Patents

Literature

216results about "Engines characterised by uniflow principle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

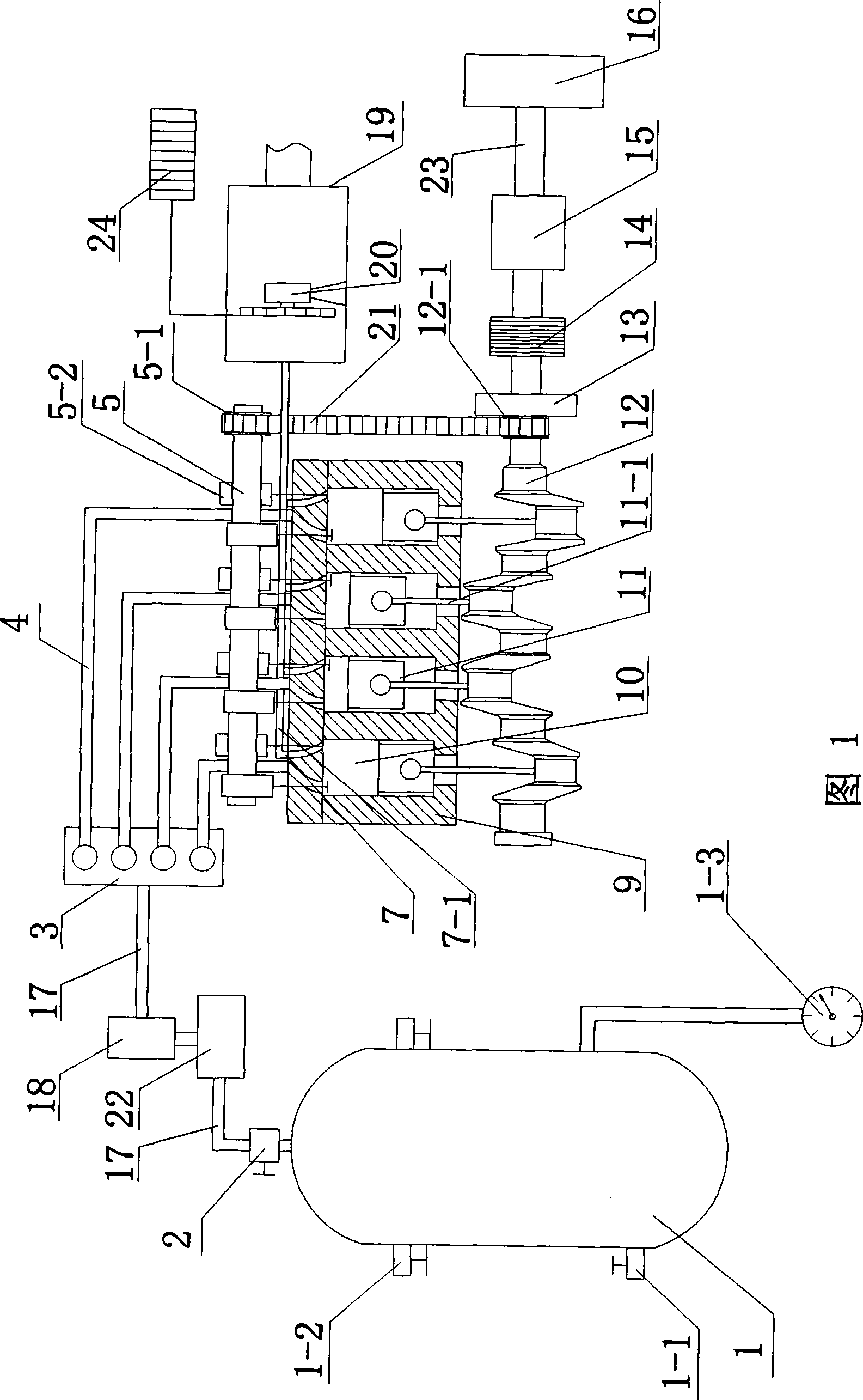

Air power engine assembly

InactiveCN101413403ALow costNo pollutionMechanical power devicesEngines characterised by uniflow principleDistributorPiston

The invention relates to an air-powered engine assembly, which comprises an air tank, an air valve, an air distributor, an intake pipe, camshafts, an intake duct, an exhaust control device, air cylinders, pistons, crankshafts, couplers, clutches, automatic gearboxes and differentials connected with the outside. The assembly is characterized in that the air valve, a constant pressure chamber and a pressure controller are arranged between the air tank and the air distributor; the air distributor is connected with a plurality of air cylinders on an air cylinder gasket; each air cylinder is connected with an exhaust chamber through an exhaust manifold; the exhaust chamber is provided with a turbine generator which is connected with a storage batter; the air cylinders are provided with the camshafts for controlling the air intake and exhaust of the air cylinders; the air cylinders are provided inside with the pistons for driving the crankshafts to rotate; the camshafts and the crankshafts are connected by chains; and the crankshafts are connected with the differentials through the couplers, the clutches and the gearboxes in turn. Therefore, doing work through air compression rather than fuel, the air-powered engine assembly has the advantages of avoiding waste gas discharge and air pollution, along with reliable operation, convenient operation, economical efficiency, practicality and so on. In addition, due to recycle of the waste gas for power generation, the air-powered engine assembly saves energy and reduces costs.

Owner:周登荣 +1

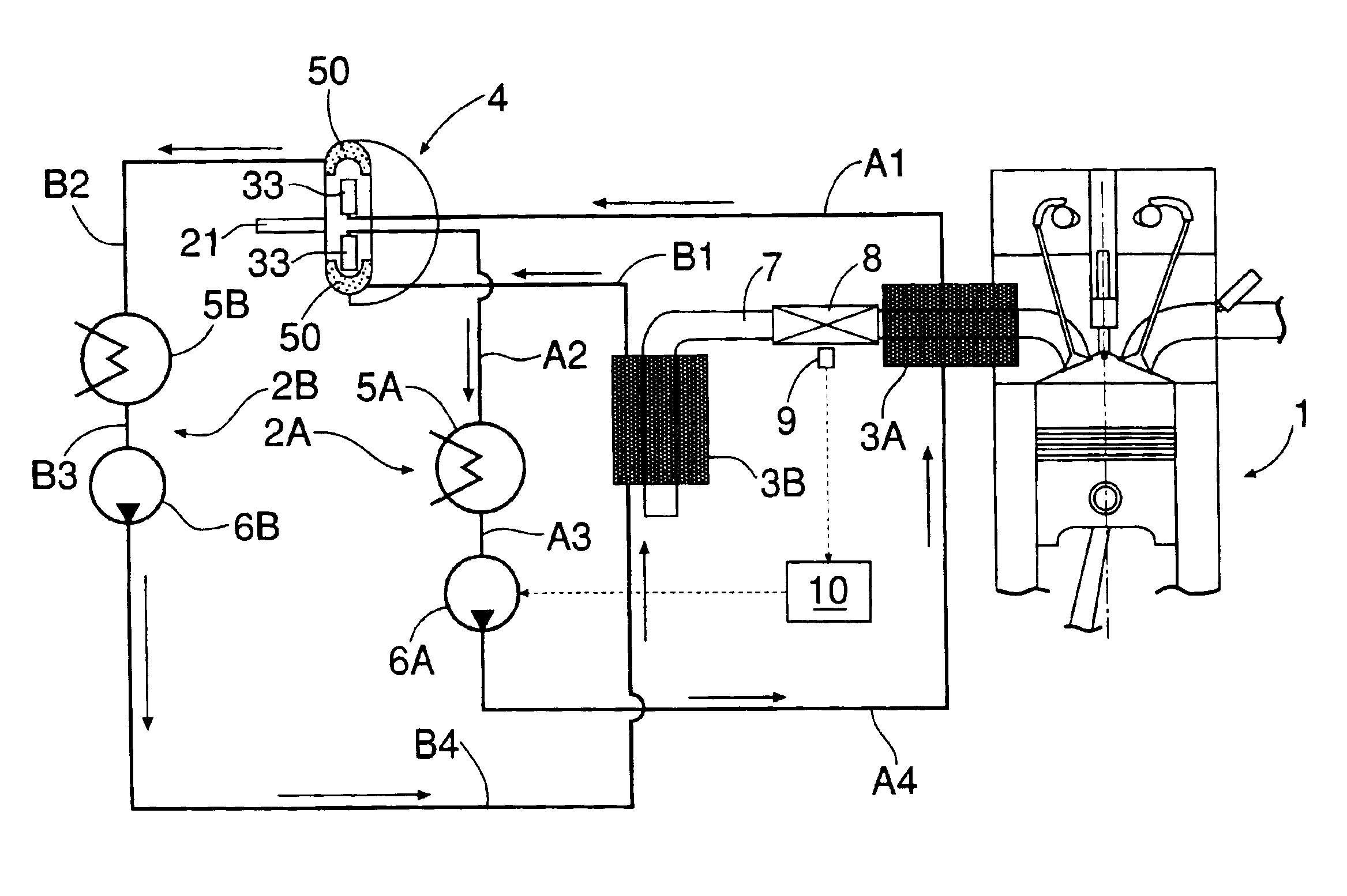

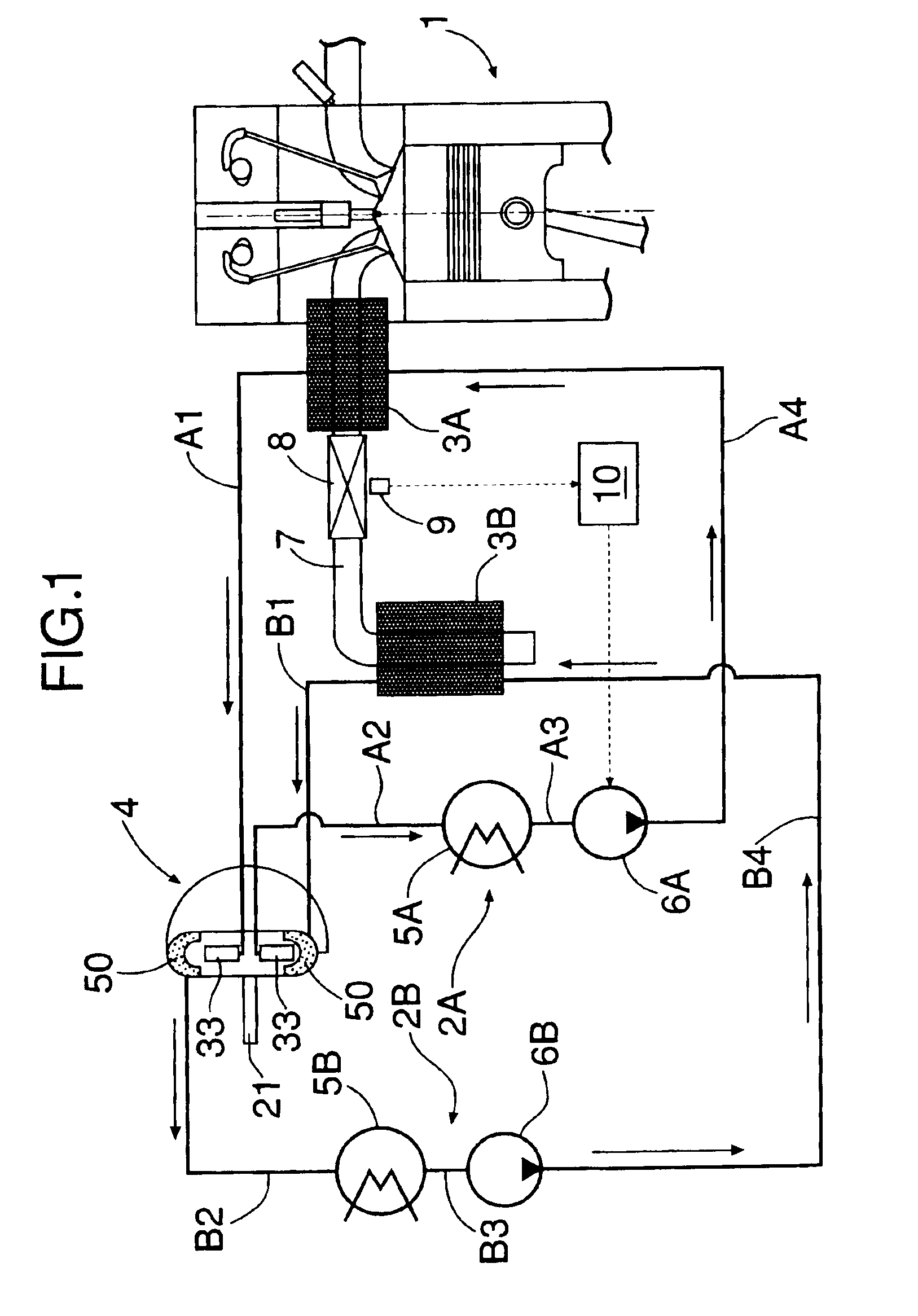

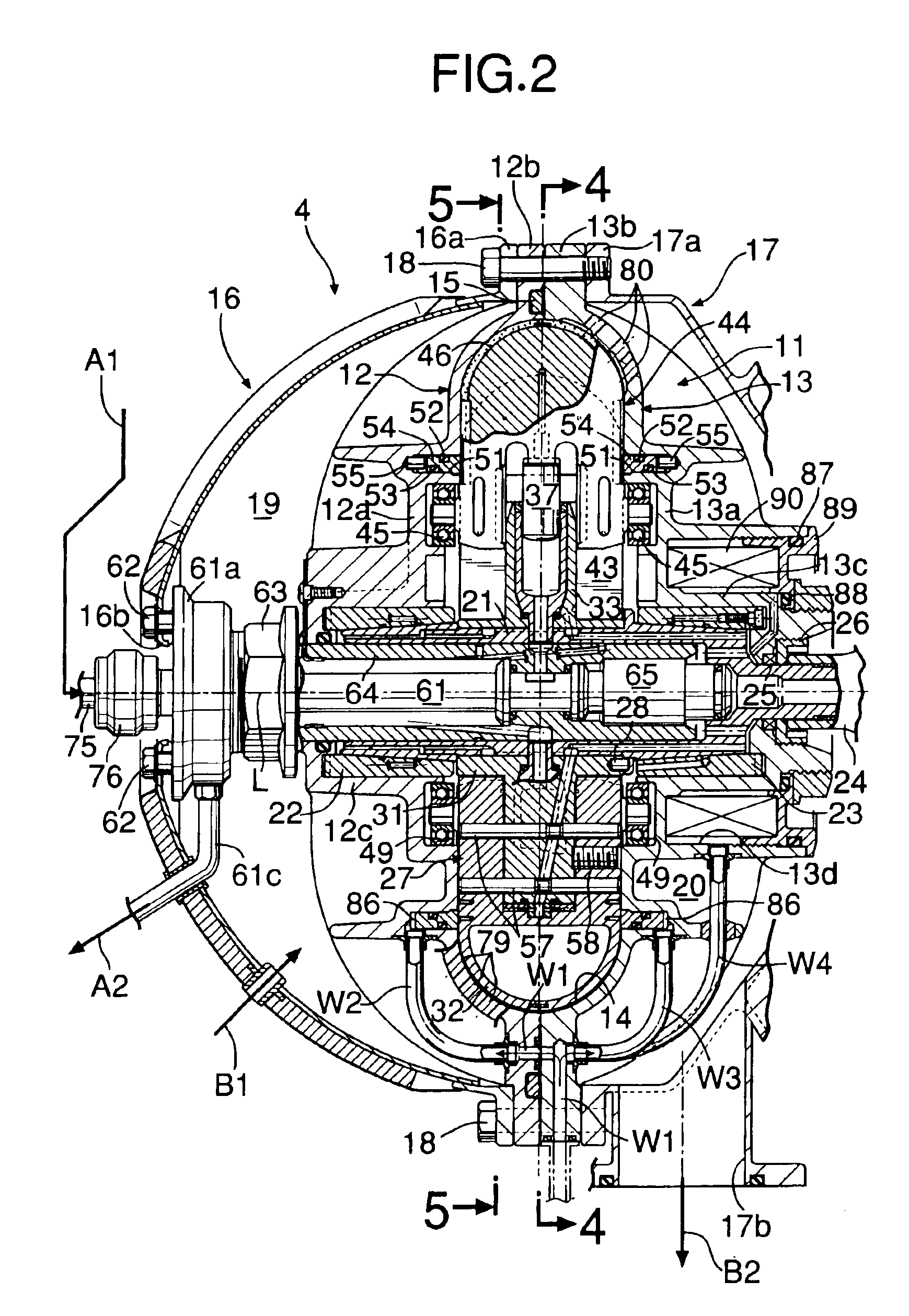

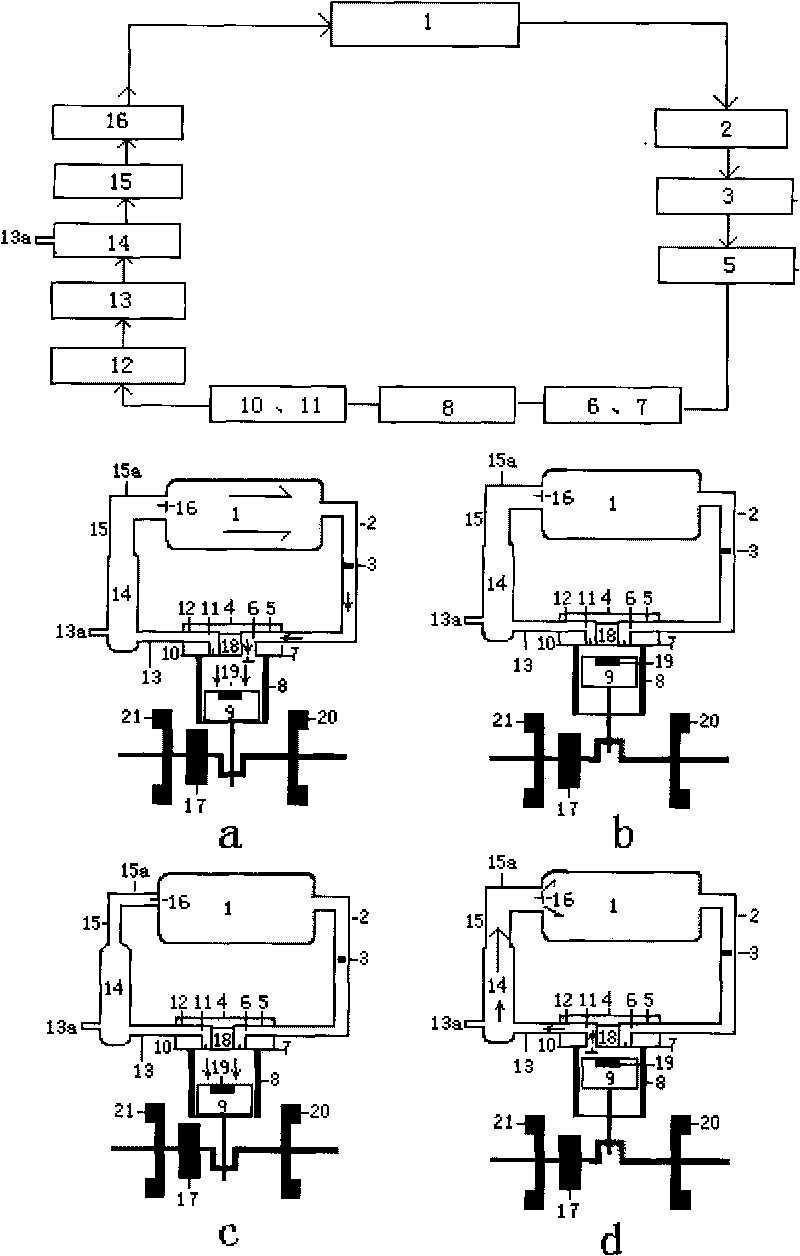

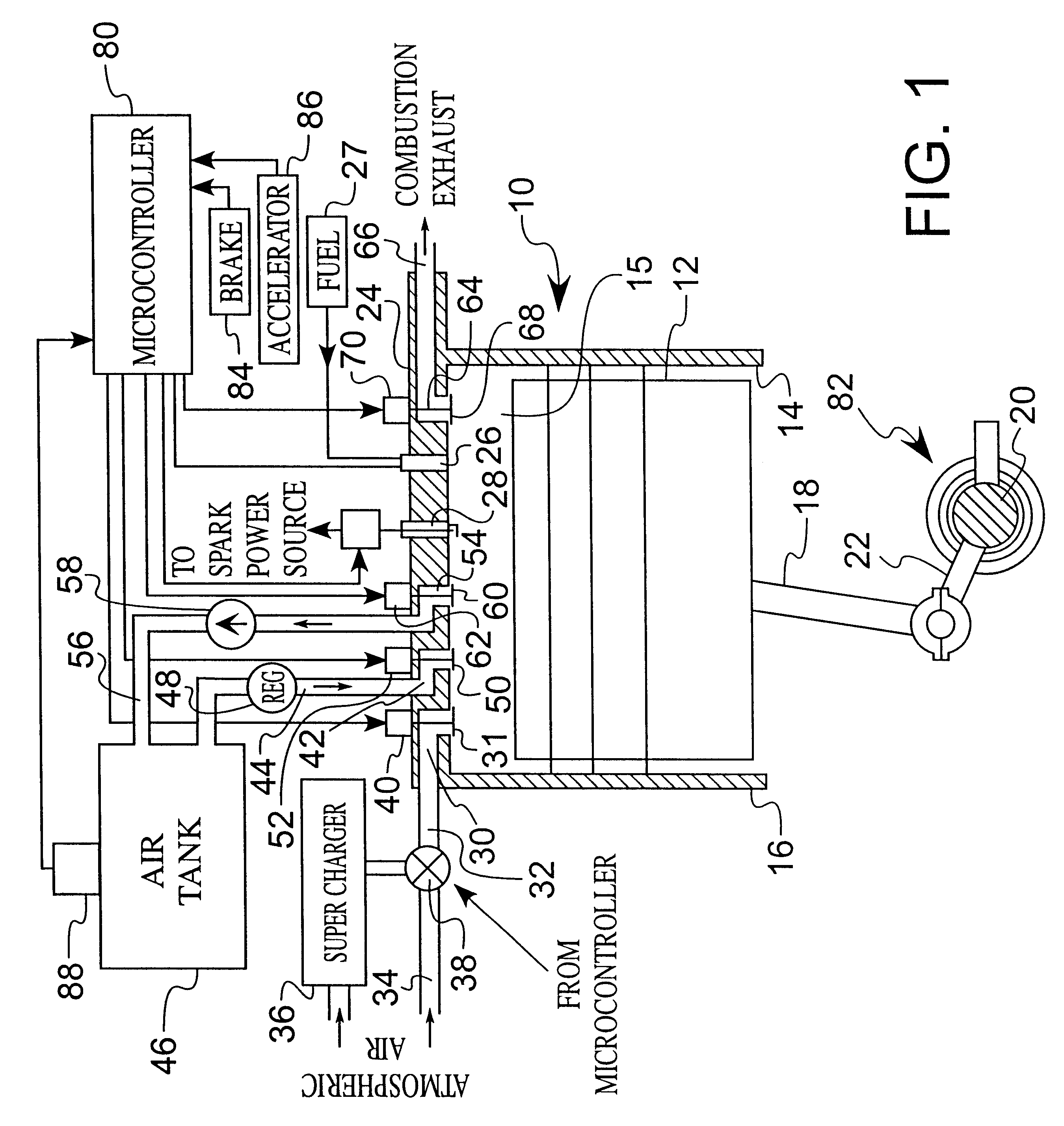

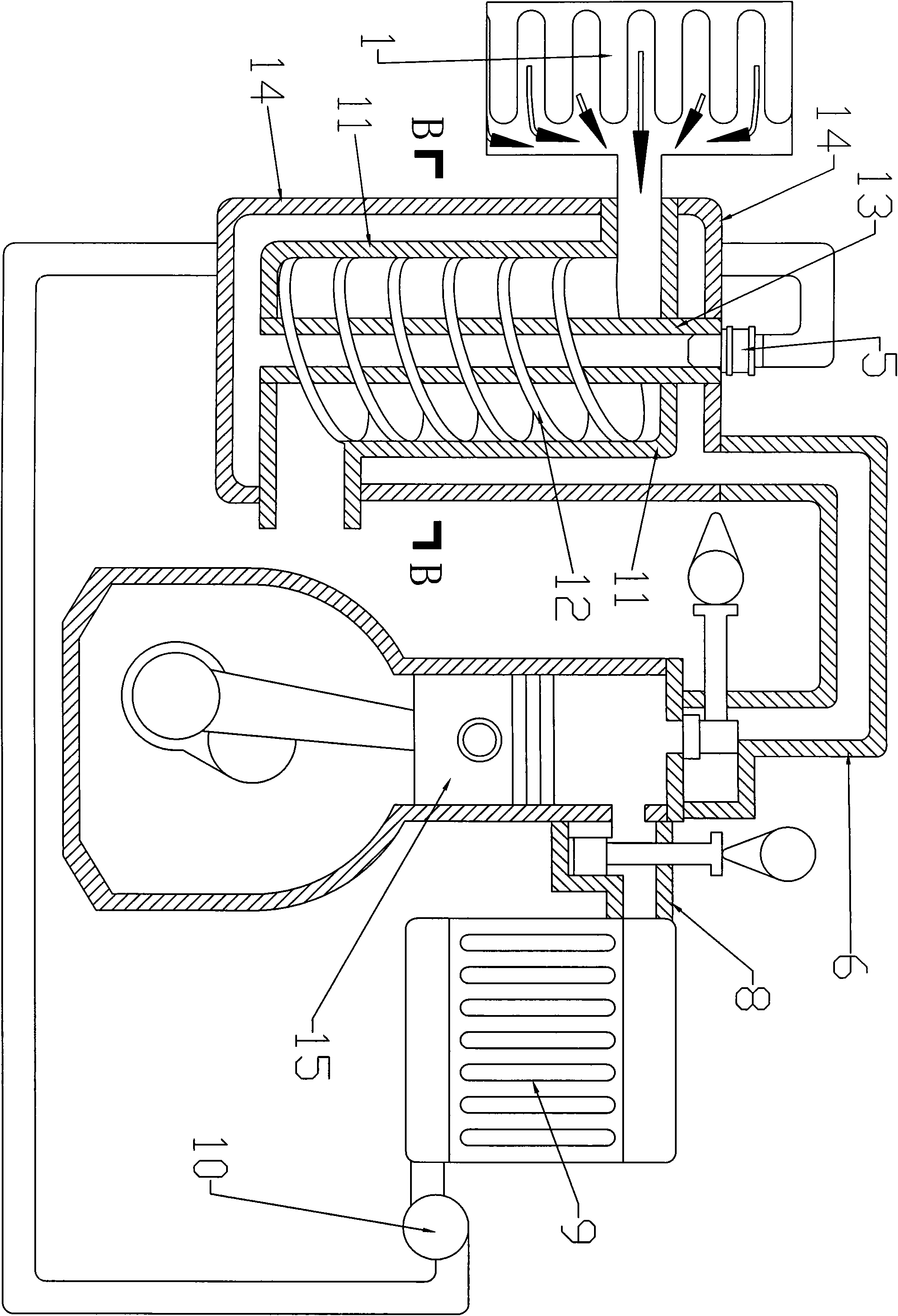

Rankine cycle device of internal combustion engine

InactiveUS6910333B2Efficiency of recovery of wasteImprove efficiencyInternal combustion piston enginesExhaust apparatusExhaust gas emissionsExhaust fumes

A Rankine cycle system includes a first Rankine cycle (2A) operated by a first working medium and a second Rankine cycle (2B) operated by a second working medium. The first Rankine cycle (2A) is constituted from an evaporator (3A), an expander (4), a condenser (5A) and a supply pump (6A), and the second Rankine cycle (2B) is constituted from an evaporator (3B), the expander (4), a condenser (5B) and a supply pump (6c). The evaporator (3A) in the first Rankine cycle (2A) and the evaporator (3B) in the second Rankine cycle (2B) are disposed at locations upstream and downstream of an exhaust emission control device (8) mounted in an exhaust passage (7) for the internal combustion engine (1). The first working medium has a boiling point higher than that of the second working medium, and the capacity of the pump (6A) in at least the first Rankine cycle (2A) is variable. Thus, the efficiency of recovery of a waste heat from the internal combustion engine by the Rankine cycle system can be enhanced to the maximum, and the activation of the exhaust emission control device can be promoted.

Owner:HONDA MOTOR CO LTD

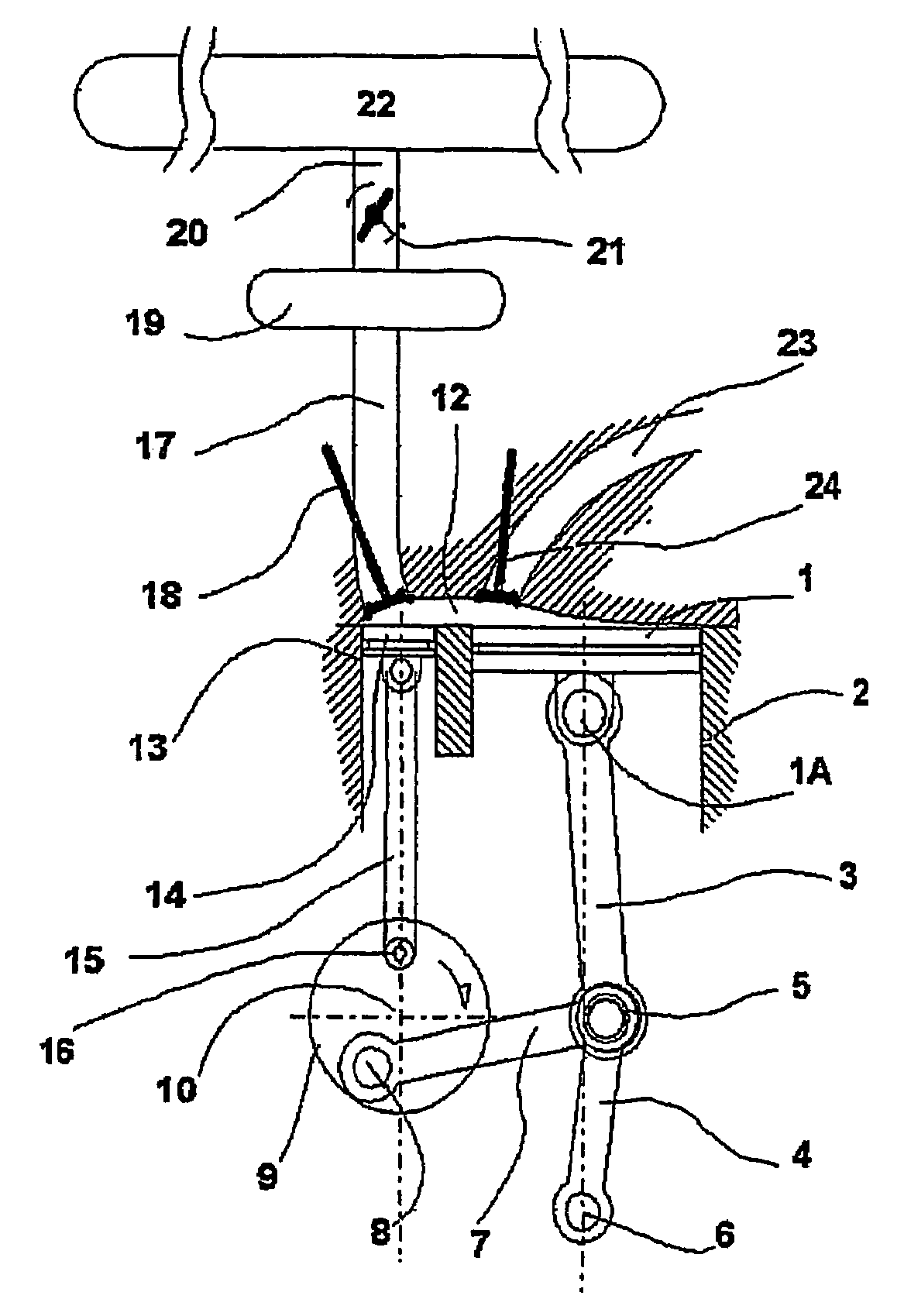

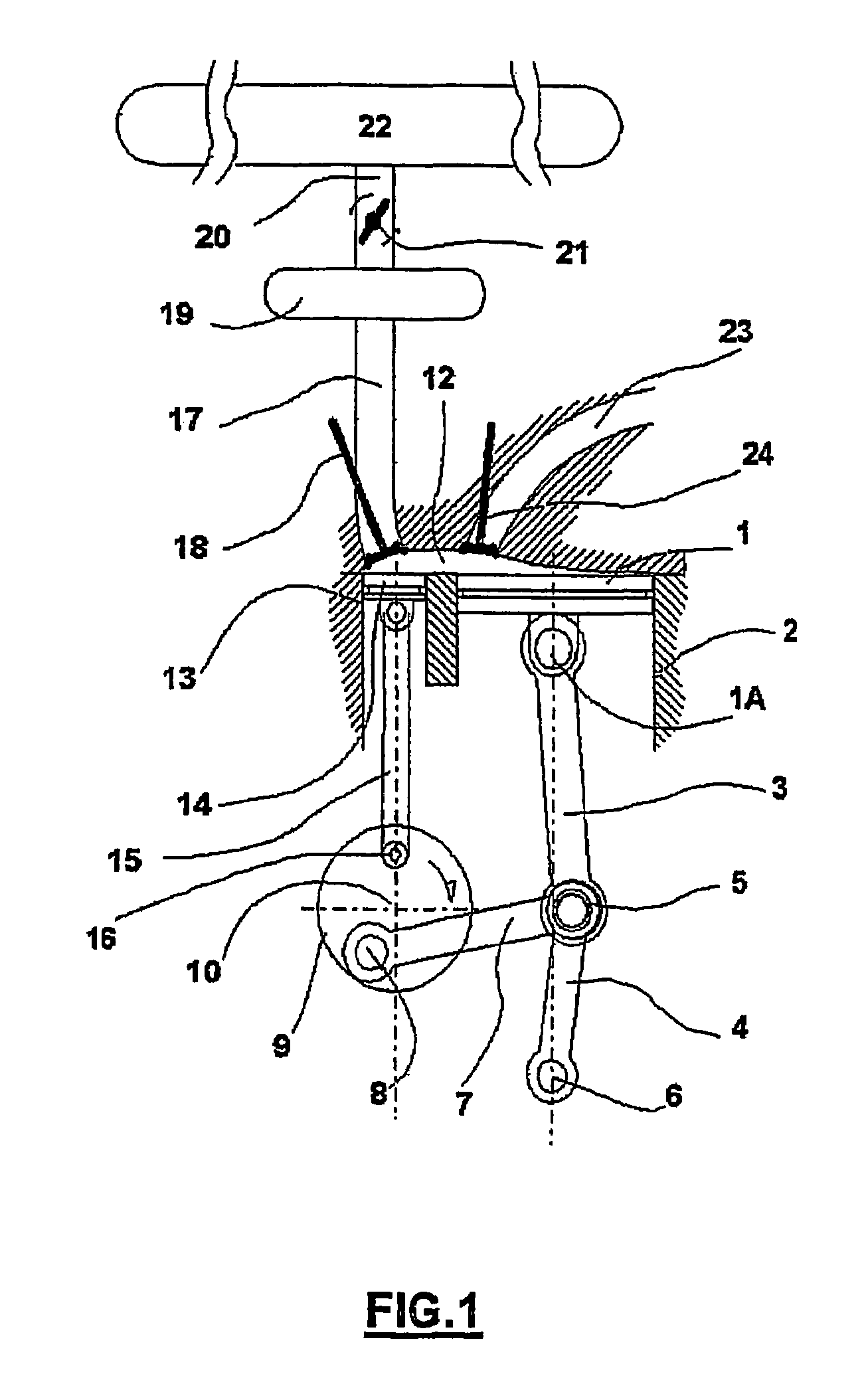

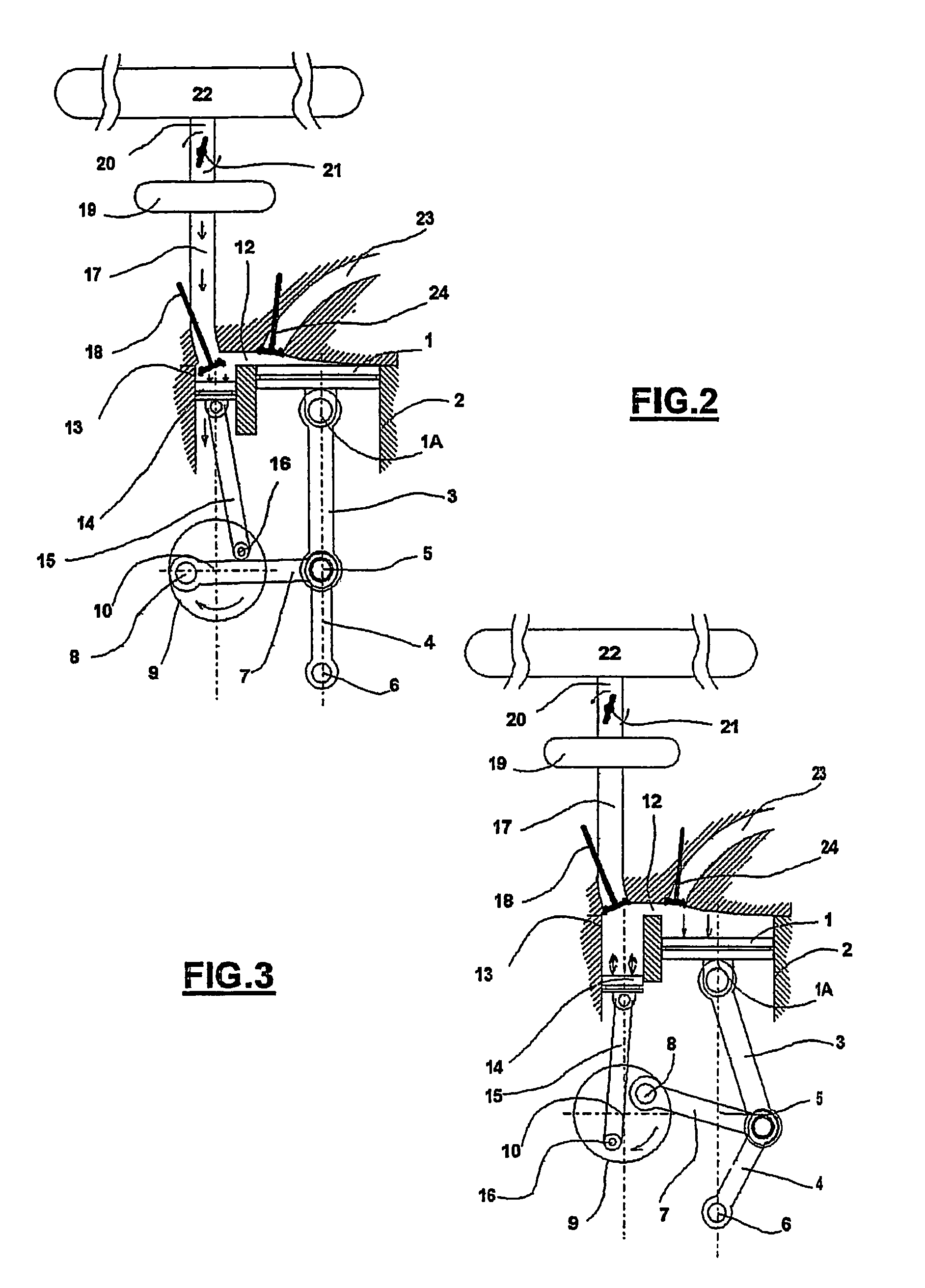

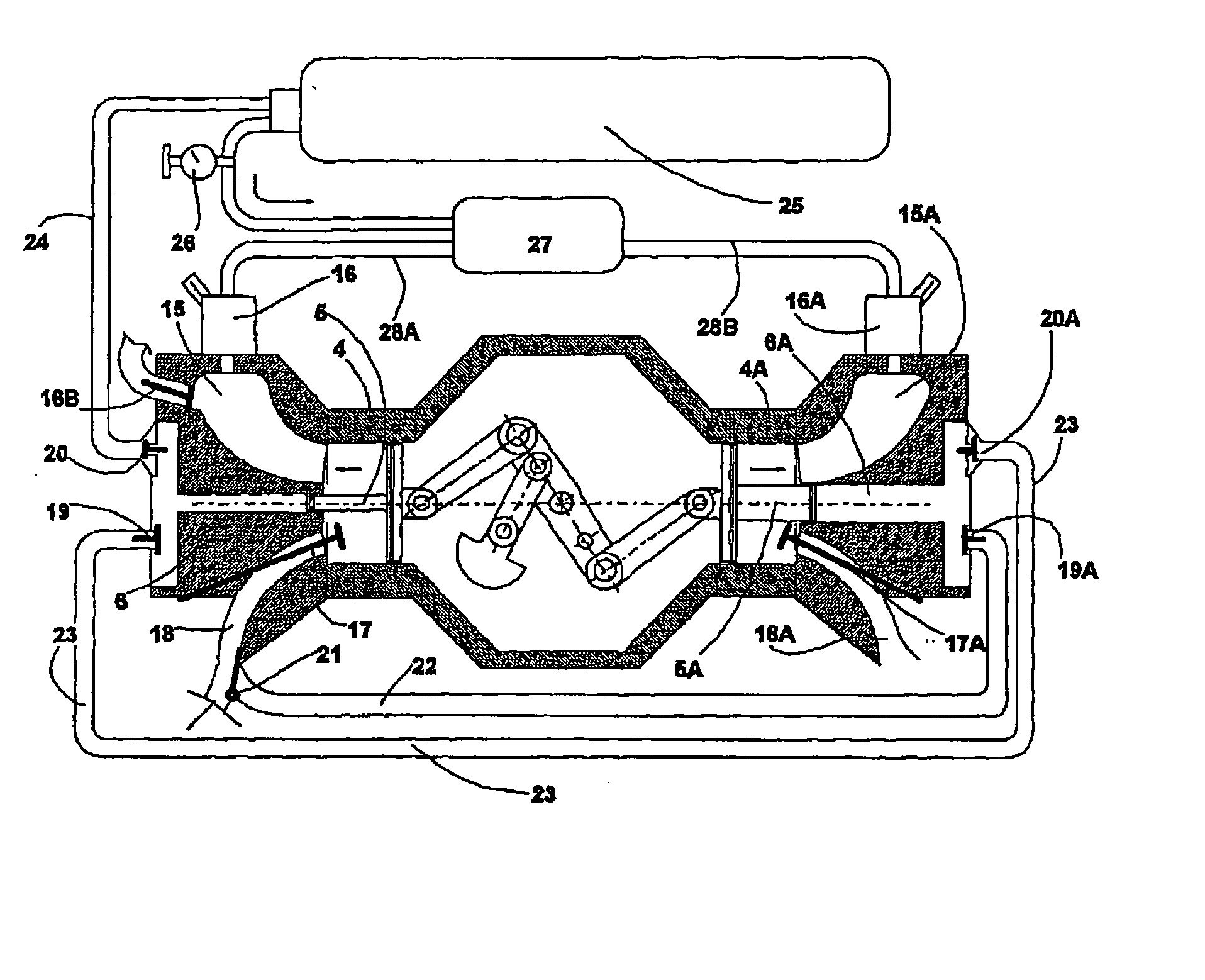

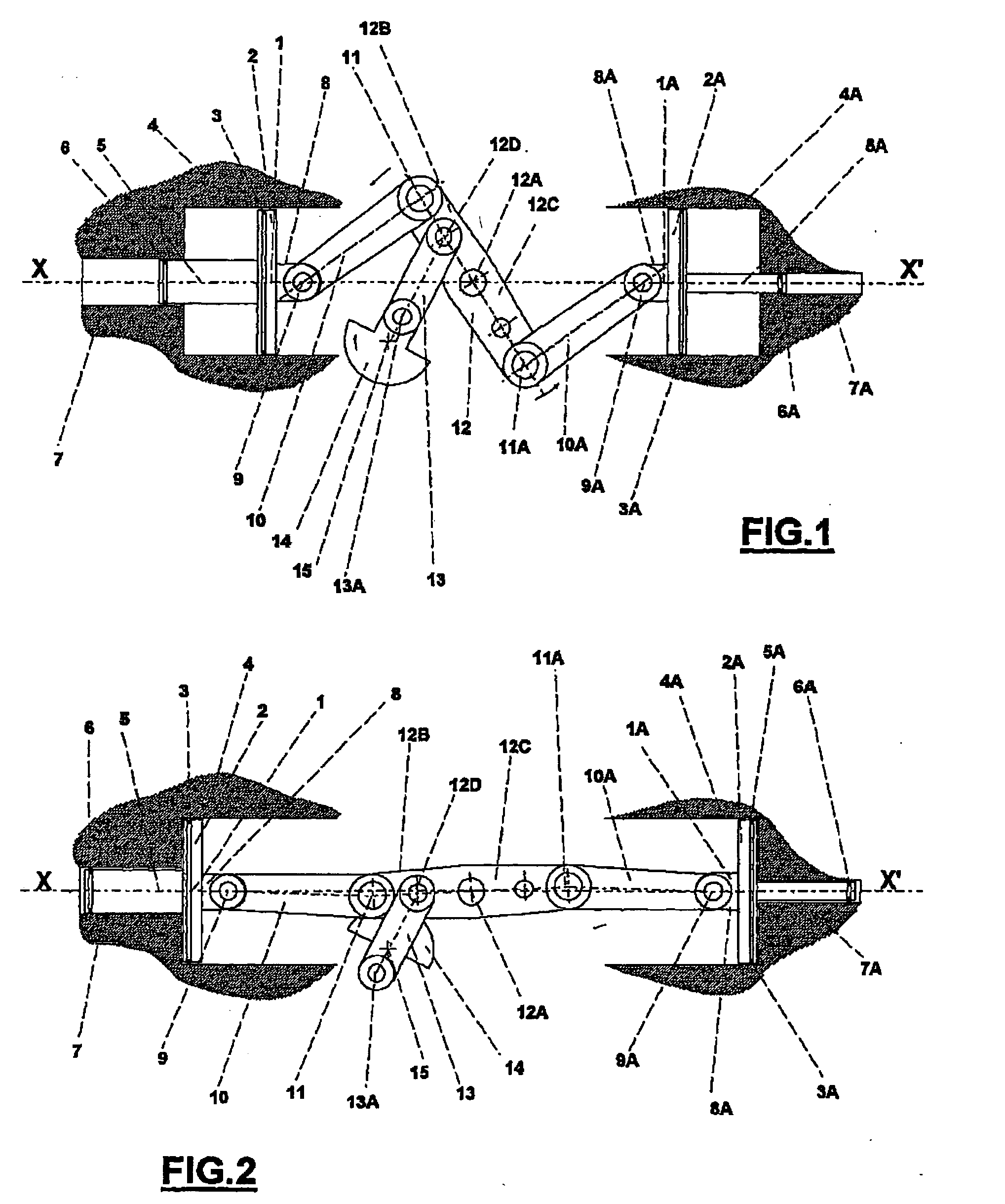

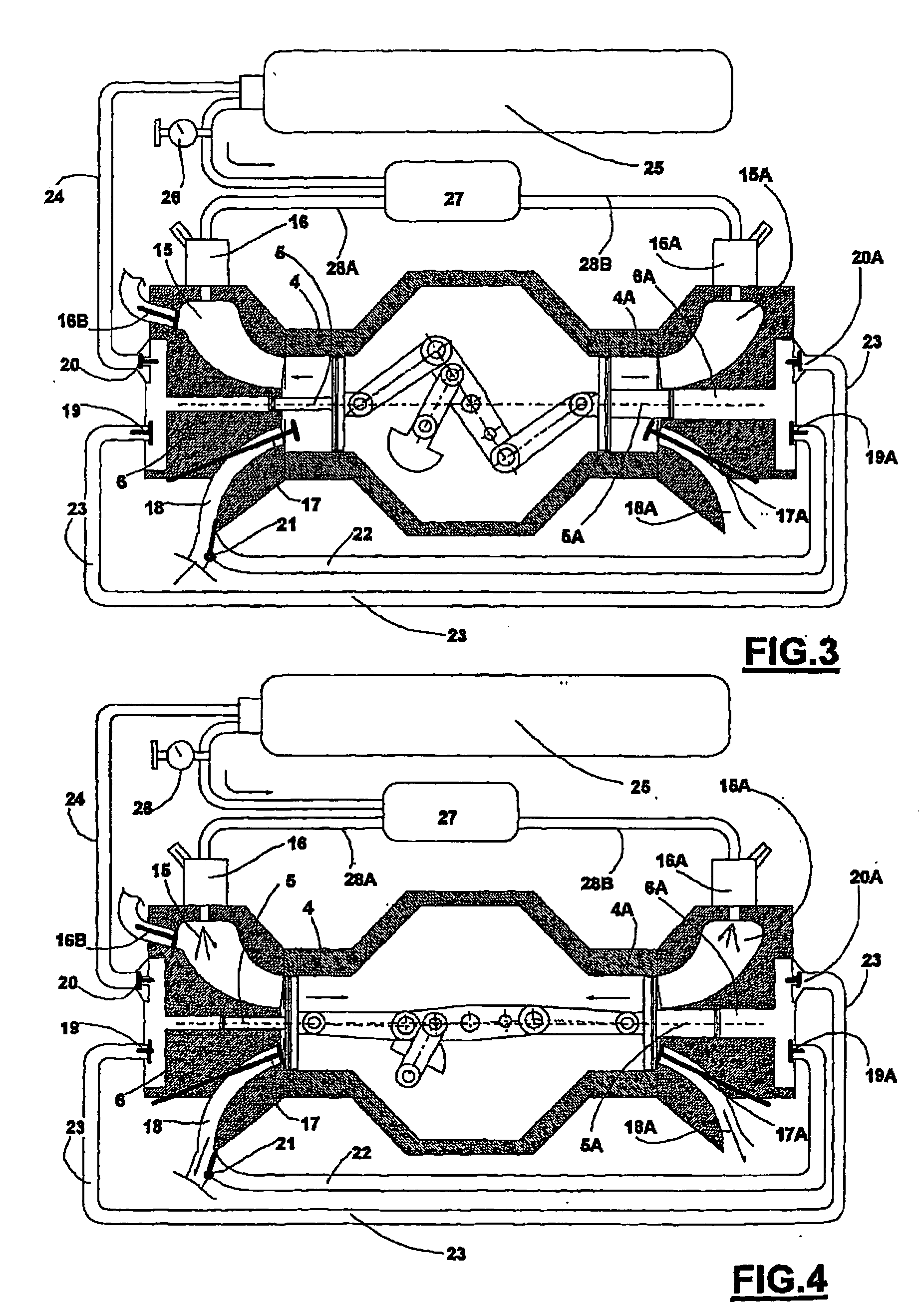

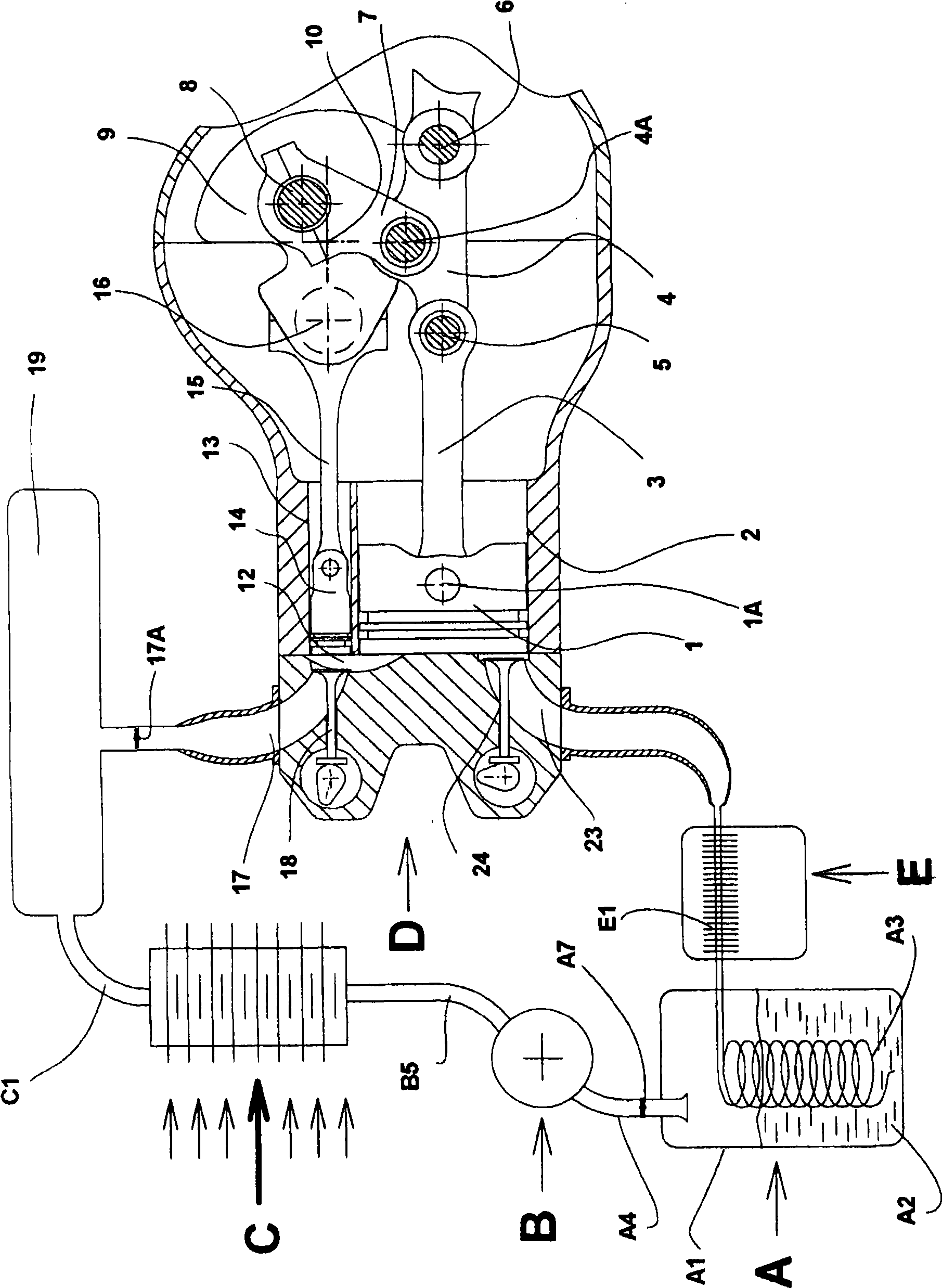

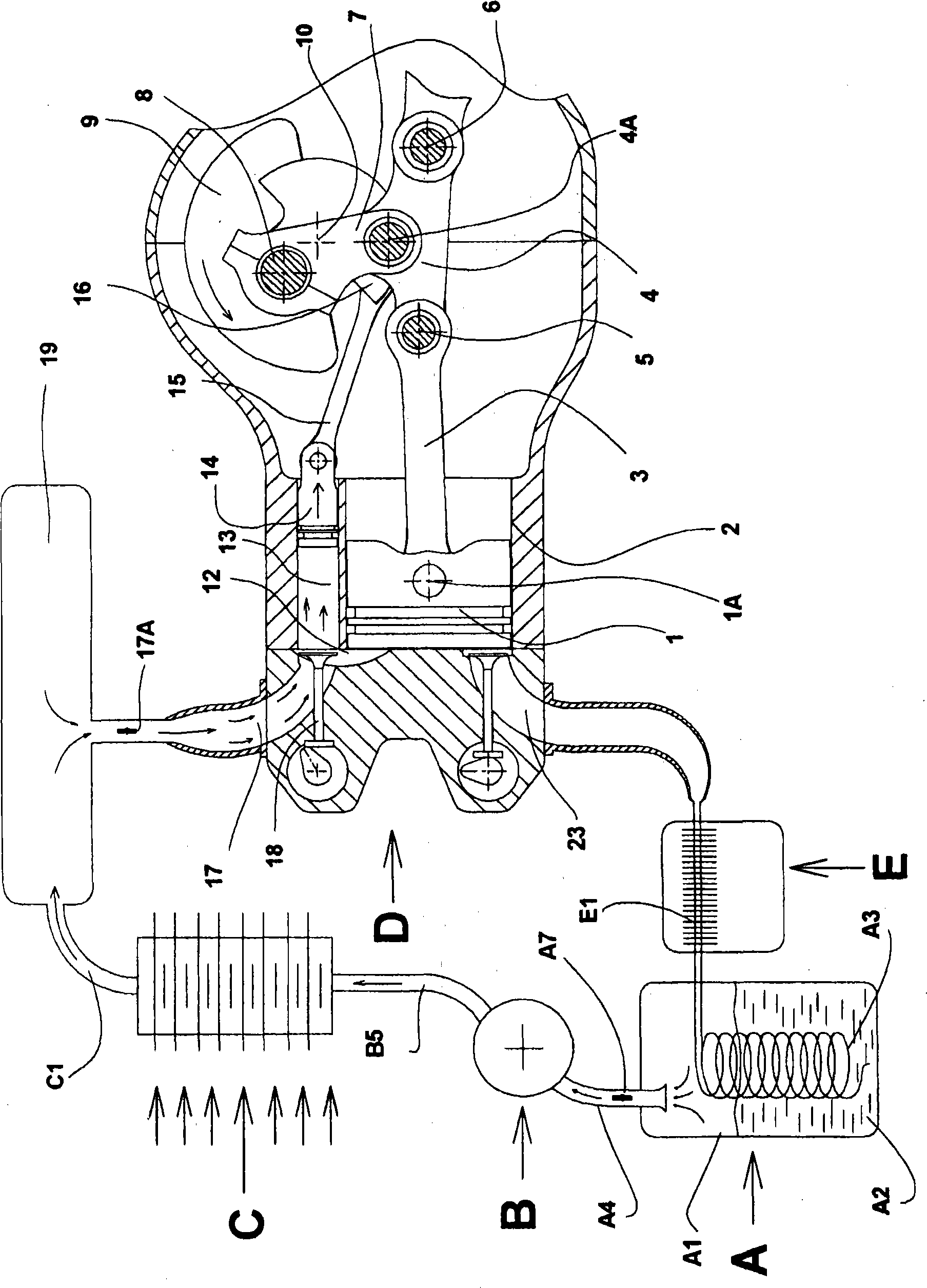

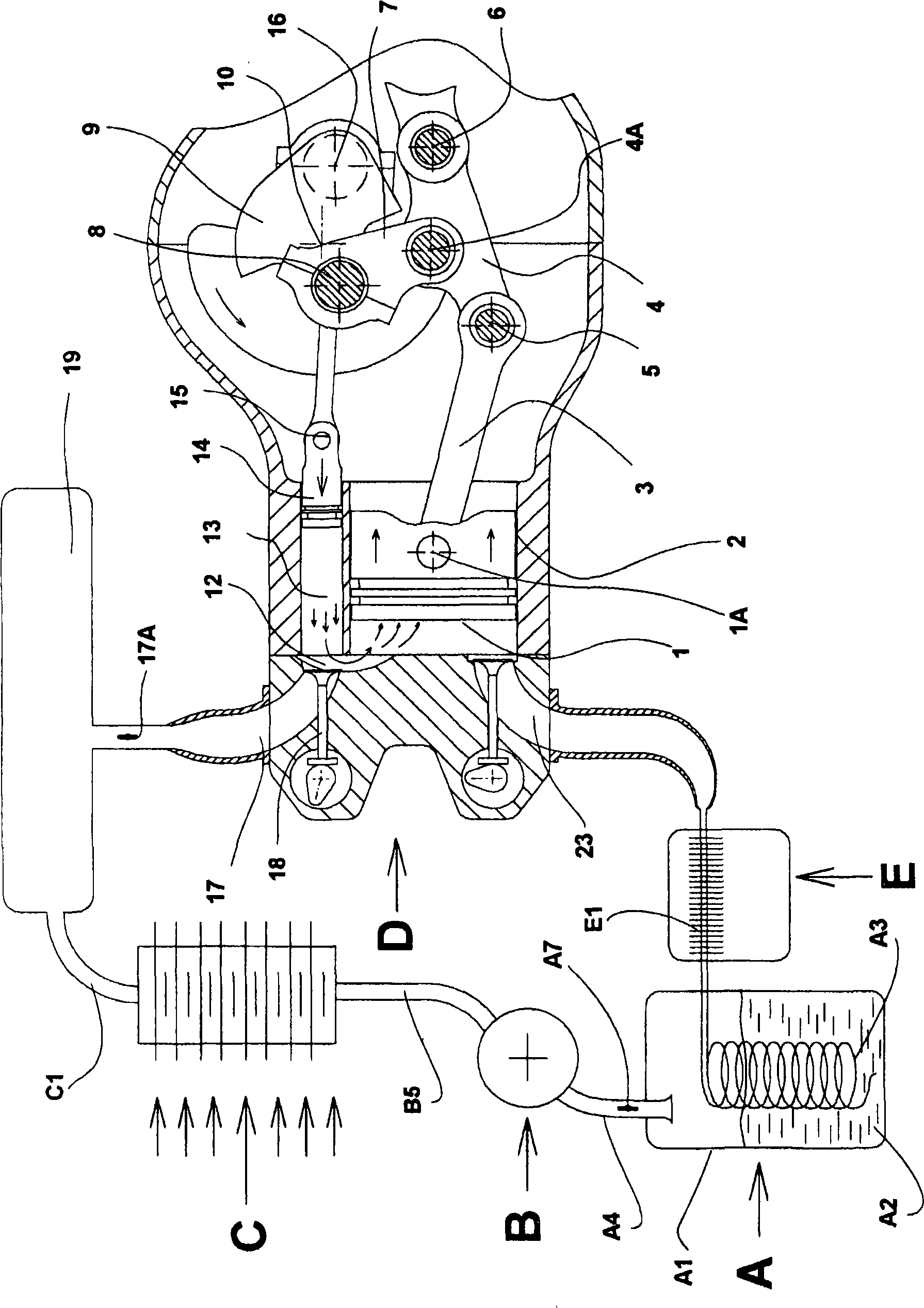

Engine with an active mono-energy and/or bi-energy chamber with compressed air and/or additional energy and thermodynamic cycle thereof

ActiveUS7469527B2Usable and available energyQuantity of usable and availableFlexible wall reciprocating enginesCombustion enginesTop dead centerEngineering

An engine uses a top dead center piston stop device. It is fed by compressed air, via a working capacity, which, in the bi-energy version, includes a device for heating the air supplied by additional energy. The active expansion chamber consists of a variable volume or charge piston sliding in a cylinder, coupled to a space above the engine piston via a passage. When stoped at upper dead center, the pressurized air is admitted into the expansion chamber with the smallest volume thereof and, under the effect of thrust, increases the volume thereof by producing work; the expansion chamber is then kept at a maximum volume during expansion of the engine cylinder driving back the engine piston in its downward stroke, providing work of its own. During exhaust, the two pistons travel in an upward stroke and simultaneously reach top dead center in order to resume a new cycle.

Owner:MDI MOTOR DEV INT SA

Motor-driven compressor-alternator unit with additional compressed air injection operating with mono and multiple energy

InactiveUS20040261415A1Characteristics of the kinetics of the assembly to be modifiedModify characteristicGas turbine plantsEngine componentsAlternatorMotor drive

Motor-driven compressor-alternator unit including pistons. Each piston has a large diameter portion and a smaller diameter portion extending from the large diameter portion. The large diameter portion slides within a first cylinder and provides a motor function. The smaller diameter portion slides within a second cylinder and provides a compressor function. An arrangement at least one of inactivates the motor function during compressor operation, inactivates the compressor function during motor operation, and activates ambient heat recovery during motor operation. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:MDI MOTOR DEV INT SA

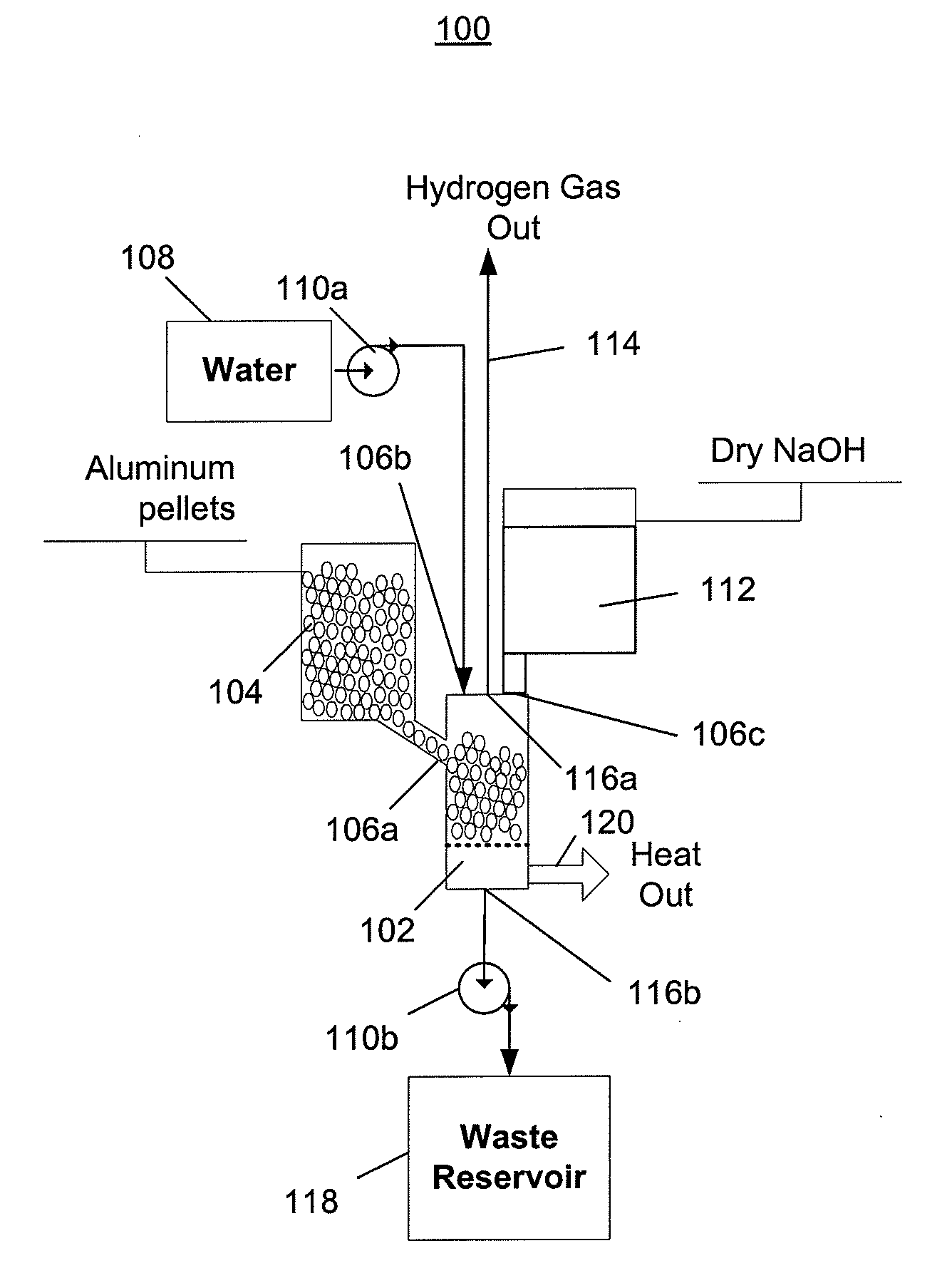

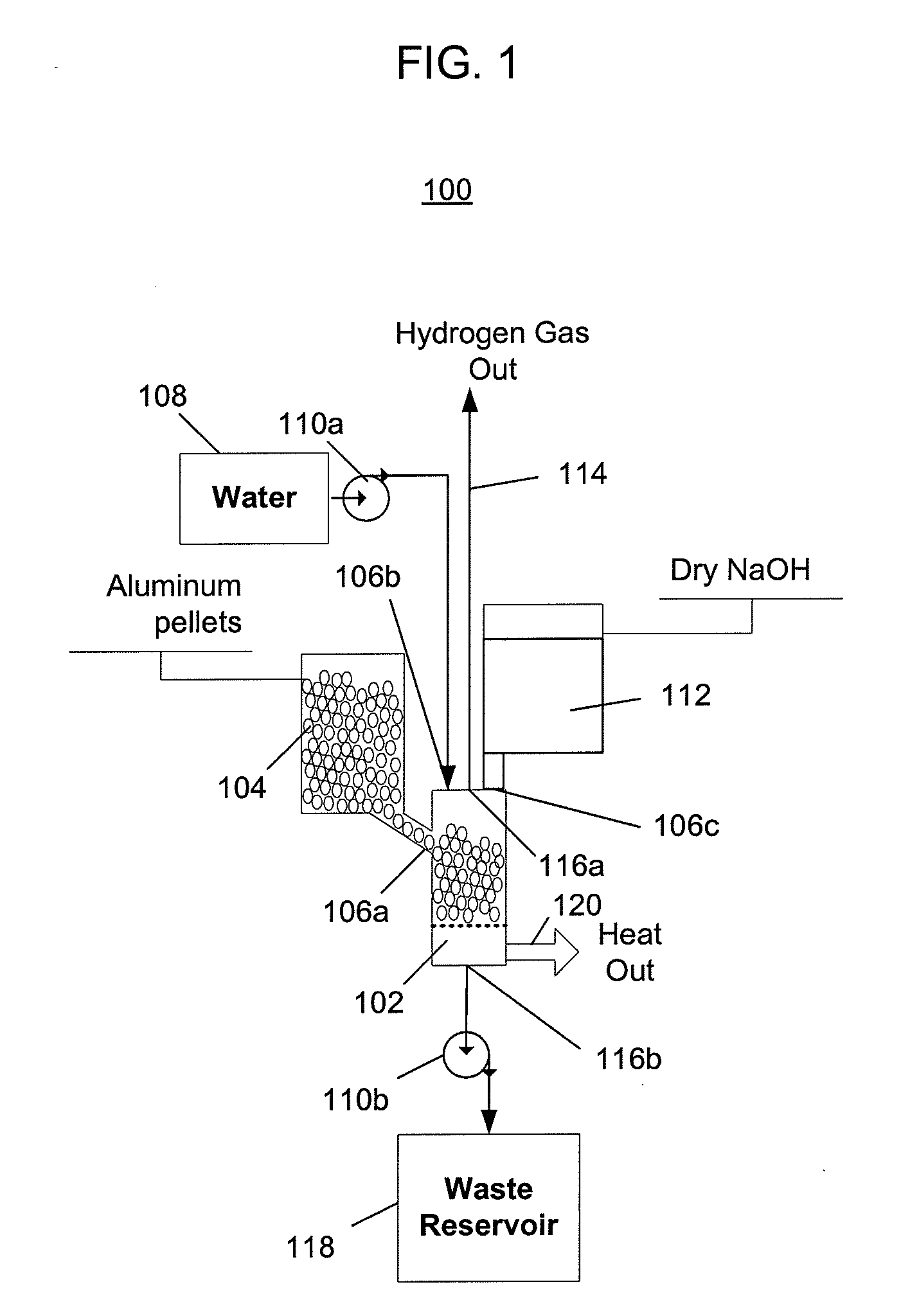

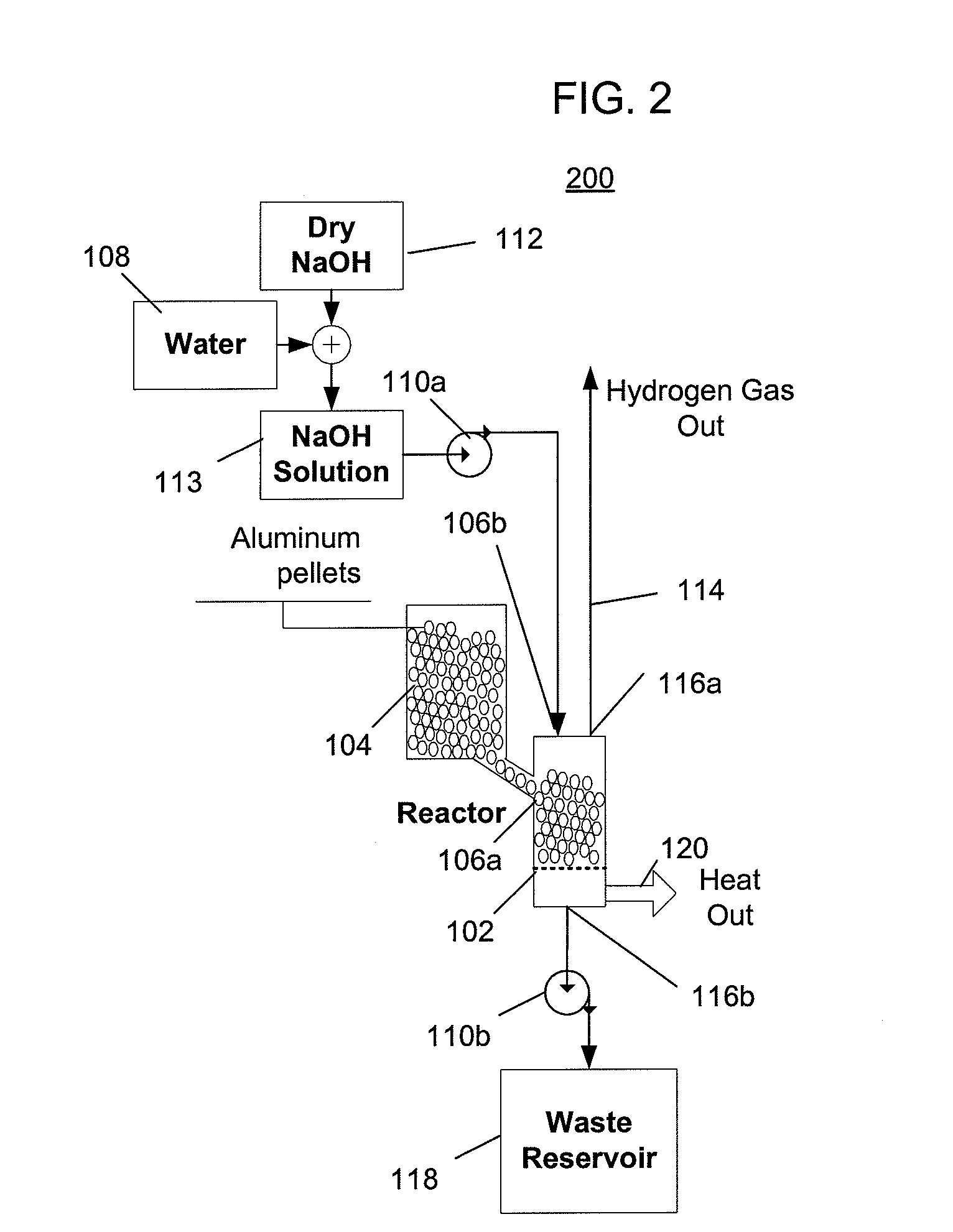

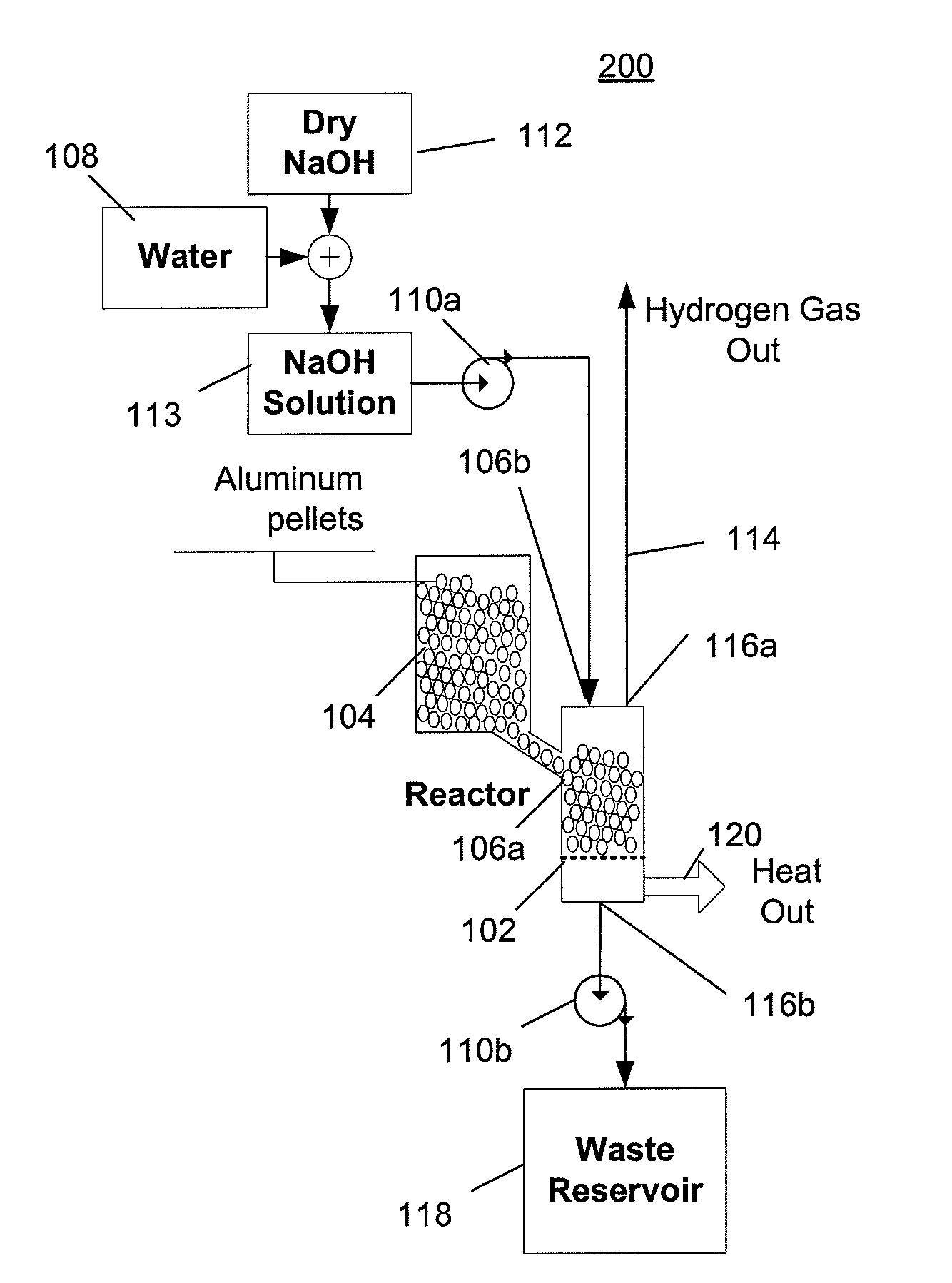

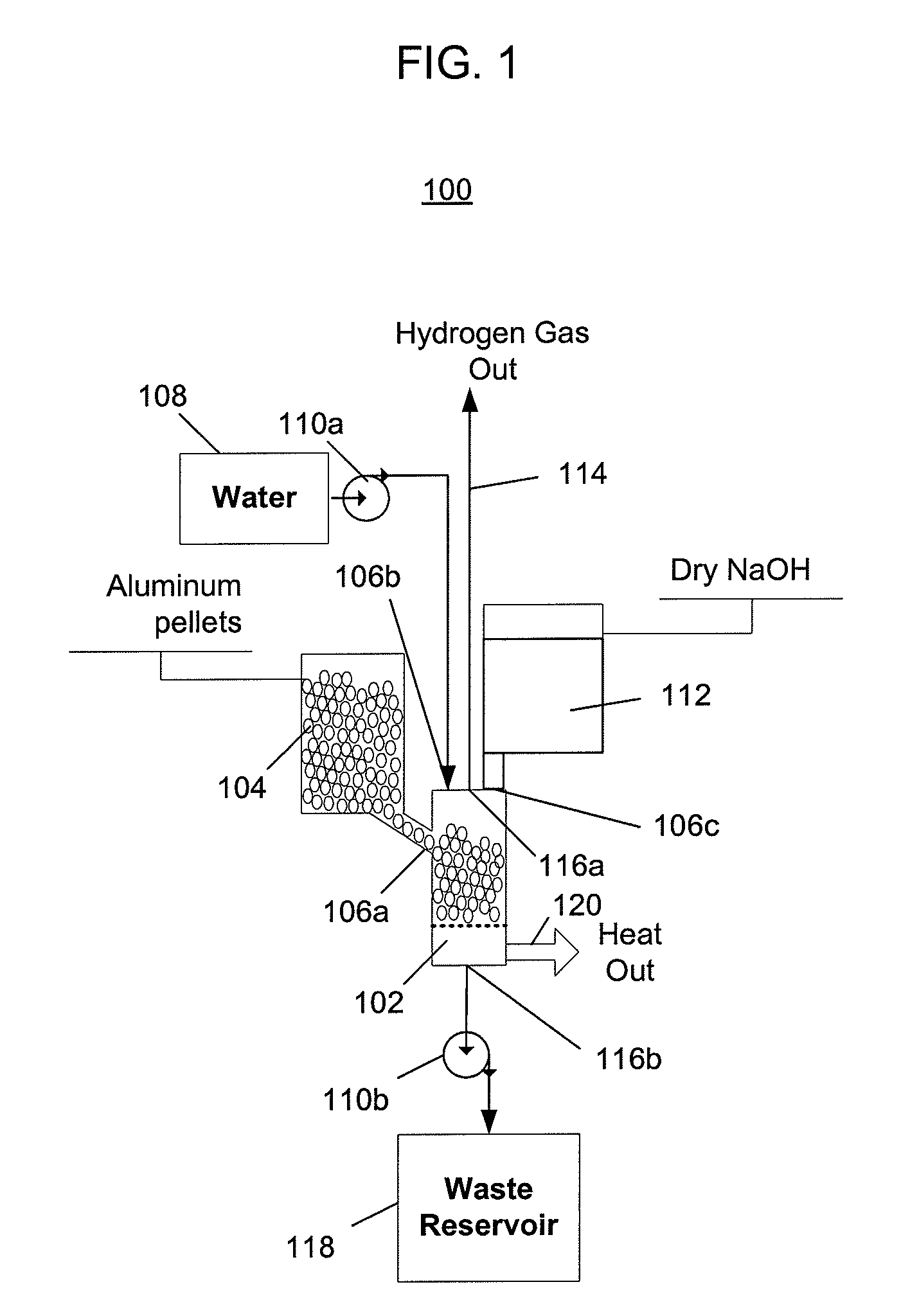

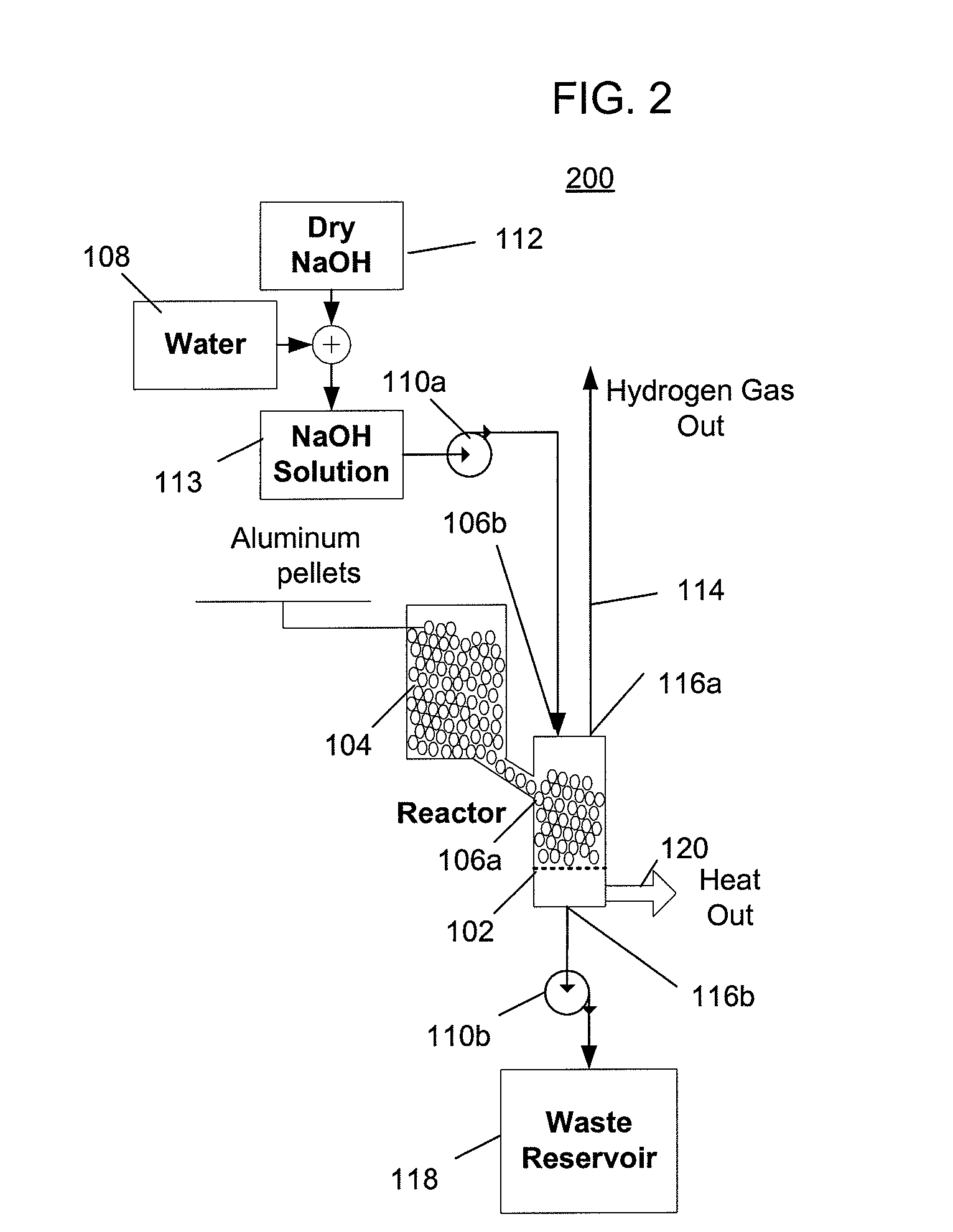

Aluminum-alkali hydroxide recyclable hydrogen generator

InactiveUS20090252671A1Cheap to storeCompact storageOxygen/ozone/oxide/hydroxideEnergy inputChemical reactionHydrogen

An aluminum-alkali hydroxide recyclable hydrogen generator is provided that enables generation of hydrogen for a consuming apparatus on demand. The hydrogen generator includes a source of aluminum, a source of a hydroxide, a source of water, and a reaction chamber, where the amount of at least one of the aluminum, sodium hydroxide, and water that is introduced into the reaction chamber is used to limit the chemical reaction to control the amount of hydrogen generated.

Owner:CEDAR RIDGE RES

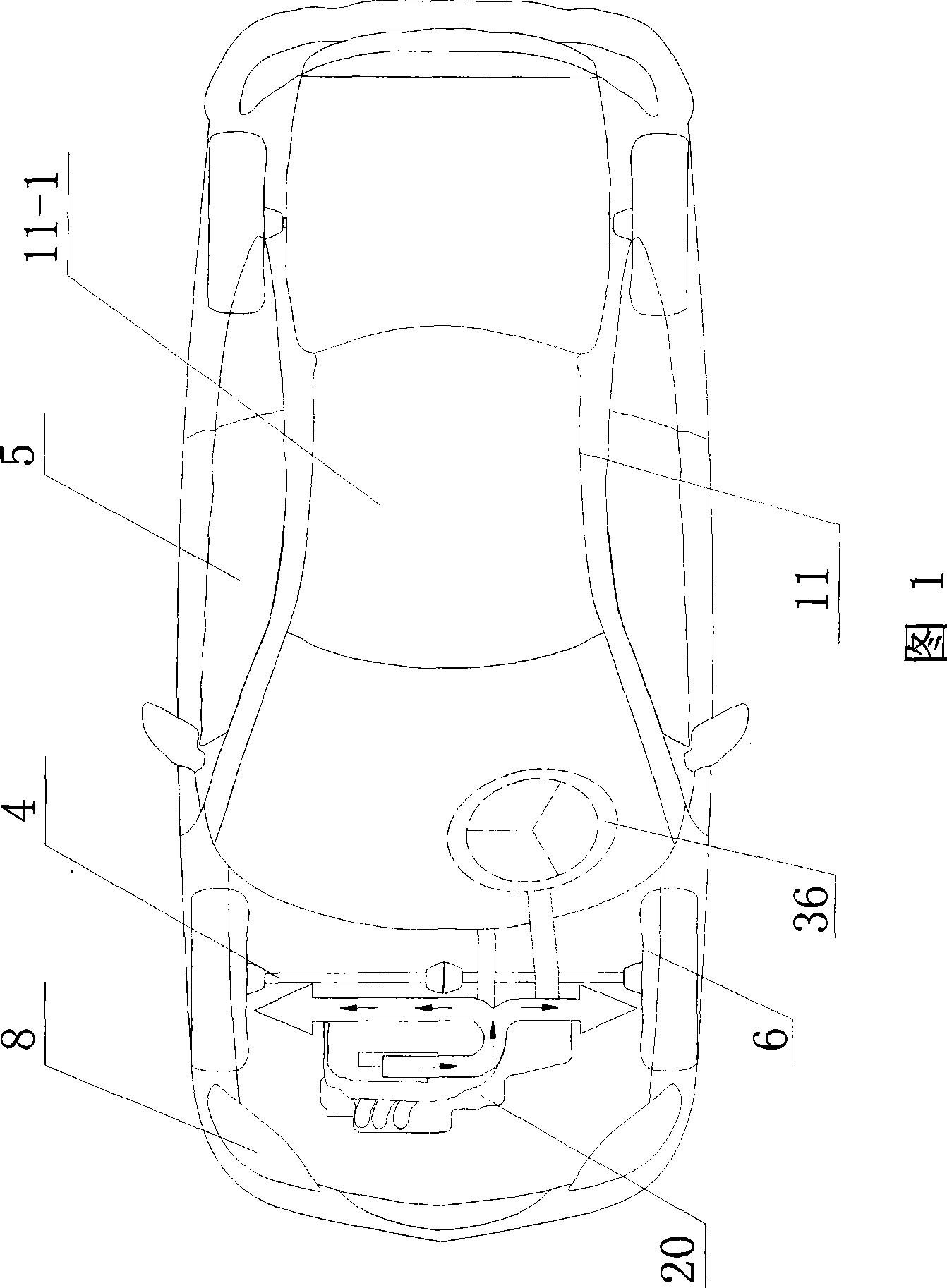

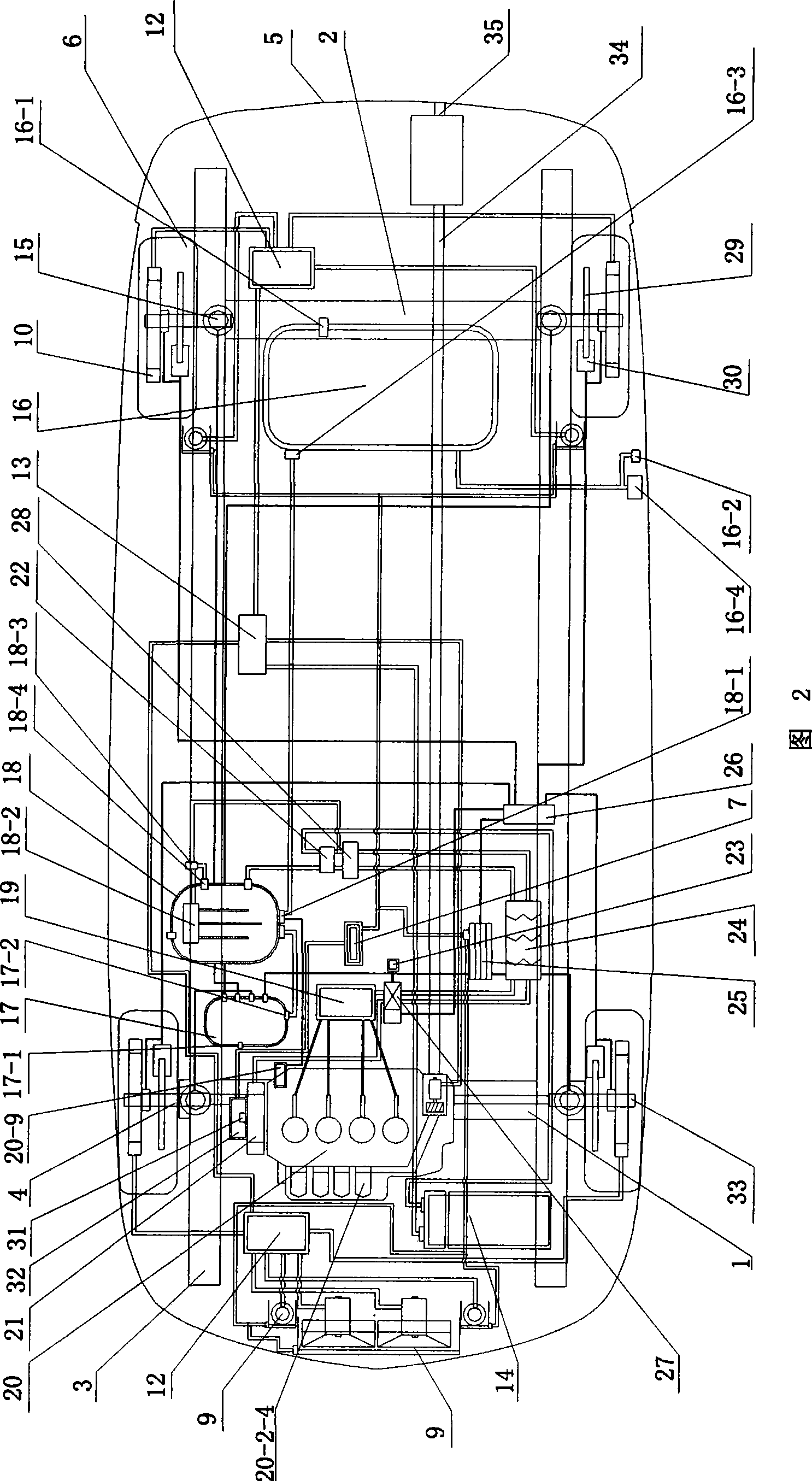

Air hybrid power motor vehicle

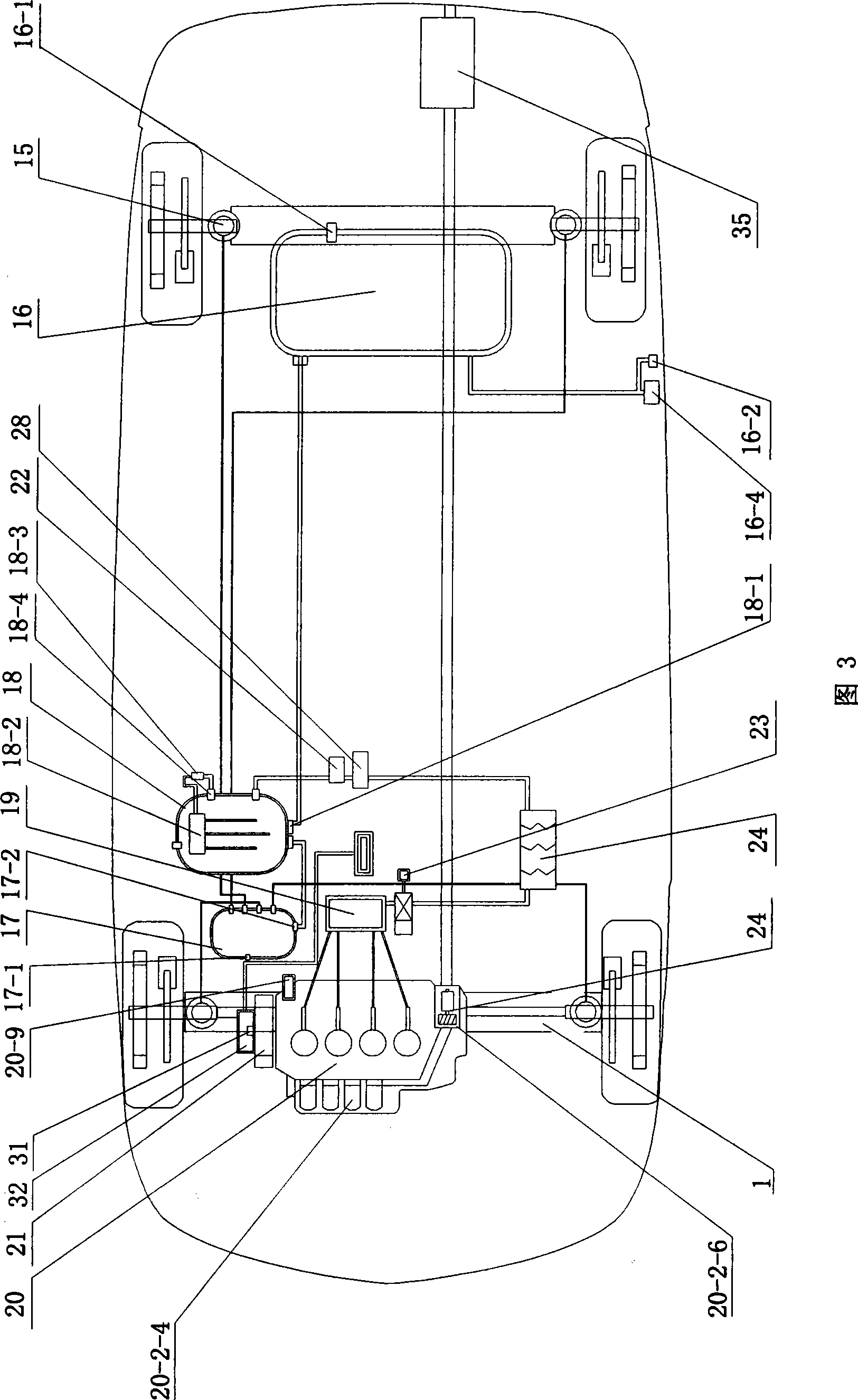

ActiveCN101428555AImprove conversion efficiencyConvenient supplementAuxillary drivesWind motor with solar radiationEnergy recoveryEngineering

The invention relates to an air incorporation power machine motor car, which comprises a steering-wheel, a front aperture axle bracket, a rear axle stand, a girder for connecting the front aperture axle bracket and the rear axle stand and a vehicle body. The motor car further comprises a hub, an energy recovery device, an energy storage device, a power drive device, a control device, a shift device and an auxiliary device which are connected to the front aperture axle bracket and the rear axle stand through transmission shafts. The energy recovery device is connected with the energy storage device; the energy storage device is connected with the power drive device; and the control device controls the energy recovery device, the power drive device and the auxiliary device. When a motor vehicle is in normal running, an air power engine supplies power; and when the motor vehicle is needed to decelerate when conducting brake, turning and downhill, the hub and impellers are started to generate electricity and collect the power and use. The power recycled by the manner is rather considerable, so that the energy of the invention can be better made up. In sum, the invention utilizes air power as main power, and the power can be recycled and utilized through multi ways. In addition, the air source collection is convenient, the energy transformation rate is high and the exhaust emission is nearly zero, thereby achieving the aims of the invention.

Owner:周登荣 +1

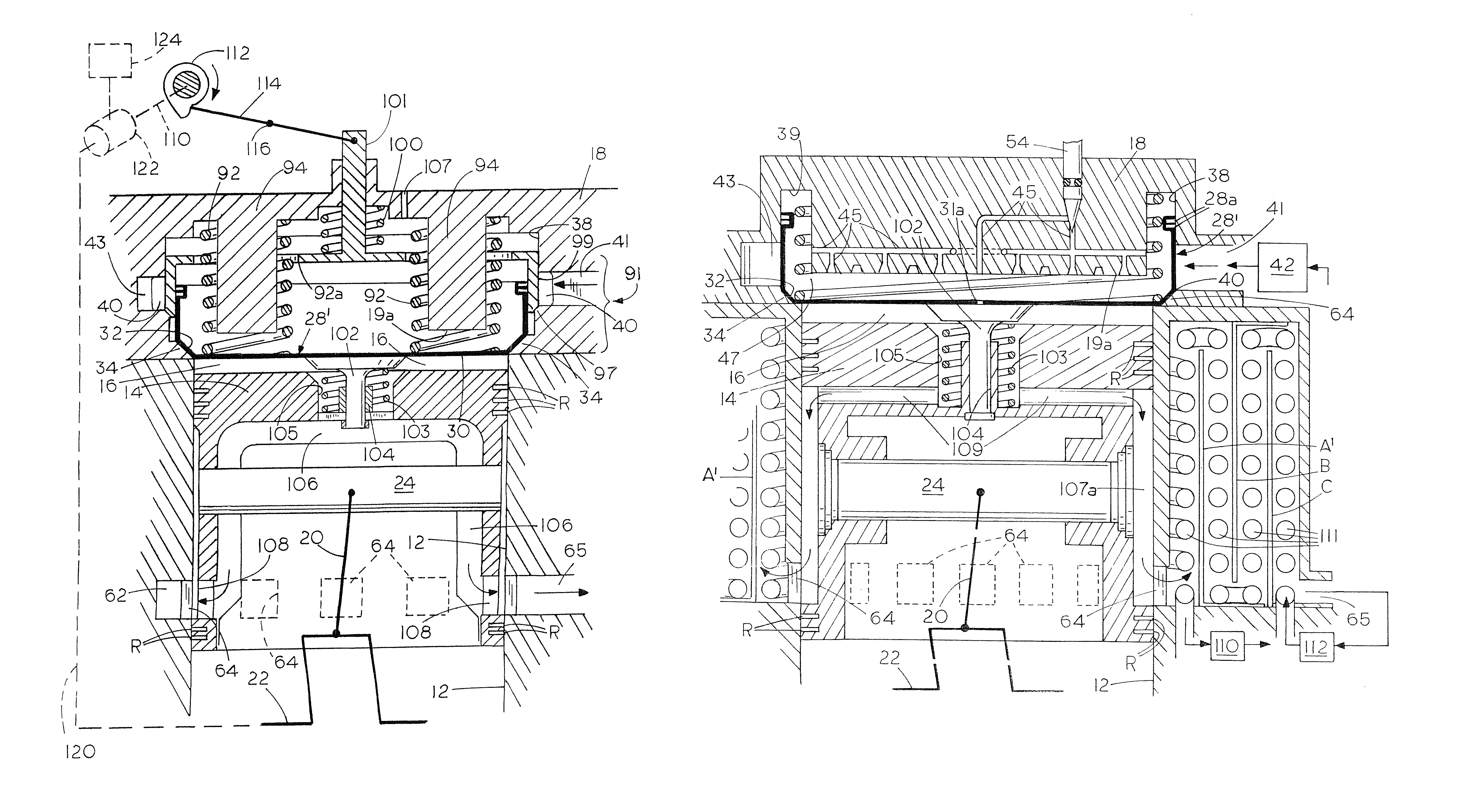

High efficiency multicycle internal combustion engine with waste heat recovery

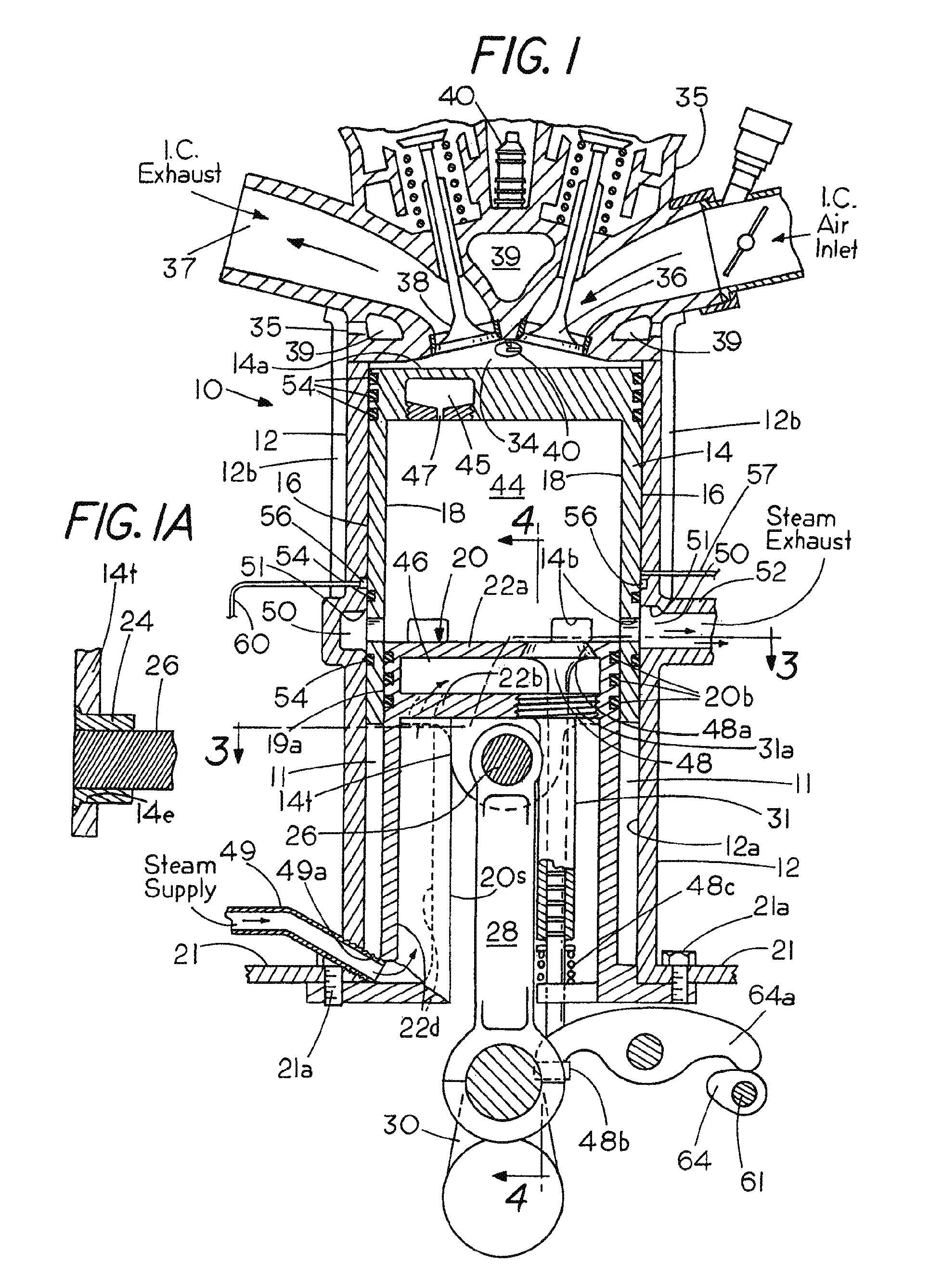

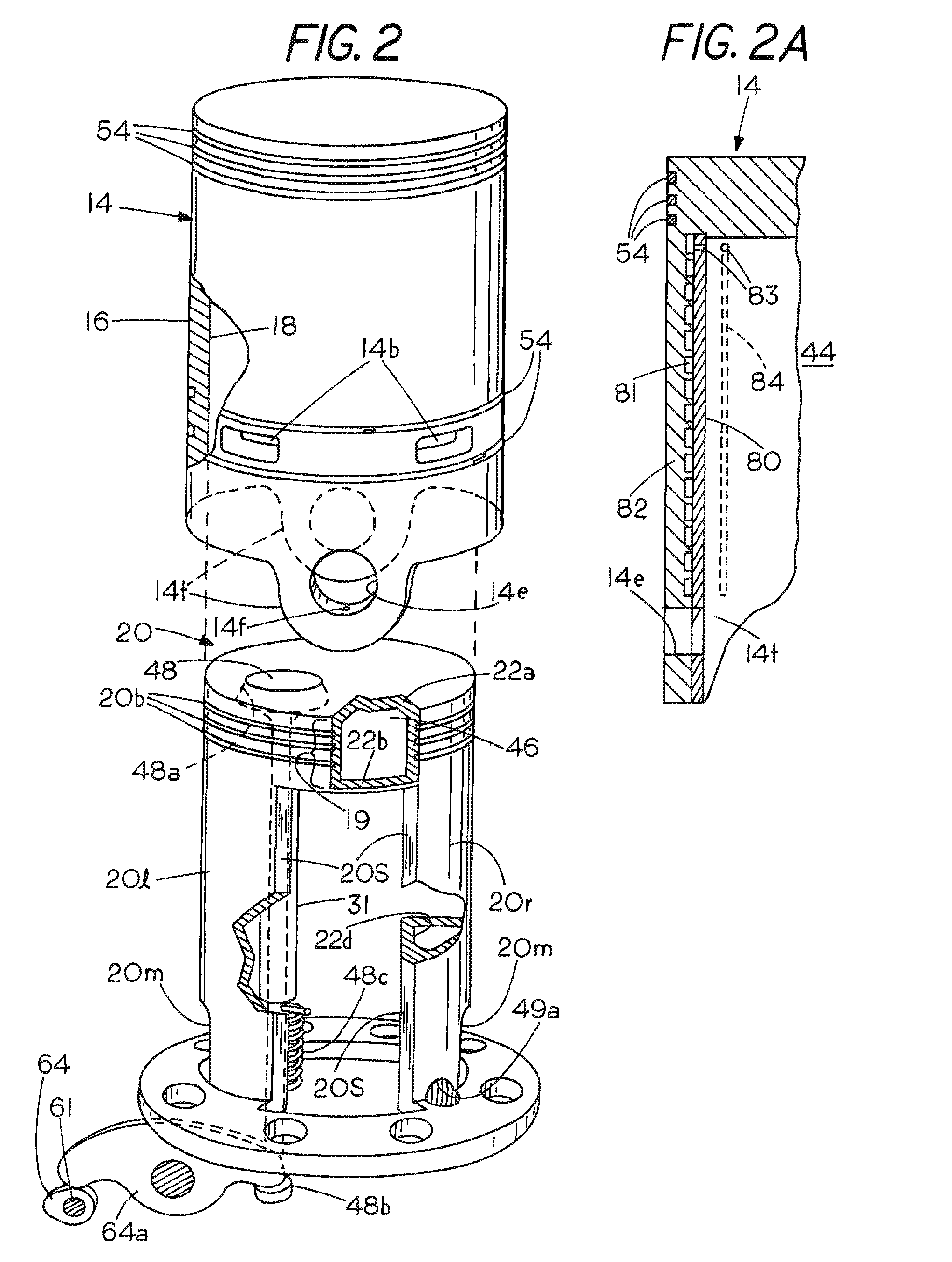

ActiveUS8061140B2Effective recoveryIncrease enthalpyReciprocating combination enginesInternal combustion piston enginesCombustion chamberInlet valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder and a piston with an internal combustion chamber outward of the piston, a fixed cylinder cap and a steam expansion chamber inside the piston. The cylinder cap can be heated to reduce condensation of steam entering from a steam generator fired by waste combustion heat. Following exhaust, residual steam can be recompressed prior to admitting the next charge of steam. A wrist pin connected to an inner end of the piston skirt inwardly of the cylinder cap is coupled to a connecting rod secured to a crankshaft. One valve or a pair of steam inlet valves are connected to communicate in series within the cylinder cap inside the piston. The steam mass admitted is regulated to reduce fuel consumption. Coolant can be superheated in the combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

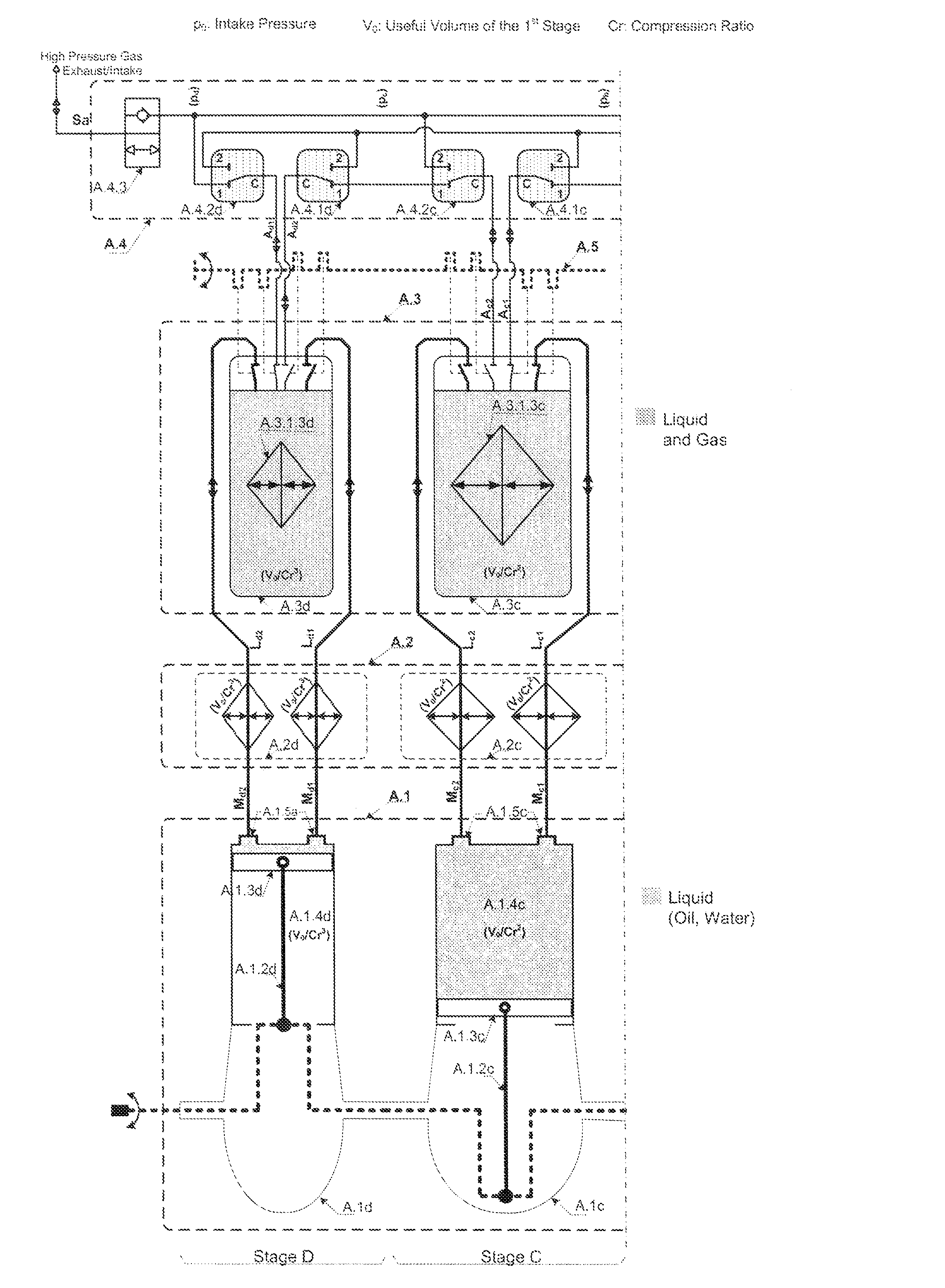

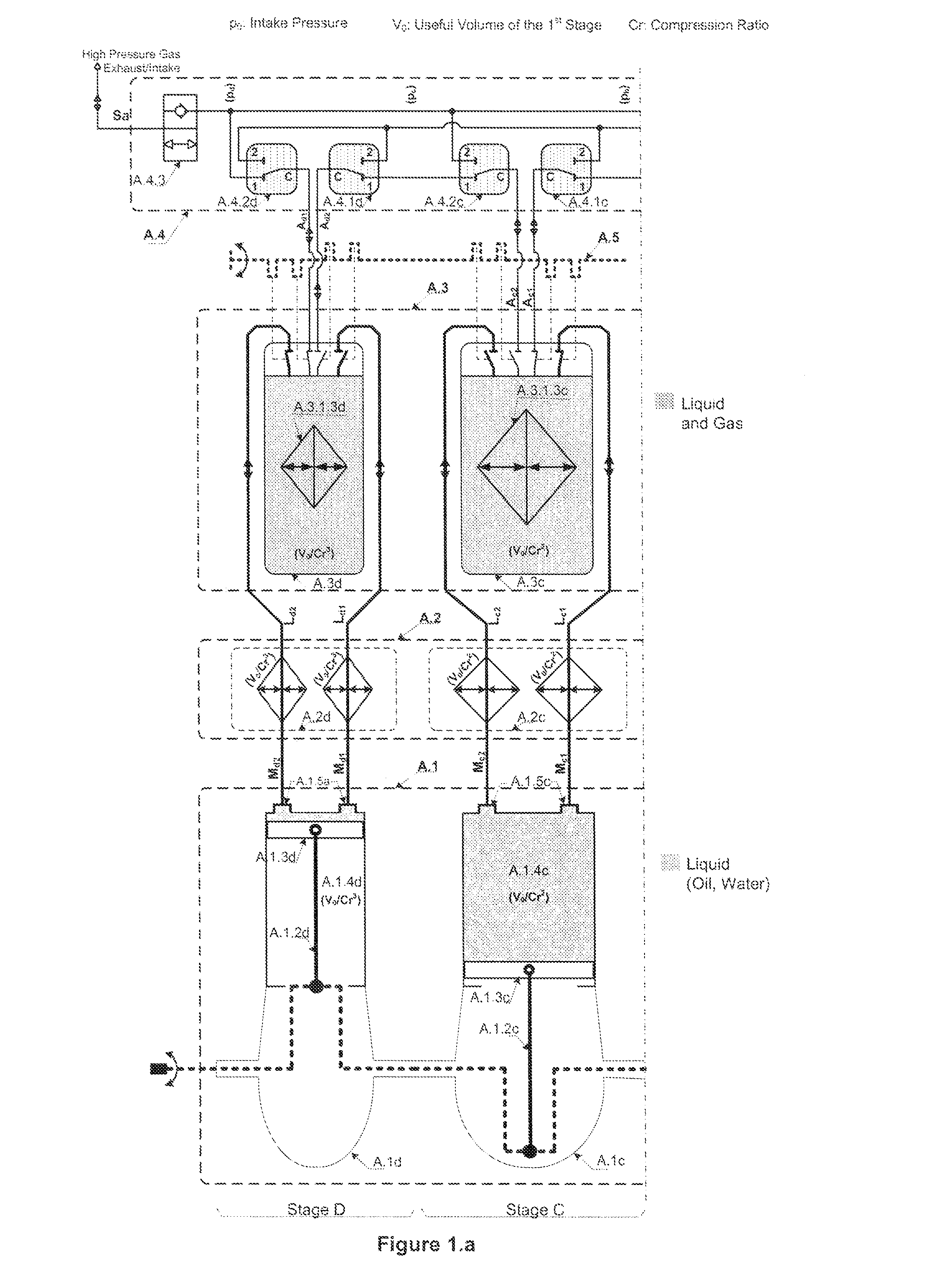

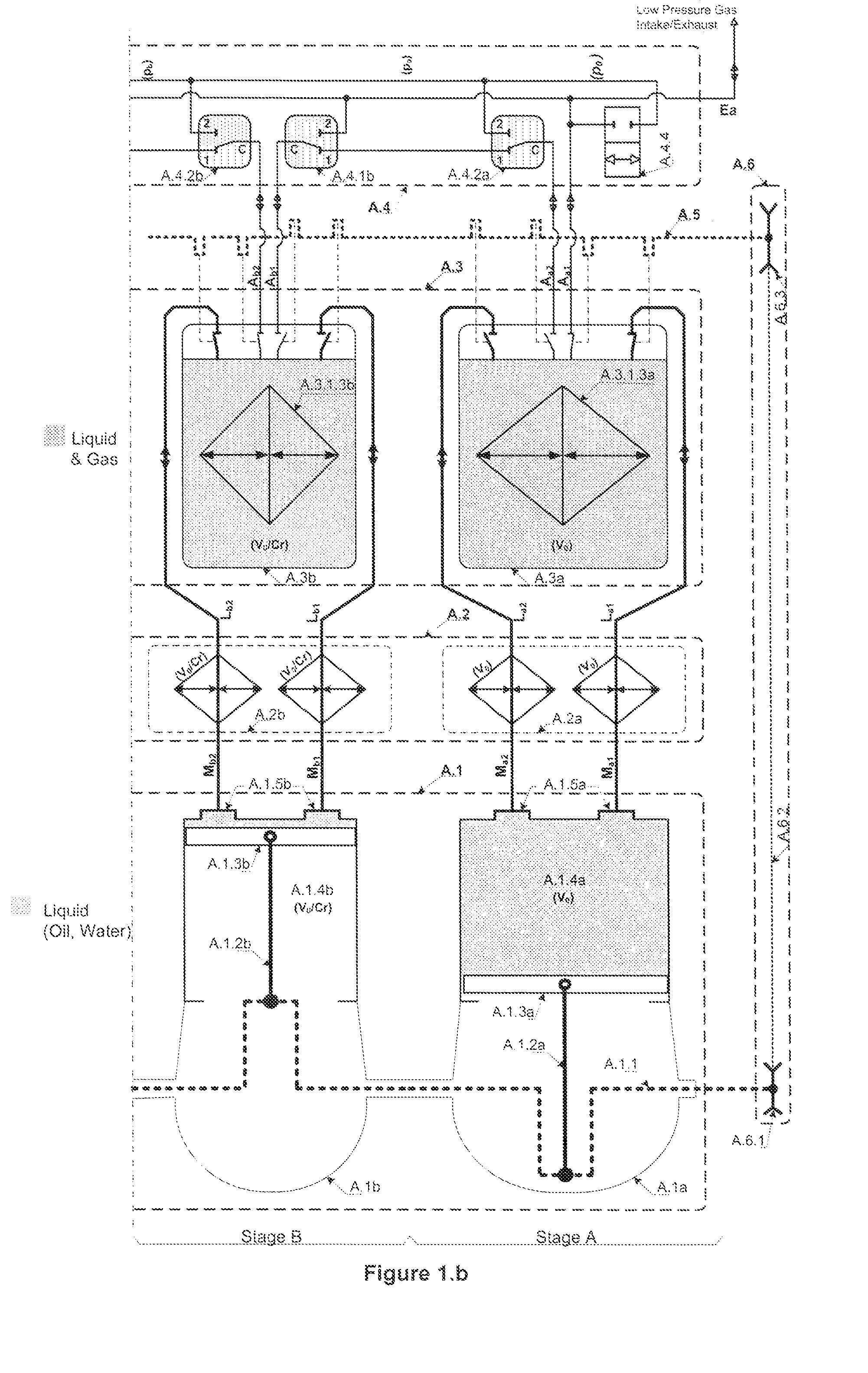

Multistage Hydraulic Gas Compression/Expansion Systems and Methods

ActiveUS20100199652A1Ease automatic control of valveElectrical storage systemRotary clutchesHydraulic motorSingle stage

Multistage hydraulic systems and methods for converting the potential energy of a pressurized gas, particularly air, into mechanical work when operating in motor, and for producing compressed gas from the mechanical work of the rotating shaft when rotating when operating in compressor mode, by performing a successive expansion / compression of the said gas. Each of the systems comprises: a multistage Compression-Expansion Unit made of several hydraulic Compression-Expansion Modules having different capacity and integrating a gas / liquid separating heat exchanger, designed to convert pressure power into a hydraulic power and vice-versa, by performing an essentially isothermal compression / expansion of the gas; a single stage or multistage, direct or indirect, external forced-air Heat Exchanger for maintaining the active liquid at ambient temperature; and a multi-circuit, multi-displacement Hydraulic Motor / Pump for converting hydraulic power into mechanical power and vice-versa.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

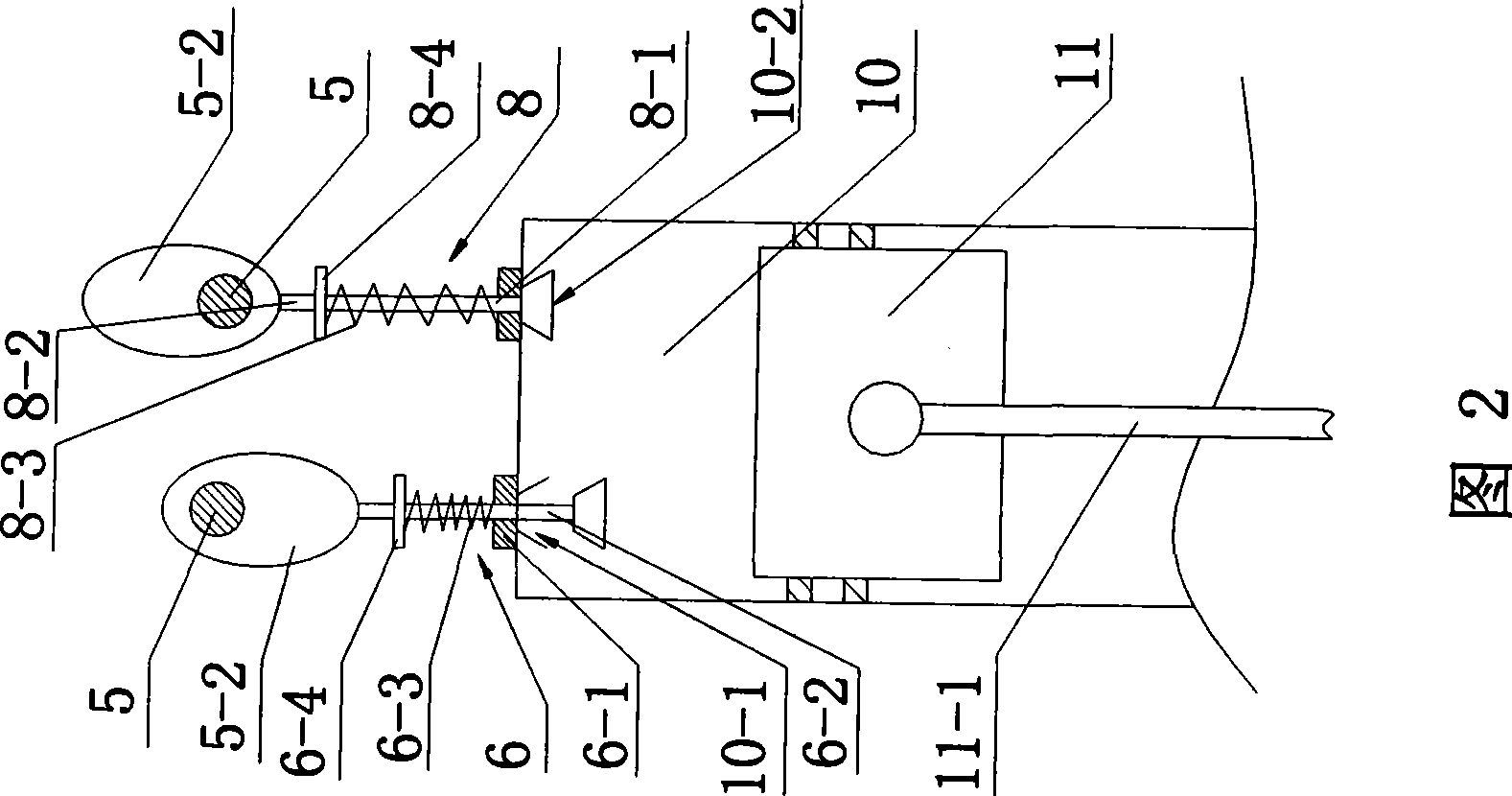

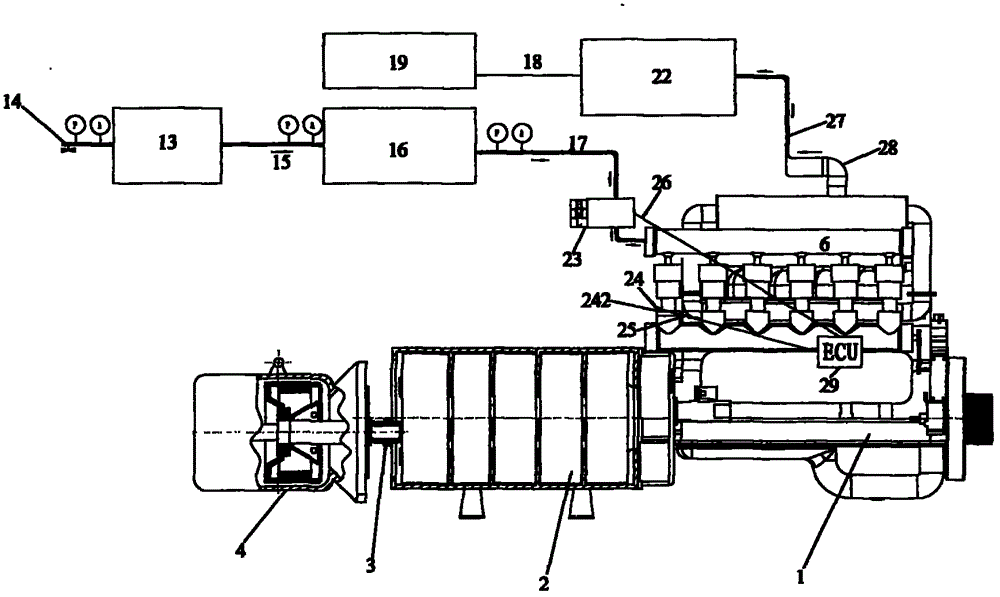

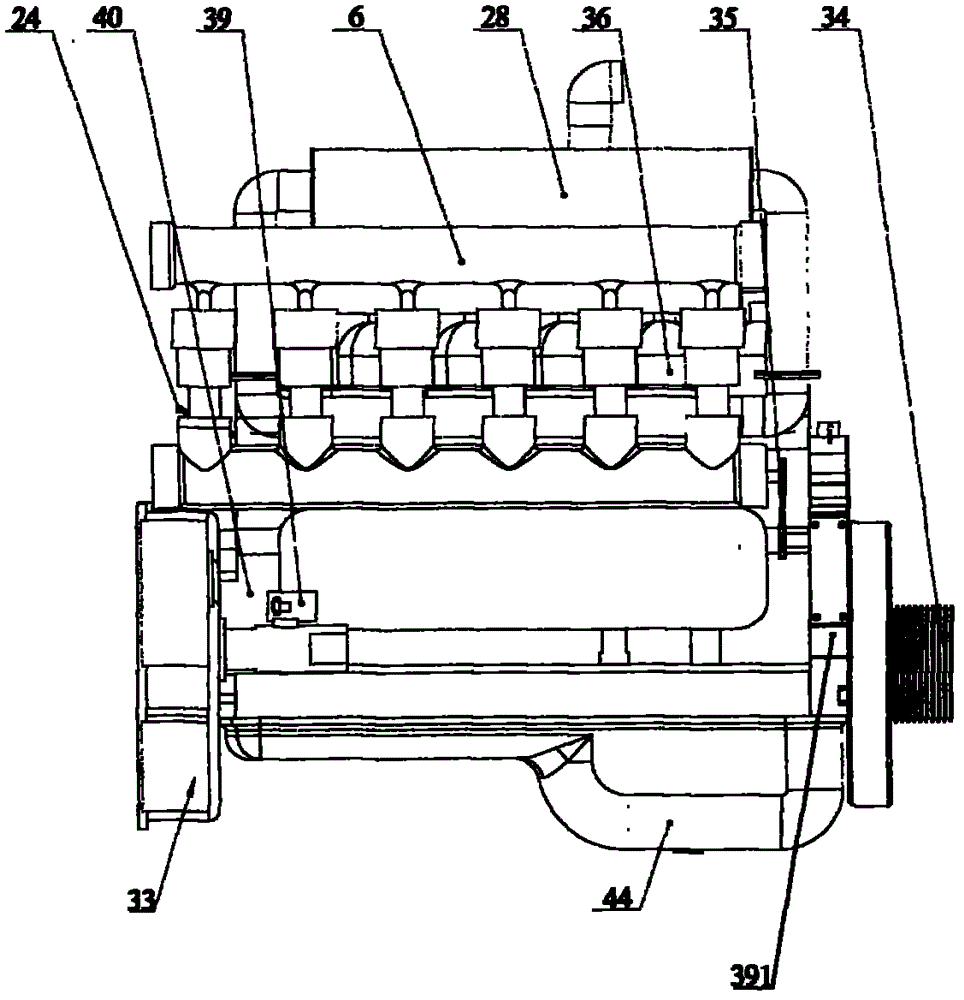

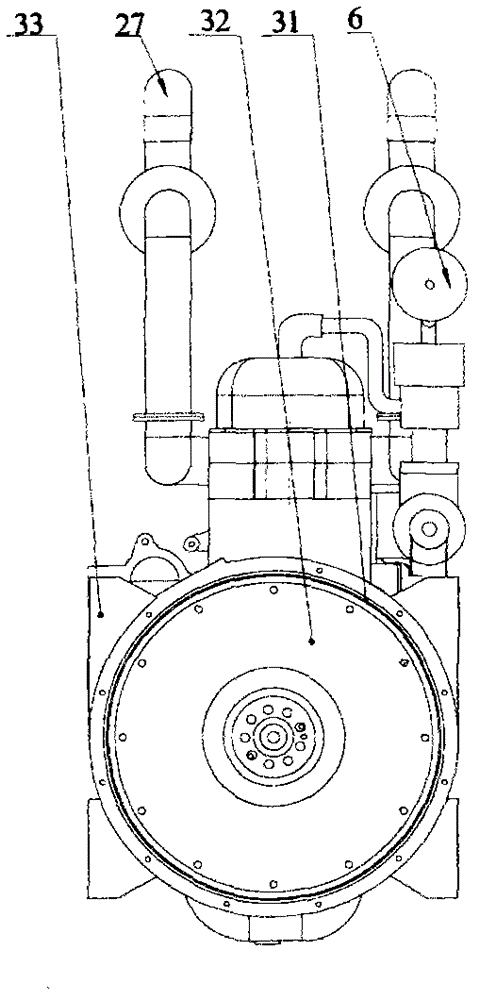

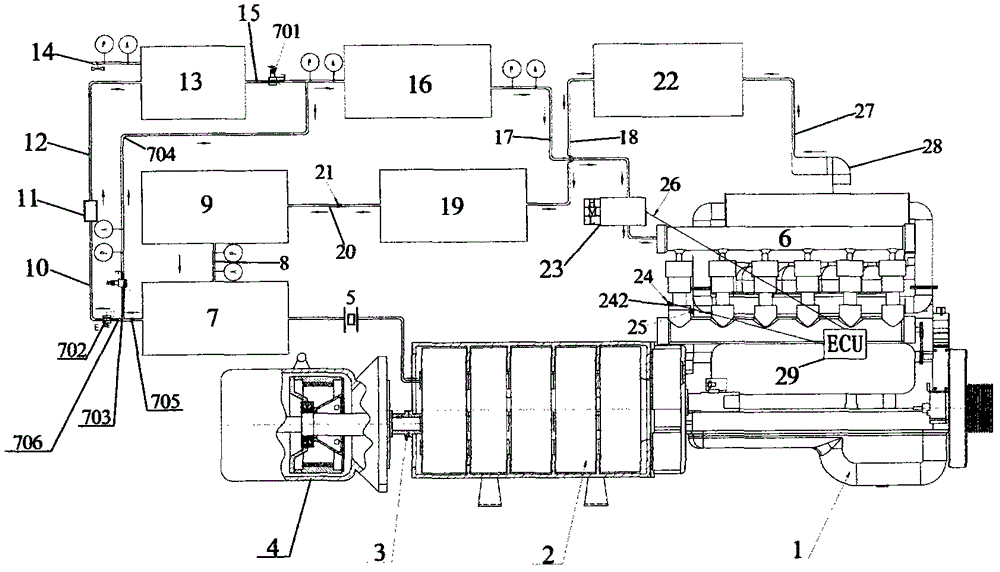

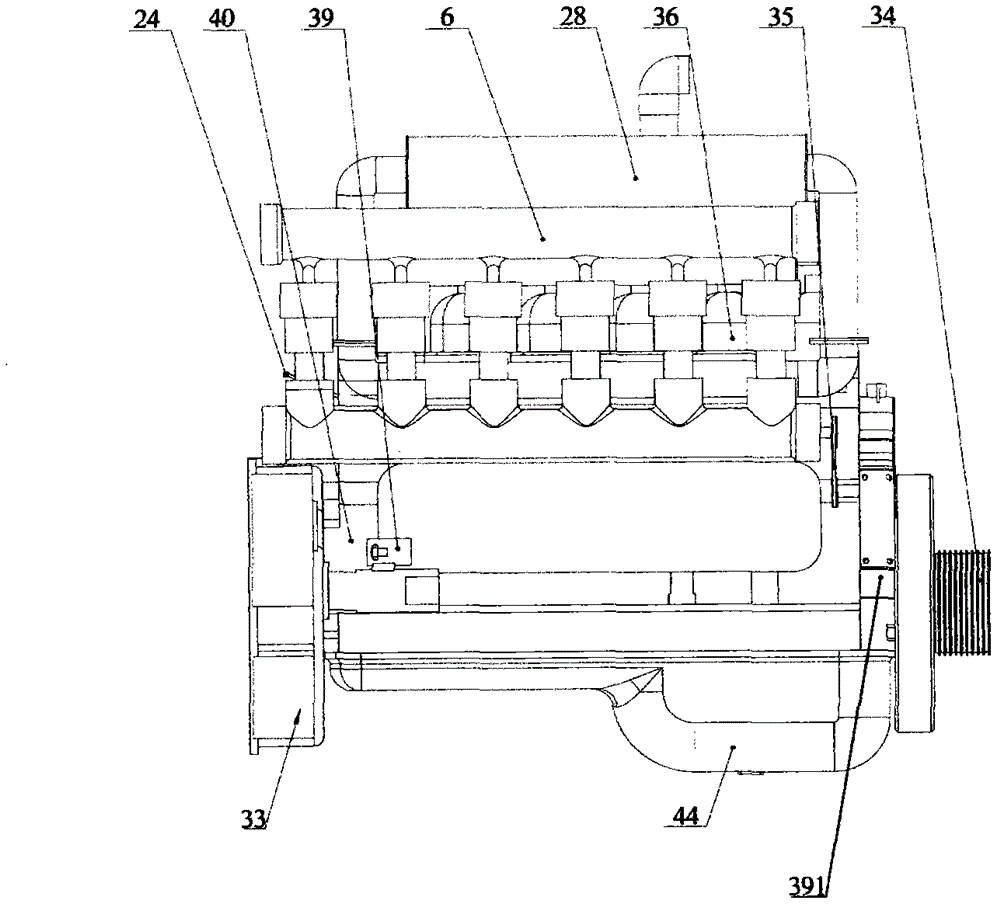

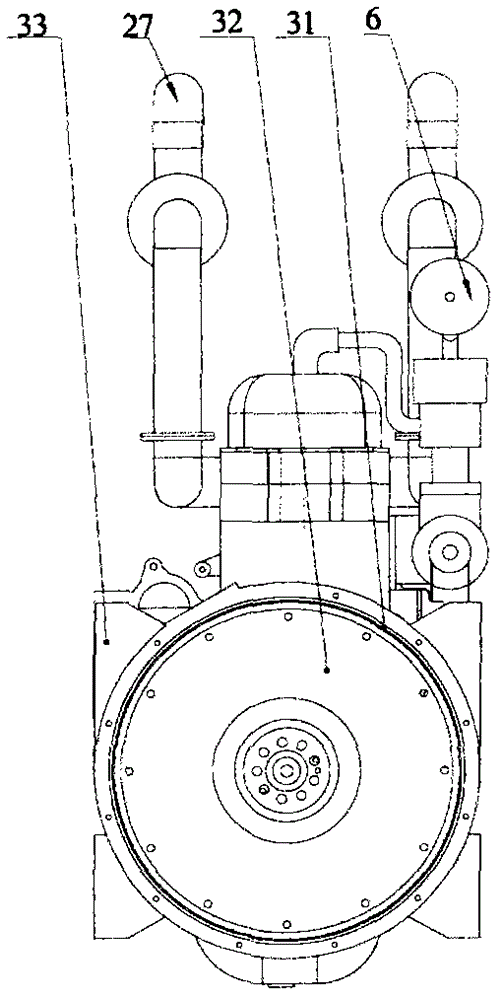

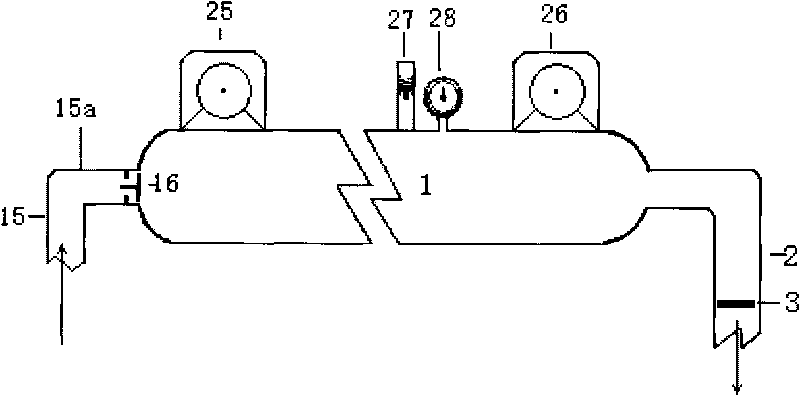

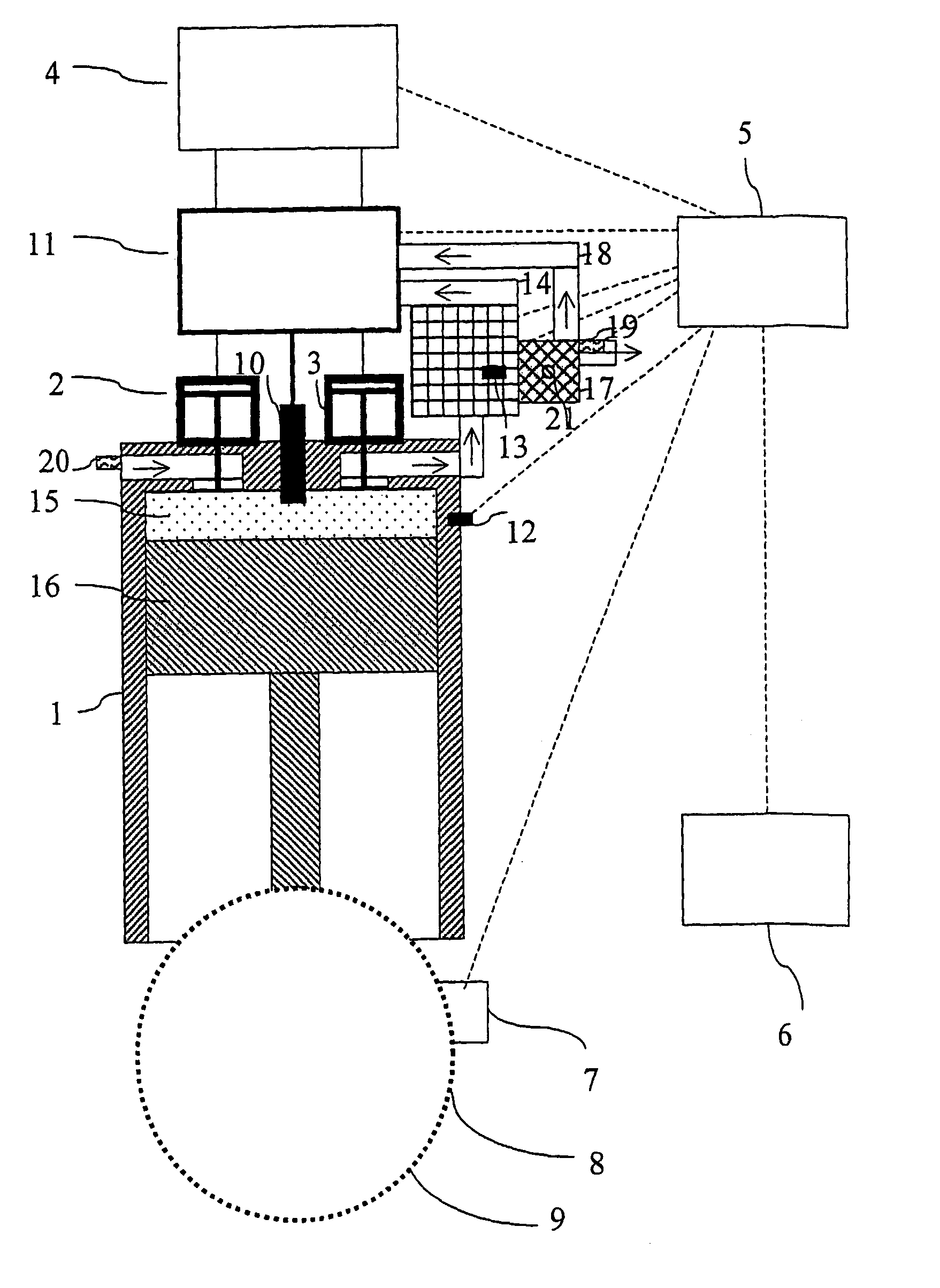

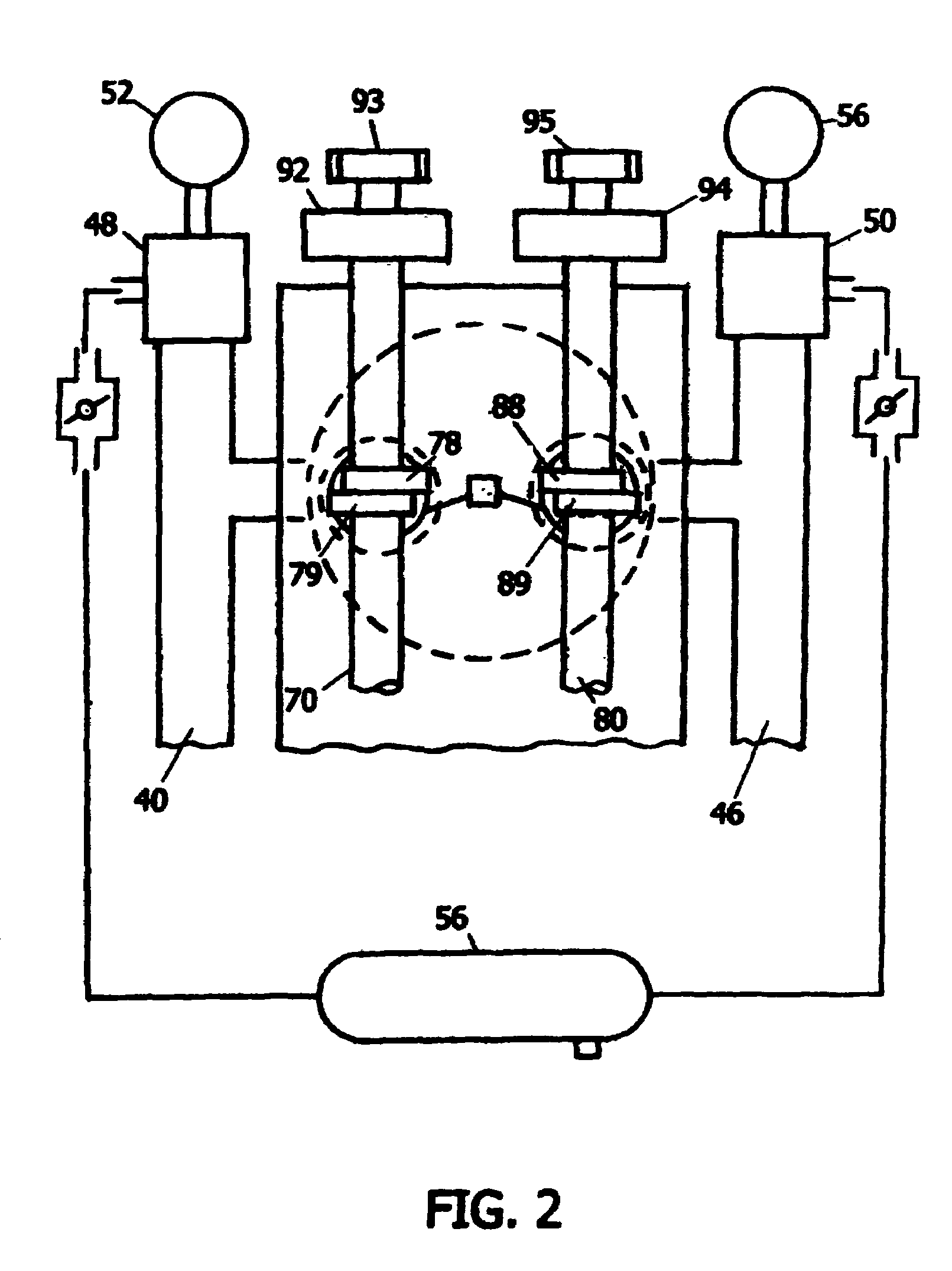

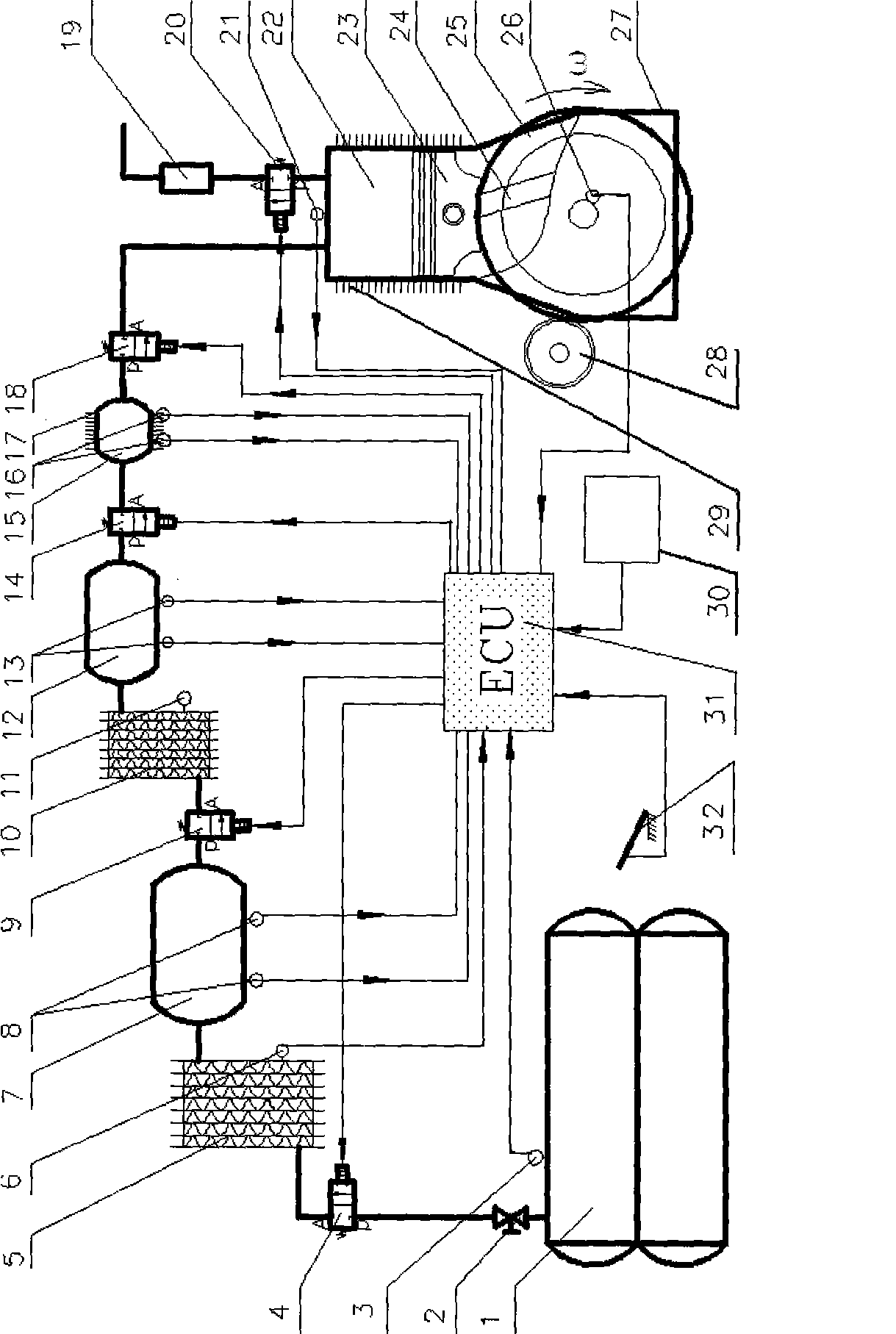

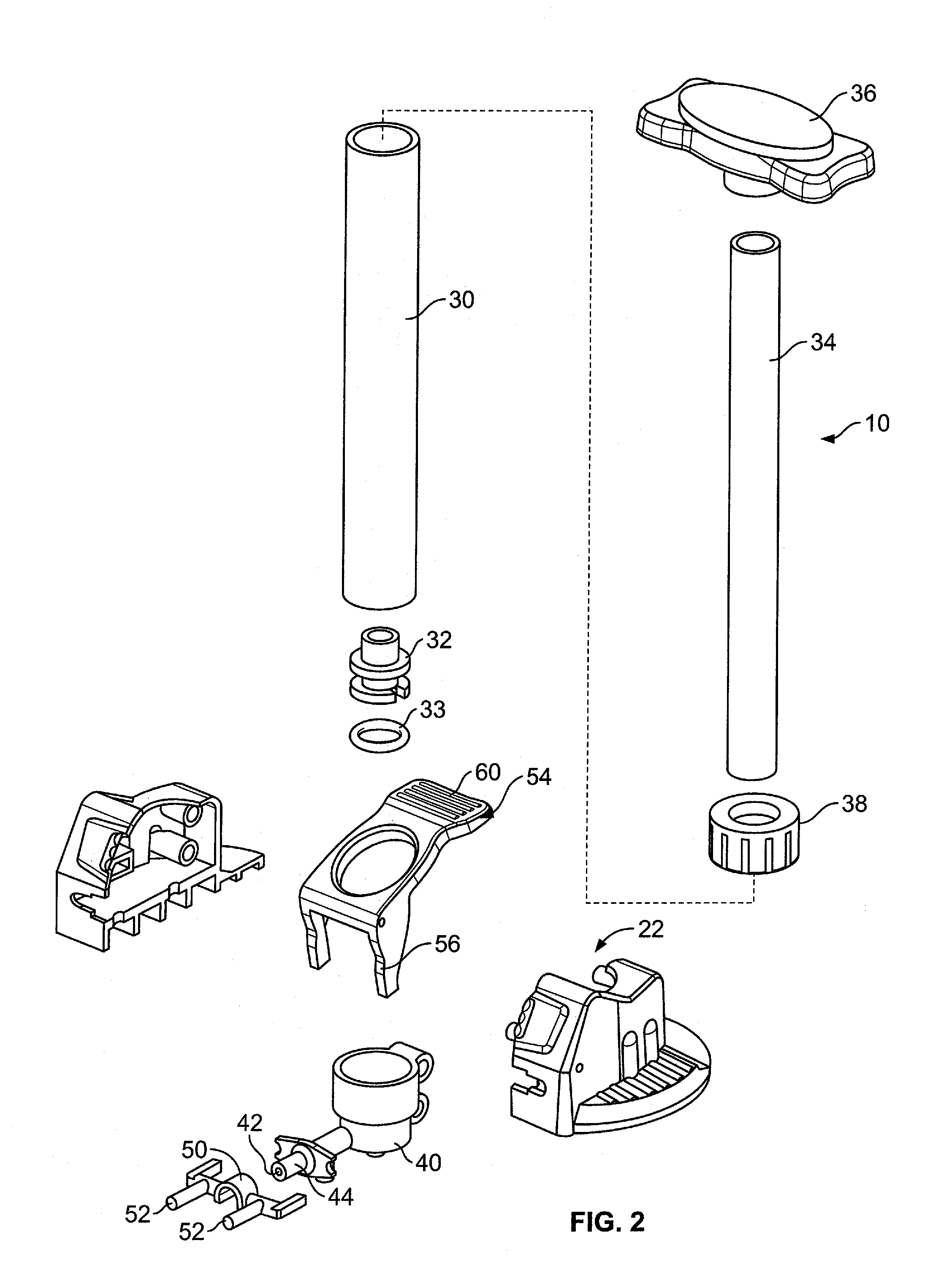

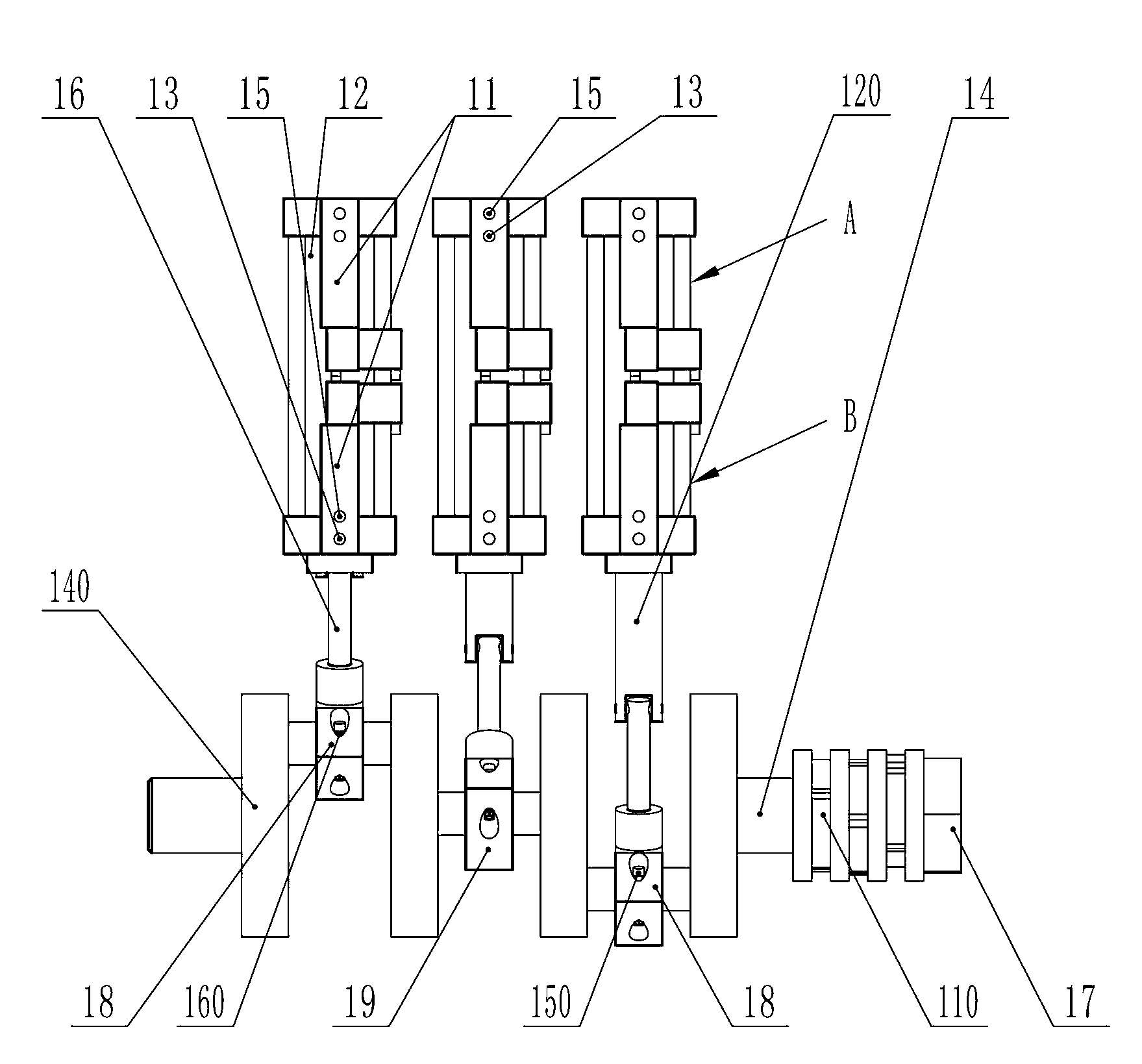

Two-stroke aerodynamic engine assembly

The invention relates to a two-stroke engine, in particular to a two-stroke aerodynamic engine assembly which takes compressed air as a power source. The two-stroke aerodynamic engine assembly comprises an engine body (1), a multicolumn power distributor (2), a power device (3), a controller system (6), an air inlet control compensated flow control valve (23), a high-pressure air tank set (13), a constant-pressure tank (16) and an electric control unit (ECU) (29).

Owner:周登荣 +1

Reciprocating compressed-air power engine

InactiveCN101705841AAvoid pollutionReduce consumption costEngines characterised by uniflow principleMechanical equipmentTransportation industry

The invention relates to mechanical equipment, in particular to an engine which repeatedly uses compressed-air power to work. The engine consists of a compressed air pressure structure, a mechanical structure, a charging, supplementing and electromagnetic system structure and an engine working process structure. The engine has the structural characteristics of repeatedly using compressed-air power to do work, can be matched to drive various maneuvering vehicles and transportation tools, also can be matched with a power generator to form a unit to generate power, and achieves the purposes of engine work, long endurance, energy conservation, environmental protection, push of traffic and transportation industry, and sustainable development.

Owner:高阳

Internal combustion engine with steam expansion stroke

InactiveUS6986252B2Need can be quite largeEfficiency advantageElectrical controlInternal combustion piston enginesCombustion chamberControl system

Owner:CARGINE ENG AB

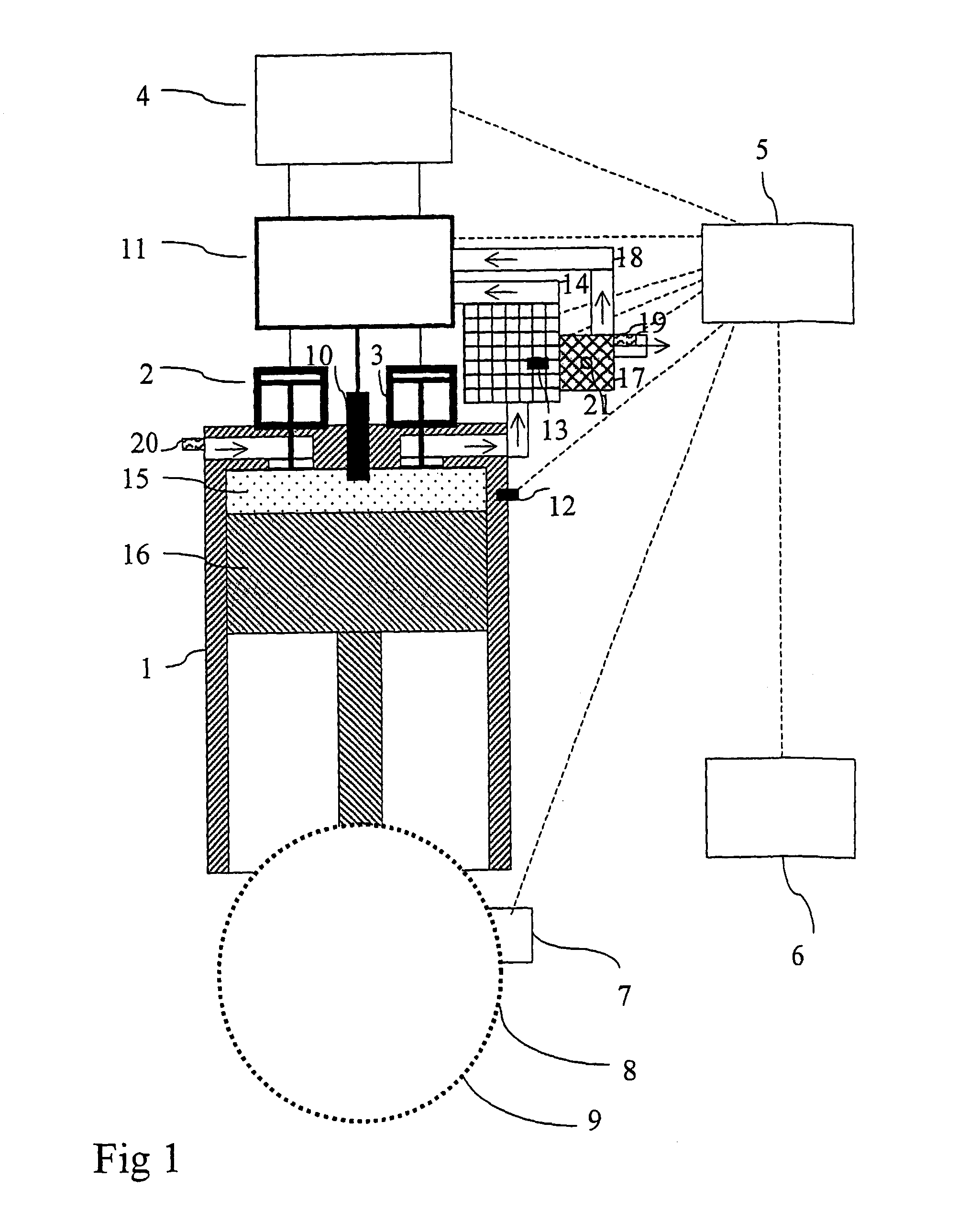

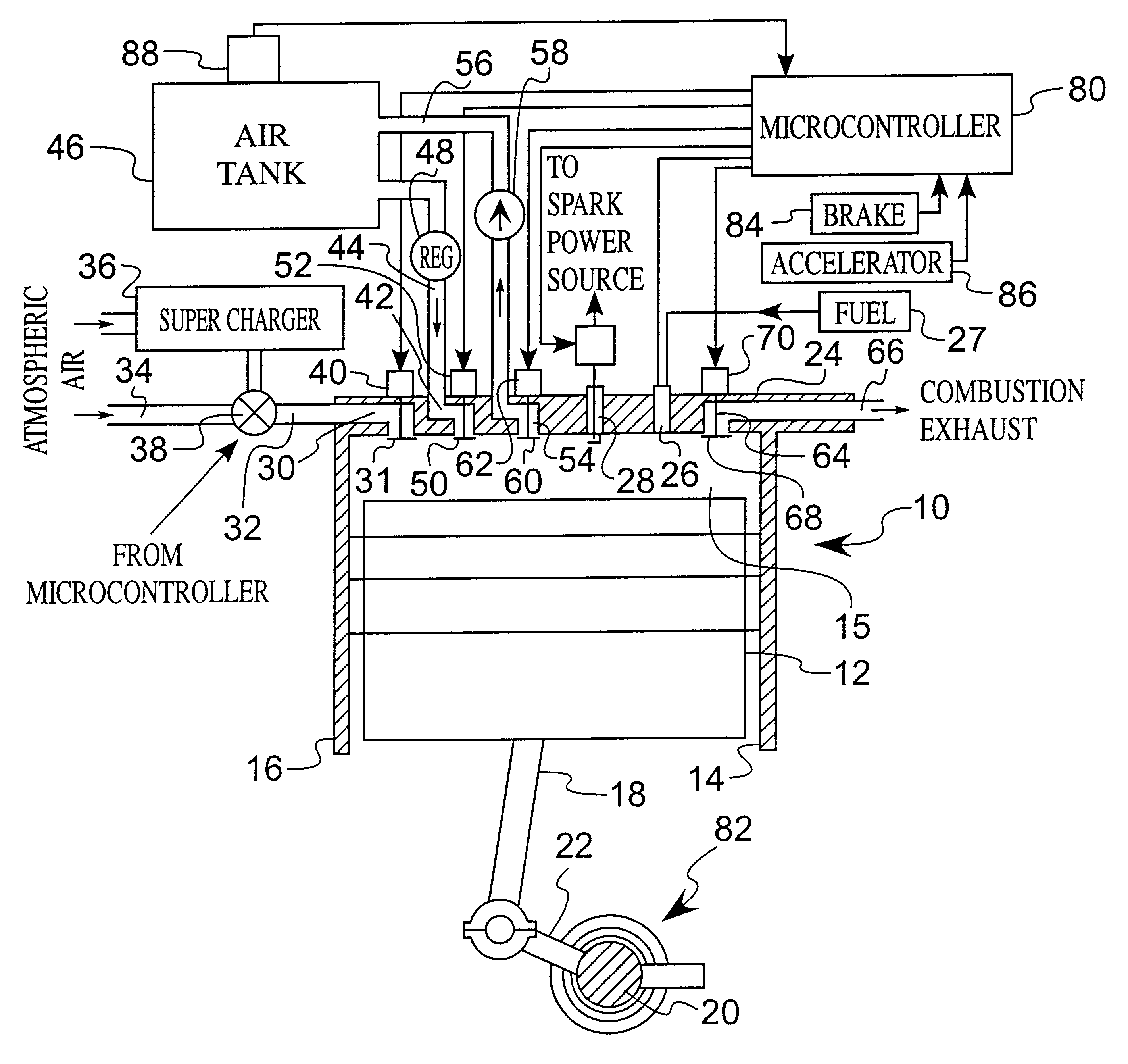

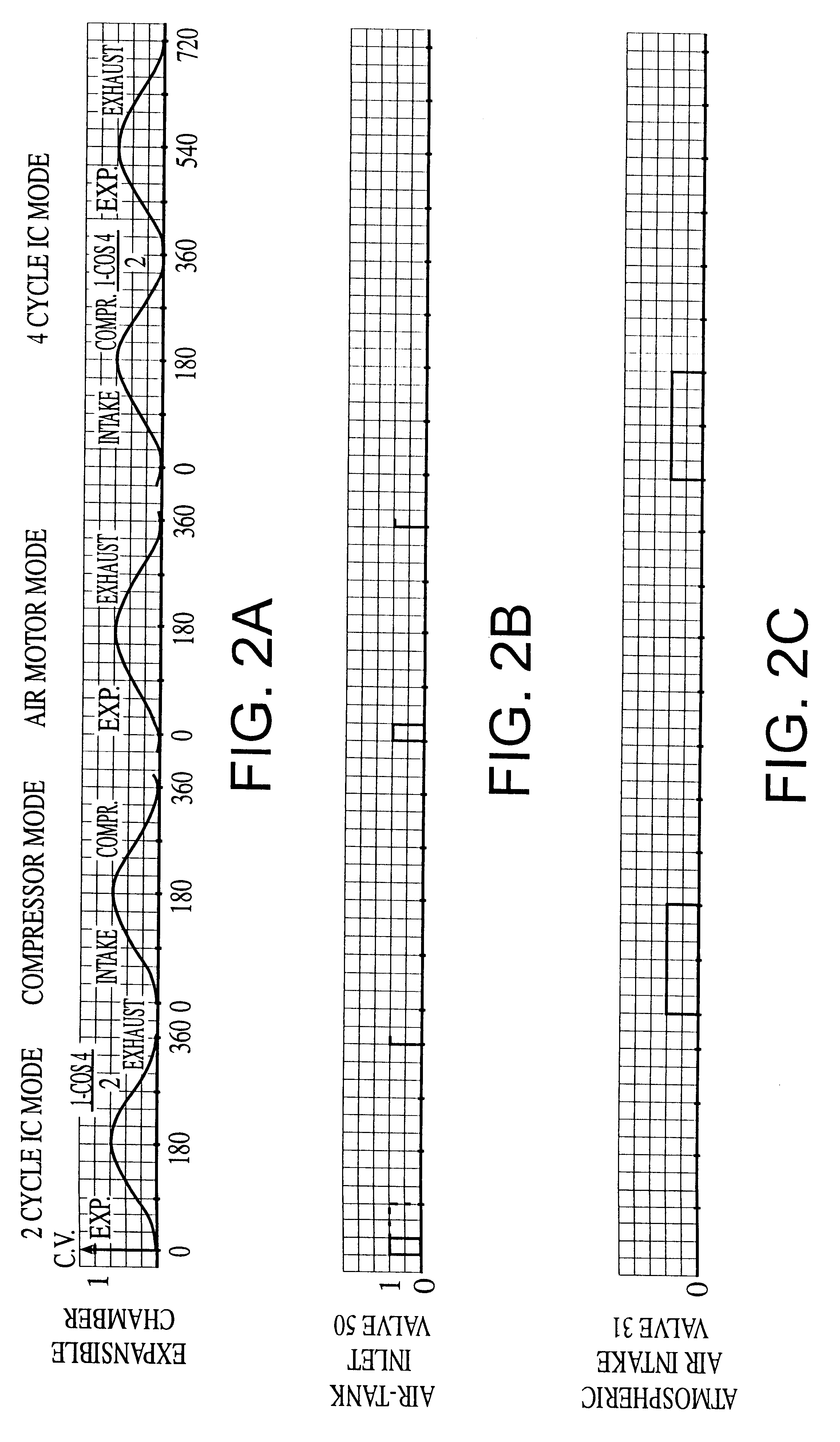

Hybrid expansible chamber engine with internal combustion and pneumatic modes

InactiveUS6568186B2Efficiently meetReciprocating combination enginesCombination enginesMicrocontrollerCombustion

A hybrid engine, having a plurality of coupled expansible chamber devices, preferably a piston in a cylinder, each capable of operating in any one of an internal combustion mode, an air pump / compressor mode and an air motor mode. The modes are controlled by a microcontroller which controls the valves, ignition source and fuel source. The mode for each expansible chamber device is computed and independently selected by the microcontroller and the combination of modes at any instant is switched to optimize engine operation for the operating conditions at that instant.

Owner:NANO PRECISION

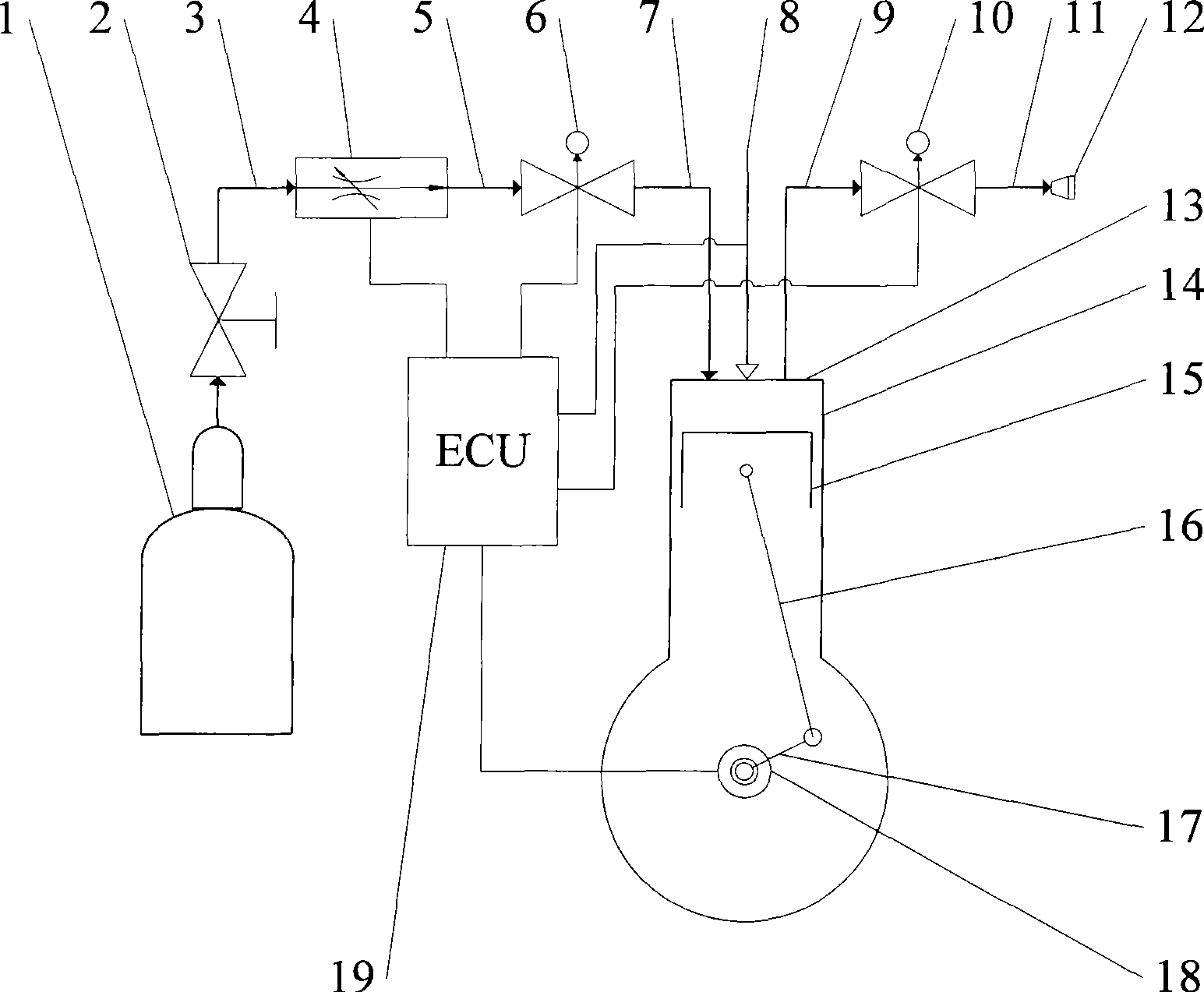

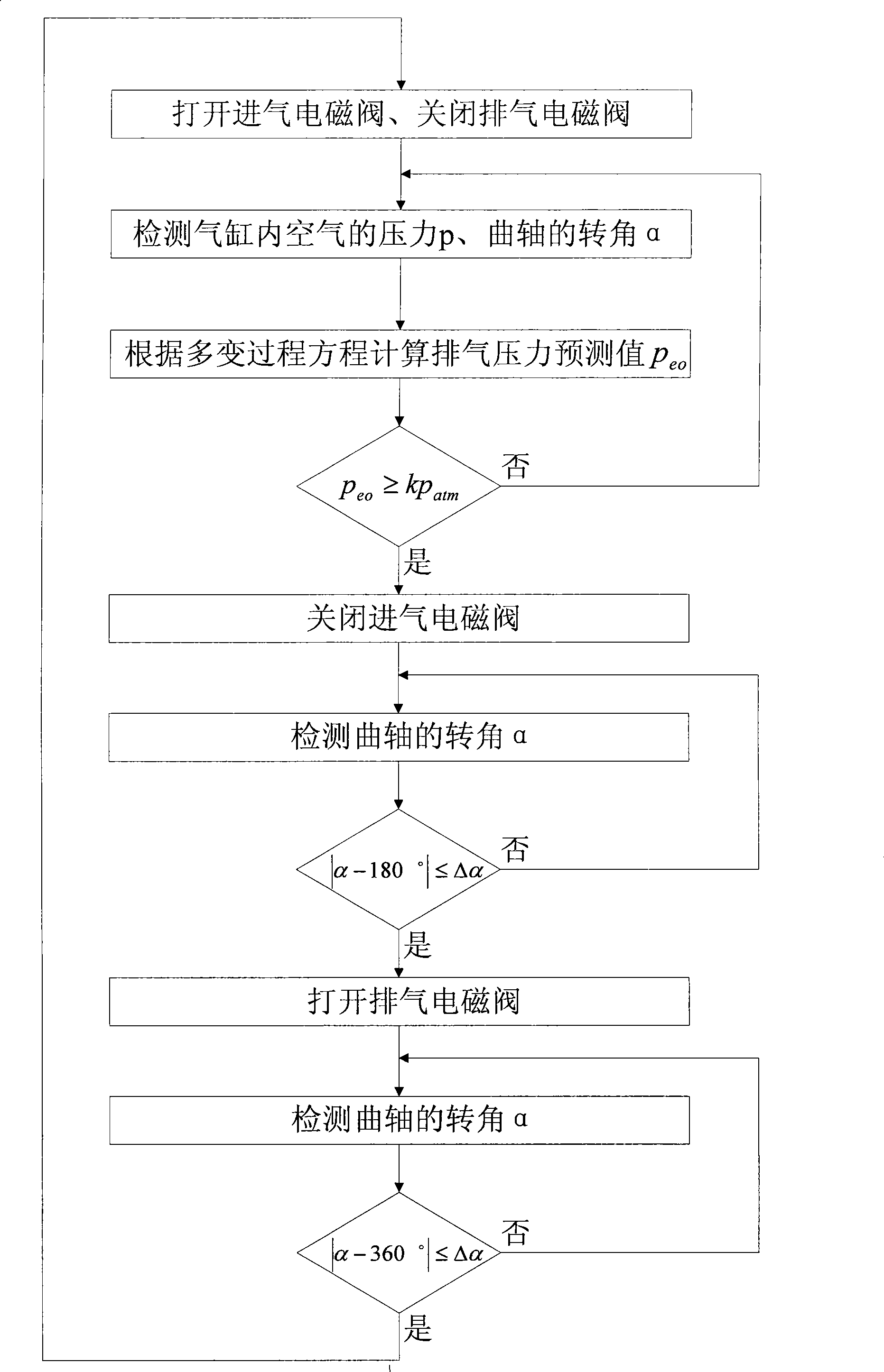

Expansion ratio adjustable pneumatic engine for automobile and its exhaust pressure control method

InactiveCN101476490AAvoid lostReduce lossesSafety/regulatory devicesEngines characterised by uniflow principleControl signalEngineering

The invention relates to a pneumatic engine for car use and discloses a pneumatic engine for car use with an adjustable expansion ratio and an exhaust pressure control method. According to the pneumatic engine for car use with the adjustable expansion ratio, compressed air is expanded in a cylinder so as to propel a piston and drive a crankshaft to rotate through a connecting rod and output rotating mechanical work to the outside. The pneumatic engine is characterized in that the pneumatic engine comprises an air inlet electromagnetic valve which is arranged in a cylinder air inlet pipe, an exhaust electromagnetic valve which is arranged in a cylinder exhaust pipe, a pressure sensor which is used for detecting the air pressure inside the cylinder, a photoelectric encoder which is used for detecting a crankshaft rotation angle, and a controller; and the controller makes a policy according to the cylinder air pressure detected by the pressure sensor and the crankshaft rotation angle of the photoelectric encoder, and sends a control signal of opening or closing to the air inlet electromagnetic valve and the exhaust electromagnetic valve. The pneumatic engine reduces the compressed air available energy loss caused by high pressure exhaust, thereby improving the energy conversion rate of the pneumatic engine.

Owner:SOUTH CHINA UNIV OF TECH

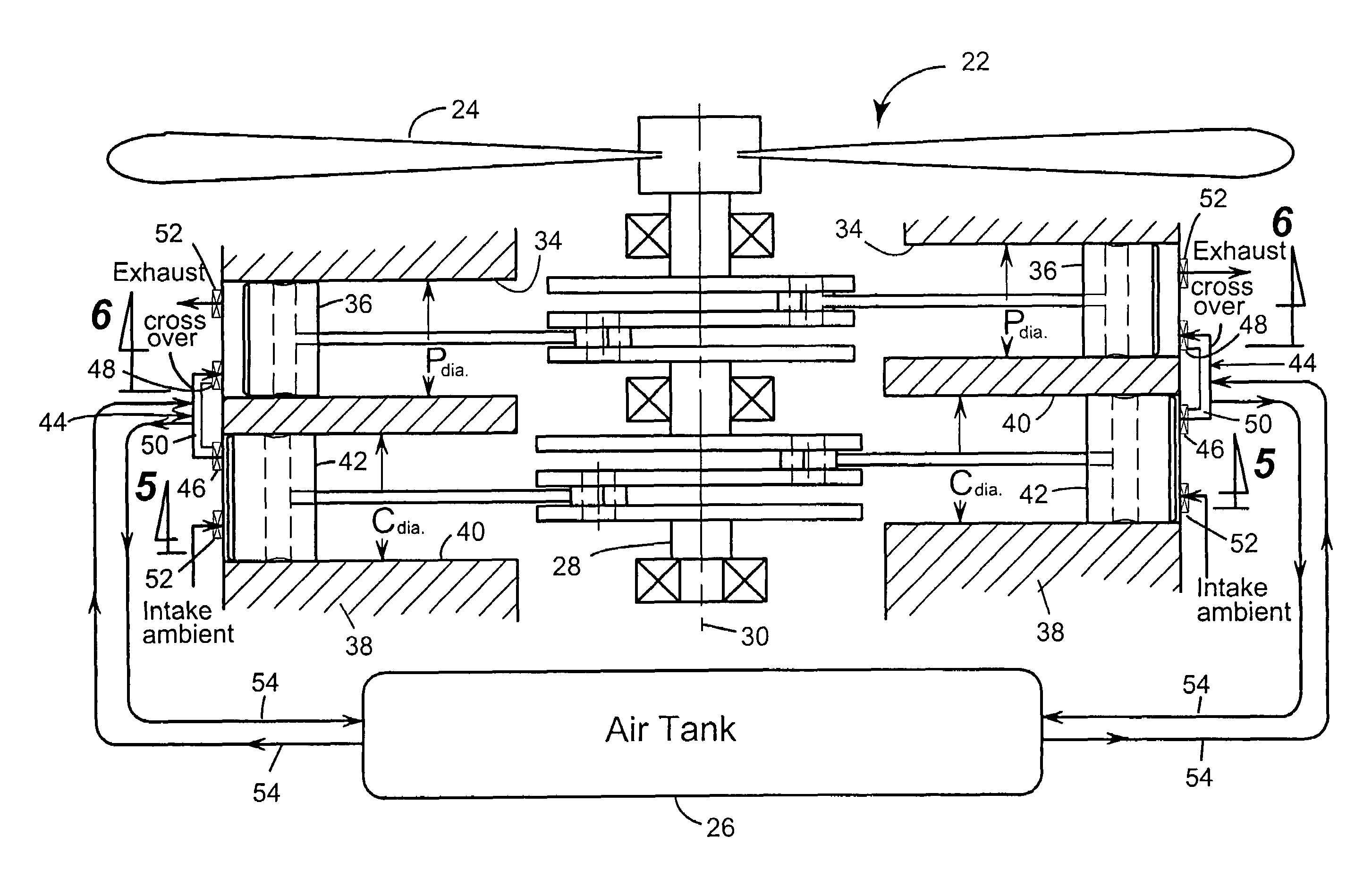

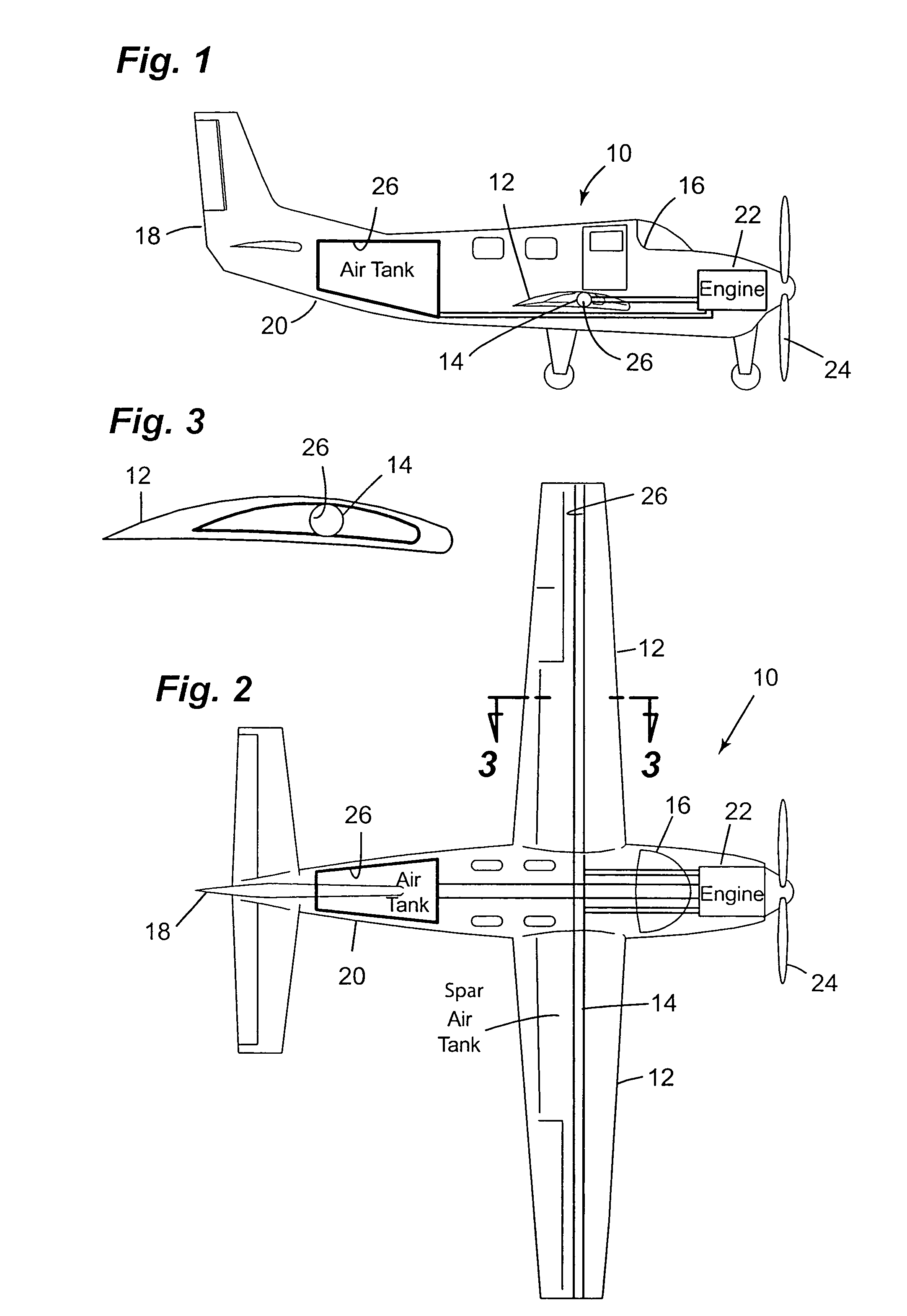

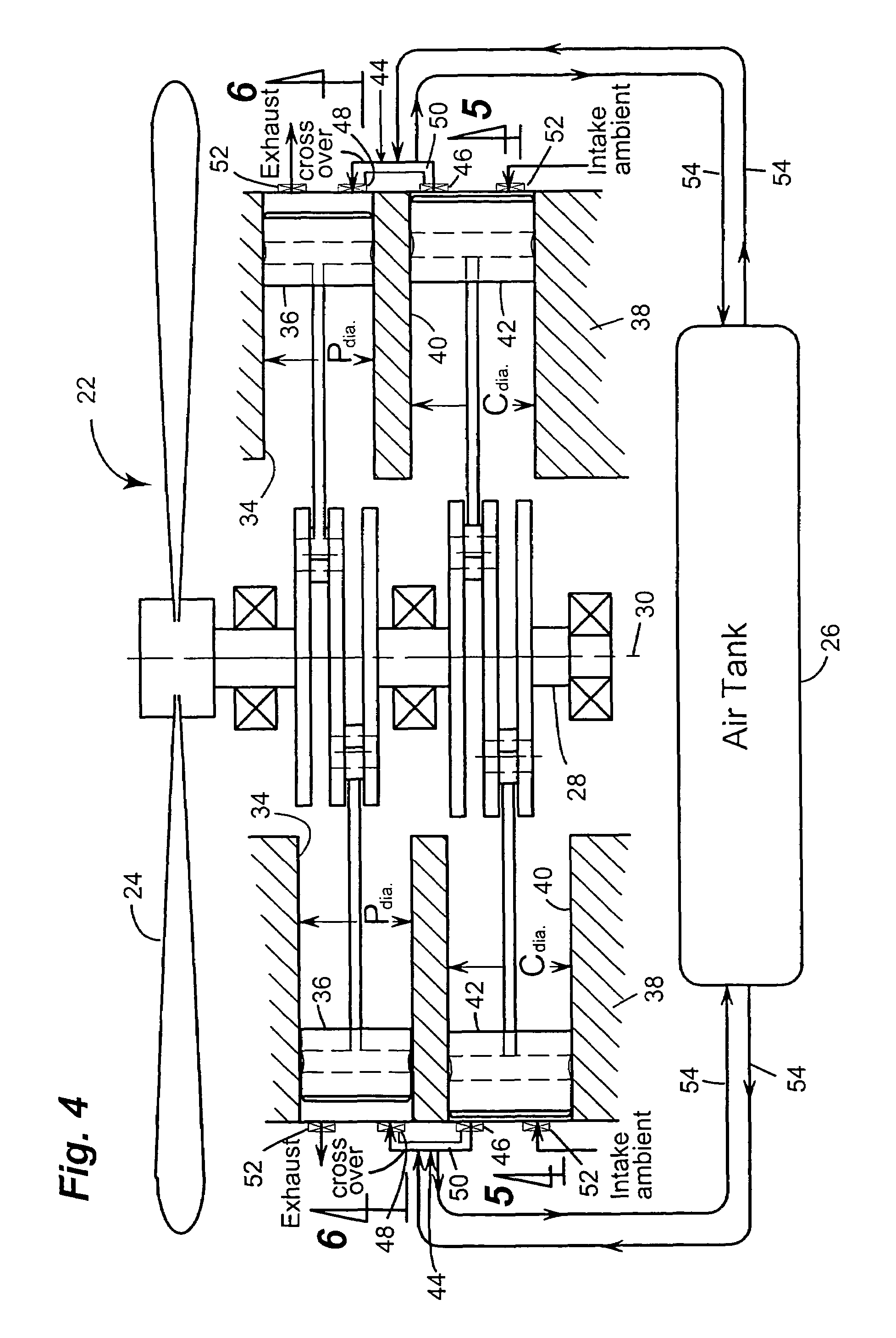

Split-cycle aircraft engine

InactiveUS7513224B2Increase air volumeLarge caliberInternal combustion piston enginesJet type power plantsReciprocating motionCrankshaft

Owner:SKADERI GRUP LLC

Operating an air-hybrid vehicle with camshaft-driven engine valves

InactiveUS7464675B1Low costReduce complexityReciprocating combination enginesAuxillary drivesEngine valveCam

An air-hybrid engine operates in two operational modes. It employs uniquely designed camshafts with cam lobe activators, and camshaft phase shifters to operate and control the engine valves. It uses a different cam lobe for operating an engine valve during each of the two operational modes, and it uses camshaft phase shifters to vary the valve event timing and duration. The system exploits non-linearity that exists in relationship between the piston motion and the camshaft rotation. Varying the phase relationship between the camshaft and the engine crankshaft in a pre-determined specific way varies the duration of the engine valve opening in the required way, thus varying the volumes of air received into and discharged from the engine.

Owner:EXXON RES & ENG CO

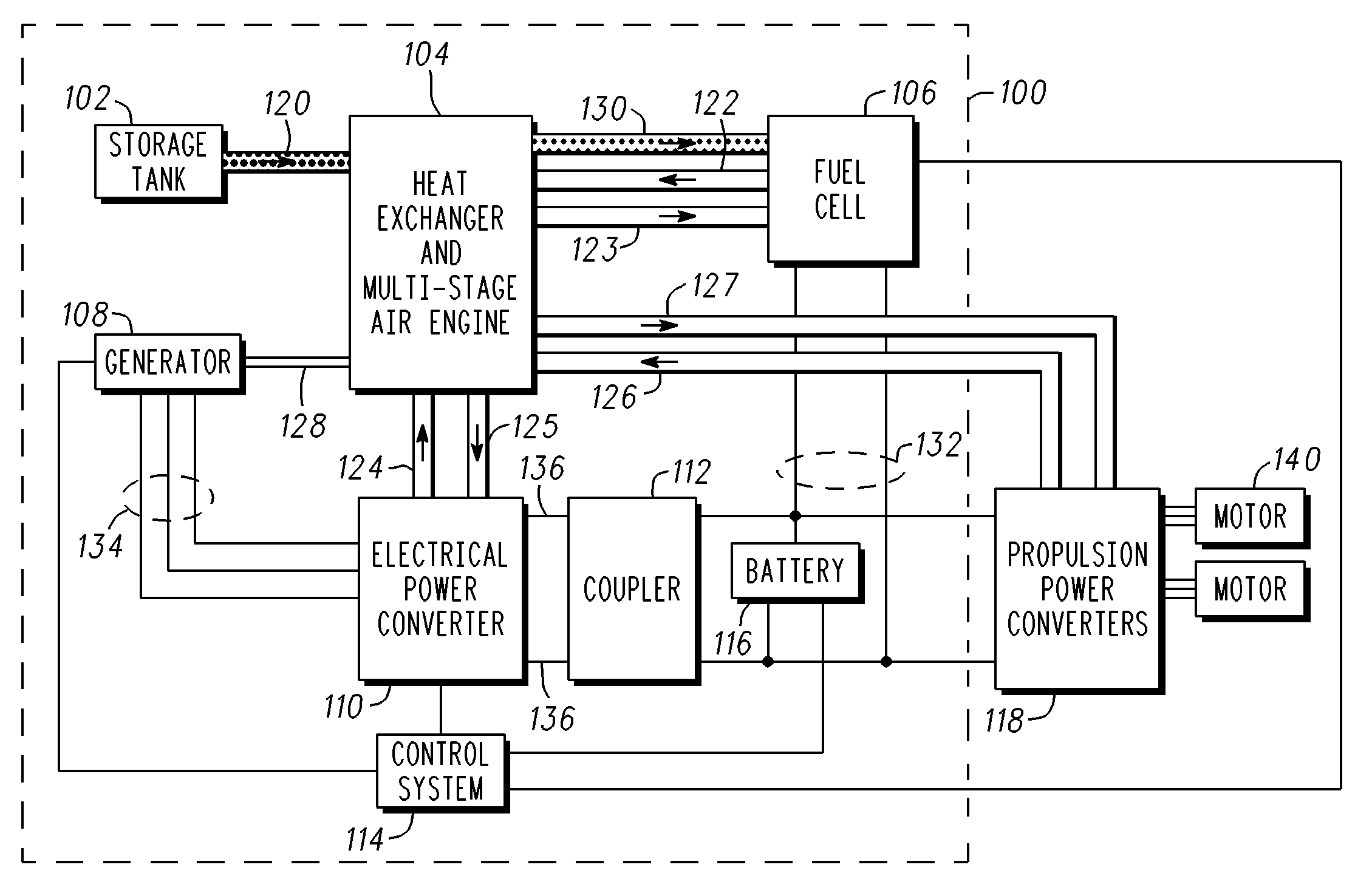

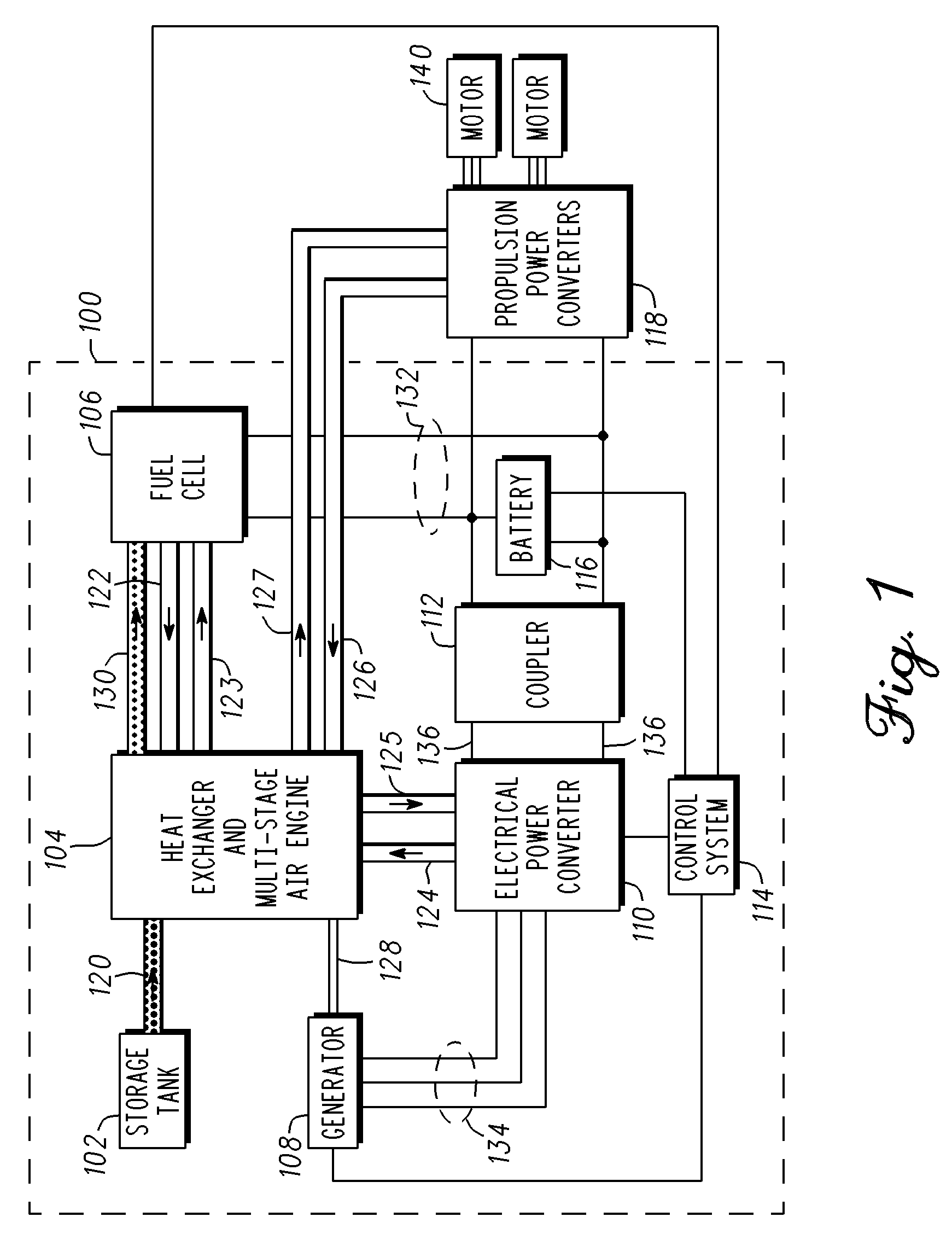

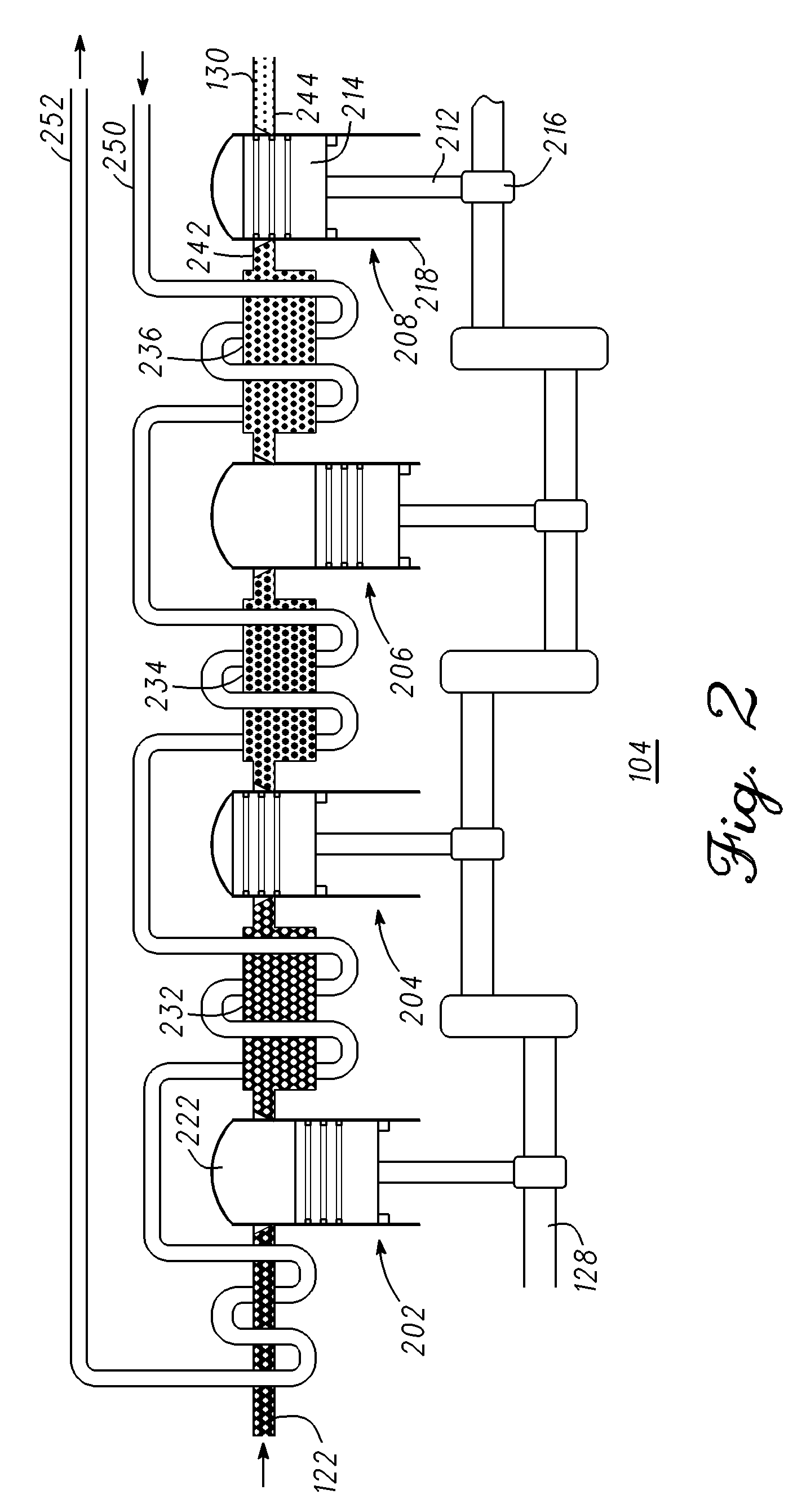

Apparatus and method using hydrogen pressure in fuel cell electric vehicle

InactiveUS20100304228A1Increase speedMore hydrogen flowBatteries circuit arrangementsElectricity cogenerationHydrogen pressureElectrical battery

A hydrogen fuel cell system (100) for charging a battery (116) of an electric vehicle, includes at least one tank (102) for storing hydrogen under pressure. A combined heat exchanger and air engine (104) expands the pressurized hydrogen and converts the expanding hydrogen into mechanical energy. A plurality of fuel cells (106) receive the expanded hydrogen for supplying heat to the heat exchanger and air engine (104) and supplying a first current for charging the battery (116). A generator (108) generates a multi-phase voltage in response to the mechanical energy. A electrical power converter (110) responsive to the multi-phase voltage provides a second current for charging the battery (116).

Owner:GM GLOBAL TECH OPERATIONS LLC

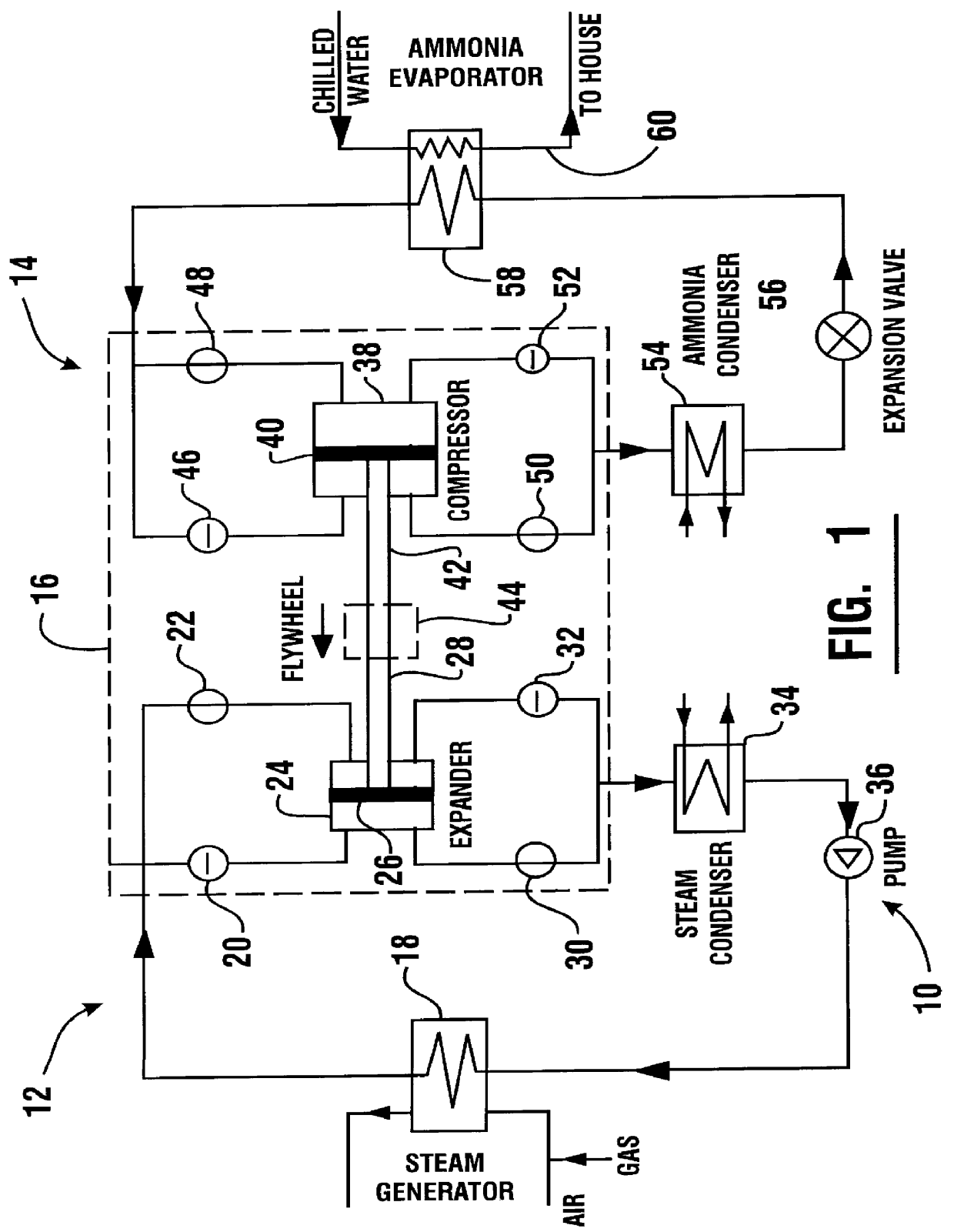

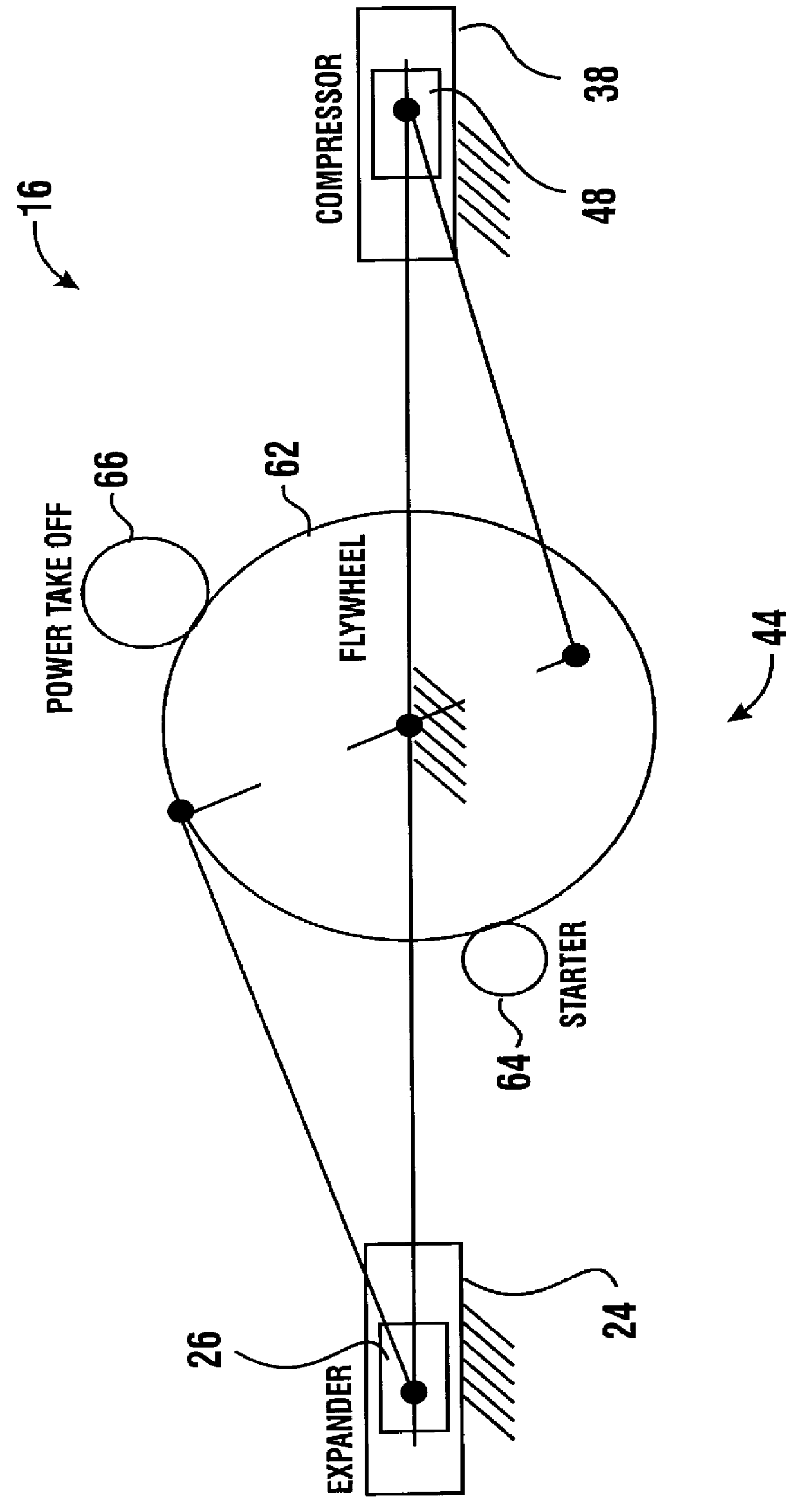

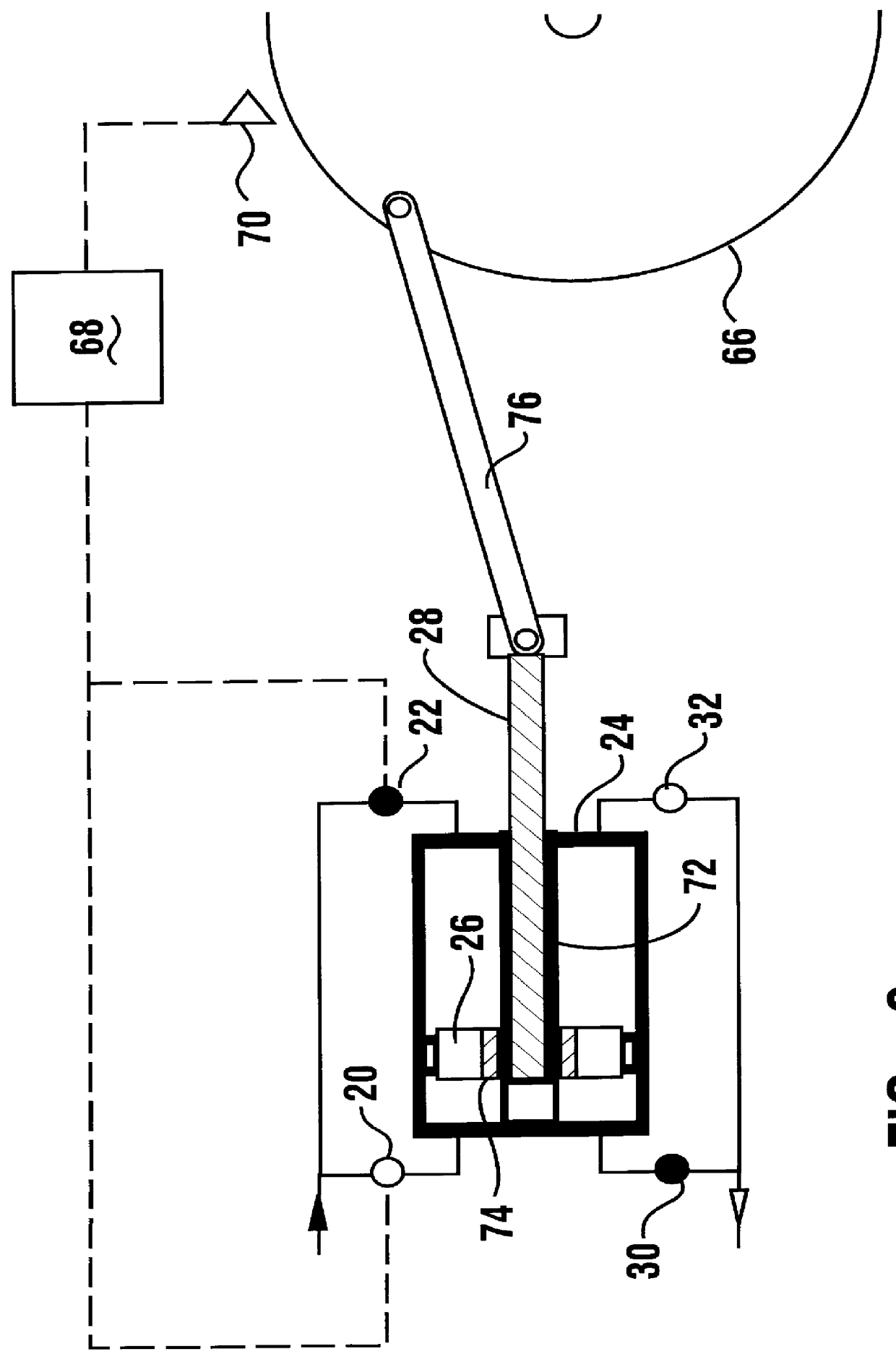

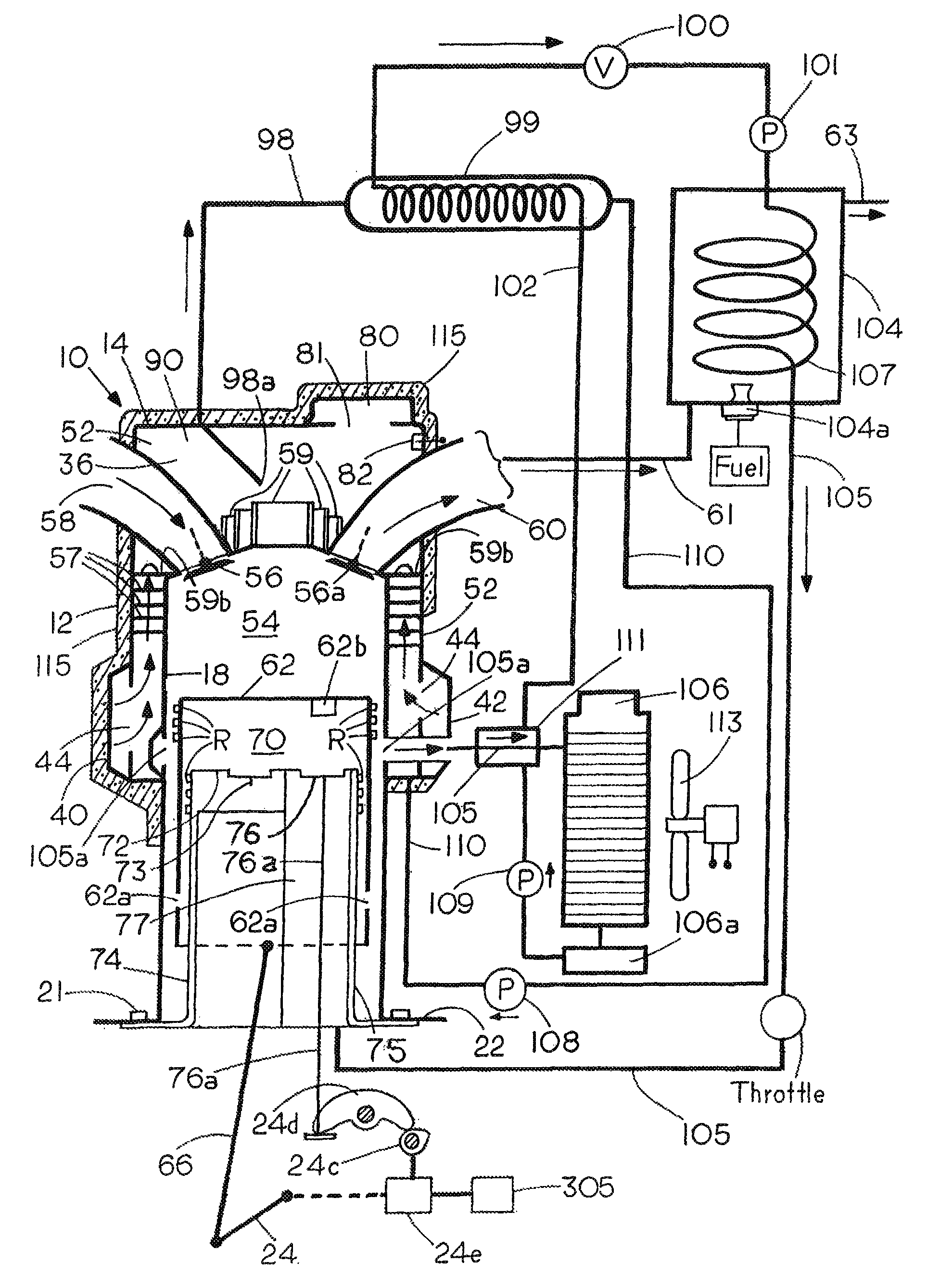

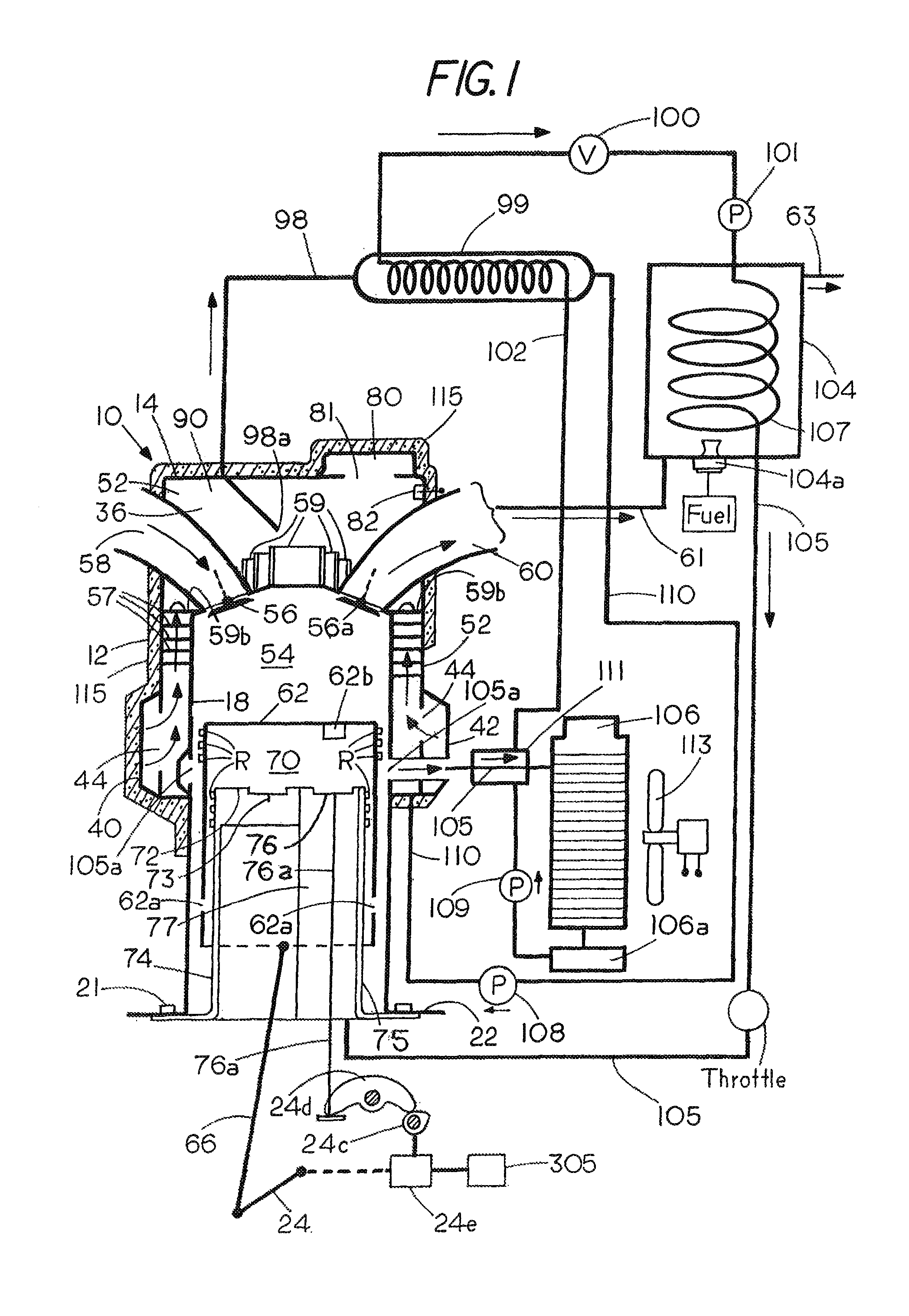

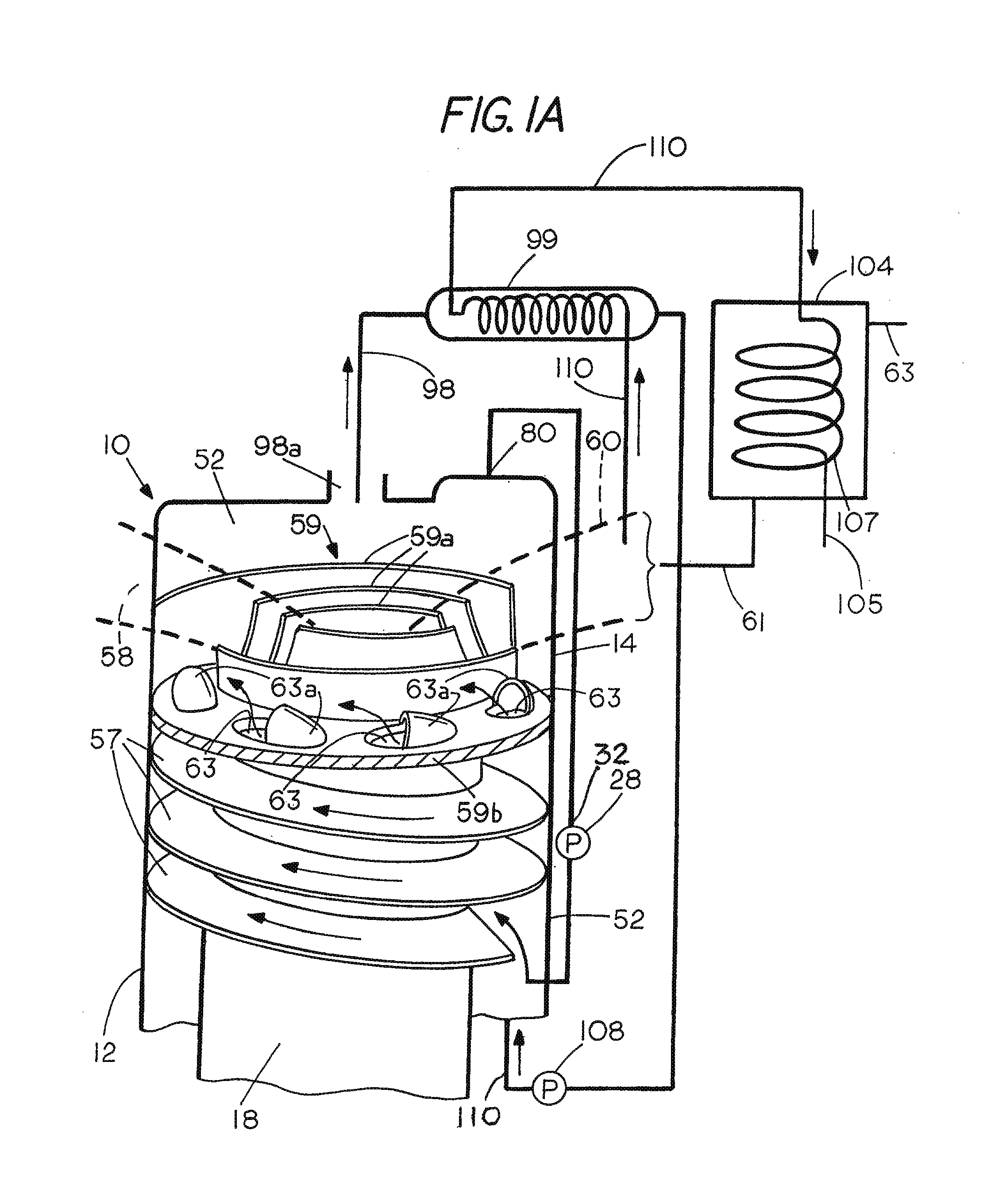

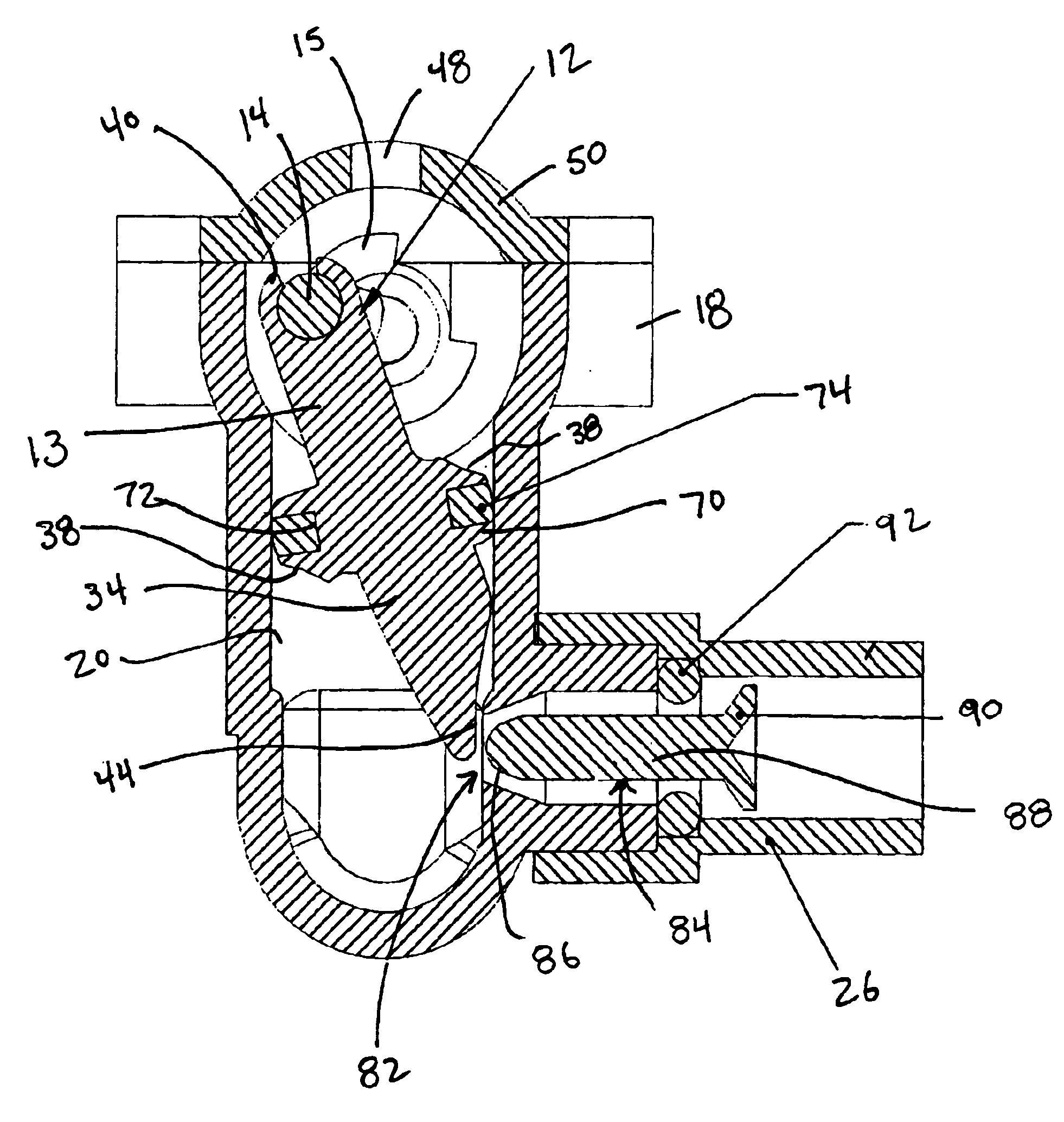

Combustion powered cooling system

InactiveUS6138457AImprove efficiencyImprove reliabilityHeat pumpsWater-tube boilersEnergy transferResidence

A combustion powered cooling system (10, 100) includes a power loop (12, 102) and a cooling loop (14, 104). Heat produced by combustion is used to produce superheated steam in a steam generator (18). The steam is used to move a reciprocating steam piston (26) in a power unit (16). Power is transferred from the steam piston through a energy transfer mechanism (44) to a compressor piston (40) in the cooling loop. Refrigerant material in the cooling loop is used to provide air conditioning for a residence or other facility through a chilled water circuit (60). The system is also operative as a heat pump for heating a residence or other facility.

Owner:APPLIED POWER TECH

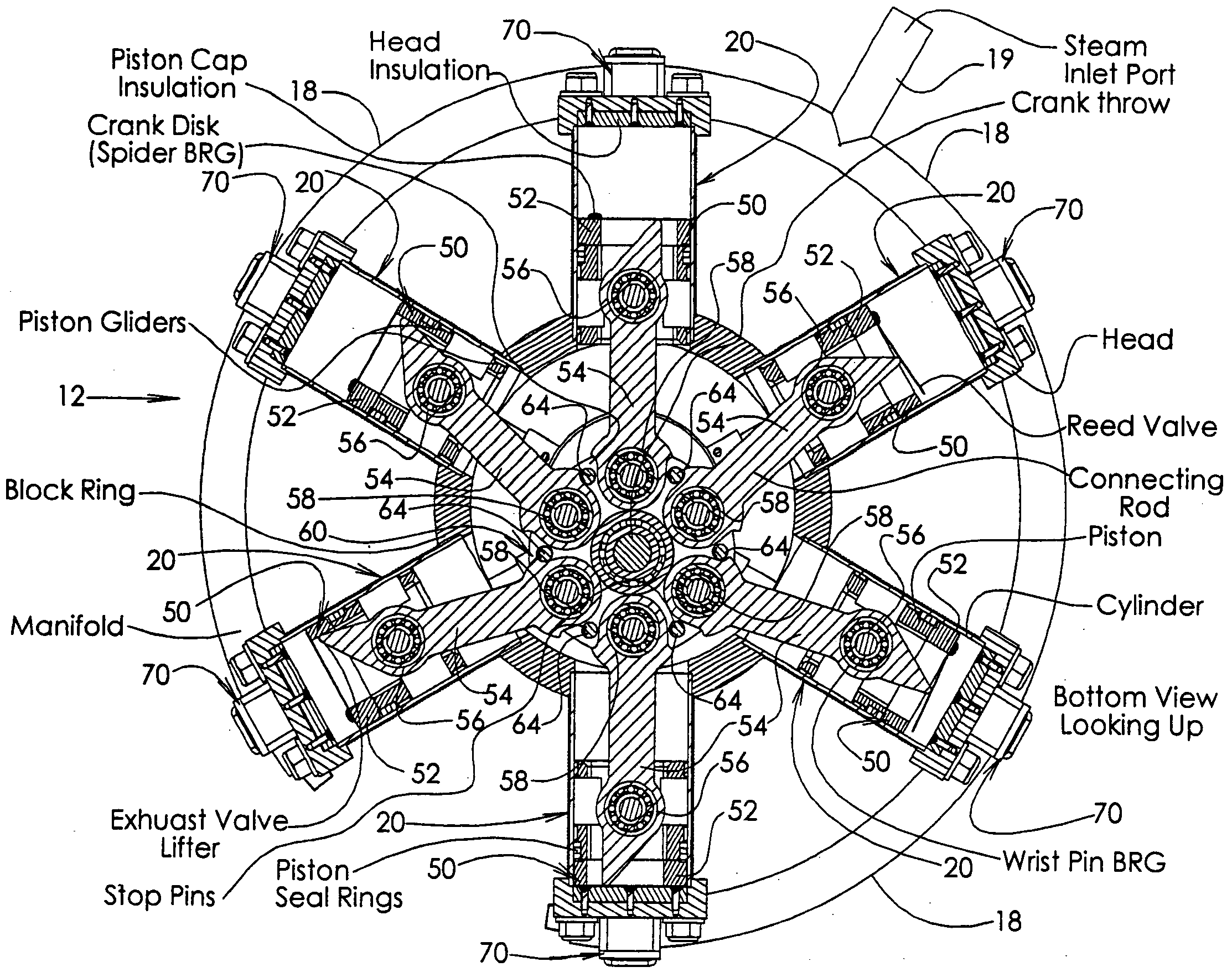

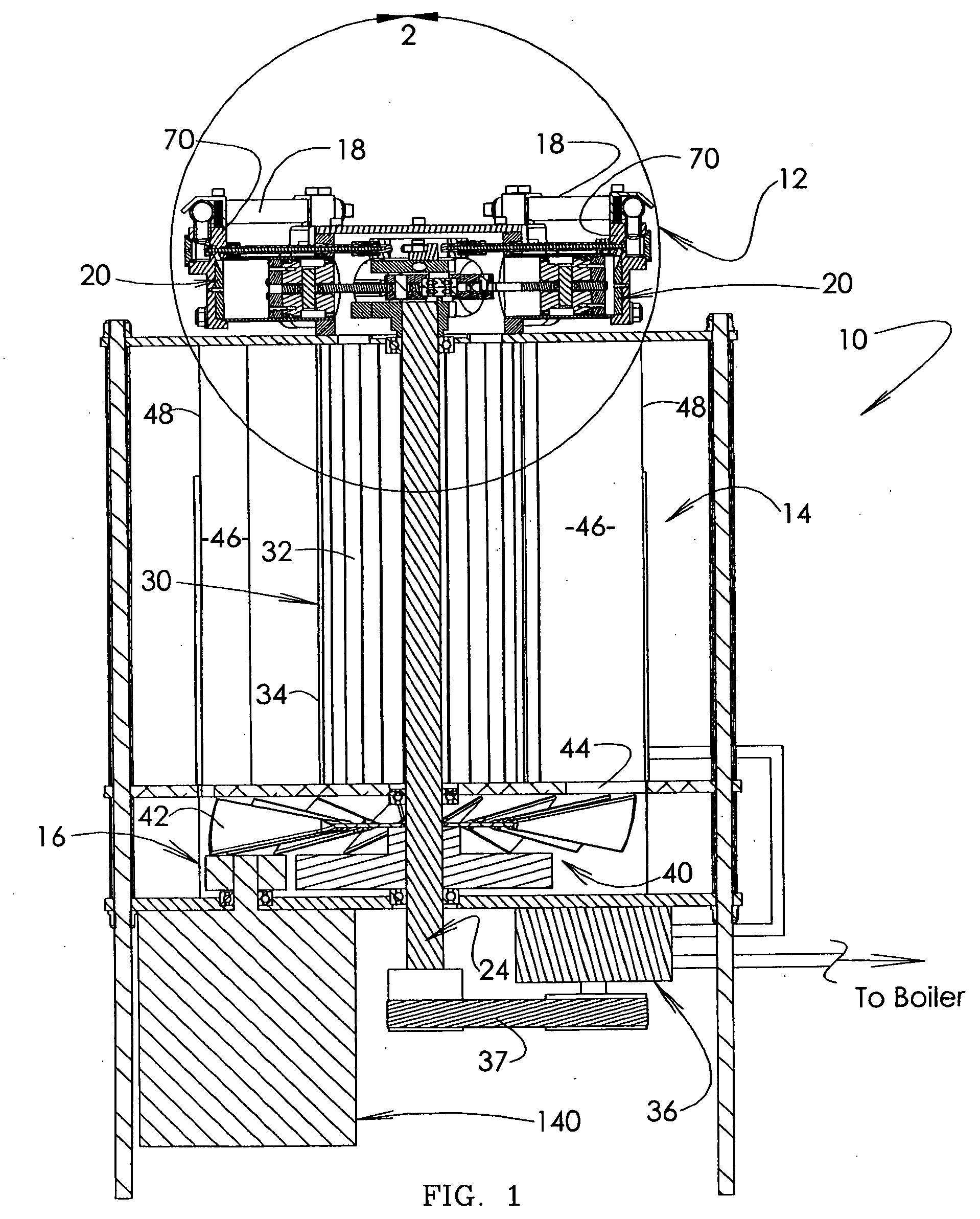

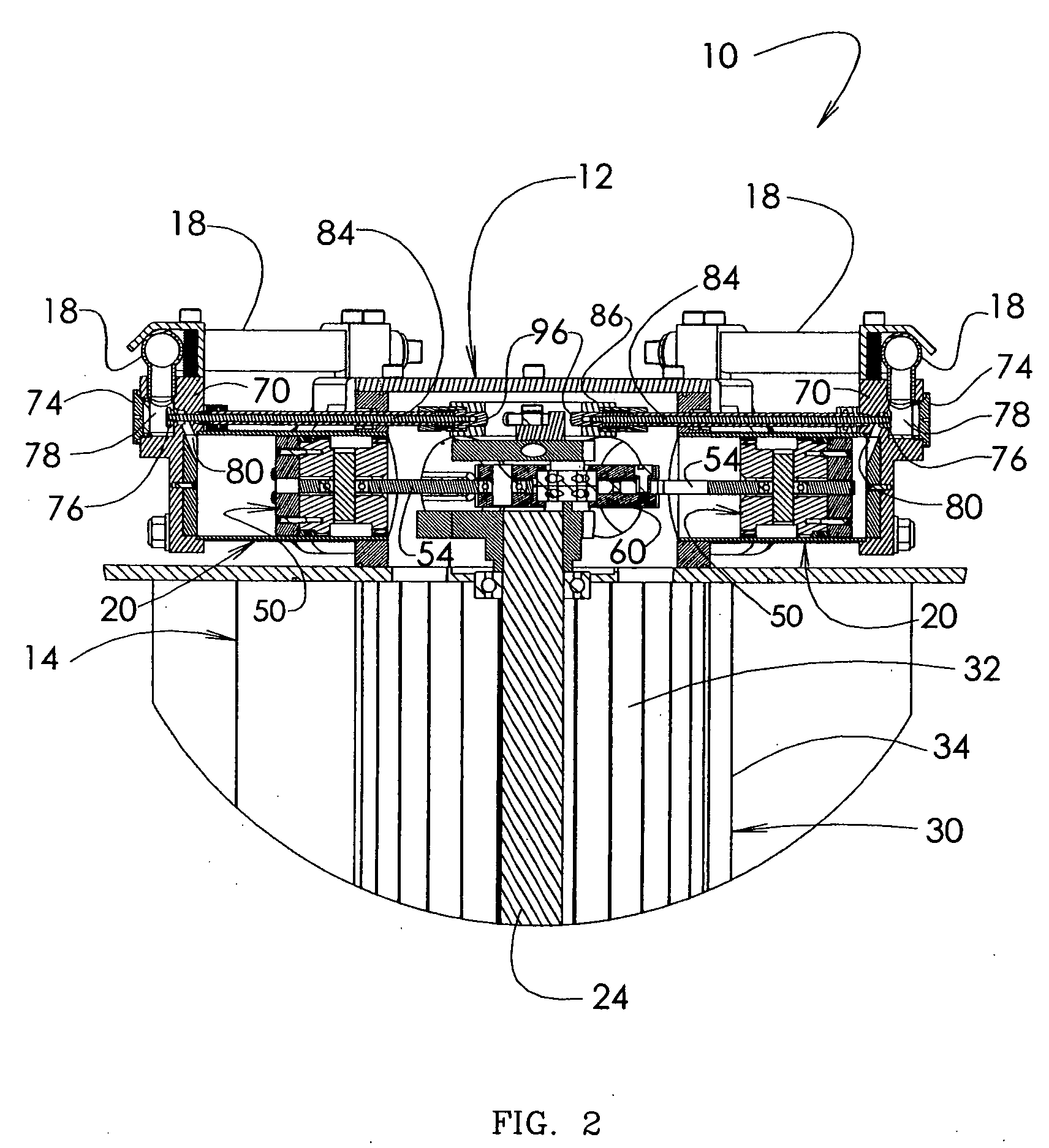

Waste heat engine

InactiveUS20100107637A1Increase and decrease sizeIncrease and decrease and outputSteam engine plantsEngines with rotating cylindersInlet valveReed valve

An engine includes a radial arrangement of cylinders each having a reciprocating piston with a piston head and a connecting rod pivotally linked to the piston head at an upper end. A lower end of each connecting rod is pivotally linked to a crank disk that is rotatably mounted on a crank arm of a crankshaft. Steam intake valves at each cylinder are momentarily opened by a bearing cam roller that is moved in a circular path by rotation of the crank disk to sequentially engage spring urged cam followers on inboard ends of radially extending valve stems. Low pressure steam or gas is injected into the top of each cylinder, as the intake valves of the cylinders are opened in sequence, thereby forcing the piston in each cylinder through a power stroke to move the crank disk and turn the crankshaft. Angular displacement of each connecting rod through the return stroke of the piston urges an exhaust reed valve on the piston head to an open position, thereby releasing exhaust steam to a condenser chamber. The engine is self-starting and operates in a low pressure, low temperature range, using waste heat from an external source, such as exhaust from an internal combustion engine, burning of refuse (e.g. garbage or other solid waste material) or solar heat.

Owner:CYCLONE POWER TECH

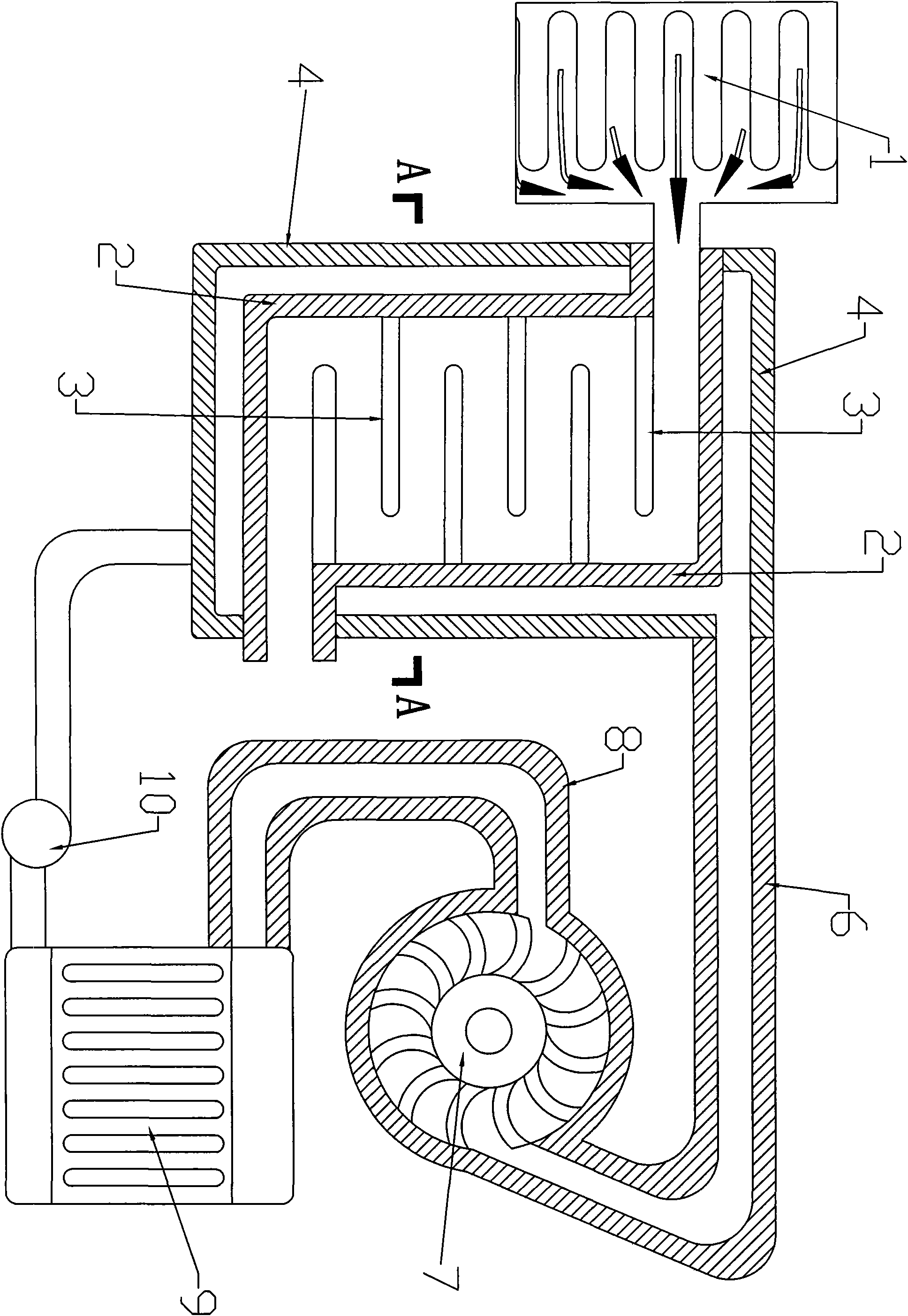

Numerical control pneumatic engine

InactiveCN101451444AEliminate frostingImprove energy efficiencyReciprocating combination enginesCombination enginesNumerical controlHigh energy

The invention discloses a numerical control pneumatic engine, which comprises an energy supply system, an energy conversion system and a control system. The energy supply system consists of a high-pressure air storage tank, a manual valve, a control electromagnetic valve A, a primary heat exchanger, a primary decompression cylinder, a control electromagnetic valve B, a secondary heat exchanger, a secondary decompression cylinder, a control electromagnetic valve C, a quantitative pre-spraying cylinder and a control electromagnetic valve D which are connected in series by pipelines. The energy conversion system comprises a body; a working cylinder is connected with a crank gear through a piston; and a fly wheel is connected with the other end of the crank gear. The control system consists of an electronic control unit, a signal acquisition device and an execution device. The numerical control pneumatic engine uses compressed air or liquid nitrogen, and has the characteristics of no pollution, convenient storage and transportation, simple manufacturing process, high energy efficiency, convenient control and the like, and can be used as a power source for daily short traffic or indoor traffic tools in seriously polluted cities.

Owner:JIANGSU UNIV

Aluminum-alkali hydroxide recyclable hydrogen generator

InactiveUS8529867B2Cheap to storeCompact storageOxygen/ozone/oxide/hydroxideEnergy inputChemical reactionHydrogen

Owner:CEDAR RIDGE RES

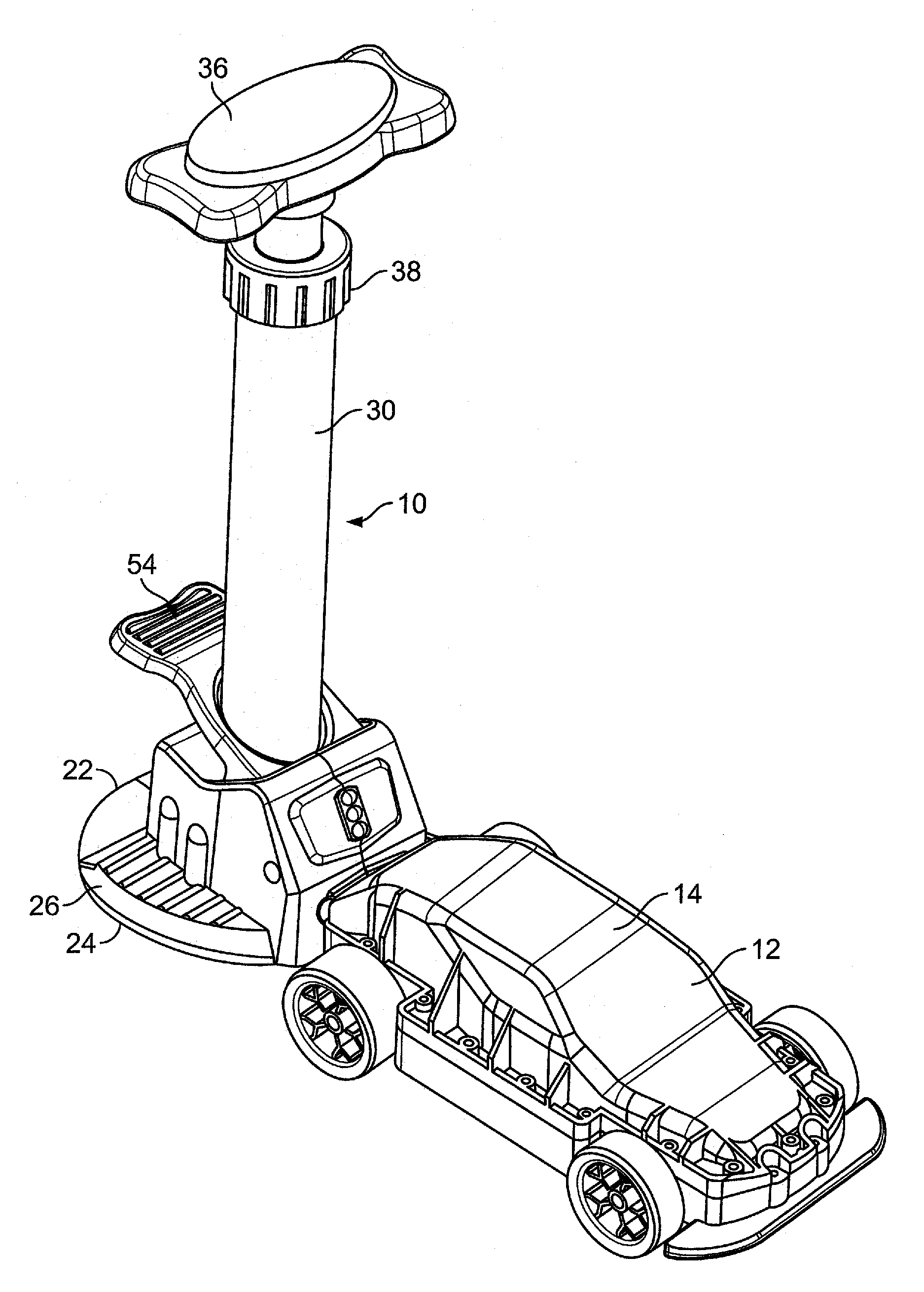

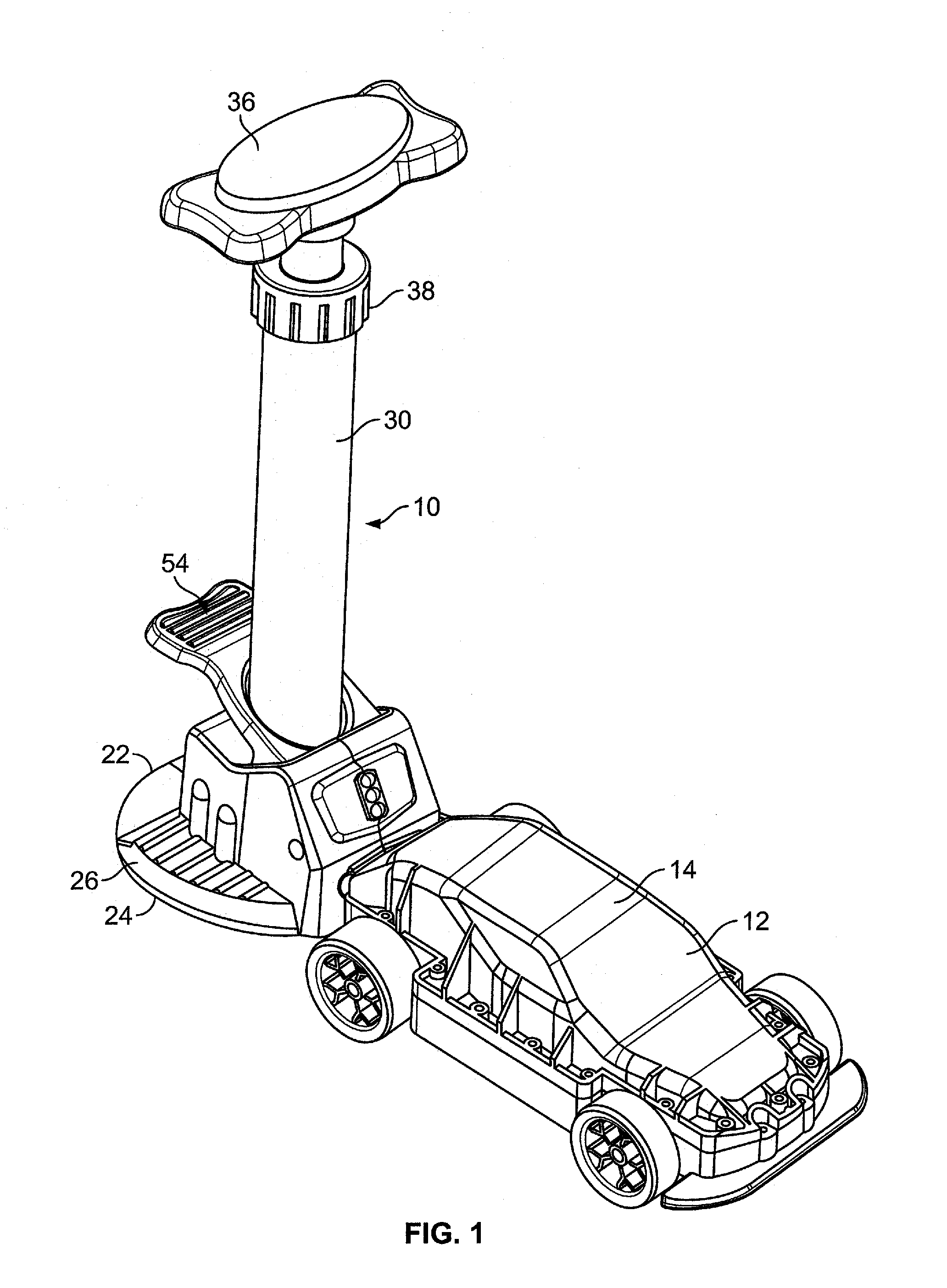

Pneumatic pump and vehicle

Owner:REHCO LLC

High-speed evaporation and circulation steam engine for directly spraying liquid onto hot wall

InactiveCN101864999AImprove thermal efficiencyReduce volumeEngine of intermeshing engagement typeSteam engine plantsLow noiseMature technology

The invention relates to a high-speed evaporation and circulation steam engine for directly spraying liquid onto a hot wall. The steam engine mainly comprises a heat source, a rectangular hot wall, a transverse guide spacer, a rectangular evaporator cover, a spray nozzle, a steam turbine, a condensing radiator, a water pump, a tubular hot wall, a spiral guide spacer, a central heat pipe, a tubular evaporator cover, a piston-type sliding air valve steam engine, a planar hot wall, an evaporator cover, a piston-type air valve-free steam engine, an enclosing shell, a porous transverse spacer, a taper pipe hot wall, a Mu Dark rotary steam engine, a sealing steel shell, a straight round tube hot wall, a petal-shaped test tube hot wall, a tubular evaporator cover, a turbine steam engine and the like. The steam engine has the advantages of high heat efficiency, energy conservation, small size, small vibration, low noise, simple structure, mature technology and the like, and can be widely applied to automobiles, planes, ships, power generation, industrial and agricultural power and the like.

Owner:王鑫弘

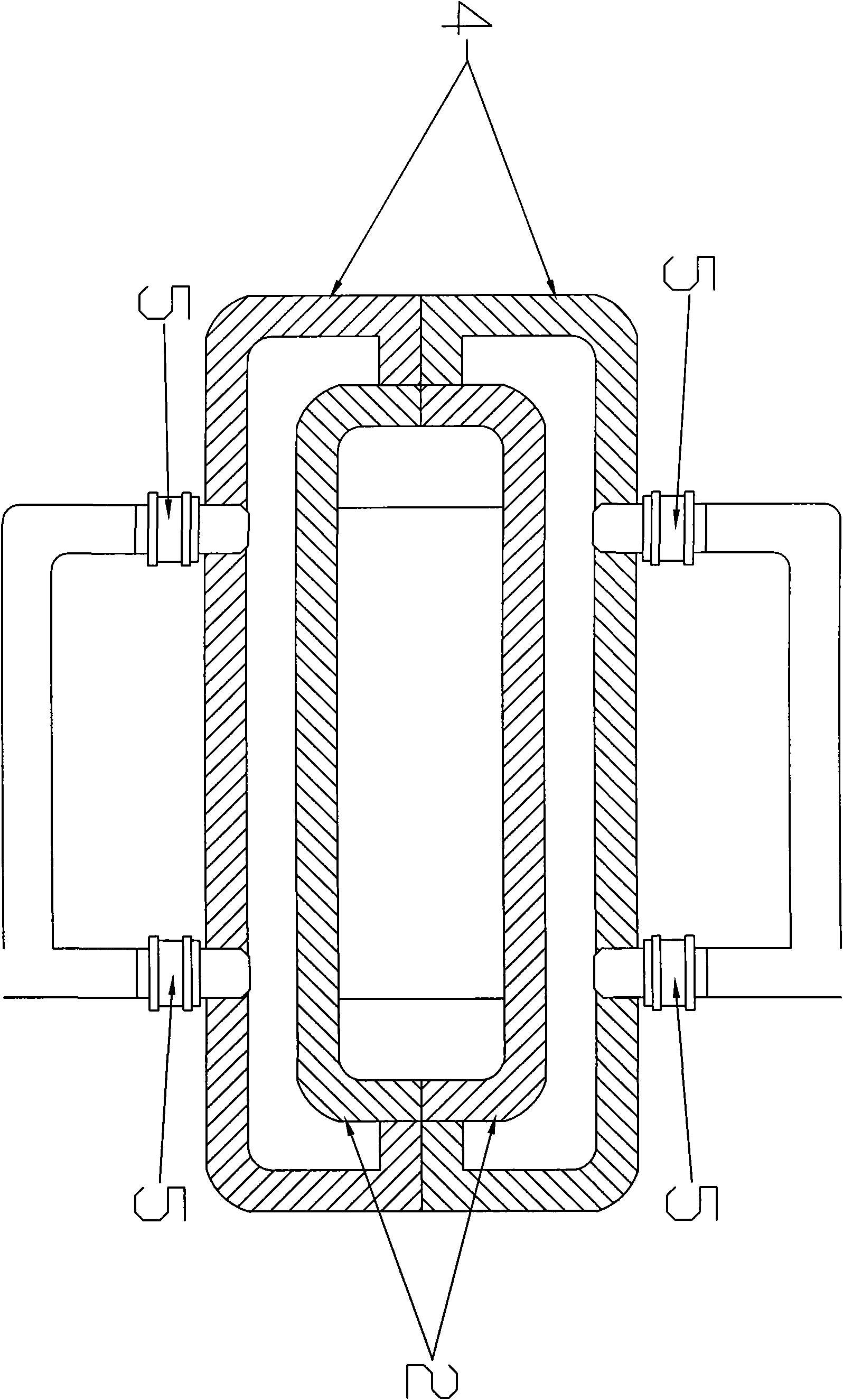

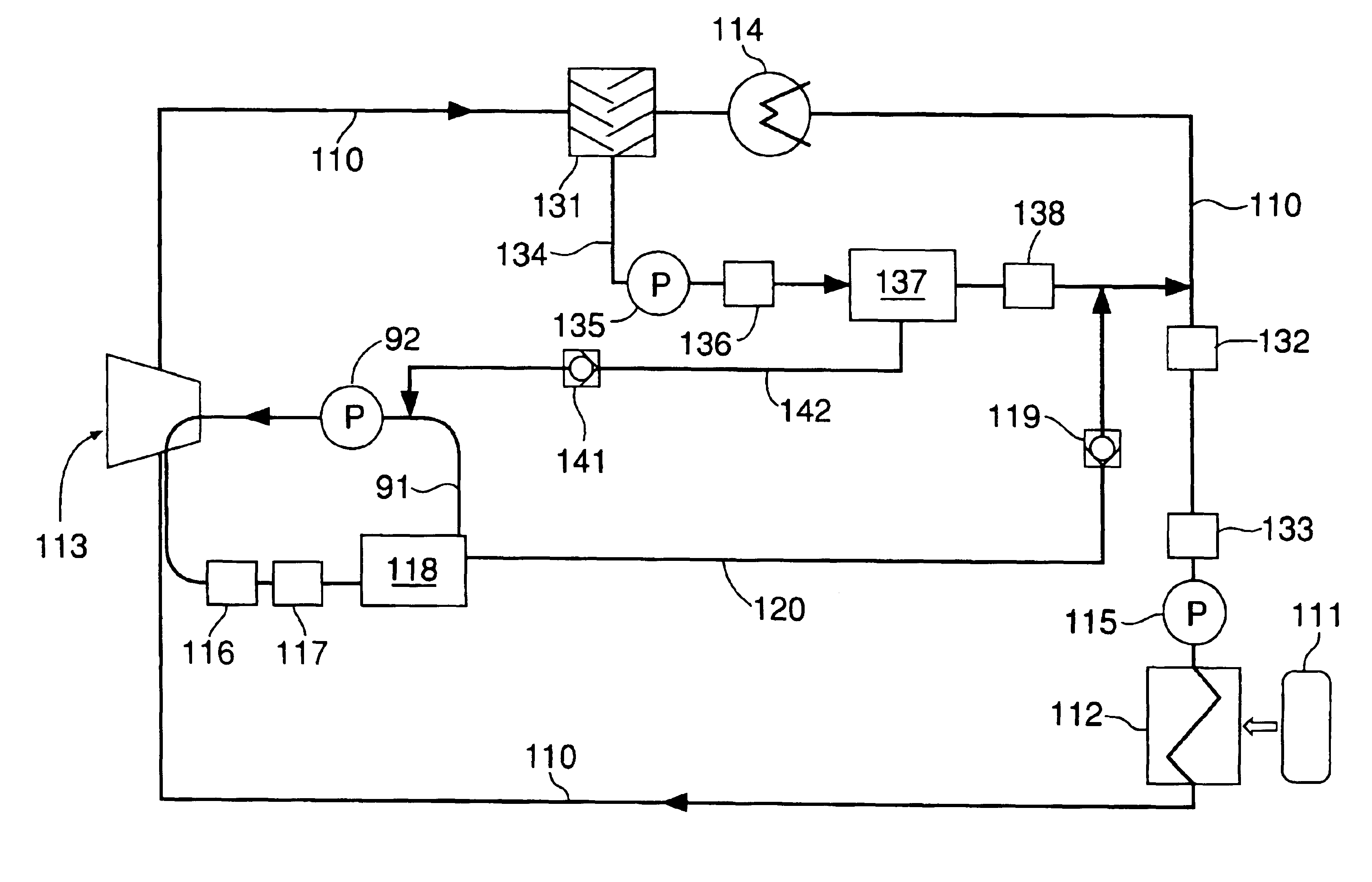

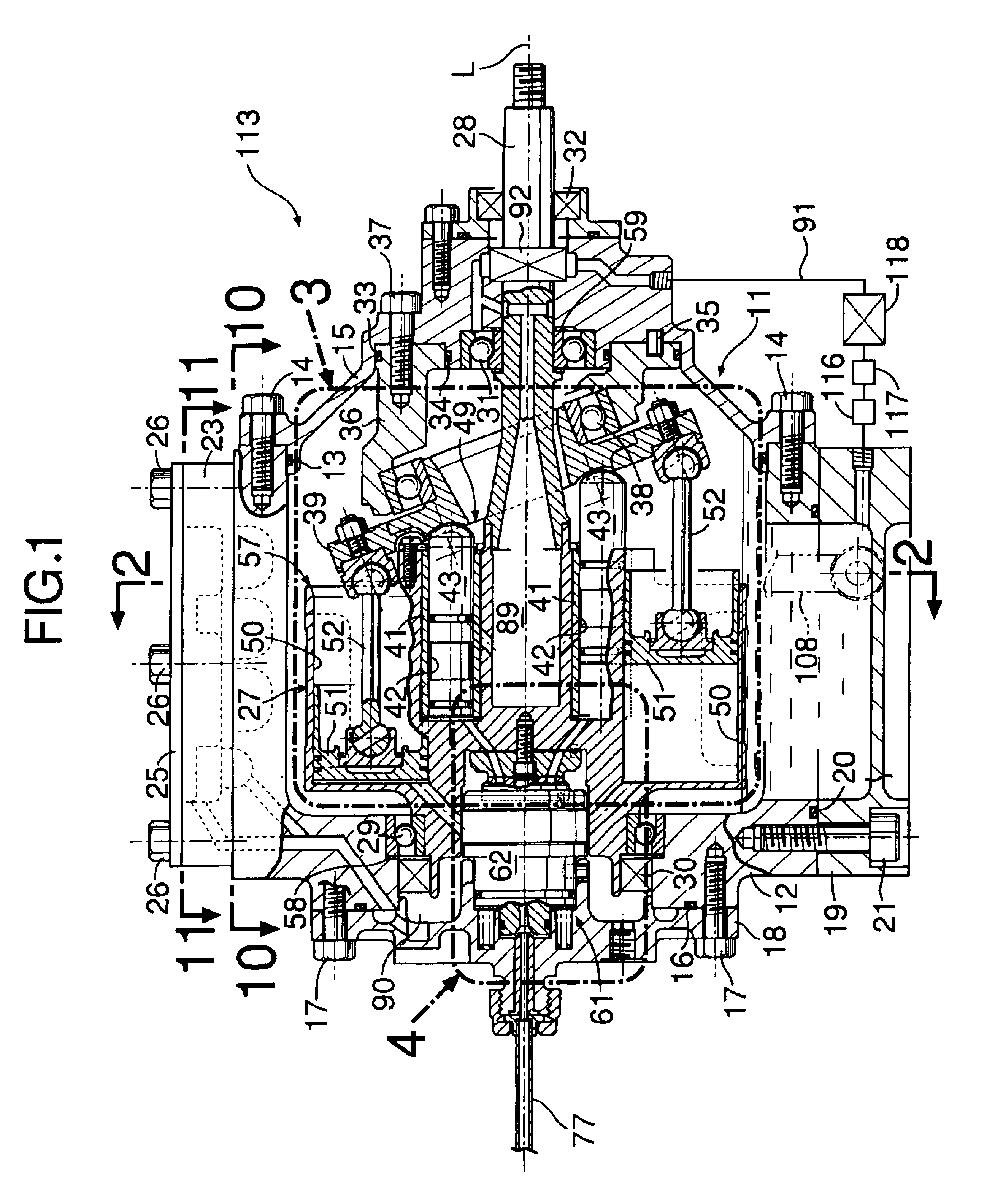

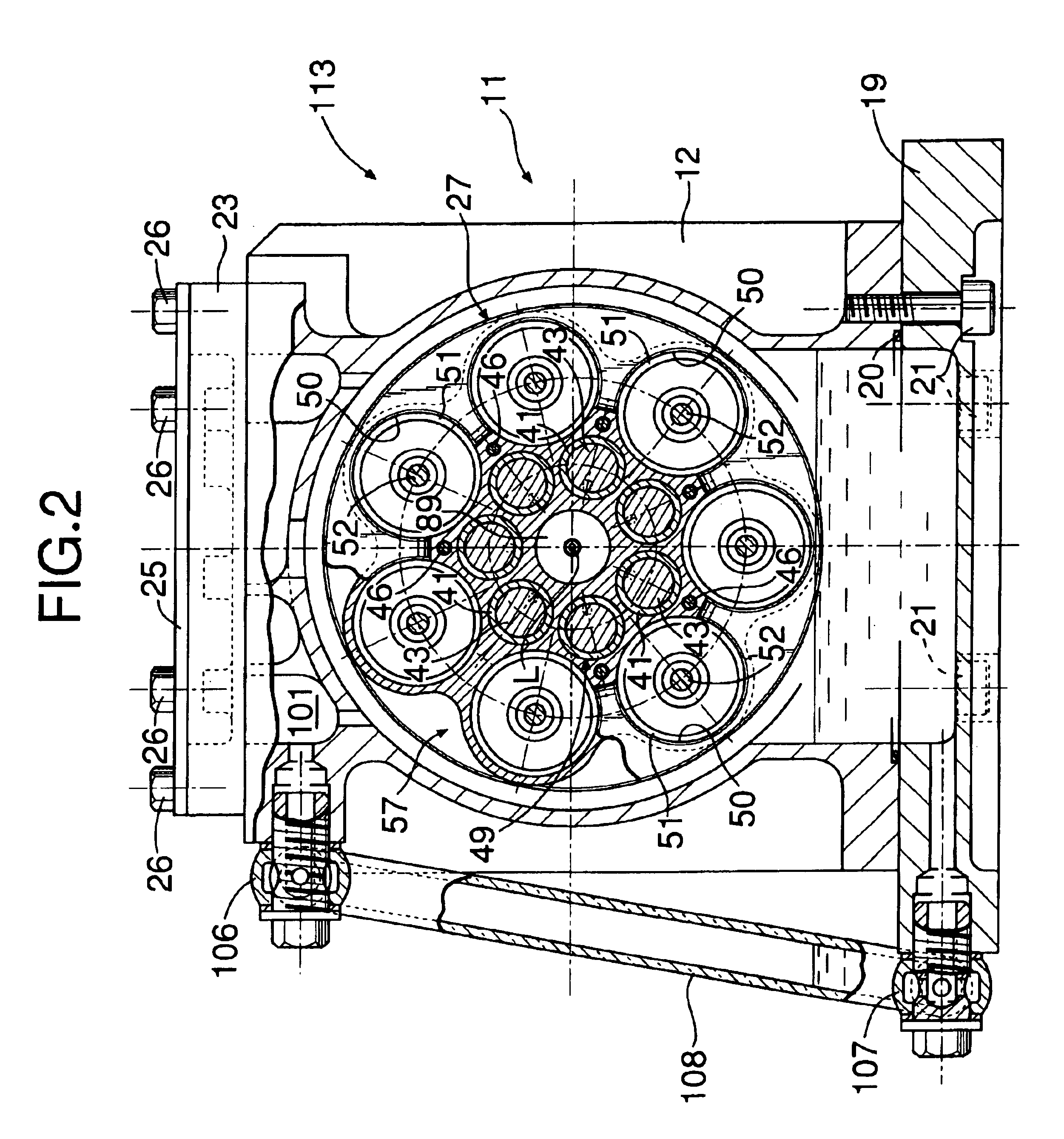

Rankine cycle system

InactiveUS6948316B2Avoid performance degradationEasy to separateReciprocating combination enginesCombination enginesEnvironmental engineeringEngineering

A Rankine cycle system having a working medium circulation circuit (110) that includes an evaporator (112), an expander (113), a condenser (114), and a feed pump (115) is provided in which a mixture of oil for lubricating the expander (113) and water, which is a working medium and has become mixed with the oil, is supplied to coalescer type water separating means (118), thus separating the water from the oil. The oil from which water has been separated in water separating means (118) is returned to the expander (113), and the water separated from the oil is returned to the working medium circulation circuit (110). It is thus unnecessary to replenish the working medium circulation circuit (110) with water or replenish the expander (113) with oil.

Owner:HONDA MOTOR CO LTD

Ambient temperature thermal energy and constant pressure cryogenic engine

InactiveCN101490366AIntake adjustmentAdjustment rateSteam engine plantsClosed-cycle gas positive displacement engine plantThermal energyCogeneration

The invention relates to an ambient temperature thermal energy cryogenic engine with constant pressure with continuous ''cold'' combustion at constant pressure and with an active chamber operating with a cryogenic fluid (A2) stored in its liquid phase, and used as a work gas in its gaseous phase and operating in a closed cycle with return to its liquid phase. The initially liquid cryogenic fluid is vaporized in the gaseous phase at very low temperatures and supplies the inlet (A4) of a gas compression device (B), which then discharges this compressed work gas, still at low temperature, and through a heat exchanger with the ambient temperature (C), into a work tank or external expansion chamber (19) fitted or not fitted with a heating device, where its temperature and its volume will considerably increase in order to then be preferably let into a relief device (D) providing work and for example comprising an active chamber according to international patent application WO 2005 / 049968. Application to land vehicles, motor vehicles, buses, motorcycles, boats, aircraft, standby generators, cogeneration sets, stationary engines.

Owner:MDI MOTOR DEV INT SA

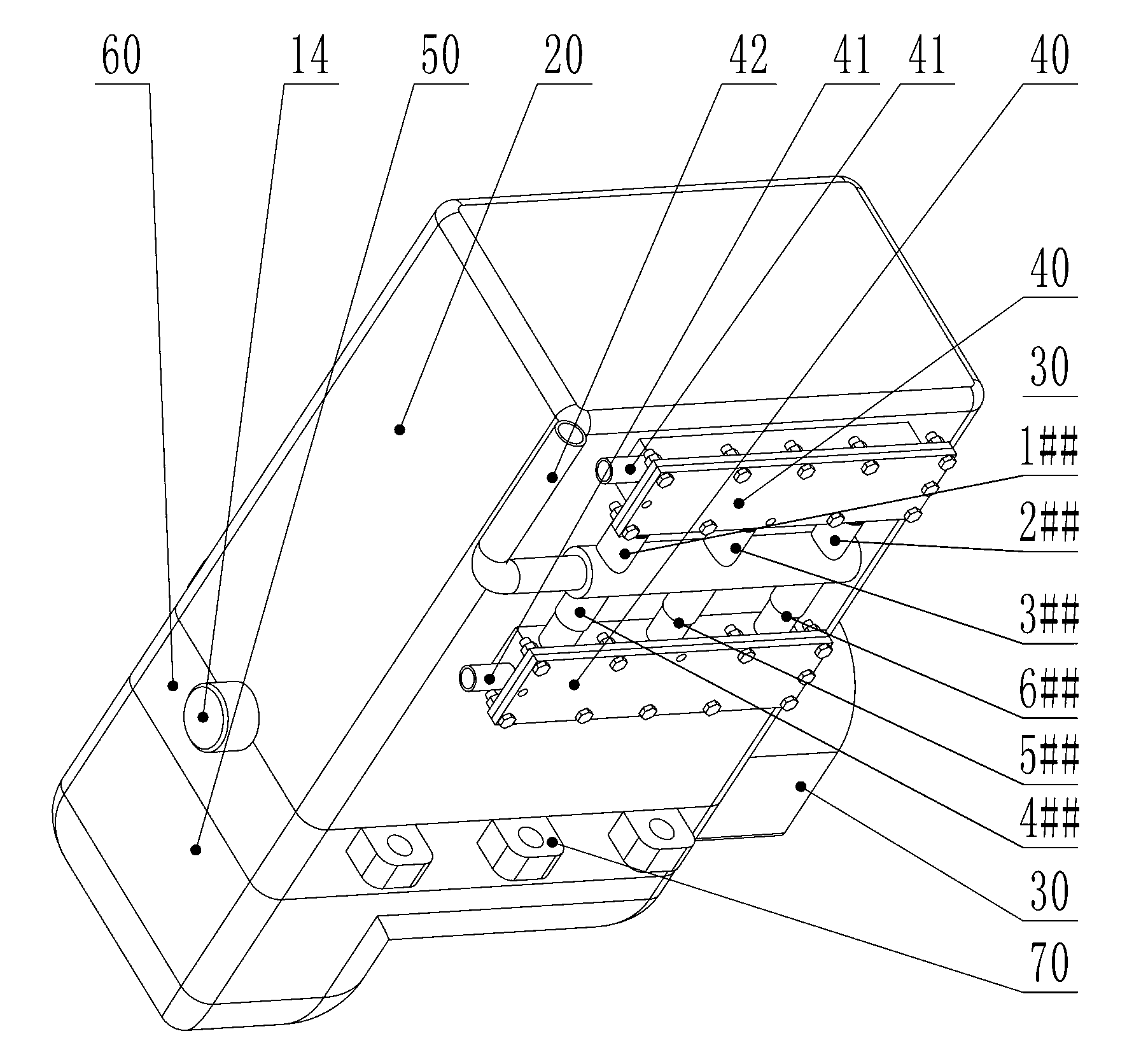

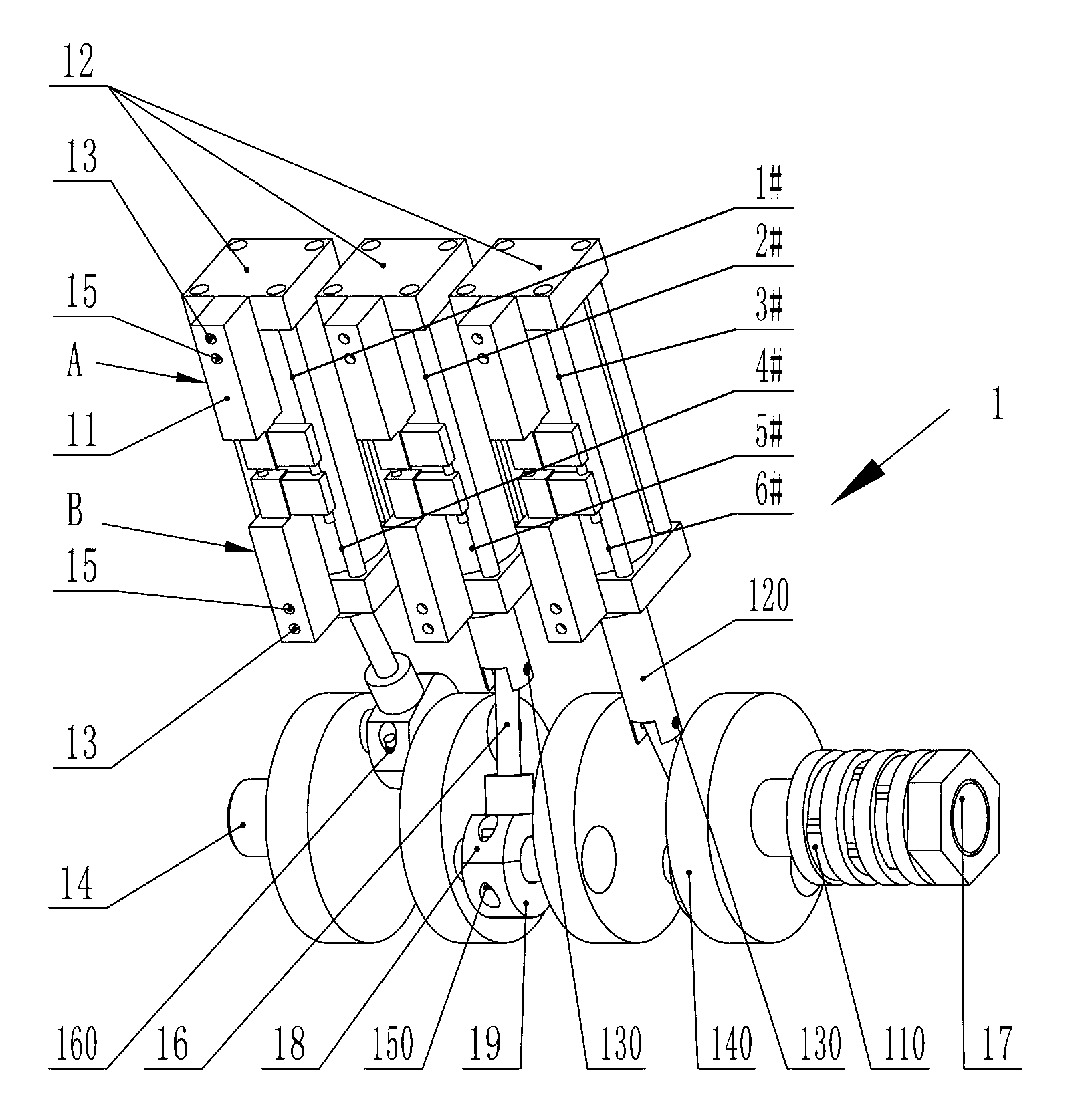

Variable multi-cylinder aerodynamic engine

ActiveCN103206251AIncrease profitImprove battery lifeEngines characterised by uniflow principleElectric controlCrankshaft

The invention relates to an engine, in particular to a variable multi-cylinder aerodynamic engine with compressed air as dynamic force. The variable multi-cylinder aerodynamic engine comprises an engine body (1), an upper box body (20), an air feeding and discharging electric control box (30), an air feeding and discharging device (40), an oil pan (50), a lower box body (60) and a fixing support (70). When an accelerator of the engine is opened, the engine starts supplying air, protrusion of an air feeding and discharging electric control shaft (17) pushes an electric control sheet (171) to be contacted with one of static sheets, corresponding electromagnetic valves (11) are connected and electrified, an air inlet door (13) is opened, the compressed air enters corresponding air cylinders (12) through the electromagnetic valves (11), and the entered compressed air pushes air cylinder rods (120) to move and simultaneously drives crank shafts (14) to rotate so as to output dynamic force.

Owner:LUCKSKY HLDG GRP

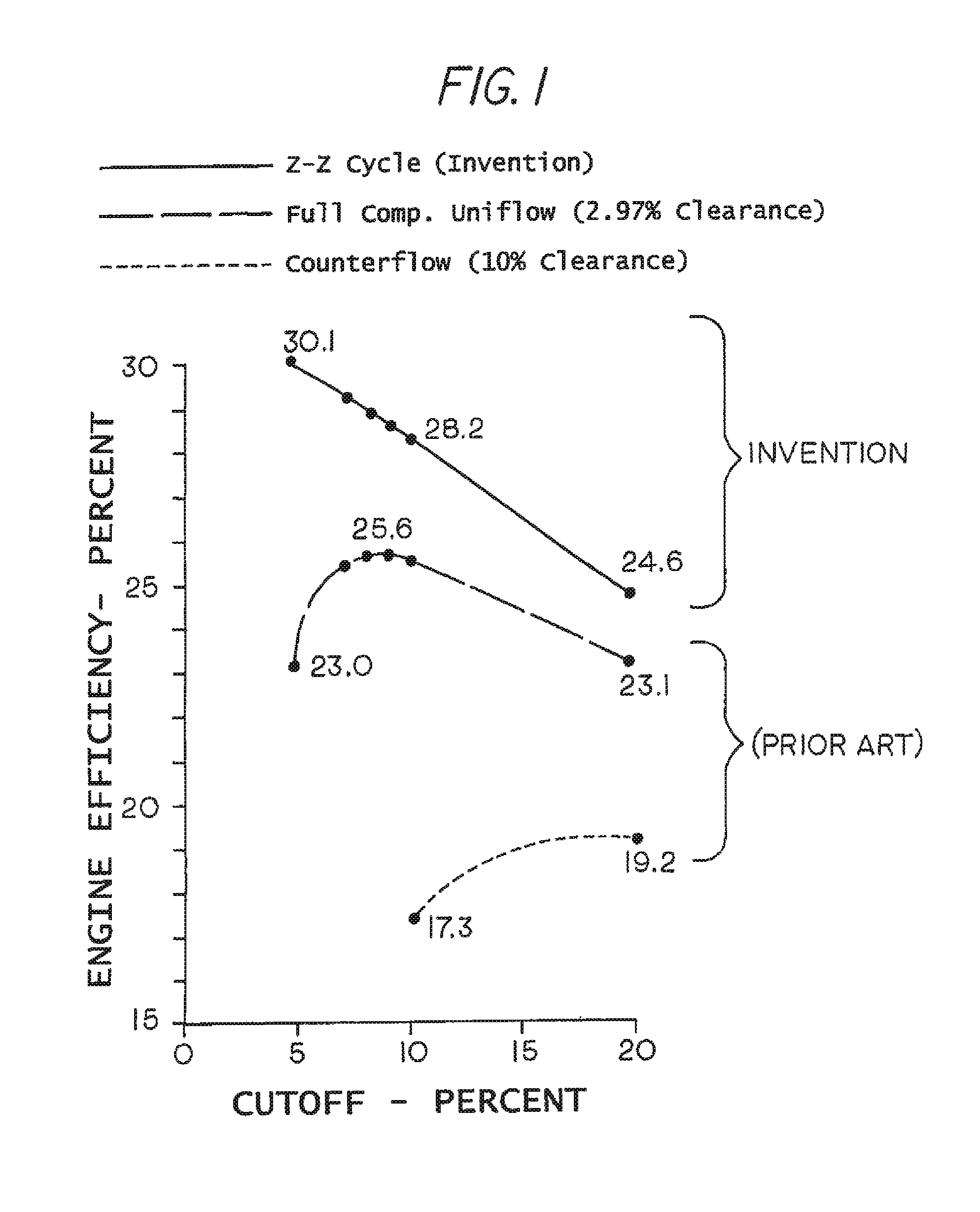

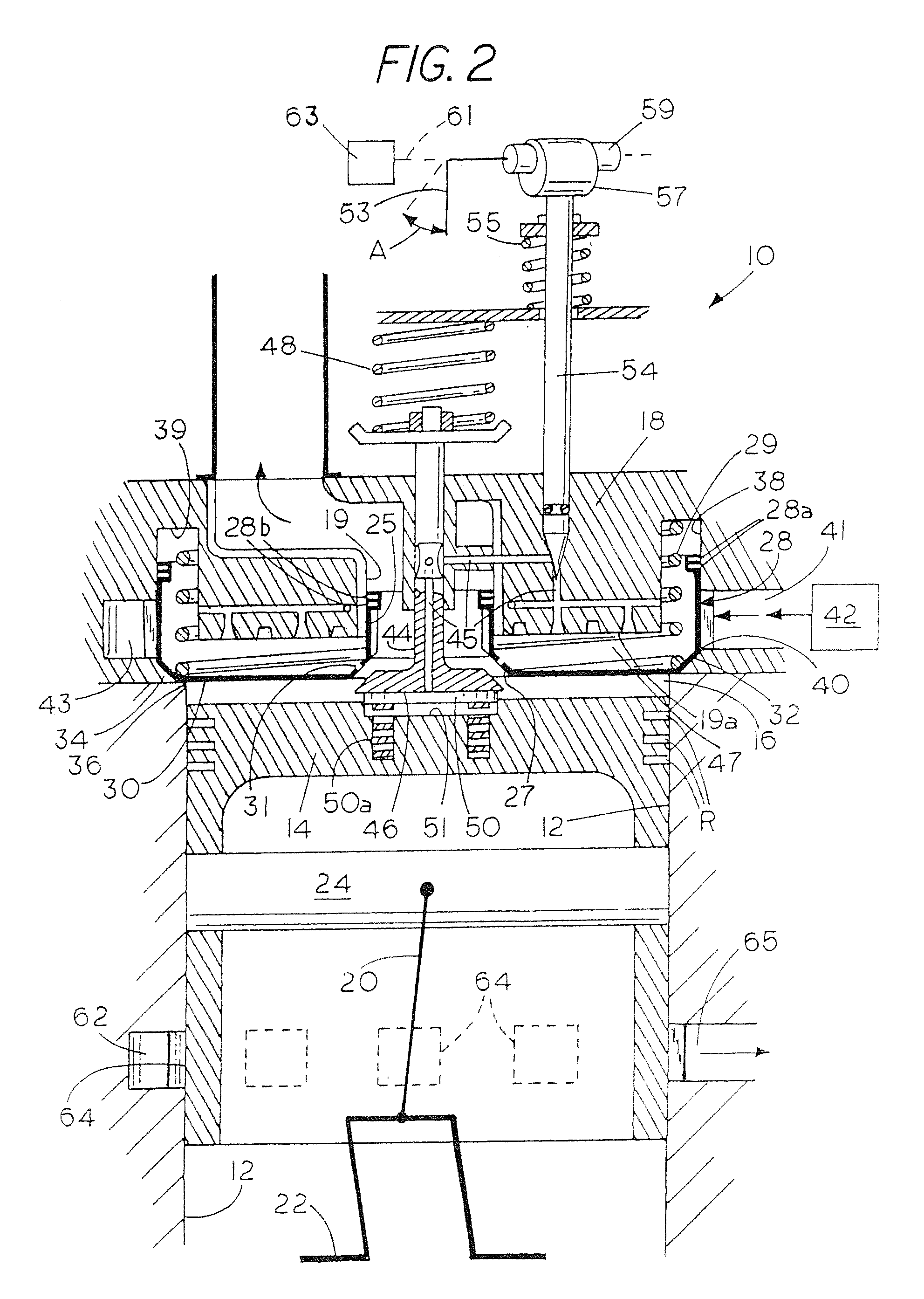

High efficiency steam engine, steam expander and improved valves therefor

ActiveUS9316130B1Operation efficiency can be improvedImprove thermal efficiencyReciprocating combination enginesInternal combustion piston enginesCylinder headAmbient pressure

An engine having a Rankine cycle steam expander includes an engine cylinder, a cylinder head and a piston in which clearance is zero together with a negligible amount of compression, such that pressure in the clearance volume is as low as to approximate ambient pressure or condenser pressure existing at the end of a return stroke when the clearance is zero. These provisions for clearance and compression working together simultaneously provide a thermal efficiency which substantially exceeds all prior known Rankine operating cycles and is referred to as “zero clearance with zero compression”. The steam admission valve is raised slightly by the piston to establish a zero clearance whereupon a steam assist then moves the steam admission valve determinately and quickly to a fully open position.

Owner:THERMAL POWER RECOVERY

High efficiency dual cycle internal combustion steam engine and method

ActiveUS8661817B2Efficient and improved heat transferImprove heat transfer performanceReciprocating combination enginesInternal combustion piston enginesCombustion chamberWorking fluid

The coolant in the cooling jacket of a dual cycle internal combustion steam engine is intentionally maintained at an elevated temperature that may typically range from about 225° F.-300° F. or more. A non-aqueous liquid coolant is used to cool the combustion chamber together with a provision for controlling the flow rate and residence time of the coolant within the cooling jacket to maintain the temperature of the coolant at a selected elevated temperature that is substantially above the boiling point of water but below the boiling point of the coolant. The coolant is passed from the jacket through a heat exchanger in a first circuit to transfer heat to a vaporizable working fluid such as water and is then returned. An optional second circuit is an intrajacket perturbation circuit within the engine can be used to disrupt and disperse pockets of vapor that may tend to form before damaging hot spots can develop around the combustion chamber. A cooling jacket design is tailored to extract heat at the highest possible temperature from each heat transfer zone as by having the coolant follow a circuitous helical pathway to achieve more efficient and improved heat transfer from the combustion chamber to the cooling medium.

Owner:THERMAL POWER RECOVERY

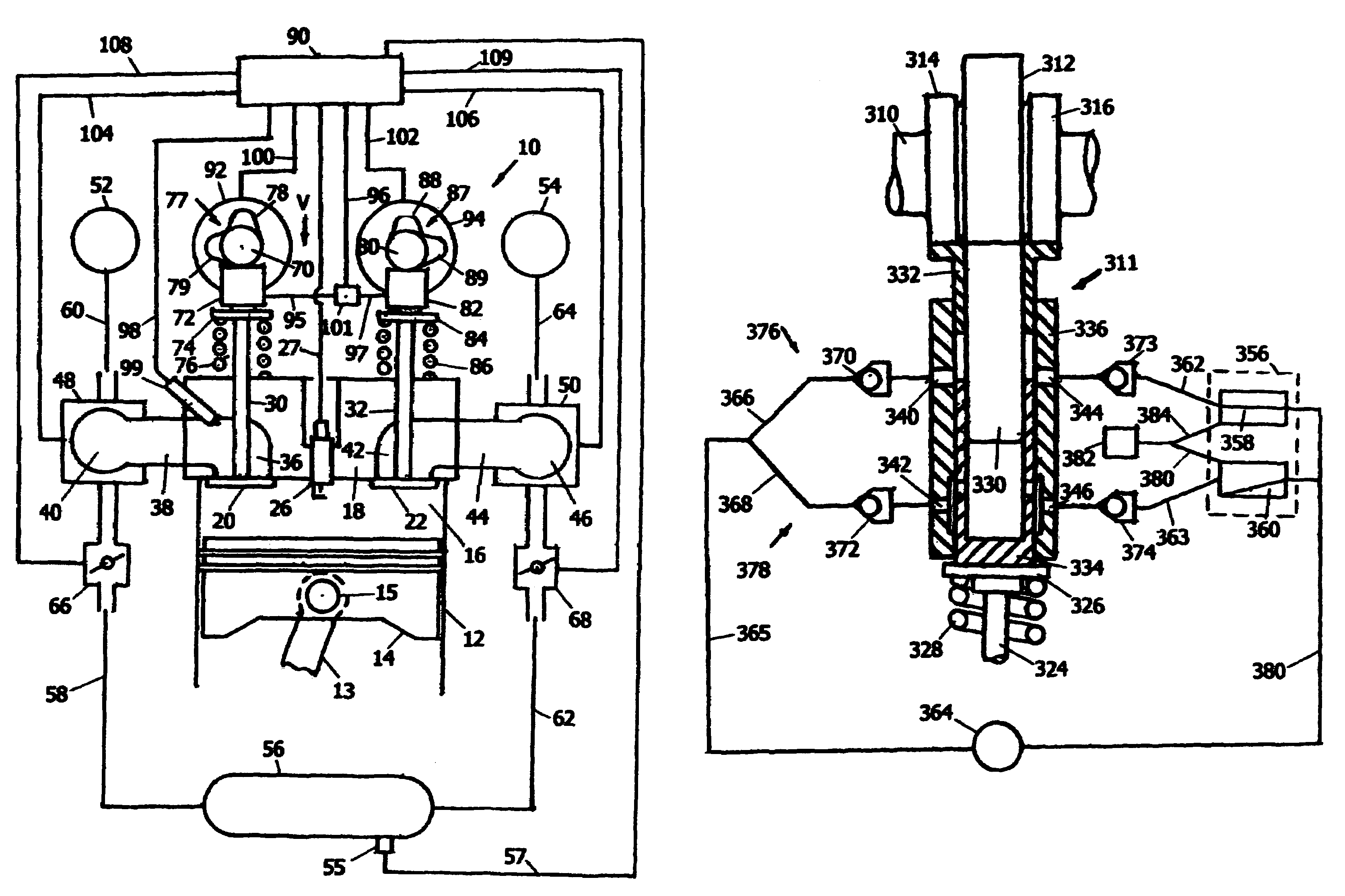

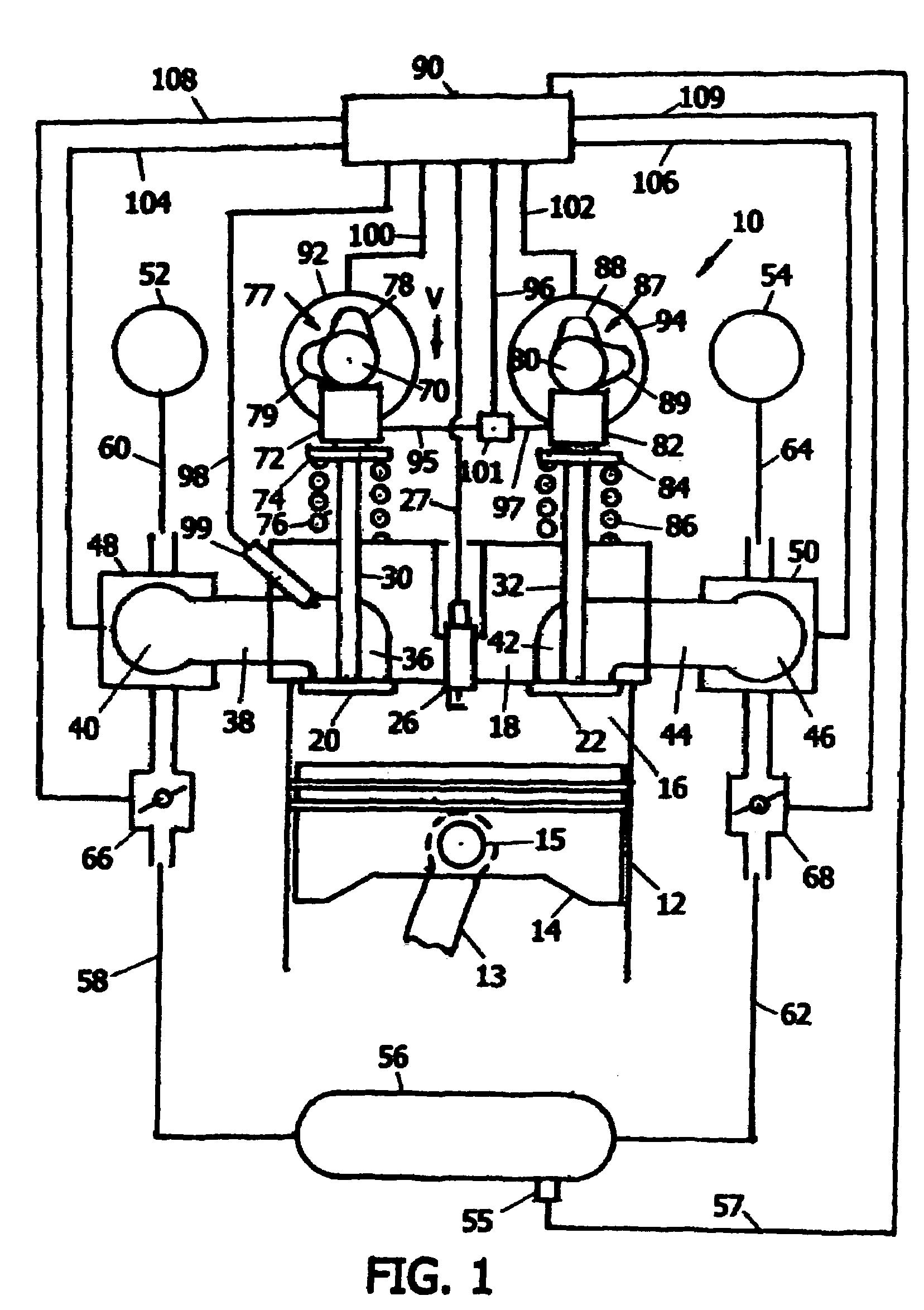

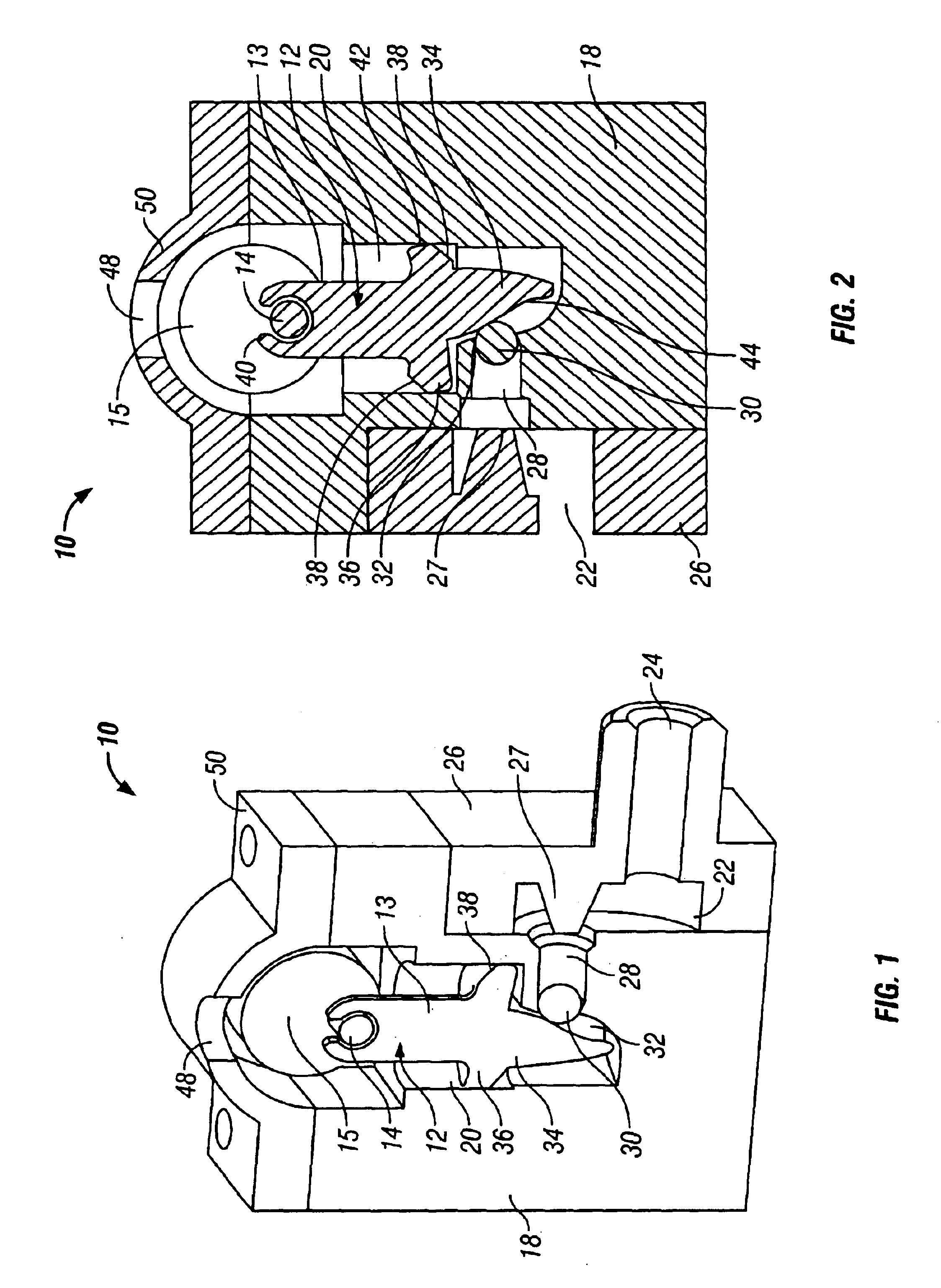

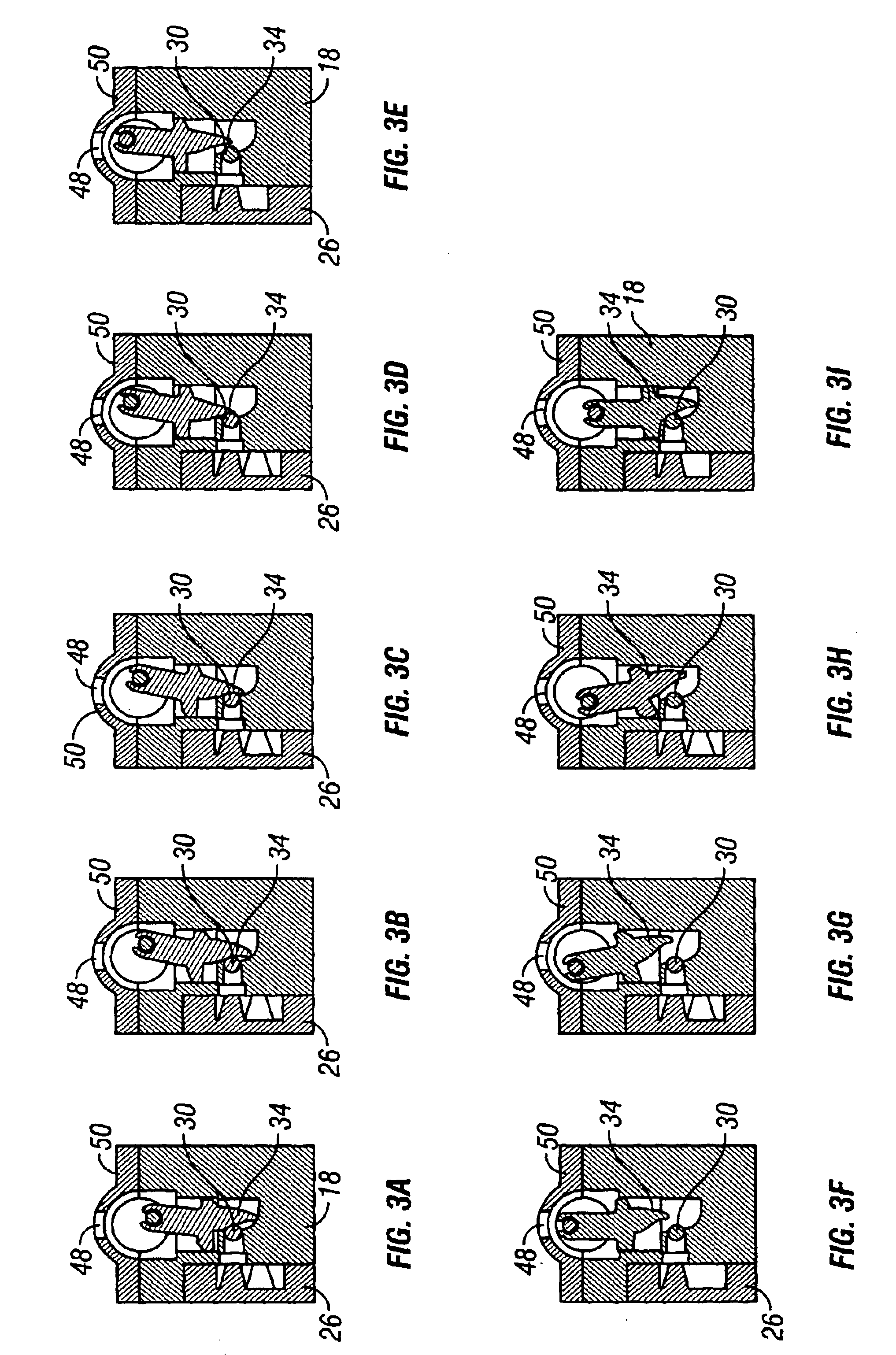

Pneumatic motor

In one embodiment a pneumatic motor is provided that includes an intake chamber in fluid communication with at least one intake channel. Each intake channel is further in fluid communication with a corresponding cylinder, which receives a piston that cycles upwardly and downwardly to rotate a motor axle. A member is placed in each intake channel to seal the corresponding cylinder from each intake channel when compressed fluid in the intake channel has a higher pressure then pressure in the corresponding cylinder. Each piston includes an actuator extending downwardly from the piston and having a profile that, during a portion of the upward cycle of the piston, causes the actuator to push the member back into each intake channel to allow compressed fluid into each of the corresponding cylinders. Each piston includes an intermediate section that has an annular groove, a seal positioned in the groove that creates a fluid tight seal against the corresponding cylinder during the upward cycle of the piston. Compressed fluid that enters the corresponding cylinder during the upward cycle will push the piston upwardly. Each section further includes exhaust grooves defined thereon such during the downward cycle of the piston the seal is broken allowing compressed fluid in the cylinder to bypass the piston and escape through a vent above each cylinder. This causes the compressed fluid in the intake channel to push the member to re-seal the cylinder. The upward movement of the piston further generates inertia that moves the piston downward to continue the cycle.

Owner:REHCO LLC

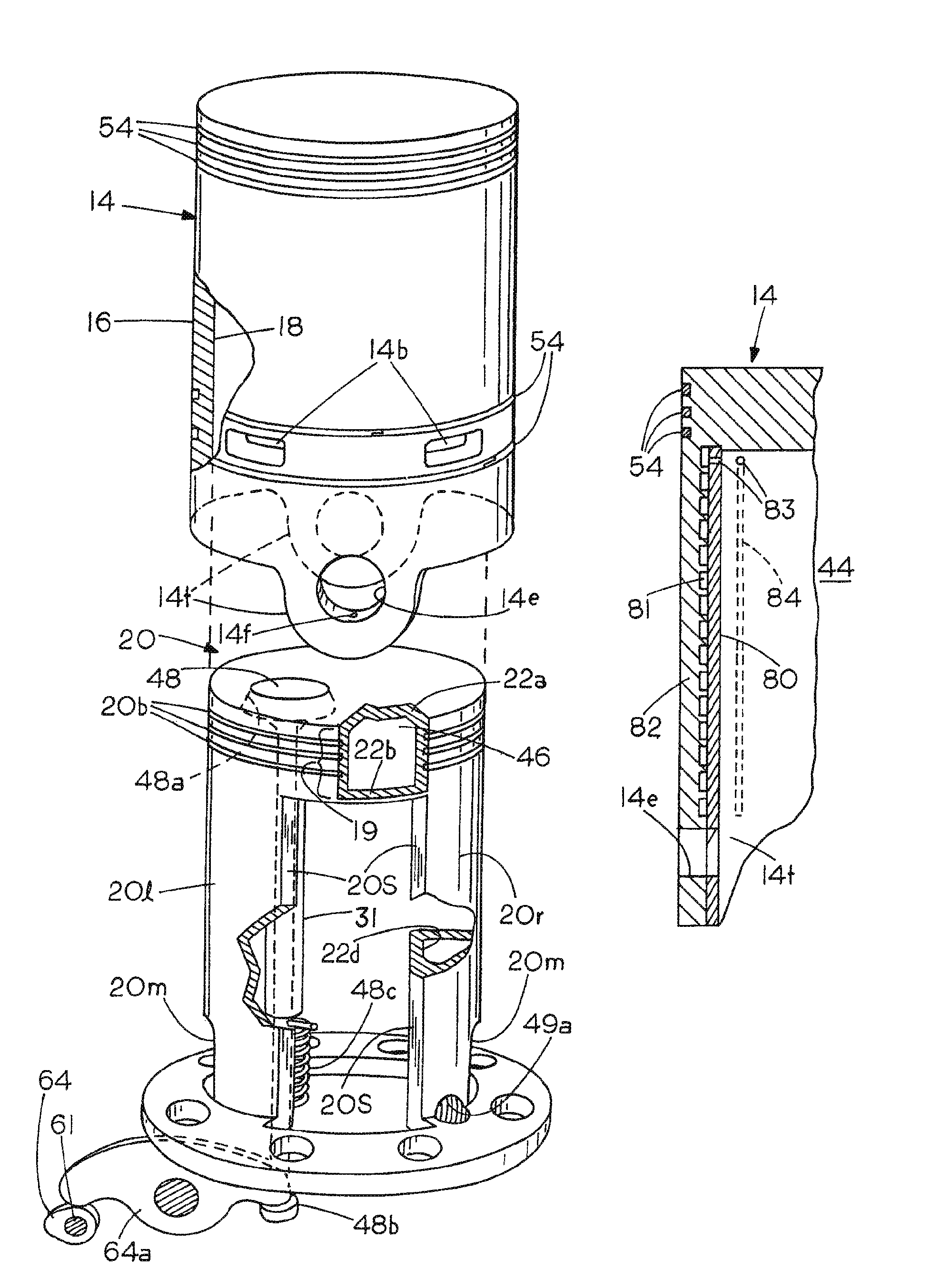

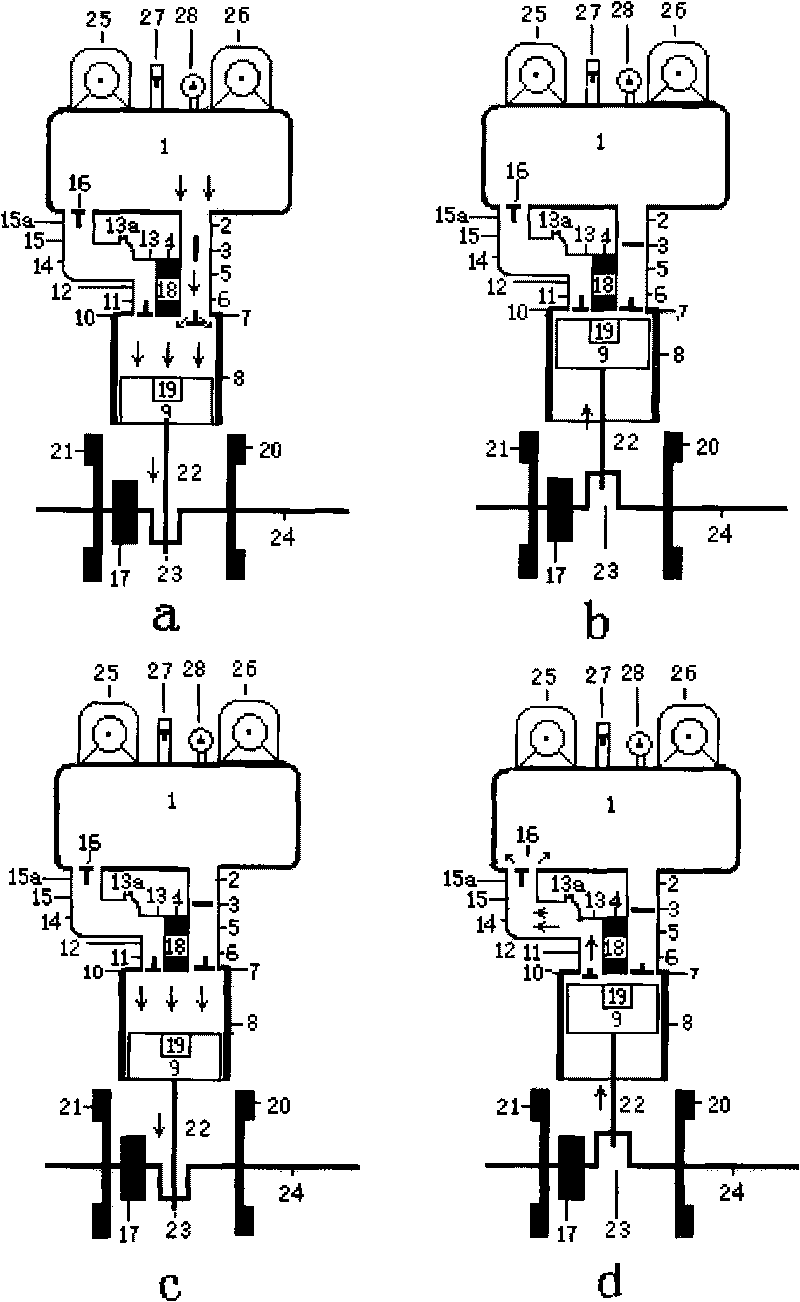

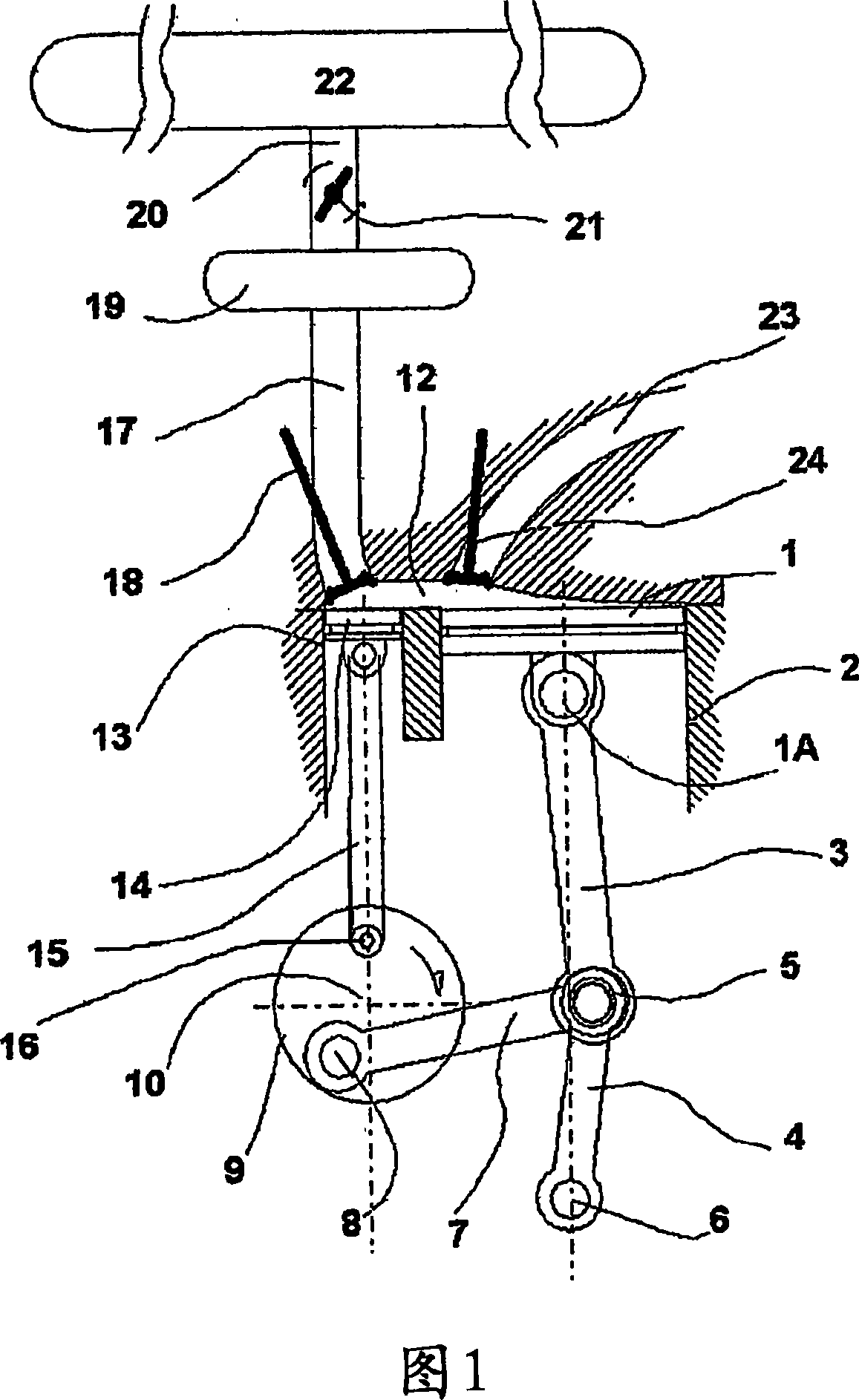

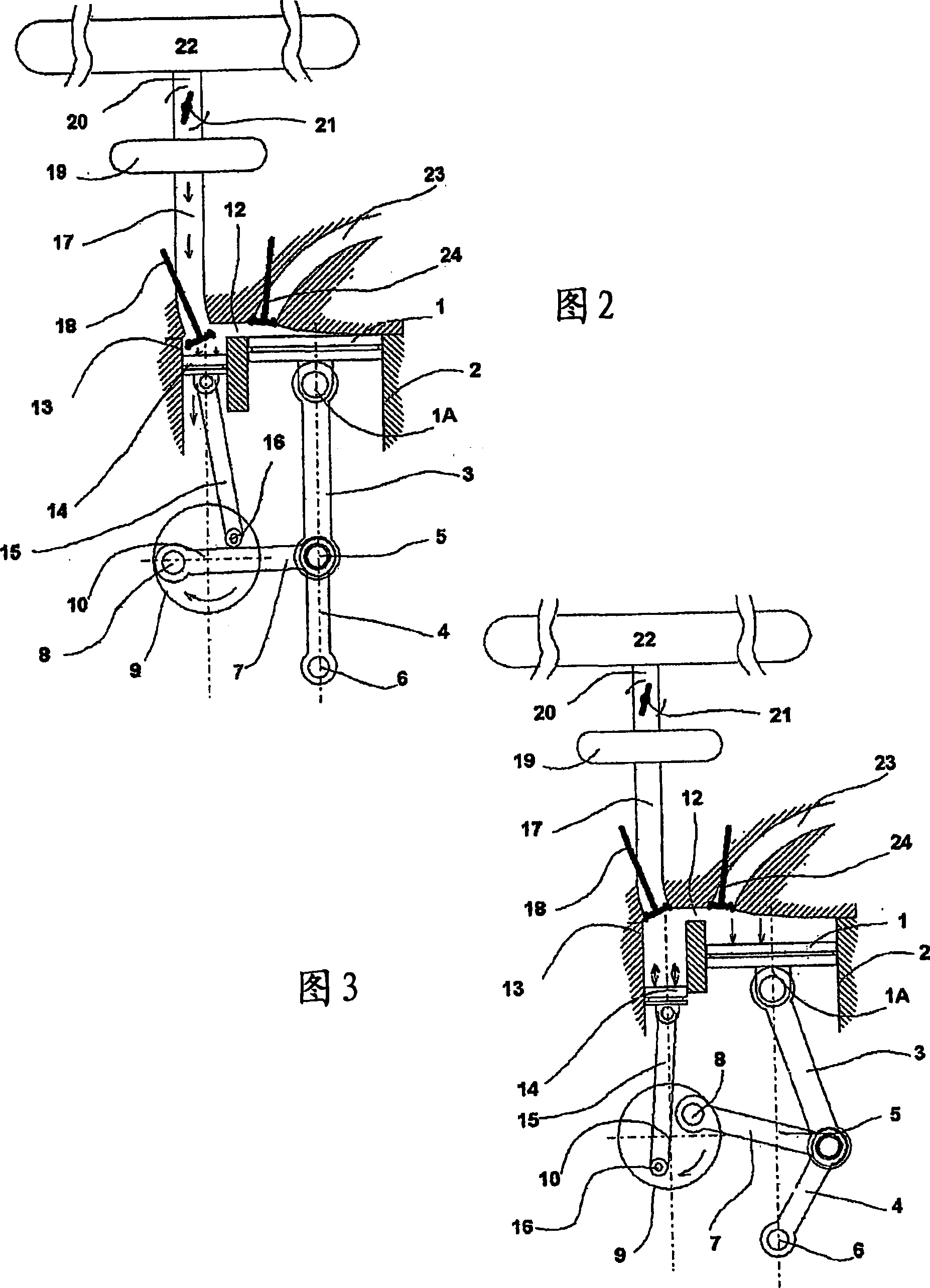

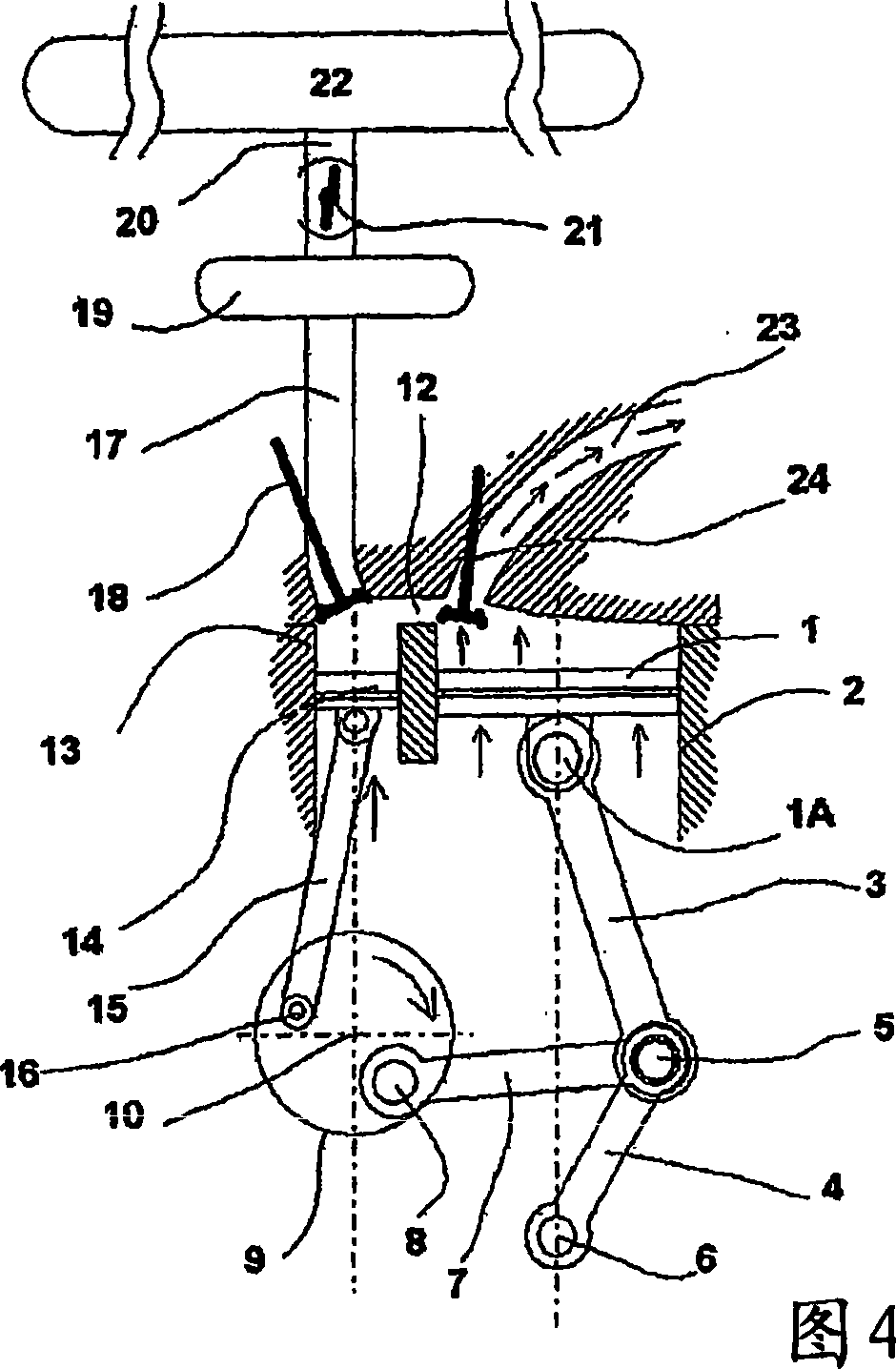

Engine with an active mono-energy and/or bi-energy chamber with compressed air and/or additional energy and thermodynamic cycle thereof

The inventive engine uses a top dead center piston stop device. It is fed by compressed air, which is contained in a high-pressure storage tank, via a working capacity (19), which, in the bi-energy version, comprises a device for heating the air supplied by additional energy. The active expansion chamber consists of a variable volume or charge piston sliding in a cylinder, coupled to space above the engine piston (1) by means of a passage (12). When stoped at upper dead center, the pressurized air is admitted into the expansion chamber with the smallest volume thereof and, under the effect of thrust, increases the volume thereof by producing work; the expansion chamber is then kept at a maximum volume during expansion of the engine cylinder (2) driving back the engine piston (1) in its downward stroke, providing work of its own. During exhaust, the two pistons (1 and 13) travel in an upward stroke and simultaneously reach top dead center in order to resume a new cycle. The invention can be used with land vehicles, cars, buses, motor bikes, boats, auxiliary generator sets, cogeneration units and fixed station motors.

Owner:MDI MOTOR DEV INT SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com