Patents

Literature

109results about How to "Taking into account strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

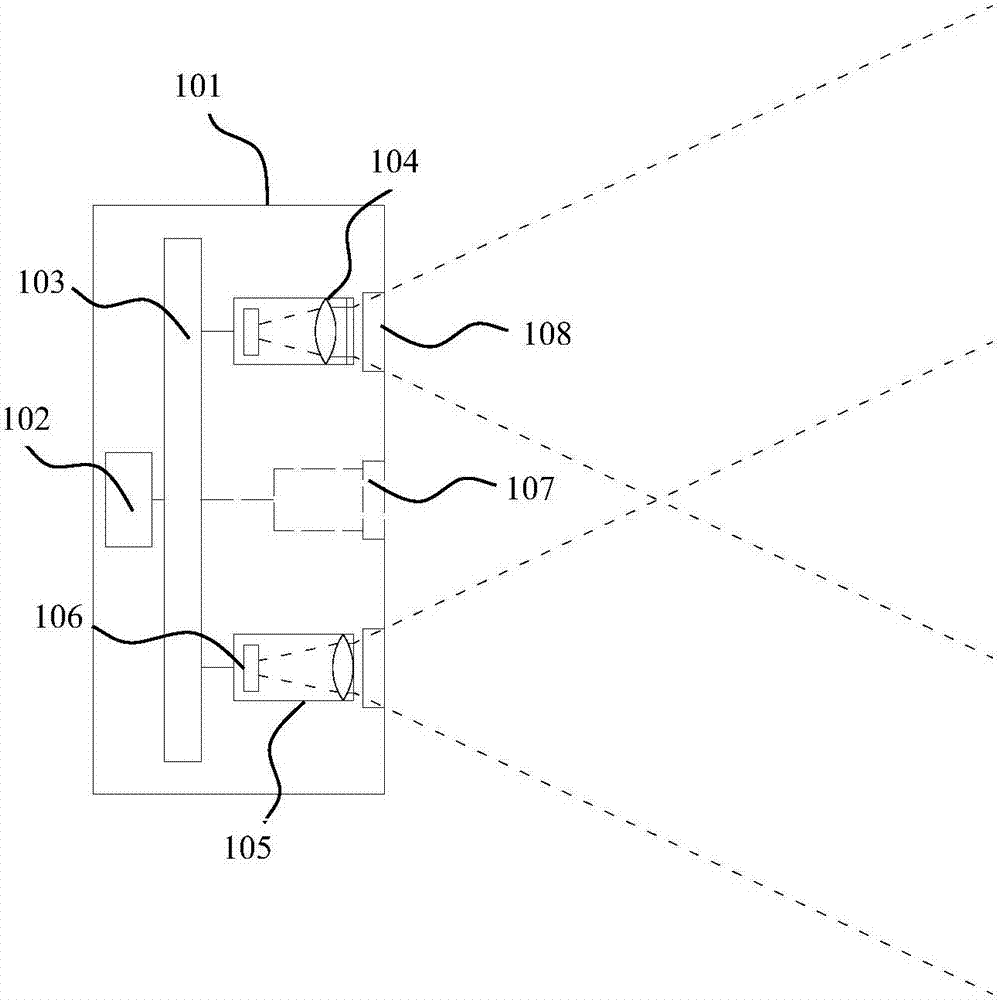

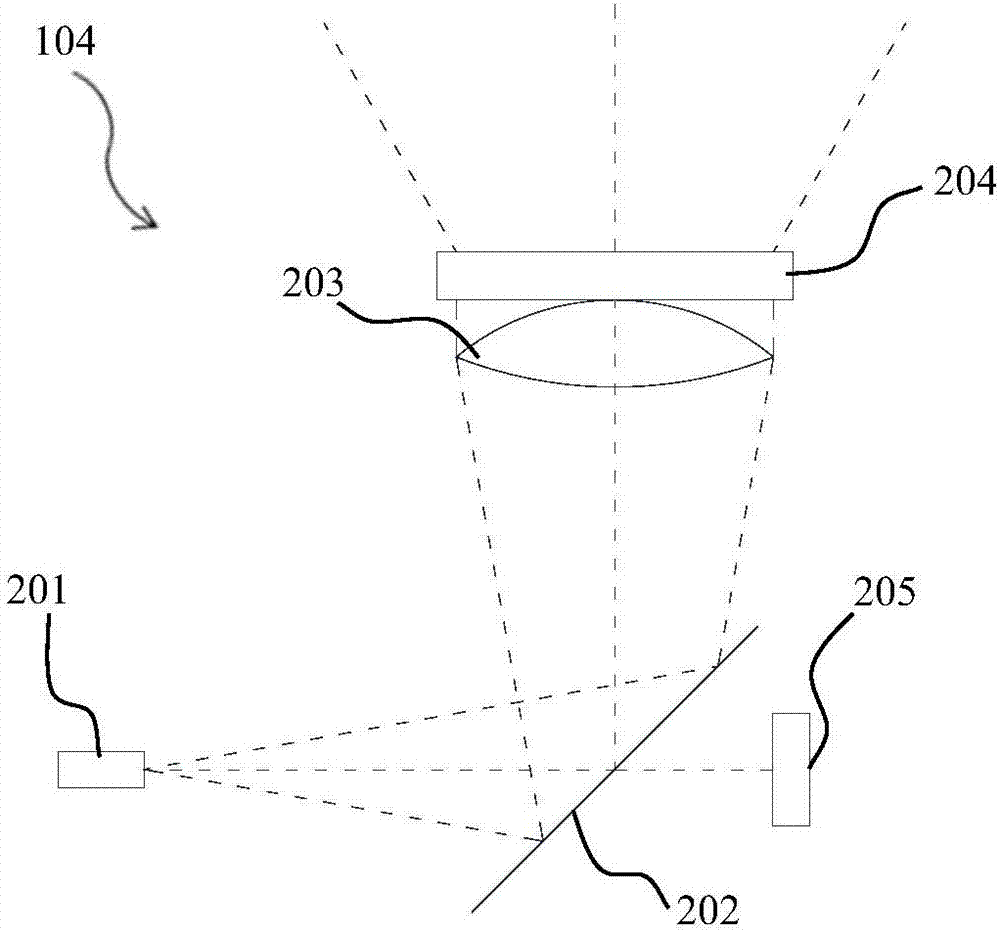

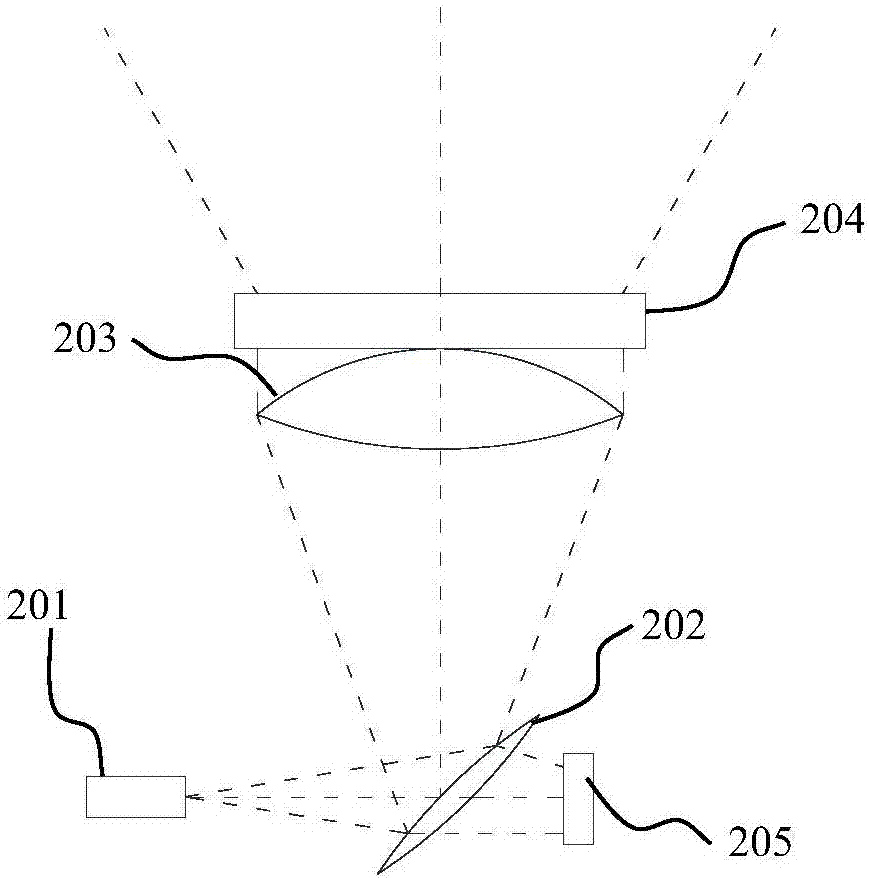

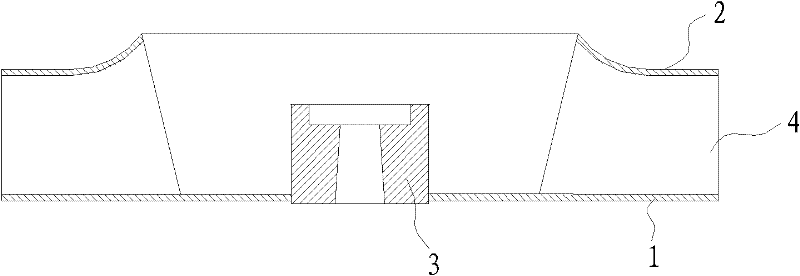

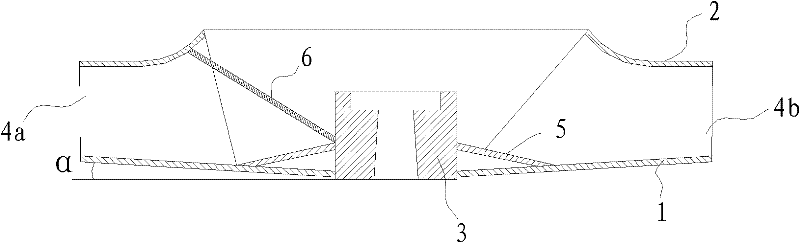

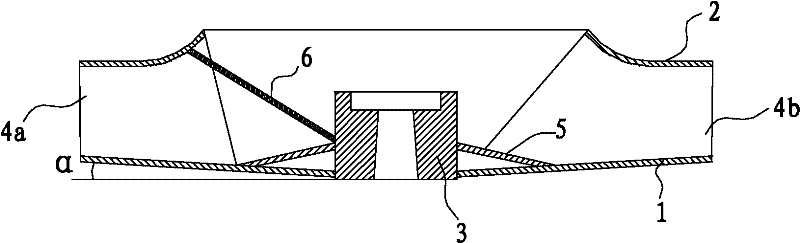

Adaptively adjusted laser projection module and depth camera

InactiveCN107167996AReduce volumeInstant detectionProjectorsCamera body detailsLight beamOptoelectronics

The invention provides an adaptively adjusted laser projection module. The module comprises a light source, a specific optical element, a pattern generator and a light beam detector. The specific optical element comprises at least one light dividing face, wherein each light dividing face is used for reflecting and transmitting at least parts of light beams emitted by the light source. The pattern generator receives light beams parts of which are reflected or transmitted through the light dividing face, and externally emitting structure light patterns. The light beam detector is used for receiving the light beams parts of which are reflected or transmitted through the light dividing face, and detecting the intensity of the light beams. The invention also provides a depth camera. The depth camera comprises the adaptively adjusted laser projection module and is used for projecting structuralized light beam images towards a target space. According to the invention, by use of the specific optical element having the reflection and transmission functions, the laser projection module has quite small size; and by combining an optical detector, the light source can be detected anytime and anywhere, so laser intensity can be further controlled and damage to human is avoided.

Owner:SHENZHEN ORBBEC CO LTD

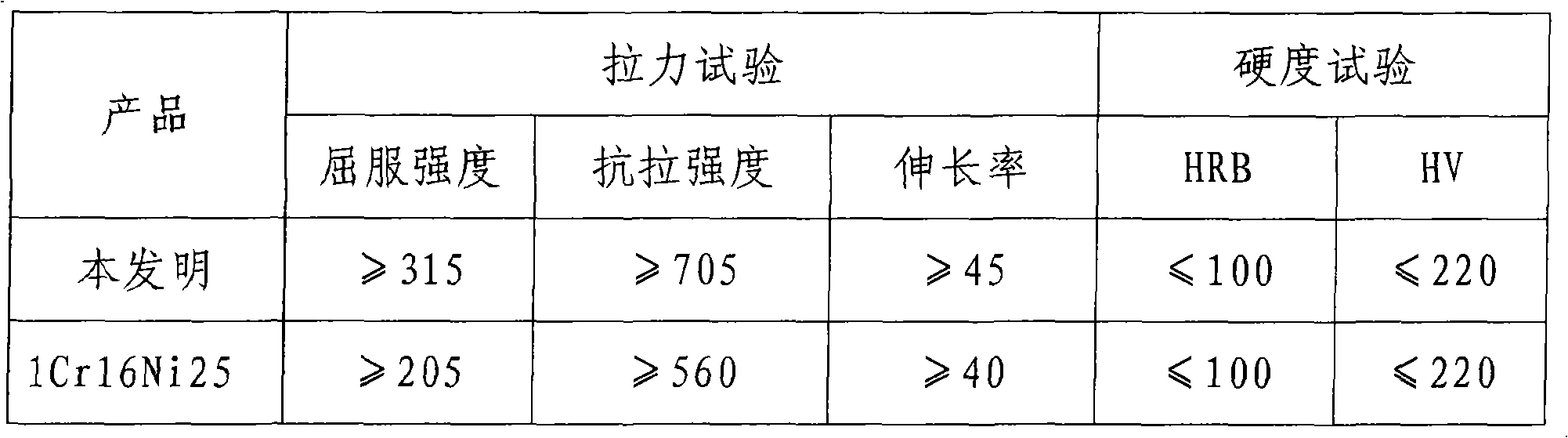

Ultra high-temperature resistant nickel-chrome alloy and manufacturing method thereof

InactiveCN101684530AImprove high temperature resistanceImprove oxidation resistanceNickelHeat processing

The invention provides an ultra high-temperature resistant nickel-chrome alloy and a manufacturing method thereof, wherein the ultra high-temperature resistant nickel-chrome alloy has a higher meltingpoint, can resist the high temperature higher than 1300 DEG C for a long time and has better tensile strength and yield strength simultaneously. The ultra high-temperature resistant nickel-chrome alloy basically comprises the following components in percentage by weight: 21-25 of Cr, 58-63 of Ni, Al which is not less than 1 and not more than 1.7, Cu which is not less than 0.5 and not more than 1.0, C which is not less than 1 and more than 0.1, Si which is not less than 0.5 and more than 0, Mn which is larger than 0 and not more than 1.0, S which is larger than 0 and less 0.015, and the balance of Fe. The manufacturing method comprises the following steps: mixing the materials according to the alloy components and then smelting; carrying out secondary refining; first heating the mixture to900-1200 DEG C, keeping the temperature for 10-40 minutes, and then forging; cold processing; and water cooling. The invention improves the high-temperature resistant performance, the tensile strength and the yield strength of the alloy, and has better comprehensive benefit. The manufacturing method solves the problems of alloy smelting and heat processing, and improves the product purity.

Owner:杭正奎

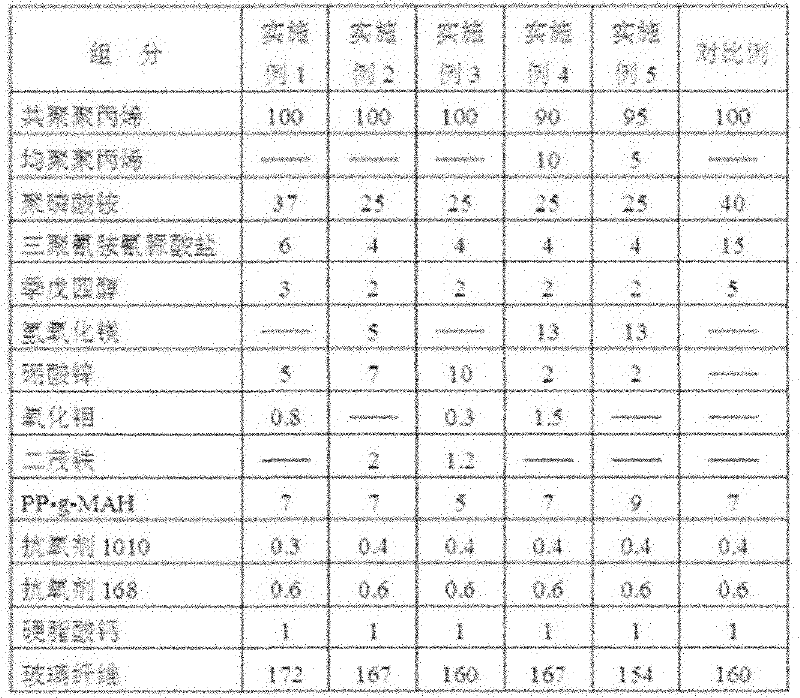

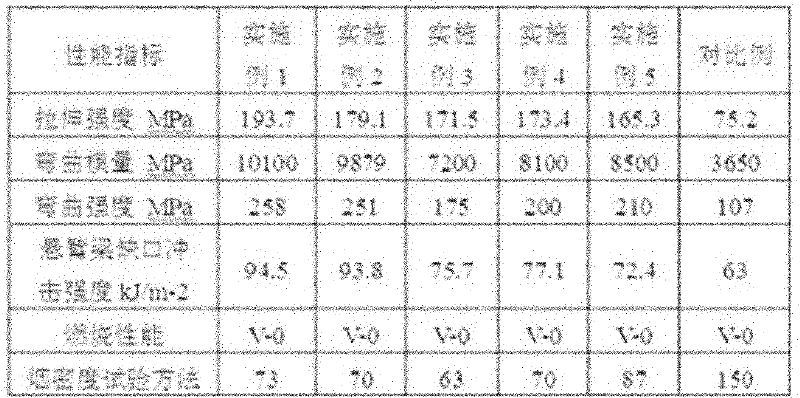

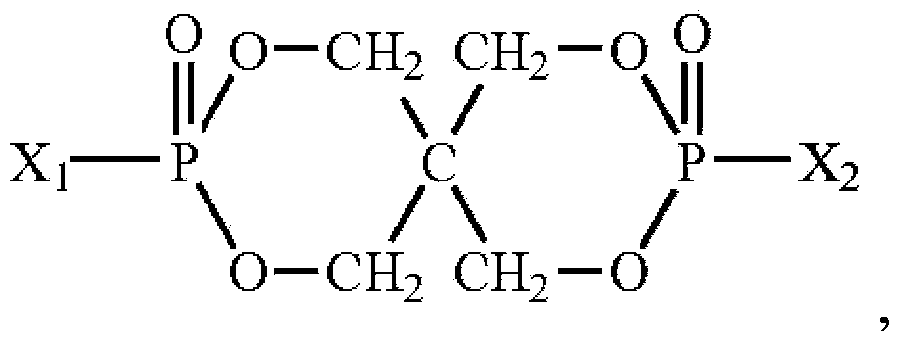

High-performance low-smoke halogen-free flame-retardant polypropylene composite material and preparation method thereof

ActiveCN102532693AImprove mechanical propertiesLow smoke productionGlass fiberPolypropylene composites

The invention discloses a high-performance low-smoke halogen-free flame-retardant polypropylene composite material which comprises the following components in parts by weight: 154-172 parts of continuous glass fiber, 100 parts of polypropylene resin, 41-60 parts of halogen-free flame retardant, 4-11 parts of flame-retardant synergist, 4-14 parts of smoke inhibitor, 5-9 parts of compatibilizer, 0.9 part of antioxidant and 1 part of lubricant. The preparation method of the high-performance low-smoke halogen-free flame-retardant polypropylene composite material comprises the following steps: preparing a low-smoke halogen-free flame-retardant polypropylene master batch; extruding the flame-retardant master batch by an extruding machine; evenly coating onto a continuous glass fiber surface to be evenly compounded with the continuous glass fiber; and carrying out multilayer high-temperature pressing to obtain a hard composite board. The high-performance low-smoke halogen-free flame-retardant polypropylene composite material has the advantages of excellent mechanical properties, excellent flame retardancy and favorable smoke elimination performance; and the preparation technique is simple, halogen-free, flame-retardant, green and environment-friendly, and can be widely used in the fields having strict requirements for flame retardancy and smoke generation amount, such as public occasions, automobile interior ornaments, decorating and the like.

Owner:LIAONING LIAOJIE SCI & TECH

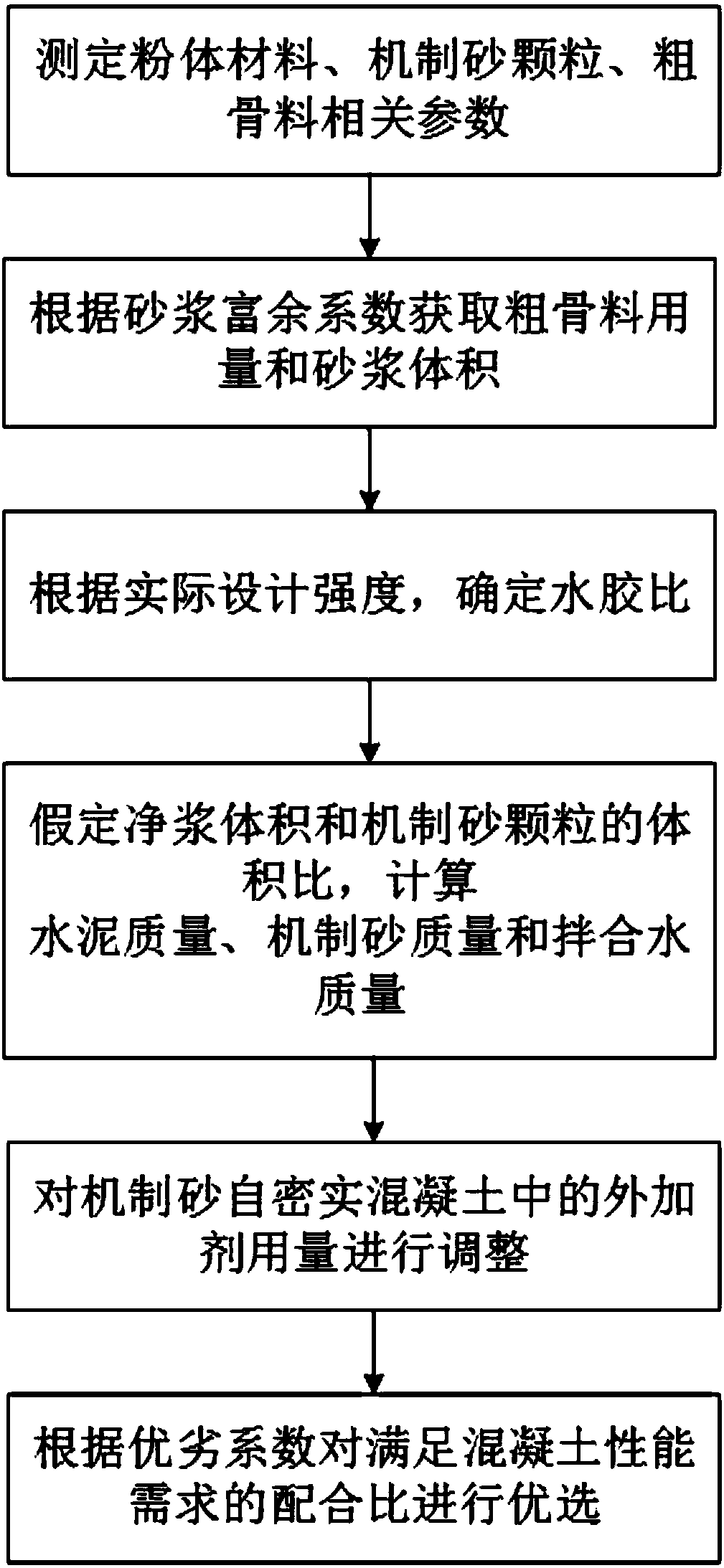

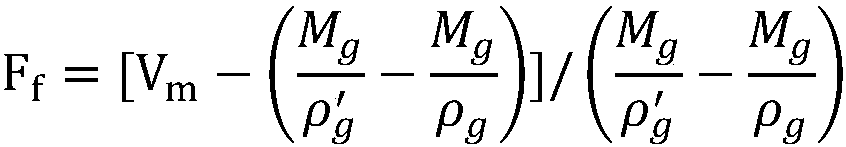

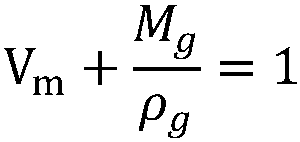

Mix proportion design and optimization method of machine-made sand self-compacting concrete

ActiveCN108395177AThe method steps are simpleSmall amount of calculationRatio controlApparent densityUltimate tensile strength

The invention relates to a mix proportion design and optimization method of machine-made sand self-compacting concrete. The method comprises the following steps: 1) determining the mass of coarse aggregate, the apparent density of the coarse aggregate and the bulk density of the coarse aggregate in a powder material, machine-made sand grains and unit volume concrete; 2) obtaining the use mount ofthe coarse aggregate and the volume of mortar according to performance requirements and the extra coefficient of the mortar; 3) determining a water-binder ratio according to design strength; 4) assuming the volume ratio of a net paste volume to the machine-made sand grains and calculating the mass of cement, the mass of the machine-made sand grains and the mass of mixing water; 5) adjusting the use amount of an additive in the machine-made sand self-compacting concrete according to the workability of the concrete; 6) optimizing a mix proportion meeting requirements on concrete performance according to an excellent-inferior coefficient. Compared with the prior art, the mix proportion design and optimization method has the advantages of simple steps, small calculation amount, wide application, workability and strength and the like.

Owner:佛山市利宇达建材有限公司

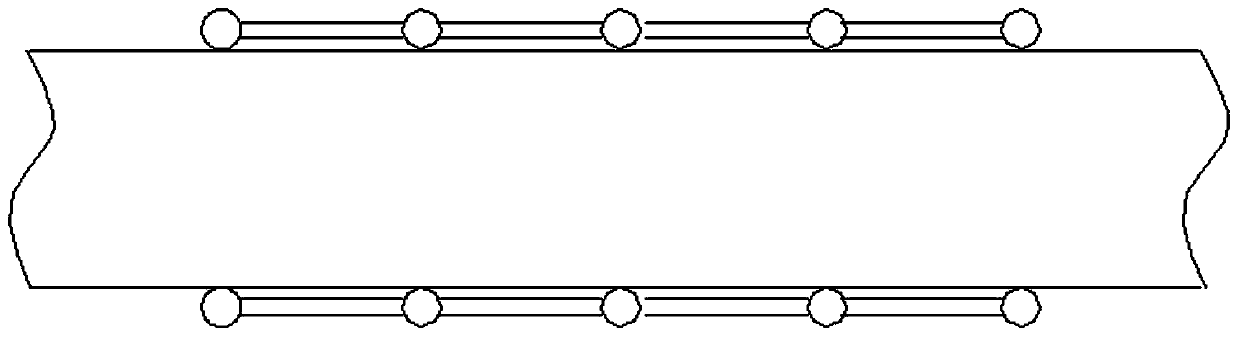

Composite and efficient oil-water-separation filter paper for hydraulic filter

InactiveCN105986512AWell dispersedGood dispersionPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperAlkali freeSisal fiber

The invention discloses composite and efficient oil-water-separation filter paper for a hydraulic filter. The composite and efficient oil-water-separation filter paper is prepared by, by weight, 50-55 parts of 3-5mm alkali-free superfine glass fiber, 55-60 parts of bleached softwood pulp, an appropriate amount of distilled water, 0.8-1 part of anionic polyacrylamide, an appropriate amount of concentrated sulfuric acid with the concentration being 98wt%, 10-12 parts of nano titanium dioxide, 20-25 parts of ferroferric oxide colloidal solution with the solid content being 30%, an appropriate amount of anhydrous ethanol, 60-65 parts of fluoro-silicon emulsion with the solid content being 40wt%, 1-1.2 parts of alkenyl succinic anhydride, 7-8 parts of sisal fiber, 3-4 parts of waste rubber powder, 0.9-1.1 parts of silane coupling agent kh550, 1.5-2 parts of organic silicon emulsion and 2-3 parts of urea. By the scientific and reasonable component proportion, the composite and efficient oil-water-separation filter paper is good in absorbability, good in hydrophobic and oleophylic performance and capable of efficiently separating oil and water. When the filter paper is applied to the hydraulic filter, hydraulic equipment can be well protected.

Owner:ANHUI PHOENIX INT CO LTD

Modified polrvinyl chloride composite material and preparation method thereof

The invention relates to a modified polrvinyl chloride composite material and a preparation method thereof. The modified polrvinyl chloride composite material contains the components in parts by weight as follows: 100 parts of polyvinyl chloride, 1-5 parts of tribasic lead sulfate, 2-6 parts of dibasic lead sulfate, 5-8 parts of pretreated nano silicon dioxide, 26-40 parts of polyurethane elastomer and 1-5 parts of other additives. The polrvinyl chloride composite material is synergistically modified with polyurethane elastomer and nano titanium dioxide, therefore the application range of the polrvinyl chloride is expanded; the strength, the rigidity and the toughness of the product are all taken account of; the impact strength and the tensile strength are excellent; and the modified polrvinyl chloride composite material has wonderful comprehensive mechanical property and is applicable for producing pipe materials or sectional materials.

Owner:常熟市威腾进出口有限公司

FeCoVWNbSc high-entropy alloy powder used for laser cladding and use method

ActiveCN108359977ATaking into account corrosion resistanceTaking into account plasticityMetallic material coating processesHigh entropy alloysHot Temperature

The invention discloses FeCoVWNbSc high-entropy alloy powder used for laser cladding and a use method, and belongs to the technical field of laser surface modification. The FeCoVWNbSc high-entropy alloy powder comprises the following components of Fe, Co, V, W, Nb and Sc, wherein the molar ratio of Fe to Co to V to W to Nb to Sc is 1:1:1:1:1:0.02:0.04; Sc is added in a quinary alloy of Fe, Co, V,W and Nb, so that the elements react with one another to present excellent high-temperature-oxidation-resistance, corrosion-resistance and the like, and the structure of a coating is excellent; a finedilution can also be formed by the coating and a substrate through laser cladding, so that metallurgical combination is formed; a good combination effect is formed between the substrate and the coating, and durability of the coating is favorably improved.

Owner:KUNMING UNIV OF SCI & TECH

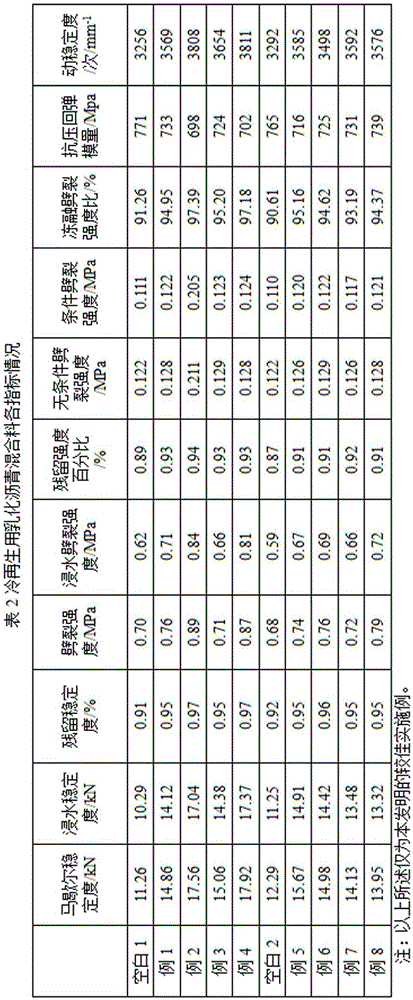

Emulsified asphalt mixture and preparing method thereof

The invention belongs to the technical field of emulsified asphalt and particularly relates to an emulsified asphalt mixture and a preparing method thereof. The emulsified asphalt mixture is prepared from, by mass, 4-8 parts of emulsified asphalt, 2-15 parts of water additionally added, 85-95 parts of stone and 0-6 parts of filler. The filler is one or more of Portland cement, coagulant, fiber, plasticizer, aluminum sodium sulfate high early strength cement, aluminum oxide and zinc oxide. Compared with the prior art, by adding the fiber and the plasticizer into the emulsified asphalt mixture to which the cement is added, the purpose of improving flexibility of the cement emulsified asphalt mixture is achieved; meanwhile, the requirement for quick opening to traffic of construction is met; in addition, amphoteric oxide, the cement, the fiber and the plasticizer in the emulsified asphalt mixture can ensure quick opening to traffic; meanwhile, properties such as road surface strength, flexibility and water damage resistance are given into consideration.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Preparation process of composite casting blanks for high-toughness thick steel plate

The invention discloses a preparation process of composite casting blanks for a high-toughness thick steel plate. The preparation process adopts continuous casting blanks with different furnace numbers, the same steel grades and different carbon contents to compound so as to meet the requirements for overall strength and core toughness, thus the composite continuous casting blanks for an extra-thick steel plate with high surface quality and excellent core impact toughness are obtained. The low carbon design of an inner layer greatly improves the metallurgical quality of the central portion andprovides strong support for improving the toughness of the center and the whole. The high carbon design of an outer layer provides a carbon source for the whole compositions to ensure the whole strength, the uniformity of the compositions is achieved through diffusion, finally the whole compositions with both toughness and strength are obtained, and the occurrence rate of surface cracks is reduced.

Owner:SD STEEL RIZHAO CO LTD

Composite CuNiIn powder, preparation method and application thereof

ActiveCN108425085AHigh strengthImprove the binding effectMolten spray coatingTransportation and packagingThermal sprayingUltimate tensile strength

The invention discloses composite CuNiIn powder, a preparation method and an application thereof. The composite CuNiIn powder comprises a dispersion strengthening phase and a self-lubricating phase. The preparation method comprises the following steps that ball milling and mixing on In powder, nickel-coated molybdenum disulfide powder and A12O3 dispersion strengthening Cu powder are carried out soas to prepare mixed raw materials; a spray drying granulator is adopted to carry out centrifugal atomization granulation on the mixed raw materials to prepare dried granules; and vacuum sintering iscarried out on the dried particles, and then the dried particles are crushed and screened to obtain the composite CuNiIn powder. The composite CuNiIn powder can be prepared into a composite CuNiIn coating containing the dispersion strengthening phase and the self-lubricating phase by adopting a thermal spraying method. The distribution state of the self-lubricating phase is changed, the strength and the toughness of the coating are improved, the generation of micro-cracks of the coating is effectively avoided, the self-lubricating service life of the coating is prolonged, and the composite CuNiIn powder has a good application value in the industries of aviation engines, gas turbines and the like.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

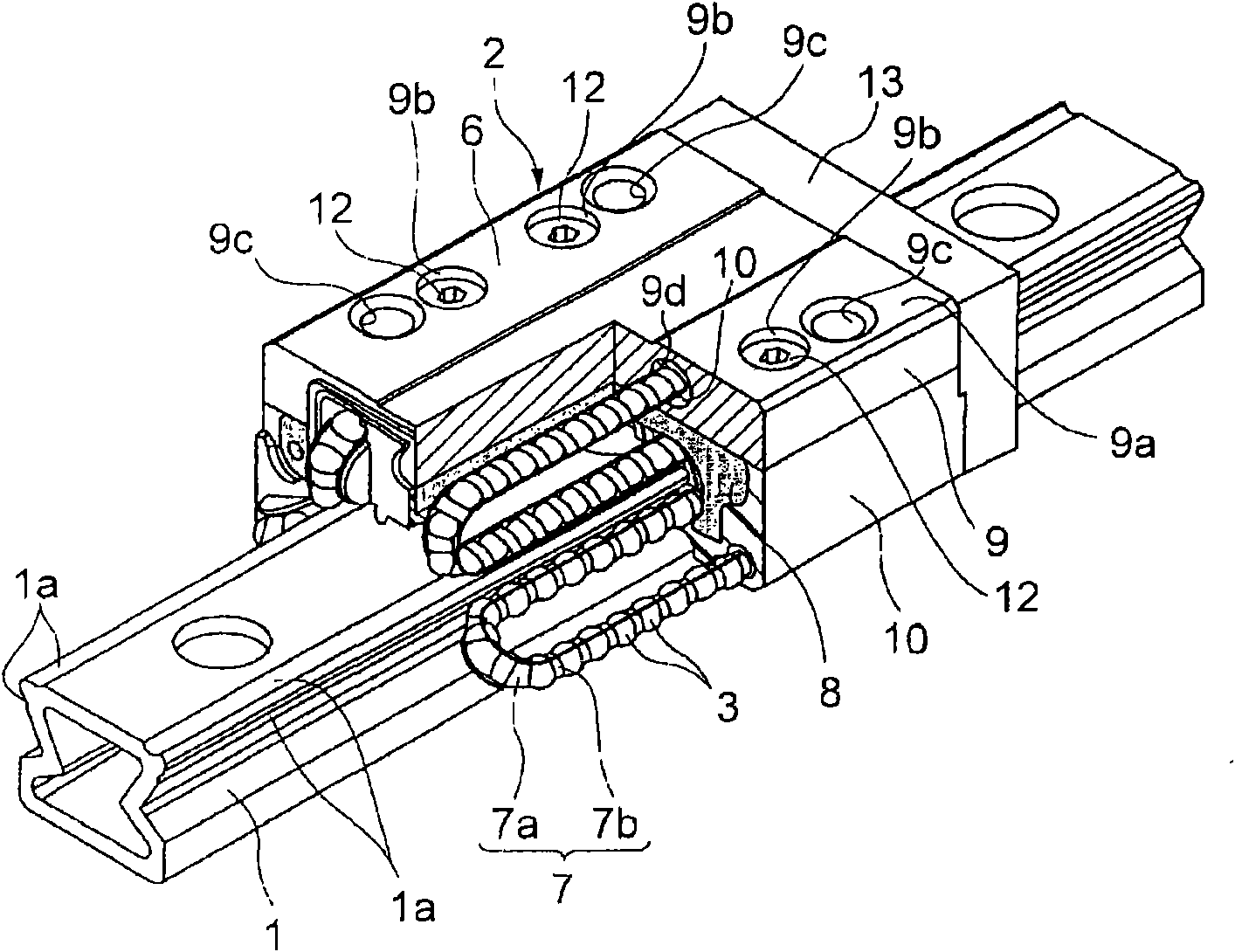

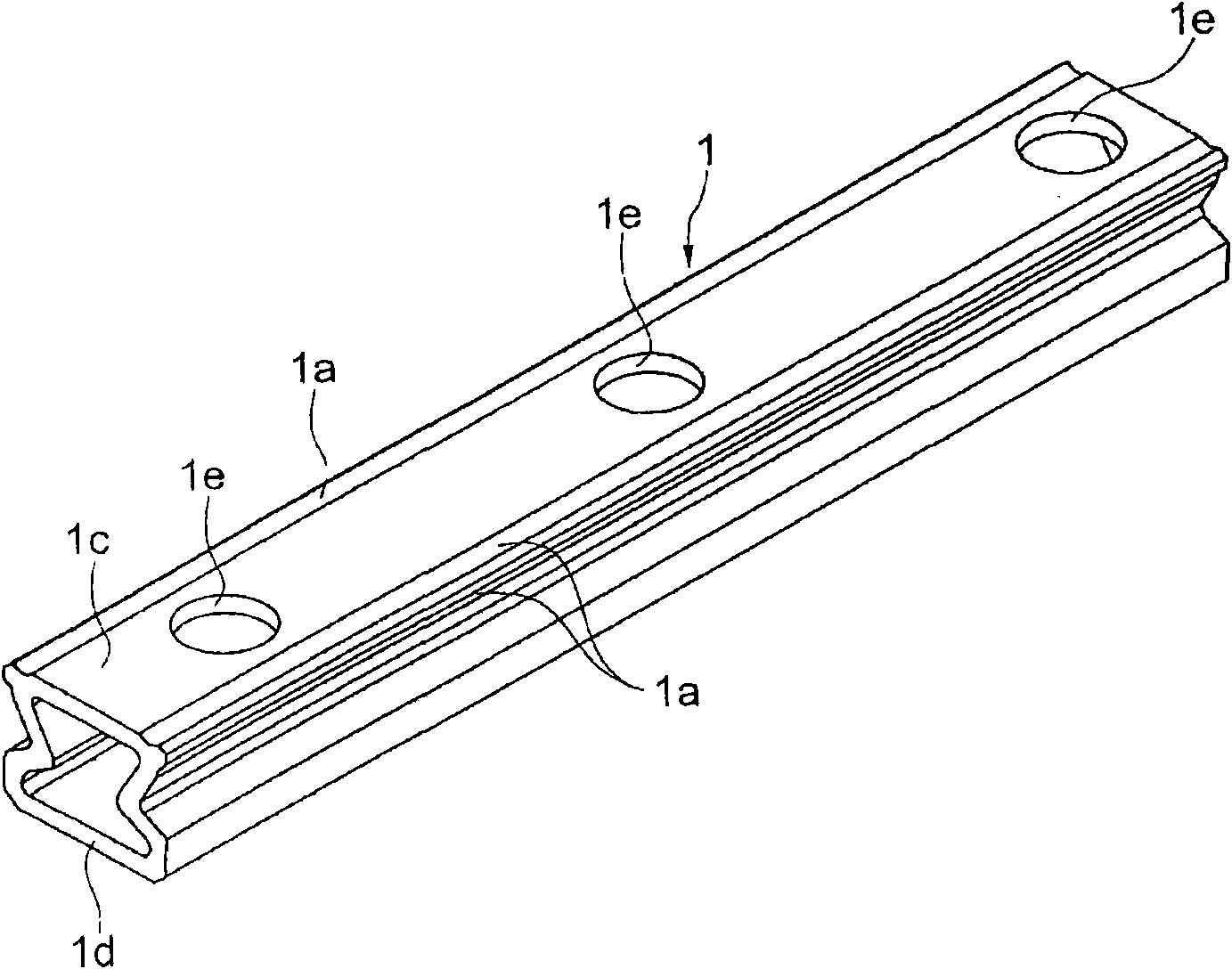

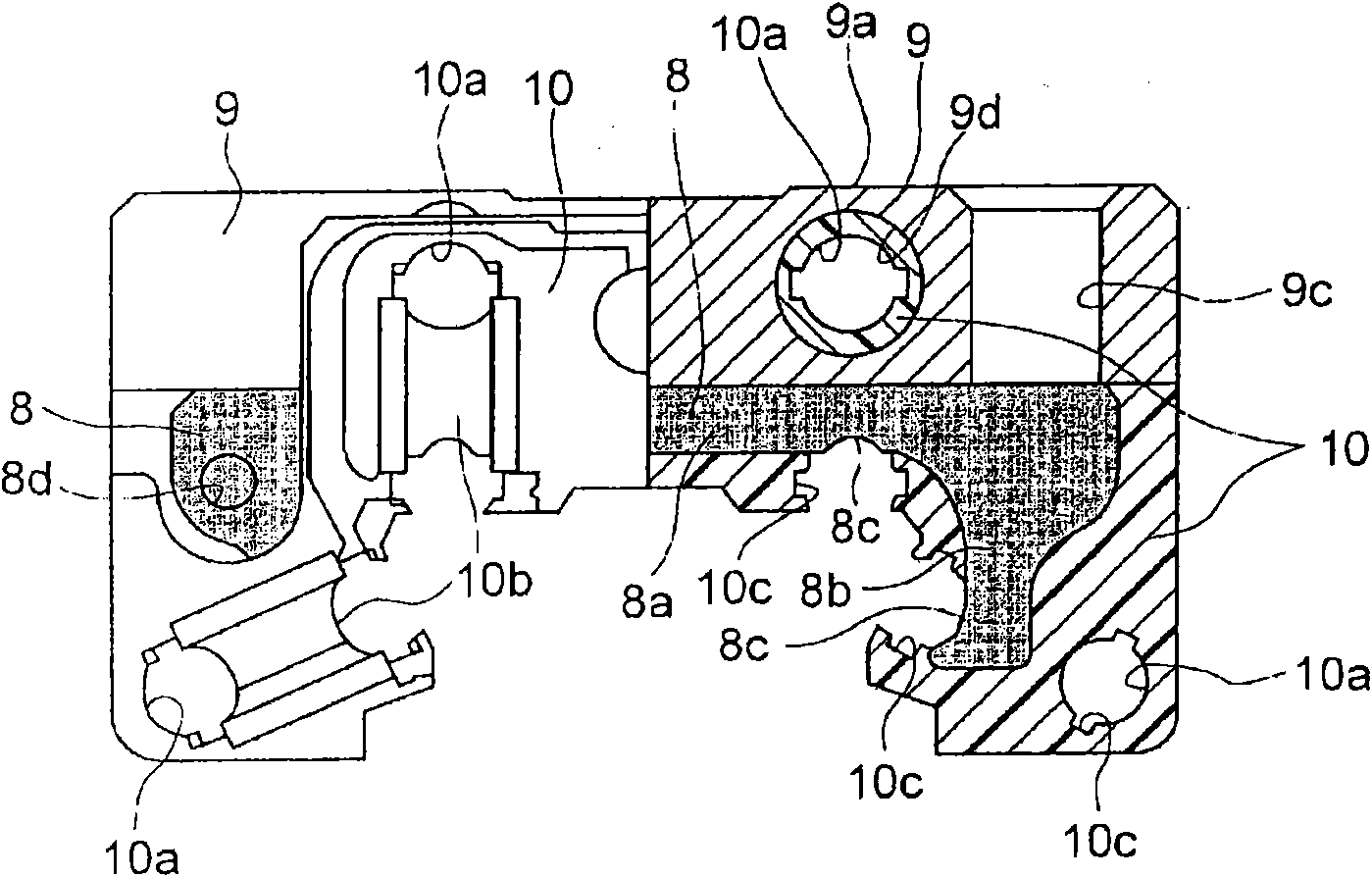

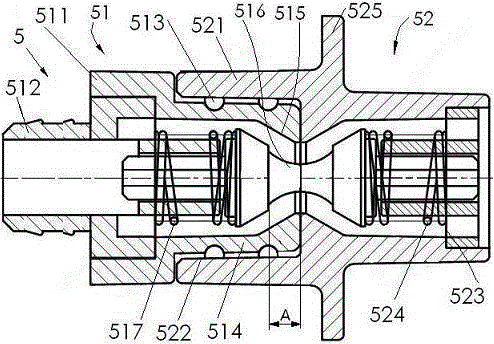

Motion guide device and method of producing the same

ActiveCN101641526ATaking into account strengthLightweightLinear bearingsEngineeringUltimate tensile strength

A motion guide device simultaneously achieves high strength and low weight and can be mass-produced in good productivity. The motion guide device includes a track rail (1) having a rolling body rolling section (1a); a movement block (2) having a loaded rolling body rolling section (8c) facing the rolling body rolling section (1a) and also having a rolling body circulation route including a rolling body return path (10a) extending substantially parallel to the loaded rolling body rolling section (8c); and rolling bodies (3) arranged in the rolling body circulation route. The movement block (2)includes a steel rolling element (8) having the loaded rolling body rolling section (8c); a metal installation element (9) joined to the rolling element (8), having an installation surface (9a) for installing the movement block (2) on a mating part, and made of metal having smaller specific gravity than the rolling element (8); and a resin return element (10) having the rolling body return path (10a). The movement block (2) simultaneously achieves high strength and low weight because the three materials having different strengths and specific gravities are arranged at appropriate places of the movement block.

Owner:THK CO LTD

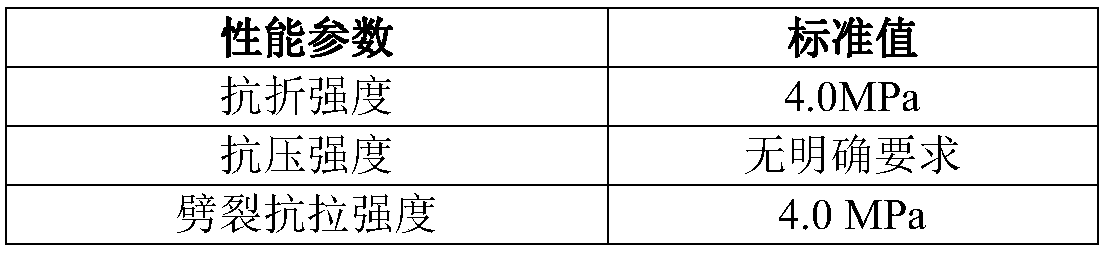

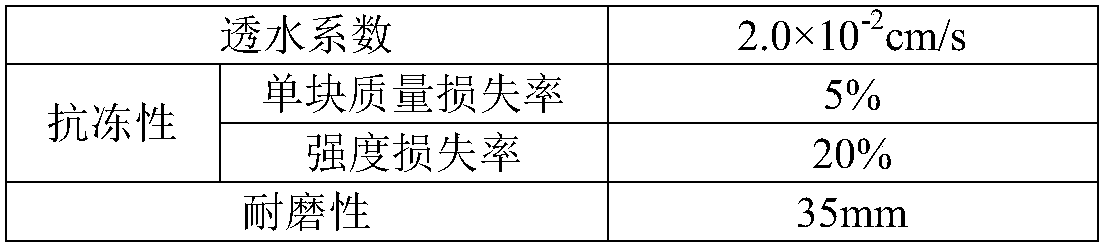

Water permeable brick prepared from construction waste and preparation method of water permeable brick

ActiveCN109796189AImprove sound absorptionGood sound absorptionCeramic materials productionCeramicwareBrickExpanded clay aggregate

The invention discloses a water permeable brick prepared from construction waste and a preparation method of the water permeable brick, and belongs to the technical field of building materials. According to the water permeable brick, the construction waste serves as an aggregate, and kaolin, fly ash, water reducing agents and water are added, wherein the construction waste aggregate mainly comprises waste concrete, waste tiles, waste stone, ceramsite, waste gypsum and waste glass. The water permeable brick has the advantages that the problem of resource waste is solved, and resources are recycled; the air permeable brick with high water permeability, high strength and good sound absorption effect is obtained through reasonable material selection and raw material grading, and has a good reduction effect on noise pollution caused by urban pavement construction, especially noise pollution caused by vehicles on the road to surrounding houses; due to the good absorbing effect on low frequency noise, the water permeable brick can be also applied to pavement laying for tunnel lights to reduce tunnel noise pollution. The preparation process of the water permeable brick is simple, and production and manufacture are facilitated.

Owner:NEIJIANG NORMAL UNIV

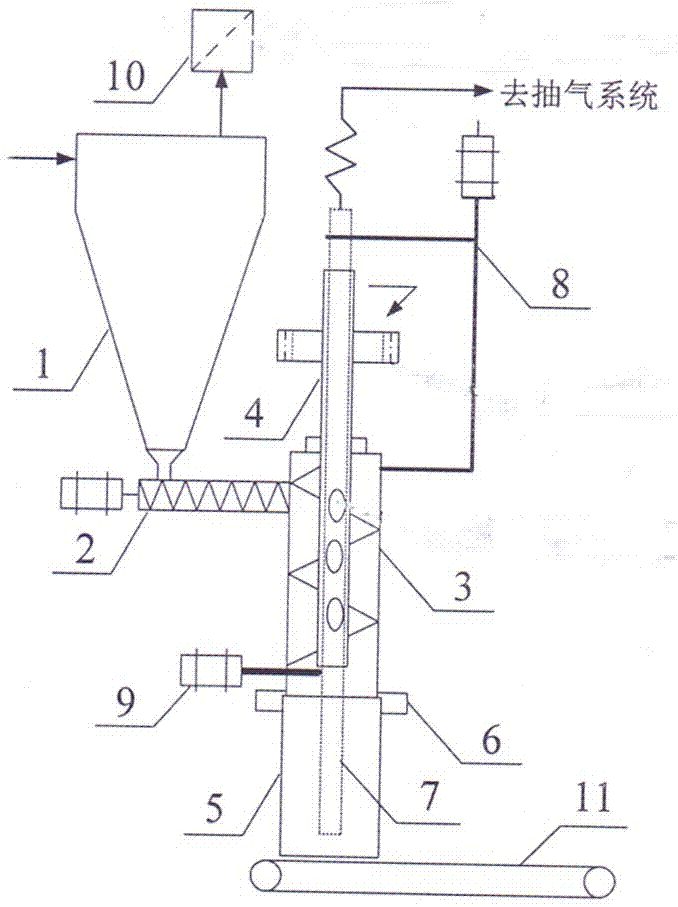

Measurement packing method for powder containing air

InactiveCN107082127ASmooth inhalationBeware of running materialsSolid materialEngineeringScrew conveyor

The invention discloses a measurement packing method for powder containing air. A powder material from an airflow conveying system is temporarily stored in a powder bin; a screw feeder arranged at the bottom of the bin feeds to a middle material cylinder; the material in the middle material cylinder is sent into a packing bag through a hollow stirring shaft; the air contained in the powder is pumped out through a filtering rod arranged inside the hollow stirring shaft in the flow direction; the air pumping process is divided into two levels; according to the first level, air pumping is conducted in a packing material cylinder; according to the second level, deep air pumping is conducted in the packing bag; when the material in the packing bag reaches 99.8% of the rated value, the air pumping filtering rod is quickly removed, and a cut-off valve is turned down; when the weight of the material in the packing bag reaches the set value, the screw conveyor stops feeding, and the cut-off valve is quickly closed; and measurement packing work is completed, and the subsequent working procedures of bag sewing and stacking are executed. According to the measurement packing method, the problem existing in the measurement packing process of the powder containing the air can be effectively solved, and efficient and accurate measurement packing is achieved.

Owner:JIANGSU JIUJIUJIU TECH

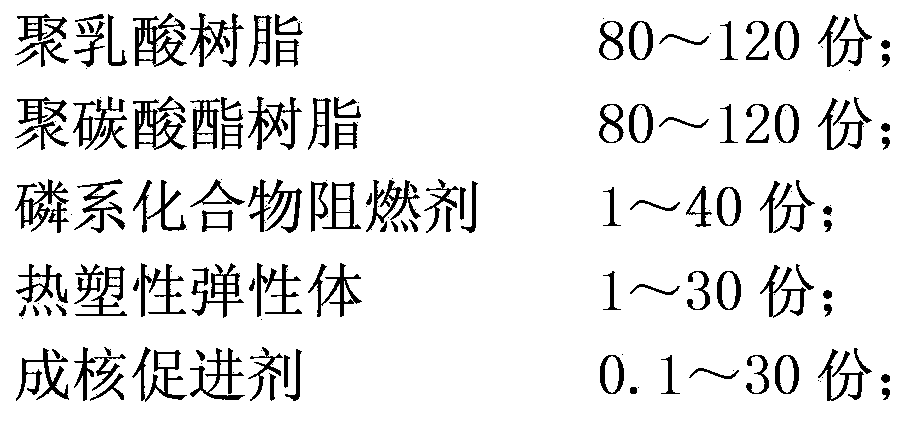

Flame-retardant polyester composite material and preparation method thereof

The invention belongs the technical field of materials, and concretely relates to a flame-retardant polyester composite material and a preparation method thereof. The preparation method comprises the steps: putting thermoplastic elastomer and processing oil in a high-speed mixed for high-speed mixing according to a ratio until the processing oil and the thermoplastic elastomer are mixed uniformly, taking out for usage; uniformly stirring the obtained mixture, polylactic acid resin, polycarbonate resin, a phosphorus-serial compound flame retardant, a nucleation promoter and an anti-droop agent in a dry mixing way according to a ratio, then introducing the mixture into a double screw extruder via a volumetric feeder for fusion mixing processing, after fusion mixing processing is finished, cooling obtained extruded strips with cold water to become solid state, and preparing cylindrical particles by using a comminutor; and drying the above resin composition particles in a hot-wind circulating baking box, and then using an ejecting molding machine to prepare a test sample strip. The flame-retardant polyester composite material obtained by using the preparation method is a PLA / PC composition giving consideration to toughness, strength, flame resistance and high durable temperature.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

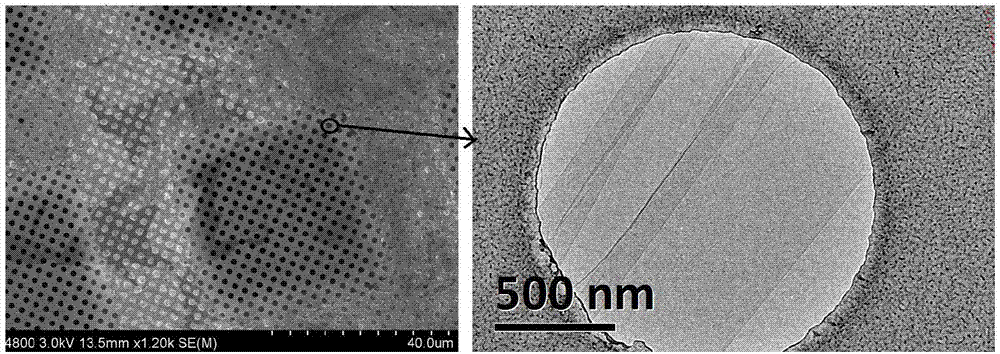

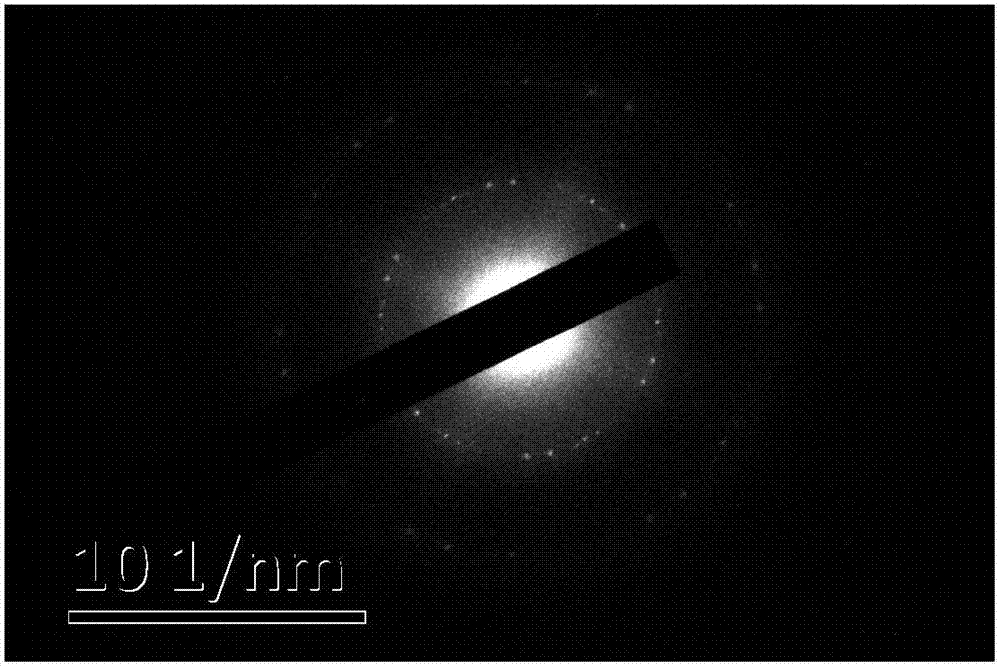

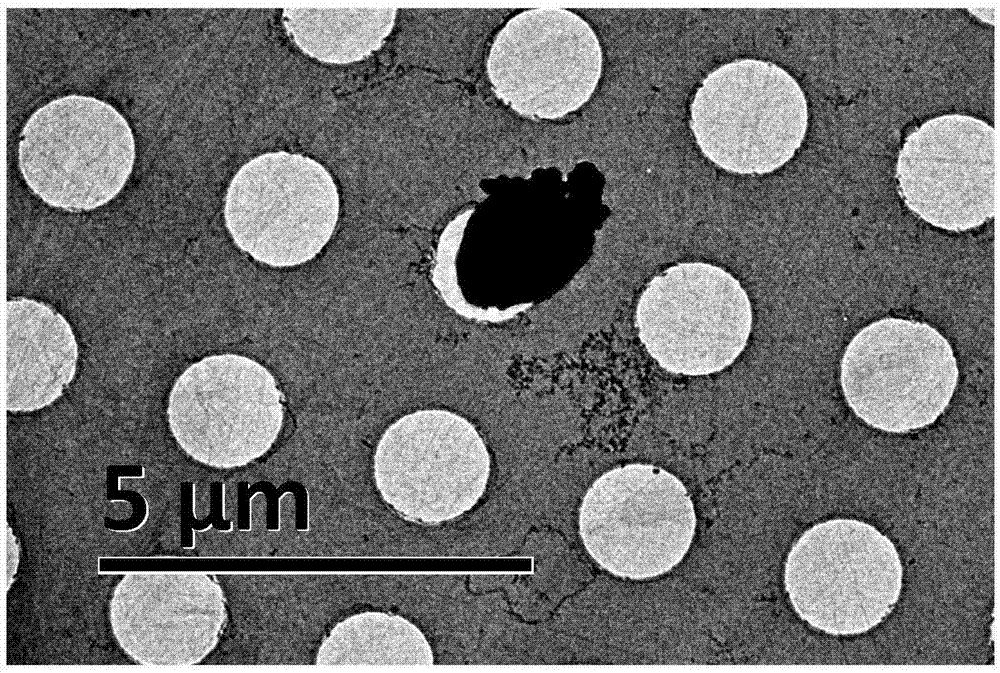

Oxidized graphene carbon support film TEM grid and preparation method thereof

InactiveCN107093543ASimple preparation processThe preparation method is simple and easyElectric discharge tubesCold cathode manufactureCarbon filmNetwork on

The invention discloses a graphene oxide carbon support film transmission electron microscope grid and a preparation method thereof. Its steps are as follows: (1) take a piece of ordinary carbon-free electron microscope grid and put it on the filter paper; (2) evenly spread the graphene oxide solution on the surface of the grid; (3) volatilize the solvent under normal temperature or heating conditions. The invention can prepare ultra-thin carbon support film to realize high contrast and high resolution. And the unreduced carbon support film has negatively charged functional groups, which can enhance the adhesion between the carbon film and the sample. The method for preparing the carbon support membrane has the advantages of simple operation, low cost and the like.

Owner:杭州德烯科技集团有限公司

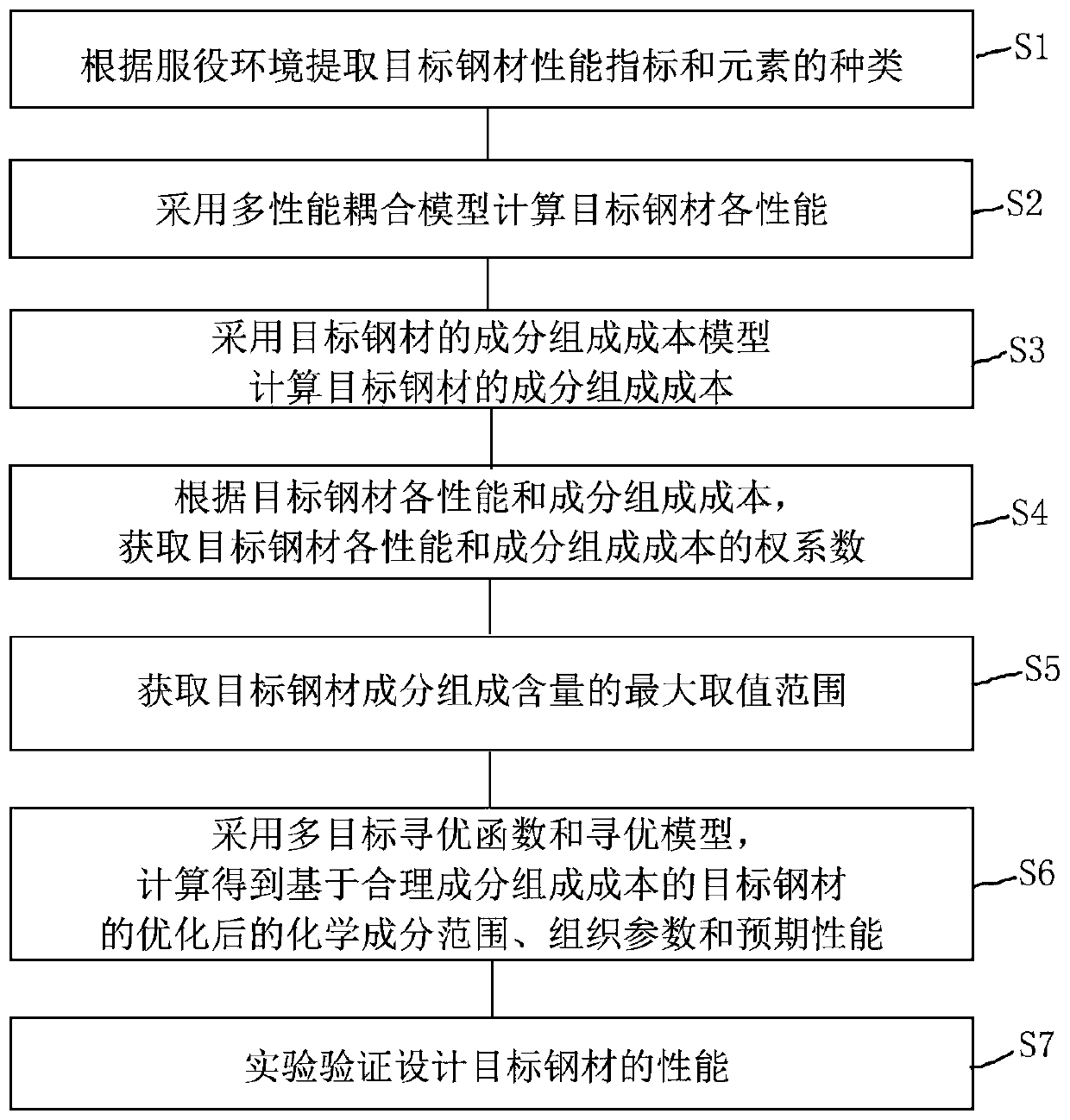

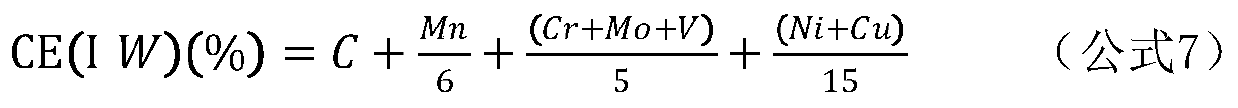

Multi-performance-coupled optimized steel optimization method

InactiveCN110164513AShorten the design cycleReduce testing workloadComputational materials scienceInstrumentsChemical compositionWeight coefficient

The invention belongs to the field of steel designing, and particularly relates to a multi-performance-coupled optimized steel optimization method. The target steel optimization method is designed foraiming at a high-strength, high-toughness and easy-welding corrosion-resisting steel material, thereby obtaining a quick optimization method for component forming element proportion in a multi-performance target requirement. The optimization method comprises the steps of extracting a target steel performance index and element kinds according to an in-service environment; calculating each performance of the target steel by means of a multi-performance coupling model; calculating the component composition cost of the target steel according to the component composition cost model of the target steel; according to each performance and the cost composition cost of the target steel, acquiring the weight coefficient of each performance and component composition cost of the target steel; acquiring a largest value range of the component composition content of the target steel; and by means of a multi-target optimization function and an optimization model, calculating the optimized chemical component range, the tissue parameter and the expected performance of the target steel based on a reasonable component composition cost.

Owner:UNIV OF SCI & TECH BEIJING

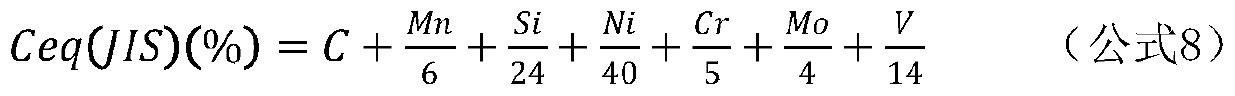

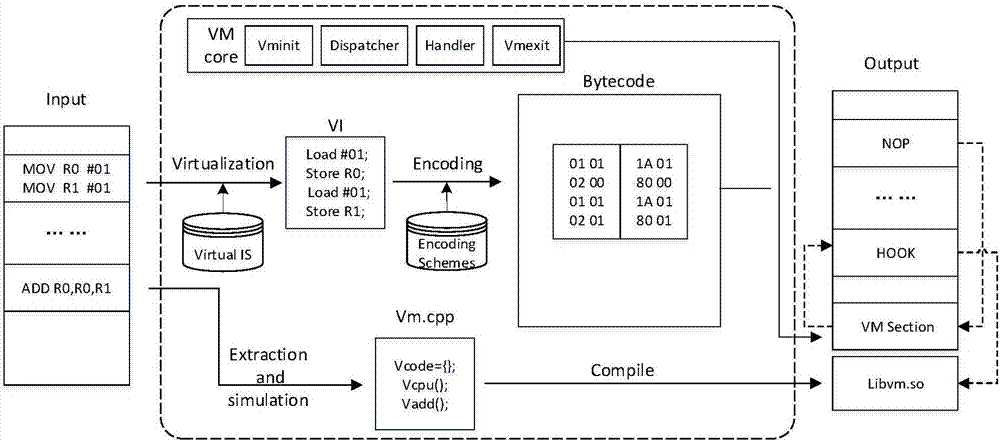

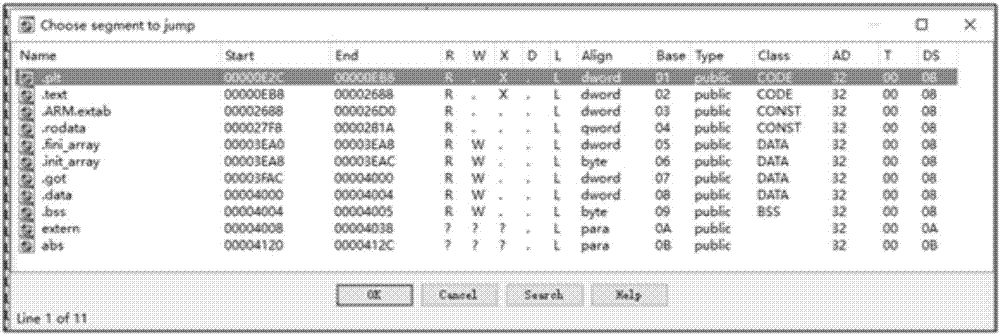

Android application program protection method based on dual ARM instruction virtualization

InactiveCN107577925AIncrease attack costProtection complexityProgram/content distribution protectionVirtualizationApplication software

The invention discloses an Android application program protection method based on dual ARM instruction virtualization. The method comprises the steps that key code segments needing to be protected ina so file are searched for, wherein the key code segments include a key code segment needing VOP protection and a key code segment needing VMP protection; Hex extraction and mapping virtualization areperformed on the key code segment needing VOP protection, and a VOP virtual machine so file is formed; the key code segment needing VOP protection is encrypted, Hook replacement is performed on the encrypted VOP key code segment, and a virtual instruction code in the VOP virtual machine so file is made to replace an encrypted code, corresponding to the encrypted VOP key code segment, in the so file; instruction virtualization is performed on the key code segment needing VMP protection, and a protected VMP virtual machine so file with virtual sections is formed; and driving data in the VMP virtual machine so file is made to replace the code, corresponding to the key code segment, in the so file. Through the method, two different virtual machine protection thoughts are combined, attack costof a reverser is increased, and the complexity of a protected program is enhanced.

Owner:NORTHWEST UNIV(CN)

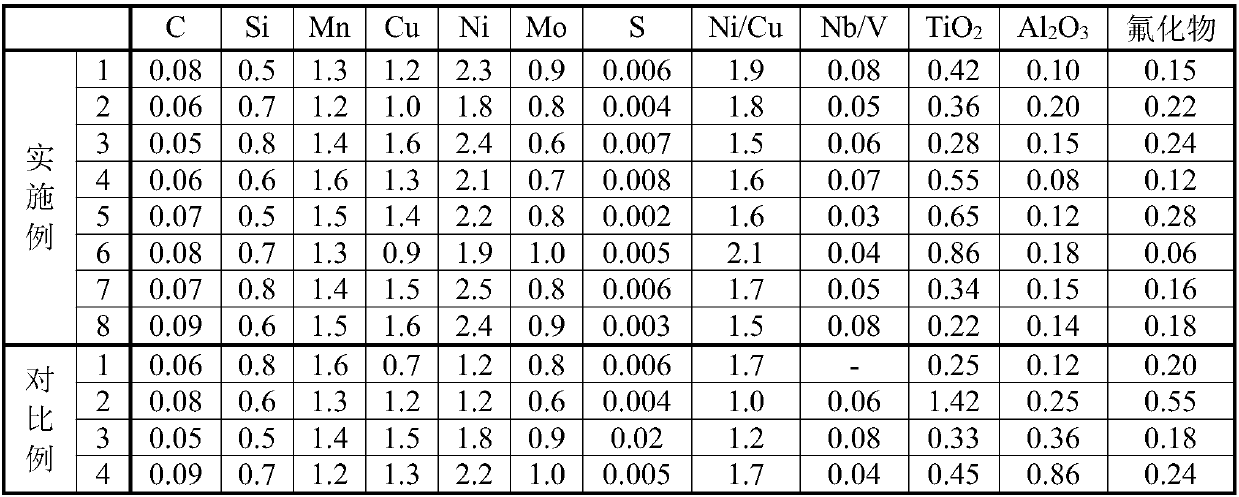

Flux-cored wire for gas shield welding of high-strength steel

InactiveCN107914100AOvercoming incomparable problemsReduce sensitivityArc welding apparatusWelding/cutting media/materialsImpact energyWeld metal

The invention relates to a high-strength steel gas-shielded welding flux-cored wire, which is composed of a steel sheath and a core powder, in terms of total weight percentage, C 0.04-0.10%, Si 0.3-0.8%, Mn 1.1-1.6%, Cu 0.9-2.0%, Ni 1.3-2.5%, Mo 0.6-1.0%, in the core powder, Ti oxide TiO2 conversion value is 0.1-1%, Al oxide Al2O3 conversion value is 0.05-0.5%, fluoride The conversion value is 0.05‑0.3%, and the tensile strength of the weld metal produced by using this welding wire is above 800MPa, and the impact energy at ‑40°C is above 60J.

Owner:张宇

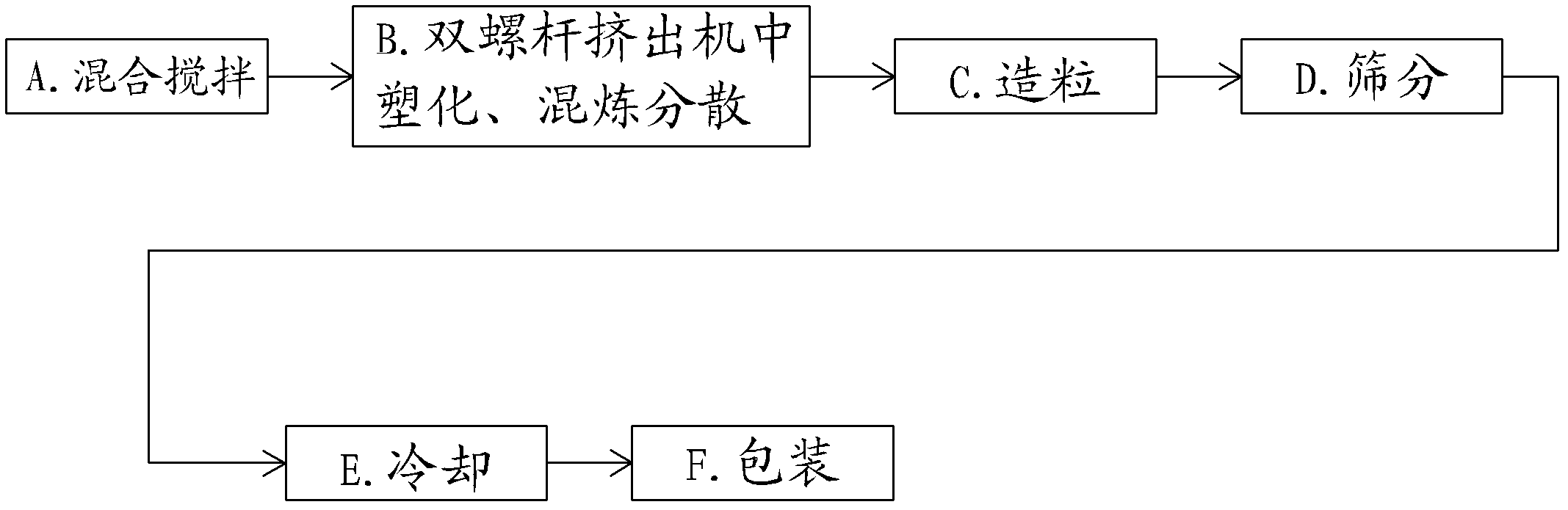

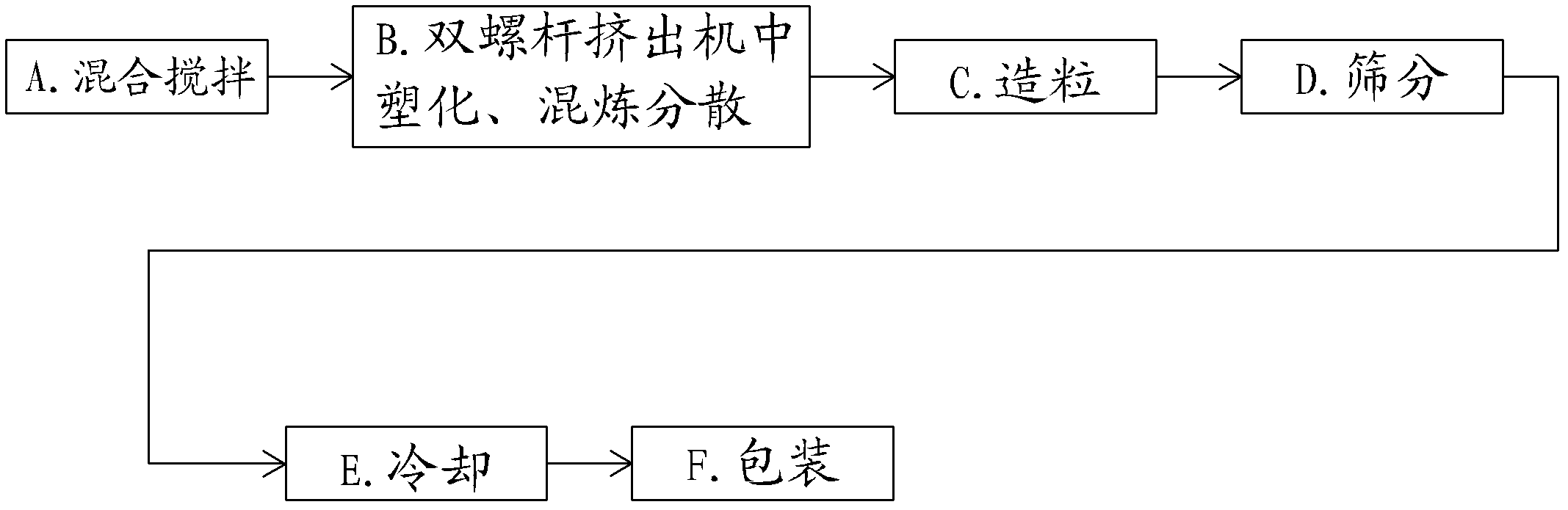

Reinforcing and toughening masterbatch for vinyl polymer and preparation method thereof

ActiveCN102277004AGive full play to the strengthening and toughening effectTaking into account strengthPolymer scienceUltra fine

The invention relates to the field of chemical materials, in particular to a master batch used for improving vinyl polymer properties and a method for preparing the same. The strengthening and toughening master batch used for a vinyl polymer comprises the following components in percentage by weight: 20-50 percent of nano silicon dioxide, 5-20 percent of ultra-fine calcium carbonate, 10-30 percent of ethylene-acrylic ester-carbon monoxide, 5-20 percent of EVA resin (ethylene-vinyl acetate copolymer), 1.1-5 percent of dispersing agent and 0-3 percent of coupling agent. The method for preparing the strengthening and toughening master batch for the vinyl polymer comprises the following steps of: 1): adding the components according to the percentage by weight into a high-speed stirring machine with a heating function to mix and stir; 2), feeding the mixed material into a twin-screw extruder to plasticize and mix and disperse; and 3): granulating through a granulating device. According to the invention, the multi-polymer and nano inorganic particle composite strengthening and toughening properties are mainly used, the strength and the toughness of materials are also used, and the master batch can be used for obtaining a vinyl polymer material with excellent comprehensive performance.

Owner:泉州兴源新材料科技有限公司

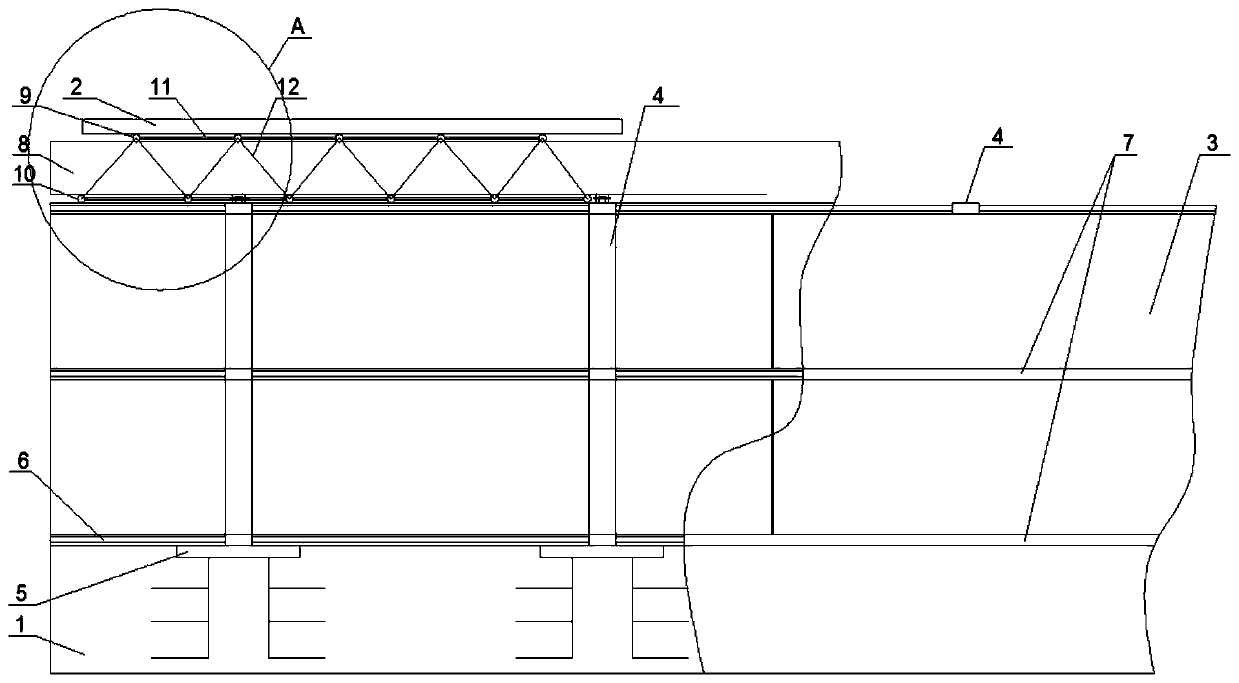

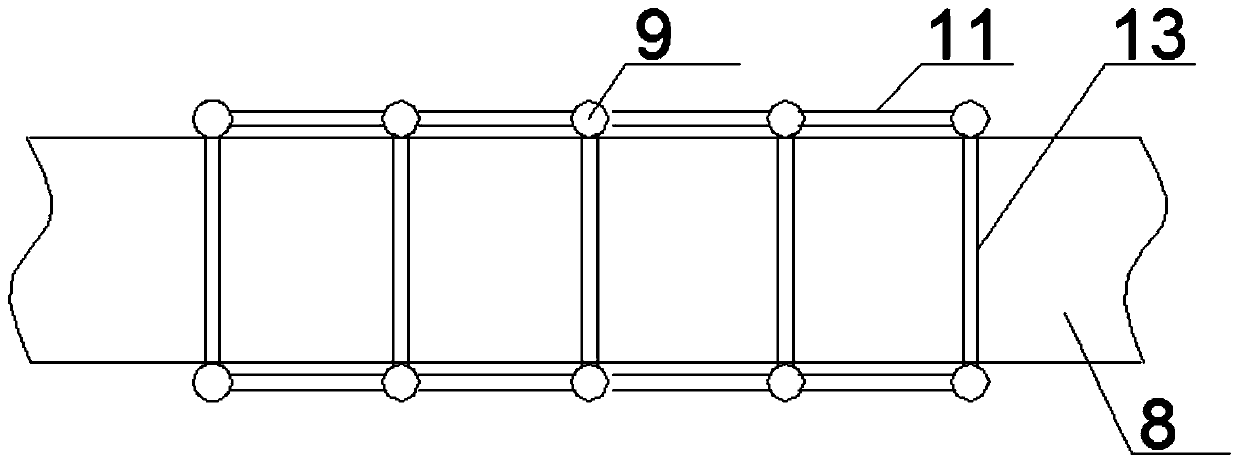

Building structure formed by connecting prefabricated wall boards through dense ribs and constructing method of building structure

The invention relates to a building structure formed by connecting prefabricated wall boards through dense ribs and a constructing method of the building structure. The building structure comprises afoundation, a prefabricated wall and a floor in sequential connection from bottom to top. The prefabricated wall comprises a group of spliced light wall boards. A group of steel pipes penetrating through the prefabricated wall serve as supporting pieces. Installing bodies with the upper surfaces fixed to the steel pipes are prefabricated in the foundation. Tie bars are arranged between every two steel pipes close to the boundaries of the left and right adjacent light wall boards. Mortar layers for sealing are arranged at the upper end and the lower end of each light wall board. The tie bars are located in the mortar layers. Beams coinciding with the upper surface of the prefabricated wall are arranged on the top of the prefabricated wall. Connecting and locking mechanisms are arranged between the tops of the steel pipes and the lower surfaces of the beams. An upper layer of the same structure is arranged on the beams. Crossing and supporting structures are arranged between the beams. The floor on the upper layer is laid on the upper end faces of the crossing and supporting structures. A ceiling is arranged on the lower end faces of the crossing and supporting structures. The building structure is convenient to construct, high in efficiency, good in thermal effect and high in integral stability.

Owner:石家庄筑佳节能产品科技有限责任公司

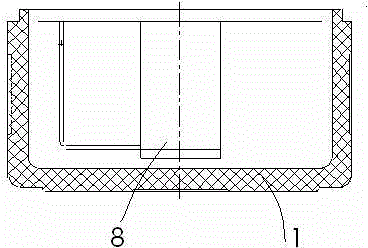

EPP insulating box with inner container

ActiveCN105035539ANo adsorption odorEasy to cleanDomestic cooling apparatusLighting and heating apparatusCold airFood storage

The invention discloses an EPP insulating box with an inner container. The EPP insulating box overcomes the defects that in the prior art, a low-temperature insulating box is poor in safety and low in strength. The insulating box with the inner container is safe, reliable, balanced in temperature, free of peculiar smell and high in strength. The insulating box comprises a box body, an upper cover and the inner container. A lower cover is lined below the upper cover. An ice box is placed in the middle of the lower cover. A plurality of vertically-communicated airflow channels are arranged in the middle of the lower cover. A cold air circulation channel is arranged between the box body and the inner container and between the upper cover and the inner container. The cold air circulation channel comprises a side channel arranged between the inner side face of the box body and the outer side face of the inner container, and a bottom channel arranged between the upper side face of the bottom of the box body and the lower side face of the bottom of the inner container. A thermometer is arranged on one side of the box body. The EPP insulating box is suitable for food storage and has the beneficial effects that insulating is good, forceful refrigerating can be achieved, the temperature is balanced, a cold air pipe connector has the self-sealing function, and safety, reliability and digital display temperature display are achieved; and the adsorption peculiar smell is avoided, cleaning is easy, and sanitation and high strength are achieved.

Owner:ZHEJIANG WUGU PAOSHIN IND

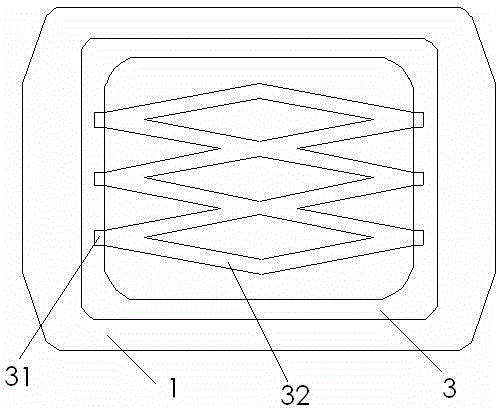

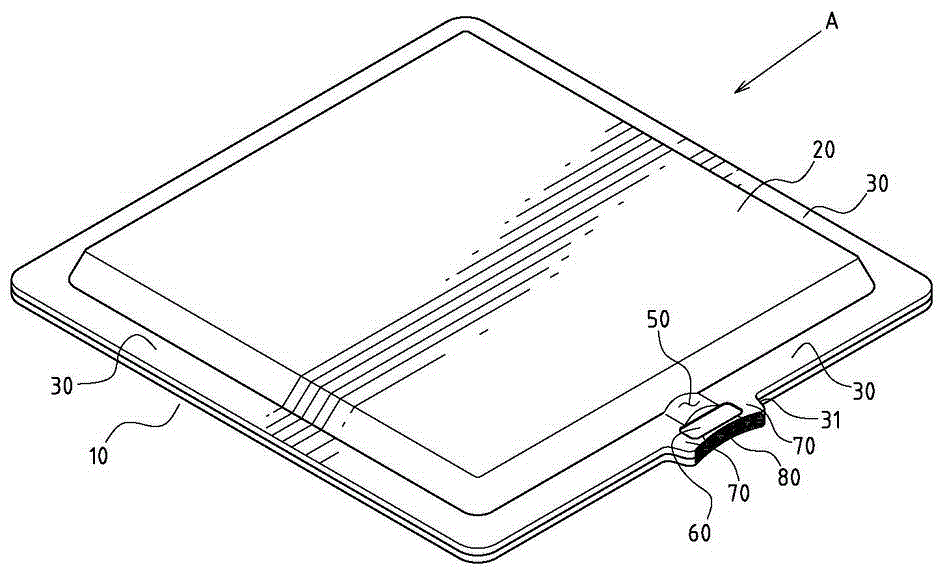

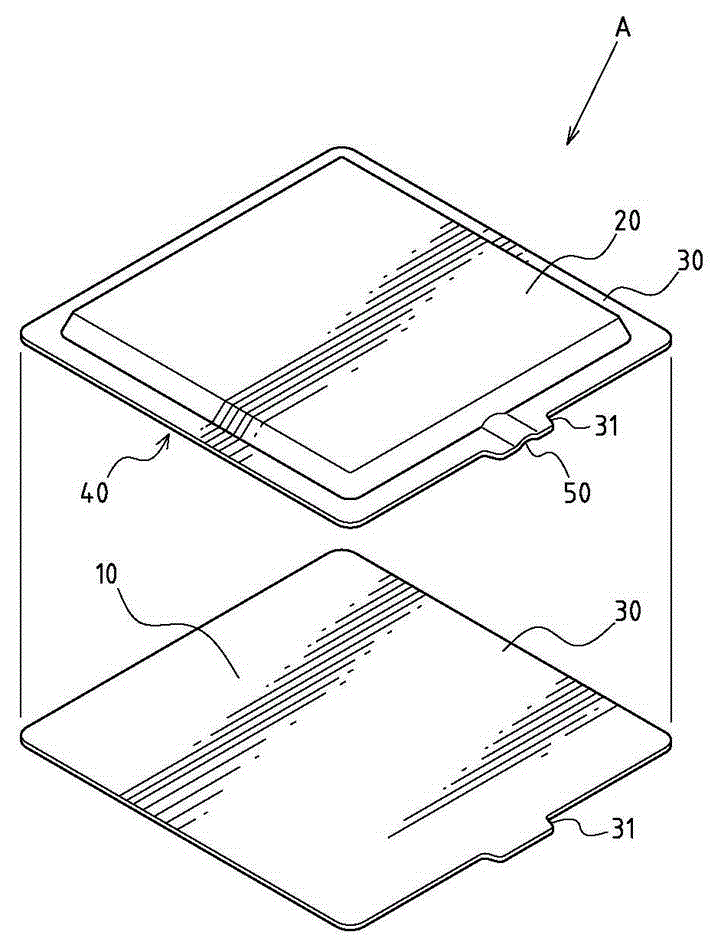

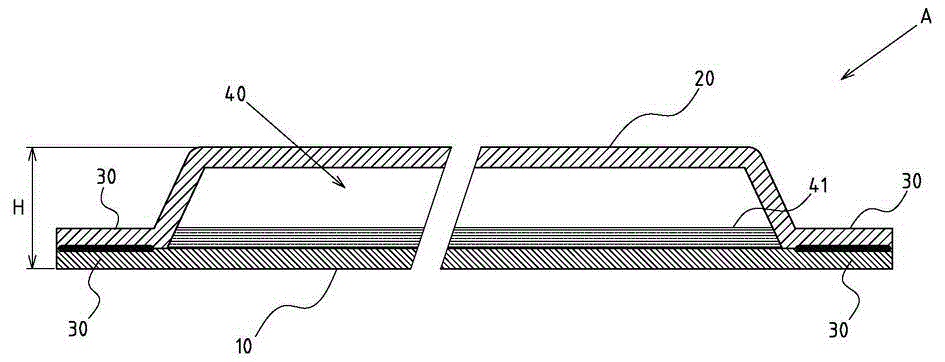

Thinning heat conduction device with pipeless sealing structure and forming method of thinning heat conduction device

InactiveCN102748967ATaking into account the blocking effectTaking into account strengthIndirect heat exchangersWelding apparatusInterior spaceWorking fluid

Disclosed are a thinning heat conduction device with a pipeless sealing structure and a forming method of the thinning heat conduction device. The thinning heat conduction device is characterized by comprising a base plate, a cover plate, a faceted joint side, an internal space, a gap channel, a press fit closing edge and spacing edges, the base plate and the cover plate are in the form of sheets and respectively have a thickness and an area, the faceted joint side is arranged on the peripheries of the base plate and the cover plate in a faceted correspondingly attached and joint sealing form, the internal space in an evacuated state is formed between the base plate and the cover plate and enclosed by the faceted joint side, working fluid is filled in the internal space, an unassembled position is reserved by the faceted joint side to form the gap channel, the section of the gap channel is in a gap form, the press fit closing edge is formed in a local section of the gap channel in a press fit form and blocks and closes the gap channel, and the spacing edges are formed between at least one side of the press fit closing edge and the outer side of the faceted joint side. Therefore, sealing components can be omitted and simplified, cost and defect rate are reduced, fine sealing quality is achieved, and the thinning heat conduction device has the advantages of fine structural strength and the like, and has practical progress.

Owner:SUZHOU FORCECON ELECTRIC

Hydraulic oil filter paper capable of separating oil from water efficiently

InactiveCN105986528AWell dispersedGood dispersionWax additionSynthetic cellulose/non-cellulose material pulp/paperSodium bicarbonateAlkali free

The invention discloses a hydraulic oil filter paper for realizing high-efficiency oil-water separation, which is prepared from the following raw materials in parts by weight: 3-5 mm alkali-free ultrafine glass fiber 50-55, bleached coniferous wood pulp 55-60, distilled water in an appropriate amount, Anionic polyacrylamide 0.8-1, an appropriate amount of concentrated sulfuric acid with a concentration of 98wt%, nano-titanium dioxide 10-12, a solid content of 30% iron ferric oxide colloid solution 20-25, an appropriate amount of absolute ethanol, and a solid content of 40wt% fluorine Silicon emulsion 60-65, dispersant NNO0.8-1, zeolite molecular sieve 3-4, sodium polystyrene sulfonate 0.2-0.3, peat soil 2-3, sodium bicarbonate 0.4-0.5, microcrystalline paraffin 0.8-1. The filter paper of the invention has good adsorption efficiency, realizes oil-water separation, improves the clarity of hydraulic oil, and prolongs the service life.

Owner:BENGBU PIONEER FILTER

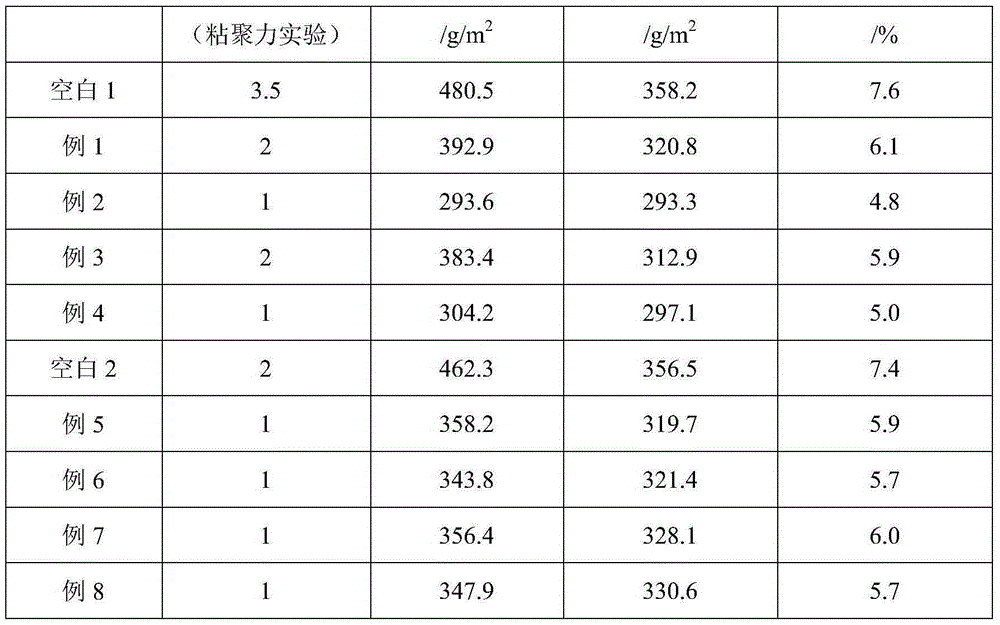

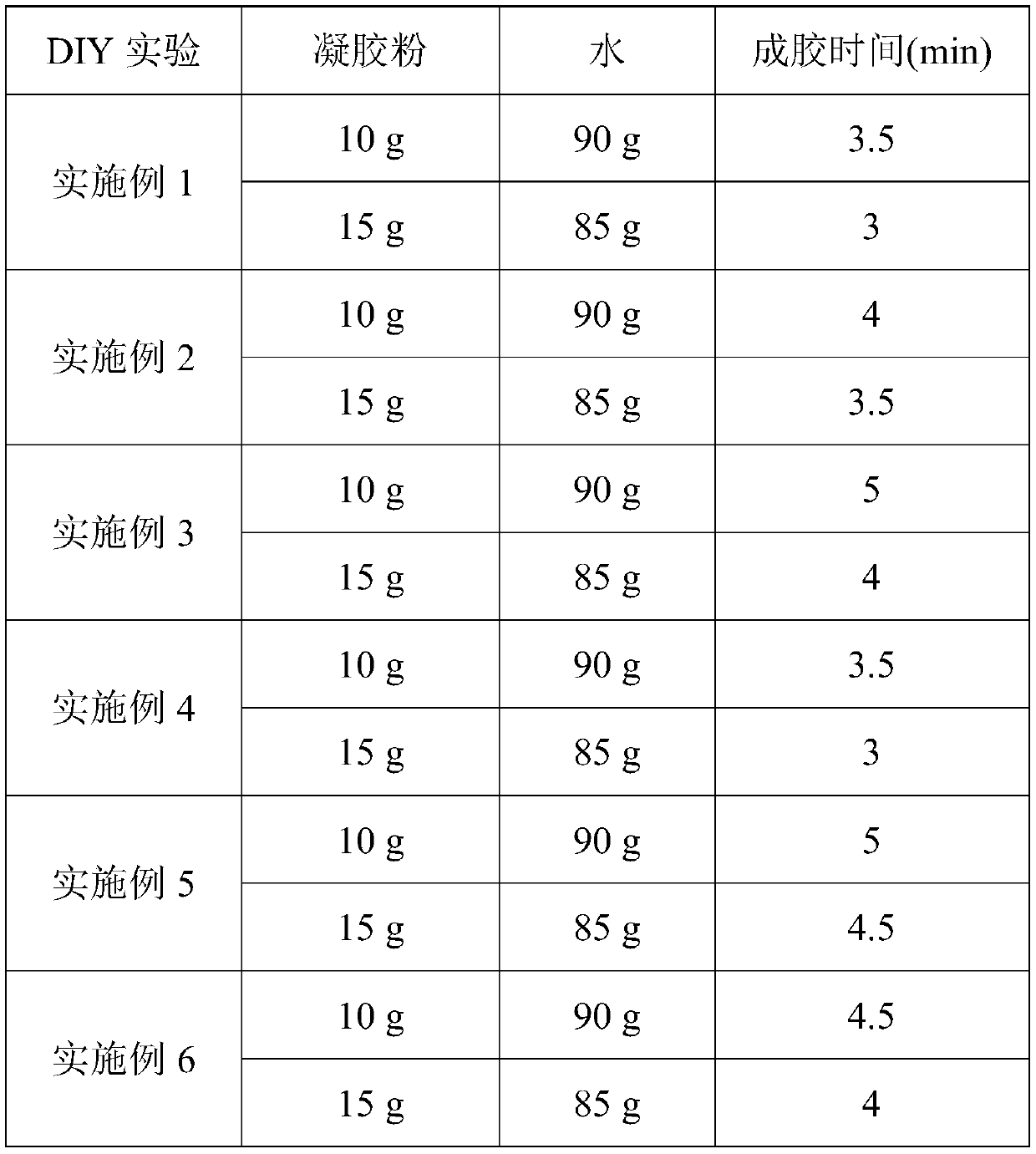

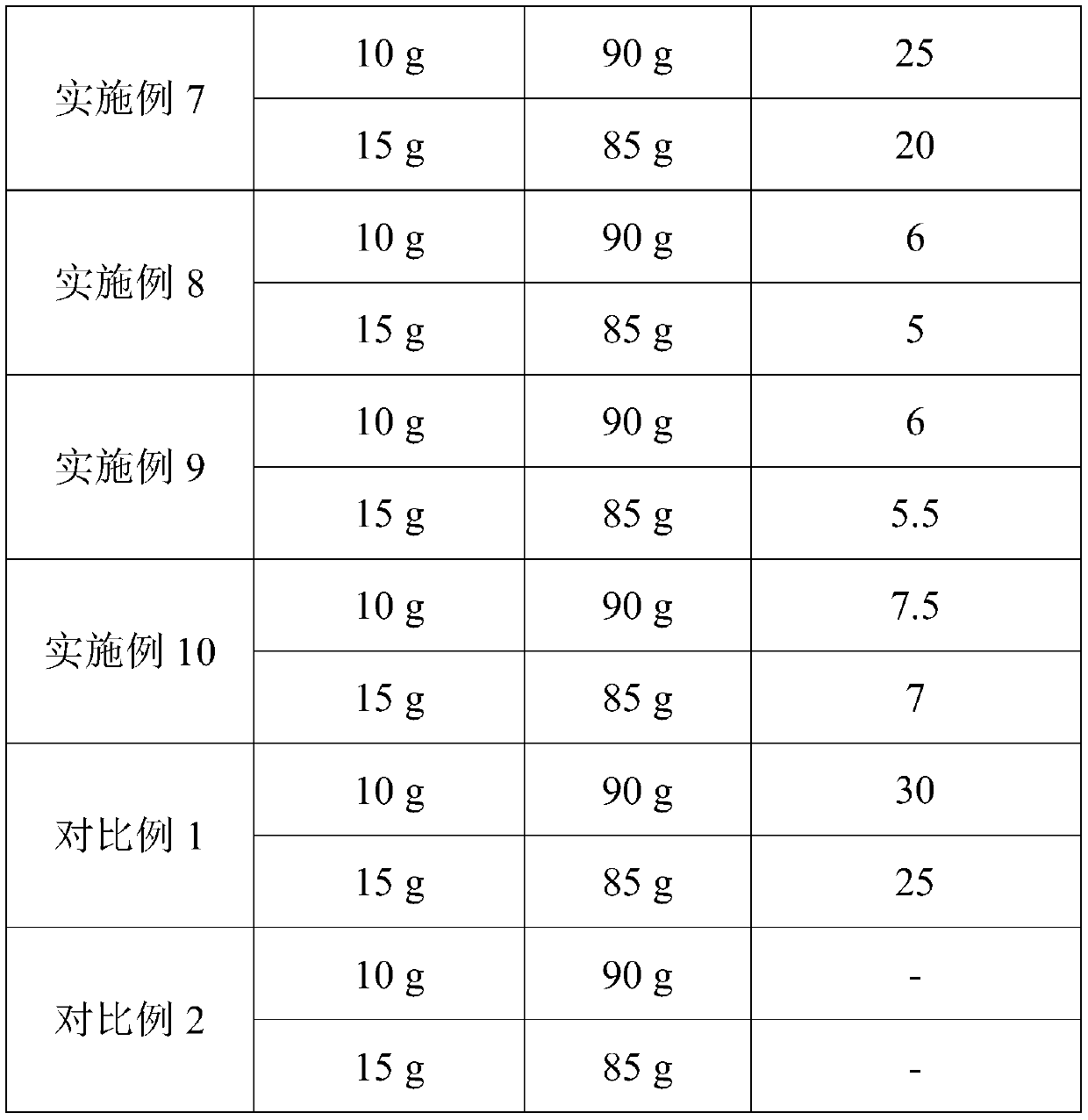

Gel powder composition as well as preparation method and application thereof

The invention provides a gel powder composition as well as a preparation method and an application thereof. The gel powder composition is prepared from the following raw materials: tamarind gum, guargum, a gelatinizing agent, agar and water. According to the gel powder composition, tamarind gum is creatively used as a main material, guar gum is used as an auxiliary material, and a gelatinizing agent, agar and water are matched, so that the gel powder composition is prepared. The gel powder composition is prepared by compounding the two gels, so that the gelling strength and speed can be considered; in addition, the gel powder composition does not contain heavy metal elements, is non-toxic and non-irritant to skin and eyes, and is more environment-friendly and safer to use. The gel powdercomposition and water are simply mixed to obtain the DIY gel toy with any shape or any combination, so that the DIY gel toy is simple and easy to operate, and the interestingness and dexterity of thegel toy are improved.

Owner:南通昕源生物科技有限公司

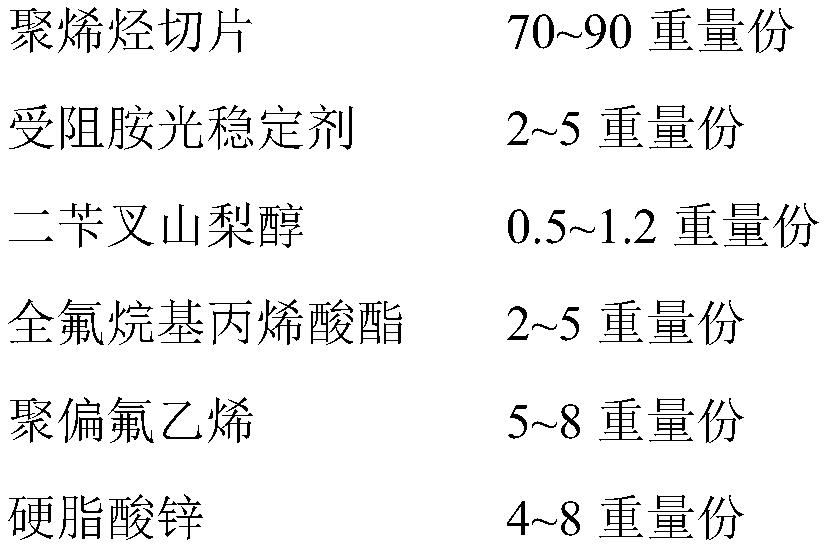

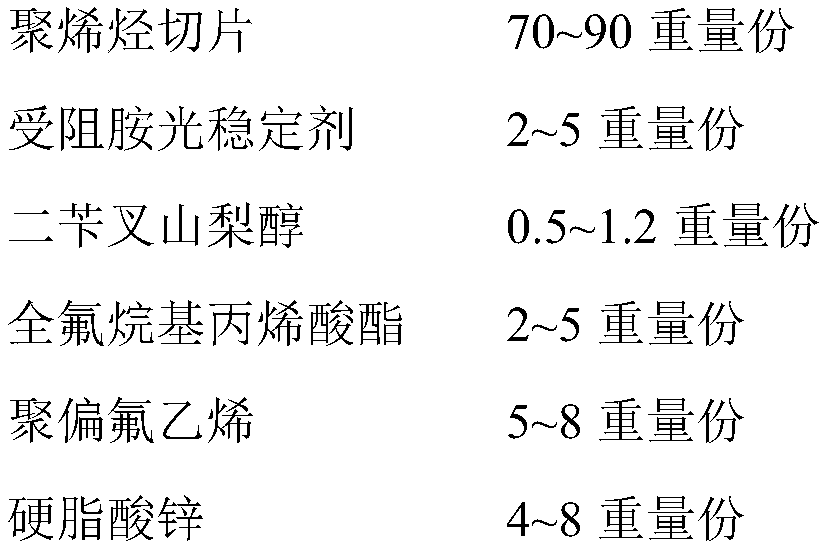

Spunbond filament electrostatic skeleton filtering material and preparation method and application thereof

InactiveCN111334935ASimple manufacturing processGood for direct discountsFibre typesFilament/thread formingPolymer scienceMelt spinning

The present invention provides a spunbond filament electrostatic skeleton filtering material and a preparation method and application thereof. The preparation method comprises the following steps of 1) melt spinning, wherein a component A and a component B are subjected to melt spinning to form continuous double-component composite filaments with skin-core structures, the component A and / or the component B contains high polymers and functional mediums with the electricity storage functions, and the high polymers in the component A and the component B are two types of fiber-forming polymers with different melting point temperatures; 2) web forming, wherein the continuous double-component composite filaments with the skin-core structures are split to form a web; 3) reinforcement forming, wherein a non-woven material is formed by hot air melt bonding; and 4) high-voltage electrostatic treatment, wherein the non-woven material is charged. The filtering material has double filtering functions of physical blockage and electrostatic adsorption, and can directly folded, the filtering efficiency can reach the level H11, and the filtering resistance is lower than 10 Pa.

Owner:上海精发实业有限公司

Heat treatment process of high-strength wear-resistant Al-Si-Cu alloy

The invention belongs to the technical field of nonferrous material manufacturing, and particularly relates to a heat treatment process of high-strength wear-resistant Al-Si-Cu alloy. Through introducing intermediate cold deformation and warm water quenching, and through primary high-temperature processing and two times of annealing processing, a second phase in the alloy is uniformly dispersed and precipitated so as to fully play a role in reinforcement, the quench-cracking tendency of the alloy is effectively inhibited, and the alloy keeps better toughness. The Al-Si-Cu alloy extruded product obtained through treating by utilizing the heat treatment process provided by the invention has the room temperature tensile strength achieving 501MPa or above, the elongation achieving not less than 5 percent, and the average crystallite size achieving 0.020 to 0.035mm, and has an excellent wear-resisting property. Meanwhile, the heat treatment process provided by the invention can be applied in silicon aluminum alloy with the total content of alloy elements achieving not less than 18 weight percent.

Owner:内蒙古蒙东高新集团有限公司 +1

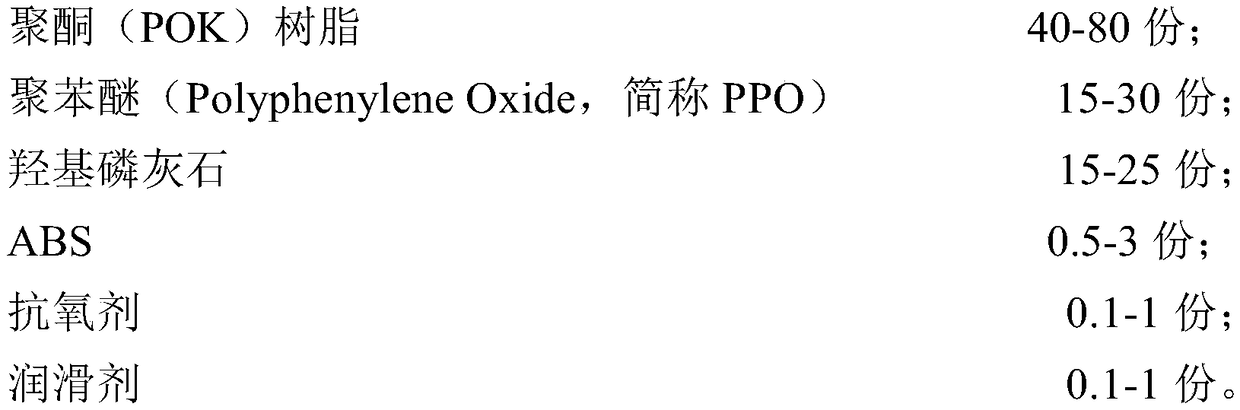

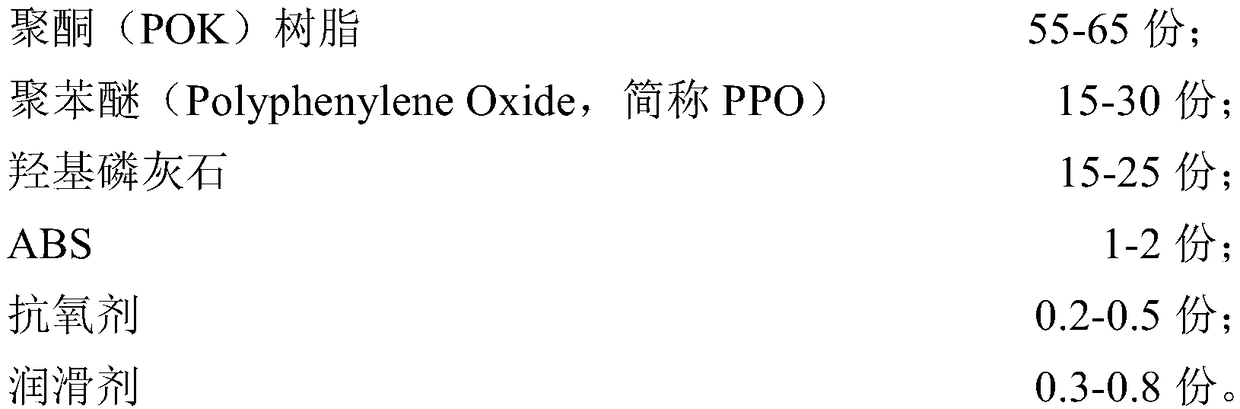

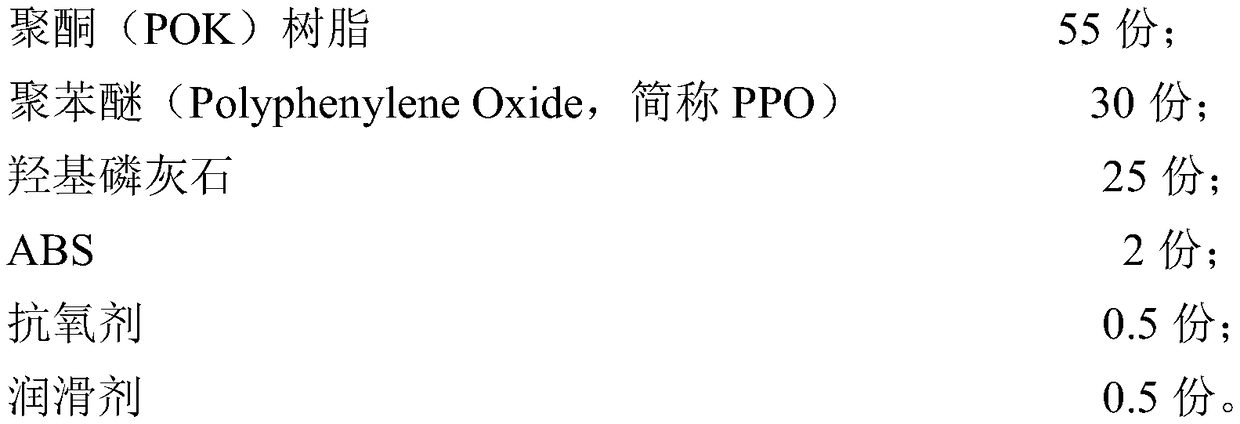

High glowing filament ignition temperature high-strength polyketone composite material and preparation method and application thereof

The invention discloses a high glowing filament ignition temperature high-strength polyketone composite material and a preparation method and an application thereof in preparing electronic components.The material is composed of the following materials by weight: 40-80 parts of polyketone resin; 15-30 parts of phenyl ether (PPO); 15-25 parts of hydroxyapatite; 0.5-3 parts of ABS; 0.1-1 part of antioxidant; 0.1-1 part of lubricant. The material is prepared by twin-screw mixing and extrusion. The material has excellent mechanical properties and good toughness and strength. At the same time, thematerial meets the ignition temperature of 750 Deg C or above, and the vertical burning UL-94 V-0 grade, is suitable for internal structural parts of electronics and appliances and particularly suitable for the preparation of electronic components.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

Fan impeller

The invention discloses a fan impeller, which comprises a hub, an annular rear disk connected to the periphery of the bottom part of the hub, a plurality of blades with the bottom edges fixed on the upper surface of the rear disk, and an annular front disk connected with the top edges of the blades, wherein a cone-ring-shaped conical stiffener is arranged between the outer wall of the hub and the upper surface of the rear disk, the blades are divided into short extended blades and long extended blades according to extended distance from the bottom edges of the blades to the hub, and the same number of short extended blades are arranged between any two adjacent long extended blades. The fan impeller has the beneficial effects that: the cone-ring-shaped conical stiffener is arranged between the outer wall of the hub and the upper surface of the rear disk, so that the strength of the rear disk is further enhanced, and the high-speed rotation of the fan impeller is ensured at high temperature without deformation. In addition, the blades with different lengths are adopted on the radial direction of the rear disk, so that both the strength and the ventilation performance of the fan impeller are taken into consideration.

Owner:TIANJIN CHANGGUANG WEIYE SPECIAL FAN

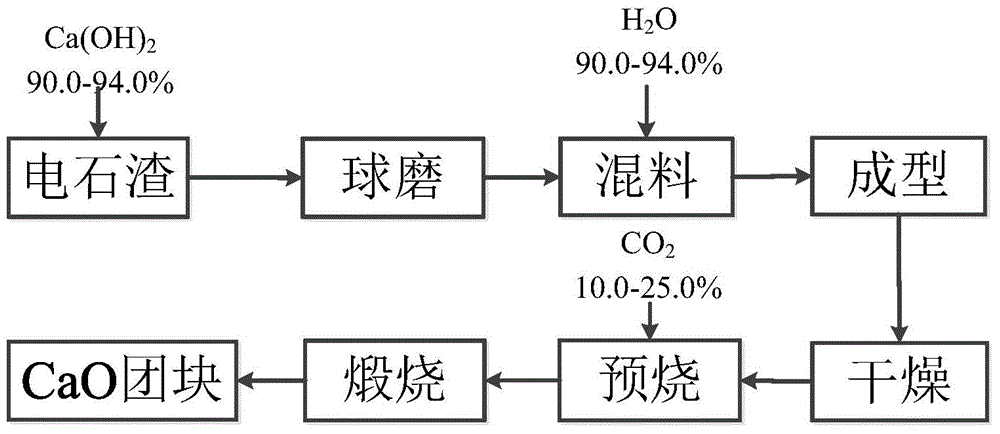

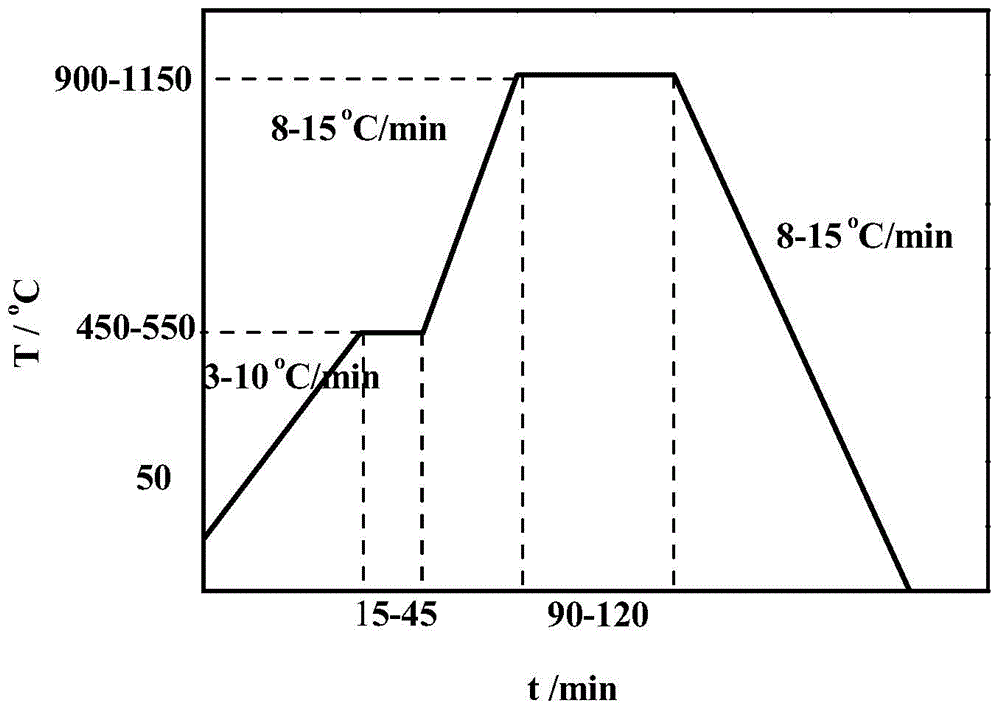

High-thermal-shock-resistance calcium oxide pellet and preparation method thereof

InactiveCN103951290ASimple operation processMature equipmentSolid waste disposalRotary kilnAtmosphere

The invention discloses a high-thermal-shock-resistance calcium oxide pellet and a preparation method thereof. The preparation method comprises the following steps: ball-milling carbide slag powder with 91.0-94.0% of Ca(OH)2 until the particle size is 60.0-150.0 mu m; adding 5.0-15.0% of H2O as a binder into the ball-milled powder, and uniformly mixing the obtained product; carrying out compression molding on the uniformly mixed powder at a molding pressure of 100.0-350.0 kgf / cm<2>, and then carrying out pressure maintaining for 0.5-3.0 min; drying the obtained product for 10.0-24.0 h; calcining the dried blank to 450.0-650.0 DEG C under an atmosphere with a CO2 concentration of 10.0-25.0%, and maintaining a constant temperature for 15.0-45.0 min; and calcining the obtained product for 90.0-120.0 min at a temperature of 900.0-1150.0 DEG C, and then carrying out furnace cooling. The strength of the calcium oxide pellet prepared according to the invention is reduced by 6.0-25.0% under the conditions that the difference between the temperature of the calcium oxide pellet and the room temperature is 500.0-1100.0 DEG C and the number of hot and cold cycles is 5.0-10.0. The method disclosed by the invention improves the thermal shock resistance of calcium oxide pellets in two stages of an application process; after being calcining in a rotary kiln, the calcium oxide pellet is subjected to quick cooling impact from 1100-1200 DEG C to 100-200 DEG C; and when being put into a calcium carbide furnace, the calcium oxide pellet is subjected to quick heating impact at a temperature of 1000.0 DEG C. Meanwhile, according to the invention, carbide slag is efficiently dealt, therefore, high environmental and economic benefits are obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

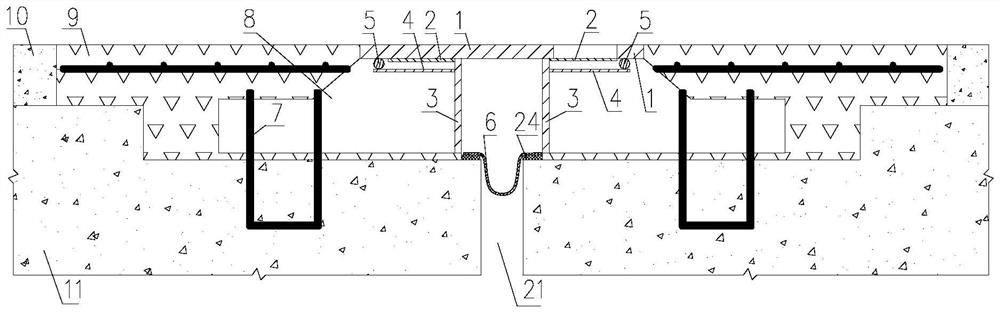

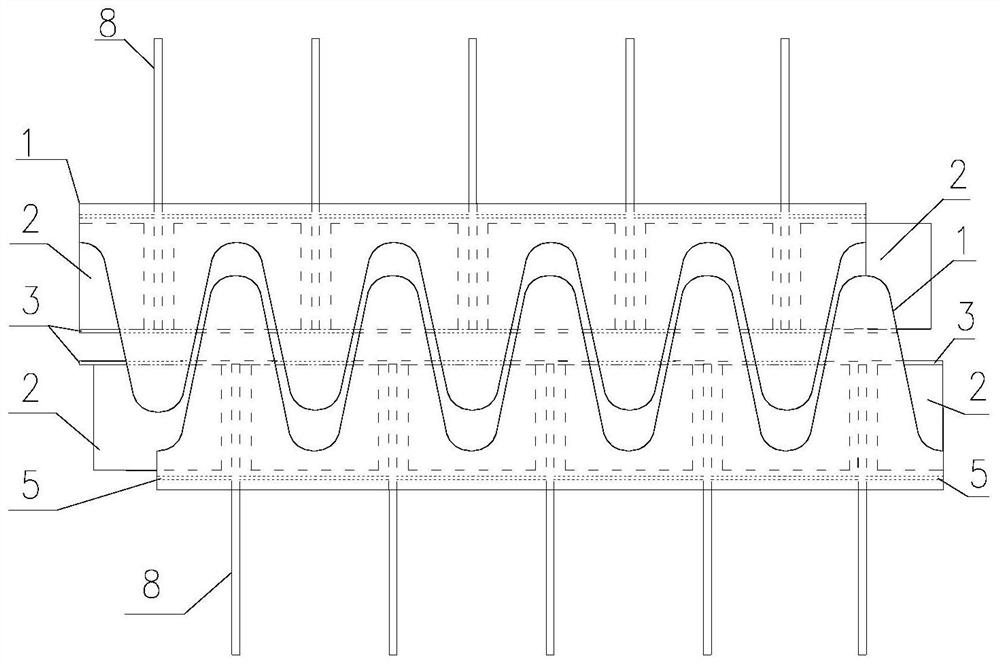

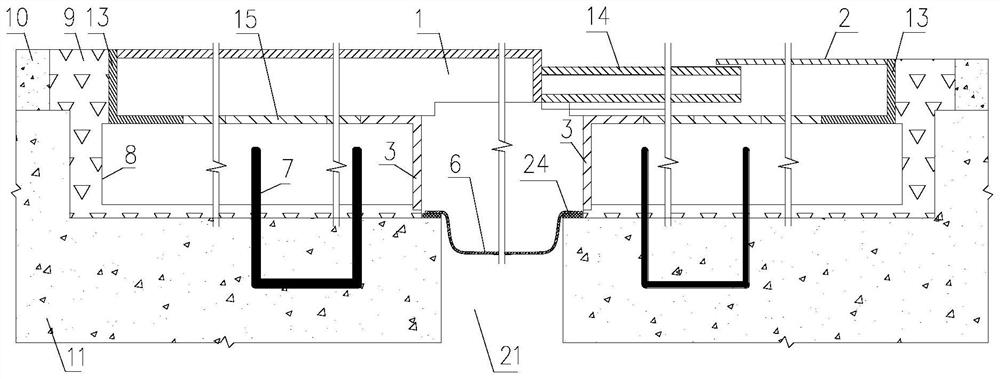

Anti-clamping cross-seam comb-tooth type bridge expansion device

PendingCN113931063ASolve the card stoneSolve the stuck wheel problemBridge structural detailsShaped beamTooth length

The invention discloses an anti-clamping cross-seam comb-tooth type bridge expansion device, and solves a problem that wheels and stones are clamped by deep and long potholes of a traditional large comb-tooth type bridge expansion device. The fixed tooth pit slot filling and lifting method comprises steps that the tooth length is increased in the post-cast strip direction of the telescopic device, pit slots with certain lengths of adjacent teeth are covered, inter-tooth cavities with certain lengths corresponding to the models are formed, inter-tooth bearing beams with the corresponding lengths are vertically and movably connected to the corresponding tooth ends, the bearing beams have enough strength, during use, the size of the top surface of the full-pit slot long inner bearing beam is only about 15mm lower than that of the tooth top. According to comb tooth beam seam bolt side pit slot filling and lifting, two steel plates are welded to the movable tooth side through the I-shaped cross section of a fixed tooth side tooth beam, and a 20-25 mm gap needed by stretching and retracting of a fixed tooth I-shaped beam web is reserved. After treatment, a top surface of a pit slot on the movable tooth side is about 20mm lower than the road surface, so the conditions of wheel clamping and stone clamping are avoided.

Owner:湖北恋桥交通工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com