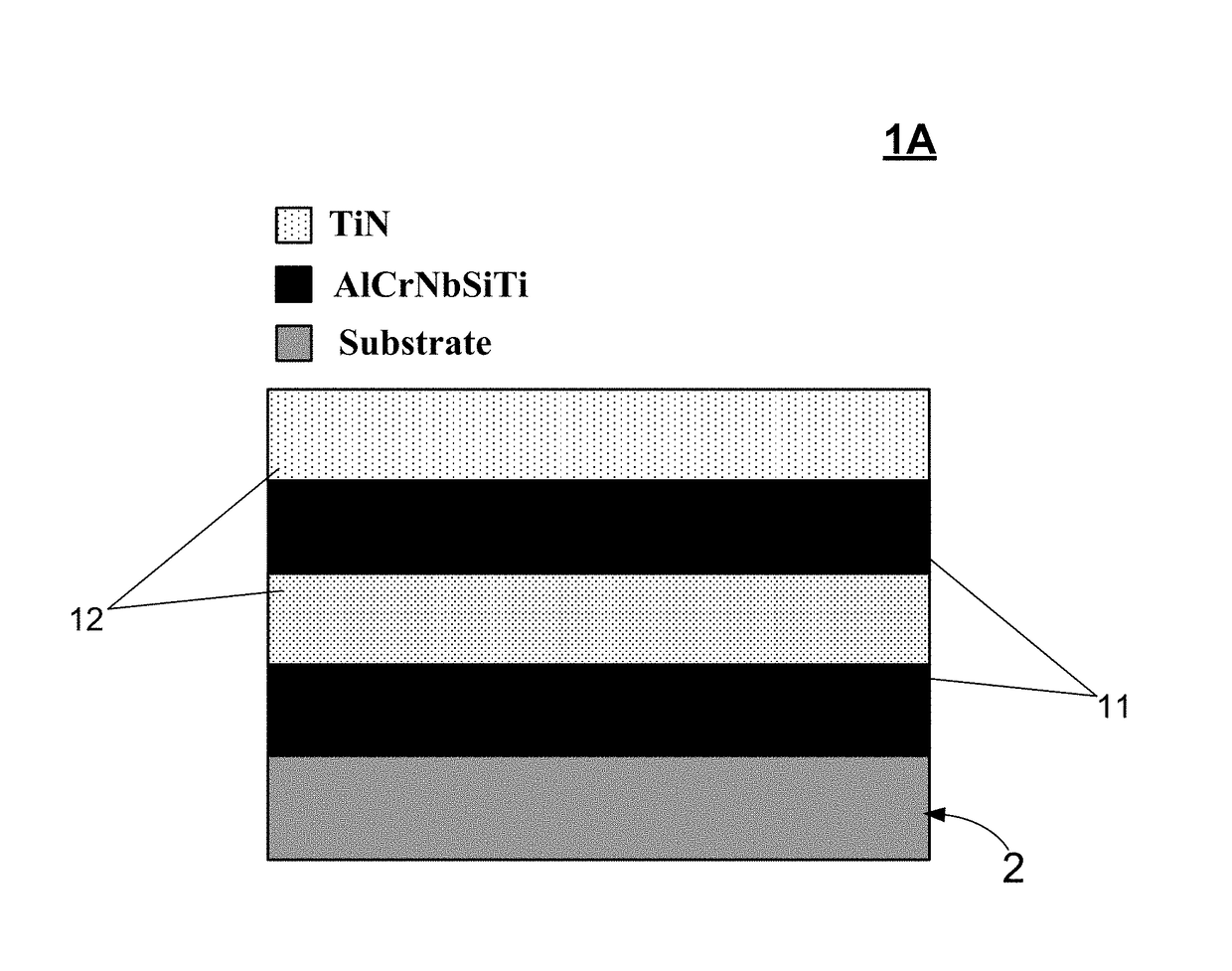

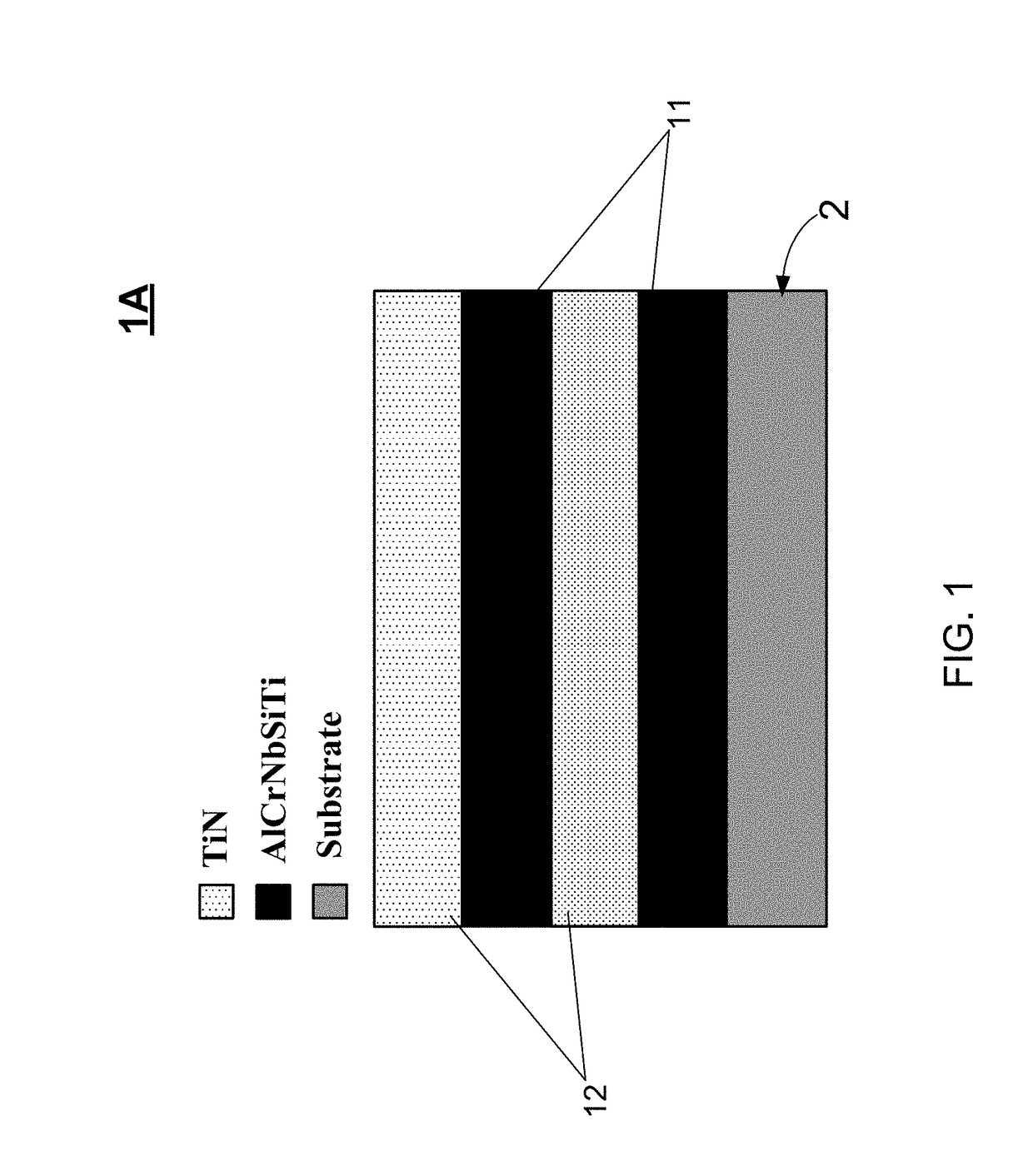

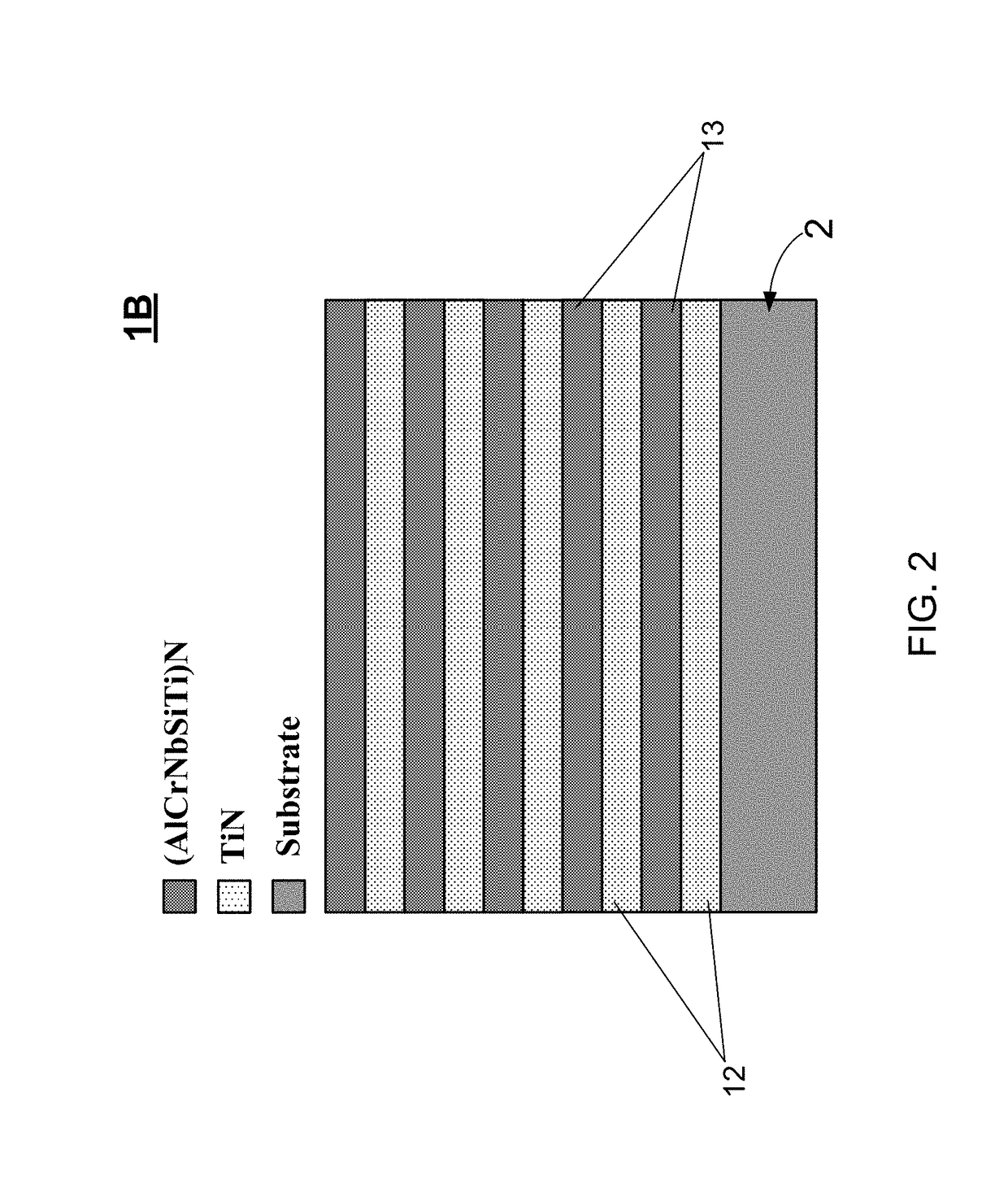

Multi-Film Structure

ActiveUS20180128952A1Reduce plastic deformationGood lookingVacuum evaporation coatingSputtering coatingEngineeringToughness

In the present invention, a multi-film structure being coated on the surface of a workpiece is disclosed. The multi-film structure is formed by making a high-entropy material film of at least two layers and a non-high-entropy material film of at least one layer be stacked on each other. In addition, the multi-film structure can also be formed by making a first high-entropy material film of at least one layer and a second non-high-entropy material film of at least one layer be stacked on each other. This multi-film structure particularly contains interlaminar interfaces to inhibit crack extension and reduce plastic deformation, so that the hardness and toughness of the workpiece coated with this inventive multi-film structure would be obviously enhanced. Moreover, the appearance color of the workpiece can also be changed by the multi-film structure, wherein the color type is dependent on the optical interferences occurring in the multi-film structure.

Owner:HIGH ENTROPY MATERIALS INC

Coloring layer coating suitable for silver alumite hot stamping foils and preparation method thereof

ActiveCN108059858AHigh hardnessStructural solutionFilm/foil adhesive primer layersCoatingsHot stampingSolvent

The invention discloses coloring layer coating suitable for silver alumite hot stamping foils and a preparation method thereof. Paint films of silver alumite hot stamping foils in the prior art are prone to efflorescence; in gold stamping, the defects of gold flying, powder falling and the like are prone to happening; thus, hot stamping quality and a production efficiency are affected. The coloring layer coating disclosed by the invention is prepared from the following raw materials in parts by weight: 15 to 25 parts of thermoplastic methacrylic resin, 1 to 5 parts of chloride-acetate resin, 1to 8 parts of styrene-maleic anhydride copolymer, 1 to 10 parts of cellulose acetate butyrate, 1 to 10 parts of methyl isobornyl acrylate, 1 to 5 parts of impact modifier and 50 to 70 parts of solvent. According to the coloring layer coating disclosed by the invention, the impact modifier is added into the formula ingredients, so that paint film toughness is effectively improved; meanwhile, the coloring layer coating has the characteristics of moderate viscosity, good adhesion with aluminum layers, simple production technology easy to control, stable quality, convenience in long-time storageand the like; a coloring layer paint film of alumite containing the coloring layer coating has the characteristics of high glossiness, large hardness, toughness, wear resistance and the like.

Owner:云南玉溪东魅包装材料有限公司

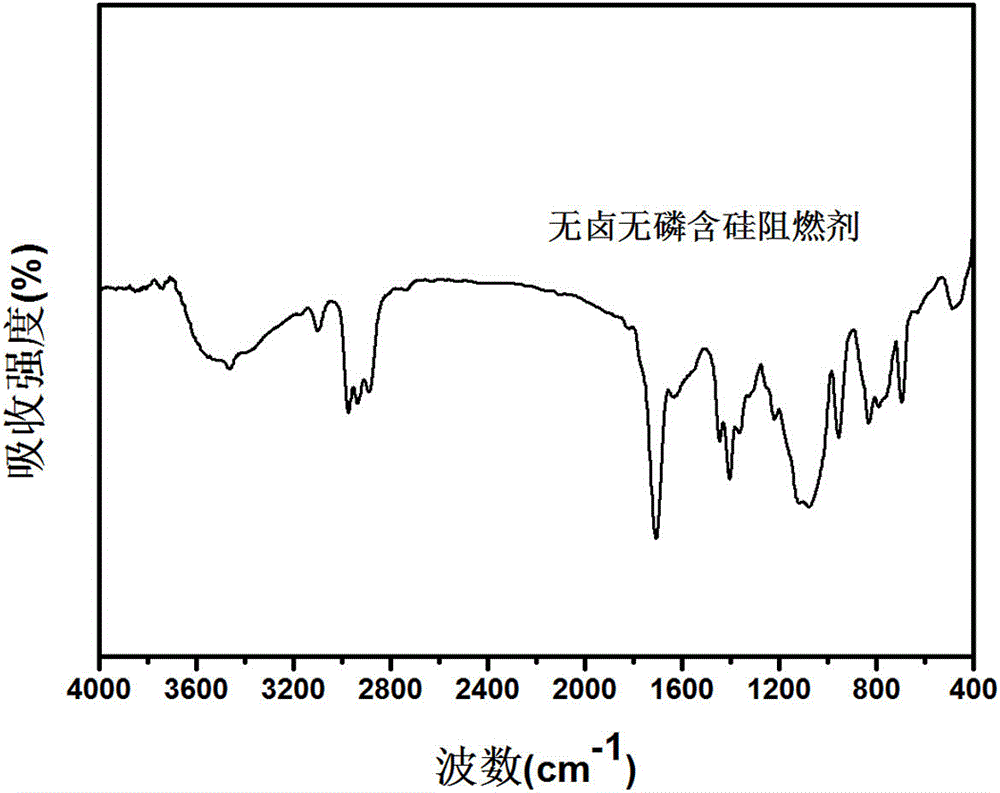

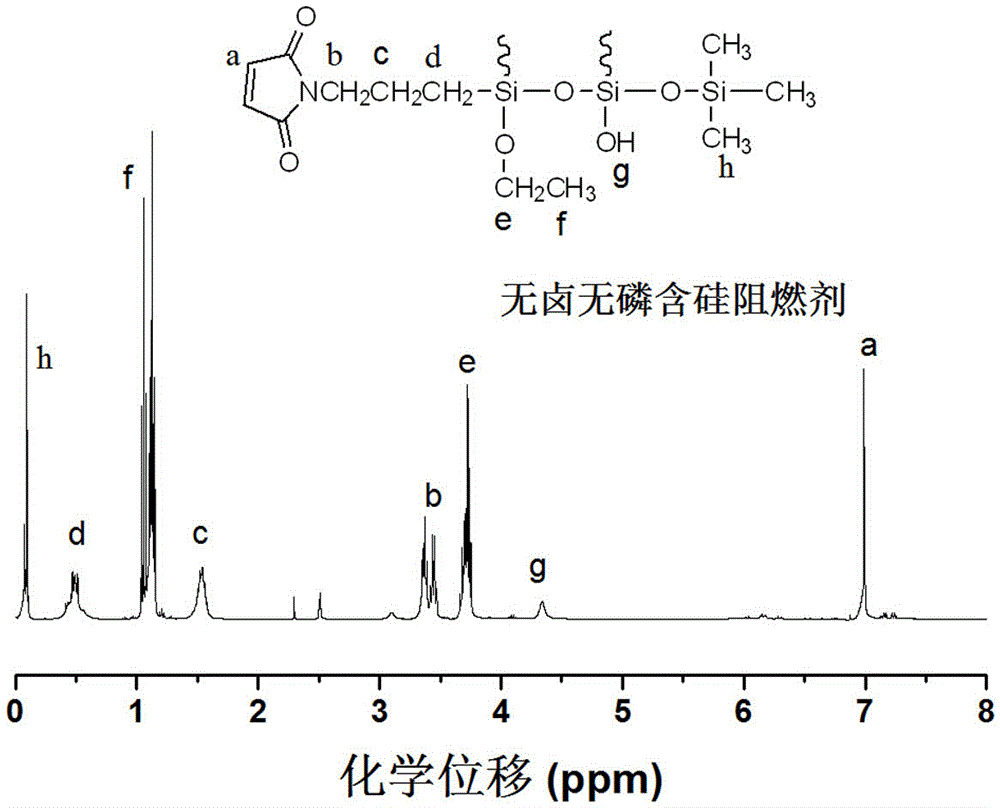

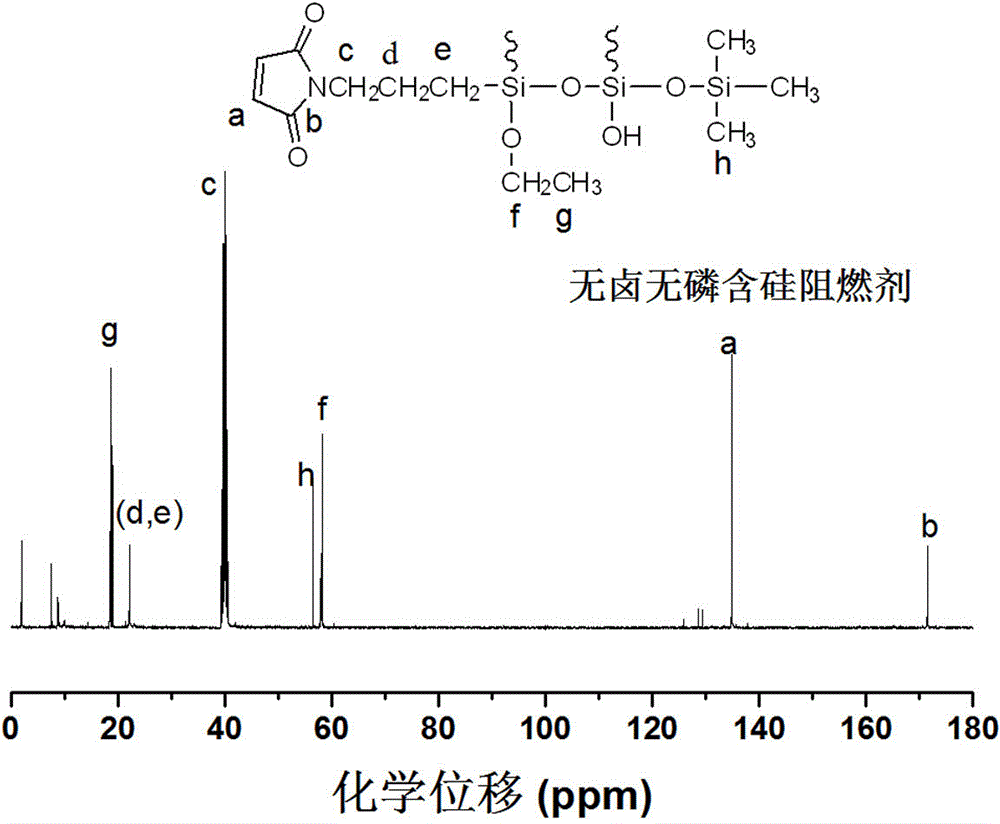

Flame-retardant bismaleimide resin and preparation method thereof

The invention discloses a flame-retardant bismaleimide resin and a preparation method thereof. The flame-retardant bismaleimide resin is prepared by the following steps: stirring 100 weight parts of bismaleimide, 0-80 weight parts of diallyl phenyl compounds and10-50 weight parts of a halogen-free non-phosphorus silicon-containing flame retardant under the temperature condition of 120-150DEG C to form a transparent liquid. The halogen-free non-phosphorus silicon-containing flame retardant is poly-maleimide hyperbranched silicon resin with the branching degree of 0.5-0.6 and the molecular weight of 2500-3400. The flame-retardant bismaleimide resin not only has excellent flame retardance performance, but also the mechanical performance can be greatly improved, in addition, the flame-retardant bismaleimide resin also maintains the excellent heat resistance, and can be used as a high-performance resin matrix, an adhesive, insulating paint and the like, and has wide application prospects in the fields of aerospace, electronic information, electrical insulation and the like.

Owner:SUZHOU UNIV

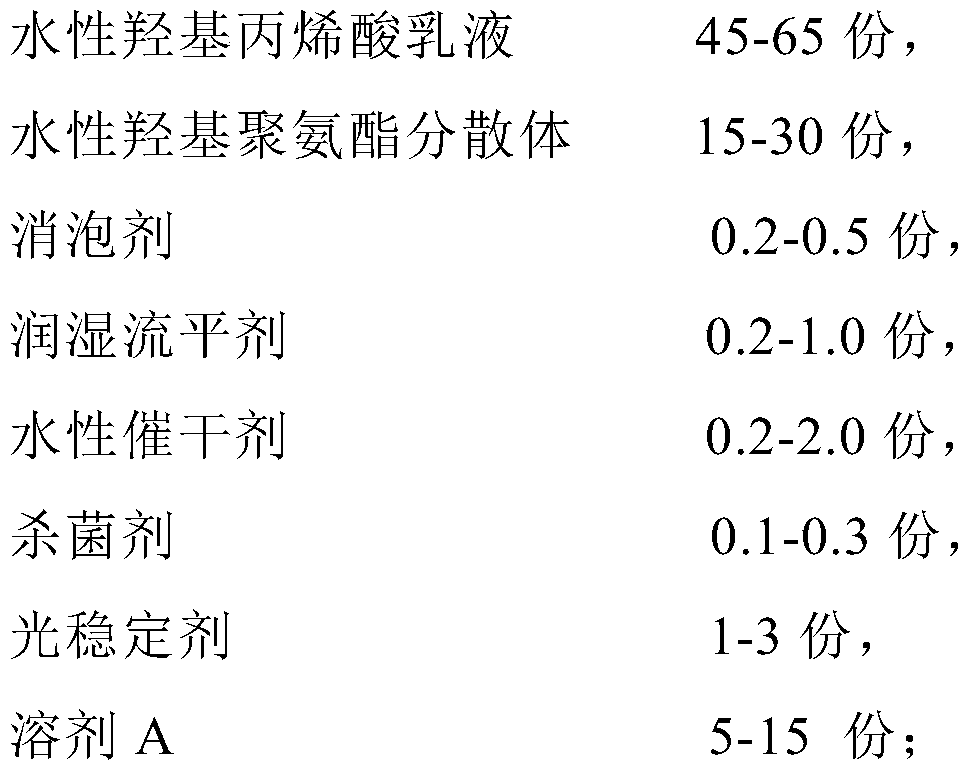

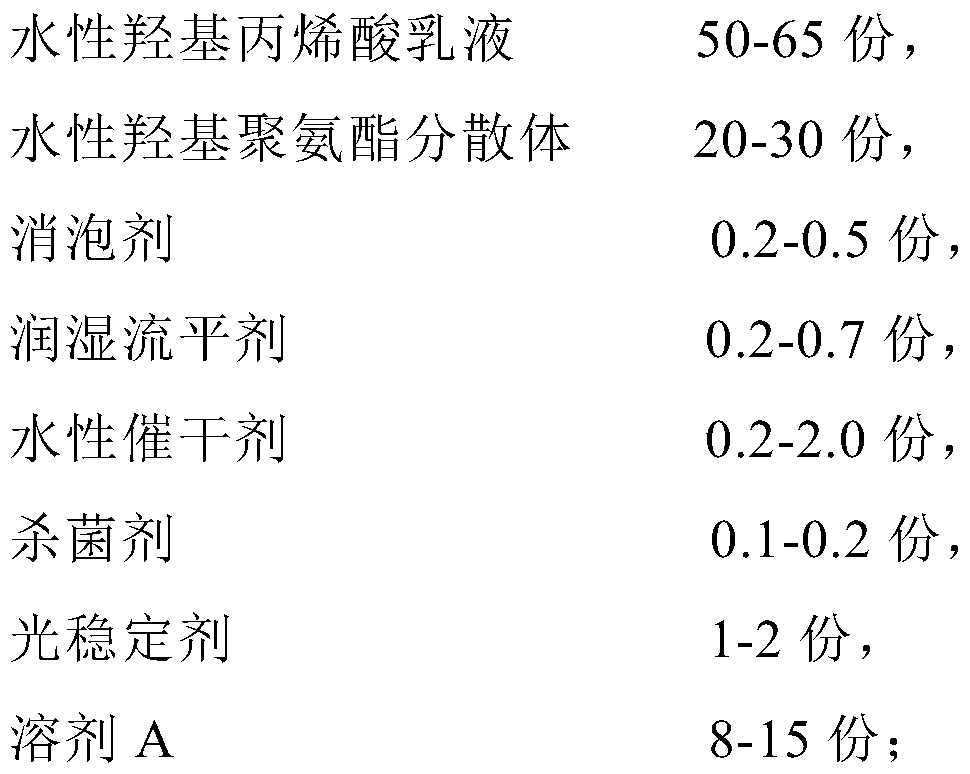

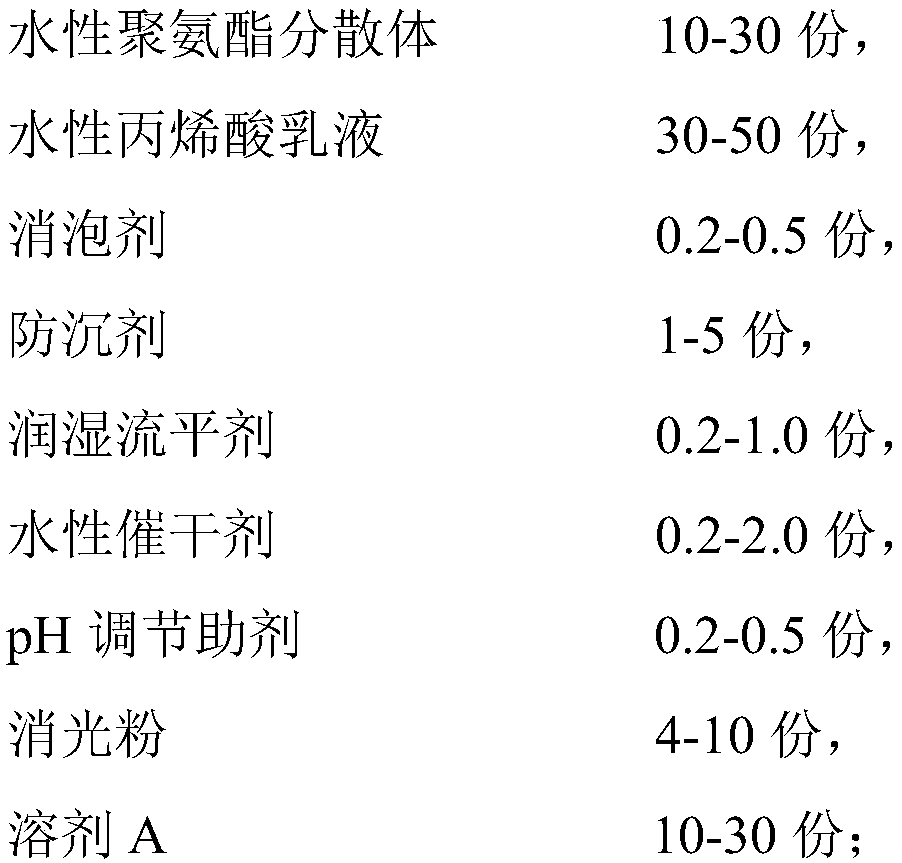

Ultra-gasoline resistant aqueous varnish and preparation method thereof

ActiveCN109749611AHigh hardnessImprove scratch resistancePolyurea/polyurethane coatingsSolventBiological activation

The invention relates to ultra-gasoline resistant aqueous varnish and a preparation method thereof. The aqueous varnish comprises a component A resin paint and a component B curing agent in a weight ratio of 3: 1, wherein the component A resin paint comprises 45-65 parts of aqueous hydroxyl acrylic emulsions, 15-30 parts of aqueous hydroxyl polyurethane dispersions, 0.2-0.5 part of a defoaming agent, 0.2-1.0 part of a wetting leveling agent, 0.2-0.6 part of an aqueous drier, 0.1-0.3 part of a bactericide, 1-3 parts of light stabilizers and 5-15 parts of solvents A; and the component B curing agent comprises 55-75 parts of curing agents and 10-30 parts of solvents B. Compared with the prior art, the preparation method is simple, raw materials are widely selected, and the prepared aqueous varnish has excellent chemical resistance, especially gasoline resistance, effectively improves surface drying speed and activation period, has good interlayer adhesion, and has the advantages of fast hardness establishment, high fullness and the like.

Owner:DONGLAI COATING TECH SHANGHAI

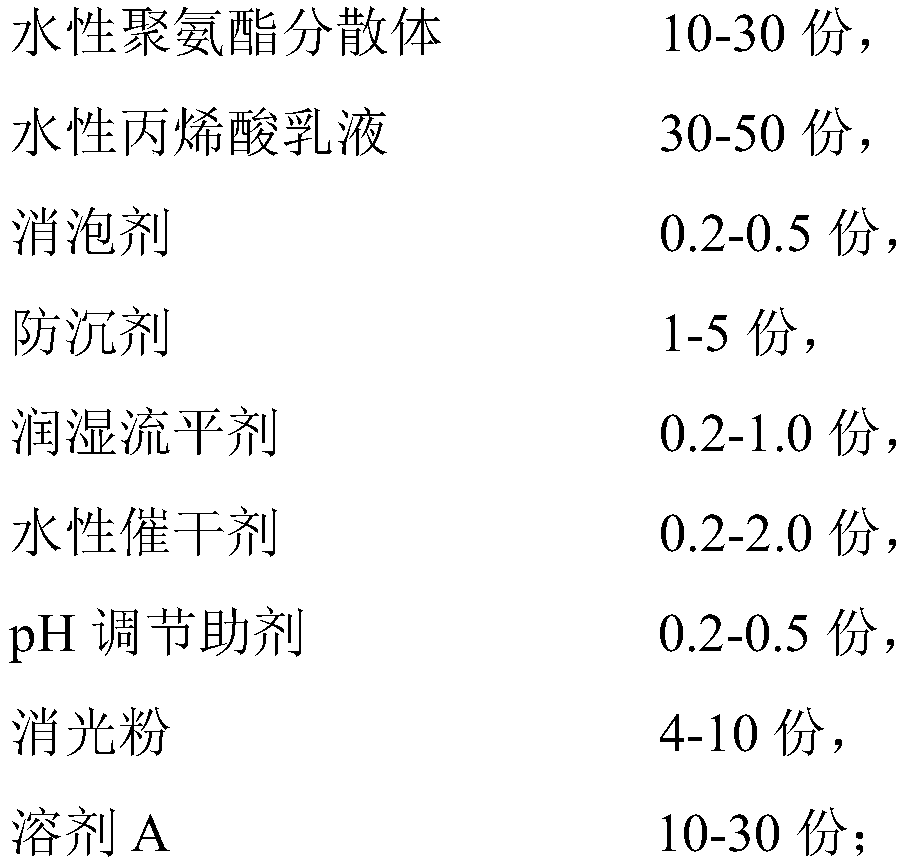

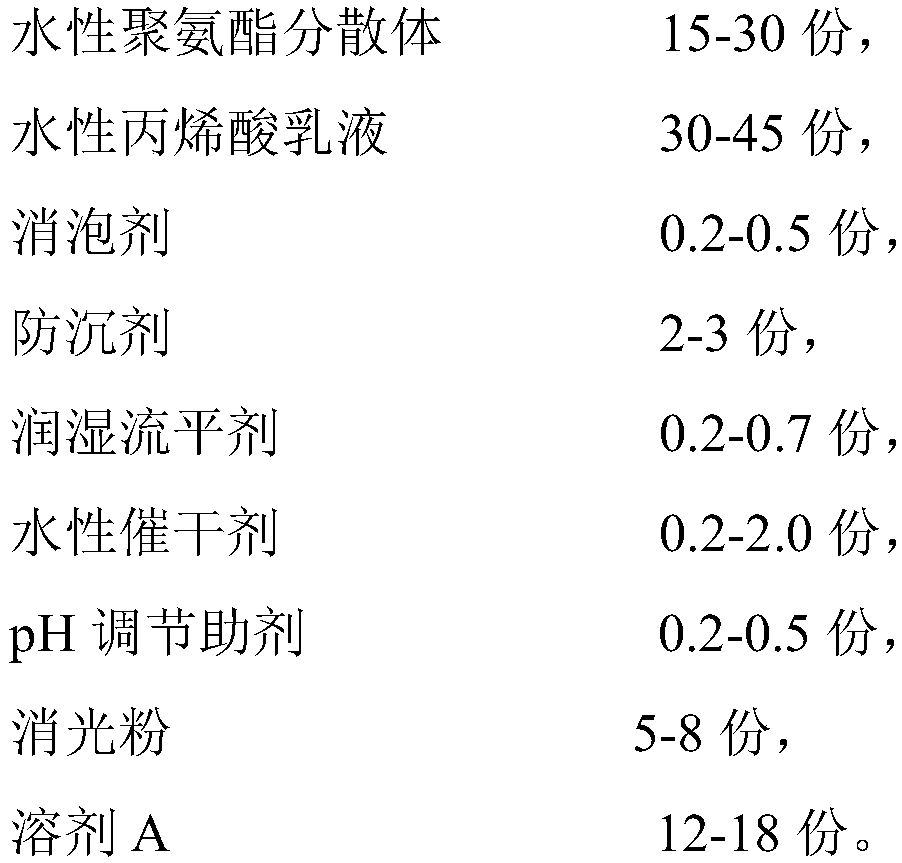

Water-based elastic paint with high drying speed and long activating period and preparation method thereof

InactiveCN107629656AGood touchGuaranteed hardnessPolyurea/polyurethane coatingsWater basedFoaming agent

The invention relates to a water-based elastic paint with high drying speed and long activating period and a preparation method thereof. The elastic paint is prepared from a component A resin paint and a component B curing agent at mass ratio of 2:1, wherein the component A resin paint comprises 10-30 parts of waterborne polyurethane dispersoid, 30-50 parts of waterborne acrylic emulsion, 1-5 parts of anti-settling agent, 0.2-0.5 part of de-foaming agent, 0.2-1.0 part of wetting flatting agent, 0.2-0.6 part of water-based drier, 0.2-0.5 part of pH regulator additive, 5-10 parts of extinction powder and 10-30 parts of a solvent A and the component B curing agent comprises 55-70 parts of a curing agent and 15-35 parts of a solvent B. Compared with the prior art, the paint has the advantagesthat the preparation method is simple, the raw material source is wide and the prepared elastic varnish surface has excellent touch feel, high drying speed, long activating period, high transparency,high interlayer adhesion, high hardness and excellent anti-scratching property.

Owner:DONGLAI COATING TECH SHANGHAI

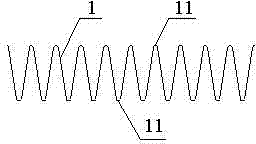

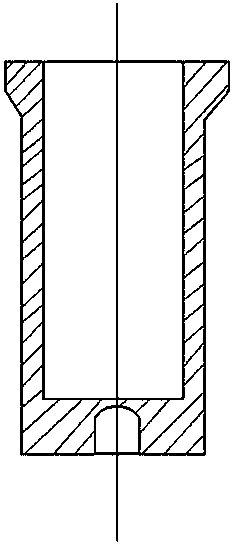

Degradable magnesium alloy esophageal stent for infants

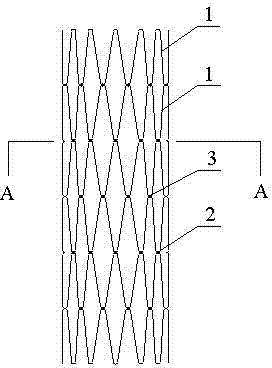

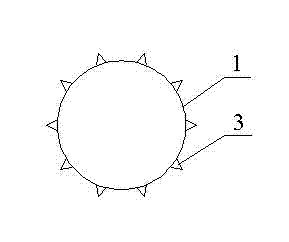

The invention discloses a degradable magnesium alloy esophageal stent for infants. The esophageal stent comprises annular single bodies, connecting points and projections, wherein each annular single body is formed in the way that a magnesium alloy metal wire is folded in the shape of W and connected to form a cylindrical shape; the annular single bodies have elasticity; bending parts are formed at the two ends of each annular single body; the annular single bodies are axially connected with one another in series by the connecting points; the bottom of each projection is positioned at each connecting point; the top end of each projection is positioned on the outer side of the esophageal stent; and after the magnesium alloy esophageal stent is expanded and released, the projections can be embedded into the esophageal wall and are used for fixing the stent. The degradable magnesium alloy esophageal stent for infants is formed by connecting a plurality of annular single bodies and the length of the esophageal stent can be determined by the number of the connected annular single bodies, so the requirements of the infants suffering from esophageal stenosis are met; the projections on the outer surface of the stent can be embedded into the inner wall of the esophagus and are used for fixing the stent to prevent the stent from moving or slipping off; and the stent can be degraded and absorbed by a human body and the degradation products have no toxicity, so growth and development of infantile patients are not influenced.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE +1

Modified polrvinyl chloride composite material and preparation method thereof

The invention relates to a modified polrvinyl chloride composite material and a preparation method thereof. The modified polrvinyl chloride composite material contains the components in parts by weight as follows: 100 parts of polyvinyl chloride, 1-5 parts of tribasic lead sulfate, 2-6 parts of dibasic lead sulfate, 5-8 parts of pretreated nano silicon dioxide, 26-40 parts of polyurethane elastomer and 1-5 parts of other additives. The polrvinyl chloride composite material is synergistically modified with polyurethane elastomer and nano titanium dioxide, therefore the application range of the polrvinyl chloride is expanded; the strength, the rigidity and the toughness of the product are all taken account of; the impact strength and the tensile strength are excellent; and the modified polrvinyl chloride composite material has wonderful comprehensive mechanical property and is applicable for producing pipe materials or sectional materials.

Owner:常熟市威腾进出口有限公司

Intumescent polylefin nanocomposites and their use

InactiveUS20070185248A1ToughnessContributes to overall flame retardancyMaterial nanotechnologyOrganic dyesThermoplasticPolyolefin

An intumescent polyolefin nanocomposite is disclosed. The nanoclay contributes stiffness, toughness and flame retardancy to the compound. The intumescent contributes flame retardancy. The compound can be processed as a thermoplastic into any practical article needing stiff, tough, and flame retardancy properties.

Owner:AMCOL INTERNATIONAL CORPORATION +1

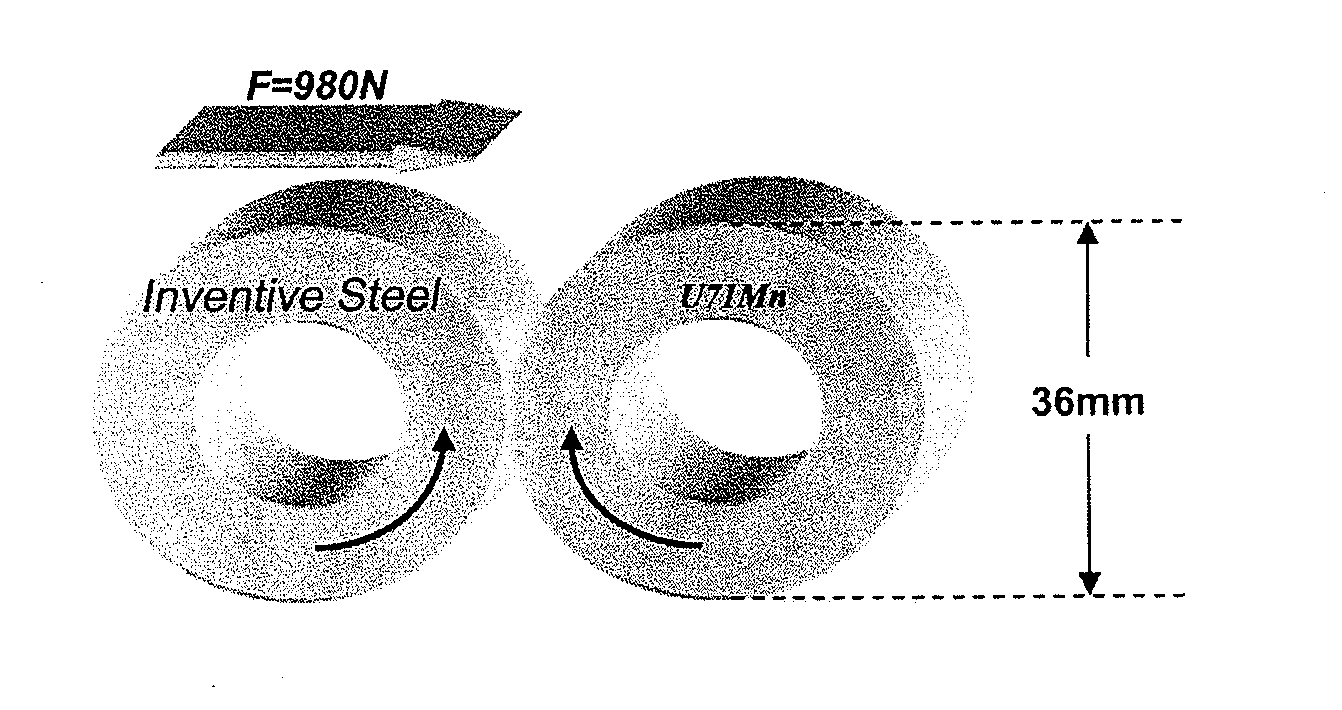

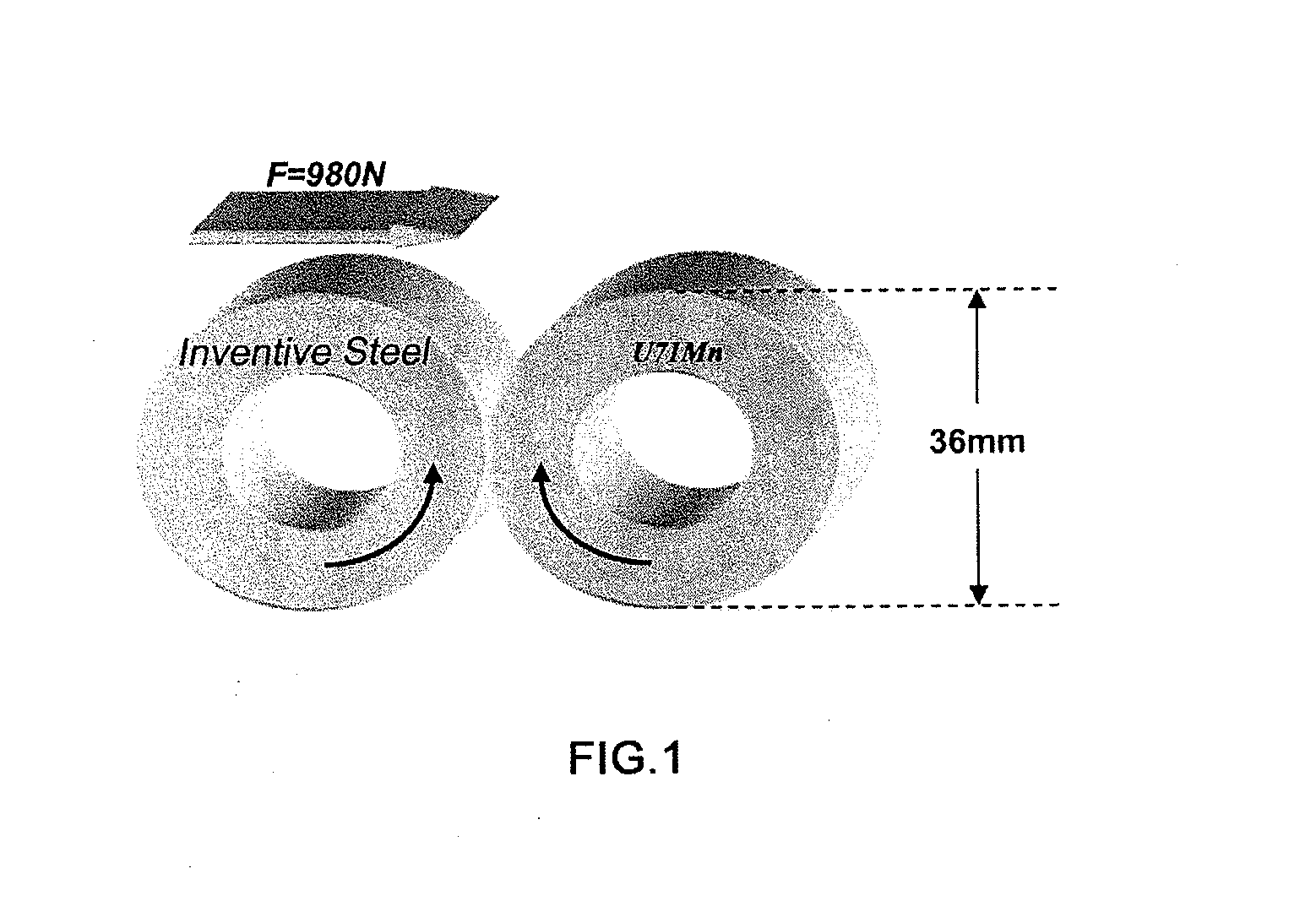

Steel rail for high speed and quasi-high speed railways and method of manufacturing the same

InactiveUS20130193223A1Excellent rolling contact fatigue propertyToughnessRailsMetal rolling stand detailsRare-earth elementRolling contact fatigue

The present discloses a steel rail for high speed and quasi-high speed railways and a manufacturing method thereof. The steel rail having a superior rolling contact fatigue property can be obtained by reducing content of carbon in conjunction with controlled cooling after rolling. The steel rail includes 0.40-0.64% by weight of C, 0.10-1.00% by weight of Si, 0.30-1.50% by weight of Mn, less than or equal to 0.025% by weight of P, less than or equal to 0.025% by weight of S, less than or equal to 0.005% by weight of Al, more than 0 and less than or equal to 0.05% by weight of a rare earth element, more than 0 and less than or equal to 0.20% by weight of at least one of V, Cr, and Ti, and a remainder of Fe and inevitable impurities. The steel rail manufactured according to the method of the present invention maintains the strength and hardness of the existing steel rail for the high speed railways, while enhancing the toughness, plasticity and yield strength, and an energy value required for initiating and expanding microcracks formed at the surface of the steel rail due to fatigue is increased, and thus under the same conditions, the rolling contact fatigue property of the steel rail can be improved, thereby finally improving the service lifetime and the transportation safety of the steel rail.

Owner:PANZHIHUA IRON AND STEEL +1

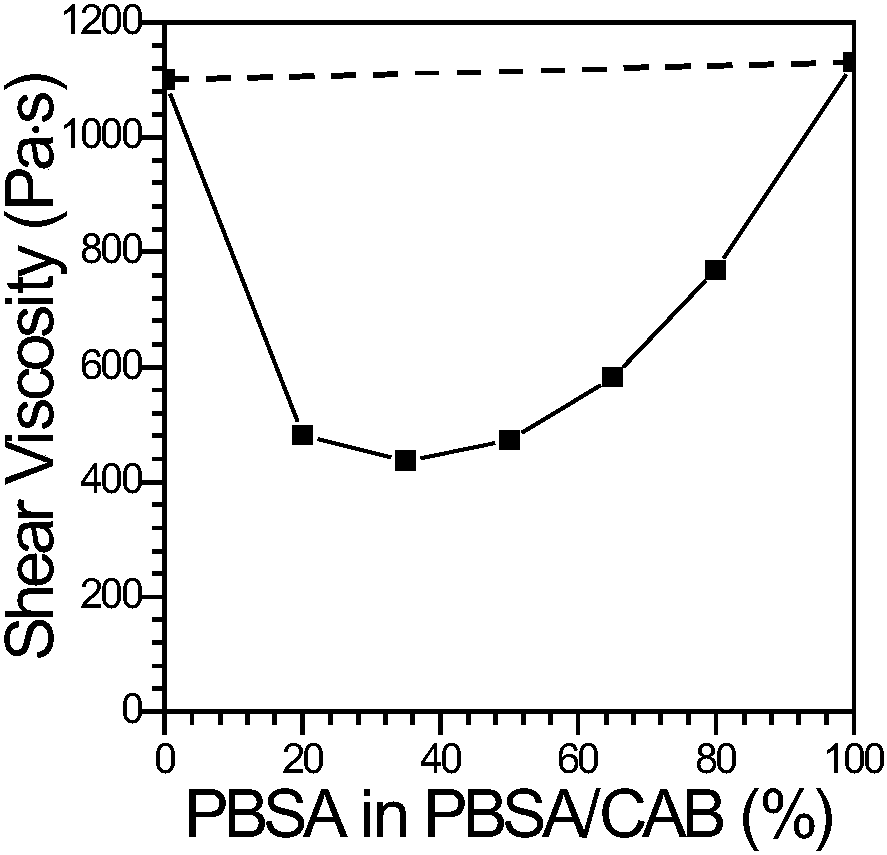

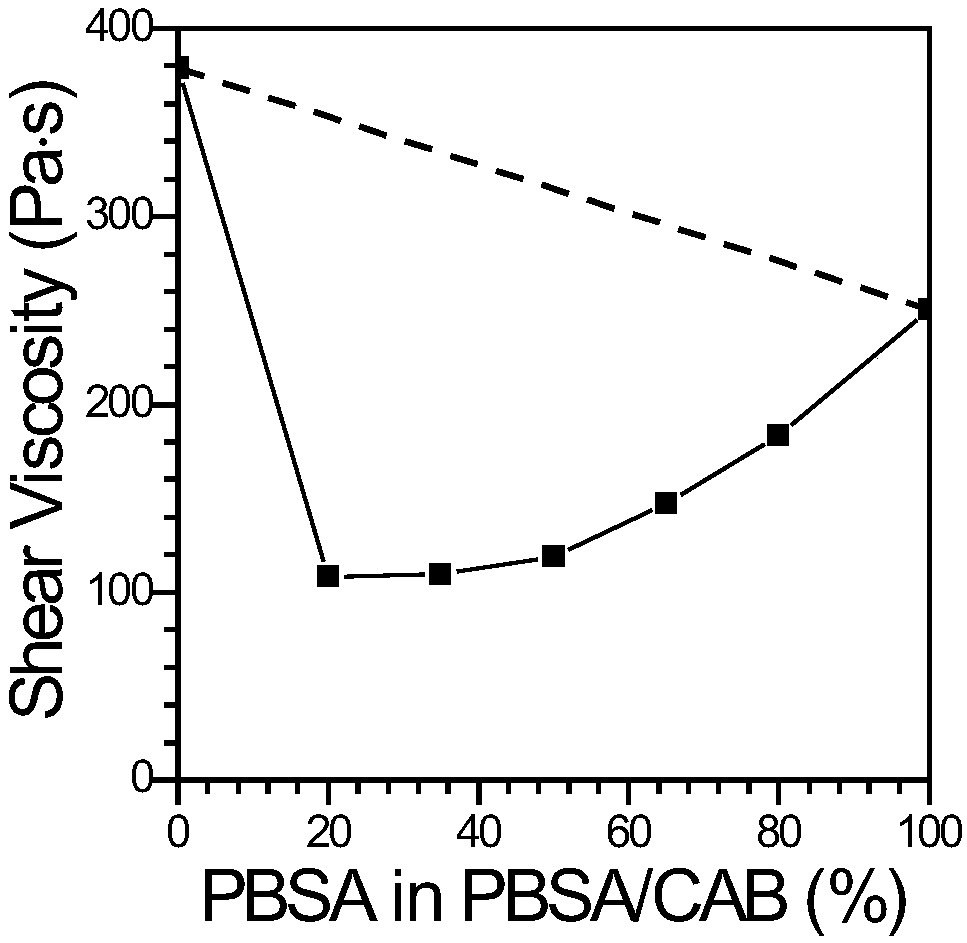

Thermoplastic cellulose and aliphatic copolyester blend 3D printed wire and preparation method

ActiveCN107793710AReduce melt viscosityImprove melt indexAdditive manufacturing apparatusCelluloseShear rate

The invention relates to a thermoplastic cellulose and aliphatic copolyester blend 3D printed wire, and mainly solves the problems in the prior art that thermoplastic cellulose is difficultly appliedto 3D printing field because of high viscosity of the thermoplastic cellulose during low-temperature processing and poor toughness of a product. According to the technical scheme, a blend consisting of 20% to 80% by mass of thermoplastic cellulose and 80% to 20% by mass of an aliphatic copolyester is employed and is prepared by a continuous melt-extrusion blending process. The melt viscosity of the blend is at least about 30% lower than a blending addition theoretical value of the two starting materials under a low shear rate condition, and is at least 30% lower than the blending addition theoretical value of the two starting materials under a high shear rate condition. The technical scheme solves the above problem better and can be used in industrial production of thermoplastic celluloseand aliphatic copolyester blend 3D printed wires.

Owner:CHINA PETROLEUM & CHEM CORP +1

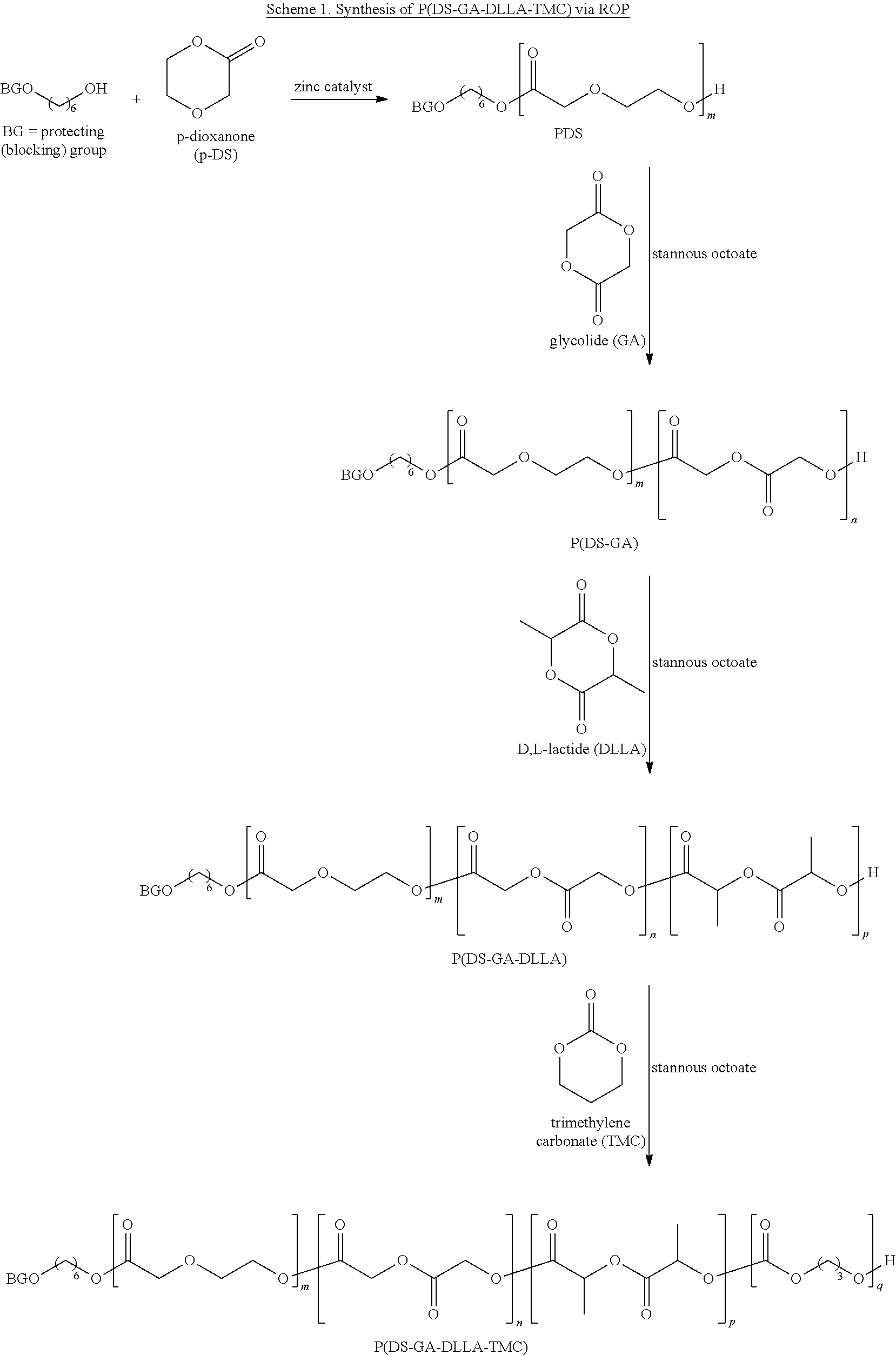

Dioxanone-based copolymers for implantable devices

InactiveUS8952123B1Reduce adverse effectsImprove mechanical propertiesStentsOrganic active ingredientsBiological propertyDevice form

The present invention is directed to polymeric materials comprising biodegradable, dioxanone-based copolymers and implantable devices (e.g., drug-delivery stents) formed of such materials. The polymeric materials can also contain at least one additional biocompatible moiety, at least one non-fouling moiety, at least one biobeneficial material, at least one bioactive agent, or a combination thereof. The polymeric materials are designed to improve the mechanical, physical and biological properties of implantable devices formed thereof.

Owner:ABBOTT CARDIOVASCULAR

Composite ceramic filter element and preparation process thereof

InactiveCN104436869AHigh strengthImprove toughnessCeramic layered productsFiltration separationFiberComposite ceramic

The invention discloses a composite ceramic filter element and a preparation process thereof. The composite ceramic filter element comprises a ceramic fiber braid filter element basal body layer, wherein a short-cut ceramic fiber layer capable of improving the flexibility of the filter element is composited onto the ceramic fiber braid filter element basal body layer, a SiC coating is deposited on the short-cut ceramic fiber layer, and a carbon transition layer which is formed by pyrolytic phenolic resin is also arranged between the SiC coating and a ceramic fiber braid filter element basal body in a compositing manner; the weight of the SiC coating is 1.8 to 2 times of the weight of the ceramic fiber braid filter element basal body, and the thickness of the basal body is 15 to 20 times of the thickness of the SiC coating. The composite ceramic filter element adopting the structural form has excellent characteristics of light weight, high strength, large flexibility, low pressure drop, corrosion resistance and controllability of aperture.

Owner:SUZHOU BOQING ADVANCED MATERIALS

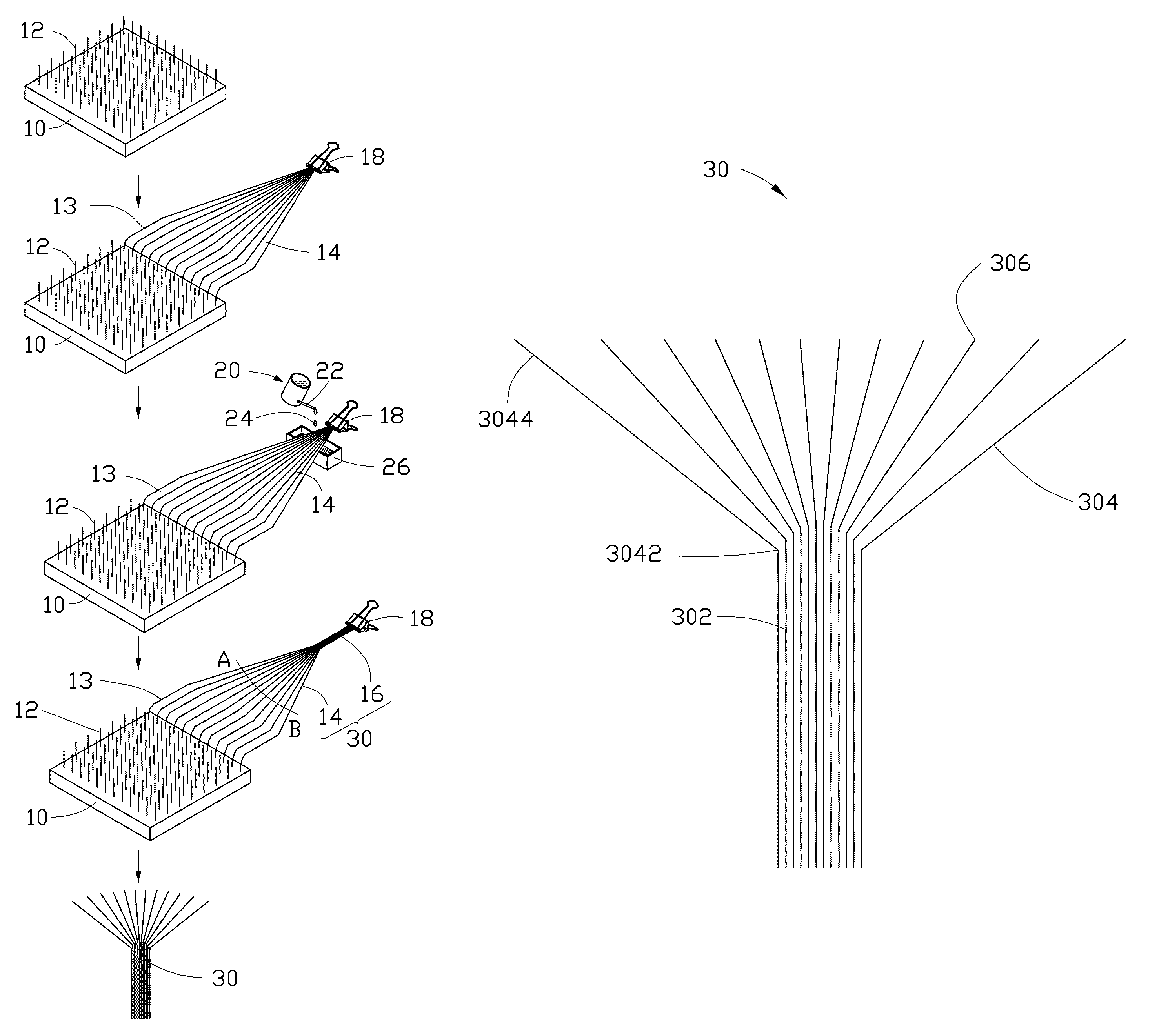

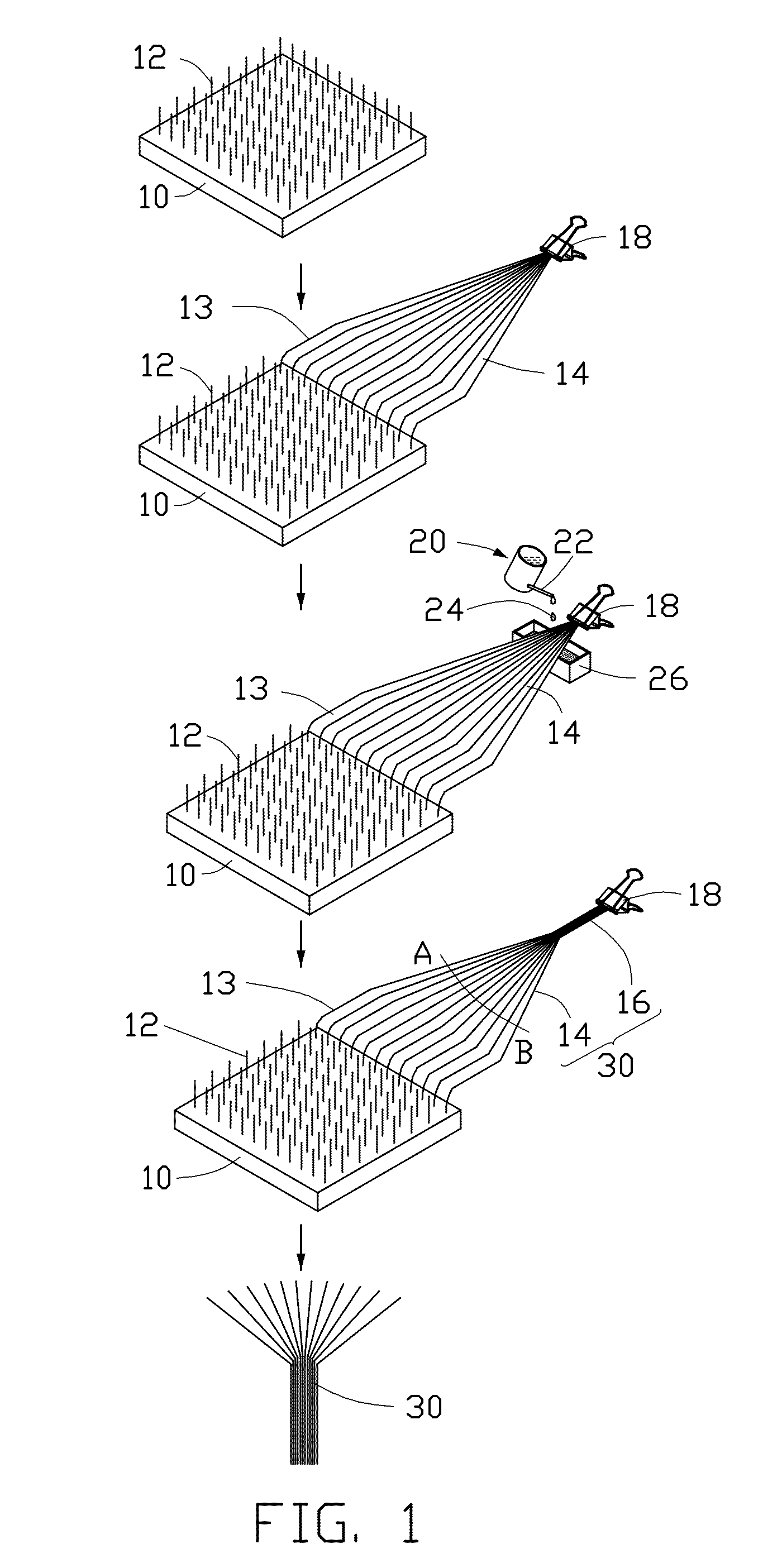

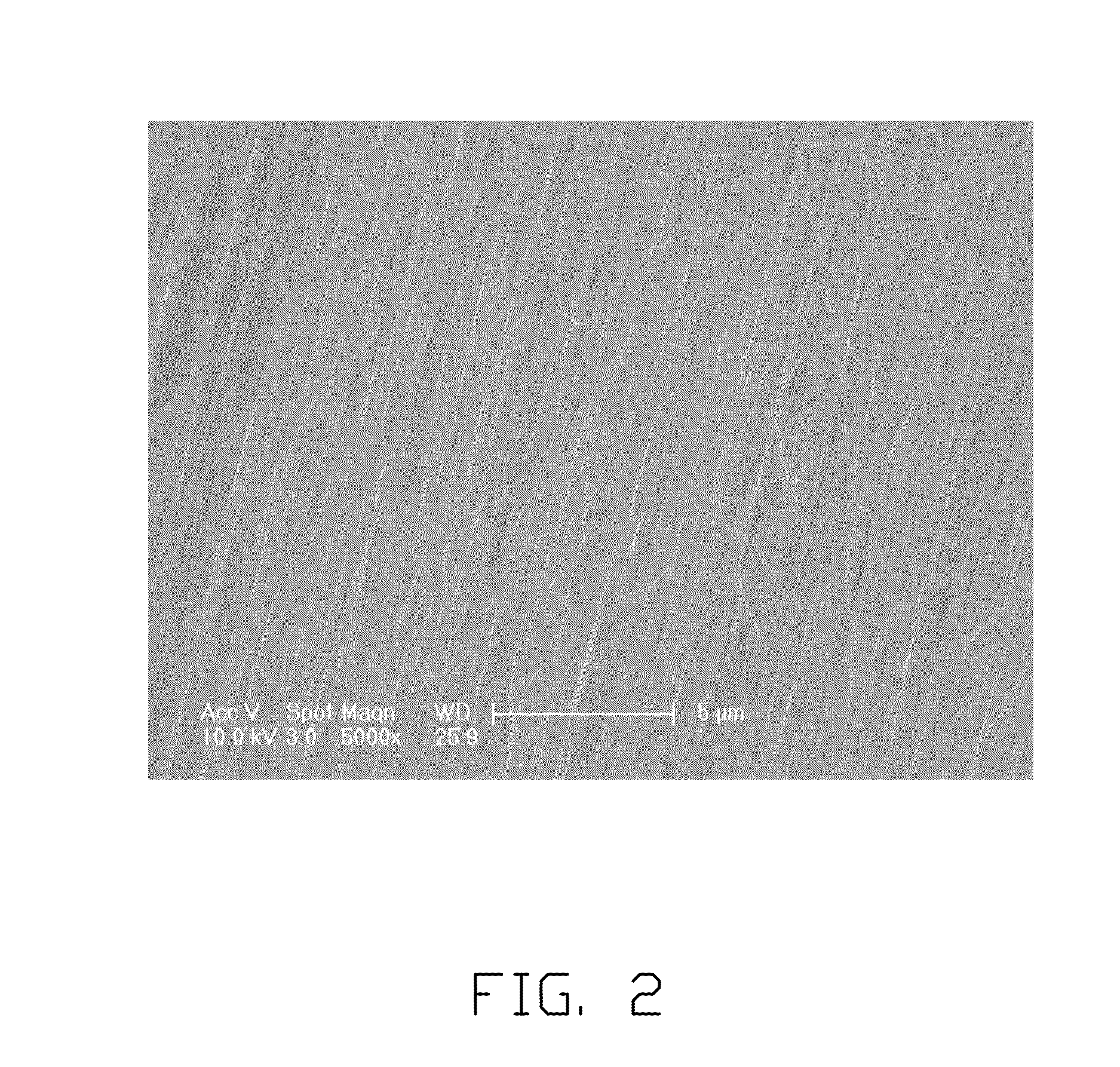

Method for making carbon nanotube field emitter

ActiveUS8900029B2Small surface areaStrengthLamp incadescent bodiesNanoinformaticsCarbon nanotubeLaser beams

Owner:TSINGHUA UNIV +1

Random propylene copolymers

InactiveUS7026421B2Easy to processHigh stiffnessMonocomponent synthetic polymer artificial filamentThin material handlingFiberAlkene

Random copolymers of propylene with other 1-alkenes having up to carbon atoms,whose content of comonomers is in the range from 0.7 to 1.4% by weight if the only comonomer present in the propylene copolymers is ethylene, orwhose content of comonomers is in the range from 0.7 to 3.0% by weight if at least one C4–C10-1-alkene is present as comonomer, andwhose cold-xylene-soluble fraction is from 1.0 to 2.5% by weight if ethylene is present as a comonomer in the propylene copolymers, orwhose cold-xylene-soluble fraction is from 0.75 to 2.0% by weight if the only comonomers present are C4–C10-1-alkenes,and a process for preparing the random copolymers of propylene is described, as is their use for producing films, fibers or moldings, and also the films, fibers and moldings themselves and biaxially stretched films made from random propylene copolymers of this type and processes for their production.

Owner:LUMMUS NOVOLEN TECH

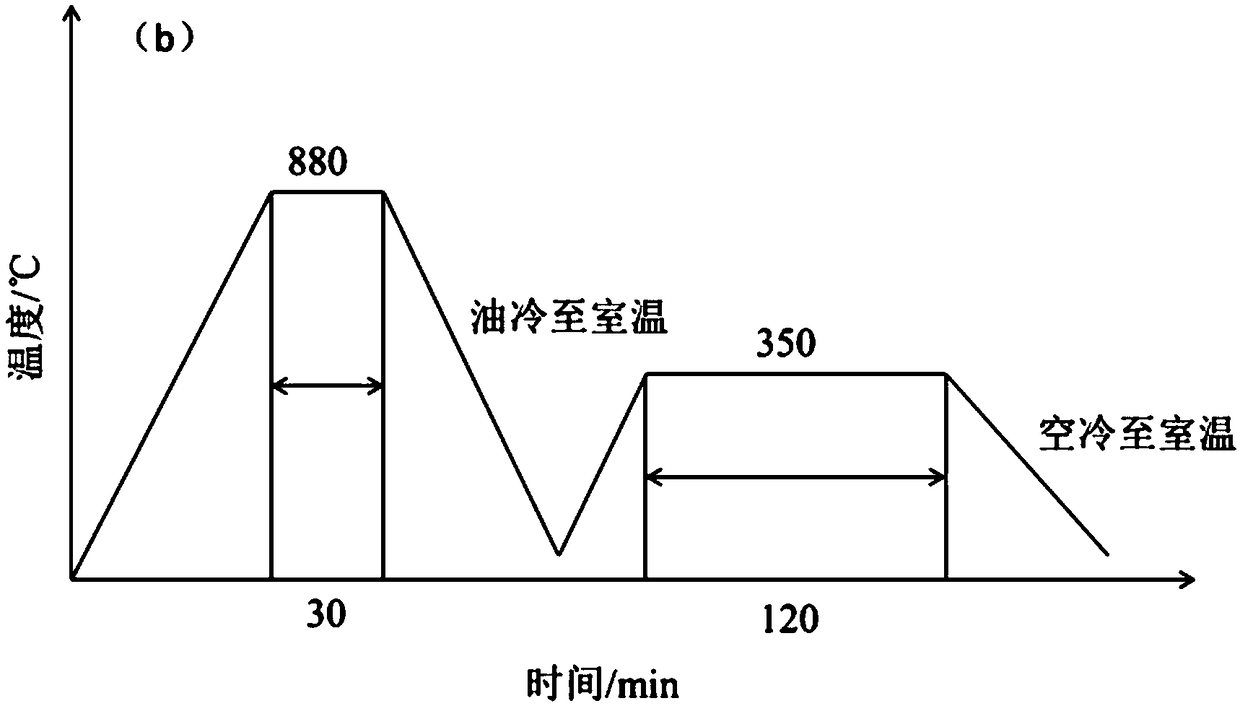

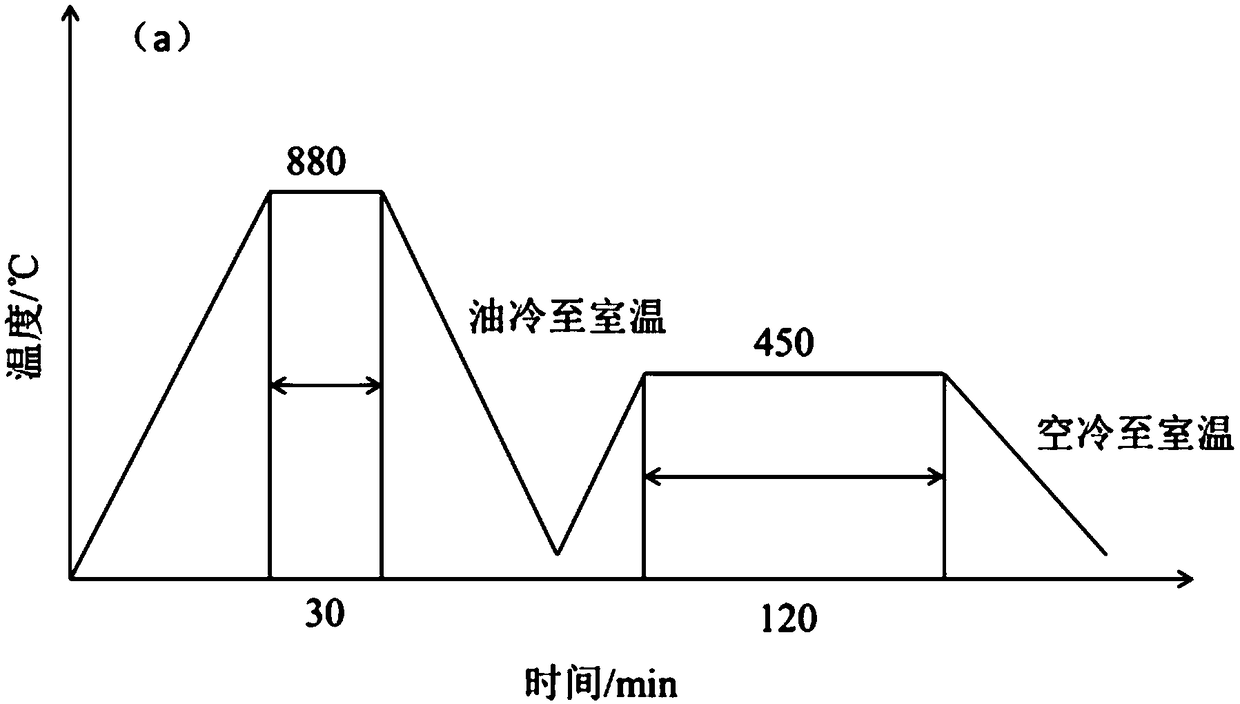

High strength spring steel and production method thereof

The invention discloses high strength spring steel and a production method thereof. The production method comprises the following steps: S1, preparing pure iron, metal chromium, ferrovanadium, manganese, industrial silicon and graphite according to components of a designed steel type: 0.51-0.65% of C, 1.20-1.60% of Si, 0.50-0.80% of Mn, 0-0.012% of P, 0-0.010% of S, 0.50-0.80% of Cr, 0-0.25% of Cuand 0.15-0.25% of V and the balance iron and inevitable impurities; S2, putting pure iron and part of graphite in a furnace to be vacuumized and heated and smelted, adding industrial silicon and metal chromium after the pure iron and graphite are fully melted, adjusting the melting temperature after the pure iron and graphite are fully melted, adding residual graphite to refine, vacuumizing the furnace at the same time, adding ferrovanadium and manganese after refining, and uniformly stirring the melted which is melted fully to obtain molten steel; S3, adjusting the temperature of the moltensteel and pouring the molten steel to a cast ingot; and S4, quenching the cast ingot, cooling the cast ingot to room temperature by oil, carrying out tempering treatment, air-cooling the cast ingot toroom temperature to obtain the high strength spring steel. The strength of the spring steel is improved greatly, and the toughness of the spring steel is considered.

Owner:NORTHEASTERN UNIV

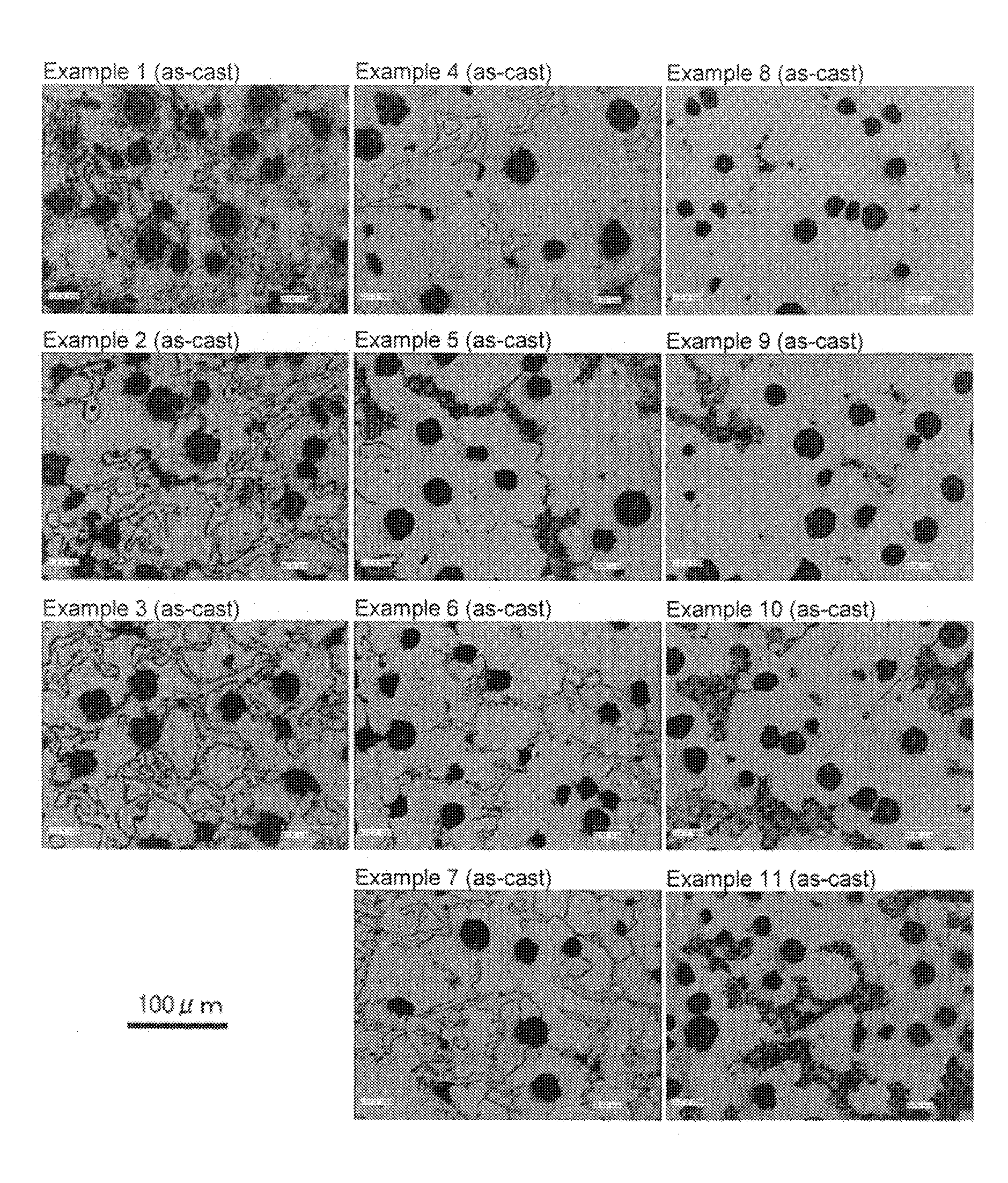

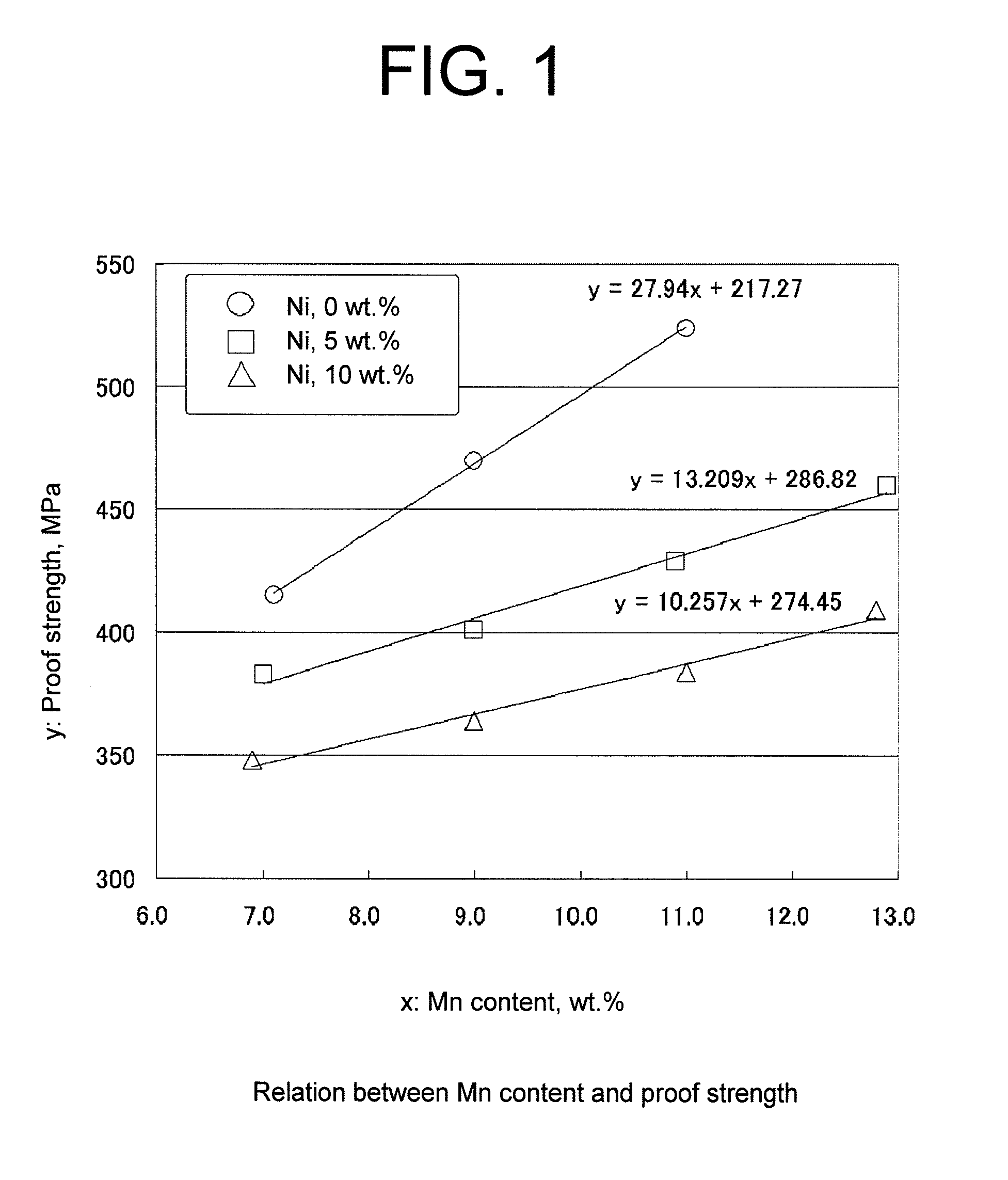

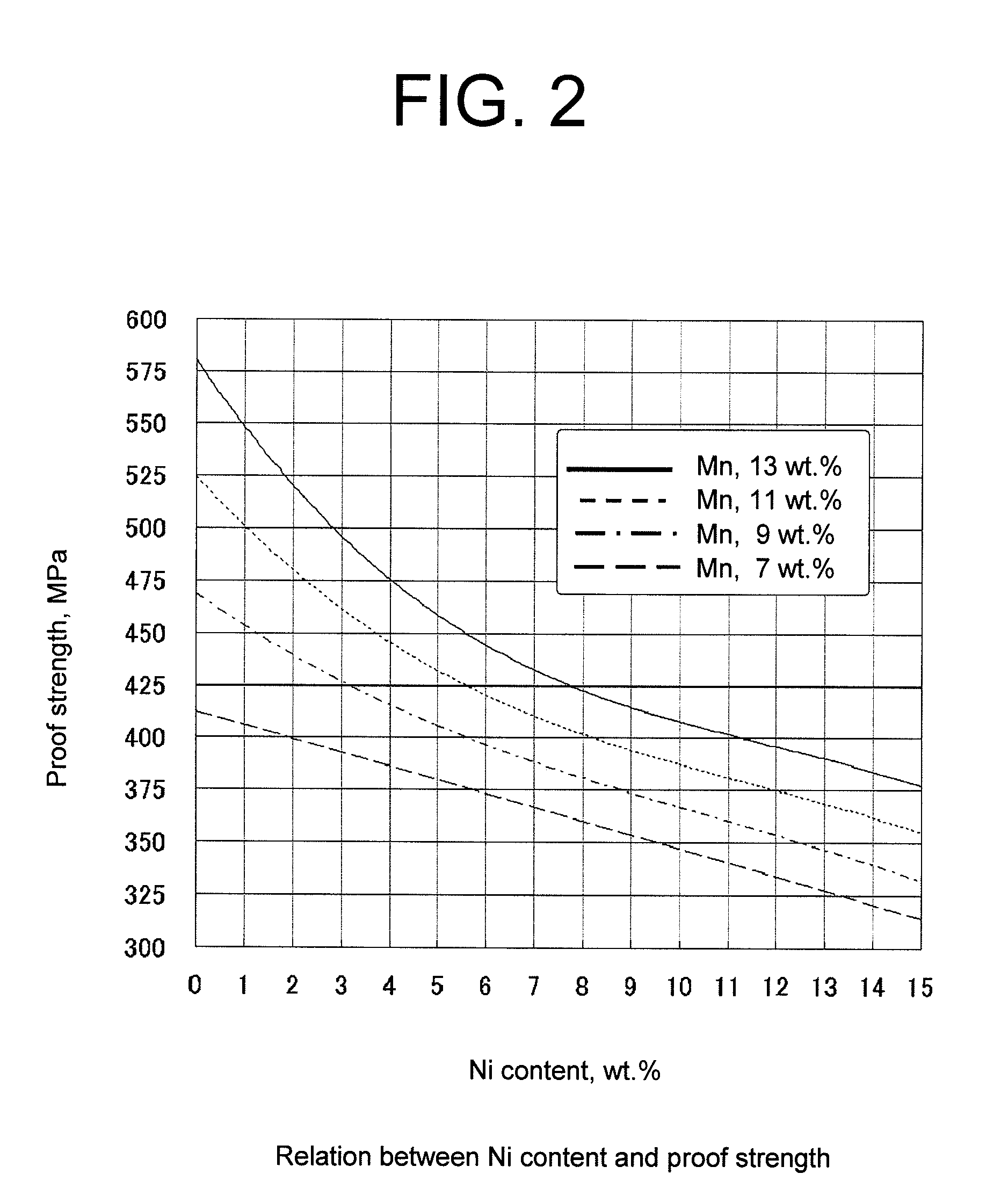

High-manganese spheroidal graphite cast iron

The manufacturing method of high-manganese spheroidal graphite cast iron with exhibiting low magnetism, and excellent wear resistance, castability, and machinability, and having a composition which consists of, 2.5 to 4.0 wt. % of C content, 1.5 to 6.0 wt. % of Si content, 7.0 to 18.0 wt. % of Mn content, and 0.015 to 0.1 wt. % of Mg content, and when the Mn content falls within the range of 7.0 to 10.0 wt. %, consists of 10.0 wt. % or smaller of Ni content, or when the Mn content falls within the range of 10.0 to 18.0 wt. %, consists of Ni content being in the range satisfies the following formula: [Mn wt. %>Ni wt. %],the method comprises heating the above cast iron to the temperature of 1073 to 1373K to decompose the carbides, and then quenching from 1073 to 1273K the resulting cast iron to form a metastable austenite matrix structure that contains no carbide or a reduced amount of carbides.

Owner:HOTSUKO KINZOKU IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com