Preparation method of gas-phase crosslinking modified polyetherimide nanofiltration membrane

A polyetherimide nano and polyetherimide technology, which is applied in the field of nanofiltration membrane preparation, can solve the problems of environmental pollution membrane solvent resistance, inability to be widely used, and high membrane production cost, and achieve low cost and stability. The effect of enhancing sexuality and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

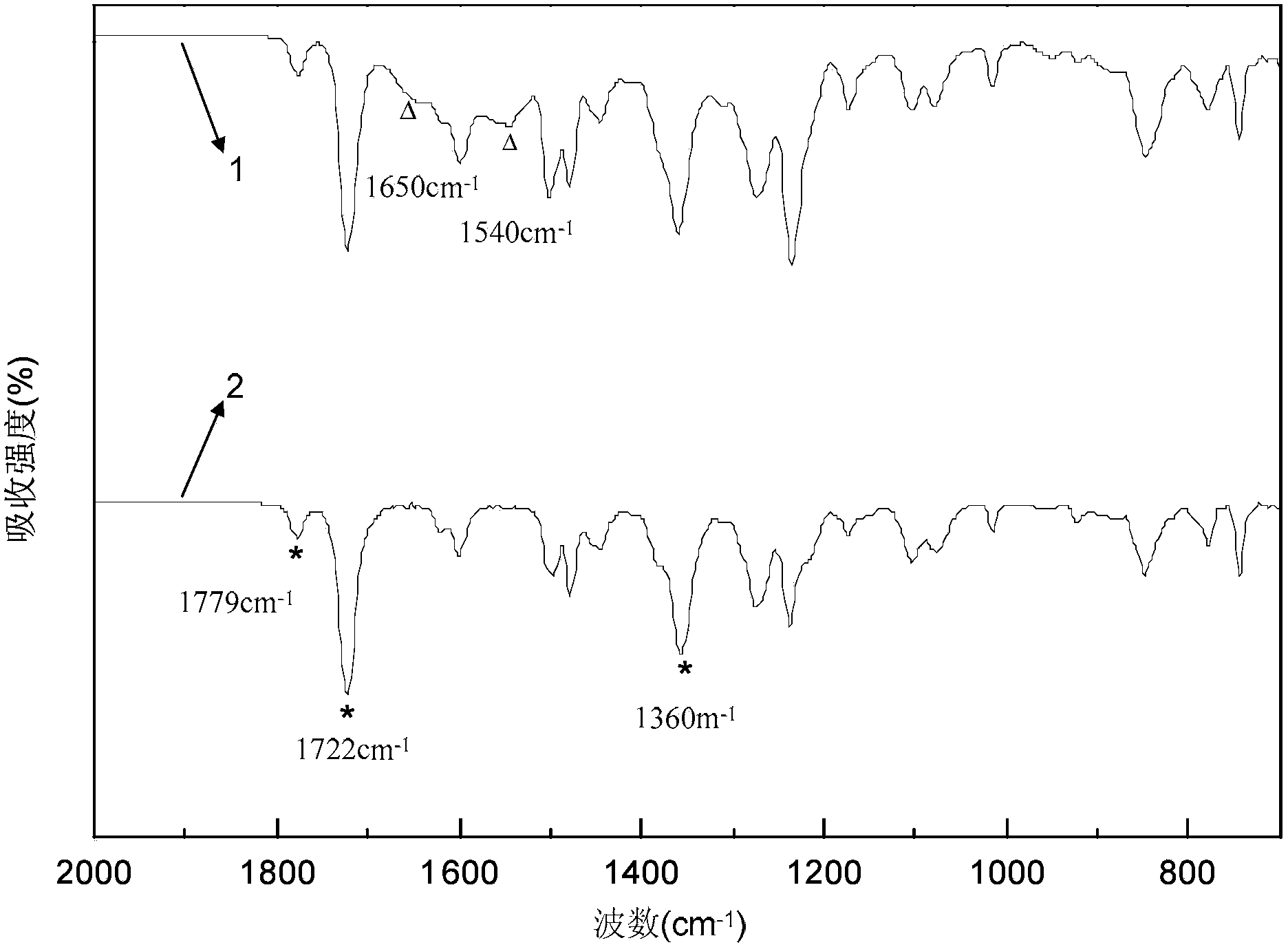

[0015] Specific embodiment one: the preparation method of a kind of gas phase cross-linking modified polyetherimide nanofiltration membrane of the present embodiment, carry out according to the following steps:

[0016] Step 1, preparing the casting solution, standing the prepared casting solution at room temperature for 24-36h; wherein, the casting solution is composed of polyetherimide and solvent, and the mass percentage of polyetherimide in the casting solution is The content is 15%-28%, the mass percentage of the solvent is 85%-72%, and the solvent is NMP, DMF or THF.

[0017] Step 2. Preparation of polyetherimide nanofiltration membrane by immersion-precipitation method: pour the above-mentioned prepared casting solution on a glass plate, scrape and coat the casting solution on the glass plate with a film scraper, and then place the film at room temperature Immerse the glass plate in deionized water. After the casting solution is solidified, a layer of film is obtained o...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that: the standing time described in Step 1 is 24 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mass percentage of polyetherimide in the polyetherimide casting solution described in step one is 20%, 23% or 25%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com