Measurement packing method for powder containing air

A technology of metering packaging and gas powder, which is applied in the field of metering and packaging of gas-containing powders, can solve problems affecting subsequent transportation, palletizing and stacking, poor metering accuracy, and low utilization rate of packaging bags, etc. Stable and reliable, ensure suction, ensure powder flow and the effect of packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

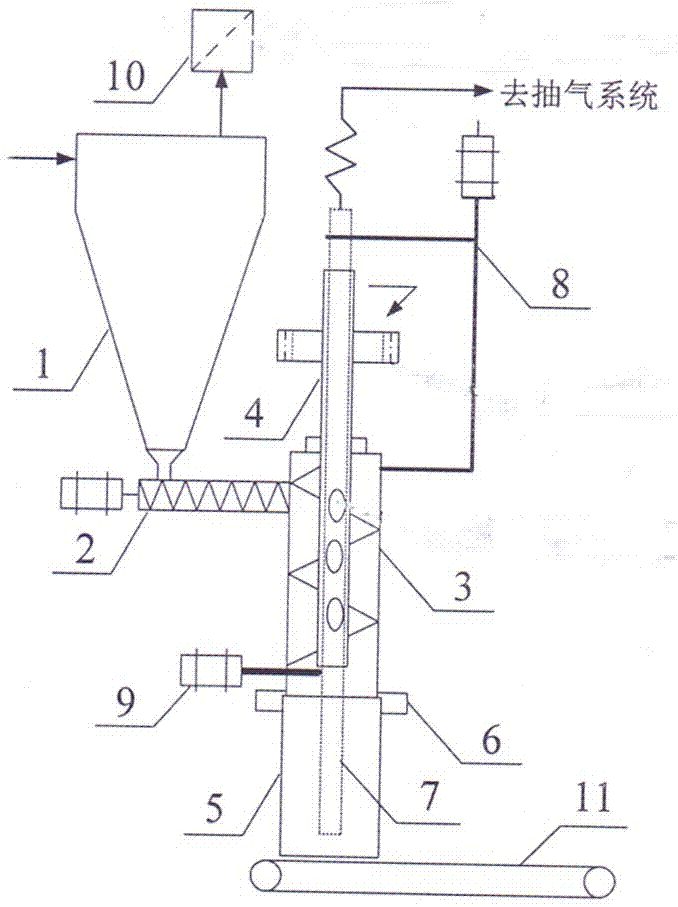

[0024] A metering and packaging method for gas-containing powder, using a metering and packaging device for gas-containing powder; the metering and packaging device for gas-containing powder includes a powder silo, a bottom outlet of the powder hopper and a screw feeding The feed port of the screw feeder is connected with the feed port of the screw feeder and the middle material tank. The middle material tank is equipped with a hollow stirring shaft connected to the transmission mechanism. Concentric metal sintered filter rod, the upper end of the filter rod is connected with the air extraction system; the outer wall of the filter rod is close to the inner wall of the hollow stirring shaft, which not only meets the flexible rotation of the stirring device, but also makes the material adsorbed on the outside of the filter rod during the upward movement and suction process be cleared; the hollow stirring shaft is provided with a suction hole; the bottom of the middle material tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com