Patents

Literature

123results about How to "Avoid overexpansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

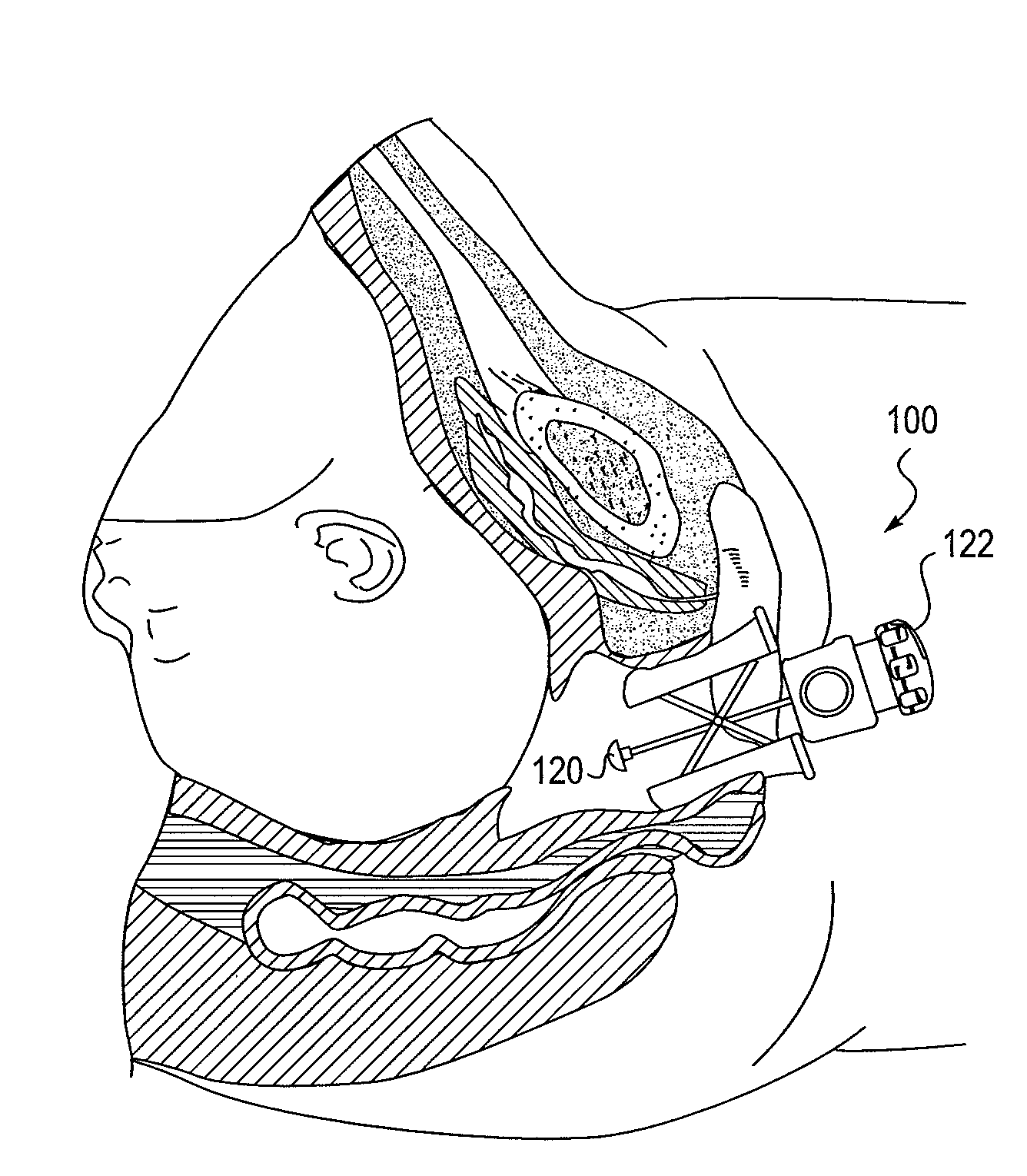

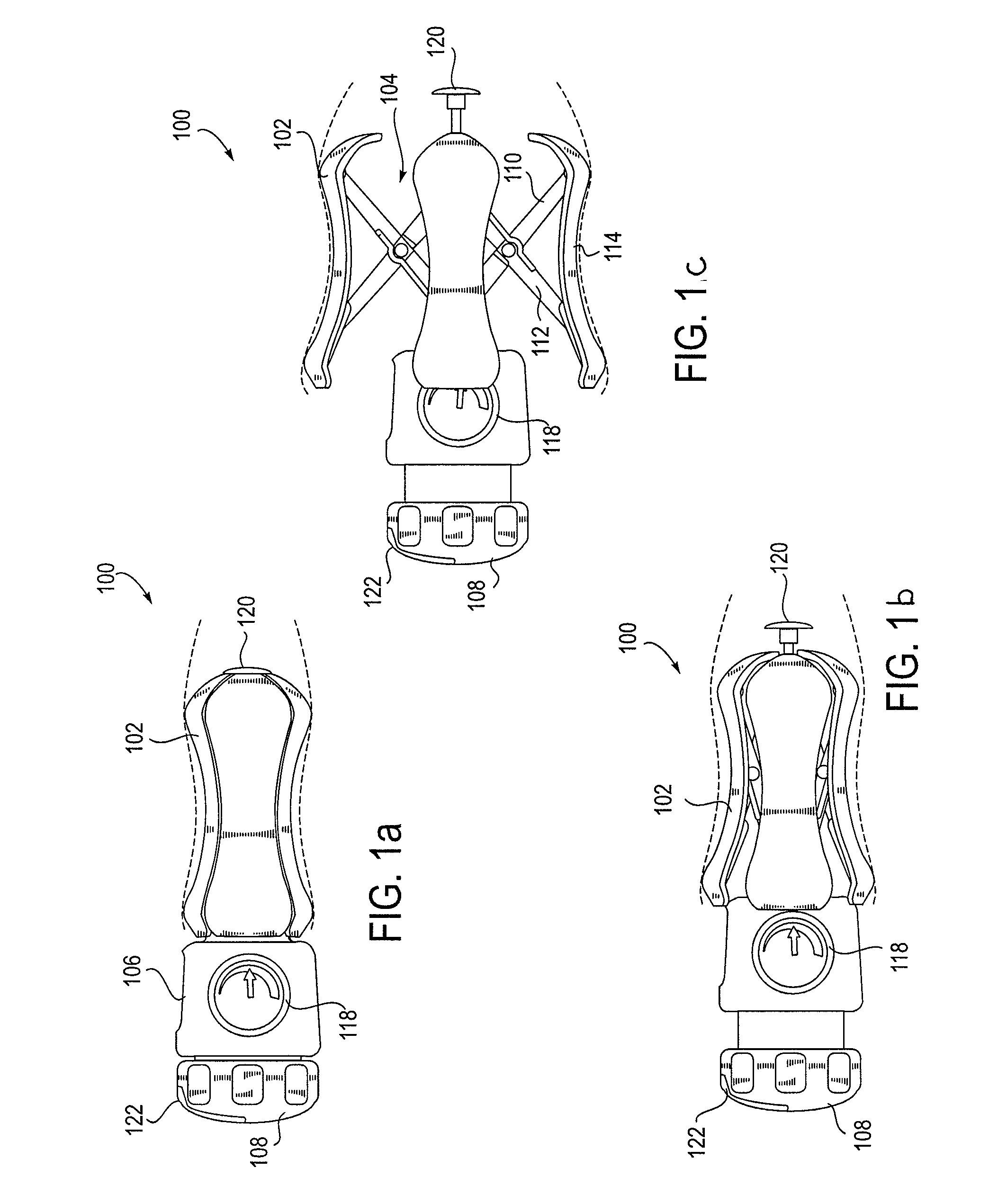

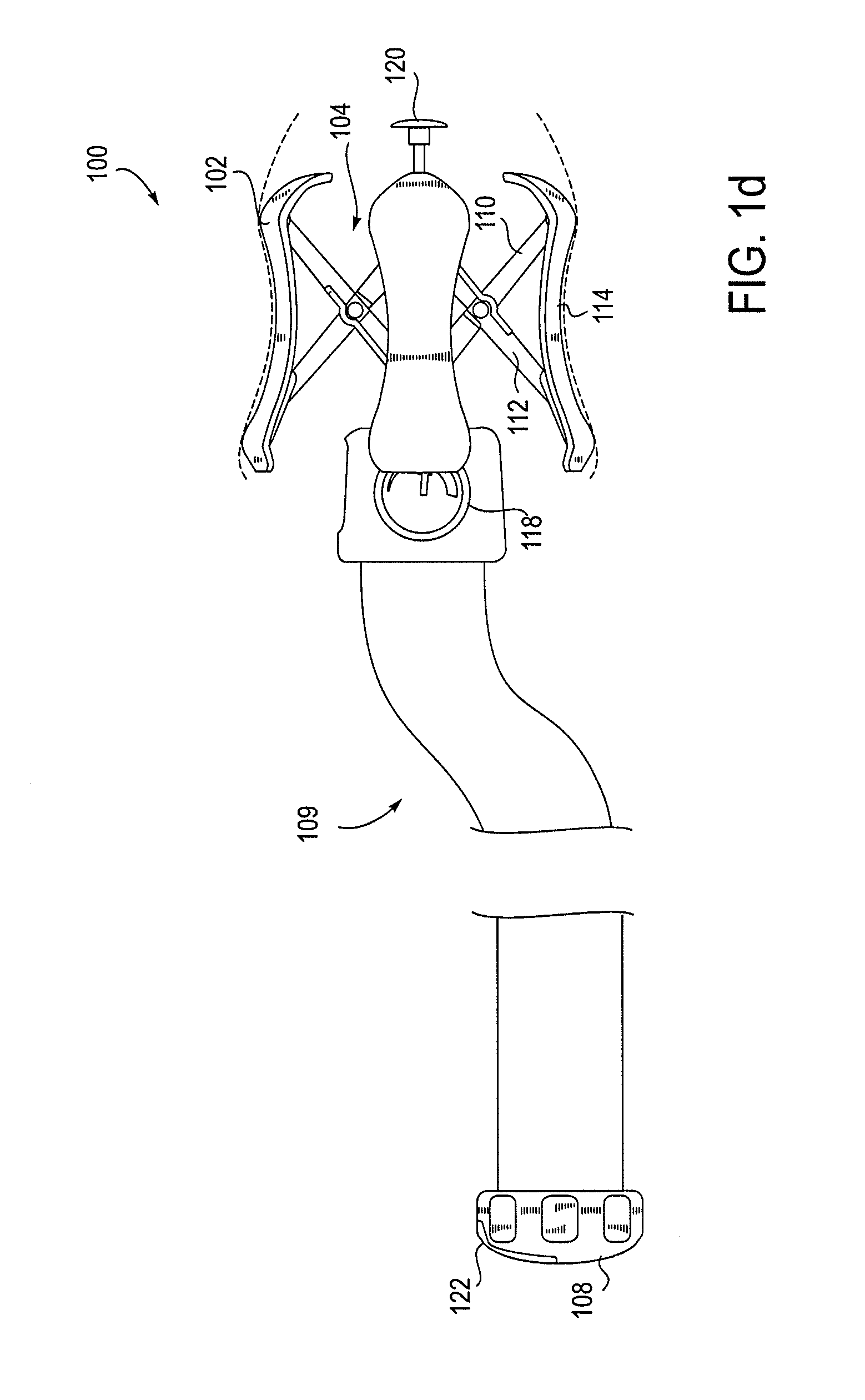

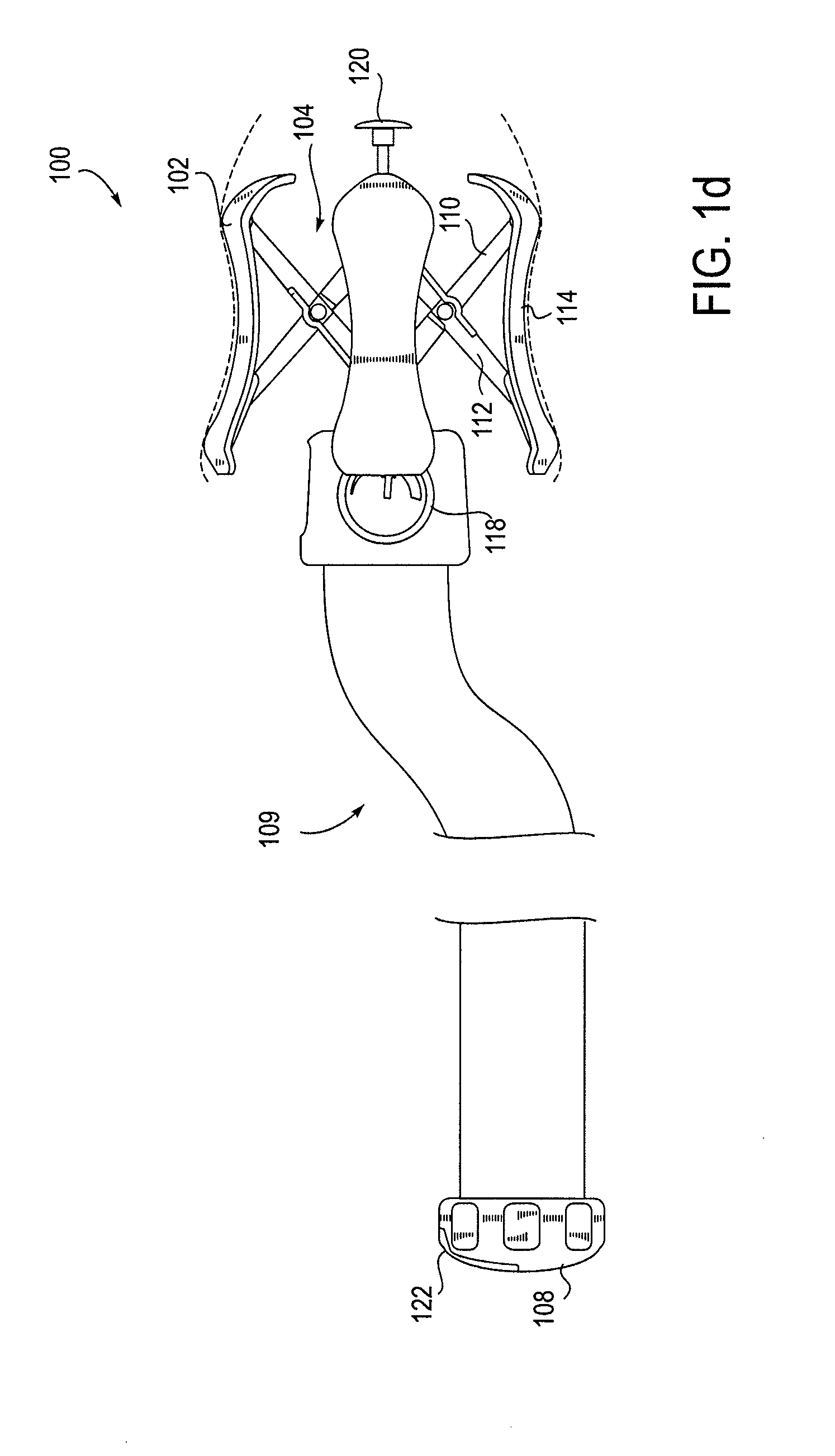

Methods and apparatus for preventing vaginal lacerations during childbirth

ActiveUS20130053863A1Avoid overexpansionPrevent pressureCannulasDilatorsVaginal dilationAutomatic control

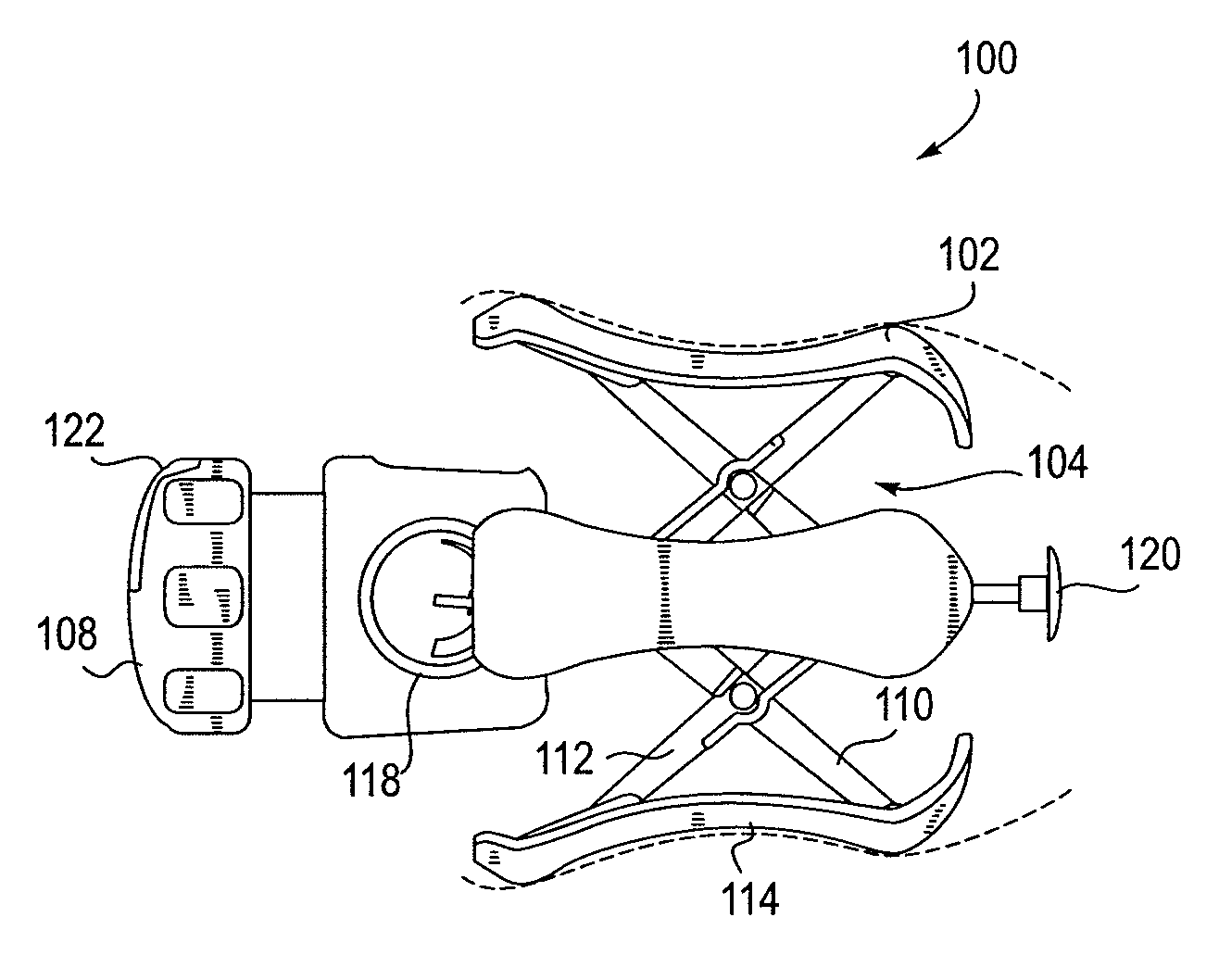

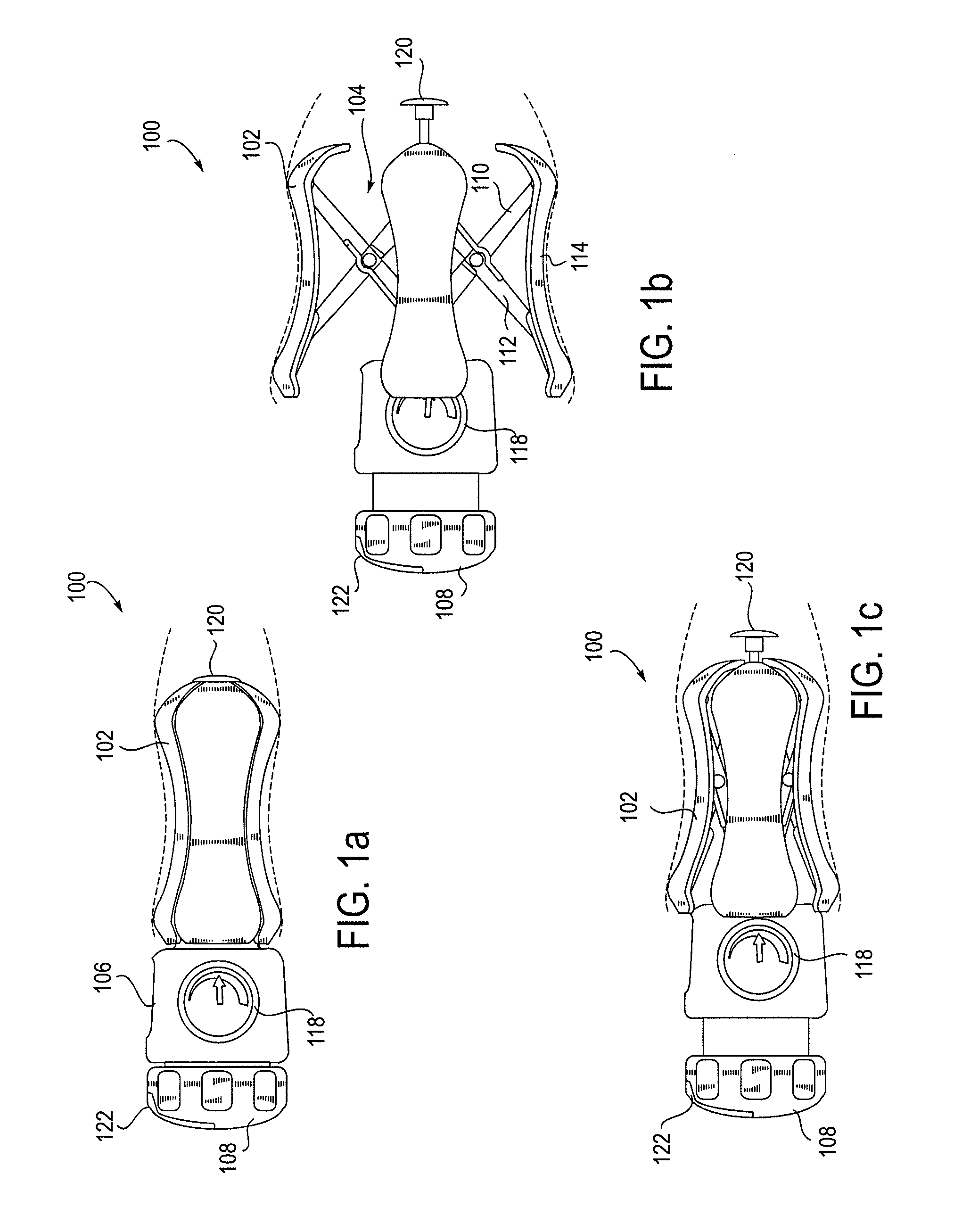

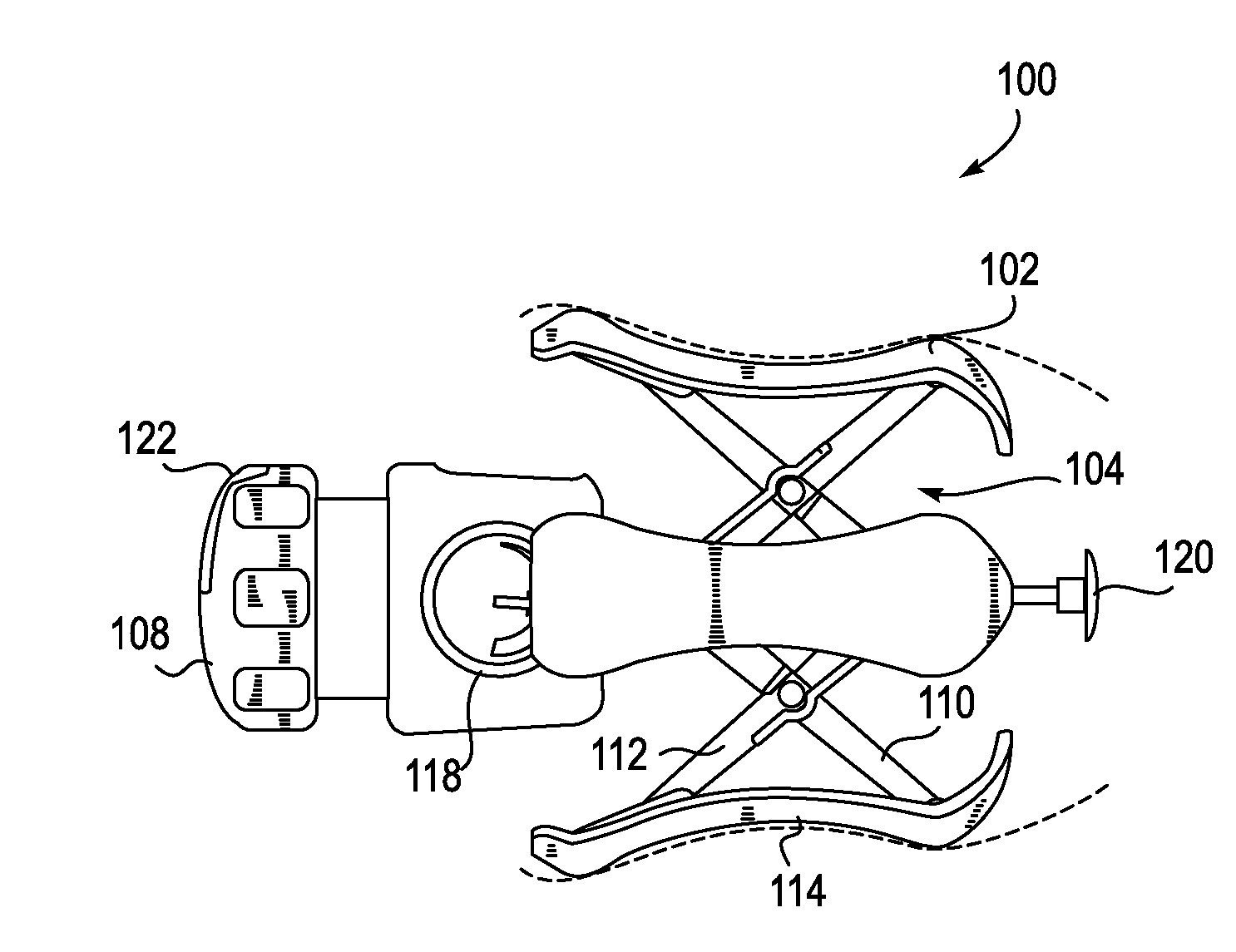

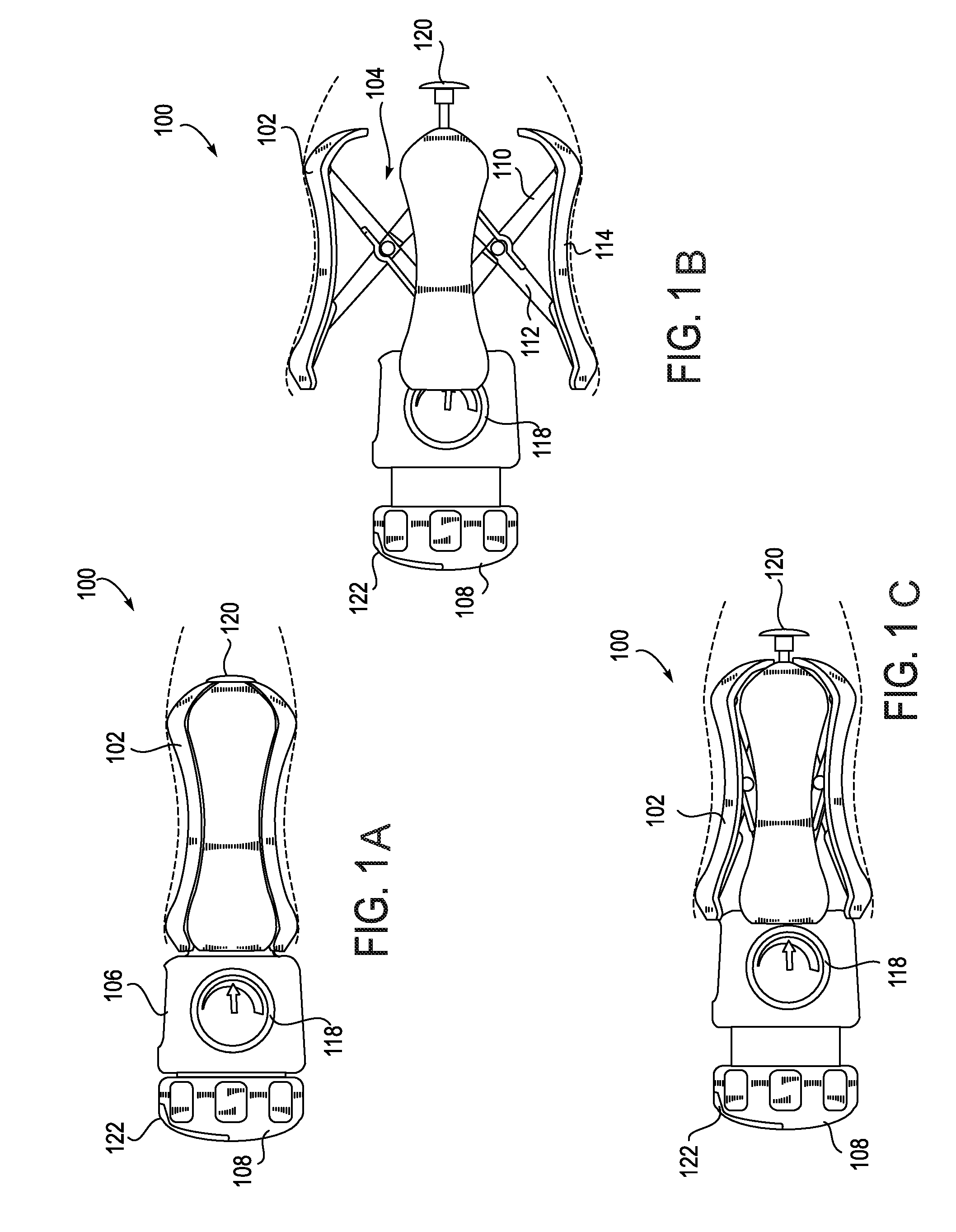

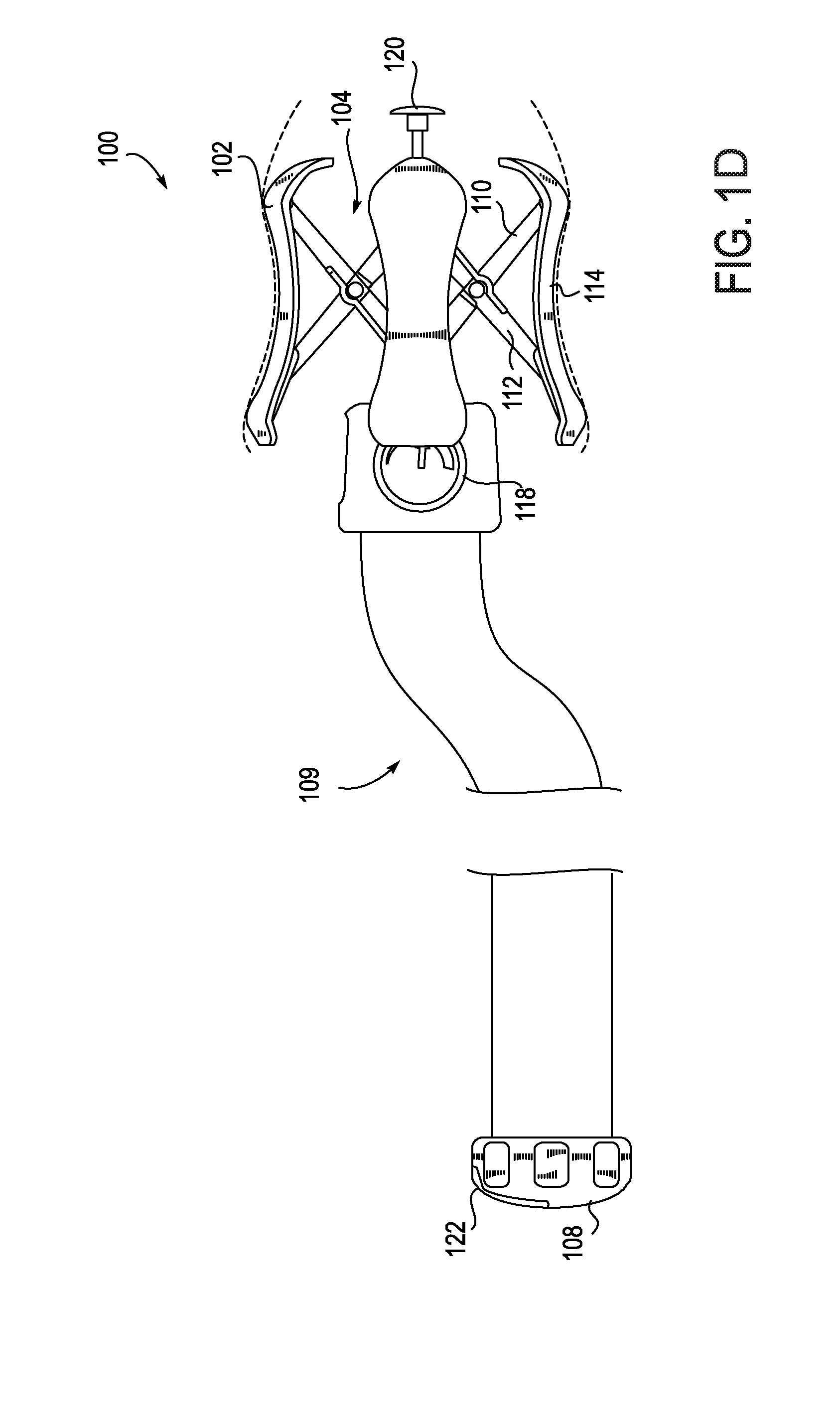

A vaginal dilation device is provided that may include any of a number of features. One feature of the vaginal dilation device is that it is configured to dilate vaginal tissue during labor to prevent tissue damage. Another feature of the vaginal dilation device is that it can be manually controlled to dilate vaginal tissue, or can be automatically controlled to dilate vaginal tissue. In some embodiments, the vaginal dilation device is configured to measure a force applied by the device to tissue. In other embodiments, the vaginal dilation device is configured to apply a constant force to tissue. In other embodiments, the vaginal dilation device is configured to expand at a constant rate. Methods associated with use of the vaginal dilation device are also provided.

Owner:MATERNA MEDICAL

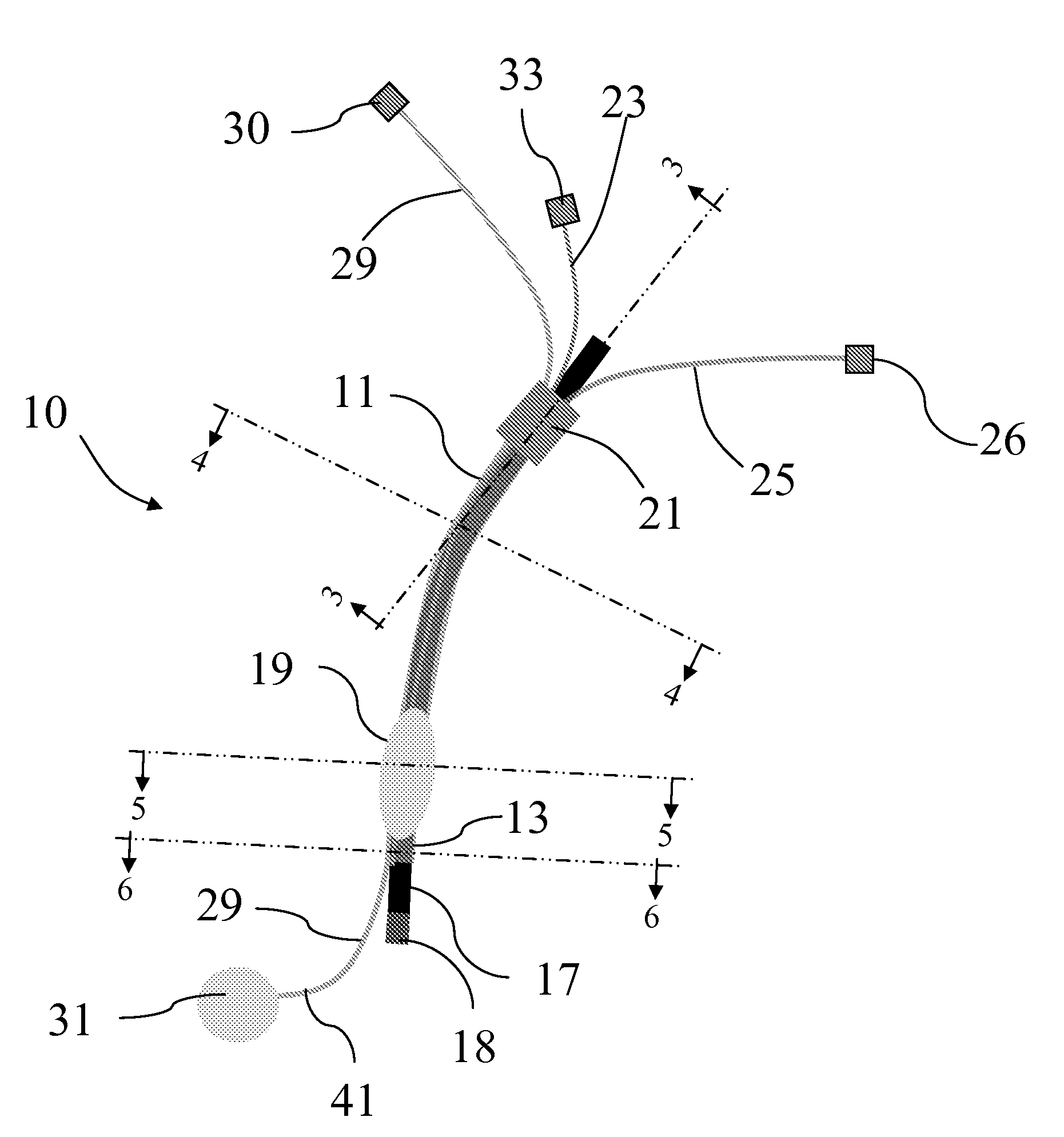

Endoscope Accessory

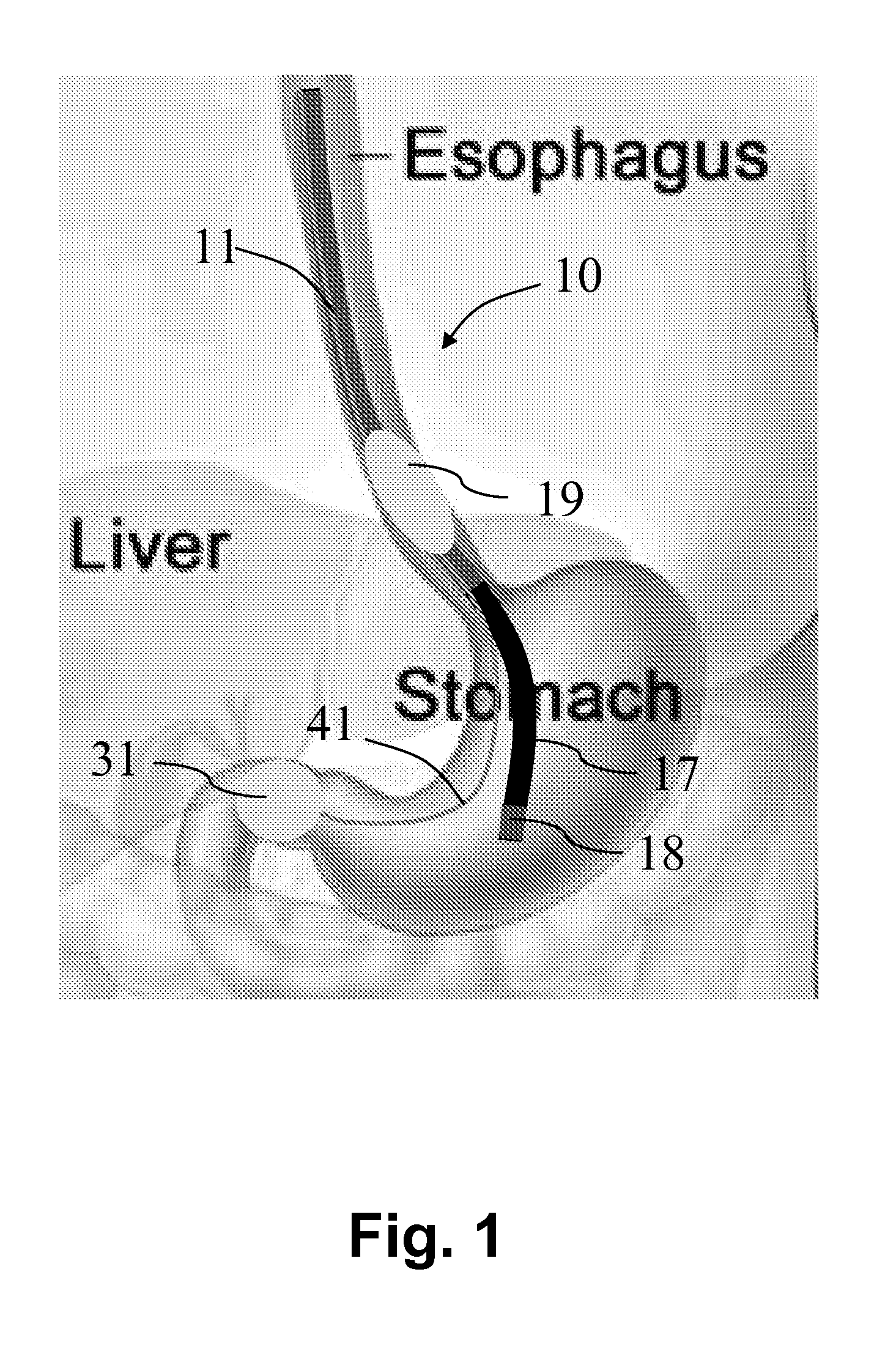

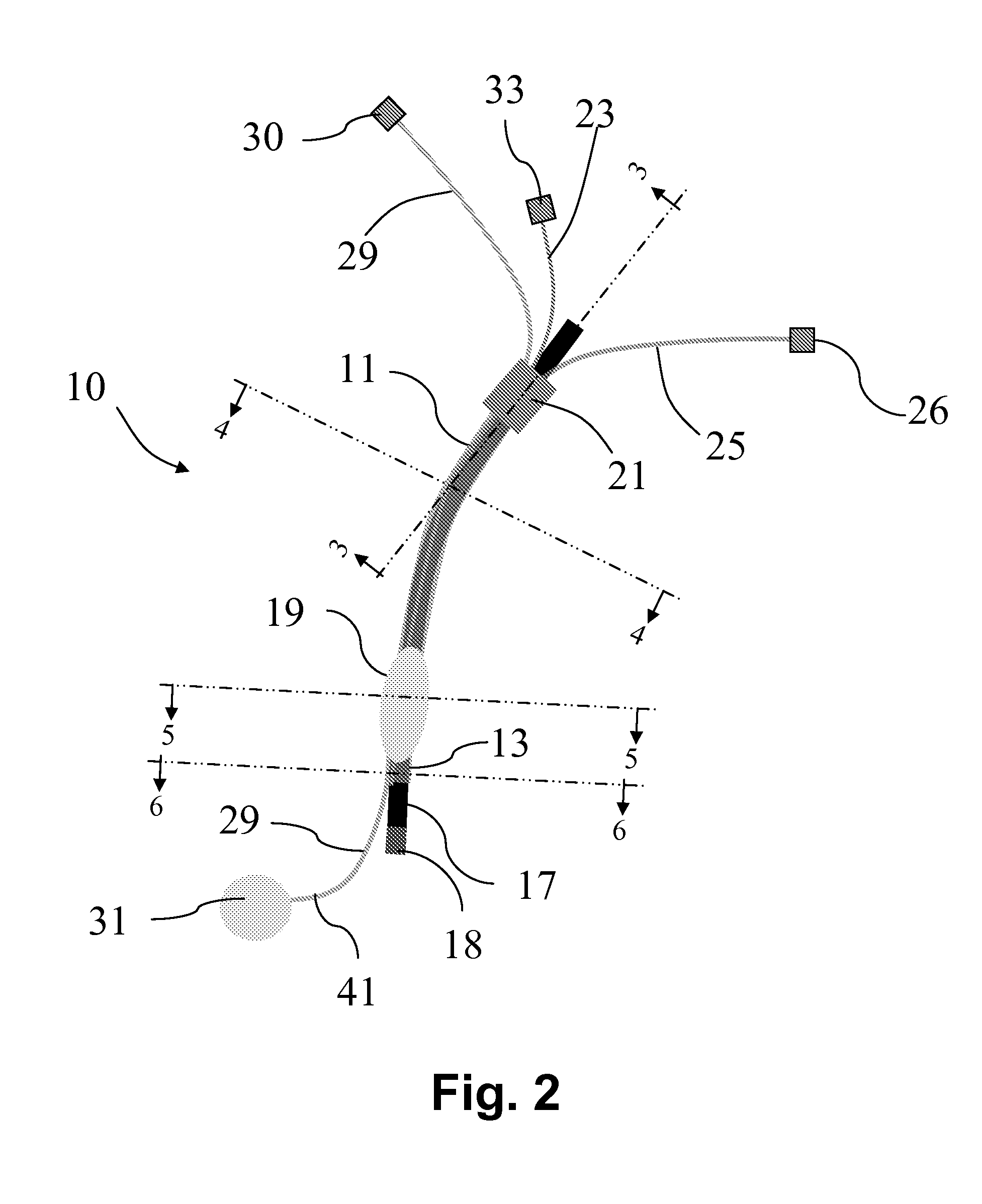

ActiveUS20100121144A1Increase capacityImproves acoustic couplingBalloon catheterGastroscopesEndoscopic AccessoryClosed space

This invention relates generally to an endoscope accessory. This device uses an overtube with an inflatable positioning balloon that can be inflated after placement of the overtube just proximal to the tip of the endoscope or echoendoscope. This balloon creates a temporary blockade of the gastrointestinal tract proximal to the portion that needs to be examined. The other part of the device is a catheter with an occlusion balloon affixed to its free endportion and can be passed through a passageway within the overtube and extended beyond the tip of the endoscope, distal to the part of the gastrointestinal tract that needs to be examined. Inflation of this balloon together with positioning balloon creates a closed space within the body cavity that can be filled with air or water for improving the quality of the examination with regular endoscope of echoendoscope, respectively, while reducing the examination complications.

Owner:IZOMED INC

Method and apparatus for preventing vaginal lacerations during childbirth

InactiveUS20130253376A1Reduce overall outer diameterAvoid overexpansionPerson identificationSensorsVaginal dilationAutomatic control

A vaginal dilation device is provided that may include any of a number of features. One feature of the vaginal dilation device is that it is configured to dilate vaginal tissue during labor to prevent tissue damage. Another feature of the vaginal dilation device is that it can be manually controlled to dilate vaginal tissue, or can be automatically controlled to dilate vaginal tissue. In some embodiments, the vaginal dilation device is configured to measure a force applied by the device to tissue. In other embodiments, the vaginal dilation device is configured to apply a constant force to tissue. In other embodiments, the vaginal dilation device is configured to expand at a constant rate. Methods associated with use of the vaginal dilation device are also provided.

Owner:MATERNA MEDICAL

Method for preparing cotton-like fabric through alkali decrement

InactiveCN102433729AThe texture of the cloth surface is dense and smoothSofter and fluffier than ultra cottonFibre typesFiberThermal insulation

The invention discloses a method for preparing cotton-like fabric through alkali decrement. The method comprises the steps of: a. first conducting unwinding treatment to polyester grey fabric, then carrying out sanding treatment; b. performing high temperature alkali decrement treatment in a high-temperature high-pressure overflow dyeing machine; c. dyeing and bleaching the treated fabric; d. carrying out shaping treatment to the dyed fabric for stabilizing the dimension; e. examining and packing a finished product. The high temperature alkali decrement technology consists of: with 10-15g / L of sodium hydroxide and 1g / L of a detergent, controlling the bath ratio at 1:15, first raising the temperature to 120-130DEG C at a speed of 2-5DEG C / min, conducting thermal insulation for 20-30min, then lowering the temperature to 50-80DEG C at a speed of 2-4DEG C / min, carrying out thermal insulation for 30-60min, and then lowering the temperature to normal temperature at a speed of 0.5-2.5DEG C / min. The fabric prepared by the method of the invention has the advantages that: 1. the fabric surface has dense and flat lines, the handfeel is soft and fluffy and surpasses cotton; 2. fibers have a strong fluffy feel, the luster is gentle, and the fabric surface can generates diffuse reflection to light and has gentle luster; 3. the fabric surface is smooth, has good permeability, and can improve chemical fibers, static resistance and stuffy feeling; the product can compare favorably with cotton fabric in terms of performances, and has lower price.

Owner:潘润华

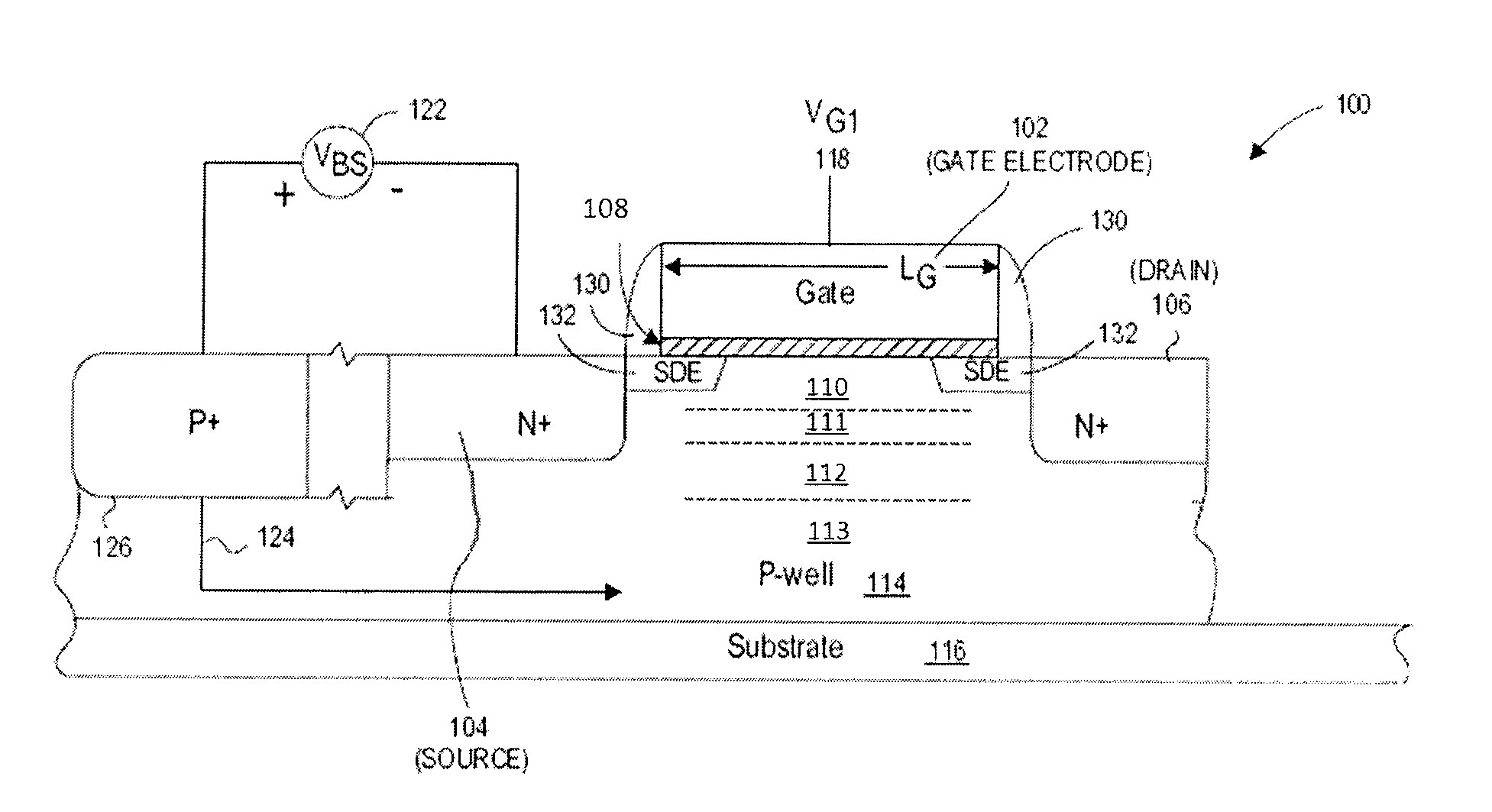

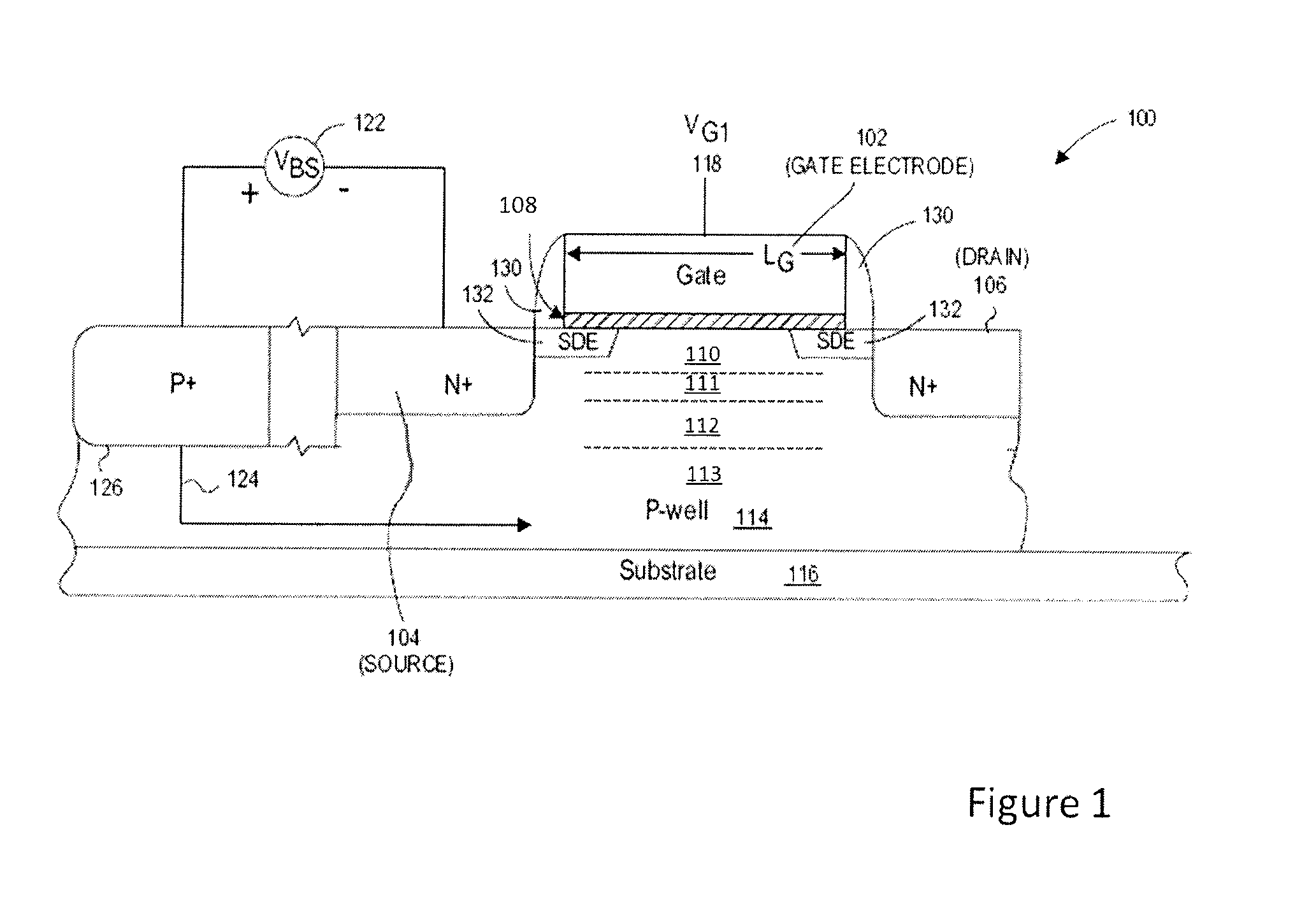

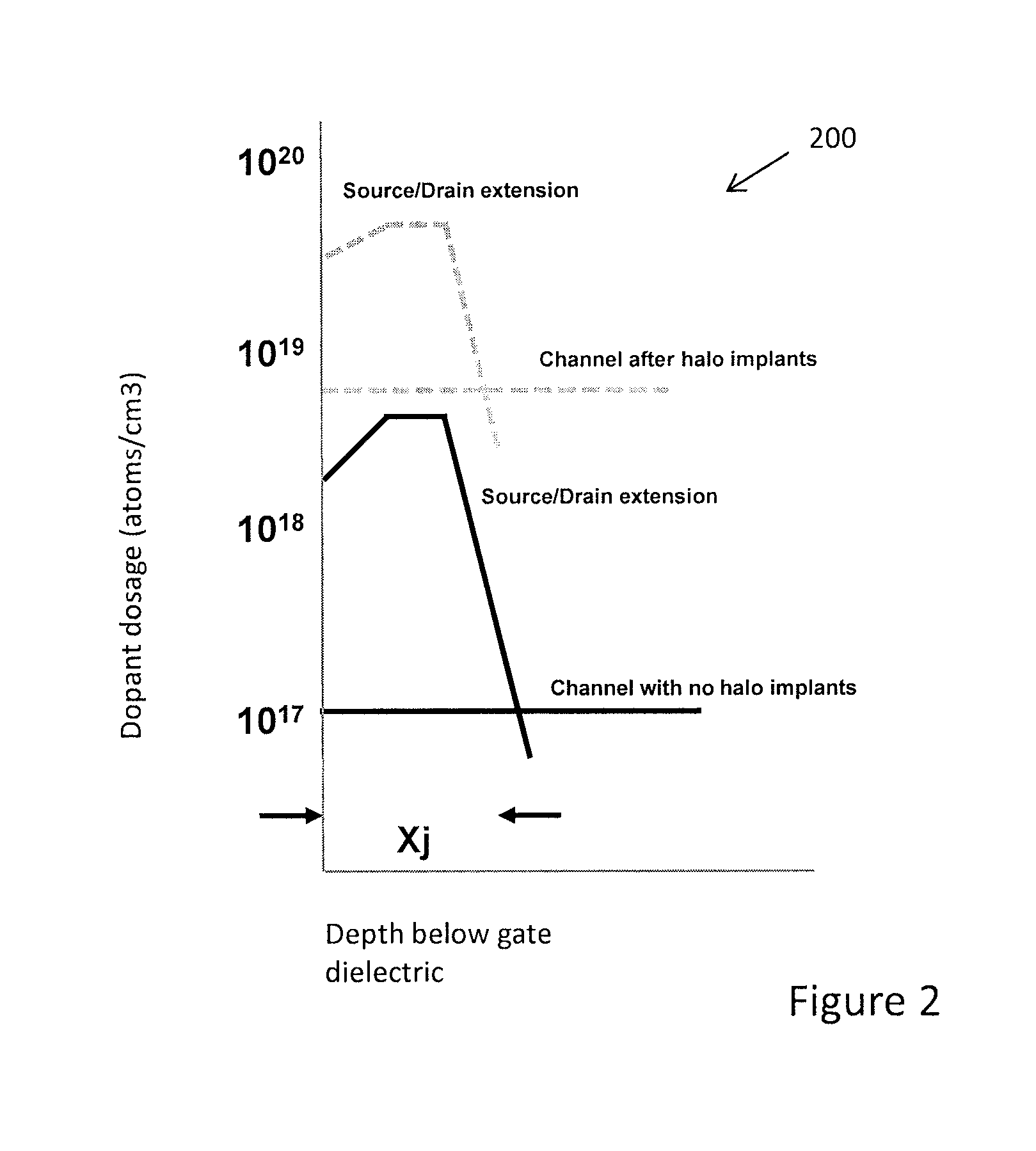

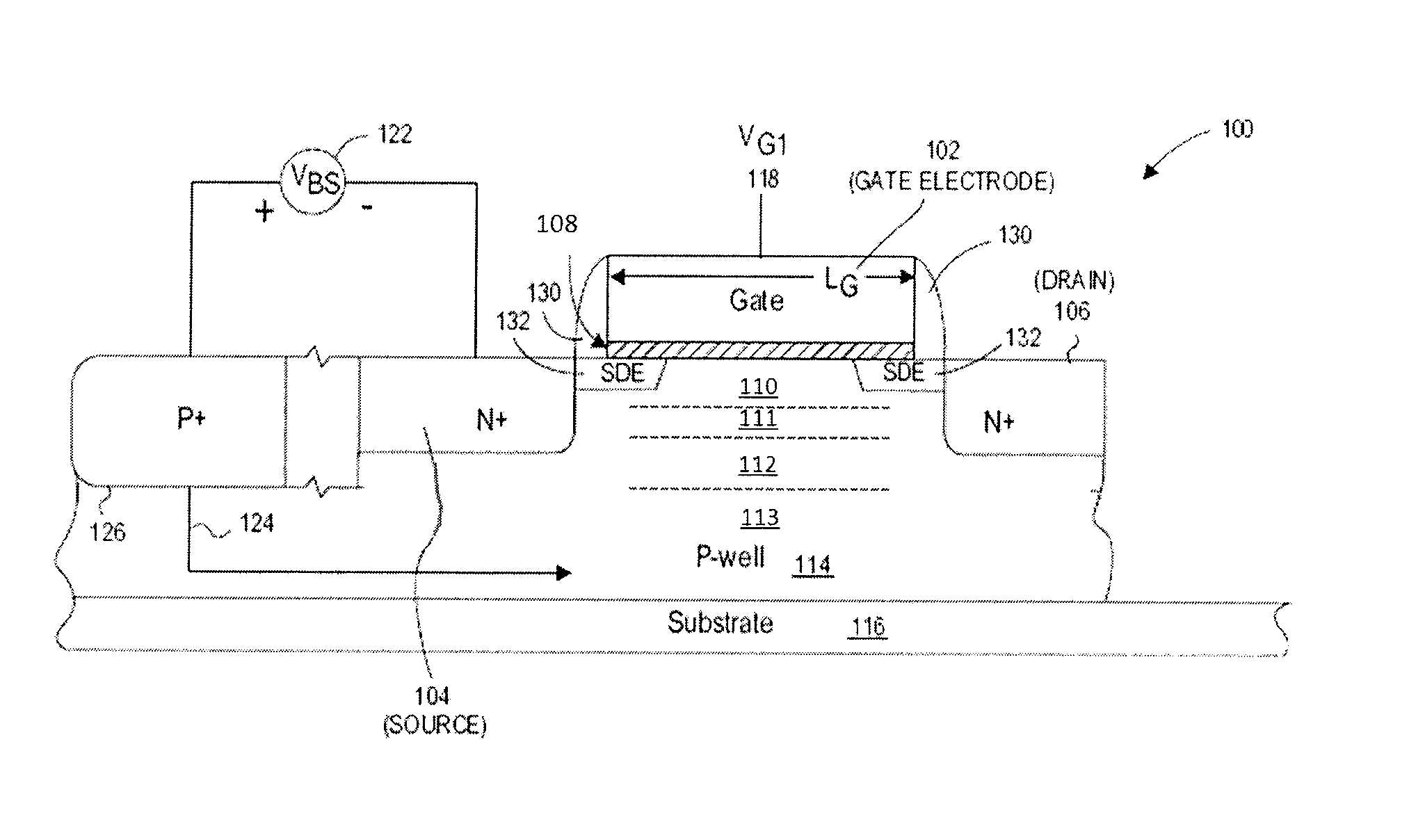

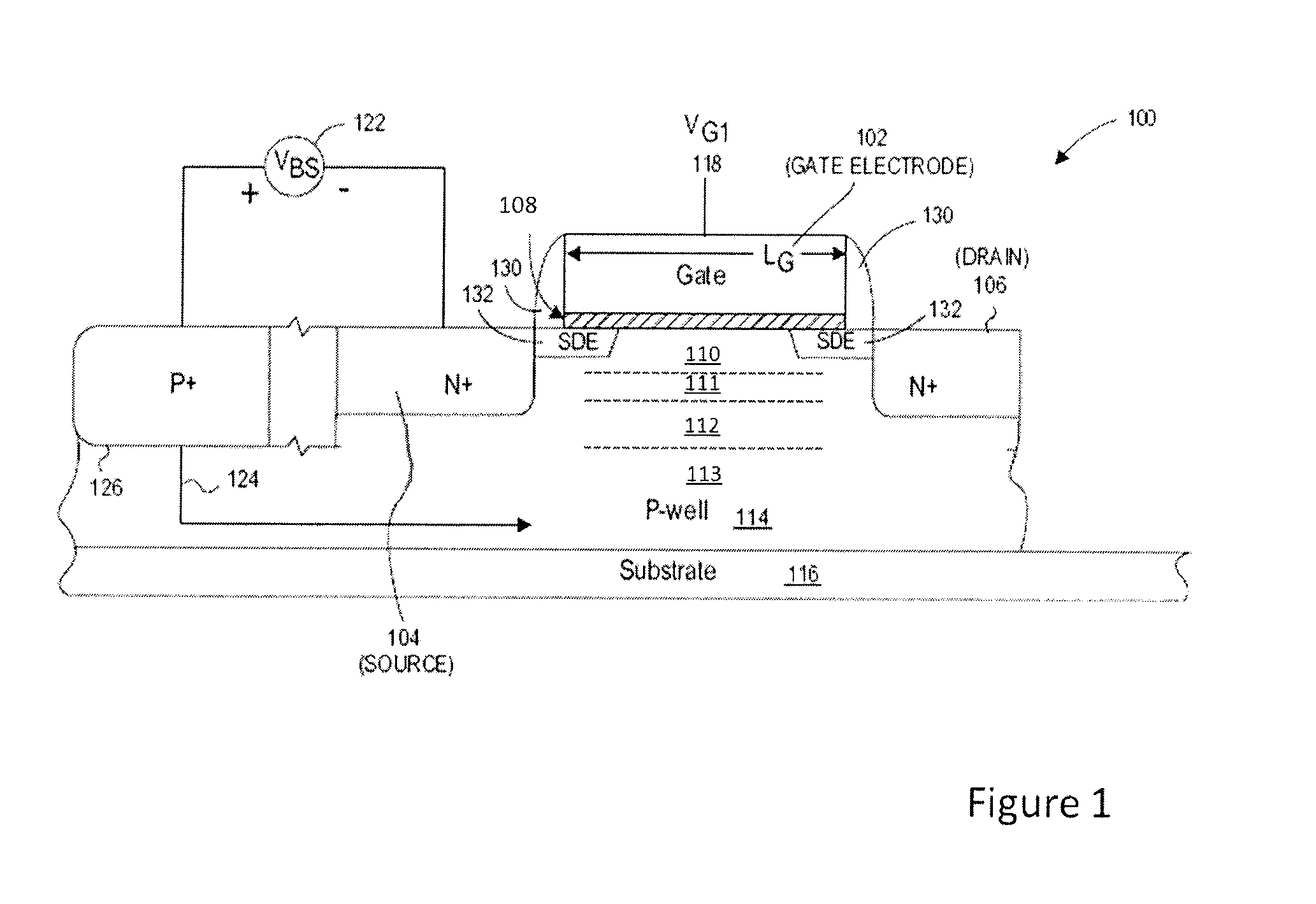

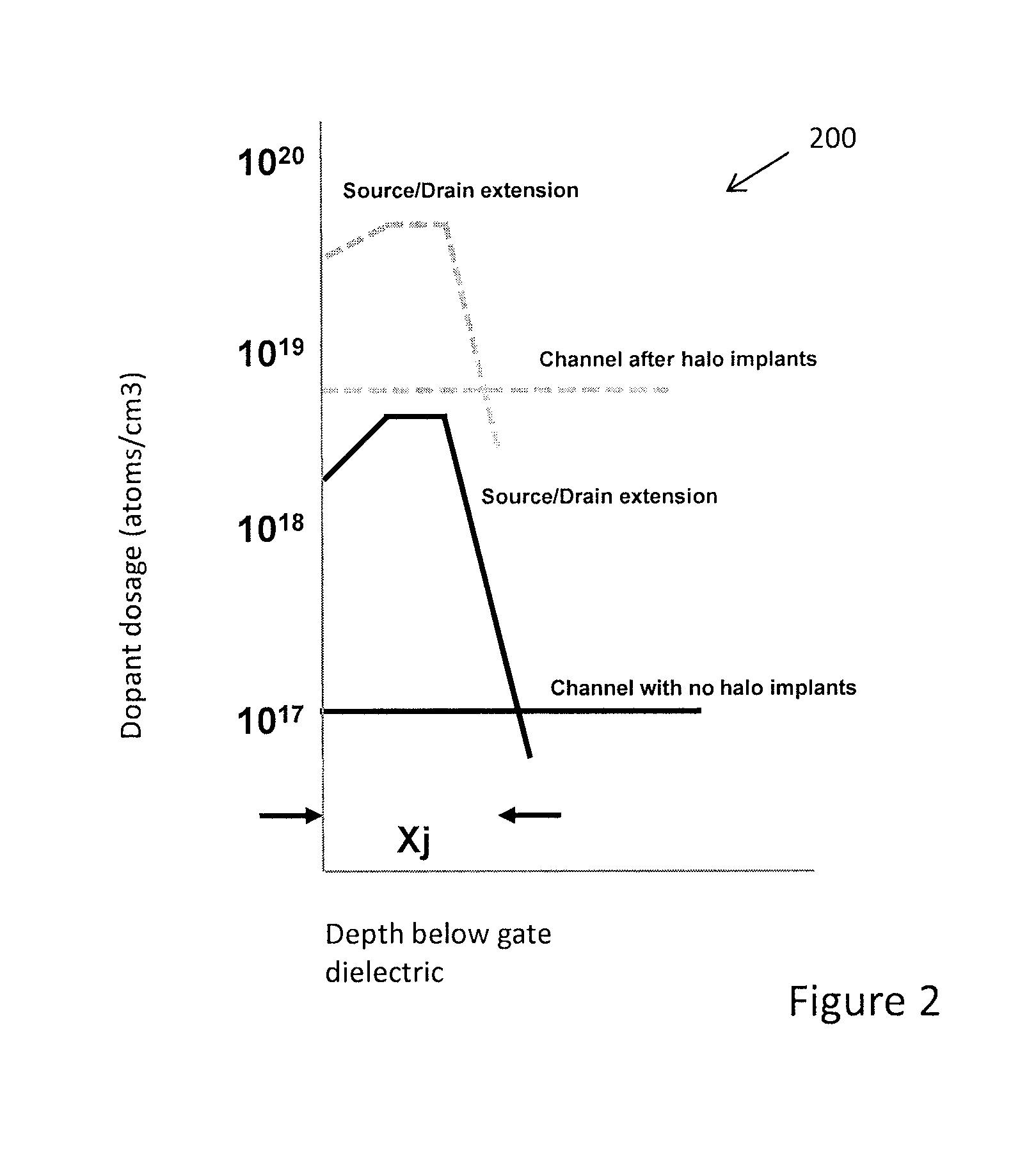

Source/drain extension control for advanced transistors

ActiveUS20120139051A1Avoid overexpansionEasy to operateTransistorSolid-state devicesDopantSemiconductor

A planar transistor with improved performance has a source and a drain on a semiconductor substrate that includes a substantially undoped channel extending between the source and the drain. A gate is positioned over the substantially undoped channel on the substrate. Implanted source / drain extensions contact the source and the drain, with the implanted source / drain extensions having a dopant concentration of less than about 1×1019 atoms / cm3, or alternatively, less than one-quarter the dopant concentration of the source and the drain.

Owner:MIE FUJITSU SEMICON

Paper holder and dispensing apparatus

InactiveUS6554222B1Preventing accidentalPrevent excessive dispersionFilament handlingDomestic applicationsRolling paperPaper sheet

Owner:LINDOW SR KENNETH T

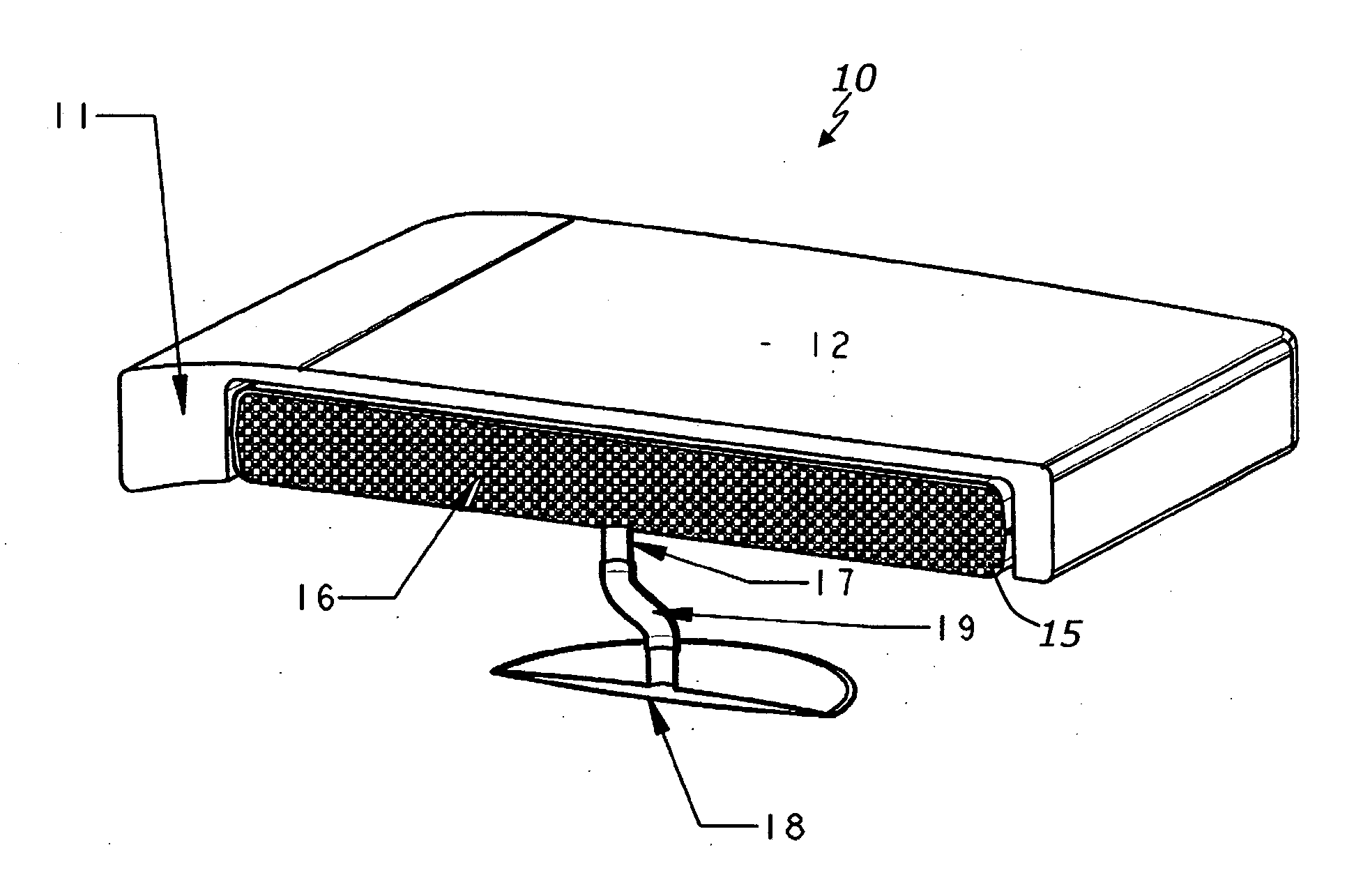

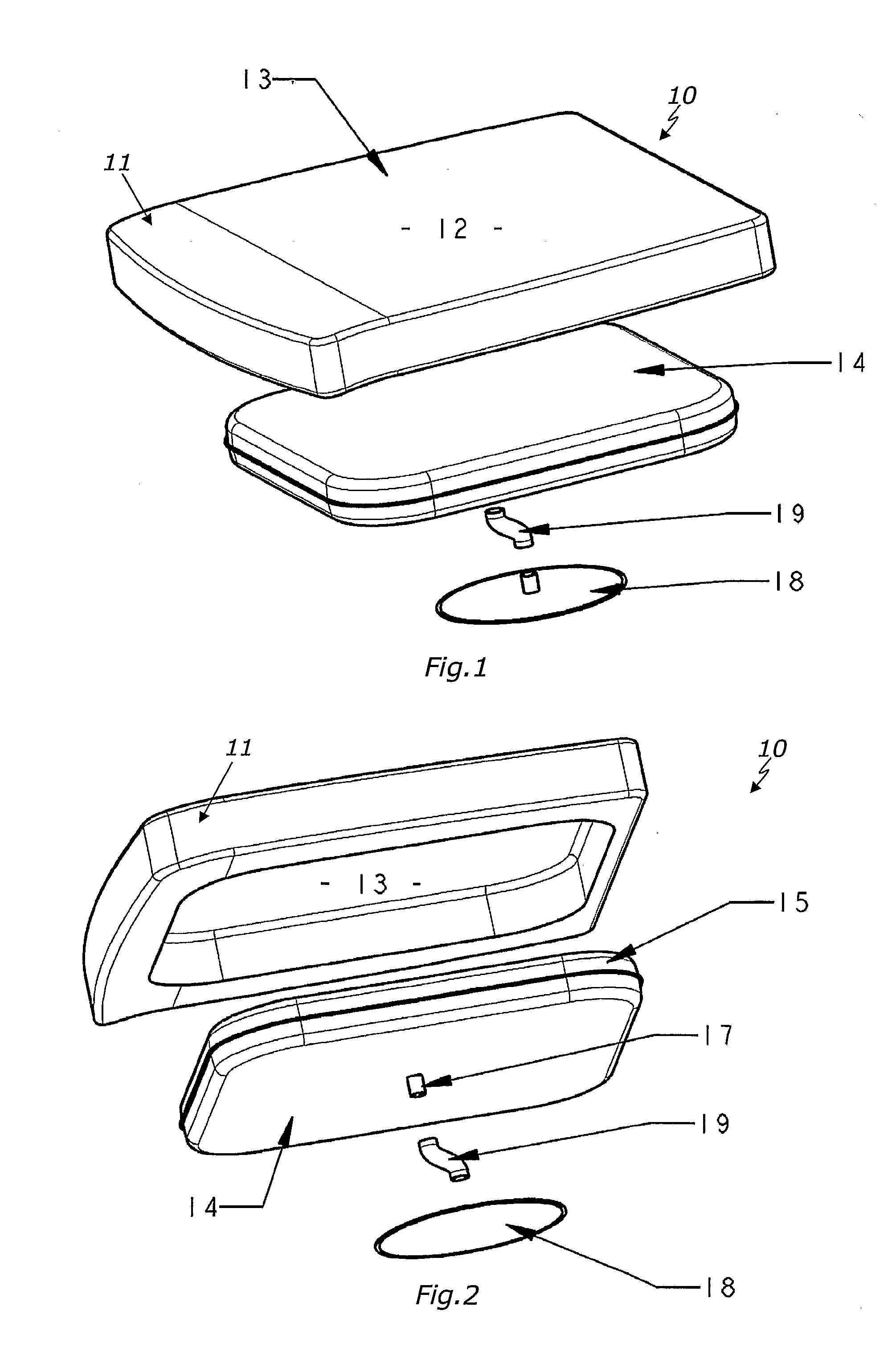

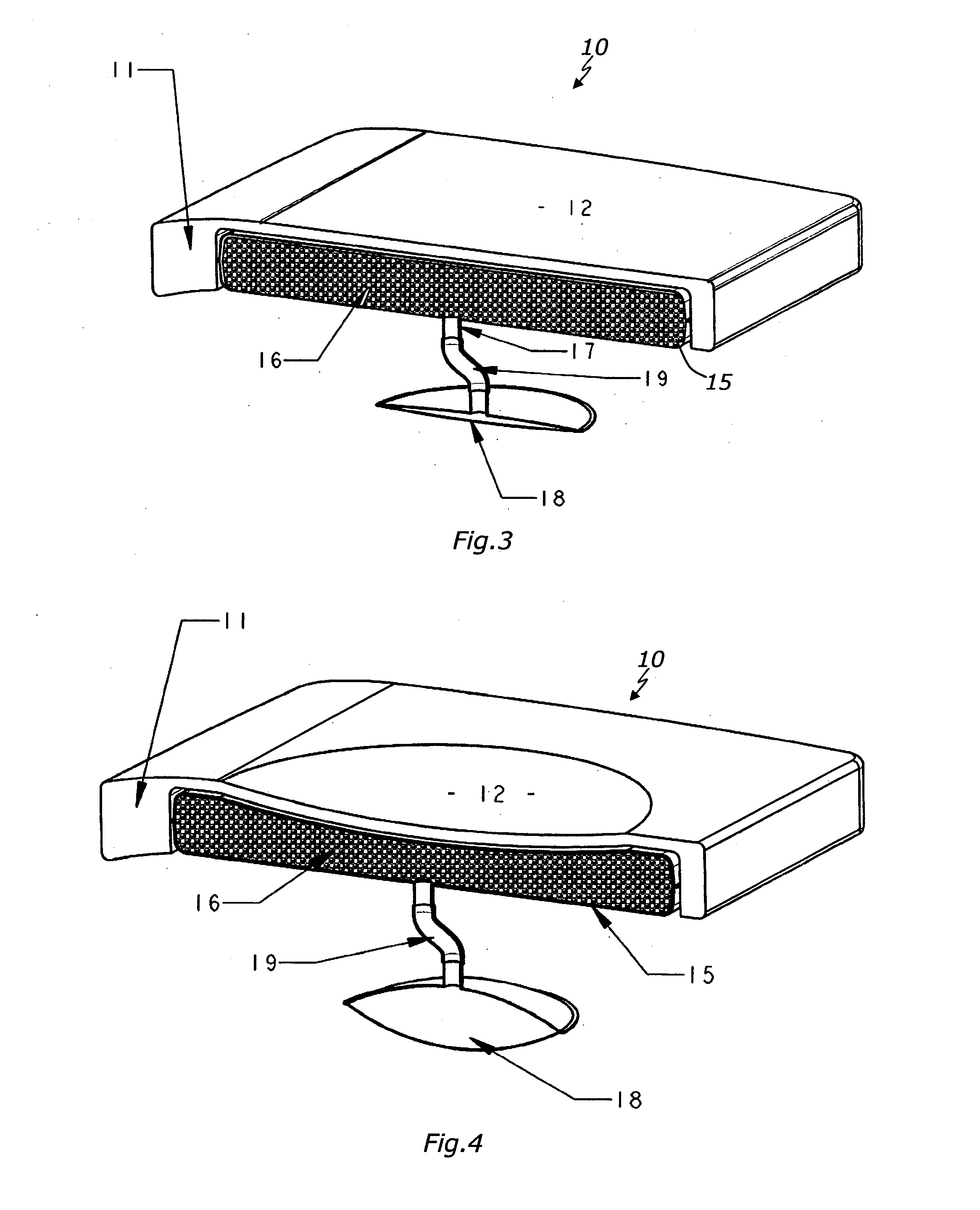

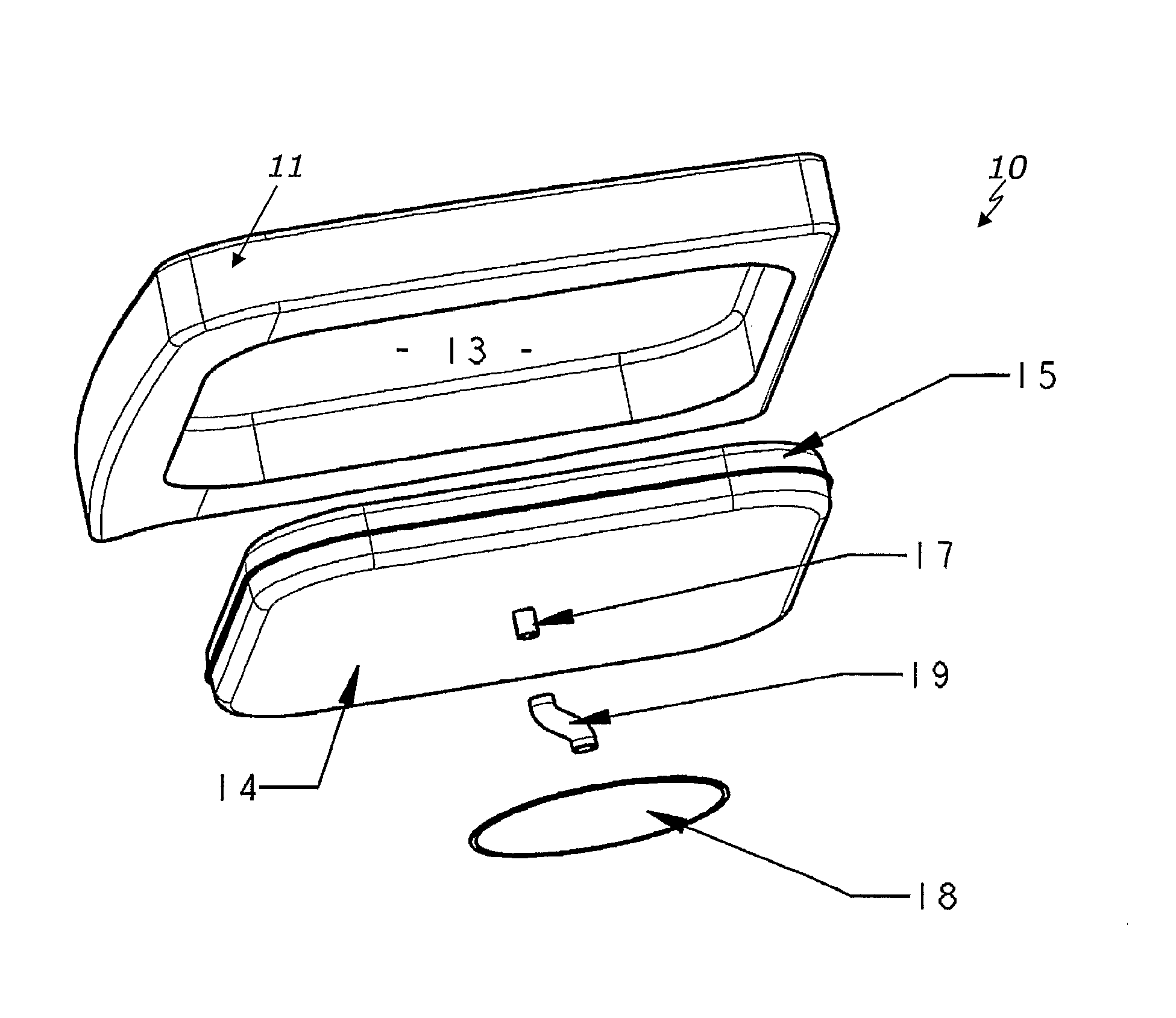

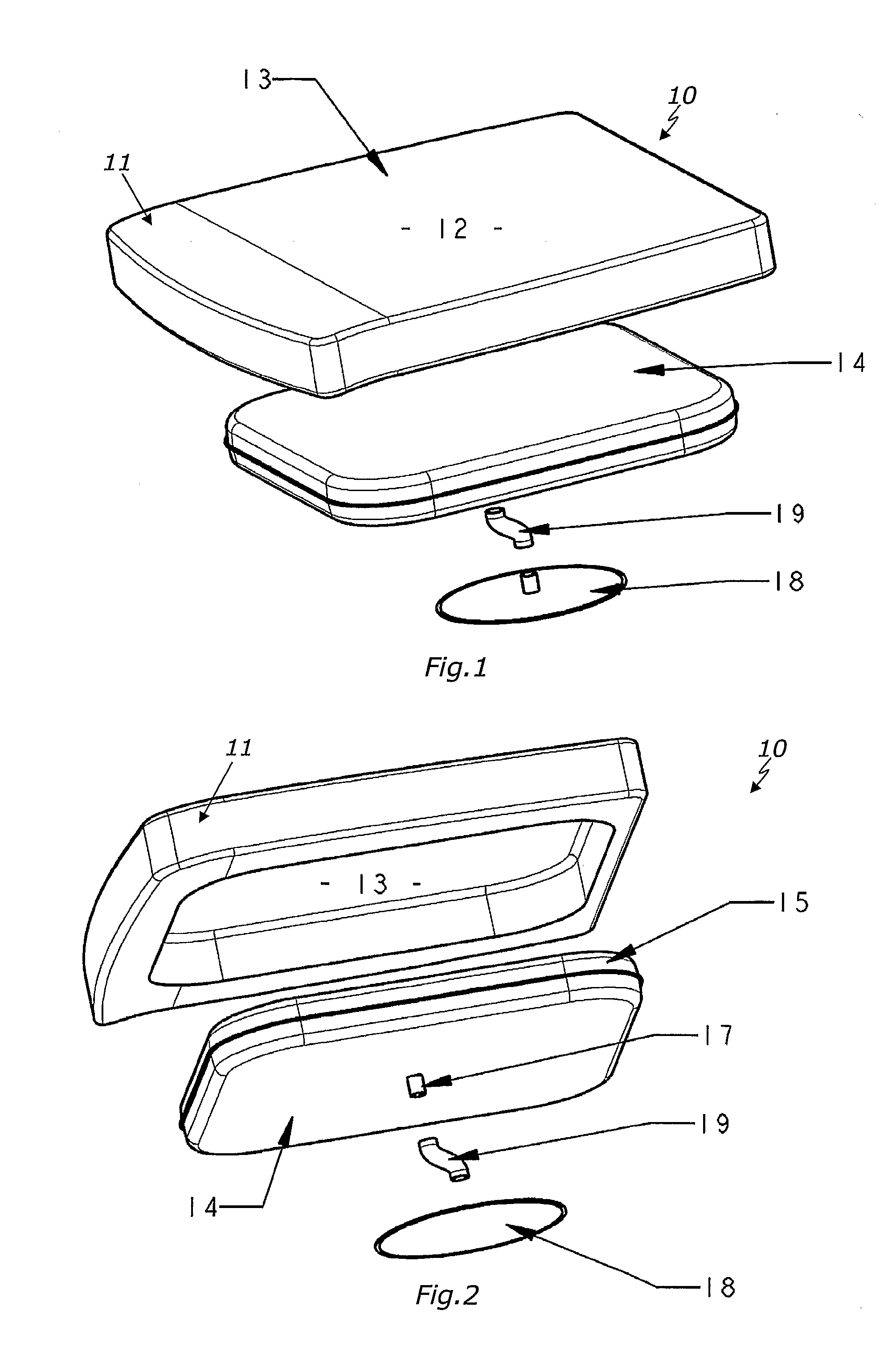

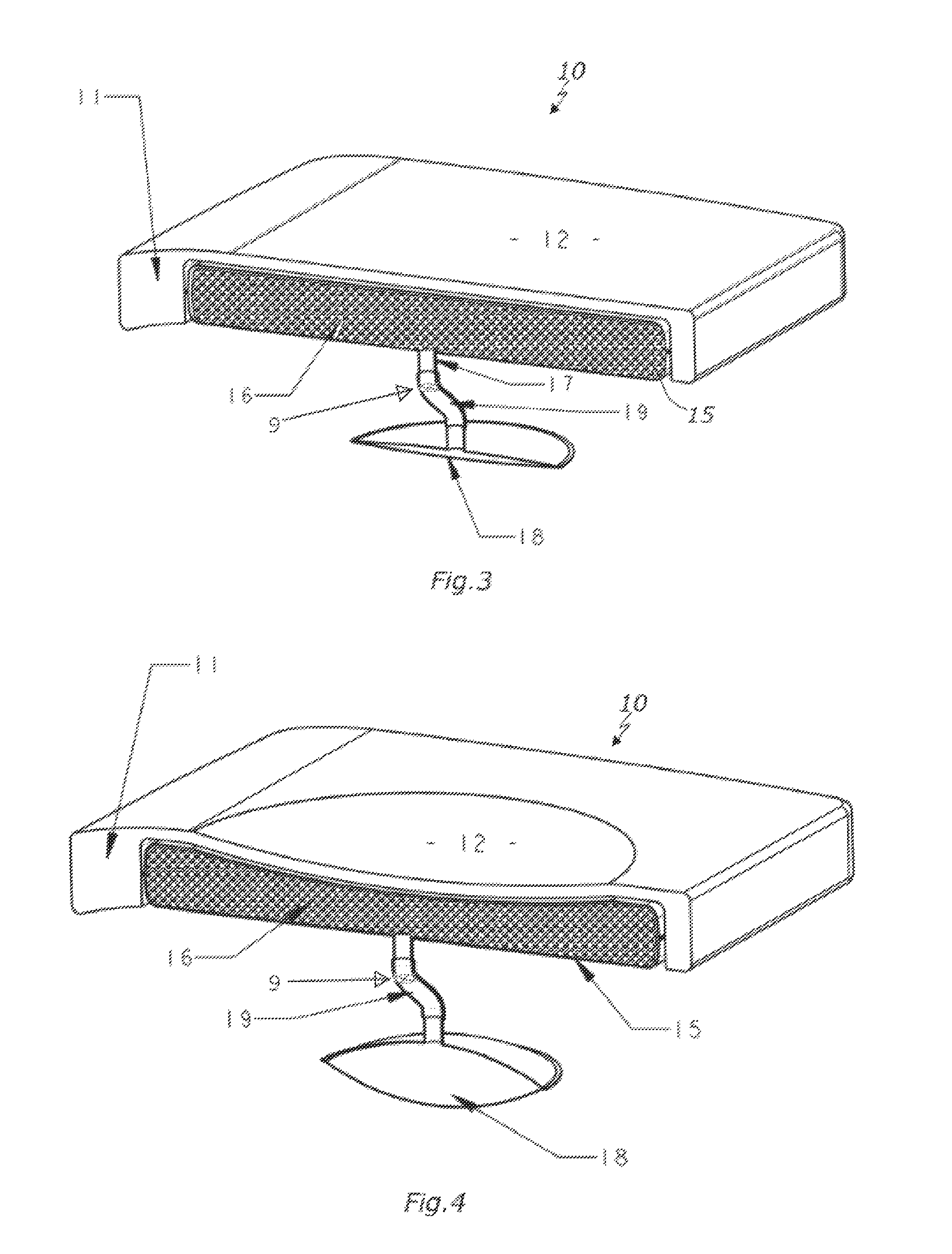

Pneumatic seat cushion system

ActiveUS20110314609A1Avoid overexpansionPrevent shock inflationVehicle seatsDismountable chairsCushionEngineering

A pneumatic seat cushion system (10) has a deformable cushion (11) having a seating surface (12) and a self inflating cushion bladder (14) positioned beneath the seating surface (12). The self inflating cushion bladder (14) has an airtight envelope (15) containing compressible material (16) which is in air communication (19) with a displacement bladder (18) such that when in use the airtight envelope (15) and the displacement bladder (18) form a closed system from which no air can enter or escape. When there is no person seated on the seating surface (12), the self inflating cushion bladder (14) is inflated and the displacement bladder (18) is deflated. When there is a person seated on the seating surface, the weight of the person compresses the compressible material (16) so as to partially deflate the self inflating cushion bladder (14) which results in the contained air passing into the displacement bladder (18) which becomes fully inflated.

Owner:COMFORT CONCEPTS

Source/drain extension control for advanced transistors

Owner:MIE FUJITSU SEMICON

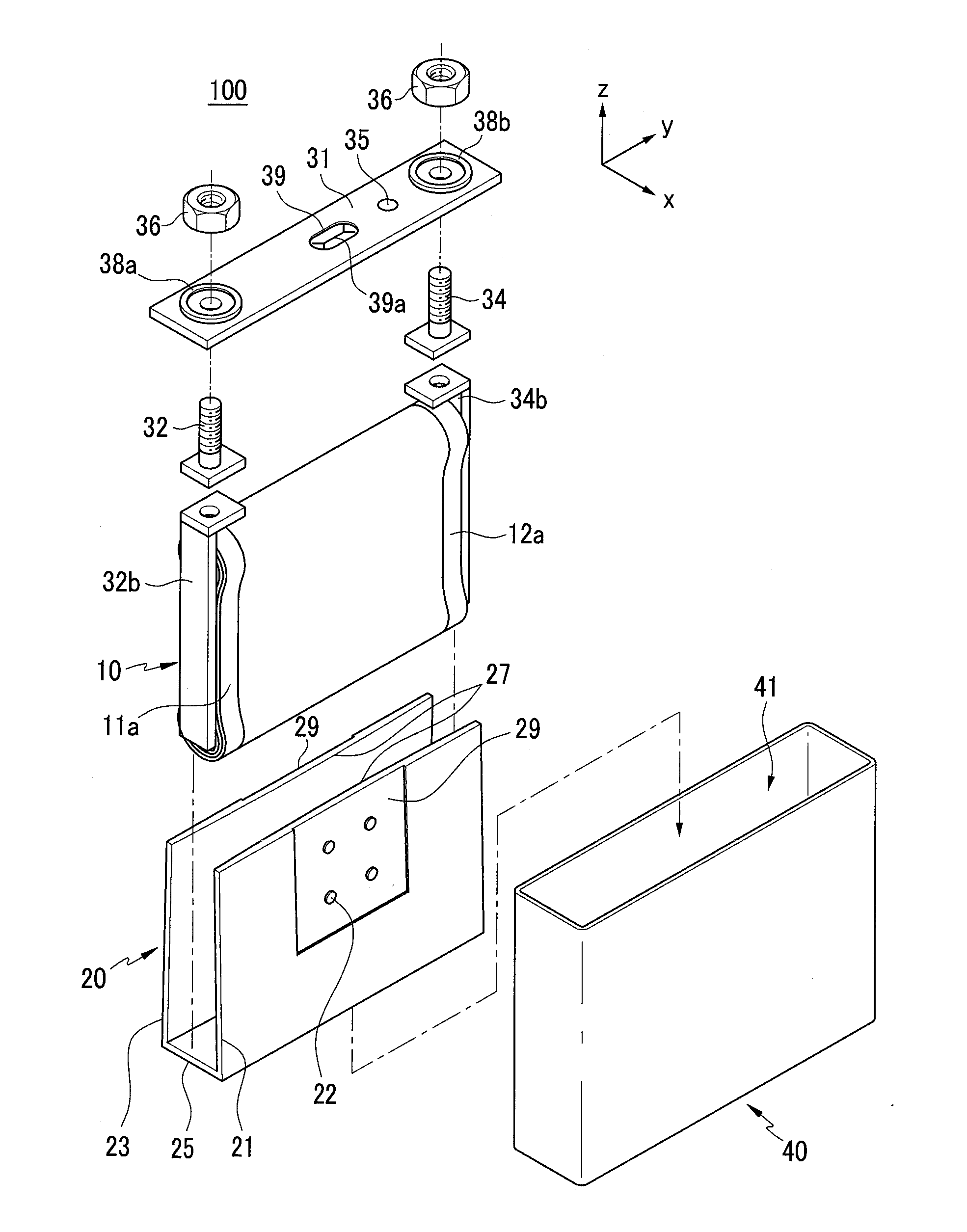

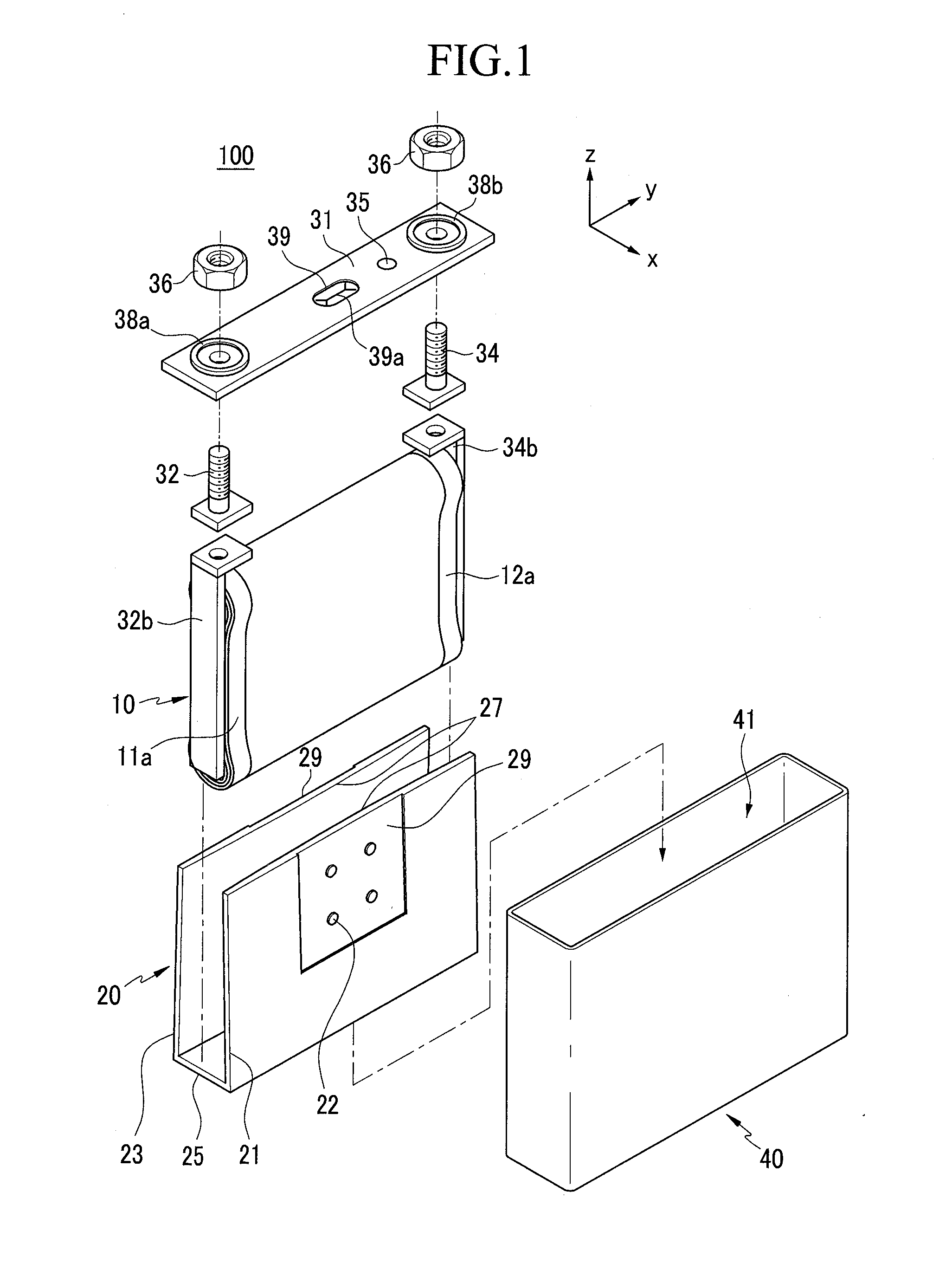

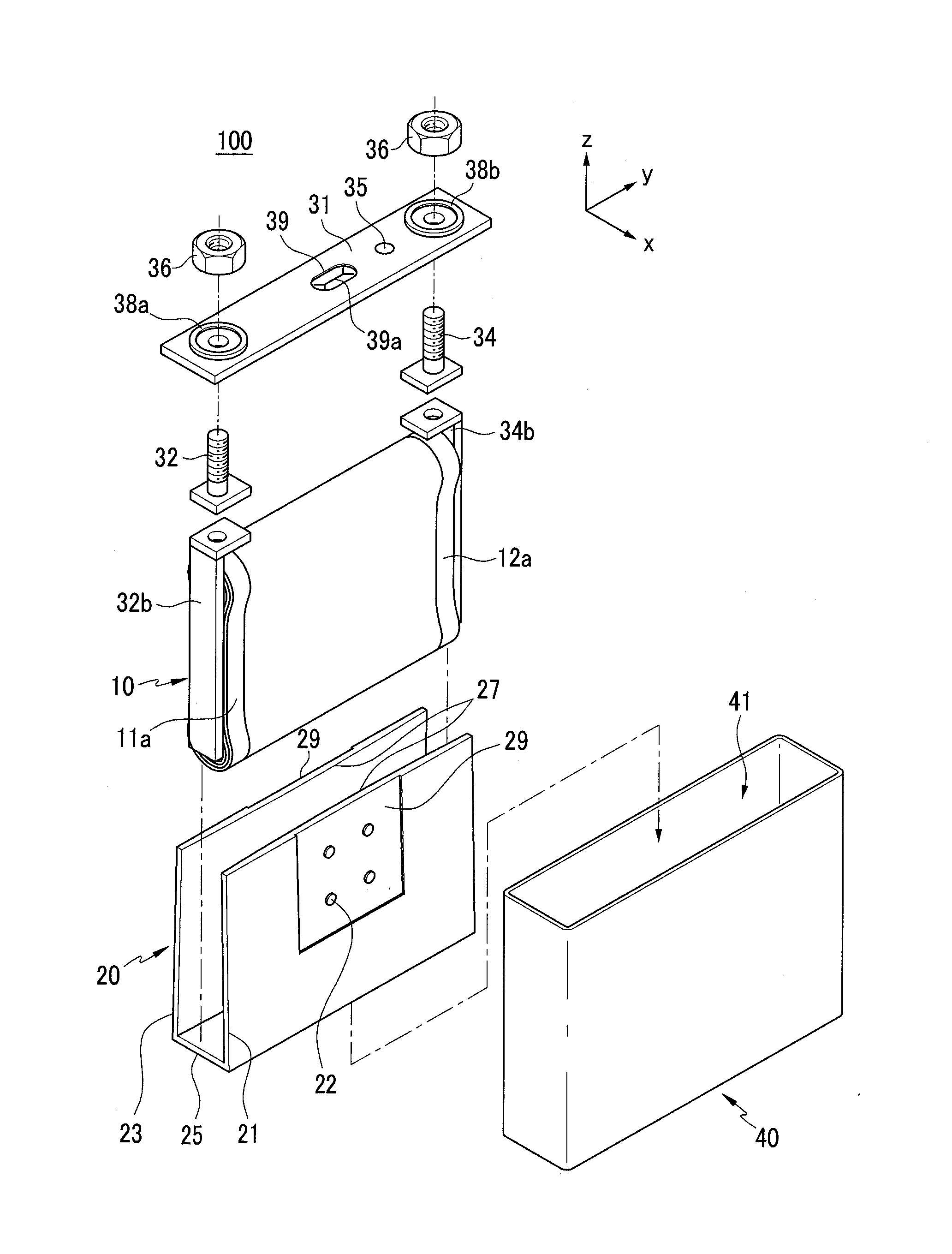

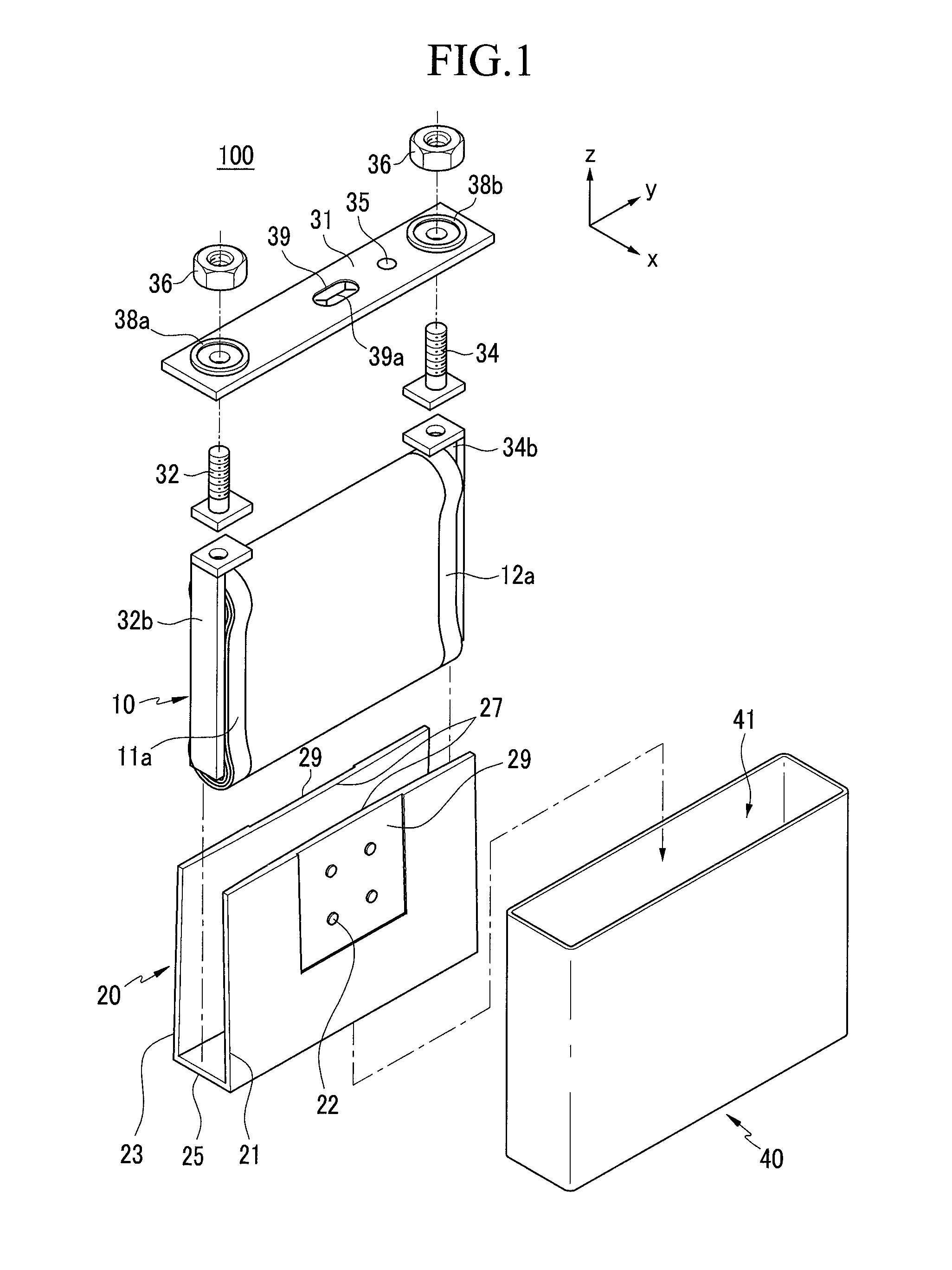

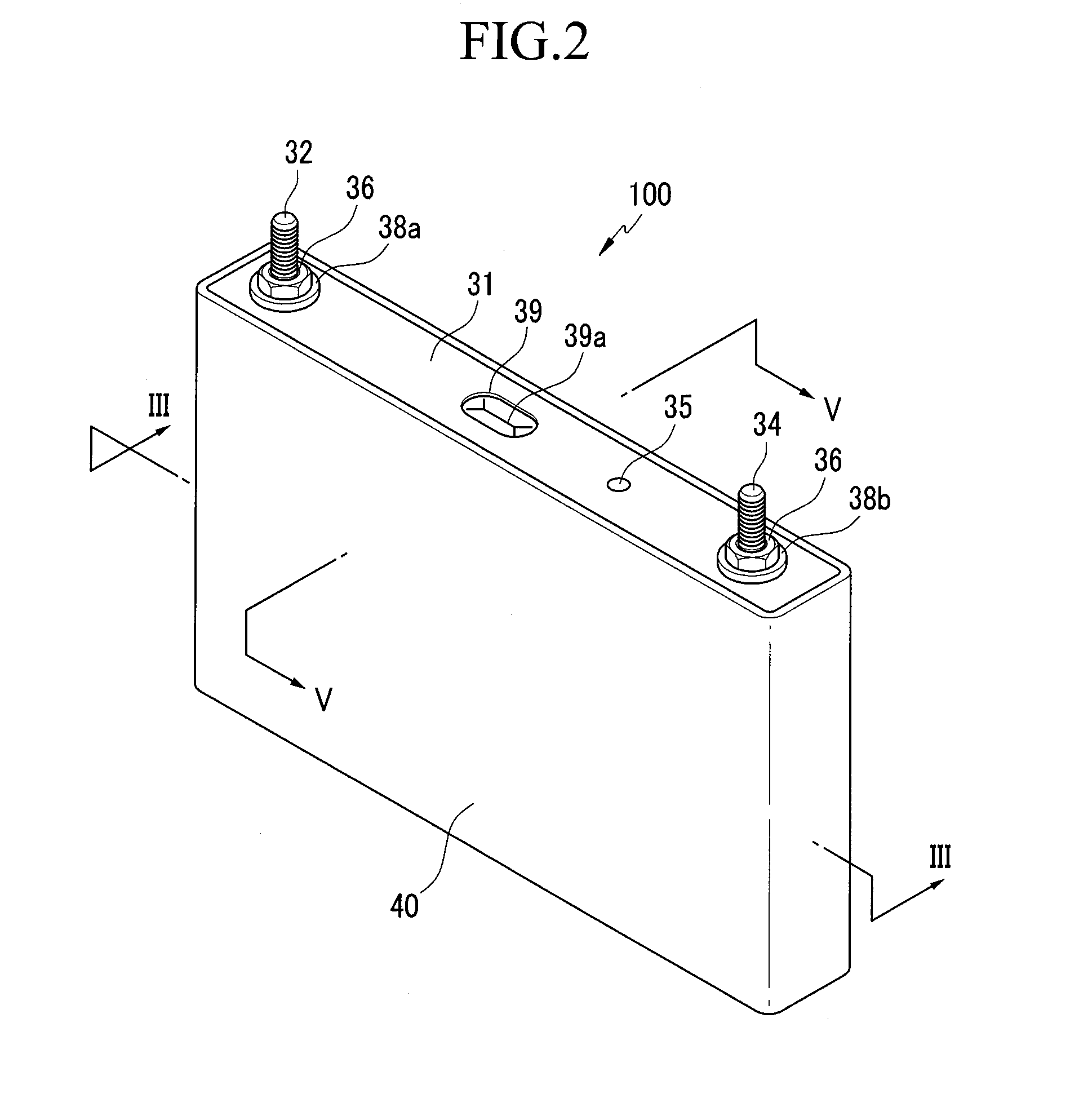

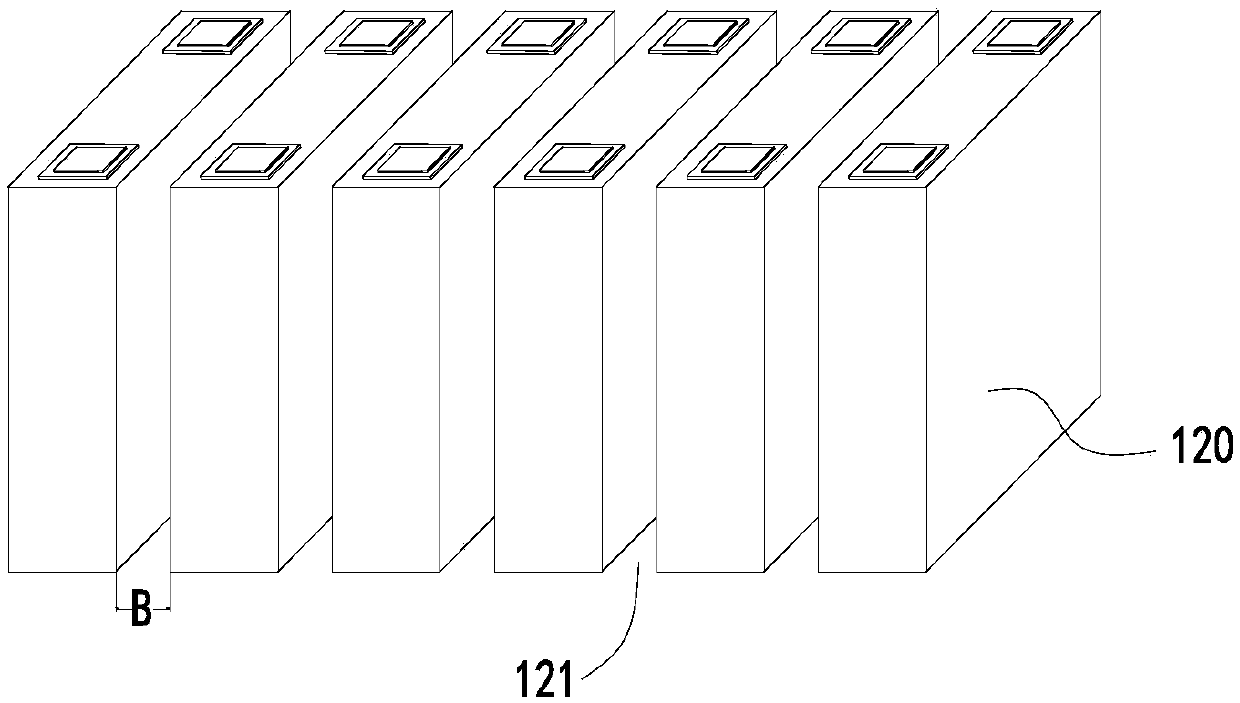

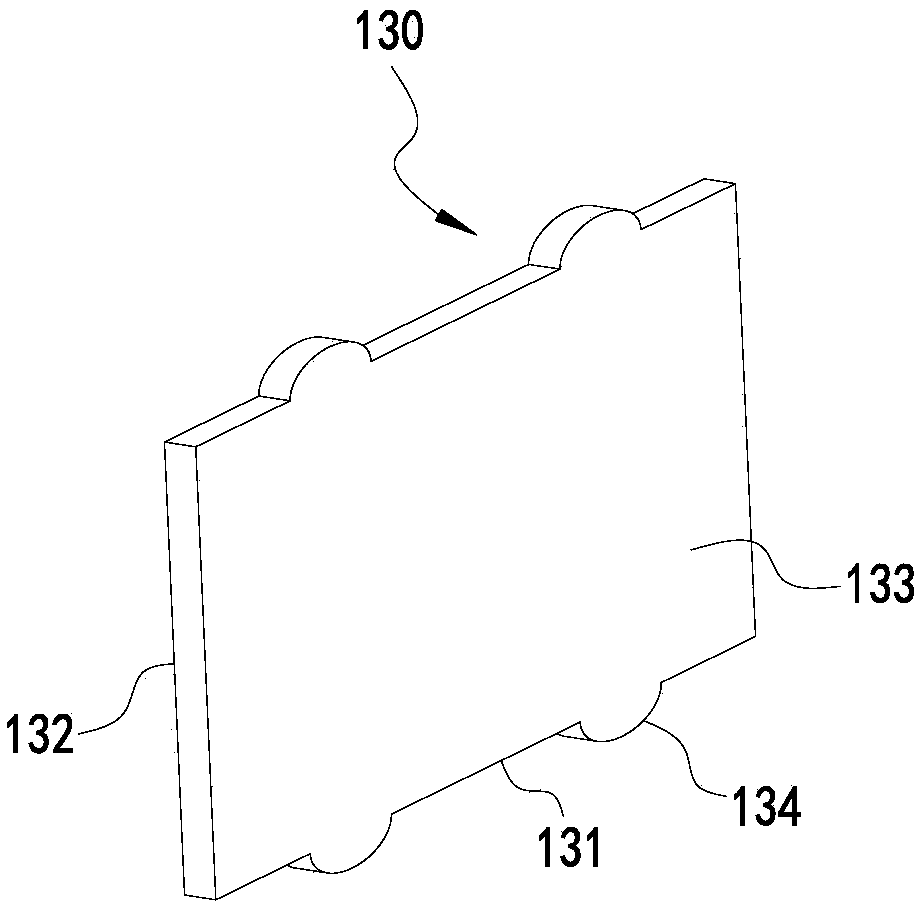

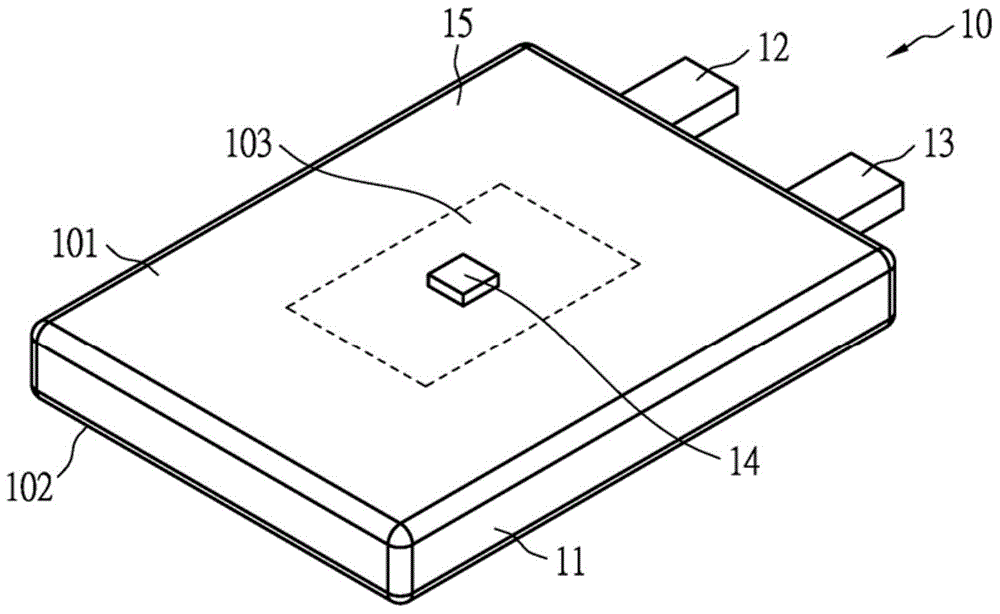

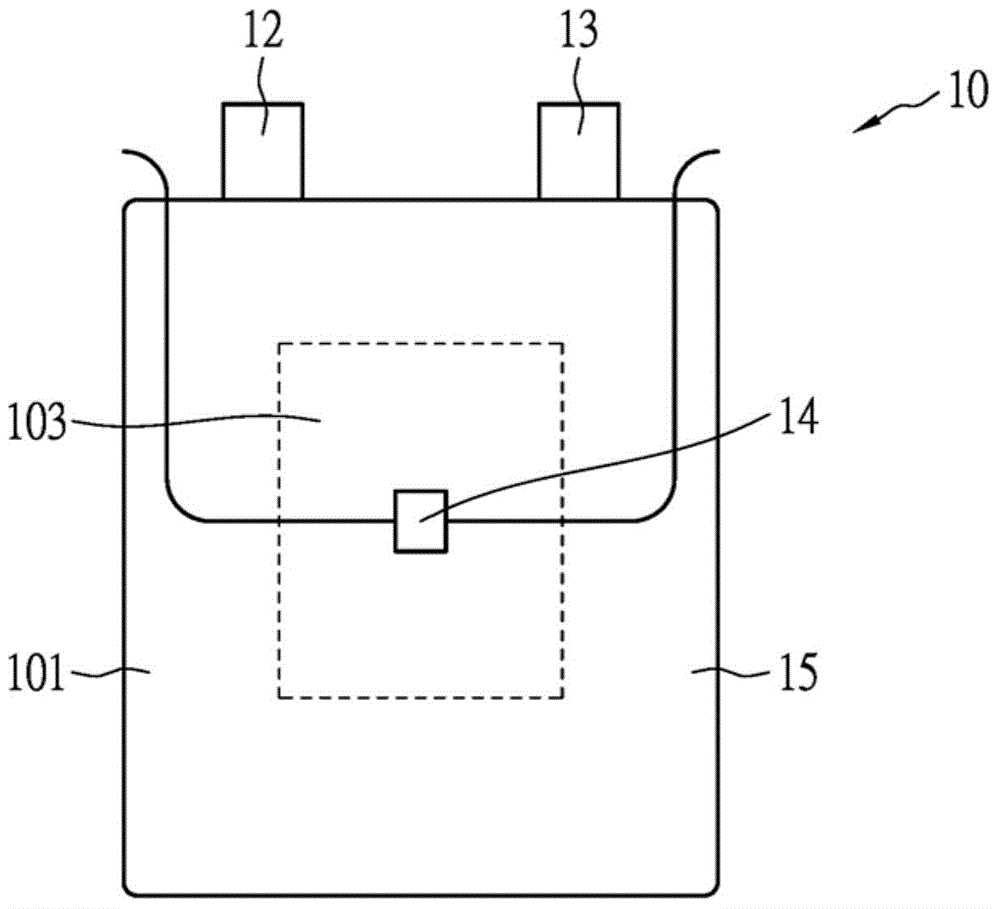

Rechargeable battery

ActiveUS20120088146A1Effective protectionGuaranteed assembly stabilityLarge-sized flat cells/batteriesFinal product manufactureRechargeable cellElectrical and Electronics engineering

A rechargeable battery includes an electrode assembly undergoing charging and discharging, a pressurization holder covering the electrode assembly and fixing the electrode assembly, a positive terminal and a negative terminal electrically connected to the electrode assembly, and a case accommodating the electrode assembly and the pressurization holder in a state in which the positive terminal and the negative terminal protrude from the case.

Owner:ROBERT BOSCH GMBH +1

Methods and apparatus for preventing vaginal lacerations during childbirth

InactiveUS20160166282A1Avoid overexpansionPrevent pressureCannulasDilatorsVaginal dilationAutomatic control

A vaginal dilation device is provided that may include any of a number of features. One feature of the vaginal dilation device is that it is configured to dilate vaginal tissue during labor to prevent tissue damage. Another feature of the vaginal dilation device is that it can be manually controlled to dilate vaginal tissue, or can be automatically controlled to dilate vaginal tissue. In some embodiments, the vaginal dilation device is configured to measure a force applied by the device to tissue. In other embodiments, the vaginal dilation device is configured to apply a constant force to tissue. In other embodiments, the vaginal dilation device is configured to expand at a constant rate. Methods associated with use of the vaginal dilation device are also provided.

Owner:MATERNA MEDICAL

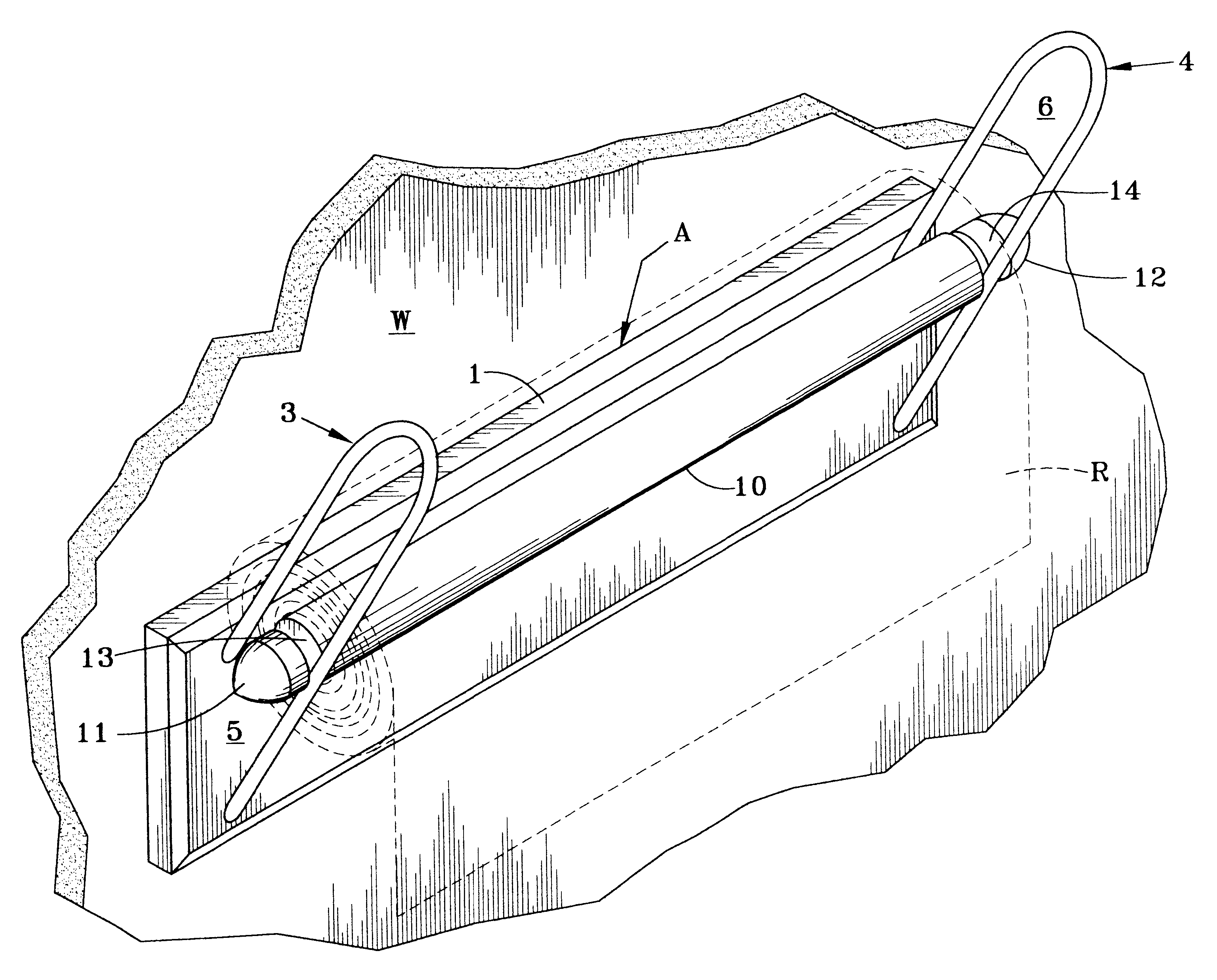

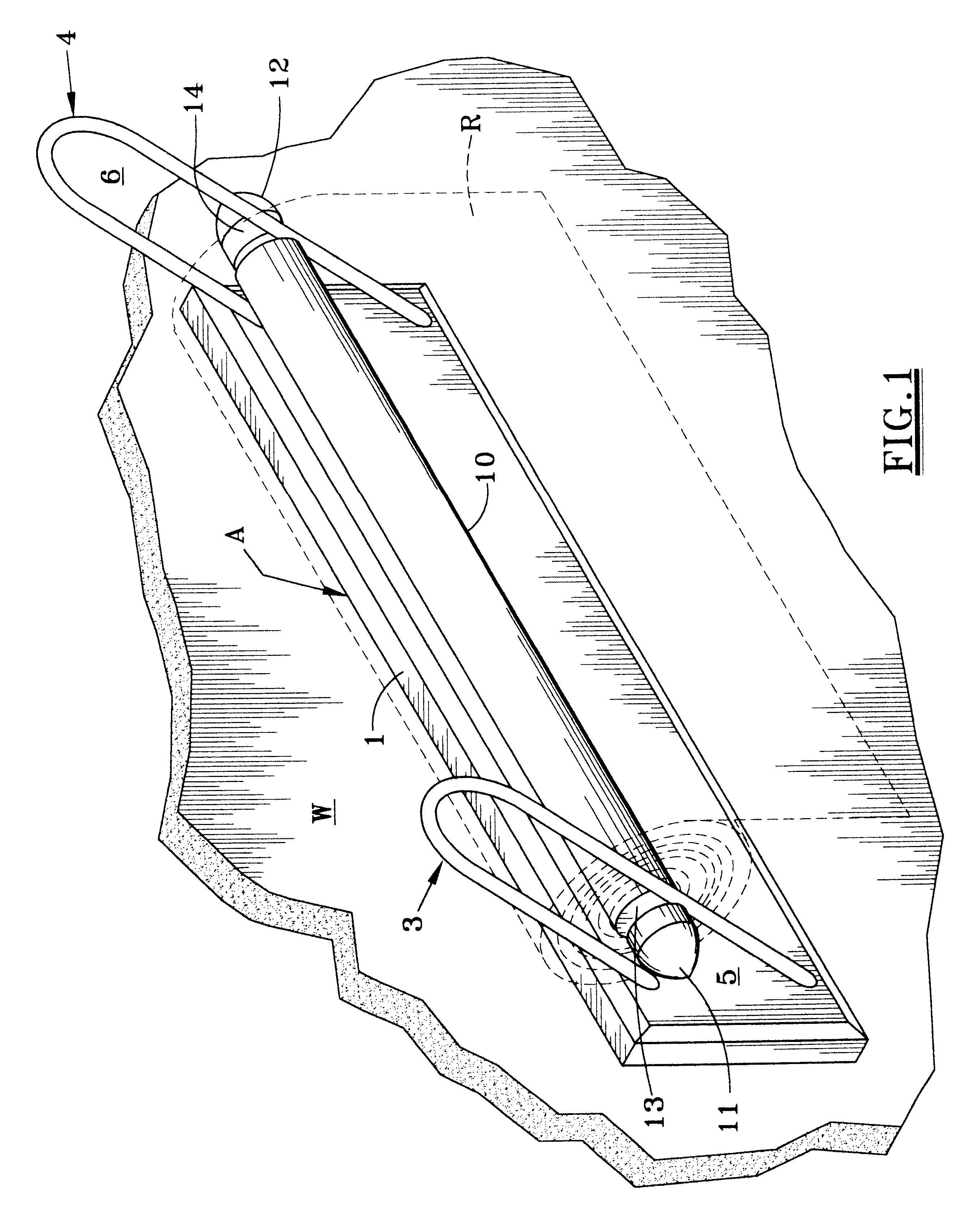

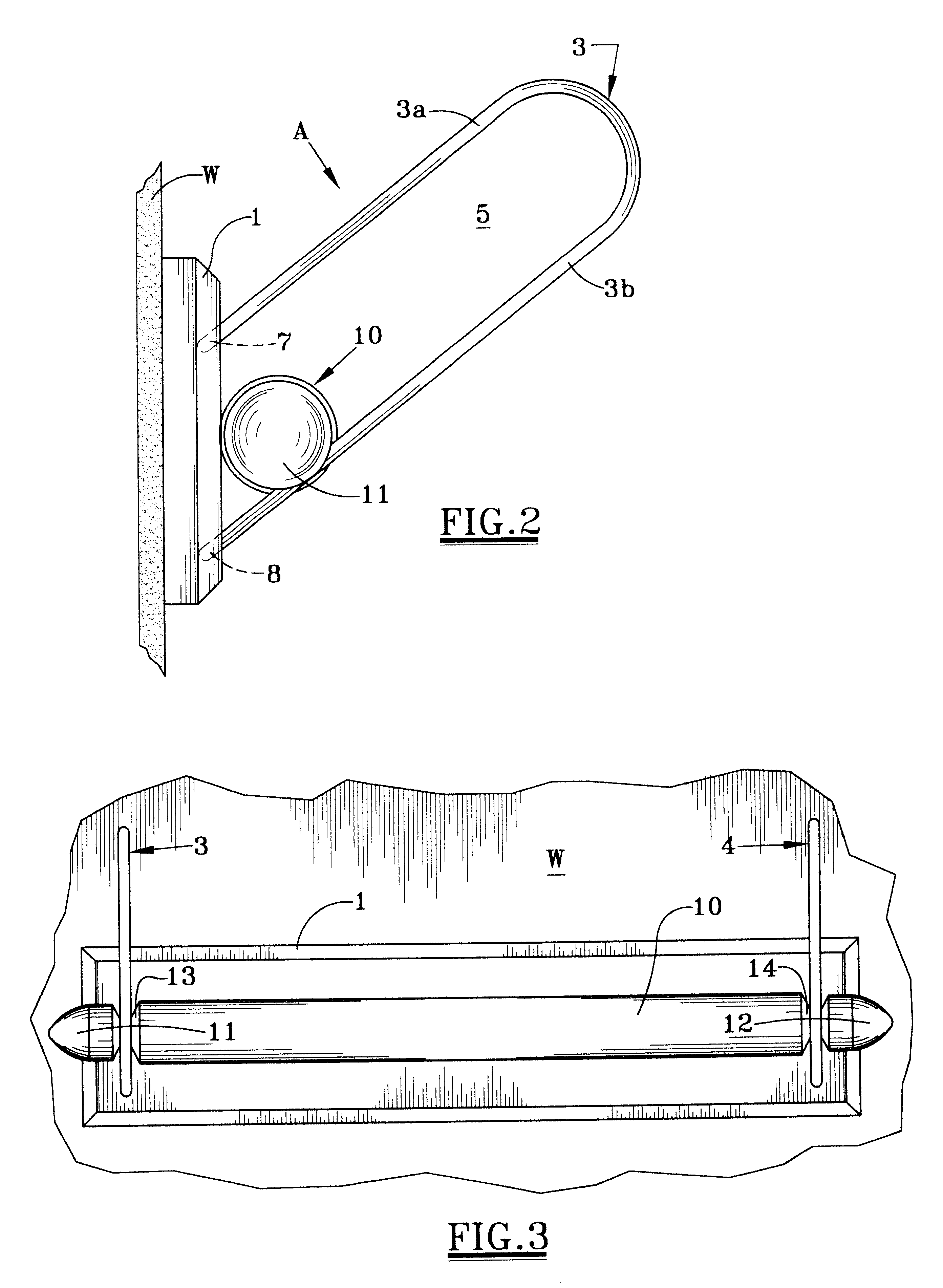

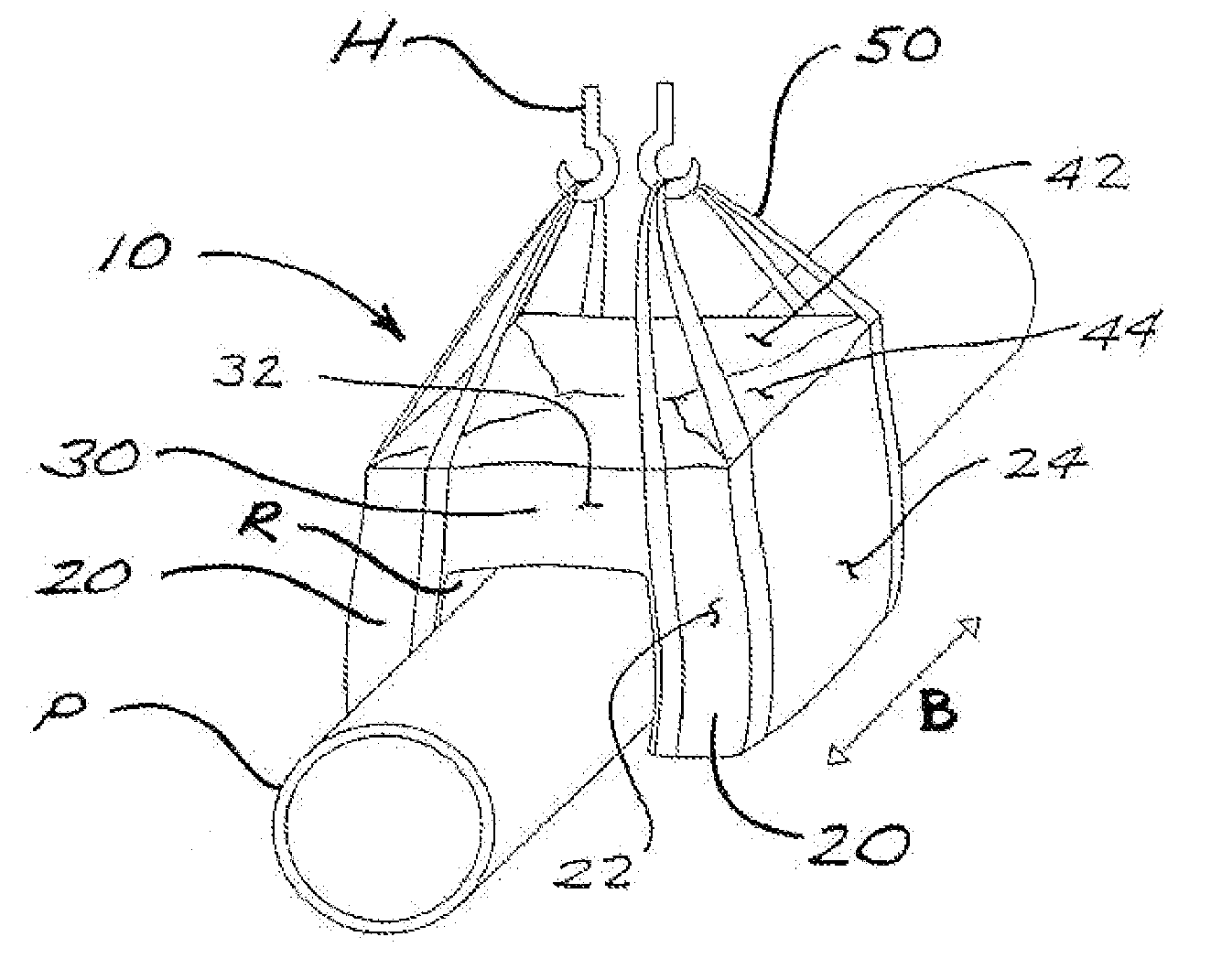

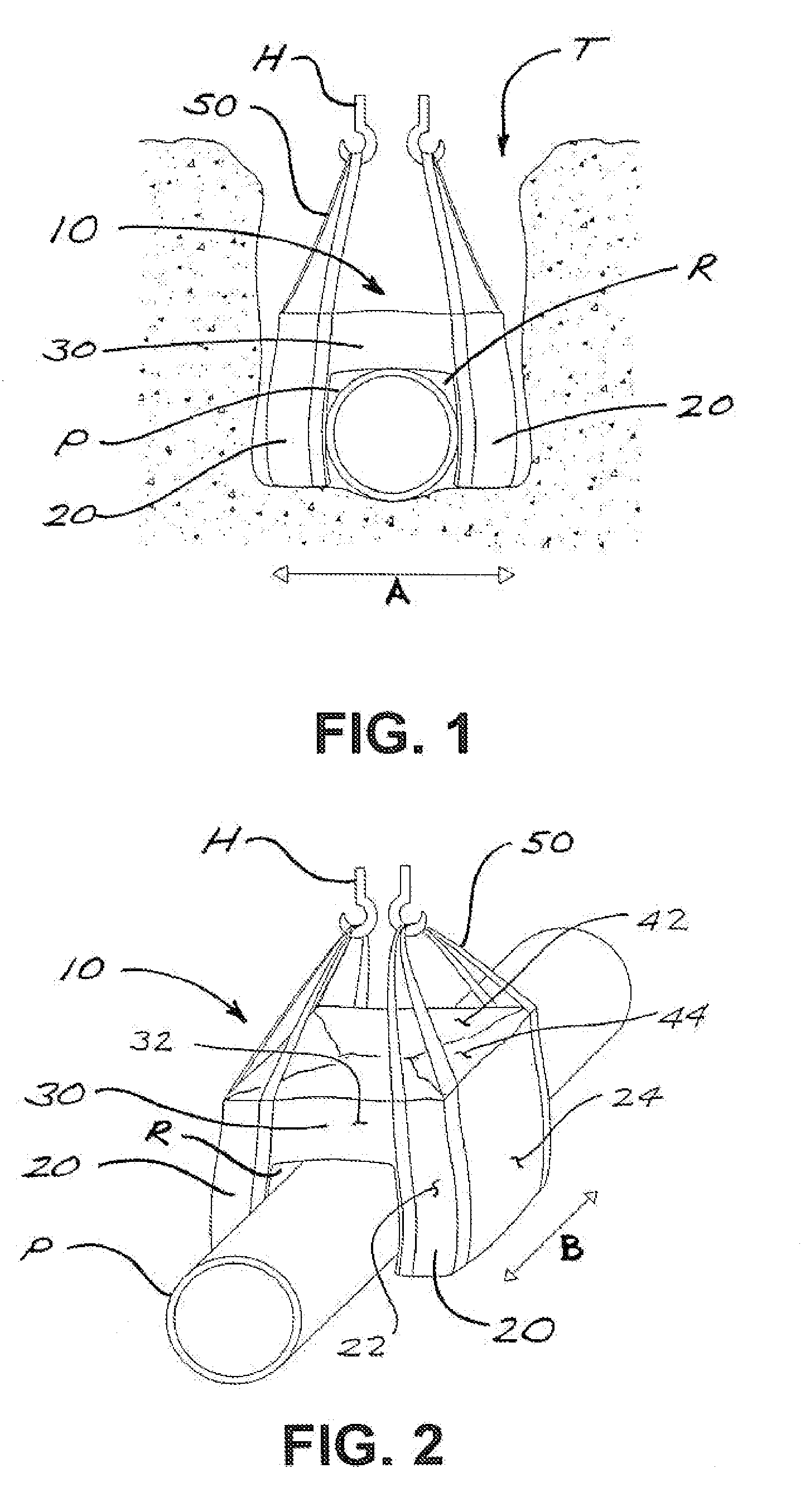

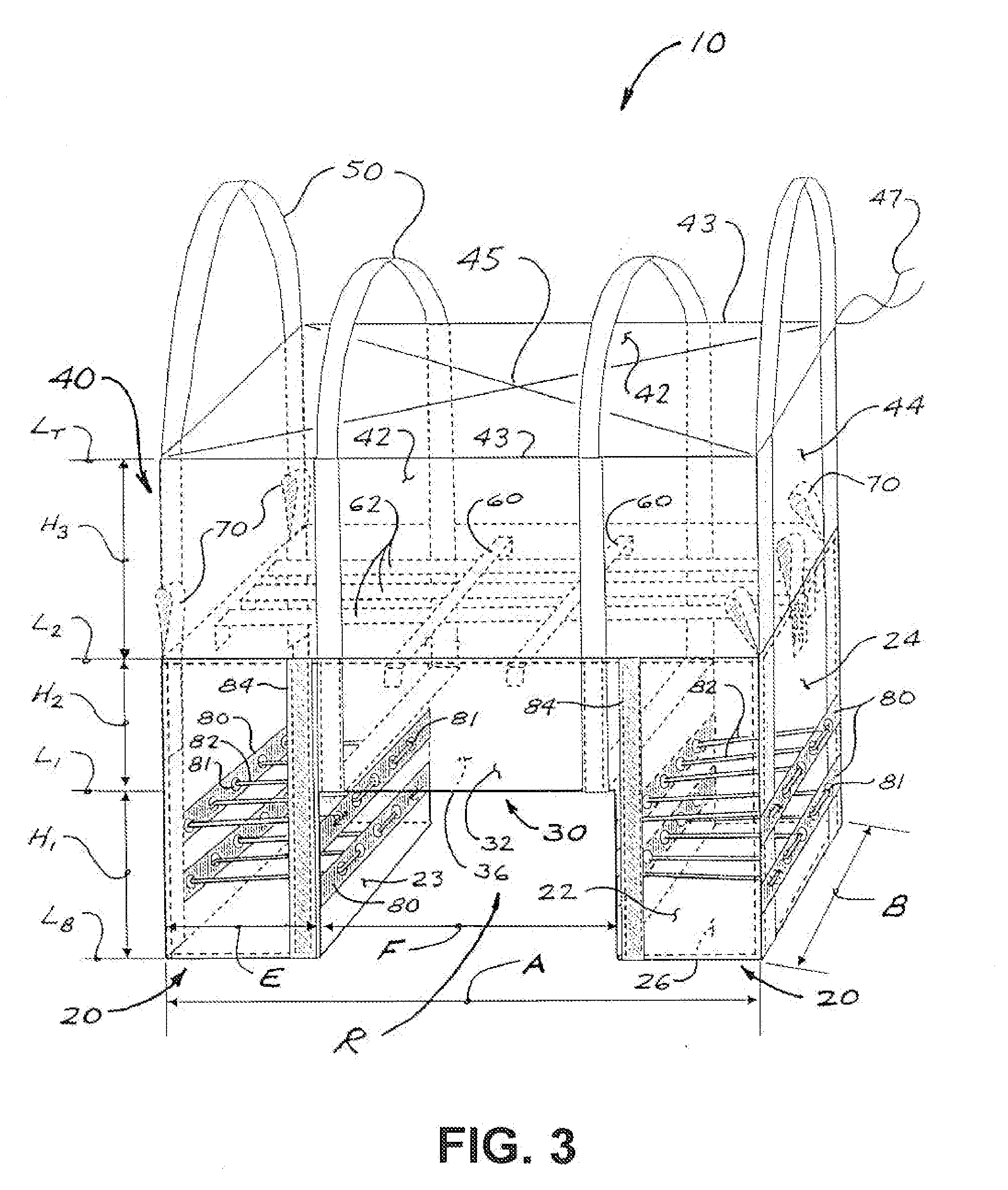

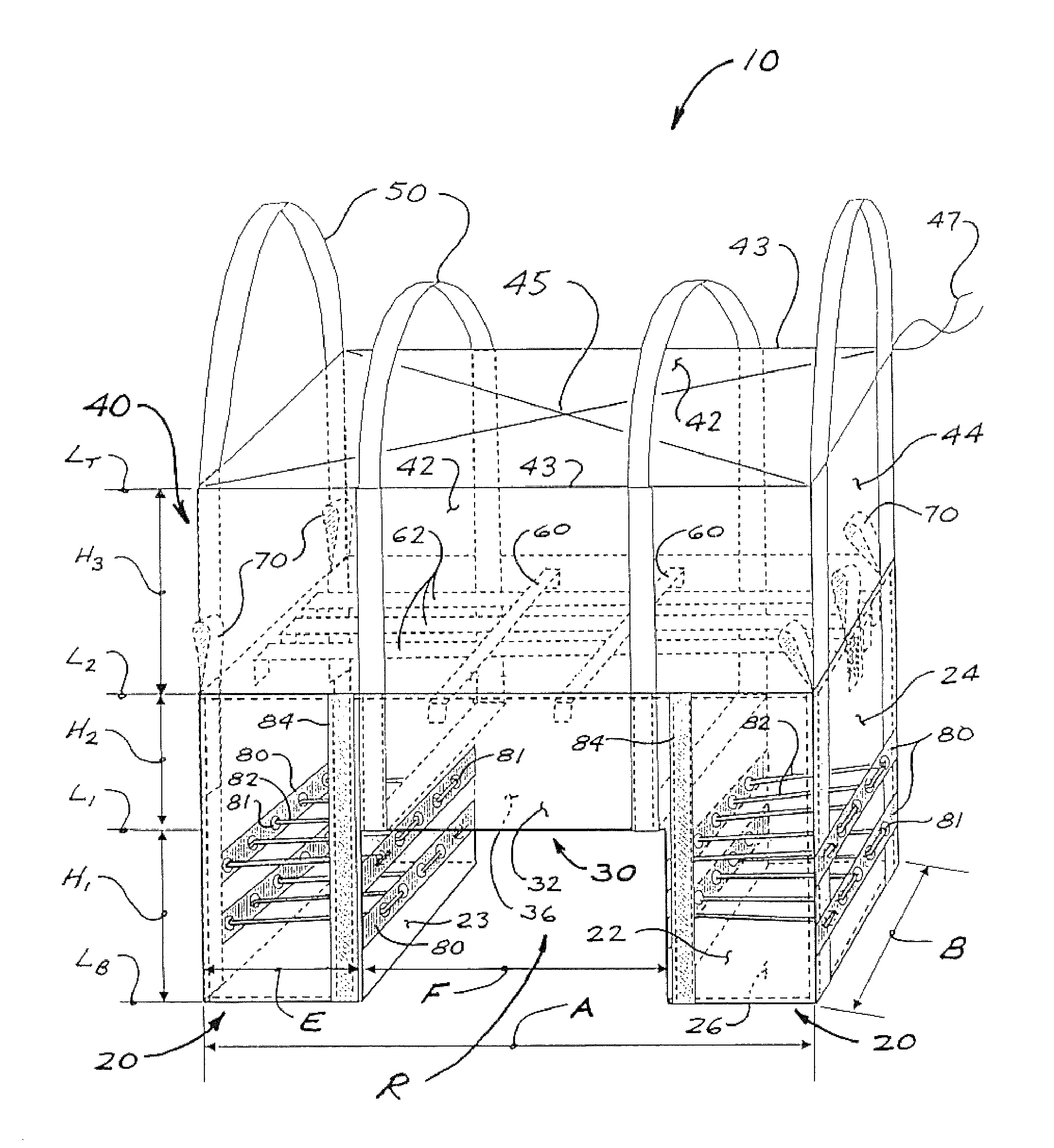

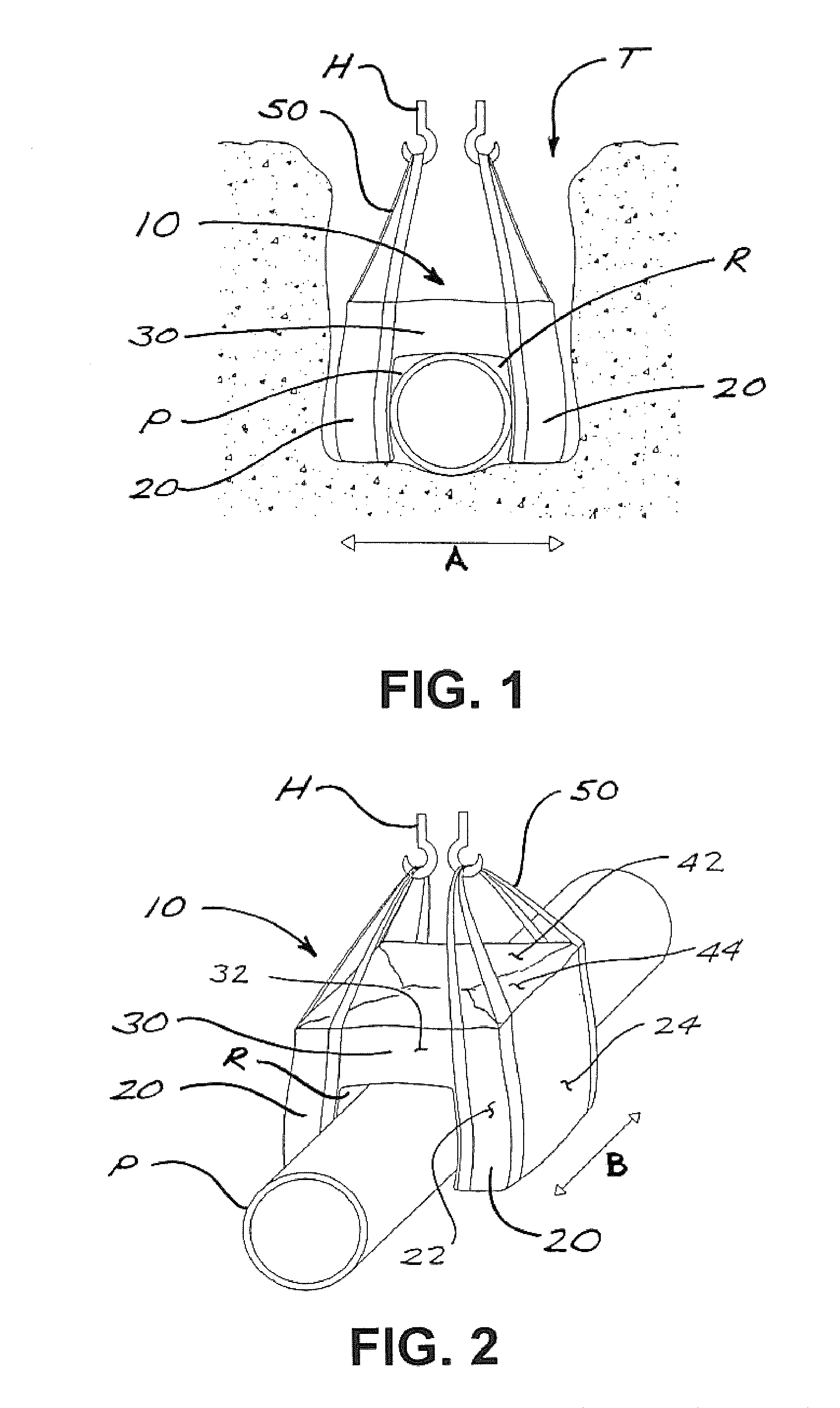

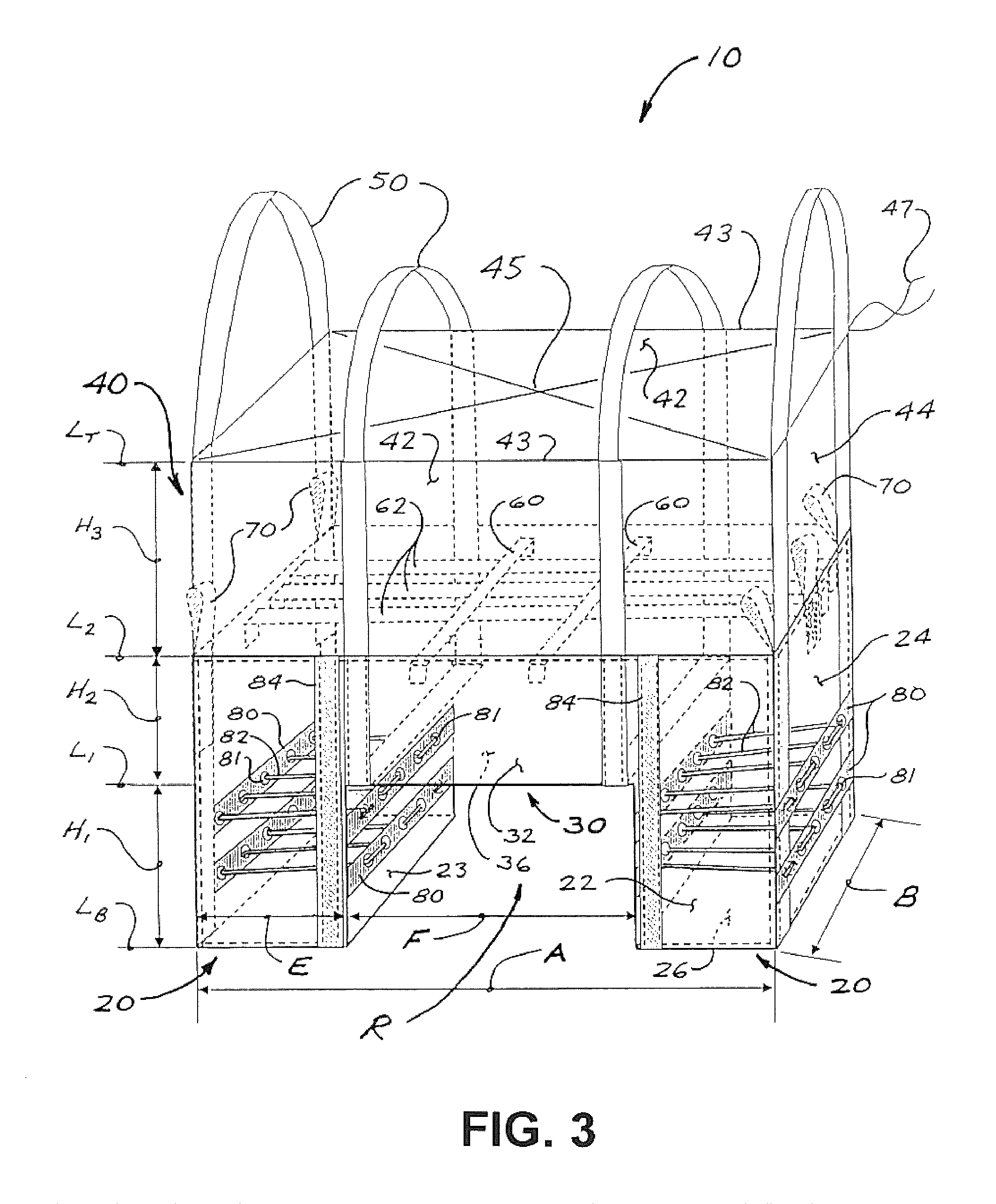

Ballast-filled pipeline weight

ActiveUS20100189514A1Avoid overexpansionFacilitate lifting and manipulationPipe supportsPipe laying and repairEngineeringBallast

A flexible bag-type pipeline weight, configured to straddle a pipeline, has internal tie means to prevent excessive bulging of the weight after being filled with ballasting material, thus facilitating installation in narrow trenches. Built-in loading loops facilitate filling the weight with ballasting material without need for special loading equipment. The bag-type pipeline weight is formed with a pair of leg sections on either side of a Central, pipeline-receiving recess. Once filled with ballast, the legs remain separated, thus facilitating installation on a pipeline. The filled pipeline weight is also freestanding and stable for purposes of transport and storage prior to installation. Hoisting slings facilitate lifting and manipulation of loaded pipeline weights without the need for spreader bars.

Owner:KEYMAY IND

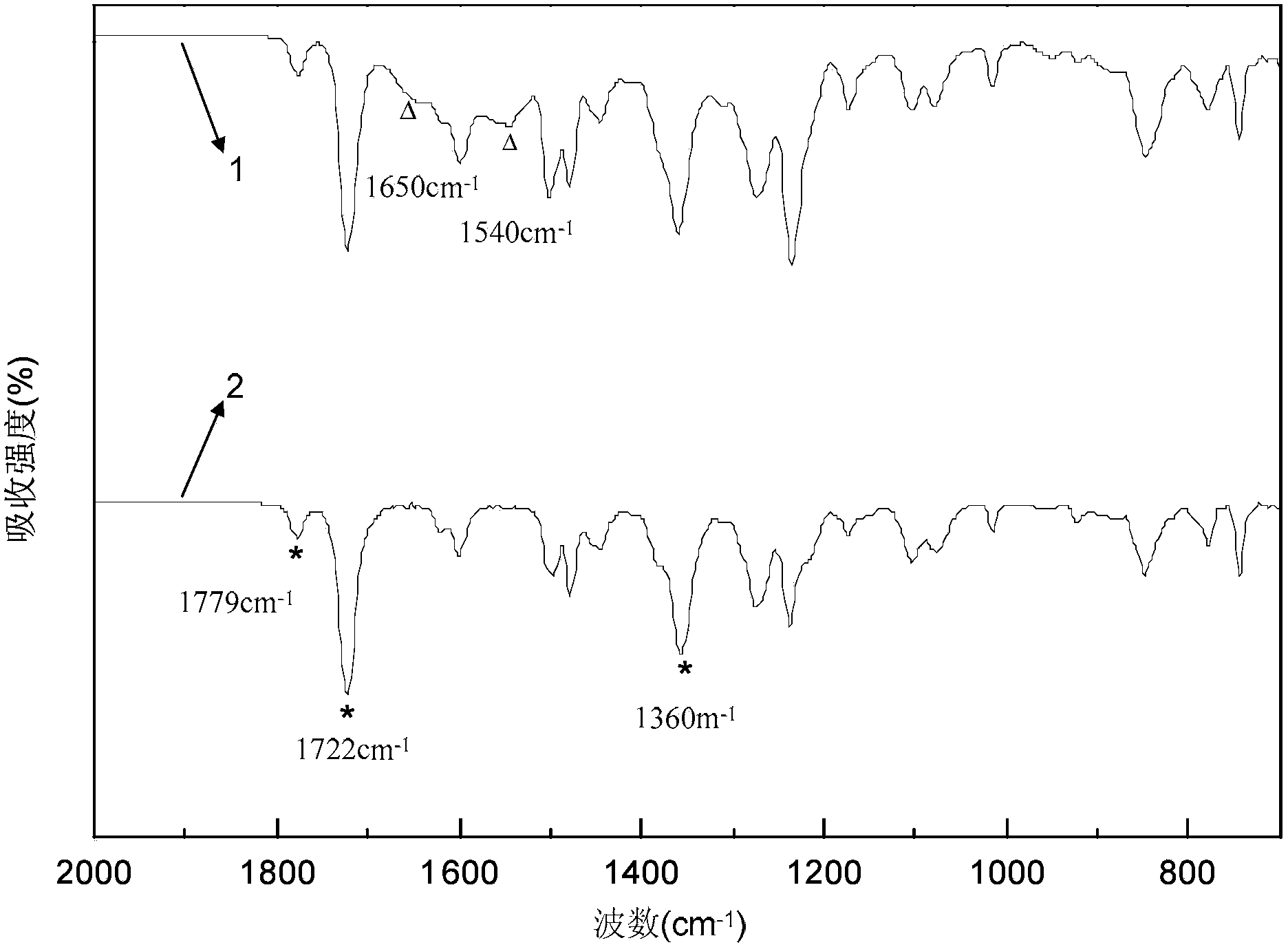

Preparation method of gas-phase crosslinking modified polyetherimide nanofiltration membrane

InactiveCN103406030AAvoid overexpansionInhibition of dissolutionSemi-permeable membranesSolventChemistry

The invention relates to a preparation method of a nanofiltration membrane, particularly a preparation method of a gas-phase crosslinking modified polyetherimide nanofiltration membrane. The invention aims to solve the problems of complex technique, high membrane preparation cost, high energy consumption, waste of solvent, environment pollution, poor solvent resistance of the prepared membrane, and incapability of wide application when the existing method is used for enhancing the solvent resistance and stability of the membrane in a non-aqueous solution system. The preparation method comprises the following steps: 1. preparing a polyetherimide film casting solution; 2. preparing a polyetherimide nanofiltration membrane by an immersion-precipitation process; 3. preparing a gas-phase crosslinking device; and 4. crosslinking the membrane in the crosslinking device to obtain the polyetherimide nanofiltration membrane. The method provided by the invention is simple to operate and low in cost, lowers the energy consumption and waste of solvent, and reduces the environmental pollution; and the obtained gas-phase crosslinking modified polyetherimide nanofiltration membrane has high solvent resistance and higher stability, and prevents over-expansion. The invention is used in the field of separation and purification of active components in the mixture in an organic solution.

Owner:HARBIN INST OF TECH

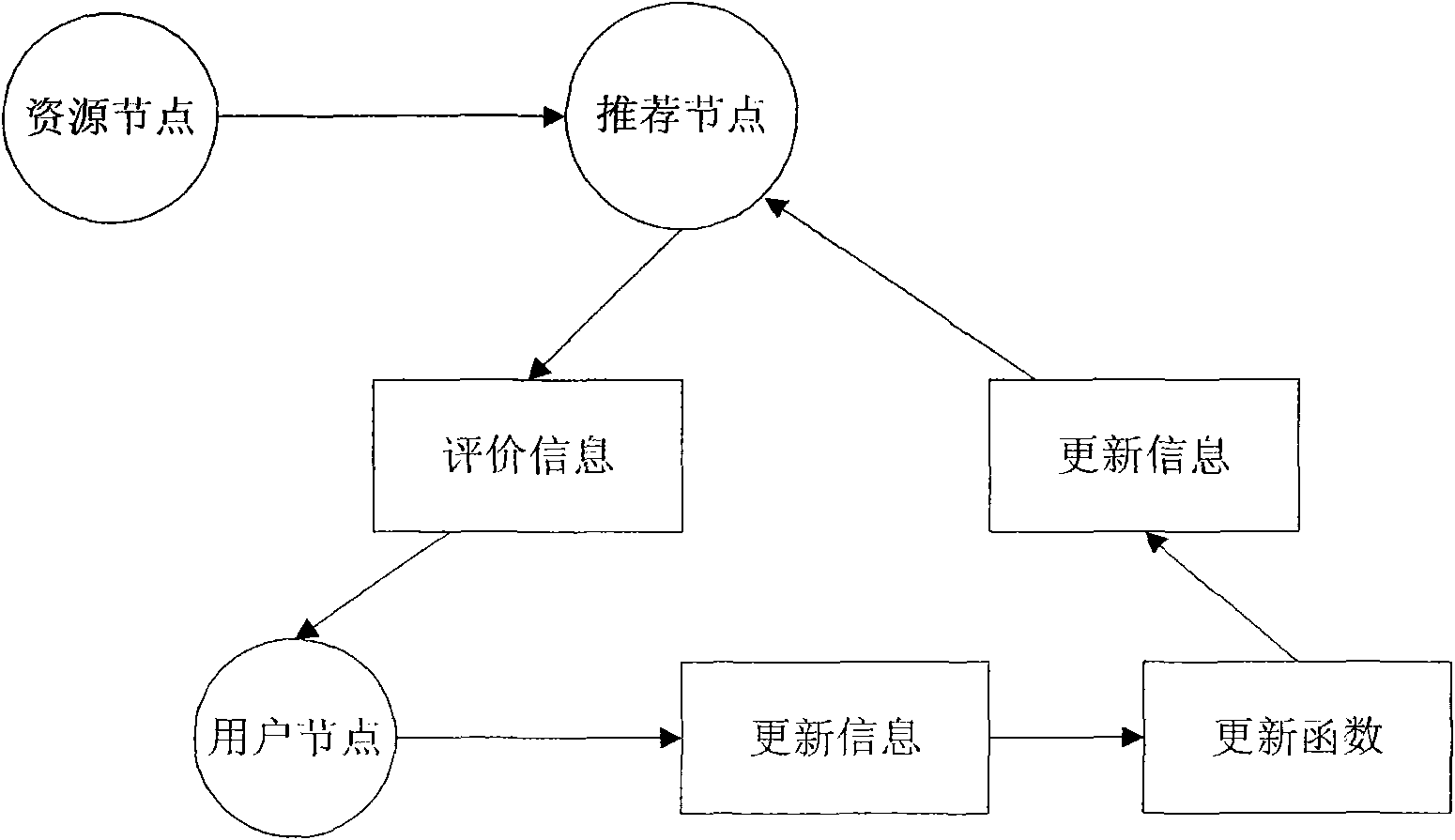

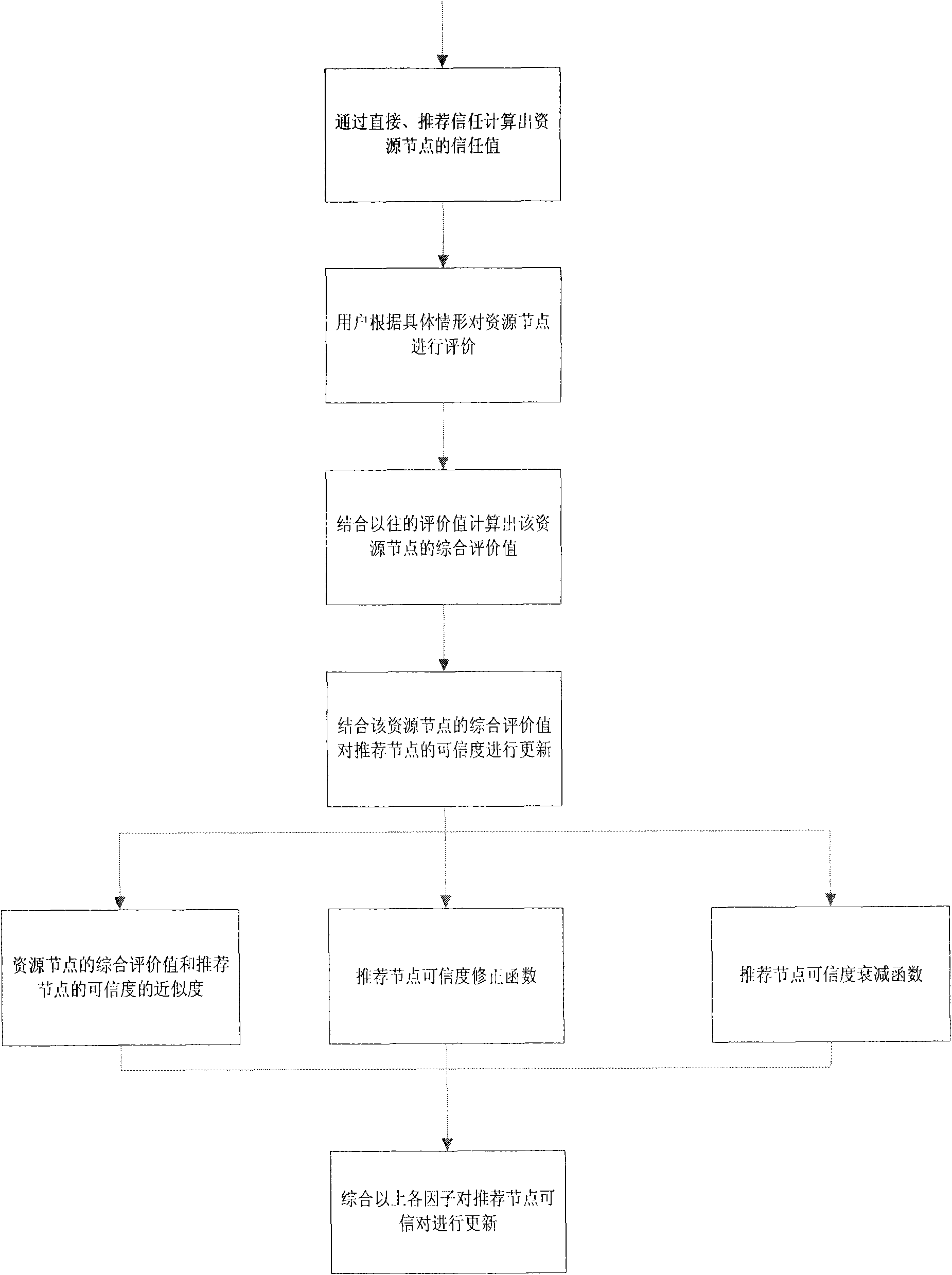

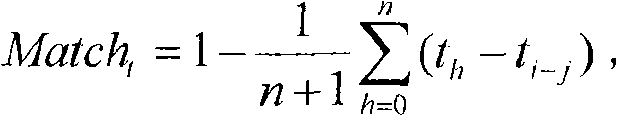

Constructing method of incentive mechanism based on recommended node credibility computation

InactiveCN101626388APrevent common cheatingPrevent problems such as simple calculation of trust valueData switching networksComputer networkCalculation methods

Owner:NANJING UNIV OF POSTS & TELECOMM

Rechargeable battery

ActiveUS9343772B2Effective protectionGuaranteed assembly stabilityLarge-sized flat cells/batteriesFinal product manufactureRechargeable cellEngineering

A rechargeable battery includes an electrode assembly undergoing charging and discharging, a pressurization holder covering the electrode assembly and fixing the electrode assembly, a positive terminal and a negative terminal electrically connected to the electrode assembly, and a case accommodating the electrode assembly and the pressurization holder in a state in which the positive terminal and the negative terminal protrude from the case.

Owner:ROBERT BOSCH GMBH +1

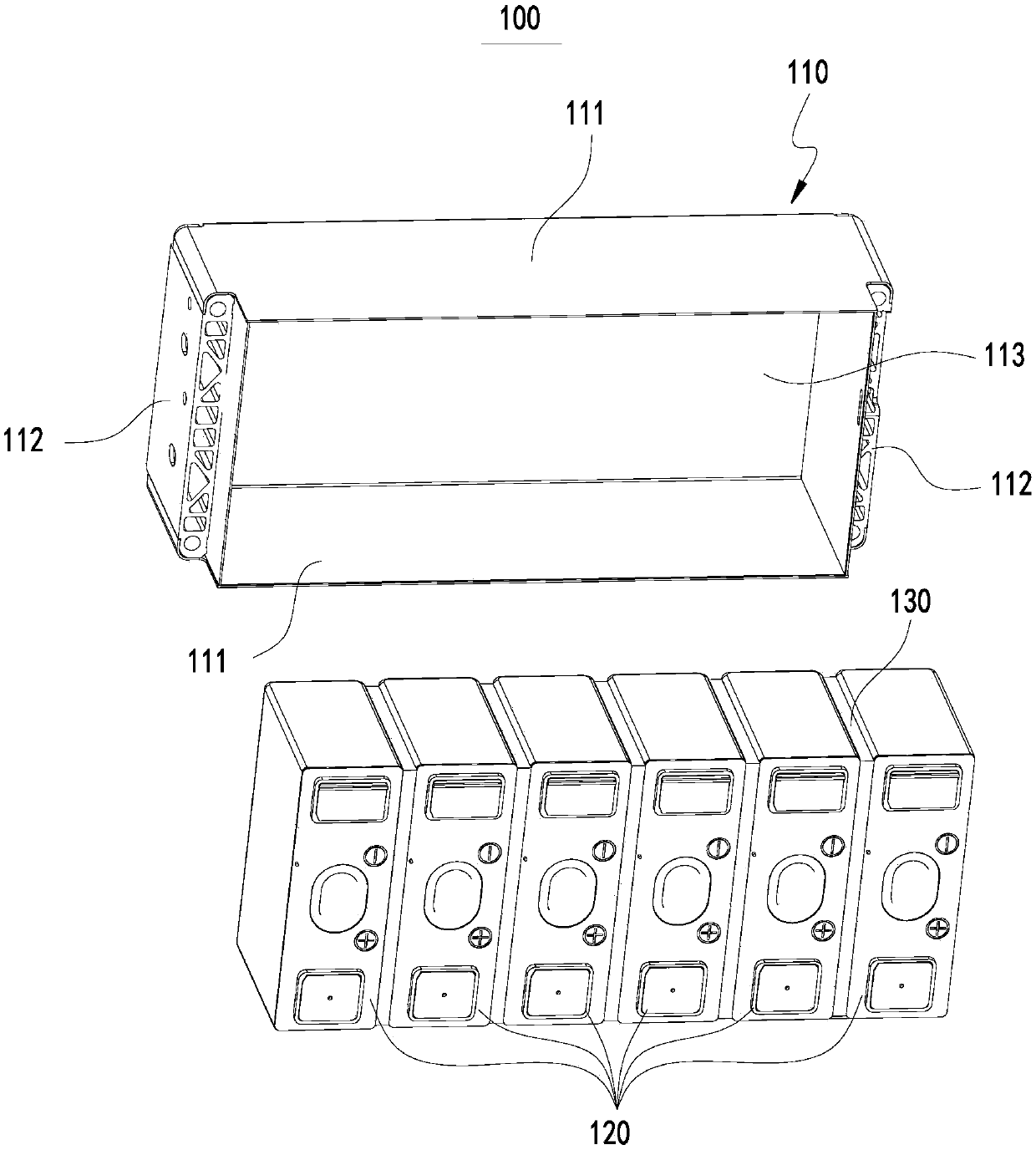

Battery module

ActiveCN110265591APromote circulationCompressibleFinal product manufactureSecondary cellsEngineeringCompressibility

The invention discloses a battery module and belongs to the technical field of energy storage. The battery module includes: a frame having a receiving space; a plurality of battery units which are successively arranged in the receiving space of the frame along the thickness direction of the battery units, wherein separating plates are disposed between adjacent battery units and have compressibility, and a compression ratio [delta]1 of the separating plates at a pressure less than or equal to 2MPa satisfies a condition of C0*[delta]1 <= A0*0.2, wherein C0 is the initial thickness of the separating plates, and A0 is the initial thickness of the battery units. The battery module provided by the invention has excellent cycle performance.

Owner:CONTEMPORARY AMPEREX TECH CO

Method for preparing resistant starch by simultaneously adopting crosslinking and heat moisture treatment

InactiveCN102190737AGood product qualitySimplify the production processFood preparationFunctional foodChemistry

The invention discloses a method for preparing resistant starch by simultaneously adopting crosslinking and heat moisture treatment, which comprises the following steps of: regulating the pH value of 30 to 45 weight percent starch milk at the temperature of between 25 and 50DEG C to be 10.5-12.5, adding sodium trimetaphosphate / sodium tripolyphosphate in an amount which is 0.2 to 12 percent based on the weight of the dry basis of starch, keeping for 30 to 240 minutes, drying until the weight percent of water is 15-45 percent, and performing heat moisture reaction at the temperature of between 100 and 140DEG C for 1 to 72 hours in a heat moisture reactor; and washing, drying, crushing and sieving to obtain a product. In the method, starch is taken as a raw material, the content of resistant starch is greatly improved by a physiochemical means, a process of preparing the resistant starch is simplified, the efficiency is effectively improved, waste liquor and pollution are avoided in the production process, and the energy consumption is reduced. The prepared resistant starch can serve as a functional food material and biochemical medicine carrier.

Owner:SOUTH CHINA UNIV OF TECH

Ballast-filled pipeline weight

ActiveUS8262320B2Avoid overexpansionFacilitate lifting and manipulationPipe supportsPipe laying and repairEngineeringMechanical engineering

A flexible bag-type pipeline weight, configured to straddle a pipeline, has internal tie means to prevent excessive bulging of the weight after being filled with ballasting material, thus facilitating installation in narrow trenches. Built-in loading loops facilitate filling the weight with ballasting material without need for special loading equipment. The bag-type pipeline weight is formed with a pair of leg sections on either side of a central, pipeline-receiving recess. Once filled with ballast, the legs remain separated, thus facilitating installation on a pipeline. The filled pipeline weight is also freestanding and stable for purposes of transport and storage prior to installation. Hoisting slings facilitate lifting and manipulation of loaded pipeline weights without the need for spreader bars.

Owner:KEYMAY IND

Pneumatic seat cushion system

ActiveUS8510884B2Prevent shock inflationAvoid overexpansionVehicle seatsDismountable chairsCompressible materialCushion

Owner:JERVIS 17 PTY LTD

Method for processing anti-retrogradation instant cooked rice using indica rice

The present invention discloses a method for processing anti-retrogradation instant cooked rice using indica rice. The indica rice is used as a raw material, and the method comprises the steps of screening and impurity removing, soaking and microwave pretreating, superheated steam pre-gelatinizing and shaping, vacuum quantitative packaging, back pressure microwave curing and instant cooked rice obtaining. The method aims at problems that the instant cooked indica rice is serious in retrogradation, poor in mouthfeel, more in broken grains, not easy for digestion, etc., uses a compound retrogradation inhibiting agent to soak the indica rice, combines the microwave pretreating and back-pressure microwave curing ripening, and effectively inhibits the retrogradation. The superheated steam fluidized state treatment is used, so that surface starch of the indica rice grains is pre-gelatinized and then an air-cooling achieves a shaping. The vacuum packaging and back pressure microwave curing are combined to prevent the rice grains from being over-expanded. The product is good in flavor, excellent in mouthfeel, advanced and reasonable in processing technology, good in quality and broad in prospects.

Owner:福建御厨食品有限公司

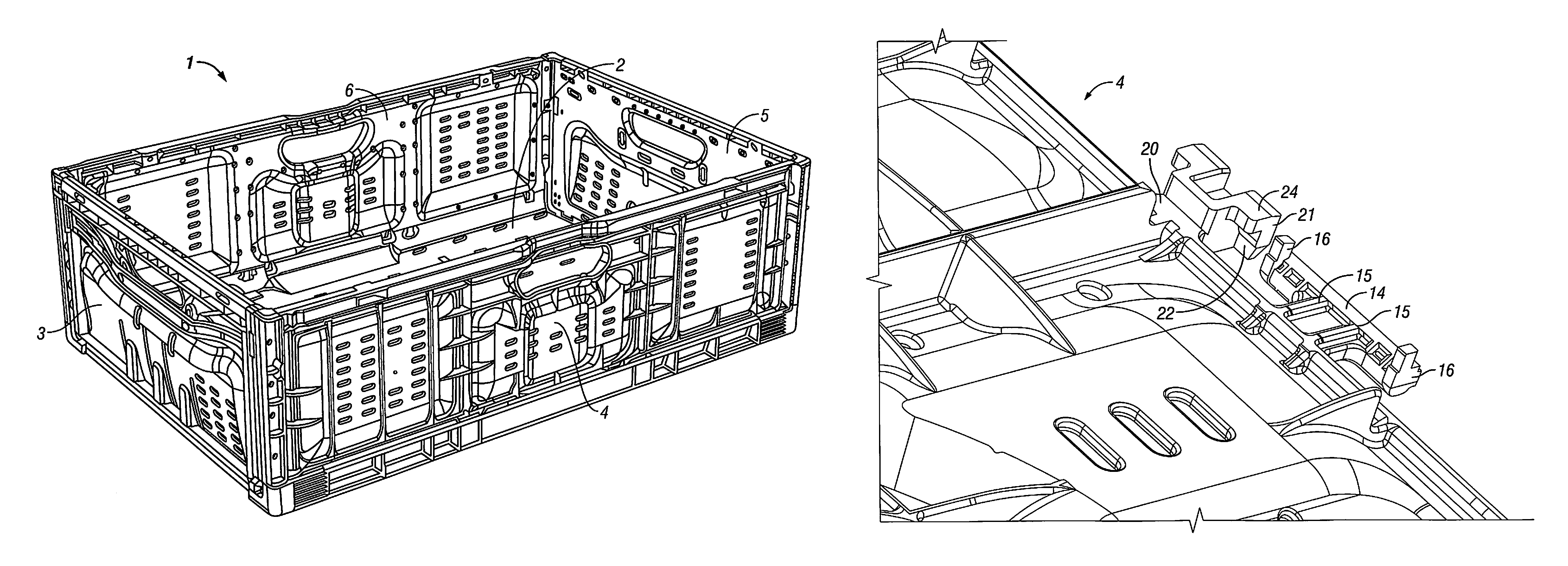

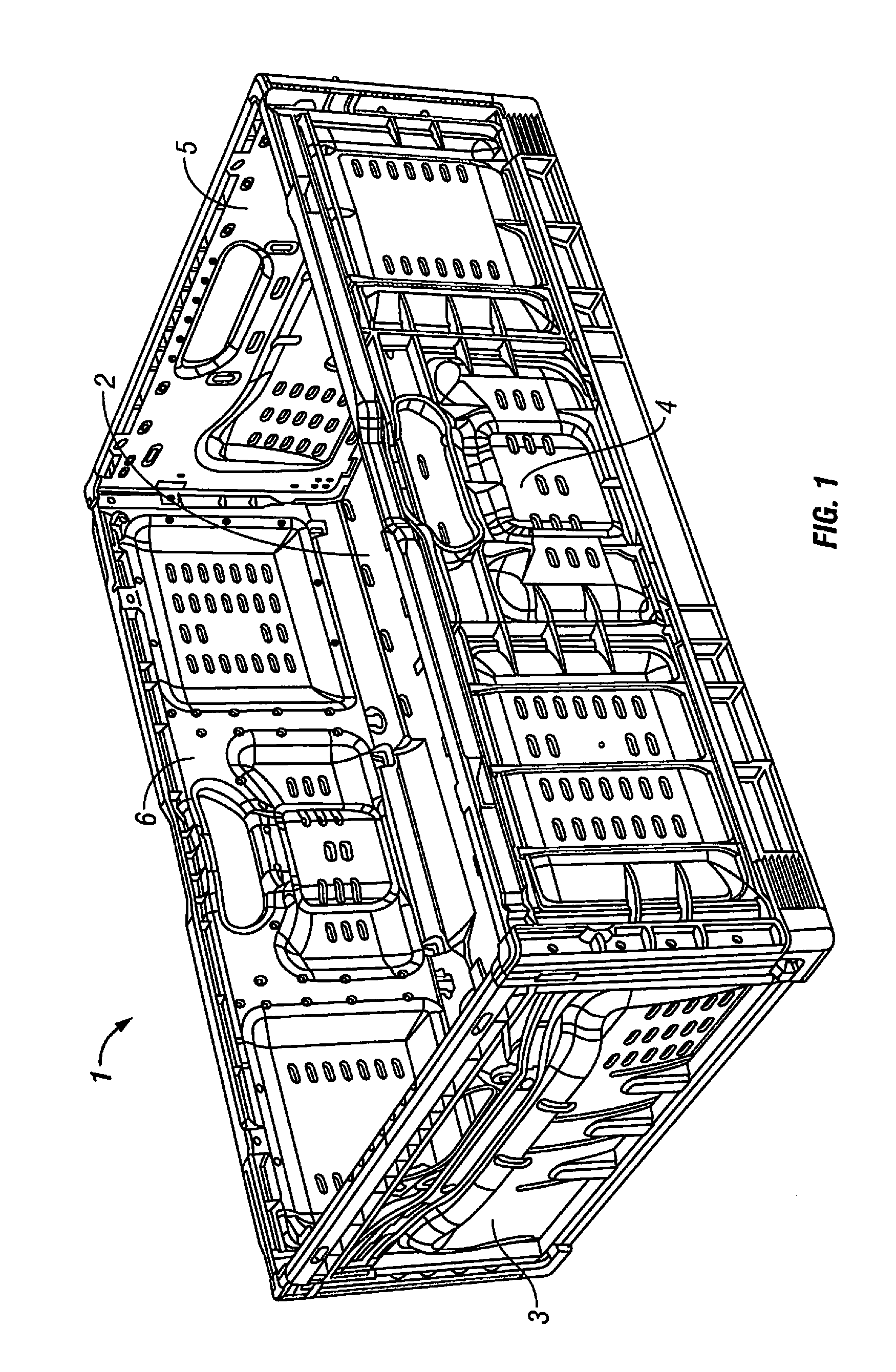

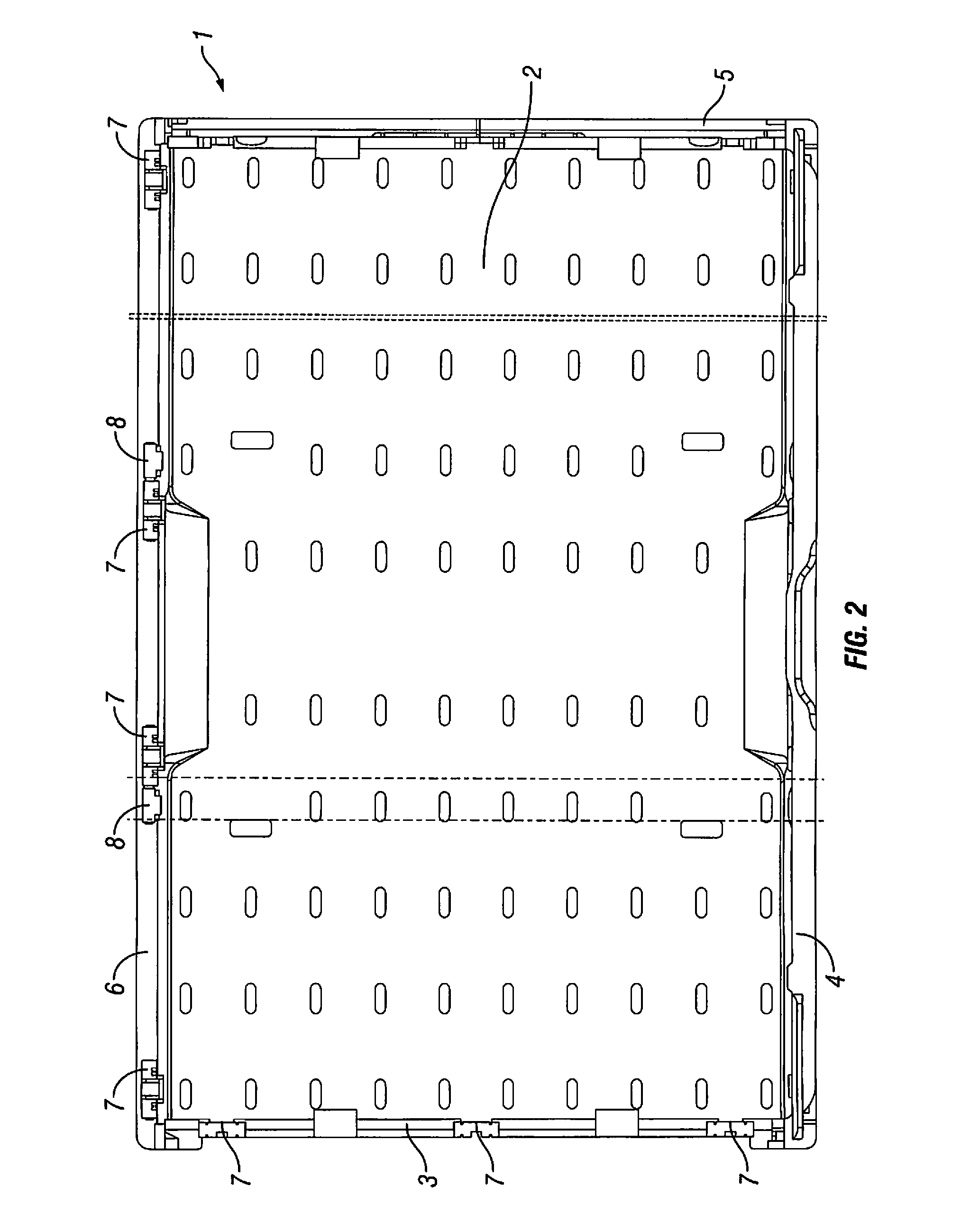

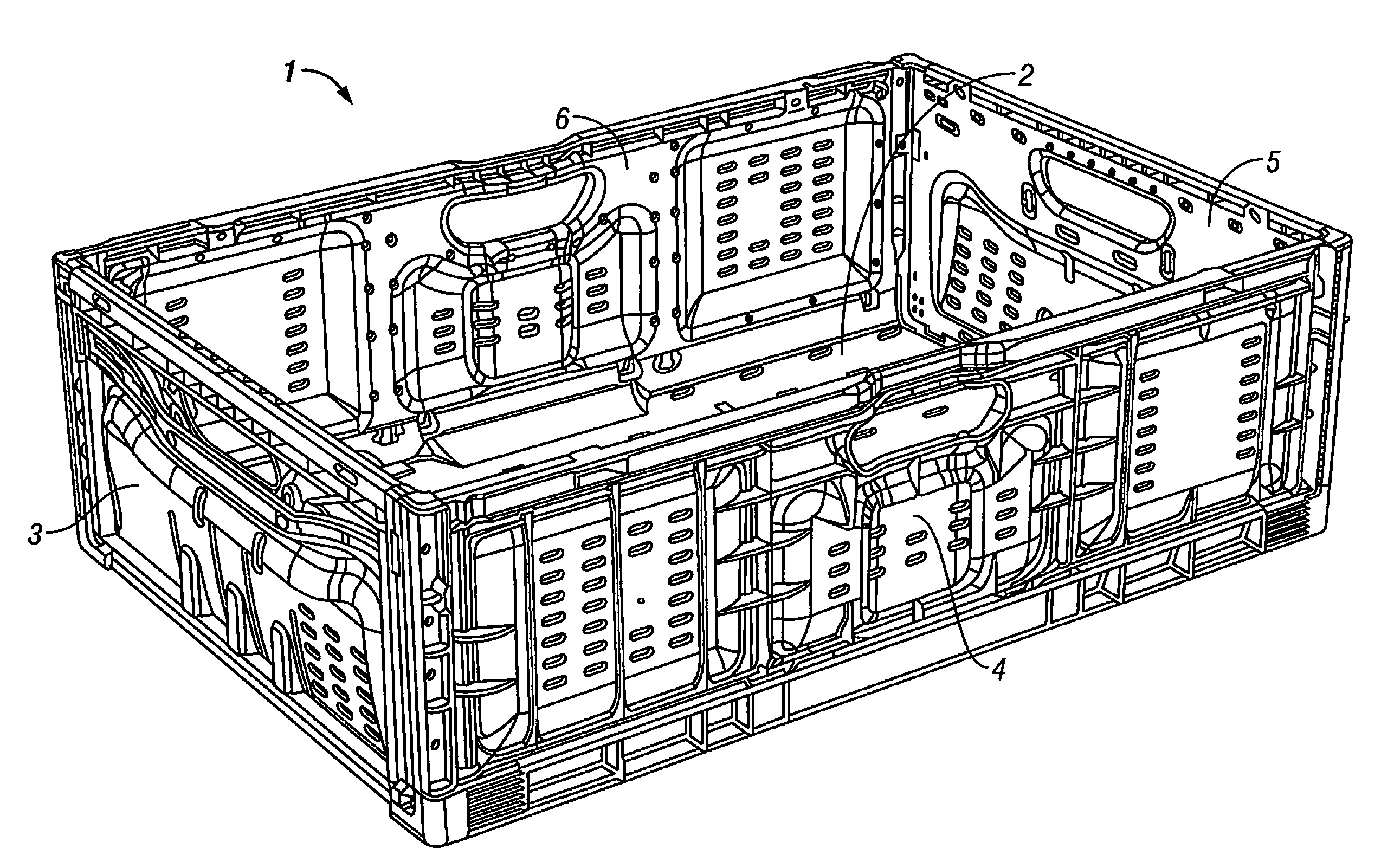

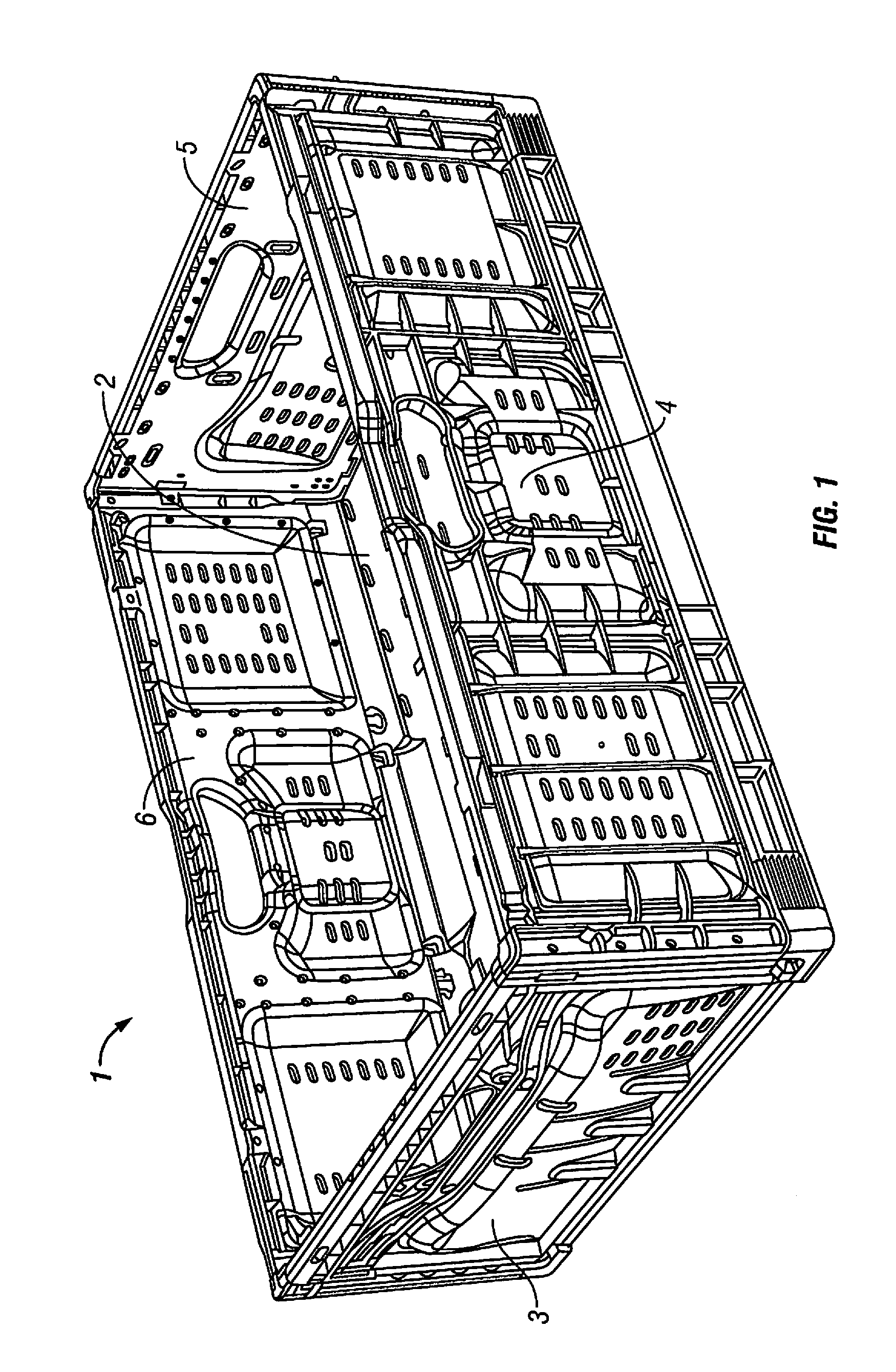

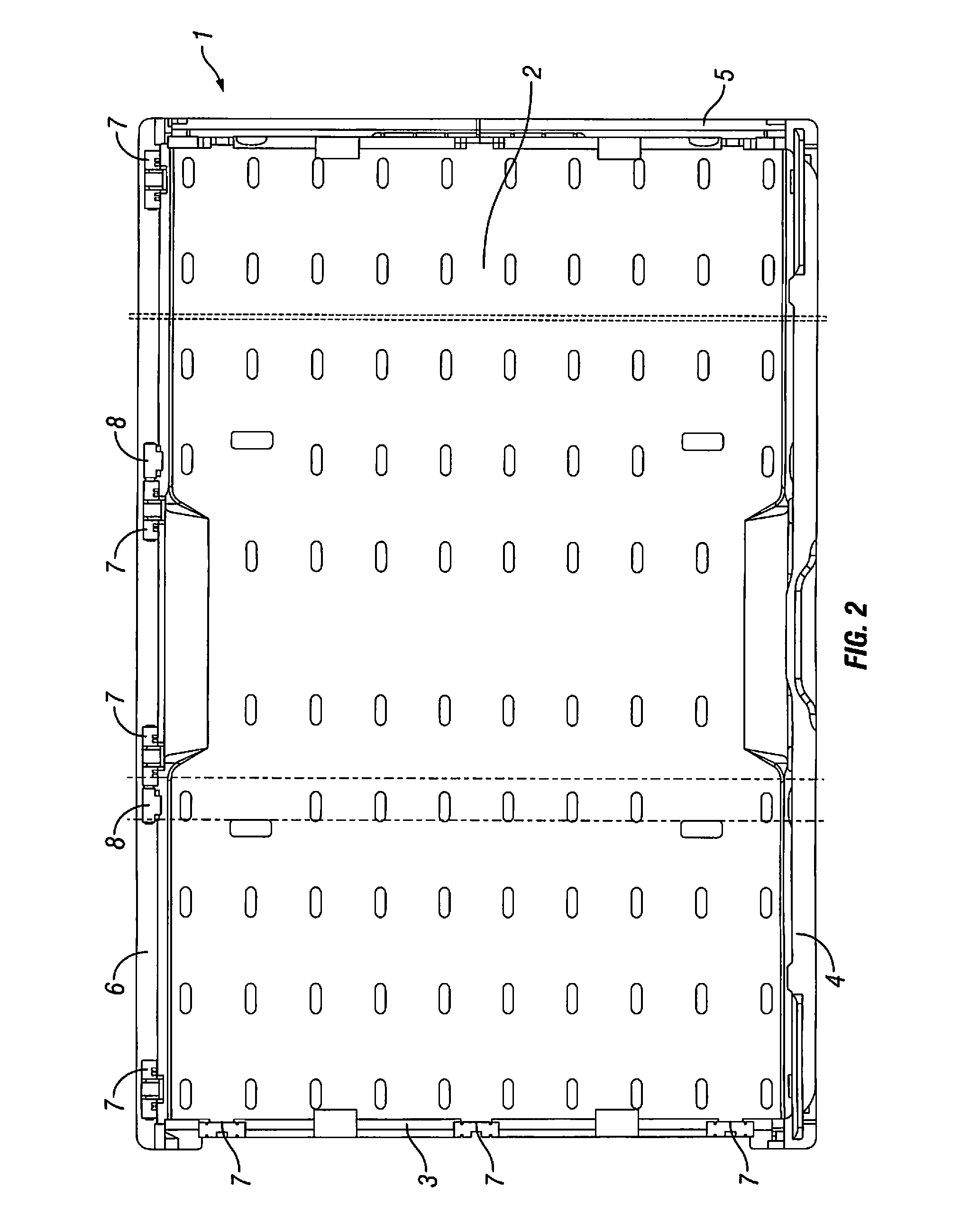

Container comprising a collapsible sidewall

ActiveUS8627973B2Effectively prevented from bendingEasy to disassembleLarge containersRigid containersInjection molding processMechanical engineering

Owner:IFCO SYST GMBH

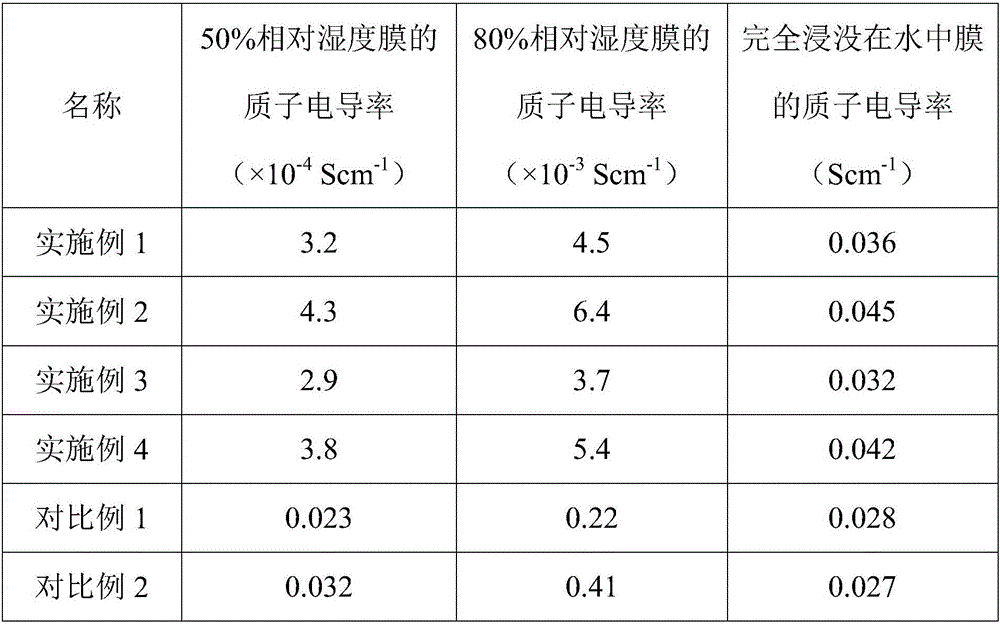

Modified halloysite nanotube for proton exchange membrane and preparation method of modified halloysite nanotube

InactiveCN106099146AImprove proton conductivityStable mechanical propertiesMaterial nanotechnologyFinal product manufactureHalogenSulfonated polymer

The invention relates to a modified halloysite nanotube for a proton exchange membrane and a preparation method of the modified halloysite nanotube. The method comprises the steps of carrying out surface coating treatment on the halloysite nanotube through dopamine hydrochloride, introducing active halogen atoms, and grafting and polymerizing a monomer with a sulfonic acid group into the halloysite nanotube through ATRP reaction to obtain the modified halloysite nanotube. The monomer with the sulfonic acid group is grafted and polymerized into the halloysite nanotube to introduce the sulfonic acid group; and the modified halloysite nanotube and a sulfonated polymer electrolyte are doped to prepare the composite proton exchange membrane with high proton conductivity and stable mechanical property.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Composite anti-freezing liquid, and method for preserving human amnion by using same

InactiveCN102763639APreserve activityImprove permeabilityDead animal preservationAnti freezingGlycerol

The invention discloses a composite anti-freezing liquid, and a method for preserving human amnion by using the same. The composite anti-freezing liquid comprises a basic anti-freezing liquid composed of DMEM culture medium, glycerol and dimethyl sulfoxide at volume ratio of (4.5-5.5):(3.5-4.5):(0.5-1.5); and trehalose having a concentration of 0.05-0.15 mol / L in the composite anti-freezing liquid. After pretreatment by the composite anti-freezing liquid, fresh human amnion can be directly preserved in liquid nitrogen without refrigerating with programmed cooling instrument, so as to simplify procedure, save cost, shorten pretreatment time, reduce pollution, and maintain amnion activity in long term.

Owner:童亚林

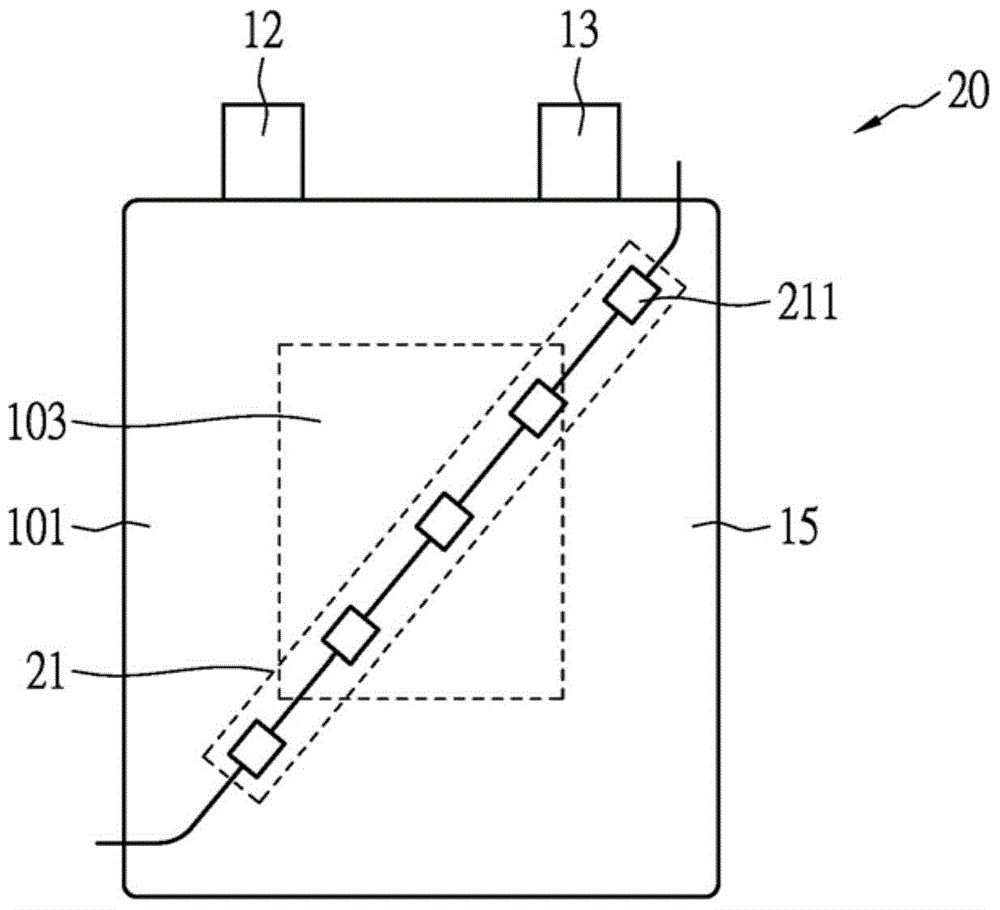

Secondary battery

ActiveCN106207980AAvoid burnsEffective and comprehensive temperature sensing effectSecondary cellsEmergency protective arrangements for automatic disconnectionElectrical resistance and conductanceControl signal

A secondary battery comprises a battery unit, at least one PTC temperature sensing device and a load switch. The battery unit is encompassed by a battery shell. The PTC temperature sensing device is disposed on a primary surface of the battery shell to effectively sense a temperature of the battery unit. The load switch connects to the battery unit and a load and determines whether the battery unit and the load switch are in electrical connection or in an open circuit state according to resistance variation of the PTC temperature sensing device. When the resistance of the PTC temperature sensing device increases to a threshold times within a specific temperature variation or time period, the load switch receives a control signal and accordingly switches to an open circuit state.

Owner:POLYTRONICS TECH CORP

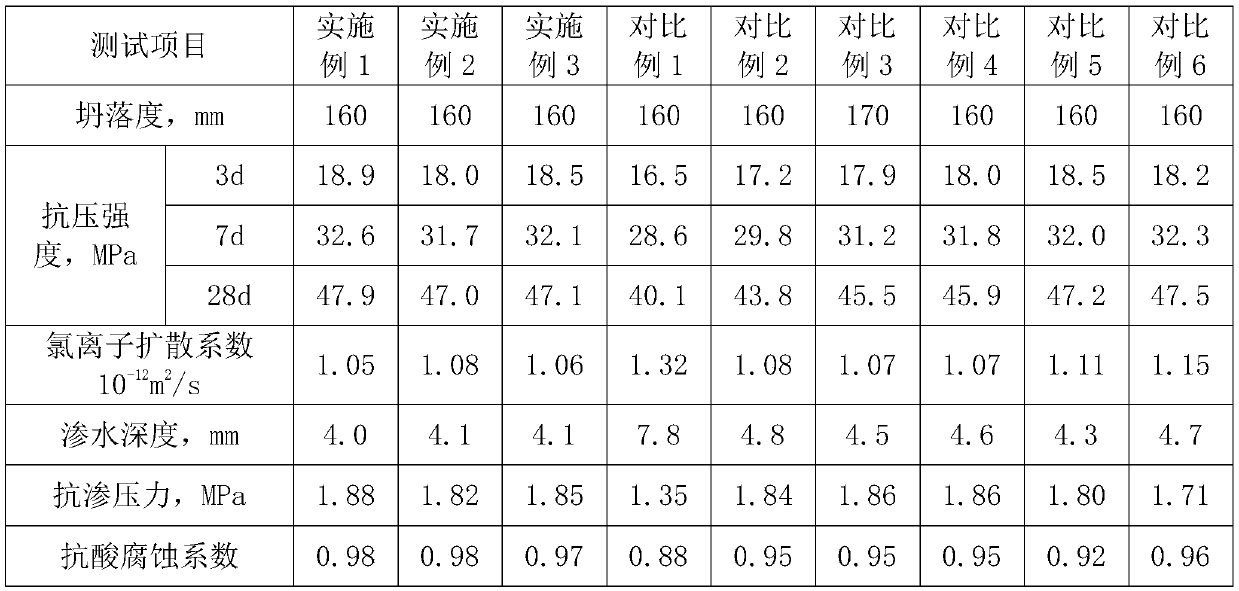

Waterproof concrete and preparation method thereof

The invention discloses waterproof concrete and a preparation method thereof, wherein the waterproof concrete is prepared from the following components in parts by weight: 300 to 350 parts of cement,600 to 700 parts of fine aggregate, 900 to 1000 parts of coarse aggregate, 100 to 120 parts of an admixture, 8 to 10 parts of an additive, 25 to 30 parts of a waterproof agent and 130 to 150 parts ofwater, wherein the preparation method of the waterproof agent comprises: taking 40-60 parts by weight of modified basalt fiber and 5-7 parts by weight of disproportionated potassium rosinate, uniformly stirring, adding 30-40 parts by weight of a UEA expanding agent, 3-5 parts by weight of sodium dodecyl sulfate and 3-5 parts by weight of ferrous sulfate, and uniformly stirring to obtain the waterproof agent. The waterproof concrete provided by the invention has excellent water resistance, excellent permeability resistance and excellent acid corrosion resistance.

Owner:成都新豪鼎盛建材有限公司

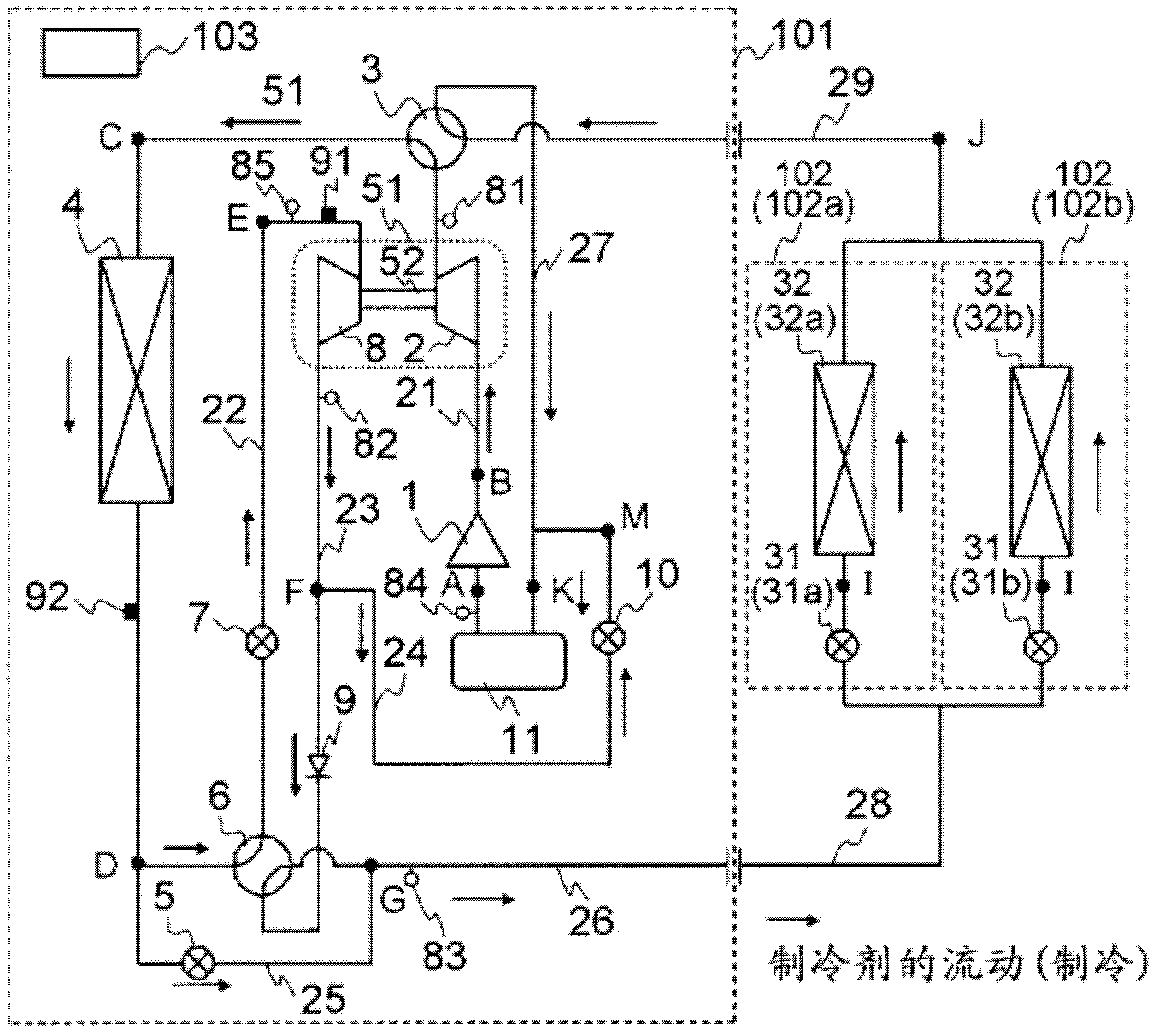

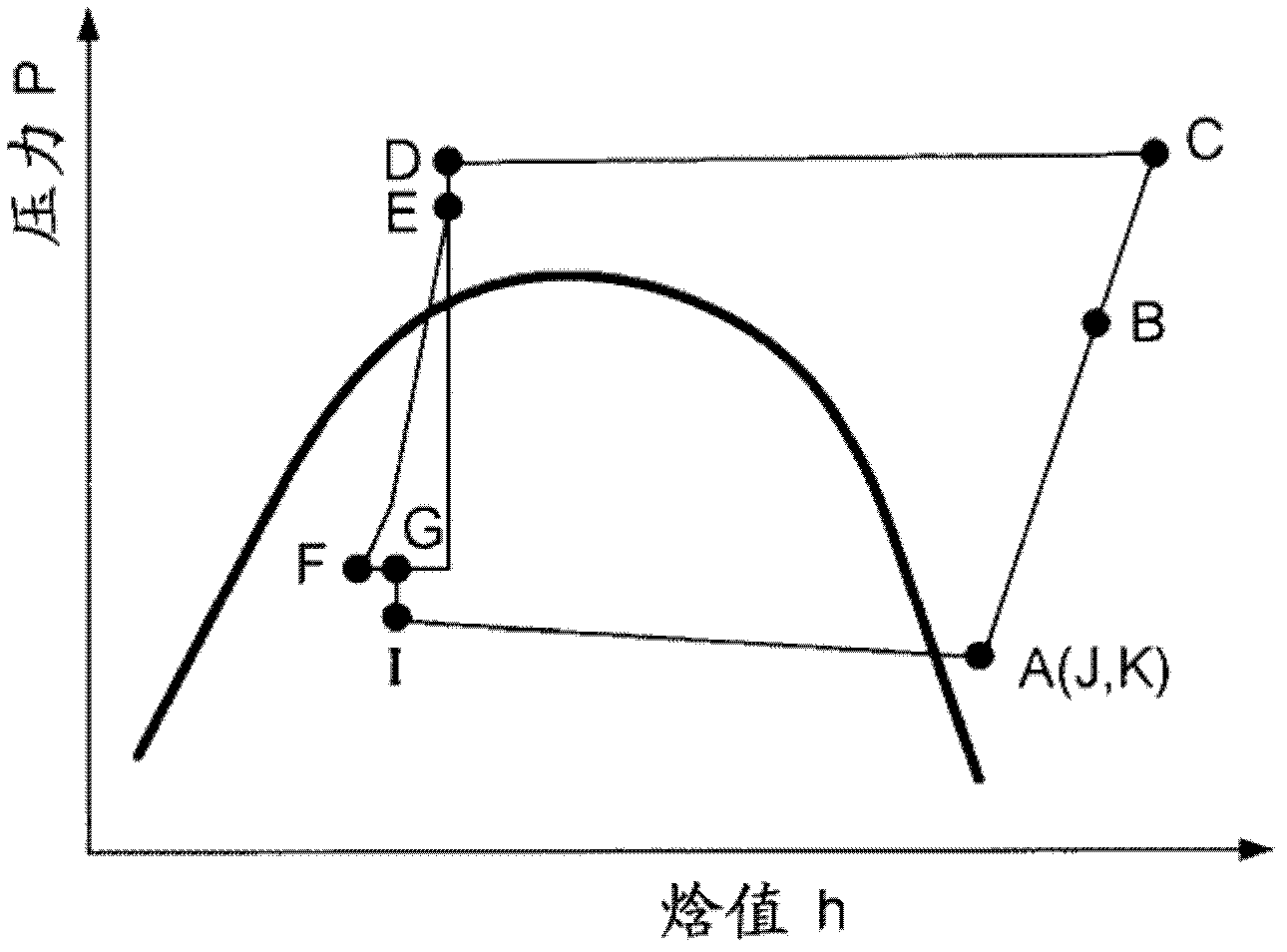

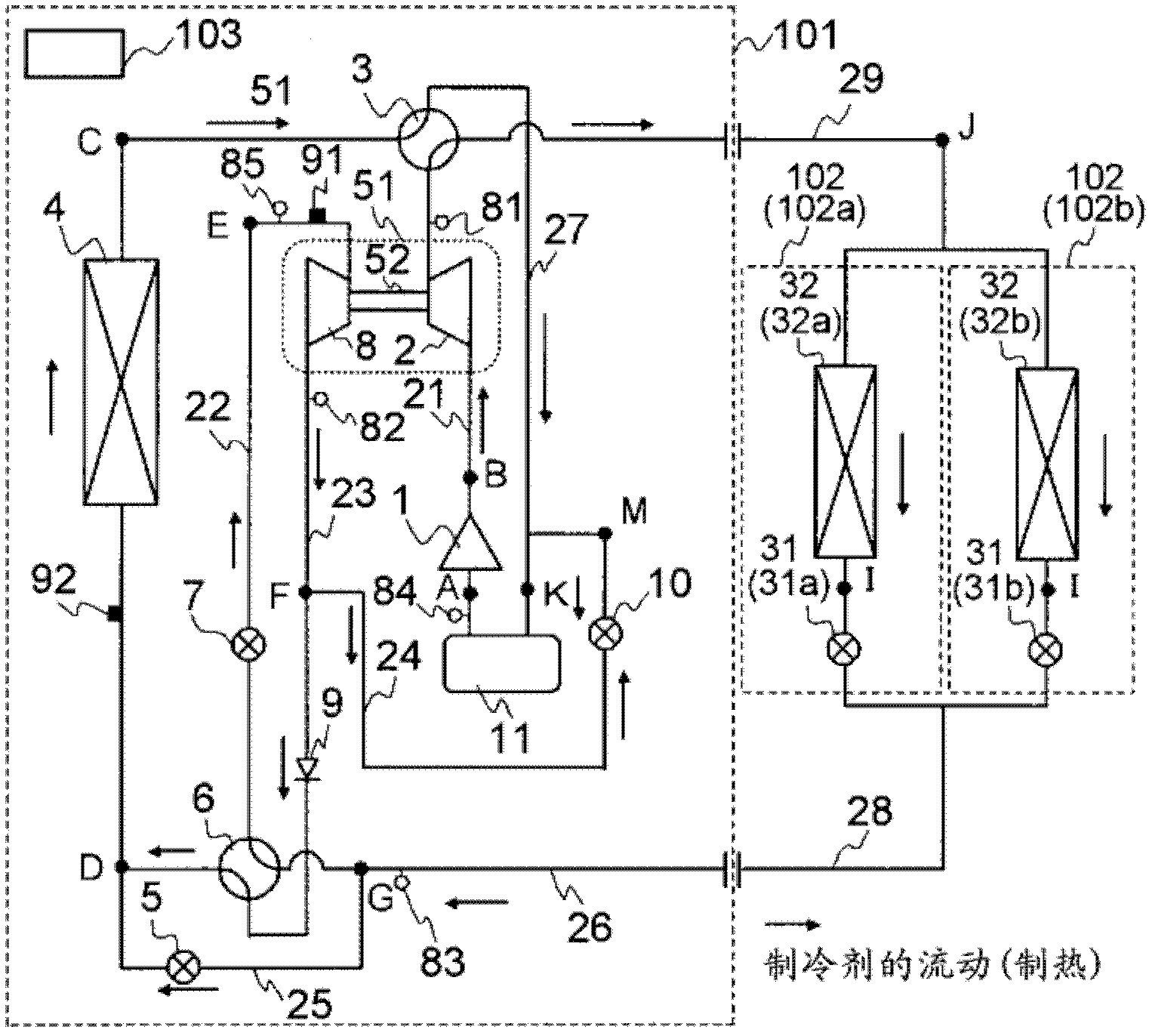

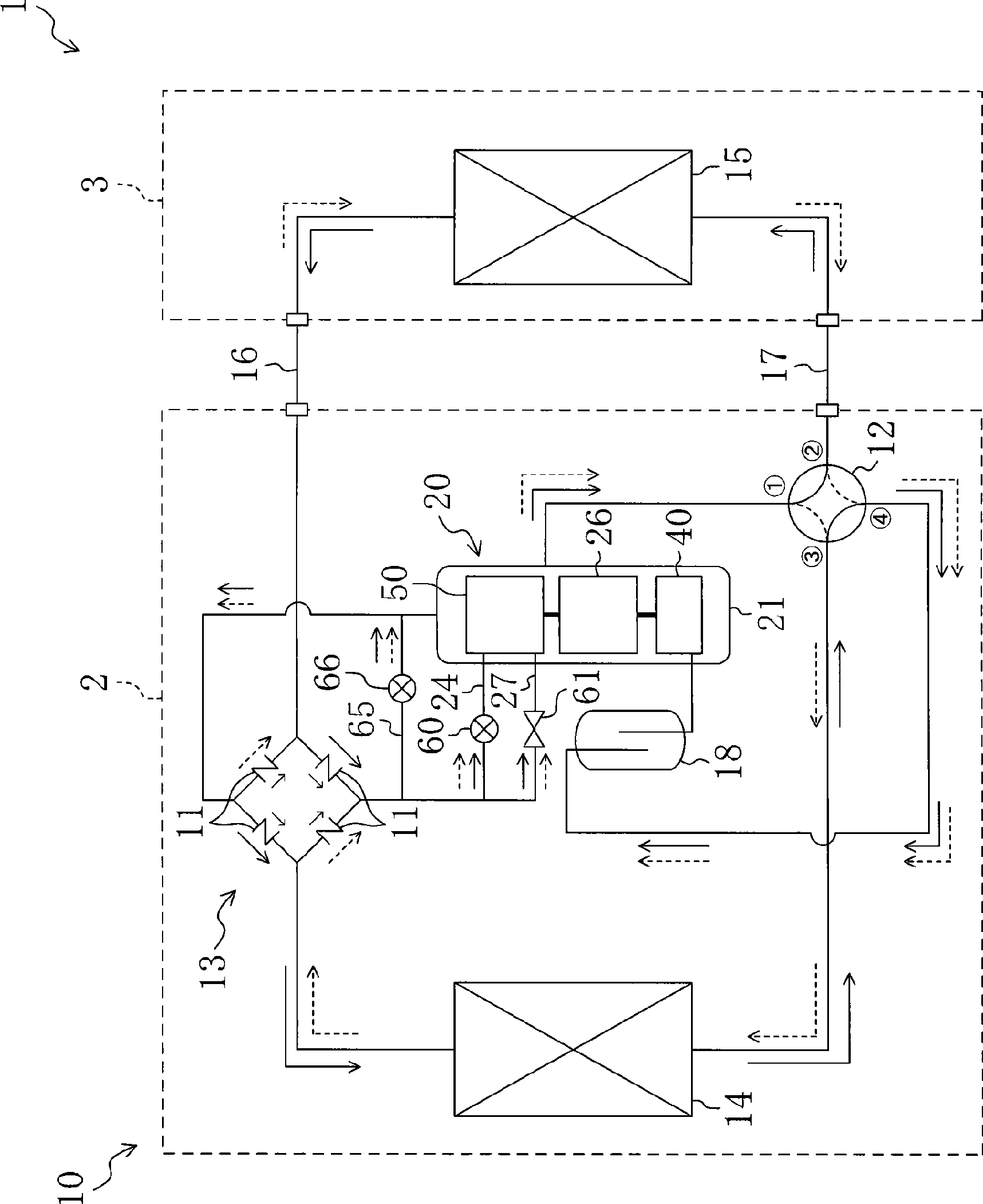

Refrigeration cycle device

ActiveCN102510985AReduce discharge pressureAvoid overexpansionCompression machines with non-reversible cycleCompression machines using turbinesRefrigerant reclamationEngineering

A refrigeration cycle device is provided with: a refrigeration cycle formed by sequentially connecting by means of piping a first compressor (1), a heat dissipater, an expander (8) for expanding a refrigerant which has passed through the heat dissipater and recovering power from the refrigerant, and an evaporator; bypass piping (24) having one end connected to the discharge piping of the expander and the other end connected to the suction piping of the first compressor; a pressure sensor (85) and a temperature sensor (91) for respectively detecting the suction pressure and the suction temperature of the expander (8) as the physical quantities of the refrigerant sucked by the expander (8); a bypass valve (10) provided to the bypass piping (24) and regulating the flow rate of the refrigerant; and a control device (103) for controlling the extent of opening of the bypass valve (10). The control device (103) determines the appropriate discharge pressure of the expander (8) on the basis of the suction pressure and the suction temperature of the expander and opens the bypass valve (10) when the pressure at which the expander (8) discharges the refrigerant is higher than the determined appropriate discharge pressure.

Owner:MITSUBISHI ELECTRIC CORP

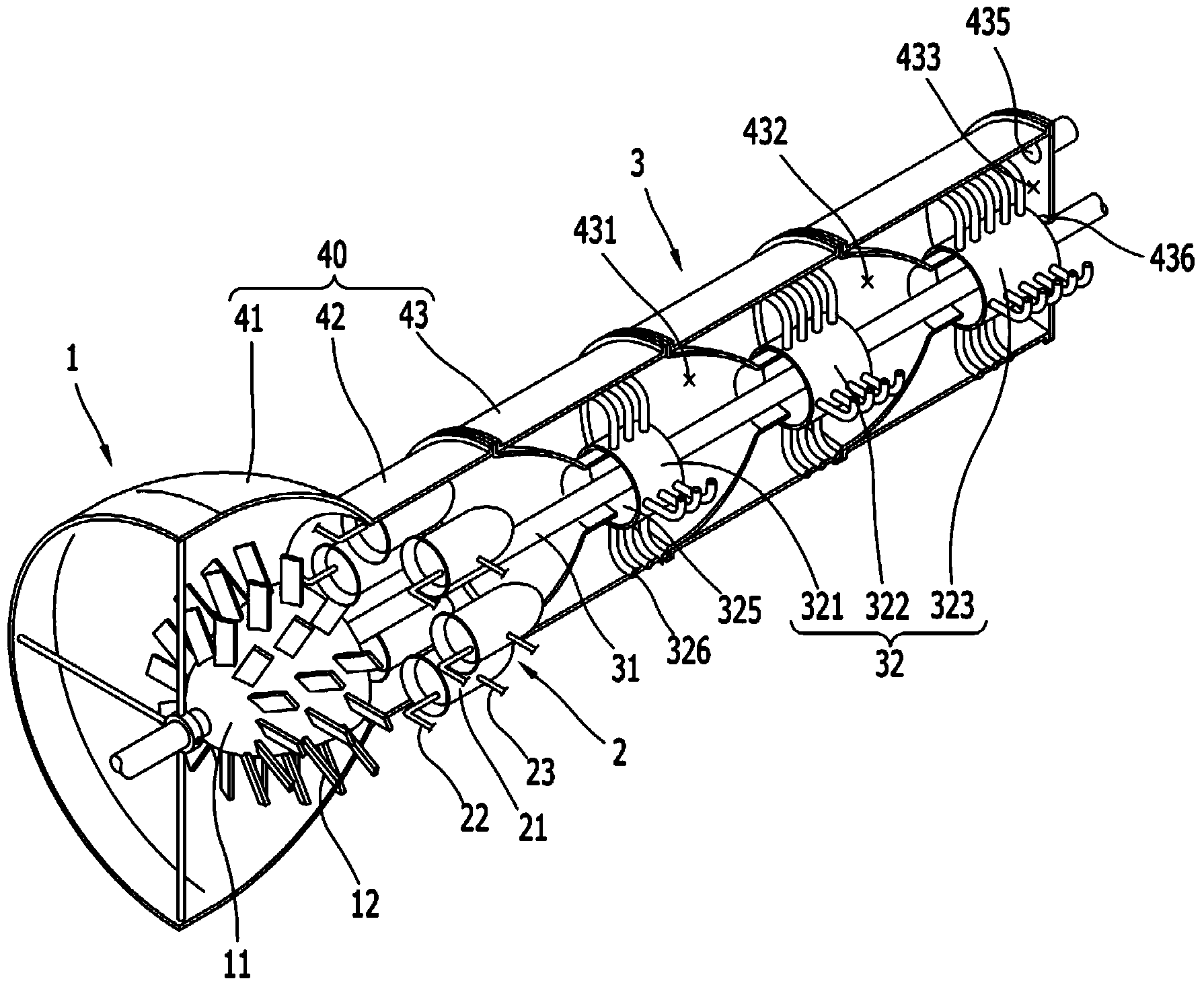

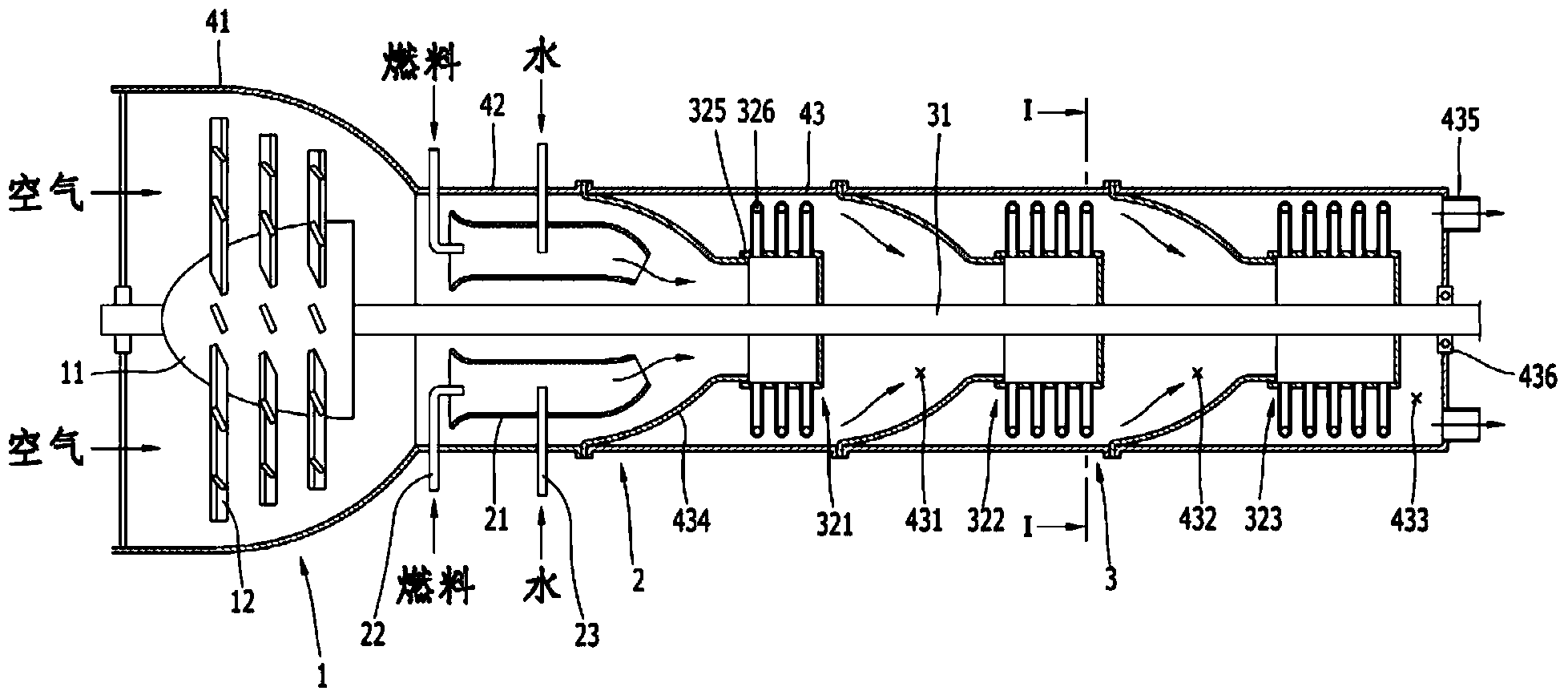

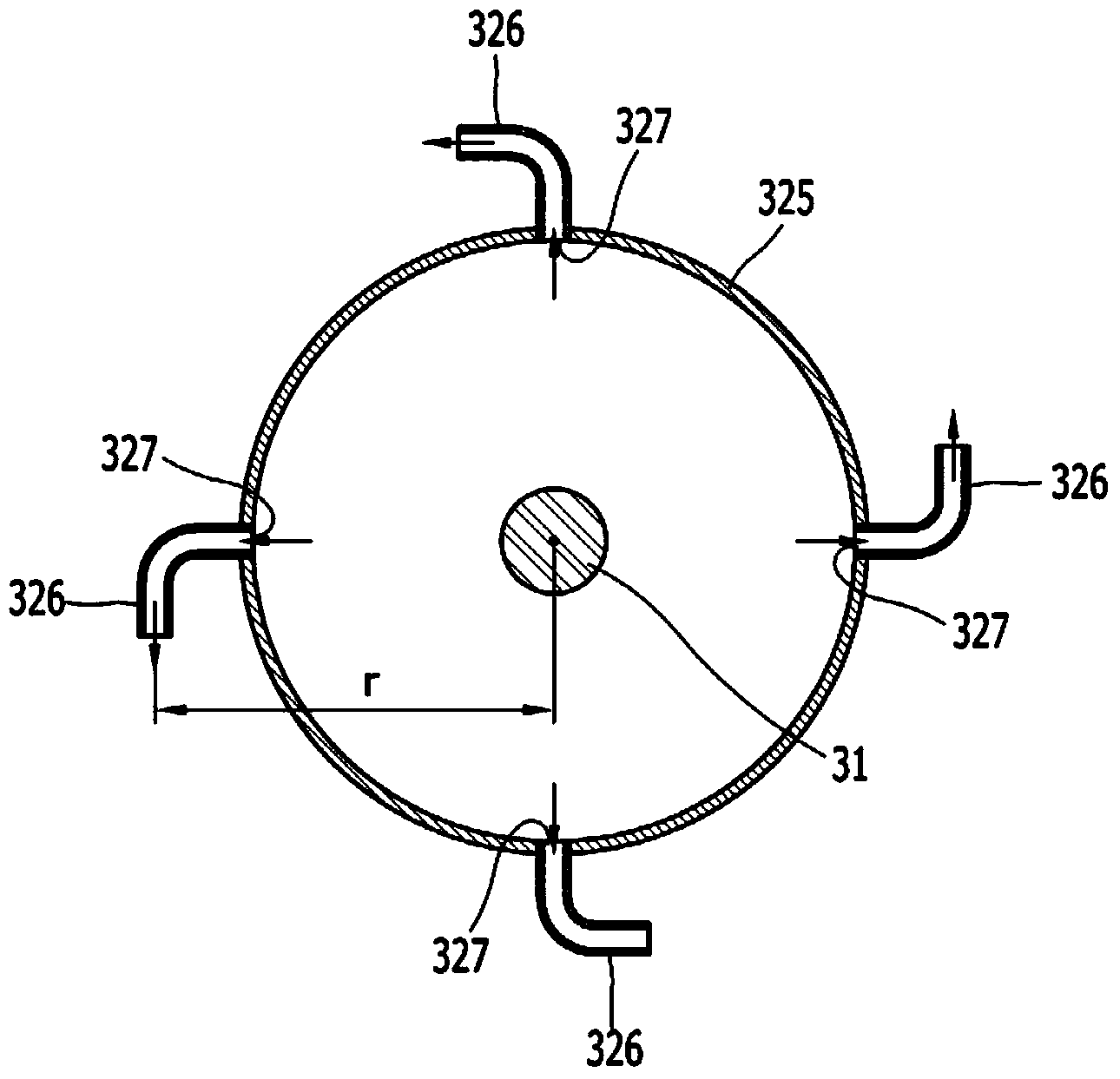

Gas turbine

InactiveCN103415684AImprove rotational energy conversion efficiencyReduce manufacturing costGas turbine plantsStatorsManufacturing cost reductionFlow resistivity

The present invention relates to a gas turbine. According to the present invention, gas may be injected in the circumferential direction in order to rotate the turbine shaft using a repulsive force, thereby improving the efficiency of the conversion of rotational energy of the turbine and reducing manufacturing costs. Also, the flow resistance to the gas may be reduced, pressure leakage may be prevented, and energy loss may be reduced so as to manufacture an inexpensive turbine having high efficiency. In addition, when turbines having capacities different from each other are manufactured, parts may be easily shared with each other, and the eccentric rotation of the turbine shaft may be prevented to significantly improve durability. Also, an air compression part, a gas expansion part, and a power generation part may be modularized, and fuel and water may be supplied together. Thus, overheating of the gas expansion part may be prevented to prevent air from being excessively expanded, and vapor may be generated to improve rotational force in addition to the impellent power of the turbine. Also, the gas turbine may be manufactured using a relatively inexpensive metal material instead of expensive high temperature ablative materials in order to reduce manufacturing costs.

Owner:金其太

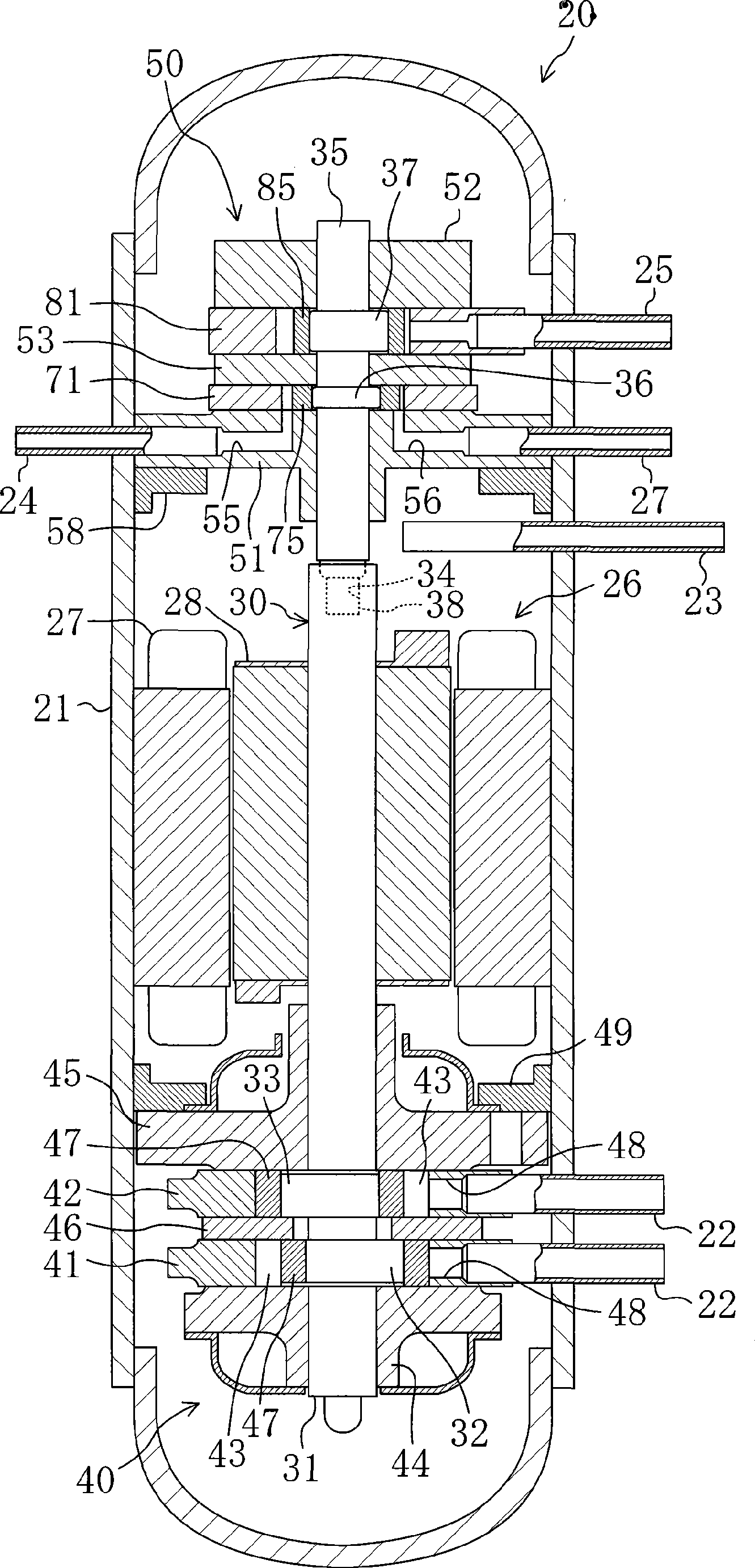

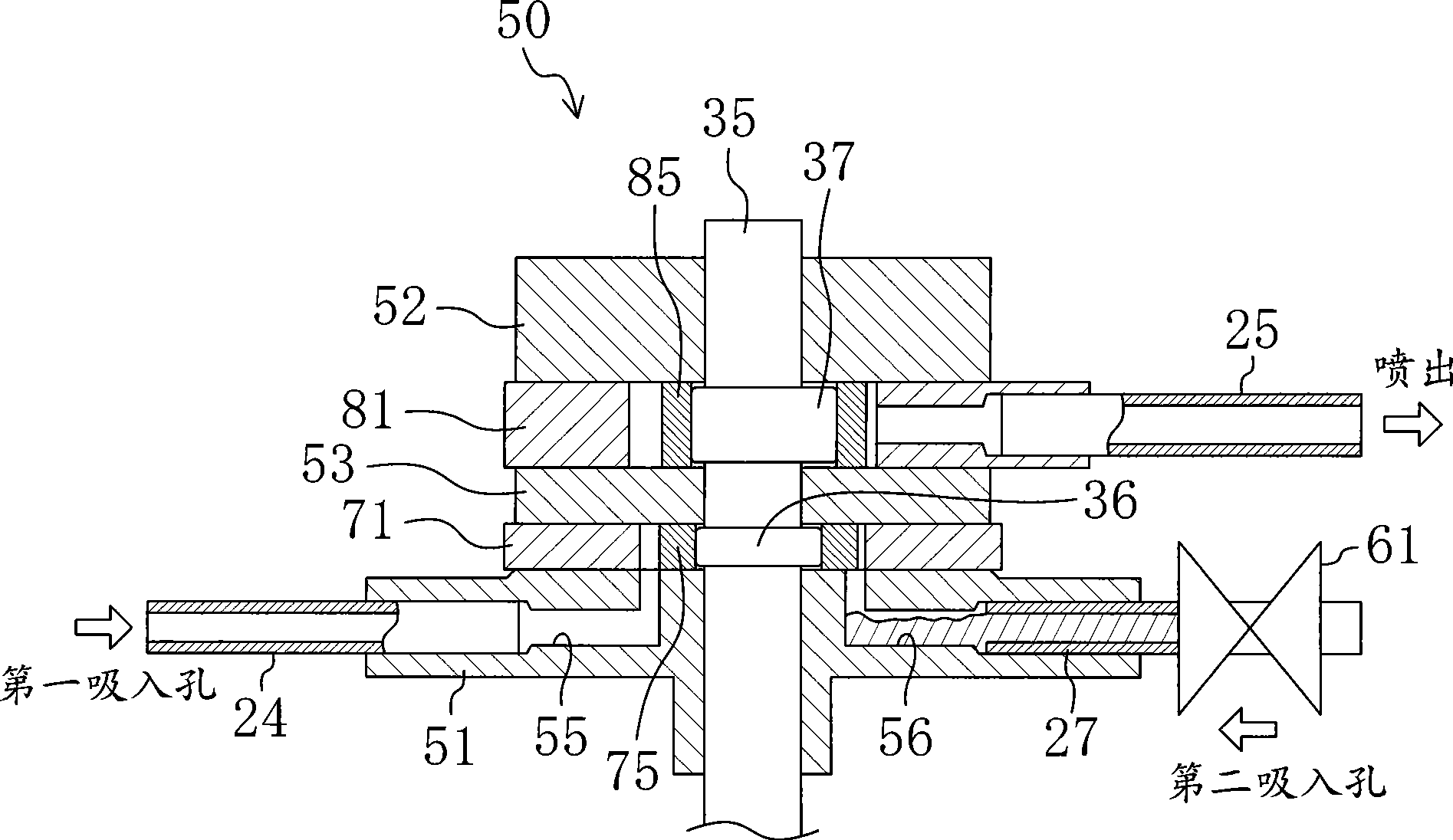

Freezing apparatus, and expander

ActiveCN101548066AAvoid blind spotsEffective expansionRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeHigh pressureRefrigerant

Provided is a freezing apparatus, which is constituted to make the inlet quantity of a coolant of an expansion mechanism variable while recovering the energy of a high-pressure coolant as a power to the maximum by the expansion mechanism. The expansion mechanism (50) is equipped with two rotary mechanism units (70 and 80) having displacements made different from each other. These rotary mechanism units are connected in series, and the rotary mechanism unit of the smaller displacement has two inlet ports (55 and 56) formed in its cylinder (71). Inlet pipes (24 and 27), as connected to the inlet ports (55 and 56), are equipped with a front throttle valve (60) and a switch valve (61). A bypass pipe (65) for bypassing the expansion mechanism (50) is equipped with a bypass valve (66). These valves (60, 61 and 66) are controlled to attain a balance between the coolant circulation rate of the expansion mechanism (50) and the coolant circulation rate of a compression mechanism (40).

Owner:DAIKIN IND LTD

Container Comprising a Collapsible Sidewall

ActiveUS20120181271A1Improve stabilityAvoid overexpansionRigid containersInjection molding processMechanical engineering

Owner:IFCO SYST GMBH

Method for manufacturing bone tissue slice by decalcification method

InactiveCN109115544AImprove transparencyReduce transparent timeWithdrawing sample devicesPreparing sample for investigationIonWax

The invention provides a method for manufacturing a bone tissue slice by a decalcification method. The method comprises the following steps that S1, bone tissues are taken and put into paraformaldehyde prepared from PBS to be fixed; S2, the bone tissues are taken out; after being flushed, the bone tissues are put into PBS-EDTA decalcification liquid until the bone tissues are primarily softened; S3, the bone tissues are cut into tissue blocks; the tissue blocks are put into a container containing inorganic acid decalcification liquid; then, the container is put into a water bath pot for decalcification; S4, the decalcified tissue blocks are flushed for removing acid; then, gradient dehydration is performed; the tissue blocks are transferred into a container containing chloroform-absolute ethyl alcohol mixed liquid, and are then transferred into a container containing chloroform solution; S5, the taken tissue blocks are subjected to wax soaking treatment and embedding; after the tissueblocks are cut into wax flakes, the wax flakes are put into distilled water; drying is performed; flake sealing is performed after the dyeing. Two-step method decalcification is provided; the PBS-EDTAdecalcification liquid has high calcium ion bonding capability; decalcification is performed under the temperature condition of 34 to 38 DEG C; the pre-decalcification time is effectively shortened;two kinds of acid are mixed for decalcification; the complete decalcification can be promoted; the decalcification speed can be also accelerated.

Owner:ANHUI SCI & TECH UNIV +1

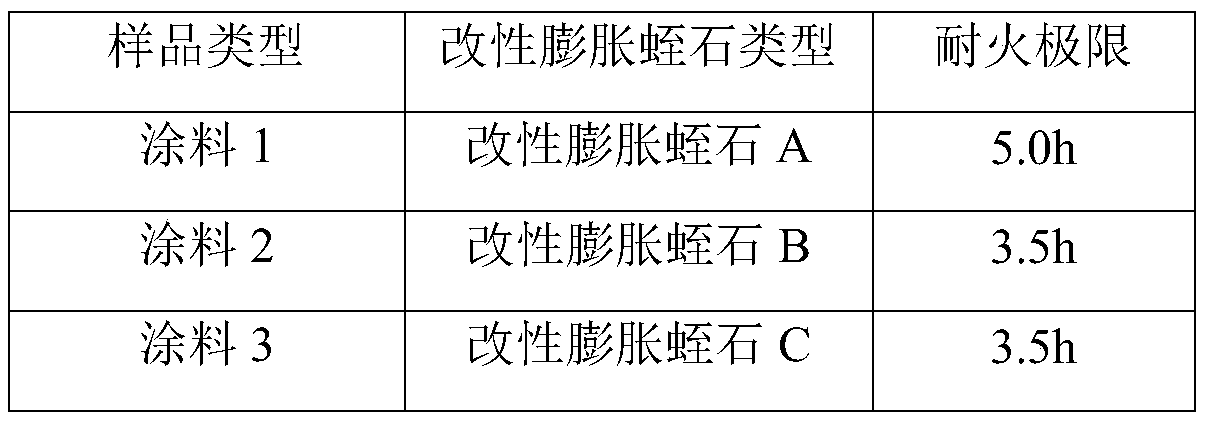

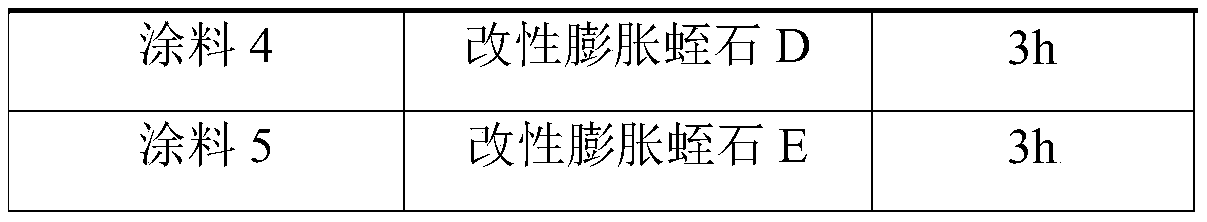

Fireproof magnesium oxide board

A fireproof magnesium oxide board is made from, by weight, 80-100 parts of magnesium oxide, 20-30 parts of anhydrous magnesium chloride,10-20 parts of a modified expanded vermiculite foaming agent, 20-30 parts of aluminum silicate fiber, 5-10 parts of sawdust, 10-15 parts of fly ash, 8-12 parts of glass magnesium board crushing powder, 1.5-5 parts of a non-woven fabric and 6-8 parts of water. Themodified expanded vermiculite is prepared in the following steps that (1) vermiculite is expanded incompletely and calcinated; (2) incompletely expanded vermiculite is added into a solvent to obtain vermiculite suspension liquid, and the suspension liquid and a carbonization catalyst are added into a closed reactor, the temperature rises, and high-speed stirring and heat preservation are conducted; (3) a low-molecular-weight carbon source and a foaming agent are added into the vermiculite suspension liquid for ultrasonic dispersion; (4) the solution is subjected to centrifugal separation, anda precipitate is dried primarily to obtain the fireproof expanded vermiculite. The fireproof magnesium oxide board has good fireproof performance and smoke suppression performance.

Owner:石家庄易辰防火保温材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com