Patents

Literature

152results about How to "Smooth inhalation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

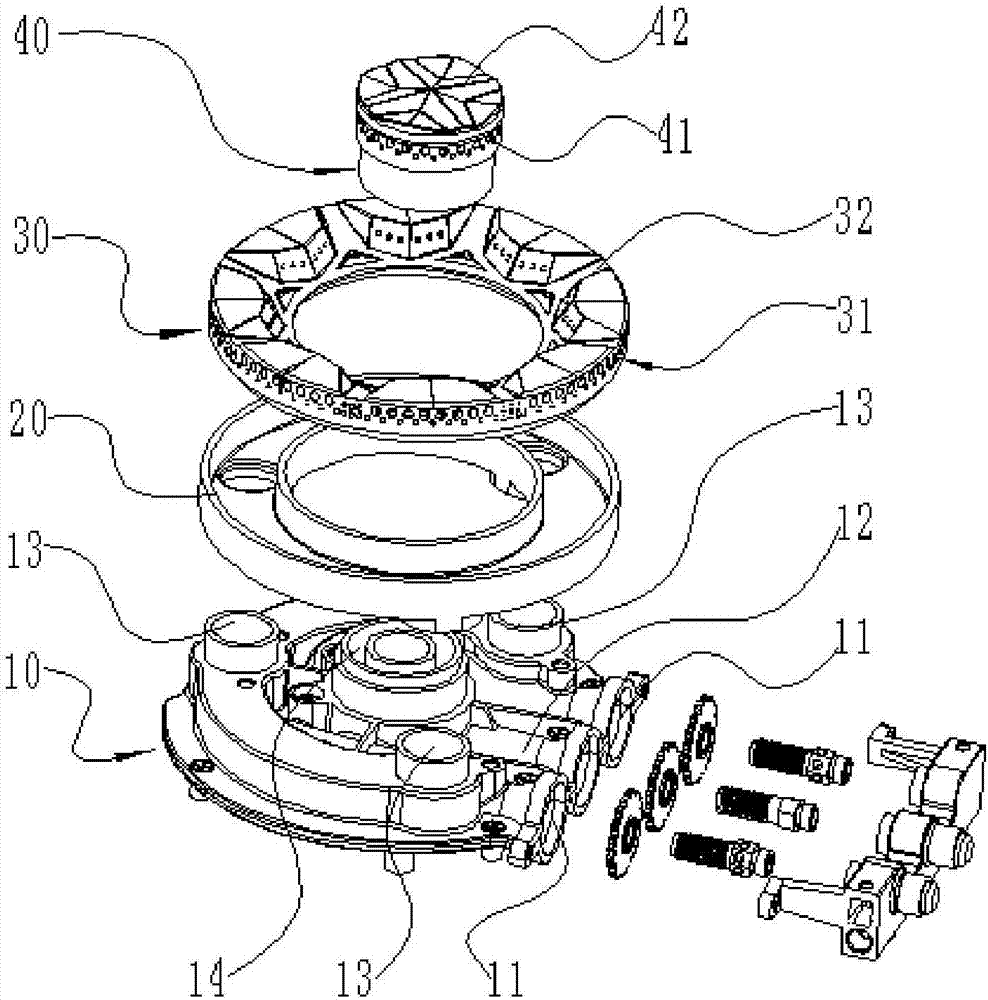

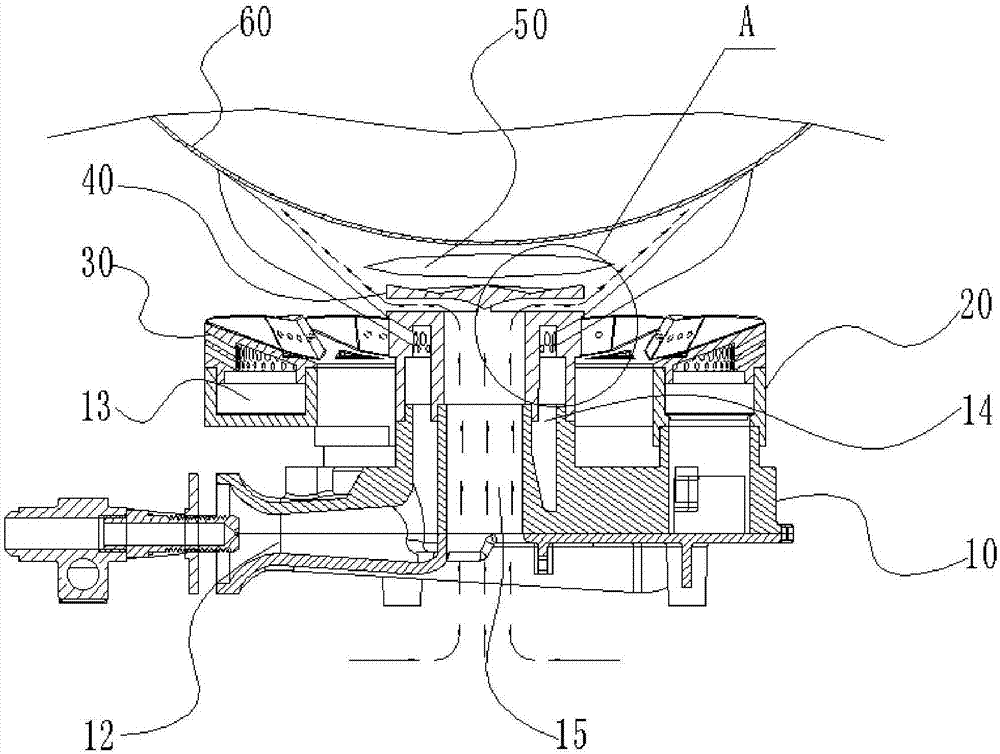

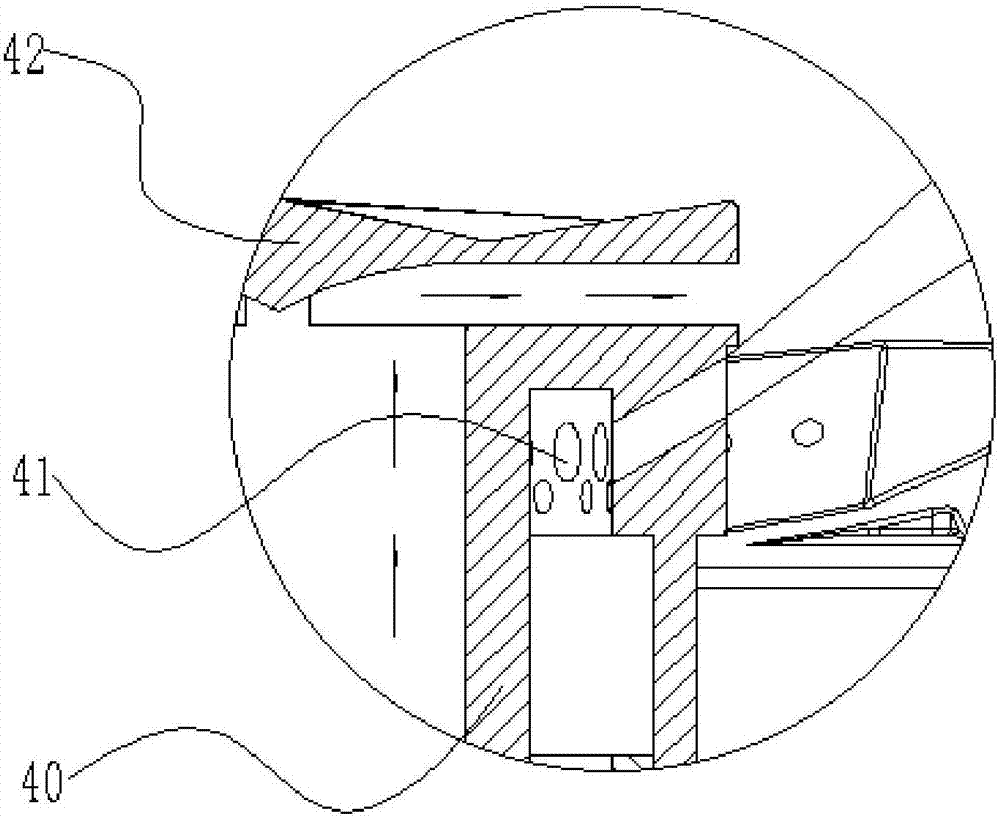

Combustor and gas stove

PendingCN107461741AImprove thermal efficiencyHigh thermal efficiencyGaseous fuel burnerMechanical engineeringGas cooking stove

The invention relates to a combustor and a gas stove, relates to the technical field of stoves, and is designed for solving the problems that an existing combustor is not full in combustion and low in thermal efficiency, and a pot frame is high. The combustor comprises an inner ring oxygen supplementing channel, wherein the inner ring oxygen supplementing channel is formed in an inner ring gas outlet; and the lower end of the inner ring oxygen supplementing channel communicates with an external environment. When the combustor works, the air in the external environment enters the inner ring oxygen supplementing channel, and flows into a region surrounded by a pot bottom and inner ring flame via an inner ring fire cover. The combustor is provided with at least one outer ring ejection tube and a plurality of outer ring gas outlets. The gas stove comprises a stove panel, a pot frame and the combustor. The combustor and the gas stove are used for heating a pot efficiently.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

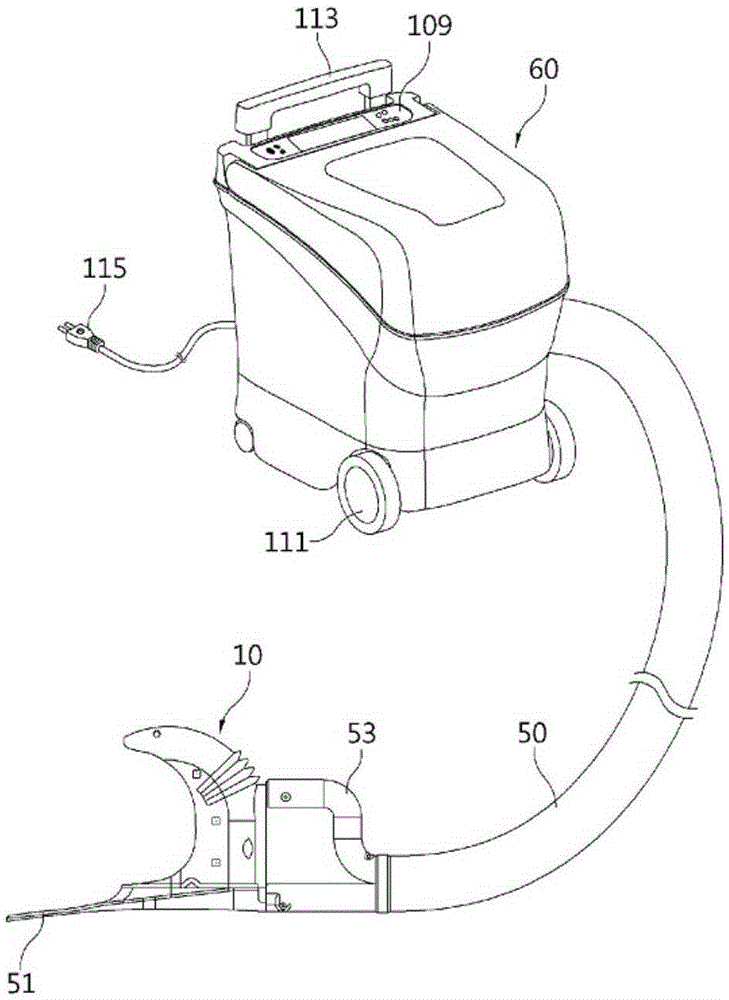

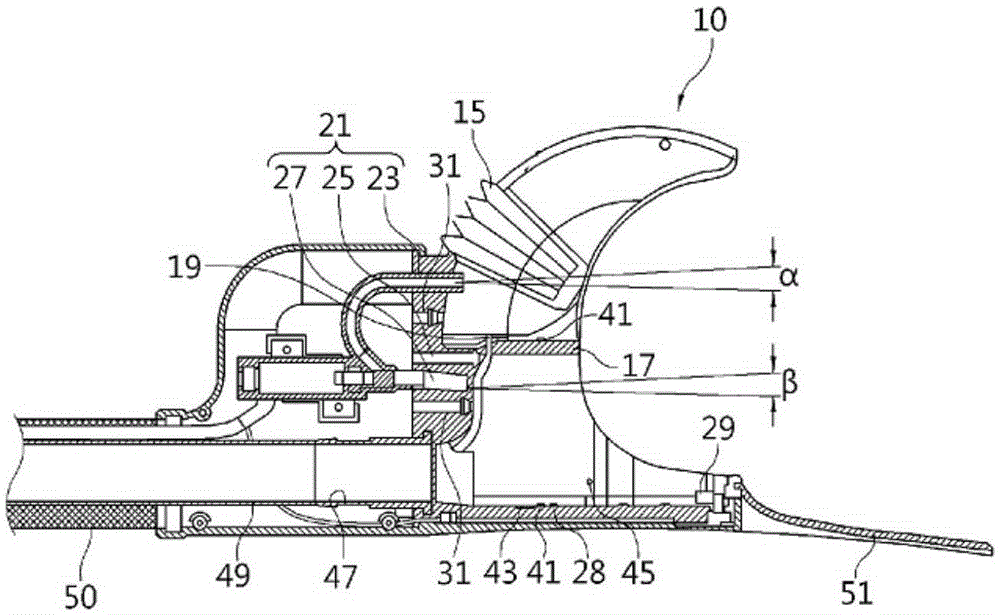

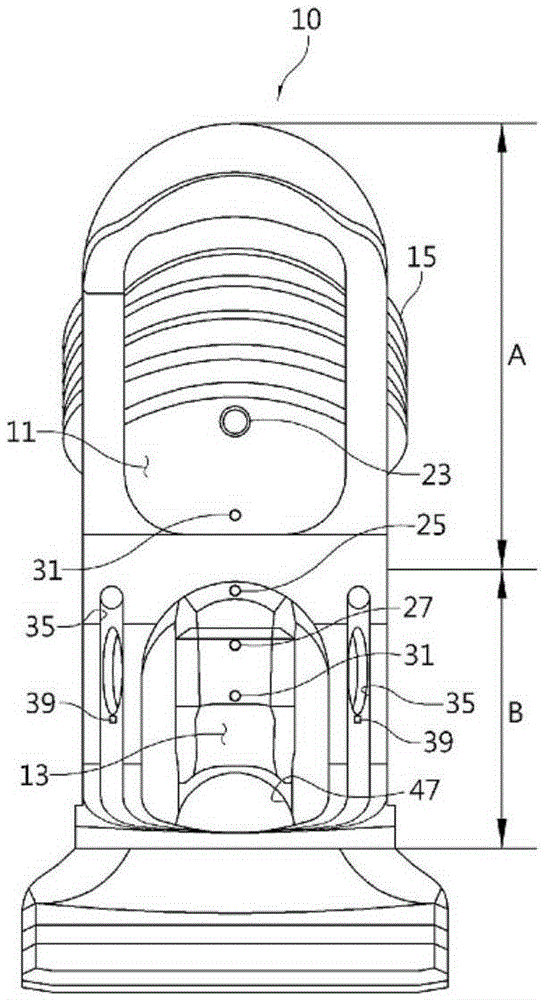

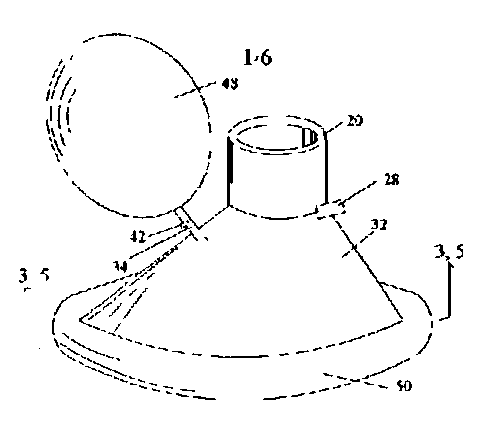

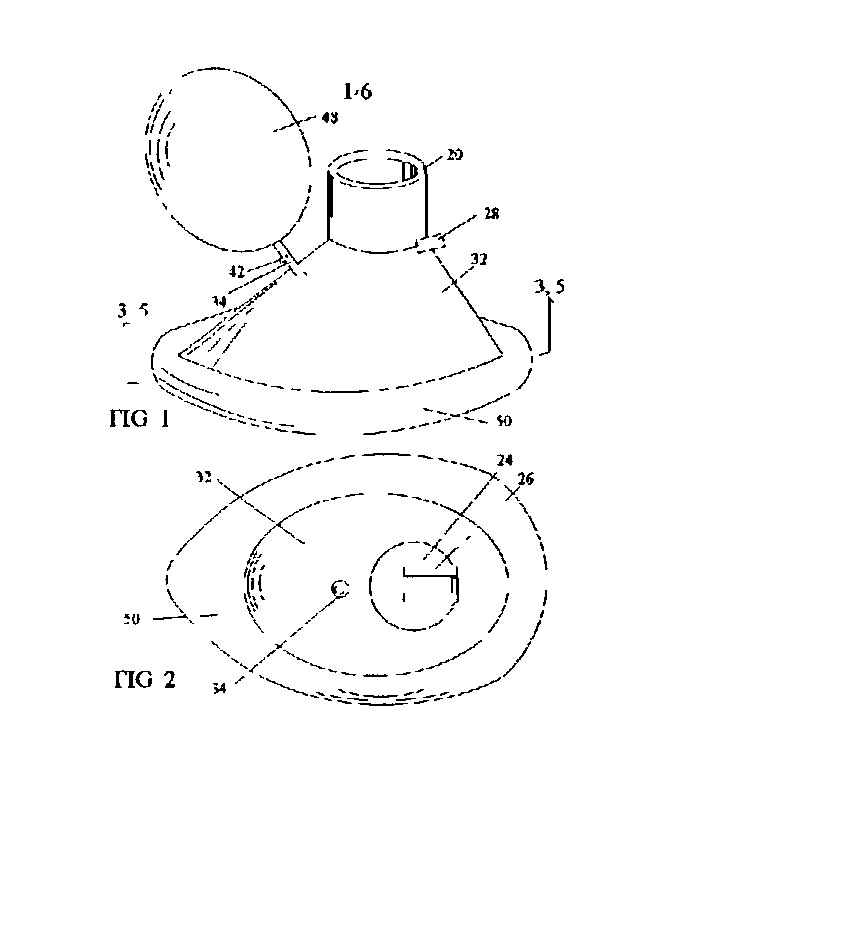

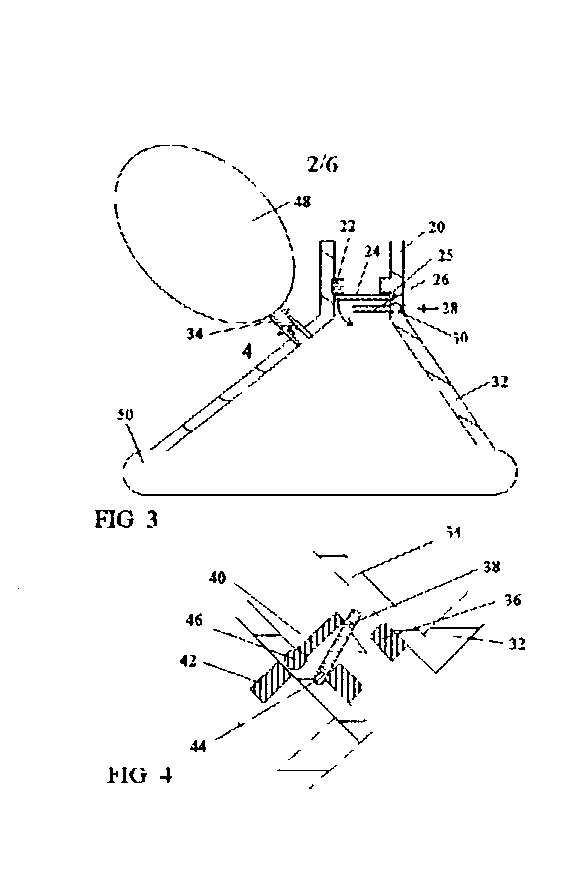

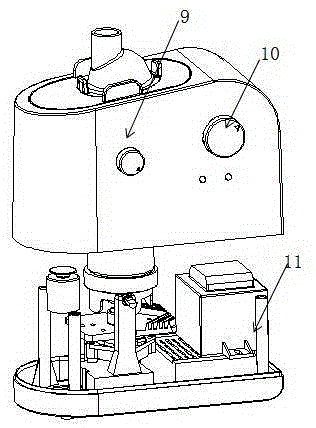

Automatic excrement processing device

The present invention relates to an automatic excrement processing device comprising: a cup unit (10) worn on a portion of a user at which the excretory organs are located, and forming a space (11) in which urine is suctioned that is partitioned from a space (13) in which feces is suctioned; an excrement processing main body (60) connected to the cup unit (10) and suctioning excrement discharged into the cup unit (10) and storing same; a sensor unit provided on the cup unit (10), connected to the excrement processing main body (60), and sensing excrement; a washing nozzle unit (21) performing a washing function; a suctioning nozzle unit (49) suctioning excrement; and a drying nozzle unit (31) performing a drying function. The present invention has the advantages that the device provides a good feeling when worn, and clean excrement processing is possible through accurate sensing of excrement.

Owner:ANGELWINGS

Oil fume absorbing and noise reducing device of range hood

ActiveCN104180412APrevent outward spreadReduce noiseDomestic stoves or rangesLighting and heating apparatusEngineeringTurbine

The invention discloses an oil fume absorbing and noise reducing device of a range hood. The device comprises a volute fixedly connected with a box body of the range hood, wherein a wind turbine and a motor driving the wind turbine to rotate are arranged in the volute, a sound absorbing member connected with the box body is arranged inside the wind turbine, the sound absorbing member comprises a sound absorbing shell which is provided with a shell cavity, a plurality of sound absorbing through holes communicated with the shell cavity are formed in the wall of the sound absorbing shell, and the shell cavity is filled with a sound absorbing material. The device is simple in structure and good in noise reducing effect.

Owner:VATTI CORP LTD

Respiratory appliances for pediatric inhalation induction

The present invention is a respiratory appliance (a face mask or a adaptor of a breathing circuit) with at least one toy, which is played by blowing. The respiratory appliance is used to connect to a breathing circuit and is suitable for pediatric inhalation induction of anesthesia. The respiratory appliance contains adjustable one way valves which control air flows for breathing in anesthetic agents and blowing the toy. Children can smoothly go to sleep when they play with the toy by blowing inside the mask.

Owner:ZHOU DR HENRY H

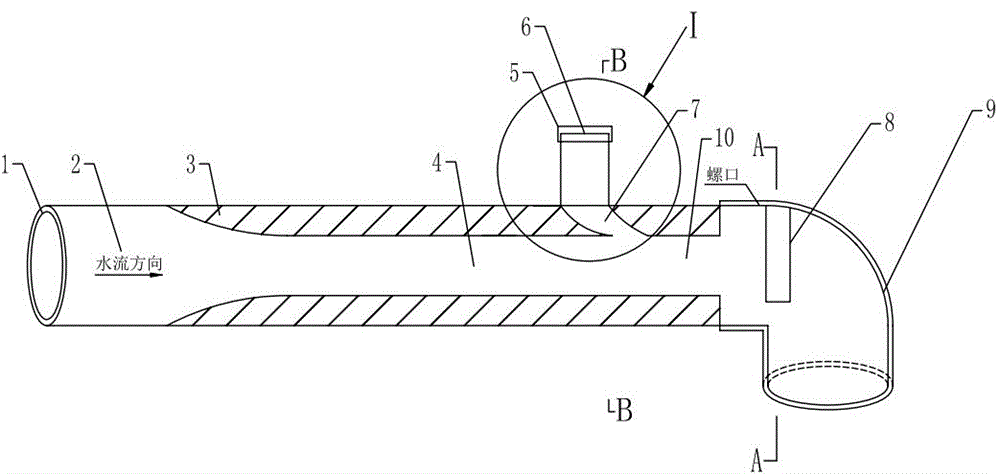

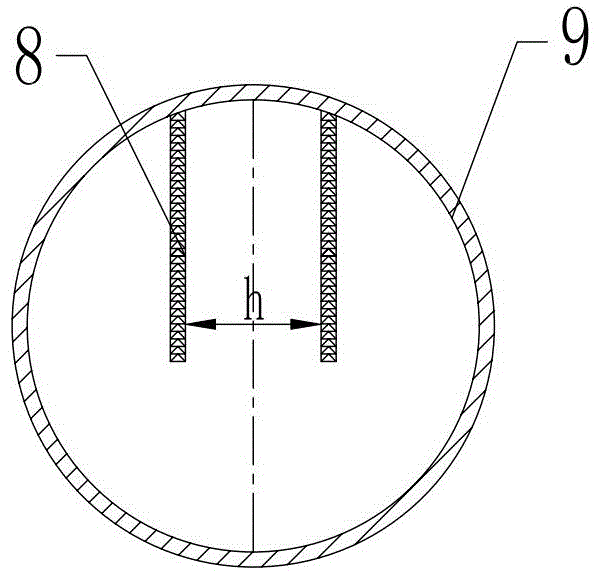

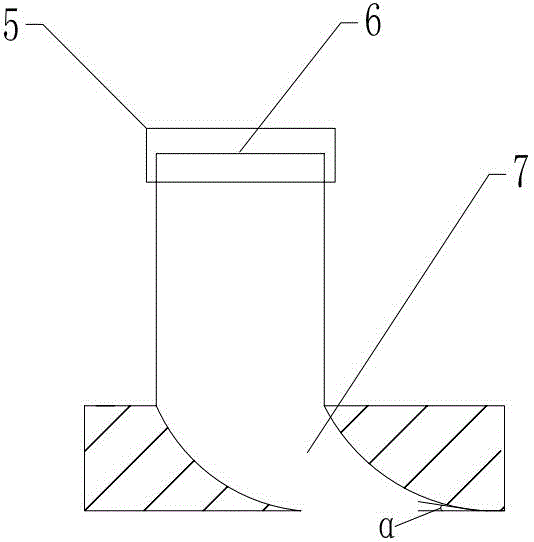

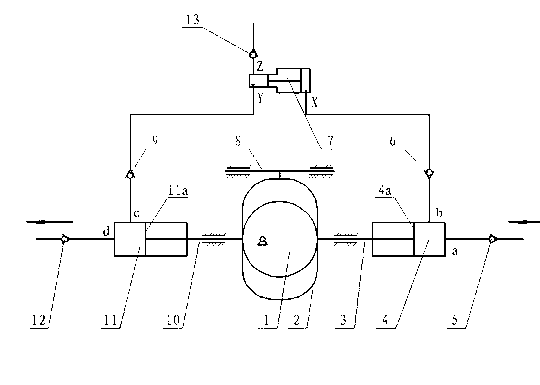

Self-pressed suction oxygen-aeration blow-off pipe

ActiveCN106186384AReasonable structureLow costWater treatment parameter controlTreatment using aerobic processesMicro bubbleEngineering

The invention relates to a self-pressed suction oxygen-aeration blow-off pipe which comprises a water inlet section (2), a contraction section (3), a throat tube (4), an air-entraining oxygen-aeration section (10) and a bend (9), wherein the bend (9) is connected to the tail end of the air-entraining oxygen-aeration section (10); an air suction cavity (7) of which the longitudinal section is arc-shaped is formed in the upper part, which is close to one end of the bend (9), of the throat tube (4); the cross sectional area of the air suction cavity (7) is gradually reduced from the exterior to the interior; an opening in the bottom of the air suction cavity (7) faces one side of a nozzle (10); the upper part of the air suction cavity (7) is connected with an air inlet tube (6); a vibrating plate (8) is fixed in the bend (9); and the vibrating plate (8) generates high-frequency vibration under water flow impact so as to break air bubbles, and the formed micro bubbles are dissolved in water so as to realize oxygen aeration. The self-pressed suction oxygen-aeration blow-off pipe is convenient to operate and maintain, low in construction cost and capable of stably and continuously increasing oxygen content in water, and has wide market prospects.

Owner:湖南省水利水电科学研究所

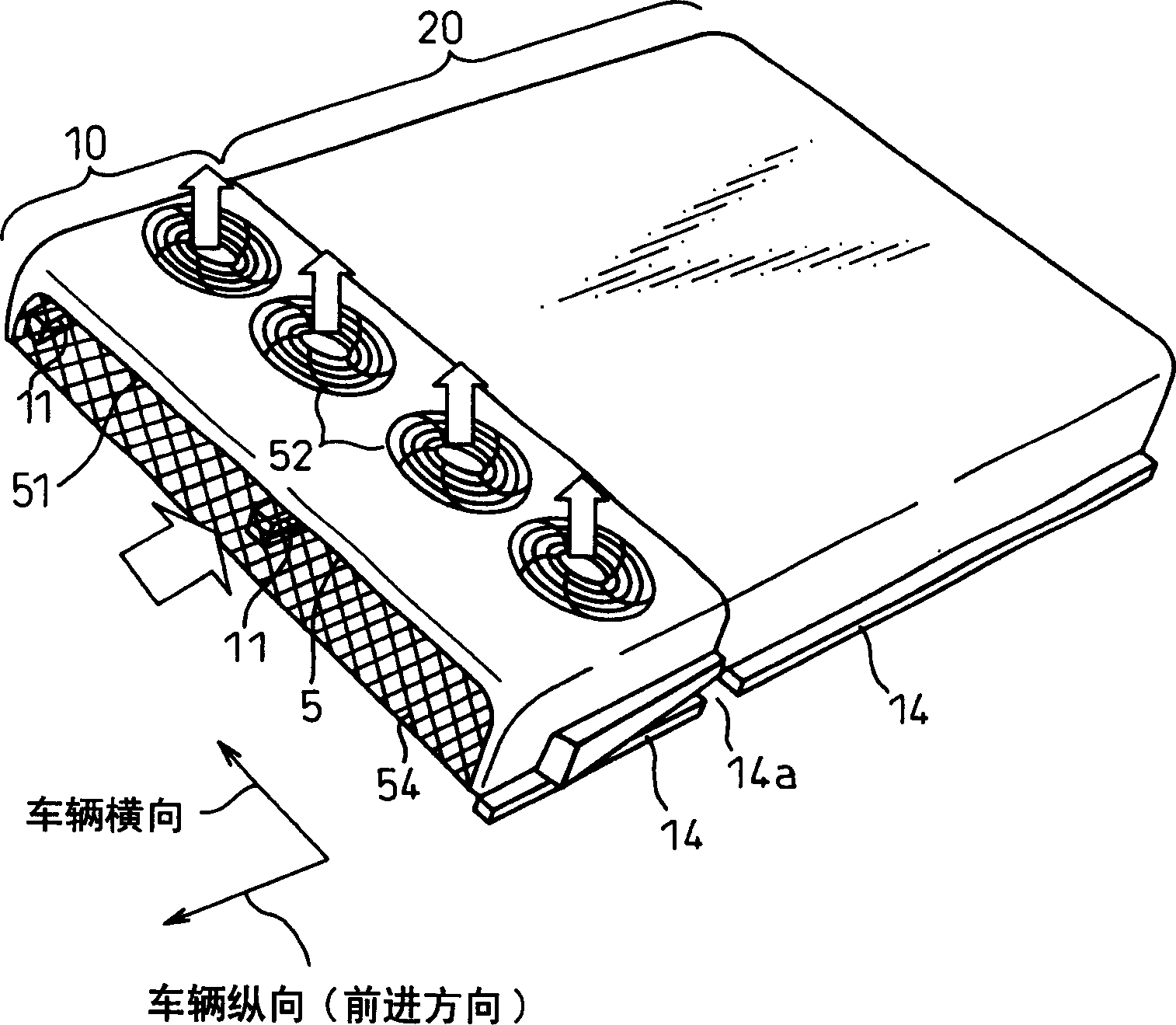

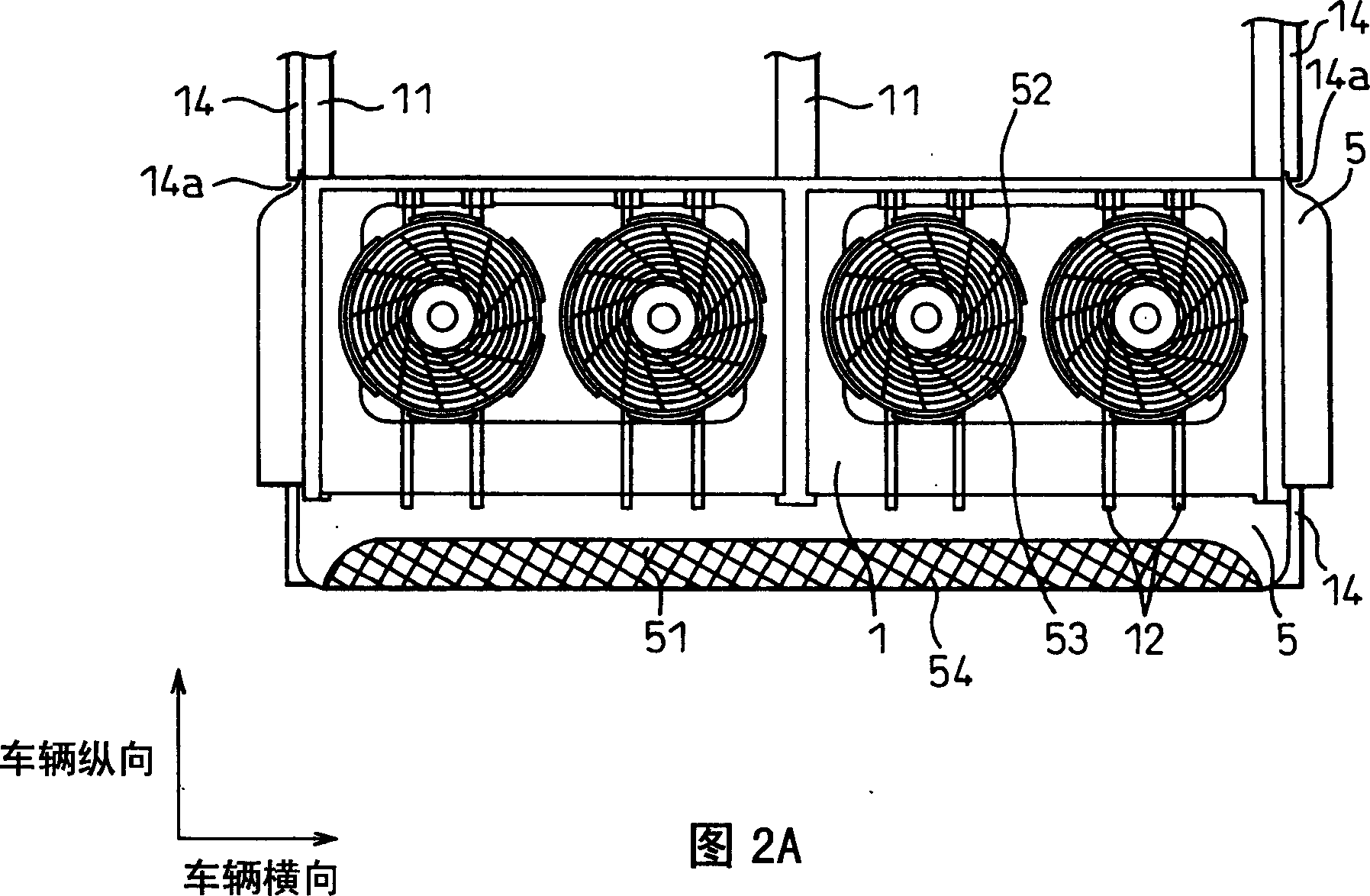

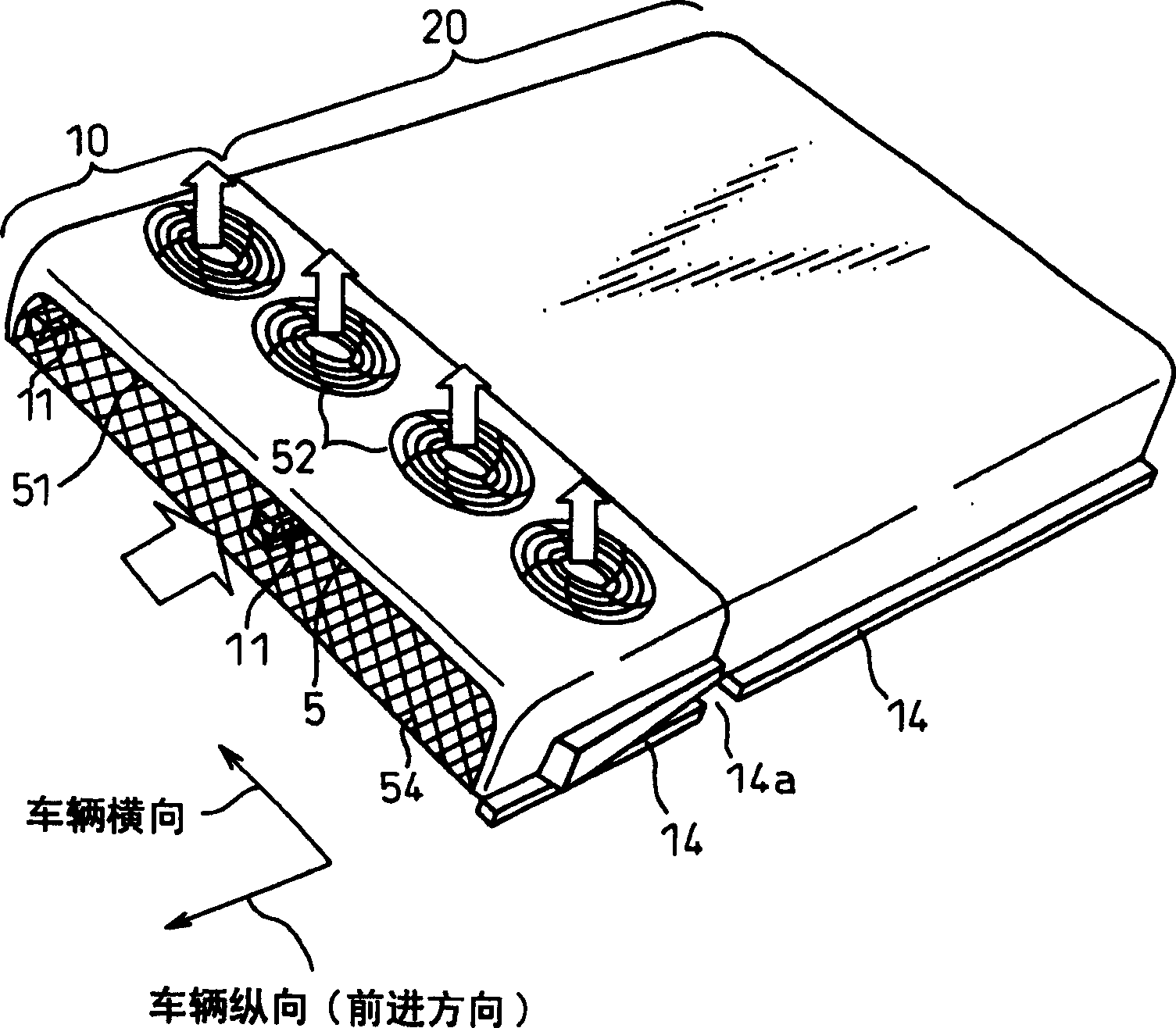

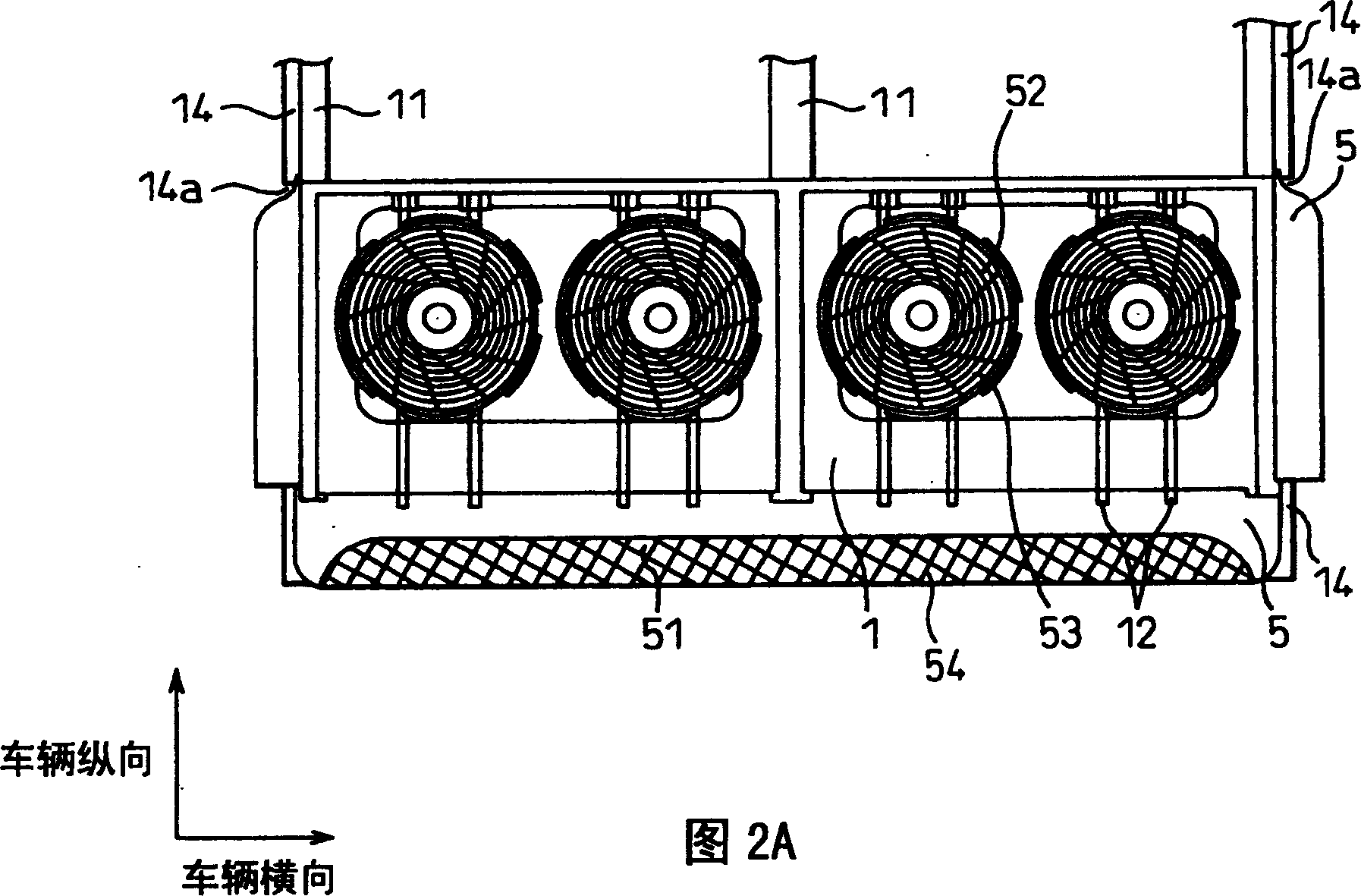

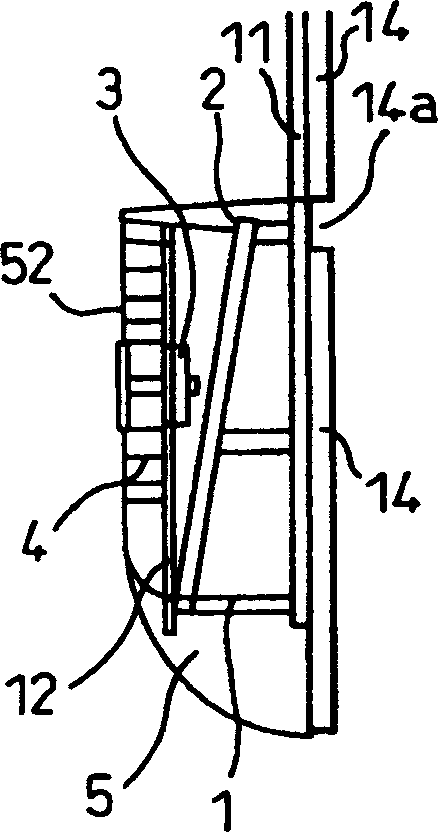

Air conditioning system for vehicle

InactiveCN1440888AReduce vertical sizeReduce discharge pressureAir-treating devicesVehicle heating/cooling devicesAir conditioningAutomotive air conditioning

In an automotive air conditioning system according to the present invention, a thin condenser 2 of a condensing unit portion 10 installed on a flat roof of a vehicle such as a bus is provided in such a manner as to be inclined downwardly from the front toward the rear of the vehicle, condenser fans 4 are provided directly above the condenser, and an air inlet 51 to the condenser is disposed in front of the condenser whereas air outlets 52 are disposed above the condenser.

Owner:DENSO CORP

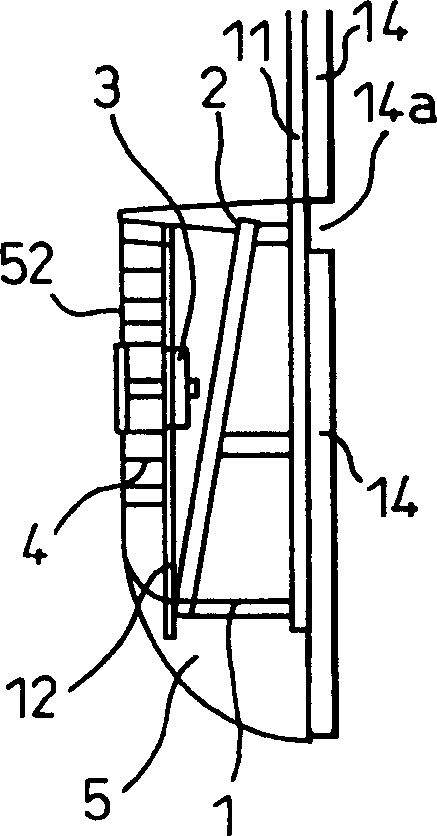

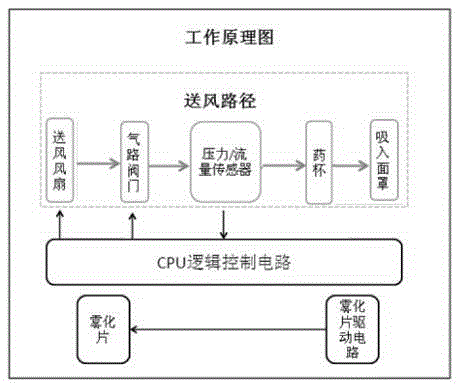

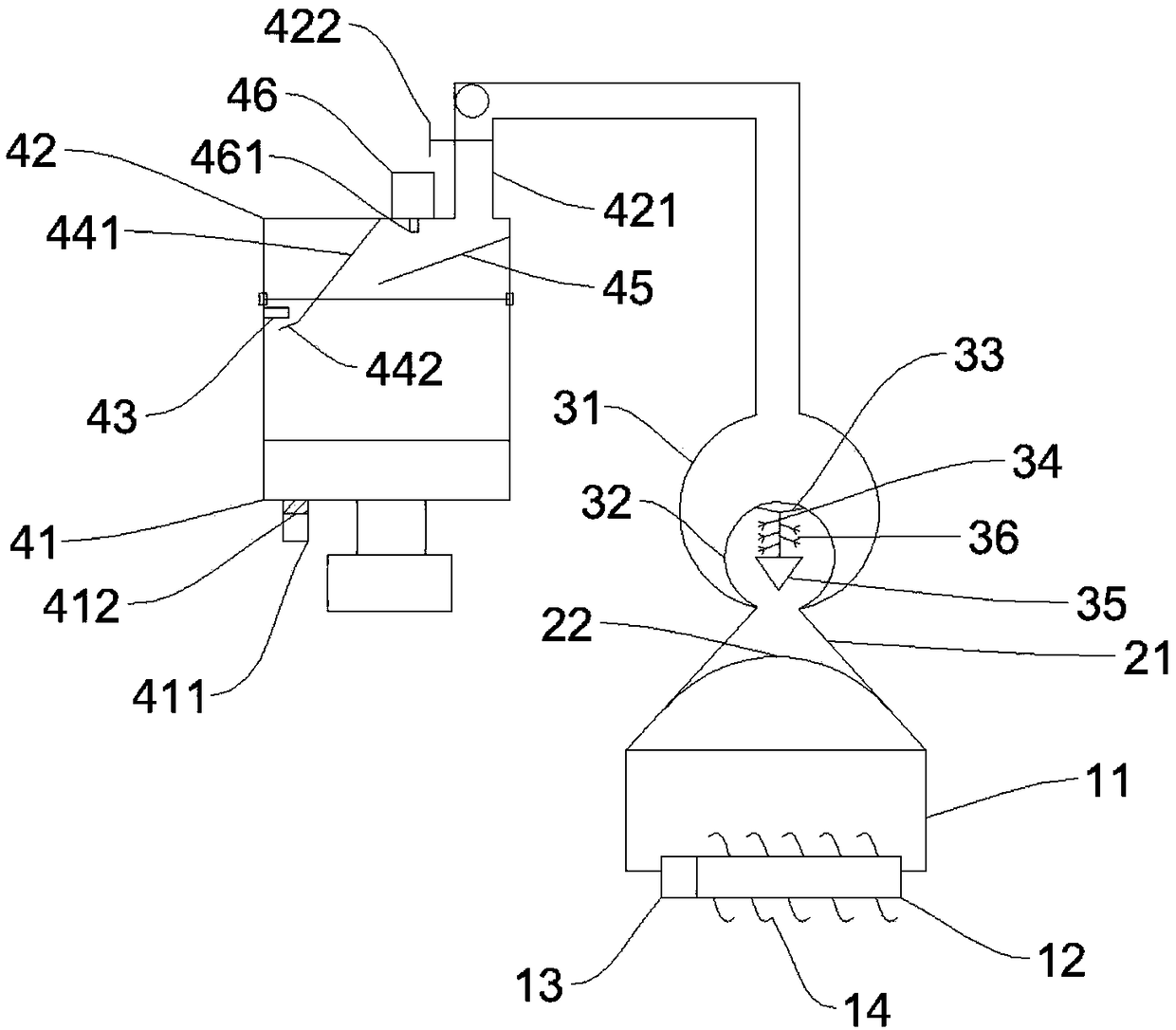

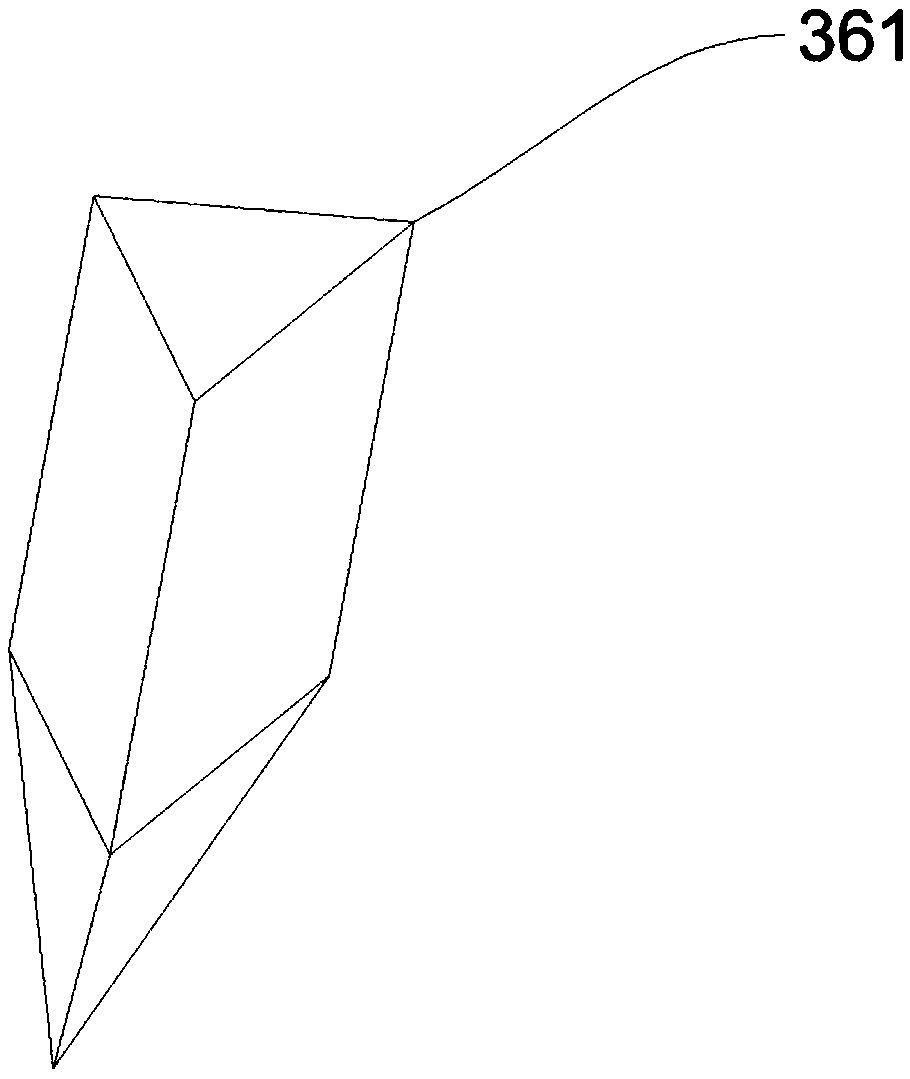

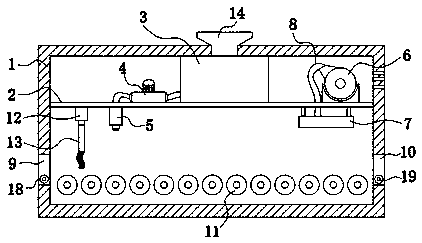

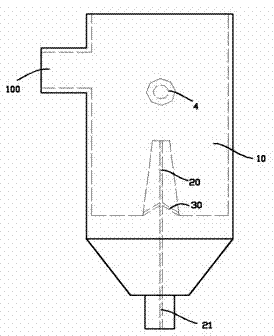

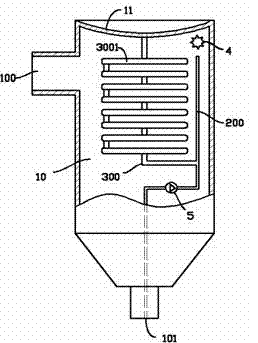

Intermittent air supply type medical ultrasonic nebulizer with inspiration induction

InactiveCN105396206AThe overall structure is ingeniously designedPracticalMedical devicesMedical atomisersBiomedical engineeringIntensive care medicine

The invention relates to an intermittent air supply type medical ultrasonic nebulizer with inspiration induction. The intermittent air supply type medical ultrasonic nebulizer is characterized in that the nebulizer comprises a nebulizer housing. A medicine glass, an air supply fan, a control valve and a CPU logic control circuit are arranged in the nebulizer housing. The nebulizer housing is connected with an inhalation mask through a pipe, and a pressure / flow sensor is arranged in the pipe led into the inhalation mask. According to the technical scheme of the nebulizer, the overall structural design is ingenious, and it is ensured that only a small amount of nebulization medicine liquid flows out of an exhaust port in the process that a user uses medical ultrasonic normally.

Owner:HONSUN NANTONG

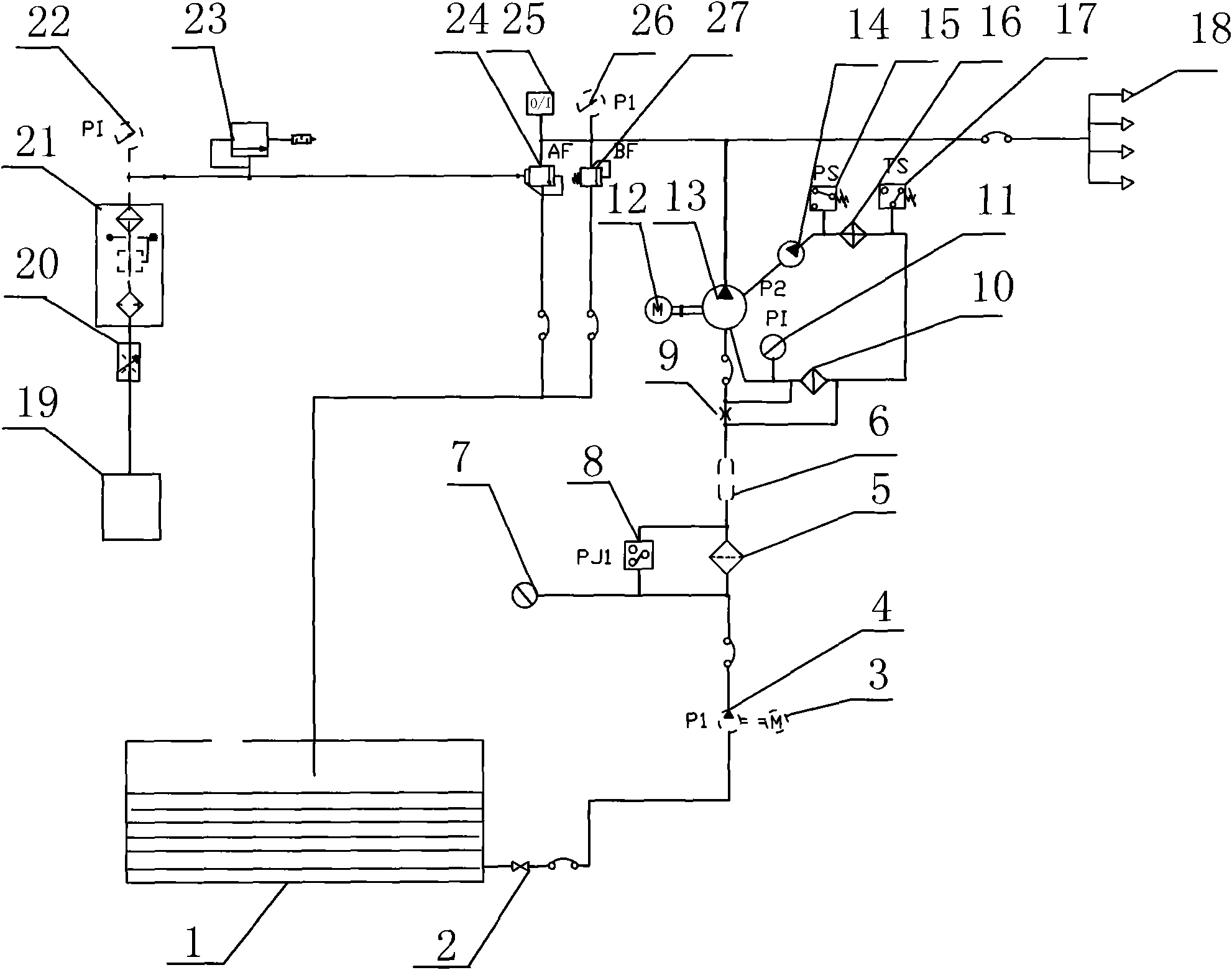

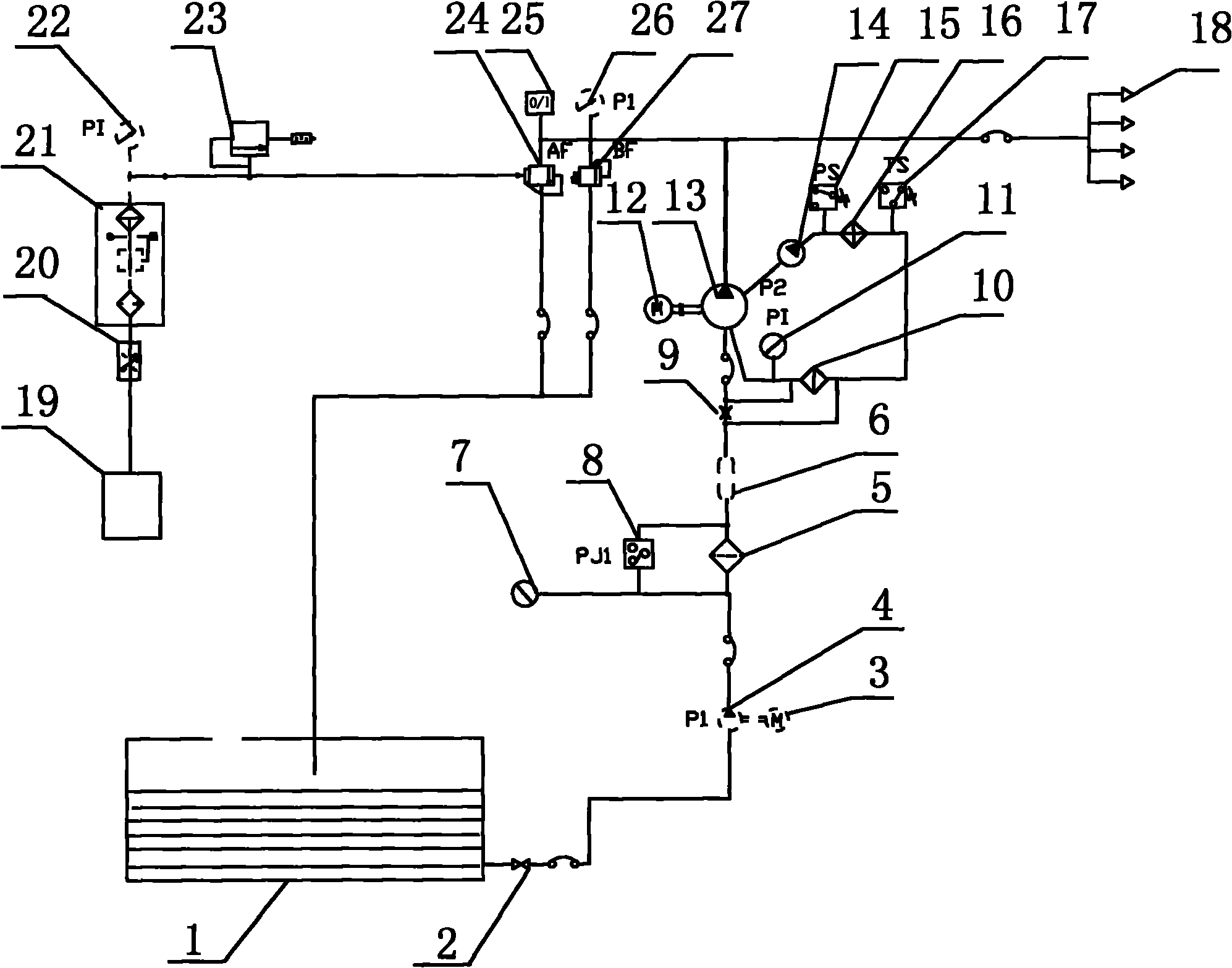

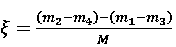

High-pressure water jet flow system for removing rust of ships and working method thereof

InactiveCN101875045ASolve delivery problemsHigh energy level densityCleaning using liquidsVolumetric Mass DensityHigh pressure water

The invention discloses a high-pressure water jet flow system for removing rust of ships and a working method thereof. The system of the invention comprises a low-pressure water pipeline, a super-high pressure water pipeline, a cooling pipeline and a pneumatic pipeline, wherein the super-high pressure water pipeline comprises a lubricating oil cooler of a super-high pressure pump, a cooling pressure gauge, an super-high pressure motor and the super-high pressure pump; one end of the lubricating oil cooler of the super-high pressure pump is also connected with the super-high pressure pump through the cooling pressure gauge; the other end is connected the super-high pressure pump sequentially through a cooling temperature relay, a cooling filter, a lubricating oil cooling pump and a cooling pressure relay; and a rust removing nozzle is installed at the output end of the super-high pressure pump. The method comprises the steps of sucking stable water flow to be converted into super-high pressure water and jetting the super-high pressure water out through the rust removing nozzle. In the invention, because the high pressure water with the pressure up to 250 MPa, which is generated by the super-high pressure pump, is directly used to be passed through a spray nozzle and the high-speed water flow with extreme high level density is jetted out, the rust removing effect is good and delivering abrasive materials is not needed.

Owner:DALIAN MARITIME UNIVERSITY

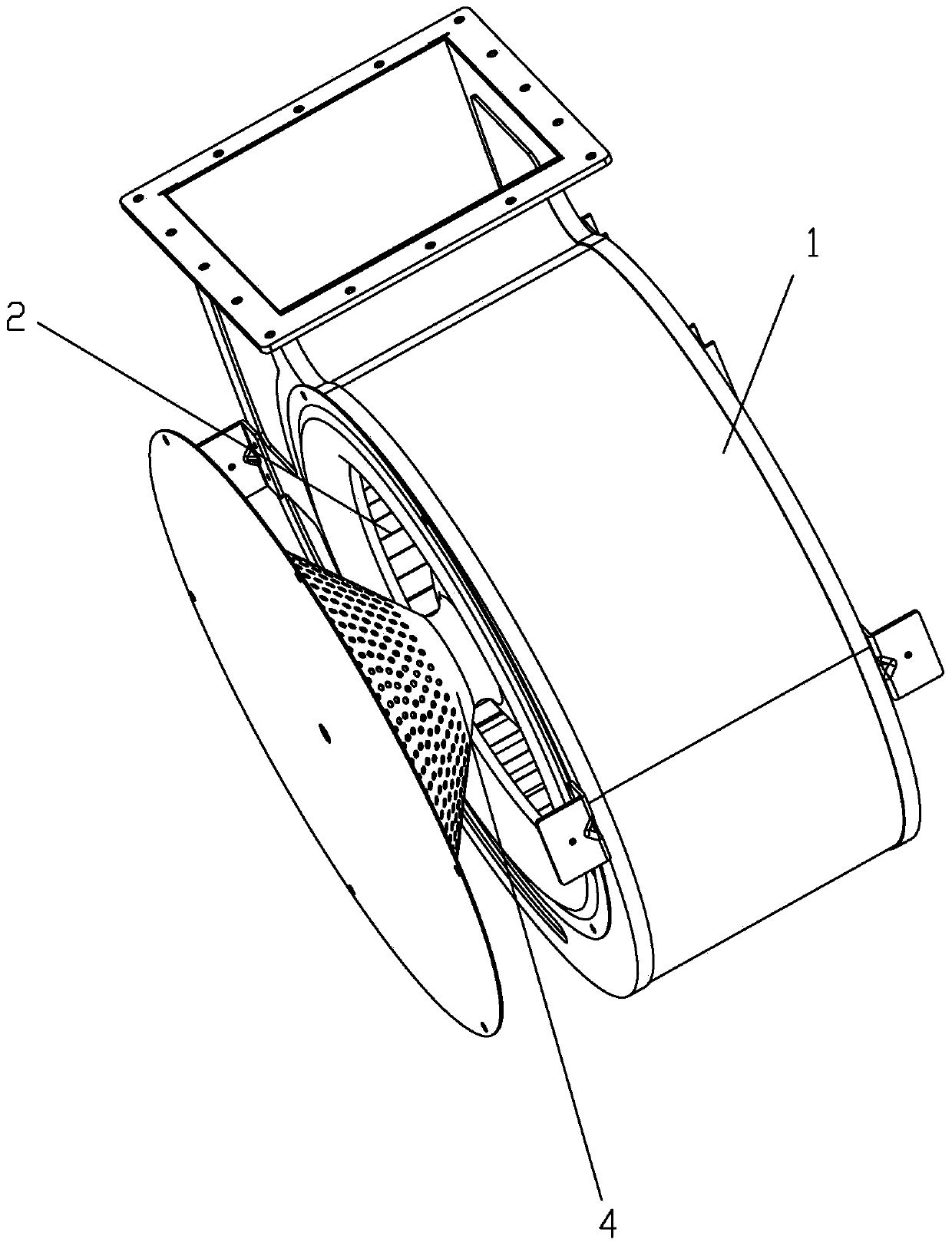

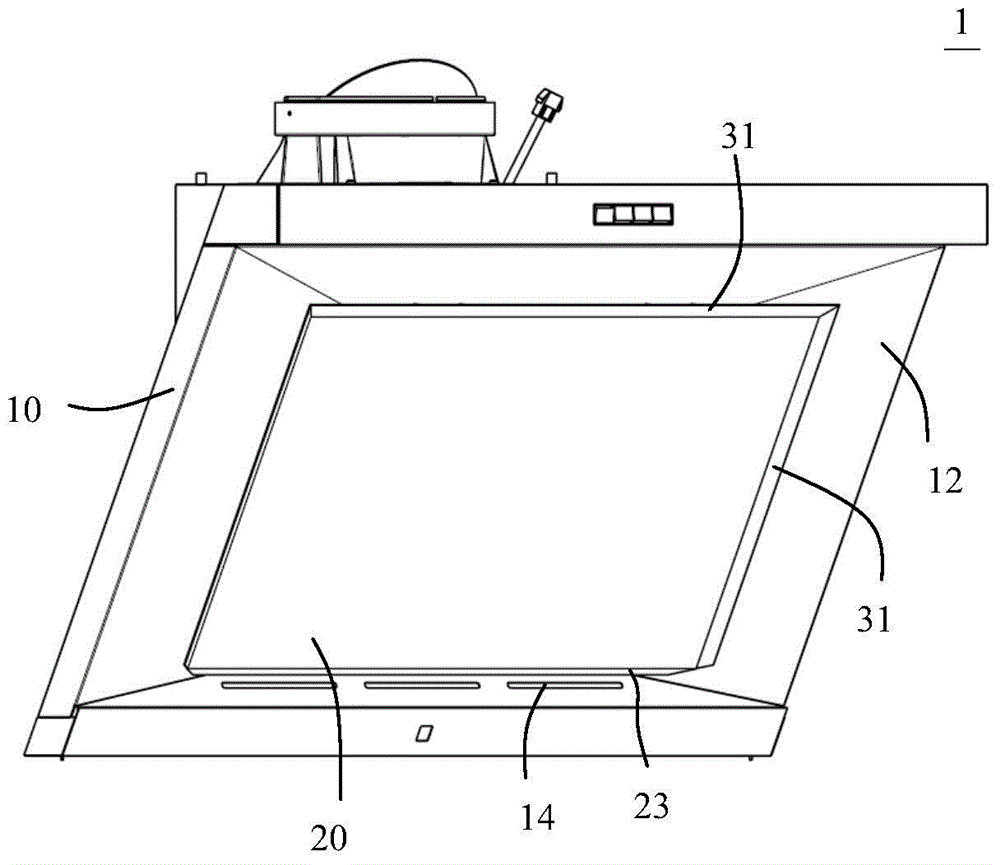

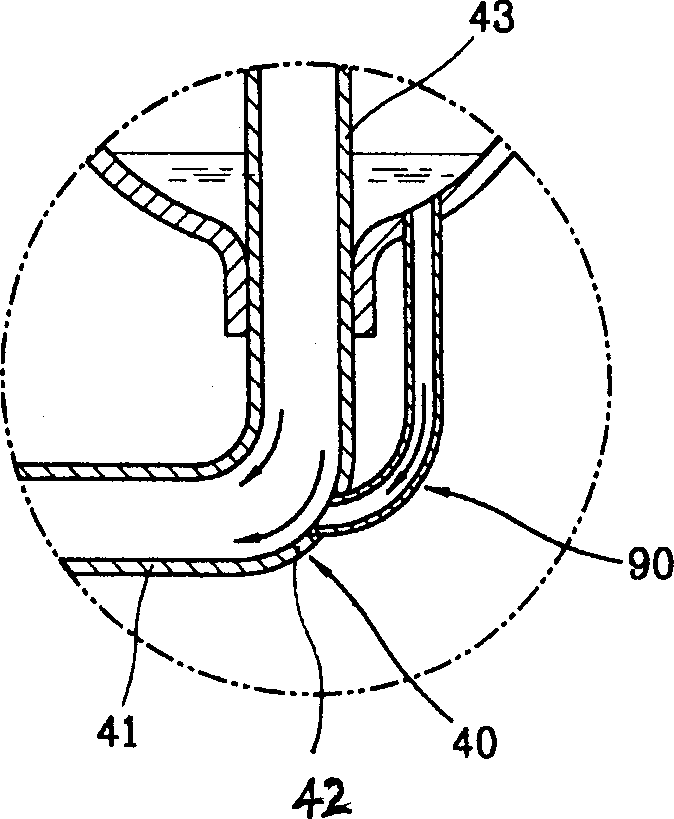

Extractor hood

ActiveCN104566575AReduce wind resistanceSmooth inhalationDomestic stoves or rangesLighting and heating apparatusExhaust fumesEngineering

The invention provides an extractor hood. The extractor hood comprises an exhaust fume collecting hood and a smoke deflector, wherein a gap allowing smoke to pass through is formed between the periphery of the exhaust fume collecting hood and the periphery of the smoke deflector; and a diversion part capable of reducing the air inlet resistance is arranged on the edge of the smoke deflector. According to the extractor hood, the air inlet resistance at the edge of the smoke deflector is reduced due to the arrangement of the diversion part, and the smoke can be sucked in smoothly.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

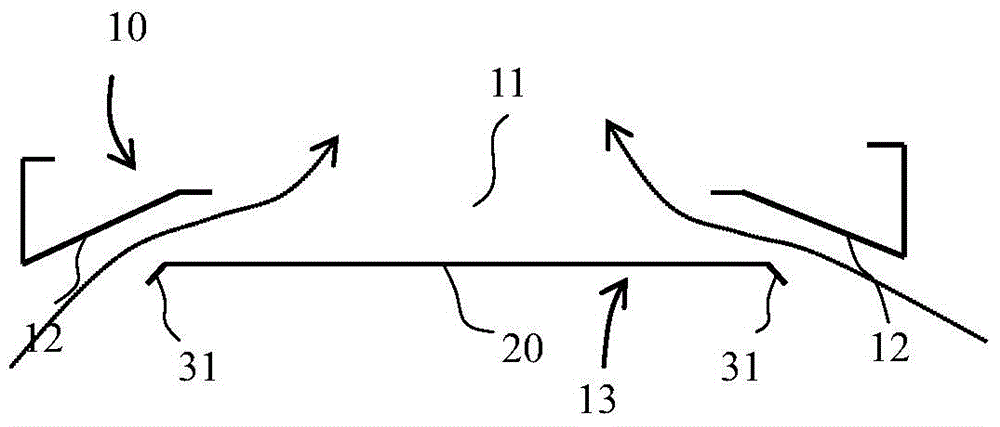

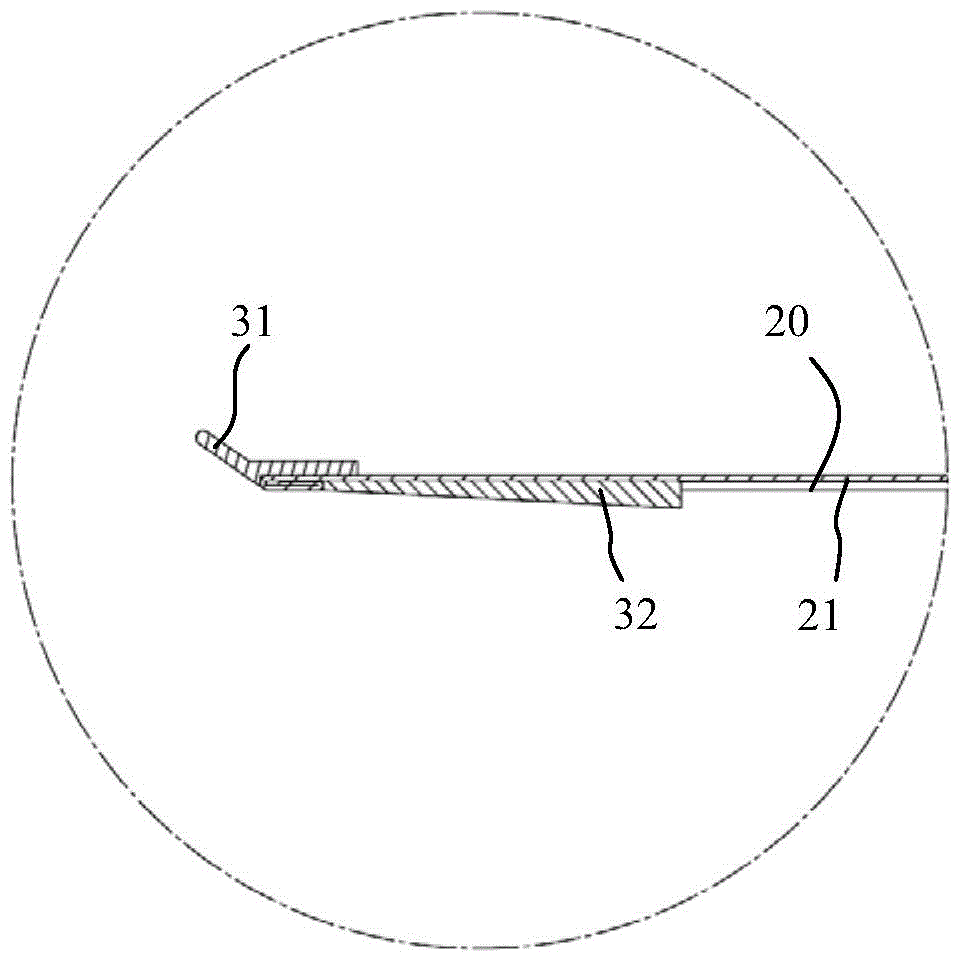

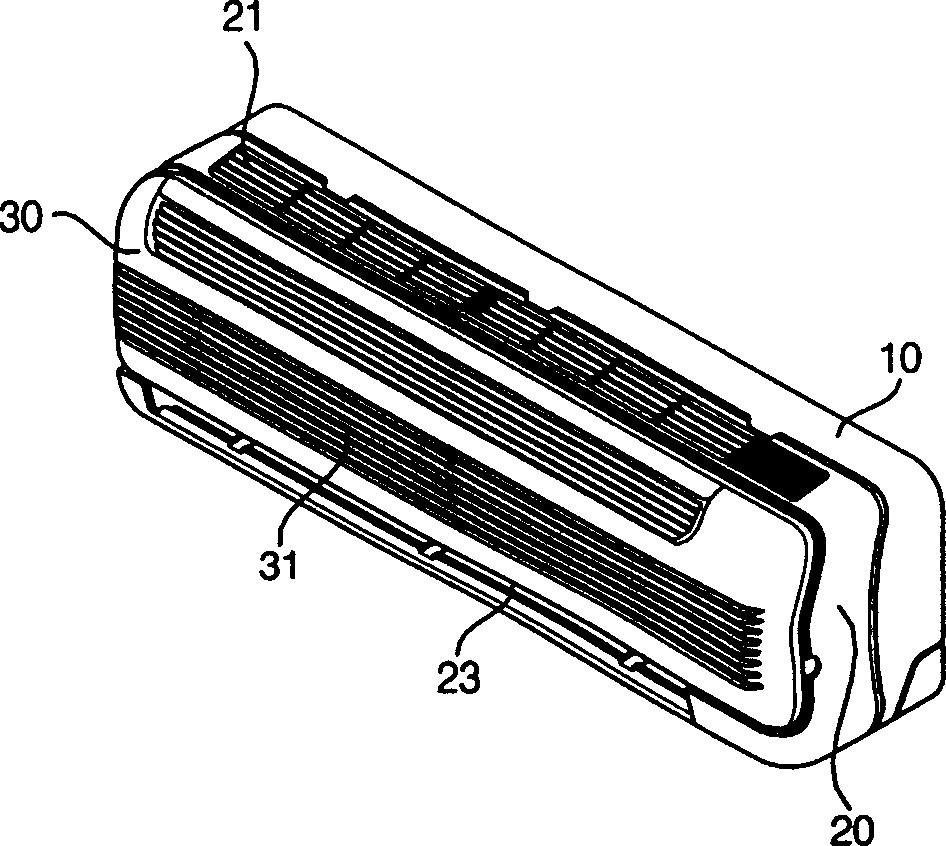

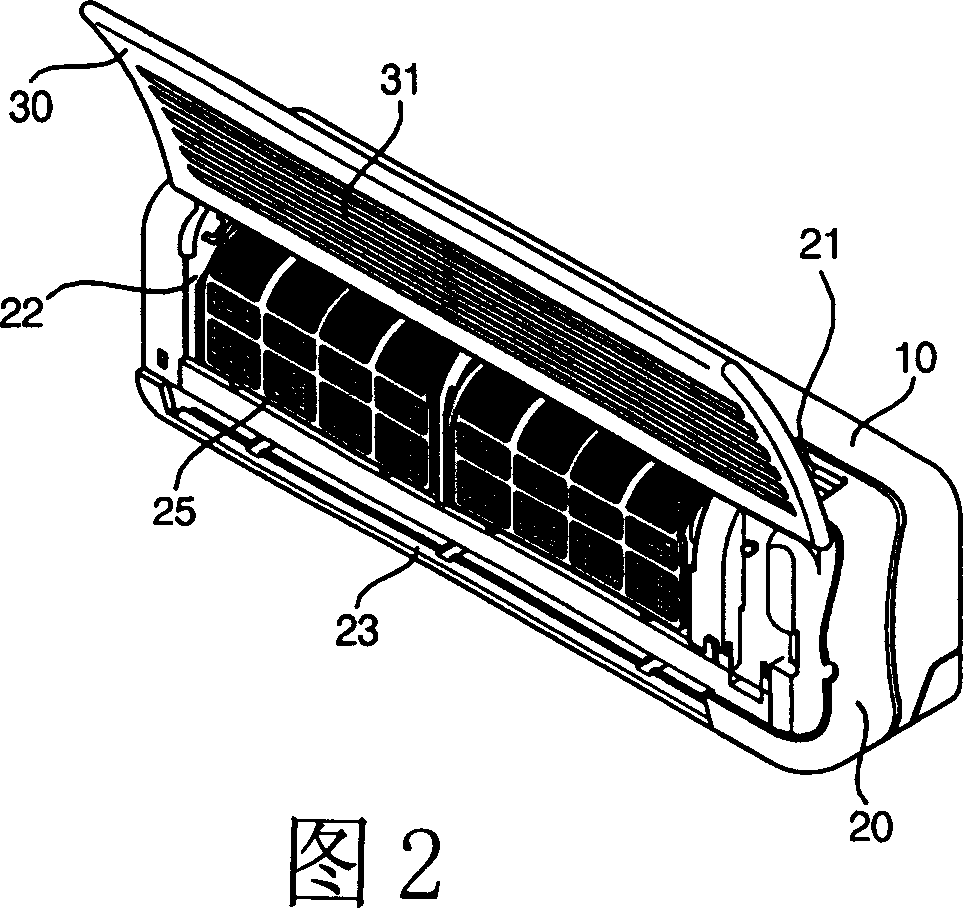

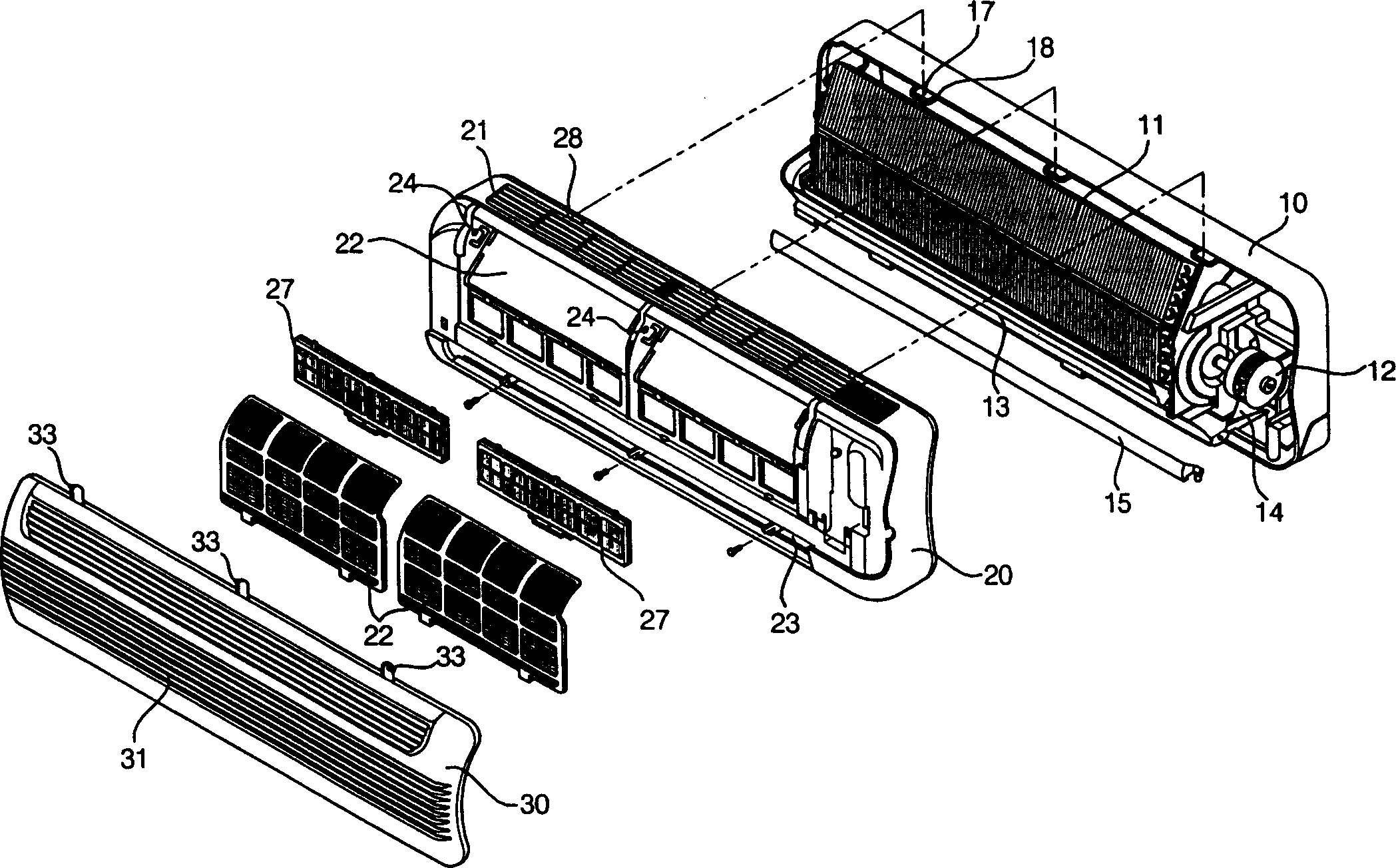

Air inlet board open/close structure for air conditioner

InactiveCN1502933ABeautiful exteriorIncreased intake air capacityAir-flow control membersRefrigerationIndoor air

The present invention relates to an opening and closing structure of air intake board of air conditioner. It includes front panel, air intake board and cover limiting device. The upper side of the front panel is formed into upper surface suction inlet, its front surface is formed into front suction inlet and its lower side is formed into discharge outlet. The lower end of the air intake board can be hung on the front panel by means of removable hooking device to cover the above-mentioned front suction inlet, and the above-mentioned cover limiting device is used for opening front suction inlet covered by air intake board so as to increase the volume of sucked air. Said structure can be used for smoothly sucking indoor air and can raise refrigeration efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

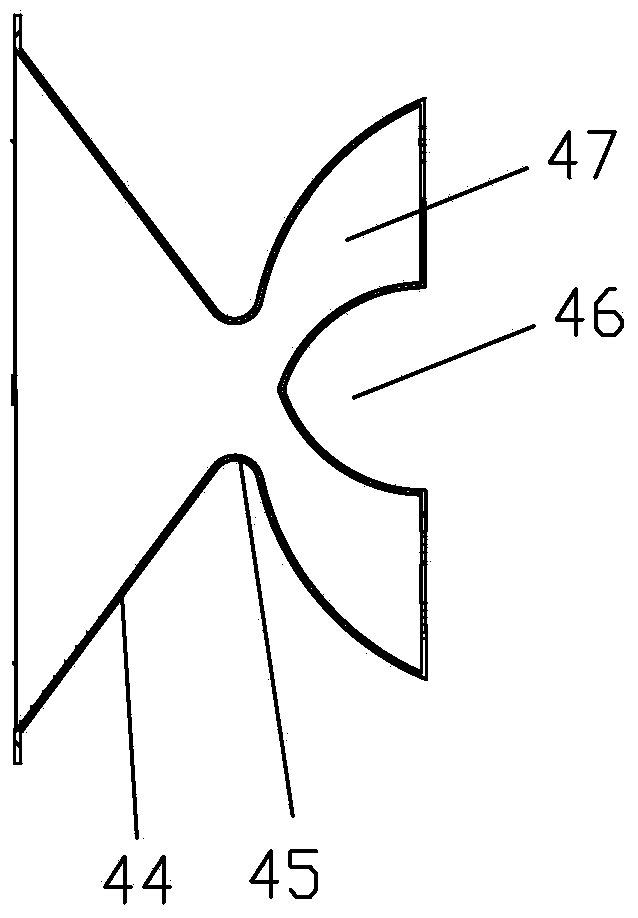

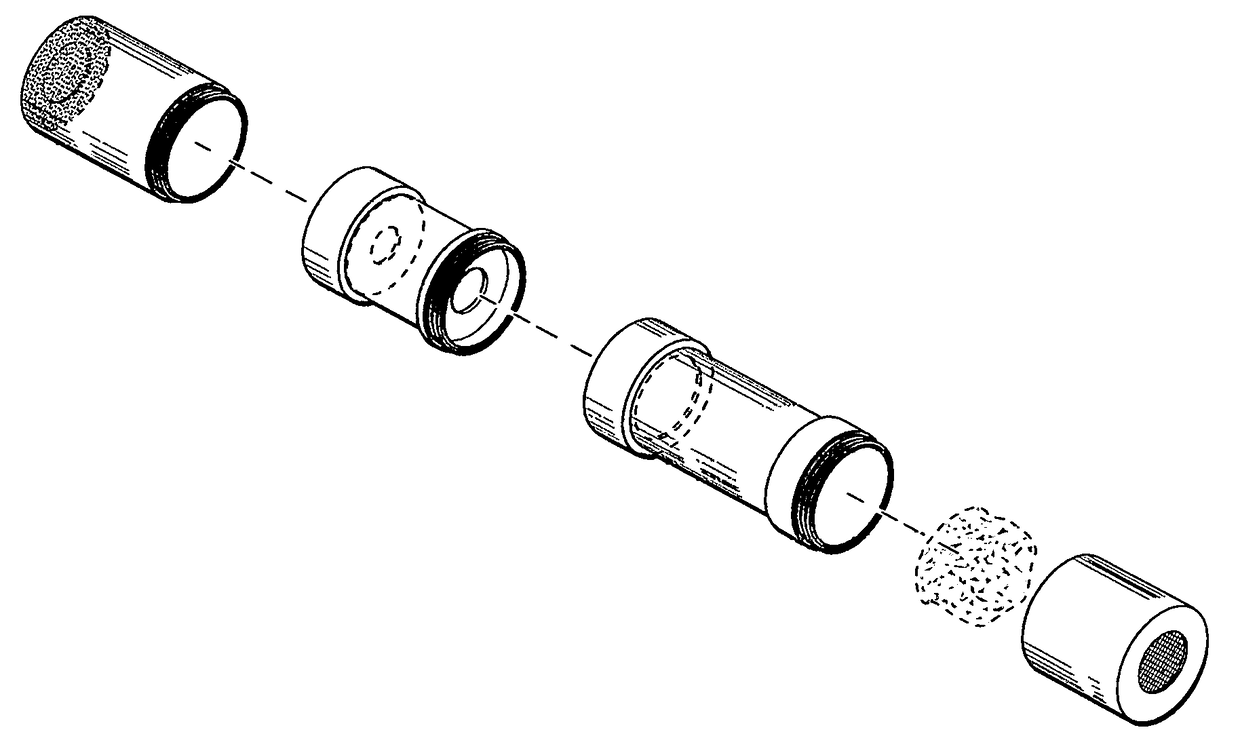

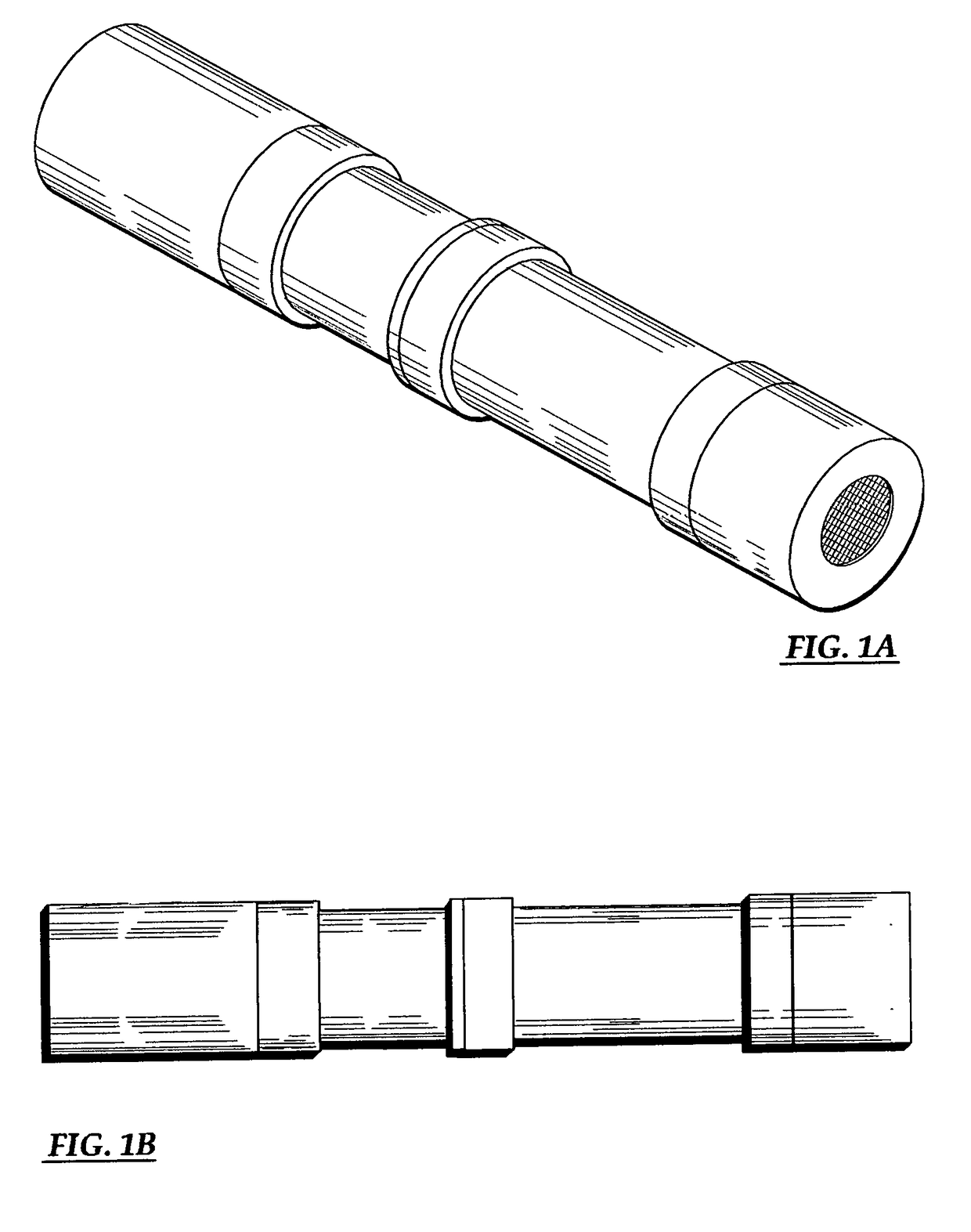

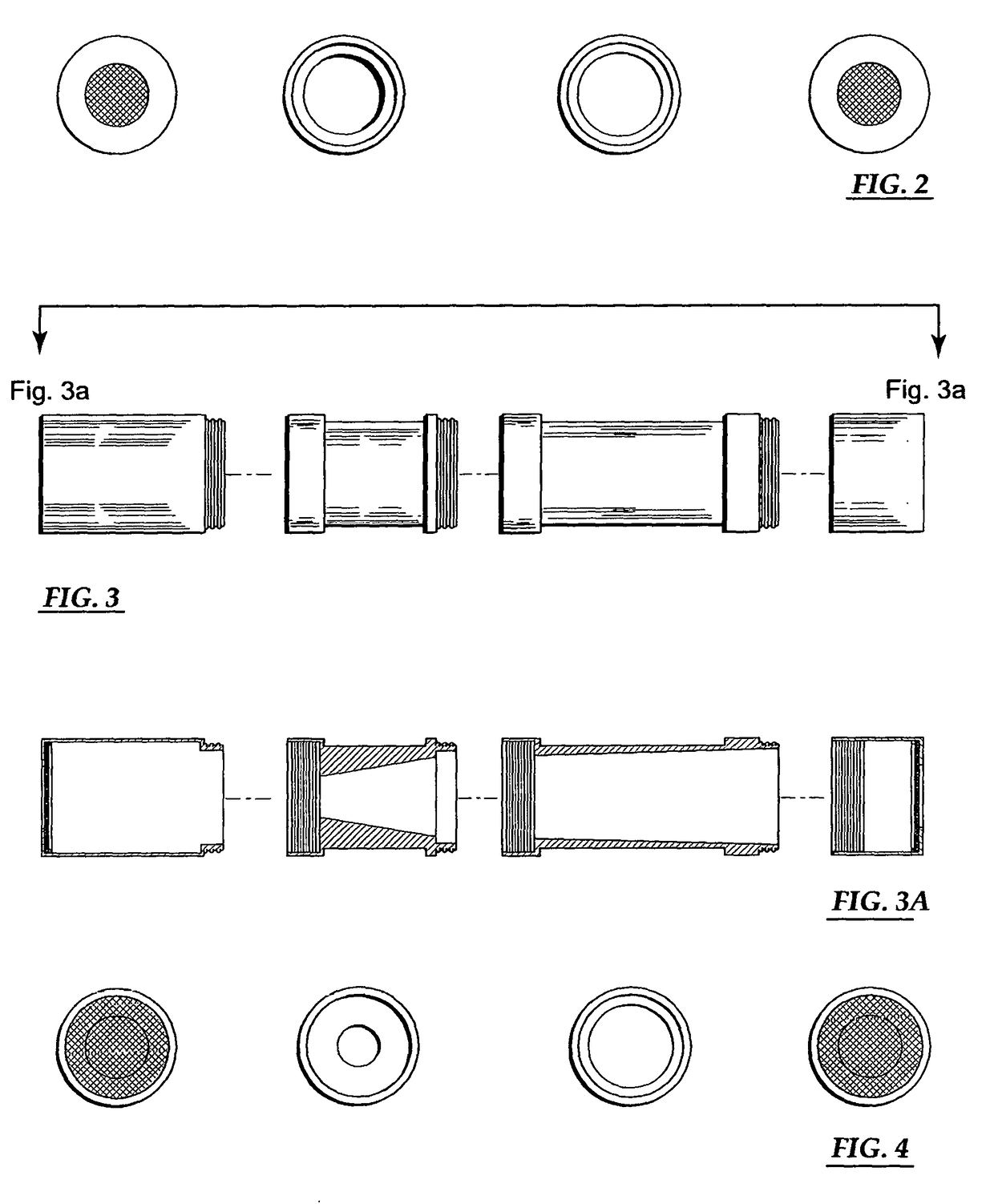

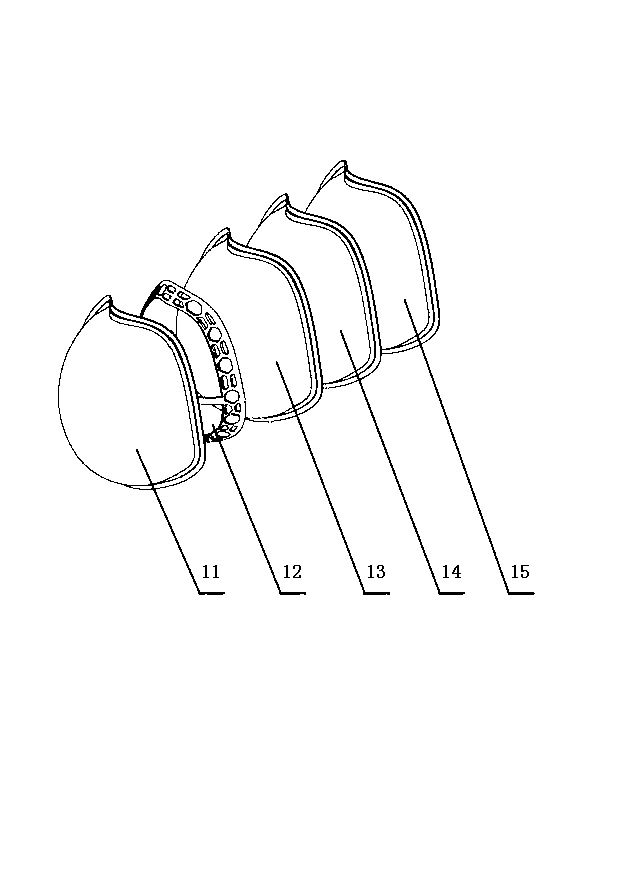

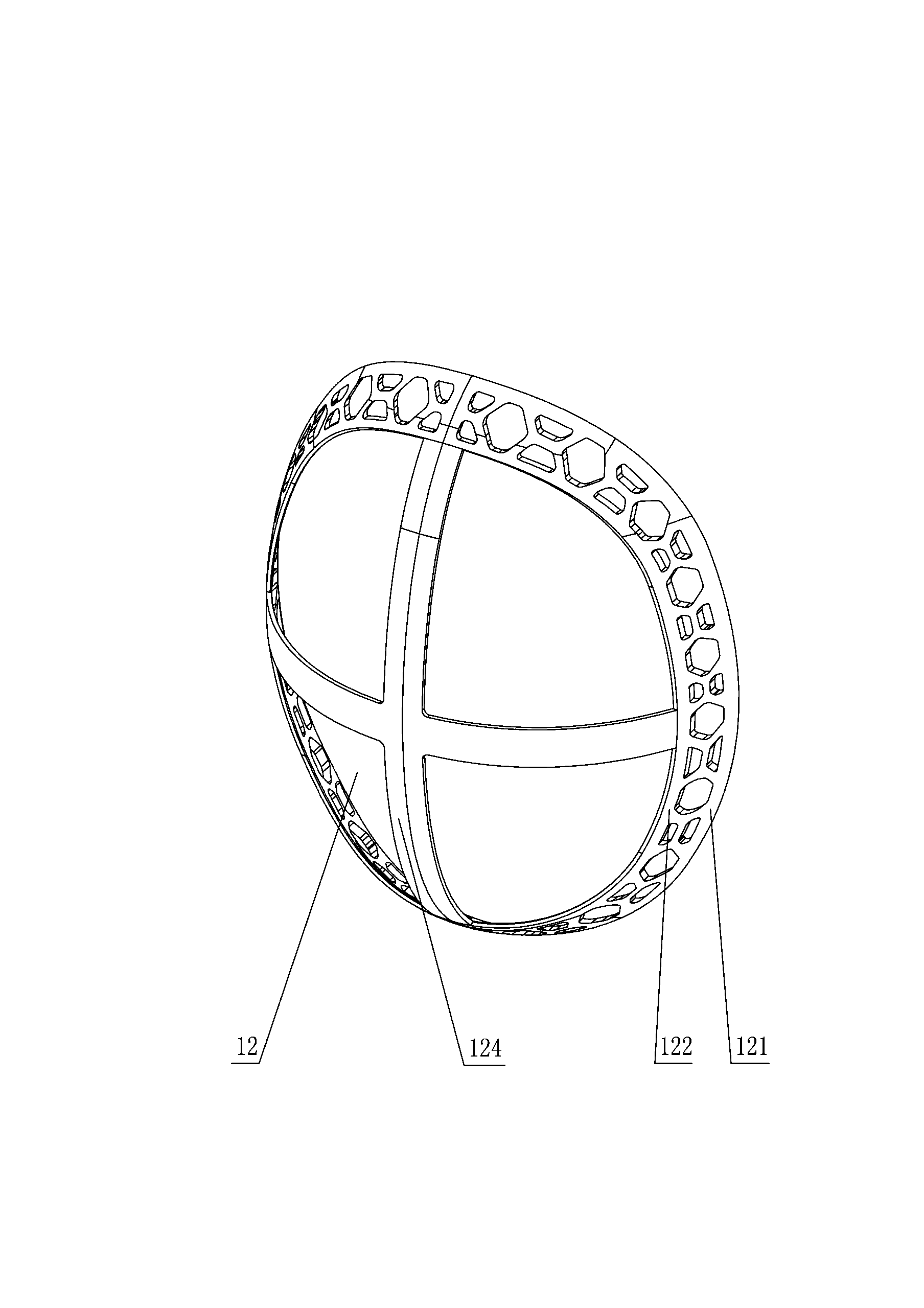

Multi Purpose Self Rolled and Paperless Smoking Apparatus for any kind of Tobacco

InactiveUS20170112189A1Large inhaleSmooth inhalationTobacco pipesPlant ingredientsRolling paperMultiple use

This invention has multiple uses for smoking self-rolled cigarettes or the bigger ones called blunts made out of cigars or cigar rolling papers and even work as a paperless cigarette, paperless joint, or paperless joint. This embodiment has 4 parts of aluminum other metals or heat resistant materials may be used and 2 metal screens. A blunt or joint may be placed into the device to be used as a holder tube 2 that is cone shaped for adjustable fitting for joints, or smaller roller cigarettes or into tube 3 that is cone shaped for adjustable fitting for blunts, or larger roller cigarettes that protects the user from getting tobacco or legal marijuana into their mouth, it may also be used as a paperless joint, cigarette or blunt, by putting the tobacco or legal marijuana direct into the device in tube (3). It can also be used to store an unfinished hand rolled or paperless rolled cigarette, legal joint or blunt. It also supply a better smoke like one would get from a water pipe because of its built in filter with screen in tube (1).

Owner:STERN ELI

Desilting device of water conservancy project

The invention discloses a desilting device of a water conservancy project. The desilting device of the water conservancy project comprises a turnover digging mechanism, a suction mechanism, a crushingmechanism and a sludge containing box, wherein the turnover digging mechanism comprises a pair of L-shaped supports which are vertically arranged and a rotating column which is horizontally arrangedin the axial direction; the suction mechanism comprises a suction cover and a stone filter screen arranged in the suction cover, and the suction cover is a circular truncated cone structure which is small in upper part, large in lower part and communicates in the axial direction; the crushing mechanism comprises an outer shell, an inner shell positioned in the outer shell, and a cutter body arranged inside the inner shell; the sludge containing box comprises a lower box body and an upper box body, wherein the lower box body and the upper box body are in sealing connection, the lower box body and the upper box body are both cylindrical structures which are vertically arranged in an axial direction. According to the device, sludge can be thoroughly cleared, the large-particle pebble hard objects are prevented from damaging a waste water pump, a pipeline cannot be blocked, the fineness of the cleared sludge is uniform, the water content is low, and the desilting device is a preferred option for preparing fertilizer.

Owner:刘兴海

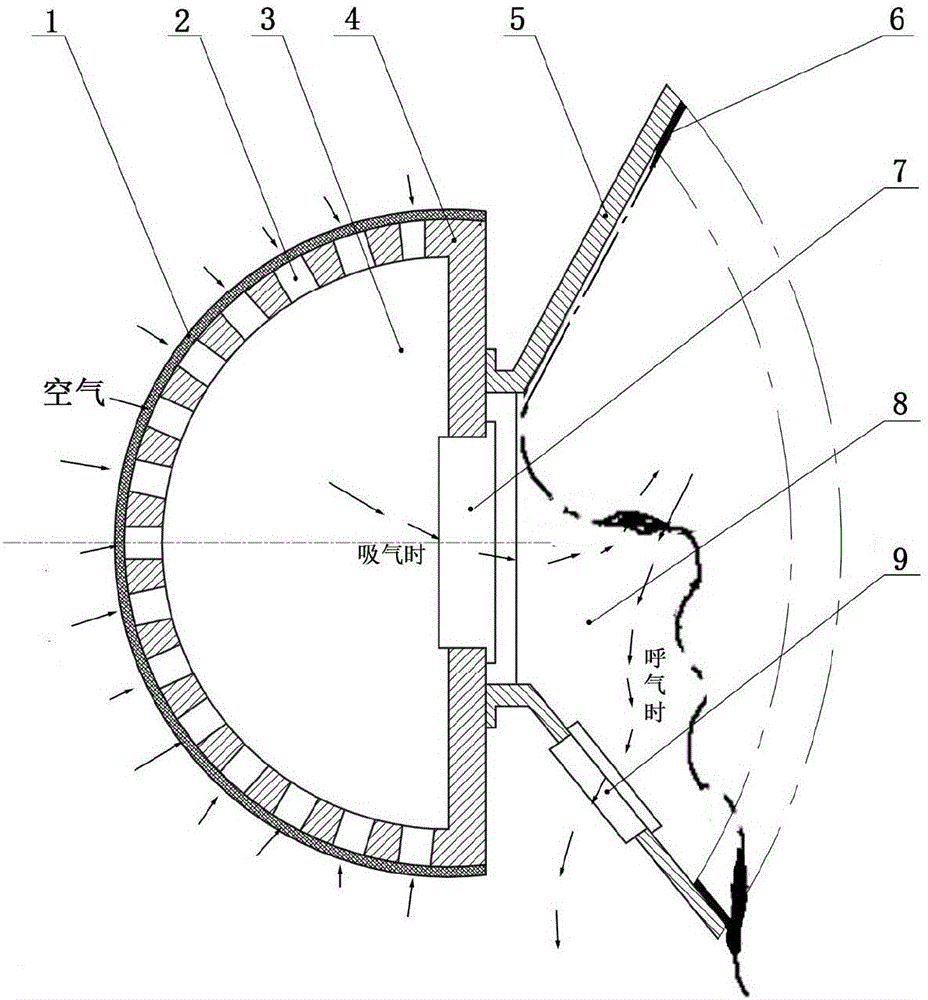

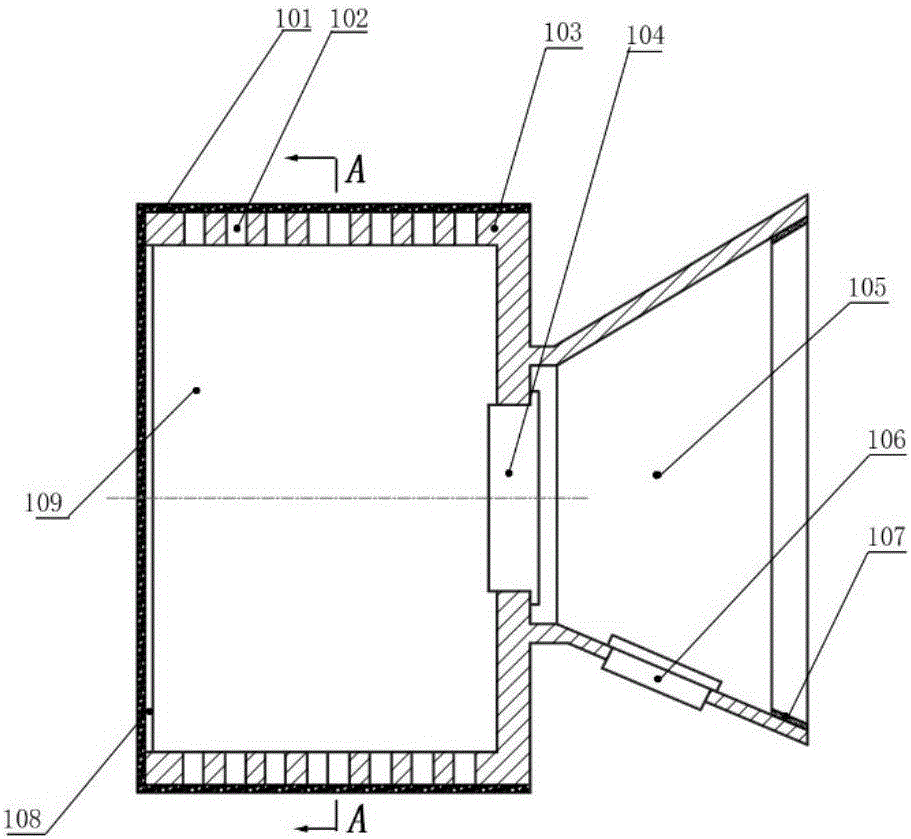

Gas filtering and exchanging device with dual-chamber structure

InactiveCN106621099ALarge confined spaceLimited spaceFire rescueRespiratory apparatusRespiratorFresh air

Aiming at the problems, the invention provides a dual-chamber structure design. The dual-chamber structure design is suitable for a mask, a breathing mask and the like; the gas exchange efficiency is improved, and the asphyxia sensation during breathing is reduced while filtering purification of air can be realized; during inspiration, a one-way valve (7) is opened, a one-way valve (9) is closed, and gas as in a fresh air cavity (3) enters an exchange cavity (8) through the one-way valve (7) and further enters a respiratory system of a person; during expiration, the one-way valve (7) is closed, the one-way valve (9) is opened, and expired gas is quickly exhausted from the exchange cavity without reservation; in the expiring process, the one-way valve (7) is closed, and outside air continuously enters the fresh air cavity through a filter screen (1) by negative pressure generated in the fresh air cavity in the inspiration process; and clear air is supplemented and prepares for next inspiration, and the steps are repeated as above.

Owner:李大国

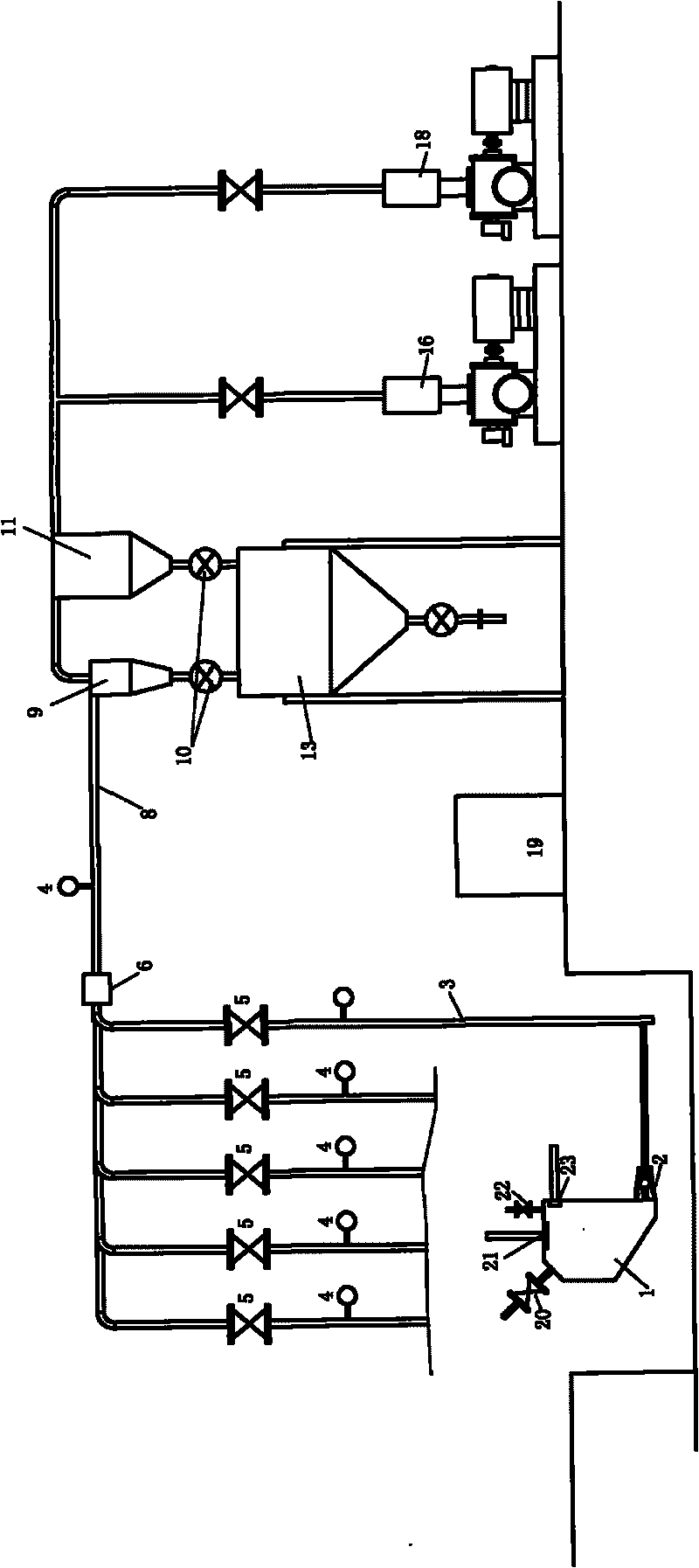

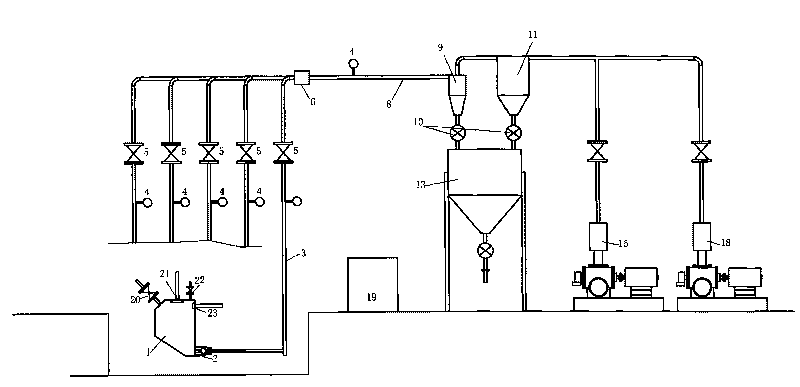

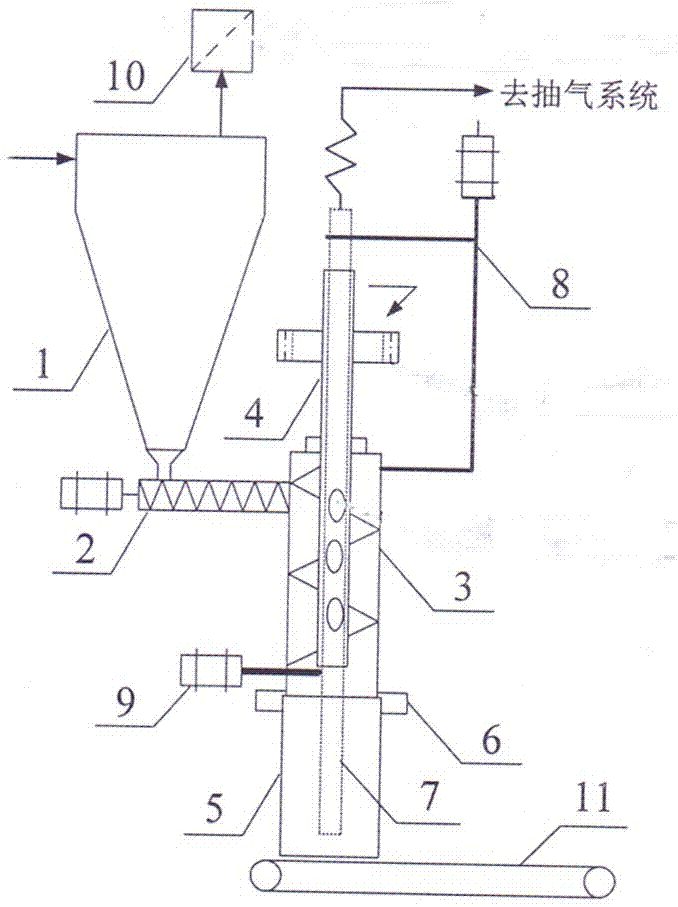

Stone coal negative-pressure conveying system

InactiveCN101745454ASmooth inhalationSmooth entryVortex flow apparatusBulk conveyorsEngineeringCheck valve

The present invention relates to a stone coal negative-pressure conveying system in a power plant coal-fired sorting and conveying system. The stone coal negative-pressure conveying system comprises a negative-pressure main pipe, wherein an inlet at the front end of the negative-pressure main pipe is connected with outlets of a plurality of stone coal hoppers through a plurality of branched pipes; the tail end of the negative-pressure main pipe orderly passing through a cyclone separating device and a dust remover is connected with a blower; and separating material outlets of the cyclone separating device and the dust remover are connected with a stone coal collecting bin. The present invention is characterized in that a suction nozzle with a check valve is arranged at the connection part of the outlets of the stone coal hoppers and the inlets of the branched pipes, and meanwhile each branched pipe passing through a junction bin is connected with the negative-pressure main pipe. The present invention can improve the reliability of material conveying, and reduce the abrasion of conveying pipes.

Owner:JIANGSU ZHONGNENG POWER EQUIP

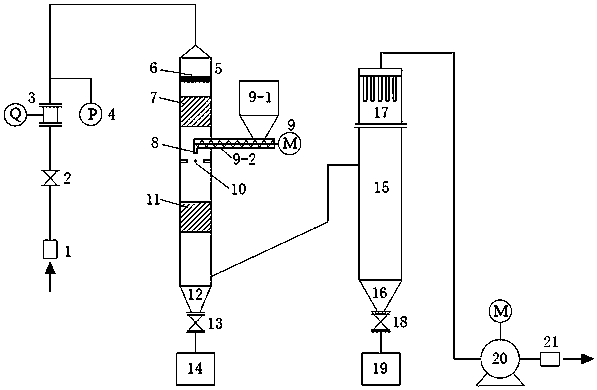

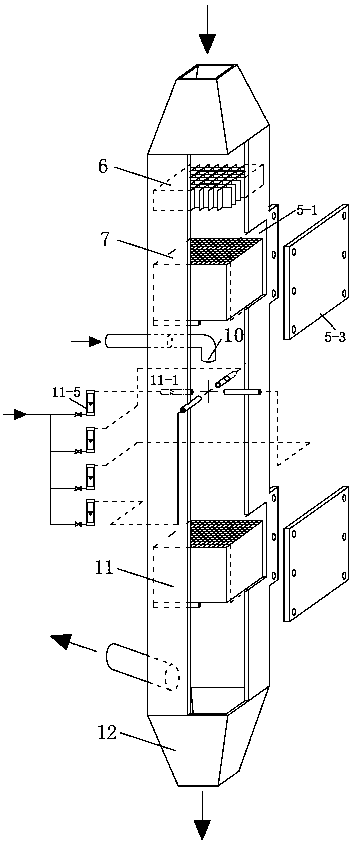

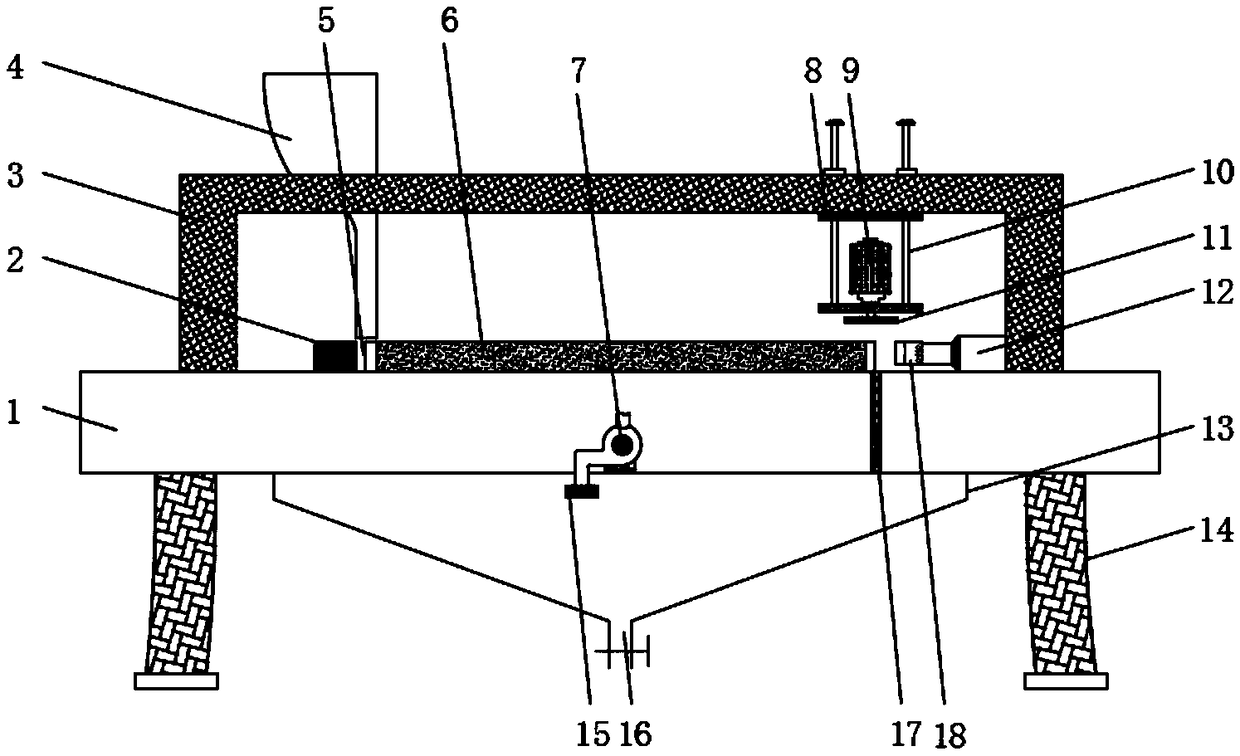

Denitration catalyst wear rate testing device and testing method

PendingCN109975149AEvenly distributedAvoid the problem of vertical differences in the degree of wearInvestigating abrasion/wear resistanceTest sampleBaghouse

The invention relates to a denitration catalyst wear rate testing device and a testing method. A wear chamber is vertically arranged in the testing device, and the top is connected with an air inlet.A first hopper is arranged at the bottom. A denitration catalyst comprises a test sample and a comparison sample. The comparison sample and the test sample are arranged in the wear chamber, and are arranged from top to bottom along the axis of the wear chamber. The discharge port of a wear agent feeder is arranged on the inner axis of the wear chamber and is located between the comparison sample and the test sample. The lower part of the wear chamber is connected with the middle of a sedimentation chamber through a connecting air duct. The joint of the connecting air duct and the wear chamberis located between the test sample and the first hopper. A second hopper is arranged at the bottom of the sedimentation chamber. A bag-type dust collector is arranged at the top. The bag-type dust collector is connected with an induced draft fan. During a test, negative pressure is formed in the device through the rear induced draft fan; the air is driven to flow in the device; the air flows fromthe top to the bottom in the vertical direction in the wear chamber; and the wear rate of the denitration catalyst is accurately tested.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

Silk-sucking mouth

ActiveCN1528963ASimple structureReduce power consumptionArtificial thread manufacturing machinesAbsorption effectTextile

The invention discloses a kind of silk absorption spout which has excellent silk absorption effect and low energy consumption, it comprises silk absorption channel, there sets a silk absorption spout at top of the channel, the channel is divided into upper and subjacent parts, there sets a switch base between the two parts, the switch can conduct or isolate the two parts, there sets a auxiliary gas inlet at the bottom part of the channel. The invention's structure is simple, and the energy consumption is low, the silk absorption is excellent. The invention can be used in silk absorption device in textile mechanism.

Owner:WUXI HONGYUAN ELECTROMECHANICAL TECH

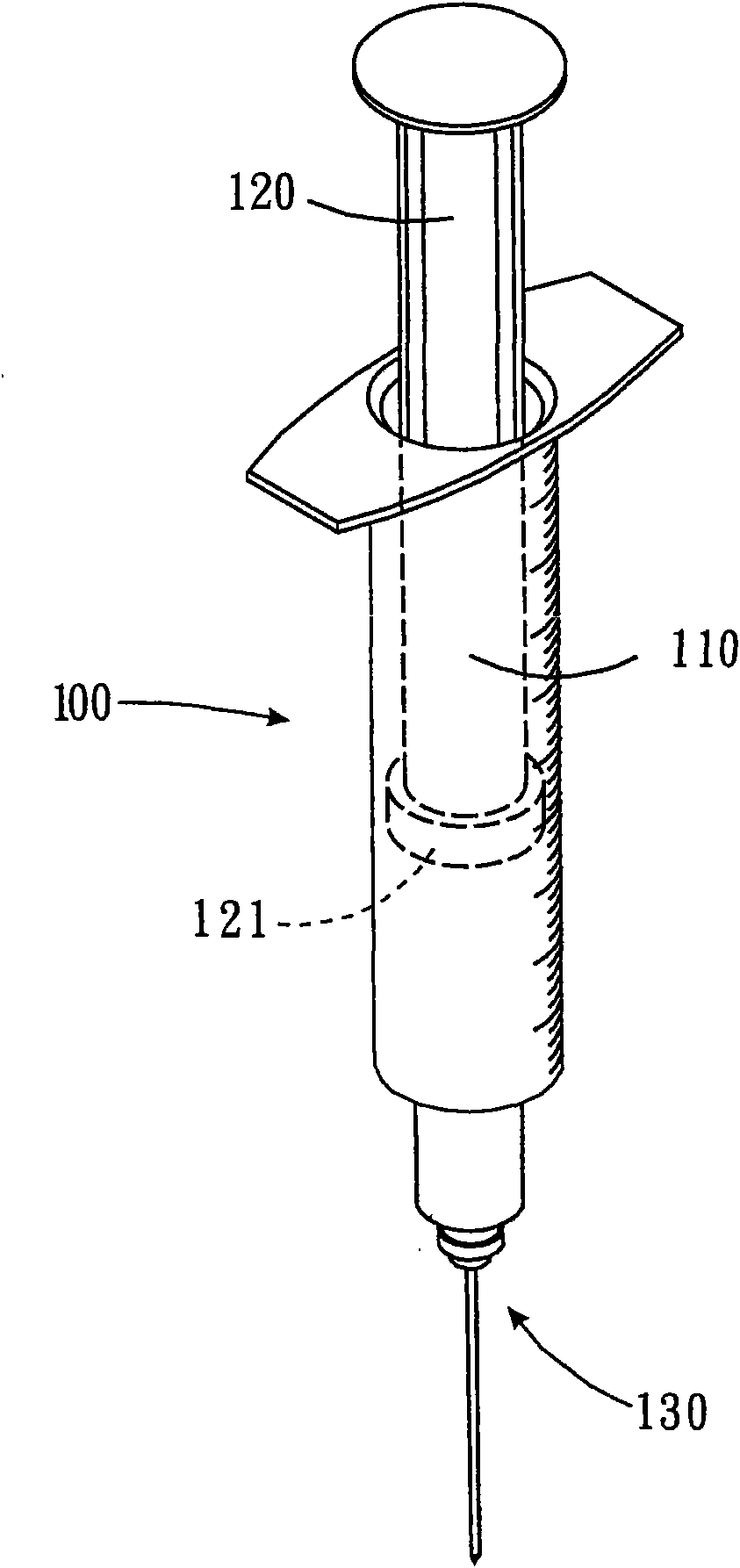

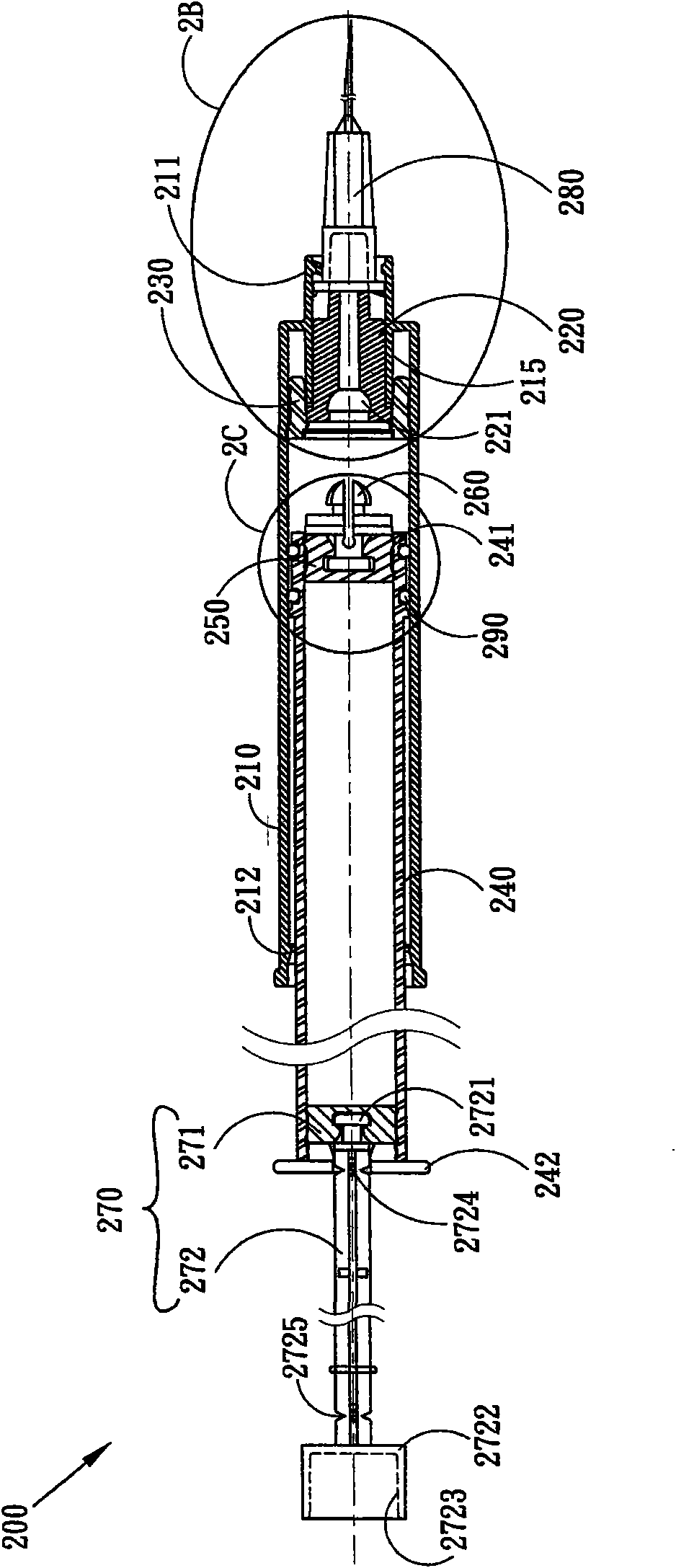

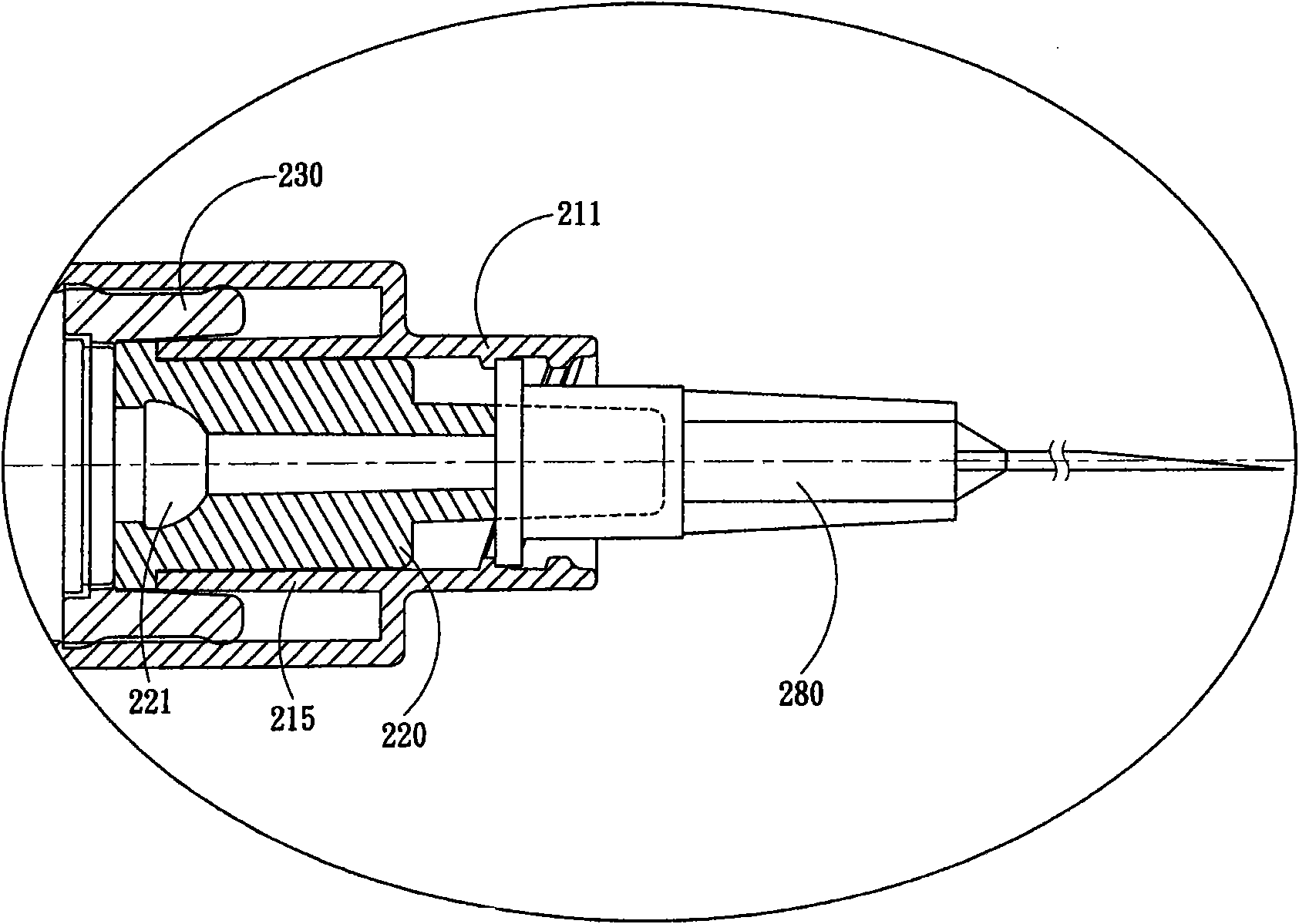

Safe needle cylinder

The invention discloses a safe needle cylinder comprising an outer cylinder, a needle stand, an outer cylinder rubber plug, an inner cylinder, an inner cylinder rubber plug, a needle clamper and a vacuum generation device, wherein the outer cylinder comprises an outer cylinder front end and an outer cylinder rear end; the needle stand is arranged in the outer cylinder front end; the outer cylinder rubber plug is arranged in the outer cylinder and is combined with the needle stand so as to fix the needle stand; the inner cylinder comprises an inner cylinder front end and an inner cylinder rear end and penetrates in the outer cylinder from the outer cylinder rear end; the inner cylinder rubber plug is arranged at the inner cylinder front end; the needle clamper is embedded with the inner cylinder rubber plug and can be combined with a rear end opening of the needle stand; the vacuum generation device is arranged in the inner cylinder; and the needle stand can sucked into the inner cylinder by dint of the low pressure generated by the vacuum generation device.

Owner:曾锡勋 +3

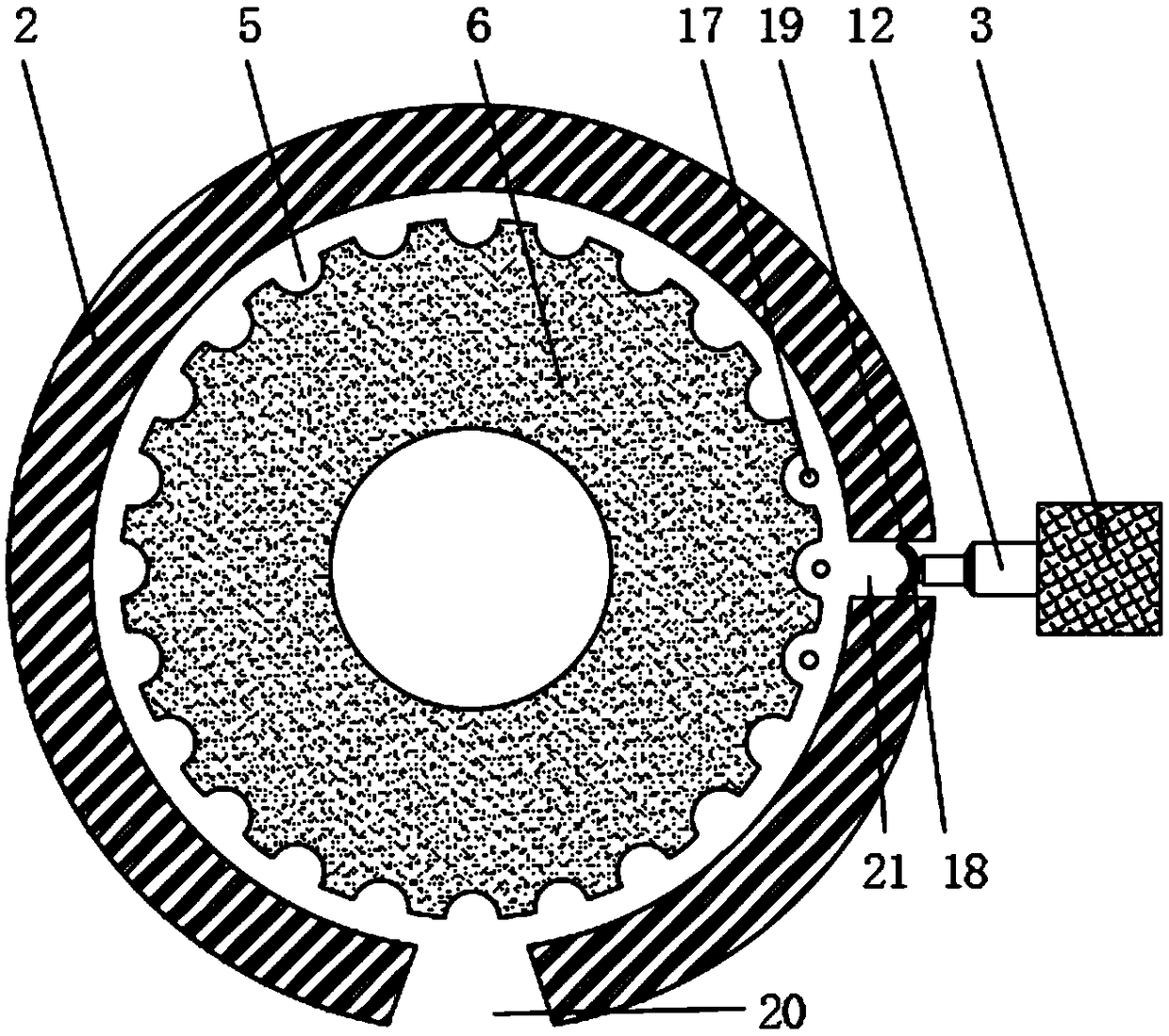

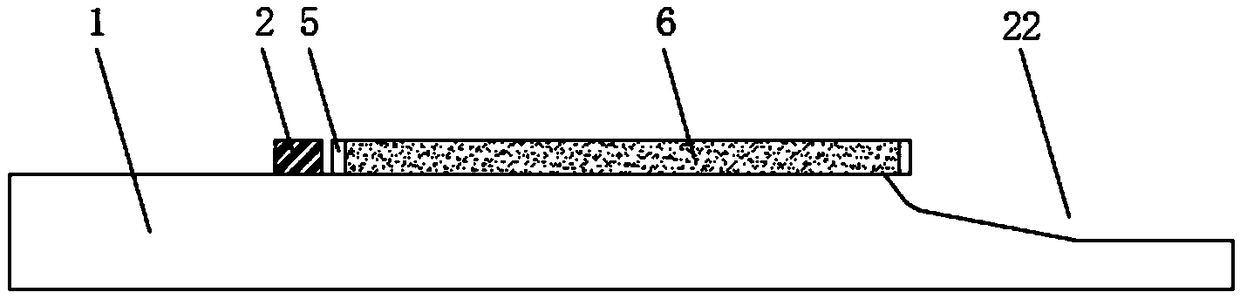

Centralized conveying synergetic system for lubricating grease

InactiveCN103016935ARealize centralized fat supplyEfficient deliveryLubricating pumpsPump installationsSuction forceEngineering

The invention relates to a centralized conveying synergetic system for lubricating grease, which comprises an eccentric gear, a reciprocating frame, rod pieces, an air cylinder, a lubricating grease cylinder, a cylinder piston, a lubricating grease cylinder piston, a pressure cylinder and check valves, wherein the eccentric gear is tangent with an inner surface of the reciprocating frame; one rod piece is respectively arranged on each of left and right two sides of the reciprocating frame; one rod piece is arranged at the upper end of the reciprocating frame; the rod pieces on the two sides of the reciprocating frame are respectively connected with the pistons of the air cylinder and the lubricating grease cylinder; part of the check valves are respectively arranged at an inlet and an outlet of the air cylinder; the other check valves are respectively arranged at the inlet and the outlet of the lubricating grease cylinder; and a front cavity of the pressure cylinder is communicated with a lubricating grease pipeline. The pressure cylinder is driven by the air injection of the air cylinder, so that the lubricating grease in a high-pressure cavity of the pressure cylinder is fed into the lubricating grease cylinder, and meanwhile, the piston in the lubricating grease cylinder is driven to move towards the right side, a negative pressure is generated by the lubricating grease cylinder, and the lubricating grease cylinder has a suction function to the lubricating grease, so that the sucking and pulling motions are combined, a synergetic conveying process is generated, and the lubricating grease with higher viscosity is effectively conveyed. The system has a simple structure and a good effect.

Owner:CHINA UNIV OF MINING & TECH

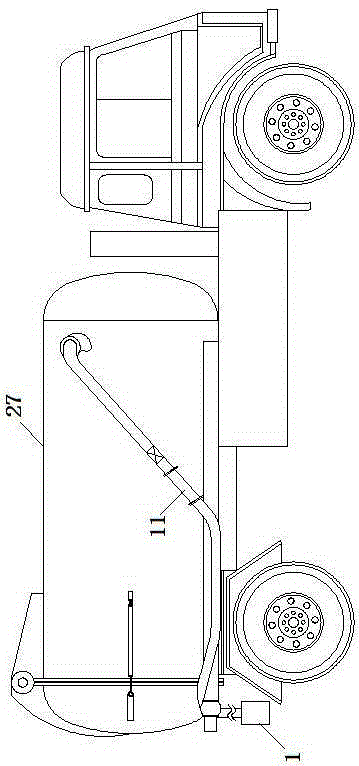

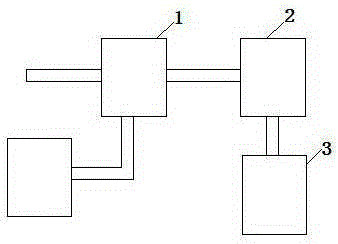

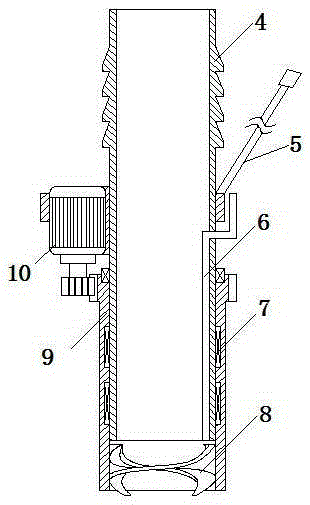

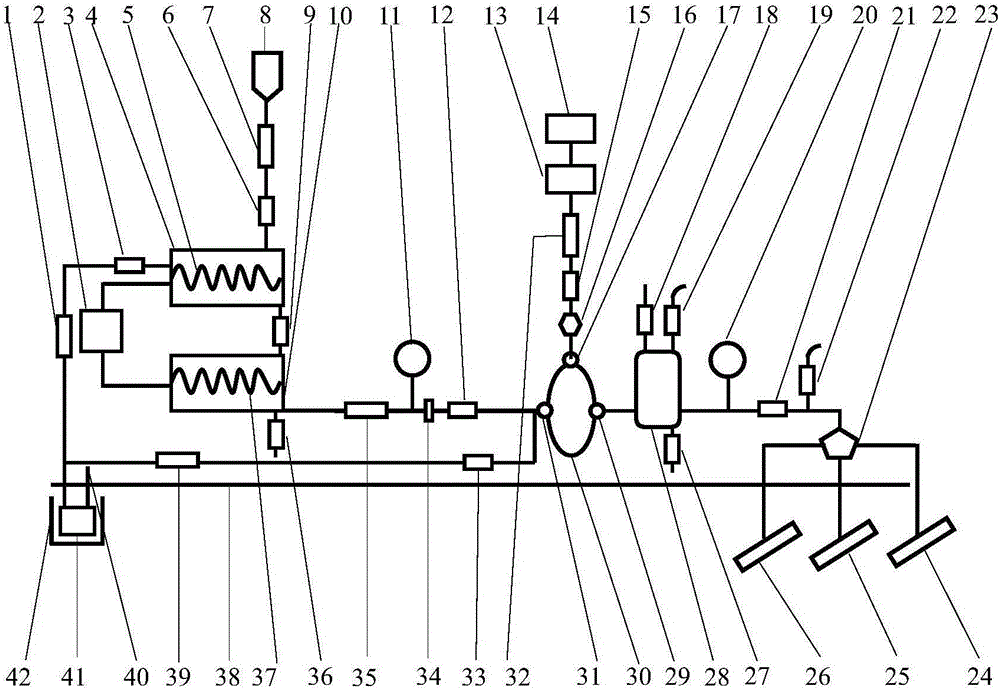

Suction sewage truck

The invention discloses a suction sewage truck. The suction sewage truck comprises a transport vehicle and further comprises a sludge suction system and a carriage. The sludge suction system and the carriage are arranged on a frame of the transport vehicle. The sludge suction system comprises a suction device, a connecting device for the suction device, and a gas exhaust device for tail gas of an engine of the transport vehicle. The suction device comprises a suction pipe, a transmission sleeve, a motor, a crushing cutter and a ventilation pipe. The connecting device comprises a connecting pipe made of transparent materials. The gas exhaust device comprises a main gas exhaust pipe and an auxiliary gas exhaust pipe. The carriage comprises a carriage body, a first-level separation device, a feeding device and a second-level separation device. The first-level separation device comprises a first-level auger and a first-level separation cavity. The feeding device comprises a feeding cavity and a feeding opening. The second-level separation device comprises a second-level auger and a second-level separation cavity. The second-level auger is arranged in the second-level separation cavity and fixedly connected with the outer cavity wall of the first-level separation cavity.

Owner:HUNAN JINSONG AUTOMOBILE CO LTD

Ship-mounted black odoriferous water treatment device

InactiveCN106006944AGuaranteed dissolution efficiencyAvoid corrosion damageTreatment using aerobic processesSpecific water treatment objectivesMicro nanoEngineering

The invention relates to a ship-mounted black odoriferous water treatment device and belongs to the technical field of water environment restoration engineering. The ship-mounted black odoriferous water treatment device comprises an agent feeding system, a micro-nano-aeration system, a control system and a power system. Through combination of a submersible pump and a filter screen, large granule foreign materials are isolated so that later equipment normal running is guaranteed, the enough solvent source and inlet liquid source are supplied for an agent preparation process and an agent spraying process and agent adding efficiency is improved. A powder automatic feeding device guarantees agent preparation convenience and fastness. Through combination of an agent storage tank and an agent feeding tank, agent feeding continuity and efficiency are guaranteed and an operation cost is saved. Through combination of the agent feeding system and the micro-nano-aeration system, a water dissolved oxygen amount is increased and the agent can be uniformly dispersed in black odoriferous water. Equipment parameter setting and data processing can be finished through the control system so that equipment operation efficiency is greatly improved.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST +1

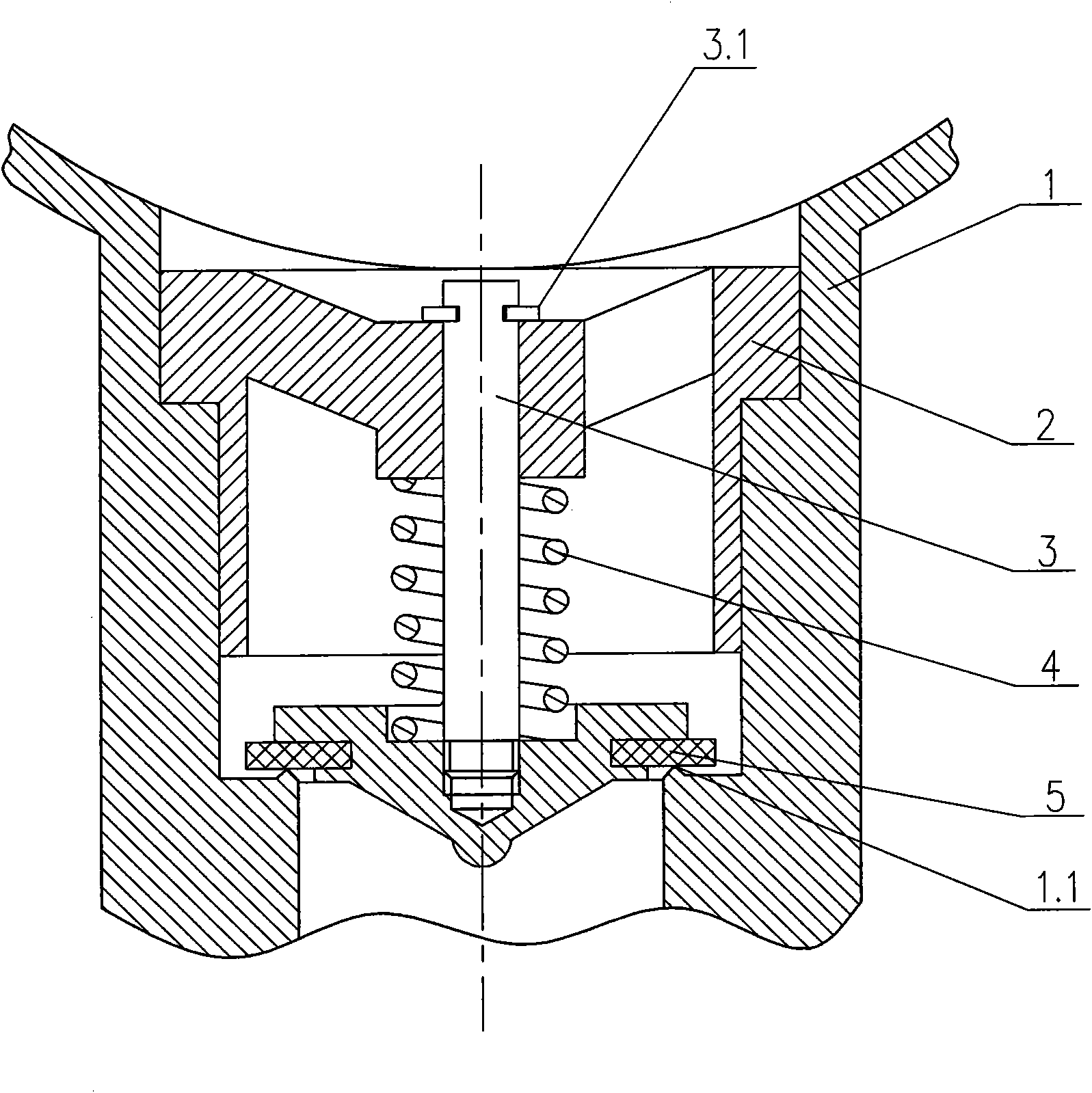

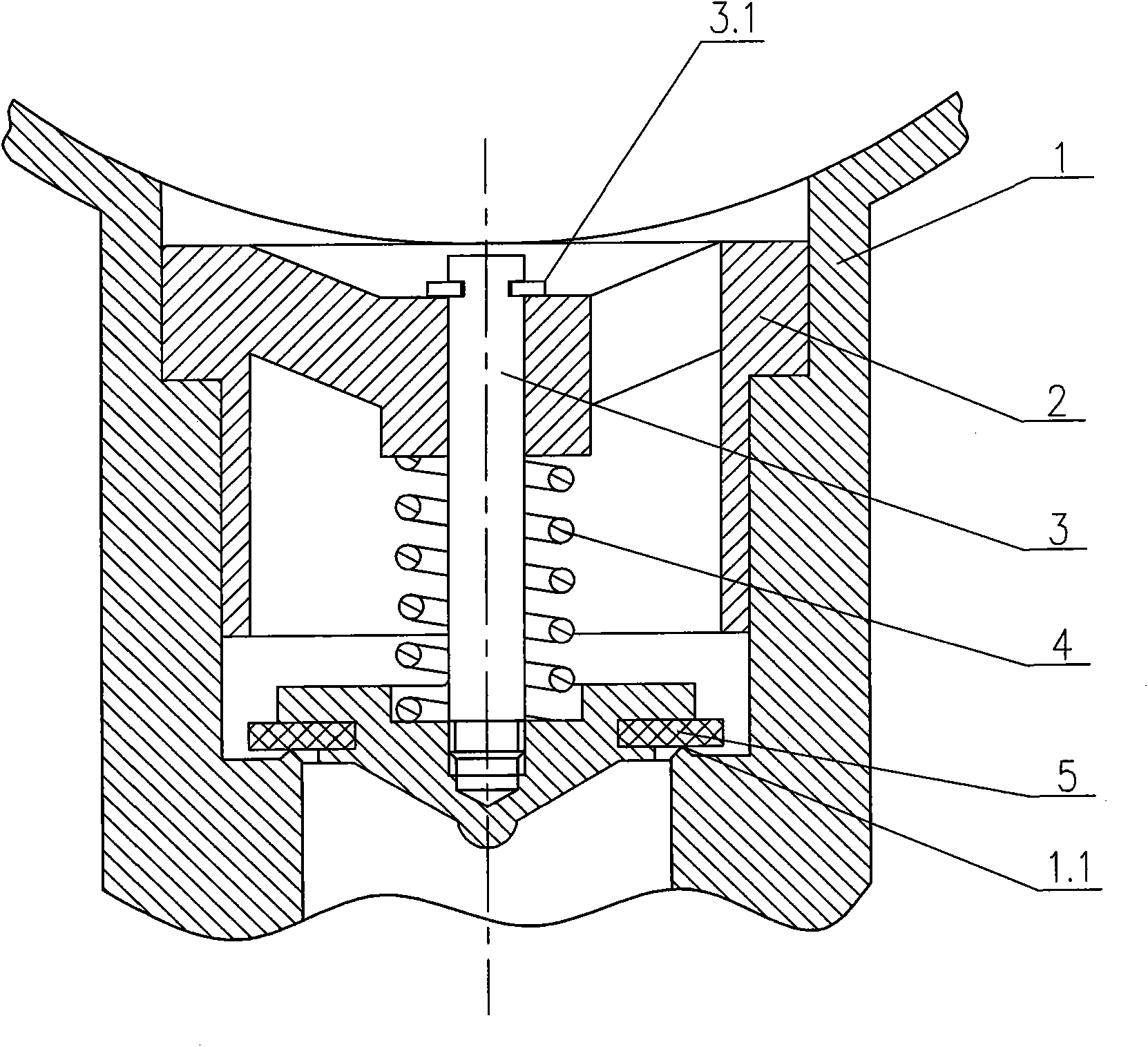

Measurement packing method for powder containing air

InactiveCN107082127ASmooth inhalationBeware of running materialsSolid materialEngineeringScrew conveyor

The invention discloses a measurement packing method for powder containing air. A powder material from an airflow conveying system is temporarily stored in a powder bin; a screw feeder arranged at the bottom of the bin feeds to a middle material cylinder; the material in the middle material cylinder is sent into a packing bag through a hollow stirring shaft; the air contained in the powder is pumped out through a filtering rod arranged inside the hollow stirring shaft in the flow direction; the air pumping process is divided into two levels; according to the first level, air pumping is conducted in a packing material cylinder; according to the second level, deep air pumping is conducted in the packing bag; when the material in the packing bag reaches 99.8% of the rated value, the air pumping filtering rod is quickly removed, and a cut-off valve is turned down; when the weight of the material in the packing bag reaches the set value, the screw conveyor stops feeding, and the cut-off valve is quickly closed; and measurement packing work is completed, and the subsequent working procedures of bag sewing and stacking are executed. According to the measurement packing method, the problem existing in the measurement packing process of the powder containing the air can be effectively solved, and efficient and accurate measurement packing is achieved.

Owner:JIANGSU JIUJIUJIU TECH

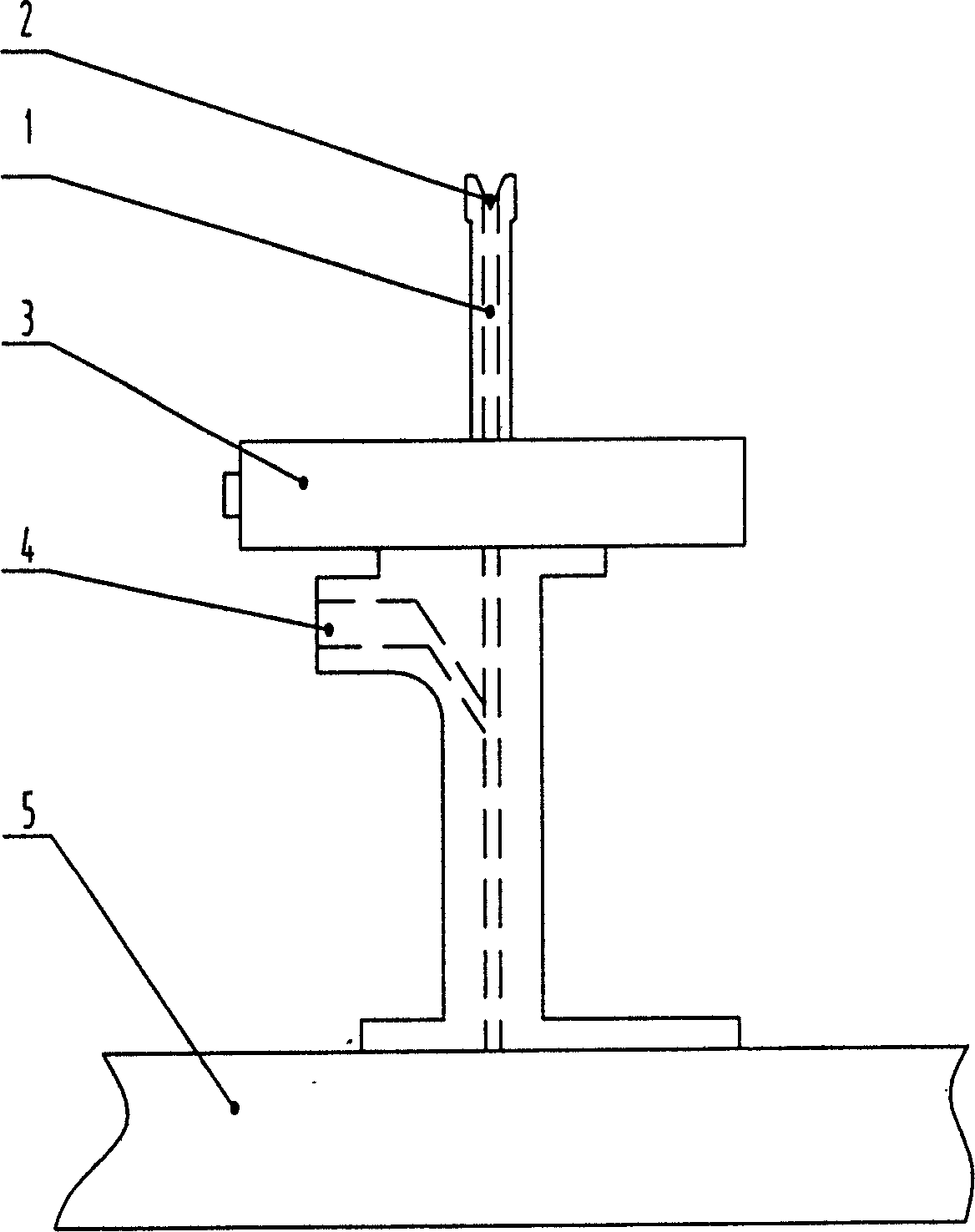

Backflow preventer of hand-operated oil pump

InactiveCN102052297ASimple structureEasy to manufacturePositive displacement pump componentsPiston pumpsBackflow prevention deviceContact mode

The invention discloses a backflow preventer of a hand-operated oil pump. The backflow preventer is arranged at an oil inlet of the pump, and comprises a built-in valve seat, a valve plug and a spring. An inner hole of the oil inlet of the pump is fitted with the valve seat, the bottom surface of the inner hole is provided with an annular step, and the axial section of the step is in the shape of isosceles triangle. Radial ribs are uniformly distributed at a big-end orifice of the valve seat, and a cross pitch point of the ribs is provided with an axial through hole; and a umbelliform valve-plug shaft section after being sleeved with the spring is in clearance fit with the axial through hole, the valve plug is axially limited by a clamp spring, and a rubber flat mat is embedded into a downward external umbrella frame. Through fitting with the annular step to form a normally closed state, the seal surface is in a line contact mode, which is helpful for separating the valve plug from the annular step under the condition of negative pressure, so that oil can be inhaled successfully. The backflow preventer is good in tightness and flexible in startup, does not affect the oil pumping efficiency, and can prevent the occurrence backflow, therefore, even if the pump stops operating, the pump still stores oil for a long time, so when being used again, the pump can output oil quickly just by shaking the pump for multiple circles by hand.

Owner:TAIZHOU BEIRUITE MACHINERY MFG

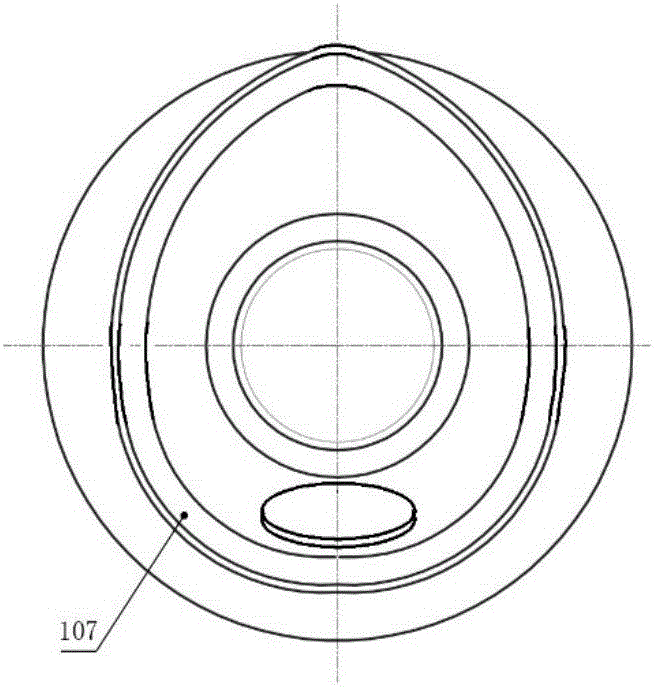

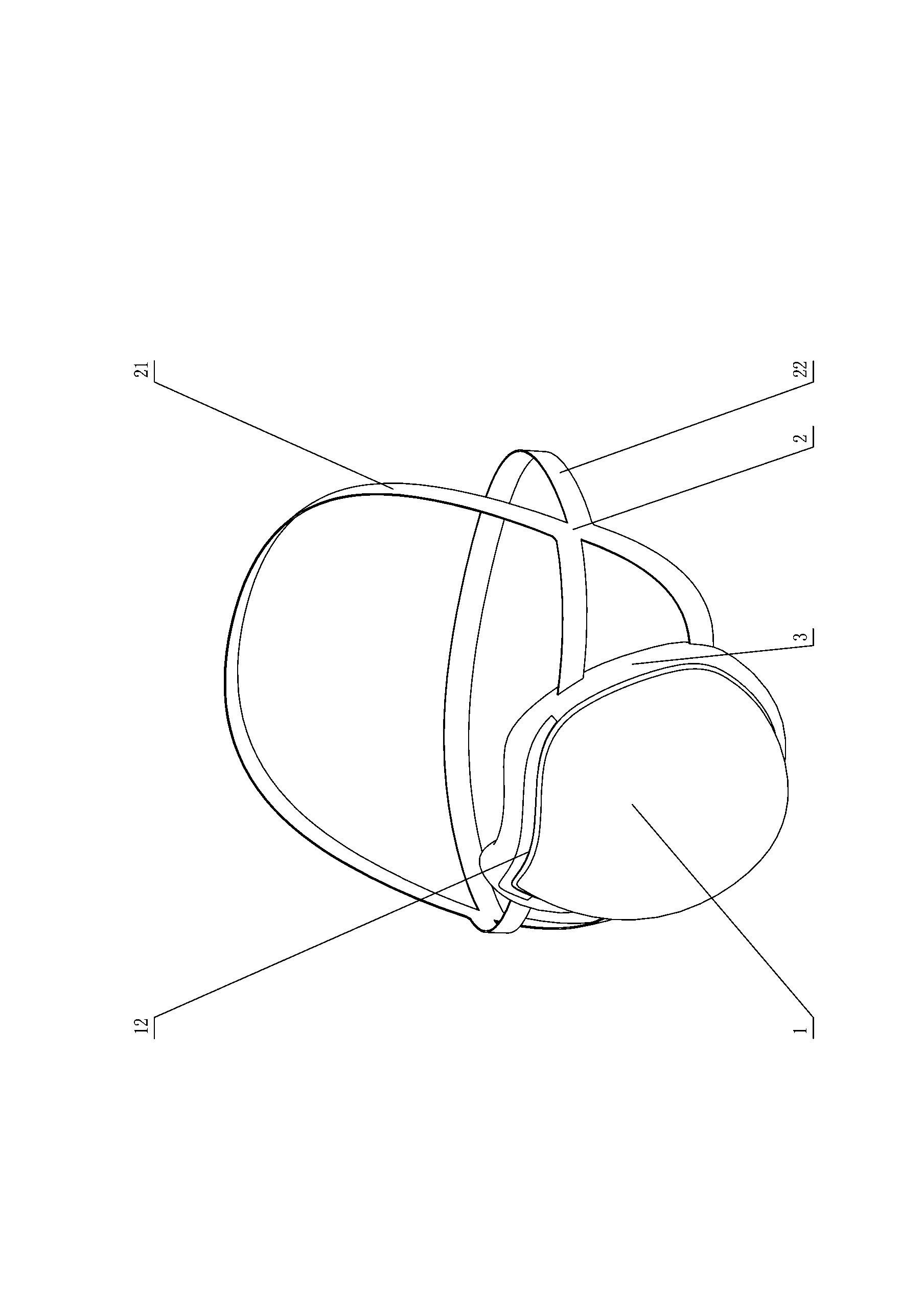

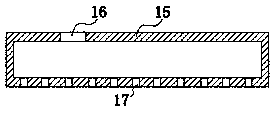

Stereoscopic cup mask

InactiveCN103211325AImprove filtering effectDoes not interfere with speechLayered productsProtective garmentEngineeringWoven fabric

The invention discloses a stereoscopic cup mask which comprises non-woven fabric layers and a filter layer, wherein the non-woven fabric layers and the filter layer are overlapped. A concave support frame is arranged in the stereoscopic cup mask; the filtering layer is a filter cotton layer; the non-woven fabric layers comprise a front non-woven fabric layer, a middle non-woven fabric layer and a rear non-woven fabric layer; and the stereoscopic cup mask comprises the front non-woven fabric layer, the support frame, the middle non-woven fabric layer, the filter cotton layer and the rear non-woven fabric layer which are sequentially overlapped. The stereoscopic structural mask has a simple structure and a good filtering effect, is comfortable to wear and does not influence normal conversation.

Owner:SHENZHONGHAI MEDICAL INC

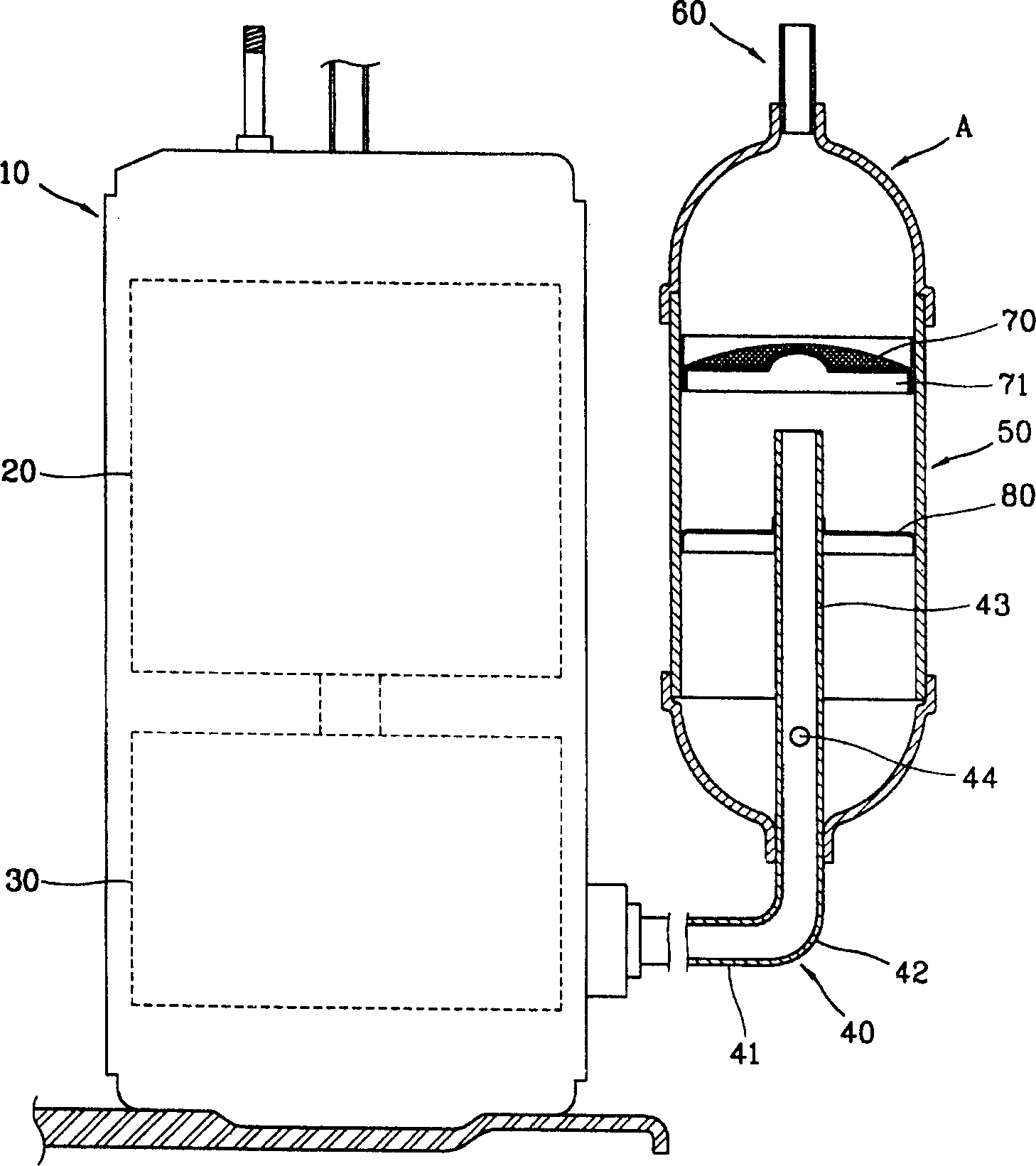

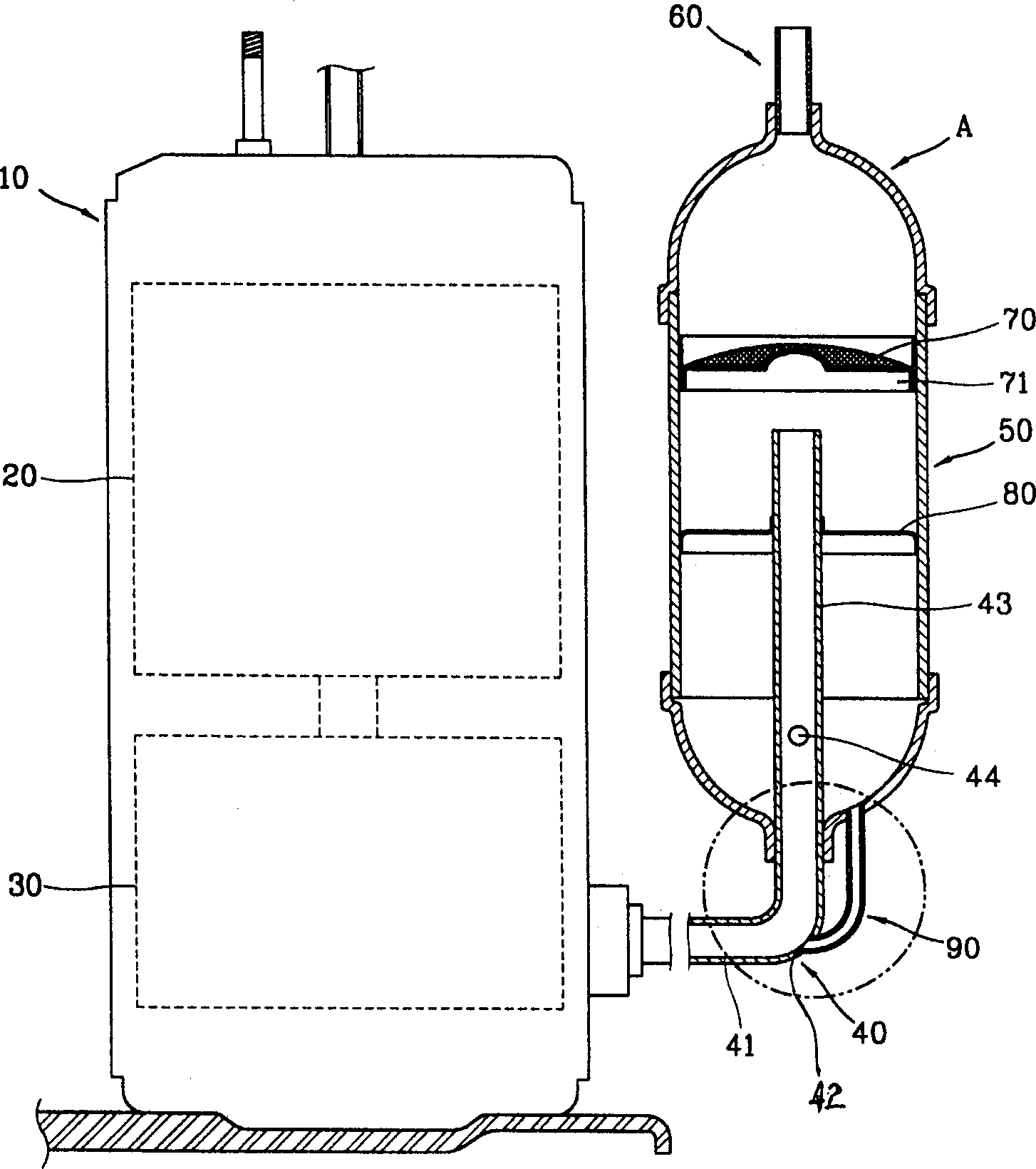

Oil recovery device of closed type compressor liquid storage tank

InactiveCN1427174AAvoid interferenceSmooth inhalationPositive displacement pump componentsPositive-displacement liquid enginesStraight tubeLiquid tank

An oil recovering unit of liquid tank for sealed compressor is composed of liquid accumulating container communicated to evaporator via refrigerating tube, connecting tube connected between compressing mechanism and liquid accumulating container, and fine oil tube connected between bottom of said container and elbow of connecting tube. It can prevent the interference between oil stream and refrigerating gas strem for reducing vibration and noise, and improve compression performance.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Wear-resistant guide rail quick paint spraying device

The invention discloses a wear-resistant guide rail quick paint spraying device. The wear-resistant guide rail quick paint spraying device comprises a case, the inner upper portion of the case is welded with a separating plate, above which a boost pump, a paint storage tank and a hot-air blower are arranged; a spray nozzle and an airflow dispersion device are arranged under the separating plate; the input end of the boost pump is communicated with the paint storage tank through a connecting pipe, the output end of the boost pump is communicated with the spray nozzle through a connecting pipe,the output end of the hot-air blower is communicated with an air outlet pipe, and one end of the air outlet pipe is communicated with the airflow dispersion device. A guide rail is fed via a feeding port, the boost pump and the hot-air blower are controlled by an external control system, the boost pump extracts paint inside the paint storage tank to the spray nozzle which sprays the paint onto theguide rail, hot air blown by the hot-air blower is dispersed and sprayed out from the airflow dispersion device so that the sprayed side of the guide rail can be rapidly aired to improve the guide rail painting efficiency, and then the aired guide rail is discharged via a discharging port.

Owner:CHUZHOU OUBOTE ELECTRONICS MFG

Air conditioning system for vehicle

InactiveCN1260078CReduce vertical sizeReduce discharge pressureAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

In the vehicle air conditioning system according to the present invention, the thin condenser 2 of the condensing part part 10 is installed on the flat roof of the vehicle (such as a bus) and slopes downward from the front to the rear of the vehicle, and the condenser fan 4 is directly arranged Above the condenser, the air inlet 51 of the condenser is arranged in front of the condenser and the air outlet 52 is arranged above the condenser.

Owner:DENSO CORP

Novel grinding equipment for spring manufacturing

The invention discloses novel grinding equipment for spring manufacturing. The novel grinding equipment comprises a worktable and a supporting frame. The top of the worktable is fixedly connected withthe supporting frame. A storing hopper is connected to one side of the top of the supporting frame in a penetrating mode. A rotating disc is mounted in the middle of the surface of the worktable, storing grooves are formed in the edge of the rotating disc, and a limiting frame is fixedly mounted on the outer sides of the storing grooves. According to the novel grinding equipment for spring manufacturing, to-be-ground springs fall into the storing grooves through the storing hopper, then the rotating disc is rotated to rotate the springs to the position under a grinding disc to be ground, andmeanwhile, a hydraulic telescopic cylinder pushes forwards to clamp the springs, so that grinding of the springs is facilitated; and through the structural design, the springs can accurately fall intoeach storing groove, fixing and transporting of each spring are facilitated, an orderly assembly line is formed, the whole grinding process is facilitated, and the grinding efficiency is improved.

Owner:南通瑞斯电子有限公司

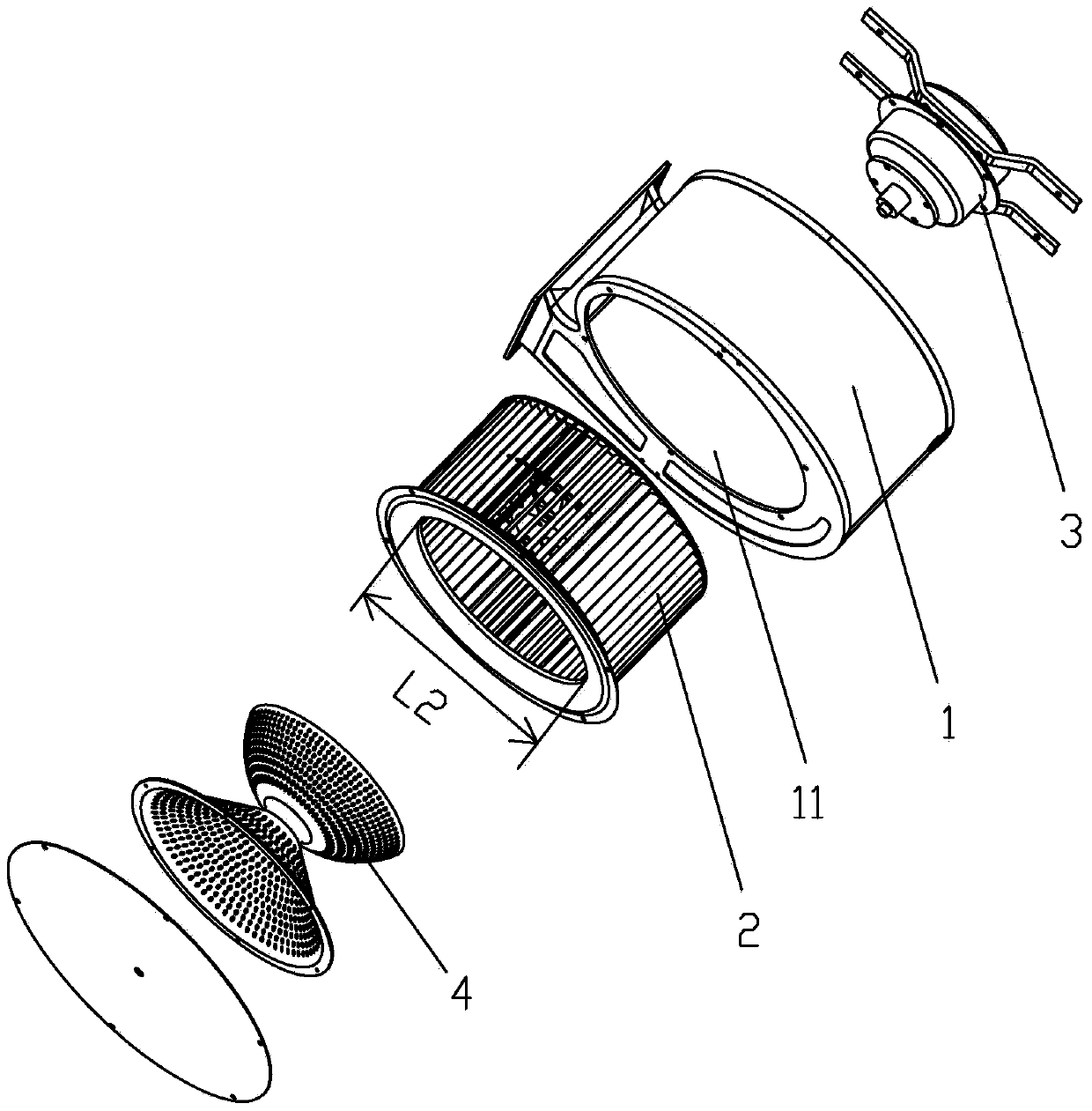

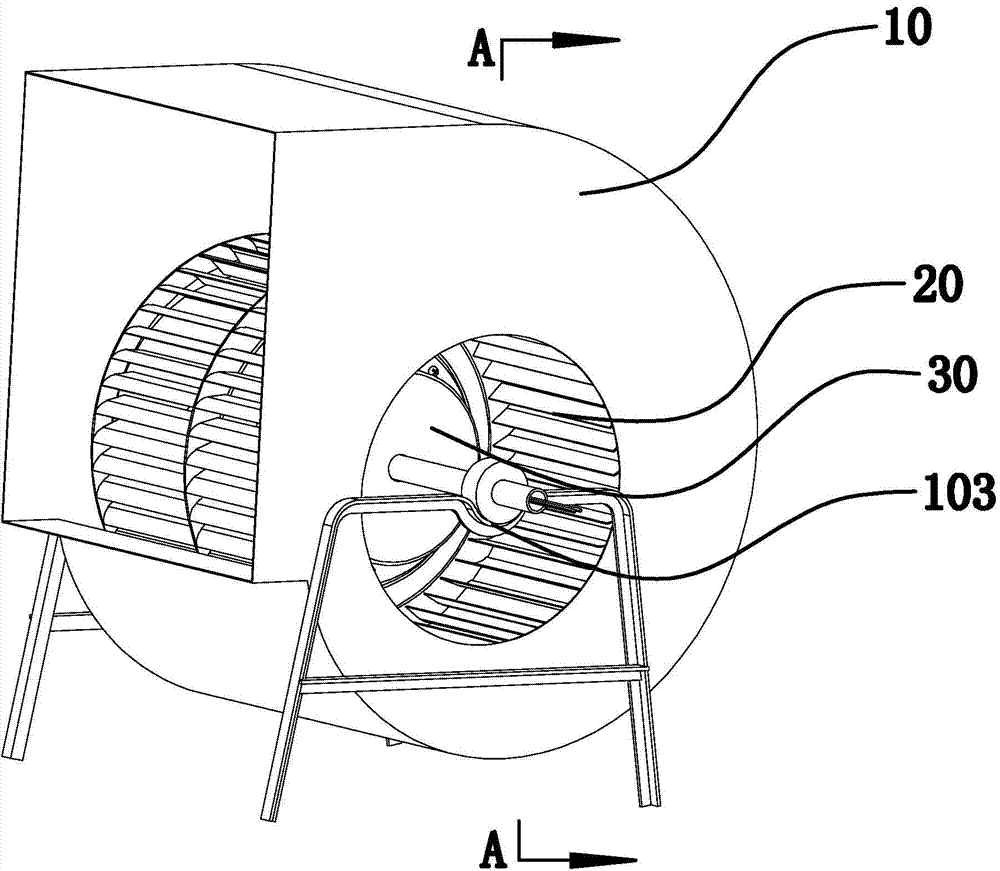

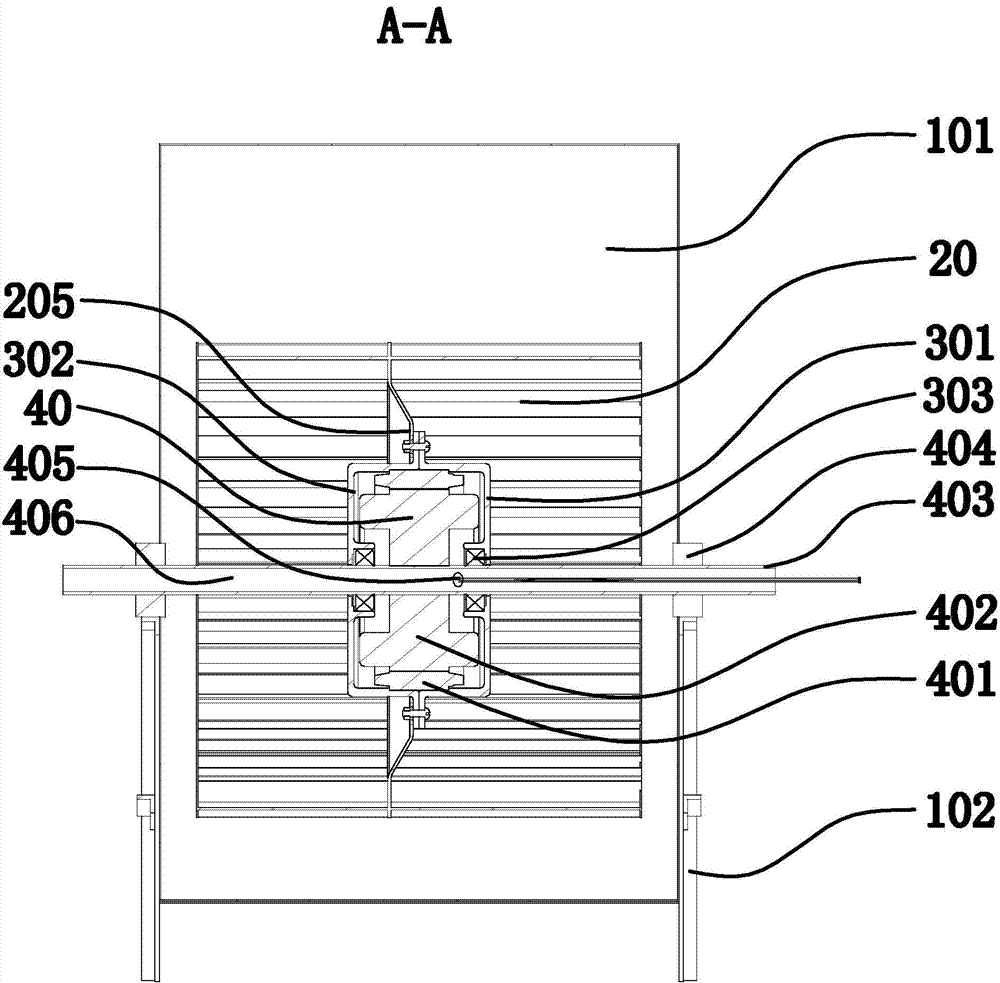

Air blower

The invention provides an air blower, belonging to the technical field of air blowers and solving the problems of low concentricity rate, high noise and inconvenience in mounting of existing air blowers. The air blower comprises a shell, motor mounting seats, impellers and a motor, wherein the motor mounting seats, the impellers and the motor are arranged in the shell, the impellers are mounted on the motor mounting seats, the motor is mounted in the motor mounting seats and can drive the impellers to rotate, and a support shaft penetrates through the motor and is bridged on the shell; the impellers comprise inner steel rings and outer steel rings, two sides of the inner steel rings are uniformly wound with fan blades, one ends of the fan blades are fixedly connected with the inner steel rings, the other ends of the fan blades are fixedly connected with the outer steel rings, the inner steel rings are provided with motor grooves, the motor mounting seats are arranged in the motor grooves, and the center of the motor coincides with the centers of the impellers. The air blower has the advantages of small movement, high concentricity rate, convenience in machining and simplicity in detaching.

Owner:NINGBO HUJIANG ELECTRIC MOTOR

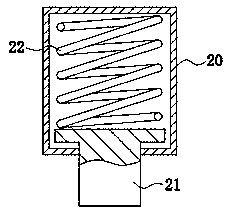

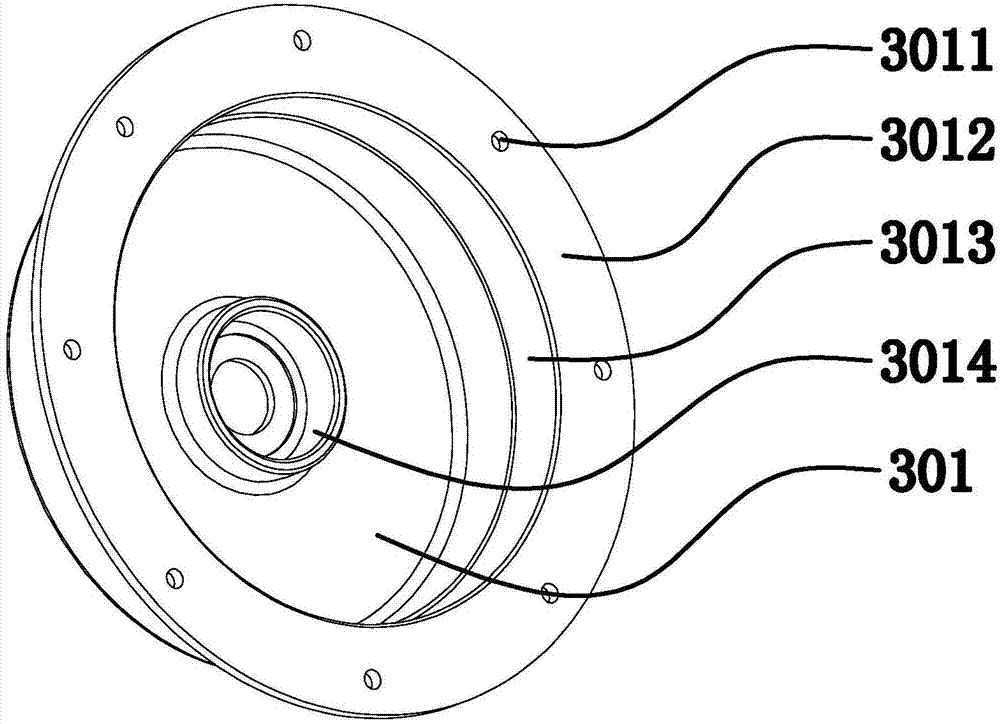

Medical atomizer

The invention provides a medical atomizer which comprises a liquid medicine cavity, wherein an air inlet is formed in the lower end of the liquid medicine cavity; one section of injection pipe is arranged by extending upwards from the air inlet; a collider is arranged above the injection pipe; a mist outlet is formed in the side face of the liquid medicine cavity; the upper end of the liquid medicine cavity is sealed by a funnel-shaped sealing plate; the center of the sealing plate is downwards communicated with a liquid medicine pipe; the liquid medicine pipe comprise more than two spiral coil pipes which are mutually connected in series; all the spiral coiled pipes are arranged in the liquid medicine cavity from top to bottom in a parallel manner; the lower end of the liquid medicine pipe is transversely communicated to the injection pipe. When the medical atomizer is used, even if the medical atomizer is positioned in a shake or turnover state, liquid medicine can be stably atomized, and actual operation is facilitated.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

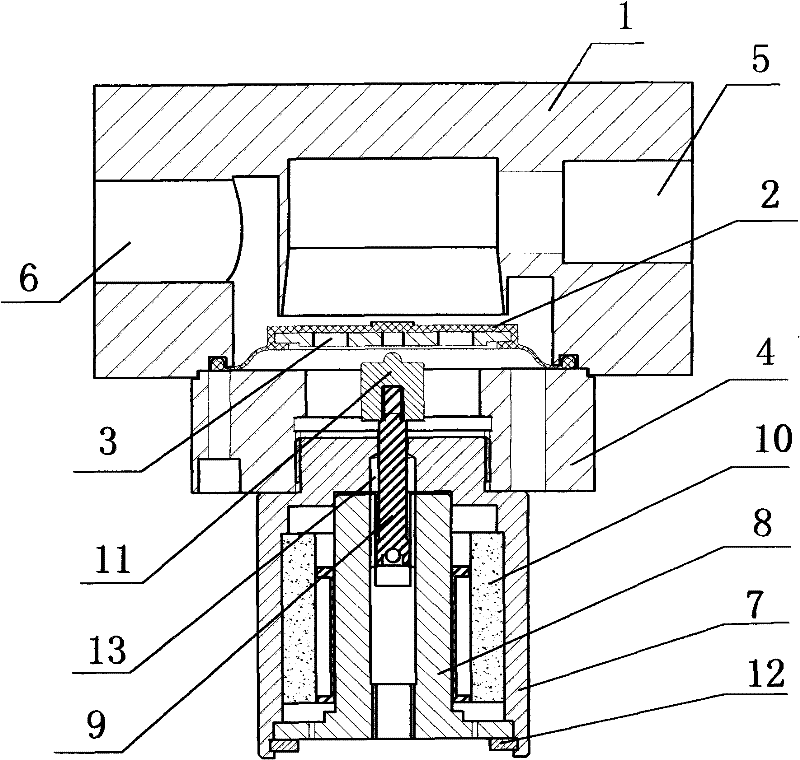

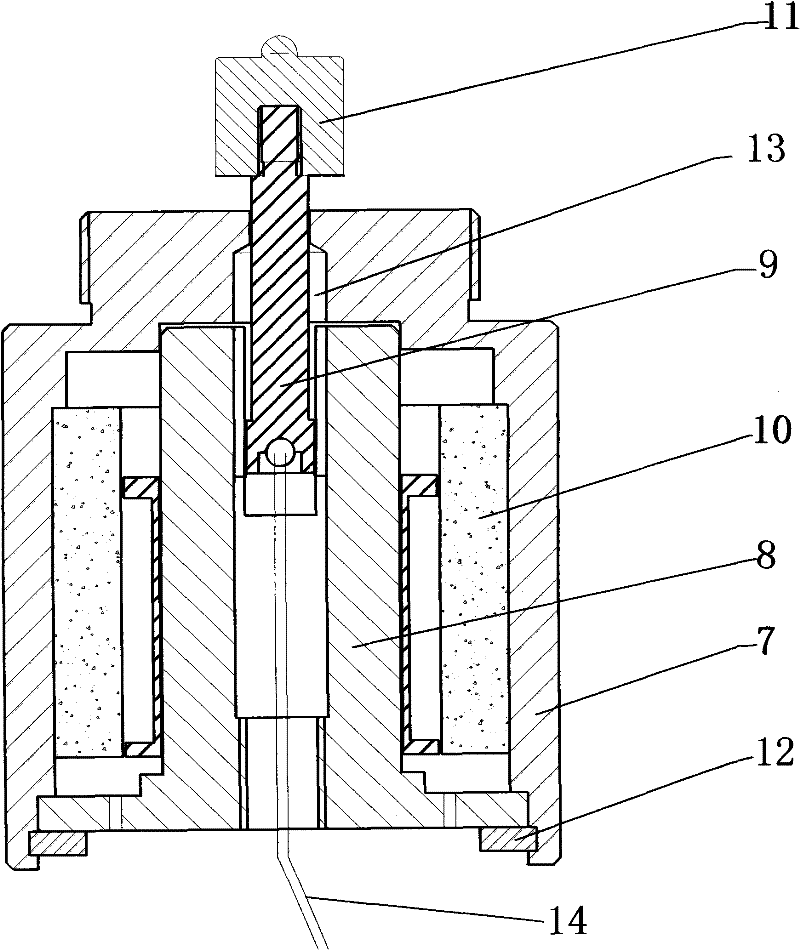

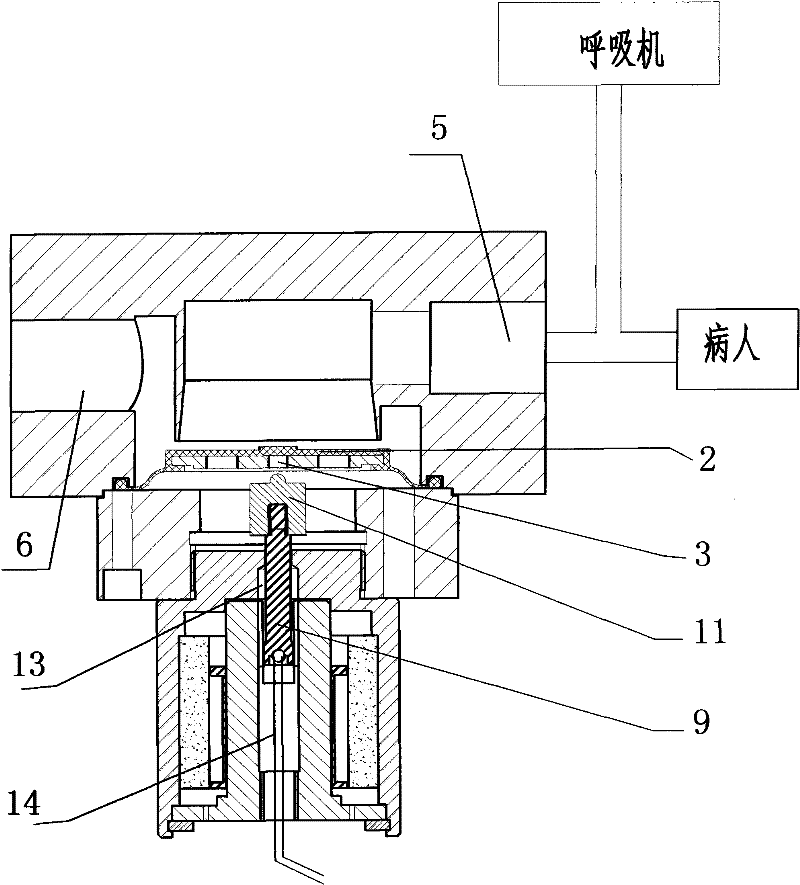

Microprocessor controlled expiratory valve

The invention discloses a microprocessor controlled expiratory valve, which comprises a valve body, a diaphragm, a pressing plate, a gland and a pressure controller, wherein the pressure controller comprises an outer magnetic yoke, an inner magnetic yoke, a coil, a plurality of magnets, a pressing head and a clamping ring; the inner magnetic yoke is positioned in the outer magnetic yoke; the magnets are positioned between the outer magnetic yoke and the inner magnetic yoke and are tile-shaped, and the magnetization direction is radial and faces an N pole on one side and faces an S pole on the other side; the magnets are uniformly distributed in an inner cavity of the outer magnetic yoke; the inner magnetic yoke is provided with a radial guide groove; one end of the coil is positioned in the guide groove, and the other end is provided with the pressing head; the clamping ring is positioned at the bottom of the outer magnetic yoke; and the outer magnetic yoke is provided with threads which are connected with the gland of the expiratory valve. A wire of the coil is connected with a microprocessor control circuit, and on and off of input current and amplitude of the current are controlled by a microprocessor, so that end-expiratory pressure of a patient can be accurately controlled.

Owner:BEIJING AEROSPACE CHANGFENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com