Patents

Literature

3724 results about "Air compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

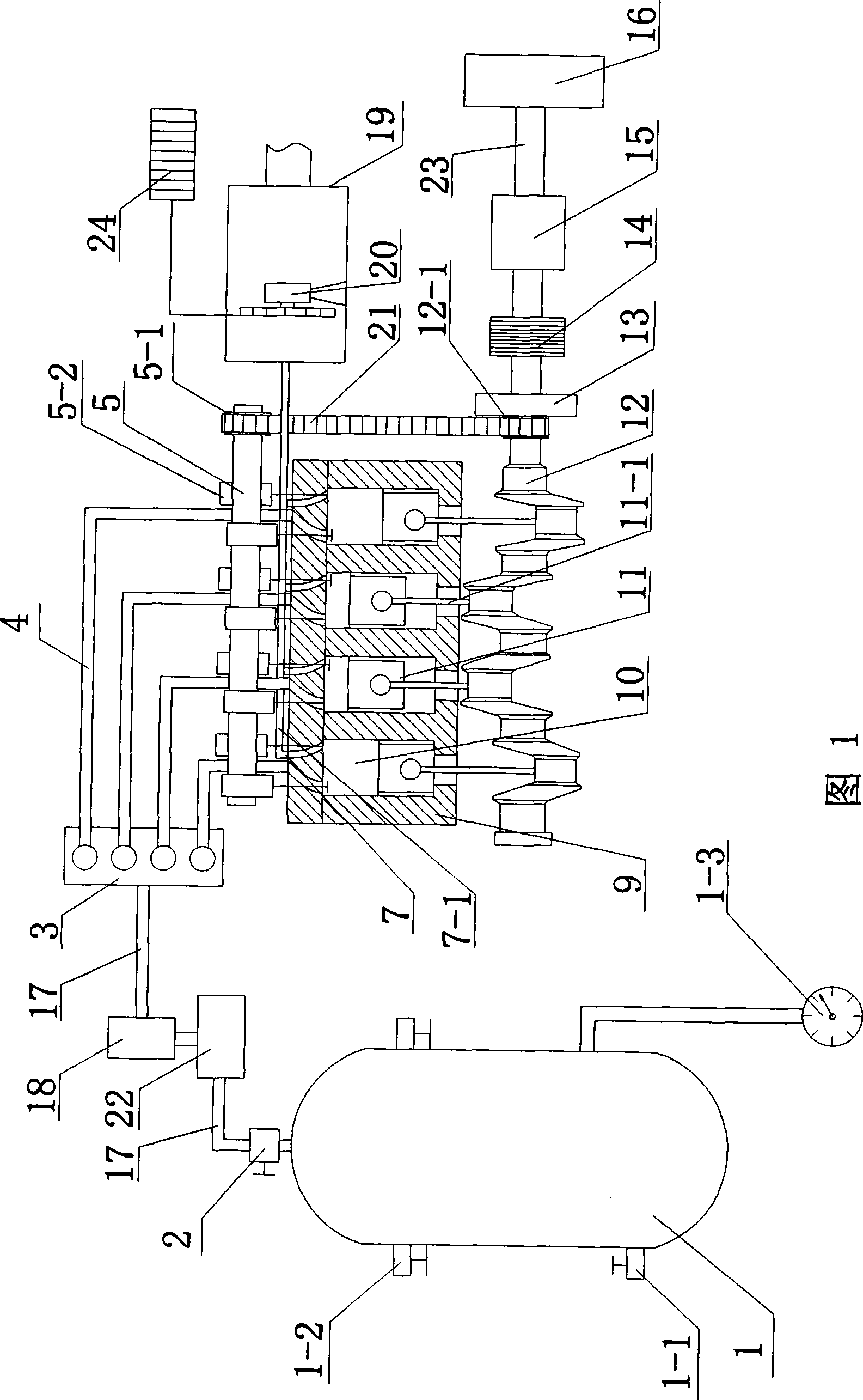

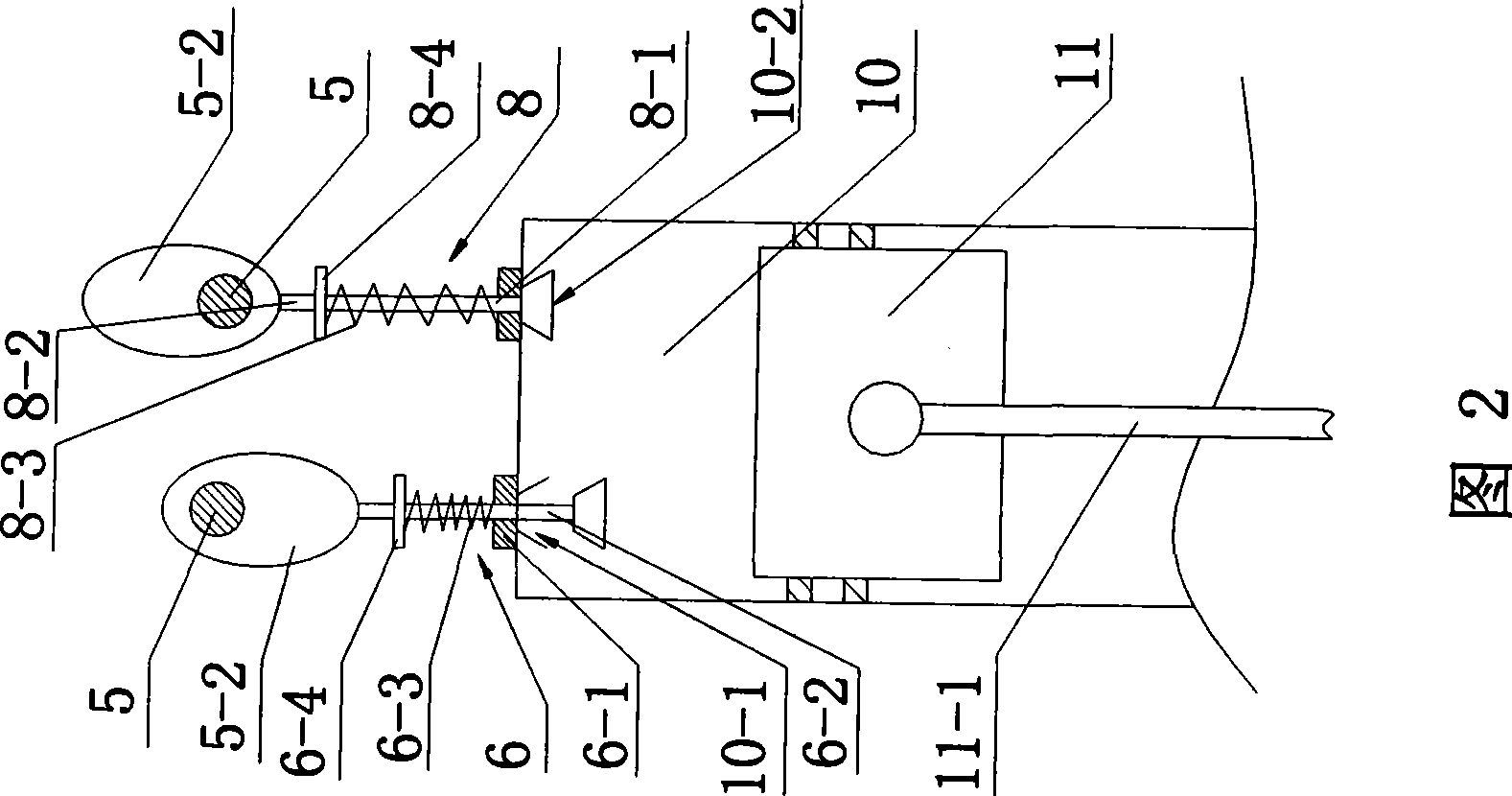

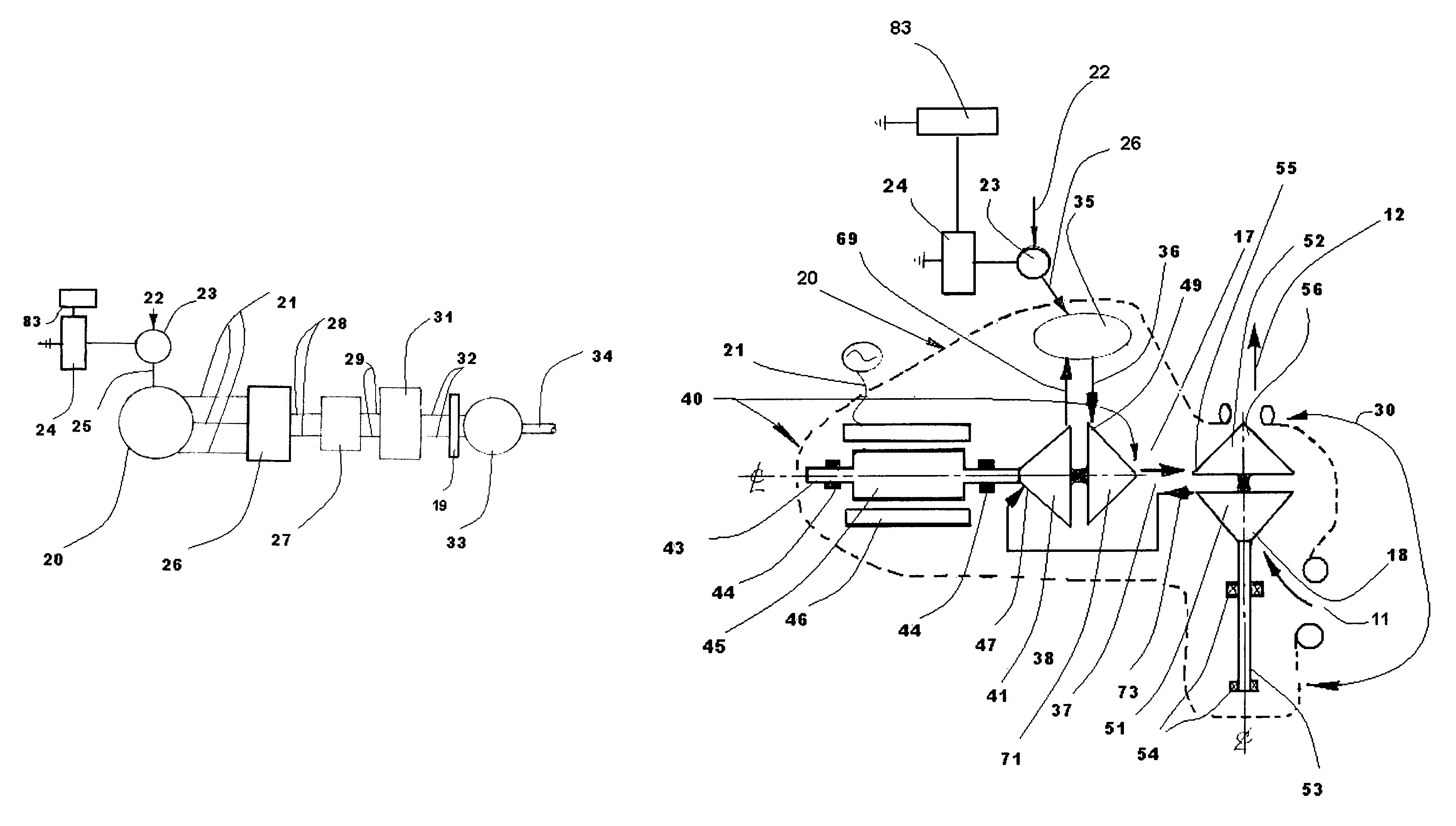

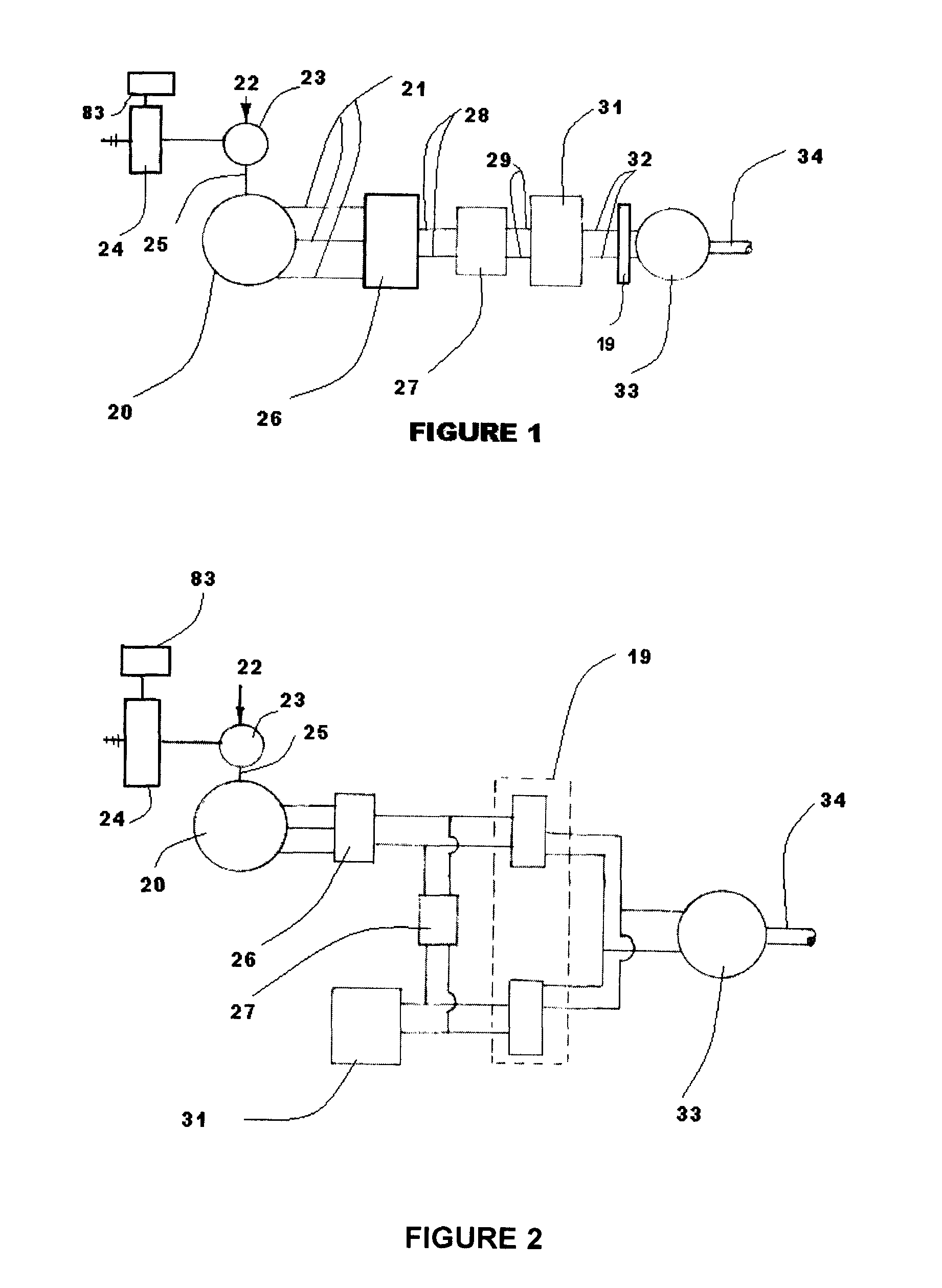

Air power engine assembly

InactiveCN101413403ALow costNo pollutionMechanical power devicesEngines characterised by uniflow principleDistributorPiston

The invention relates to an air-powered engine assembly, which comprises an air tank, an air valve, an air distributor, an intake pipe, camshafts, an intake duct, an exhaust control device, air cylinders, pistons, crankshafts, couplers, clutches, automatic gearboxes and differentials connected with the outside. The assembly is characterized in that the air valve, a constant pressure chamber and a pressure controller are arranged between the air tank and the air distributor; the air distributor is connected with a plurality of air cylinders on an air cylinder gasket; each air cylinder is connected with an exhaust chamber through an exhaust manifold; the exhaust chamber is provided with a turbine generator which is connected with a storage batter; the air cylinders are provided with the camshafts for controlling the air intake and exhaust of the air cylinders; the air cylinders are provided inside with the pistons for driving the crankshafts to rotate; the camshafts and the crankshafts are connected by chains; and the crankshafts are connected with the differentials through the couplers, the clutches and the gearboxes in turn. Therefore, doing work through air compression rather than fuel, the air-powered engine assembly has the advantages of avoiding waste gas discharge and air pollution, along with reliable operation, convenient operation, economical efficiency, practicality and so on. In addition, due to recycle of the waste gas for power generation, the air-powered engine assembly saves energy and reduces costs.

Owner:周登荣 +1

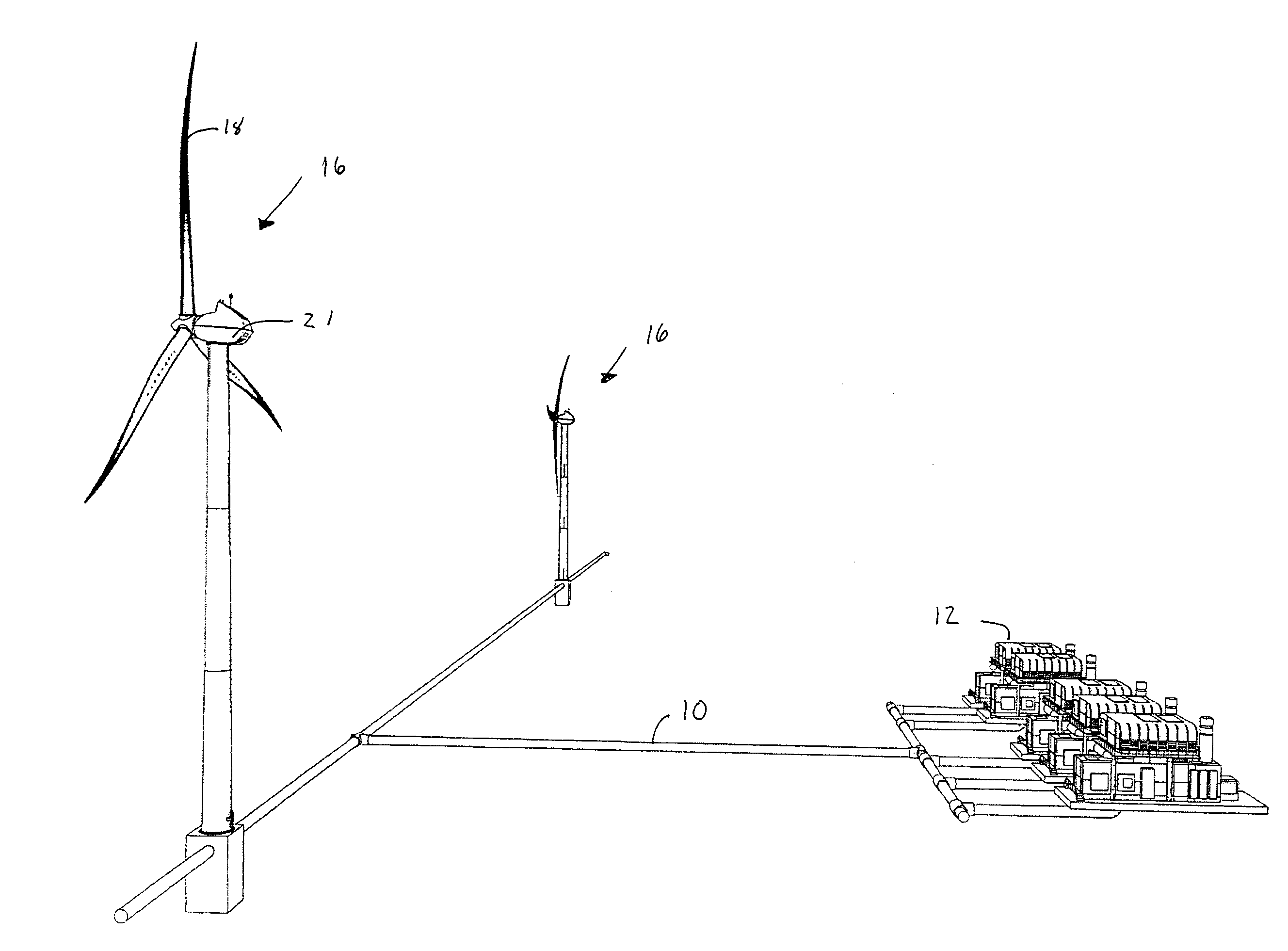

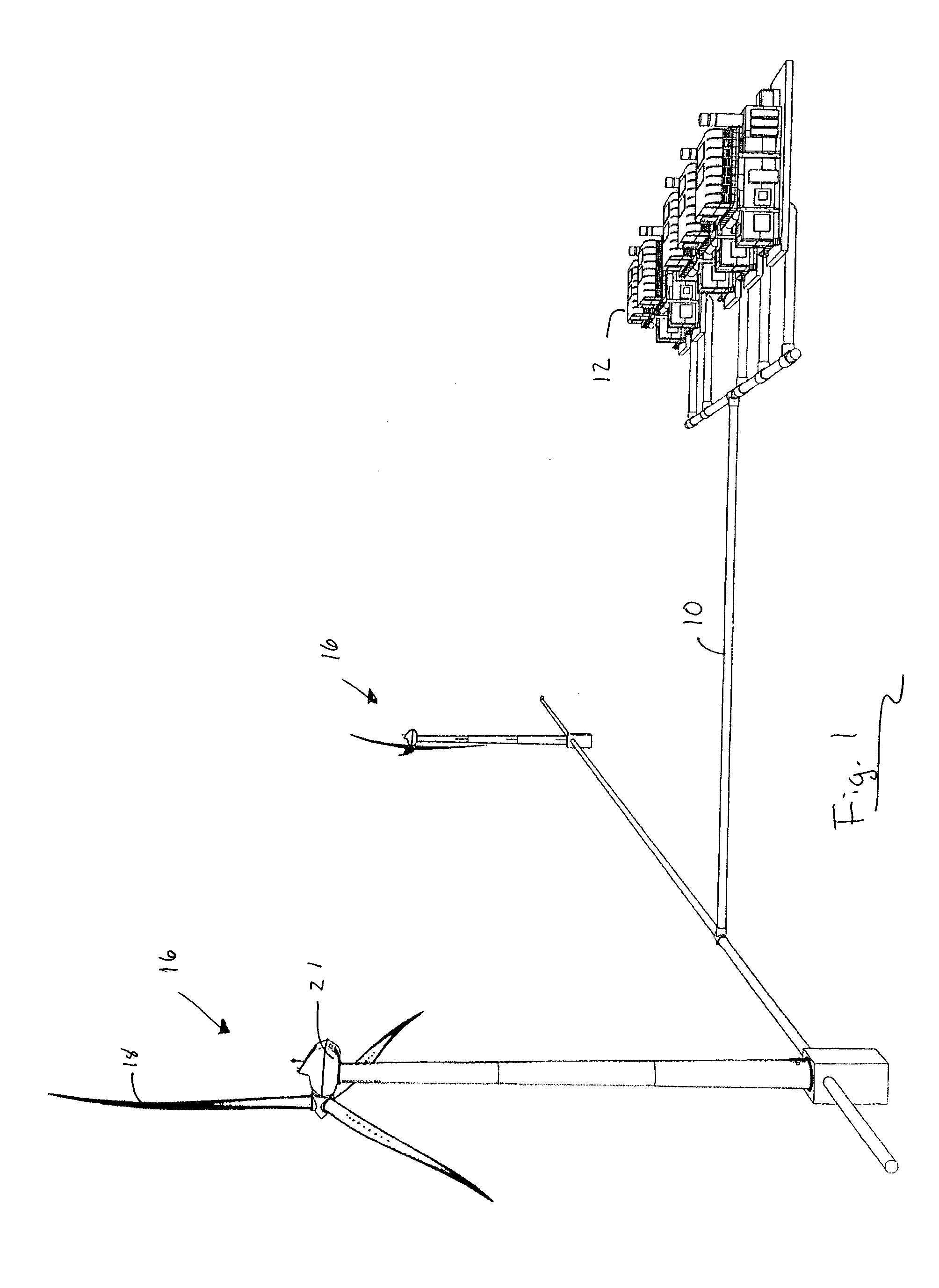

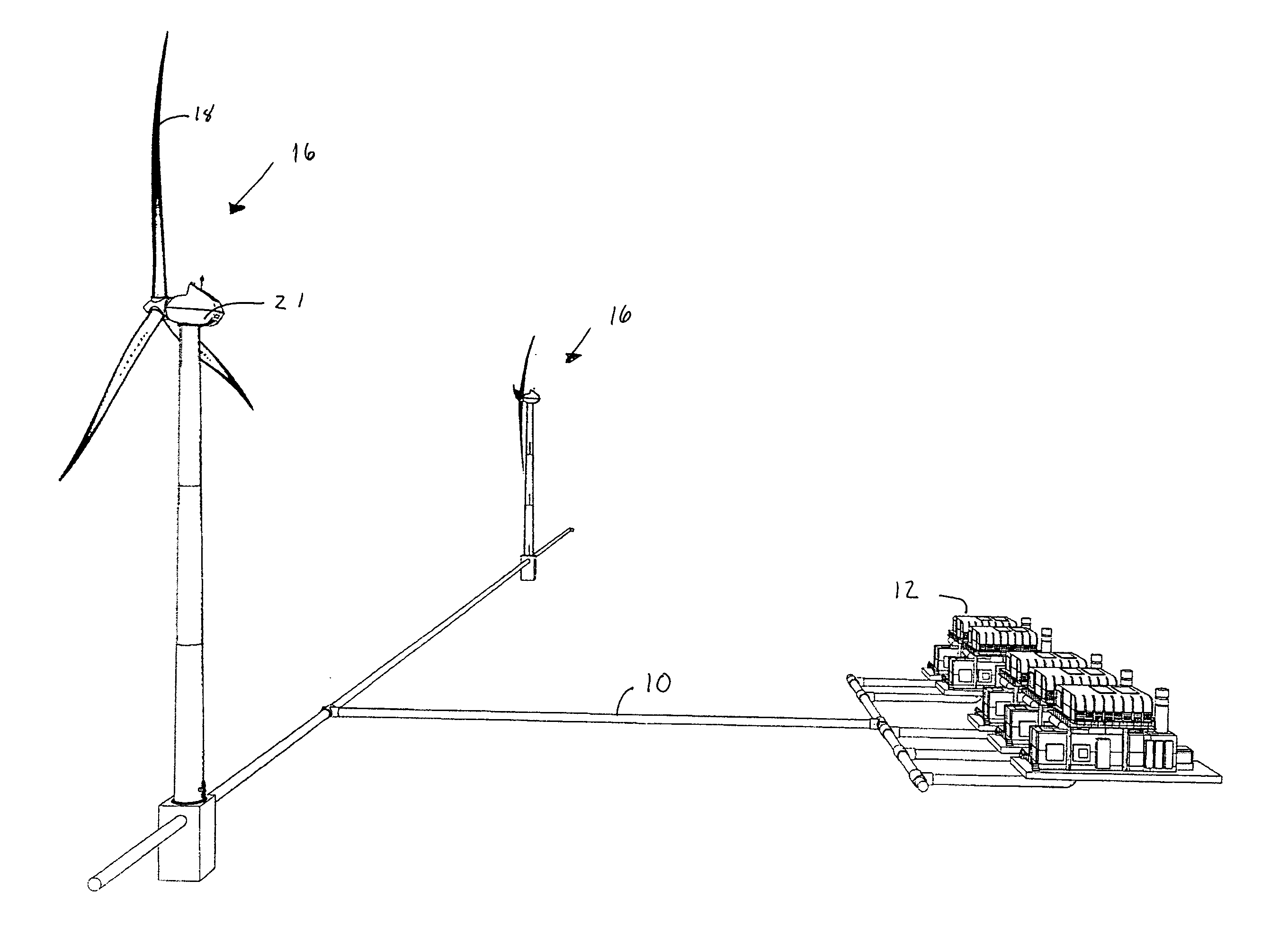

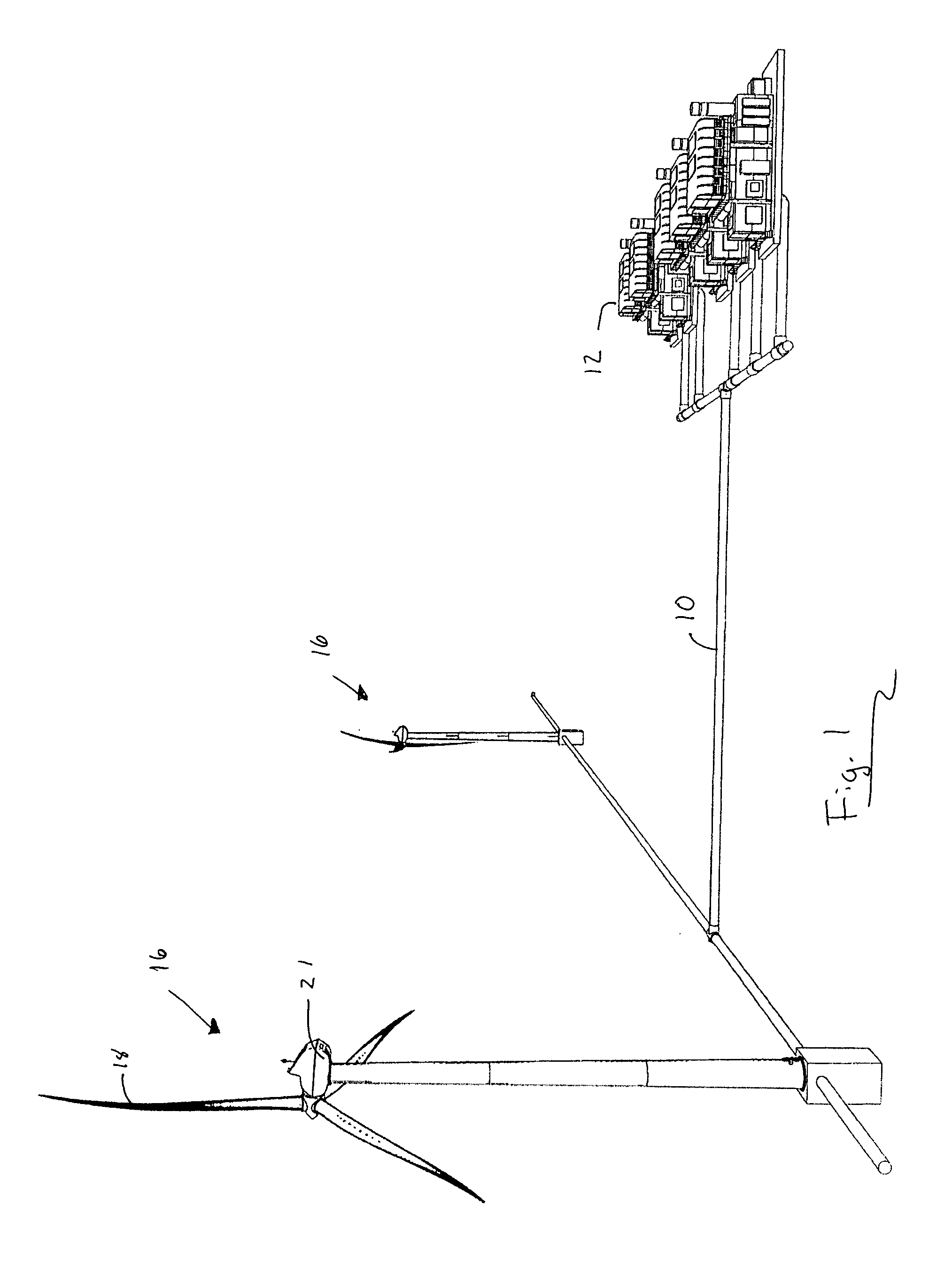

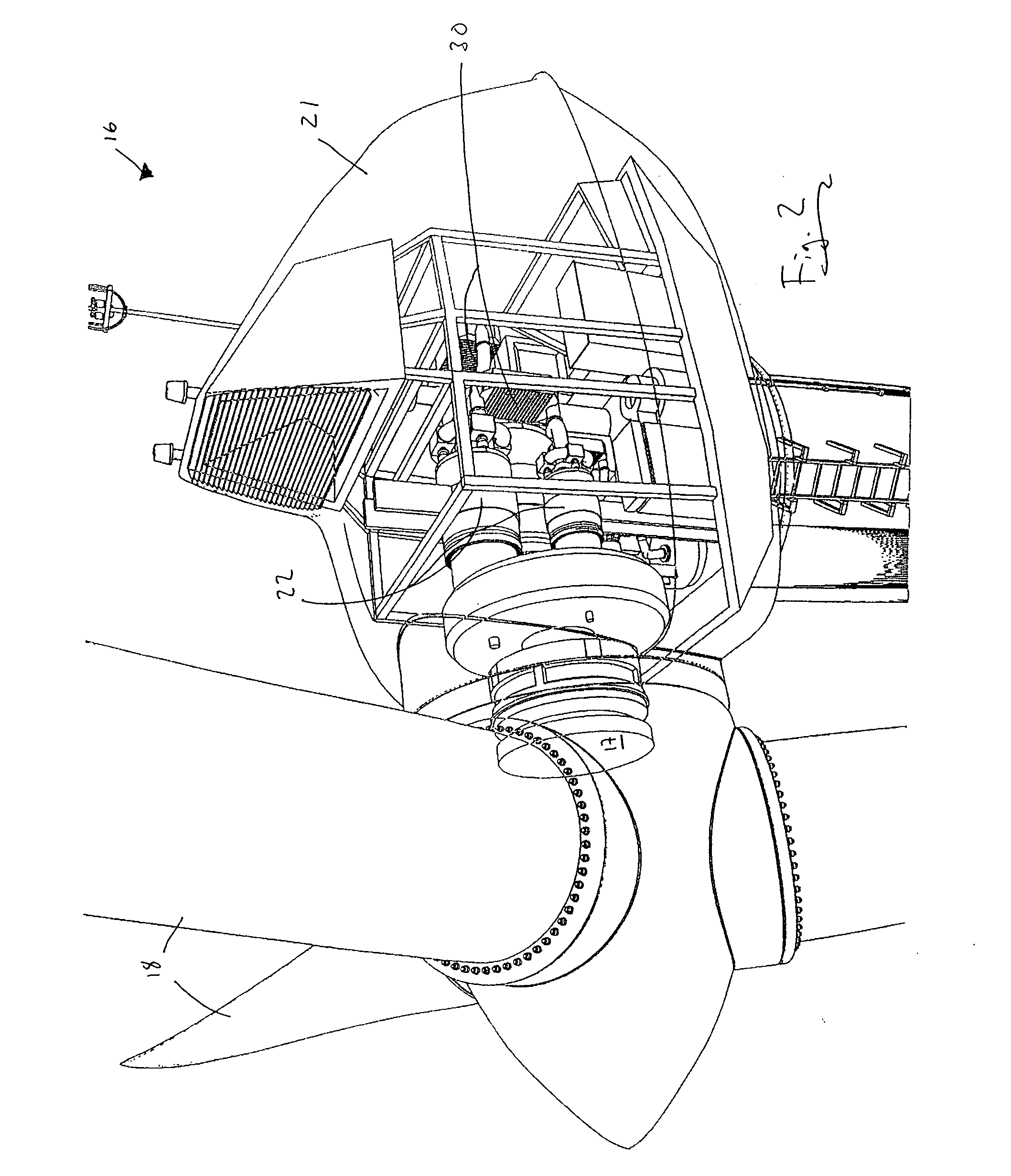

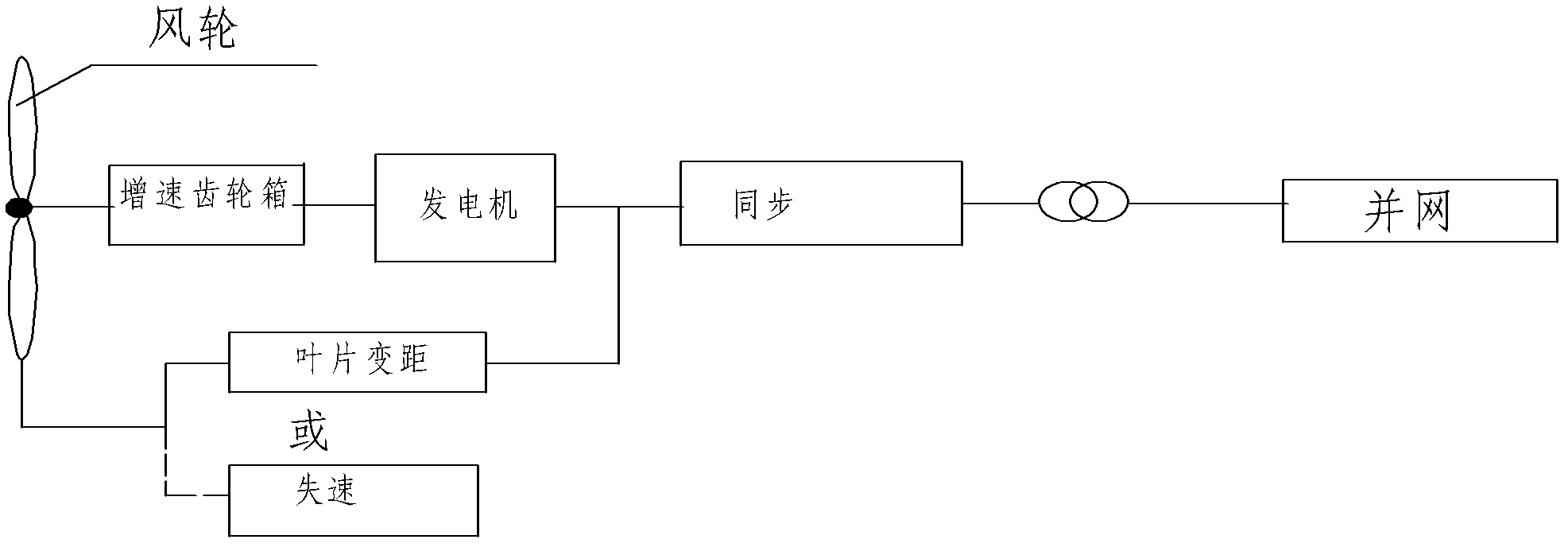

Wind turbine system

A wind turbine system for producing compressed air from wind energy. The wind turbine harvests energy from wind to produce mechanical energy. A compressor receives mechanical energy from the wind turbine to compress air to an elevated pressure. Thermal energy may be removed from the air, and the air is stored in a storage devices, such that the air may be released from the storage device on demand.

Owner:GENERAL COMPRESSION

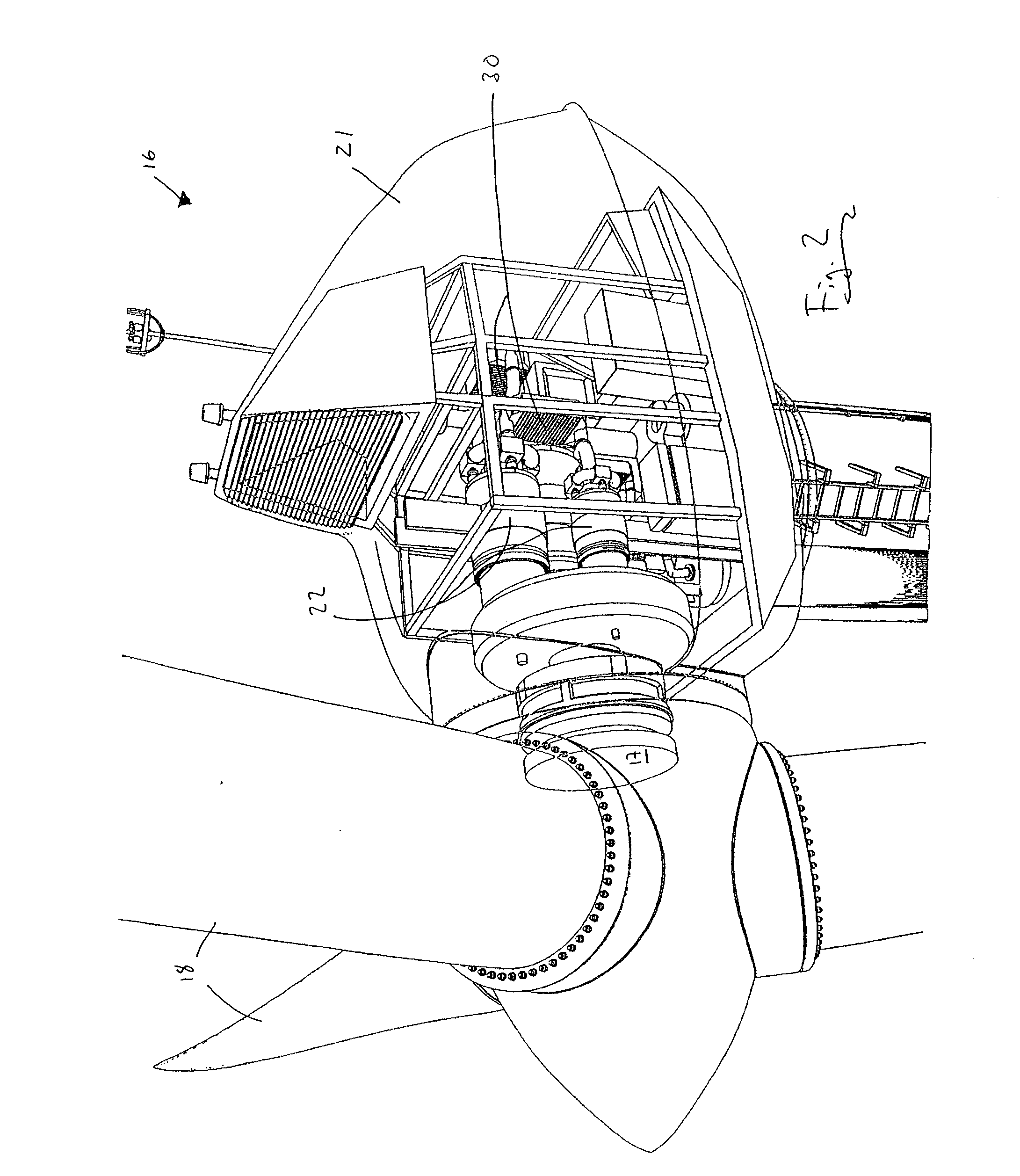

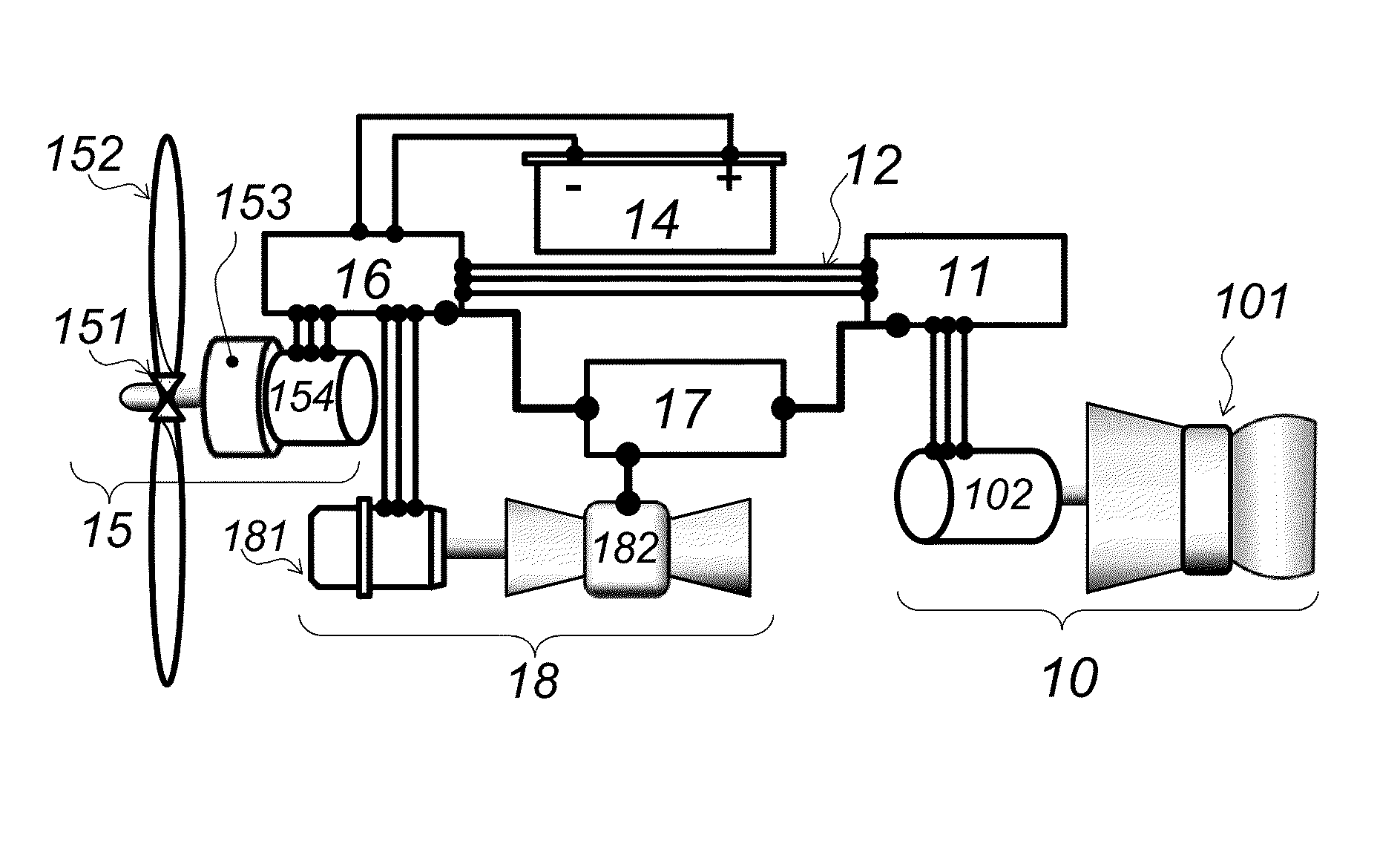

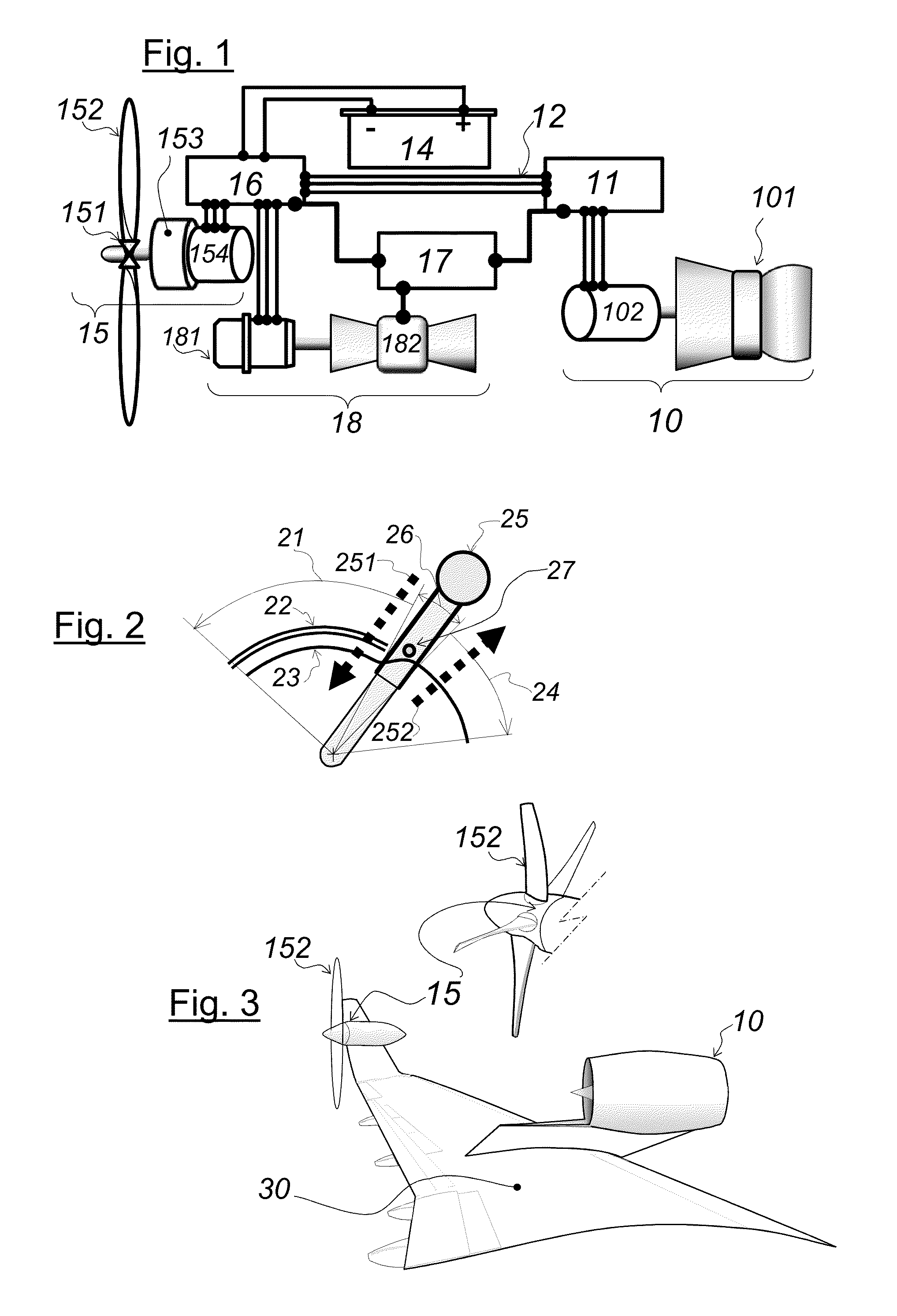

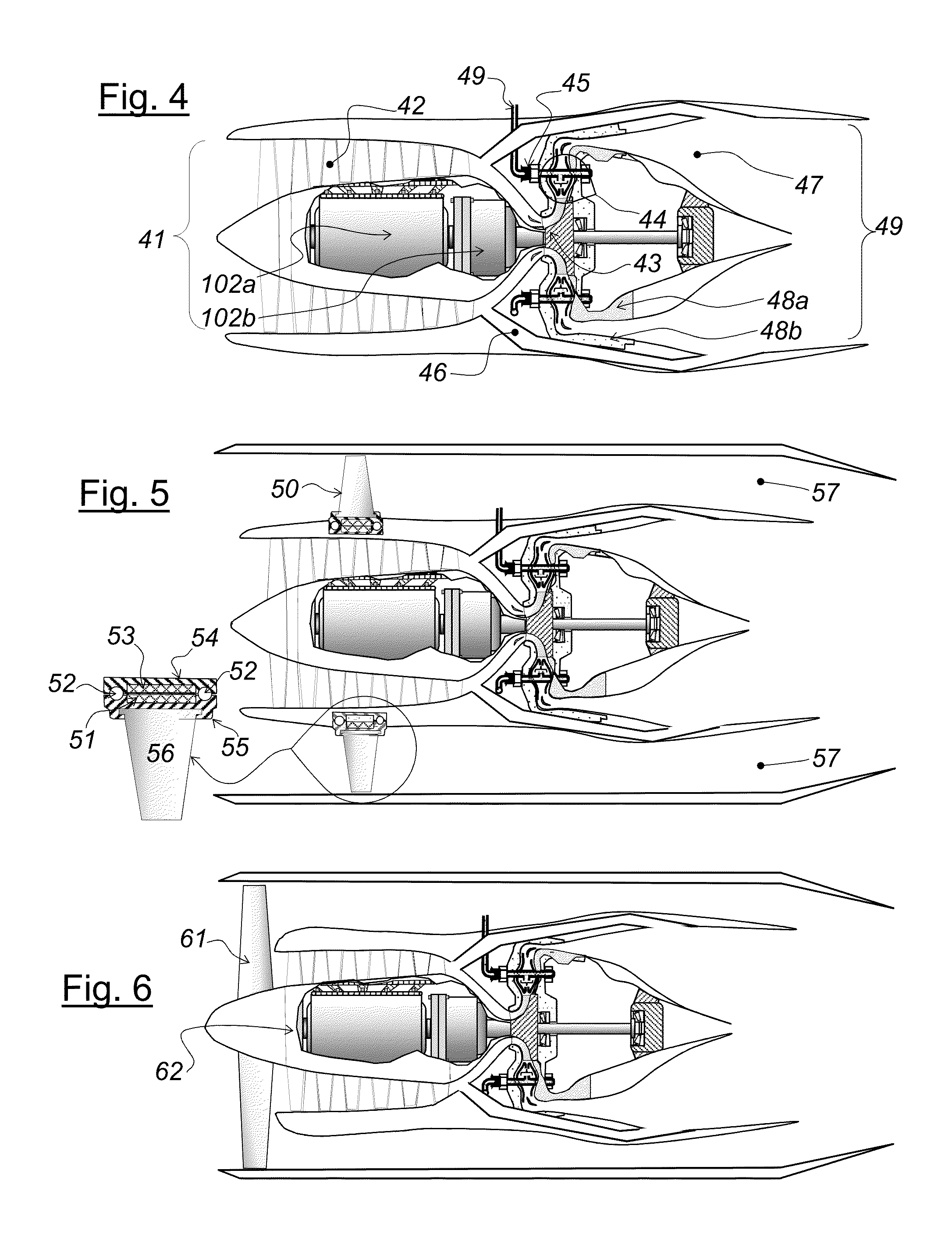

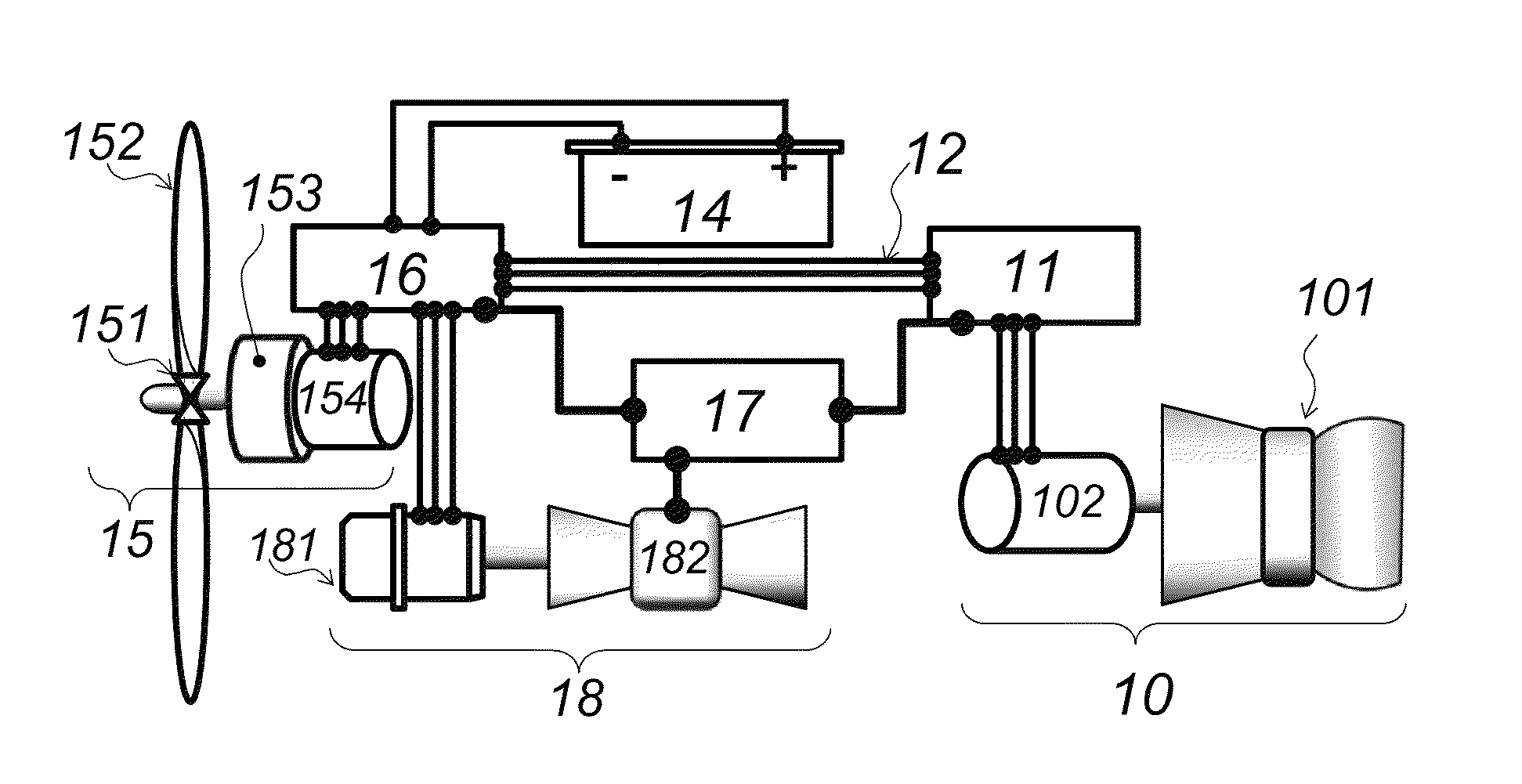

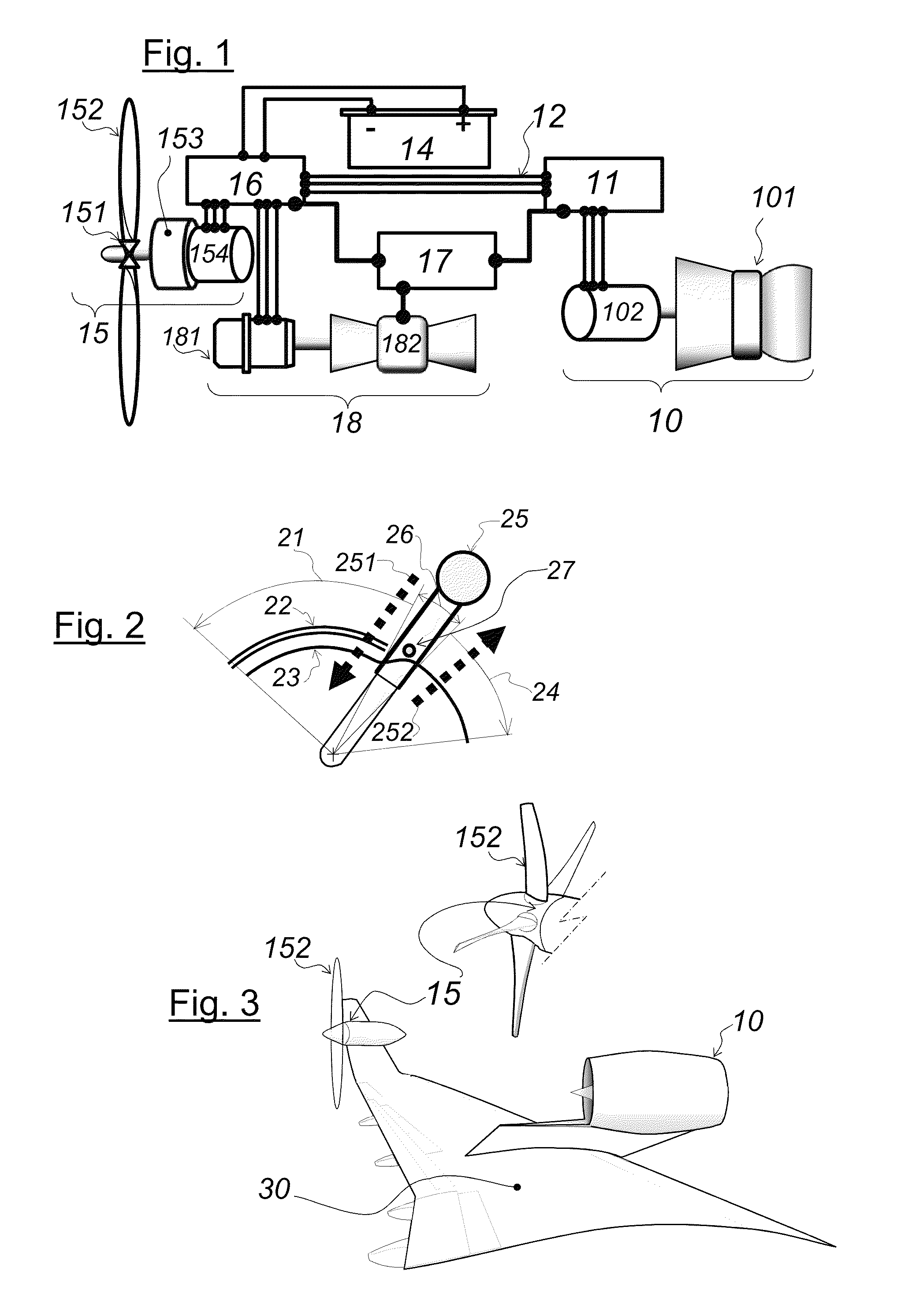

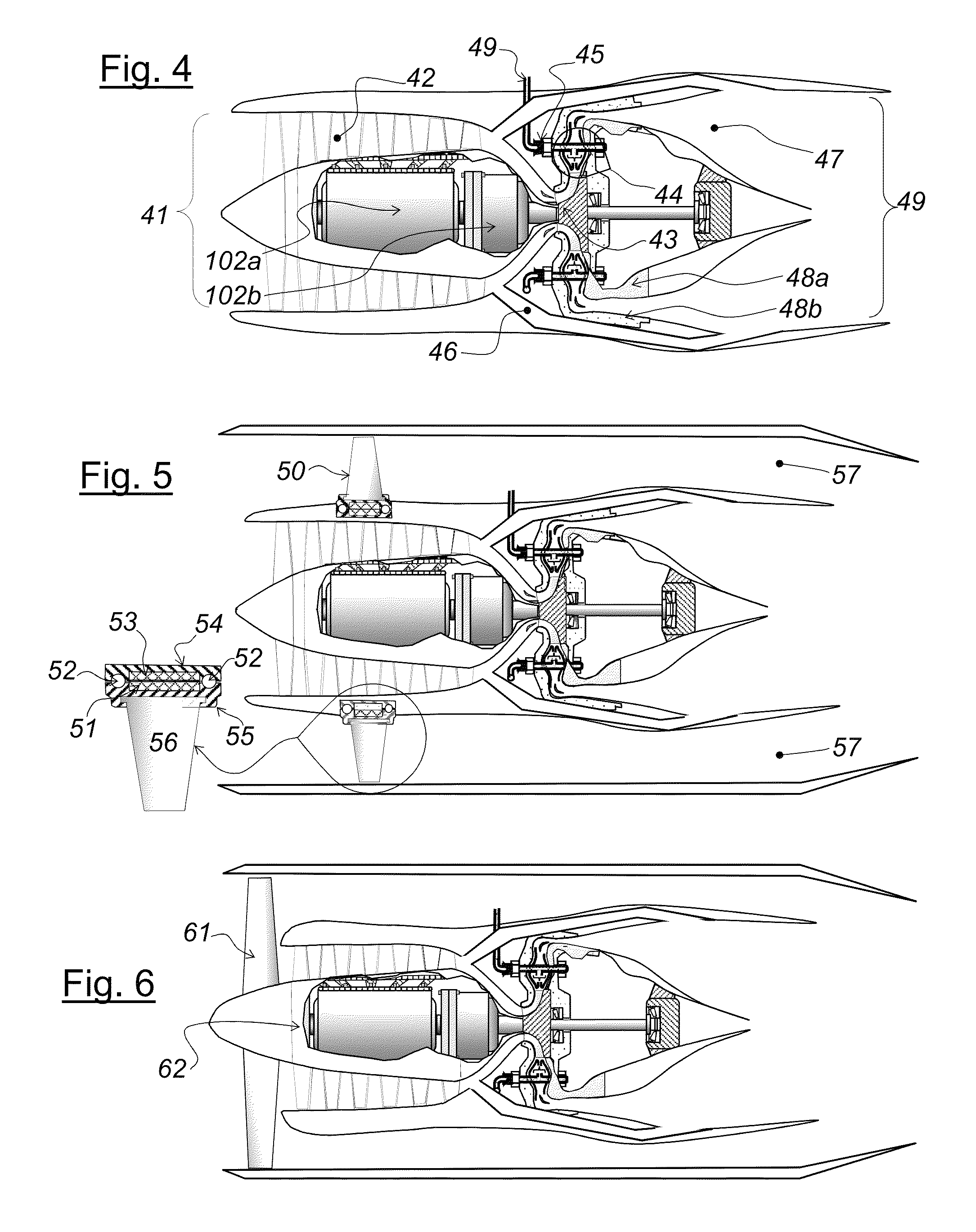

Hybrid Gas Turbine Propulsion System

ActiveUS20150013306A1Reduce fuel consumptionImprove responsivenessGas turbine type power plantsEfficient propulsion technologiesAir compressionDual-thrust

A hybrid aerodynamic thrust system as a prime mover for aircraft or other high-speed vehicles. An arrangement of dual thrust resources to alternately accommodate low and high airspeed regimes. Electromotive force is used in lieu of hot section power turbines to achieve engine air compression or alternately perform thrust work at low velocities.

Owner:SHELLEY RUDOLPH ALLEN

Wind turbine system

A wind turbine system for producing compressed air from wind energy. The wind turbine harvests energy from wind to produce mechanical energy. A compressor receives mechanical energy from the wind turbine to compress air to an elevated pressure. Thermal energy may be removed from the air, and the air is stored in a storage device, such that the air may be released from the storage device on demand.

Owner:GENERAL COMPRESSION

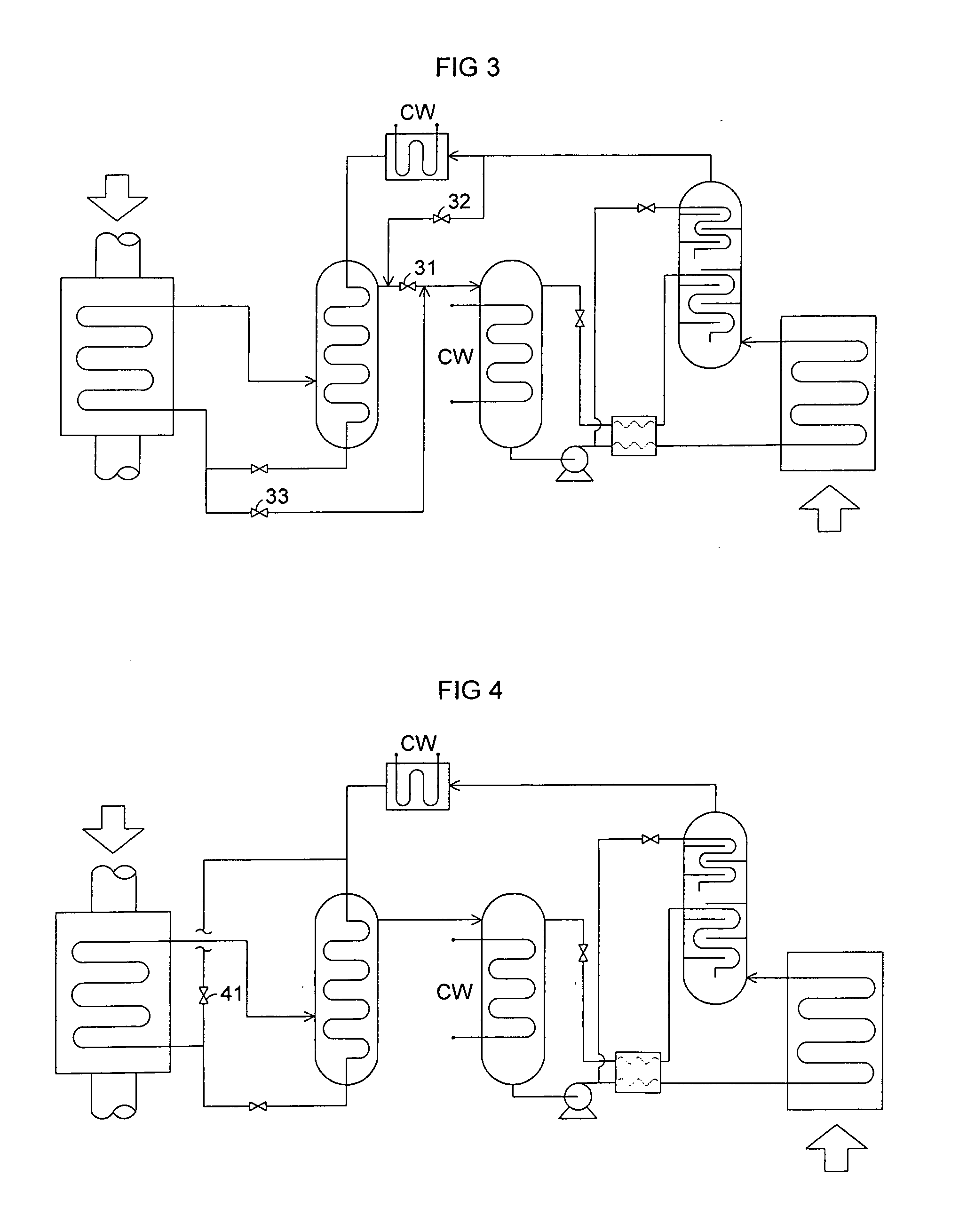

Cryogenic air separation method and system

ActiveUS20120237881A1Increase pressureEfficient productionSolidificationLiquefactionAir compressionWorking fluid

The present invention relates to a cryogenic air separation process that provides high pressure oxygen for an oxy-fired combustion of a fuel (e.g., a carbonaceous fuel). The air separation process can be directly integrated into a closed cycle power production process utilizing a working fluid, such as CO2. Beneficially, the air separation process can eliminate the need for inter-cooling between air compression stages and rather provide for recycling the adiabatic heat of compression into a process step in a further methods wherein an additional heat supply is beneficial.

Owner:8 RIVERS CAPTTAL LLC

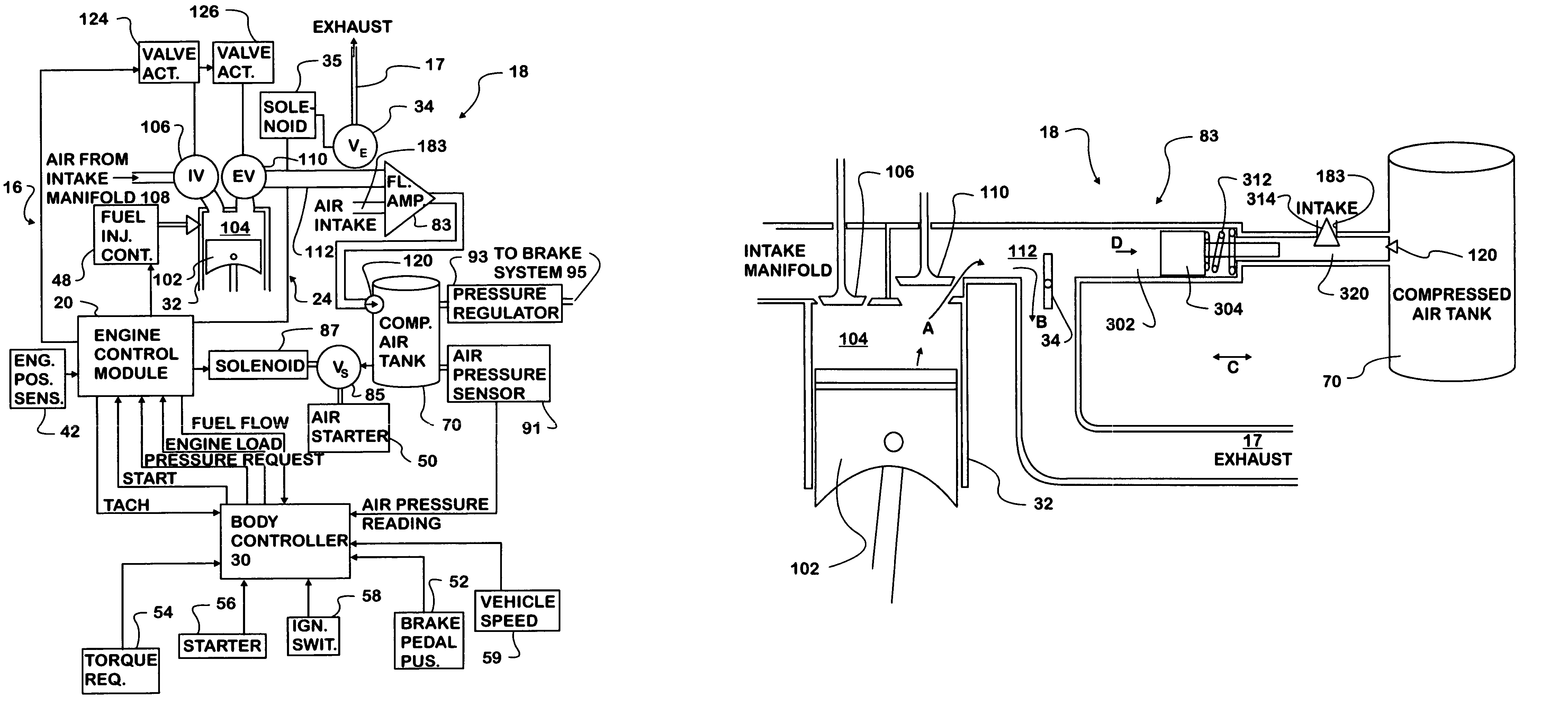

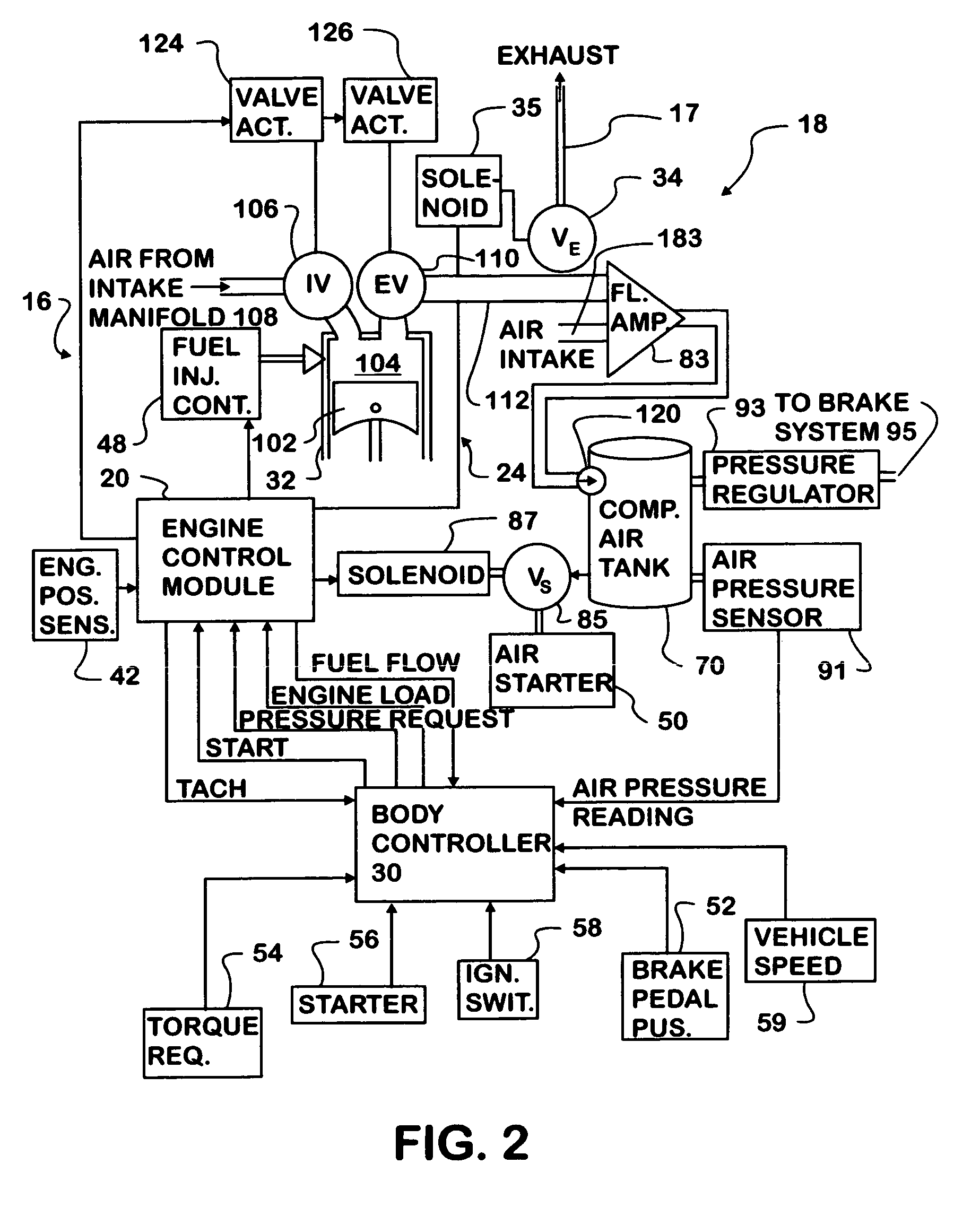

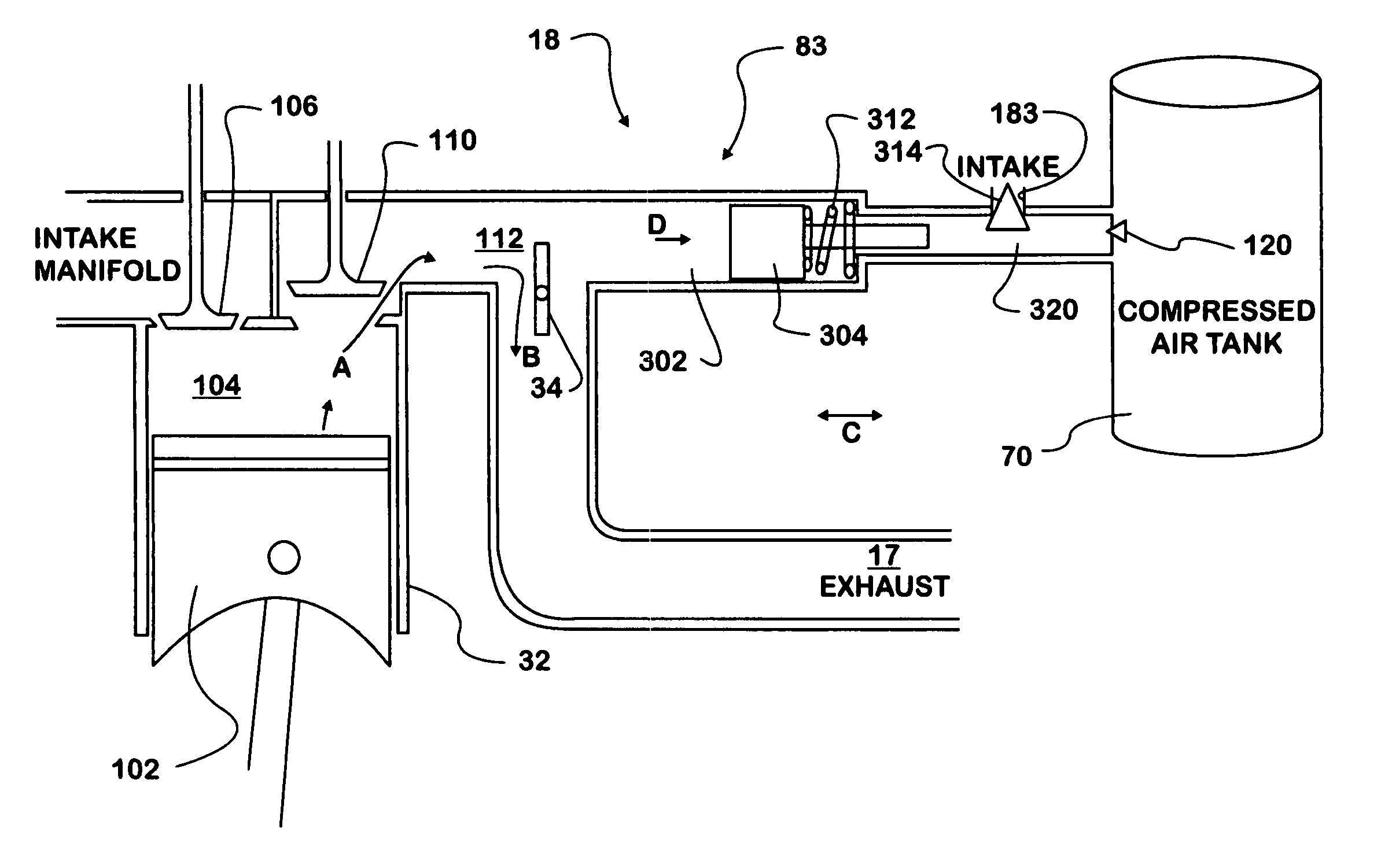

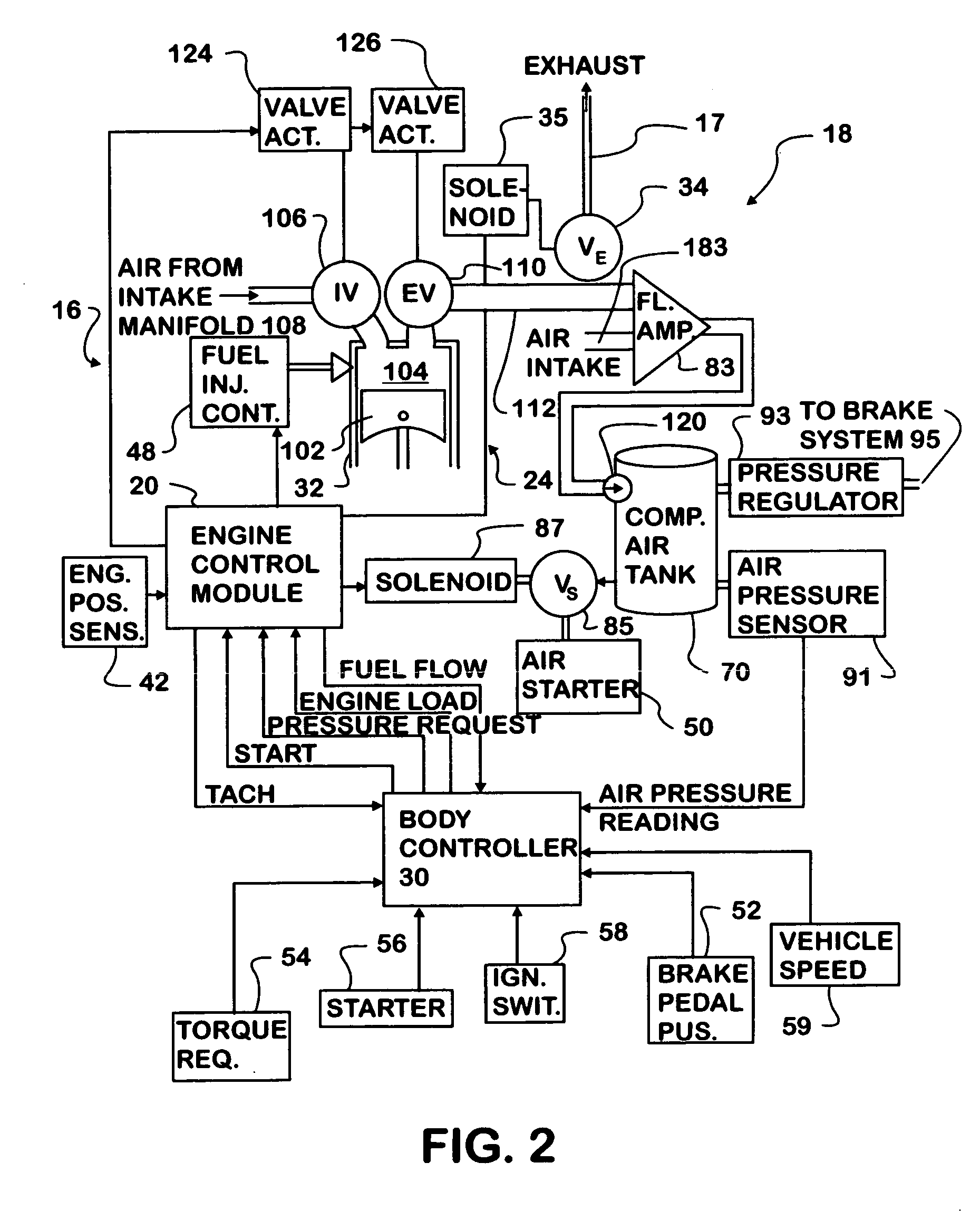

Engine based kinetic energy recovery system for vehicles

ActiveUS6922997B1Improve efficiencyEfficient use ofPower operated startersElectrical controlAir compressionHigh pressure

A motor vehicle kinetic energy recovery system uses one or more cylinders of an internal combustion engine as the first or primary stage in a multi-stage high pressure air compression system, a compressed air storage system, compressed air operated drive train boosters and vehicle management electronics to provide cooperation between the air compression, storage and booster systems. The multi-stage, high pressure air compressor system is operable through engine compression braking allowing kinetic energy of a vehicle to be recaptured during retardation of vehicle speed.

Owner:INT TRUCK INTPROP LLC

Engine based kinetic energy recovery system for vehicles

ActiveUS20050166592A1Improve efficiencyEfficient use ofElectrical controlInternal combustion piston enginesAir compressionHigh pressure

A motor vehicle kinetic energy recovery system uses one or more cylinders of an internal combustion engine as the first or primary stage in a multi-stage high pressure air compression system, a compressed air storage system, compressed air operated drive train boosters and vehicle management electronics to provide cooperation between the air compression, storage and booster systems. The multi-stage, high pressure air compressor system is operable through engine compression braking allowing kinetic energy of a vehicle to be recaptured during retardation of vehicle speed.

Owner:INT TRUCK INTPROP LLC

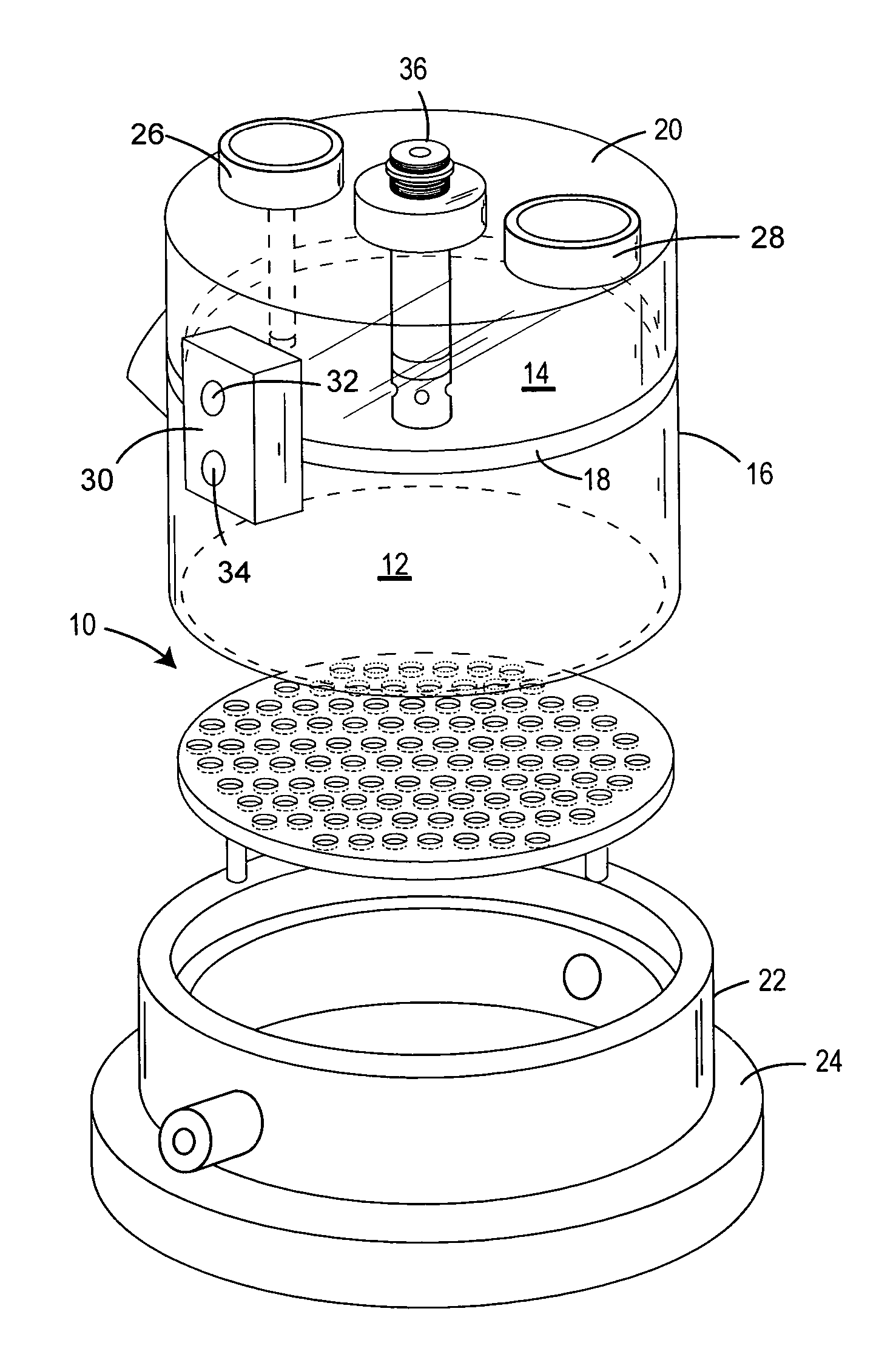

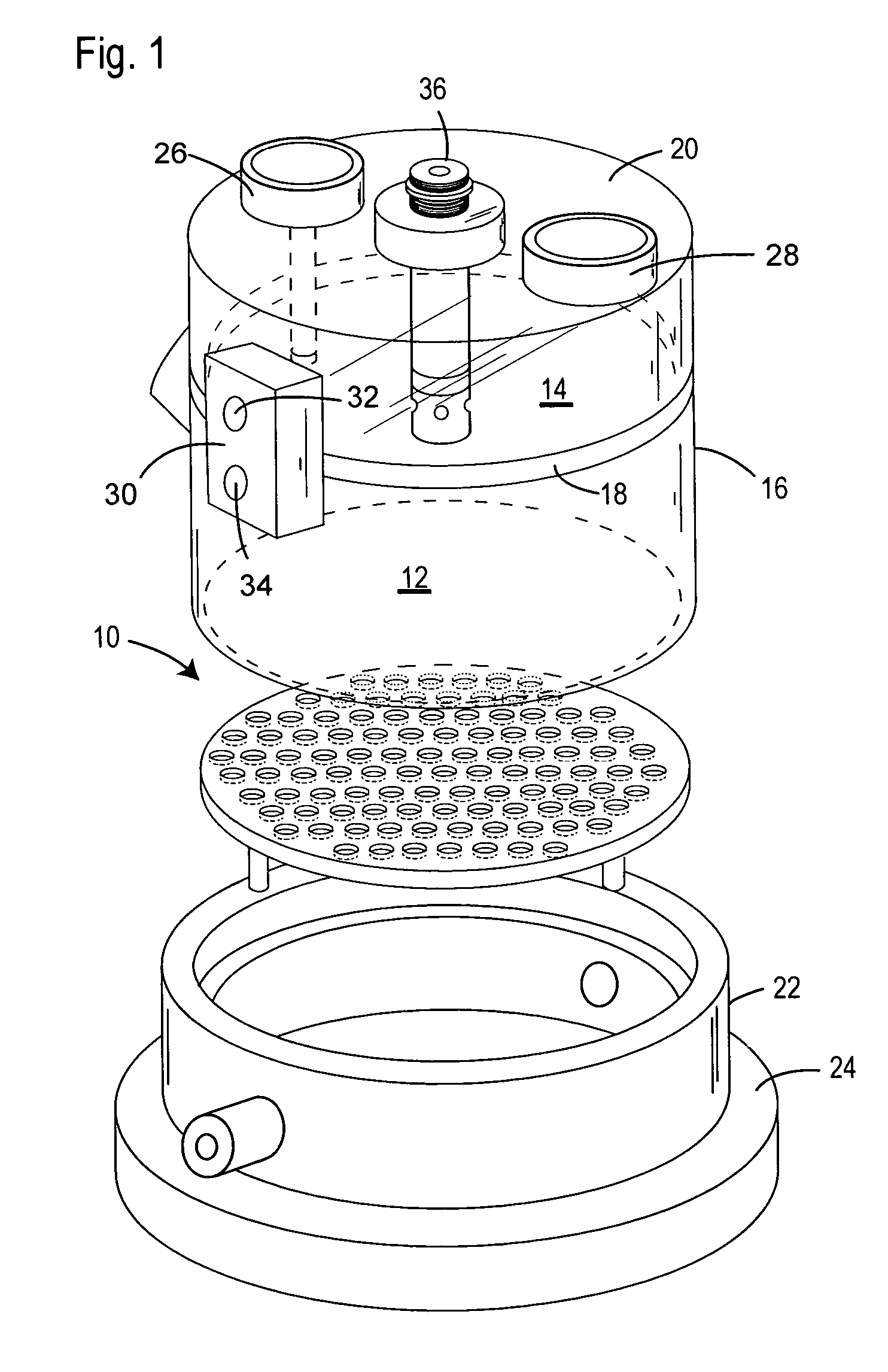

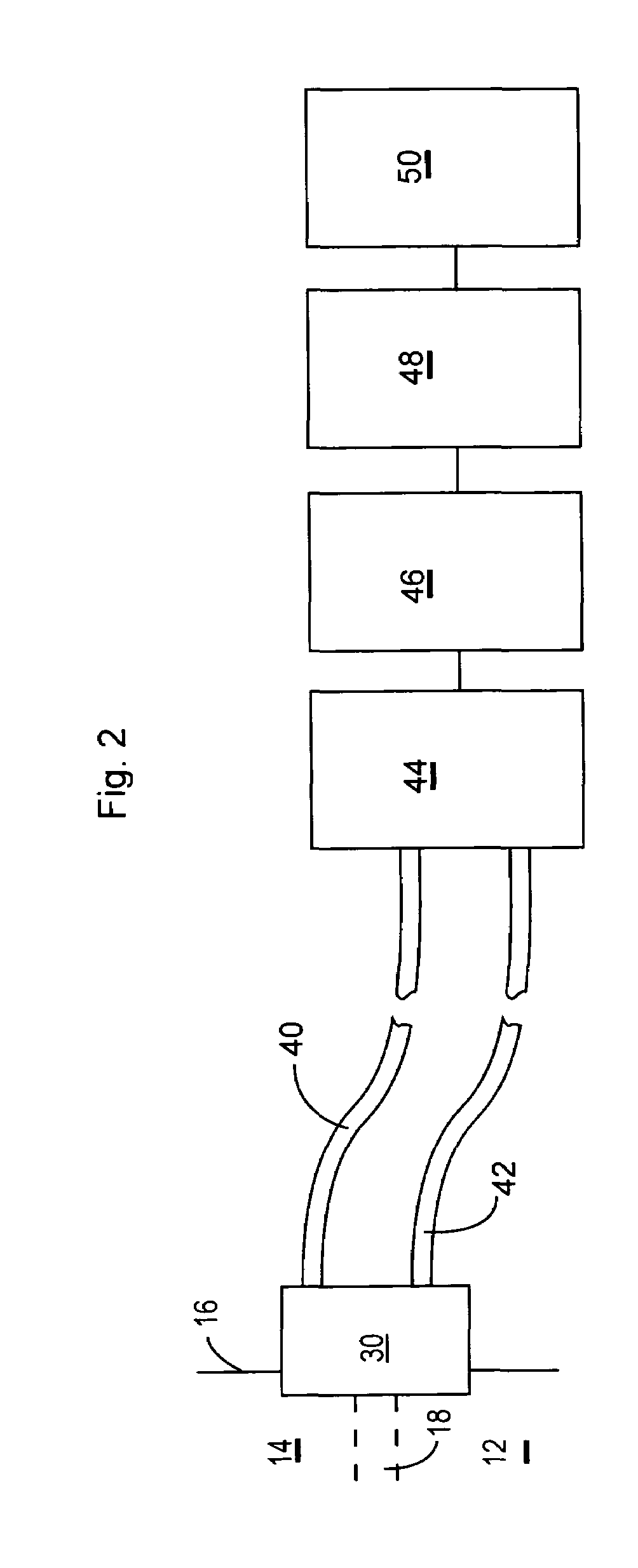

Cough/sneeze analyzer and method

ActiveUS7104962B2Improve analysis accuracyImprove accuracyAuscultation instrumentsRespiratory organ evaluationAir compressionMedicine

A cough event is differentiated from a sneeze event of a test subject enclosed within a plethysmograph test chamber by measuring air pressure changes during the event, and comparing the pressure changes against criteria indicative of a cough to determine the likelihood that the event is a cough. Air pressure changes are recorded as pressure and / or sound values. A graphical record of a waveform of changes in the air pressure during an event relative to a baseline value is recorded, and a value is calculated that is indicative of the likelihood that the event is a cough based on the sizes of areas between the waveform and baseline during the event, said areas including a first area indicative of the change in air pressure during air inspiration, a second area indicative of the change in air pressure during air compression, and a third area indicative of the change in air pressure during expiration.

Owner:DATA SCI INT

Hybrid electric power for vehicular propulsion

ActiveUS8552575B2Increase rangeIncrease usageNetwork traffic/resource managementRoad vehicles traffic controlElectric powerThrottle

Owner:TEETAB JOSEPH MICHAEL +1

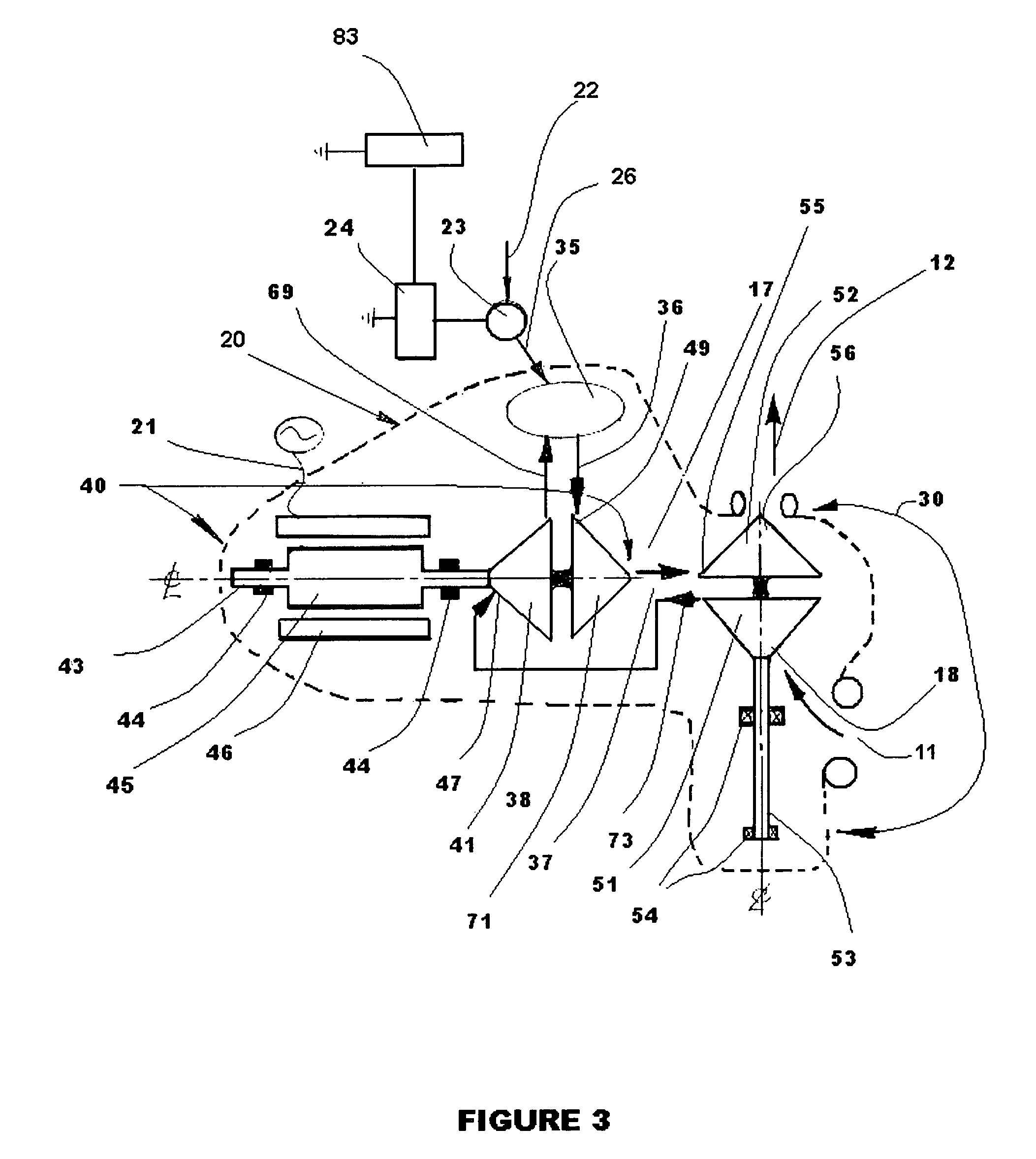

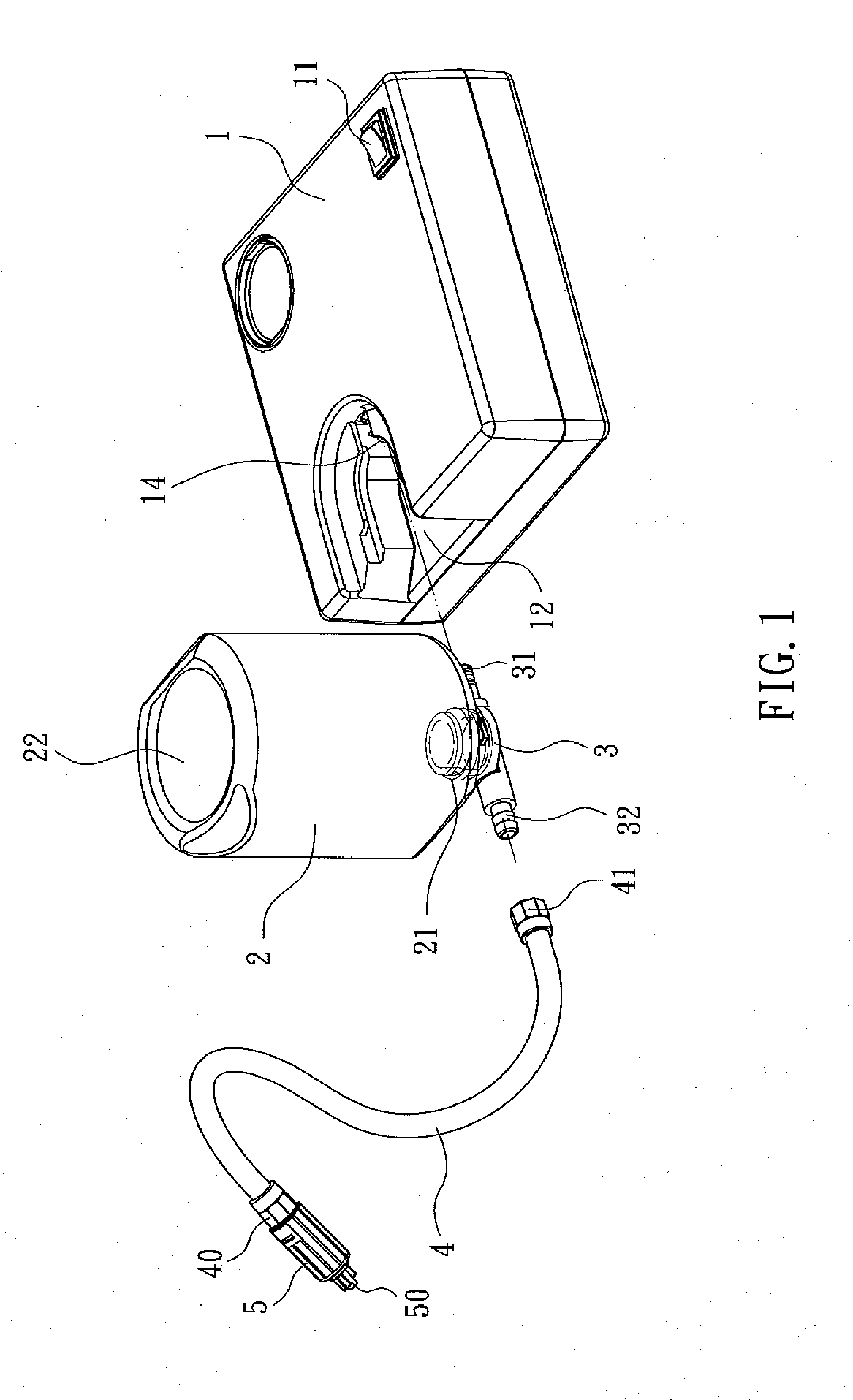

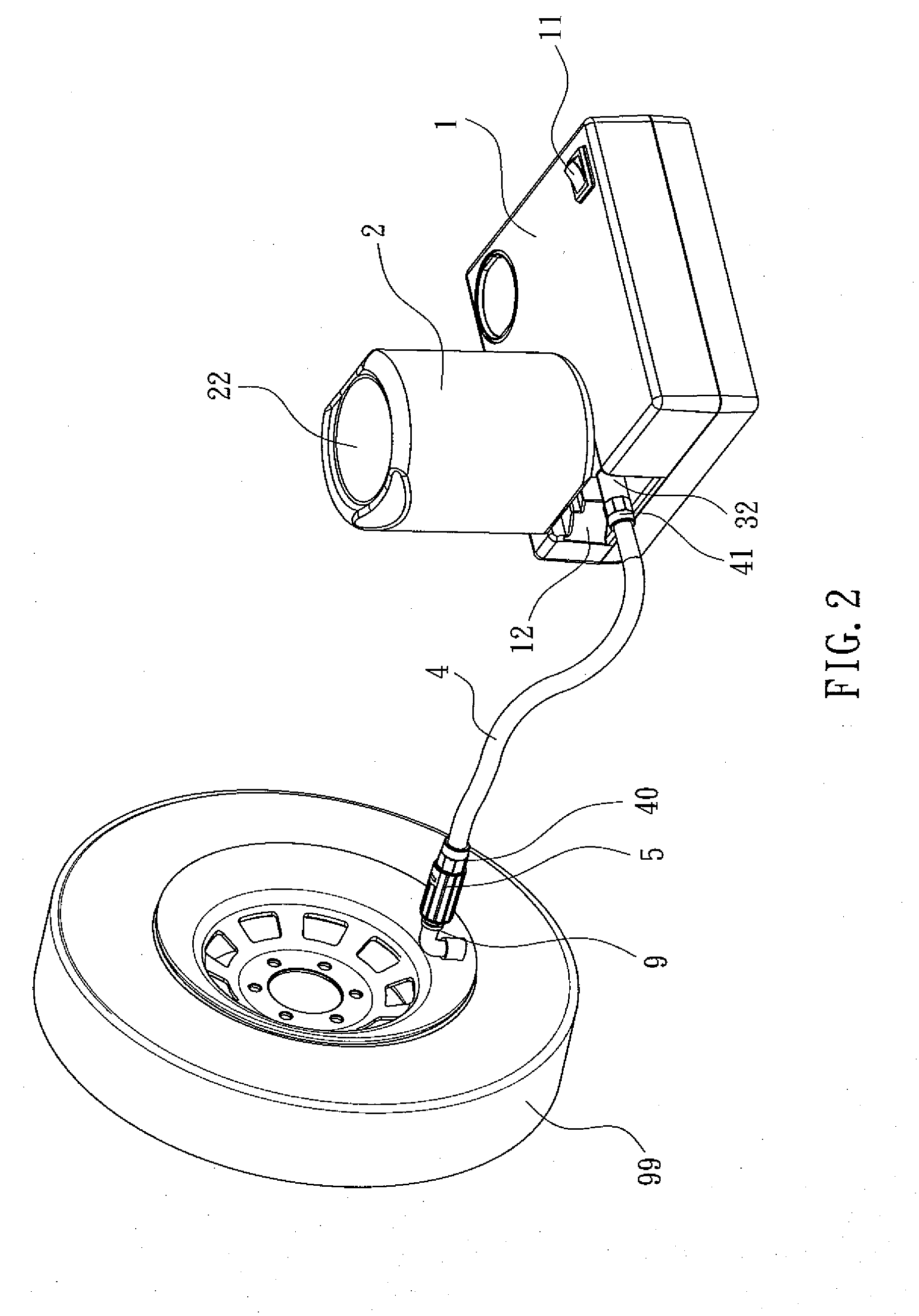

Vehicle-carried Air Compression Device

A vehicle-carried air compression device includes a case installed with an air compressor therein, a tire repairing container containing a liquid adhesive, and a flexible linking tube. An air inlet coupler of the tire repairing container is connected with an air outlet manifold of the air compressor. An end of the flexible linking tube is coupled to an adhesive outlet coupler of the tire repairing container, and the other end of the flexible linking tube is combined with a protection adapter for coupling to a tire nipple. Before the protection adapter is connected with the tire nipple, the other end of the flexible linking tube is closed by the protection adapter, so that the liquid adhesive in the tire repairing container will not shoot out suddenly because of improper handling.

Owner:UNIK WORLD IND CO LTD

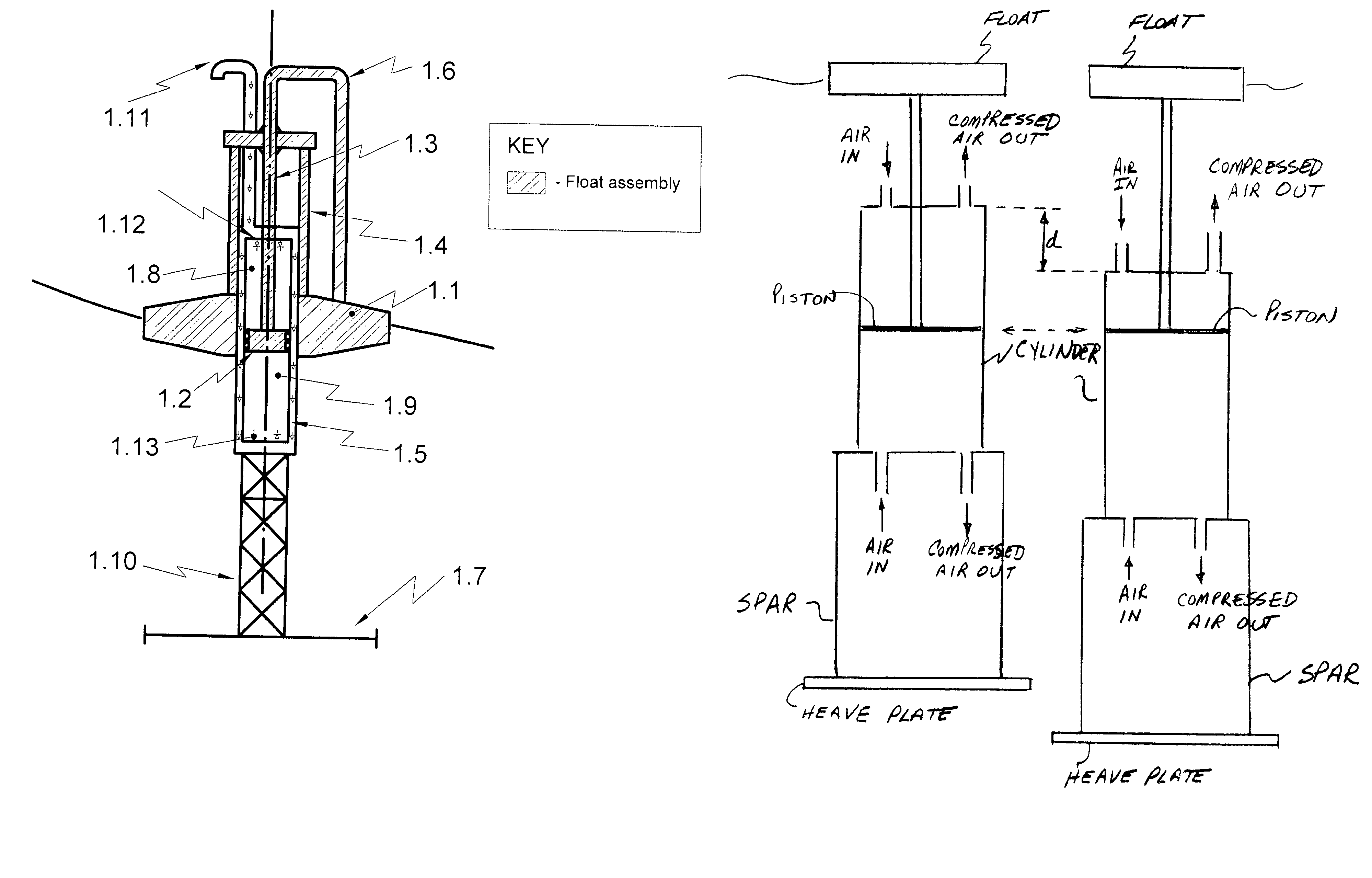

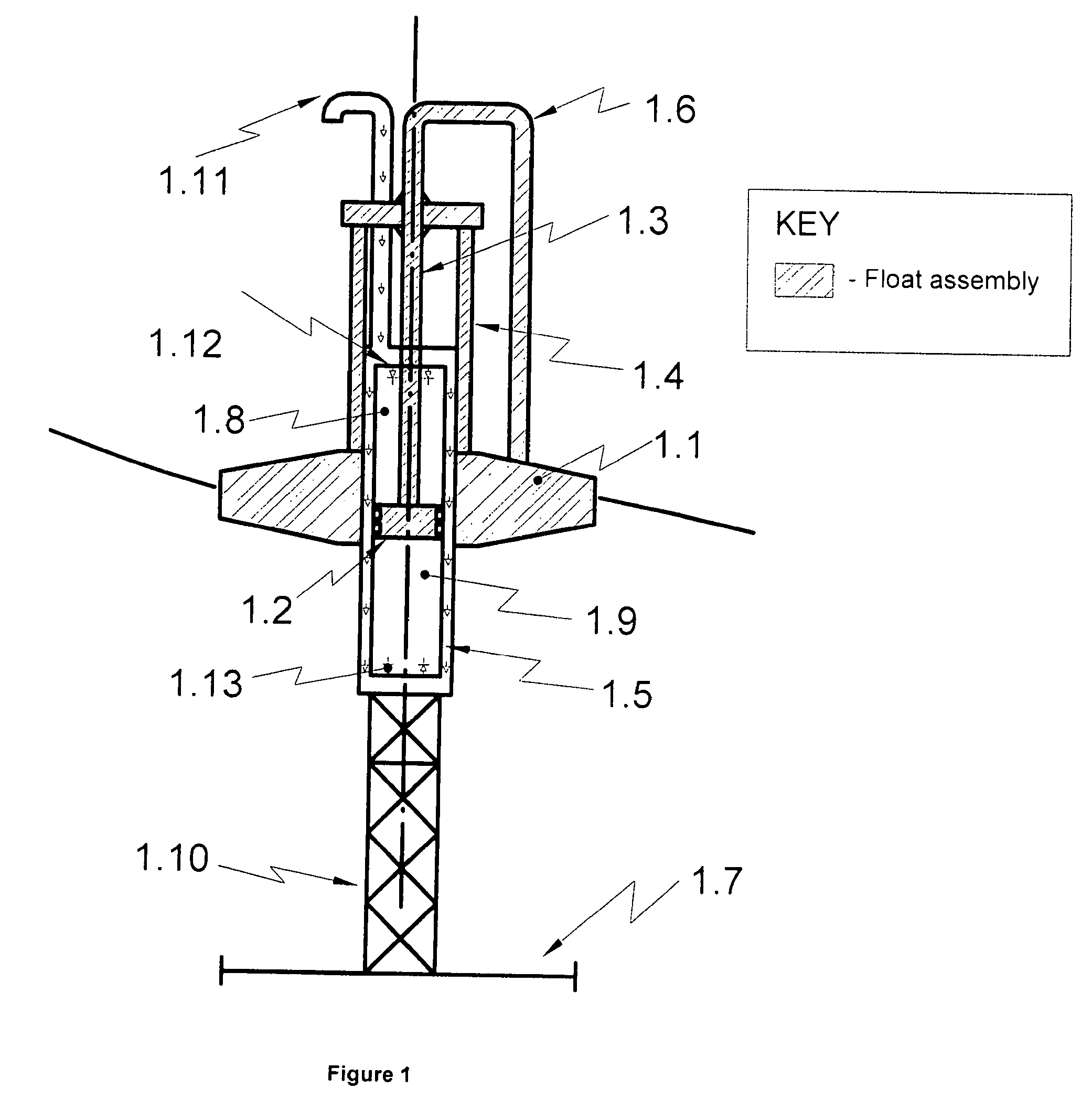

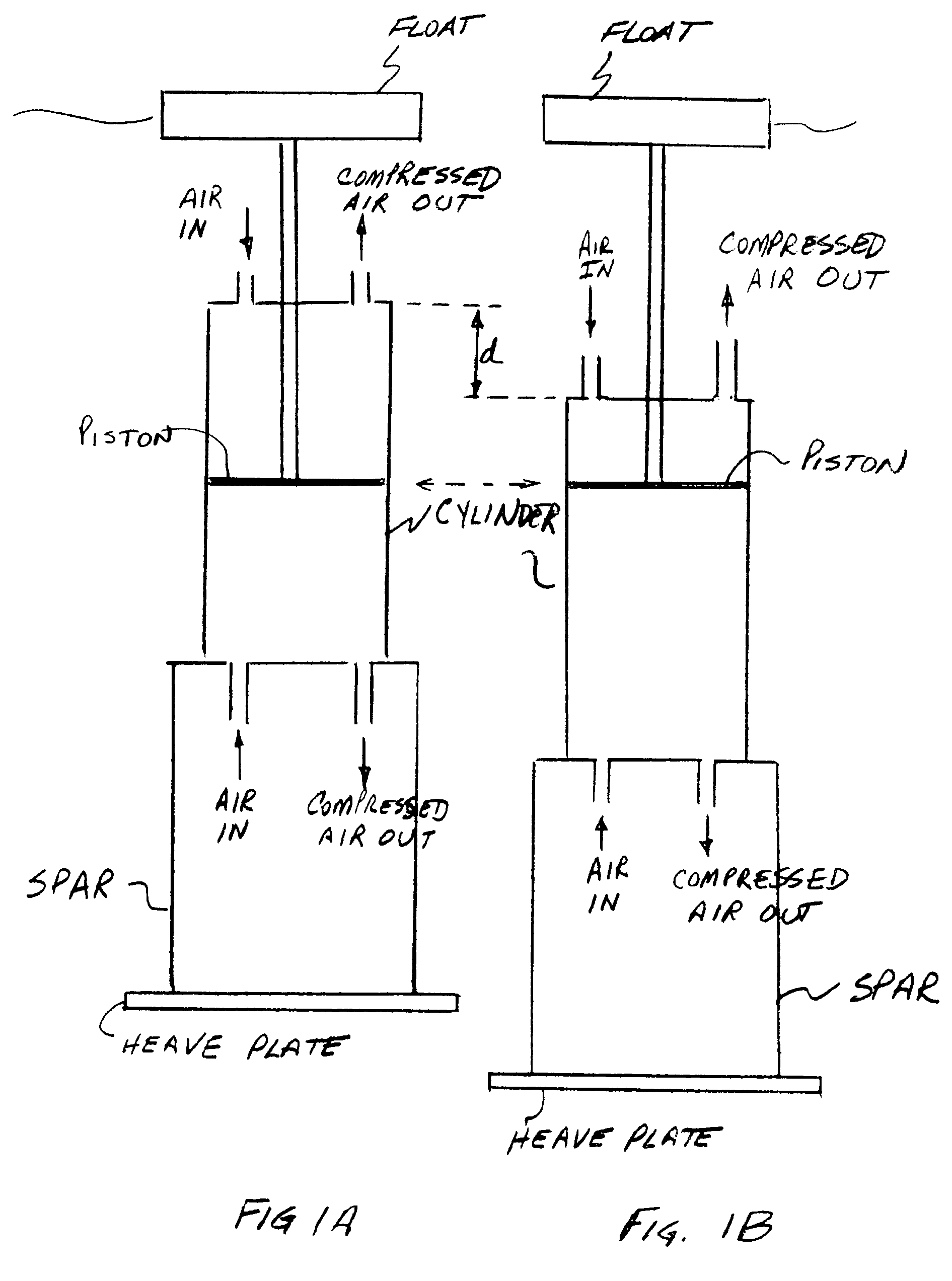

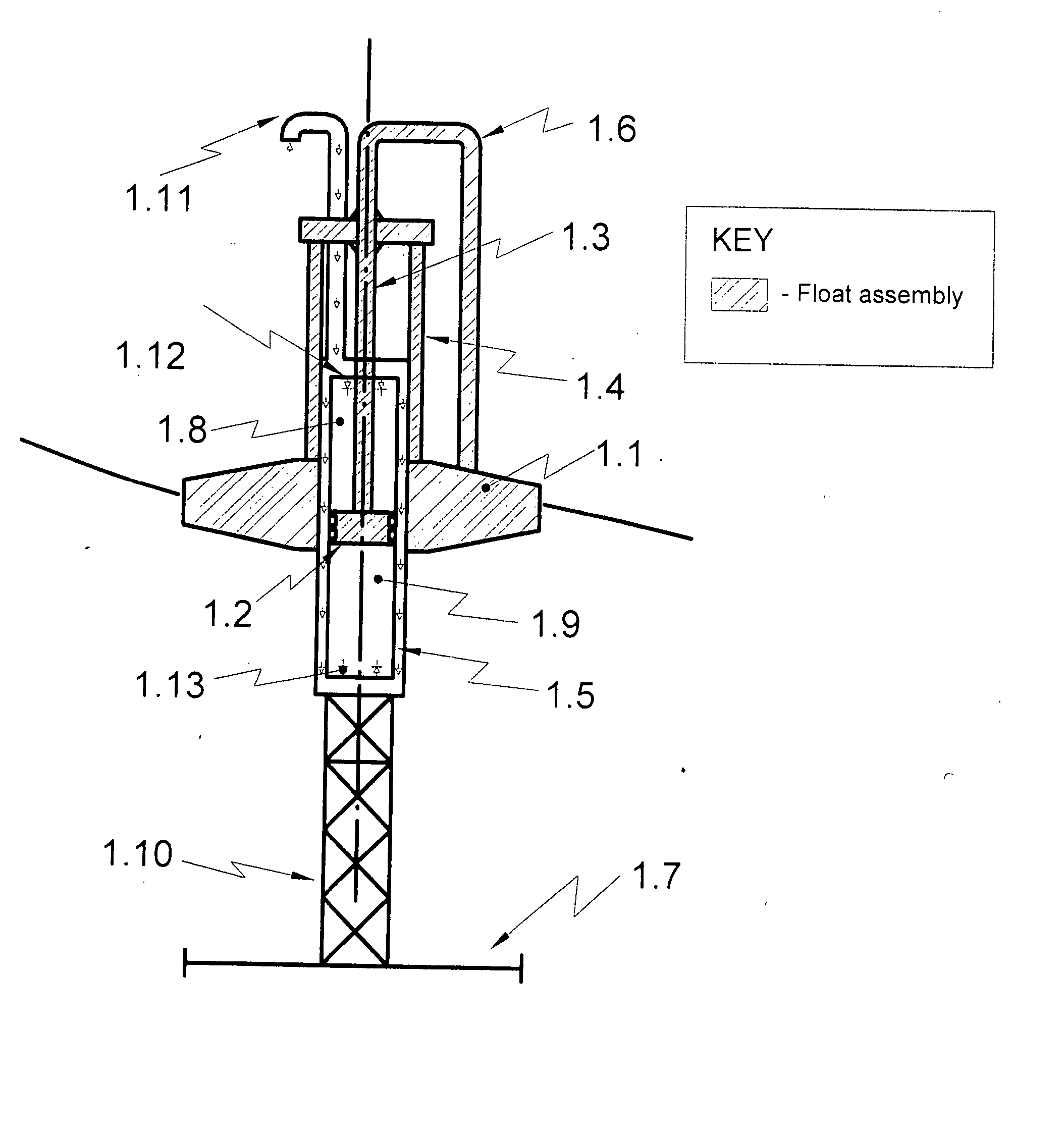

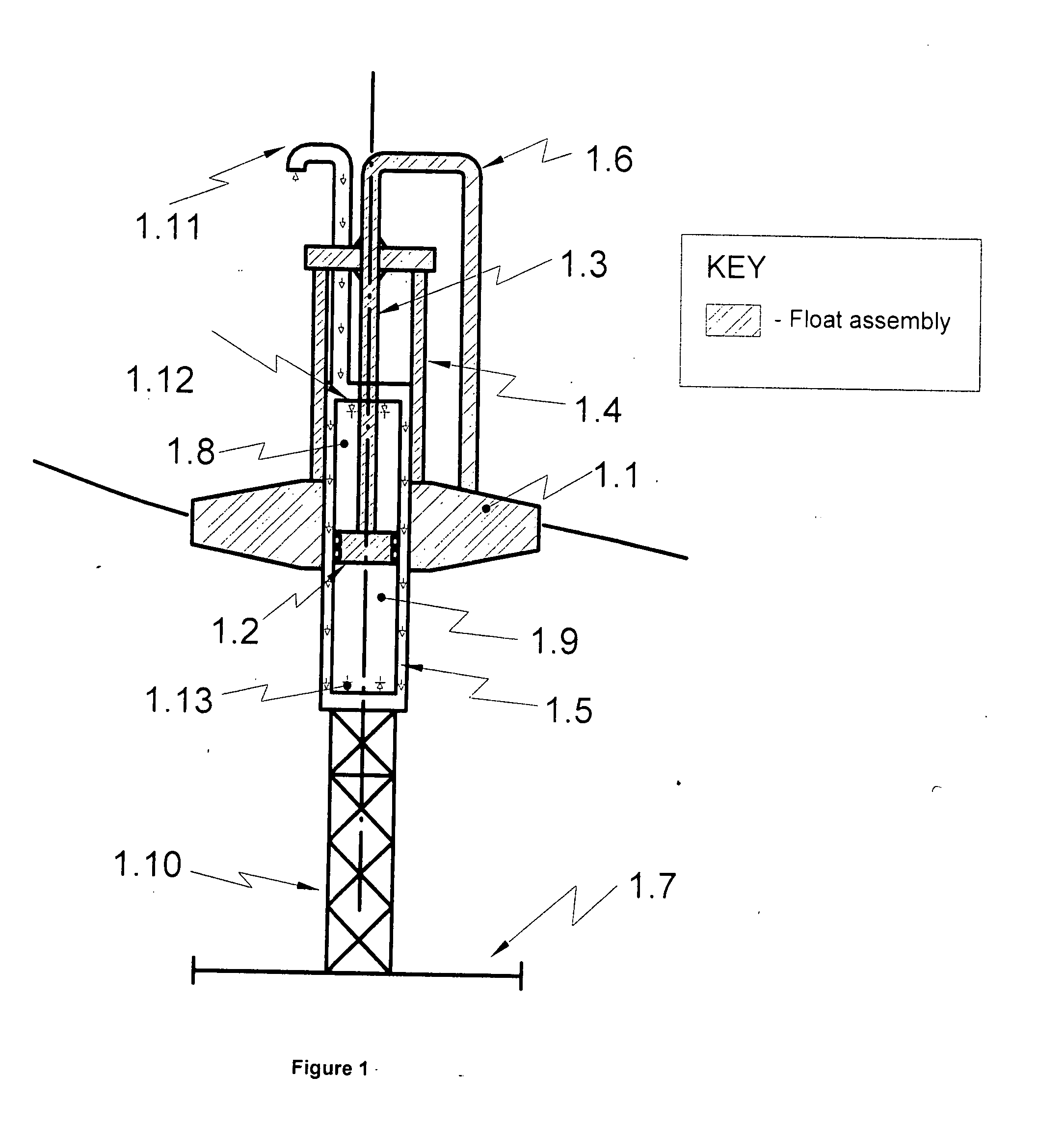

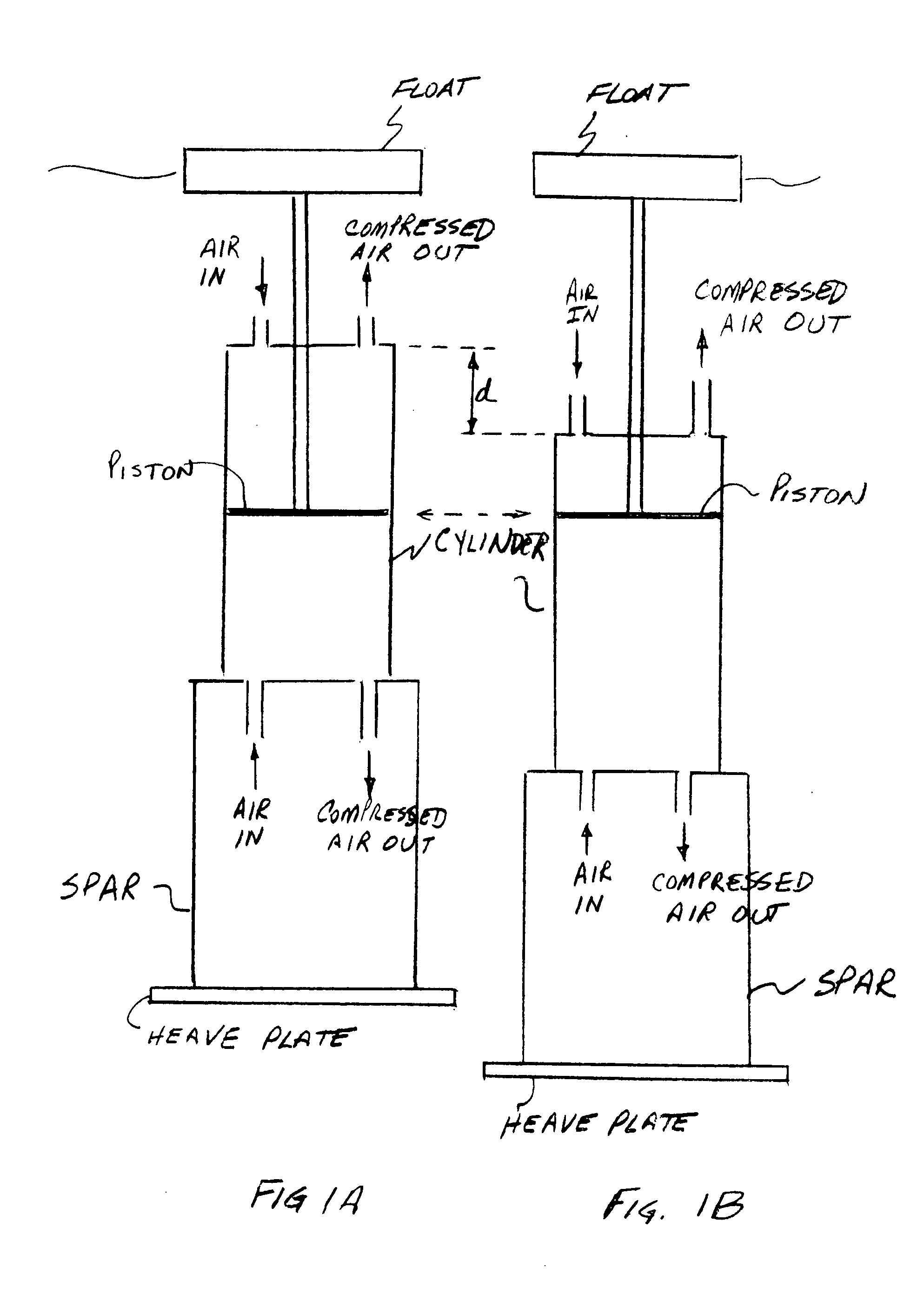

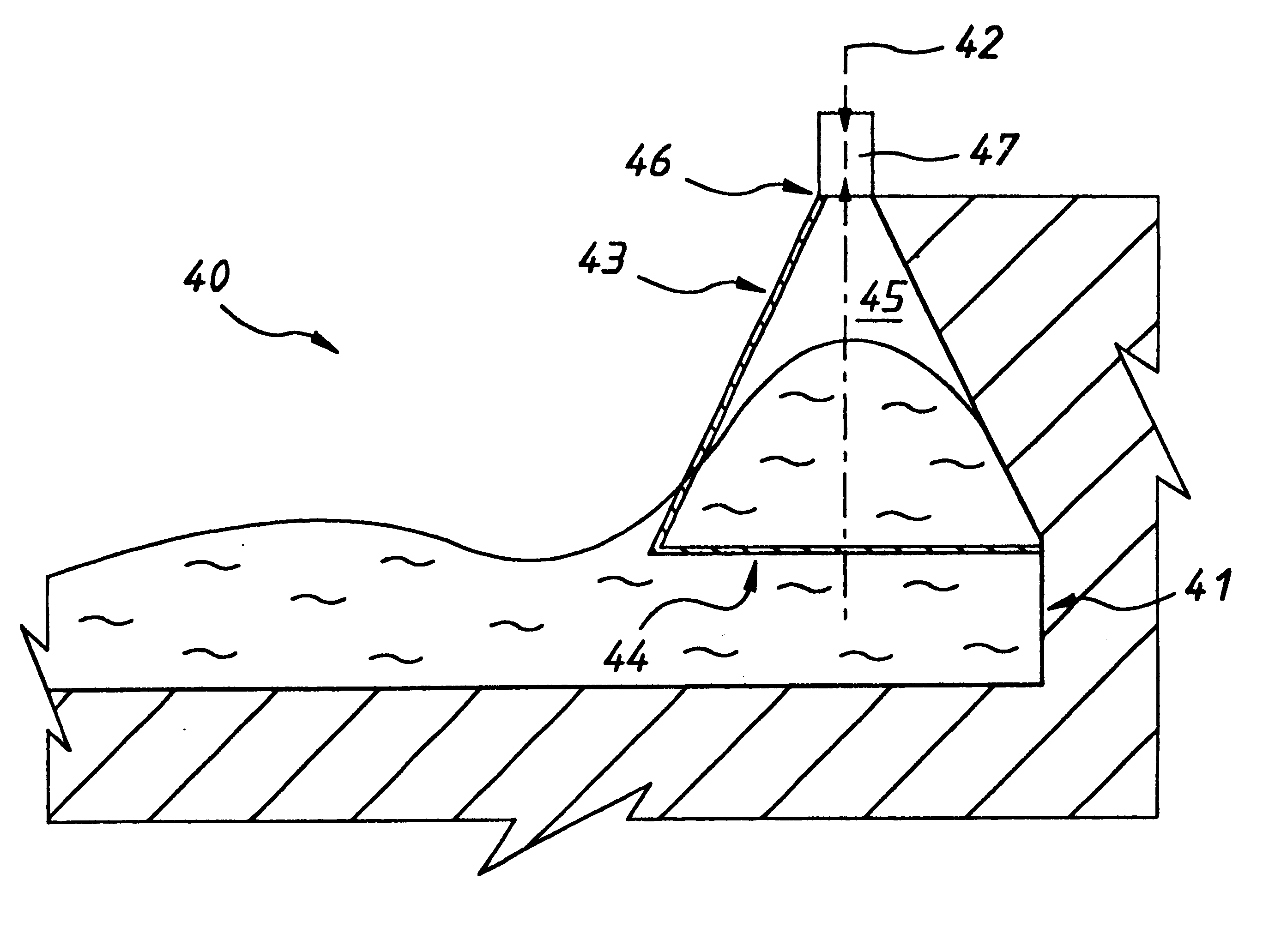

Wave energy converter with air compression (WECWAC)

InactiveUS7781903B2Simple designSize/volume of the upper chamber to be decreasedEngine componentsMulti-stage pumpsAir compressionSmall amplitude

A wave energy converter with air compression (WECWAC) includes a cylinder and a piston located within the cylinder dividing the cylinder into an upper chamber and a lower chamber. The cylinder is fixedly attached to a spar whose up / down (heave) motion is restrained. The piston is fixedly attached to, and driven by, a float which moves generally in phase with the waves. Under typical wave conditions the piston functions to compress air within the upper chamber on its up stroke and within the lower chamber on its down stroke, i. e., the system is thus double-acting. In still water, the spar and cylinder combination is designed to drift down into the body of water relative to the piston whereby the size / volume of the upper chamber is decreased (while that of the lower chamber is increased). For small amplitude waves the piston continues to compress air in the upper chamber and this asymmetrical compression continues until the waves reach a predetermine level when “double-action” is resumed. Controlling the position of the cylinder relative to the piston enables the WECWAC to automatically regulate its compression ‘stroke’ to suit varying wave conditions. The pressurized air from a WECWAC may be stored and / or processed to drive a turbo-generator or it may be combined with the outputs of other WECWACs to drive a single large and highly efficient turbo-generator.

Owner:OCEAN POWER TECHNOLOGIES

Wave energy converter with air compression (WECWAC)

InactiveUS20080012344A1Simple designEfficient system operationEngine componentsMulti-stage pumpsSmall amplitudeAuto regulation

A wave energy converter with air compression (WECWAC) includes a cylinder and a piston located within the cylinder dividing the cylinder into an upper chamber and a lower chamber. The cylinder is fixedly attached to a spar whose up / down (heave) motion is restrained. The piston is fixedly attached to, and driven by, a float which moves generally in phase with the waves. Under typical wave conditions the piston functions to compress air within the upper chamber on its up stroke and within the lower chamber on its down stroke, i. e., the system is thus double-acting. In still water, the spar and cylinder combination is designed to drift down into the body of water relative to the piston whereby the size / volume of the upper chamber is decreased (while that of the lower chamber is increased). For small amplitude waves the piston continues to compress air in the upper chamber and this asymmetrical compression continues until the waves reach a predetermine level when “double-action” is resumed. Controlling the position of the cylinder relative to the piston enables the WECWAC to automatically regulate its compression ‘stroke’ to suit varying wave conditions. The pressurized air from a WECWAC may be stored and / or processed to drive a turbo-generator or it may be combined with the outputs of other WECWACs to drive a single large and highly efficient turbo-generator.

Owner:OCEAN POWER TECHNOLOGIES

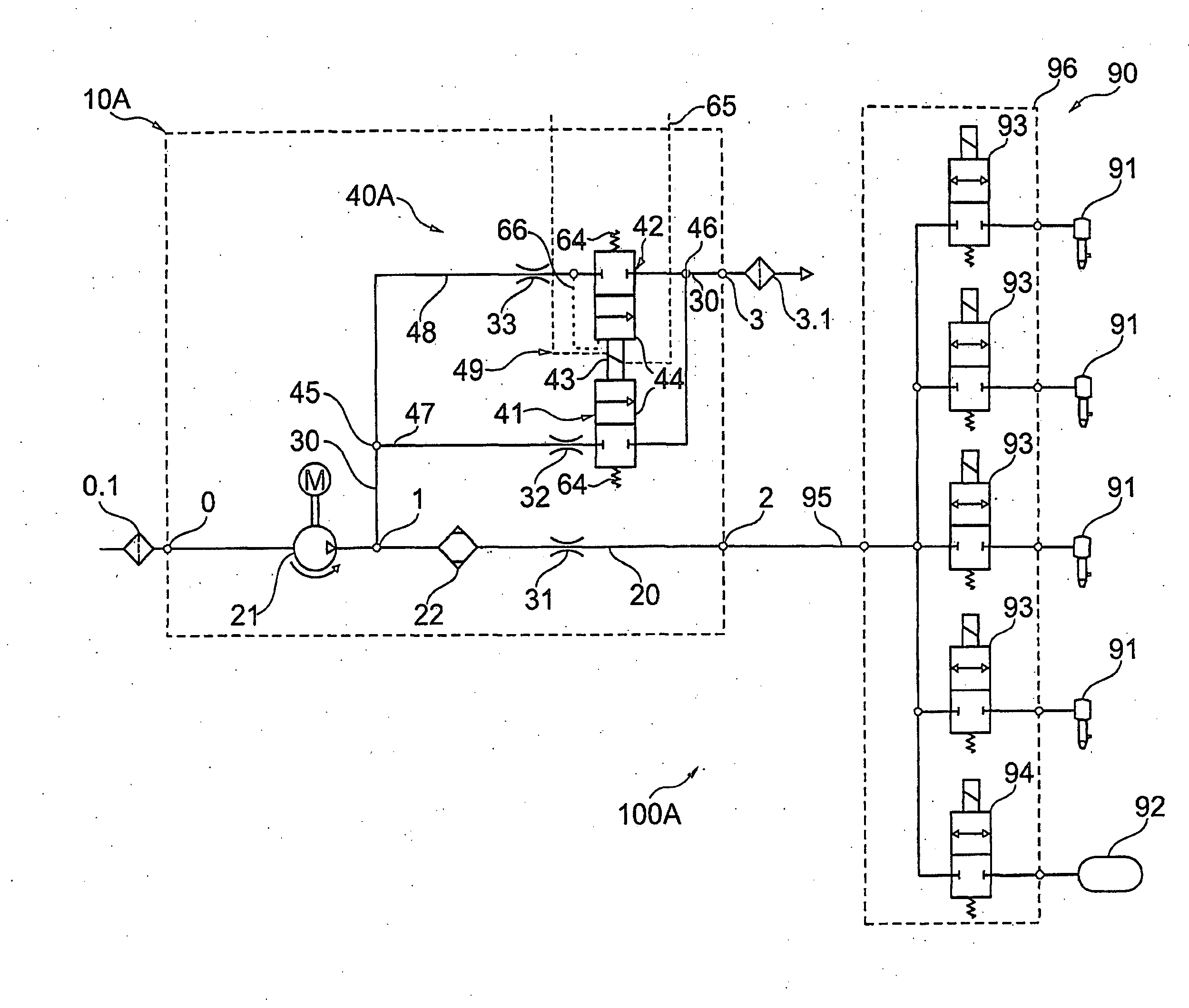

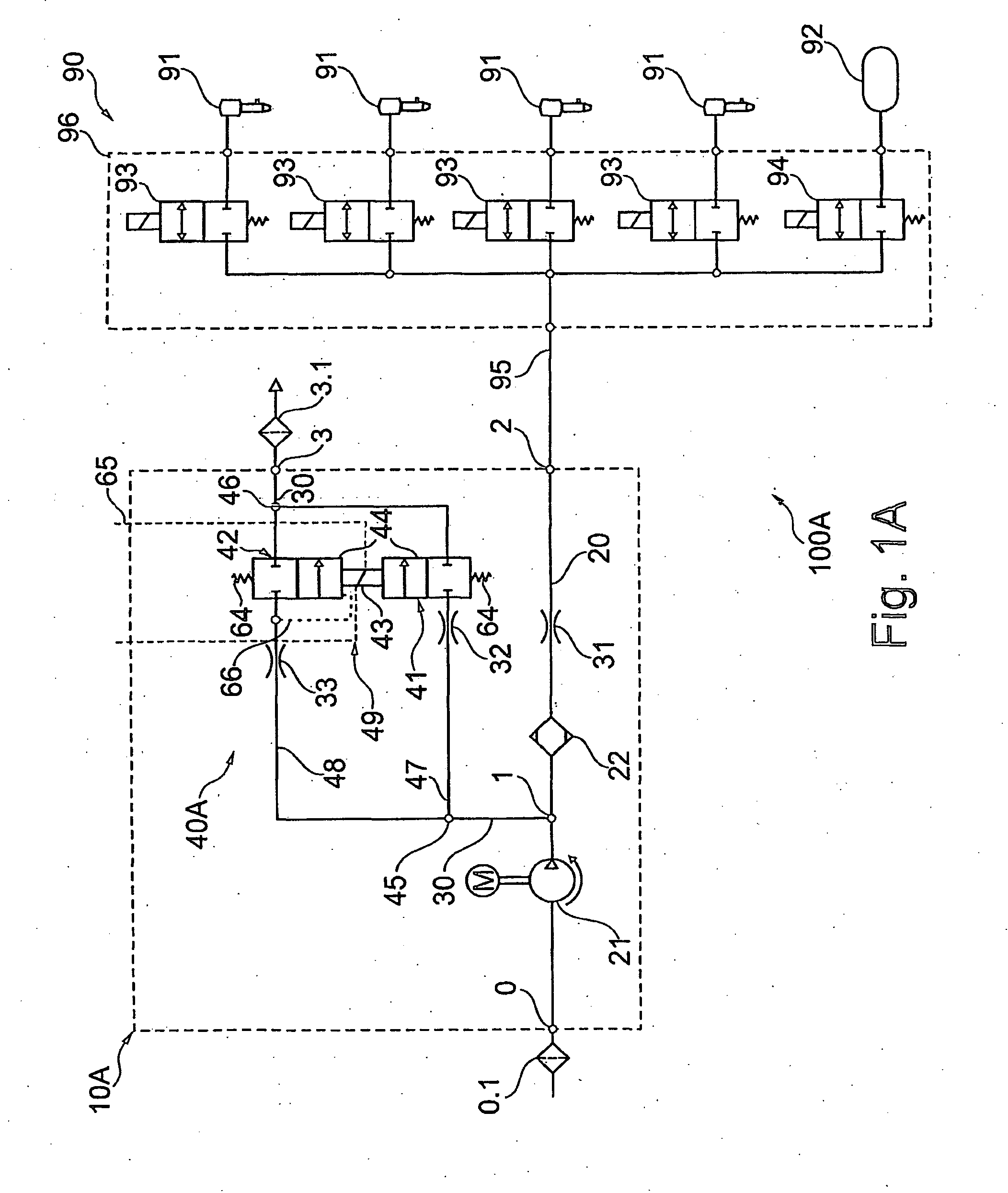

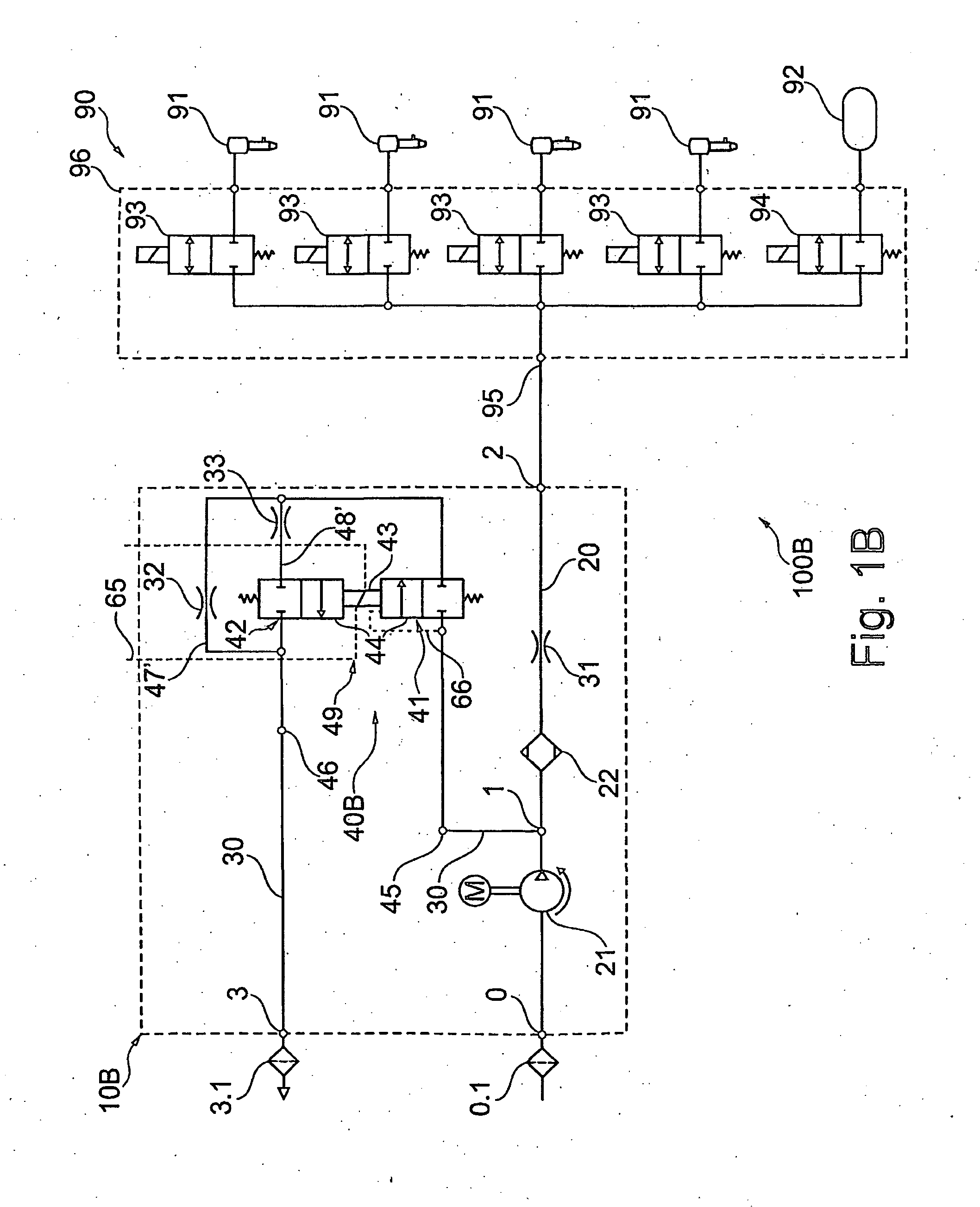

Compressed Air Supply Installation, Pneumatic System and Method

ActiveUS20130318954A1Reliable and yet flexibleFast principle of operationRotary clutchesResilient suspensionsAir compressionSolenoid valve

A compressed air supply installation for operating a pneumatic installation, especially an air suspension installation of a vehicle, includes: an air supply unit and an air compression unit for supplying a compressed air supply unit with compressed air, a pneumatic connection, especially a bleeding line, comprising a bleeding valve system in the form of a controllable solenoid valve system and a bleeding port for bleeding air, and a pneumatic connection, especially a compressed air supply line, comprising an air drier and a compressed air port for supplying the compressed air. The solenoid valve system comprises a primary valve and a secondary valve, which are actuatable by a controller of the solenoid valve system that is common to both valves and acts upon both valves.

Owner:ZF CV SYST EURO BV

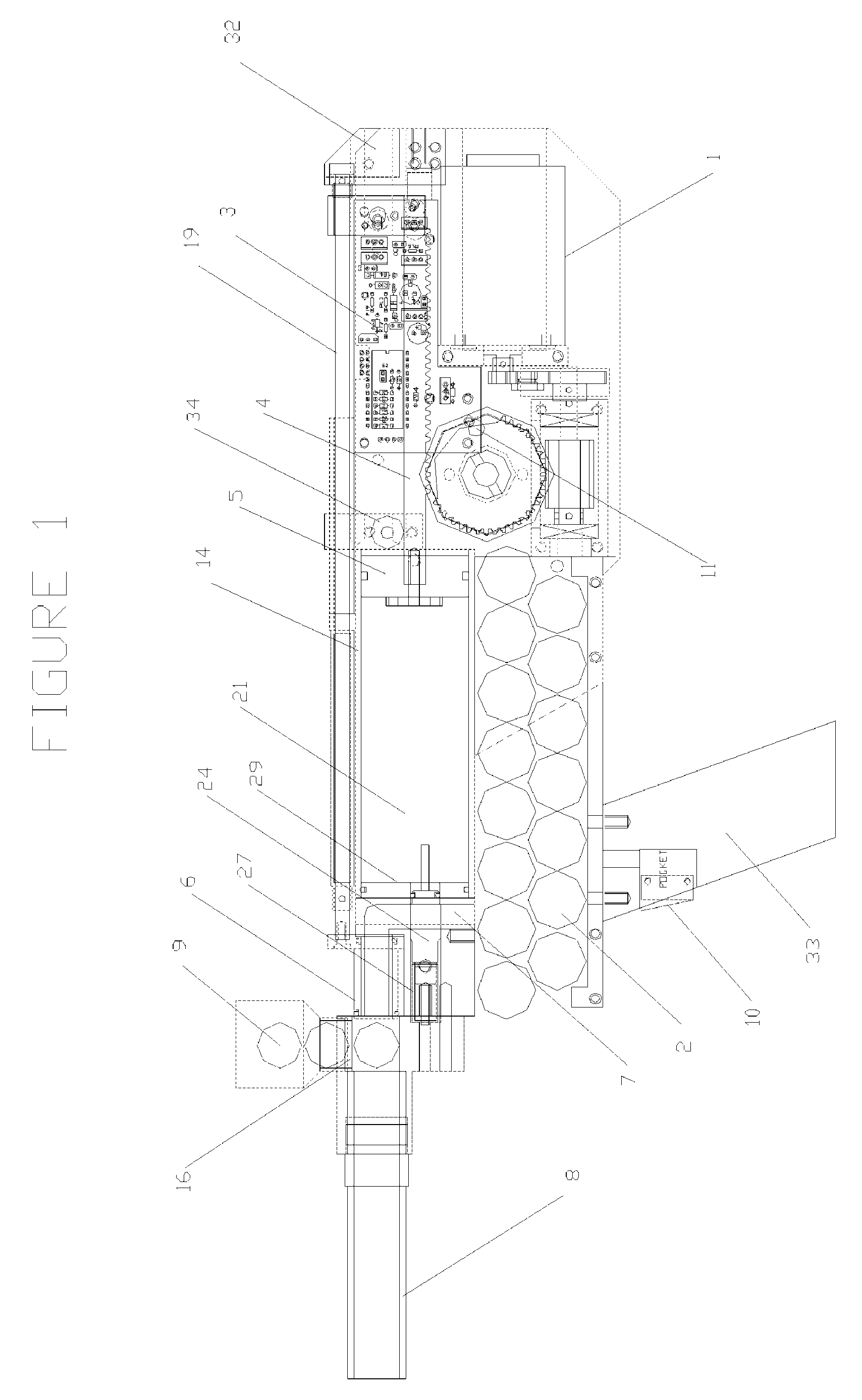

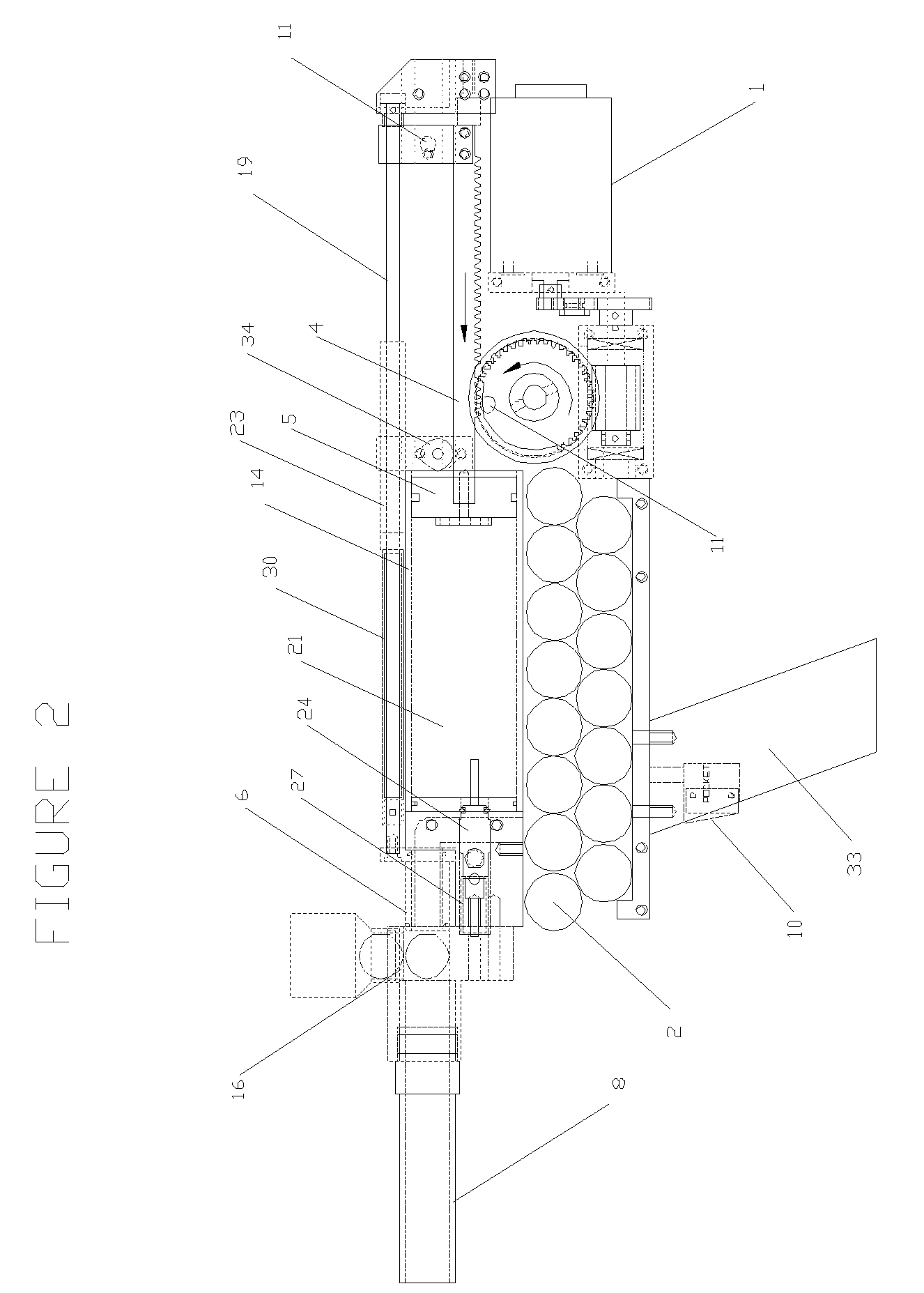

Portable electric motor driven compressed air projectile launcher

ActiveUS7730881B1Improve securityEasy to operateCompressed gas gunsPiston pumpsAir compressionLinear motion

A portable motor driven air gun powered by a power source includes a motor that is coupled to a linear motion converter which drives a piston. The piston compresses air in a chamber against a forward air compression valve producing high-pressure air. When sufficient energy is stored within the air stream by the piston, the compression valve opens which releases the compressed air to push a projectile through a barrel. The engagement and disengagement of the linear motion converter and the connected piston to the motor can be controlled using sensors. The linear motion converter further is coupled to a bolt thru a lost motion device to facilitate positioning of the projectile for firing. The direction speed and operative modes of the gun may be controlled with an electric circuit. The power source is preferably rechargeable, allowing the air gun to be operated independent from either a wall outlet or a compressed air supply.

Owner:TRICORD SOLUTIONS INC

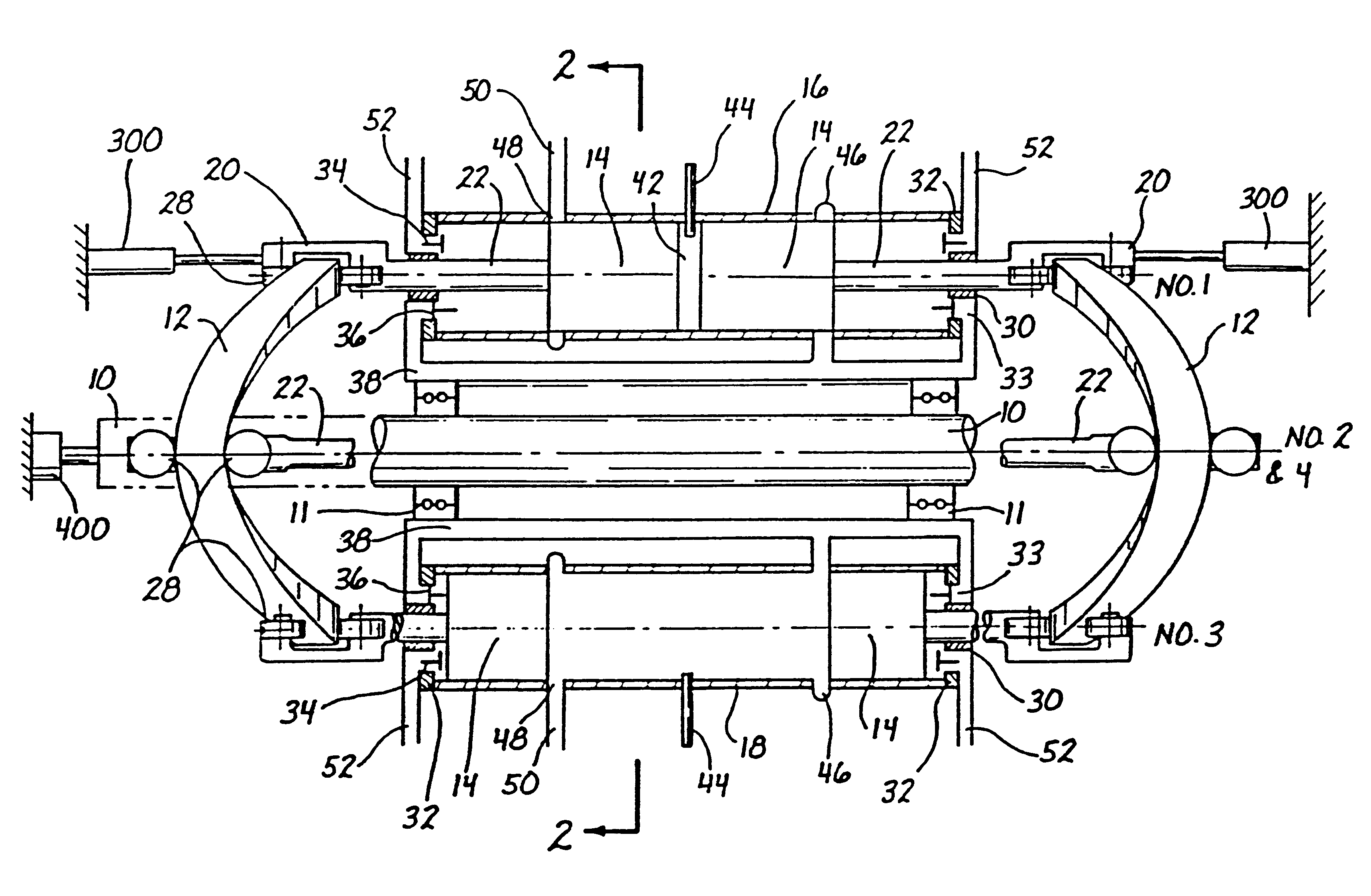

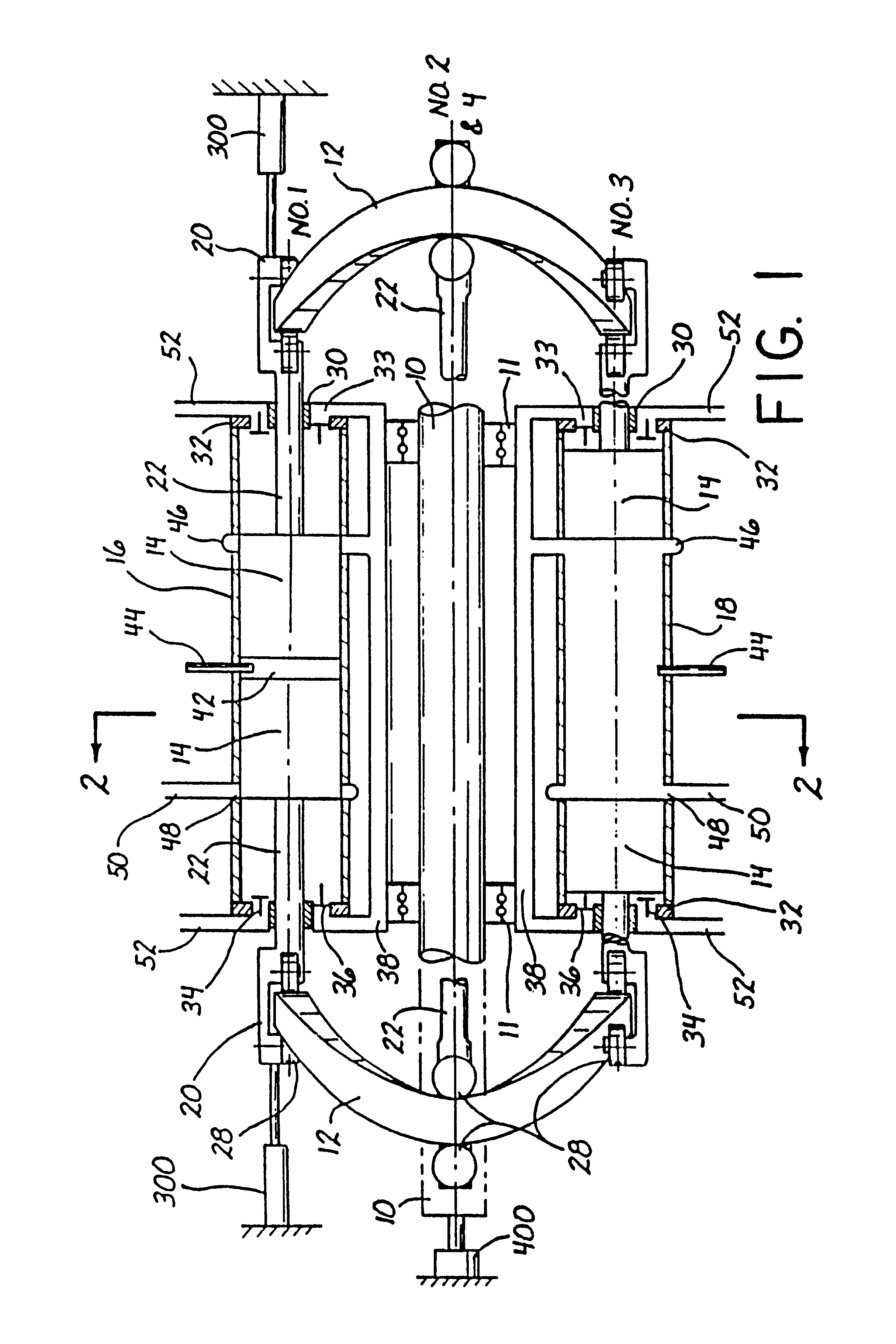

Adiabatic, two-stroke cycle engine having novel scavenge compressor arrangement

InactiveUS6279520B1Improve thermal efficiencyReduce heat lossReciprocating piston enginesAir compressionExhaust valve

An engine structure and mechanism that operates on various combustion processes in a two-stroke-cycle without supplemental cooling or lubrication comprises an axial assembly of cylindrical modules and twin, double-harmonic cams that operate with opposed pistons in each cylinder through fully captured rolling contact bearings. The opposed pistons are double-acting, performing a two-stroke engine power cycle on facing ends and induction and scavenge air compression on their outside ends, all within the same cylinder bore. The engine includes a novel compressor arrangement having an intake valve comprising a V-shaped double reed valve with an apex pointing toward the intake port and an exhaust valve having a V-shaped double reed valve with an apex pointing away from the exhaust port. The compressor arrangement may further include rectangular intake and exhaust ports, a rectangular piston rod and rectangular crosshead bearings.

Owner:LOWI JR ALVIN

Storage tower of wind power generator

InactiveCN101042115ANo pollutionLess investmentWind energy with garvitational potential energyWind motor supports/mountsAir compressionOperational costs

It provides a wind mill energy storage device, through wind vane driving air compression device, using compressed air to store energy, make the tower of the wind generator into a big hollow container being able to bear high pressure to be the storage for compressed air, so as to reduce equipment investment, operation cost, free from pollution.

Owner:FANGXIA ENTERPRISE INFORMATION CONSULTING WUJIANG

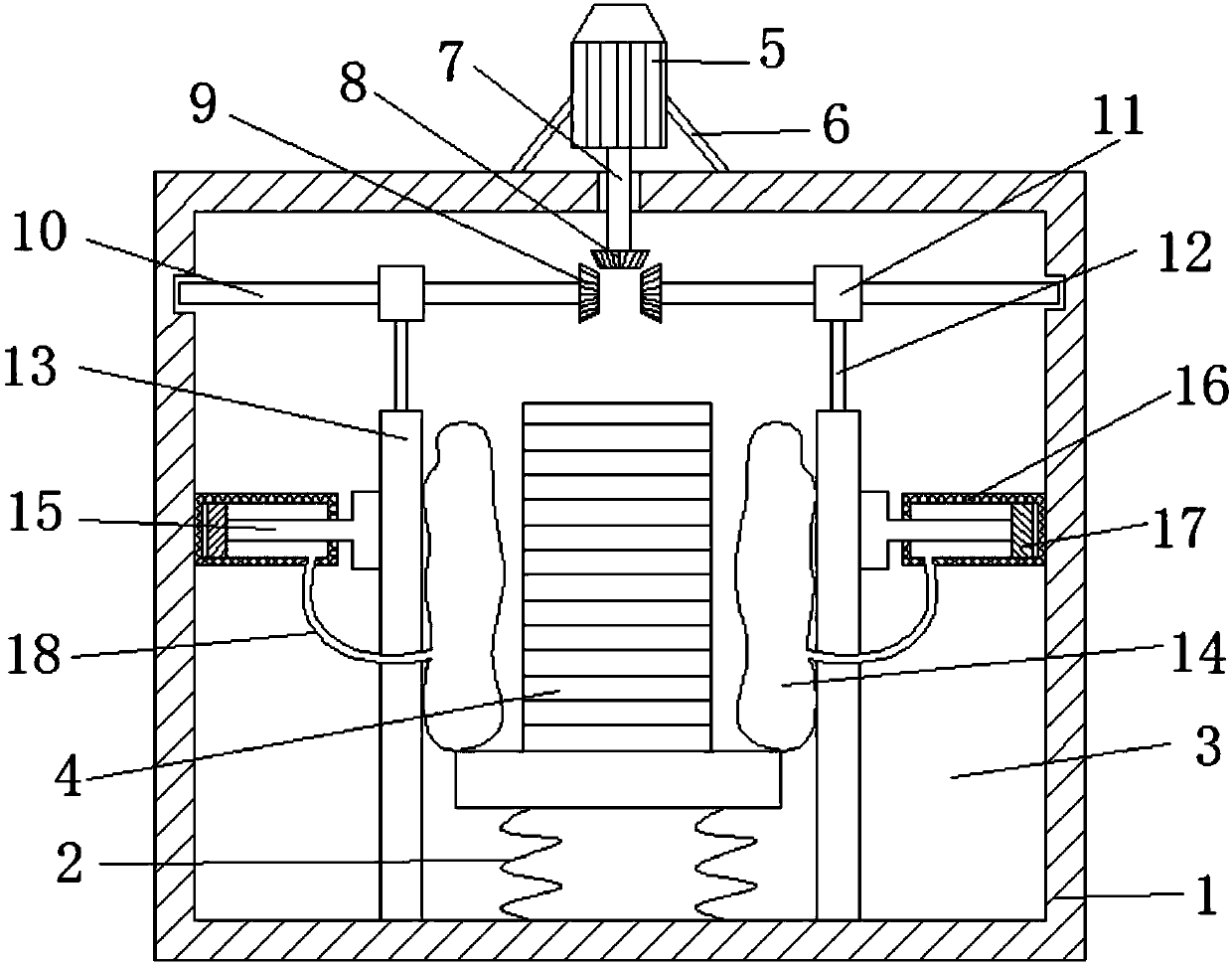

Protection device for furniture transporting

InactiveCN107934157AEffective protectionReduce vibrationContainers to prevent mechanical damageRigid containersAir compressionDrive shaft

The invention discloses a protection device for furniture transportation, which includes a box body, a spring, a bottom plate and a furniture body. The protection device for furniture transportation has a simple structure. The furniture body is placed on the upper end of the bottom plate, and the spring at the lower end of the bottom plate is effective. Buffer the vibration in the vertical direction of the furniture body; start the motor, the first shaft at the lower end of the motor drives the first bevel gear to rotate, the first bevel gear meshes with two opposite second bevel gears, drives the two screw rods to rotate, and the reverse thread is connected to the The nut on the screw drives the two baffles close to each other through the connecting rod, and fixes the furniture body horizontally; at the same time, the movement of the baffle drives the piston to squeeze the air in the inner cavity of the sleeve, and the air in the inner cavity of the sleeve enters through the through hose The air bag is inflated between the furniture body and the baffle, which effectively protects the furniture body and at the same time fully buffers the vibration of the furniture body in the horizontal direction.

Owner:郭姗姗

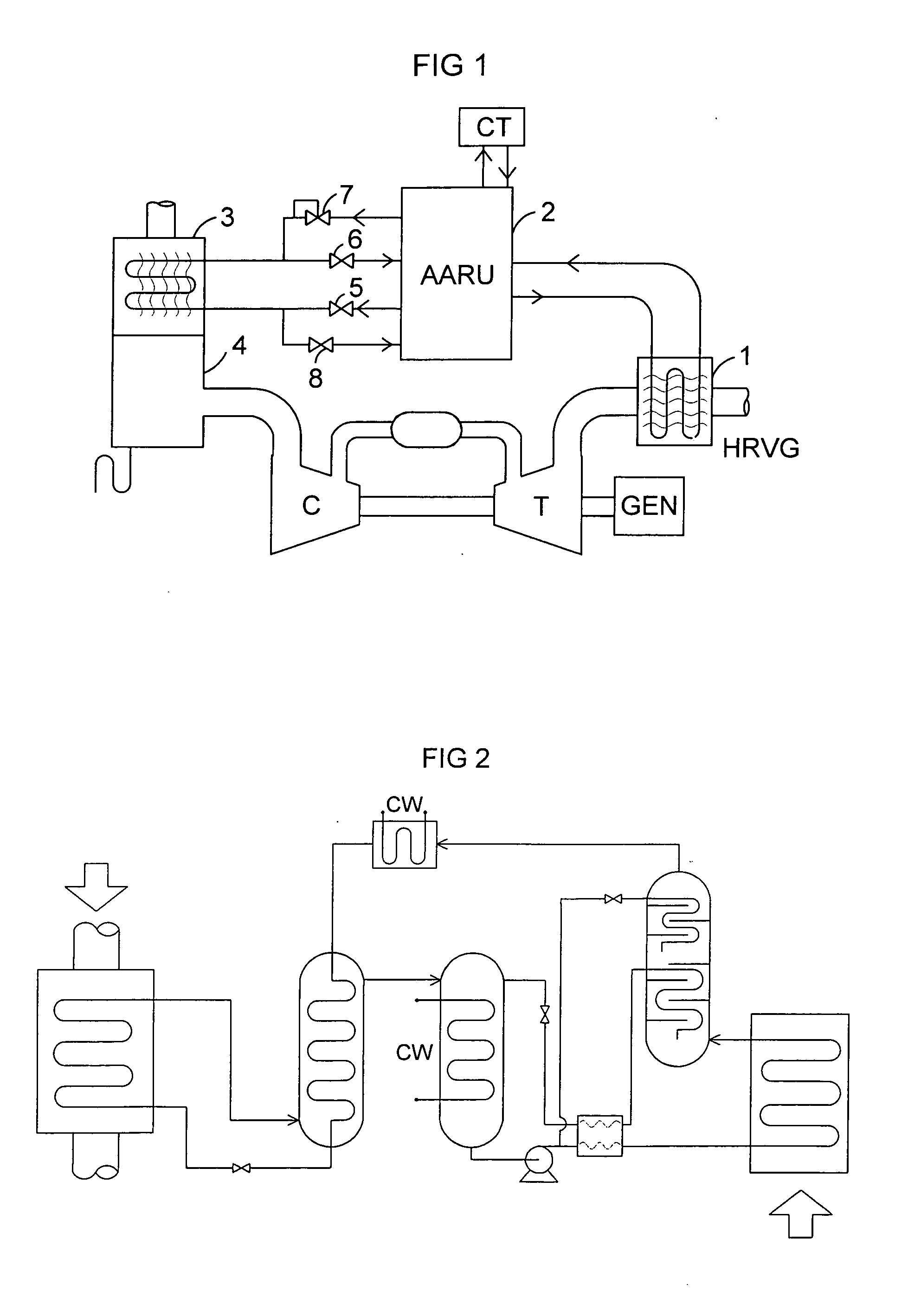

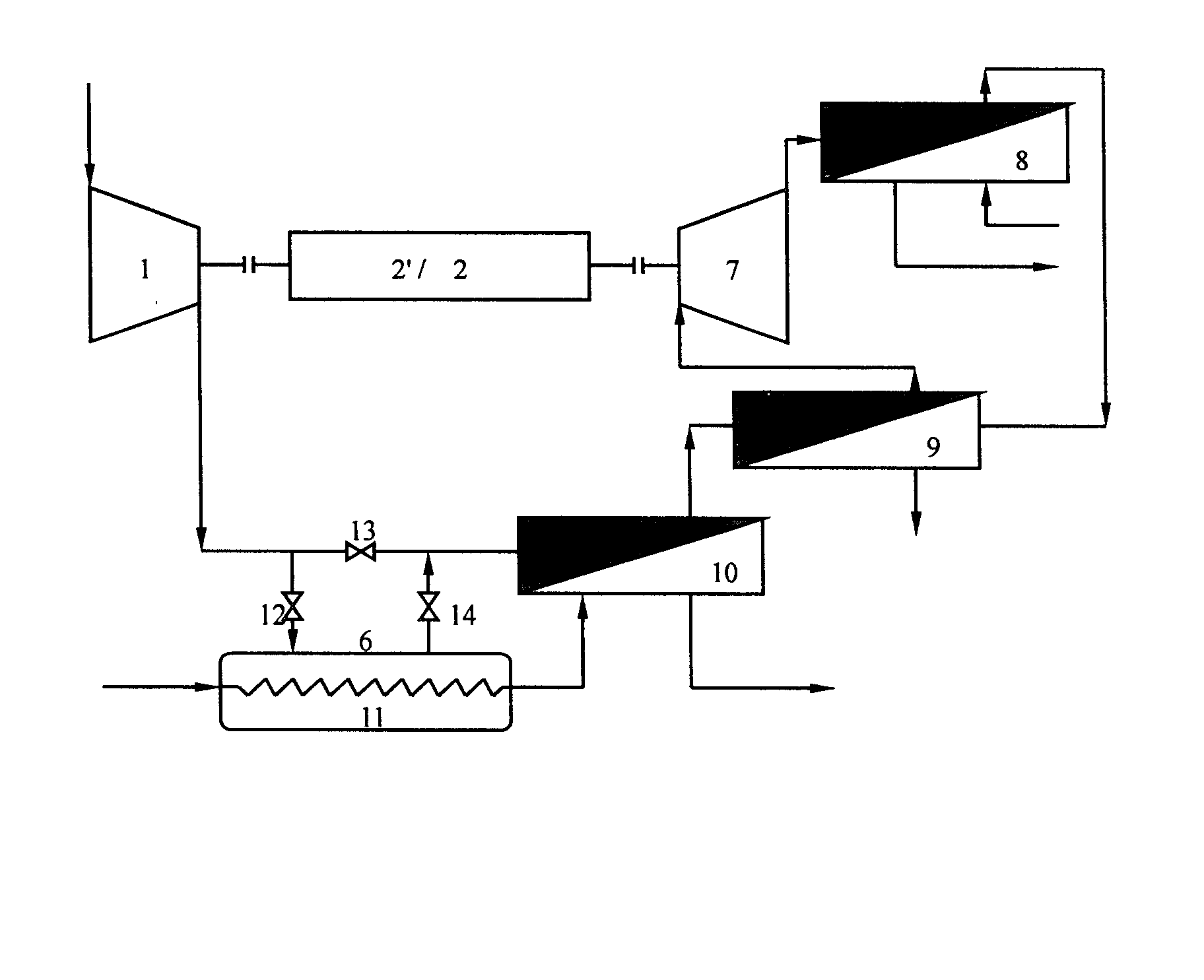

Combined Cycle CAES Technology (CCC)

InactiveUS20150000248A1Size reduction requirementsImprove efficiencySteam accumulatorsGas turbine plantsBrayton cycleAir compression

This is a system that stores energy by compressing atmospheric air and confining it in tanks or caverns, combining the thermodynamic cycle followed by the atmospheric air (Brayton cycle) with another thermodynamic cycle followed by an auxiliary fluid, that is confined in the same cavern within a membrane, following two sections of a Rankine cycle, one during the air compression and entry into the cavern process and the other during the air outlet and turbininig process, using heat from the exhaust gases from the turbine as a heat source for an additional Rankine cycle, and being able to use the tanks or caverns for making an extra constant volume heating of compressed air and I or of the auxiliary fluid

Owner:PREXTOR SYST

Method for preparing compressed air by pneumatic air compressor

InactiveCN101162073AIncrease productionImprove powerContainer filling under pressureElectricityAir compression

The invention relates to a preparation process for compressed air, in particular to a preparation process for compressed air, in which, a wind turbine sends the produced power to an air compression fan for air compression, then the compressed air is conveyed into a gas storage tank or directly conveyed to a pneumatic air compression fan of the user. The prior preparation process for compressed air mainly adopts that a motor is electrically driven in second energy conversion mode to produce the compressed air, which causes the vast waste of the energy during the conversion; wind is the never-ending renewable energy, and the compressed air produced by wind has no pollution to the environment and can be repeatedly used for a long time.

Owner:邸慧民

Tower-pressure type wind power generator

InactiveCN101070822AReduce lossesWind energy with garvitational potential energyEnergy storageAir compressionDrive shaft

Owner:FANGXIA ENTERPRISE INFORMATION CONSULTING WUJIANG

Hybrid gas turbine propulsion system

ActiveUS9212625B2Reduce fuel consumptionImprove responsivenessGas turbine type power plantsGas turbine plantsJet aeroplaneAir compression

Owner:SHELLEY RUDOLPH ALLEN

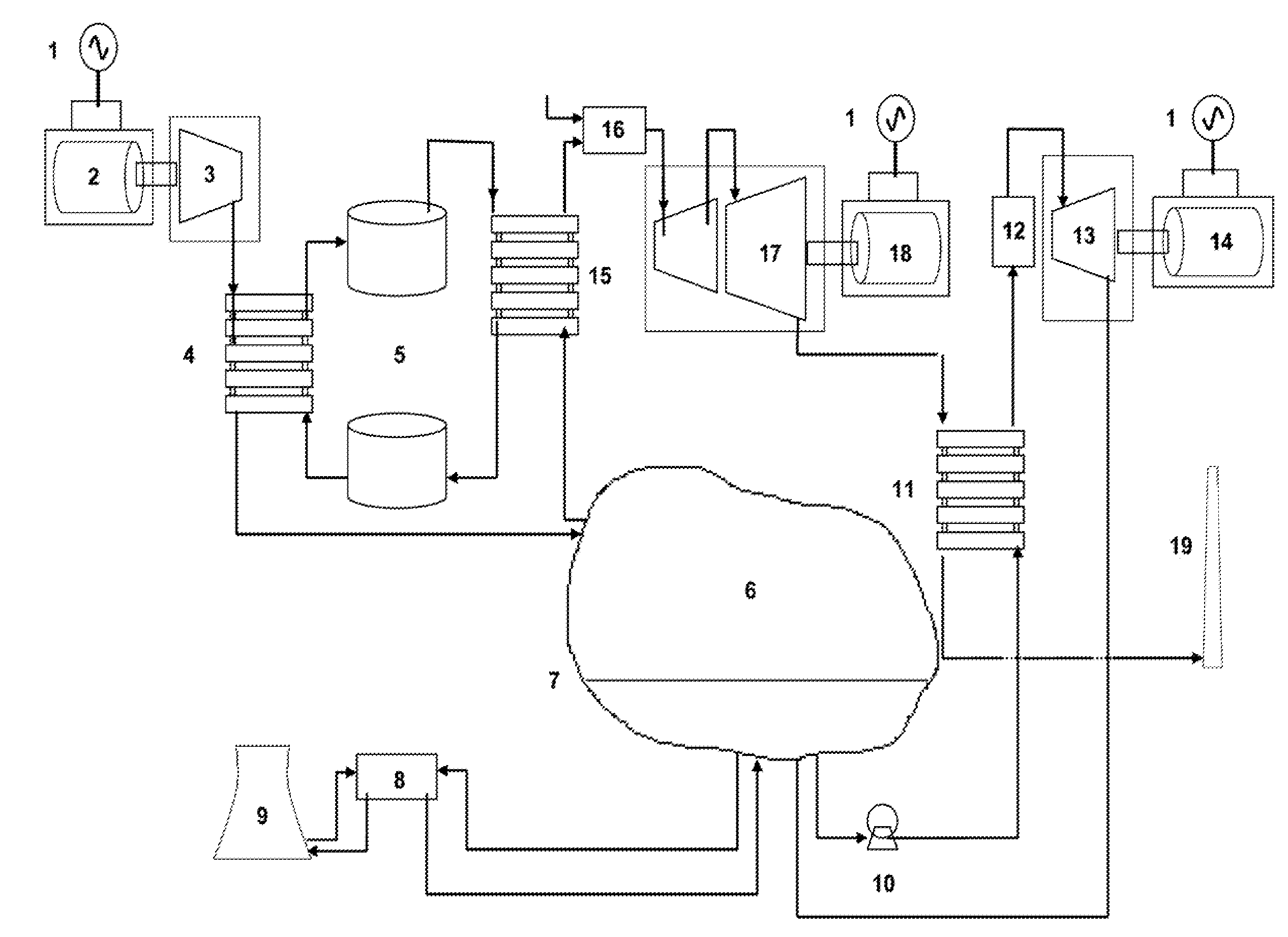

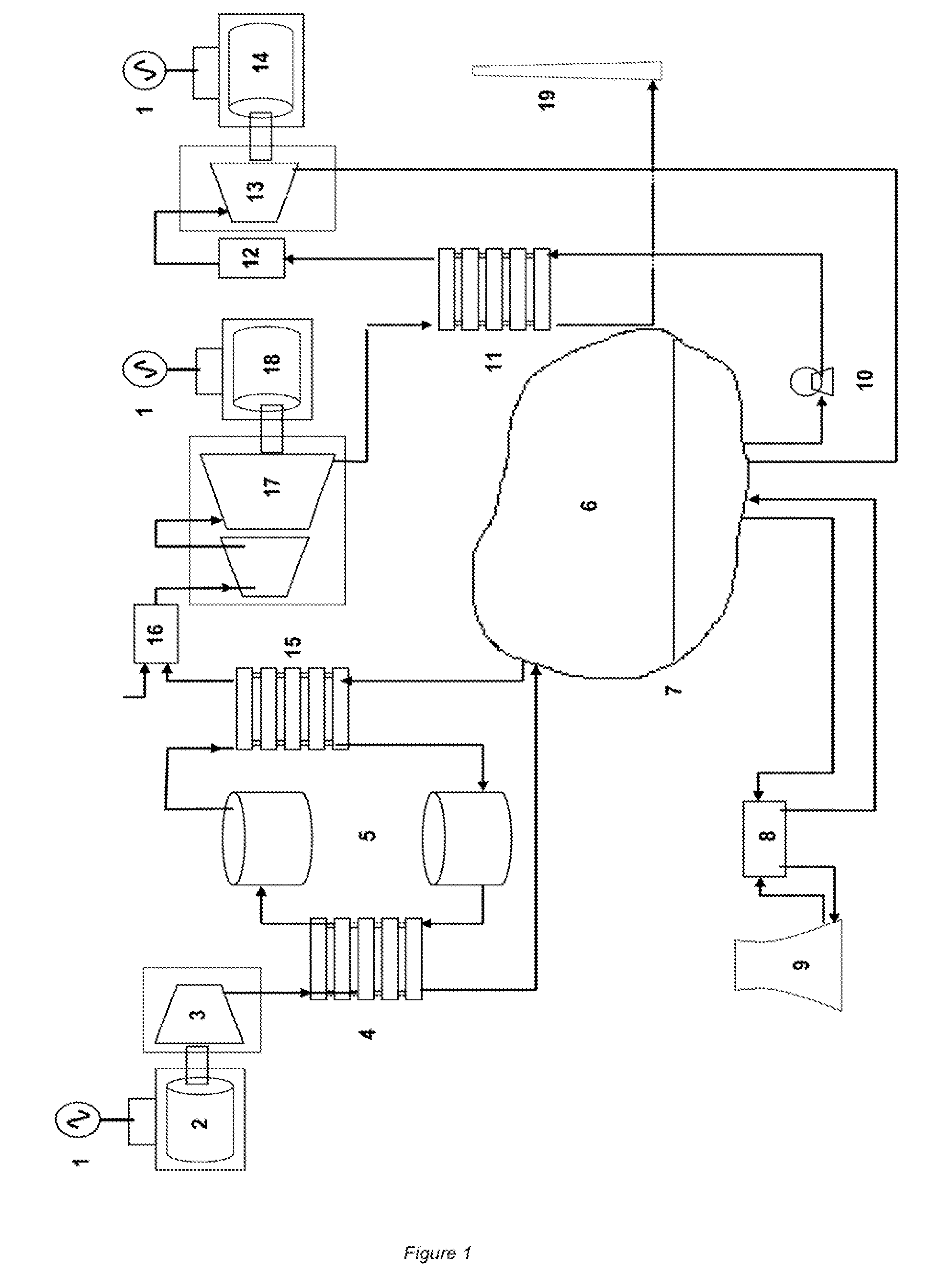

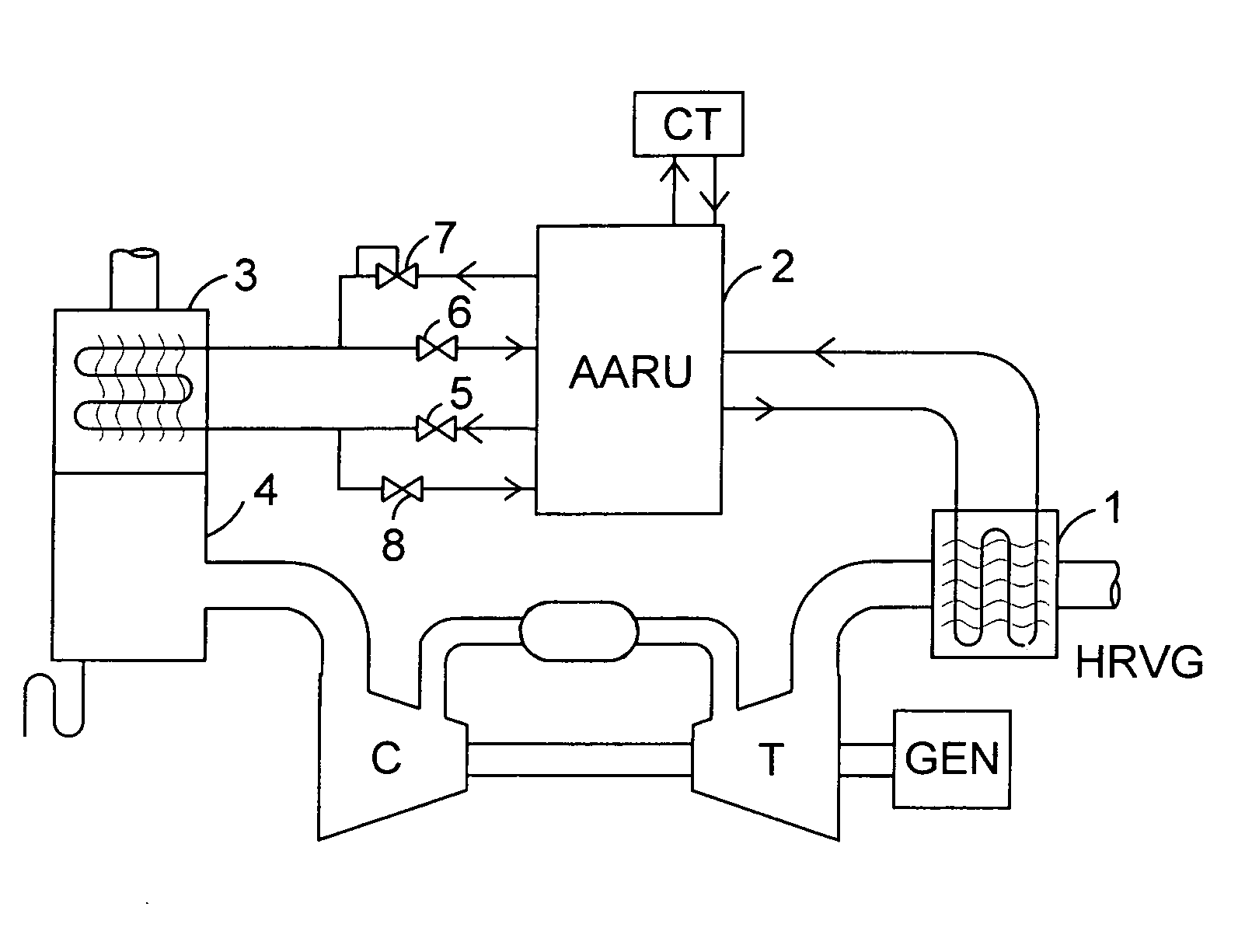

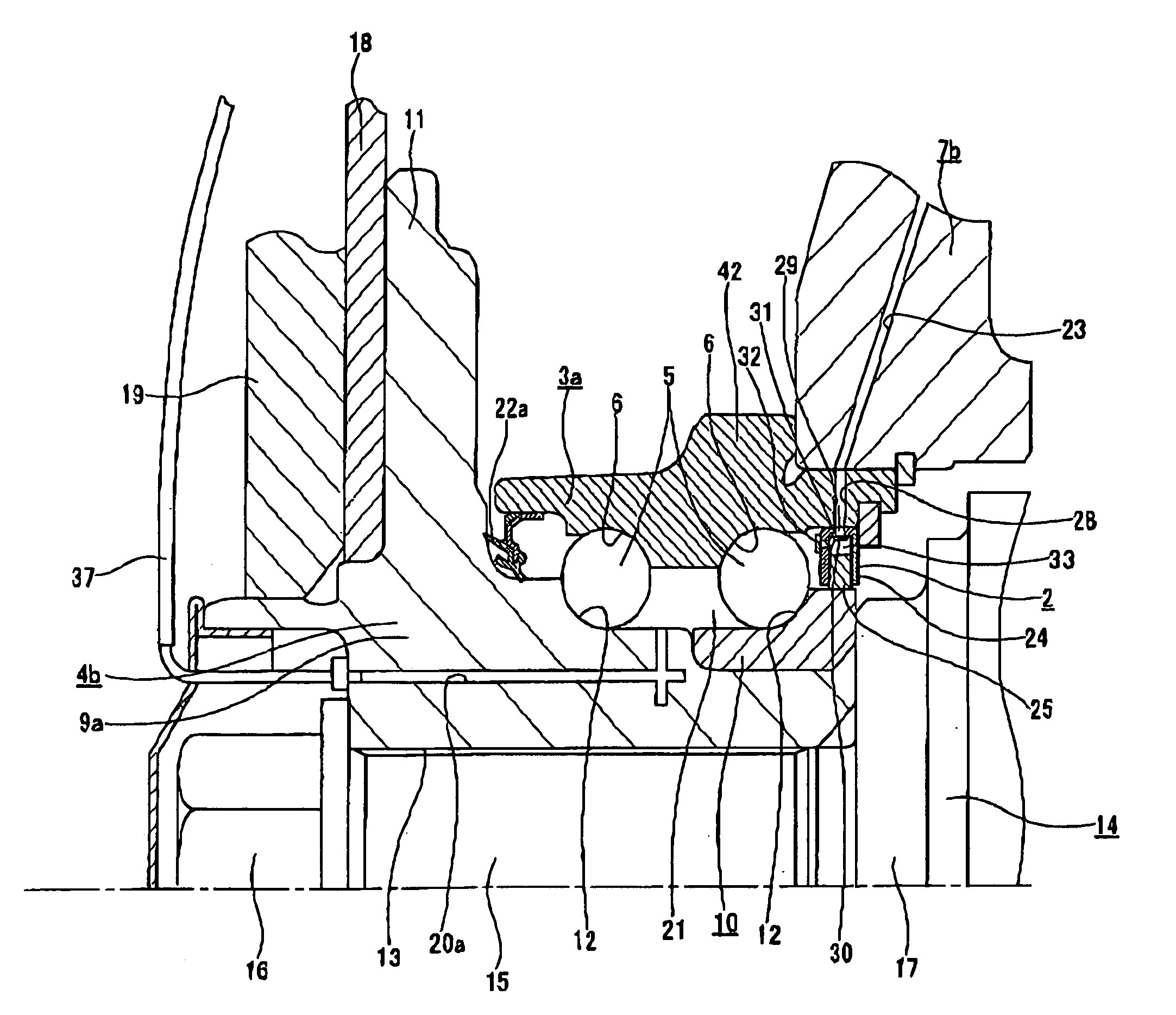

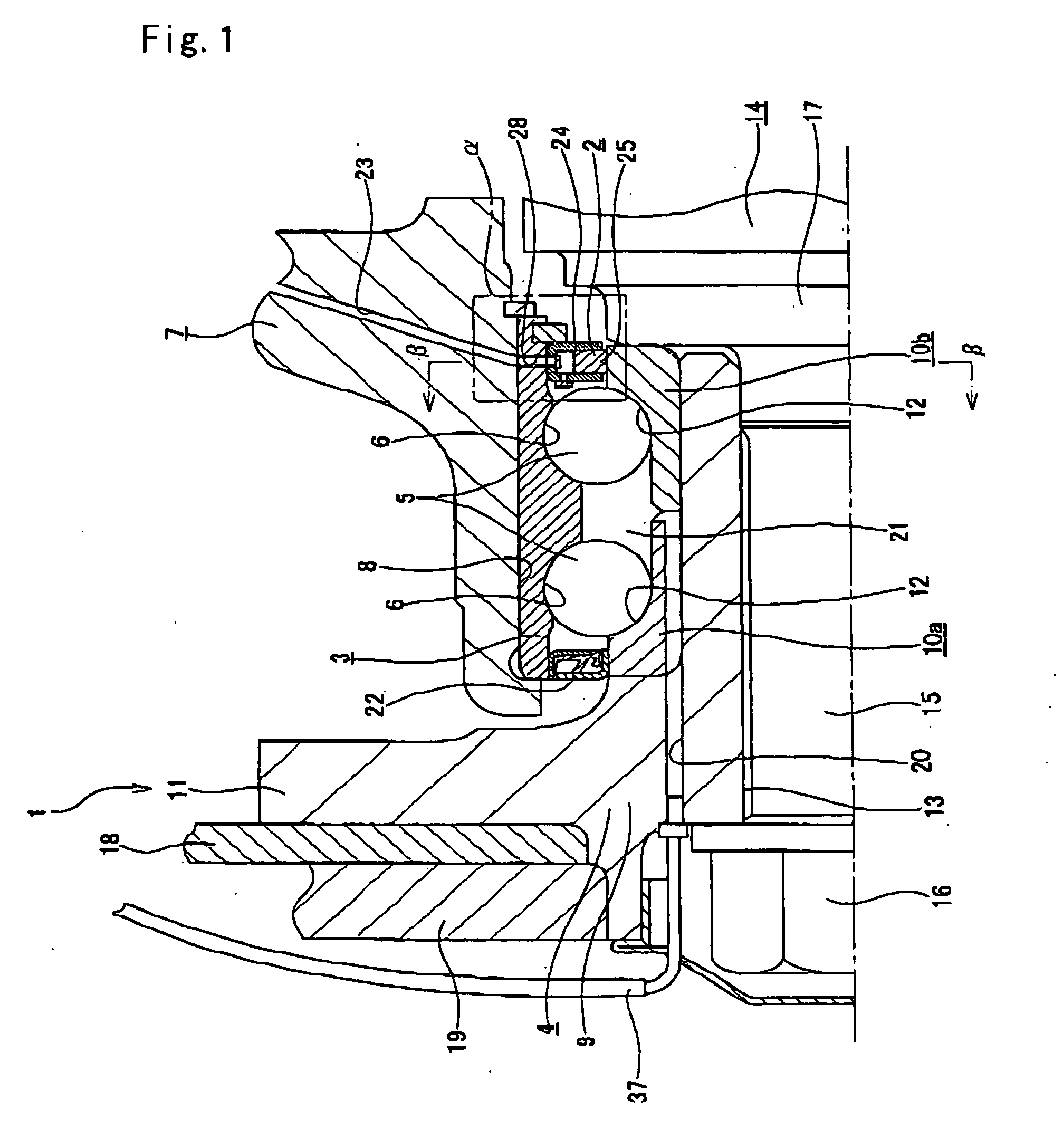

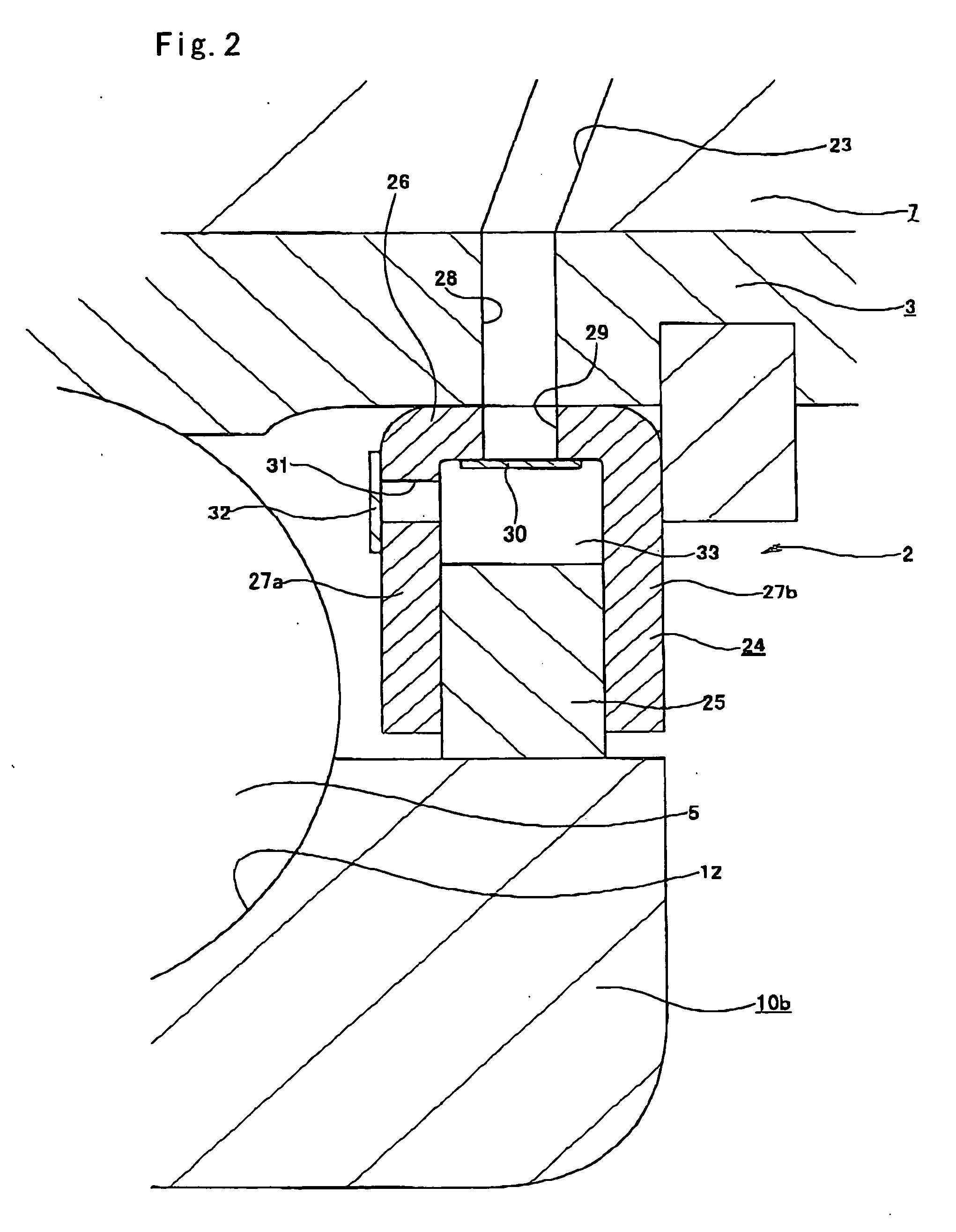

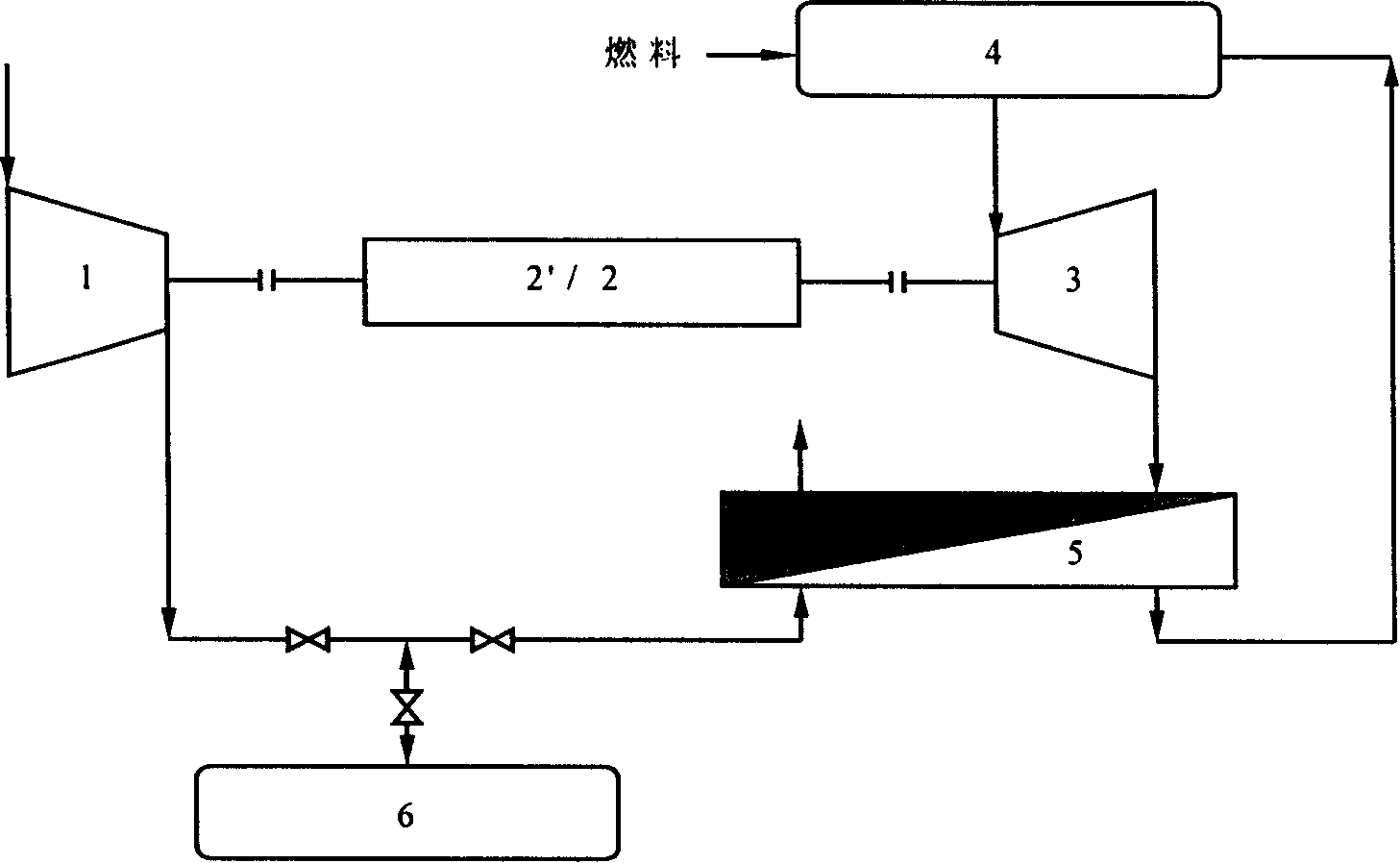

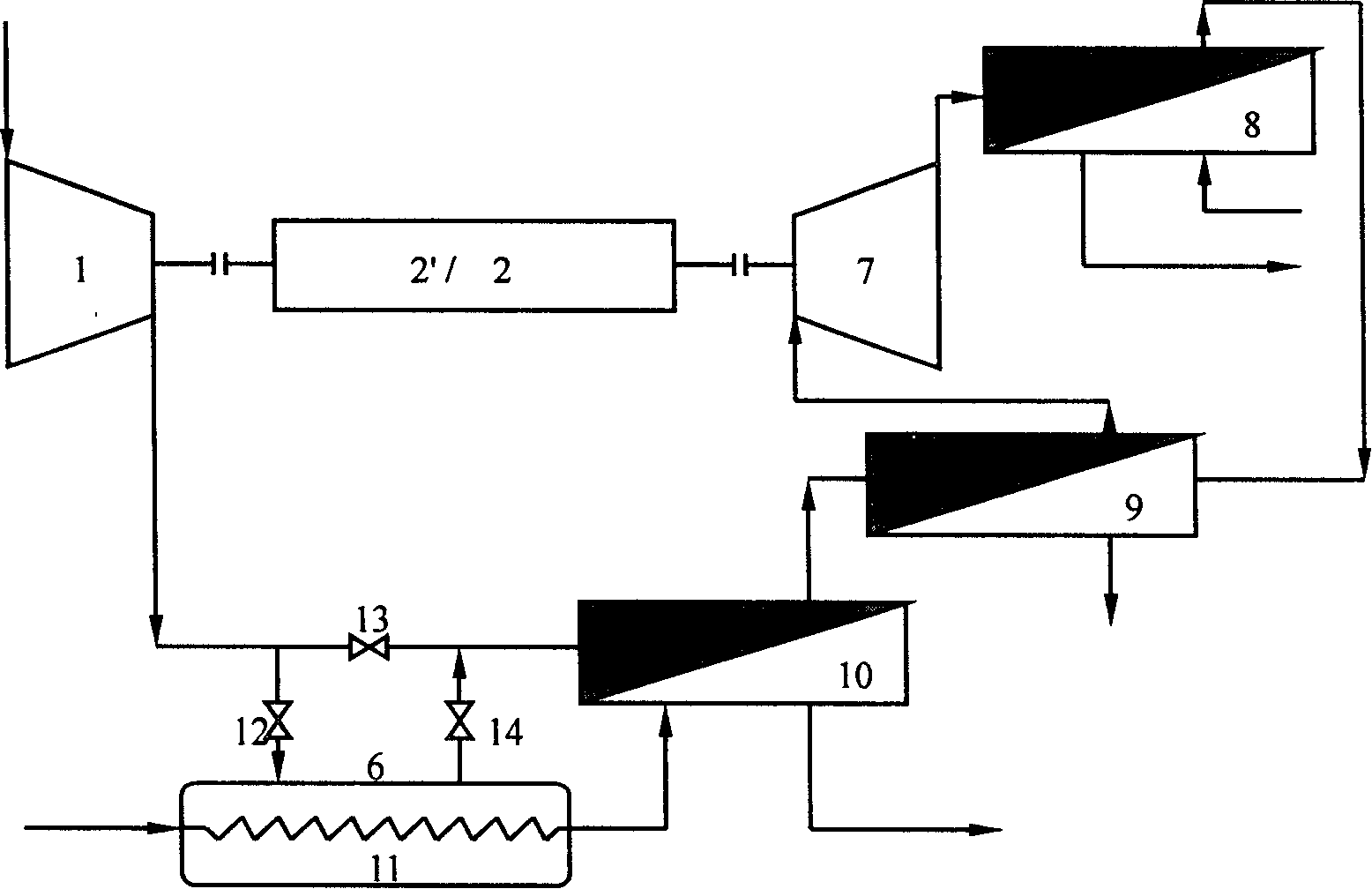

Thermally powered turbine inlet air chiller heater

InactiveUS20090049836A1Turbine/propulsion engine coolingEnergy efficient heating/coolingEngineeringAir compressor

An improvement to the air compressor of a combustion turbine system is disclosed, which makes the air compression more energy efficient plus have higher capacity on warm days. The same equipment with minimal modification is used to prevent inlet air icing conditions on cold days. Referring to FIG. 1, inlet air conditioner 3 supplies conditioned (chilled or heated) air to the combustion turbine, and heat recovery unit 1 supplies turbine exhaust heat to ammonia absorption refrigeration unit 2. Control valves 5, 6, 7, and 8 selectively supply either chilling refrigerant liquid or heating vapor to conditioning coil 3.

Owner:ERICKSON DONALD CHARLES +1

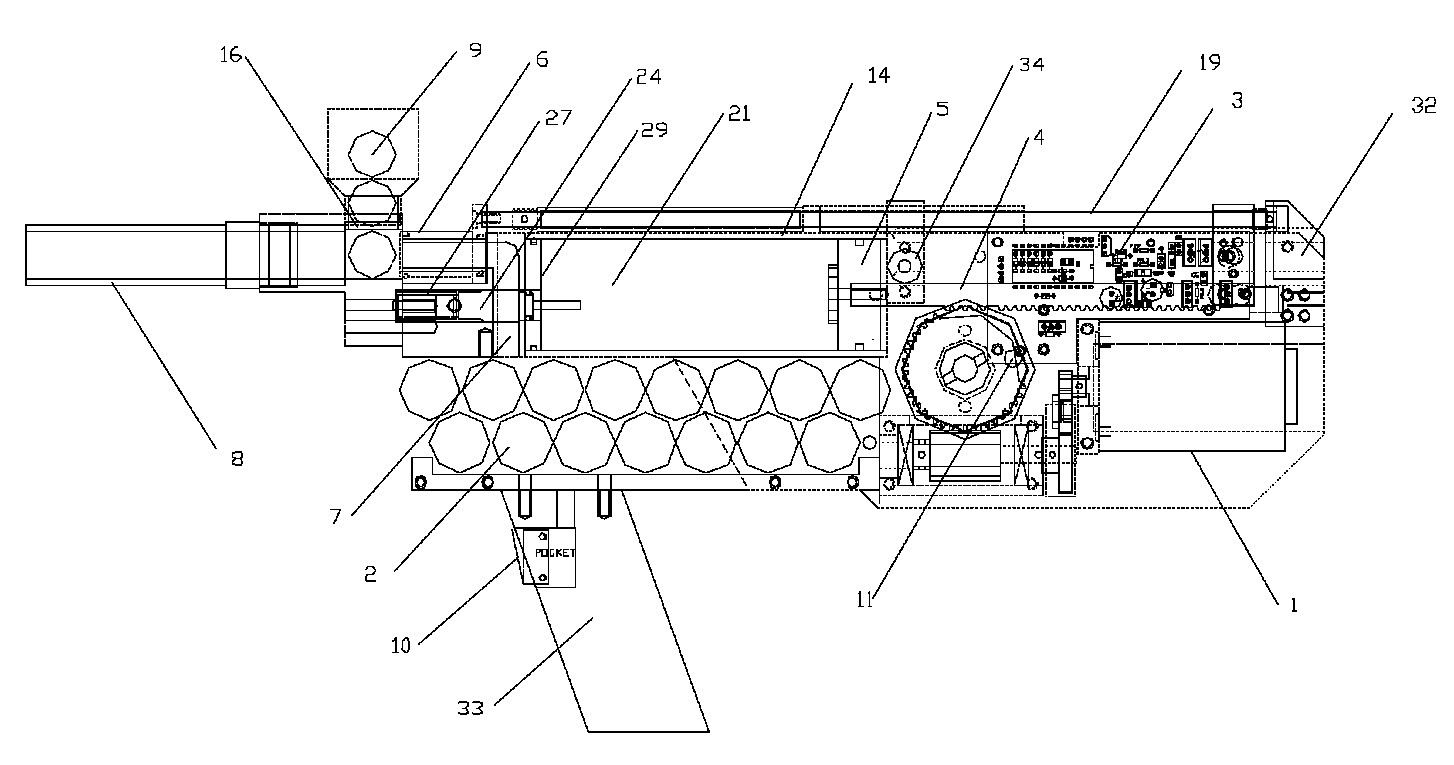

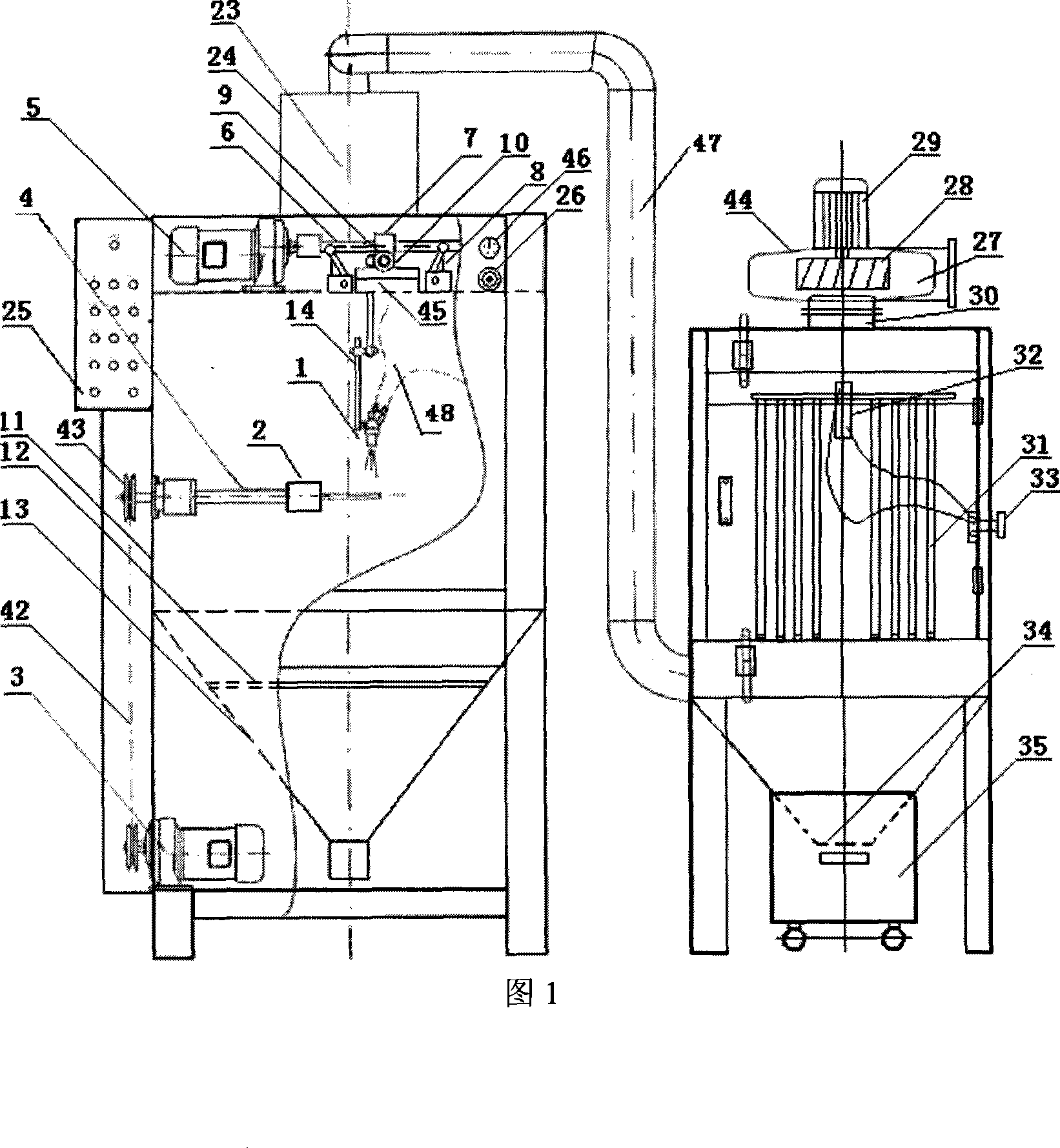

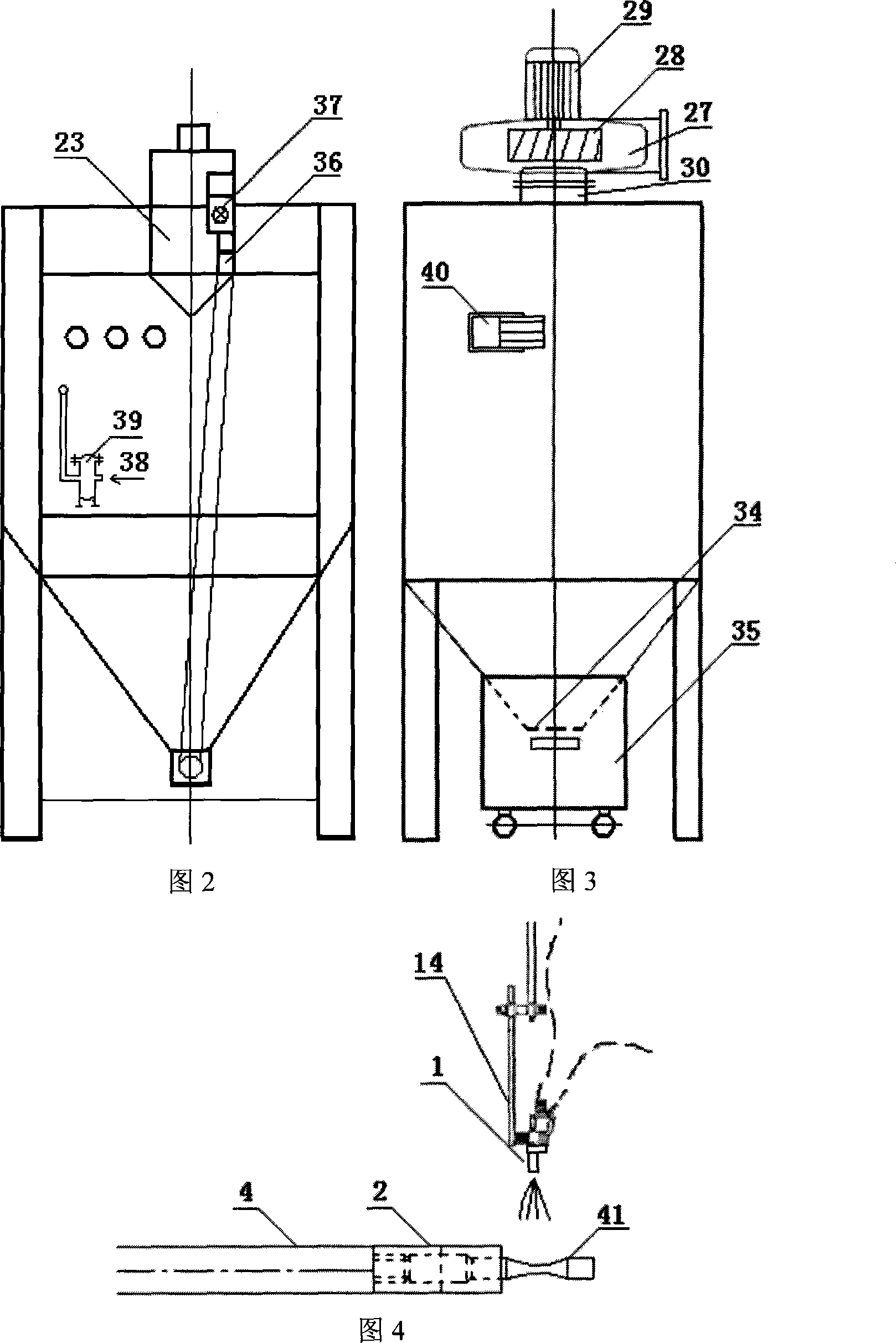

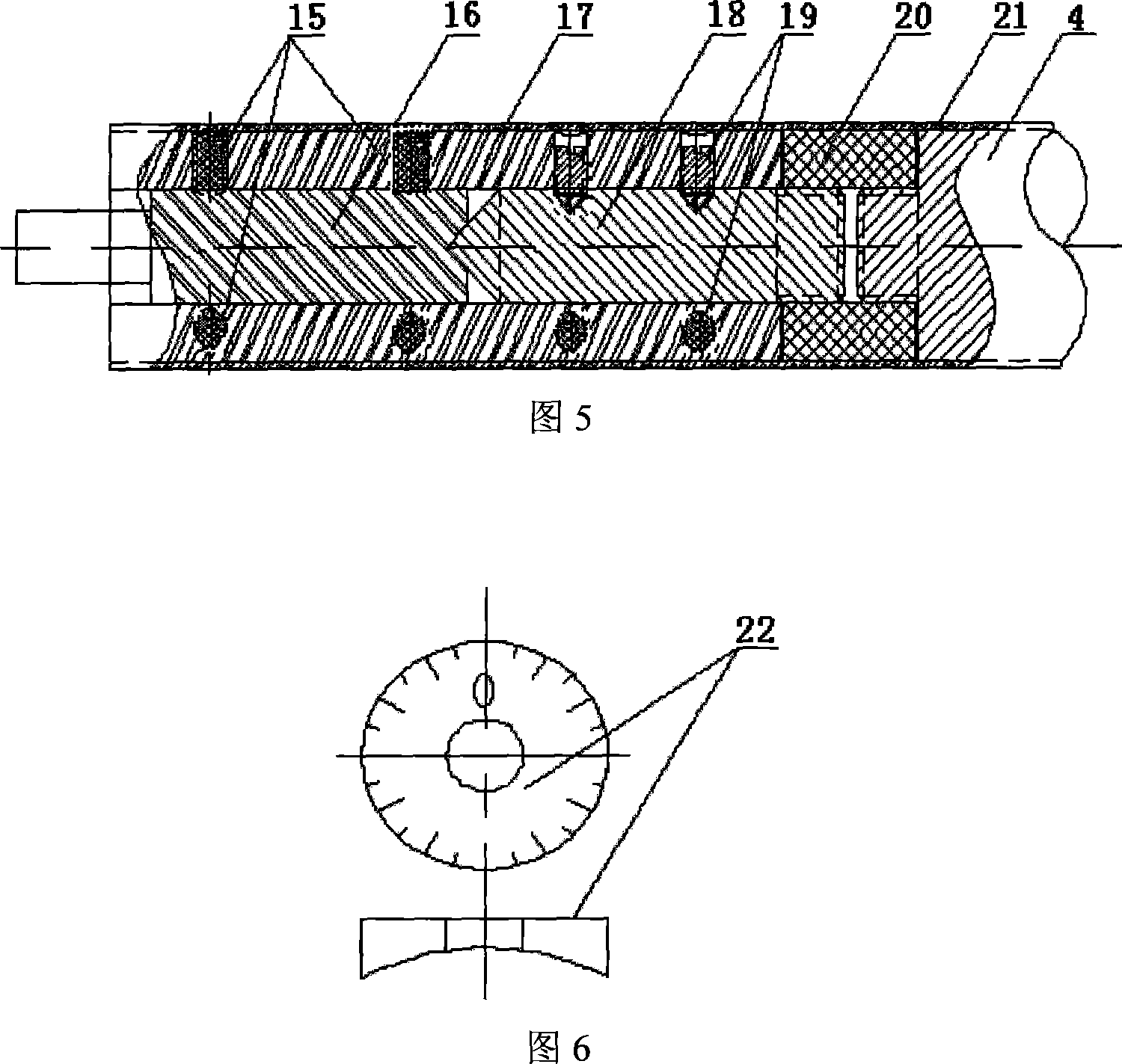

Shot peening machine for processing surface deformation strengthening treatment to magnesium alloy sample

InactiveCN101214633AGuaranteed concentricityGuaranteed parallelismImpeller wheelsBlast gunsAir compressionAbrasive blasting

The present invention relates to a device in the technical field of material processing, in particular to a peener which carries out the surface deformation strengthening process on magnesium alloy samples. The present invention comprises a main peening system, an upper whirlwind separation system, a dedusting system, an air compression system and an electric system, wherein, the upper whirlwind separation system is positioned on the upper end of the main peening system, the lower part of the upper whirlwind separation system is communicated with the main peening system, the upper part is connected with the dedusting system, which is positioned outside the main peening system, the air inlets of both the dedusting system and the main peening system are connected with the air compression system, and the electric system is connected with the main peening system, the upper whirlwind separation system, the dedusting system and the air compression system. The present invention can conveniently assemble and disassemble the samples of the shaft class, the range of the generated peening strenghth is wide, the effect and uniformity of peening is good, and moreover, pollution can be prevented.

Owner:SHANGHAI AIERSI LIGHT ALLOY

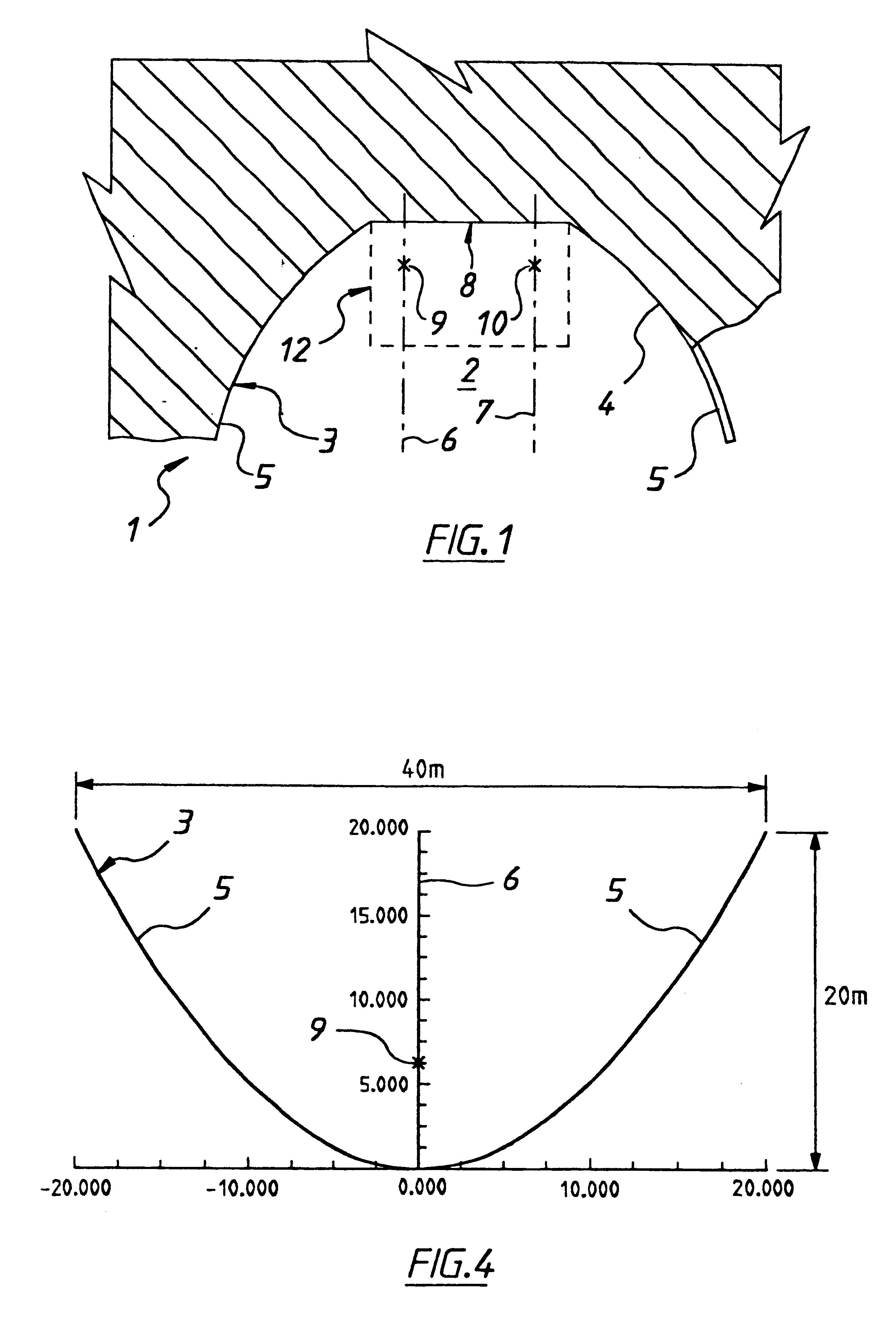

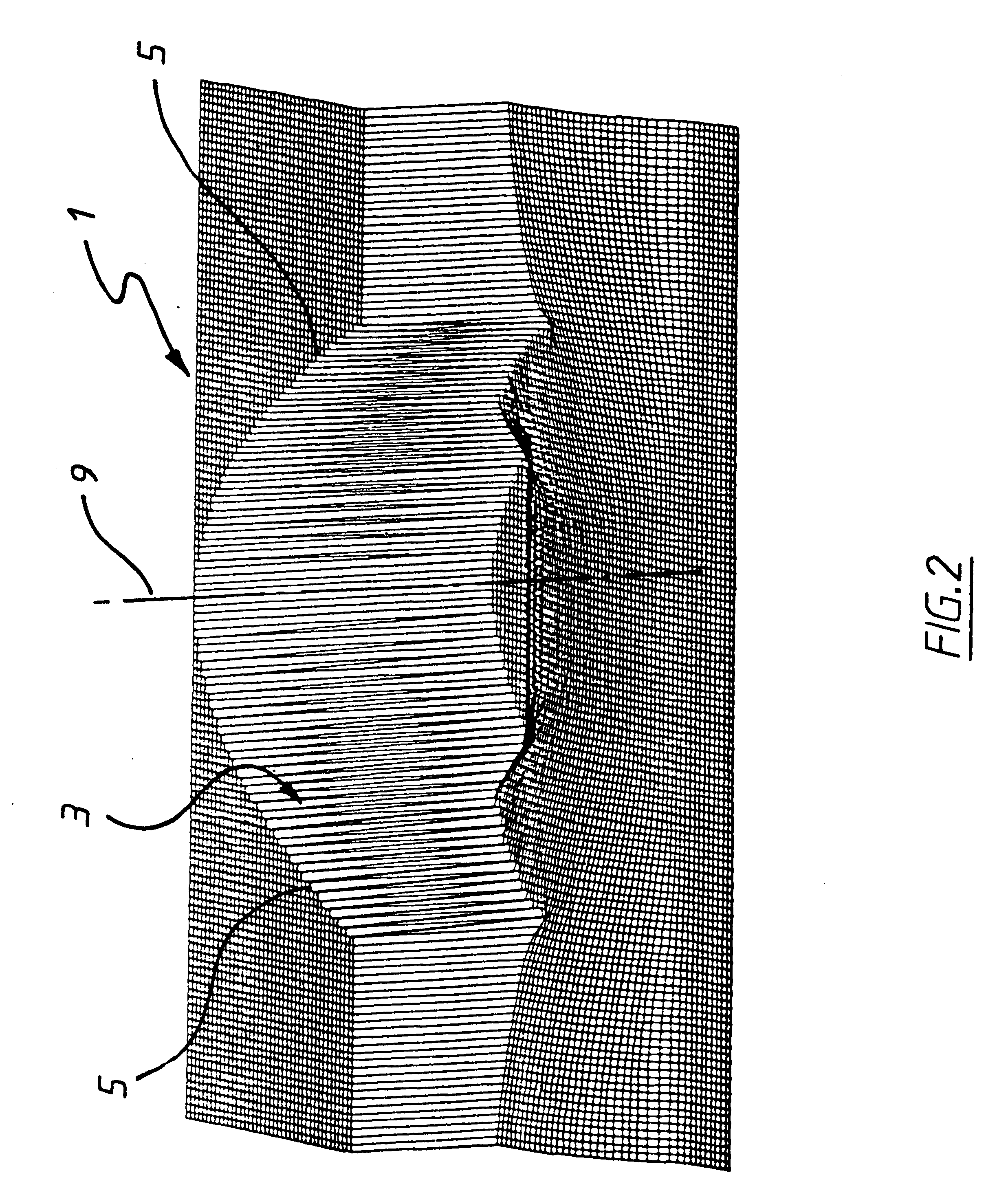

An ocean wave energy extraction system and components thereof

InactiveUS6622483B2Less-costly to constructMaximise the wave magnificationFluid couplingsWater-power plantsAir compressionEngineering

The invention relates to wave powered energy extraction systems and the components thereof, in which the oscillating ocean wave motion is used to displace a volume of air to drive a wind operated turbine connected to an electrical generator. The various aspects of the invention include: a parabolic or part parabolic wave focusing device (1); an air compression chamber arrangement particularly suited for use with the wave focusing device; a wind turbine operable to rotate unidirectionally under periodically reversing air flow conditions of the kind contemplated above.

Owner:ENERGETECH AUSTRALIA

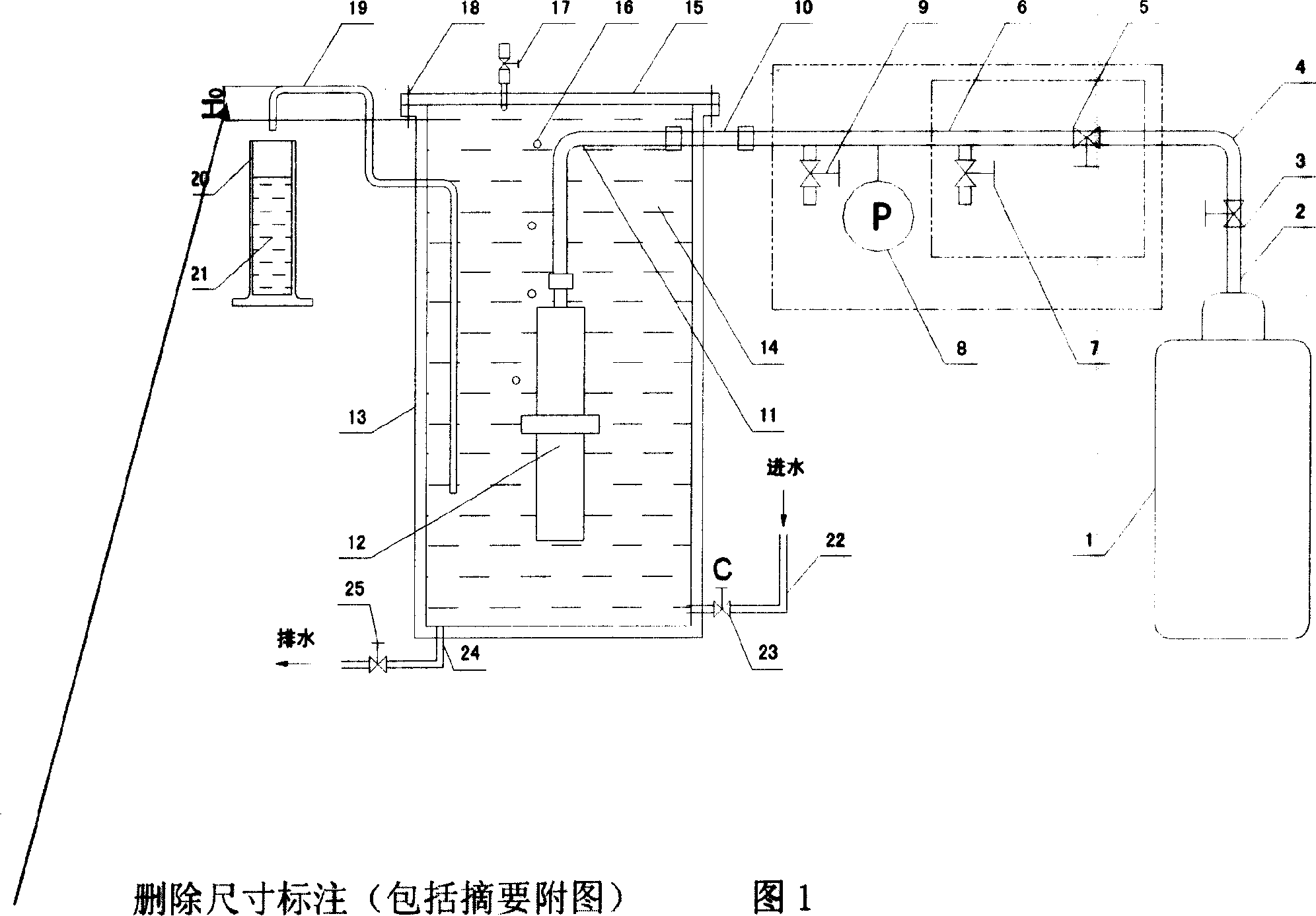

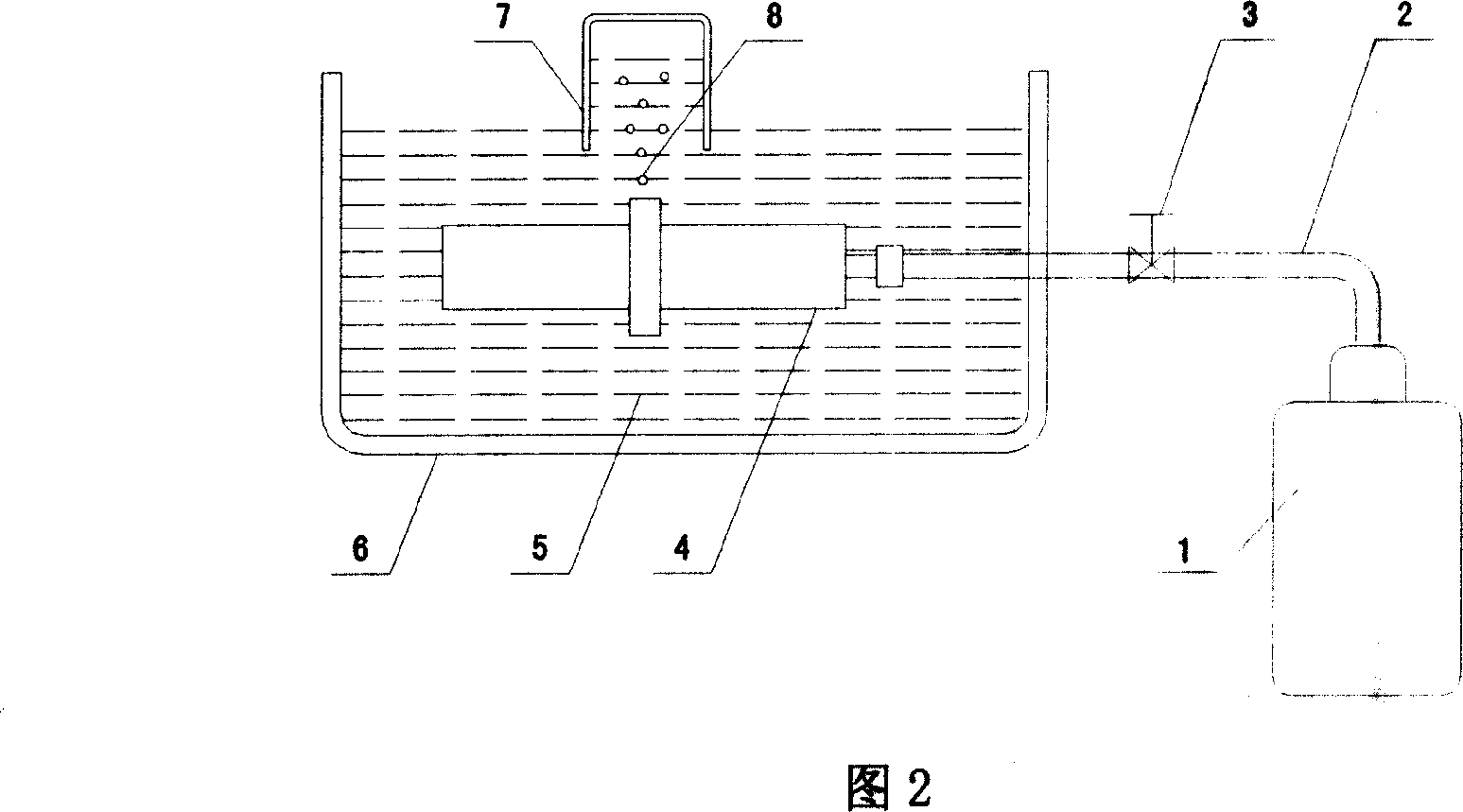

Airtight type tested pieces air-leakage detecting device

ActiveCN1932464AThe collection method is scientific and reliableEnsure consistencyDetection of fluid at leakage pointVolume measurement apparatus/methodsAir compressionWater storage

The invention discloses a detecting device for the leakage of gas-tight test piece including the aqua storage tank of the watertight test piece and the air compressing device to fill the pressure to the gas-tight test piece and the measuring cup to collect the leaking gas. The aqua storage tank is connected with the test piece inside and the conduit of the air compressing device in outside which is installed with the stabilizing voltage device. The water storage vessel has a flooding pipe connected to the out and a measuring cup. The invention transforms the reverse scale reading of the original air volume to the forward scale reading of the liquid volume by the liquid drained by leaking gas of the closed test piece. Therefore, it can assure the coherence of the reading and the fact leaking quantity.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

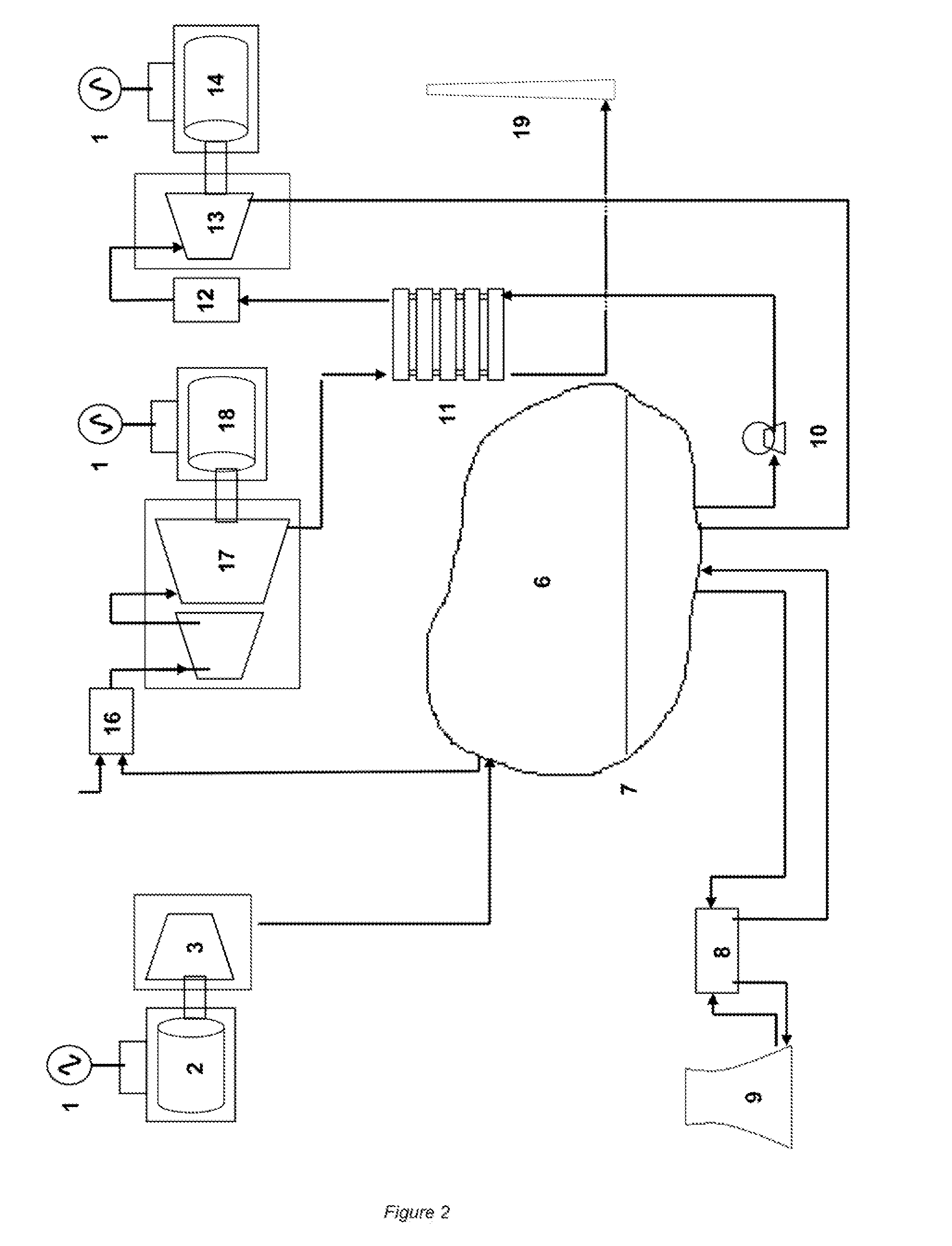

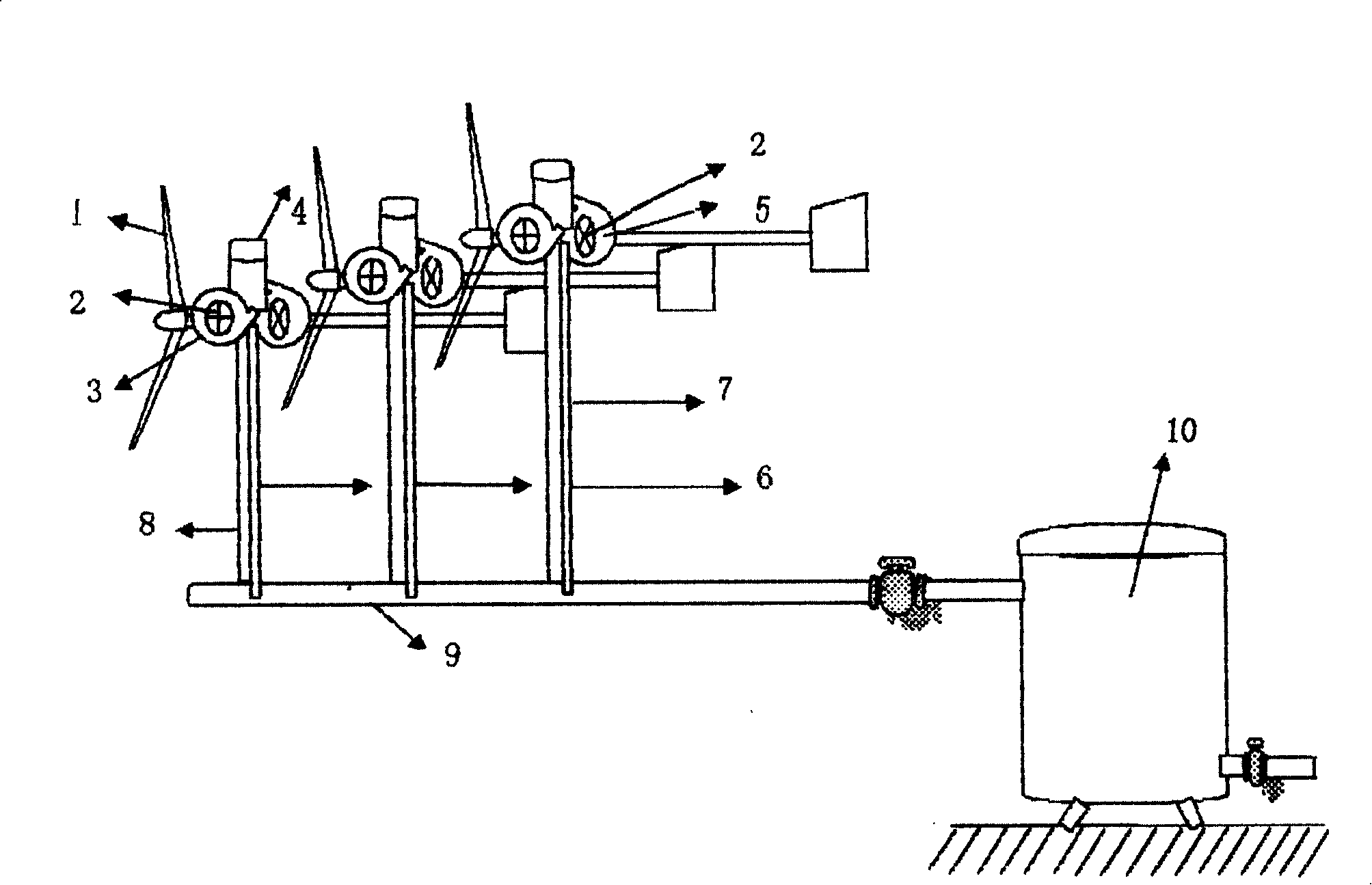

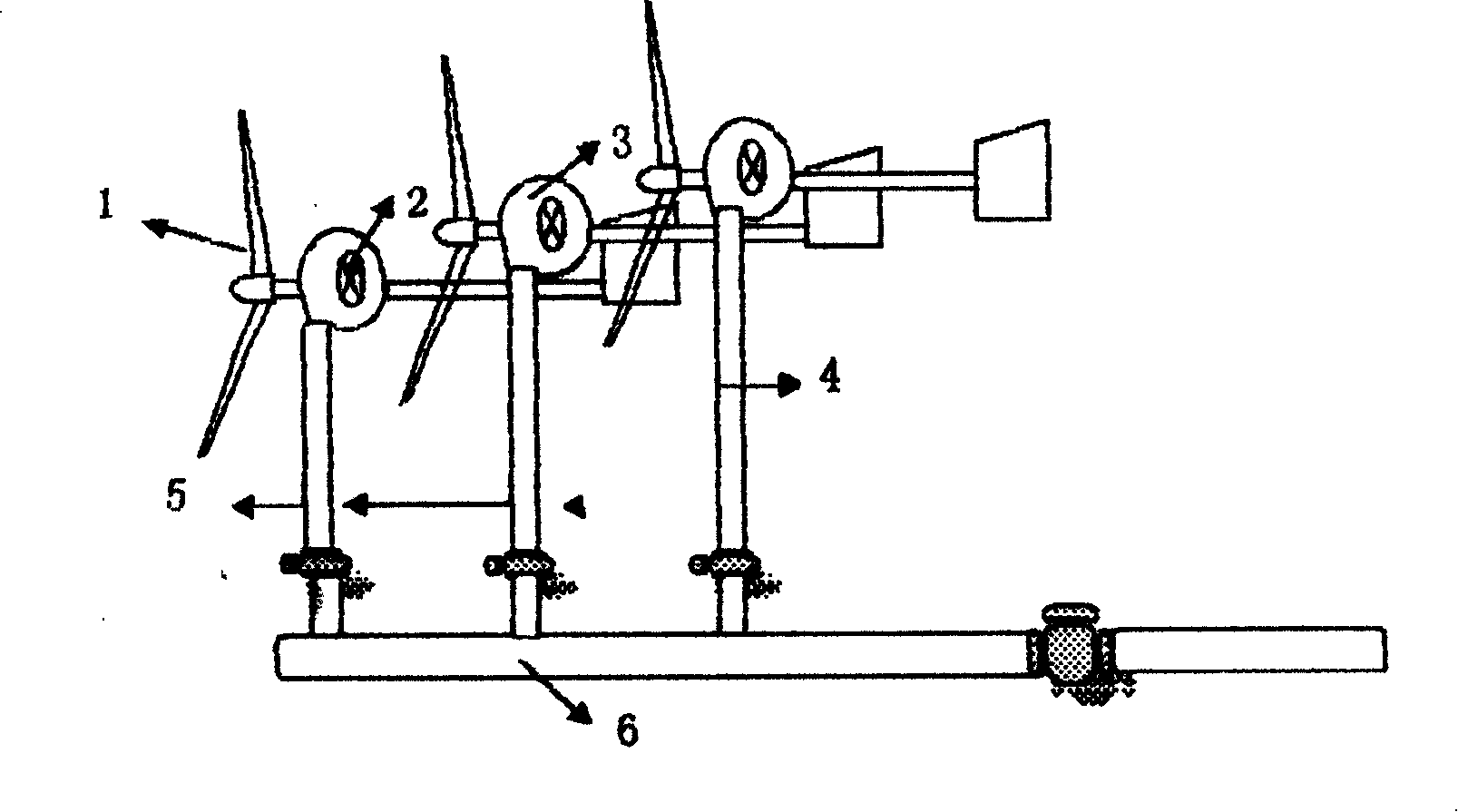

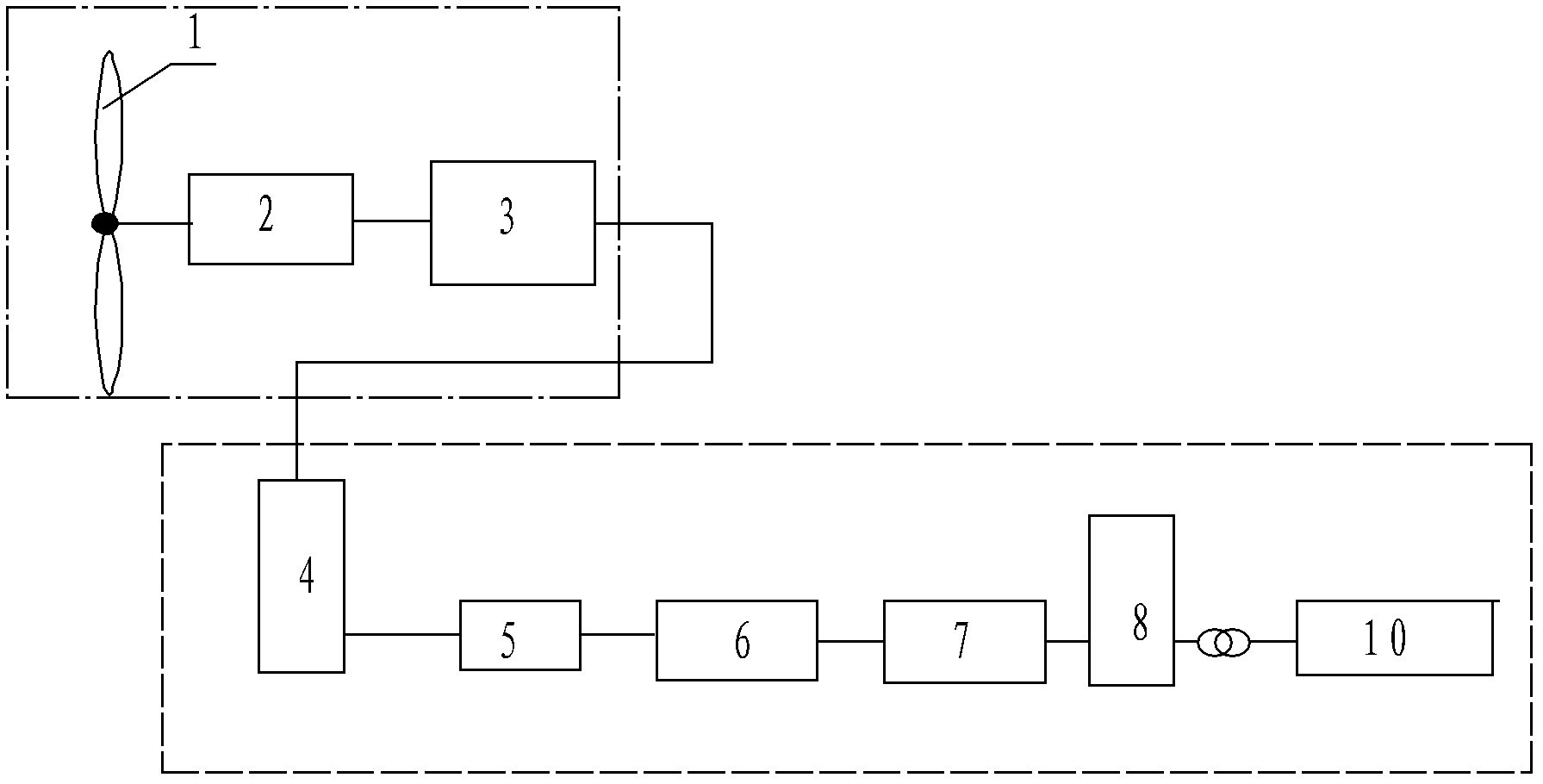

Air compression energy storage wind power generation method and generating set thereof

InactiveCN102305193AImprove efficiencySmall radius of rotationFrom solar energyFinal product manufactureMechanical energyAir compressor

The invention discloses an air compression energy storage wind power generation method and a generating set thereof for overcoming the rotation rate limitation and the problems of a rigid drive system in the prior art. The air compression energy storage wind power generation method comprises the following steps: 1, wind wheels convert the kinetic energy of wind into mechanical energy; 2, the wind wheels drive an air compressor to work so as to generate compressed air; 3, an air storage tank stores the compressed air; 4, the compressed air drives an air motor or a steam turbine; 5, the air motor or the steam turbine drives the generator to generate electricity; and 6, the surplus electric energy is stored. The invention also provides an air compression energy storage wind power generating set and a surplus electric energy storage device. The air compression energy storage wind power generating set comprises wind wheels, a speed increasing gear case, an air compressor, an air storage tank, an electric control valve, an air motor or a gas turbine and a generator. In the surplus electric energy storage device, the wind wheels and the speed increasing gear case of the air compression energy storage wind power generating set are replaced by electromotors, and other parts are the same as those of the air compression energy storage wind power generating set.

Owner:初立森

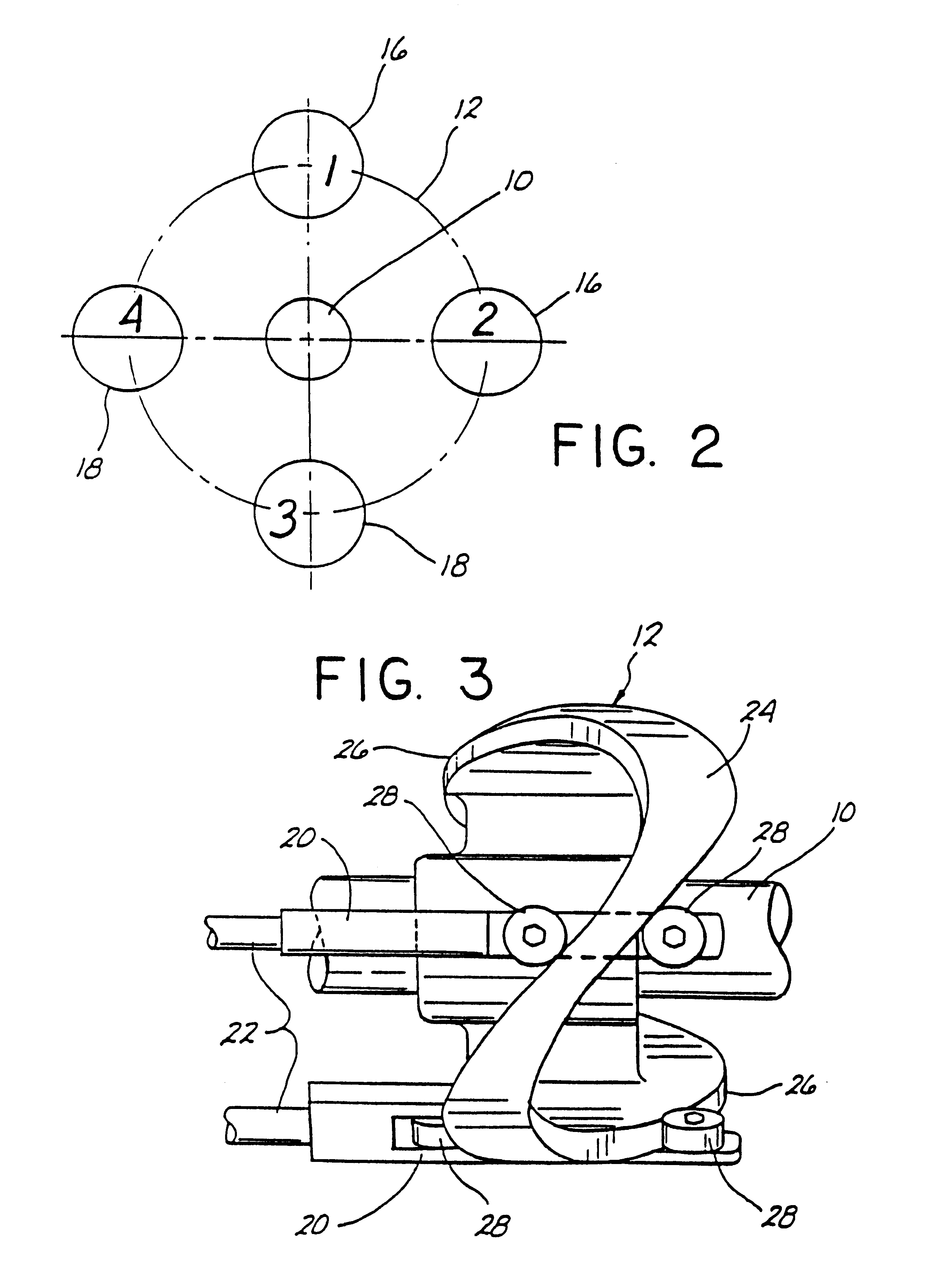

Rolling bearing unit for supporting a wheel with an air compressor

ActiveUS20080006357A1Lower resistanceImprove balanceRolling contact bearingsBearing assemblyAir compressionRolling-element bearing

A wheel-supporting roller-bearing unit with air compressor that is compact and capable of keeping resistance against the rotation of the hub 4c low while at the same time maintaining good balance, and when necessary, is capable of obtaining compressed air having sufficient pressure regardless of the traveling speed of the vehicle. A plurality of cylinder holes 53 are located at a plurality of locations that are evenly spaced around the circumferential direction on the inside of a cylinder block 50 that is connected and fastened to the inside end section in the axial direction of the hub 4c. Pistons 54 fit inside these cylinder holes 53 and are moved back and forth by a piston-drive mechanism 62 as the cylinder block 50 rotates. The air compressor 2c is a reciprocating-piston compressor, so it is possible to obtain the required air pressure regardless of rpm. Also, by placing a plurality of cylinder holes 53 and pistons 54 at uniform intervals around in the circumferential direction, it is possible to suppress the resistance against the rotation of the hub 4c.

Owner:NSK LTD

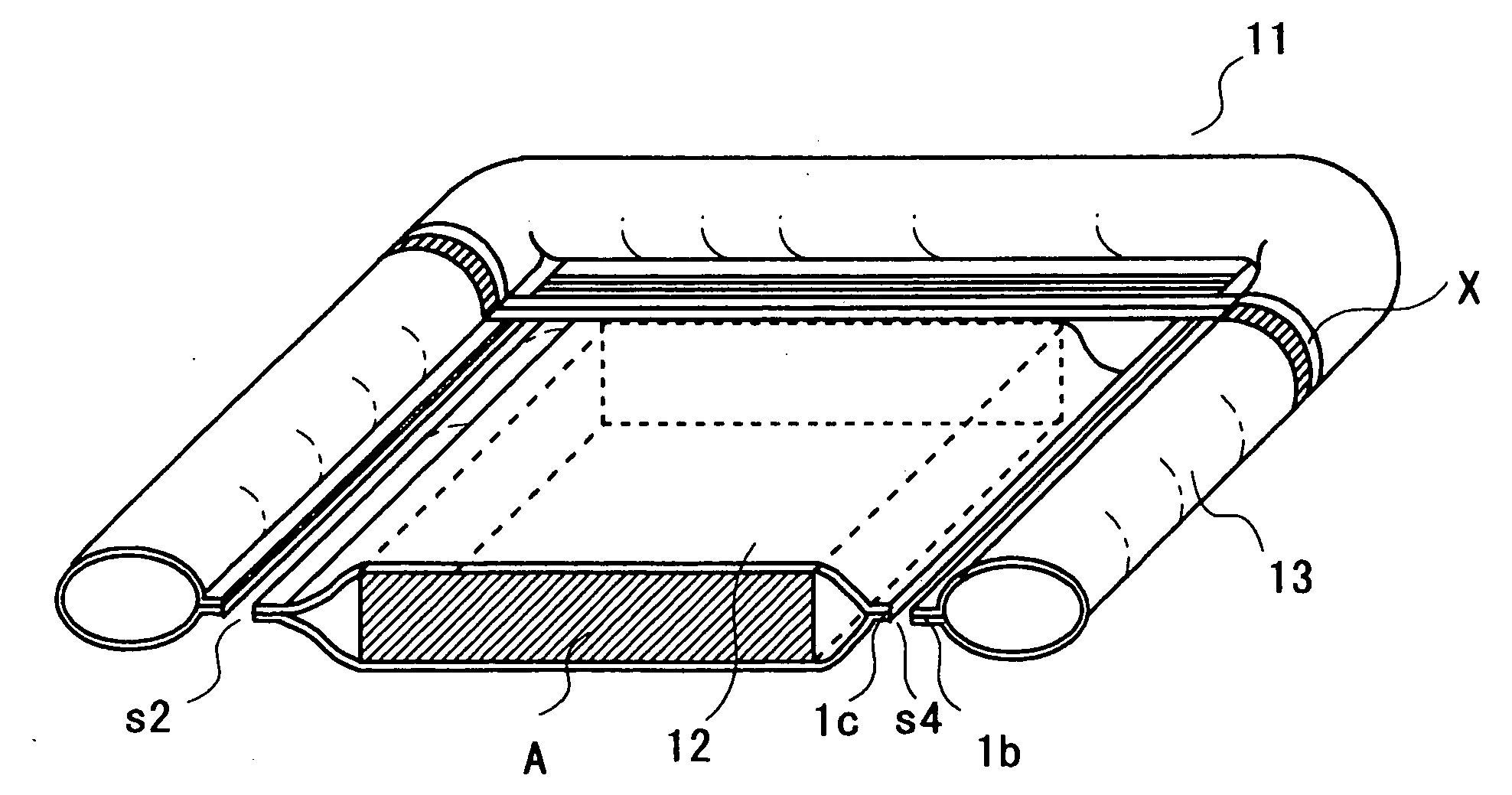

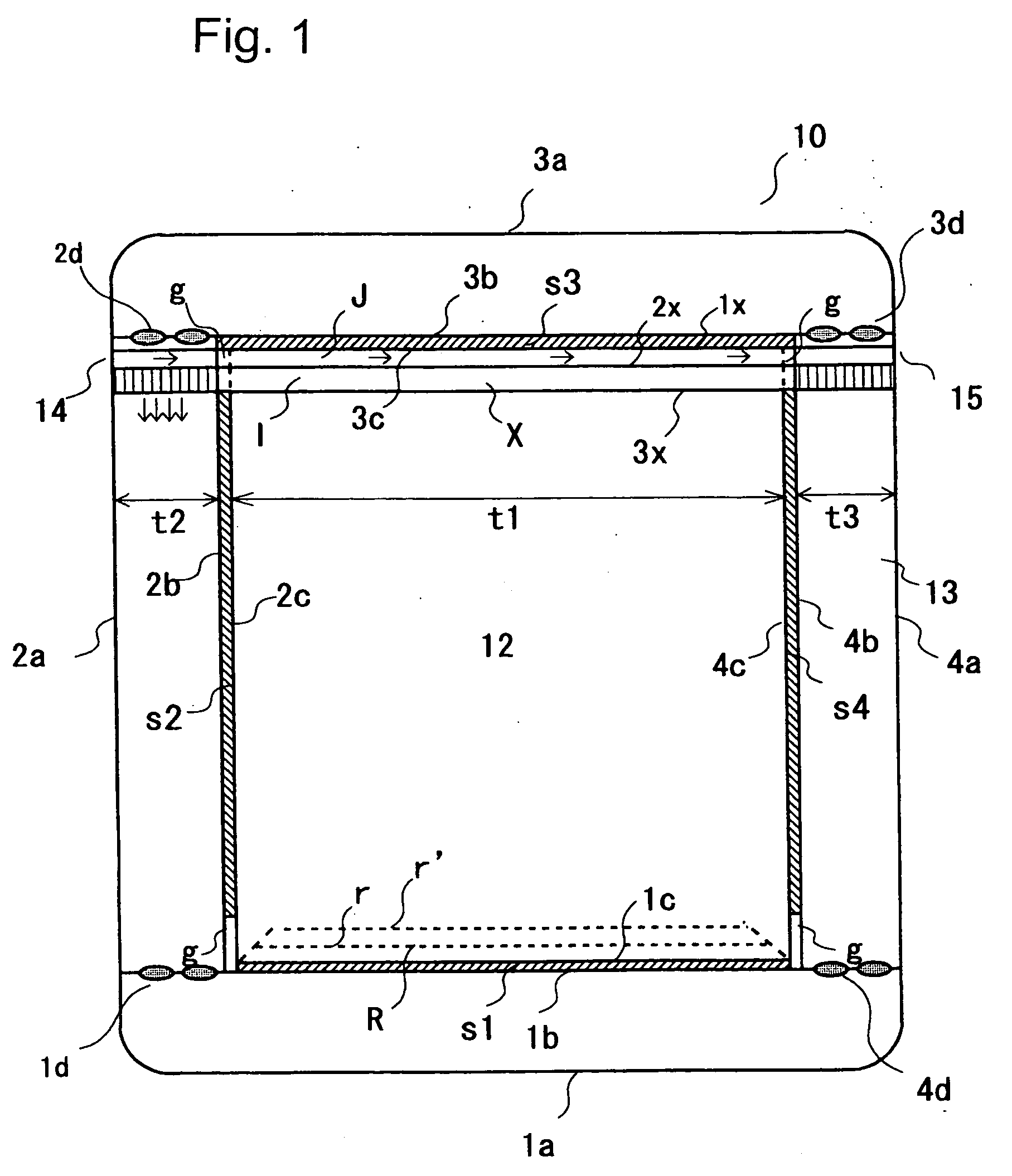

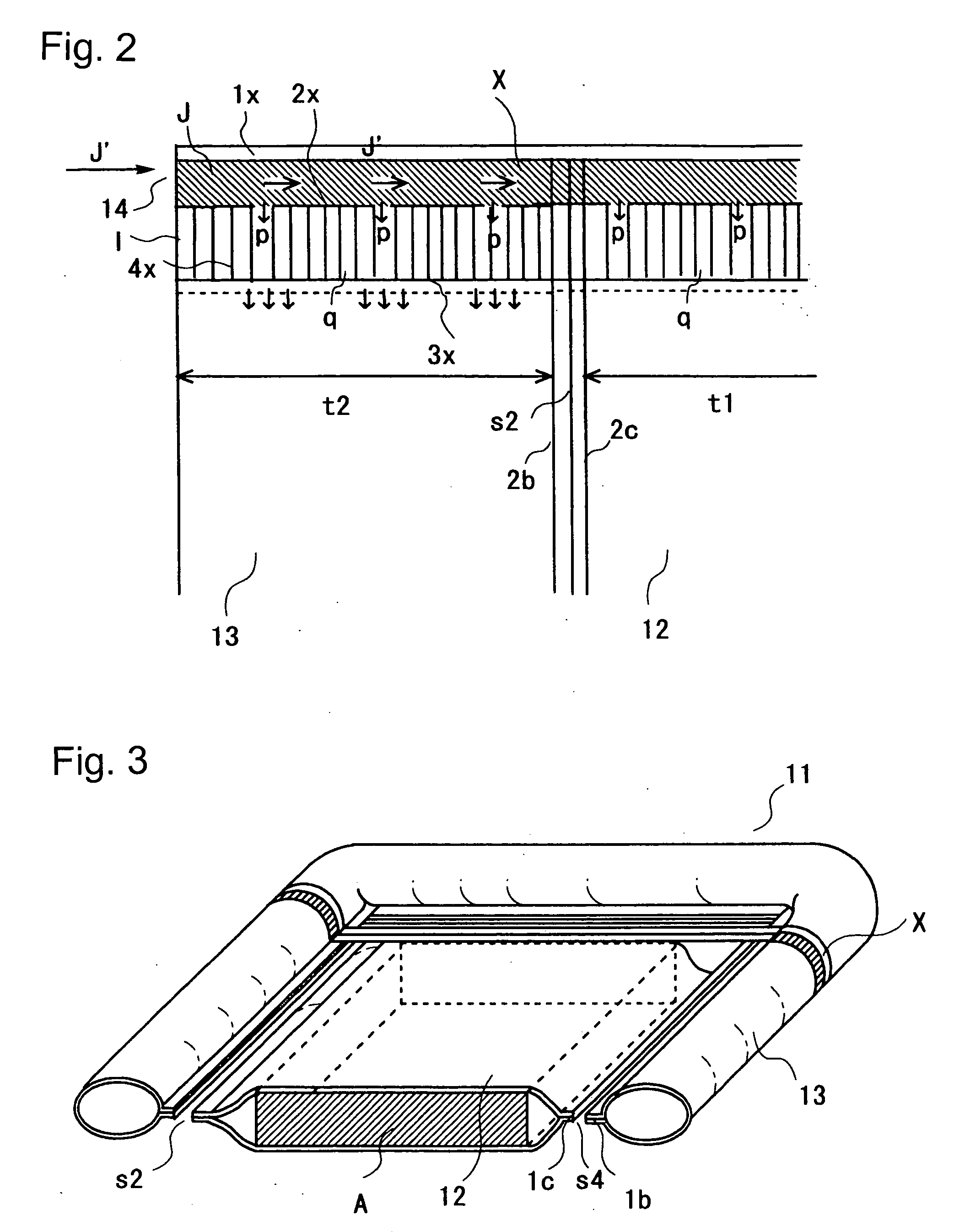

Cushion material for packaging product therein and suspension air-packing method using same

A cushion material for packaging a product is capable of absorbing shocks and impacts and being used for various types of product in a multipurpose manner. A large volume of the cushion materials can be produced through an automatic production process at a low cost. A suspension air-packing method using the cushion material packs the product in a mid-hanging manner. The cushion material includes at least two flexible films facing one another and the edges of the two films are heat-sealed, a bag portion for holding the product therein, and a cushion portion established on the outer periphery of the bag portion which will be inflated by the air when the compressed air.

Owner:YOSHIDA TAEKO

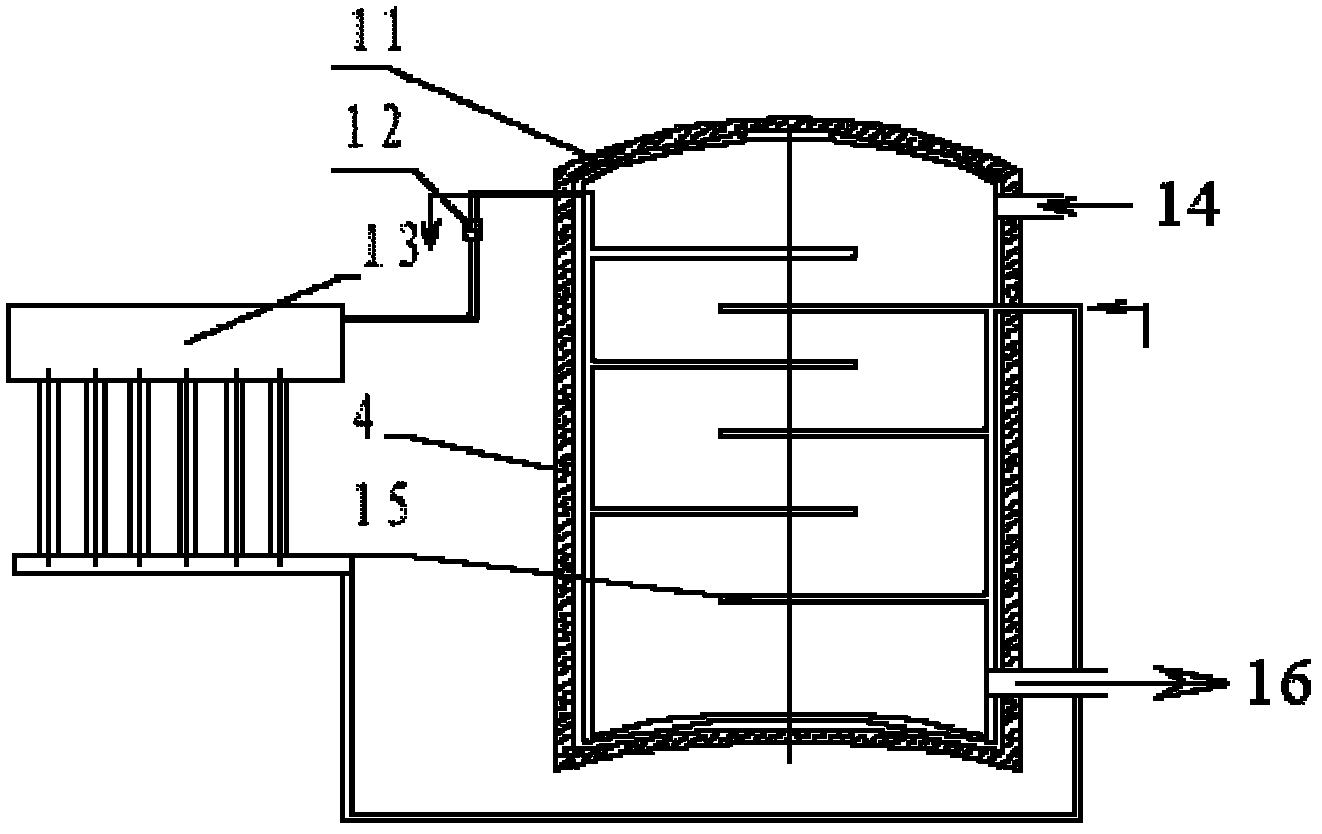

Electricity, heat and cool co-productive compressed air energy storage apparatus and method

InactiveCN1482349AReduce consumptionNo pollutionCompression machinesEnergy industryThermal energyAtmospheric air

The invention discloses an electricity, heat and cool co-productive compressed air energy storage apparatus and method, wherein an air storage chamber and an air-water heat exchanger are connected intandem between the compressor and the heat regenerator, the heating tube in the air storage chamber is used for transmitting the heat energy carried by the air to the heat transfer medium, and supplying heat to the outside through the water channel of the air-water heat exchanger, an air is also connected between the compressor and the heat regenerator, the air flowing out from the air storage chamber flows through the air duct of the air-water heat exchanger and the hot air channel of the heat regenerator, which is cooled down and enters the air turbine for working by expansion, driving the electric generator for power generation, and transforming the air compression energy into electrical energy.

Owner:XI AN JIAOTONG UNIV

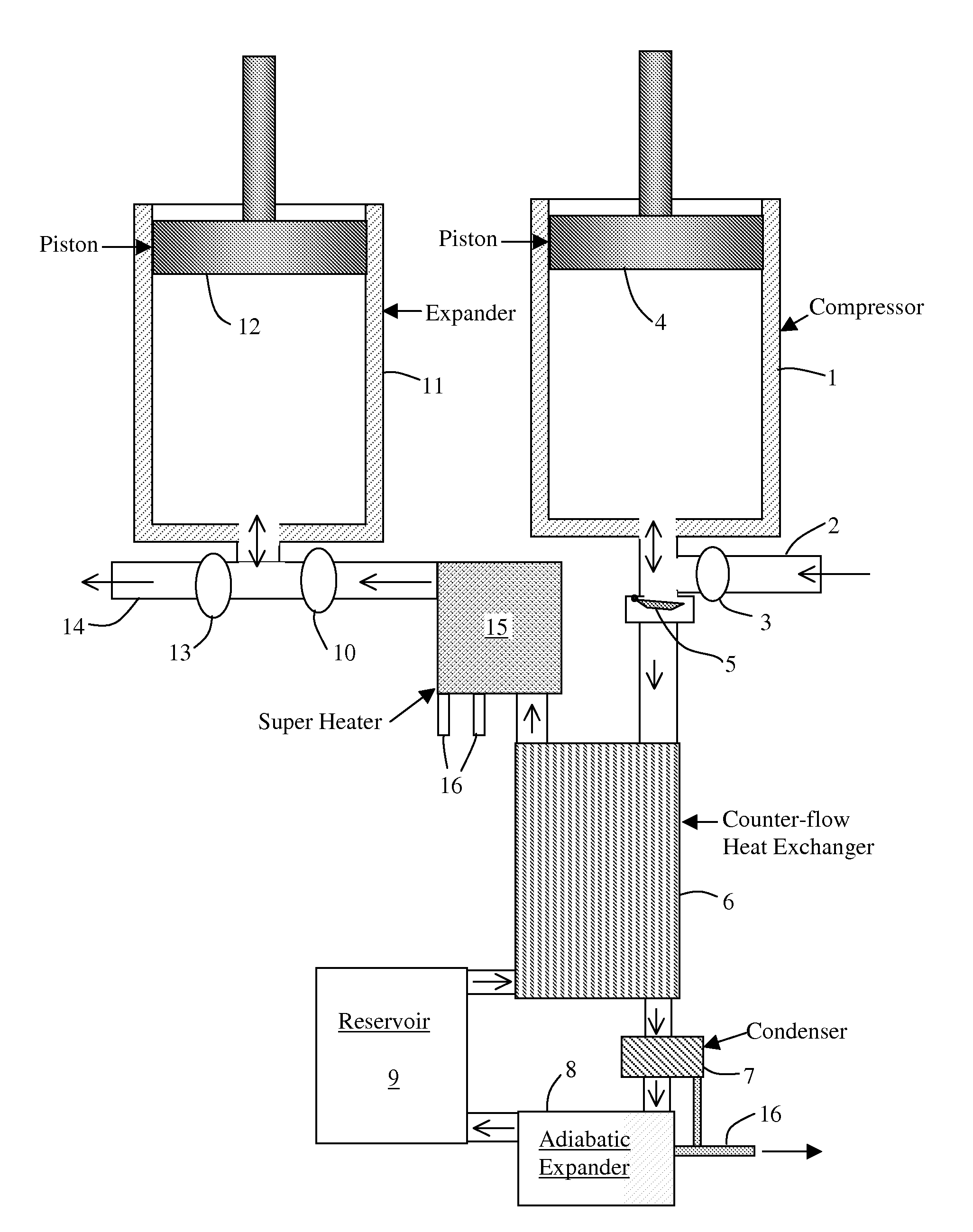

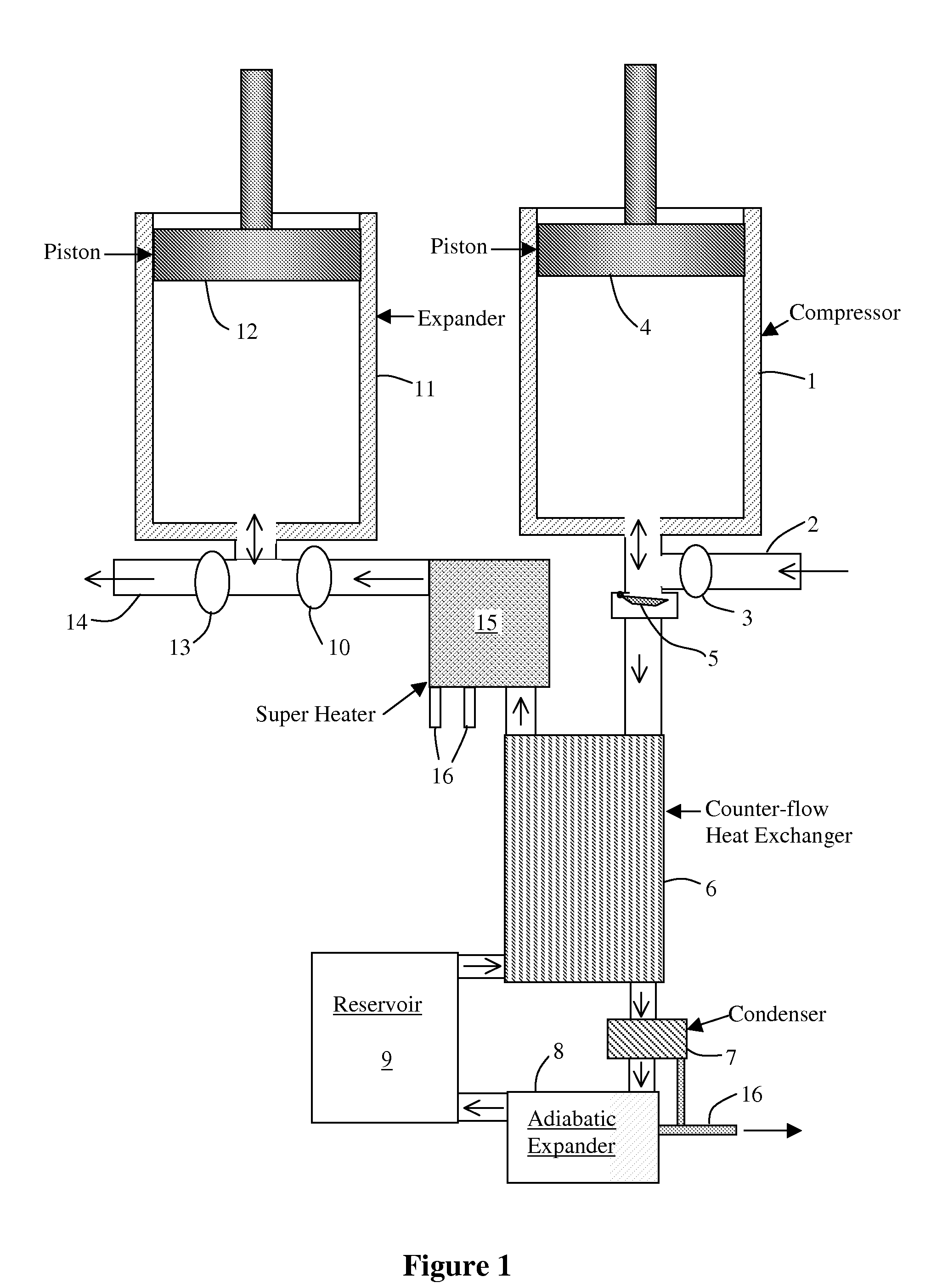

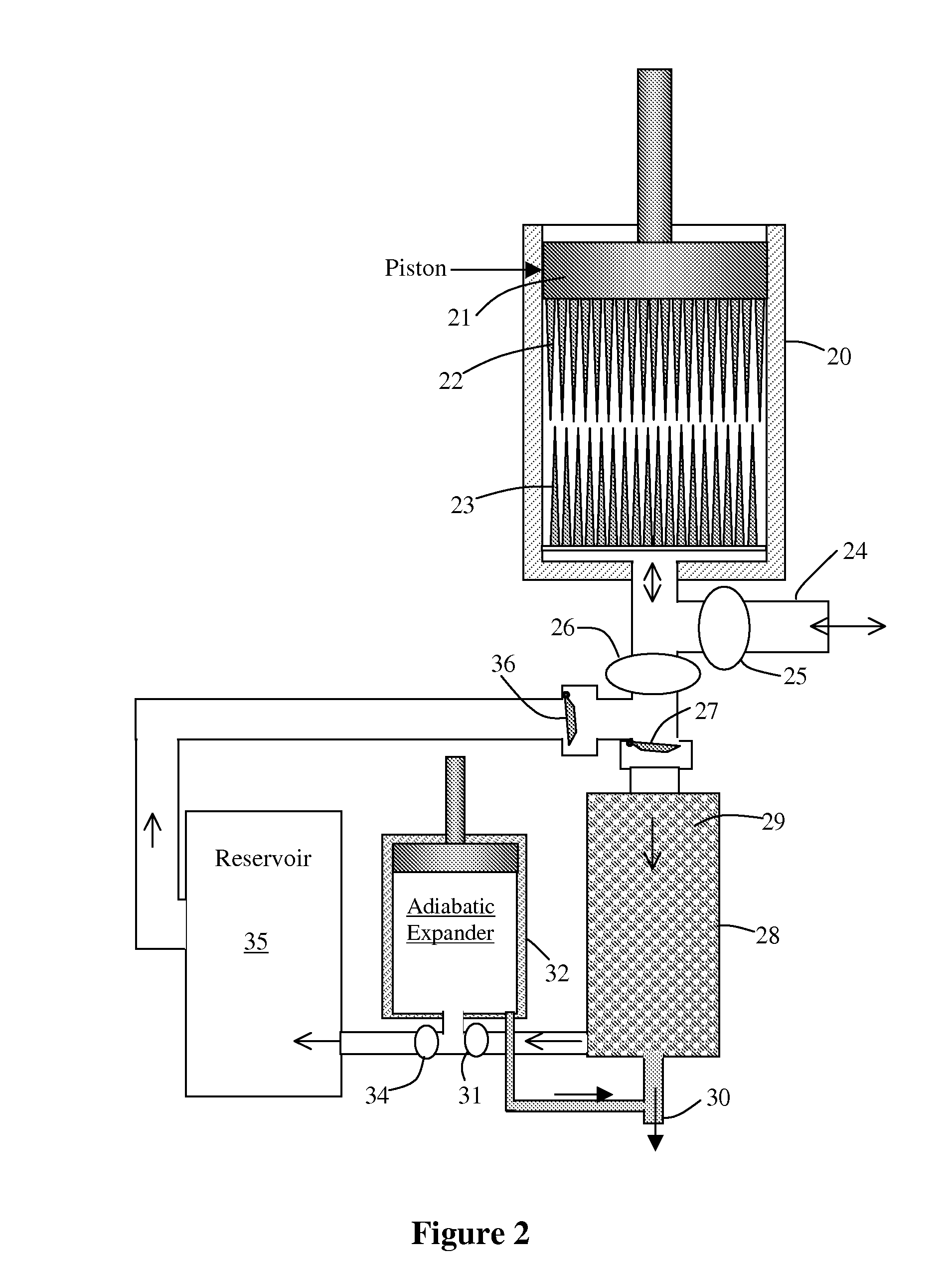

Water extraction from air and desalination

InactiveUS20070256430A1Simple methodEasy to useGeneral water supply conservationLighting and heating apparatusAir compressionCounter flow

This invention is a water producer that extracts water from the air. One embodiment of the invention adiabatically compresses and heats the air. The heated air is cooled through a counter-flow heat exchanger so that it becomes supersaturated and water condenses. The air is then cooled further and passed back through the heat exchanger to recover its former heat. It then passes through an adiabatic expander to recover energy. A second embodiment utilizes a unique isothermal compressor / expander to compress the humid air isothermally so that the air becomes supersaturated with water, and the water condenses. The air is then cooled to remove the heat of condensation of the water and returned to the isothermal compressor / expander to recover energy. A third embodiment draws in humid air through a counter-flow heat exchanger to cool it down below its dew point so that water is collected. The air is then cooled adiabatically and passed back through the counter-flow heat exchanger and on to a compressor, which compresses the air back to ambient pressure and pushes the air out. These embodiments can be used to desalinate seawater, brackish water, or desiccant aqueous solutions by having a humidifier evaporate water from the liquids to make the input air to the water producer very humid.

Owner:PRUEITT MELVIN L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com