Gas turbine

A gas turbine and turbine shaft technology, applied to gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of waste of propulsion energy, inability to generate rotational force, etc., and achieve the effect of improving eccentric rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the gas turbine of the present invention will be explained more fully based on embodiments.

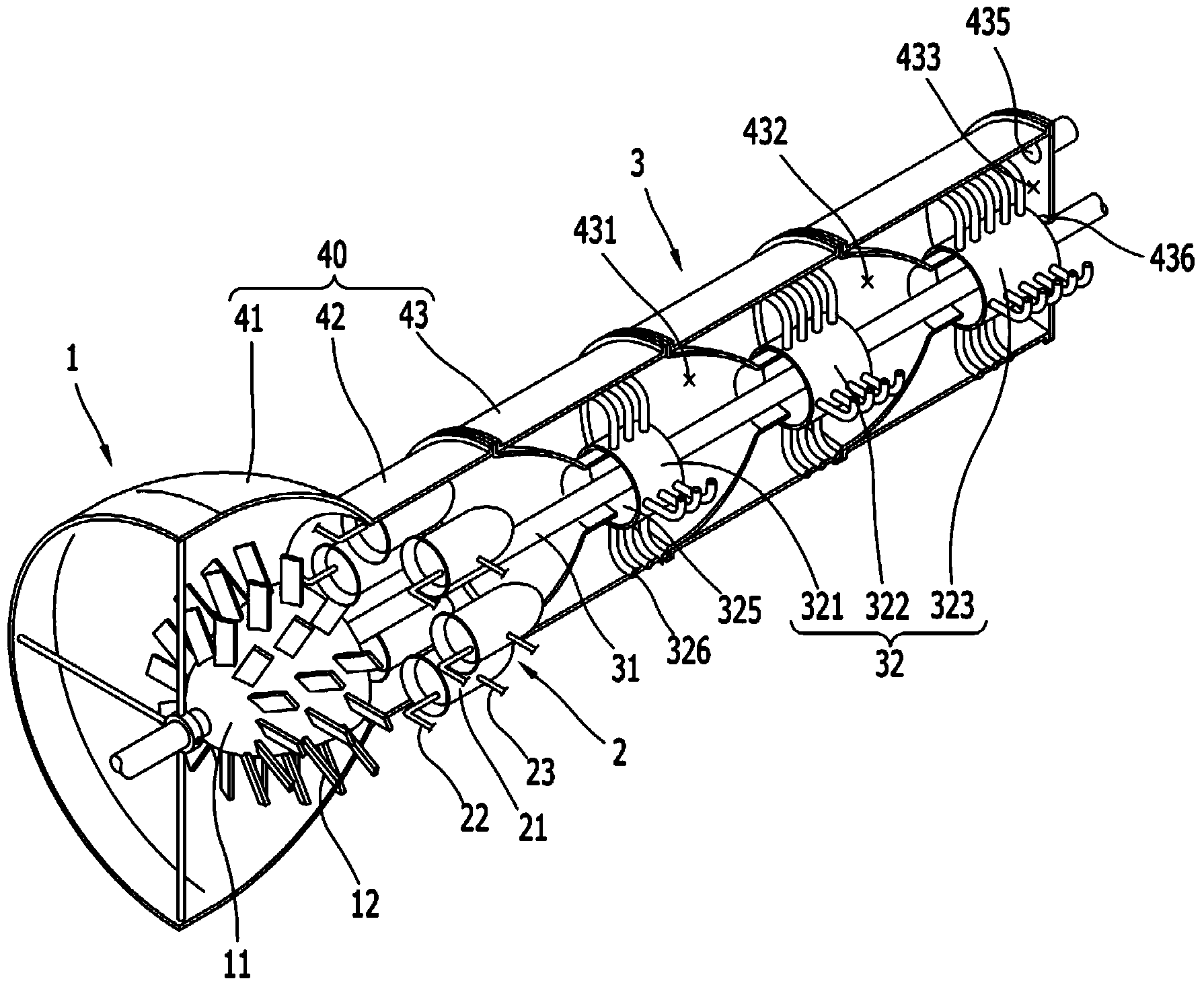

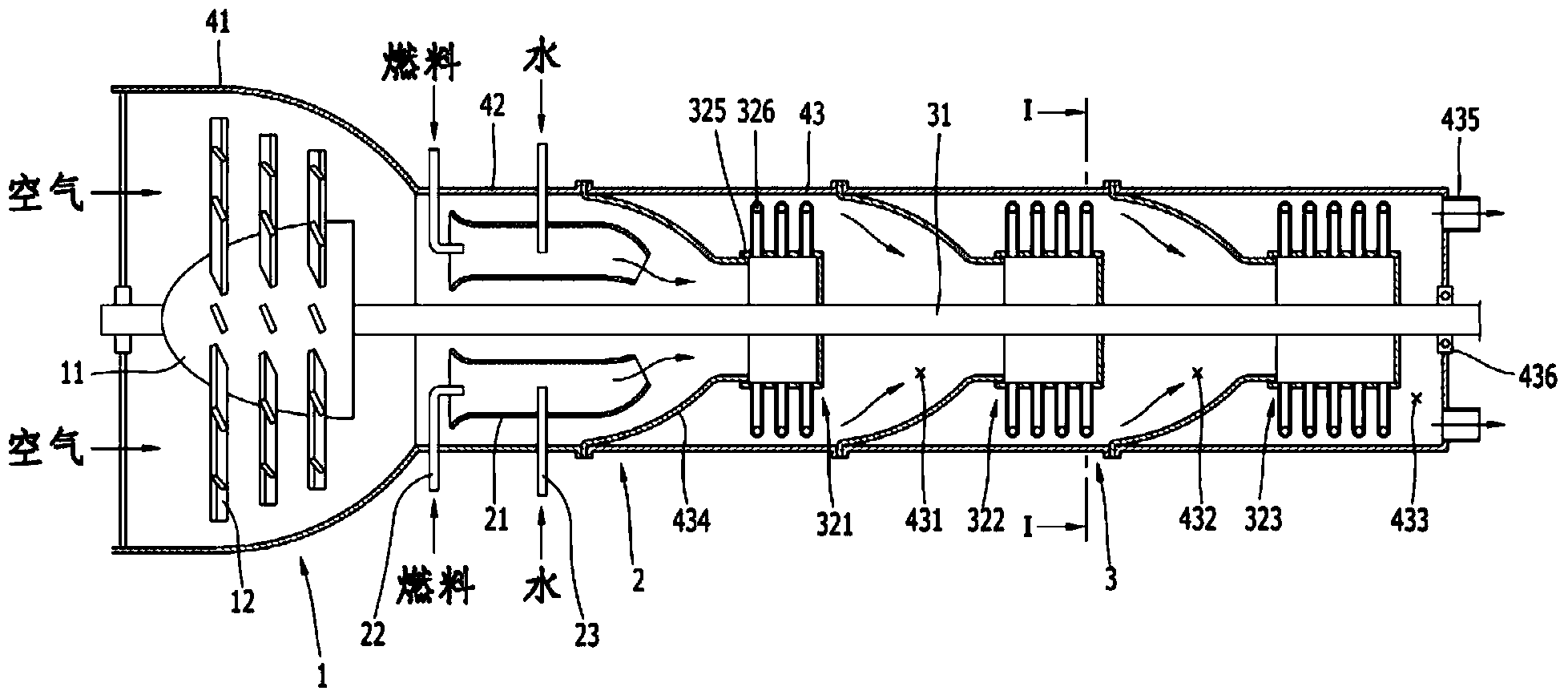

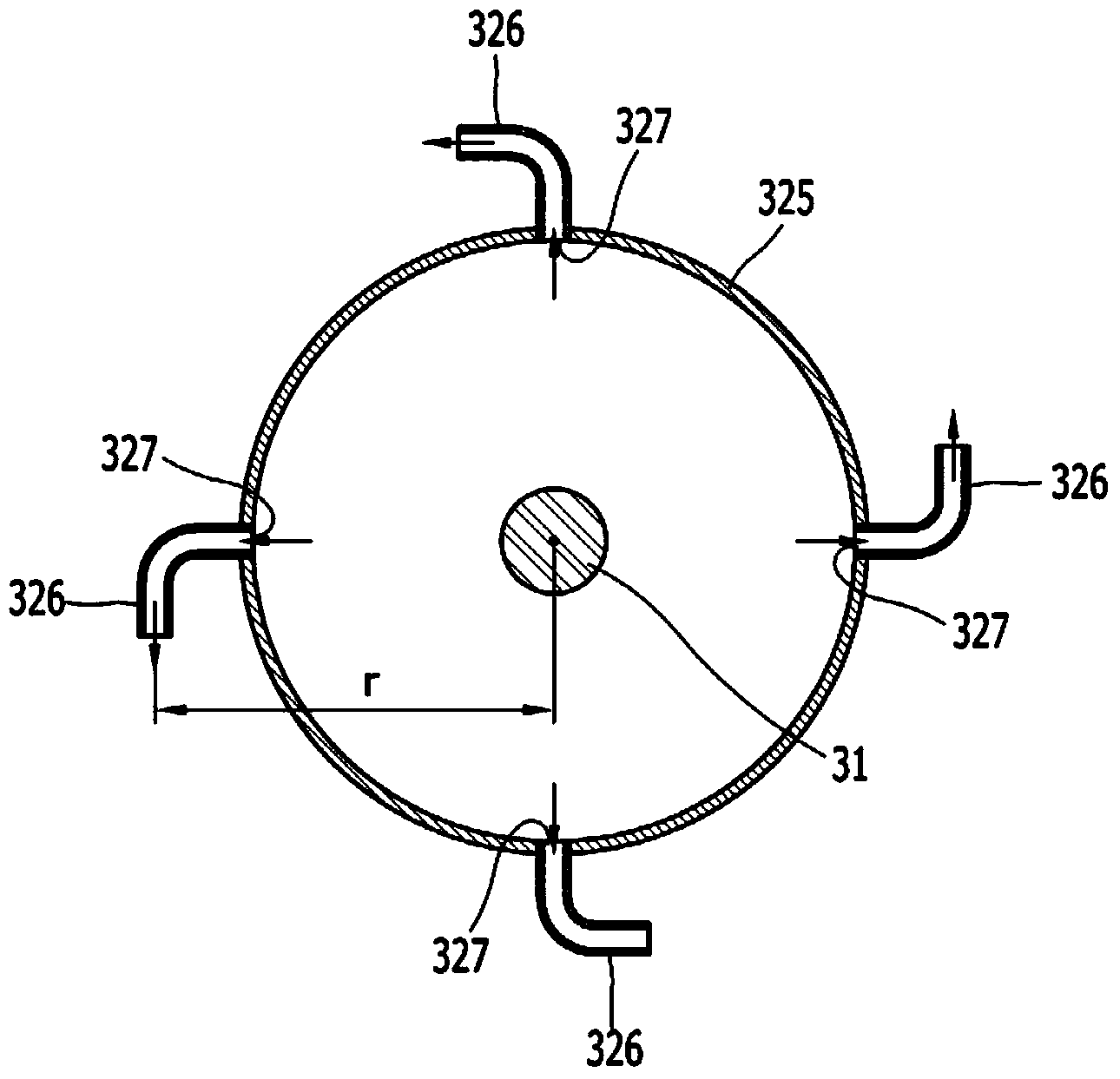

[0031] figure 1 Is a perspective view illustrating the inside of a gas turbine according to an embodiment of the present invention, figure 2 Is illustrated figure 1 A cross-sectional view of the interior of the gas turbine shown in.

[0032] Reference figure 1 with figure 2 , The gas turbine includes: an air compression part 1 for compressing air; a gas expansion part 2 which expands the air compressed by the air compression part 1 to increase the flow rate of the air; and a power generation part 3 when the gas expansion part 2 When the expanded high-temperature and high-pressure air is injected in the circumferential direction, the power generation unit 3 generates rotational force. The air compression part 1, the gas expansion part 2, and the power generation part 3 are sequentially installed inside the housing 40. The air compression part 1 is configured to be comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com