Patents

Literature

98results about How to "Reduce discharge pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

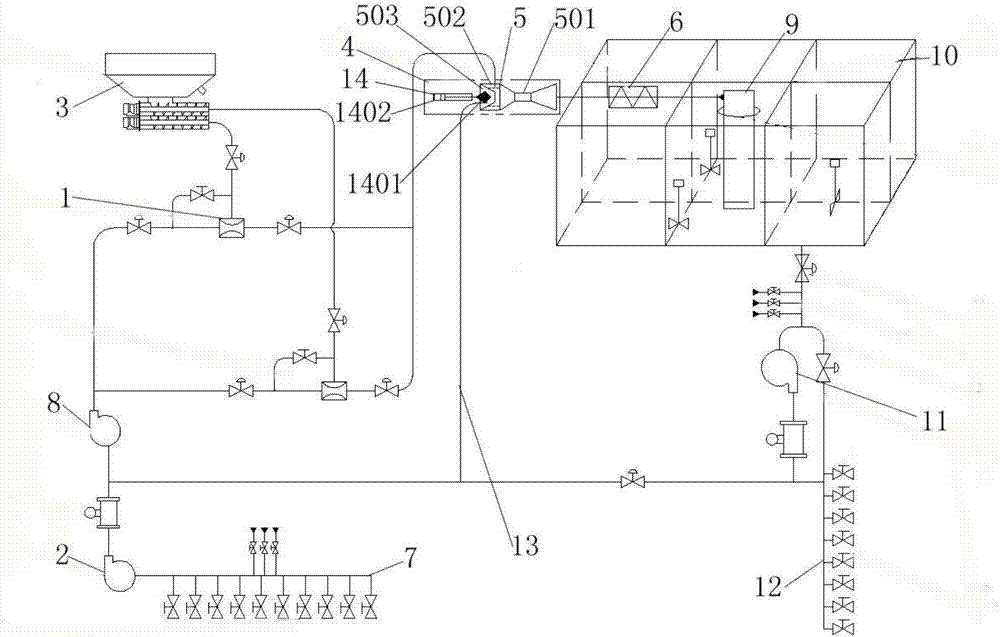

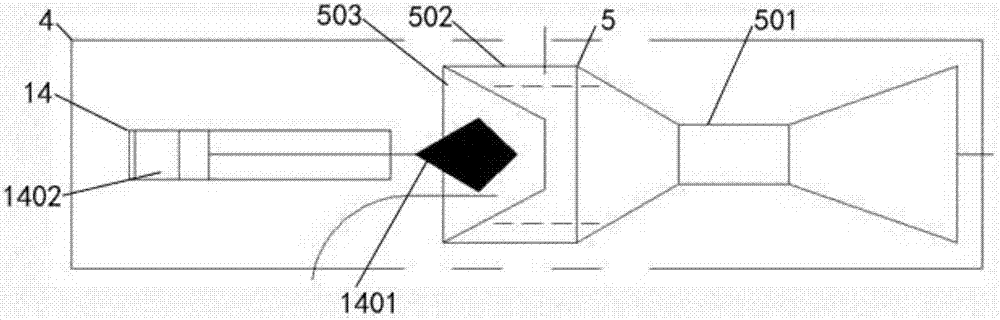

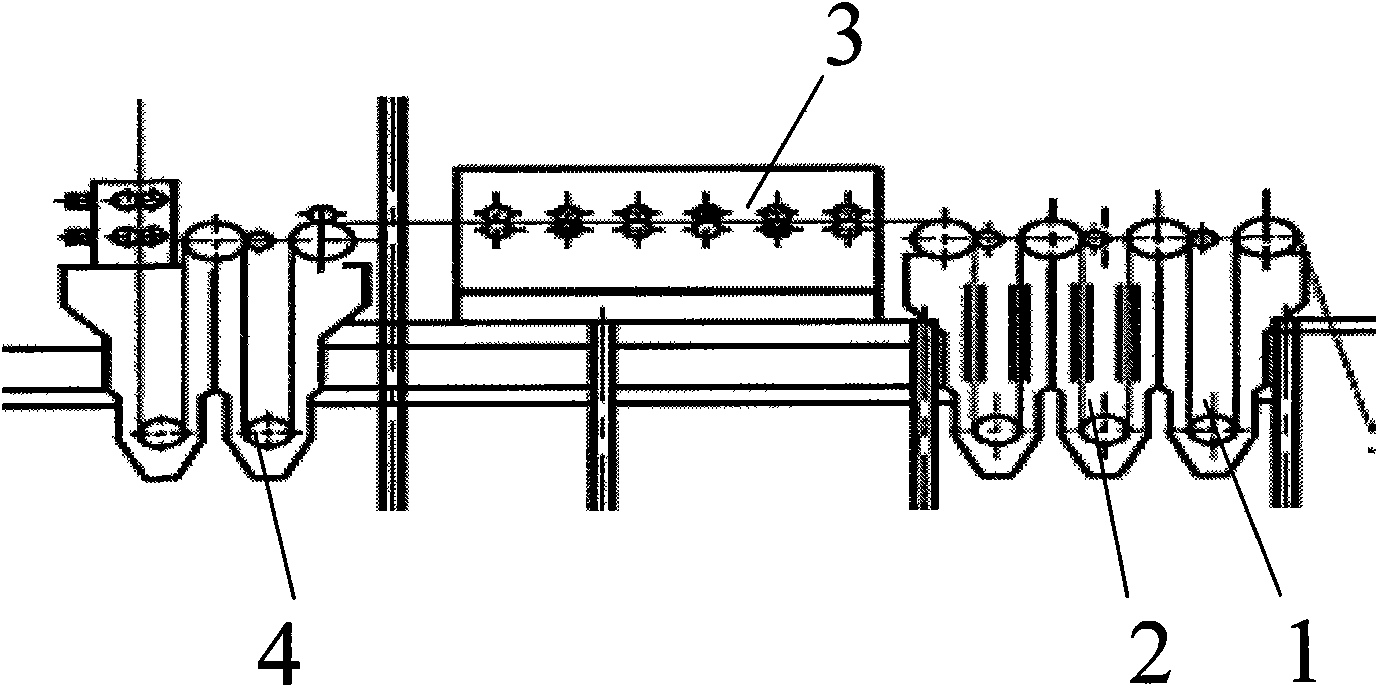

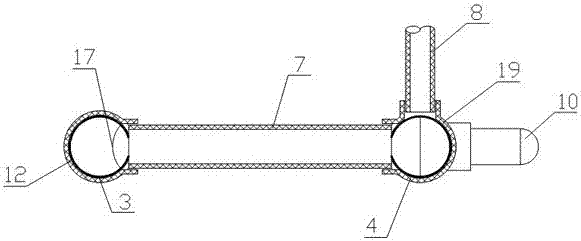

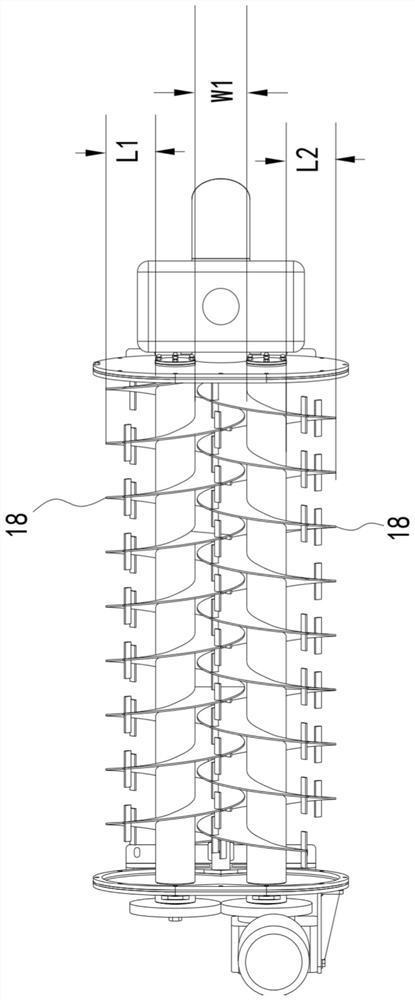

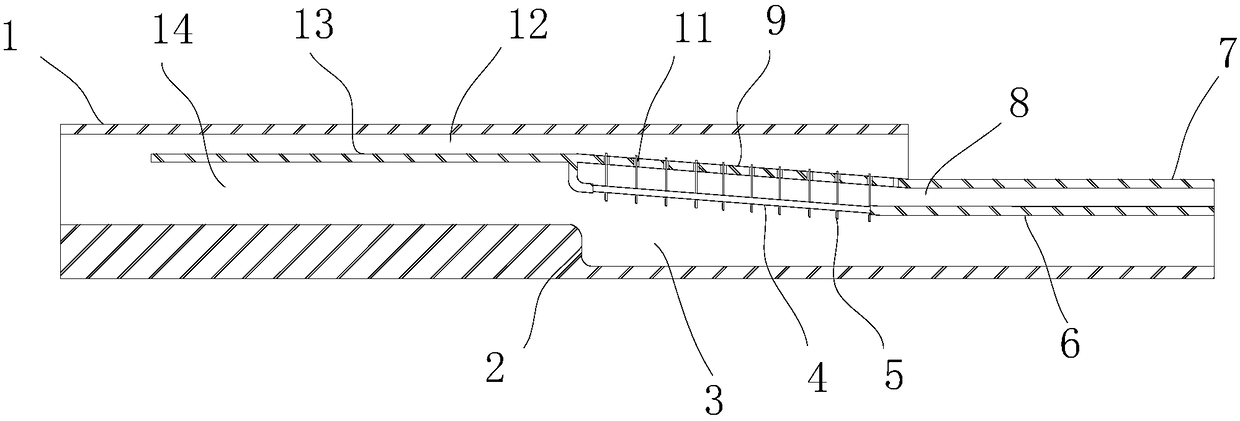

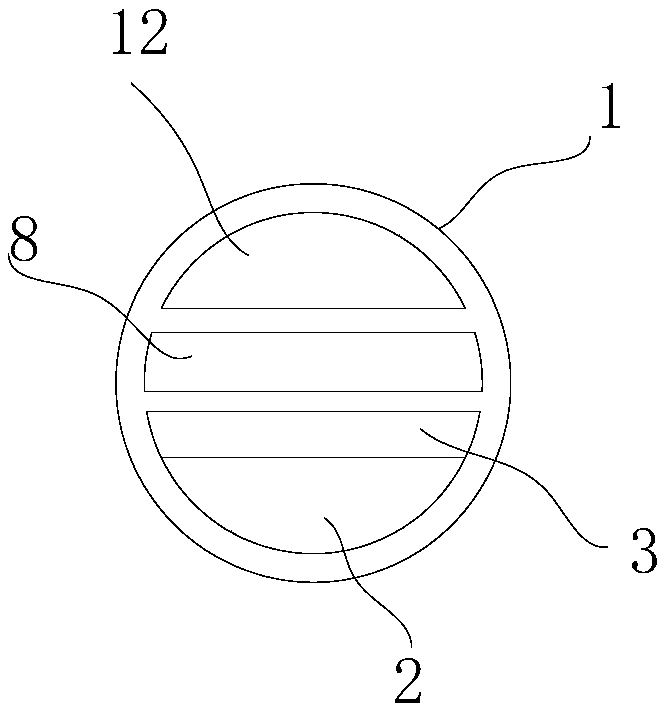

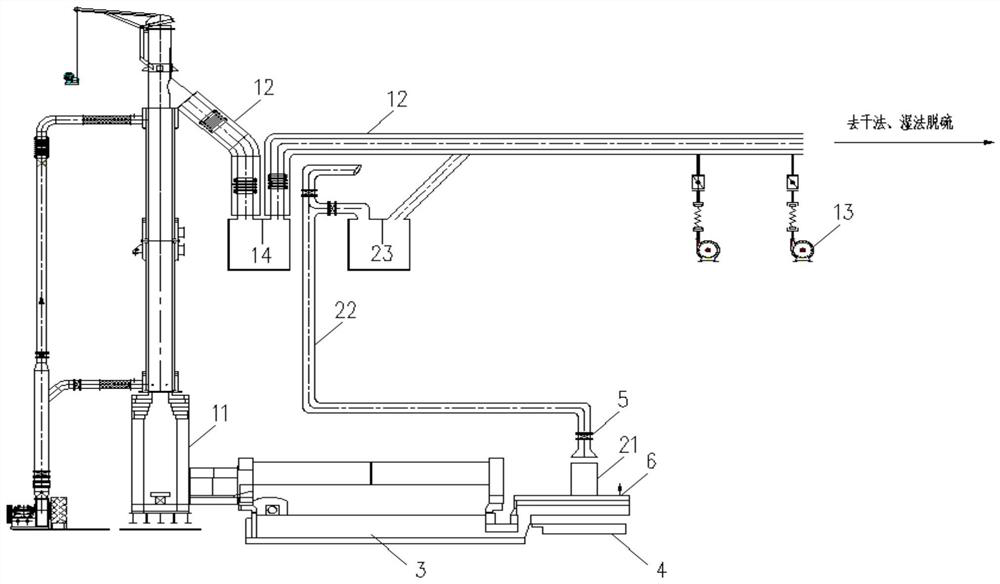

Mixing system of fracturing fluid and mixing method thereof

ActiveCN107159046AHigh work pressureReduce discharge pressureFlow mixersTransportation and packagingFluid viscosityFracturing fluid

The invention provides a mixing system of fracturing fluid, which comprises a first mixer, a base fluid supply piece and a powder supply piece; the first mixer is a jet mixer, and a base fluid input end of the first mixer is connected with the base fluid supply piece; a powder input end of the first mixer is connected with the powder supply piece, and the first mixer is linked in parallel with a parallel pipeline capable of conveying the base fluid; the base fluid input end of the parallel pipeline is connected with the base fluid output end of the base fluid supplier, and the first mixer is linked with a second mixer in series; the second mixer is a variable flow jet type mixer, a fracturing fluid input end of the second mixer is connected with a fracturing fluid output end of the first mixer; the base fluid input end of the second mixer is connected with the base fluid output end of the parallel pipeline. The mixing system of fracturing fluid can meet the emission and fluid viscosity of the fracturing fluid simultaneously.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD +1

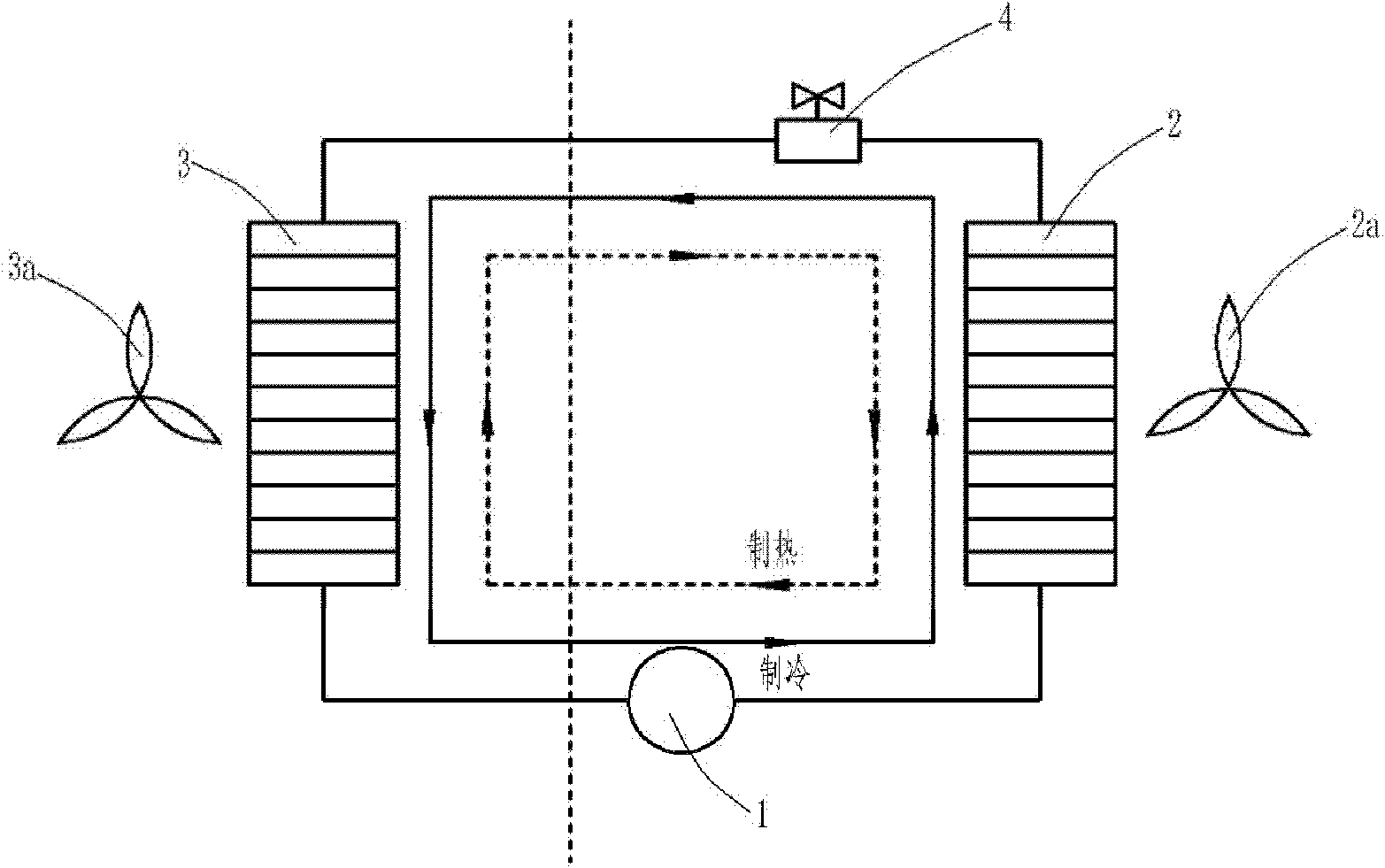

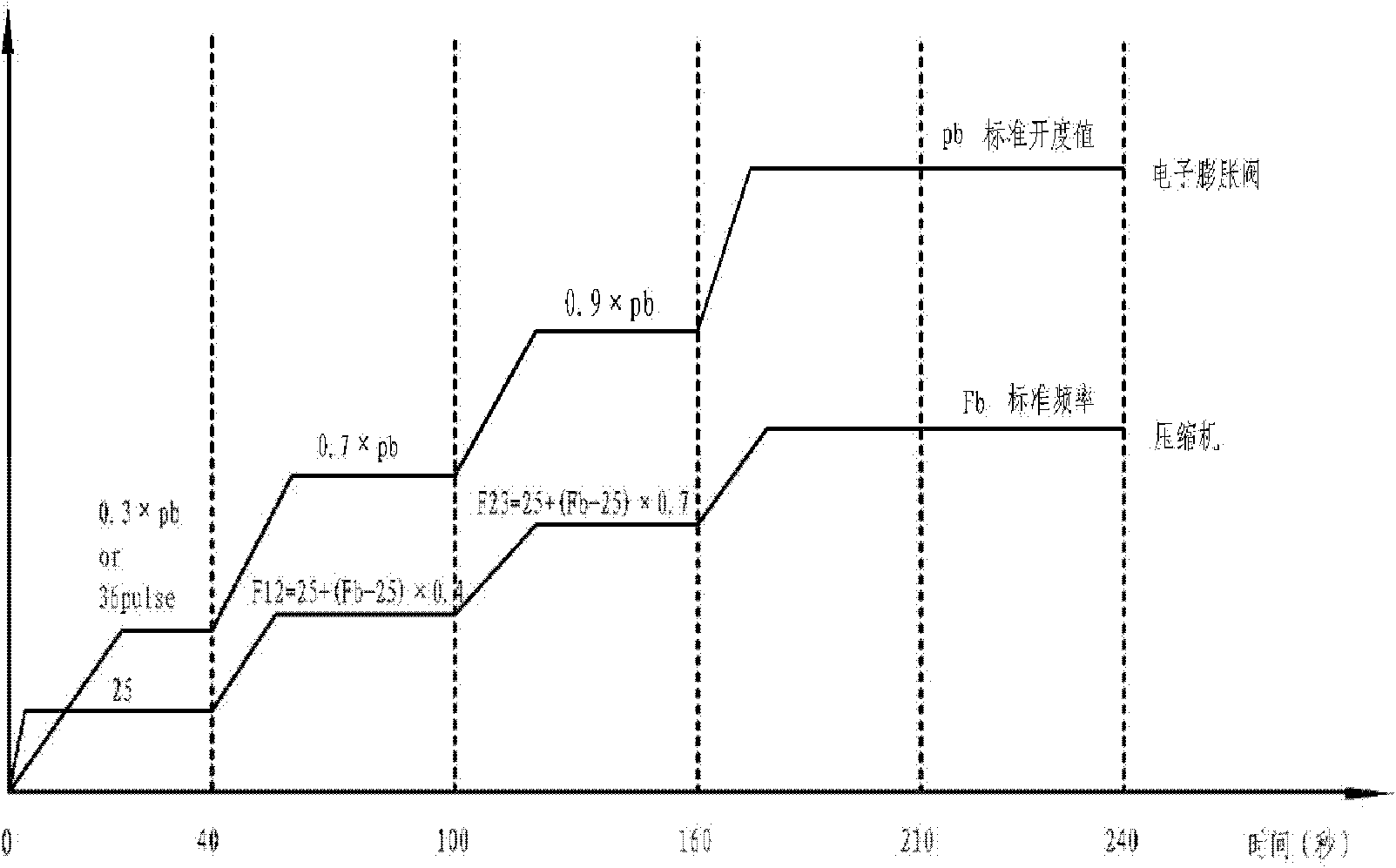

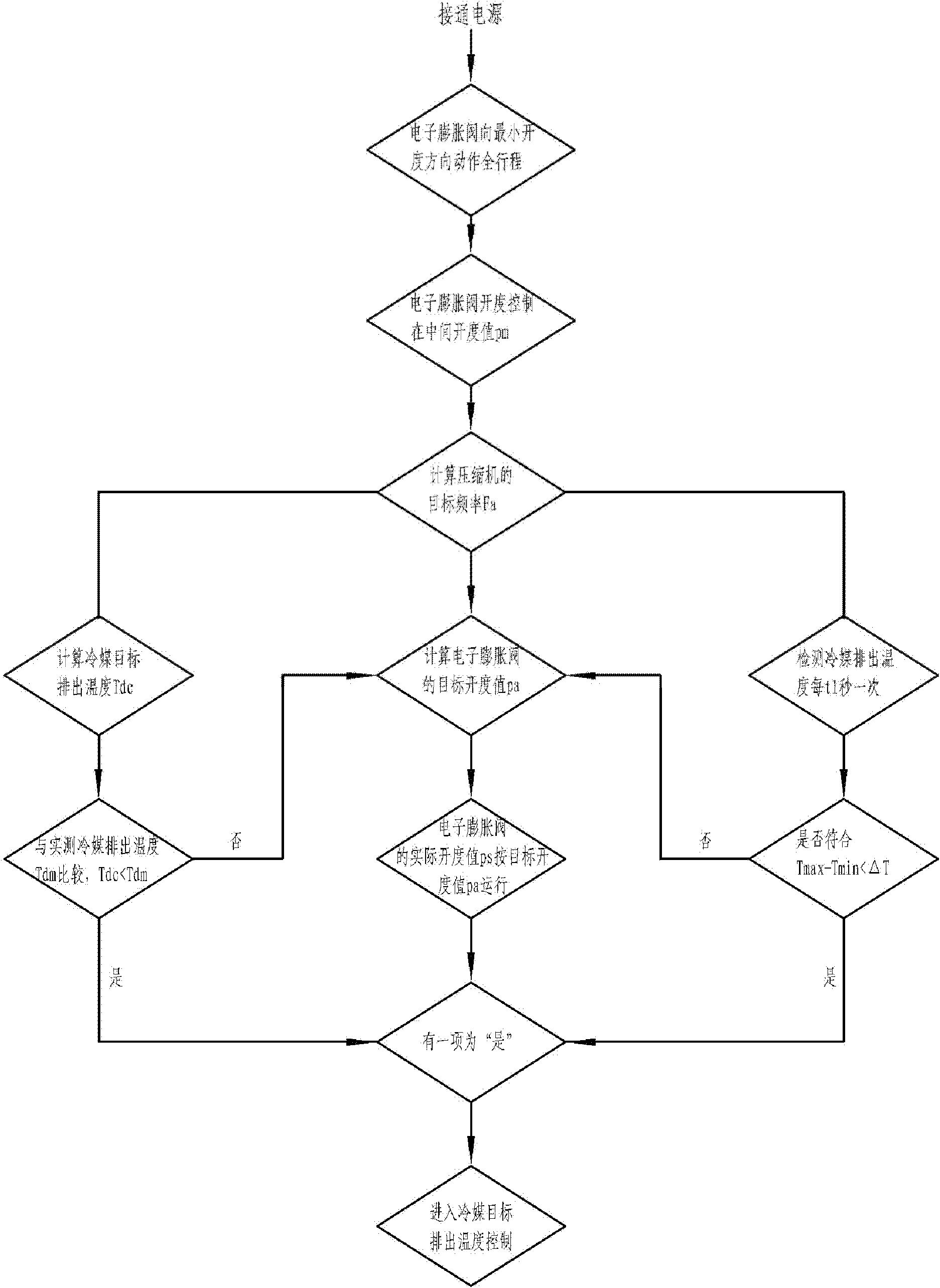

Method for controlling electronic expansion valve of variable-frequency air conditioner

ActiveCN102147174AReduce loadEasy to moveSpace heating and ventilation safety systemsSpace heating and ventilation control systemsTemperature controlEngineering

The invention discloses a method for controlling an electronic expansion valve of an air conditioner, which comprises initial aperture control and refrigerant target exhaust temperature control. When the air conditioner starts to operate, the electronic expansion valve is in an aperture after initialization, thereby being beneficial to the flow of a refrigerant, effectively reducing the exhaust pressure of the refrigerant, realizing the movement from the aperture after initialization to a target aperture value, shortening the stroke from the minimum aperture to the target aperture value, and effectively shortening the operating time. After the air conditioner operates, the aperture of the electronic expansion valve can be adjusted according to the outdoor air temperature which is measuredby a machine, the exhaust temperature of the refrigerant and the operating efficiency of a compressor, thus the aperture of the electronic expansion valve is controlled to be the optimum aperture value, the exhaust temperature of the refrigerant is effectively reduced, and the exhaust pressure of the refrigerant and the load of the air conditioner are reduced.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

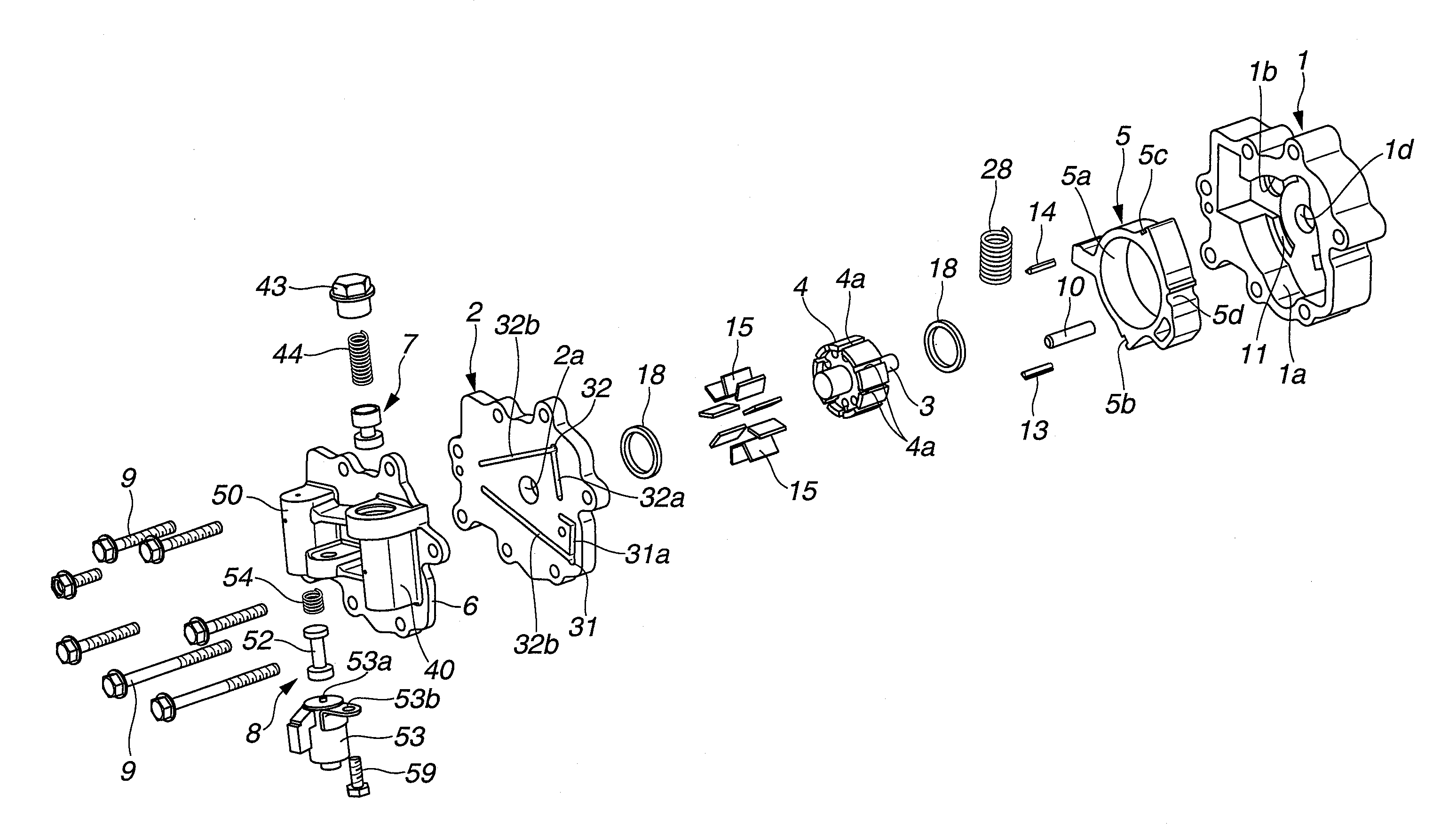

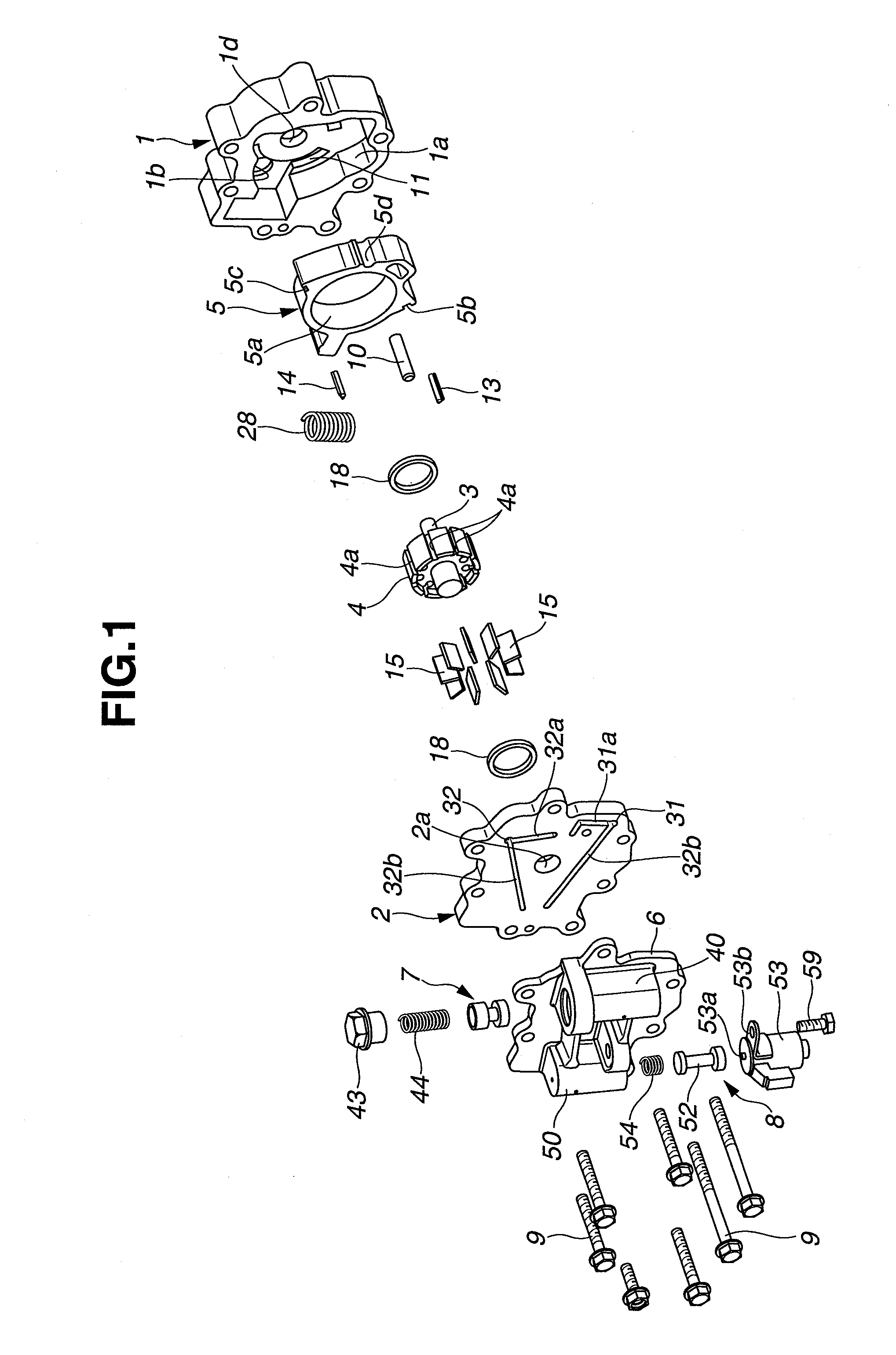

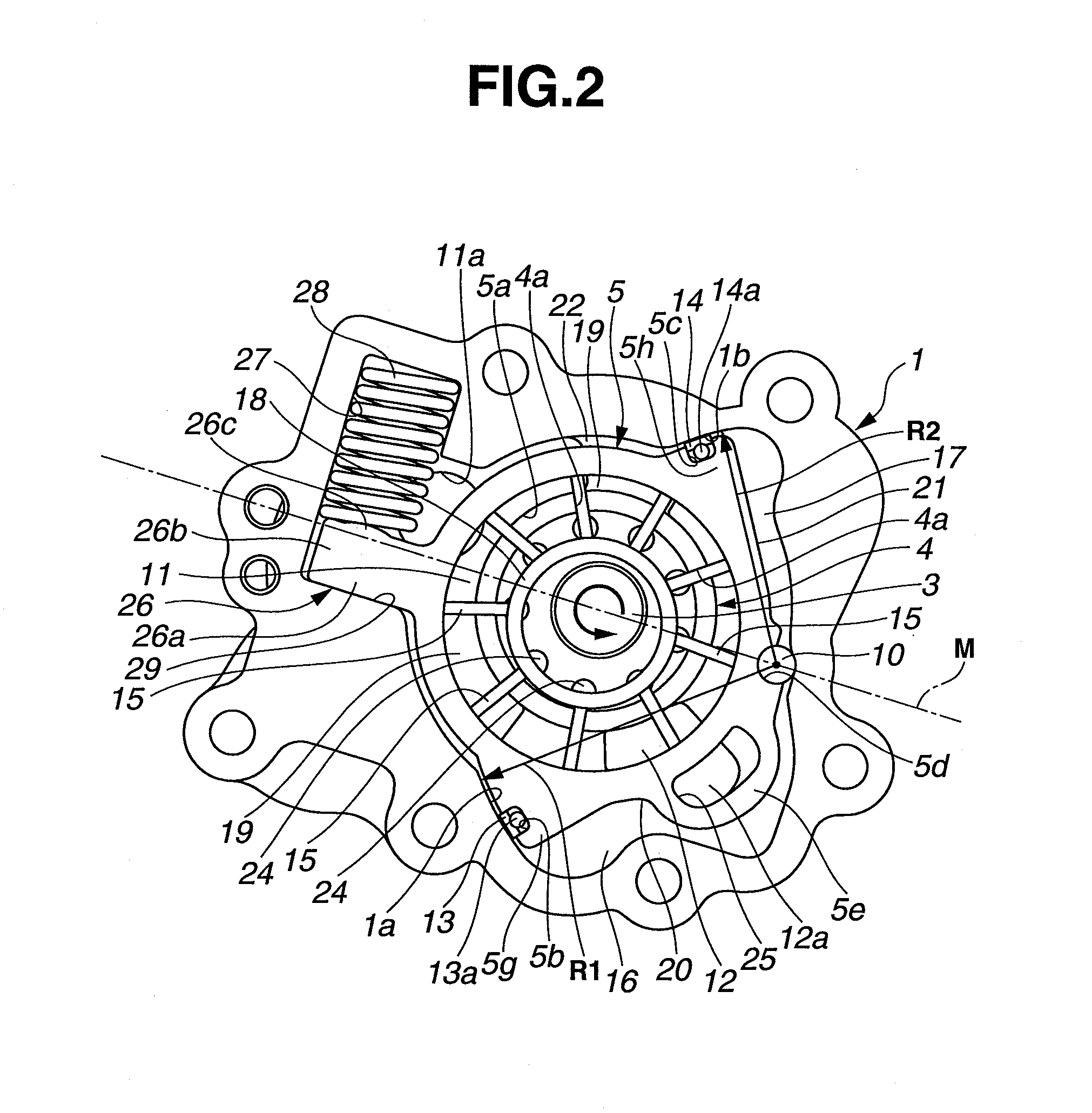

Variable displacement pump

ActiveUS20130164163A1Reduce discharge pressureEasy dischargeOscillating piston enginesRotary piston pumpsCamDischarge pressure

A variable displacement pump includes: a first control oil chamber which moves a cam ring toward a direction against a biasing force of a biasing member when a discharge pressure is introduced thereinto; a second control oil chamber which acts a hydraulic pressure upon the cam ring by cooperating with the biasing force of the biasing member when hydraulic oil is introduced thereinto; a switching mechanism which switches between one state in which hydraulic oil whose pressure is decreased than a discharge pressure is introduced to the second control oil chamber from the discharge section and another state in which hydraulic oil is discharged from the second control oil chamber; and a control mechanism operated before an eccentricity of the cam ring becomes a minimum and which discharges a greater amount of hydraulic oil within the second control oil chamber as the discharge pressure becomes larger.

Owner:HITACHI ASTEMO LTD

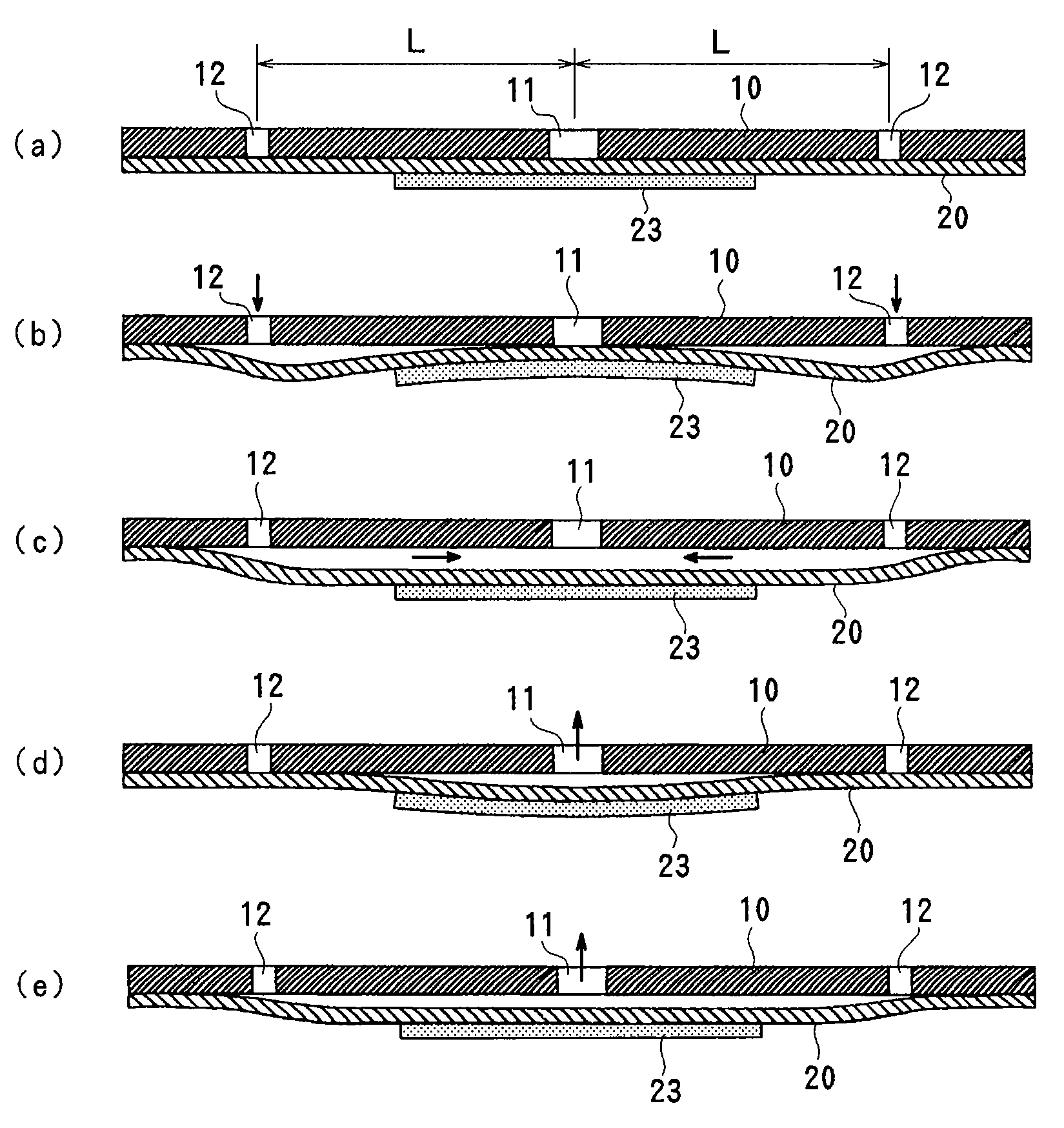

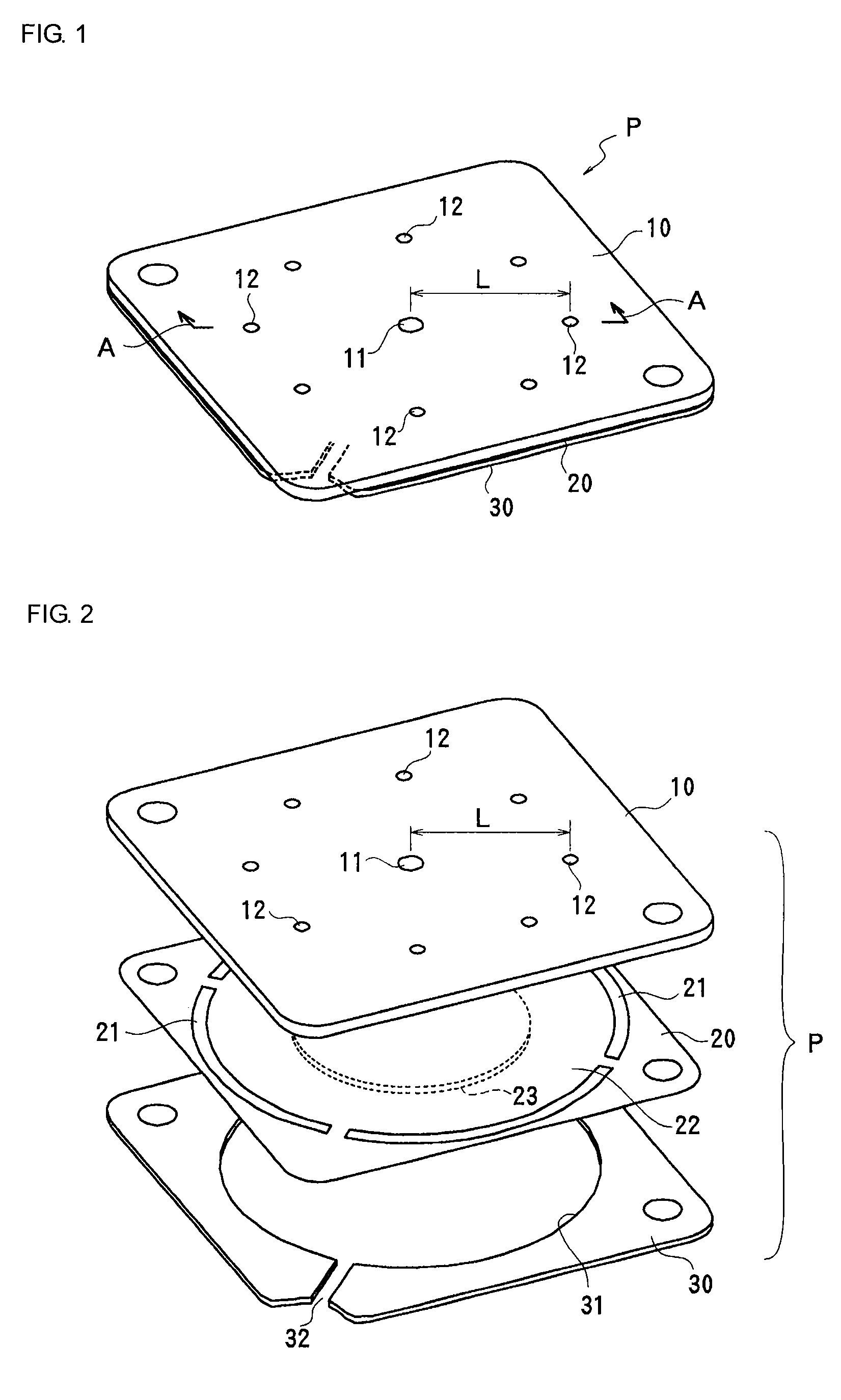

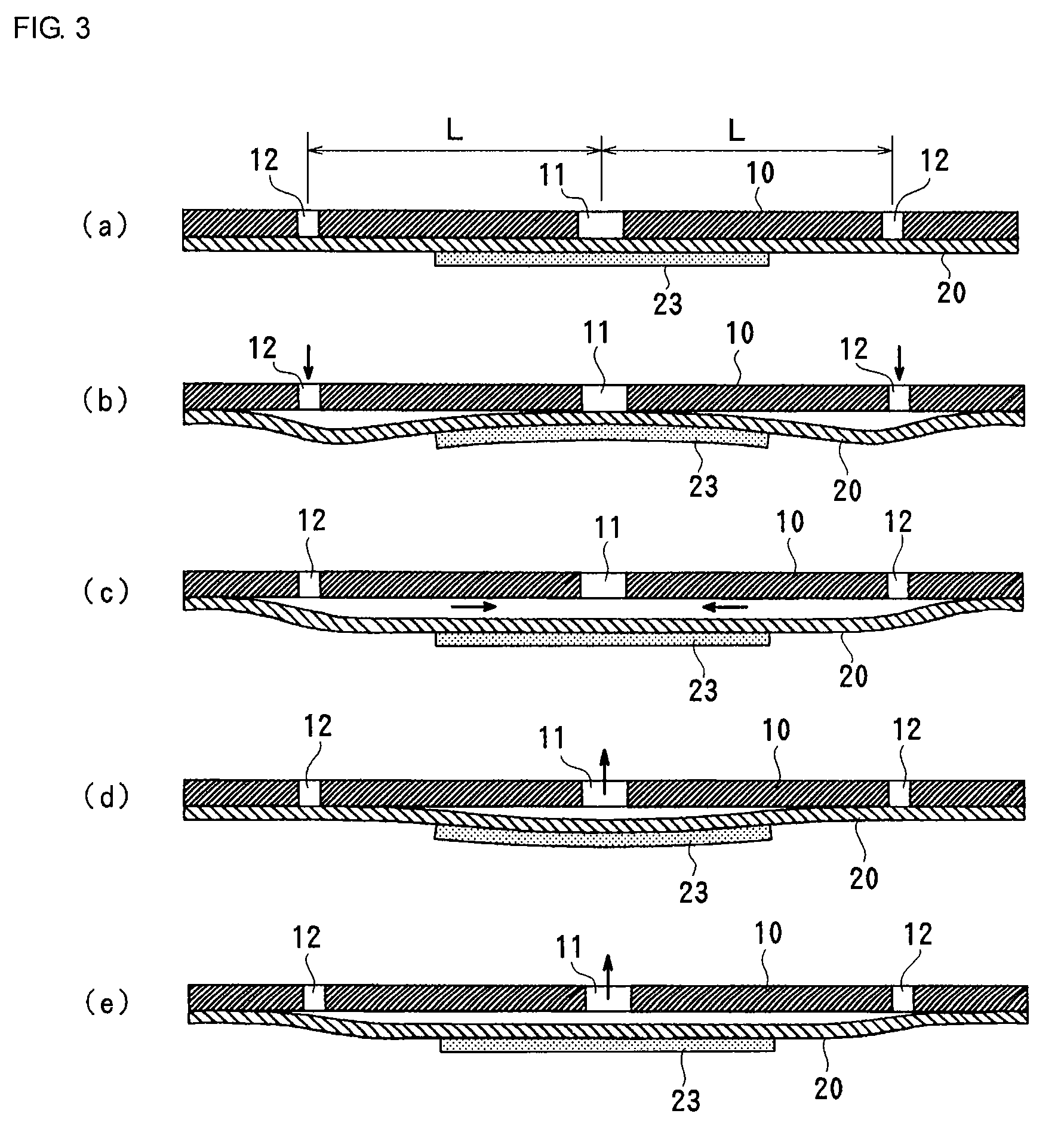

Piezoelectric Pump

InactiveUS20090148318A1Increase discharge pressureEffective bendingEngine fuctionsWorking fluid for enginesElectricityResonance

A piezoelectric pump having a first opening in a center portion of a pump body, and a second opening apart from the center. An outer peripheral portion of a metal diaphragm is fixed to the pump body, and a piezoelectric element having a size that covers the first opening and does not cover the second opening is bonded to a back center portion of the diaphragm. By applying a voltage near the resonance frequency to the piezoelectric element, a portion of the diaphragm opposing the first opening and a portion of the diaphragm opposing the second opening are bent in opposite directions so that fluid is drawn in from one of the first opening and the second opening and is discharged from the other opening. Such a piezoelectric pump can increase the discharging pressure, and can reliably discharge the fluid even under a condition where the pressure on the discharging side is high.

Owner:MURATA MFG CO LTD

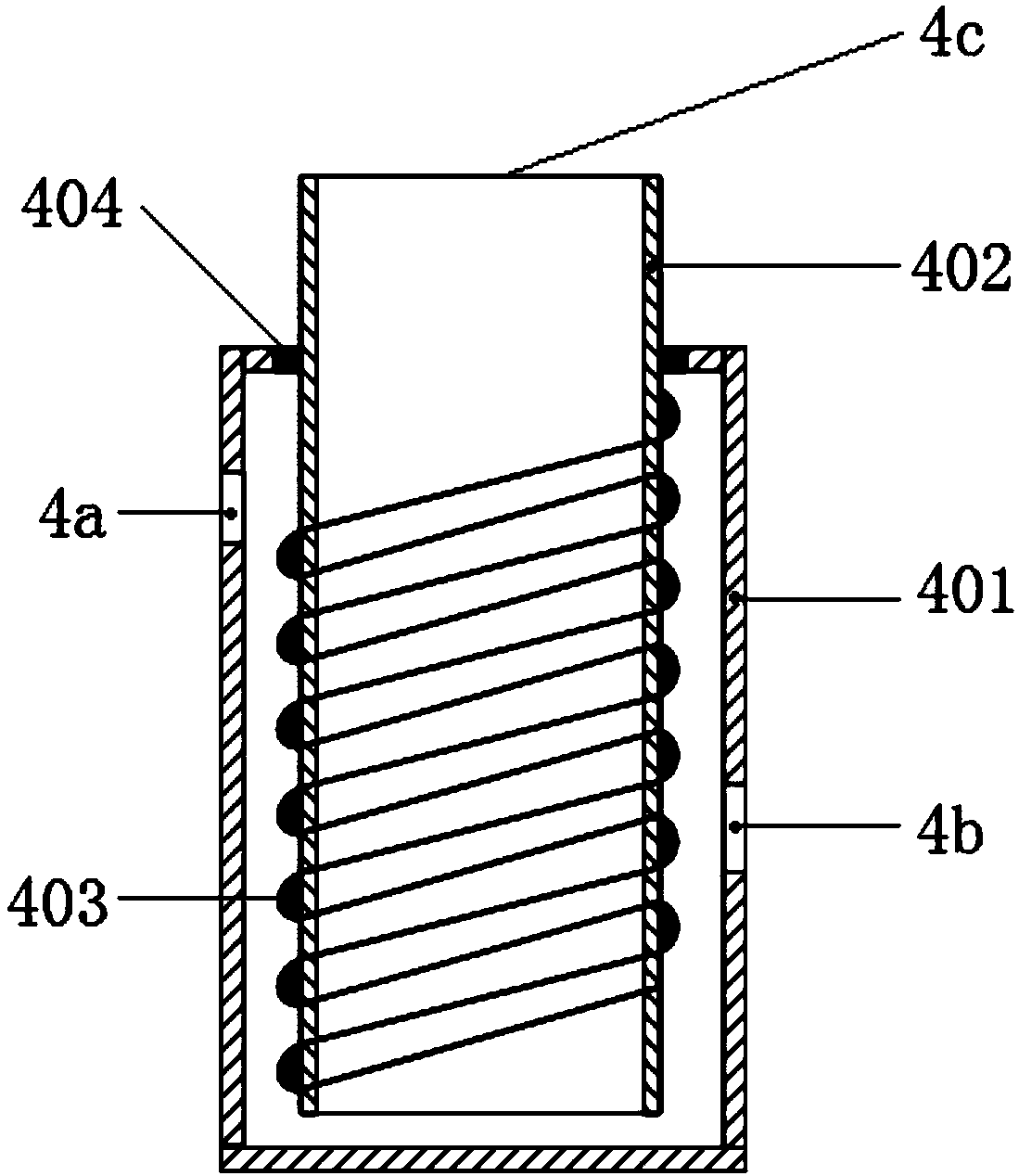

Cooling module and cooling system for vehicle

ActiveCN105492232AImprove efficiencyReduce loadAir-treating devicesEvaporators/condensersComputer moduleHigh pressure

A cooling module (1000) of the present invention comprises: a first radiator (100) for cooling an engine; a second radiator (200) which is located at the front side of the first radiator (100) in an air flowing direction, and which cools electric components; a first condenser (300) which is located at the front side of the second radiator (200) in the air flowing direction, and which condenses a refrigerant by exchanging heat with outside air; and a second condenser (400) which is provided inside the second radiator (200), and which condenses a refrigerant by exchanging heat with an electric component coolant. Thus, the cooling module (1000) of the present invention enables a high-temperature and high-pressure refrigerant to pass through the air-cooled first condenser (300) after passing the water-cooled second condenser (400) so as to increase cooling efficiency of the refrigerant, thereby improving the efficiency of a cooling system (2000) for a vehicle.

Owner:HANON SYST

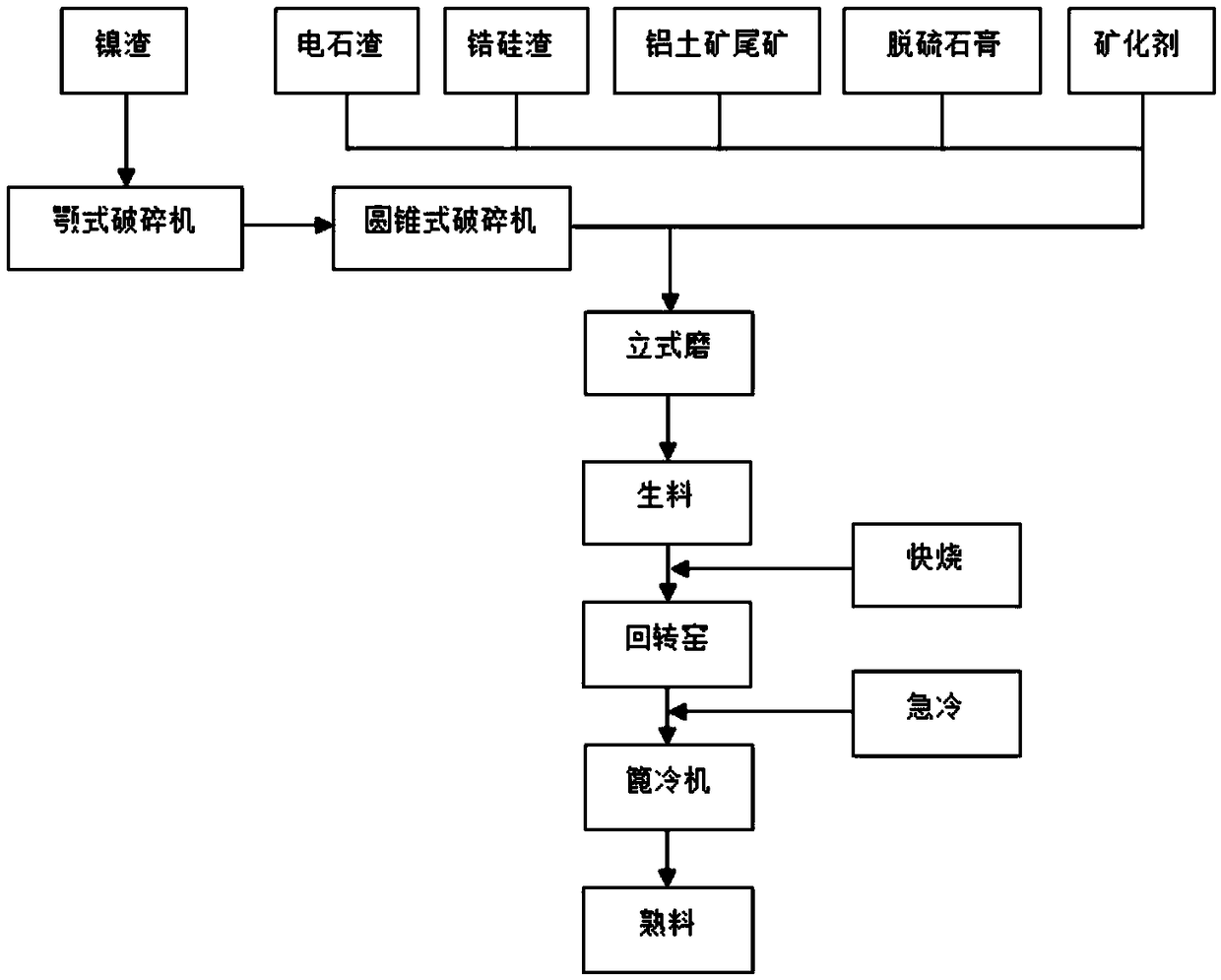

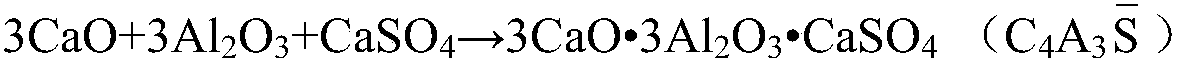

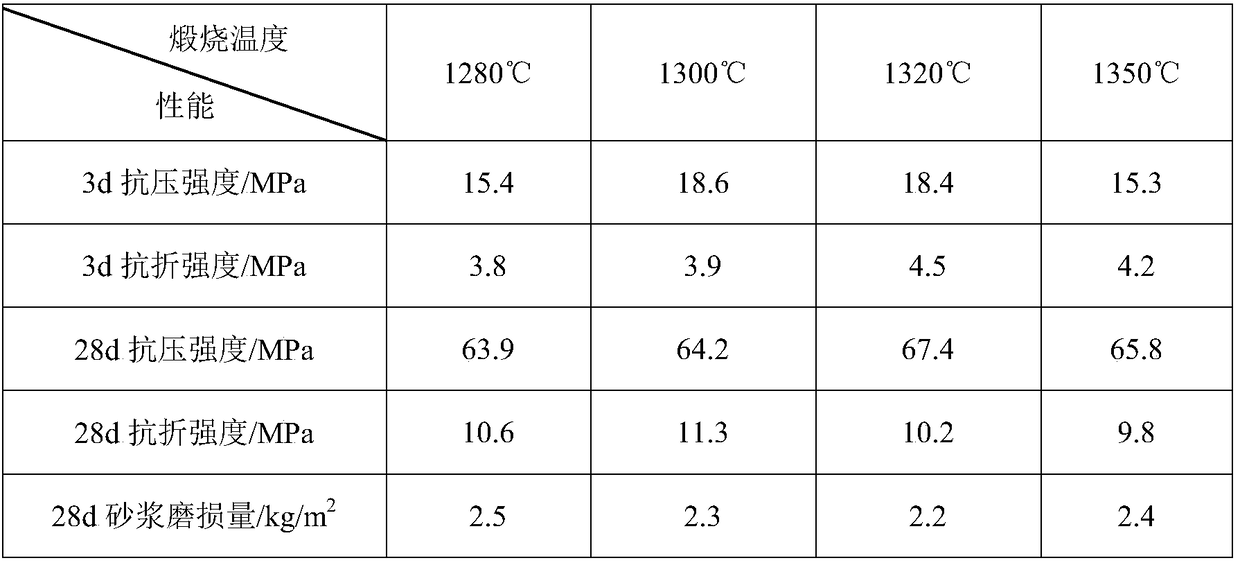

Road silicate cement clinker on basis of industrial waste residues and method for preparing road silicate cement clinker

ActiveCN109081615AStrong mechanical propertiesReduce consumptionCement productionSlagToxic industrial waste

The invention discloses road silicate cement clinker on the basis of industrial waste residues and a method for preparing the road silicate cement clinker. The road silicate cement clinker comprises nickel slag, calcium carbide residues, zirconium-containing silica residues, bauxite tailing, desulfurization gypsum and mineralizers. The method includes mixing, grinding and homogenizing the nickel slag, the calcium carbide residues, the zirconium-containing silica residues, the bauxite tailing, the desulfurization gypsum and the mineralizers to obtain cement raw materials; preheating the cementraw materials, then calcining the cement raw materials under the condition of the temperature of 1280-1350 DEG C for 30-35 min and then carrying out cooling to obtain the road silicate cement clinker.The road silicate cement clinker and the method have the advantages that the 28 d compressive strength of the road silicate cement clinker can reach 63.9-75.2 MPa, the strength grade of the road silicate cement clinker can reach 62.5 grade, the 28 d breaking strength of the road silicate cement clinker can reach 9.8-18.2 MPa, the 28 d mortar abrasion loss of the road silicate cement clinker is lower than 2.5 kg / m<2>, cement is high in stability, and the road silicate cement clinker is high in abrasion resistance and excellent in work performance; the method is simple, complicated working procedures can be omitted, and the road silicate cement clinker and the method are low in cost.

Owner:哈尔滨太行兴隆水泥有限公司

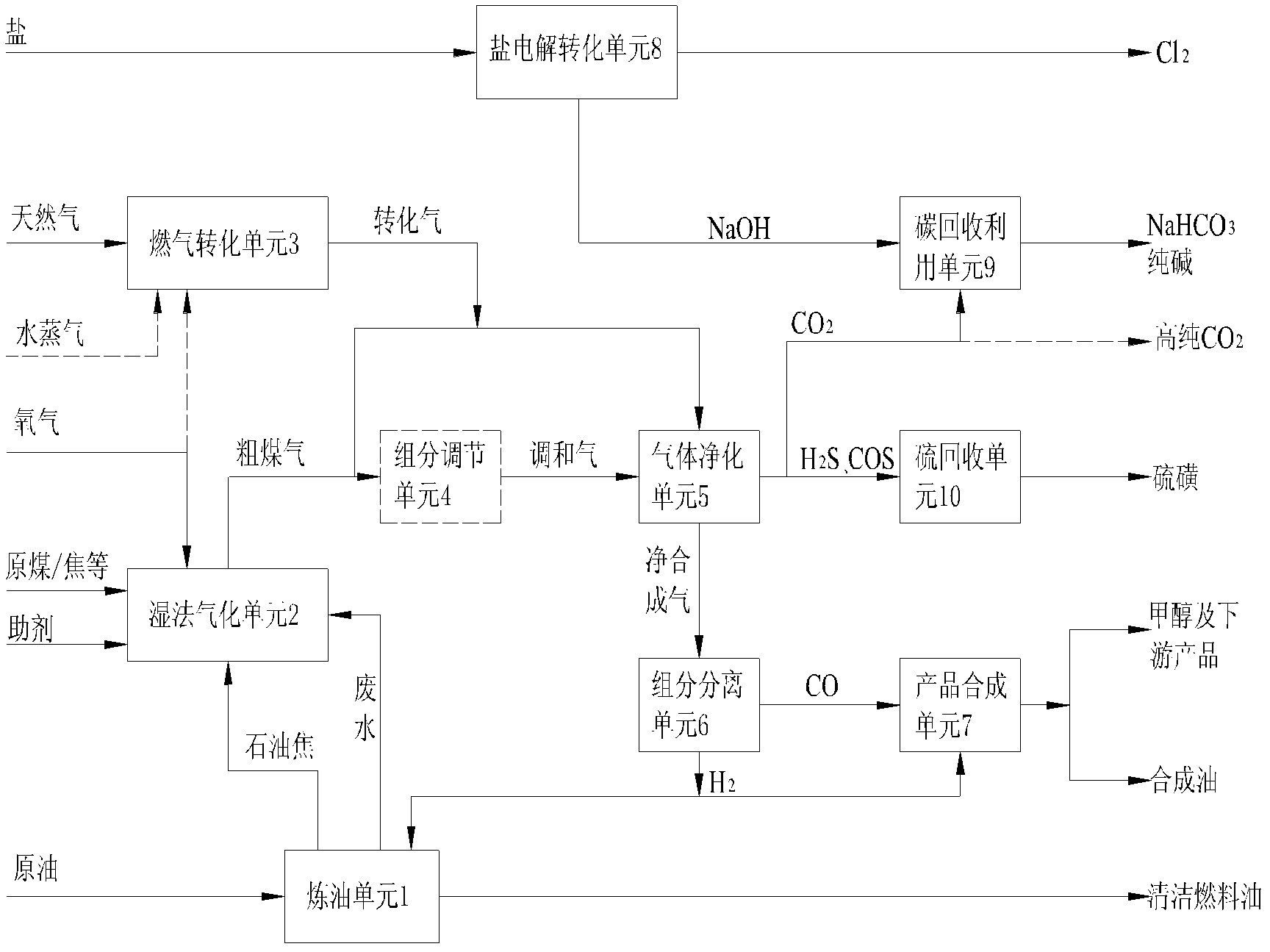

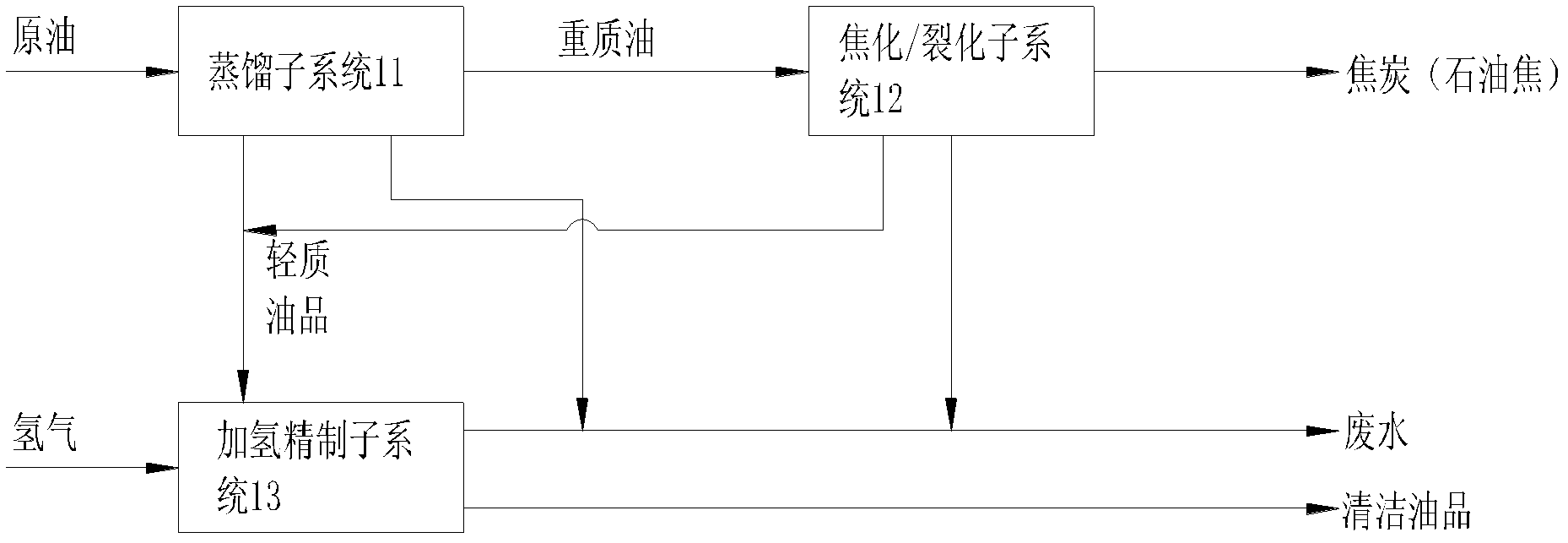

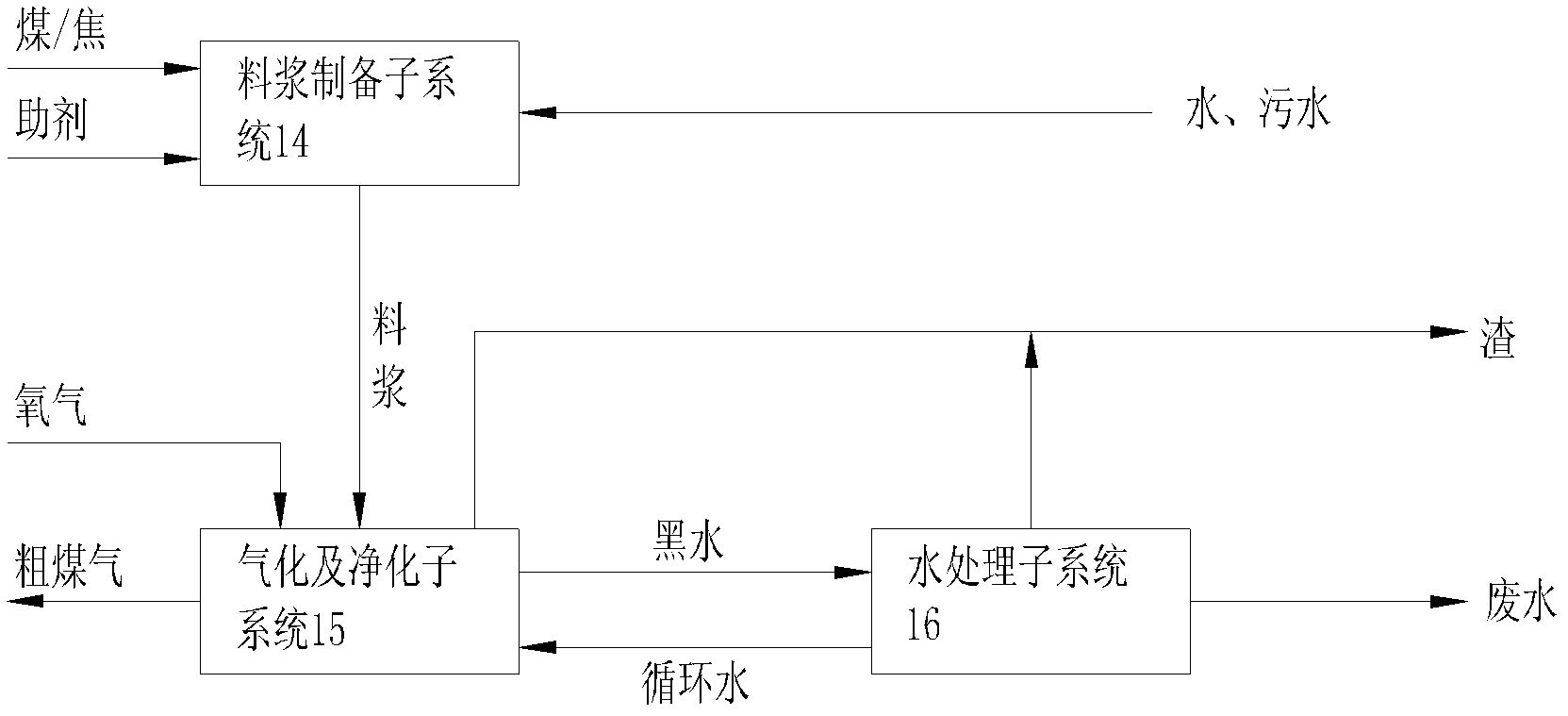

Method for co-producing various chemical products by taking coal, petroleum, natural gas and salt as raw materials

ActiveCN102660330ASolve the problem of clean utilizationQuality improvementHydrogenOrganic compound preparationOil processingElectrolysis

The invention relates to a method for co-producing various chemical products by taking coal, petroleum, natural gas and salt as raw materials. The method includes the steps of petroleum processing, slurry gasification, natural gas conversion, chemical product synthesis and salt electrolysis conversion. By reasonably using the coal, the petroleum, the natural gas and the salt resources, the energyand chemical overall goals of saving non-renewable resources and relieving environmental pollution can be achieved, and construction basis, solution and technical support are provided for Chinese large and super-huge energy industry base construction.

Owner:SHAANXI YANCHANG PETROLEUM GRP +1

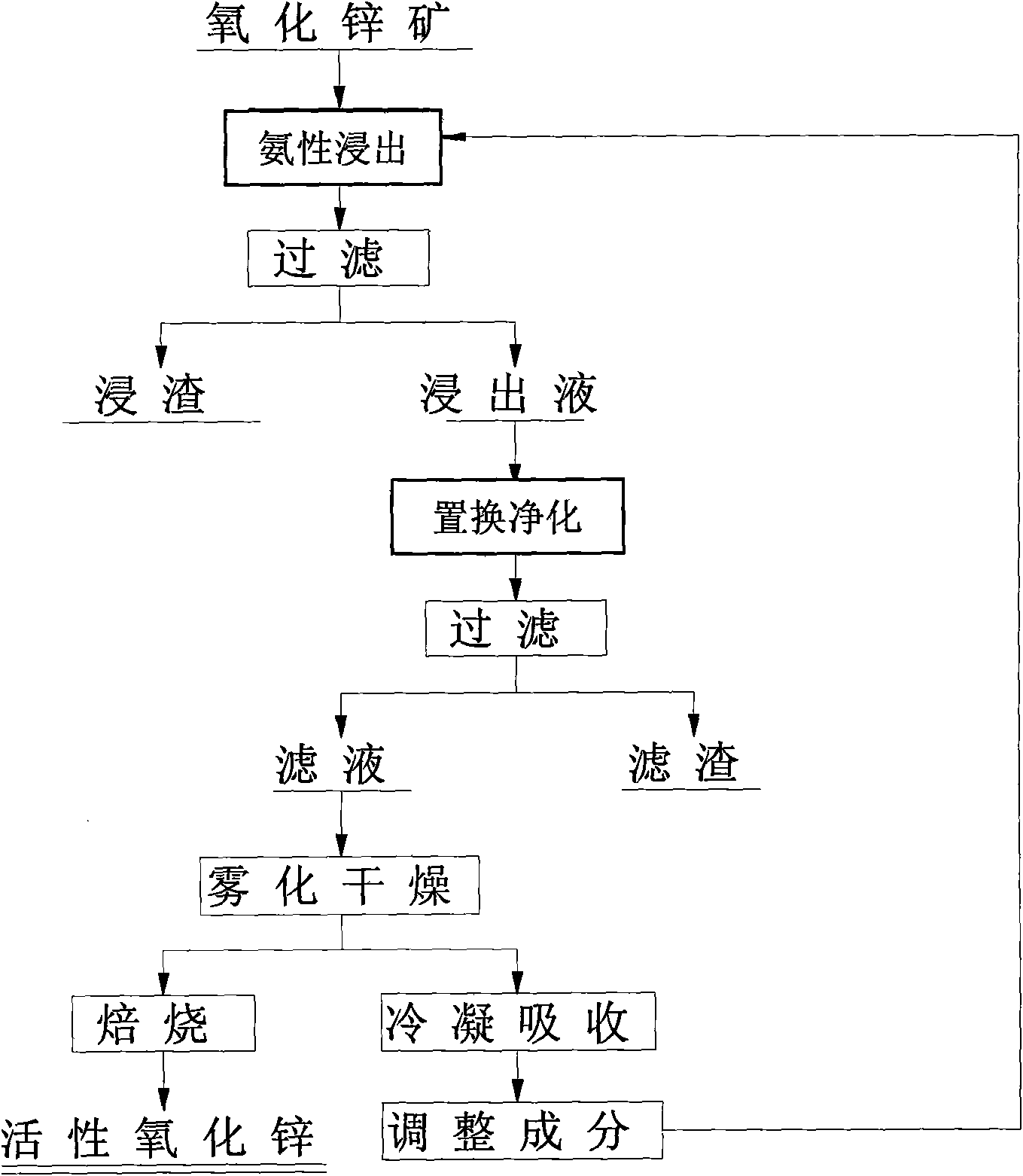

Method for processing zinc oxide ore or zinc oxide secondary resource to prepare superfine active zinc oxide

The invention relates to a method for processing zinc oxide ore or zinc oxide secondary resource to prepare superfine active zinc oxide. The method comprises the following steps: ammonium leaching: using zinc oxide ore containing 2-60% of zinc or complex zinc oxide secondary resource as raw material, extracting in an ammonium system coordinately, filtering to remove the residue, wherein the filtrate is applied to the next process; replacement and purification: replacing and purifying the extracted filtrate with zinc powder to eliminate impure elements, and then filtering and removing the residue, wherein the filtrate is applied to the next process; pulverization and drying: decomposing the purified filtrate through high-temperature pulverization to prepare powder A, condensing, spraying and absorbing the tail gas which is then returned to the leaching process to prepare the extracting agent; and toasting: toasting the powder A to obtain superfine active zinc oxide. The purified liquidcan be used for directly preparing even powder through efficient pulverization and drying. The technological process of the method has a circular loop so that a small amount of waste gas and waste water is discharged. The method has a rational tail gas heat exchanger. Ammonia gas is recycled in a condensing manner to prepare the leaching liquid. The rest of the ammonia gas is absorbed through spraying, thereby reducing the discharge pressure of three wastes, namely, waste gas, waste water and industrial residue.

Owner:JIANGXI UNIV OF SCI & TECH

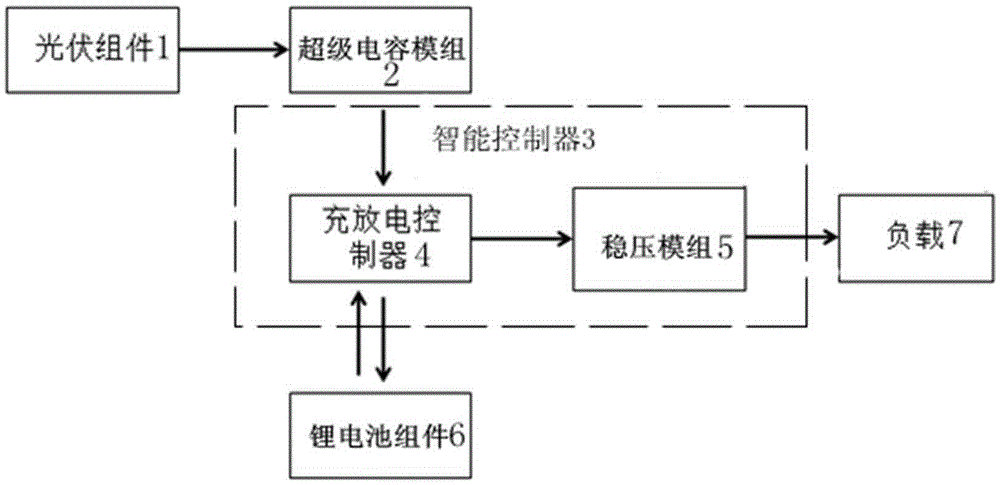

Long-acting integrated power supply system based on thin-film solar battery and charging method

ActiveCN105391157ALight in massReduce weightBatteries circuit arrangementsElectric powerVoltage regulator moduleLow voltage

The invention discloses a long-acting integrated power supply system based on a thin-film solar battery. The long-acting integrated power supply system comprises energy storage equipment which comprises a thin-film photovoltaic module, a super capacitor module, a charging and discharging controller, a voltage regulator module and a lithium battery component, wherein an output end of the thin-film photovoltaic module is connected with an input end of the super capacitor module; the output end of the super capacitor module is connected with the input end of the charging and discharging controller; the output end of the charging and discharging controller is connected with the voltage regulator module; the lithium battery component is connected with the charging and discharging controller; the thin-film photovoltaic module is a flexible or rigid thin-film solar battery; and the rated voltage of the thin-film photovoltaic module is higher than the maximal voltage of the lithium battery component. According to the long-acting integrated power supply system, which is light, efficient and long in lifetime, based on the thin-film solar battery and the charging method, the weak light power generating performance of the thin-film photovoltaic module and the low-voltage charging performance of the super capacitor are fully utilized; and the long-acting integrated power supply system has the advantages of efficient weak light power generation and high overall system efficiency.

Owner:浙江尚越新能源开发有限公司

Method for plating chrome on surface of thin plate

The invention discloses a method for plating chrome on a surface of a thin plate. The method comprises the following steps: 1) alkali washing, including alkali liquor leaching, electrolysis washing and alkali washing; 2) pickling, including electrolysis pickling and acid washing; 3) electroplating, including chromeplating and washing; and 4) oiling. The method sufficiently utilizes the performance advantage of CrO3+NH4 plating solution, optimizes the pre-treatment pickling process and electroplating parameters, particularly controls the solution concentration of alkali washing and pickling, strictly controls the current efficiency of an electroplating section and the electroplating concentration, overcomes the defects in the tradition process, generates compact metal chrome and chromic oxide layers on the surface of strip steel, realizes one-step production of an electrolytic chromium steel plate the strip steel surface of which is plated with optimally combined metal chromium and chromic oxide so as to obtain the excellent chromeplated plate with bright and uniform plating layer. Meanwhile, the method saves energy consumption, reduces pressure environment-friendly emission, reduces cost for production and maintenance, and creates a condition for improving the chromeplated plate, thus having excellent popularization and application prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

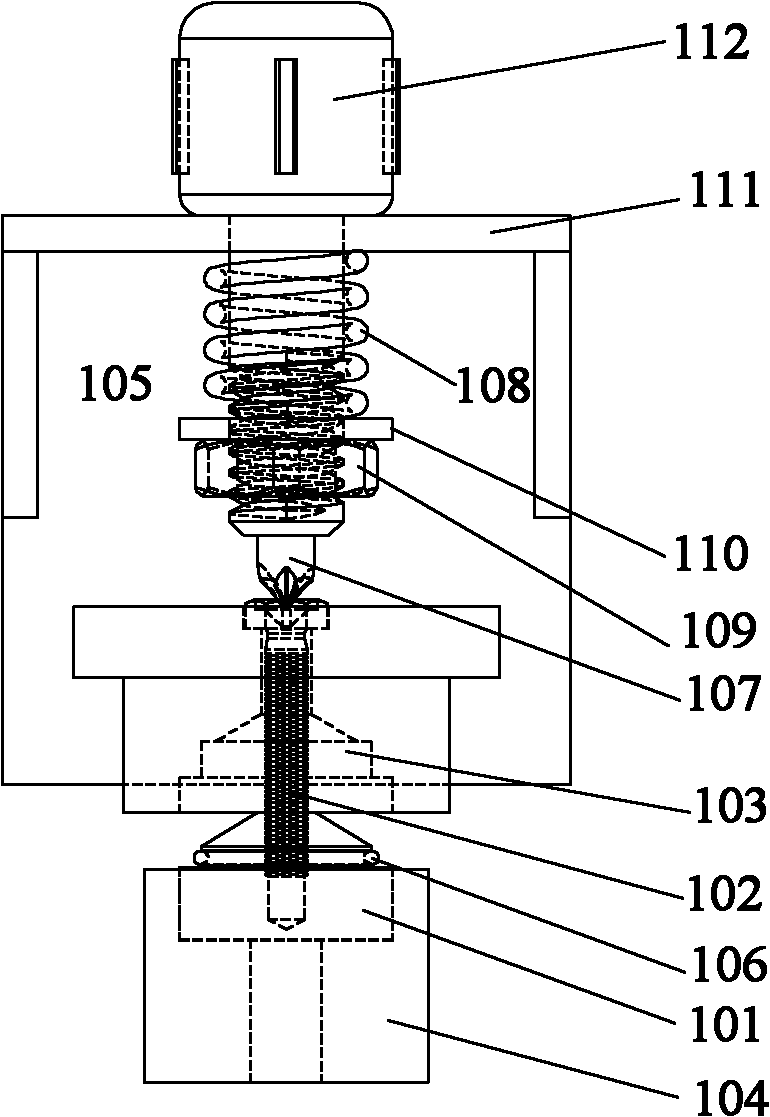

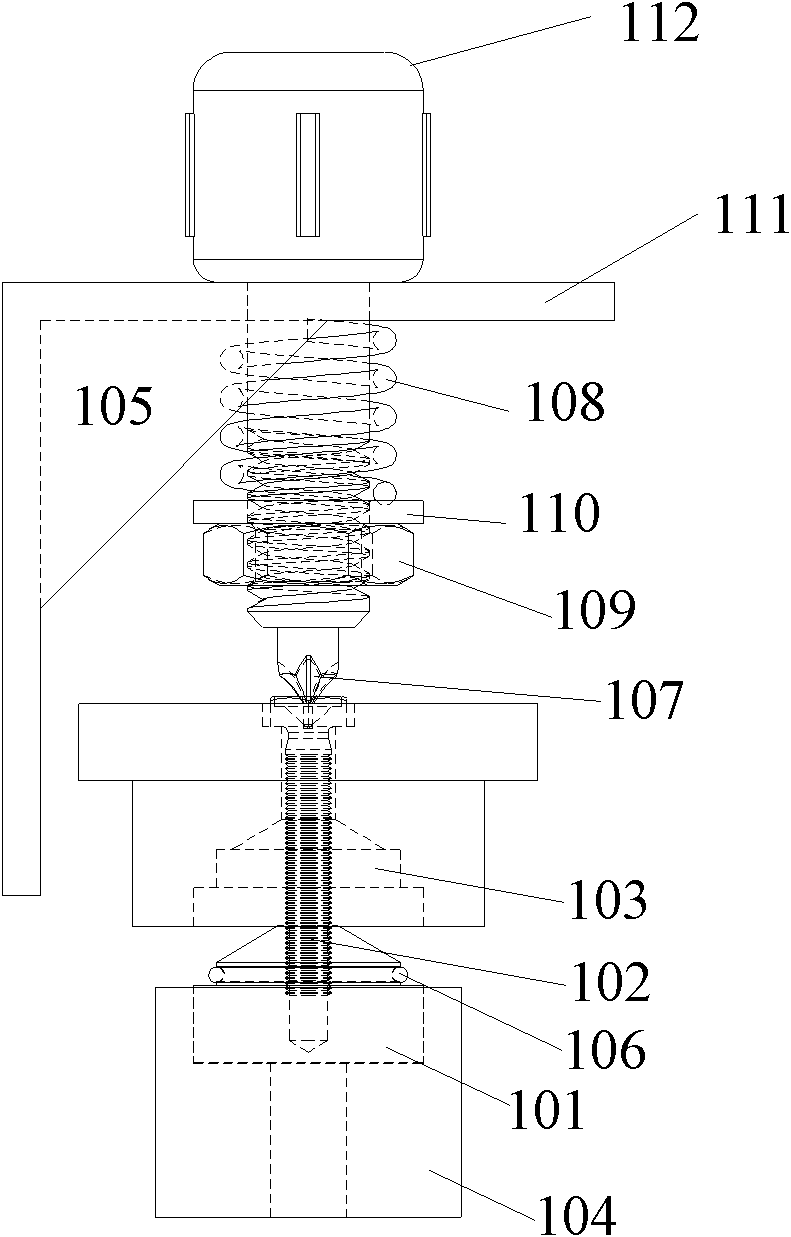

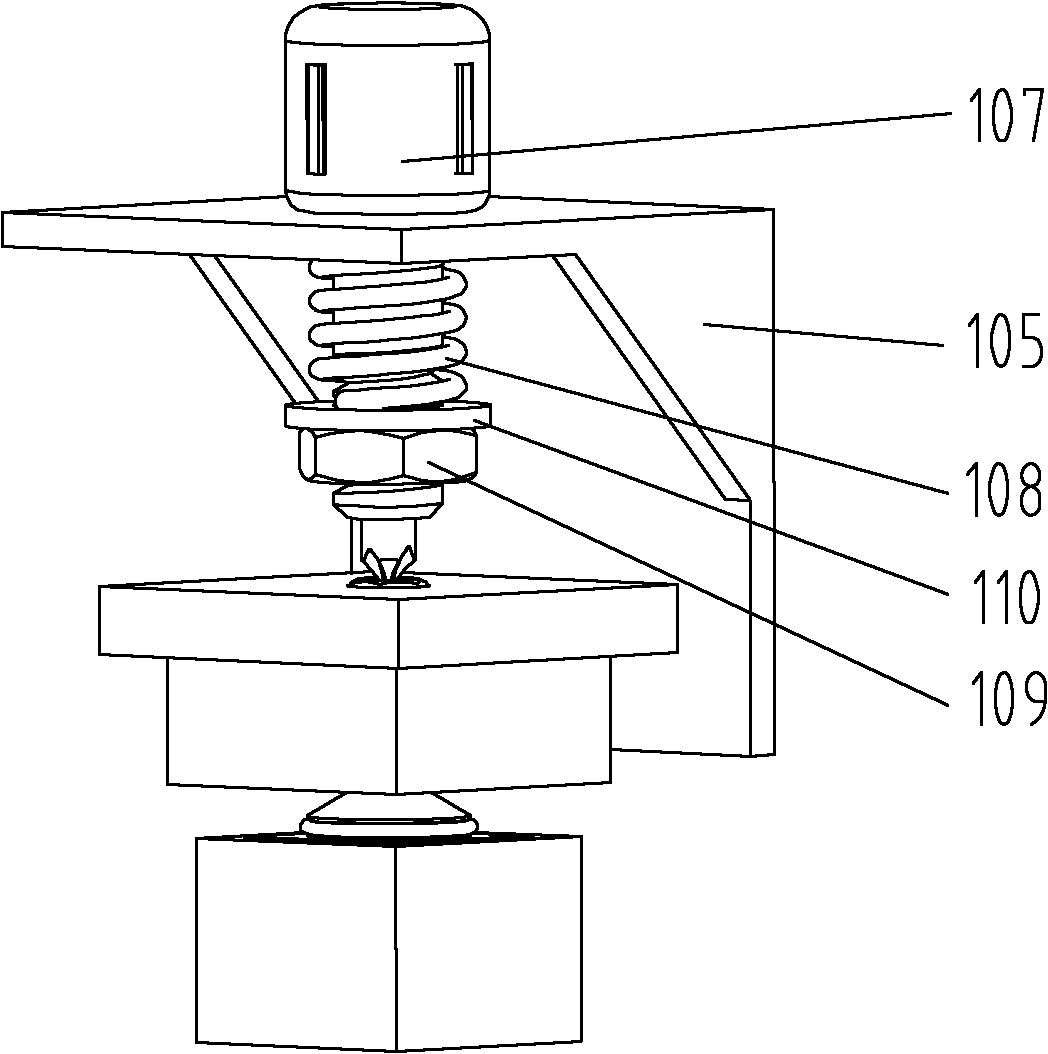

Battery injection and formation control device

ActiveCN102169975AGuaranteed air tightnessReduce bloatFinal product manufactureSecondary cells manufacturePositive pressureEngineering

The invention discloses a battery injection and formation control device which comprises an internal piston, an external piston, an injection hole arranged in a battery shell cover plate, a plastic bracket in a battery shell and a piston packaging device capable of controlling gas emission pressure, wherein the internal piston is detachably fixed in the plastic bracket and internally provided with a threaded hole matched with the external piston, the threaded hole is mutually aligned with the injection hole, and the external piston is connected with a thread in the threaded hole of the internal piston for closing the injection hole after penetrating through the injection hole. Positive pressure in a battery acts on the internal piston to press a sealing surface of the internal piston, thus airtightness of the injection hole is ensured. Through controlling the gas emission pressure during battery formation, gas pressure in the battery can be reduced, and battery expansion is lightened;and electrochemical properties of active materials and electrolyte of the battery are changed, safety and property of the battery are improved, thus the invention is suitable for all batteries with large specific energy and high reliability.

Owner:GUANGZHOU LITHIUM FORCE ENERGY TECH

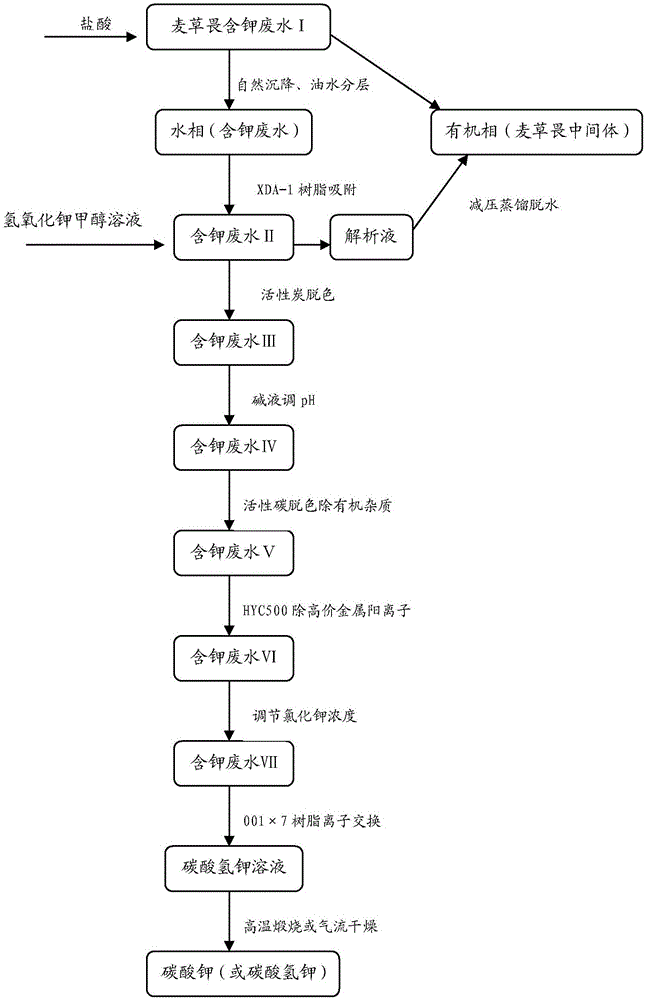

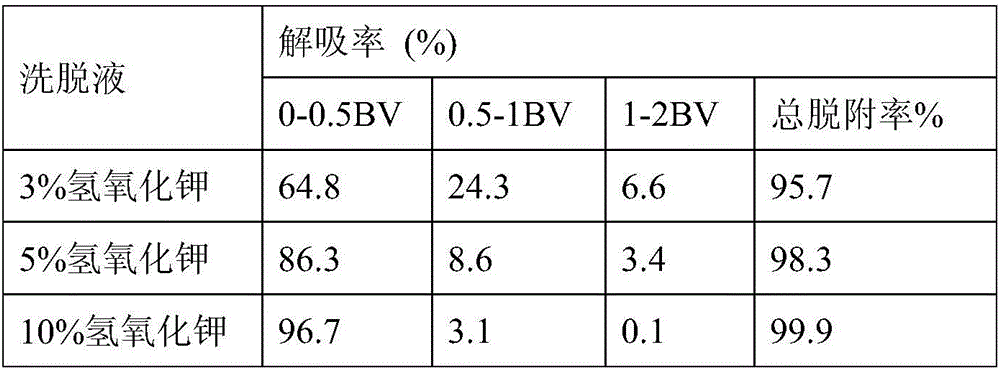

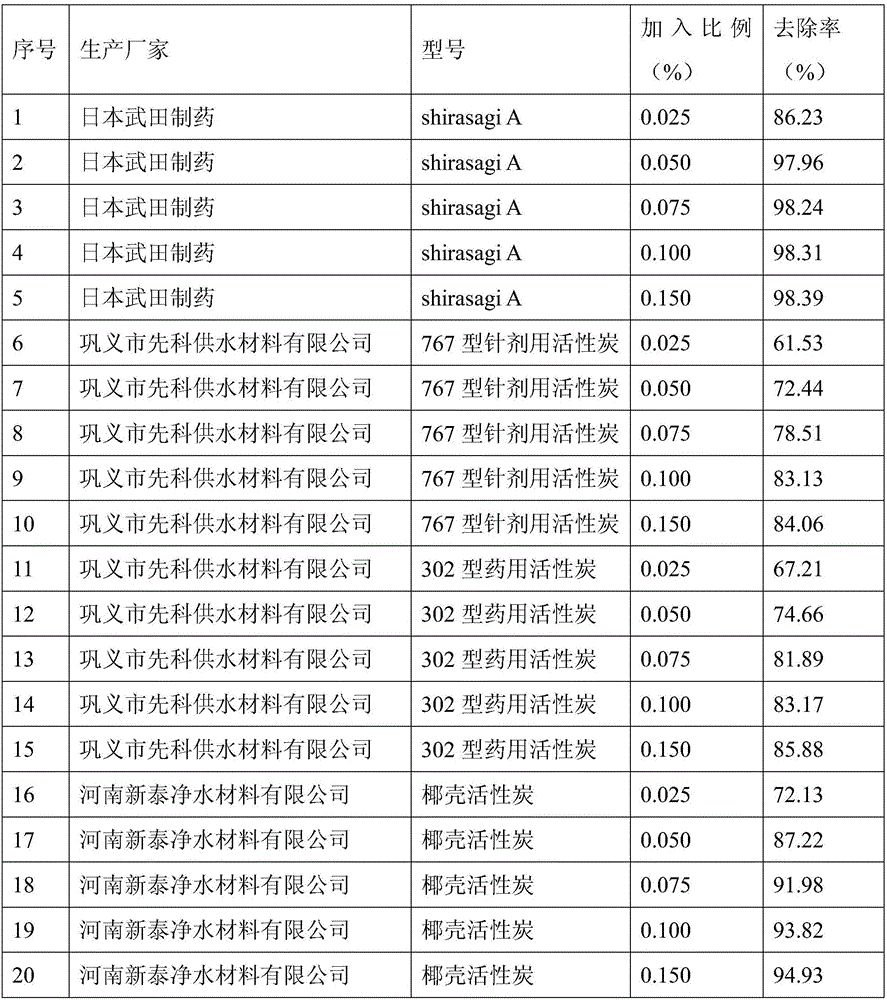

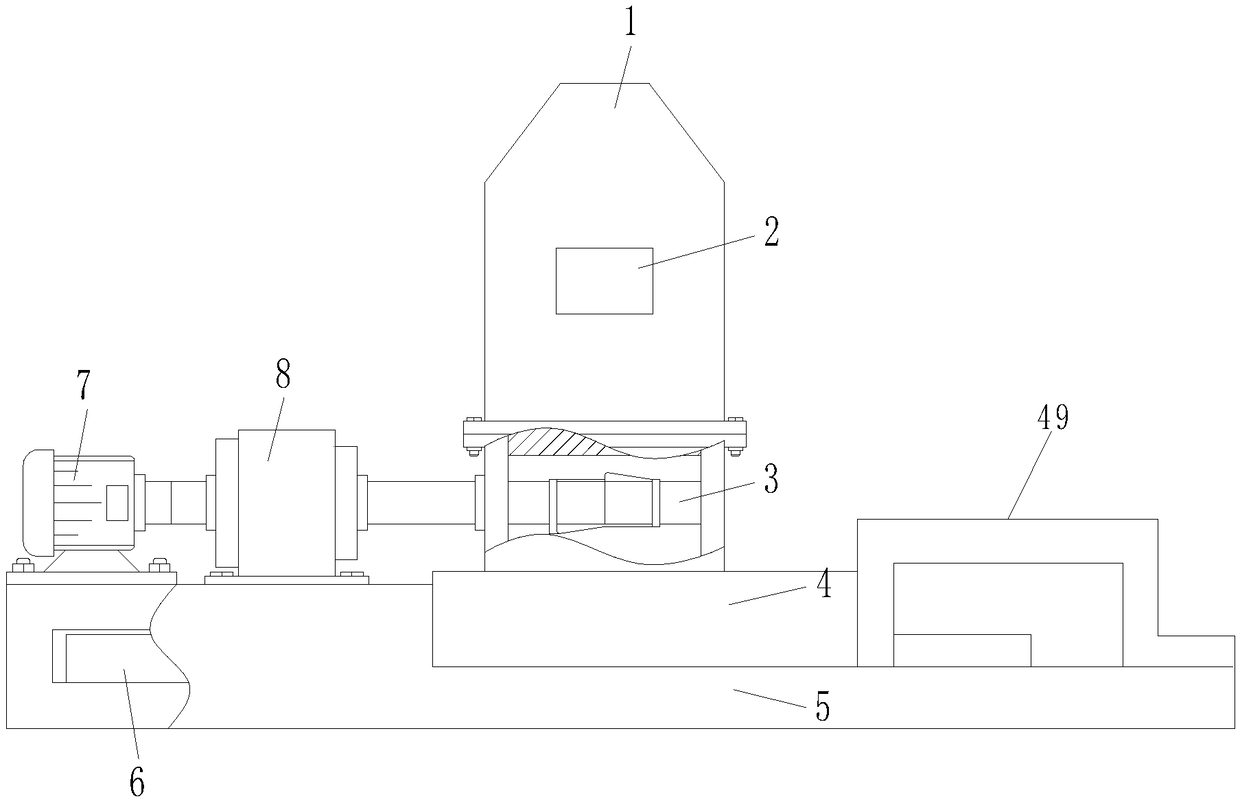

Comprehensive recycling utilization method of potassium-containing wastewater generated in synthesis process of dicamba

ActiveCN106830478ARealize the big cycleImprove competitive advantageTreatment involving filtrationOxygen compounds purification/separationIon exchangePotassium

The invention discloses a comprehensive recycling utilization method of potassium-containing wastewater generated in a synthesis process of dicamba. The comprehensive recycling utilization method comprises the following steps: adding acid into potassium-containing wastewater I generated in the synthesis process of the dicamba, and naturally depositing; conveying a water layer obtained by layering into a macroporous adsorption resin bed through a pump; adsorbing and recycling dicamba intermediates, namely 2,5-dichlorophenol and 3,6-dichlorosalicylic acid, in the water layer through the macroporous adsorption resin bed; adding active carbon and stirring and filtering; adding alkali liquid to adjust the pH (Potential of Hydrogen); adding active carbon into potassium-containing wastewater IV; stirring and filtering; conveying the wastewater into a chelating resin bed through the pump; removing high-valent metal cations in the alkaline potassium-containing wastewater IV through ion exchange; conveying the wastewater into a cation exchange resin bed through the pump; carrying out the ion exchange to obtain a potassium hydrogen carbonate solution and an ammonium chloride solution respectively; and drying an obtained potassium hydrogen carbonate wet product to obtain potassium hydrogen carbonate, or calcining the potassium hydrogen carbonate wet product at a high temperature to obtain potassium carbonate.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

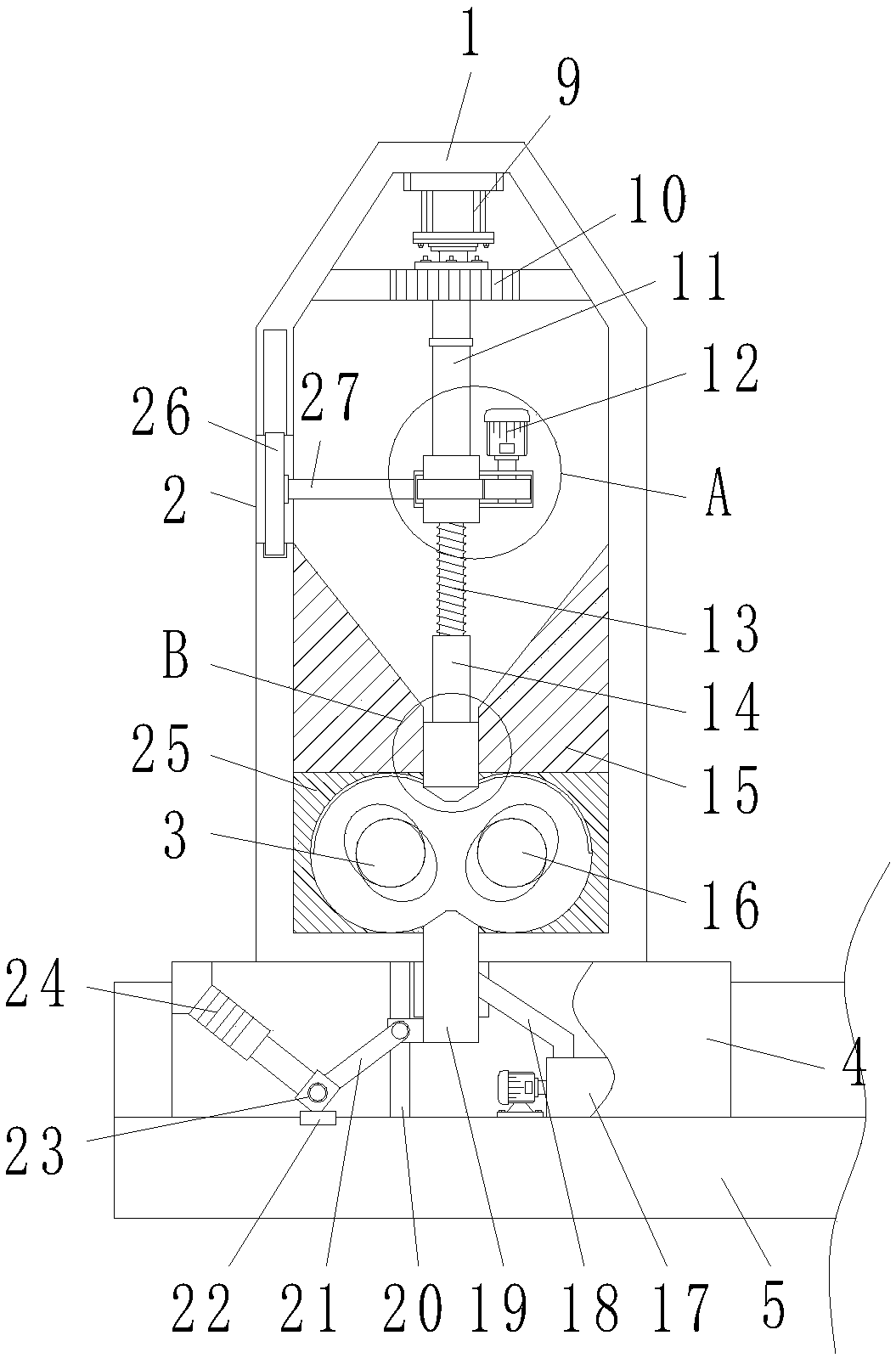

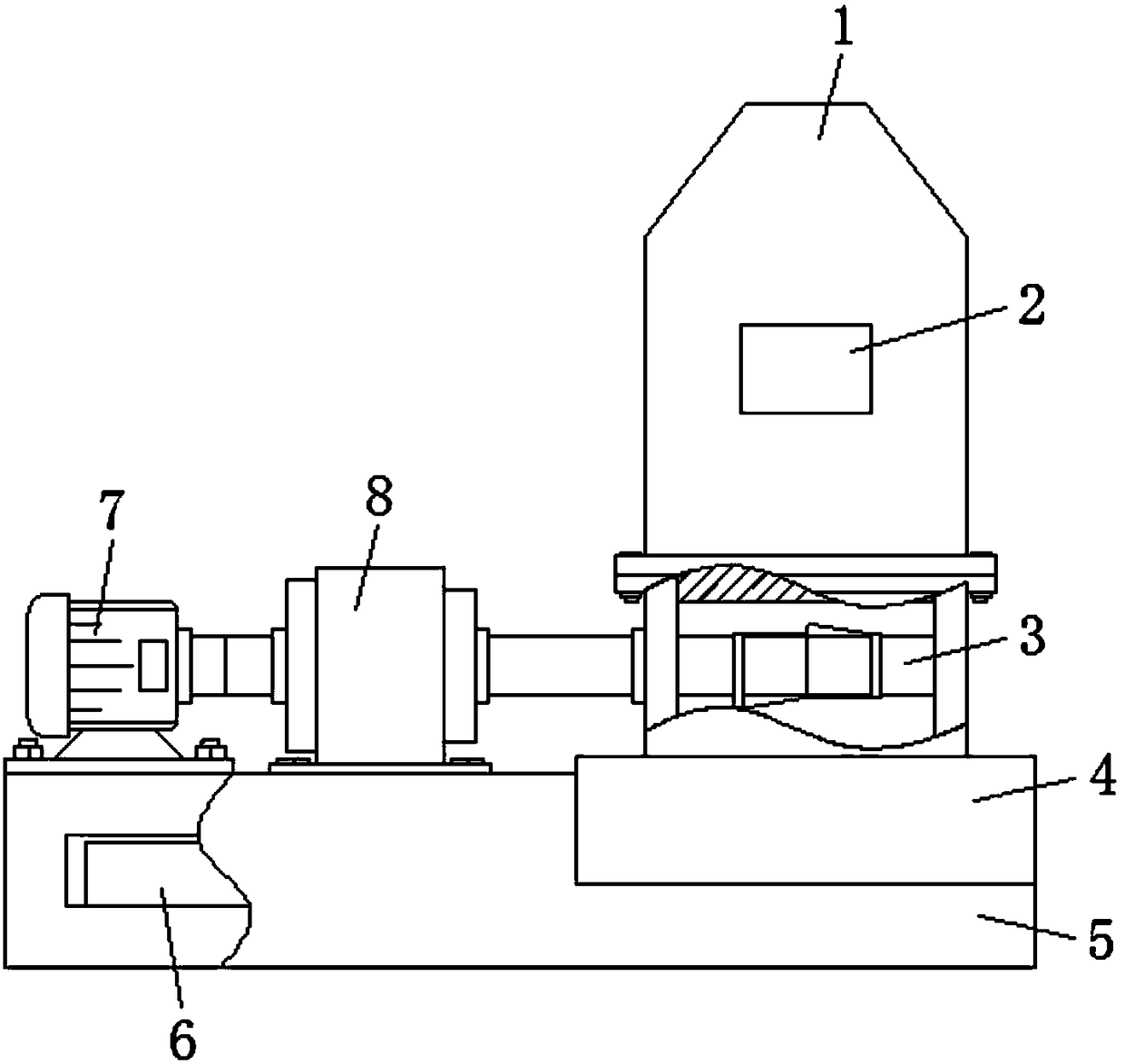

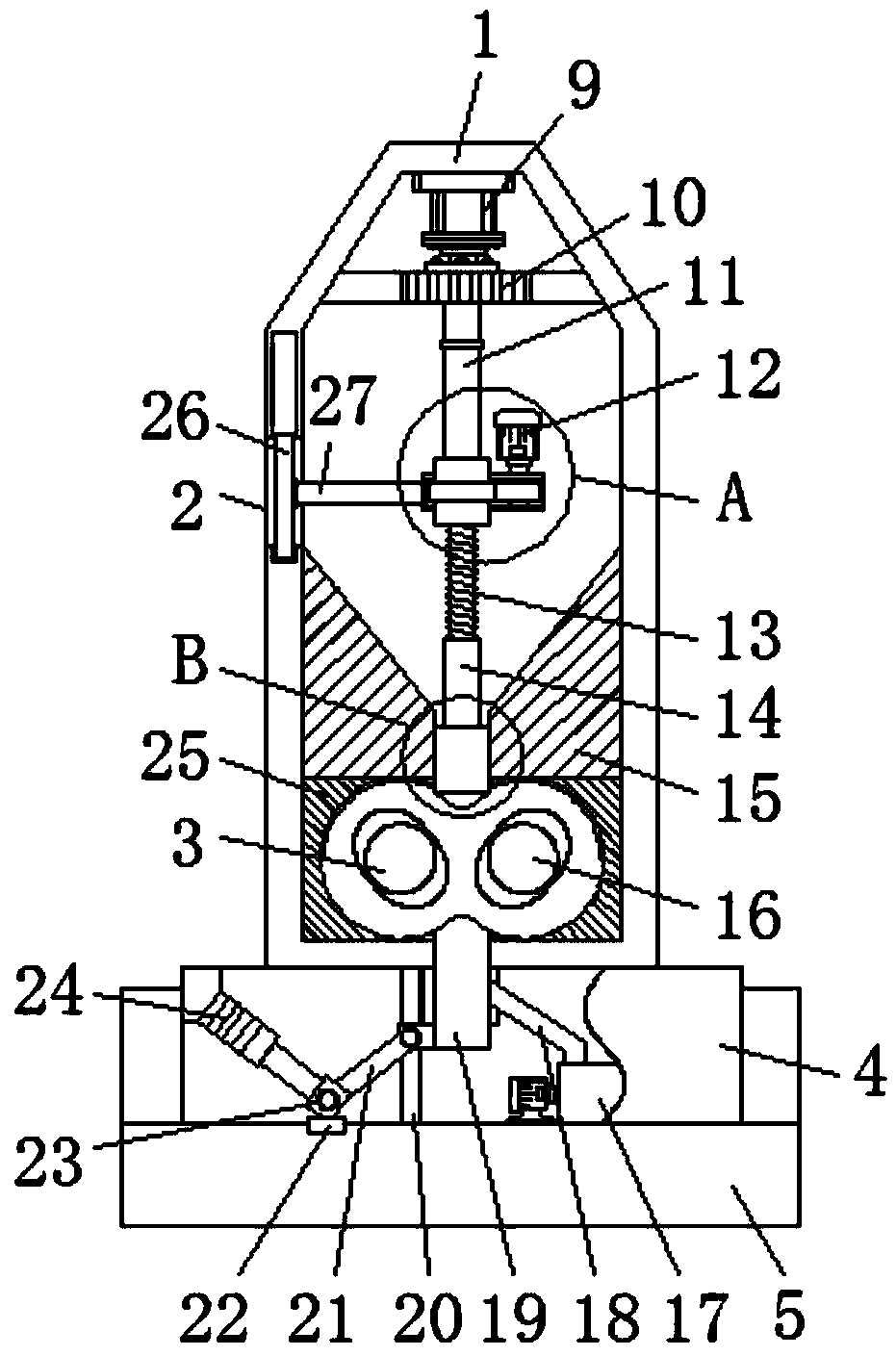

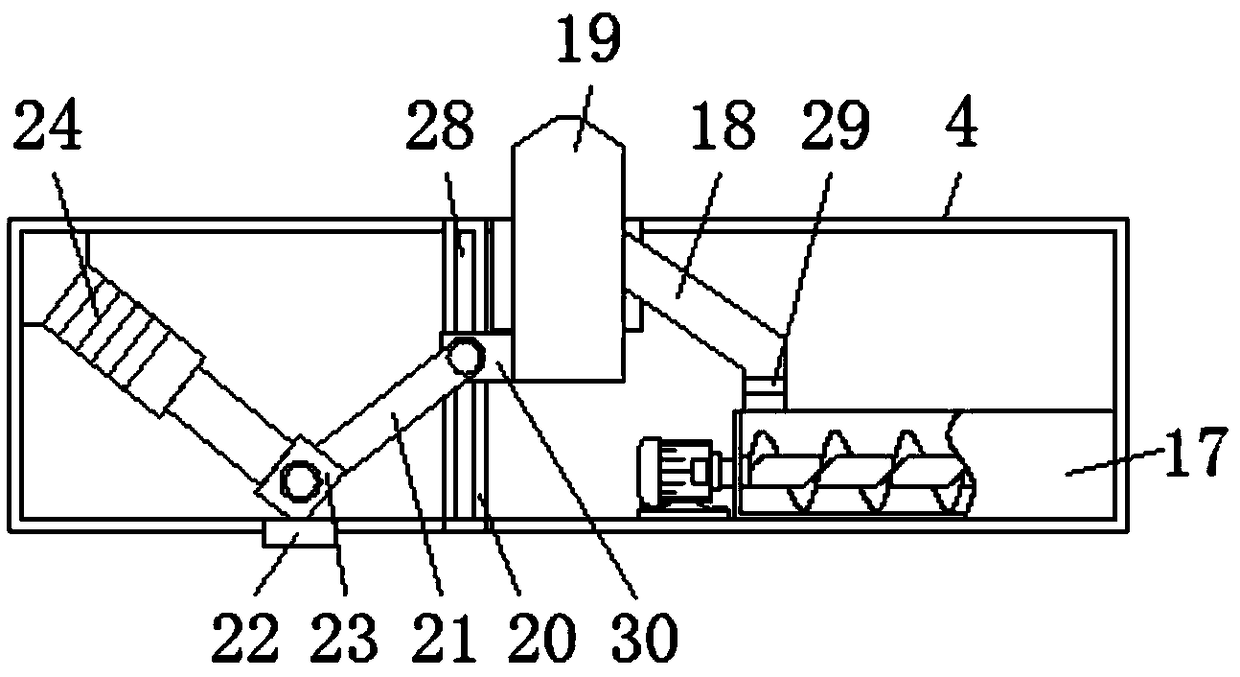

Internal mixer with dust-sucking and cooling device

ActiveCN108995068AAvoid burnsAvoid crushing the rubberUsing liquid separation agentDirt cleaningMotor driveGear drive

The invention discloses an internal mixer with a dust-sucking and cooling device. The internal mixer comprises an internal mixer body; a feeding port is formed in the outer wall of one side of the internal mixer body; a feeding hopper and a mixing chamber are arranged in the internal mixer body; the feeding hopper is positioned above the mixing chamber; an upper top bolt is arranged in the middleposition of the feeding hopper; the internal mixer is provided with a second motor, a screw rod, a second guide rod, a fixed base, a driving gear, a driven gear, a screw rod sleeve, a water pump, a dust-sucking pipeline, a centripetal annular spray head and a side wall; during unloading, a PLC controller controls a first motor to start to work, the first motor drives the driving gear through a rotating shaft to rotate, the driving gear is engaged with the driven gear, the driven gear drives the screw rod sleeve to rotate, and the screw rod sleeve is screwed with the screw rod when rotating, sothat the aim of ascending the screw rod is fulfilled, and the second guide rod drives the upper top bolt to move upwards when the screw rod ascends until one end of the second guide rod is contactedwith the screw rod sleeve; the upper top bolt is started in the unloading process, so that the discharging pressure of a lower top bolt can be reduced; in addition, when an adhesive material is cooled, dust is removed and the removed dust is fused into water for cooling, so that the processes are reduced and environmental friendliness is achieved.

Owner:沧州启航橡胶制品有限公司

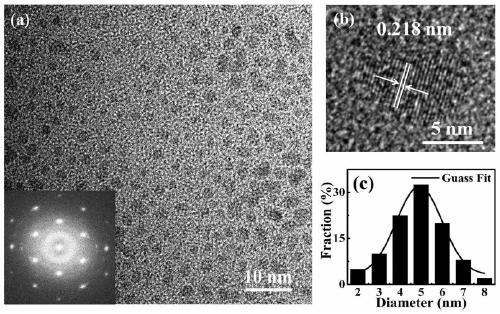

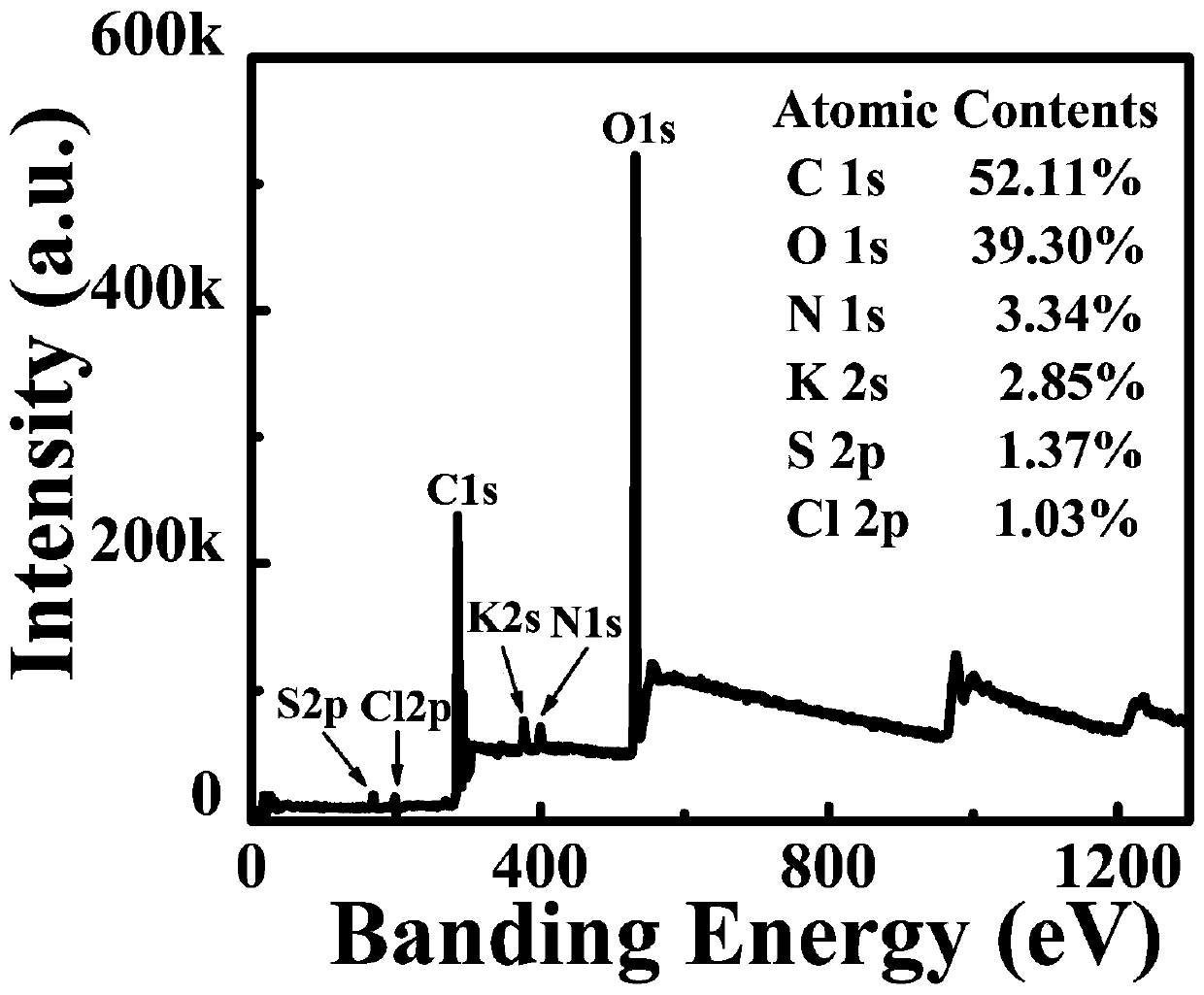

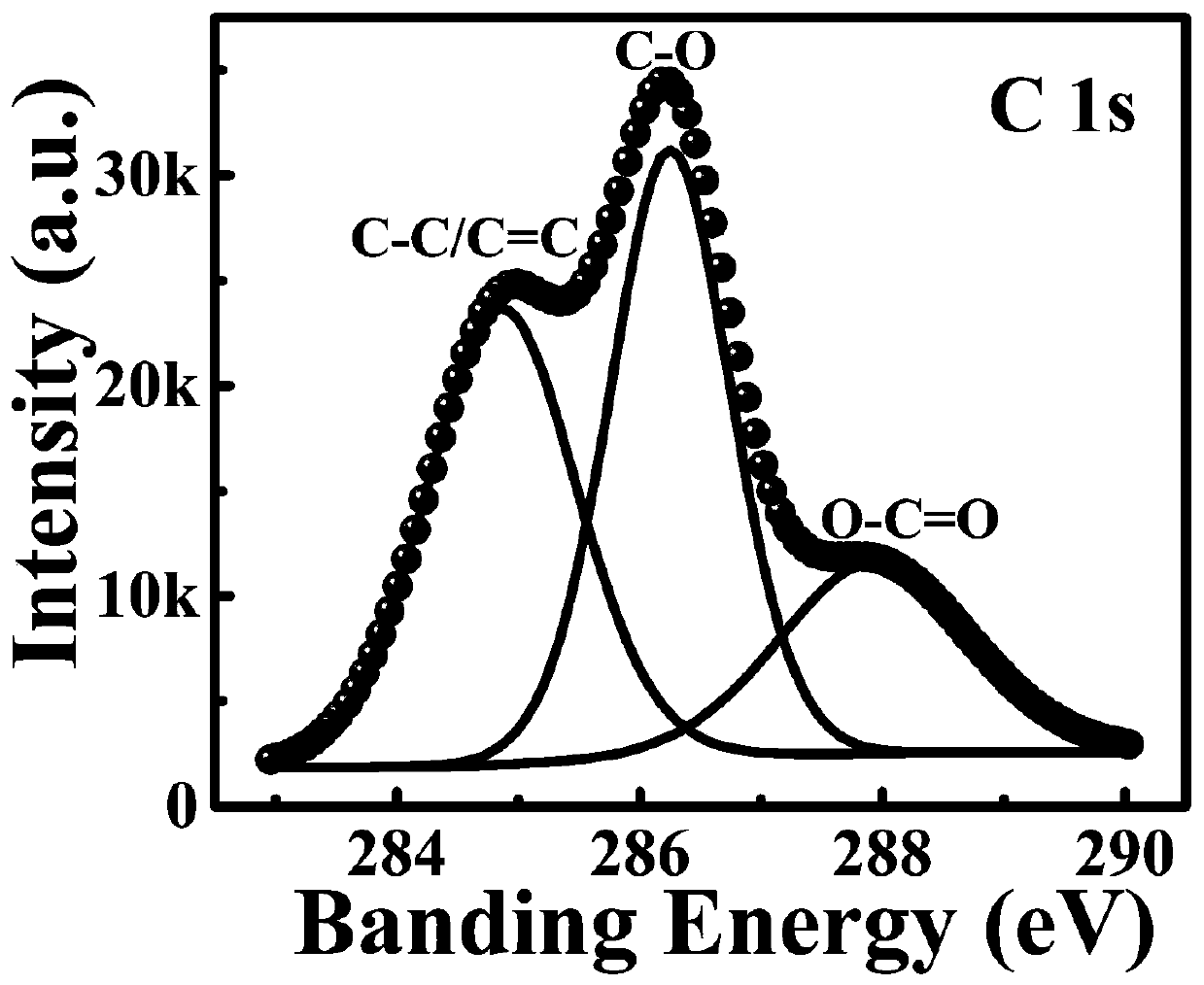

Method for preparing multicolor fluorescent carbon quantum dots through tobacco wastewater

The invention discloses a method for preparing multicolor fluorescent carbon quantum dots through tobacco wastewater and belongs to the technical field of carbon quantum dot preparation. The method comprises the steps that the tobacco wastewater is heated up to 200-300 DEG C at the constant speed, a heating reaction is conducted for 1-3 h within the temperature range of 200-300 DEG C till organicmatter is dehydrated, carbonized and discolored, and thus a reaction product A is obtained; after the reaction product A is cooled to the room temperature, a modifier is added into the reaction product A, and even mixing is conducted to obtain a mixed solution B; and the mixed solution B is stirred for 5-10 min, then ultrasonic treatment is conducted for 5-10 min, after still standing is conducted, supernatant is taken to be centrifuged, then still standing is conducted, supernatant is taken, and thus the multicolor fluorescent carbon quantum dots dispersed into a modifier are obtained. The tobacco wastewater are adopted as a carbon source, the carbon quantum dots are prepared through a simple pyrolytic reaction and dispersed by adopting ethyl alcohol, deionized water, oxalic acid and a sodium hydroxide solution as the modifier correspondingly, and the fluorescence emission wavelength of the carbon quantum dots can be regulated from a blue light area to a yellow light area.

Owner:YUNNAN UNIV

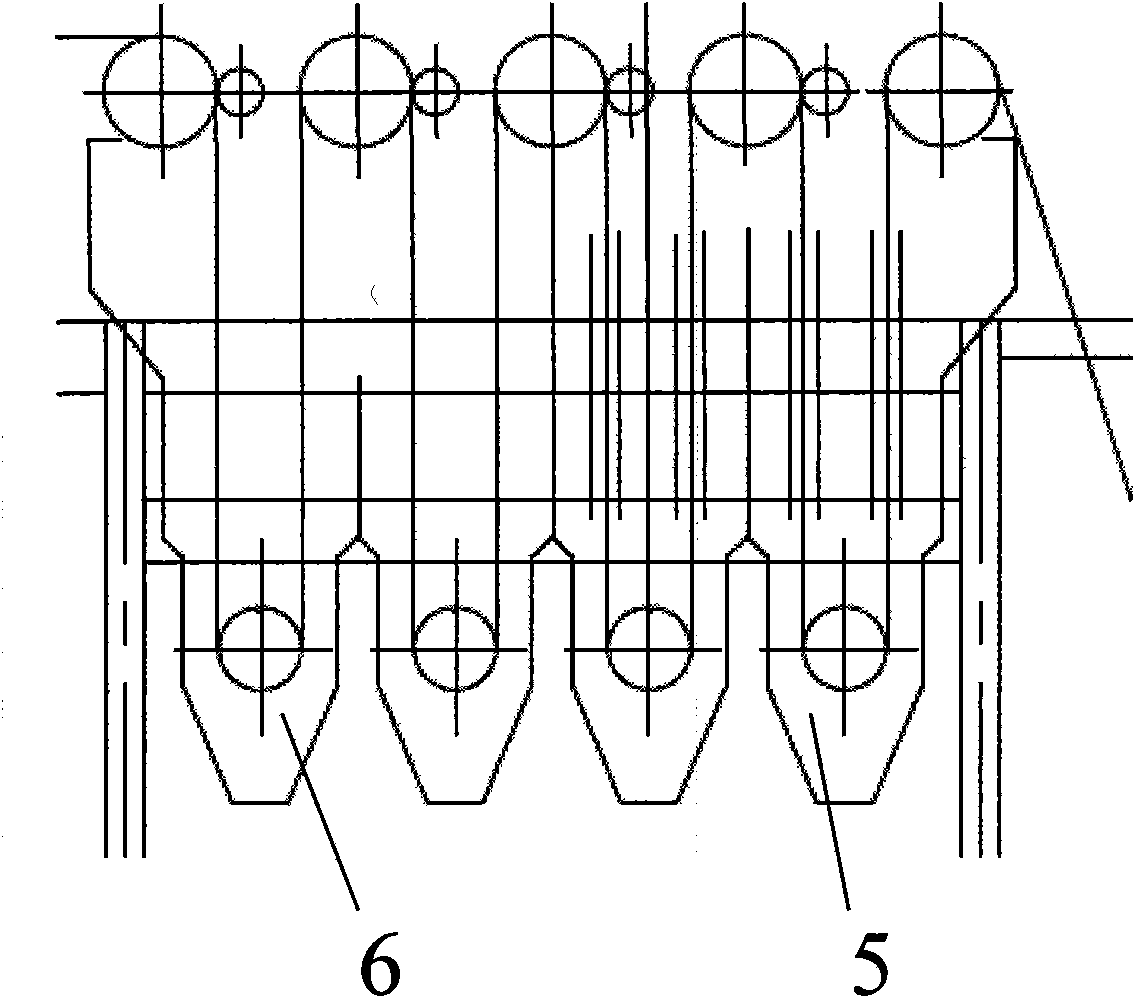

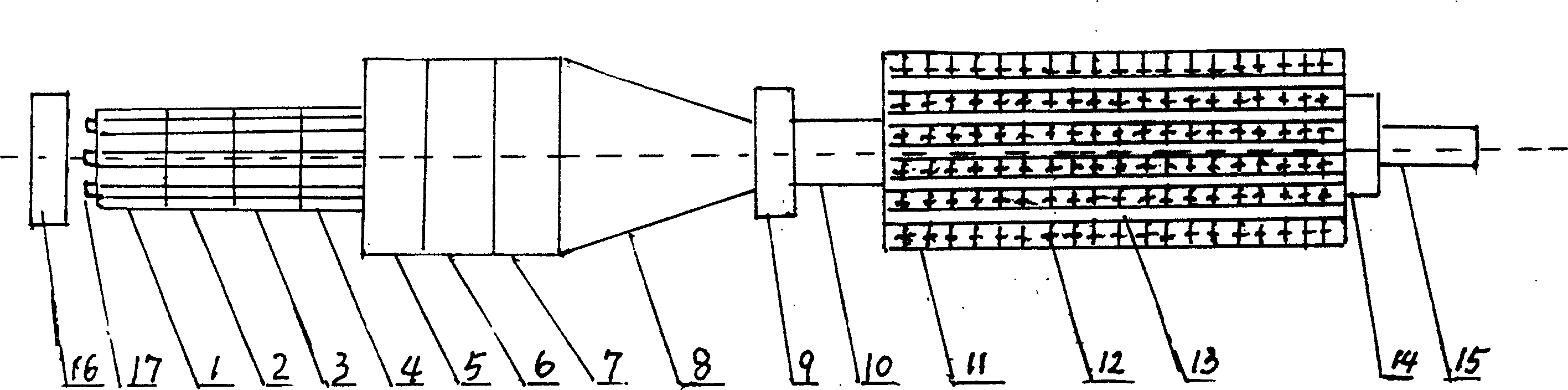

Integrated momentum exchanger for preventing and treating waste gas pollution

InactiveCN1724853AReduce discharge pressureReduce weightInternal combustion piston enginesExhaust apparatusExhaust fumesEngineering

The invention provides an integrated momentum exchanger able to process all waste gas pollution, characterized in that it is composed of several stages of momentum exchangers arranged in parallel (able to be arranged independently and also able to be highly integrated on a mechanical made plane), each stage momentum exchanger has a different number of momentum exchangers (determined by waste gas quantity) and is composed of injection receiving pipe, diffusion pipe, conic hole and negative hole highly integrated on a mechanical made plane, there are several parallel pressure pipes (the number of them can be increased or decreased according to the amount of waste gas discharge) arranged between the first and fourth stages. The one end of the first stage momentum exchanger is directly connected with a waste gas exhaust outlet, and the other end is connected to a noise reducing rectifier, again connected with a gas exhaust pipeline through a flange and finally connected with a tail end gas exhaust outlet through a pressure reducing gas collecting rectifier, thus preventing the waste gas and wastes discharged outward.

Owner:张裕光

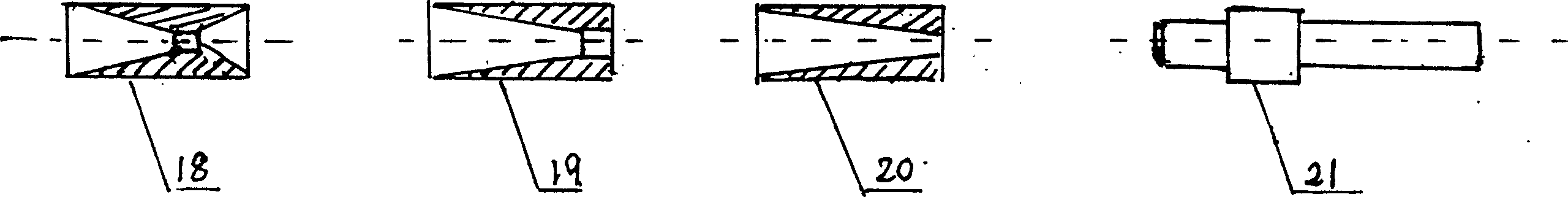

Infiltrating road gutter inlet having secondary silt settling function

PendingCN107460938AEffective load bearingReduce cloggingFatty/oily/floating substances removal devicesSewerage structuresRainwater harvestingWater collection

The invention discloses an infiltrating road gutter inlet having a secondary silt settling function. The infiltrating road gutter inlet comprises a rainwater collecting and primary settling well and a silt settling and inflating well, wherein the rainwater collecting and primary settling well and the silt settling and inflating well are arranged in an adjacent mode and the silt settling and inflating well is deeper than the rainwater collecting and primary settling well; a primary collecting device is movably arranged in the rainwater collecting and primary settling well; a secondary collecting device is movably arranged in silt settling and inflating well; a cover plate, which is provided with a rainwater grate, is arranged on the top side of the rainwater collecting and primary settling well; a well cover, which is free from a rainwater grate, is arranged on the top side of the silt settling and inflating well; the upper side of the rainwater collecting and primary settling well is connected to the upper side of the silt settling and inflating well by virtue of a communicating pipe; an overflow pipe, which communicates with a road rainwater inspection well, is arranged at the upper side of the silt settling and inflating well; a secondary filtering section and a secondary silt settling section are arranged on the lower section of the silt settling and inflating well sequentially from top to bottom; and an inflating pipe, which is connected to surrounding soil bodies, is arranged on the secondary filtering section. The gutter inlet provided by the invention can effectively reduce emission pressure of a road rainwater main pipe and relieve or avoid the occurrence of road basement settlement and waterlogging phenomenons; and the technology for forming the gutter inlet is mature, convenient to construct and easy for daily maintenance.

Owner:ZHEJIANG URBAN & RURAL PLANNING DESIGN INST

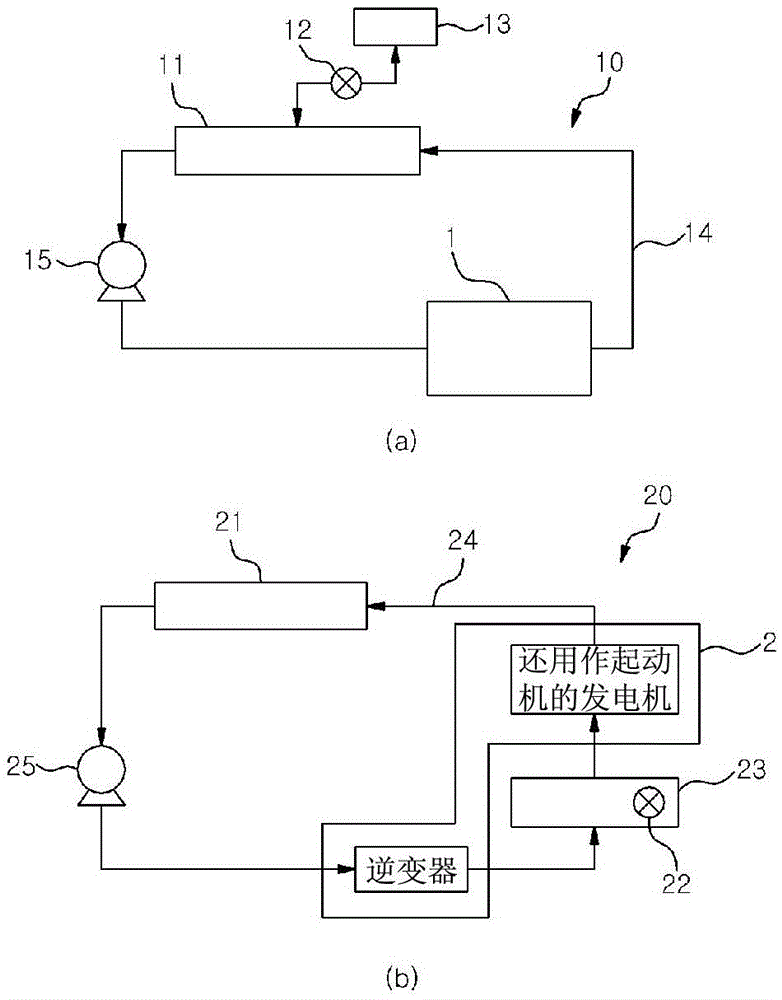

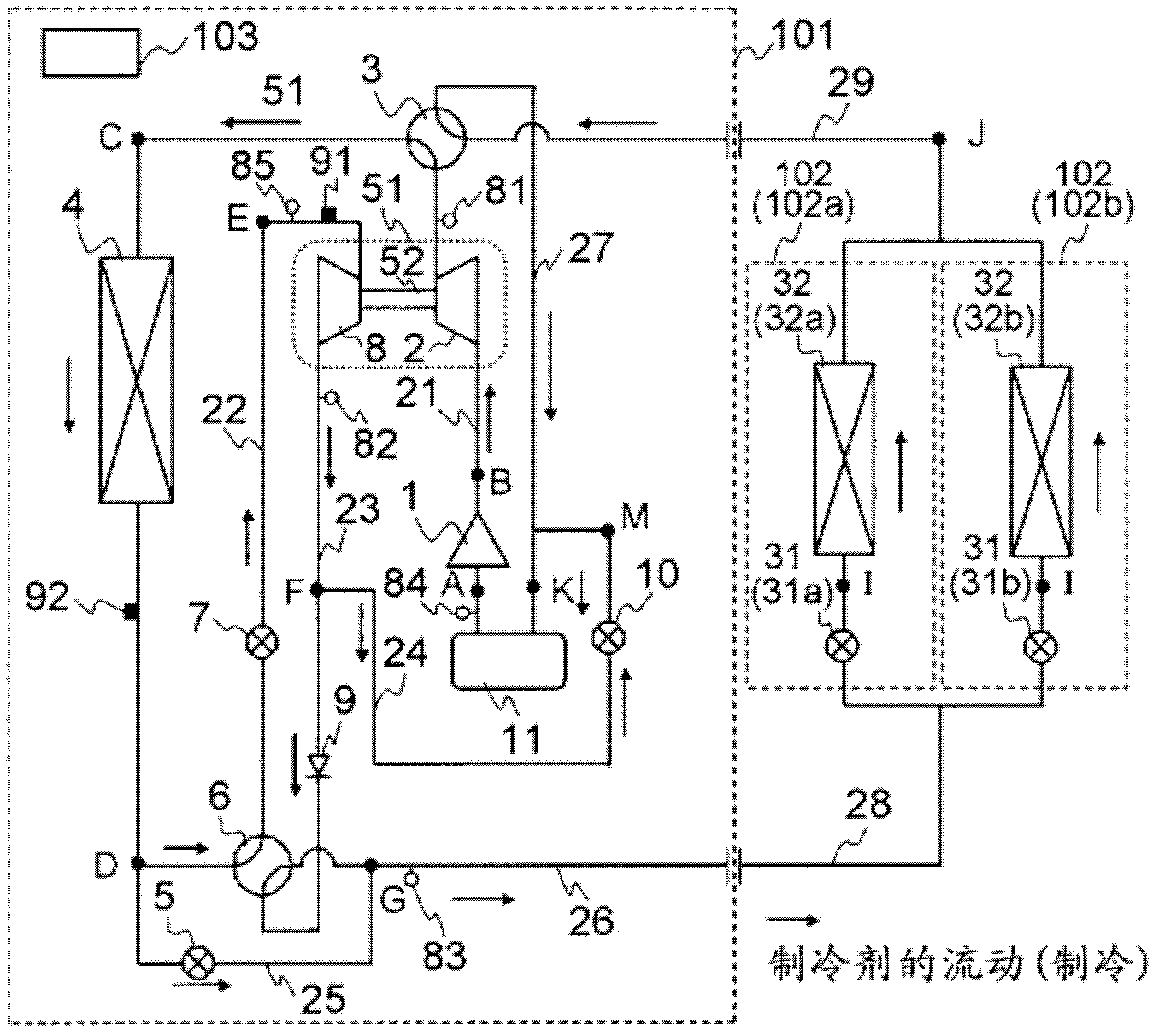

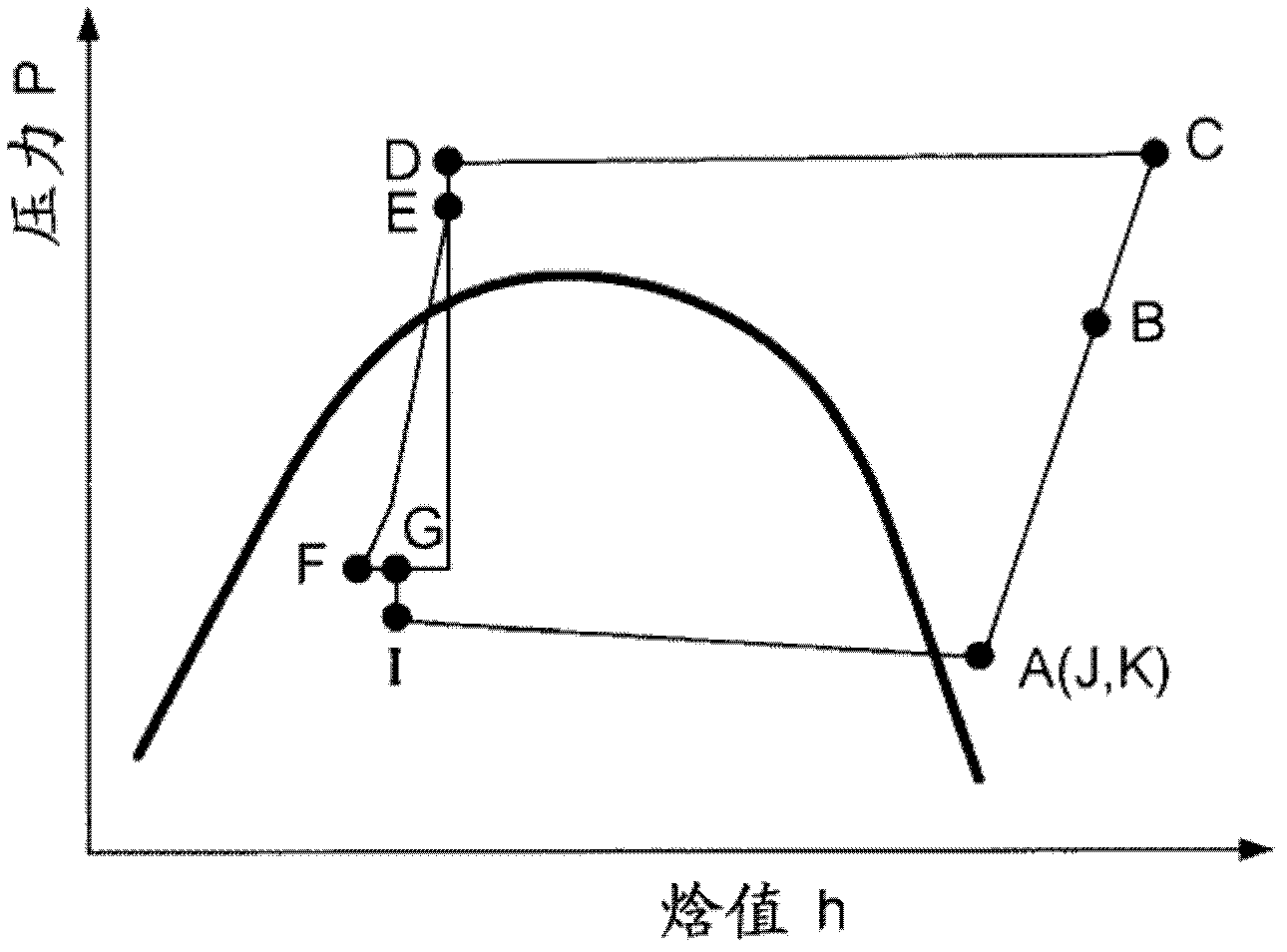

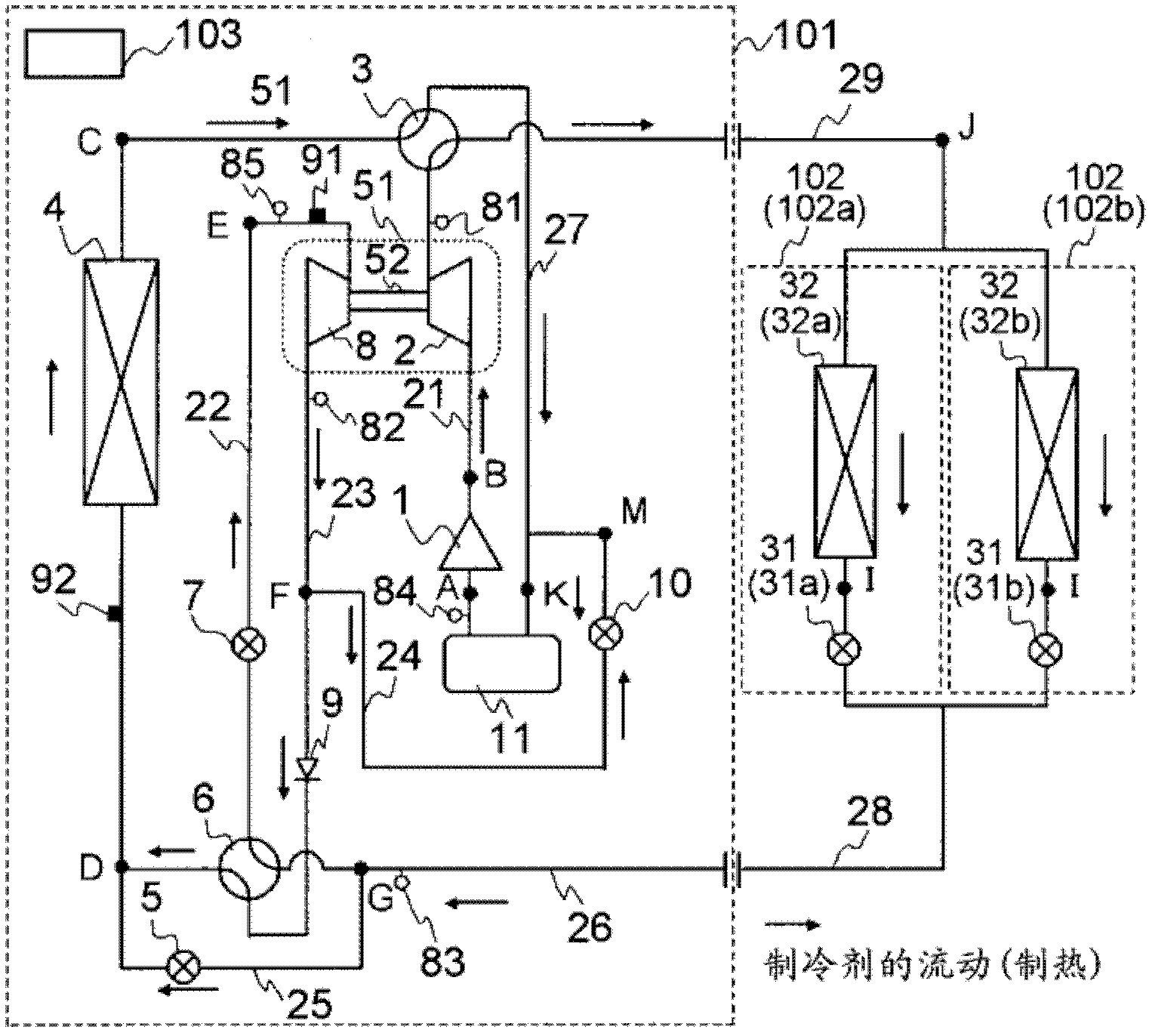

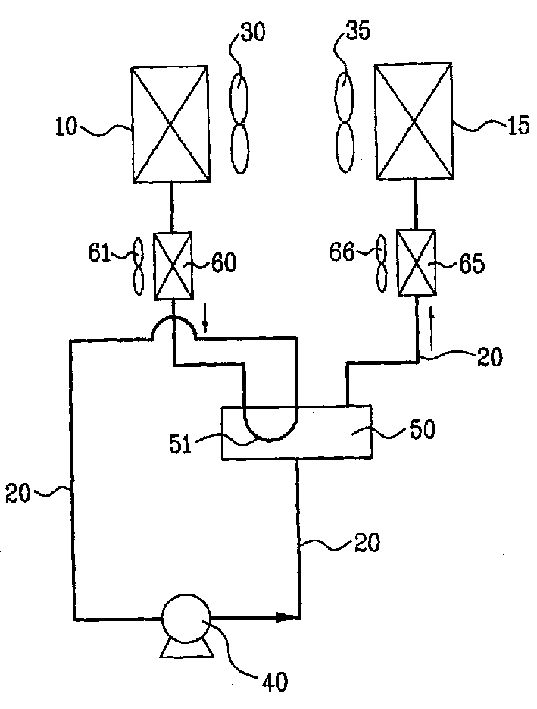

Refrigeration cycle device

ActiveCN102510985AReduce discharge pressureAvoid overexpansionCompression machines with non-reversible cycleCompression machines using turbinesRefrigerant reclamationEngineering

A refrigeration cycle device is provided with: a refrigeration cycle formed by sequentially connecting by means of piping a first compressor (1), a heat dissipater, an expander (8) for expanding a refrigerant which has passed through the heat dissipater and recovering power from the refrigerant, and an evaporator; bypass piping (24) having one end connected to the discharge piping of the expander and the other end connected to the suction piping of the first compressor; a pressure sensor (85) and a temperature sensor (91) for respectively detecting the suction pressure and the suction temperature of the expander (8) as the physical quantities of the refrigerant sucked by the expander (8); a bypass valve (10) provided to the bypass piping (24) and regulating the flow rate of the refrigerant; and a control device (103) for controlling the extent of opening of the bypass valve (10). The control device (103) determines the appropriate discharge pressure of the expander (8) on the basis of the suction pressure and the suction temperature of the expander and opens the bypass valve (10) when the pressure at which the expander (8) discharges the refrigerant is higher than the determined appropriate discharge pressure.

Owner:MITSUBISHI ELECTRIC CORP

Preparation method of jujube fruit residue dietary fiber

InactiveCN103907938AIncrease added valueReduce discharge pressureFood dryingFood preparationFiberEnzymatic hydrolysis

The invention discloses a preparation method of jujube fruit residue dietary fiber. The jujube fruit residue dietary fiber is prepared by adopting jujube fruit residues after red dates are juiced as raw materials, micro-grinding the raw materials through a high shear wet method, adding cellulase and xylanase for composite enzymatic hydrolysis, concentrating and drying the product. The invention provides a recycling method of jujube fruit residues as a by-product during the processing of red dates; by adopting the method, not only is the additional value of red dates improved, but also the discharge pressure of the jujube fruit residues to the environment is reduced.

Owner:JIANGNAN UNIV

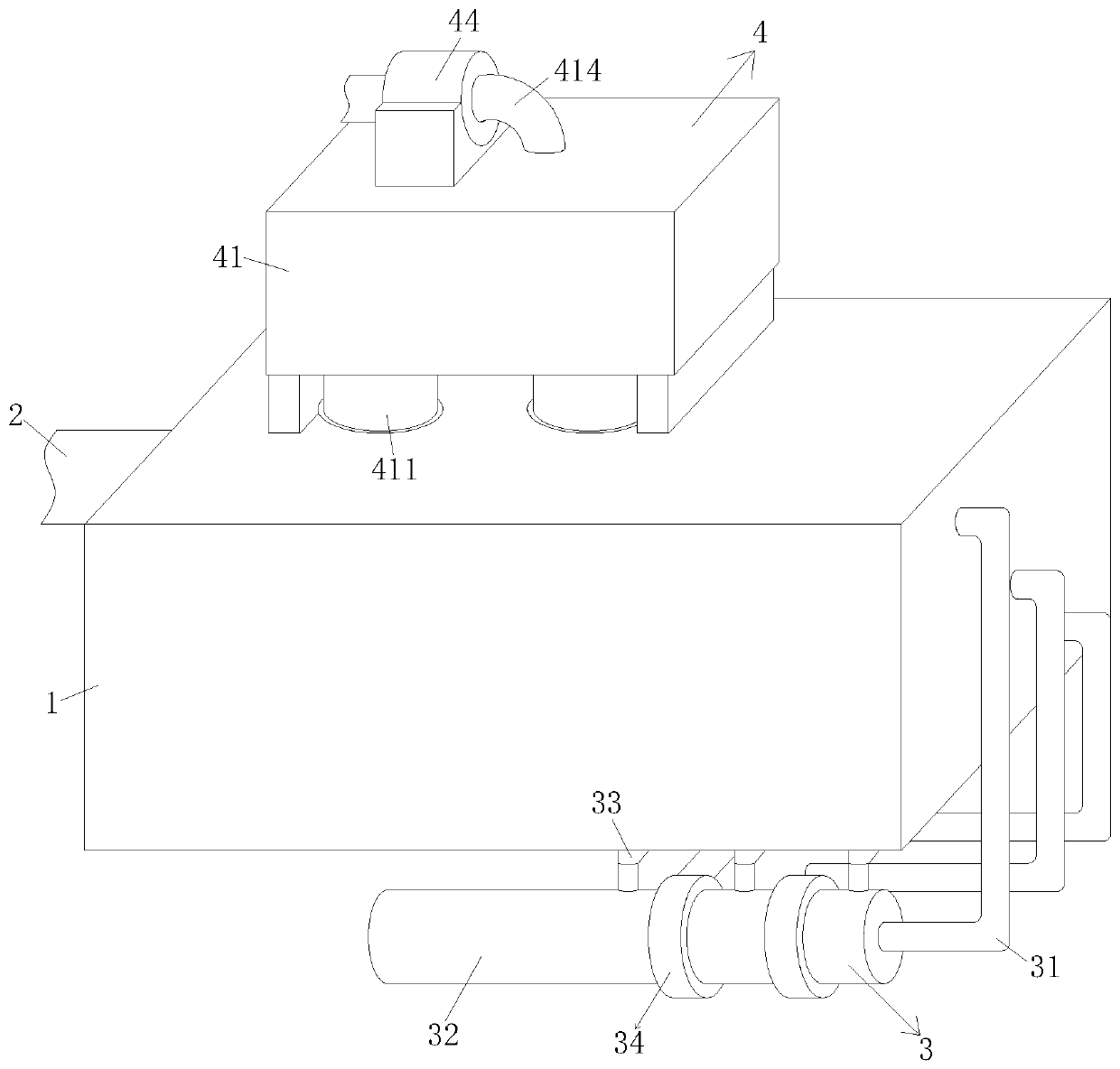

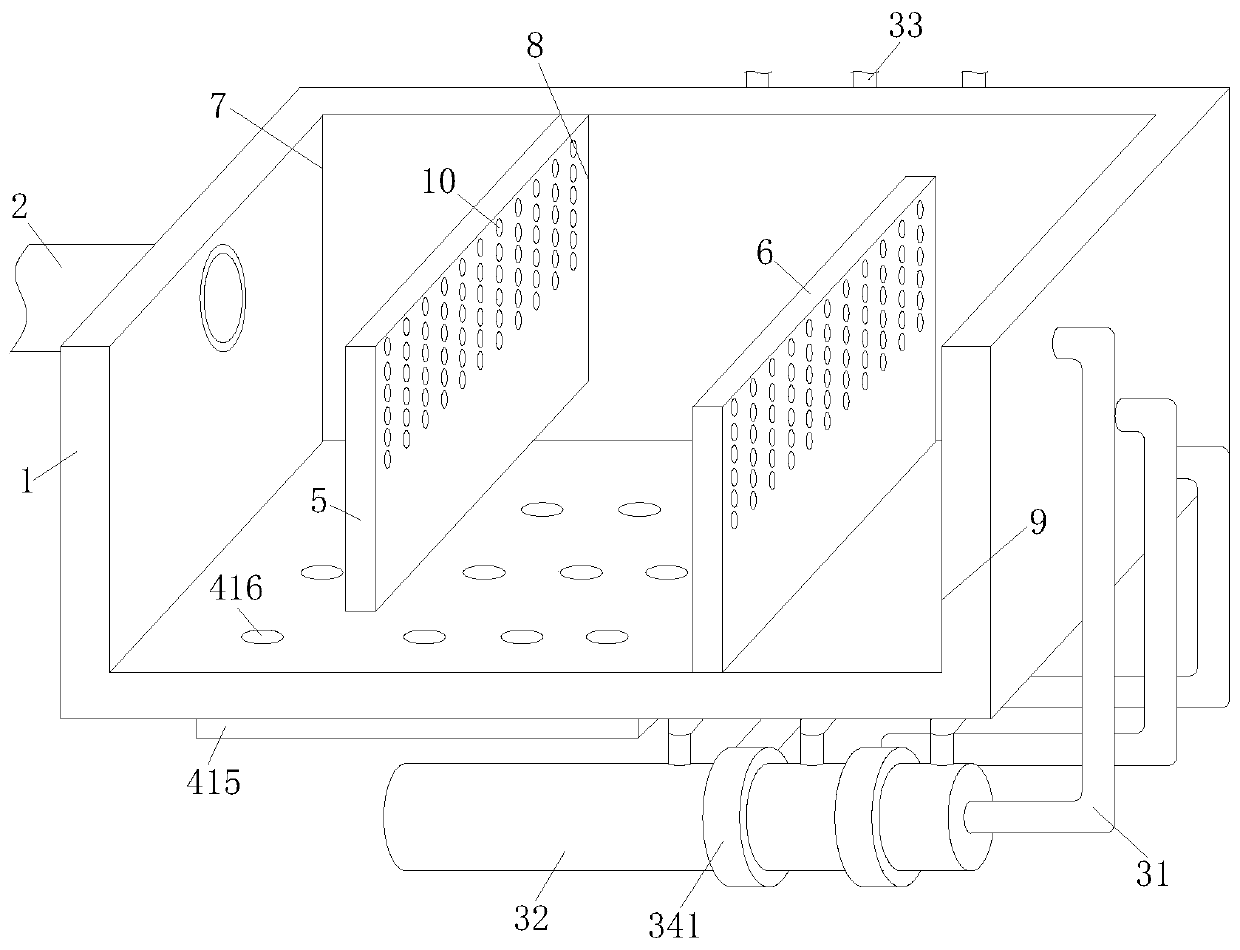

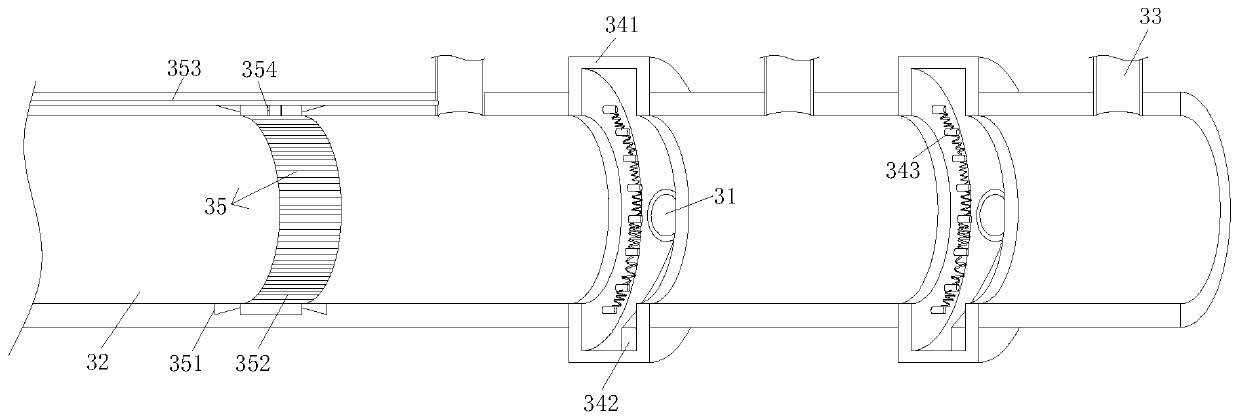

Septic tank sewage odor-resistant discharge device for municipal environmental protection engineering

ActiveCN110981139AReduce discharge pressureRelieve stressBiological sludge treatmentSewage dischargeWater resource management

The invention provides a septic tank sewage odor-resistant discharge device for municipal environmental protection engineering, and belongs to the field of septic tank. The septic tank sewage odor-resistant discharge device comprises a septic tank body, a sewage inlet pipe, a partial pressure deodorization discharge mechanism for discharging sewage and a biogas collection mechanism for collectingbiogas, wherein the partial pressure deodorization discharge mechanism is located below the septic tank body, the biogas collection mechanism is located above the septic tank body, and a first partition plate is fixedly connected to the inner wall of the septic tank body. According to the septic tank sewage odor-resistant discharge device for municipal environmental protection engineering, throughthe discharge mechanism, gas and sewage discharge of the whole septic tank is integrally communicated; pressure dynamic balance is kept between gas and liquid; gas leakage can be avoided, discharge pressure can be relieved, and therefore the problems that a common septic tank discharge device bears large pressure, a large amount of biogas dissolved in sewage easily occupies the conveying space and even causes pipeline leakage, and the septic tank and a pipeline are prone to biogas leakage to pollute soil and air are effectively solved.

Owner:湖南久清环保工程有限公司

Internal mixer for rubber mixing

The invention discloses an internal mixer for rubber mixing. The internal mixer comprises an internal mixer body. A feeding opening is formed in the outer wall of one side of the internal mixer body,and a feeding hopper and a mixing chamber are formed in the internal mixer body. The feeding hopper is located above the mixing chamber, and an upward-jacking bolt is mounted in the middle of the feeding hopper. A second motor, a screw, a second guide rod, a fixing seat, a driving gear, a driven gear and a screw sleeve are arranged, during unloading, firstly, an PLC controls a first motor to startto work, the first motor drives the driving gear to rotate through a rotary shaft, the driving gear is engaged with the driven gear and drives the screw sleeve to rotate through the driven gear, thescrew sleeve is in rotating fit with the screw when rotating, and thus the purpose of screw ascending is achieved; and when ascending, the screw drives the upward jacking bolt to move upwards throughthe second guide rod till one end of the second guide rod makes contact with the screw sleeve, in the unloading process, the upward jacking bolt is started, and on the one hand, the discharging pressure of a downward jacking bolt can be relieved.

Owner:ANHUI LIXIN RUBBER TECH CO LTD

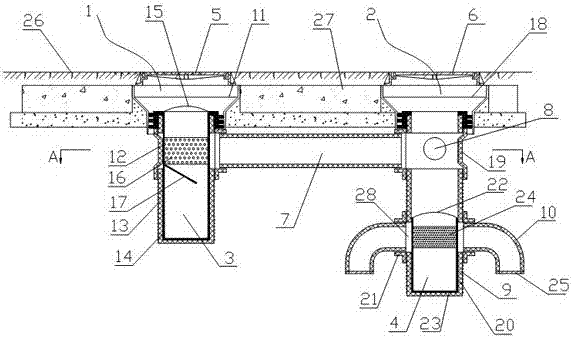

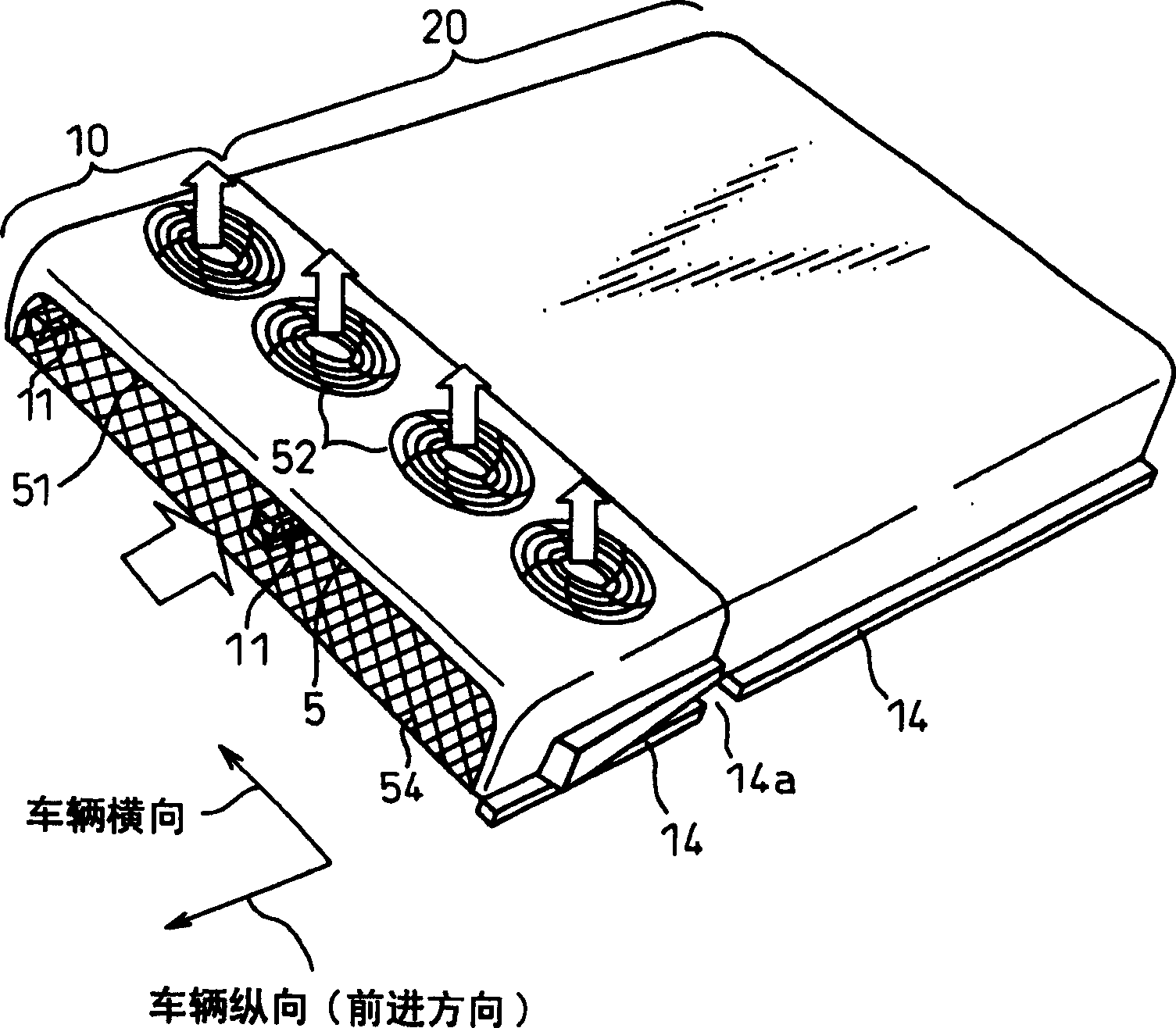

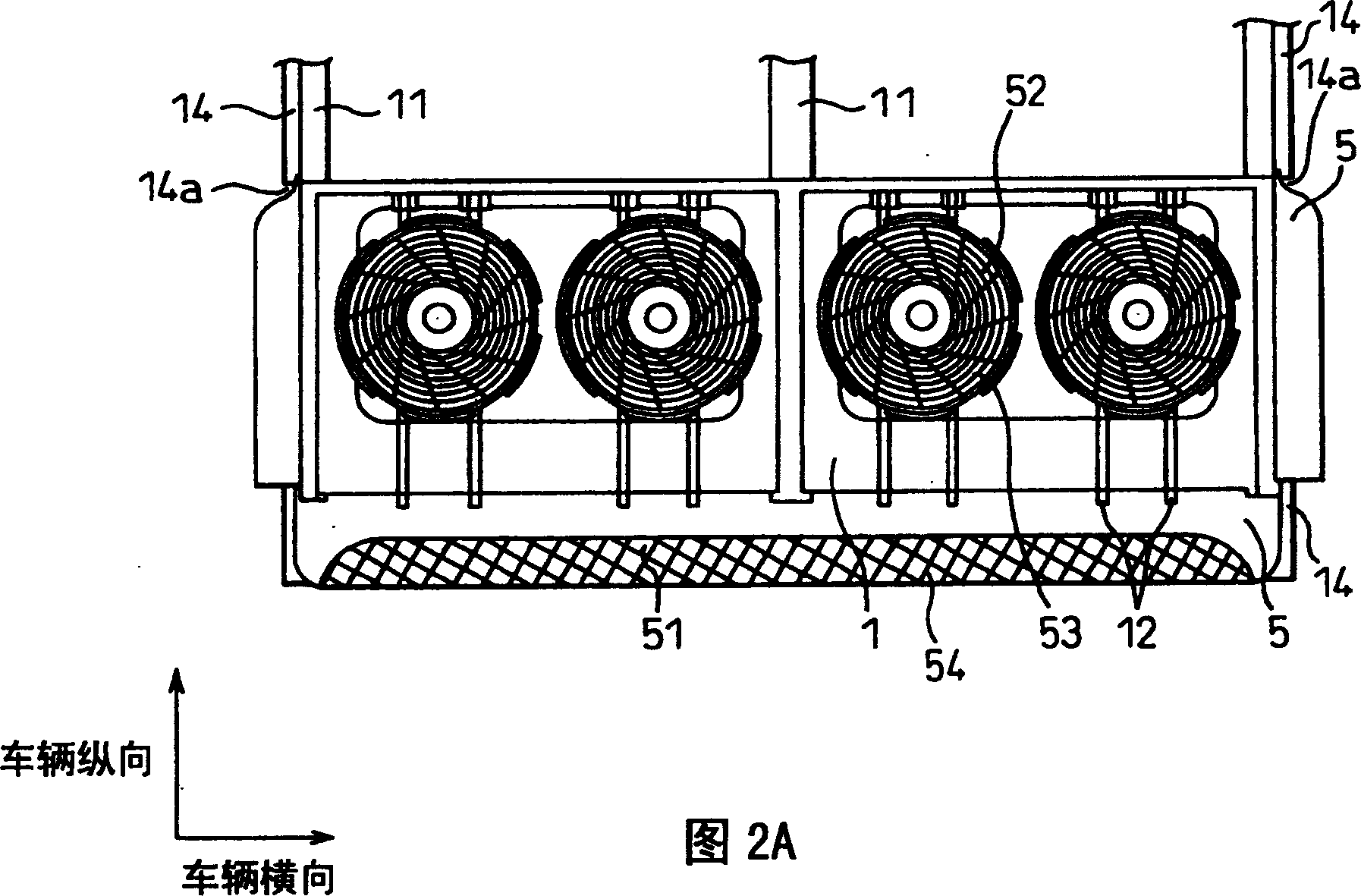

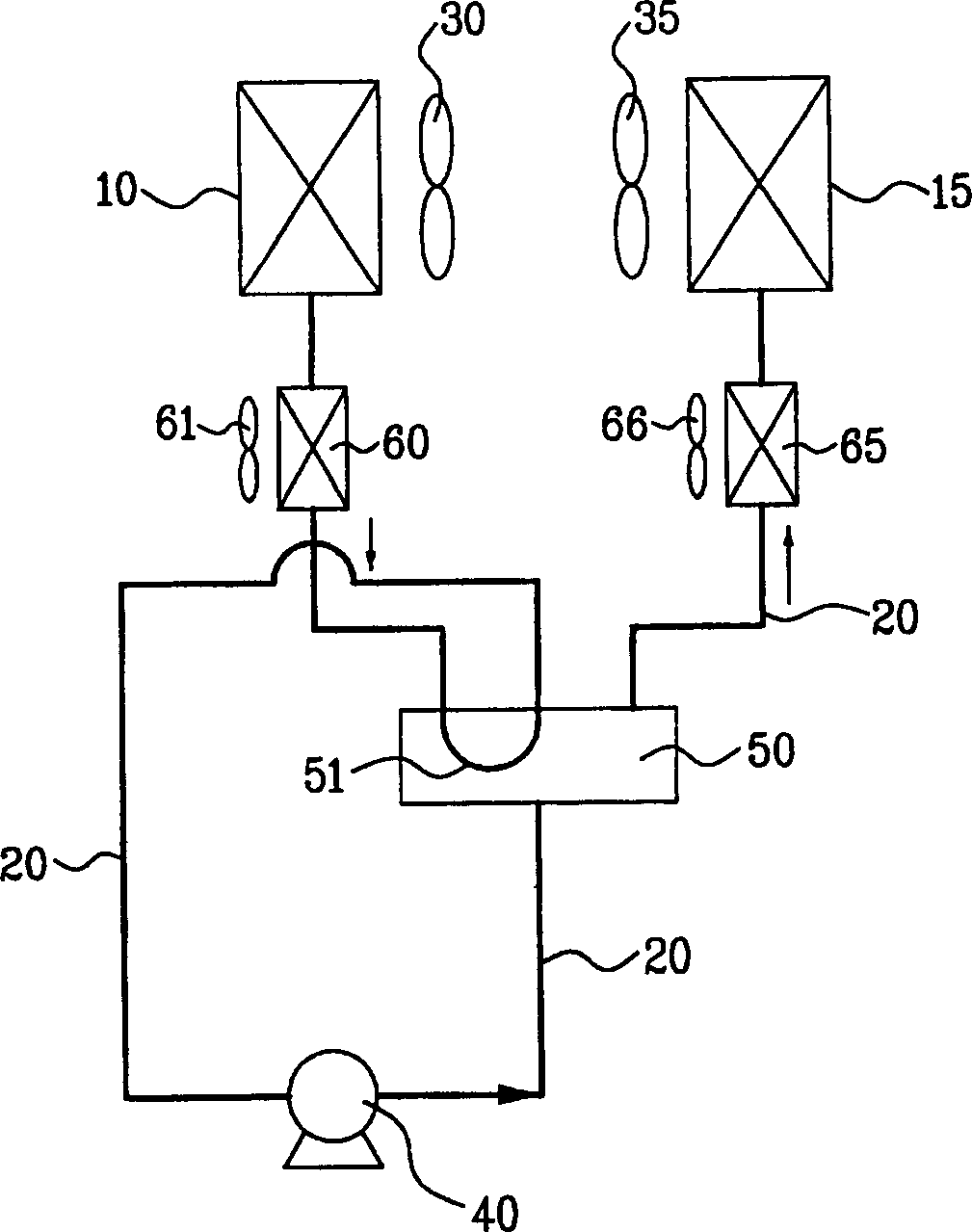

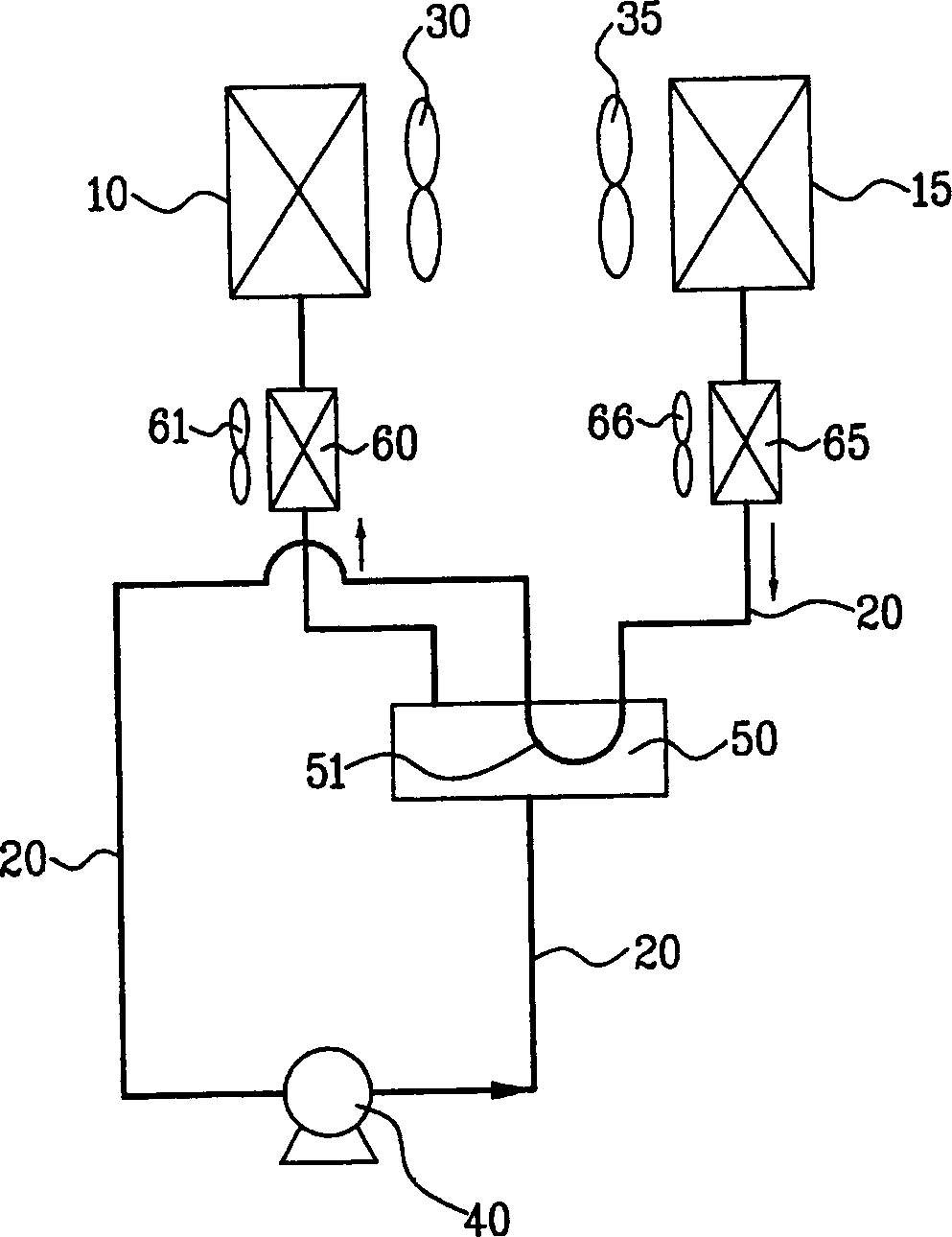

Air conditioning system for vehicle

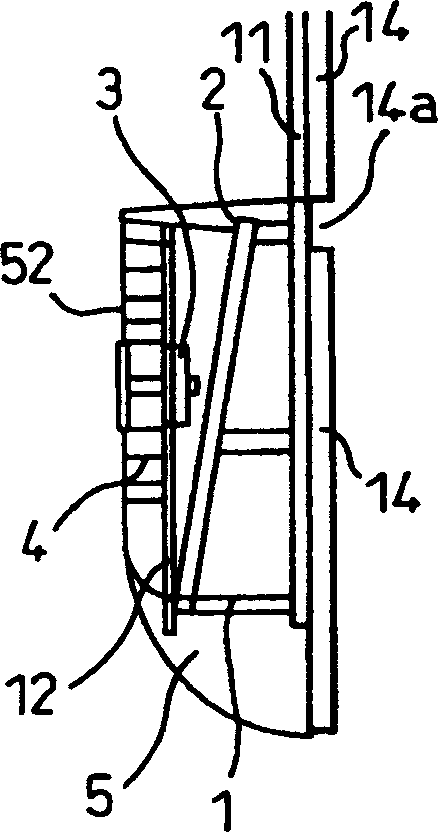

InactiveCN1260078CReduce vertical sizeReduce discharge pressureAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

In the vehicle air conditioning system according to the present invention, the thin condenser 2 of the condensing part part 10 is installed on the flat roof of the vehicle (such as a bus) and slopes downward from the front to the rear of the vehicle, and the condenser fan 4 is directly arranged Above the condenser, the air inlet 51 of the condenser is arranged in front of the condenser and the air outlet 52 is arranged above the condenser.

Owner:DENSO CORP

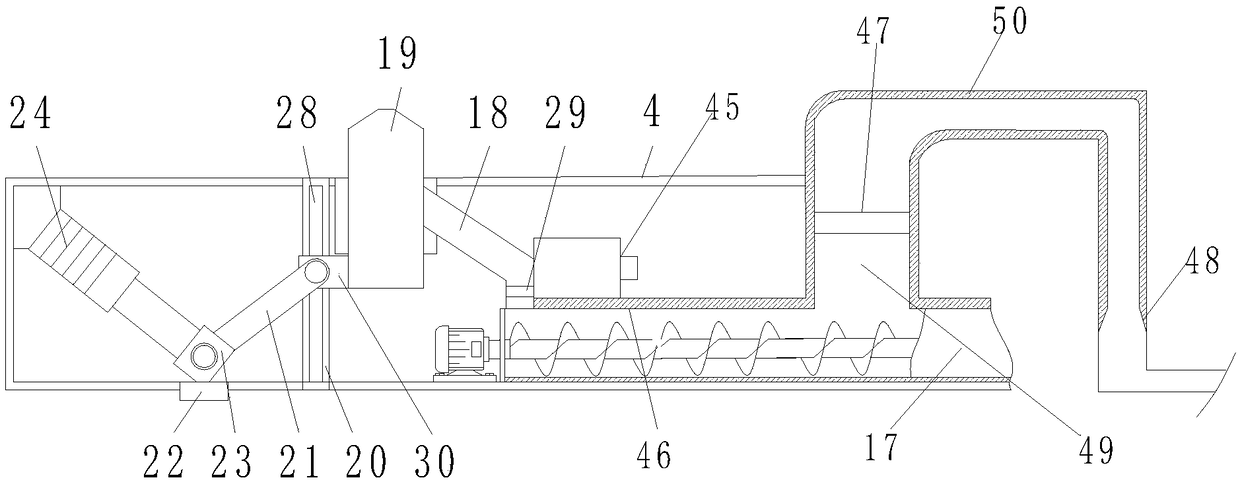

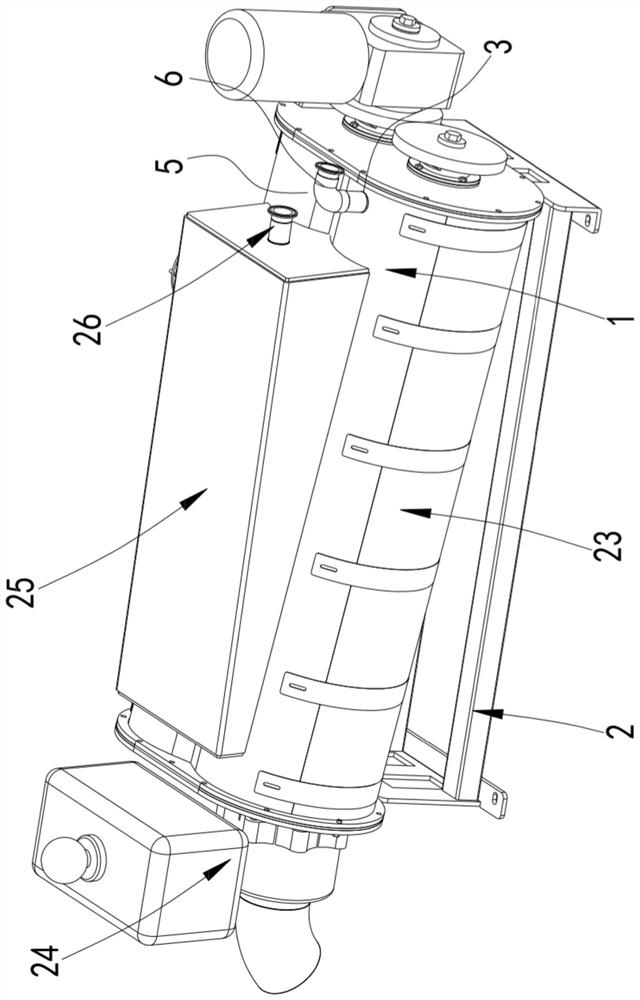

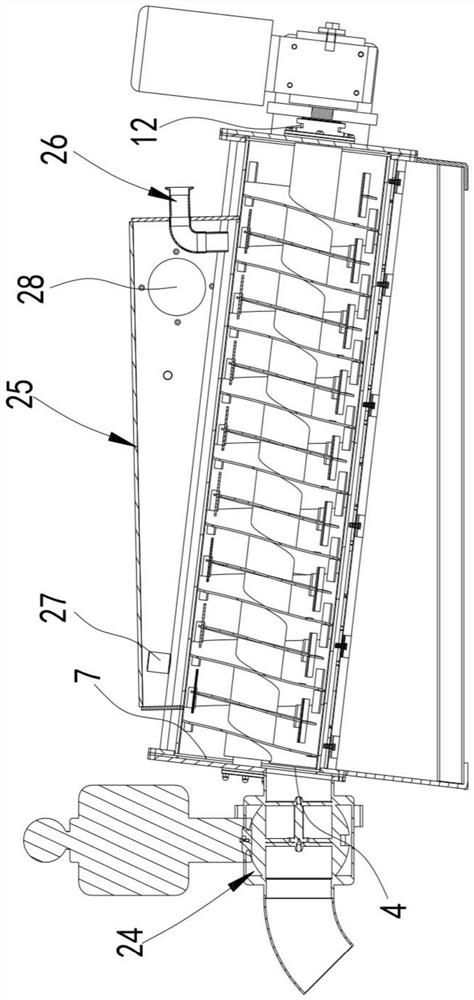

Drying device, garbage treatment device and material machining method

PendingCN112414017AMeet the requirements of stable deliveryGreat driving forceDrying solid materials without heatGrain treatmentsEngineeringRefuse Disposals

The invention discloses a drying device, a garbage treatment device and a material machining method. The drying device comprises a bin body with a feed port and a discharge port and further comprisestwo rotating shafts, a drying device and a heating device, wherein the two rotating shafts are arranged in the bin body in parallel, each rotating shaft is provided with a spiral conveying blade, thedistance between the two rotating shafts is larger than the linear distance between the edge of any spiral conveying blade and the rotating shaft where the spiral conveying blade is located and smaller than the sum of the linear distances between the two spiral conveying blades and the respective rotating shafts where the spiral conveying blades are located, the driving device drives the two rotating shafts to rotate around own axes, the rotating directions of the two rotating shafts are opposite, and the heating device is used for heating the interior of the bin body. According to the scheme,the two mutually-engaged spiral conveying blades are adopted for synchronous conveying, the driving force during conveying is effectively increased, the stable conveying requirement of crushed solidwaste with certain humidity and viscosity can be met, and the drying stability can be guaranteed beneficially.

Owner:环川环保设备(苏州)有限公司

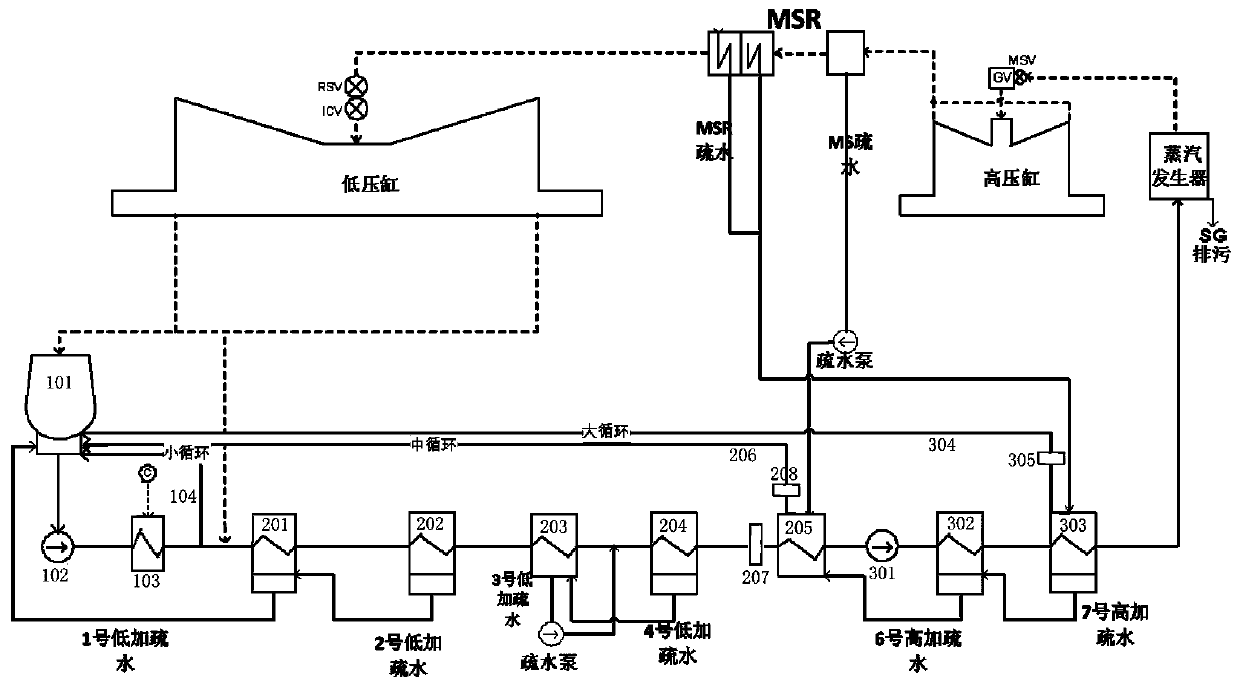

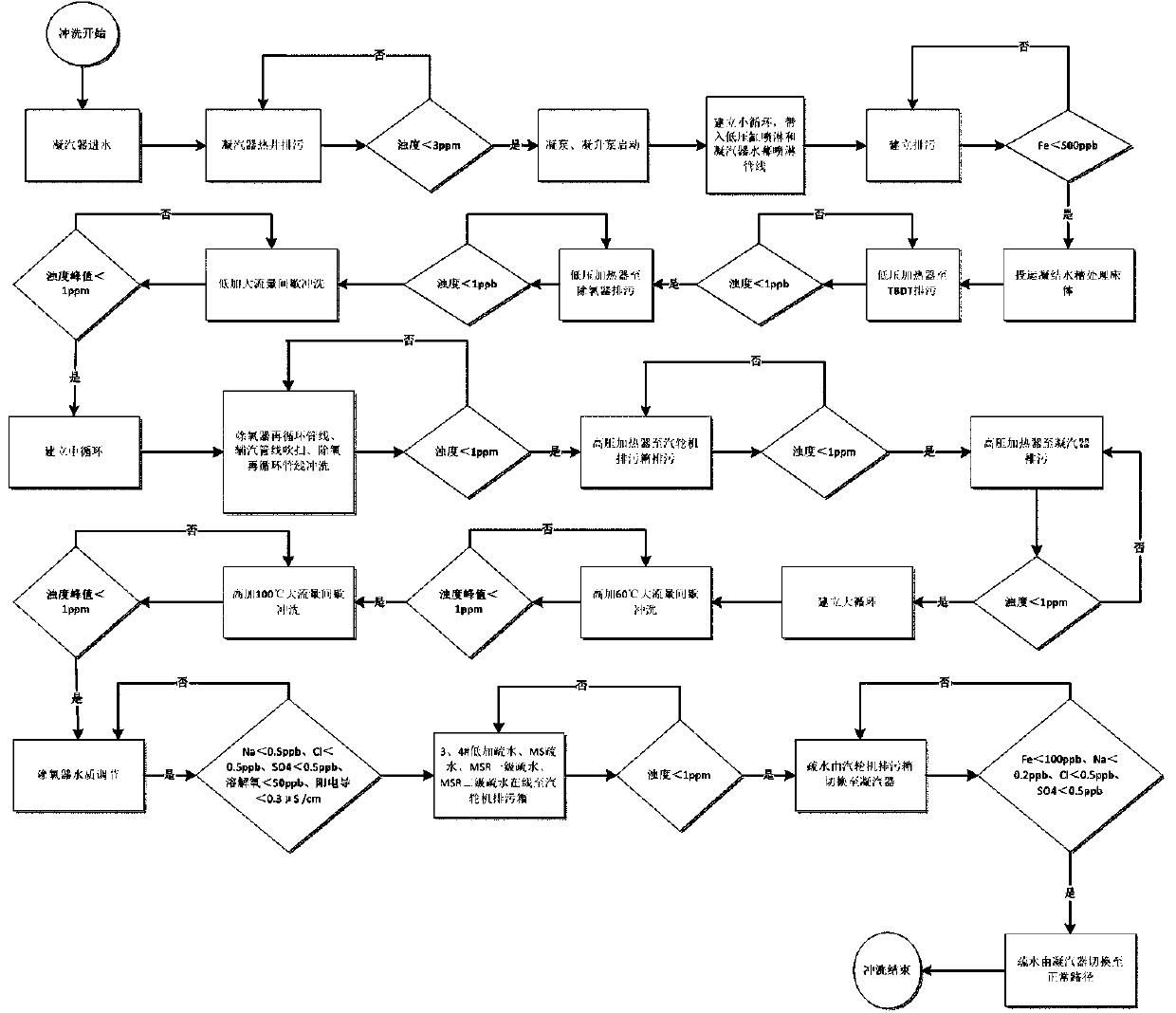

Nuclear power plant start secondary circuit flushing method

InactiveCN111550764AReduce consumptionReduce discharge pressureLiquid degasificationNuclear energy generationNuclear plantRinse water

A nuclear power plant start secondary circuit flushing method comprises the steps of small cycle flushing, medium cycle flushing and large cycle flushing started in sequence. After the small cycle flushing is completed, a condensate polishing system for purifying circulating water is put into operation, and the medium cycle flushing and the large cycle flushing are established, wherein the requirement after the small cycle flushing is that the concentration of Fe is less than 500 ppb; the requirement after the medium cycle flushing is that the turbidity is less than 1 ppm; and the requirementafter the large cycle flushing is that the peak turbidity value is less than 1 ppm. According to the flushing method, a flushing path is standardized, flushing indicators at each stage are clarified,and the process is strictly controlled to achieve the effect of refinement treatment; after the small cycle is established, a polishing bed body can be put into operation, flushing water is purified through polishing, and in a subsequent path flushing process, the flushing water consumption is effectively reduced, and the flushing efficiency is improved.

Owner:SANMEN NUCLEAR POWER CO LTD

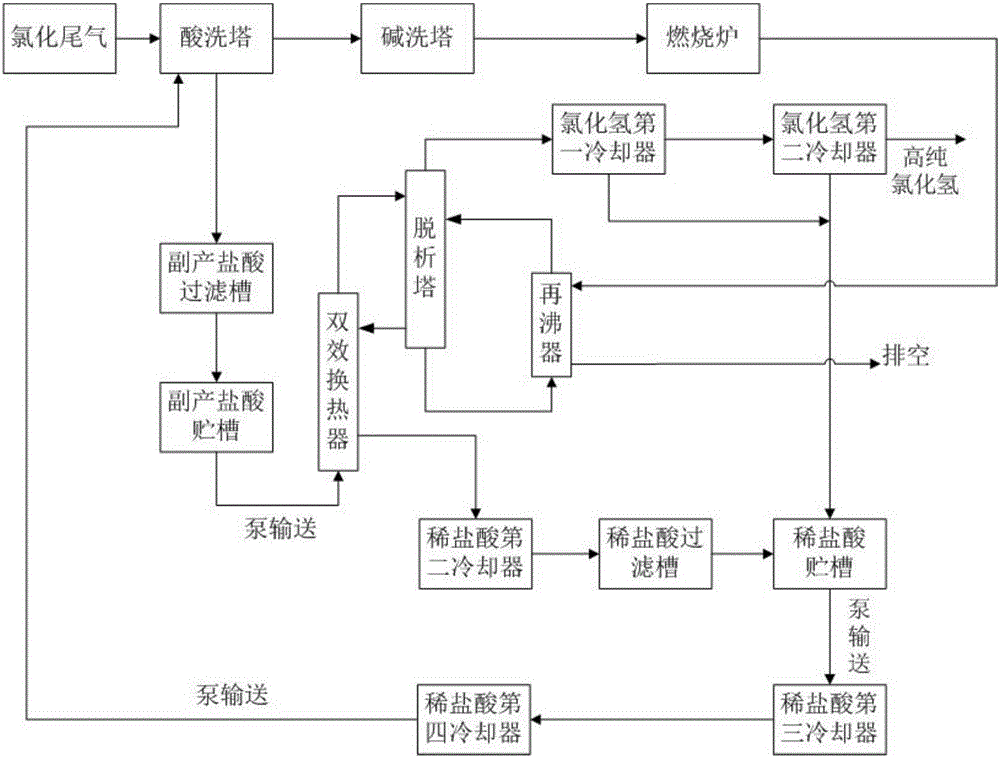

Method for comprehensively utilizing chlorination tail gas in chlorination-process titanium dioxide powder production procedures

ActiveCN106044708AAvoid wastingAchieve effective useChlorine/hydrogen-chloride purificationPreparation from chloridesDischarge pressureExhaust gas

The invention relates to a method for treating chlorination tail gas in chlorination-process titanium dioxide powder production procedures. Carbon monoxide in the chlorination tail gas can be used as a heat source, and byproduct hydrochloric acid which is obtained after the chlorination tail gas is subjected to acid pickling can be desorbed to obtain high-purity hydrogen chloride by the aid of the method. The method includes carrying out acid pickling and alkali washing on the chlorination tail gas, then combusting the chlorination tail gas in a combustion furnace, feeding generated hot flue gas into a reboiler and ultimately venting the flue gas; filtering the byproduct hydrochloric acid obtained after the chlorination tail gas is subjected to acid picking, carrying out heat exchange on the byproduct hydrochloric acid, then feeding the byproduct hydrochloric acid into a desorption tower, continuously heating and evaporating the byproduct hydrochloric acid by the aid of a reboiler to obtain hydrogen chloride gas, exhausting the hydrogen chloride gas from the top of the desorption tower and draining evaporated diluted hydrochloric acid from the bottom of the desorption tower; carrying out heat exchange on the diluted hydrochloric acid by the aid of a double-effect heat exchanger and cooling the diluted hydrochloric acid until the temperature of the diluted hydrochloric acid reaches the normal temperature; condensing the hydrogen chloride gas to obtain high-purity hydrogen chloride gas. The method has the advantages that carbon resources can be effectively utilized; the recycled hydrochloric acid can be converted into the high-purity hydrogen chloride, and accordingly the resource utilization rate can be increased; the desorbed diluted hydrochloric acid is used as acid pickling absorption liquid, accordingly, the recycling rate of the byproduct hydrochloric acid can be increased, discharge pressures can be relieved, and the production cost can be lowered.

Owner:YIBIN TIANYUAN GRP CO LTD +1

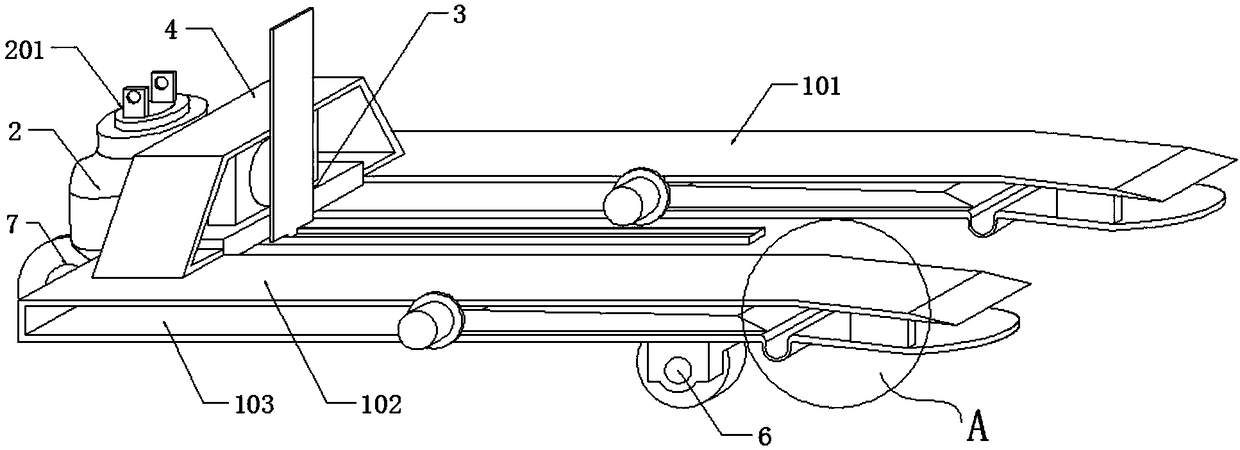

Transporting vehicle convenient to dismount

InactiveCN108715144AReduce the burden of feedingReduce frictionVehicle with rollersVehicle with loading rampBogieEngineering

The invention discloses a transporting vehicle convenient to dismount. The transporting vehicle comprises a first carrying plate, a second carrying plate, a steering frame, an unloading mechanism, a baffle frame, first rolling wheels and a second rolling wheel, wherein the first carrying plate and the second carrying plate are arranged side by side and are connected through a baffling frame; the steering frame is arranged on one side of the baffling frame and is fixedly connected with the baffling frame, the second rolling wheel is mounted at the bottom of the steering frame, and the first rolling wheels are respectively mounted at the bottoms of the first carrying plate and the second carrying plate; and the unloading mechanism is arranged on the inner side of the baffling frame and comprises a building plate, a hydraulic rod, a sliding chute plates and a pushing plate, the building plate is welded with the baffling frame, the sliding chute plate is connected to one side of the othersliding chute plate through screws, the hydraulic rod is fixedly mounted on the surface of the building plate, and a movable end of the hydraulic rod is fixedly connected with the pushing plate. Compared with an existing transporting vehicle convenient to mount and dismount, the transporting vehicle disclosed by the invention has the advantages that the constitution structure is simple, the operation is convenient, meanwhile, a mounting and dismounting mechanism can be folded, the labor can be effectively saved during the loading and unloading of the materials, the transporting vehicle is easyto popularize, and the like.

Owner:浙江杭力鼎盛机械有限公司

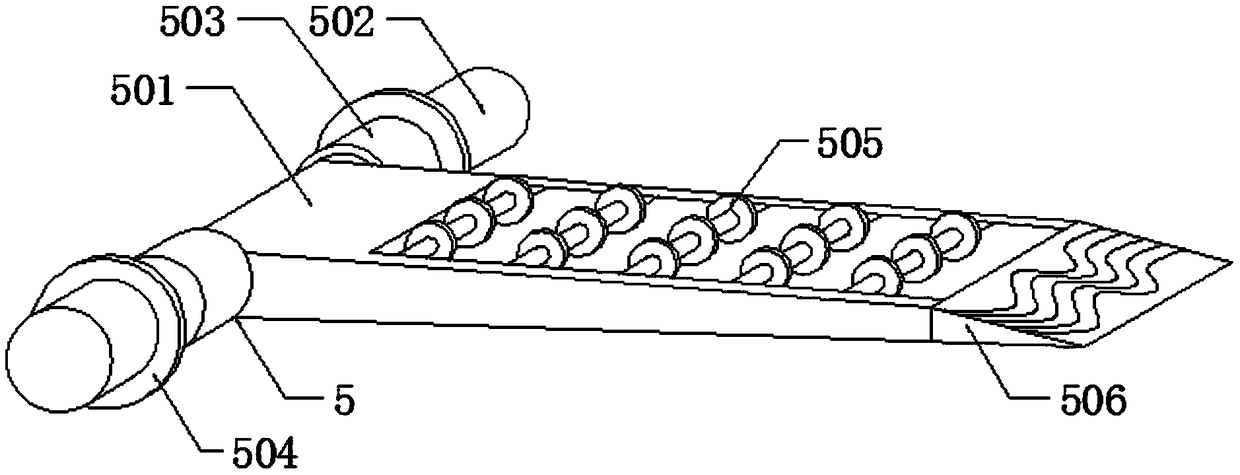

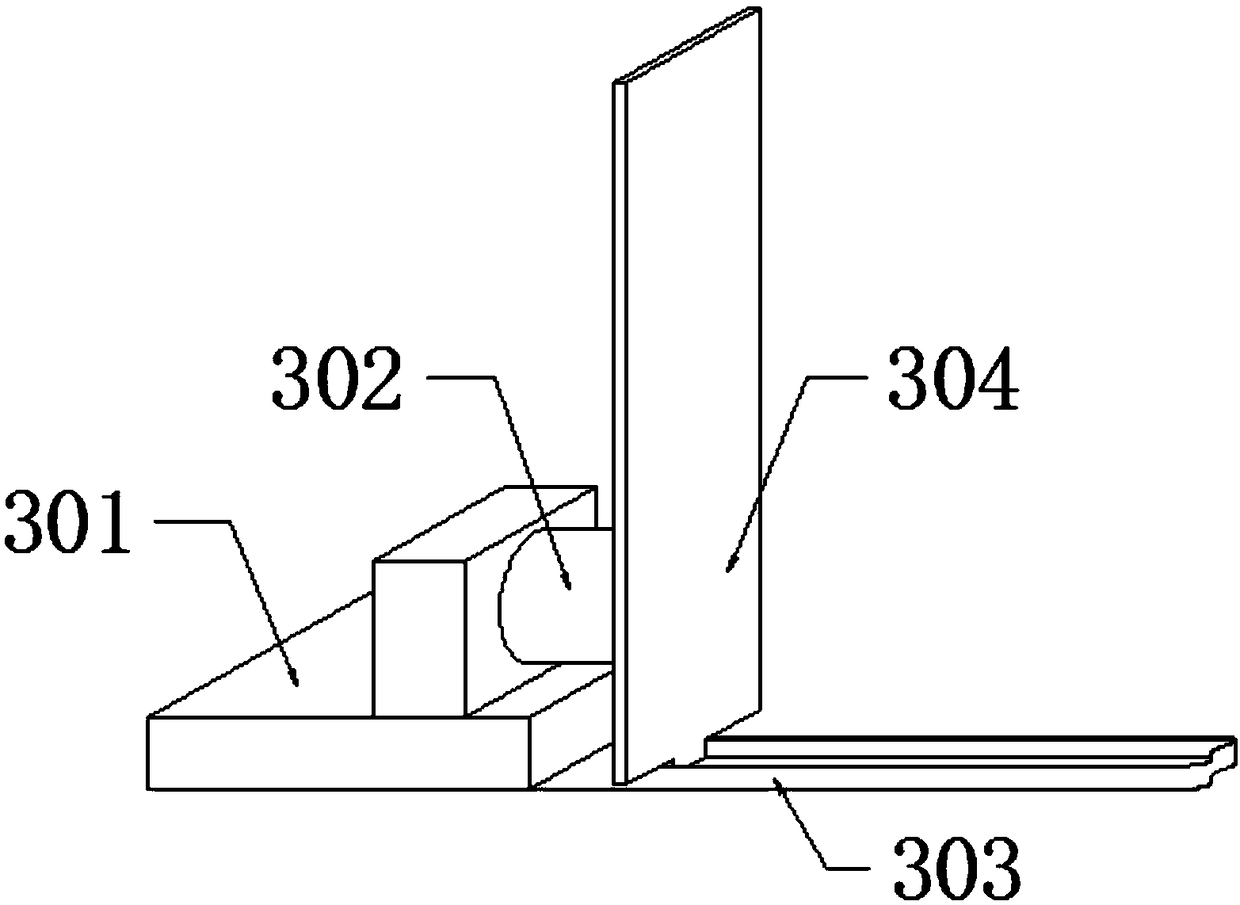

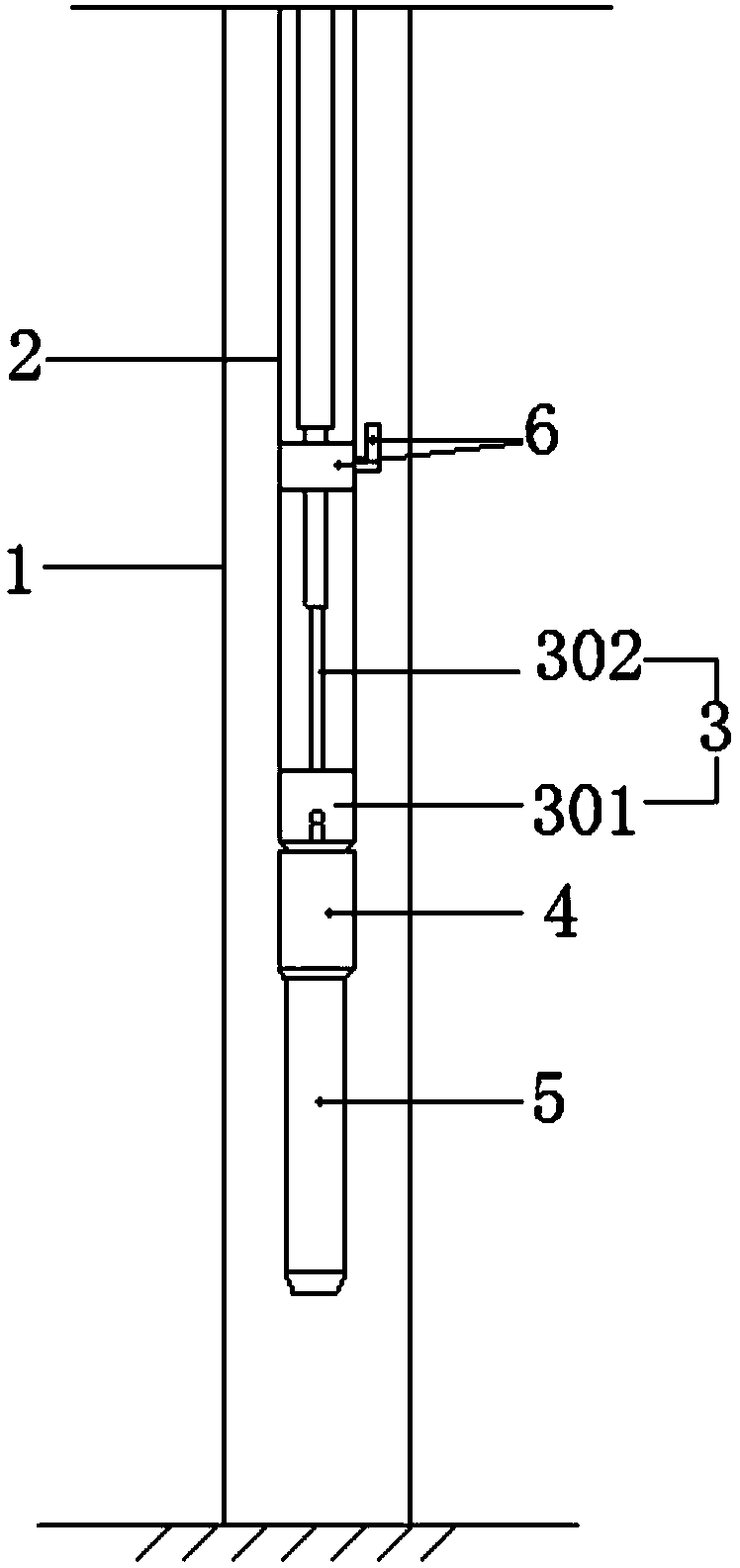

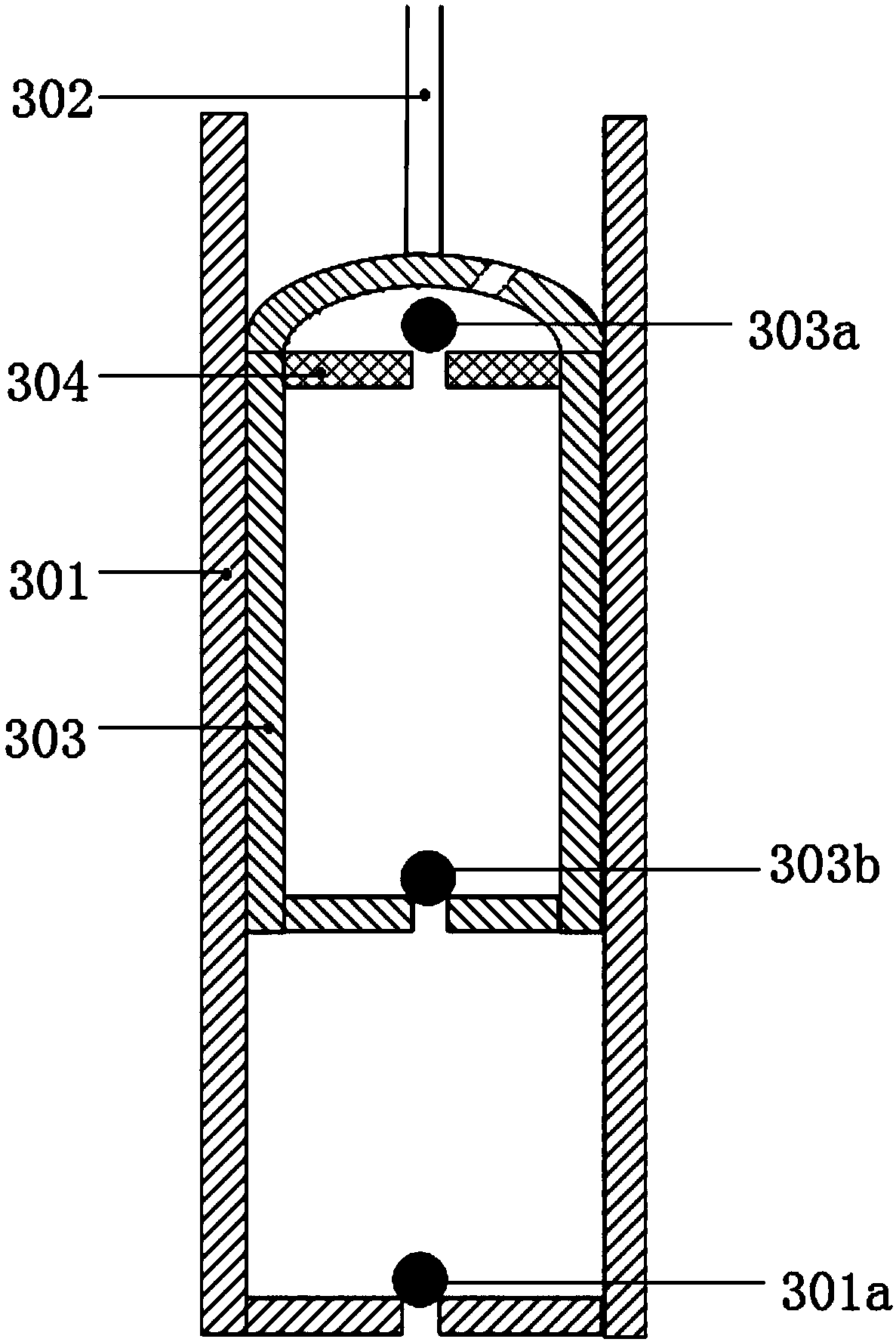

Gas-preventing oil well lifting system

The invention discloses a gas-preventing oil well lifting system and belongs to the field of oil recovery. The gas-preventing oil well lifting system comprises a casing and an oil pipe. The oil pipe is arranged in the casing in a sleeving manner. The system also comprises a heavy ball pump, a gas-preventing device and a tail pipe separately located in the casing; the lower port of the oil pipe communicates to a liquid outlet of the heavy ball pump and a gas lifting valve is arranged at the lower port; the gas-preventing device is used for separating crude oil and gas in an annulus of an oil jacket, and is provided with an inlet, an exhaust port and an oil drain outlet communicating to the liquid inlet of the heavy ball pump; the upper port of the tail pipe is connected to the gas-preventing device and the lower port is closed. The gas-preventing oil well lifting system can separate the crude oil and the gas in the annulus of the oil jacket effectively through the gas-preventing device,not only can prevent the gas from entering into the heavy ball pump, improve the pressure at the pump inlet so as to improve the pump filling coefficient and the pump efficiency, but also can feed the separated gas into the oil pump to be mixed with the crude oil in the oil pipe, so that lifting-assisting and load-reducing action is exerted.

Owner:PETROCHINA CO LTD

Refrigerating and heating device with hydrogen storage alloy

InactiveCN1532479AReduce sizeSuppression of suction pressure riseSorption machinesProcess engineeringEngineering

The refrigerating and heating device with hydrogen and hydrogen storing alloy includes reactor, blower fan, hydrogen pipes, compressor, flow passage control valve and cooling unit. One pair of reactors is filled with hydrogen storing alloy; the blower fan forces the sucked air to indoor or outdoor; the hydrogen pipes are connected to the reactors for hydrogen to flow through; the compressor is connected to the hydrogen pipes to force hydrogen from one reactor to the other; the flow passage control valve set in the hydrogen passage can alter the hydrogen flow direction between the reactors; and the cooling unit cools hydrogen exhausted from the compressor before being sucked into one reactor.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Self-drainage sewage pipe

ActiveCN108894299ARelieve stressReduce discharge pressureFatty/oily/floating substances removal devicesSewerage structuresSewage treatmentDischarge pressure

A self-draining sewage pipe includes a pipe body portion and an extension section arranged on one side of the pipe body portion, A sewage discharge channel is arranged in the middle of the pipe body part, A first partition plate is arranged in the middle of the sewage discharge passage close to the sewage passage outlet, the first partition plate divides the entire sewage passage into a sewage chamber at the upper end and a first sewage chamber at the bottom, The output end of the first diaphragm is provided with a filter section, the output end of the bottom of the filter section is connectedwith the extension section, a second diaphragm is arranged at the bottom of the filter section, and a closed intermediate cavity is formed between the second diaphragm and the filter section and theextension section at the upper end. The sewage pipe of the invention can automatically remove the scum floating on the sewage surface and automatically discharge and collect the scum, thereby reducingthe sewage treatment pressure at the later stage and reducing the discharge pressure of the pipe.

Owner:东阳市特意新材料科技有限公司

Glass fiber kiln waste gas treatment device and method

PendingCN112197604AImprove device safetyImprove working environmentFurnace monitoring devicesIncrustation removal devicesExhaust fumesProcess engineering

Owner:CHONGQING POLYCOMP INT

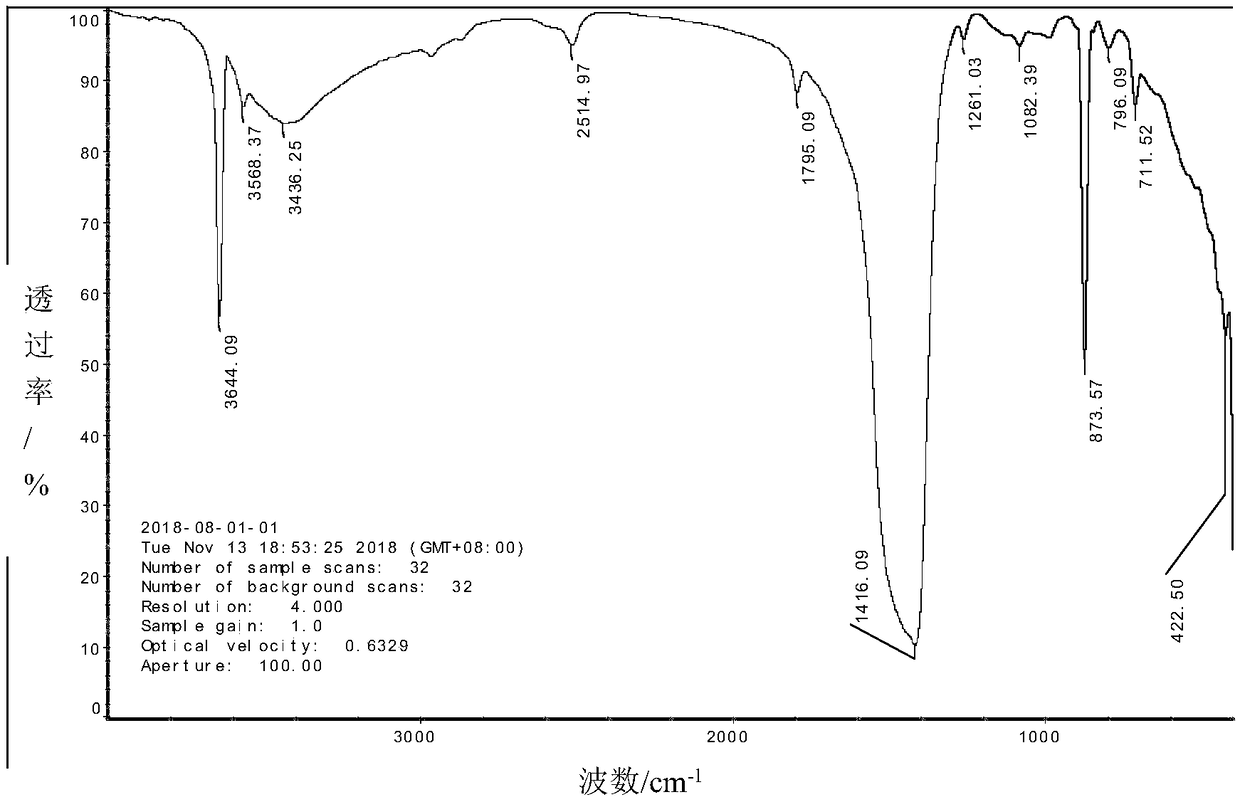

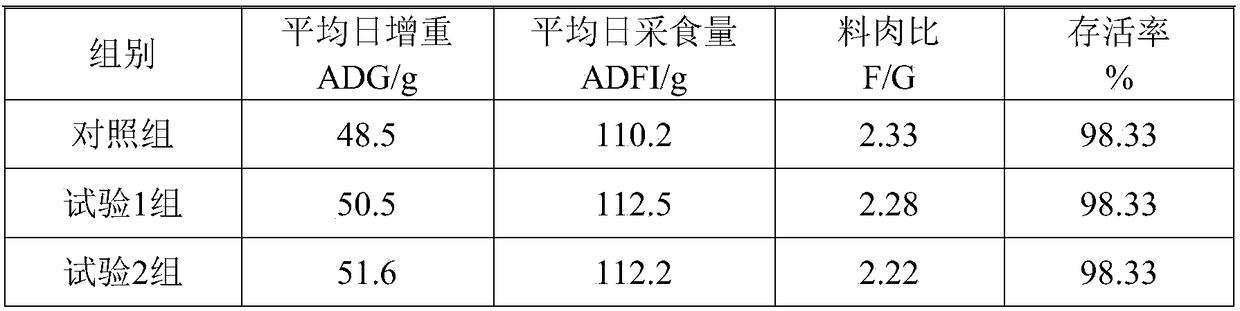

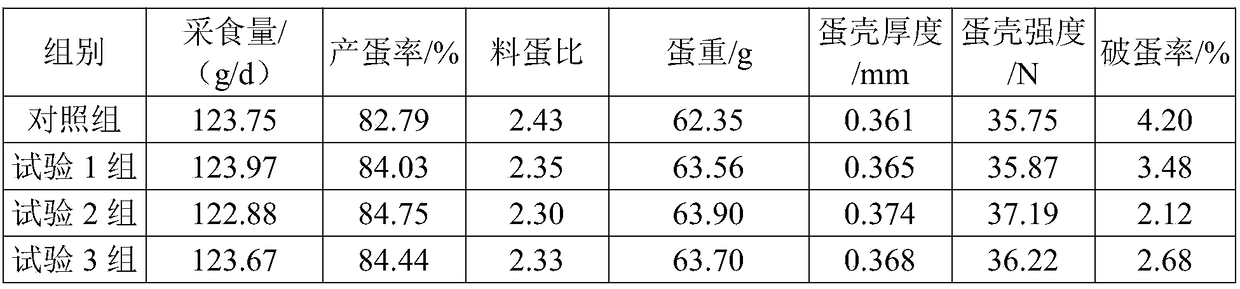

Preparation method for hydroxycalcium carbonate and application of hydroxycalcium carbonate in animal feed field

ActiveCN109399686AWeak alkalineMild responseCalcium/strontium/barium carbonatesAccessory food factorsReaction rateAcid substances

The invention discloses a preparation method for hydroxycalcium carbonate for an animal feed. The preparation method comprises the following steps: adding a calcium source to water and warming, addingbicarbonate in a stirring condition, reacting in a constant temperature, after ending a reaction, cooling and crystallizing, filtering and drying, to obtain the hydroxycalcium carbonate. The preparation method is more moderate in reaction rate, controllable in process, more uniform in obtained product particles, less in by-product generation, high in bioavailability of the hydroxycalcium carbonate, and low in processing cost. The invention further discloses an application of the hydroxycalcium carbonate in the animal feed field. While the hydroxycalcium carbonate is used for a pig feed, an additive amount thereof is 1-12 kg / t of a mixed feed; while the hydroxycalcium carbonate is used for a poultry animal feed, the additive amount thereof is 1-23 kg / t of the mixed feed; and while the hydroxycalcium carbonate is used for a ruminant animal feed, the additive amount thereof is 0.1-4 kg / t of a full mixed daily ration feed. The application is capable of neutralizing acidic materials in thefeed, and preventing or delaying metamorphism of the feed.

Owner:XINGJIA BIO ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com